Reciprocating device of flash pressing machine

A technology of reciprocating device and edge closing machine, which is applied in mechanical equipment, threaded fasteners, connecting components, etc., can solve the problems of reducing production efficiency, increasing manpower, power and transportation costs, and improving production efficiency and saving human resources. and cost, the effect of reducing production safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below according to the accompanying drawings and embodiments.

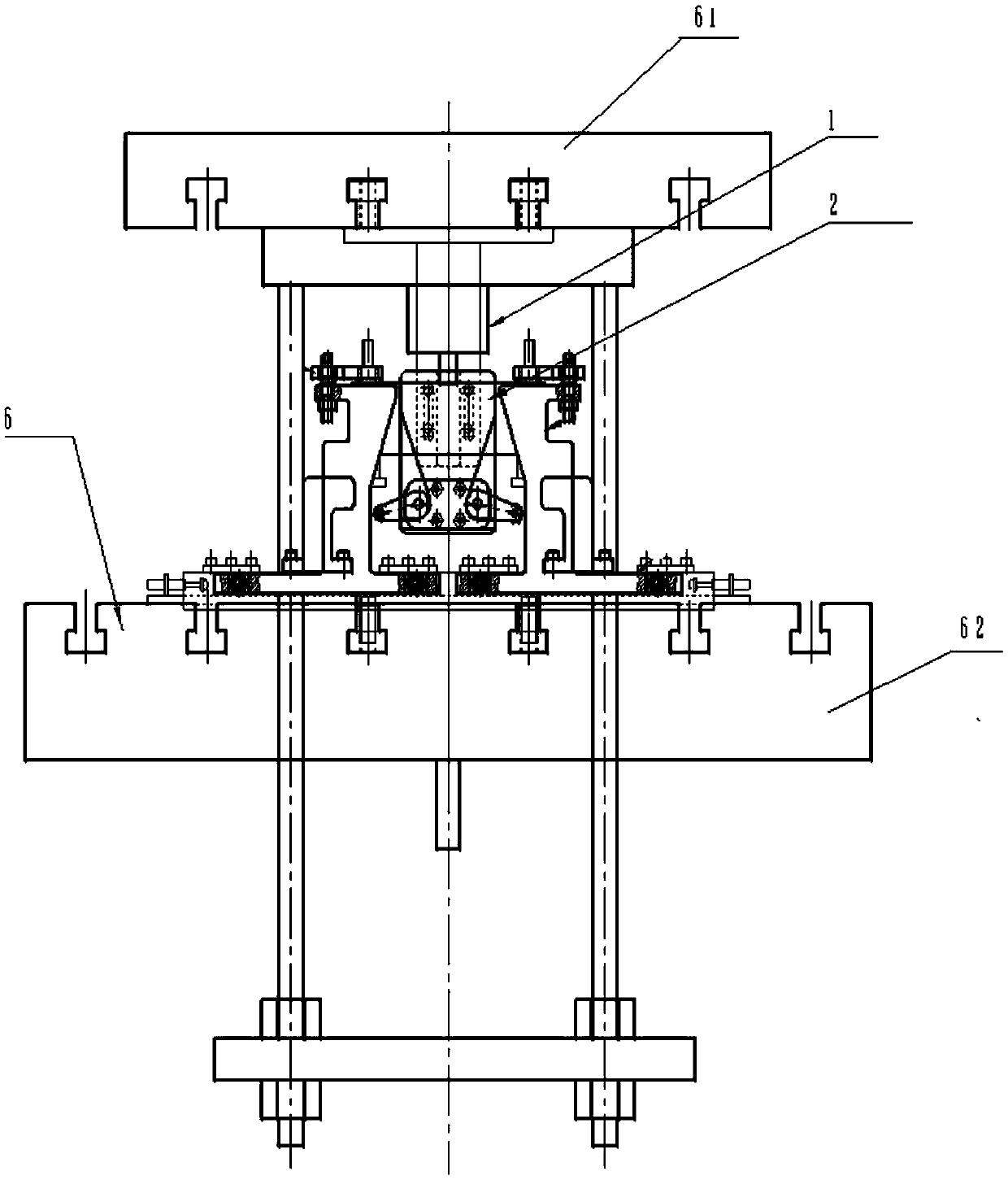

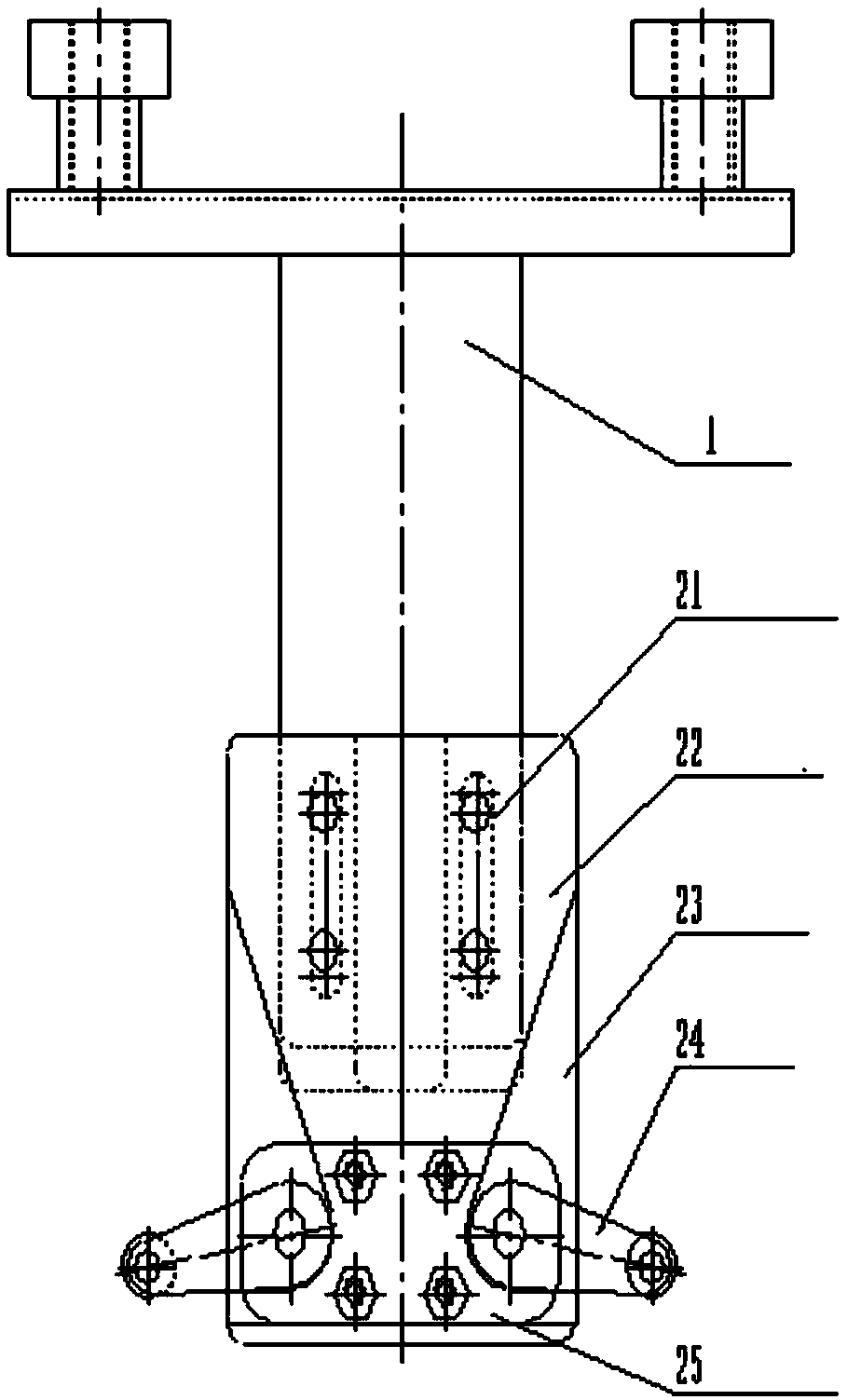

[0017] refer to Figure 1-Figure 3 , In the present invention, the reciprocating device of the edge closing machine includes: a press 6 and a reciprocating mechanism 2 .

[0018] The press 6 includes an upper part 61 of the press and a lower part 62 of the press. The upper part 61 of the press can move up and down, the bottom of the press 6 is fixedly provided with the upper seat 1, and the lower part 62 of the press is fixed in position.

[0019] The press 6 is the new main power mechanism of the present invention. The work task of the upper part 61 of the press is to move up and down, so as to drive the various mechanisms that cooperate with it to operate, and the lower part 62 of the press is the fixed base of each device.

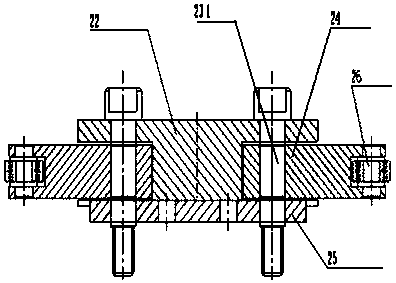

[0020] The reciprocating mechanism 2 includes a center block 22, two ratchet seats 24, and two ratchet wheels 26. The cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com