Patents

Literature

44results about How to "Improve single crystal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large single crystal graphene and preparation method thereof

ActiveCN104674343AEasy to prepareReduce nucleation densityPolycrystalline material growthFrom chemically reactive gases1,3,5-TriazineSingle crystal

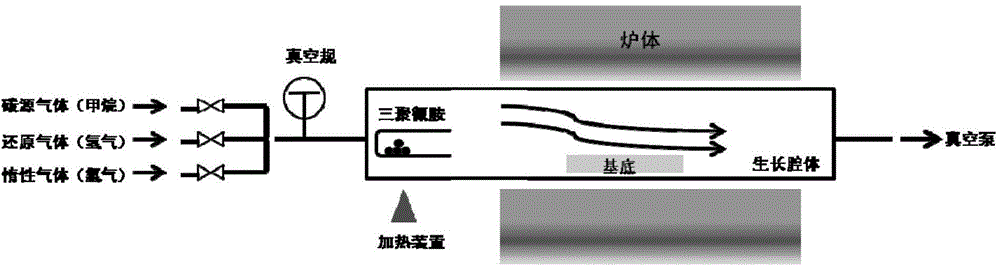

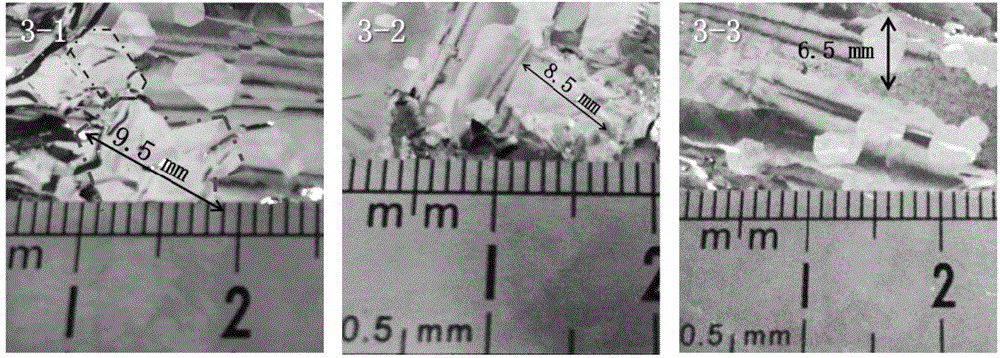

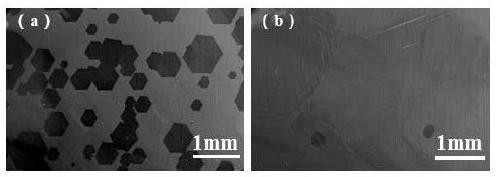

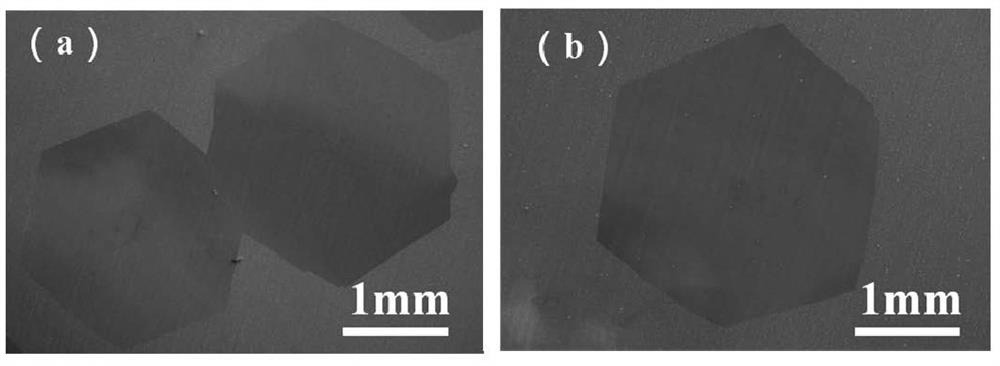

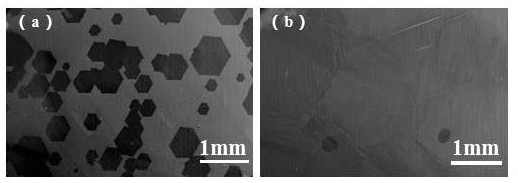

The invention relates to a large single crystal graphene and preparation method thereof. The preparation method comprises the following steps: 1) annealing a copper base under reducing atmosphere to obtain annealed copper base; 2) under triazine derivative steam atmosphere, treating the copper base annealed after the annealing treatment in the step 1) to obtain the copper base after the triazine derivative treatment, wherein the triazine derivative is selected from at least one of tripolycyanamide, 2,4-diamino-6-methyl-1,3,5-triazine, and 2-amino-4-methyl-6-methoxy-1,3,5-triazine; 3) depositing graphene on the surface of the copper base subjected to triazine derivative biological treatment by adopting a chemical vapor deposition method to obtain the large single crystal graphene. The preparation method is simple and suitable for large-scale production, the single crystal domain size achieves sub-centimeter level, and the single crystal quality is high and can be applied to the electronics.

Owner:PEKING UNIV

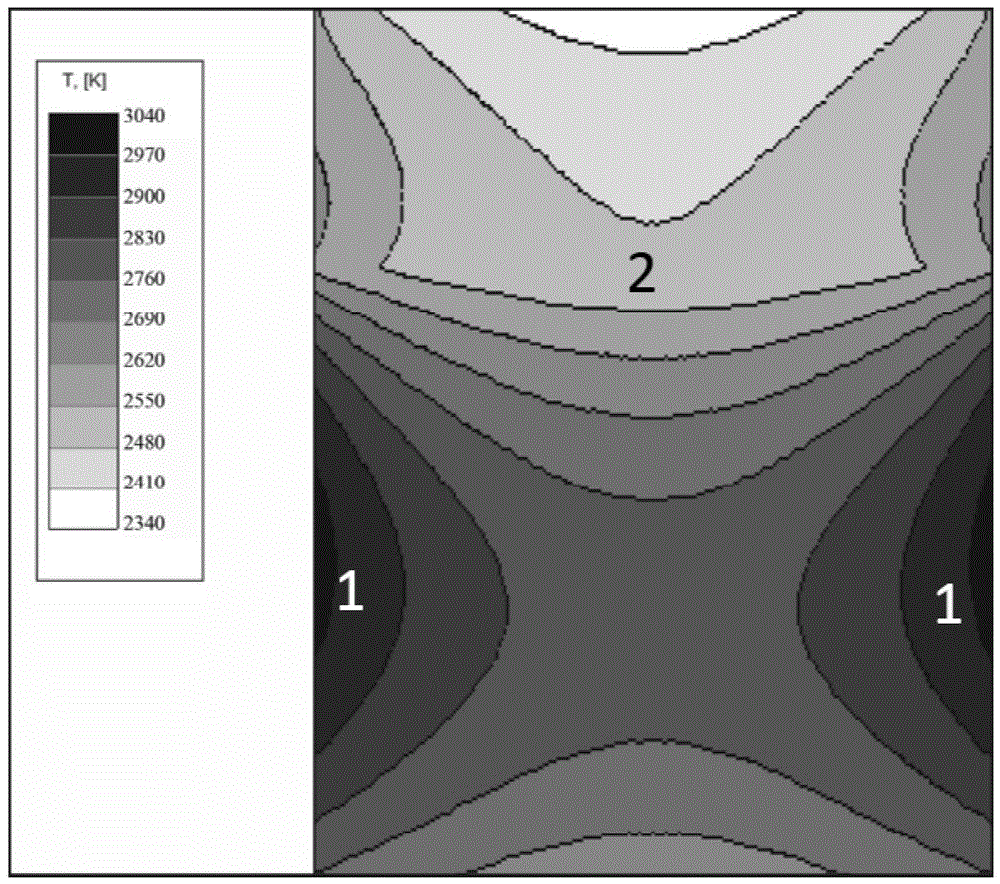

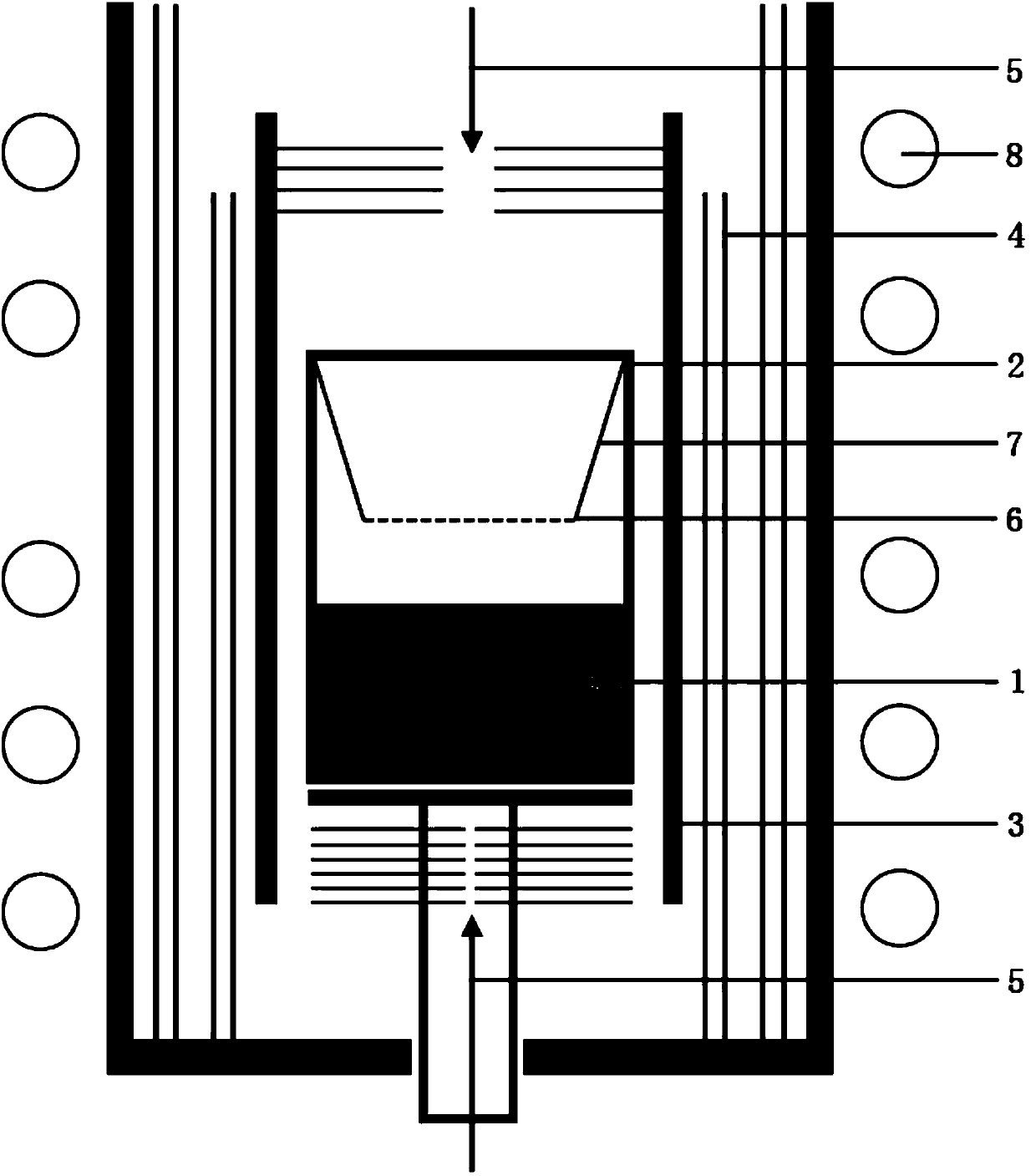

Growth method of germanium-doped SiC body single-crystal material

InactiveCN105568385AControl vapor pressureEvenly dopedPolycrystalline material growthFrom condensed vaporsDopantCrucible

