Patents

Literature

369results about How to "Reduce rebound rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

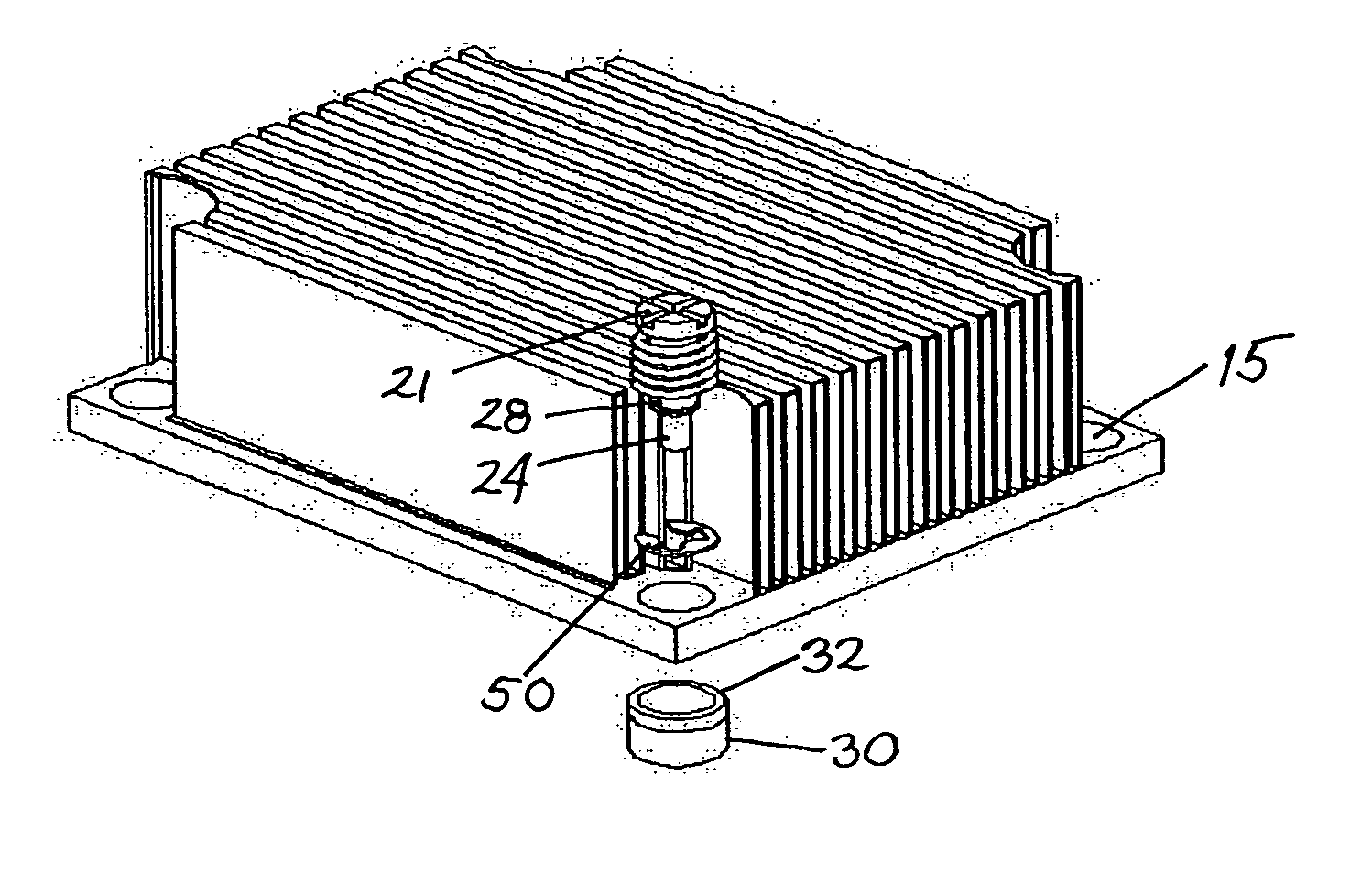

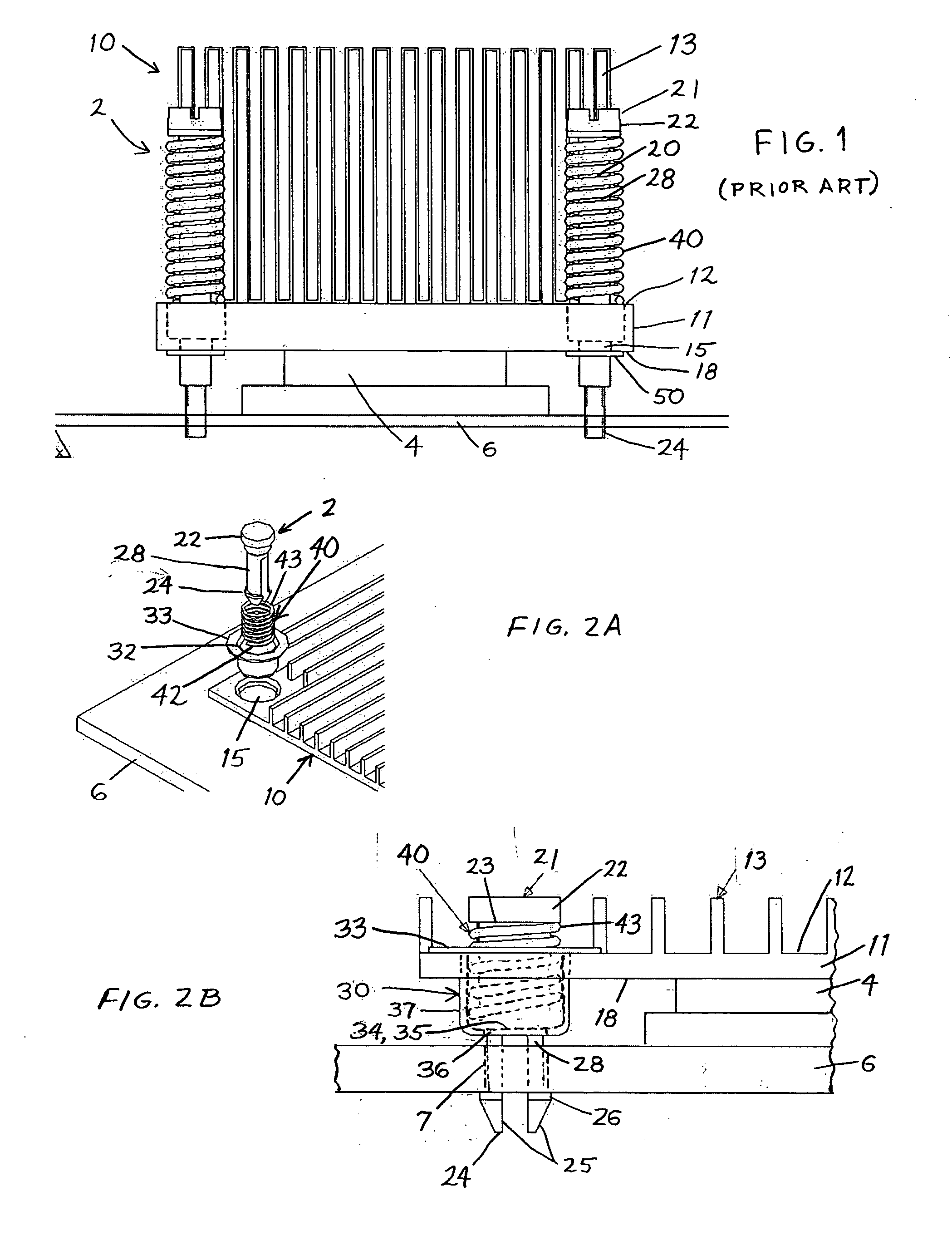

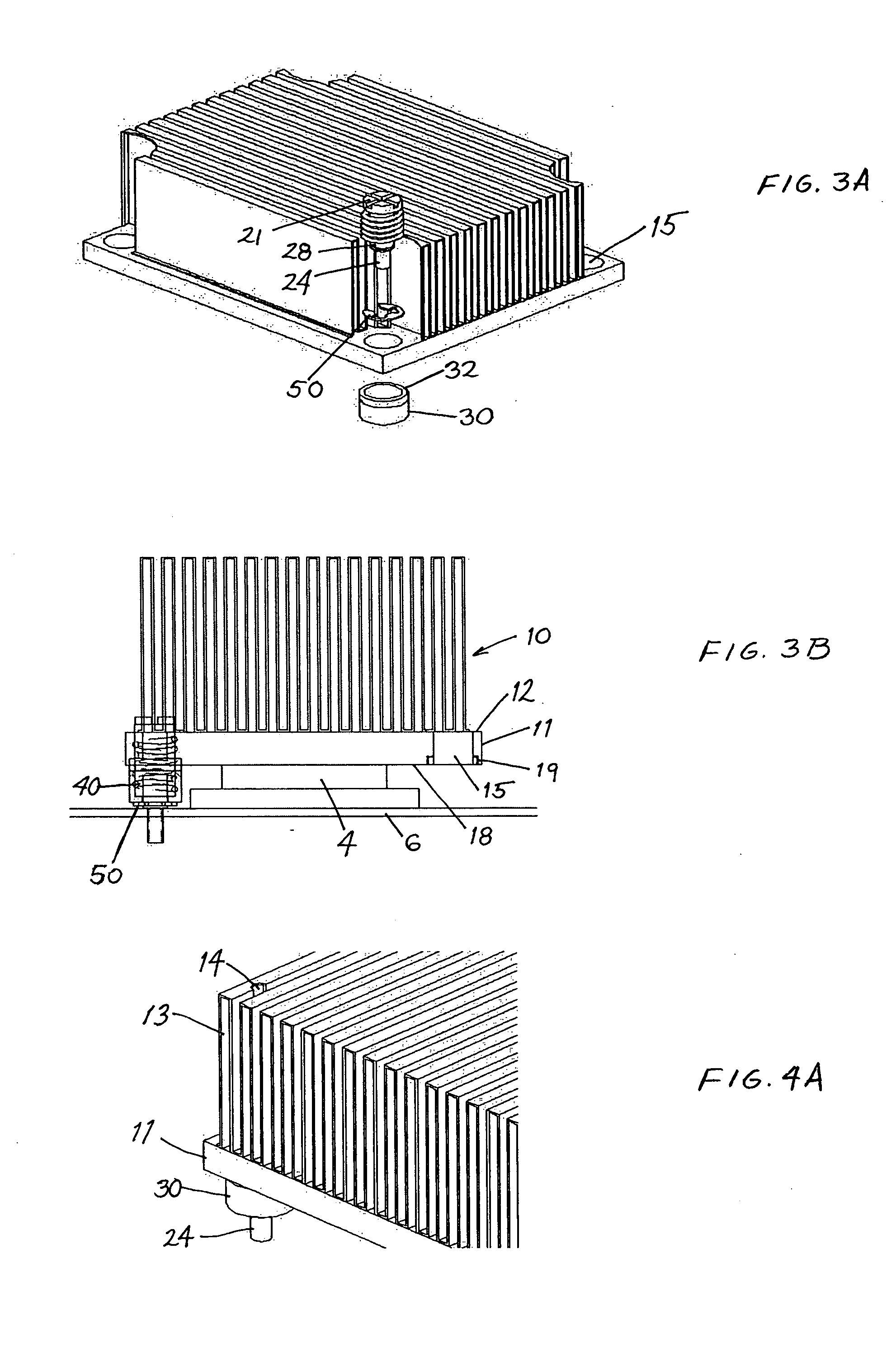

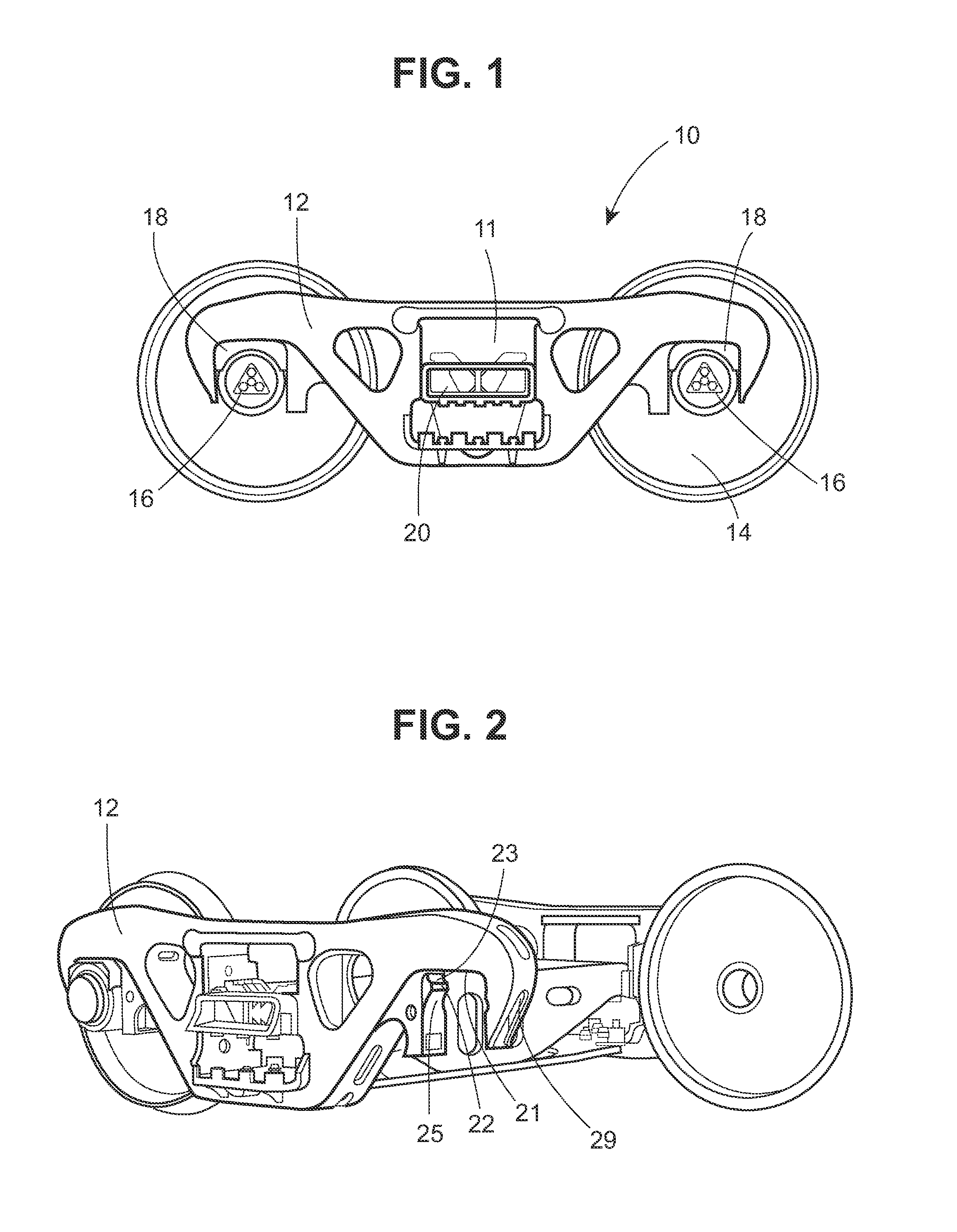

Heat sink assembly and connecting device

InactiveUS20050072558A1Low costFew partsSemiconductor/solid-state device detailsSolid-state devicesBearing surfacePrinted circuit board

A heat sink assembly includes a heat sink with a base plate having a top surface with fins for dissipating heat and an opposed bottom surface for placing against an electronic device mounted on a printed circuit board, and at least one connecting device for loading the heat sink against the electronic device. The connector includes a mechanical fastener such as a push pin having an end which engages the circuit board, a compression spring received against a shoulder on the fastener, and a cup member which is installed in an aperture in the base plate so that a floor of the cup member provides a bearing surface for the spring which is below the bottom surface of the base plate. An alternative connector utilizes a conical spring received through the base plate and receiving the fastener therein to load the spring in tension against the electronic device.

