Patents

Literature

52results about How to "Low surface requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

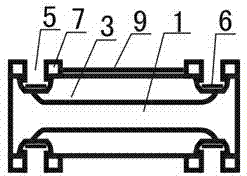

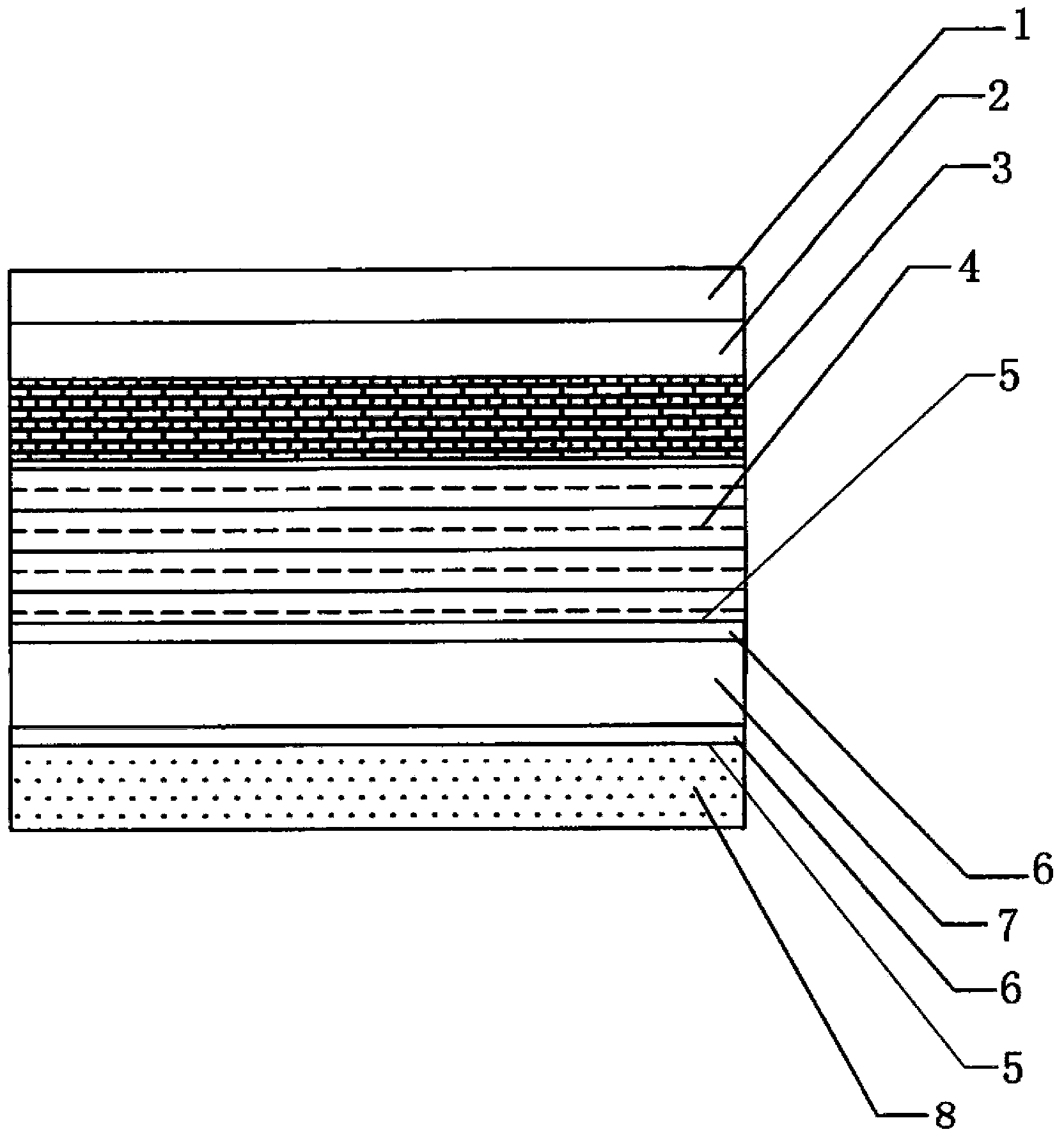

Preparation method for lamination blocking type package materials

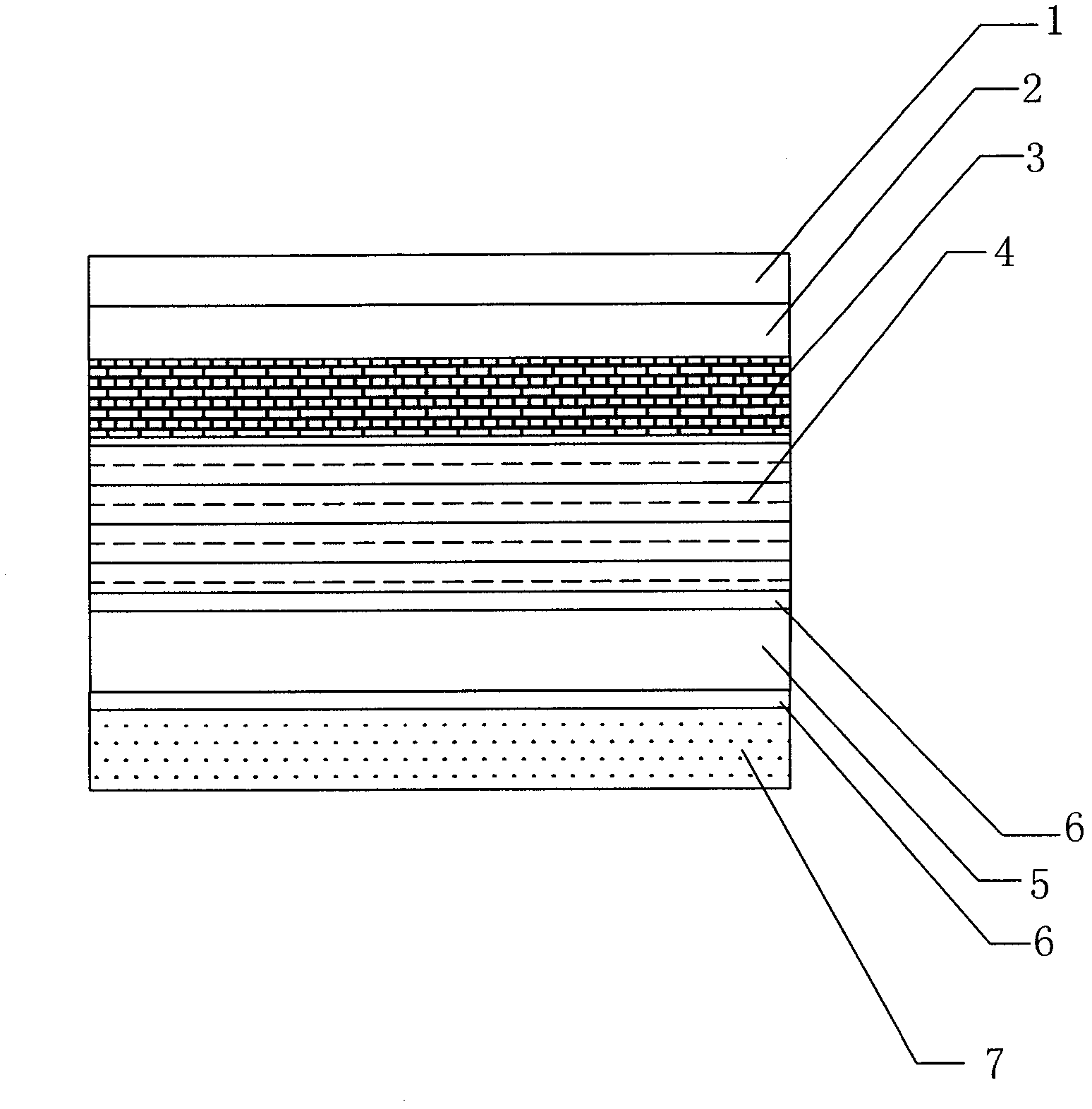

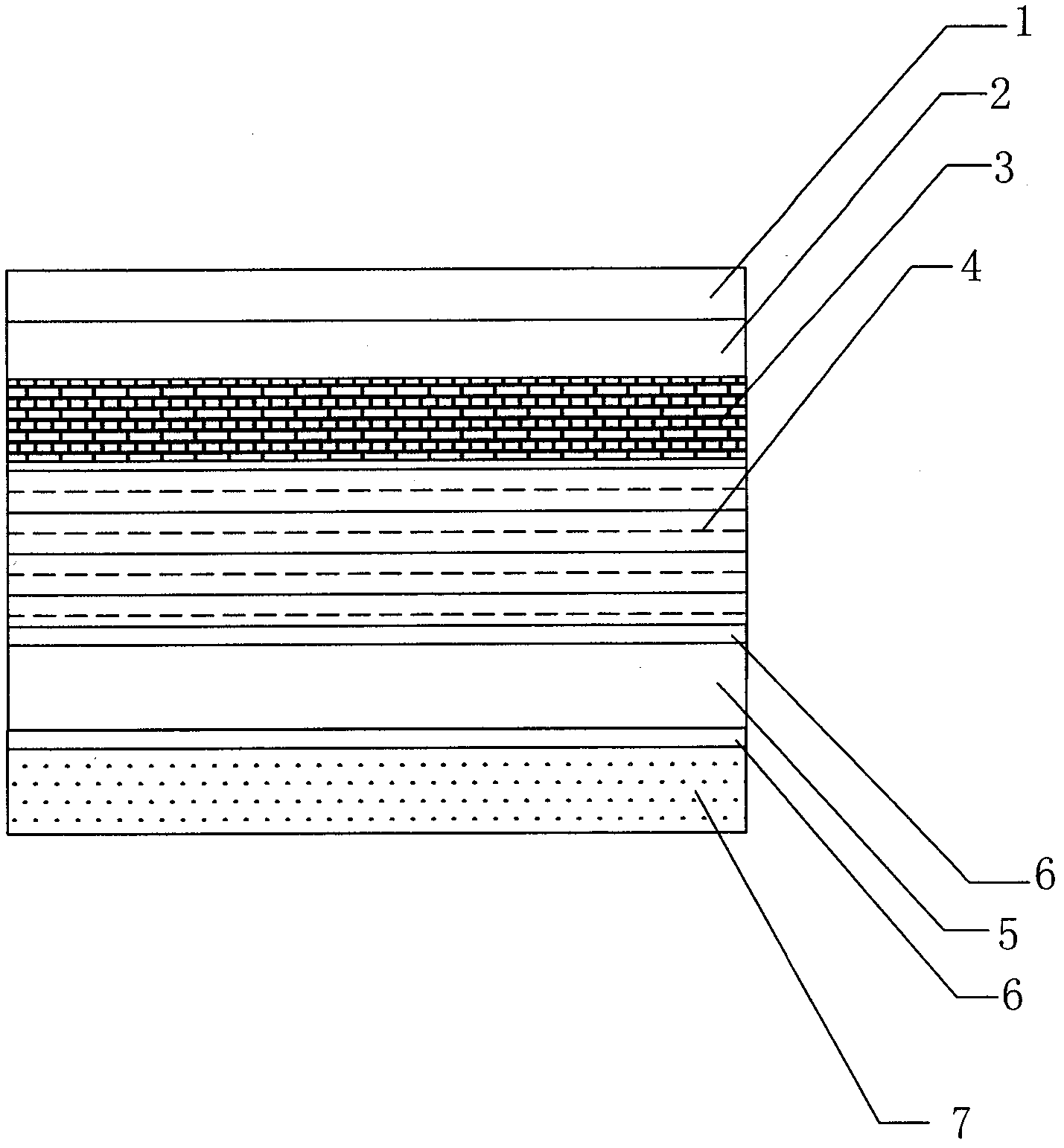

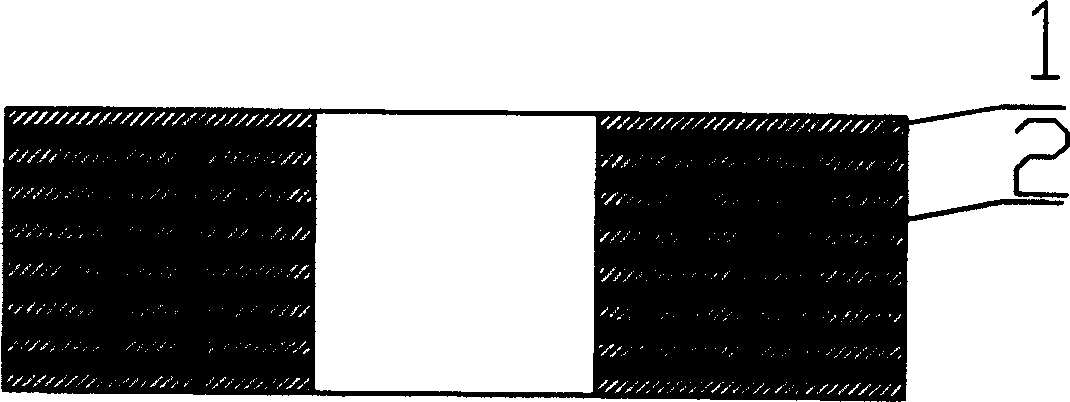

ActiveCN102380989AAvoid damageLower surface statePackage recyclingFlexible coversCardboardImage resolution

The invention relates to a preparation method for lamination blocking type package materials, which comprises the steps that: a laminated film is extruded at least one side surface of a support layer base material, simultaneously, the surface treatment is carried out on the laminated support layer base material, blocking type coating liquid is coated onto the surface of the laminated film, a blocking layer is prepared through baking, a composite hot sealing layer is extruded on the outer surface of the prepared blocking layer, a light shading layer is compounded on one side surface of the support layer base material, in addition, the surface tension reaches higher than 38 dynes through pretreatment, in addition, printing layer coating liquid is coated on the outer side surface of the light shading layer, a printing layer is obtained after baking, and a protection layer is extruded on the outer side surface of the printing layer, so the printing layer and the protection layer are compounded. The light shading layer and the printing layer are compounded on the support layer, the requirement on paper boards by printing is reduced, the resolution ratio of images can be greatly improved, simultaneously, the cost is reduced, in addition, an oxide coating is used for replacing an aluminum foil to be used as the blocking layer, the problems of difficult recovery and difficult degradation caused by aluminum foil discharge are reduced, and simultaneously, high oxygen blocking performance is provided.

Owner:GREATVIEW BEIJING TRADING CO LTD

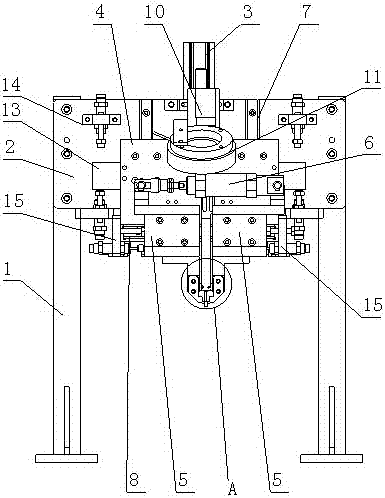

Precision measurement device for tree walk increment

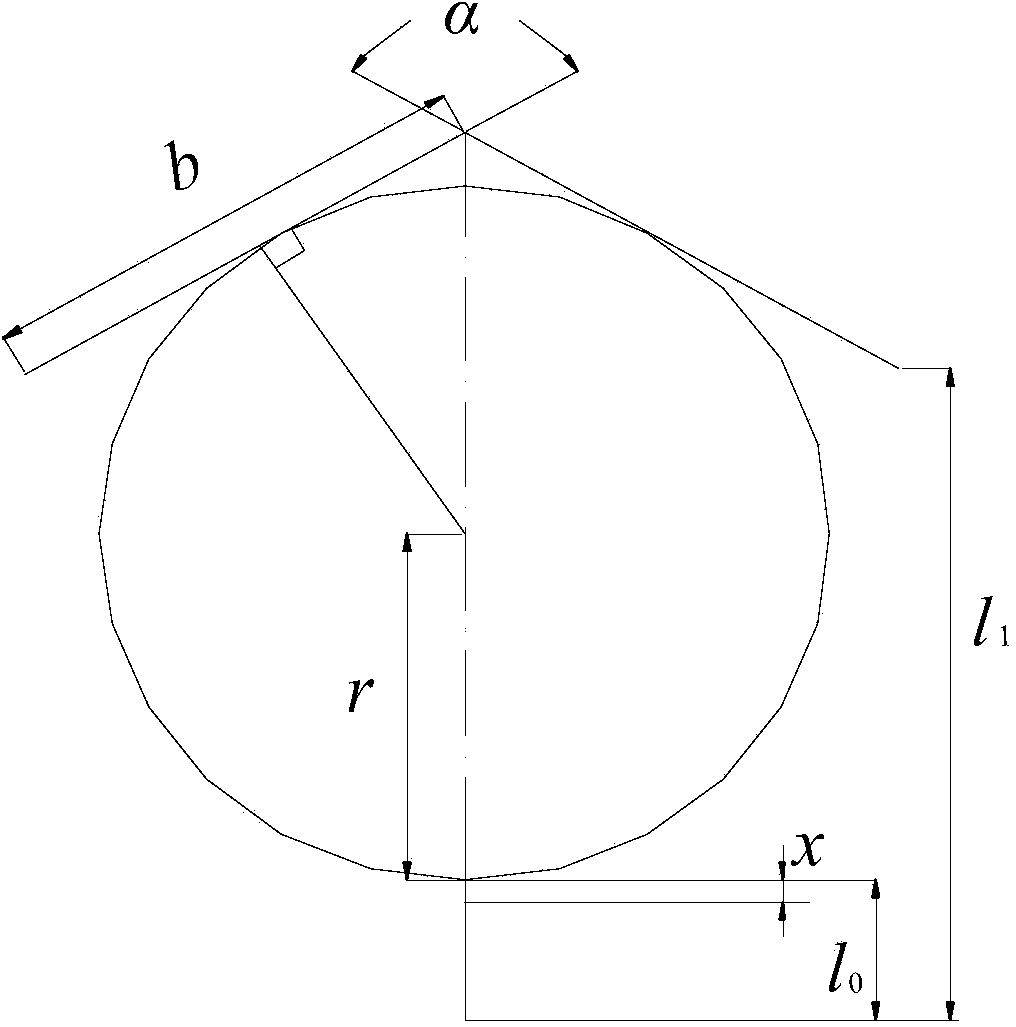

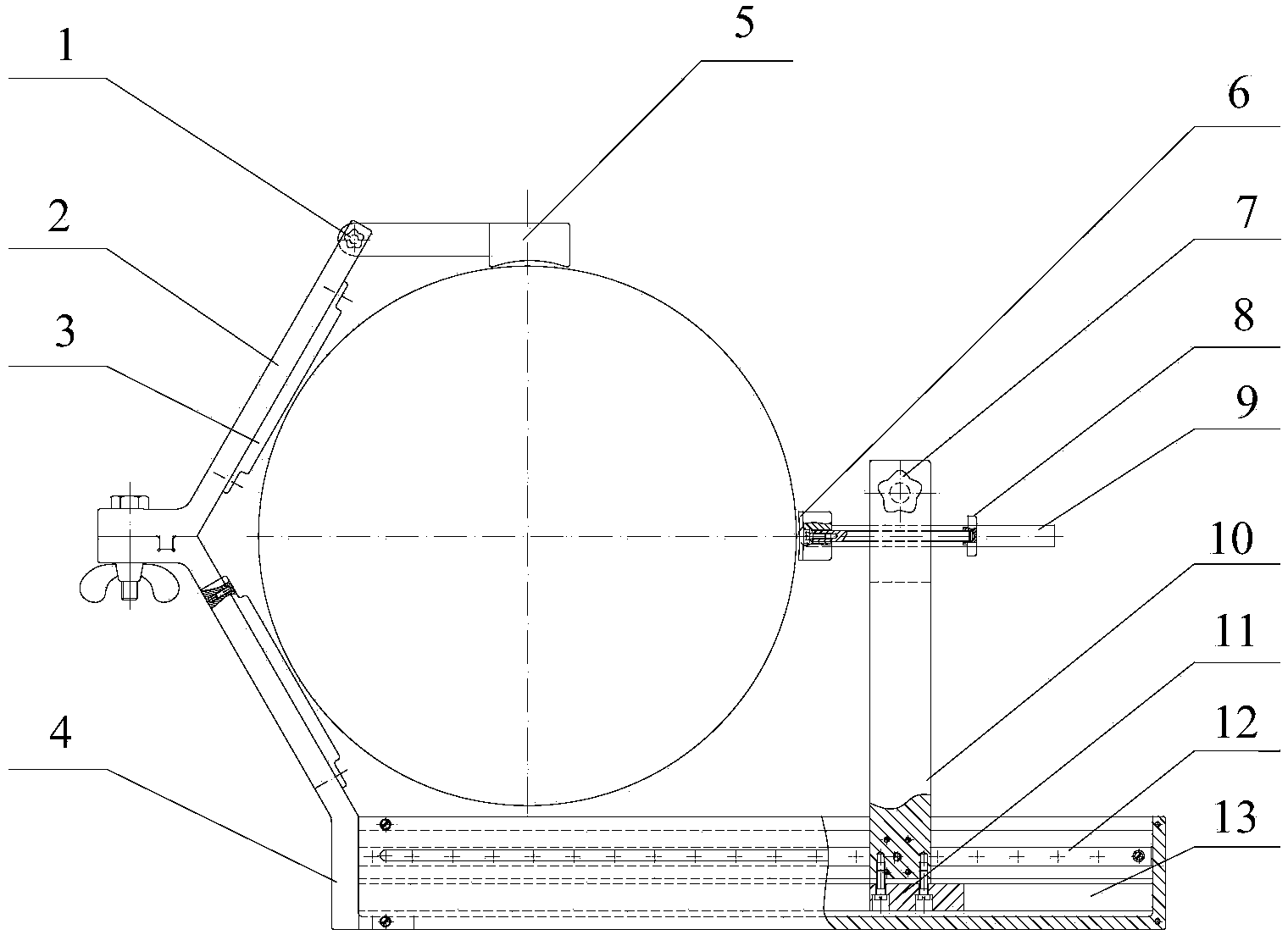

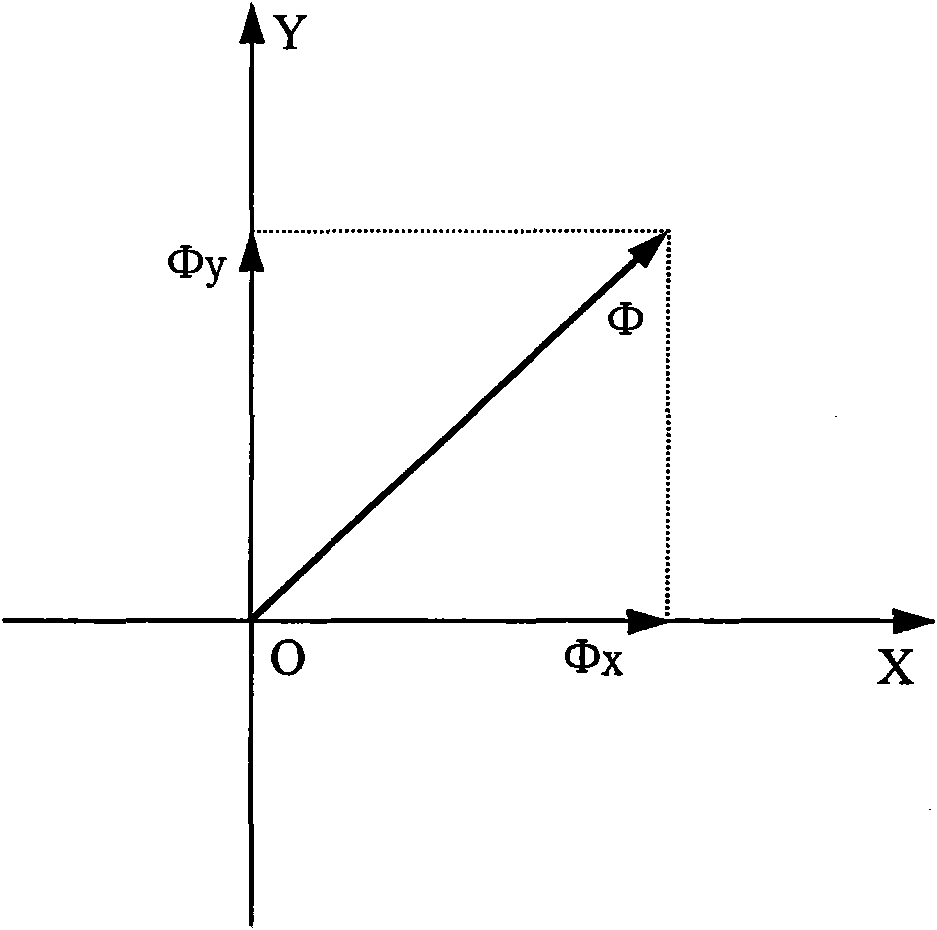

ActiveCN104006784ALow surface requirementsLarge measuring rangeMeasurement devicesMeasurement deviceDiagonal

