Patents

Literature

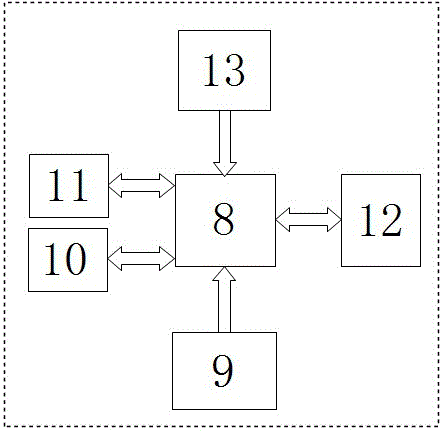

32results about How to "Reduce compression deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

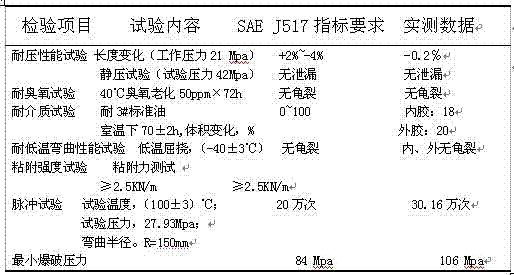

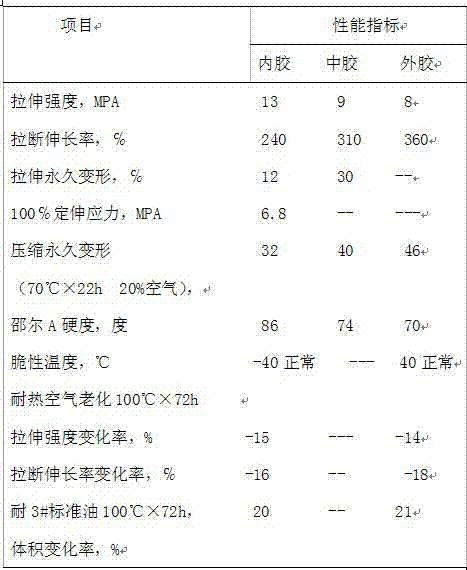

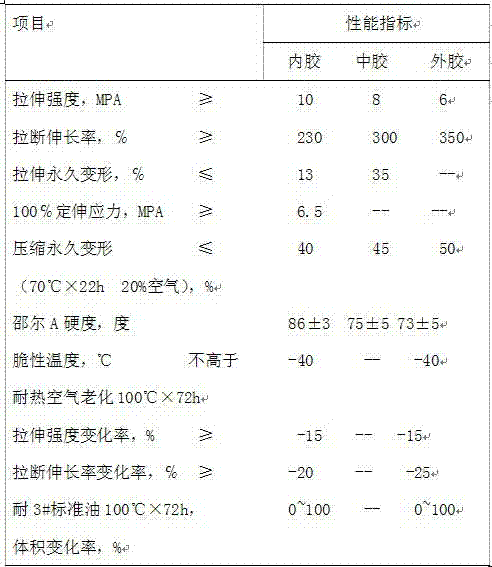

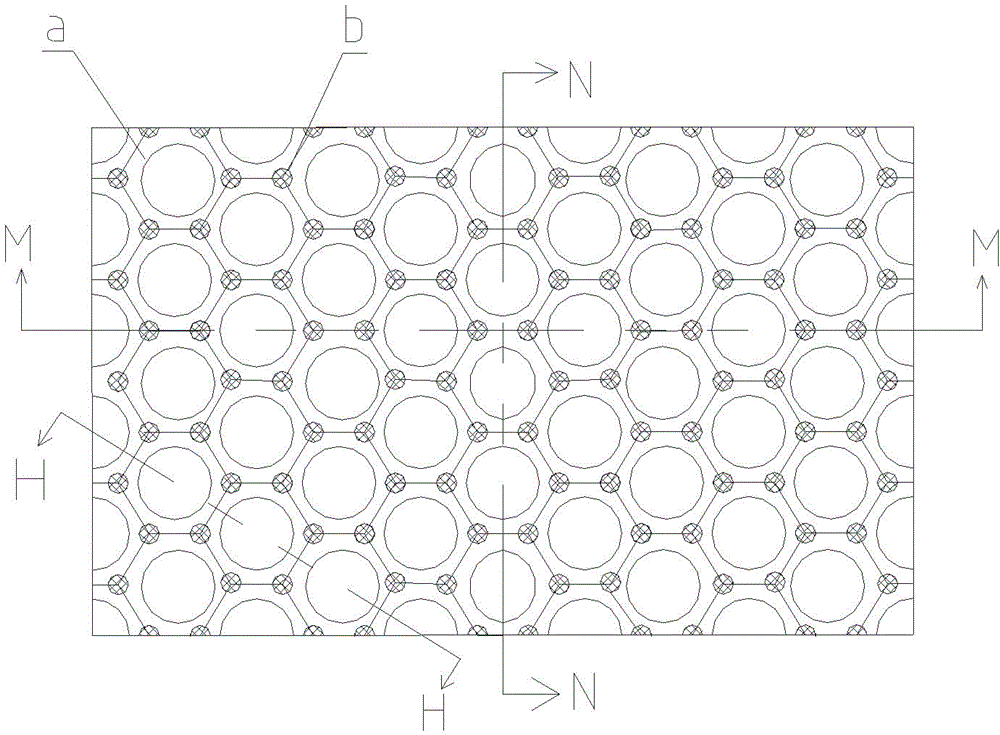

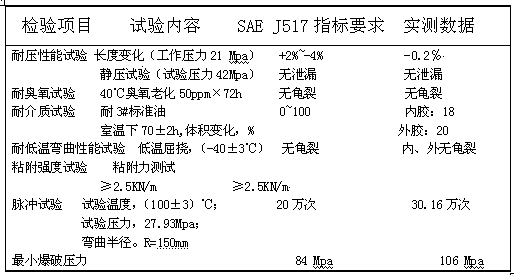

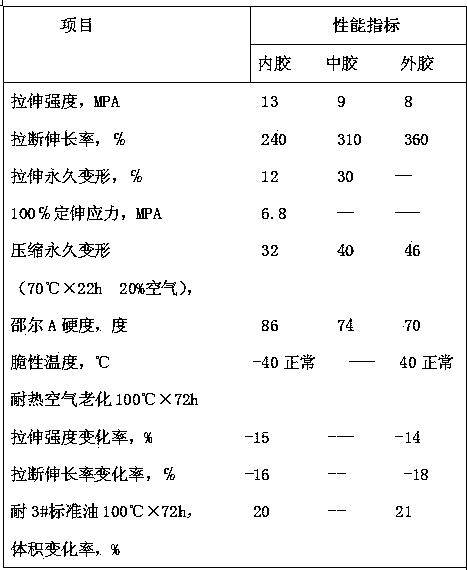

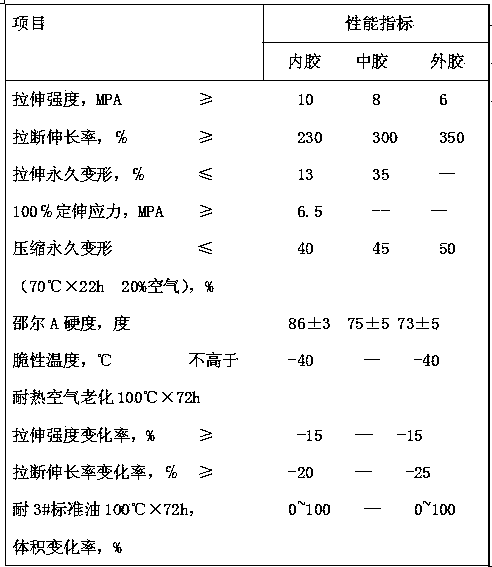

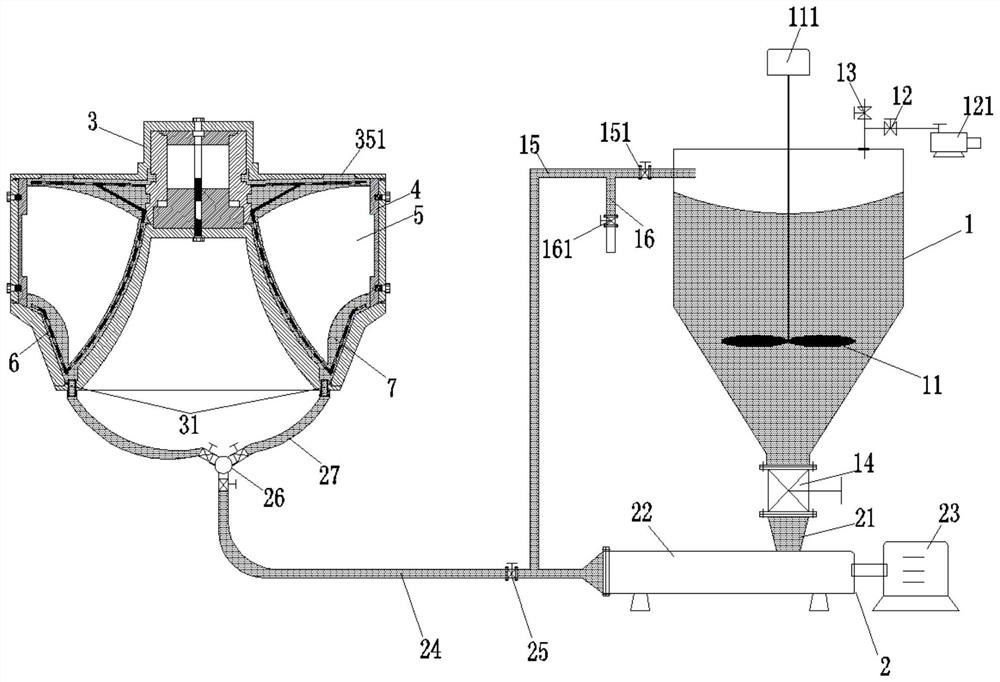

Compact steel wire braided rubber hose and preparation method thereof

The invention discloses a compact steel wire braided rubber hose, which comprises an inner rubber layer, two steel wire layers which are braided outside the inner rubber layer, a middle rubber layer between the two steel wire layers and an outer rubber layer outside the steel wire layers. The inner rubber of the inner rubber layer, the middle rubber of the middle rubber layer and the outer rubber of the outer rubber layer are made of the following raw materials: raw rubber, reinforcing agents, softening agents, minor ingredients, adhesive and accelerating agents. The invention additionally discloses a preparation method of the compact steel wire braided rubber hose. The compact steel wire braided rubber hose has the advantages that the structure is reasonable, the pulse compression deformation is small, the weight of the rubber hose is light, the bending radius is small, all performances of the finished product satisfy requirements in notes of SAEJ517R17, the pulse performance is stable, the pulse times exceeds 300 thousand and the service life of the rubber hose is greatly prolonged.

Owner:LUOHE LETONE RUBBER

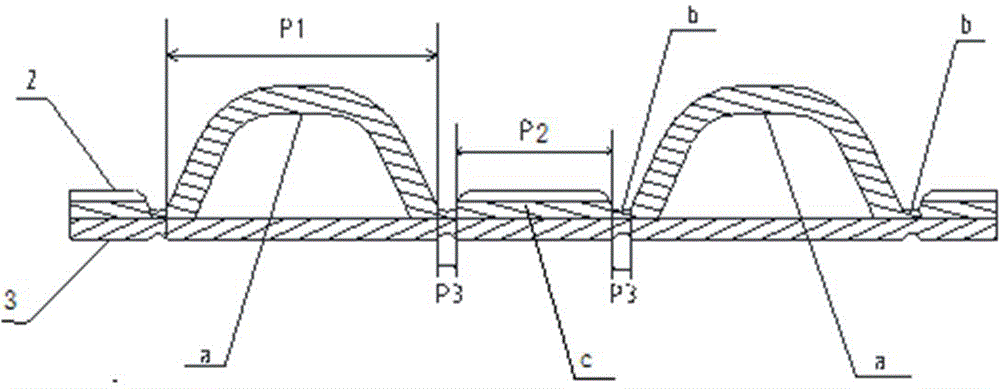

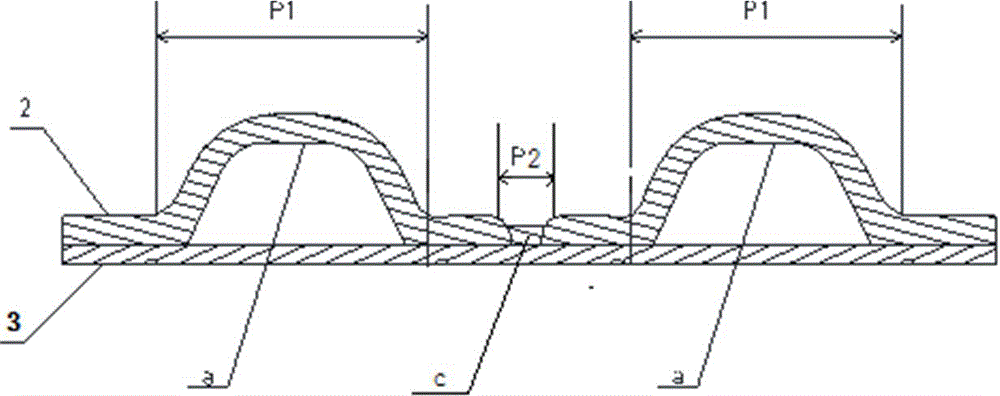

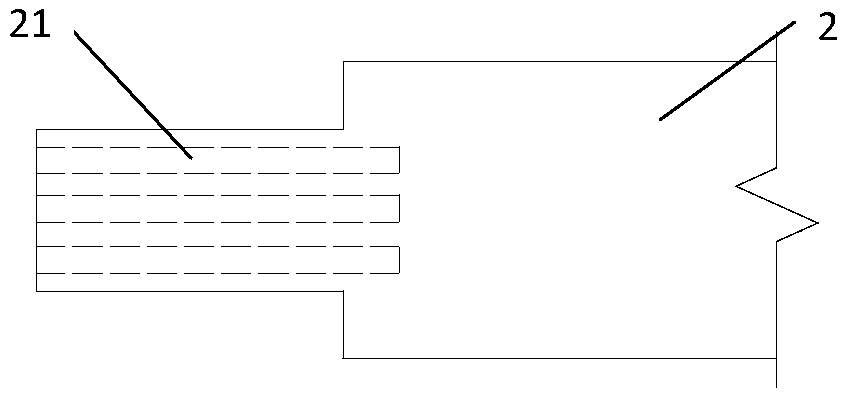

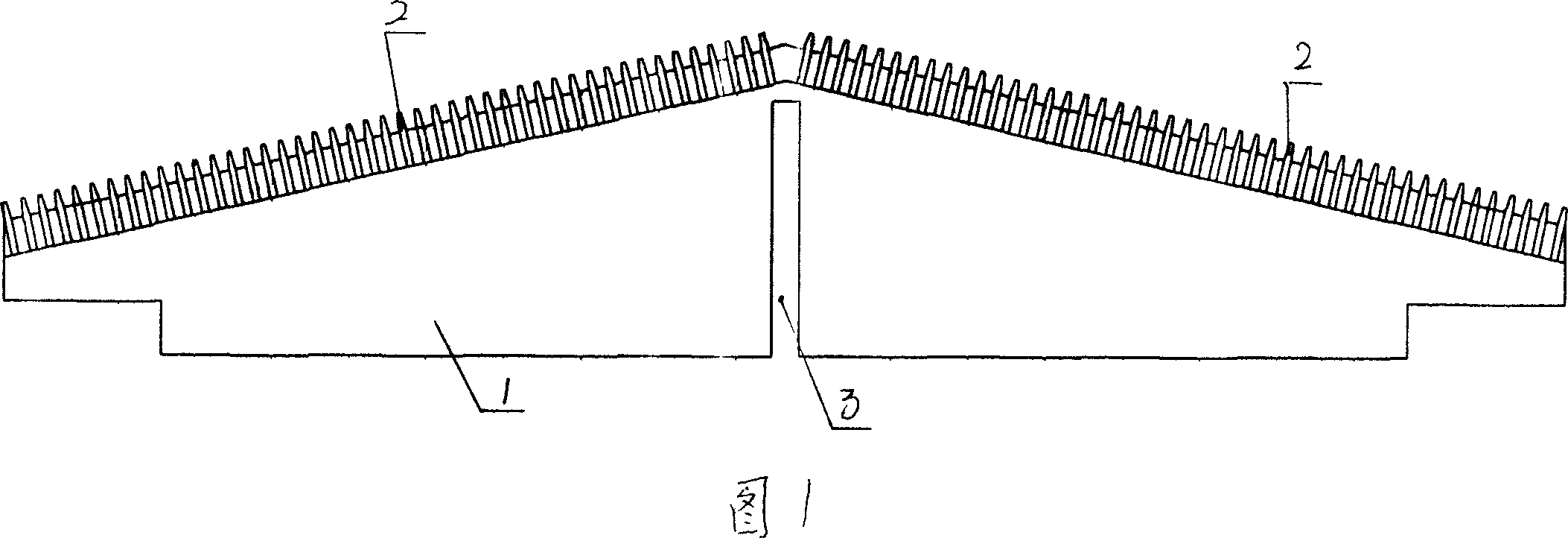

Composite sheet for absorbing type sanitary product

InactiveCN104523378AReduce compression deformationRaised in good conditionAbsorbent padsBandagesBiomedical engineeringCompressive deformation

The invention relates to the technical field of absorbing type sanitary products and discloses a composite sheet for an absorbing type sanitary product. The composite sheet comprises a first sheet body and a second sheet body, wherein the first sheet body and the second sheet body are combined, multiple hollow protrusions are arranged on the first sheet body and located away from the second sheet body, multiple bonding pits are formed in the round root of each protrusion and enable the first sheet body and the second sheet body to be bonded together, the number of the bonding pits is larger than that of the protrusions, and the size of each bonding pit is smaller than that of each protrusion; every two adjacent bonding pits are connected through a bonding section, and the bonding depth of each bonding section is larger than that of each binding pit. By means of the convex-concave structure formed by the two layers of materials, when the composite sheet makes contact with human skin, compressive deformation of the protrusions is light, the state of the protrusions is good, and ventilation and dry-touch effect are realized in the true sense.