Owner:AAVID THERMALLOY

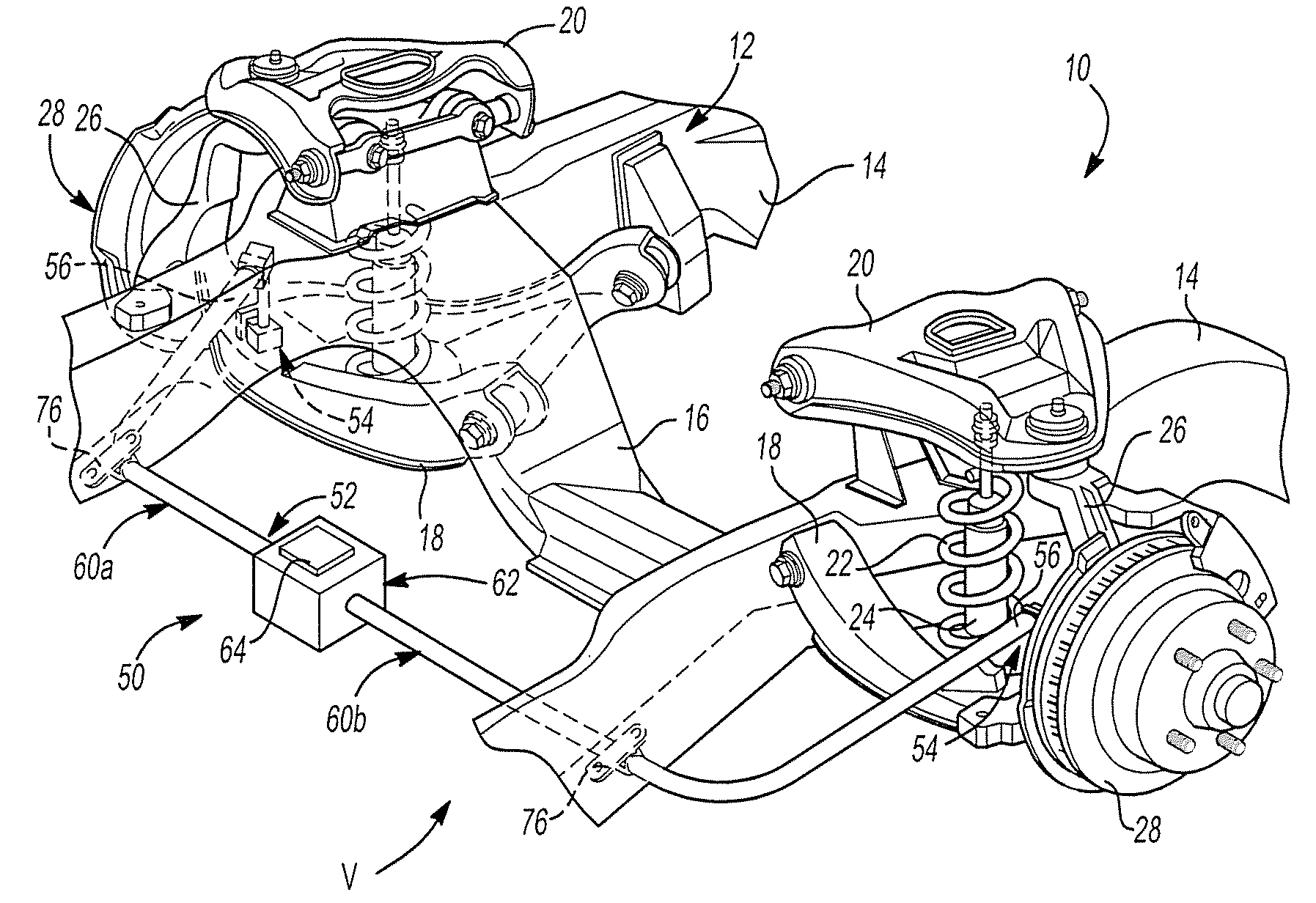

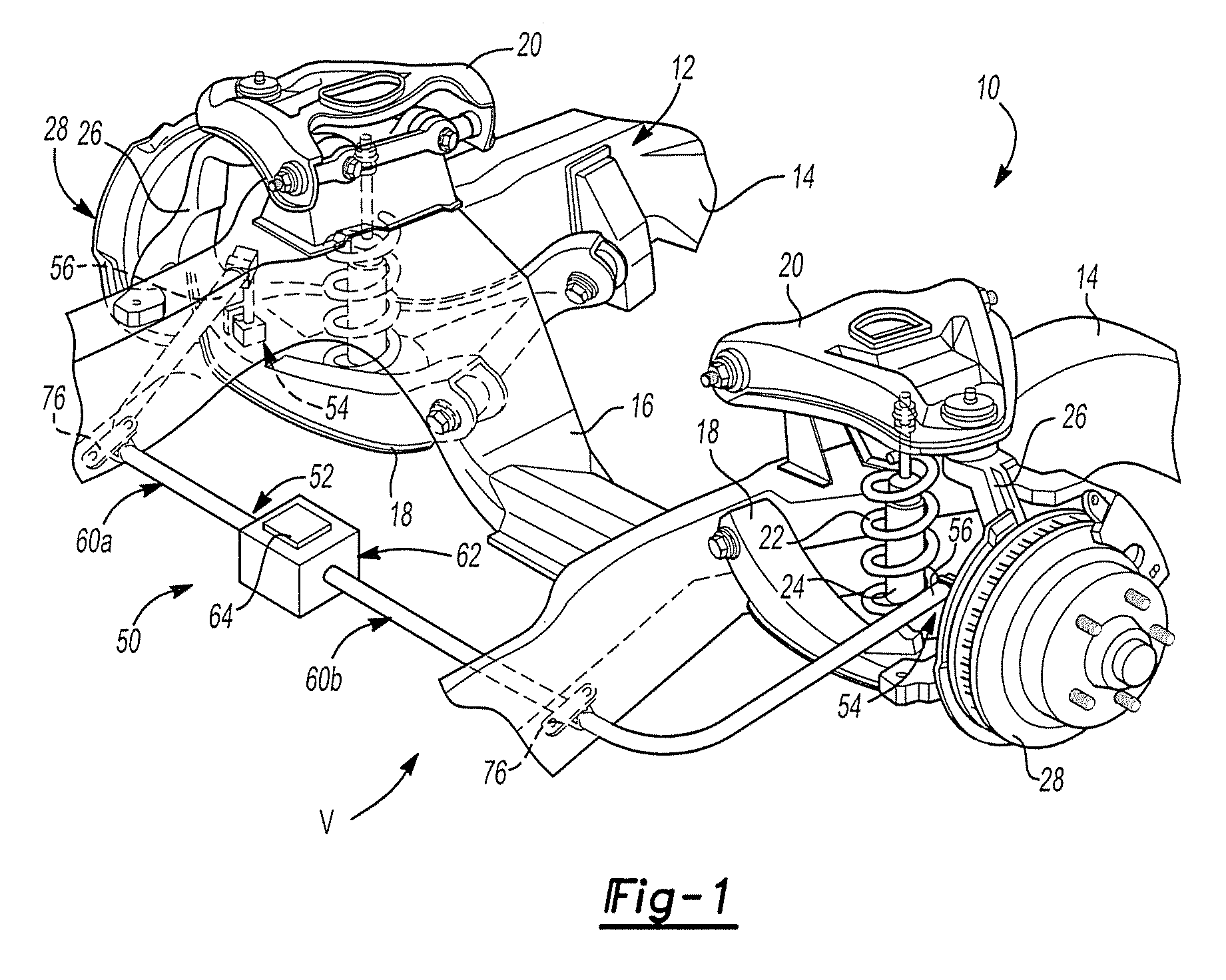

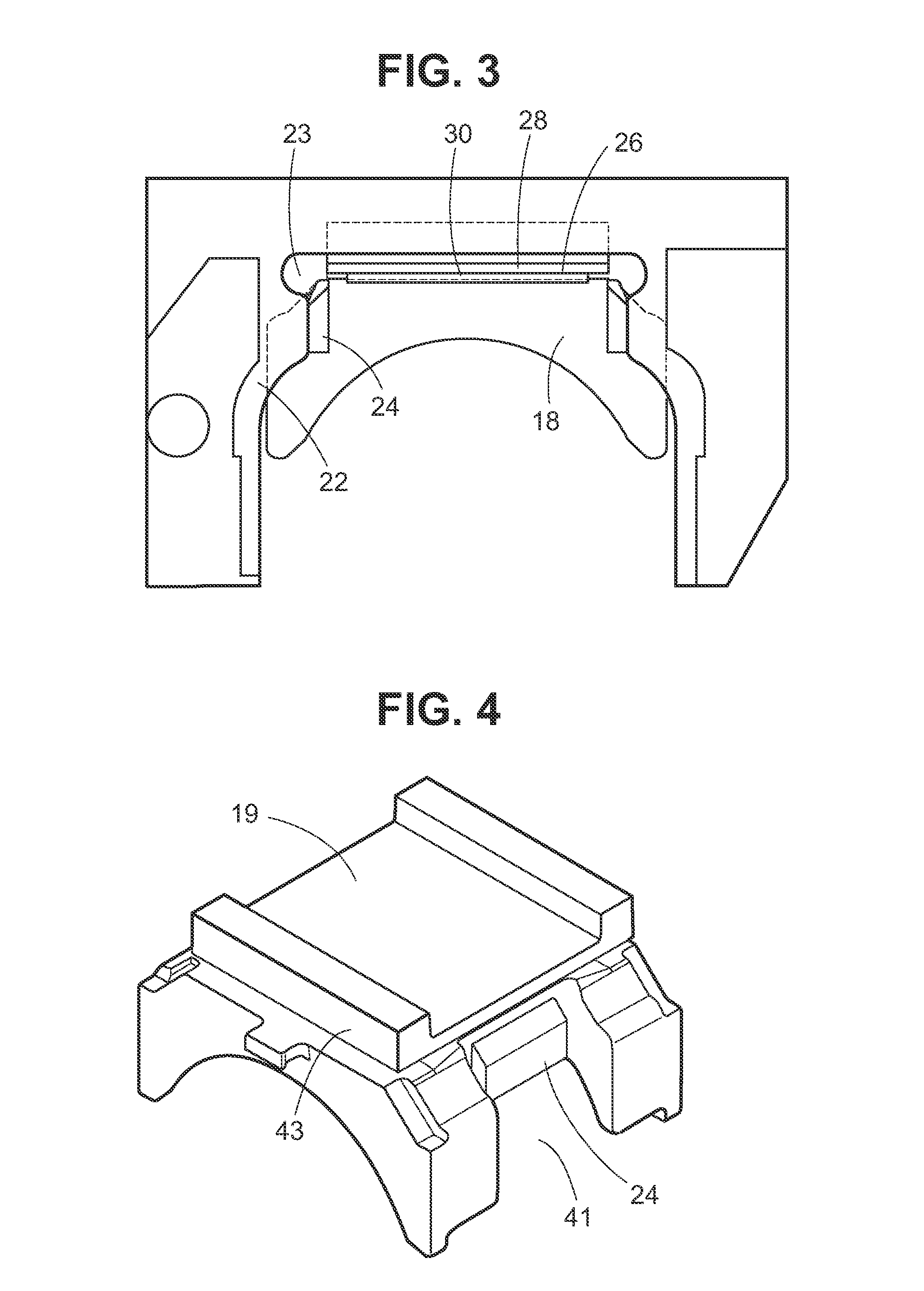

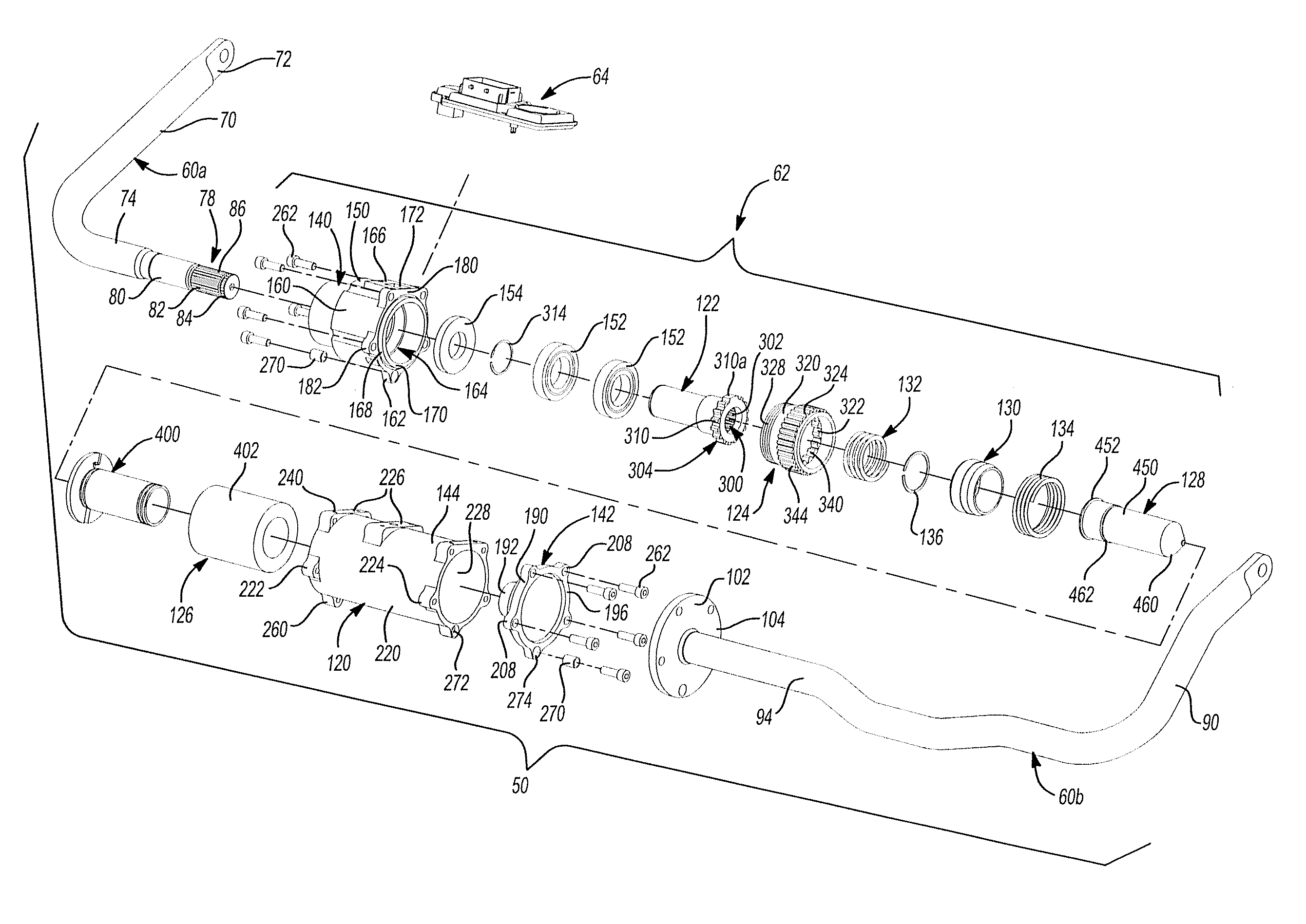

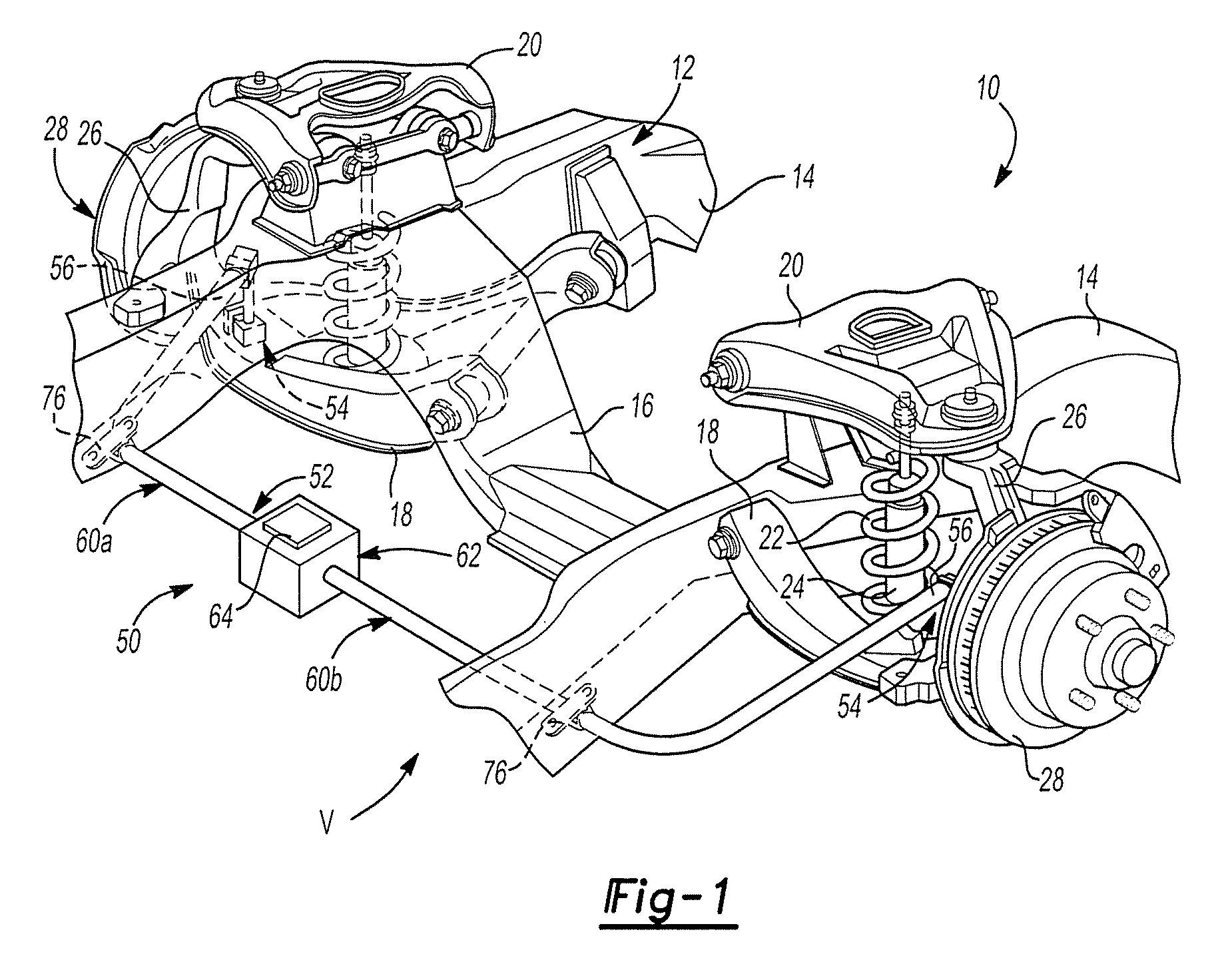

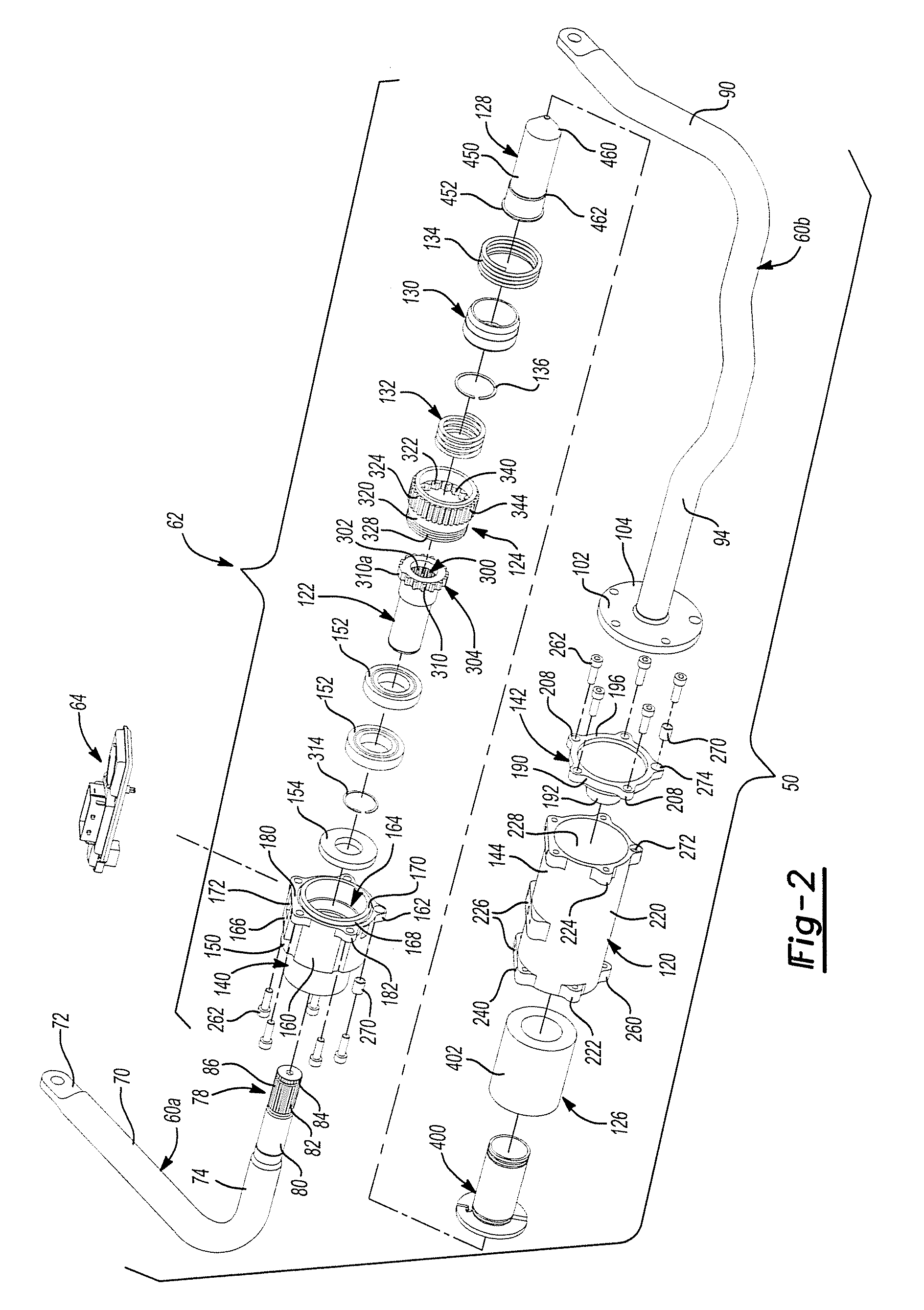

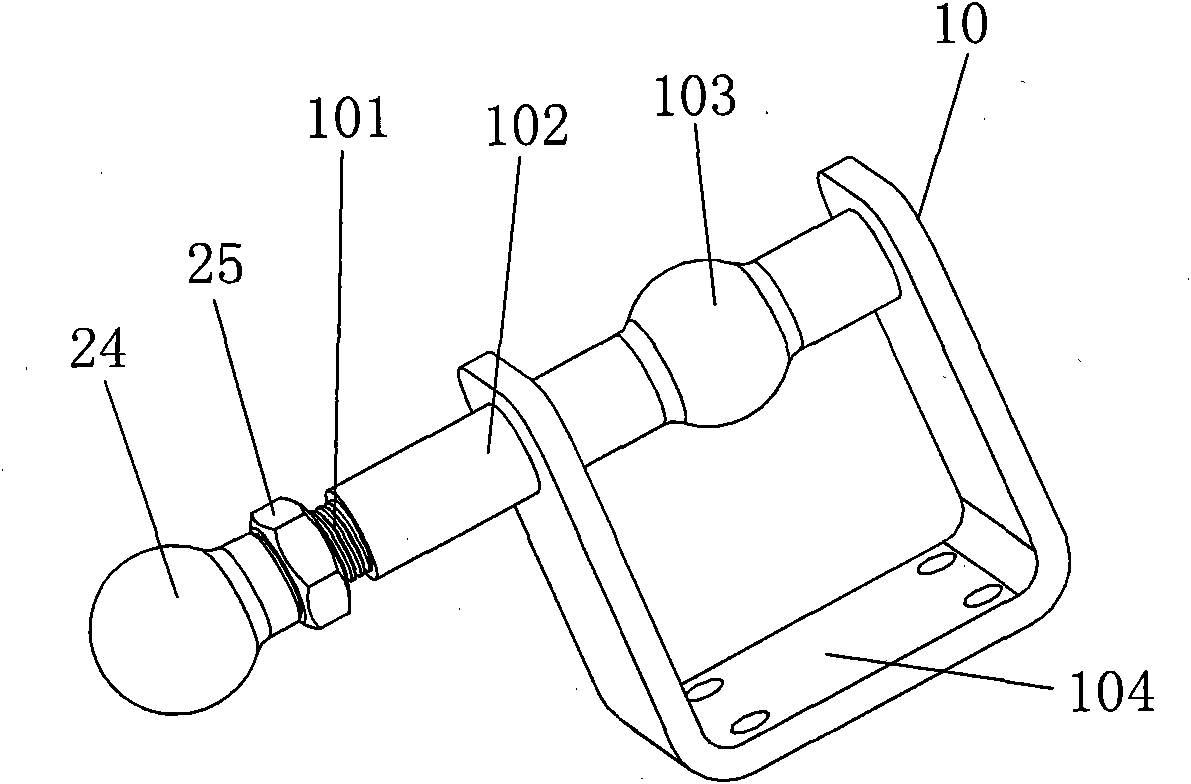

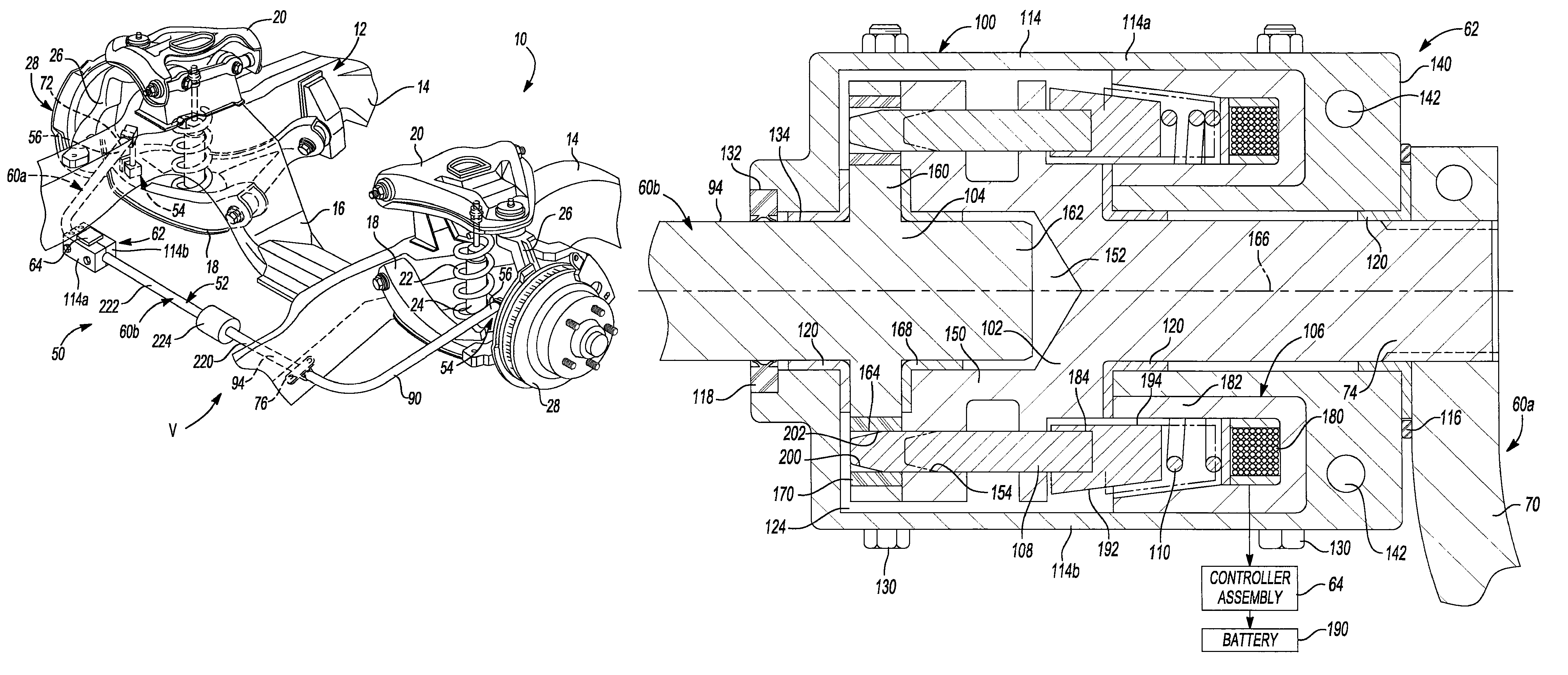

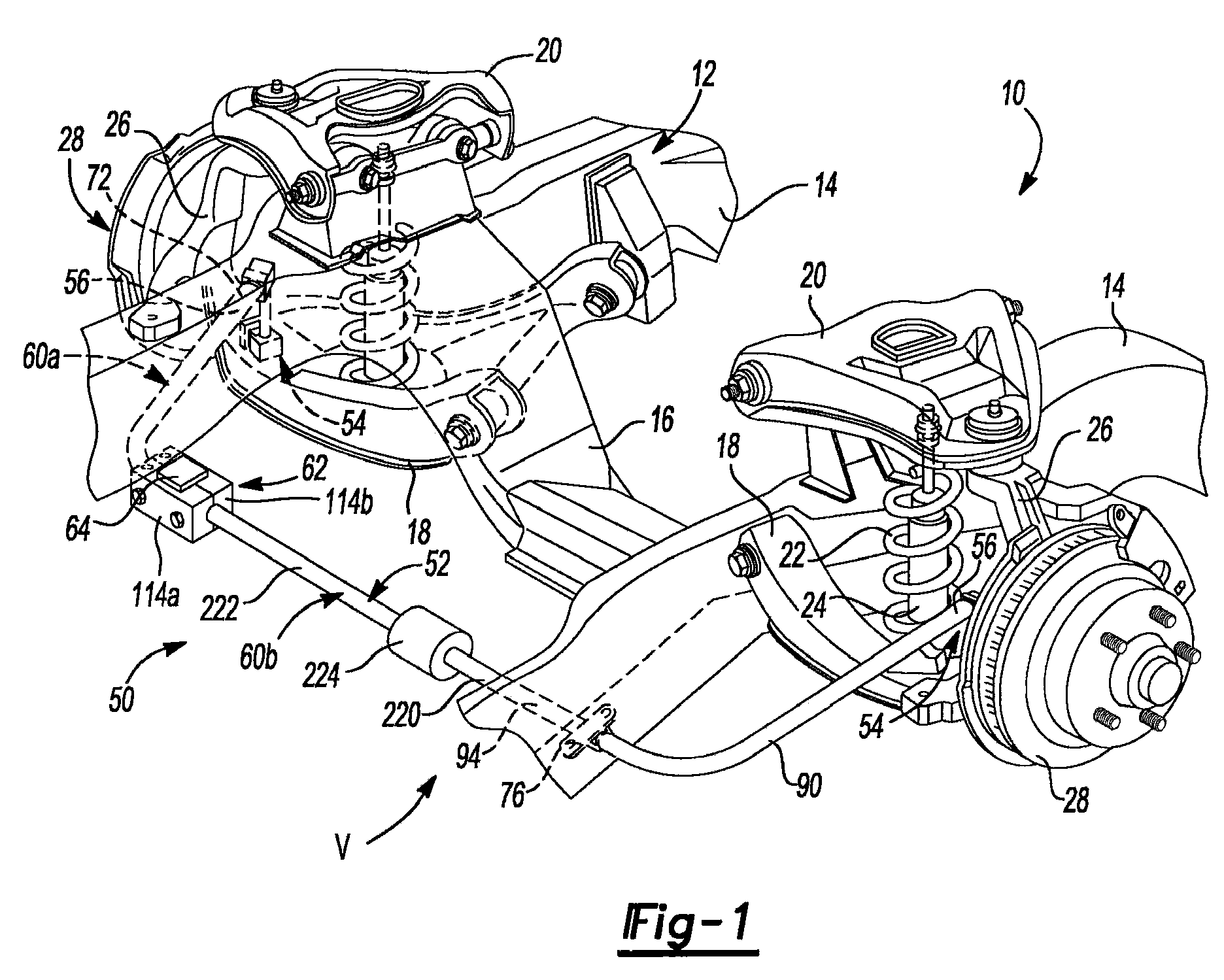

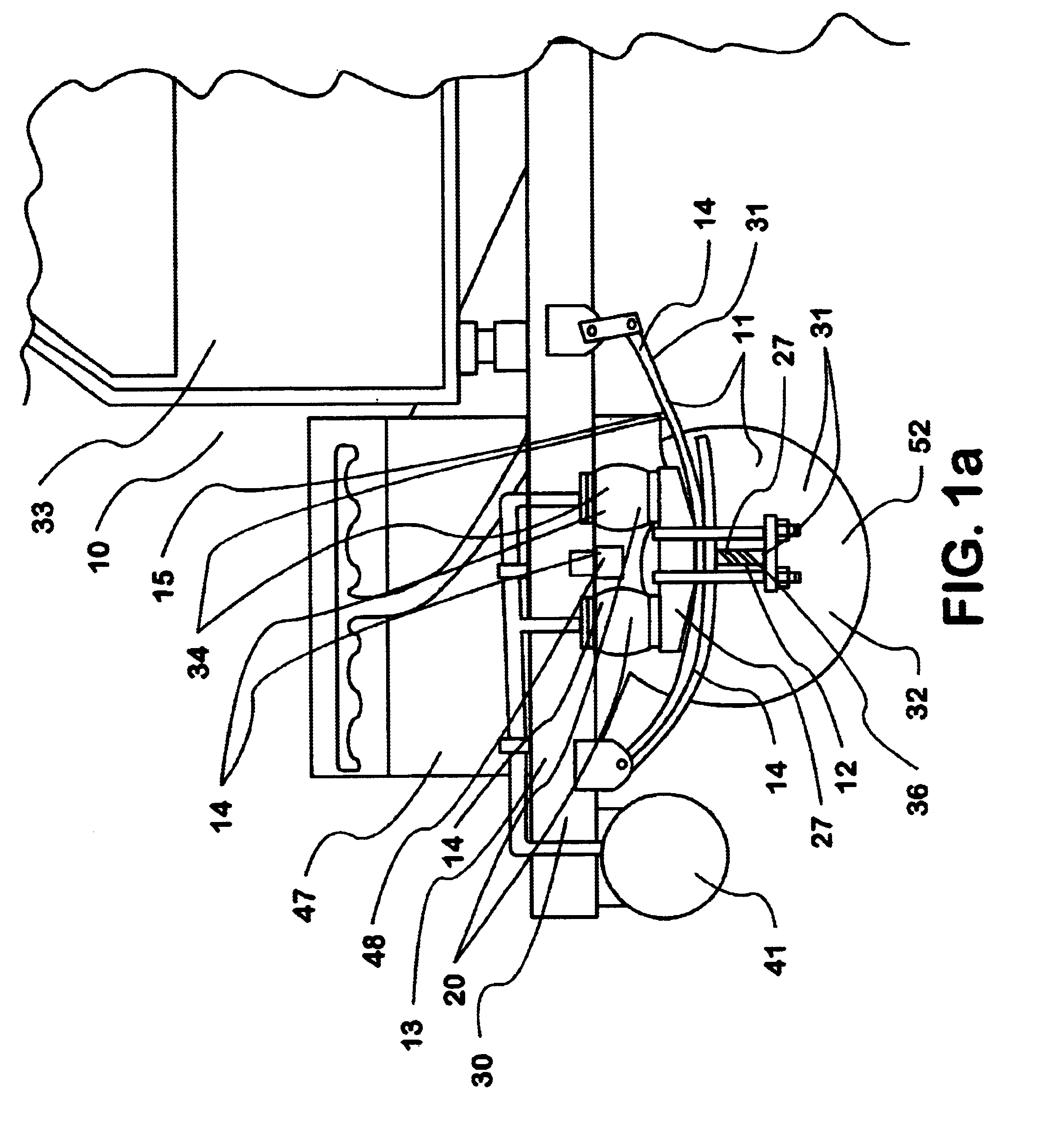

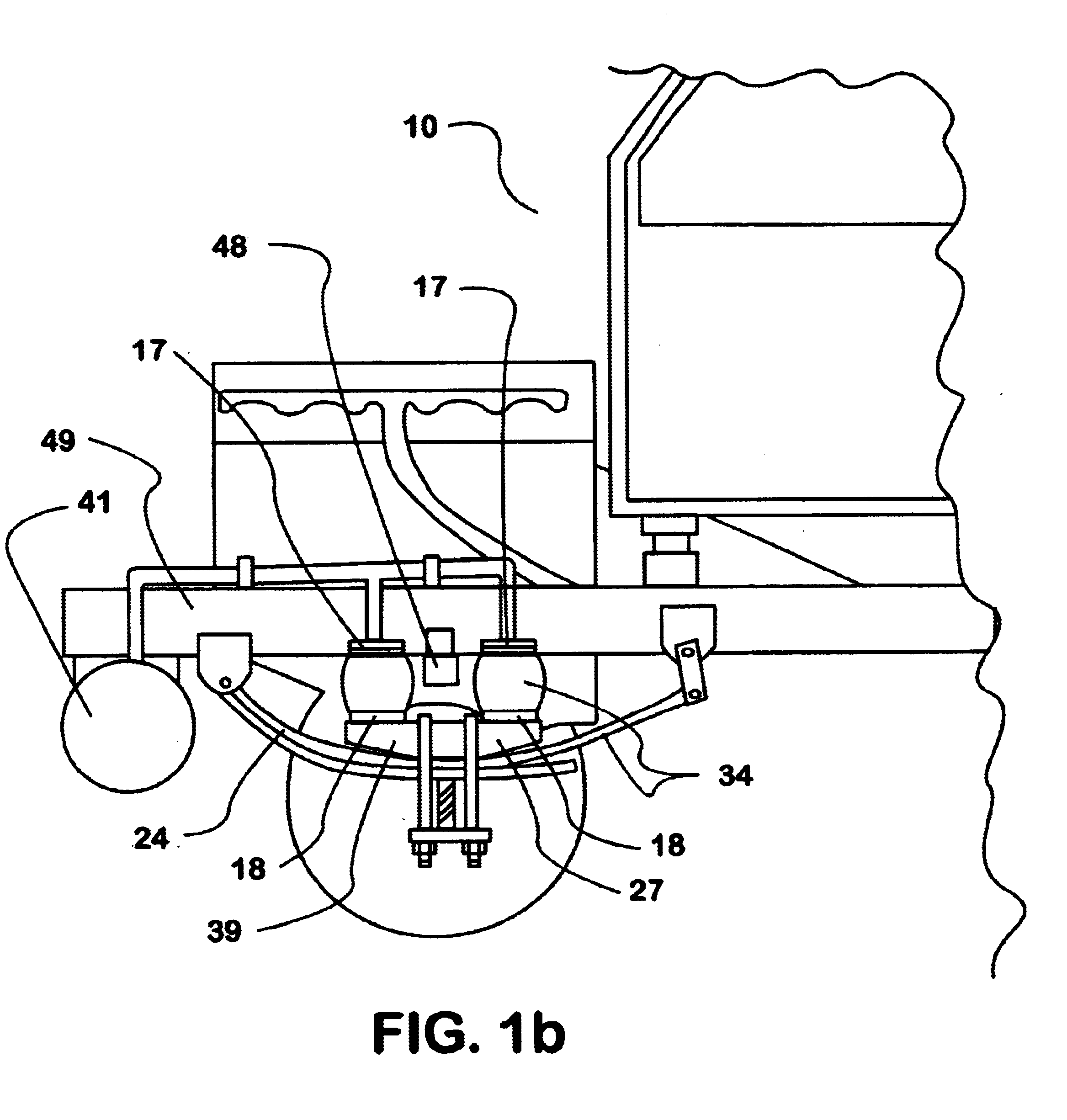

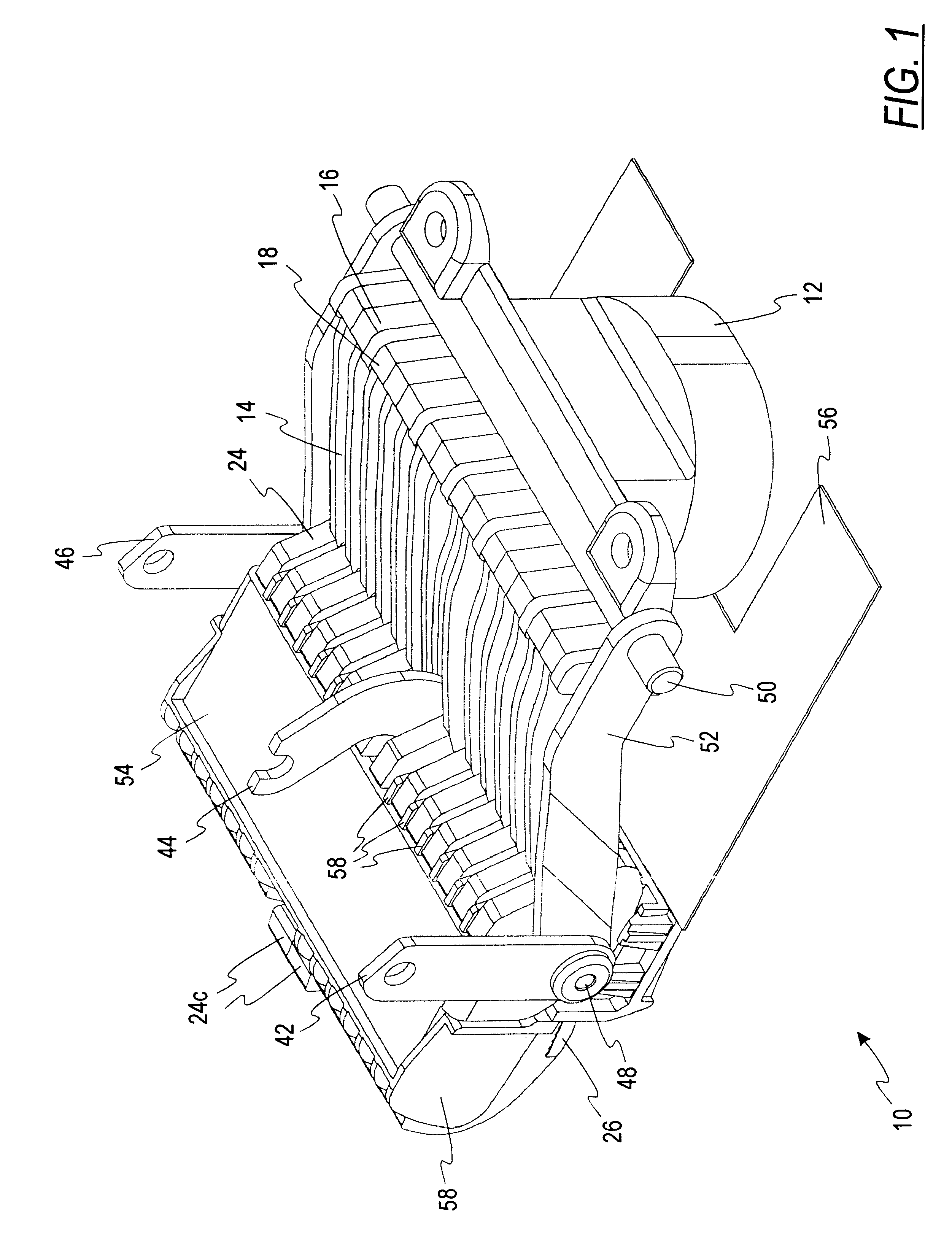

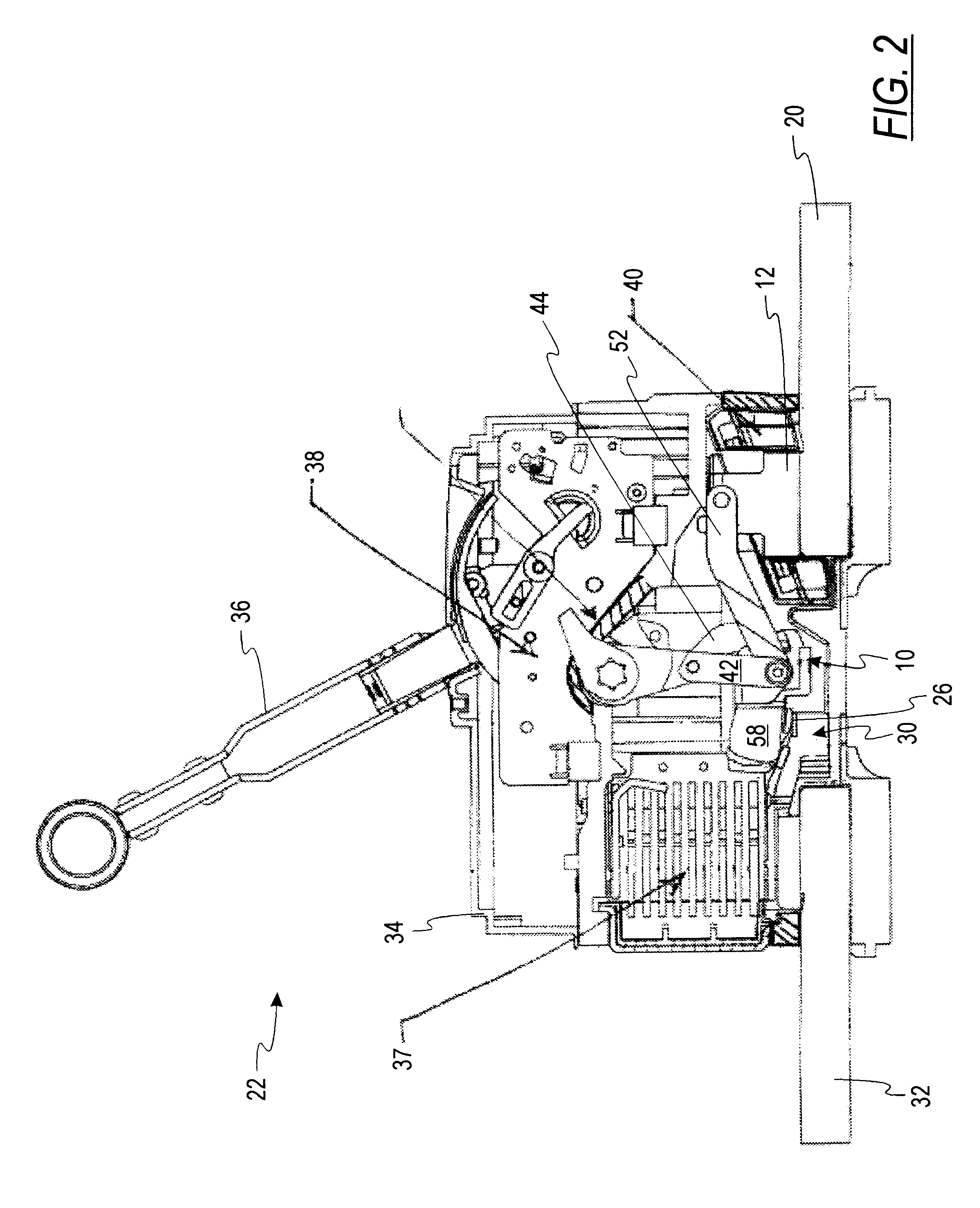

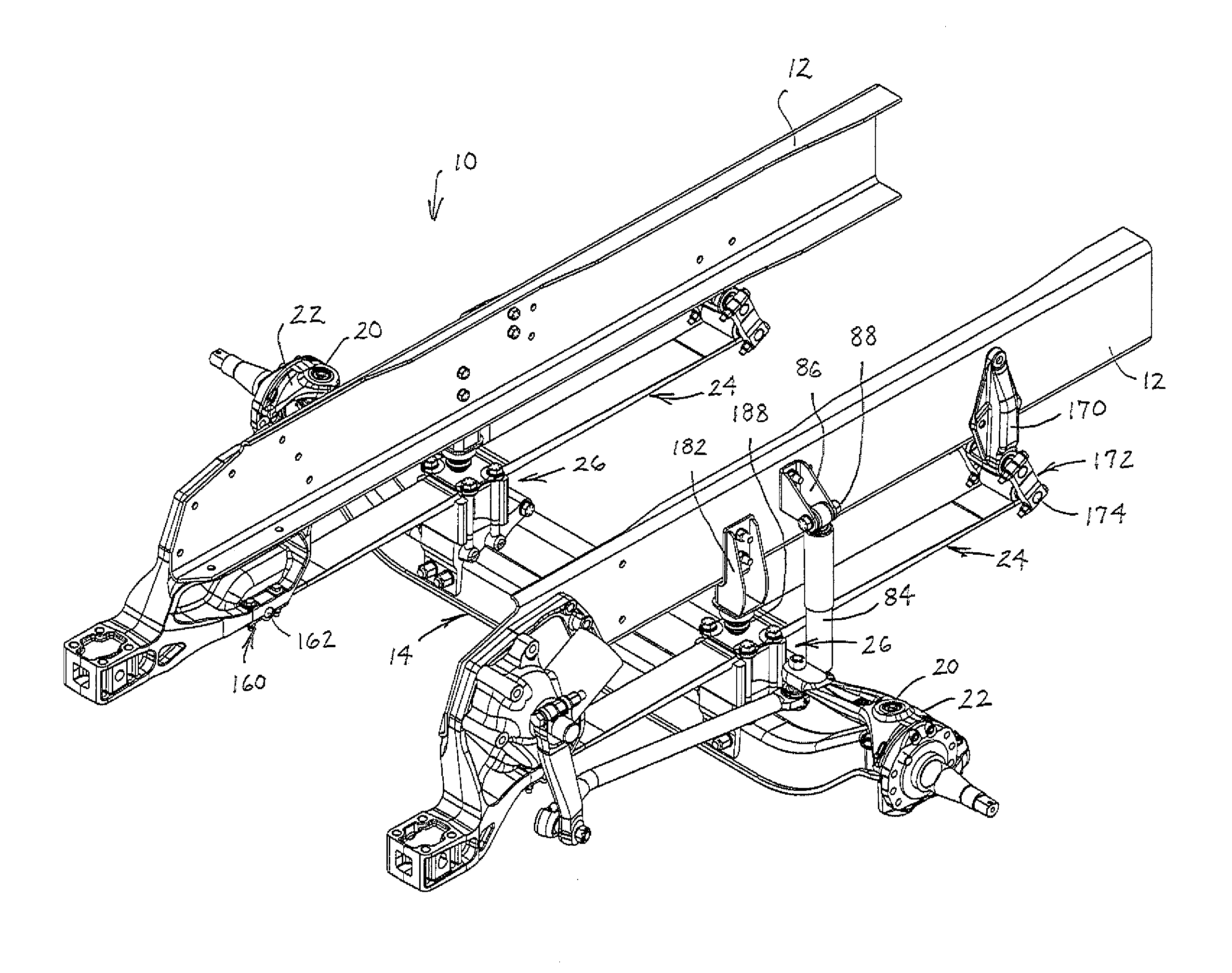

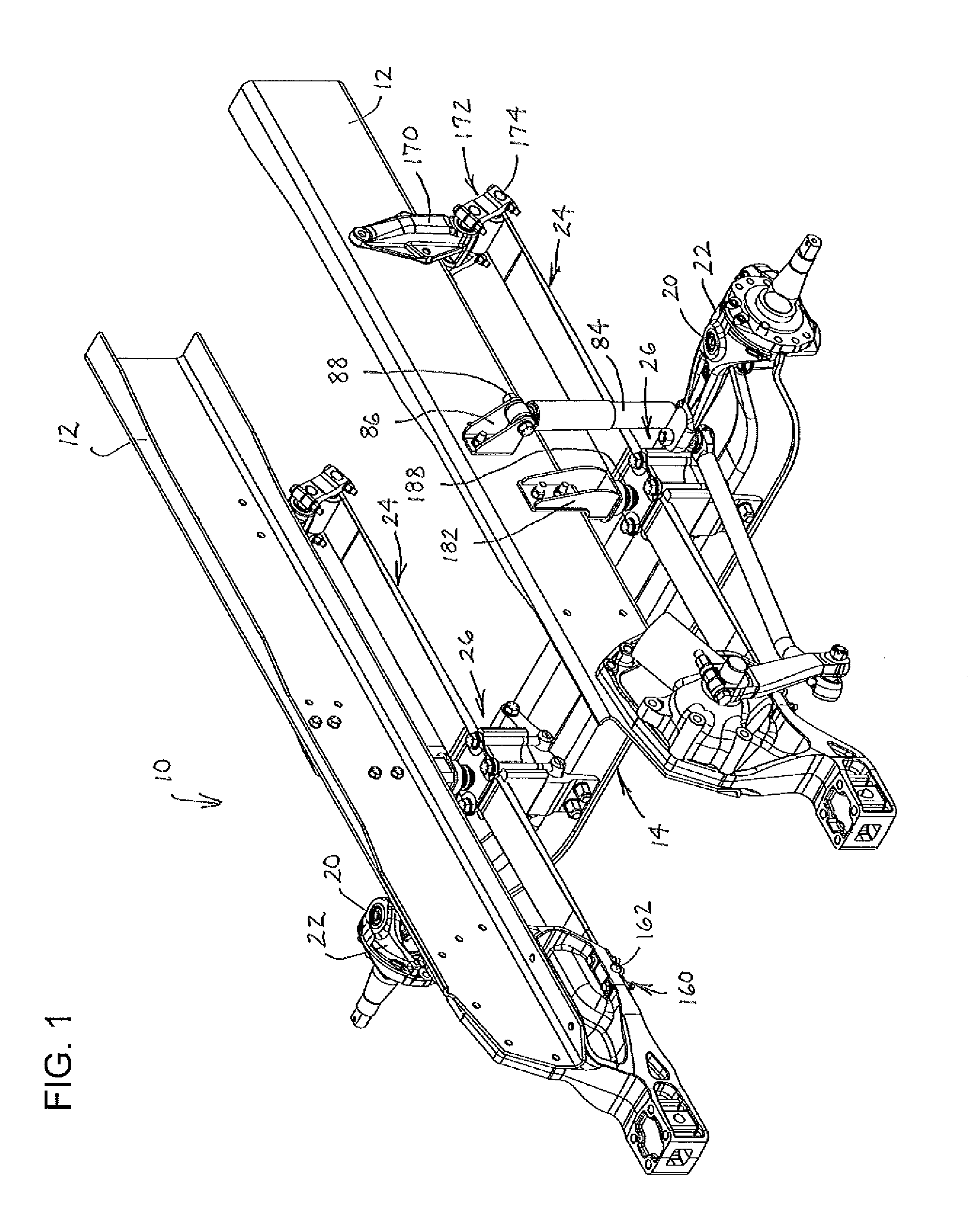

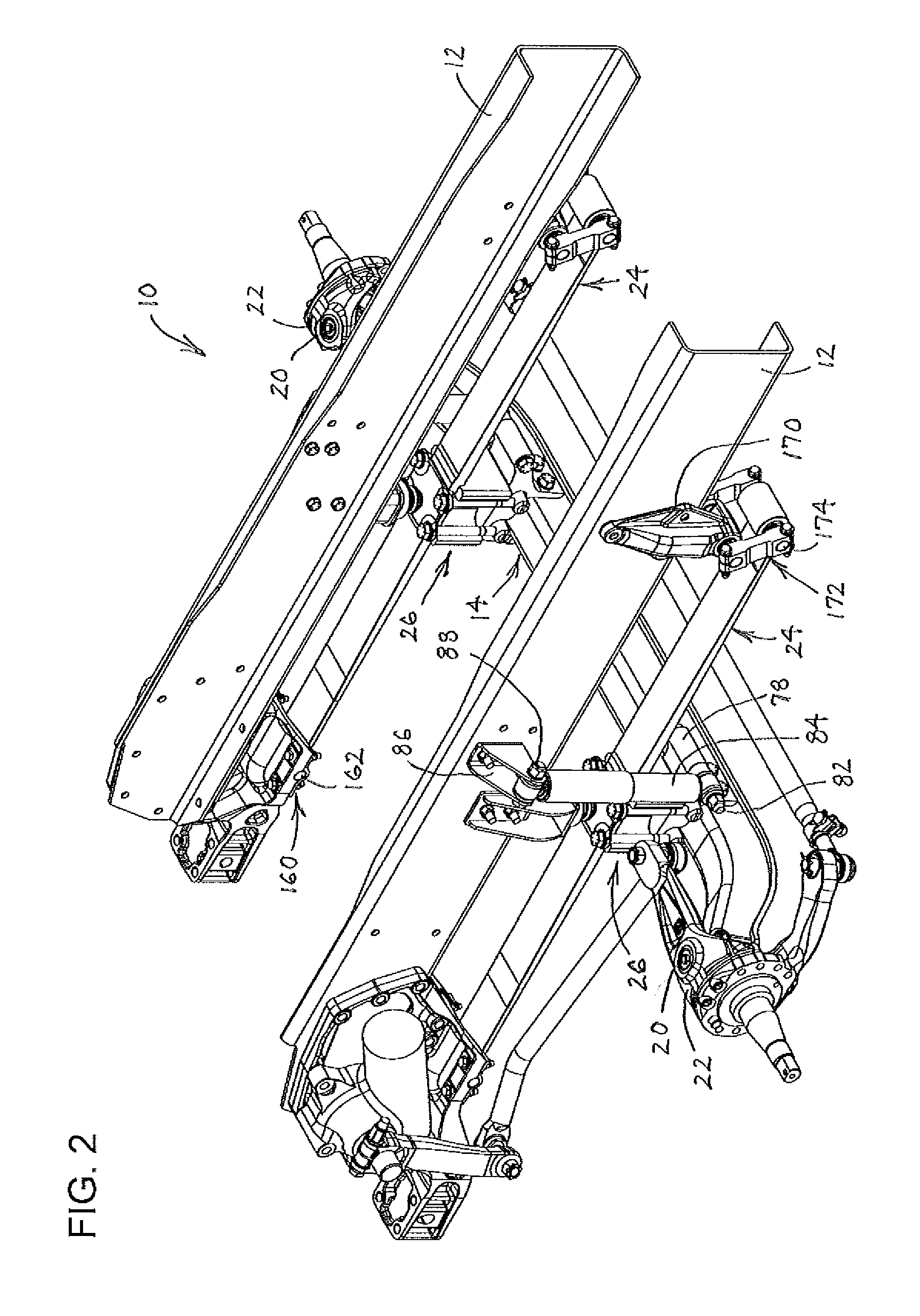

Apparatus and method for coupling a disconnectable stabilizer bar

ActiveUS20080106055A1Prevent rotationSevere impulsive forceTorsion springsMagnetically actuated clutchesEngineeringActuator

A vehicle stabilizer bar assembly having a pair of stabilizer bar members that are selectively uncoupled via a clutch. The clutch includes a moving element that can be selectively moved via an actuator to effect the uncoupling of the stabilizer bar members. The actuator is configured to apply a force to the moving element concentrically about the axis along which the moving element translates. The clutch is configured to transmit torque from one of the stabilizer bar members to the other stabilizer bar member concentrically about the axis. A method for operating a vehicle stabilizer bar assembly is also provided.

