Patents

Literature

68results about How to "Improve accuracy retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

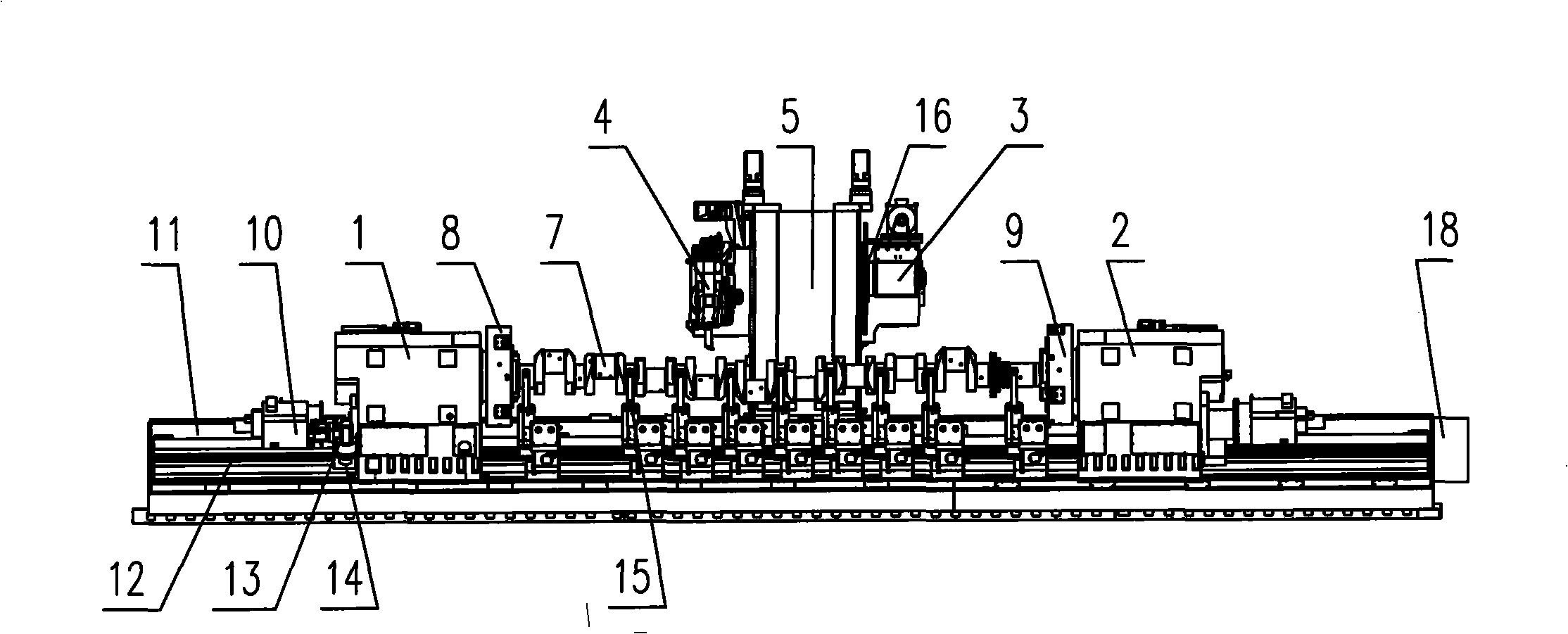

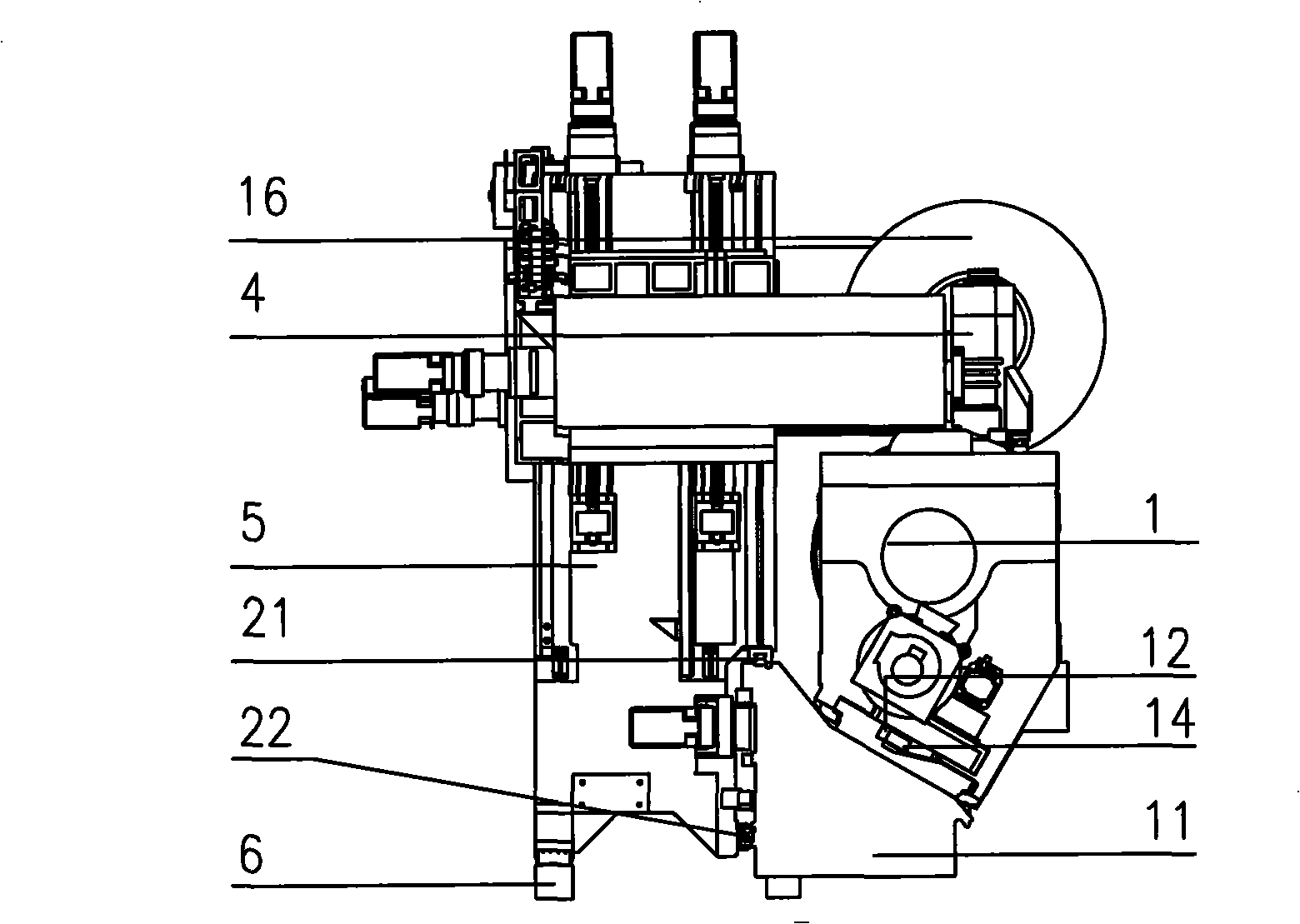

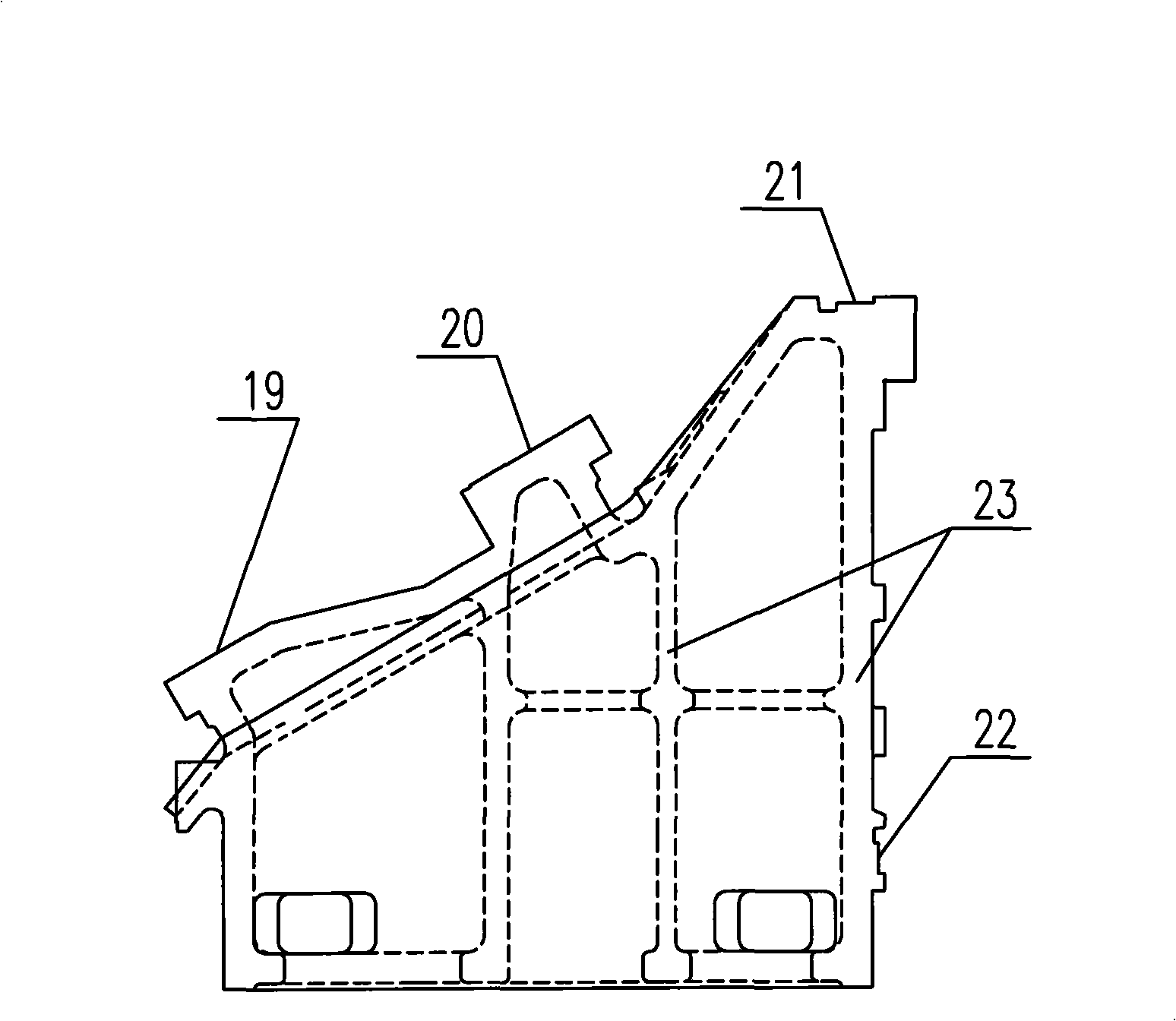

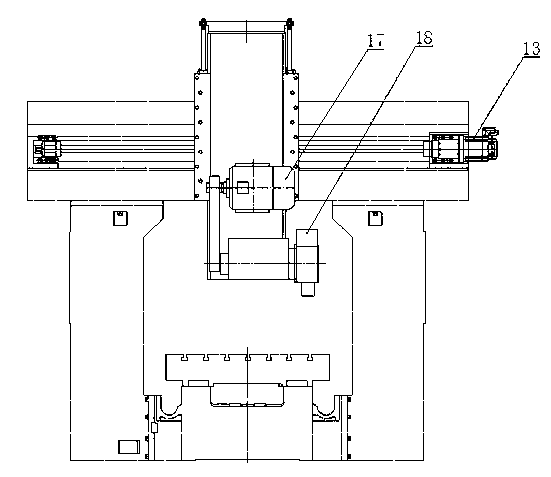

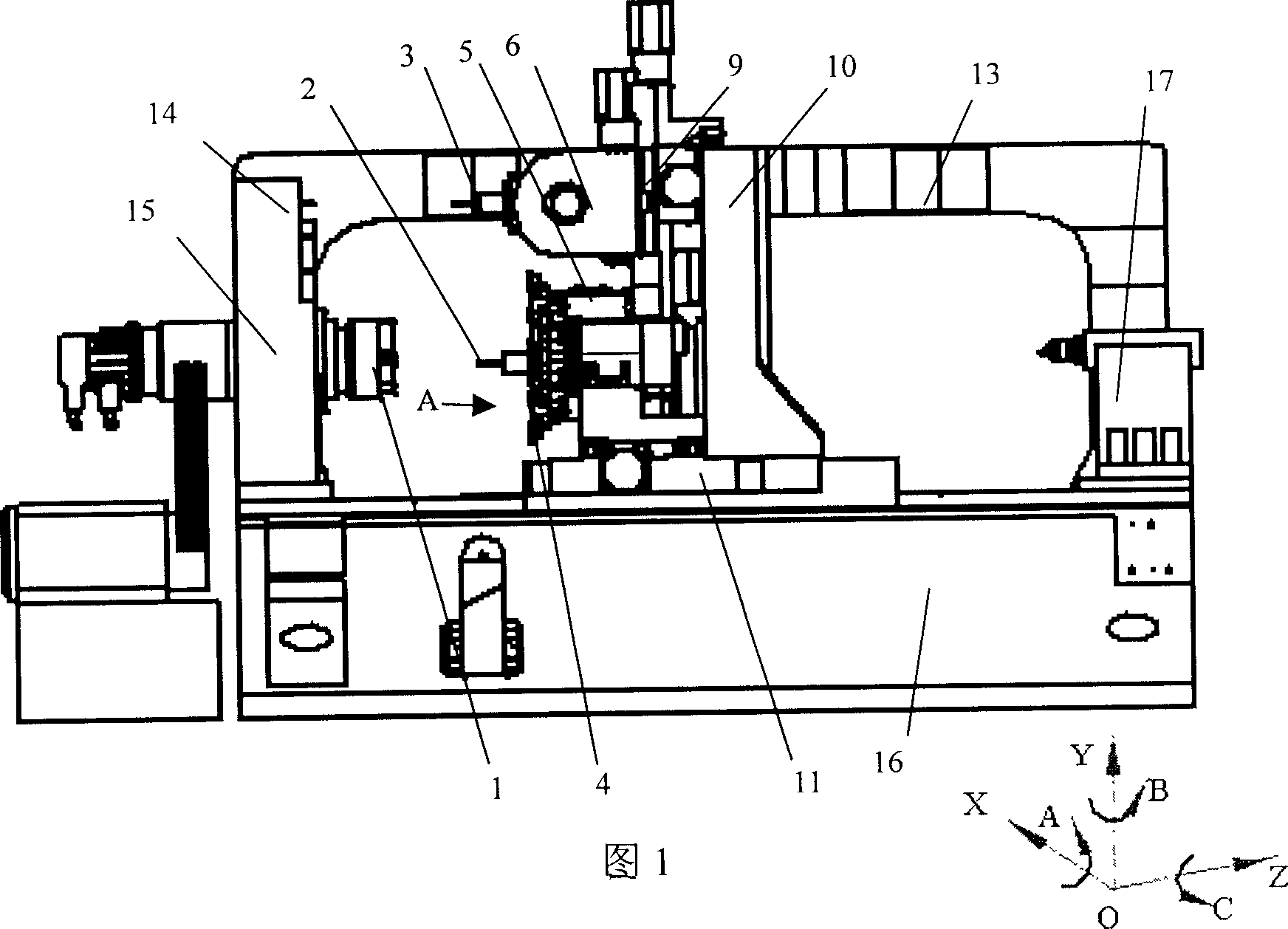

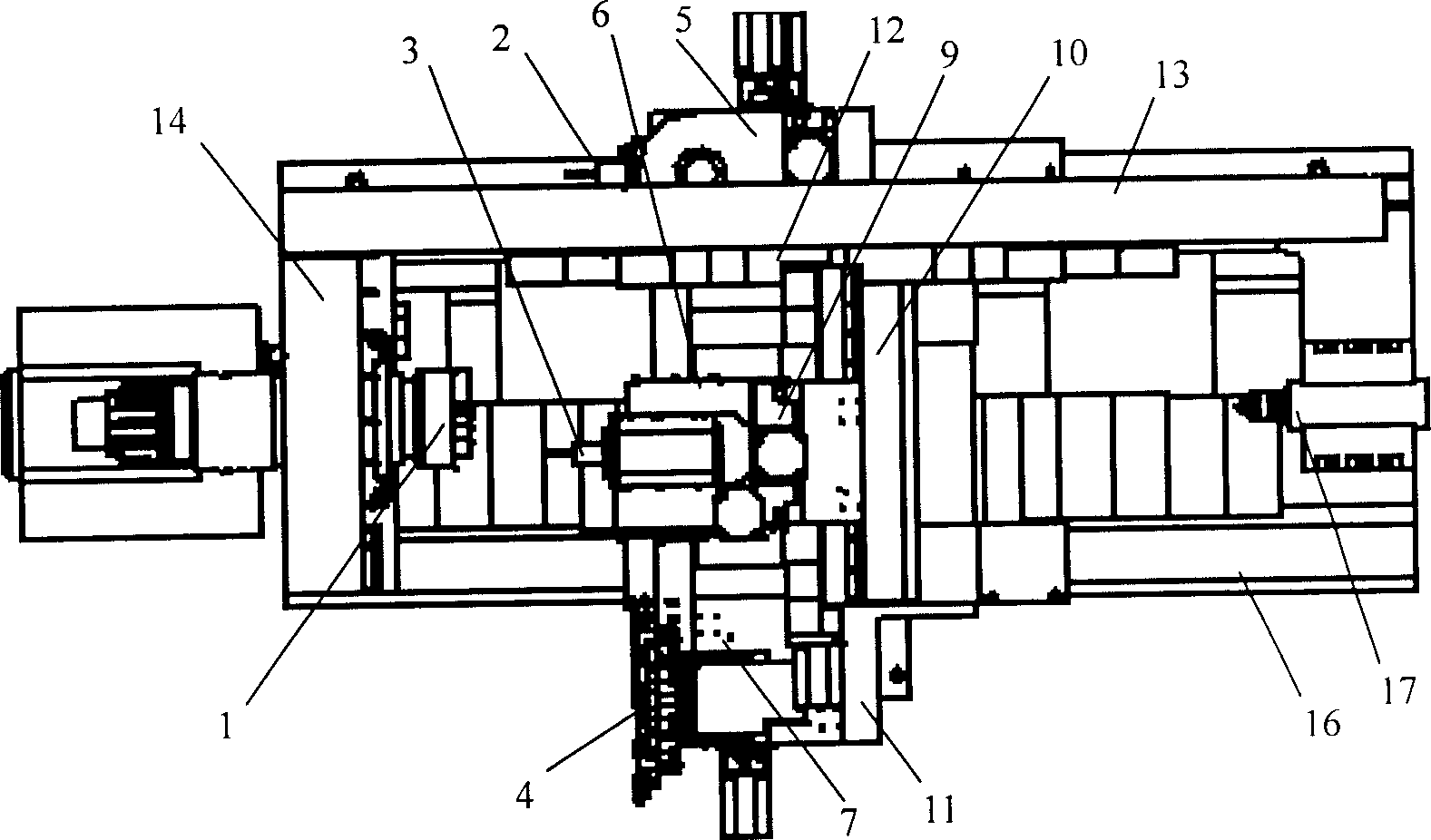

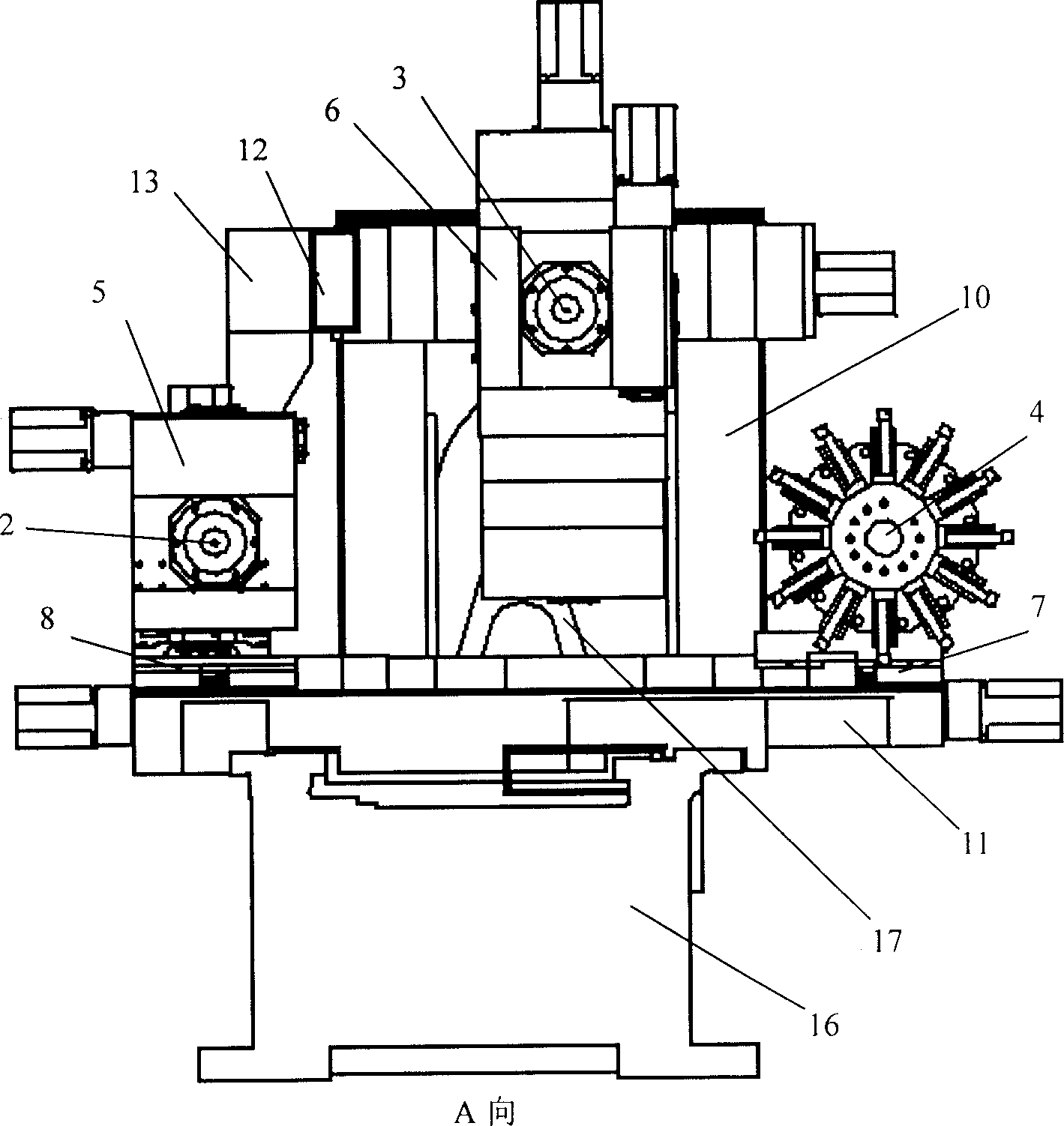

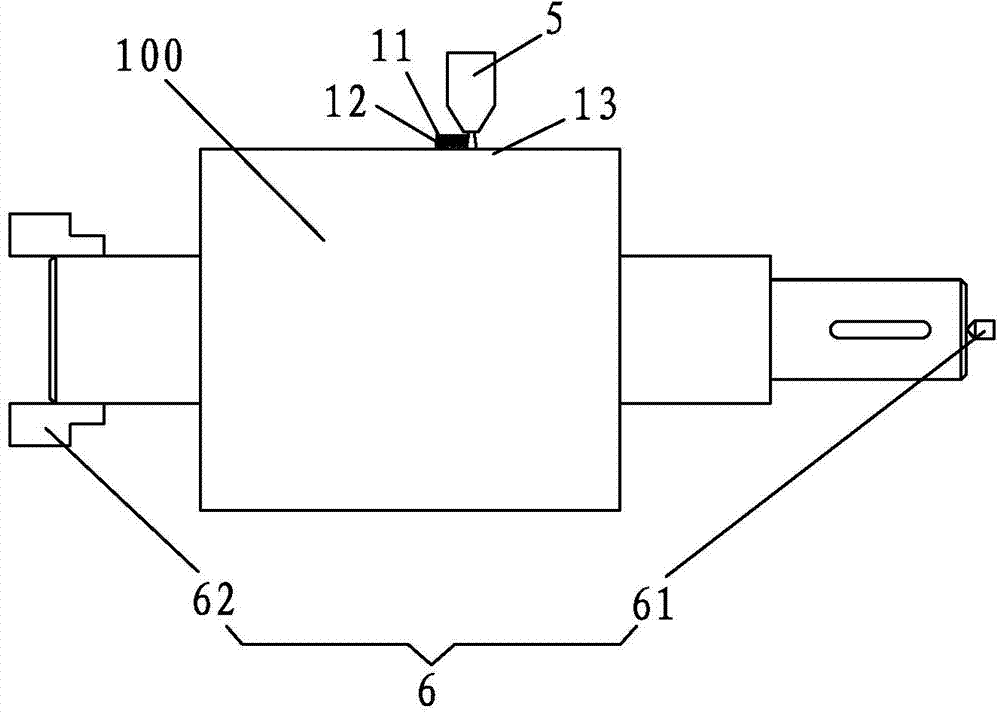

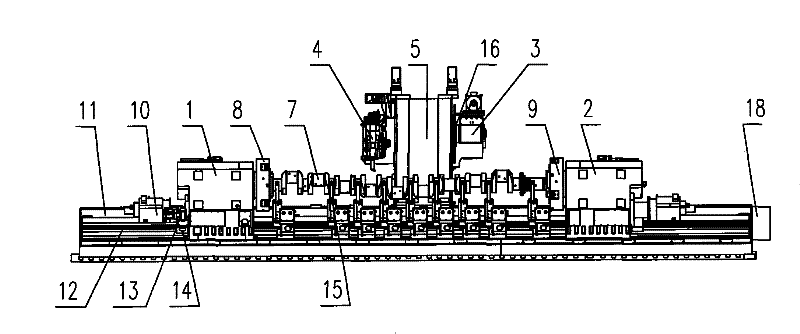

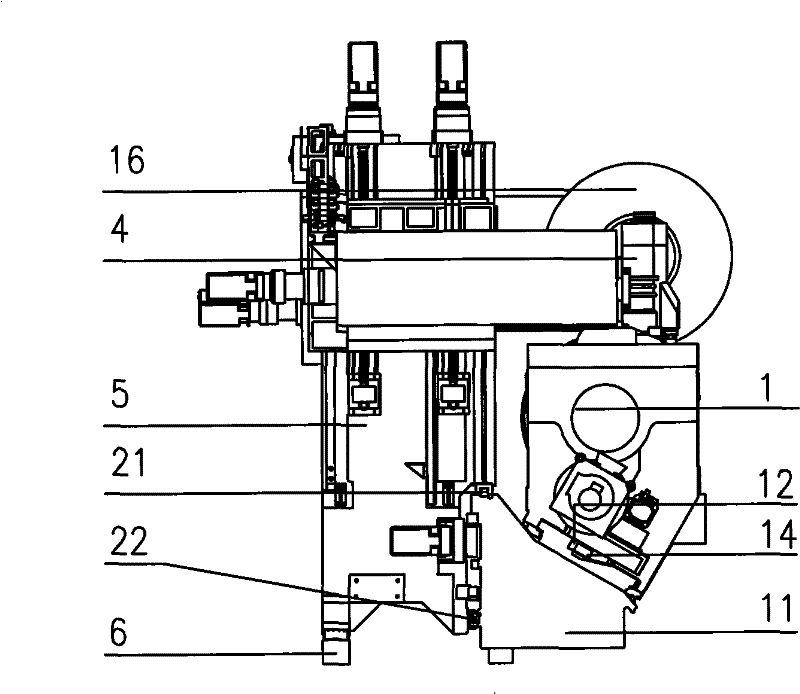

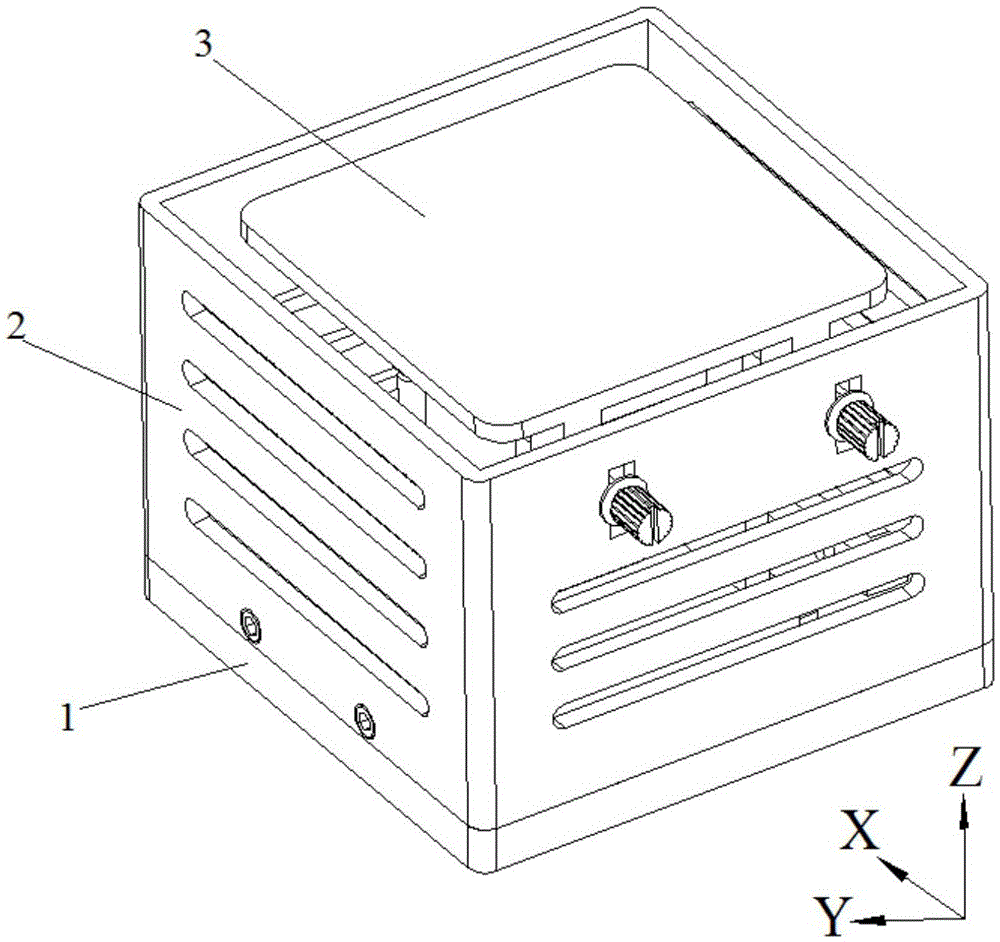

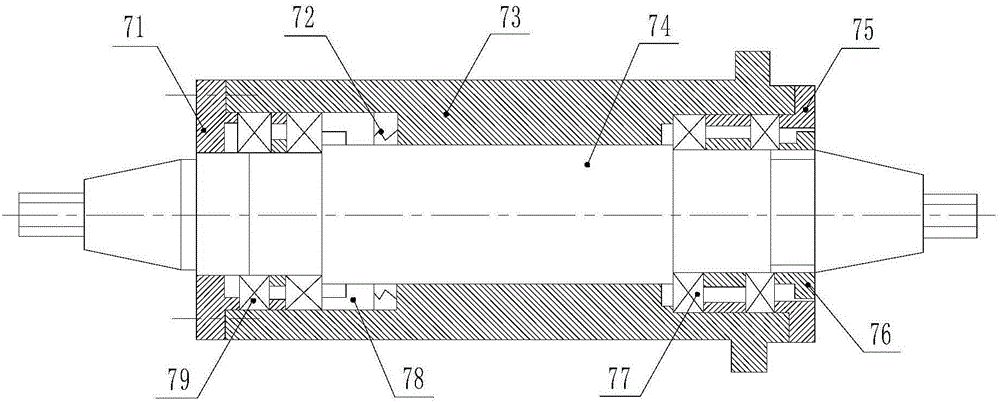

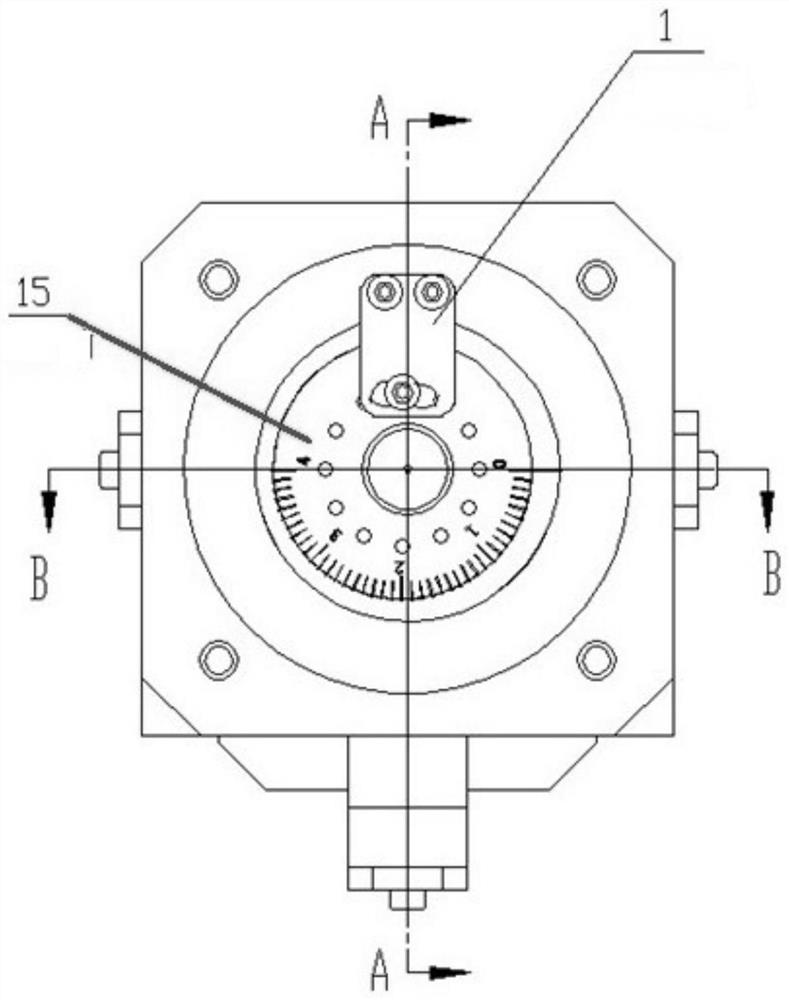

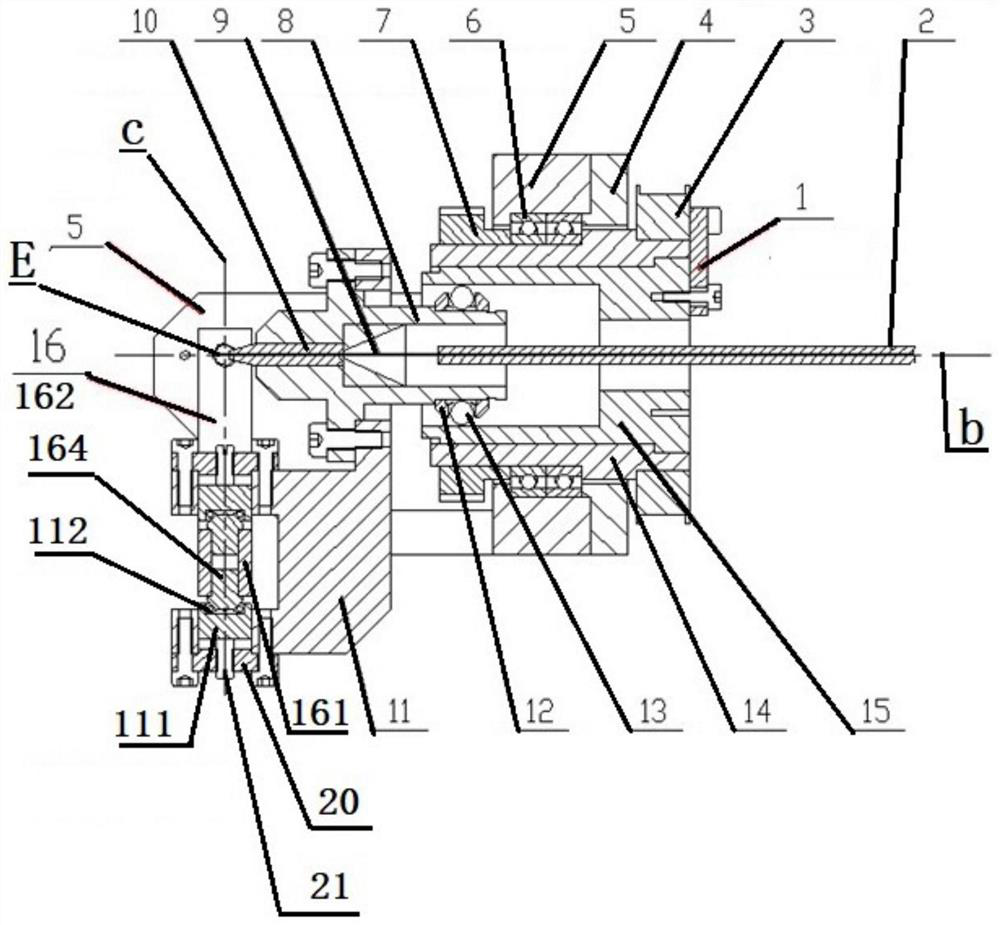

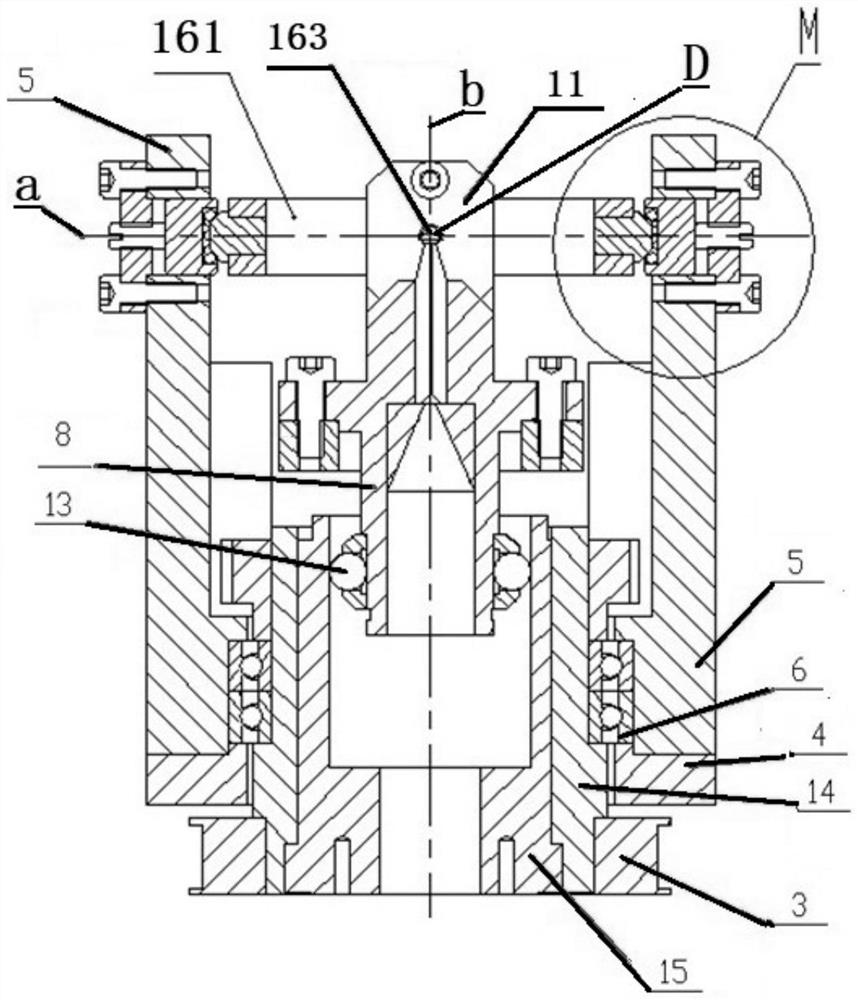

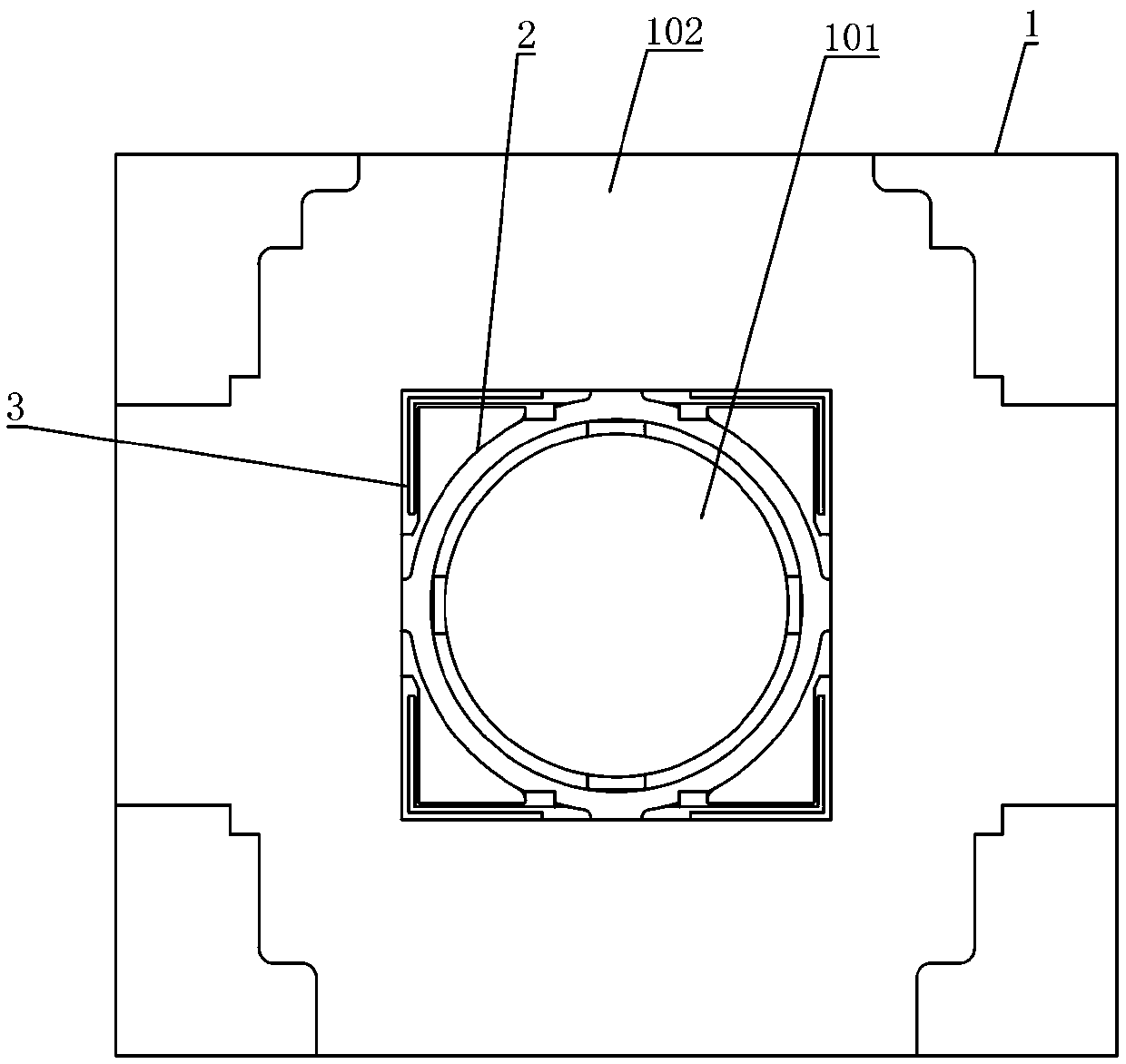

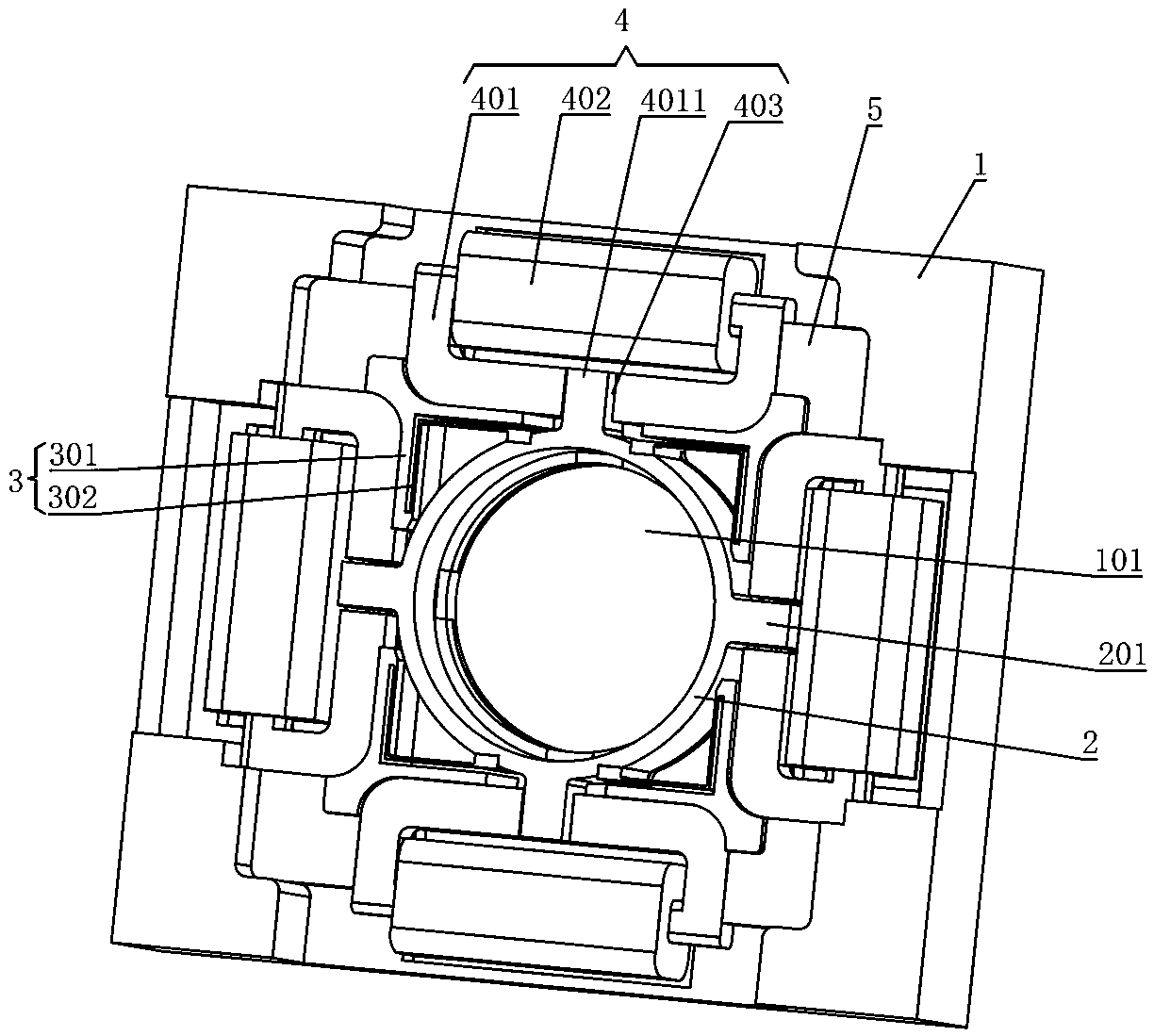

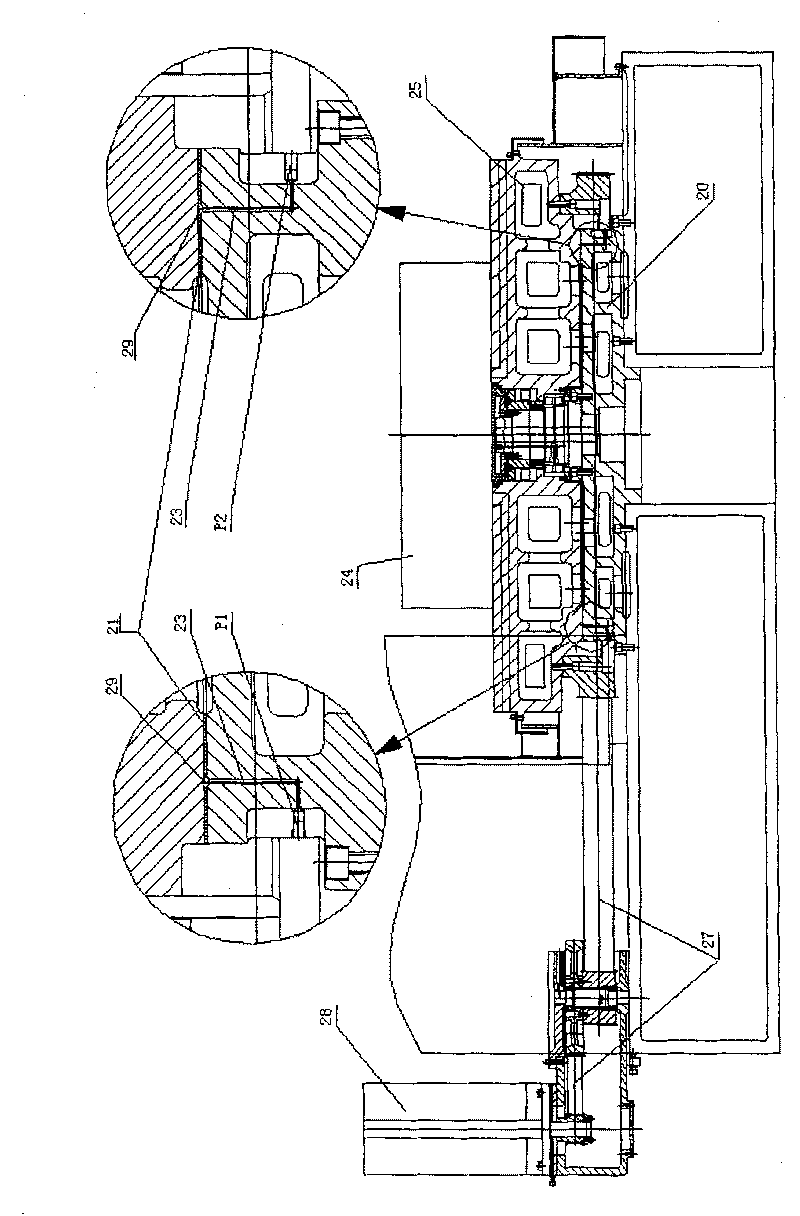

Integral structure of a turn-milling complex machining center

ActiveCN101513720AGuaranteed stabilityWeight optimizationMetal working apparatusMilling cutterHeavy load

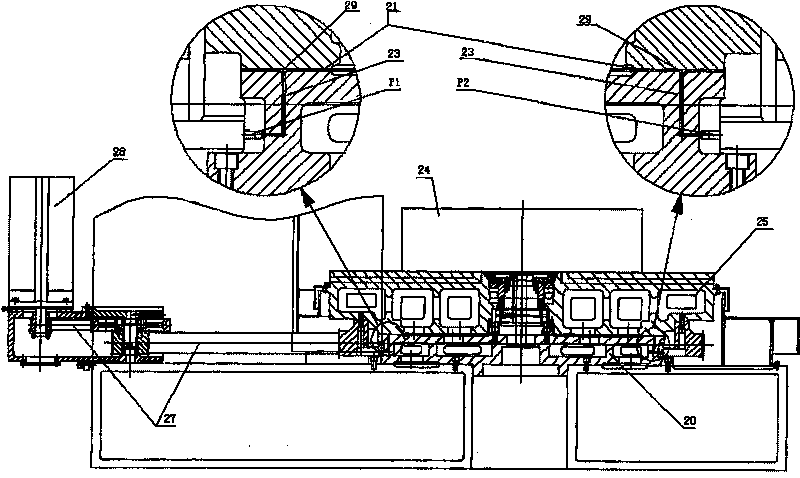

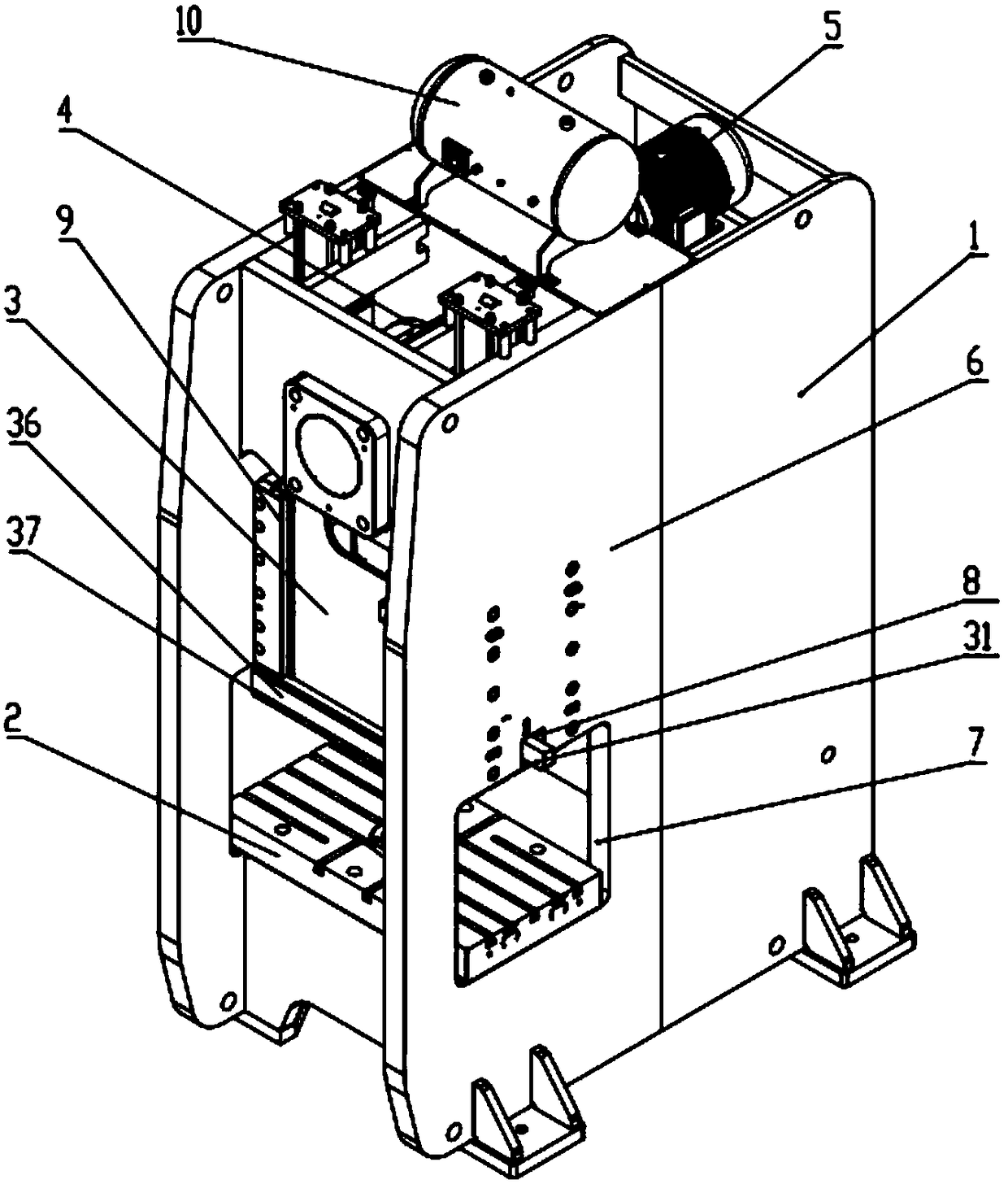

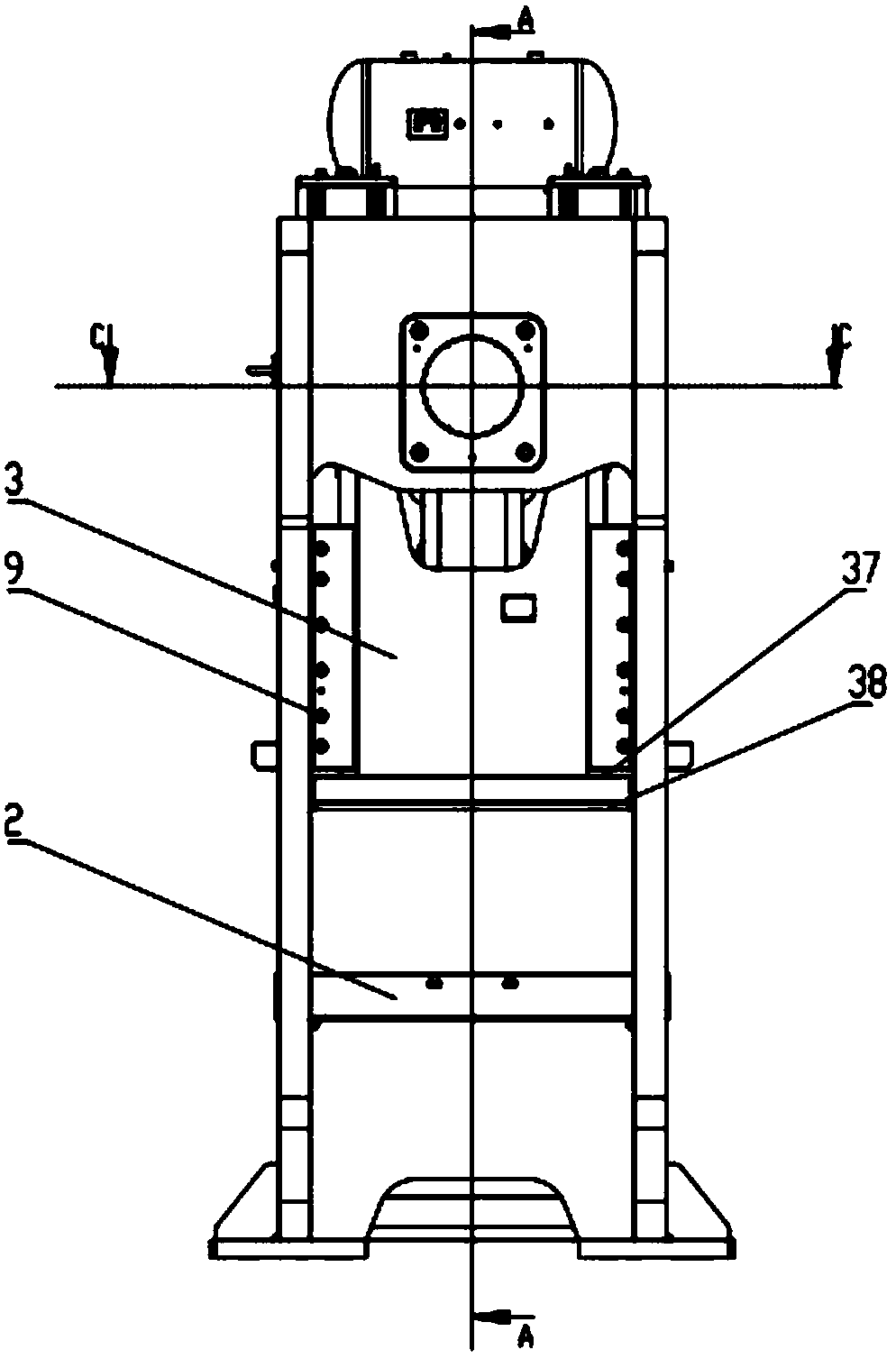

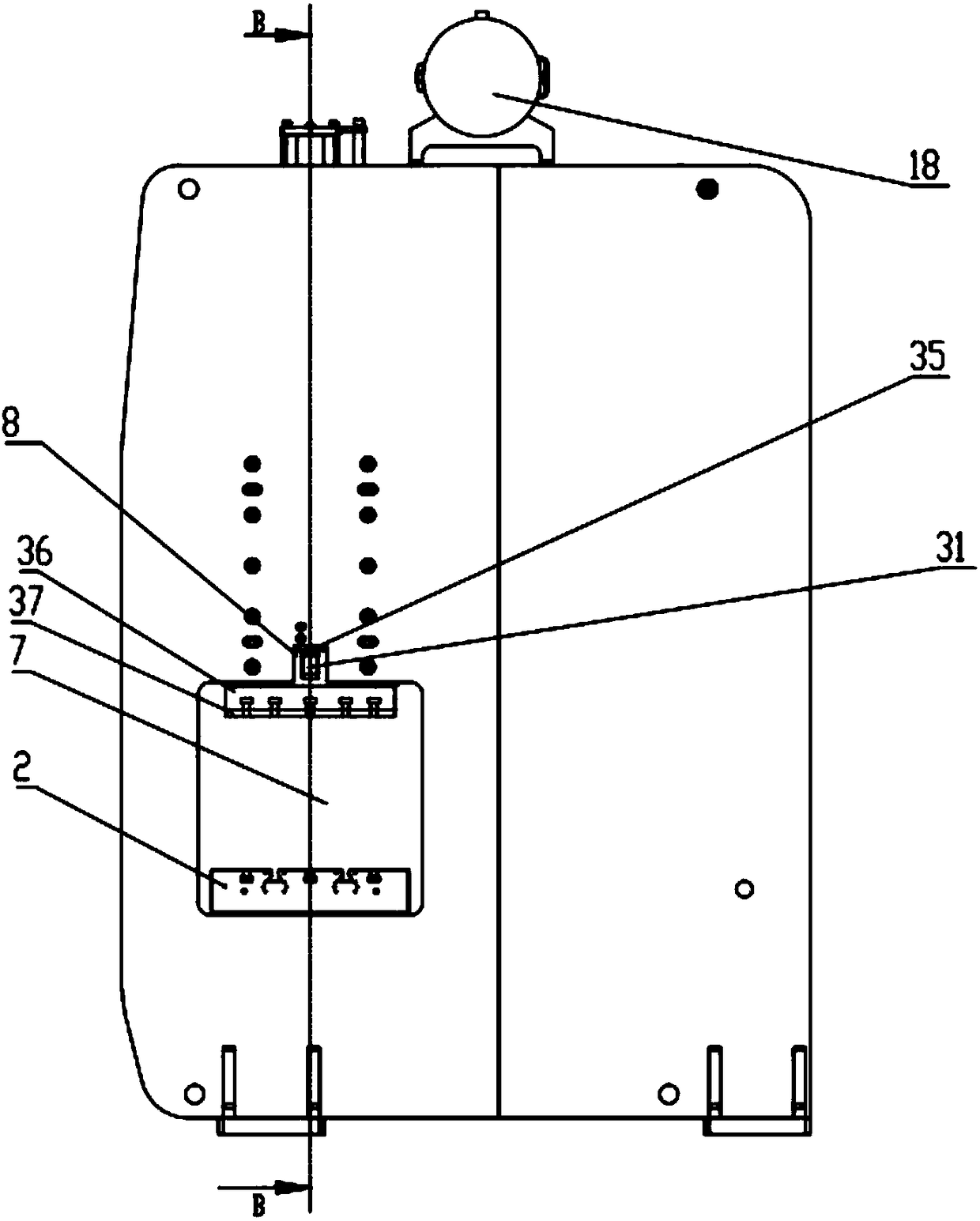

An integral structure of a turn-milling complex machining center is disclosed, characterized by a single post and feeding boxes hung at two sides. The left-suspending feeding box is provided with a B-axis cutter holder device with cutters at three locations. The B-axis cutter holder device is used for the working procedures for crank machining like turning, milling, boring, deep-hole drilling, threading and the like. The right-suspending feeding box can be provided with a large-scale milling cutter disc for external milling machining of the crank shaft. Two spindle boxes have two Cf-axis structures, the two spindle boxes are movable along a Z-axis on the machine body, and the tip of the right spindle box is stretchable. The machine is fitted with a plurality of hydraulic self-centering center rests that have high precision retentivity. A guide rail on the machine body forms an angle of inclination of 30 degrees with a horizontal plane, and the plane of the machine body is completely ground to ensure the absence of scraps and dead corners. The entire machine is fully protected. An inner cavity of the guide rail for the operation of the single post of the machine body is supported by double ribs, and two sets of corners remain stressed all the time in the process of the operation of the post. A front support bearing of the spindle employs an imported large-diameter double-column cylindrical roller bearing. The invention solves three problems and the machining for parts of a main journal and a connecting journal of the crank prior to grinding can be completed by one-time mounting on a machine, thus realizing high-precision and high efficient machining for the crank shaft of a medium speed machine for ships; in addition, the invention bears heavy load and is fully-protected.