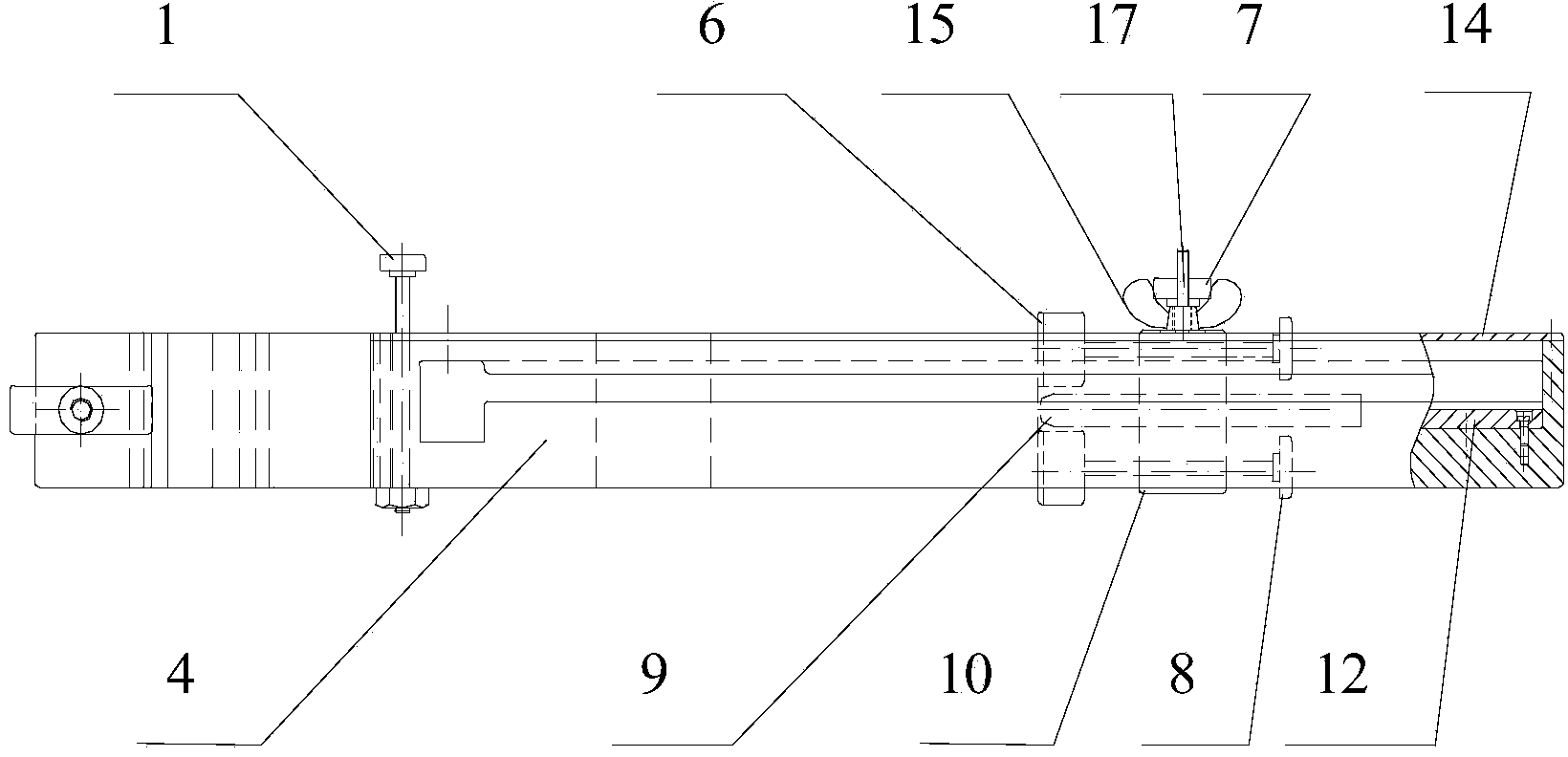

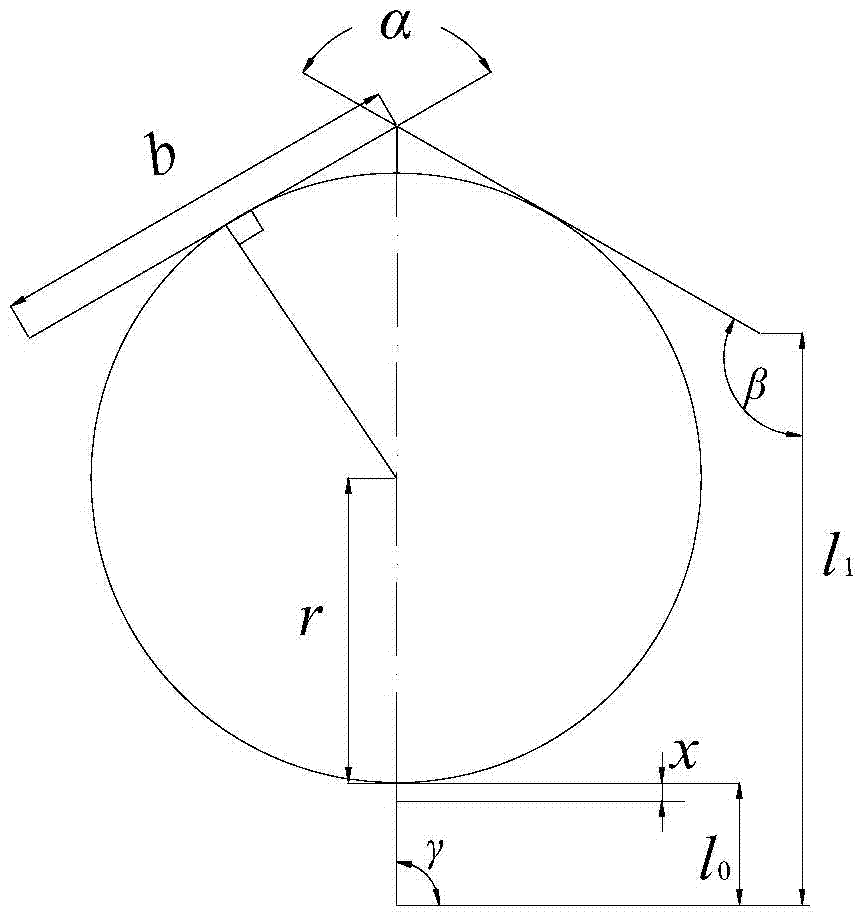

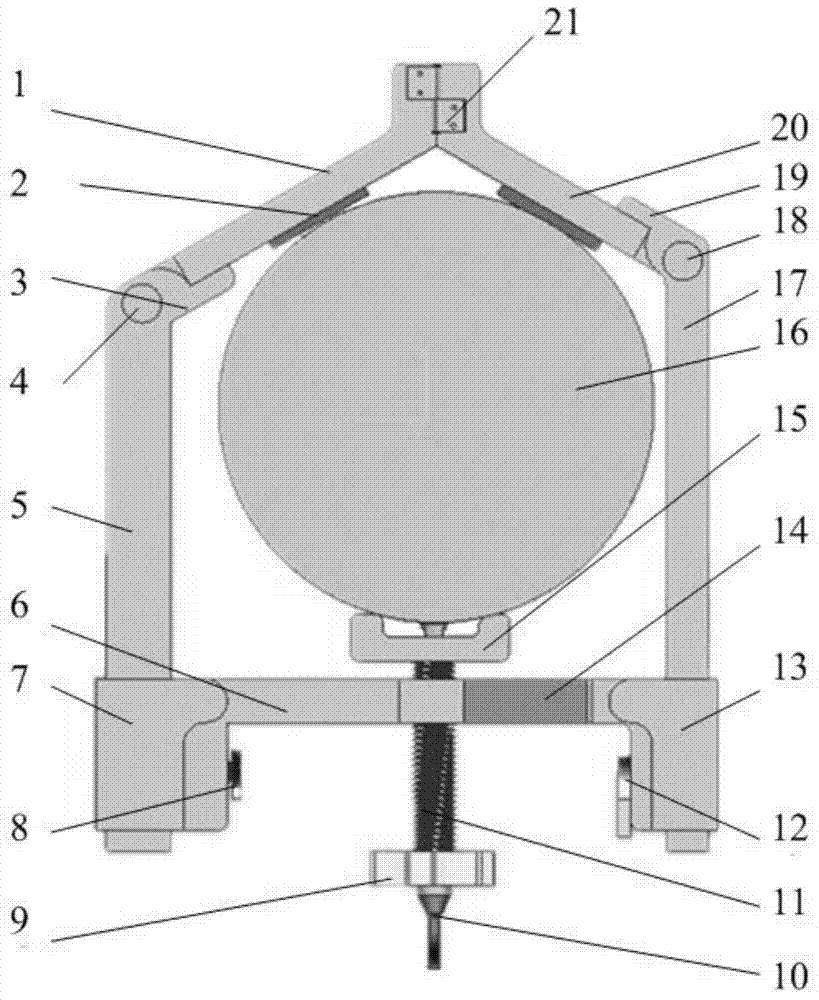

The invention discloses a precision measurement device for tree walk increment. The device can measure the diameter of a tree in real time and reduce errors. The measurement device comprises a support, a magnetic railing ruler, a sensor clamp, a micron-level displacement sensor and a signal transmission processing circuit. According to the support, the diameter is measured through a three-point method, and two parts are assembled to form a V-shaped body with an included angle ranging from 90 degrees to 150 degrees. With the combination of micron-level displacement sensor arranged at the coinciding position of diagonals of the V-shaped angle, measurement of the tree walk is achieved. The micron-level displacement sensor and the magnetic railing ruler conduct remote data transmission with an upper computer through the signal transmission processing circuit. By means of the precision measurement device for tree walk increment, the tree walk and the micro-change amount of the tree walk can be stably measured at the same time and in real time, and the measurement errors are reduced. The device applies small pressure on plants, and the device is simple in structure, convenient to use, light in weight, small in size and easy to carry.

Owner:CHINA JILIANG UNIV

Folding type tree diameter growth real-time precision measurement instrument

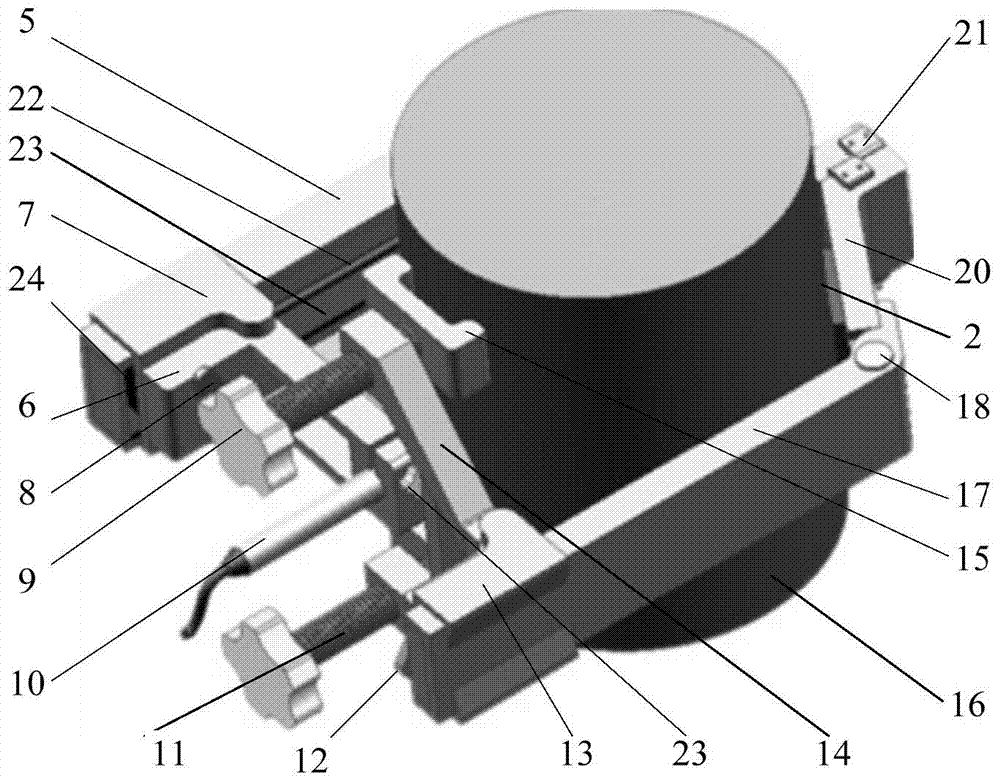

ActiveCN104330017AProduction Material OptimizationOptimize the production processElectrical/magnetic diameter measurementsMeasurement deviceEngineering

The invention discloses a folding type tree diameter growth real-time precision measurement instrument. The device can accurately measure tree diameter in real time, the size of the device is small, the device can be folded, and the device is convenient to carry. The measurement device comprises a bracket, a gate ruler, a sensor fixture, a micron displacement sensor and a signal transmission processing circuit. According to the device, the mode of multi-point positioning and three-point measurement of diameter is used, two parts are assembled to form a V-shaped body with an included angel of 90 degrees to 150 degrees, and combined with the micron displacement sensor installed at the diagonal coincide part of a V-shaped angle, the measurement of the tree diameter is realized. The micron displacement sensor and the gate ruler carry out remote data transmission with a host machine through the signal transmission processing circuit. According to the folding type tree diameter growth real-time precision measurement instrument, the tree diameter and the micro change amount can be stably measured in real time at the same time, and a measurement error is reduced. The device can be folded and is convenient to carry, the device is convenient to use, the weight of the device is small, the size of the device is small, and the damage to a trunk by the fixture is small.

Owner:CHINA JILIANG UNIV

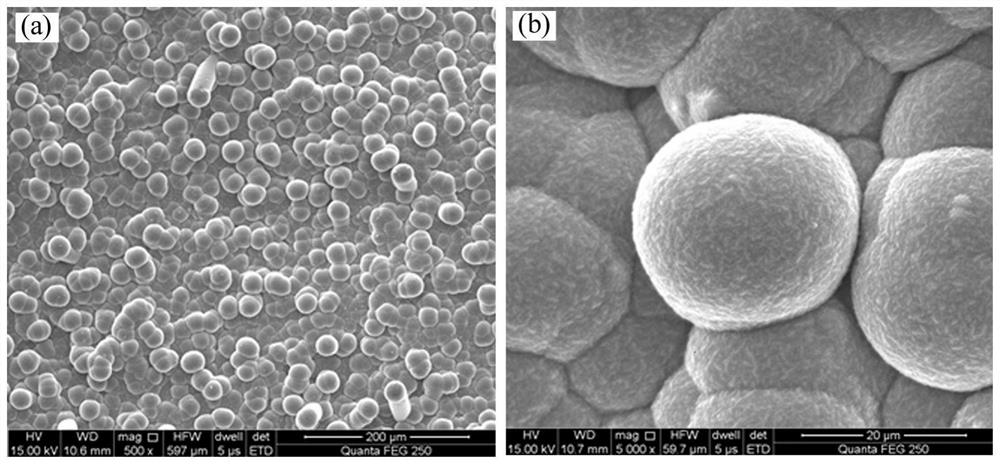

Surface enhanced Raman scattering substrate and manufacturing method thereof

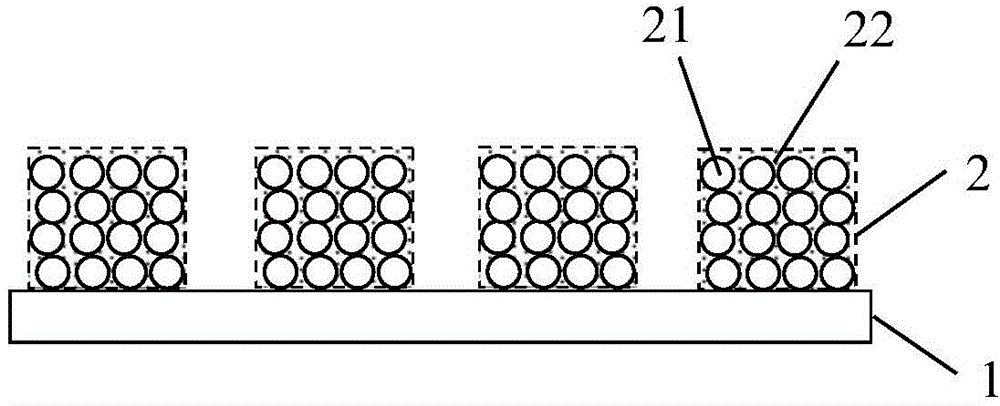

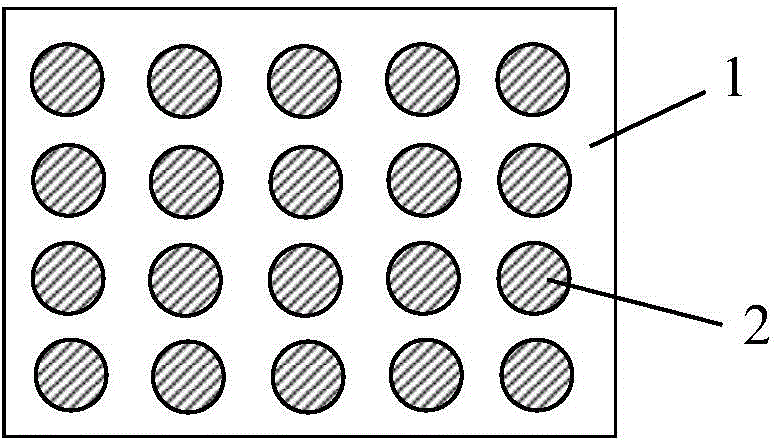

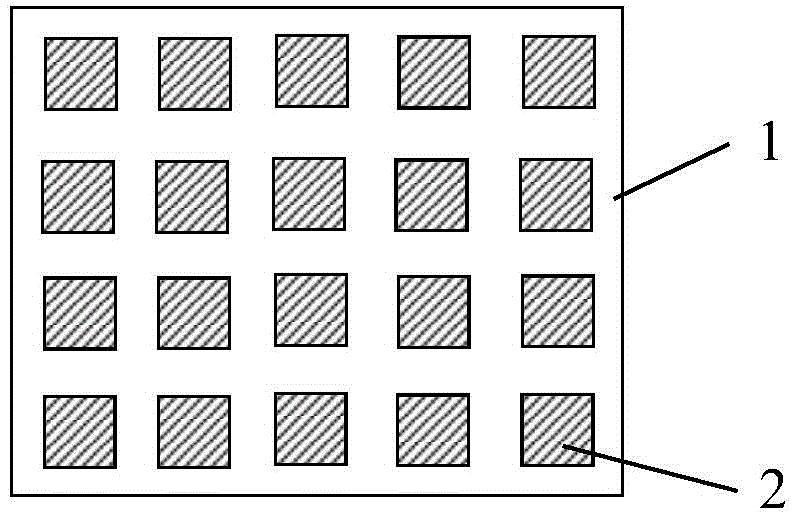

The invention discloses a surface enhanced Raman scattering substrate. The surface enhanced Raman scattering substrate comprises a base and a metal nano unit array arranged on the base, wherein each metal nano unit is formed by fixedly adhering metal powder particles by an adhesive; the adhesive is an inorganic adhesive or an organic adhesive; and the height of each metal nano unit is 400nm-800nm and the distance between the two adjacent metal nano units is 1-2 microns. The invention further provides a manufacturing method of the substrate; the metal powder particles are adhered through 3D printing equipment by using the adhesive to form a metal nano unit array structure on the base; and the surface enhanced Raman scattering substrate is obtained by adopting sintering and annealing processes. The surface enhanced Raman scattering substrate disclosed by the invention has a stable structure and the high surface activity; the adhering method is simple and the manufacturing cost is reduced; and the shape and the position of the nano array structure are easy to control and the repetitive rate is high.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

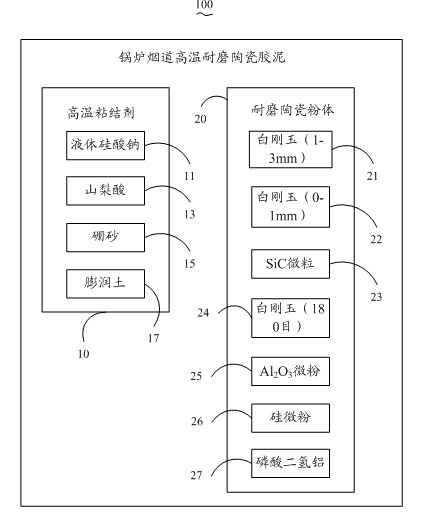

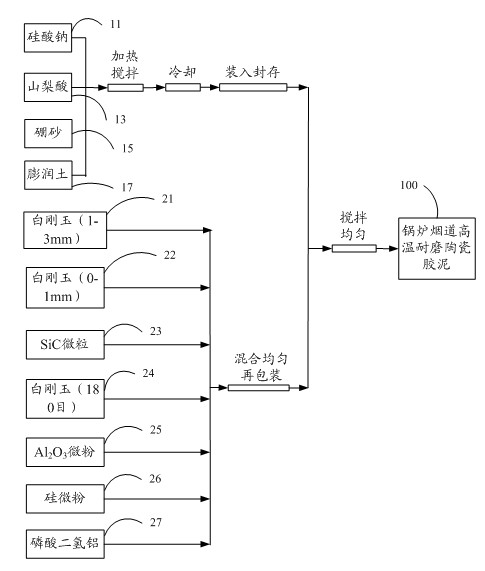

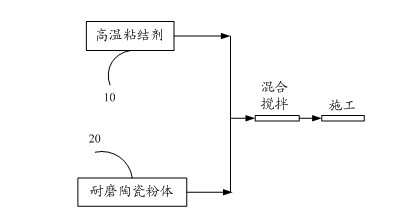

High-temperature wear-resistant ceramic cement for boiler flue

The invention relates to a boiler flue high-temperature wear-resistant ceramic cement, which includes a high-temperature binder with a component ratio of 1:3.5 and wear-resistant ceramic powder, and the high-temperature binder includes a component ratio of 100:0.5: 1.5:1.5 sodium silicate, sorbic acid, borax and bentonite, the wear-resistant ceramic powder includes white corundum with a component of 20% and a diameter range of 1-3 mm, and a component of 30% with a diameter range of 0 -1 mm white corundum, 20% silicon carbide particles with a diameter ranging from 0 to 1 mm, 20% white corundum with 180 mesh, 5% three-dimensional silicon carbide particles with a diameter of about 5 microns Aluminum oxide micropowder, silicon micropowder with a component of 2.5% and a diameter of about 1 micron, and a component of 2.5% aluminum dihydrogen phosphate. The boiler flue high-temperature wear-resistant ceramic cement adopts the method of coating, which is convenient for construction, does not have high requirements on the surface of the substrate, can repair local wear parts, and can resist high-temperature corrosion and particle erosion under complex working conditions. Erosion wear.