Owner:ZUIKO (SHANGHAI) CORP

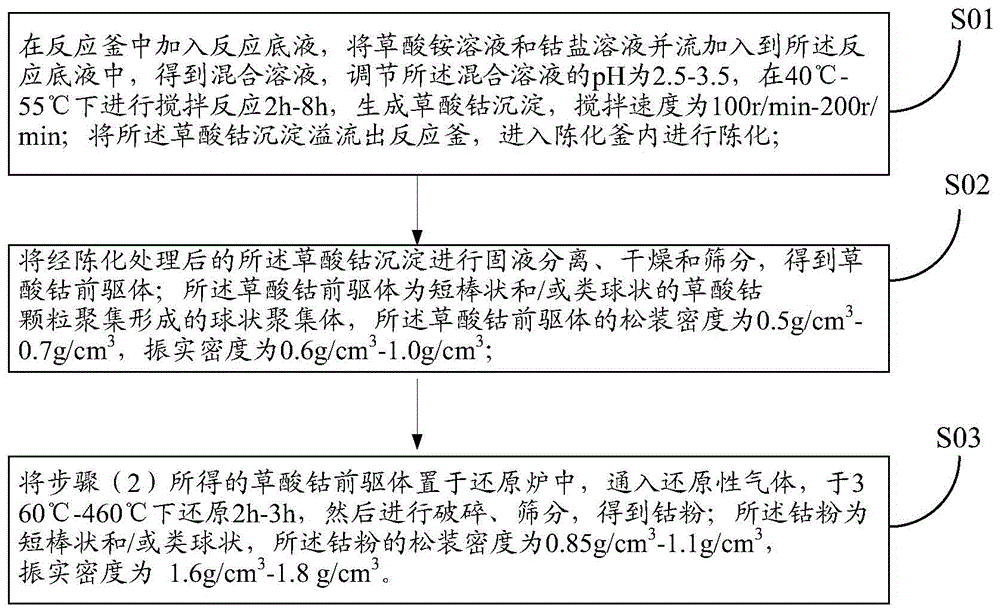

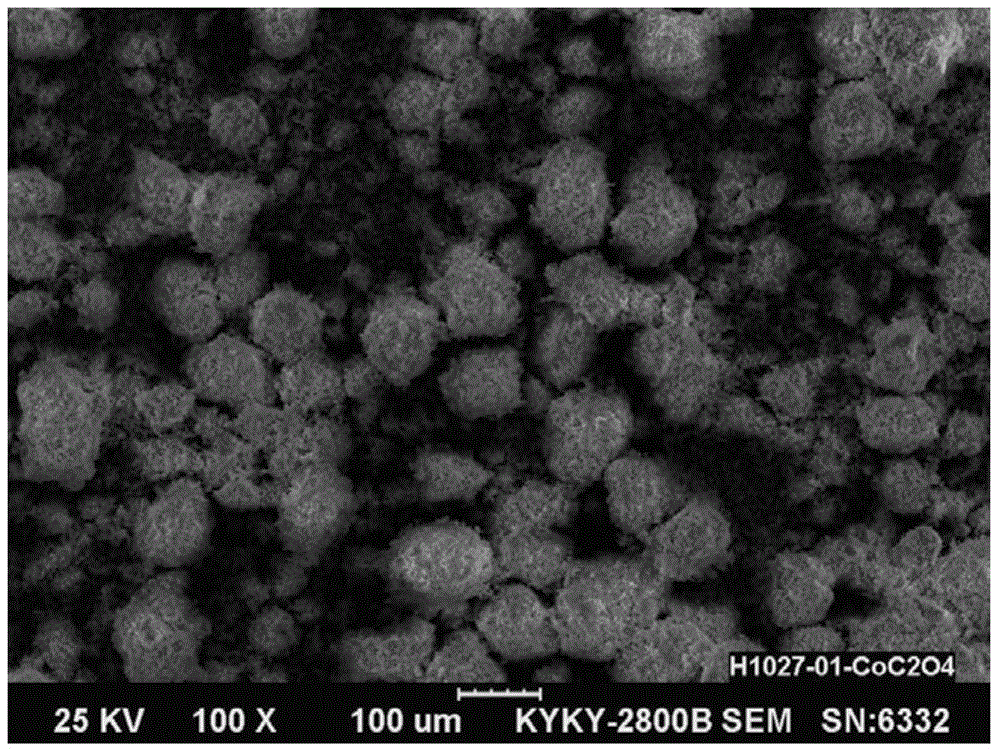

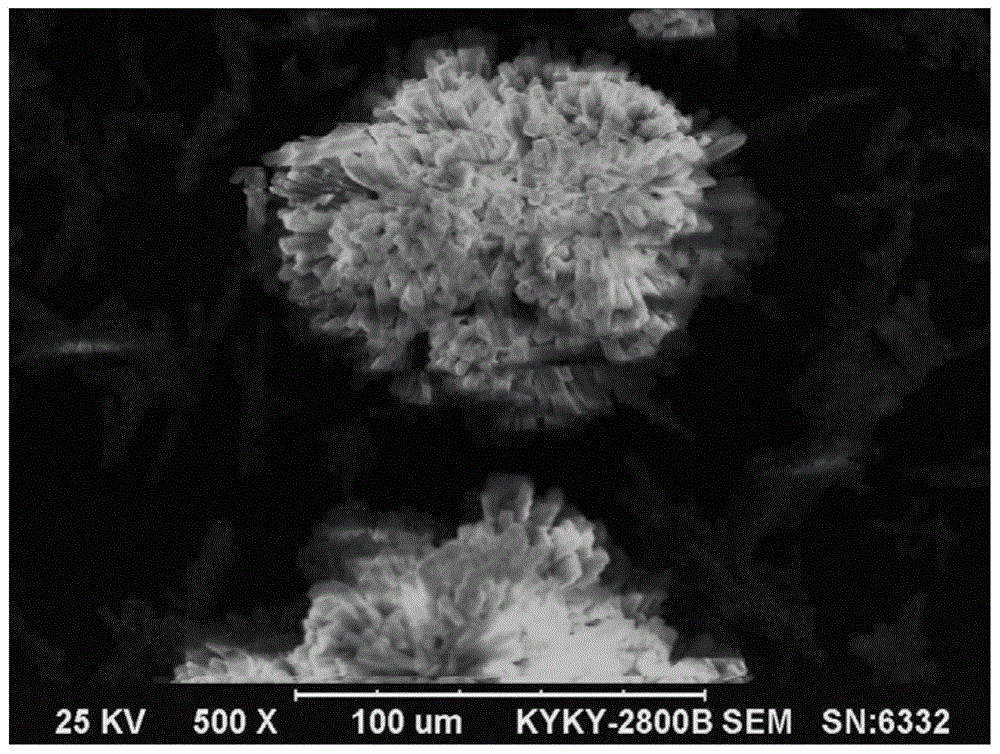

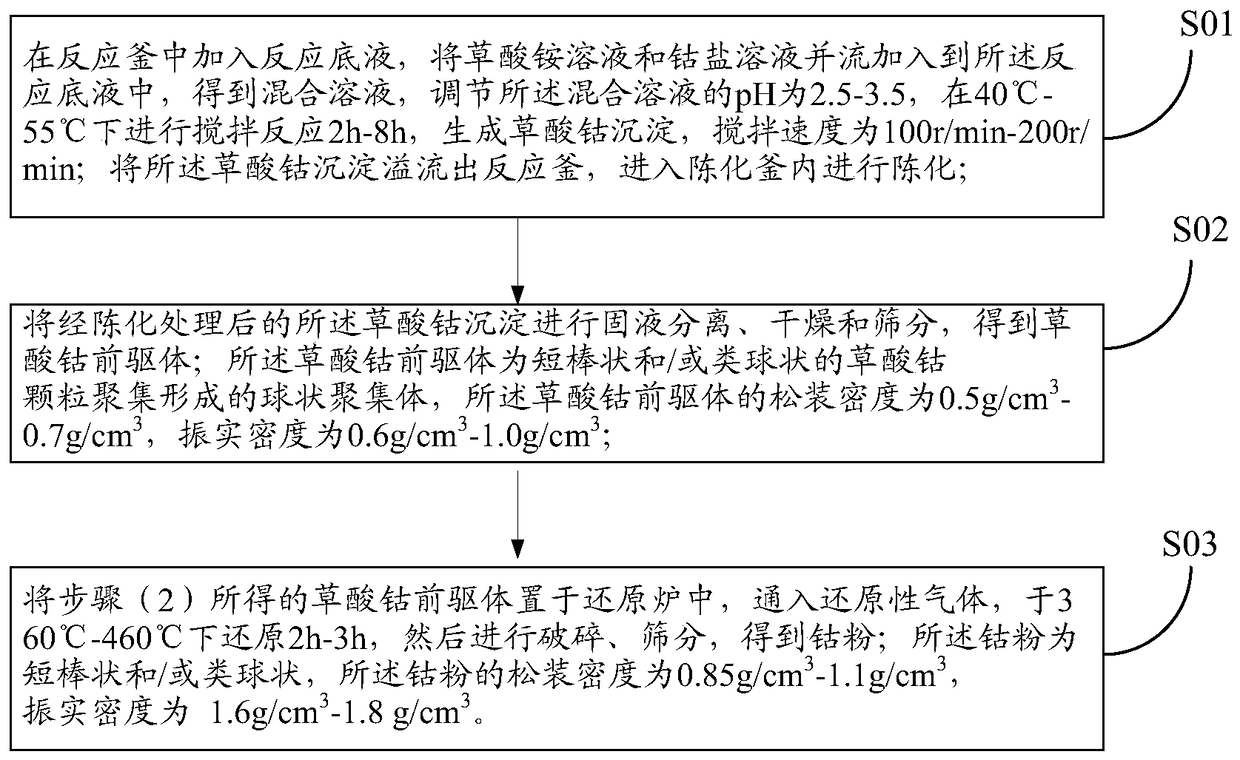

Cobalt powder and preparation method thereof, cobalt oxalate precursor and preparation method thereof

ActiveCN105798318ALarge laser particle sizeGood for mixing uniformityCarboxylic acid salt preparationApparent densityOxalate

The invention provides cobalt powder which is short rod-like and / or near-spherical. The apparent density of the cobalt powder ranges from 0.85 g / cm<3> to 1.1 g / cm<3>, and the tap density of the cobalt powder ranges from 1.6 g / cm<3> to 1.8 g / cm<3>. The apparent density and the tap density of the cobalt powder are similar, and the specific surface area of the cobalt powder is high; when the cobalt powder is applied to the field of hard alloy, high-quality hard alloy can be obtained. The invention also provides a cobalt powder preparation method. A continuous synthesis process is employed in the preparation method, the particle size of the cobalt powder is stable and controllable, and the cobalt powder is suitable for industrial production. The invention also provides a cobalt oxalate precursor. The cobalt oxalate precursor is a spherical aggregation which is formed by aggregating short rod-like and / or near-spherical cobalt oxalate particles, the apparent density of the cobalt oxalate precursor ranges from 0.5 g / cm<3> to 0.7 g / cm<3>, and the tap density of the cobalt oxalate precursor ranges from 0.6 g / cm<3> to 1.0 g / cm<3>. The invention also provides a cobalt oxalate precursor preparation method.

Owner:JINGMEN GEM NEW MATERIAL

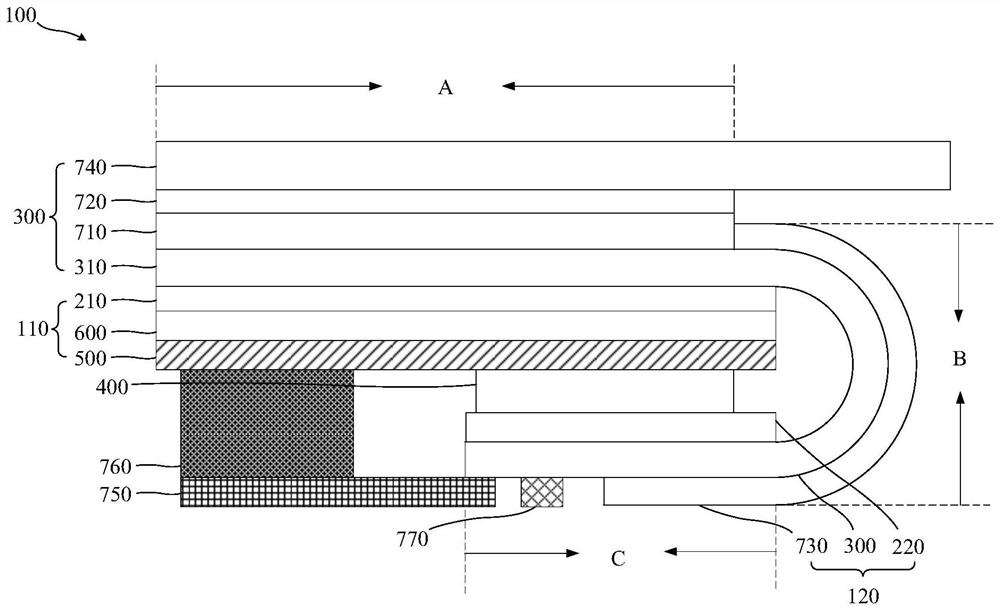

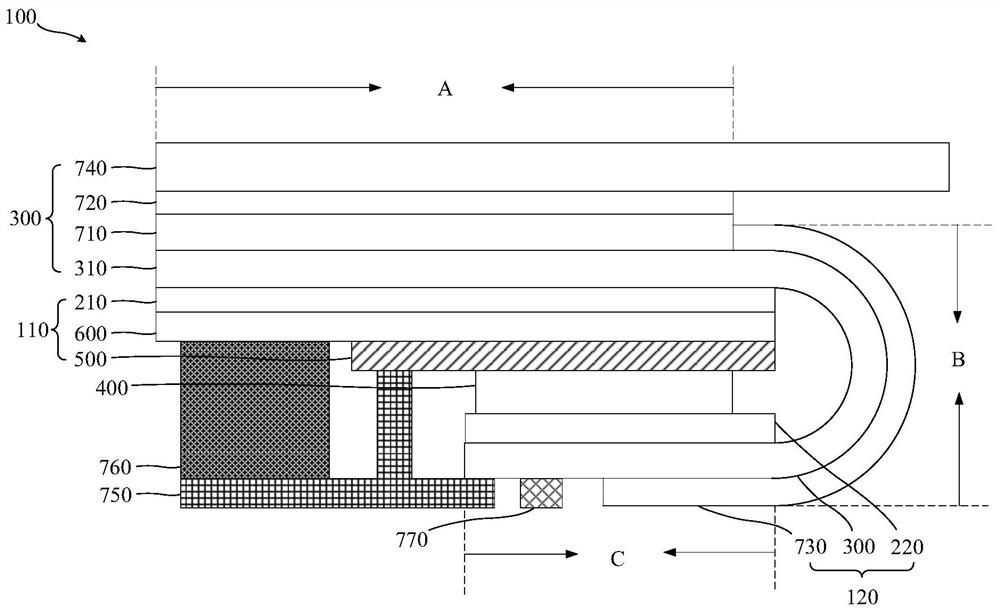

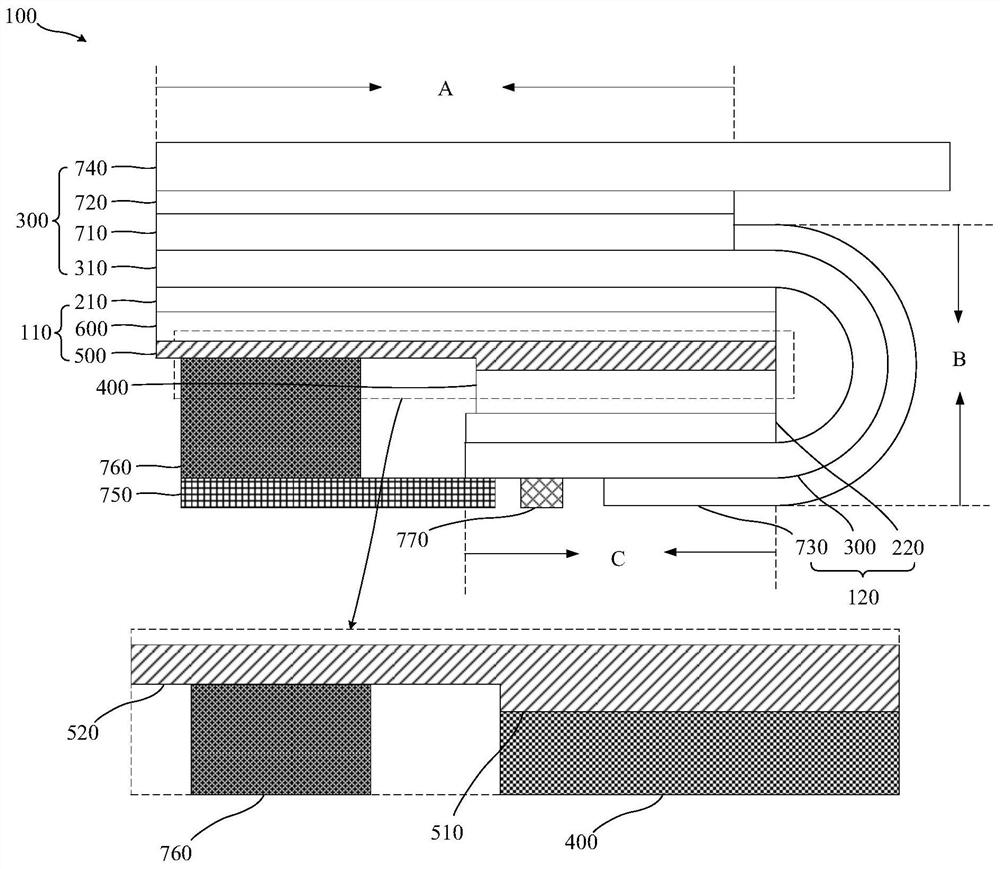

Display panel and display device

ActiveCN112863347AReduce marksReduce compression deformationIdentification meansDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel comprises a first area, a second area far away from one side of the first area and a bending area located between the first area and the second area. The display panel comprises: a display panel main body; a first layer located in the first area, wherein the first layer comprises a third layer located on one side of the display panel body and a reinforcing layer located on one side of the third layer; a second layer located in the second area, wherein the second layer is located on the side, away from the display panel main body, of the reinforcing layer; and a connecting member located between the reinforcing layer and the second layer, wherein the hardness of the reinforcing layer is greater than that of the third layer. According to the embodiment of the invention, the reinforcing layer with high hardness is arranged between the display panel main body and the connecting member, so that the pressed deformation quantity of the film layer of the display panel is reduced in the bending and attaching process of the film layer, and the impressions of the display panel are reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

