Patents

Literature

41 results about "Particle erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

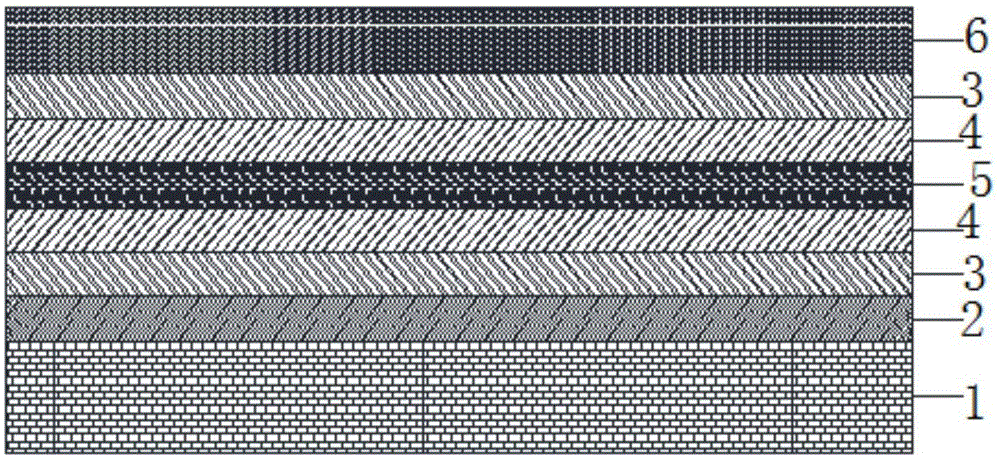

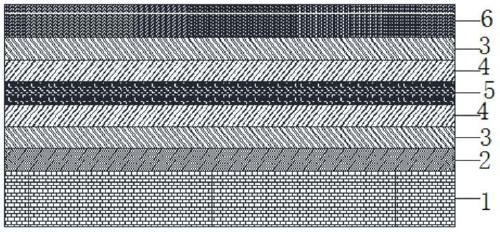

Solid Particle Erosion Resistant Surface Treated Coat and Rotating Machine Applied Therewith

ActiveUS20090123737A1Improve fatigue strengthHigh erosion resistance and oxidation resistance and fatigue strengthLiquid surface applicatorsPump componentsAxial compressorSolid particle

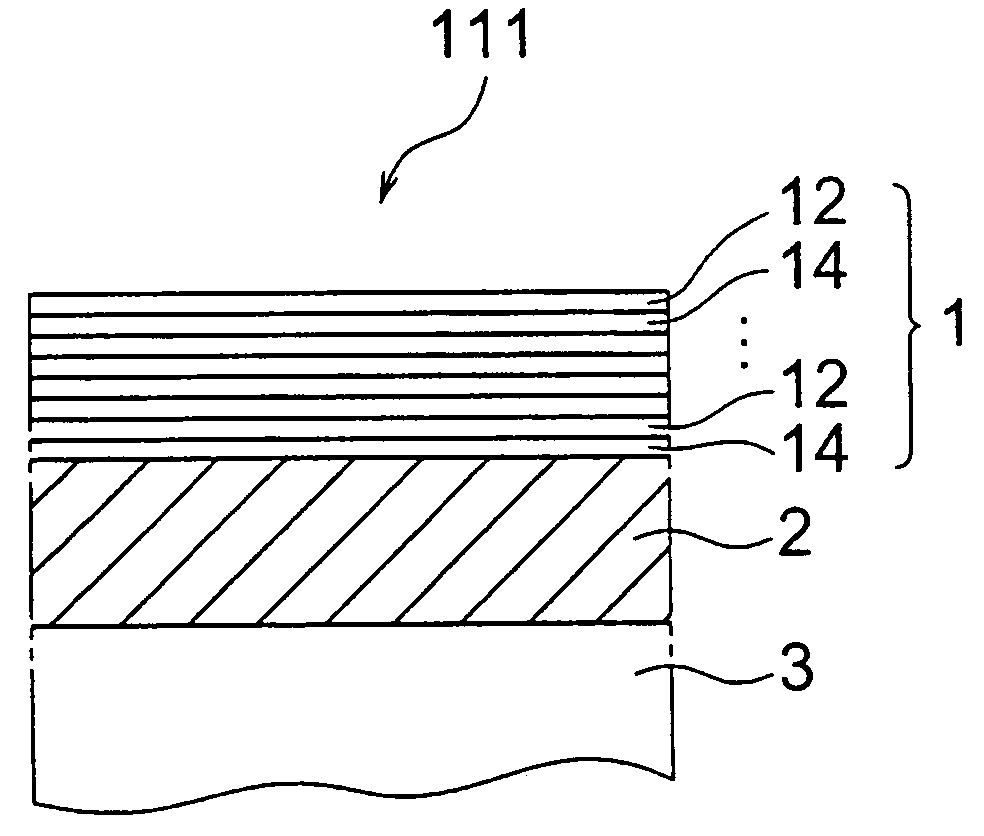

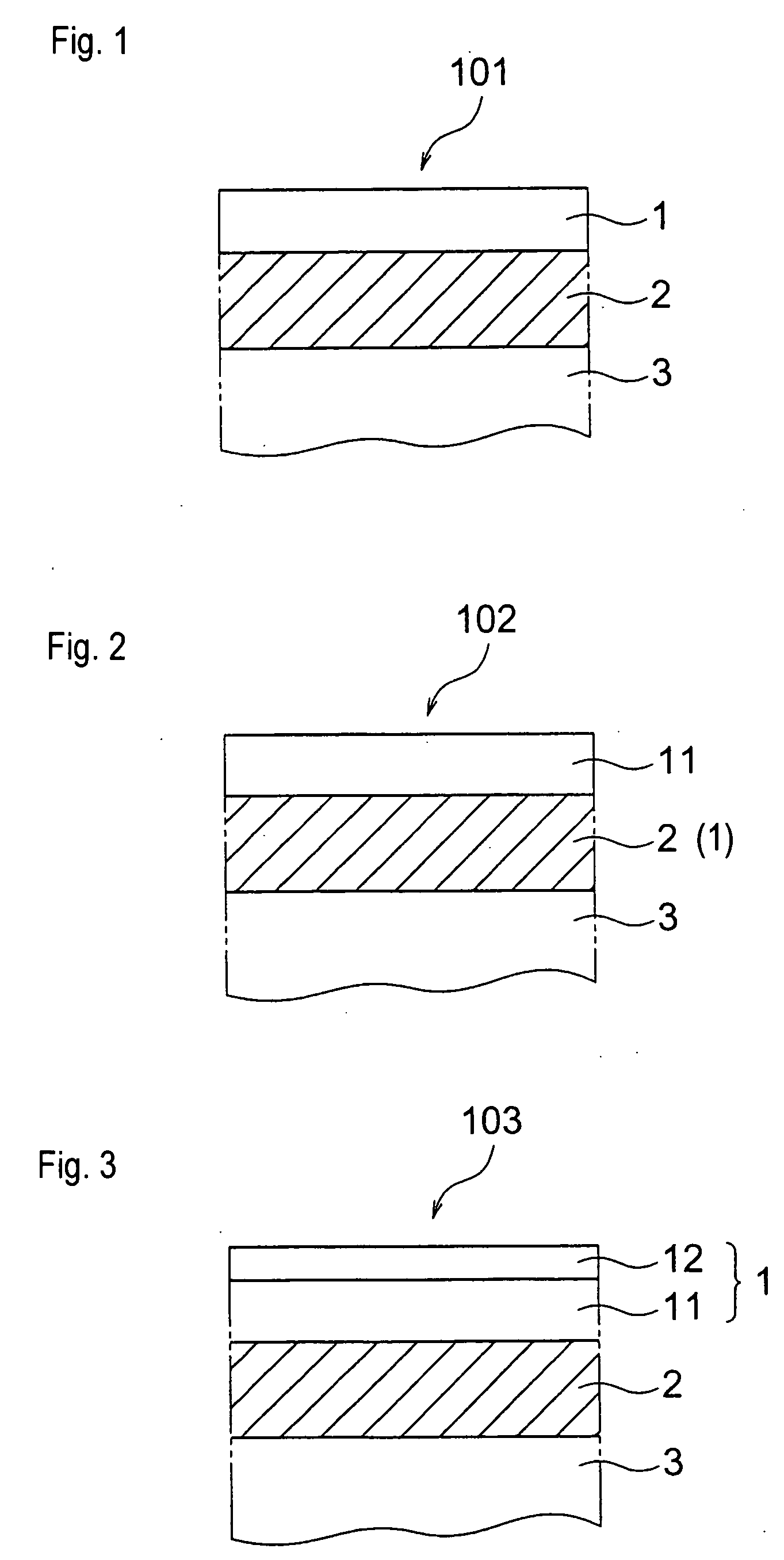

A solid particle erosion resistant surface treated coat is provided by which a solid, particle erosion resistance is largely enhanced and a rotating member is given with an oxidation resistance without deteriorating a fatigue strength. Also, a rotating machine, such as a steam turbine, axial compressor or the like, applied with this coat is provided. The solid particle erosion resistant surface treated coat comprises a nitrided hard layer formed on a surface of base material and a PVD (physical vapor deposition) hard layer of at least one layer formed on the nitrided hard layer by a PVD method. The nitrided hard layer has a thickness of at least 30 μm. The PVD hard layer has a total thickness of at least 10 μm. Deformation of the base material by collisions by solid particles is prevented and crack of the coat comprising the nitrided hard layer formed on the base material and the PVD hard layer formed on the nitrided hard layer is prevented. Thereby, the solid particle erosion resistance is secured, life of the solid particle erosion resistant surface treated coat can be elongated and the oxidation resistance and fatigue strength are enhanced.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