Owner:通用技术集团沈阳机床有限责任公司

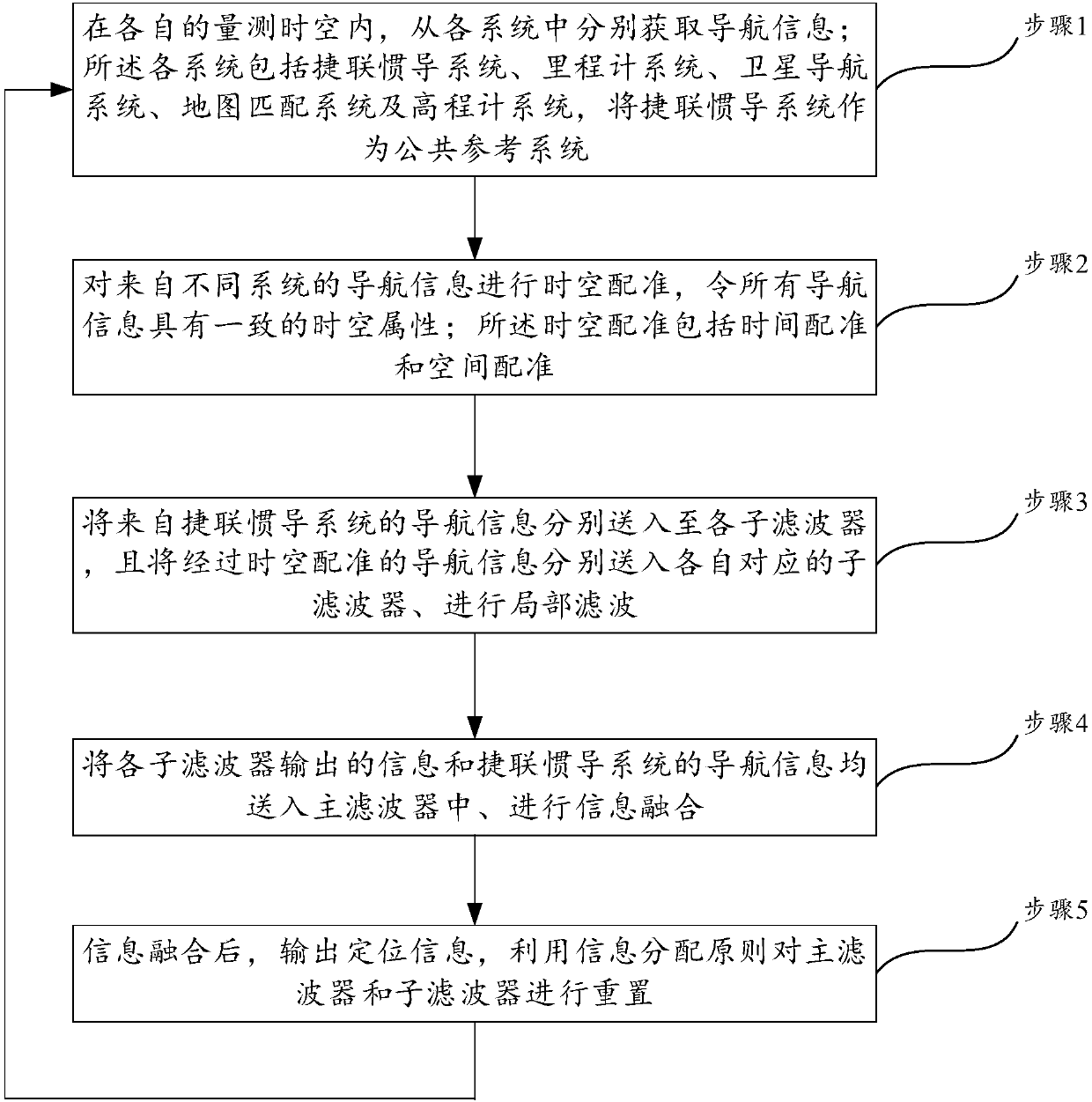

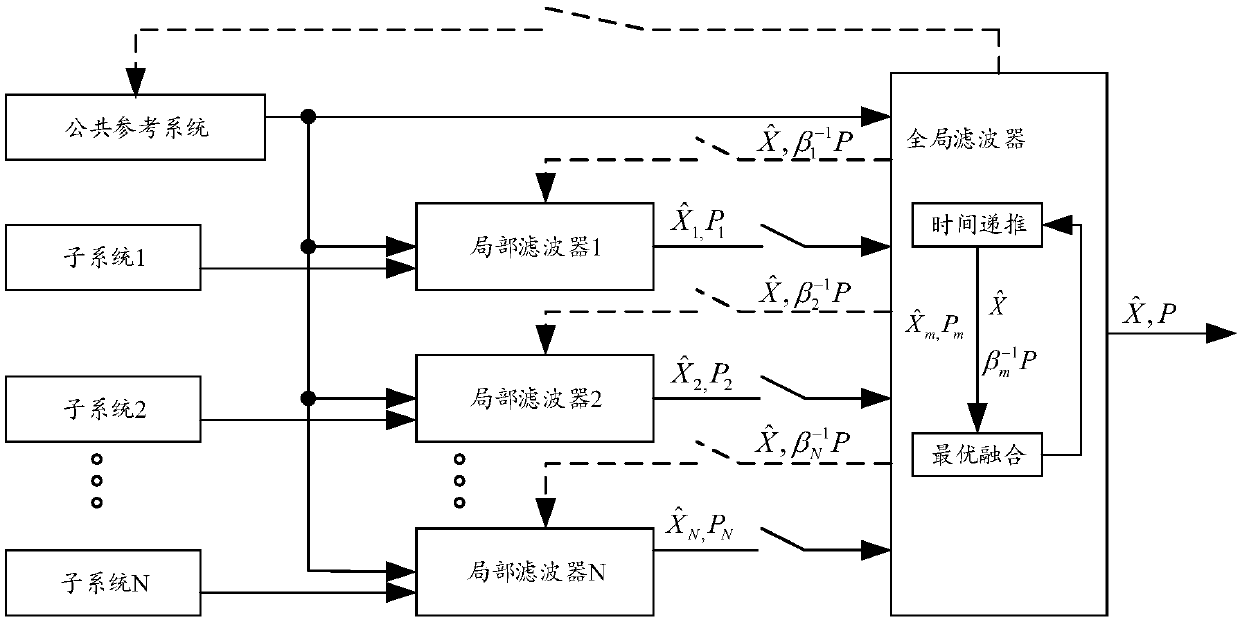

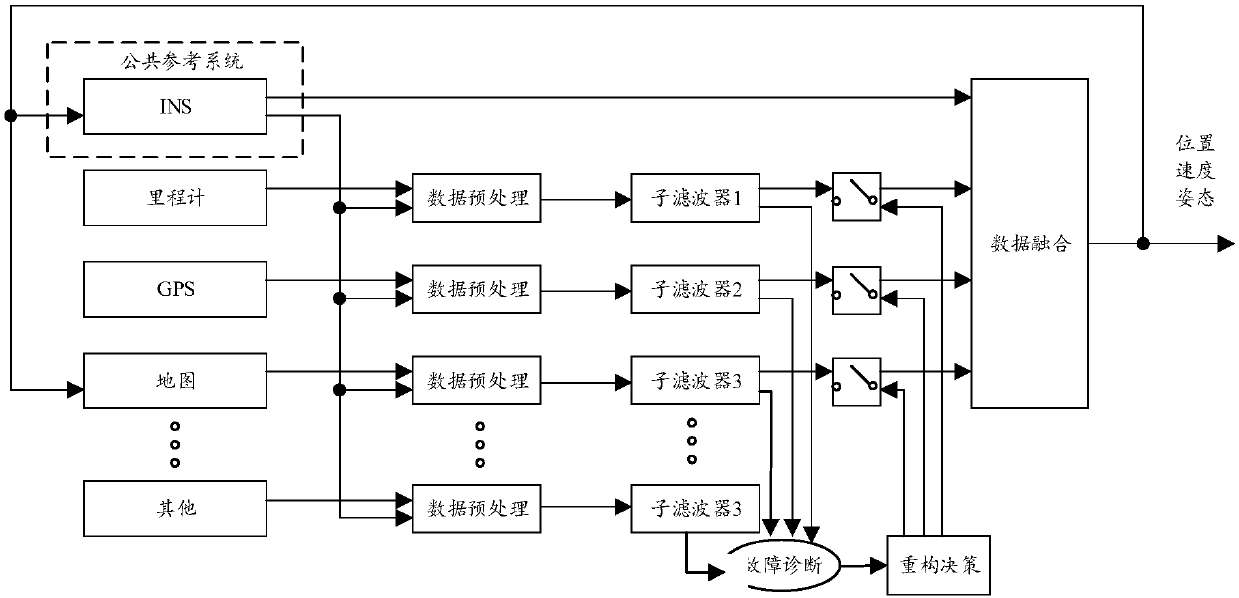

Vehicle-mounted positioning method based on multi-source information fusion

ActiveCN107656301ATo achieve the purpose of learning from each otherHigh precisionNavigation by speed/acceleration measurementsSatellite radio beaconingLand basedMarine navigation

The invention discloses a vehicle-mounted positioning method based on multi-source information fusion, and the method comprises the following steps: 1, respectively obtaining the navigation information from each system; 2, carrying out the time-space registration of the navigation information from different systems; 3, carrying out the local filtering; 4, carrying out the information fusion; 5, outputting positioning information after information fusion, carrying out the reconfiguration of a main filter and a subfilter through an information distribution principle, and then returning to step 1. The invention innovatively provides the vehicle-mounted positioning method based on multi-source information fusion, and the method achieves the fusion of the position information provided by different positioning systems, improves the system redundancy, enables the positioning systems to complement each other's advantages, improves the dynamic adaptability of the systems, enables the total system to obtain the precision which is better than the precision of the local systems, improves the vehicle-mounted positioning capability, and enables a land-based weapon launching system to have the long-time and large-range maneuvering capability.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

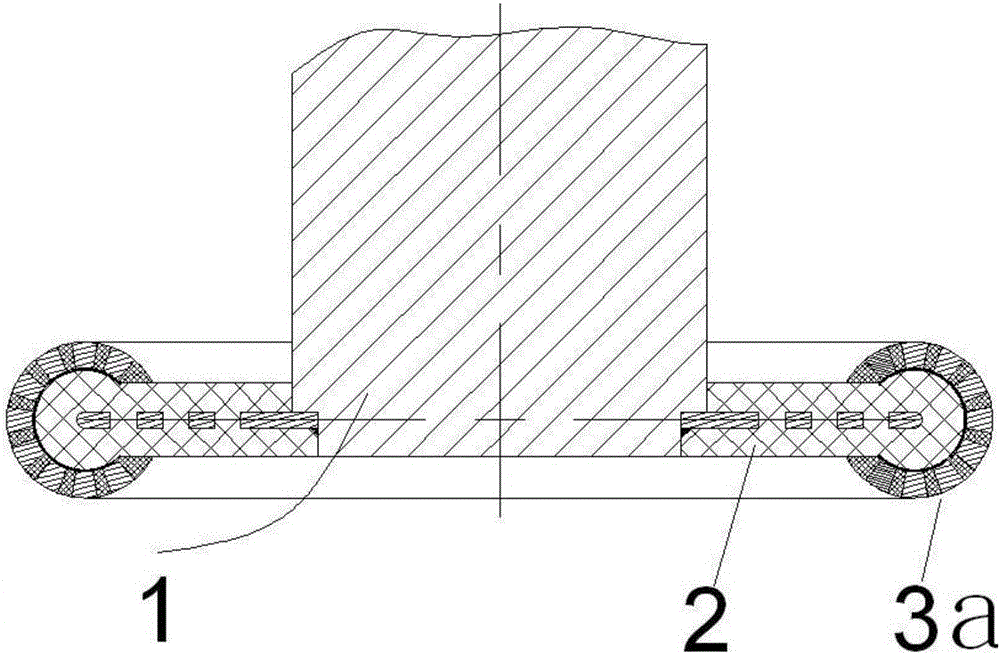

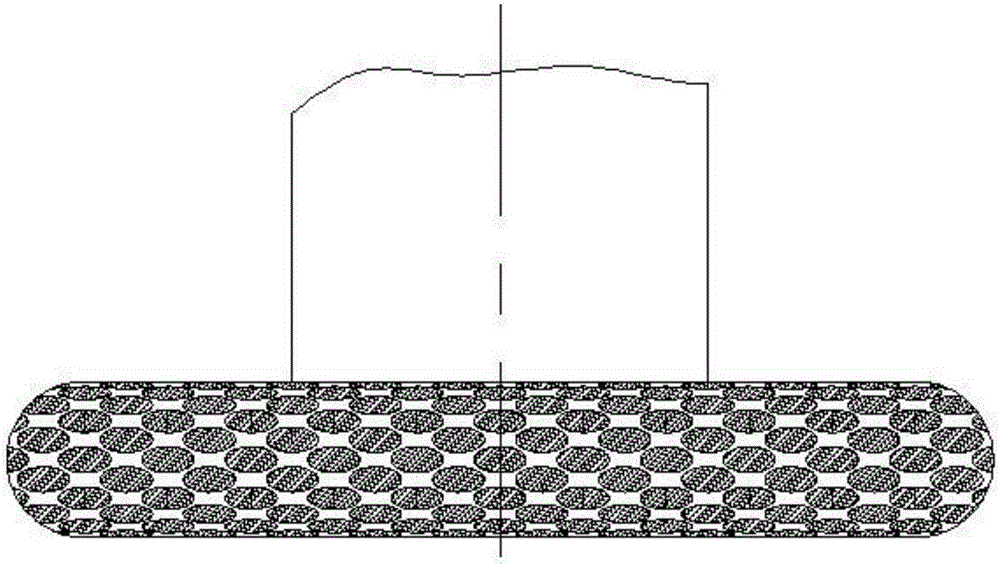

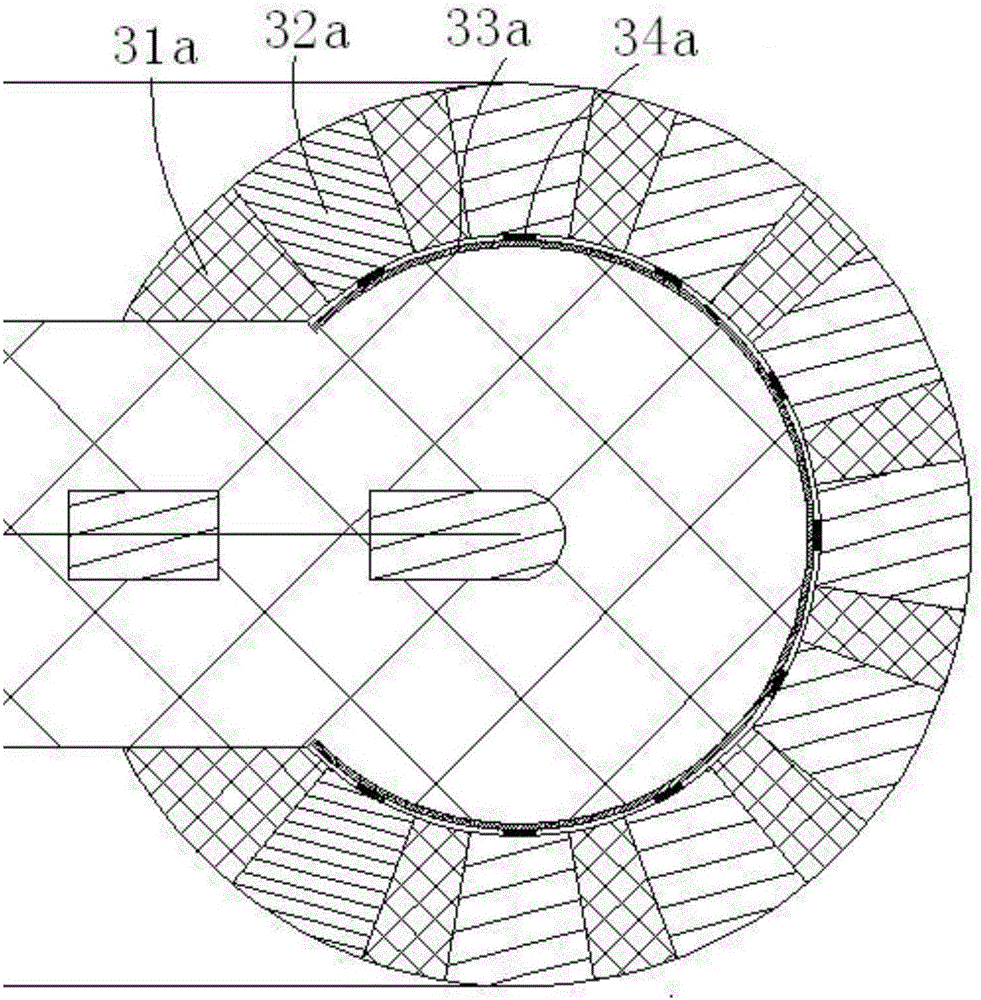

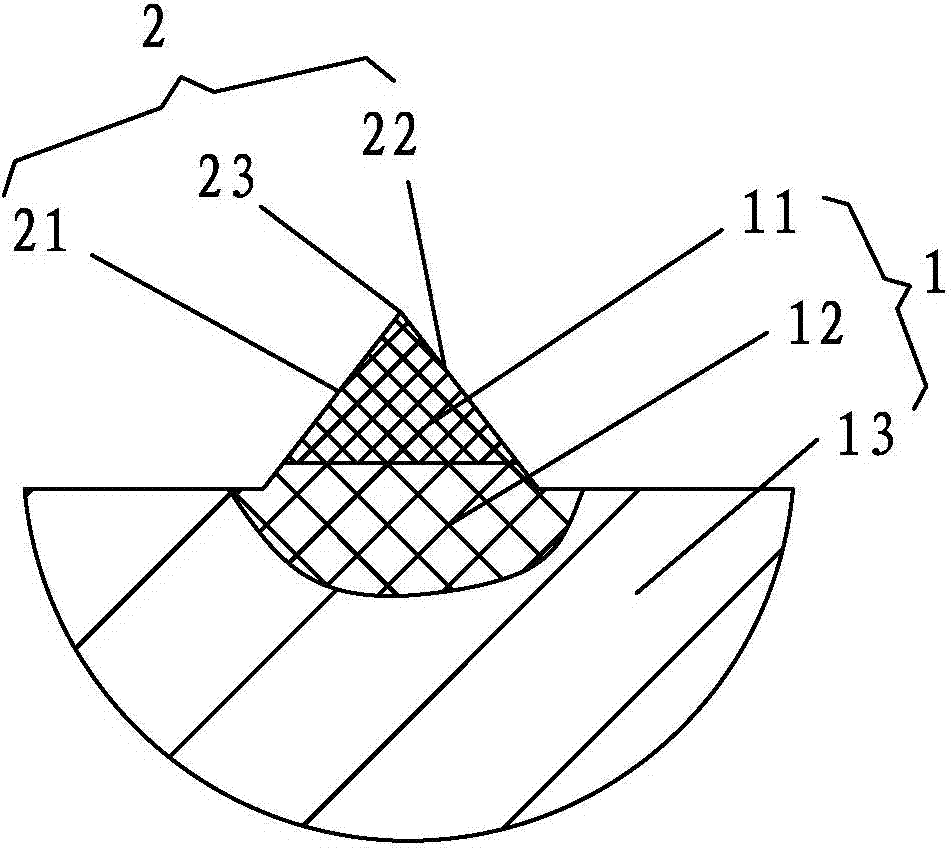

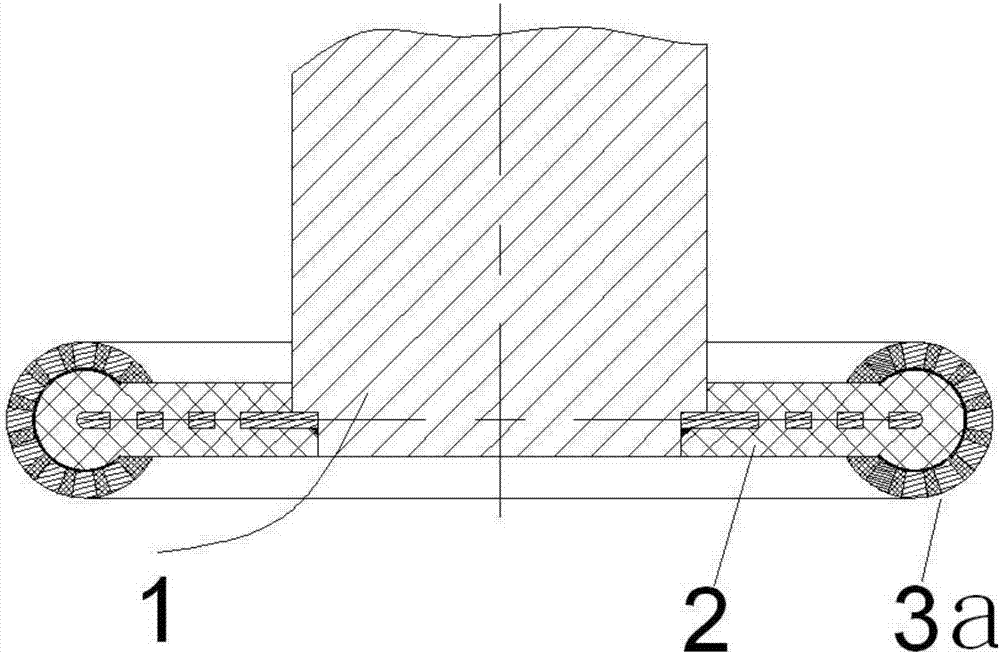

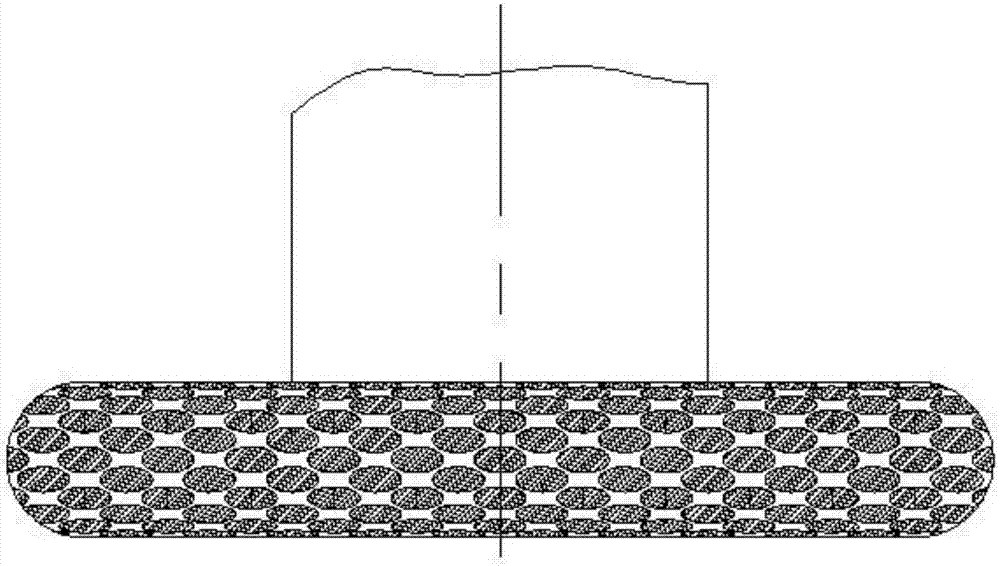

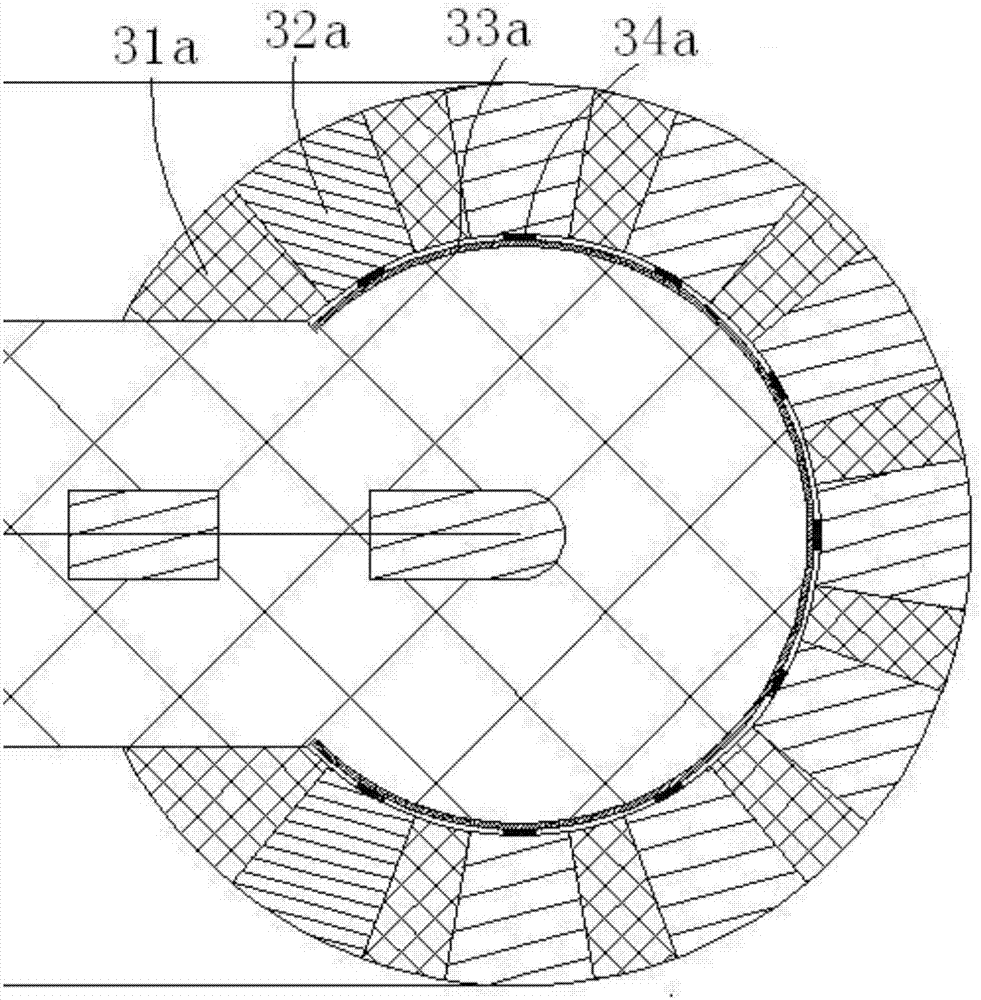

Complex generatrix polishing wheel with local reinforcement structure and manufacturing method thereof

ActiveCN105818008AImprove accuracy retentionImprove automationFlexible-parts wheelsGrinding devicesHardnessEngineering

The invention provides a complex generatrix polishing wheel with a local reinforcement structure. The complex generatrix polishing wheel comprises three different structures including a direct electroplating polishing wheel body, an electroplating abrasive cloth forming polishing wheel structure and an abrasive material block polishing wheel body. By adding the necessary reinforcement structure or enhancement materials into abrasive materials and elastic base bodies, the bonding force of the abrasive materials is enhanced, and the local supporting strength of the abrasive materials is controlled. A method specifically comprises the step that diamonds and other superhard abrasive materials are solidified to the surfaces of the base bodies of the metallic or non-metallic reinforcement structure through the electroplating or sintering methods, and the diameter of the base bodies is about 1 mm or smaller. The reinforcement structure has the hardness obviously higher than that of a polishing wheel base body and the geometric dimension far larger than that of the abrasive materials. The small abrasive material blocks are solidified to rubber of the polishing wheel bodies or other types of soft base bodies through the bonding or other proper methods, so that the polishing wheel with the reinforcement structure is formed, the abrasive materials of the polishing wheel protrude easily, and the polishing wheel has a sufficient grinding effect. The problems that conventional polishing wheel abrasive materials are small in size and bonding force, capable of easily sinking into the base bodies, prone to falling off, low in grinding capacity and the like are solved.