The invention provides a growth method of a germanium-doped SiC body single-crystal material. The method adopts a sublimation method to make germanium-doped single crystals grow in a high-temperature single-crystal growth furnace and comprises the specific growth steps that the positions of high and low temperature zones are determined according to the shape of a residual material left at the bottom of the inside of a crucible after crystal growth; a dopant is put at the corresponding positions of the high and low temperature zones respectively to make the crystals grow; cooling is performed to reach room temperature, and high-quality germanium-doped SiC single crystals are obtained. The method enables the germanium element to be put in the high and low temperature zones respectively according to the temperature field distribution characteristics of induction heating, achieves uniform doping in the whole crystal growth process, controls the vapor pressure of the germanium at a preliminary growth stage, prevents germanium atom agglomeration on the growth face and achieves uniform doping in the radial and axial directions. The crystal defects and internal stress are reduced. Obtained single-crystal defects are few, the single-crystal quality is high, and the stress is small.

Owner:SHANDONG UNIV

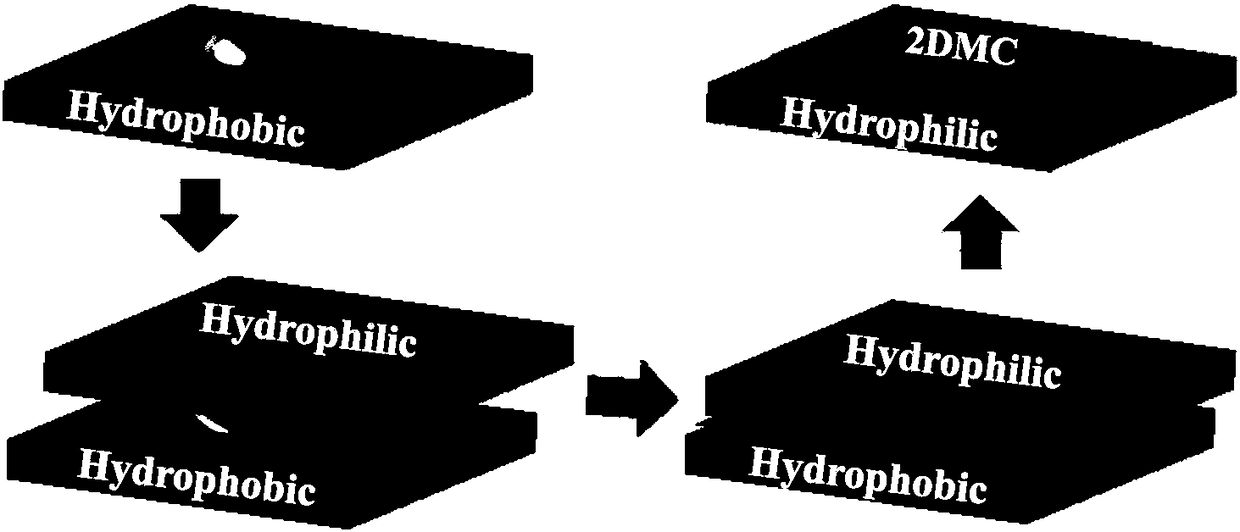

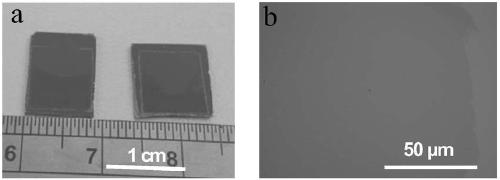

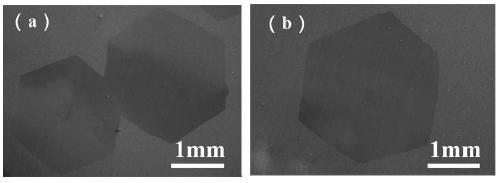

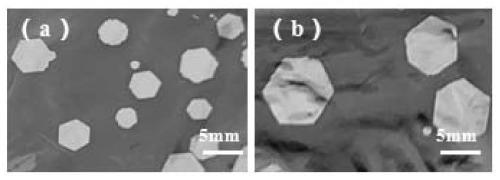

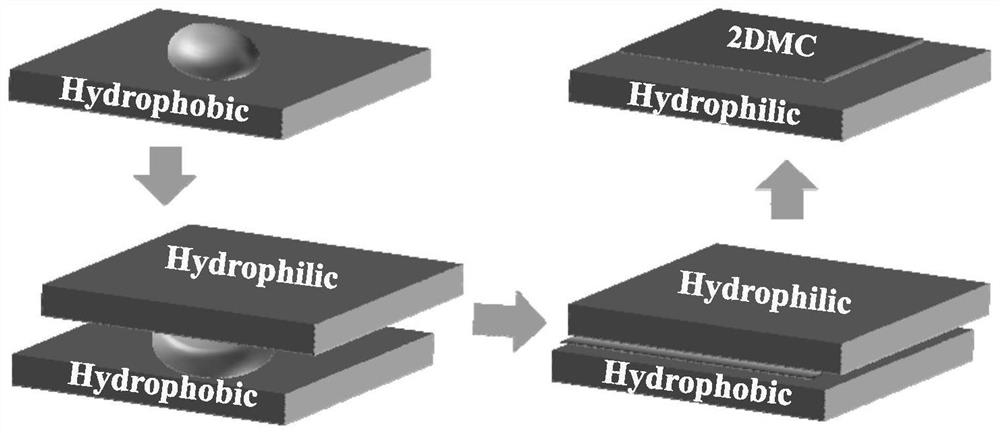

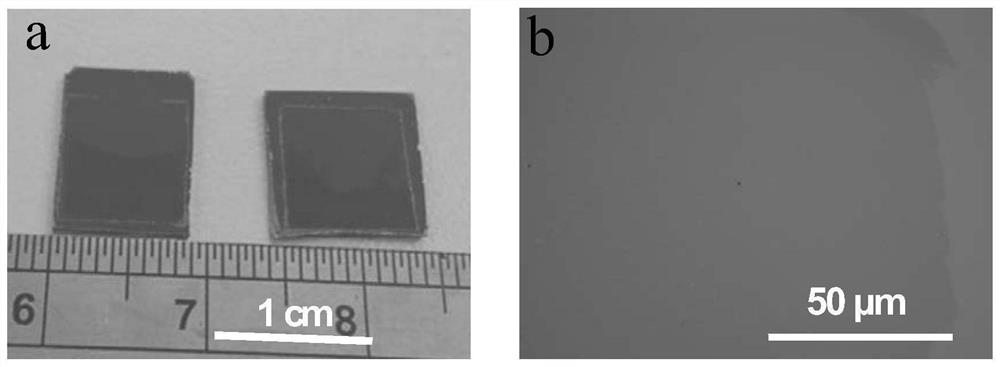

