Continuous cyclic drilling process applicable to air drilling

A technology of air drilling and technology, which is applied in the direction of wellbore/well parts, earthwork drilling, flushing wellbore, etc. It can solve the problems that air drilling cannot be applied, so as to avoid cross-card leakage, ensure downhole safety, and solve complex processes problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

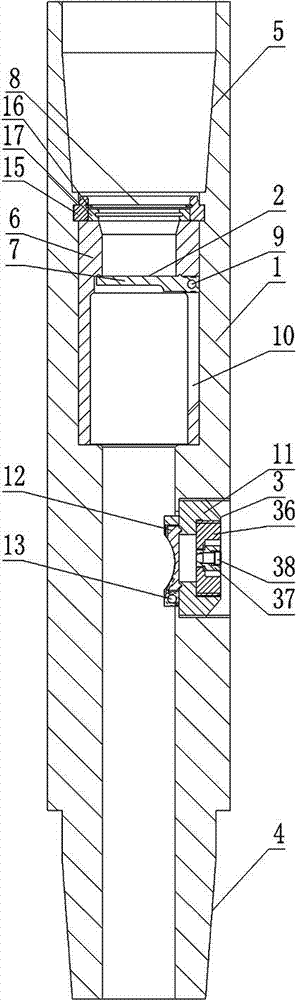

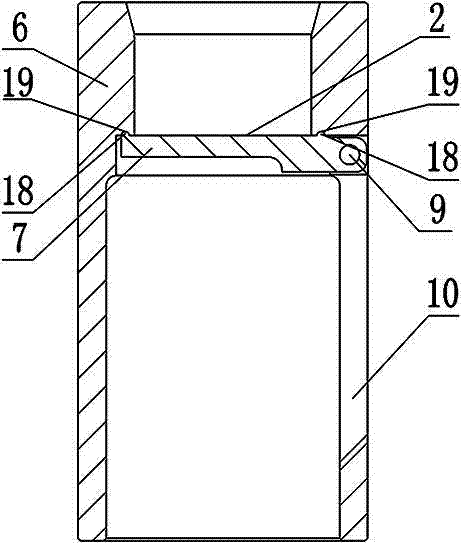

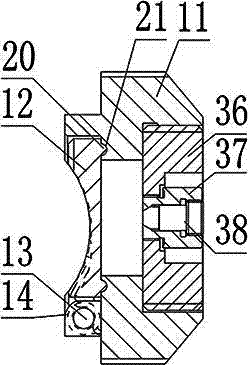

[0031] Such as figure 1 As shown, a continuous cycle short circuit suitable for air drilling, it includes a short circuit body 1, a central check valve 2 arranged on the upper part of the inner cavity of the short circuit body 1, and a lateral valve provided on the side wall of the short circuit body 1. Vertical one-way valve 3, a positioning device 8 for pressing the central one-way valve 2 is also provided in the inner cavity of the short-circuit main body 1. The central one-way valve 2 includes a valve body A6 and a valve plate A7, and the valve plate A7 passes through the rotary shaft A99 Hinged on the side wall of the valve body below the valve hole, the side wall of the valve body A6 is provided with a cavity 10 matching the opening position of the valve plate A7; the valve plate A7 and the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com