Patents

Literature

64 results about "Oxygen flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

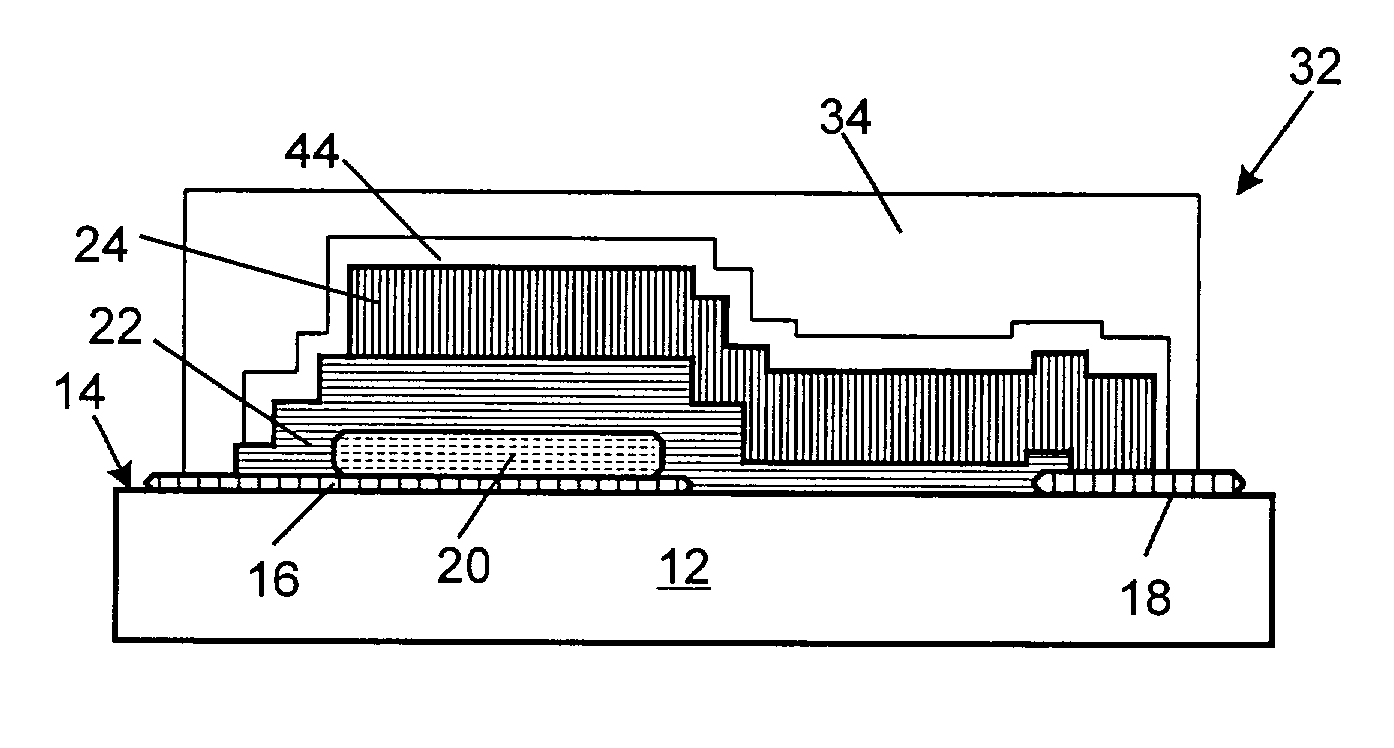

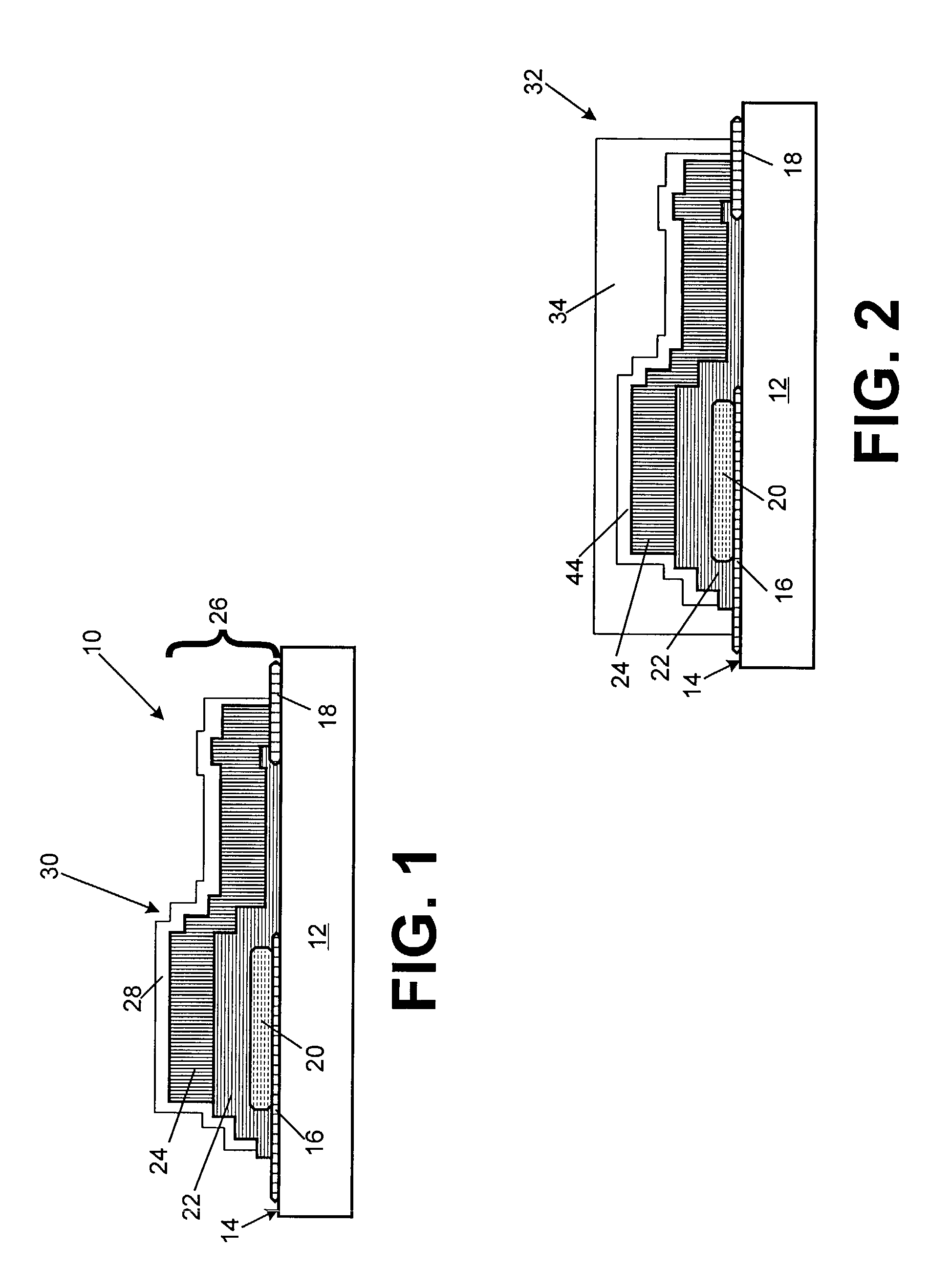

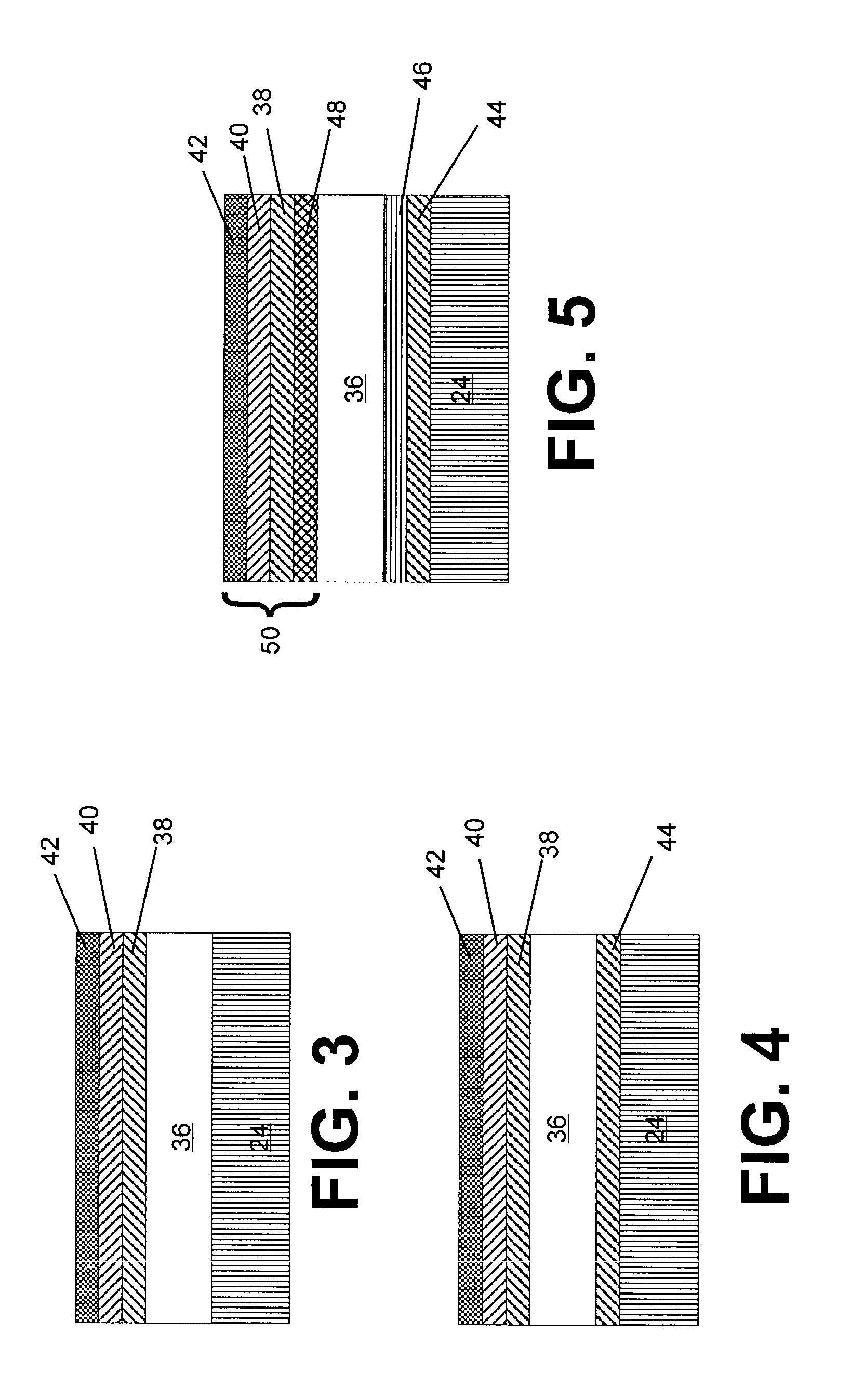

Long life thin film battery and method therefor

InactiveUS6994933B1Extend battery lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsOxygen fluxSurface roughness

A thin film battery including an anode layer, a cathode layer and a solid electrolyte layer. The battery also includes, a planarization layer applied to the thin film battery. The planarization layer has a surface roughness of no more than about 1.0 nanometers root mean square and a flatness no larger than about 0.005 cm / inch. A barrier layer is applied to the planarization layer. The barrier layer is provided by one or more layers of material selected from the group consisting of polymeric materials, metals and ceramic materials. The planarization layer and barrier layer are sufficient to reduce oxygen flux through the barrier layer to the anode layer to no more than about 1.6 μmol / m2-day, and H2O flux through the barrier layer to the anode layer to less than about 3.3 μmol / m2-day thereby improving the life of the thin film battery.

Owner:OAK RIDGE MICRO ENERGY

Converting process for converter low-silicon molten iron

ActiveCN101117651AOxygen blowing time shortenedGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

The present invention provides a siliconeisen iron melt blowing and refining method in a converter, and the method includes the steps as follows: (1) waste steel and iron melt are loaded into the converter, and oxygen blowing and steel making begin, the oxygen flux is 900Nm3 / min to 1050Nm3 / min, the height that the oxygen gun spraying head departs the metal liquid surface in the melt pond is 1.8-3.0m; (2) a first batch of slag charge is added after oxygen is blown in the first batch of the slag charge is 60-80 percent of the total slag charge, and the rest slag charge can be charged in 2-3 batches after the first batch of the slag charge is melted. The consumption of the slag charge: the lime 18-28kg / t steel, the light calcined dolomite 15-25kg / t steel, the ironstone 5-10kg / t steel, the carbonaceous heat generating agent 0-7kg / t steel, the compound slag 0-6kg / t steel; and the rest process are same as the prior art. The oxygen blowing duration of the present invention decreases 1.8min per furnace averagely, and the problem that the heat quantity is short and the slag forming is difficult can be solved simultaneously, and the present invention can make the converter steel-making to produce efficiently.

Owner:BAOSHAN IRON & STEEL CO LTD +1

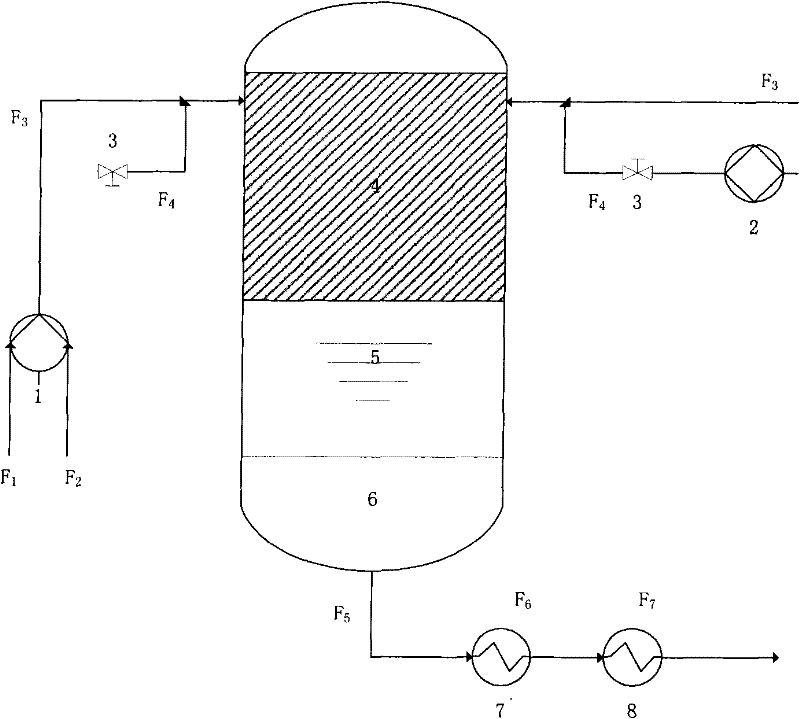

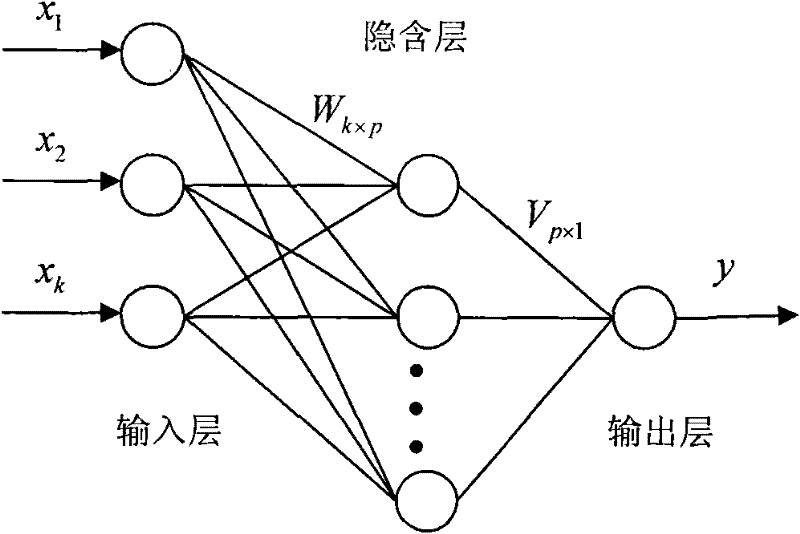

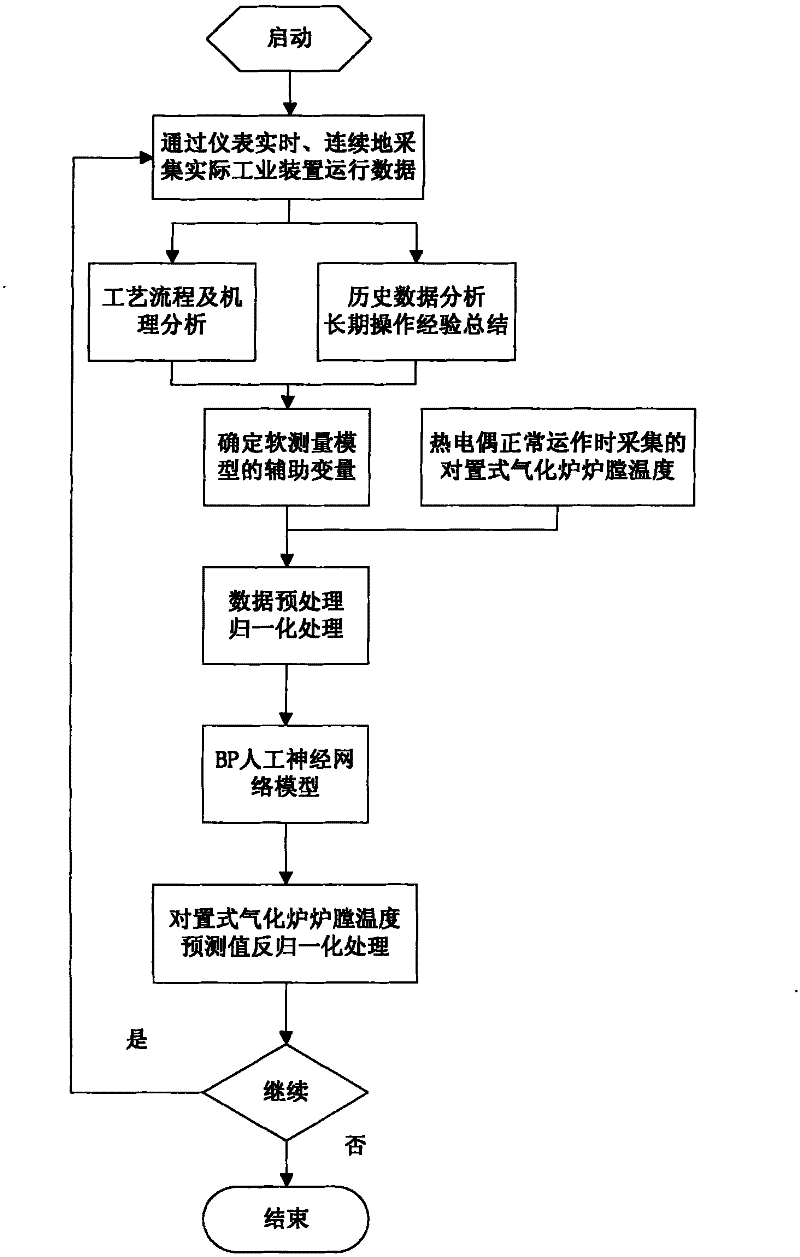

Soft measurement method for fire box temperature of multi-nozzle opposed coal water slurry gasification furnace

ActiveCN102175345AEmission reductionImprove conversion efficiencyThermometer applicationsNeural learning methodsCoal waterSpray nozzle

The invention relates to a soft measurement method for fire box temperature of a multi-nozzle opposed coal water slurry gasification furnace. The method comprises the following steps of: choosing a plurality of measurable process status auxiliary variables, including dried basis coal, oxygen flux at furnace entrance center, coal to oxygen ratio and content of H2, Co and CH4 synthesized at an exit, as input variables of a soft measurement model; simultaneously, acquiring practical operation data of an industrial device, and preprocessing the acquired data; and based on a BP artificial neural network, choosing a 6*6*1 three-layer network topology to train the model through a Levenberg-Marquardt learning algorithm so as to implement the soft measurement for the fire box temperature of the multi-nozzle opposed coal water slurry gasification furnace. The soft measurement technology can provide effective fire box temperature information for the multi-nozzle opposed coal water slurry gasification furnace so as to guide optimal running operations in a gasification process, and the method is also suitable for the soft measurement for the fire box temperature of coal water slurry gasification furnaces of other prior technologies.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid

InactiveCN102701944AStable chemical propertiesImprove thermal stabilityPhysical/chemical process catalystsOrganic compound preparation2-Ethylhexanoic acidReaction temperature

The invention discloses a method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid, and relates to a method for preparing a chemical preparation. The method comprises the following steps: weighing molybdovanadophosphoric acid and dissolving the molybdovanadophosphoric acid in distilled water at first and then in hydrochloric acid to prepare a catalyst solution; adding 2-ethylhexanal and the prepared catalyst in an ordinary-pressure reaction device, slowly heating and stirring the mixture, regulating oxygen flux, and starting to introduce oxygen when the temperature rises to the reaction temperature; after the reaction is ended, separating out the aqueous phase solution on the lower layer to obtain organic phase matter on the upper layer; and depressurizing and distilling the organic phase matter to obtain colorless transparent and pungent oily liquid, 2-ethyl hexanoic acid. By changing the ratio of molybdenum to vanadium of the catalyst and optimizing the reaction condition, the conversion rate of the 2-ethylhexanal reaches above 99%, and the selection and yield of the 2-ethyl hexanoic acid reach above 98% respectively.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

