Two-axis precision movement platform for X-ray diffraction instrument

A technology of precision motion and diffractometer, applied in the field of two-axis precision motion platform of X-ray diffractometer, can solve the problems of low precision retention, low motion precision, low integration degree, etc., achieve rapid response, reduce size, and improve integration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

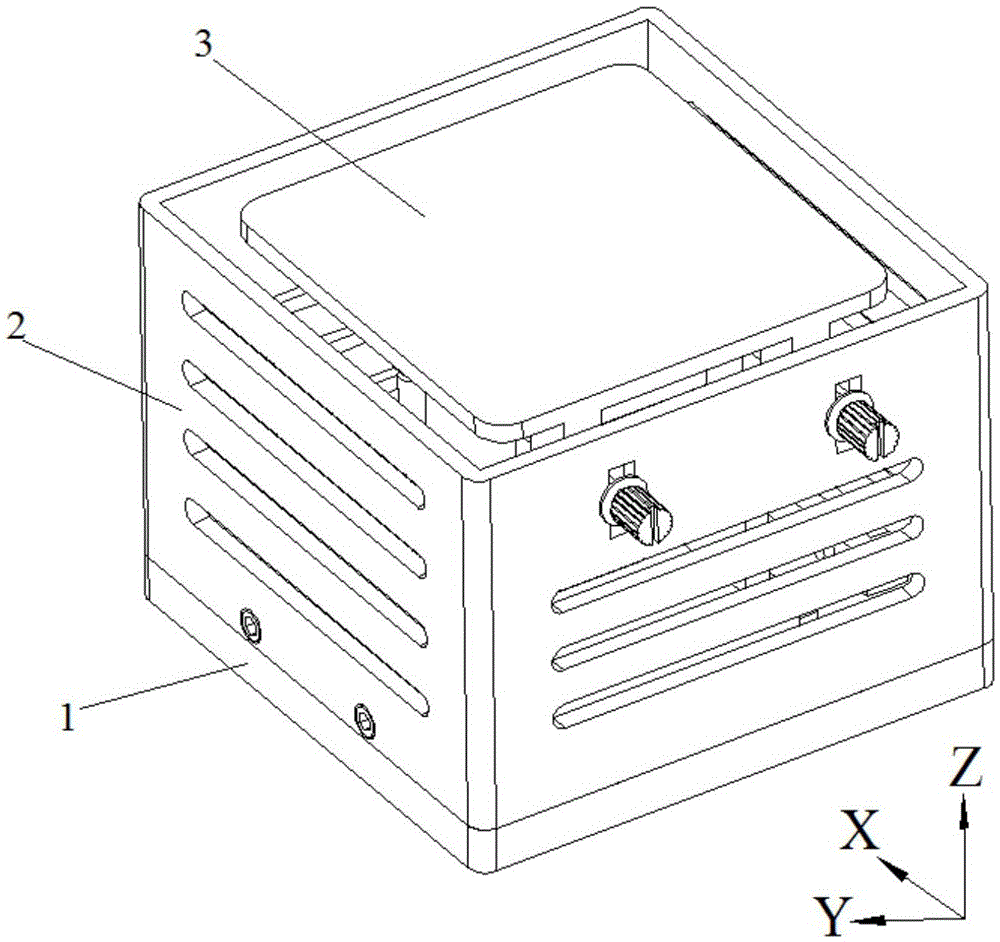

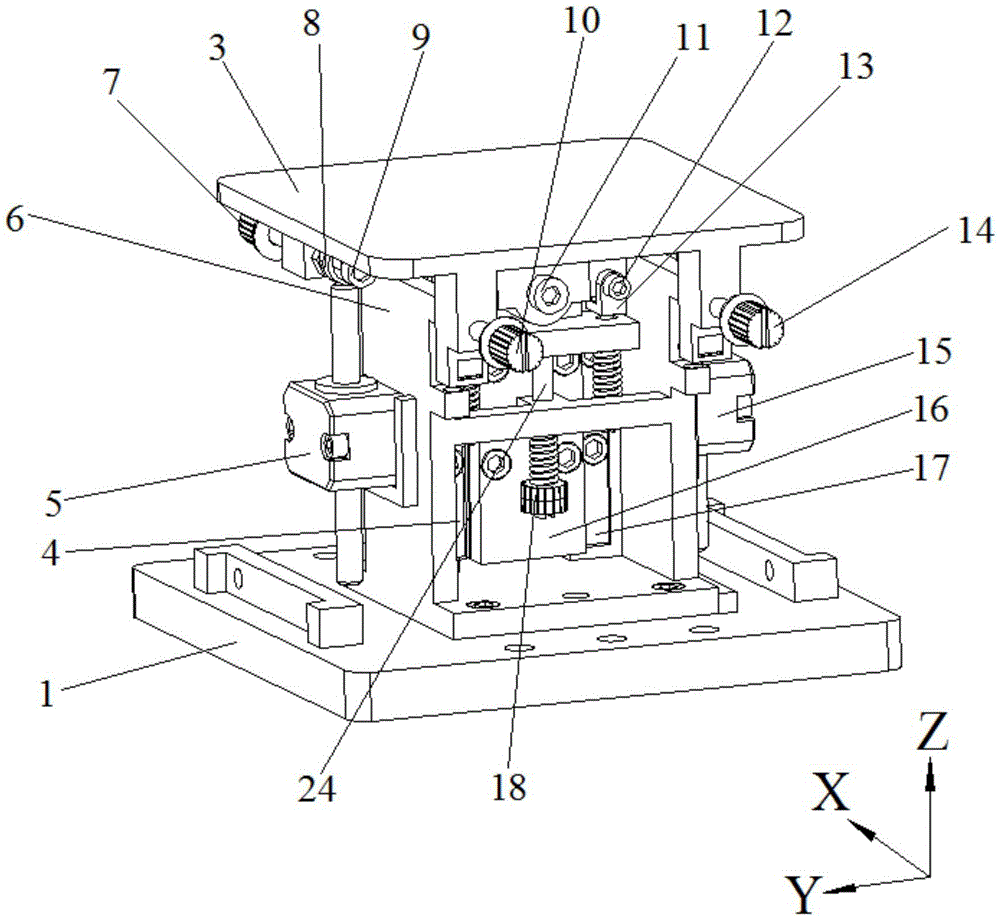

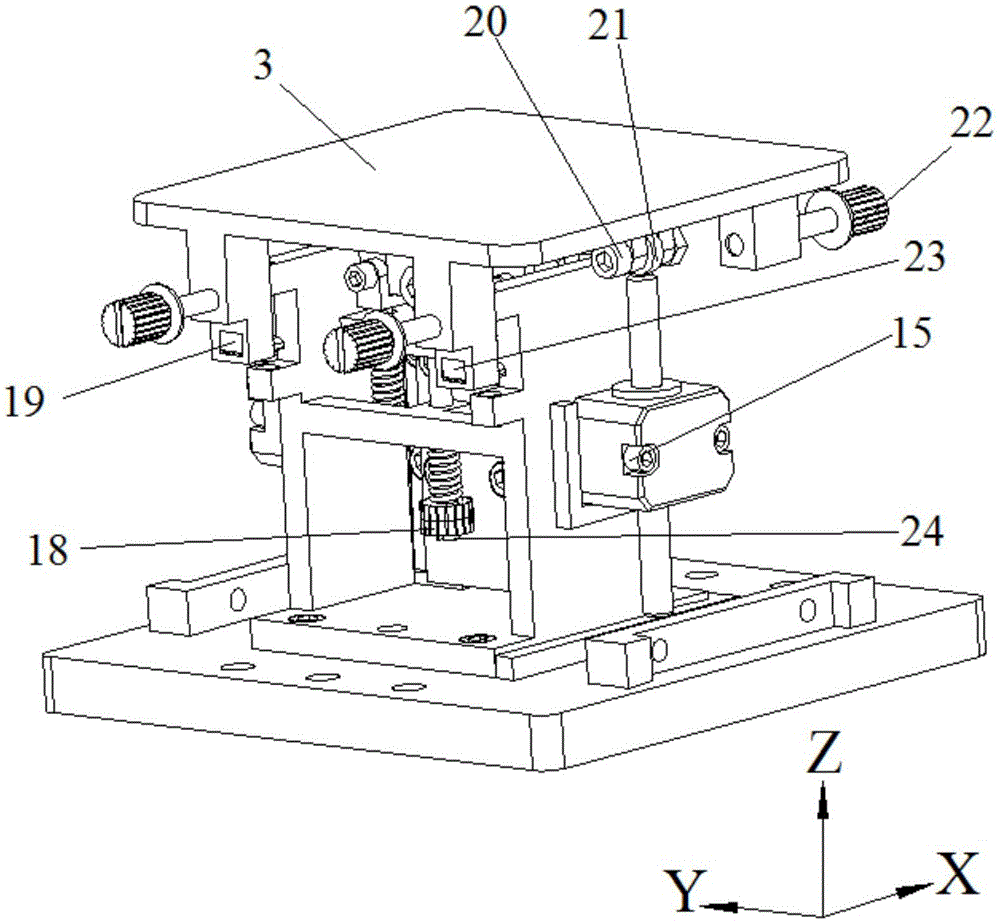

[0032] The box body 2 and the main bracket 6 are installed on the bottom plate 1, the box body 2 has a slot 201 for system heat dissipation, the main bracket 6 is used to support the drive system, Z-direction piezoelectric linear motor 1 and Z-direction piezoelectric linear motor 2 15 are installed on both sides of the main bracket 6 respectively, and there are bosses 1 606 and 2 607 for positioning the Z-direction piezoelectric linear motor 5 and the Z-direction piezoelectric linear motor 2 15 on both sides of the main bracket 6 , and the Z-direction Guide rail 1 4 and Z guide rail 2 17 are installed side by side in parallel inside the main support 6, Z slide block 16 is installed on Z guide rail 1 4 and Z guide rail 2 17, and specimen workbench 3 passes through the large gap in the middle of its bottom. The boss 301 and the shaft 3 11 are hingedly installed on the Z-direction slider 16, so as to realize the rotation of the specimen table 3 around the X direction and the Z-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com