Patents

Literature

101results about How to "Save time drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

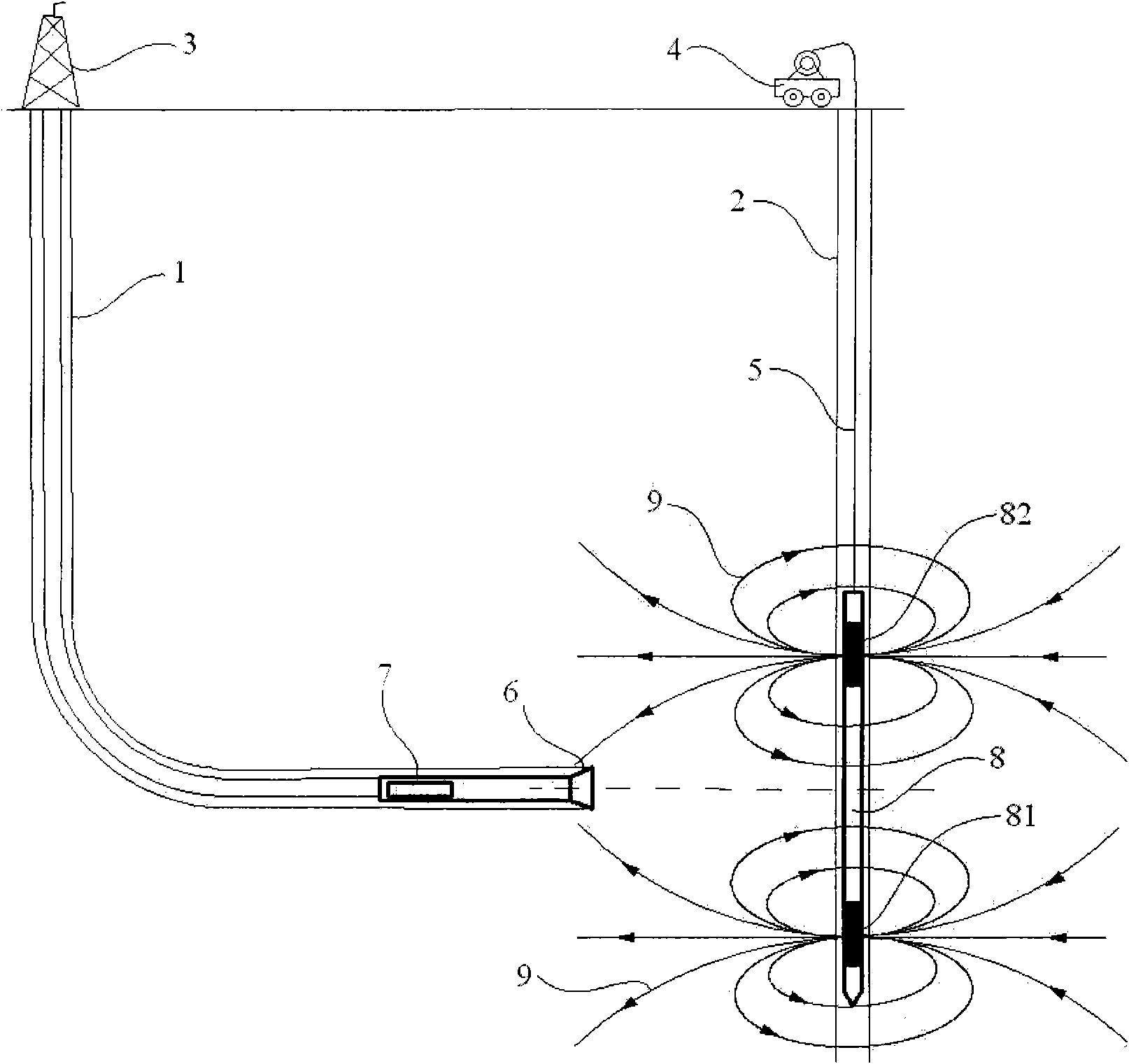

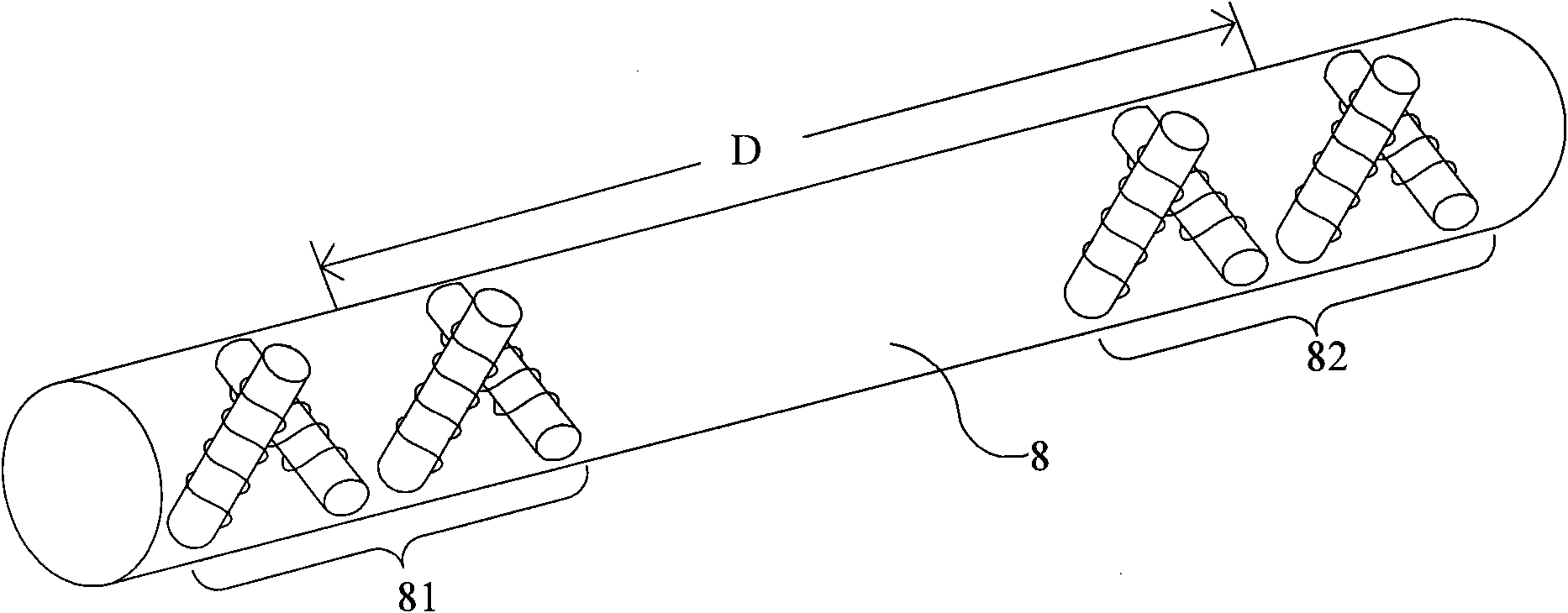

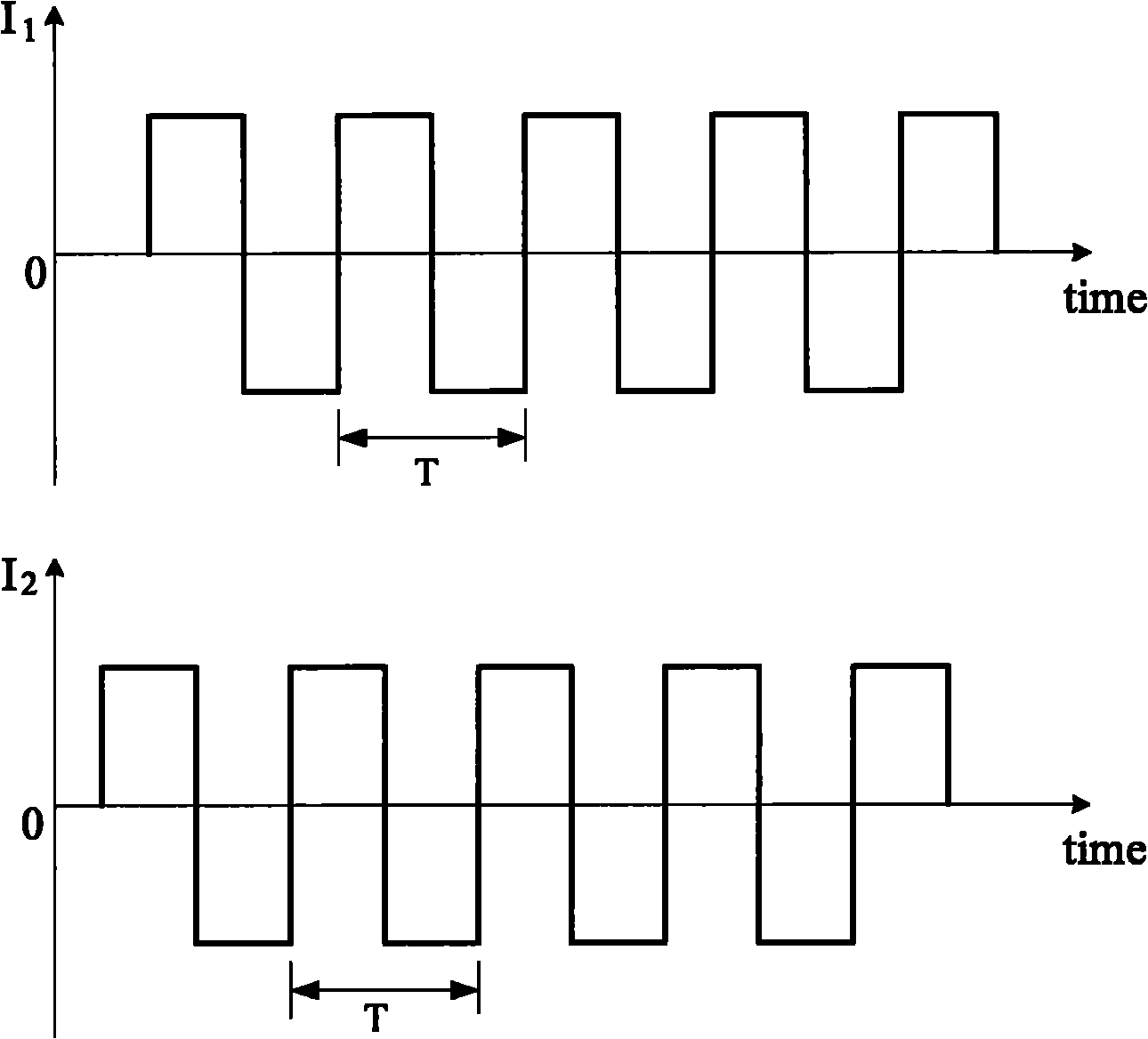

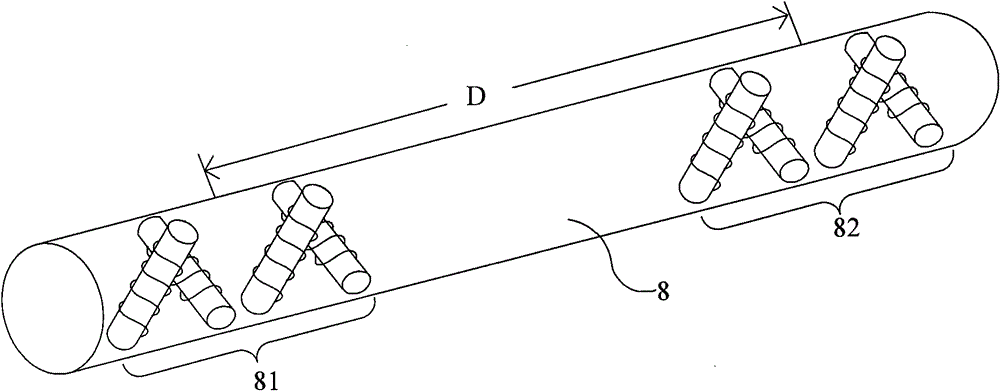

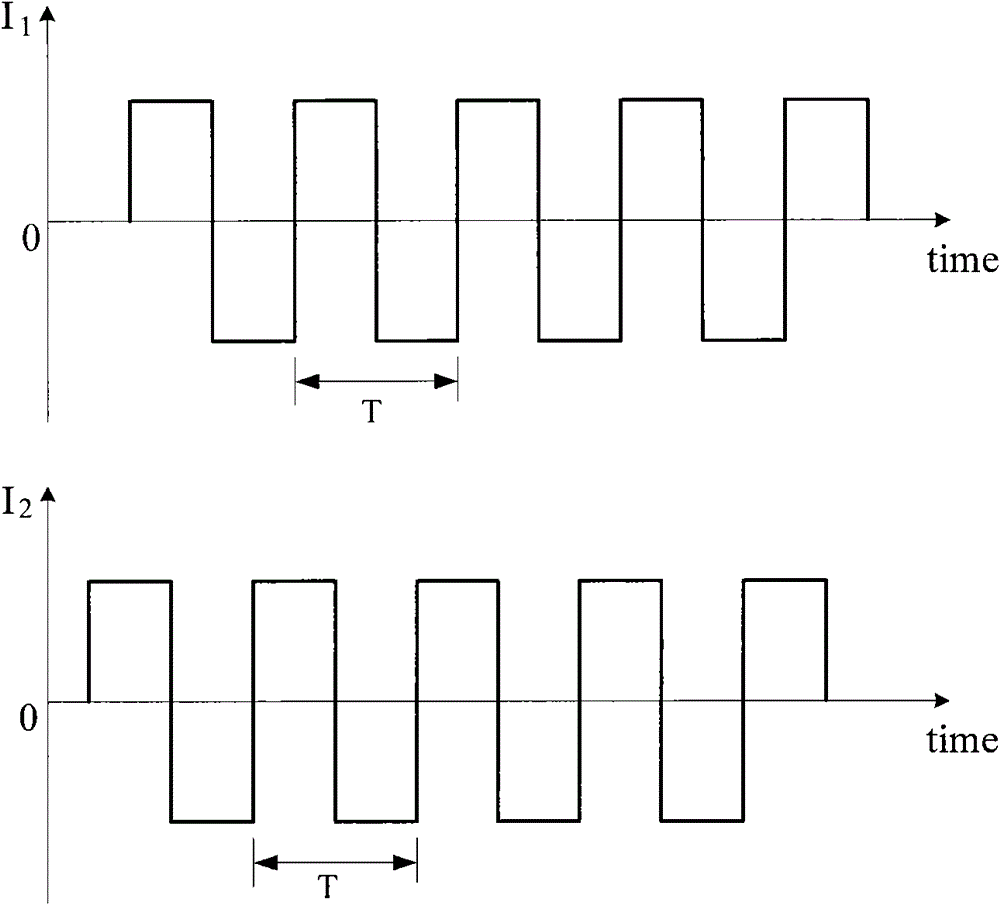

Electromagnetic distance measurement guide system for double solenoid set during drilling

InactiveCN101852078AEasy to change intensityHigh precisionSurveyConstructionsHorizontal wellsData transmission time

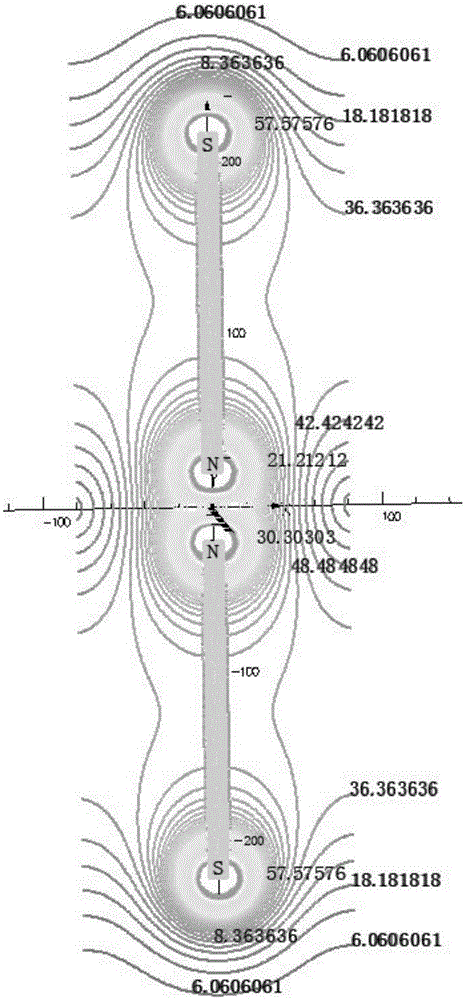

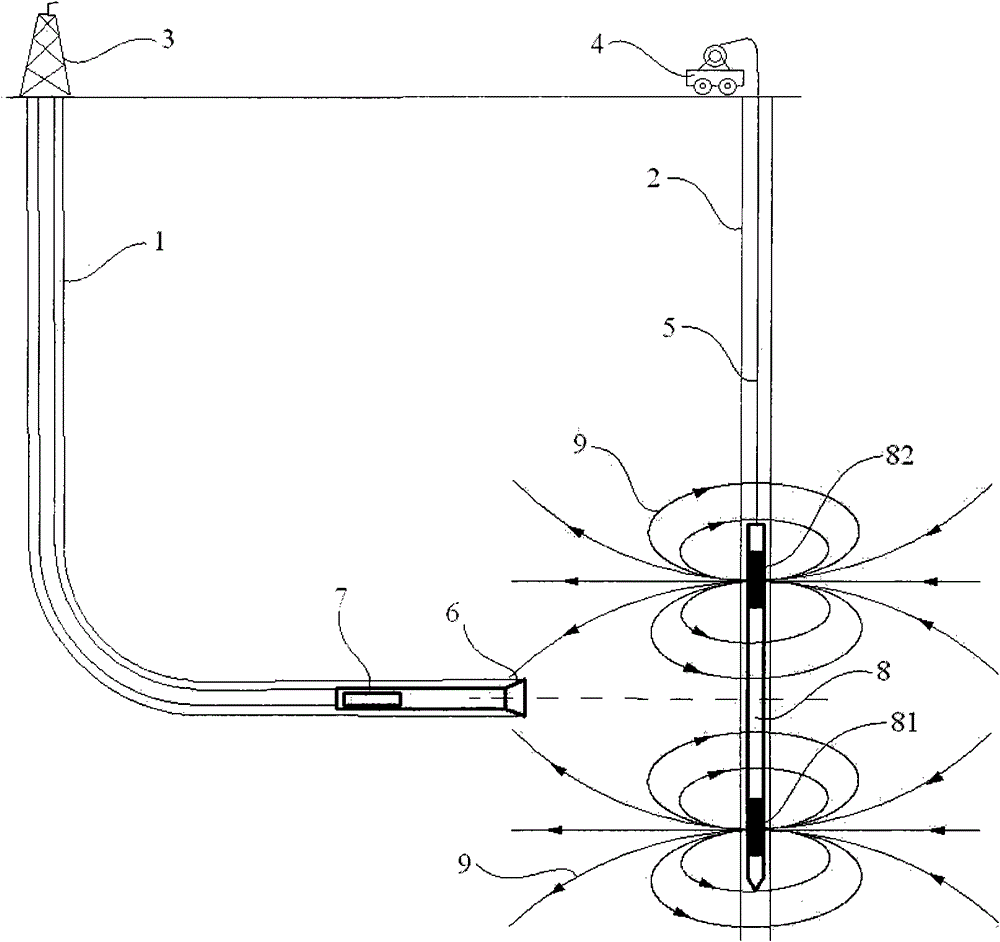

The invention discloses an electromagnetic distance measurement guide system for a double solenoid set during drilling. The system can provide accurate guide measurement and calculation for well track control of double horizontal wells, communicated wells, U-shaped wells, infill wells, and other complex-structure wells. The system mainly comprises a double solenoid set pup joint, a converted MWD,a ground display system, ground equipment, and the like. The double solenoid set pup joint serving as a magnetic signal emission source is put into a drilled well, two rotating magnetic fields with different frequencies are generated, and the system has the measurement accuracy equivalent to the RMRS. During measurement and calculation, the spacing between adjacent wells and relative azimuth can be accurately detected and calculated without dragging the double solenoid set pup joint. Therefore, the measurement can be finished in short time. The data analysis and adjacent well spacing calculation program of the system can be put underground, only a little of calculated necessary data is transmitted to the ground, and the data transmission time is saved. Meanwhile, by improving the current intensity of a solenoid coil, and the like, the intensity of the magnetic signal emission source is improved, and the distance measurement range of the system is easily increased. The system has the advantages of high guide accuracy, wide distance measurement range, short measurement time, and simple structure, and is an effective high-tech means for the detection and control of the distance between the adjacent wells during drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

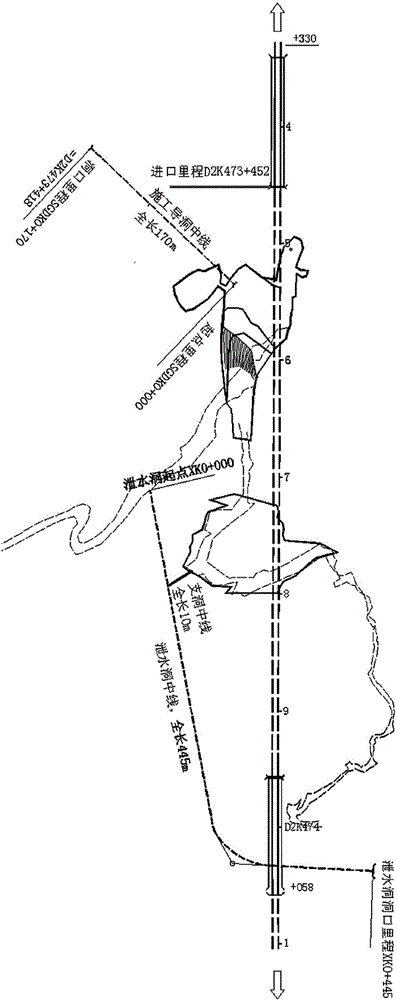

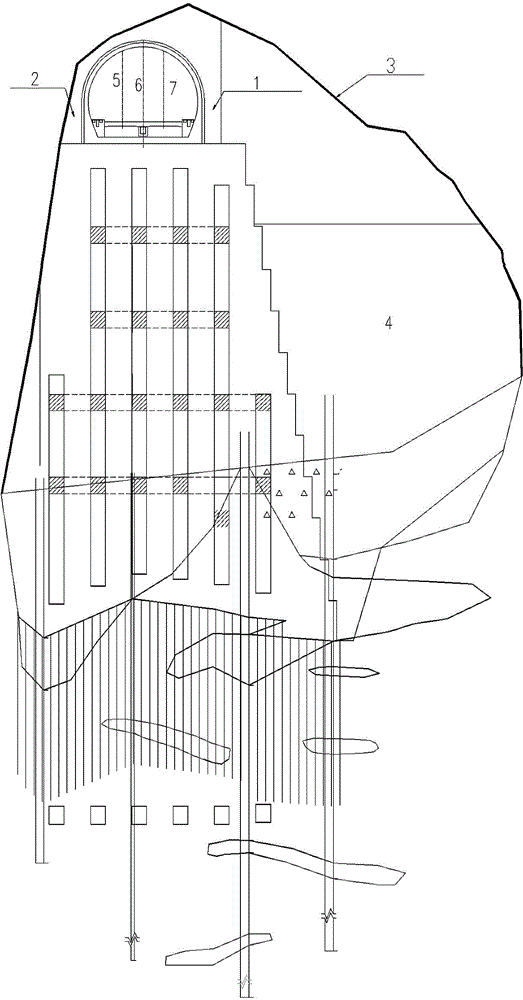

Extra-large karst cave bottom treatment construction method

InactiveCN104532821AReduce dosageGuarantee the effect of grouting reinforcementTunnel liningSoil preservationGeomorphologyKarst