Owner:AMERICAN AXLE & MFG

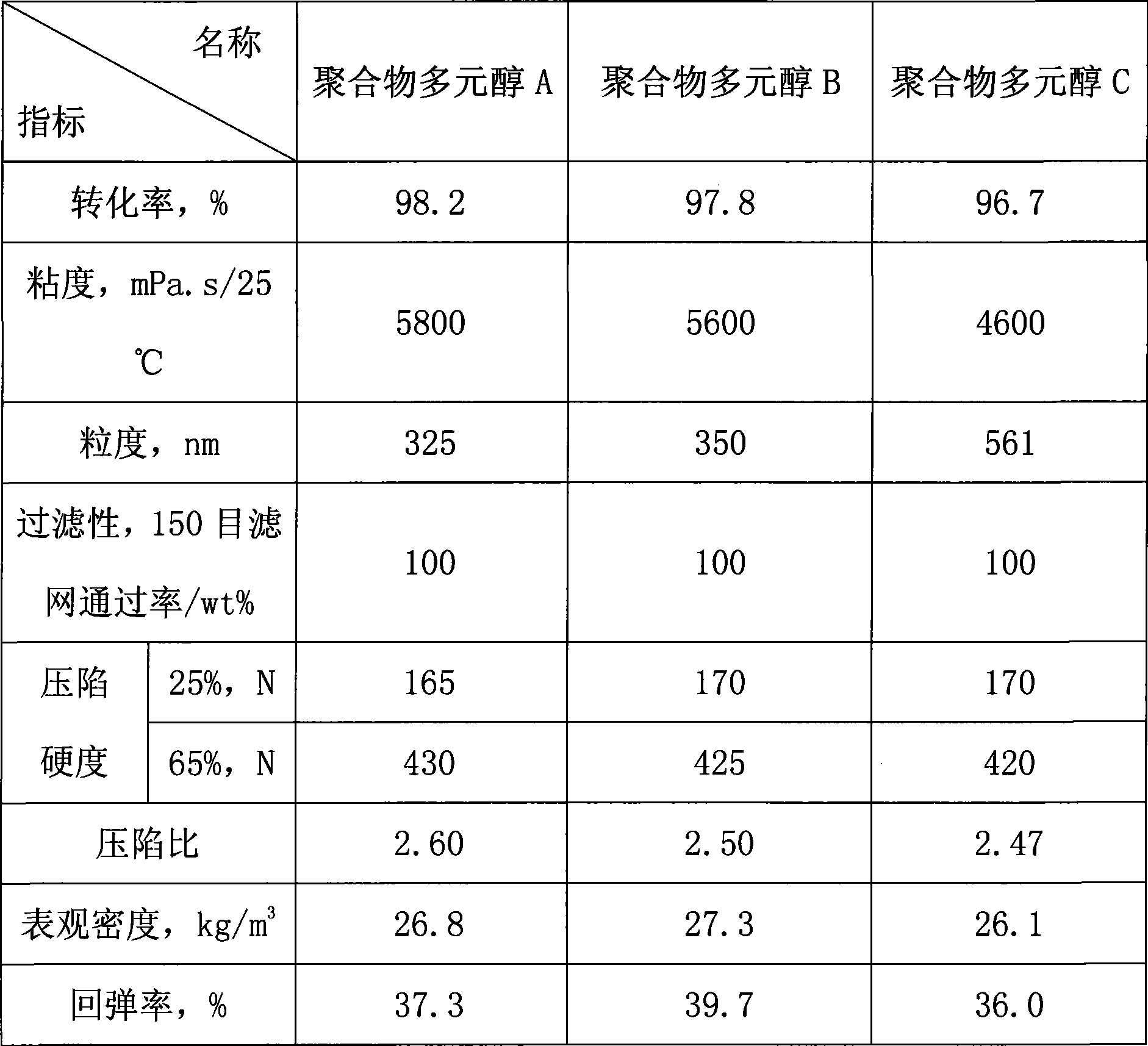

Method for producing high-solid content low-viscosity polymer polylol

The invention relates to a method for preparing polymer polyol with high solid content and low viscosity. The method adopts an intermittent method or a continuous method, and uses a basic polyether polyol as a continuous phase to perform in situ polymerization on a vinyl monomer, polyether polyol, a dispersing agent, and a chain transfer agent under the action of a free radical initiator to produce the polymer polyol with high solid content and low viscosity; or the method uses a certain amount of the polymer polyol with target solid content as a substrate material, mixes the raw materials such as the basic polyether polyol, the free radical initiator, the vinyl monomer, the dispersing agent, and the chain transfer agent evenly according to certain mixture ratio, and adds the mixture to the substrate material continuously to be polymerized so as to obtain the polymer polyol with high solid content and low viscosity. The polymer polyol produced by the method has the advantages of low viscosity, stable dispersion of solid particles, small average particle size of the solid particles, and even particle size. The polymer polyol improves the physical mechanical properties of products applying the polymer polyol, and has wide application range.

Owner:TIANJIN DAGU CHEM CO LTD

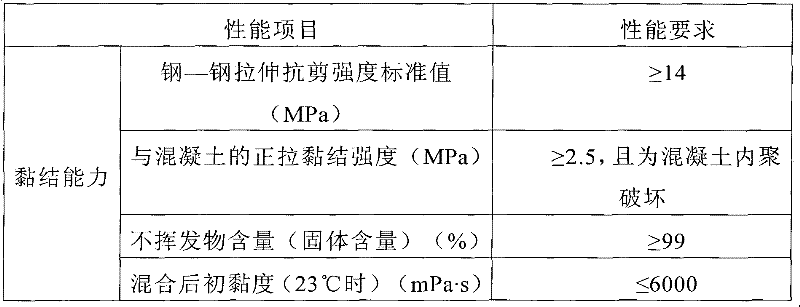

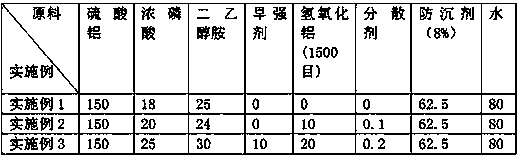

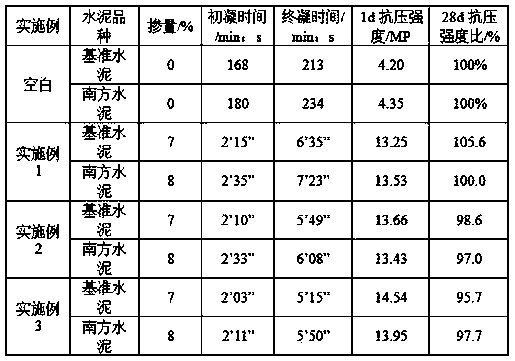

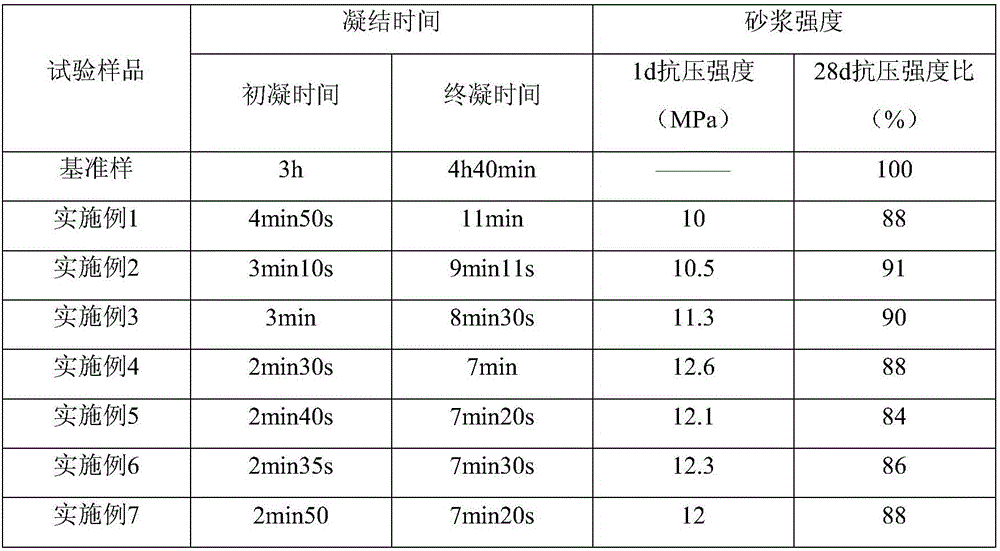

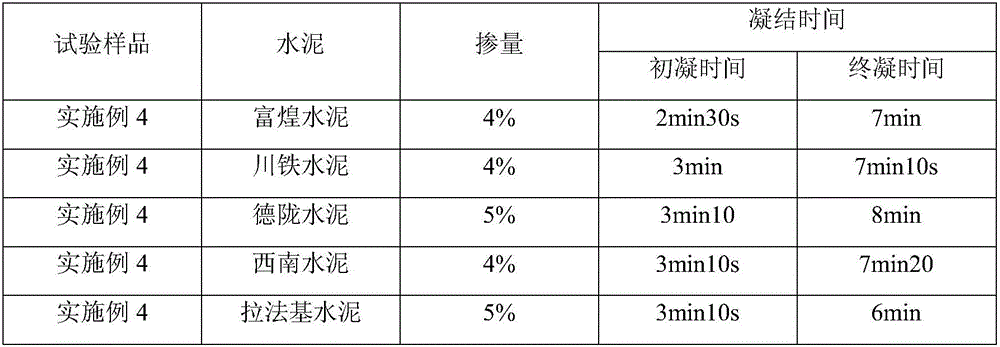

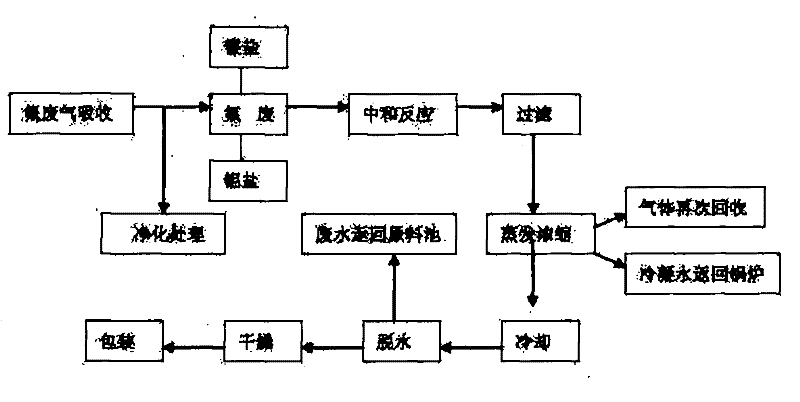

Preparation method of novel alkali-free liquid accelerator

The invention discloses a preparation method of a novel alkali-free liquid accelerator. The ingredients and the proportion of the accelerator are as follows: 30-50% of aluminum sulfate, 10-20% of aluminum citrate, 2-10% of hydroxycarboxylic acid, 5-10% of ammonium hydroxide at the concentration of 20%, 0.01-0.05% of polyacrylamide and the balance of water. The preparation method comprises the following technological production steps: feeding the raw materials into a reaction kettle according to different feeding sequences, heating and uniformly mixing the raw materials at 60-80 DEG C, and cooling the mixture to obtain a colorless or light green thick liquid. The preparation method disclosed by the invention has the following advantages that due to the introduction of multi-hydroxyl functional group molecules, the coordination crosslinking of an aluminum crosslinking system and polyacrylamide molecules is promoted, a composite aluminum citrate crosslinking system with high activity is prepared, the hydration rate of cement is obviously increased, and furthermore the action effect of the accelerator is enhanced. The setting time of the cement mortar doped with the accelerator is greatly shortened, the initial setting time is shorter than 2 minutes, the final setting time is shorter than 6 minutes, the 1d (Day) compressive strength is higher than 10MPa, and the 28d compressive strength rate is higher than 140%.

Owner:BEIJING ACAD OF BUILDING ENG

Wheelset to side frame interconnection for a railway car truck

InactiveUS20140060380A1Increase the spring rateReduce the spring rateAxle-boxesBogiesHysteresisEngineering

The invention relates to a railway car truck incorporating a novel interconnection between the side frame and bearing adapter characterized by a low lateral spring constant relative to the longitudinal spring constant. The interconnection provides a proportional restoring force with minimal internal friction and hysteresis. In embodiments, the interconnection comprises compressed elastomeric members positioned between the thrust lug of the side frame and the bearing adapter in the longitudinal direction and a low friction interface between the roof of the pedestal jaw and the top of the bearing adapter.

Owner:STRATO AG

Concrete maintenance and reinforcement treatment method

InactiveCN102220813AGood sealingIncreasing the thicknessBuilding repairsBridge erection/assemblyFiberAdhesive

The invention relates to a concrete maintenance and reinforcement treatment method. The method comprises the following steps: (1) carrying out nondestructive treatment on the concrete base surface defects; (2) carrying out rust-proof treatment on reinforcing bars; (3) carrying out concrete alkalinity recovery treatment; (4) carrying out concrete crack repairing treatment; (5) daubing new and old concrete adhesives; (6) daubing inorganic polymer mortar and carrying out curing; (7) sticking carbon fiber cloth; (8) brushing an inorganic water and salt injury resistant concrete protective agent; and (9) brushing a surface self-cleaning material, thus completing construction. The method has the following beneficial effects: rust can be removed or prevented from the reinforcing bars to protect the reinforcing bars and prevent further corrosion; by adopting the carbon fiber cloth for reinforcement, the concrete structure has the characteristics of high strength, light weight, simpleness and convenience in construction and corrosion resistance; the bearing capability of the beam body is improved; the deflection of the structure is reduced; the construction efficiency is greatly improved by adopting the airless spraying and coating operations; the coating is saved by 30%; and by brushing the self-cleaning material, the structure has the self-cleaning capability, thus avoiding cleaning or reducing the cleaning frequency.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

Apparatus and method for coupling a disconnectable stabilizer bar

ActiveUS7832739B2Severe impulsive forceFlexible supportTorsion springsMagnetically actuated clutchesEngineeringActuator

A vehicle stabilizer bar assembly having a pair of stabilizer bar members that are selectively uncoupled via a clutch. The clutch includes a moving element that can be selectively moved via an actuator to effect the uncoupling of the stabilizer bar members. The actuator is configured to apply a force to the moving element concentrically about the axis along which the moving element translates. The clutch is configured to transmit torque from one of the stabilizer bar members to the other stabilizer bar member concentrically about the axis. A method for operating a vehicle stabilizer bar assembly is also provided.

