Windmill blade male die replacing plate and using method thereof

A technology that replaces boards and wind turbine blades. It is applied to wind engines, wind power generation, wind engines, etc. that are consistent with the wind direction. It can solve a lot of time and labor costs, and the problems of blades being unusable, so as to achieve simple structure, save manpower and cost. , the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

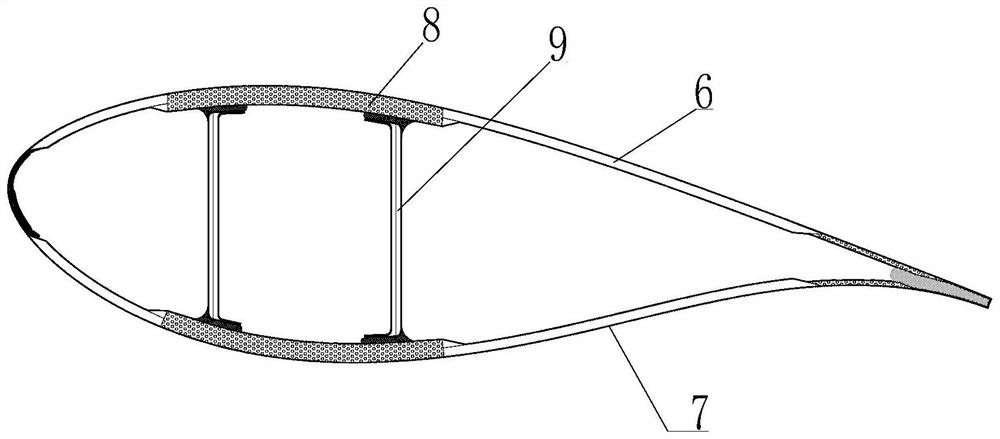

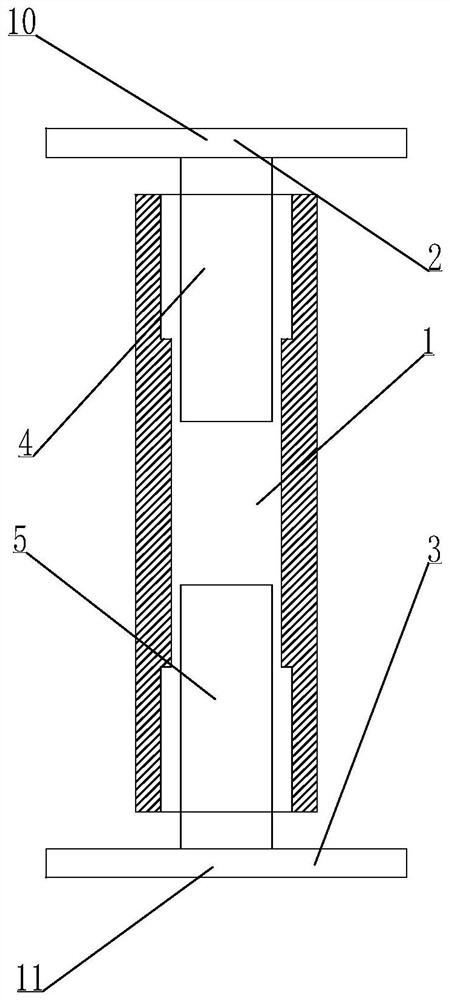

[0027] As shown in the figure, the male mold substitute plate for wind power blade manufacture of the present invention can replace the male mold web 9 to make a female mold, and the male mold substitute plate includes a threaded sleeve 1, a first T-shaped bracket 2 and a second T shaped bracket 3, the first T-shaped bracket 2 is welded by the first base 10 and the first screw rod 4, the second T-shaped bracket 3 is welded by the second base 11 and the second screw rod 5, the first screw rod 4 and the second screw rod 5 are welded The two screw rods 5 are penetrated into the threaded sleeve 1, and the expansion and contraction of the two T-shaped brackets are adjusted through the threaded sleeve 1, so as to adjust the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com