The invention belongs to the technical field of tunnel traversing extra-large karst cave construction, aims at solving the problem that an existing foundation construction method cannot be suitable for extra-large karst caves and provides an extra-large karst cave bottom treatment construction method. A pipe-following drilling process is adopted to synchronously follow a sleeve in the drilling process, the sleeve penetrates through an easily-collapsed stratum to partition the easily-collapsed stratum, the pipe-following drilling is stopped at the karst cave position, then fine aggregate concrete is adopted for backfill, and continuous drilling is completed after backfill is completed. Working efficiency is greatly improved, cost is reduced, and time is saved. The pipe-following drilling process is effective compared with construction of the easily-collapsed stratum and can be universally applied to slope protection under similar geological conditions and foundation base reinforcement treatment projects. A full-automatic casting recording instrument is adopted for recoding, treatment is timely performed in an intermittent or slurry mixture ratio adjusting mode if one-single casting amount is too large or no pressure exists for long time, meanwhile the requirements for casting pressure and casting amount are ensured, and casting reinforcement effect is ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

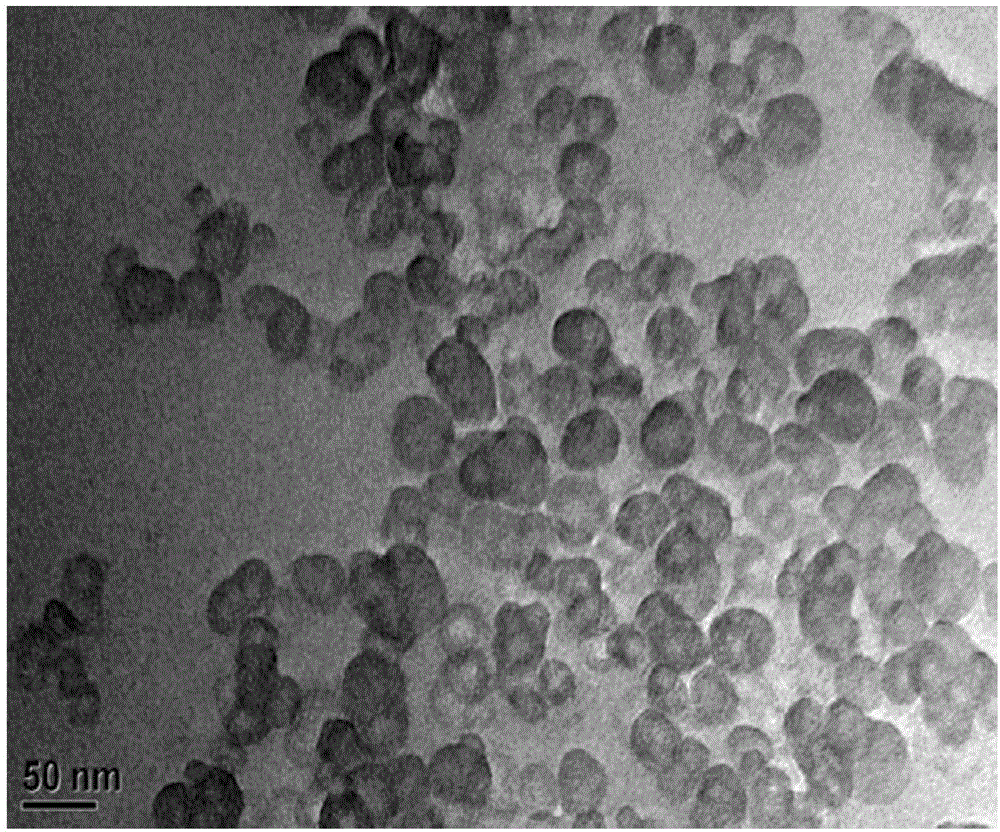

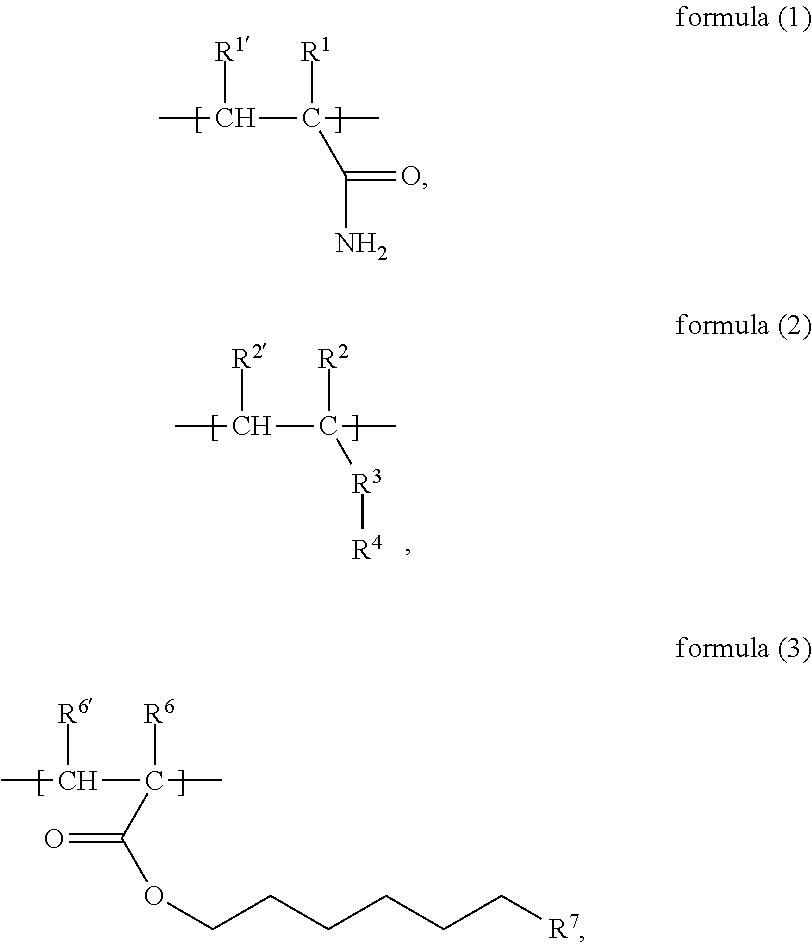

Drilling fluid additive composition application thereof and water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof

ActiveCN106634878AImprove pressure bearing capacityEnhance smoothness and densityDrilling compositionWell drillingDimer acid

The invention relates to the field of well drilling in petroleum industry, in particular to a drilling fluid additive composition application thereof and a water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof. The composition contains a plugging agent, a nano blocking agent, a shear strength improving agent, a bionic wall fixing agent and a bionic shale inhibitor, wherein the plugging agent is a weak crosslinking copolymer, the content of a crosslinking structure in the weak crosslinking copolymer is 0.1-1% by weight, the nano blocking agent is modified silicon dioxide nano-particles, the shear strength improving agent is a dimer acid-organic amine copolymer, and the bionic wall fixing agent is carboxymethyl chitosan grafted with groups deviated from dopamine on main chains. The composition can make a water-based drilling fluid added with the composition as an additive produce an excellent plugging effect in the process of plugging while drilling through the matching effect of the plugging agent, the nano blocking agent, the shear strength improving agent, the bionic wall fixing agent and the bionic shale inhibitor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

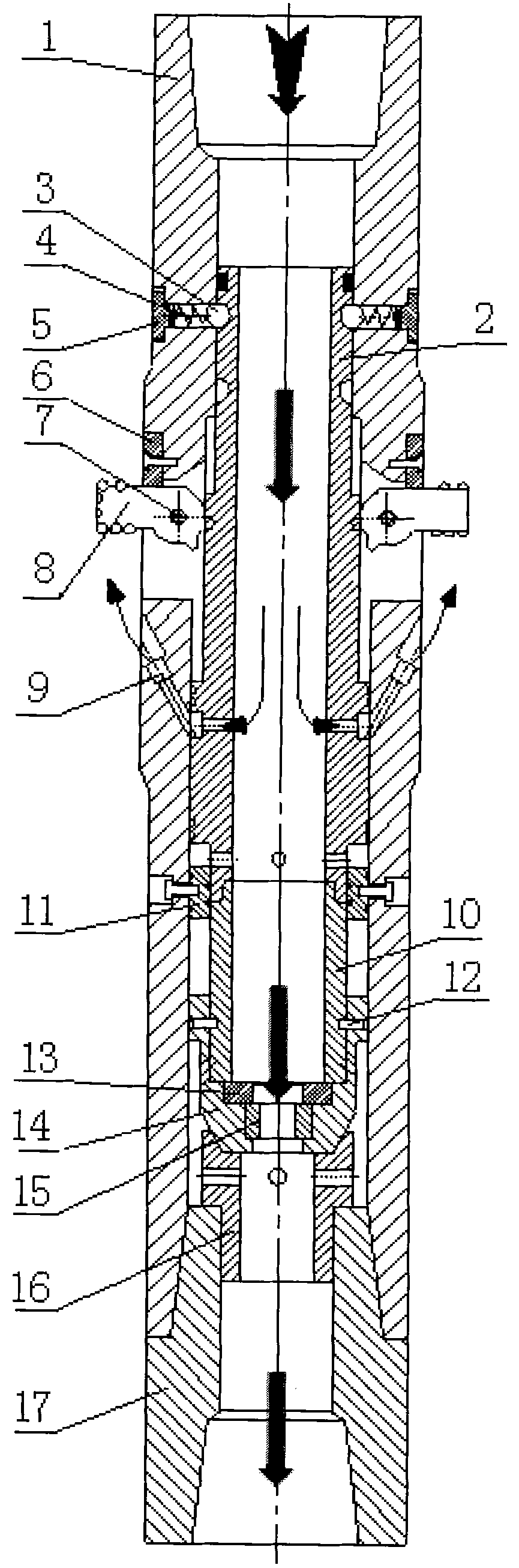

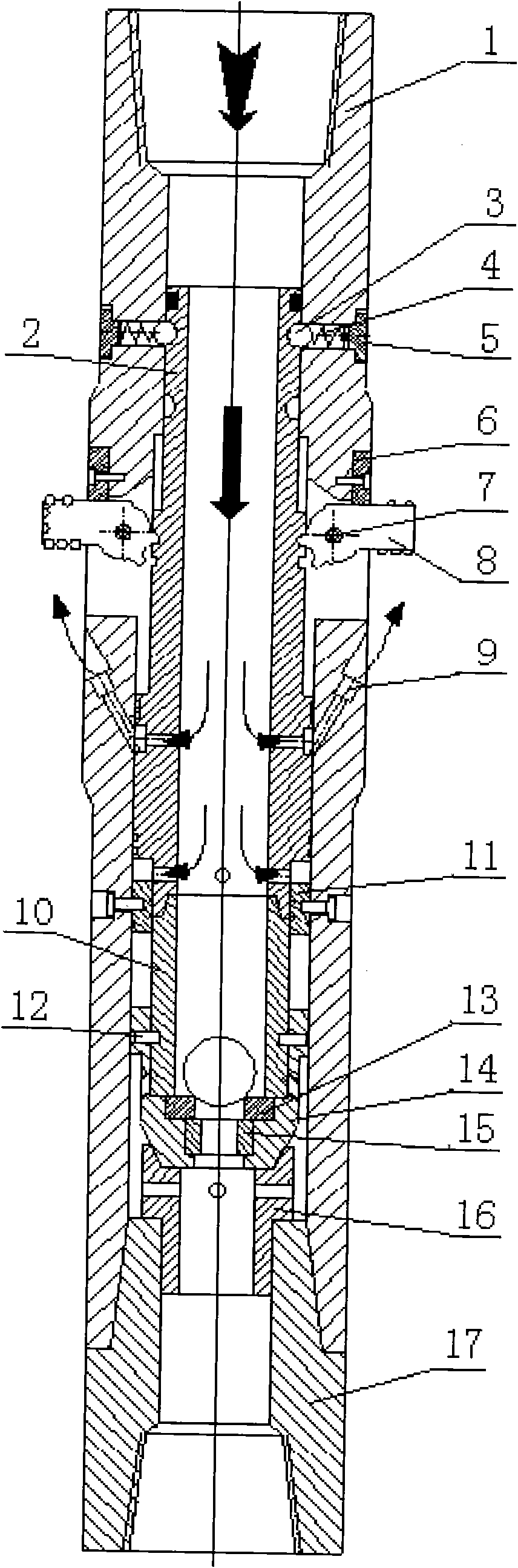

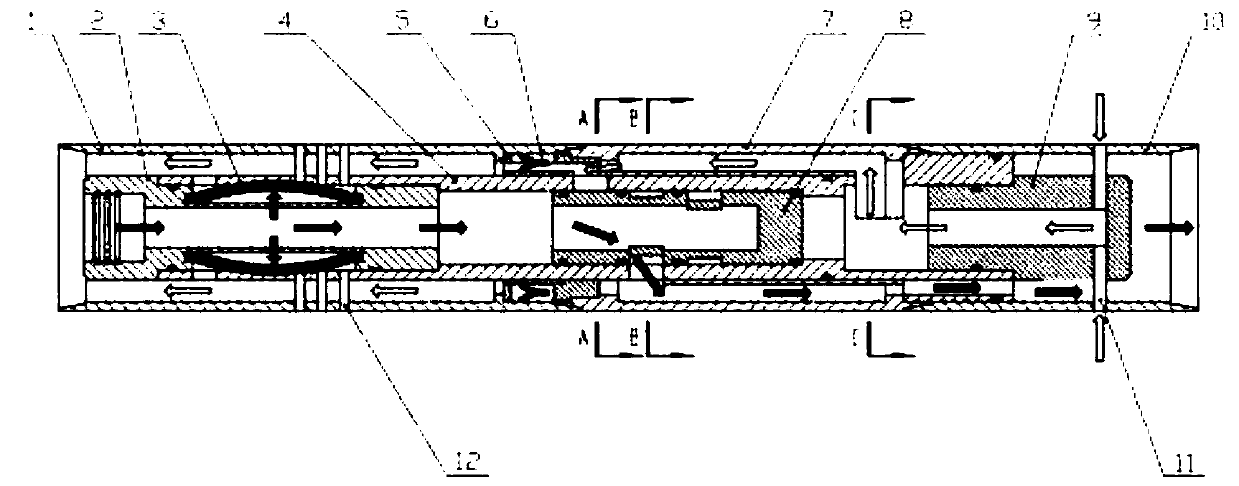

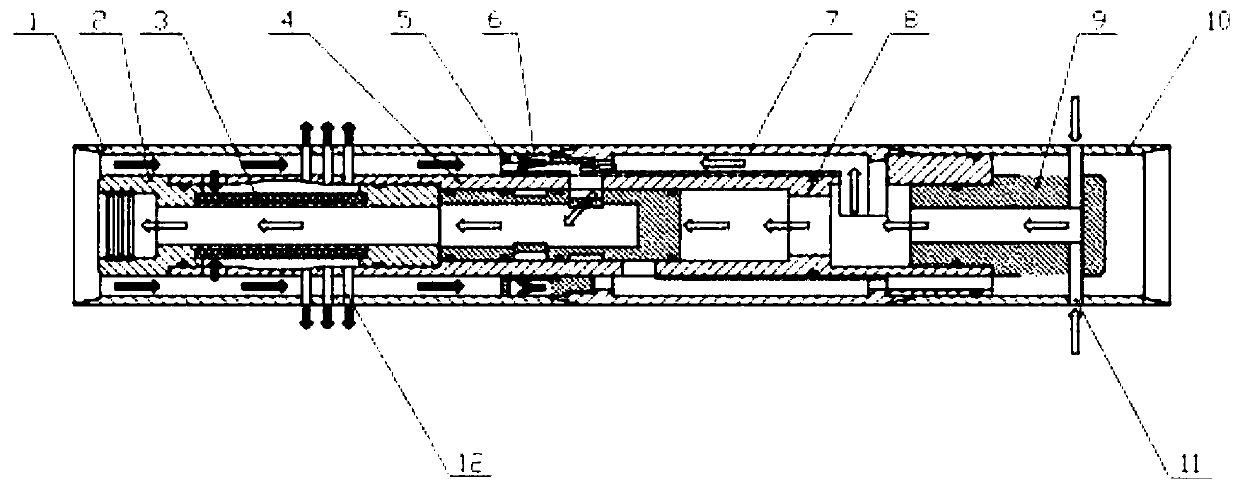

Pressure-while-drilling measuring device and measurement method thereof

The invention relates to a pressure-while-drilling measuring device and a measurement method thereof. The pressure-while-drilling measuring device is characterized by comprising an outer shell in which a central flow channel is formed; the outer shell is provided with a split-flow pressurization mechanism, an execution mechanism and an oil line reversing mechanism sequentially; the execution mechanism is provided with a pumping mechanism; the split-flow pressurization mechanism controls the opening and closing of the execution mechanism by using the acting force of slurry in the central flow channel and a split-flow piston; and the execution mechanism and the oil line reversing mechanism are matched with each other to push out and reset all sliding blocks in the pumping mechanism, so thatthe stretching and retraction of a probe can be realized, and bottom fluid is pumped by a pumping cylinder and a piston rod of the pumping mechanism and is measured. The pressure-while-drilling measuring device can accurately acquire the underground formation pressure in real time, staff can timely identify the complex underground geological factors by using the formation pressure data and further adjust the drilling parameters, and the complex conditions of leakage, collapse, overflowing, blowing and the like during drilling can be effectively avoided, so that the pressure-while-drilling measuring device can be widely used in the drilling process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

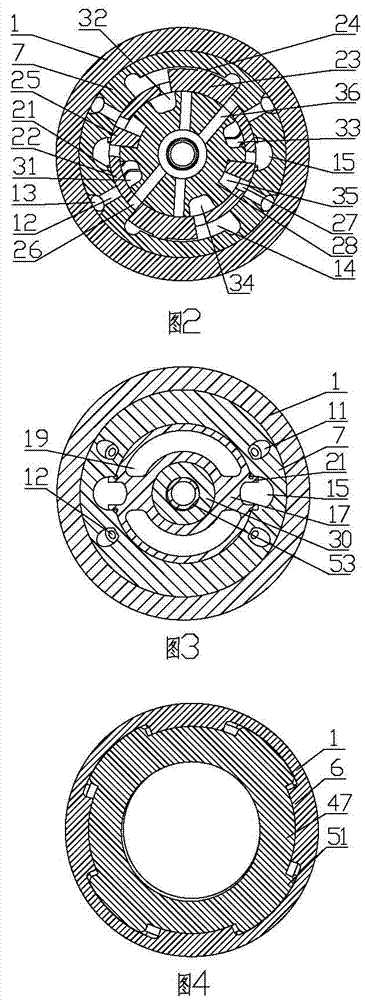

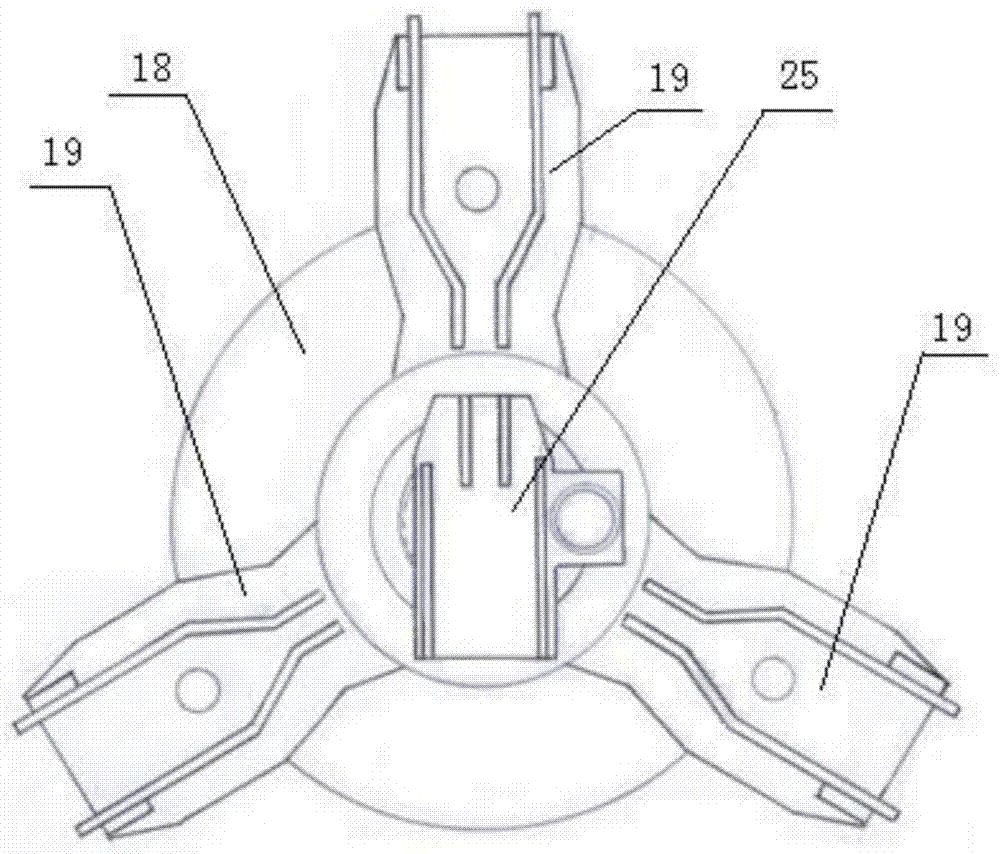

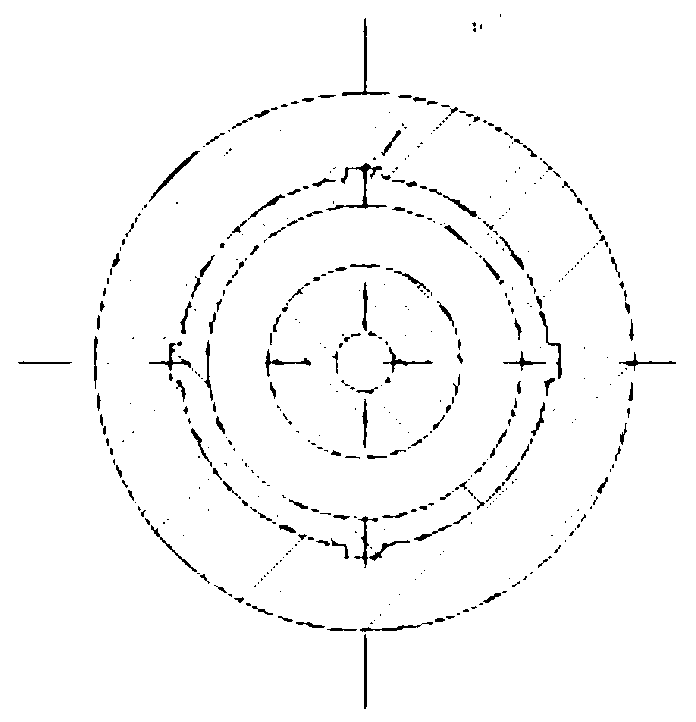

Full-hydraulic reamer

The invention relates to a full-hydraulic reamer applied to the fields of drilling and reaming operation for oil and gas exploration and development. A stepped cylinder is arranged on the outer wall of a mandrel piston, the lower end of the mandrel piston is in threaded connection with a mandrel nipple, an annular sealed limit ring is arranged in an annular space between the mandrel nipple and the shell, a mandrel cap is sleeved on an outer wall at the lower end of the mandrel nipple, a main nozzle and a main nozzle gland are fixed in a stepped central hole in the mandrel cap, a bypass hole is arranged on the wall of the mandrel cap, a lower joint is fixed at the lower end of the shell, a mandrel seat is fixed at the upper end of the lower joint, three rectangular windows are uniformly distributed on the shell wall along the circumferential direction, rectangular reaming cutter wings are arranged in each rectangular window through a cylindrical pin, and an incomplete gear is arranged at the inner end of each reaming cutter wing and engaged with a rack on a normal triangular prism in the middle of the mandrel piston. After a drill string is rotated to increase the pump displacementand open the cutter wings, reaming can be started, after the reaming is finished, the reaming cutter wings are withdrawn after a ball is placed, and drilling is normally continued after the reaming is finished, therefore drilling time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