Owner:AMERICAN AXLE & MFG

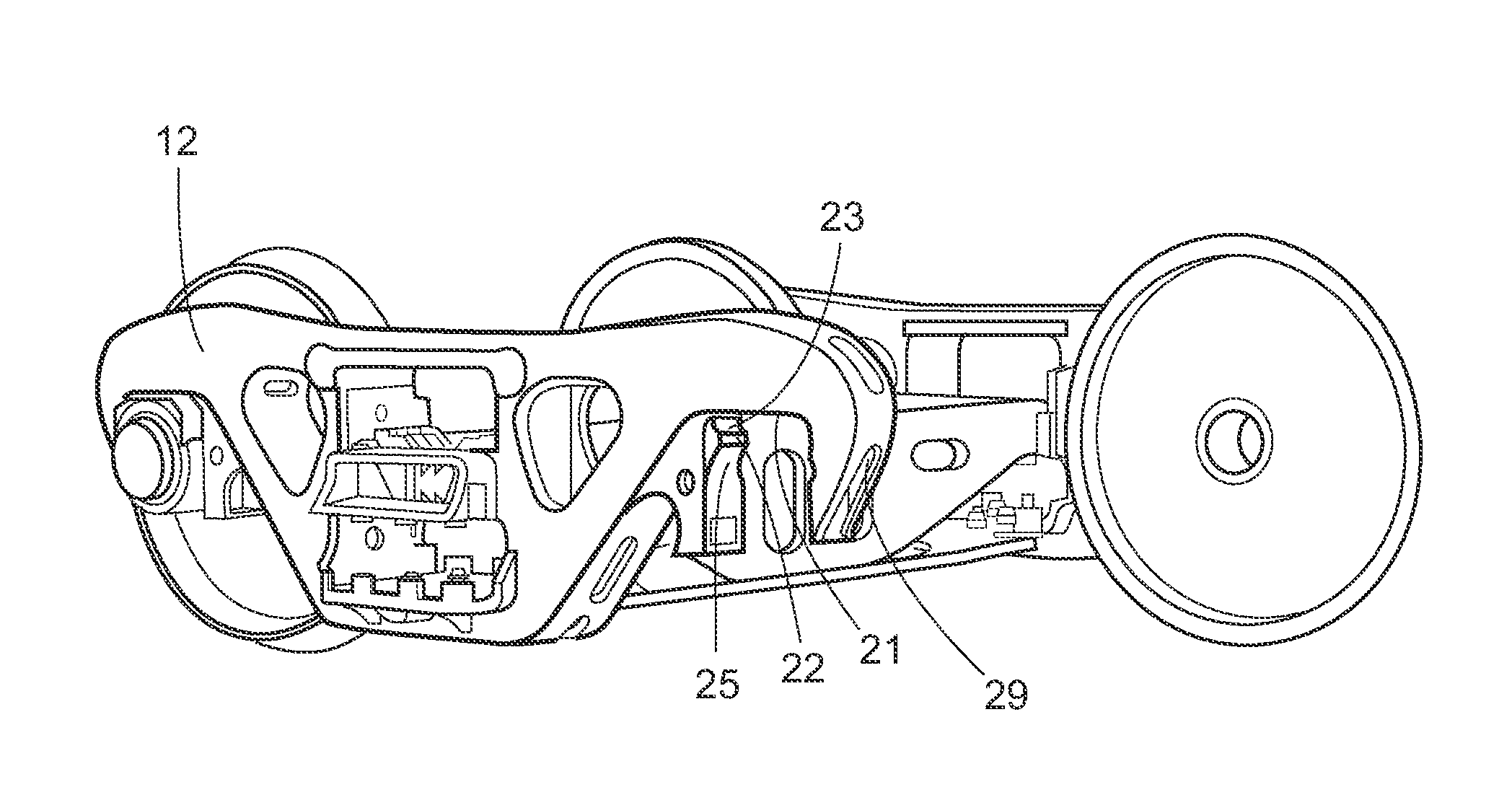

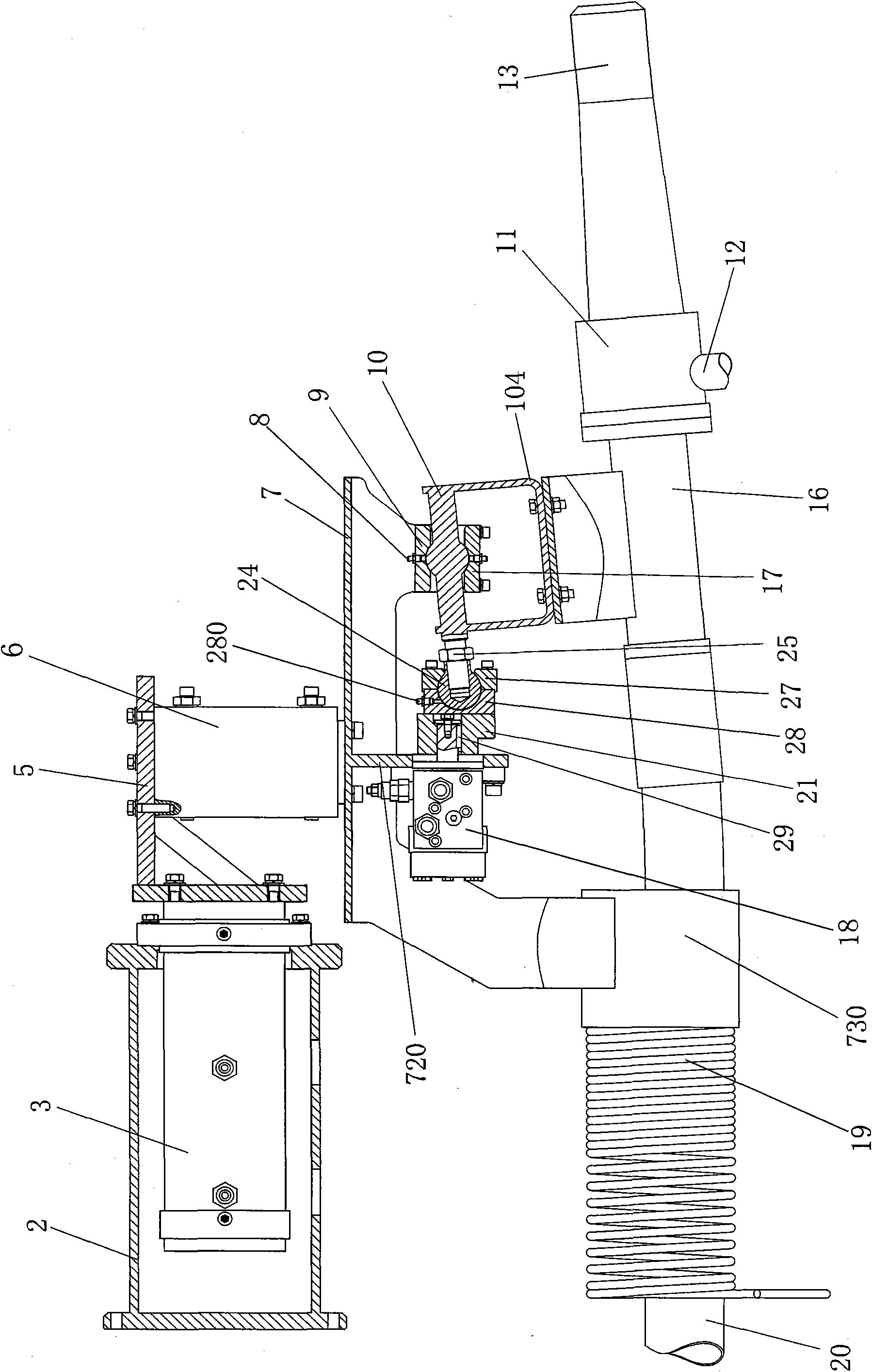

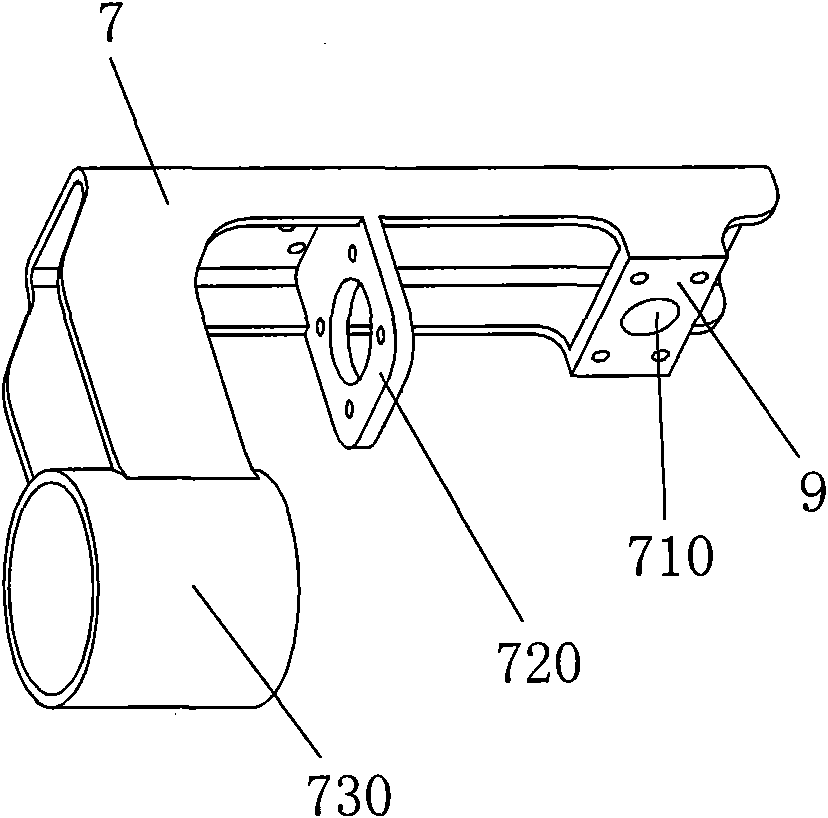

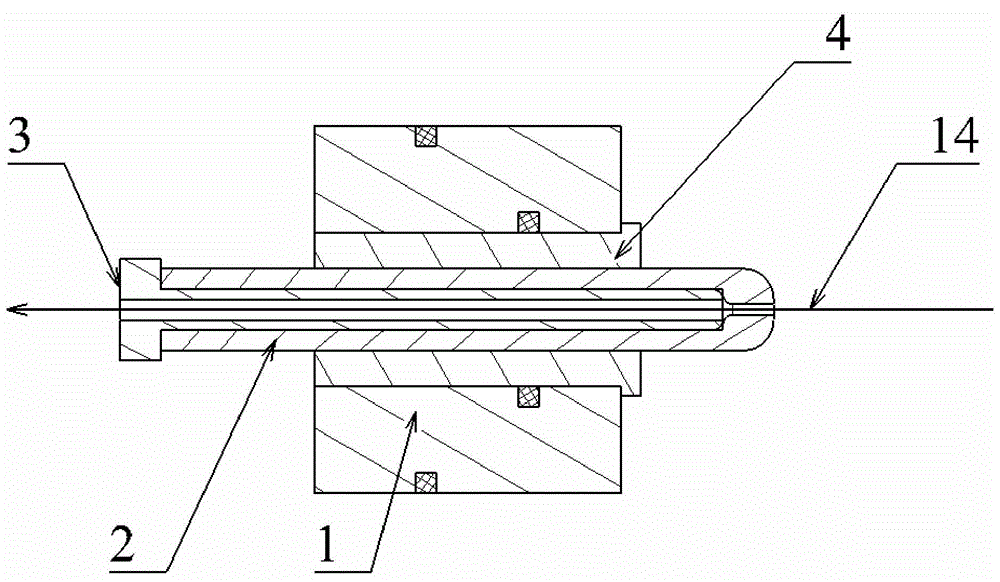

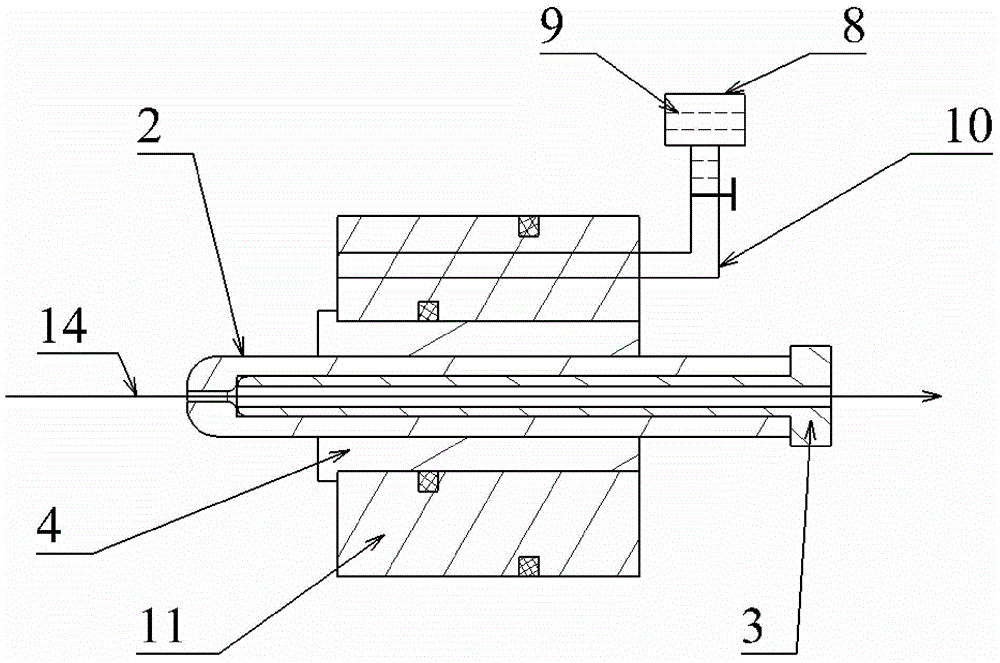

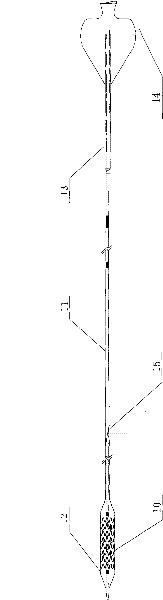

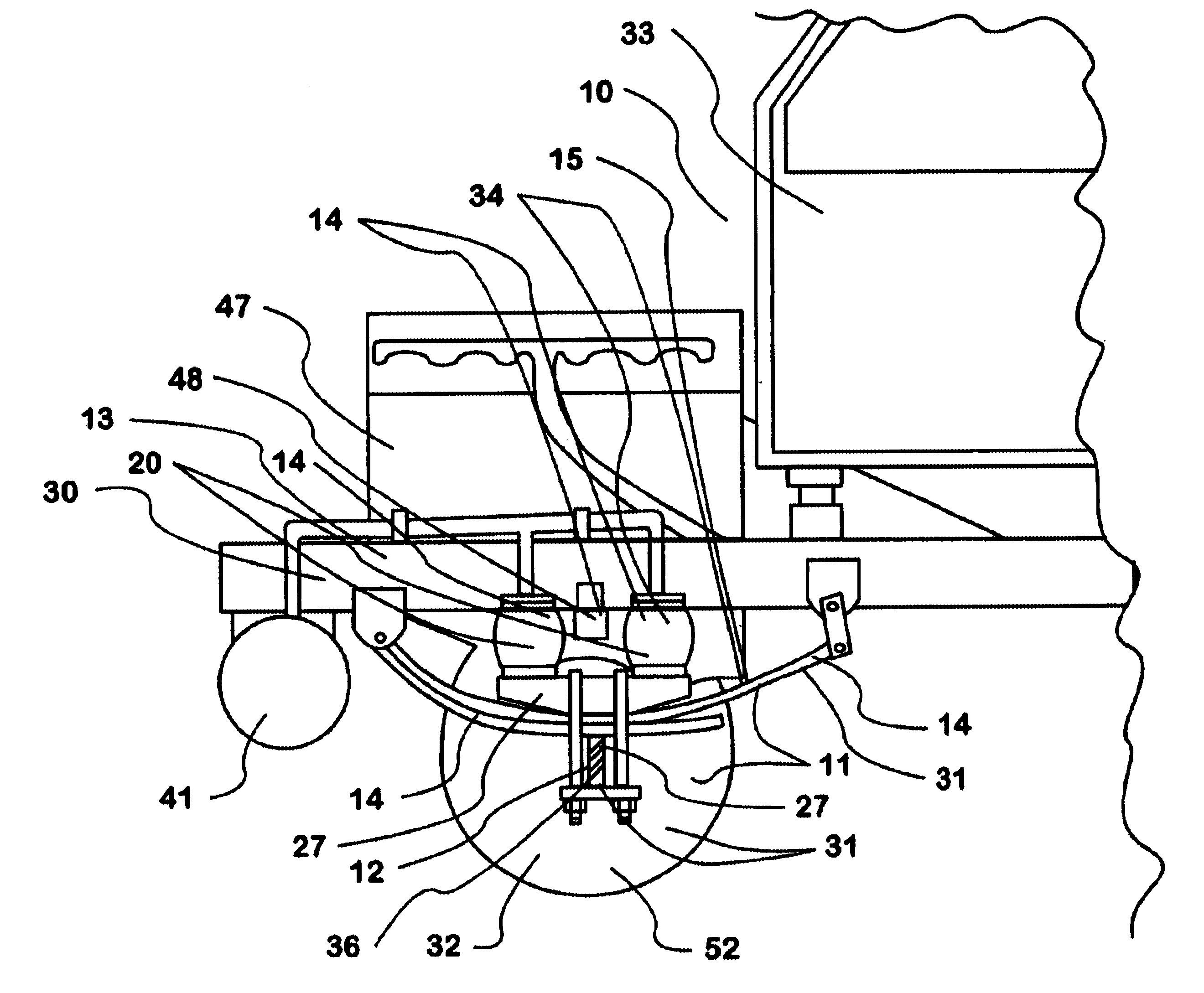

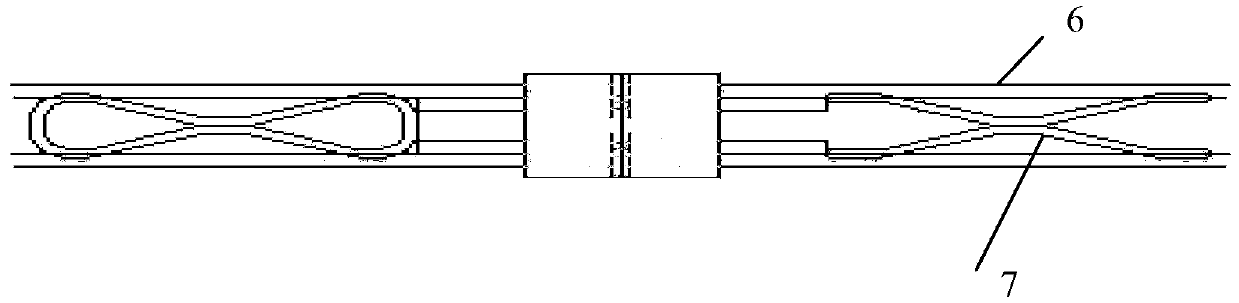

Brush-type spraying device for concrete sprayers

InactiveCN101806221AWide range of working directionsReduce rebound rateUnderground chambersLiquid spraying apparatusHydraulic motorSprayer

The invention relates to a brush-type spraying device for concrete sprayers. The brush-type spraying device comprises a hollow cylindrical spraying device mounting seat 2, a first hydraulic motor 3, a second hydraulic motor 6 and a third hydraulic motor 18, wherein the first hydraulic motor 3 is installed in the cavity of the spraying device mounting seat 2; the first hydraulic motor 3 is connected with the second hydraulic motor 6 through a right-angled mounting rack 5, and the second hydraulic motor 6 is connected with a spraying nozzle mounting rack 7; the spraying nozzle mounting rack 7 is provided with a third motor seat 720 and a brush rack hinged support 9; the protruding end of a swing axle 102 is connected with the output shaft of the third hydraulic motor 18 through an eccentric disc 21 and a knuckle bearing, and the swing axle 102 is connected with the brush rack hinged support 9 through a ball joint structure; and a concrete delivery hard pipe 16 is fixed on a brush rack 10. The invention has the advantages of reducing the resiliency and the slump of concrete spraying, increasing the utilization ratio of the concrete, improving the tunnel construction environment, enhancing the concrete spraying quality and the like.

Owner:上海鸿得利重工有限公司

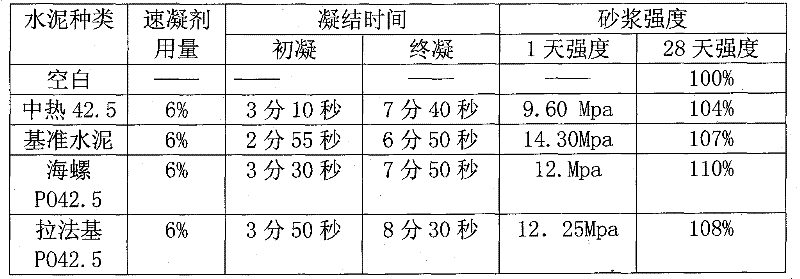

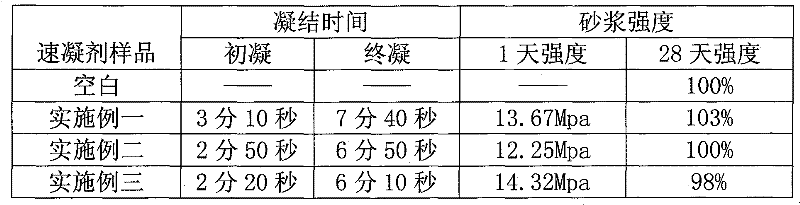

Alkali-free liquid setting accelerator for shotcrete and preparation method thereof

The invention discloses an alkali-free liquid setting accelerator for shotcrete and a preparation method thereof; the setting accelerator comprises the following raw materials: aluminum sulfate, an acidity regulator, aluminum hydroxide, organic alcohol amine, an early strength agent, a dispersant, an anti-settling agent and water. The preparation method comprises the steps: firstly adding water into a reactor, starting to stir, sequentially adding the dispersant, the anti-settling agent and the acidity regulator, and starting to heat; when the solution is heated to 90 DEG C-100 DEG C, adding aluminum hydroxide and the early strength agent, and stirring and carrying out heat preservation at the temperature of 80-90 DEG C; after completion of heat preservation, adding aluminum sulfate and completing addition in batches, and keeping the temperature of the system at 80-100 DEG C; after completion of addition, carrying out heat preservation for half an hour until the solution is clarified;and finally adding organic alcohol amine, and after completion of addition, carrying out heat preservation for 2-3 hours. The setting accelerator has the characteristics of wide cement adaptability, stable performance, good storage stability and the like. Besides, the shotcrete using the setting accelerator has the characteristics of low mixing amount, low resilience rate, low dust pollution and the like.

Owner:JIANGSU NIGAO SCI & TECH

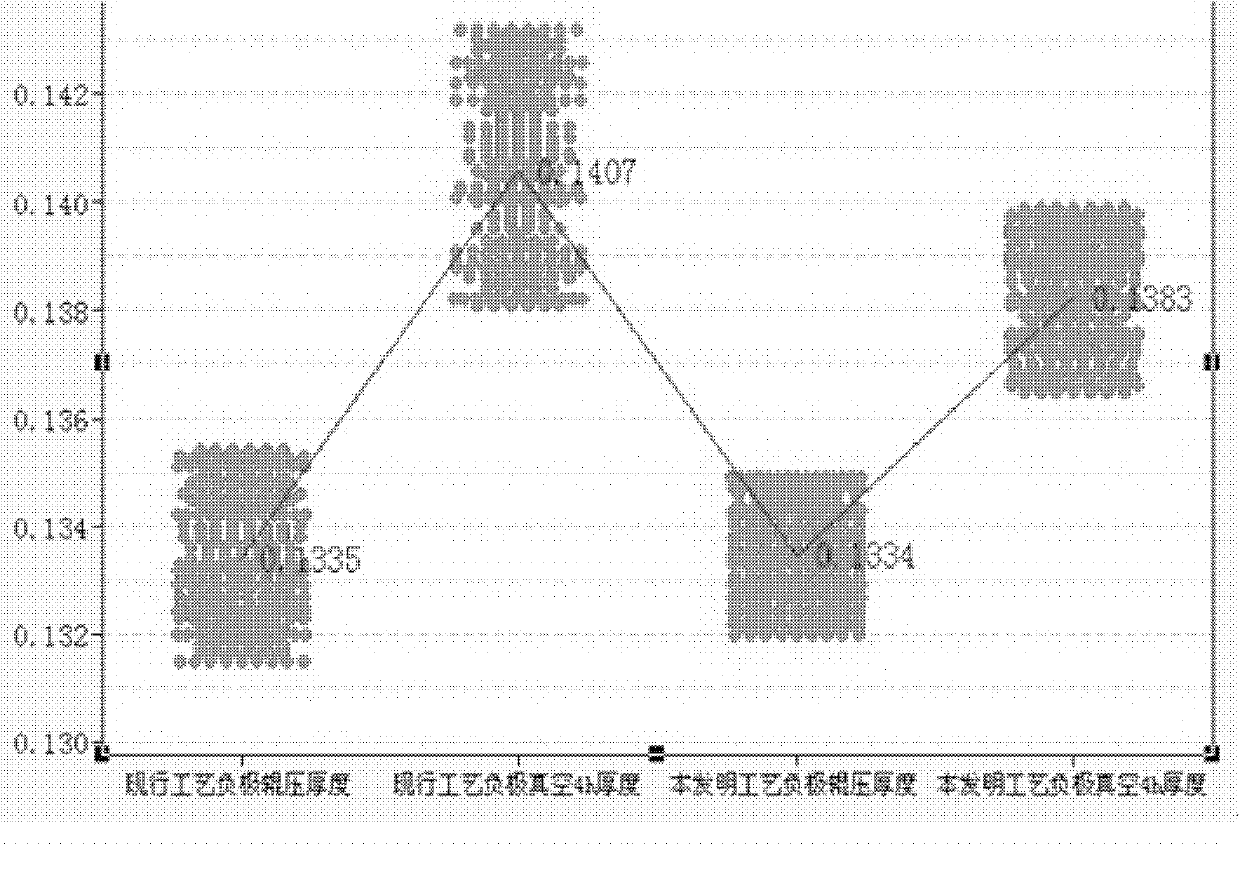

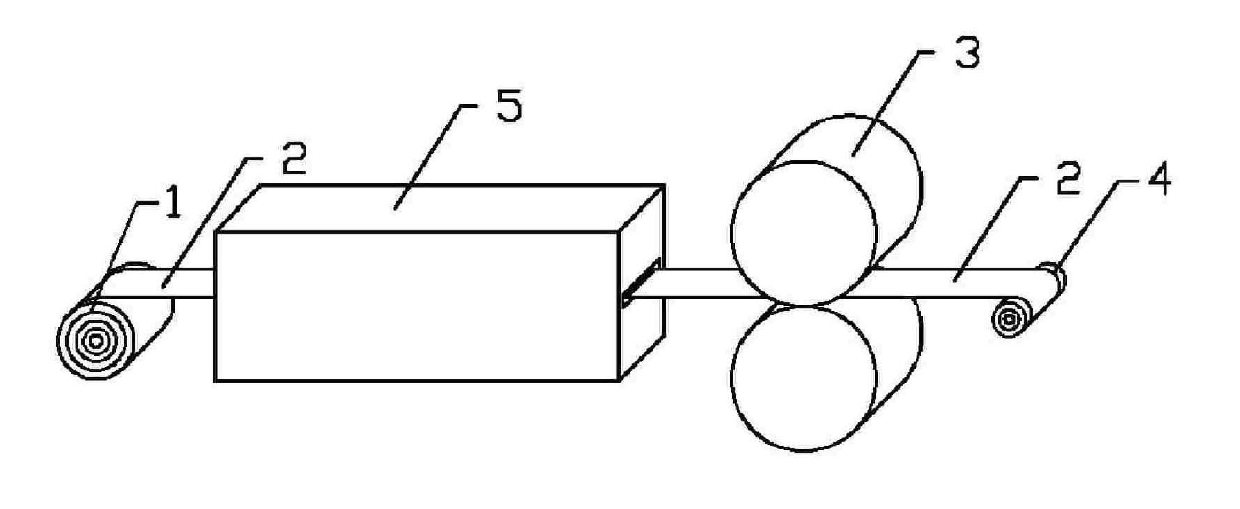

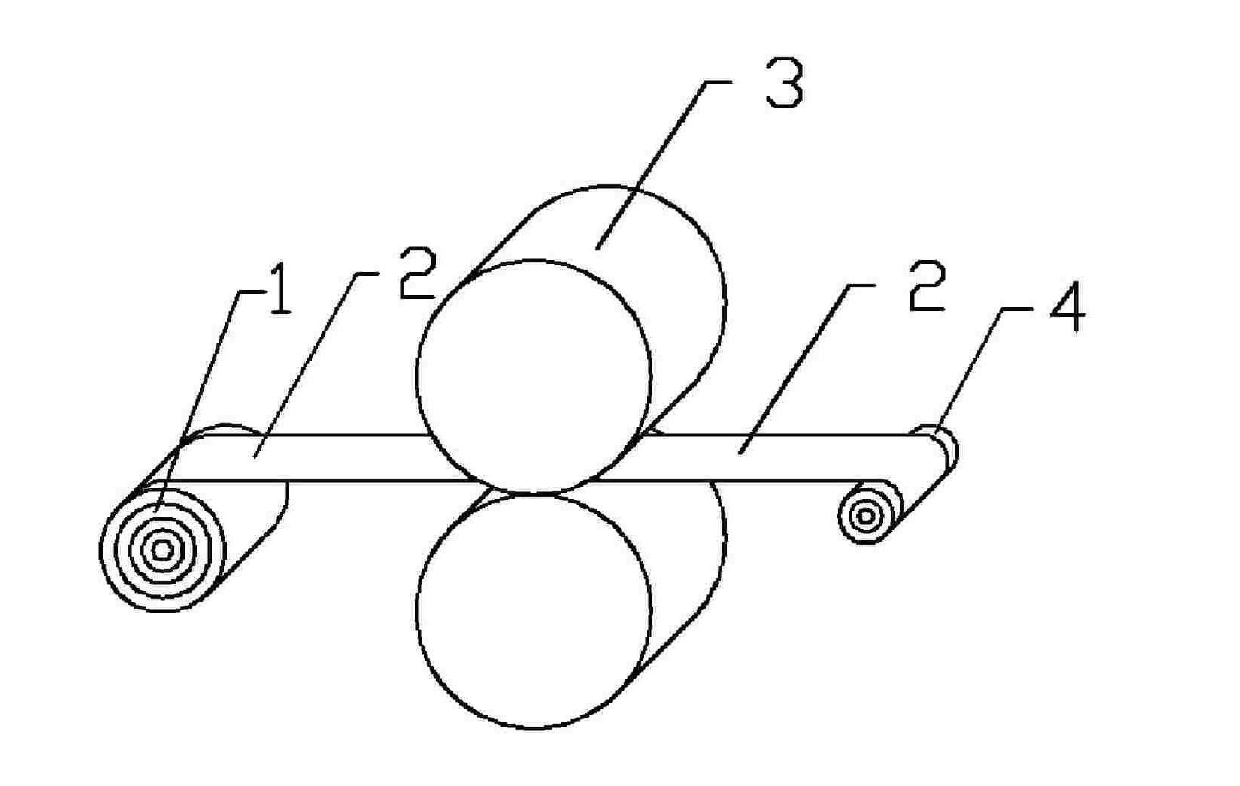

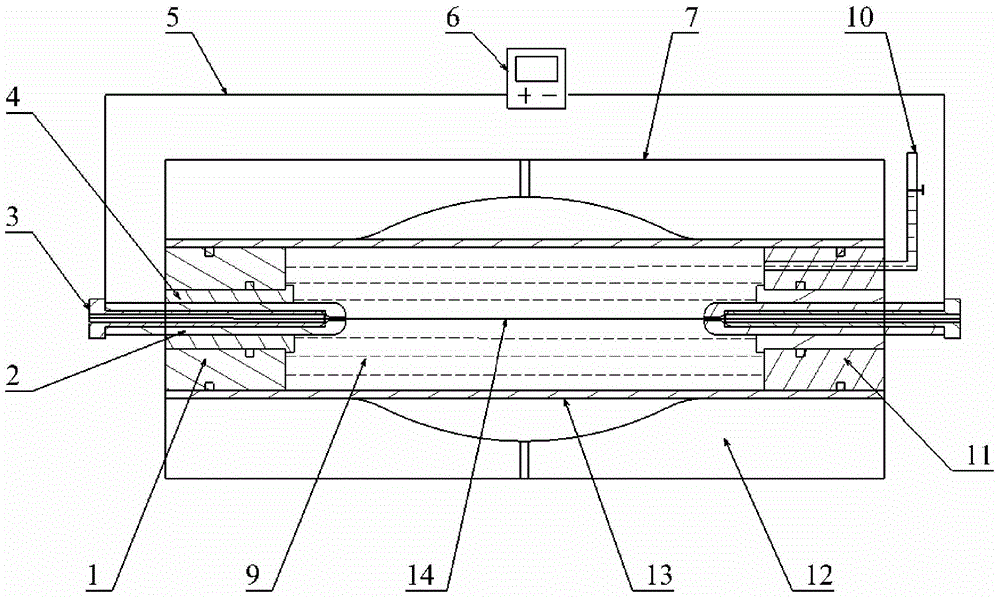

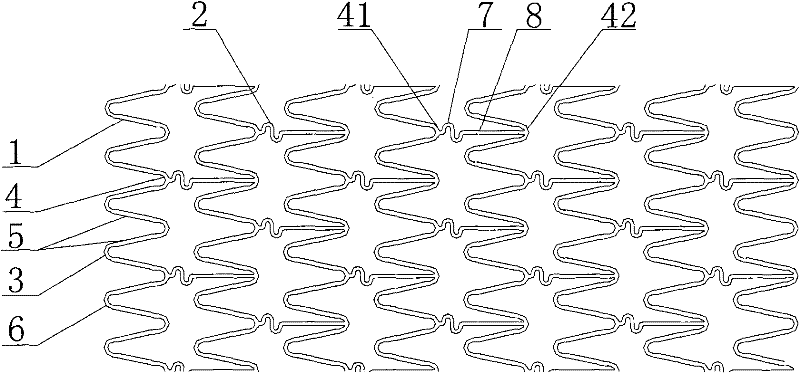

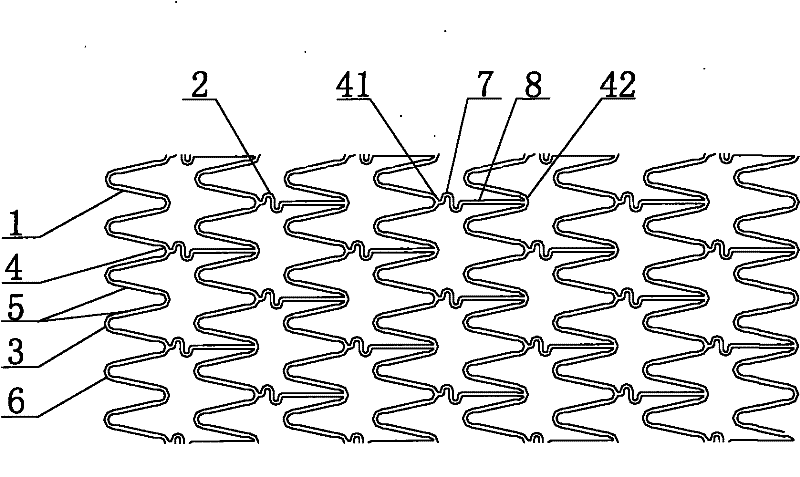

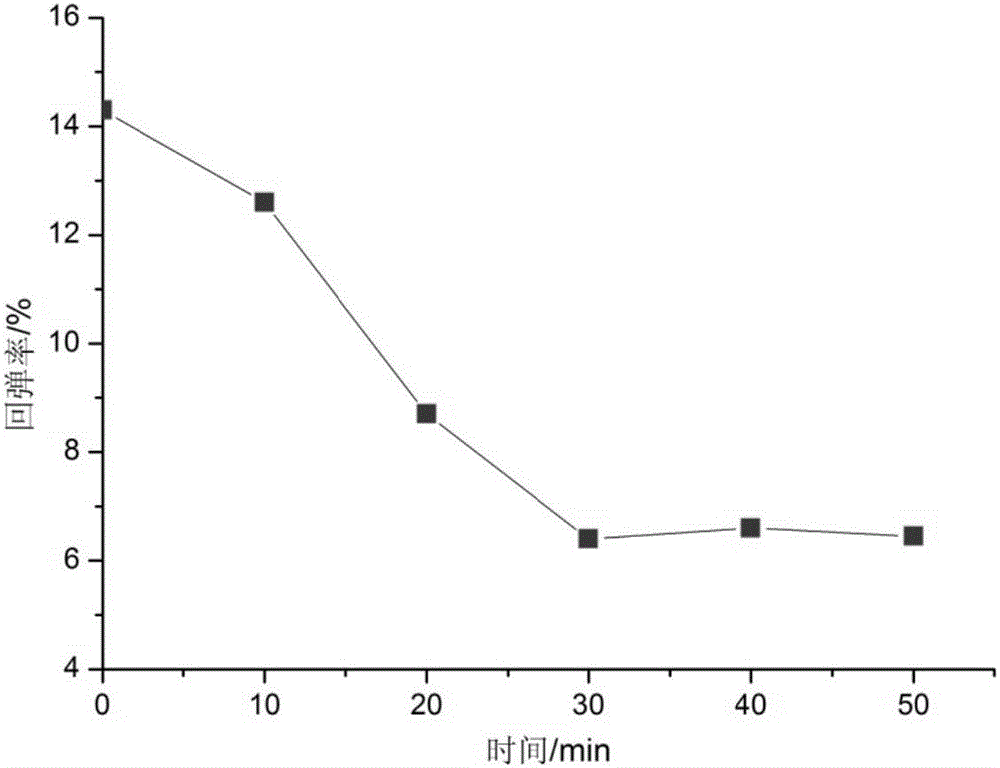

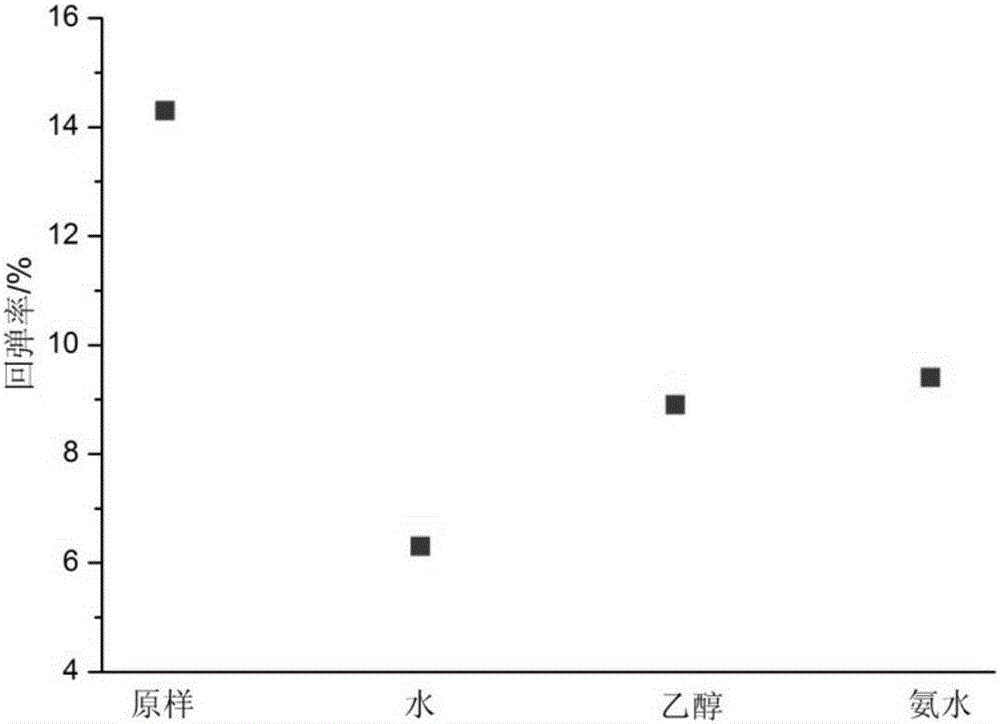

Continuous rolling process for lithium-ion battery electrode and device thereof

InactiveCN101877397AIncrease volume capacityImprove plasticityElectrode manufacturing processesRotary pressBiochemical engineeringVolumetric Mass Density

The invention discloses a continuous rolling process for a lithium-ion battery electrode and a device thereof. The process is characterized in that an electrode plate adopts a low-temperature hot rolling process. The used device is characterized in that a heating device is increased between an unrolling shaft and a roll. The process has the advantages of ensuring the dryness of the electrode, increasing the plasticity of the electrode plate, reducing the rebound rate of the rolled electrode plate and properly increasing the single-side density of the electrode plate, thereby promoting the volume rate capacity of the battery; and the device has a simple structure and convenient operation.

