Patents

Literature

366results about How to "Small bending radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

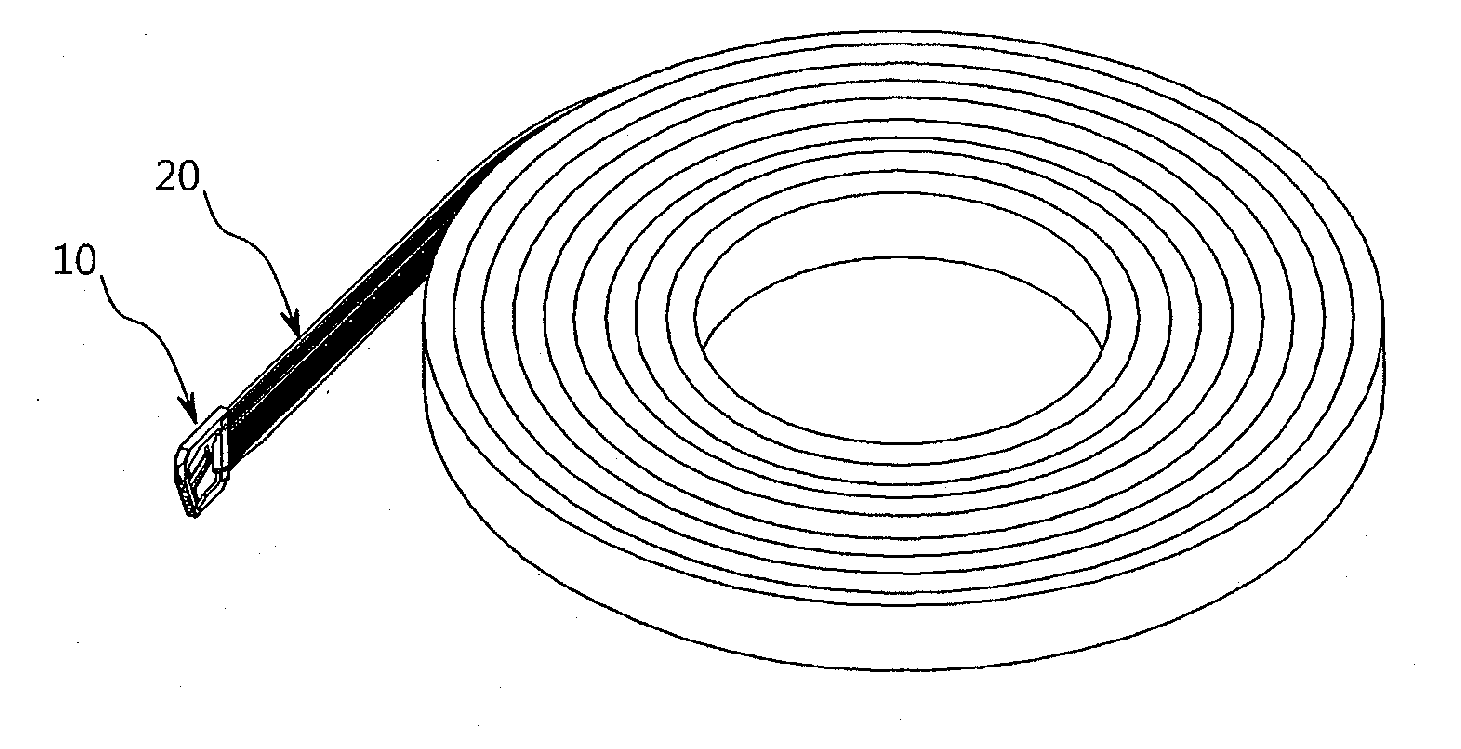

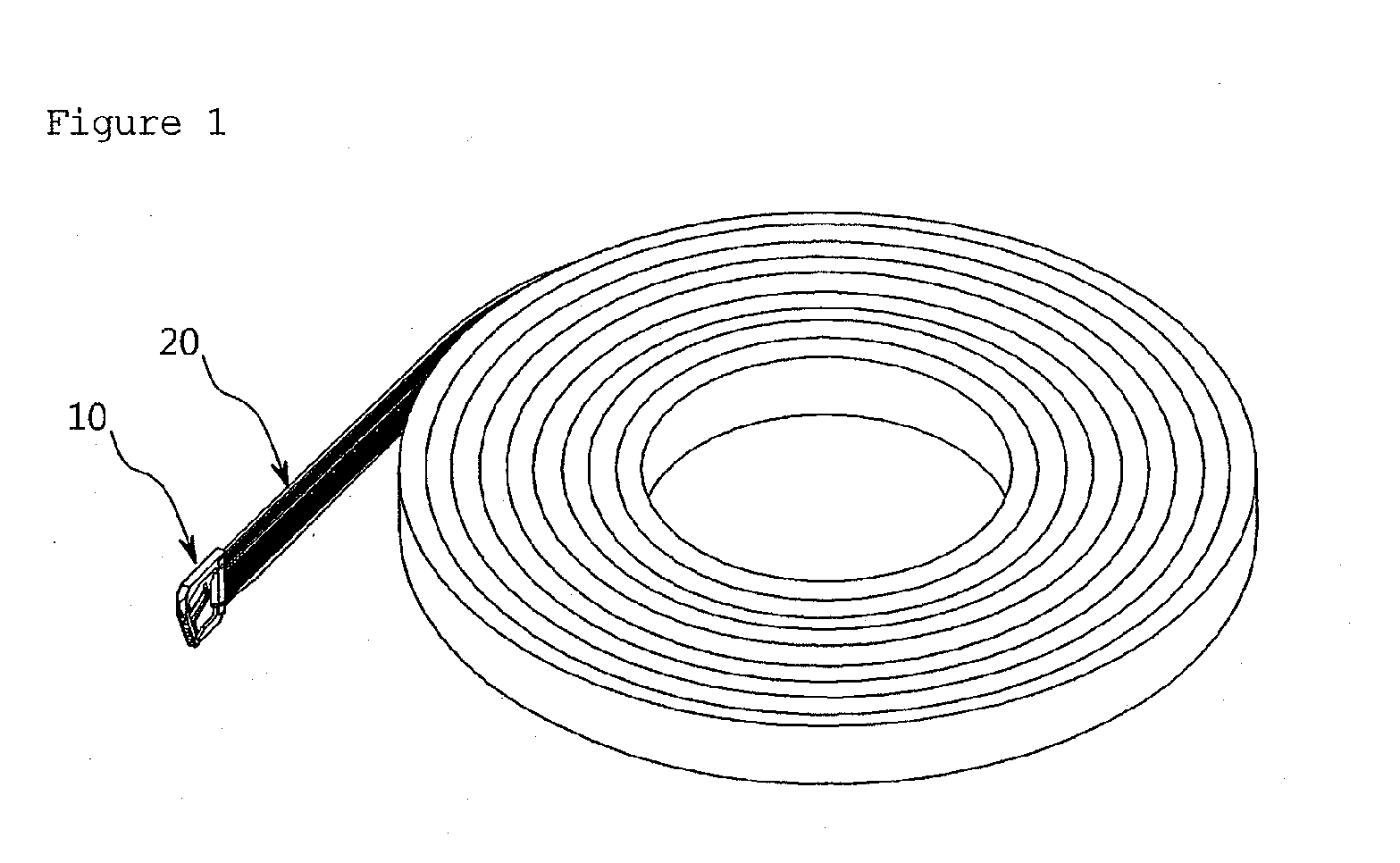

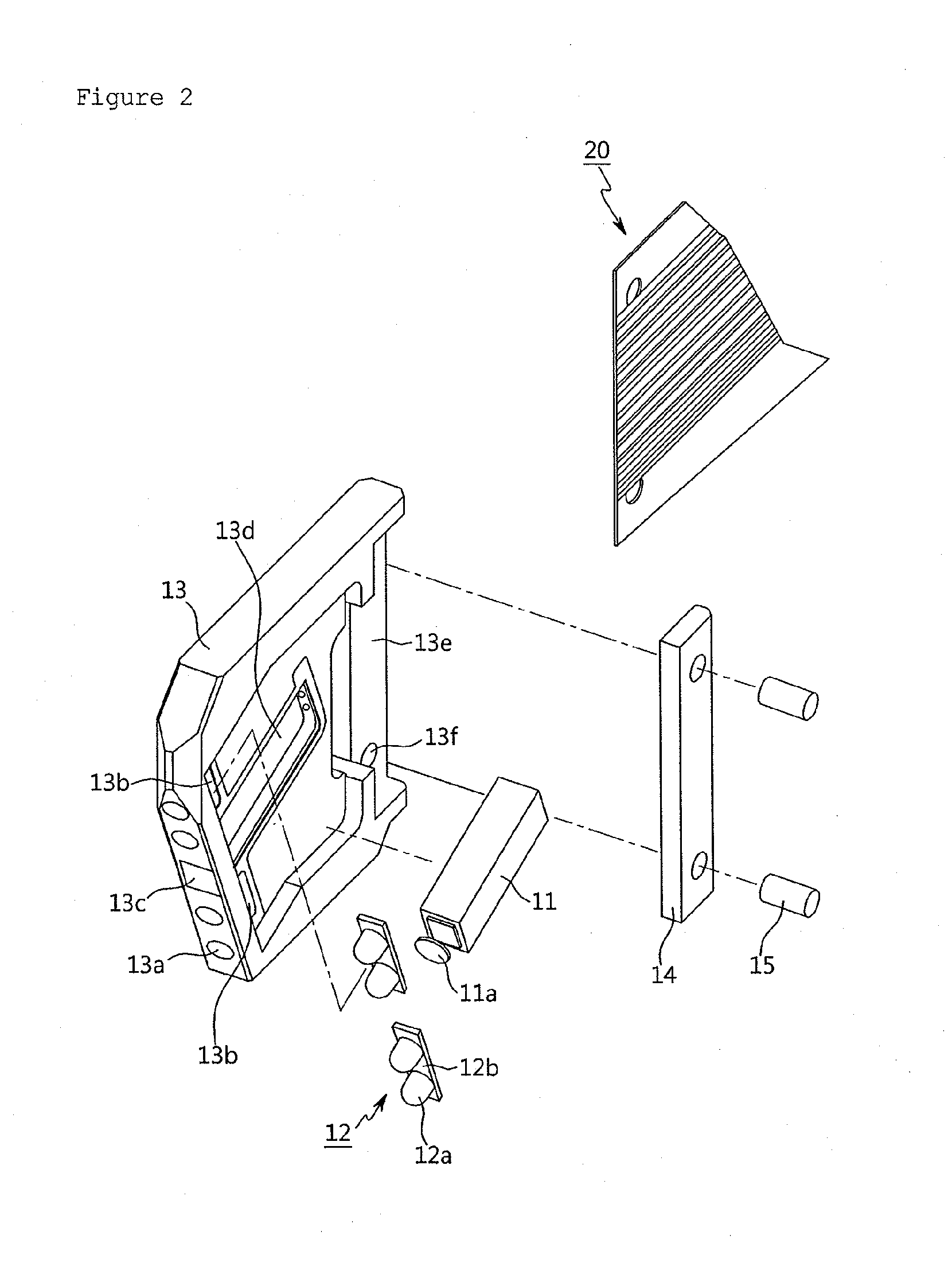

Arc-shaped flexible printed circuit film type endoscope using imaging device

Disclosed herein is an arc-shaped flexible printed circuit film type endoscope using an imaging device. The endoscope includes an image photographing means and an object insertion means. The image photographing means includes a head housing to which an imaging device and an illumination means are mounted, and functions to photograph an image. The object insertion means includes an arc-shaped flexible thin foil, an insulating adhesive film, a circuit film and an insulating protective film which are layered and inserted into an interior of an object to be inspected. The object insertion means is connected at one end thereof to the image photographing means and connected at the other end to a transmission cable via a connector.

Owner:KOREA PLANT SERVICE & ENG CO LTD

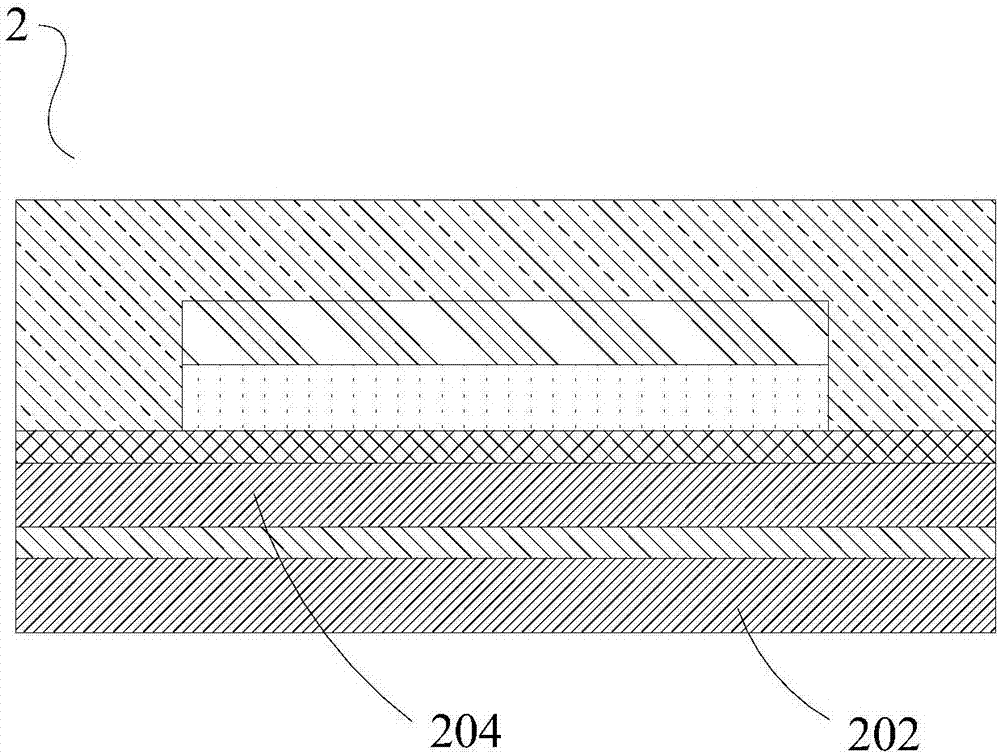

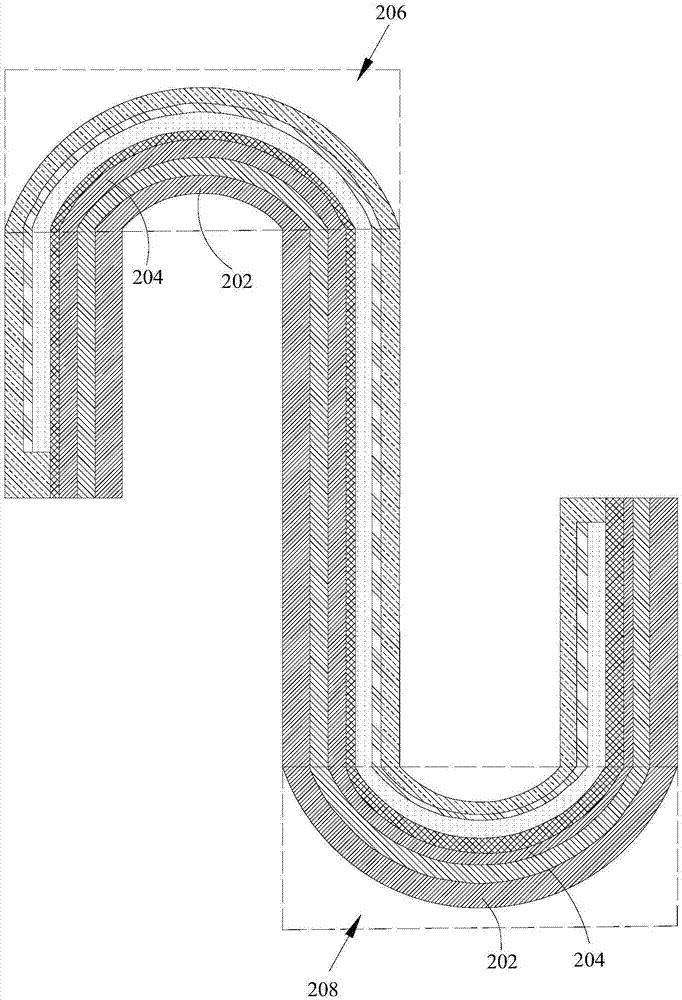

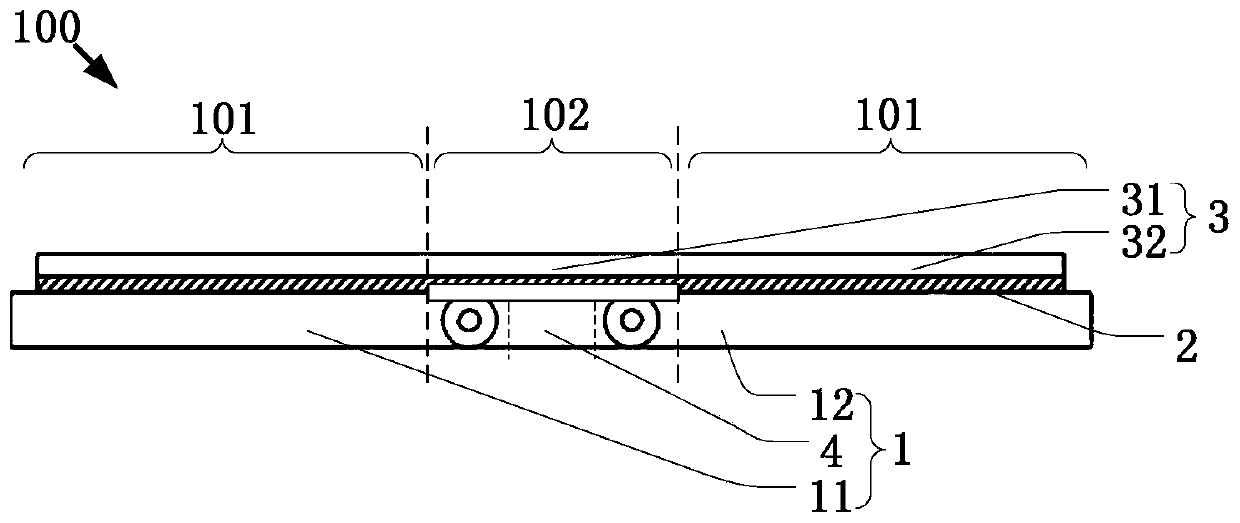

Flexible display panel and display device

ActiveCN107578707AGood bending propertiesSmall bending radiusIdentification meansDisplay deviceEngineering

The invention relates to a flexible display panel and a display device. The display panel comprises a first film, a second film, a first area and a second area, the elastic modulus of the first film is larger than that of the second film in the first area, and the elastic modulus of the first film is smaller than that of the second film in the second area. When the flexible display panel is bent,the positions of the first film and the second film in the display panel are different, and the first film and the second film are different in deformation during bending. Therefore, bending stress applied to the first film and the second film with corresponding different elastic modulus is balanced, the bending property of the flexible display panel is improved, and the flexible display panel canbear a smaller bending radius.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