Owner:HEFEI KEDE SURFACE TECH

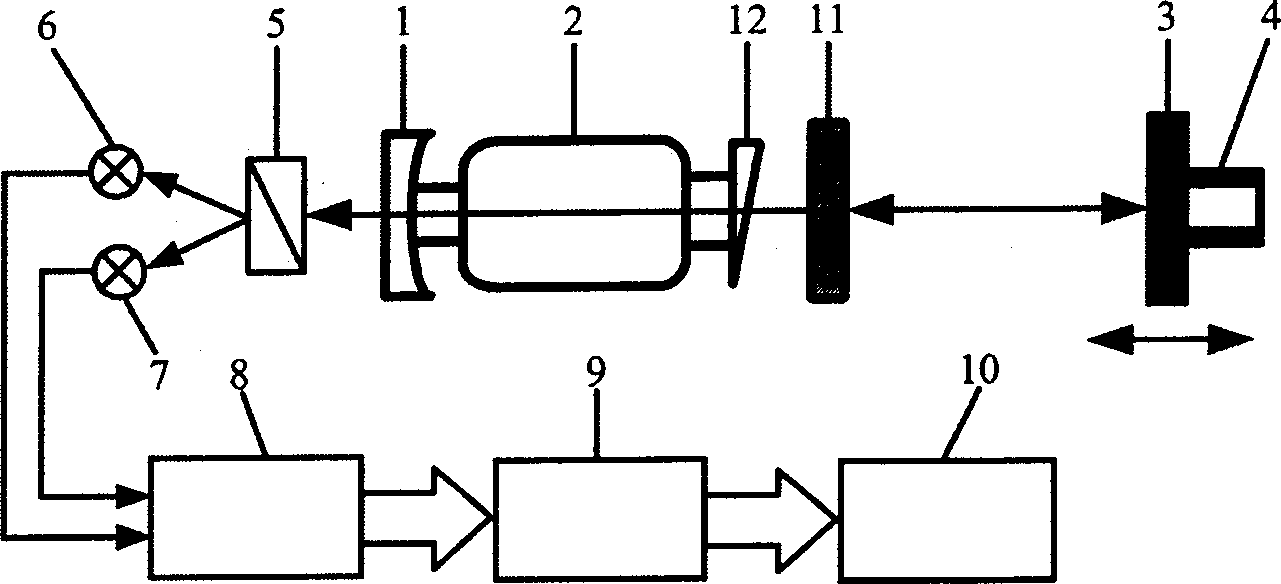

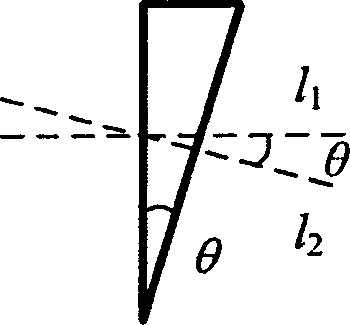

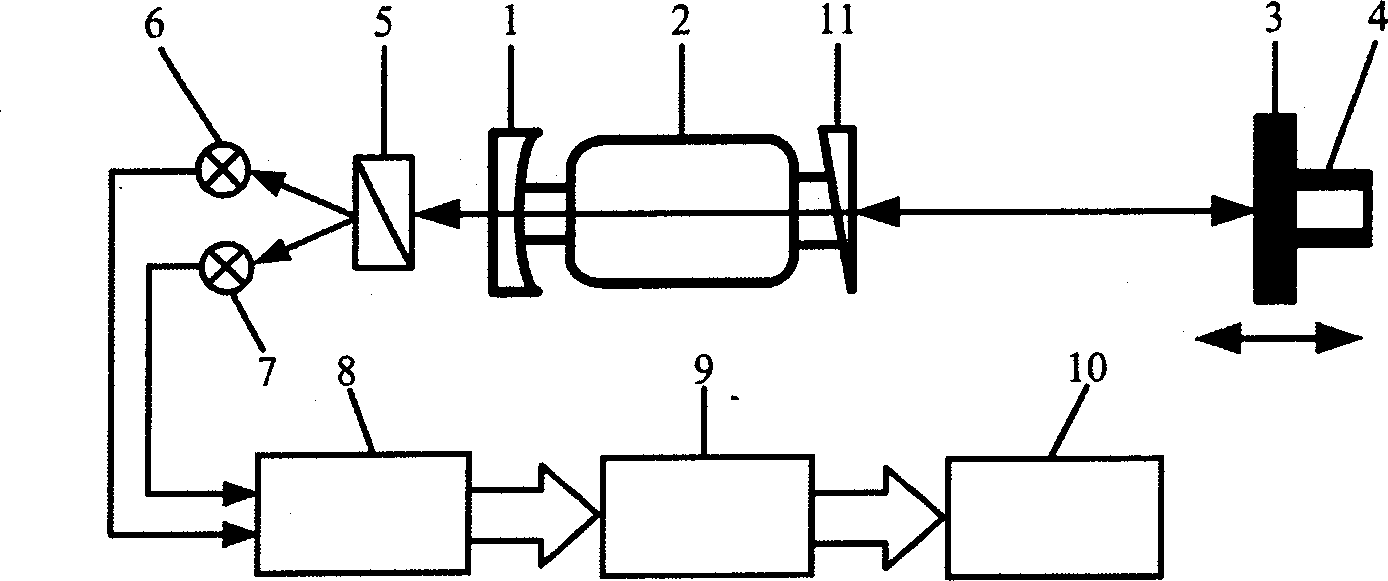

Laser feed-back displacement sensor based on frequency locked double-frequency laser

InactiveCN1851392ALow surface requirementsEasy to identifyUsing optical meansLight waveOptoelectronics

The invention relates to a laser feedback location sensor based on frequency lock two-frequency laser. Putting the quartz crystal with 0-2.9 degree wedge angle is fixed in the cavity of laser to form frequency lock two-frequency laser. It uses the laser and the reflecting or dispersion object to form laser feedback system to measuring the displacement. The invention has simple and tight structure, high measuring accuracy, low cost and has large measuring range.

Owner:TSINGHUA UNIV

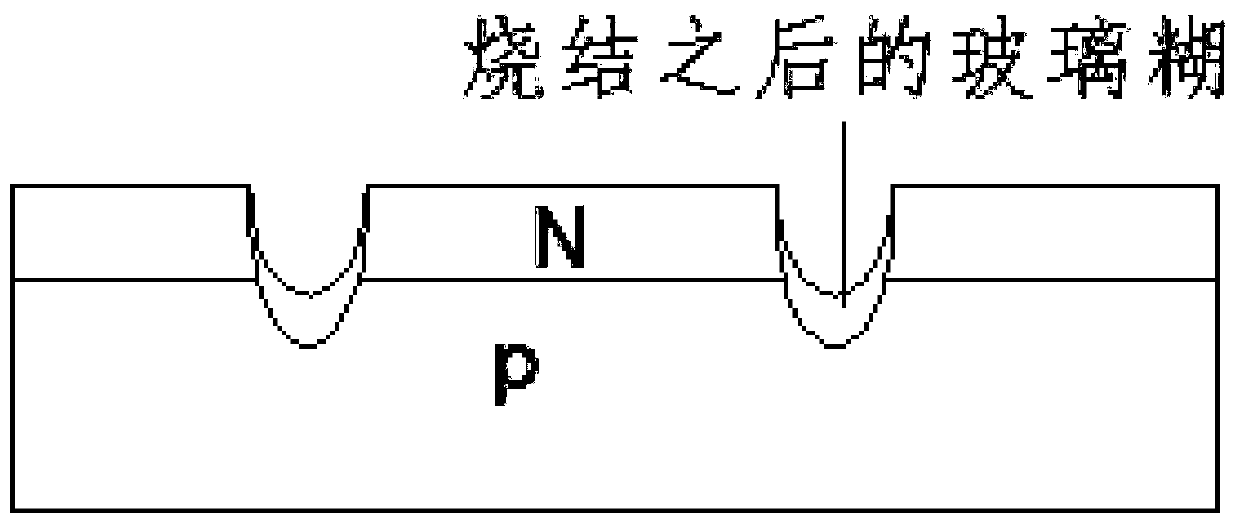

Flat and lug combined bidirectional diode chip and manufacturing process thereof

ActiveCN102244104AHigh mechanical strengthImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDiffusion layer

The invention discloses a flat and lug combined bidirectional diode chip which is processed by a P-type primary wafer; primary oxidization layers are arranged at positions, close to both ends, on two faces of a chip; the two faces of the chip are provided with phosphorous diffusion layers; secondary oxidization layers are arranged on the primary oxidization layers and the phosphorous diffusion layers; lug slots are formed in overlapped regions between the secondary oxidization layers and the primary oxidization layers; silicon nitride passivation layers are arranged on the lug slots; and the surfaces of the two faces of the chip are provided with nickel layers. The invention also discloses a manufacturing process for the flat and lug combined bidirectional diode chip. The manufacturing process comprises the following steps of: oxidizing for the first time, photoetching, diffusing phosphorous, oxidizing for the second time, photoetching the lug slots, passivating, photoetching lead wire holes, electroplating nickel and cutting to obtain the independent chip. The invention has the advantages that: as the mechanical intensity of the wafer and the wafer is hard to smash, the scribing (or cutting) efficiency is improved greatly; and compared with the scribing (or cutting) efficiency in a glass passivation process (GPP), the scribing (or cutting) efficiency is improved by over 40 percent, so the area of the whole graph can be saved by about 20 percent.

Owner:CHONGQING PINGWEI ENTERPRISE

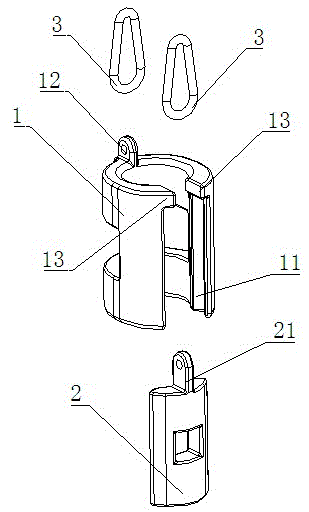

Counterweight hammer and hoisting device

InactiveCN102720800AEasy to assemble and disassembleSafe and reliable structureCounterweightsLoad-engaging elementsPhysicsEngineering

The invention discloses a counterweight hammer and a hoisting device and belongs to the technical field of limit switch application in hoisting devices. The counterweight hammer comprises a counterweight hammer body 1 and an inserting block 2, wherein the inserting block 2 and the counterweight hammer body 1 are connected into a whole in an inserting mode through an inserting port 11 of the counterweight hammer body 1, the inserting port of the counterweight hammer body 1 is provided with a limiting member, the limiting member is used for preventing the inserting block 2 from falling out of the upper portion of the counterweight hammer body 1, a first hook member 21 is arranged at the top of the inserting port 2, and a second hook member 12 is arranged at a position of the counterweight hammer body 1, which is symmetric with the first hook member 21 relative to the gravity center of a height limiter counterweight hammer. The technical scheme has the advantages that the counterweight hammer body and the inserting block are formed in an inserting mode, and the disassembly is convenient and rapid; the inserting block is prevented from loosening and falling through a structure that the width of a spring hook is larger than that of the upper portion of the inserting port; the counterweight hammer body is prevented from loosening and falling from a working position through a hoisting lug of the spring hook, which is hung on the counterweight hammer body, and the structure is safe and reliable; and the whole counterweight hammer is a casting part, requirements for the surface are low and the cost is low.