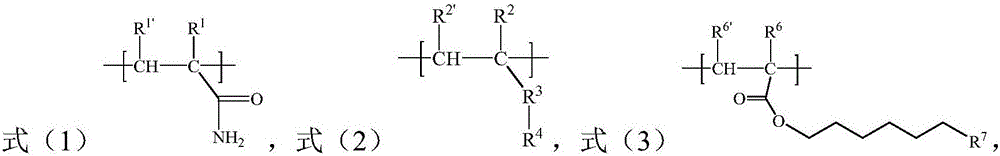

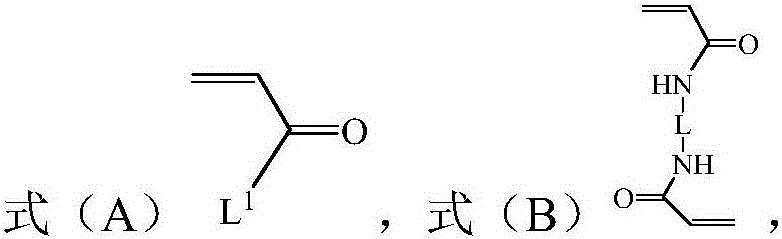

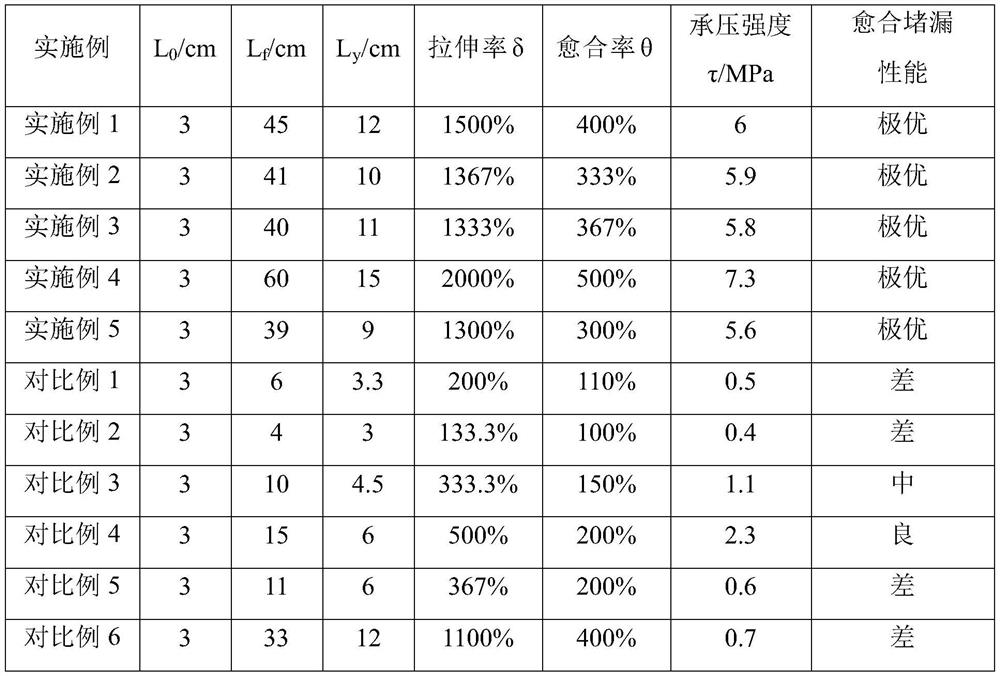

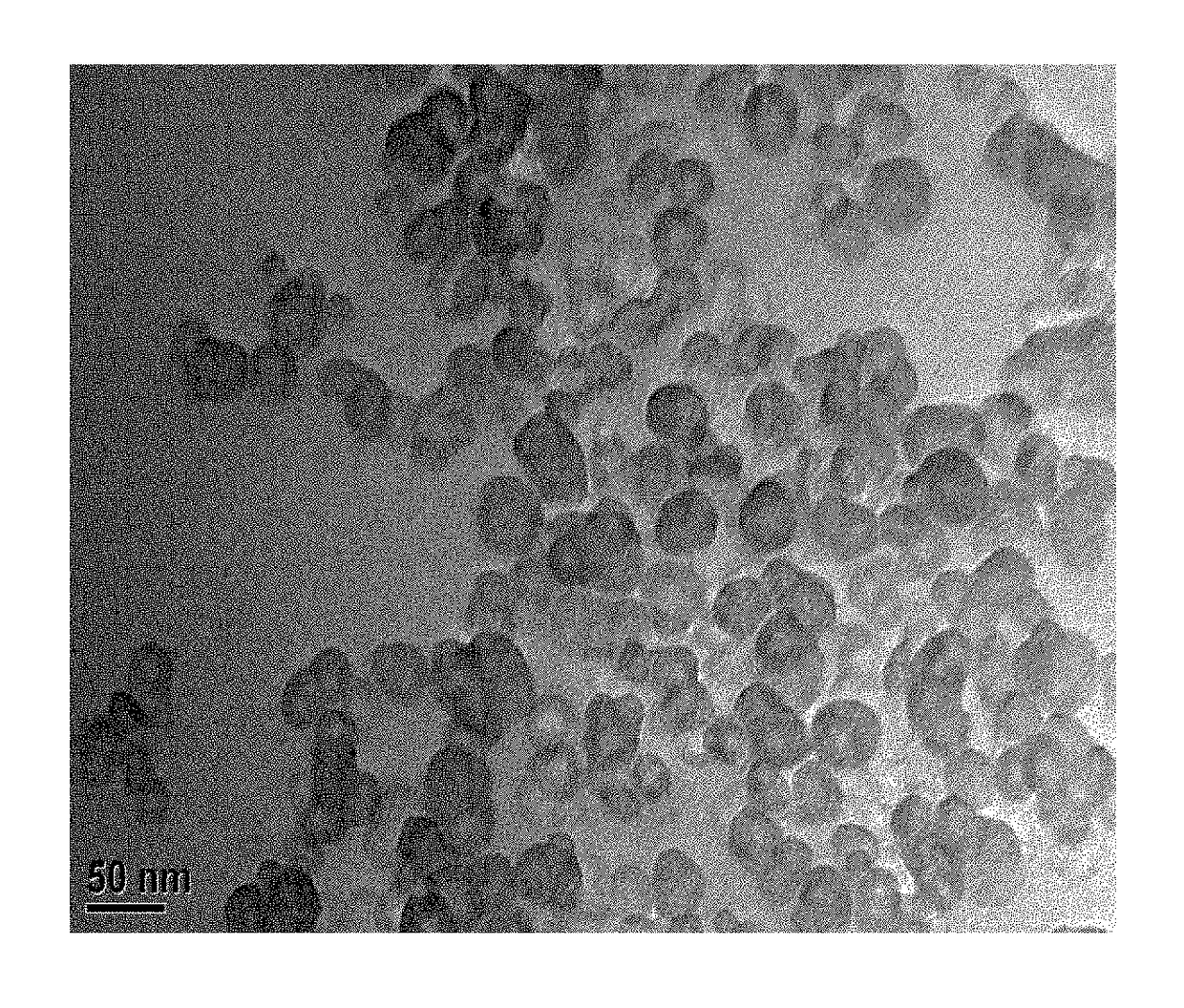

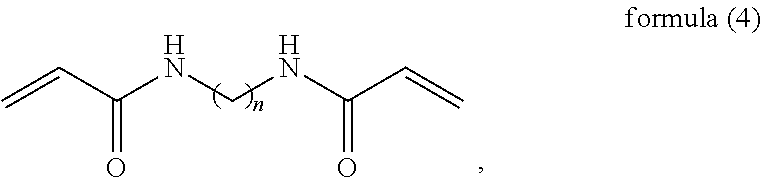

Gel particle plugging agent with self-healing characteristic as well as preparation method and application thereof

ActiveCN112250787AGuaranteed bearing strengthSimple construction processDrilling compositionComposite materialActive agent

The invention provides a gel particle plugging agent with a self-healing characteristic. The gel particle plugging agent is prepared from the following raw materials in parts by mass: 15-35 parts of acopolymerization reaction monomer, 0.1-20 part of a surfactant A, 0.01-0.9 part of an initiator I, 0.01-0.1 part of a cross-linking agent and 0.5-5 part of cationic latex particles; wherein the copolymerization monomer comprises a hydrophilic monomer and a hydrophobic monomer, the hydrophilic monomer is a combination of acrylic acid and an acrylamide monomer, and the hydrophobic monomer is an acrylate monomer. The invention also provides a preparation method and a healing performance evaluation method of the gel particle plugging agent. The self-healing plugging material disclosed by the invention has the characteristic of recoverability after being damaged, is injected into stratum cracks in a particle form, and can form integral gel after being healed, so that the purpose of effectivelyplugging crack pores is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Frequency-adjustable torque force impact acceleration device

The invention relates to the technical field of well drilling hydraulic torque force impact tools, and provides a frequency-adjustable torque force impact acceleration device. The frequency-adjustable torque force impact acceleration device comprises an outer cylinder, an impact cylinder, a reversing sleeve base, an impact hammer, a reversing sleeve, a gland, a diversion filter screen, a bearing pedestal and a lower connector. An upper step hole, a middle step hole and a lower stop hole are formed in the outer cylinder, wherein the inner diameters of the upper step hole, the middle step hole and the lower step hole are sequentially decreased. The frequency-adjustable torque force impact acceleration device is reasonable and compact in structure, few in part and convenient to assemble, interval parts are not prone to damage and can not get stuck, an internal thread in the inner wall of the lower connector below the outer cylinder and an annular table does not need to be connected with a drill stem through a conversion connector any more, and the impact frequency can be regulated according to requirements by regulating a spray nozzle. Meanwhile, impact force can be directly transmitted to a drill bit and is converted into mechanical impact force through drilling hydraulic force, and therefore the drill bit can obtain stable torque and unceasingly cut a stratum to eliminate stick slip, the service life of the drill bit is prolonged, the drilling speed in hard rock layers is increased, great drilling cost and drilling time are saved, and the application range is wide.

Owner:CANGZHOU GREAT DRILL

Drilling fluid additive composition and water-based drilling fluid suitable for high-pressure plugging

ActiveUS9890318B1Good plugging effectHigh pressure bearing capabilityDrilling compositionWell drillingDimer acid

The present invention relates to the well drilling field in petroleum industry, in particular to a drilling fluid additive composition and a water-based drilling fluid suitable for high pressure plugging while drilling. The composition contains a bridging agent, a nano-plugging agent, a rheological modifier, a bionic wall bracing agent, and a bionic shale inhibitor, wherein, the bridging agent is a weak-crosslinked copolymer, in which the content of cross-linker structures is 0.1-1 wt. %; the nano-plugging agent is modified nanometer silicon dioxide particles; the rheological modifier is a dimer acid-organic amine copolymer; and the bionic wall bracing agent is carboxymethyl chitosan with a dopamine-derived base group grafted on its main chain. With a synergistic effect among the bridging agent, the nano-plugging agent, the rheological modifier, the bionic wall bracing agent, and the bionic shale inhibitor in the composition provided in the present invention, the water-based drilling fluid containing the composition as additive can attains an excellent plugging effect in a drilling process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

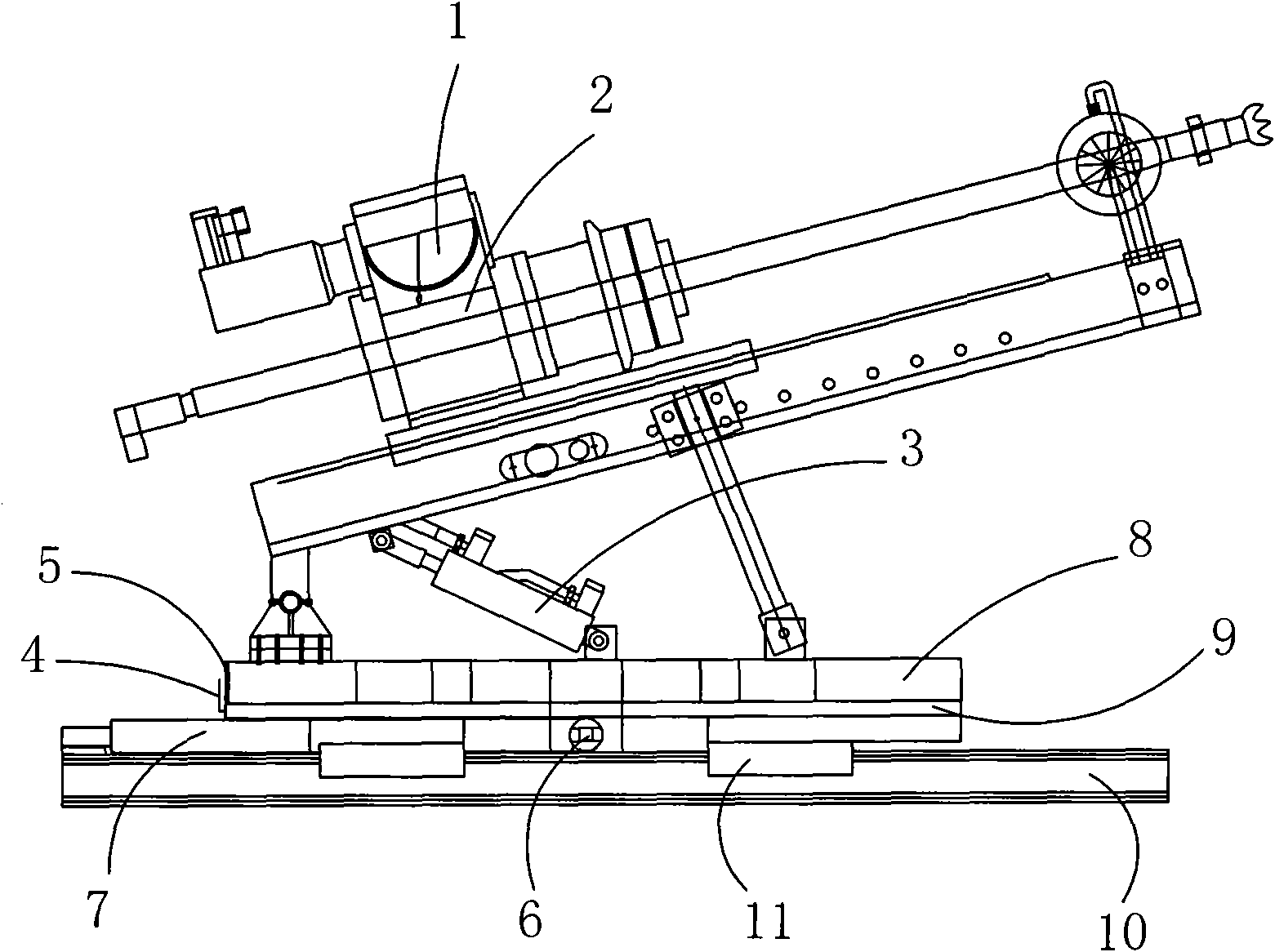

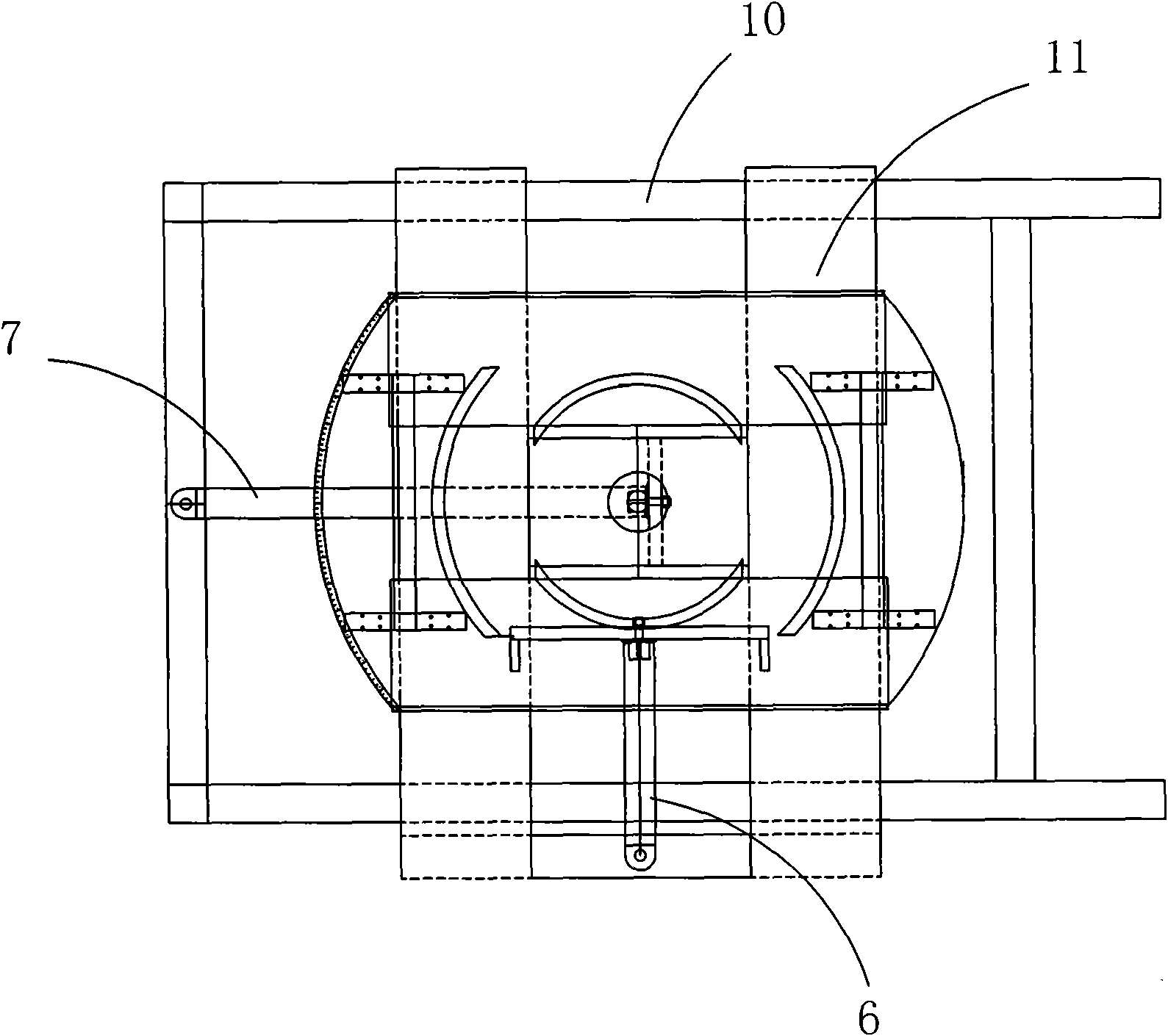

Drilling machine capable of rapidly and accurately locating

InactiveCN101864901APositioning is intuitiveEasy to operateConstructionsDerricks/mastsDrilling machinesChassis

The invention discloses a drilling machine capable of rapidly and accurately locating. The drilling machine comprises a drilling machine under frame and a power head part, and is characterized by being provided with a chassis and a tray fixedly welded with the drilling machine under frame; the chassis takes a rectangular frame as a base; a pair of longitudinal lateral frames arranged in parallel on the rectangular frame forms a longitudinal track; a pair of horizontal tracks arranged in parallel can move longitudinally along the track on the longitudinal track; a drilling machine platform is supported on the horizontal tracks, and can move horizontally along the tracks on the horizontal tracks; and the tray is supported on the drilling platform through a turntable bearing, and can rotate 360 degrees horizontally on the drilling machine. The invention has simple, easy, convenient and accurate location and easy operation.