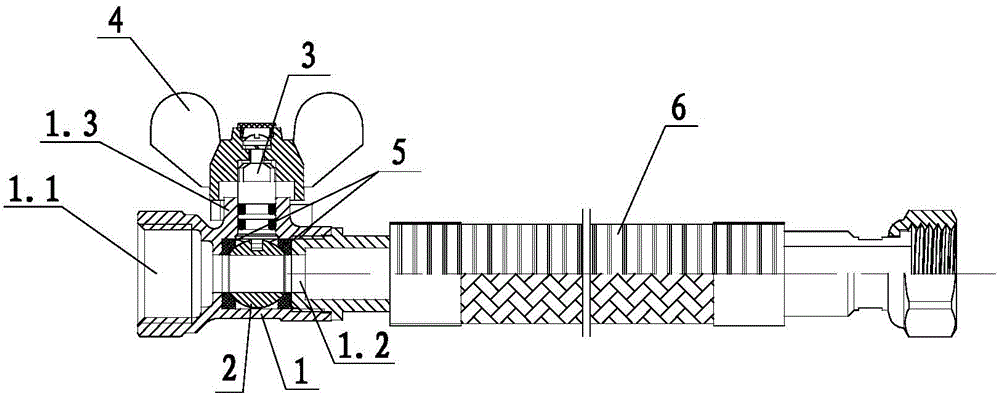

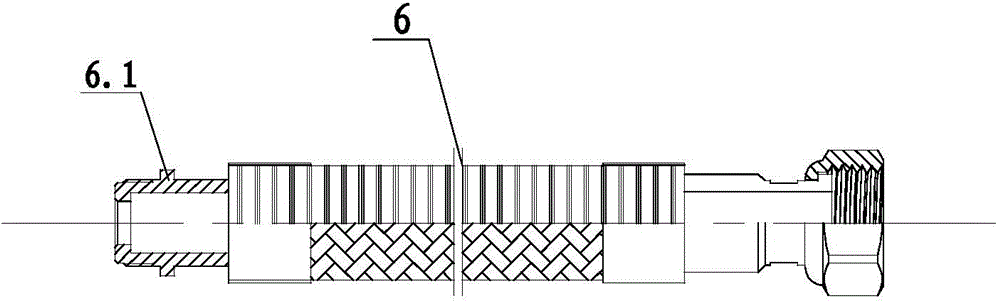

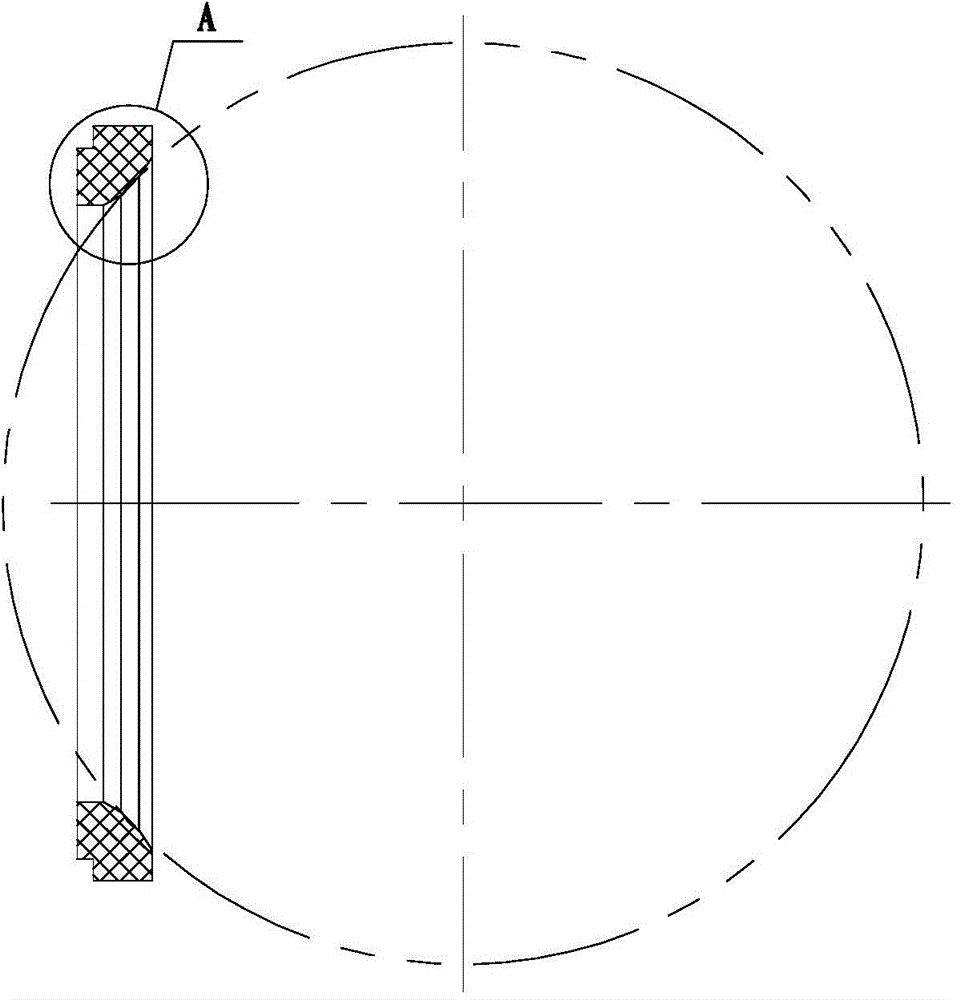

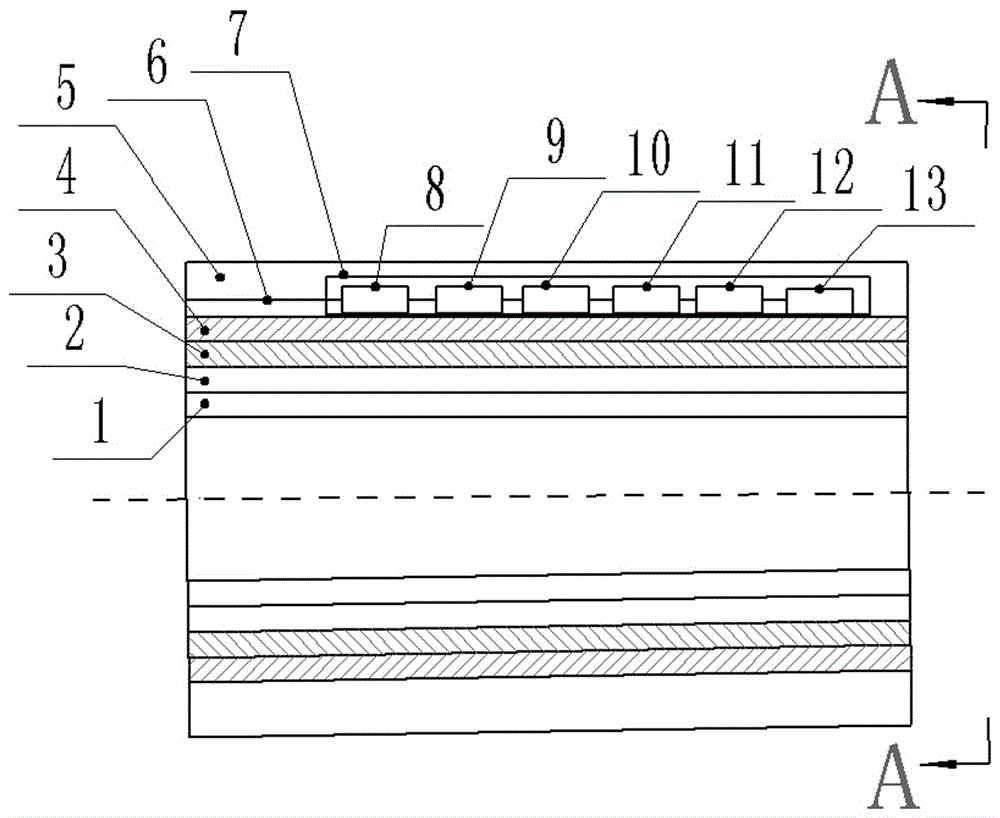

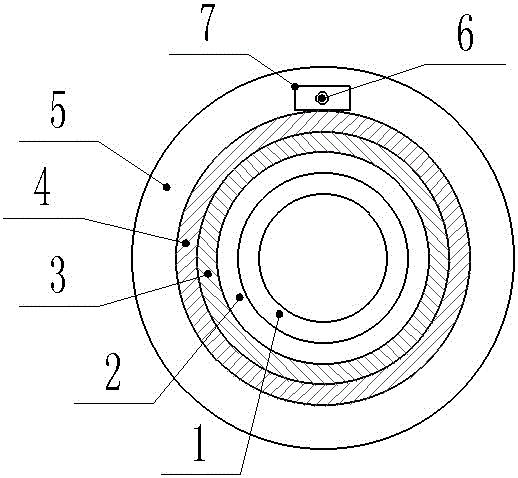

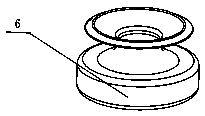

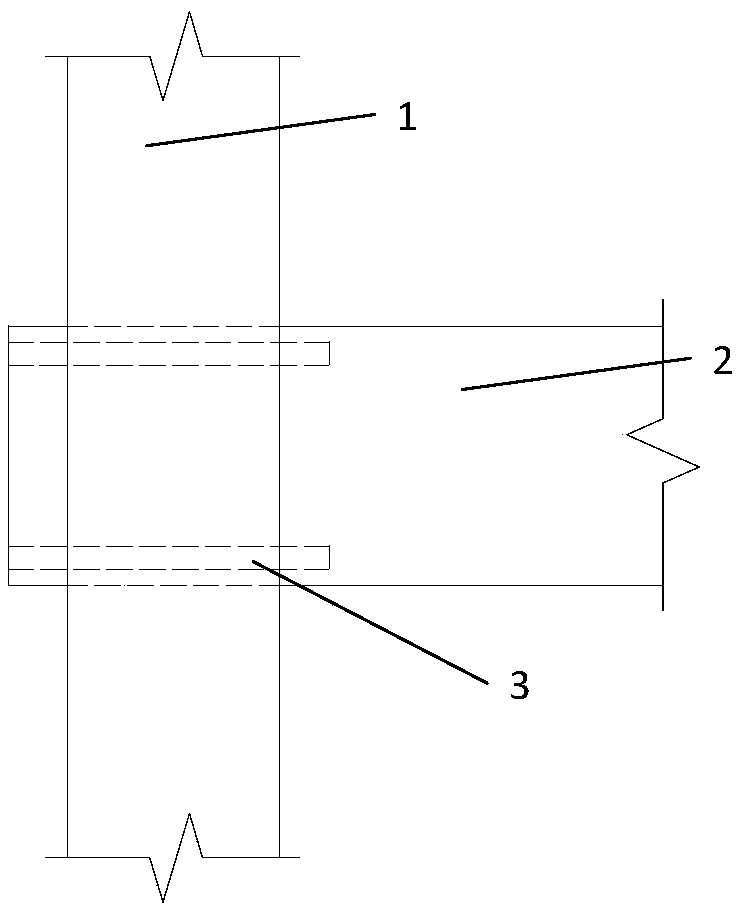

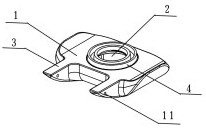

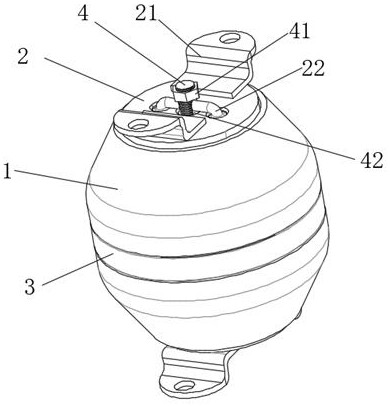

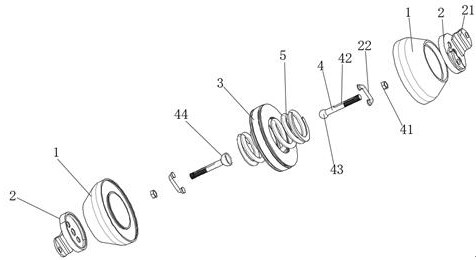

Combined type ball valve provided with corrugated pipe

InactiveCN104696540AReduce external leakage pointsEliminates the risk of air leaksPlug valvesValve housingsEngineeringBall valve

The invention discloses a combined type ball valve provided with a corrugated pipe. The combined type ball valve comprises a valve body (1) provided with an inlet end (1.1) and an outlet end (1.2) as well as a valve core (2), wherein the valve core (2) is mounted in the valve body (1); sealing pieces (5) are arranged on two sides of the valve core (2); one end of the corrugated pipe (6) is fixedly connected with the outlet end of the valve body (1); and the end surface of one end of the corrugated pipe (6) is propped against the sealing piece (5) close to the outlet end (1.2) of the valve body (1). With the adoption of the combined type ball valve provided with the corrugated pipe, the external leakage point between the corrugated pipe and the ball valve can be eliminated.

Owner:NINGBO ZHIQING INDAL

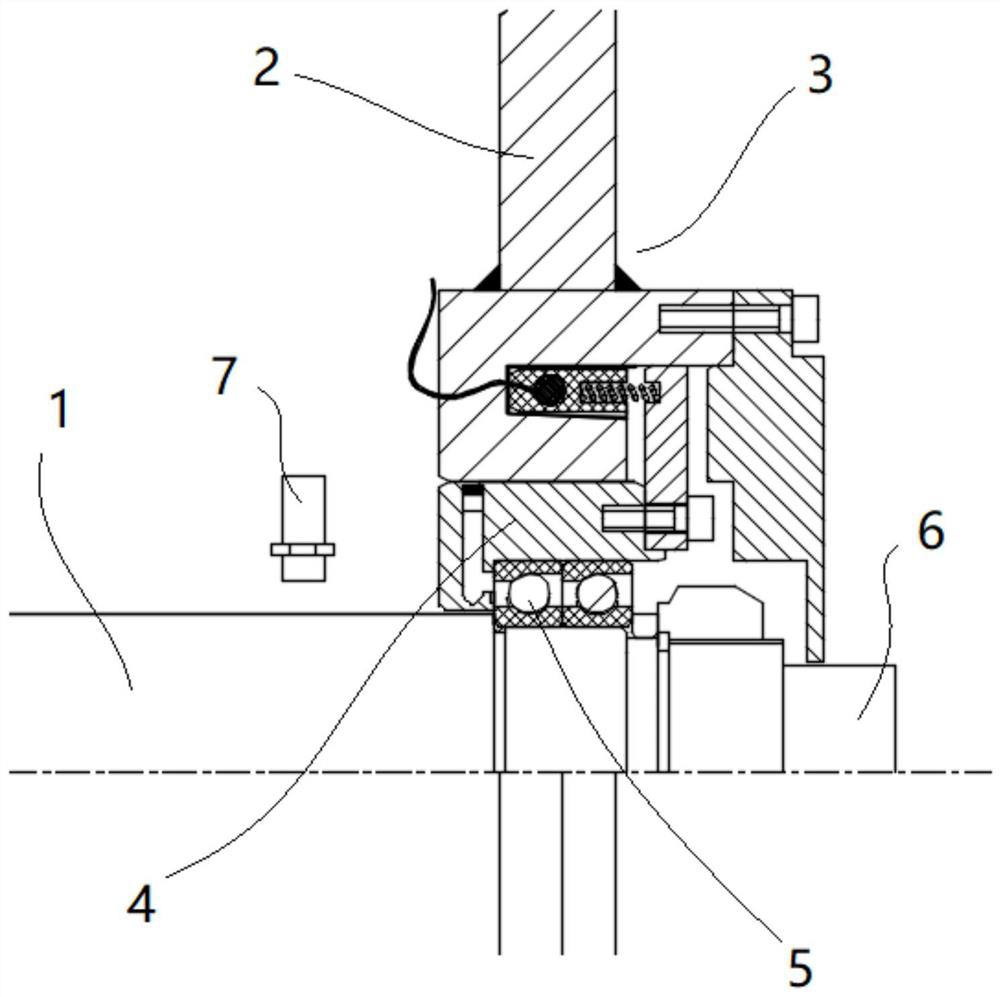

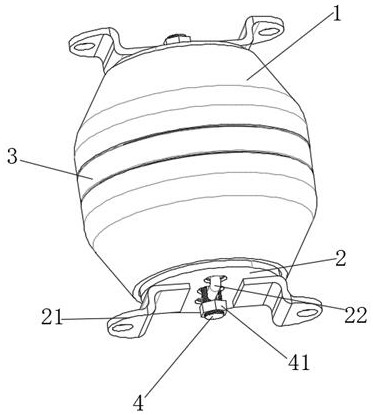

Motor

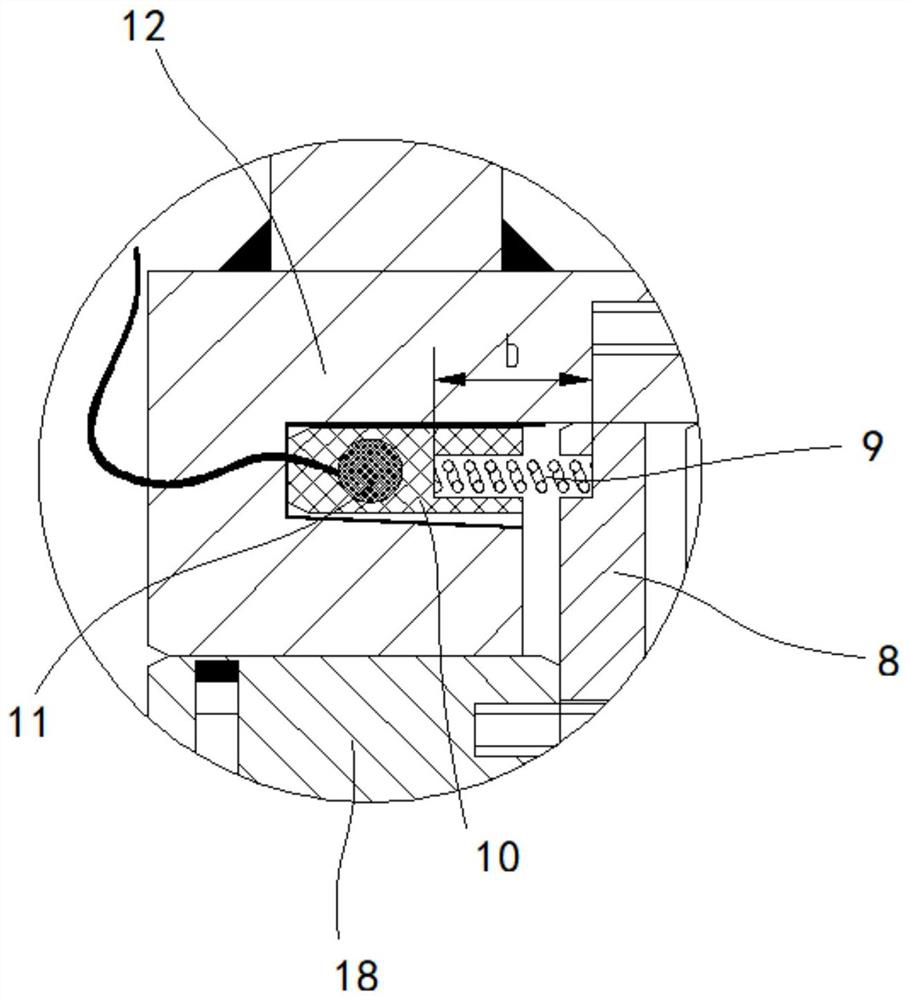

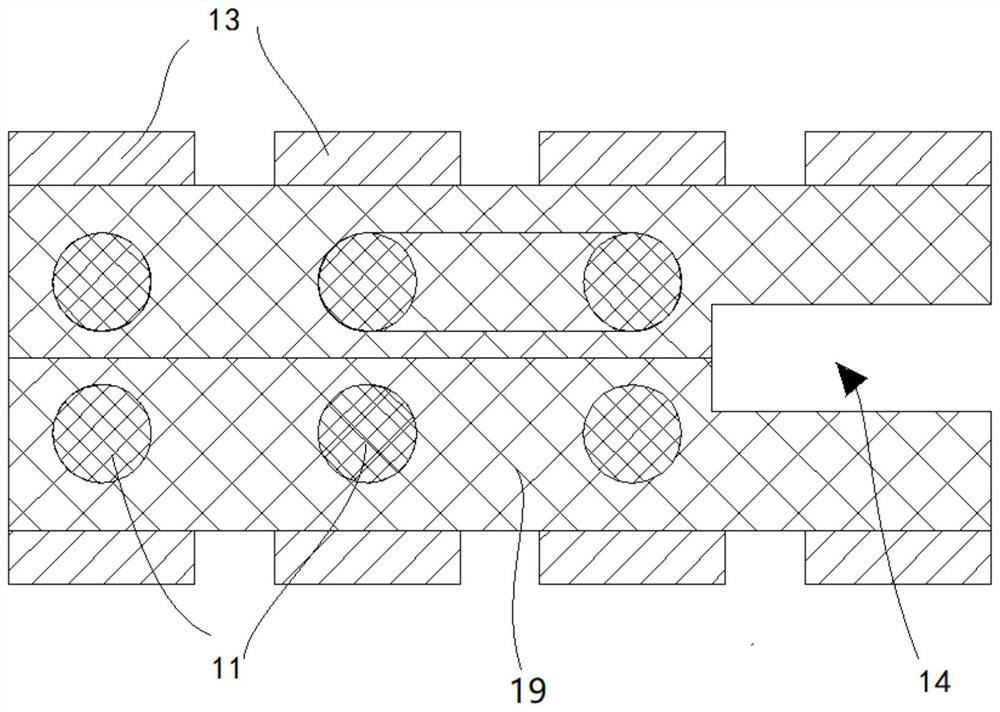

ActiveCN113659759AExtrusion force decreases or disappearsReduce compression deformationSupports/enclosures/casingsElectric machineEngineering

The invention relates to high-speed rotating equipment, in particular to a motor. The motor provided by the invention comprises a rotor, a bearing, a bearing seat, a shell assembly, a base and an elastic piece; the rotor is provided with an extending end and a tail end which are opposite; the bearing sleeves the rotor and is close to the tail end; the bearing seat is matched with the shell assembly and abuts against the end face of one side, close to the extending end, of the bearing; the base is matched with the shell assembly; the elastic piece can generate elastic force in the axial direction of the rotor; the elastic piece is provided with a first end and a second end which are opposite in the elastic force direction, the first end is matched with the base, and the second end is matched with the bearing seat; and a heating piece is arranged in the base, the base can be heated to expand in the elastic force direction of the elastic piece, and the base can be cooled to retract in the direction opposite to the expansion direction. The pretightening force between the bearing and the bearing seat can be adjusted when the rotor rotates.

Owner:TIANJIN EMAGING TECH

Continuous flexible reinforced adhesion-type composite tube

PendingCN106838494AHigh strengthExtended service lifePipe heating/coolingPipeline systemsPhysical chemistryOil field

The invention relates to a composite tube used for an oil field, in particular to a continuous flexible reinforced adhesion-type composite tube. The composite tube comprises a lining layer, an anti-permeation layer, a compression-resistive reinforced layer, a tensile reinforced layer and an outer protective bush layer. The composite tube is characterized in that the anti-permeation layer, the compression-resistive reinforced layer, the tensile reinforced layer and the outer protective bush layer are sequentially arranged on the outer surface of the lining layer; a power line and a control module are arranged on the outer surface of the tensile reinforced layer. The composite tube has the advantages that the adhesion-type structure is good in integrality, the anti-permeation capacity is high, and ring stiffness and an axial tensile property are good; the composite tube can bear high pressure and is small in deformation caused by pressing, allows local heating, further has quite high functions of information collecting and monitoring alarming, and is convenient to use, suitable for delivering water, natural gas, petroleum oil and others from a long distance and particularly suitable for deeply passing through roads, villages and other working conditions that the composite tube can not be laid through ditching at a long distance.