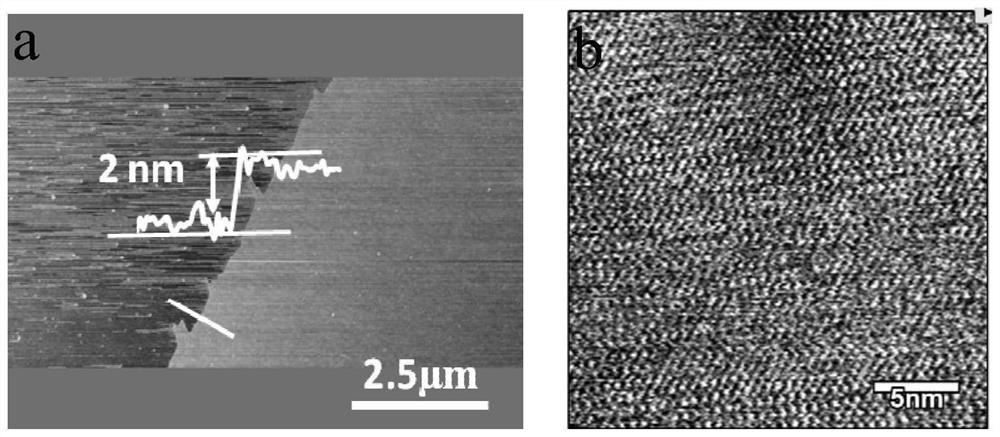

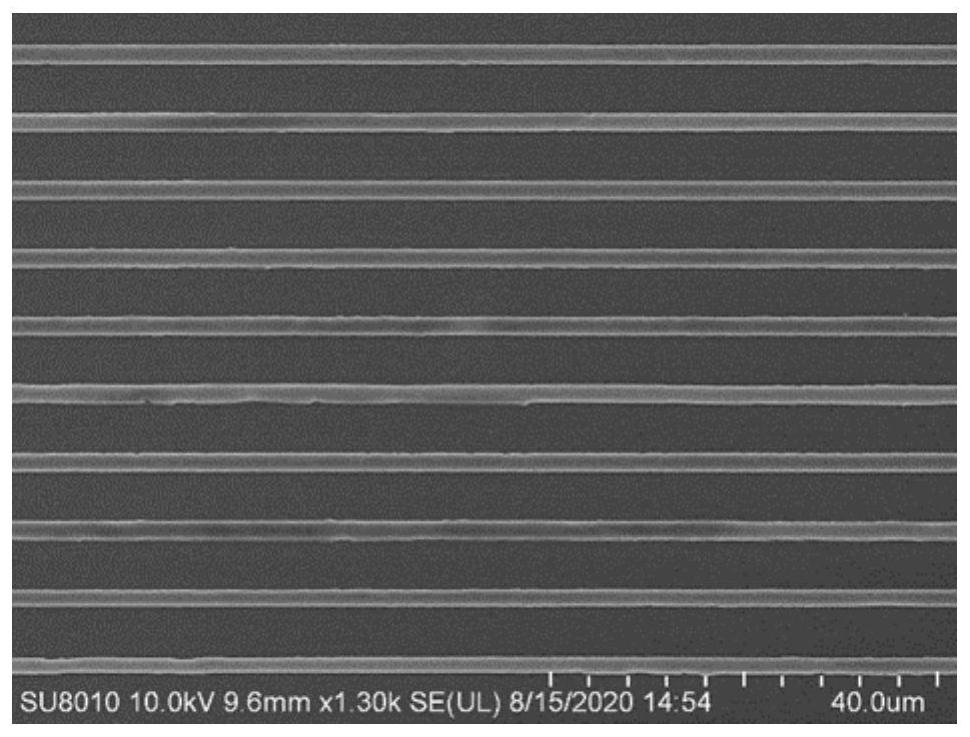

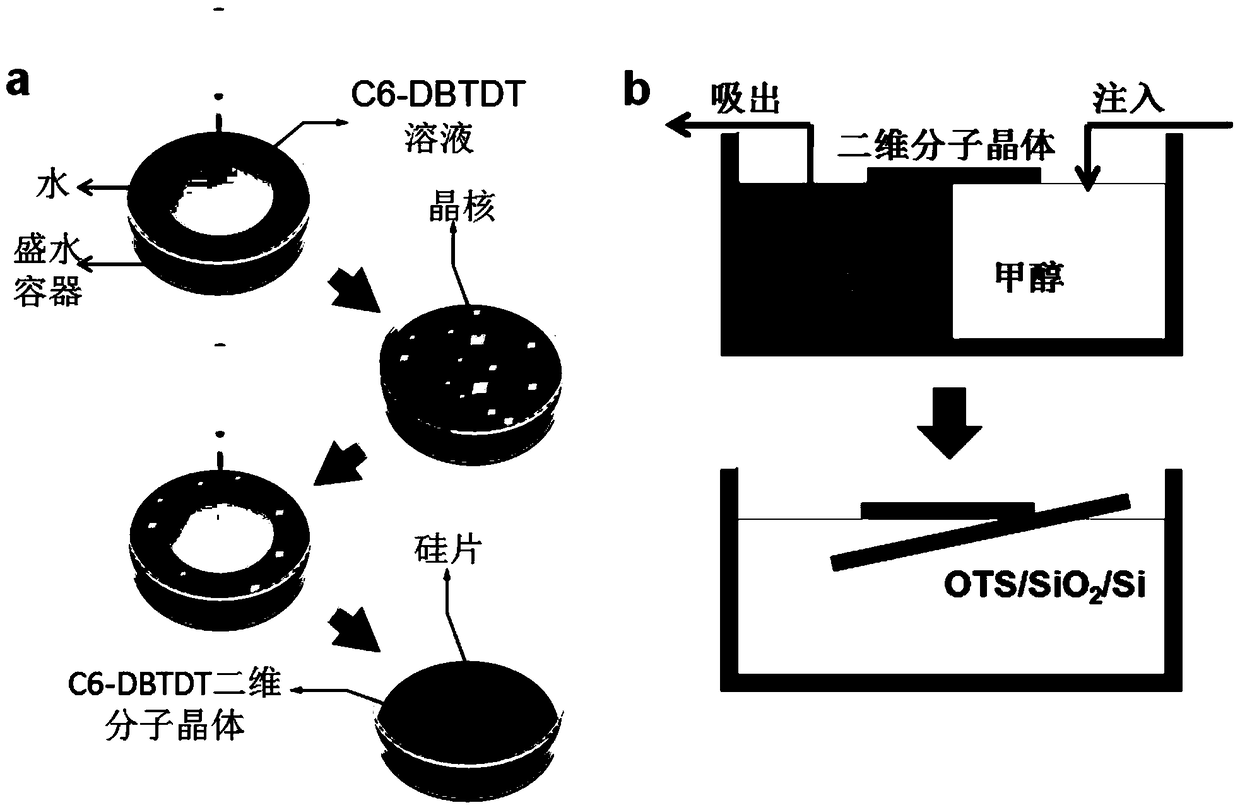

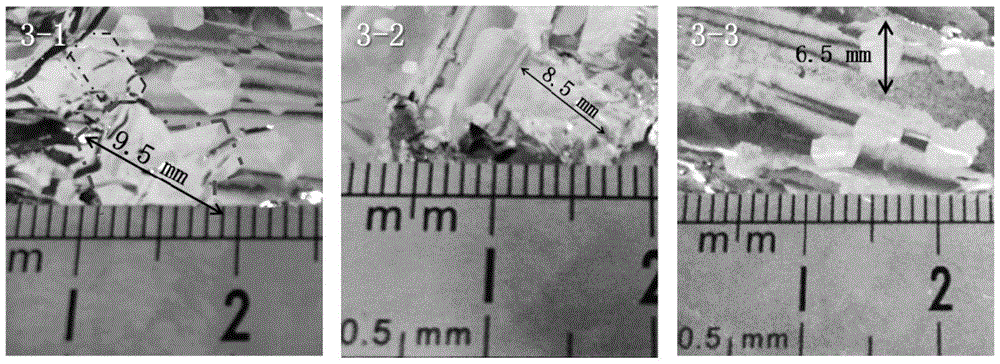

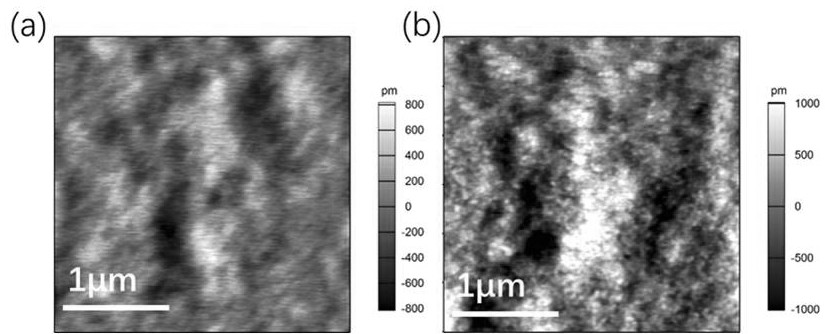

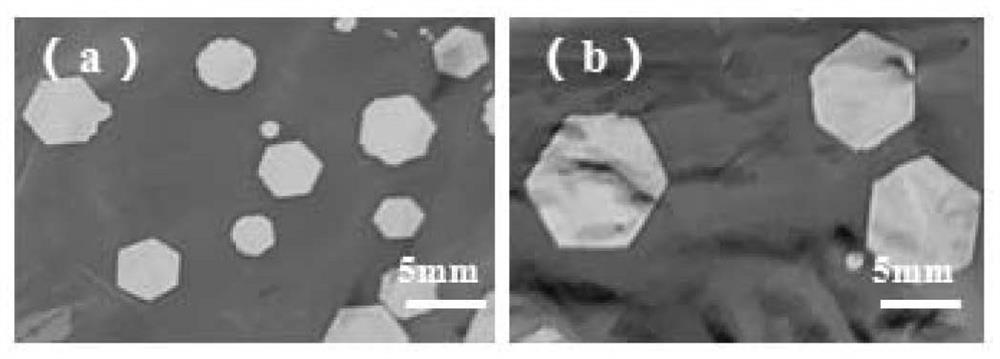

Large-area molecular crystal and preparation method thereof

ActiveCN109137083AImprove uniformityFlat surfacePolycrystalline material growthLiquid-phase epitaxial-layer growthHeterojunctionChlorobenzene

The invention discloses large-area molecular crystal and a preparation method thereof. The preparation method for the large-area molecular crystal comprises the following steps that an organic semiconductor solution is placed on a substrate with a hydrophobic property, a substrate with a hydrophily property covers the substrate with the hydrophobic property, and after growth, molecular crystal canbe obtained on the substrate with the hydrophily property; the organic semiconductor solution adopts at least one of chlorobenzene solvent, trichloromethane solvent, dichlorobenzene solvent and xylene solvent; the mass volume density of the organic semiconductor solution is 0.01 mg / mL-15 mg / mL; the solutes of the organic semiconductor solution are organic semiconductor molecules. The large-area molecular crystal has the advantages of a large area, high uniformity and a flat surface, a field effect transistor prepared by the large-area two-dimensional molecular crystal has higher carrier mobility rate and lower threshold voltage, and solid foundation is laid for the preparation of later P-N heterojunction.