Owner:安徽省皖北煤电集团孟庄煤矿

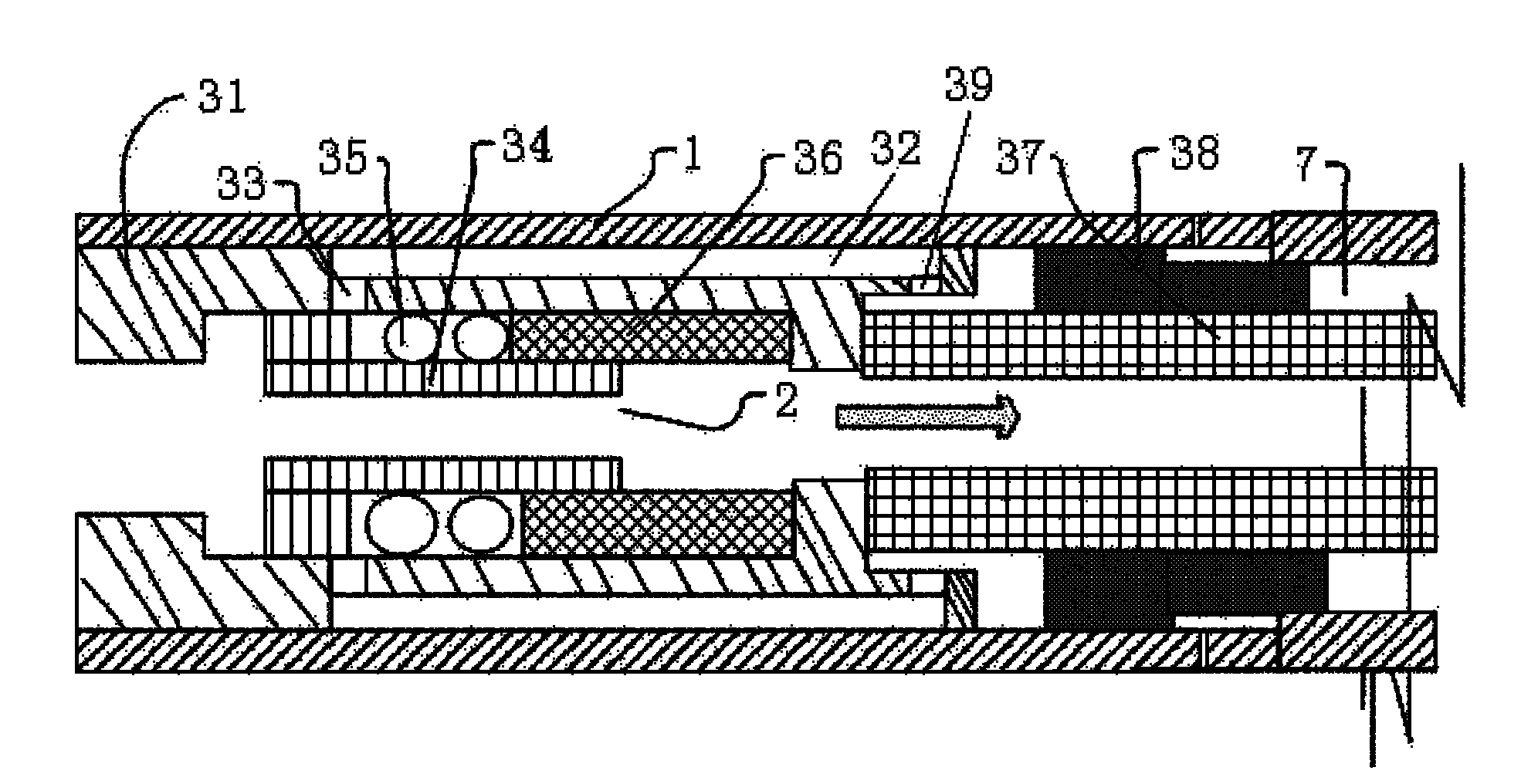

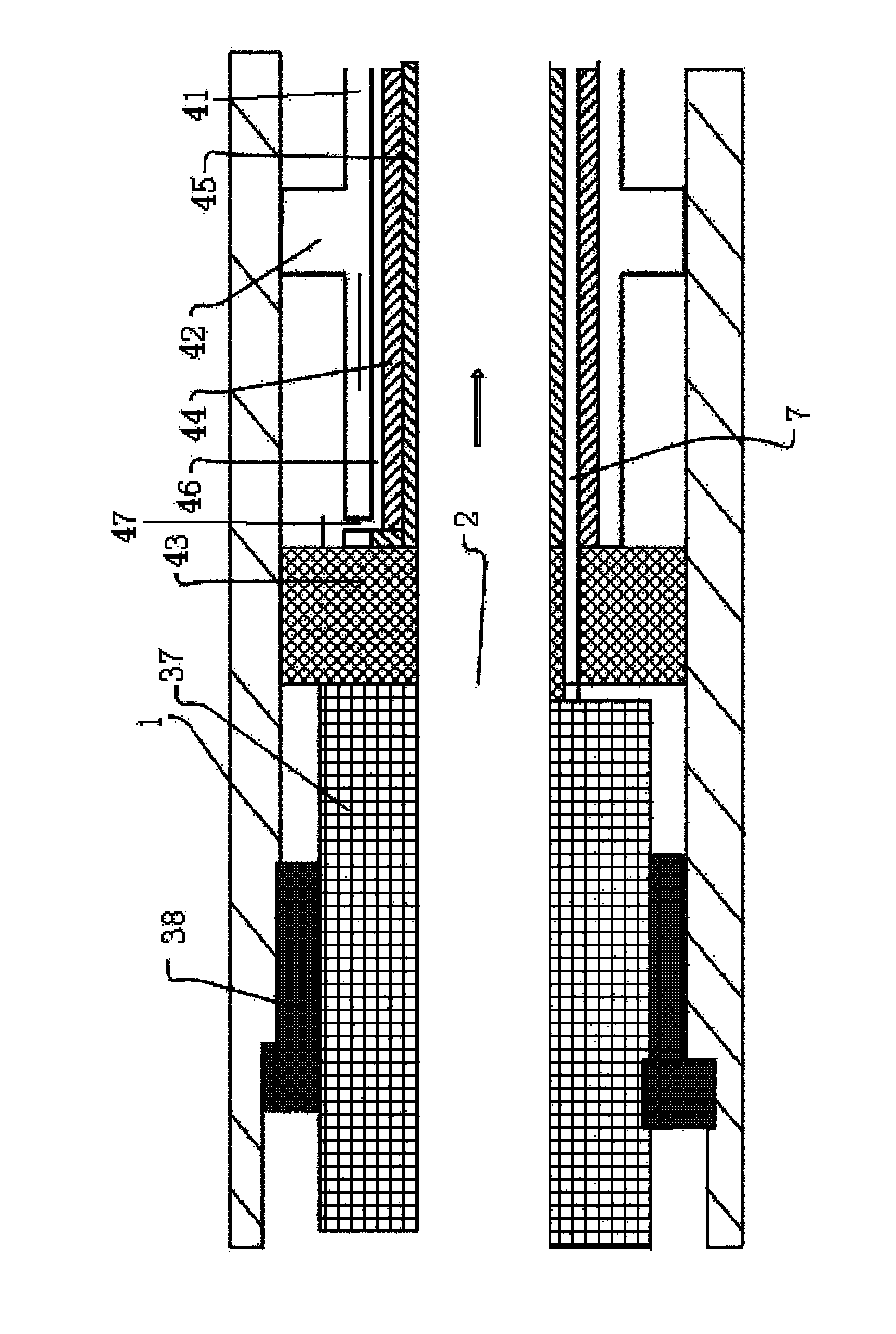

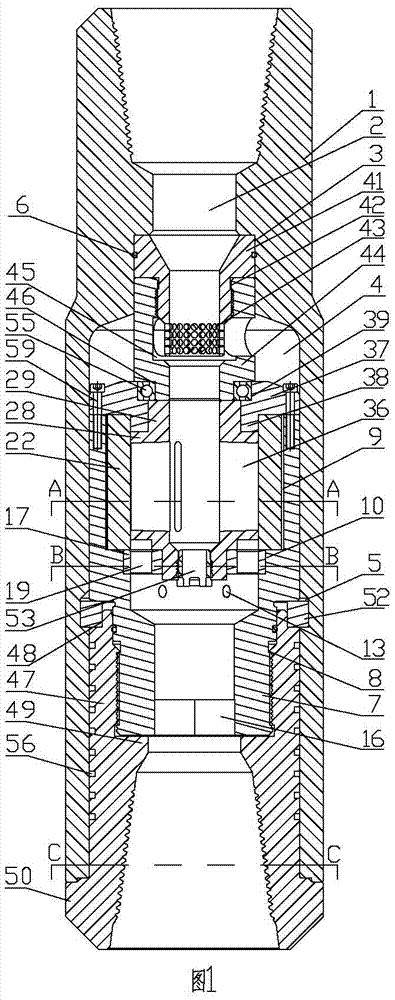

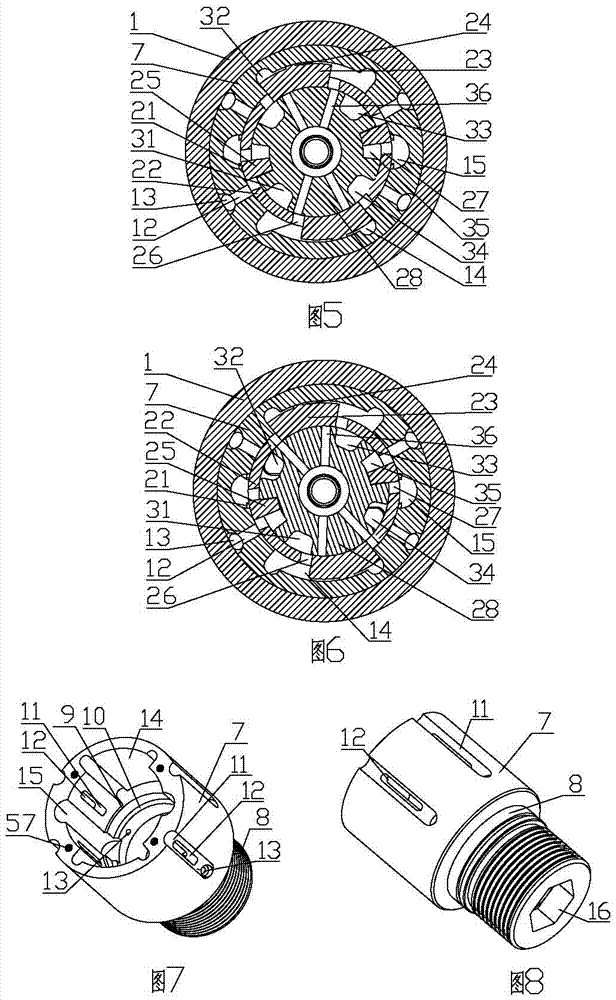

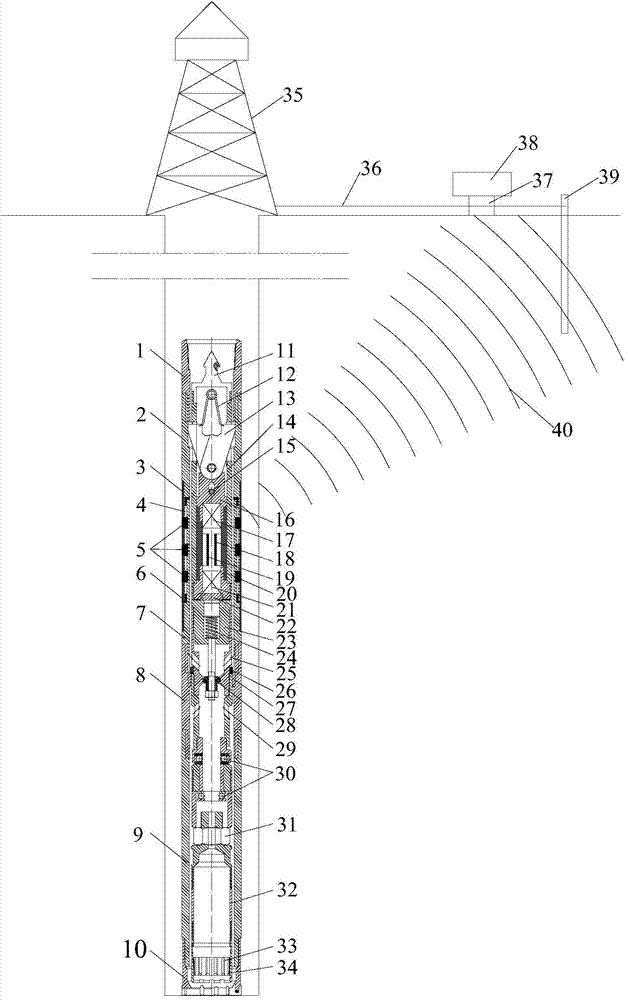

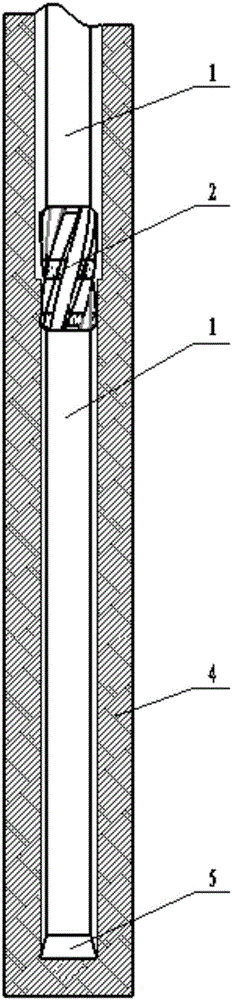

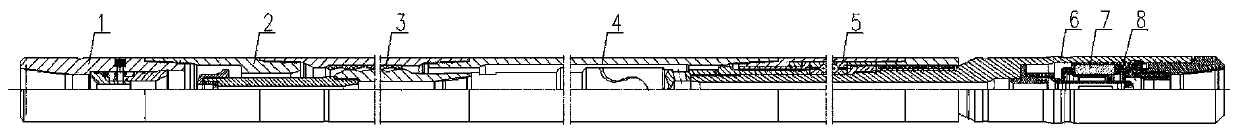

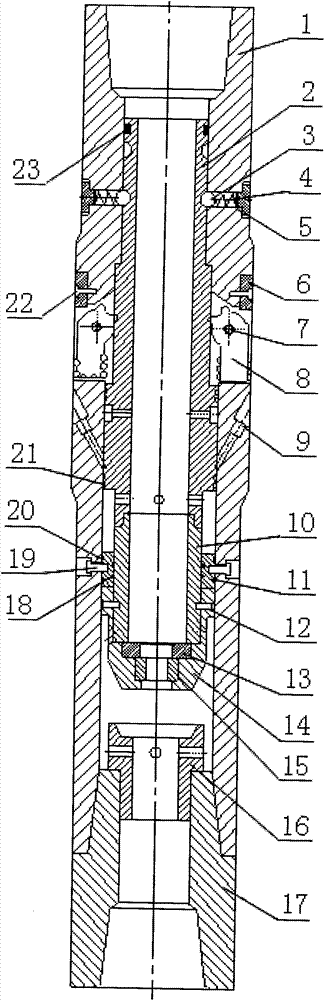

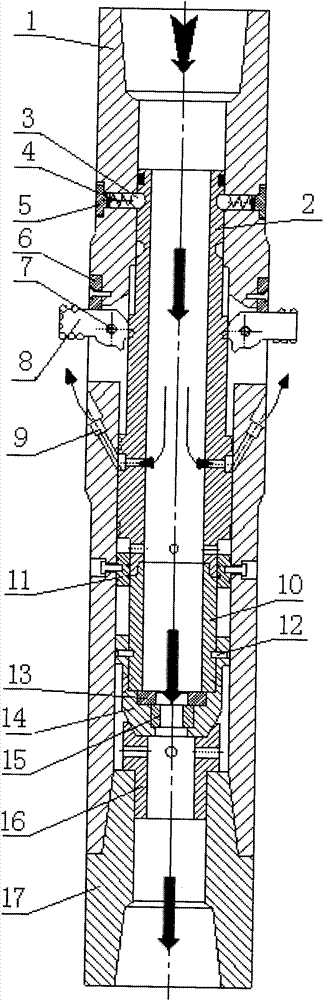

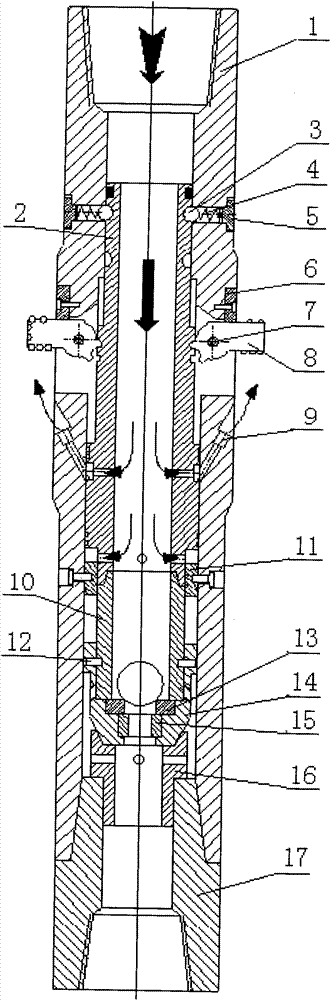

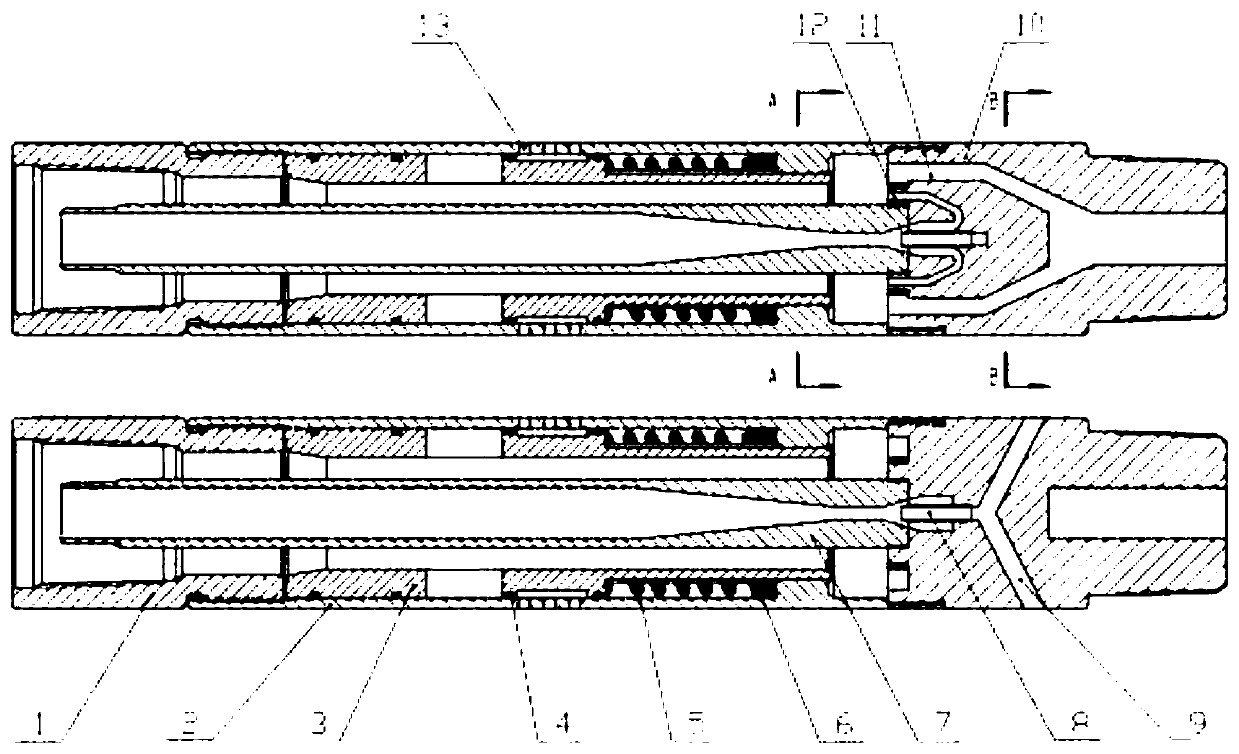

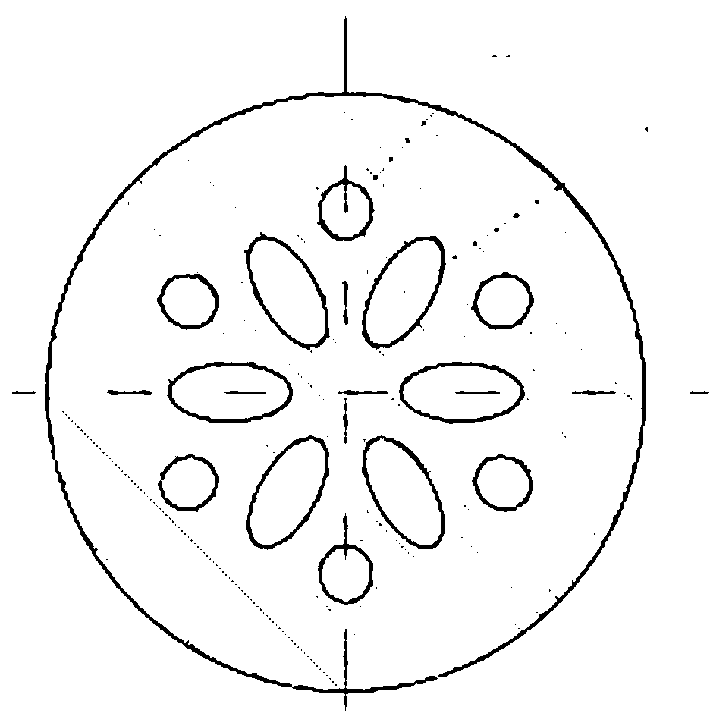

Electromagnetic measurement while drilling system for wire line core drilling

InactiveCN104196479ASave time drillingImprove drilling efficiencySurveyConstructionsEngineeringPipe insulation

The invention relates to an electromagnetic measurement while drilling system for wire line core drilling. The electromagnetic measurement while drilling system comprises a down-hole drilling tool and a ground receiving system. The down-hole drilling tool comprises an outer pipe assembly and an inner pipe assembly. The outer pipe assembly comprises an upper connector, an elastic clamping chamber, an insulation ring, an insulation connector, an intermediate connector, an outer core barrel and a drill bit. The inner pipe assembly comprises a salvaging spearhead, a recovery pipe, a hoisting connector, a battery pack, a control circuit board, an emission circuit board, an inner pipe insulation part, a gauging nipple, a pipe plug, a core valve sleeve, a core valve, a core inner pipe, a clamping spring and a clamping spring seat. The ground receiving system comprises a drill tower, a receiver, a computer and an antenna, and the drill tower, the receiver, the computer and the antenna are connected. According to the electromagnetic measurement while drilling system for wire line core drilling, the advantages of the wire line core drilling technology can be utilized, tripping operation time is substantially saved, drilling efficiency is improved, and in the drilling process, parameters such as a drill hole track and state can be transmitted to the ground in real time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