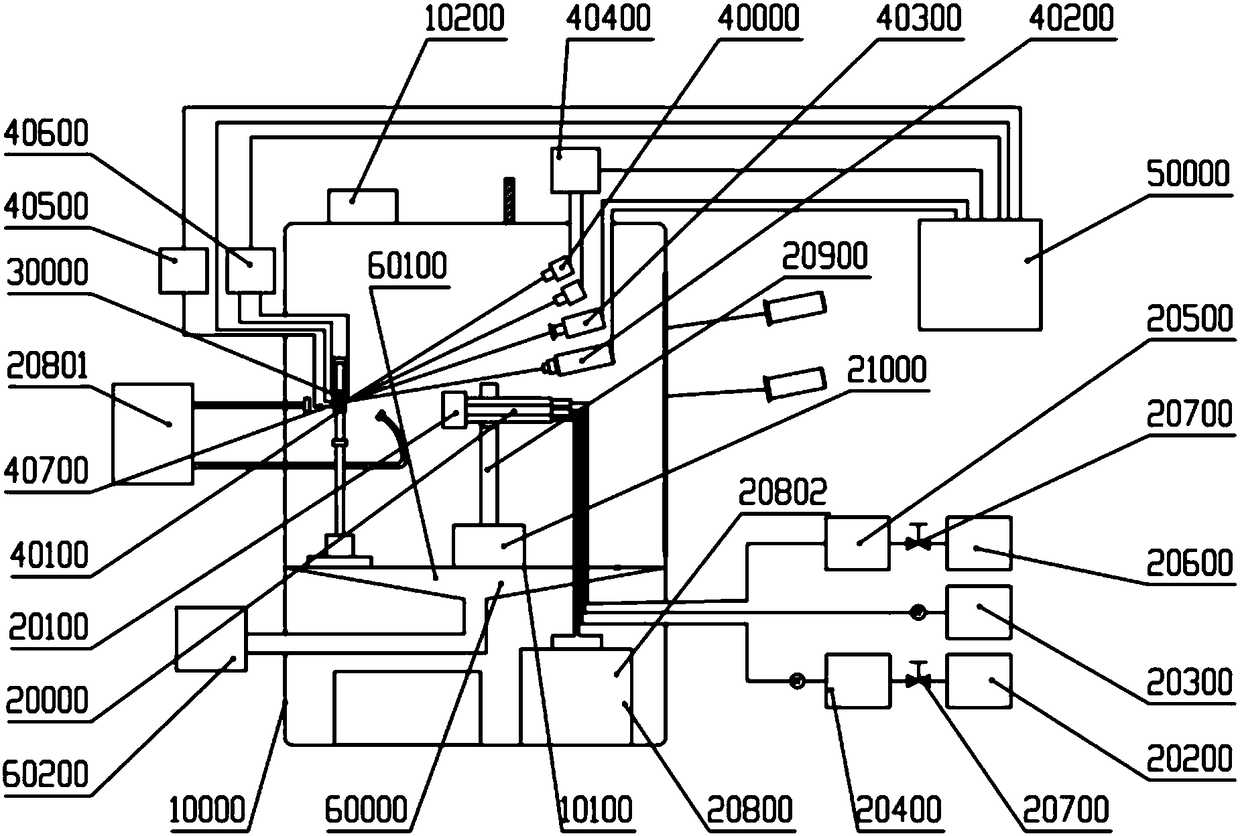

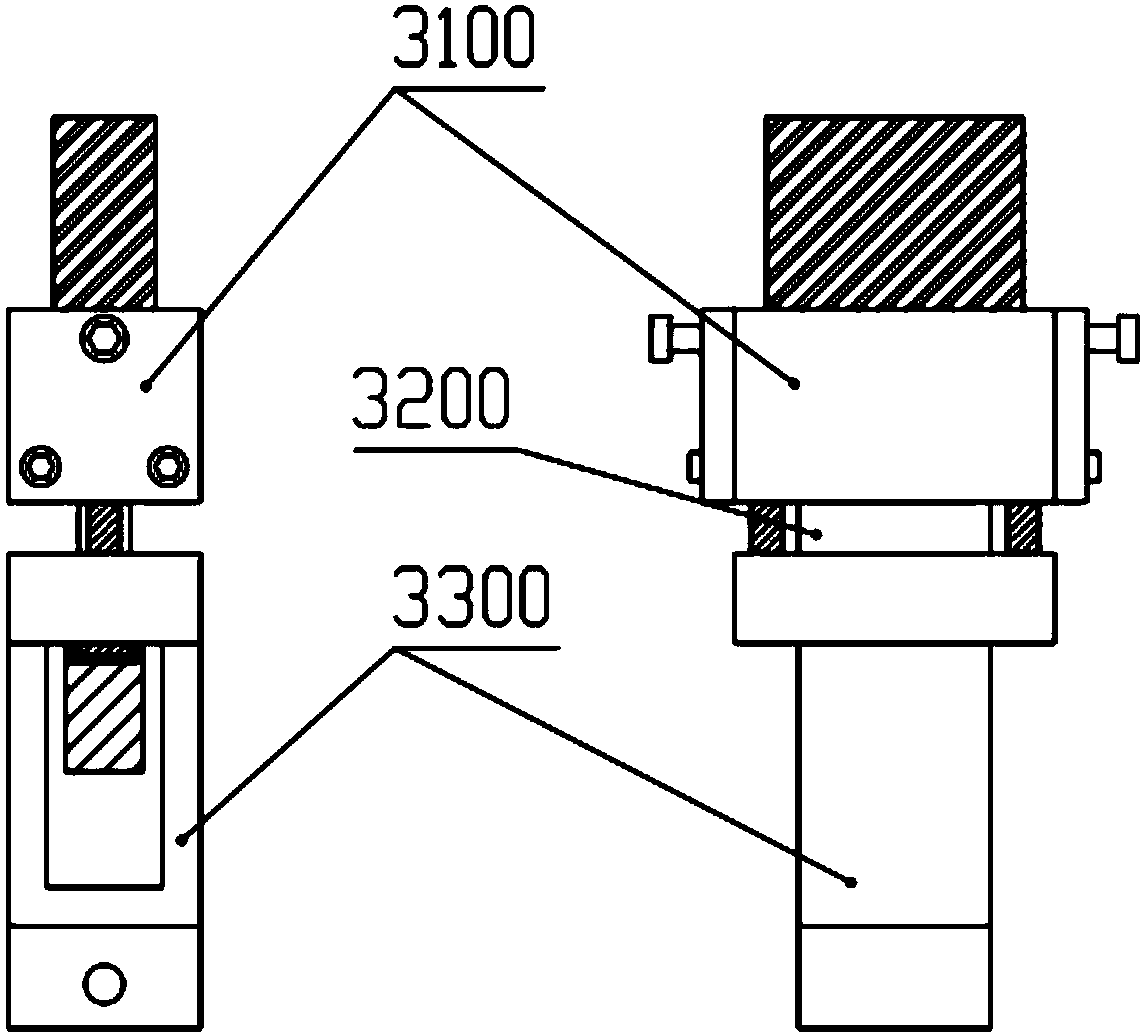

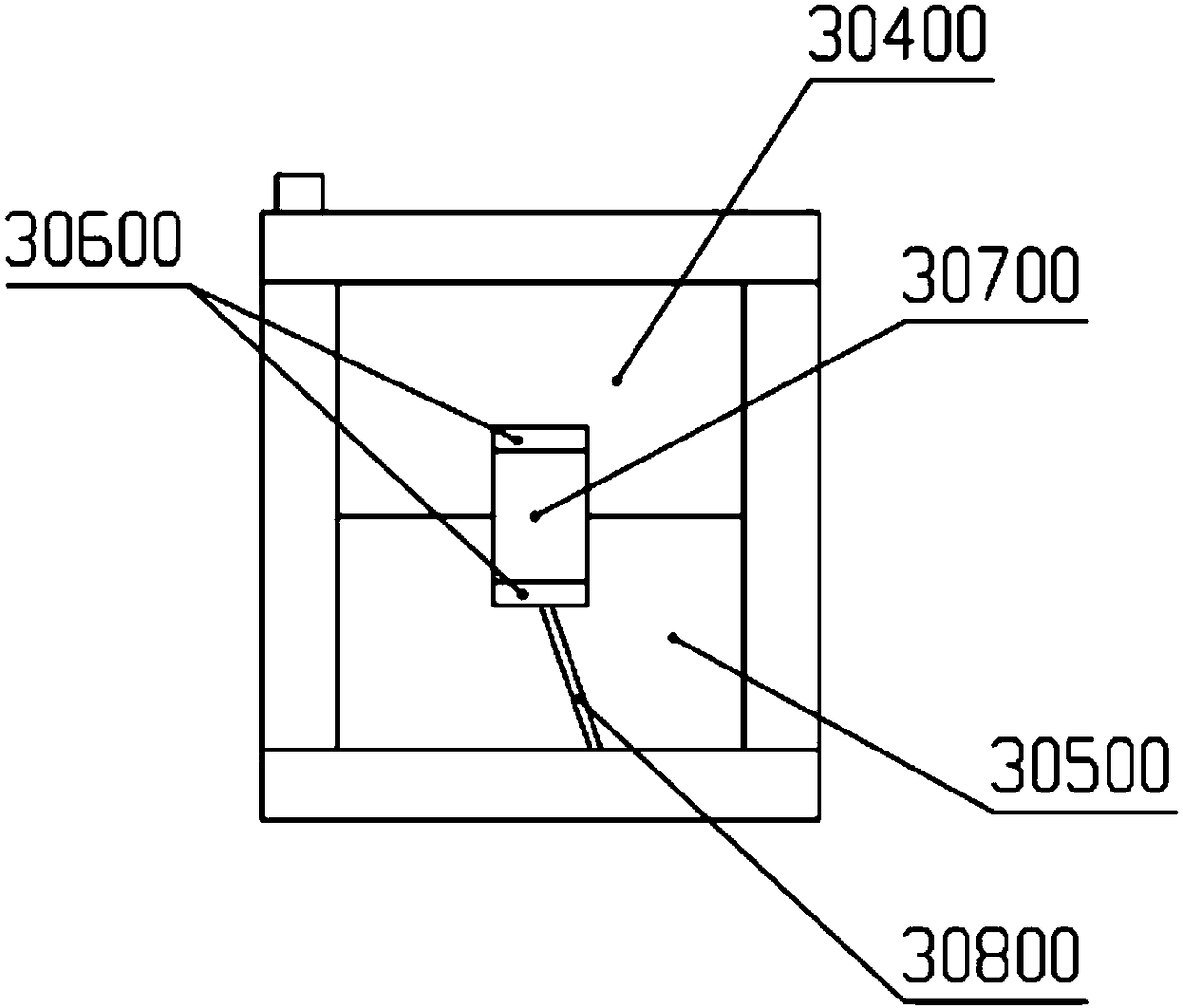

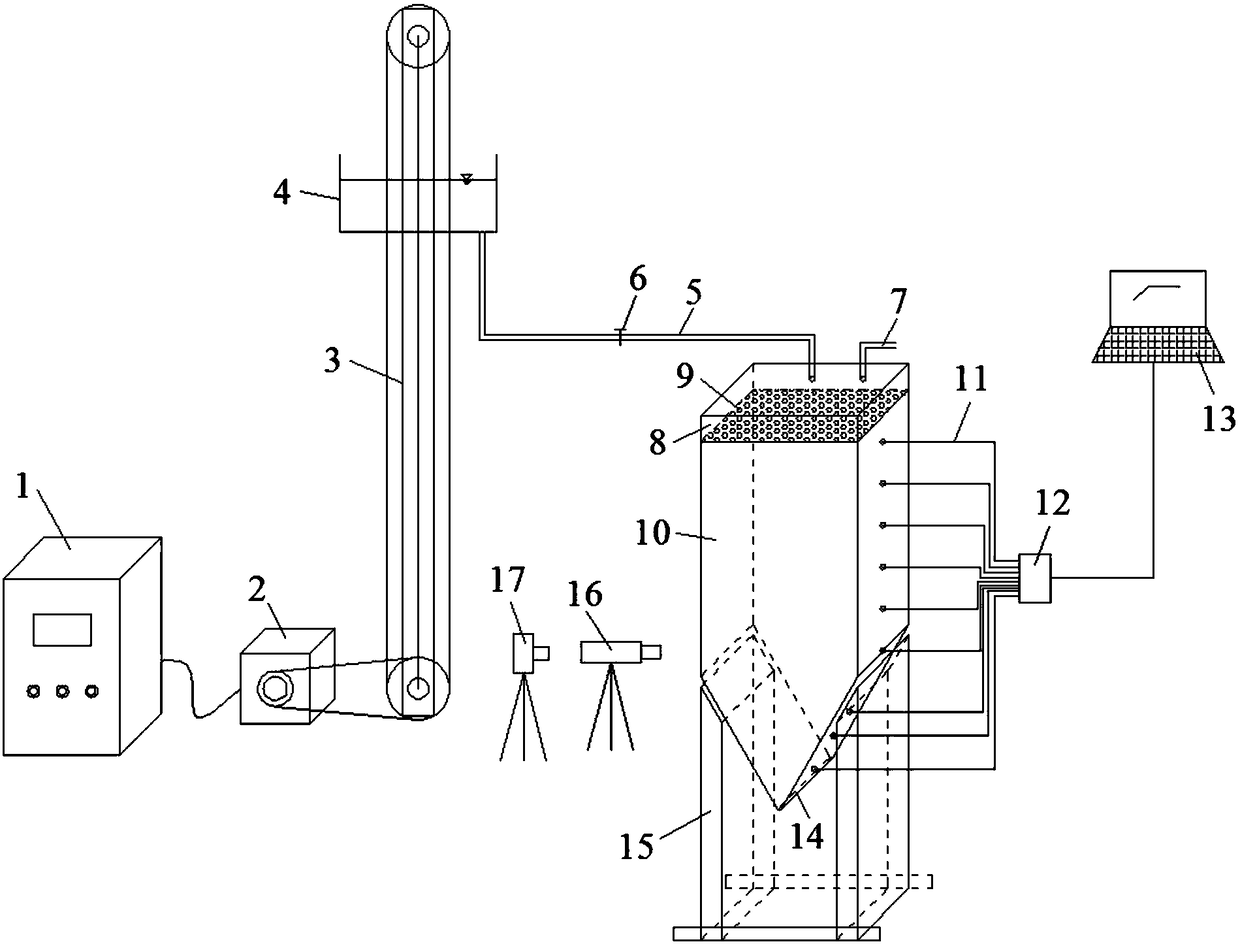

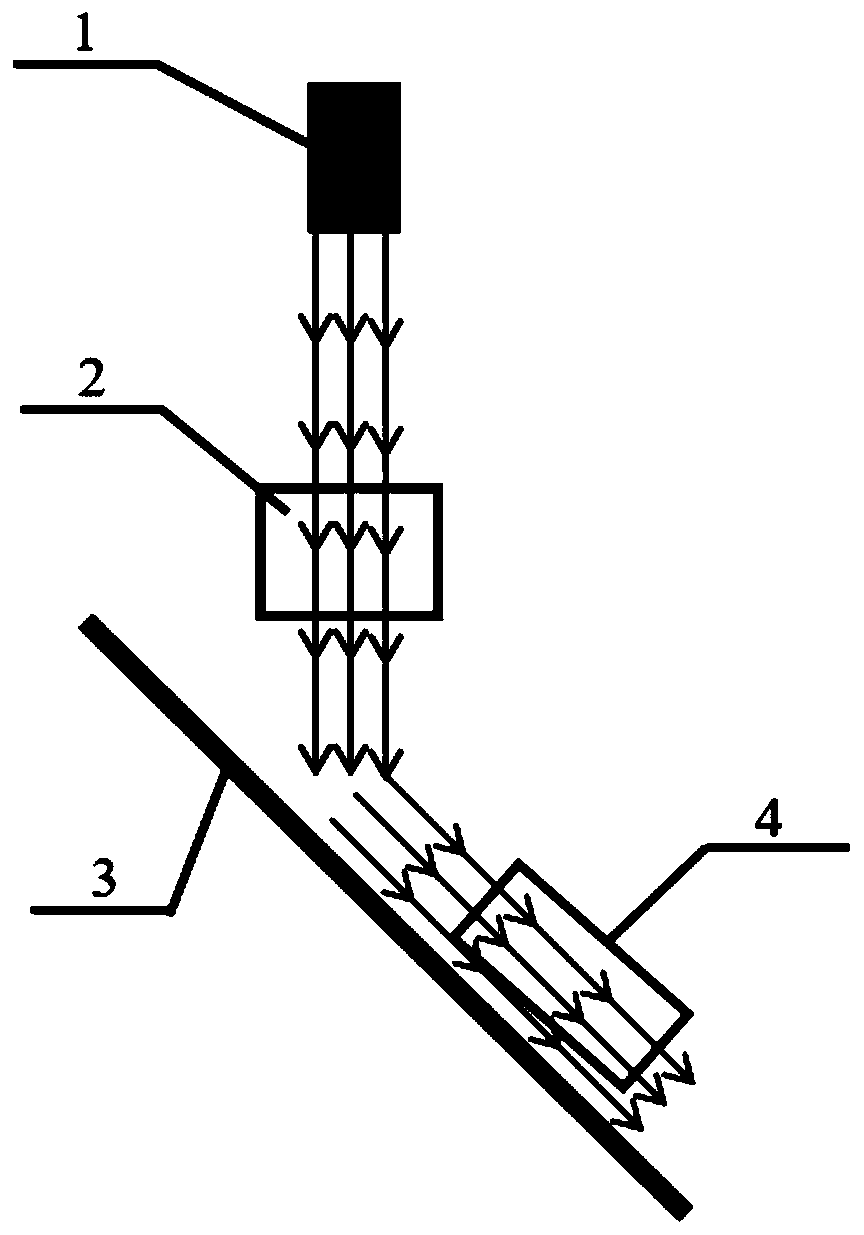

Thermal barrier coating working condition simulation and real-time monitoring device

InactiveCN108254275AWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMulti fieldEngineering

The invention provides a thermal barrier coating working condition simulation and real-time monitoring device. The device comprises a box, a working condition simulation assembly, a sample clamping assembly, a monitoring assembly and a system control assembly, wherein the working condition simulation assembly is used for simulating the working condition of a sample to be tested; the sample clamping assembly is arranged inside the box; the sampling clamping assembly is used for clamping the sample to be tested; the monitoring assembly is used for collecting and processing test data in the simulation process; a detection assembly is electrically connected with the system control assembly, and the system control assembly is used for controlling the simulation process. Through the arrangementof the working condition simulation assembly, the working condition of an aircraft engine can be simulated, and real-time monitoring is performed on the simulation process by using the monitoring assembly, so that an extreme multi-field coupling environment can be realized, and the complex multi-field coupling service environments, such as high temperature thermal shock, hard particle erosion andhigh temperature corrosion, of the thermal barrier coating material in the real service process can be simulated.

Owner:XIANGTAN UNIV

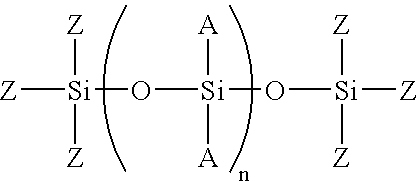

Composite coating for imparting particle erosion resistance

InactiveUS20030152785A1High strengthImproving resistance to abrasionSynthetic resin layered productsPretreated surfacesSilsesquioxaneParticle erosion

Erosion resistant coating compositions comprising a poly(Bisphenol A-co-epichlorohydrin) glycidyl end-capped component, an active hydrogen compound, a linear siloxane and a silsesquioxane. Protective coatings formed from such a composition impart particle-erosion resistance to parts having such a coating disposed on some portion of their surface.

Owner:ANALYTICAL SERVICES & MATERIALS

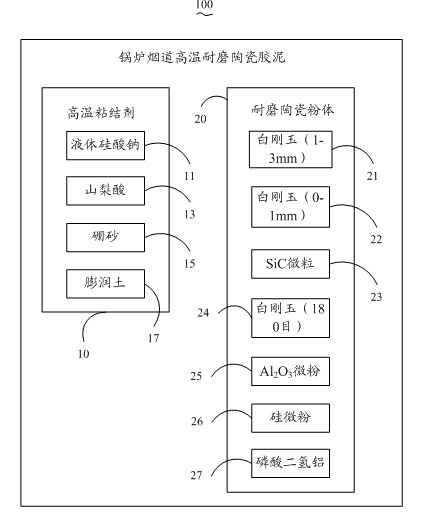

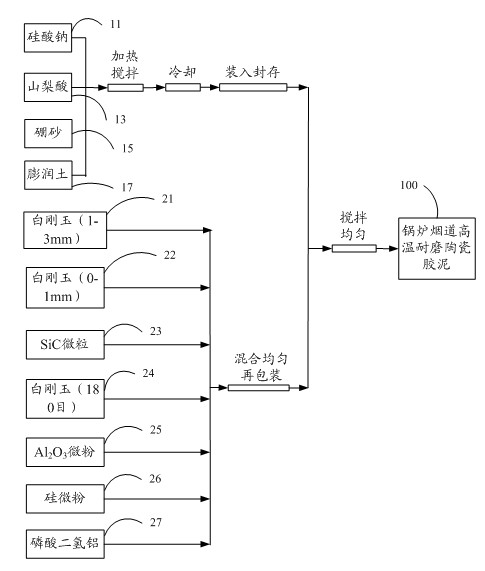

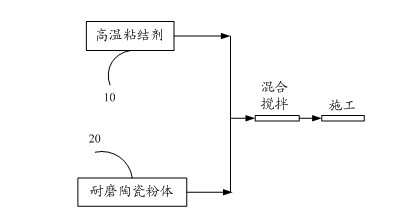

High-temperature wear-resistant ceramic cement for boiler flue

The invention relates to a boiler flue high-temperature wear-resistant ceramic cement, which includes a high-temperature binder with a component ratio of 1:3.5 and wear-resistant ceramic powder, and the high-temperature binder includes a component ratio of 100:0.5: 1.5:1.5 sodium silicate, sorbic acid, borax and bentonite, the wear-resistant ceramic powder includes white corundum with a component of 20% and a diameter range of 1-3 mm, and a component of 30% with a diameter range of 0 -1 mm white corundum, 20% silicon carbide particles with a diameter ranging from 0 to 1 mm, 20% white corundum with 180 mesh, 5% three-dimensional silicon carbide particles with a diameter of about 5 microns Aluminum oxide micropowder, silicon micropowder with a component of 2.5% and a diameter of about 1 micron, and a component of 2.5% aluminum dihydrogen phosphate. The boiler flue high-temperature wear-resistant ceramic cement adopts the method of coating, which is convenient for construction, does not have high requirements on the surface of the substrate, can repair local wear parts, and can resist high-temperature corrosion and particle erosion under complex working conditions. Erosion wear.

Owner:HEFEI KEDE SURFACE TECH

Thermal barrier coating, as well as preparation method and application thereof, and aero-engine turbine blade

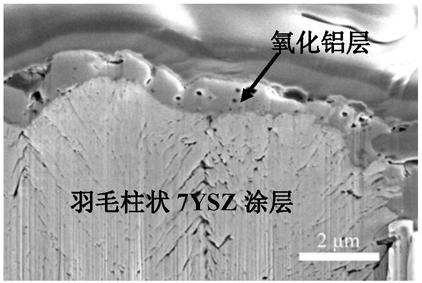

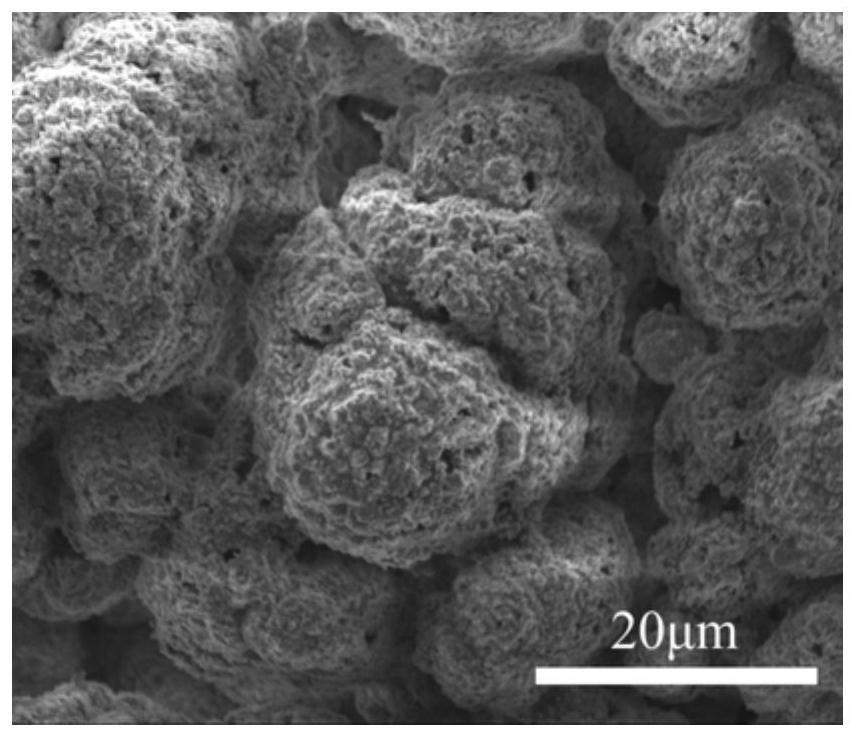

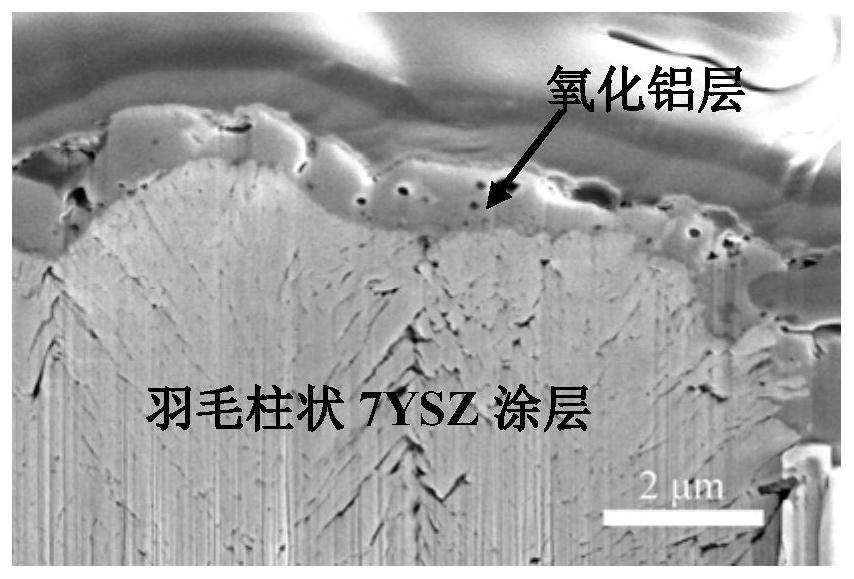

ActiveCN109628929AImprove heat insulationImprove stress toleranceMolten spray coatingBlade accessoriesThermal insulationGas phase

The invention relates to a thermal barrier coating, as well as a preparation method and application thereof, and an aero-engine turbine blade, and belongs to the field of aero-engine hot end part protection coatings. The thermal barrier coating comprises a 7YSZ ceramic layer and an aluminum oxide layer arranged on the surface of one side of the 7YSZ ceramic layer, wherein the 7YSZ ceramic layer isin a feather column shape; and aluminum oxide in the aluminum oxide layer is nanocrystals. The thermal barrier coating not only has high thermal insulation and high stress tolerance, but also has favorable fused salt corrosion resistance and resistance to high temperature oxidation and particle erosion. The preparation method comprises the steps of adopting a plasma spraying-physical vapor deposition method for preparing the 7YSZ ceramic layer; adopting a magnetron sputtering technology for preparing the aluminum oxide layer; and then carrying out vacuum treatment. The method is simple, and the uniform thermal barrier coating can be prepared. The thermal barrier coating is applied to be arranged on an aero-engine hot end part such as the surface of a turbine blade, so that the turbine blade has favorable resistance to high temperature oxidation, CMAS corrosion and particle erosion.

Owner:GUANGDONG INST OF NEW MATERIALS

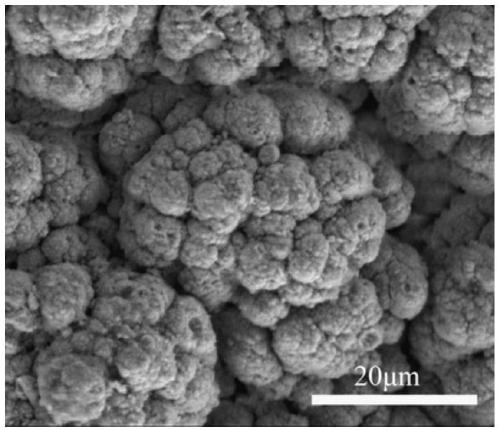

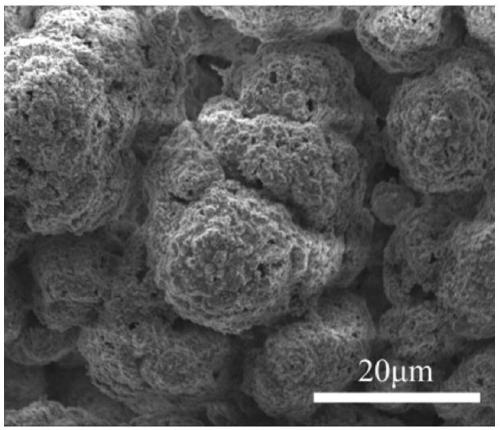

Cobalt-based spray powder used for aero-engine abrasion-resistant parts and preparation method thereof

InactiveCN106975742AExcellent resistance to abrasive wearExcellent hard surface wearMolten spray coatingWear resistantSpray coating

The invention belongs to the technical field of wear-resistant coating materials, and in particular relates to a cobalt-based spraying powder for aero-engine wear-resistant parts, and also relates to a method for preparing the above-mentioned spraying powder. The composition and weight percentage of the spray powder are: chromium: 20%~30%; nickel: 7%~15%; tungsten: 5%~12%; carbon: 0.1%~1%; cobalt: 45%~65% %; the particle size range of the above spray powder is 5 μm to 45 μm; the coating obtained by using the spray powder is suitable for working at high temperature, and has excellent anti-abrasive wear, hard surface wear, fretting wear and particle erosion wear performance ;After spraying, the bonding strength is high, and it is not easy to fall off; after spraying, the coating has a uniform texture, smooth surface, no delamination and cracks; at the same time, the cobalt content in the material determines that the coating is an excellent anti-oxidation coating; in addition , the powder coating also has good coating grinding and polishing properties and high coating hardness, and can be widely used in the application of engine parts.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

Test device for coupling complex atmosphere corrosion with high-temperature solid-phase erosion corrosion

PendingCN110763617AWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceCorrosion reactionMaterial Erosion

The invention discloses a test device for coupling complex atmosphere corrosion with high-temperature solid-phase erosion corrosion. The test device comprises a medium distribution system, a corrosionreaction system and a tail gas treatment system; the test device not only can control the speed of particle erosion by controlling the flow of various gases, but also perform corrosion and erosion tests of multiple test pieces simultaneously; the distance among multiple test pieces can be adjusted at arbitrarily, and a working condition thereof is closer to an abrasion condition between the tubewalls of heat exchangers in an actual boiler.

