Vibrating creep forming method and device for metal member

A metal component and creep technology, which is applied in the field of metal component vibration creep forming, can solve the problems of low forming efficiency, poor forming precision, and high component springback rate, and achieve improved forming efficiency, good dimensional stability, and component springback The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

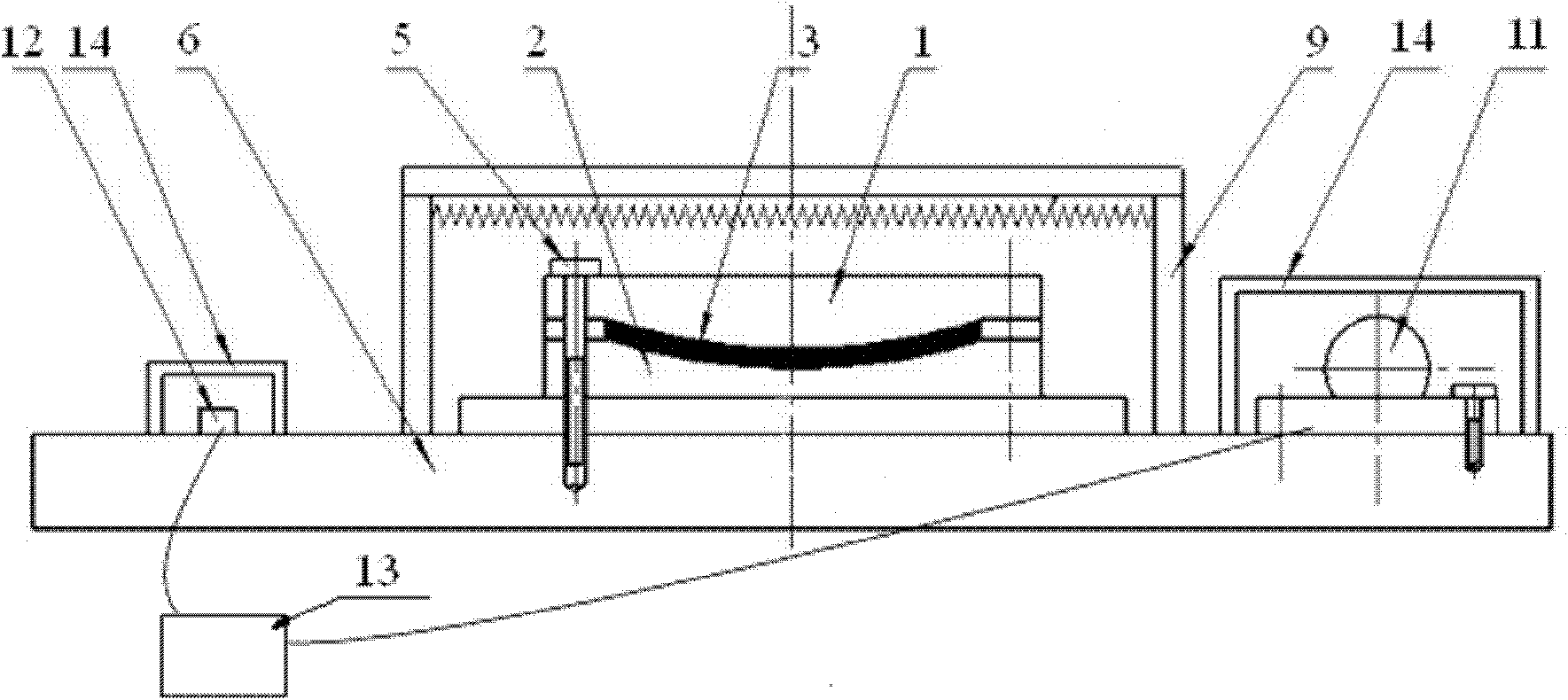

[0022] see figure 1 According to the geometric size and curvature characteristics of the required components, the upper mold 1 and the lower mold 2 are prepared, and the pre-prepared component 3 to be formed is placed in the mold cavity formed by the upper mold 1 and the lower mold 2. Make the upper mold 1, the lower mold 2 closely contact with the component to be formed 3 and keep the pressure, open the locking mechanism 5, fix the upper mold 1, the lower mold 2 and the component to be formed 3 on the vibration platform 6, pass the heating device 9 for heating. The 2024 aluminum alloy billet to be formed has a width of 130mm, a length of 230mm, and a thickness of 5mm. The radius of curvature of the upper and lower molds along the length direction of the plate is R = 1000mm. An exciter is installed on the vibration platform. The heating system during the forming process is 185°C / 6h. During the heating process, the loading time of each vibration is 10 minutes, the intermittent...