Owner:康红艳 +1

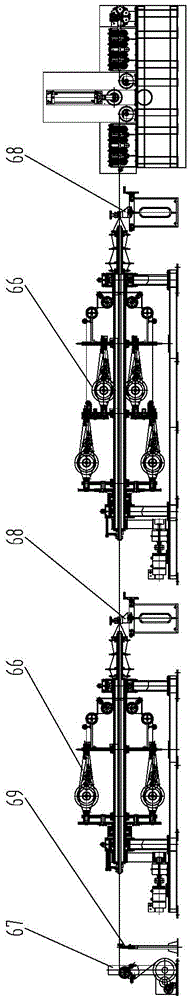

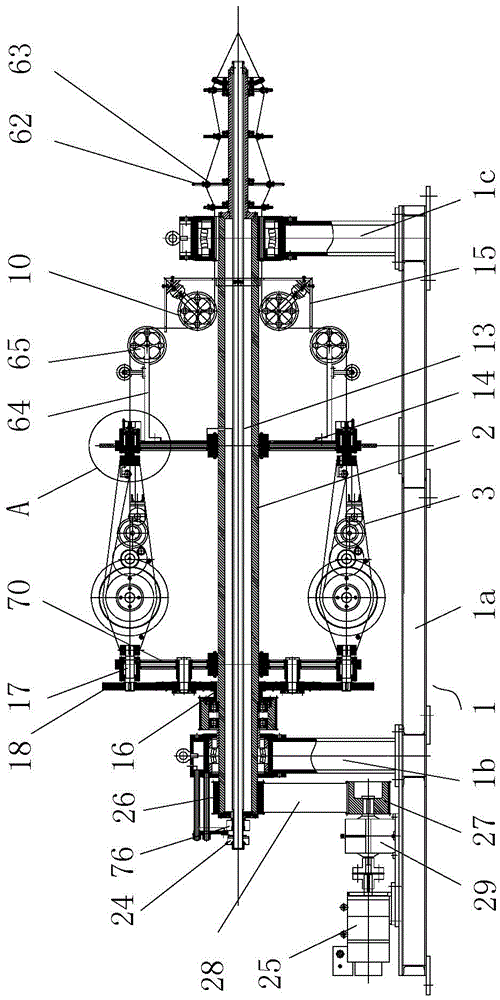

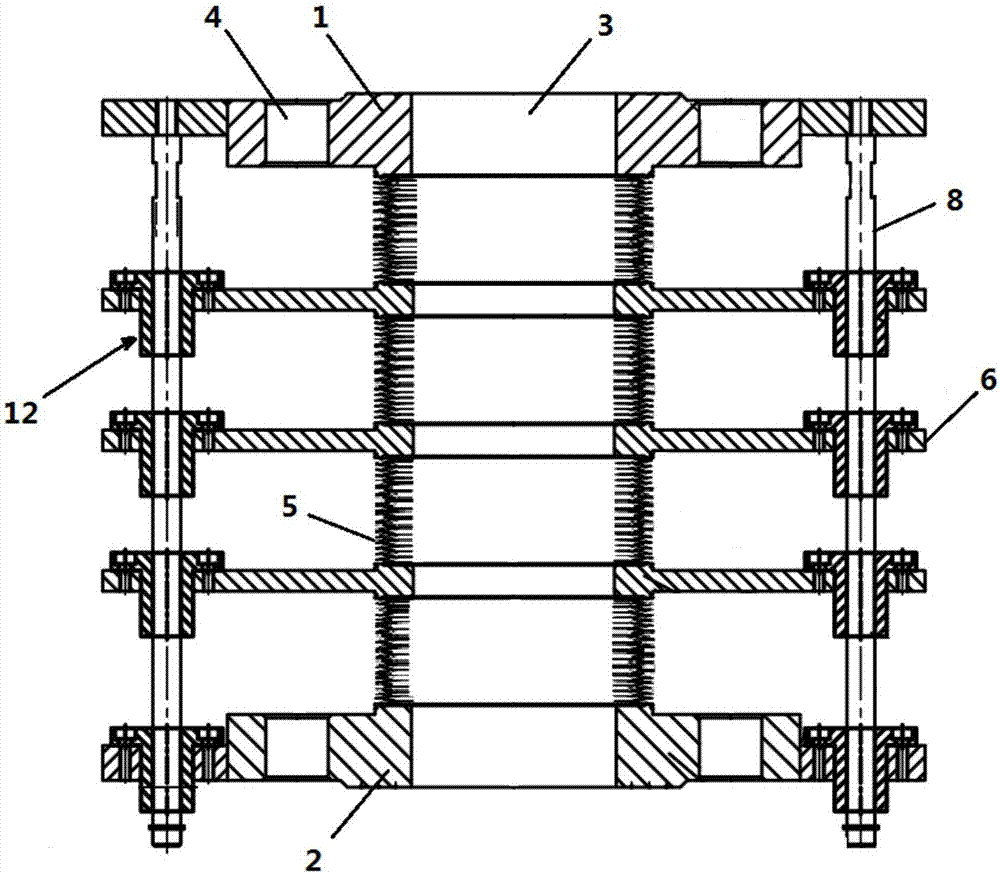

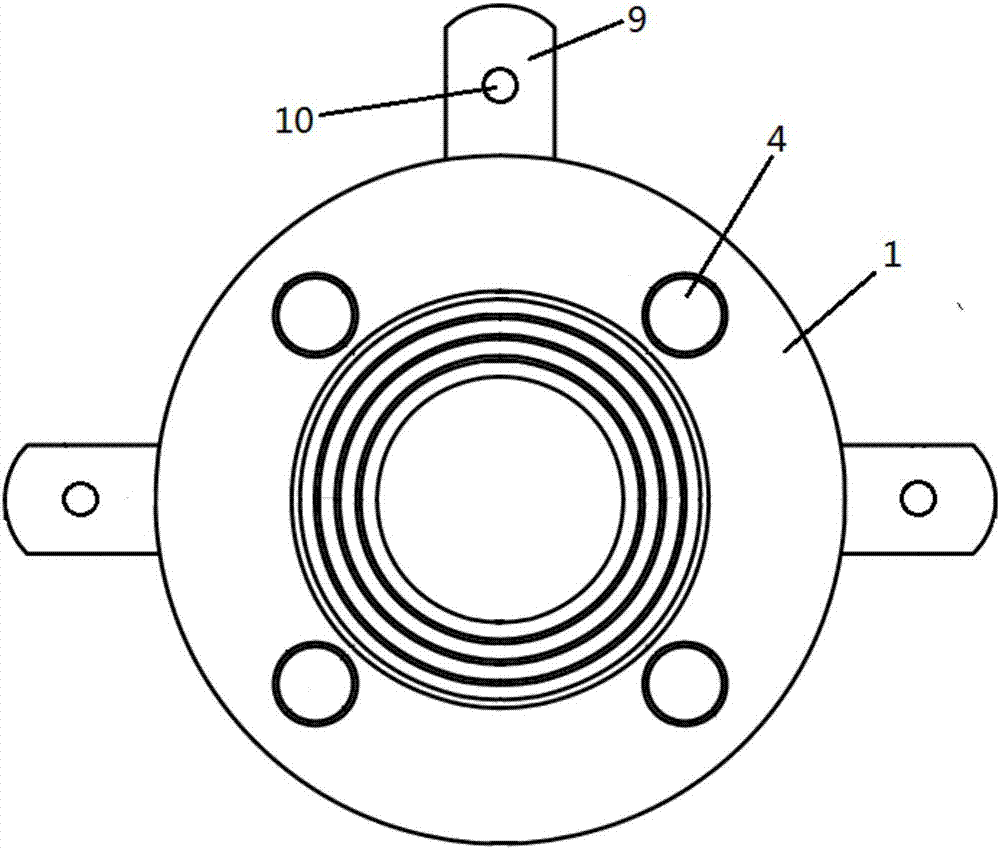

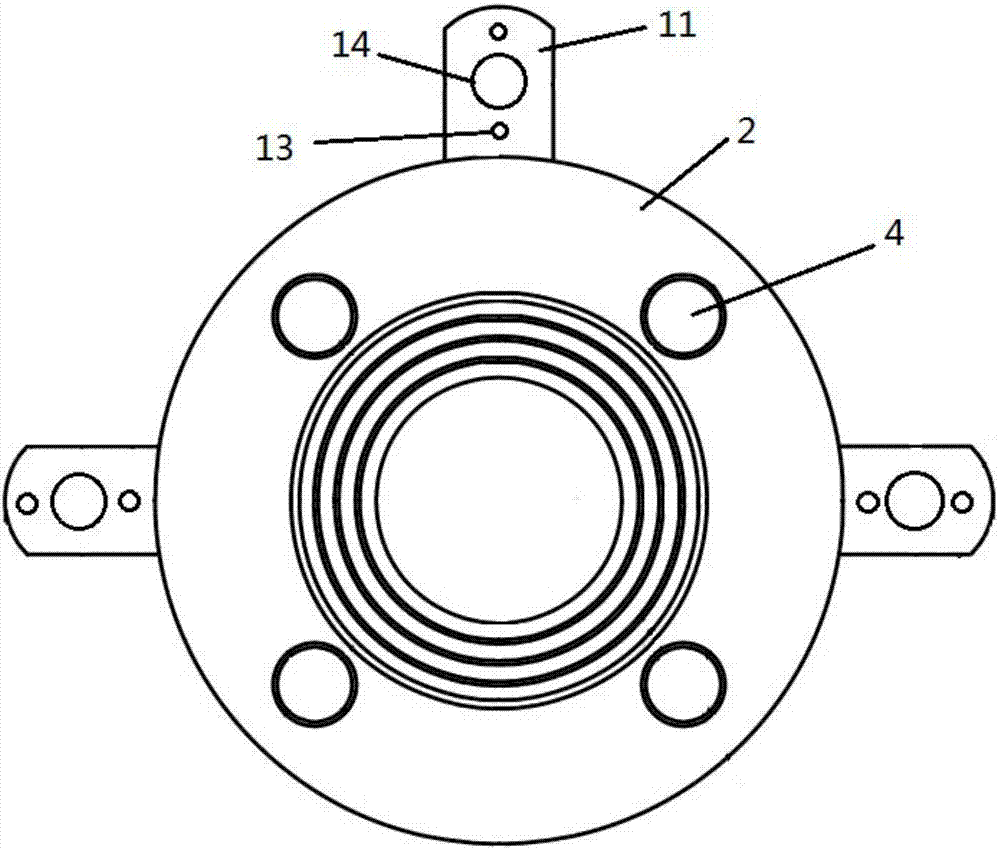

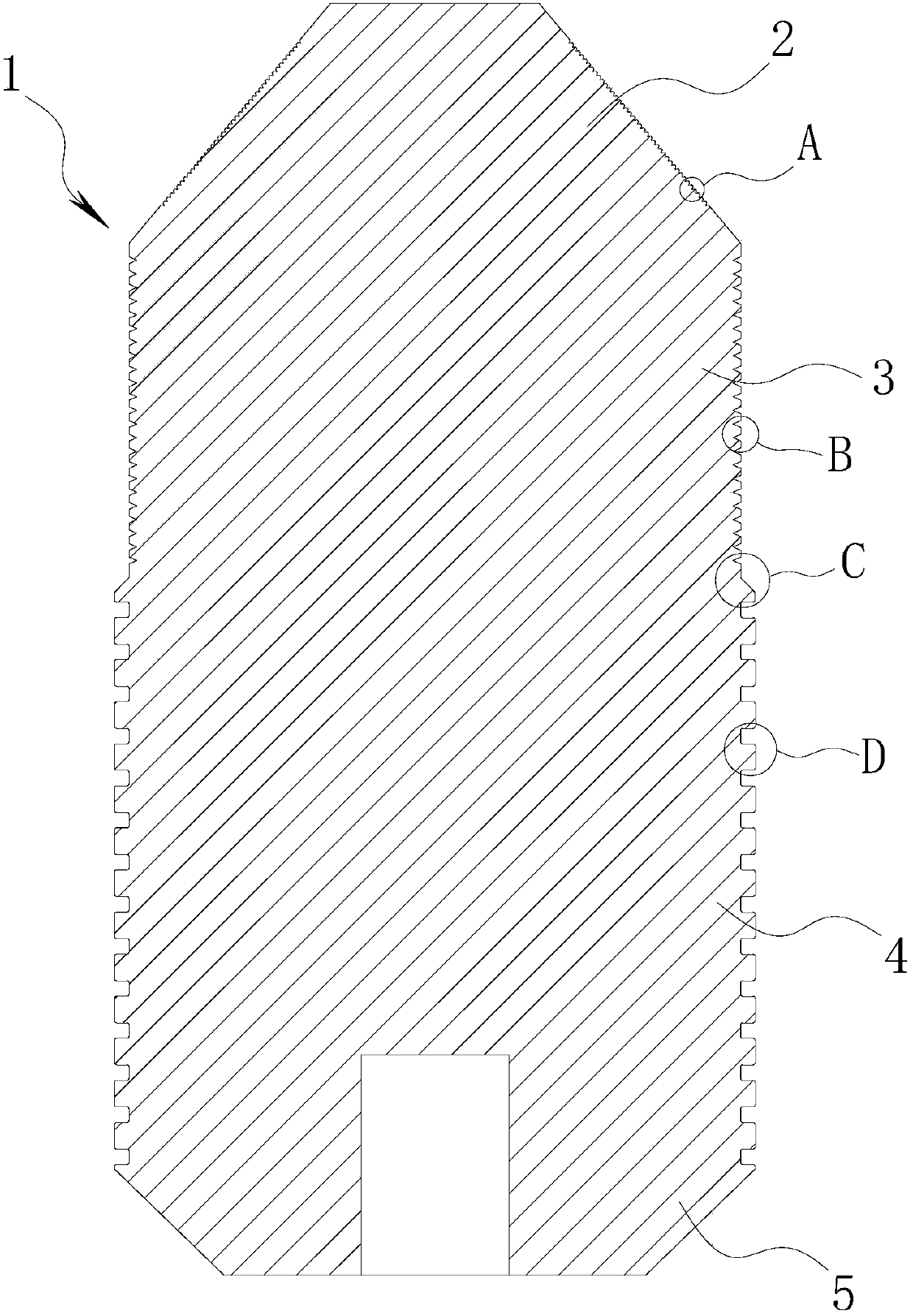

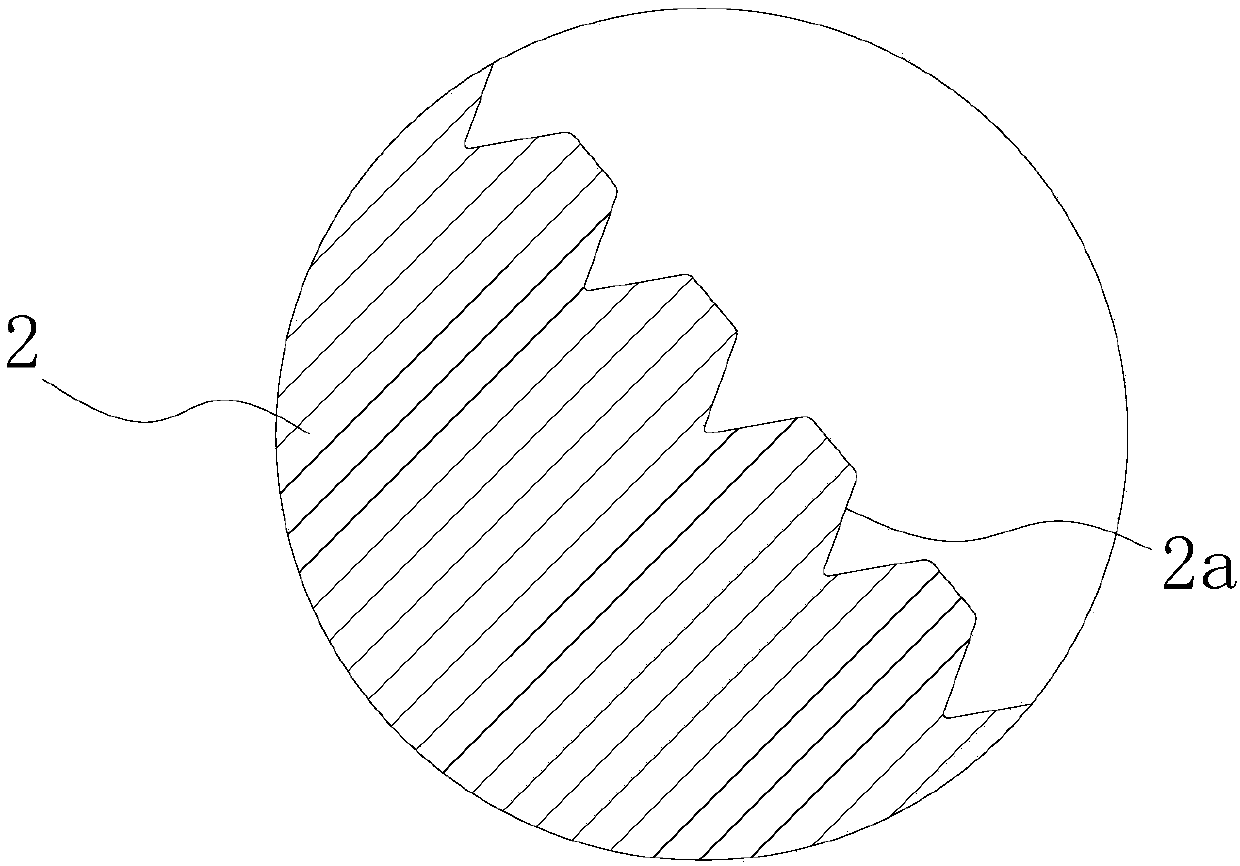

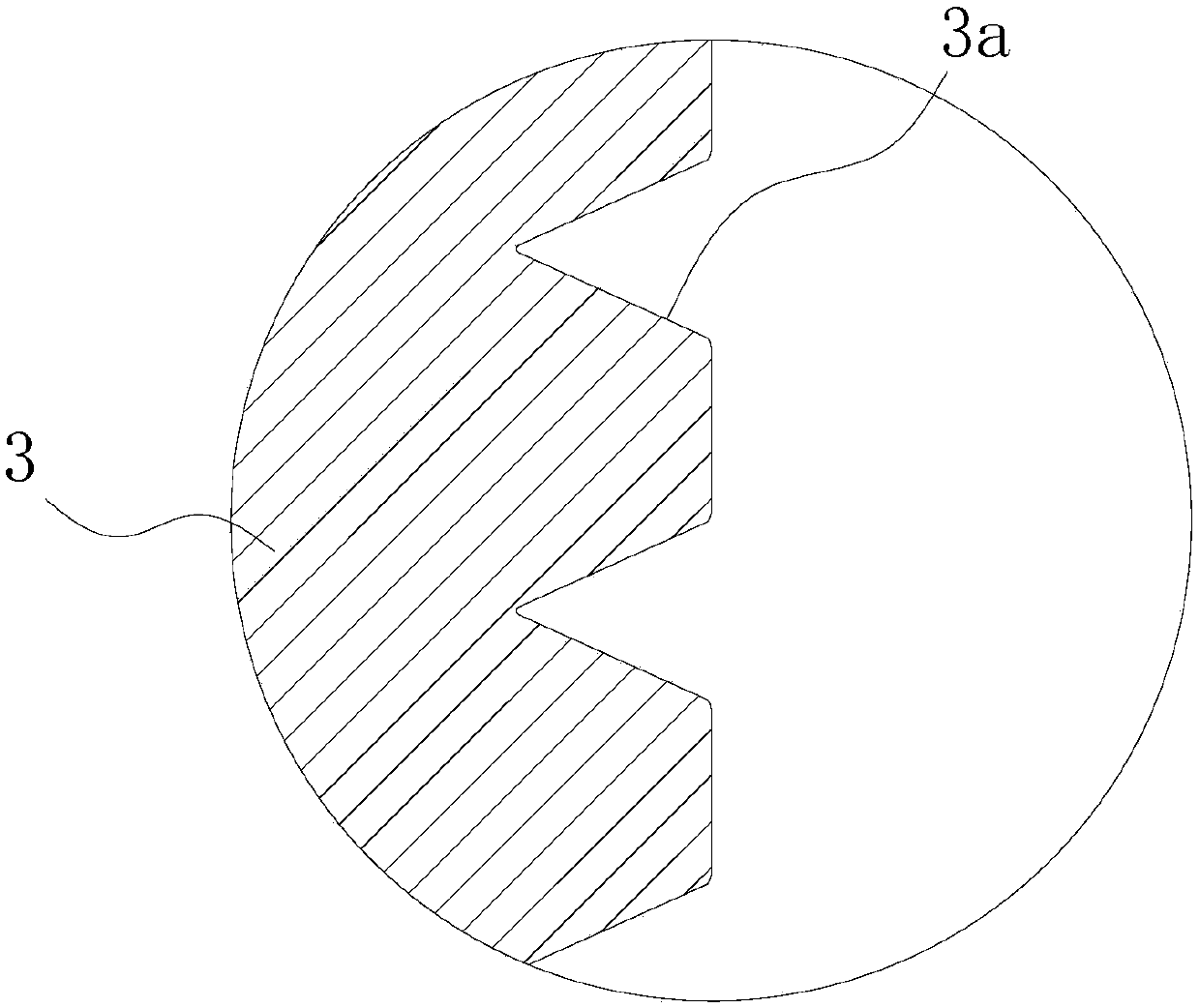

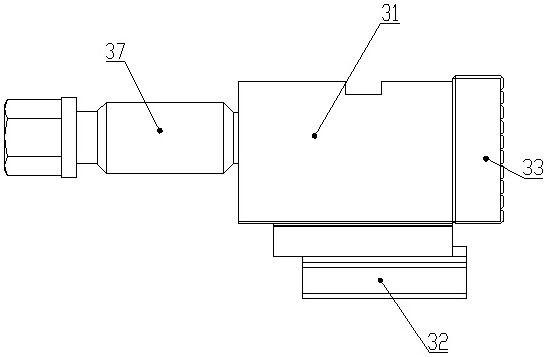

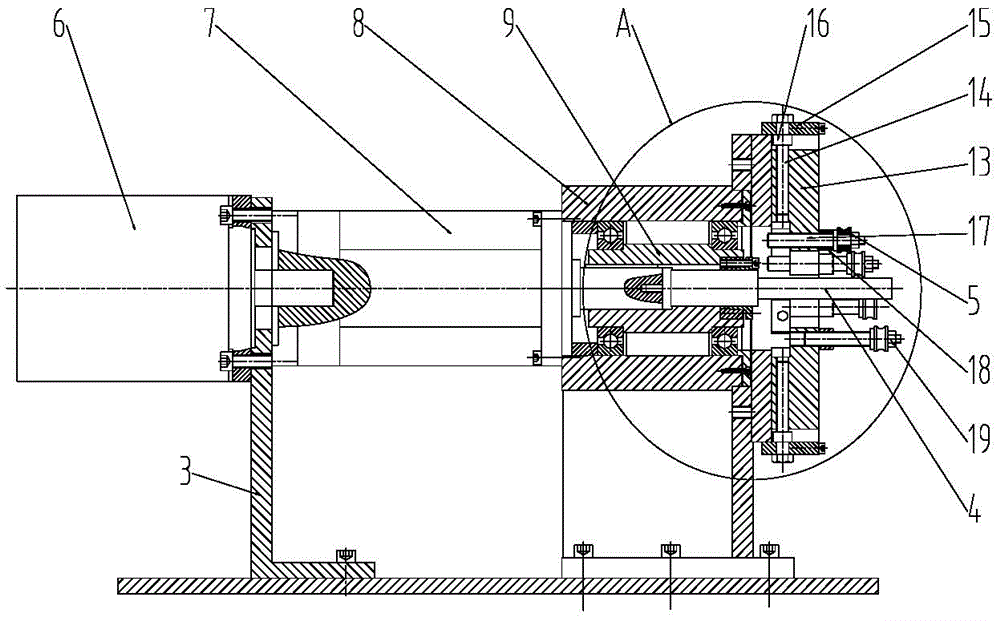

Modular multi-strand coil spring CNC machining machine

A modularization NC machining tool for stranded-wire helical springs comprises a strand twisting device, stranded-wire helical spring continuous spring coiling devices and a control system. The strand twisting device comprises at least one stranded-wire helical spring rotary strand twisting device which are connected in series, central passive unreeling machines which are farthest from the spring coiling device and arranged corresponds to the stranded-wire helical spring rotary strand twisting devices and doubling die holders which are arranged corresponds to each stranded-wire helical spring rotary strand twisting device. Each stranded-wire helical spring continuous spring coiling device comprises a spring coiling device and a traction pushing device. The modularization NC machining tool for the stranded-wire helical springs can realize accurate rotating speed matching among each device, accurately control the distances of steel ropes and the screw pitch of the springs, strictly ensure that the tension of each strand of steel wires is even and the size is the same, and eliminate the twist internal stress or provide the twist prestress at any back-twist rates of the steel ropes. Therefore, the quality of the finished stranded-wire helical springs can be ensured and the service life can be prolonged.