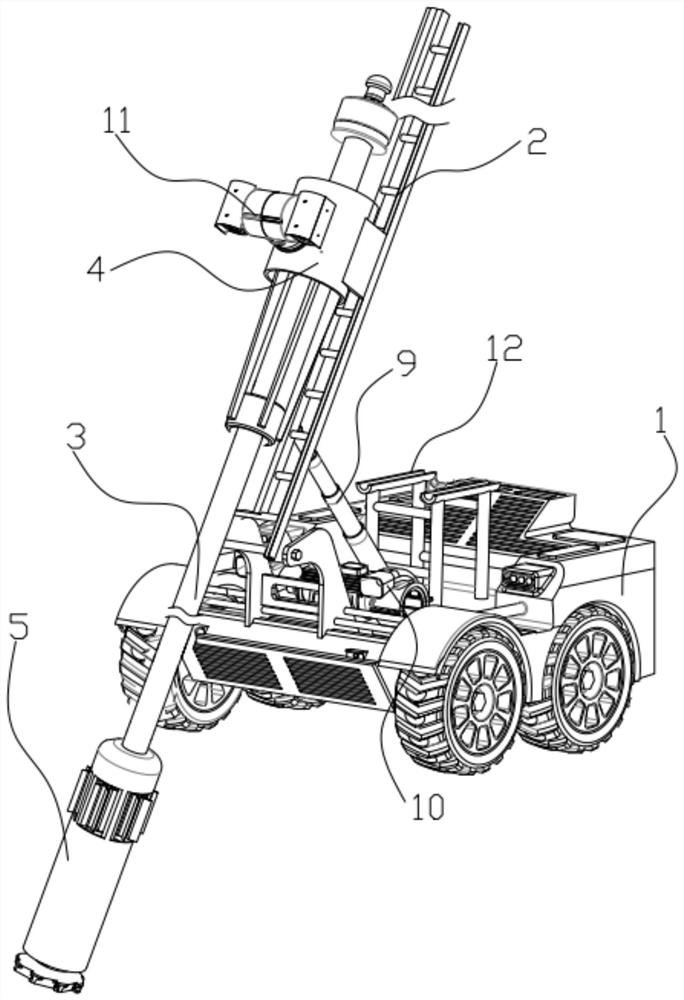

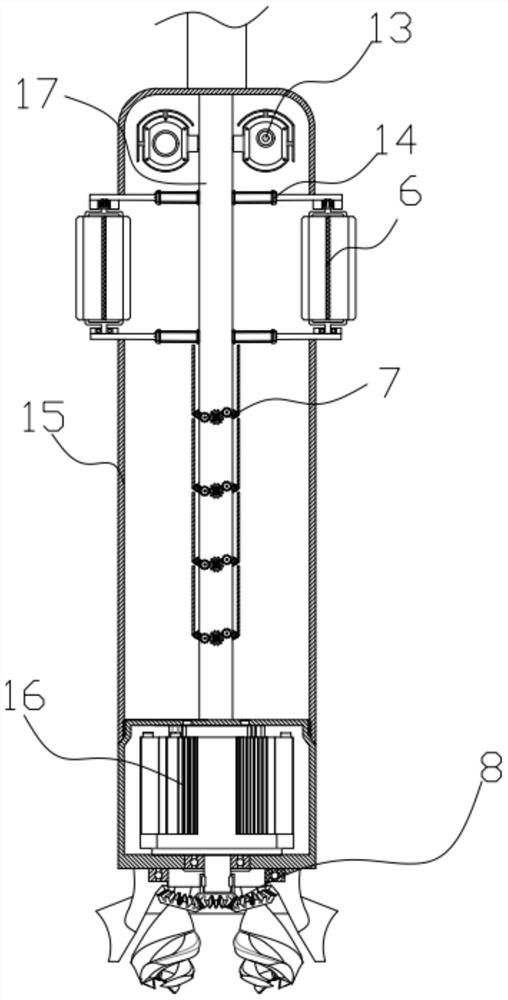

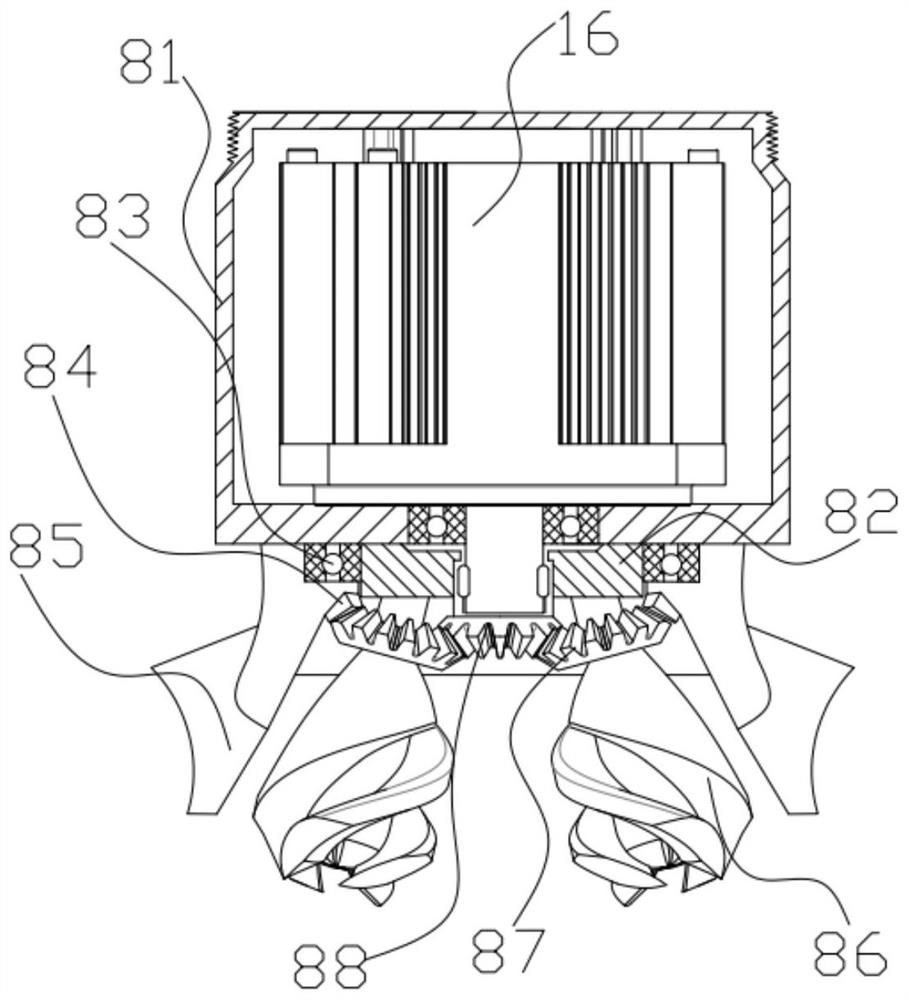

Multifunctional efficient drilling device for geological survey

ActiveCN111929098AHigh torqueImprove drilling efficiencyElectric/magnetic detection for well-loggingWithdrawing sample devicesMining engineeringGear wheel

The invention discloses a multifunctional efficient drilling device for geological survey. The device comprises a detection assembly, a derrick and a sliding mechanism, wherein the derrick is rotatably mounted on the base through an adjusting mechanism, the sliding mechanism can move along the derrick through a motor in a gear and rack driving mode, the sliding mechanism is fixedly connected withthe upper end of the drilling rod, a detection assembly is fixed to the bottom of the drilling rod, and the detection assembly can collect samples with different depths from the side face. Compared with the prior art, the multifunctional efficient drilling device is short in transmission distance, small in torsion loss and accurate in sample scraping position, the samples are prevented from leaking in the drill bit taking-back process, and the samples of different depths can be taken through one-time drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

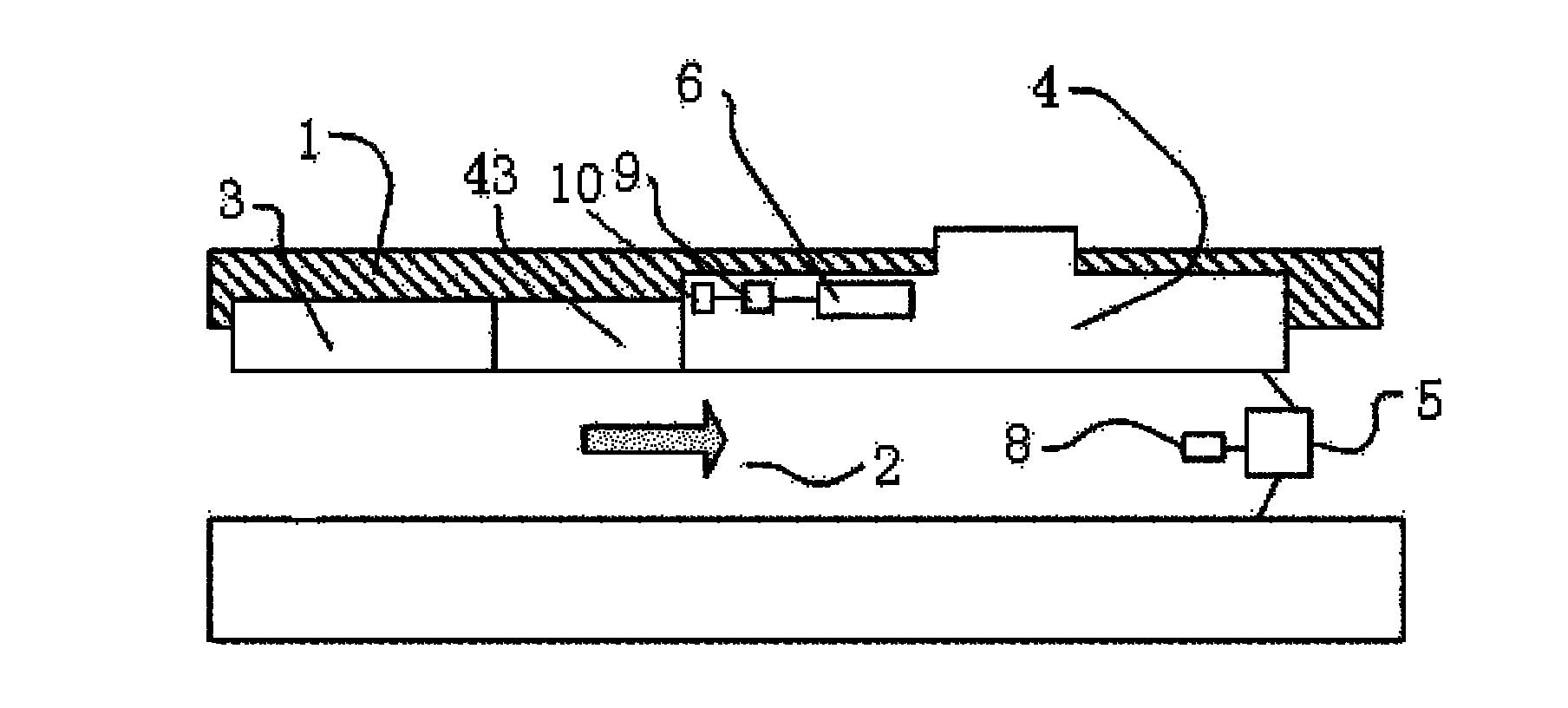

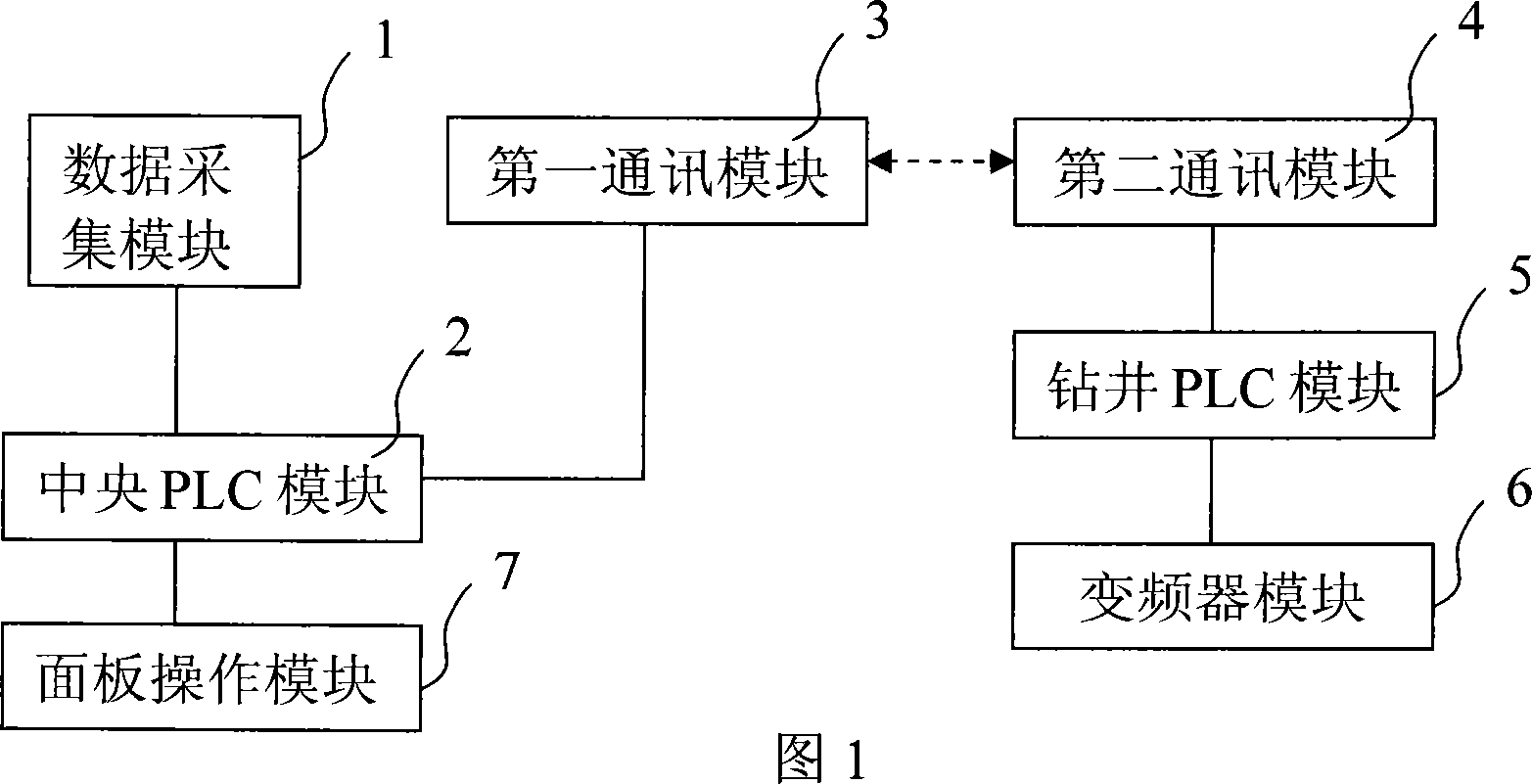

Drill platform power management system

InactiveCN101086200AAchieve economyAutomated management for short changeover timesElectric signal transmission systemsDerricks/mastsFrequency changerData acquisition

A drilling platform power management system includes: the data acquisition module (1), the central PLC module (2), the first communications module (3), the second communication module (4), the drilling PLC module (5) and the frequency-changer modules (6); the data acquisition module (1) is connected with the first communication module (3)through the central PLC module (2), the second communication module (4) is connected with the frequency-changer modules (6) through the drilling PLC module (5). The invention achieves the function of unmanned cabin, marine engineers need not wait out the cabin to increase or reduce the units according the need of drilling condition, so more time can be used to check and service other auxiliary equipments. In addition, the station automatic management conversion time is short, the management is swift, valuable drilling time is saved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

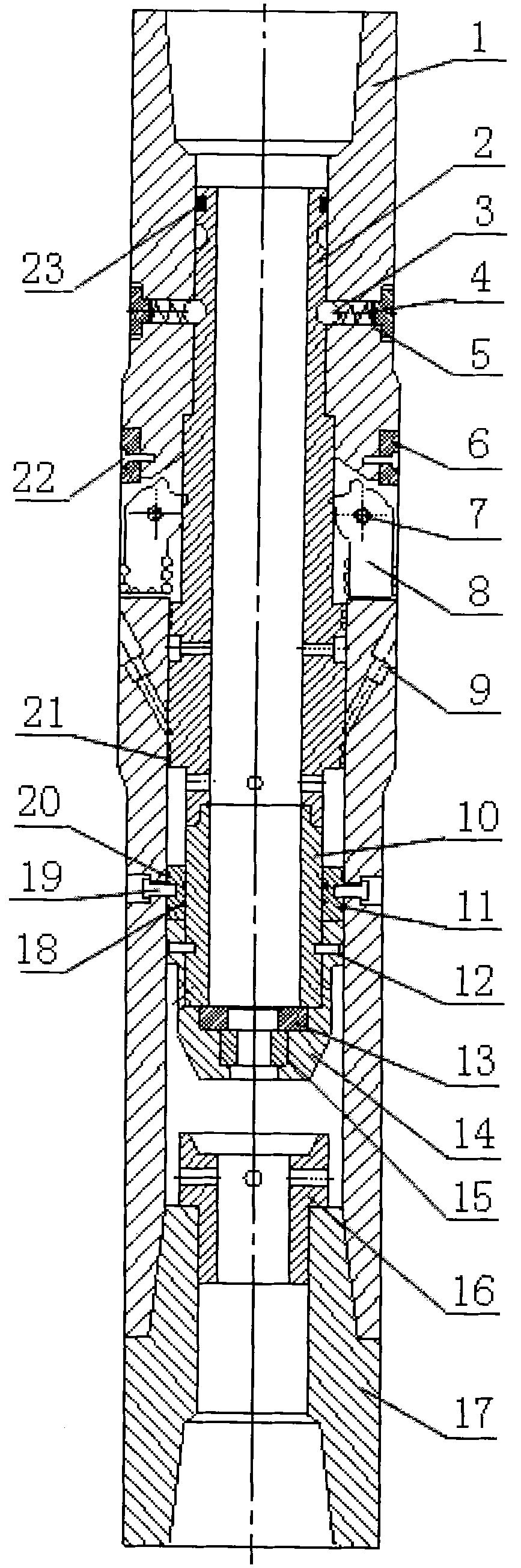

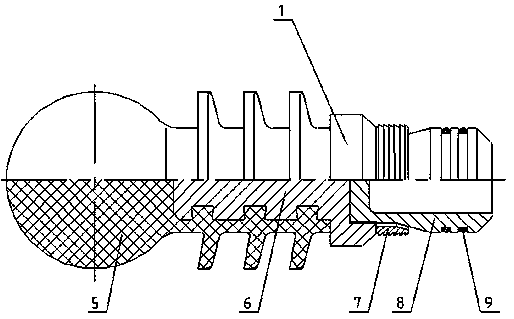

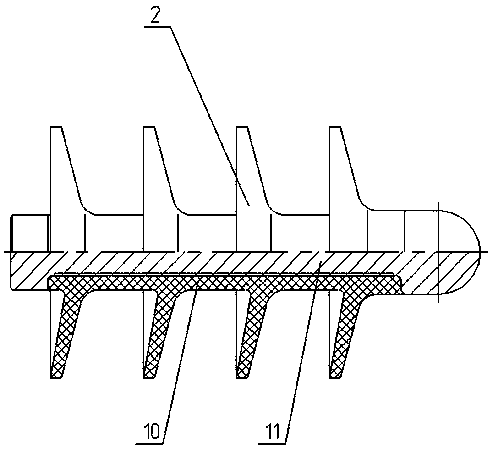

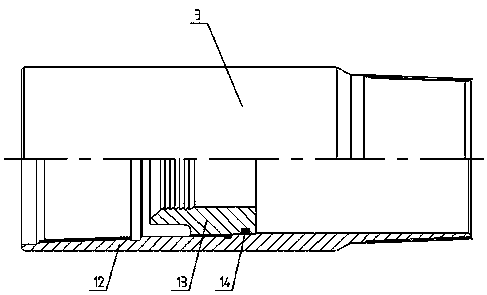

Hydro-hammer

ActiveCN104563859AImprove work efficiencySave time drillingBorehole drivesSocial benefitsWell drilling