Owner:BEIHANG UNIV

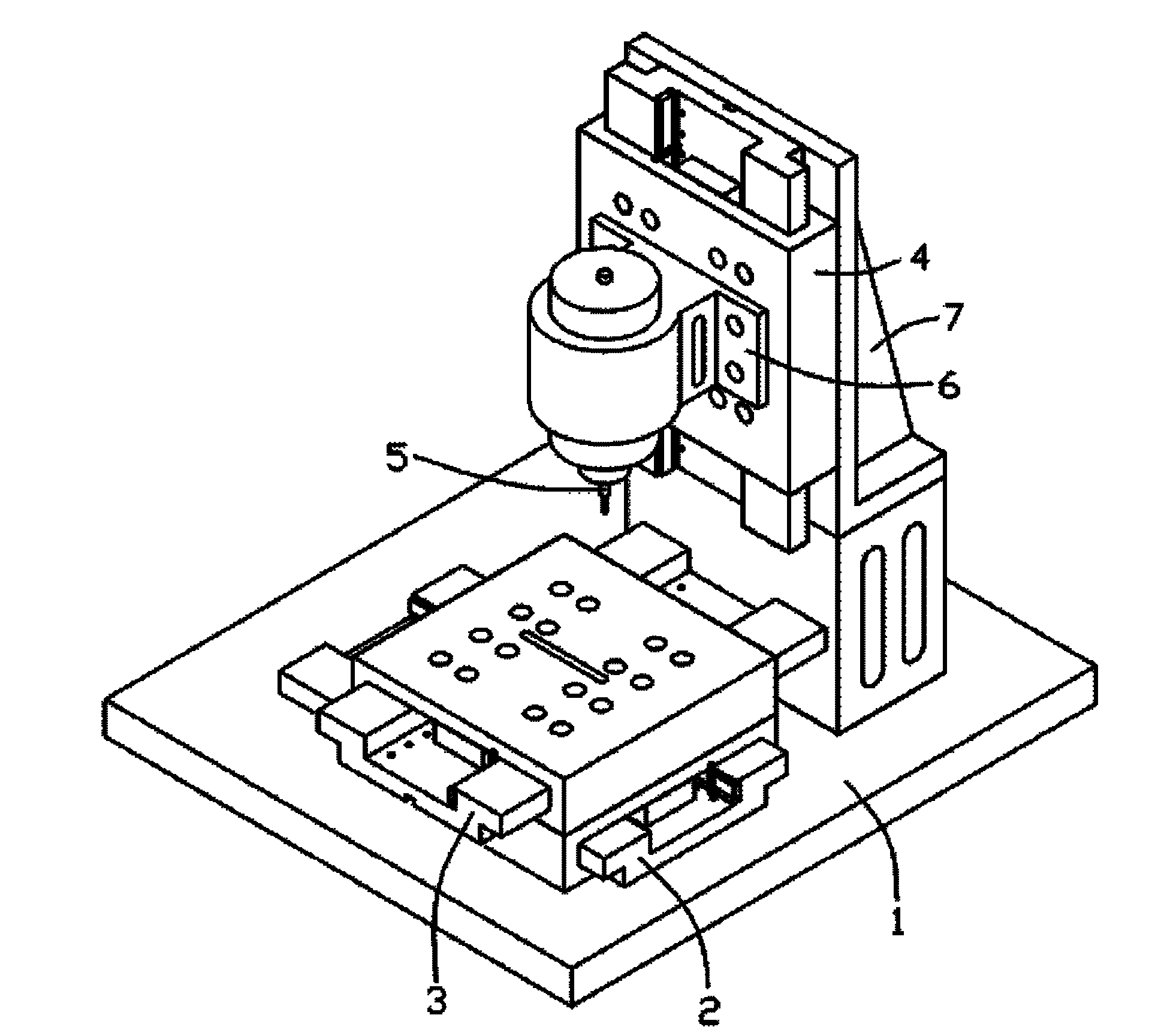

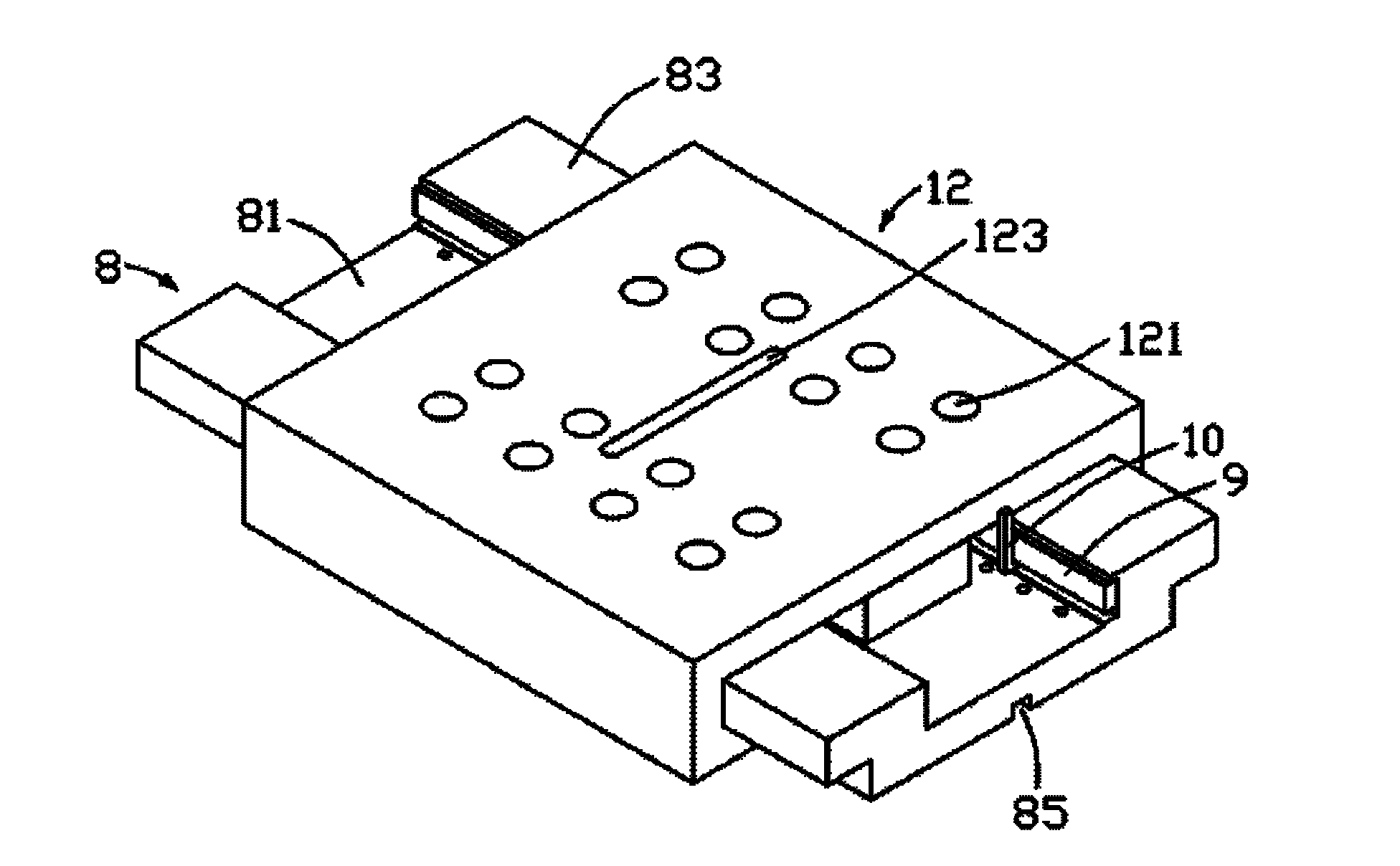

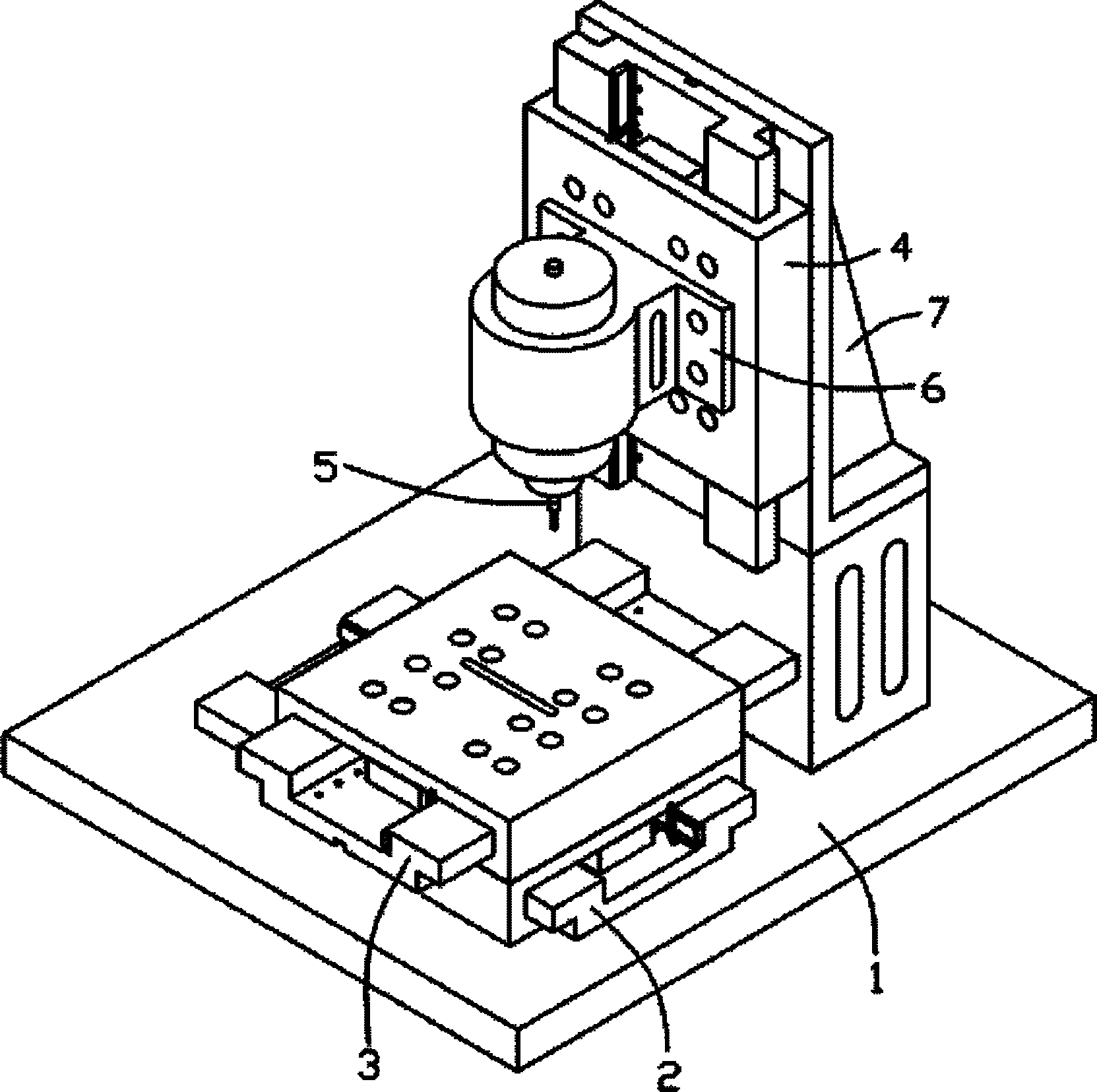

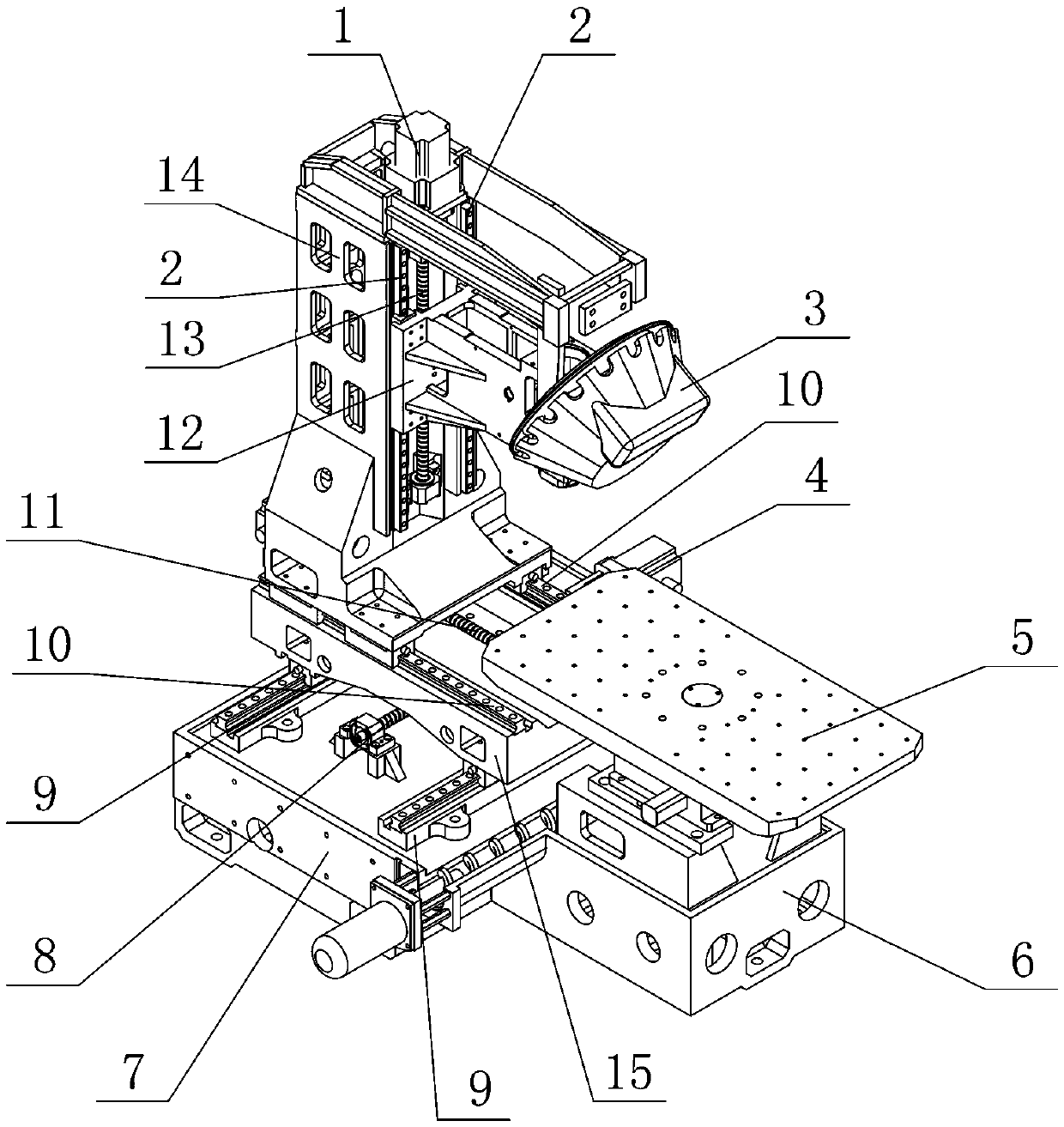

Tabletop milling machine, gantry tabletop milling machine and combined motion platform

ActiveCN102145456AReduce frictional resistanceReduce volumeLarge fixed membersEngineeringLinear motor

The invention discloses a tabletop milling machine, a gantry tabletop milling machine and a combined motion platform. The tabletop milling machine comprises an X-axis motion platform, a Y-axis motion platform and a Z-axis motion platform, wherein both the X-axis motion platform and the Y-axis motion platform respectively comprise a sliding platform and a sliding base; the sliding base of the Y-axis motion platform is fixed above the sliding platform of the X-axis motion platform; each sliding base comprises air floatation guide rails formed at both sides of the sliding base and a first grooveformed at the middle part of the sliding base; both the X-axis motion platform and the Y-axis motion platform respectively comprise a linear motor; each linear motor comprises a stator and a rotor; each stator is fixed at the bottom of the corresponding first groove; and each rotor is fixed on the bottom surface of the corresponding sliding platform and is arranged relative to the corresponding stator. By the mode, the feeding motion in the X-axis, Y-axis and Z-axis directions can be realized and the utilization rate of the space is improved.

Owner:BEIJING A&E TECH

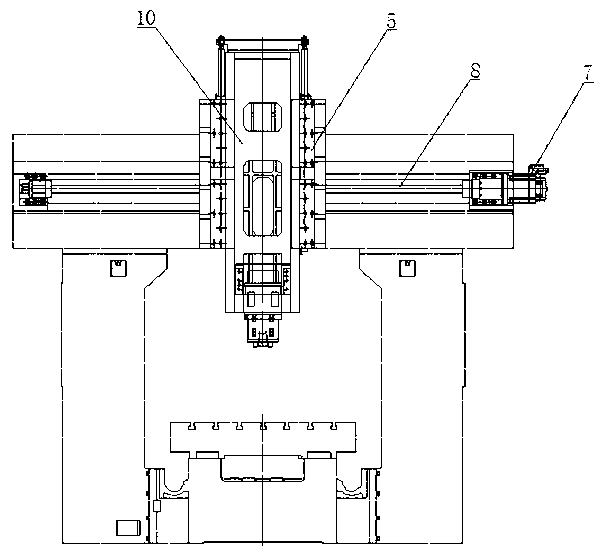

Numerical control gantry milling machine of fixed beam

InactiveCN102699685AImprove machining efficiency and precisionReduce work intensityOther manufacturing equipments/toolsLarge fixed membersEngineeringBall screw

The invention relates to a numerical control gantry milling machine of a fixed beam, comprising a machine body, wherein a work table which can extend along the direction of the machine body is arranged on the machine body, vertical columns are respectively arranged at the two sides of the machine body, and the top ends of the vertical columns are connected with a cross beam. The innovation of the numerical control gantry milling machine is that the front side and the rear side of the cross beam are respectively provided with a milling sliding seat and a grinding sliding seat, and the milling sliding seat and the grinding sliding seat are provided with corresponding components and can be used for milling and grinding the workpieces on the work table after being installed and clamped for one time, so that the time for assembling, detaching and positioning the workpieces can be reduced, the process efficiency and the process precision can be improved, and the utilization rate of the equipment can be improved. The cross beam has a roller guide rail structure which is distributed in a stepped shape, so that the roller guide rail has enough flexural stiffness and torsional stiffness, and long enough precision retaining ability. The weights of a ram and a main gear box are balanced through a hydraulic balance oil box, so that the no-load twisting moment of a bead screw shaft can be reduced, the attrition of the bead screw shaft can be reduced, and the precision stability of the bead screw shaft can be kept.

Owner:南通京鼎机械科技有限公司

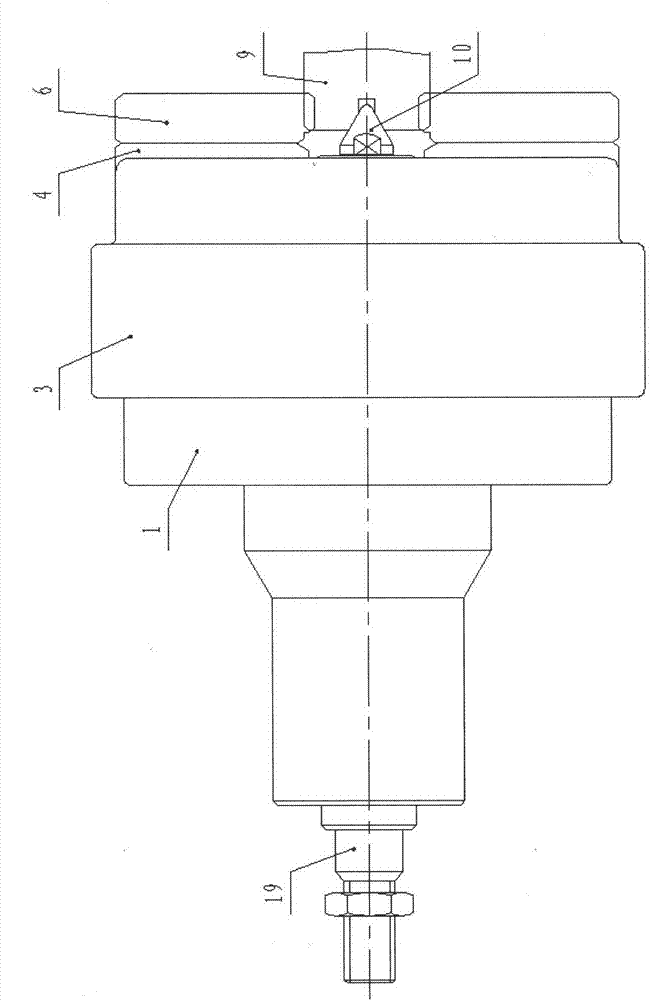

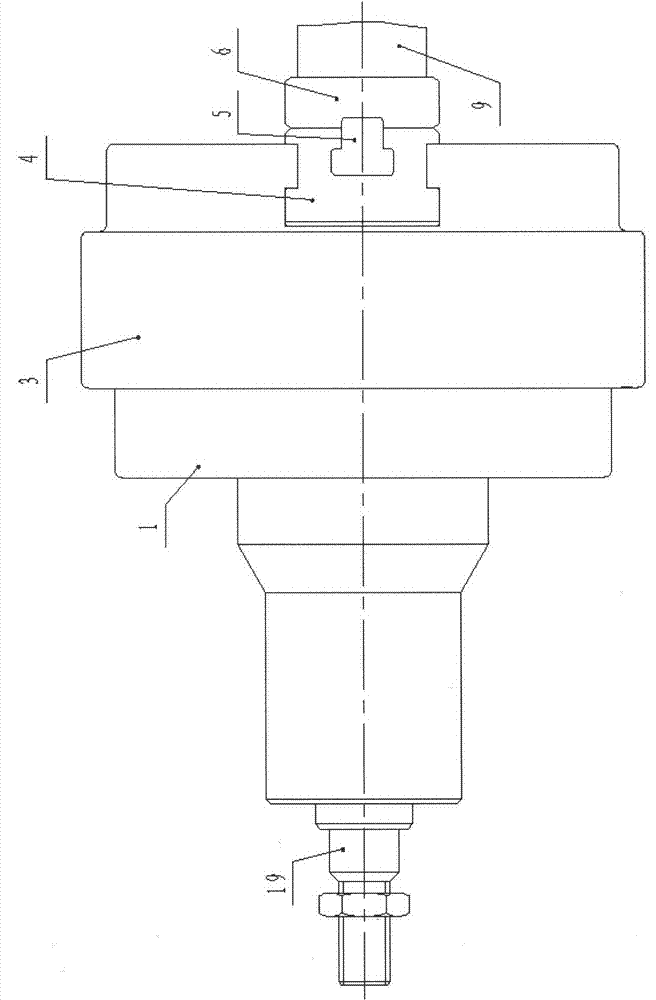

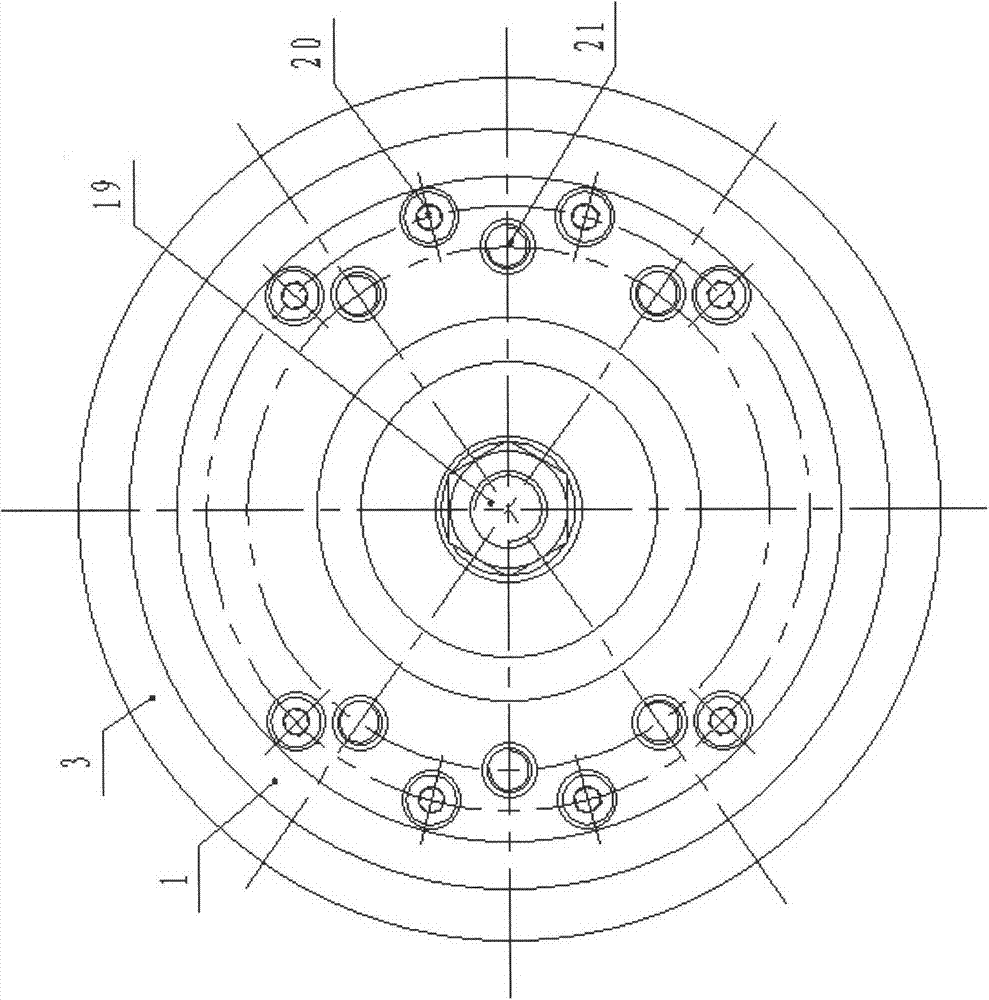

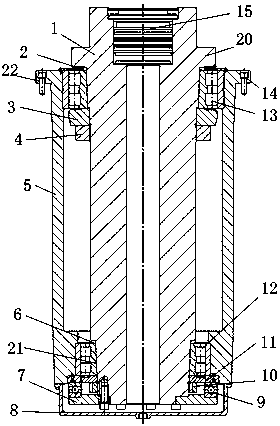

Retractable chuck

A retractable chuck is composed of a chuck base, a centre, a pull rod and a chuck head. The chuck base is fixedly installed on a main shaft of a machine tool, the centre is placed in the center of the front end of the chuck, and the tail portion of the pull rod extends out of the center of the chuck base to be connected with the power of a drive chuck. The chuck head is formed by two or more clamping jaws, a sliding chuck body and an assembly arranged on the sliding chuck body, and the chuck head is arranged on the chuck base and a chuck chip in a sleeved mode. When the pull rod is pushed by external force to move forwards, the chuck head extends forwards, and only when the chuck head moves forwards and reaches the limiting position, the clamping jaws begin to clamp a workpiece. Or otherwise, when the pull rod is pulled by the external force to move backwards, the clamping jaws loose the workpiece, and only when the clamping jaws reach the limiting position, the chuck head begins to retreat backwards.

Owner:山东济清科技服务有限公司

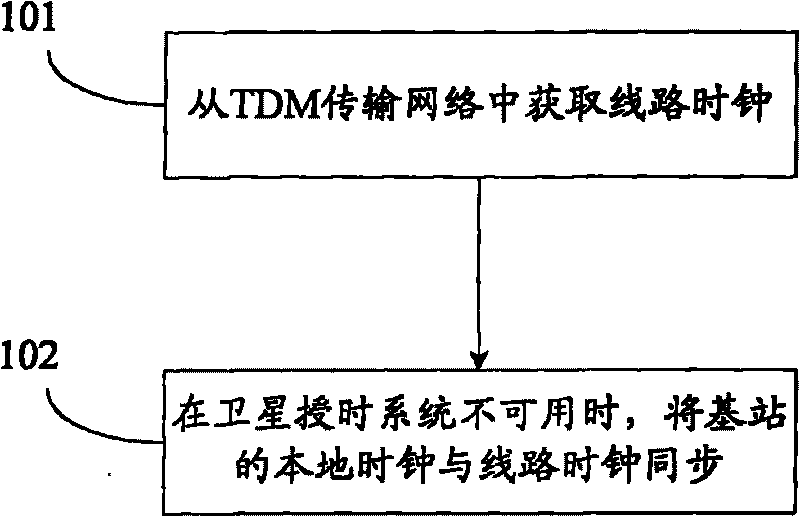

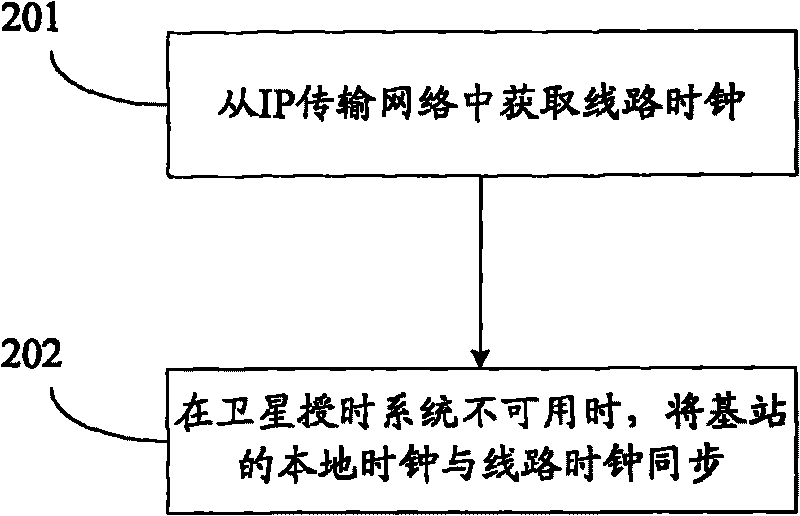

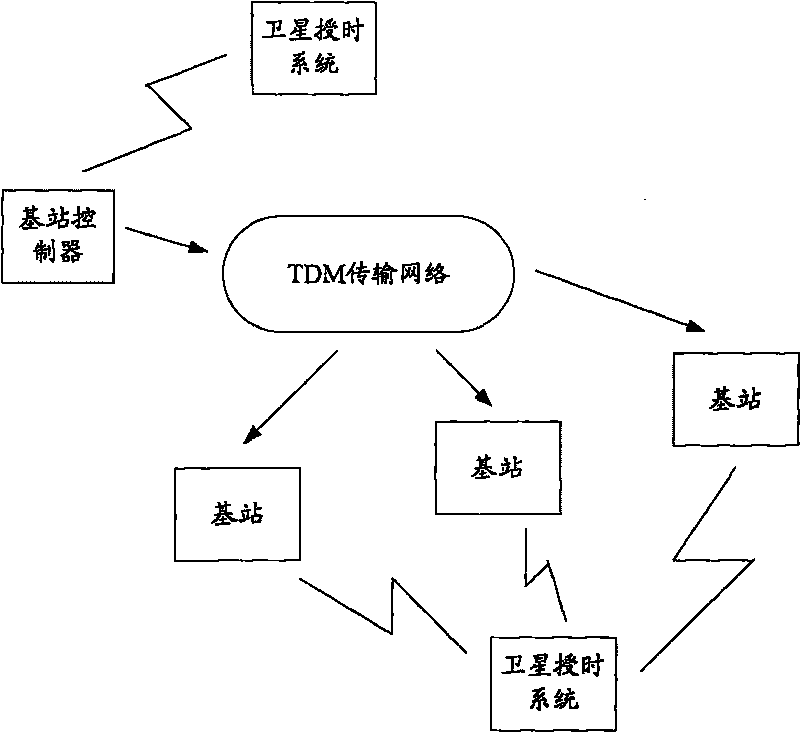

Clock synchronization method, clock synchronization device and clock synchronization system

ActiveCN101765198AImprove accuracyImproved accuracy retentionSynchronisation arrangementRadio transmission for post communicationTiming systemComputer science

The embodiment of the invention discloses a clock synchronization method, a clock synchronization device and a clock synchronization system. The method comprises the following steps: acquiring a line clock from a transmission network; and synchronizing a local clock of a base station and the line clock when a satellite timing system is unavailable. In the embodiment of the invention, under the condition of the unavailability of the satellite timing system, the line clock is acquired from the transmission network and then is synchronized with the local clock, which improves local clock accuracy keeping performance and improves the reliability of the system on the basis of not increasing cost.