Owner:XINJIANG UNIVERSITY +1

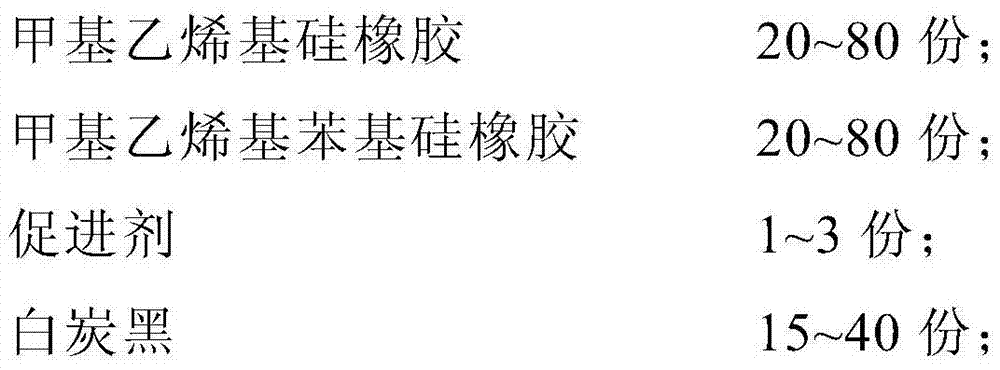

Silicone rubber heat-insulating material for integral solid rocket ramjets and preparation method thereof

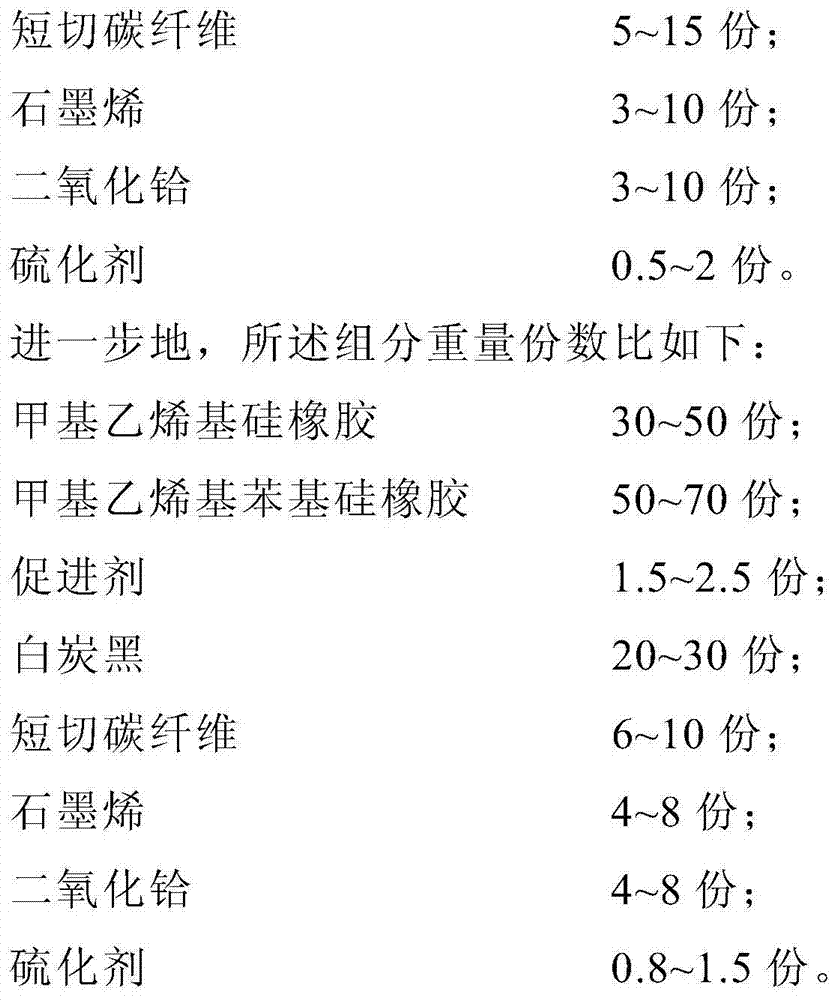

The invention discloses a silicone rubber heat-insulating material for integral solid rocket ramjets and a preparation method thereof. The silicone rubber heat-insulating material comprises the following components in parts by weight: 20-80 parts of methylvinyl silicone rubber, 20-80 parts of methylvinylphenyl silicone rubber, 1-3 parts of accelerator, 15-40 parts of silica white, 5-15 parts of chopped carbon fiber, 3-10 parts of graphene, 3-10 parts of hafnium oxide and 0.5-2 parts of vulcanizing agent. The silicone rubber heat-insulating material for integral solid rocket ramjets can form a high-melting-point ceramic-like layer in the ablation process, has the advantages of high temperature resistance, ablation resistance, favorable elasticity, high micromolecule migration resistance and the like, and can satisfy the operating environments of oxygen enrichment, high-temperature high-speed gas flow and particle erosion.

Owner:湖北三江航天江北机械工程有限公司

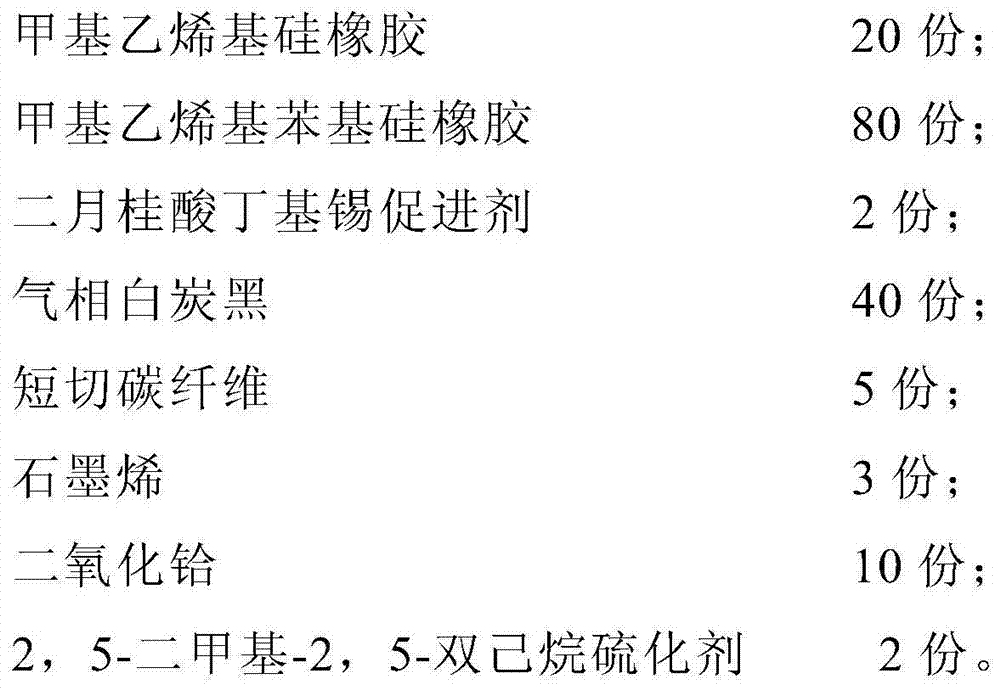

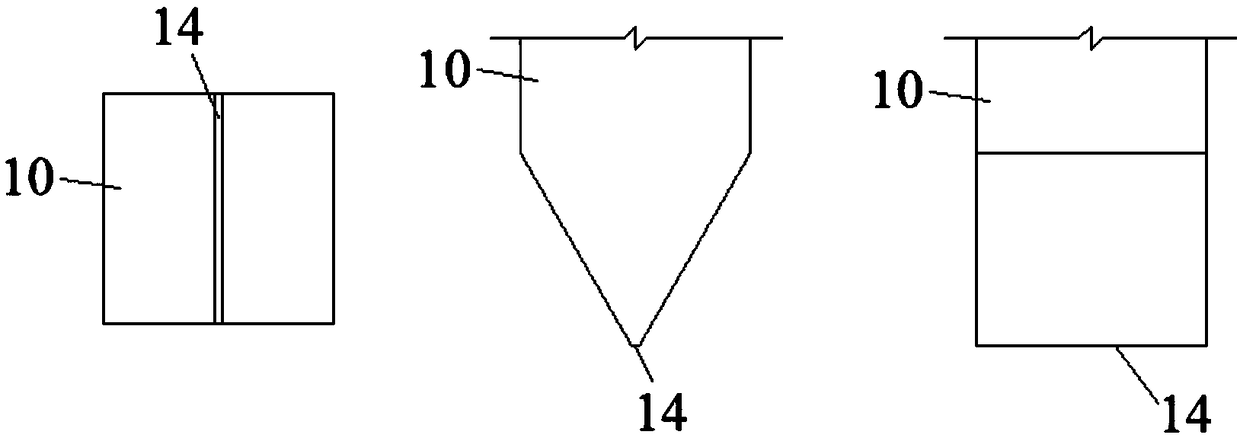

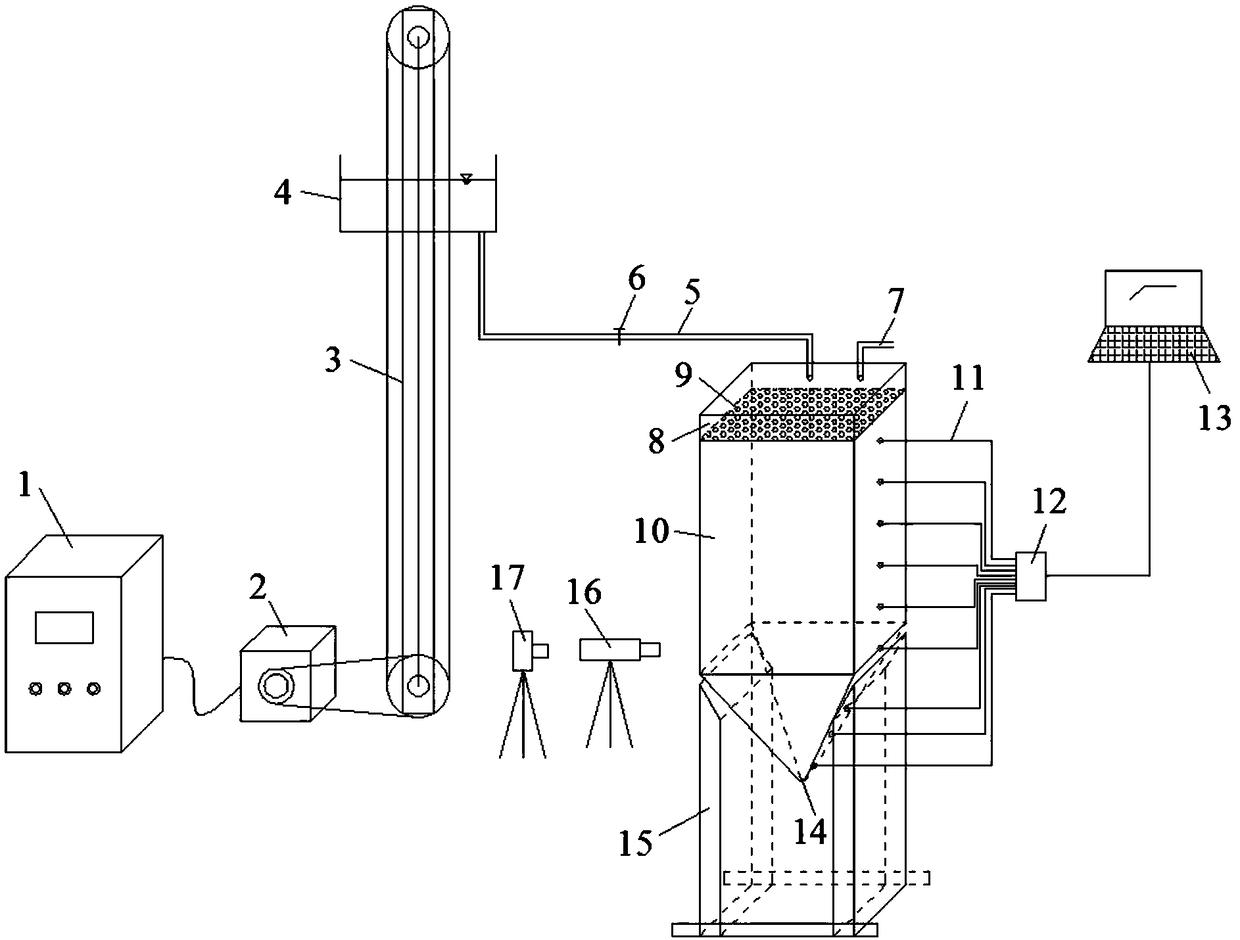

Experimental device and test method for studying two-dimensional and three-dimensional seepage and soil particle erosion law

InactiveCN108562526AFully reflect the erosion processFully reflect the lawPermeability/surface area analysisSoil scienceComputer terminal

The invention discloses an experimental device for studying two-dimensional and three-dimensional seepage and soil particle erosion law, including a steel support, a test box arranged on the steel support, a sand screen arranged inside the test box and an intelligent water tap for adding water to the test box; the sand screen is arranged inside the test box along horizontal direction and divides the test box into an upper water inlet area and a lower sample area; the bottom of the test box is provided with a water outlet; a plurality of water pressure sensors are arranged on side walls corresponding to sample area of the test box and each water pressure sensor is connected with a computer terminal in communication junction. The experimental device and a test method for studying two-dimensional and three-dimensional seepage and soil particle erosion law can relatively and accurately reflect the erosion process and law of soil under seepage function.

Owner:HUATIAN ENG & TECH CORP MCC

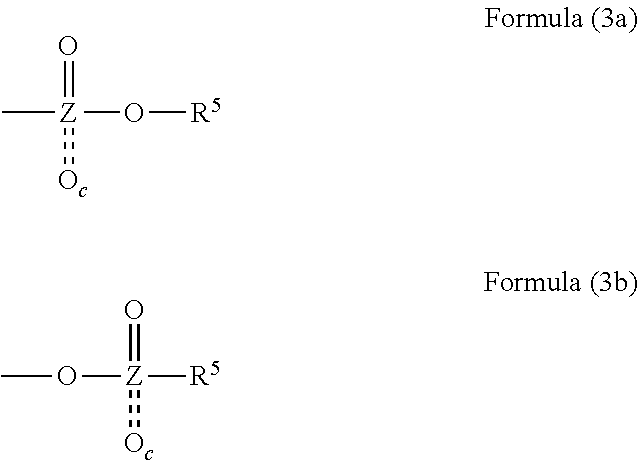

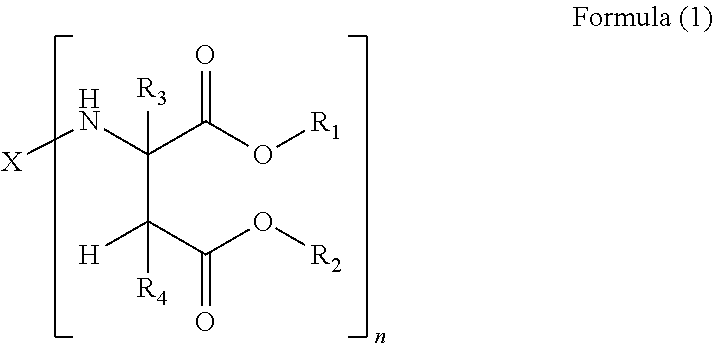

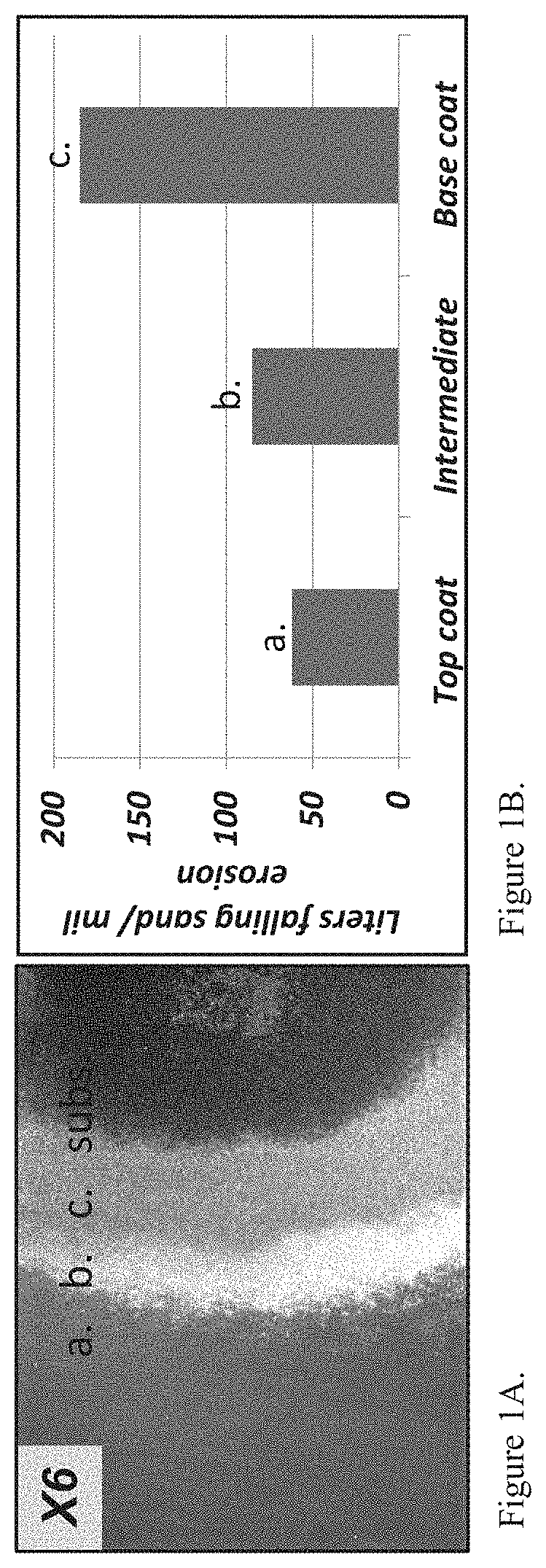

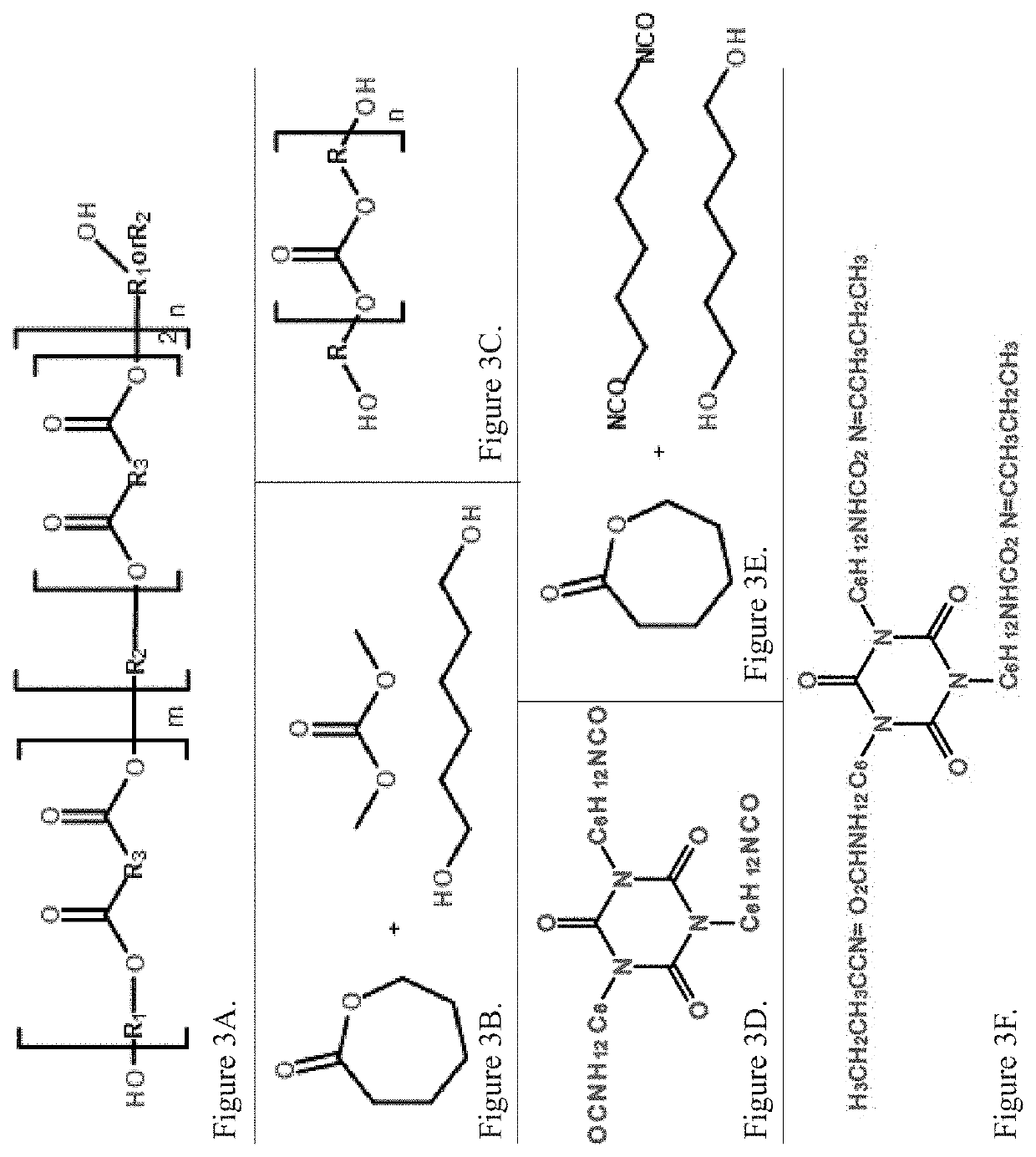

Coating Composition

InactiveUS20170015862A1Improve rain erosion resistance and solid-particle erosion resistanceImprove erosion resistanceEngine manufactureMachines/enginesPolyureaPolymer chemistry

The invention relates to coating compositions which have a low VOC (less than 250 g / l), are fast drying, and have excellent erosion resistance. These coating compositions comprise a film forming resin comprise one or more polyamine(s) containing secondary amine groups and specific aliphatic and / or aromatic esters. The coating compositions are particularly suitable for use in coating wind blades. The present invention also relates to a method of protecting a substrate against rain erosion or solid particle erosion using the coating composition, a coated wind blade or a part thereof, and the use of specific ester(s) in a polyurea-based coating composition for improving the rain erosion resistance or solid-particle erosion resistance of a coating.