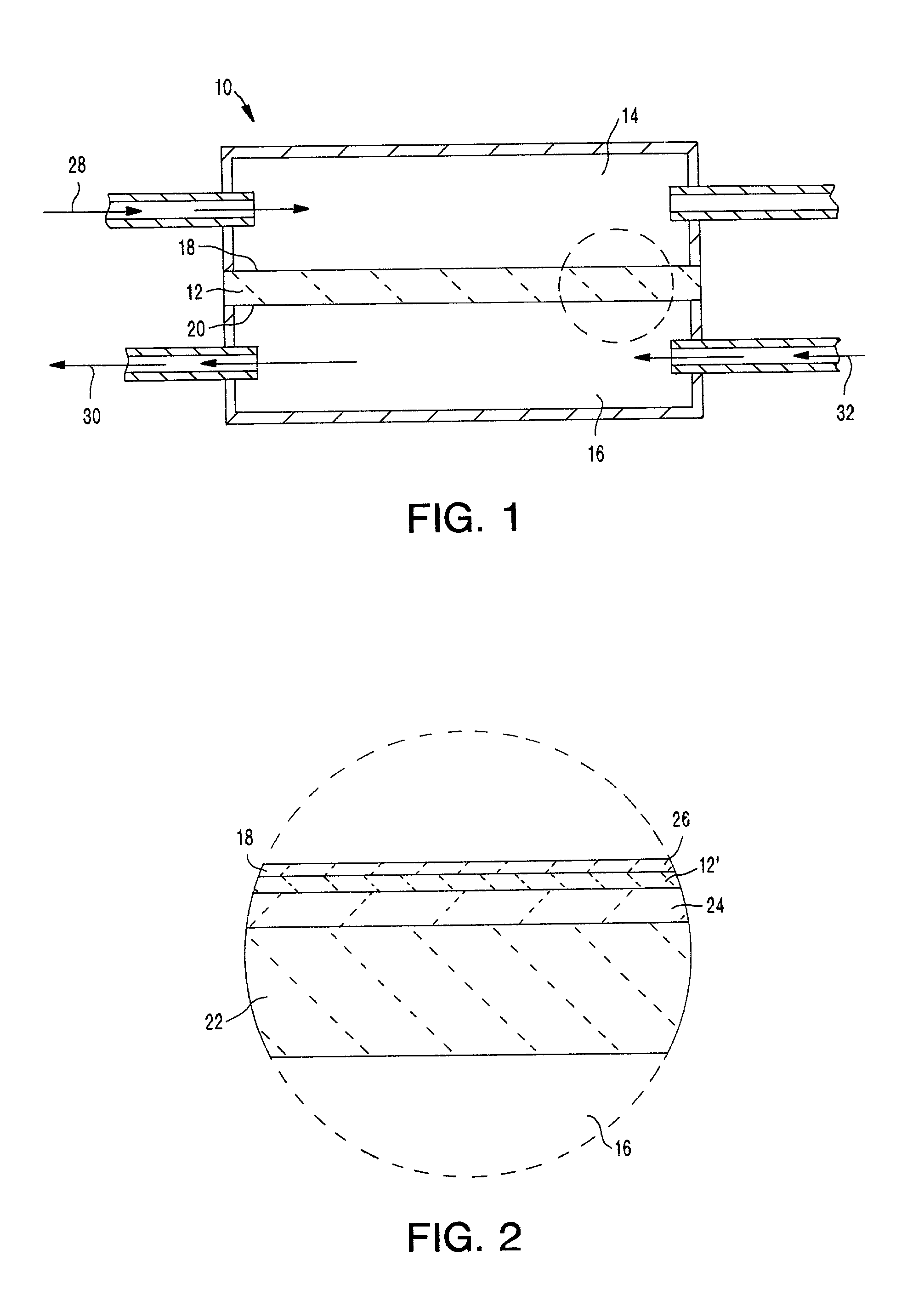

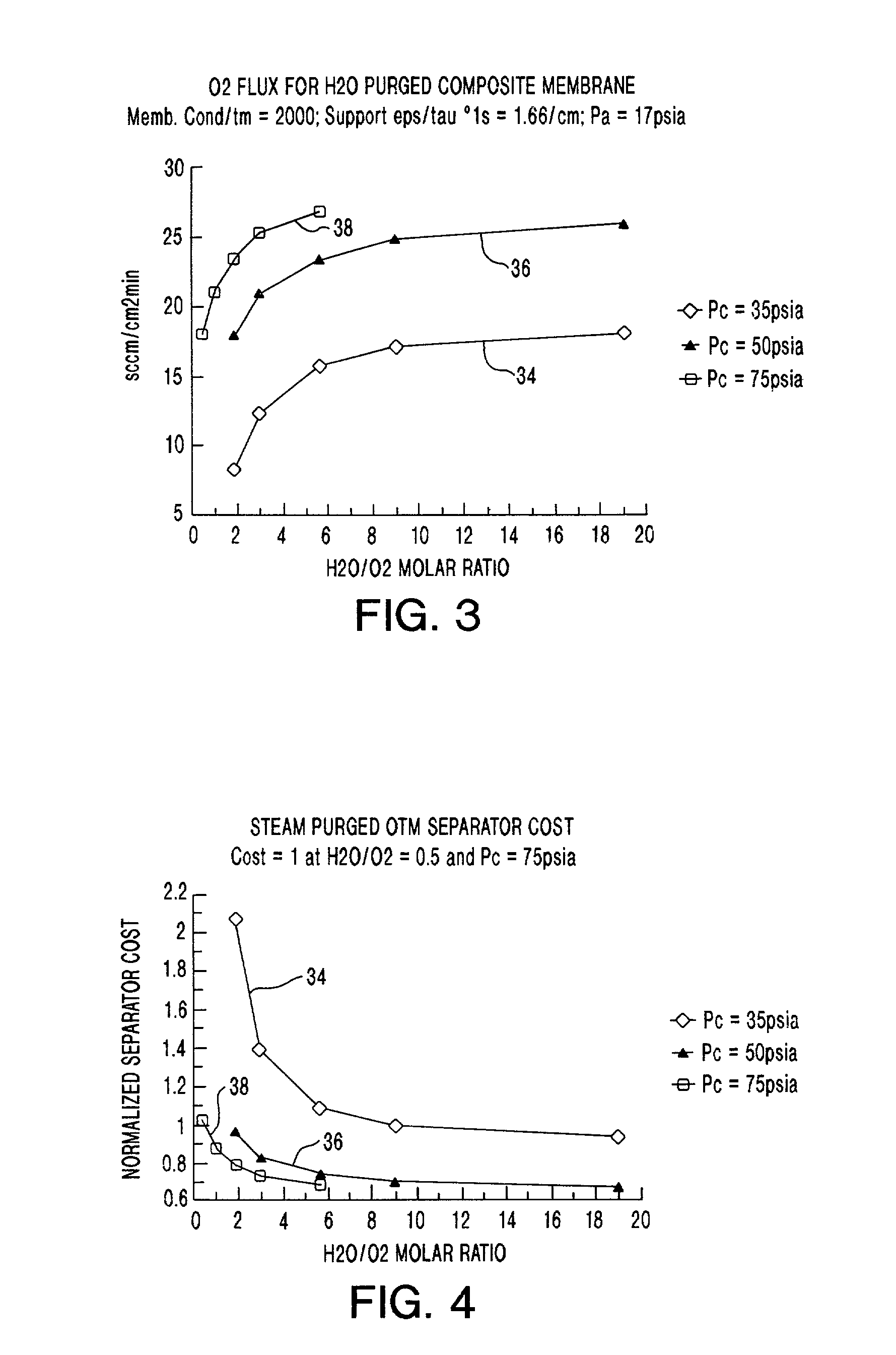

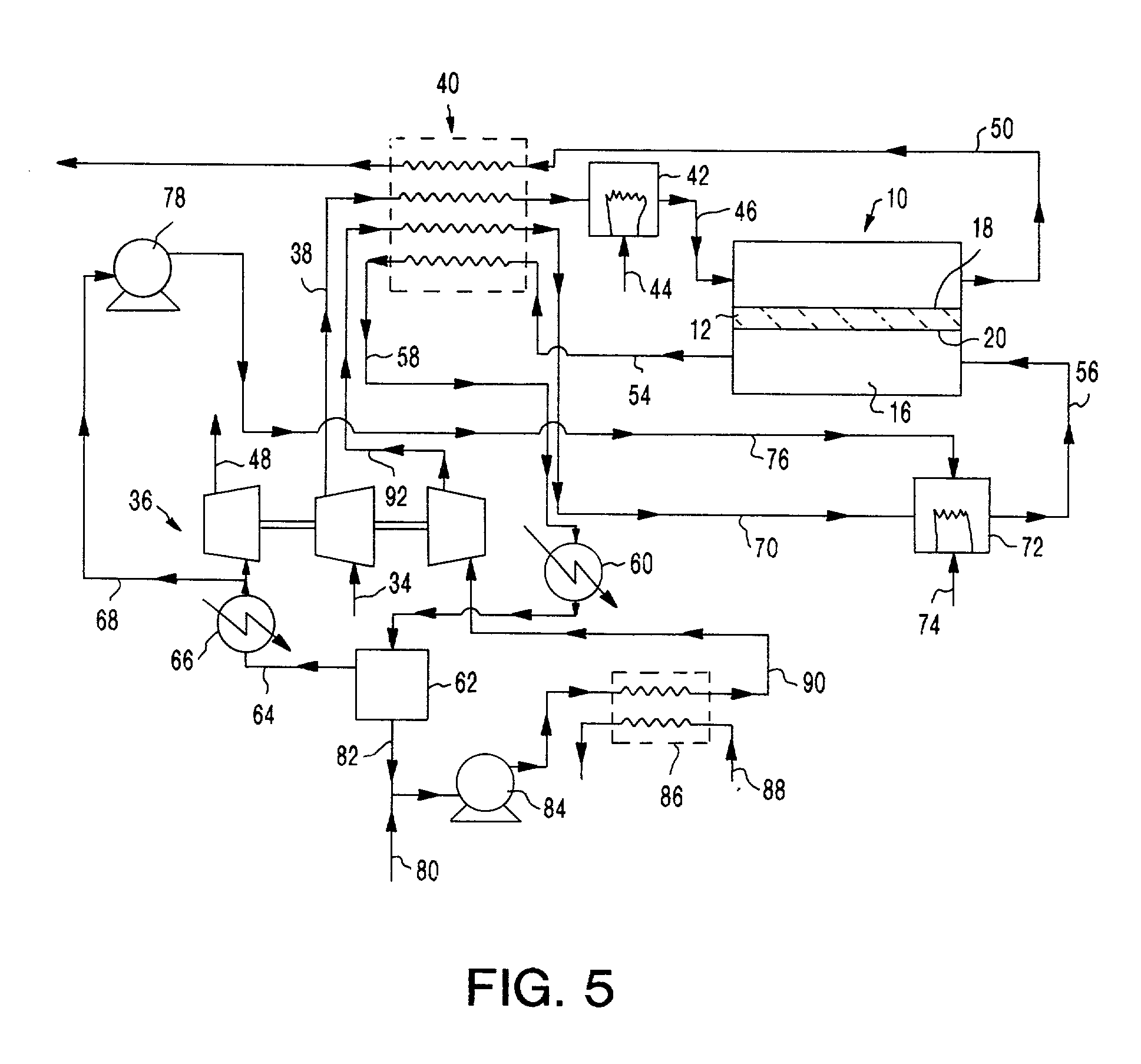

Low pressure steam purged chemical reactor including an oxygen transport membrane

InactiveUS20020127177A1Efficient transportHydrogenHydrocarbon from carbon oxidesSteam reformingPartial oxidation

Owner:PRAXAIR TECH INC

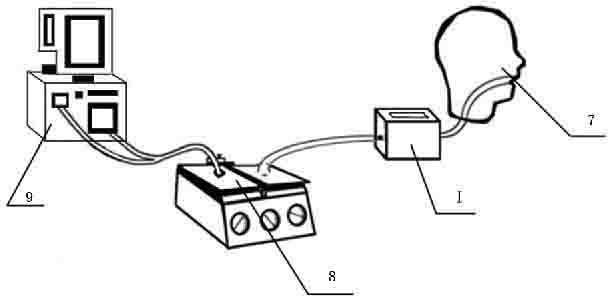

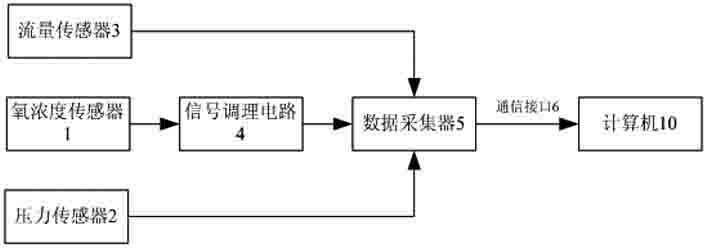

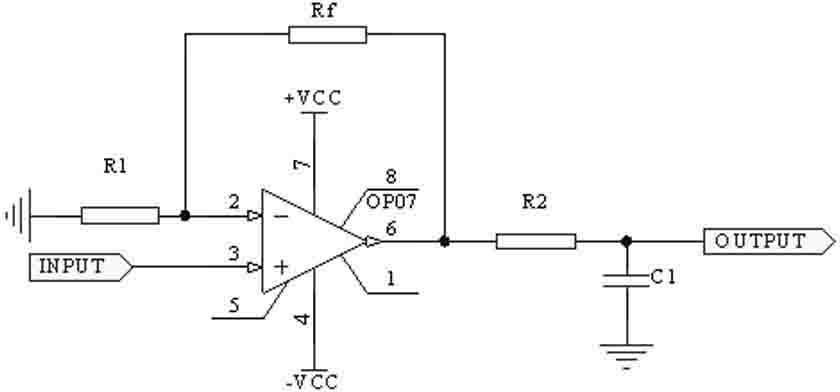

Apparatus for actively simulating autonomous respiration of human body in vitro and gas analyzing method employing the same

The invention, which belongs to the psychological research filed of respiratory medicine, relates to an apparatus for actively simulating autonomous respiration of a human body in vitro and a gas analyzing method employing the same. The apparatus includes a circulating gas circuit formed by a driving respirator, a dual-cavity simulation lung device and a head dead space model; and the output end of the dual-cavity simulation lung device is connected with the head dead space model by a gas analyzing device. The gas analyzing method comprises the following steps that: data are collected; integration is carried out on results by multiplication of obtained real-time oxygen concentration inside the apparatus and inspiration / expiration flow rates so as to obtain oxygen fluxes and tidal volumes of expiration / inspiration in each respiratory cycle; and division operation is carried out on the oxygen fluxes and tidal volumes to obtain mean effective inspired oxygen concentration in inspiratory / expiratory phases. According to the invention, the apparatus having a compact structure can be applied to scientific research and training of various ventilation modes; and the applied gas analyzing method enables a detection result to be accurate and to approach a real one.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV +1

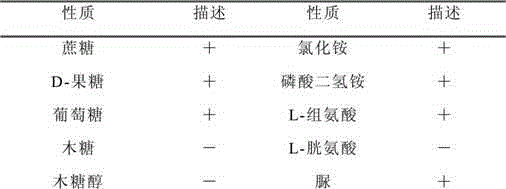

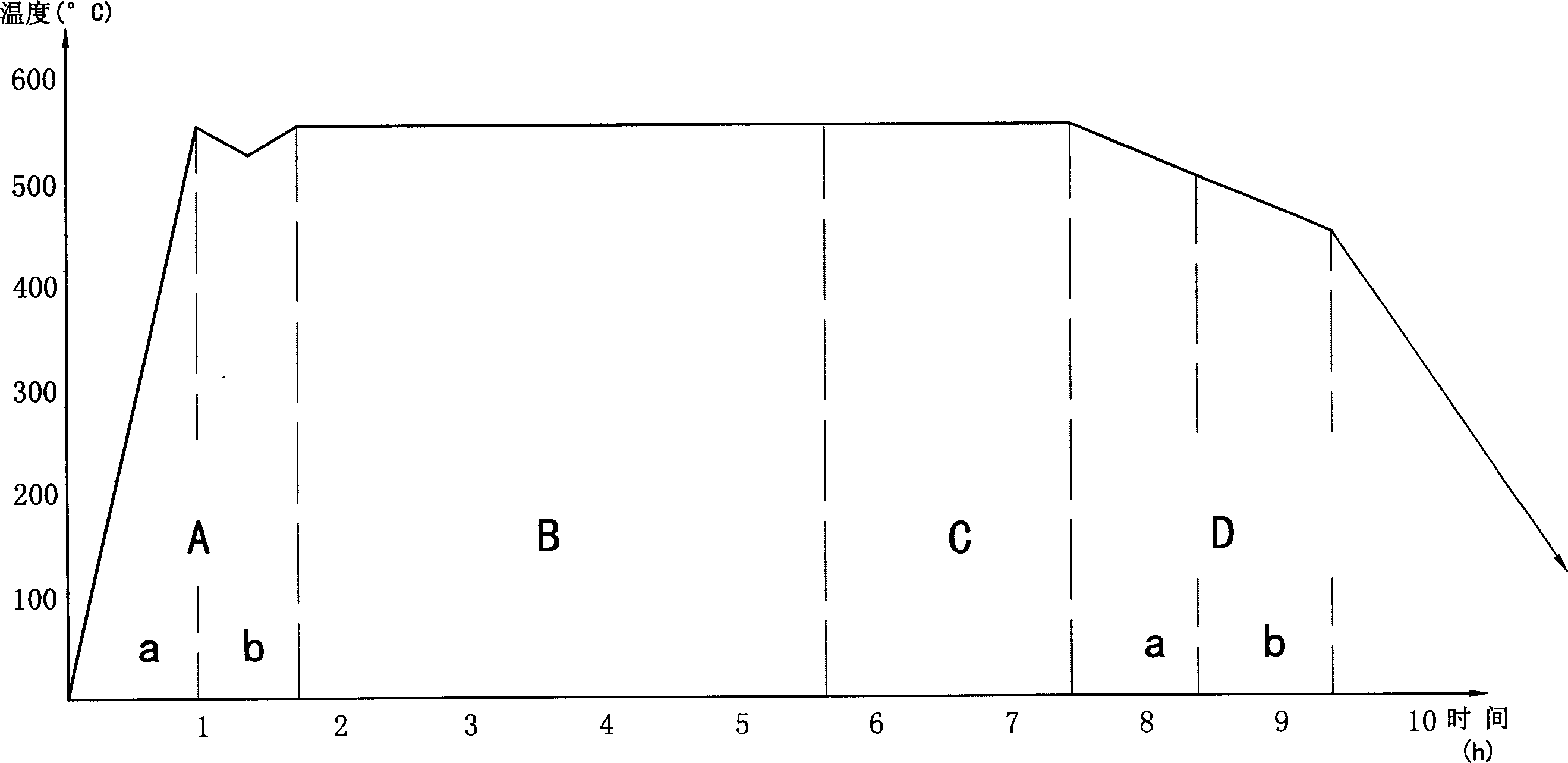

Gibberella and method for fermentation production of gibberellin GA4+7

The invention discloses a gibberella and a method for fermentation production of a gibberellin GA4+7. The method belongs to the field of fermentation engineering. The method comprises the following steps of plate culture, seed culture and fermentation culture, wherein in the fermentation culture, condition control is carried out. A mixed carbon source is added into a fermentation culture medium; and at a particular moment, the fermentation culture medium with the mixed carbon source is added with vegetable oil and a characteristic precursor and an oxygen flux of the fermentation culture medium with the mixed carbon source is increased so that a GA4+7 valence is improved. The gibberellin GA4+7 obtained by gibberella fermentation has a high valence and a low cost, is convenient for operation and is conducive to industrial production.

Owner:NANJING UNIV OF TECH

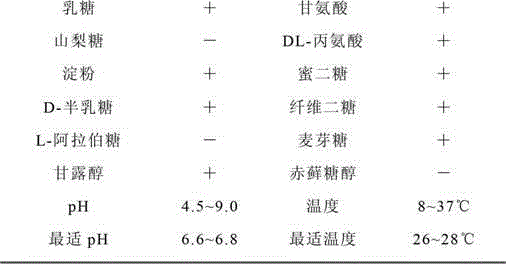

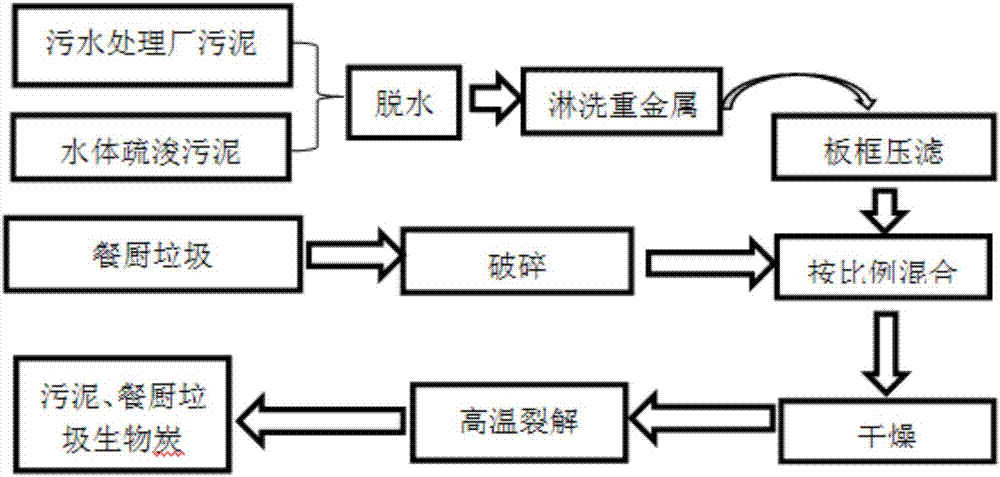

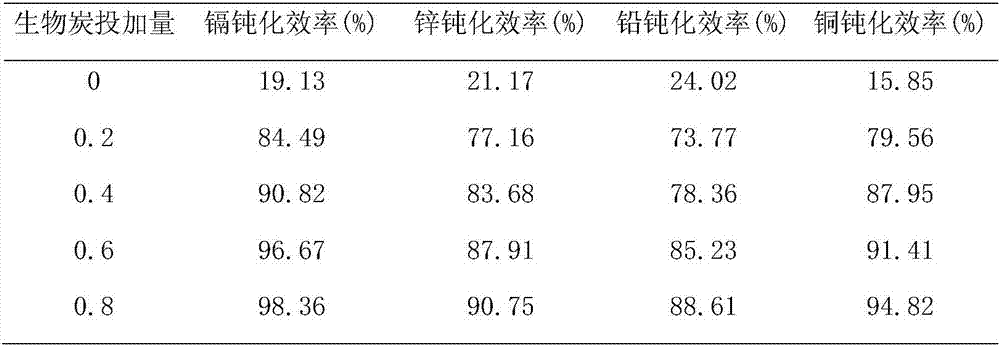

Preparation method of sludge and kitchen waste biochar soil heavy metal passivator

InactiveCN107252676AImprove adsorption capacityInhibit migrationOther chemical processesContaminated soil reclamationSludgeSoil heavy metals

The invention relates to a preparation method of a sludge and kitchen waste biochar soil heavy metal passivator. The problem that heavy metals are continuously accumulated and increased in soil due to discharge and improper disposal of pollutants such as a large amount of industrial 'three wastes' and urban domestic garbage can be effectively solved. According to the technical scheme for solving the problem, raw materials include sludge and kitchen waste, wherein the sludge is sludge of an urban sewage treatment plant or dredging sludge at the bottom of water body and is used after being dehydrated, and the kitchen waste is one or mixture of more of shells, pomace, pericarp and vegetables. The biochar prepared by adopting the preparation method has strong adsorption capability on the heavy metals, can prevent the heavy metals in the soil from migrating to underground water and prevent and treat underground water pollution, and a carbon source is provided for heterotropic microorganisms in the soil, so that absorption of plants on moisture and soil nutrients is facilitated, oxygen flux in the soil of a surface layer is increased, and the biochar preparation method provided by the invention is innovative.