Owner:HUAWEI TECH CO LTD

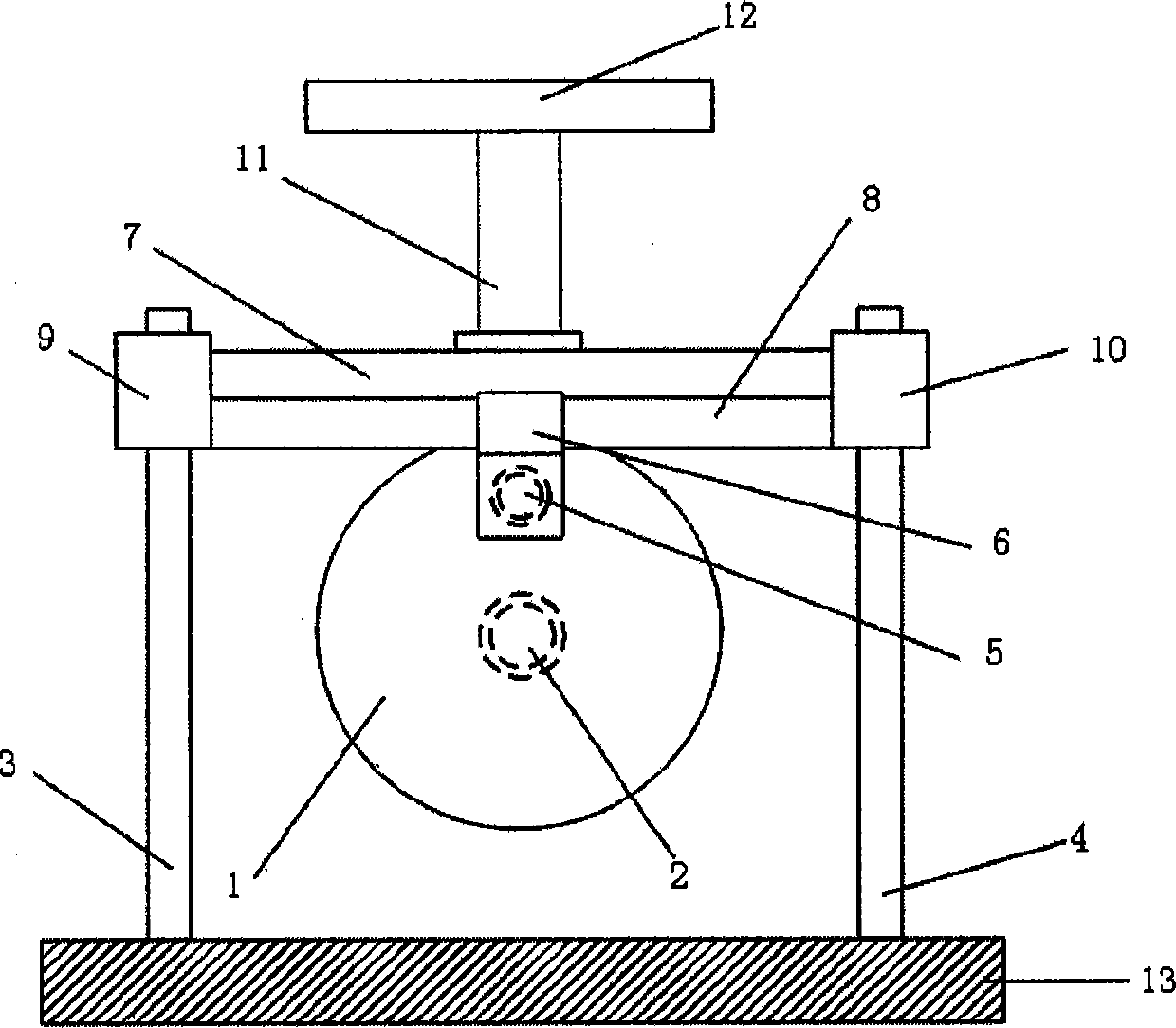

High-precision high-acceleration low-frequency sinusoidal vibration system

InactiveCN104180820AAvoid many problems with experimentationEasy to testMeasurement devicesVibration amplitudeHigh acceleration

The invention relates to a high-precision high-acceleration low-frequency sinusoidal vibration system which comprises a rotating motor, a crank disc, a crankshaft, a horizontal rolling guide rail, a vertical rolling linear bearing, an upright post, a worktable, a balance weight and a position sensor, wherein a left guide post and a right guide post are arranged on a base; a left linear bearing and a right linear bearing are respectively arranged on the left guide post and the right guide post and can move up and down on the guide posts; two ends of a transverse beam are respectively connected with the left linear bearing and the right linear bearing; the horizontal rolling guide rail is fixedly connected to the transverse beam; a horizontal guide rail slide block can move from left to right on the horizontal rolling guide rail; and the upright post and the worktable are arranged on the transverse beam. According to the mechanical system, high-precision and high-acceleration low-frequency sinusoidal vibration can be realized, the defects of a centrifuge test are overcome, the flexibility of research trial is improved, the problems that a low-frequency section of the conventional vibration table is low in vibration amplitude and vibration frequency precision, the testing requirements of a high-precision inertia type instrument cannot be met and the like are solved, and a high-order error item coefficient of the inertia type instrument is tested.

Owner:HARBIN INST OF TECH

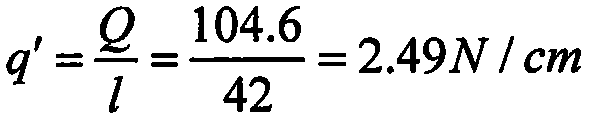

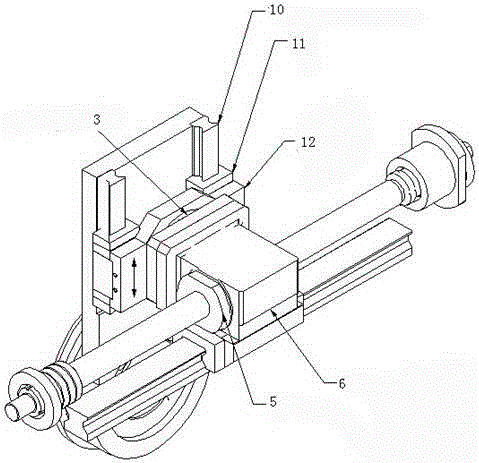

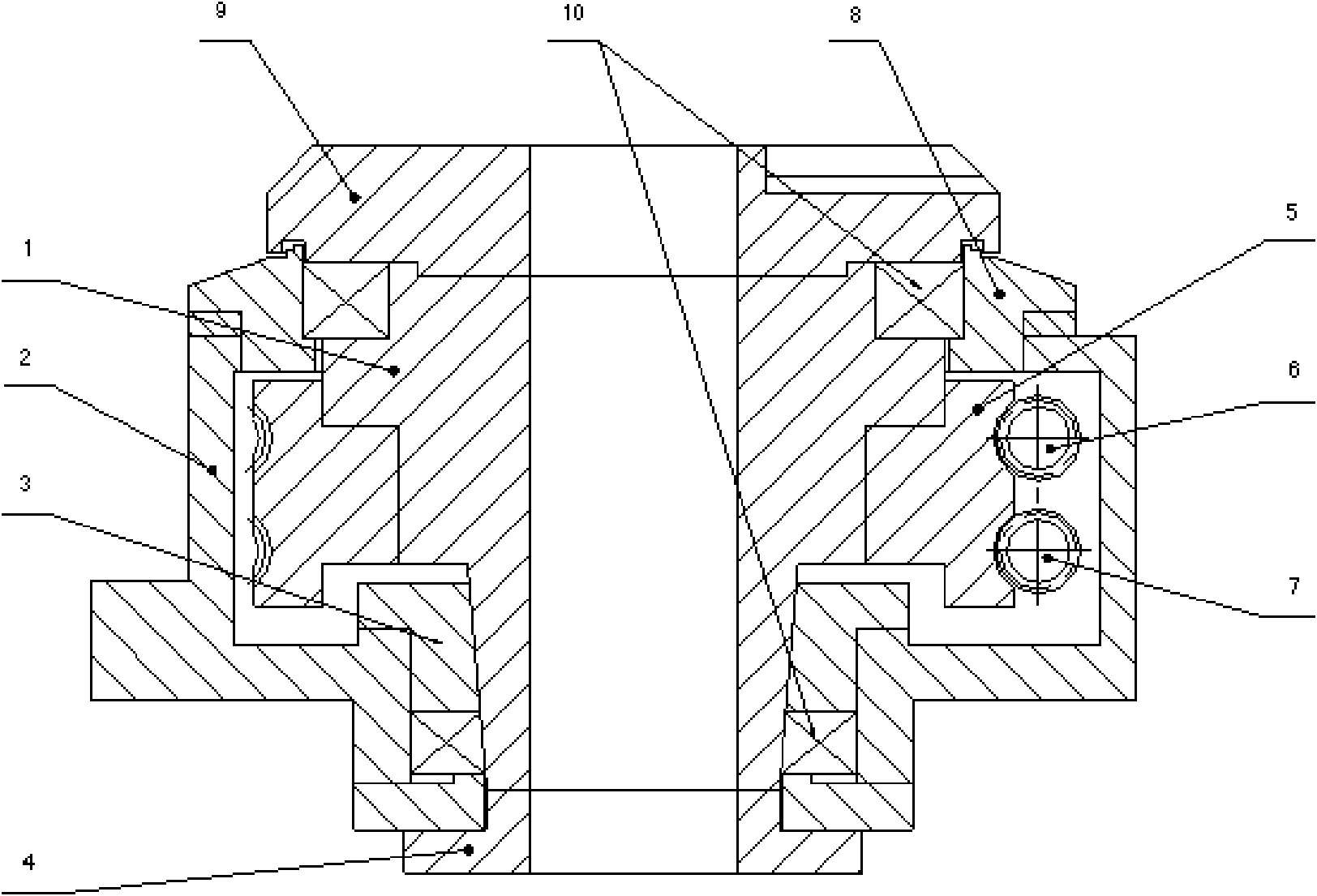

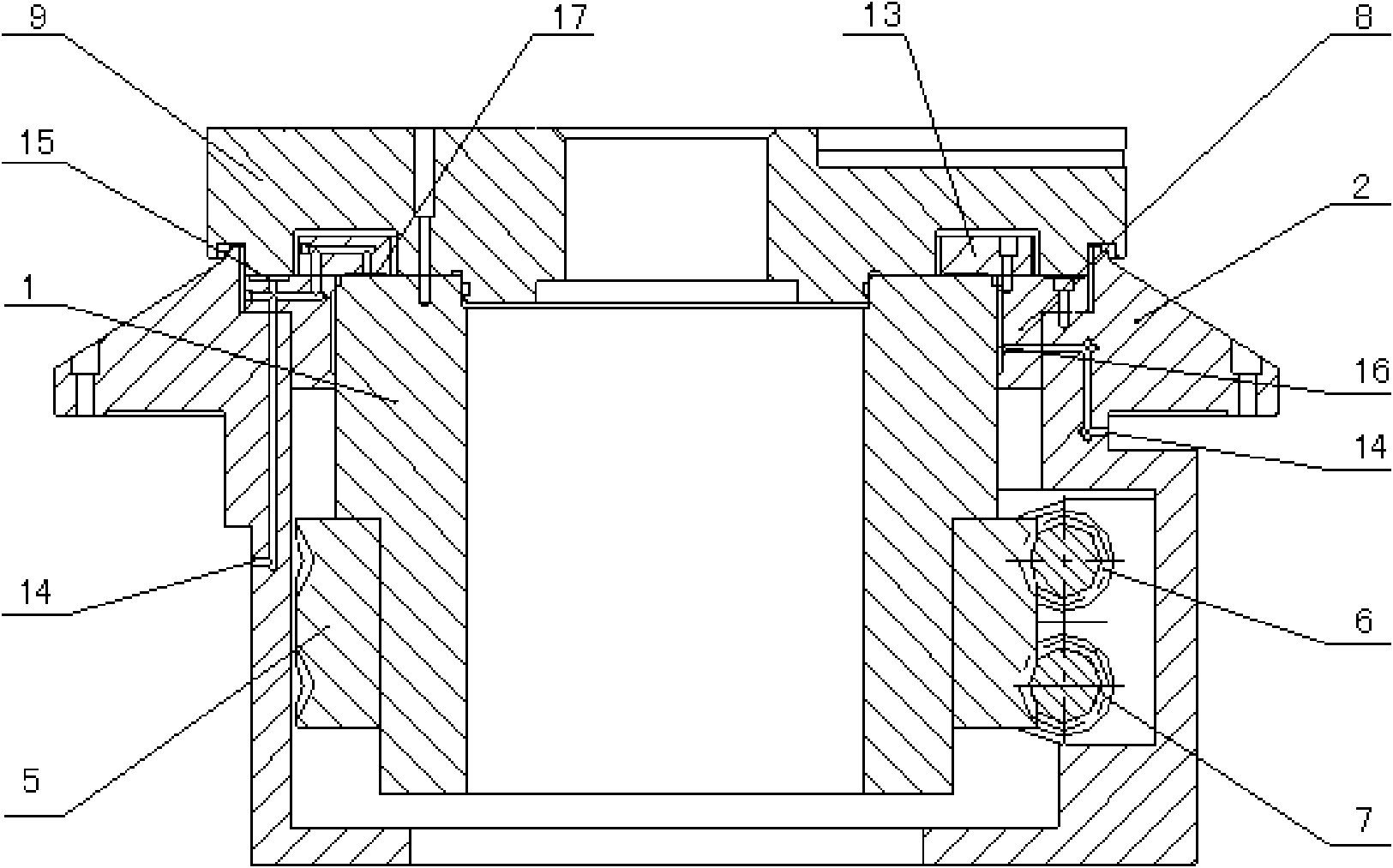

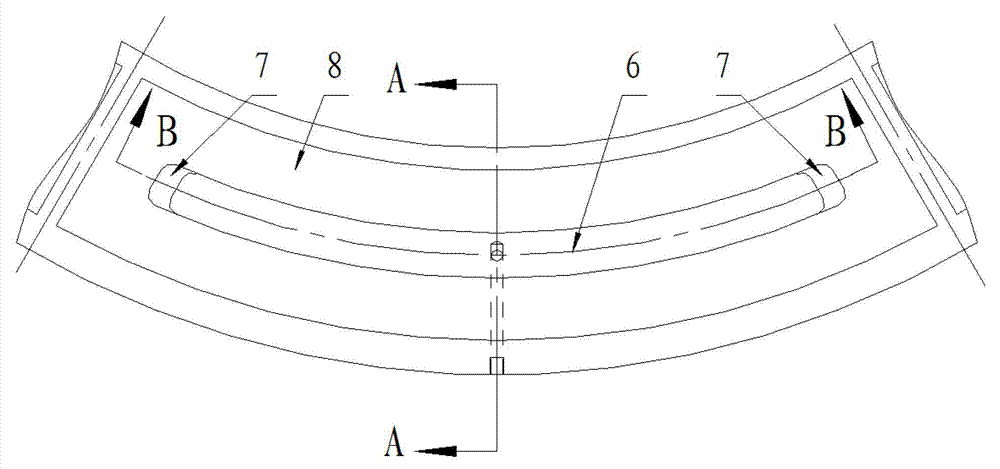

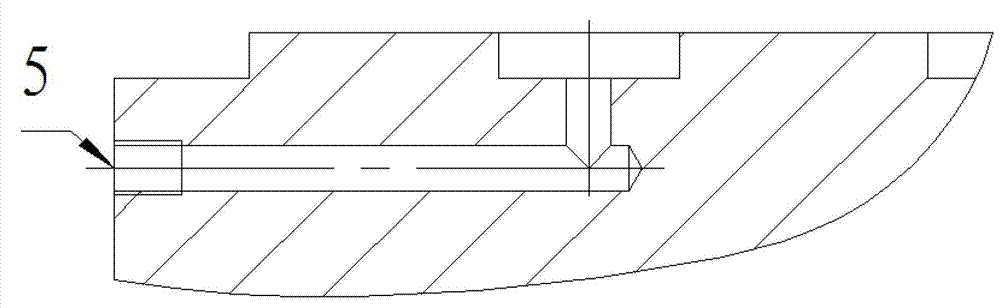

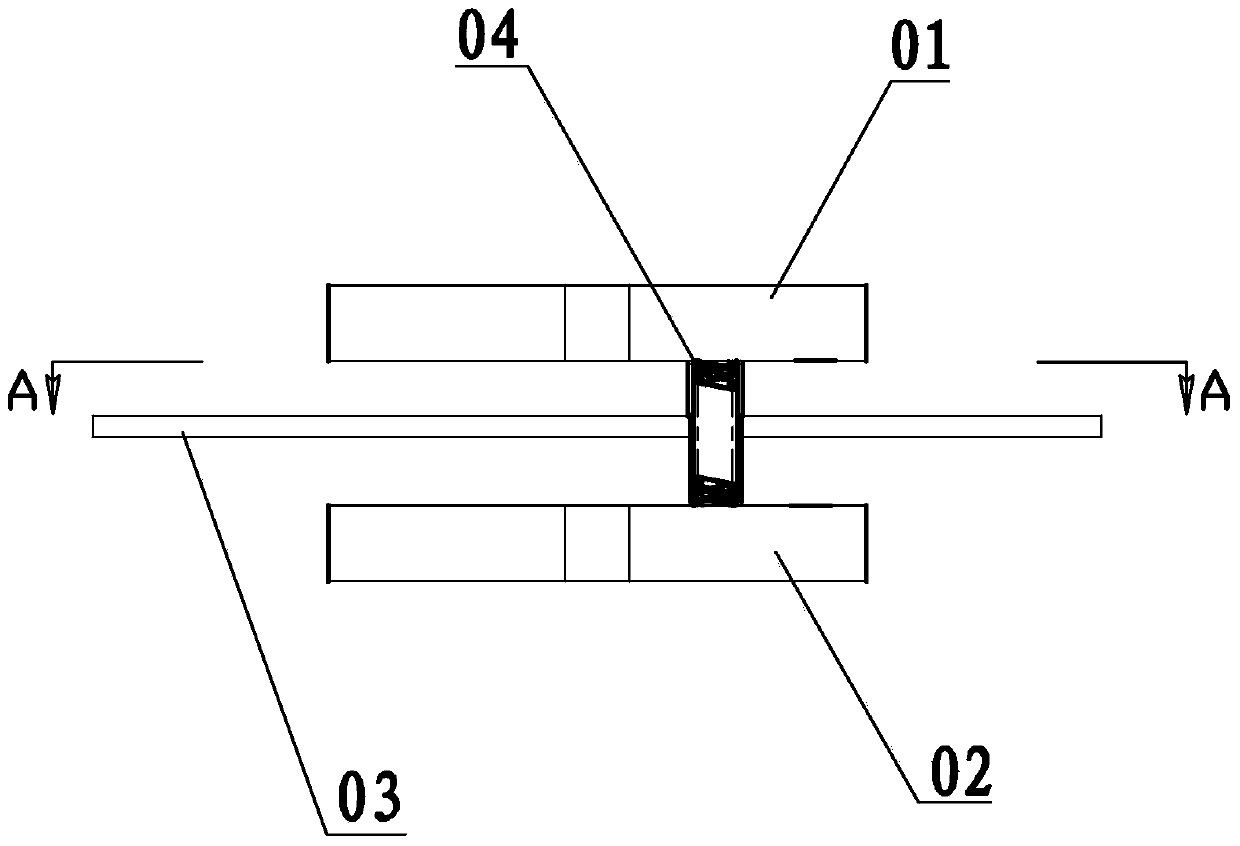

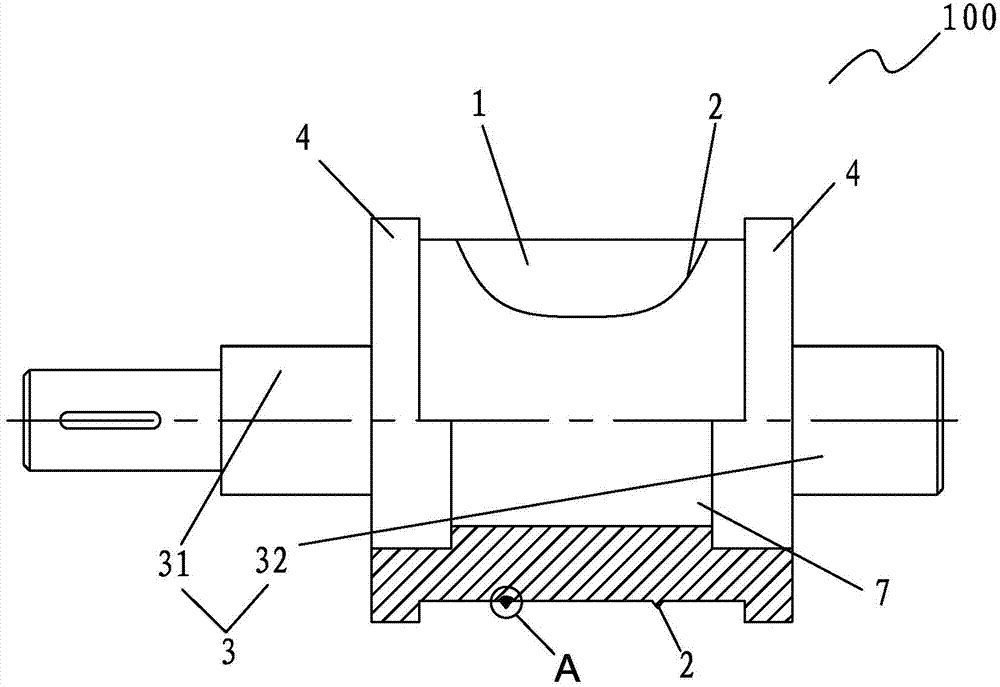

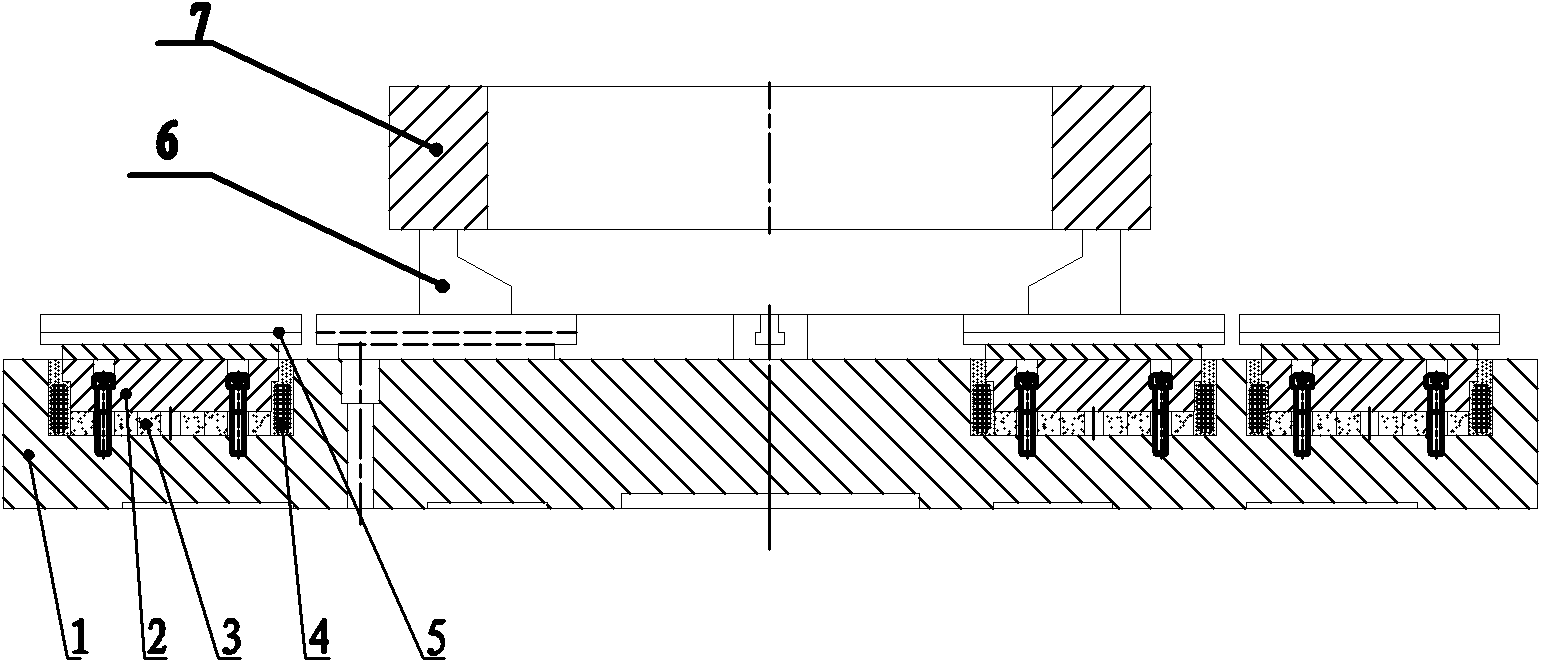

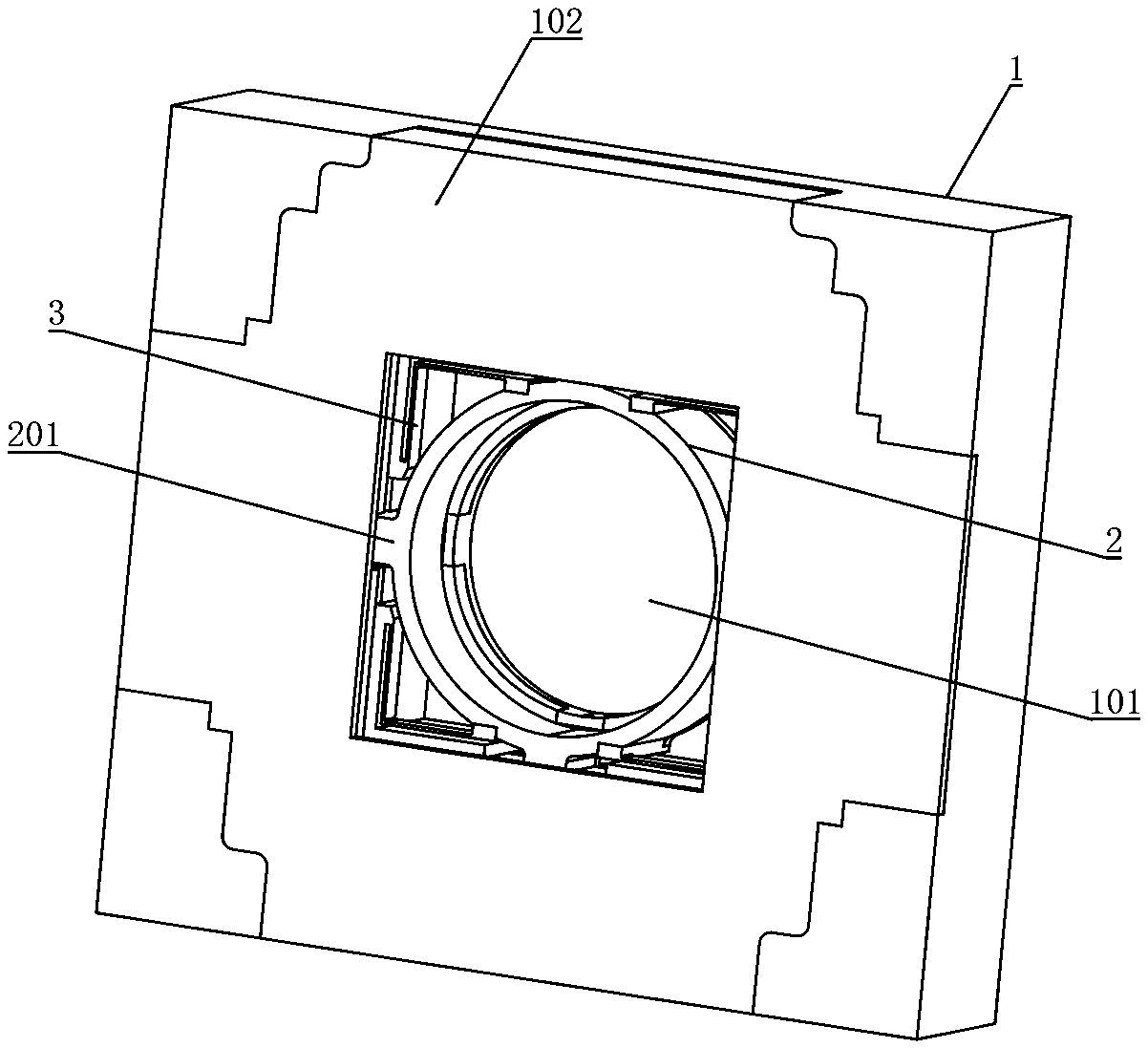

Zero-clearance arc swing mechanism based on machine tool and implementation method thereof

The invention discloses a zero-clearance arc swing mechanism based on a machine tool. The zero-clearance arc swing mechanism based on the machine tool mainly solves the problems that in the prior art, assembly transmission clearances exist, and transmission accuracy is low. The zero-clearance arc swing mechanism based on the machine tool comprises a transverse linear drive mechanism, a vertical linear guide mechanism, a first centripetal thrust combination bearing (2) and a second centripetal thrust combination bearing (3). The transverse linear drive mechanism is connected with the vertical linear guide mechanism through the second centripetal thrust combination bearing (3), the vertical linear guide mechanism is installed on a driven swing element (1), and the first centripetal thrust combination bearing (2) is used for being connected with the driven swing element and a rack. The zero-clearance arc swing mechanism based on the machine tool thoroughly eliminates clearances of a whole transmission chain, improves transmission accuracy and rigidity, can achieve lasting accuracy retaining capability and effectively overcomes defects of the prior art.

