Patents

Literature

92results about How to "Reduce the risk of safety production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

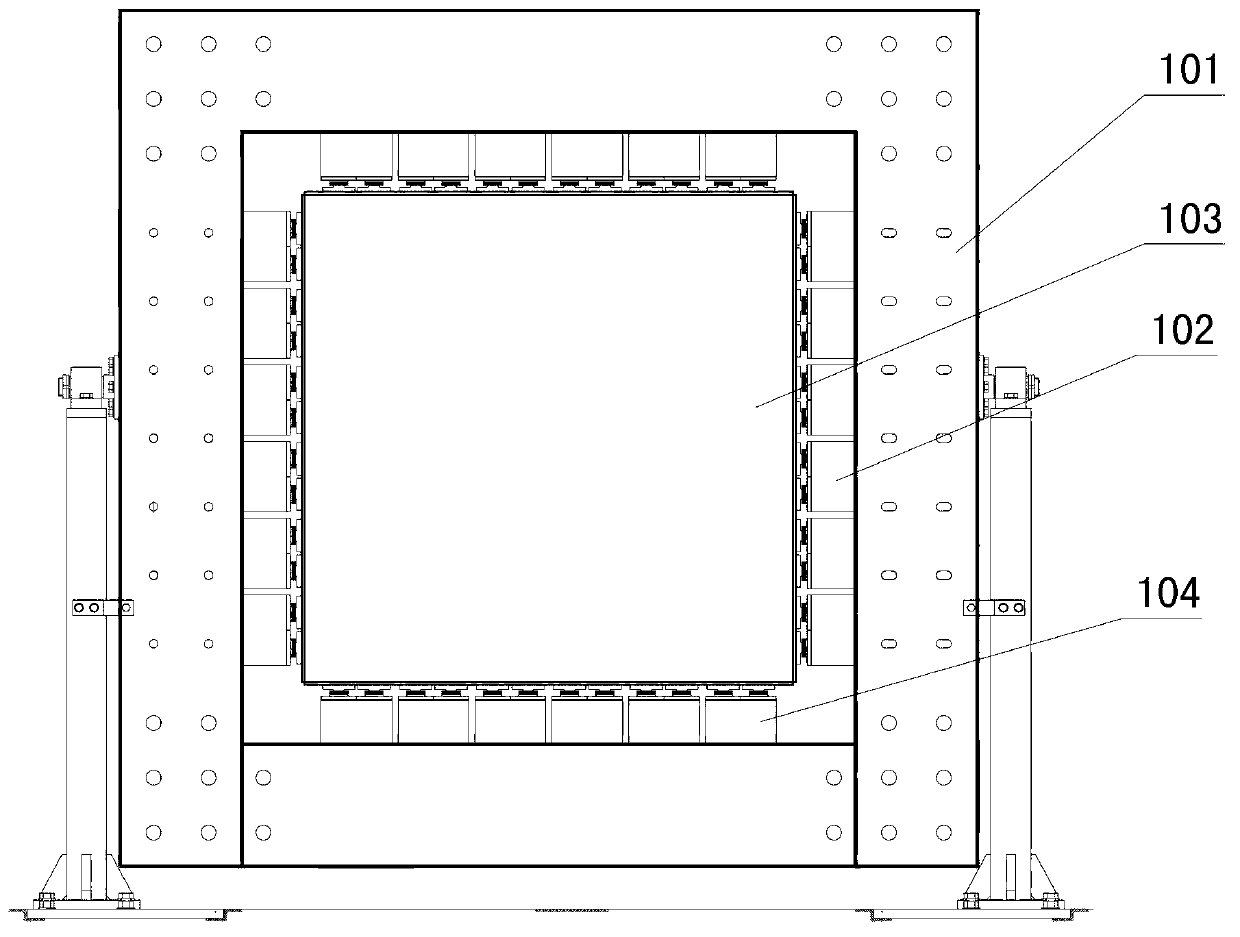

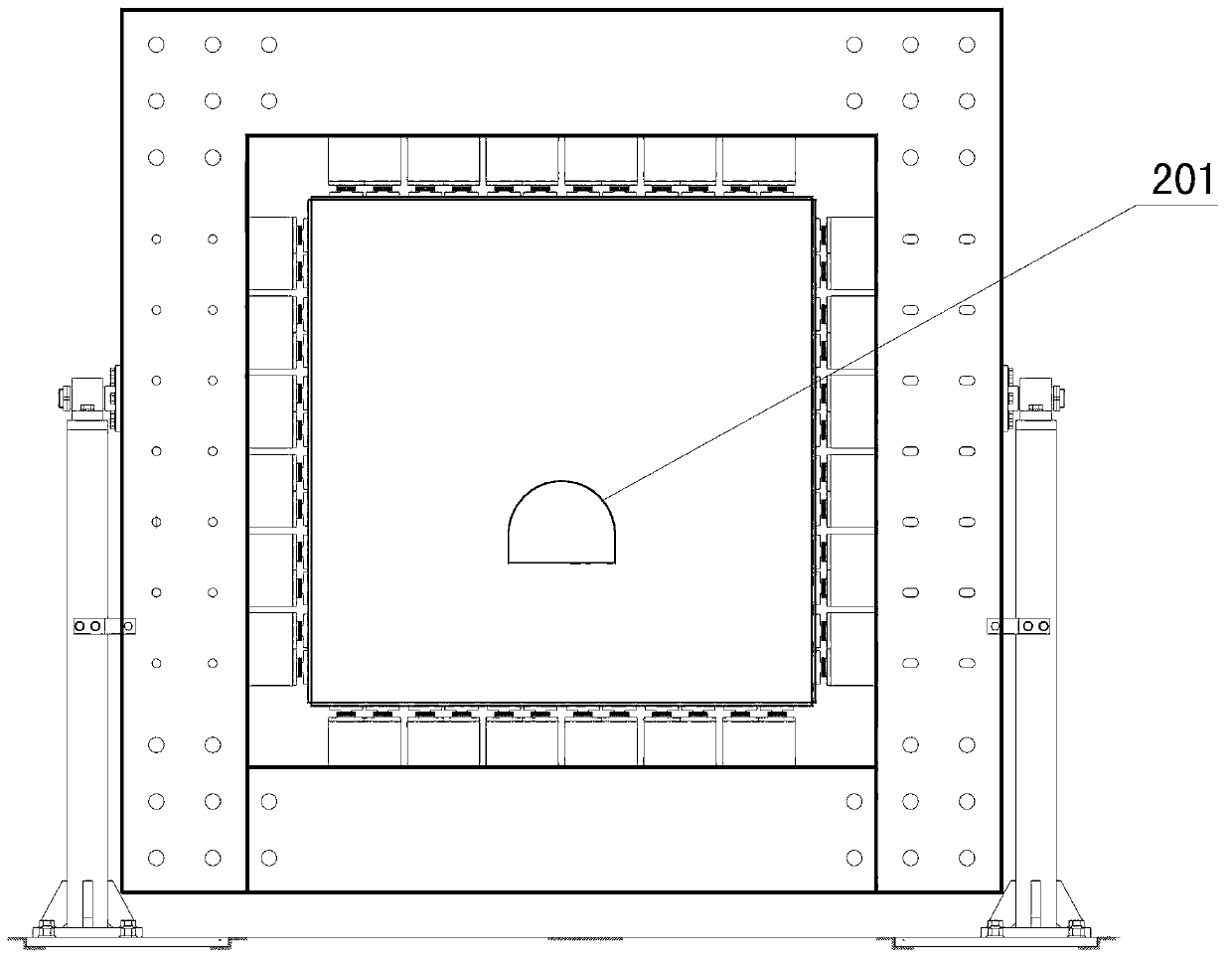

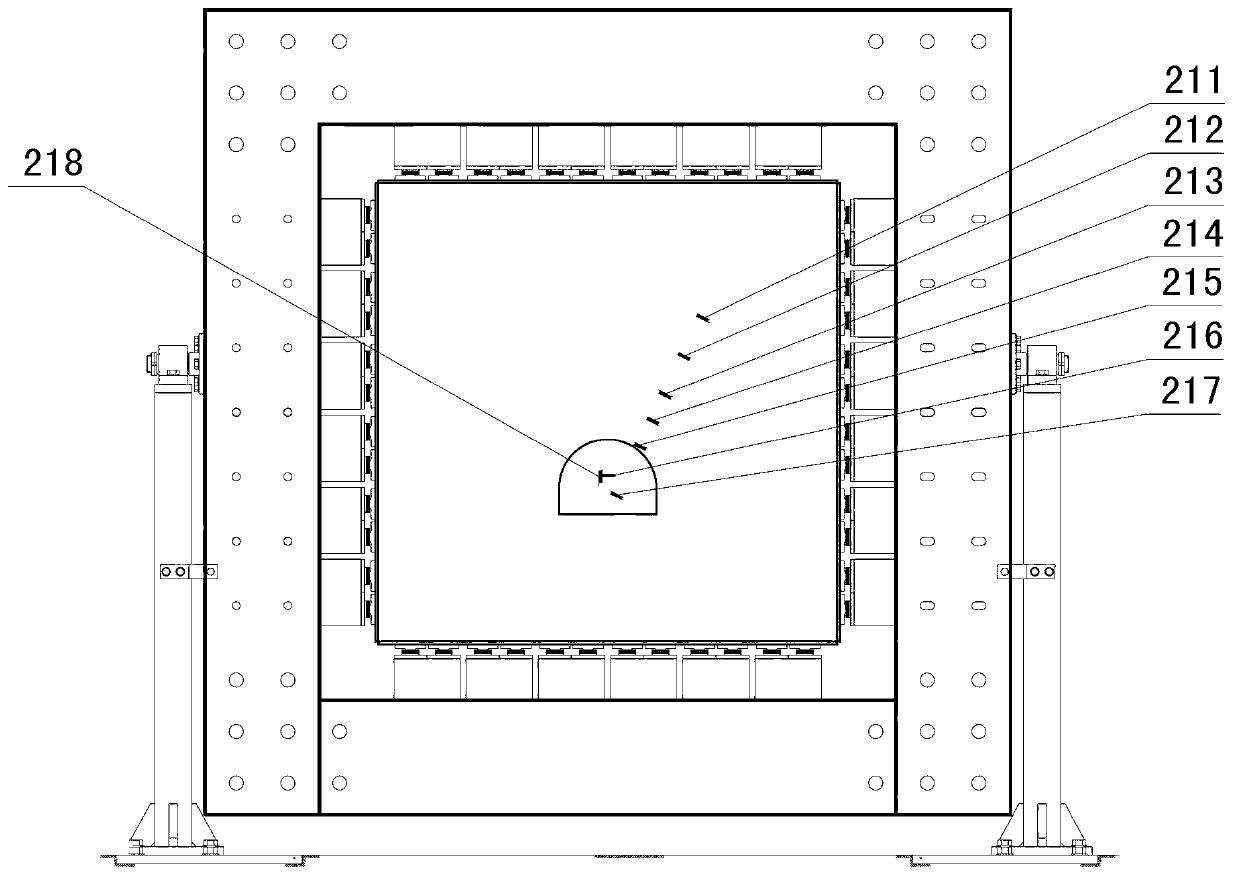

Method for simulating roadway rock burst based on coaction of static load and blast load

InactiveCN103344491AReduce the risk of safety productionIncrease productivityMaterial strength using tensile/compressive forcesDetonatorModel testing

The invention discloses a method for simulating roadway rock burst based on coaction of a static load and a blast load. The method comprises the following steps of: A, selecting cement mortar and ramming a model in a rock model testing machine, and embedding a pressure sensor, an acceleration sensor and a strain gage in the model body; B, maintaining the model body within 28 days, applying initial crustal stress to the model body by utilizing the rock model testing machine, and testing force and deformation field distribution characteristics of the model body under the action of the static load; C, simulating actual cavern excavation characteristics, and measuring force and deformation field distribution characteristics in the model body after excavation each time; and D, drilling in the model body, mounting explosive cartridges and detonators in the drill bores, filling with loess, and detonating the explosive. By utilizing the method, the occurrence scale and time of deep roadway rock burst can be effectively predicted, damage of rock burst disasters on mine production settings can be reduced, the mine safety production risk is greatly reduced, and the production efficiency of the mine is greatly improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

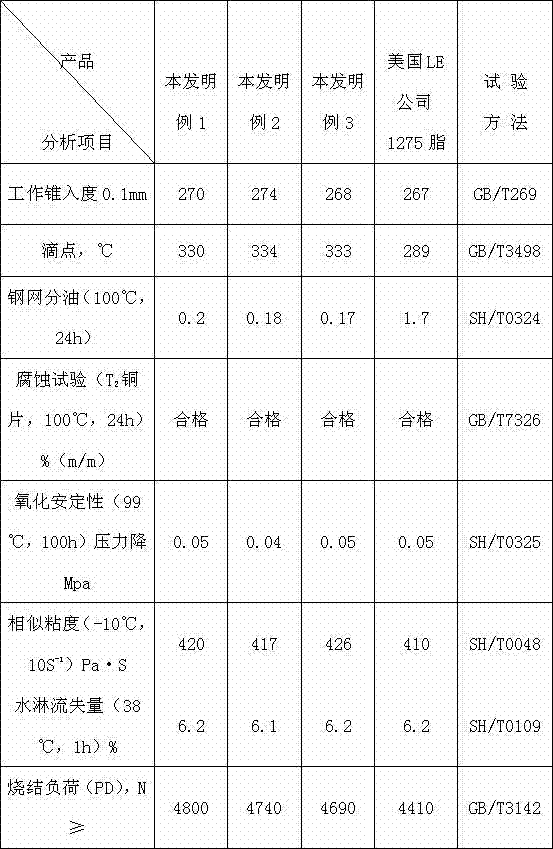

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

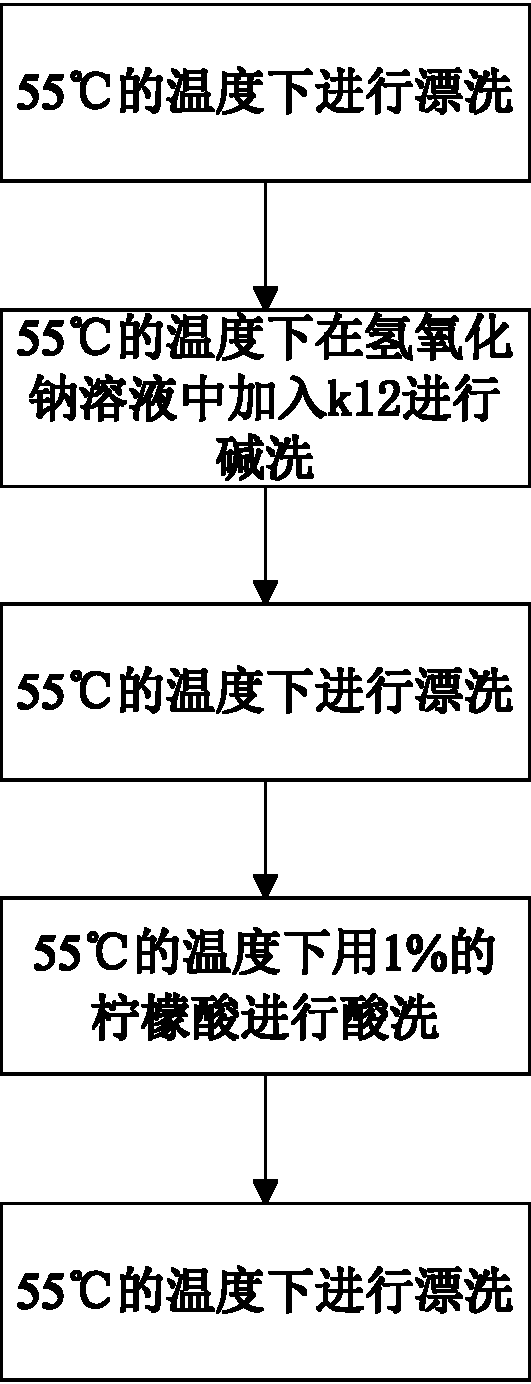

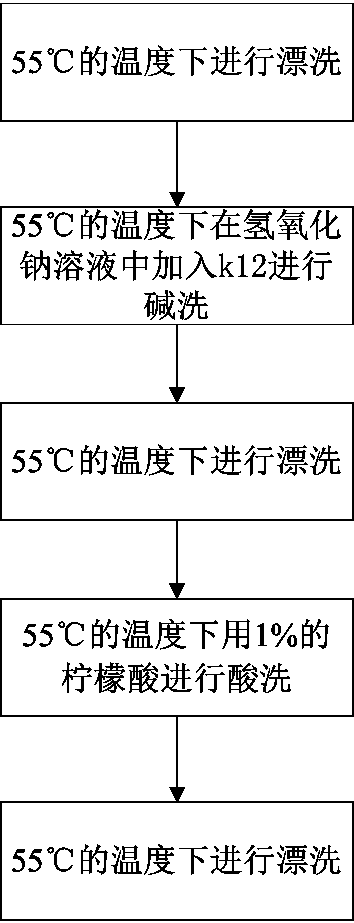

Inorganic ceramic membrane washing method

InactiveCN102512967APrevent eutrophicationImprove the on-site operating environmentSemi-permeable membranesEutrophicationAcid washing

The invention discloses an inorganic ceramic membrane washing method comprising the following steps: considering citric acid as an acid washing agent to carry out the acid-washing on an inorganic ceramic membrane, and adding sodium dodecyl sulfate in an alkaline washing agent to carry out the alkaline-washing on the inorganic ceramic membrane. Through the use of the inorganic ceramic membrane washing method, the difficulty in purchase and transportation caused by that nitric acid is used as an acid washing agent is solved, the eutrophication of the water body caused by that nitric acid is used as the acid washing agent is avoided, the field operation environment is improved, the production safety risk is reduced, and the alkaline-washing effect is enhanced greatly since an assistant washing agent (namely, sodium dodecyl sulfate) is added at the alkaline-washing stage.