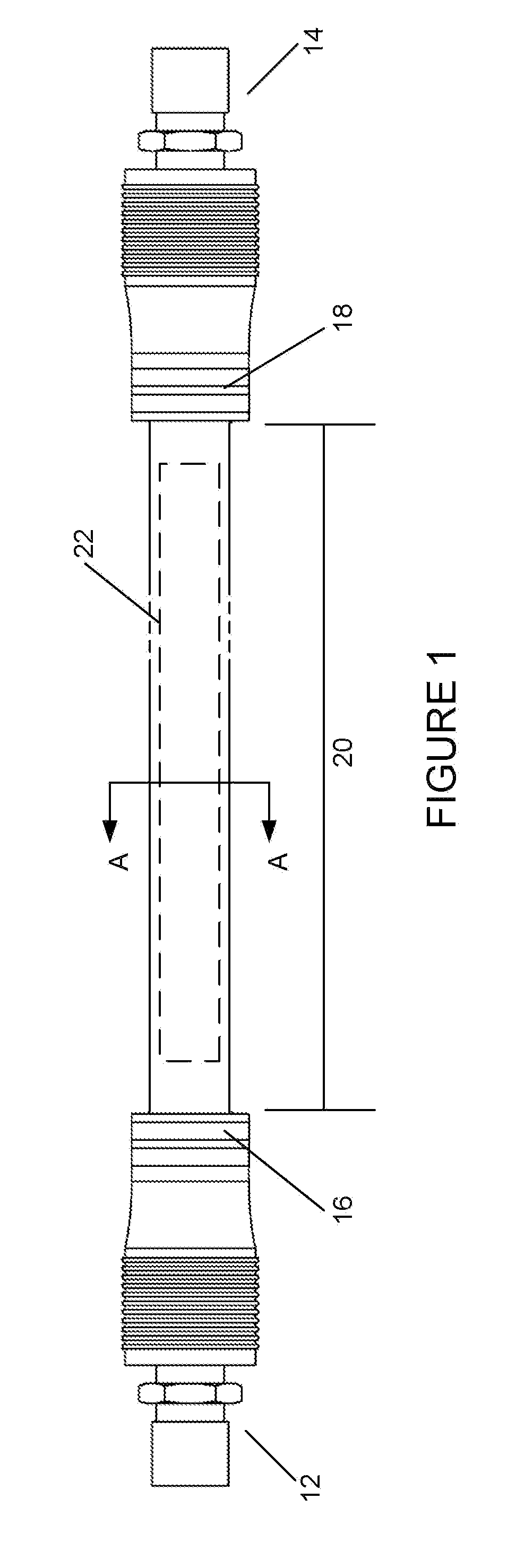

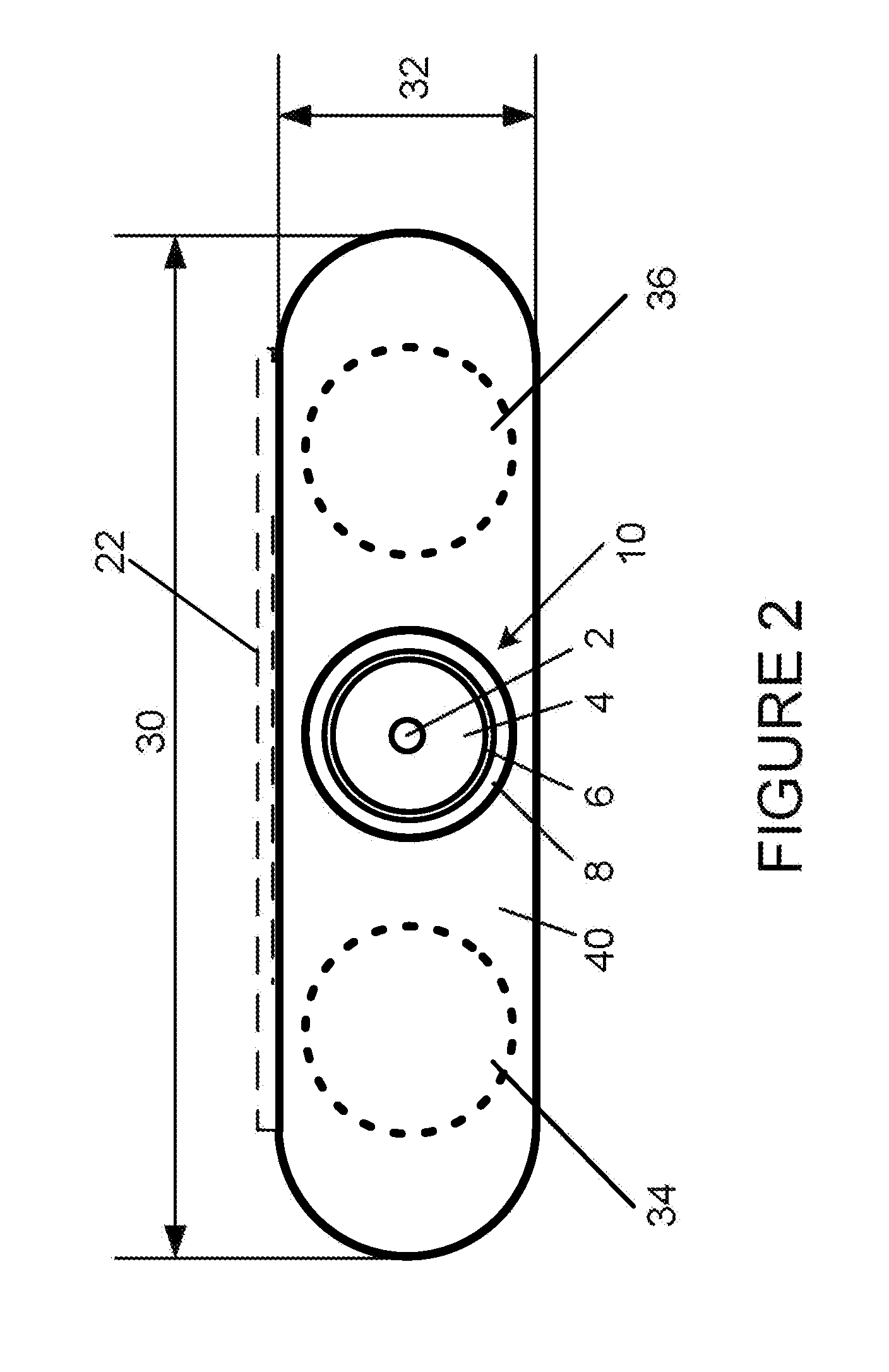

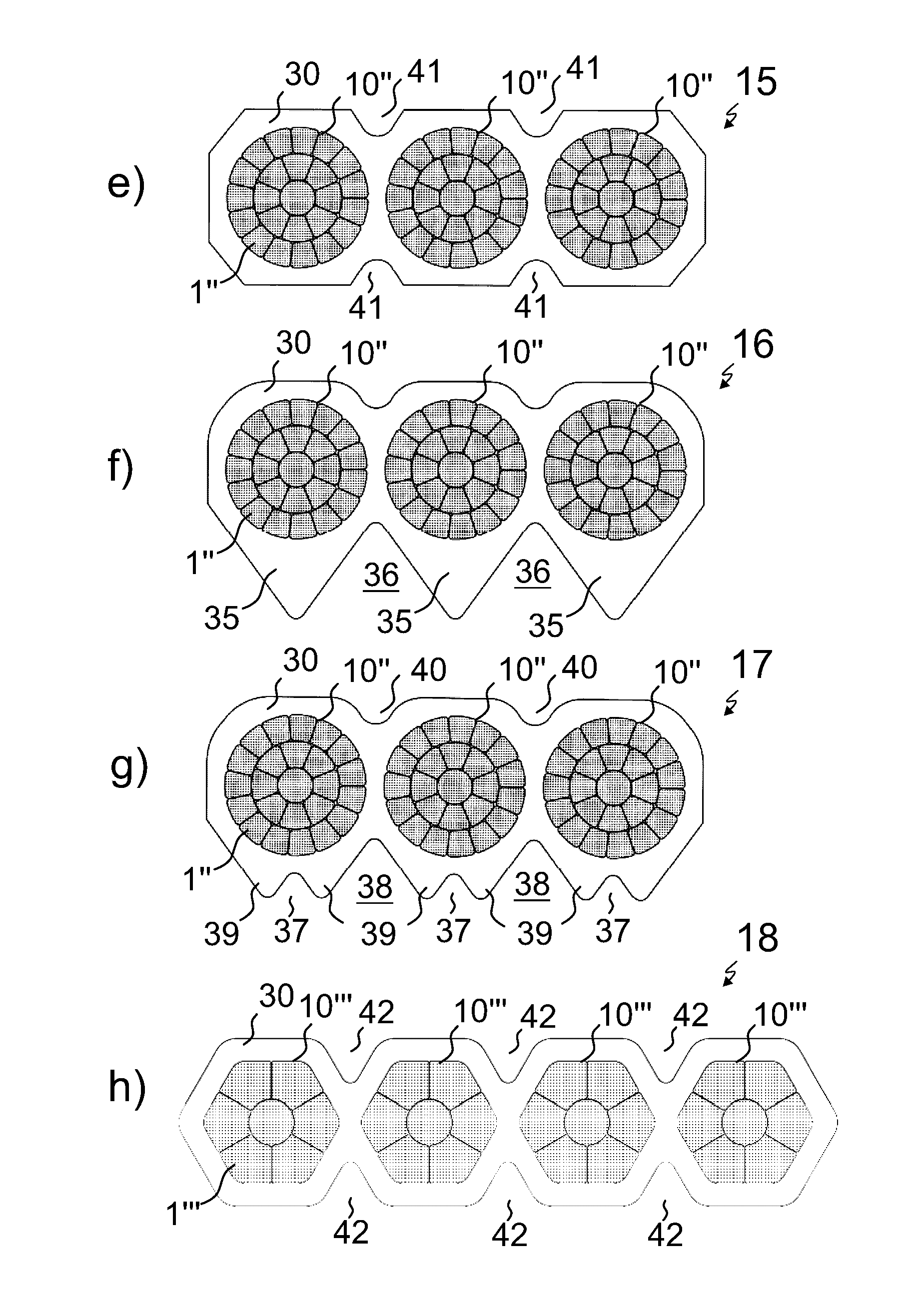

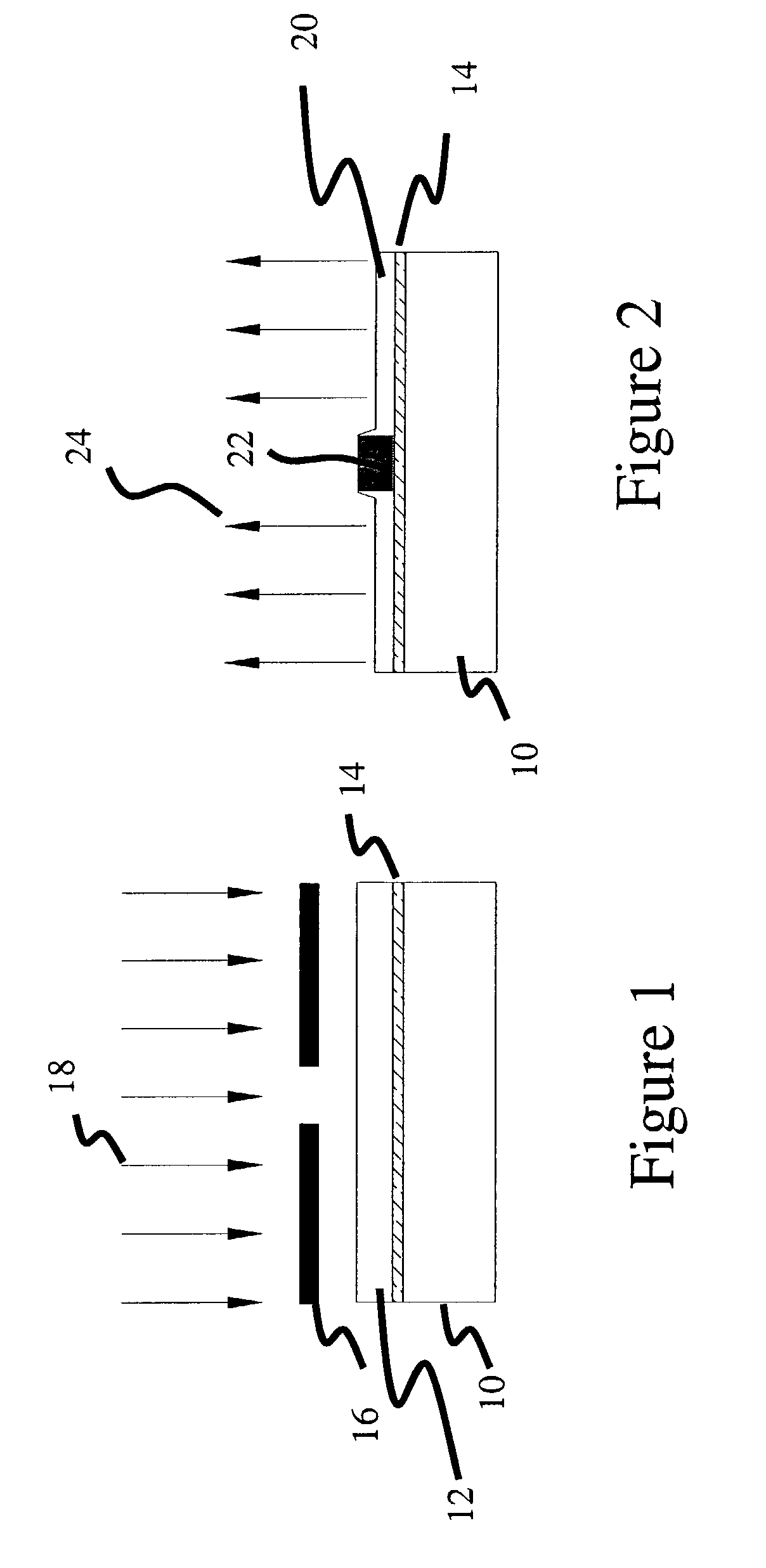

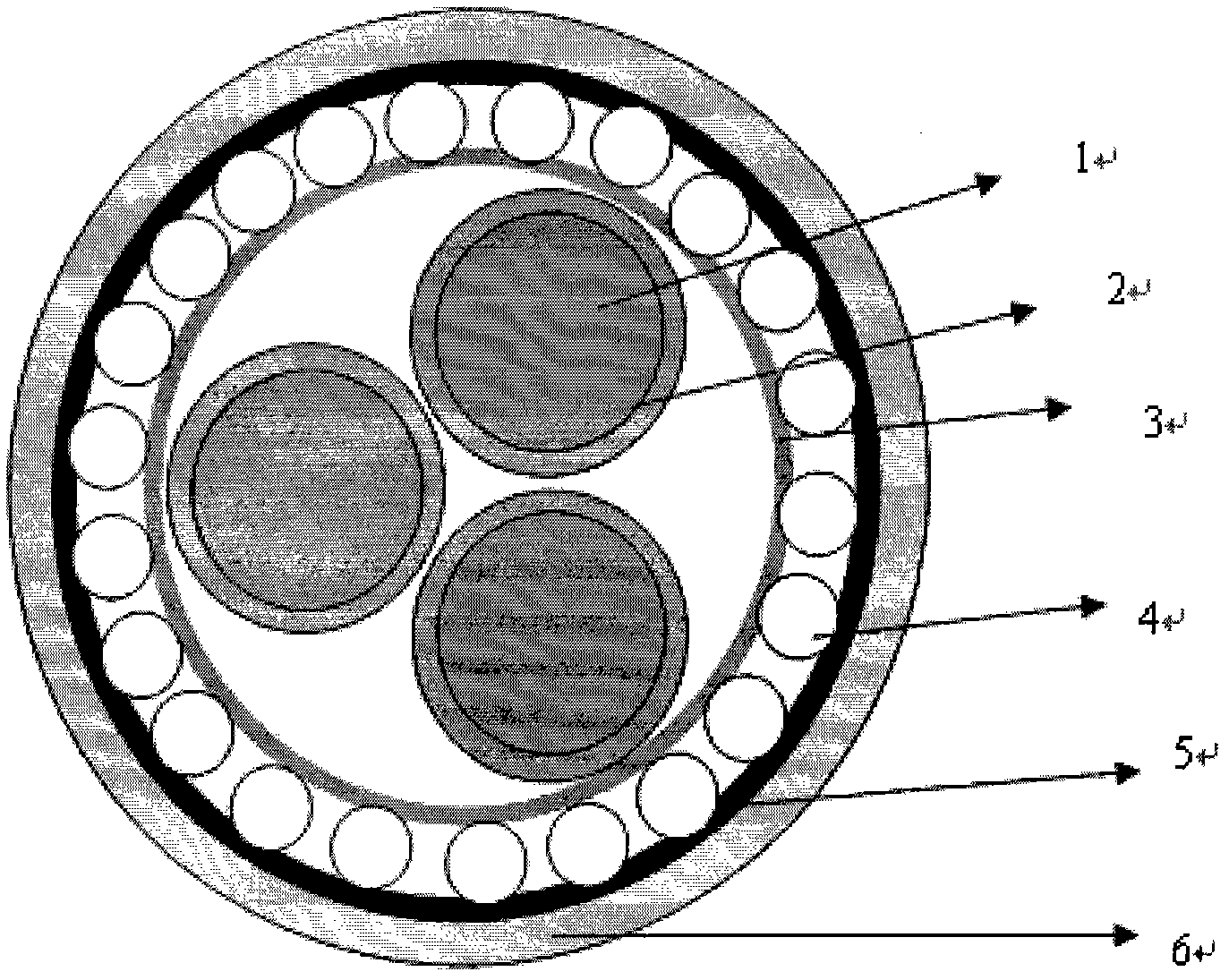

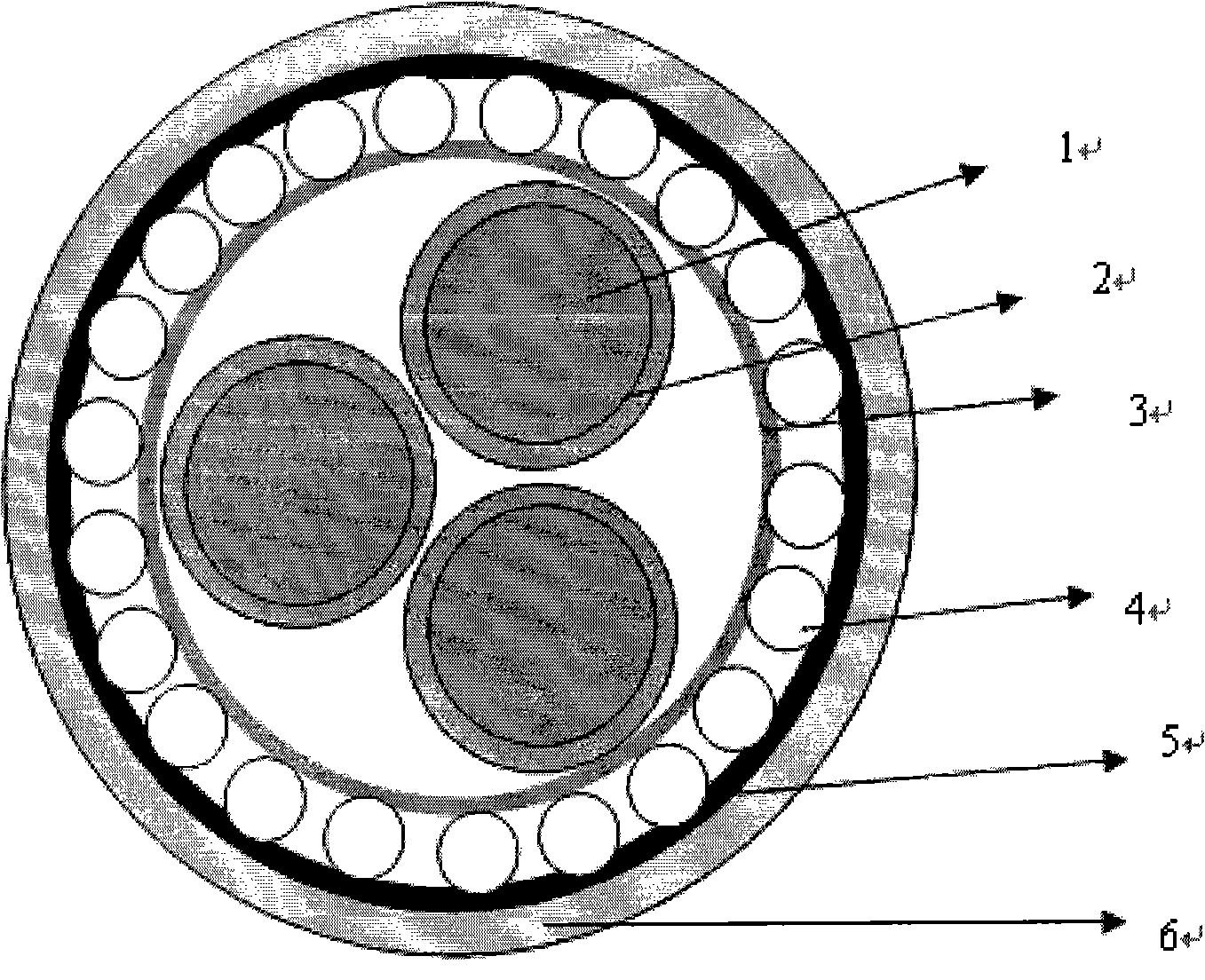

Thin format crush resistant electrical cable

InactiveUS20110021069A1Small bending radiusElectrically conductive connectionsPower cables with screens/conductive layersElectrical conductorCoaxial cable

A thin format crush resistant electrical cable that includes at least one bundle, having each bundle comprising a central conductor, an insulator that encapsulates the central conductor, a shielding that encapsulates the insulator, and a jacket that encapsulates the shielding wherein the jacket is crush resistant and thin format in cross section wherein a height of the jacket is smaller than a width of the jacket in cross-section and which enables a small bending radius. One or more embodiments include a small coaxial cable with width less than the jacket height in which the coaxial cable resides. Additional form fitting elements may be utilized as one or more additional bundles to provide for direction changes of the cable that may be implemented by bending the cable wherein the form fitting elements or wires maintain the form desired. The additional bundles may be conductive wire in any geometry.