Owner:AKZO NOBEL COATINGS INT BV

Corrosion/erosion-resistant coating for waste incineration boiler heating surface

The invention provides a corrosion / erosion-resistant coating for a waste incineration boiler heating surface. The coating has excellent corrosion resistance on molten salt hot corrosion and solid micro-particle erosion and is excellent in protective performance. According to the core protection layer of the coating, a titanium carbide-nickel-chromium alloy serves as a protection material, construction is performed by adopting a high velocity oxy-fuel mode, the nickel-chromium alloy layer is combined for bottoming, excellent protective performance is guaranteed, and the coating has excellent thermal shock resistance and adhesive force.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

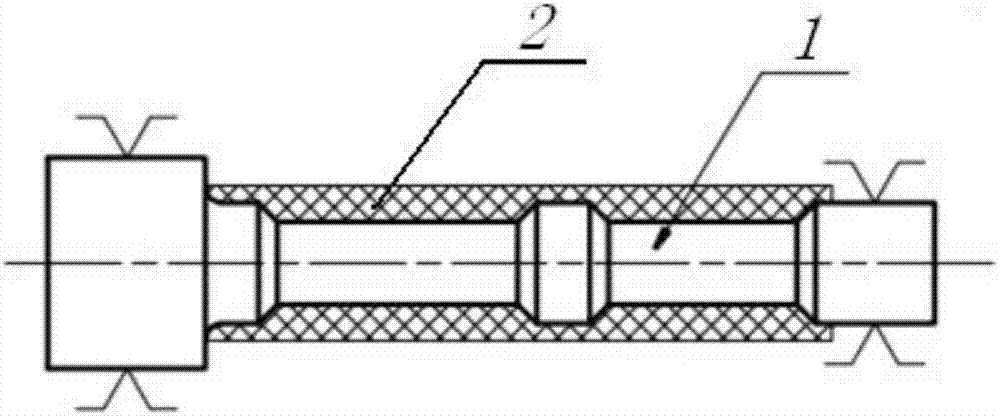

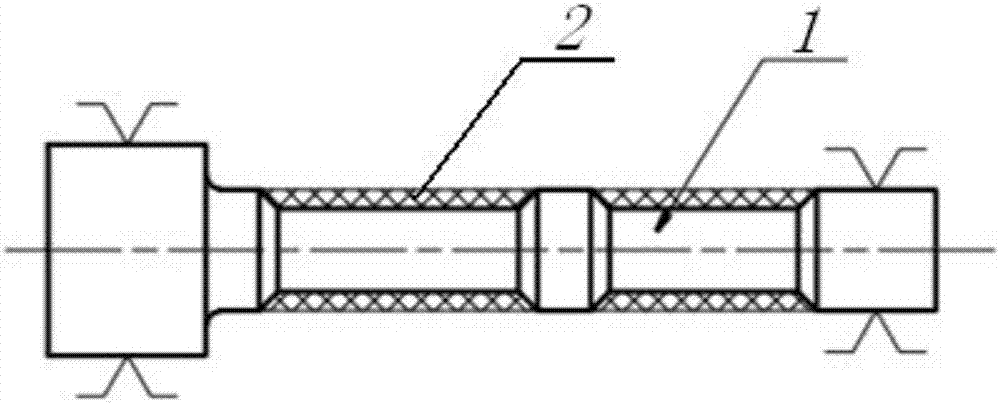

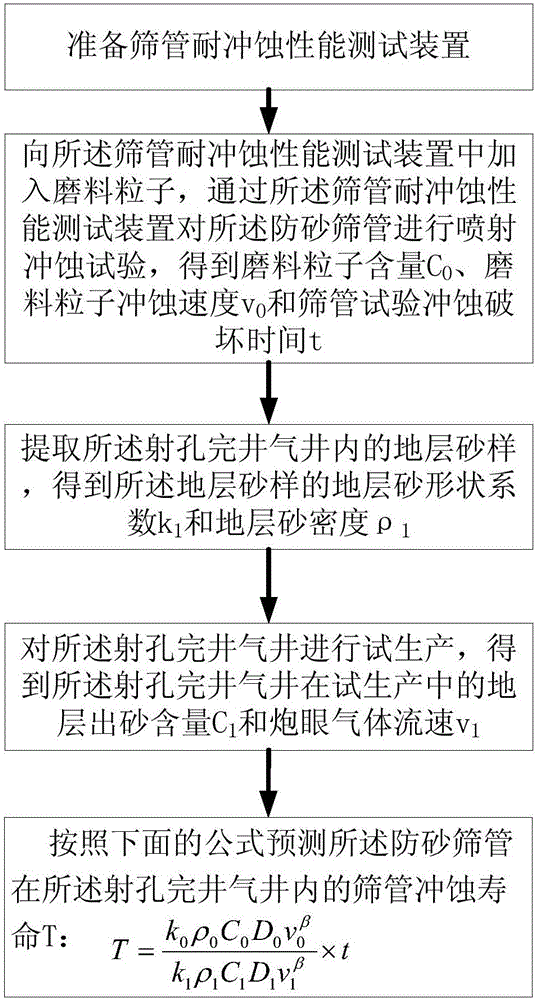

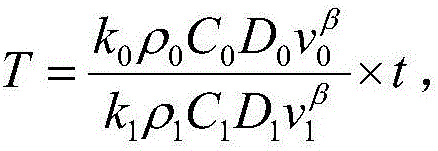

Prediction method for erosion life of sand control screen pipe in perforation completion gas well

ActiveCN106596312AErosion Life PredictionAccurate prediction of erosion lifeInvestigating abrasion/wear resistanceSand sampleParticle erosion

The invention provides a prediction method for erosion life of a sand control screen pipe in a perforation completion gas well. The method includes the steps of: S1. preparing a screen pipe erosion resistance testing device; S2. adding abrasive particles into the screen pipe erosion resistance testing device to perform jet erosion test on the sand control screen pipe so as to obtain the abrasive particle content C0, the abrasive particle erosion velocity v0 and the screen pipe test erosion destruction time t; S3. extracting a formation sand sample in the perforation completion gas well to obtain formation sand shape coefficient k1 and the formation sand density rho1; S4. performing pilot production on the perforation completion gas well to obtain the formation sand production content C1 and blasthole gas flow rate v1; and S5. predicting the erosion life of the sand control screen pipe in the perforation completion gas well according to the following formula as shown in the specification. The method provided by the invention can truly and accurately predict the erosion life of the sand control screen pipe in the perforation completion gas well, and provides basis for selection of an appropriate sand control screen pipe in gas well sand control operation.

Owner:PETROCHINA CO LTD

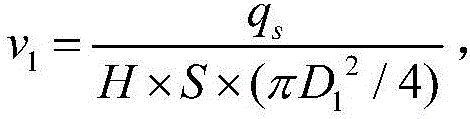

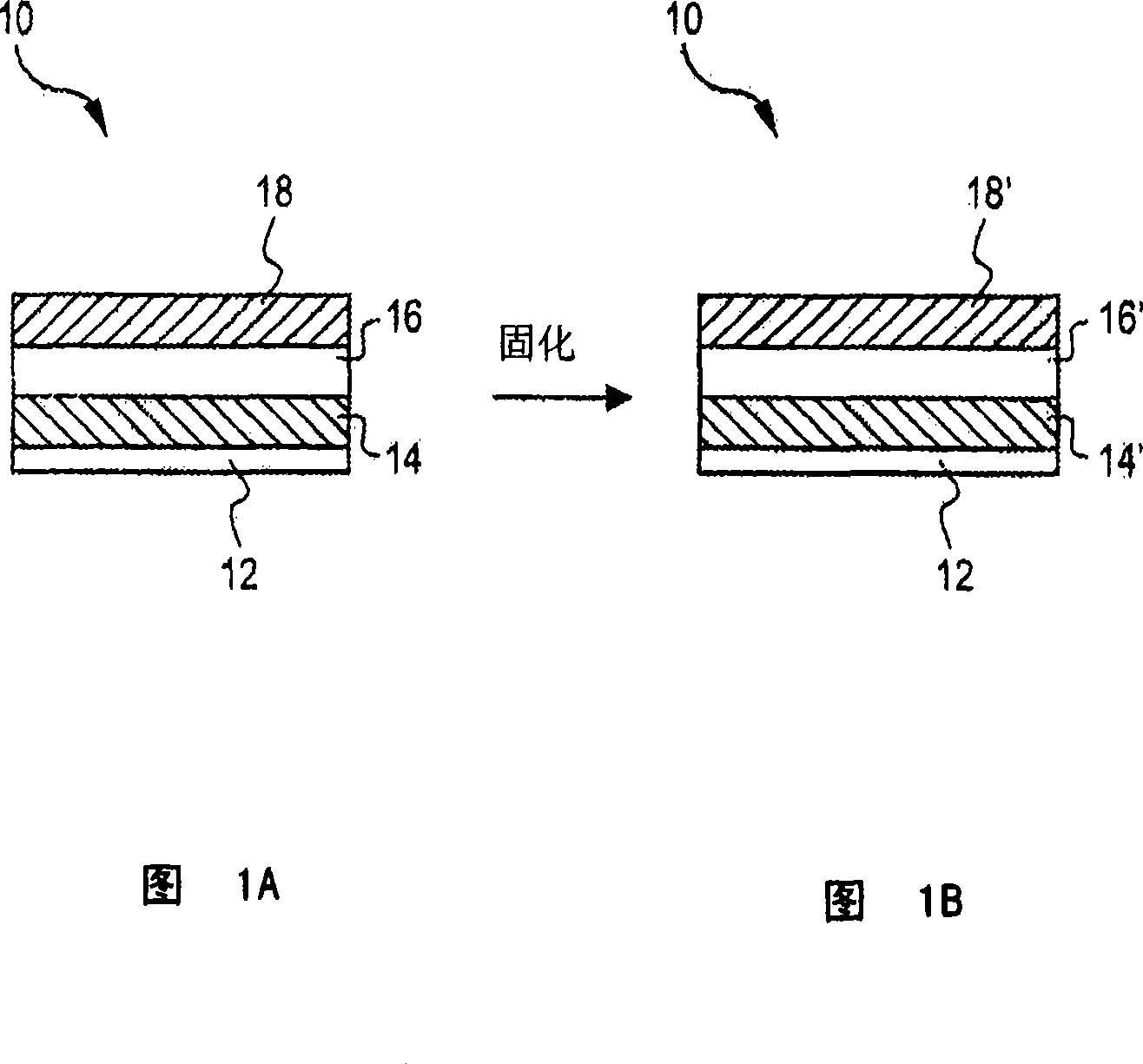

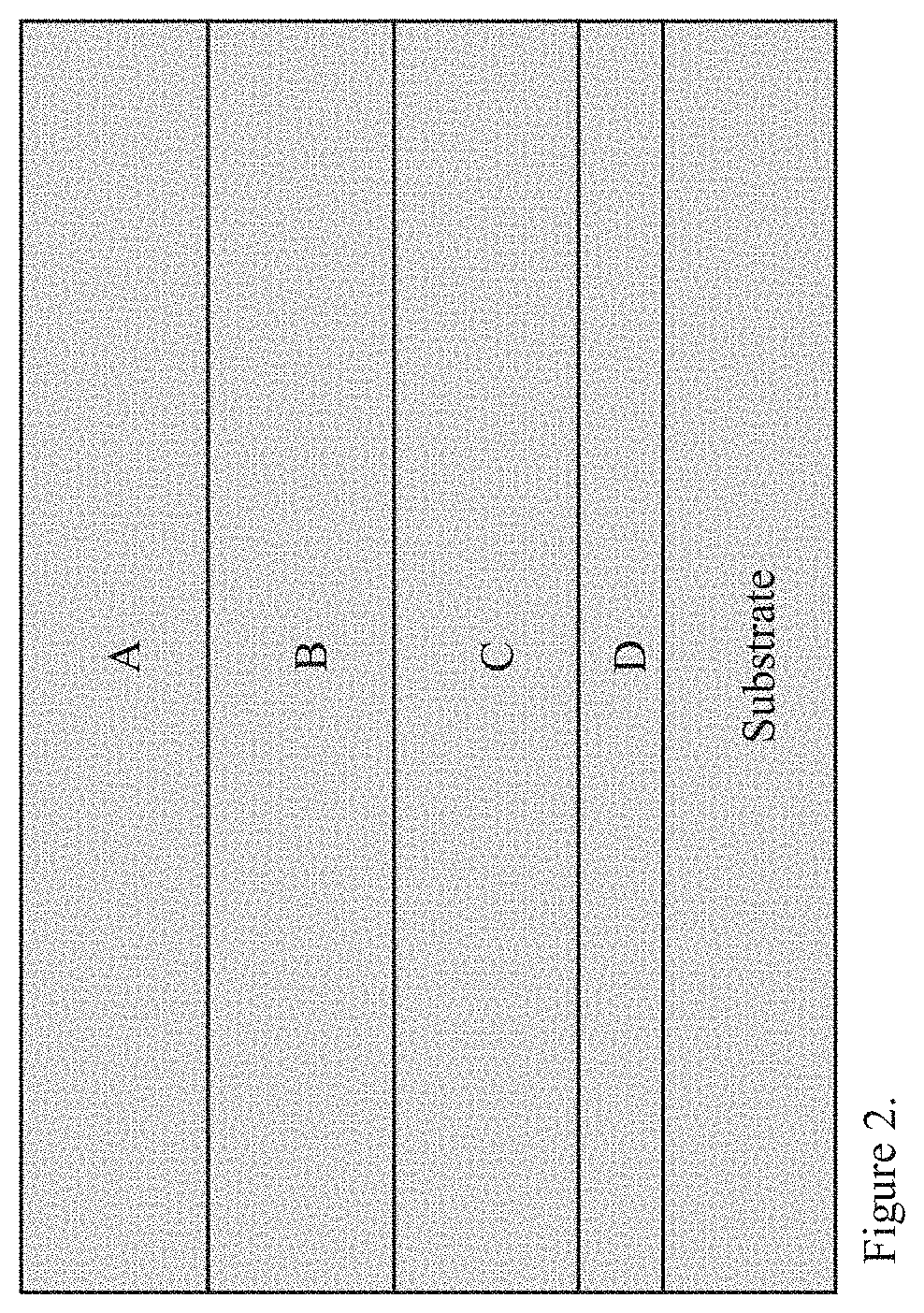

Methods of forming composite powder coatings and articles thereof

A method of forming a composite powder coating comprises depositing multiple layers of a powder coating composition onto a substrate, wherein adjacent layers are formed of a different powder coating composition; and curing the multiple layers of the powder coating composition in a single thermal curing step. The layers can be used to protect power generation equipment from aqueous corrosion, particle erosion, slurry erosion, fretting, and fouling.

Owner:GENERAL ELECTRIC CO

Thermal barrier coating and preparation method thereof

ActiveCN105039892AImprove thermal shock resistanceSimple preparation processMolten spray coatingEfficient propulsion technologiesIsolation layerThermal barrier coating

The invention provides a thermal barrier coating which comprises a base layer, a heat-isolation layer and a protective layer. At least one transition layer is arranged between the base layer and the heat-isolation layer. According to the thermal barrier coating, component preparation of the coating is reasonable, the preparation process is simple and convenient, and the transition layer and the heat-isolation layer of the coating contain oxides capable of forming oxidation films easily. Besides, the content of the oxides has gradient changes, so that the thermal barrier coating has good thermal shock resistance. Meanwhile, high-temperature particle erosion resistance is outstanding.

Owner:江苏海泰新材料科技有限公司

Self-crosslinking silicon-boron-containing high polymer matrix ablation-resistant heat insulation material and preparation method

ActiveCN109486201AImprove ablation resistance and heat insulation performanceGood compatibilityRubber materialFiber

The invention discloses a self-crosslinking silicon-boron-containing high polymer matrix ablation-resistant heat insulation material and a preparation method, and belongs to the field of high polymercomposite materials. The material comprises, by weight, 100 parts of heat-vulcanized silicone rubber, 10-30 parts of polyborosiloxane prepolymers, 10-30 parts of white carbon black, 5-10 parts of fibers, 10-20 parts of light ablation-resistant fillers, 3-5 parts of vulcanizing agents and 1-3 parts of hydroxyl silicone oil. The method includes the steps: mixing the polyborosiloxane prepolymers andthe light ablation-resistant fillers; sequentially adding all materials to a mixer and performing plasticating; vulcanizing mixed rubber materials for three times to obtain the self-crosslinking silicon-boron-containing high polymer matrix ablation-resistant heat insulation material. The material serves under the condition of oxygen enrichment and high temperature, is subjected to carbonizing andceramic reaction in a high-temperature environment, serves as a high-temperature ablation-resistant protective layer and directly bears combined action of thermochemical ablation, gas denudation and particle erosion, and the ablation-resistant heat insulation performance of the material is effectively improved.