Owner:SHANGHAI SANY TECH

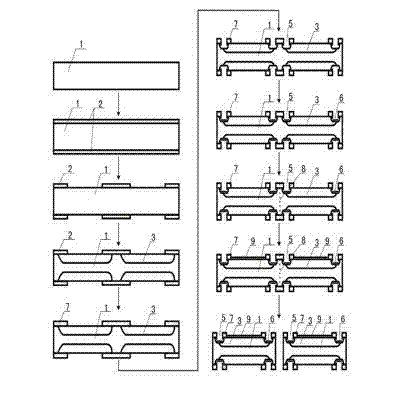

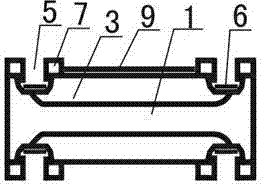

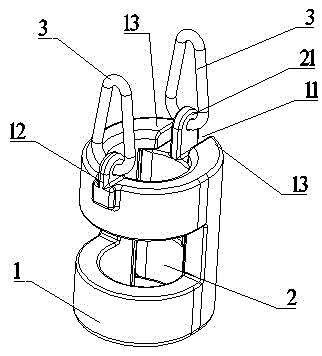

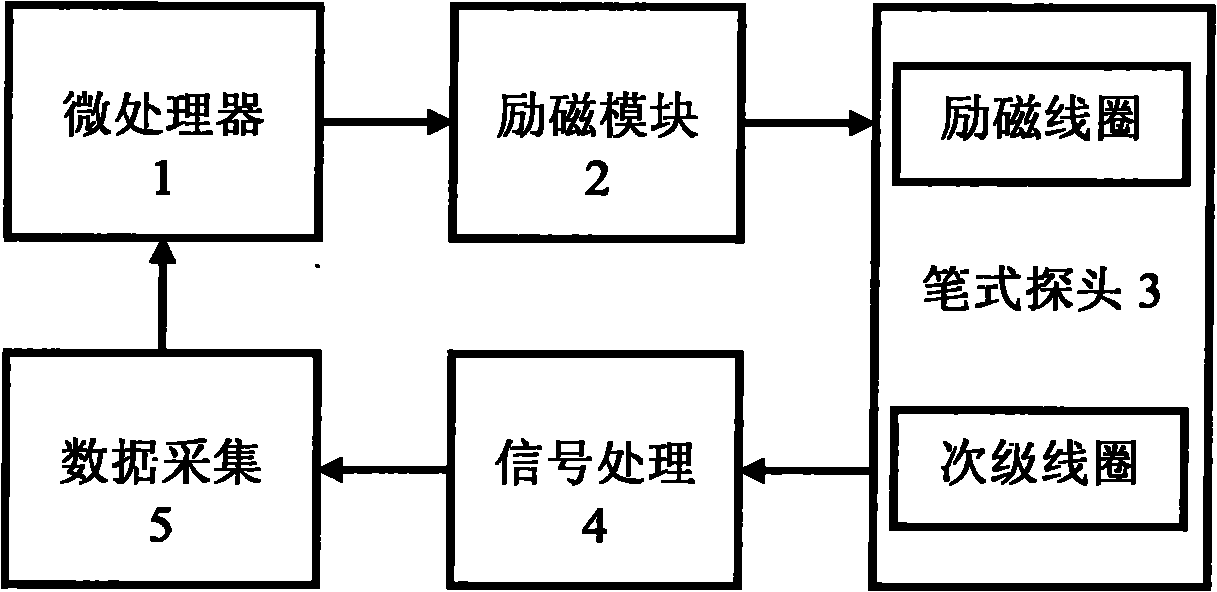

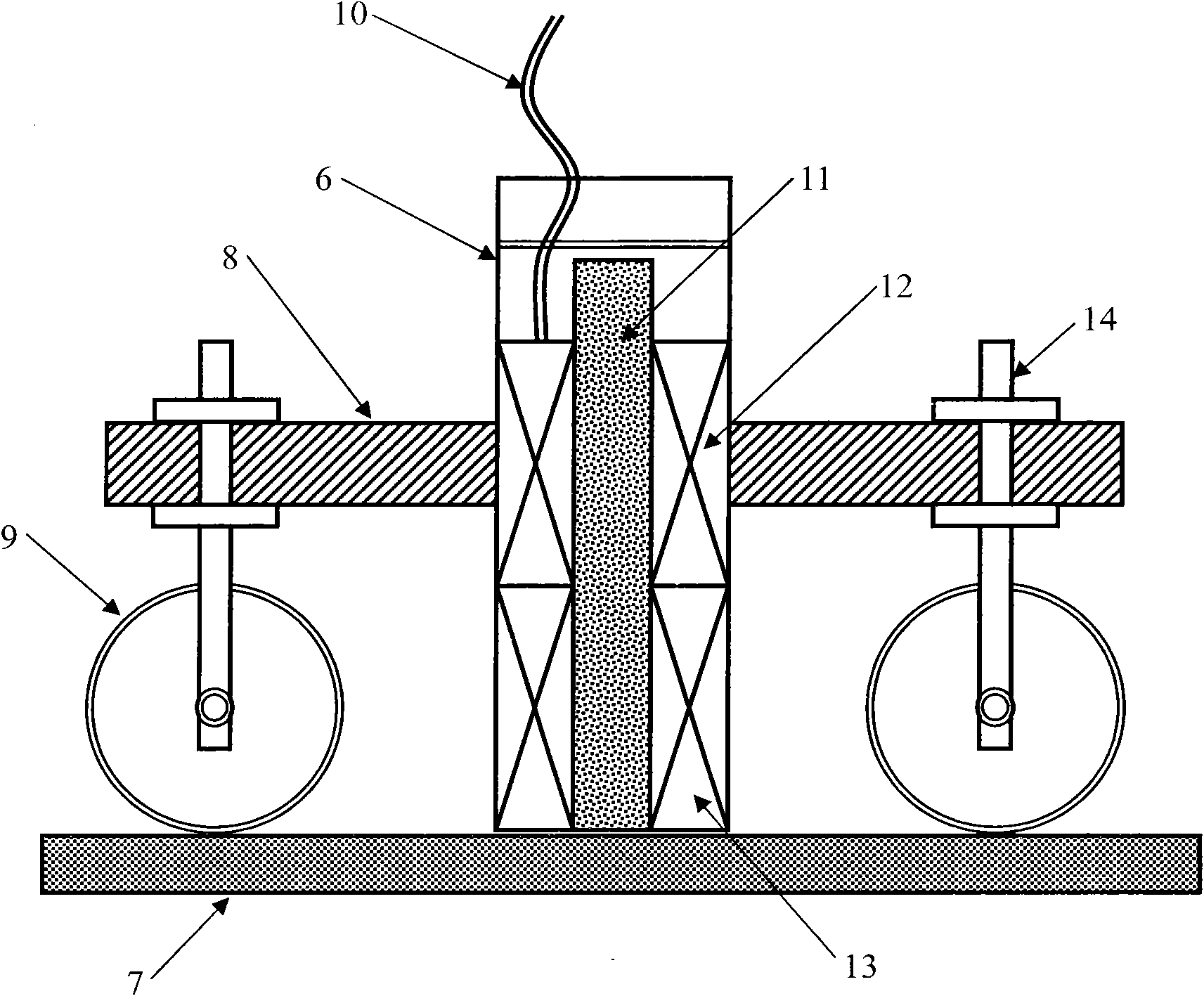

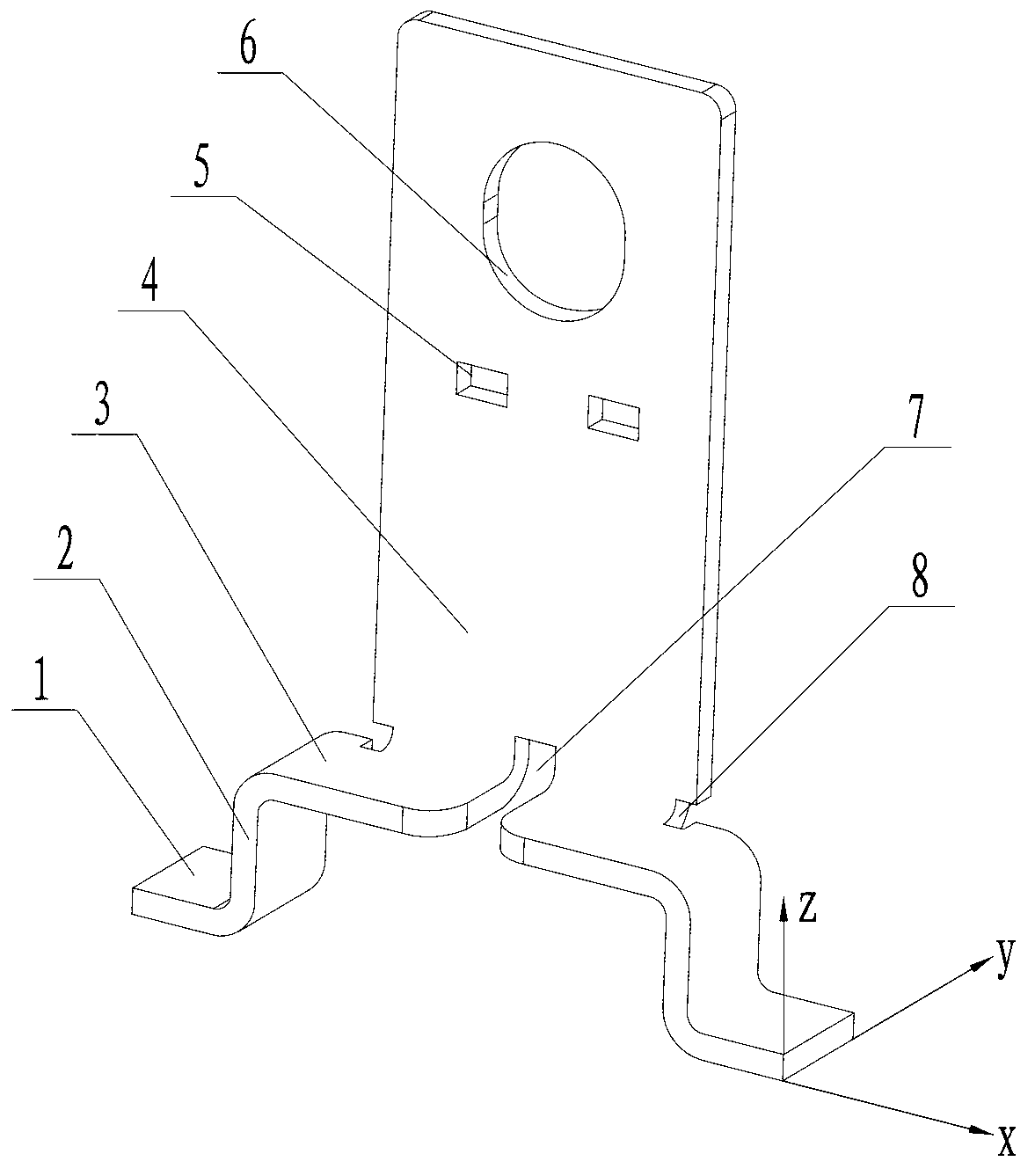

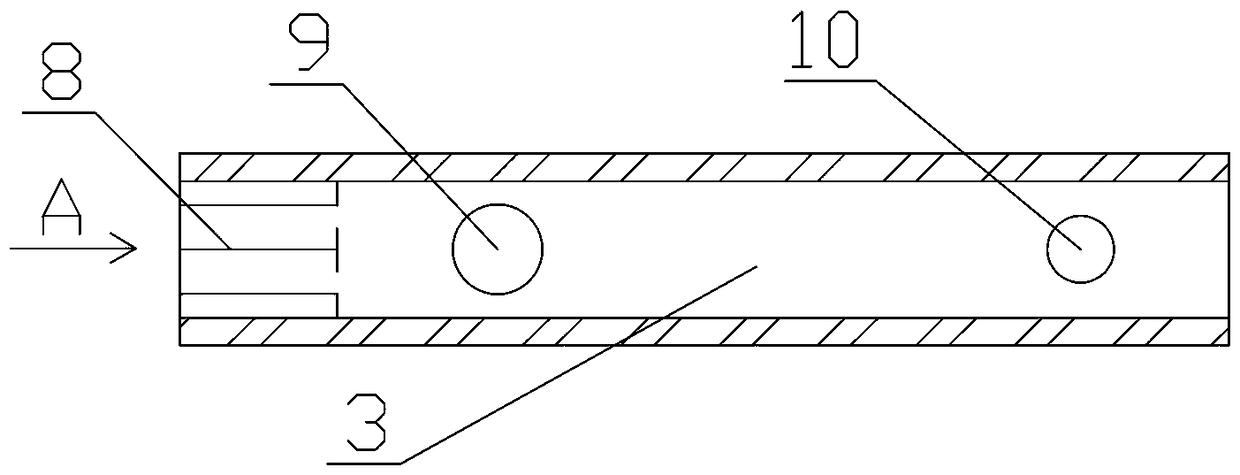

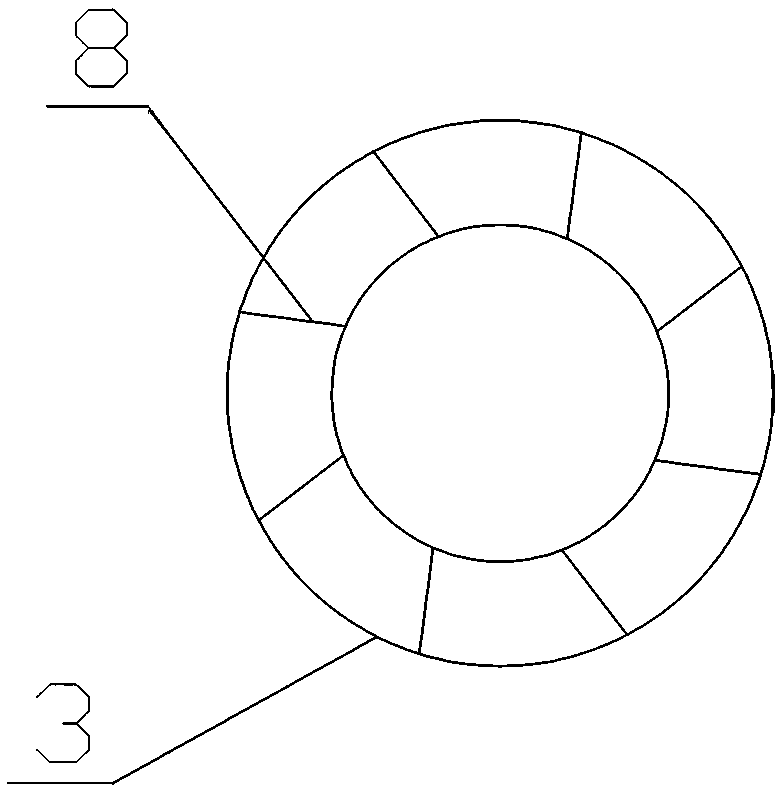

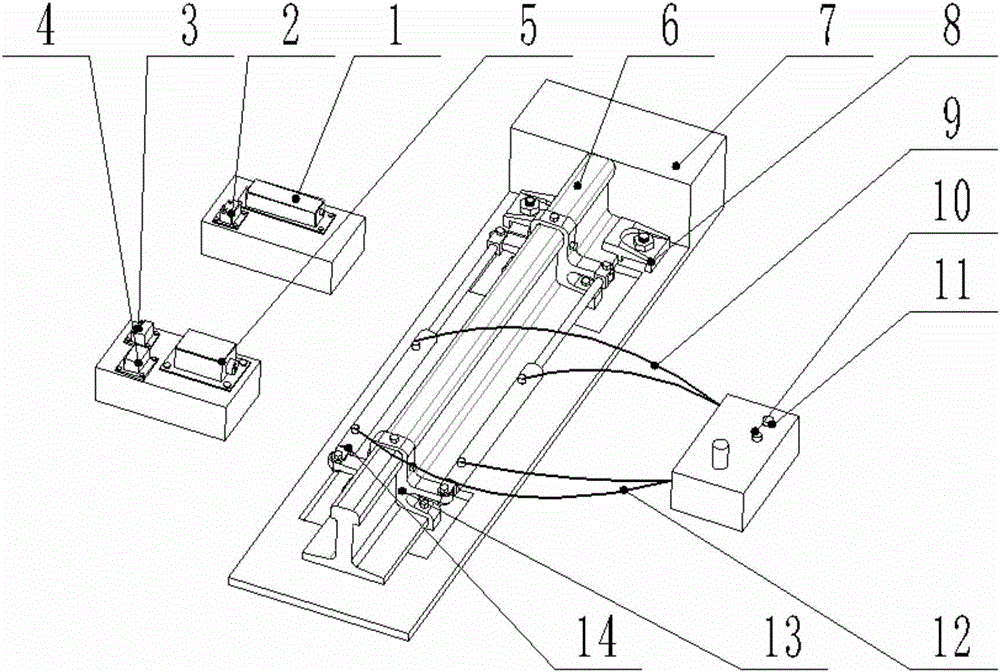

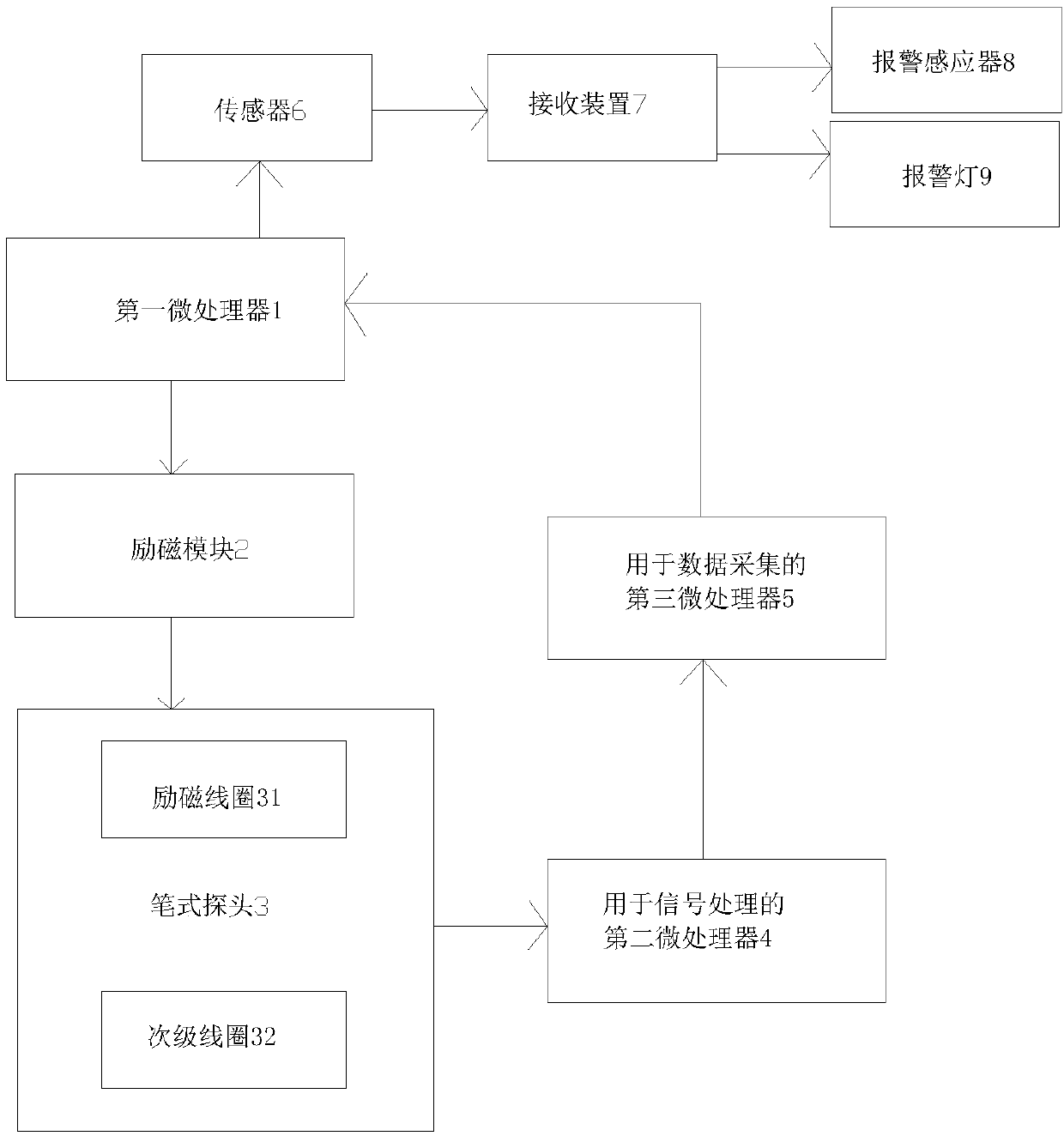

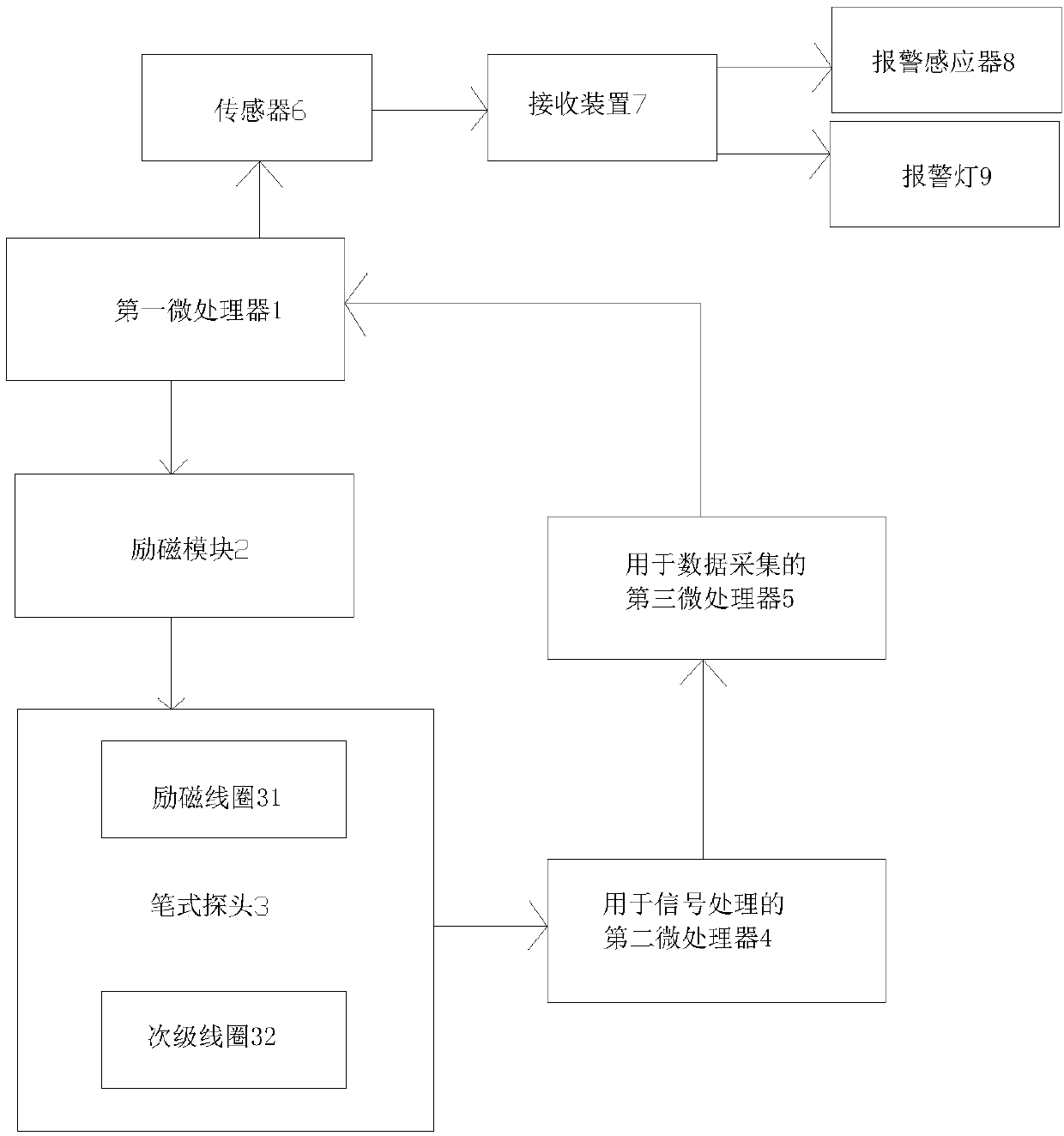

Ferromagnetic material crack warning detection method and apparatus

InactiveCN101858887ALow surface requirementsMaterial magnetic variablesCorrelation coefficientMaterial Crack

The invention discloses a crack detection warning method and a crack detection warning apparatus for monitoring the quality of a ferromagnetic material. The apparatus comprises a microprocessor 1, an excitation module 2, a pen-type probe 3, a signal processor 4 and a data acquisition device 5, wherein the pen-type probe comprises a probe shell 6, the ferromagnetic material 7, a probe bracket 8, rollers 9, a probe lead 10, a ferrite magnetic core 11, an excitation coil 12, a secondary coil 13 and roller brackets 14. The method is characterized by comprising the following steps of: monitoring the material quality anomaly of the ferromagnetic material by detecting the fluctuation of an initial magnetic conductivity parameter, and judging a crack or the probability of a potential crack trend according to the material quality anomaly; and if the shapes of the one-dimensional or two-dimensional data of detection results are different, a great amount of data scattered beyond the interval of ['mean value-standard difference', 'mean value+standard difference'] appears at a certain position, and a correlation coefficient between the current data and historical data of an area is less than a certain characteristic value beta (beta is more than or equal to 0 and less than or equal to 1), determining the material quality anomaly exists in the area where the position is, and suspecting the crack or the existence of the potential crack trend according to the material quality anomaly.

Owner:帅立国

Composite waterproof layer and construction method thereof

ActiveCN102206950AImprove flatnessImprove reliabilityBuilding material handlingBuilding insulationsBasementLap joint

The invention relates to a composite waterproof layer and a construction method thereof, belonging to the technical field of construction process waterproofing work. The construction method comprises the following steps of: firstly coating a rigid waterproof coating on the surface of a basement layer; under the condition that the rigid waterproof coating is wet and uncured, covering a reinforcing rib layer on the surface of the rigid waterproof coating; and finally coating an elastic waterproof coating on the surface of the reinforcing rib layer under the condition that the rigid waterproof coating is wet and uncured, thus complete sealing is realized. The invention has the beneficial effects that the composite waterproof layer formed by adopting the construction method provided by the invention has high evenness, no lap joint, low requirement to the surface of the basement layer and good integral waterproofness, and no water channelling is caused.

Owner:JIANGXI BEISITE TECH

Machining method of target surface

ActiveCN102632447ANo deformationImprove uniformityBelt grinding machinesTarget surfaceChemical reaction

The invention discloses a machining method of a target surface, which belongs to the technical field of the machining process of the target surface. The method utilizes mechanical grinding and polishing equipment to machine. The invention provides equipment conditions for machining a target. A parallel roller shaft with an adjustable opening width is used, and water sand paper or cloth with the granularity of 20-2000 meshes covers the roller shaft; the water sand paper which is from the rough to the fine is firstly utilized and then the cloth is used; and meanwhile, de-ionized water is used for lubricating to grind and polish a metal material. After the grinding and the polishing, the high-pressure de-ionized water is used for washing the surface. In the specific application, the metal material comprises one or more of nickel, copper, silver, titanium, aluminum and vanadium. The machining method has advantages of no requirements on the target surface, fast grinding and polishing speed, no need of using cutting liquid and lubricating liquid for mechanically machining, no chemical reaction on the surface, thin stress layer, high whole uniformity, and no deformation of the whole body. The machining method of the target surface is a simple, reliable, economical and efficient machining method which is adapted to the target with a large area, a great length and a large thickness ratio.

Owner:GRIKIN ADVANCED MATERIALS

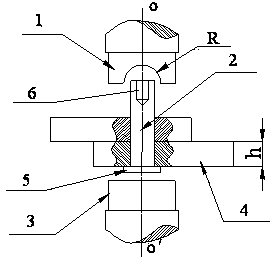

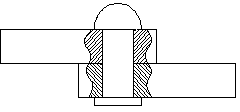

Heating connection method for thermoplastic plastic adopting rivet

The invention discloses a heating connection method for a thermoplastic plastic adopting a rivet. The heating connection method comprises the following steps: (1) punching: pre-punching the geometric centre of the lapped joint of a plate according to the diameter of the chosen semi-tubular rivet, wherein the hole diameter is equal to the diameter of the rivet, so that the rivet is in close contact with the connected base material; (2) assembling: implanting the rivet in the pre-punched hole of the connected plate, and tightly pressing the plate, wherein a rivet head (5) is in close contact with the connected plate, and the redundant part of the rivet is left at a semi-tubular side, the assembled joint is placed between two electrodes, the rivet head (5) is placed on the first electrode (3), a semi-tubular end (6) is opposite to the second electrode (1), and the semi-tubular rivet (2), the second electrode (1) and the first electrode (3) are located on the same axis (OO'); and (3) riveting.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

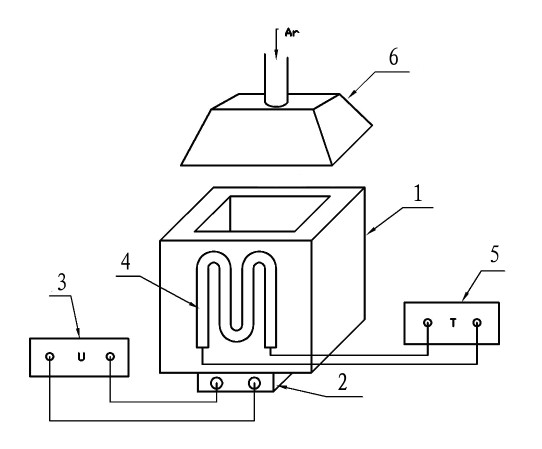

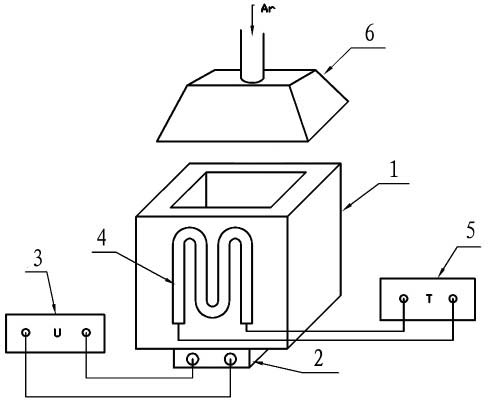

Copper/aluminum ultrasonic liquid-phase diffusion brazing process and brazing device

InactiveCN102513635ASimple structureIngenious designMetal working apparatusSoldering auxillary devicesMolten stateMetallurgy

The invention discloses a copper / aluminum ultrasonic liquid-phase diffusion brazing process and a brazing device. The brazing process adopts the technical scheme that the copper / aluminum ultrasonic liquid-phase diffusion brazing process adopts Sn-9Zn eutectic alloy brazing filler metal, and does not adopt brazing flux; the brazing temperature is low; and the requirements on the surface and the structure of a copper / aluminum brazing connector are not high. The brazing process has the beneficial effects that the brazing process is accomplished in brazing filler metal at a molten state, and the problem of heat preservation of the brazing filler metal during the brazing is eliminated; the controllability of brazing technological parameters is high, the operation process is simple, and the efficiency is high; the copper / aluminum connector adopting the brazing process is smooth, and the performances of the copper / aluminum connector are remarkably improved; and the anti-corrosion capability and both the high and low temperature impact resistance of the copper / aluminum brazing connector meet the requirements of national relevant standards.