Owner:WISDRI ENG & RES INC LTD

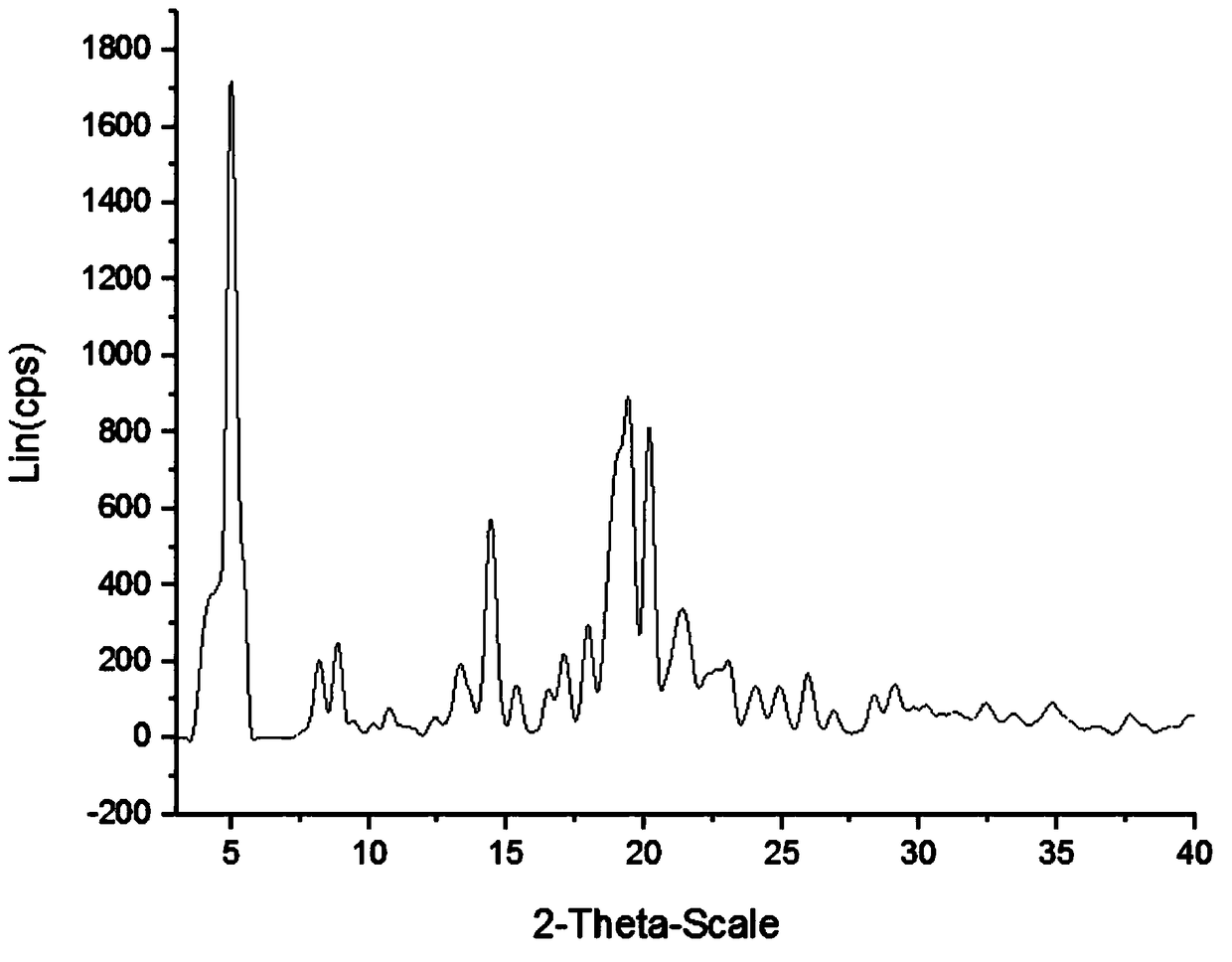

Hydro-thermal synthesis method of high-transmittance nano-scale magnesium lithium silicate

ActiveCN105800626ALow hydrothermal reaction temperatureLow reaction temperatureNanotechnologySilicon compoundsLithiumSilicic acid

The invention discloses a hydro-thermal synthesis method of high-transmittance nano-scale magnesium lithium silicate. The hydro-thermal synthesis method is characterized by comprising steps as follows: firstly, montmorillonite is acidized and calcined; then, water-soluble lithium salt and water-soluble sodium salt are added, the matching ratio is adjusted, and the amount of substances of all elements in a reaction system meets the proportional relation: 0.2<m(Li) / m(montmorillonite)<0.8, 1<m(Na) / m (montmorillonite)<3; finally, the mixture is subjected to a reaction at the temperature of 60-95 DEG C for 1-3 h and fully dried at the temperature of 110-150 DEG C until the water content is not higher than 2%, and magnesium lithium silicate is prepared. Defects in the prior art are overcome, and the safe, environment-friendly, efficient and low-cost synthesis method of nano-scale magnesium lithium silicate is provided; according to the synthesis method, high-purity montmorillonite which has vast reserves in the natural world is taken as a starting raw material, and the nano-scale magnesium lithium silicate with high transmittance, excellent thickening and thixotropy and high adsorption force is produced by optimizing technological parameters of production and the ratio of reaction raw materials.

Owner:JIANGSU HEMINGS NEW MATERIALS TECH CO LTD

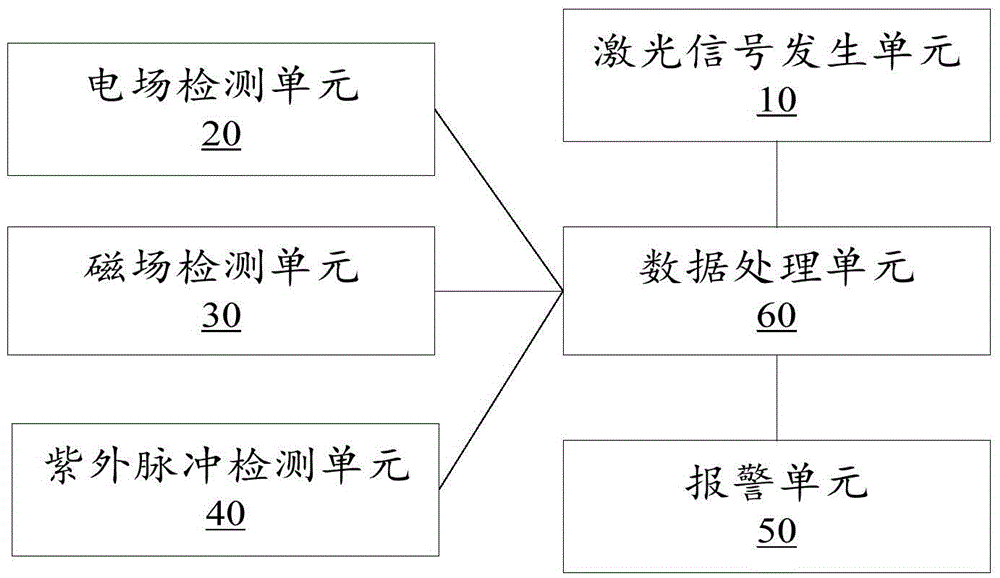

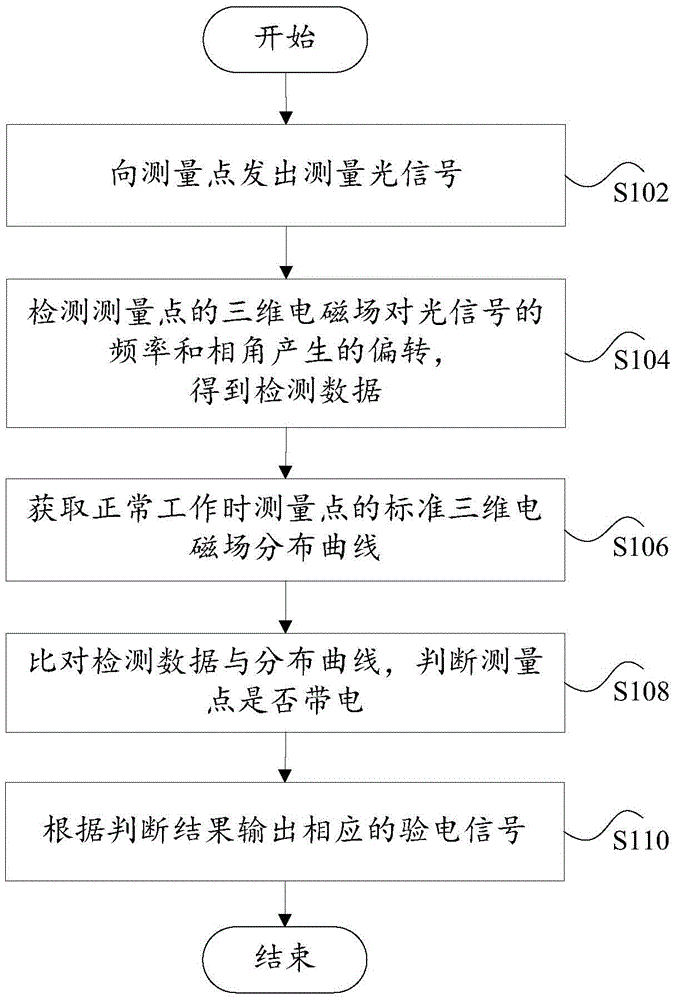

Electroscope and electroscopic method

InactiveCN105606878AReduce the risk of safety productionImprove securityIndicating presence of current/voltagePhysicsElectric field

The invention discloses an electroscope and an electroscopic method. The electroscope comprises a laser signal generation unit, an electric field detection unit, a magnetic field detection unit, a UV pulse detection unit, an alarm unit and a data processing unit, wherein the laser signal generation unit, the electric field detection unit, the magnetic field detection unit, the UV pulse detection unit and the alarm unit are connected with the data processing unit, and the data processing unit is used to control a UV sensor power supply in the UV pulse detection unit, count UV pulses, process 3D electric and magnetic field data, and control the alarm unit to raise the alarm. According to the invention, long-distance non-contact electroscopy can be realized, and the risk of safe production is effectively reduced.

Owner:浙江安侣智能科技有限公司

Marine low-speed diesel engine rack monolithic welding method

InactiveCN111168315AReduce weightReduce complexityWelding/cutting auxillary devicesAuxillary welding devicesDieselingWeld seam

The invention aims to provide a novel marine low-speed diesel engine rack monolithic welding method. The assembling and welding sequence is optimized according to marine low-speed diesel engine rack monolithic welding parts, weld joint layout and quality requirements. According to the method, the mode of assembling and welding a web plate, guide rail plates and then wing plates in the existing marine low-speed diesel engine rack monolithic welding sequence is changed; and the guide rail plates and the wing plates are assembled and welded firstly, and then the two sets of guide rail plates andwing plates are assembled and welded together through the web plate. Due to the fact that the overall welding mode is adjusted to separate welding and then assembly welding, the weight of a single setof welding bodies is reduced, the complexity is reduced, ground level operation can be achieved, climbing is not needed, the safety production risk is effectively reduced, a special welding supporting tool does not need to be manufactured, and the production cost is saved. Rack monolithic welding is carried out according to the assembling and welding sequence, the risk of falling from high altitude can be avoided, the production efficiency is improved, the production cost is reduced, and the welding quality is guaranteed.

Owner:中国船舶重工集团柴油机有限公司

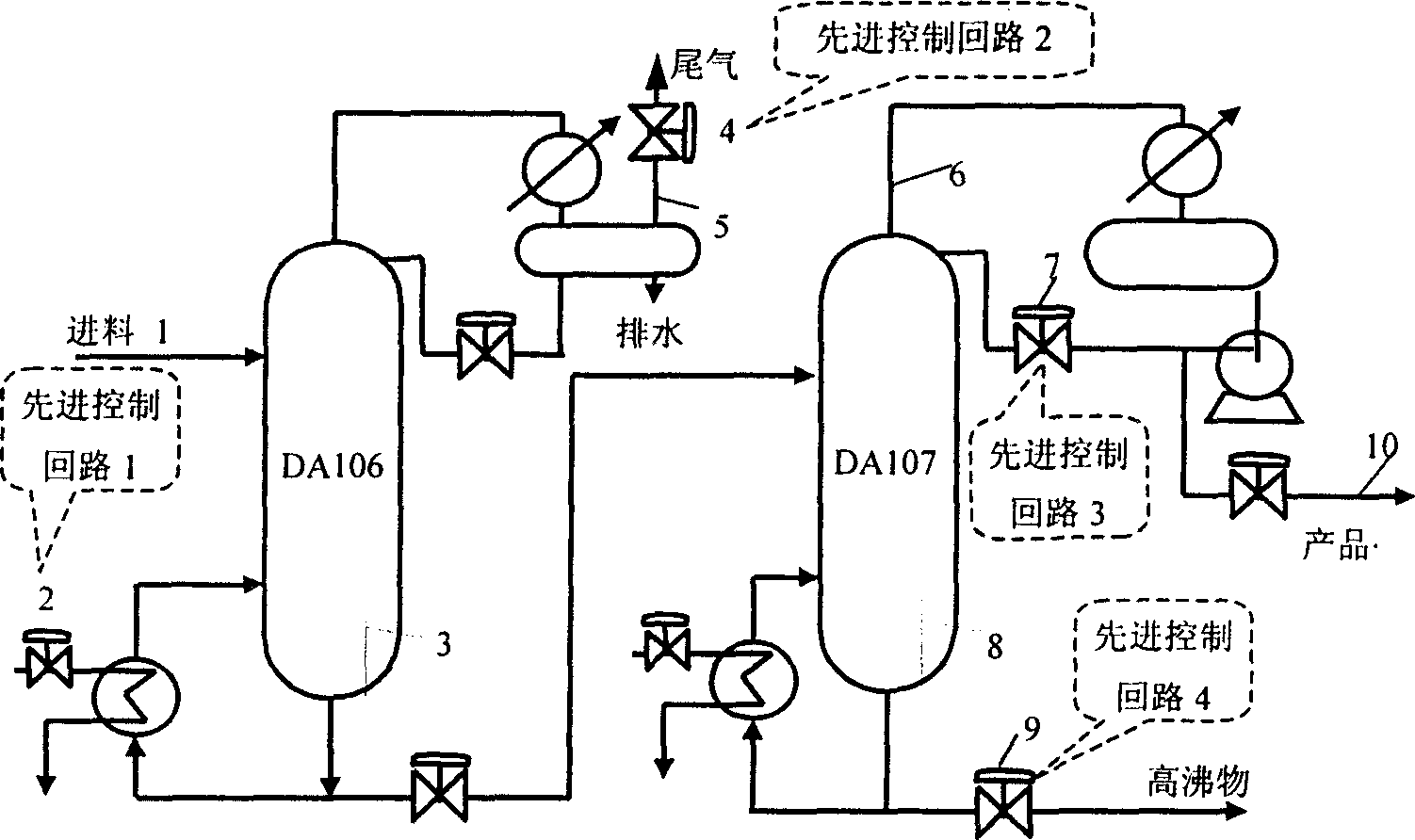

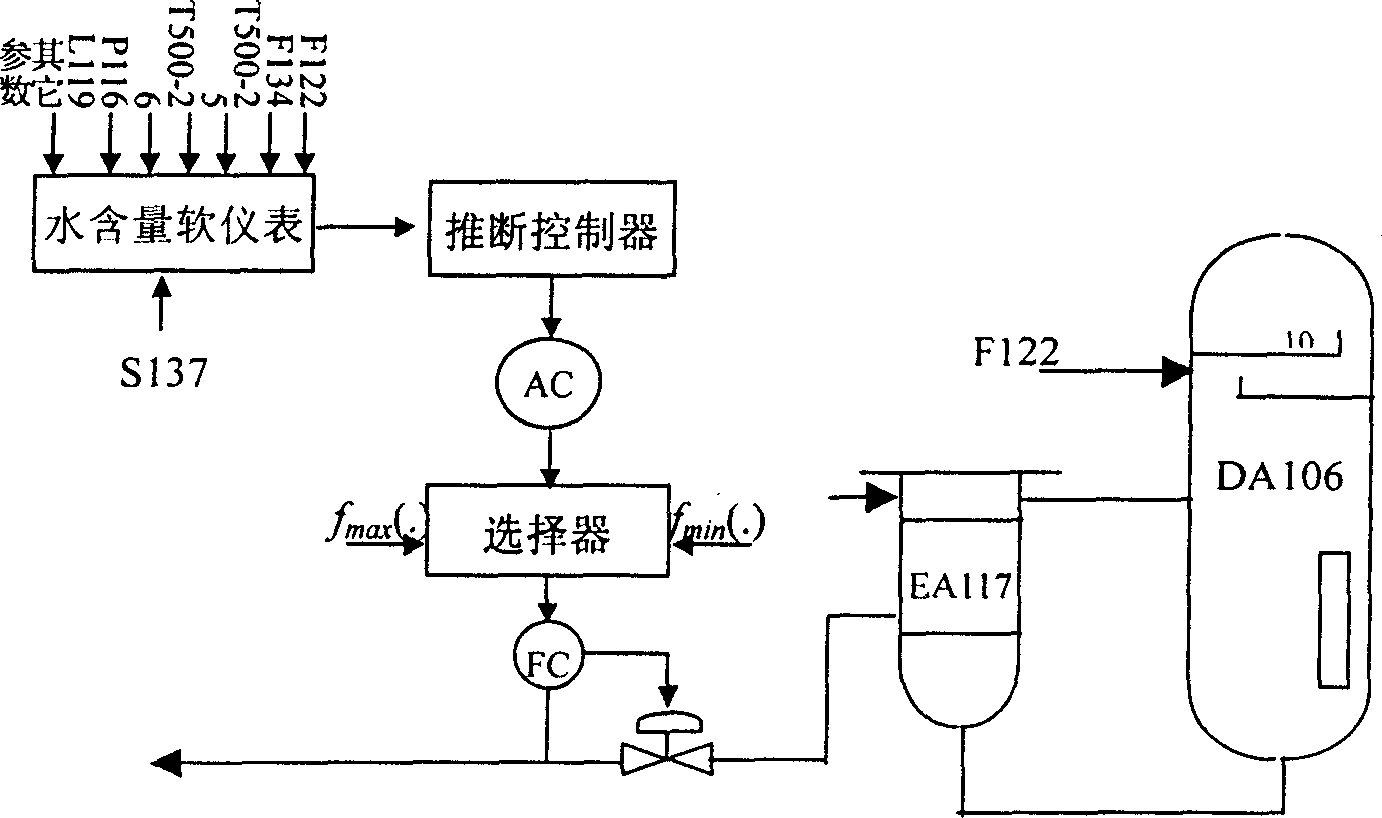

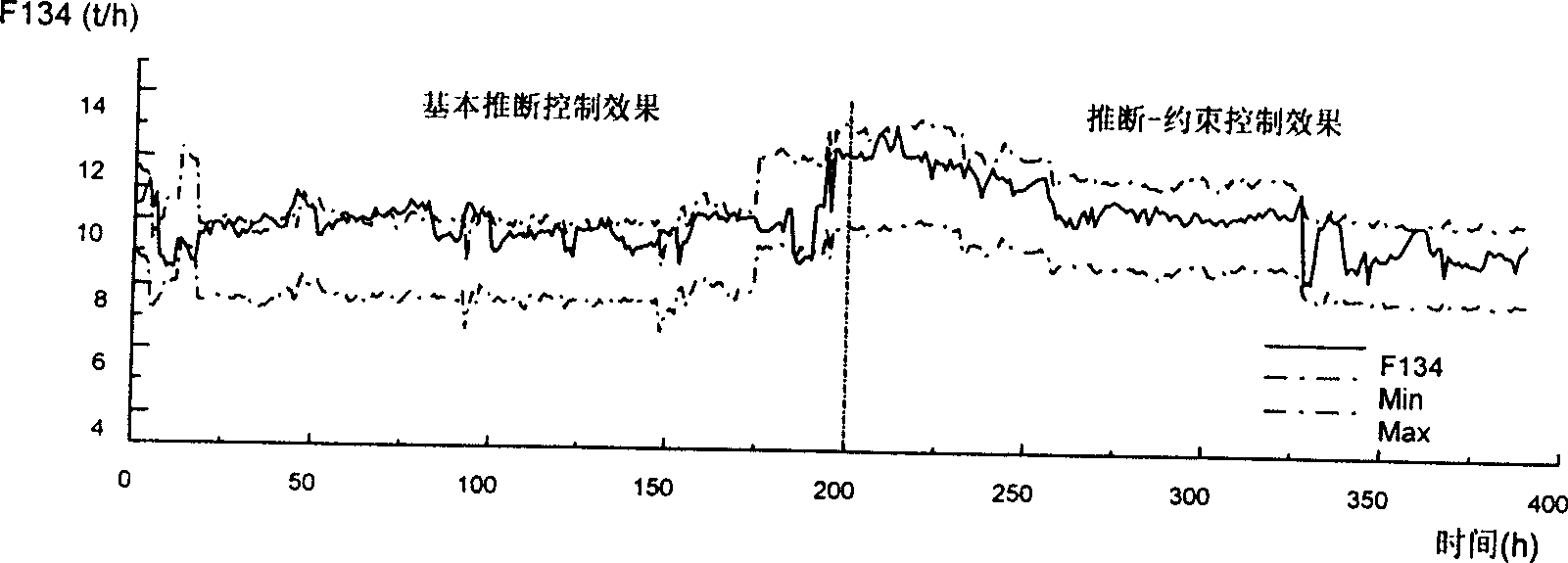

Process for advanced controlling rectifying apparatus of butadiene

ActiveCN1693297APure excessProduct quality is easy to controlDistillation regulation/controlDistillation purification/separationReal-time dataControl system

An advanced control method for the butadiene rectifying apparatus consisting of the first and the second rectifying towers include such steps as measuring the real-time data of the first rectifying tower, filtering, running the soft measuring model, inputting the filtered data to it to obtain the water contant of its tower still and the methyl ethyne content of its tower top, and in-line closed-loop optimizing control on the basis of DCS.