Owner:SHENYANG LIGONG UNIV

Bismaleimide resin/silicone rubber ablation-resistant thermal insulation composite material and preparation method thereof

Owner:湖北三江航天江北机械工程有限公司

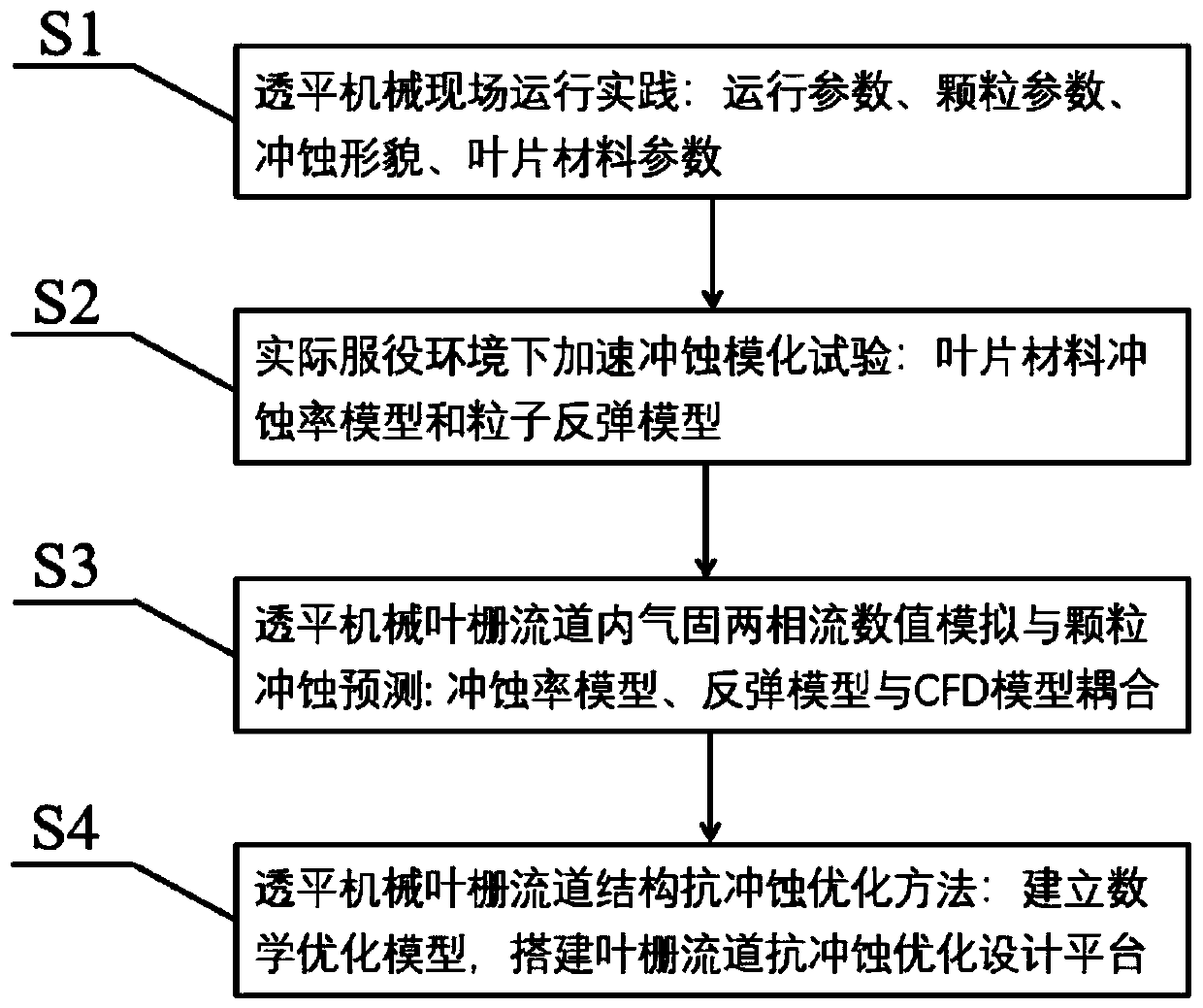

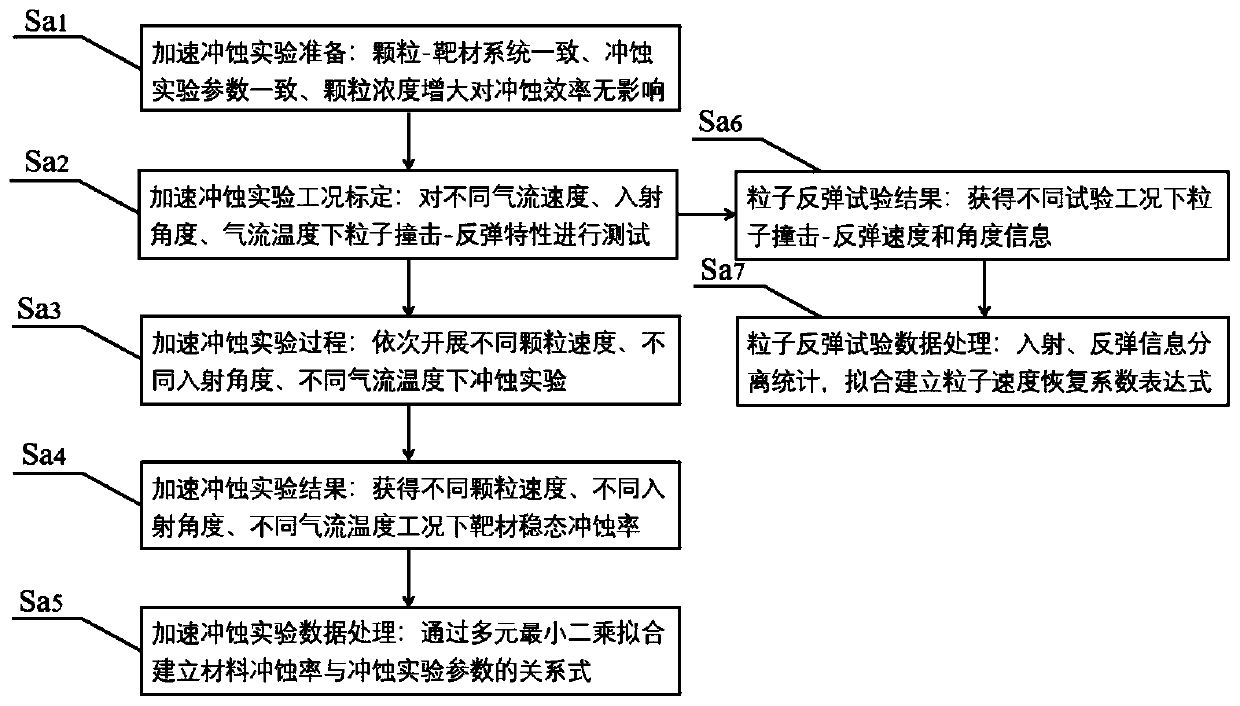

Method for optimizing particle erosion resistance of turbomachinery blade runner structure

ActiveCN111143982ARealize automatic optimization of anti-particle erosionGeometric CADDesign optimisation/simulationMaterial ErosionEngineering

The invention discloses a method for optimizing particle erosion resistance of a turbomachinery blade runner structure. The method comprises the following steps: 1) acquiring field data during turbomachinery operation; 2) simulating a blade material accelerated erosion test in an actual service environment of the turbomachinery based on the field data of the turbomachinery during operation, and establishing a turbomachinery material erosion rate model and a particle rebound model; 3) establishing a turbomachinery flow channel gas-solid two-phase flow numerical simulation and erosion predictionmethod; and (4) building an anti-erosion optimization platform of the turbine machinery blade grid flow channel structure, achieving automatic optimization of particle erosion resistance of the bladeflow channel structure. According to the method, automatic optimization of particle erosion resistance of the blade flow channel structure can be achieved, and meanwhile accurate prediction of particle movement and erosion distribution in the turbine machinery blade grid flow channel can be achieved.

Owner:XI AN JIAOTONG UNIV

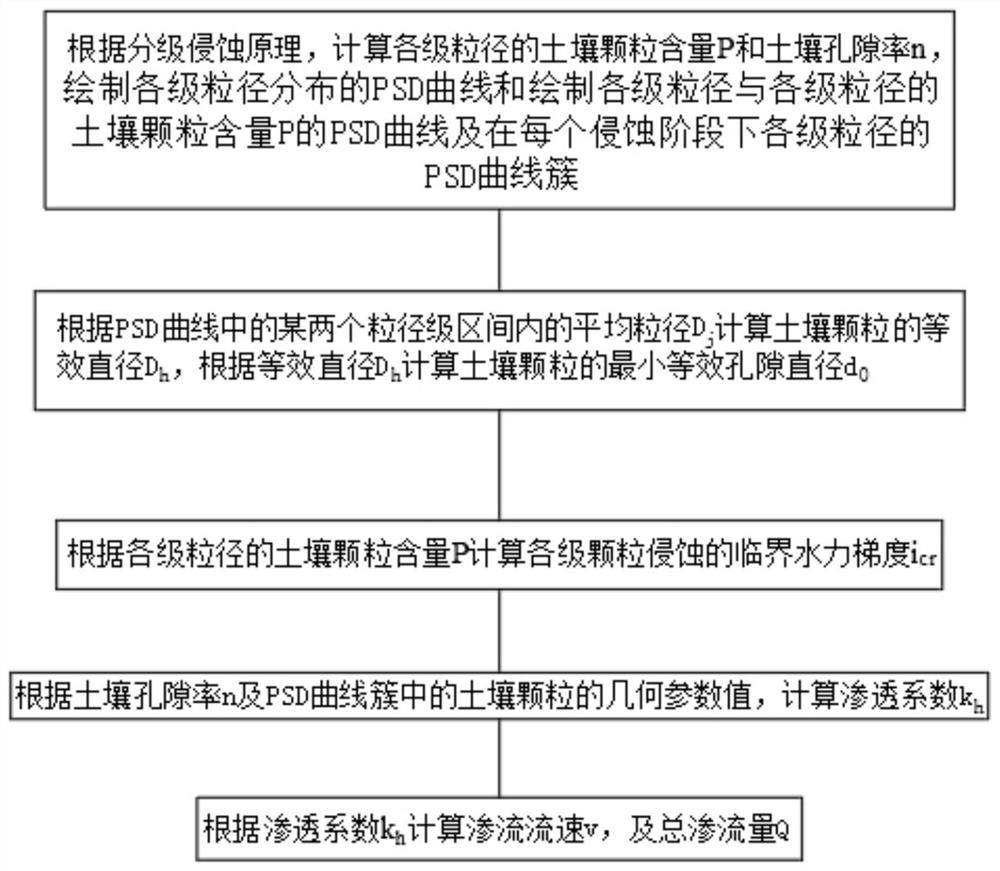

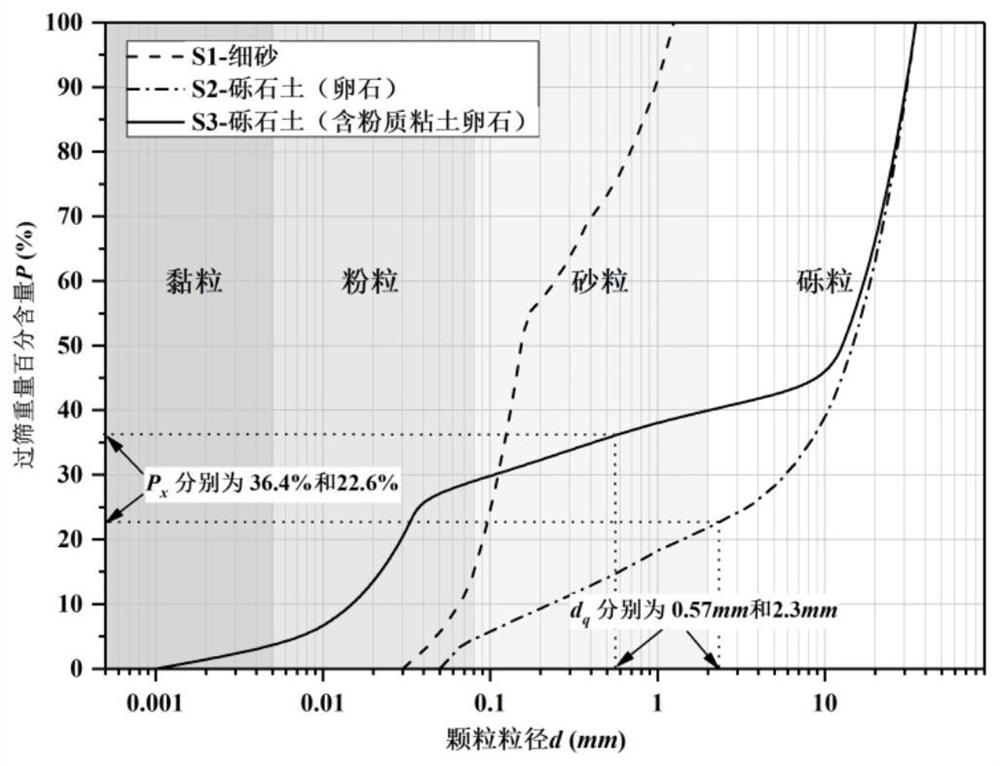

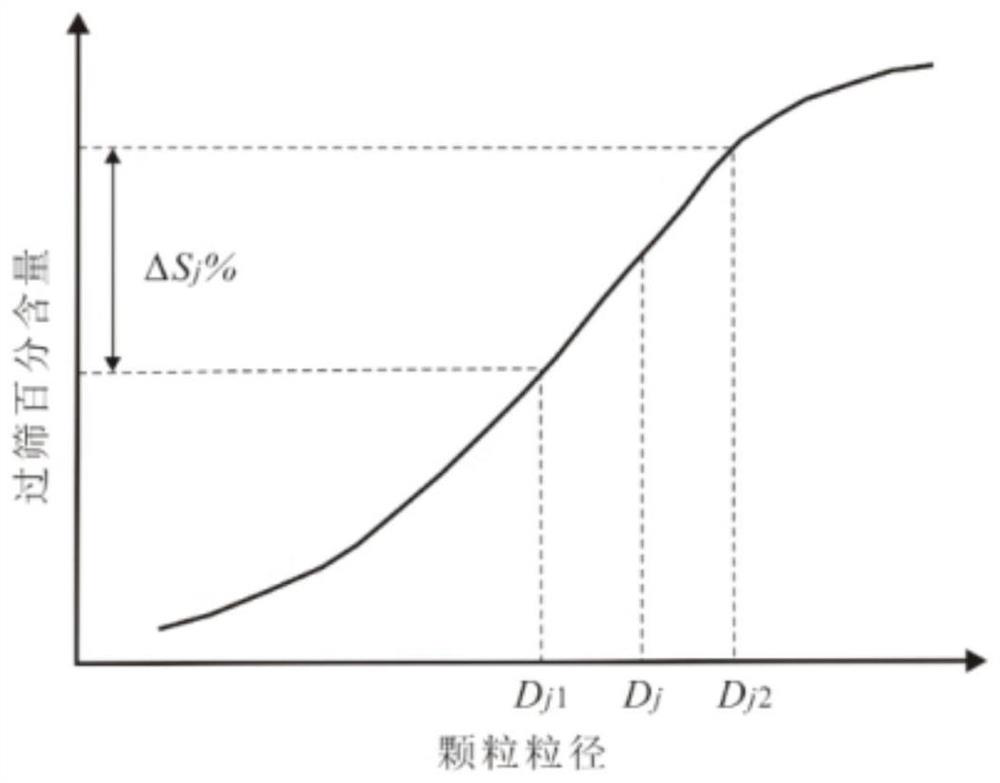

Method for determining hydraulic parameters and water inflow in gravelly soil erosion stage

ActiveCN113075106AAvoid accidentsSurface/boundary effectEarth material testingSoil scienceSoil porosity

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

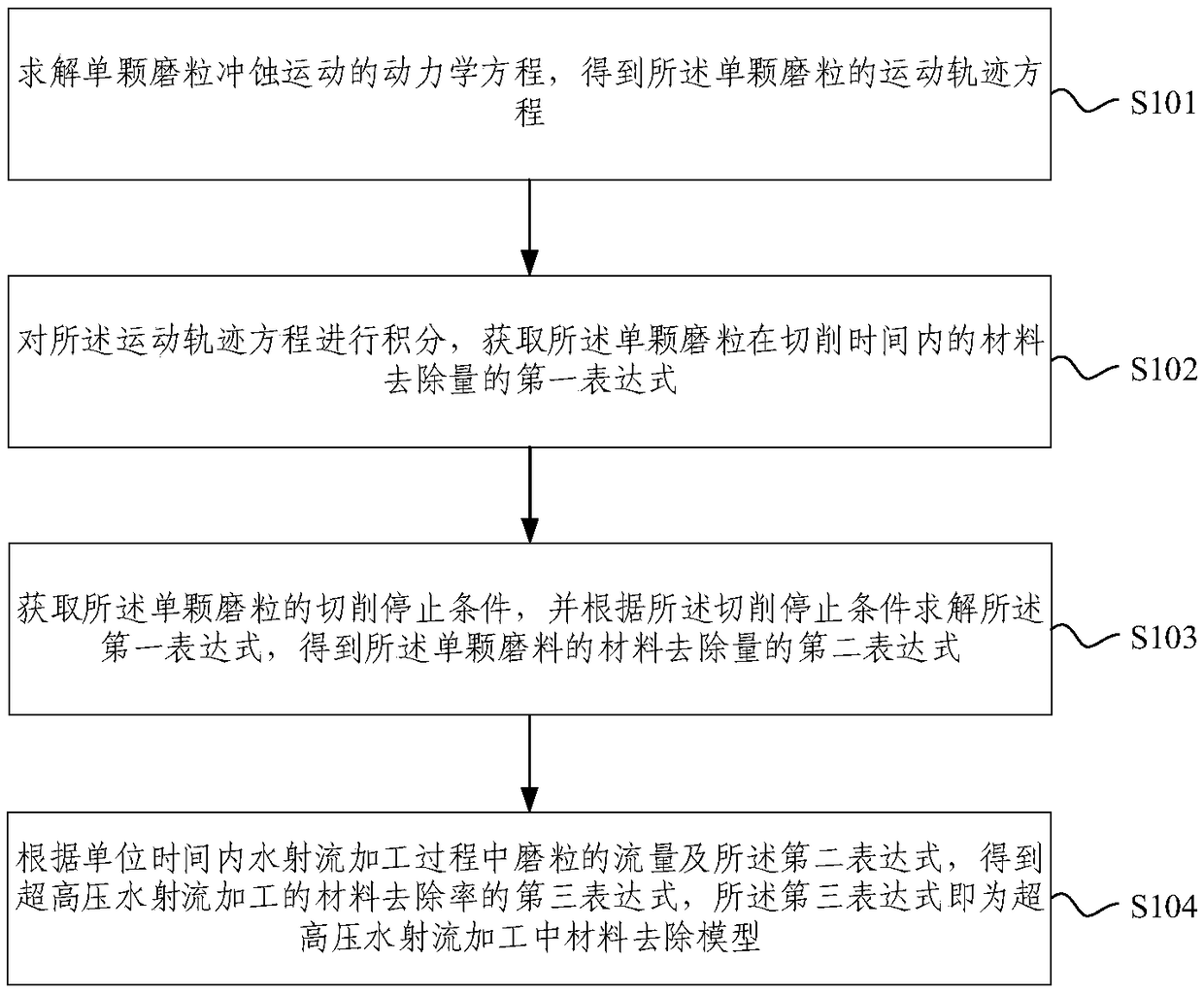

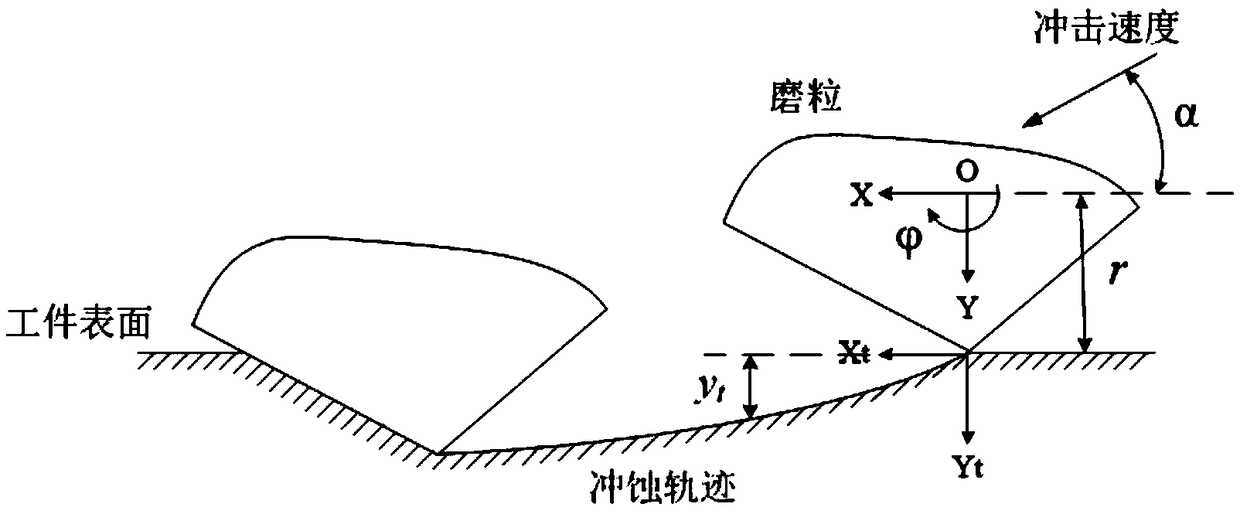

A method and system for acquiring a material removal model in ultra-high pressure water jet machine

ActiveCN109508472AEffectively guide the optimization of efficient precision machining processAccurate predictionGeometric CADDesign optimisation/simulationUltra high pressureMaterial removal

According to the emdoiment, A method for acquiring a material removal model in ultra-high pressure water jet machine includes solving a kinetic equation of a single abrasive particle erosion motion toobtain a motion trajectory equation of that single abrasive particle; Integrating the motion trajectory equation to obtain a first expression of the material removal amount of a single abrasive particle in the cutting time; Obtaining a cutting stop condition of a single abrasive particle, and solving a first expression according to the cutting stop condition to obtain a second expression of a material removal amount of the single abrasive particle; According to the flow rate of abrasive particles and the second expression, the third expression of material removal rate in ultra-high pressure water jet machining is obtained. The third expression is the material removal model in ultra-high pressure water jet machining. Considering the mechanism of material removal, the model can predict themachining process more accurately, and can guide the optimization of high efficiency and precision machining process in practical machining, which has theoretical guidance and engineering applicationsignificance.