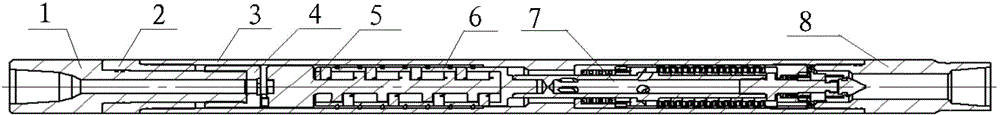

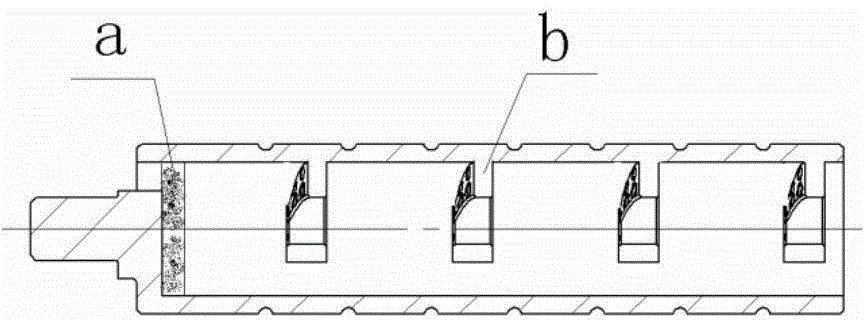

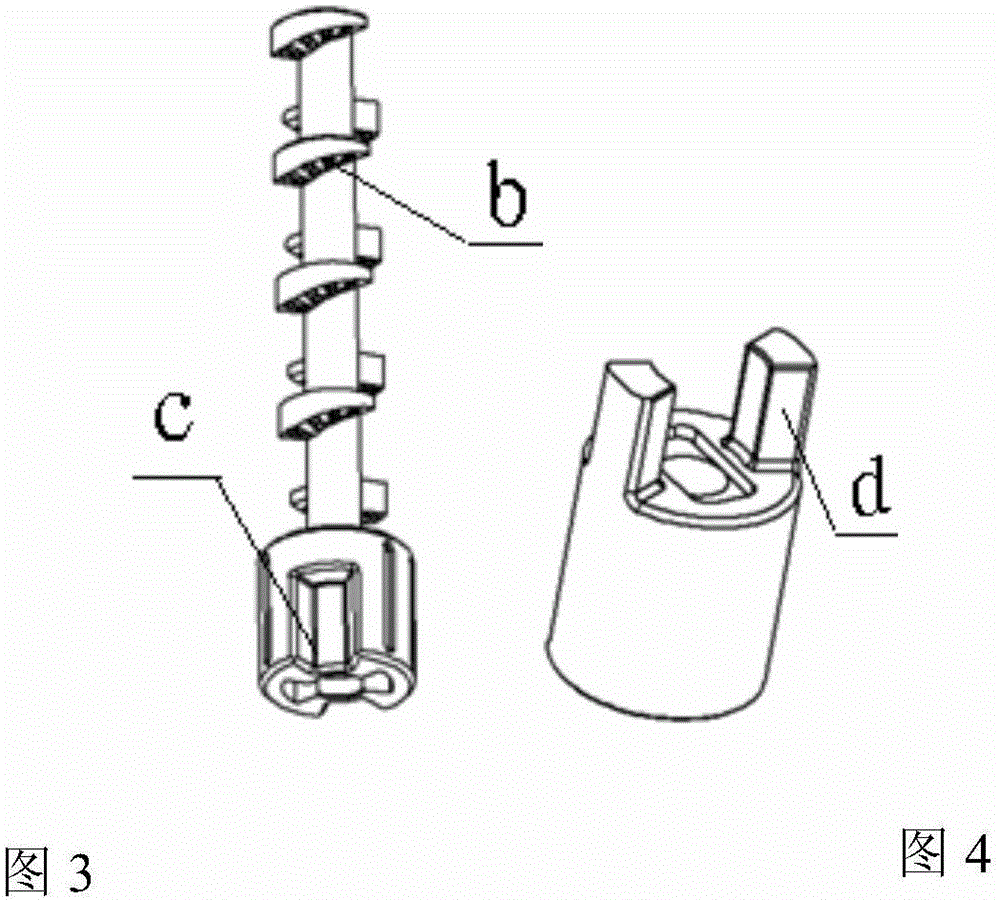

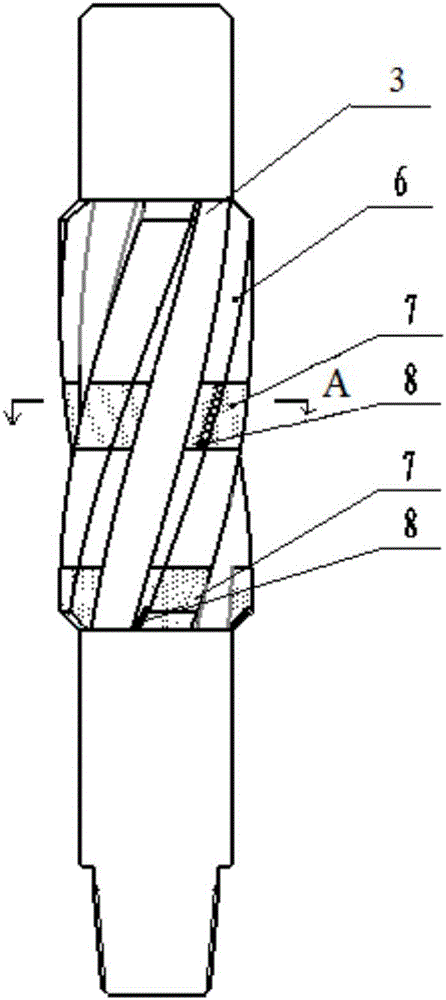

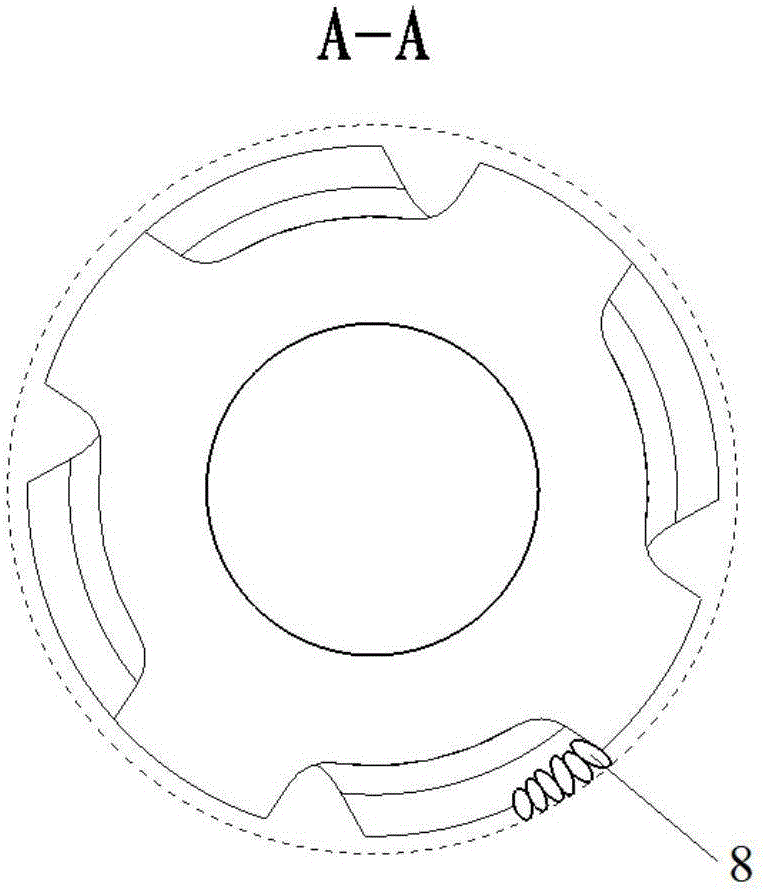

The invention discloses a hydro-hammer. The hydro-hammer comprises an impacting seat 1, a drive sleeve 2, a shell 3, a guide sleeve 4, a hammerhead component 5, a rotator component 6, a turbine component 7 and a connector 8. High-pressure fluids flow into the hydro-hammer from the connector 8 which is connected with the turbine component 7, the turbine component 7 is connected with the rotator component 6 through a drive shaft, the rotator component 6 sleeves the hammerhead component 5, and the hammerhead component 5 can reciprocate along the axis direction of the hydro-hammer under drive of the rotator component 6. When the rotator component 6 rotates around own axis under drive of the turbine component 7, a changeable space a can be formed above the hammerhead component 5, and high-speed fluids enter the changeable space to provide storage energy for downward impacting. The hydro-hammer has the advantages that kinetic energy of the high-pressure fluids are converted into periodic impacting actions to enable a hammerhead to reciprocate to impact a drill bit interruptedly, underground operation efficiency can be improved substantially according to the principle, and accordingly, well drilling time is shortened, drilling cost is saved and economic and social benefits are improved.

Owner:CHENGDU EN SHAIN TECH INC +1

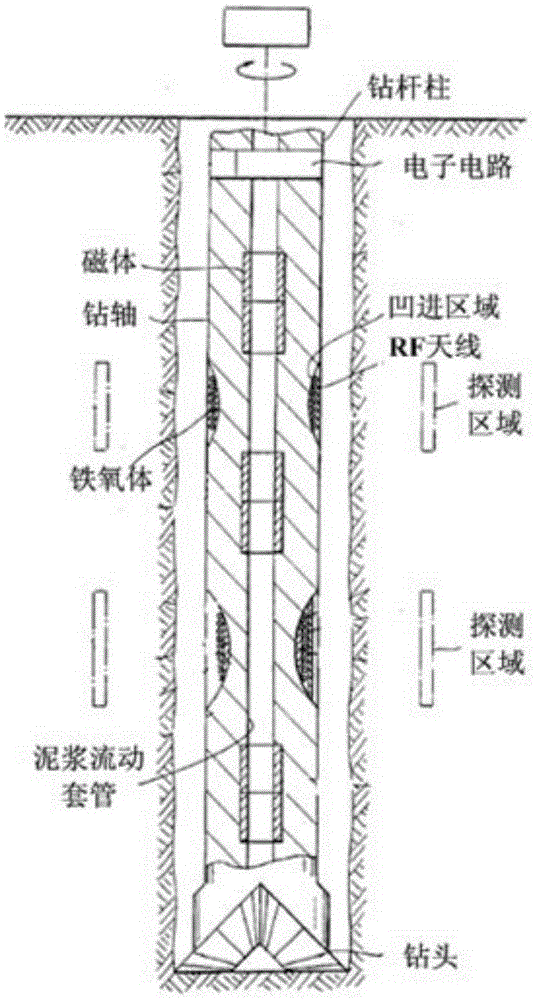

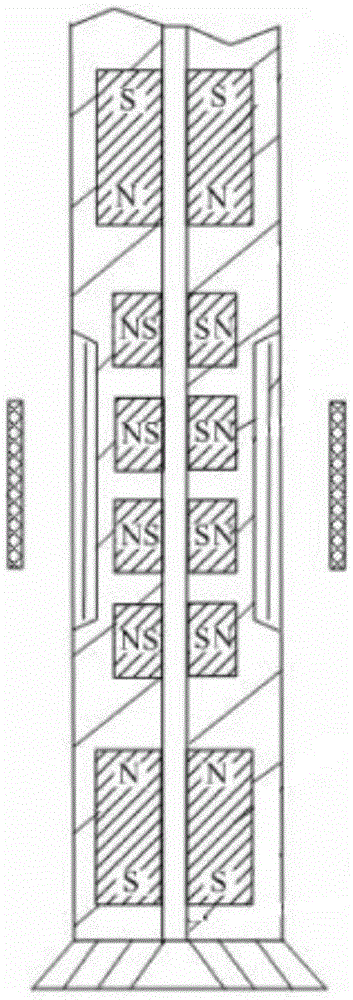

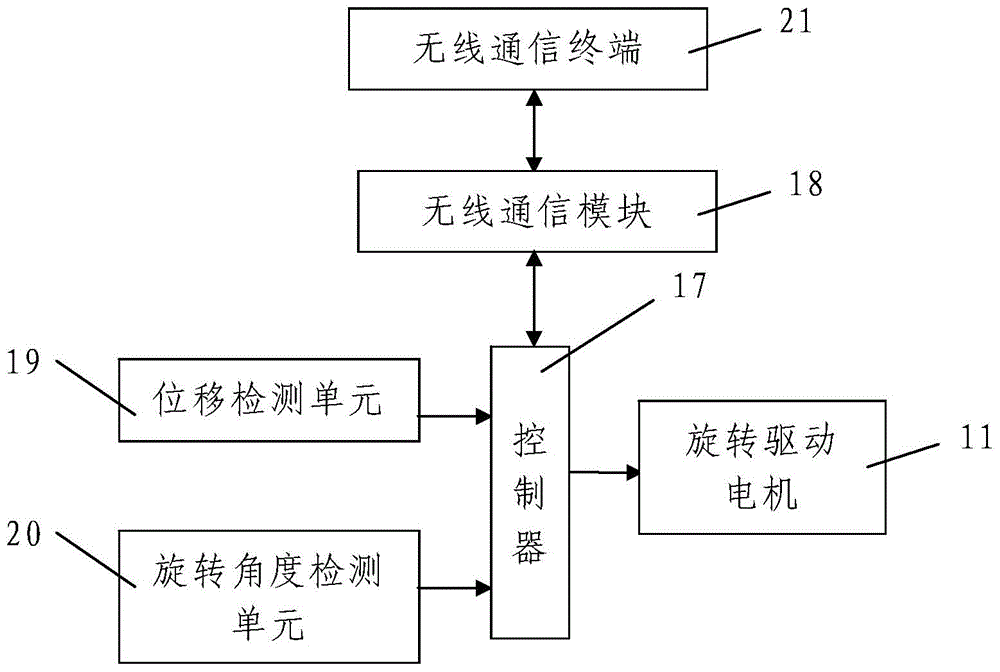

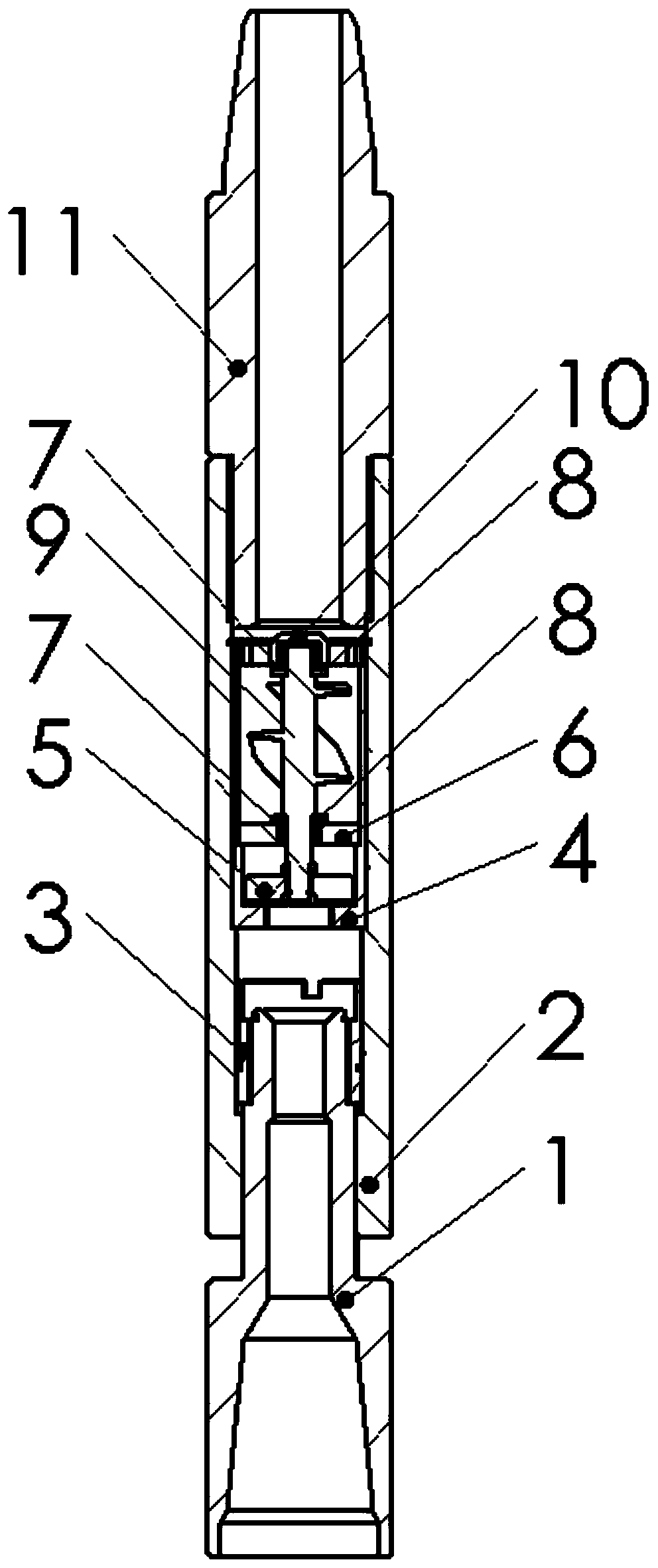

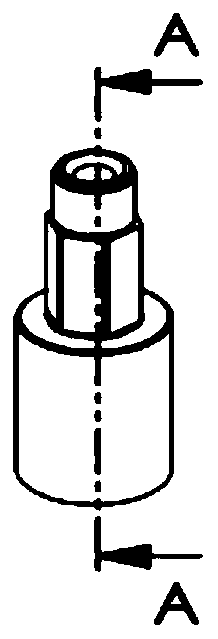

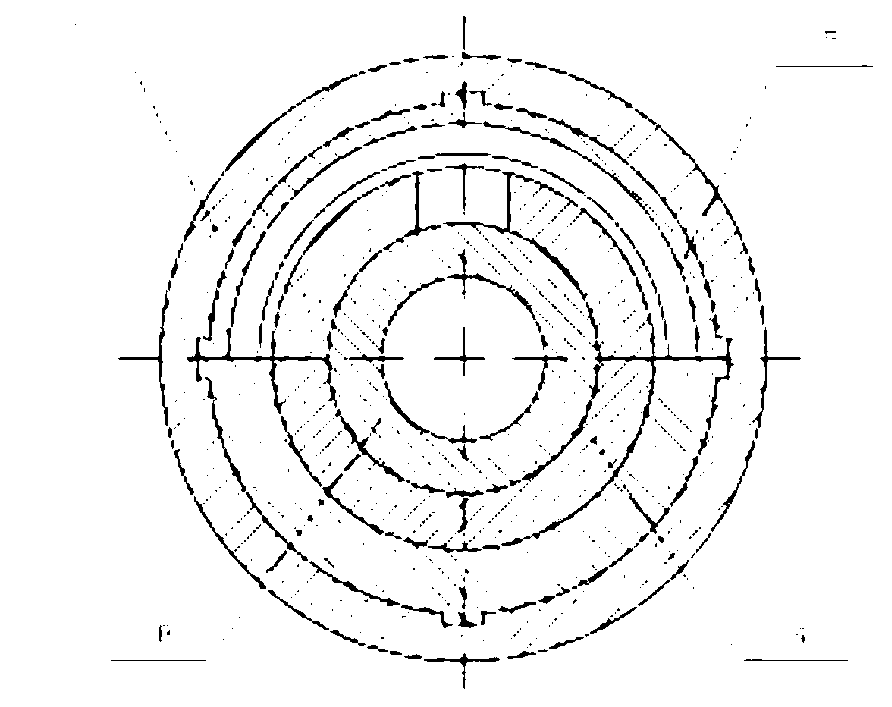

Downhole controllable nuclear magnetic resonance well logging during drilling device

ActiveCN105298486AReduce the impactExtended service lifeElectric/magnetic detection for well-loggingAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceWell logging

The invention discloses a downhole controllable nuclear magnetic resonance well logging during drilling device. The device comprises an axially and vertically arranged device body, an electronic circuit part and a measurement probe part, wherein the device body is supported by a non-magnetic drill collar (10); the upper side of the device body is connected with a drill bit driving part (1), and the lower side of the device body is connected with a drill bit (11); the device body is provided with an axial mud channel (3) through which drilling fluid flows; the electronic circuit part is accommodated in an electronic circuit cabin (2) and is used for receiving and processing a signal from the measurement probe part; the measurement probe part comprises a main magnetic body pair consisting of two axially arranged main magnetic bodies (4a and 4b) with opposite magnetic poles; the two main magnetic bodies (4a and 4b) are symmetrically arranged in the axial direction relative to the axial center of the device body; the axial distance between the two main magnetic bodies can be changed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

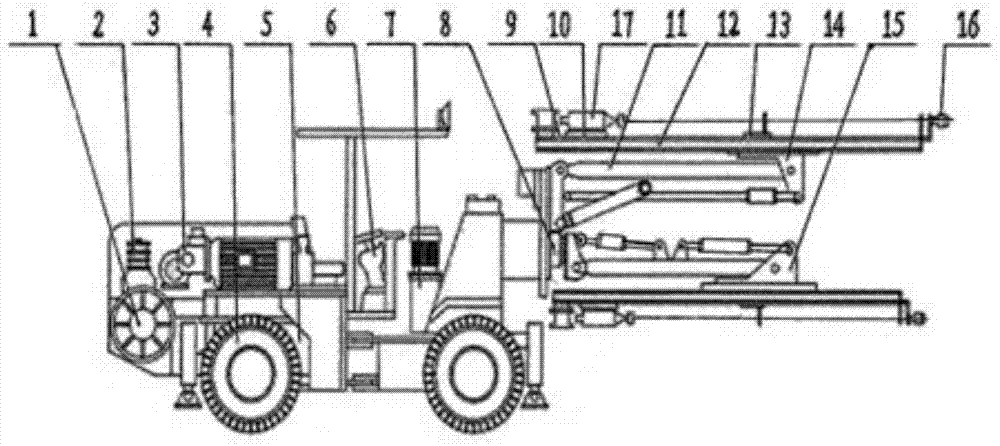

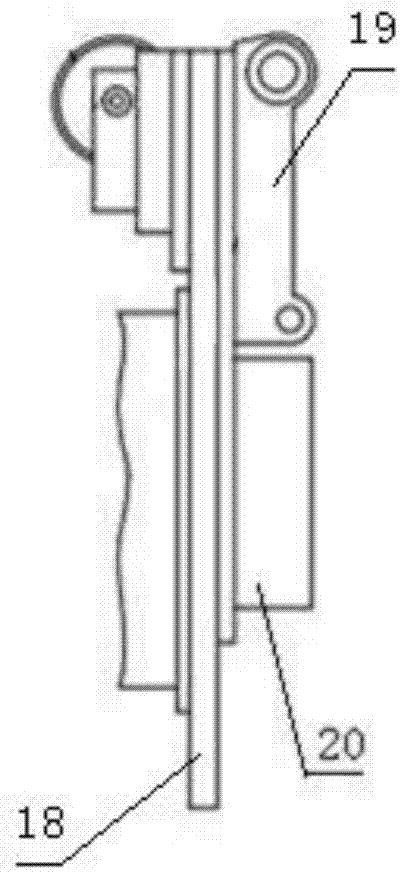

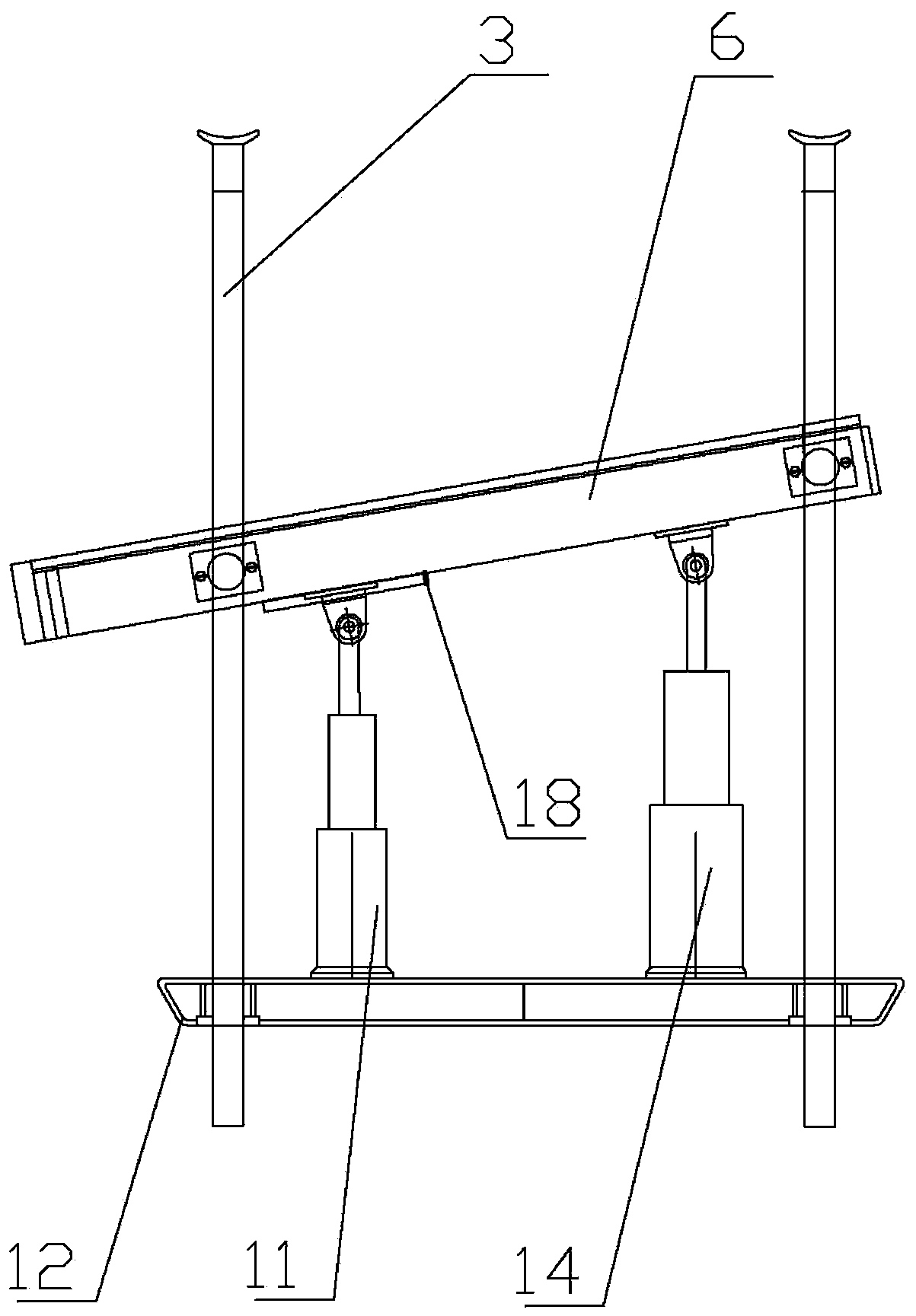

Pole disc type multi-boom drill jumbo

ActiveCN104775754AAccurate drilling positioningEasy to operateDerricks/mastsDrilling machines and methodsDrilling machinesRolling chassis

The invention discloses a pole disc type multi-boom drill jumbo, which comprises a chassis traveling mechanism, a machine frame, an engine, a hydraulic system, a cooling system, an electric system, a slag removal system, an operating system, a pole disc mechanism, a plurality of main boom assemblies, a pushing beam assembly and a rock drilling machine, wherein the machine frame is arranged on the chassis traveling mechanism and comprises a front machine frame and a back machine frame; the front machine frame and the back machine frame are hinged; the engine, the hydraulic system, the cooling system, the electric system, the slag removal system and the operating system are arranged on the back machine frame; the pole disc mechanism is arranged on the front machine frame; the main boom assemblies are arranged on the pole disc mechanism; the pushing beam assembly is arranged on the main boom assemblies, and the rock drilling machine is arranged on the pushing beam assembly. The pole disc type multi-boom drill jumbo has the advantages that the operation is simple, the drilling and positioning speed is high, the rock drilling operation efficiency is high, and the ideal equipment for mountain cutting and tunnel excavation is provided.