Owner:SINOPEC YANGZI PETROCHEM

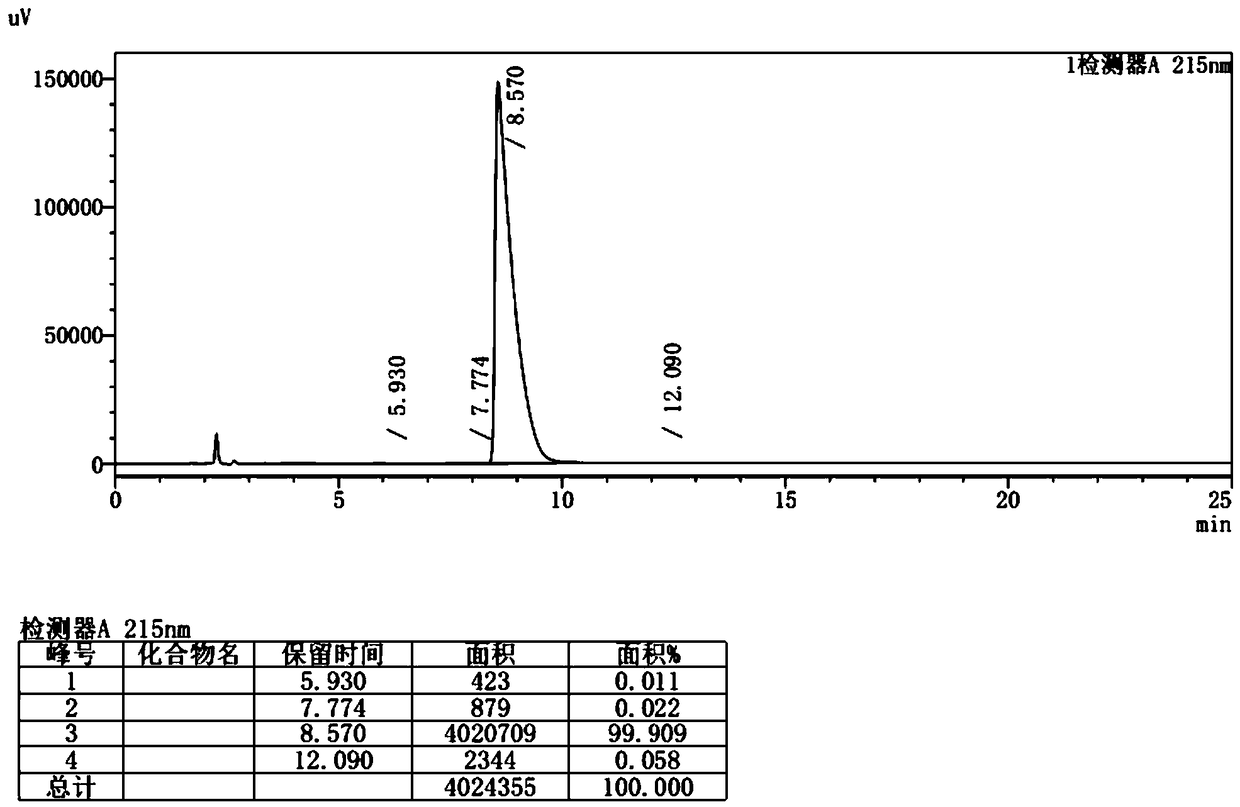

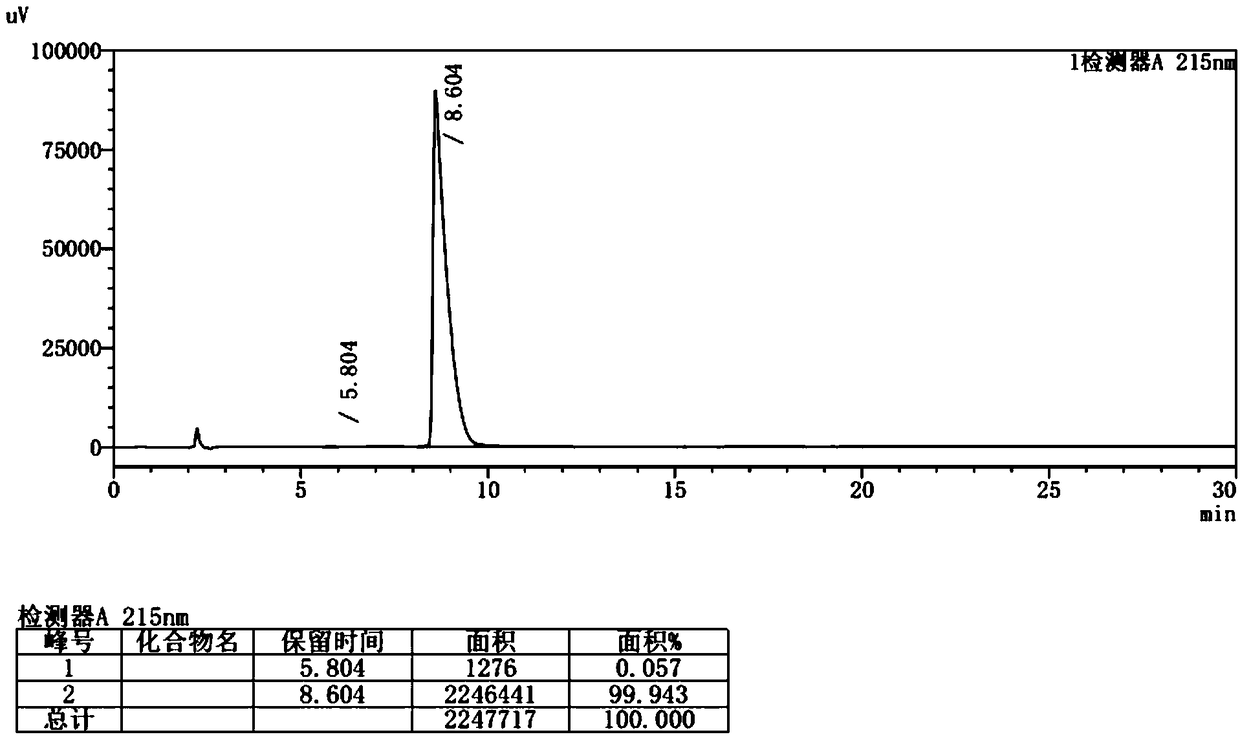

Preparation method of pimavanserin key intermediate

ActiveCN108794351AReduce the risk of safety productionReduce usageIsocyanic acid derivatives preparationCarboxylic acid nitrile preparationToxicityChemistry

The invention discloses a preparation method of a pimavanserin key intermediate. A synthesis route comprises a process shown in the description. According to the method disclosed by the invention, used raw materials are safe and the cost is low, so that the production cost is effectively reduced. The method disclosed by the invention has moderate reaction conditions and the utilization of phosgenewhich has great toxicity and is not easy to operate can be avoided, so that the method is easy to realize in industry.

Owner:LIVZON NEW NORTH RIVER PHARMA

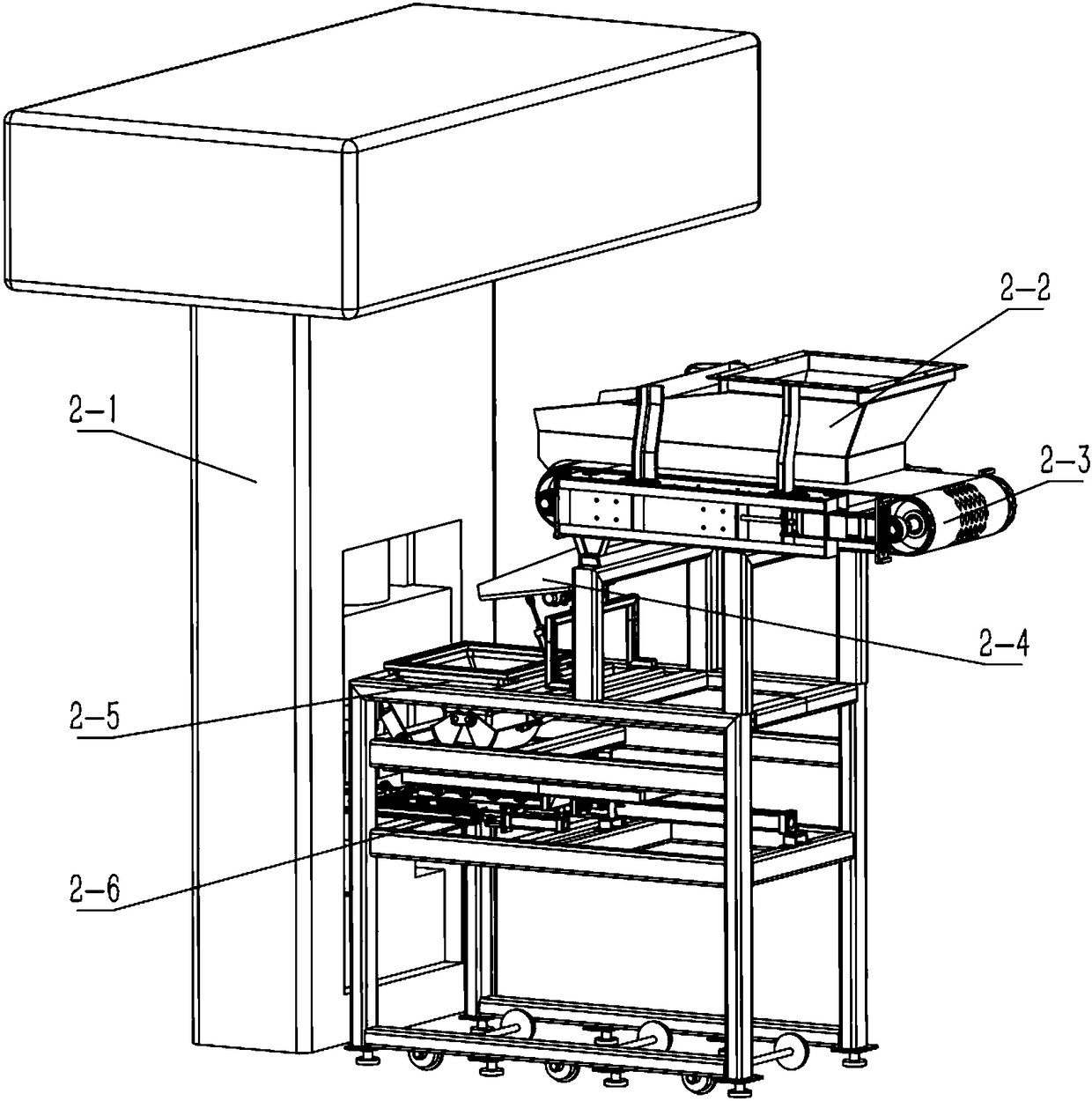

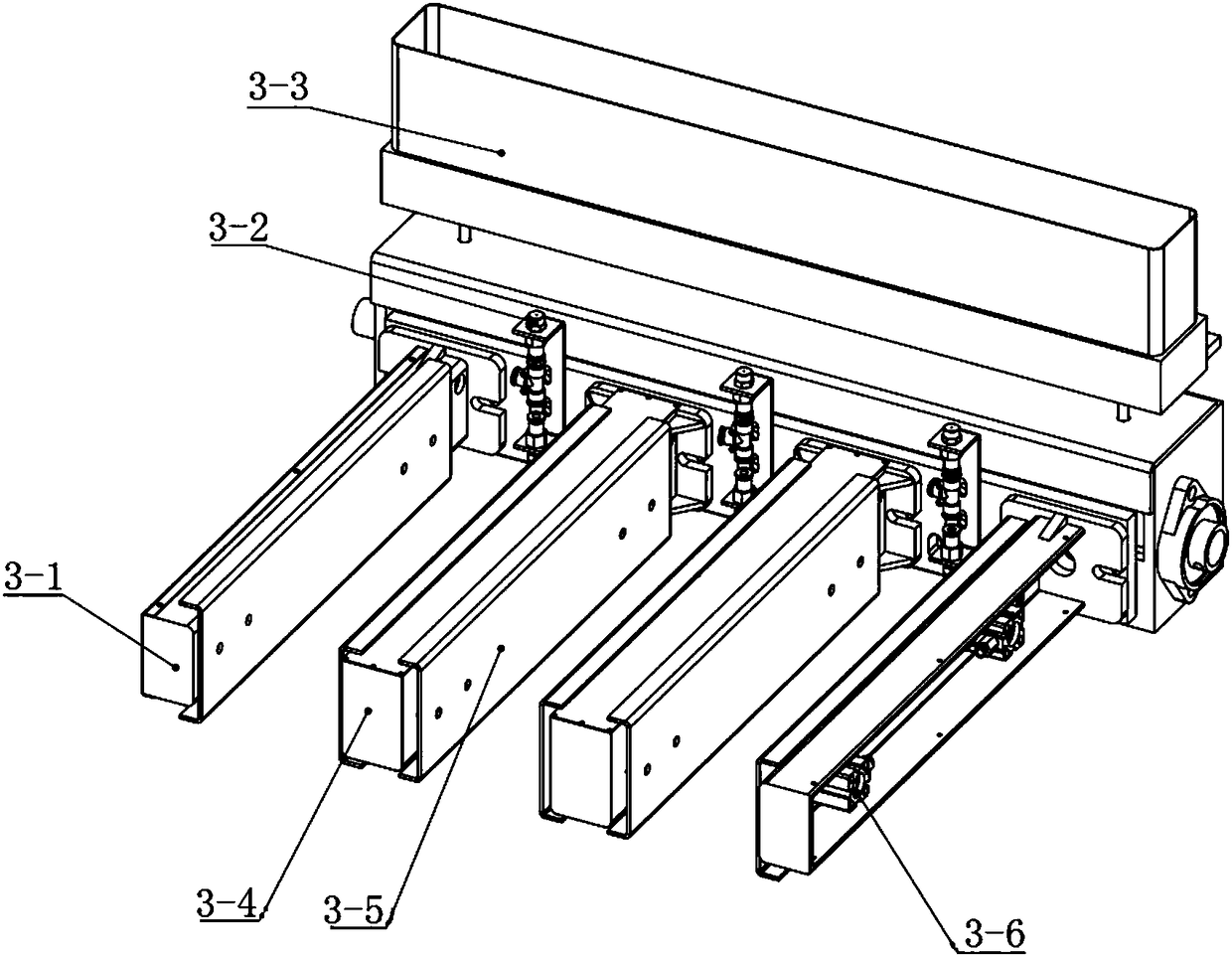

Intelligent manufacturing production-line for refractory bricks

InactiveCN108327060AIncrease productivityReduce investmentCeramic shaping plantsProduction lineBrick

The invention discloses an intelligent manufacturing production-line for refractory bricks, and belongs to the technical field of refractory brick manufacturing. The intelligent manufacturing production-line for the refractory bricks comprises an intelligent control system, a conveying assembly line, an automatic material-distributing and brick-pressing device, an automatic brick-clamping mechanical hand, a visual inspection device, an automatic line-moving device, an automatic plate-superposing device and a circulating vehicle driving device. By digital and automatic facilities being introduced or existing devices being updated intellectually, each process of refractory brick manufacturing can be automatically performed, operating workers are reduced, standardized production is realized,the whole producing process is carried out without artificial participation, and automation operation is completely realized. Further, the refractory bricks are made by using an intelligent assembly line, personal injuries of production process and risks of safety production is greatly reduced, influence of dust on personnel health during brick pressing is reduced, labor intensity is lowered, production efficiency is improved, production capacity is expanded, and great benefits are brought to enterprises and local economy.