Owner:BEIHANG UNIV

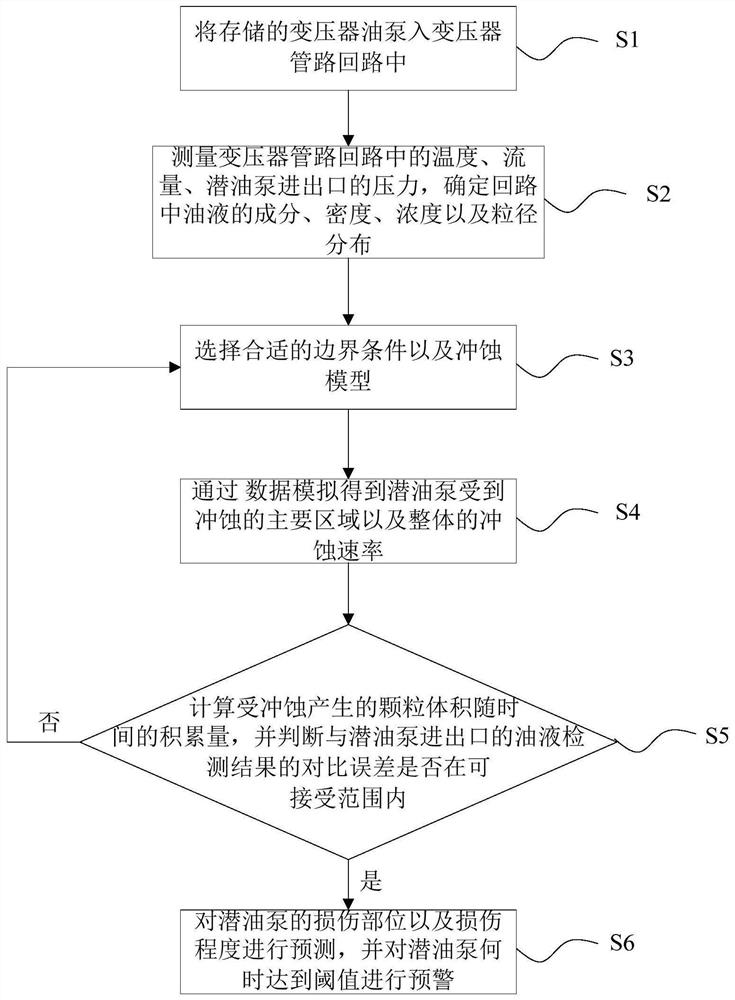

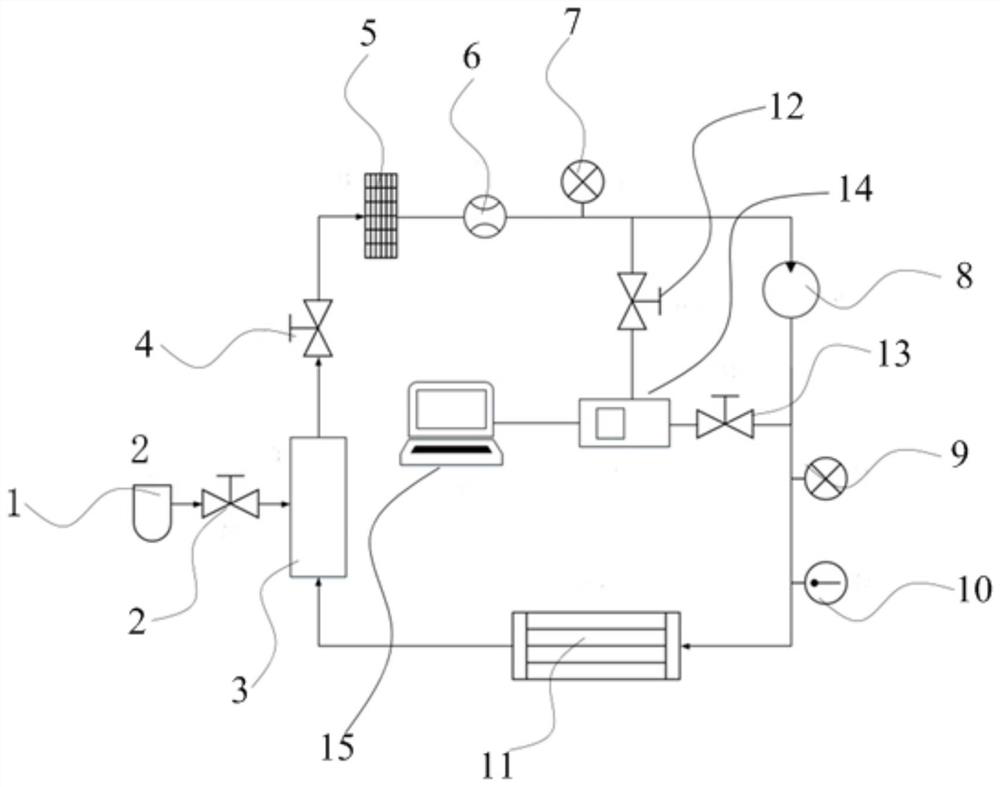

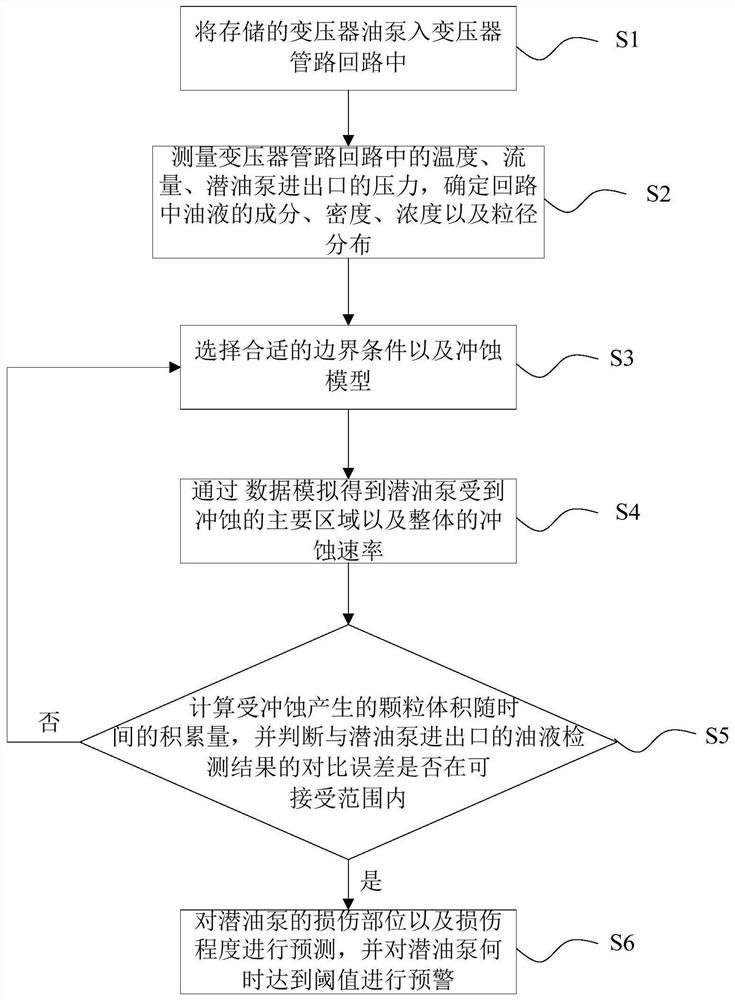

Oil-submerged pump damage degree evaluation method and system based on particle analysis

ActiveCN113958495AFlexible adjustmentThe simulation effect is accuratePump testingMeasurement devicesErosion rateSolid particle

The invention relates to an oil-submerged pump damage degree evaluation system and method based on particle analysis. The method comprises the steps: measuring the temperature, pressure and flow of transformer oil through a measuring system; detecting the components and granularity of solid particles in oil at an inlet and an outlet of an oil-submerged pump by using an oil granularity detector; determining boundary conditions according to the temperature, the pressure, the flow, and the components, the density and particle size distribution of the oil at the inlet and the outlet of the oil-submerged pump; selecting a proper erosion model for numerical simulation of a main eroded area and the overall erosion rate of the oil-submerged pump; calculating the accumulation of the volume of the oil-submerged pump generated by particle erosion along with time; detecting the particle concentration and particle size distribution of the inlet and the outlet of the oil-submerged pump after a specific period of time, and comparing with a simulation result of the erosion model; and predicting the damaged part and damage degree of the oil-submerged pump through the simulation model after comparison and calibration, and giving a warning when the oil-submerged pump reaches a threshold value.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

Erosion and Corrosion Resistant Overlay Coating Systems for Protection of Metal Components

PendingUS20200248007A1Enhanced particle erosion resistanceImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsCoating systemPhysical chemistry

Polyurethane-based coatings which exhibit superior erosion and heat resistance combined with antifouling and chemical resistance that are useful for protection of metal components are provided. The coatings are characterized by enhanced particle erosion resistance and enhanced heat resistance and are derived from specific multicomponent slurry compositions.

Owner:PRAXAIR ST TECH INC

Anti-corrosion and erosion coating for heating surface of waste incineration boiler

The invention provides a corrosion / erosion-resistant coating for a waste incineration boiler heating surface. The coating has excellent corrosion resistance on molten salt hot corrosion and solid micro-particle erosion and is excellent in protective performance. According to the core protection layer of the coating, a titanium carbide-nickel-chromium alloy serves as a protection material, construction is performed by adopting a high velocity oxy-fuel mode, the nickel-chromium alloy layer is combined for bottoming, excellent protective performance is guaranteed, and the coating has excellent thermal shock resistance and adhesive force.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

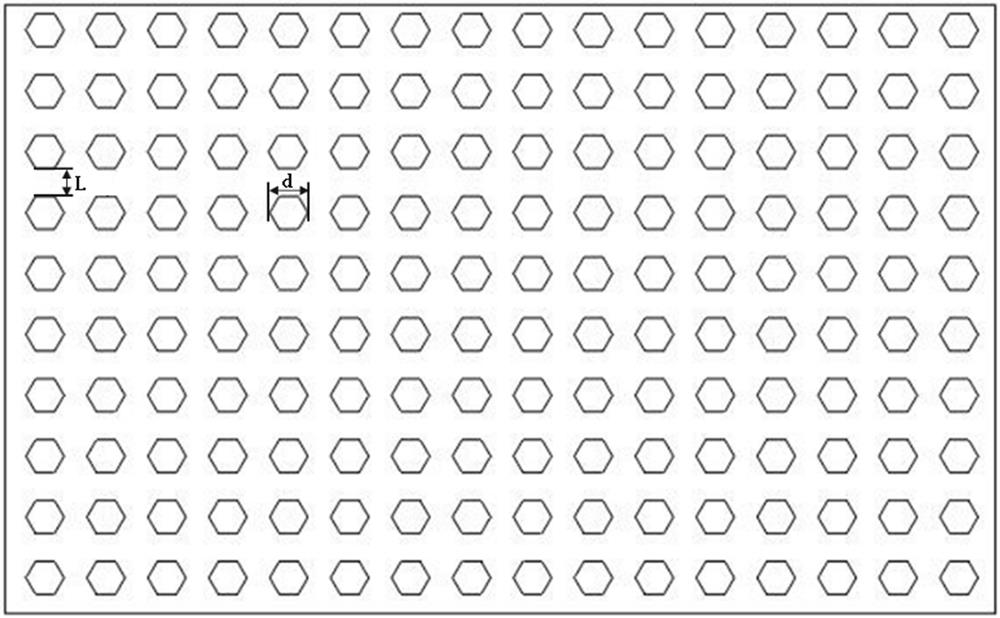

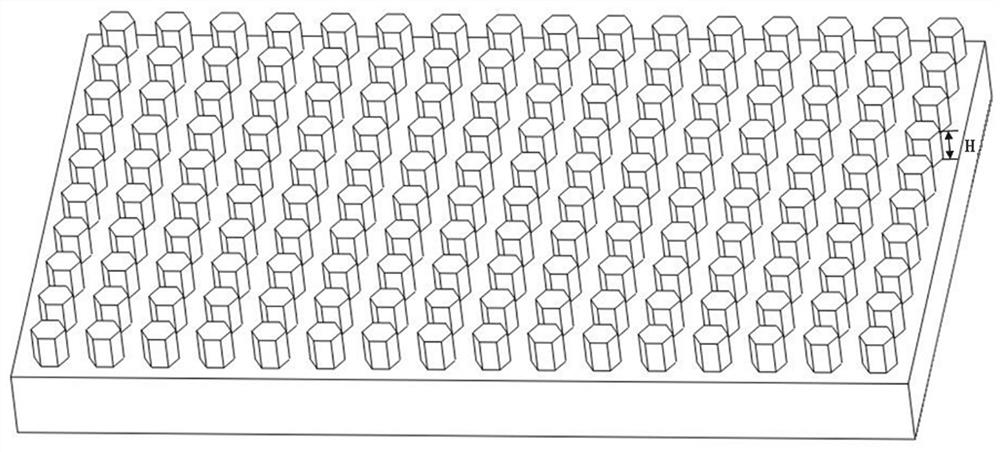

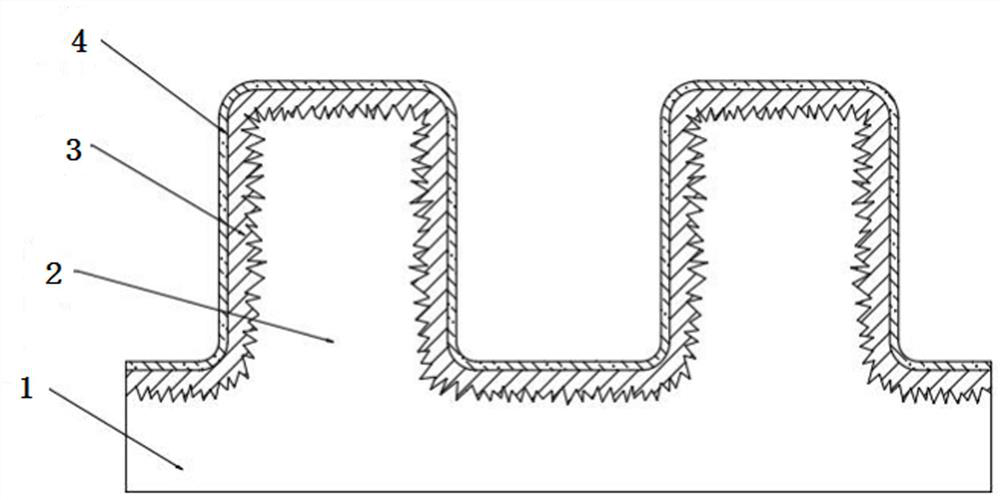

Dustproof film for lens surface of optical device

InactiveCN114185120AGuaranteed light transmittanceReduce the adverse consequences of light transmittance dropOptical elementsLaser etchingOptical transmittance

The invention discloses a dustproof film for the surface of an optical device lens, and the dustproof film comprises a micro-texture layer which is disposed on the surface of the optical device lens through a chemical etching method, a particle erosion method or a laser etching method. The micro-texture layer is composed of a plurality of micro-texture units which are arranged on the surface of the lens of the optical device at intervals in a regular arrangement mode or a crossed and staggered arrangement mode. The micro-texture layer is coated with an anti-reflection wear-resistant layer or a composite coating through a vacuum coating method, a chemical vapor deposition method or a sol-gel method. According to the dustproof film, the light transmittance can be guaranteed while the function of preventing dust deposition is achieved, collision damage of microparticles to a certain degree is resisted, the durability is high, and the service life is long.

