Integral structure of a turn-milling complex machining center

A compound machining center and overall structure technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as lack of precision, and achieve the effects of improving efficiency, smooth chip removal, and high precision retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

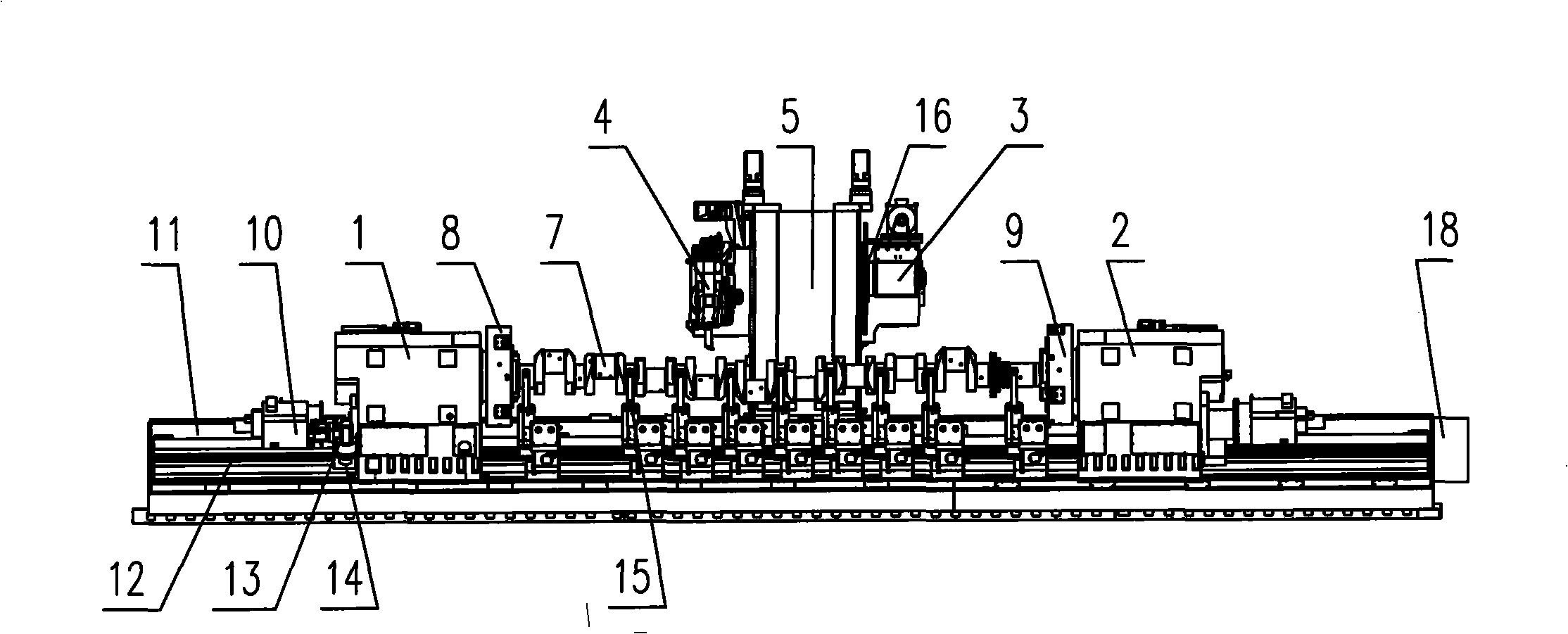

[0018] The overall structure of the turning-milling compound machining center is a special structure designed for machining the crankshaft of a medium-speed marine machine, and realizes the machining of each part of the crankshaft main journal and connecting rod journal before grinding on one machine tool. It is characterized in that it consists of the following five parts. :