Owner:陕西道一智能科技有限公司

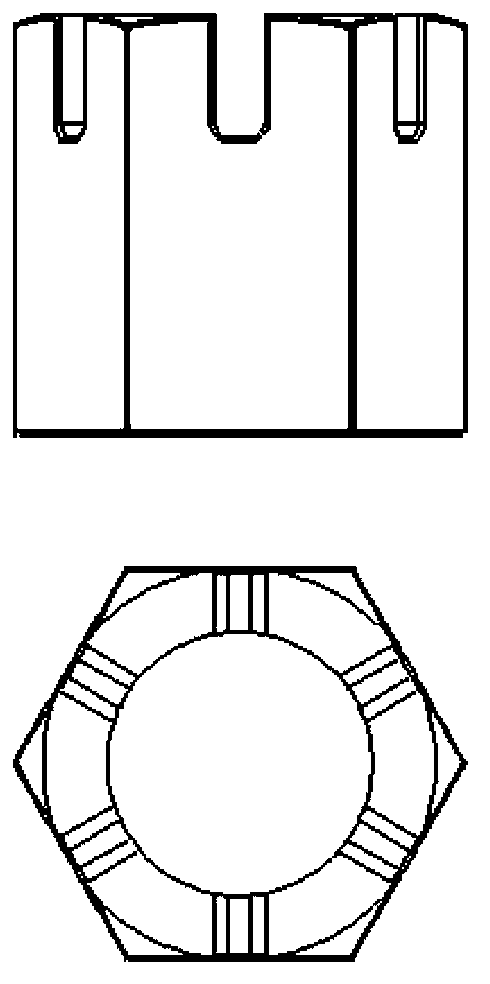

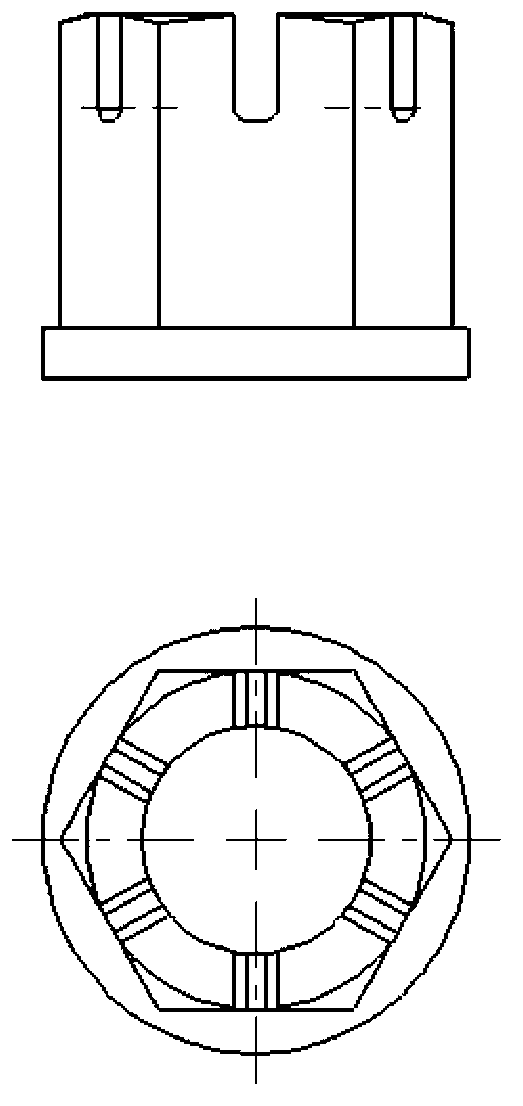

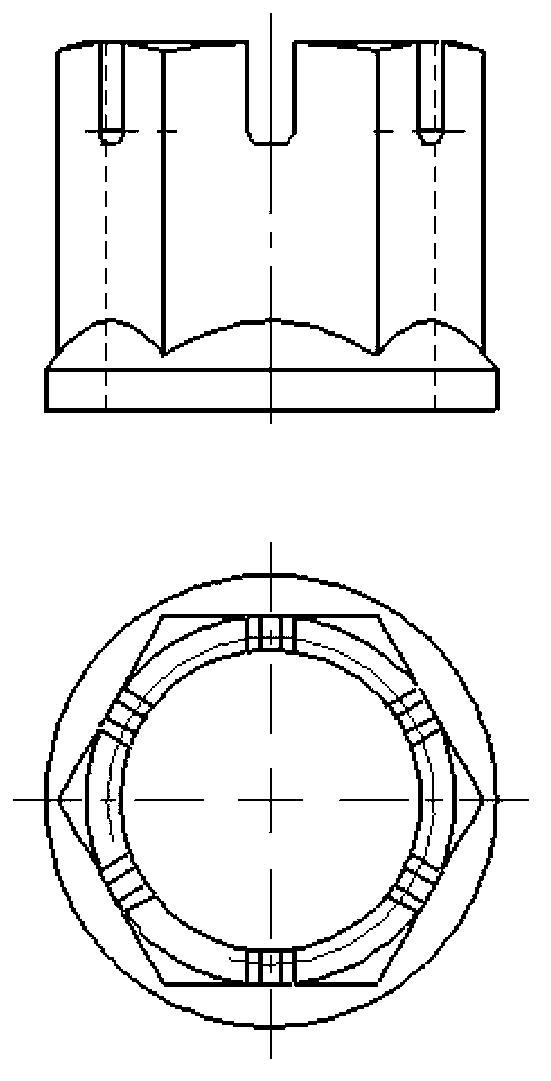

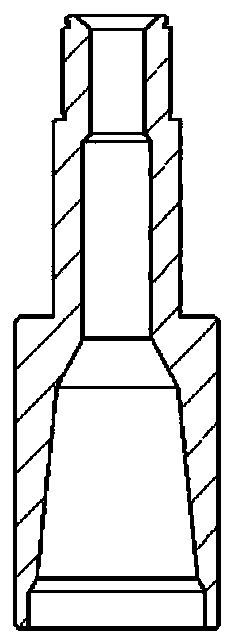

Cold-extrusion forming process of high-temperature alloy high-strength skirt type self-locking hexagonal nut

The invention discloses a cold-extrusion forming process of a high-temperature alloy high-strength skirt type self-locking hexagonal nut. The cold-extrusion forming process comprises the following steps of: firstly selecting a high-temperature alloy rod with a suitable casting diameter to do solid melting treatment; and then, carrying out extrusion on the rod section in a cold-extrusion forming mould to form an internal blind hole cavity of the nut, form a skirt bottom end cavity of the nut, form an outer hexagon of the nut and form a short cylinder straight footstep of the nut to be connected with a skirt of a cone of 45 degrees. After the high-temperature alloy high-strength skirt type self-locking hexagonal nut disclosed by the invention is extruded up and down, metal fibers are continuously distributed from the skirt to the hexagon; and the metal fibers in a hole can be vertically combed under the extrusion of strong extrusion force, so that the toughness of a product is improved.

Owner:QINHAN PRECISION IND CO LTD

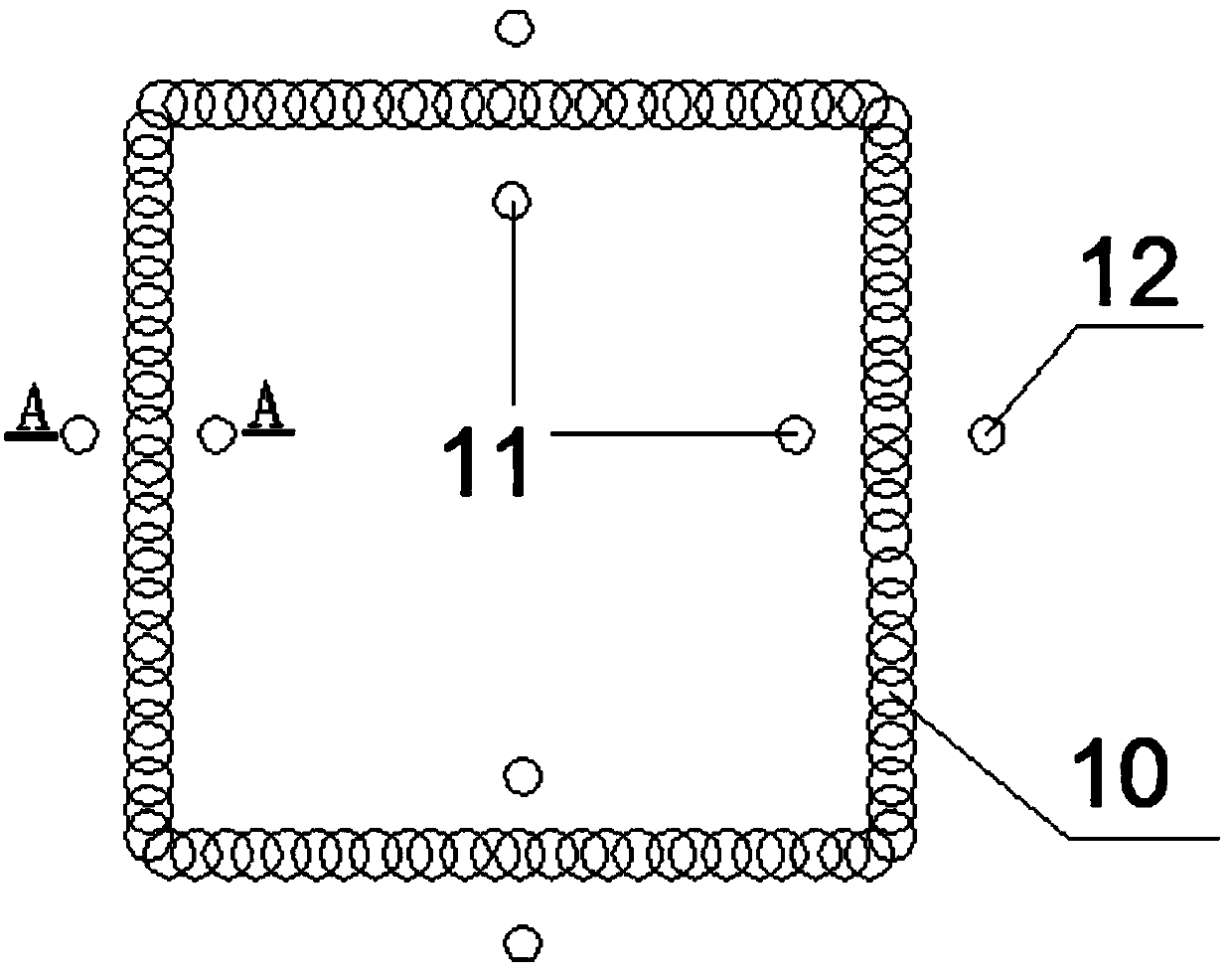

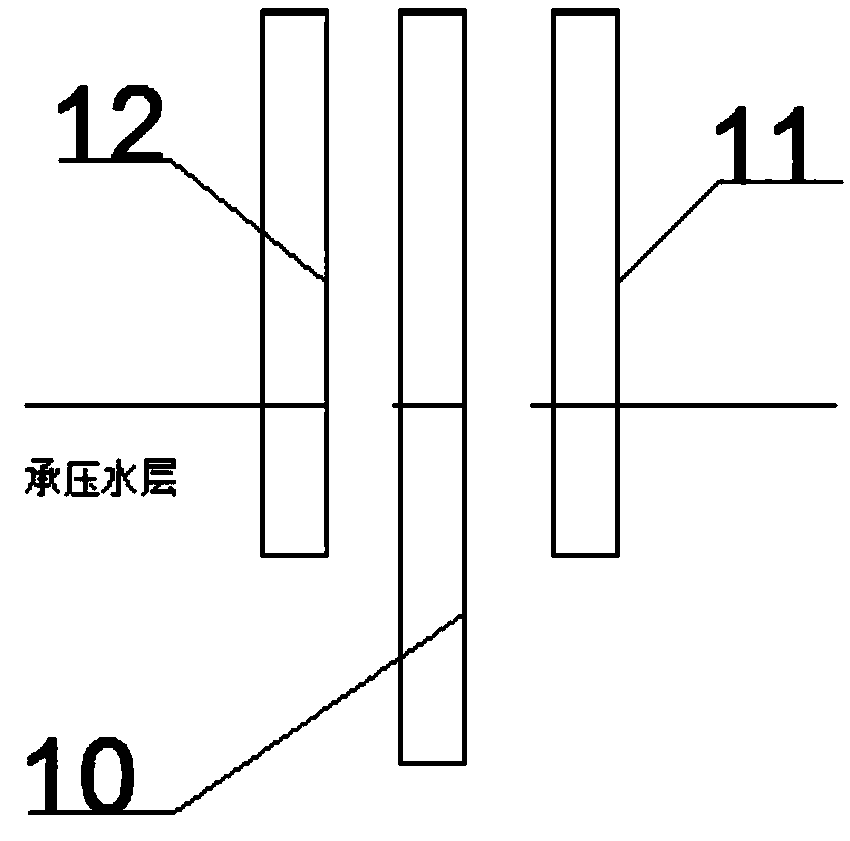

Method for quickly judging construction quality of waterproof curtain

The invention discloses a method for quickly judging the construction quality of a waterproof curtain, and belongs to the field of building construction. According to the method for quickly judging the construction quality of the waterproof curtain, inner water level observation wells and outer water level observation wells are drilled at equal intervals on the inner and outer sides of a water-stop curtain pile, the inner part of the waterproof curtain pile is cleaned, a pipeline is placed under the waterproof curtain pile, sand and gravel filter materials are put into the waterproof curtain pile for filtering, and finally backfilling and tamping are carried out on the outer part of the pipeline; the water level difference between the inner water level observation wells and the outer waterlevel observation wells is detected by performing constant flow pumping, whether the rule that the water level of each inner water level observation well and the water level of each outer water levelobservation well are simultaneously lowered and the water level difference is greater than 150mm is met or not is judged, if the rule is met, the water level observation well at the position is marked for subsequent accurate detection to perform key detection with expanded scope conveniently. If the rule is not met, only the inner water level observation wells and the adjacent inner water level observation wells and the central point need to be detected.

Owner:CHINA MCC17 GRP

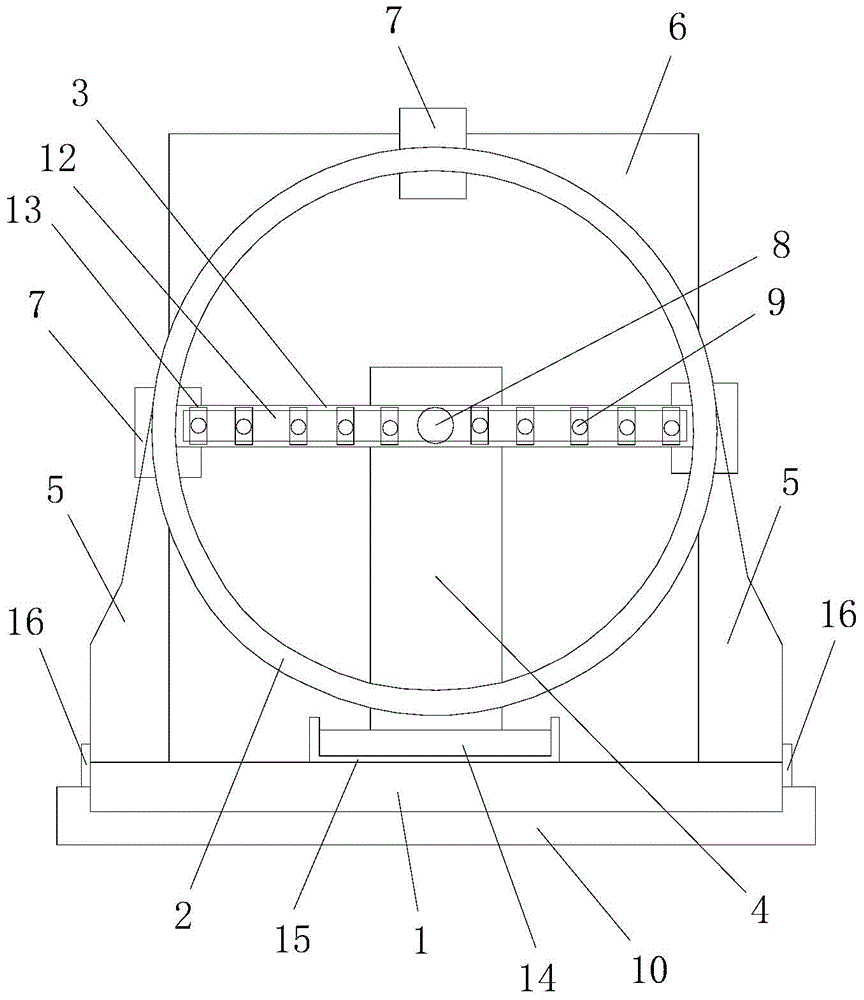

Hole drilling hole position and depth self-adjusting type tunnel blasting hole drilling device

InactiveCN105696939ASimple structureReasonable designDerricks/mastsDrilling machines and methodsHydraulic cylinderEngineering

The invention discloses a hole drilling hole position and depth self-adjusting type tunnel blasting hole drilling device, which comprises a horizontal base plate, a horizontal bottom plate, a hole drilling device and a jacking mechanism, wherein the hole drilling device is arranged above the horizontal bottom plate and can forwards and backwards move on the horizontal plane; the jacking mechanism pushes the hole drilling device to forwards and backwards move and correspondingly regulates the hole drilling depth of the hole drilling device; the hole drilling device comprises an annular rail, a hole drilling machine frame, two rail support seats and a vertical installing seat; the vertical installing seat is positioned at the back side of the annular rail; a transverse slide moving rail is arranged at the front side of the hole drilling machine frame; a plurality of drilling tool installing seats capable of doing transversely slide moving are arranged on the transverse slide moving rail; the jacking mechanism comprises a jacking plate and a plurality of jacking hydraulic cylinders; and a horizontal slide moving seat is arranged at the bottom of the vertical installing seat. The hole drilling hole position and depth self-adjusting type tunnel blasting hole drilling device has the advantages that the structure is simple; the design is reasonable; the installation and the arrangement are convenient; the use and the operation are simple and convenient; the use effect is good; the hole drilling process of a plurality of blast holes in a blasting surface can be simply, conveniently and fast completed; and the hole drilling hole position and the hole drilling depth can be simply and conveniently regulated.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

Plugging resin system and application thereof

InactiveCN111793480AImprove liquidityImprove mechanical propertiesDrilling compositionPolymer scienceFirming agent

The invention provides a plugging resin system and application thereof. The plugging resin system is obtained by a reaction of a component A and a component B, the mass ratio of the component A to thecomponent B is 1: 1 to 3: 2, the component A at least comprises epoxy resin, and the component B at least comprises an epoxy resin curing agent. Epoxy resin and a curing agent are mixed and stirred according to different proportions, the mixture is pumped into a casing leakage breaking section, the resin and the curing agent are subjected to addition polymerization reaction within specified timeand under the condition of proper formation temperature to generate a cured product of a net structure, and the purpose of plugging is achieved. And the gelling time can be controlled by the dosages of the components A and B. The compressive strength is greater than 80 MPa, and the chemical plugging construction requirements of the casing damage well are met. According to the plugging resin system, the compressive strength is met, meanwhile, the resin hardness is reduced, the resin toughness is improved, and the resin drillability is improved. And the plug drilling speed can reach 2.5 m / h under the same condition of the plug drilling process, so that the plug drilling time is greatly saved.

Owner:PETROCHINA CO LTD

While-drilling micro-bore-enlarging well wall trimming tool and using method thereof

The invention discloses a while-drilling micro-bore-enlarging well wall trimming tool and a using method thereof. The trimming tool comprises a cylindrical body, a plurality of centralizing belts arranged on the surface of the cylindrical body, and cutting teeth. The cylindrical body can be connected to a drill collar and rotate along with rotation of the drill collar. Every two centralizing belts are parallel, and each centralizing belt is spirally arranged on the surface of the body in a protruding mode. The upper and lower ends of the centralizing belts are in arc transition with the body. Hard alloy layers are arranged at the bottoms of the centralizing belts, the cutting teeth are inlaid in the area, with the hard alloy layer, of one centralizing belt in the longitudinal direction, and the diameter of the part with the cutting teeth is larger than that of a drill bit. In the use process, the trimming tool is installed on the drill collar on the upper side of the drill bit and can automatically trim well wall micro-steps and irregular well sections and perform micro-enlarging on a wellbore in the normal drilling process, the diameter of the enlarged wellbore is larger than that of the drill bit, a casing pipe can be lowered without drilling-down or pigging, and thus drilling time is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electromagnetic distance measurement guide system for double solenoid set during drilling

InactiveCN101852078BEasy to change intensityHigh precisionConstructionsHorizontal wellsData transmission time

The invention discloses an electromagnetic distance measurement guide system for a double solenoid set during drilling. The system can provide accurate guide measurement and calculation for well track control of double horizontal wells, communicated wells, U-shaped wells, infill wells, and other complex-structure wells. The system mainly comprises a double solenoid set pup joint, a converted MWD,a ground display system, ground equipment, and the like. The double solenoid set pup joint serving as a magnetic signal emission source is put into a drilled well, two rotating magnetic fields with different frequencies are generated, and the system has the measurement accuracy equivalent to the RMRS. During measurement and calculation, the spacing between adjacent wells and relative azimuth can be accurately detected and calculated without dragging the double solenoid set pup joint. Therefore, the measurement can be finished in short time. The data analysis and adjacent well spacing calculation program of the system can be put underground, only a little of calculated necessary data is transmitted to the ground, and the data transmission time is saved. Meanwhile, by improving the current intensity of a solenoid coil, and the like, the intensity of the magnetic signal emission source is improved, and the distance measurement range of the system is easily increased. The system has the advantages of high guide accuracy, wide distance measurement range, short measurement time, and simple structure, and is an effective high-tech means for the detection and control of the distance between the adjacent wells during drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydraulic impactor driven by spiral impeller

The invention relates to a hydraulic impactor driven by a spiral impeller. The hydraulic impactor driven by the spiral impeller comprises a transmission pup joint, a threaded lock, an impact cavity, arectifier, an impeller shaft and an impactor main body; one end of the rectifier is open and the other end of the rectifier is provided with a closed plate; the closed plate is provided with run-through drainage hole and main flow channel; an impeller is arranged on the impeller shaft; an upper fixed plate and a lower fixed plate are arranged on the impeller shaft positioned above and below the impeller correspondingly; a transmission plate is arranged at the tail end of the impeller shaft; the upper fixed plate and the lower fixed plate are provided with flow channel mouths correspondingly;the transmission plate is provided with an overflow hole; the impeller shaft is positioned in the rectifier; the transmission plate is positioned on one side of the closed plate and positioned above the closed plate; the impact cavity adopts a hollow run-through structure; the top of the impact cavity is in threaded connection with the impactor main body; the threaded lock is positioned blow the internal part of the impact cavity; one end of the transmission pup joint is inserted into the impact cavity and is in threaded connection with the threaded lock; and the transmission pup joint and theimpact cavity are matched through an orthohexagnal surface. The hydraulic impactor driven by the spiral impeller can solve the problems that the existing impactor has too short life and too small single-time impact force.