Owner:HENAN UNIV OF SCI & TECH

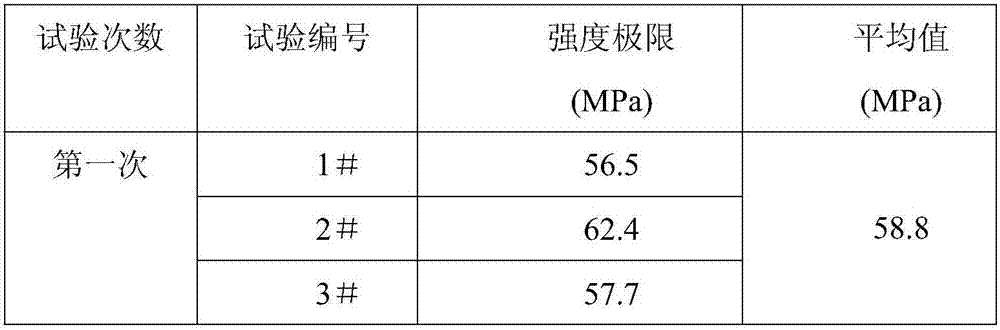

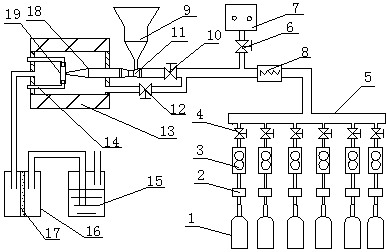

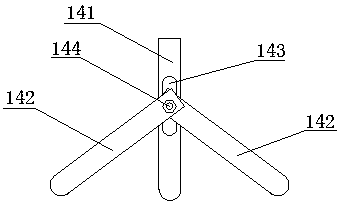

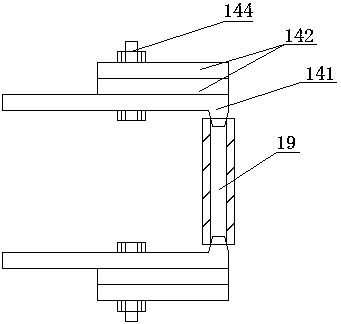

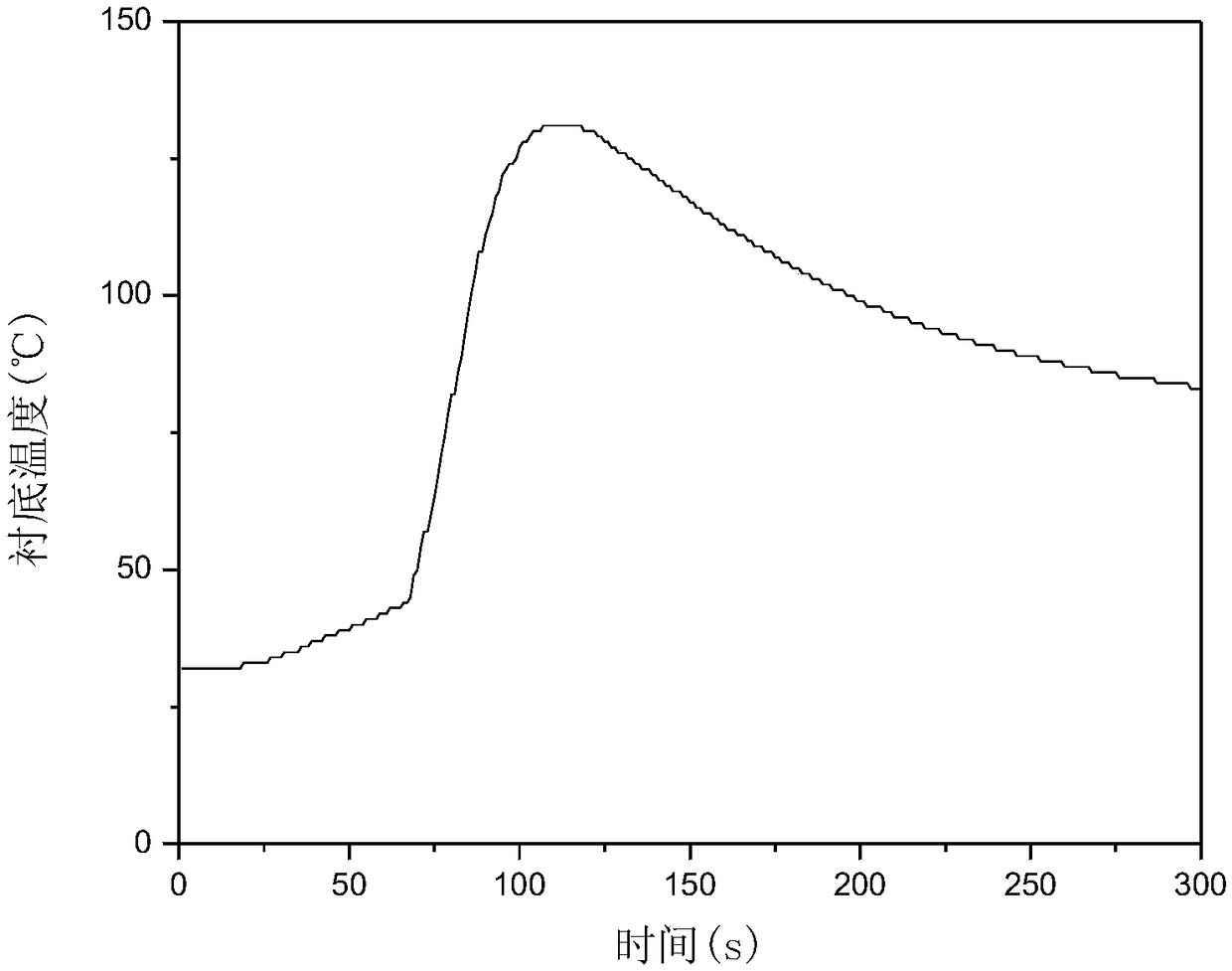

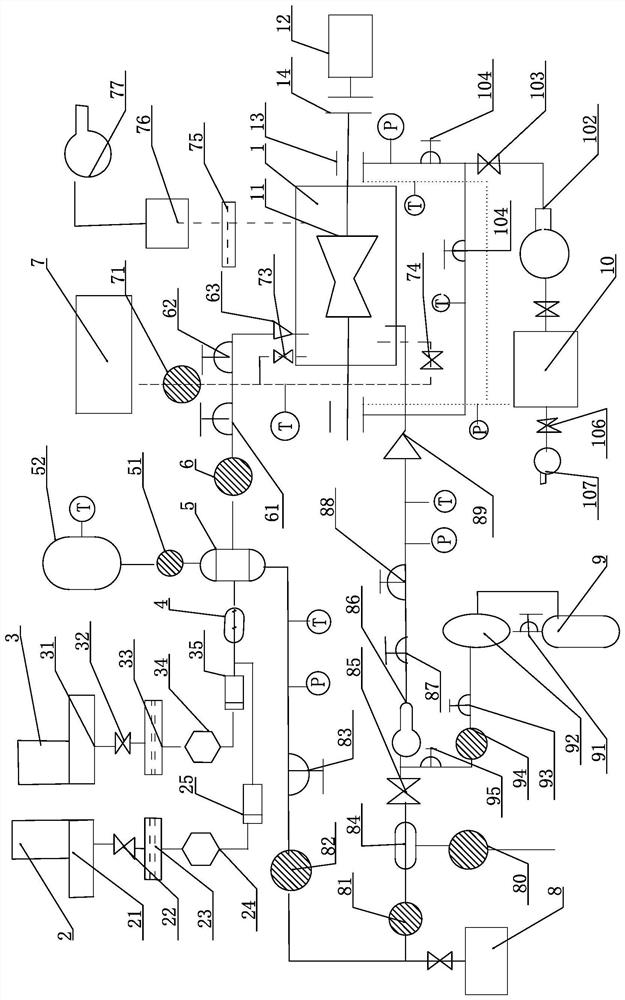

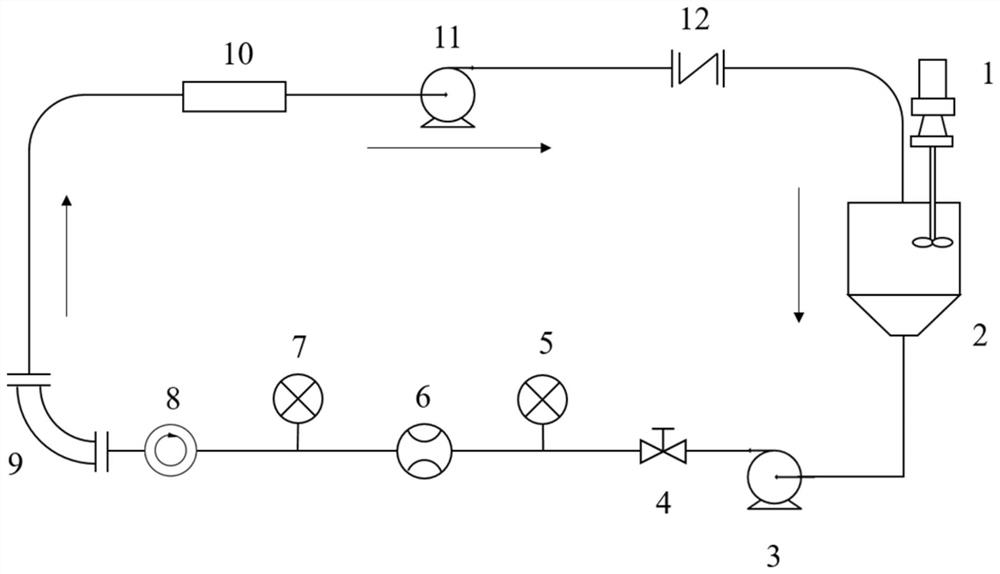

A deep peaking steam turbine blade erosion test system and its test method

ActiveCN110160946BRealize salt accumulation testVersatileWeather/light/corrosion resistanceSteam turbine bladeProcess engineering

The invention discloses a blade erosion test system and a test method of a deep peak-shaving steam turbine. The present invention includes steam turbine test equipment, a particle erosion system and a droplet erosion system; the particle erosion system includes a particle tank, a vibrating device installed under the particle tank, a screening device, a weighing machine, a propulsion device, a high-frequency Electric heating furnace, mixer and particle injector. The particles in the particle tank enter the screening device after passing through the vibrating device. The screened particles enter the propulsion device through the weighing machine. The propulsion device is used to push the particles into the high-frequency electric heating furnace. The frequency electric heating furnace heats the particles, and after heating, the particles enter the mixer, and then enter the particle injector, and the particle injector sprays the particles into the test chamber for the particle erosion test. The invention can be used to study the influence of different experimental conditions on the erosion of steam turbine blades, has the advantages of multiple functions and strong applicability, and is therefore especially suitable for the research on the vibration of deep peak-shaving steam turbines.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