Owner:HENAN INST OF ENG

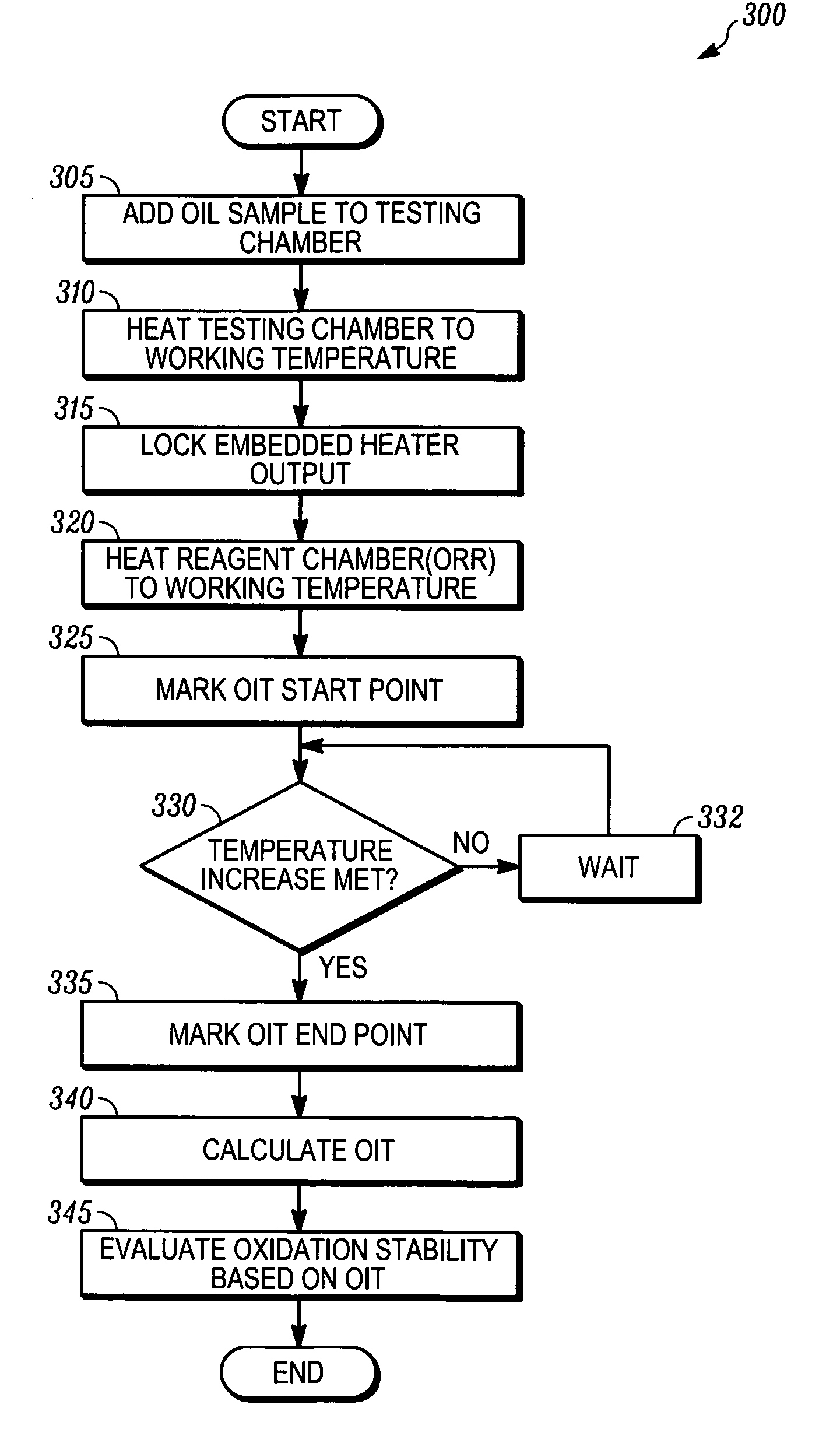

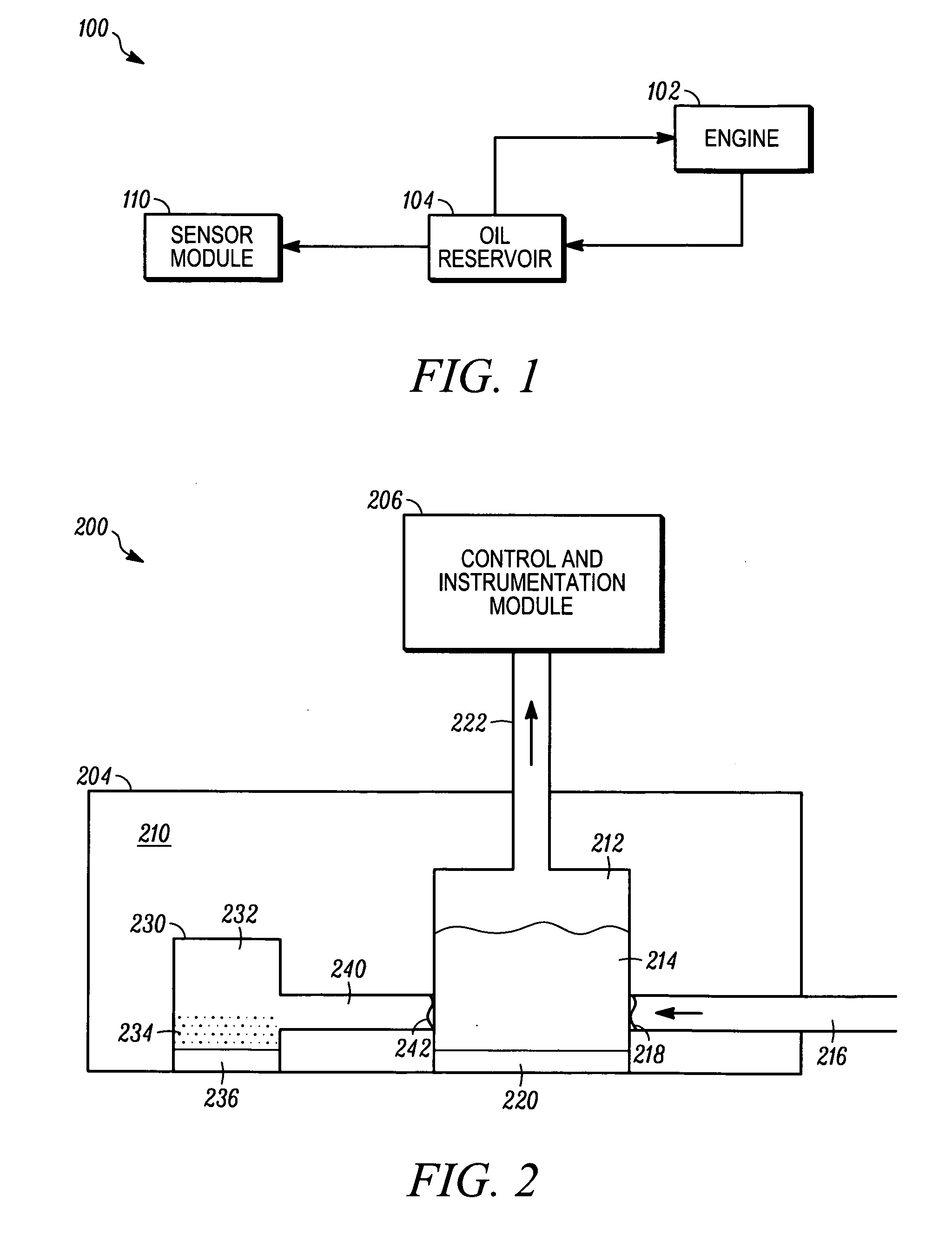

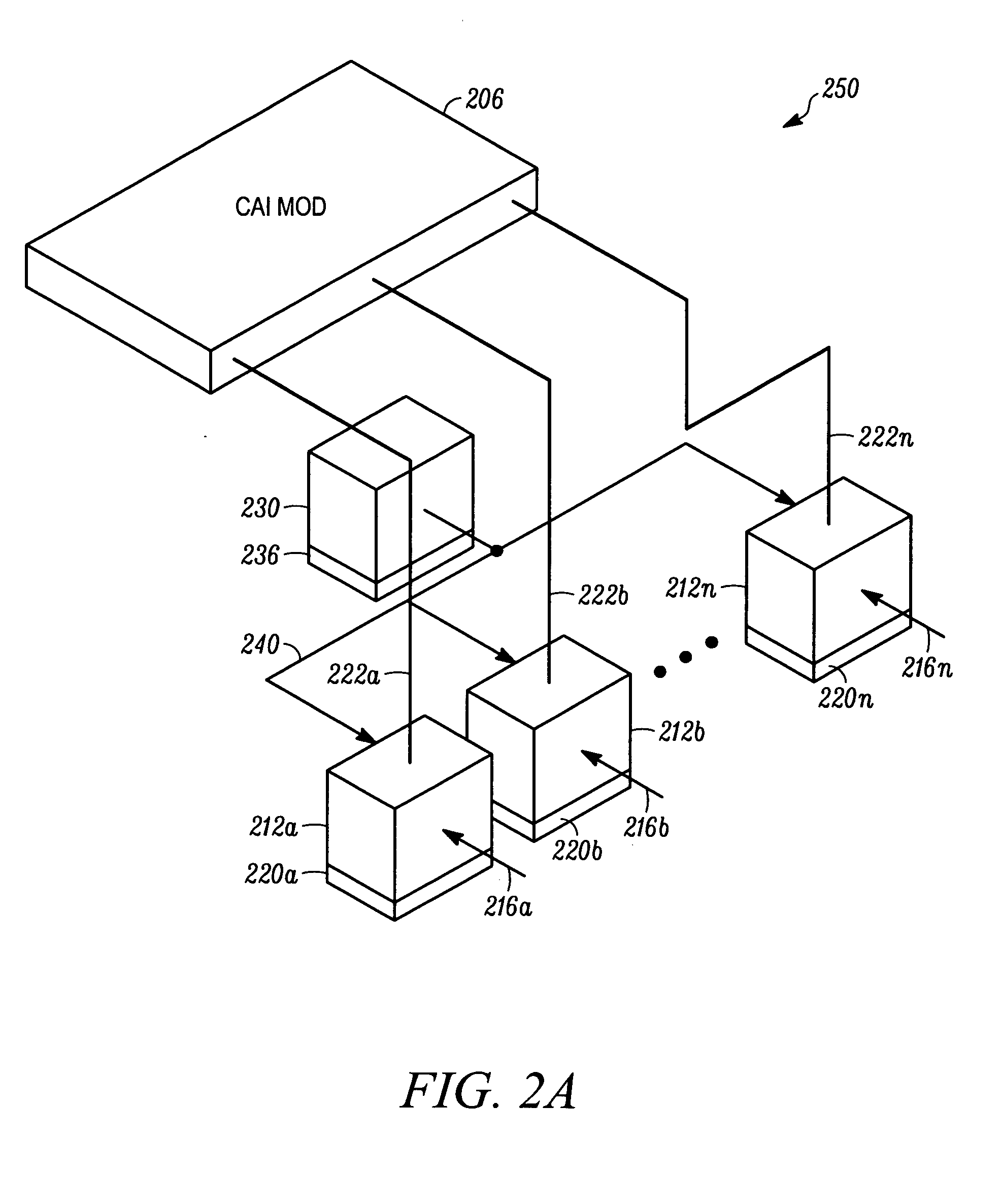

Oxidation stability measurement for oil condition management

InactiveUS20080022757A1Easy to optimizeHeat can be suppliedMaterial testing goodsTest roomOxygen flux

A sensor apparatus is disclosed that includes a testing chamber or testing chamber arrays configured to receive a sample of oil to be tested. A first embedded heater is coupled to the testing chamber or testing chamber arrays and configured to supply heat to the sample. An oxygen flux chamber is coupled to the testing chamber or testing chamber arrays and configured to provide a substantially stable oxygen flux to the testing chamber. A control module is coupled to the testing chamber, the first embedded heater, and the oxygen flux chamber. The control module is configured to monitor the temperature of the sample, direct the first embedded heater to supply heat to the sample, direct the oxygen flux chamber to provide oxygen flux to the testing chamber, measure an oxygen induction time (OIT), and evaluate the oxidation stability of the sample based on the OIT. A method for thermal analysis of oil oxidation stability is also disclosed.

Owner:HONEYWELL INT INC

Method for preparing Zn-doped p-type beta-Ga2O3 nanowire according to chemical vapor deposition method

InactiveCN105197983AOvercome preparation difficultiesEasy to operateGallium/indium/thallium compoundsNanotechnologyGas phaseSource material

The invention discloses a method for preparing a Zn-doped p-type beta-Ga2O3 nanowire according to a chemical vapor deposition method. The method provided by the invention comprises the following steps: carrying out evaporation to form a metal catalyst layer which is 1-50 nm thick on a cleaned substrate; sufficiently mixing a Ga source and a Zn source according to a certain mass ratio to prepare a reaction source material; putting the reaction source material and the substrate on which the metal catalyst layer is formed through evaporation into a quartz boat, and then putting the quartz boat into a high-temperature heating zone in a chemical vapor deposition system growth chamber, wherein the substrate is positioned in the downstream direction of gas flows and 1-2 cm away from the reaction source material, injected high-purity argon gas is carrier gas, and the argon gas flux is 50-500 ml / min; when the heating temperature reaches 600-1100 DEG C, injecting oxygen and keeping the oxygen flux of 1-5 ml / min for 15-30 minutes; stopping the oxygen injection, keeping the argon gas flux, cooling to 100 DEG C and below, and taking out an obtained sample.

Owner:徐州永丰磁业有限公司

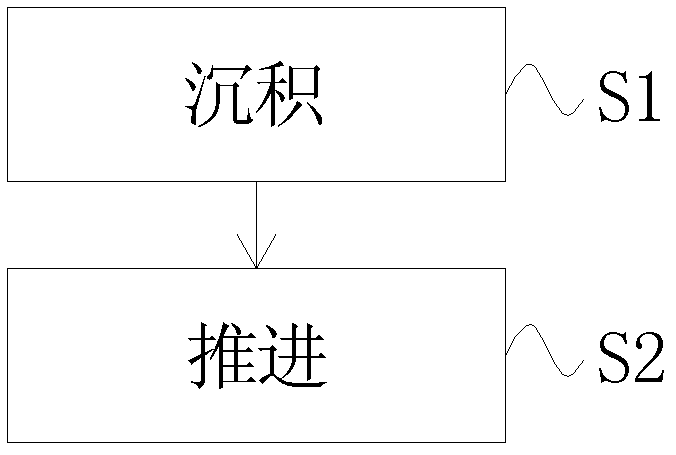

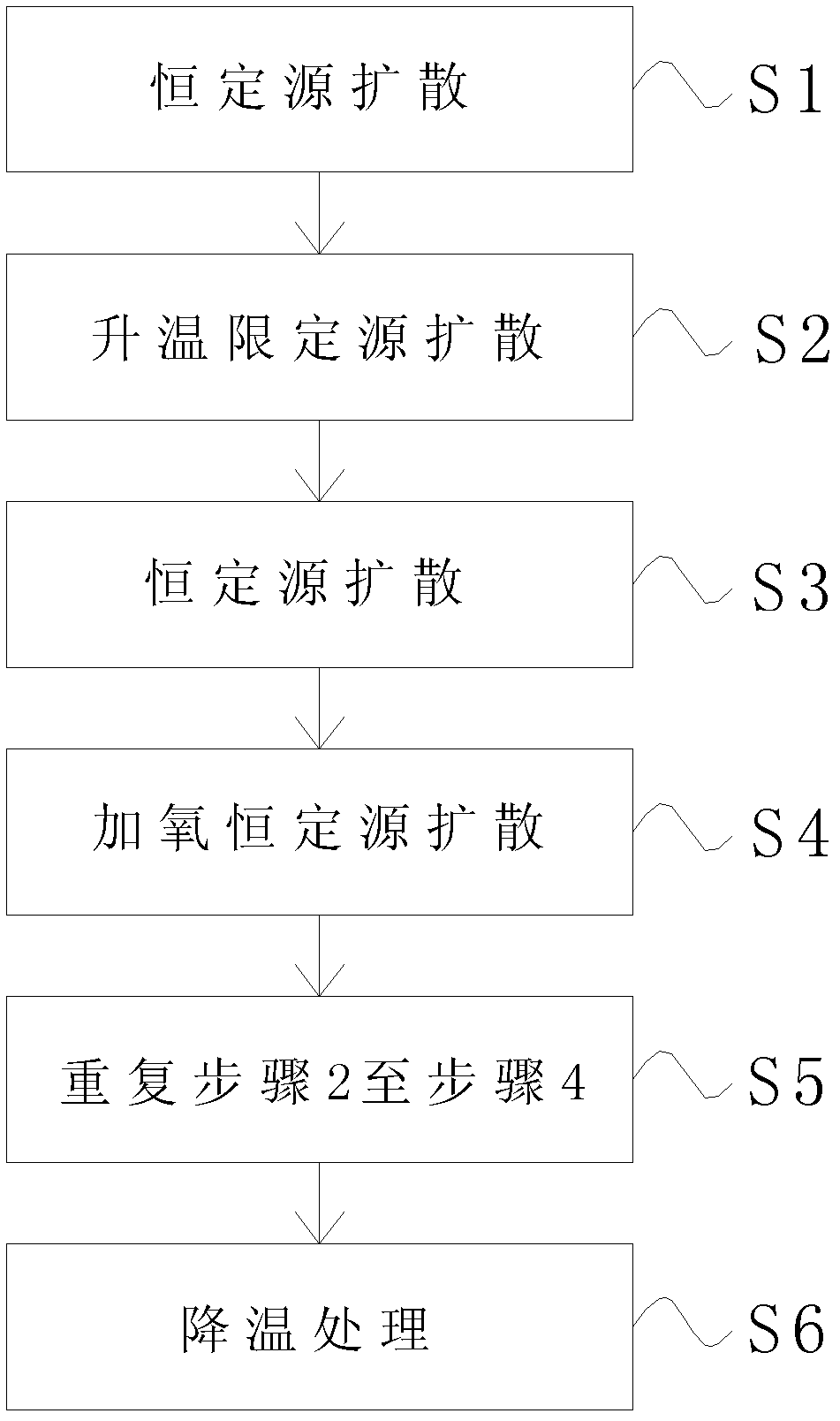

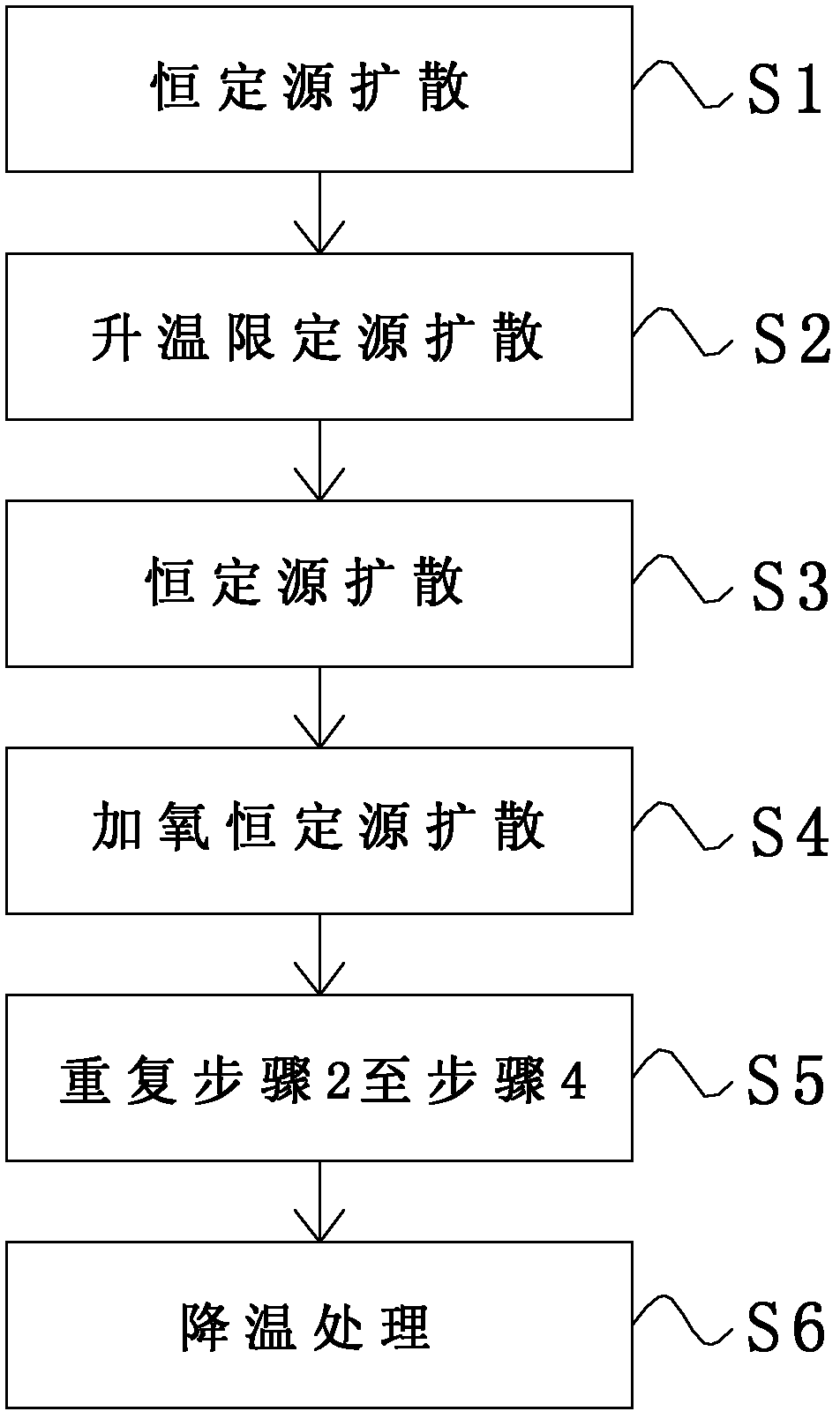

Multi-diffusion manufacturing method for polycrystalline silicon wafer

ActiveCN102544238ASolve the problem that the front and back colors are not easy to distinguishFinal product manufactureDiffusion/dopingDiffusionSurface layer

The invention discloses a multi-diffusion manufacturing method for a PN junction manufactured of a polycrystalline wafer. The multi-diffusion manufacturing method comprises the following steps of: S1, depositing, by constant source diffusion, an impurity source of certain concentration on the surface layer on which a P layer is required to be formed; S2, heating finite source diffusion to perform internal diffusion on a deposited impurity source phase polycrystalline wafer to control junction depth of the PN junction and gradient distribution of an impurity source; S3, depositing, by the constant source diffusion, the impurity source of the certain concentration on the surface layer of the P layer of the polycrystalline wafer again; S4, increasing, by oxygenation constant source diffusion, flux of oxygen under the conditions of unchanged temperature and a continuous flux source, wherein the step aims to increase the surface color of the P layer of the polycrystalline wafer, so that a front face and a back face of the polycrystalline wafer are differentiated during subsequent operation, and the hydrophilicity of the P layer can also be improved by increase in oxygen flux, so that an over large etching edge is reduced; and S5, repeating the step S2 to the step S4. Through the steps, the aim of solving the problem of difficulty in differentiating the colors of the front face and the back face existing after manufacturing of the PN junction of the polycrystalline wafer can be fulfilled.

Owner:YINGLI ENERGY CHINA

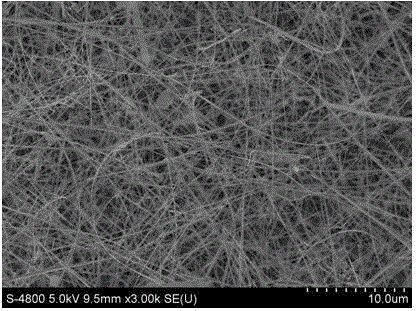

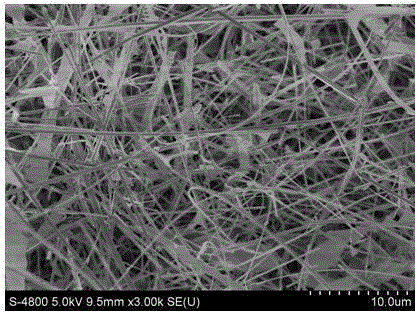

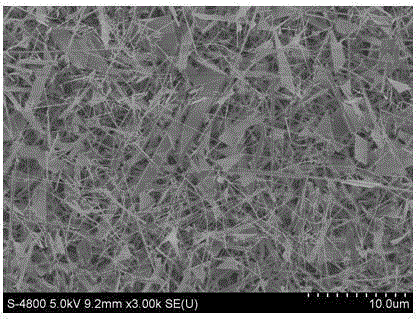

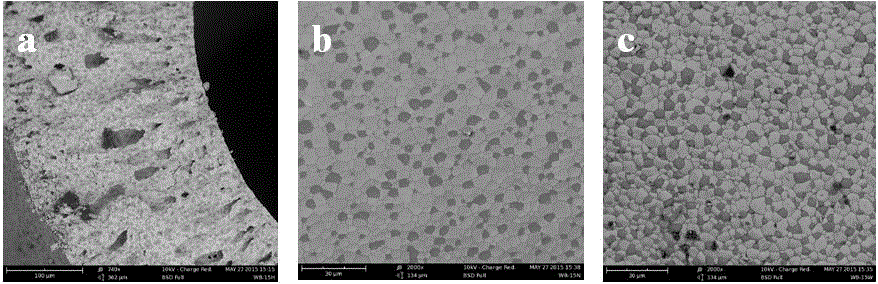

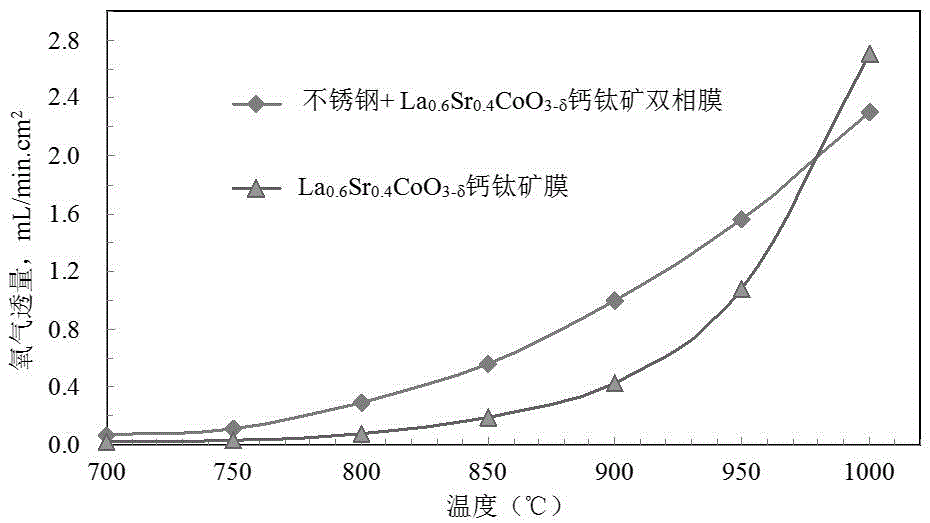

Stainless steel doped perovskite ceramic two-phase composite hollow fiber oxygen-permeating membrane and preparation method thereof

The invention belongs to the technical field of inorganic membranes, and particularly relates to a stainless steel doped perovskite ceramic two-phase composite hollow fiber oxygen-permeating membrane and a preparation method thereof. Being doped with 3 to 10 percent of stainless steel powder, a perovskite ceramic hollow fiber oxygen-permeating membrane can be greatly higher in strength. The preparation method comprises the following steps: preparing a casting solution containing perovskite ceramic powder, stainless steel powder, a polymer binder, a solvent and an additive; preparing a stainless steel / perovskite ceramic two-phase composite hollow fiber oxygen-permeating membrane precursor adopting an asymmetric structure according to a spinning phase inversion method; preparing the stainless steel doped perovskite ceramic two-phase composite hollow fiber oxygen-permeating membrane according to a certain high-temperature sintering program. The stainless steel doped perovskite ceramic two-phase composite hollow fiber oxygen-permeating membrane prepared according to the method is high in oxygen flux and mechanical strength, is easy to be assembled into a membrane component, and has the advantages that the practicability of a ceramic hollow fiber oxygen-permeating membrane is improved; the preparation process is simple; no complex equipment is required; convenience is brought for industrial production.

