Drilling machine capable of rapidly and accurately locating

An accurate positioning and drilling rig technology, which is applied in the direction of rotary drilling rigs, earthwork drilling, drilling equipment, etc., can solve the problems of increasing the labor intensity of drilling construction, narrow drilling rig base, and accidents in the hole, so as to increase the construction drilling time , saving time for steady drilling and improving the operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

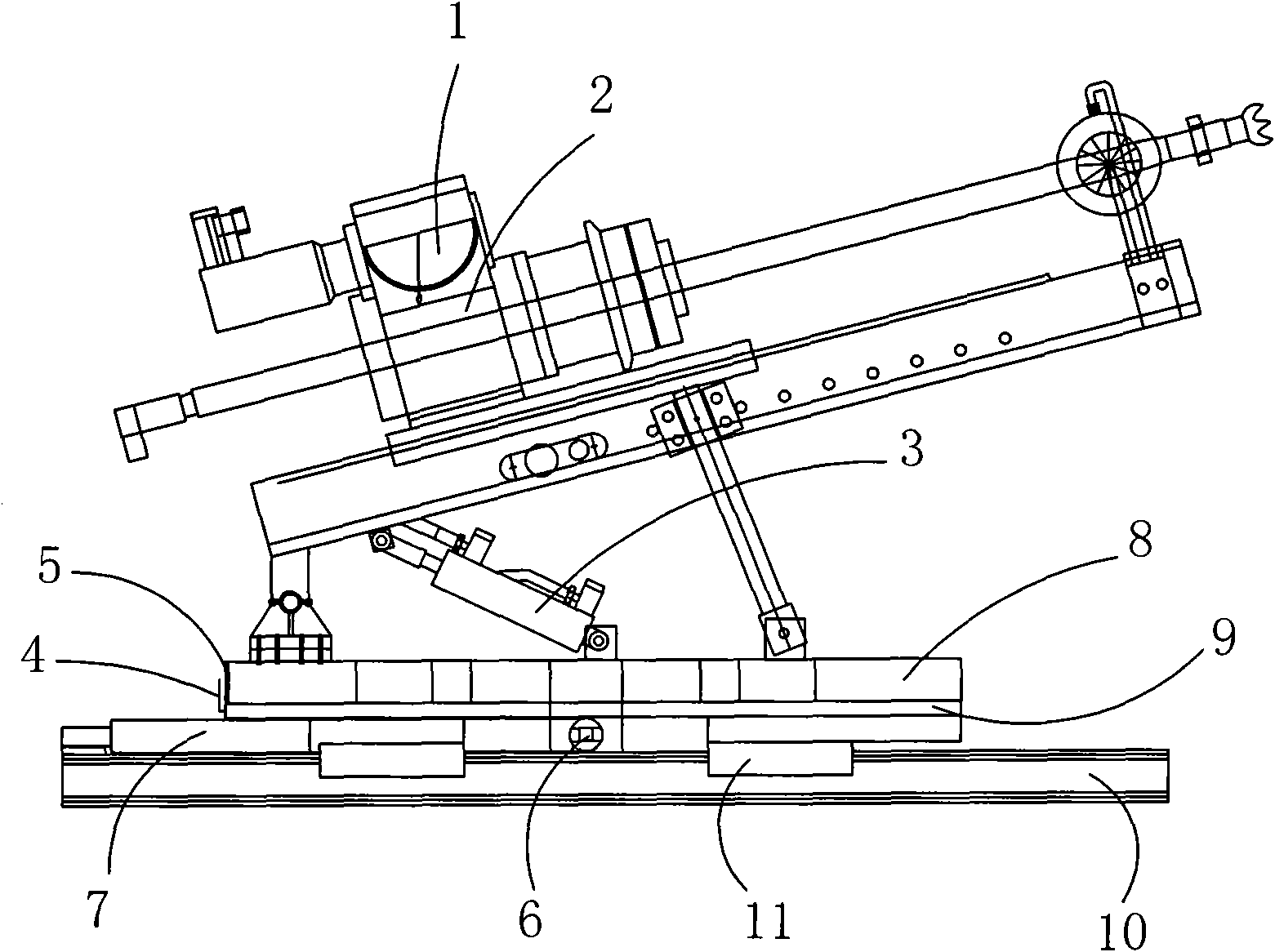

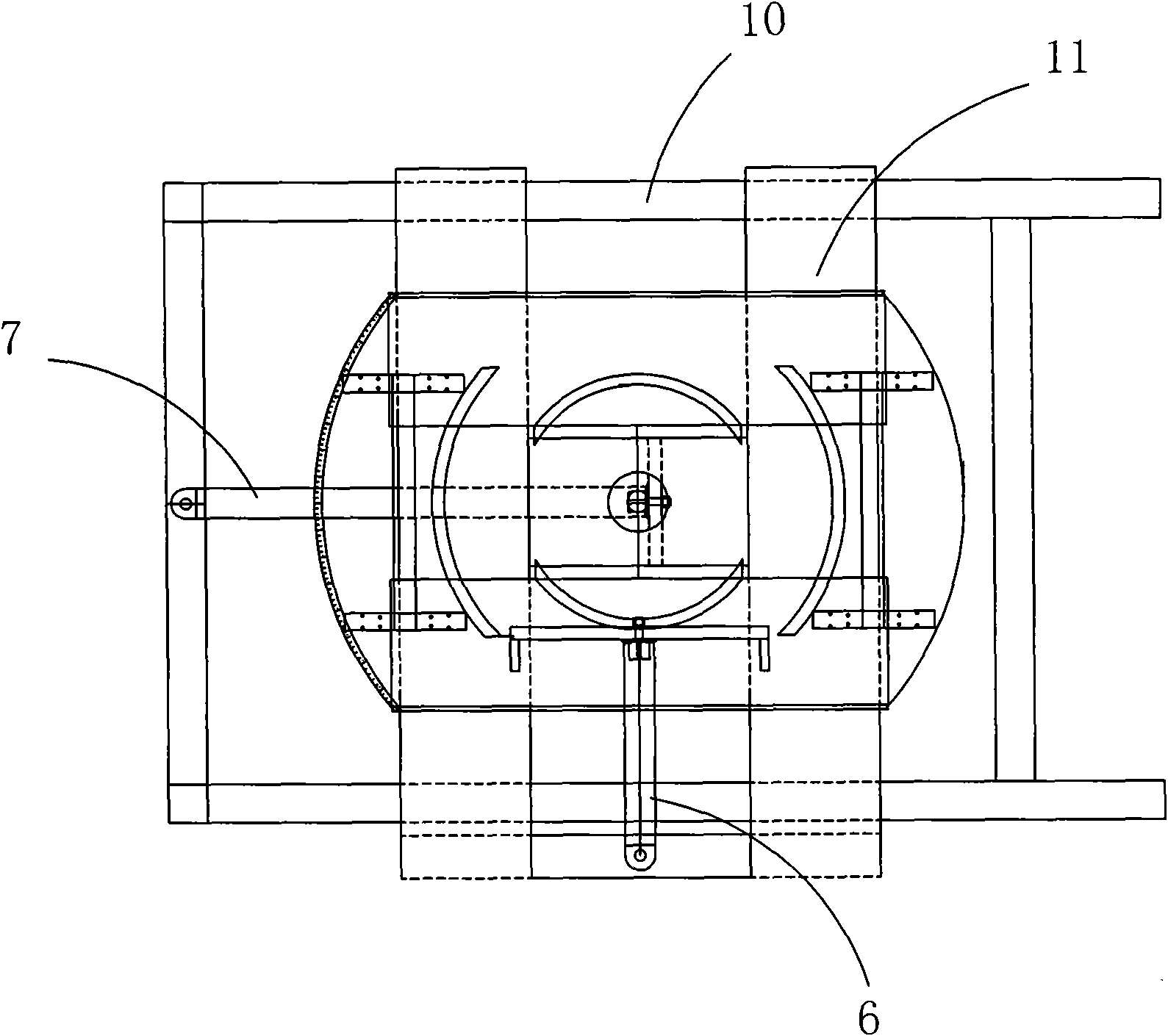

[0021] The chassis of the drilling rig and the power head part 2 adopt the existing configuration form. In the present embodiment, a chassis is set. The chassis is based on a rectangular frame, and a pair of parallel longitudinal side frames on the rectangular frame form a longitudinal track 10; The horizontal rails 11 arranged in parallel can move longitudinally along the rails on the longitudinal rails 10; the drilling platform 9 is supported on the horizontal rails 11, and the drilling platform 9 can move laterally along the rails on the lateral rails 11;

[0022] A pallet 8 that is fixedly welded to the chassis of the drilling rig is set, and the pallet is supported on the drilling rig platform 9 by a turntable bearing, and can be horizontally rotated 360 degrees on the drilling rig platform 9 .

[0023] In specific implementation, the longitudinal propulsion cylinder 7 capable of driving the transverse rail 11 to move longitudinally on the longitudinal rail 10 and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com