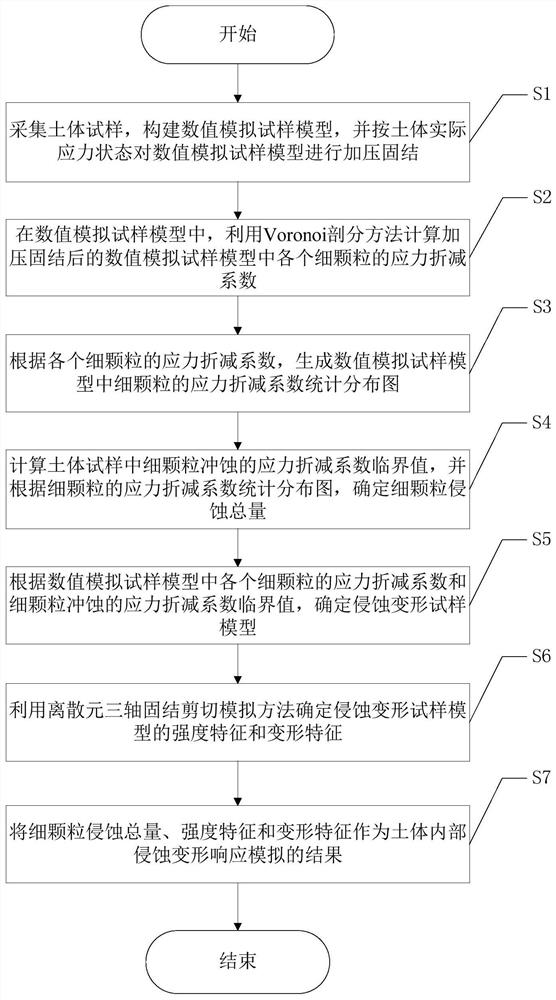

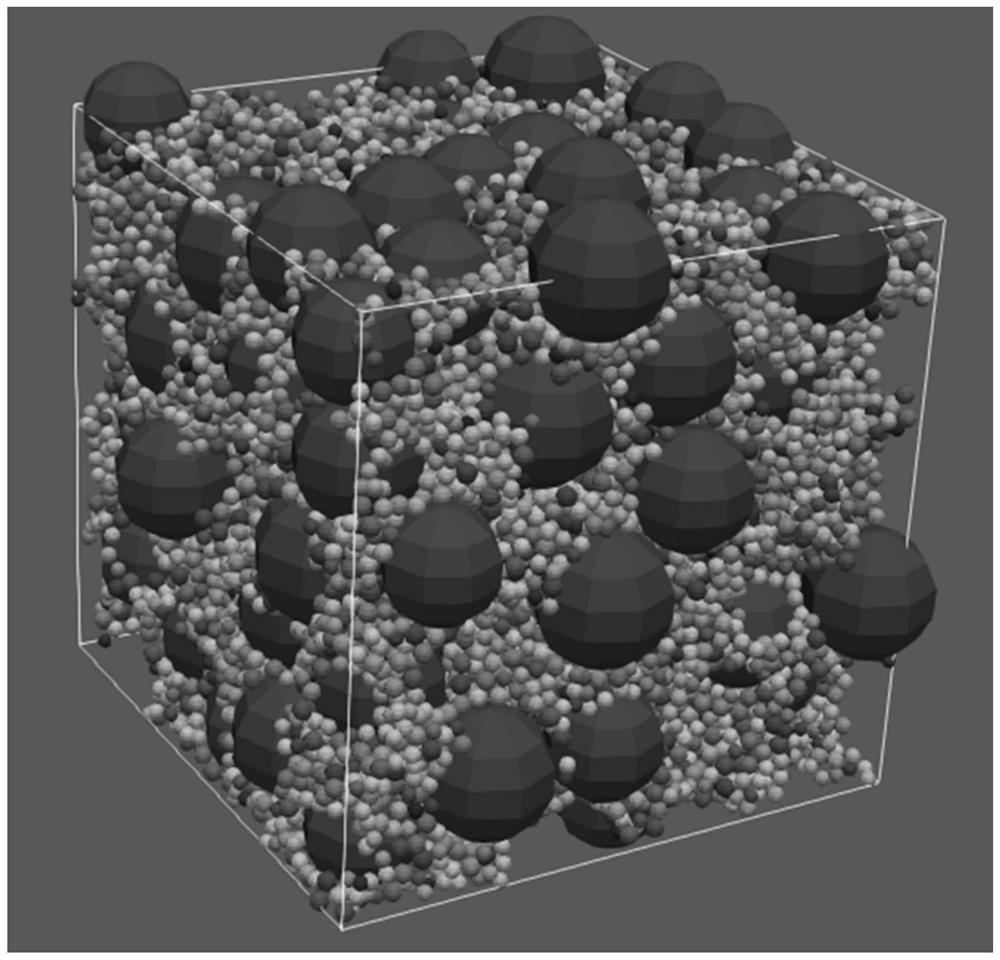

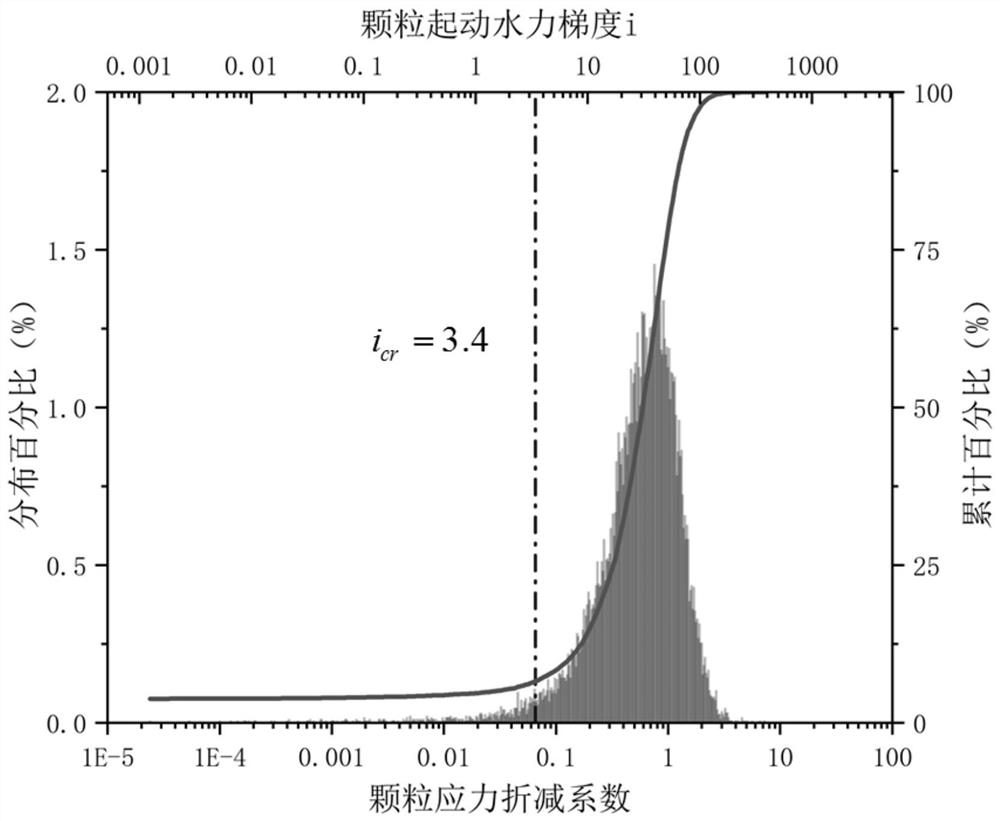

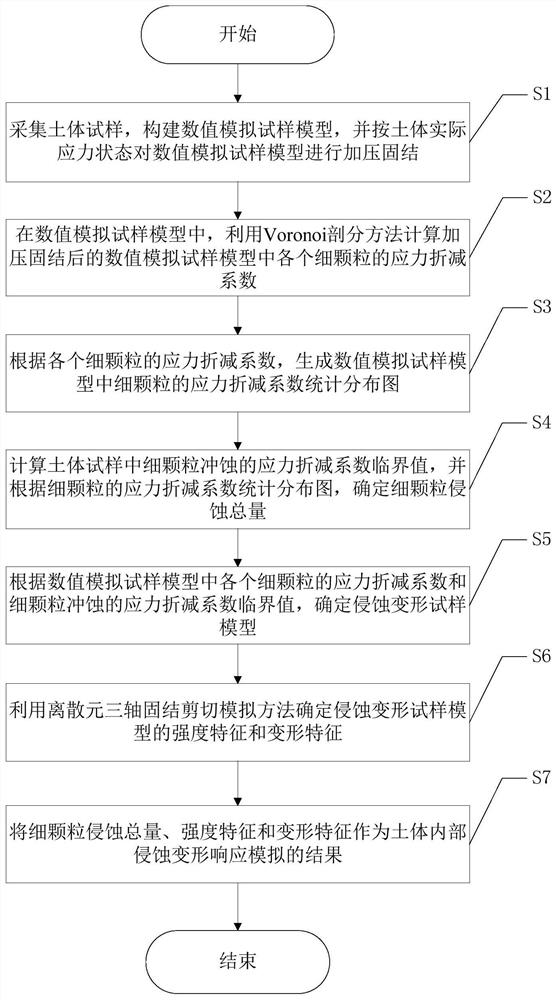

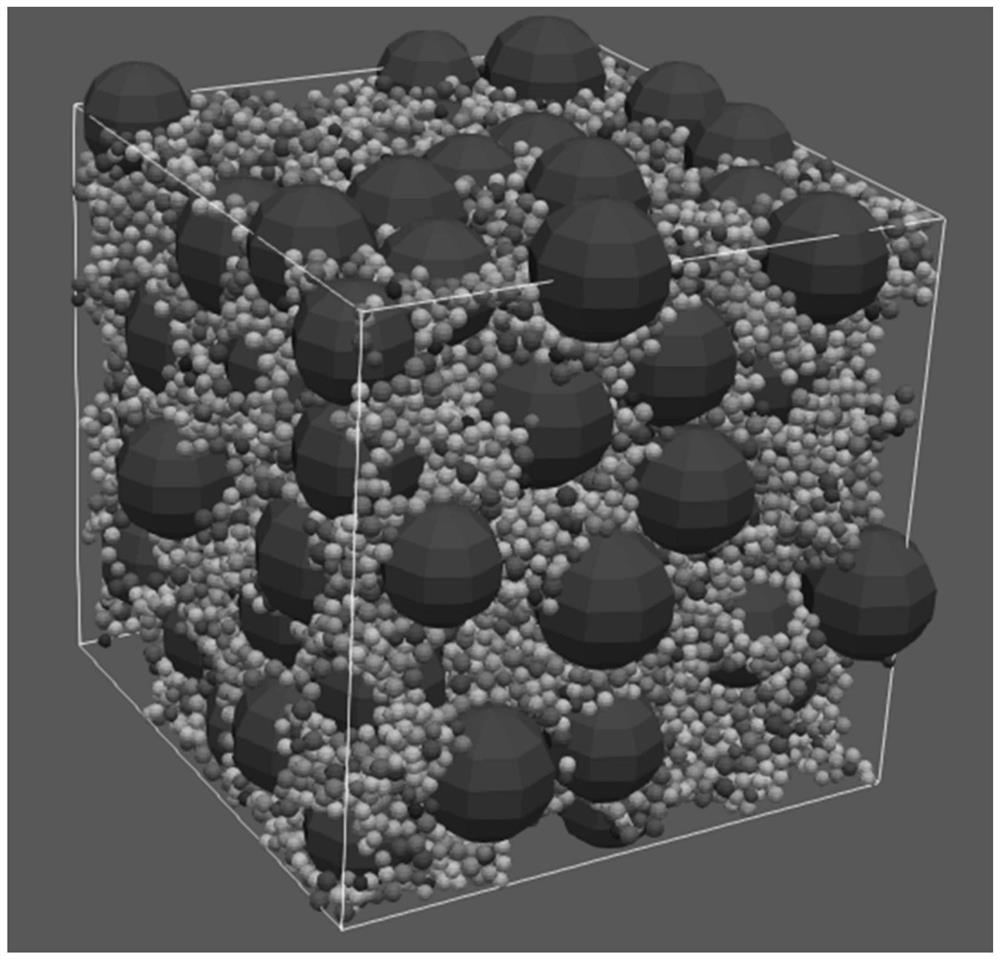

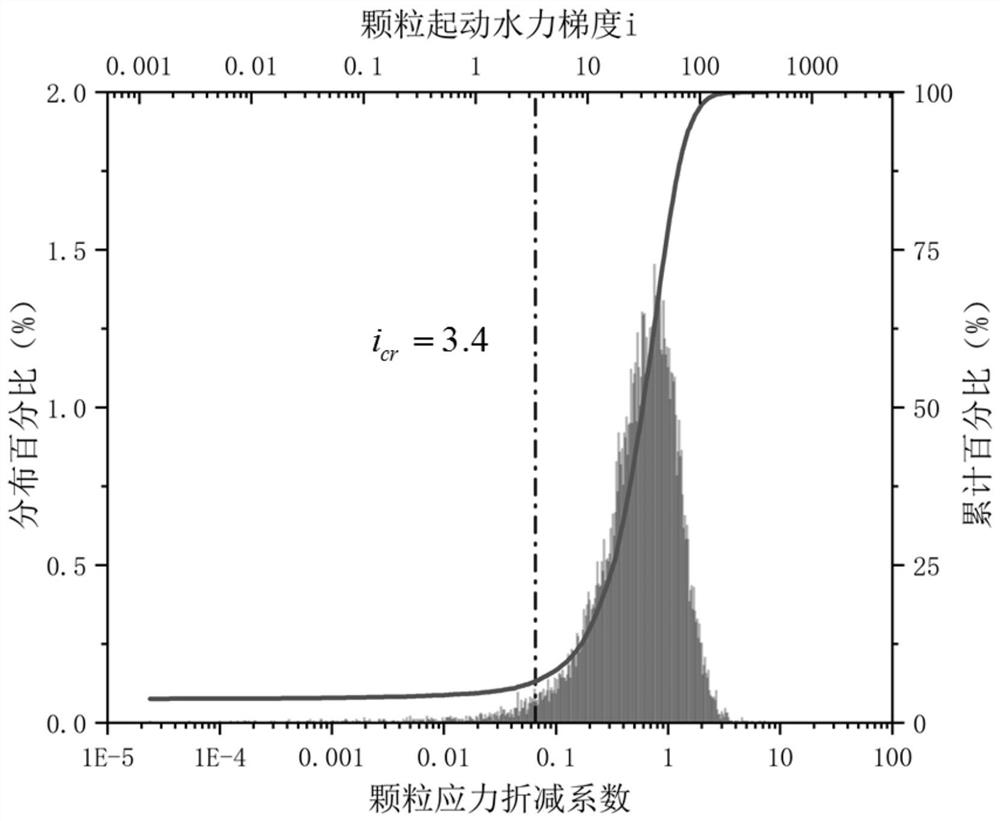

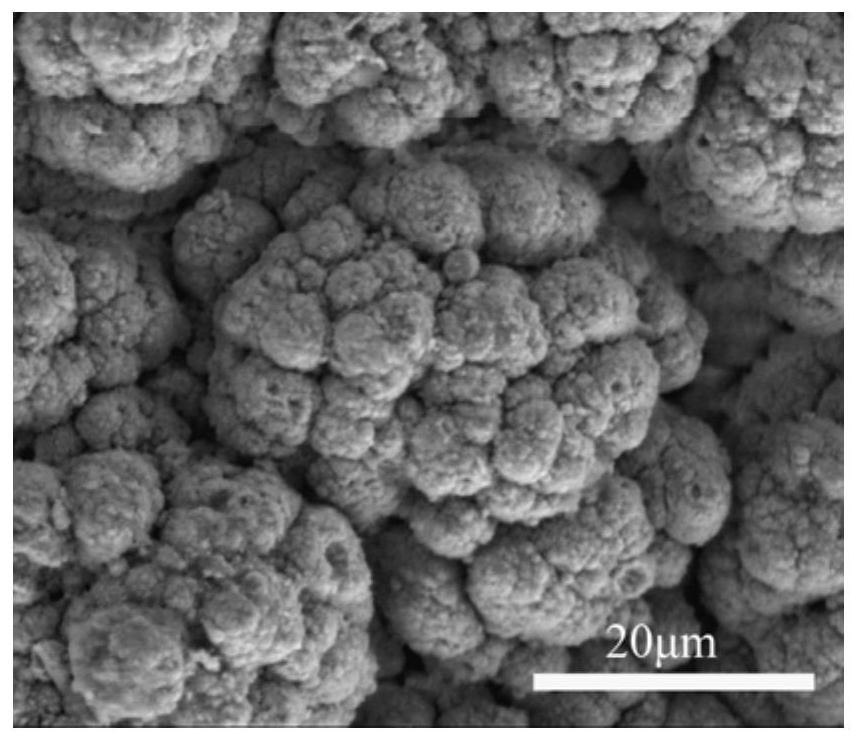

A Simulation Method of Soil Internal Erosion Deformation Response

ActiveCN113237722BImprove accuracyIn line with the actual erosion situationPreparing sample for investigationEarth material testingSoil scienceInternal erosion

The invention discloses a soil internal erosion deformation response simulation method, comprising the following steps: S1: collecting a soil sample, constructing a numerical simulation sample model, and pressurizing the numerical simulation sample model according to the actual stress state of the soil Consolidation; S2: Calculate the stress reduction coefficient of each fine particle in the numerical simulation sample model; S3: Generate the statistical distribution map of the stress reduction coefficient of fine particles in the numerical simulation sample model; S4: Calculate the fine particle in the soil sample The critical value of the stress reduction coefficient of particle erosion is to determine the total amount of fine particle erosion; S5: determine the erosion deformation sample model; S6: determine the strength characteristics and deformation characteristics of the erosion deformation sample model; S7: determine the total amount of fine particle erosion , strength characteristics and deformation characteristics as the simulation results of soil internal erosion deformation response. The invention judges the erodible particles based on the stress state of the particles and the hydraulic gradient to be applied, which conforms to the actual erosion conditions.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Soil body internal erosion deformation response simulation method

ActiveCN113237722AImprove accuracyIn line with the actual erosion situationPreparing sample for investigationEarth material testingInternal erosionParticle erosion

The invention discloses a soil body internal erosion deformation response simulation method which comprises the following steps of: S1, collecting a soil body sample, constructing a numerical simulation sample model, and pressurizing and solidifying the numerical simulation sample model according to the actual stress state of a soil body; S2, calculating a stress reduction coefficient of each fine particle in the numerical simulation sample model; S3, generating a stress reduction coefficient statistical distribution diagram of the fine particles in the numerical simulation sample model; S4, calculating a stress reduction coefficient critical value of erosion of the fine particles in the soil body sample, and determining the total erosion amount of the fine particles; S5, determining an erosion deformation sample model; S6, determining strength characteristics and deformation characteristics of the erosion deformation sample model; and S7, taking the erosion total amount of the fine particles, the strength characteristics and the deformation characteristics as results of soil internal erosion deformation response simulation. According to the method, the erodible particles are judged based on the stress state of the particles and a hydraulic gradient to be applied, and the actual erosion condition is met.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

A kind of thermal barrier coating and its preparation method and application, aeroengine turbine blade

ActiveCN109628929BImprove heat insulationImprove stress toleranceMolten spray coatingBlade accessoriesThermal insulationParticle erosion

The invention relates to a thermal barrier coating, as well as a preparation method and application thereof, and an aero-engine turbine blade, and belongs to the field of aero-engine hot end part protection coatings. The thermal barrier coating comprises a 7YSZ ceramic layer and an aluminum oxide layer arranged on the surface of one side of the 7YSZ ceramic layer, wherein the 7YSZ ceramic layer isin a feather column shape; and aluminum oxide in the aluminum oxide layer is nanocrystals. The thermal barrier coating not only has high thermal insulation and high stress tolerance, but also has favorable fused salt corrosion resistance and resistance to high temperature oxidation and particle erosion. The preparation method comprises the steps of adopting a plasma spraying-physical vapor deposition method for preparing the 7YSZ ceramic layer; adopting a magnetron sputtering technology for preparing the aluminum oxide layer; and then carrying out vacuum treatment. The method is simple, and the uniform thermal barrier coating can be prepared. The thermal barrier coating is applied to be arranged on an aero-engine hot end part such as the surface of a turbine blade, so that the turbine blade has favorable resistance to high temperature oxidation, CMAS corrosion and particle erosion.

Owner:GUANGDONG INST OF NEW MATERIALS

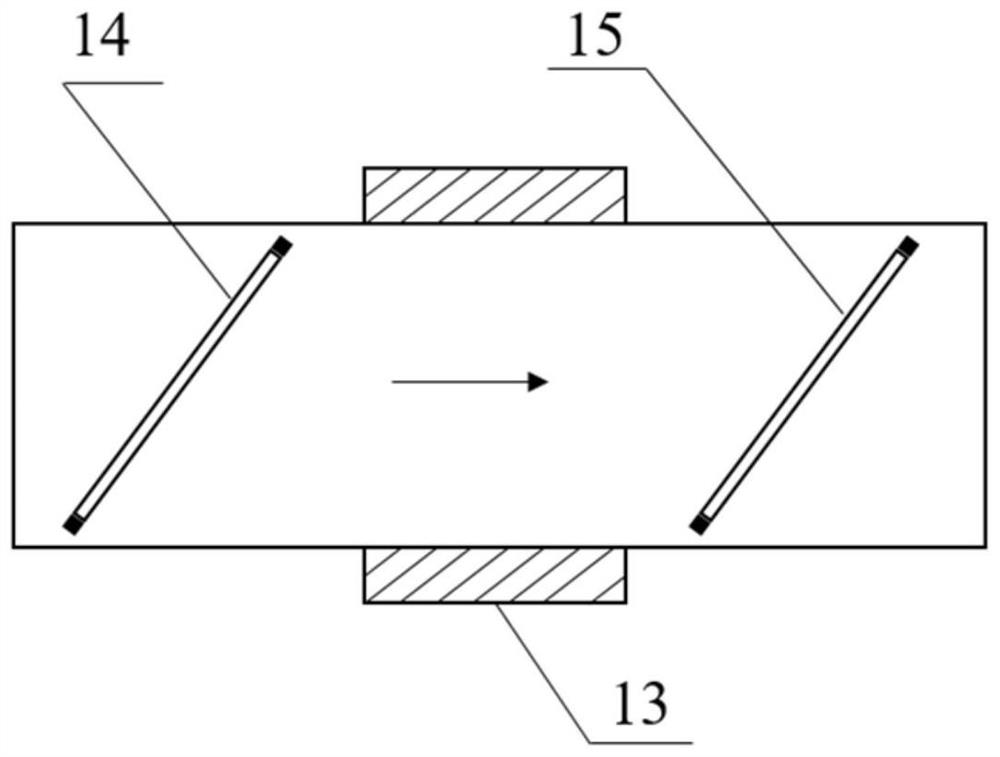

Experimental system for testing association rule of particle concentration and surface damage

PendingCN114184509AErosion predictionInvestigating abrasion/wear resistanceParticle flowParticle erosion

The invention discloses an experimental system for testing a particle concentration and surface damage association rule. The experimental system comprises a particle flow mixing section, an erosion testing section and a particle collecting section, the particle flow mixing section is used for ensuring uniform distribution of particles in the loop, the erosion testing section is used for carrying out a particle erosion test, and the particle collecting section is used for temporarily collecting particles in the loop of the whole experimental device. The test elbow in the experiment system can be detached, so that the weight loss measurement of the eroded sample is realized. Besides, the particle collecting device can temporarily store the particles, so that after the test elbow is weighed, the test elbow can be arranged back to the erosion loop, and the next round of erosion experiment can be carried out on the basis of the existing particle accumulation. According to the experimental system provided by the invention, the correlation rule of the particle concentration and the surface damage under the time dimension can be obtained, and an important reference basis is provided for predicting the erosion of the particles in the pipe.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

Thermal barrier coating and preparation method thereof

ActiveCN105039892BImprove thermal shock resistanceSimple preparation processMolten spray coatingEfficient propulsion technologiesIsolation layerParticle erosion

The invention provides a thermal barrier coating which comprises a base layer, a heat-isolation layer and a protective layer. At least one transition layer is arranged between the base layer and the heat-isolation layer. According to the thermal barrier coating, component preparation of the coating is reasonable, the preparation process is simple and convenient, and the transition layer and the heat-isolation layer of the coating contain oxides capable of forming oxidation films easily. Besides, the content of the oxides has gradient changes, so that the thermal barrier coating has good thermal shock resistance. Meanwhile, high-temperature particle erosion resistance is outstanding.

Owner:江苏海泰新材料科技有限公司

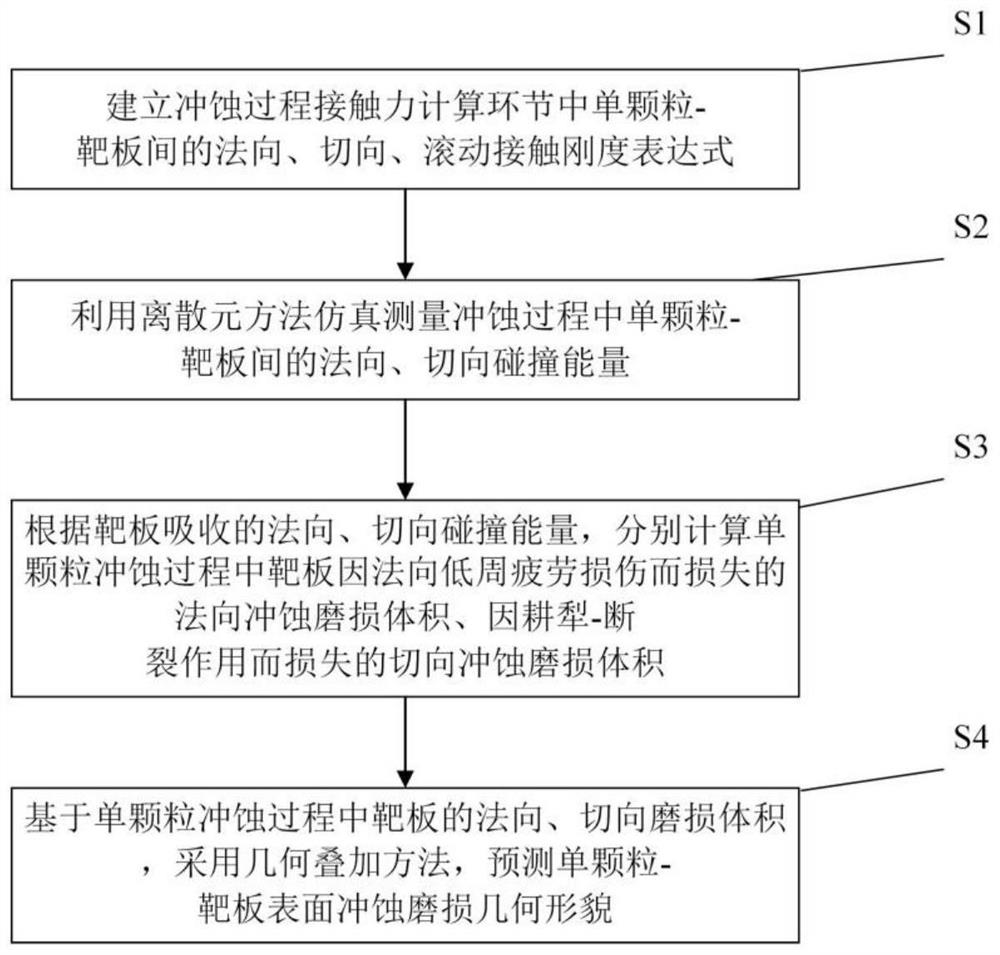

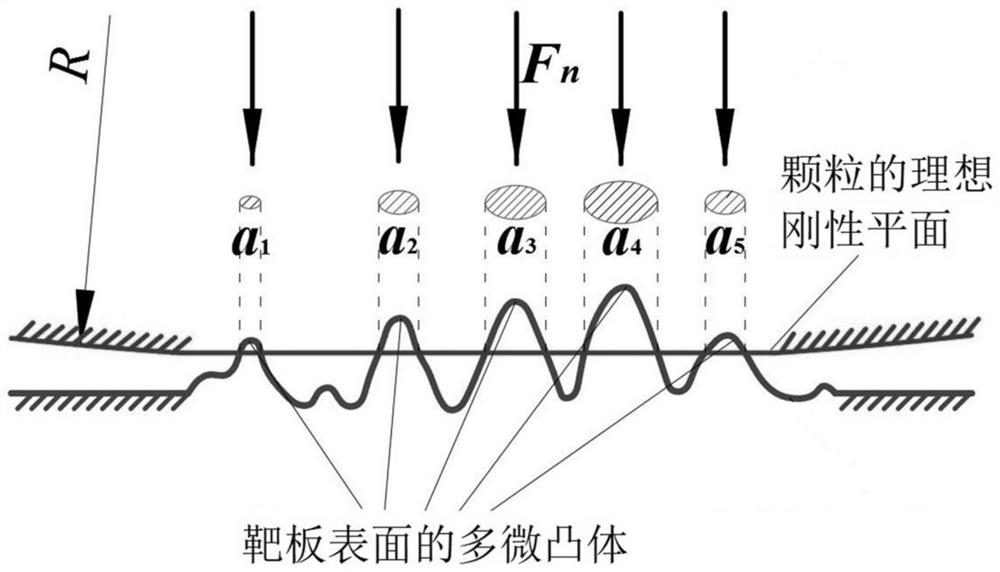

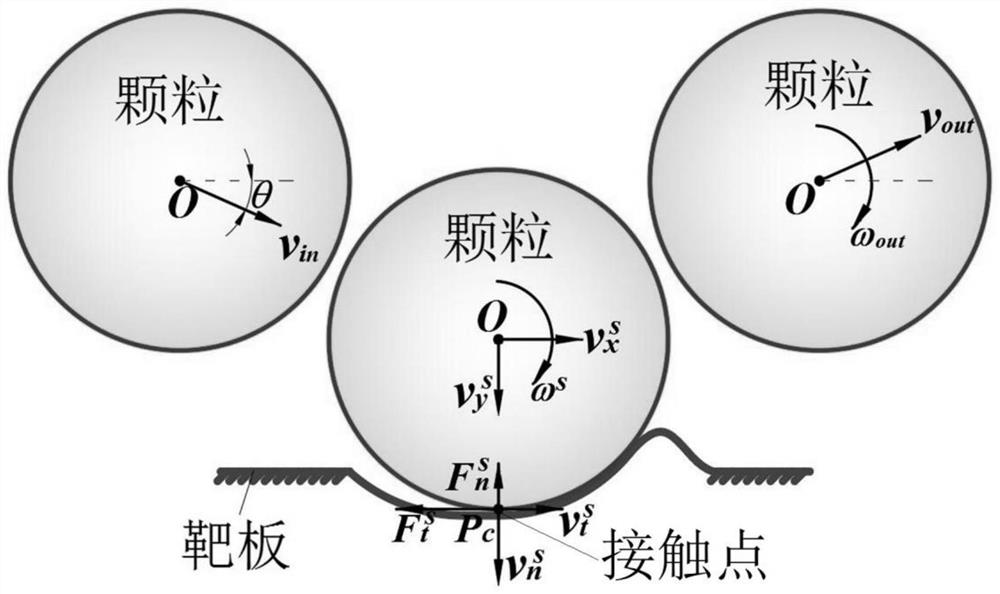

Single particle-target plate erosion morphology prediction method based on energy conversion mechanism

PendingCN114218843AEfficient description of elastoplastic contact propertiesAccurate simulation measurementGeometric CADDesign optimisation/simulationFatigue damageDiscrete element method

The invention discloses a single particle-target plate erosion morphology prediction method based on an energy conversion mechanism, and belongs to the field of numerical simulation prediction. The simulation prediction method comprises the following steps: establishing normal, tangential and rolling contact stiffness expressions between a single particle and a target plate in a contact force calculation link in an erosion process; simulating and measuring normal and tangential collision energy between a single particle and a target plate in an erosion process by using a discrete element method; according to the normal collision energy and the tangential collision energy absorbed by the target plate, the normal erosive wear volume lost due to normal low-cycle fatigue damage of the target plate and the tangential erosive wear volume lost due to the ploughing-fracture effect in the single-particle erosion process are calculated respectively; and based on the normal and tangential wear volumes of the target plate in the single particle erosion process, predicting the single particle-target plate surface erosion wear geometric morphology by adopting a geometric superposition method. According to the method, the erosive wear morphology of the surface of the single particle-plastic metal target plate at different incident angles can be effectively predicted.

Owner:JIANGHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com