Owner:上海穗杉实业股份有限公司 +1

Serratia marcescens strain and synchronous extraction and fermentation method thereof

InactiveCN103627650AIncrease productionPurification and recovery process is simple and fastBacteriaMicroorganism based processesOxygen fluxSerratia species

The invention provides a Serratia marcescens Xd-1 strain with an accession number of CGMCC No. 7734 and a synchronous extraction and fermentation production method for prodigiosin by using the strain. The method is characterized by comprising the following steps: preparing primary seed liquid of the strain; preparing secondary seed liquid of the strain; mixing a liquid fermentation medium with a volume of V and the secondary seed liquid with a volume of 1 to 8% of V in a container and carrying out fermentation for 6 to 18 h under the fermentation conditions of a rotating speed of 130 to 200 r / min, oxygen flux of 0.5 to 1.5 v / (v.m) and fermentation temperature of 25 to 35 DEG C; and adding an extractant with a volume of 8 to 20% of V into the container and continuing fermentation under the fermentation conditions, wherein total fermentation time is 32 to 64 h.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

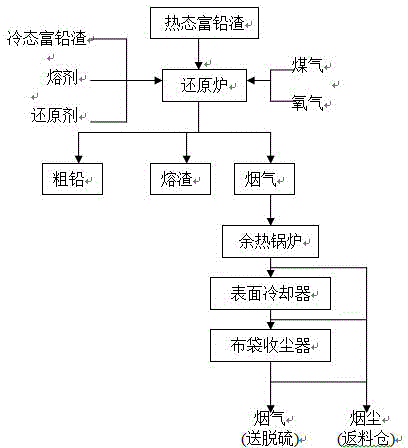

Method for treating cold-state lead-rich slag with hot slag side-blowing reduction furnace

The invention relates to a method for treating cold-state lead-rich slag with a hot slag side-blowing reduction furnace, and belongs to the technical field of thermometallurgy. The method comprises the following steps: (1) adding 70-90 t of hot-state lead-rich slag, 3-6 t / h of cold-state lead-rich slag, 1.5-2.5 t / h of limestone, 3-4 h / t of iron calcine, 2-3 t / h of coke nut and 0.8-1.6 t / h of crushed coal; (2) after a siphon mouth lead liquid level rises to the lead liquid flowing height in a lead-rich slag adding process, carrying out lead tapping and ingotting; (3) adding 3-10 t of zinc calcine, 2.2-3.5 t of limestone, 3-6 t of iron calcine, 2-3.5 t of coke nut, and 2.5-4 t of crushed coal into each furnace, and controlling the gas flux, oxygen flux, molten pool temperature and in-furnace negative pressure within 3200 to 3600 Nm<3> / h, 950 to 1200 Nm<3> / h, 1100 to 1300 DEG C and -20 to -40 pa respectively; (4) after the lead-rich slag adding process is finished, continuously adding crushed coal at 1000-1250 DEG C for 1-2 hours' smelting, observing the lead content of molten slag with a slag detection bar till the lead content is lower than or equal to 2.2%, and then carrying out 0.5 hour's heating for slag tapping; (5) conducting waste heat recovery and dust collection on flue gas in a smelting process, and then sending the treated flue gas into a desulphuration system. The method is simple in technology and has the advantages that the conventional technology is sufficiently utilized, the defect in stockpiling of the cold-state lead-rich slag is effectively overcome, the recovery rate of valuable metal is improved, and the like.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

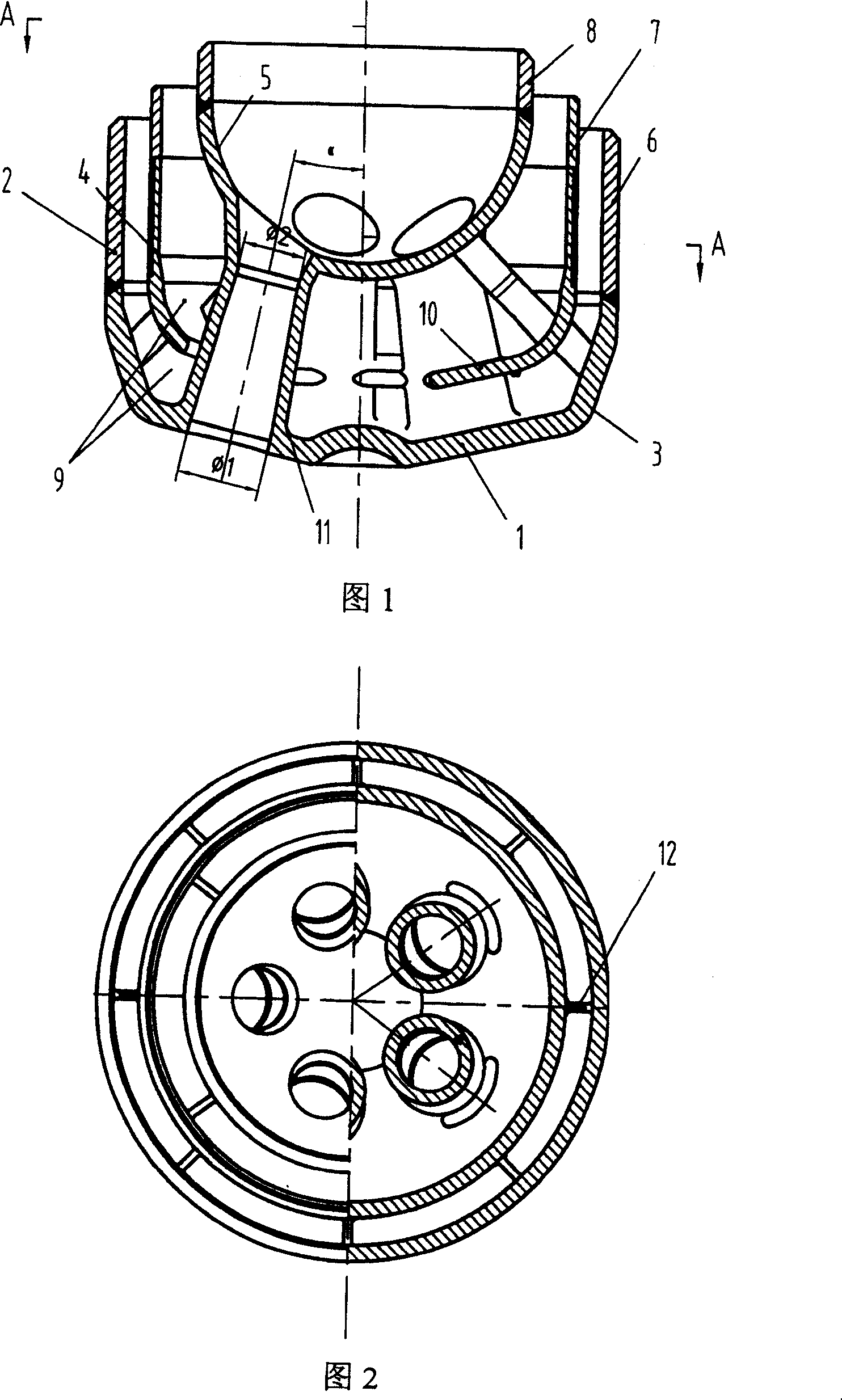

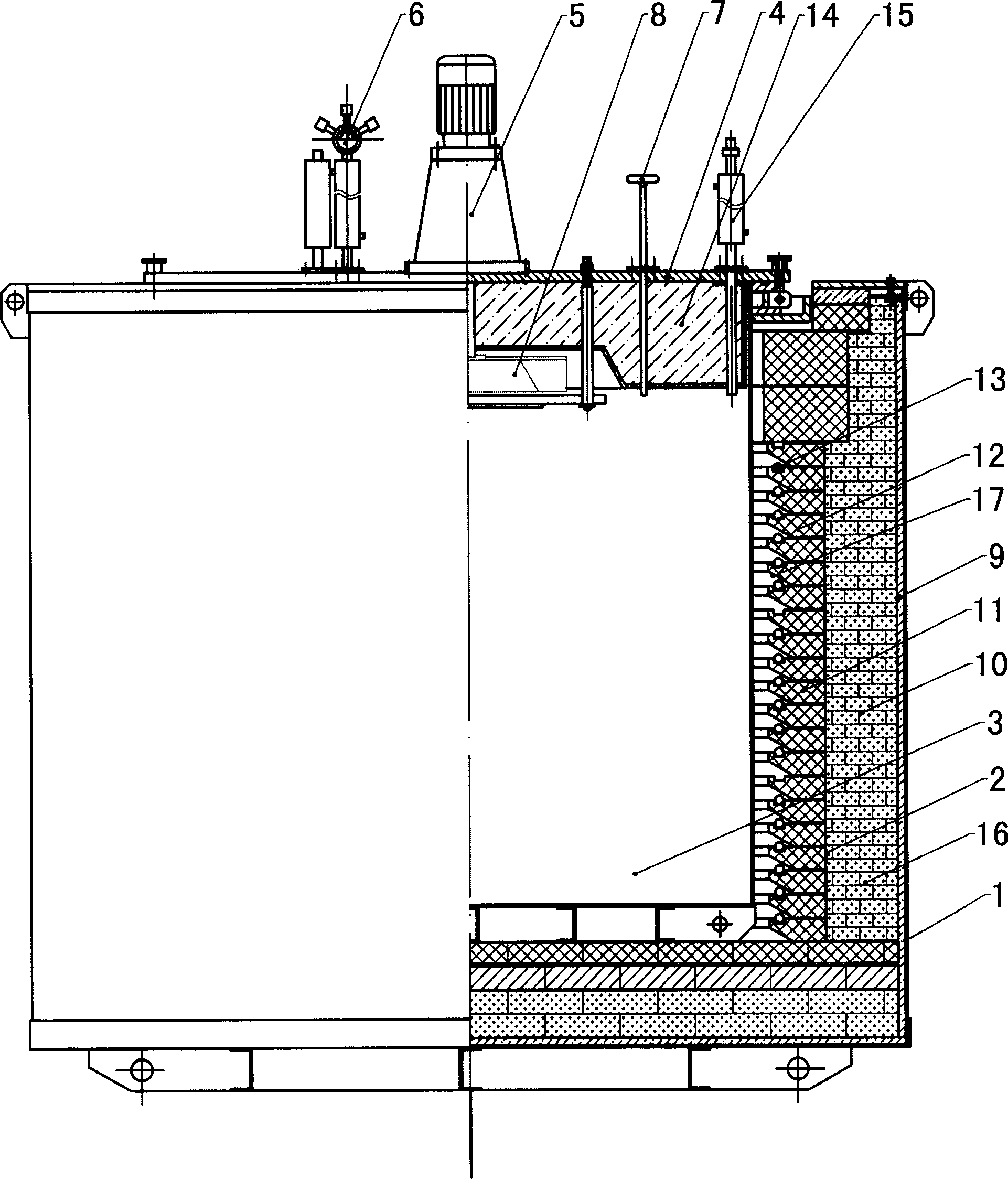

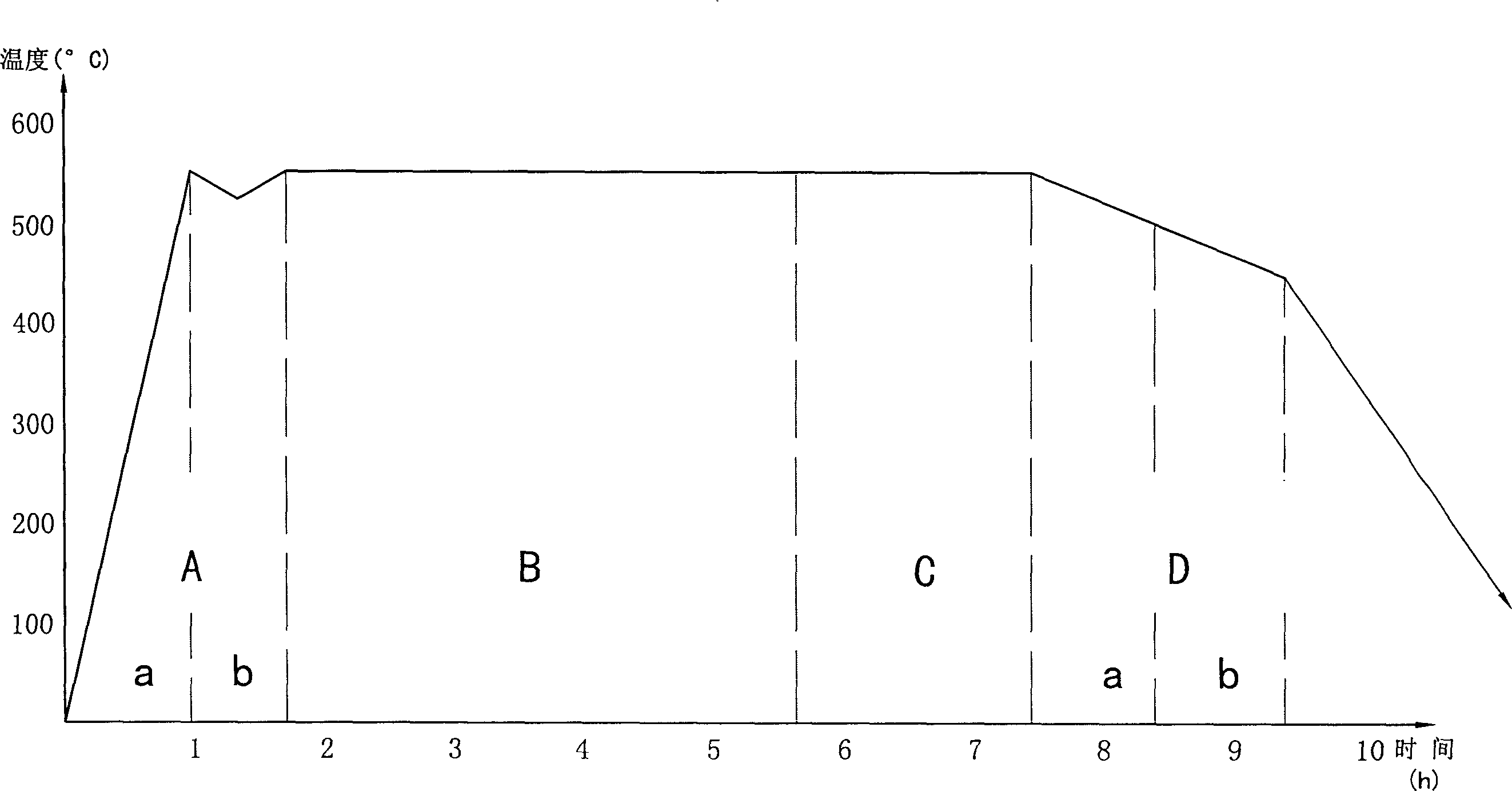

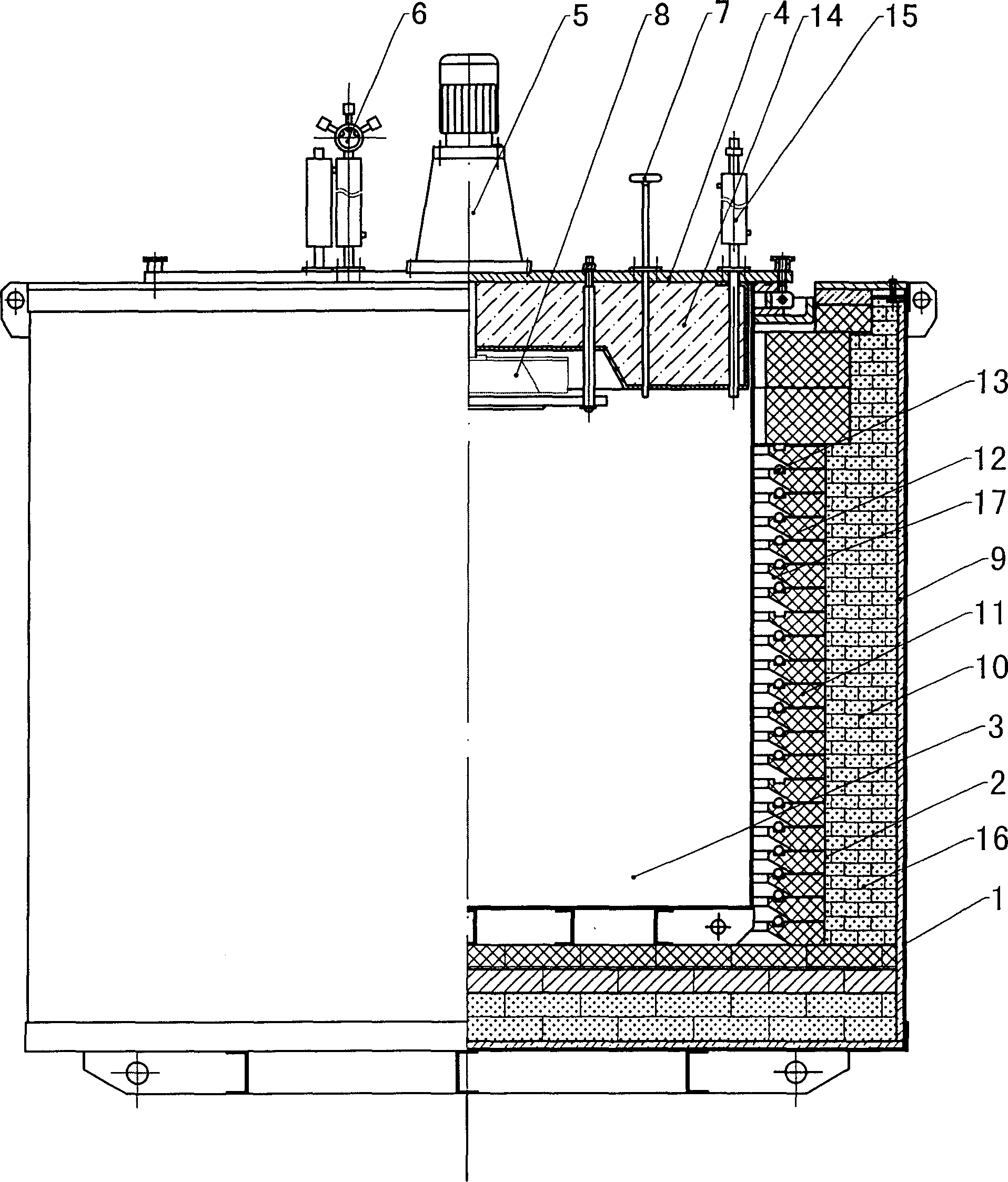

Treatment technique for strengthening surface through concurrent infiltrations from five aspects for tire mold

InactiveCN1563475AEasy to useExtended service lifeSolid state diffusion coatingBrickThermal insulation

This invention relates to a tire mold five part common penetration surface intensifying process technology and its devices characterizing that at the temperature rising, the workpiece and sponge Ti are inserted and large flux methyl alcohol is injected for exhausting, at the force penetration and diffusion stage, alcohol and rare earth organic solution dropped volume, ammon flux, oxygen flux, pressure, and time are controlled, the temperature decreasing stage: controlling ammon resolution ratio, pressure, air-cooling and oil-cooling. Devices include a furnace, a furnace connecting medium charging device, air pressure regulation and exhaust exit and automatic temperature control device, the lining is made up of a thermal insulation and a fire resisting layer with wire rest bricks, the common penetration tank in the lining with cooling and sealed device.

Owner:GREATOO INTELLIGENT EQUIP INC

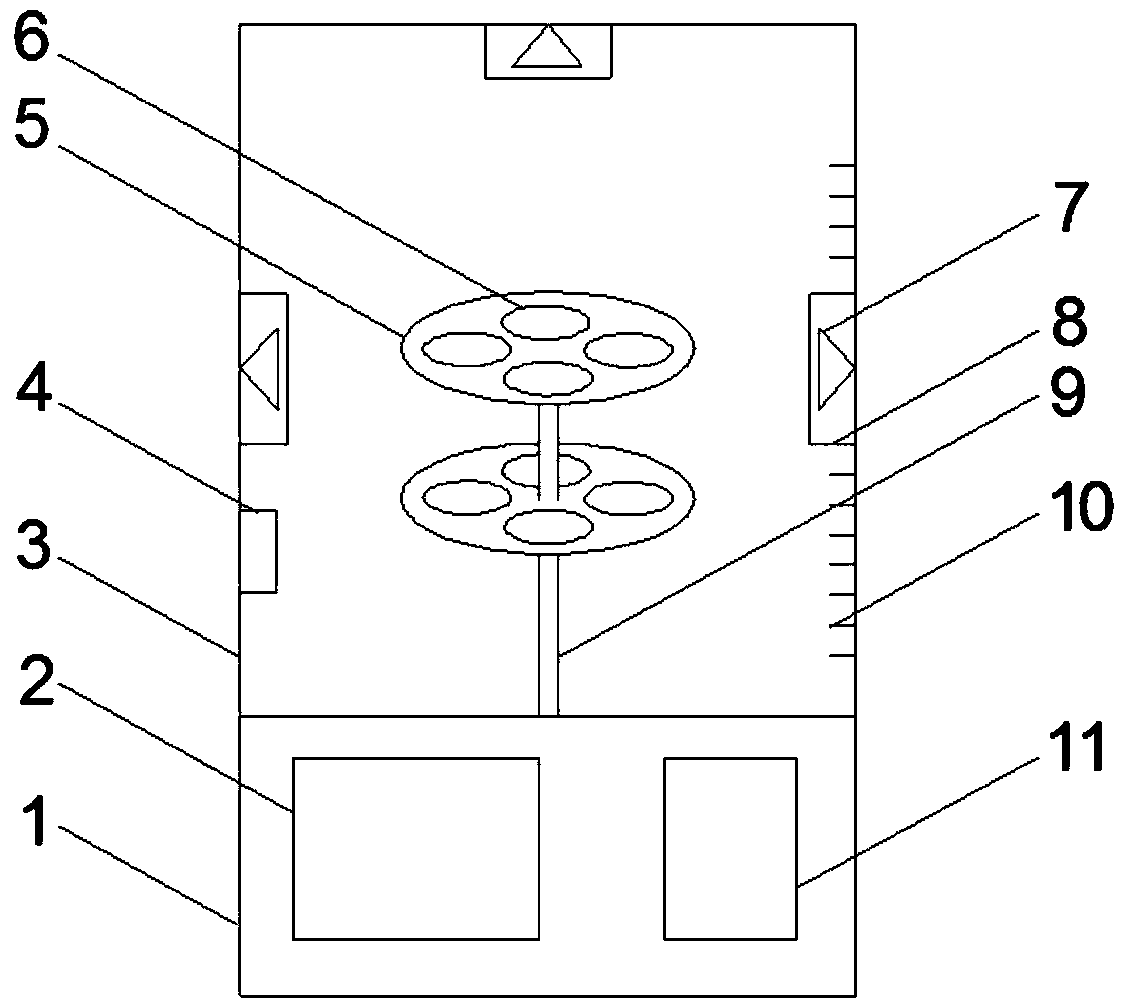

Ultraviolet radiation-oxygen-temperature-humidity coupled asphalt aging testing device and method

The invention discloses an ultraviolet radiation-oxygen-temperature-humidity coupled asphalt aging testing device and method. The ultraviolet radiation-oxygen-temperature-humidity coupled asphalt aging testing device comprises a control box, an environment box, a power assembly arranged in the control box, an object carrier stage and a rotating shaft, wherein the object carrier stage and the rotating shaft are arranged in the environment box; a control panel is arranged on the control box; the control box is positioned at the bottom of the environment box; an output shaft of the power assemblyis connected with the lower end of the rotating shaft; the object carrier stage is arranged on the upper part of the rotating shaft and is distributed aslant; a sample accommodating dish is arrangedon the object carrier stage; a plurality of ultraviolet lamps and sensor groups for detecting temperature, humidity and oxygen concentration in the environment box are arranged on the inner wall of the environment box; an outlet of an air blast system communicates with an air inlet of the environment box; the control panel is connected with a control end of the air blast system, the output ends ofthe sensor groups and the control end of the power assembly. According to the device and the method disclosed by the invention, an asphalt aging test on intensity of ultraviolet rays, the temperature, the oxygen flux and the humidity under constant and transforming modes can be realized.

