Vibration table fatigue crack online detection system and detection method based on computer vision

A technology of computer vision and fatigue cracks, which is applied in the directions of calculation, measuring devices, and optical testing of flaws/defects, etc. It can solve problems such as the difficulty in realizing dynamic real-time detection and the inability to obtain the precise shape of cracks, and achieve intuitive positioning, convenient layout, and saving Labor and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

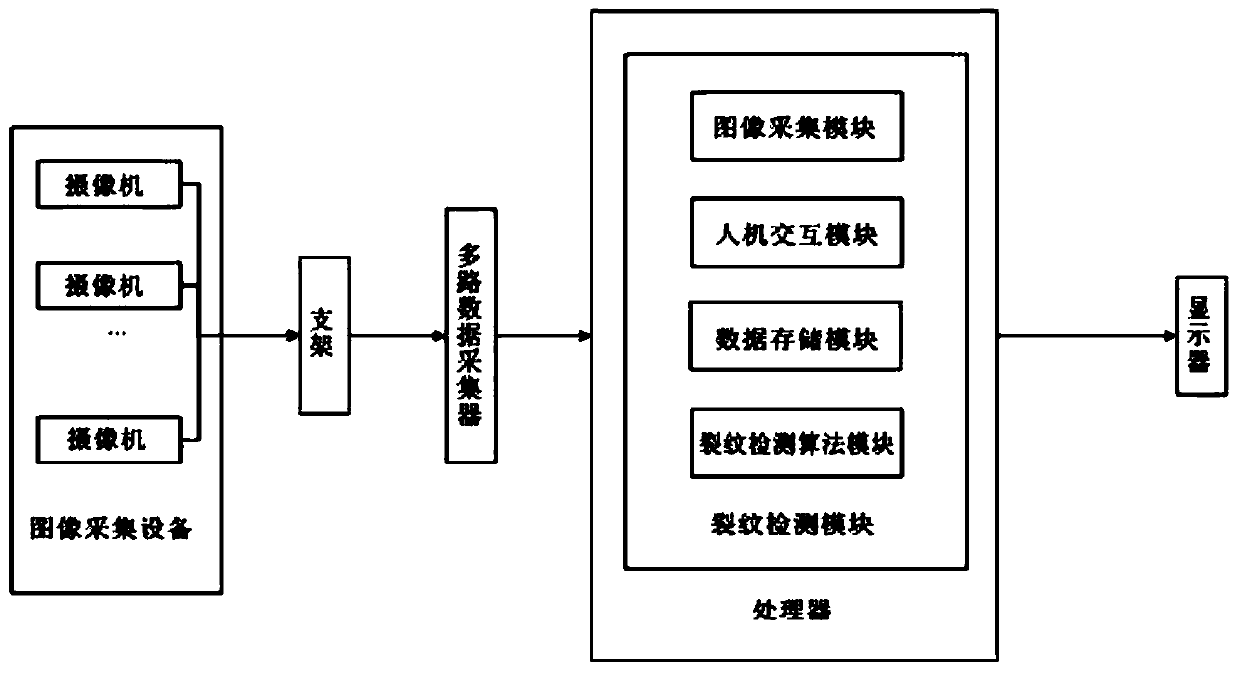

[0038] like figure 1 As shown, a computer vision-based vibration table fatigue crack online detection system includes an image acquisition device, a bracket, a multi-channel data collector, a processor, a display, and a crack detection module.