Owner:CNPC BOHAI DRILLING ENG

Hydrate jet recovery device with double-layer pipe forward and reverse injection function

ActiveCN111395978ASave time drillingReduce operating costsDrilling rodsFluid removalPilot holeUpper joint

The invention discloses a hydrate jet recovery device with a double-layer pipe forward and reverse injection function. The hydrate jet recovery device comprises an outer pipe, an inner pipe, an innerpipe upper joint, an inner pipe lower joint, a check valve and a sliding block, wherein the outer pipe consists of three sections, the upper end of the outer pipe is connected with an outer pipe of adouble-layer continuous pipe, and the lower end of the outer pipe is connected with downhole tools such as a drill bit; the upper part of the inner pipe is in plug-in sealing connection with an innerpipe of the double-layer continuous pipe through the inner pipe upper joint, and nozzle sleeves are inserted in jet holes in the walls of the inner pipe and the outer pipe to form circumferential fixation; the check valve is fixed by steps at the upper section and the middle section of the outer pipe; and a sliding block can freely slide in an inner pipe cavity. According to the hydrate jet recovery device, the switching of pilot hole drilling and dragging crushing of hydrate exploitation can be realized, the drilling cost is reduced, the drilling-down time is shortened, and the drilling and recovery efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

High-frequency circumferential impact type screw drilling tool structure

The invention provides a high-frequency circumferential impact type screw drilling tool structure. The structure comprises a bypass valve assembly, an anti-fall assembly, a motor assembly, a universalshaft assembly, a transmission shaft assembly and a circumferential impact assembly which are connected in sequence. The high-frequency circumferential impact type screw drilling tool structure has the beneficial effects that the high-frequency circumferential impact type screw drilling tool structure cooperates with a PDC drill bit to be used together, the phenomenon that one or more vibrations(in the transverse, longitudinal and torsional direction) and clamping slip occur during downhole drill bit motion is eliminated, and the torque of a whole drill column keeps stable and is transmittedto the drill bit in a balanced mode; and according to the rock breaking mechanism, impact breaking is mainly conducted, a rock layer is subjected to high-frequency rotational shear, accordingly, quick and smooth drilling is achieved, the well drilling efficiency is improved, and the well drilling cost is reduced.

Owner:SHANDONG LUHAI GASOLINEEUM EQUIP

Full-hydraulic reamer

The invention relates to a full-hydraulic reamer applied to the fields of drilling and reaming operation for oil and gas exploration and development. A stepped cylinder is arranged on the outer wall of a mandrel piston, the lower end of the mandrel piston is in threaded connection with a mandrel nipple, an annular sealed limit ring is arranged in an annular space between the mandrel nipple and the shell, a mandrel cap is sleeved on an outer wall at the lower end of the mandrel nipple, a main nozzle and a main nozzle gland are fixed in a stepped central hole in the mandrel cap, a bypass hole is arranged on the wall of the mandrel cap, a lower joint is fixed at the lower end of the shell, a mandrel seat is fixed at the upper end of the lower joint, three rectangular windows are uniformly distributed on the shell wall along the circumferential direction, rectangular reaming cutter wings are arranged in each rectangular window through a cylindrical pin, and an incomplete gear is arranged at the inner end of each reaming cutter wing and engaged with a rack on a normal triangular prism in the middle of the mandrel piston. After a drill string is rotated to increase the pump displacementand open the cutter wings, reaming can be started, after the reaming is finished, the reaming cutter wings are withdrawn after a ball is placed, and drilling is normally continued after the reaming is finished, therefore drilling time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

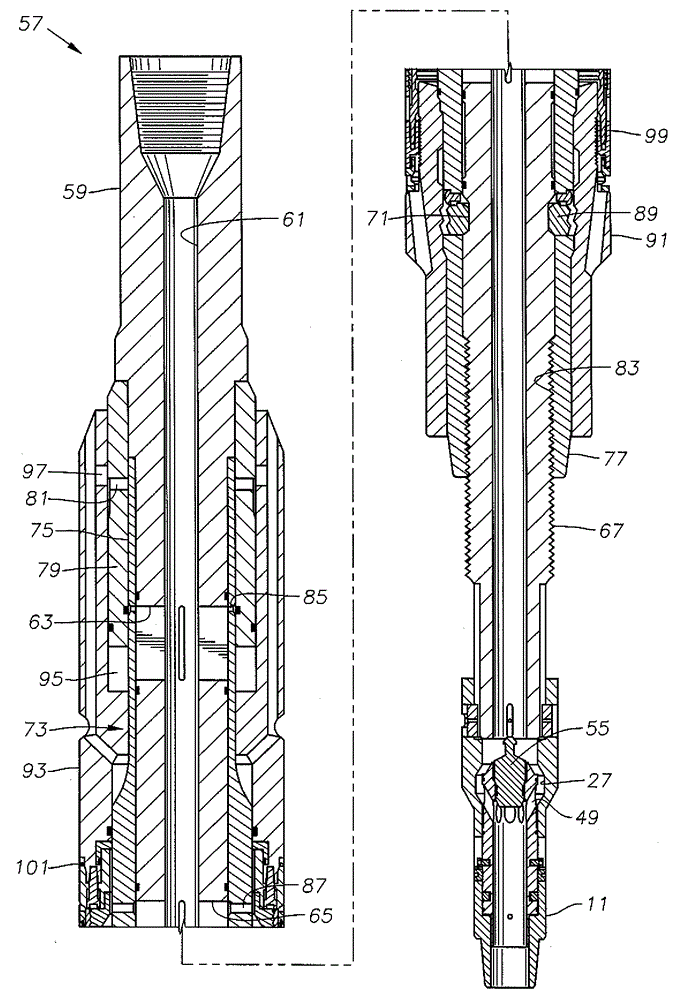

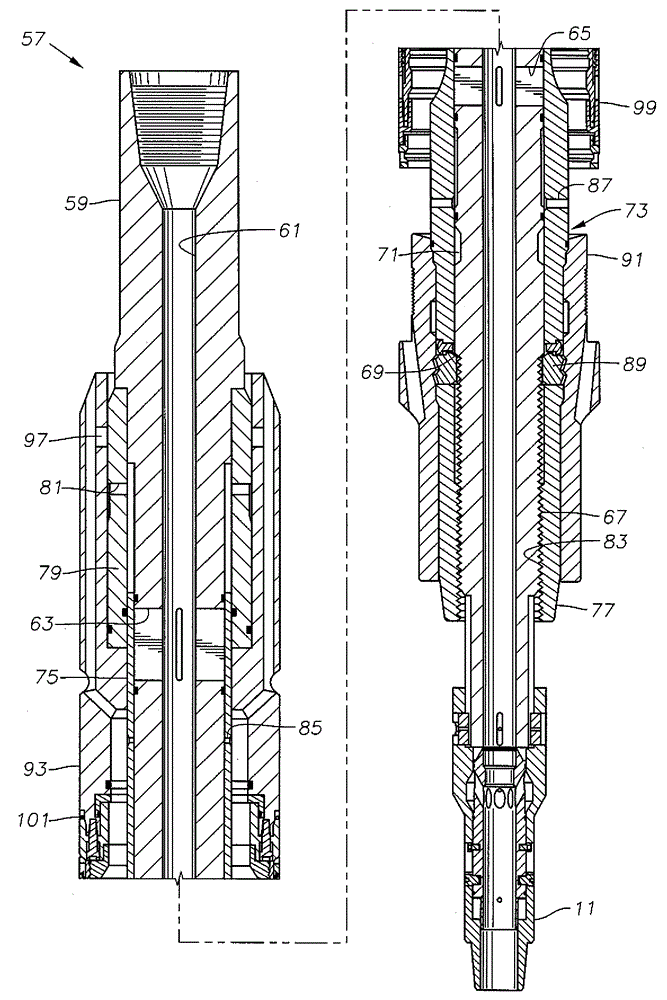

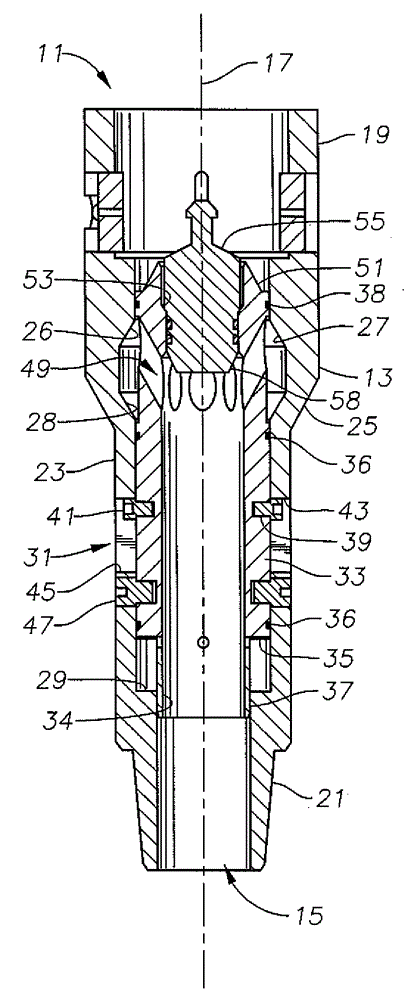

Receptacle sub

The invention relates to a receptacle sub, and discloses the receptacle sub (11) which improves discharging flow rate during a period a running tool (57) is got back. A tool or sub 11 includes a sleeve 33 with a bypass port 49 in a central bore 15 defined by a tubular body 13. The sleeve is selectively moveable from an upper position to a lower position. A seal 38 on the sleeve seals the sleeve to the bore while a retainer 47 holds the sleeve in the upper position. A bypass passage 27 in the body is in fluid communication with the bypass port. A drop member 55 lands on the sleeve, blocking downward flow through the sleeve so that pressure builds up until retainer or shear pin 47 shears, thus enabling fluid to flow from above the bore through the bypass passage and via the port. Other inventions relate to a running tool with a hydraulically actuated function and a bypass passage with a cross sectional flow area that is at least equal to a flow area through a central passage.

Owner:VETCO GRAY

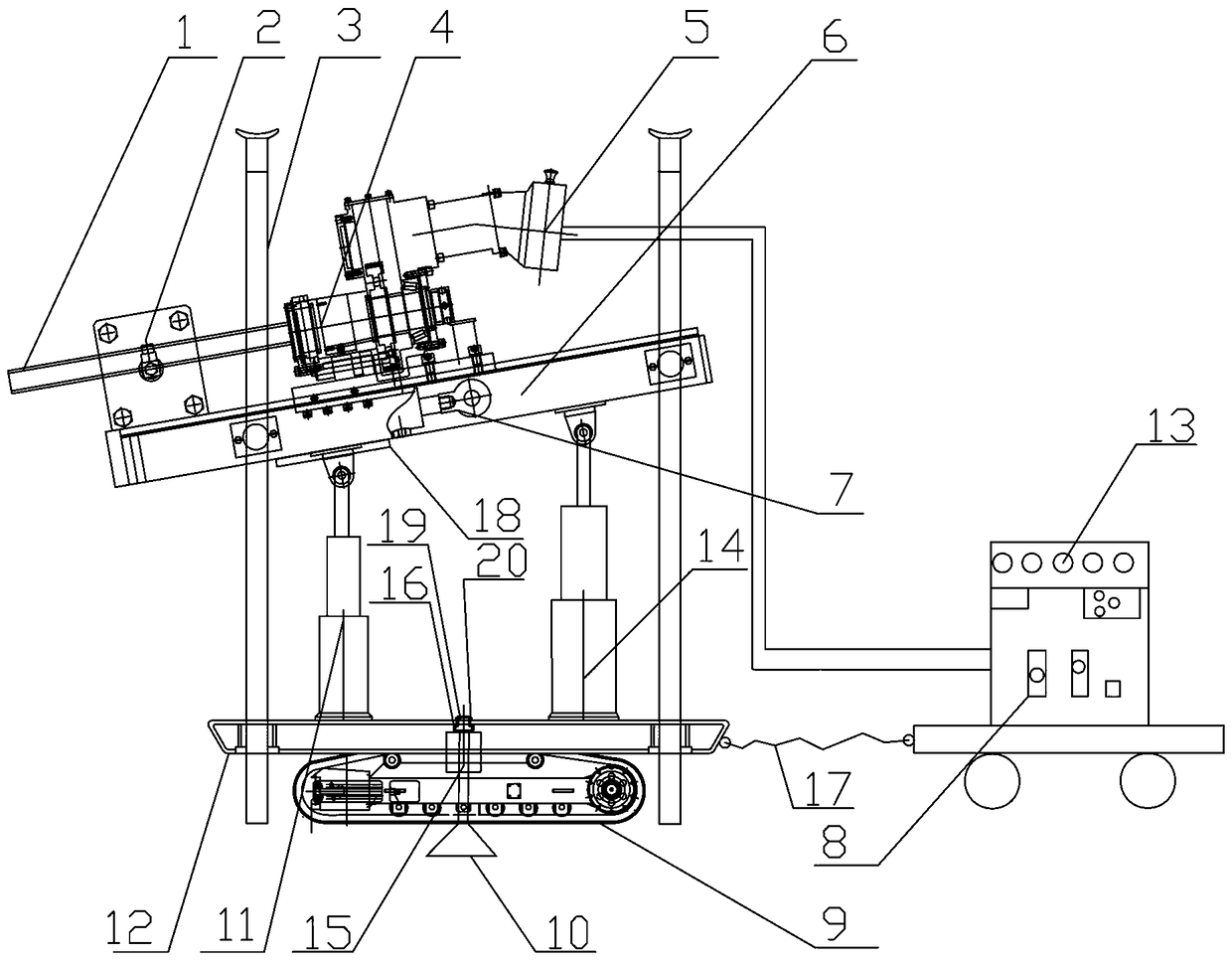

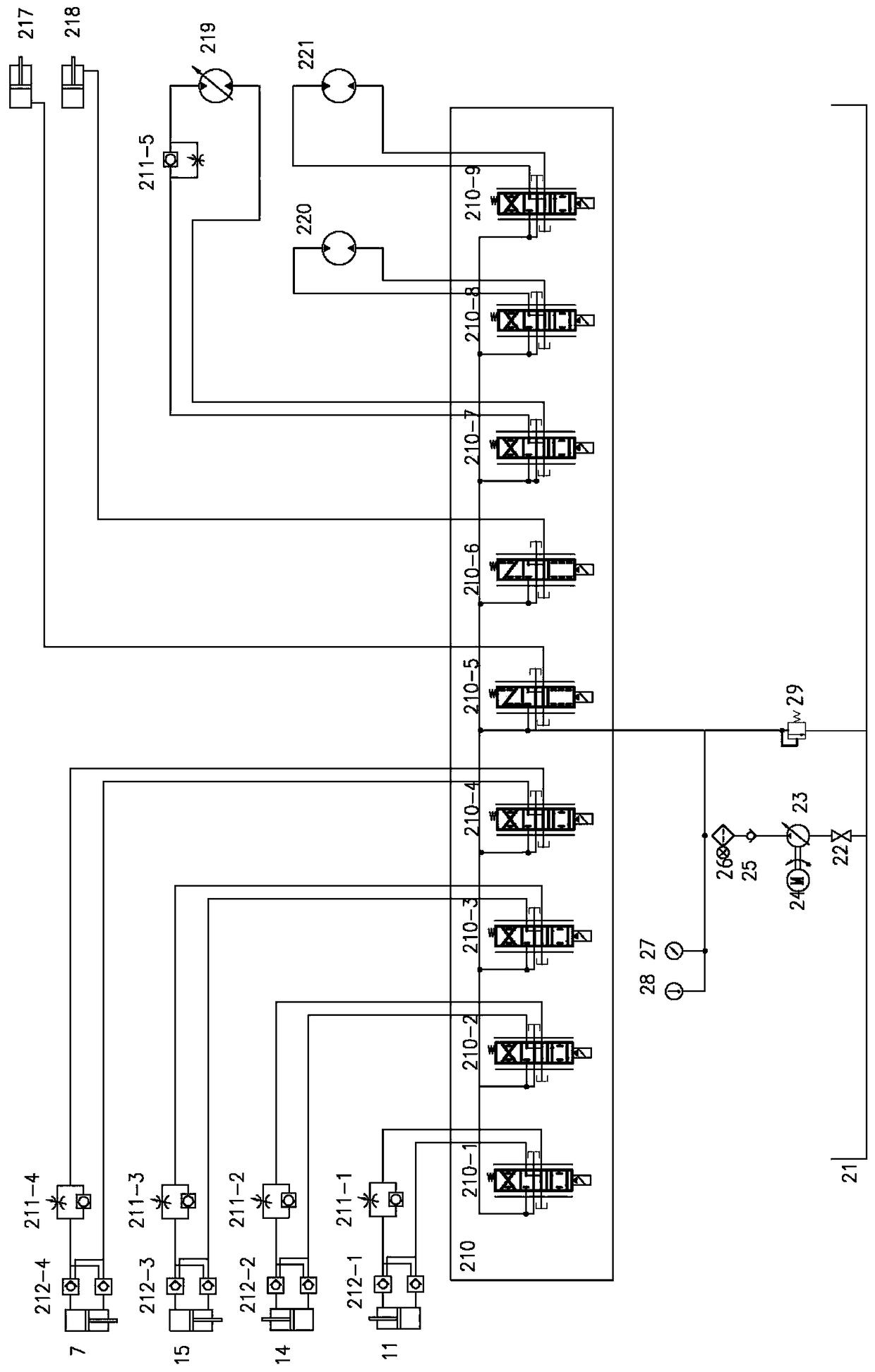

Automatic lifting drilling machine for high-position punching of medium-thickness coal seams and implementation method thereof

ActiveCN108166924ASolve the problem of not being able to automatically adjust the punching heightWith automatic liftingConstructionsDerricks/mastsHydraulic cylinderPunching

The invention discloses an automatic lifting drilling machine for high-position punching of medium-thickness coal seams. The automatic lifting drilling machine comprises a lifting unit, a rotating unit and a punching unit. The lifting unit comprises a front hydraulic cylinder and a rear hydraulic cylinder, cylinder bodies of the front hydraulic cylinder and the rear hydraulic cylinder are fixed tothe rotating unit, and piston rods of the front hydraulic cylinder and the rear hydraulic cylinder are connected with the punching unit. The automatic lifting drilling machine has the following advantages that the problems that an existing drilling machine cannot effectively conduct high-position punching of the medium-thickness coal seams, and adjusting of the punching angle is not flexible aresolved, automatic lifting, adjusting of the punching pitch angle, and adjusting of the horizontal rotating angle can be achieved, and the punching accuracy, the high-position punching efficiency and safety are improved.

Owner:SHANDONG UNIV OF SCI & TECH

Jet flow crushing suction recovery device suitable for natural gas hydrate exploitation

InactiveCN111350476ASave Drilling TimeImprove drilling efficiencyLiquid/gas jet drillingFluid removalPilot holeWell drilling

The invention relates to a jet flow crushing suction recovery device suitable for natural gas hydrate exploitation. The device comprises an upper connector, a differential pressure sliding sleeve, a casing pipe, a flow dividing connector, a nozzle and an inner pipe. The upper joint is connected with a double-layer continuous pipe outer pipe and the casing pipe, the differential pressure sliding sleeve is located in a casing pipe cavity and abuts against the end face of the upper connector under the action of a spring, and the flow dividing connector is connected with the inner pipe, the casingpipe and a lower downhole tool; and the nozzle is mounted on the flow dividing connector, and a mixing cavity, a throat part and a diffusion section are machined in an inner cavity of the inner pipeand are connected with a double-layer continuous pipe inner pipe through insertion type sealing. By means of the jet flow crushing suction recovery device, switching of hydrate pilot hole drilling anddrag-back crushing and negative pressure suction and lifting of hydrate slurry can be achieved, the drilling cost is reduced, the drilling time is saved, and the drilling recovery efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Wearproof and anti-backflow double-rubber-plug system for well cementation and using method

The invention discloses a wearproof and anti-backflow double-rubber-plug system for well cementation and a using method. The system comprises a wearproof and anti-backflow upper rubber plug, a lower rubber plug, a bump pressure holder and a leak-off basket. A rib and a sealing head are arranged on the wearproof and anti-backflow upper rubber plug, a self-locking tooth is arranged on the sealing head, and the rib is provided with a caster angle. A rib provided with a caster angle is arranged on the lower rubber plug. The bump pressure holder comprises a shell and a self-locking bump pressure seat, the shell and the self-locking bump pressure seat are both arranged in an axial penetrating mode, the self-locking bump pressure seat is fixed in the shell, and a self locking structure matched with the self-locking tooth on the sealing head is arranged on the inner wall of the self-locking bump pressure seat. After the rib of the lower rubber plug deforms, the maximum outer diameter at the rib of the lower rubber plug is shorter than the inner diameter of the self-locking bump pressure seat. The leak-off basket is matched with the lower rubber plug to form a fluid flow channel in the construction process of well cementation. According to the wearproof and anti-backflow double-rubber-plug system for well cementation and the using method, effective separation of cement paste from mud infront and back can be achieved in a casing pipe.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Stratum reinforcement PSC construction method

ActiveCN104775412AReduce wasteReduce waste costsIn situ soil foundationSoil preservationArchitectural engineeringStructural engineering

The invention discloses a stratum reinforcement PSC construction method which comprises the following construction steps: lofting hole sites; performing first hole construction; determining slurry proportion; performing stratum drainage construction; performing stratum reinforcement grouting; repeating the previous steps, thereby finishing all the stratum reinforcement PSC construction steps. The stratum reinforcement PSC construction method has the beneficial effects that equipment used in the stratum reinforcement method is relatively small in size and flexible in movement among hole sites; the slurry consolidation time can be regulated according to practical situations; the slurry penetrability is favorable; the slurry can be consolidated under the condition of circulating water, is difficult to dissolve and good in water stop effect; the reinforcement method is applicable to various strata, wide in application range, good in environment-friendly functional effect, less in environment pollution, good in safe operation function and high in construction speed; by virtue of adopting the technology for construction, the construction process includes advancing-type construction and backing-type construction, additional hole guiding is not needed, the additional hole guiding time is saved, and hole collapse is avoided; the preparation of construction is simple, around-the-clock construction can be performed and the engineering cost is low.

Owner:广东欣龙隧道装备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com