Device and method for preparing high-density twin crystal material

A high-density, twinning technology, applied in the field of twinning, can solve problems such as difficulty in preparing twinning, and achieve the effects of convenient operation, low energy consumption, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

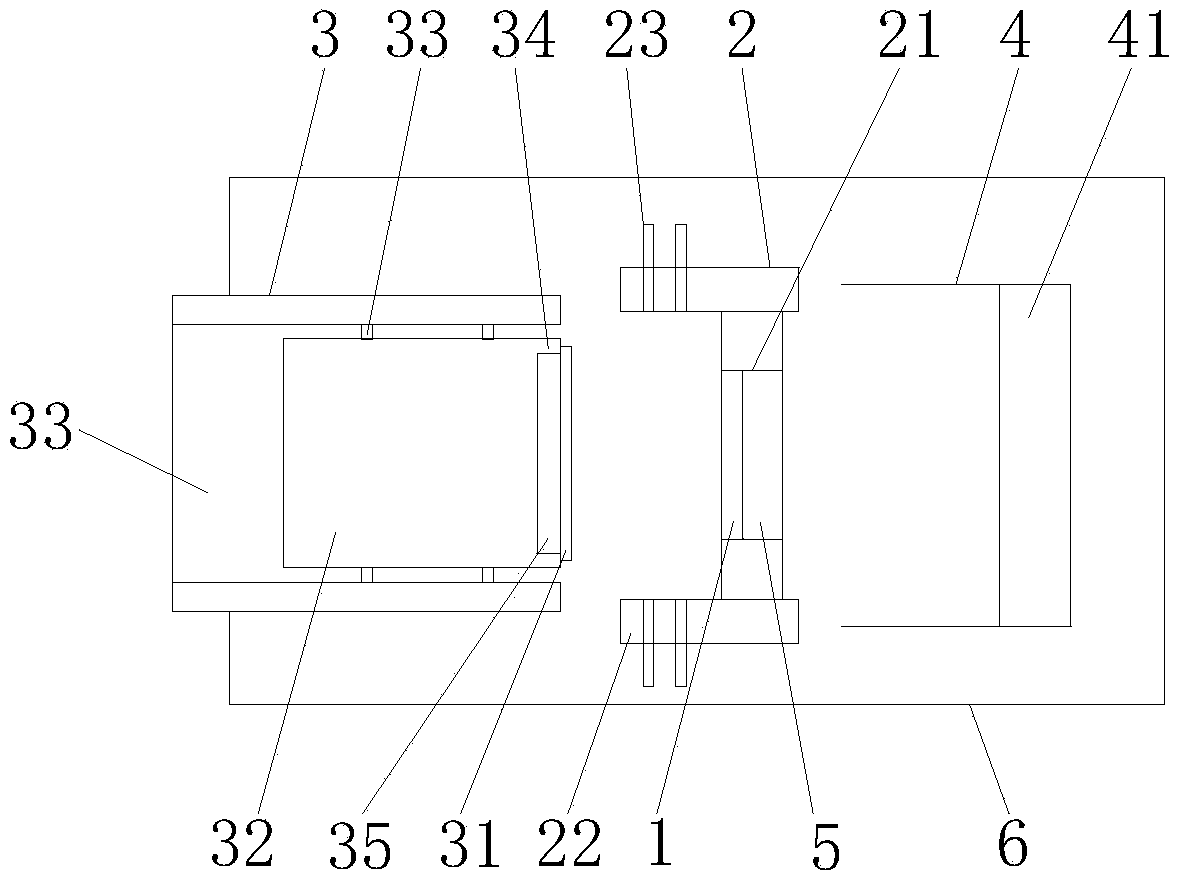

[0055] The equipment for preparing high-density twinned material according to the specific embodiment of the present invention is as figure 1 As shown, it includes a fixing device 2 for fixing the sample 1, a launching device 3 arranged in front of the sample 1, and a recovery device 4 arranged at the rear of the sample 1; the fixing device 2 includes a through hole 21 matching the size of the outer edge of the sample 1; Described launching device 3 comprises the flying sheet 31 that matches with the shape of sample 1 and is parallel, the bullet holder 32 that carries flying sheet 31 to move toward sample 1 and the gun barrel 33 that flies for bullet holder 32; The rearmost buffer layer 41 ; a window 5 connected with the sample 1 and made of the same material is provided behind the sample 1 . Wherein, the fixing device 2 , the launching device 3 and the recovering device 4 are all arranged in the target chamber 6 .

[0056] Said fixing device 2 comprises a fixing frame 22 arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com