Owner:NINGBO VEKEN BATTERY

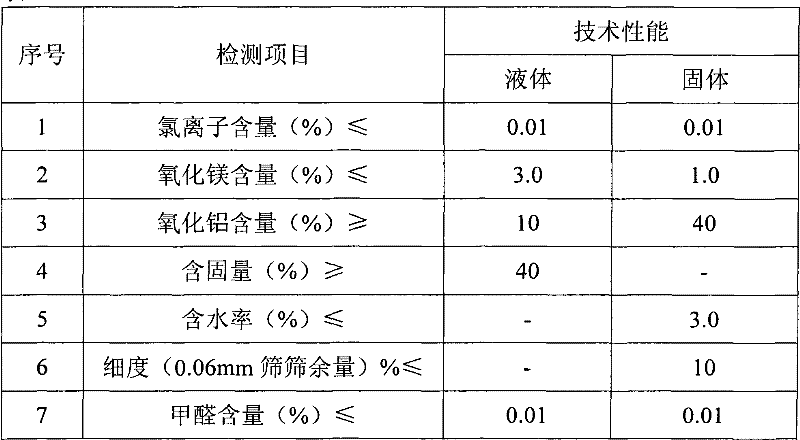

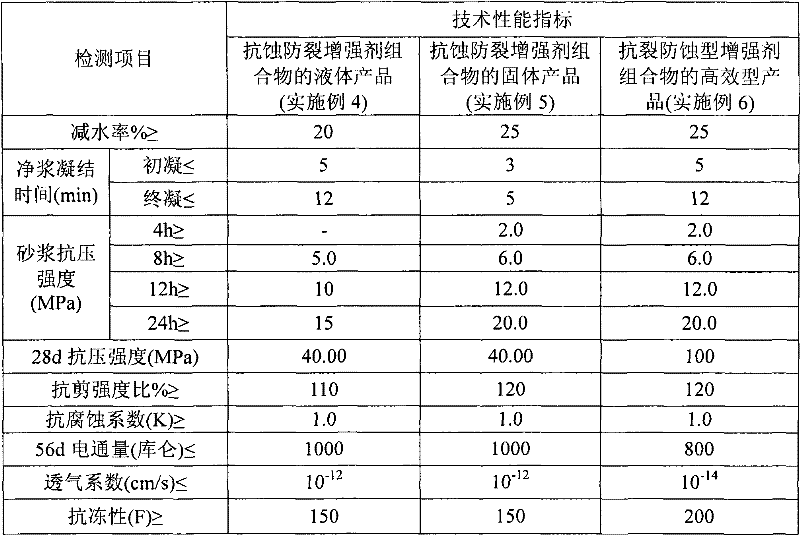

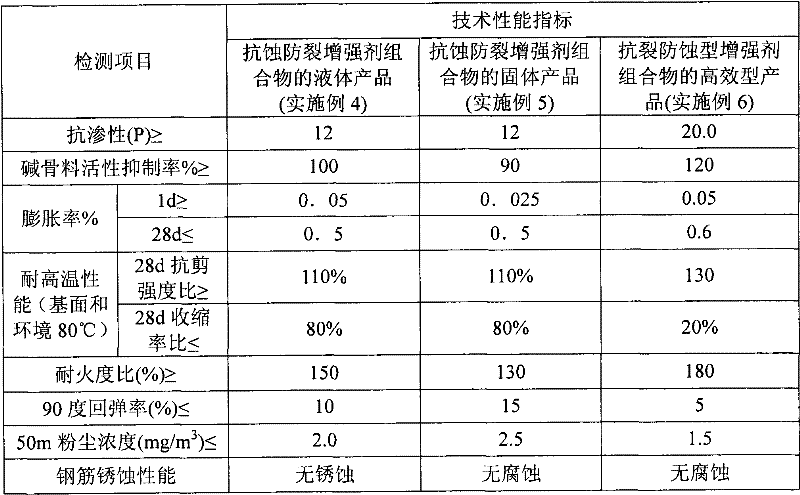

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

Liquid accelerator for sprayed concrete and preparation method and application thereof

The invention relates to a low rebound low-alkaline liquid accelerator for sprayed concrete, and a preparation method and application thereof, belonging to the technical field of mine and tunnel construction. The liquid accelerator comprises the following components in parts by mass: 35-45 parts of aluminum sulfate, 4-8 parts of triethanolamine, 3-9 parts of sodium fluoride, 1-3 parts of regulating component, 6-12 parts of rebound inhibitor component and 35-55 parts of water. The accelerator can effectively solve the general problem at present that the sprayed concrete has high rebound rate, low strength and poor durability, so that the sprayed concrete has characteristics of high workability (low rebound rate and less dust) and high durability (high strength, high anti-permeability and high corrosion resistance), the construction production environment condition of the sprayed concrete is improved, and long-term safe usability of the sprayed concrete structure is improved.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

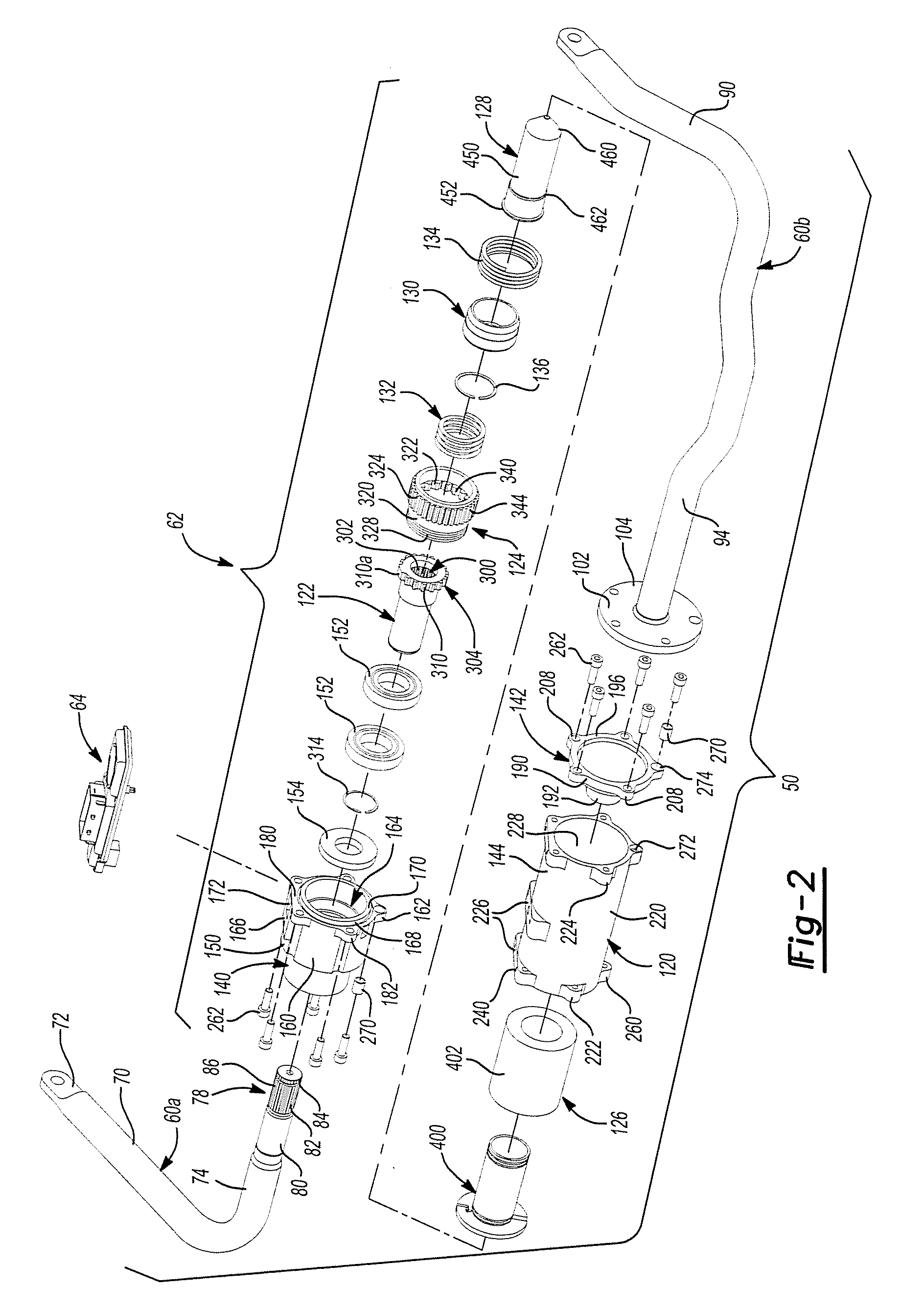

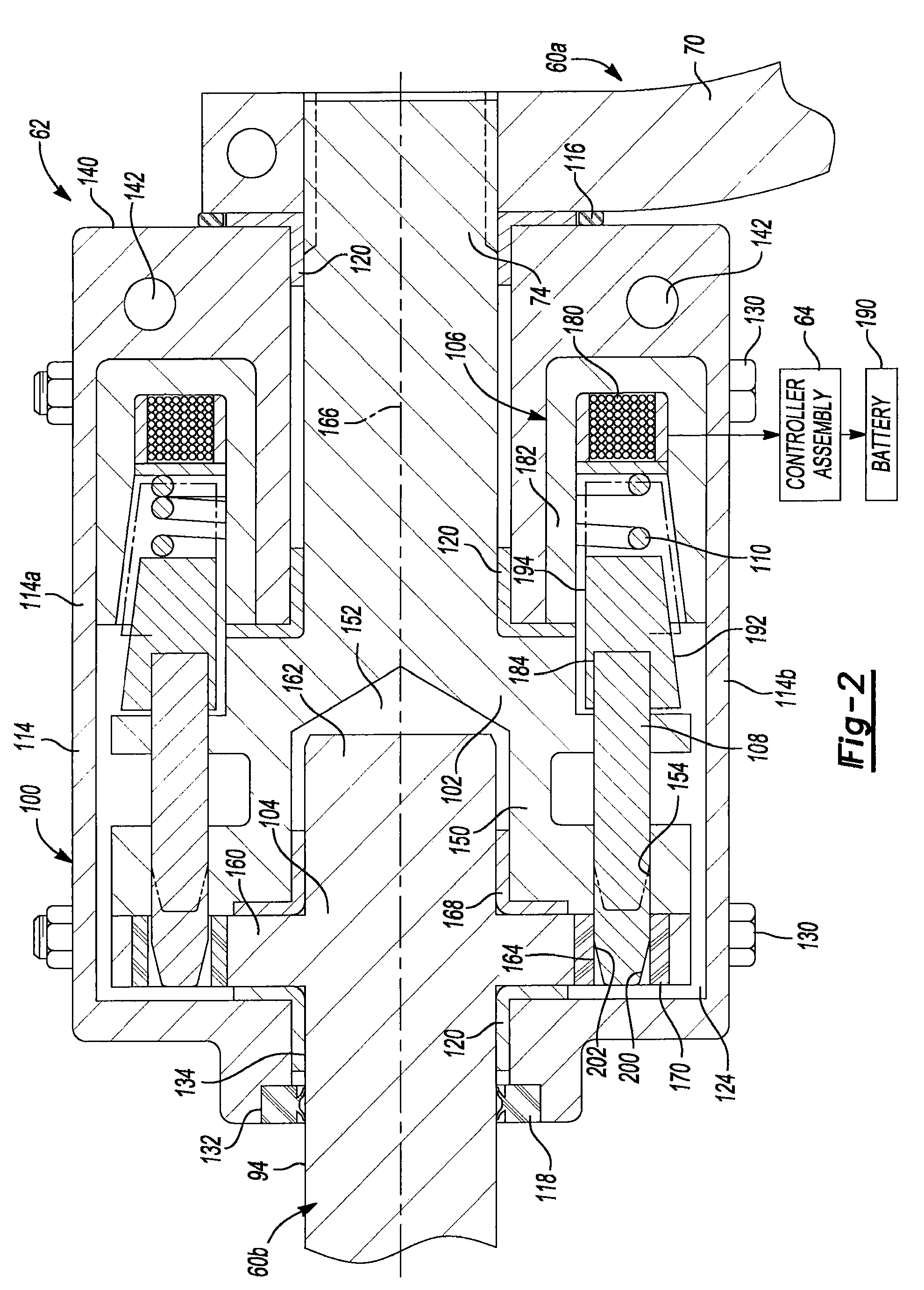

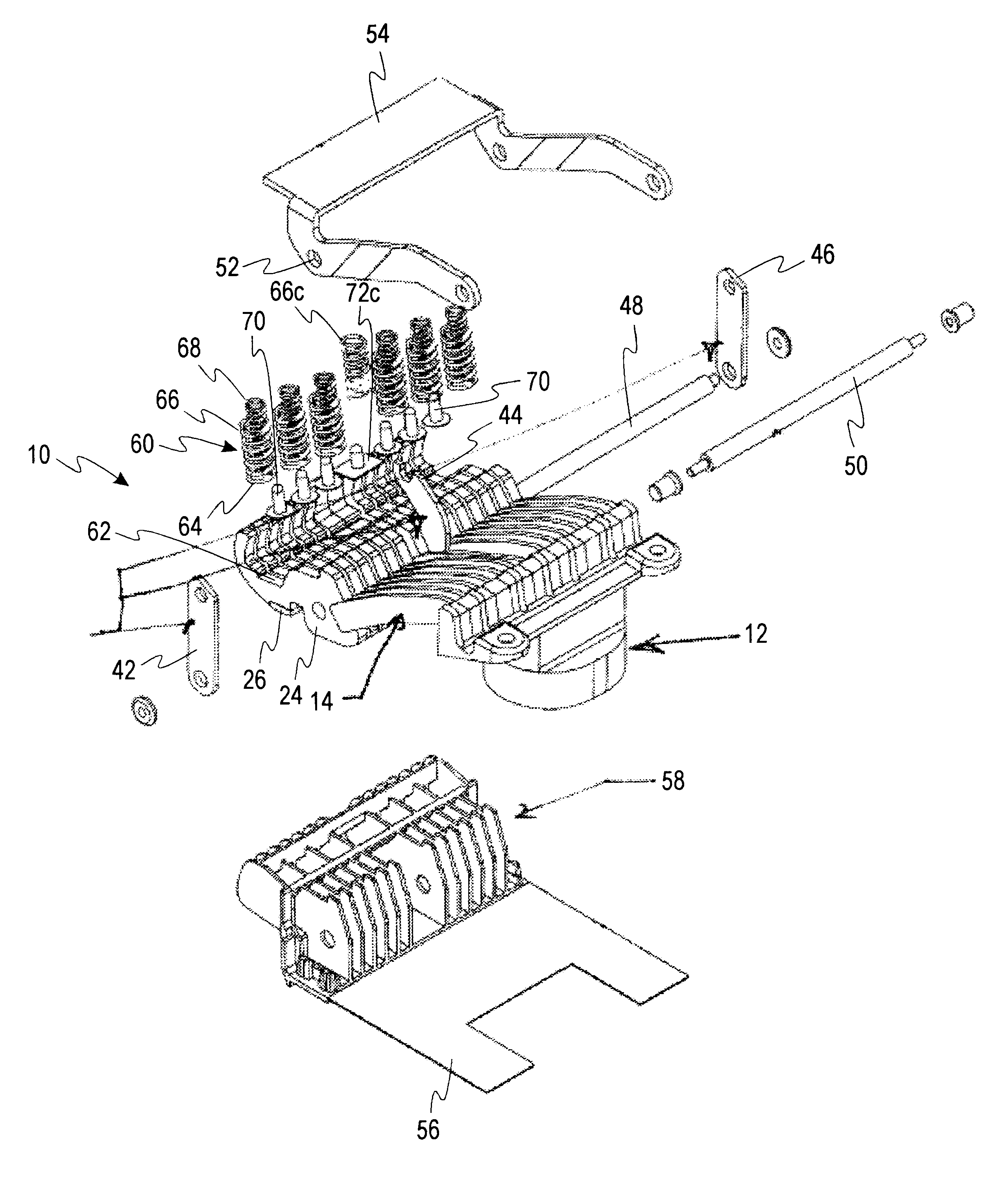

Actuator for disconnectable stabilizer bar system

ActiveUS7717437B2Easy to participatePrevent rotationTorsion springsFriction clutchesEngineeringActuator

A vehicle stabilizer bar assembly having a pair of stabilizer bar members that are selectively uncoupled via a clutch. The clutch includes a plurality of engagement pins that can be selectively moved via an actuator to effect the uncoupling of the stabilizer bar members. The actuator is configured to apply a force to the moving element concentrically about the axis along which the moving element translates. A method for operating a vehicle stabilizer bar assembly is also provided.

Owner:AMERICAN AXLE & MFG

Cereal diet meal replacement powder and making method thereof

PendingCN106889521AKeep the tasteRetain nutrientsFood mechanical treatmentFood dryingMeal replacementRed bean

The invention discloses cereal diet meal replacement powder and a making method thereof. The cereal diet meal replacement powder includes raw materials yam, red dates, Chinese wolfberry fruits, oats, red beans, black beans, black sesame, walnut kernels, dried apples, chia seeds, quinoa and probiotics. The cereal diet meal replacement powder has the effects of moderating, nourishing and tonifying qi, nourishing the kidney, nourishing the blood, nourishing the intestines and detoxifying the intestines and expelling toxin, is suitable for all people, is homological in medicine and food, natural and health-care and can replace the three meals.

Owner:北京幸福人生健康科技发展有限公司

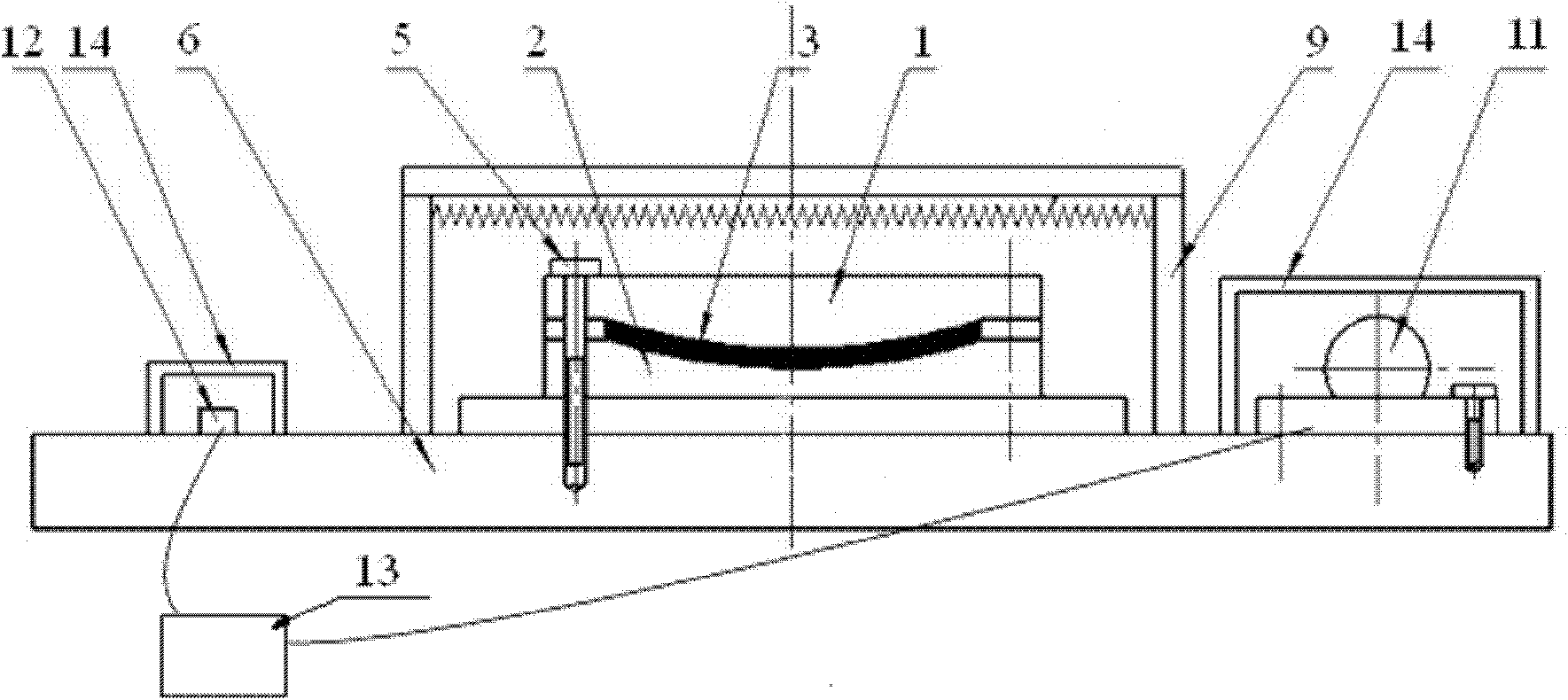

Electro-hydraulic forming device for pipe fitting and forming method

The invention discloses an electro-hydraulic forming device for a pipe fitting and a forming method. The electro-hydraulic forming device comprises a bulging die, a power source, a water pipe, a water storage tank, an aqueous medium, a metal wire, a positive electrode and a negative electrode. The metal wire is made to penetrate through the installed positive electrode, the pipe fitting to be formed and the negative electrode in sequence, and the positive electrode and the negative electrode are installed in the two ends of the pipe fitting respectively. Water is injected into the sealed pipe fitting. High-energy pulses are transmitted to the metal wire through a wire, in this way, the size of the metal wire is increased rapidly after the metal wire is gasified due to heating, impact waves are generated in the medium around the metal wire, the impact waves act on the pipe fitting, the required pipe fitting is obtained through bulging through electro-hydraulic forming based on discharging of the metal wire. The forming performance of materials is improved, the rebound rate is reduced, the forming precision of the pipe fitting is improved, in this way, a part with the forming quality and precision meeting requirements is obtained, and the pipe fitting is promoted to burgle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Cobalt-chromium alloy artery stent with full-biodegradation medicine coating, stent system and preparation method thereof

ActiveCN101745153AImprove flexibilityShorten repair timeStentsSurgeryPercent Diameter StenosisCvd risk

The invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating; the full-biodegradation coating of the stent has good stent flexibility, pathological change permeability and radial bearing force; the invention further provides a preparation method of the stent; multi-level coating applying technology, metallic support surface inert gas processing process and the like are adopted, the firmness of the stent surface coating, the toughness and tensile strength thereof are greatly improved, thereby being beneficial to keeping the integrity of the coating; in addition, the invention provides a cobalt-chromium alloy artery stent with full-biodegradation medicine coating, which is prepared by radial grading squeezing process, the damage of the coating can be avoided to the greatest extent, the retention force between the stent and a conveying system is greatly improved, the possibility that the stent is migrated in the conveying process is avoided, the clinical using risk is reduced, and the problems of coronary artery stenosis and restenosis are effectively solved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Suspension system for a vehicle

InactiveUS6739608B2Reduce hysteresisSimple processInterconnection systemsResilient suspensionsLeaf spring

A novel suspension-system for a vehicle has two or more leaf-spring groups that vertically support a portion of the weight of a suspended structure of the vehicle. The novel suspension-system further includes pneumatic springs that are engaged to spring-support components of the novel suspension-system and also the suspended structure supported by the novel suspension-system in such a manner that the pneumatic springs assist the leaf-spring groups of the novel suspension system in vertically supporting the weight of the suspended structure.