Owner:希望银蕨智能科技有限公司

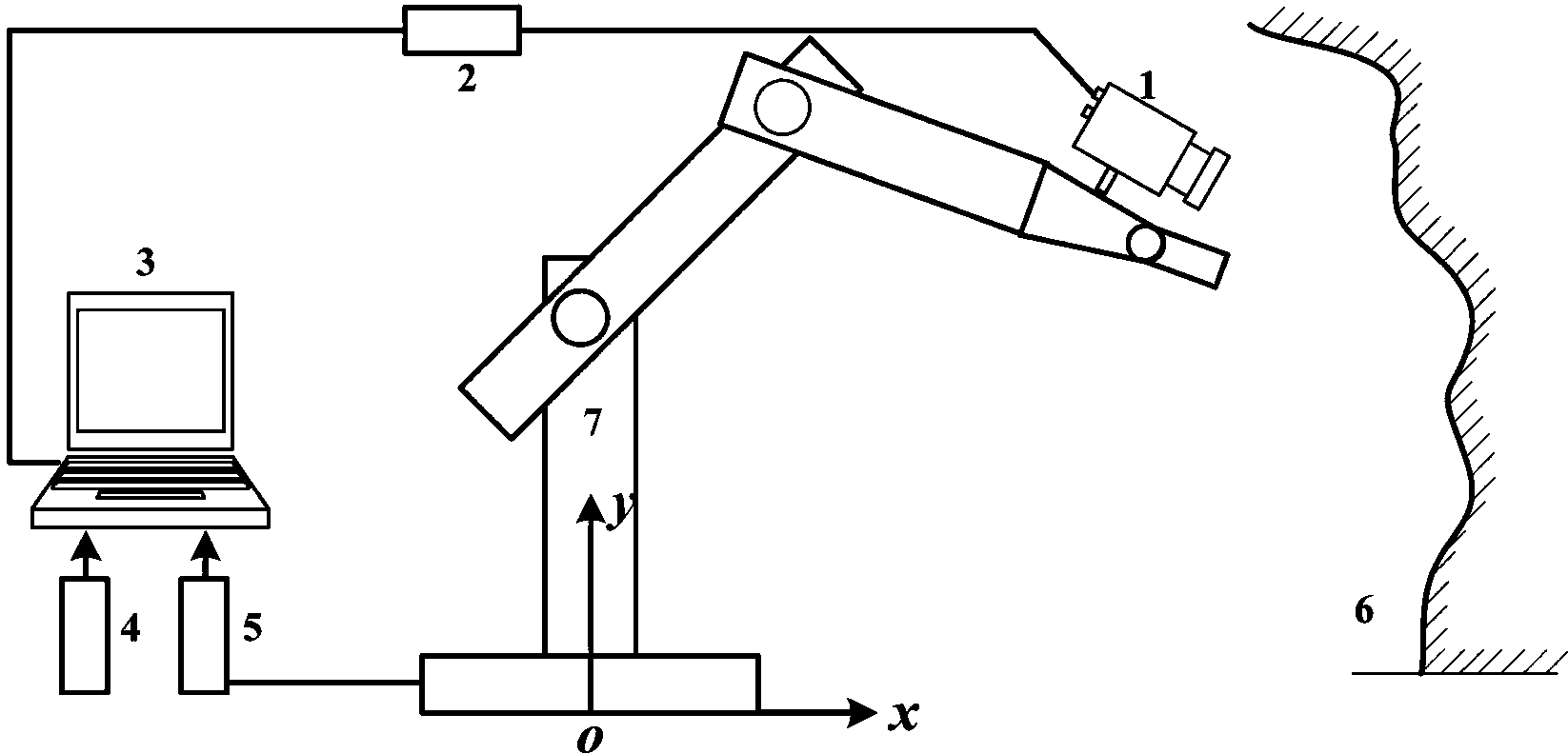

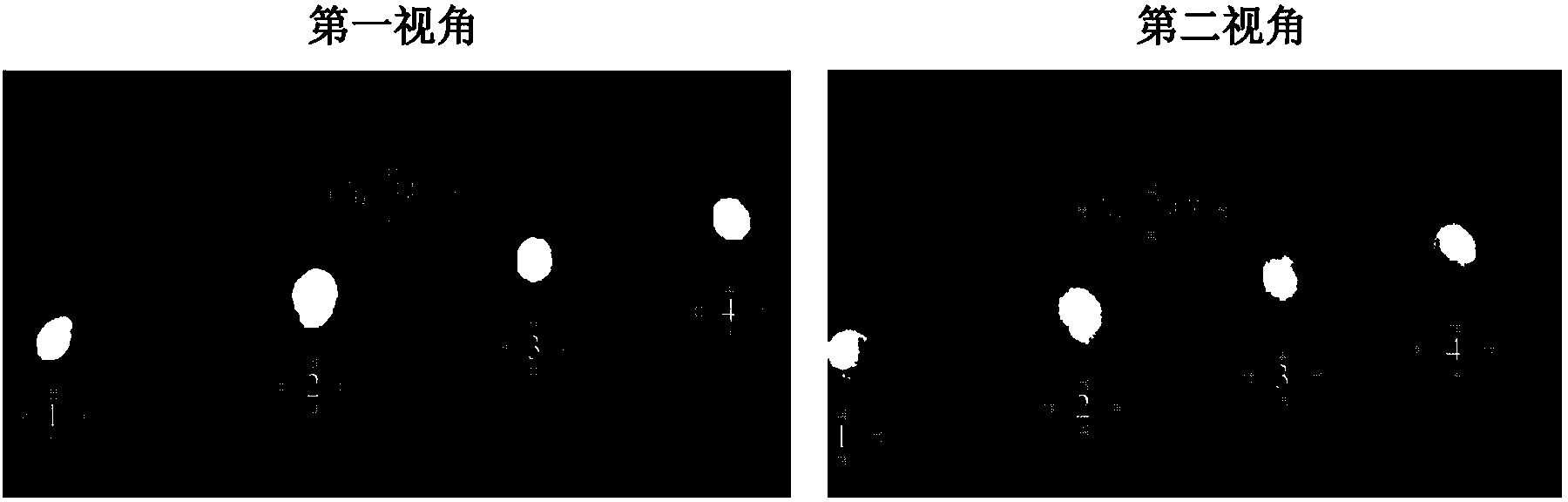

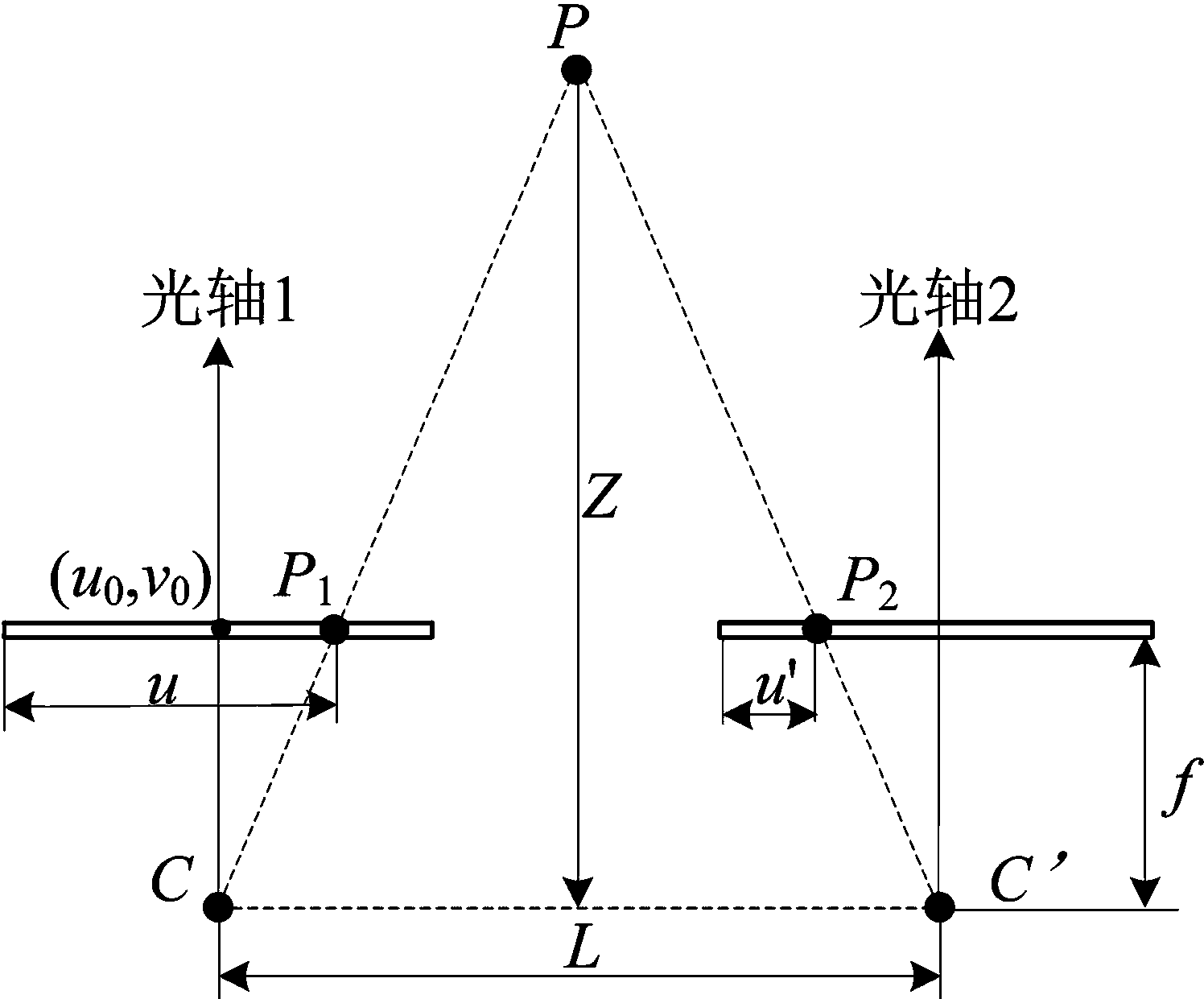

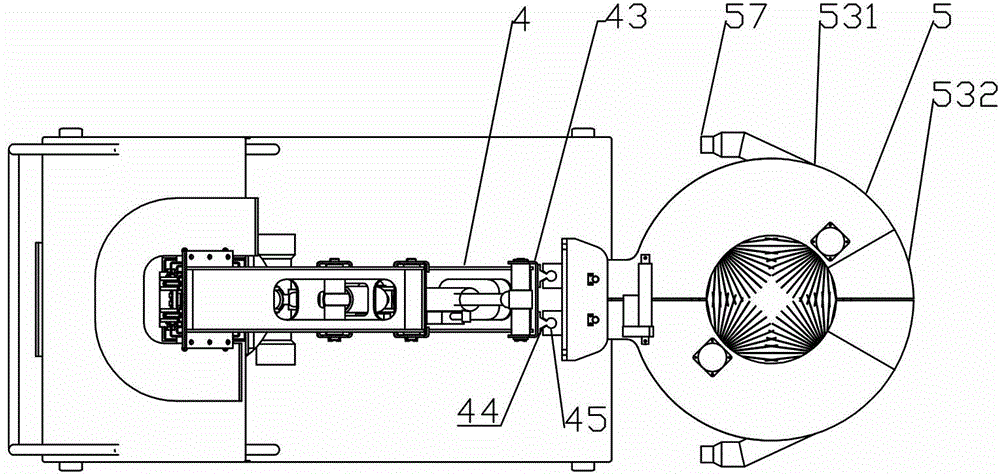

Stone wall blasthole detecting and positioning device based on virtual binocular vision and positioning method

The invention discloses a stone wall blasthole detecting and positioning device based on virtual binocular vision and a positioning method. The device mainly comprises a vision module, a control module and an explosive implantation manipulator. According to the device, one video camera is utilized for conducting searching, partitioning and locking on a hole at different viewing angles; after the target hole is locked, a target hole image obtained at another angle is called and combined with a target hole image obtained before to conduct binocular calibration, coordinates obtained through calibration are converted to a coordinate system of a base of the manipulator, and then the current space coordinate position of the target hole relative to the working manipulator can be positioned.

Owner:山东越浩自动化设备有限公司

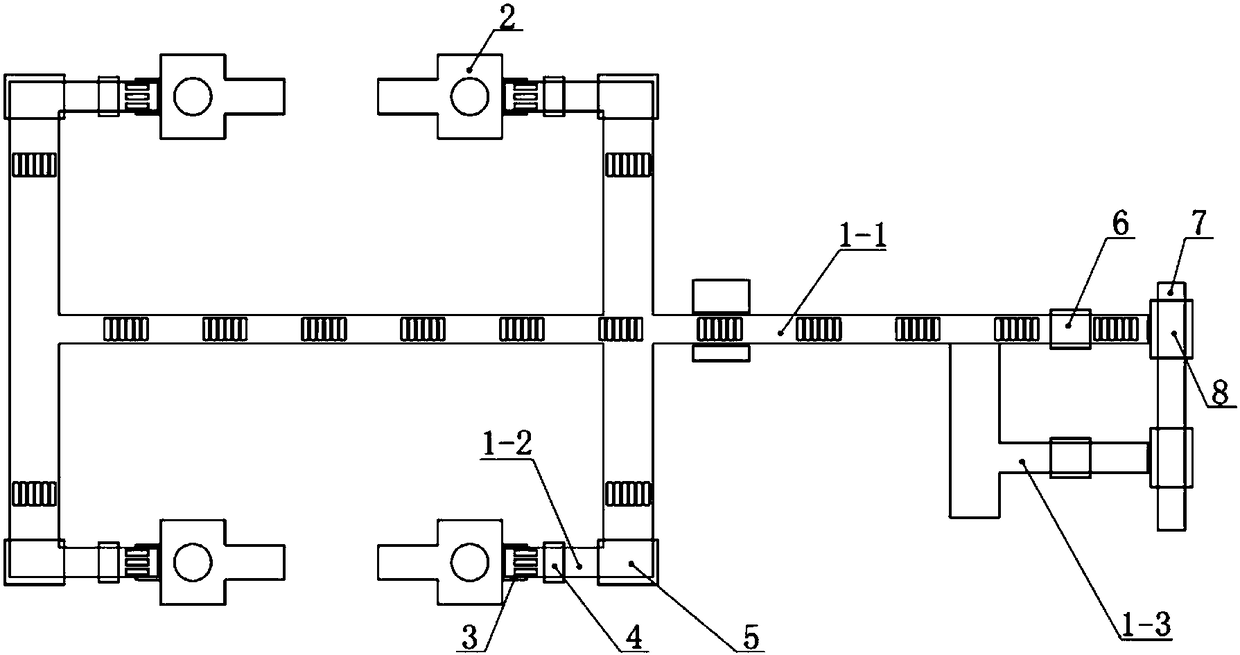

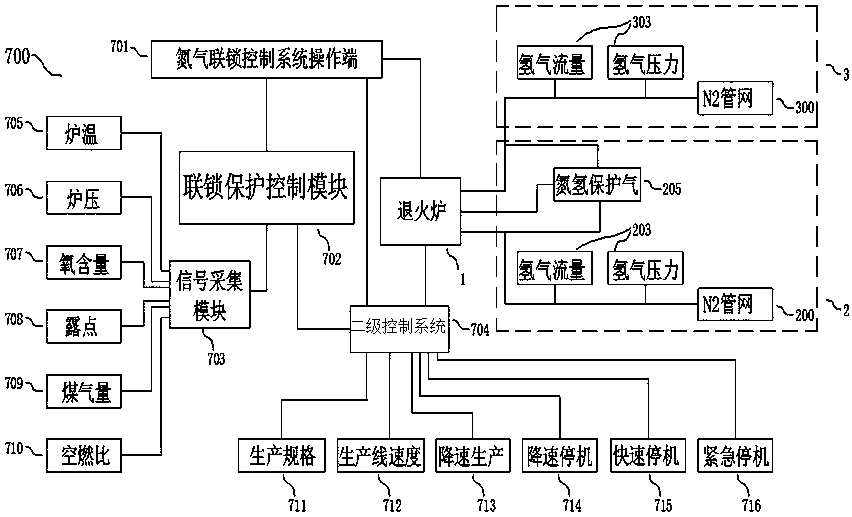

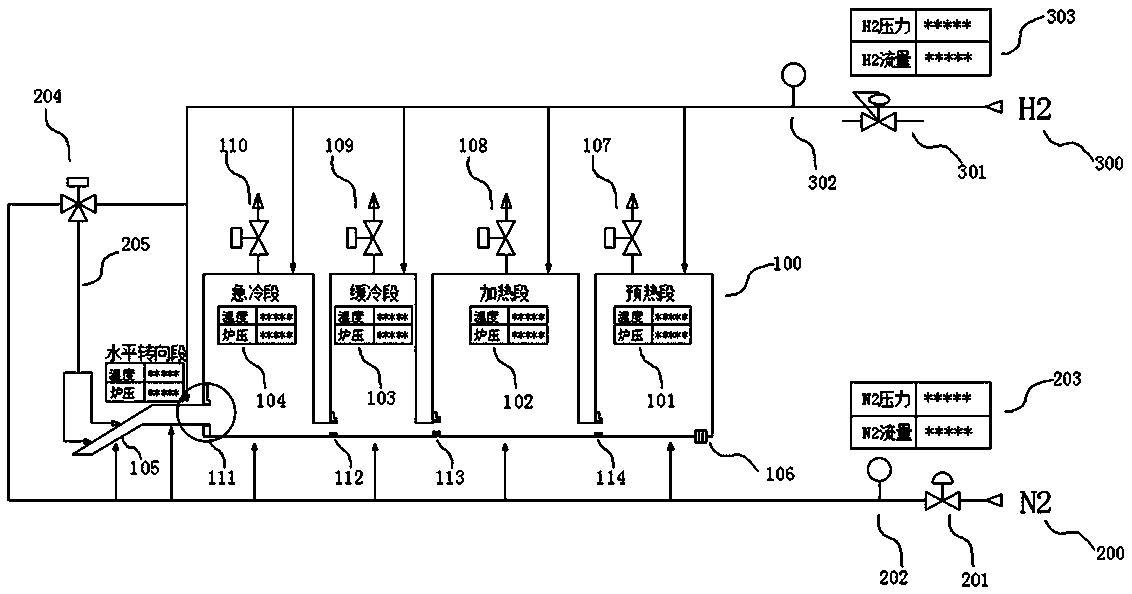

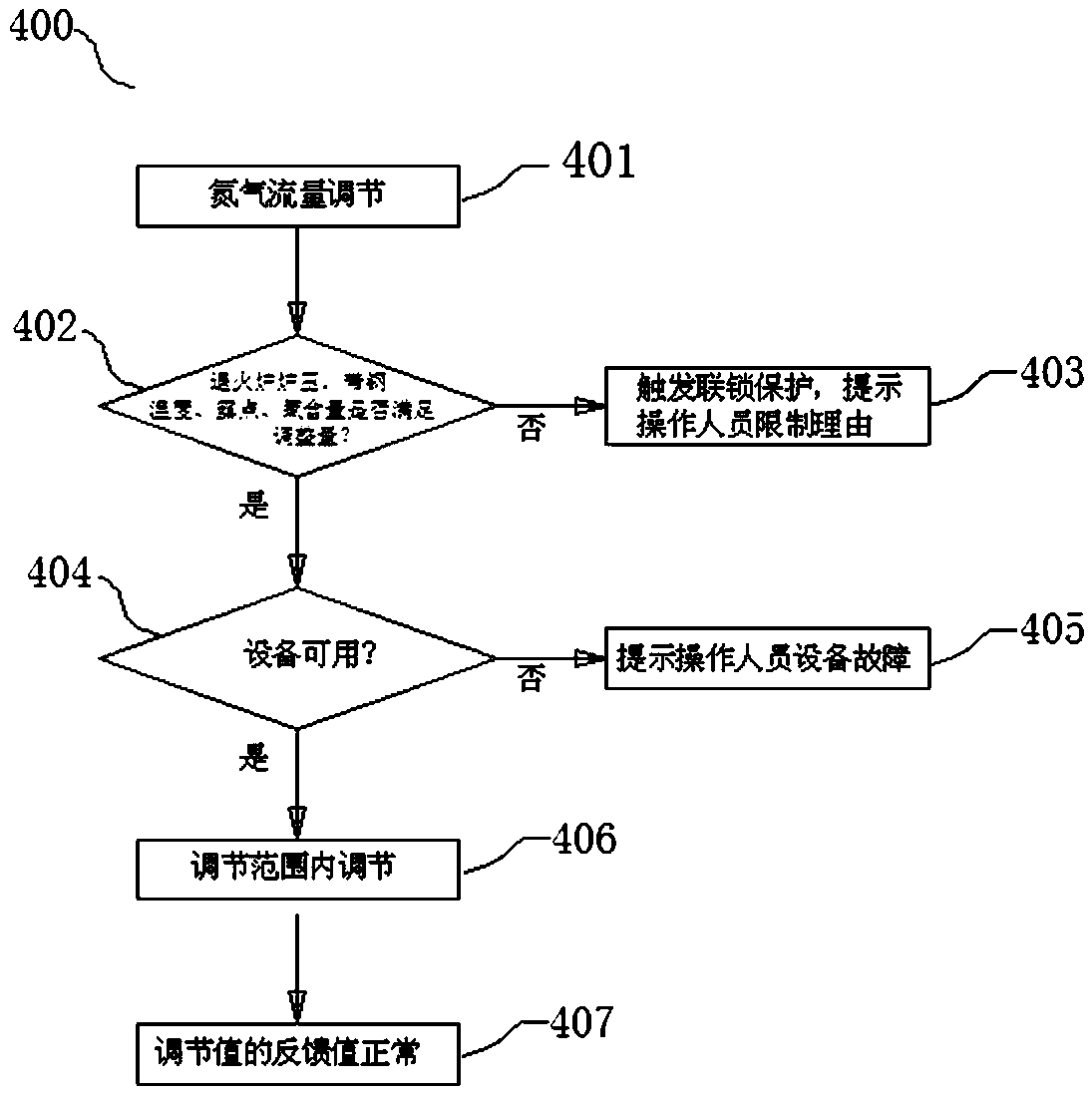

Telescopic type maze isolation nitrogen interlocking control system operation method for hot galvanizing vertical annealing furnace