Owner:CHONGQING UNIV

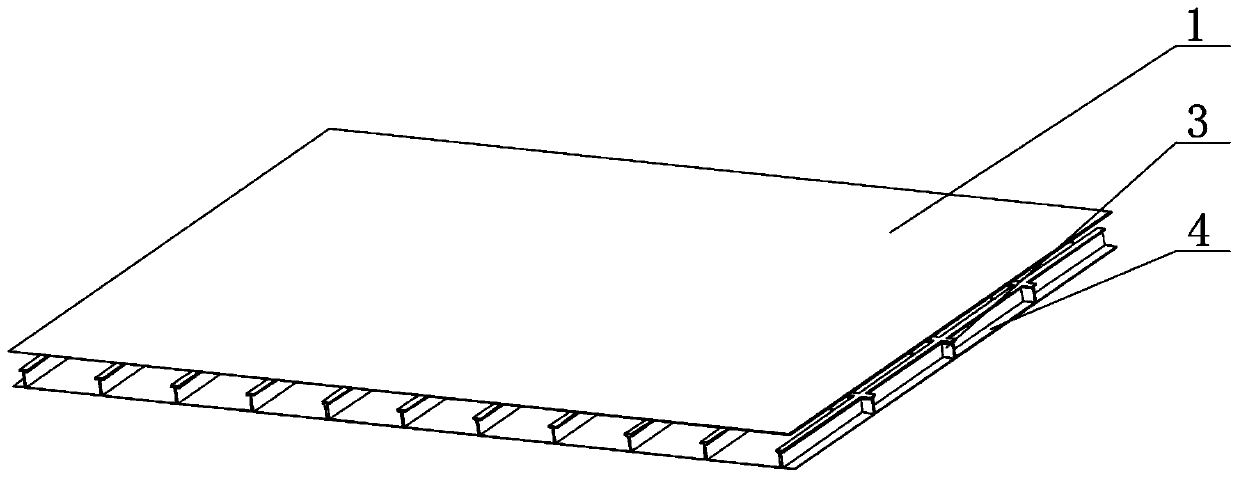

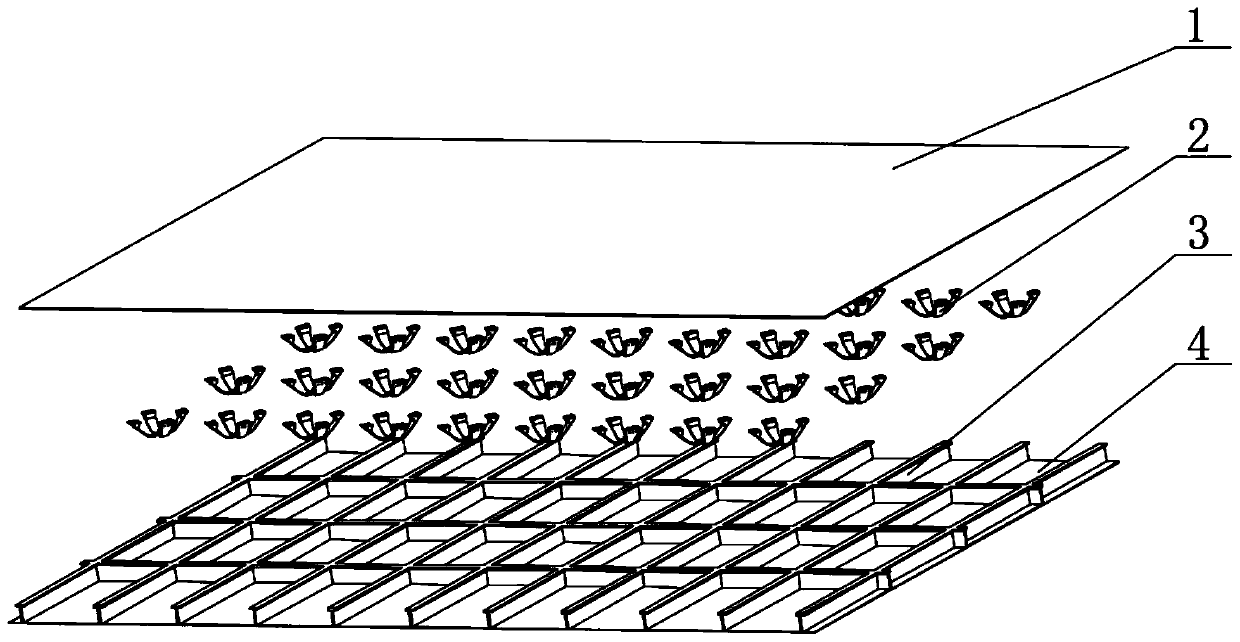

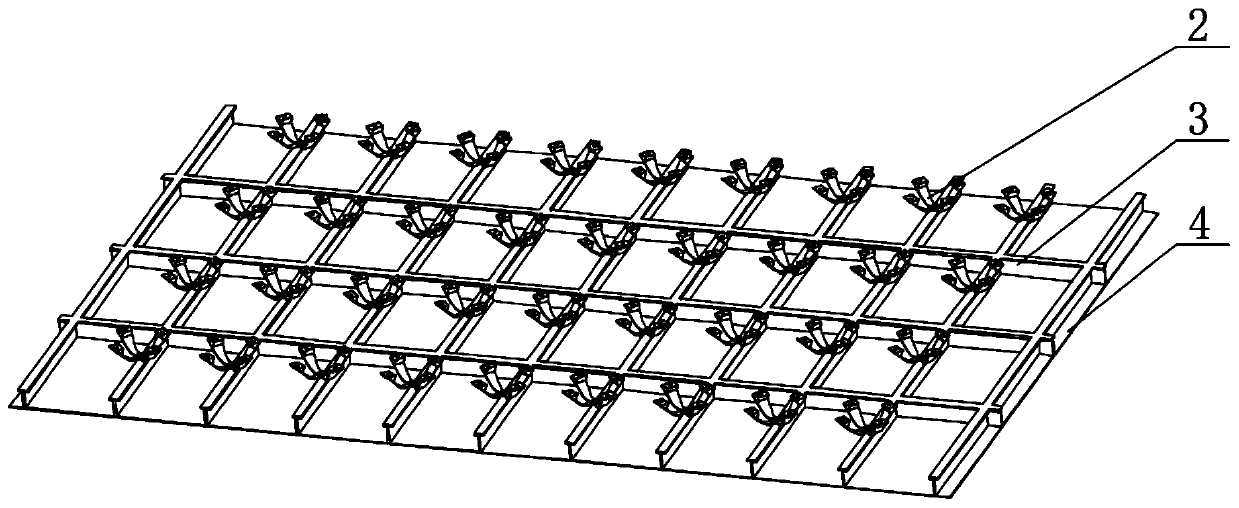

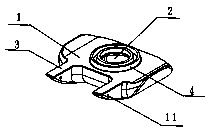

Nonlinear elastic shock absorption bed board

ActiveCN110539842AGood deformation memoryFunction increaseHull panellingsFuselage insulationEngineeringFastener

The invention relates to a nonlinear elastic shock absorption bed board which comprises a bottom plate. T-shaped steel arranged vertically and transversely at intervals is welded to the upper surfaceof the bottom plate. The upper surfaces of the T-shaped steel are located at the same plane position. Multiple supporting spring piece assemblies are evenly distributed on the upper surfaces of the T-shaped steel at intervals, and a face plate is installed at the upper portions of the supporting spring piece assemblies through fasteners. A double-layer plate structure form is adopted, the T-shapedsteel is installed on the bottom plate to serve as a reinforced flat plate, the face plate is a single-layer flat plate, and nonlinear euler spring pieces are adopted in the middle for connecting andsupporting. In order to ensure the bearing performance of a bed board structure, the face plate can be subjected to strengthening treatment in a thickening manner or a reinforcing manner or other manners so that the bearing capability of the face plate can be improved, and stress deformation of the face plate is reduced.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

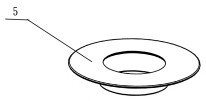

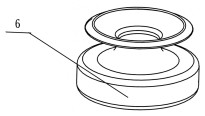

Defecation trousers

Defecation trousers for solving defecation mainly comprise a sponge cushion (1), a funnel (5), an excrement storage bag (6), a paper diaper (7) and hasp trousers (9), wherein an excrement storage hole(2) narrowing from bottom to top is formed in the center of the sponge cushion (1), a bulging push elastic band (4) is arranged above the excrement storage hole (2), two extension crotch pieces (3) extend in front of the excrement storage hole (2), and the excrement storage bag (6) likes a balloon, but is wide at the opening and has a hook-shaped section. When the excrement storage bag (6) penetrates through the hole of the funnel (5), the upper side covers the large round edge of the funnel (5) after being folded to be combined and then penetrates through the paper diaper (7) with a leakingport (8) to be placed in the excrement storage hole (2), and the periphery of the bottom of the sponge cushion (1) is designed into curved chamfers and bonded with the back part of the hasp trousers (9) on the outer layer through a bonding piece (10).

Owner:高利苗

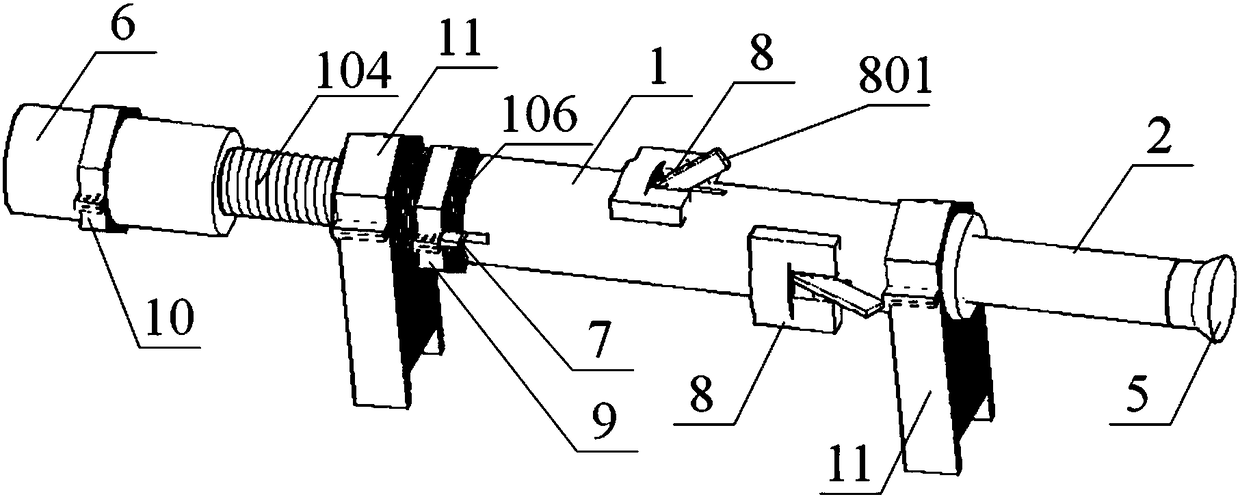

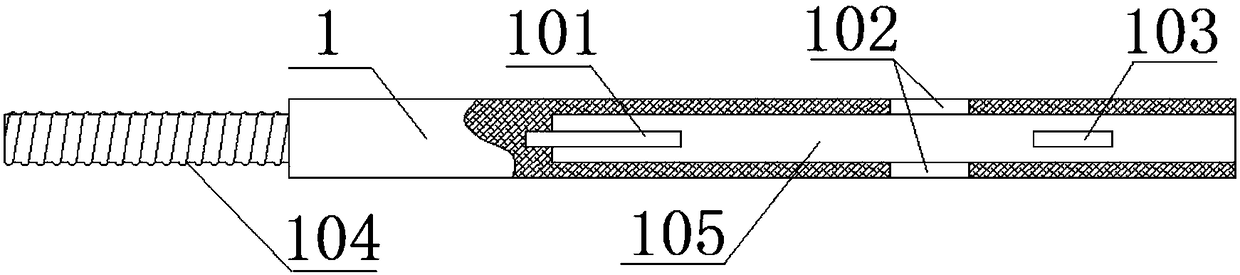

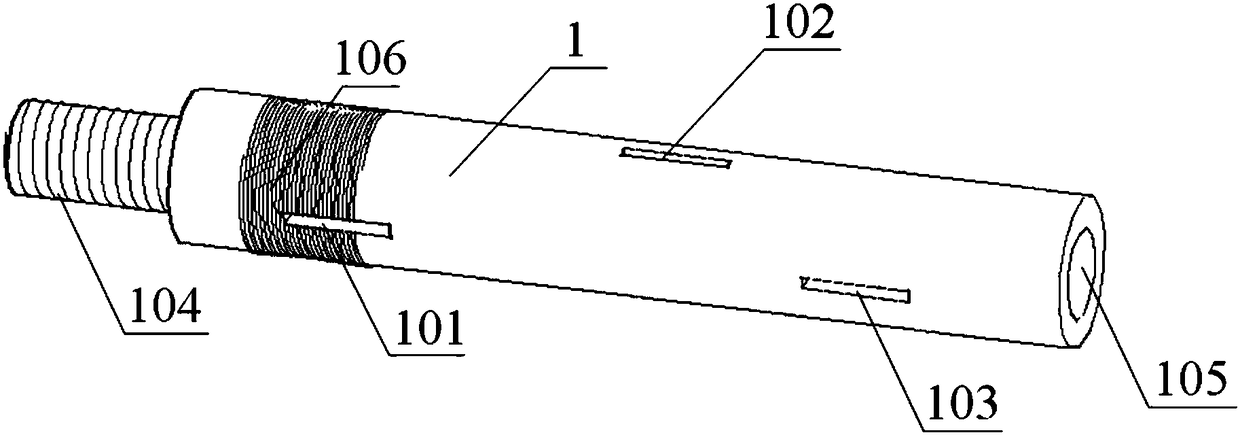

Outer one-way adjustable telescopic corrugated pipe

PendingCN106931264AReduce compression deformationEnsure safetyPipeline expansion-compensationEngineering

The invention discloses an external one-way adjustable telescopic bellows, comprising a first fixing piece and a second fixing piece, a telescopic bellows device is arranged between the first fixing piece and the second fixing piece, and the telescopic bellows The pipe device includes a bellows, a limit piece, a transmission bearing and a transmission rod. The body of the bellows is provided with a limit piece, and the edge of the limit piece is provided with a third fixed ear extending outward. The third fixed lug is provided with a second shaft hole, and both sides of the second shaft hole are provided with second fixed holes, and the transmission bearing is matched with the first shaft hole and the second shaft hole respectively, The transmission rod is installed in the transmission bearing, and one end of the transmission rod is connected with the screw hole; the present invention aims to provide an external one-way adjustable telescopic bellows with high safety, convenient transportation, telescopic and dislocation installation. Tube.

Owner:FOSHAN GAOMING GAS

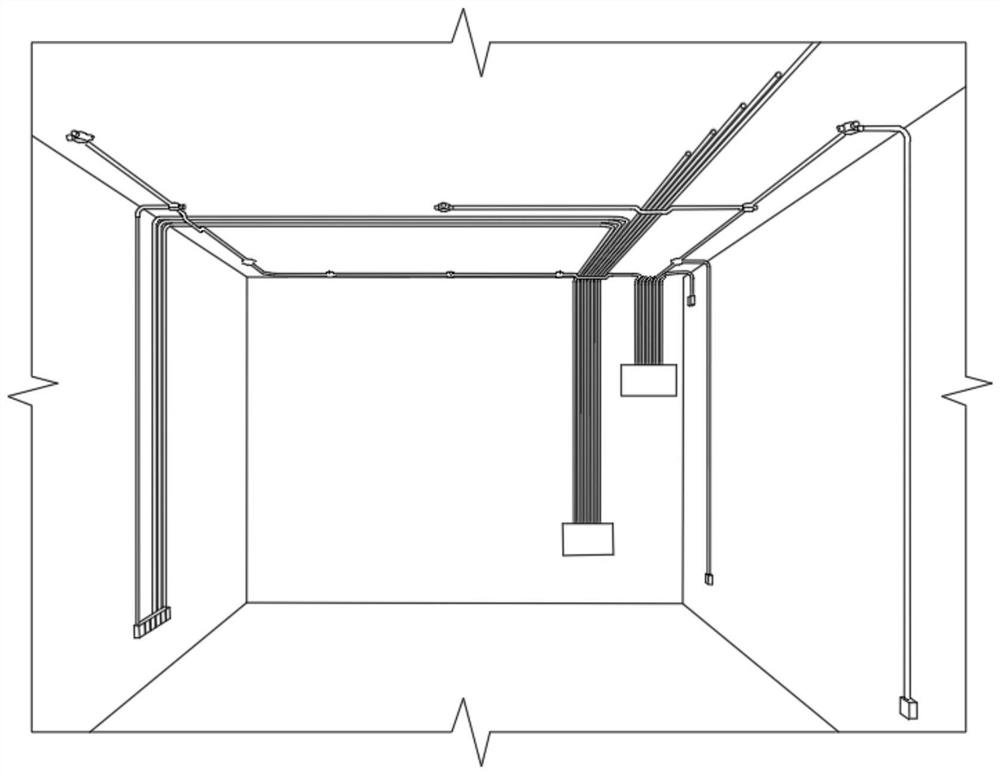

Construction method of fabricated building electrician system

PendingCN113363862AAvoid damageAvoid Elbow FrictionApparatus for laying cablesButt jointPipe fitting

The invention discloses a construction method of a fabricated building electrical system, and belongs to the technical field of electrical system construction. The method comprises the following steps that (1) a building electrician main pipe is pre-buried in a factory; (2) pipe fittings with customized lengths are prefabricated in a segmented mode; (3) an indoor part adopts an open installation mode for wiring, pipes are designed according to the top moving principle, and field constructors penetrate electric wires into the sectional pipes in advance according to the design scheme for series wiring; (4) the segmented pipes are connected, and the connected segmented pipes are directly fixed to the indoor wall face or the ceiling through pipe clamps; (5) the segmented pipes are connected at the turning position through an open-close type elbow; and (6) a shallow-depth wire box is selected at the tail end to avoid grooving. According to the method, the problem of pipe dislocation during butt joint of all plates of the fabricated building is solved, the steps of grooving, pipe bending and the like and tools are omitted in the construction process, the problem of difficult threading is solved, and the construction efficiency is improved.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Packaging method for automobile three-way catalyst converter

InactiveCN105370350AEasy to installEasy to disassembleInternal combustion piston enginesExhaust apparatusHoneycombSmear layer

The invention relates to the field of manufacturing of automobile three-way catalyst converters, in particular to a packaging method for an automobile three-way catalyst converter. The method includes the following steps that a purifying agent layer is formed on a honeycomb-shaped carrier; the carrier with the purifying agent layer is calcinated for 1 hour to 2 hours at the temperature ranging from 400 DEG C to 600 DEG C and then cooled in the environment with the temperature ranging from 0 DEG C to 4 DEG C; the carrier with the purifying agent layer is placed in a half of a catalyst converter shell, two halves of the structure of the catalyst converter shell are combined, a certain distance is reserved between the carrier with the purifying agent layer and the inner wall of the catalyst converter shell, and a locating board is pressed downwards, so that the inner wall and the outer wall of the catalyst converter shell are compressed, and the carrier with the purifying agent layer is attached to the inner wall of the catalyst converter shell. By the adoption of the method, the carrier with the purifying agent layer can be conveniently installed and detached, and the stressed deformation of the carrier with the purifying agent layer is reduced; and a purifying agent of specific components is adopted and smeared layer by layer, so that the catalysis effect is improved.