Owner:成都煜鼎特种加工技术有限公司

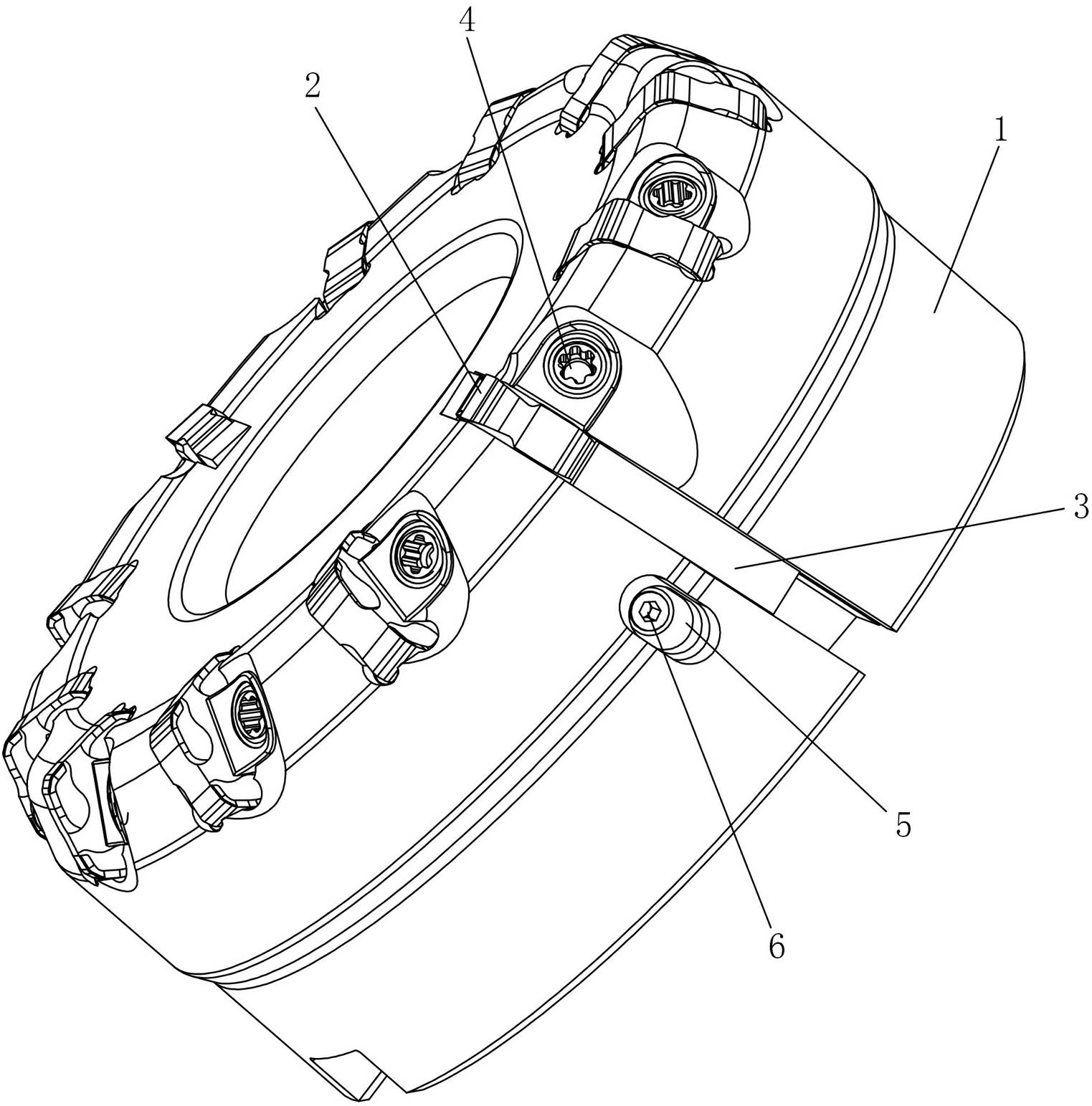

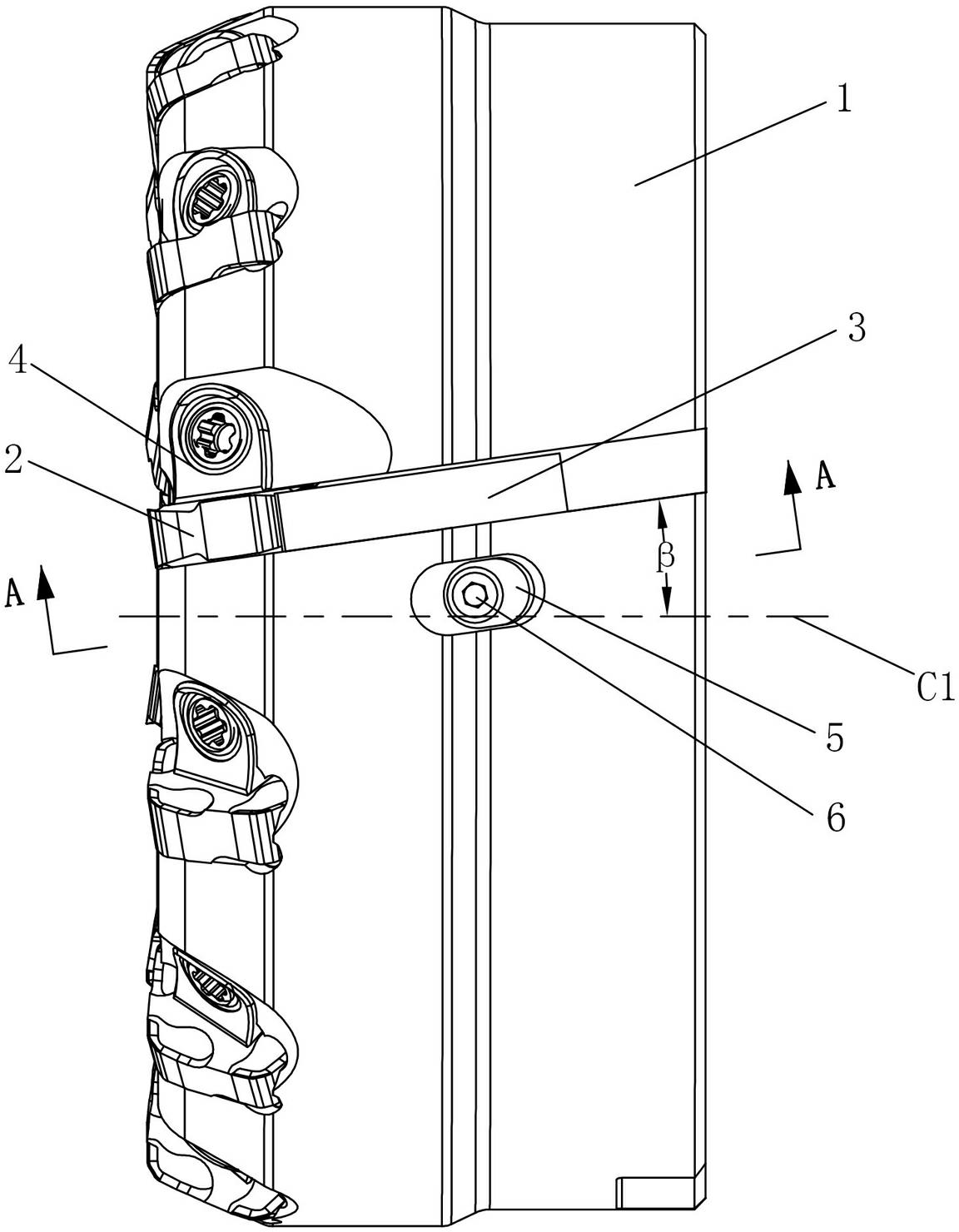

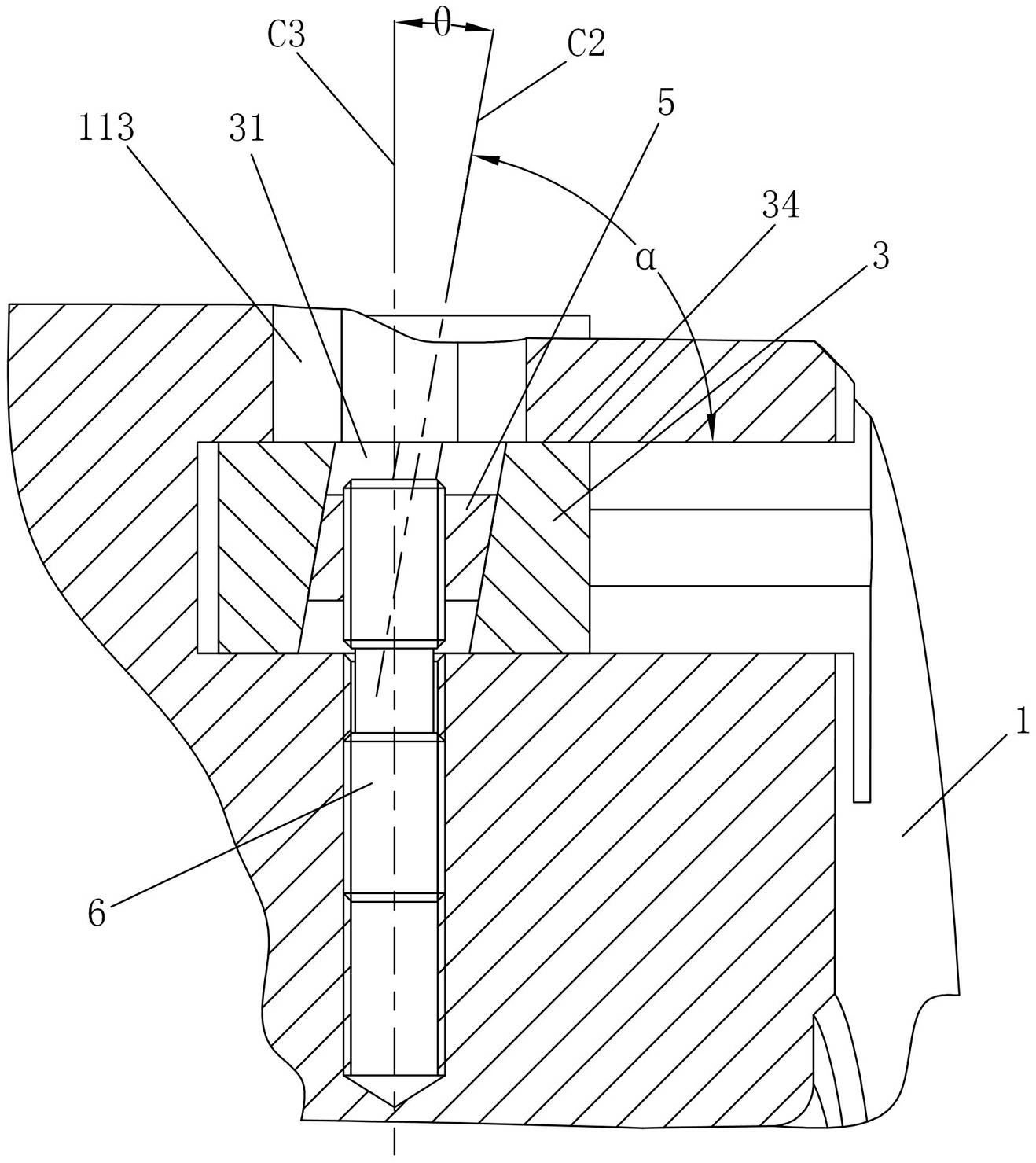

Milling cutter with adjustable finish machining face

ActiveCN102632288AImprove machining accuracyRealize two-way adjustmentMilling cuttersMilling cutterEngineering

The invention discloses a milling cutter with an adjustable finish machining face, comprising a cutter body, a cutting blade, an axial positioning block and a locking piece, wherein at least one of containing chambers capable of containing the axial positioning block are arranged on the cutter body, the axial positioning block is slidably arranged in the containing chambers, the cutting blade is arranged at one end of the axial positioning block and fixed by the locking piece, an axial driving hole is formed on the axial positioning block, the inner wall of the axial driving hole is provided with a pair of opposite axial positioning faces, the axial driving hole is internally and slidably provided with an adjusting block, the outer wall of the adjusting block is in close contact with a pair of the axial positioning faces, the adjusting block is connected with the cutter body by a dowel screw, the axial cross section of the cutter body which passes through the point of a knife of the cutting blade is a datum plane, and an inclined angle between the projection line of the central axis of the axial driving hole in the datum plane and the projection line of the central axis of the dowel screw in the datum plane is not equal to 0 degree. The milling cutter with the adjustable finish machining face has the advantages of being capable of being bilaterally adjusted, and being continuously, equivalently and gradually adjusted.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

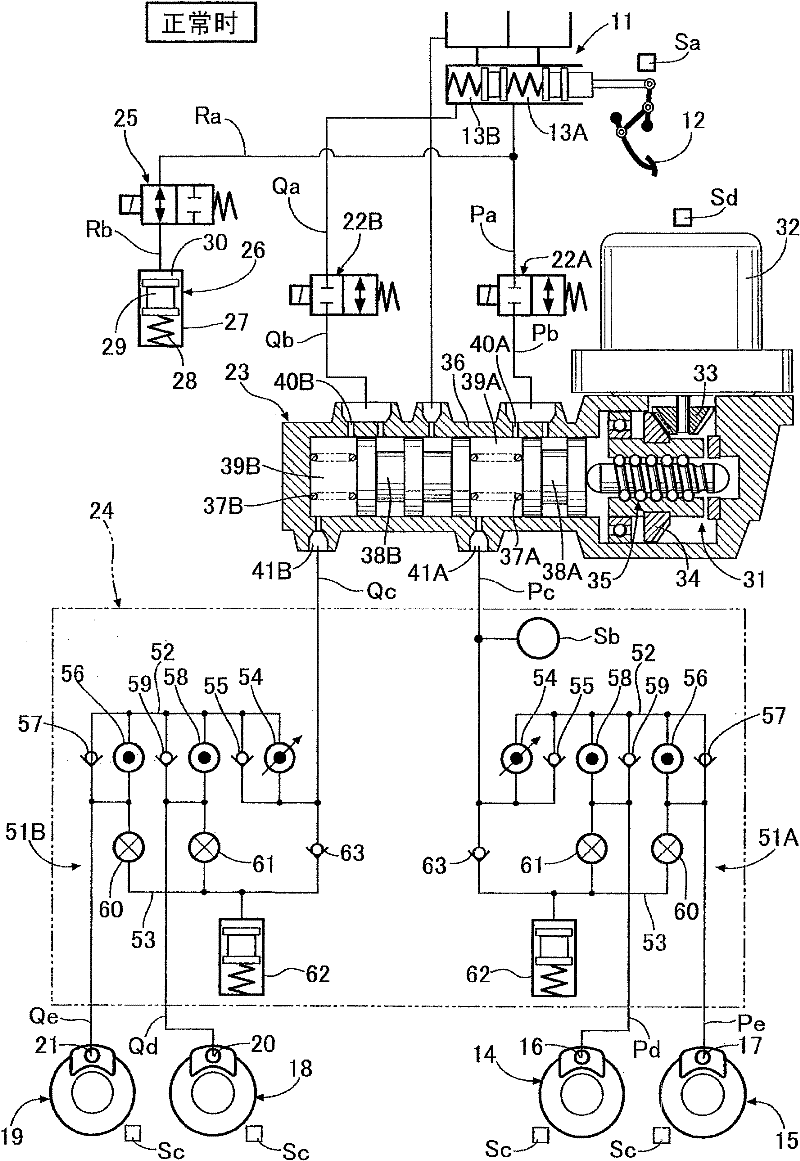

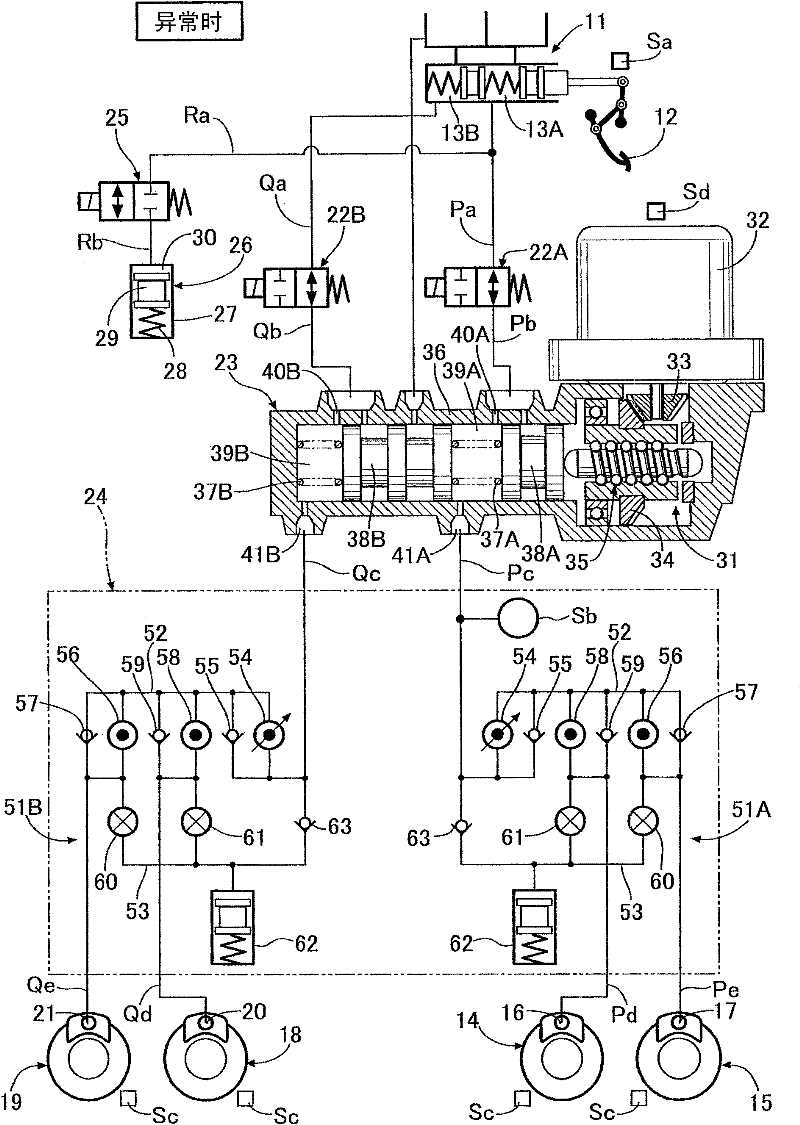

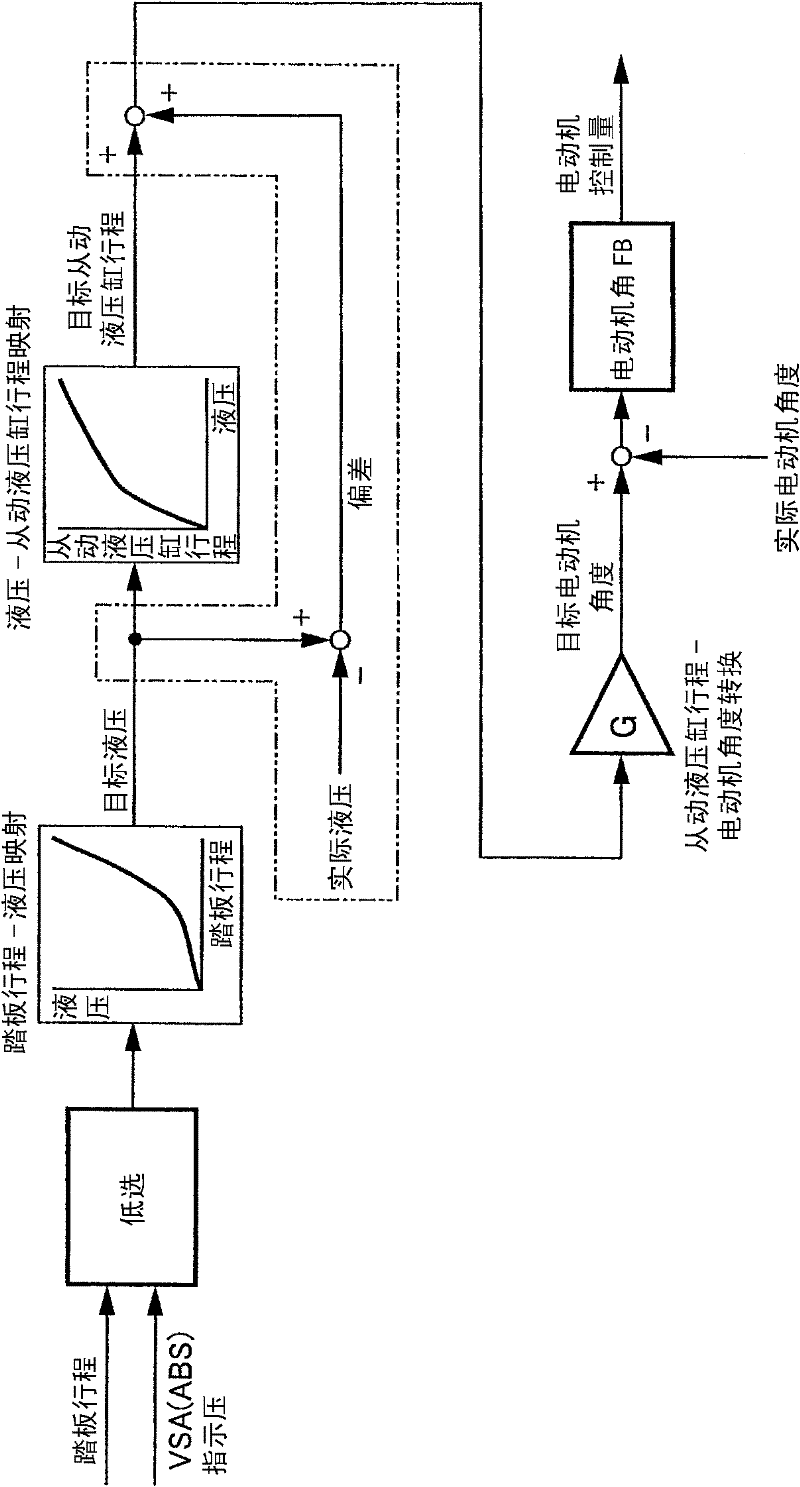

Vehicle brake device

A VSA device (24), which controls vehicle behavior by individually controlling the pressure of brake fluid supplied from a slave cylinder (23) to a wheel cylinder (16, 17; 20, 23), is provided with: an accumulator (62) which can be connected to the wheel cylinder and the slave cylinder (23); an out-valve (60, 61) disposed on a fluid path between the wheel cylinder and the accumulator (62); a check valve (63) that allows only flow of brake fluid from the accumulator (62) to the slave cylinder (23); and a regulator valve (54) disposed on a fluid path between the wheel cylinder and a path between the check valve (63) and the slave cylinder (23). Brake fluid is discharged from the accumulator (62) to the slave cylinder (23) by reducing the driving force of an electric motor (32) of the slave cylinder (23), thereby rendering a special pump unnecessary and making it possible to reduce the weight, cost, and component count.

Owner:HONDA MOTOR CO LTD

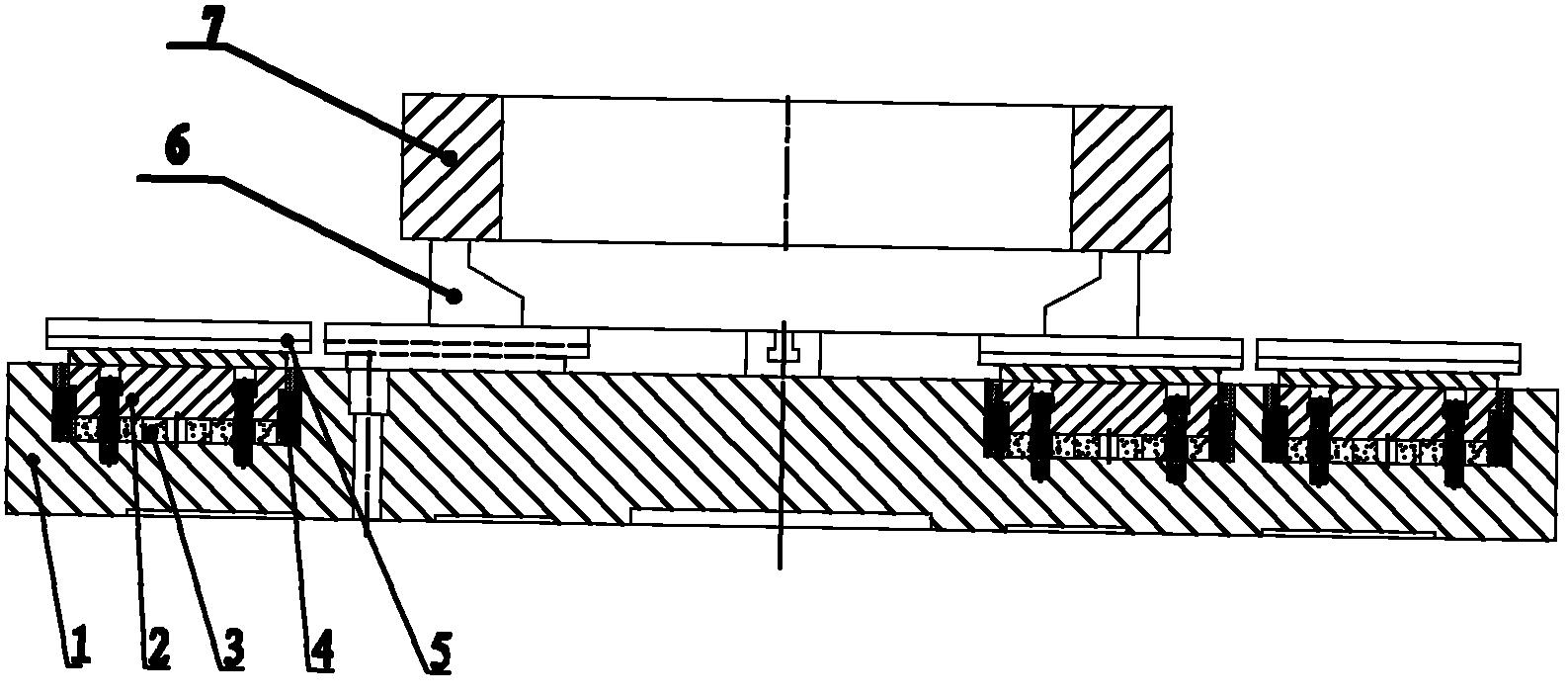

Double-division auxiliary static-pressure bearing and turning worktable of machine tool

ActiveCN101633120AReduce frictionImproved accuracy and stabilityLarge fixed membersMicrometerOil pressure

The invention relates to a double-division auxiliary static-pressure bearing and turning worktable of a machine tool, comprising a box body, a supporting ring, a circular ring pressure plate, a mandrel, a driving worm, a damping worm, a worm wheel and a table top, wherein the supporting ring is fixedly arranged on the upper end surface of the box body, one end of the mandrel is inserted into a central through hole of the supporting ring and connected with the table top into a whole, the circular ring pressure plate is arranged between the table top and a mandrel contact surface, oil grooves which are communicated with an external pressure oil pipe are evenly distributed on contact surfaces among the supporting ring, the table top, the mandrel and the circular ring pressure plate, and an oil film with a thickness of 2-4 micrometers is quickly and evenly generated between two turning surfaces which are in mutual contact by regulating oil pressure in the oil grooves so as to support and lubricate the turning surfaces. The double-division auxiliary static-pressure bearing and turning worktable has reasonable and simple structure, smooth running, high rotating speed, good rigidity, low exotherm, good precision maintenance and reliable operation, is easy to process and manufacture, can obviously increase the processing precision of workpieces and is suitable for being matched with different types of gear hobbing machines.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

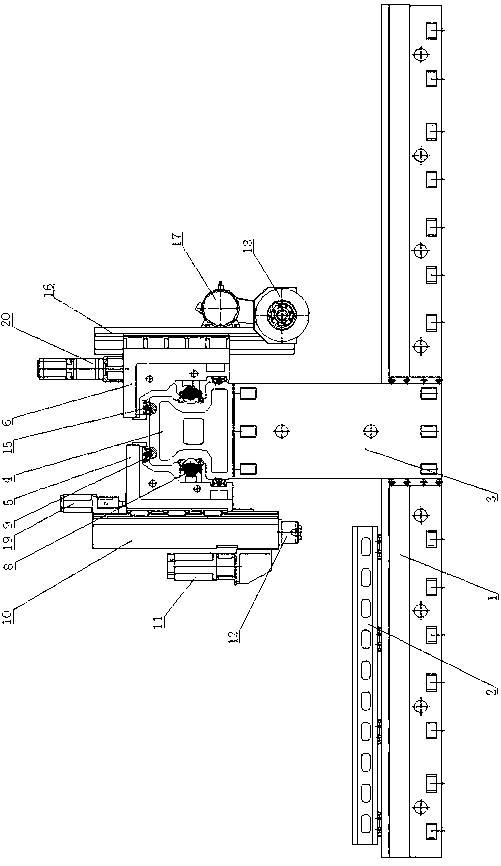

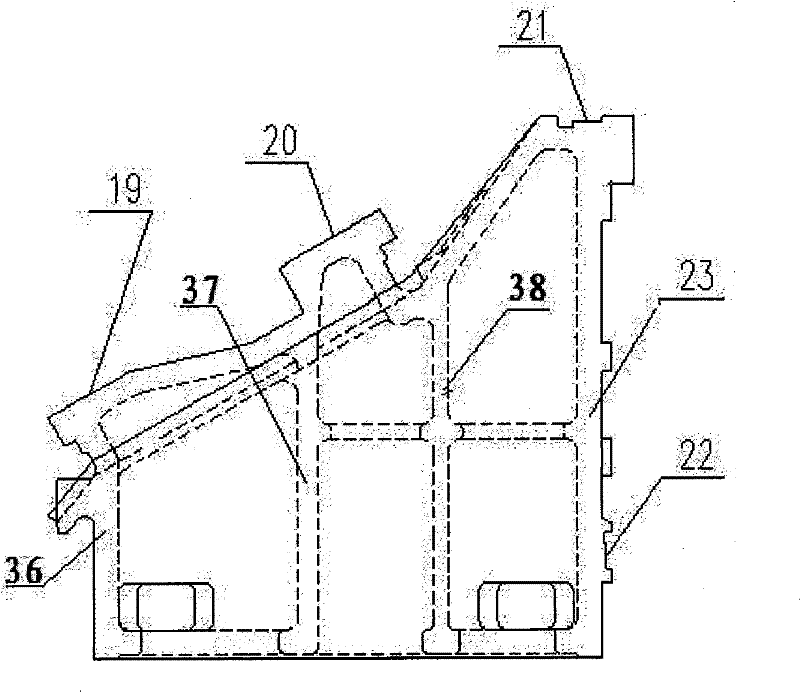

Three-axis double door frame double drive five linkage combination production center

InactiveCN1546278AImprove accuracy retentionAccuracy Retention GuaranteeOther manufacturing equipments/toolsDigital controlMachine tool

The invention discloses a kind of digital control compound processing centre which has three primary axis heads and three blade brackets to provide double drives, it is made up of turning primary axis head, milling axis head, fine machining primary head, turning blade bracket, milling blade bracket components, straight lade bracket component, saddle, transverse sliding boards, small door bracket component, a bed, the side door bracket component, tail bracket component and blade bank. The fine machining primary head can be changed, it can assemble high speed milling head, grinding head; the primary axis has servo axis function, the other two primary axes is servo axis. The bathe has at least nine servo axes, it can have twenty servo axes at most, it can realize five-axes linked control; the piece can realize turning, milling, boring, drilling and screwing, and high speed milling and so on. The raw and fine process can be separated, in order to upgrades the precise maintaining of bathe.