ActiveCN110669911AEnsure personal safetyReduce bending deformationFurnace typesHeat treatment process controlControl systemStructural engineering

The invention discloses a telescopic type maze isolation nitrogen interlocking control system for a hot galvanizing vertical annealing furnace. The annealing furnace is partitioned. Zones are separated through partitions. Gaps are reserved between the partitions to allow a steel strip to pass through. A telescopic isolation device is arranged between the gaps. Signal interlocking control is builtbetween the isolation device and an interlocking protection control module as well as a signal acquisition module. When one zone of the annealing furnace sends an abnormal signal, the isolation deviceacts to close the gaps, thus the abnormal zone is isolated, and the normal zones keep positive pressure. The telescopic type maze isolation nitrogen interlocking control system has the beneficial effects that through the structure of zone isolation and the telescopic type isolation device, segmented sealing is achieved, in-furnace pressure of all other zones can be kept in time, and thus fault loss is lowered to the minimum.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Tire crane prewelding technology

ActiveCN105108367AGuaranteed positioning sizeAvoid rework correctionsWelding apparatusFillet weldEngineering

The invention relates to a tire crane prewelding technology. The technology includes the following steps that a crossbeam structural component is manufactured, wherein in the crossbeam manufacturing process, inner side deflection is reversely deformed by 5 mm, and forming arch camber is increased by 5-10 mm; primary scribing is conducted, wherein a crossbeam center line and a rack positioning center line are scribed out; a rack bottom plate is mounted and welded, wherein a rack, a base plate and a bottom plate are collected and connected through service bolts, and the rack bottom plate is positioned and welded according to the crossbeam center line and the rack positioning center line; secondary scribing is conducted, wherein a crossbeam center line and a track pressing plate position line are scribed out again after the rack is welded; a track pressing plate is assembled, wherein the track pressing plate is positioned and welded through a positioning formwork, and the gap allowance of the pressing plate and a track is noted; the track pressing plate is welded, wherein a long continuous fillet weld is welded first and then a short fillet weld is welded; the crossbeam arch camber and the side-deflection degree are measured. The tire crane prewelding technology has the advantages that the crossbeam arch camber and the reserve deformation of the side deflection can be determined accurately, and rework is avoided; the positioning dimension of the track pressing and the rack bottom plate is guaranteed; moreover, the technological size and welding quality meet the requirement; working high above the ground is avoided, so that more safety is achieved, and the paint face is attractive.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

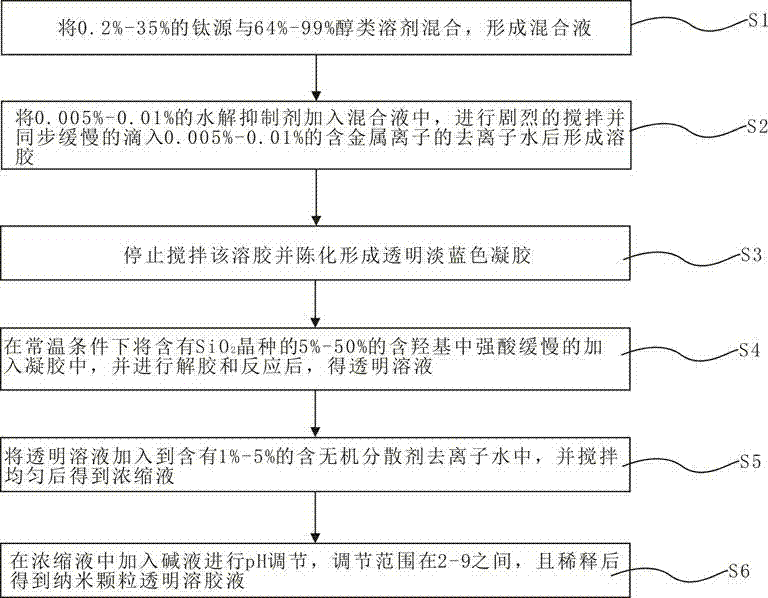

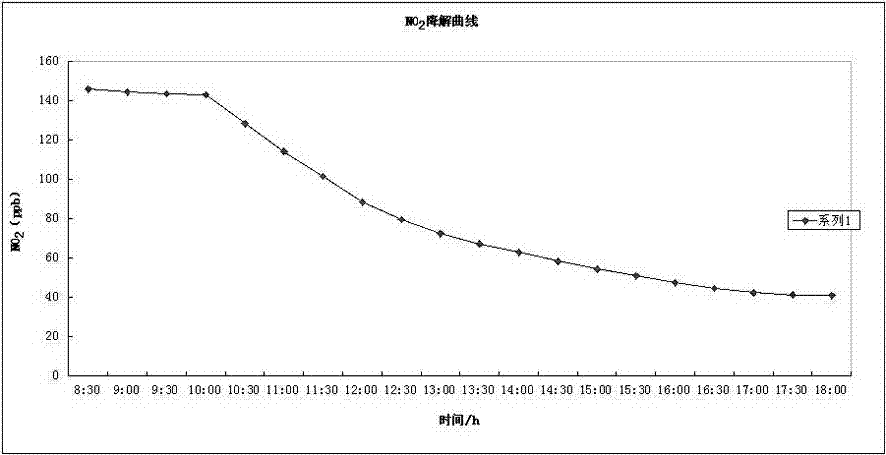

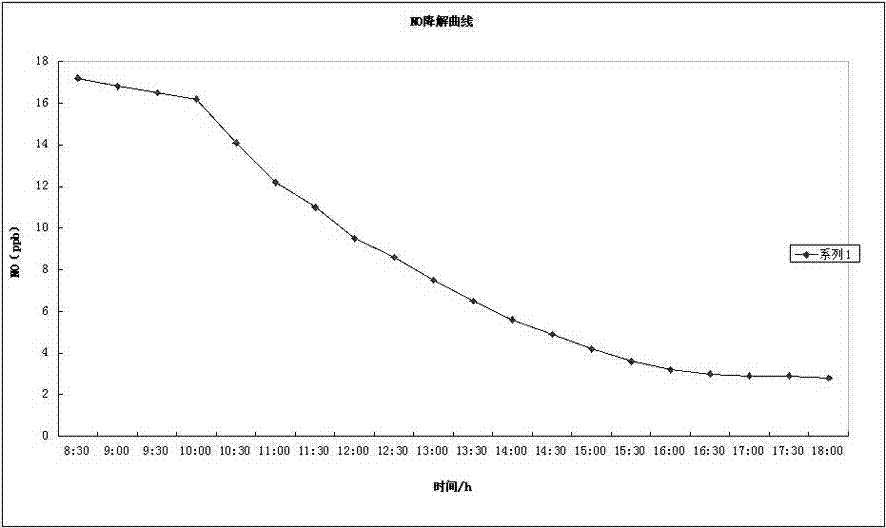

Nanometer spherical porous weak light photocatalyst for degrading nitrogen oxide, and preparation method and application thereof

ActiveCN104209146AImprove adhesionHigh hardnessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrogen oxidesNanoparticle

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

Full-automatic home roll wire arrangement device for multi-wire cutting machine

ActiveCN104441286ACompact structureHigh degree of automationWorking accessoriesFine working devicesControl systemWire cutting

The invention discloses a full-automatic home roll wire arrangement device for a multi-wire cutting machine. A steel wire wound around a wire winding and unwinding shaft is wound in a wire groove of a home roll through a guide wheel. An electric linear platform is fixed between the guide wheel and the home roll. The electric linear platform is fixedly connected with the top end of a fixing plate. A position sensor and a reel are mounted at the lower end of the fixing plate. The steel wire is led out of the guide wheel and then wound in the wire groove of the home roll through the reel. A mounting block is fixed to the bottom end of the fixing plate. A detection sensor is fixed to the mounting block. The detection sensor and the position sensor can both be driven by the electric linear platform to move in the axial direction of the home roll. The detection sensor is close to the home roll and opposite to the wire groove in the home roll in position. The electric linear platform, the detection sensor, a rotary encoder and the position sensor are all connected with a control system of the multi-wire cutting machine. The full-automatic home roll wire arrangement device is compact in structure, high in automation degree, easy to operate, flexible in wire arrangement and high in adaptability.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

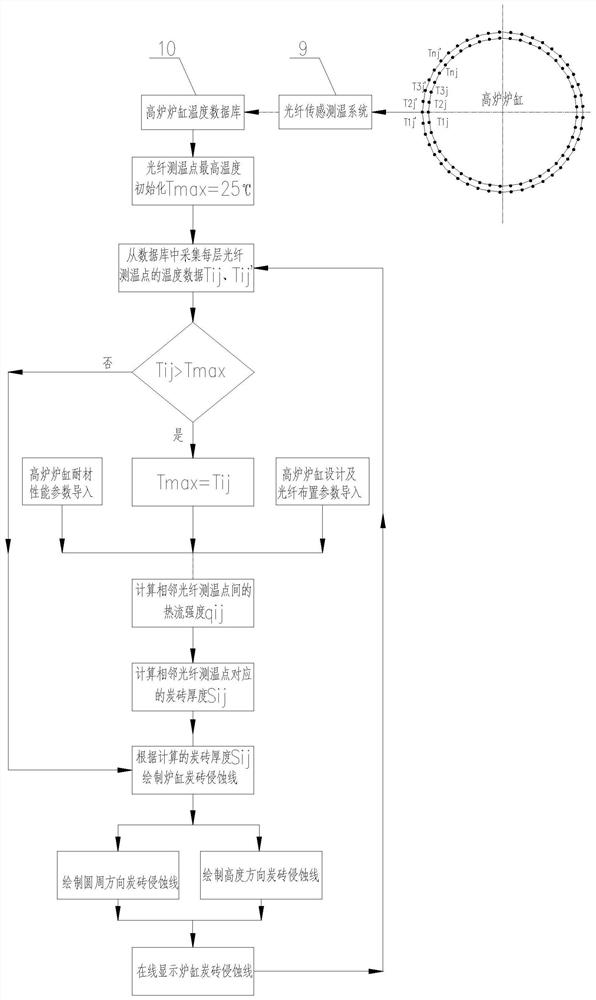

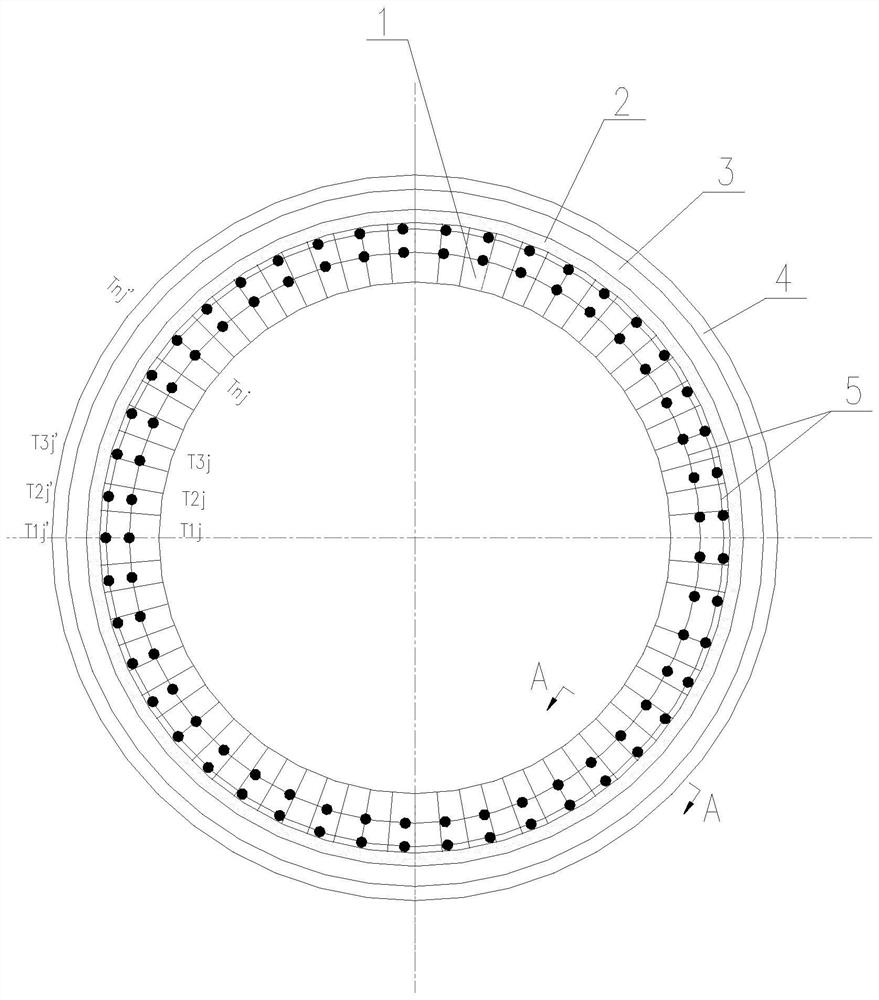

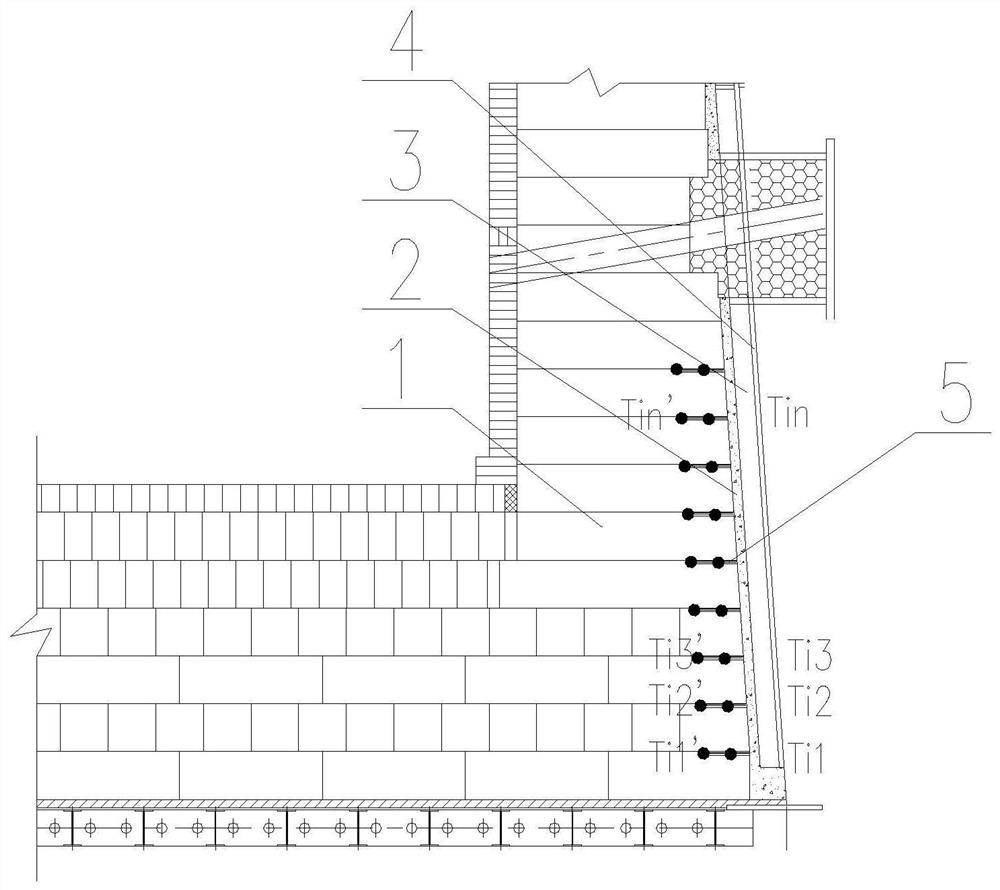

Blast furnace lining thickness calculation device and method based on distributed optical fiber temperature measurement

PendingCN111854668AFast and accurate calculation in real timeRapid positioningThermometers using physical/chemical changesRayleigh scatteringRayleigh Light Scattering

The invention relates to a blast furnace lining thickness calculation device and method based on distributed optical fiber temperature measurement, and belongs to the technical field of blast furnaces. The device comprises a refractory lining, a joint mixture, cooling equipment, a blast furnace shell, distributed optical fibers, an optical fiber sensing and temperature measuring system and a blastfurnace hearth temperature database. Based on the optical fiber temperature measurement principle, the optical fibers are laid in the industrial furnace lining in the circumferential direction and the height direction of the furnace lining respectively, the temperatures of the corresponding positions of corresponding scattering areas can be obtained through Rayleigh scattering light, Raman scattering light and Brillouin scattering light obtained in all the scattering areas in the optical fibers, and the minimum distance between every two adjacent temperature measurement points can reach the millimeter level; meanwhile, a heat transfer theory is utilized to calcualte the heat flow intensity and the residual thickness of the blast furnace hearth lining, so that the traditional thermocoupletemperature monitoring mode can be replaced, the abnormal erosion point of the lining can be positioned for 24 hours according to the temperature and the residual thickness of the blast furnace hearthlining, the safety production risk of the blast furnace is reduced, and a guarantee is provided for efficient and safe production of the blast furnace.