Owner:SUZHOU LIANCHI ENVIRONMENTAL SCI & TECH DEV CO LTD

Biomass particle erosion hole light fireproof material and preparation method thereof

The invention discloses a biomass particle erosion hole light fireproof material and a preparation method thereof. The biomass particle erosion hole light fireproof material contains a basic material,the basic material is prepared from, by mass, 30-35 parts of biomass particles, 20-25 parts of calcined bauxite micro powder, 15-20 parts of bauxite raw granular material, 10-15 parts of calcined mullite micro powder and 5-8 parts of a-aluminium oxide micro powder. The biomass particle erosion hole light fireproof material and the preparation method thereof have the advantages that the biomass particle erosion hole light fireproof material is obtained through lower cost and a more environment-friendly preparation method, the material is green and environment-friendly, the volume density is small, the high temperature structure strength is large, the thermal shock stability is better, the heat conductivity coefficient is lower, and the erosion-resisting performance is strong.

Owner:醴陵友立特种陶瓷有限公司

A Hopkinson strut damper

InactiveCN105823678BIn line with modern design conceptsLow costSpringsShock absorbersLocking mechanismEnergy absorption

The invention discloses a Hopkinson pressure bar damper which comprises a damping cylinder and a damping rod. The center of the damping cylinder is provided with a cavity of which one end is open, the inner end of the damping rod is inserted into the cavity, the cavity is further provided with a pushing plate and a damping spring, and the damping spring is located between the pushing plate and the inner end of the damping rod; an annular limiting groove is formed in the portion, close to the inner end, of the damping rod, the damping cylinder is provided with two sets of spring lock mechanisms at different positions in the axis direction of the damping cylinder, and when the damping rod moves to the annular limiting groove of the damping rod to correspond to the front ends of locking sections of the spring lock mechanisms, the damping rod can be locked. Compared with the prior art, the Hopkinson pressure bar damper has the following advantages of being good in compression resistance, small in compressive deformation, high in energy absorption efficiency, long in service life, high in independence of all the parts and suitable for Hopkinson pressure bar experiments at the different elastic speeds, different rod qualities, different rod lengths, different rod diameters and different test sample lengths.

Owner:HEFEI UNIV OF TECH

A kind of cobalt powder and its preparation method and cobalt oxalate precursor and its preparation method

ActiveCN105798318BLarge laser particle sizeGood for mixing uniformityCarboxylic acid salt preparationOxalateApparent density

Owner:JINGMEN GEM NEW MATERIAL

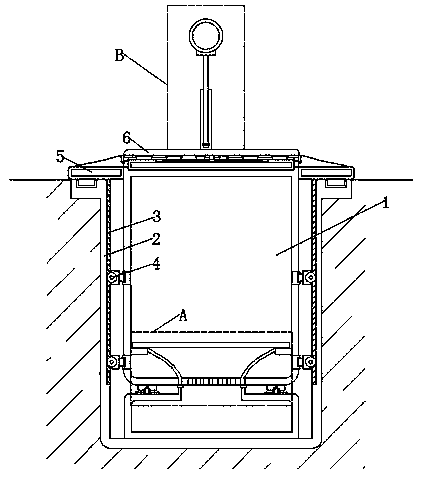

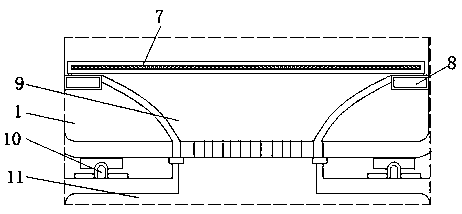

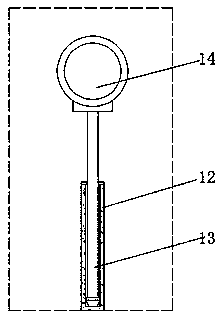

Deeply-buried garbage can convenient to lift

The invention discloses a deeply-buried garbage can convenient to lift. The deeply-buried garbage can comprises an internal garbage can body, an external garbage can body, a filter screen and liftingrings. Sliding wheels are fixedly mounted on the two sides of the internal garbage can body. Sliding grooves are arranged on the inner walls of the two sides of the external garbage can body. The sliding wheels are embedded in the sliding grooves. Handles are fixedly mounted at the two ends of the top of the internal garbage can body. According to the deeply-buried garbage can, design is carried out through combination of a traditional garbage can structure, operation of facilitating lifting work of the garbage can needs to be considered, and meanwhile good dirt water collection capacity is achieved; and a cover body is firm to use, the protection effect of the cover body is improved, convenience is brought to use of people, and the overall device is rich in structure and diversified in function, and the use cost is reduced.

Owner:江苏沃华智能科技股份有限公司

Anode structure for short-arc xenon-mercury lamp

PendingCN107845562AHigh strengthIncrease costGas discharge lamp detailsEngineeringMechanical engineering

The invention discloses an anode structure for a short-arc xenon-mercury lamp and belongs to the technical field of xenon-mercury lamps; technical key points of the anode structure are that the anodestructure comprises a cylindrical body which consists of a circular platform part, a heat dissipation part, an auxiliary heat dissipation support part and a support inverted circular platform part that are sequentially arranged from the top to the bottom. The outer diameter of a lower end of the circular platform part is the same as the outer diameter of the heat dissipating part; the outer diameter of the heat dissipating part is smaller than the outer diameter of the auxiliary heat dissipation support part by 0.4-0.8 mm; the ratio of the total height of the circular platform part and the heat dissipation part to the total height of the auxiliary heat dissipation support part and the support inverted circular platform part is 1:1.2-1.4; a number of first annular heat dissipation grooves are evenly distributed on an outer wall of the heat dissipation part in a spaced manner along the axial direction. All of the first annular heat-dissipation grooves are circumferentially arranged alongthe heat dissipation part. The present invention is aim at providing the anode structure for the short-arc xenon-mercury lamp, the anode structure is reasonable in structure, high in strength and reasonable in heat-dissipating effect; the anode structure is used for the mercury-xenon lamp.

Owner:MEIZHOU LIANGRUZHOU TECH CO LTD

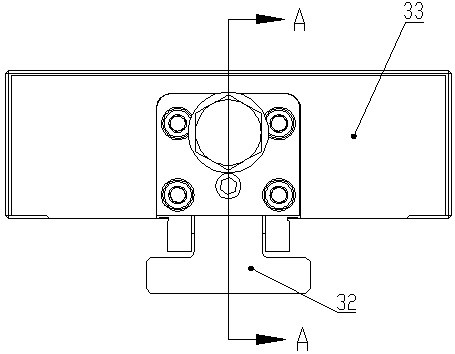

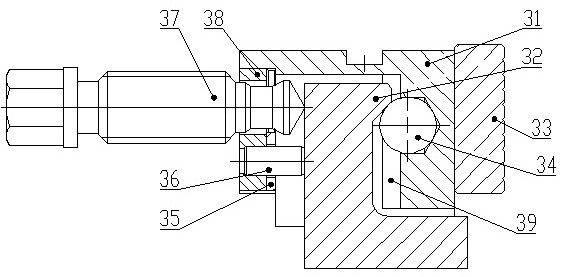

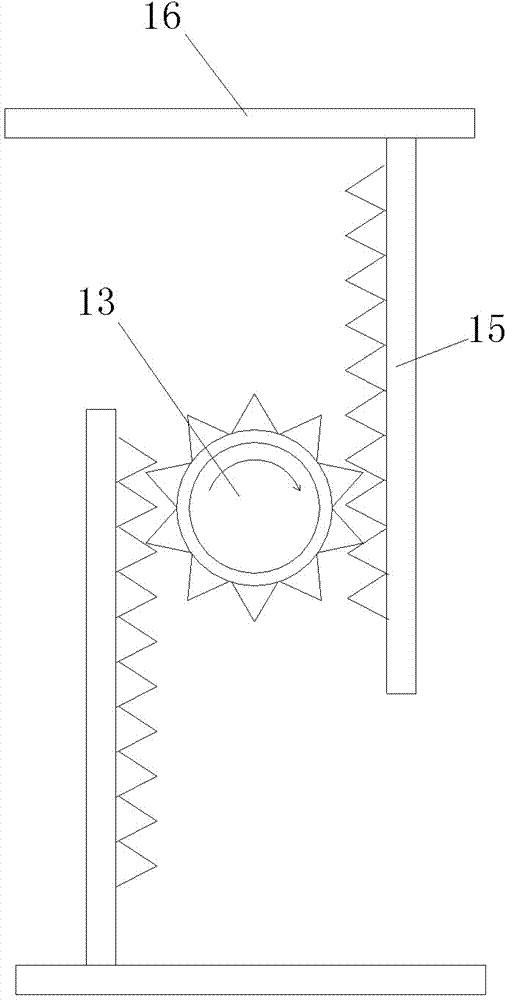

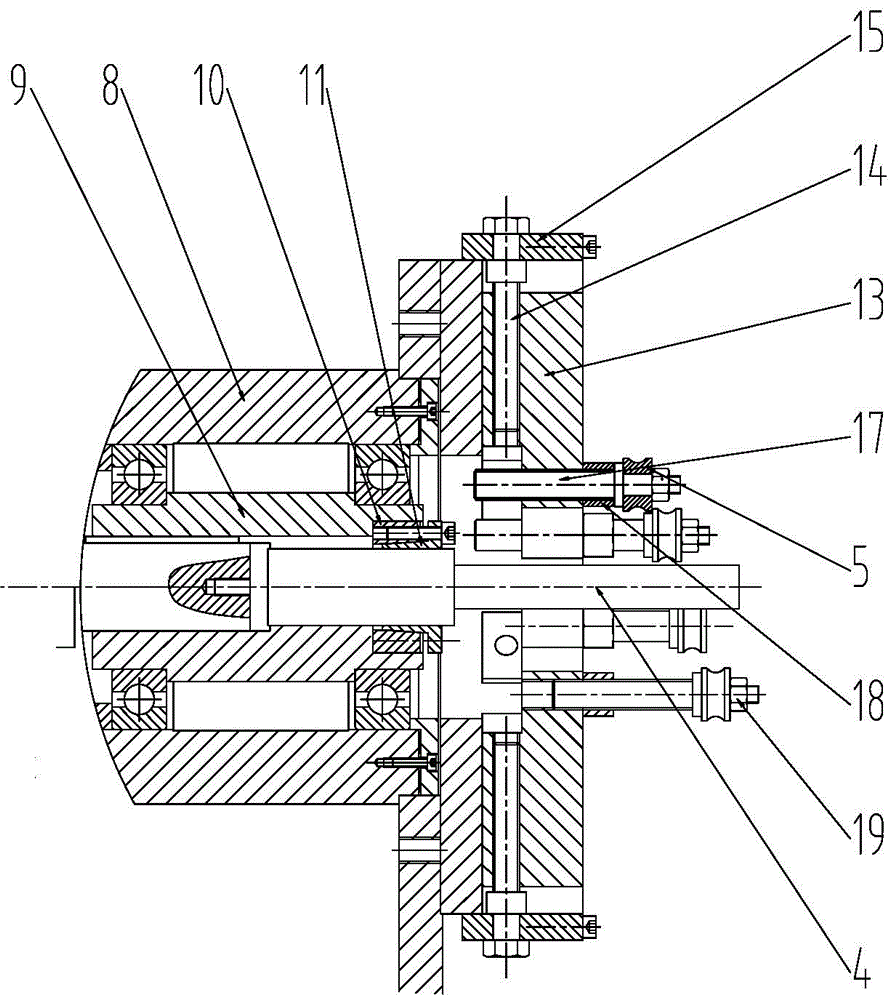

Oblique pressing ball type movable plier mechanism of flat tongs

PendingCN113183052AGuaranteed not to floatMeet the needs of high-precision machiningClampsSteel ballScrew thread

The invention discloses an oblique pressing ball type movable plier mechanism of flat tongs. The oblique pressing ball type movable pliers mechanism is characterized in that the lower end face of a movable plier body is connected to the upper end face of a flat tongs body in a linear sliding mode, a jaw is fixed to the front end face of the movable plier body, an inclined pressing block mounting groove is reserved in the middle of the movable plier body, a clamping plate is fixed to the rear end of the movable plier body, and a baffle is fixed to the rear end of the clamping plate; a lead screw is in threaded connection in a threaded hole I of a supporting seat of the flat tongs, and after the front end part of the lead screw penetrates through a via hole of the baffle, the head part of the lead screw abuts against the rear end face of an L-shaped inclined pressing block; the L-shaped inclined pressing block is arranged in the inclined pressing block mounting groove, the lower end face of the L-shaped inclined pressing block is connected into a T-shaped groove of the flat tongs body in a linear sliding mode, and the upper end face of an inner clamping opening of the L-shaped inclined pressing block is an inclined face; and at least more than 1 / 2 of the part of a steel ball is tightly assembled in a steel ball accommodating hole formed in the front end wall of the inclined pressing block mounting groove of the movable plier body, and the inclined face of the L-shaped inclined pressing block is pressed at the upper end of the rear end of the steel ball. The oblique pressing ball type movable plier mechanism of flat tongs is low in cost and easy to machine; and the flat tongs adopting the oblique pressing ball type movable plier mechanism are accurate in positioning, high in positioning precision and good in stability.

Owner:河北昊特机械配件加工有限责任公司

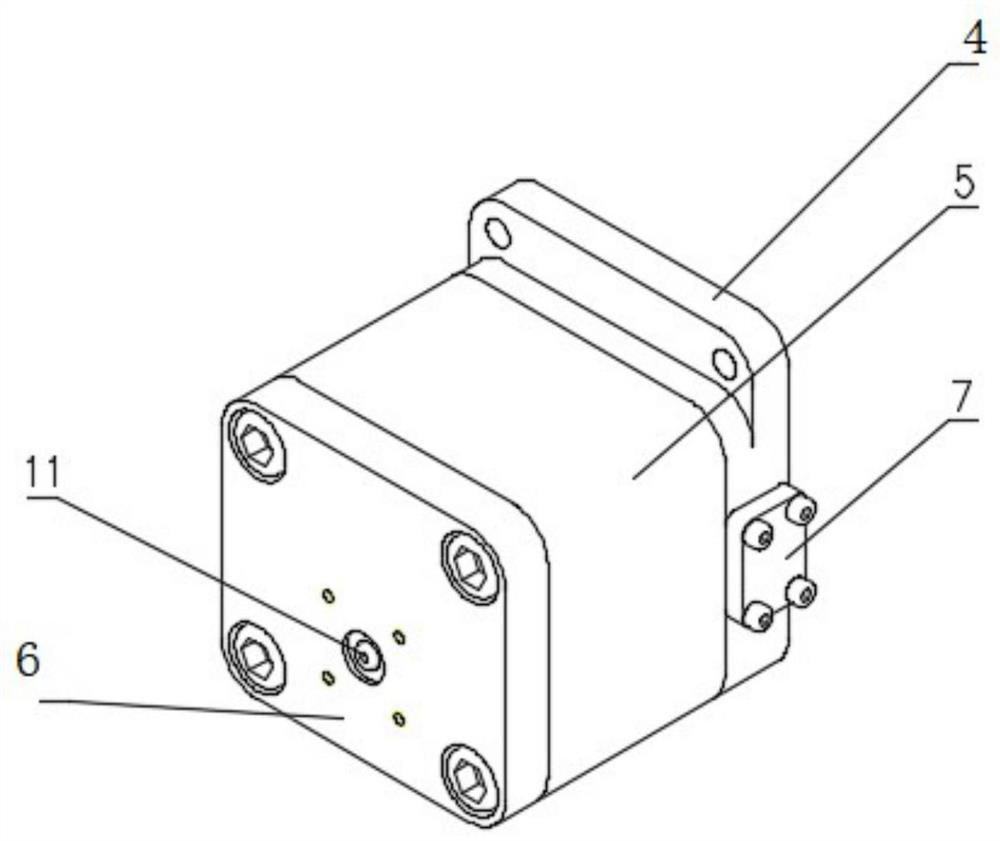

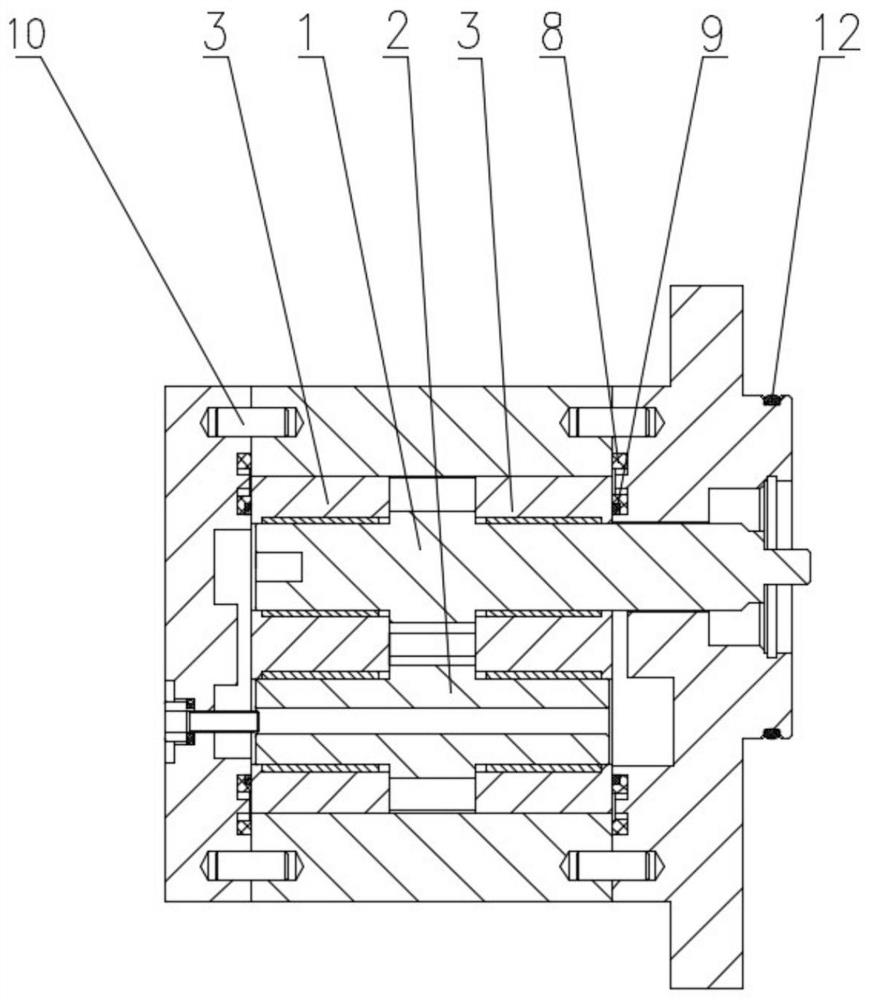

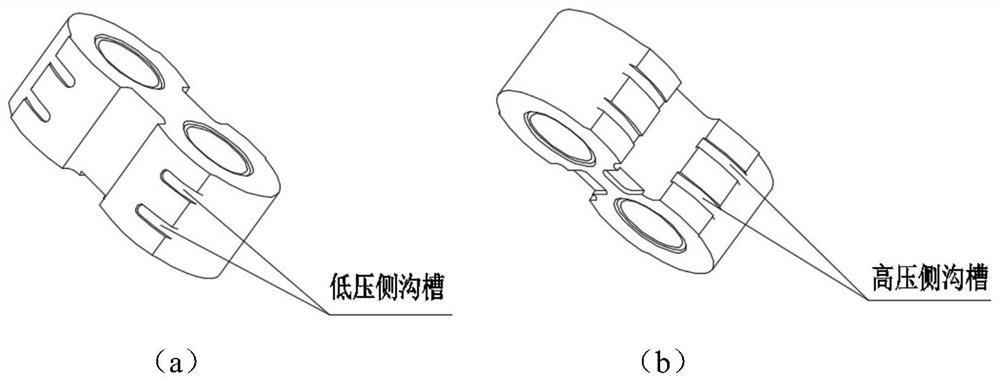

Radial static pressure balance floating type gear pump

PendingCN113931838AReduced outer surface areaImprove floating characteristicsRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention relates to a radial static pressure balance floating type gear pump which comprises an upper plate, a middle plate, a lower plate, a driving gear shaft, a driven gear shaft and floating shaft sleeves, wherein the driving gear shaft, the driven gear shaft and the floating shaft sleeve are located in a cavity of the middle plate, the two sides of the middle plate are fixedly connected with the upper plate and the lower plate respectively, the upper plate is provided with a connector and a blanking cap, and gears on the driving gear shaft and the driven gear shaft are meshed with each other. The driving gear shaft and the driven gear shaft are mounted in the floating shaft sleeves at the two ends; each floating shaft sleeve is 8-shaped and comprises two symmetrical circular arc bodies, and the circular arc radius of the middle part of each circular arc body is smaller than the circular arc radiuses of the two sides; two sides of each circular arc body are respectively provided with a first groove and a second groove which have the same radius as the middle circular arc, the length of the first groove is the same as that of the circular arcs on two sides of the circular arc body, and two end areas are communicated; and the length of the second groove is smaller than the circular-arc length of the two sides of each circular arc body; one end of the second groove is communicated with the middle part of the circular arc body. The volume efficiency of the gear pump can be remarkably improved, and oil leakage of the gear pump is reduced.

