Combined catalyst for improving denitration performance and application thereof

A technology for combining catalyst and performance, applied in the field of catalyst segment combination, can solve the problems of difficulty in meeting diesel vehicles, catalyst poisoning and high operating temperature, and achieve the effects of high selectivity, low cost and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

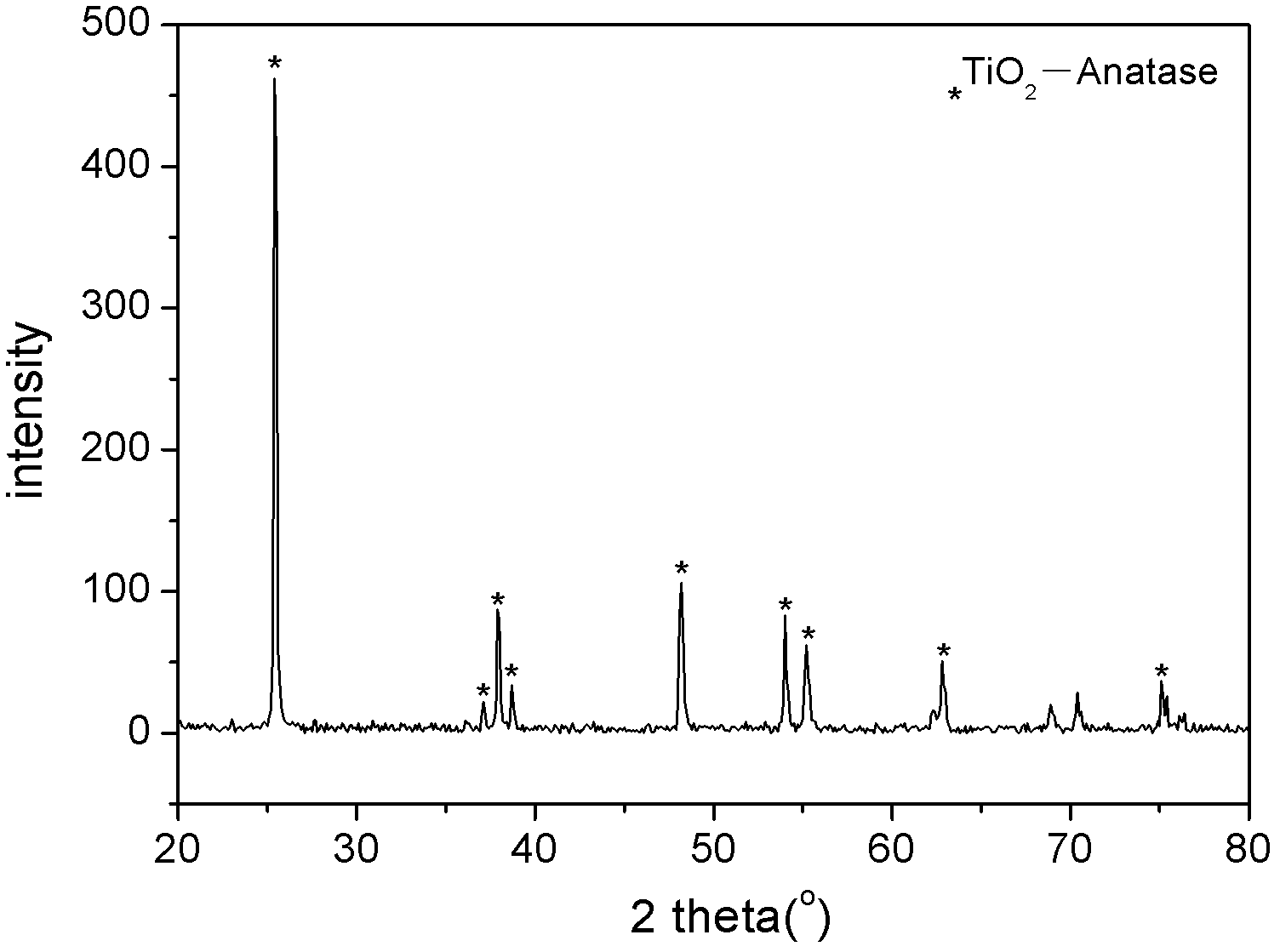

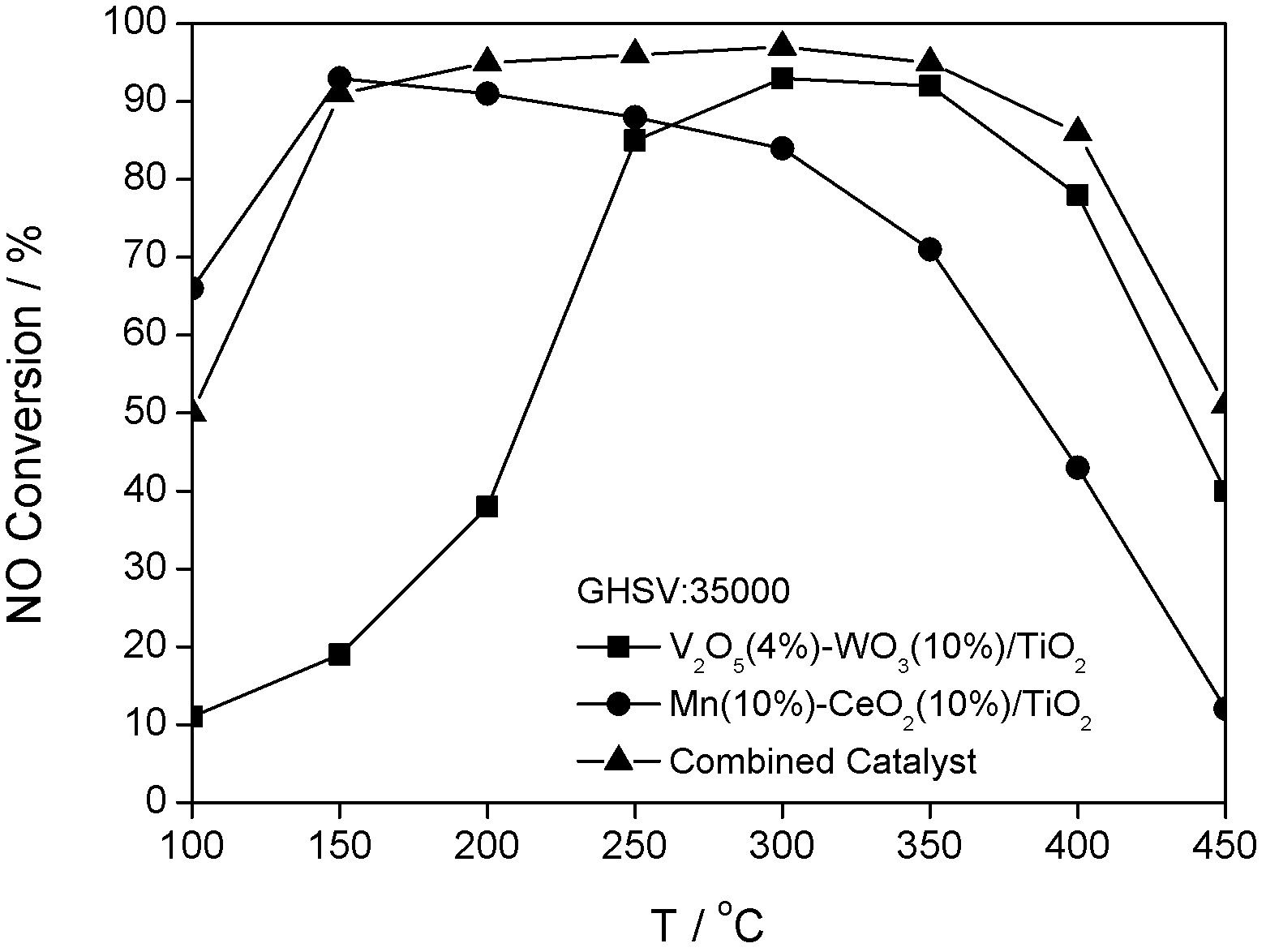

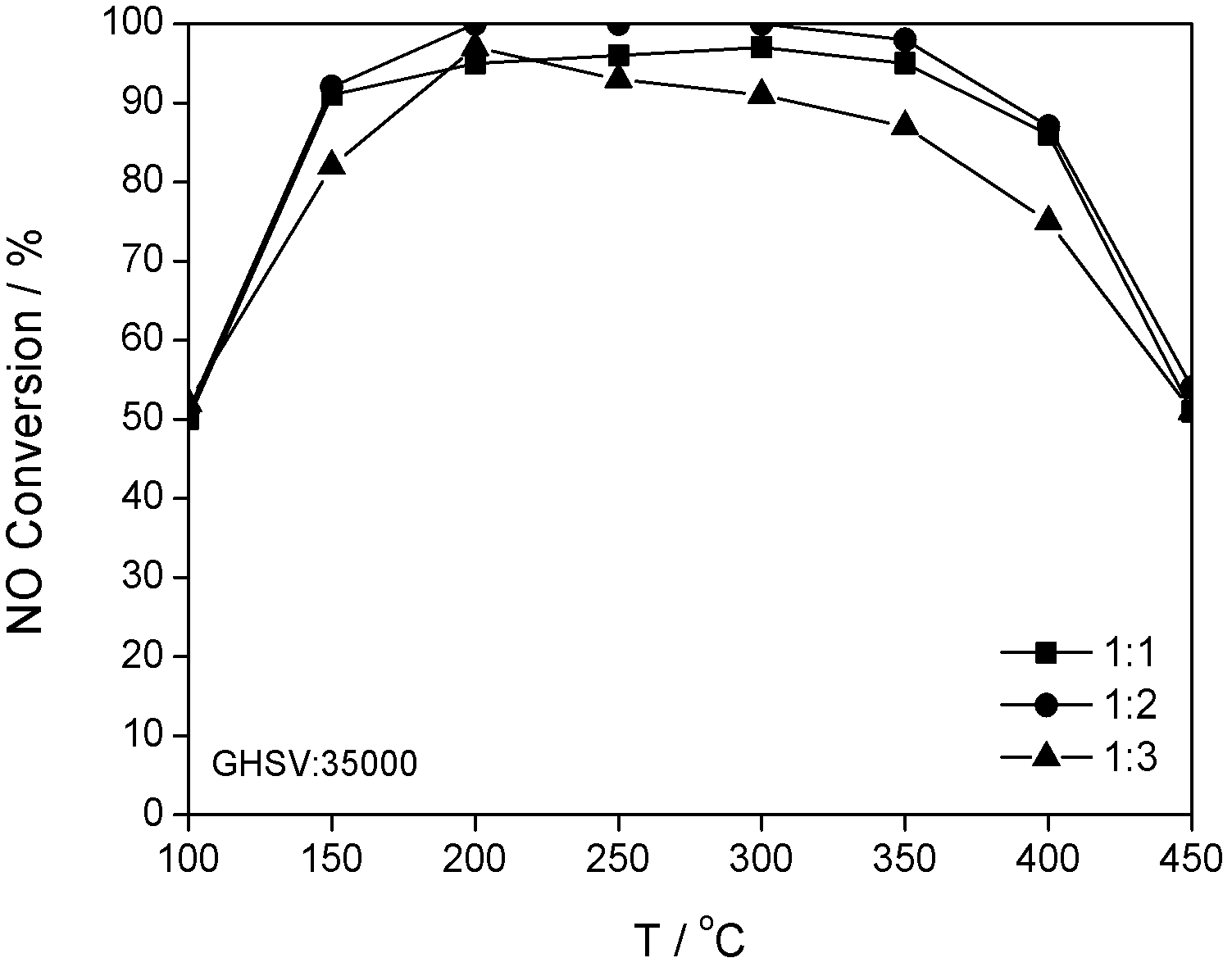

[0034] Staged Catalyst Preparation

[0035] Weigh the mass of the precursor according to the result calculated in step (1), and divide it into two beakers to prepare V 2 o 5 -WO 3 / TiO 2 with MnO x -CeO 2 / TiO 2 . Slowly add the weighed ammonium metavanadate, ammonium paratungstate, manganese nitrate, and cerium nitrate into two 1000ml beakers that have taken 500ml of deionized water, and stir in a water bath at 40°C to promote the complete dissolution of the precursor. liquid, and then a certain amount of industrial anatase TiO 2 Add them to the impregnating