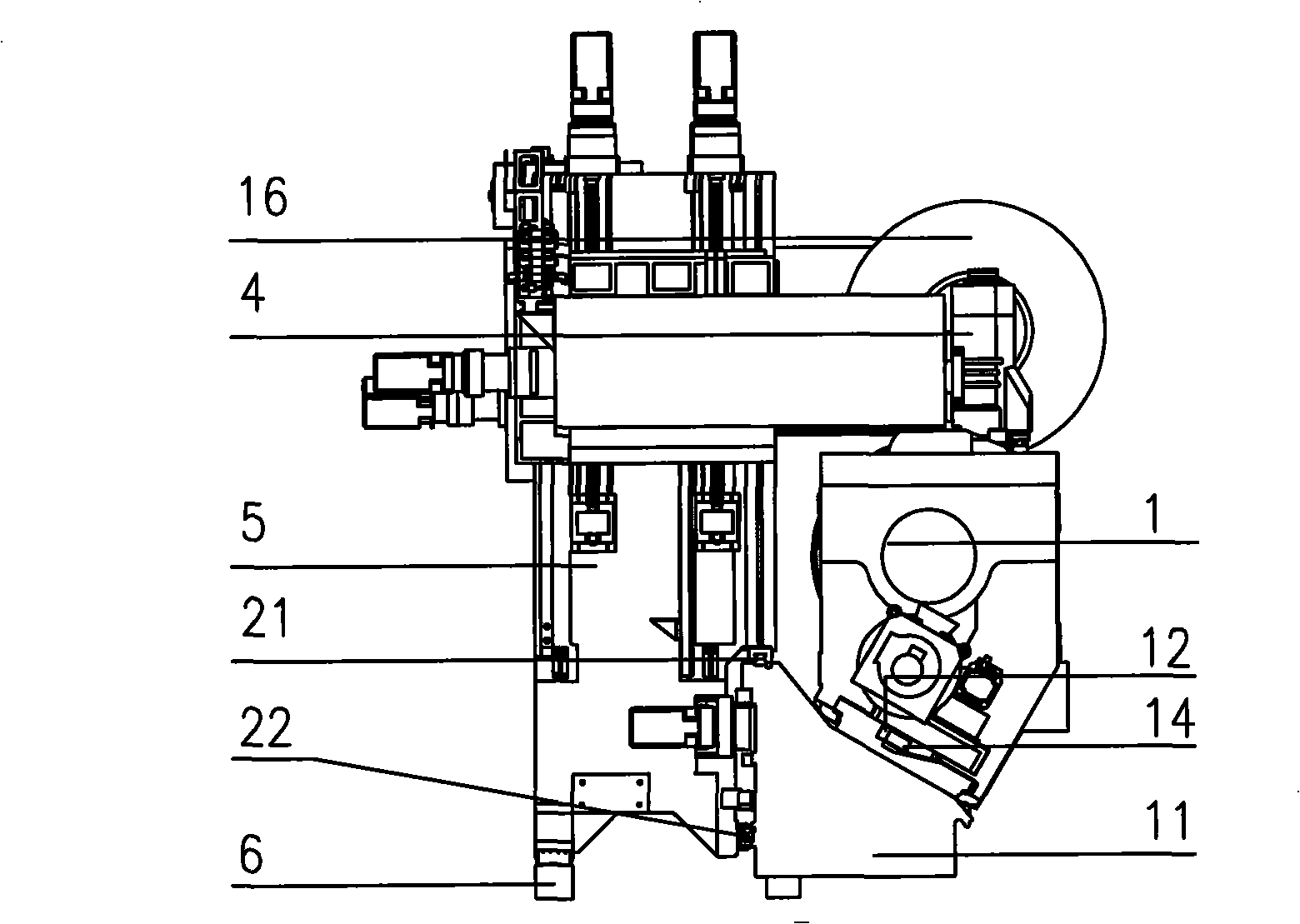

[0019] 1. Single column, double side hanging feed mechanism

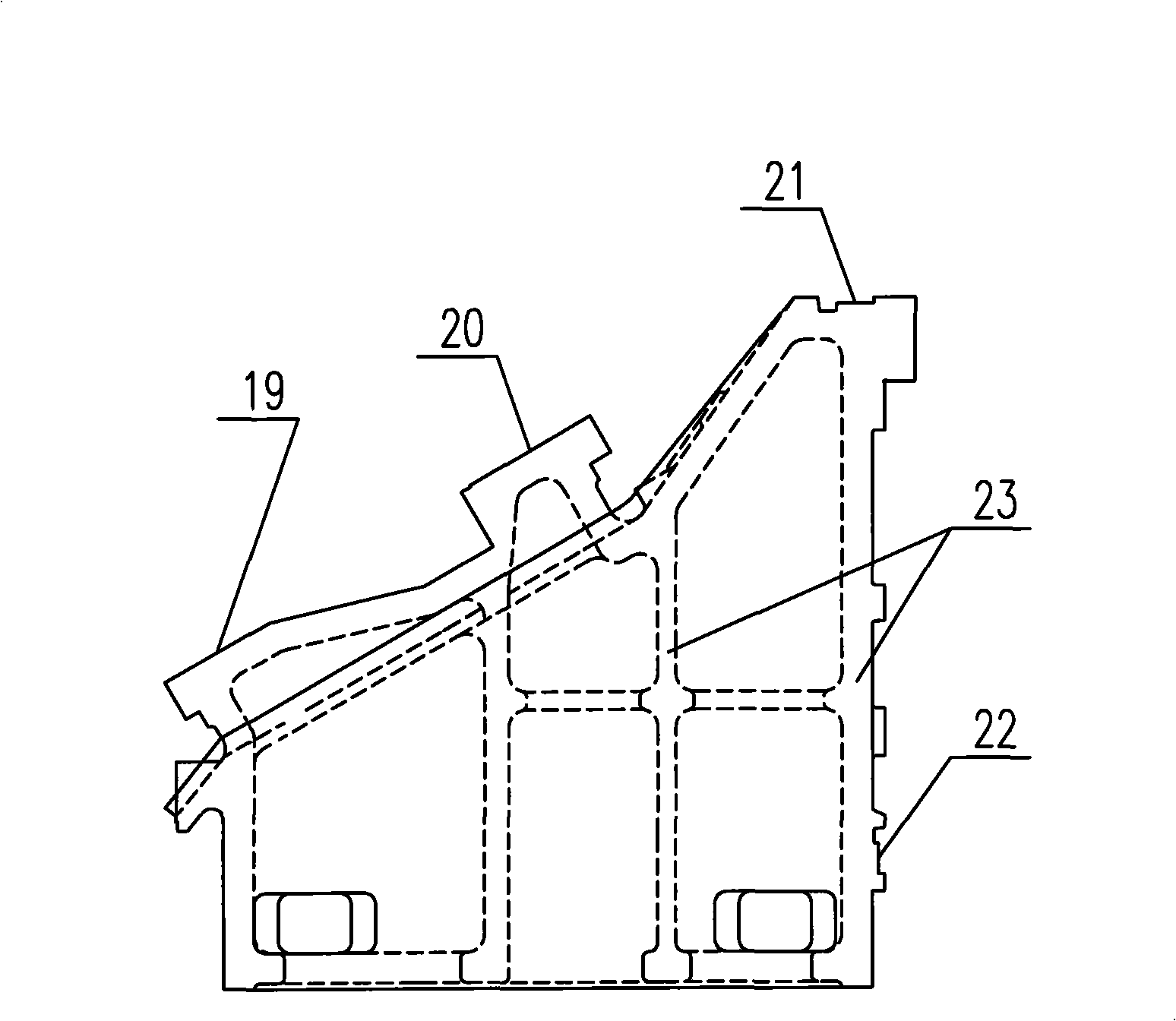

[0020] Such as figure 1 , figure 2 As shown, the single column 5 is located at the rear side of the bed, its lower front end is located in the rolling guide rails 21, 22 on the bed, and the rear end runs in the ground auxiliary guide rail 6. The stroke of the single column 5 is determined by the length of the workpiece. The single column 5 The left and right feeding mechanisms 4 and 3 are respectively hung on both sides, and the left feeding mechanism 4 is equipped with a B-axis tool holder device with three-point cloth knives. Knife and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com