Owner:SHANDONG JIANZHU UNIV

Electrode terminal of power module and welding method thereof

ActiveCN102800833AGood for stress reliefOptimized stress relief structureCell component detailsNon-electric welding apparatusComputer moduleEngineering

The invention relates to an electrode terminal of a power module. The electrode terminal comprises a support saddle and a run-off plate which are integrated, wherein a through hole is formed in the run-off plate; the support saddle comprises a transverse plate and upright plates, wherein the upright plates are arranged at two ends of two sides of the transverse plate and subject to arc curve transition, and moreover, connecting plates outwardly bent are arranged at the bottom of the upright plates; the bottom of the run-off plate is in curve transition to the transverse plate; an intermediate notch on the transverse plate extends to the curve transition part between the transverse plate and the run-off plate; and side notches are respectively arranged on two side surfaces of the curve transition part between the run-off plate and the transverse plate. The electronic terminal of the power module has a reasonable structure and can effectively release the stress caused by a welding part of the electronic terminal when being bent, prolong the service life and improve the welding efficiency.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

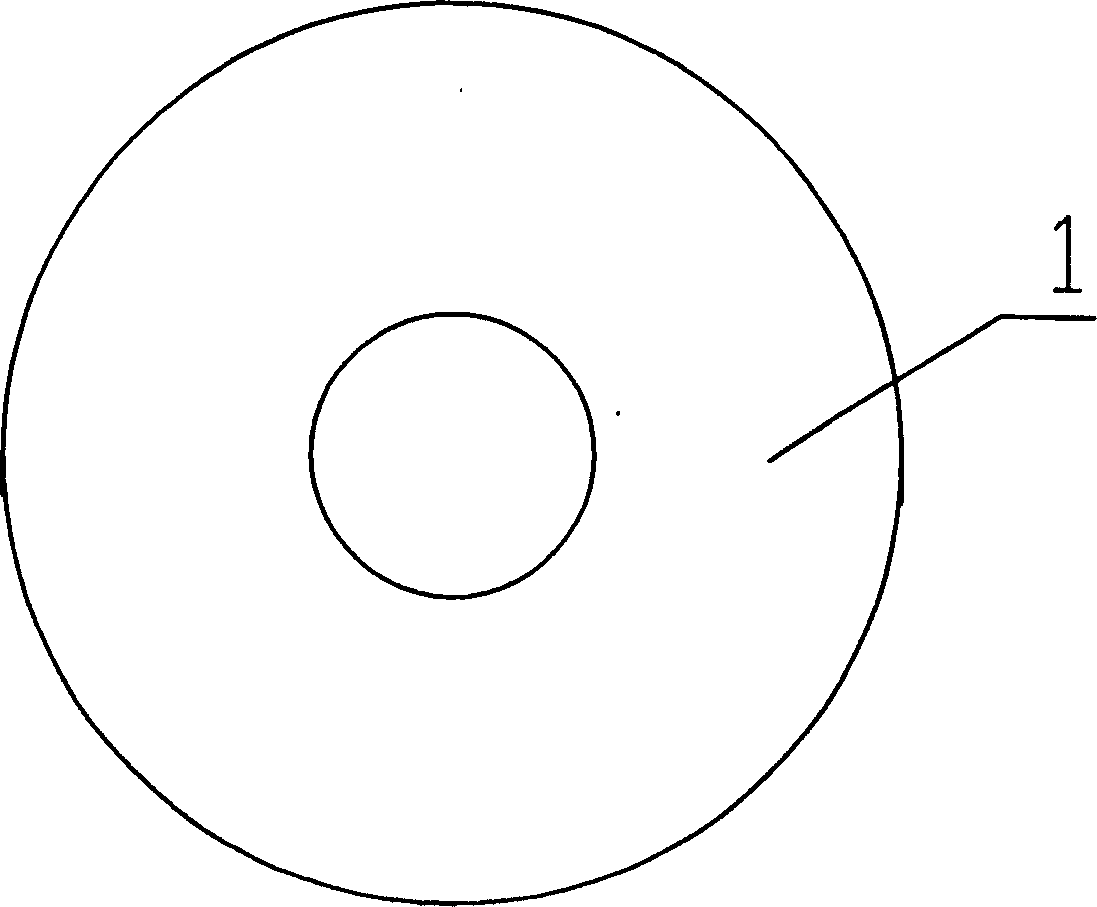

Adjusting washer and method for making same

InactiveCN1865720AHigh matching precisionFast curingWashersLayered productsThermal treatmentAdhesive

The invention discloses an adjustable gasket, which comprises layered gaskets whose thickness is 0.05mm, and the adhesive between said gaskets. Its production comprises following steps that: A, molding the gaskets in 0.05mm thick; feeding the gasket material, via longitudinal cutting and thermal treatment, to be finished rolled to obtain the gasket coil; and according to the needed size, cutting the gasket coil to be processed via compound punching; B, layering technique that coating adhesive on the gaskets in the step A, to be compressed.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

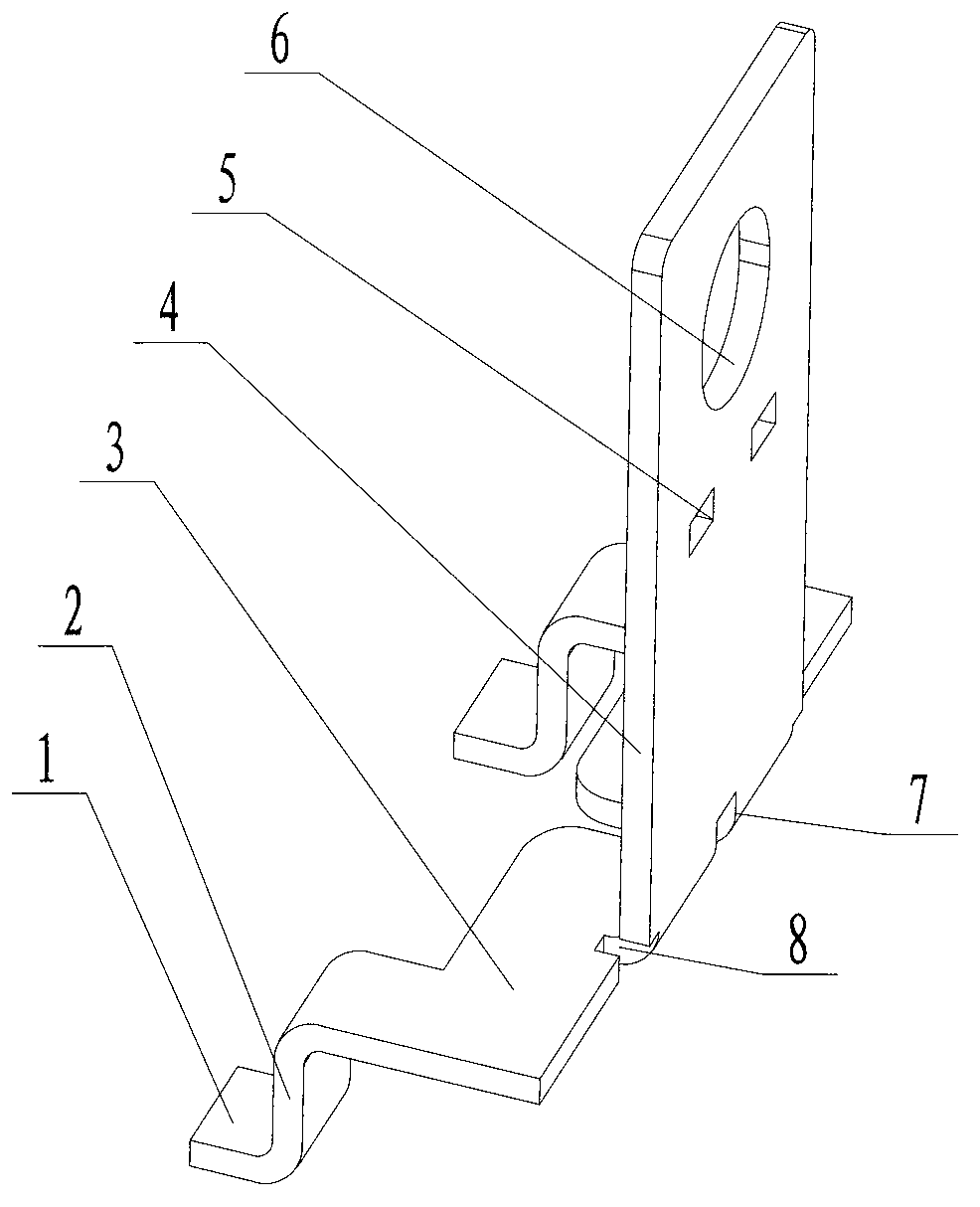

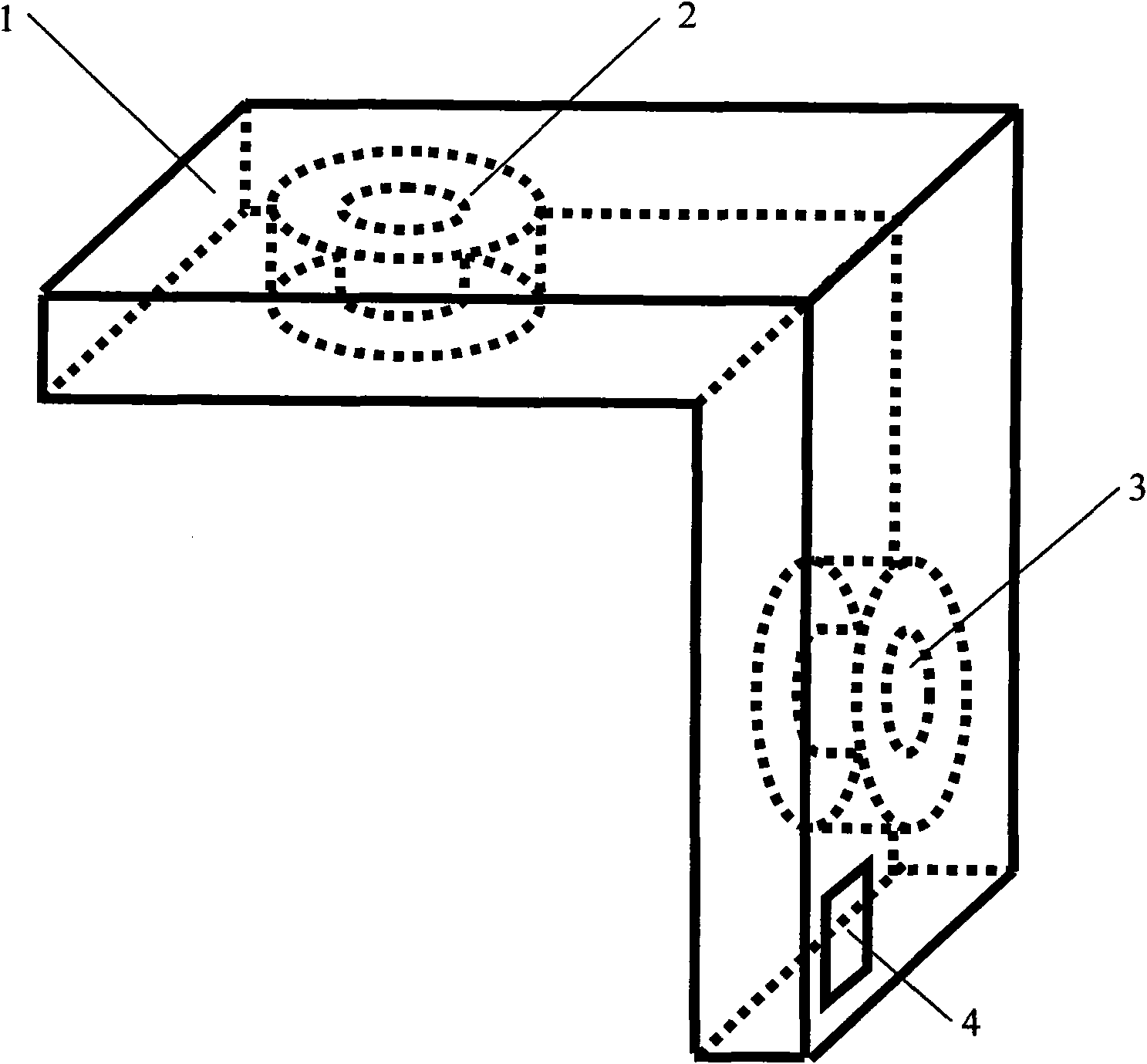

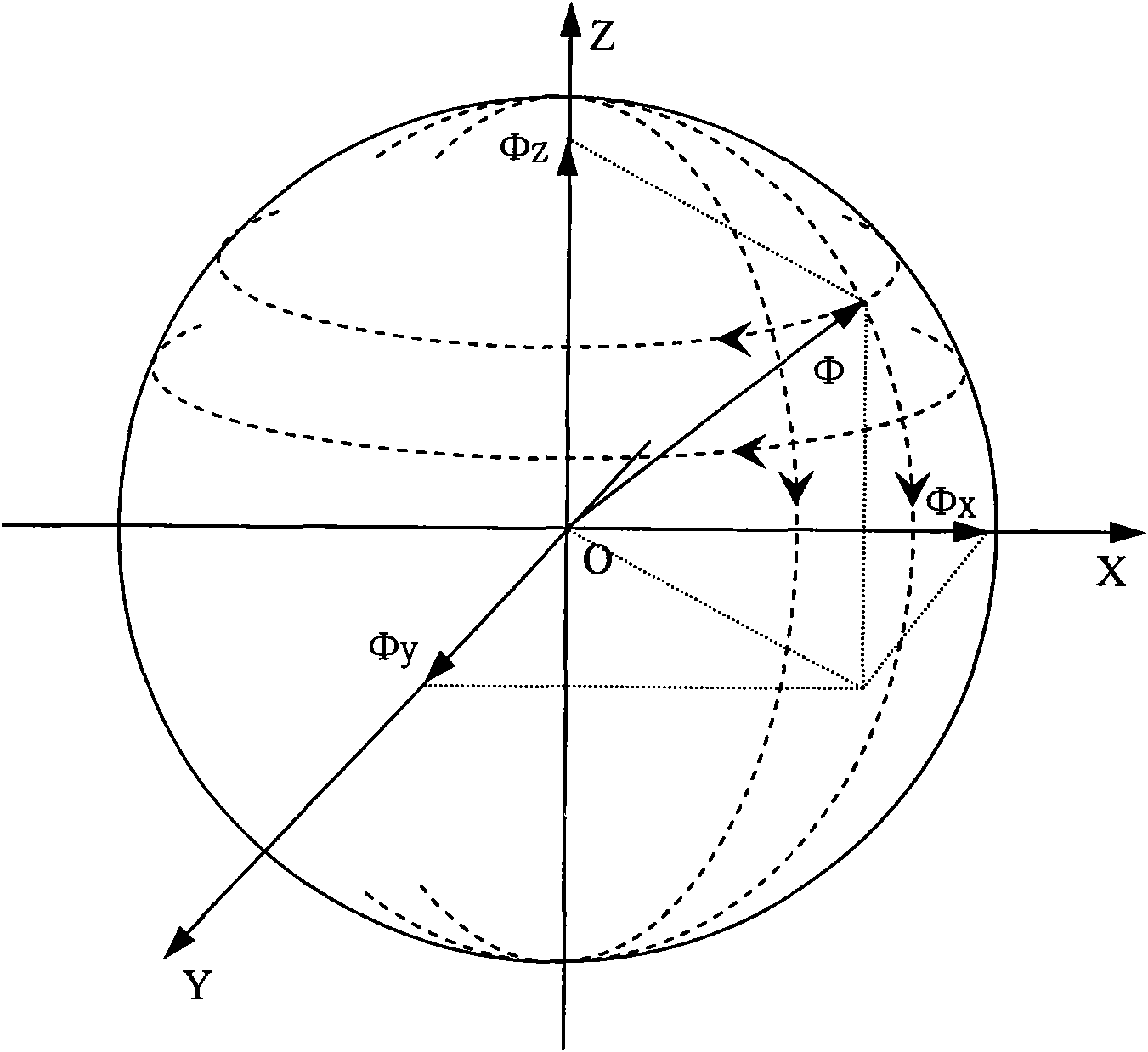

Two-dimensional electromagnetic detector and magneticrotation detection method

InactiveCN101666778ABroad market prospectLow surface requirementsMaterial magnetic variablesCell materialField coil

The invention provides a two-dimensional electromagnetic detector for nondestructive detection and evaluation on metal materials and a magneticrotation detection method. The electromagnetic detector comprises a detector body 1, a detection coil 2, a detection coil 3 and a wiring port 4. The invention is characterized in that each group of the detecting coils comprises a pair of field coils and a pair of detecting coils; field current of the coils in each group is reasonably adjusted, which can provide a plane rotating magnetic field with a constant size for the two-dimensional magneticrotationdetection; a homograph similar to a detected workpiece is generated by a result obtained by the magneticrotation detection after treatment; the abnormal material is reflected by obvious evagination or pit of the homograph, which enables the material distribution characteristics of the metal materials to be clear, thus facilitating inspectors to evaluate the quality of the detected workpiece quickly. The invention not only can detect and evaluate components, mechanical property and tissue uniformity, but also can perform early warning on abnormal tissues such as cracking and the like.

Owner:帅立国

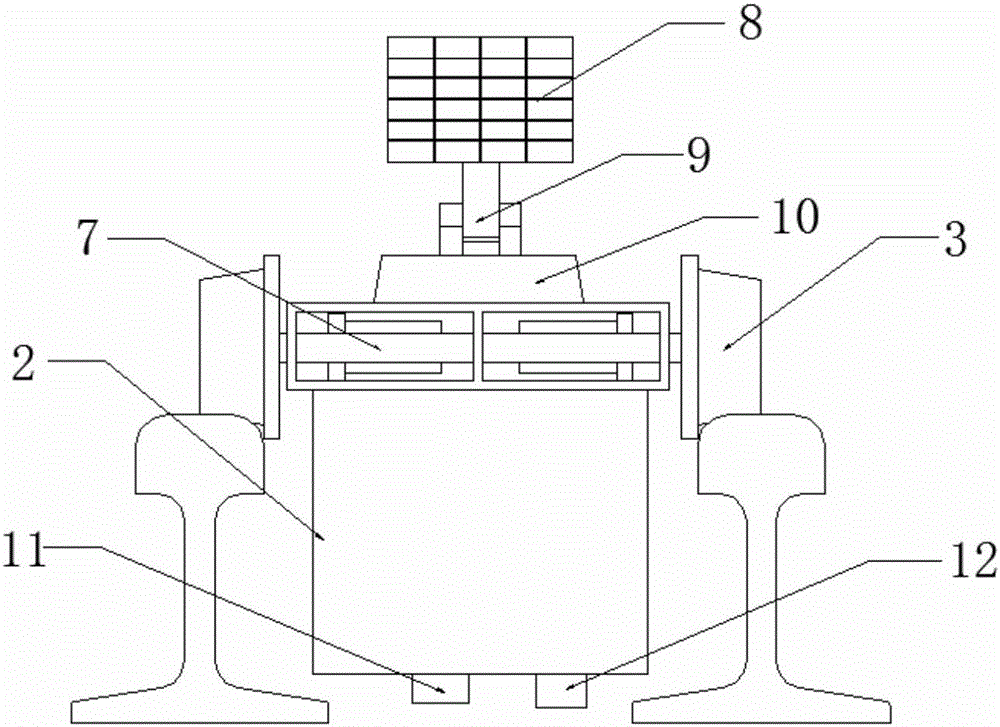

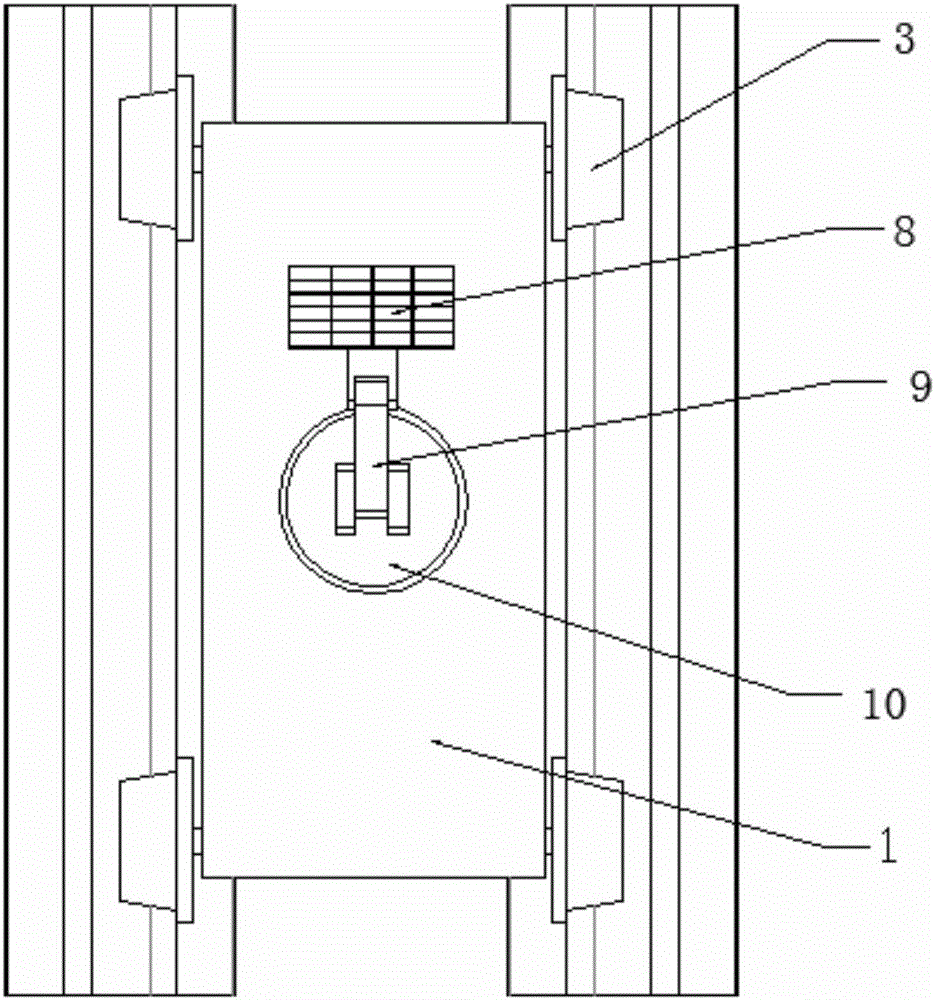

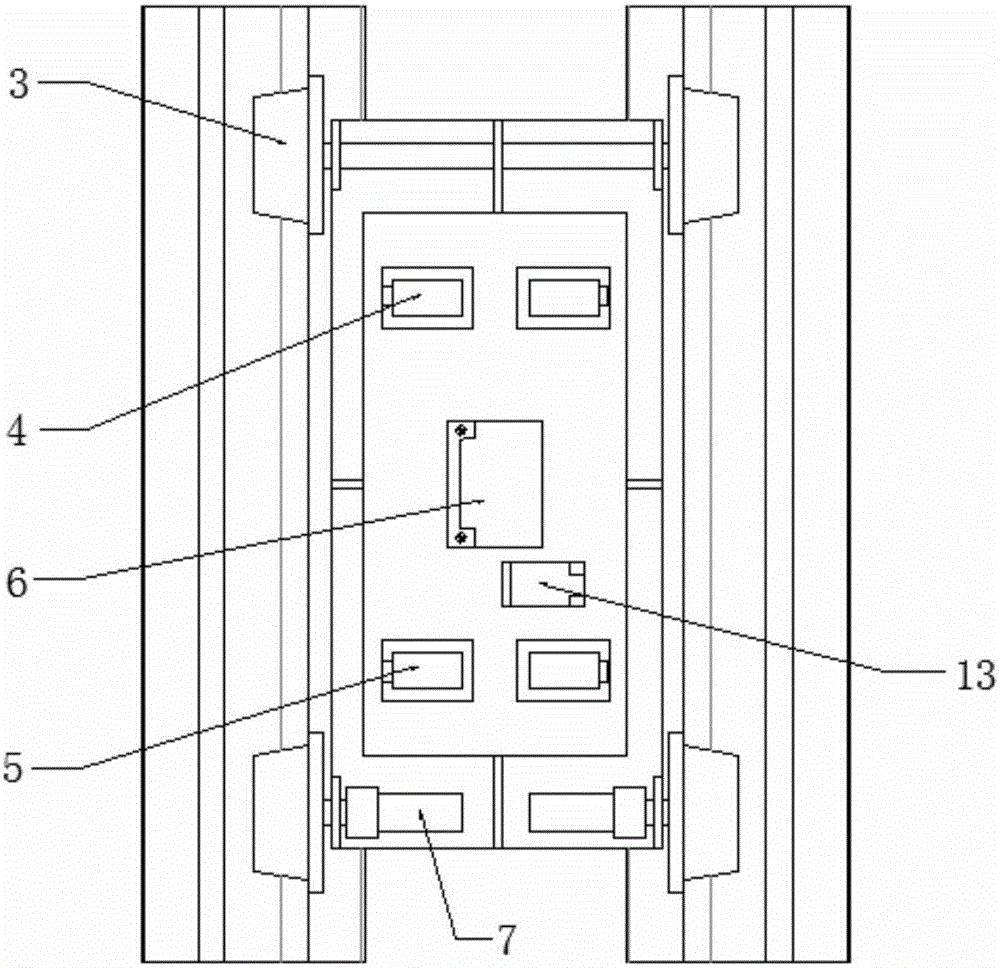

Device and method of monitoring steel rail temperature stress in real time based on laser ultrasonic method