Owner:CHANGAN UNIV

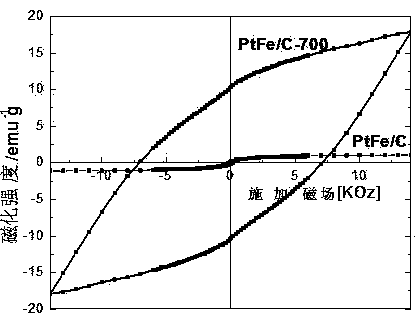

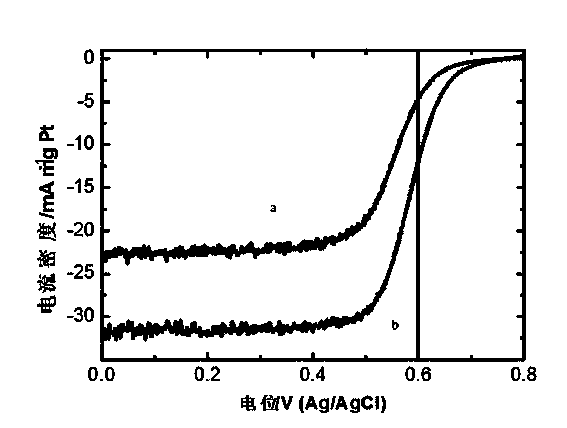

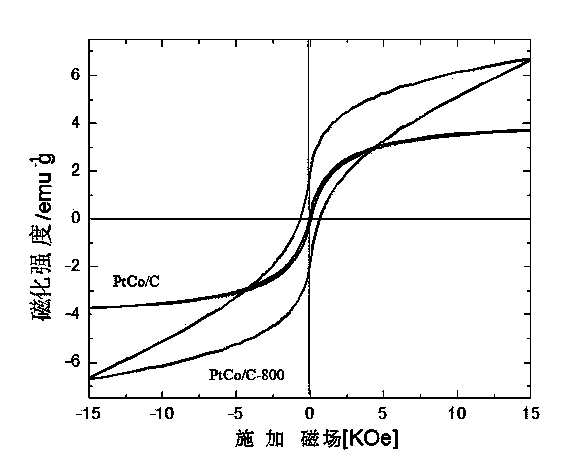

Method for preparing electrocatalyst for cathode of ferromagnetic fuel cell

The invention discloses a method for preparing an electrocatalyst for a cathode of a ferromagnetic fuel cell. The method comprises: preparing a carbon-carried fuel cell electrocatalyst by a general impregnation reduction, treating the carbon-carried fuel cell electrocatalyst in inert atmosphere under certain heat treatment conditions, regulating and changing ferromagnetic performances of the catalyst, and applying the catalyst in an oxygen reduction reaction of the cathode of the fuel cell. The prepared electrocatalyst for the ferromagnetic fuel cell when used in the oxygen reduction reaction of the cathode, because of special superparamagnetism of oxygen molecules, increases oxygen flux, thereby raising oxygen reduction activity. The property of the ferromagnetic oxygen reducing catalyst prepared by the method, compared with that of a non-ferromagnetic catalyst, is raised for 50-300% (0.6V oxygen reduction current density). The method has advantages of simple and fast preparation technology, low cost, and easy realization of batch and industrialization production.

Owner:氢电中科(广州)新能源设备有限公司

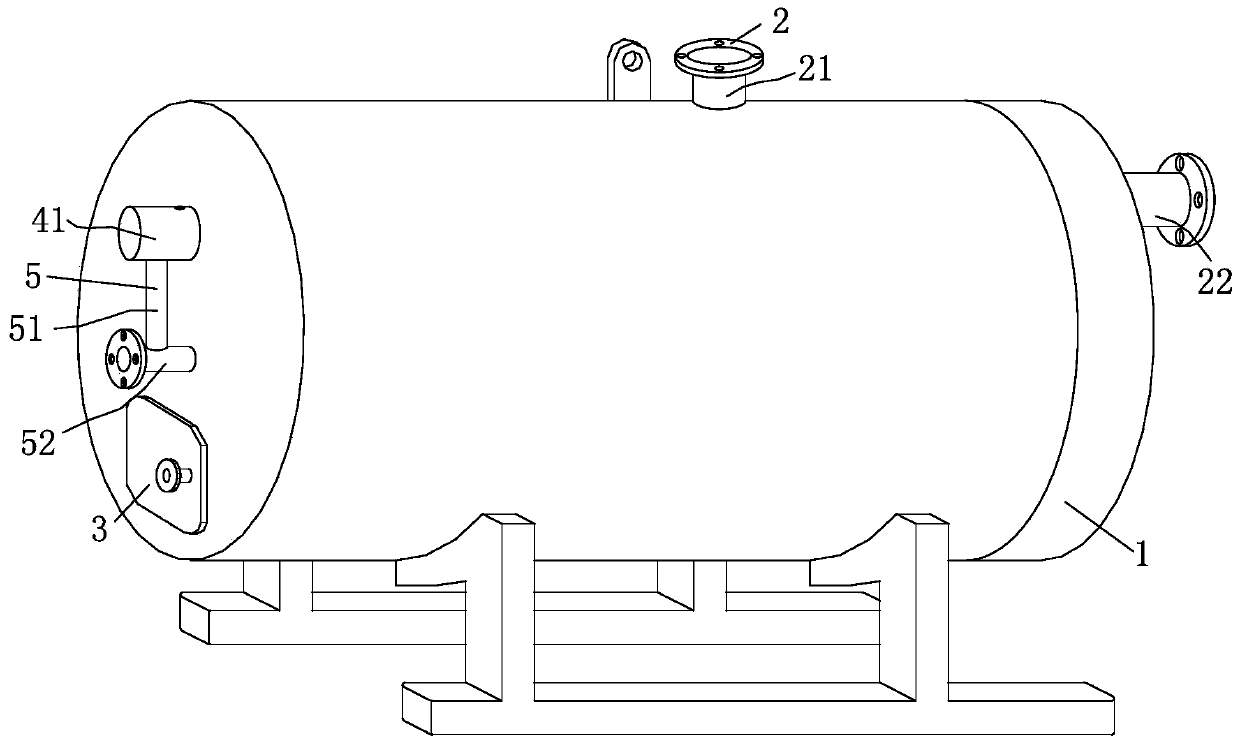

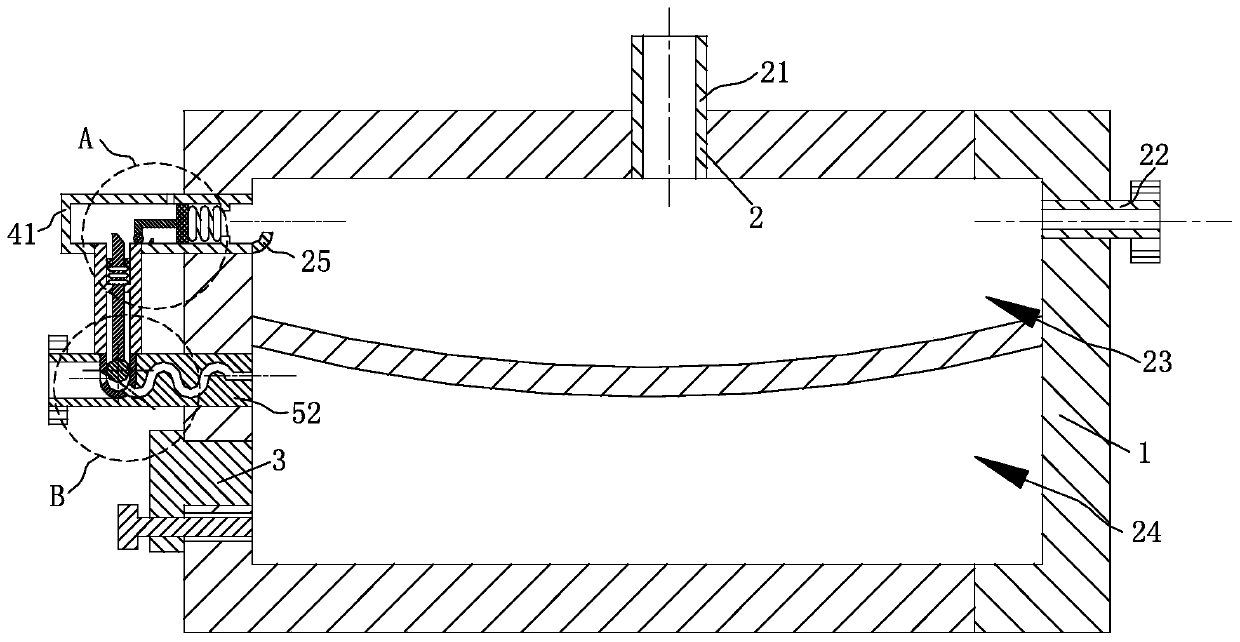

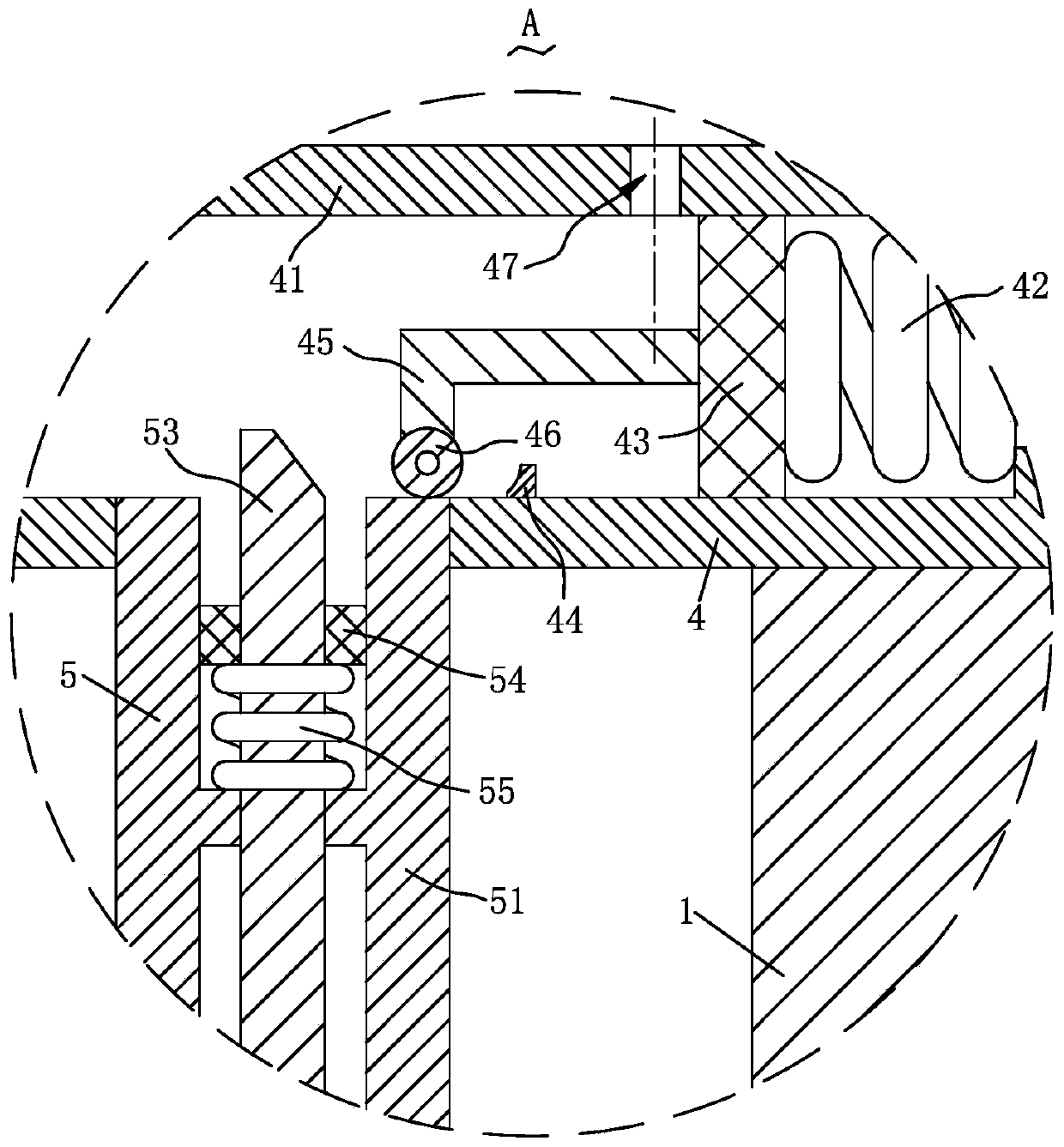

Industrial boiler

ActiveCN110332510AAvoid damageReduce lossesAir/fuel supply for combustionSteam boilersInternal pressureCombustion

The invention relates to the technical field of boilers, in particular to an in industrial boiler. The industrial boiler comprises a boiler body, a switch door, a storage mechanism, a pressure reliefstructure and an air inlet mechanism. The boiler body for supplying coal to combust and exchange heat is connected to the switch door for adding coal, the boiler body is connected to the storage mechanism used for adding water and discharging steam, the boiler body is connected to the pressure relief structure for relieving pressure of water vapor, the boiler body is connected to the air inlet structure for conveying oxygen to combust the coal, and the air inlet structure is connected to the pressure relief structure; and the pressure relief structure is matched with the air inlet structure touse. The oxygen flux in a storage room is reduced while the pressure of the water vapor in a water storage room is relieved by means of the pressure relief structure, the combustion rate of the coalin the storage room is reduced, and the boiler body is prevented from being damaged as a result of too large pressure in the water storage room, so that the water vapor generation capacity in the pressure relief process of the water storage room is reduced, the water vapor amount flowing from a pressure relief port is reduced, and the loss of the water vapor relived in pressure is reduced.

Owner:日照菁英传媒科技有限公司

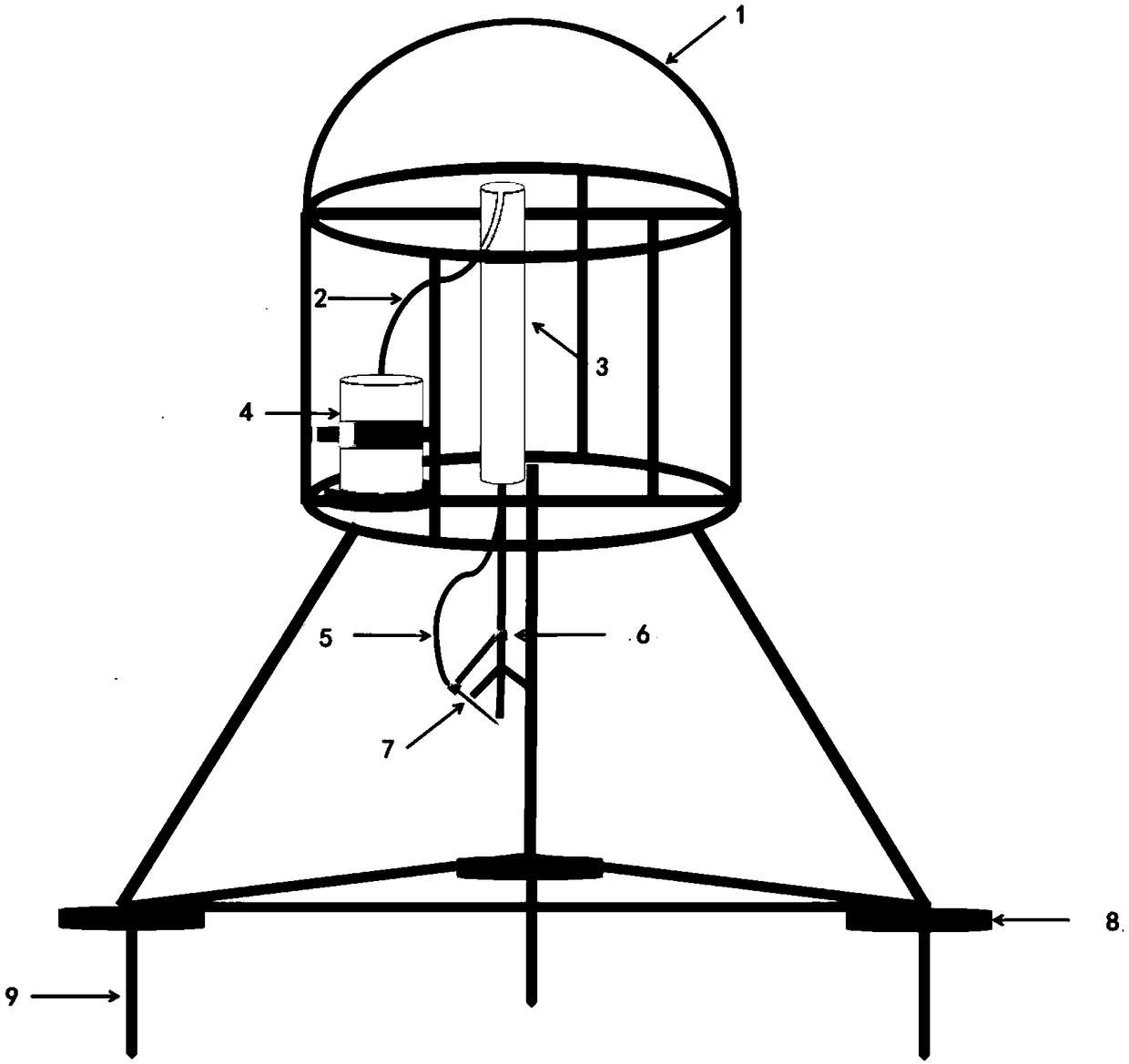

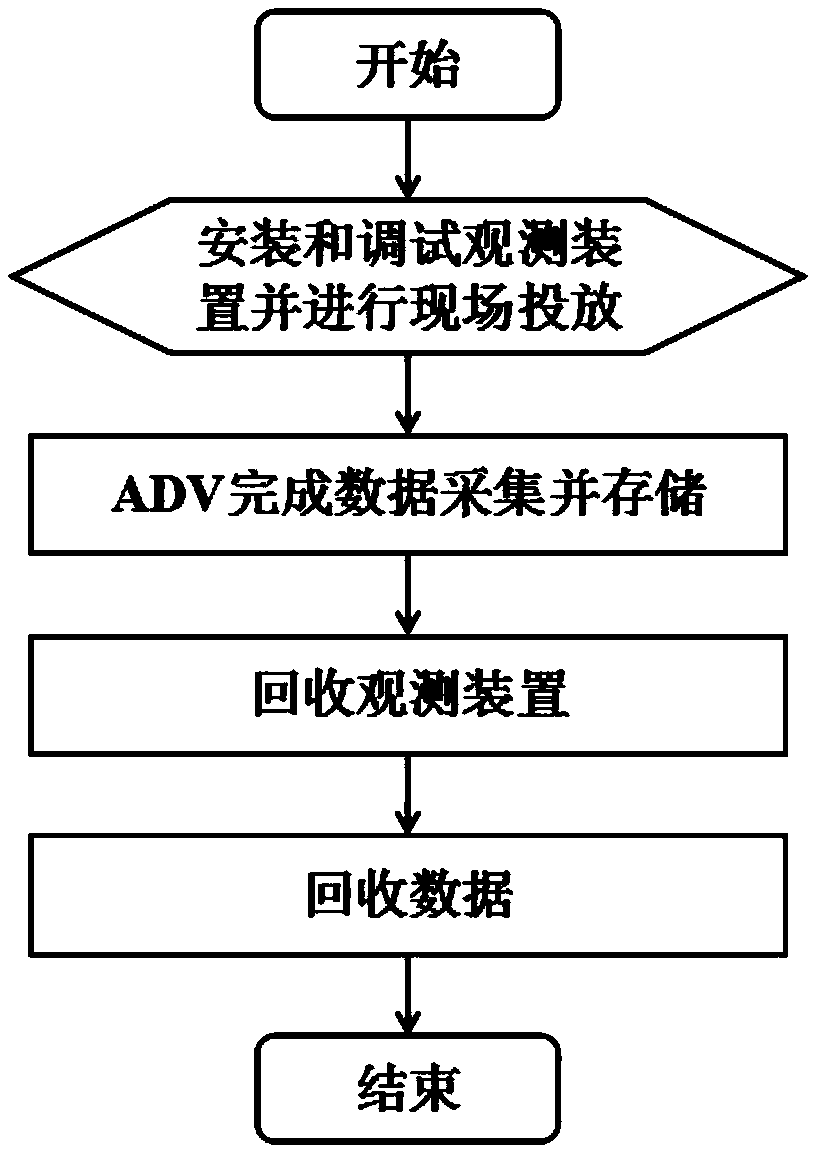

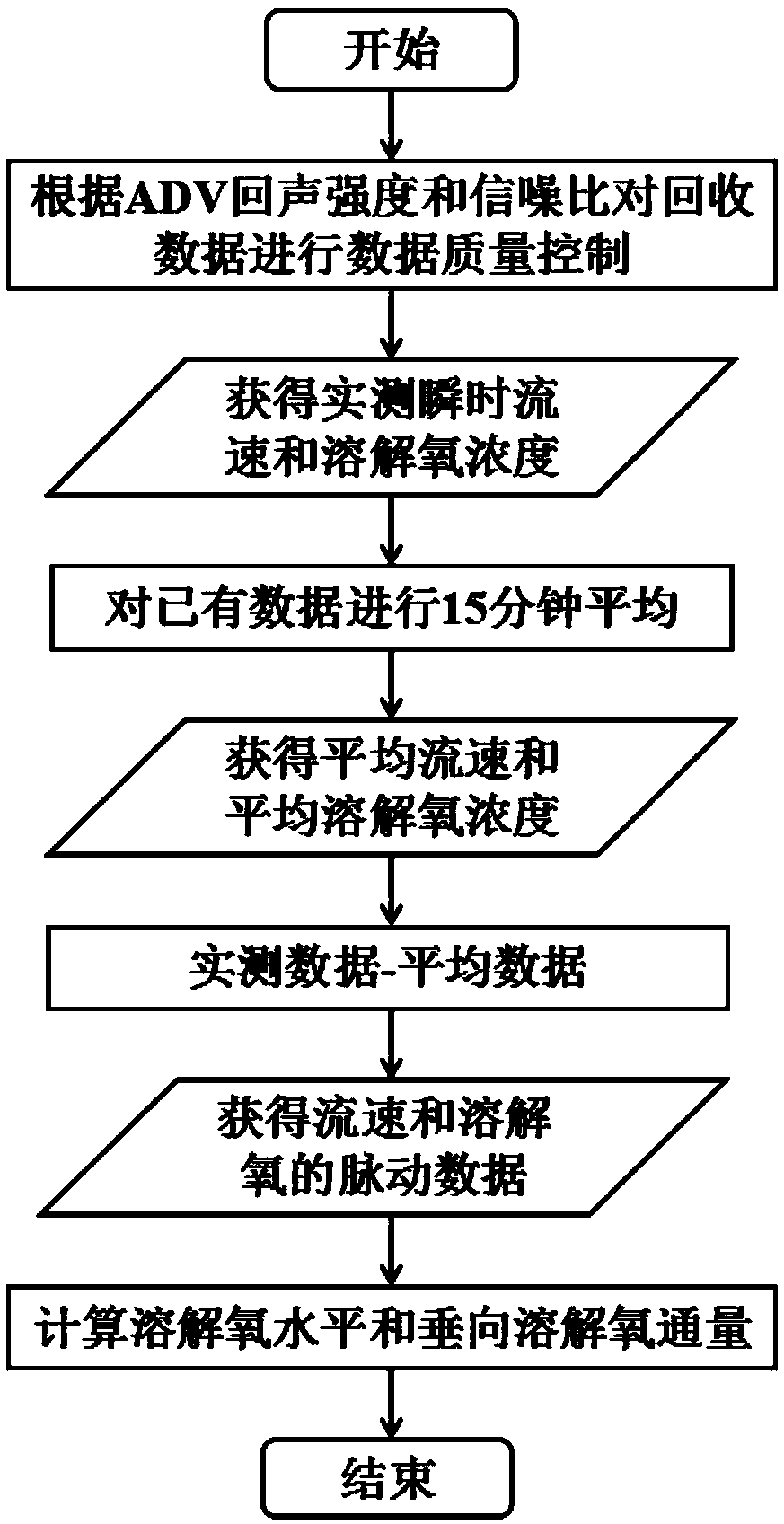

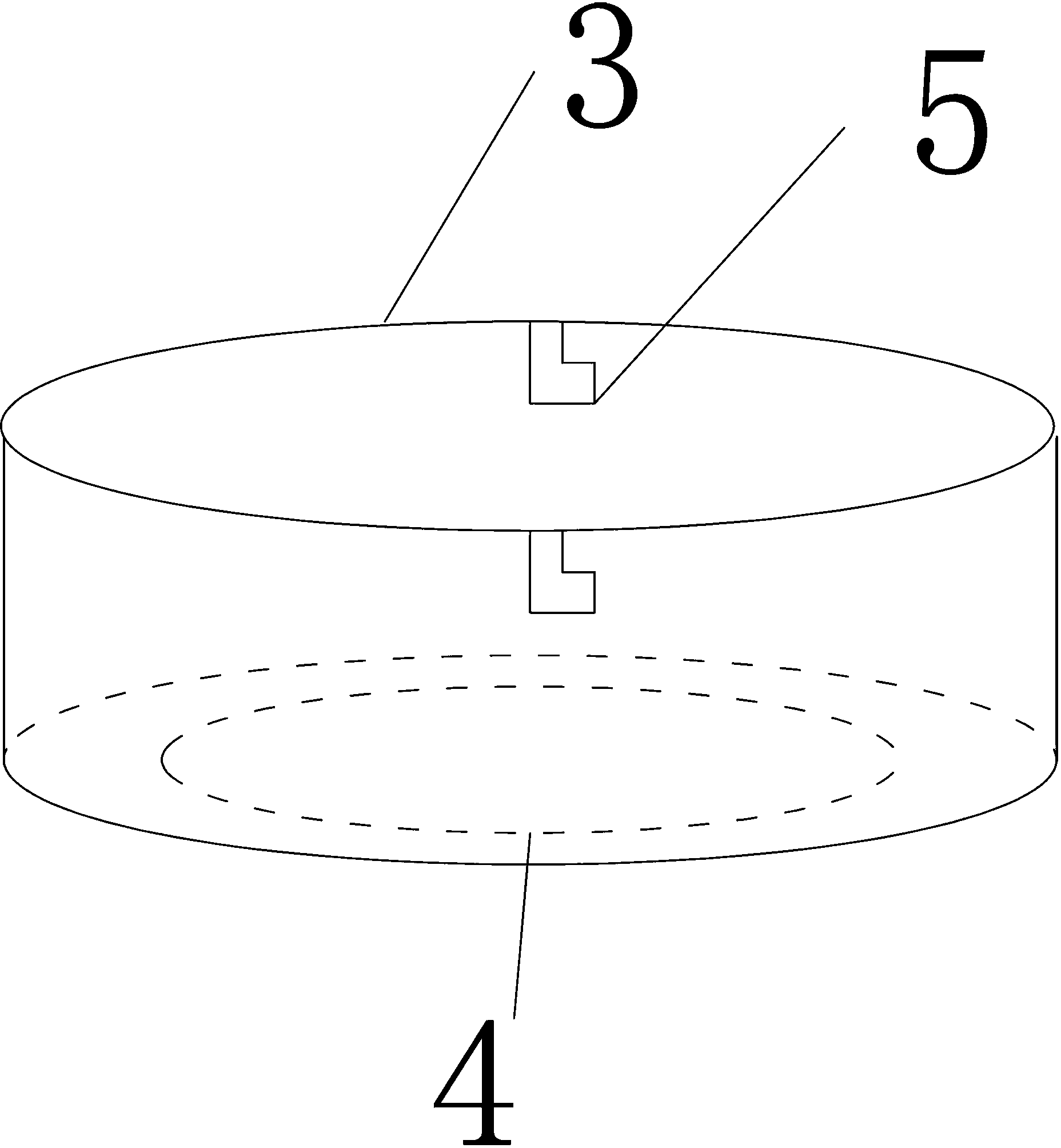

Method for measuring dissolved oxygen flux of marine near-bottom boundary layer

InactiveCN109212152AEffective observationImprove accuracyTesting waterFluid speed measurementOriginal dataHorizontal and vertical

