Cerium-base bulk amorphous alloys and method for preparation thereof

An amorphous alloy and bulk technology, applied in the alloy field, can solve the problems of low oxygen resistance and high preparation cost, and achieve the effect of low elastic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, Ce 60 Al 10 Ni 10 Cu 20 Preparation of Bulk Amorphous Alloy

[0039] Use Ce, Al, Ni and Cu with a purity of more than 99.5% and a molar ratio of 60:10:10:20 to prepare a cerium-based bulk amorphous alloy. First, the four components are prepared in proportion and then adsorbed on titanium. Melting in an electric arc furnace with an argon atmosphere, mixing evenly, and cooling to obtain a master alloy ingot of a Ce-Al-Ni-Cu quaternary alloy; then using a conventional metal mold casting method to remelt this master alloy alloy ingot, Using the suction casting device in the electric arc furnace, the master alloy melt is sucked into the water-cooled copper mold, and the composition is Ce 60 Al 10 Ni 10 Cu 20 , a bulk amorphous alloy with a diameter of 1 mm.

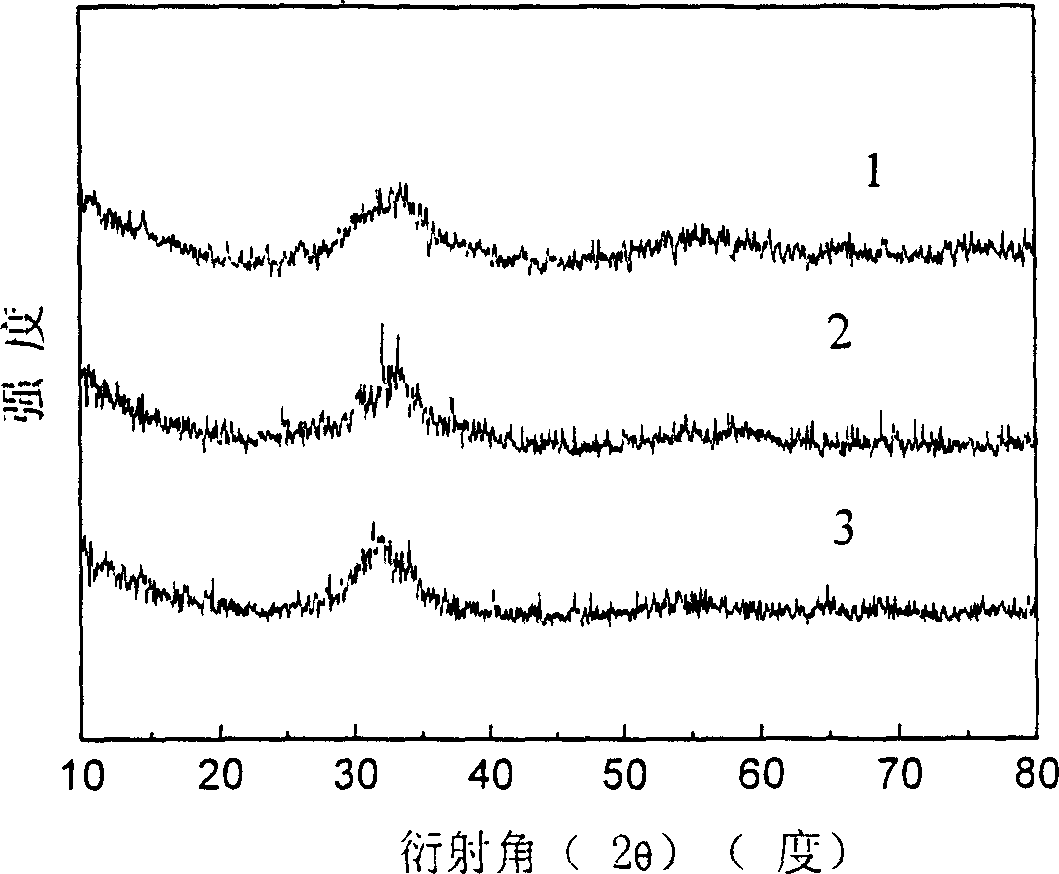

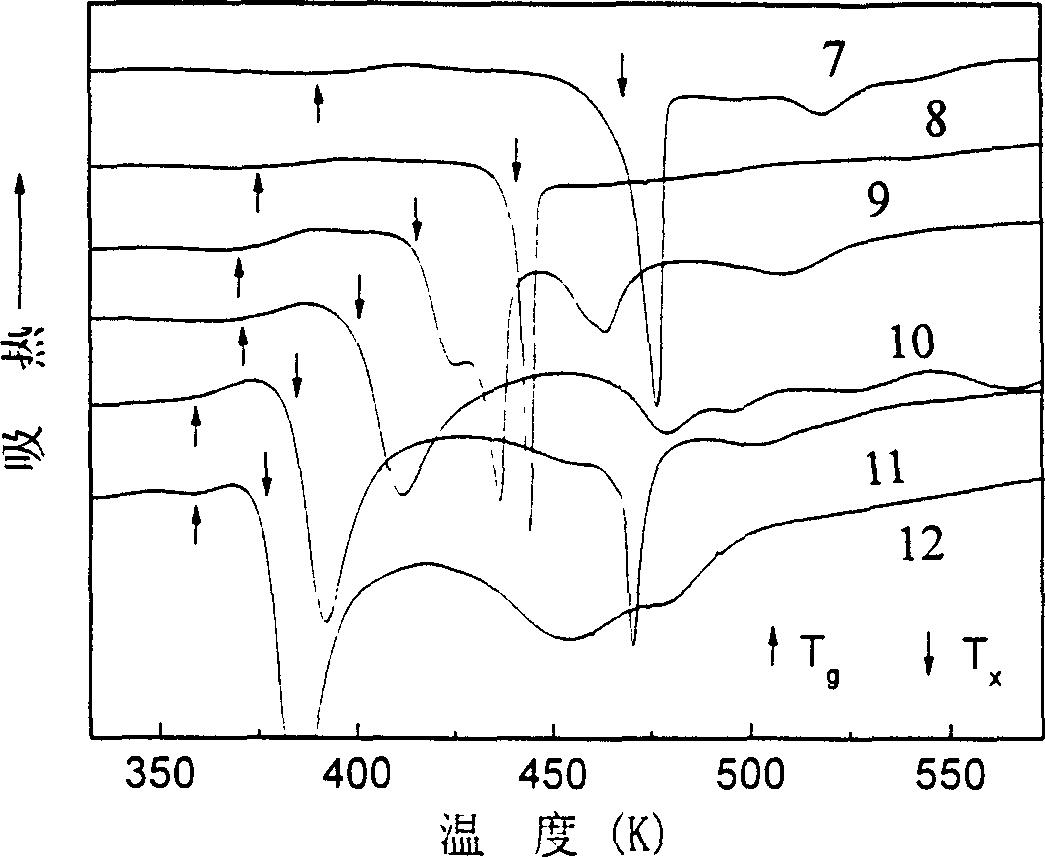

[0040] Such as figure 1 X-ray diffraction (XRD) shown proves that the alloy is completely amorphous. Such as image 3 The thermal analysis (DSC) diagram shown, its glass transition temperature (T ...