Owner:STEREN ELECTRONICS INT

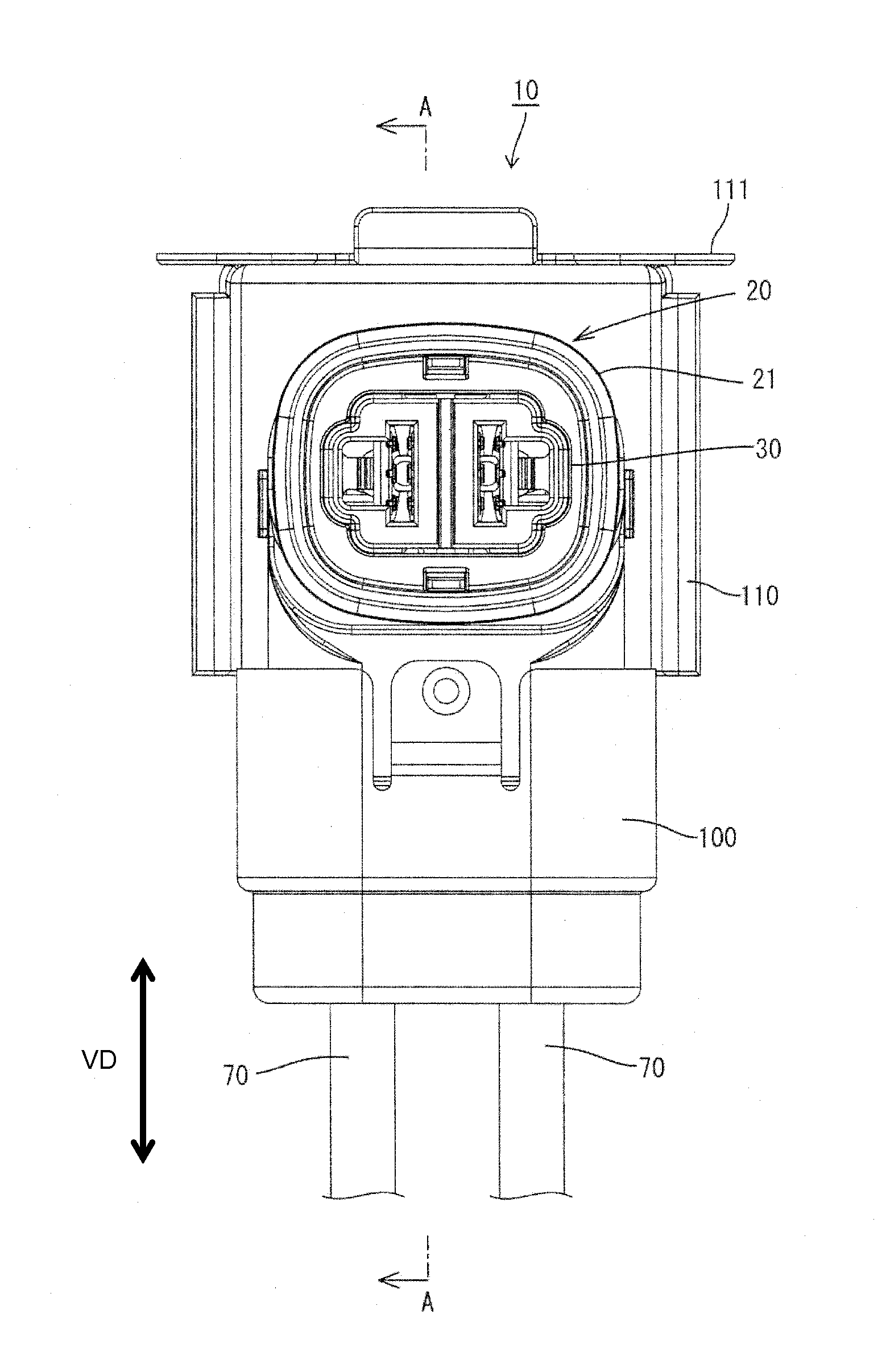

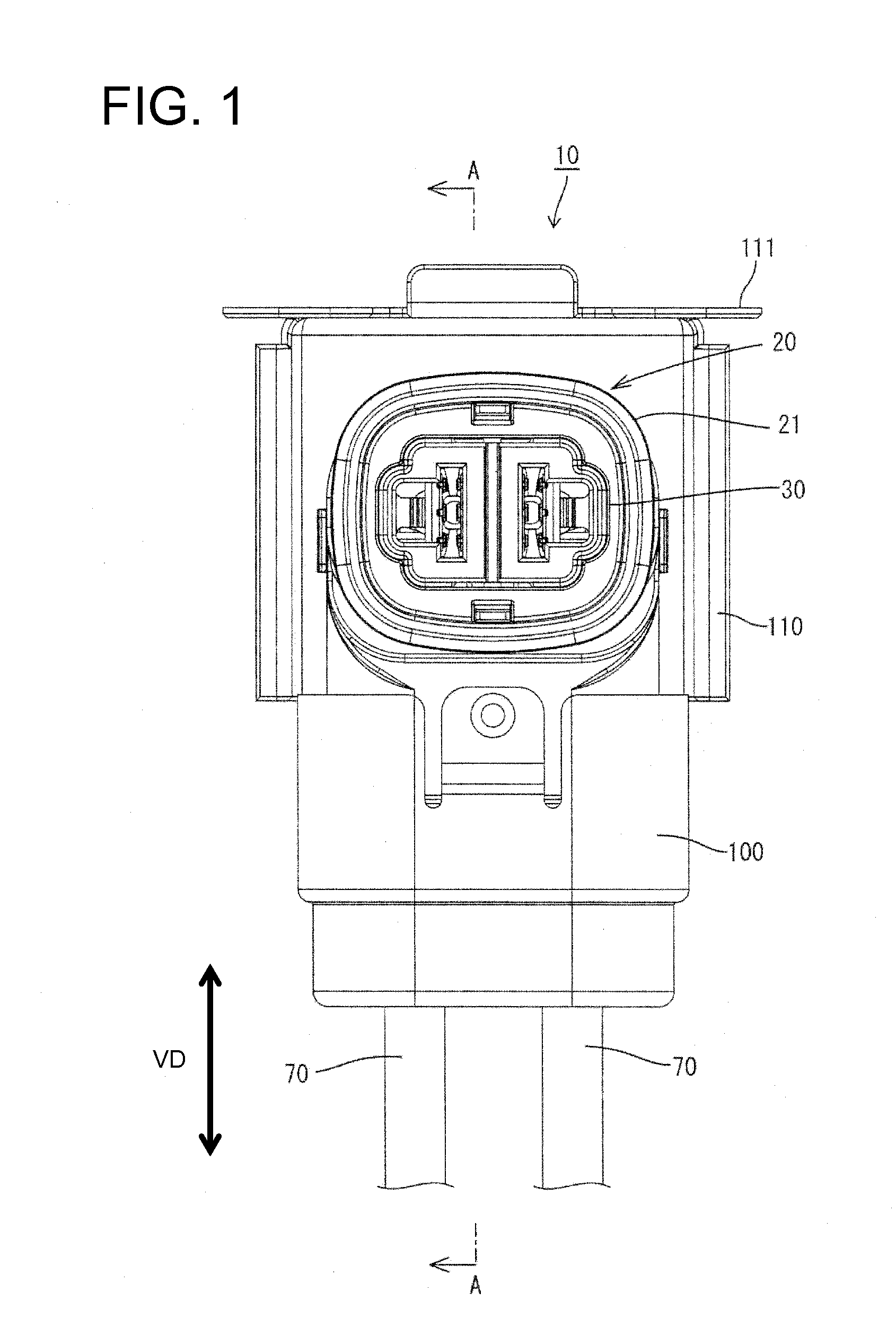

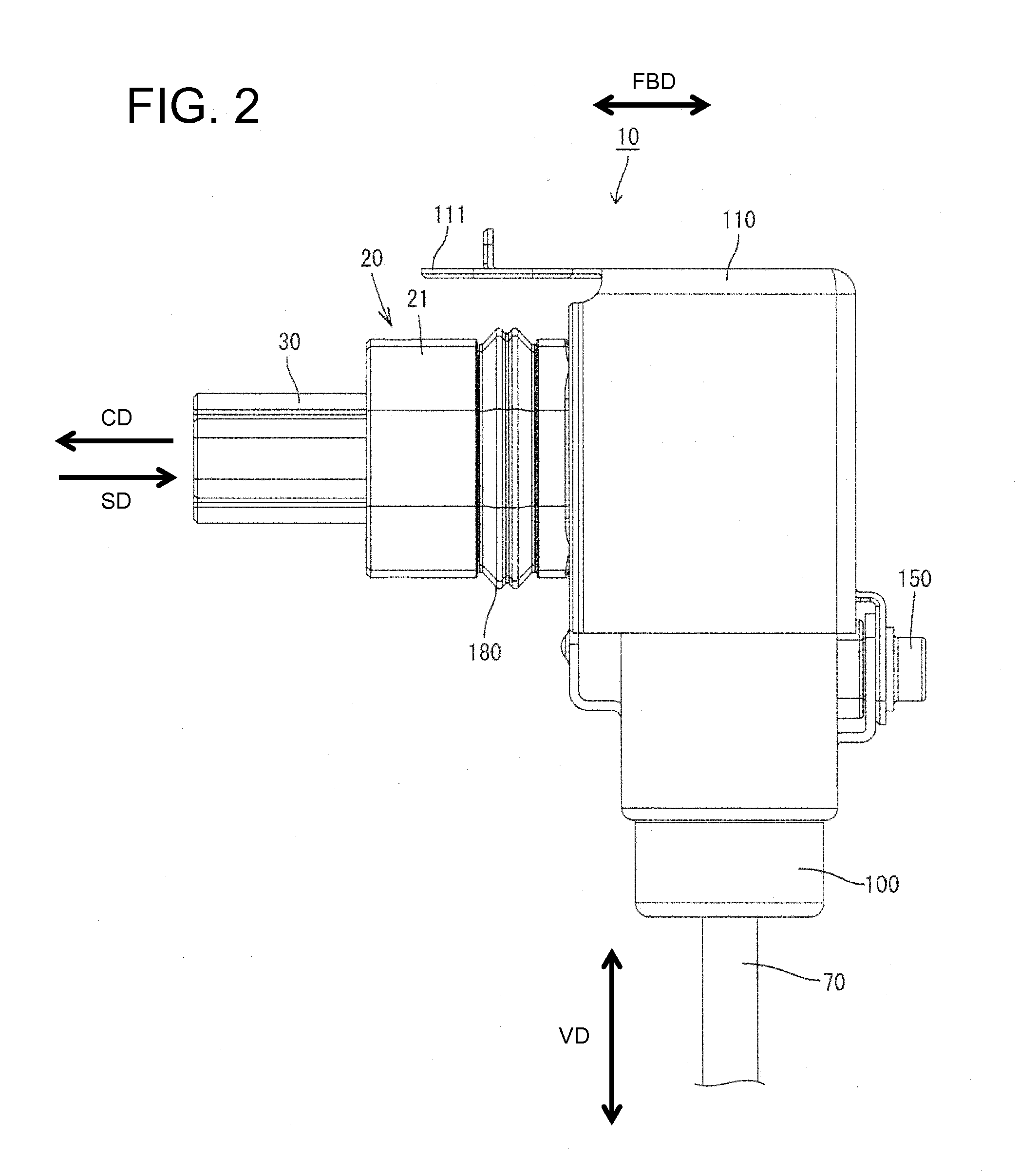

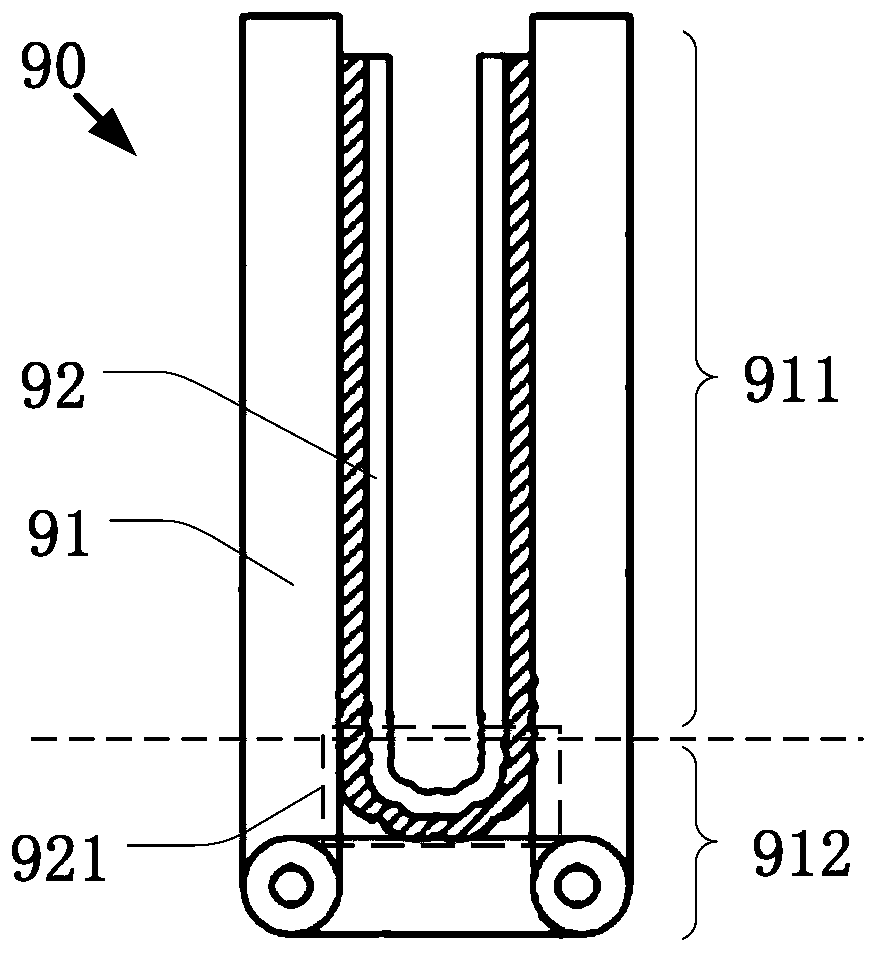

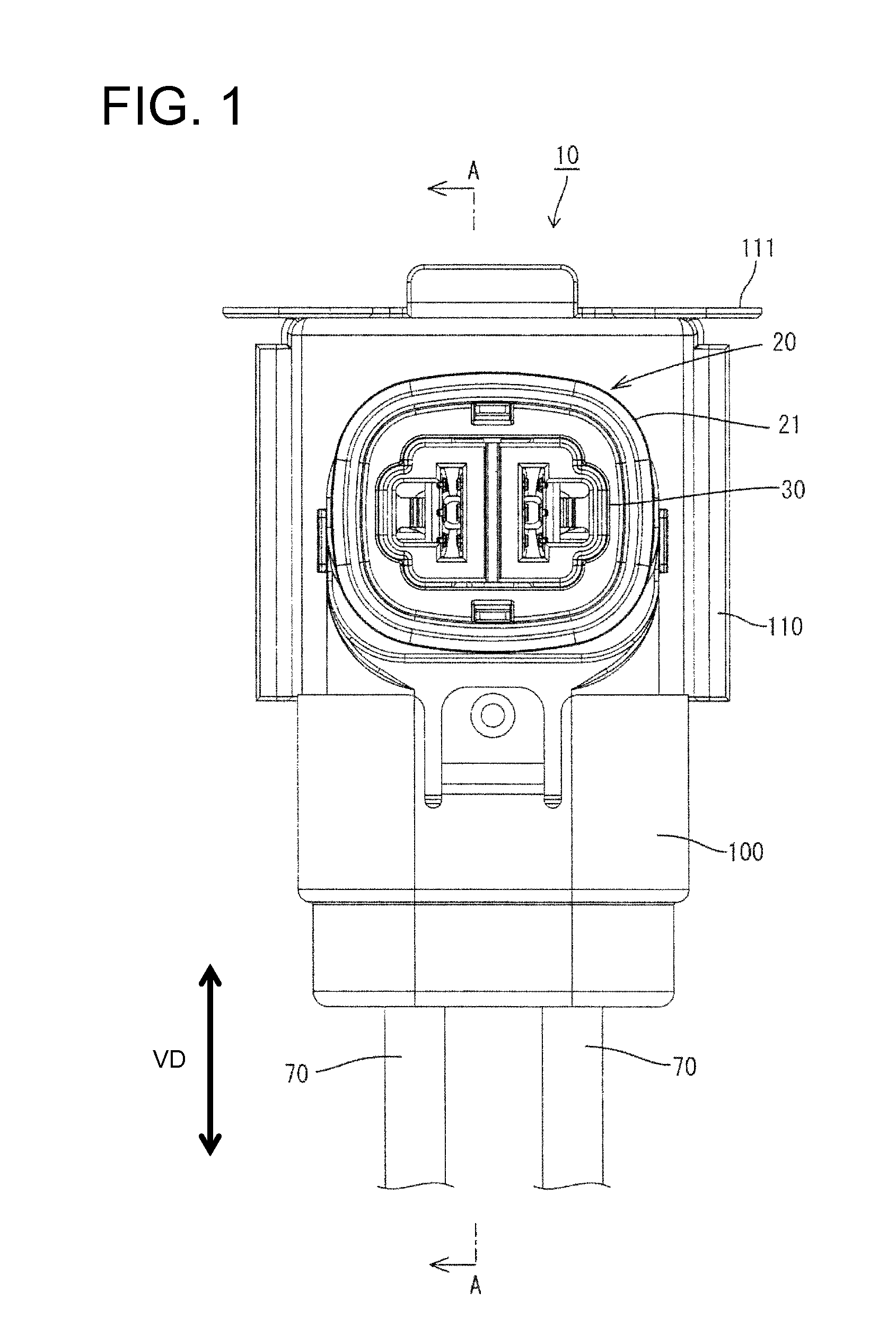

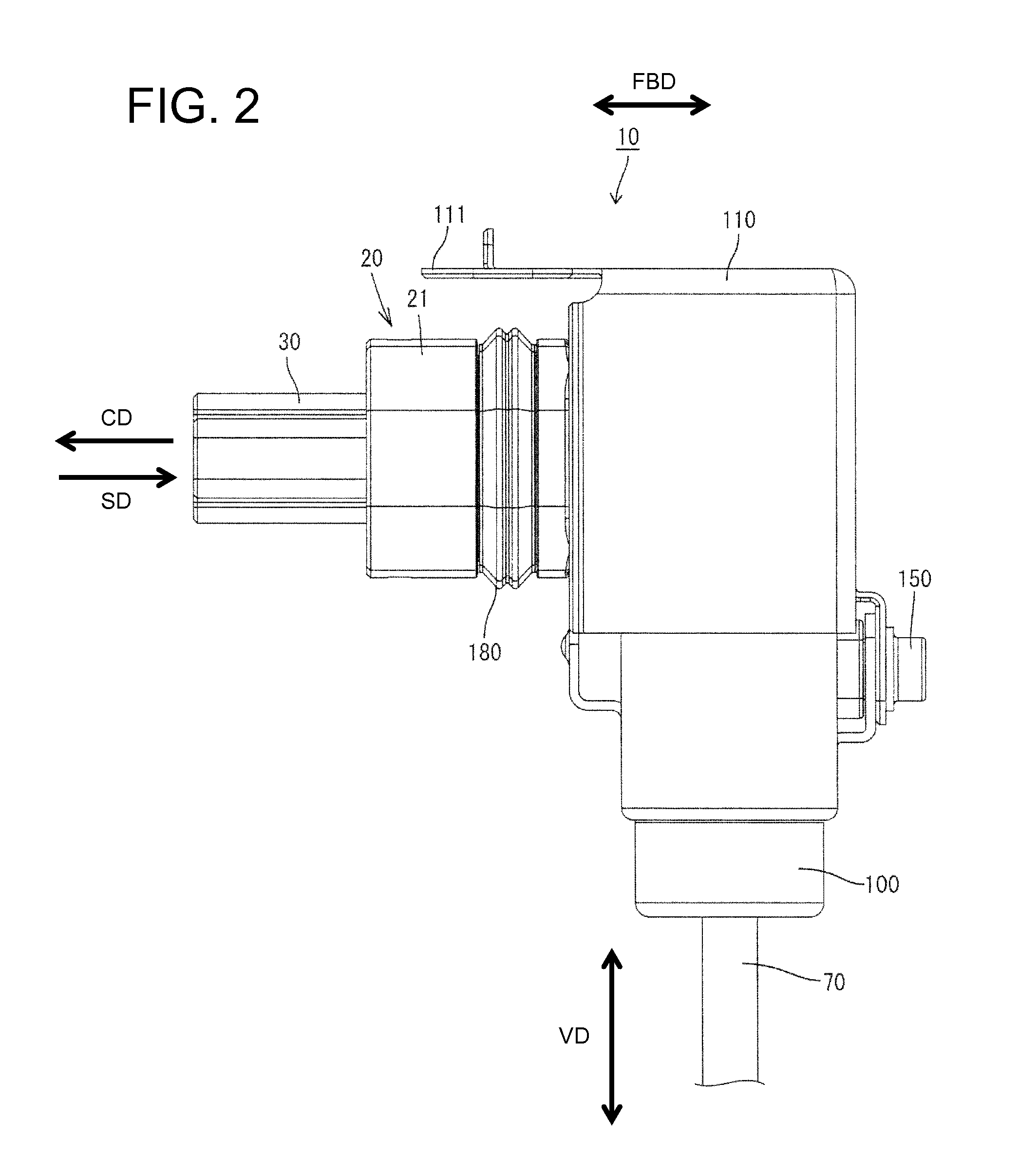

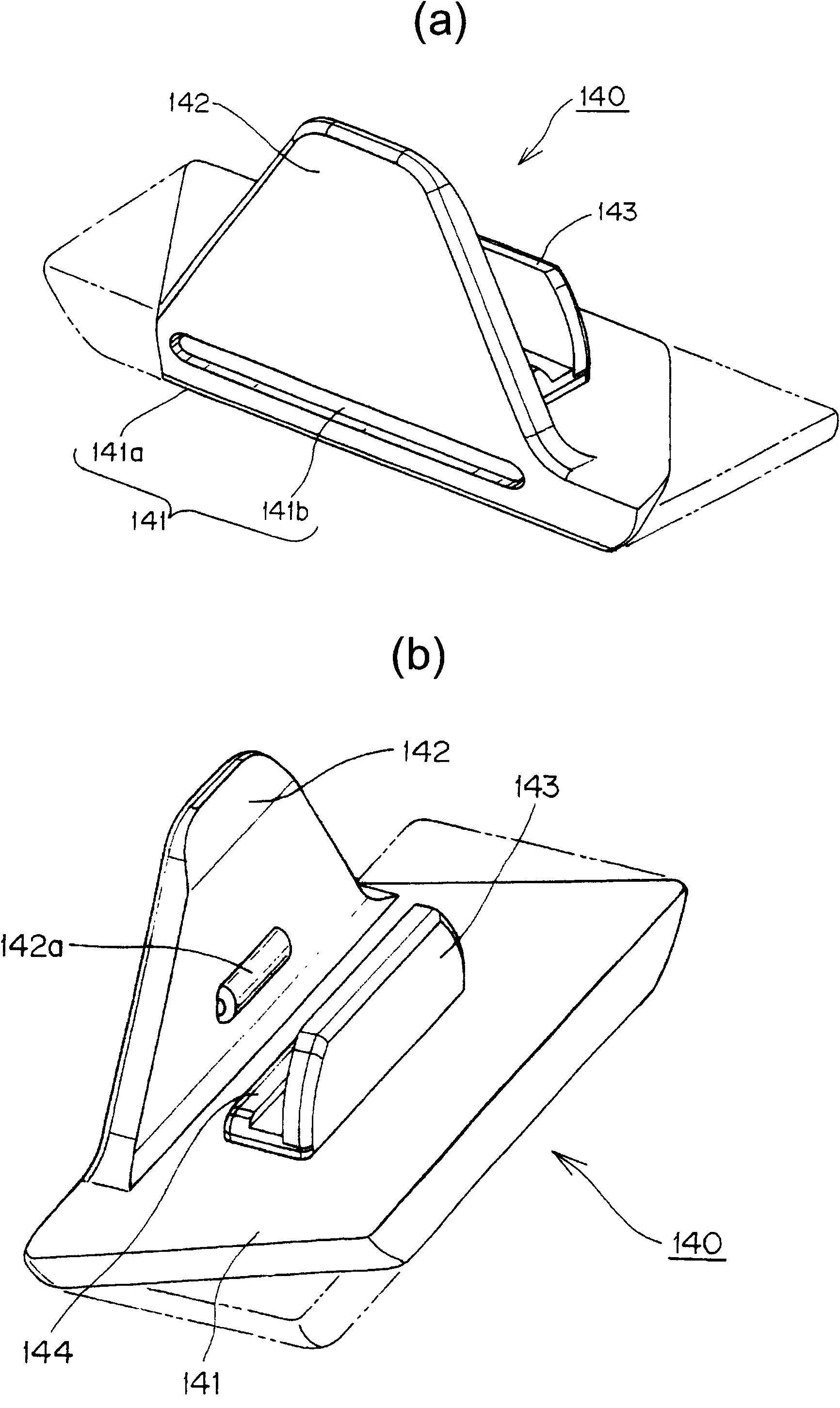

Connector

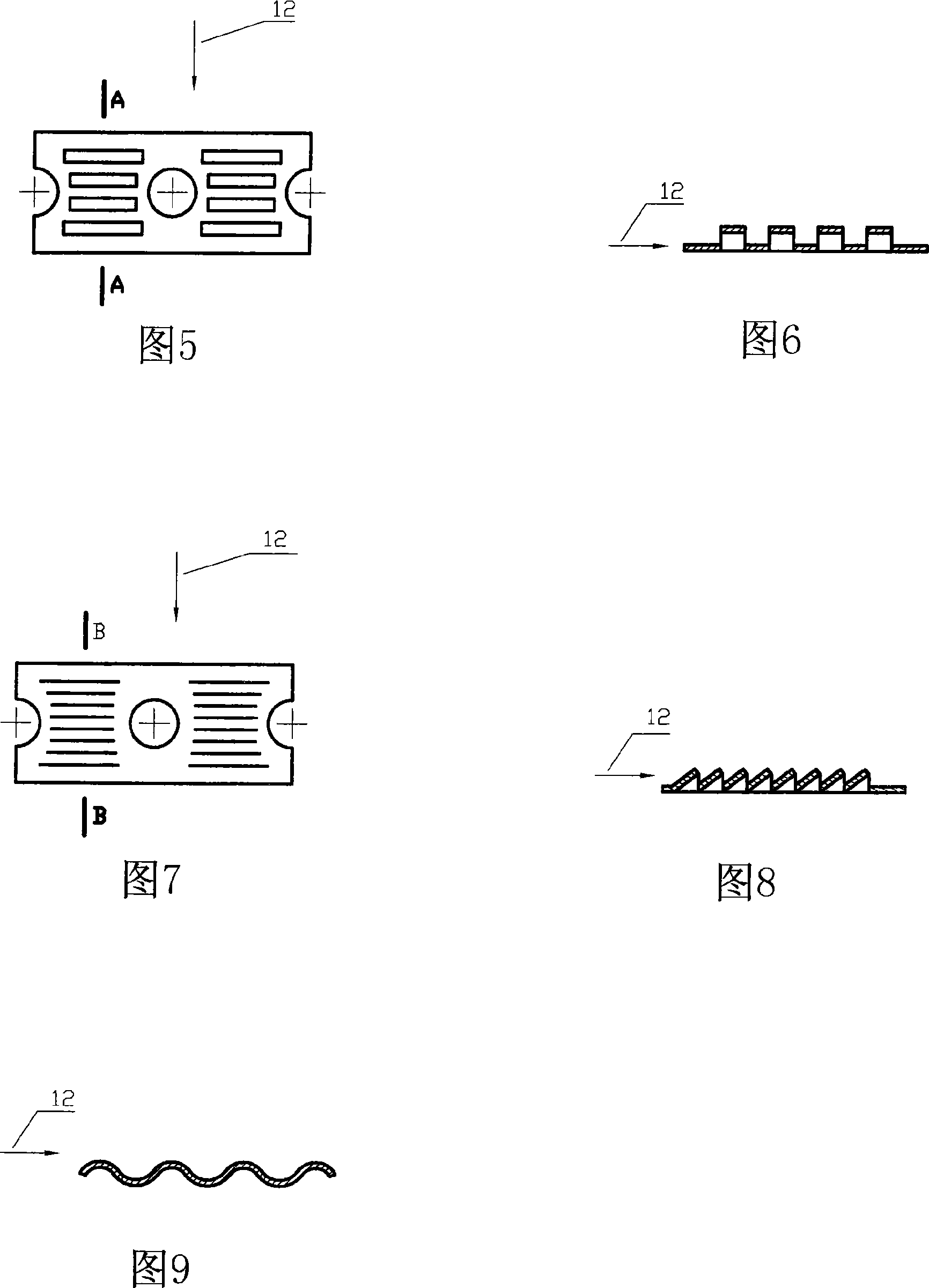

InactiveUS20140051286A1Small bending radiusImprove impact performanceTwo pole connectionsElectric discharge tubesMetalElectrical and Electronics engineering

A connector (10) includes a housing (20) connectable to a mating housing of the mating connector. A female terminal (52) is held in the housing (20) and includes a terminal connecting portion (52A) to be connected to a mating terminal provided in the mating connector and a barrel (52B) connected to the terminal connecting portion (52A). A flexible outer wire (70) is pulled out to outside from the interior of the housing (20). An inner conductive member (50) connects the barrel (52B) and the outer wire (70) in the housing (20) and includes an intermediate portion (53C) formed by bending a metal plate material substantially at a right angle. The intermediate portion (53C) is fixed to the housing (20).

Owner:SUMITOMO WIRING SYST LTD

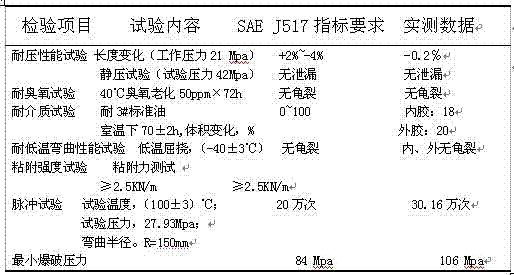

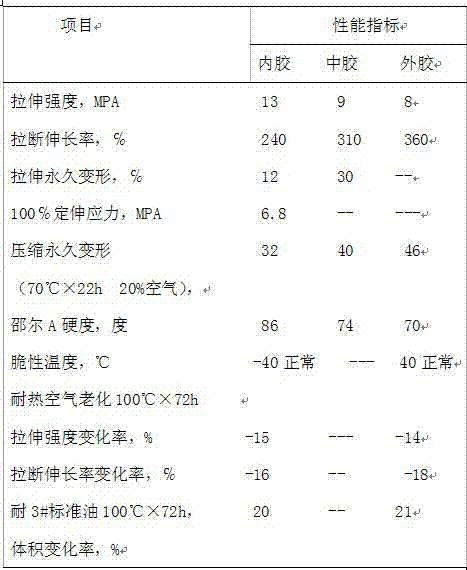

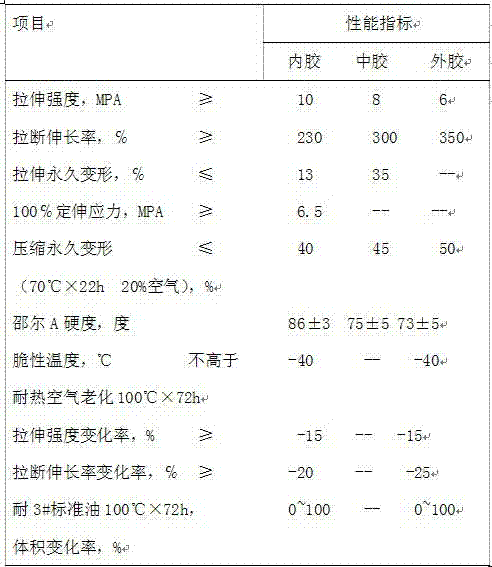

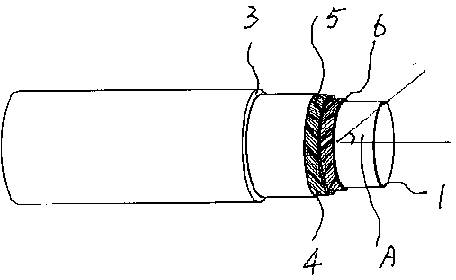

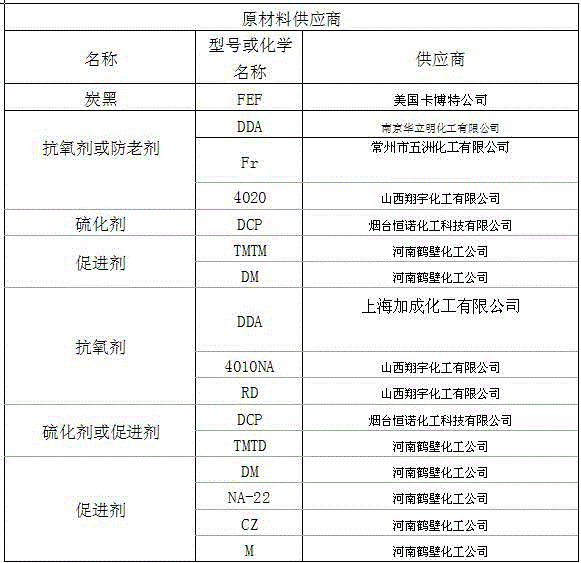

Compact steel wire braided rubber hose and preparation method thereof

The invention discloses a compact steel wire braided rubber hose, which comprises an inner rubber layer, two steel wire layers which are braided outside the inner rubber layer, a middle rubber layer between the two steel wire layers and an outer rubber layer outside the steel wire layers. The inner rubber of the inner rubber layer, the middle rubber of the middle rubber layer and the outer rubber of the outer rubber layer are made of the following raw materials: raw rubber, reinforcing agents, softening agents, minor ingredients, adhesive and accelerating agents. The invention additionally discloses a preparation method of the compact steel wire braided rubber hose. The compact steel wire braided rubber hose has the advantages that the structure is reasonable, the pulse compression deformation is small, the weight of the rubber hose is light, the bending radius is small, all performances of the finished product satisfy requirements in notes of SAEJ517R17, the pulse performance is stable, the pulse times exceeds 300 thousand and the service life of the rubber hose is greatly prolonged.

Owner:LUOHE LETONE RUBBER

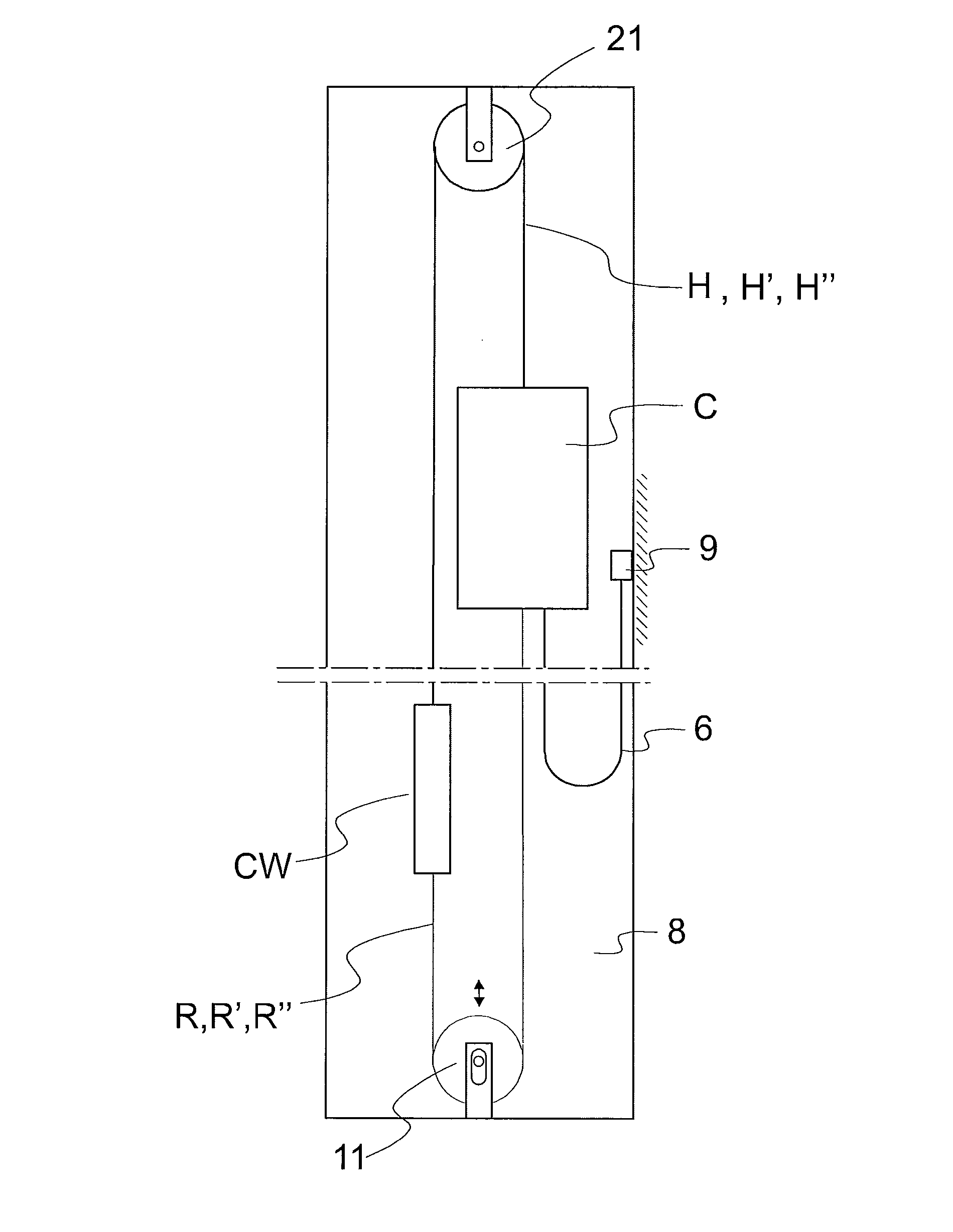

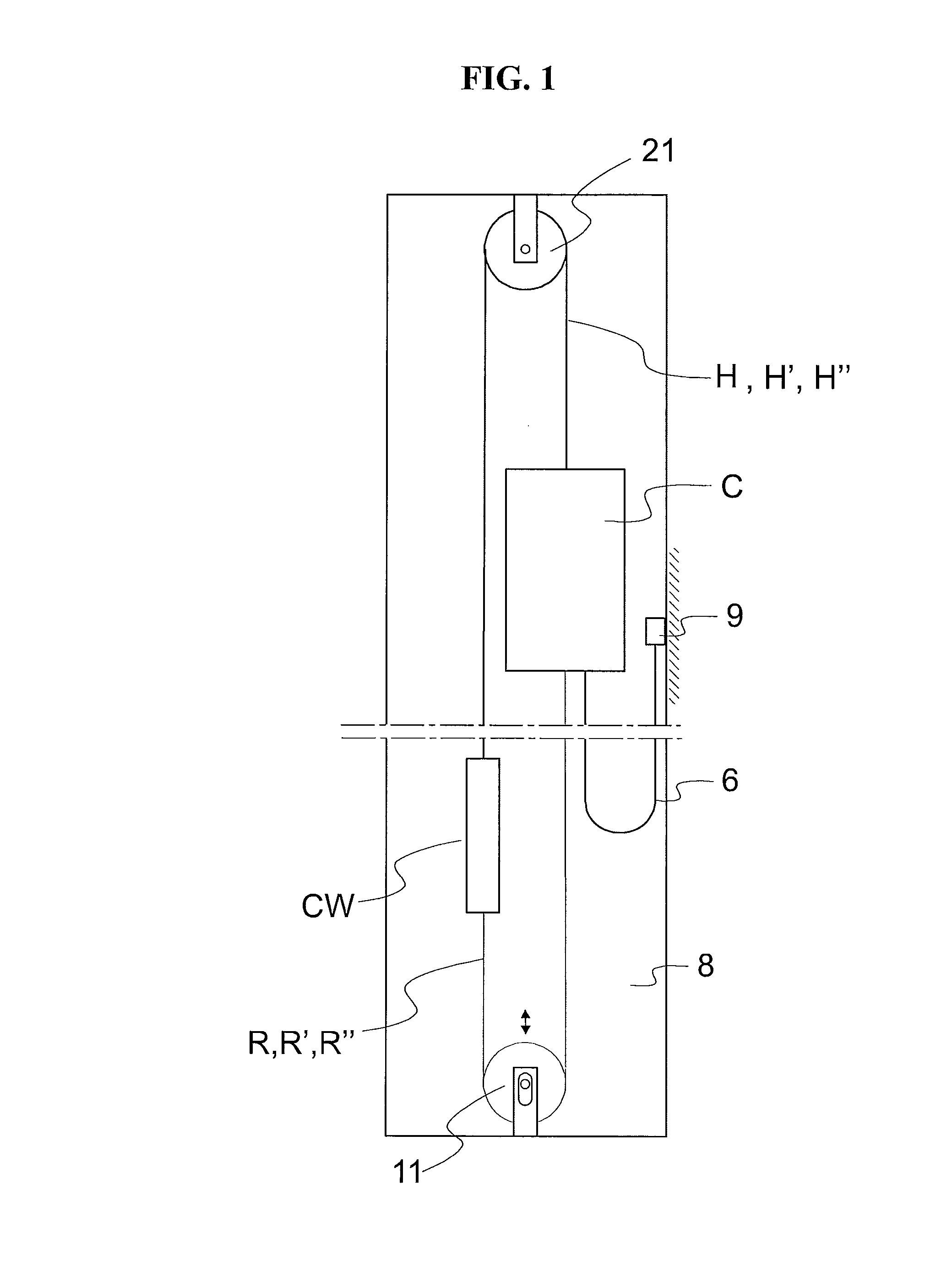

Elevator

ActiveUS20130048432A1Easy to useSmall bending radiusElevatorsBuilding liftsTransmitted powerMetallic materials

Elevator, which includes at least an elevator car and a device for moving the elevator car, preferably along guide rails, and a counterweight, and one or more ropes, which rope connects the elevator car and the counterweight and is separate from the supporting function and passes around a diverting pulley mounted on the bottom end of the elevator hoistway. The rope comprises a power transmission part or a plurality of power transmission parts, for transmitting power in the longitudinal direction of the rope, which power transmission part is essentially fully of non-metallic material.