Embodiment 2

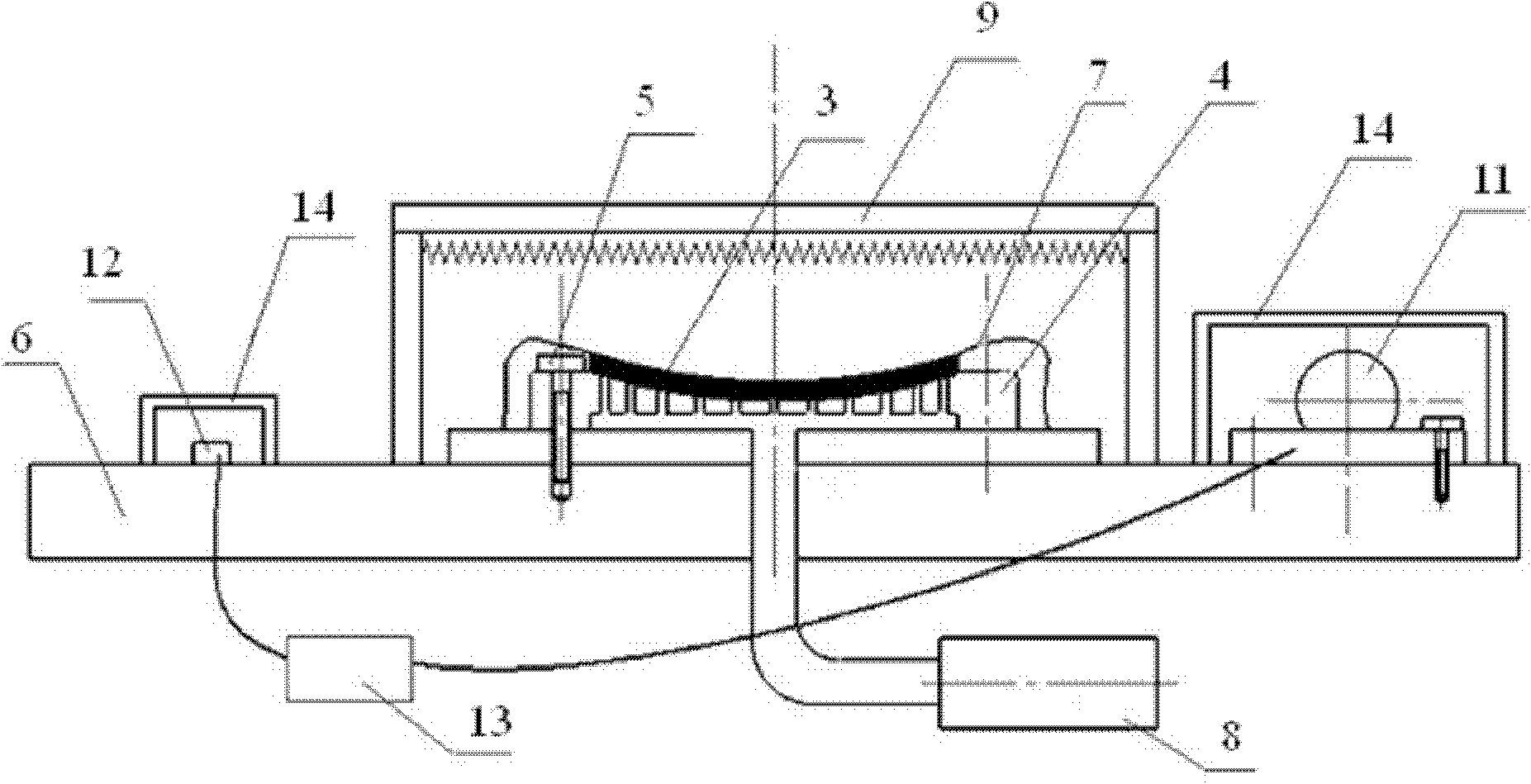

[0024] see figure 2 Prepare the mold 4 according to the geometric dimensions and curvature characteristics of the required components, the mold 4 and the vibration platform 6 are fixed by the locking mechanism 5, put the pre-prepared component 3 to be formed on the mold 4, and seal it with a plastic bag 7 The mold 4 and the blank 3 are pumped to the plastic bag 7 with a vacuum pump 8 until the pressure in the bag drops below 3000 Pa, and the component 3 to be formed is molded under the action of atmospheric pressure, and heated by the heating device 9 . The 7075 aluminum alloy billet to be formed has a width of 65mm, a length of 130mm, and a thickness of 0.5mm. The radius of curvature of the mold along the direction of the plate width is R=1000mm, and the radius of curvature of the mold along the direction of the plate is R=2000mm. Two exciters are installed on the vibration platform. The pressure is 1500Pa, and the heating regime during the forming process is 80°C / 100h. Dur...

