Anode structure for short-arc xenon-mercury lamp

An anode structure, mercury-xenon lamp technology, applied in the parts of gas discharge lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of life deviation of anode strength lamps, affecting heat dissipation effect, etc., to achieve guaranteed strength, good heat dissipation effect, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

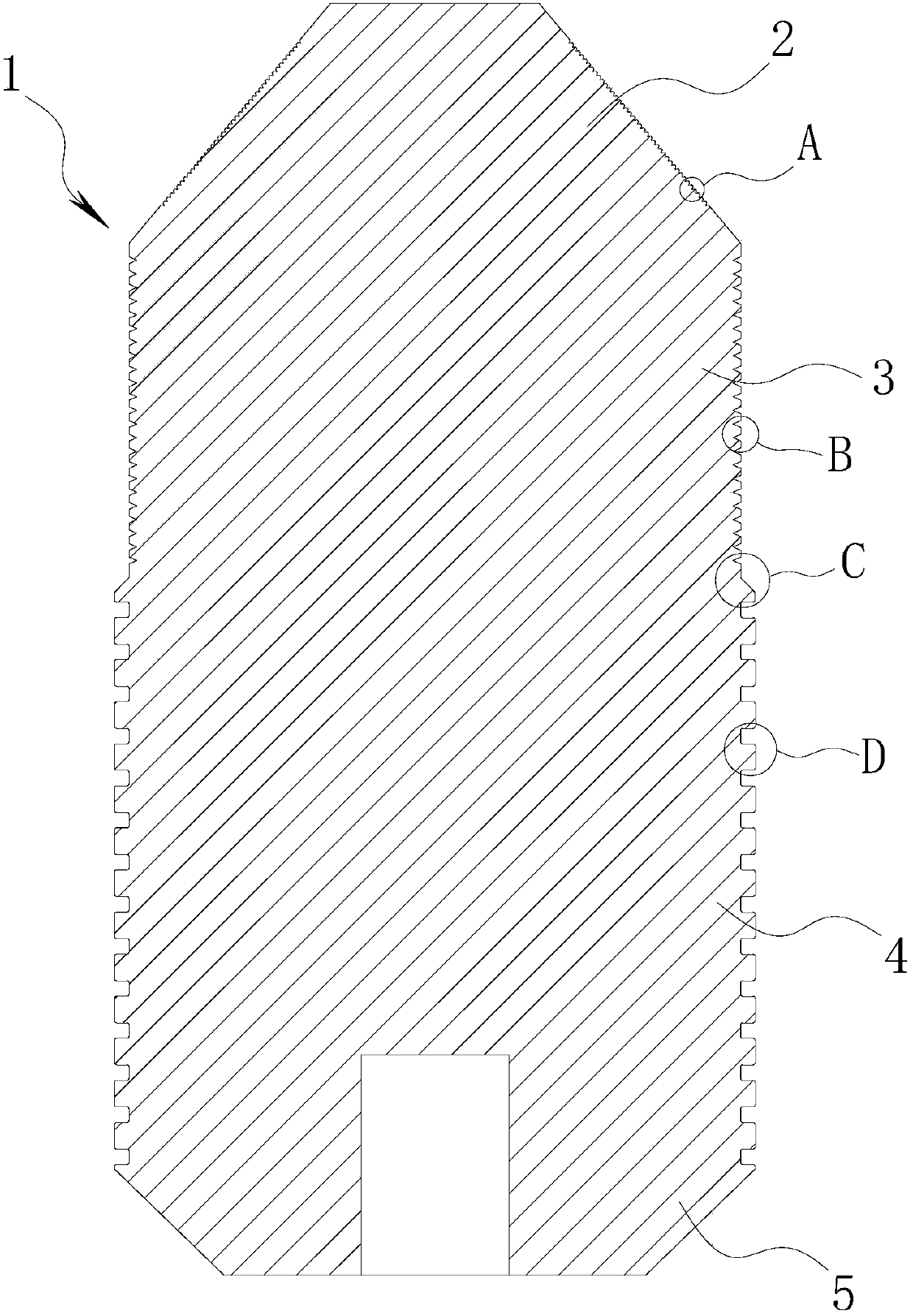

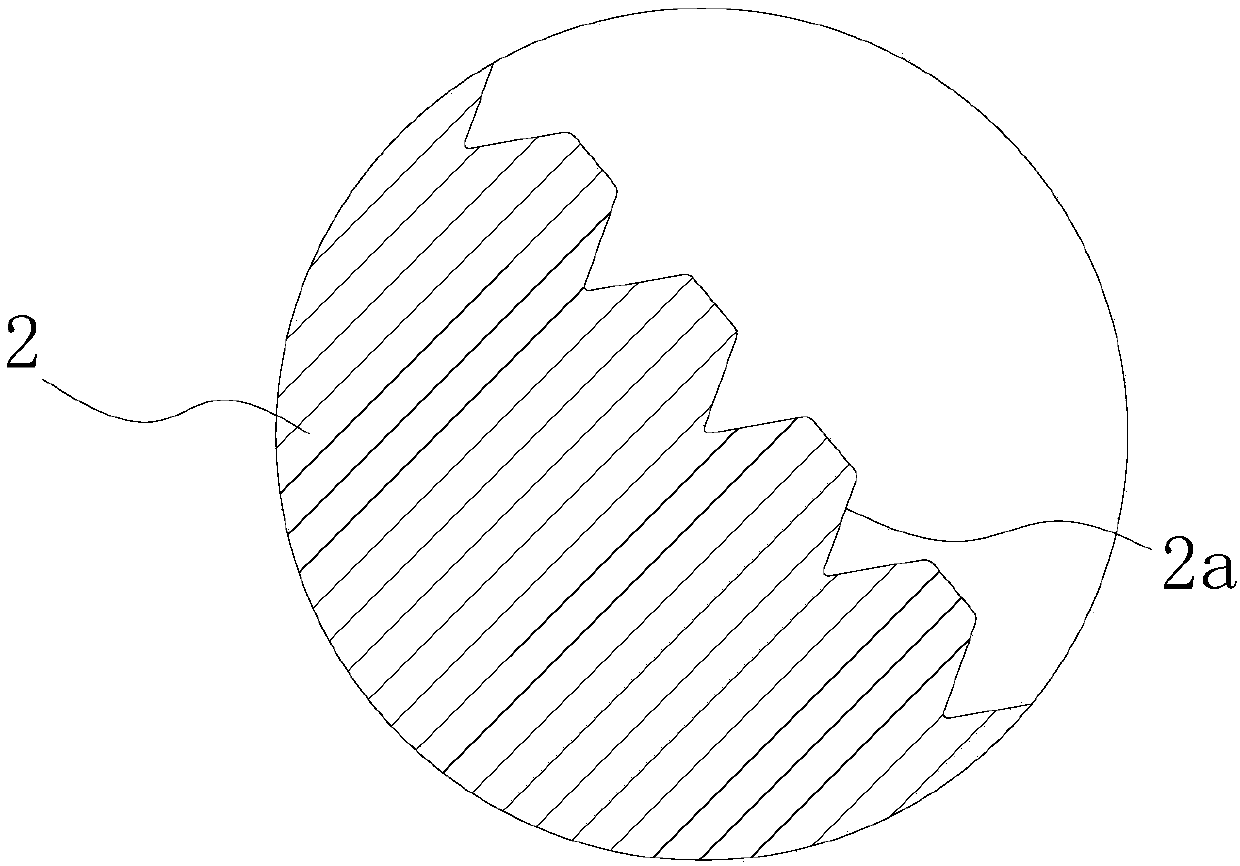

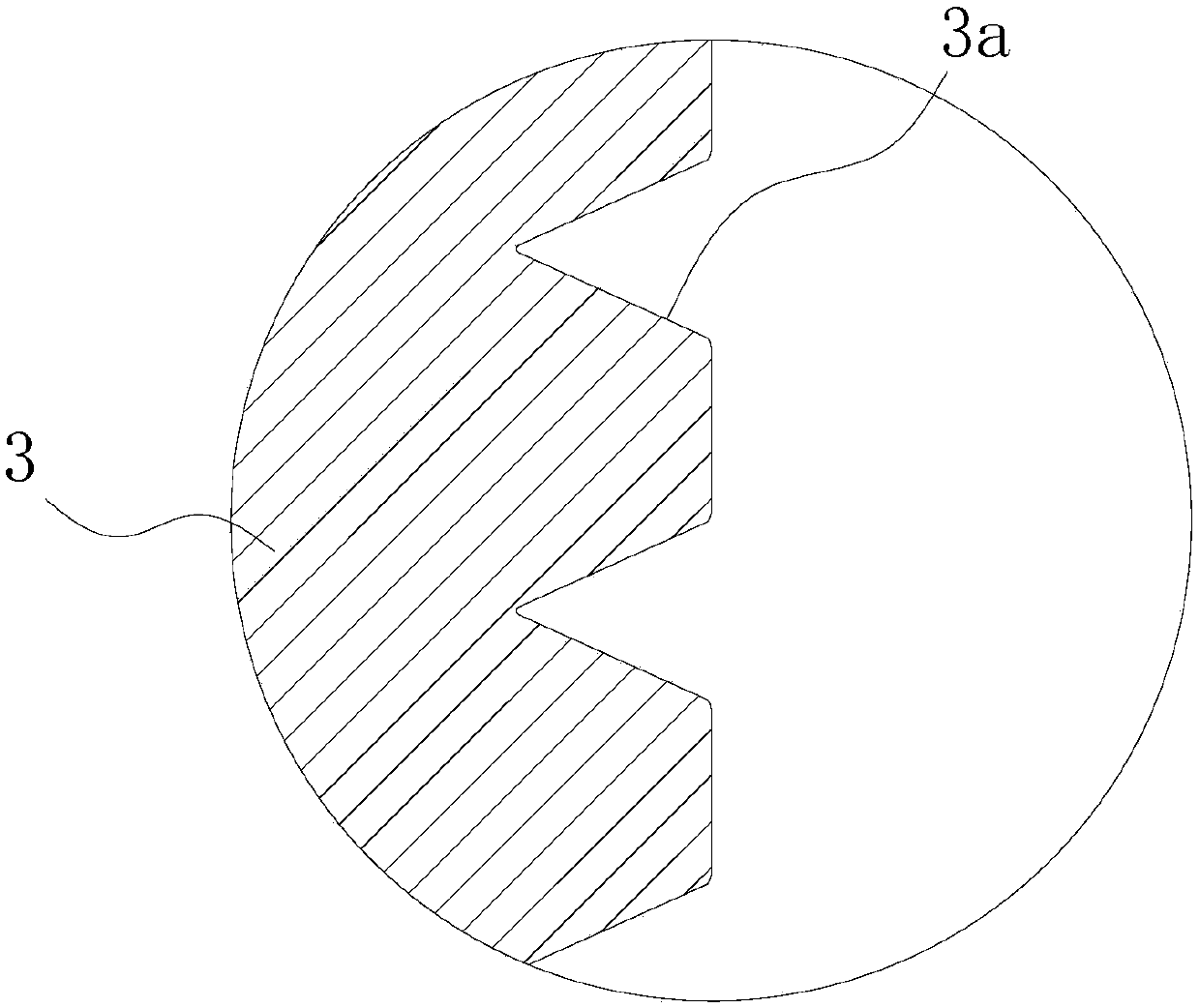

[0026] refer to Figure 1 to Figure 5 As shown, an anode structure for a short-arc mercury-xenon lamp of the present invention includes a cylindrical body 1, and the body 1 is sequentially composed of a circular frustum portion 2, a heat dissipation portion 3, and an auxiliary heat dissipation support portion 4 from top to bottom. Consists of a supporting rounded platform portion 5; the outer diameter of the lower end of the circular platform portion 2 is the same as the outer diameter of the heat dissipation portion 3; the outer diameter of the heat dissipation portion 3 is 0.4-0.8mm smaller than the outer diameter of the auxiliary heat dissipation support portion 4; the circular platform The ratio of the total height of the part 2 and the heat dissipation part 3 to the total height of the auxiliary heat dissipation support part 4 and the supporting rounded platform part 5 is 1:1.2-1.4.

[0027] In order to make the body structure more compact and reduce excessive friction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com