Owner:KONE CORP

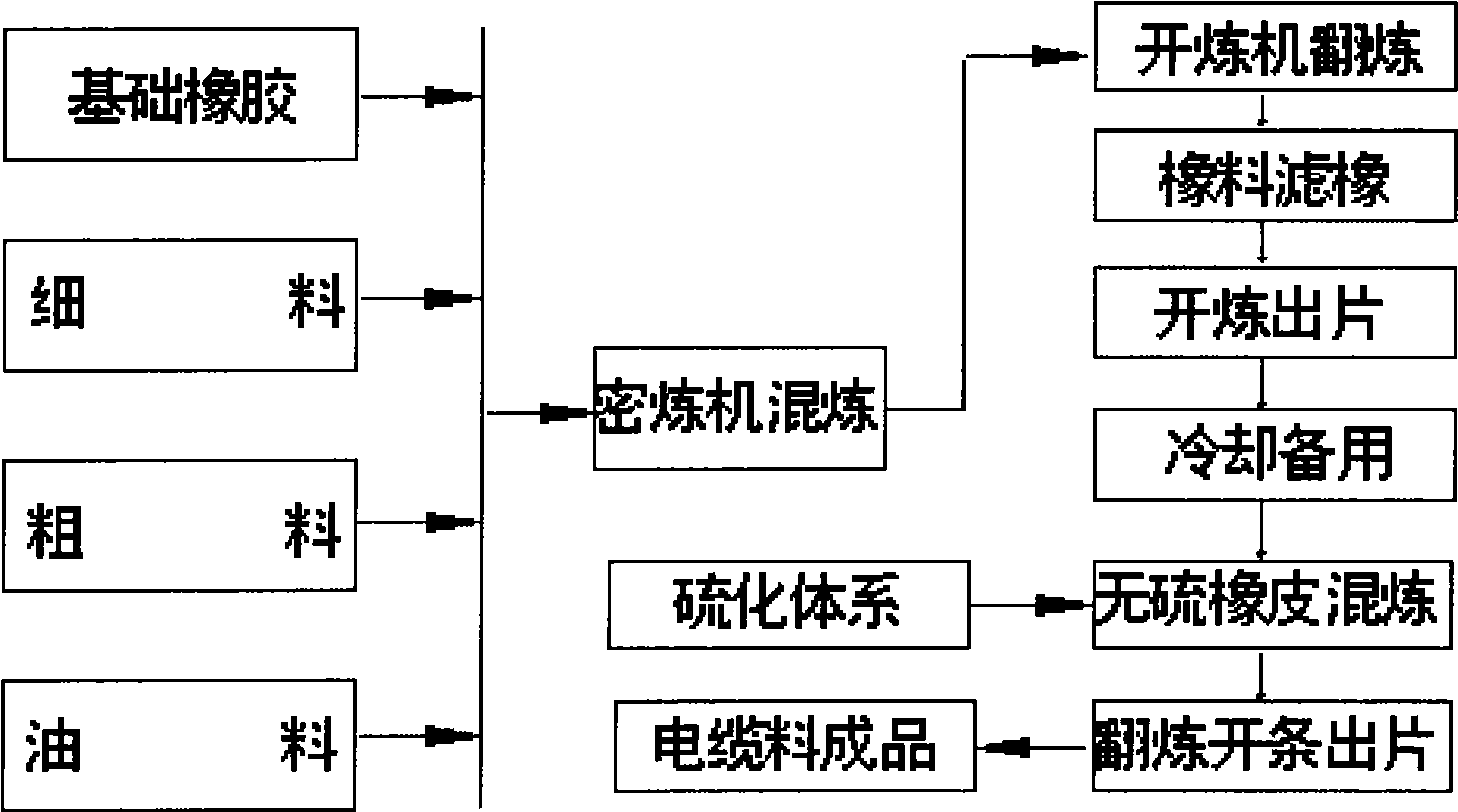

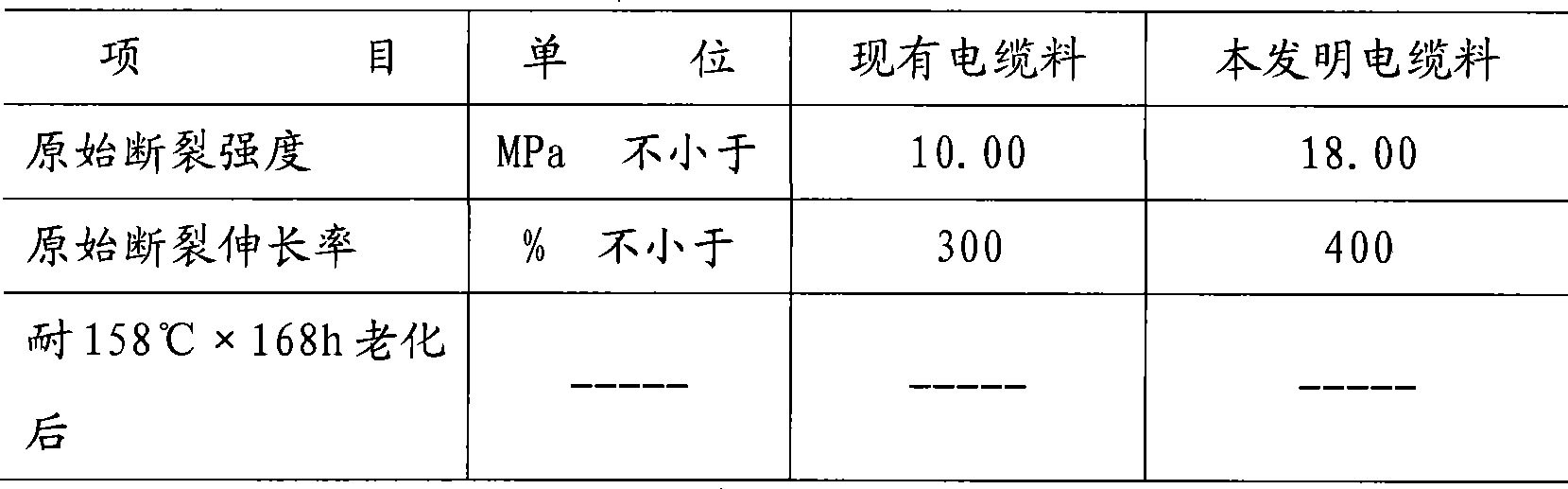

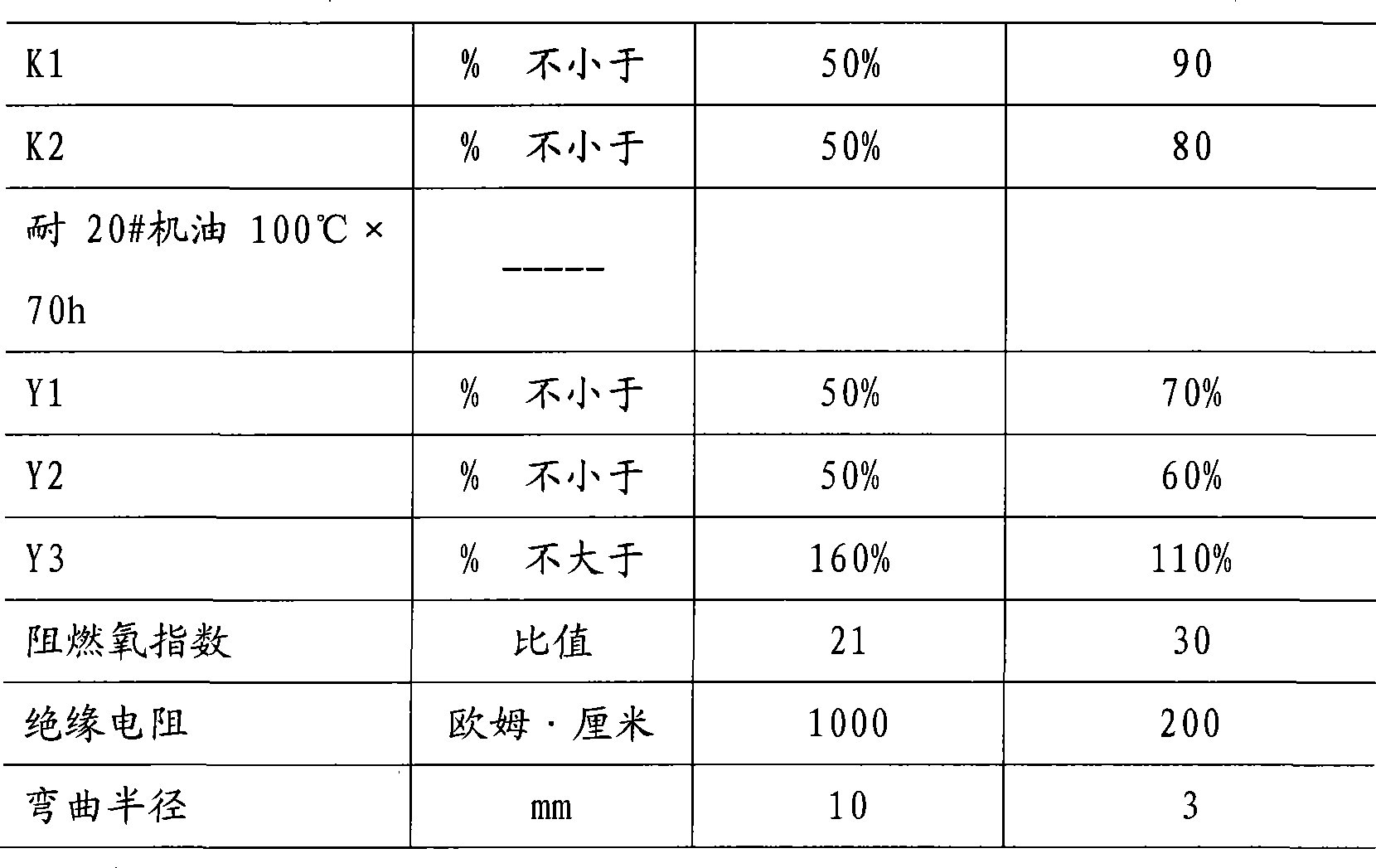

Electric wire and cable for flexible composite drag links and manufacturing process thereof

InactiveCN101140815ACompact structureSmall footprintFlexible cablesCable/conductor manufactureBatch productionUnevaluable

The invention belongs to the technical field of wire and cable, especially relating to wire and cable for a flexible composite towline and its manufacturing process, which comprises a conductor, cable materials and stuffing. The cable materials are set outside of the conductor and stuffing. The conductor is a copper conductor while the stuffing is polypropylene reticular tearing fiber. The said cable materials is the insulating compound and covering materials which is composed of polyvinyl chloride soft packing, butyronitrile compound and elastomer. The cable provided in the invention has the advantages of compact structure in reason with less space occupation, outstanding flexibility in continuous bending and low price. The successful development of the wire and cable for flexible composite towline supplies a gap in domestic production. Batch production of the cable not only creates a business opportunity for enterprises, but also drives the same trades to make batch production of the wire and cable for the flexible composite towline, which brings invaluable economic efficiency of enterprises and inestimable social benefit.

Owner:SHENYANG SHIELDING CABLE

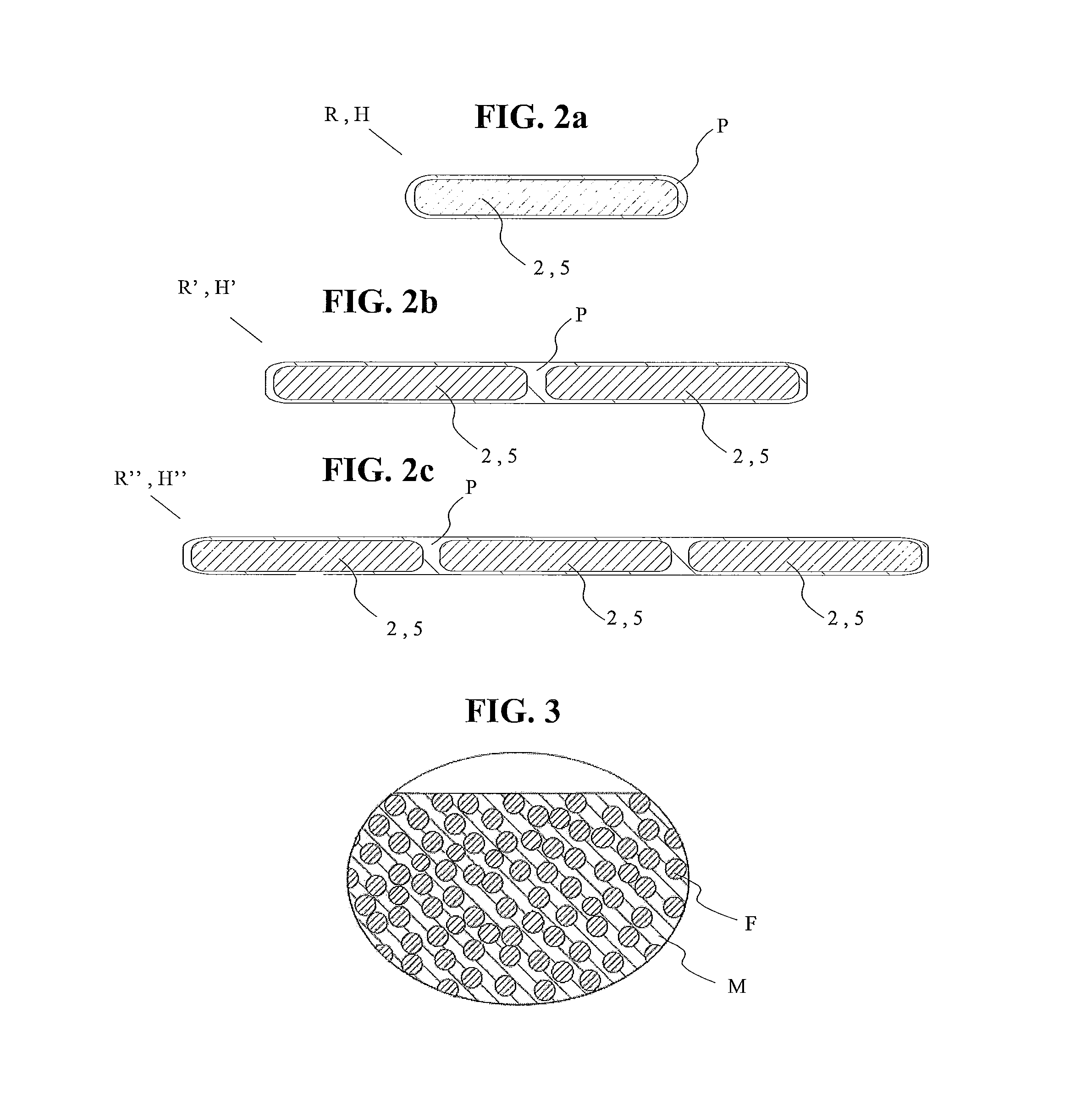

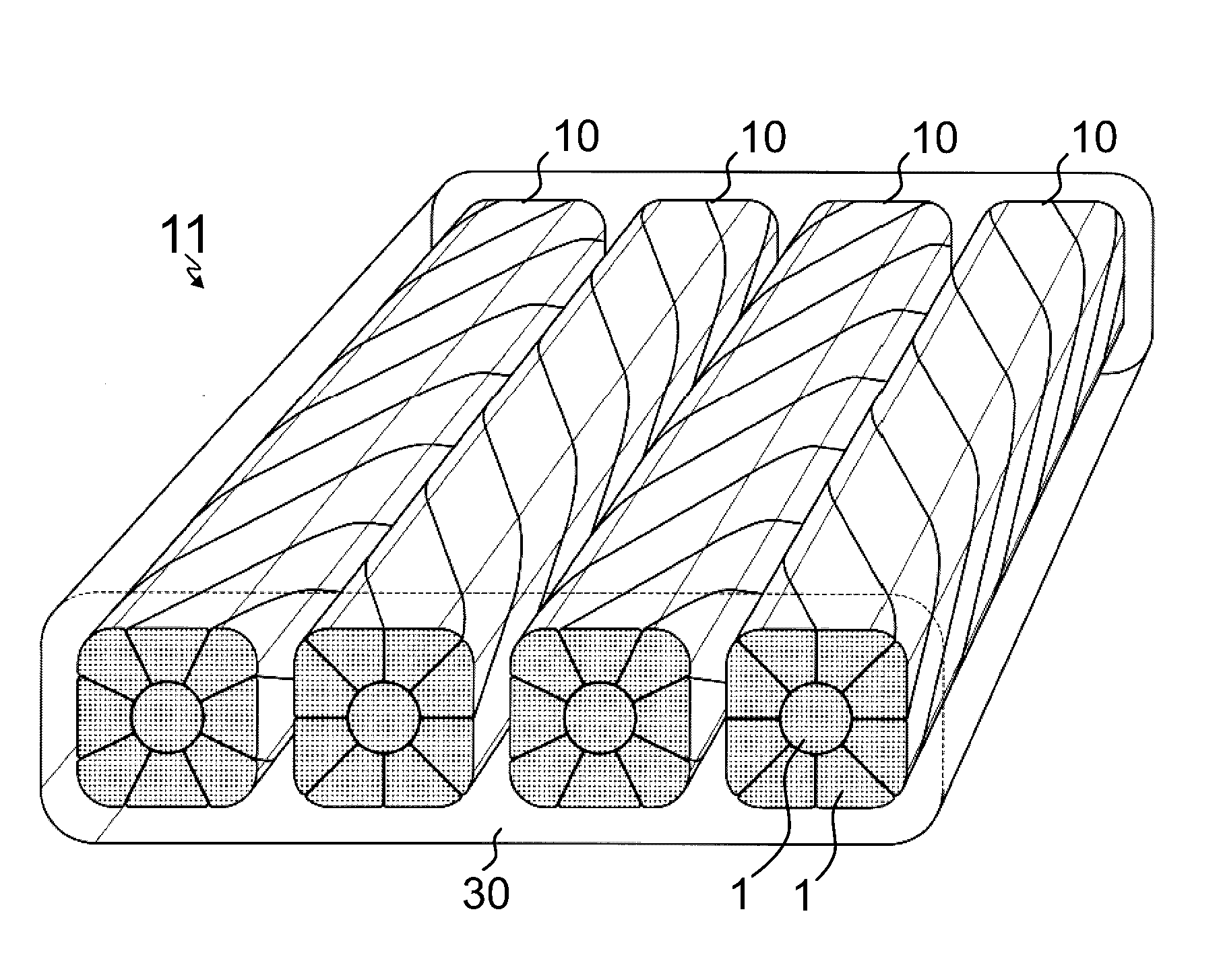

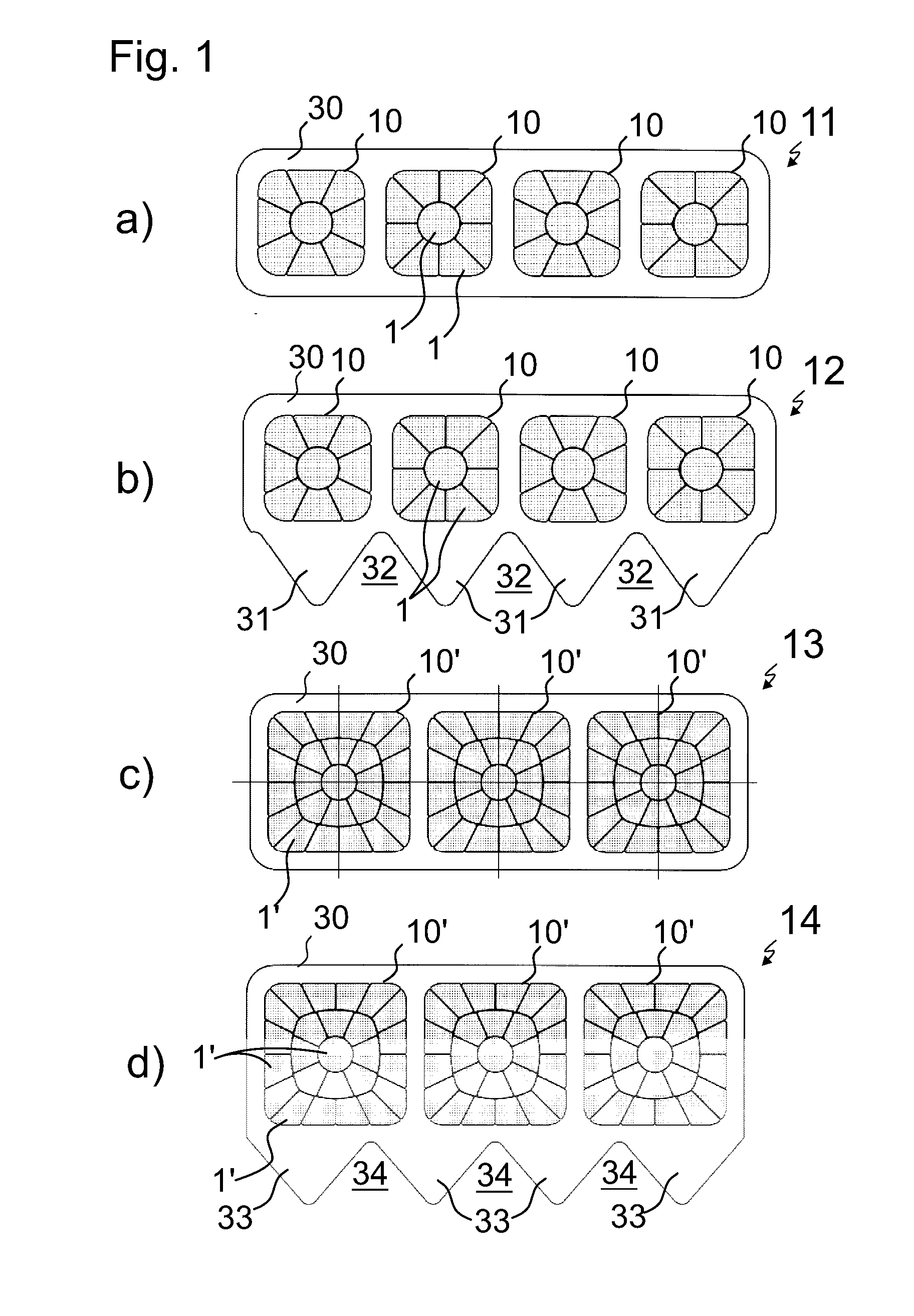

Rope for a hoisting device and elevator

ActiveUS20150101888A1High load bearing abilityFacilitate useSynthetic resin layered productsCeramic layered productsFiberMechanical engineering

A rope for a hoisting device, which rope is belt-shaped and includes several load bearing members spaced apart in the width direction of the belt-shaped rope and embedded in a common coating, each of the load bearing members including several load bearing strings twisted together. The load bearing strings are made of composite material including reinforcing fibers embedded in polymer matrix.

Owner:KONE CORP

125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material

InactiveCN101544790AIt has the characteristics of green environmental protectionGood softnessShielded cableActive agent

The present invention discloses a 125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material, including 100.00 shares of ethylene / ethylene acetic acid rubber, 60.00 to 100.00 shares of conductive carbon black, 40.00 to 60.00 shares of light calcium carbonate, 10.00 to 15.00 shares of plasticizer, 0.50 to 1.00 shares of active agent, 1.50 to 2.00 shares of anti-aging agent, 0.50 to 1.00 shares of technology operating agent, 1.50 to 2.00 shares of Di(tert-butylperoxyisopropyl)benzene, and 1.00 to 3.00 shares of triallyl isocyanurate. The rubber shielding cable material has characteristics of high temperature resistance, high conductivity, low smoke, non halogen, oil resistance, very plasticity and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

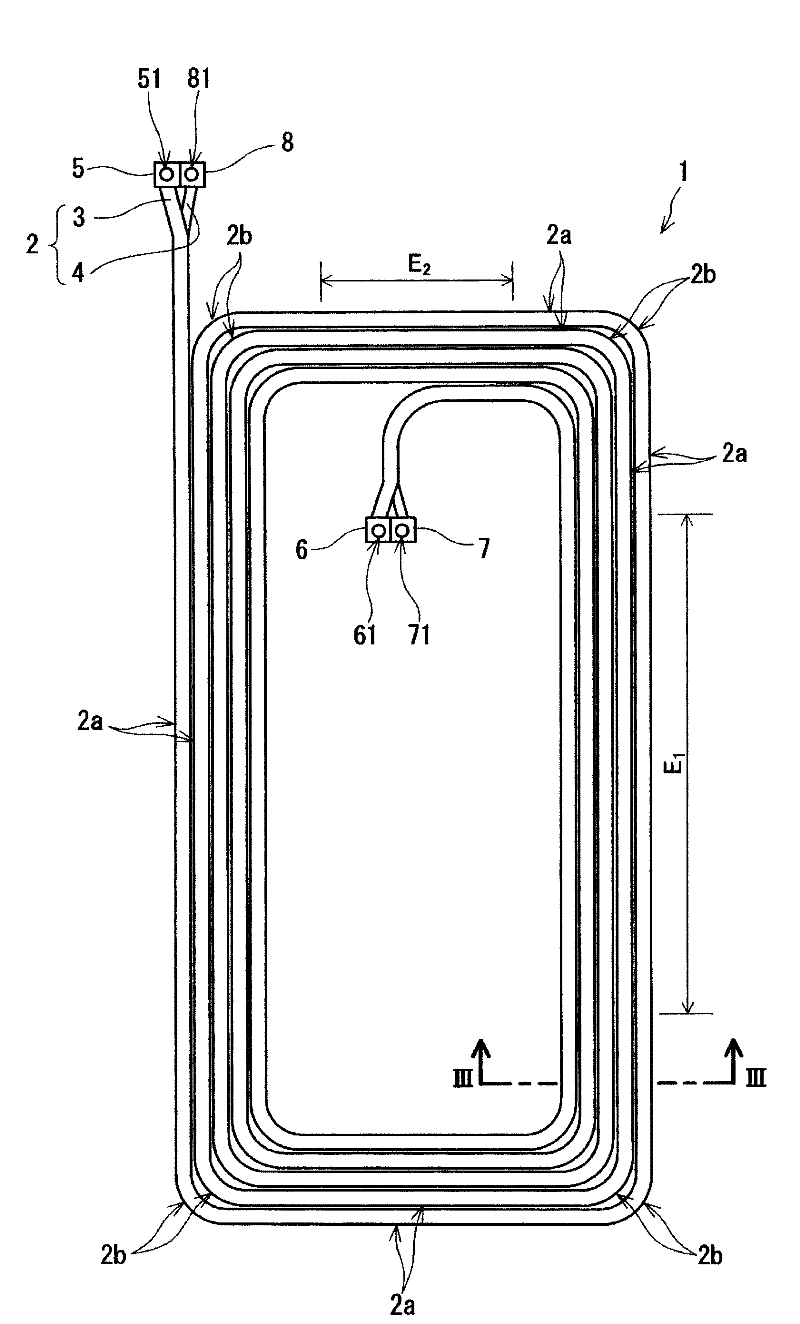

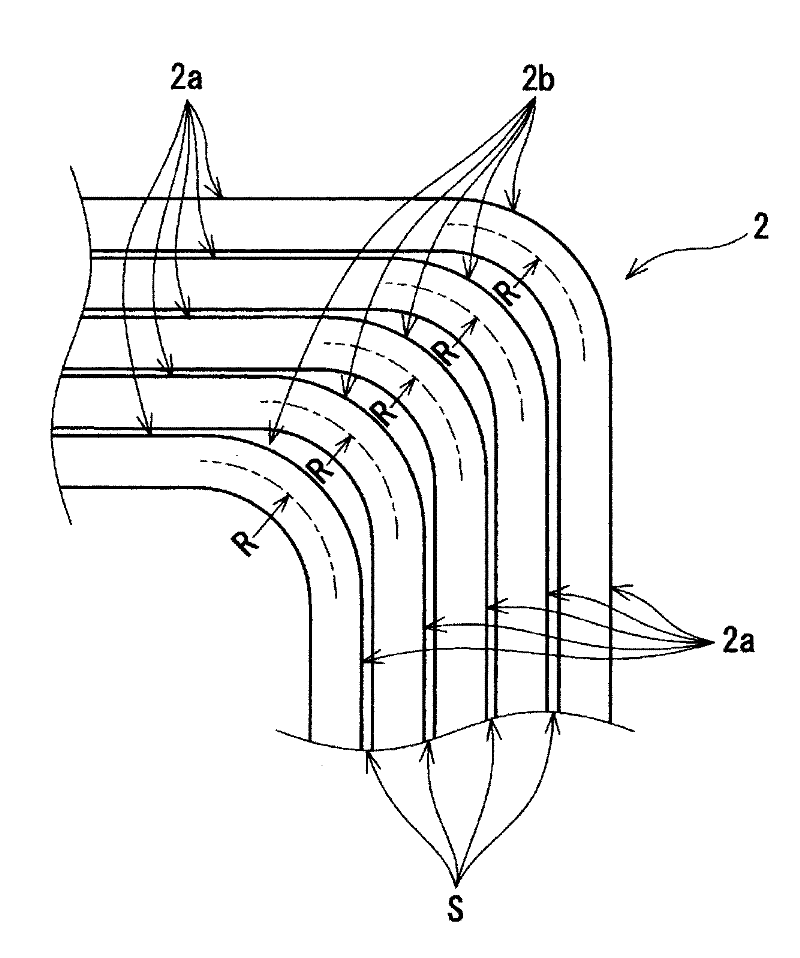

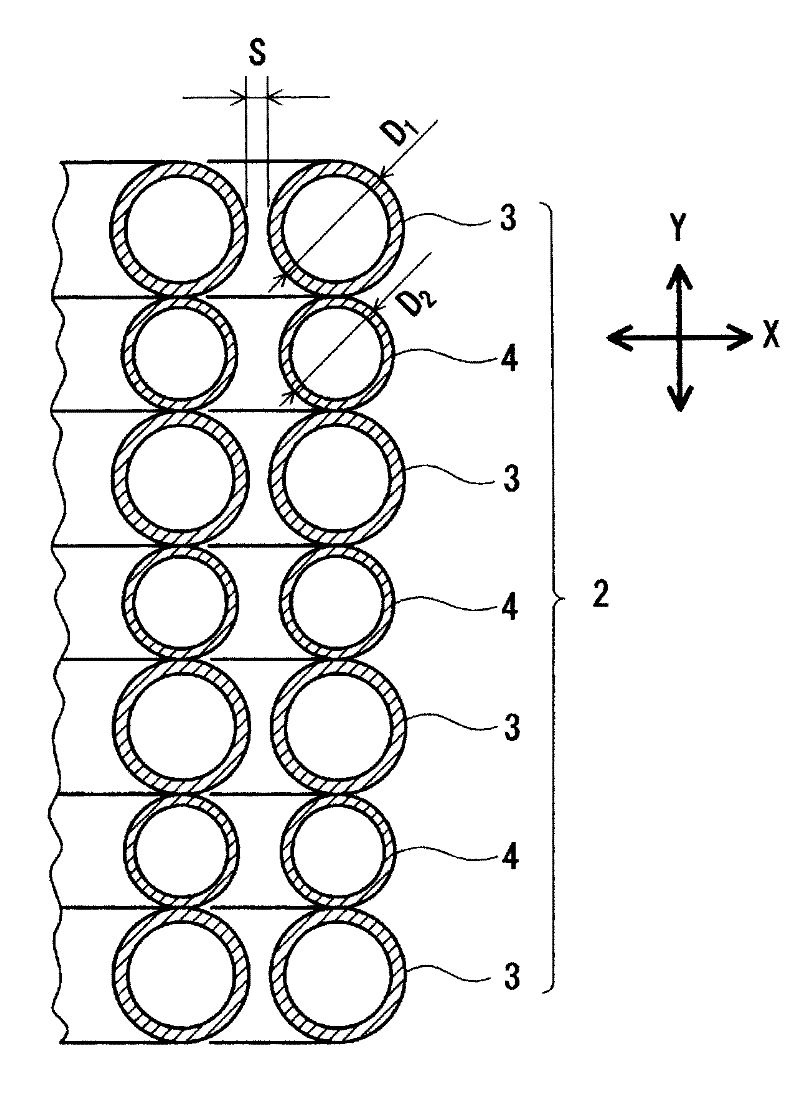

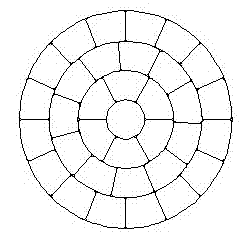

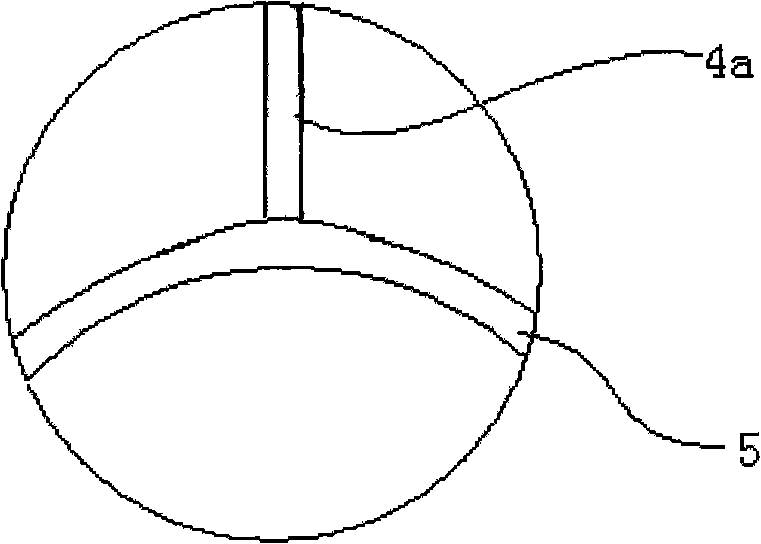

heat exchanger

InactiveCN102301197AImprove temperature uniformityImprove heat exchange efficiencyFluid heatersHeating fuelEngineeringHeat transfer tube

A heat exchanger includes a heat transfer tube group in which a plurality of first heat transfer tubes (3) through which a first fluid flows and a plurality of second heat transfer tubes (4) through which a second fluid that exchanges heat with the first fluid flows are arranged alternately while being in contact with each other. The heat transfer tube group is formed in a spiral shape by being wound in X direction perpendicular to Y direction in which the first heat transfer tubes (3) and the second heat transfer tubes (4) are arranged. A plurality of concave portions (3a) are provided on both sides, in the X direction, of an outer circumferential surface (31) of each of the first heat transfer tubes (3), along an extending direction of the first heat transfer tube (3). The plurality of concave portions (3a) form convex portions on an inner circumferential surface of the first heat transfer tube (3).