Owner:XIAN UNIV OF TECH

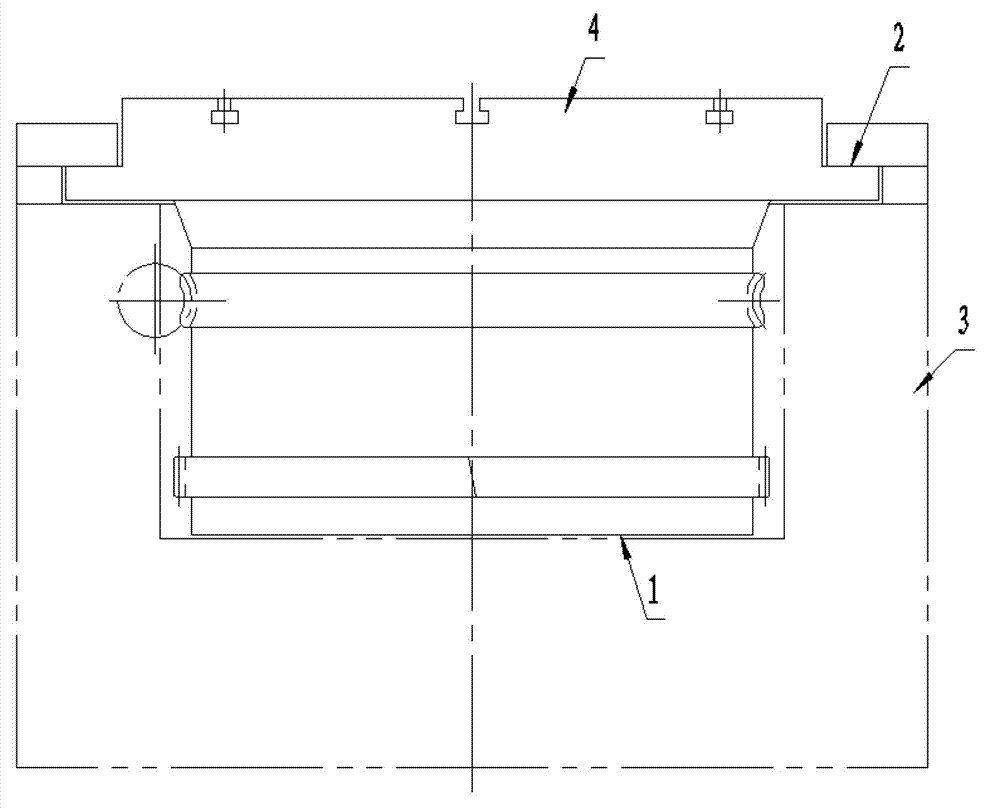

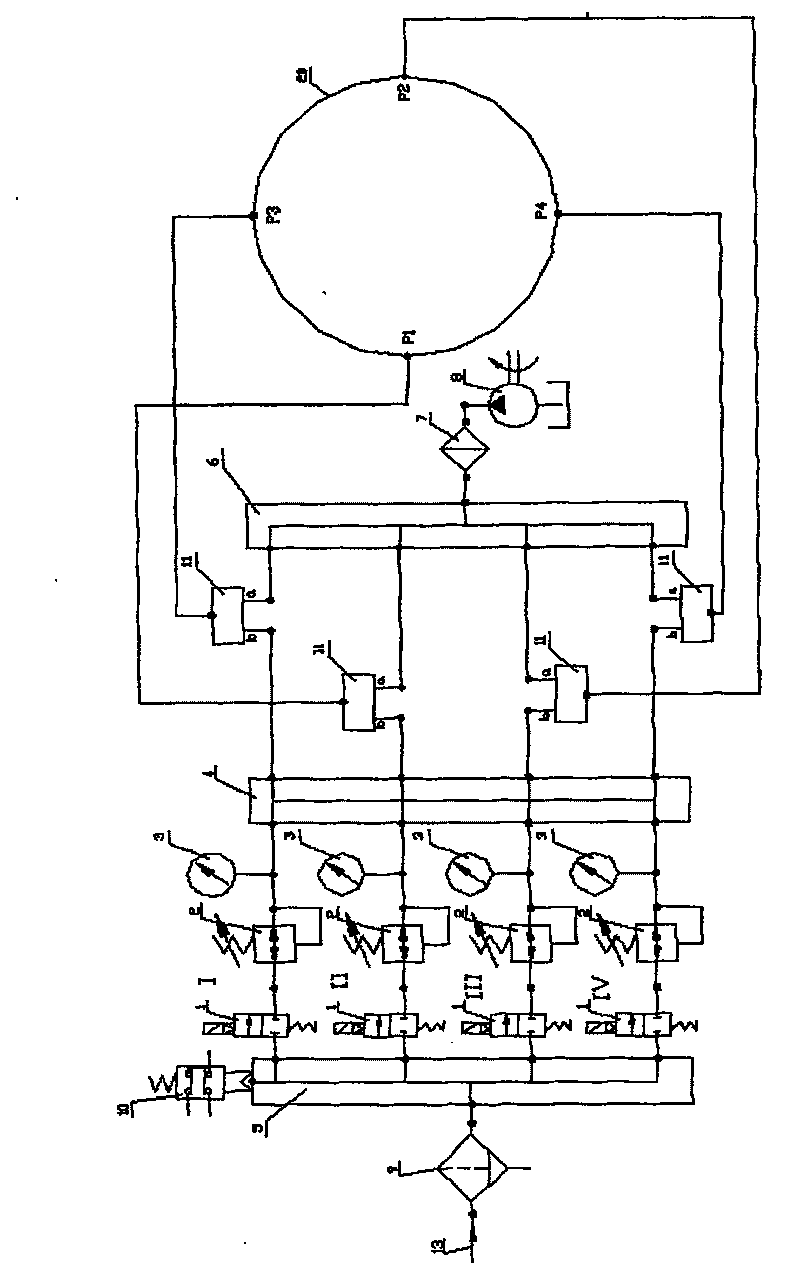

Constant-current and constant-voltage composite type floating hydrostatic guide rail and control method thereof

ActiveCN103028954AMeet high and low speed motion requirementsFunctionalLarge fixed membersLow speedEngineering

The invention relates to a constant-current and constant-voltage composite type floating hydrostatic guide rail, which comprises a main guide rail (1), a reverse preloading guide rail (2), a base (3) and a worktable surface (4), wherein the main guide rail (1) and the reverse preloading guide rail (2) form a closed type hydrostatic guide rail to realize a supporting function, the main guide rail (1) is a constant-current hydrostatic guide rail, and consists of a movable guide rail and a fixed guide rail, the main guide rail (1) on the worktable surface (4) is the movable guide rail, the main guide rail (1) on the base (3) is the fixed guide rail, and the reverse preloading guide rail (2) is the constant-current and constant-voltage composite type floating hydrostatic guide rail. The constant-current and constant-voltage composite type floating hydrostatic guide rail has the advantages that a high-speed and low-speed indexing function of a rotary table is met, and an assembly process and a control method are simple and reliable.

Owner:NANJING GONGDA CNC TECH

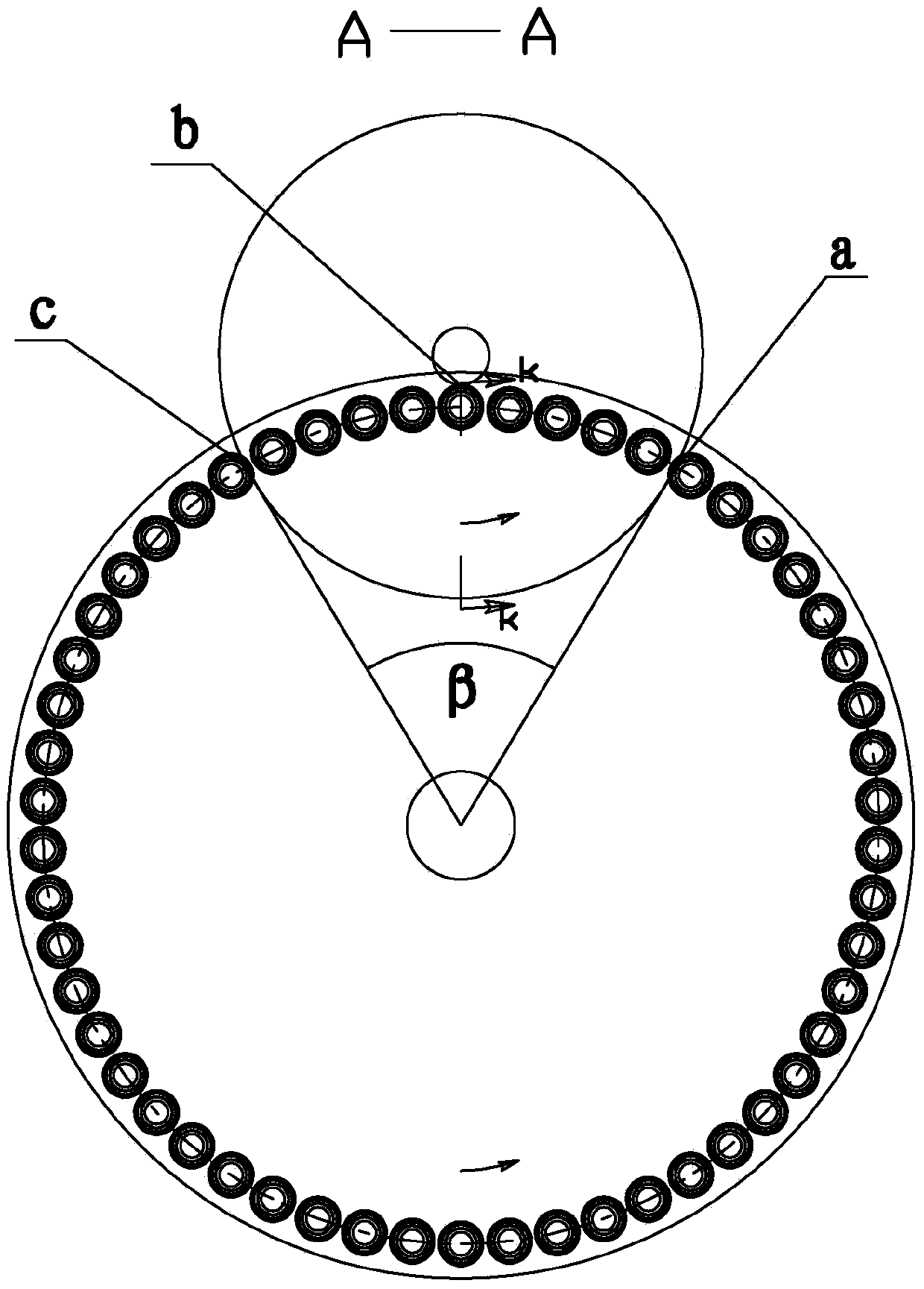

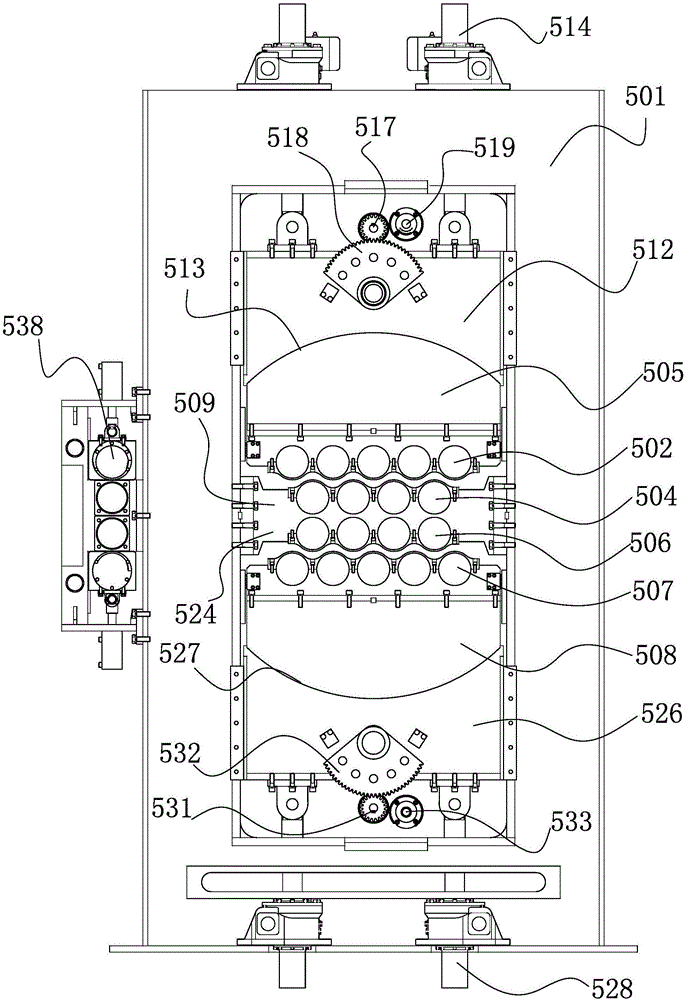

Spring grinding mechanism

ActiveCN103786081AIncrease productivityUniform wearGrinding headsGrinding work supportsGrinding wheelMaterials science

The invention relates to the field of spring grinding, in particular to spring grinding mechanism. The spring grinding mechanism comprises an upper grinding wheel, a lower grinding wheel and a grinding disc. The grinding disc is located between the upper grinding wheel and the lower grinding wheel. The upper grinding wheel or the lower grinding wheel comprises an inner grinding wheel and an outer grinding wheel, wherein the inner grinding wheel sleeves the outer grinding wheel, the inner grinding wheel or the outer grinding wheel is driven by a transmission mechanism, and the rotation directions of the inner grinding wheel and the outer grinding wheel are opposite. By the arrangement, a spring is ground under self-rotation, and the quality and yield of ground springs can be increased. In addition, the spring grinding mechanism is energy saving, environmental friendly, low in grinding cost, good in stress performance, long in mechanism precision retaining ability and good in stability.

Owner:SHAOXING JIADU SPRING MACHINE

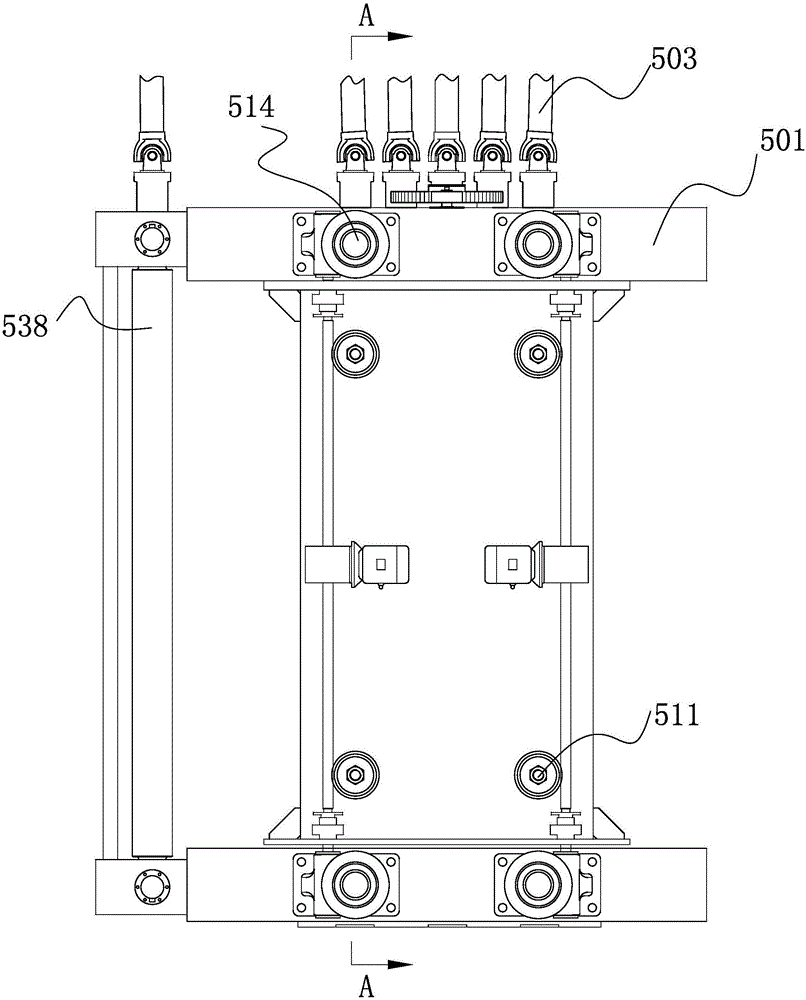

Double-layer composite board leveling machine

The invention discloses a double-layer composite board leveling machine, and relates to leveler equipment. The double-layer composite board leveling machine comprises a portal frame, and an upper-layer leveling roller system and a lower-layer leveling roller system arranged on the portal frame; the upper-layer leveling roller includes an upper roller system upper leveling roller, and an upper roller system lower leveling roller driven by a power device; the upper roller system upper leveling roller is arranged on an upper movable cross beam of the portal frame; the lower-layer leveling roller system includes a lower roller system upper leveling roller and a lower roller system lower leveling roller driven by a power device; and the lower roller system lower leveling roller is arranged on a lower movable cross beam of the portal frame. The double-layer composite board leveling machine can synchronously level an upper double-metal composite board and a lower double-metal composite board, is high in production efficiency, and reduces the production cost.

Owner:山东易川新材料科技股份有限公司

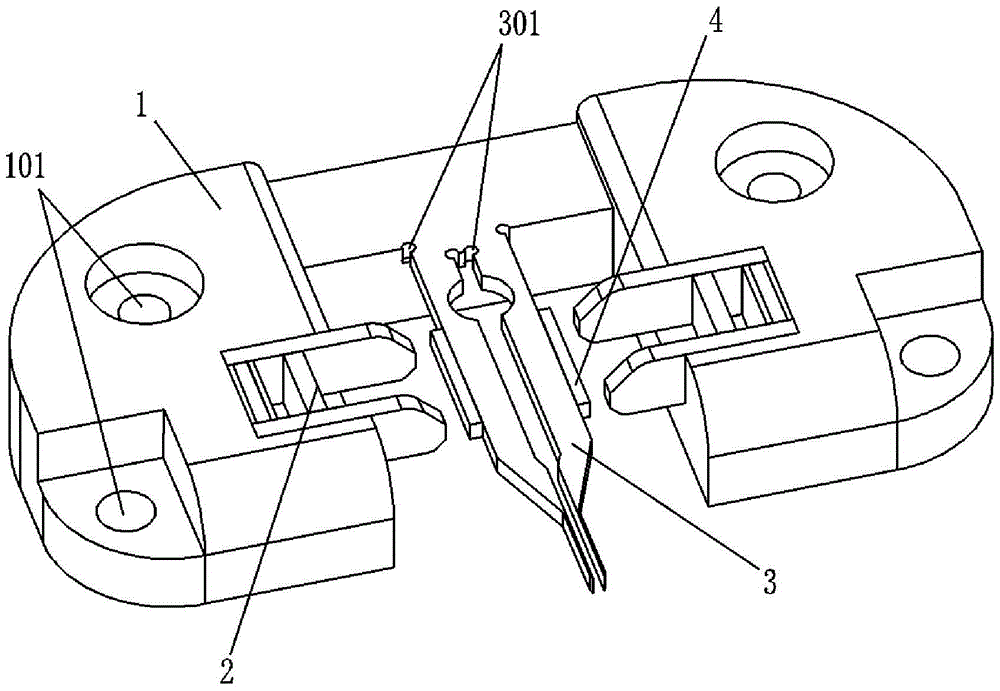

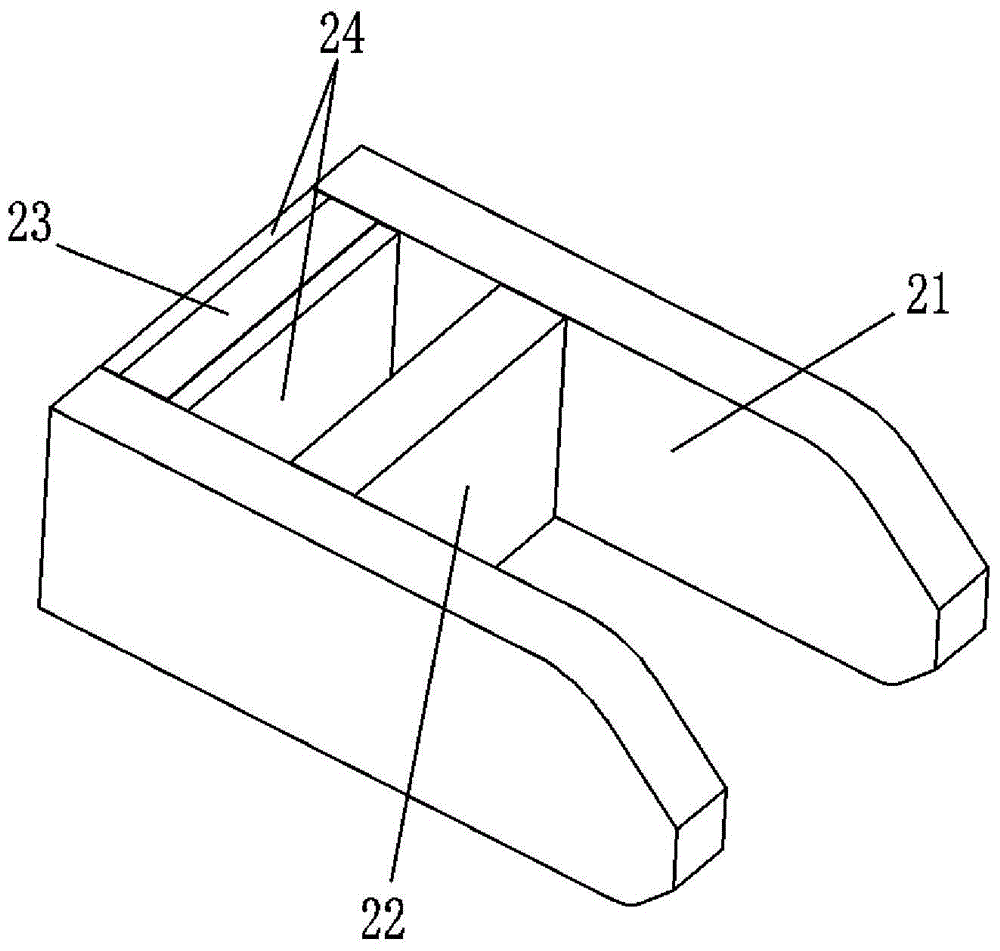

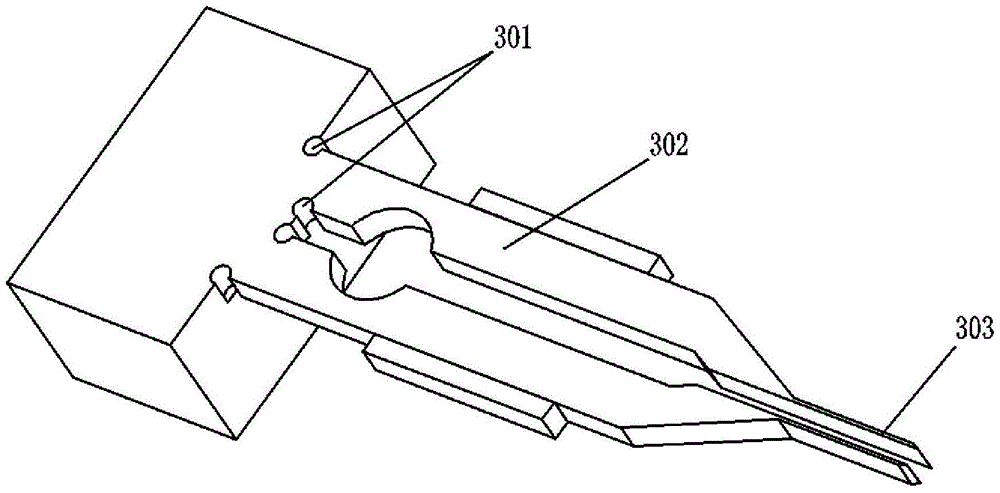

High-precision micro-gripper

InactiveCN105773573AIncreased Force Adjustment AccuracyImprove accuracy retentionMicromanipulatorPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention discloses a high-precision micro-gripper. The high-precision micro-gripper comprises a platform base, micro-force drivers, micro gripping pliers and a stress magnet. The platform base is of a symmetrical structure and provided with symmetrically-distributed screw holes. The micro-force drivers are arranged on the platform base symmetrically. The micro gripping pliers are arranged on the symmetrical center face of the platform base. Each micro-force driver comprises two piezoelectric ceramic pieces, a super-magnetic expansion piece located between the two piezoelectric ceramic pieces, a permanent magnet arranged parallel to the super-magnetic expansion piece and two magnetic fixing yokes. The two magnetic fixing yokes are located at the two ends of the super-magnetic expansion piece, the piezoelectric ceramic pieces and the permanent magnet and grip the super-magnetic expansion piece and the permanent magnet. According to the high-precision micro-gripper, the controlled precision of the magnitude of the gripping micro force of the micro-gripper is high. In addition, the power consumption is low, the amount of emitted heat is small, and the precision stability is good.

Owner:陈昊哲

Rotary die-cutting die roller directly formed by laser cladding

ActiveCN104760088AImprove processing efficiencyCost controlMetallic material coating processesMetal working apparatusLayered structureMaterial hardness

The invention relates a rotary die-cutting die roller directly formed by laser cladding, and provides a die roller of a rotary die-cutting device. The die roller comprises a roller body on which a blade is arranged; a cladding layer, a transition layer and a layered structure of a base body are formed on the roller body from inside to outside in a sequence by the laser cladding process, wherein the cladding layer is used for forming the blade; the transition layer is connected with the blade and the base body; the roller body is of a hollow structure. According to the die roller formed by the laser cladding process, different materials can be subjected to metallurgical combination; the dilution rate is small; the hardness and wear resistance of the blade body material are maintained; the flexibility of the base body material is remained; the blade body material and the base body material can be combined well; the section of a blade body is of a near net shape, so that the later precision processing workload can be reduced; the cladding track can be digitally controlled; any complex blade curved line can be pre-designed; the roller body is of the hollow structure so that the heat dispersing performance of the base body is improved, and the mechanical property of the blade can be improved; in addition, the weight of the die roller is reduced, and thus the rotary inertia of the die roller can be increased.