Embodiment 3

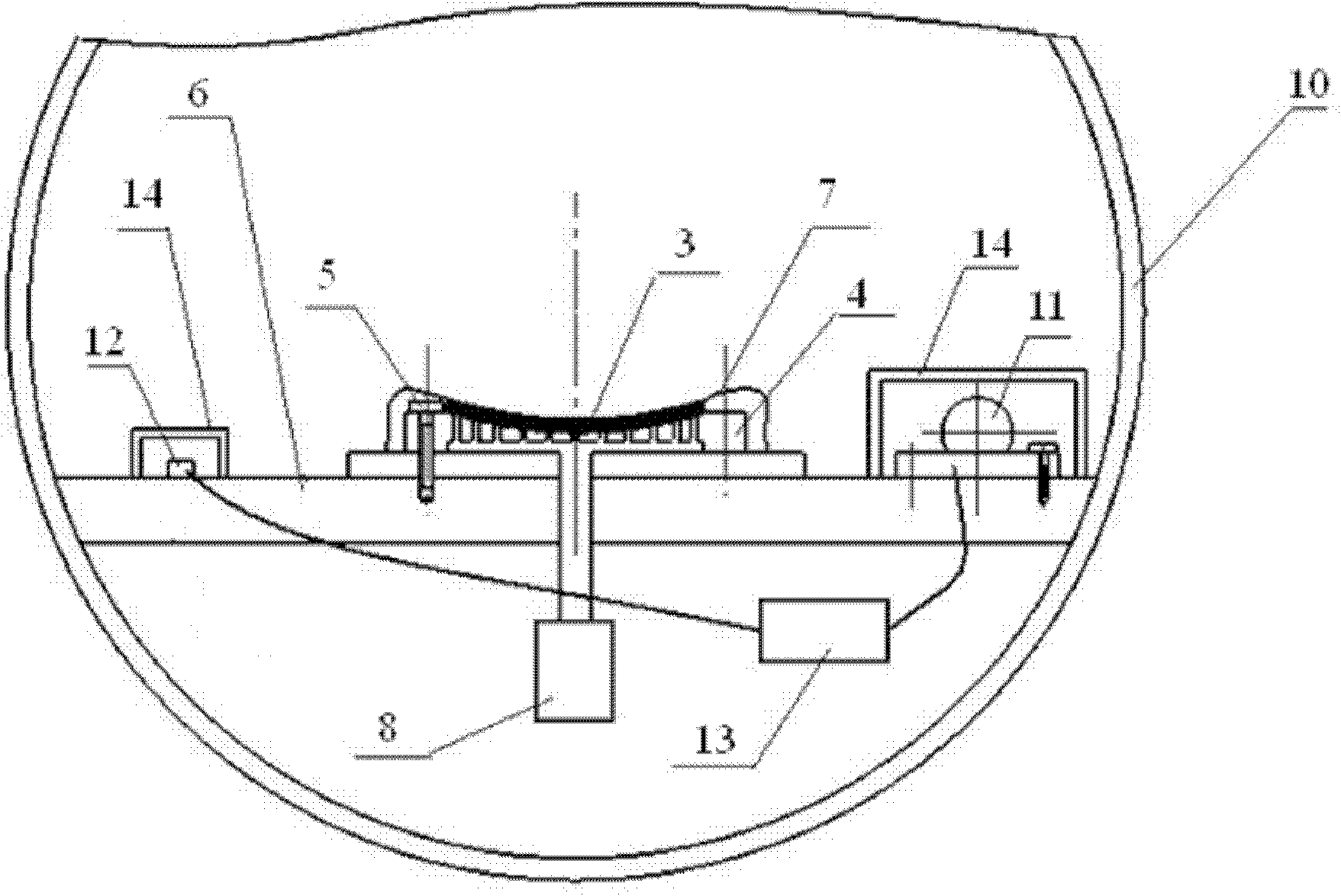

[0026] see image 3Prepare the mold 4 according to the geometric dimensions and curvature characteristics of the required components, the mold 4 and the vibration platform 6 are fixed by the locking mechanism 5, put the pre-prepared component 3 to be formed on the mold 4, and seal it with a plastic bag 7 Mold 4 and blank 3, before or after the sealed plastic bag 7, mold 4, blank 3 and vibration platform are sent into the autoclave 10, the plastic bag 7 is evacuated with a vacuum pump 8 until the pressure in the bag drops below 3000Pa, etc. After the autoclave 10 is sealed, the component to be formed 3 is molded under the action of the air pressure inside the tank, and heated by the autoclave 10 . The 2024 aluminum alloy billet to be formed has a width of 1600mm, a length of 3800mm, and a thickness of 100mm. The radius of curvature of the mold along the length direction of the plate is R=5000mm, the pressure inside the autoclave is 5MPa, and the pressure inside the bag is 2500P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com