Owner:PANASONIC CORP

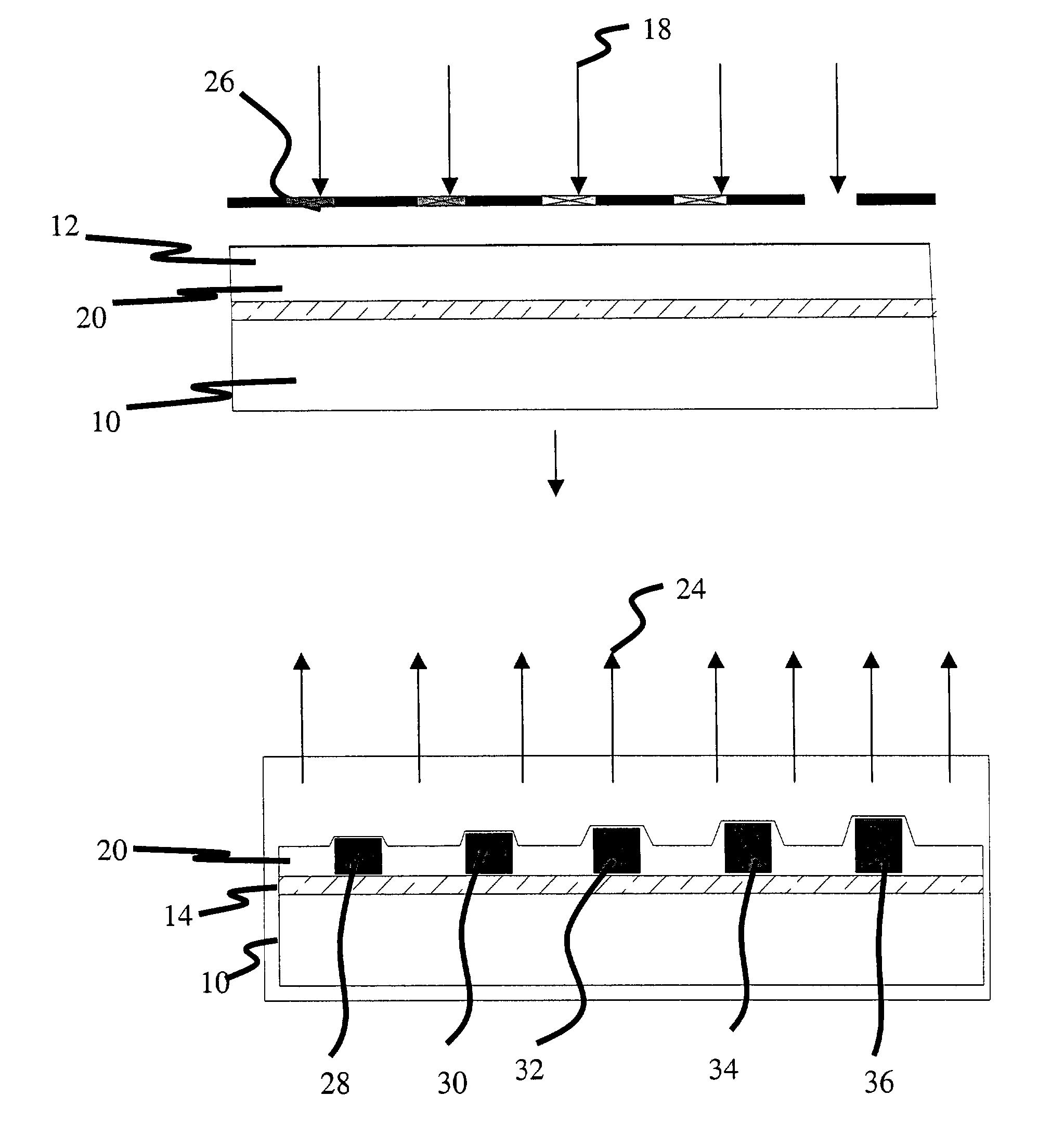

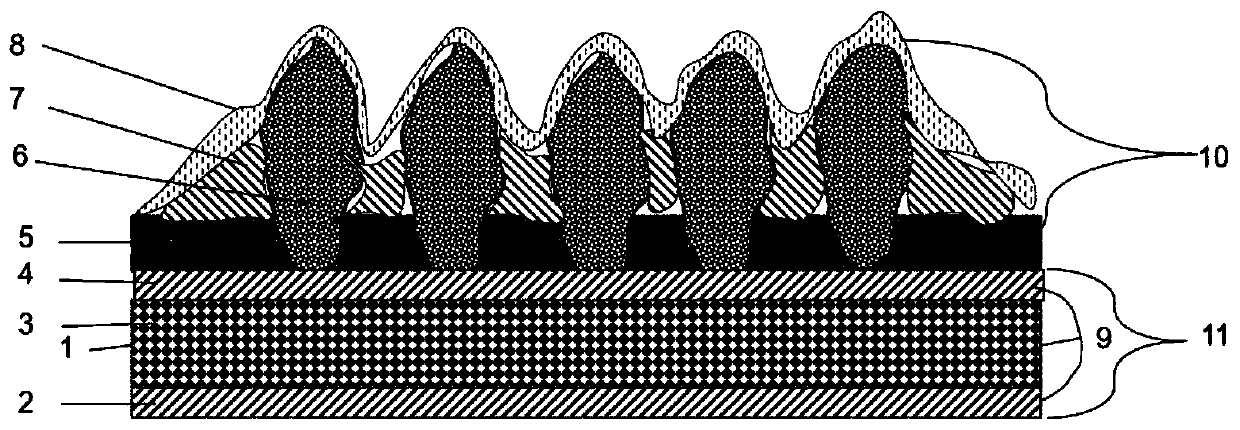

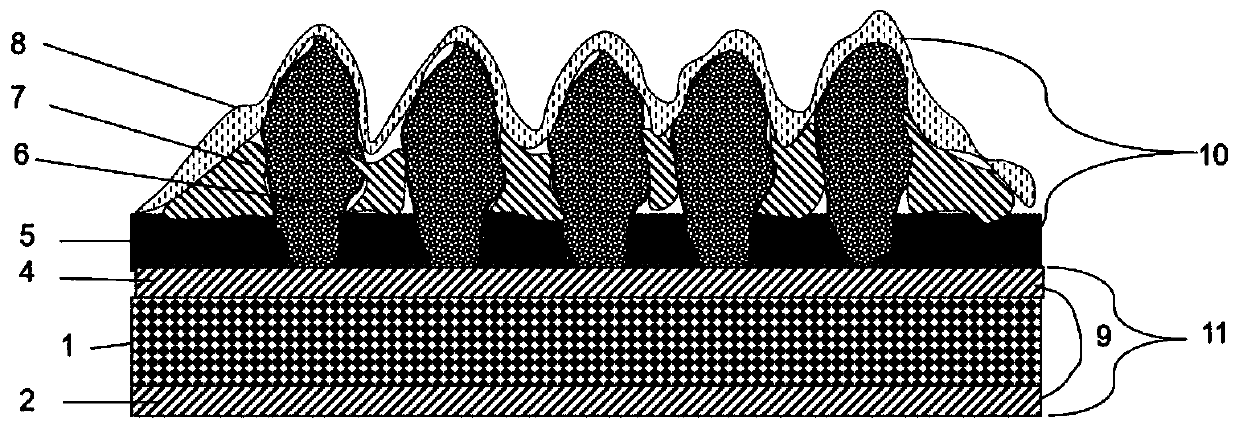

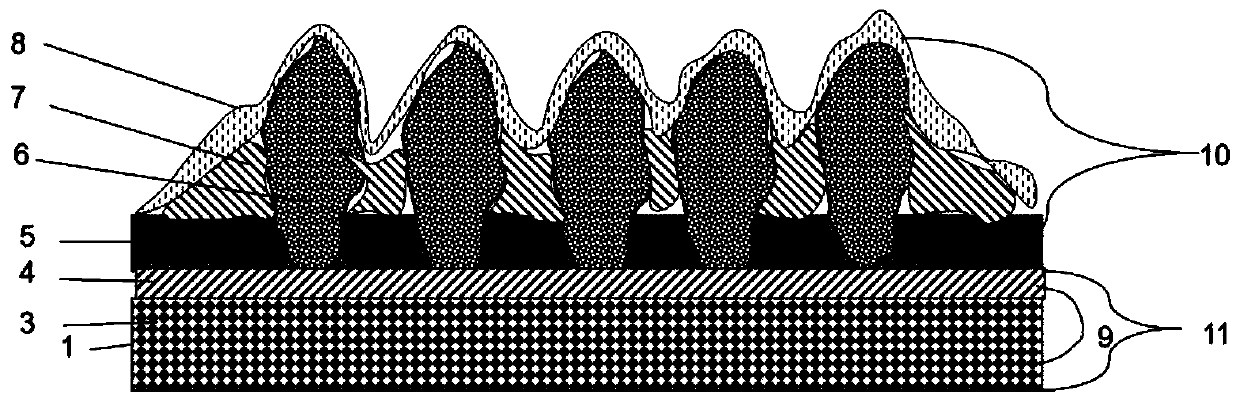

Optical device structures based on photo-definable polymerizable composites

InactiveUS20040101268A1Significant differenceSmall bending radiusOptical waveguide light guideLensRefractive indexSingle mode waveguides

An optical device structure comprising a substrate and at least one topological feature. The topological feature comprises a polymeric composite material formed from a polymerizable binder and an uncured monomer. The topological feature has a controlled topological profile and a controlled refractive index across the topological feature. The optical device structure may be a multimode waveguide device, a single mode waveguide device, an optical data storage device, thermo-optic switches, or microelectronic mechanical system.

Owner:GENERAL ELECTRIC CO

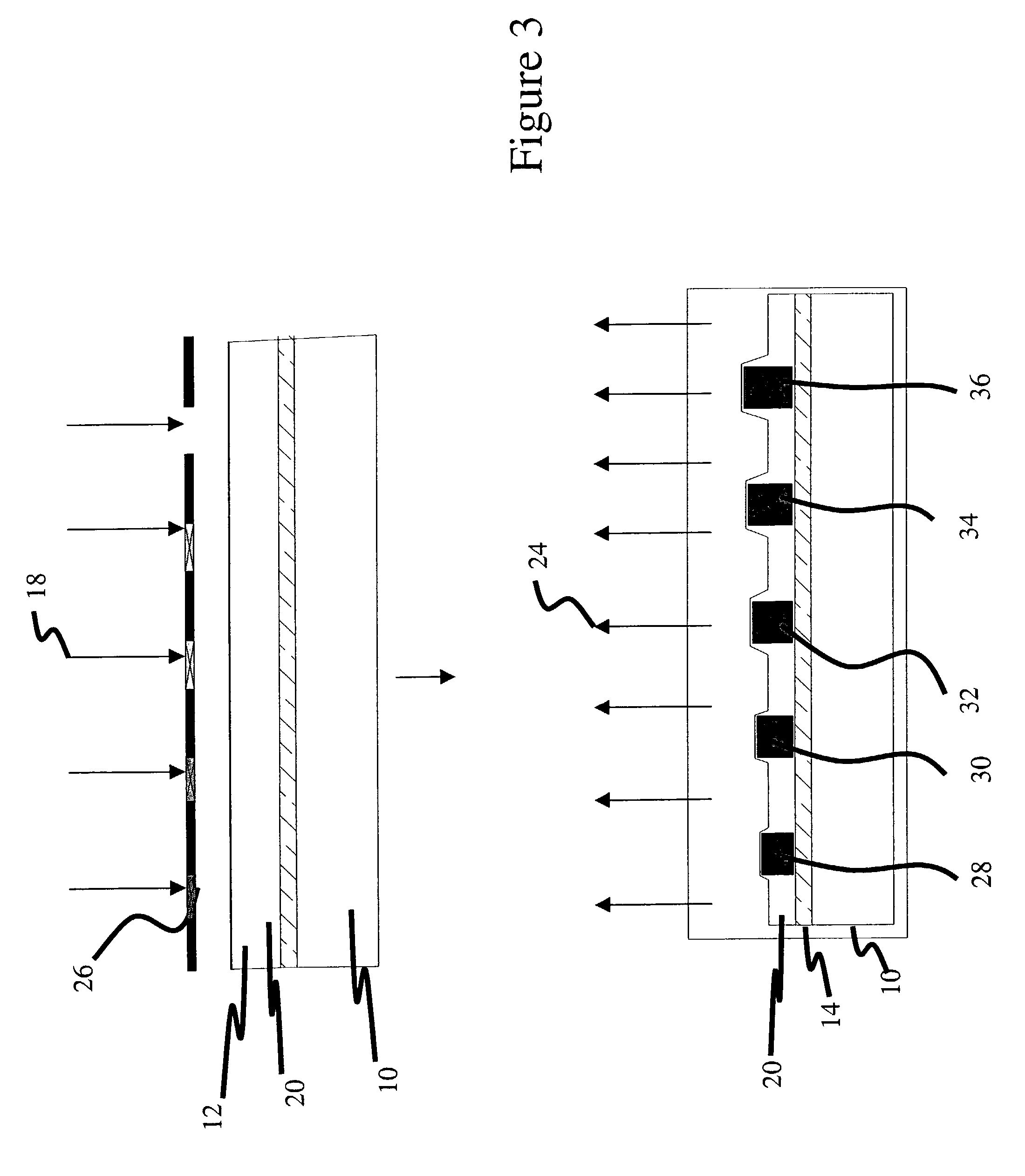

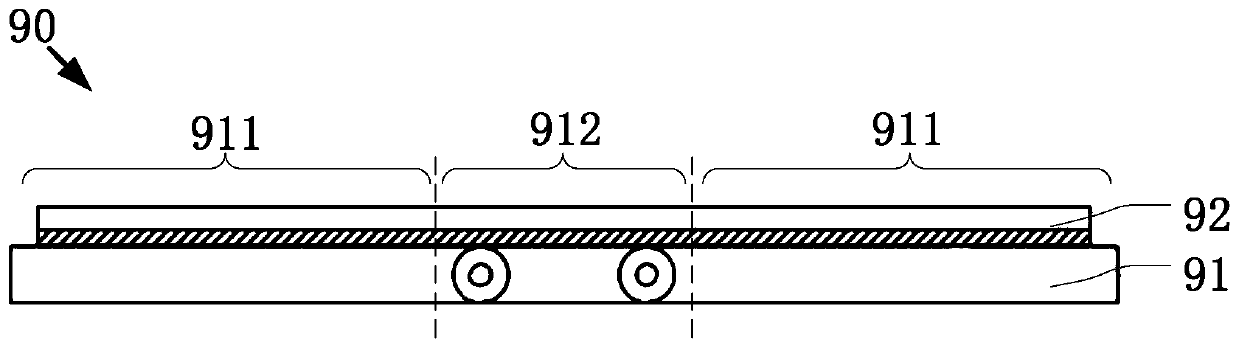

Folding display device

InactiveCN110718155AResolve the breakSmall bending radiusIdentification meansDisplay deviceEngineering

The invention provides a folding display device. The folding display device comprises a foldable module, sliding devices and a display panel. The foldable module comprises a first substrate, a secondsubstrate and a bending mechanism, wherein the first substrate and the second substrate are arranged oppositely, and the bending mechanism is arranged between the first substrate and the second substrate; the at least two sliding devices are arranged on the first substrate and the second substrate respectively; the display panel is mounted on the sliding devices; the display panel comprises a panel folding area and a non-folding area; the panel folding area is opposite to the bending mechanism; and when being bent, the display panel can slide relative to the foldable module through the slidingdevices. The folding display device solves the technical problem that breakage or wrinkling of the display panel is easily caused due to the fact that the stress of a bending area of the flexible display panel in the folding display device is excessively concentrated, so that the bending radius of the bending area is smaller.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

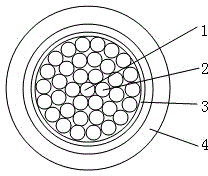

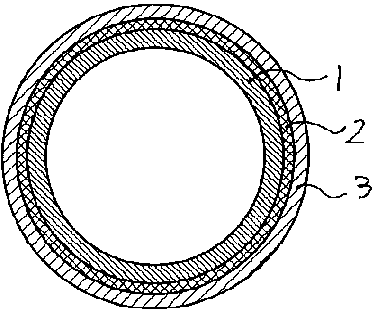

Cleaning-type oil-resistant cable

InactiveCN102082004ALarge leakage currentWear-resistantClimate change adaptationInsulated cablesCopper conductorCross-link

The invention belongs to the technical field of electrical wire and cable production processes, and particularly relates to a cleaning-type oil-resistant cable. Conductors (1) are copper conductors, the structures of the conductors adopt a first type or a second type, a cross-linked polyethylene insulating layer (2) is extruded on the conductors (1) respectively by applying a warm water cross-linking technology to serve as a cable core, an inner lining layer (3) is arranged outside the cable core, an armor layer (4) is armored by back-twist type galvanized fine steel wires, aluminum-plastic composite tapes are longitudinally coated and welded outside the armor layer (4) to form a water and tide blocking layer (5), and a flame-retardant jacket layer (6) made of a butyronitrile material is arranged at the outermost layer. With a double-layer co-extrusion mode to extrude, the arrangement of the high-strength water and tide blocking layer capable of longitudinally preventing tension in the overall cable and a process of double-layer co-extrusion protection layers, the cleaning-type oil-resistant cable has not only very strong resistance to abrasion and oil, but also better resistance to cleaning, thereby the quality stability of the oil-resistant cable is improved and a new technical field is developed for the development of the cleaning-type oil-resistant cable.

Owner:HENAN HUATAI SPECIAL CABLE

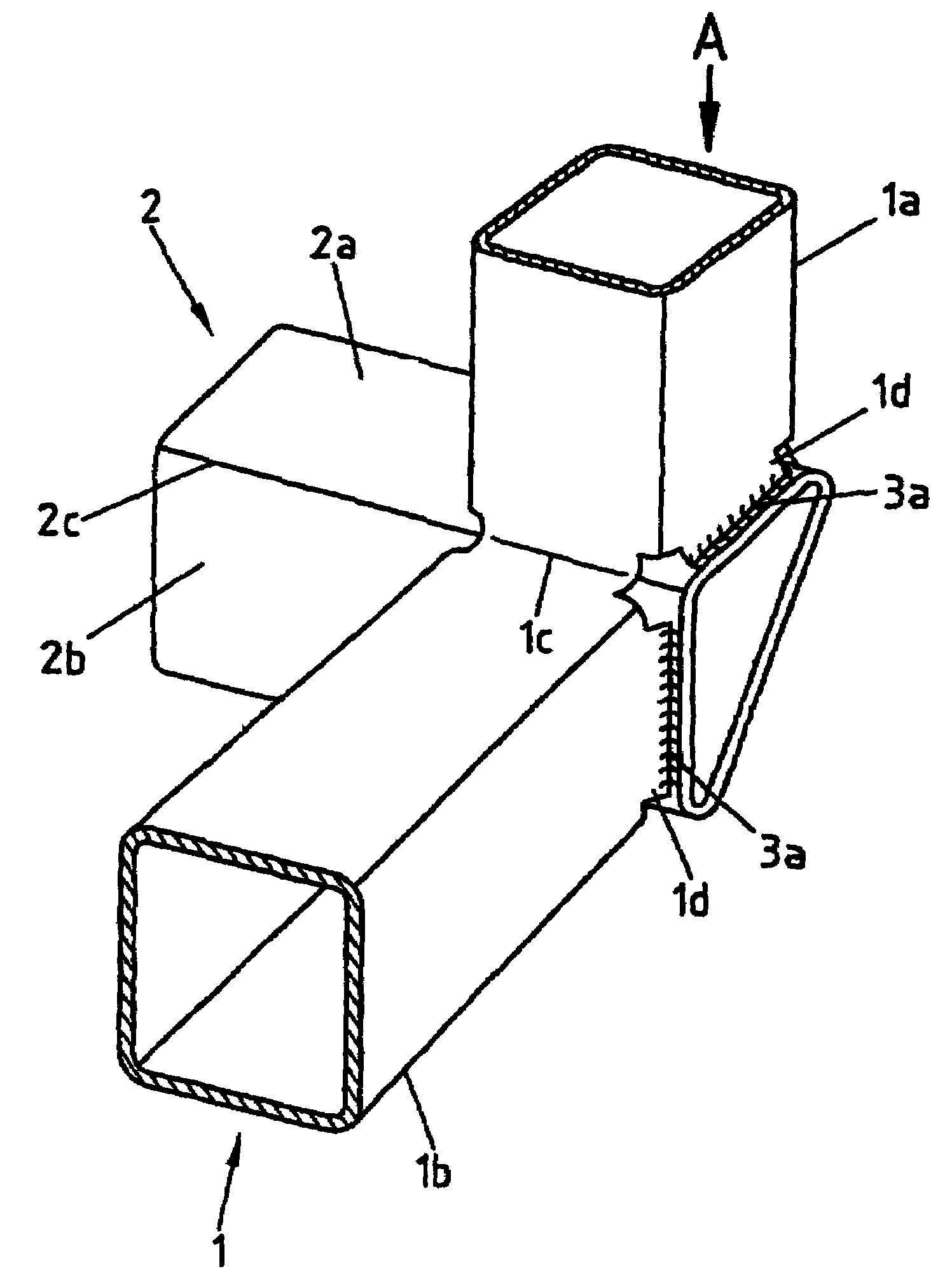

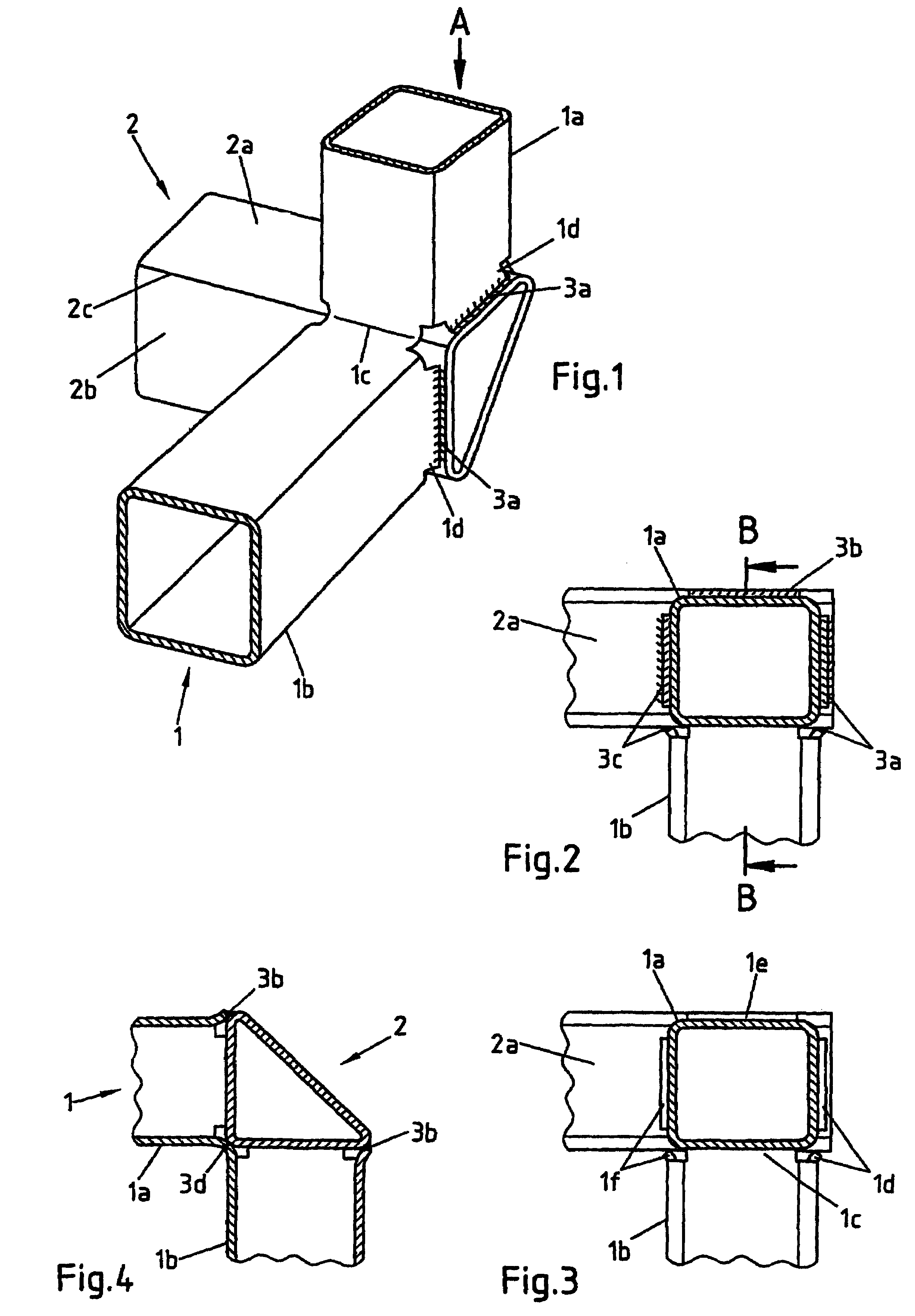

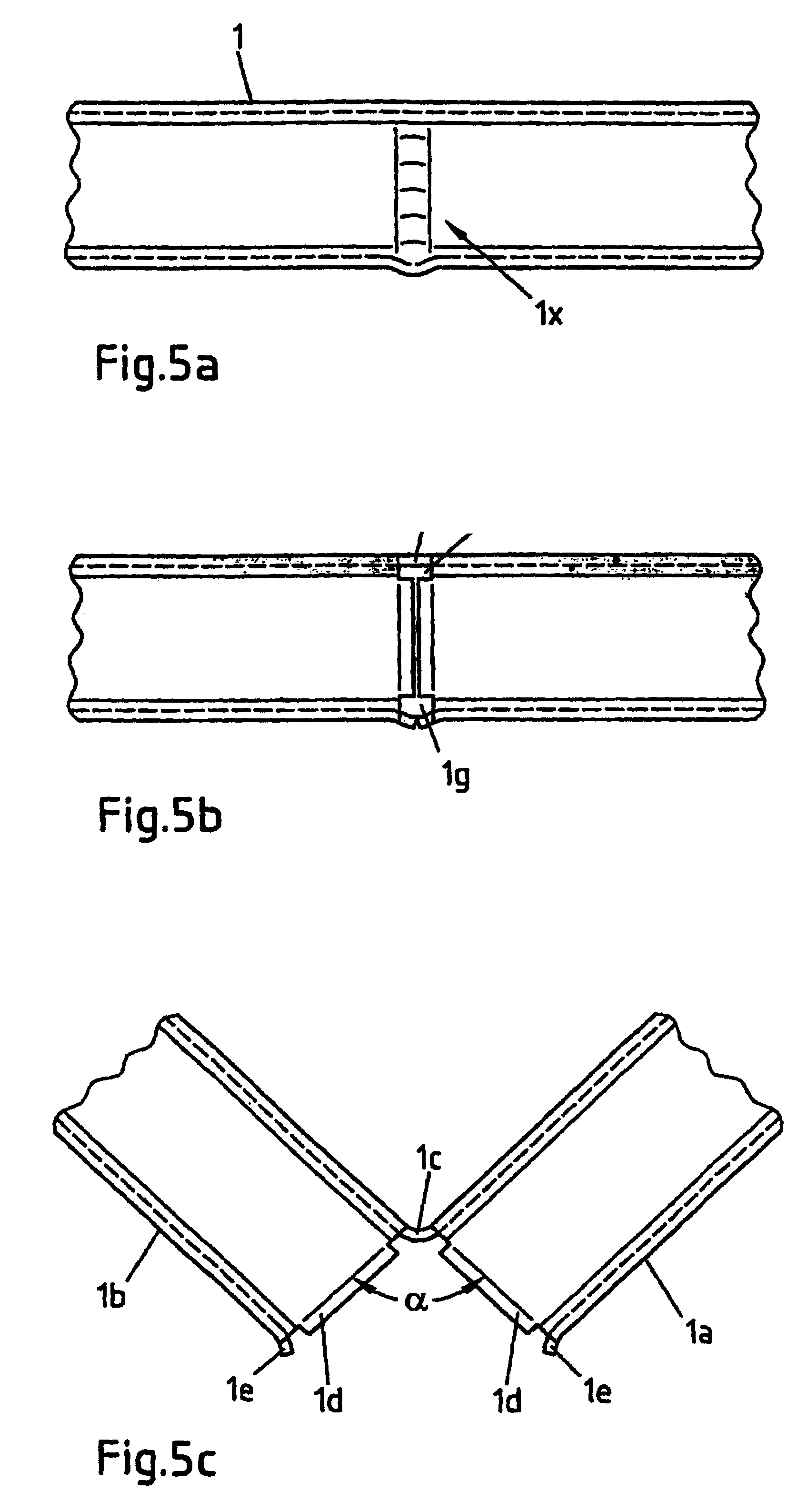

Three-dimensional node structure

InactiveUS7500802B2Small bending radiusHigh rigidityVehicle seatsDoors/windowsEdge regionEngineering

A three-dimensional joint structure of a support frame for vehicles can include two hollow profiles, of which the first hollow profile has at least one planar side and is cut through around its circumference except for a web lying in this planar side and is bent around this web. The second hollow profile has at least two planar sides that press against the ends of the first hollow profile resulting from the cutting and bending. The two hollow profiles are integrally joined to one another at the edge region of the ends.