Owner:INT TRUCK INTPROP LLC

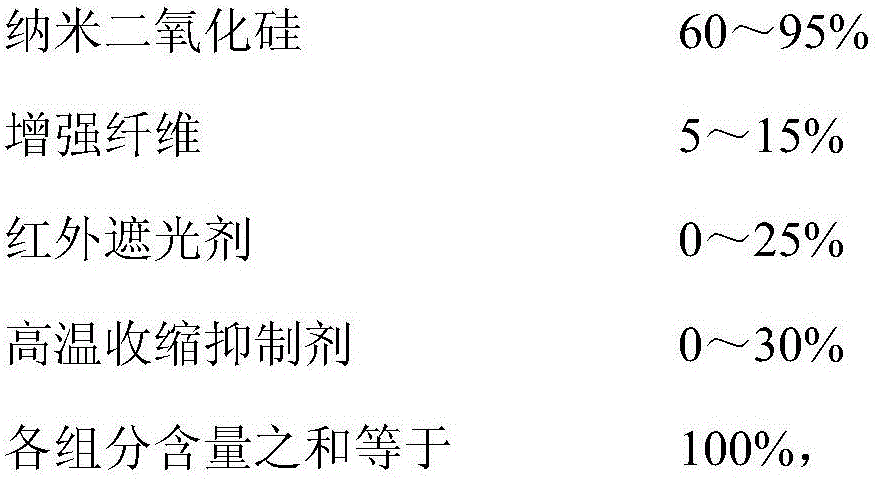

Preparation method of nano-silica powder-based super composite thermal insulation material

The invention provides a preparation method of a nano-silica powder-based super composite thermal insulation material. Nano-silica powder and a functional additive are taken as raw materials, the nano-silica powder accounts for over 60% of total weight of the raw materials and the functional additive at least comprises reinforced fibers; the preparation method comprises the steps of stirring and dispersing the reinforced fibers at a rotating speed of 400-1,000r / min for 0.5-1.5 minutes; mechanically fusing the dispersed reinforced fibers, the nano-silica powder and other functional additives to complete coating modification on the surface of the functional additive by the nano-silica powder; and making the fused materials in full contact with steam at 80-85 DEG C for 28-32 minutes, extruding air and carrying out pressing, molding and drying to obtain the high-performance nano-silica powder-based super composite thermal insulation material. According to the preparation method, the supercritical drying process with strict conditions in an existing preparation technology is abandoned; and the nano-silica powder-based super composite thermal insulation material with excellent performance is prepared through a simple dry process.

Owner:GUANGXI UNIV

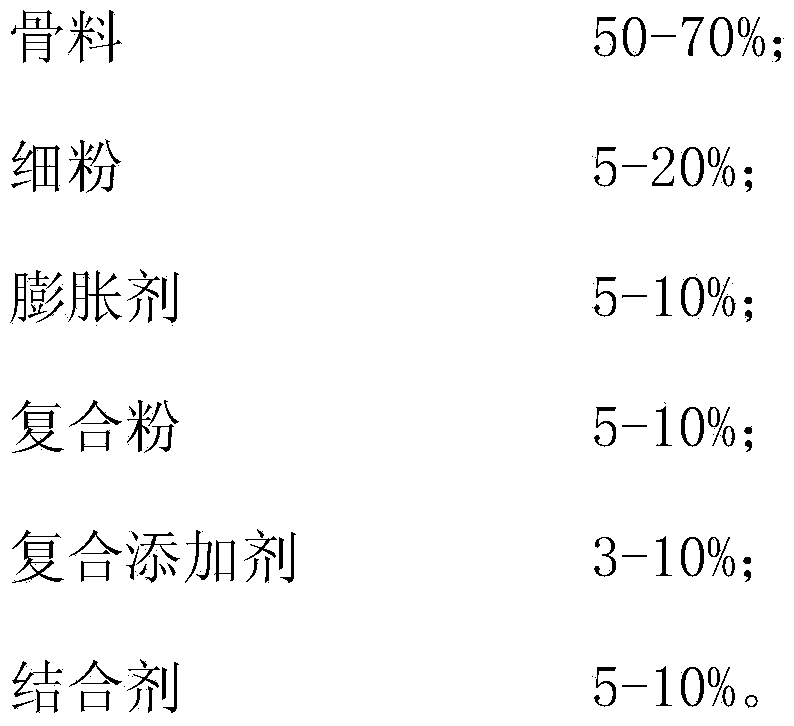

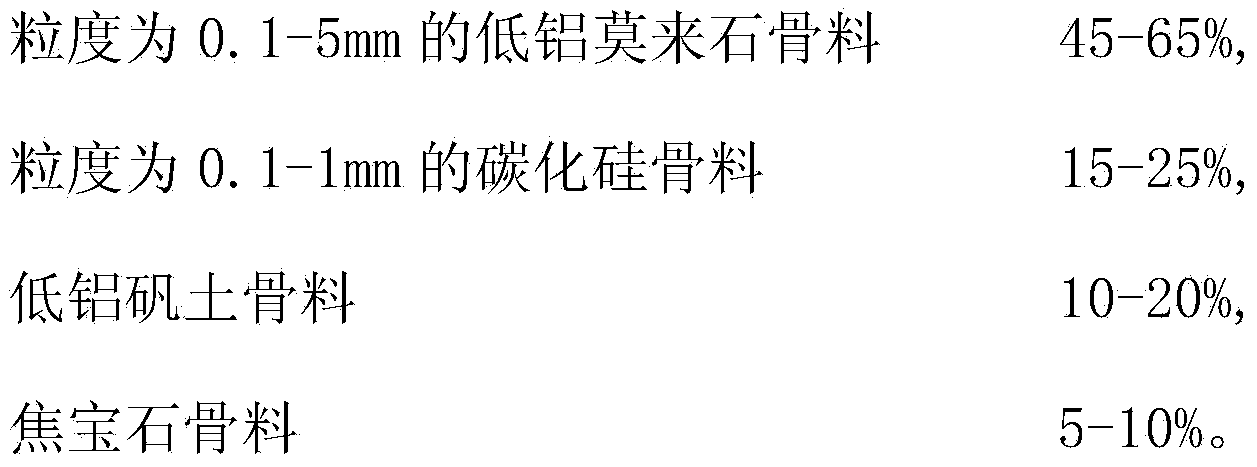

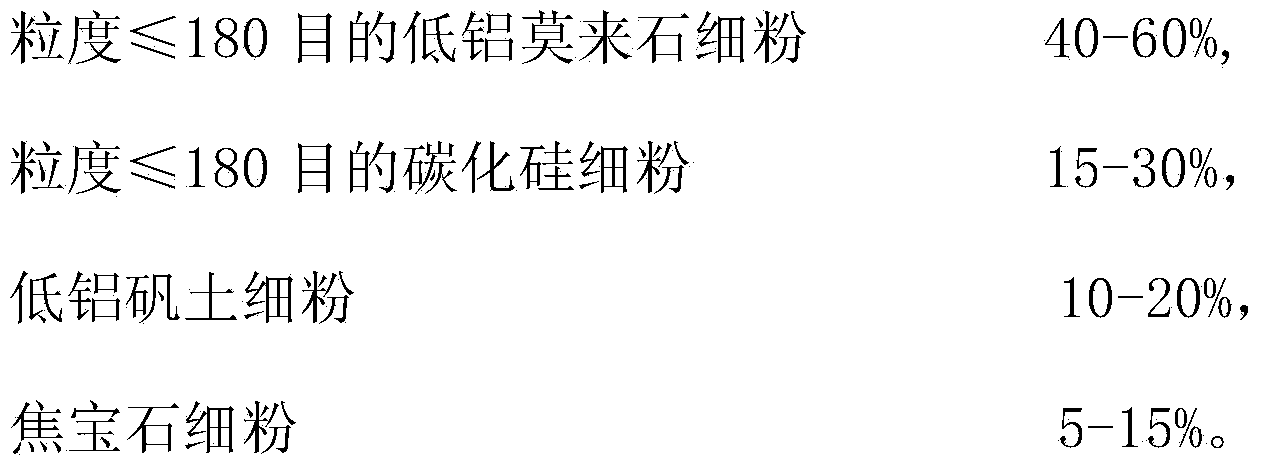

Silicon carbide anti-skinning fire-resistant spray paint

The invention discloses silicon carbide anti-skinning fire-resistant spray paint which comprises the following components in percentage by mass: 50-70% of bone powder, 5-20% of fine powder, 5-10% of swelling agent, 5-10% of compound powder, 3-10% of compound additive and 5-10% of bonding agent. The spray paint is high in strength, favorable in wear resistance, anti-skinning, favorable in stickability, low in rebound rate and long in service life, can be used instead of bricks and castable materials in many occasions without formwork erecting on site, achieves the advantages of convenient and fast construction, short maintenance time and short furnace baking period, and can save a large mount of time and accelerate the turnover rate and utilization ratio of equipment.

Owner:长兴兴鹰新型耐火建材有限公司

High-performance chlorine-free alkali-free liquid accelerating agent

The invention discloses a high-performance chlorine-free alkali-free liquid accelerating agent which is prepared from the following materials by weight percent: 6 to 15 percent of magnesium aluminum fluoride, 20 to 50 percent of aluminum sulfate, 2 to 6 percent of organic amines, 0 to 2 percent of stabilizer, and the balance of water. The production process comprises the following steps of: adding water at the given weight percent to a stirring drum, adding magnesium aluminum fluoride and stirring to dissolve, adding organic amines and stirring to dissolve, adding aluminum sulfate and stirring to dissolve, and making the final product. The high-performance chlorine-free alkali-free liquid accelerating agent is free of chlorine and alkali and non-corrosive to human beings and steel-bar-made machines, and has the advantages of long holding period, low addition amount, quick setting action, low rebound rate, high one-day strength, substantially no loss of long-term strength and good material compatibility. The production process is simple, pollution-free and noise-free, does not produce gas discharge or waste water, and is safe and environment-friendly. The materials are abundant, the production cost is low, and the social and economic benefits are extremely good.

Owner:昆明合起工贸有限公司

Admixture special for high performance shotcrete

Belonging to the technical field of construction engineering, the invention in particular relates to an admixture special for high performance shotcrete. The special admixture comprises two main components: a cohesive component and an early strength component in a mass ratio of 60-70:30-40. Specifically, the cohesive component is a mixture of modified latex powder and a superfine mineral admixturein a mass ratio of 20-30:70-80, and the early strength component is high activity tricalcium aluminate. Through the synergistic effect of the cohesive component and the early strength component, thespecial admixture provided by the invention effectively improves the cohesiveness and early strength of shotcrete, thereby reducing the resilience of shotcrete and improving the compactness. The material can provide an effective way for really realizing high performance of shotcrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

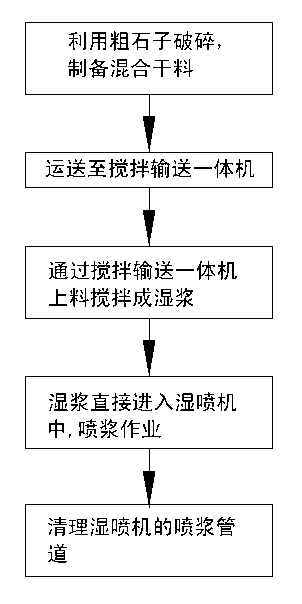

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

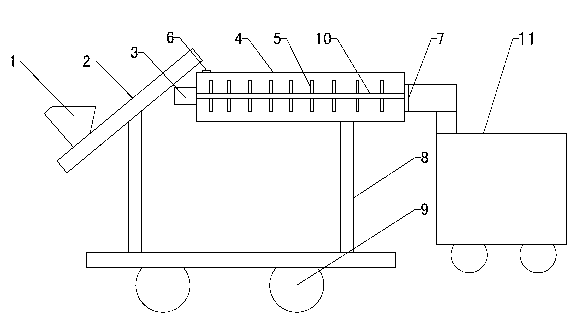

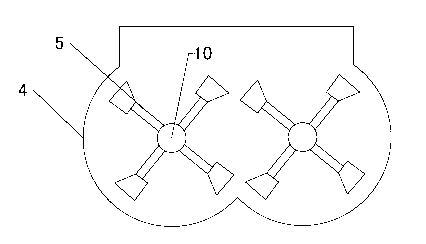

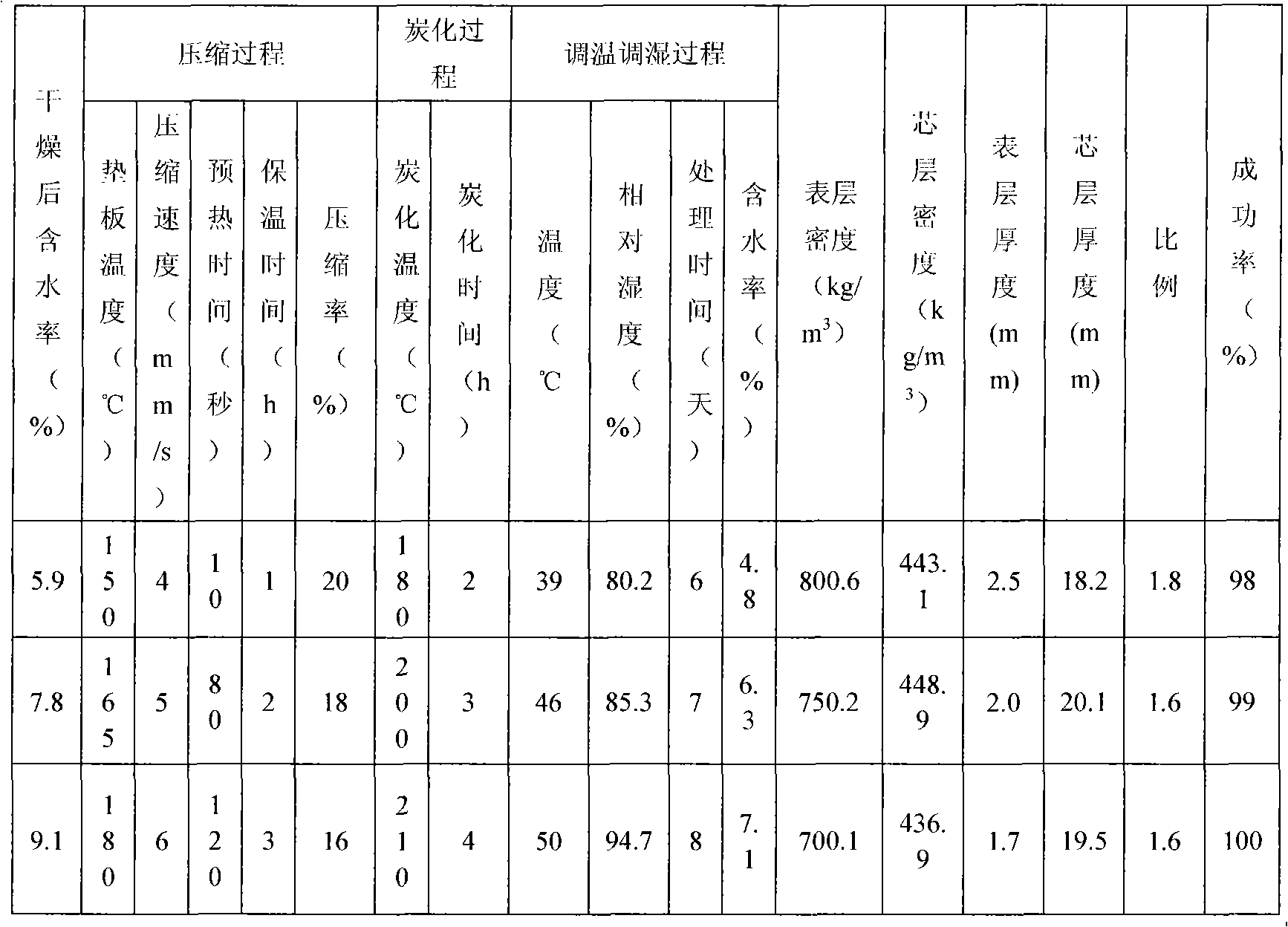

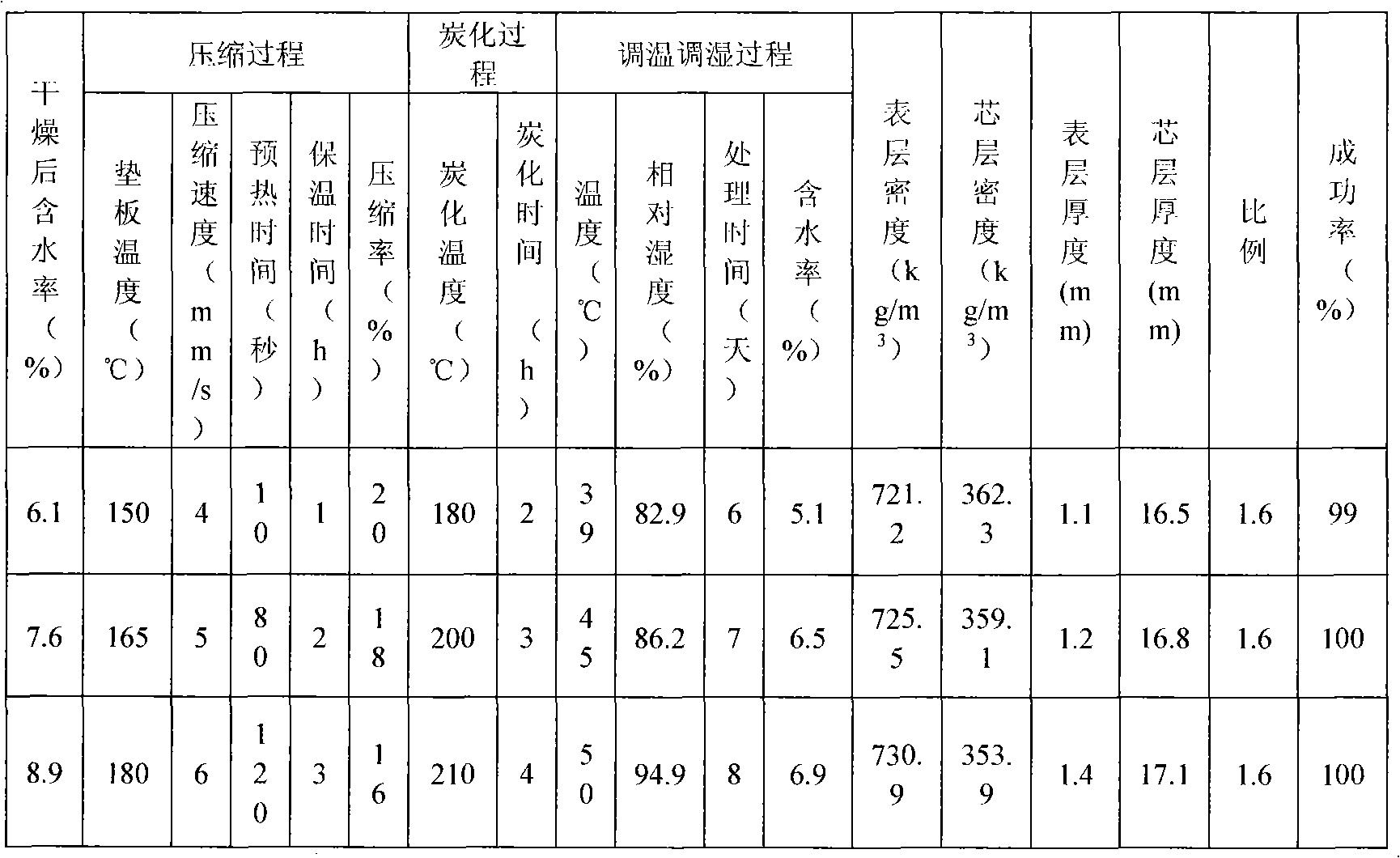

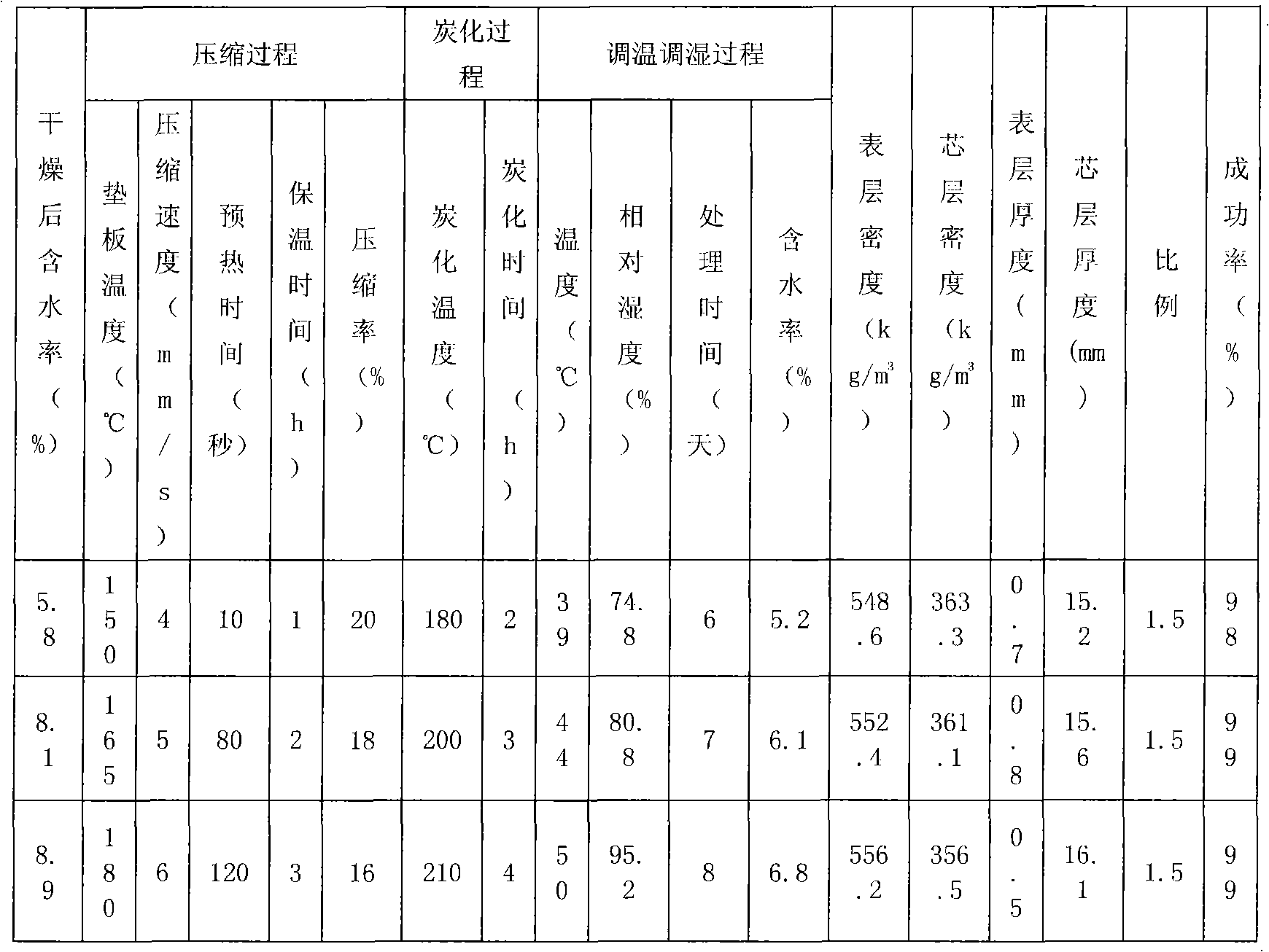

Cork solid wood flooring and manufacturing method thereof

ActiveCN102107452AUniform water contentAvoid deformationWood compressionWood treatment detailsSolid woodCarbonization

The invention relates to a method for manufacturing a floor, in particular to the method for manufacturing a solid wood flooring. The method is realized through the techncial scheme as follows: the method for manufacturing the solid wood flooring comprises eight steps consisting of the wood making step, the drying step, the polishing step, the improvement step, the humidifying step, the dyeing step, the paper sticking step and the mortising and slotting step, wherein, in the improvement step, fast growth flooring blanks are polished and dried from four sides, modified blanks are obtained through functional improvement, and the functional improvement refers to a wood compression method or a wood carbonization method or a wood compression carbonization method; and in the humidifying step, the modified blanks are processed through a humidifying method in a conventional drying kiln or a humidifying temperature-regulating chamber so as to obtain modified humidified blanks of which the water content is restored to 5 to 10 percent. The method is mainly used for manufacturing the fast growth solid wood flooring.