Owner:CISDI ENG CO LTD +1

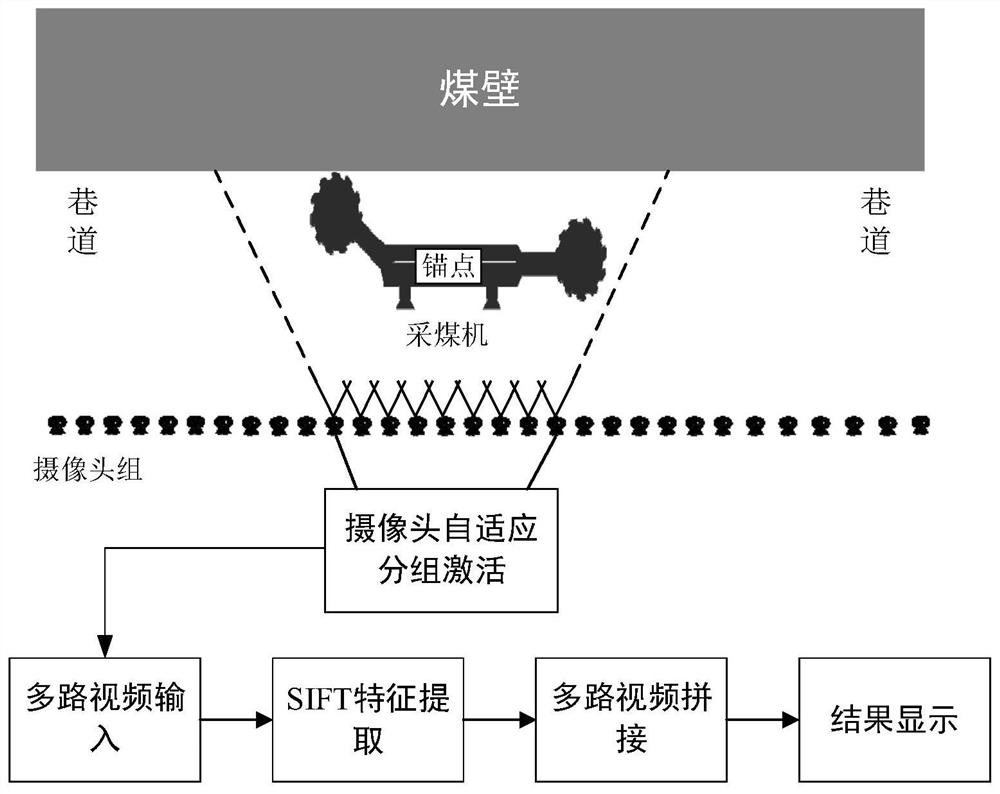

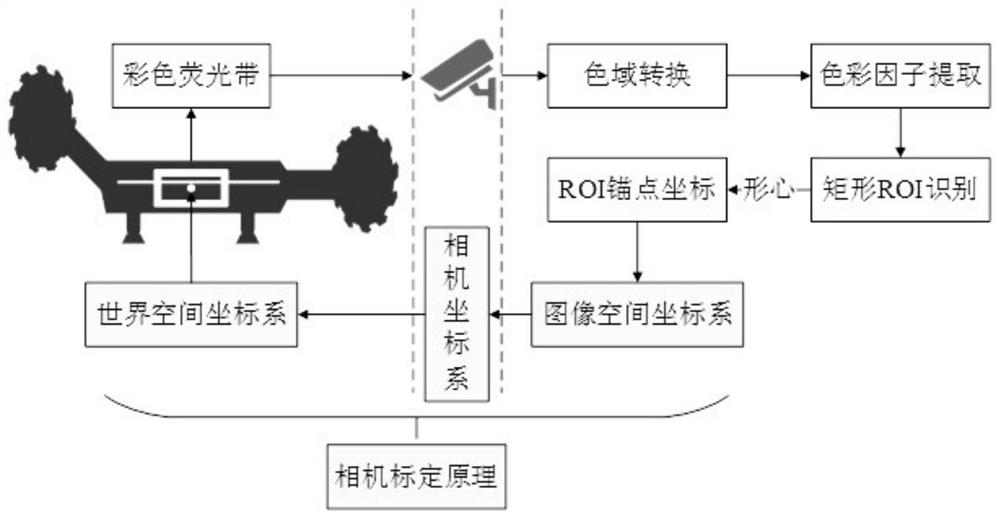

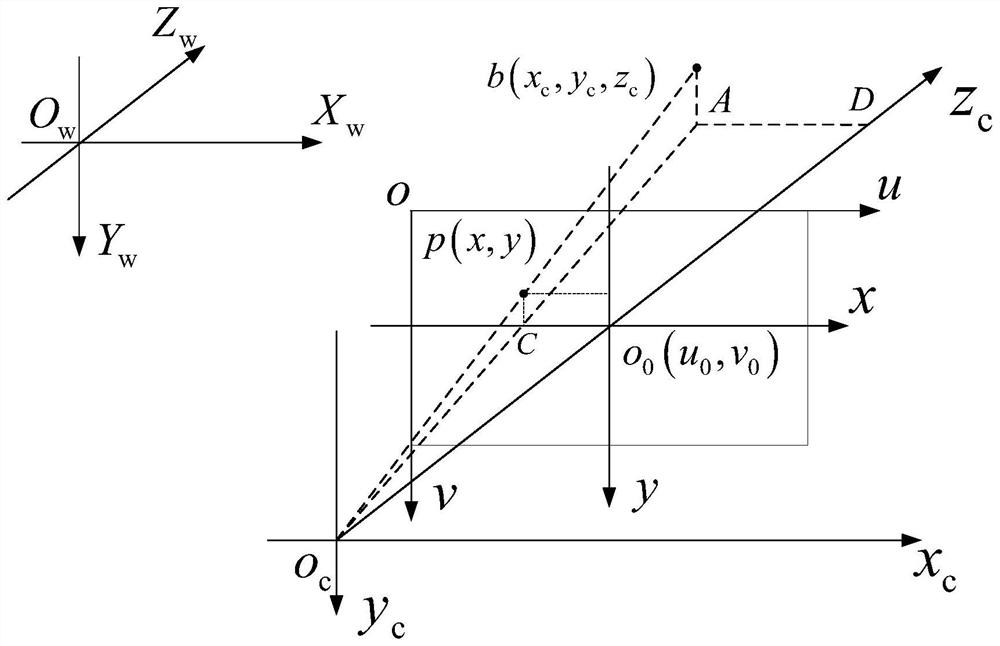

Self-adaptive coal mining machine follow-up tracking multi-camera video splicing method

PendingCN112215925AReduce the impact of condition monitoringRealize adaptive follow-up monitoringImage enhancementImage analysisPattern recognitionParallax

The invention discloses a self-adaptive coal mining machine follow-up tracking multi-camera video splicing method, belongs to the technical field of intelligent monitoring, and combines a camera groupself-adaptive follow-up tracking method with a coal mining machine video splicing algorithm to improve the splicing effect of coal mining machine monitoring videos under the condition of large parallax of a coal mining working face. The influence of monitoring dead angles of the cameras on the state monitoring of the coal mining machine is reduced; firstly, a colorful fluorescent band is used formarking the position of a machine body, and real space coordinates are obtained through a camera calibration principle; the cameras deployed on a coal mining working surface are activated in groups based on a camera group self-adaptive follow-up tracking method, and the currently activated camera group completes a video splicing task of a coal mining machine picture. The coal mining machine videosplicing algorithm comprises the following steps: splicing corresponding frame images of two monitoring videos by using an image splicing algorithm; screening SIFT feature points based on an RANSAC algorithm for registration of the two images; and finally, splicing the two images by searching for the optimal suture line, and thus large-range monitoring of operation of the coal mining machine is achieved.

Owner:CHINA UNIV OF MINING & TECH

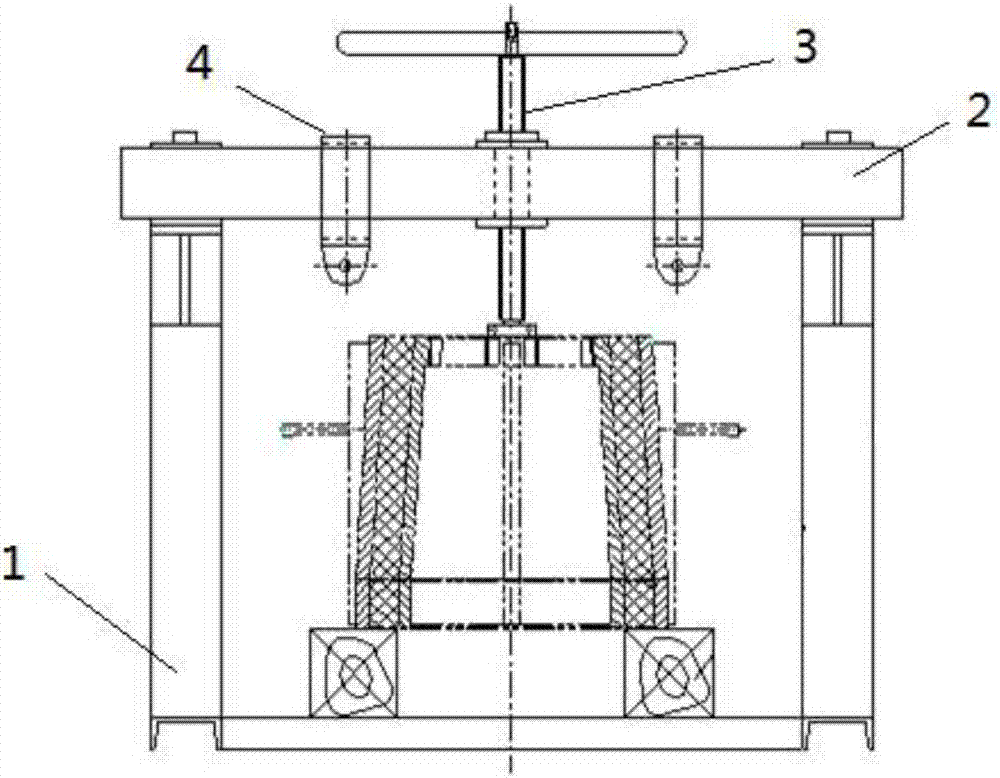

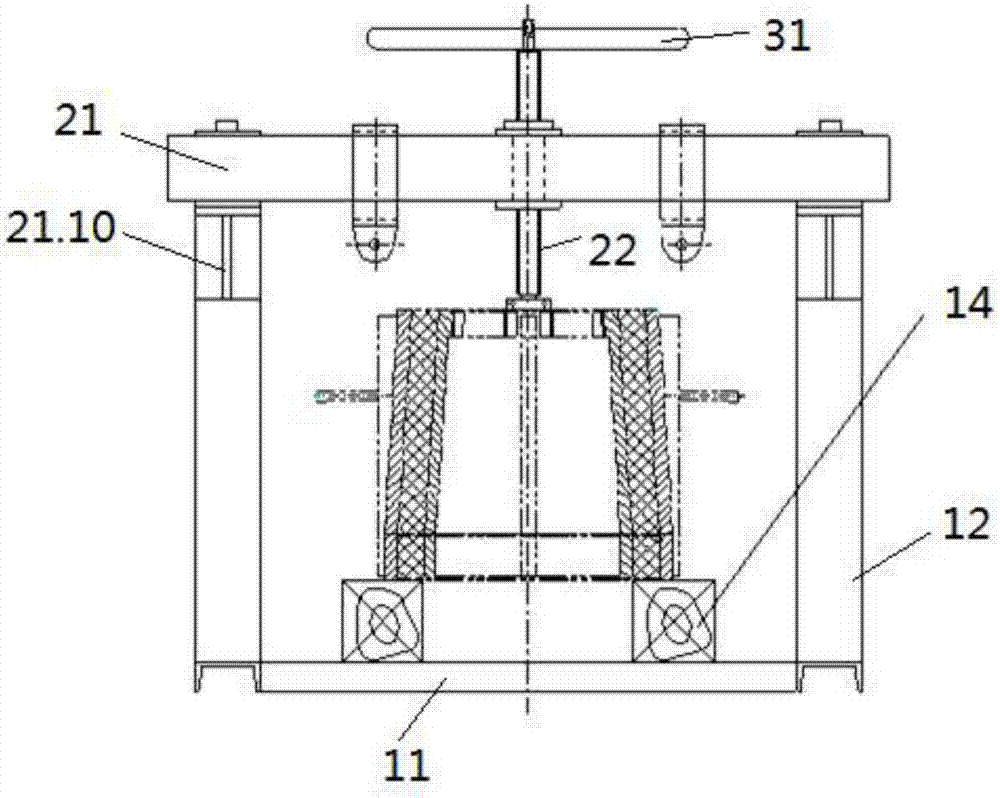

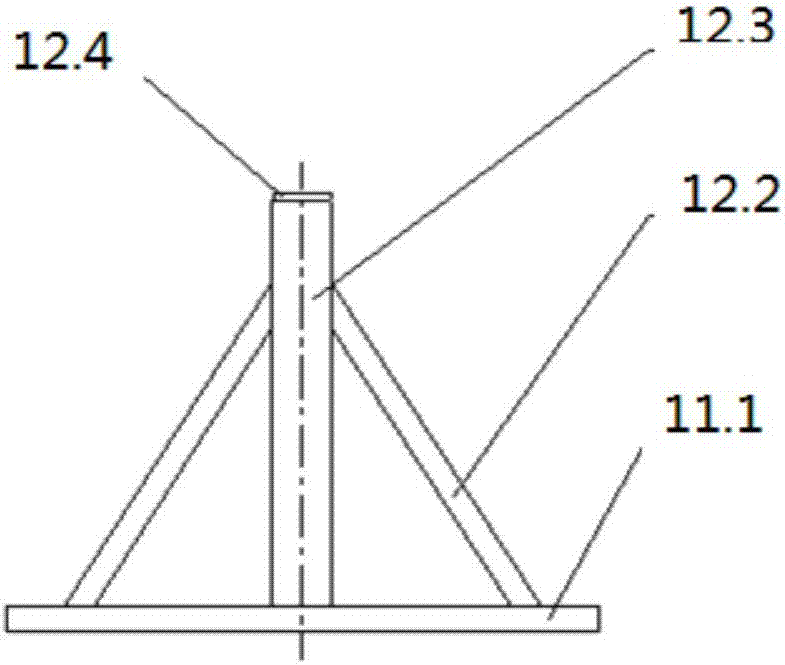

Foaming forming demoulding device for annular structural piece

The invention discloses a foaming forming demoulding device for an annular structural piece. The device comprises a support assembly, a hanging rod assembly, a hand wheel assembly and flying ring assemblies. The support assembly comprises a base and holders arranged on the two sides of the base correspondingly. The hanging rod assembly comprises a hanging rod and an ejector rod. One end of the hanging rod is connected with the top end of the first holder through a rotation shaft, the hanging rod can rotate around the rotation shaft, and the other end of the hanging rod and the top end of the second holder are fixedly connected through a bolt. The ejector rod is inserted in the middle portion of the hanging rod in a threaded manner, and the top end of the ejector rod is connected with the hand wheel assembly. Each of the two sides of the ejector rod 22 of the hanging rod assembly sleeves the corresponding flying ring assembly used for die hoisting. According to the foaming forming demoulding device, the die design can be simplified, the die producing and manufacturing cost is reduced, meanwhile, the product production efficiency is improved, the production safety risks are reduced, the foaming forming demoulding device is particularly suitable for demoulding of the type of large die, and the problem that in the prior art, a die can only be hoisted through a crane to be demoulded, and consequently potential safety hazards are caused is solved.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