Owner:THYSSENKRUPP STEEL EURO AG

Conductor wire core for novel power cable

InactiveCN102403051AEasy to coordinate and deformSmall bending radiusNon-insulated conductorsPower cablesElectrical conductorPower cable

The invention relates to a conductor wire core for a novel power cable, comprising an inner-layer molded wire and an outer-layer molded wire. The molded wires are produced by a molded wire filament drawing machine of which a molded wire filament drawing mold has the finish of less than 5; the single filaments of the inner-layer molded wire adopt round wires or combined round wires formed by combining 2 to 6 filaments with fan-shaped cross sections; the single filaments of the outer-layer molded wire are shaped like tiles and spirally stranded towards the same direction by using a frame-type strander; and the stranded wire core has a round cross section. The external diameter of the conductor wire core can be effectively reduced, and the consumption of outer-layer materials of the power cable can be saved. The conductor wire core has a smooth surface so that the risk of insulation breakdown is reduced. In addition, the rigidity and bend radius of the power cable are reduced so that the related power cable can be laid more conveniently.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

Tape winding type optical unit optical cable and manufacturing process thereof

ActiveCN104808303ALight weightSmall bending radiusFibre mechanical structuresEngineeringConductor Coil

The invention discloses a tape winding type optical unit optical cable and a manufacturing process thereof. The tape winding type optical unit optical cable comprises an optical unit and an outer sleeve layer, wherein the optical unit comprises a tape winding type optical fiber tape and an aramid fiber at the center, wherein a water-resisting material, a ribbon and a sleeve sequentially cover the tape winding type optical fiber tape. The manufacturing process comprises the following steps: 1, manufacturing a plurality of optical fibers into the optical fiber tape by a tape combining mold; 2, winding the optical fiber tape into a closed ring through a U-shaped molding trumpet mold and forming an optical fiber column by a sizing mold; covering the water-resisting material and binding the ribbon, and putting the optical fiber column into the sleeve to form the optical unit; and 3, preparing a tape winding type central pipe optical cable or a layer hinged type optical cable, and arranging a tape combining resin pressing-in pipe on the tape combining mold, wherein the optical fiber difference between the layers of the optical fiber column is 6, the outer diameter of the optical fiber column with 6-90 cores is 636-2332 microns and the layer quantity is 1-5, and the diameter of the prepared optical unit is 1.4-4.8mm. The sleeve has a smaller diameter and the prepared optical cable has light weight and small diameter; the bending radius of the prepared optical cable is small and the construction and pavement are easy; the net-shaped optical cable tape can be in primary fusion welding and the construction is convenient.

Owner:江苏通光电子线缆股份有限公司

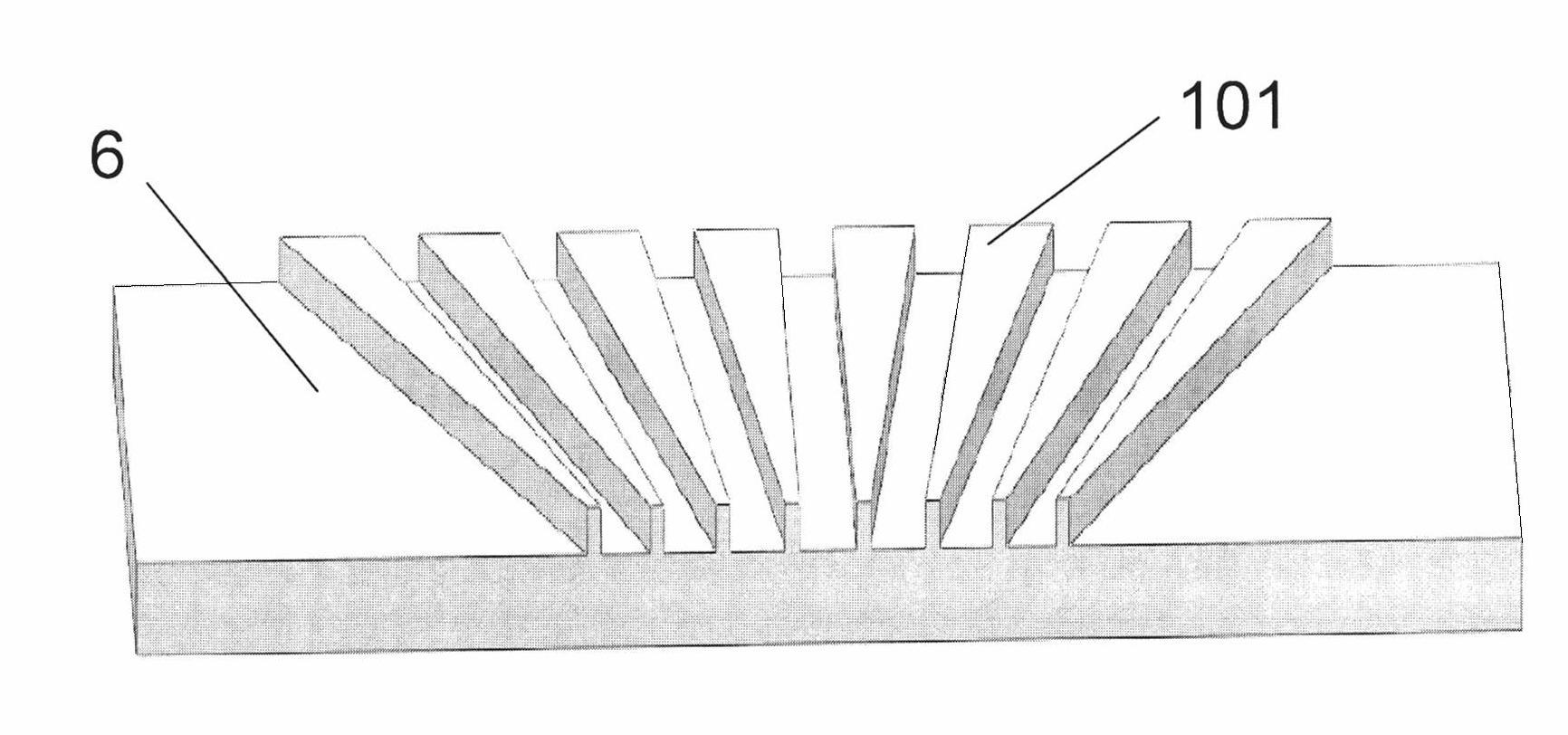

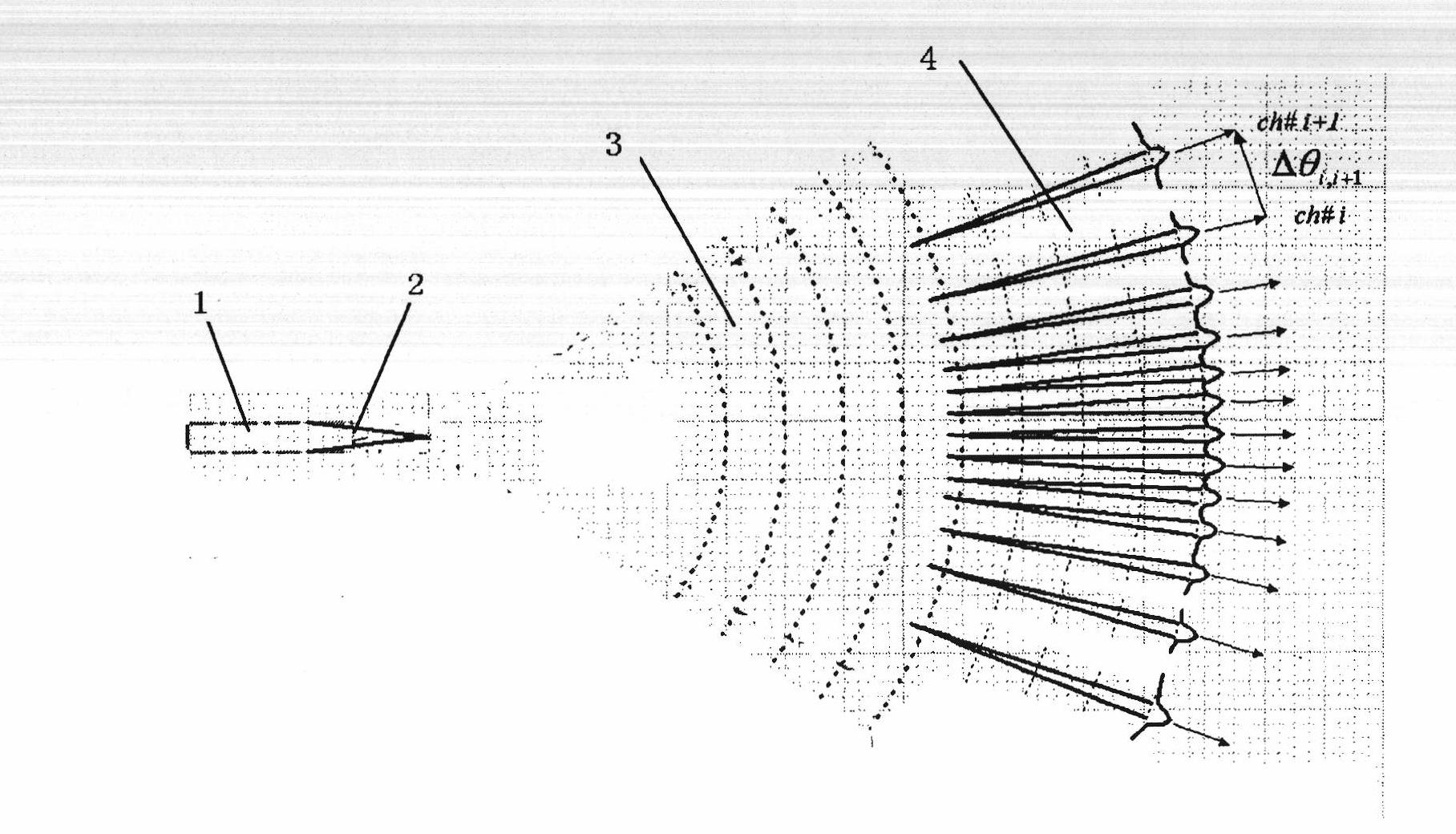

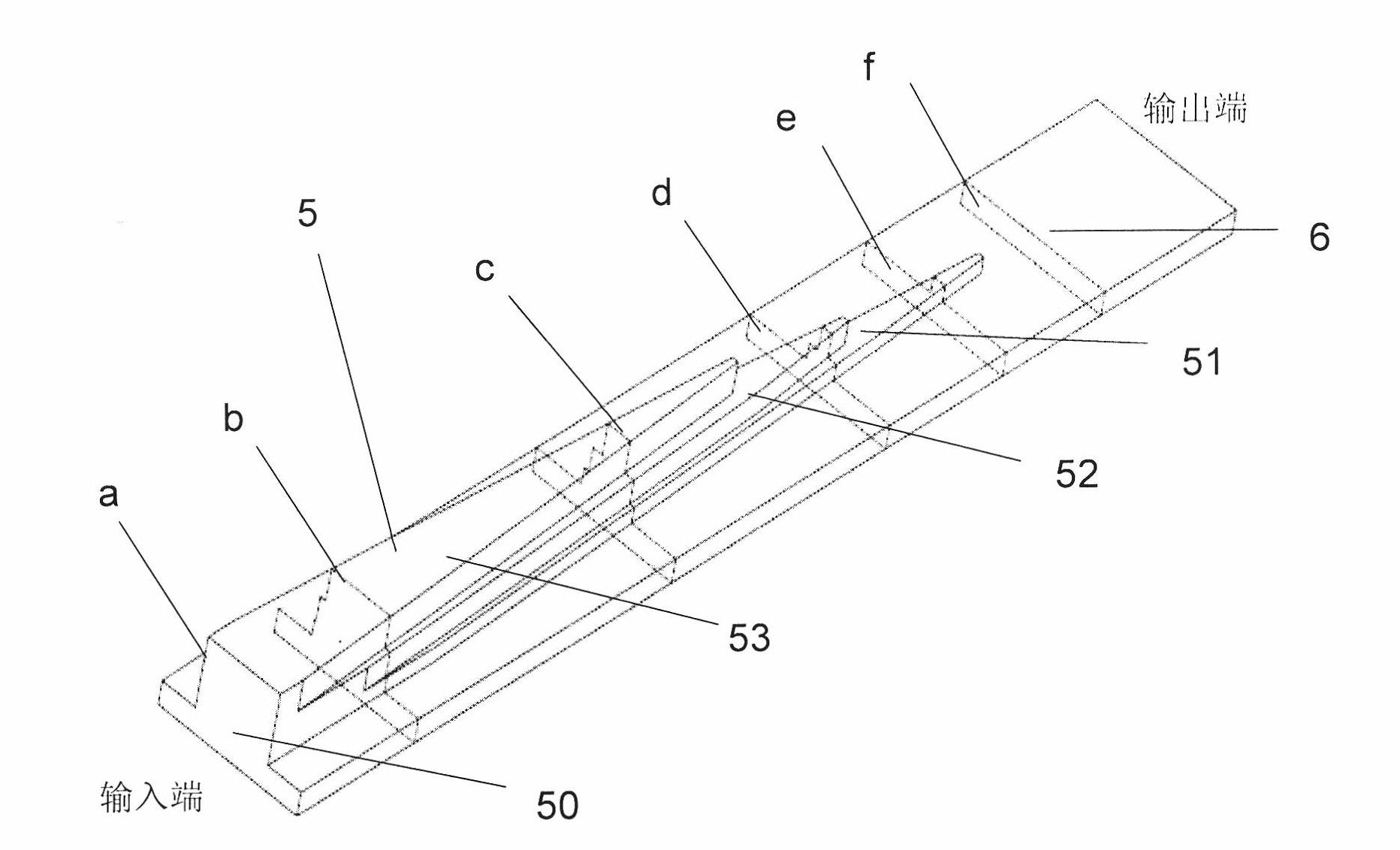

Mode converter having multi-layer structure and optical branching device

ActiveCN102156324AImprove coupling efficiencyReduce one etching processOptical waveguide light guideRidge waveguidesOptical flat

The invention discloses a mode converter having a multi-layer structure and an optical branching device. The mode converter comprises flat waveguides and at least three layers of ridge waveguides which are arranged on the flat waveguide, wherein the width of each layer of ridge waveguides is gradually decreased from an input end to an output end; when the width is decreased to a certain value, the layer of ridge waveguides is cut off, namely one layer of the at least three layers of ridge waveguides is reduced, so that the height of the ridge waveguides is reduced gradually; the input end is farther away from a cut-off position of the ridge waveguides of the optical flat waveguides; and the output end of the mode converter consists of the single-layer flat waveguides and the single-layer ridge waveguides. A transverse free propagation area of the optical branching device consists of the flat waveguides without transverse limitation. Compared with the prior art, a technology provided by the invention has the advantages that: the efficiency of coupling from optical fibres to an optical device can be improved, a one-step etching process is reduced, and the stability of mode transmission in the optical device is improved at the same time.

Owner:SHANGHAI SILIGHT TECH

Ultra-flexible coated abrasive cloth and manufacturing method thereof

ActiveCN110405645ASmall bending radiusAchieve anti-cloggingAbrasion apparatusAdhesiveSurface grinding

The invention discloses ultra-flexible coated abrasive cloth, and relates to the technical field of coated abrasive tool products. The ultra-flexible coated abrasive cloth comprises a substrate, an abrasive and a composite adhesive layer; the substrate and the abrasive are coated with the composite adhesive layer, and the abrasive is fixed to the substrate through the composite adhesive layer; thesubstrate comprises a base material and a flexible adhesive layer, and the composite adhesive layer comprises a bottom adhesive layer, a composite adhesive layer body and a coating layer which are distributed from bottom to top in sequence; the flexible adhesive layer comprises one layer of or combination of multiple layers of an upper adhesive layer, a lower adhesive layer and an inner adhesivelayer, the upper adhesive layer and the lower adhesive layer are arranged on the upper surface and the lower surface of the base material correspondingly, and the inner adhesive layer is distributed in the base material; and the base material adopts a cloth base of which the absolute dry weight is 25-180 g / m<2>. The good surface evenness of the coated abrasive cloth can be obtained, the flexible bending radius is 1-3 mm, the ultra-flexible coated abrasive cloth is suitable for grinding of light-load planes and curved surfaces, is resistant to breaking and blocking during grinding, and has thecharacteristics of being good in economical efficiency, light and thin.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

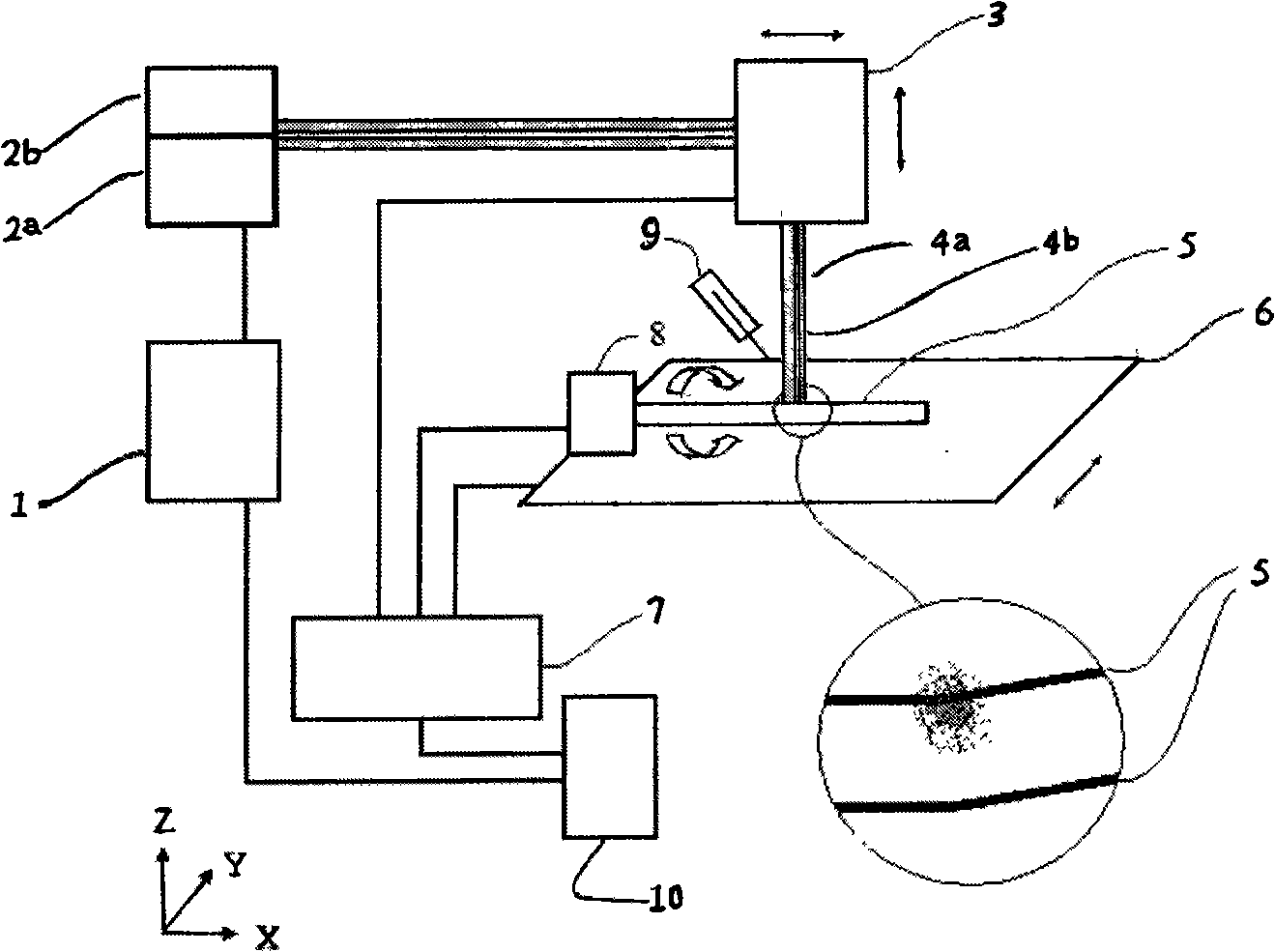

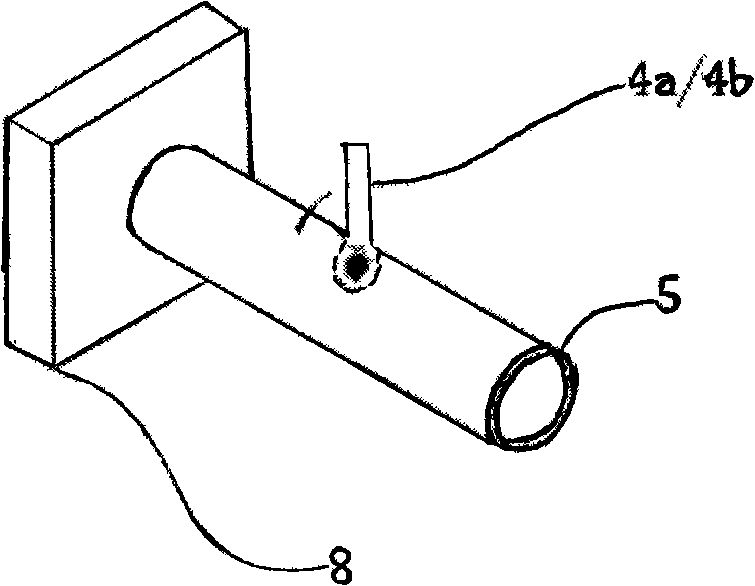

Laser bending shaping method and device of light-wall conduit

InactiveCN101332536AImprove fatigue lifeSmall bending radiusLaser beam welding apparatusControl systemTitanium

The invention discloses a laser bending forming method of a thin-walled tube and a special device used for realizing the method. The method adopts two laser beams to act on the thin-walled tube, wherein one laser beam is used for heating the thin-walled tube to soften the thin-walled tube and producing thermal stress along the thickness direction of the tube wall so as to cause the tube to bend and deform; the other laser beam forms a plasma on the surface of the tube, and further bends the thin-walled tube by the shock action produced by the plasma to obtain a fine grain structure. The special device for realizing the laser bending forming method of the thin-walled tube is composed of a laser generator system, a laser head system, a workbench system and a motion control system. By adopting the method, metal and alloy tubes made from steel, aluminum, copper, titanium and the like can be machined, which is a high-flexibility dieless forming technology.

Owner:SHANDONG UNIV

Coiled plastic composite pipe reinforced with fibre

ActiveCN103062528ASmall bending radiusEasy to transportFibre treatmentFlexible pipesPolyesterGlass fiber

The invention belongs to the technical field of a plastic composite pipe, and discloses a coiled plastic composite pipe reinforced with fibre. The technical scheme includes that an inner tube layer is made of polymer materials, the outer wall of the inner tube layer is wound or braided a wear-resistant fibrous layer constituted by polyester industrial fibers, aramid fibers and glass fibers, the outer surface of the fibrous layer is coated with a modified polymer corrosion protection layer, and the inner tube layer, the fibrous layer and the protective layer composite into one integral structure. The coiled plastic composite pipe reinforced with fibre has the advantages of small bending radius, high pressure resistance and high temperature resistance.