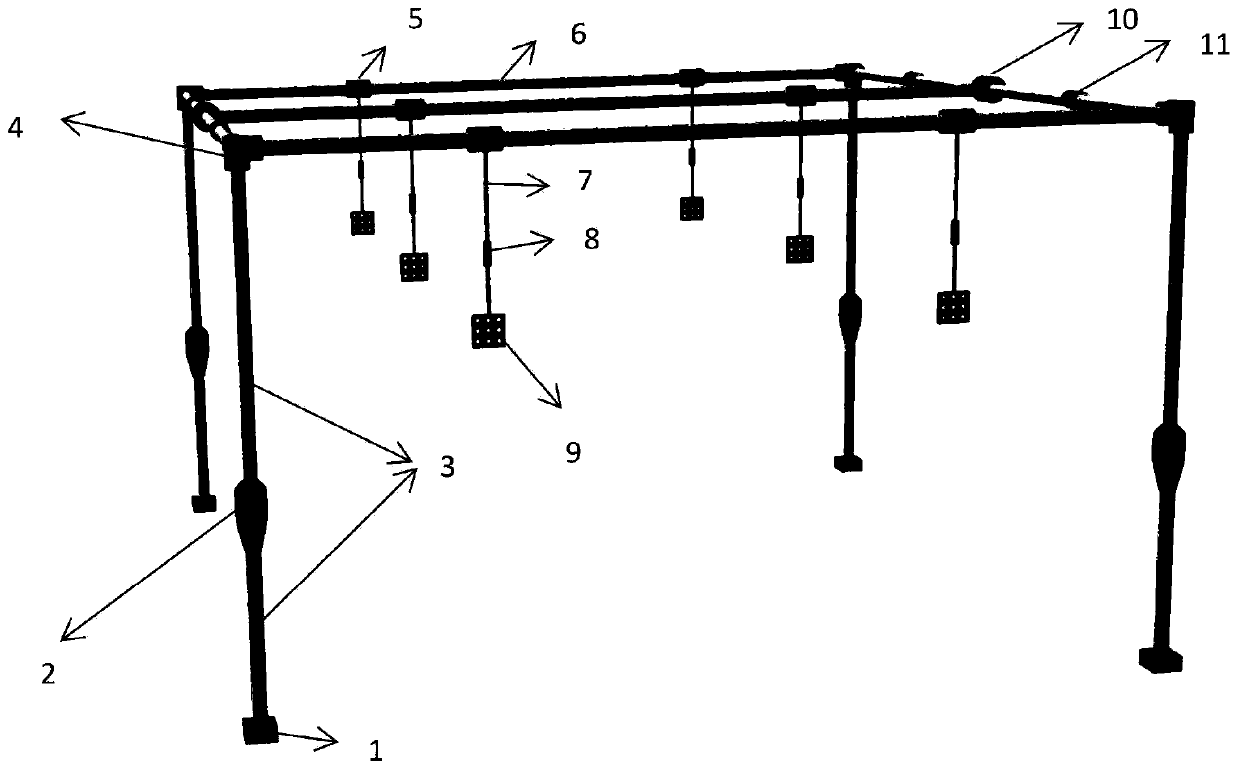

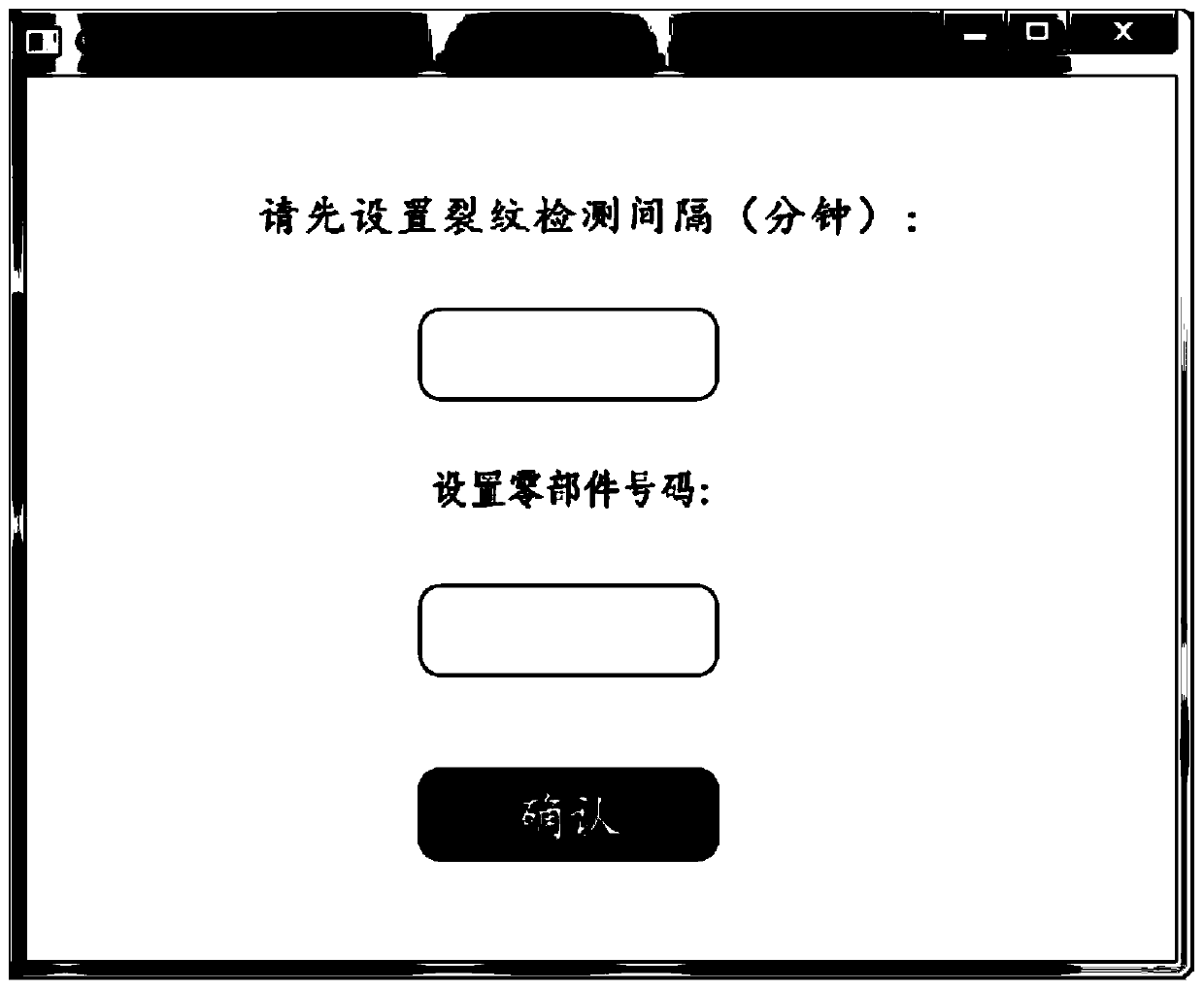

[0039] When testing, the bracket is first placed near the parts, and each camera in the image acquisition equipment is fixed on the corresponding suspension device on the bracket by screws, facing the area to be tested on the surface of the parts, which is prone to cracks, to collect image / video information ;Multiple cameras are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com