Owner:JIANGSU JINLING INST OF INTELLIGENT MFG CO LTD

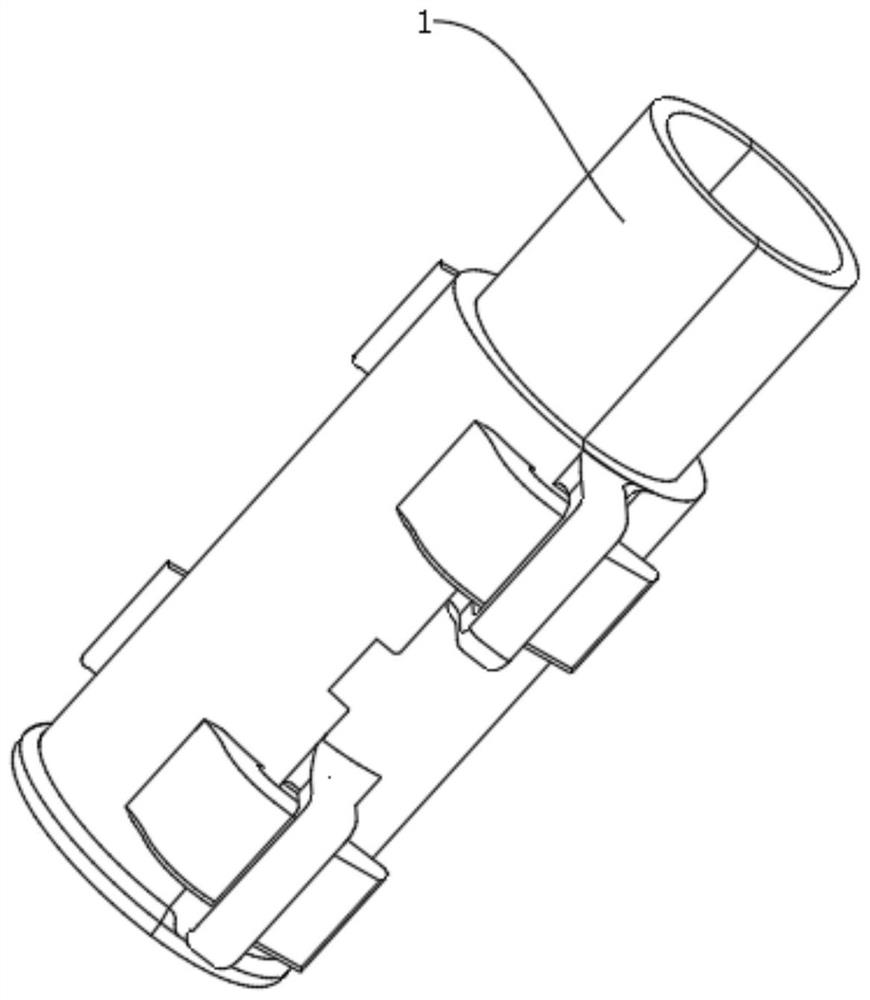

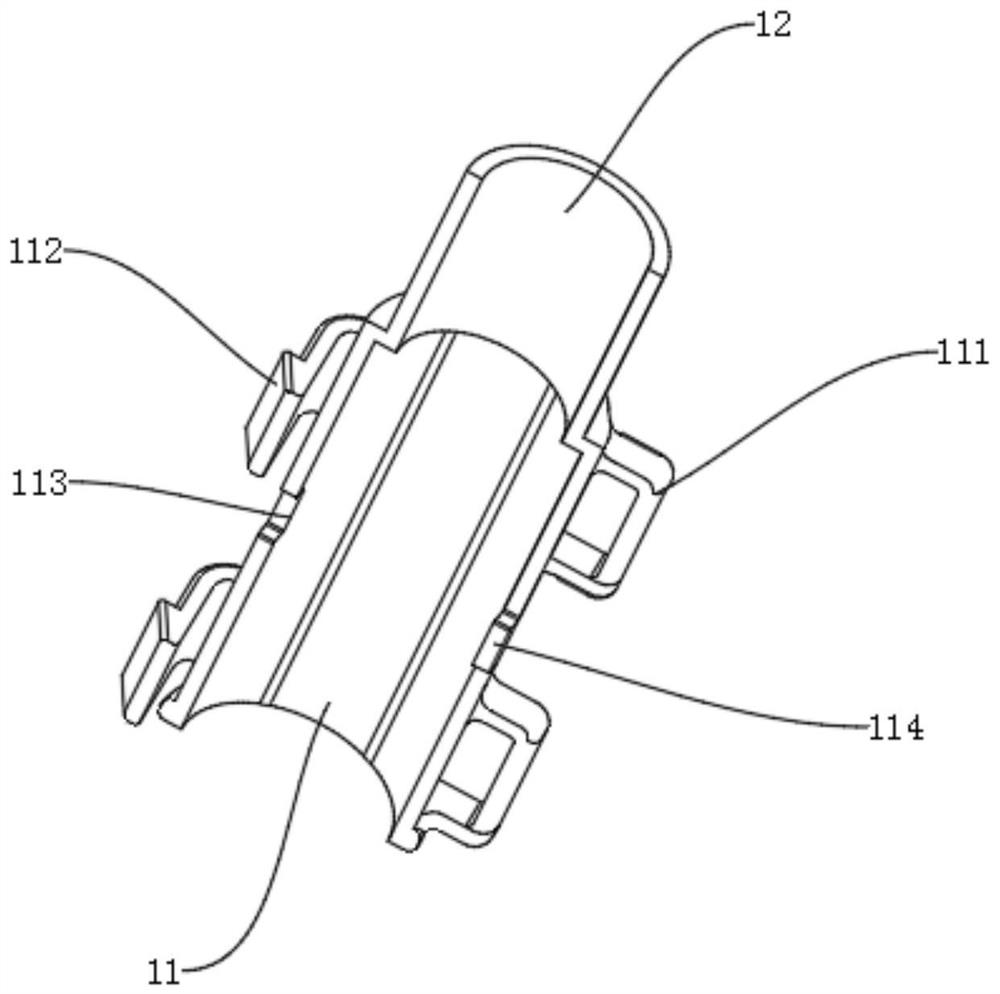

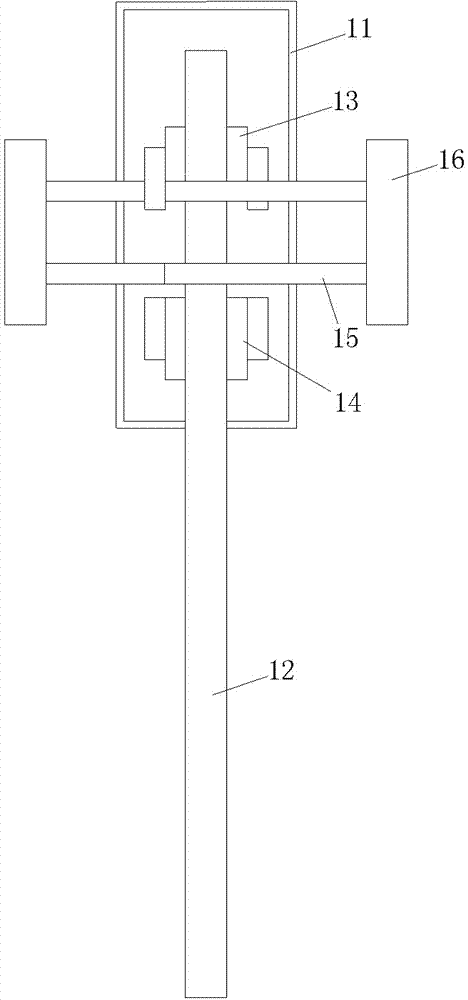

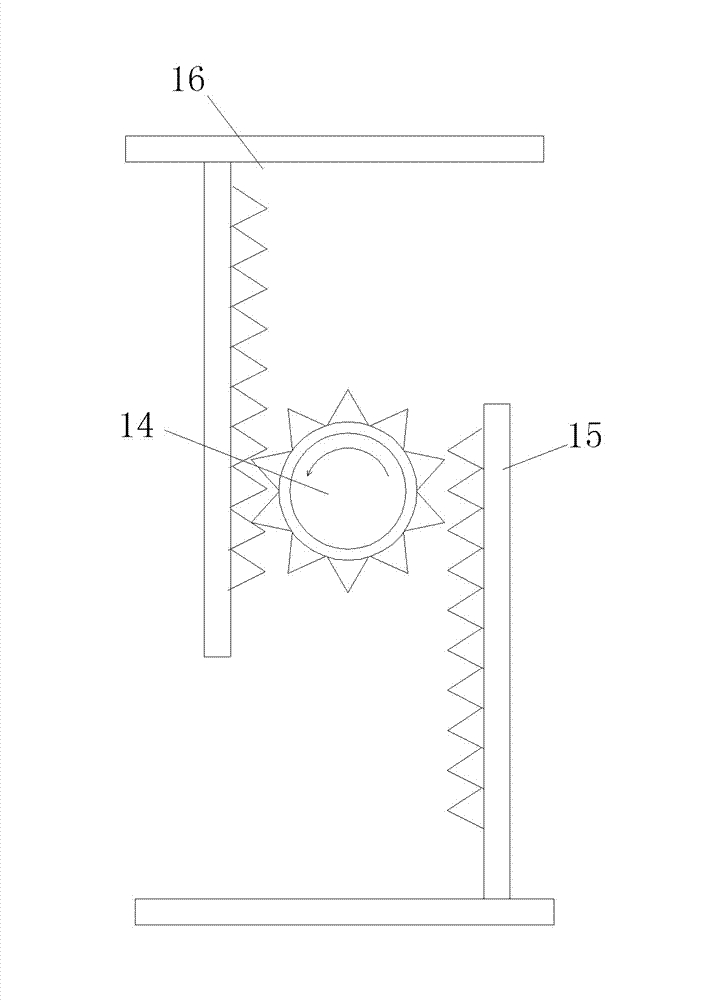

hand driven screwdriver

The invention relates to the field of mechanical disassembling tools, in particular to a grip drive type screwdriver. The grip drive type screwdriver comprises a holder and a toolbar. The toolbar is rotationally assembled on the holder, racks are radially assembled on the holder, unidirectional transmission wheels which correspond to the racks are assembled on the toolbar and include a forward transmission wheel and a reverse transmission wheel, the forward transmission wheel and the reverse transmission wheel are axially arranged along the toolbar, a transmission direction of the forward transmission wheel is opposite to a transmission direction of the reverse transmission wheel, and when one of the forward transmission wheel and the reverse transmission wheel is meshed with the corresponding rack, the other transmission wheel and the rack corresponding to the other transmission wheel are axially staggered from each other along the toolbar. The grip drive type screwdriver has the advantages that a user only needs to grip the holder by a hand when using the screwdriver, the toolbar axially relatively moves, and the turning direction of the toolbar can be changed, so that a head of the toolbar does not need to be changed when screws are screwed down of screwed off, and the grip drive type screwdriver is quite convenient.

Owner:HENAN UNIV OF SCI & TECH

Compact steel wire braided rubber hose and preparation method thereof

The invention discloses a dense steel wire braided rubber hose and a preparation method thereof. The dense steel wire braided rubber hose includes an inner rubber layer, two steel wire layers braided outside the inner rubber layer, a middle rubber layer between the two steel wire layers and the outside of the steel wire layer outer rubber layer. The inner rubber of the inner rubber layer, the middle rubber of the middle rubber layer and the outer rubber of the outer rubber layer are all prepared from the following raw materials in parts by weight: raw rubber, reinforcing agent; softener, sample, adhesive and accelerator . The invention also discloses a preparation method of the dense steel wire braided rubber hose. The invention has the following advantages: the compact braided rubber hose of the invention has reasonable structure, small deformation under pulse pressure, light rubber hose, small bending radius, all properties of the finished product meet the requirements of SAEJ517R17 remarks, stable pulse performance, and the number of pulses exceeds 300,000 Second, greatly increasing the service life of the hose.

Owner:LUOHE LETONE RUBBER

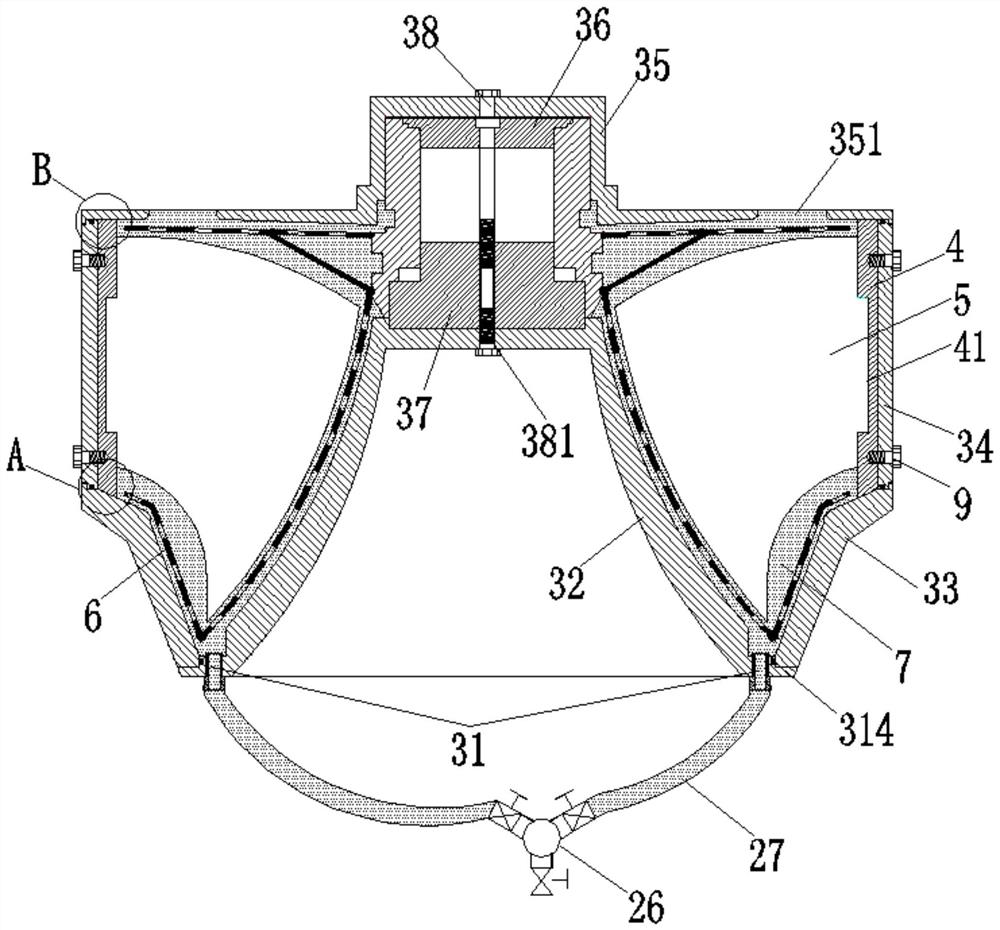

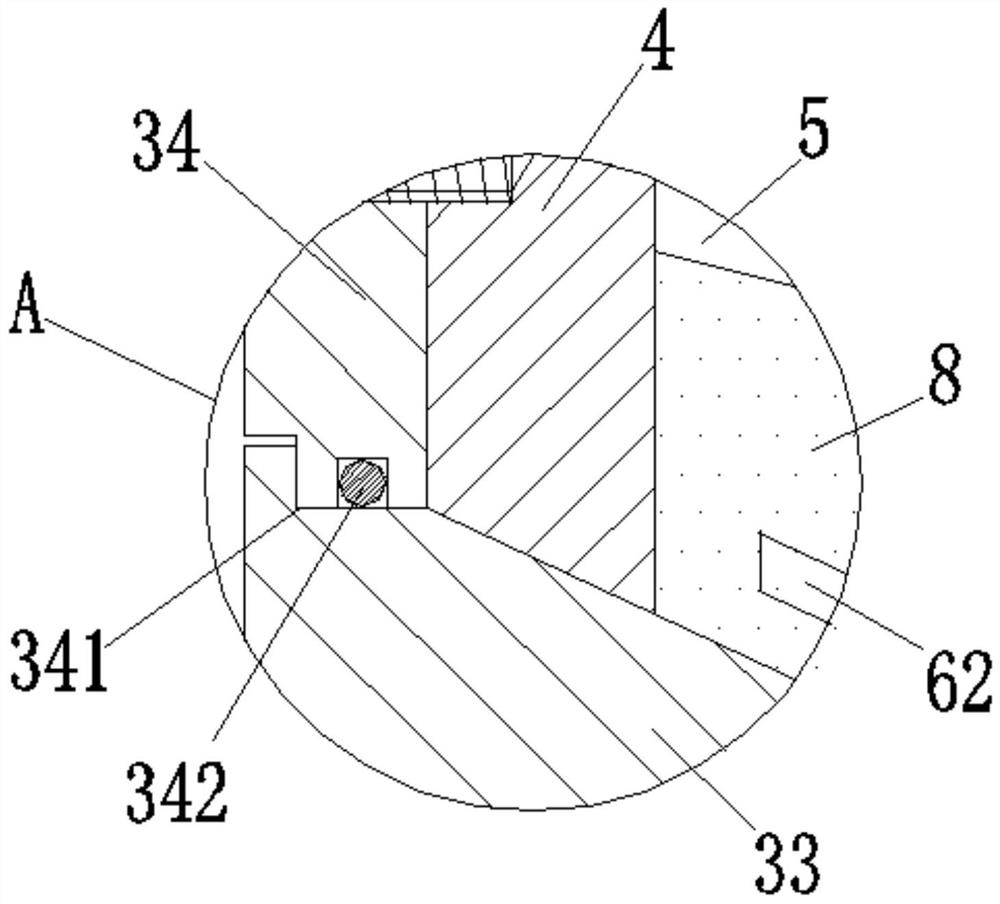

A kind of manufacturing method of composite ceramic closed impeller containing metal skeleton

ActiveCN110053157BEasy to clean upReduce the difficulty of operationCeramic shaping apparatusMaterials preparationImpeller

Owner:上海邦聚工程材料技术有限公司

A mortise and tenon joint of wood structure reinforced by tenon shallow layer planting reinforcement

ActiveCN107386445BEasy constructionConstruction quality is easy to controlBuilding constructionsMortise and tenonSurface layer

The invention provides a tenon shallow embedded steel bar reinforced wood-structured mortise-tenon joint, and belongs to the technical field of architectural structure engineering. The wood-structured mortise-tenon joint comprises a wood column, a wood beam and reinforcements; the wood column and the wood beam are in mortise-tenon connection through a mode of inserting a tenon of the wood beam in a mortise of the wood column; a row of holes parallel to the wood pattern direction is respectively drilled in the upper and lower surfaces of the tenon of the wood beam; the reinforcements are respectively put in the holes; and structural gluing agents are injected in all the holes to firmly bond the reinforcements with the tenon of the wood beam. The transverse pattern compression bearing capacity and rigidity on the surface layer of the tenon can be improved; the pressed deformation of the surface layer of the tenon is reduced; the embedded reinforcements can resist the pull and pressure stress of the tenon, improve the flexural capacity and the rigidity of the tenon, and improve overall bearing capacity and rigidity of the mortise-tenon joint; the building appearance is not influenced; and the construction is simple and convenient.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