Owner:河北宇通特种胶管有限公司

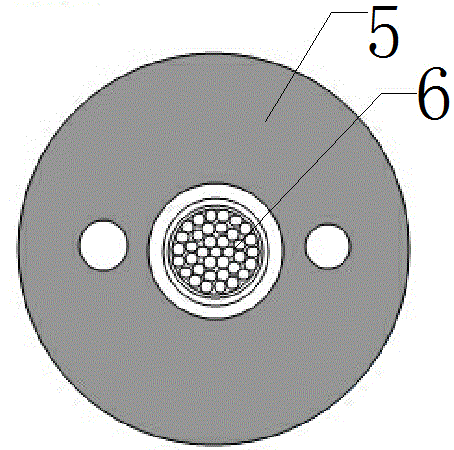

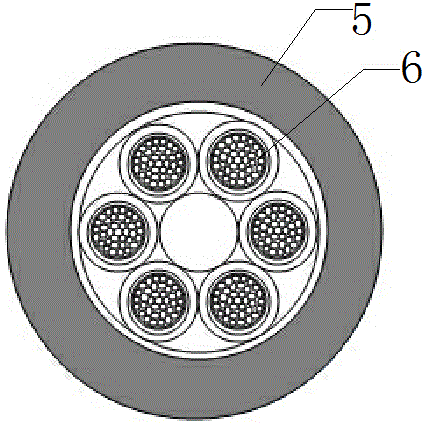

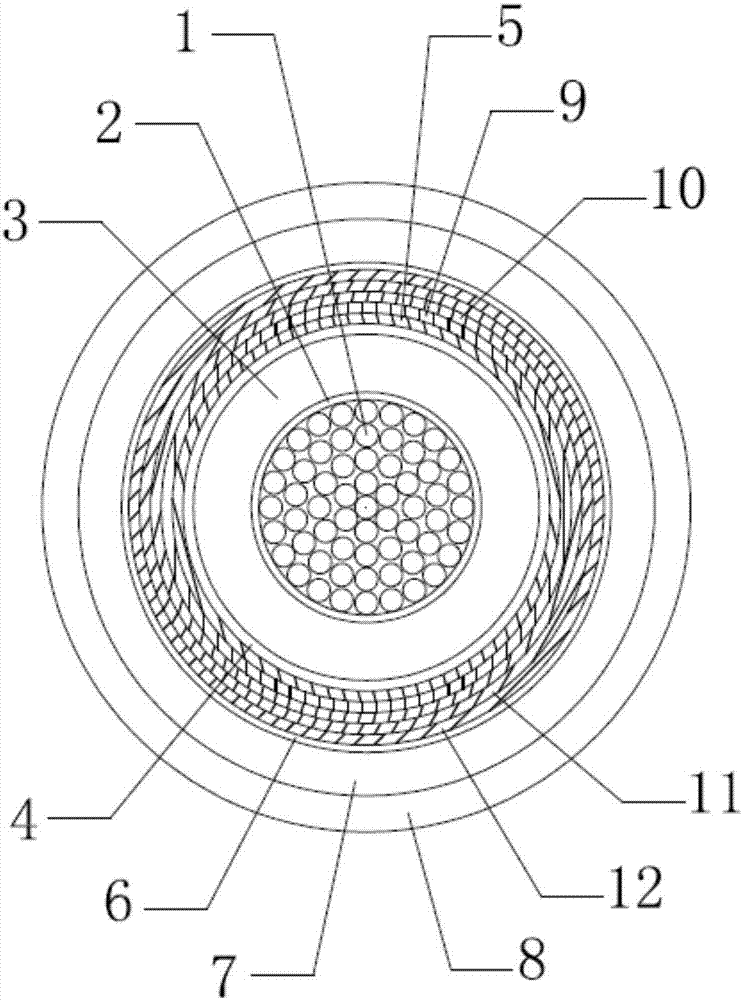

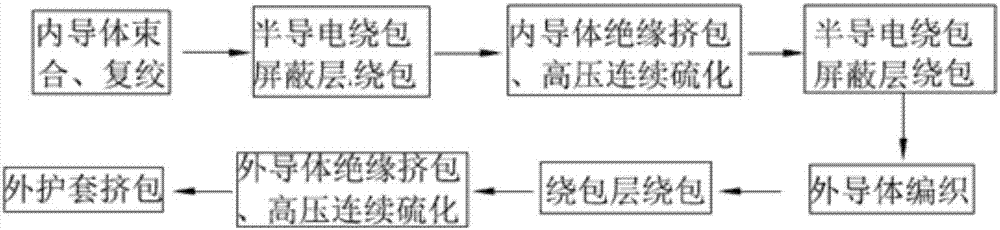

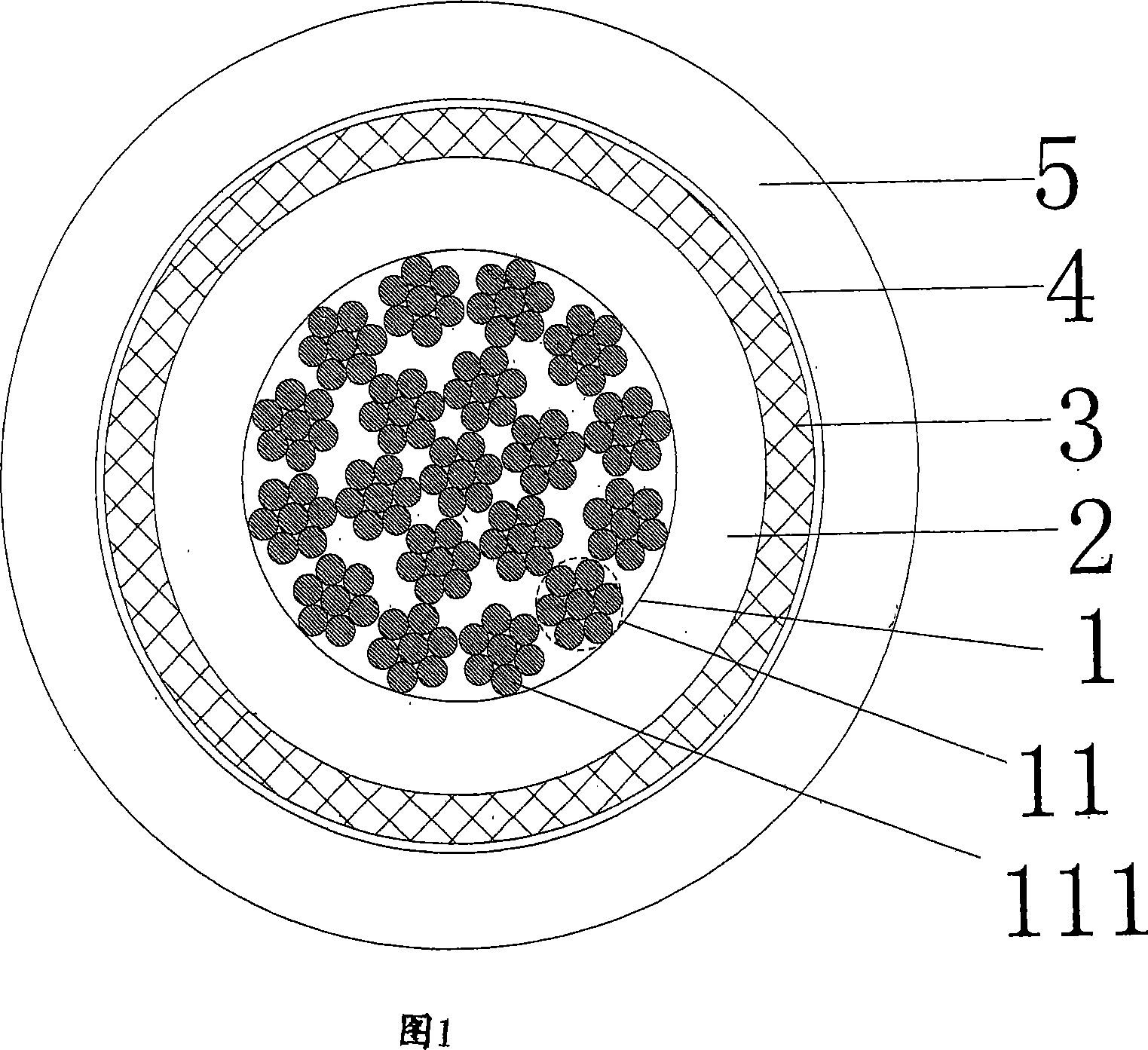

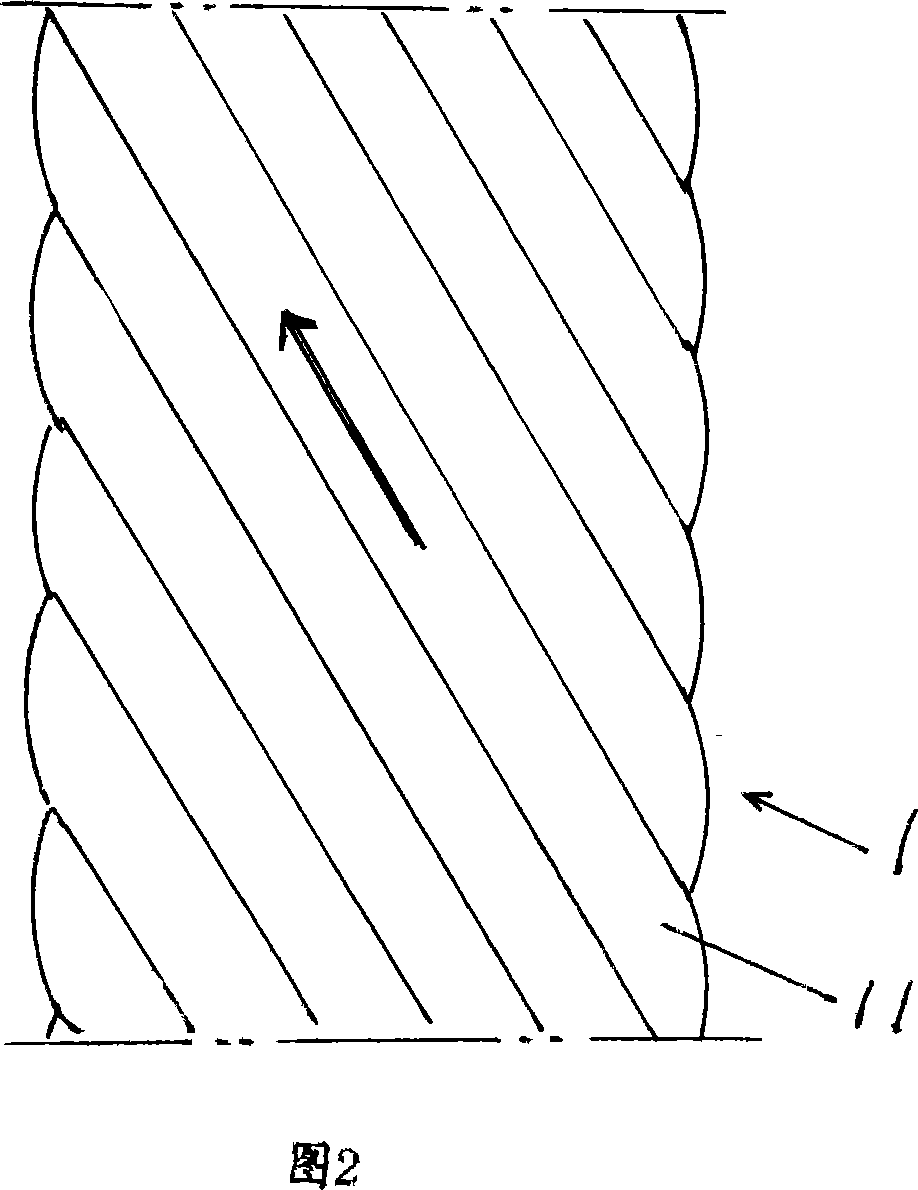

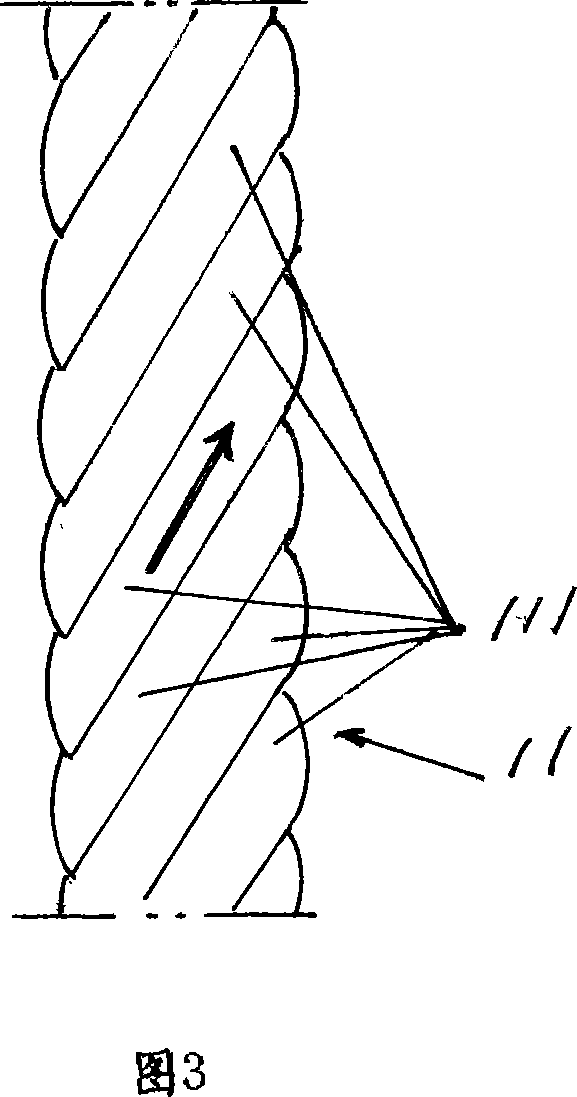

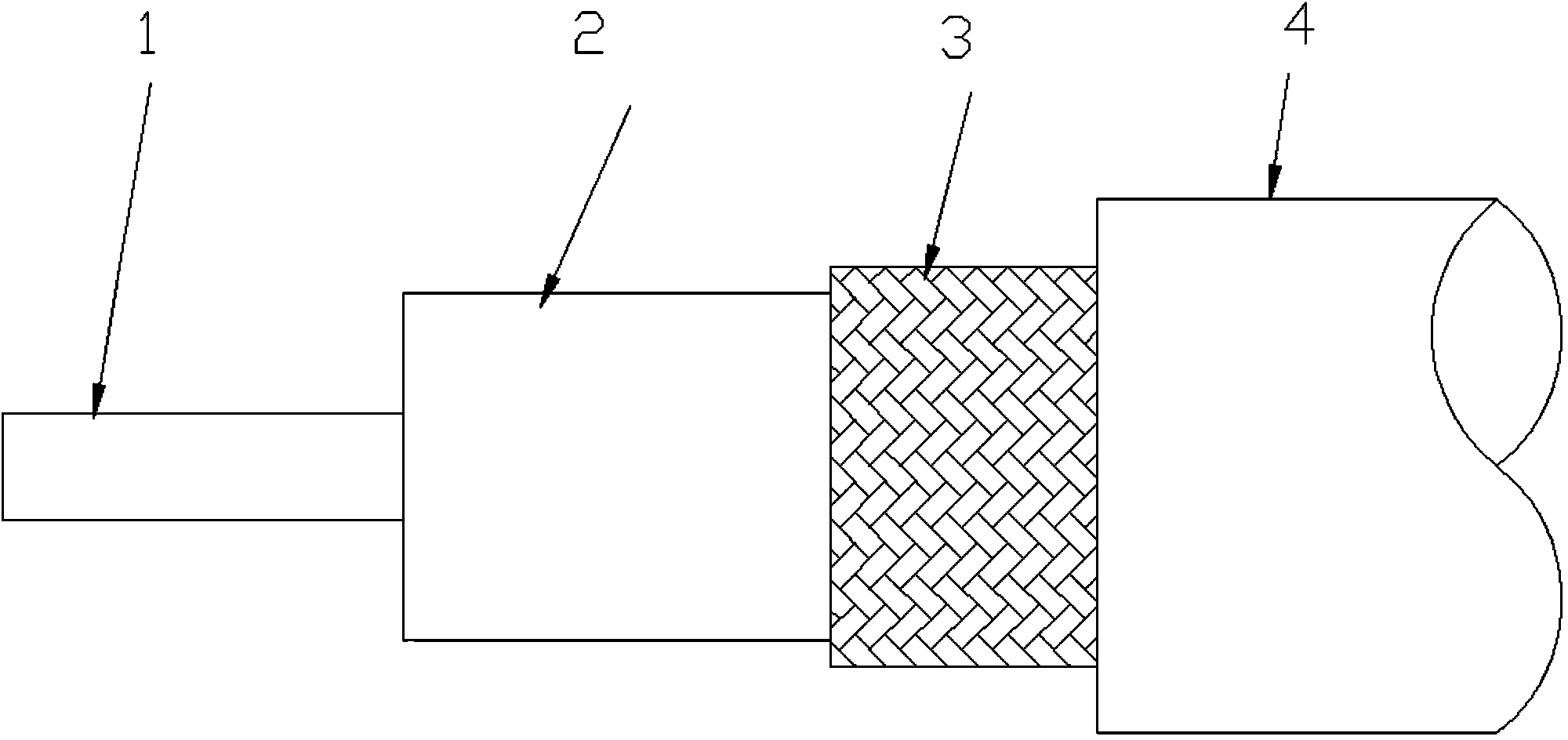

Manufacturing method of cable for high power transmission equipment and cable

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

Electric cable for hybrid power electric automobile

InactiveCN101075484AImprove temperature resistanceImprove flexibilityPlastic/resin/waxes insulatorsInsulated cablesInsulation layerIsolation layer

A cable for hybrid vehicle includes the cable core and the outer insulation layer, as well as shielding layer, isolation layer and protection layer out of the insulation layer in order. The cable core is composed by electric conducting units kinked together, each of the units is composed by kinked wires. The cable is capable of bearing 125oC for long term and 250oC for short term.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

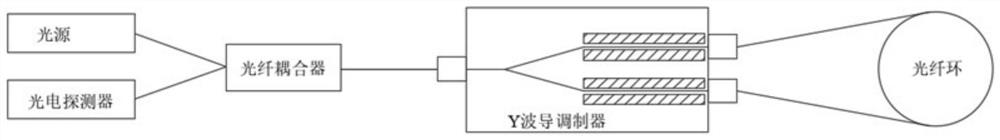

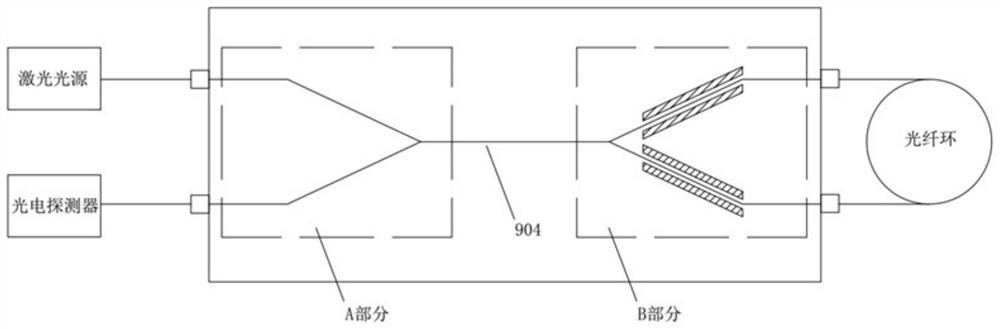

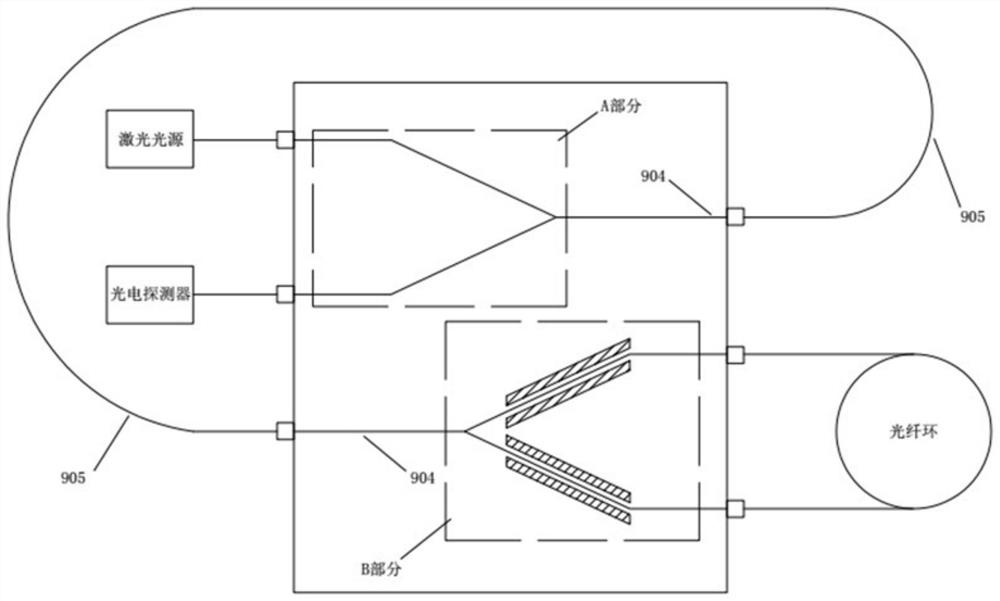

Photon integrated chip and interference type fiber-optic gyroscope

InactiveCN112833873ASmall bending radiusSmall sizeSagnac effect gyrometersOptical waveguide light guideEngineeringPolarizer

The invention discloses a photonic integrated chip and an interference type fiber-optic gyroscope, and the photonic integrated chip can achieve high-density integration of functions of various photoelectric devices such as a waveguide coupler, a polarizer, a mode filter and a phase modulator on a thin film substrate through a photonic circuit structure. The four ports of the photonic integrated chip are placed on the same side of the chip, so that polarization crosstalk or parasitic phase errors caused by substrate radiation mode light waves formed by an asymmetric mode and polarization filtering are reduced, and the error influence on the performance of the fiber-optic gyroscope system is reduced. According to the interference type fiber-optic gyroscope, optical fibers are respectively placed at four ports of a photonic integrated chip and are respectively connected with a light source, a photoelectric detector and two ports of a fiber-optic ring, so that a light path structure of the interference type fiber-optic gyroscope is formed.

Owner:天津领芯科技发展有限公司

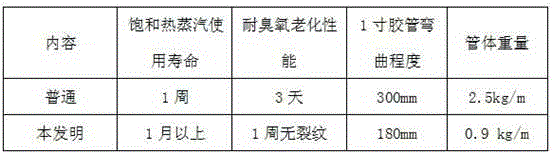

Hot steam rubber tube resisting temperature of 208 DEG C and preparation method thereof

ActiveCN102942748ANo abnormal phenomena such as cracksSmall bending radiusFlexible pipesTubular articlesVulcanizationStearic acid

The invention discloses a hot seam rubber tube resisting the temperature of 208 DEG C and a preparation method of the hot seam rubber tube resisting the temperature of 208 DEG C. The hot seam rubber tube comprises manufacture methods of an inner rubber tube, an outer rubber tube and a whole tube. The preparation method of the material of the inner rubber tube comprises the following steps of: weighting inner rubber raw materials of the inner rubber tube in parts by weight, plasticating chlorinated butyl rubber in an internal mixer, adding high-activity magnesium oxide, nano-zinc oxide, antiager and paraffin oil into the internal mixer for mixing, adding white carbon black, carbon black, light calcium carbonate, stearic acid and antioxygen, mixing, rubber sheet unloading and stopping, discharging rubber and vulcanizing; the preparation method of the material of the outer rubber tube comprises the following steps of: weighing raw materials of the outer rubber layer in parts by weight; plasticating ethylene-propylene diene copolymer in the internal mixer, adding high-activity magnesium oxide, nano-zinc oxide, antiager and paroline into the internal mixer for mixing, adding white carbon black, carbon black, light calcium carbonate, stearic acid and antioxygen for mixing, adding a vulcanizing agent, an accelerant and iron oxide red, rubber sheet unloading and stopping, and discharging rubber; and preparing the inner rubber layer and outer rubber layer of the inner rubber tube, and then preparing the hot seam rubber tube resisting the temperature of 208 DEG C.

Owner:LUOHE LETONE RUBBER

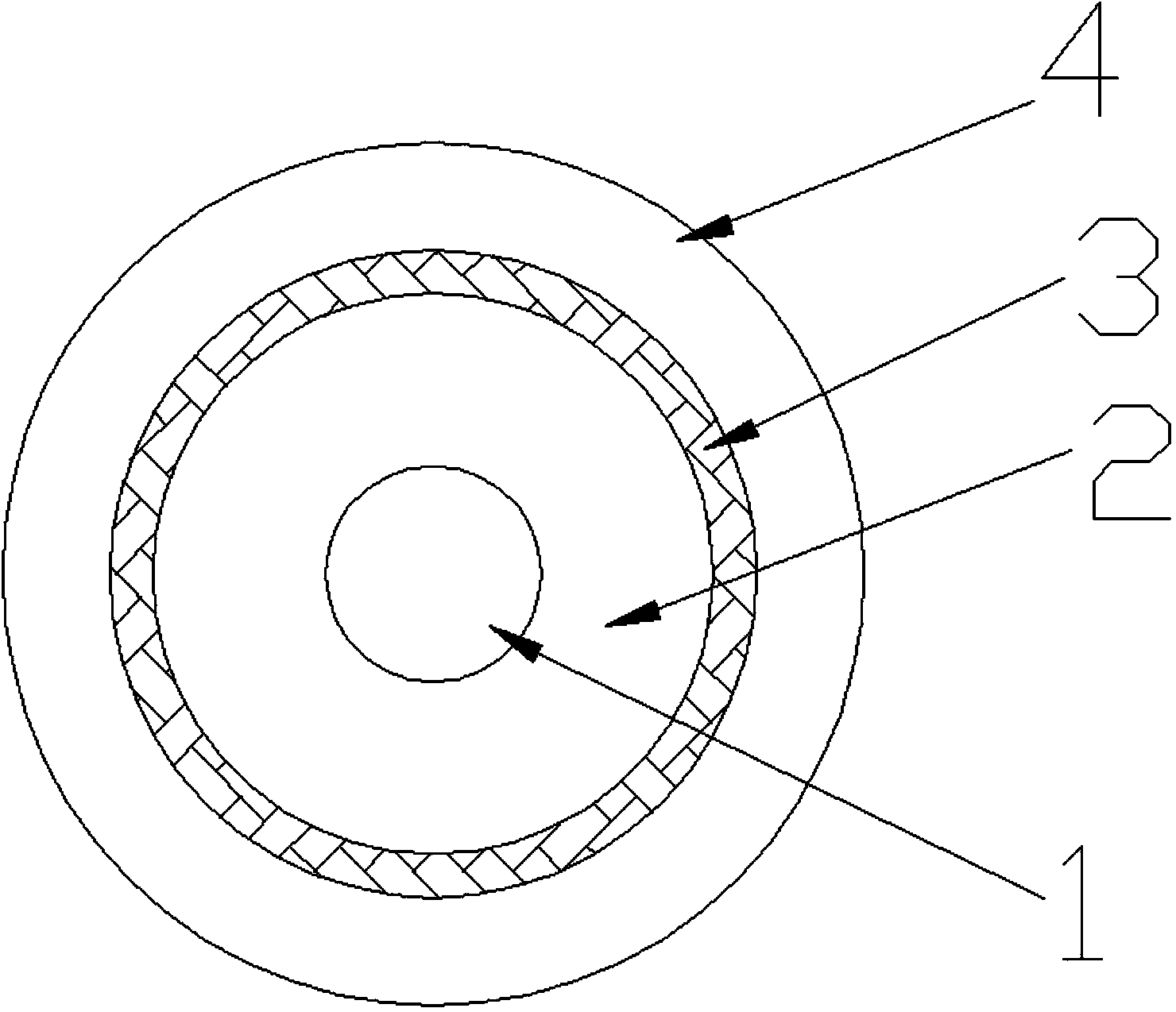

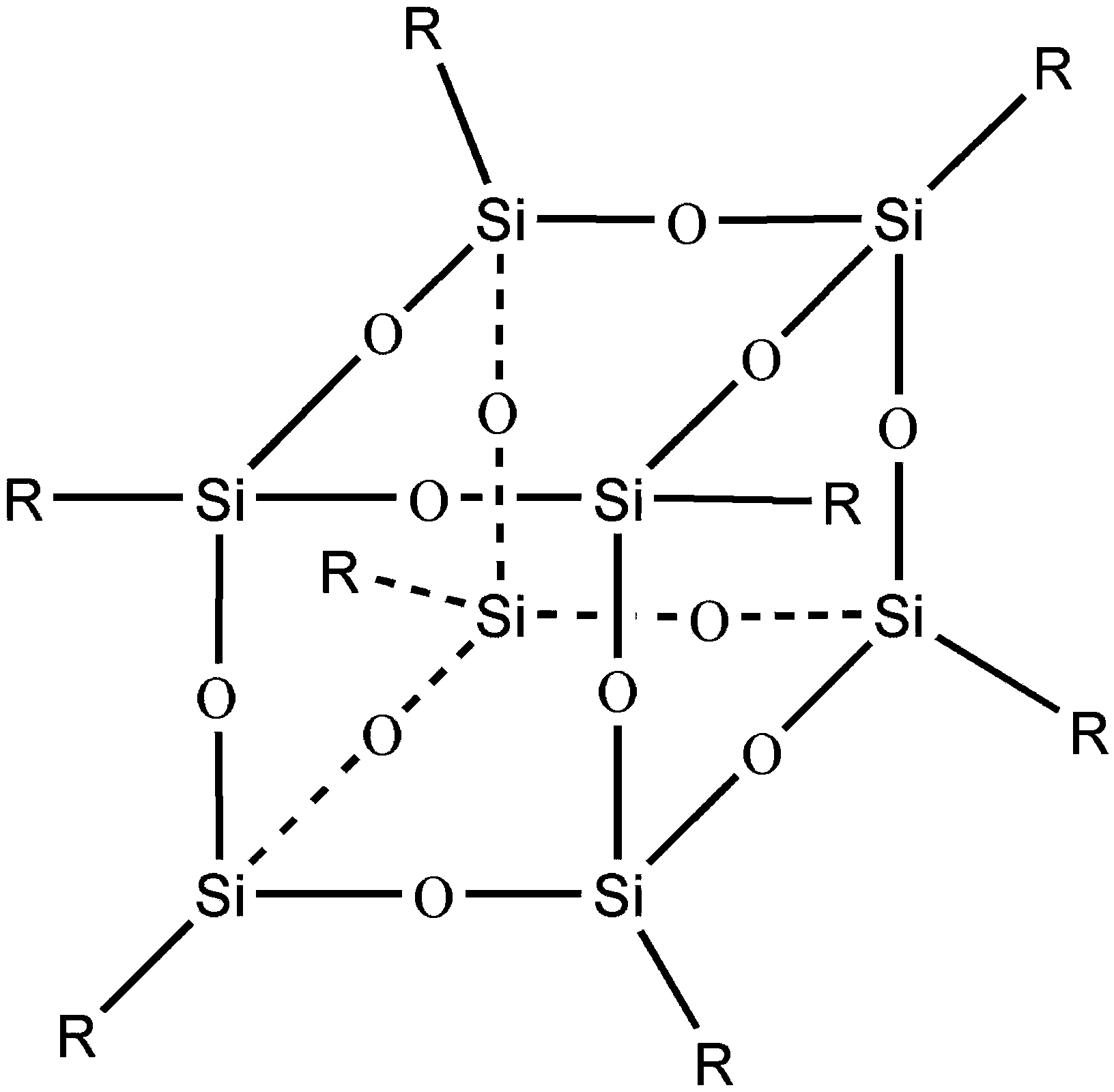

High-temperature-resistant low-loss compound insulation coaxial cable

InactiveCN104319008AImprove high-frequency communication performanceLow densityCoaxial cables/analogue cablesInsulated cablesPolytetrafluoroethyleneOrganic inorganic

Provided is a high-temperature-resistant low-loss compound insulation coaxial cable. The high-temperature-resistant low-loss compound insulation coaxial cable is characterized in that a solid or stranded inner metal conductor (1), a polytetrafluoroethylene micropore compound insulation layer (2), an outer conductor (3) and a sheath layer (4) are arranged from inside to outside in sequence, the solid or stranded inner metal conductor (1) longitudinally extends along the central axis of the cable, the outer conductor (3) is formed by knitting metal or is additionally provided with an inner shielding layer, the sheath layer (4) is made of FEP copolymer or low-smoke halogen-free flame retardant polyolefin, and the inner metal conductor (1) and the outer conductor (3) are separated by the polytetrafluoroethylene micropore compound insulation layer (2); the polytetrafluoroethylene micropore compound insulation layer (2) is made of modified polytetrafluoroethylene organic-inorganic nanocomposites filled with nano polyhedral oligomeric silsesquioxanes (POSS). According to the coaxial cable, the dielectric constant of the insulation layer of the cable is reduced. A traditional solid polytetrafluoroethylene insulation dielectric constant is reduced to 1.2-1.6 from 2.1 and is reduced by about 24 percent to 43 percent, and the signal attenuation of cable high-frequency communication is reduced.

