Telescopic type maze isolation nitrogen interlocking control system operation method for hot galvanizing vertical annealing furnace

A technology of vertical annealing furnace and interlock control, which is applied in heat treatment process control, heat treatment furnace, furnace, etc. It can solve the problems of small internal space, high safety risk, and long replacement detection time, so as to reduce the difficulty of handling accidents, The effect of ensuring personal safety and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

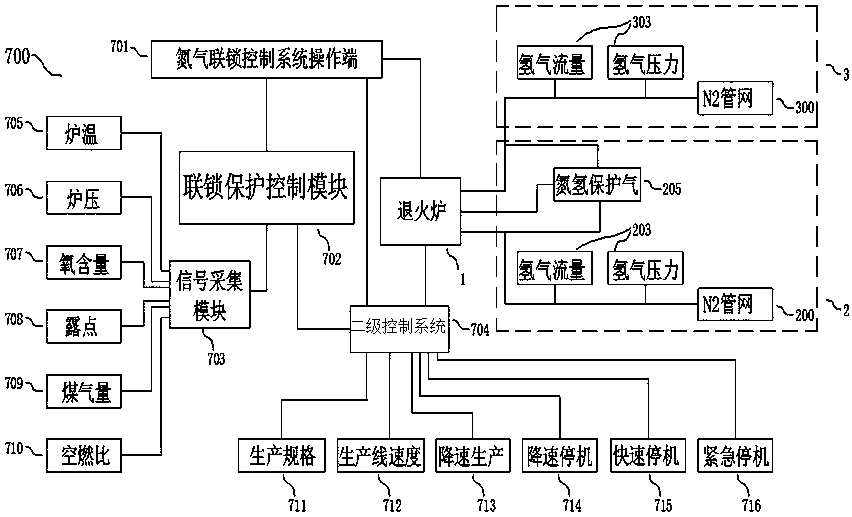

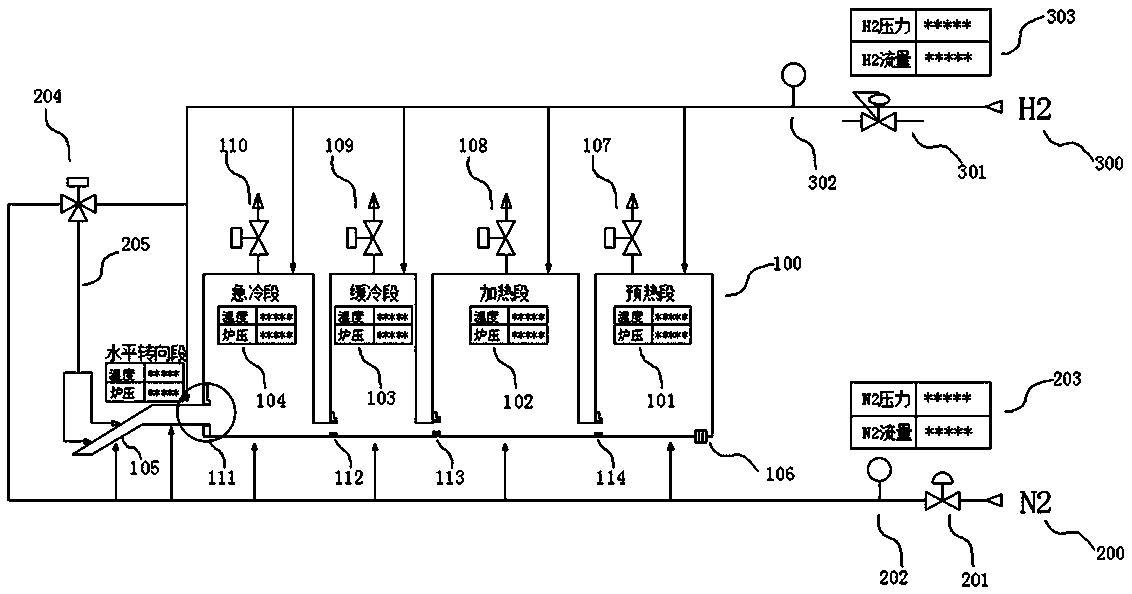

[0026] A telescopic labyrinth isolation nitrogen interlock control system for a hot-dip galvanizing vertical annealing furnace. The section is separated by a partition wall, and a gap is left in the partition wall to allow the steel belt to pass through, forming a maze-like structure. There is an isolating device between the gaps, and the isolating device is equipped with a position control encoder with a distance controllable. The isolating device is an upper telescopic type The labyrinth isolation device and the lower telescopic labyrinth isolation device, the upper telescopic labyrinth isolation device and the lower telescopic labyrinth isolation device are equipped with electric drive cylinders, and the electric drive cylinder moves to push the upper and lower isolation baffles to tightly seal or open the gap, and the electric drive cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com