ActiveCN105818822AMonitor temperature stressGuaranteed safe operationRailway inspection trolleysForce measurement by measuring optical property variationLaser probeData memory

The invention discloses a device and a method of monitoring steel rail temperature stress in real time based on a laser ultrasonic method. The device comprises a monitoring trolley and a power pack, wherein the monitoring trolley comprises an upper trolley body, a lower trolley body, wheels, a positioner and a temperature meter; a laser ultrasonic monitoring unit and a data analyzing and processing unit are arranged inside the lower trolley body; the laser ultrasonic monitoring unit comprises pulse lasers, laser probes and a signal conditioning amplification circuit; the data analyzing and processing unit comprises a data storage unit, a processor and a wireless transmission module; the pulse lasers and the laser probes are arranged on the front side and the rear side of the lower trolley body; and the signal conditioning amplification circuit, the data storage unit and the wireless transmission module are connected to the processor by data lines. The pulse lasers send pulse laser to act on steel rails and ultrasonic waves are produced; ultrasonic wave signals are received by the laser probes; a measurement time value is transmitted to the processor; the steel rail temperature stress is accurately monitored in real time; and a new means is provided for steel rail nondestructive testing, and is significant for guaranteeing the safe running of the steel rails.

Owner:WENZHOU UNIVERSITY

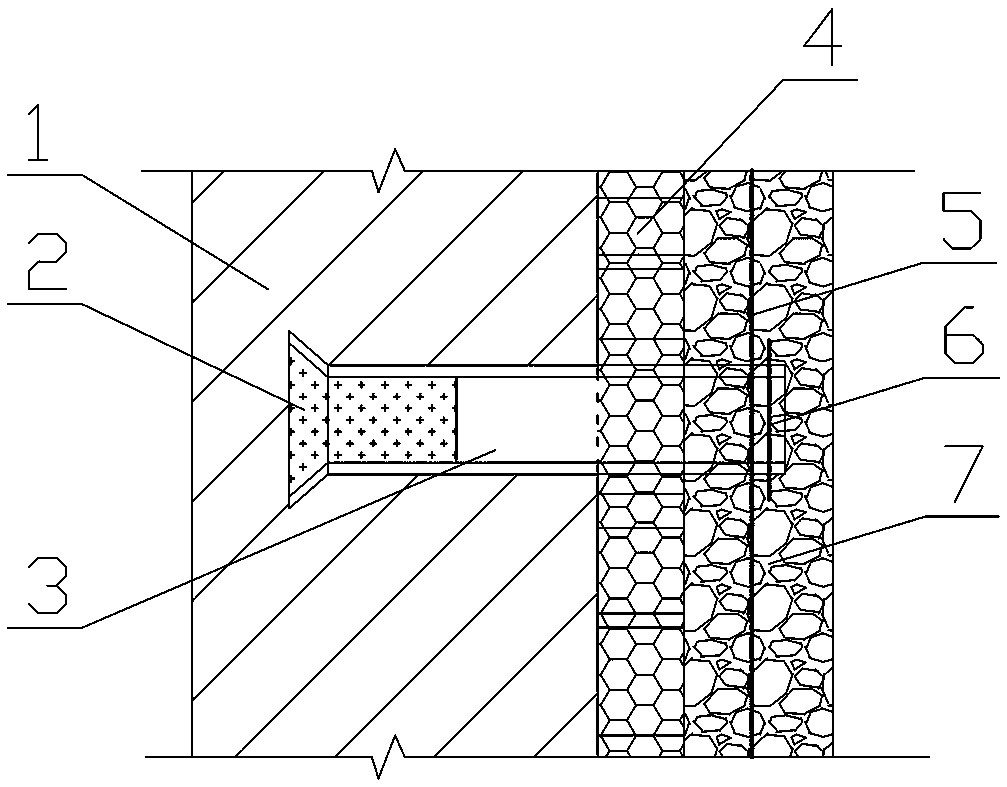

Integrated thermal insulation structure of existing building exterior wall and construction method

InactiveCN108360698AIncrease the shear areaImprove firmnessCovering/liningsHeat proofingRebarThermal insulation

The invention discloses an integrated thermal insulation structure of an existing building exterior wall. The integrated thermal insulation structure comprises an existing wall body, a thermal insulation board and a surface layer. The inner side of the thermal insulation board adheres to the outer side of the existing wall body. The outer side of the thermal insulation board is connected with thesurface layer. A gridded mesh reinforcement is longitudinally arranged in the surface layer. Communicating round holes are reserved in the existing wall body, the thermal insulation board and the surface layer. Connecting pipes are horizontally laid inside the round holes. Small seams are evenly formed in the end faces, laid in the existing wall body, of the connecting pipes. Pipe cushions are arranged at the ends, where the small seams are formed, of the connecting pipes. The ends, laid in the surface layer, of the connecting pipes penetrate through the mesh reinforcement and are longitudinally provided with fixing reinforcements. The invention also provides a construction method of the integrated thermal insulation structure of the existing building exterior wall. The method comprises the following procedures of drilling holes, installing the connecting pipes and the pipe cushions, expanding the connecting pipes, grouting, pasting the thermal insulation board and binding the mesh reinforcement, and painting and maintaining the surface layer. The integrated thermal insulation structure of the existing building exterior wall realizes the integration of existing building exterior wall thermal insulation and the structure, so that the same serviceable life of the exterior wall external thermal insulation and the structure is ensured.

Owner:河南省华亿绿色建材有限公司 +2

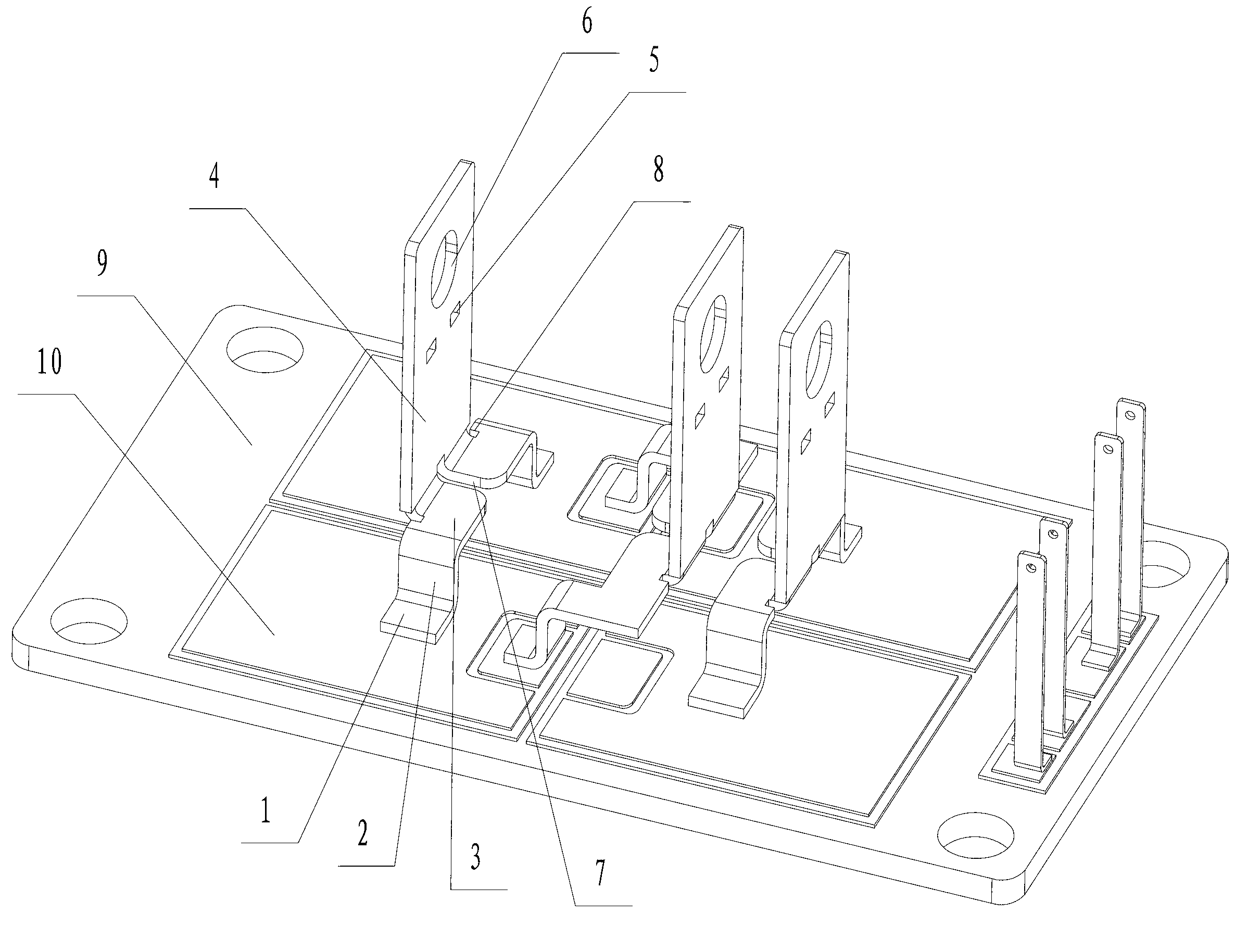

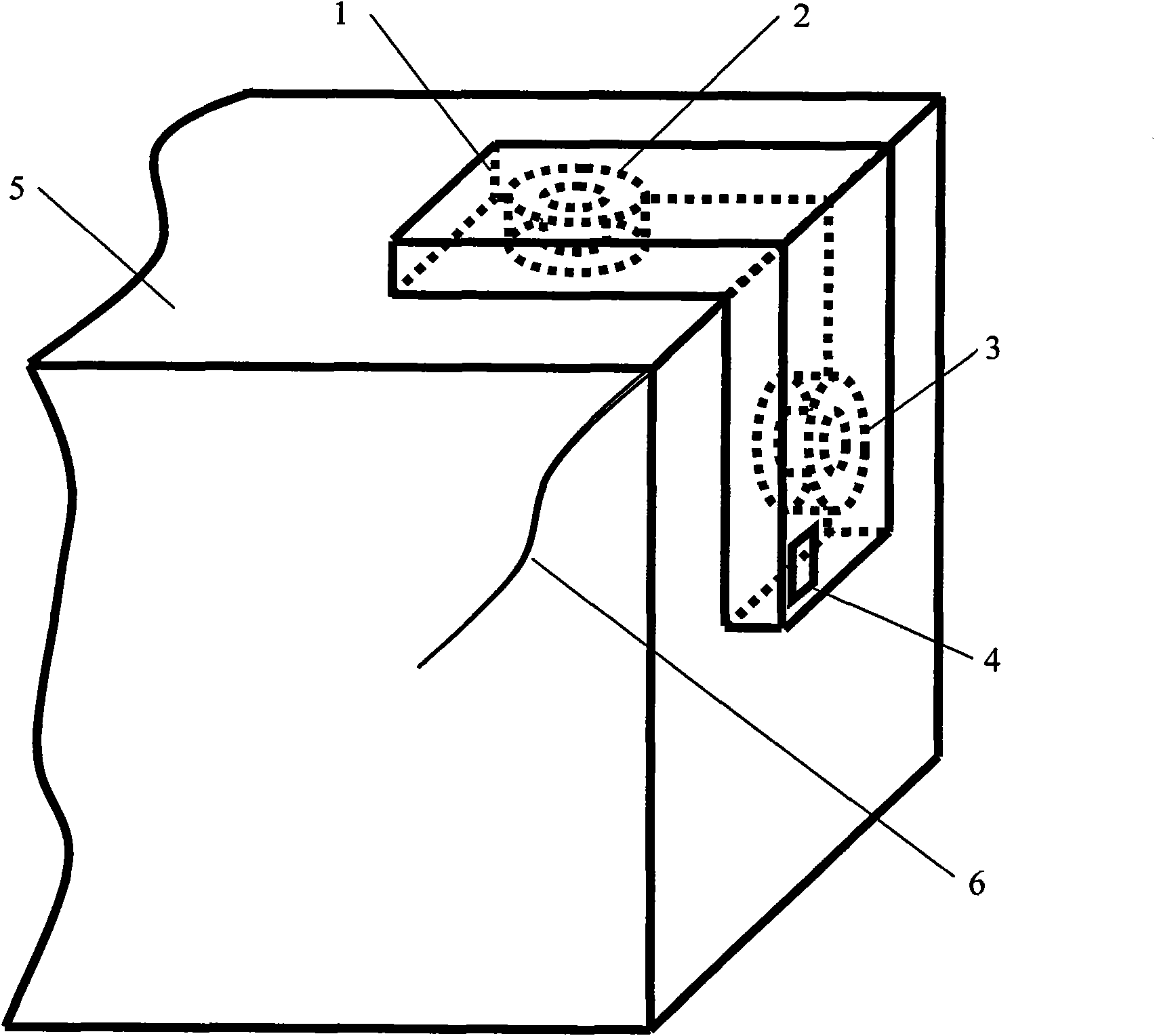

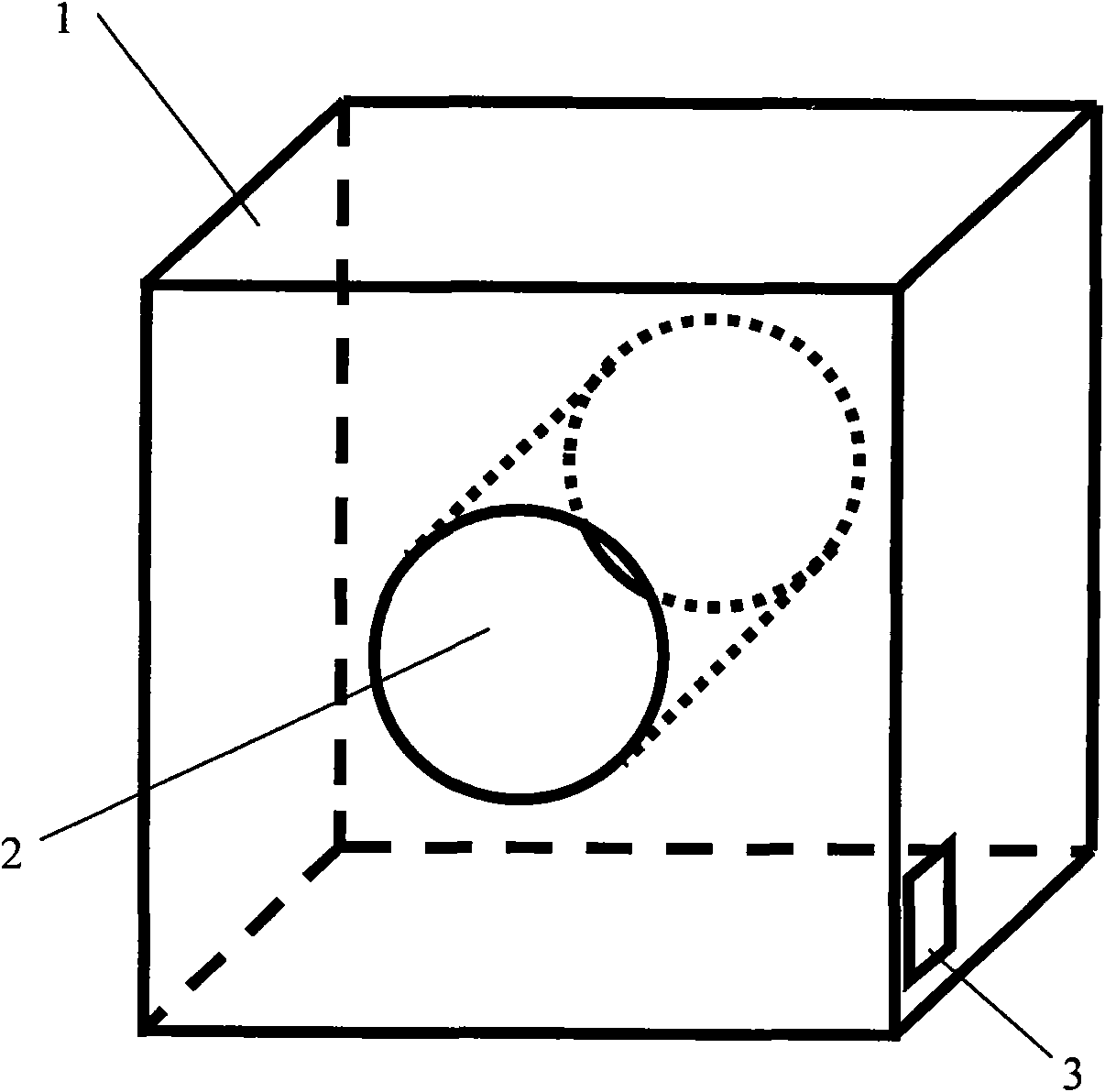

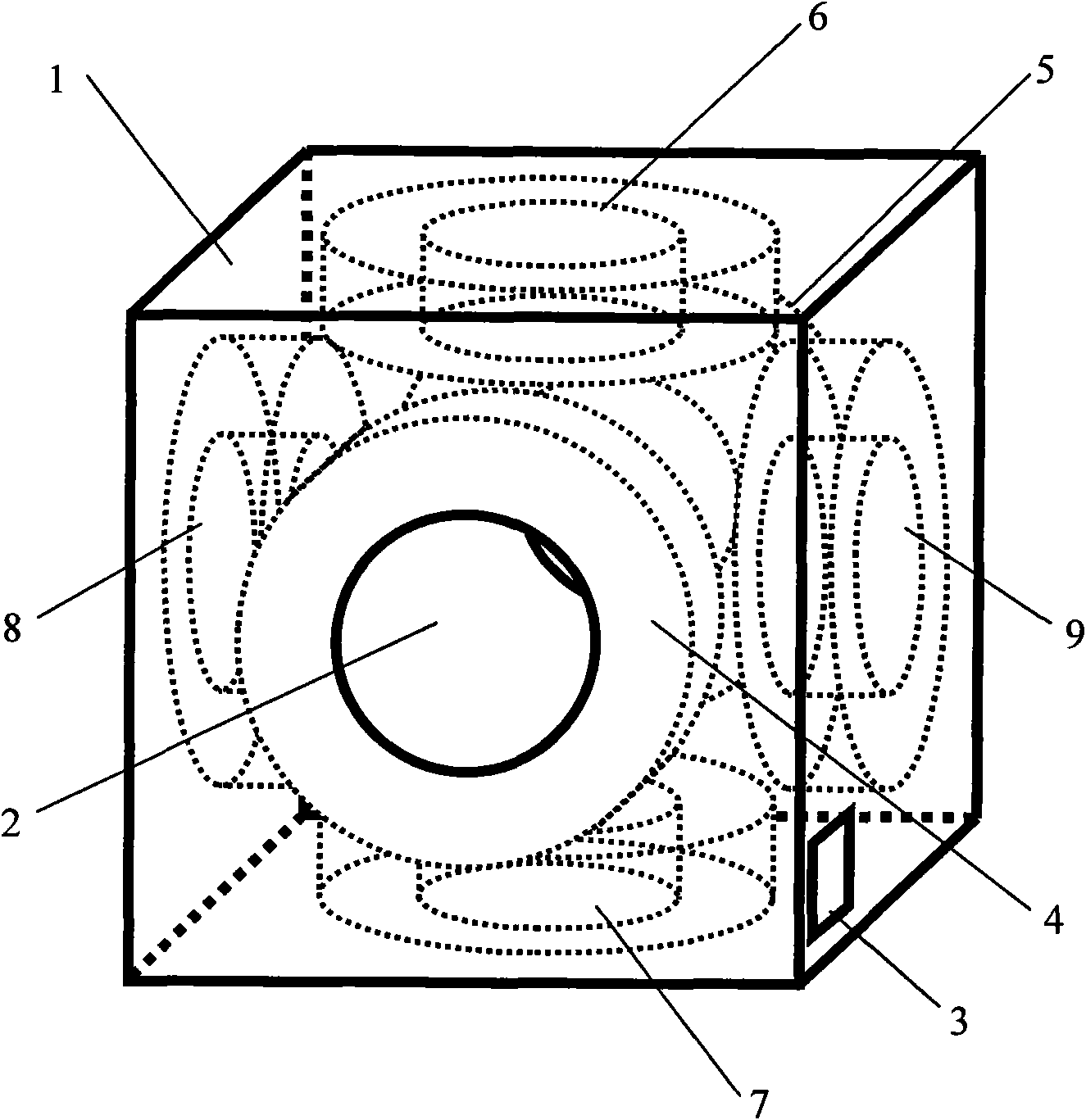

Three-dimensional electromagnetic probe and gyromagnetic detection method

InactiveCN101661018AOvercoming detectionOvercome functionMaterial magnetic variablesAdditive ingredientMetallic materials

The invention relates to a three-dimensional electromagnetic probe and gromagnetic detection method for metal material nondestructive detection and evaluation. The electromagnetic probe comprises a probe body 1, a probe hole 2, a connection port 3, a front detection coil 4, a rear detection coil 5, an upper detection coil 6, a lower detection coil 7, a left detection coil 8 and a right detection coil 9. The probe is characterized in that each detection coil comprises a pair of magnet exciting coils and a pair of detection coils, exciting current of each coil is reasonably adjusted, thus providing a constant spatial rotating magnetic field for gyromagnetic detection. The result obtained by gromagnetic can generate an analog similar to the detected work piece by three-dimensional data visualization, abnormal material quality can be shown by obvious evagination or sinking on the analog, material quality uniformity and abnormal tissue in the interior of metal material can be obviously reflected, thus being helpful for detection personnel to rapidly evaluate the quality of the detected work piece. The invention not only can be used for detection and evaluation of ingredient, mechanic performance and tissue uniformity but also can detect and early warn of tissue abnormality such as crack by non-uniformity of material quality distribution.