Owner:ZHEJIANG SHIYOU TIMBER +1

Current carrying assembly for a circuit breaker

InactiveUS6570116B2Good body shapeIncrease volumeCircuit-breaking switches for excess currentsProtective switchesEngineeringBearing surface

Owner:SQUARE D CO

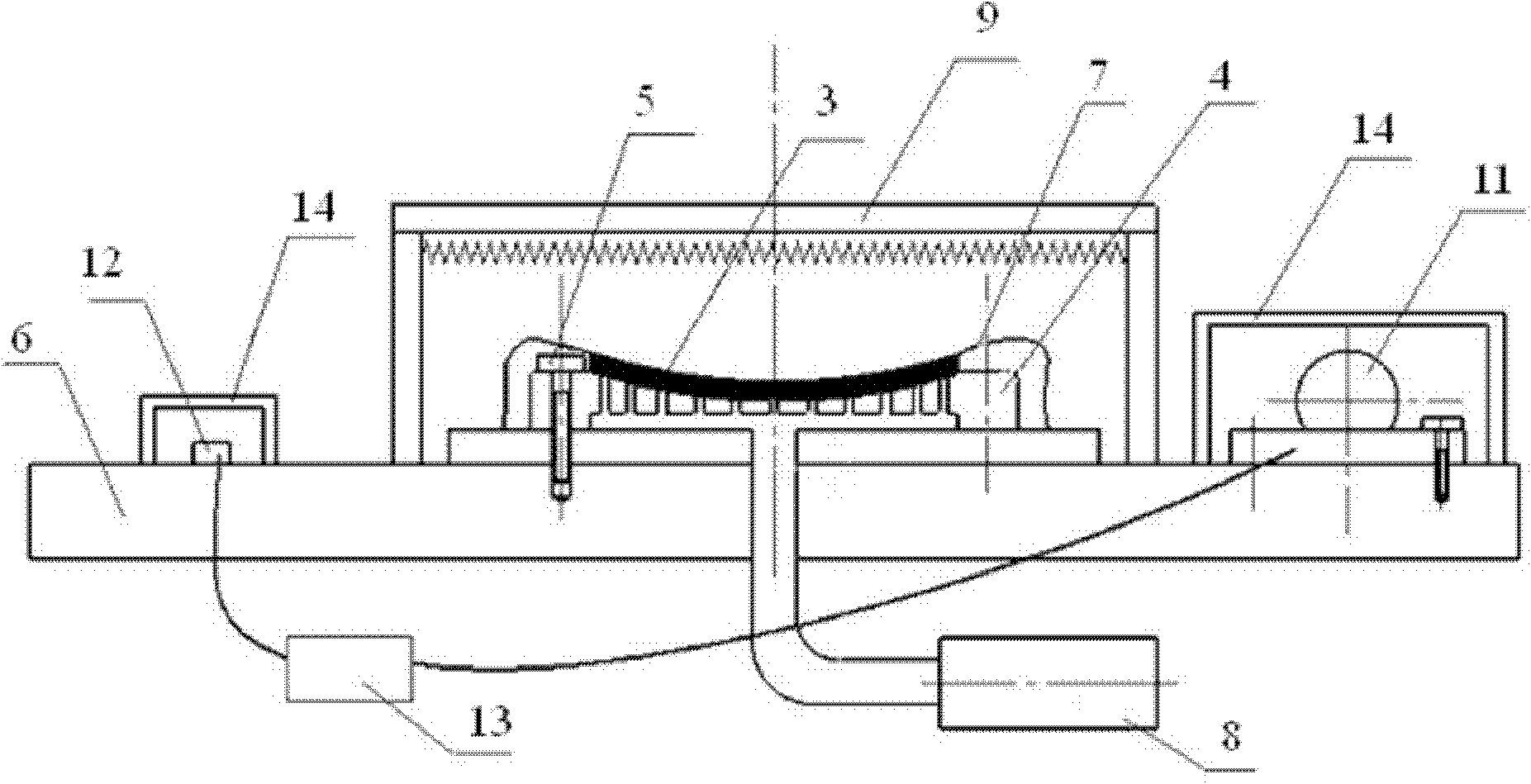

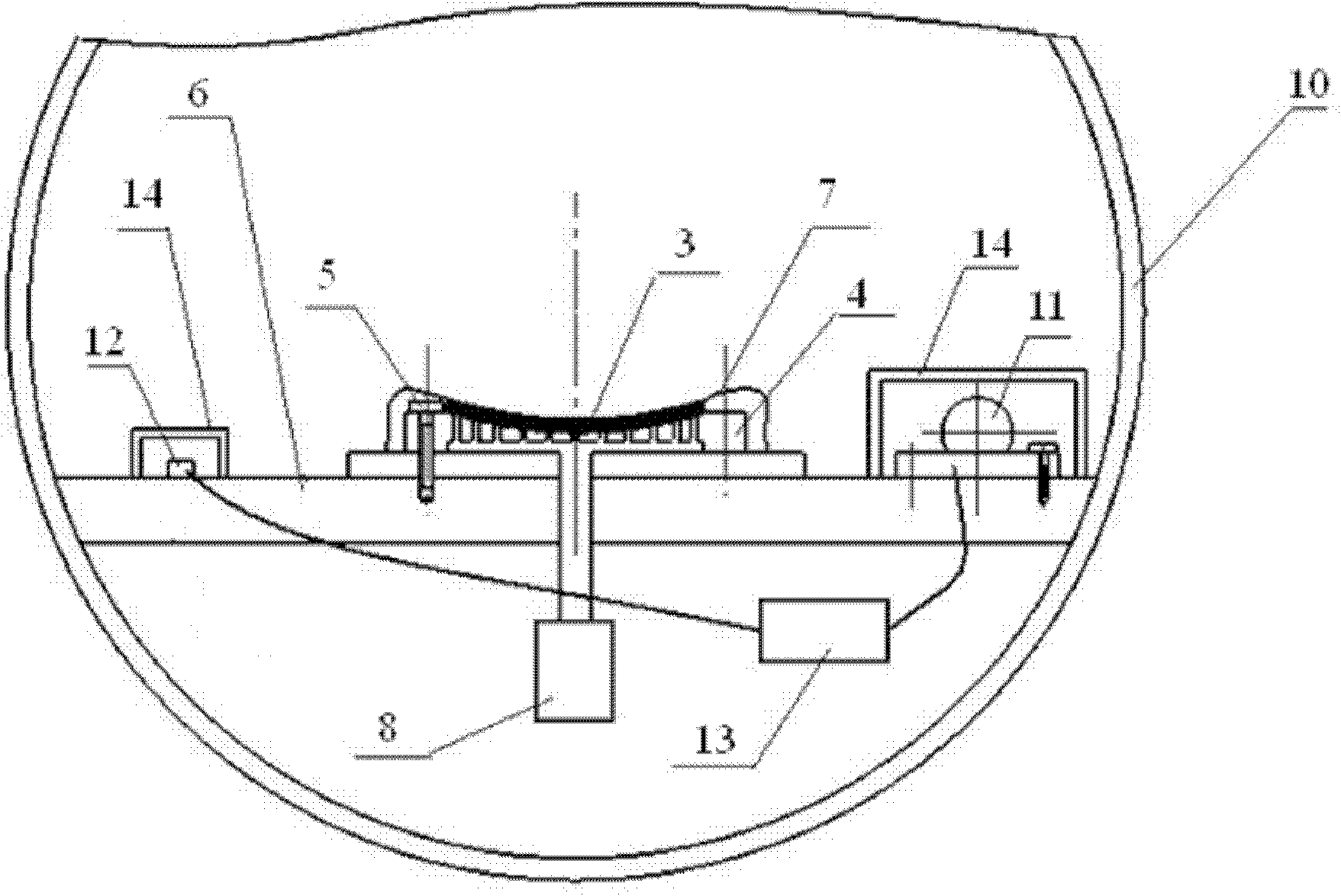

Vibrating creep forming method and device for metal member

The invention discloses a vibrating creep forming method for a metal member. A vibrating platform is vibrated by a vibration exciter in the heating process of the member; the device comprises a creep mold, a locking mechanism, the vibrating platform, at least one vibration exciter, an acceleration probe and a frequency-acceleration synchronous tester; the creep mold is fixed on the vibrating platform through the locking mechanism; the vibration exciter and the acceleration probe are fixed on the vibrating platform; and the vibration exciter and the acceleration probe are respectively electrically connected to the frequency-acceleration synchronous tester. According to the method and the device, the member is formed by adopting creep and using micro plastic deformation generated by vibration, so the rebound of the creep formed member can be greatly reduced.

Owner:CENT SOUTH UNIV

Conductor wire core for novel power cable

InactiveCN102403051AEasy to coordinate and deformSmall bending radiusNon-insulated conductorsPower cablesElectrical conductorPower cable

The invention relates to a conductor wire core for a novel power cable, comprising an inner-layer molded wire and an outer-layer molded wire. The molded wires are produced by a molded wire filament drawing machine of which a molded wire filament drawing mold has the finish of less than 5; the single filaments of the inner-layer molded wire adopt round wires or combined round wires formed by combining 2 to 6 filaments with fan-shaped cross sections; the single filaments of the outer-layer molded wire are shaped like tiles and spirally stranded towards the same direction by using a frame-type strander; and the stranded wire core has a round cross section. The external diameter of the conductor wire core can be effectively reduced, and the consumption of outer-layer materials of the power cable can be saved. The conductor wire core has a smooth surface so that the risk of insulation breakdown is reduced. In addition, the rigidity and bend radius of the power cable are reduced so that the related power cable can be laid more conveniently.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

Suspension System Having A Leaf Spring

ActiveUS20140035248A1Light weightImprove roll stiffnessInterconnection systemsResilient suspensionsEngineeringLeaf spring

Suspension systems, leaf springs and methods of providing a leaf spring in a suspension system are disclosed. The suspension systems, leaf springs and methods of providing a leaf spring in a suspension system allow use of a lighter weight leaf spring while providing customized roll stiffness and vertical spring rate that are complemented by a bumper that engages the leaf spring assembly when compressed to at least a preselected position.

Owner:HENDRICKSON USA L L C

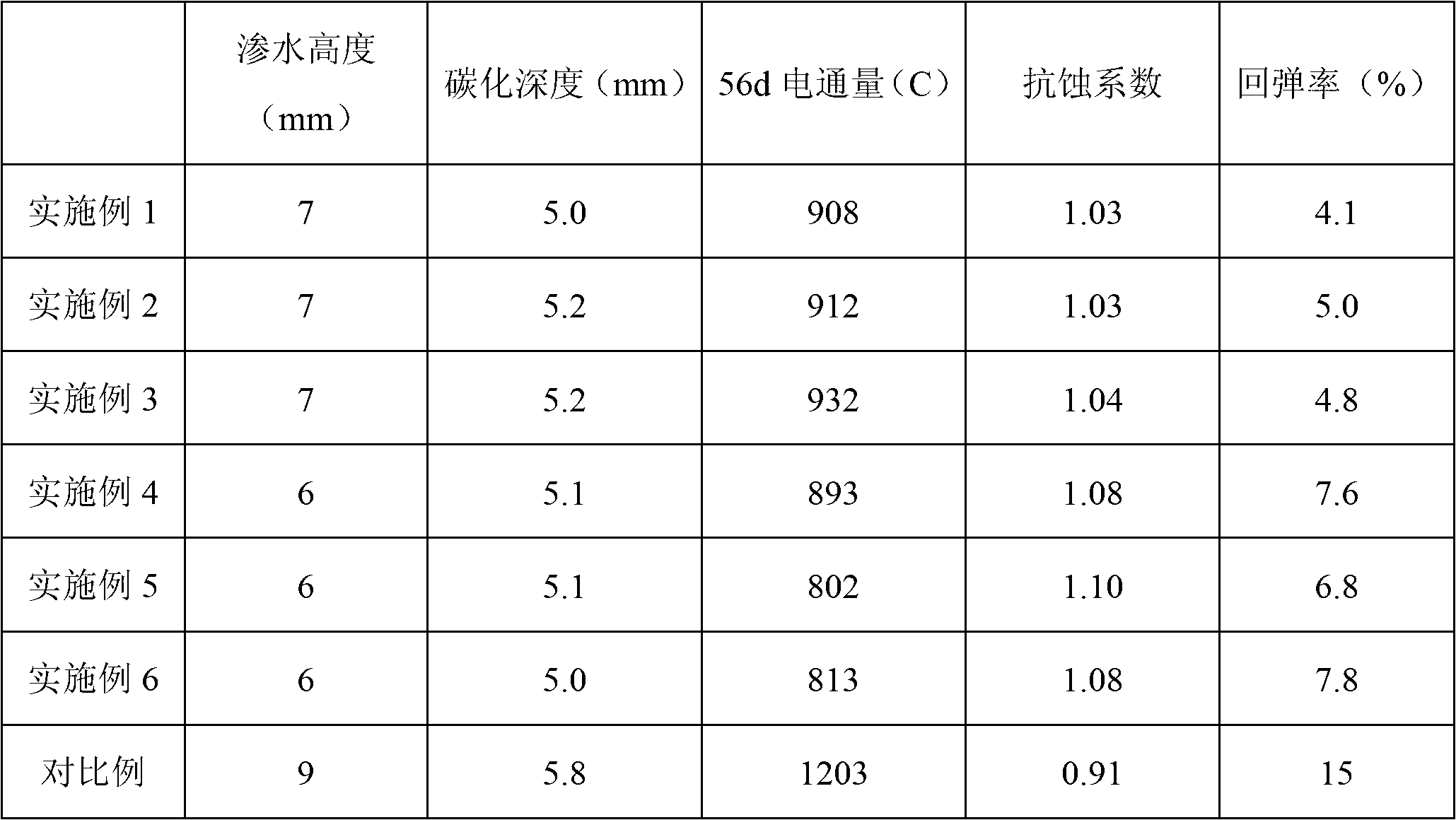

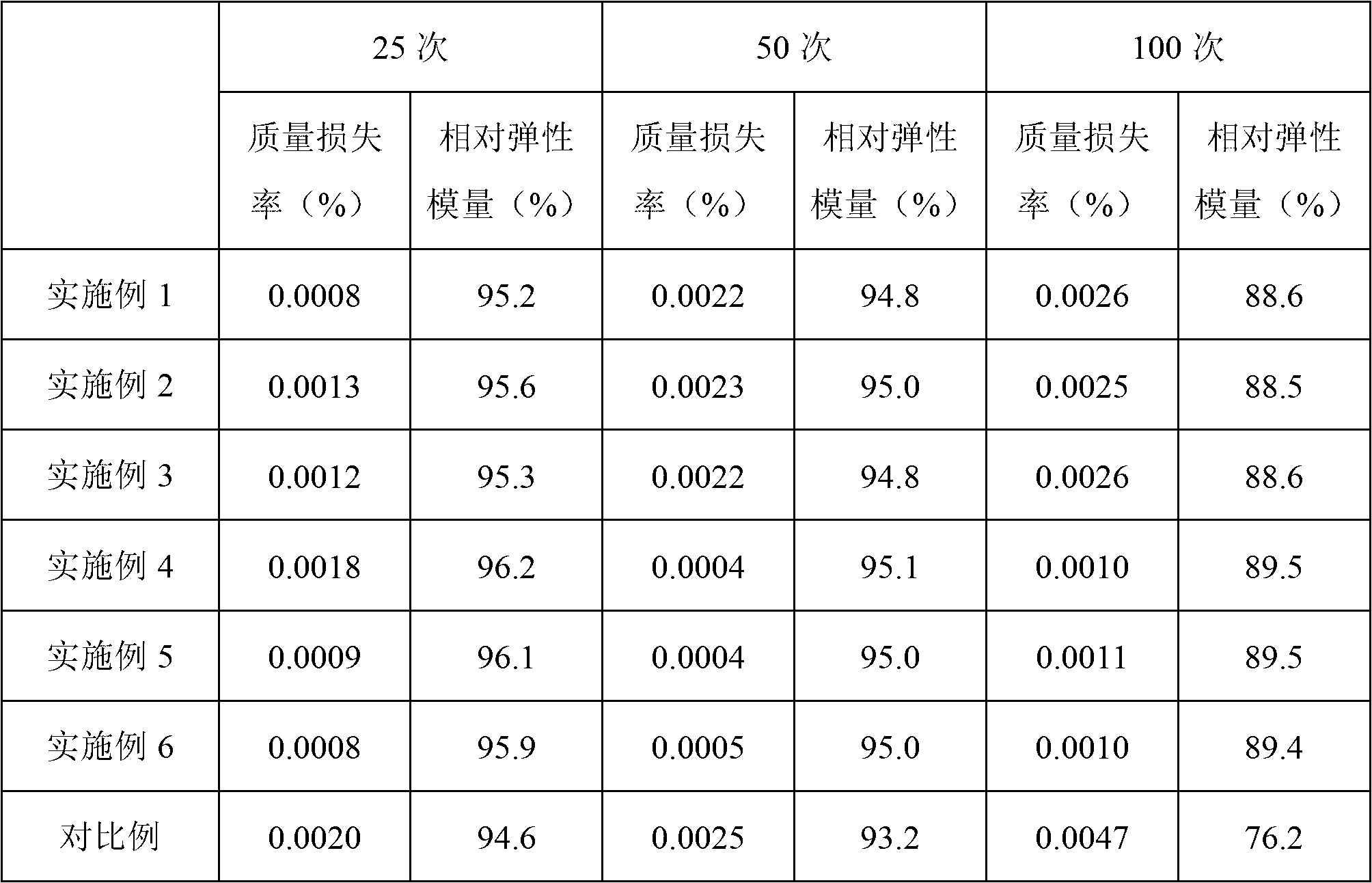

High-performance concrete gel material for tunnel and application thereof

The invention discloses a concrete gel material which comprises cement and silica solution. The invention further discloses a high-performance concrete for tunnel prepared through the concrete gel material provided by the invention. The high-performance concrete is suitable to be applied to injecting concrete, moulding concrete and others. Through the adoption of the concrete gel material or the high-performance concrete for the tunnel provided by the invention for injecting the concrete, the rebound ratio can be effectively reduced and even reduced to 4.1% to the minimum; and the concrete gel material or the high-performance concrete is good in working performance; the obtained concrete finished product is high in early strength, and good in freezing resistance; the waterproof performance and the wearable performance are improved; the quantity of used cement can be reduced; the carbon emission can be reduced; and good economic benefit and environment-friendly benefit are brought.

Owner:中铁西南科学研究院有限公司

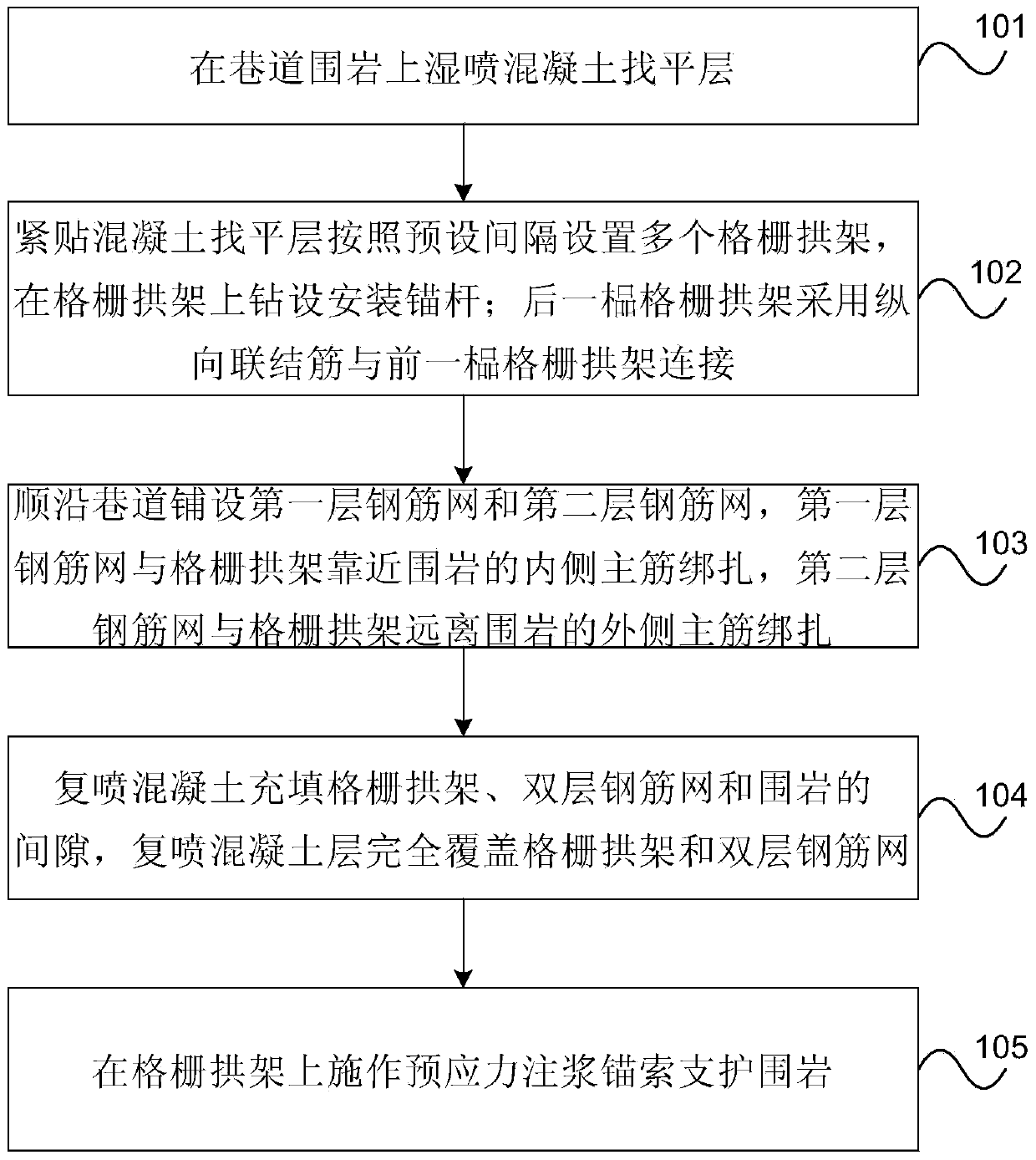

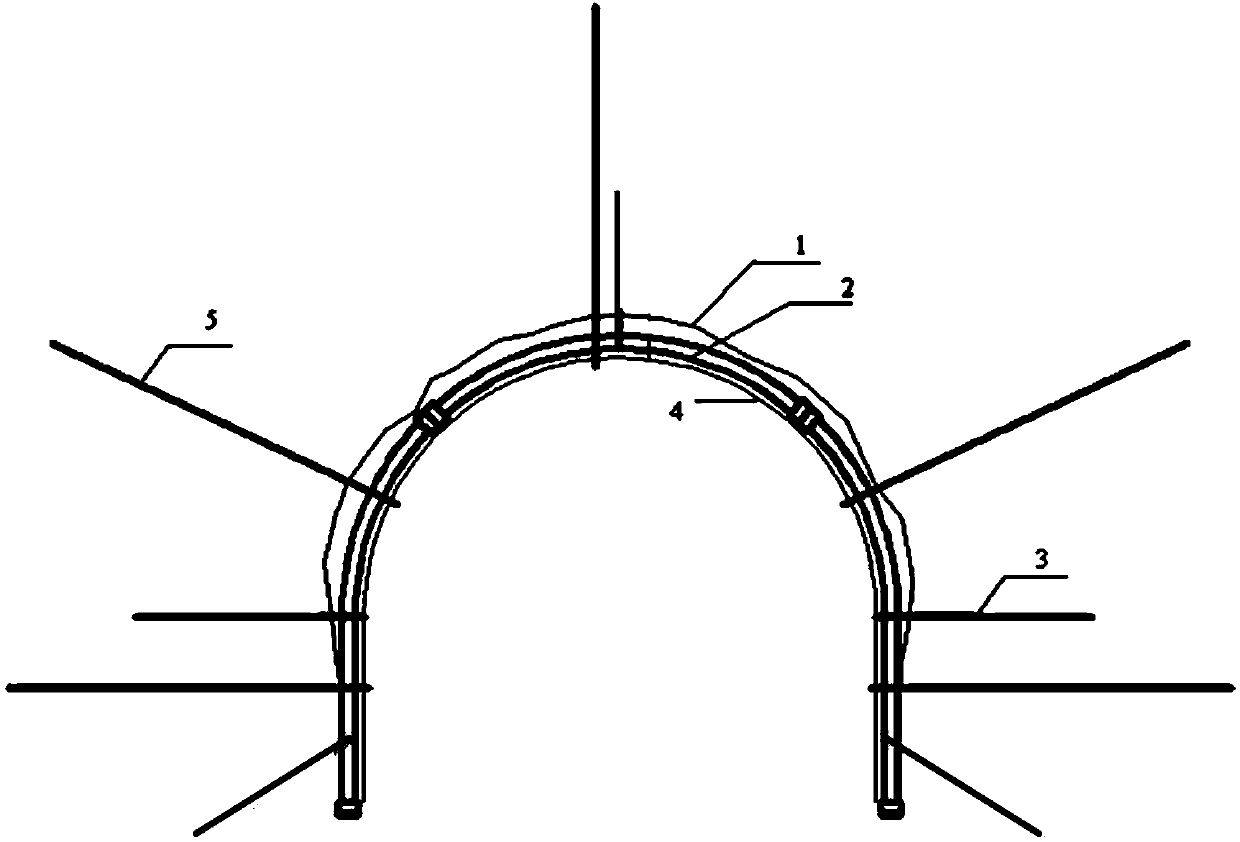

Rapid roadway construction method for soft and broken surrounding rocks of deep coal mine and support system

InactiveCN103993891ASimple structureReduce steel consumptionUnderground chambersTunnel liningSupporting systemMesh reinforcement

The invention provides a rapid roadway construction method for soft and broken surrounding rocks of a deep coal mine and a support system. The rapid roadway construction method for the soft and broken surrounding rocks of the deep coal mine includes the steps that a concrete leveling layer is sprayed to the roadway surrounding rocks in a wet mode; a plurality of grid arches are tightly attached to the concrete leveling layer at preset intervals; mounting anchor rods are arranged on the grid arches in a drilling mode; the grid arches are connected through longitudinal linkage ribs; a first layer of reinforcing mesh and a second layer of reinforcing mesh are laid along a roadway, wherein the first layer of reinforcing mesh is bound with the inner side main ribs, close to the surrounding rocks, of the grid arches, and the second layer of reinforcing mesh is bound with the outer side main ribs, away from the surrounding rocks, of the grid arches; concrete is sprayed again for filling of gaps among the grid arches, the two layers of reinforcing meshes and the surrounding rocks; a concrete layer is sprayed again to completely cover the grid arches; prestress grouting anchor cables are manufactured on the grid arches to support the surrounding rocks. By the method, the soft and broken surrounding rocks can be rapidly and effectively supported, and material waste and adverse impact on the environment are reduced to the maximum extent in the construction process.

Owner:HUAINAN MINING IND GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com