Owner:INST OF CHEM CHINESE ACAD OF SCI

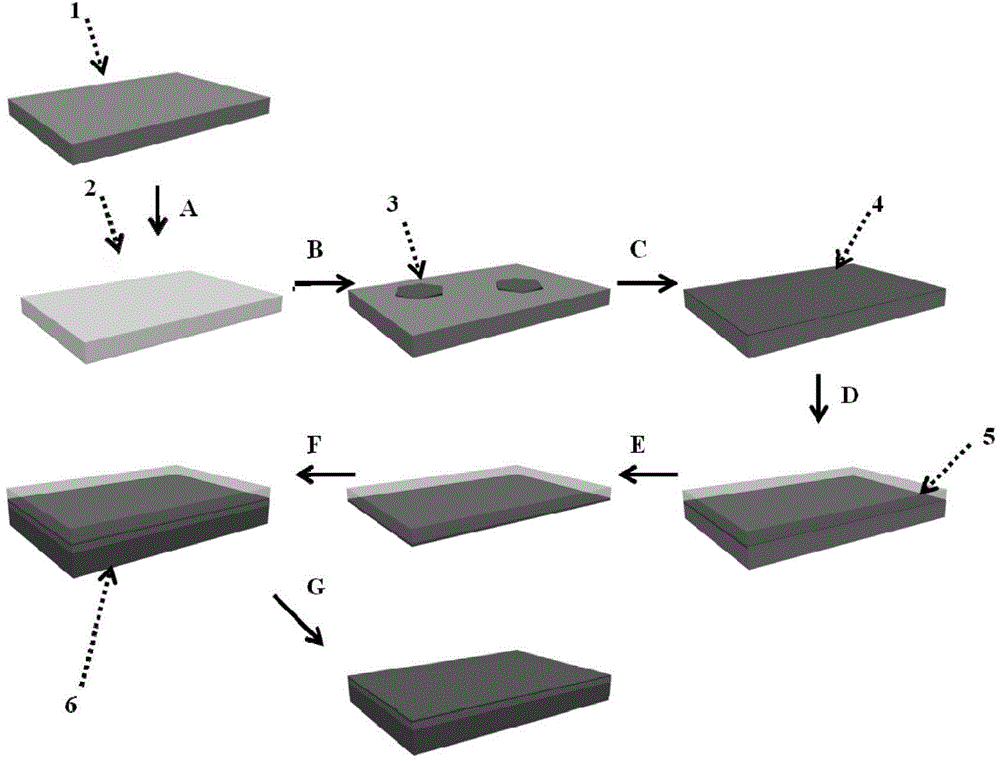

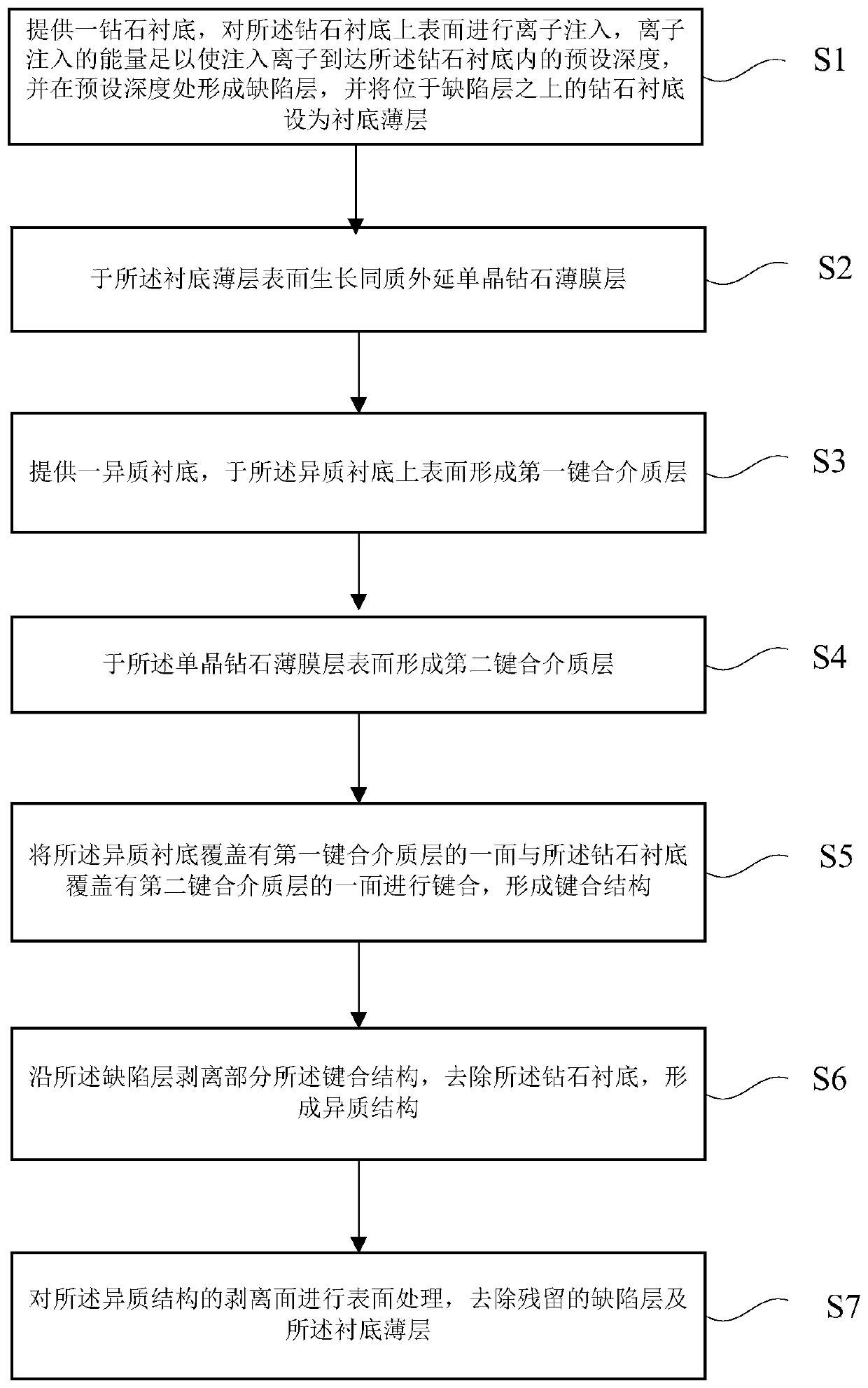

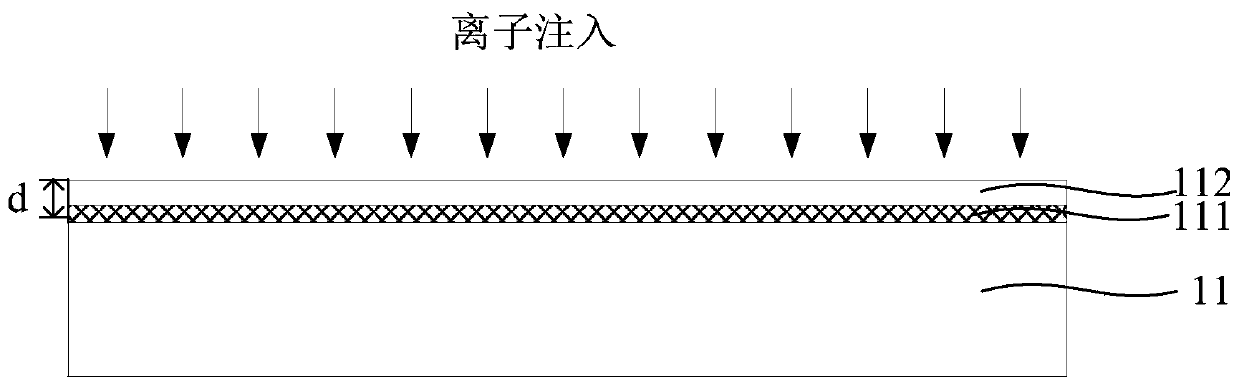

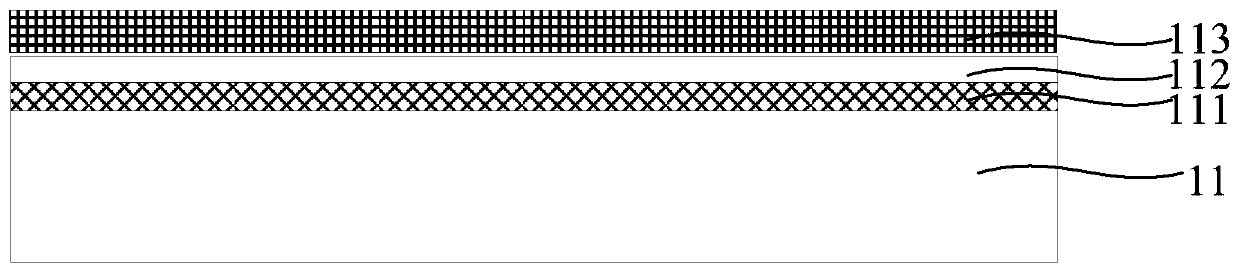

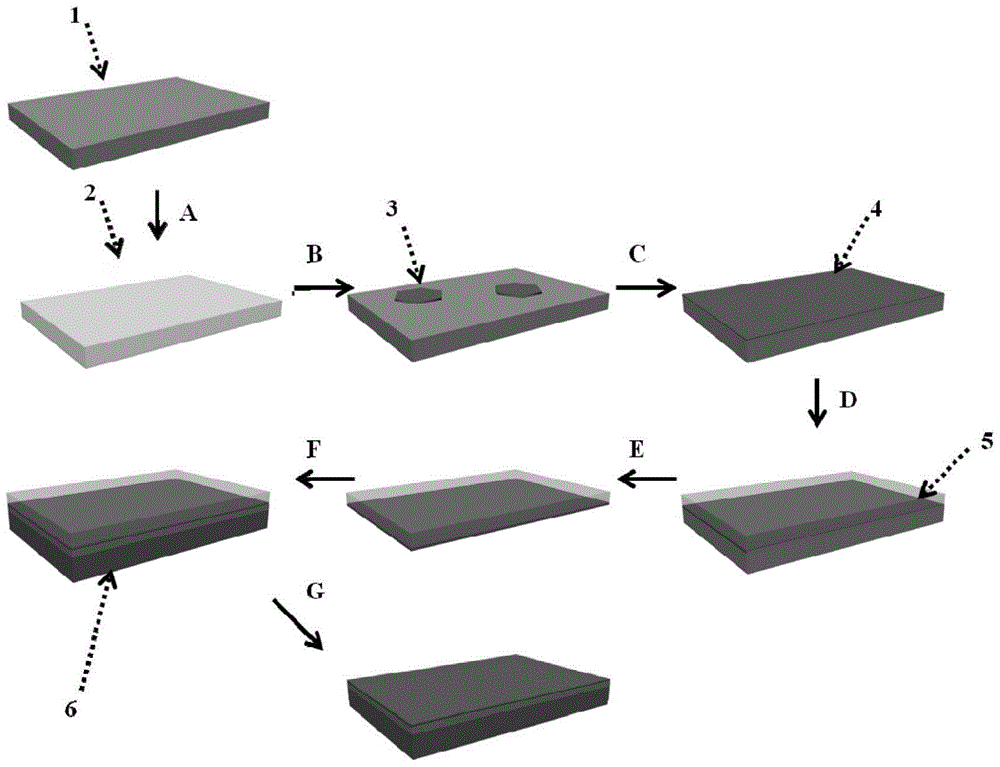

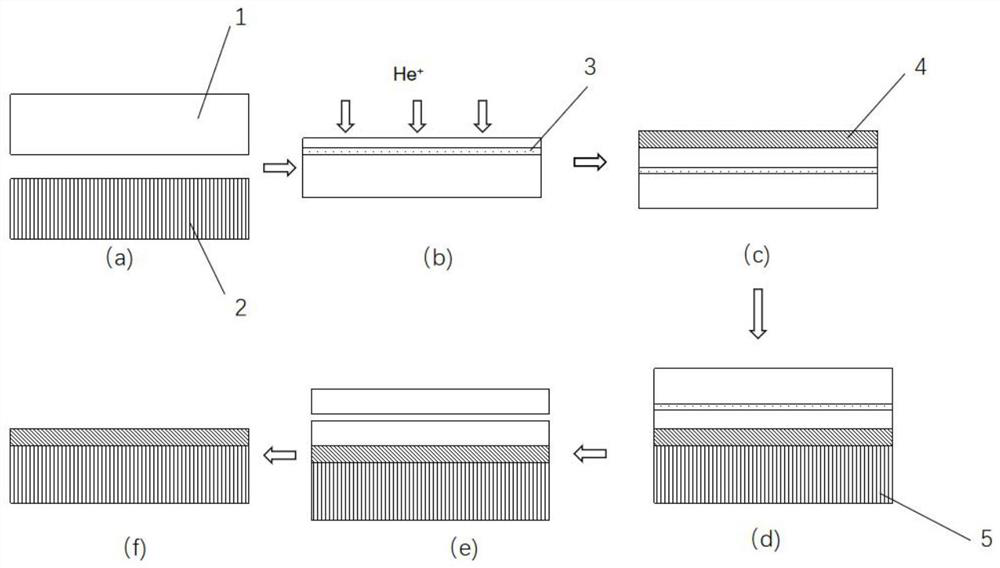

Preparation method of heterogeneous integrated monocrystal diamond film

InactiveCN110970363AImprove single crystal qualitySemiconductor/solid-state device manufacturingHeterojunctionBonding process