Embodiment 2

[0041] Example 2, Ce 70 Al 10 Ni10 Cu 10 Preparation of Bulk Amorphous Alloy

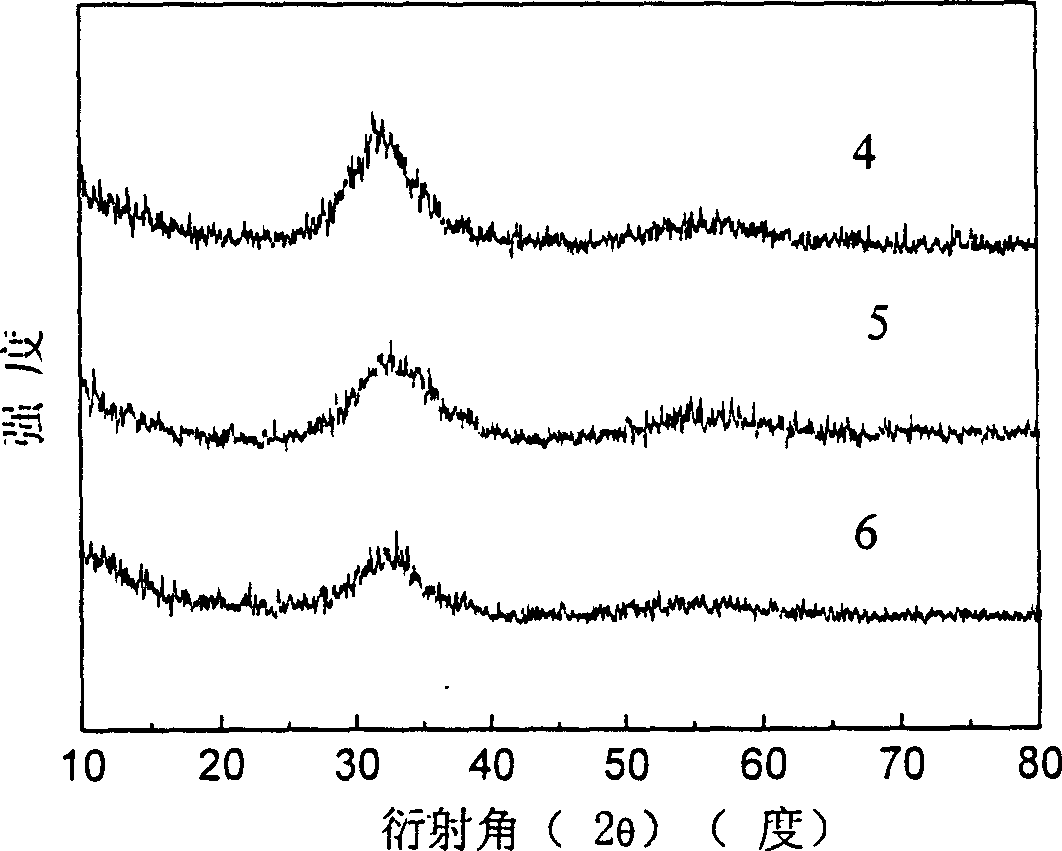

[0042] According to the method for embodiment 1, prepare bulk amorphous alloy Ce 70 Al 10 Ni 10 Cu 10 . The glass transition temperature of the alloy is lowered (359K), and the supercooling range is narrowed (18K), but the glass forming ability is lower than that of Ce in Example 1. 60 Al 10 Ni 10 Cu 20 The bulk amorphous alloy has been improved, and an amorphous rod with a diameter of 3mm can be obtained, such as Figure 4 shown. Ultrasonic tests prove that the amorphous alloy is a "soft" metallic glass, and its bulk modulus (K), shear modulus (G) and Young's modulus (E) are 27GPa, 11.5GPa and 30.3GPa ( See Table 1. These modulus values are similar to the corresponding modulus values of amorphous carbon and relatively close to those of organic polymers.

Embodiment 3~23

[0044] The magnesium-based bulk amorphous alloy of various proportions is prepared by the method of embodiment 1, and its X-ray diffraction (XRD) is as follows figure 1 and figure 2 As shown, the thermal analysis (DSC) diagram is shown in image 3 The composition and thermophysical parameters of all alloys are listed in Table 1.

[0045] The cerium required by the cerium-based bulk amorphous alloy provided by the invention is an industrial raw material with a purity of 99.5%. Therefore, the cost of the cerium-based bulk amorphous alloy is lower than that of other precious metals. Moreover, my country is a big rare earth country, and cerium resources are very rich, so this is a bulk amorphous system that is very suitable for the characteristics of my country's resources. Because cerium has strong metal activity, it can absorb a large amount of oxygen at room temperature, so the metal has good anti-oxidation performance. Even if it absorbs a lot of oxygen during the preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com