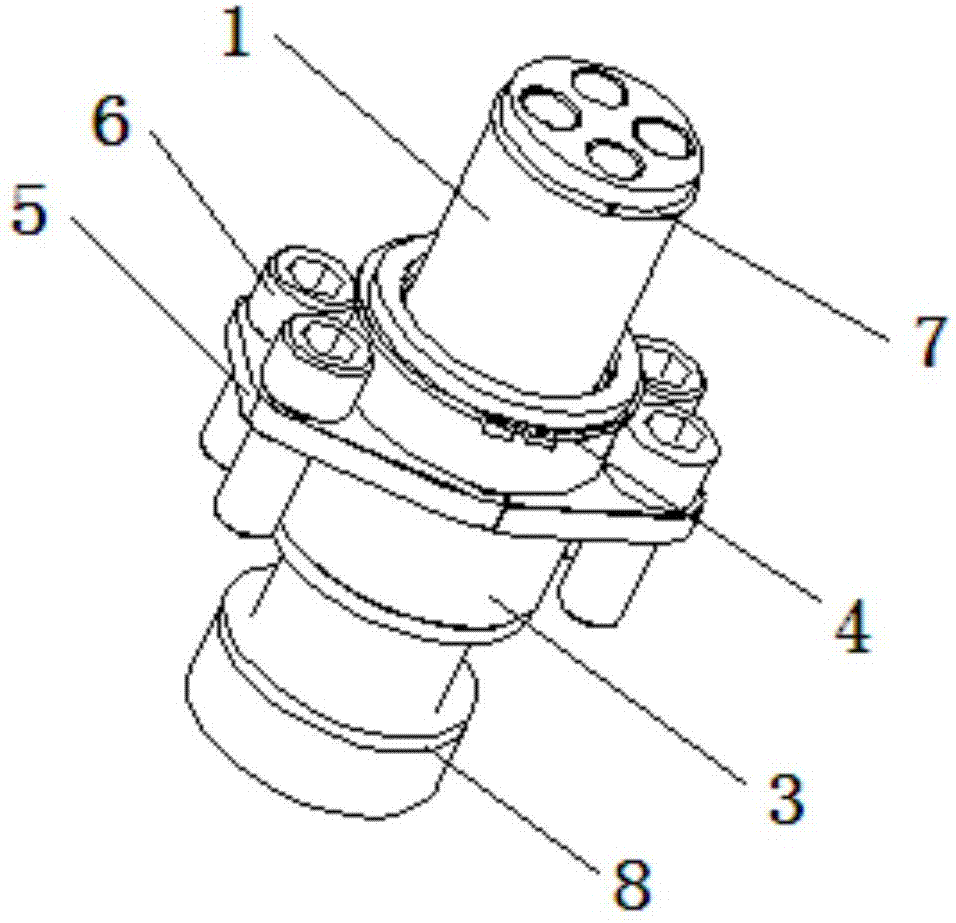

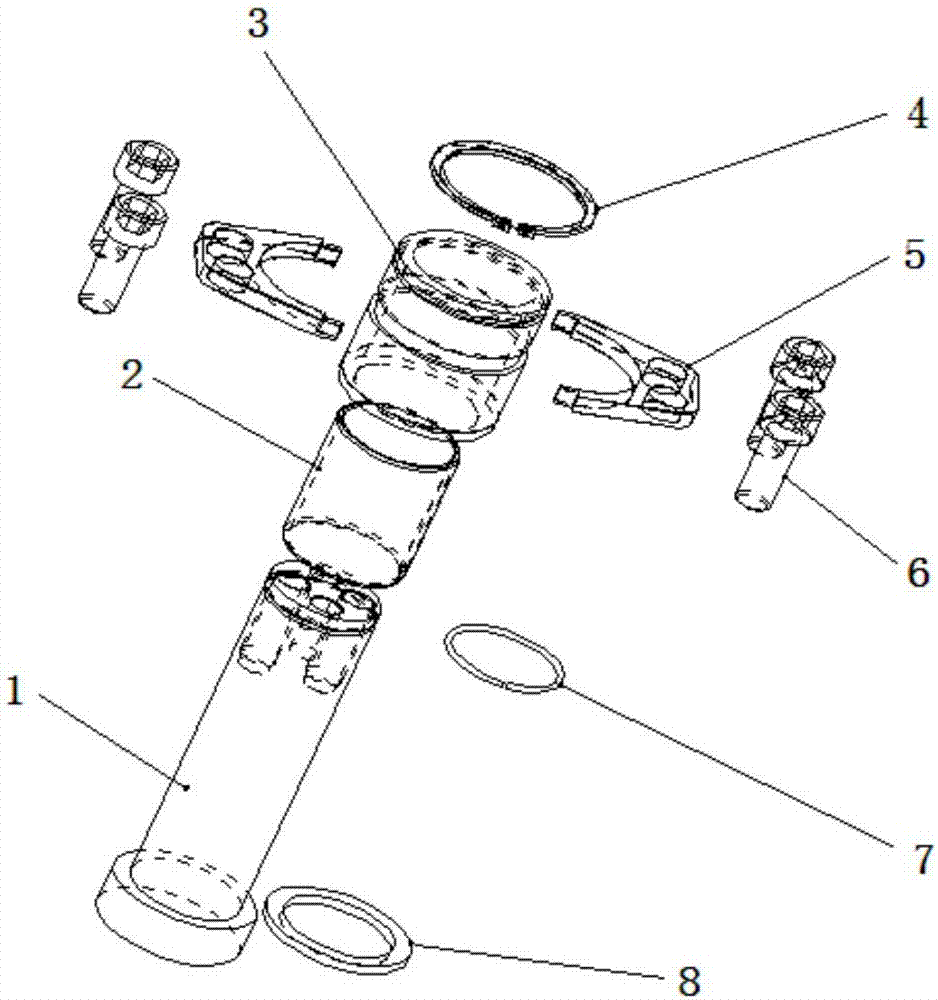

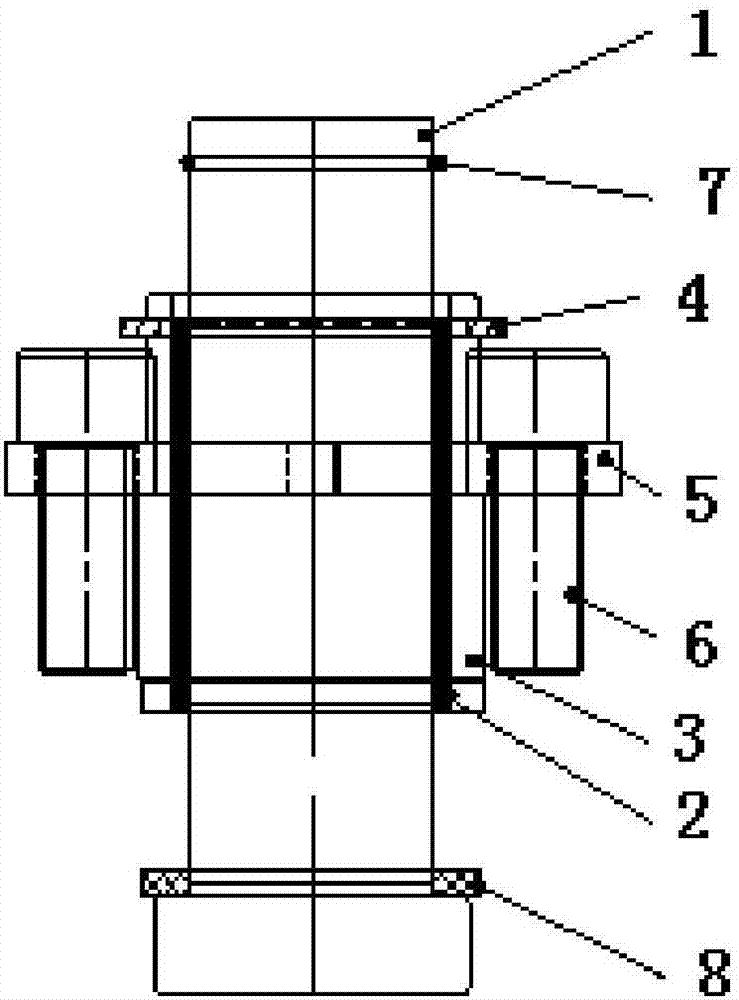

Self-lubricating guiding piece

The invention discloses a self-lubricating guiding piece. The self-lubricating guiding piece comprises a guiding column (1), a self-lubricating guiding sleeve (2) and a steel sleeve (3); the self-lubricating guiding sleeve (2) is installed in the steel sleeve (3); the self-lubricating guiding sleeve (2) and the steel sleeve (3) are installed on the guiding column (1) as a whole; an installing flange (5) is installed on the steel sleeve (3); a limiting check ring (7) is arranged in a groove in the upper end of the guiding column (1); and a buffering cushion (8) is arranged at the bottom of the guiding column (1). The self-lubricating guiding piece is simple and reliable in structure and convenient and fast to use, and solves various problems happening in the using process of a common type self-lubricating guiding piece.

Owner:JOUDER PRECISION INDAL KUSN

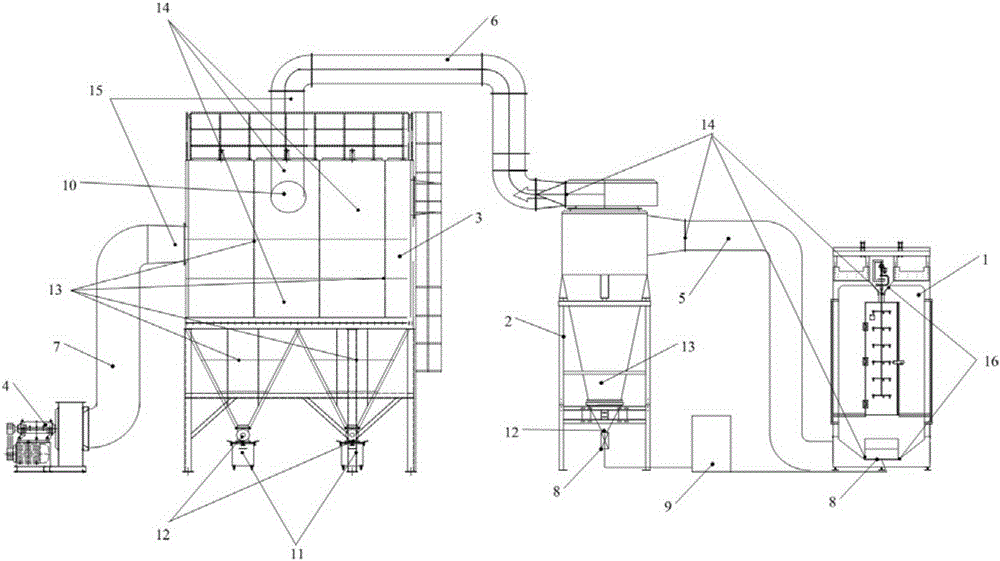

Explosion-preventing spark monitor and interlock protection system for electrostatic powder spraying

ActiveCN106881226AReduce the risk of safety productionAvoid explosionLiquid surface applicatorsCoatingsEngineeringProtection system

The embodiment of the invention discloses an explosion-preventing spark monitor and interlock protection system for electrostatic powder spraying in order to solve the problem that a conventional manufacturing process of electrostatic powder spraying is present with great potential safety hazards. In the embodiment, the explosion-preventing spark monitor and interlock protection system for electrostatic powder spraying comprises a spraying chamber, a first-stage de-duster, a second-stage de-duster and an exhaust fan. An outlet of the spraying chamber is connected with an inlet of the first-stage de-duster through a first-stage connecting pipeline. An outlet of the first-stage de-duster is connected with an inlet of the second-stage de-duster through a second-stage connecting pipeline. An outlet of the second-stage connecting pipeline is connected with the exhaust fan through a third-stage connecting pipeline. Bottoms of the spraying chamber and the first-stage de-duster are provided with dust recovery ports connected with a recovery device. The inlet of the second-stage de-duster is provided with an explosion-leaking device.

Owner:GUANGDONG JINFANGYUAN SAFETY TECH TESTING CO LTD

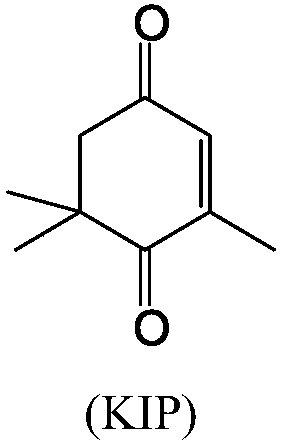

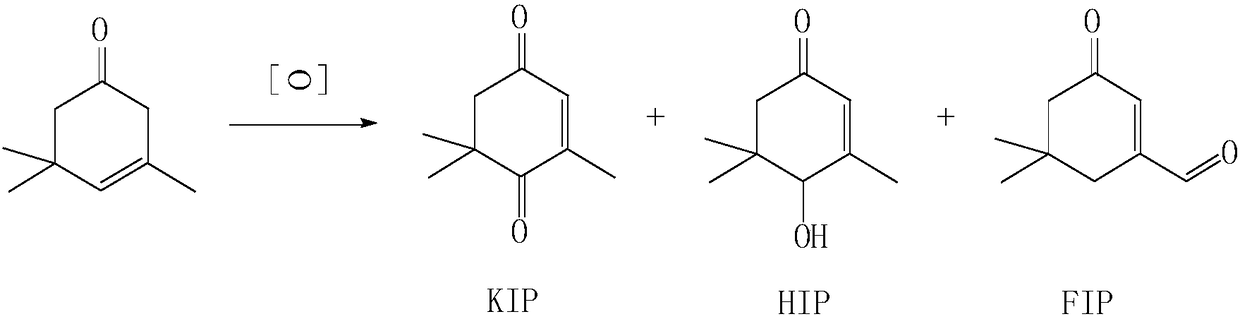

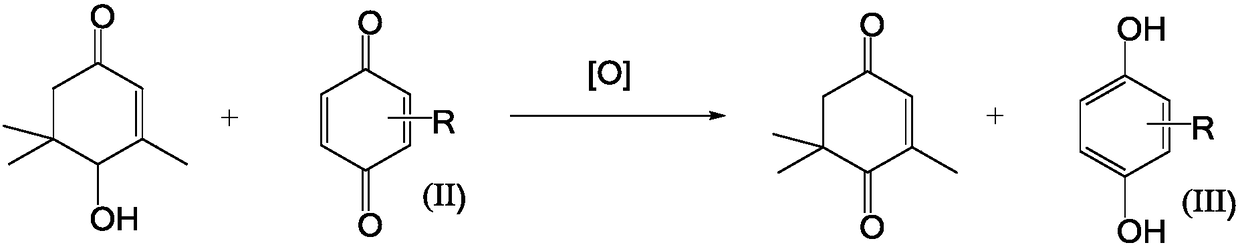

Synthesis method of oxo-isophorone

ActiveCN109456153AEmission reductionMolecular utilization is highOrganic compound preparationCarbonyl compound separation/purificationBenzoquinone Compound2 cyclohexene 1 one

The invention relates to a synthesis method of oxo-isophorone. The method is characterized in that 3, 5, 5-trimethyl-4-hydroxyl-2-cyclohexene-1-one (HIP) is used as a raw material, p-benzoquinone compounds (II) are used as an oxidizing agent and a catalyst; oxygen or air is introduced, and an oxidation reaction is carried out in an inert solvent, so that the oxo-isophorone (KIP) and hydroquinone compounds (III) are generated.

Owner:SHANGYU NHU BIOCHEM IND +2

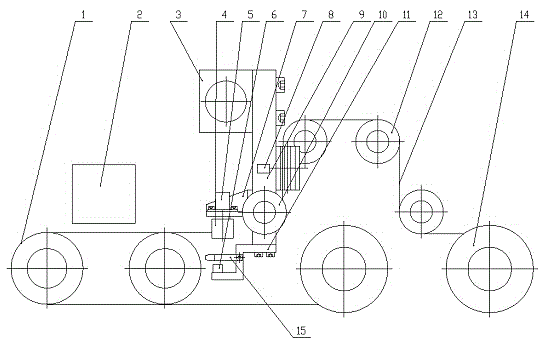

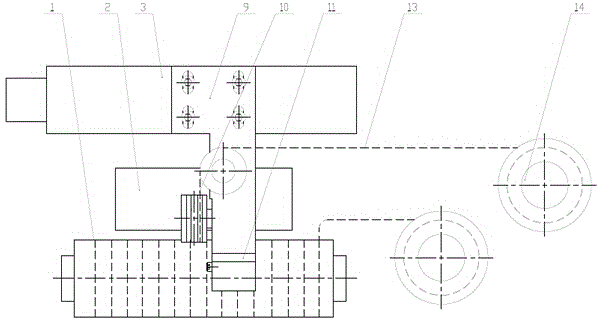

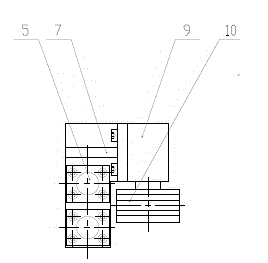

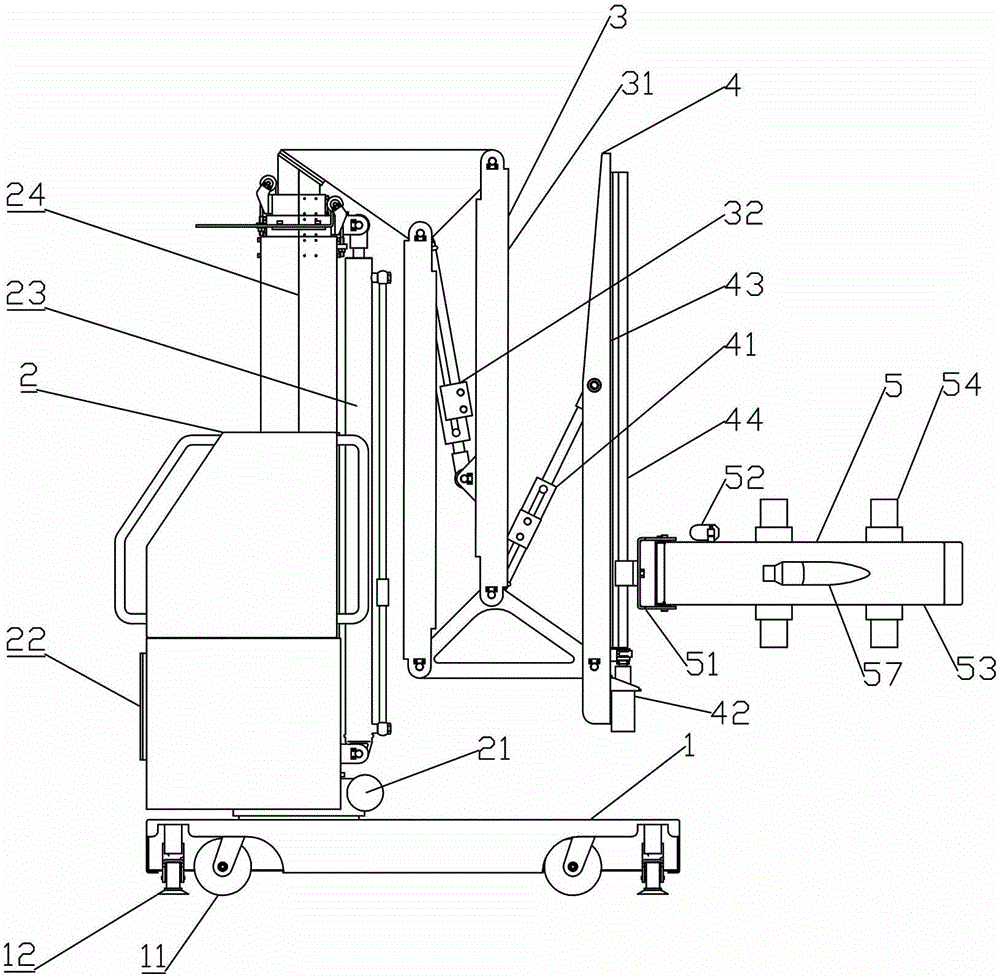

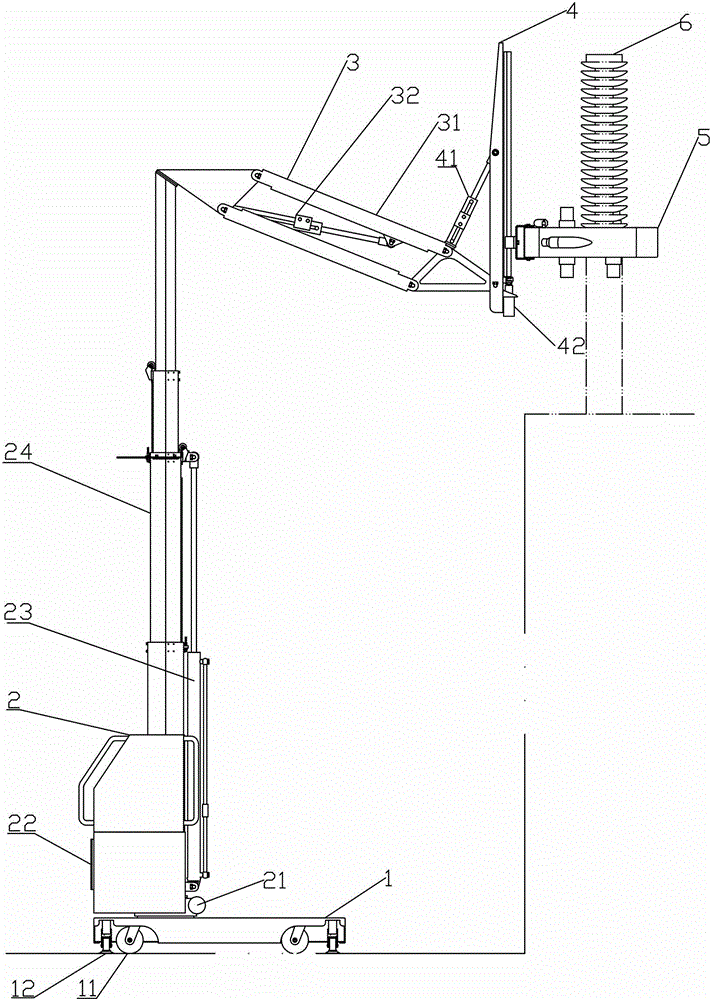

Washing machine for post insulator

ActiveCN103331272BAvoid secondary pollutionAvoid pollutionDirt cleaningCleaning using toolsPower gridEngineering

The invention discloses a washing machine for a post insulator. The washing machine for the post insulator comprises a moving platform, a lifting rotary device and a washing head used for sweeping the post insulator, wherein the lifting rotary device is arranged on the moving platform, the lifting rotary device comprises a telescopic component used for controlling the washing head to rise and descend, and a rotary component used for controlling the washing head to swing in a left-and-right mode, a front-and-back adjusting device which is used for controlling the washing head to move forwards and backwards is arranged on the top of the telescopic component, an inclined lifting device which is used for controlling the inclination angle of the washing head, and controlling upward-and-downward lifting operation of the washing head is arranged at the front end of the front-and-back adjusting device, and the washing head is arranged on the inclined lifting device. The washing machine for the post insulator can be popularized and be used in a power grid system, can be serve as a dedicated anti-pollution flashover overhauling device, improves the level of standardized operation, improves overhauling quality, creates economic value for safe operation of a power grid, reduces safe production risks, and reduces safe production cost.

