Adjusting washer and method for making same

A technology for adjusting gaskets and manufacturing methods, applied in the direction of gaskets, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems that cannot meet the precise or fine fit of gaskets, and achieve fast curing, easy operation, and high fit The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: urethane acrylate 92%, polymerization initiator-hydroxyanisole peroxide 3%, accelerator-dimethyl-p-toluidine 4.5%, and stabilizer-saccharin 0.5%

Embodiment 2

[0018] Example 2: urethane acrylate 94%, polymerization initiator-hydroxyanisole peroxide 3%, accelerator-dimethyl-p-toluidine 2.3%, and stabilizer-saccharin 0.7%

Embodiment 3

[0019] Example 3: urethane acrylate 90%, polymerization initiator-hydroxyanisole peroxide 5%, accelerator-dimethyl-p-toluidine 4.5%, and stabilizer-saccharin 1%

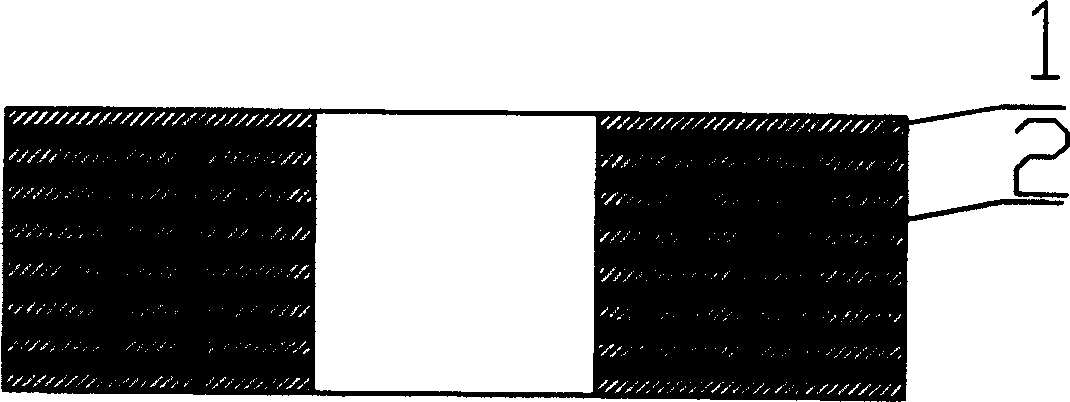

[0020] The manufacturing method of the adjustable adjusting washer, the manufacturing method of the tinplate or stainless steel adjustable adjusting washer is taken as an example, and the concrete steps of its making are:

[0021] A. Forming of 0.05mm thick gasket sheet:

[0022] Place an order for the tinplate or stainless steel used, after slitting, and then finish rolling after heat treatment, to make tinplate or stainless steel coils, and then divide the finished tinplate or stainless steel coils according to the size of the adjustable washer to be made Cut, and then carry out composite die punching on the thin slices obtained after cutting, so as to obtain a gasket sheet with a thickness of 0.05 mm in the required size;

[0023] B. Overlay composite process:

[0024] Coat the 0.05mm-thick gasket sheet obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com