The invention discloses a method for measuring the dissolved oxygen flux of a marine near-bottom boundary layer. The method comprises the steps of: (1), adjusting a seabed observation device and parameters; (2), arranging an observation device; (3), obtaining original high-frequency data; (4), pre-processing the original data, and calculating the pulsating quantity of the average flow speed and the average dissolved oxygen concentration; and (5), calculating the horizontal flux and the vertical flux by utilizing the pulsating quantity of the flow speed and the dissolved oxygen concentration calculated in the step (4). The observation device of the observation method comprises a battery compartment, an acoustic Doppler point type current meter and a needle type dissolved oxygen sensor. Themethod in the invention has the benefits that: observation is synchronously carried out through multiple sets of instruments; high-frequency data of the flow speed and the dissolved oxygen concentration in a water body is synchronously obtained in situ; long-time observation and storage are realized; the data resolution is high; and the dissolved oxygen level and the vertical flux can be obtainedmore accurately in a non-interfered water body environment.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

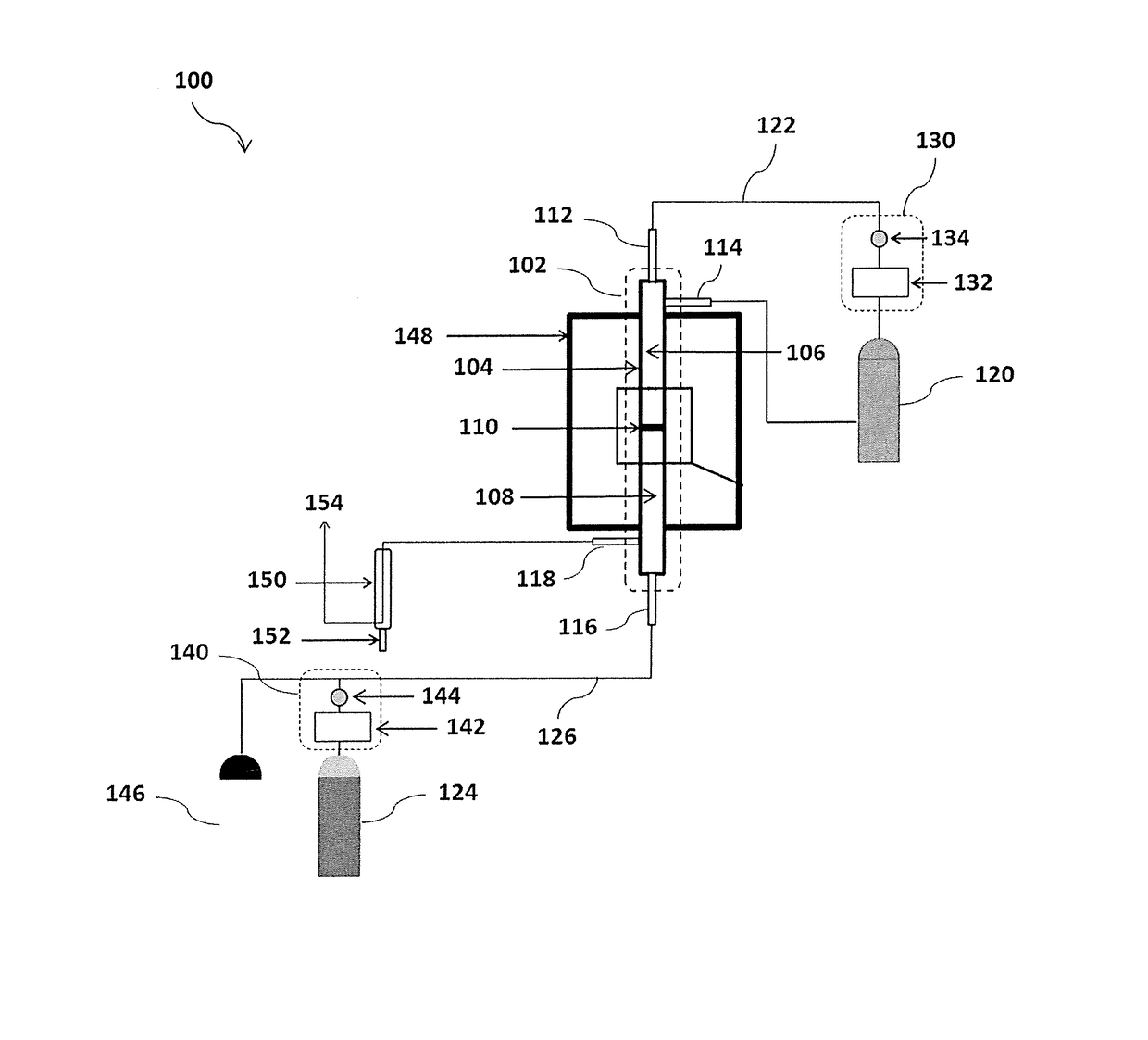

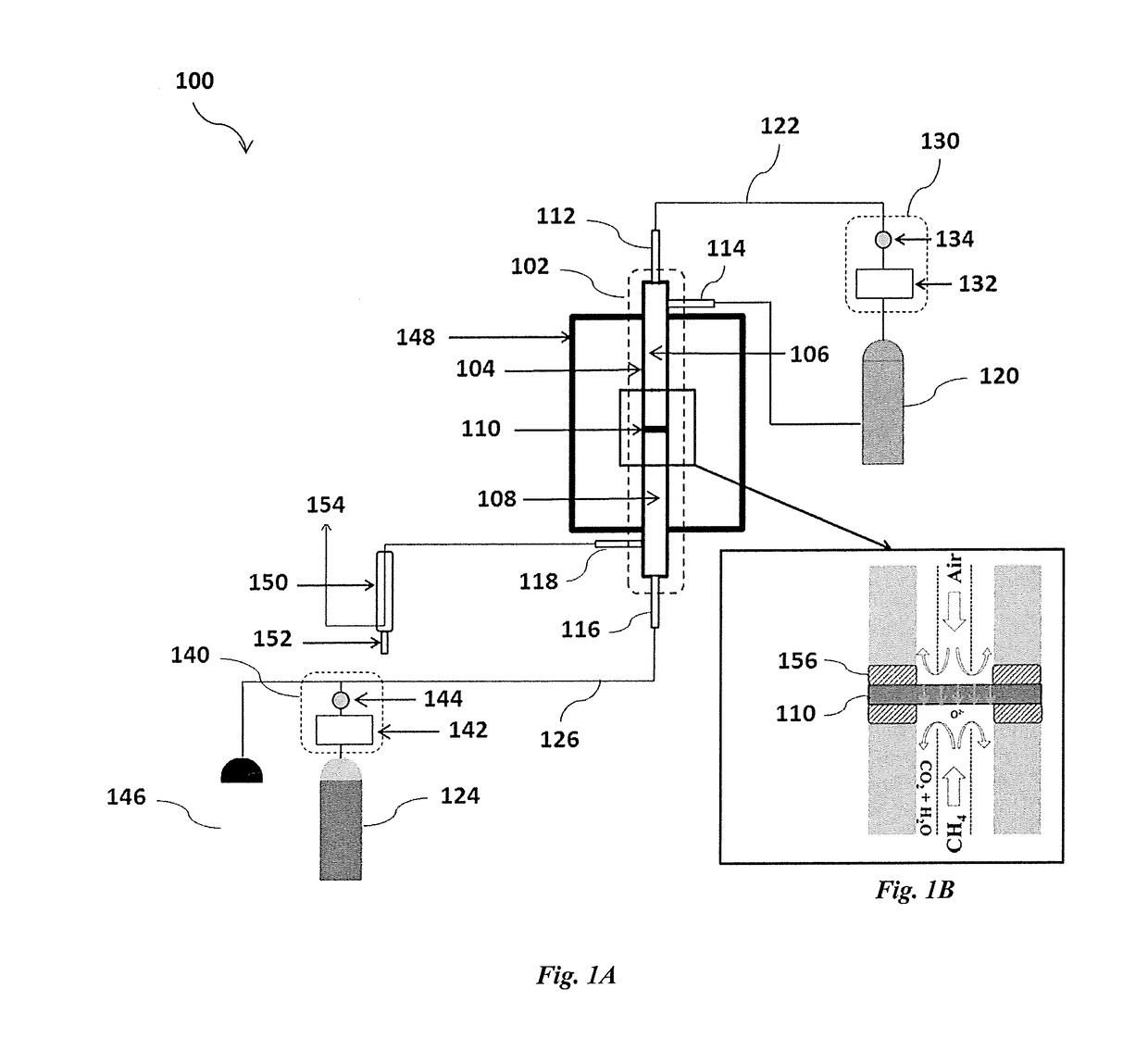

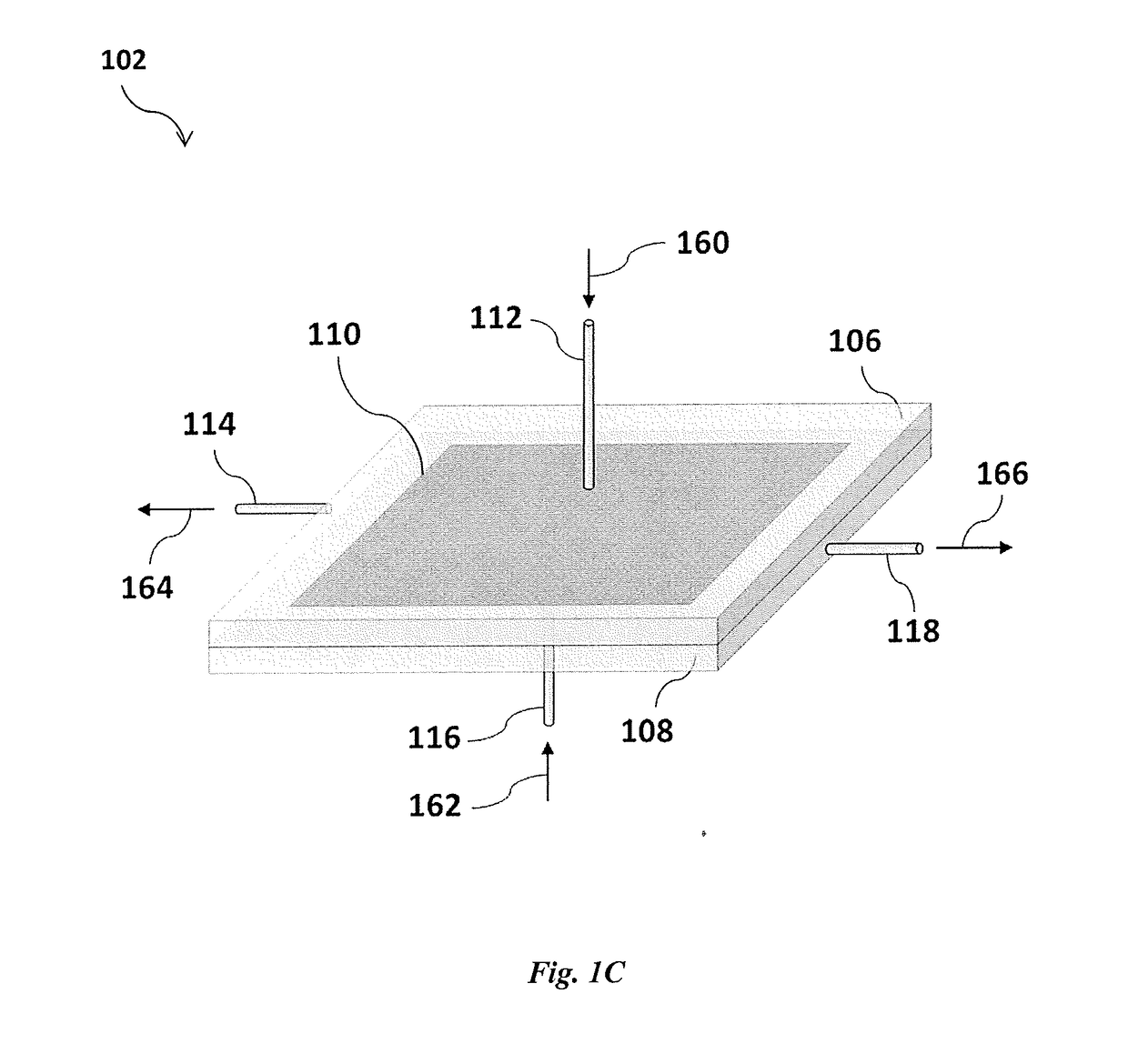

System for combusting a methane stream and a method of combustion

ActiveUS20170356647A1Indirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCombustionOxygen flux

A system for combusting a methane stream in an ITM combustion reactor and a method of combusting the methane stream, wherein an optimized volumetric flow rate of the methane stream provides an off-stoichiometric molar ratio of methane to oxygen, which is provided by an ITM in the ITM combustion reactor, and the method further offers a relatively constant oxygen flux via the ITM as well as a prolonged membrane stability. Various embodiments of the system and the method are also provided.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Culture bottle for edible mushroom stock and use method of culture bottle

The invention discloses a culture bottle for an edible mushroom stock and a use method of the culture bottle. The culture bottle consists of four parts, namely a bottle body, a buckling cap, a series of bottom caps and an air filtering part, wherein ventilating ports which are suitable for different growth stages of the edible mushrooms and have different sizes are arranged on the series of bottom caps; during use, the buckling cap is screwed and the bottom caps are unscrewed; composts are filled from the bottom of the bottle body; an aseptic filtering part is additionally arranged between the bottle bottom and the bottom caps and then the bottom caps are screwed and the sterilization and the inoculation are performed; the bottom caps with the ventilating ports in the different sizes are replaced in time. The culture bottle disclosed by the invention has the advantages of sufficient oxygen flux, convenience for opening and closing, convenience for charging and digging and the like; mycelia are quick in germination, are uniform in growth vigor, are not easy for ageing and are low in pollution rate; during use, the culture bottle is labor and time-conserving and is easy for operation.

Owner:山西省长治市微生物研究所

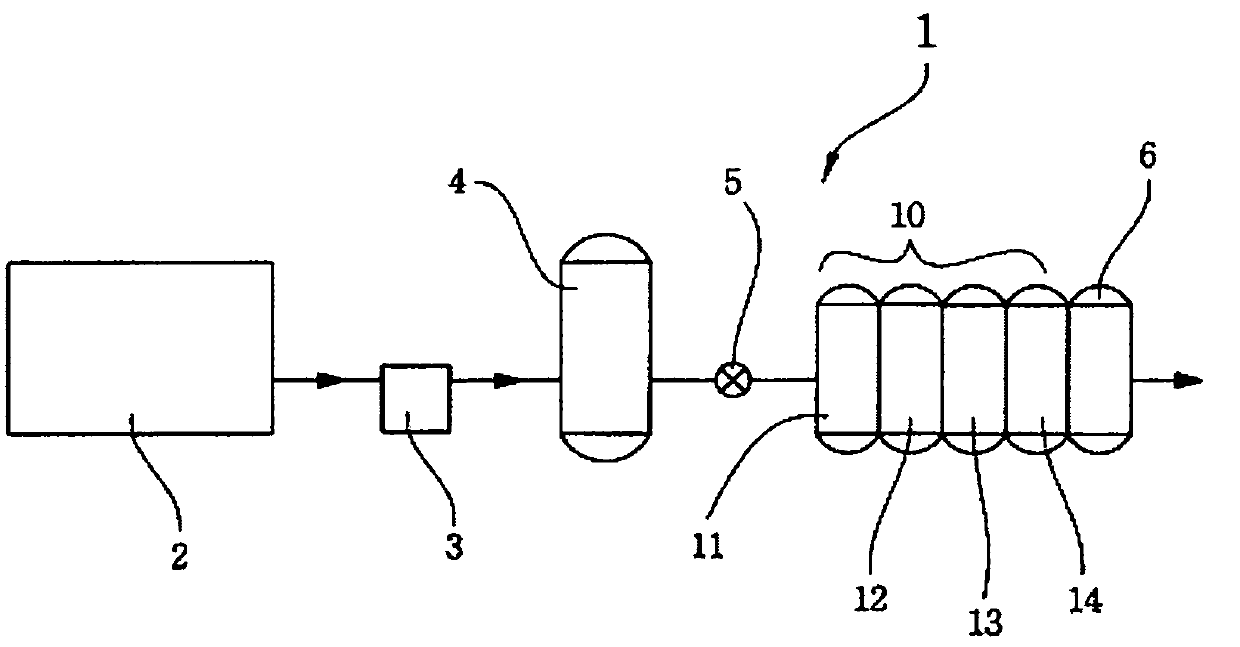

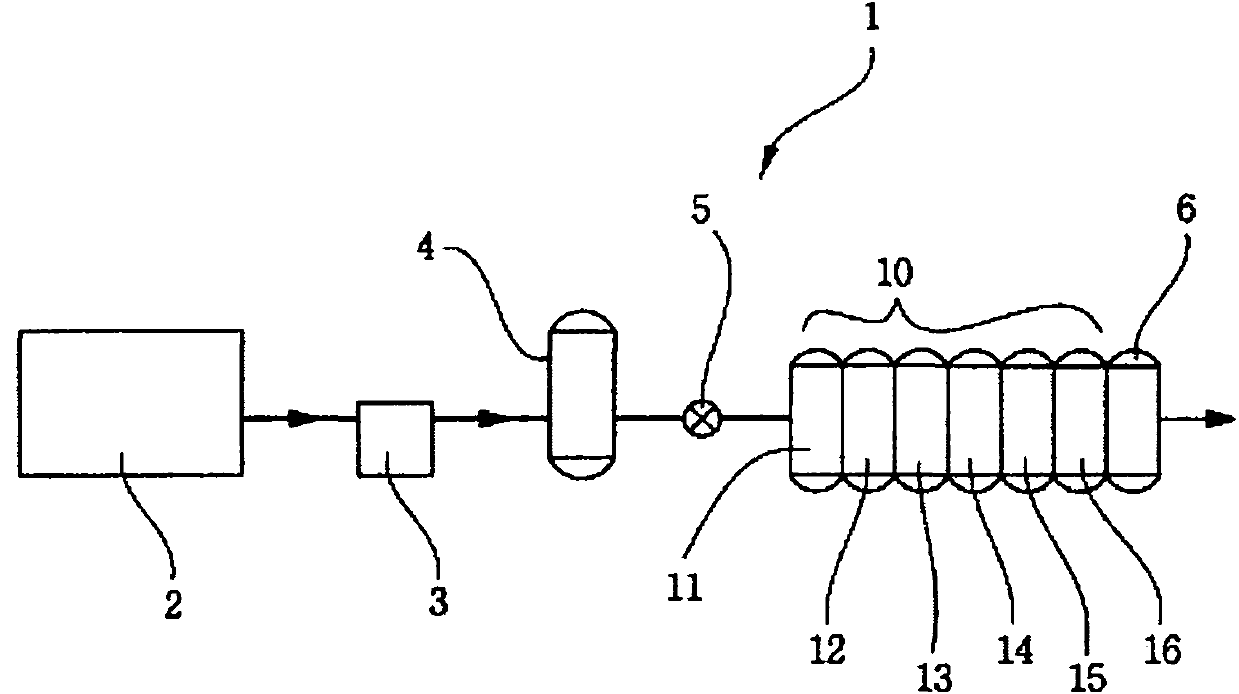

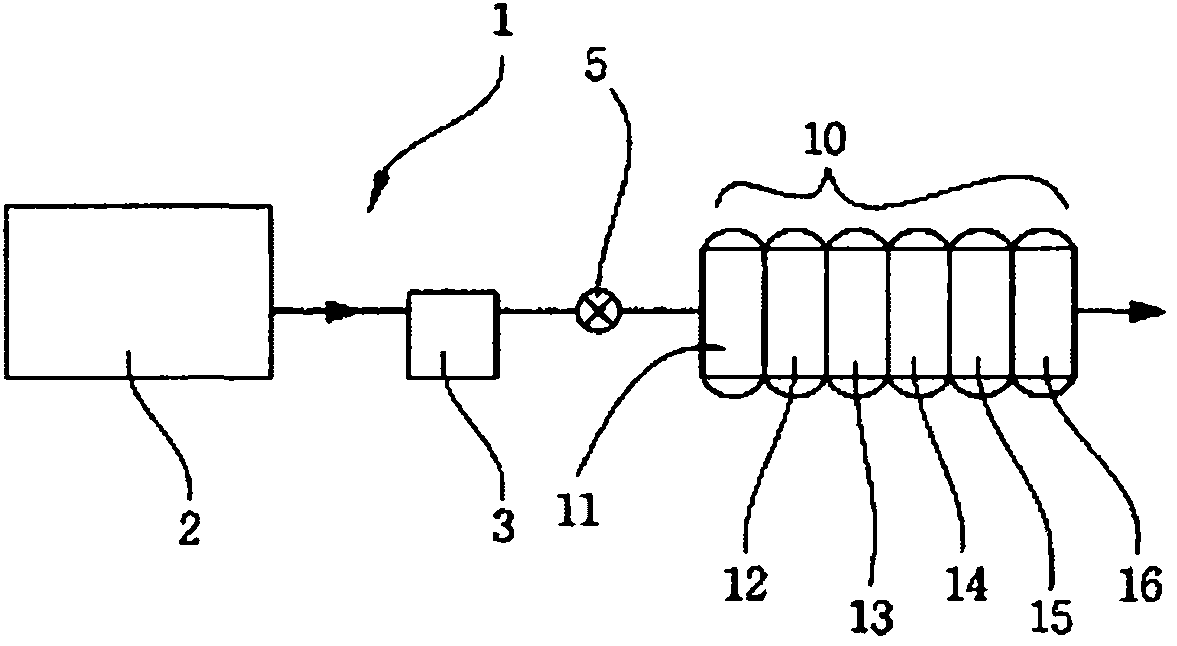

Multi-adsorption column for an oxygen generator, and control method thereof

ActiveCN101993044AReduce traffic fluctuationsLow costGas treatmentDispersed particle separationPressure amplitudeAbsorption column

The present invention relates to an adsorption column for an oxygen generator and a control method thereof, concretely to a multi-adsorption column formed by two or three groups of absorption columns, each group is composed of two adsorption columns, furthermore, an air supply calandria, a nitrogen discharge calandria, an oxygen supply calandria, an uniformization calandria and the like constitute a group, which is arranged on an inlet and an outlet of the absorption column respectively. The multi-absorption column is controlled by valves to perform adsorption (oxygen generation) and disengaging (nitrogen discharge) and uniformization operation by each group by turns for some time, so as to effectively reduce compressed air flux discharged from an air compressor and oxygen flux discharged from the adsorption column as well as pressure amplitude, furthermore, an air compressor for generating oxygen and an oxygen storage tank are all minimized, so as to save cost of the oxygen generator, reduce mounting area of the oxygen generator and mounting height of the absorption column to solve a problem of being limited by a space in mounting the oxygen generator.