Owner:FUJIAN UNIV OF TECH

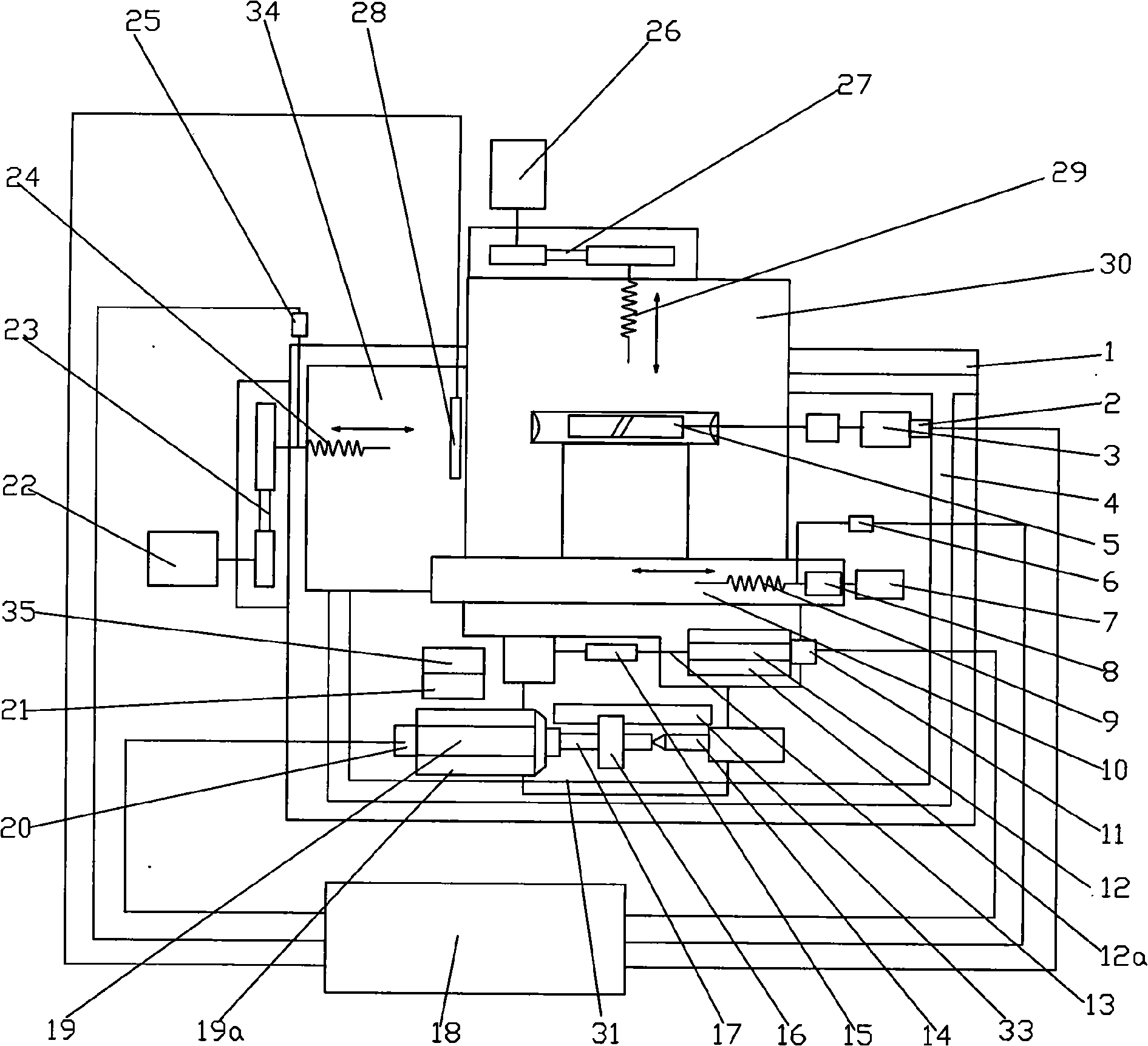

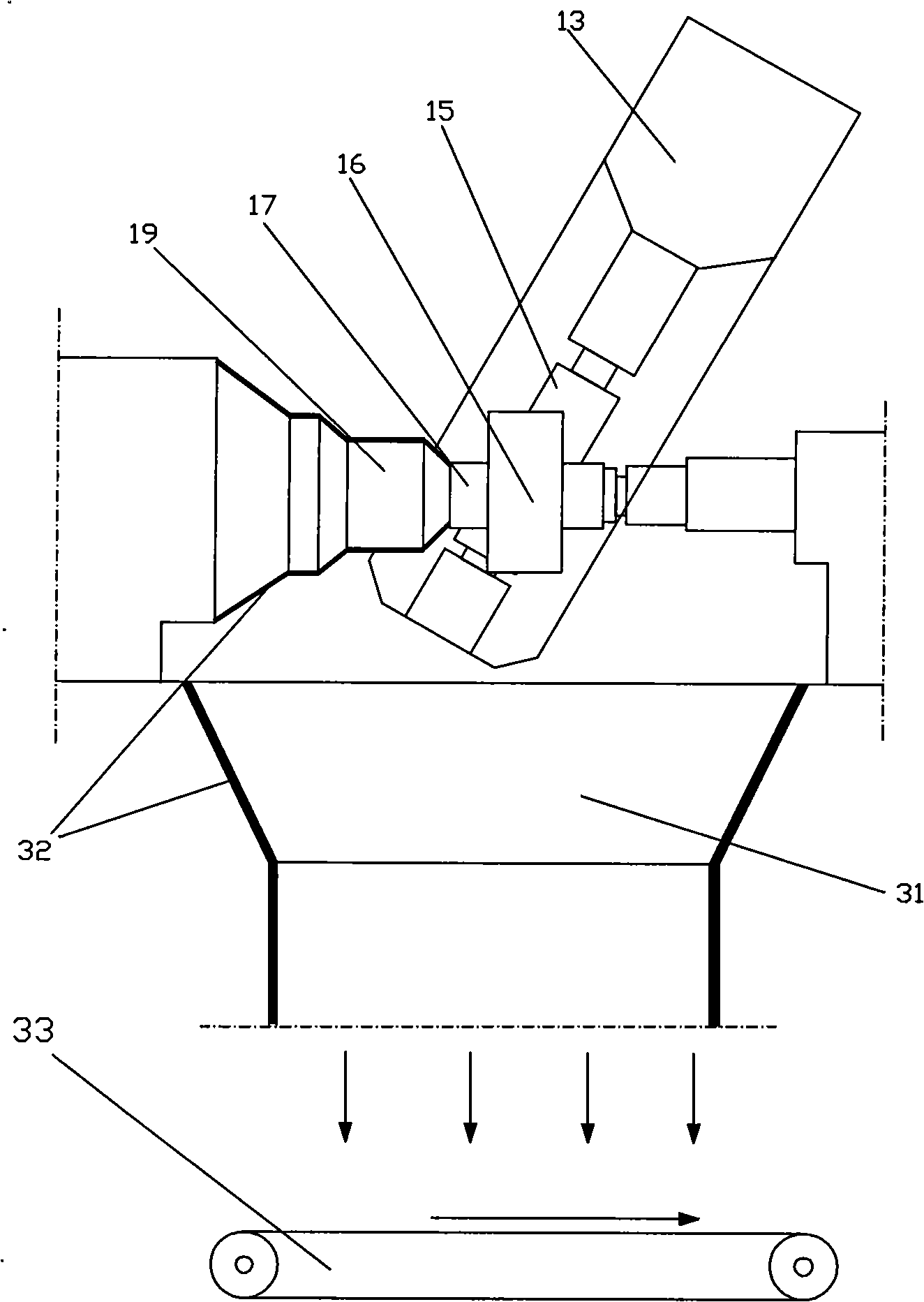

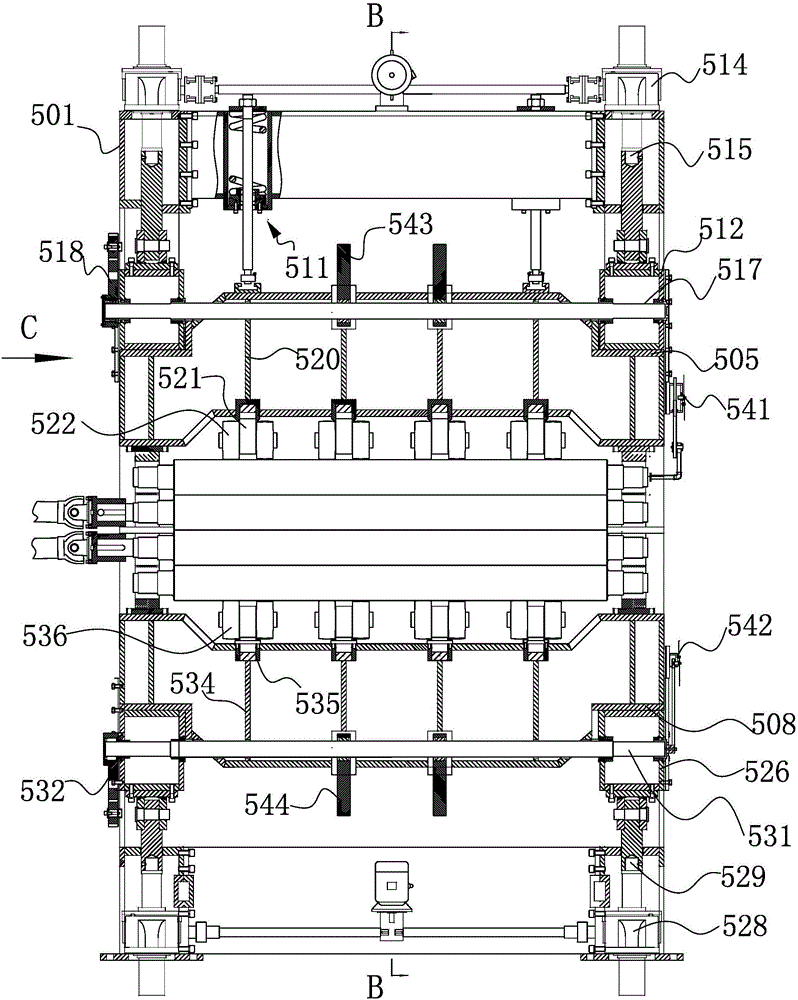

The overall structure of the turning and milling compound machining center

ActiveCN101513720BGuaranteed stabilityWeight optimizationMetal working apparatusMilling cutterEngineering

The overall structure of the turning-milling compound machining center is characterized by a single column and a feed box hung on both sides. The feed box on the left is equipped with a three-point cloth knife B-axis tool holder device. The B-axis tool post device is used for turning, milling, boring, deep hole drilling, tapping and other processes of crankshaft processing. The feed box hung on the right side can hold a large-sized milling cutter head for external milling of the crankshaft. Double spindle box and double Cf axis structure, the two spindle boxes can move along the Z axis on the bed, and the top of the right spindle box can be retracted. The machine tool is equipped with multiple hydraulic self-centering steady rests with high precision retention. The guide rail of the bed is at an inclination angle of 30° to the horizontal plane, and the upper plane of the bed is completely ground to ensure that there is no dead space for debris. The whole machine is fully protected. The inner cavity of the guide rail used for the operation of the single column of the bed is supported by double ribs, and the force of the two groups of corners is always maintained during the operation of the column. The front support bearing of the main shaft adopts imported large-diameter double-row cylindrical roller bearings. The present invention solves three problems. Only one clamping on a machine tool can complete the machining of the main journal of the crankshaft and each part of the connecting rod journal before grinding, and realize the high-precision and efficient machining of the crankshaft of the marine medium-speed engine. Great, full protection.

Owner:通用技术集团沈阳机床有限责任公司

A kind of manufacturing method of complex busbar polishing wheel with local reinforcement structure

ActiveCN105818008BImprove accuracy retentionImprove automationFlexible-parts wheelsGrinding devicesHardnessAdamite

The invention provides a complex generatrix polishing wheel with a local reinforcement structure. The complex generatrix polishing wheel comprises three different structures including a direct electroplating polishing wheel body, an electroplating abrasive cloth forming polishing wheel structure and an abrasive material block polishing wheel body. By adding the necessary reinforcement structure or enhancement materials into abrasive materials and elastic base bodies, the bonding force of the abrasive materials is enhanced, and the local supporting strength of the abrasive materials is controlled. A method specifically comprises the step that diamonds and other superhard abrasive materials are solidified to the surfaces of the base bodies of the metallic or non-metallic reinforcement structure through the electroplating or sintering methods, and the diameter of the base bodies is about 1 mm or smaller. The reinforcement structure has the hardness obviously higher than that of a polishing wheel base body and the geometric dimension far larger than that of the abrasive materials. The small abrasive material blocks are solidified to rubber of the polishing wheel bodies or other types of soft base bodies through the bonding or other proper methods, so that the polishing wheel with the reinforcement structure is formed, the abrasive materials of the polishing wheel protrude easily, and the polishing wheel has a sufficient grinding effect. The problems that conventional polishing wheel abrasive materials are small in size and bonding force, capable of easily sinking into the base bodies, prone to falling off, low in grinding capacity and the like are solved.

Owner:BEIHANG UNIV

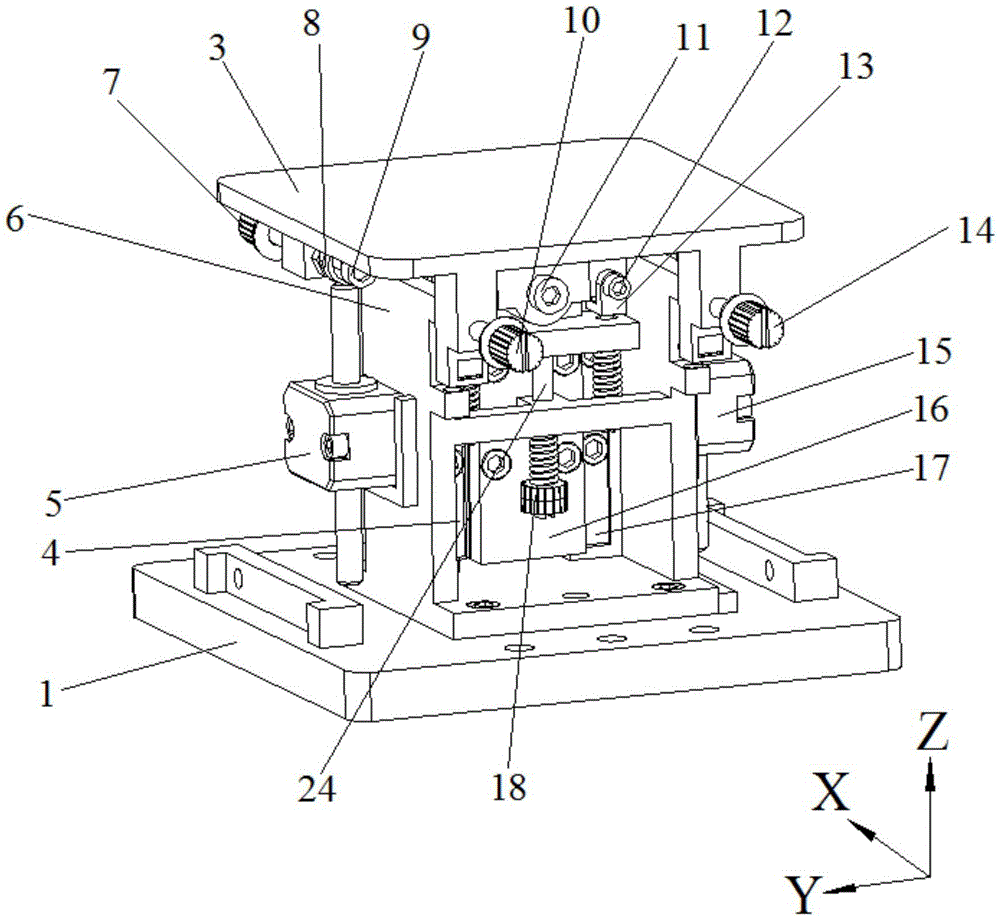

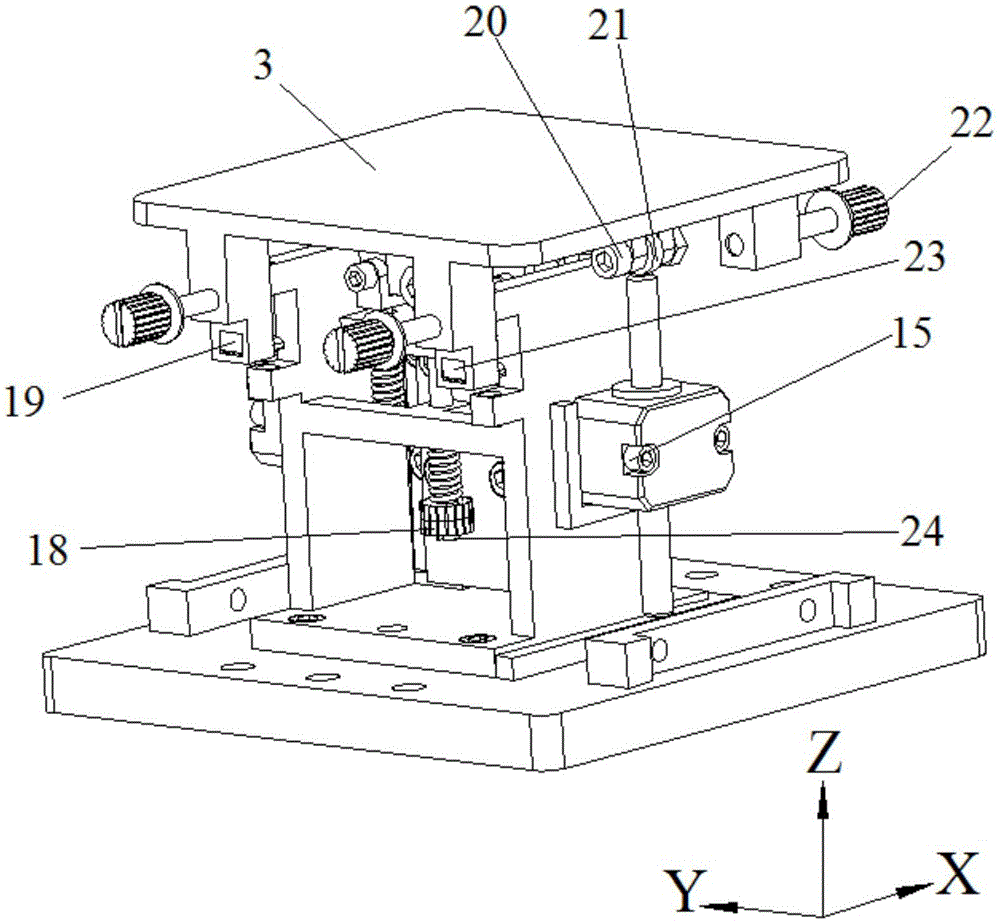

Two-axis precision movement platform for X-ray diffraction instrument

ActiveCN105572156AHighly integratedImprove accuracy retentionMaterial analysis using radiation diffractionDiffractometerRange of motion

The invention provides a two-axis precision movement platform for an X-ray diffraction instrument, and belongs to the field of X-ray and multi-axis precision movement platforms. Two piezoelectric linear motors arranged in parallel in the Z direction are adopted to push a test piece workbench, Z-direction movement of the test piece workbench is produced through synchronous movement of the two Z-direction piezoelectric linear motors, two Hall sensors are adopted as displacement detection elements of the two Z-direction piezoelectric linear motors respectively, and a spring and a connecting rod are used for pretightening the contact portions of motor rods of the piezoelectric linear motors and the test piece workbench and the hinged portions of the test piece workbench and an Z-direction sliding block. The two-axis precision movement platform has the advantages that the precision piezoelectric linear motors are adopted as the driving components, the movement distance is long, response is rapid, and positioning precision is high; the Hall sensors are used for providing limiting signals and initial position signals, and movement parts are prevented from exceeding the movement range. The two-axis precision movement platform is applicable to movement and multi-angle irradiation analysis of test pieces in X-ray diffraction analysis.

Owner:JILIN UNIV

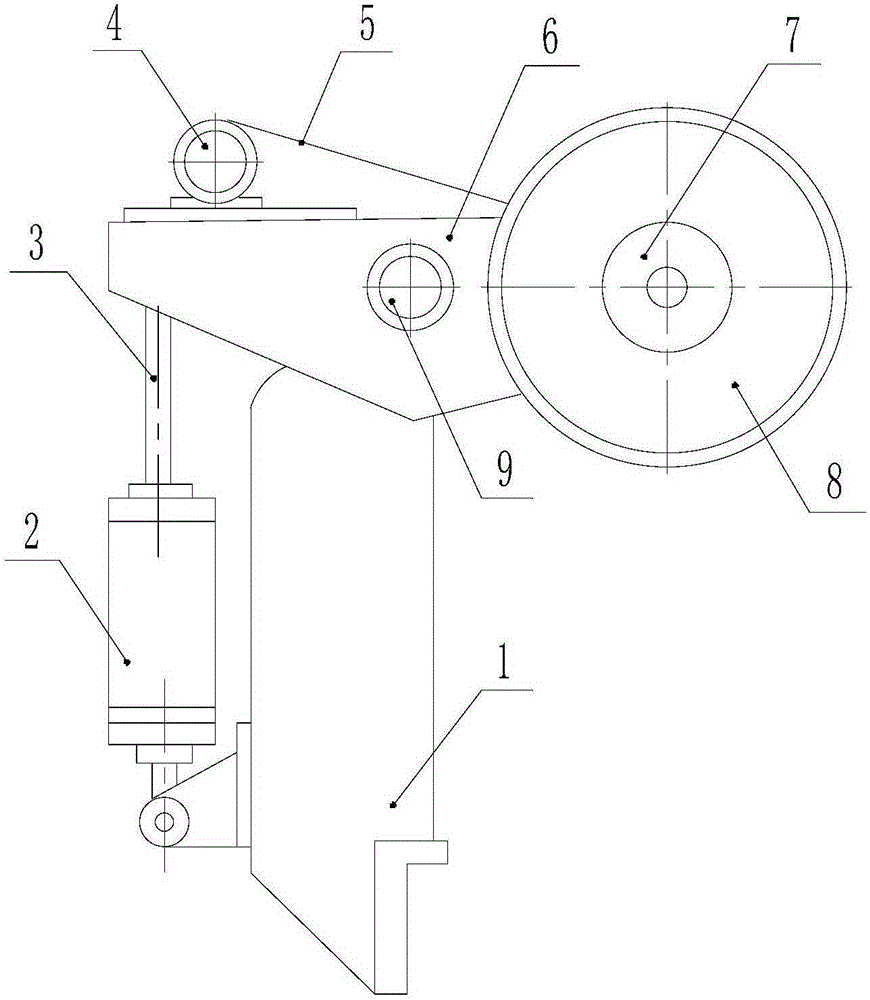

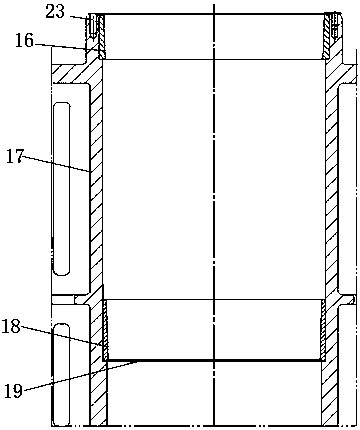

Cutting device of slicer for machining solar panel

The invention discloses a cutting device of a slicer for machining a solar panel. The cutting device is characterized in that the bottom end of a cutting cylinder is mounted on a base through a hinge; the top end of a piston rod is mounted on a swing arm through a hinge; the swing arm is mounted on the base through a central shaft and can rotate around the central shaft; a driving motor is mounted on the swing arm; the driving motor is provided with a driving pulley; a main shaft device is composed of a back through cover, a spring, a housing, a main shaft, a front through cover, a locking nut, a front bearing set, a disc and a back bearing set; the back conical surface of the main shaft is provided with a driven pulley; the driving pulley drives the driven pulley to rotate through a synchronous belt; the inner ring of the back bearing set is mounted at the back end of the main shaft; the back through cover is mounted on the back end surface of the housing through screws; the locking nut is mounted on the screw thread of the main shaft; the front through cover is mounted on the front end surface of the housing through screws; and a cutter head is mounted on the front conical surface of the main shaft.

Owner:江苏宇搏机械设备有限公司

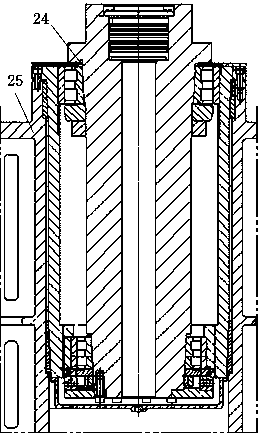

Disassembling structure of large heavy-load spindle

ActiveCN109210091AGuaranteed maintainabilityAchieving complete disassemblyShaftsMetal working apparatusMaintainabilityEngineering

The invention provides a disassembling structure of a large heavy-load spindle. The disassembling structure of the large heavy-load spindle comprises a spindle system and a spindle box. The spindle system is detachably connected into the spindle box. The spindle box is assembled in the large heavy-load spindle. When the disassembling structure is used, the spindle system can be integrally disassembled, operation is easy and practical, the periphery of a structural component of the spindle does not need to bear an eccentric load when the spindle is disassembled, and the maintainability of the large high-precision spindle system is effectively ensured. When the spindle system is maintained, the spindle system can be safely and rapidly separated from the spindle box through vertical hoisting,and integral disassembling of the spindle system is achieved; and a traditional complex stepwise maintenance mode that a spindle and a spindle box are synchronously removed to disassemble the spindleshaft system is changed, so that disassembling and maintenance are more reasonable and reliable and safer.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Cross hinge type electric spark micro inverted cone hole machining mechanism

Owner:北京市电加工研究所有限公司

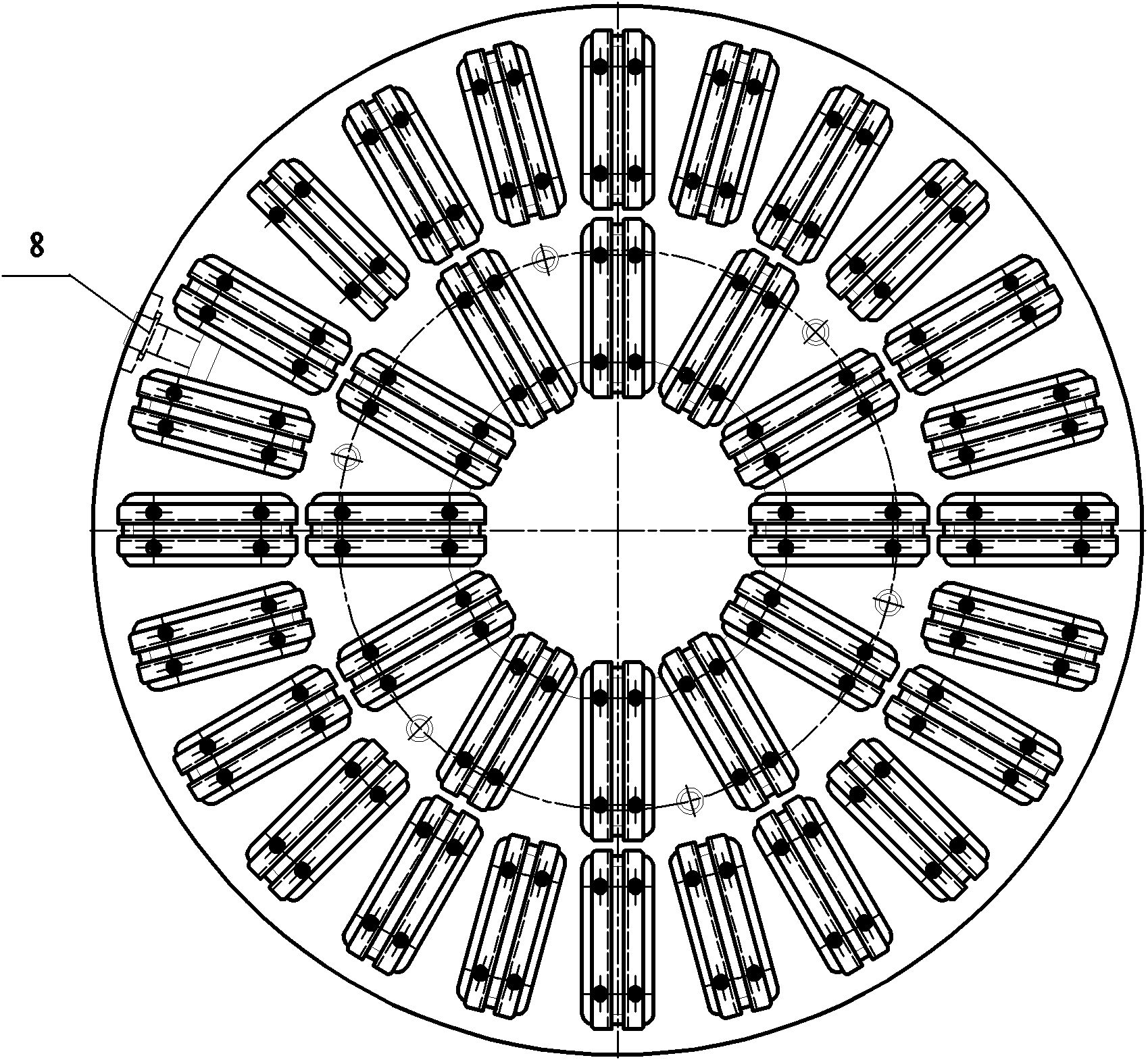

Circular electro-permanent magnetic chuck for vertical lathe

InactiveCN101934481AHave general characteristicsSimple structurePositioning apparatusMetal-working holdersStable stateSuction force

The invention relates to a circular electro-permanent magnetic chuck for a vertical lathe, in particular to a magnetic fixture for a vertical lathe for realizing rapid machining by way of taking the place of grinding by turning. The circular electro-permanent magnetic chuck for a vertical lathe comprises a chuck body, magnetic poles, a magnetic steel, a magnet exciting coil and a magnetic cushion, wherein a plurality of strip-shaped holes are arranged above the chuck body, the magnetic poles are pressed on the magnetic steel, and the magnet exciting coil is arranged on an outer ring of the magnetic steel; the magnetic cushion is arranged above the magnetic poles, the magnetic cushion and the magnetic poles are integrated and arranged in the strip-shaped holes above the chuck body by bolts, and the wires of the magnetic poles are led out from the chuck body. The magnetic poles are straight-strip-shaped magnetic poles with same width. The two adjacent polarities of the straight-strip-shaped magnetic poles are opposite, and even magnetic poles are arranged on a same circumference in pairs. The invention has strong suction force, can satisfy the requirement for machining, has good retentivity of accuracy and stable state in the process of machining, can satisfy the requirement for finish machining, exempts the process of grinding, does not cause the phenomenon of divergent magnetic field, and can effectively avoid the influence of magnetic fields on cutting tools and iron filings in the process of machining.

Owner:江苏无锡建华机床附件集团有限公司

Dual-exchange table vertical machining center structure

InactiveCN107932088AEasy compositionGood accuracy and stabilityLarge fixed membersPositioning apparatusBall screwEngineering

The invention discloses a dual-exchange table vertical machining center structure which comprises a base. The upper surface of the base is provided with a saddle driving ball screw and two saddle linear guide rails, the saddle driving ball screw is arranged between the two saddle linear guide rails, one end of the saddle driving ball screw is provided with a saddle driving motor, a saddle is arranged above the saddle driving ball screw and the two saddle linear guide rails, the upper surface of the saddle is provided with a stand column driving ball screw and two stand column linear guide rails, the stand column driving ball screw is installed between the two stand column linear guide rails, and stand columns are arranged above the stand column linear guide rails and the stand column driving ball screw. Dual exchange working tables are adopted and only do rotary motion, a tool changer does constant mass motion on the X, Y and Z axes, the accuracy stability is good, the accuracy keepingperformance is high, the clamping time is shortened, the working efficiency is improved, and several machines can be operated by one person at a time.

Owner:广州市佳速精密机械有限公司

Micro-positioning device based on normal stress electromagnetic driving

ActiveCN110323919ASimple and compact structureLarge outputPropulsion systemsRange of motionMoment of inertia

The present invention discloses a micro-positioning device based on normal stress electromagnetic driving, which comprises a base, a mover ring, a flexible transmission assembly and multiple sets of normal stress electromagnetic actuators. A mounting cavity is arranged on the base, and the mover ring is mounted in the mounting cavity through the flexible transmission assembly. The multiple sets ofnormal stress electromagnetic actuators are mounted on the base which is on the circumferential side of the mover ring in a ring shape; each normal stress electromagnetic actuator comprises stator yokes and coil windings wound on the stator yokes. A plurality of contact heads in one-to-one correspondence with the stator yokes are arranged on the circumferential side of the mover ring; each statoryoke is provided with a through slot; each contact head is located in the through slot of the corresponding stator yoke; and a working air gap is formed between the contact head and the through slot.The micro-positioning device based on normal stress electromagnetic driving of the invention has the advantages such as simple and compact structure, large output force, fast response speed, large motion range, high positioning accuracy and small rotational inertia.

Owner:NAT UNIV OF DEFENSE TECH

Pneumatic load-removing plastic-sticking guiding rail

InactiveCN101125403BReduce coefficient of frictionReduce frictionLarge fixed membersProcess qualityAir filter

Owner:天津市第二机床有限公司

Semi-closed type press machine

The invention discloses a semi-closed type press machine. The semi-closed type press machine comprises a machine body, a workbench, a sliding block, a transmission mechanism and a drive motor. Each ofthe two sides of the head end of the machine body is provided with a main wall board. The board wall of each of the two main wall boards is provided with a workbench installing port. The two ends ofthe workbench are arranged on the tops of the bottom end faces of the two workbench installing ports correspondingly. The sliding block is arranged at the top end of the workbench and located betweenthe two main wall boards. The sliding block is connected with the main wall boards through guide rail mechanisms, the sliding block is in transmission connection with the transmission mechanism, and the transmission mechanism is connected with the drive motor. According to the provided semi-closed type press machine, the deformation of a traditional press machine body is obviously reduced, the service life of a die is prolonged, and the quality level of a workpiece is improved.

Owner:浙江高精装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com