The invention relates to a preparation method of a heterogeneous integrated monocrystal diamond film. The preparation method at least comprises the following steps: providing a diamond substrate, carrying out ion implantation on the upper surface of the diamond substrate, forming a defect layer at a preset depth, and setting the diamond substrate on the defect layer as a substrate thin layer; growing a homogeneous epitaxial diamond film layer on the surface of the substrate thin layer; forming a first bonding dielectric layer on the surface of the diamond film layer; providing a heterogeneoussubstrate, and forming a second bonding dielectric layer on the upper surface of the heterogeneous substrate; bonding the first bonding dielectric layer and the second bonding dielectric layer to forma bonding structure; stripping the bonding structure along the defect layer to form a heterostructure; and performing surface treatment on the stripping surface of the heterostructure to remove the residual defect layer and the substrate thin layer. According to the method, the homoepitaxy monocrystal diamond film is integrated on the heterogeneous substrate through the ion implantation and bonding process, the large-area and high-quality diamond film is obtained, and an advanced material platform is provided for photon and quantum sensing device application.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

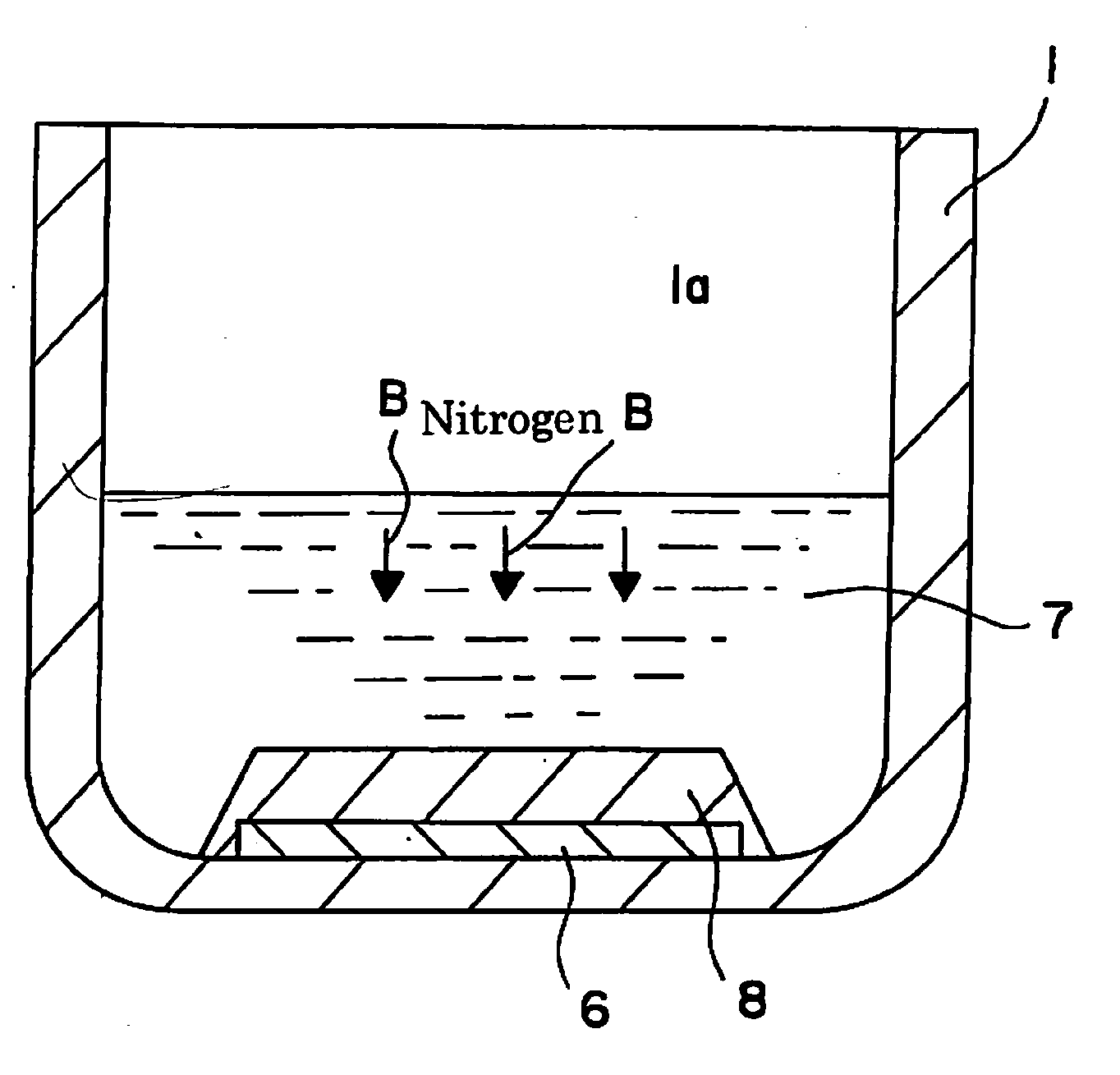

Nitride single crystal manufacturing apparatus

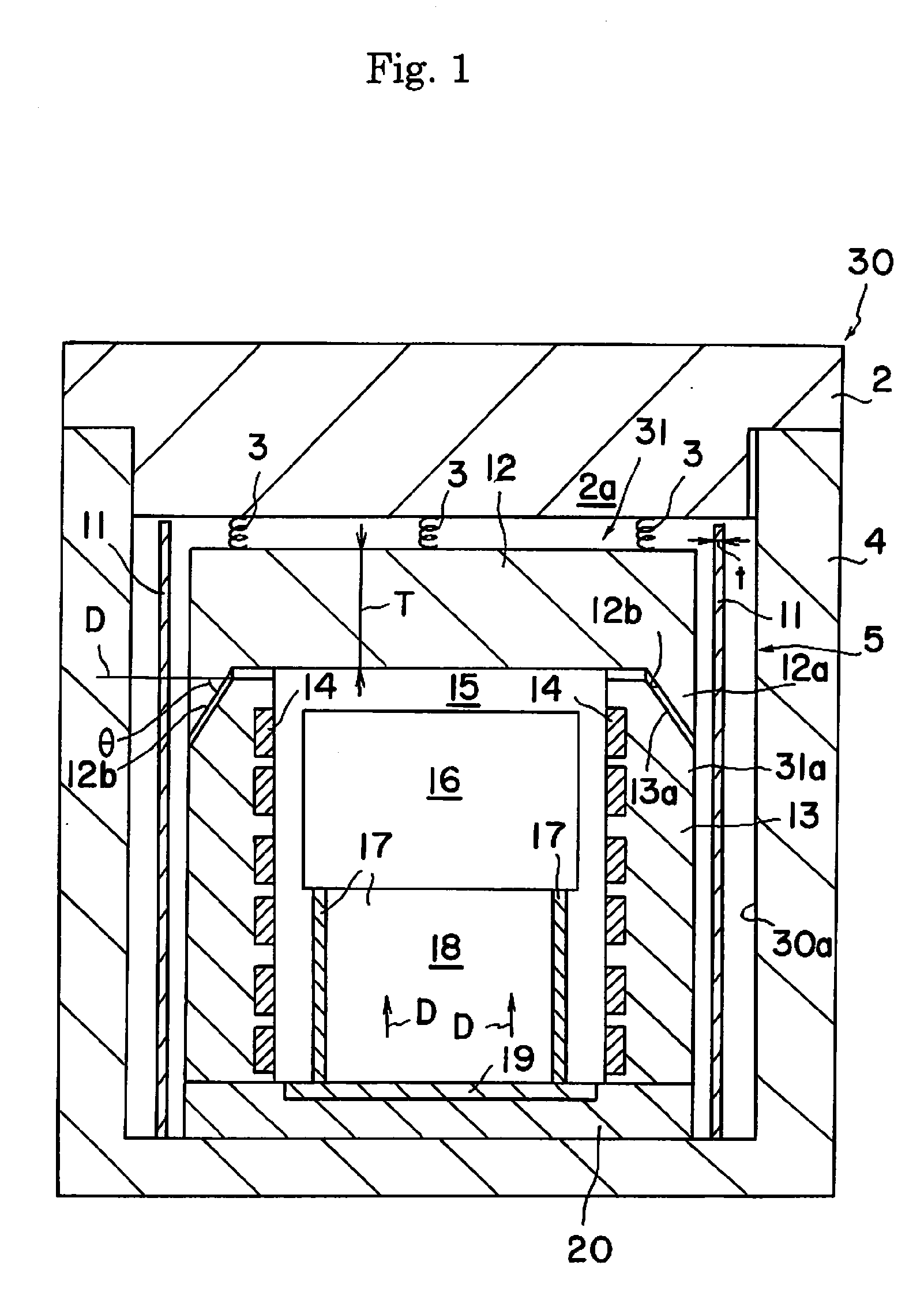

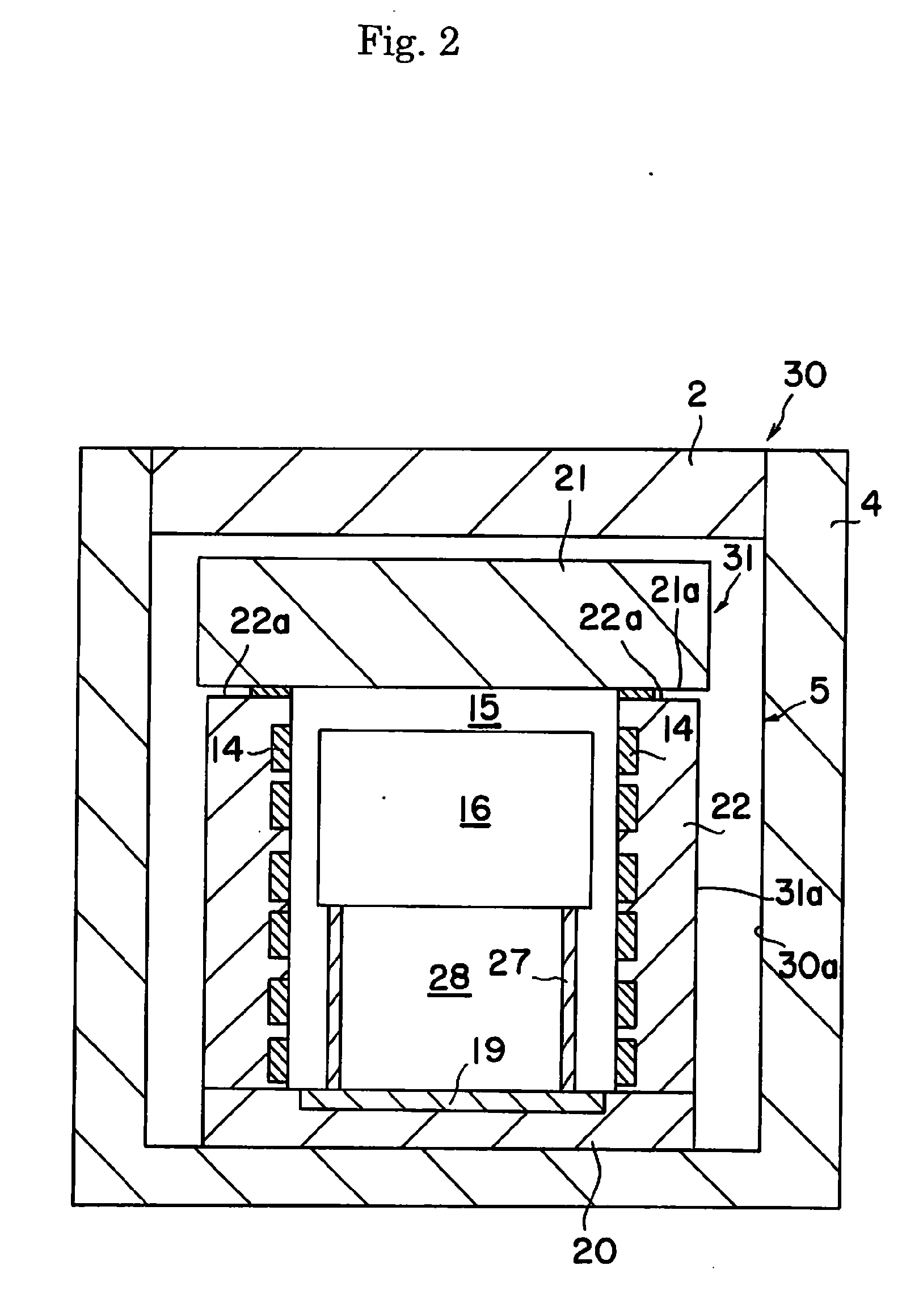

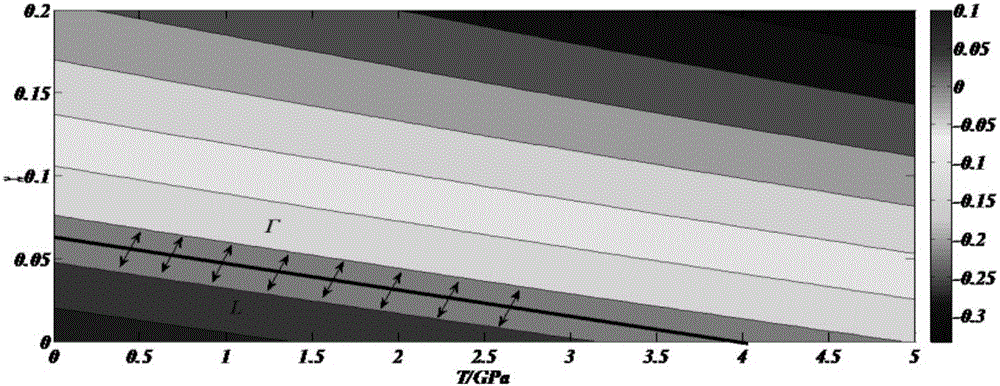

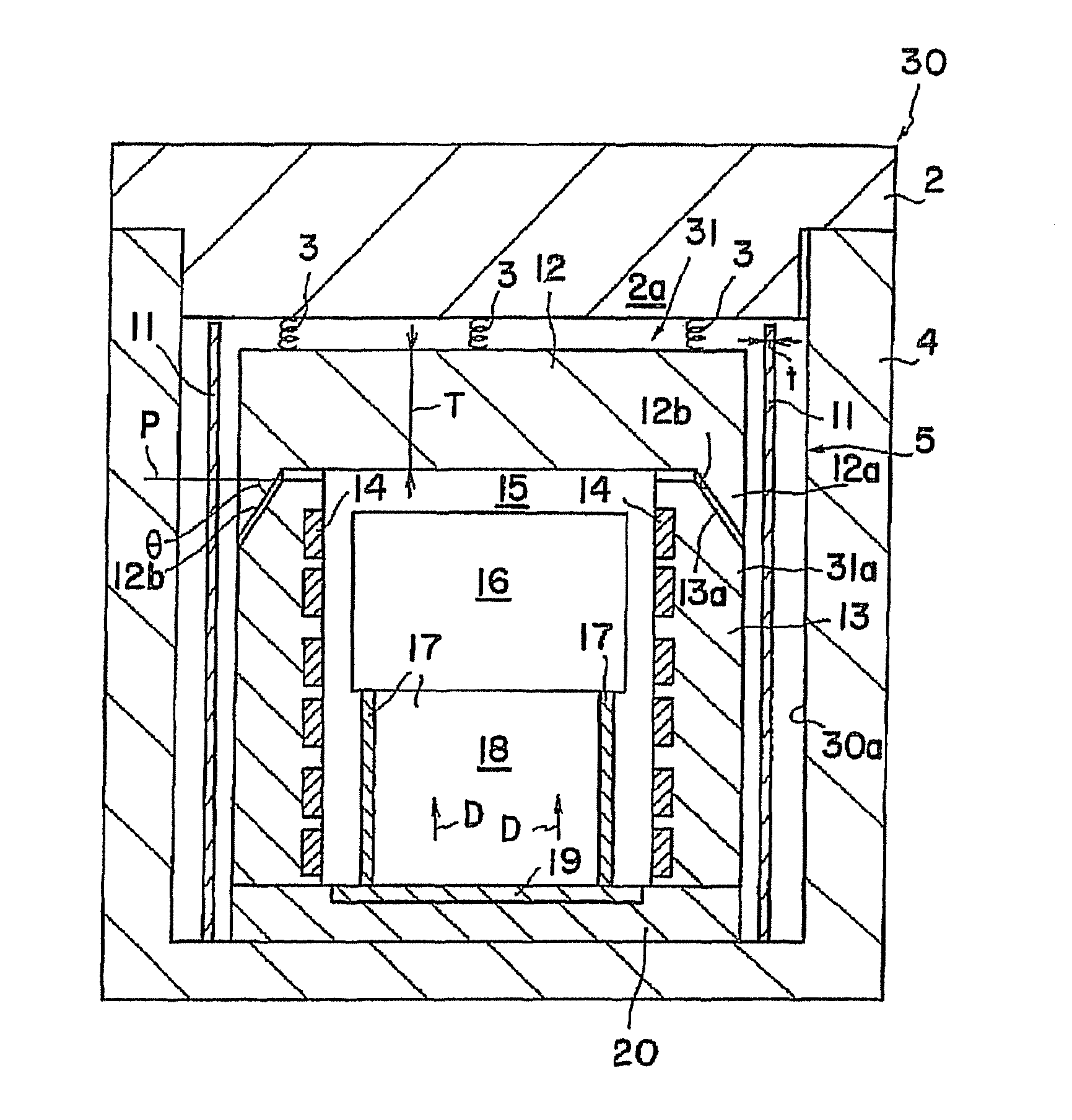

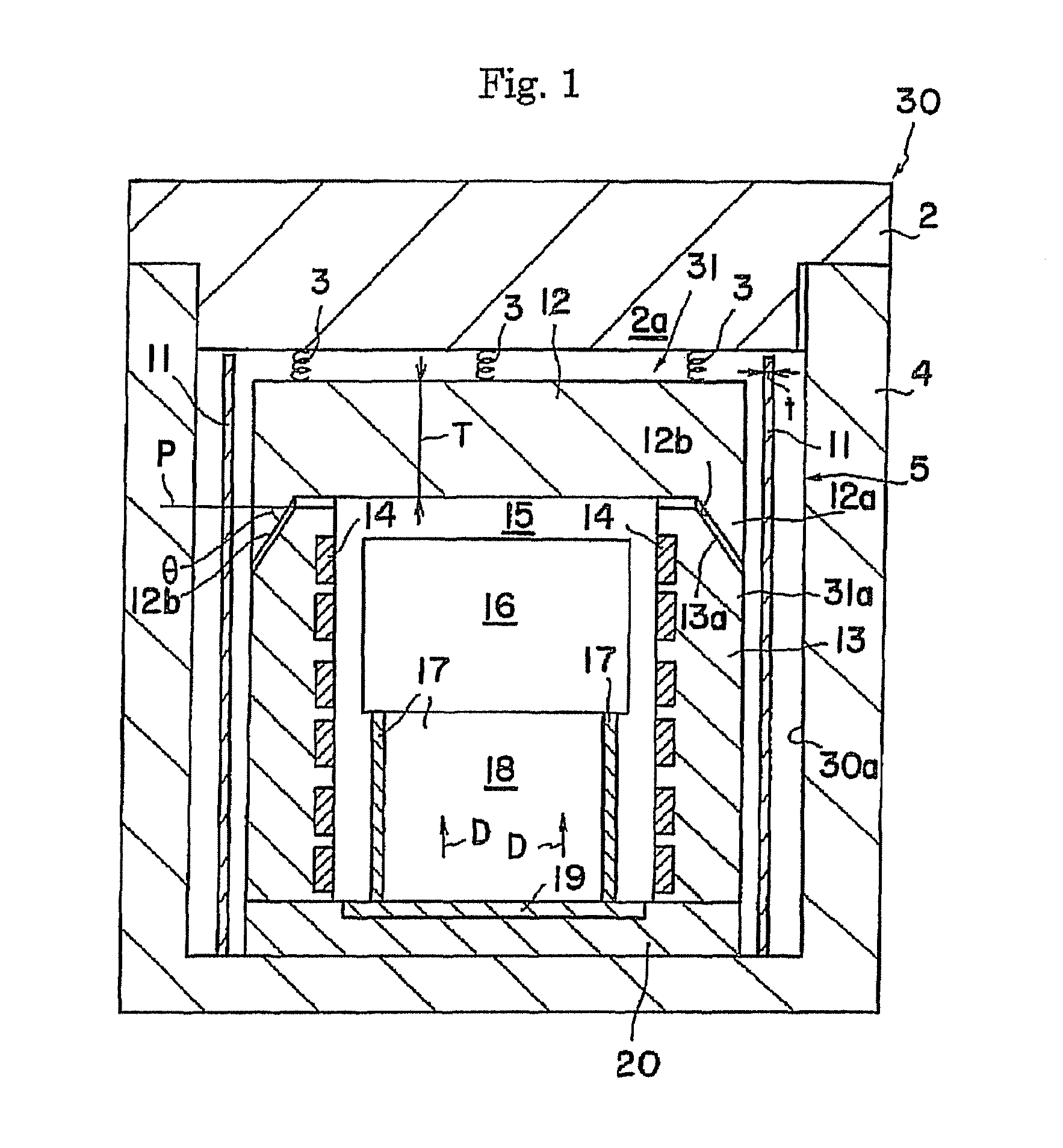

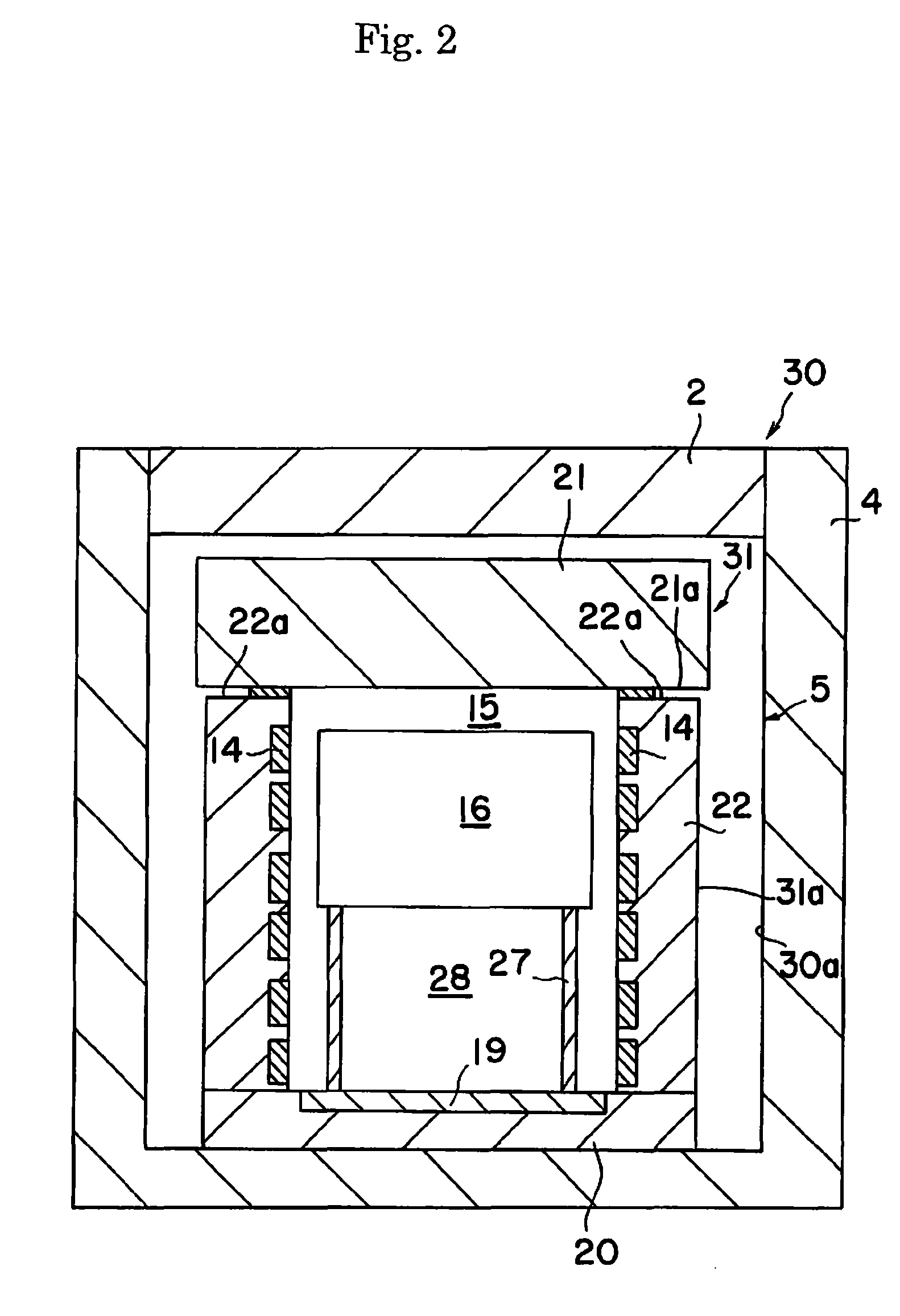

ActiveUS20080282971A1Increase ratingsReduce gradientAfter-treatment apparatusPolycrystalline material growthCrucibleEngineering

The apparatus has a crucible for storing a solution; an inner container 16 for storing a crucible; a heating container 31 for storing the inner container 16, the heating container 31 including heating elements 14, a container body 13 provided with the heating elements 14 and a lid 12 combined with the container body 13; and a pressure vessel 30 for storing the heating container 31 and for charging an atmosphere comprising at least nitrogen gas. The lid 12 has a fitting surface 12b to the container body inclined to a horizontal plane P.