liquid respectively, keep stirring in a water bath for 12-24 hours, then use a rotary evaporator to remove the water in the impregnating liquid, dry them in an oven, take them out and calcinate them in a muffle furnace. The obtained two calcined products are cooled, ground, pressed into tablets, and 40-60 mesh particles are screened out to obtain the corresponding V2 o 5 -WO 3 / TiO 2 with MnO x -CeO 2 / TiO 2...

Embodiment 1

[0053] Weigh 0.651gMn(NO 3 ) 2 (chemically pure, 50%), 0.252g Ce(NO 3 ) 3 ·6H 2 O (analytical pure), and dissolve it in water to make an impregnation solution, then weigh 1g of anatase TiO 2 Add it into the impregnating solution, stir in a water bath at 40°C for 24 hours, then use a rotary evaporator to remove the moisture in the impregnating solution, place it in an oven to dry for 6 hours, and finally place the above-mentioned loaded catalyst in an air atmosphere at 2°C / min The temperature was raised to 500°C for 6 hours, and the obtained calcined product was cooled, ground, pressed into tablets, and 40-60 mesh particles were screened out to obtain a loading capacity of 10wt% Mn, 10wt% CeO 2 Loaded MnO x -CeO 2 / TiO 2 catalyst.

[0054] Weigh 0.0514g NH 4 VO 3 (analytically pure), 0.113g 5(NH 4 ) 2 O·12WO 3 ·5H 2 O (analytical pure), and dissolve it in water to make an impregnation solution, then weigh 1g of anatase TiO 2 Add it into the impregnating solution,...

Embodiment 2

[0057] Weigh 0.651g Mn(NO 3 ) 2 (chemically pure, 50%), 0.202g Ce(NO 3 ) 3 ·6H 2 O (analytically pure), all the other preparation methods are the same as in Example 1, and the loading capacity obtained is 10wt% Mn, 8wt% CeO 2 MnO x -CeO 2 / TiO 2 catalyst.

[0058] Weigh 0.0514g NH 4 VO 3 (analytically pure), 0.09g 5(NH 4 ) 2 O·12WO 3 ·5H 2 O (analytically pure), all the other preparation methods are the same as in Example 1, and the loading capacity that can be obtained is 4wt%V 2 o 5 , 8wt% WO 3 V 2 o 5 -WO 3 / TiO 2 catalyst.

[0059] Catalyst segmented combination mode and activity evaluation means are the same as embodiment 1, NO x See Table 1, 2, 3, 4 for details of conversion rate and each reaction product yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com