Circular electro-permanent magnetic chuck for vertical lathe

An electric permanent magnet chuck and circular technology, which is applied in the field of circular electric permanent magnet chuck for vertical lathes, can solve problems such as low processing efficiency, achieve the effects of good precision retention, stable state, and meet the needs of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

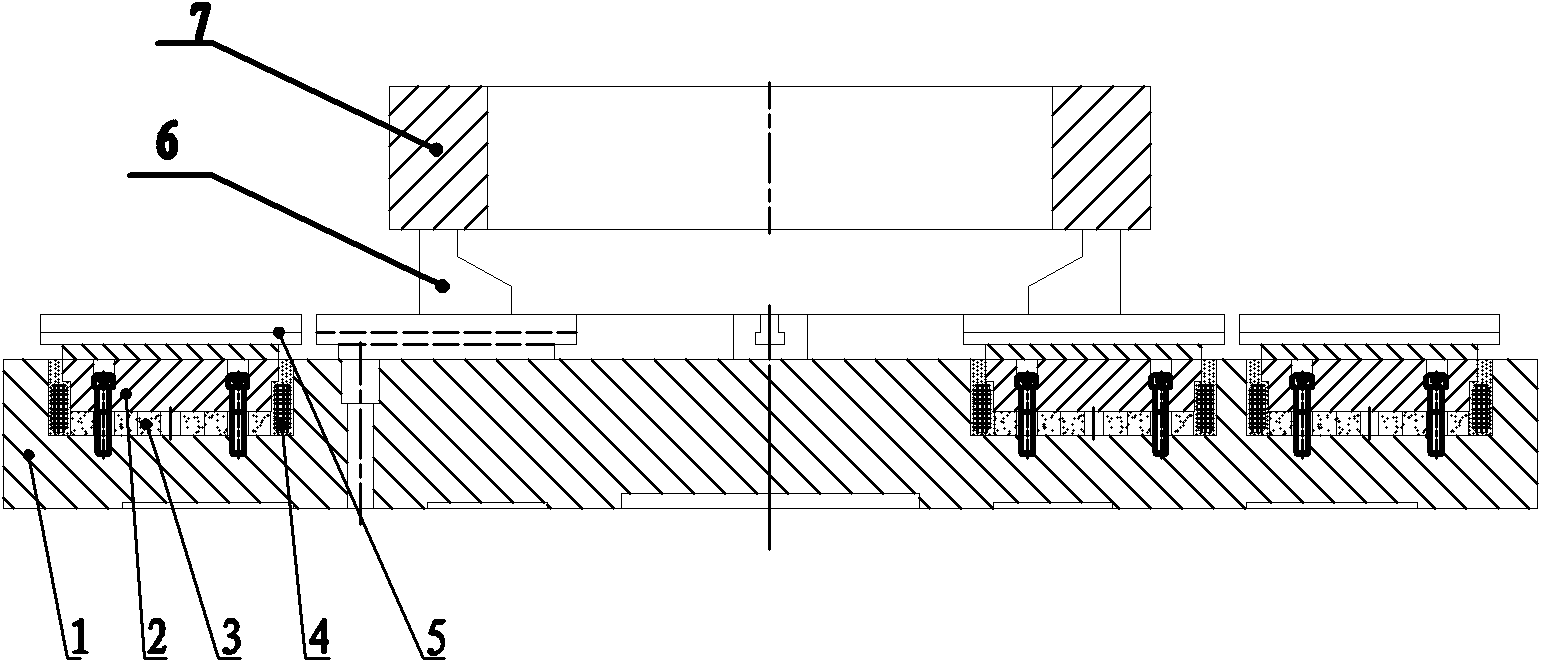

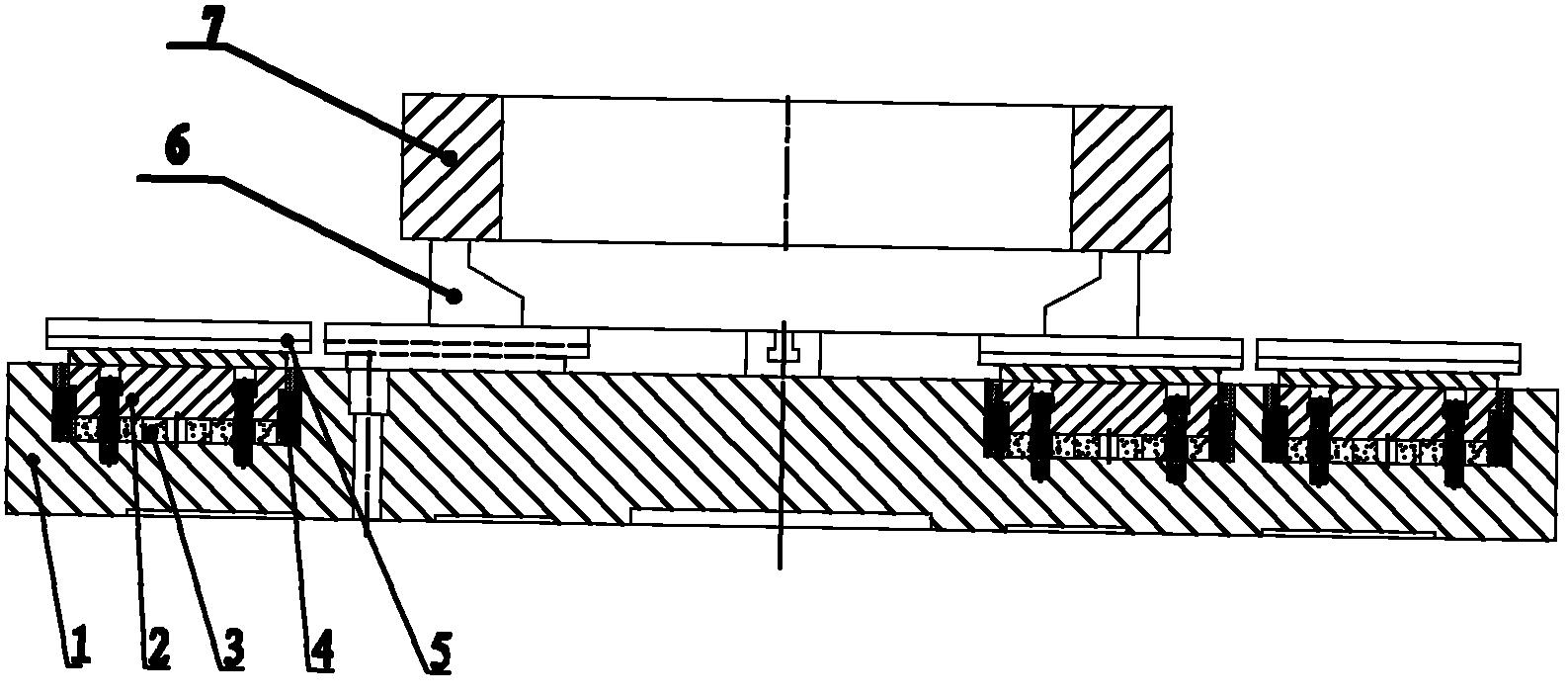

[0011] Such as Figure 1 ~ Figure 2 Shown: including disc body 1, magnetic pole 2, magnetic steel 3, excitation coil 4, magnetic pad 5, support block 6 and parts 7; a plurality of strip holes are arranged on the top of the disc body 1, and the magnetic pole 2 is pressed on the magnetic On the steel 3, the excitation coil 4 is installed on the outer ring of the magnetic steel 3, and the magnetic pad 5 is installed above the magnetic pole 2 to form a whole, and is installed in the strip hole above the disk body 1 with screws, and the wire of the magnetic pole 2 is led out of the disk body 1. The disc body 1 is equipped with a socket 8 .