Owner:NGK INSULATORS LTD +2

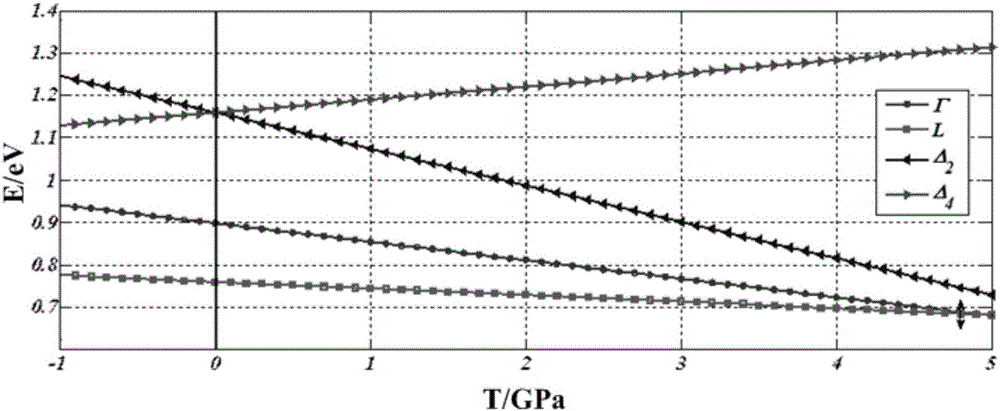

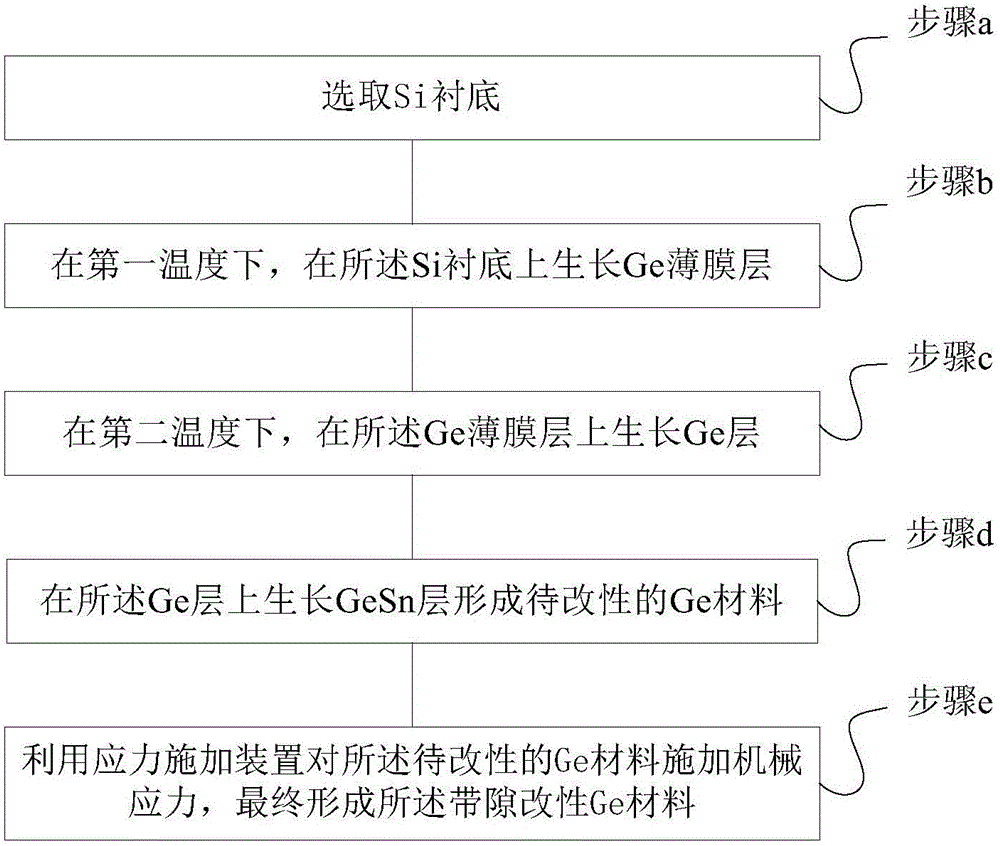

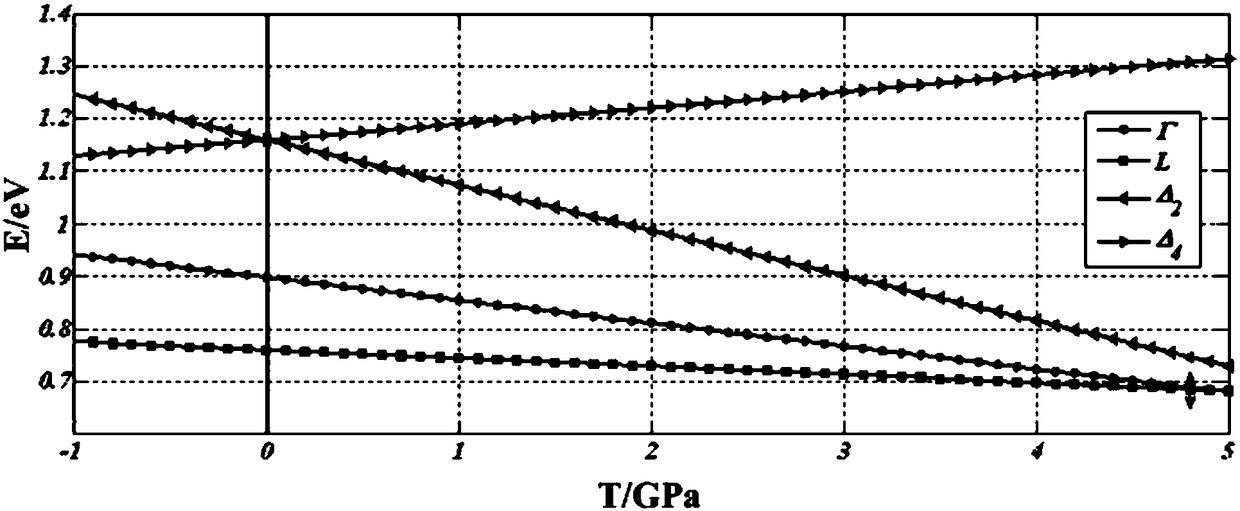

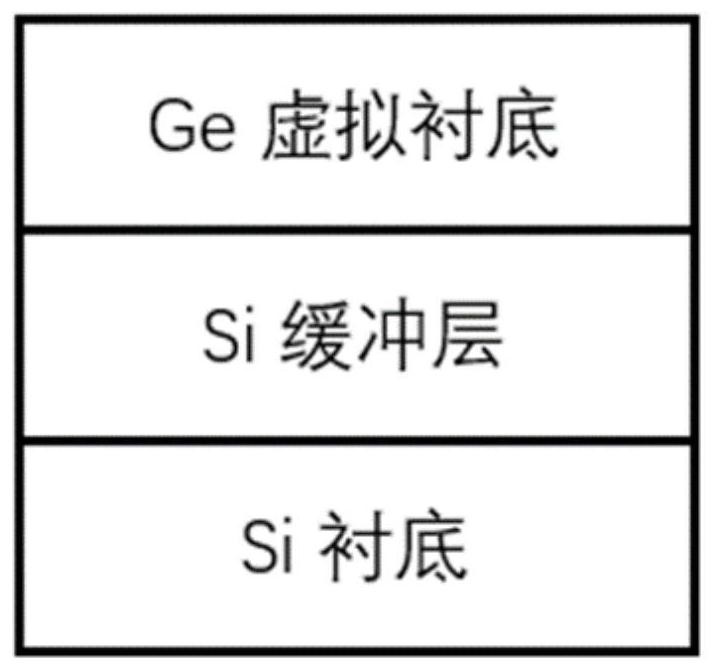

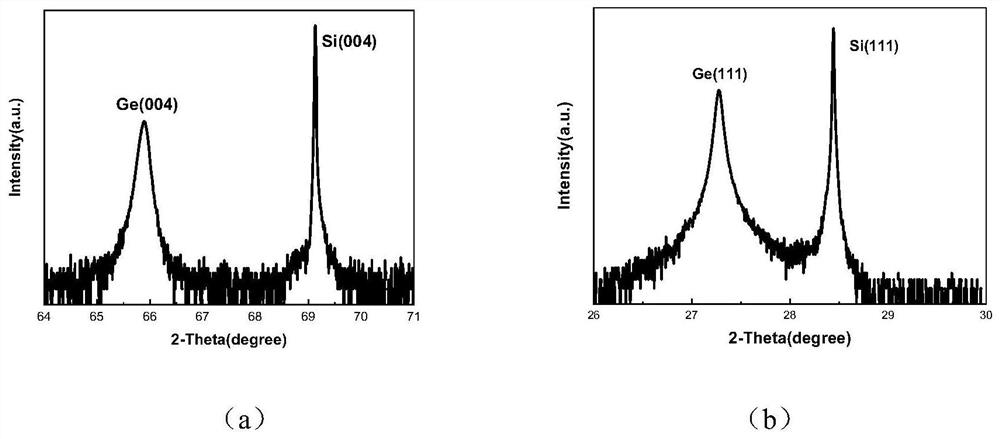