Owner:南亮压力容器技术(上海)有限公司

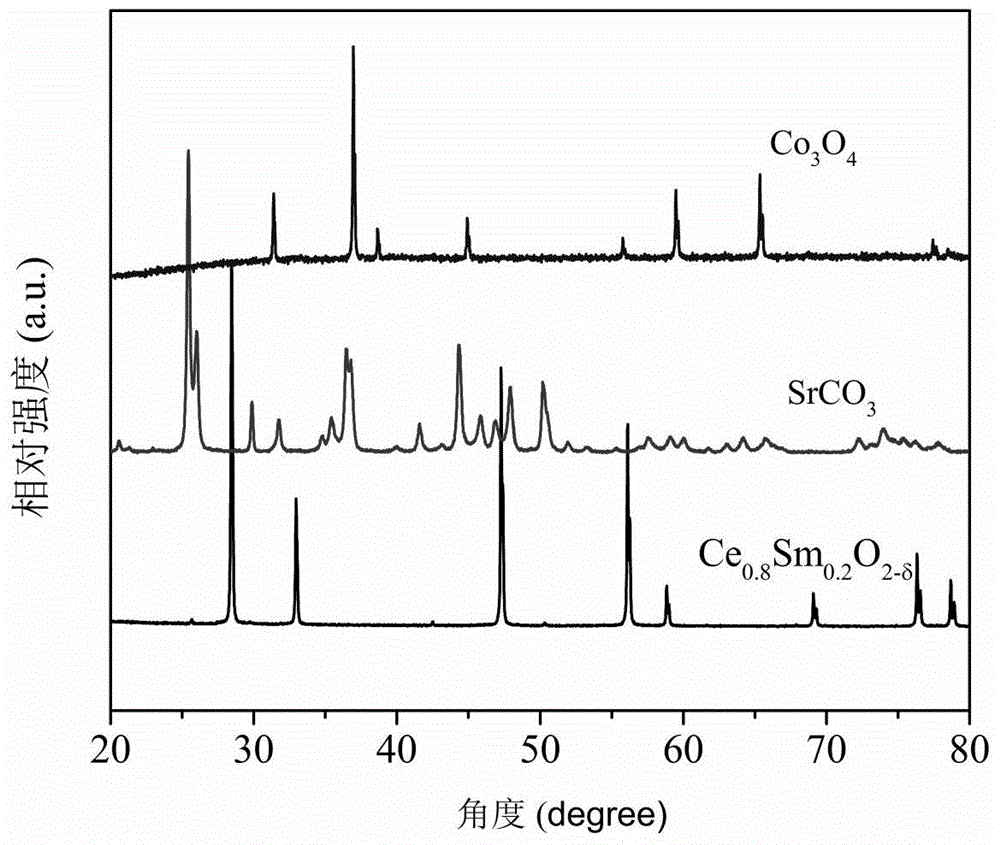

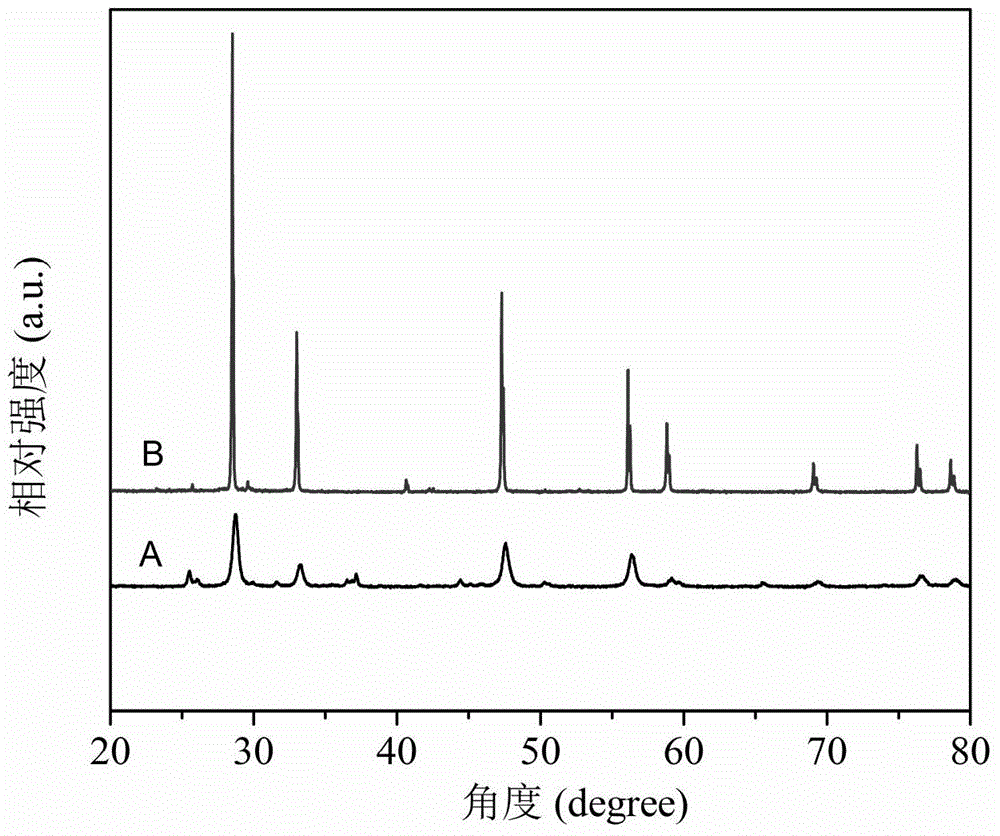

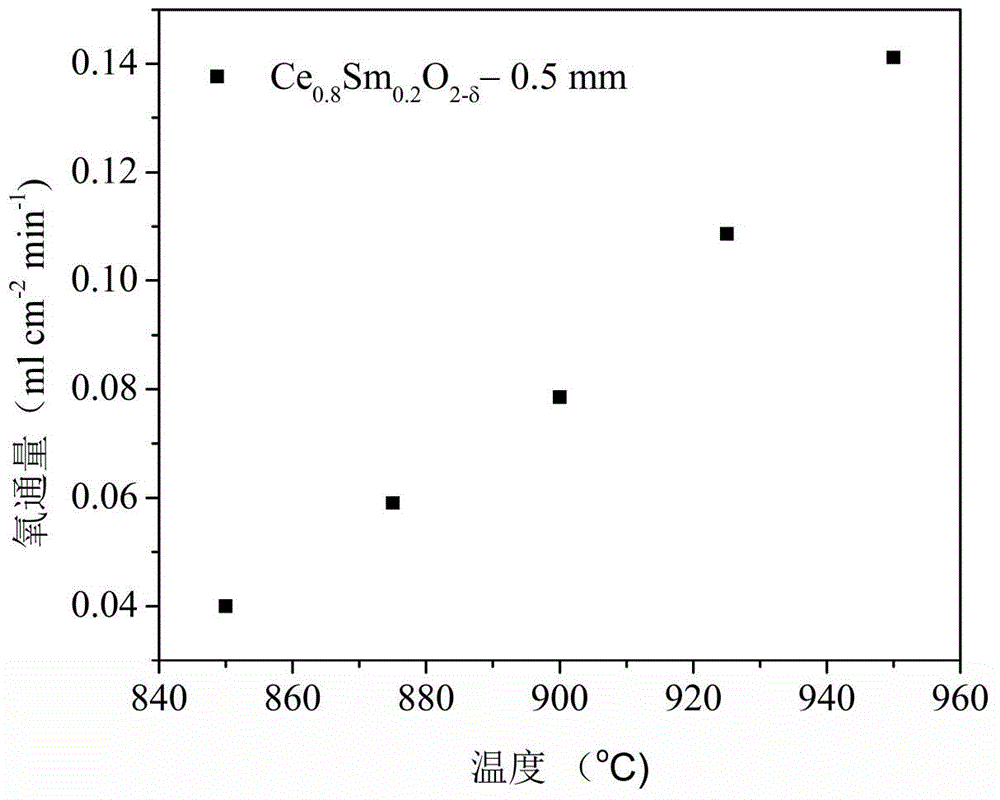

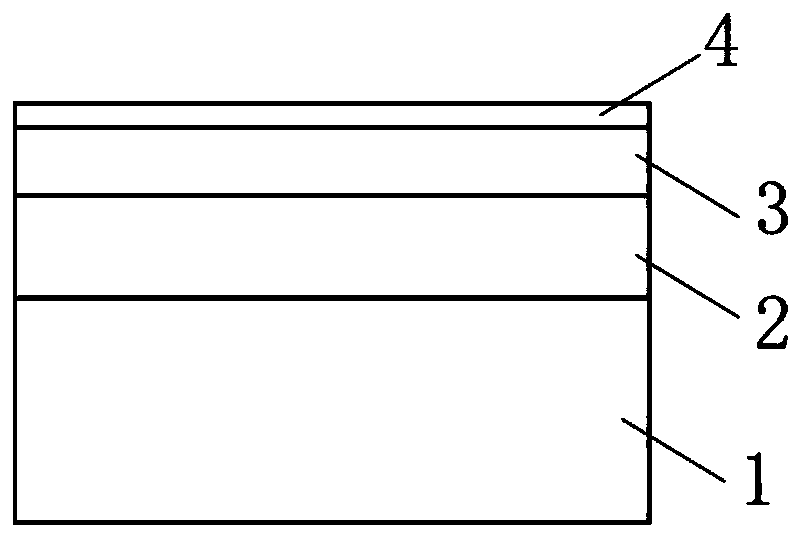

Method for increasing oxygen flux of fluorite type ion conductor membrane material

ActiveCN104624063ASemi-permeable membranesDispersed particle separationElectrical conductorHigh energy

The invention relates to a method for increasing the oxygen flux of a fluorite type ion conductor membrane material. A substance having high electron conduction capacity is added into the fluorite type ion conductor membrane material through a high-energy mechanical ball-milling method, so that a mixed multi-phase oxygen permeable membrane material having an expression of M0+M1 is formed, wherein the structural formula of a fluorite type ion conductor membrane material M0 is AxB<1-x>O<2-delta>; an A-site positive ion is one or more of rare-earth metal ions; a B-site positive ion is one or more of rare-earth metal ions different from the A-site positive ion; x is more than 0.1 and less than 0.9; delta is more than or equal to 0 and less than or equal to 1; a substance M1 having high electron conduction capacity is one or more of metallic oxides or metal carbonate; and the mass percentage of M1 to M0 is 10%-40%. The temperature of the multi-phase oxygen permeable membrane prepared by the method is in the range of 600-900 DEG C; and therefore, the oxygen flux is obviously increased.

Owner:NANJING UNIV OF TECH

Surface treatment method for stripping single crystal thin film through ion implantation

ActiveCN111403596AImprove single crystal qualityReduce secondary damageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingOxygen vacancy

The invention belongs to the technical field of single crystal thin films, and particularly relates to a surface treatment method for stripping a single crystal thin film through ion implantation. According to the surface treatment method for stripping the single crystal thin film through ion implantation, argon ion etching is selected for accurately removing a damaged layer on the surface of thesingle crystal thin film prepared through the ion implantation stripping technology; and besides, the problems of oxygen vacancy defects and surface modification of the film after the damaged layer isremoved are solved by respectively controlling the oxygen flux, the working power and the working parameters of the cleaning time in the oxygen plasma cleaning process, the cleaning effect is verified through the contact angle test, and finally, the single crystal thin film is completely infiltrated, so that the subsequent preparation of a graphical device structure is facilitated. According to the method, the single crystal quality of the single crystal thin film is greatly improved, the introduced secondary damage is minimum, and the process complexity is simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Household integrated multi-functional fermentation device and fermentation method

PendingCN106801011AEasy to operateReduce volumeBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlAgricultural engineering

The invention provides a household integrated multi-functional fermentation device and a fermentation method. The household integrated multi-functional fermentation device comprises a reaction vessel, a thermal conductive layer, a shell, a temperature control module, an oxygen flux control module, a sealing cover, a display panel, a power supply and an operation panel. According to the household integrated multi-functional fermentation device, the fermentation temperature and the oxygen flux can be adjusted at the same time; the household integrated multi-functional fermentation device is suitable for various fermented foodstuffs; the household integrated multi-functional fermentation device is simple in operation, small in size, multiple in function and low in cost.

Owner:FOSHAN UNIVERSITY

Method for culturing magnetosome-producing iron oxidizing bacteria

InactiveCN109207414AEasy to synthesizeGood magnetosome productionBacteriaMicroorganism based processesProduction rateOxygen flux

The invention relates to a method for culturing magnetosome-producing iron oxidizing bacteria, comprising the following steps: inoculating the magnetosome-producing iron oxidizing bacteria into a culture medium, fermenting and culturing, wherein the culture temperature is 20 DEG C and the fermentation temperature is 20 DEG C; 25 DEG C. In addition to the culture temperature, the invention furtherconsiders the influence of the composition of the culture medium, the oxygen flux and other parameters on the production of ferrooxidizing bacteria magnetosomes, and finally realizes the purpose of significantly increasing the production rate of magnetosomes.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

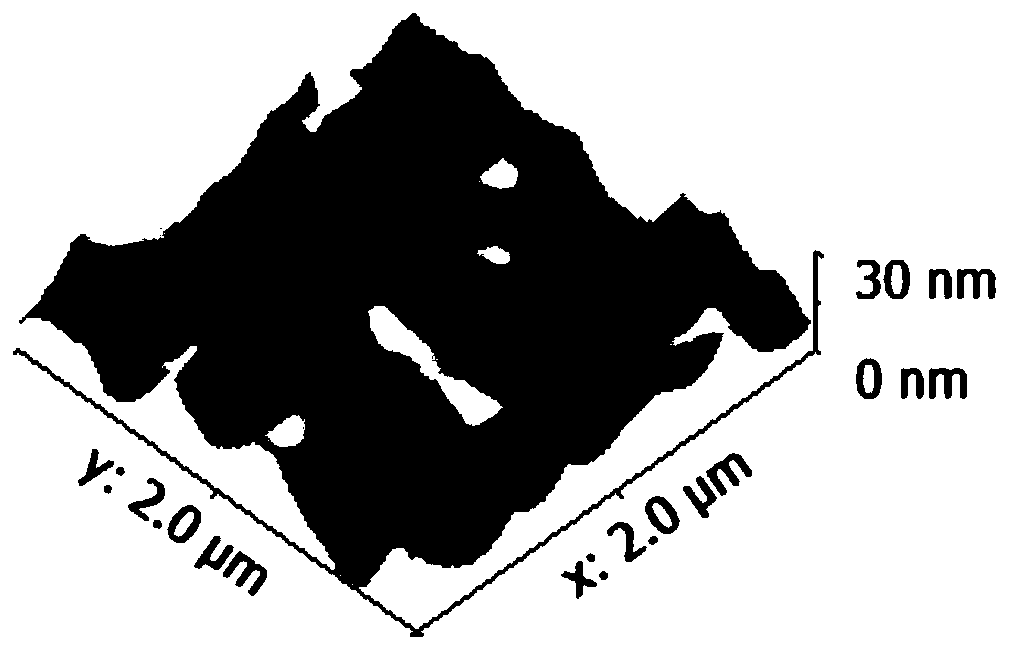

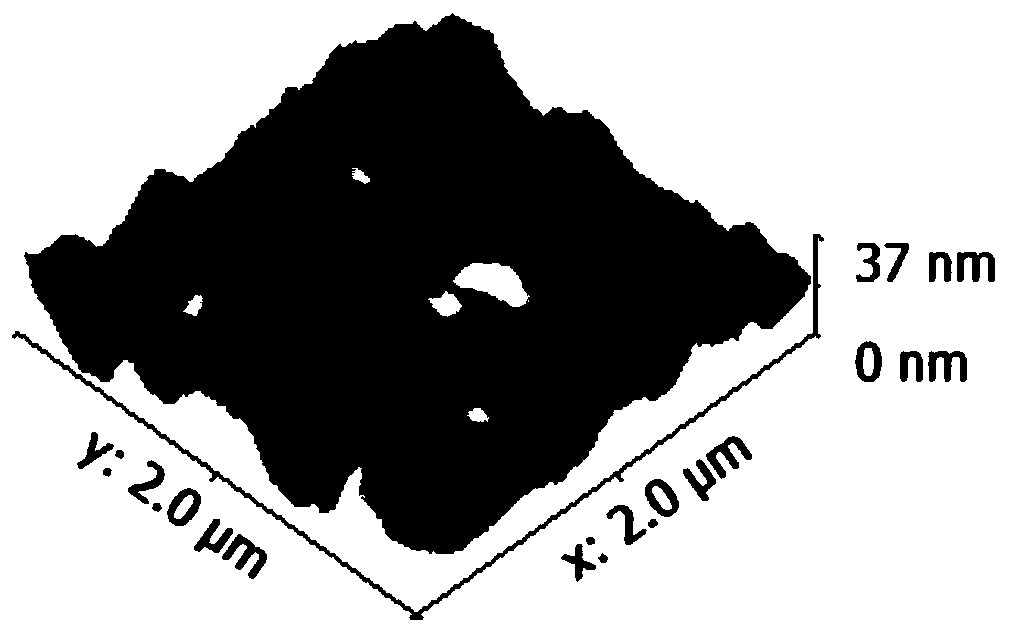

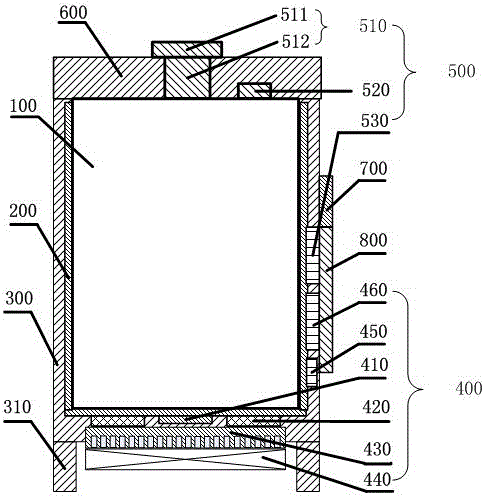

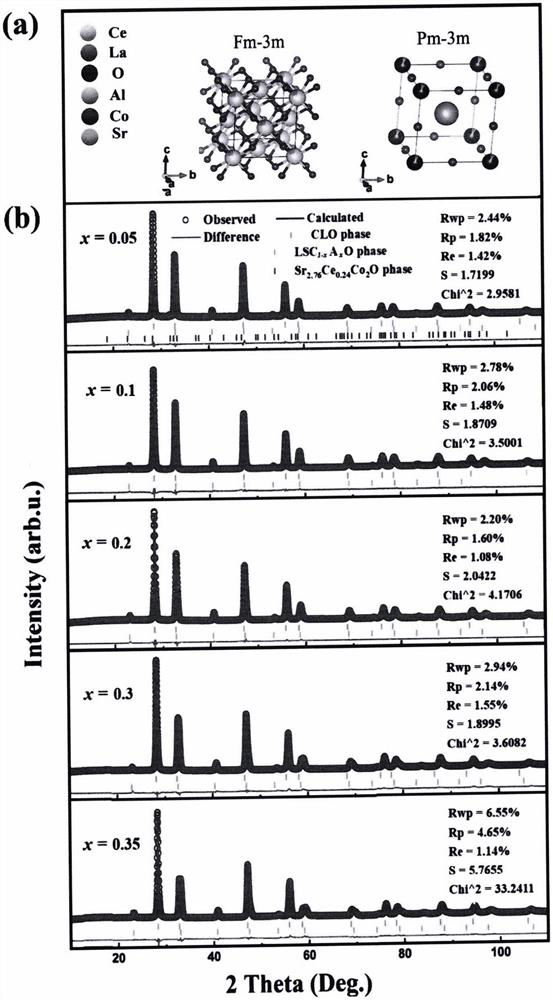

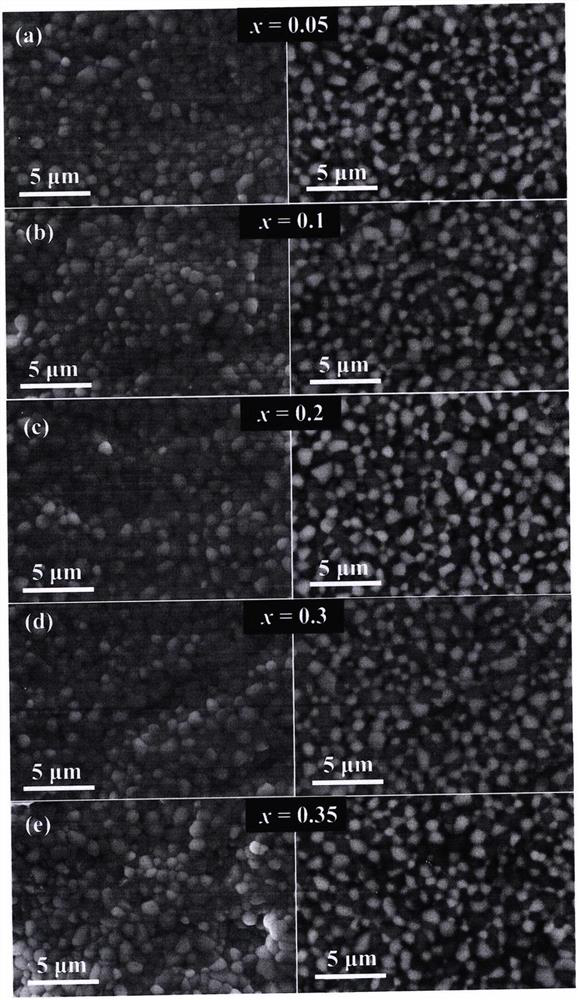

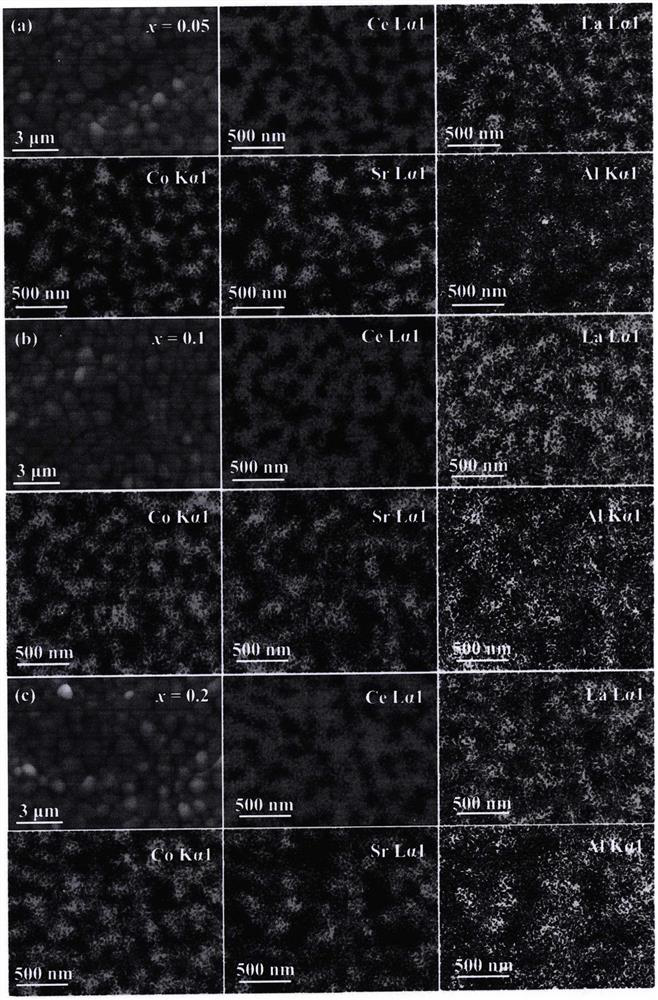

Aluminum-containing biphase mixed conductor oxygen permeation membrane material with good stability and preparation method thereof

InactiveCN113121231ADense surfaceImprove mechanical propertiesSemi-permeable membranesMethane captureElectrical conductorMixed conductor

The invention designs and prepares an aluminum-containing biphase mixed conductor oxygen permeation membrane material with high oxygen permeation amount, and belongs to the technical field of inorganic functional ceramic manufacturing. The general formula of the biphase mixed conductor oxygen permeation membrane material is 60Ce0.9La0.1O< 2-delta>-40La0.6Sr0.4Co<1-x>AlxO<3-delta> (x is equal to 0.05, 0.1, 0.2, 0.3 or 0.35). The preparation method comprises the steps of preparing required powder by using an improved one-pot-sol-gel method, calcining the powder in a muffle furnace at the temperature of 950 DEG C for 12 hours to obtain a precursor, tabletting the powder, and sintering at the temperature of 1250 DEG C to finally obtain the required mixed conductor oxygen permeation membrane. The mixed conductor oxygen permeation membrane material with high oxygen permeation amount is obtained by regulating and controlling the proportion of the multivalent and economical Al element. The biphase membrane material prepared by the method has excellent oxygen flux under the purging of gases such as helium / carbon dioxide. The material shows good long-term stability in low-oxygen argon and corrosive carbon dioxide atmospheres, and can be used as a novel oxygen source to be applied to the high-temperature complex atmosphere oxygen industry, such as the fields of oxygen-enriched combustion, water decomposition and methane coupling.