Owner:STATE GRID CORP OF CHINA +1

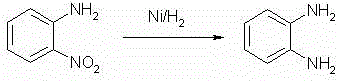

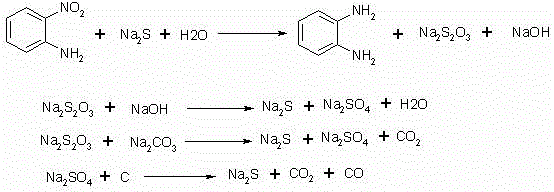

An improved synthetic method for preparing o-phenylenediamine by reduction of o-nitroaniline

ActiveCN105017028BHigh recovery rateAvoid security issuesOrganic compound preparationAlkali metal sulfides/polysulfidesSynthesis methodsReaction temperature

The invention relates to an improved synthetic method for preparing o-phenylenediamine by reducing o-nitroaniline. The method comprises adding o-nitroaniline and sodium sulfide according to the molar ratio of 1:1.5-2 into a reaction vessel, injecting water, controlling the weight ratio of sodium sulfide to water to be 1:1-20, controlling the reaction temperature to be 50-150 DEG C, reacting for 1-5 h, crystallizing and separating o-phenylenediamine, so as to obtain reaction waste water; concentrating the reaction waste water to obtain a solid residue; performing medium-temperature calcining on the residue, concretely adding an inorganic base into the residue and controlling the temperature of medium-temperature calcining to be 300-600 DEG C; performing high-temperature calcining on the residue, concretely mixing with carbon powder, and controlling the temperature of high-temperature calcining to be 900-1200 DEG C; and performing separation filtering, concretely using water to dissolve the post-calcined product, filtering and recovering superfluous carbon powder and obtaining a filtrate which is a sodium sulfide aqueous solution. The method realized continuous efficient wastewater processing, is beneficial for reducing discharge of ' three wastes (waste gas,waste water and industrial residue) ', reduces safe production risk, improves sodium sulfide recovery rate, and is relatively suitable for large-scale production of o-phenylenediamine in industry.

Owner:江阴市华亚化工有限公司

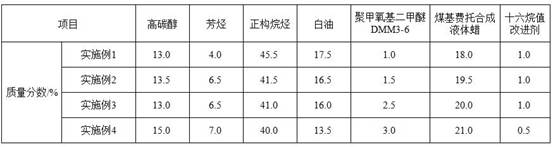

Alcohol-based fuel for compression ignition type internal combustion engine and preparation method of alcohol-based fuel

ActiveCN114369479AReduce manufacturing costReduce use costLiquid carbonaceous fuelsFuel additivesAlkaneInternal combustion engine

The invention discloses an alcohol-based fuel for a compression ignition type internal combustion engine and a preparation method of the alcohol-based fuel. The alcohol-based fuel is prepared from the following raw materials in percentage by mass: 40 to 45.5 percent of n-alkane, 13.5 to 17.5 percent of white oil, 13 to 15 percent of high alcohol, 4 to 7 percent of aromatic hydrocarbon, 1 to 3 percent of polyoxymethylene dimethyl ether DMM3-6, 18 to 21 percent of coal-based Fischer-Tropsch synthesis liquid wax and 0.5 to 1 percent of cetane number improver. The main raw materials are derived from a coal-to-oil process and value-added utilization of oxygen-containing oil (heavy), the raw materials are convenient to obtain and low in price, the production cost of enterprises and the use cost of terminal users are reduced, compared with diesel oil, the product has the advantages that the emission of carbon, sulfur and oxynitride is reduced, the heat efficiency is improved, and in the preparation process, besides the treatment of high-carbon alcohol and the earlier-stage process, the production cost is reduced. Core preparation sections of the alcohol-based fuel all adopt continuous physical embedding reaction at normal temperature and pressure, so that the energy consumption and the safety risk are reduced.

Owner:玉门祥天新能源产业发展有限公司

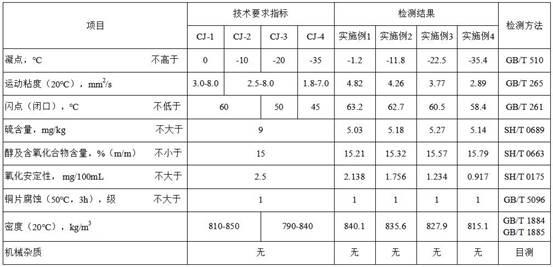

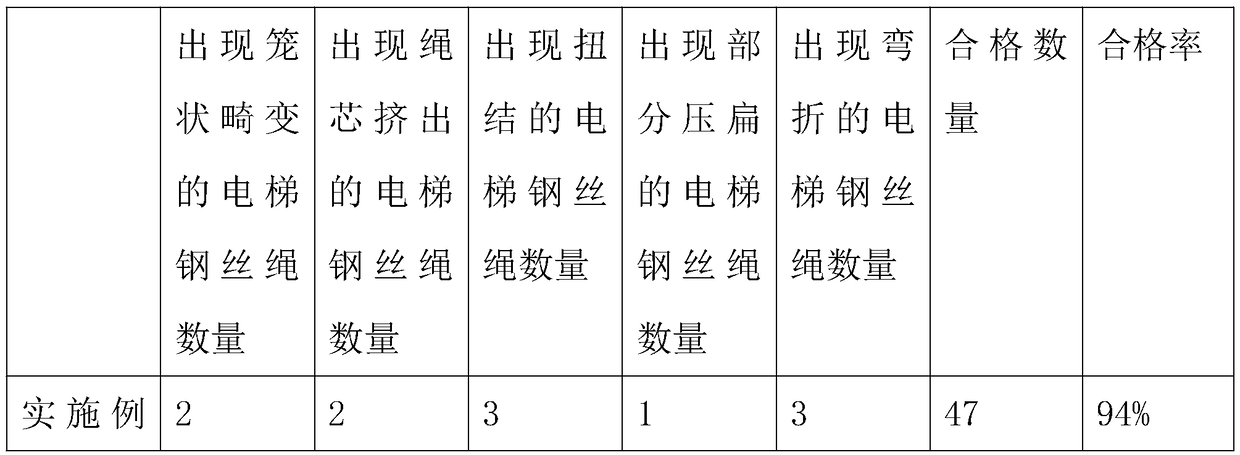

Rapid elevator steel wire rope installing method capable of prolonging service life

ActiveCN109230951ACircumstances that shorten the service lifeExtended service lifeElevatorsProduction riskEngineering

The invention discloses a rapid elevator steel wire rope installing method capable of prolonging the service life. The method specifically comprises the following step of 1 equipment detection, wherein an elevator steel wire rope is detected, the detection mode is visual detection, whether or not cage shaped deformation, rope core extrusion, twisting, partial pressing and bending appears is detected visually, then, an electronic scale is adopted for weighing the elevator steel wire rope, and whether the mean mass of the elevator steel wire rope is larger than or equal to 0.41-0.61 kilogram / meter or not is detected. The rope is paid off in a natural mode, and the phenomenon that the service life of the steel wire rope is shortened due to the fact that abrasion at the deformation position isexcessively large or rapid and stress on an elevator dragging wheel is not uniform when the elevator steel wire rope is twisted or deformed is avoided; the service life of the elevator steel wire rope is effectively prolonged, meanwhile the integrated rope take-up and pay-off operation can be completed by one person, the working efficiency is effectively improved, the installing speed is increased, and the safety production risk is lowered.

Owner:广东恩晟电梯有限公司

A kind of hydrothermal synthesis method of nanoscale magnesium lithium silicate with high light transmittance

ActiveCN105800626BLow hydrothermal reaction temperatureLow reaction temperatureNanotechnologySilicon compoundsSynthesis methodsSodium salt

The invention discloses a hydro-thermal synthesis method of high-transmittance nano-scale magnesium lithium silicate. The hydro-thermal synthesis method is characterized by comprising steps as follows: firstly, montmorillonite is acidized and calcined; then, water-soluble lithium salt and water-soluble sodium salt are added, the matching ratio is adjusted, and the amount of substances of all elements in a reaction system meets the proportional relation: 0.2<m(Li) / m(montmorillonite)<0.8, 1<m(Na) / m (montmorillonite)<3; finally, the mixture is subjected to a reaction at the temperature of 60-95 DEG C for 1-3 h and fully dried at the temperature of 110-150 DEG C until the water content is not higher than 2%, and magnesium lithium silicate is prepared. Defects in the prior art are overcome, and the safe, environment-friendly, efficient and low-cost synthesis method of nano-scale magnesium lithium silicate is provided; according to the synthesis method, high-purity montmorillonite which has vast reserves in the natural world is taken as a starting raw material, and the nano-scale magnesium lithium silicate with high transmittance, excellent thickening and thixotropy and high adsorption force is produced by optimizing technological parameters of production and the ratio of reaction raw materials.

Owner:JIANGSU HEMINGS NEW MATERIALS TECH CO LTD

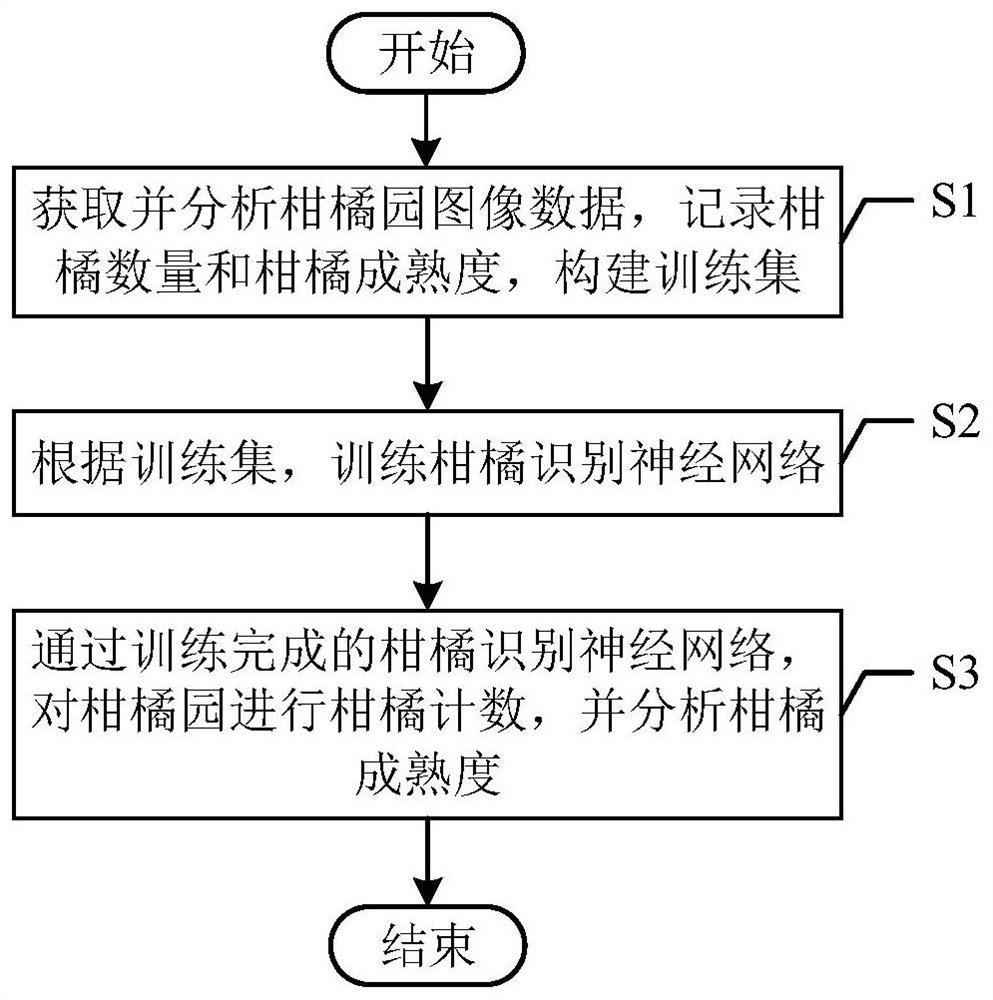

Electro-optical effect sensing technology-based signal acquisition method for wireless PT

PendingCN111856376AReduce the risk of safety productionEasy to useVoltage/current isolationTransformerElectric power equipment

The invention relates to the technical field of power equipment and relates to an electro-optical effect sensing technology-based signal acquisition method for a wireless PT. The method comprises thefollowing steps that: 1, an electro-optical effect transformer is installed, specifically, the electro-optical effect transformer is installed on a high-voltage wire through an insulating connecting piece, and the vertical distance between the electro-optical effect transformer and the high-voltage wire is 2 m; 2, the electro-optical effect transformer installed in the step 1 is rotated, debuggedand used; 3, the debugged electro-optical effect transformer in the step 2 is fixed; and 4, data acquisition and research of the installed photoelectric effect transformer are facilitated. According to the electro-optical effect sensing technology-based signal acquisition method for the wireless PT of the invention, a wireless PT (10kV) capable of performing all-weather, long-distance and non-contact operation can be developed on the basis of an existing PT mode and is convenient to use, safe and reliable, can effectively reduce the safety production risk of a power plant, and makes up the defects of a conventional PT mode.

Owner:浙江浙能绍兴滨海热电有限责任公司

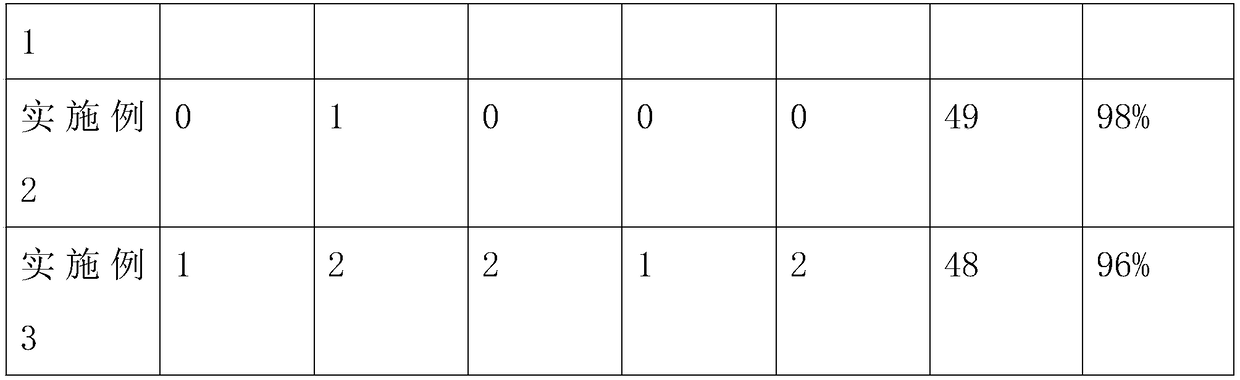

Citrus identifying and counting method

PendingCN114120155AMaturity can be monitoredThe recognition result is reliableCharacter and pattern recognitionNeural architecturesMachine learningFruit maturation

The invention discloses a citrus recognition and counting method, and relates to the technical field of machine learning image recognition, and the method comprises the steps: obtaining and analyzing the image data of a citrus orchard, recording the number and maturity of citrus, and constructing a training set; training a citrus recognition neural network; and through the citrus identification neural network, citrus counting is performed on the citrus orchard, and the maturity of citrus is analyzed. According to the invention, citrus fruit counting and fruit ripening state determination in an unmanned state are realized, the fruit ripening degree of an orchard can be monitored, the blank that the fruit ripening degree cannot be tracked in real time in the prior art is filled, the output reliability is high, a more reliable identification result is obtained, and the identification efficiency is improved. The method can help guide orchard production and comprehensive utilization and development of by-products thereof, reduce safety production risks, improve product yield and reduce production cost.

Owner:TIBET UNIV

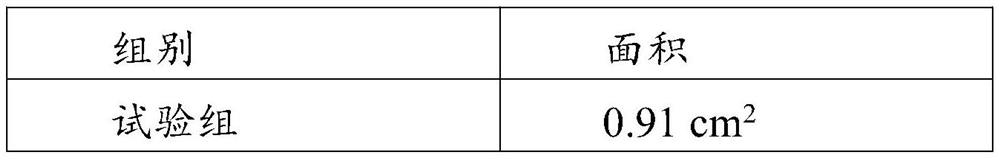

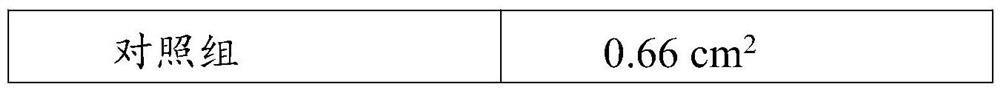

Skin repairing dressing and preparation method thereof

PendingCN112120958AFast swelling rateAffect chemical propertiesCosmetic preparationsToilet preparationsCelluloseGlycerol

The invention discloses a skin repairing dressing and a preparation method thereof, and belongs to the technical field of cosmetics. The skin repairing dressing comprises a carrier and essence; and the essence comprises the following raw materials in percentage by mass: 0.05-0.2% of high-molecular-weight collagen, 0.05-0.15% of low-molecular-weight collagen peptide, 0.5-5% of glycerol, 0.02-1.0% of sodium hyaluronate, 0.1-1.0% of hydroxyethyl cellulose, 0.1-2.0% of xanthan gum, 0.1-1.0% of ceramide and the balance of purified water. The invention also provides a preparation method. The repairing dressing in the invention can effectively improve the skin moisturizing capacity and enhance the skin repairing effect, and can be popularized and used in the fields of medical treatment and cosmetic surgery.

Owner:三亚悦美科技有限公司

Molded inductor made of water-borne epoxy resin and manufacturing process thereof

InactiveCN110828104ALower security level requirementsReduce health risksInductances/transformers/magnets manufactureInductance with magnetic coreOrganosolvFirming agent

The invention discloses a molded inductor made of a water-borne epoxy resin and a manufacturing process thereof. According to the technical scheme, the molded inductor made of a water-borne epoxy resin comprises, by mass, 0.5-25% of a composition and 25-99.5% of magnetic metal powder, and the composition comprises epoxy resin capable of being dispersed or dissolved in water, a curing agent and anauxiliary. In the whole process of manufacturing the inductor, an organic solvent is not used, and only water is used as a solvent or a dispersing agent. The safety level requirement of a production workshop is greatly reduced. Almost all solvents used for dissolving resin belong to class A in a traditional process, and therefore, the workshop and the warehouse are required to be class A. The useof flammable, explosive, precursor or toxic organic solvents is avoided, and the production safety risk and the health risk of personnel are greatly reduced. Water is used as a solvent or a dispersingagent and is finally recycled or evaporated into the atmosphere in the whole manufacturing process, so that a zero-emission green and environment-friendly manufacturing process is achieved.

Owner:上海太朔材料技术有限公司

Novel special-shaped aluminum veneer curtain wall modular keel mounting process

PendingCN114622725ASolve the problem of difficult positioning and high precision requirementsReduce dependenceWallsBuilding material handlingKeelEngineering

The invention discloses a novel special-shaped aluminum veneer curtain wall modular keel installation technology which comprises the steps that according to a curtain wall design drawing, secondary keels of all models are decomposed and grouped, and the secondary keels of all models subjected to decomposition and grouping are subjected to hot bending machining; manufacturing and processing a positioning lofting underframe; the modeling secondary keels are positioned and welded; the modeling secondary keels are assembled; the aluminum veneer is installed; the modeling secondary keels are positioned on the building wall surface; and the modeling secondary keels are hoisted and fixed. The technical problems that building wall positioning is difficult, errors are large, cost is high, the rework rate is high, efficiency is low, and potential safety hazards are caused by long-time high-altitude operation are solved.

Owner:明威科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com