Oxygen permeation membrane materials with stable oxygen flux in carbon dioxide-containing atmosphere

A carbon dioxide, oxygen-permeable membrane technology, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve problems such as the instability of oxygen-permeable membrane materials, and improve the stability of unstable or H2S and other reducing gases. The effect of stabilizing and stabilizing oxygen flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

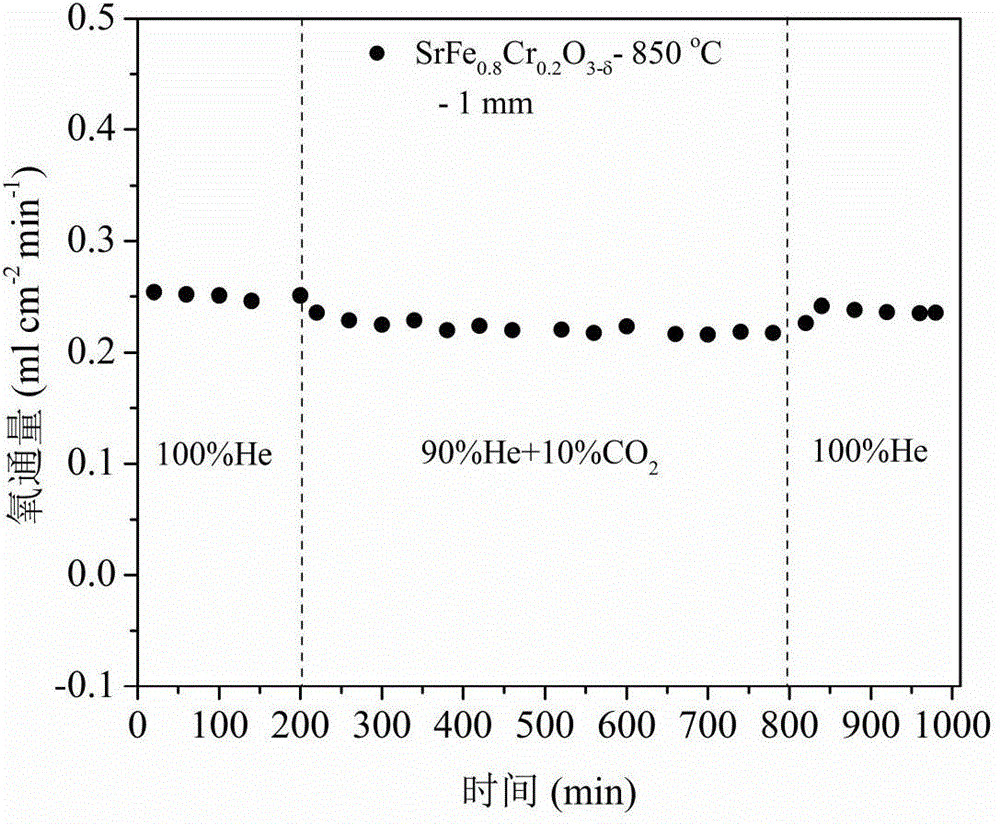

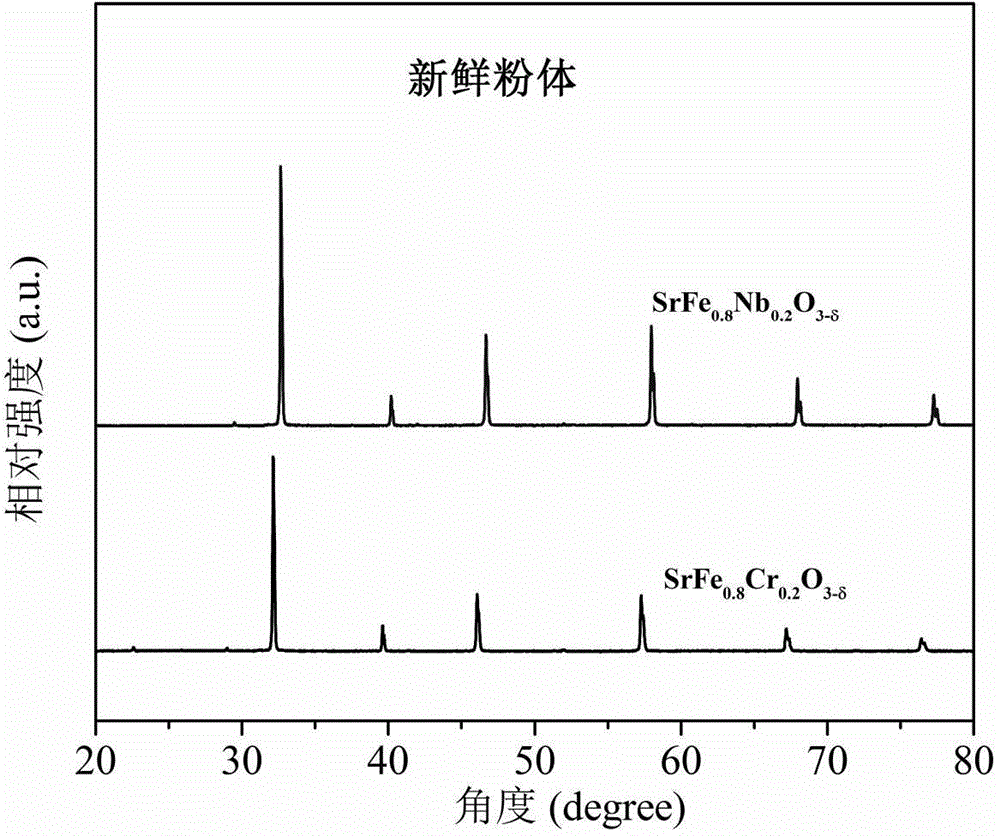

[0023] Example 1: SrFe 0.8 Cr 0.2 o 3-δ Preparation of Oxygen Permeable Membrane

[0024] SrFe 0.8 Cr 0.2 o 3-δ The specific preparation process of the oxygen permeable membrane diaphragm is mainly divided into two steps: SrFe 0.8 Cr 0.2 o 3- δ Powder preparation and SrFe 0.8 Cr 0.2 o 3-δ Membrane preparation.

[0025] SrFe 0.8 Cr 0.2 o 3-δ The method adopted for the preparation of the powder is EDTA-CA sol-gel combined complexation method. First, by SrFe 0.8 Cr 0.2 o 3-δ Stoichiometric ratio was weighed Sr(NO 3 ) 2 , Fe(NO 3 ) 3 , Cr(NO 3 ) 3Put the particles into a beaker, stir and heat, wait until all the particles are dissolved, add EDTA, CA two complexing agents, and add NH 3 ·H 2 O adjusts the pH of the solution to around 6. Secondly, put the beaker on the heating table and keep stirring until it becomes a sol, and put it in an oven at 250°C for 5 hours to obtain SrFe 0.8 Cr 0.2 o 3-δ precursors. Finally, the SrFe 0.8 Cr 0.2 o 3-δ Put th...

Embodiment 2

[0028] Example 2: SrFe 0.9 W 0.1 o 3-δ Preparation of Oxygen Permeable Membrane

[0029] SrFe 0.9 W 0.1 o 3-δ The specific preparation process of the oxygen permeable membrane diaphragm is mainly divided into two steps:

[0030] SrFe 0.9 W 0.1 o 3-δ Powder preparation and SrFe 0.9 W 0.1 o 3-δ Membrane preparation.

[0031] SrFe 0.9 W 0.1 o 3-δ The method adopted for the preparation of the powder is EDTA-CA sol-gel combined complexation method. First, by SrFe 0.9 W 0.1 o 3-δ Stoichiometric ratio was weighed Sr(NO 3 ) 2 , Fe(NO 3 ) 3 , (NH 4 ) 10 W 12 o 41 Put the particles into a beaker, stir and heat, wait until all the particles are dissolved, add EDTA, CA two complexing agents, and add NH 3 ·H 2 O to adjust the pH of the solution to 6.5. Secondly, put the beaker on the heating table and keep stirring until it becomes a sol, and put it in an oven at 250°C for 3 hours to obtain SrFe 0.9 W 0.1 o 3-δ precursors. Finally, the SrFe 0.9 W 0.1 o 3...

Embodiment 3

[0034] Example 3: CaFe 0.95 Zr 0.05 o 3-δ Preparation of Oxygen Permeable Membrane

[0035] CaFe 0.95 Zr 0.05 o 3-δ The specific preparation process of the oxygen permeable membrane diaphragm is mainly divided into two steps:

[0036] CaFe 0.95 Zr 0.05 o 3-δ Powder preparation and CaFe 0.95 Zr 0.05 o 3-δ Membrane preparation.

[0037] CaFe 0.95 Zr 0.05 o 3-δ The method adopted for the preparation of the powder is EDTA-CA sol-gel combined complexation method. First, by CaFe 0.95 Zr 0.05 o 3-δ Stoichiometric ratio was weighed Ca(NO 3 ) 2 , Fe(NO 3 ) 3 , Zr(NO 3 ) 4 Put the particles into a beaker, stir and heat, wait until all the particles are dissolved, add EDTA, CA two complexing agents, and add NH 3 ·H 2 O to adjust the pH of the solution to 6. Secondly, put the beaker on the heating table and keep stirring until it becomes a sol, and put it in an oven at 250°C for 6 hours to obtain CaFe 0.95 Zr 0.05 o 3-δ precursors. Finally, the CaFe 0.95 Zr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com