Owner:帅立国

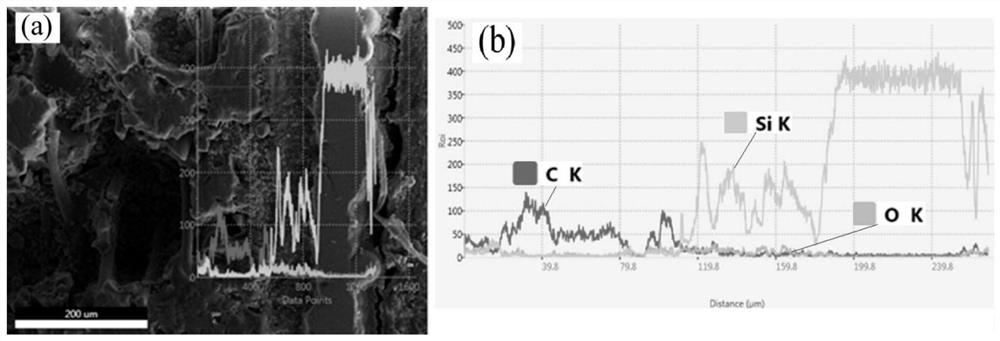

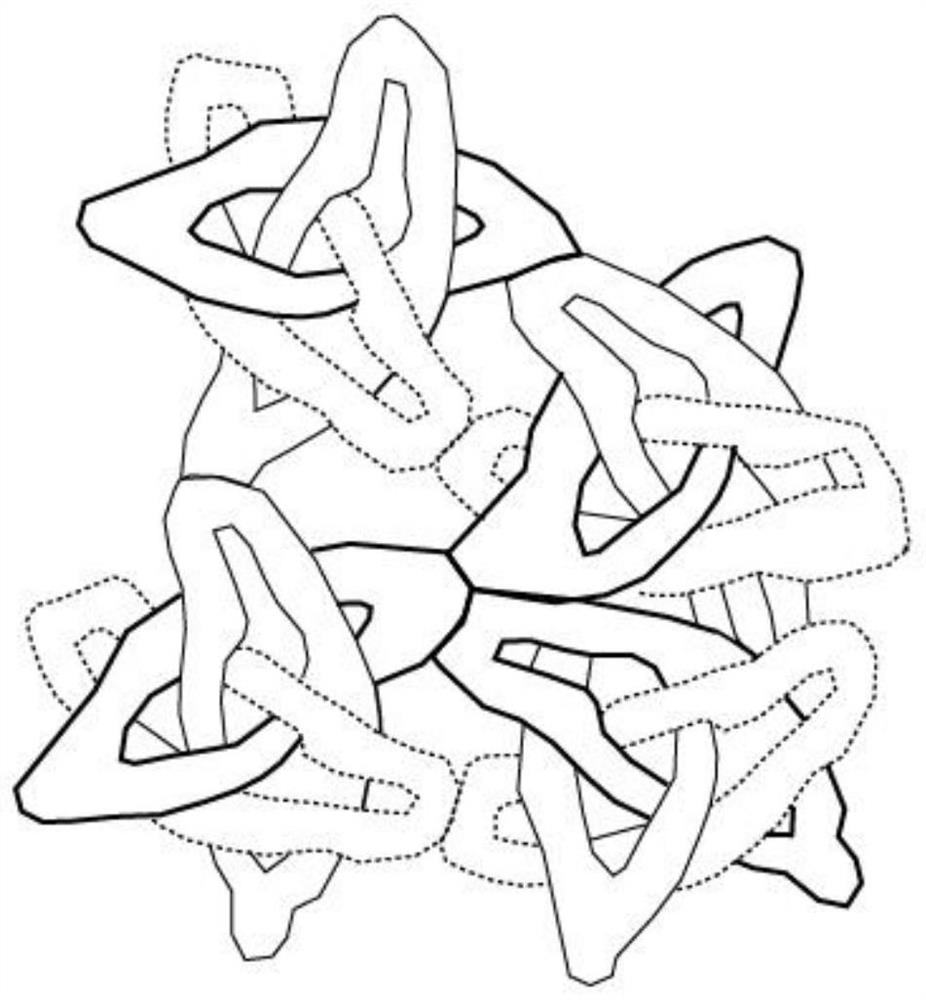

SiC composite coating for porous thermal insulation carbon material and preparation method thereof

ActiveCN112174684ASolve Oxidation Protection ProblemsGuaranteed performanceThermal insulationPorous carbon

The invention provides a SiC composite coating for a porous thermal insulation carbon material and a preparation method of the SiC composite coating. The coating sequentially comprises a carbon sealing and filling layer, a SiC transition layer prepared through a brush coating reaction and a SiC outer coating prepared through a chemical vapor deposition method from inside to outside. According to the invention, the performance of the porous heat-insulating carbon material is ensured, the oxidation protection problem of the porous heat-insulating carbon material is effectively solved, and the high-temperature oxidation resistance of the material can be effectively improved. The structure of the carbon sealing and filling layer can effectively prevent a coating raw material from permeating into the porous carbon felt body, the carbon sealing and filling layer can form pinned interface combination with the porous carbon felt and form firm chemical combination with the SiC transition layerprepared through a brush coating reaction, and the combining capacity of the coating and a porous carbon felt is improved. Besides, the coating preparation process has low requirements on the surfaceof a base material and equipment, is not limited by the shape and the size of the base material, has the advantages of simple equipment process, easiness in operation, capability of preparing large-size and complex-shape special-shaped parts and the like, and has a wide industrial application prospect.

Owner:湖南金钺新材料有限责任公司

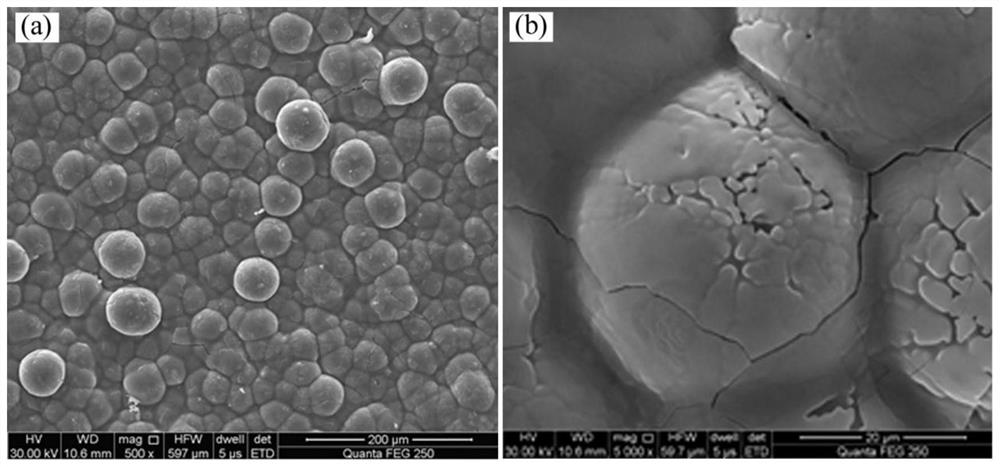

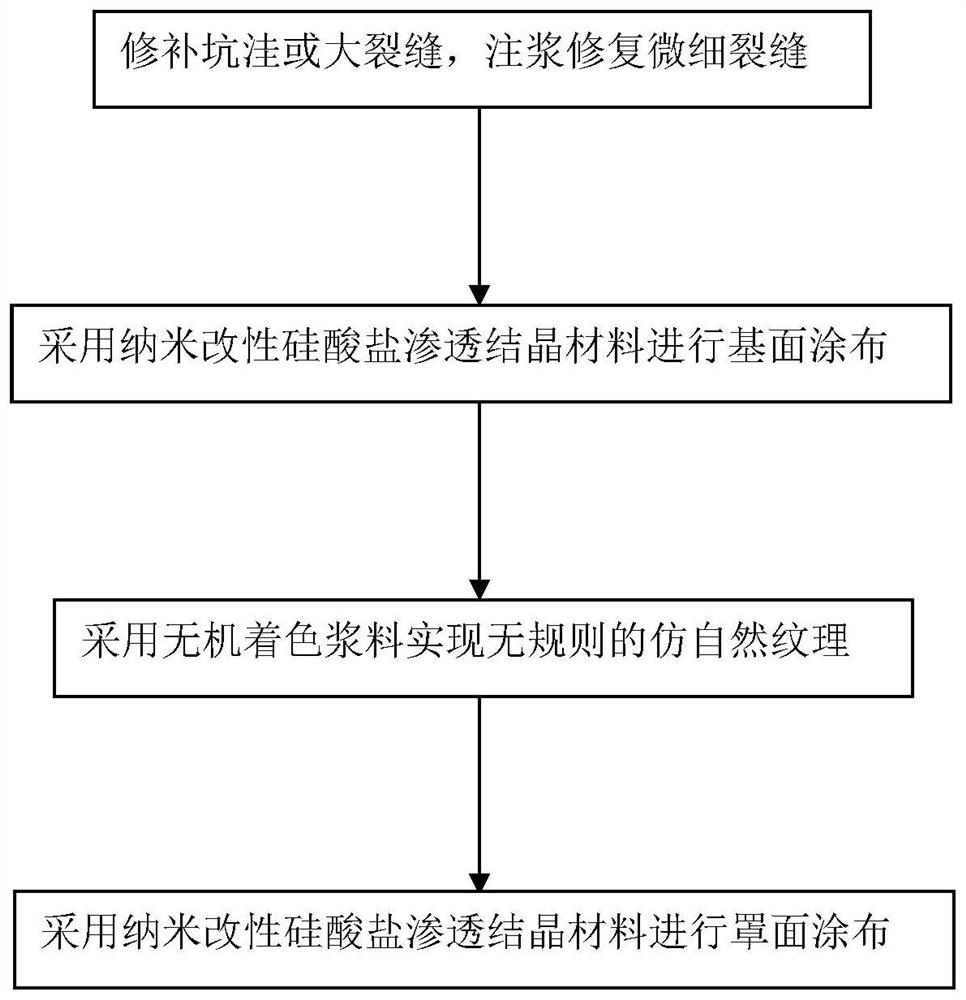

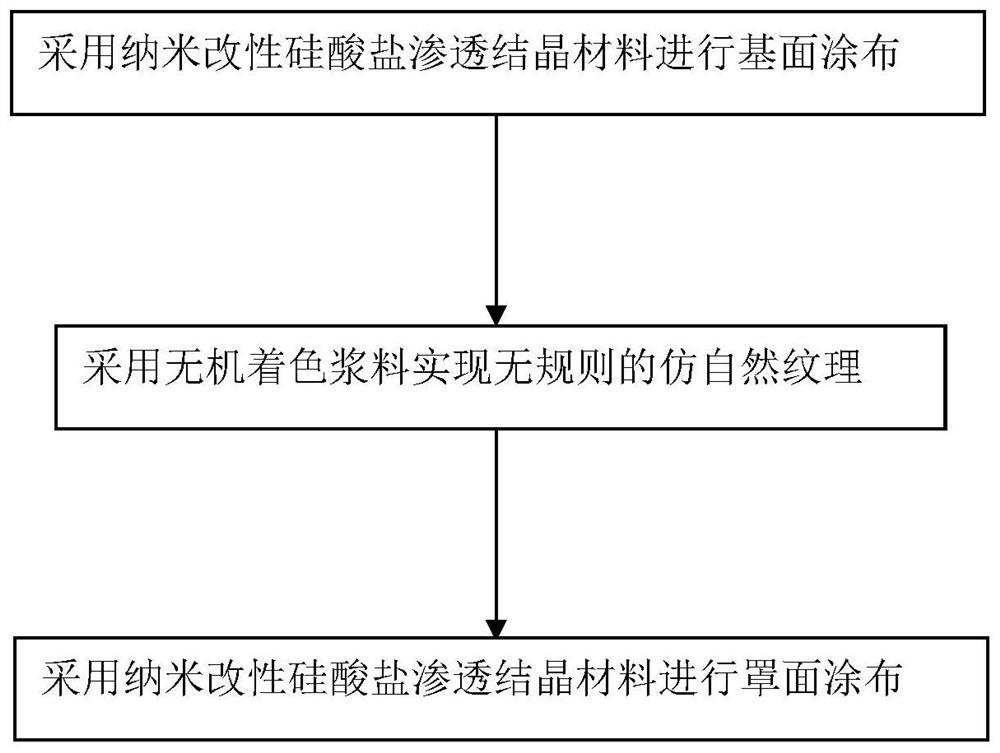

Construction method for creating fair-faced effect on concrete base surface

PendingCN112411910ALow surface requirementsShort intervals between processesCovering/liningsAlkali metal silicate coatingsAdhesiveSilicic acid

The invention relates to a construction method for creating a fair-faced effect on a concrete base surface. The construction method comprises the following steps that 1, concrete base surface coatingis carried out by adopting a nano-modified silicate capillary crystalline material; 2, the concrete base surface is coated with the coloring paste to cover the concrete base surface and / or form surface textures, the coloring paste is prepared by stirring cement-based inorganic powder and an adhesive and adding an inorganic pigment for color mixing; and 3, after the coloring paste is dried, finish-coat coating is carried out by adopting a nano-modified silicate capillary crystalline material, the nano-modified silicate capillary crystalline material comprises the following components of, in parts by mass, 5 parts-30 parts of sodium silicate, 5 parts-20 parts of potassium silicate, 0.05 part-0.5 part of a surfactant, 0.1 part-1 part of a reaction retarder, 0.1 part-0.5 part of a reducing agent, 0.1 part-2 parts of a reaction promoter, 0.01 part-0.5 part of an anti-freezing agent, 0.1 part-1 part of a metal ion blocking agent, 0.1 part-1 part of a surface enhancer, 0.1 part-0.5 part of anantirust agent and 40 parts-70 parts of deionized water. The construction method has a lasting protection effect on concrete, can be particularly applied to the outdoor roof surface of a concrete building, and can maintain the fair-faced decorative effect for a long time.

Owner:北京易晟元环保工程有限公司

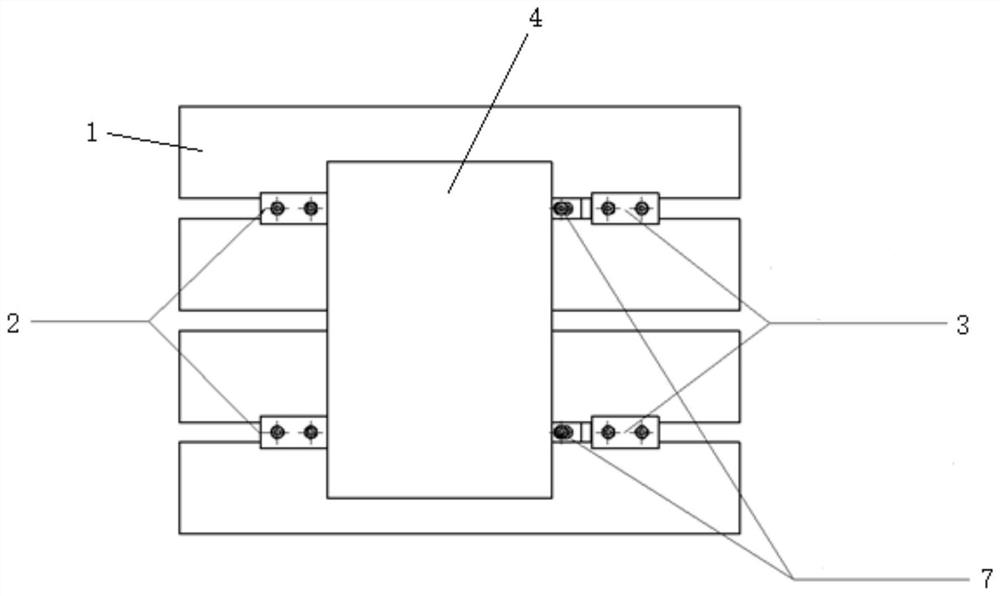

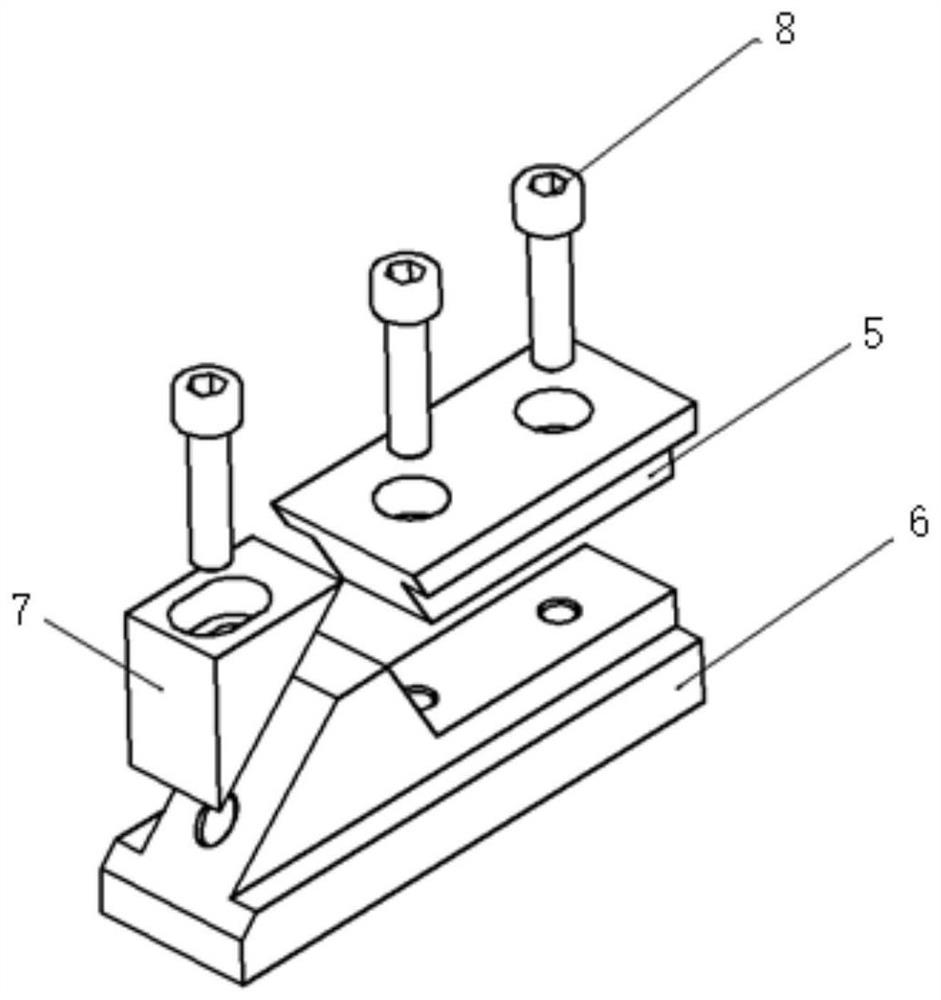

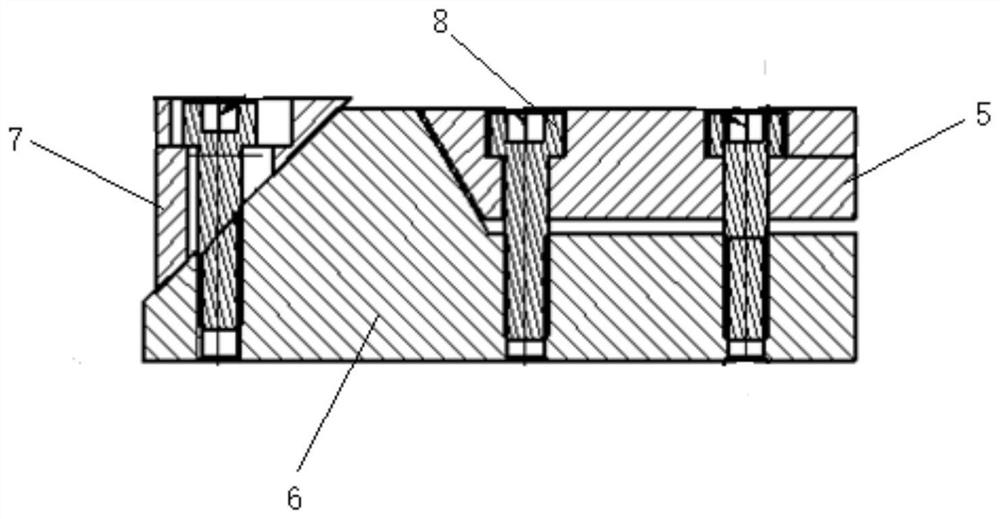

Universal fixture for flat plate type parts subjected to milling

ActiveCN113369940ALow surface requirementsAvoid deformationPositioning apparatusMetal-working holdersStructural engineeringMachine tool

The invention provides a universal fixture for flat plate type parts subjected to milling. The universal fixture for the flat plate type parts subjected to milling comprises positioning assemblies and locking assemblies, wherein the positioning assemblies and the locking assemblies are detachably connected with a machine tool workbench; and the positioning assemblies and the locking assemblies are arranged on the two sides of the parts in a one-to-one correspondence mode and abut against the side walls of the parts respectively. When the fixture provided by the invention is in use, a workpiece only needs to be flatly laid on the workbench, the positioning assemblies abut against one side of the workpiece, the locking assemblies and the workbench are locked on the other side of the workpiece, then bolts are slowly tightened to enable sliding locking blocks to abut against the other side of the workpiece, and the workpiece is locked in a side pressing mode through a small contact face; the workpiece is directly placed on the workbench, so that the bottom face of the workpiece has a good supporting effect during machining, and cutter vibration is not prone to being generated; downward pressing force does not exist, so that deformation caused by external force due to the fact that clamping force is too large or the surface of a blank is uneven can be avoided; and the requirement for the appearance and the surface of the workpiece is low due to the fact that the clamping position is adjustable, so that clamping can be conducted even if the two side faces are not parallel, and the applicability is high.