Owner:JIANGSU TRIGIANT TECH

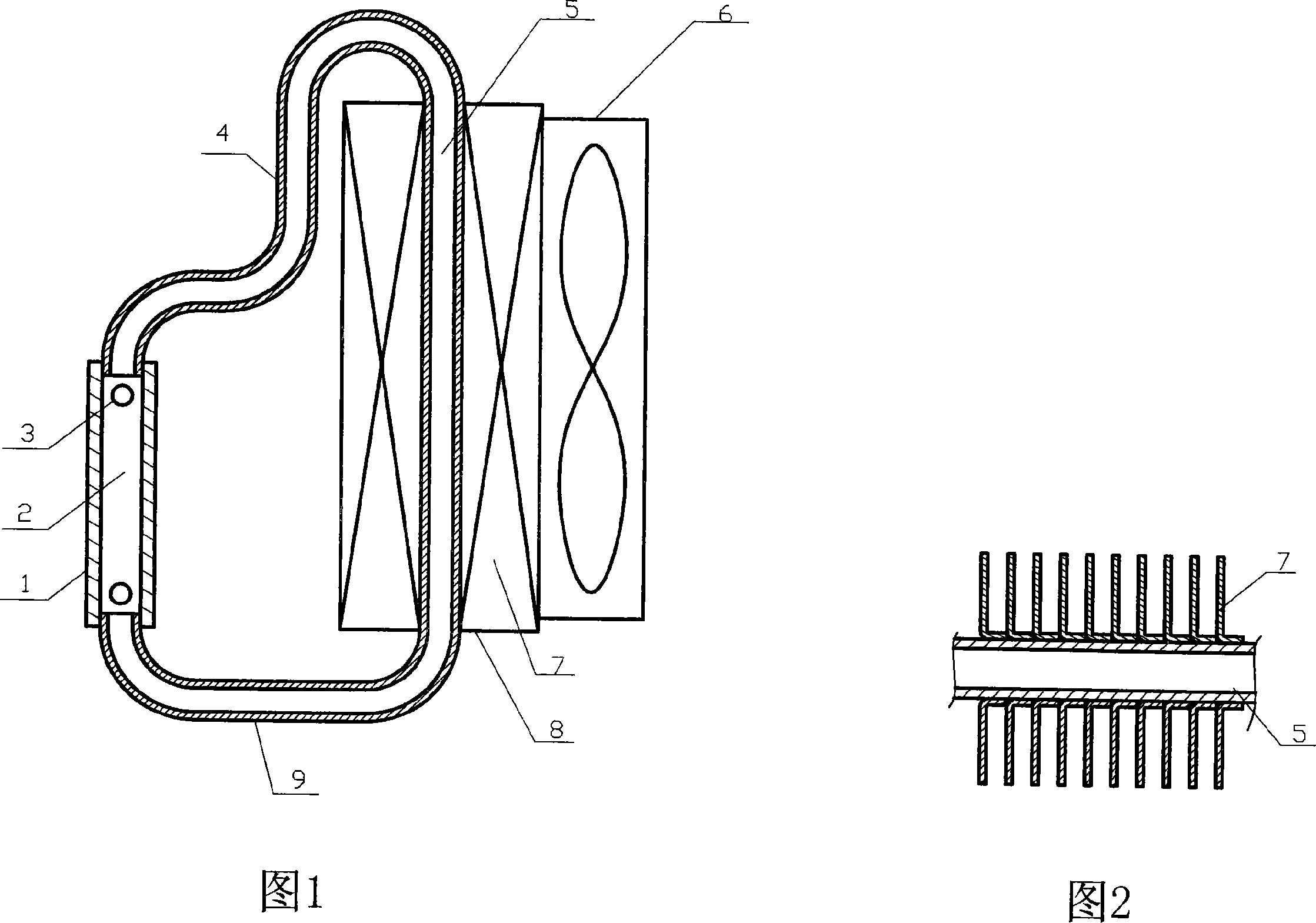

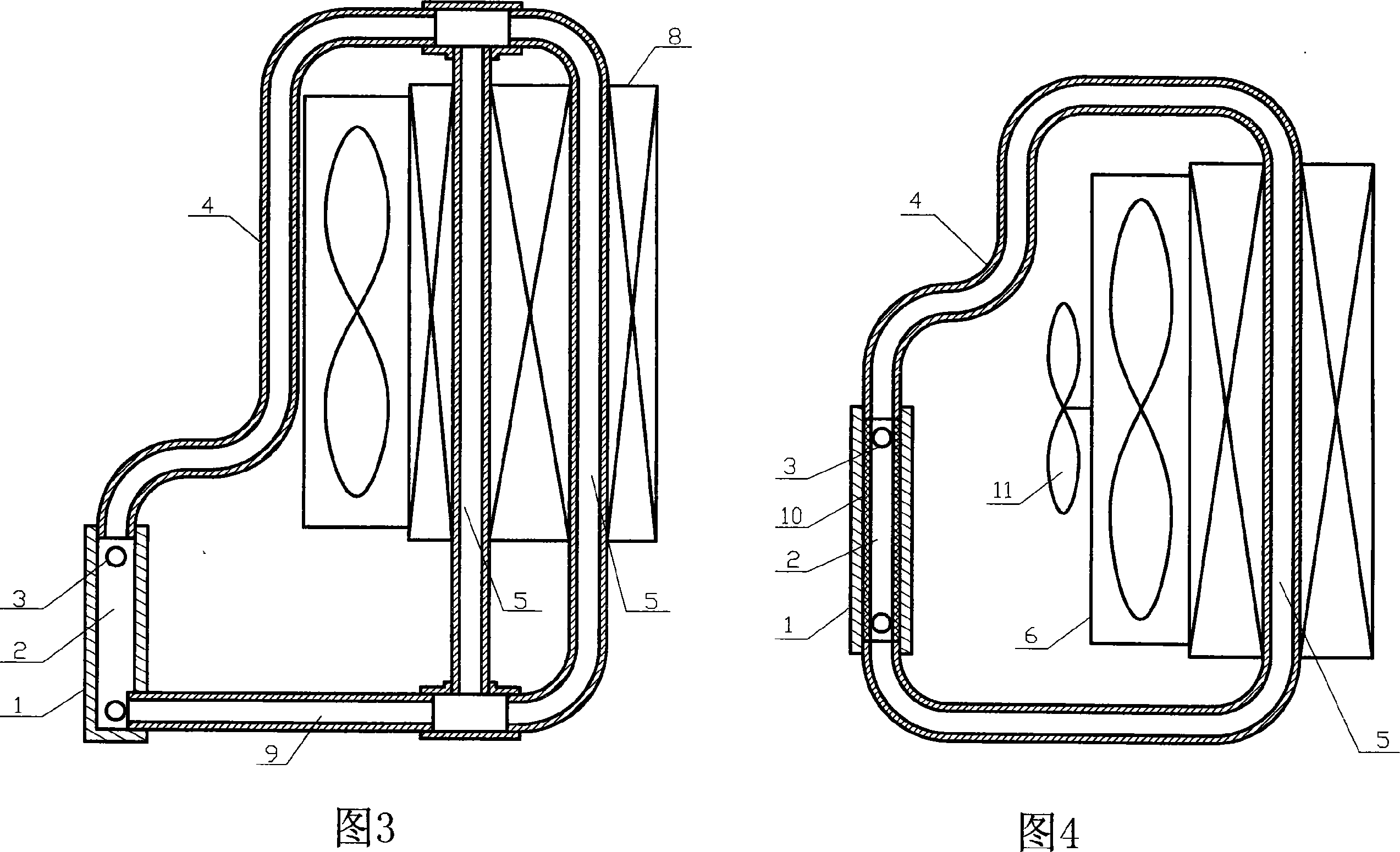

Circulating hot tube type radiator

InactiveCN101022097ALow costSmall bending radiusDigital data processing detailsSemiconductor/solid-state device detailsSiphonHeat transmission

This invention relates to a heat pipe radiator of a circulation structure applying the thermal siphon theory, which can apply high efficient and cheap expand tube technology to solve the problem of contact heat resistance by introducing an intensified cross-vetilation heat-transmission structure to optimize the design of fins, which not only reduces cost for raw materials and manufacture but also increases heat radiation volume.

Owner:秦彪

Connector having inner conductive member

InactiveUS9124024B2Small bending radiusImprove impact performanceTwo pole connectionsSecuring/insulating coupling contact membersMating connectionEngineering

A connector (10) includes a housing (20) connectable to a mating housing of the mating connector. A female terminal (52) is held in the housing (20) and includes a terminal connecting portion (52A) to be connected to a mating terminal provided in the mating connector and a barrel (52B) connected to the terminal connecting portion (52A). A flexible outer wire (70) is pulled out to outside from the interior of the housing (20). An inner conductive member (50) connects the barrel (52B) and the outer wire (70) in the housing (20) and includes an intermediate portion (53C) formed by bending a metal plate material substantially at a right angle. The intermediate portion (53C) is fixed to the housing (20).

Owner:SUMITOMO WIRING SYST LTD

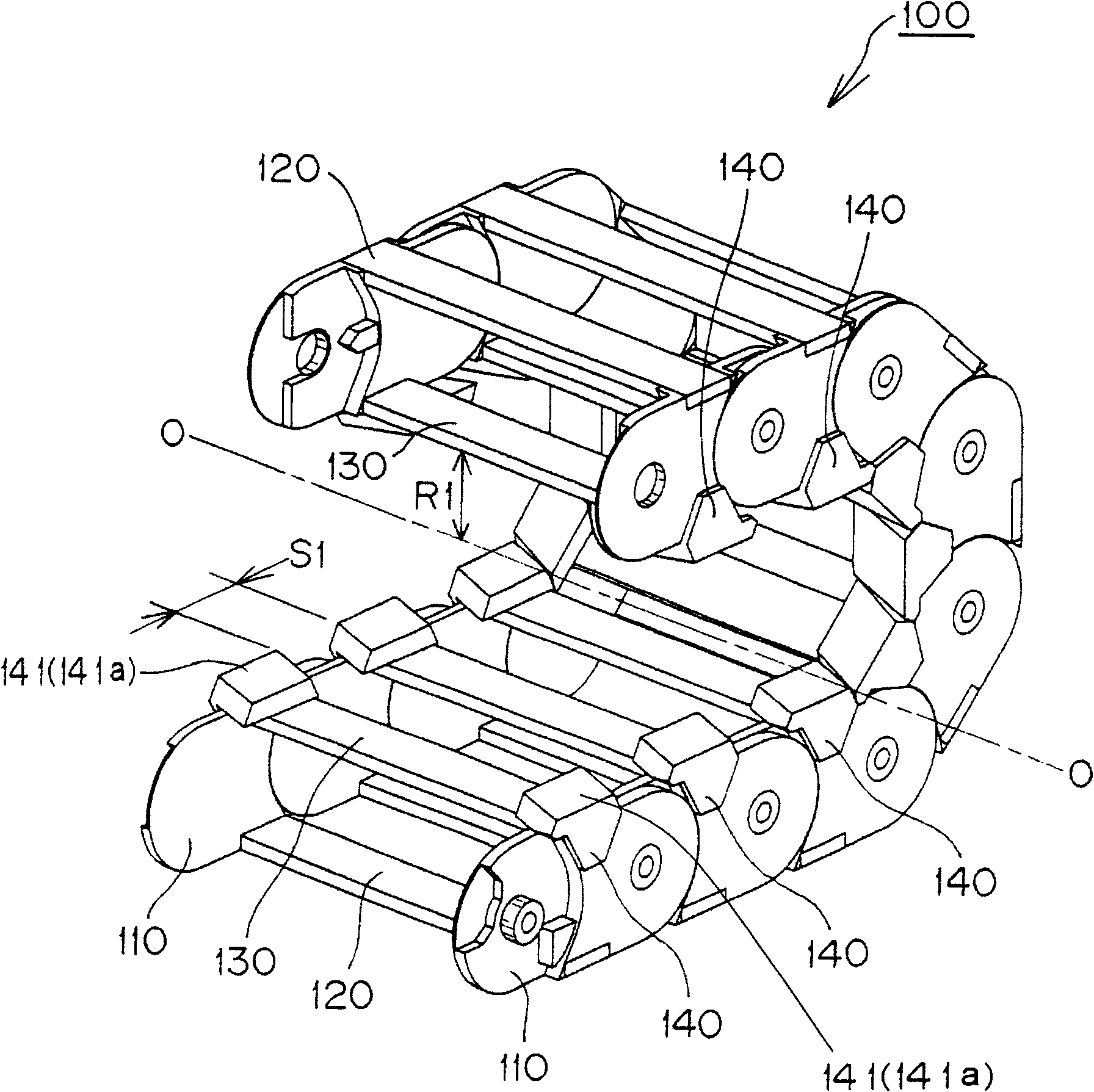

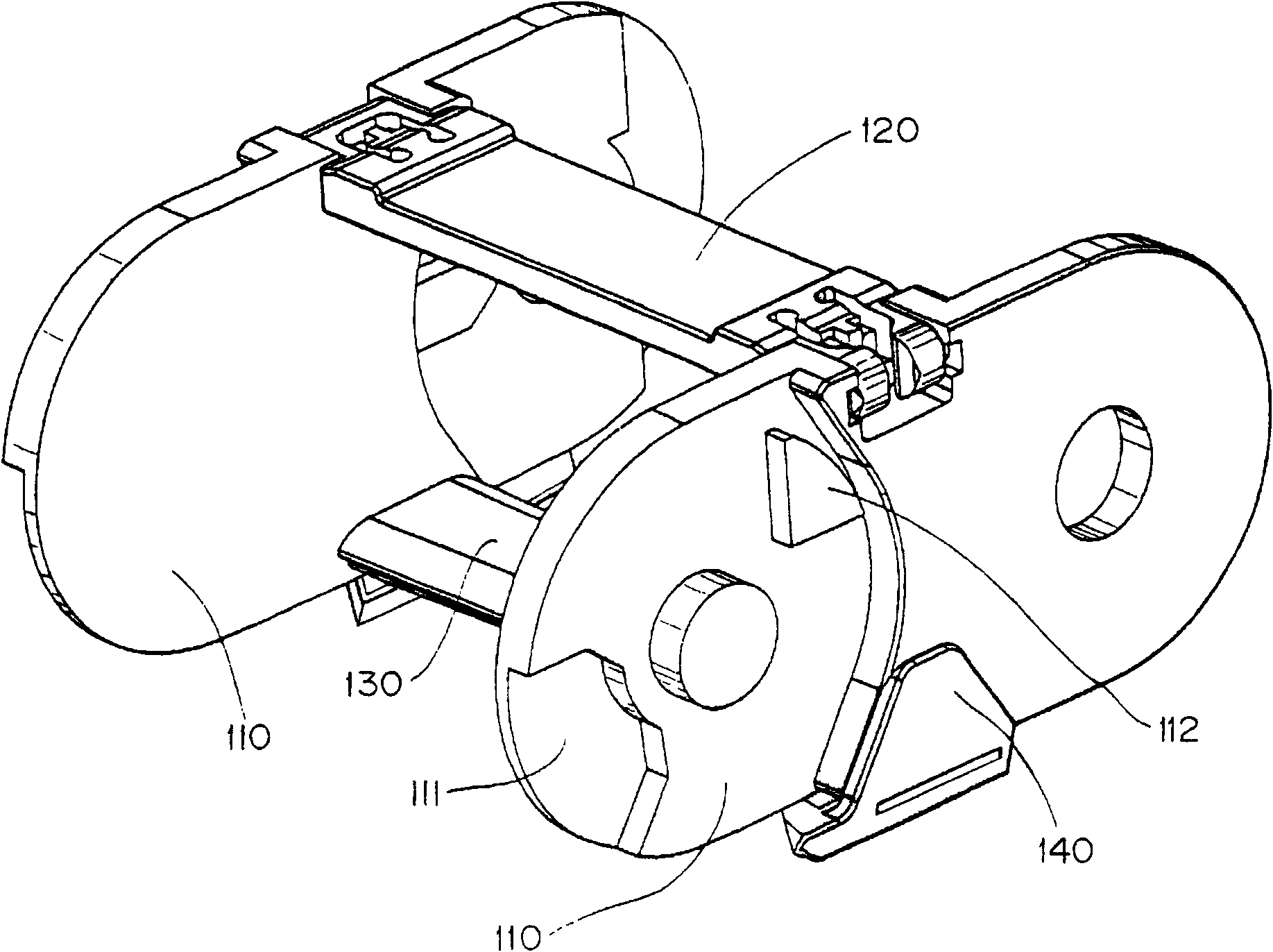

Cable or the like protecting and guiding device

InactiveCN102141115AIncrease freedomSmall bending radiusHauling chainsHoisting chainsLine tubingEngineering

Owner:TSUBAKIMOTO CHAIN CO

Method for manufacturing small-pitch aluminum stranded wire

The invention discloses a method for manufacturing a small-pitch aluminum stranded wire. A lay plate with a proper size and a distance between the wire distributing plate and an inlet of a closing die are selected on a fork wire-stranding machine set; an angle between an aluminum wire which is led out of a wire hole on the external periphery of the lay plate and then enters the inlet of the closing die and a core wire which is led out of an axle tube and then enters the inlet of the closing die is between 45 and 63 degrees when the aluminum stranded wire on the outermost layer is stranded and is between 35 and 50 degrees when the aluminum stranded wires on the other layers are stranded; and the obtained lay ratio value of the outermost layer is between 3.5 and 4.5 and the lay ratio value of the other layers is between 6.5 and 8.5. The aluminum wire which is subjected to heat treatment is taken as a raw material; the ratio of a pitch of the cylindrical helix-shaped aluminum wire in each layer of the aluminum stranded wire to the diameter of a cylindrical surface on which the cylindrical helix-shaped aluminum wire on the layer is arranged is relatively small; the aluminum stranded wire is easily bent; the allowable bending radius is relatively small; and after being bent into small bends, the aluminum stranded wire does not bridle wire, deform or get out of a sleeve, and has a smooth, round and flat surface and a stable structure and is suitable for serving as the aluminum stranded wire for connecting electric contacts of power distribution equipment in a high-voltage substation and a high-voltage converter station.

Owner:TIELING DAYUAN ELECTRIC CABLE

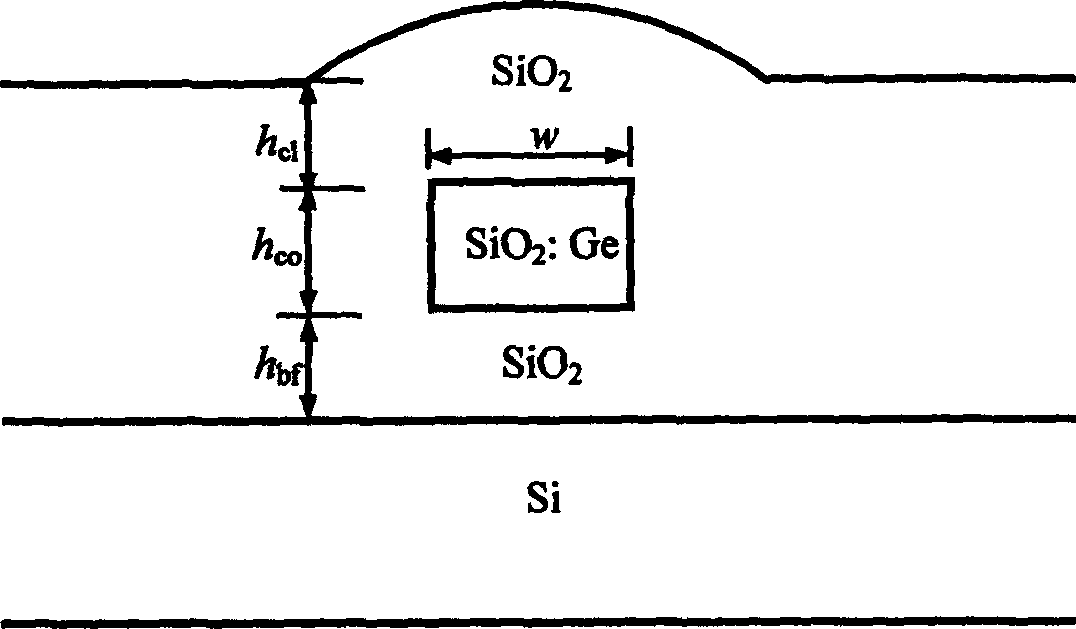

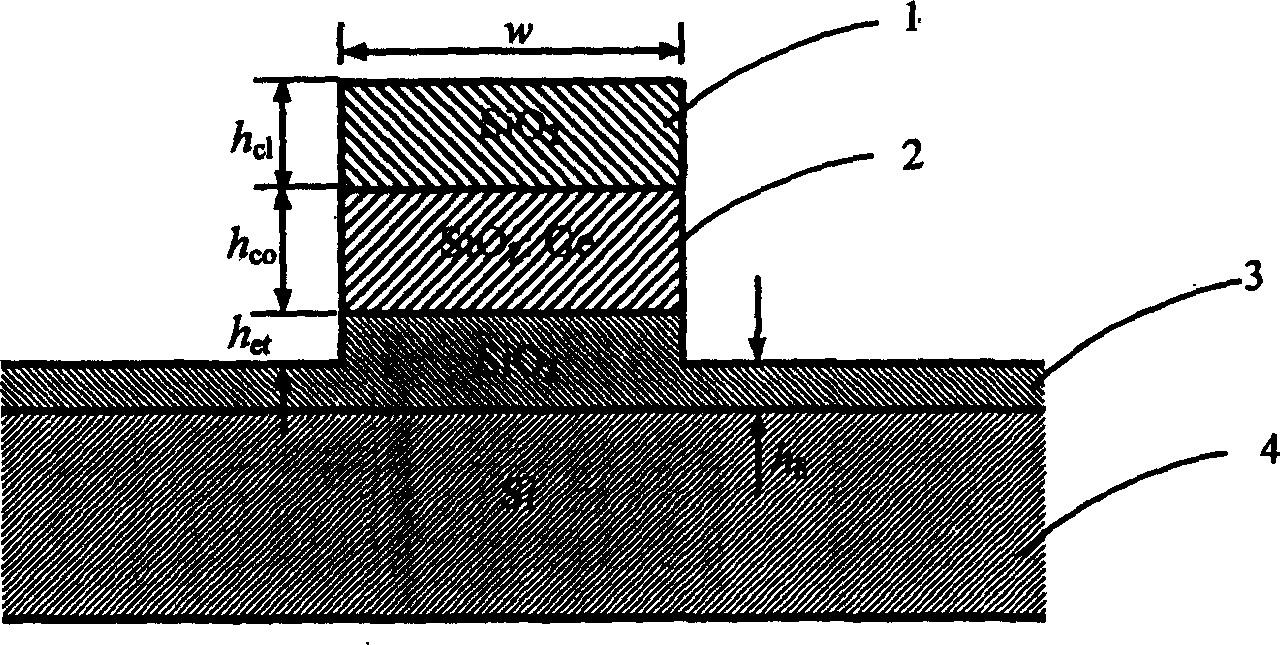

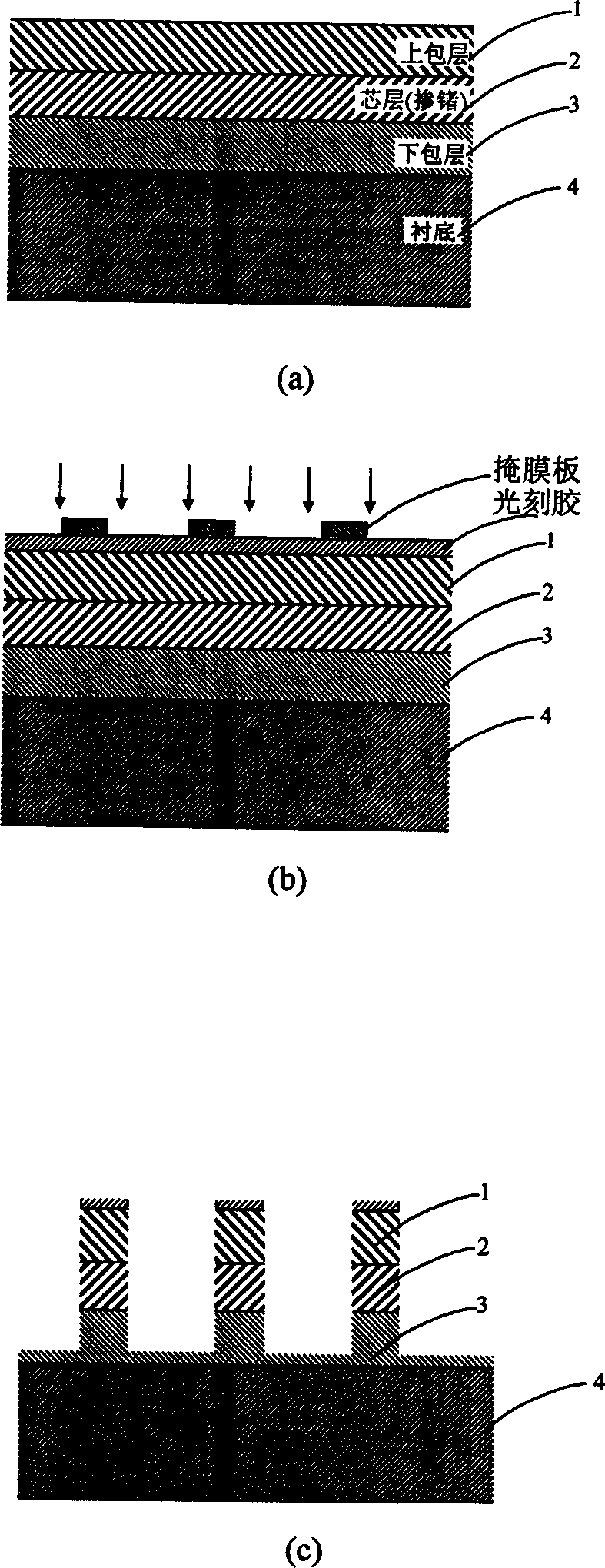

Deep-etched SiO2 ridge waveguide and its preparing process

InactiveCN1743880AStrengthen restrictionsSmall bending radiusOptical fibre with multilayer core/claddingWaveguideSilicon dioxide

This invention discloses deep etched silicon dioxide rib waveguides and preparation thereof, which contains in turn depositing lower cladding, core cladding and upper cladding on substrate by silicon dioxide film deposition technology, etching penetrating upper cladding and core cladding by deep etching technology, etching part or all lower cladding, In said invention, the light field limitation is increased with reduced curve semidiameter and raised light integrity.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com