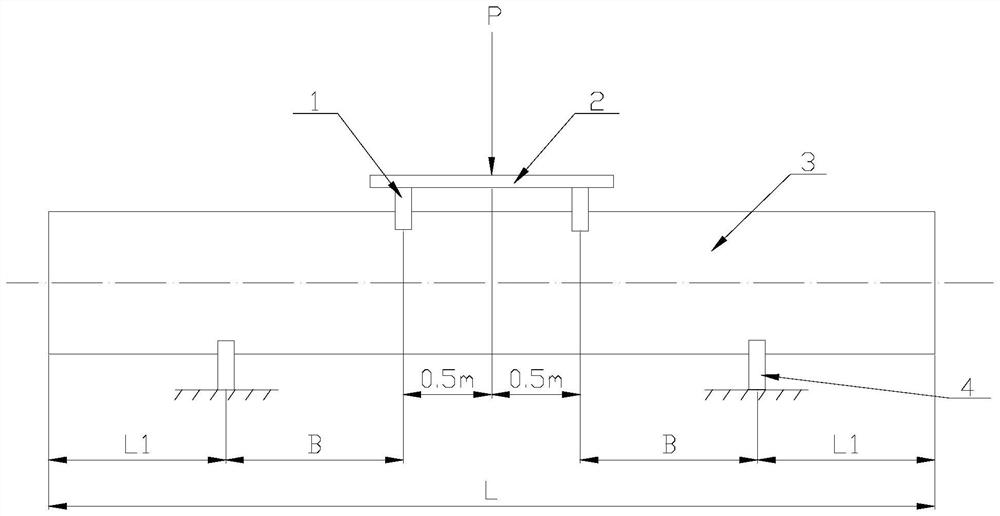

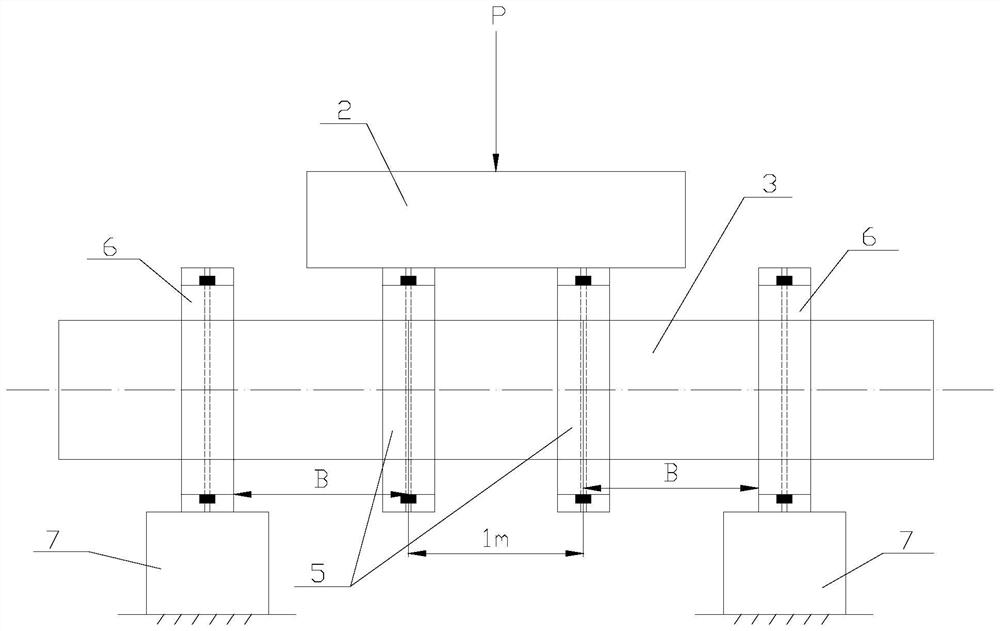

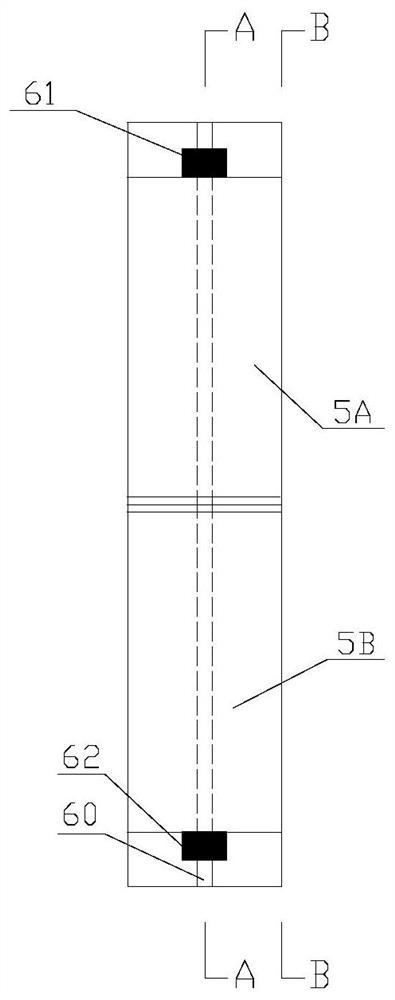

Arrangement structure for PHC tubular pile shear test

PendingCN111811931AReduce compression deformationReasonable results for crack resistanceMaterial strength using steady shearing forcesArchitectural engineeringShear force

The invention discloses an arrangement structure for a PHC tubular pile shear test. The arrangement structure comprises a PHC tubular pile for a test, two inner clamping type support seats, two outerclamping type support seats, a distribution beam and two piers. The PHC tubular pile for the test is horizontally arranged; the two inner clamping type support seats and the two outer clamping type support seats are symmetrically arranged at a position 0.5m away from the two sides of the length center of the PHC tubular pile for the test and the position 0.5m+ shear span B away from the two sidesof the length center of the PHC tubular pile for the test. The distribution beam is arranged on the top surfaces of the two inner clamping type support seats; and the two piers are arranged on the bottom surfaces of the two outer clamping type support seats. The inner clamping type support seats and the outer clamping type support seats are the same in structure and comprise upper half clamping seats, lower half clamping seats and two connecting screw rods. And the two connecting screw rods enable the upper half clamping seats and the lower half clamping seats to tightly hold the PHC tubular pile for the test through an upper nut and a lower nut respectively. According to the structure, a damage mode of the PHC tubular pile in a shear test can be closer to oblique pressure damage or shearpressure damage, and a result of an anti-cracking shear force is more reasonable.

Owner:CCCC THIRD HARBOR ENG

toilet pants

ActiveCN110393637BSatisfy the volume of spaceReduced inlet diameterBandagesAnatomyBiomedical engineering

A kind of toilet pants for defecation, mainly composed of a sponge cushion (1), a funnel (5), a toilet bag (6), a paper diaper (7) and buckle pants (9), the sponge cushion (1) There is a stool storage hole (2) in the center of the toilet, which is small at the top and large at the bottom. There is a protruding push belt (4) on the top, and two extension pieces (3) protrude from the front. The stool storage bag (6) looks like a balloon, but The opening is wide and the cross-section is in the shape of a folded hook. When the poop storage bag (6) is passed through the hole of the funnel (5), the big round edge of the funnel (5) is covered with a reflex on the upper part, and the large round edge of the funnel (5) is combined into one, and then the urine with the leak (8) is passed through Put the sheet (7) into the toilet storage hole (2), and the bottom of the sponge cushion (1) is designed to be chamfered with a curved surface, and stick the sheet (10) to the rear part of the outer buckle pants (9). as one.

Owner:高利苗

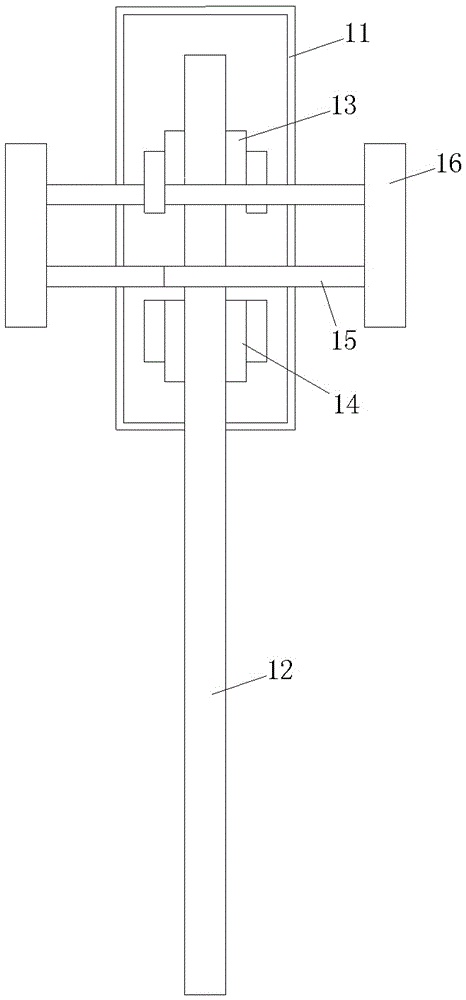

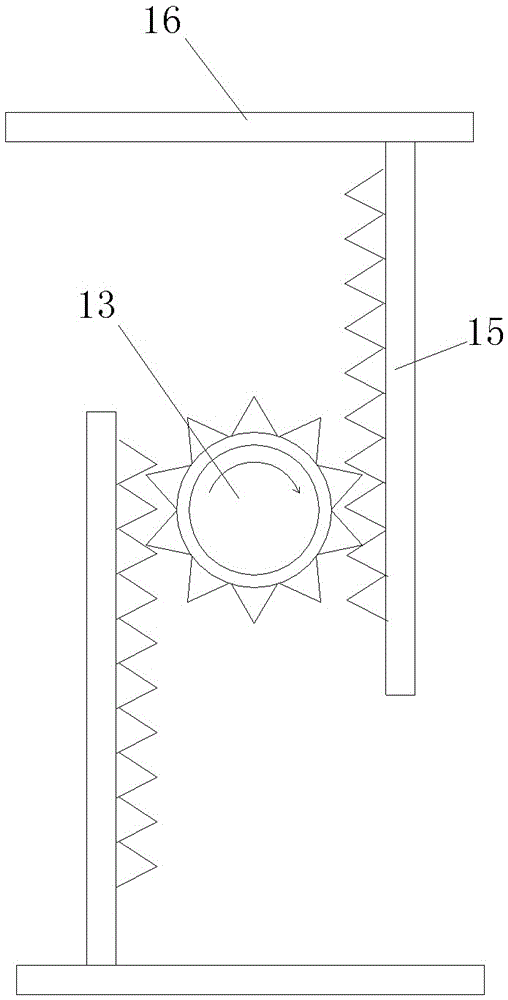

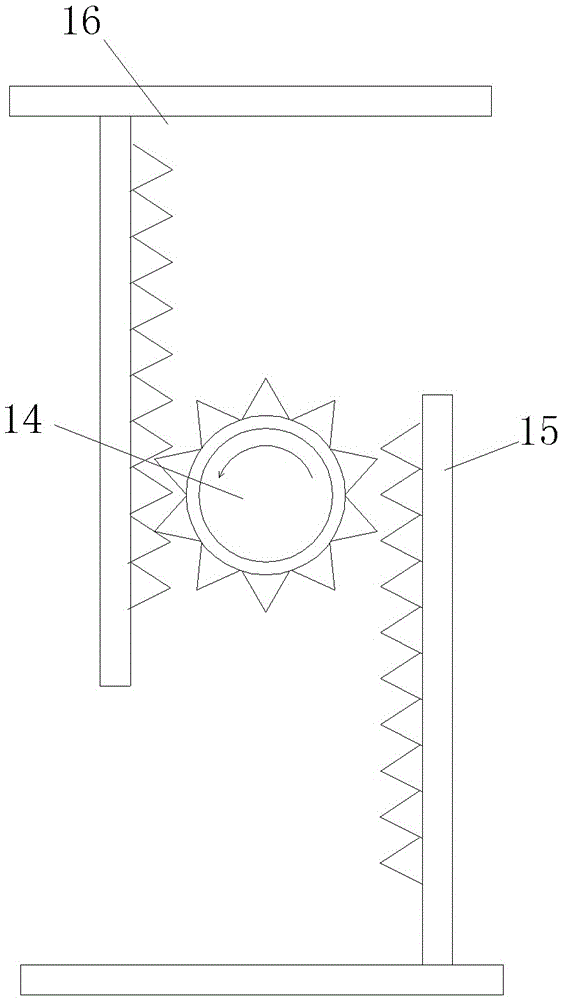

Grip drive type screwdriver

InactiveCN103753463AImprove balanceReduce compression deformationScrewdriversEngineeringMechanical engineering

The invention relates to the field of mechanical disassembling tools, in particular to a grip drive type screwdriver. The grip drive type screwdriver comprises a holder and a toolbar. The toolbar is rotationally assembled on the holder, racks are radially assembled on the holder, unidirectional transmission wheels which correspond to the racks are assembled on the toolbar and include a forward transmission wheel and a reverse transmission wheel, the forward transmission wheel and the reverse transmission wheel are axially arranged along the toolbar, a transmission direction of the forward transmission wheel is opposite to a transmission direction of the reverse transmission wheel, and when one of the forward transmission wheel and the reverse transmission wheel is meshed with the corresponding rack, the other transmission wheel and the rack corresponding to the other transmission wheel are axially staggered from each other along the toolbar. The grip drive type screwdriver has the advantages that a user only needs to grip the holder by a hand when using the screwdriver, the toolbar axially relatively moves, and the turning direction of the toolbar can be changed, so that a head of the toolbar does not need to be changed when screws are screwed down of screwed off, and the grip drive type screwdriver is quite convenient.

Owner:HENAN UNIV OF SCI & TECH

Lemon cutting blade with lower open

InactiveCN101058190AQuick cutReduce the stress areaMetal working apparatusMetal-working hand toolsKnife bladesH shaped

The invention relates to a H shape lemon cutter with top of the narrow shape iron sheet being the blades with notches, center of the iron having a H shape notch1. 6 in width and 14mm in height, which matches with other blades to cut the lemon into equal blocks quickly.

Owner:秦永刚

Adjustable composite damping rubber pad

ActiveCN114810940AReduce compression deformationExtended service lifeNon-rotating vibration suppressionEngineeringMechanical engineering

The invention discloses an adjustable composite damping rubber pad, and belongs to the field of rubber pads, the adjustable composite damping rubber pad comprises two oppositely arranged rubber pads, a buffer device is arranged between the two rubber pads, the buffer device comprises a flexible rubber sleeve, two groups of friction rings are arranged in the flexible rubber sleeve, the friction rings are of a circular ring structure with an L-shaped section, and the friction rings are arranged in the flexible rubber sleeve. The two friction rings are arranged in a buckled mode, the sides, away from each other, of the two friction rings are fixedly connected with the rubber pad, a fixed magnetic ring is arranged on one side of a circular ring of each friction ring, a cavity is formed in the other side of the circular ring of each friction ring, a sliding magnetic ring is slidably connected into each cavity, and the magnetism of the sliding magnetic rings is the same as that of the fixed magnetic rings. According to the rubber pad, the compression deformation quantity of the rubber pad can be effectively reduced, the service life of the rubber pad is prolonged, and the rubber pad has market prospects and is suitable for popularization.

Owner:海门市华洋汽车配件制造有限公司

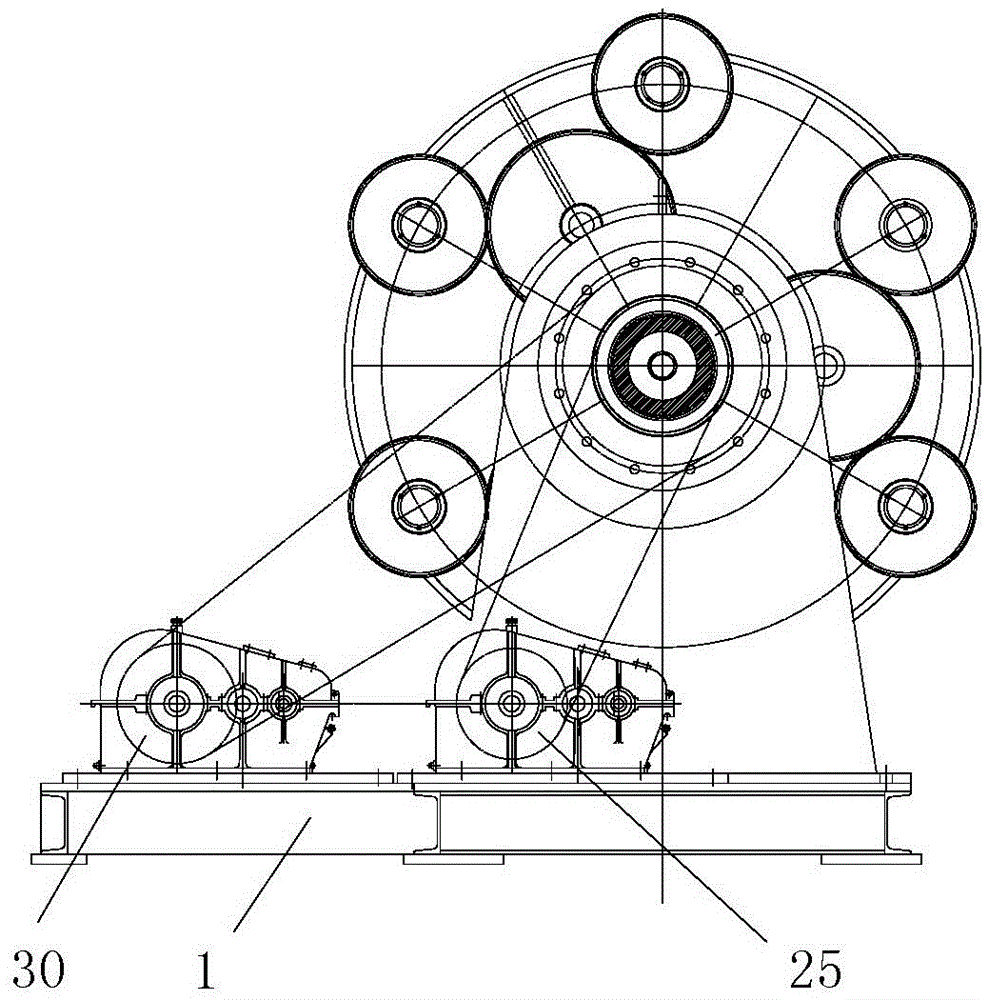

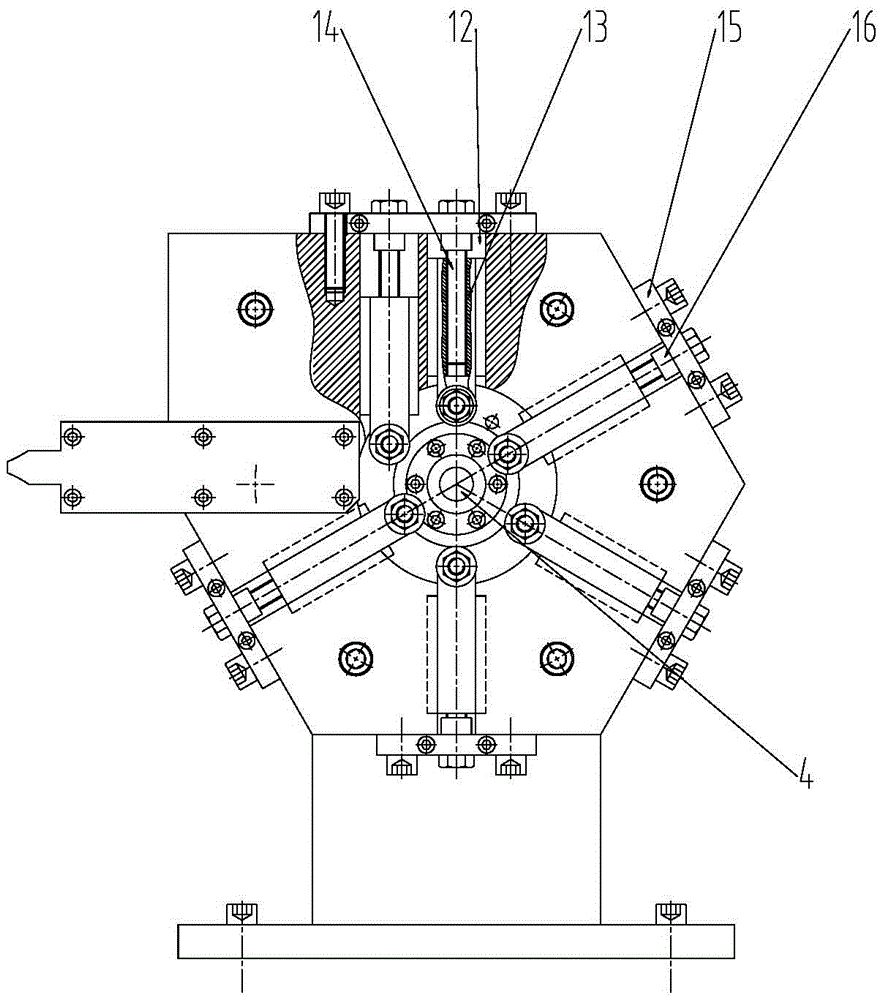

Multi-strand coil spring continuous coil spring device

ActiveCN104550565BMeet continuous coil spring requirementsIncrease productivityRadial positionCoil spring

A multi-strand spiral spring continuous spring coiling device comprises a machine frame; a spring coiling device which is used for manufacturing a steel cable roll into a plurality of strands of spiral springs and a traction push device which is used for pushing steel cables to the spring coiling device are arranged on the machine frame; the spring coiling device comprises a spring coiling supporting base which is fixedly installed on the machine frame; the spring coiling supporting base is provided with a spring winding shaft which is matched with the spring coiling supporting base in a rotary mode and a spring coiling driving mechanism which is used for driving the spring wind shaft to rotate; the periphery of the spring winding shaft is provided with a plurality of spring winding rollers which are used for limiting the steel cable and winding the cable on the spring winding shaft in a spiral mode; the spring coiling supporting base is provided with a spring winding roller radial position adjusting mechanism which is used for adjusting radial position of the spring winding shaft and a spring winding roller axial position adjusting mechanism which is used for adjusting the axial spring winding roller position of the spring winding shaft. The multi-strand spiral spring continuous spring coiling device has the advantages of satisfying the rolling machining requirement of multi-strand spiral springs and being high in production efficiency, high in machining accuracy and high in automatic degree.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com