Owner:AEROSPACE PRECISION PROD INC LTD

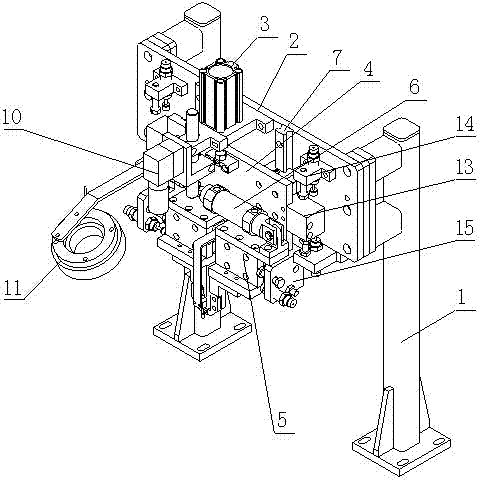

Square full-automatic welding machine

PendingCN107538125ALow surface requirementsNot fragile metal propertiesNon-electric welding apparatusUltrasonic weldingSlide plate

The invention discloses a square full-automatic welding machine. The square full-automatic welding machine comprises a clamping mechanism and an ultrasonic welding machine, wherein the clamping mechanism comprises a bracket, a bracket connecting plate arranged on one side of the bracket, a vertical cylinder arranged on the bracket connecting plate, a vertical sliding plate arranged below the vertical cylinder, horizontal sliding plates arranged below the vertical sliding plate, and a horizontal cylinder arranged on the horizontal sliding plates; an output shaft end of the vertical cylinder isconnected with the vertical sliding plate; vertical guide rails are arranged between the vertical sliding plate and the bracket connecting plate; horizontal guide rails are arranged between the horizontal sliding plates and the vertical sliding plate; the two horizontal sliding plates can horizontally slide on the horizontal guide rails; conducting wire clamps are arranged under the two horizontalsliding plates; the conducting wire clamps are oppositely arranged and are used for clamping to-be-welded conducting wires; and a detection camera used for detecting the welding position and weldingquality of welding parts and a light source are further arranged on the bracket connecting plate. The square full-automatic welding machine has the beneficial effects that welding efficiency is high,welding joints are neat, and size uniformity is high.

Owner:ANWHA SHANGHAI AUTOMATION ENG

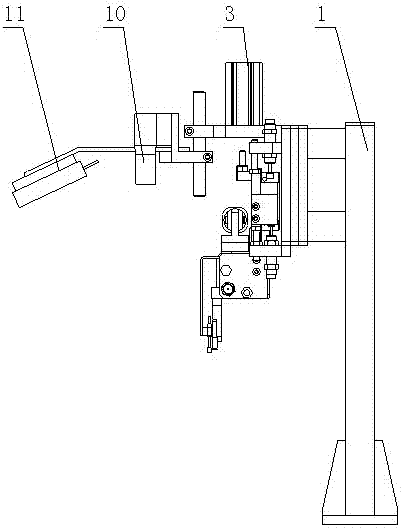

Laser ultrasonic method-based steel rail temperature stress calibration platform

ActiveCN105784269AChange stress stateLow surface requirementsForce/torque/work measurement apparatus calibration/testingTemperature stressPull force

The invention discloses a laser ultrasonic method-based steel rail temperature stress calibration platform, which comprises a steel rail fixing device, a steel rail tension and compression device, a laser ultrasonic excitation device and a laser ultrasonic receiving device, wherein the steel rail tension and compression device comprises steel rail locking mechanisms, oil cylinders and reversing valves, the front end and the rear end of the steel rail are respectively fixed with one steel rail locking mechanism, the oil cylinders are arranged between the same sides of the front steel rail locking mechanism and the rear steel rail locking mechanism, an oil port of a rod cavity of each oil cylinder is connected with the reversing valve via an oil pipe, an oil port of a rodless cavity of each oil cylinder is connected with the reversing valve via an oil pipe, and the reversing valve is connected with a hydraulic power unit via a pipeline. Tension or compression is applied to the steel rail via the steel rail tension and compression device, the stress state of the steel rail is changed, ultrasounds are excited on the surface of the steel rail by the laser ultrasonic excitation device, the laser ultrasonic receiving device receives ultrasonic signals, and the receiving time under different stresses is marked. Pulse laser is adopted to excite the ultrasounds, a coupling agent is not needed, a non-contact mode is provided, requirements on the surface of the steel rail are low, the detection speed is quick, and the efficiency and the precision are high.

Owner:WENZHOU UNIVERSITY

Preparation method for lamination blocking type package materials

ActiveCN102380989BAvoid damageLow surface requirementsPackage recyclingFlexible coversCardboardImage resolution

The invention relates to a preparation method of laminated packaging material with barrier property. The preparation method comprises a step of performing a surface treatment method for two side surfaces of base materials with the barrier property to obtain a double-sided barrier layer; a step of compositing one side surface of a supporting-layer base material with one surface of the barrier layer in step 1 through extruding; and a step of compositing a protection layer with the other surface of the barrier layer in step 2, and compositing a heat-sealing layer with the other side surface of the supporting-layer base material. The supporting layer is composed with a light shielding layer and a printing layer, thereby reducing requirements of printing for cardboard, greatly improving resolution of images and reducing cost at the same time. By using a plasma method to process the barrier base material, the barrier layers, instead of aluminium foil, are formed at two side surface of the barrier base material, so that problems of difficult recovery and degradation caused by discharging of the aluminium foil can be reduced, and blocking rate of oxygen can be improved at the same time.

Owner:GREATVIEW BEIJING TRADING CO LTD

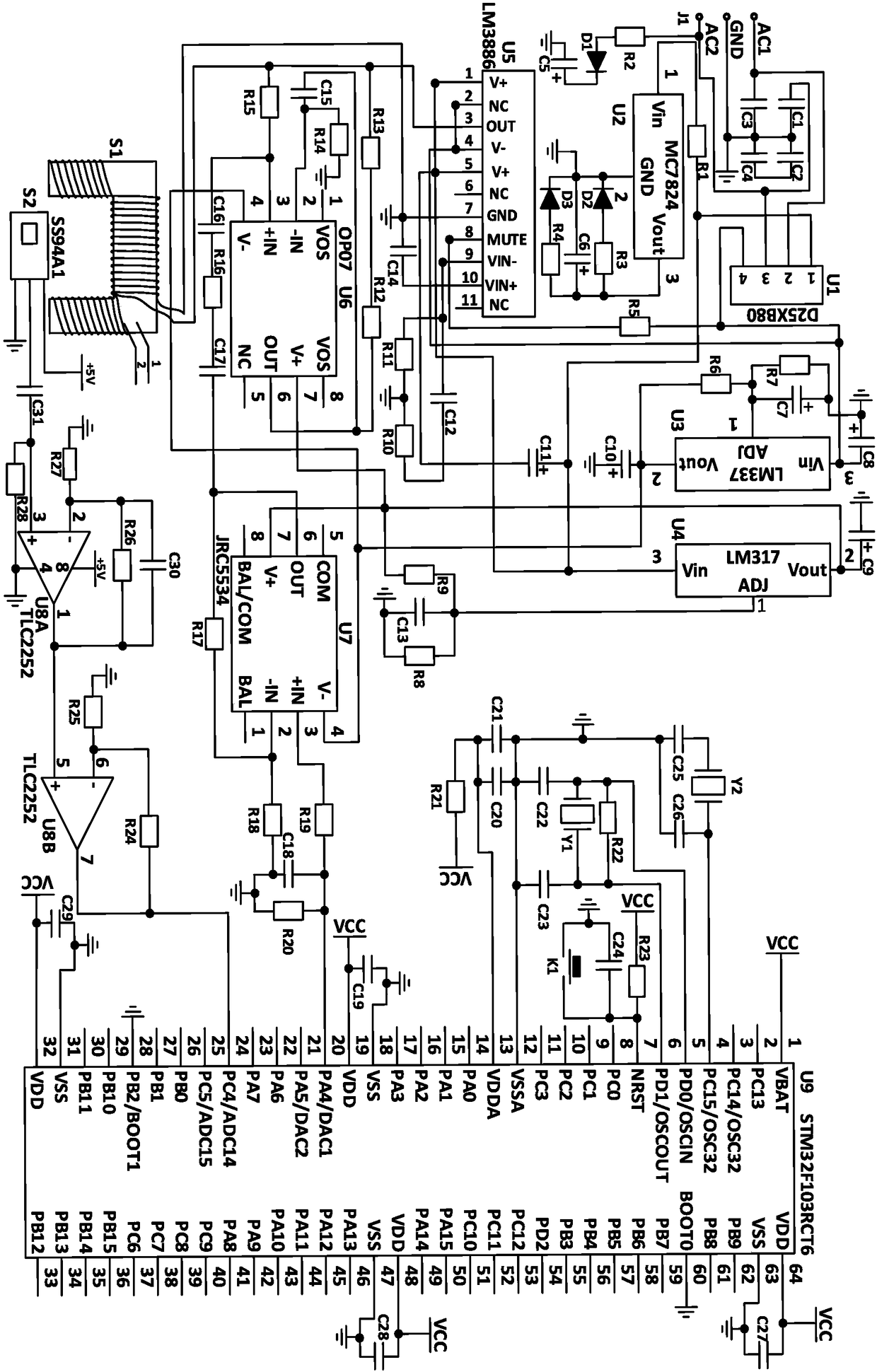

Low-frequency leakage flux based internal flaw detection circuit for ferro magnetic material

ActiveCN108205011AHighly integratedSmall sizeMaterial magnetic variablesSignal processing circuitsSignal on

The invention discloses a low-frequency leakage flux based internal flaw detection circuit for a ferro magnetic material, and belongs to the field of electromagnetic application and nondestructive testing. The low-frequency leakage flux based internal flaw detection circuit is characterized by consisting of a front amplifying circuit, a servo circuit, a power amplifying circuit, a magnetizing circuit, a signal acquiring circuit, a signal processing circuit and a power supply circuit, wherein the front amplifying circuit adopts a JRC5534 chip as a signal amplifier; the servo circuit adopts an OP07 servo chip; the power amplifying circuit adopts an LM3886 power amplifying chip; the magnetizing circuit adopts zinc ferrite manganese oxide and an enameled wire; the signal acquiring circuit adopts SS94A1 as a hall effect sensor and adopts a TLC2252 as a signal amplifier; the signal processing circuit adopts an STM32F103RCT6 single chip microcomputer; and the power supply circuit adopts LM317and LM337 chips as an AC / DC voltage-reducing module. A collected magnetic field signal on the surface of the ferro magnetic material is compared with an exciting signal, and a defect position of a tested part can be preliminarily detected through a phase difference of two signals.

Owner:CHINA JILIANG UNIV

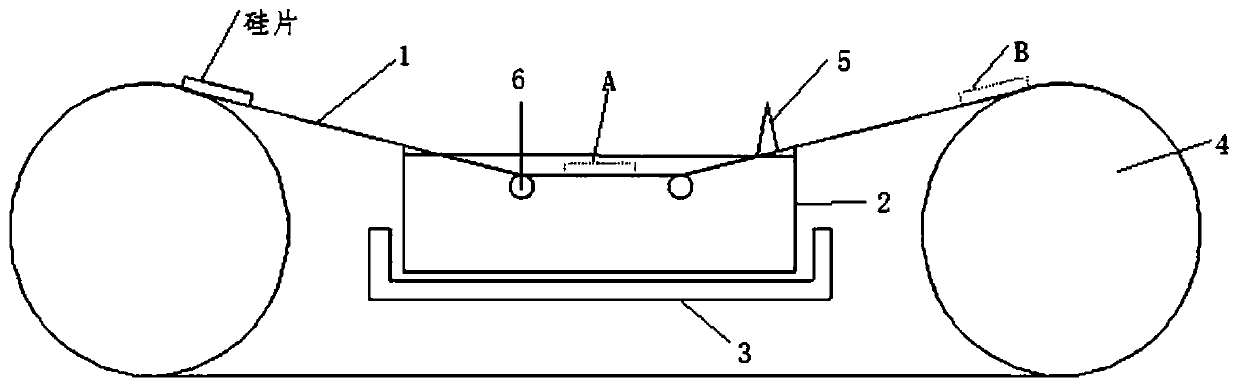

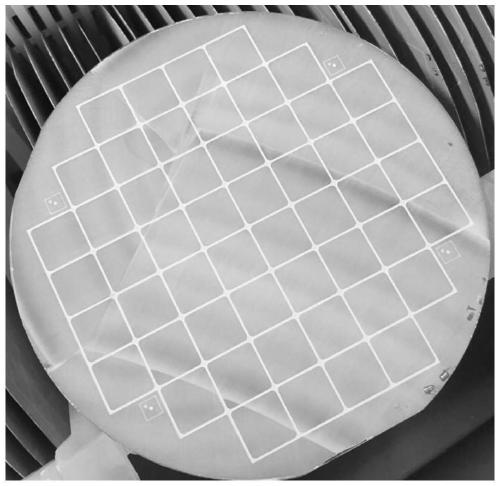

Device and method for automatically powdering silicon wafer

PendingCN111564378ALow surface requirementsUniform coatingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon chip

The invention provides a device and a method for automatically powdering a silicon wafer. The device comprises transmission equipment, a powder scraping plate and powdering equipment, wherein the powdering equipment is used for coating a silicon wafer with glass paste, the powdering equipment comprises ultrasonic equipment and a storage tank, the storage tank is used for containing the glass paste, and the ultrasonic equipment is used for ultrasonically treating materials in the storage tank; and the transmission equipment is used for transmitting the silicon wafer, sending the silicon wafer into the glass paste of the storage tank, carrying the powdered silicon wafer away from the glass paste, and removing the redundant glass paste on the surface of the powdered silicon wafer through thepowder scraping plate. The invention further provides an automatic powdering method completed through the automatic powdering equipment. According to the automatic powdering device and method, a glassfilm is uniformly coated, a passivation area is well protected, the automation degree is high, and the efficiency is high.

Owner:捷捷半导体有限公司

Machining method of target surface

ActiveCN102632447BNo deformationImprove uniformityBelt grinding machinesTarget surfaceChemical reaction

The invention discloses a machining method of a target surface, which belongs to the technical field of the machining process of the target surface. The method utilizes mechanical grinding and polishing equipment to machine. The invention provides equipment conditions for machining a target. A parallel roller shaft with an adjustable opening width is used, and water sand paper or cloth with the granularity of 20-2000 meshes covers the roller shaft; the water sand paper which is from the rough to the fine is firstly utilized and then the cloth is used; and meanwhile, de-ionized water is used for lubricating to grind and polish a metal material. After the grinding and the polishing, the high-pressure de-ionized water is used for washing the surface. In the specific application, the metal material comprises one or more of nickel, copper, silver, titanium, aluminum and vanadium. The machining method has advantages of no requirements on the target surface, fast grinding and polishing speed, no need of using cutting liquid and lubricating liquid for mechanically machining, no chemical reaction on the surface, thin stress layer, high whole uniformity, and no deformation of the whole body. The machining method of the target surface is a simple, reliable, economical and efficient machining method which is adapted to the target with a large area, a great length and a large thickness ratio.

Owner:GRIKIN ADVANCED MATERIALS

Early-warning system capable of preventing magnetic material cracks

InactiveCN109884170ANo damageLow surface requirementsMaterial magnetic variablesInductorMaterial Crack

The invention discloses an early-warning system capable of preventing magnetic material cracks. The early-warning system comprises a first microprocessor, an excitation module, a pen-type probe, a second microprocessor for signal processing and a third microprocessor for data collection. According to an automatic early-warning device against the ferromagnetic material cracks, under the situation that a ferromagnetic technical part is about to generate cracks as a result of various factors or excessive fatigue and overload in the production and using process, a signal is sent to the automatic early-warning device through the first microprocessor, the excitation module, the pen-type probe, the signal processing microprocessor and the data collection microprocessor, so that an alarm from an alarm inductor and a caution from an alarm lamp are caused. According to the device, a series of organization states of a ferromagnetic material are effectively monitored, and therefore potential cracks and other organization anomalies are assessed and early-warned. The device has the advantages of not damaging a workpiece and not having a high requirement on a part surface.

Owner:徐晓静

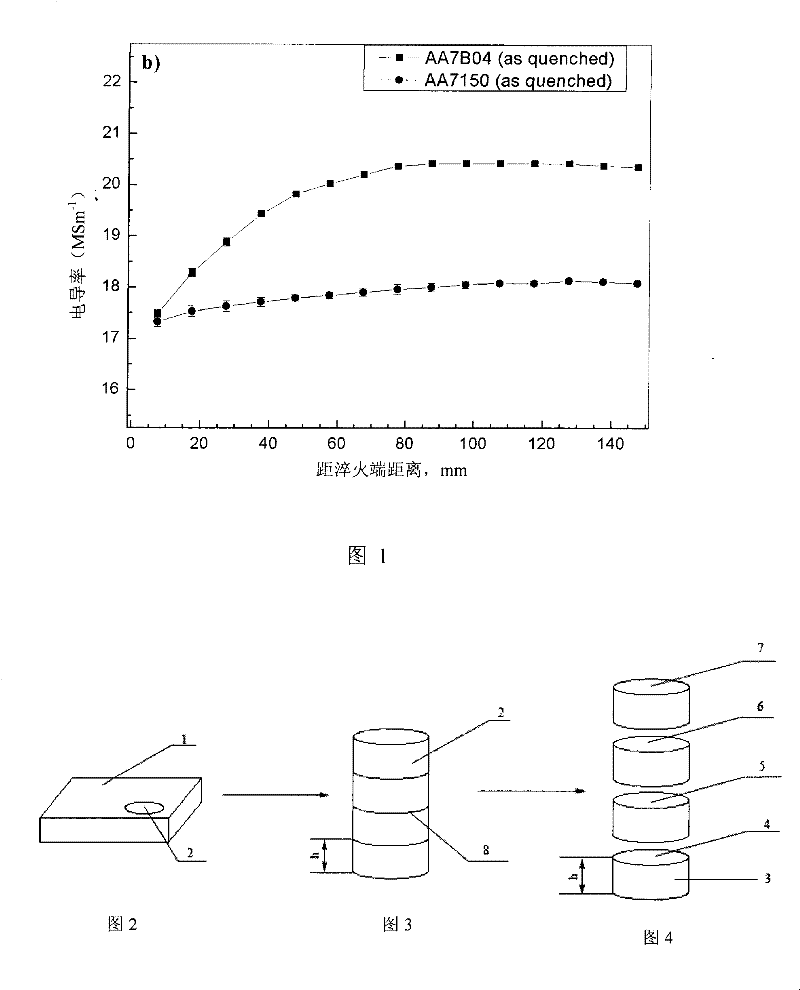

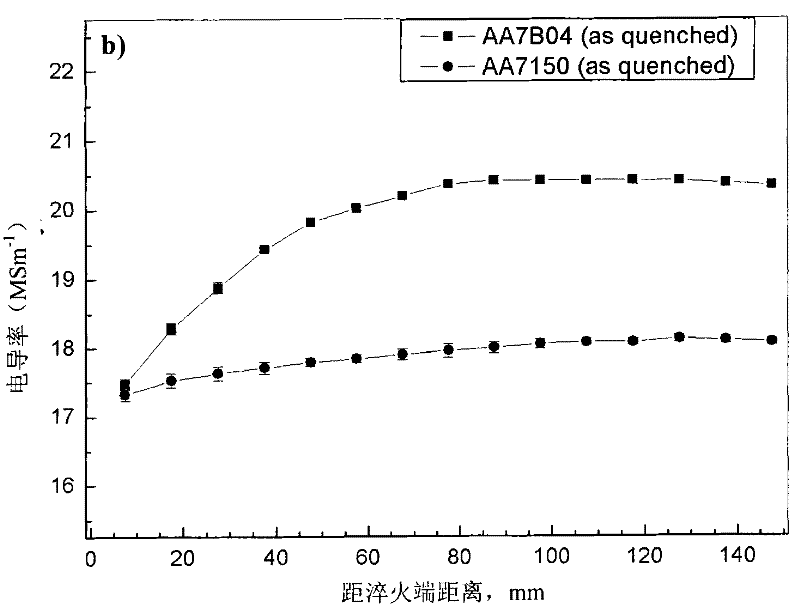

Fast detection method for aluminum alloy hardenability by electro-conductibility

ActiveCN101477073BEasy to operateReal-time detectionMaterial resistanceSolution treatmentSolid solution

The invention provides a method for rapidly detecting the hardenability of aluminum alloy by utilizing electrical conductivity. The method comprises the following steps that: an aluminum alloy material comprises an aluminum alloy board or forging; after the aluminum alloy material is subjected to solution treatment, the solid-solution state aluminum alloy material is subjected to end quenching treatment; the electrical conductivity of the positions on the solid-solution state aluminum alloy material after end quenching treatment is measured, wherein the positions are at different distances from an end quenching surface where a quenching end is; and by taking a distance from the quenching end as abscissa and taking the electrical conductivity of the positions at different distances from the quenching surface as ordinate, the measured electrical conductivity of the positions at different distances from the quenching surface is connected into a curve so as to determine the hardenability of the aluminum alloy material. Due to the detection method, the hardenability of wrought aluminum alloy can be rapidly and accurately evaluated.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com