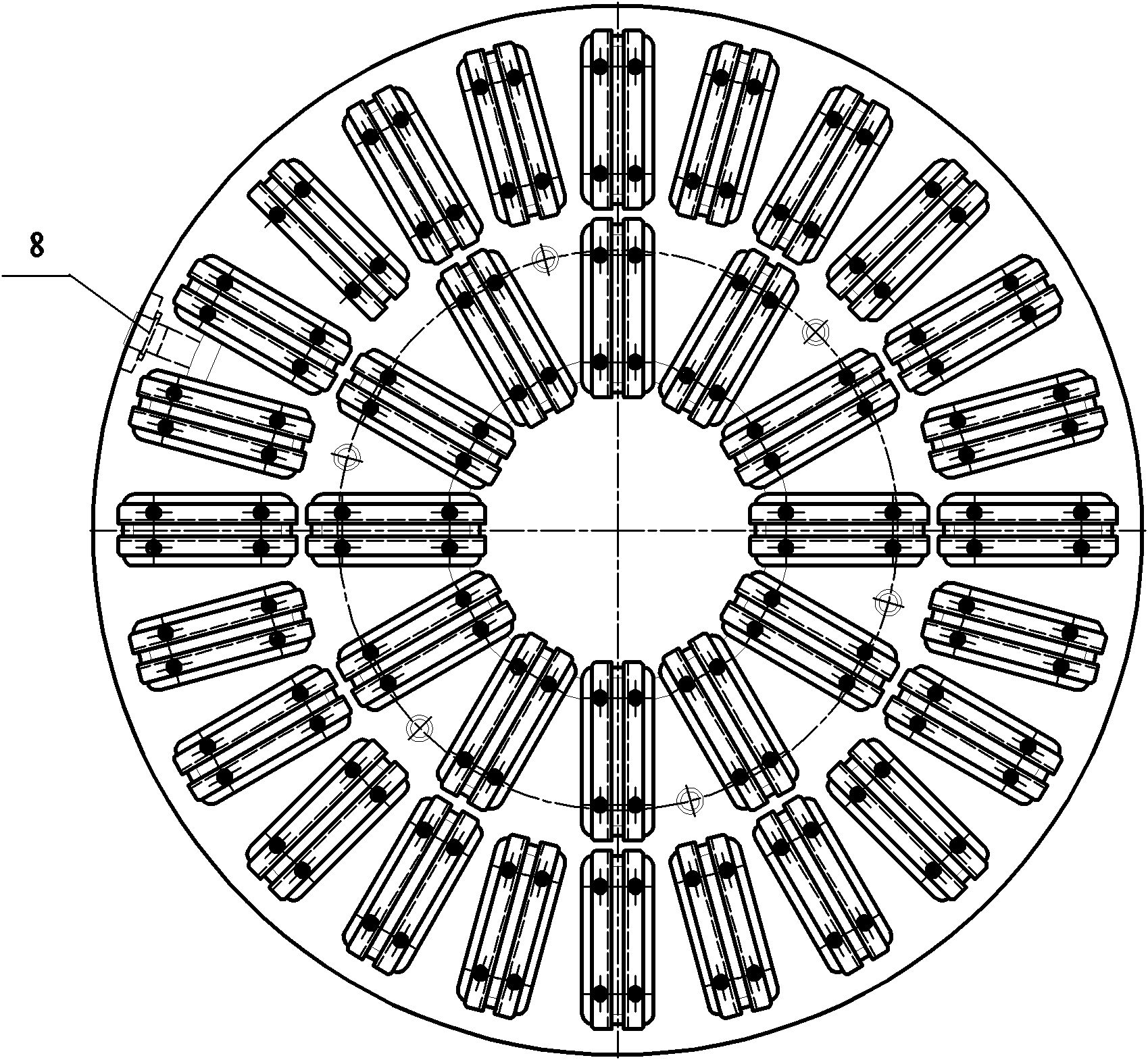

[0012] Such as figure 2 As shown, it can be seen that the magnetic poles 2 on the disk body 1 are arranged in sections from the inside to the outside according to the size of the specification, the number of magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com