Laser ultrasonic method-based steel rail temperature stress calibration platform

A technology of laser ultrasound and temperature stress, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems that the simulation method cannot simulate the authenticity, the field test method takes a long time, and achieve the detection The effect of fast speed, simple structure and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

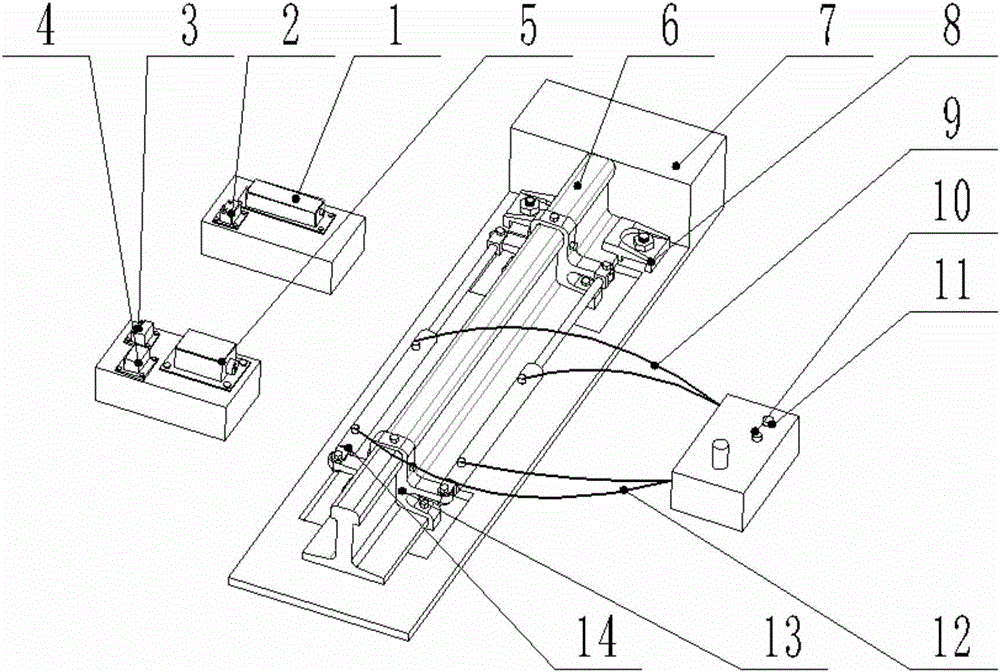

[0018] The rail temperature stress calibration platform based on the laser ultrasonic method includes a rail fixing device for fixing the rail, a rail tension and compression device for applying tension or pressure to the rail to change the stress state of the rail, and a laser ultrasonic for exciting ultrasound on the rail surface An excitation device and a laser ultrasonic receiving device for receiving ultrasonic signals and calibrating the receiving time under different stresses.

[0019] Such as figure 1 As shown, the rail fixing device includes a concrete base 7 for carrying the rail 6 and a pressing plate 8 for pressing and fixing the rail. .

[0020] The rail pulling and pressing device includes a rail locking mechanism 13, an oil cylinder 14 and a reversing valve 11. A rail locking mechanism 13 is respectively fixed at the front and rear ends of the rail, and an oil cylinder 14 is arranged between the front and rear rail locking mechanisms on the same side. The oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com