Owner:SUN YAT SEN UNIV

Treatment technique for strengthening surface through concurrent infiltrations from five aspects for tire mold

InactiveCN1257306CEasy to useExtended service lifeSolid state diffusion coatingInsulation layerBrick

The invention relates to a tire mold five-element co-infiltration surface strengthening treatment process. Technical features: The process of the treatment process: in the heating stage, the workpiece and titanium sponge are placed, and a large flux is dropped into methanol for exhaust; in the strong infiltration and diffusion stage, the amount of ethanol and rare earth organic solution dripping, ammonia flux, oxygen Flux, control pressure, time; cooling stage, control ammonia decomposition rate and control pressure, air cooling or oil cooling. The required equipment: including the furnace body, the medium adding device connected to the furnace body, the air pressure adjustment, the exhaust gas outlet and the automatic temperature control device; The infiltration tank is placed in the furnace lining, and the mouth of the co-infiltration tank is equipped with a cooling and sealing device. It has the advantages of low energy consumption, small deformation, fast seepage speed, and the tire mold after the process has high wear resistance, good corrosion resistance, good seizure resistance and good adhesion resistance. The invention is suitable for the surface modification treatment of the tire mold.

Owner:GREATOO INTELLIGENT EQUIP INC

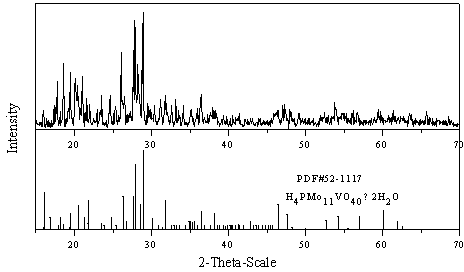

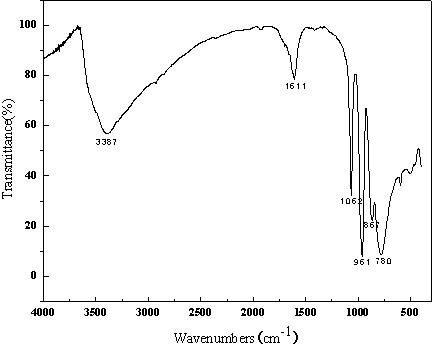

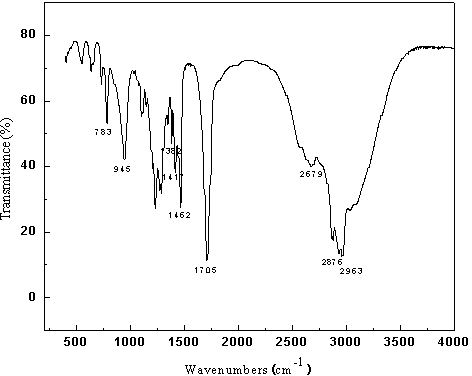

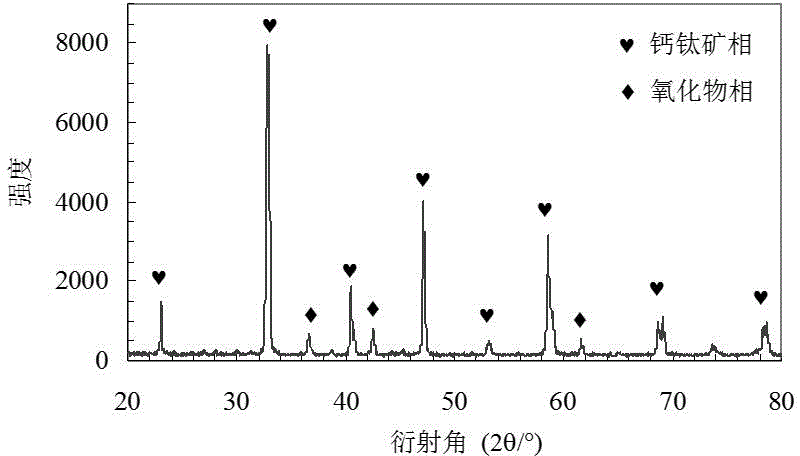

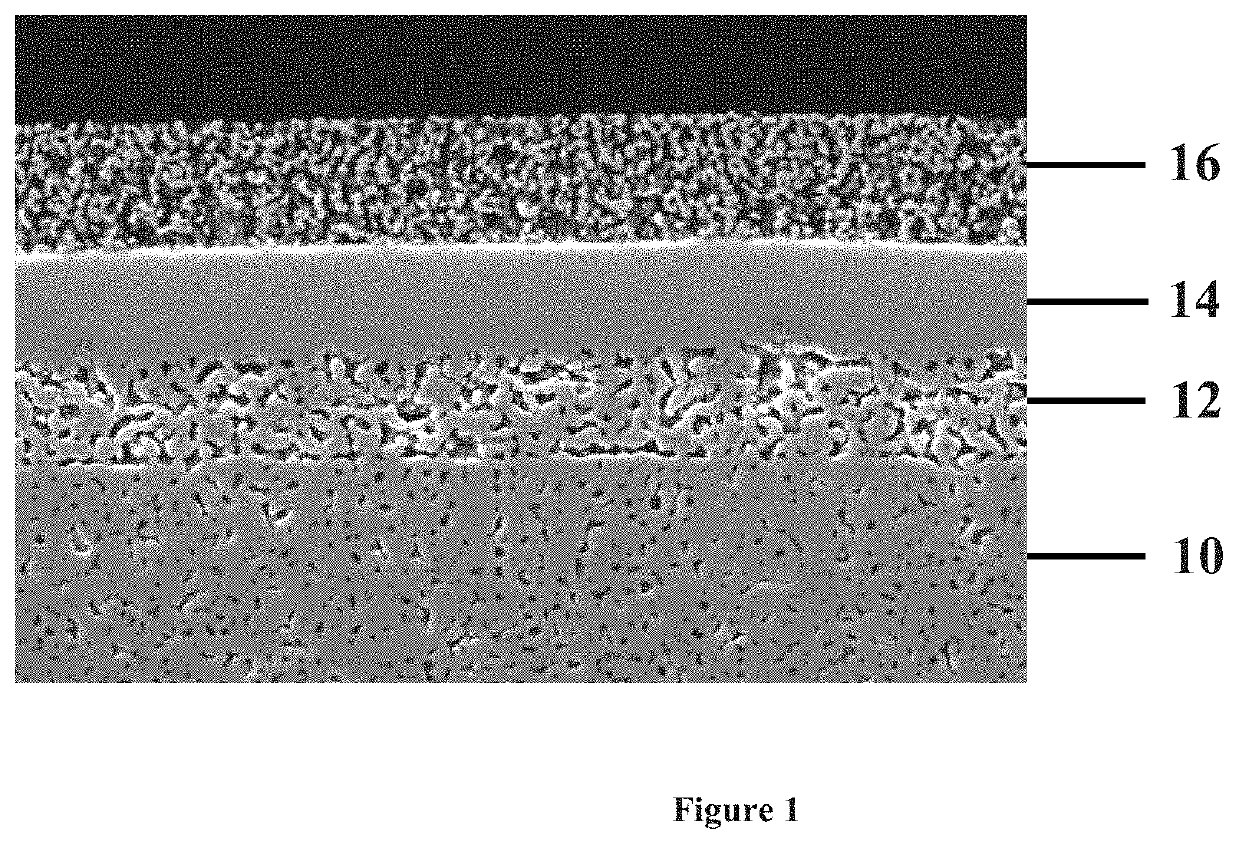

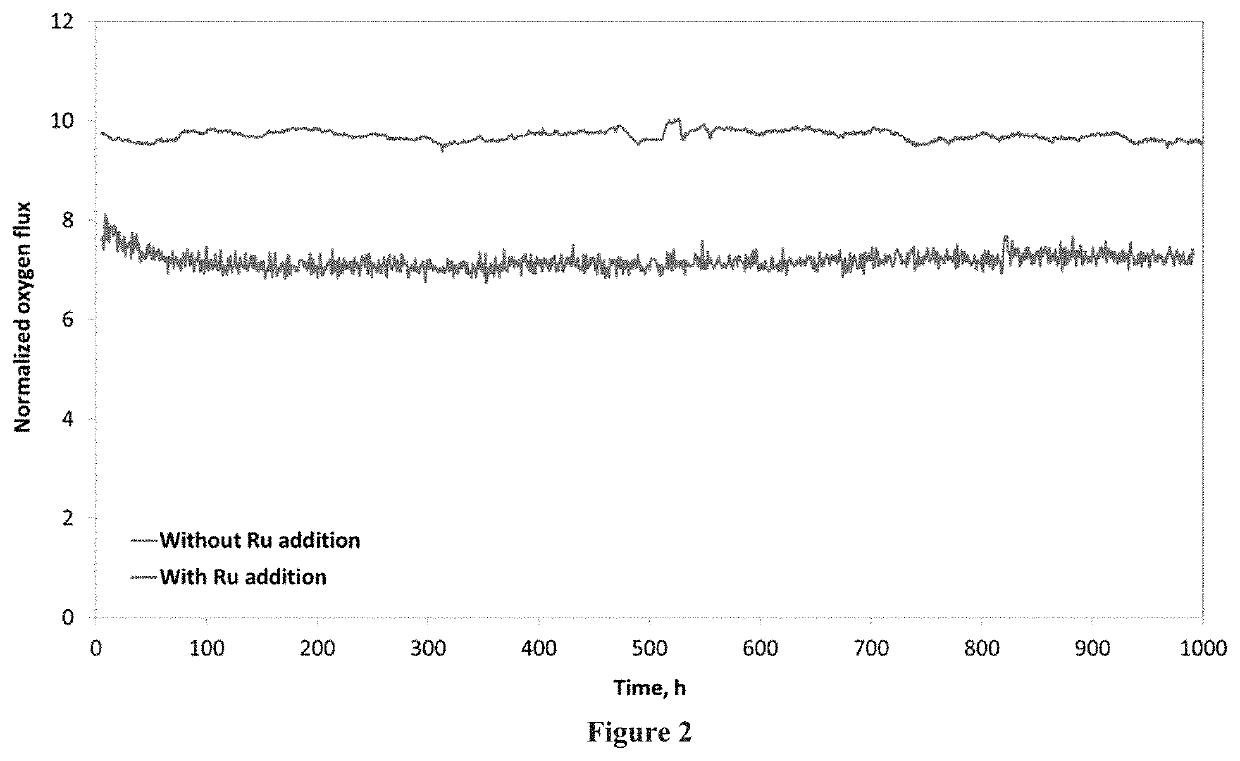

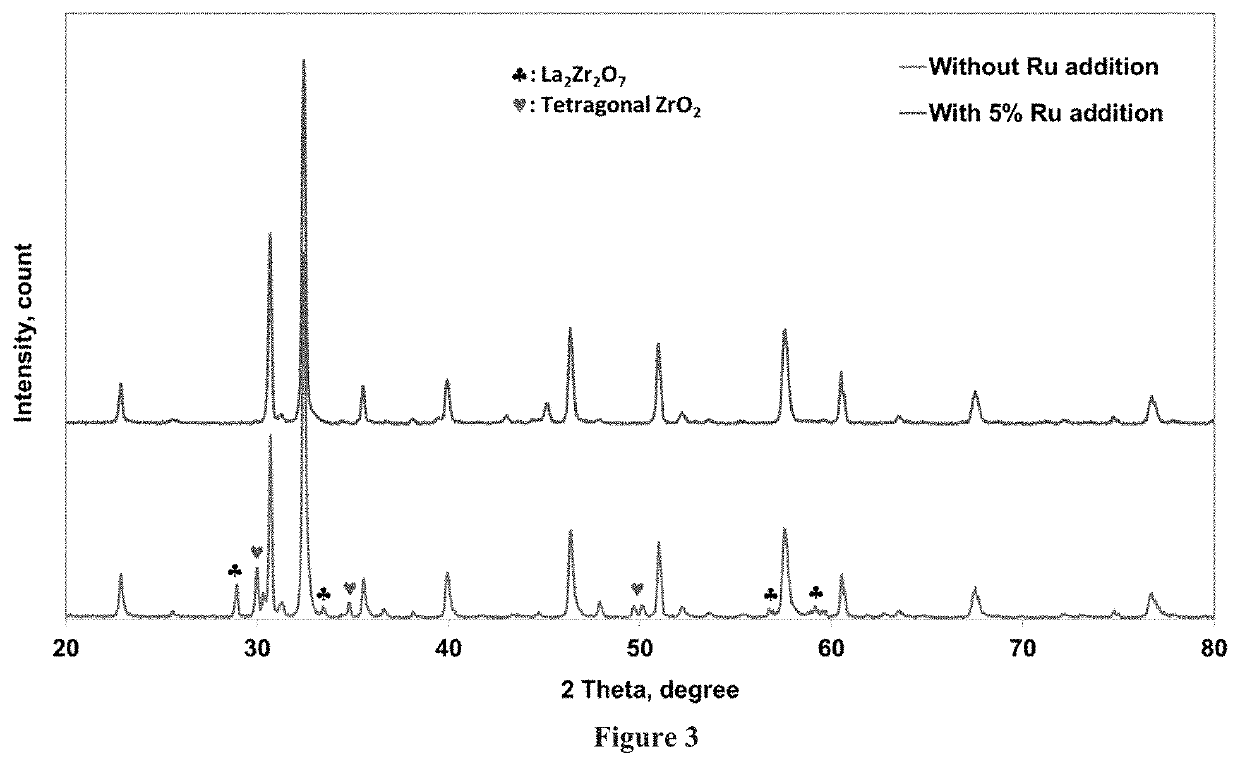

Catalyst-containing oxygen transport membrane

A method is described of producing a catalyst-containing composite oxygen ion membrane and a catalyst-containing composite oxygen ion membrane in which a porous fuel oxidation layer and a dense separation layer and optionally, a porous surface exchange layer are formed on a porous support from mixtures of (Ln1−xAx)wCr1−yByO3−δ and a doped zirconia. Adding certain catalyst metals into the fuel oxidation layer not only enhances the initial oxygen flux, but also reduces the degradation rate of the oxygen flux over long-term operation. One of the possible reasons for the improved flux and stability is that the addition of the catalyst metal reduces the chemical reaction between the (Ln1−xAx)wCr1−yByO3−δ and the zirconia phases during membrane fabrication and operation, as indicated by the X-ray diffraction results.

Owner:PRAXAIR TECH INC

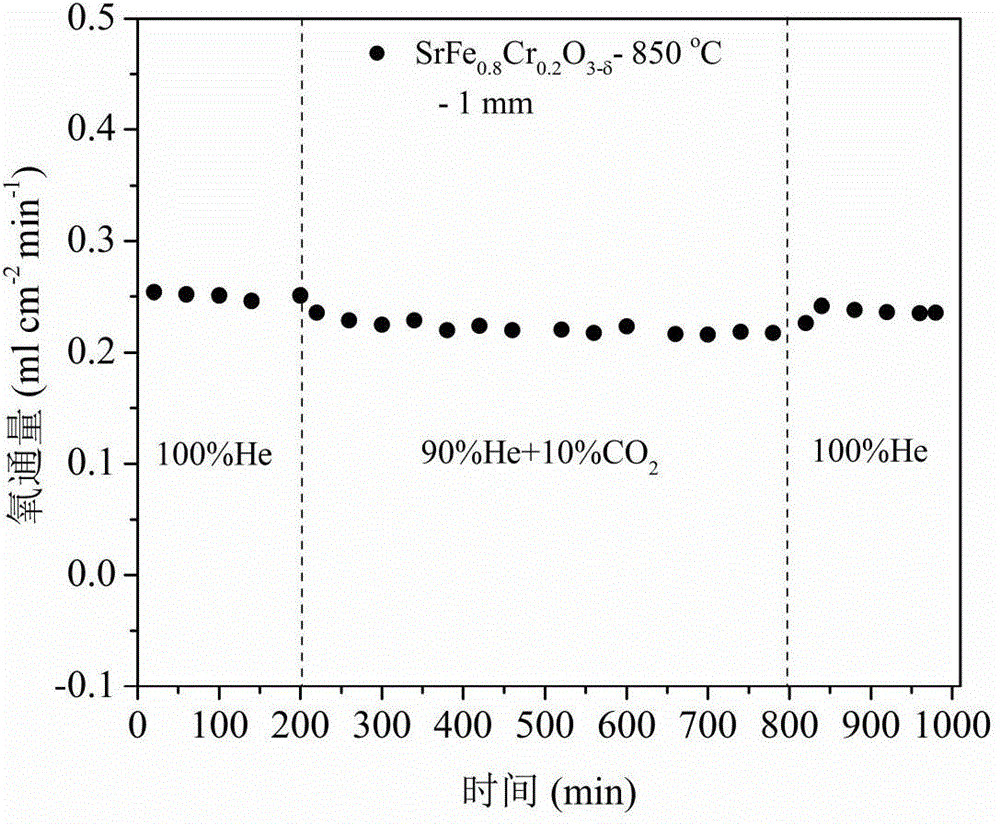

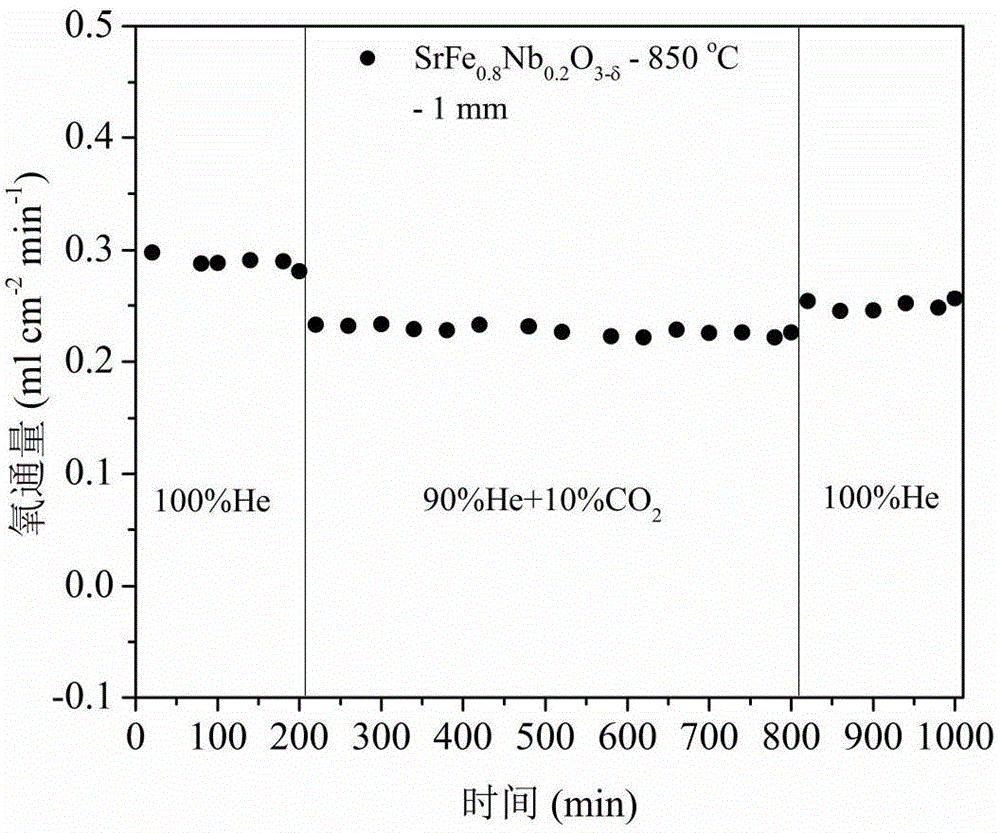

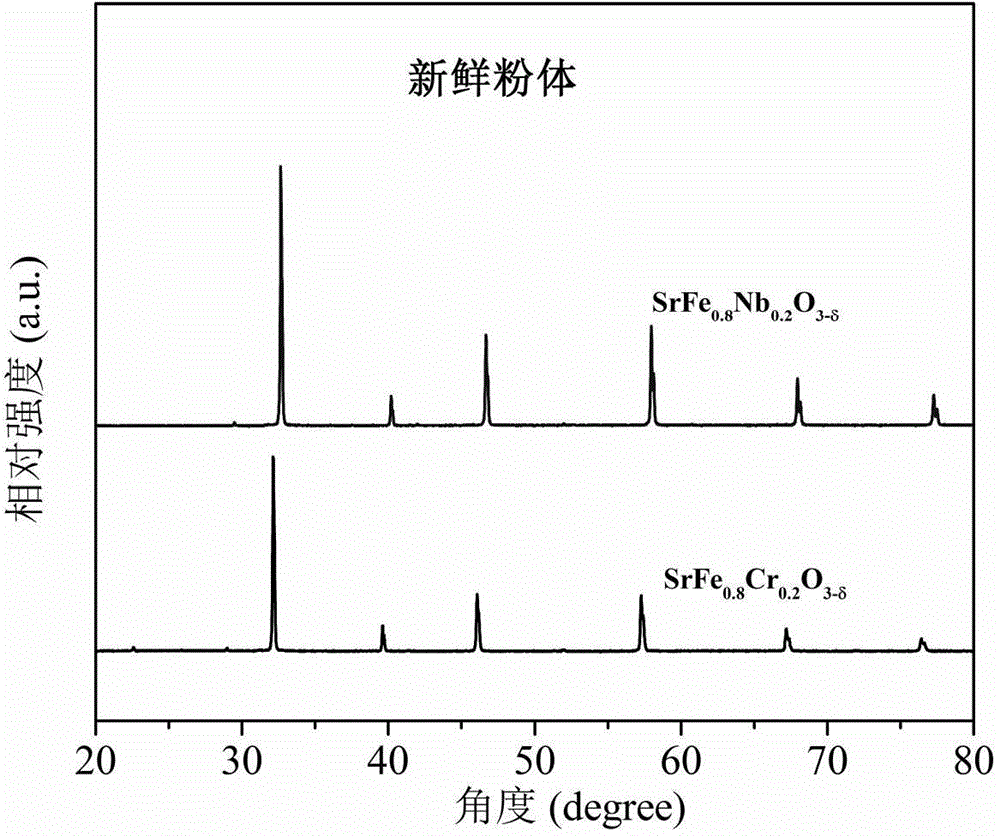

Oxygen permeation membrane materials with stable oxygen flux in carbon dioxide-containing atmosphere

ActiveCN104548957AHas industrial application valueImprove stabilitySemi-permeable membranesDispersed particle separationAlkaline earth metalElectrical conductor

The invention relates to oxygen permeation membrane materials with stable oxygen flux in a carbon dioxide-containing atmosphere. The oxygen permeation membrane materials are characterized in that the structural general formula is AB1-yMyO3-delta, wherein A is one or a mixture of Sr or Ca in alkali earth metal ions; B refers to the transition metal ion Fe; M refers to one or several in Cr, Mo, Nb, Ti, W or Zr; and y is more than or equal to 0.05 and less than or equal to 0.2. The mixed conductor oxygen permeation membrane materials of the type can simultaneously have a certain oxygen permeation flux and CO2 poisoning resistance in a temperature range of 600-900 DEG C. Therefore, a material with a certain oxygen permeation flux can be provided in the presence of CO2, so that the oxygen permeation membrane can have industrial application values in oxygen-enriched combustion and membrane reactors.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com