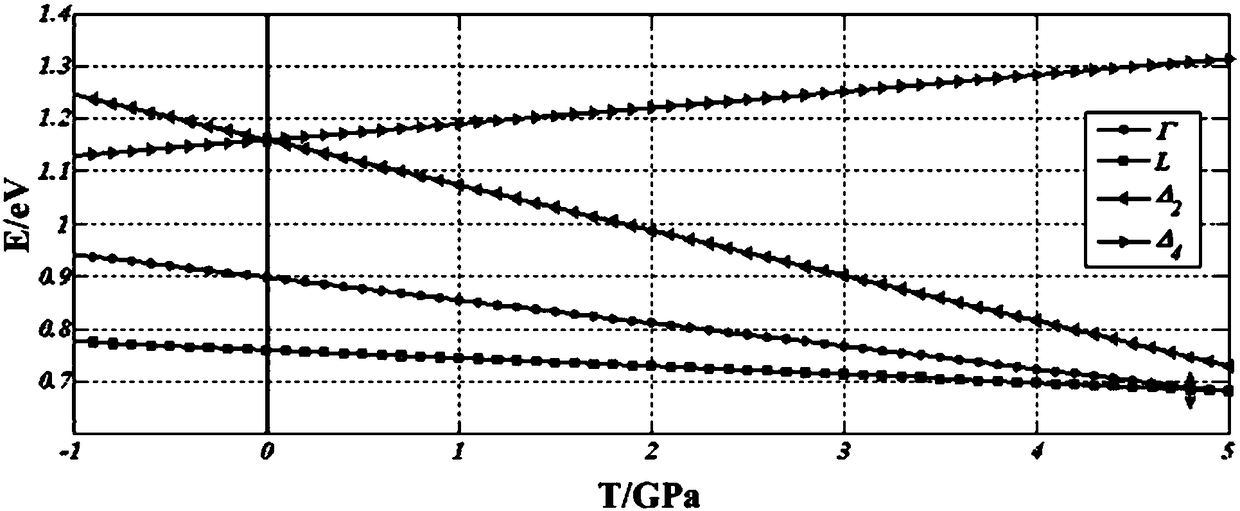

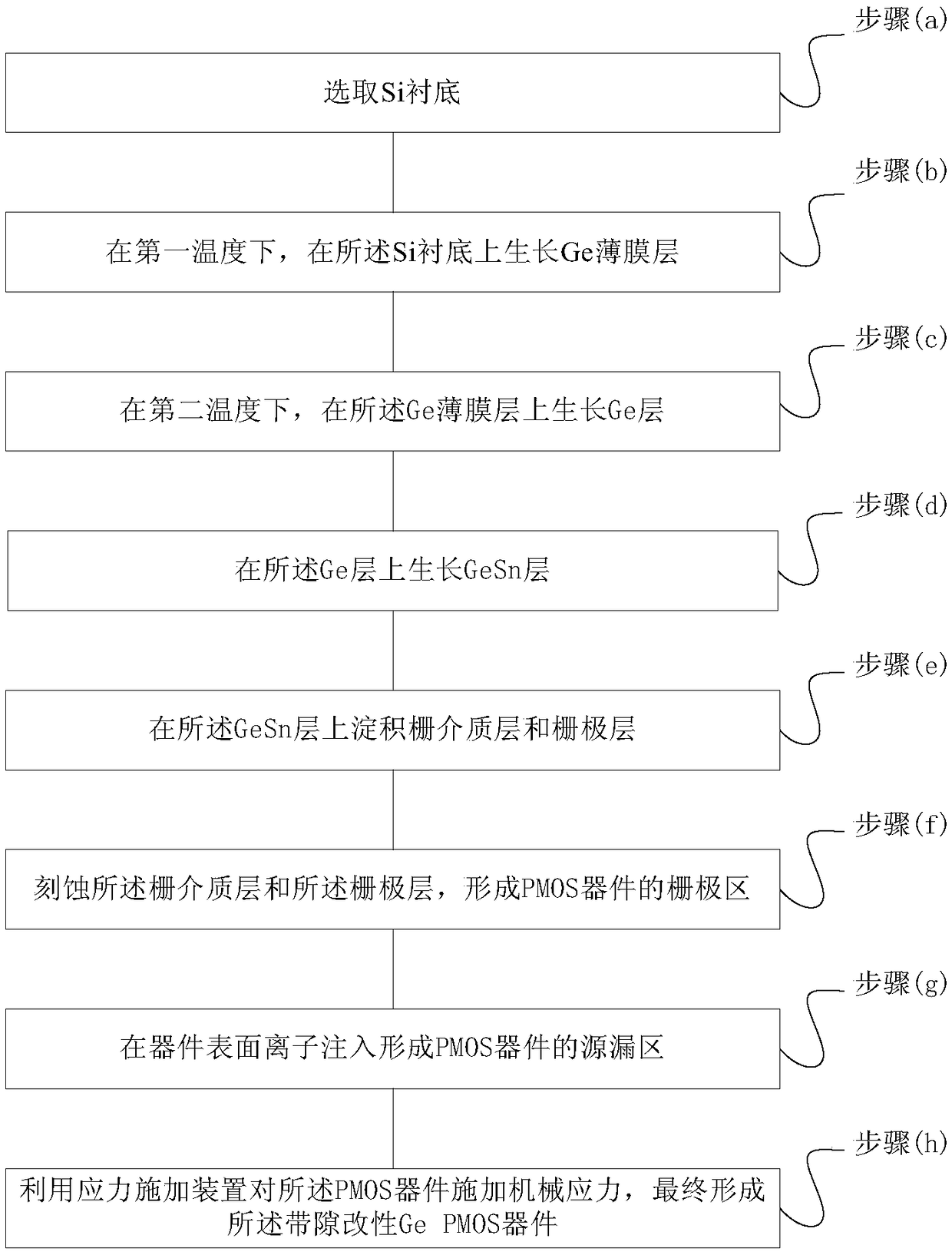

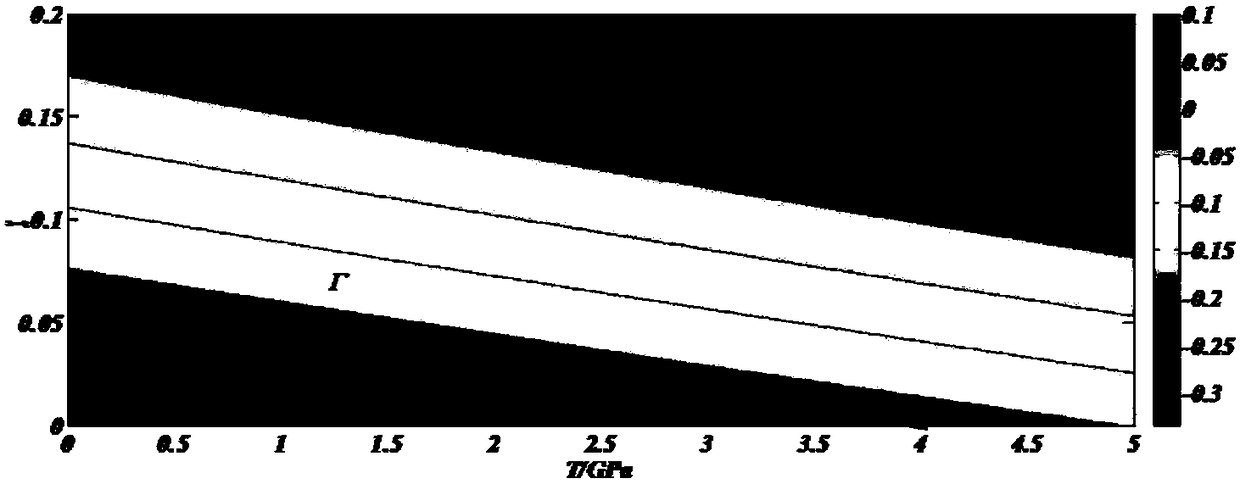

Band-gag-modified Ge material and preparation method thereof

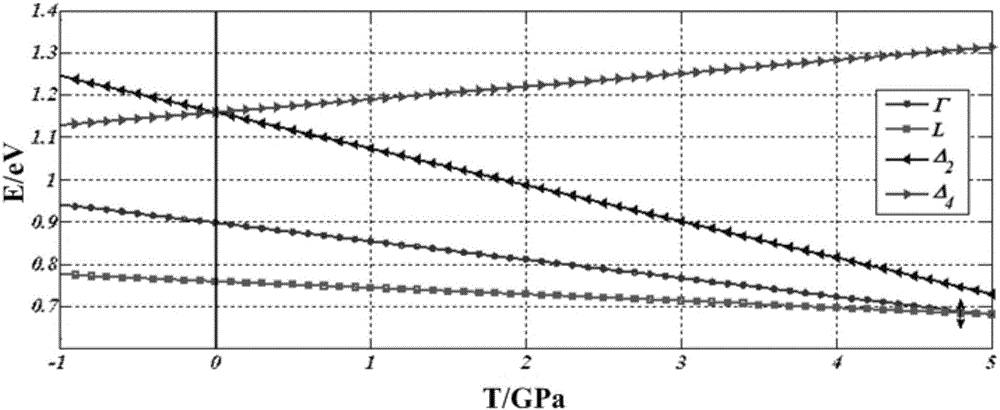

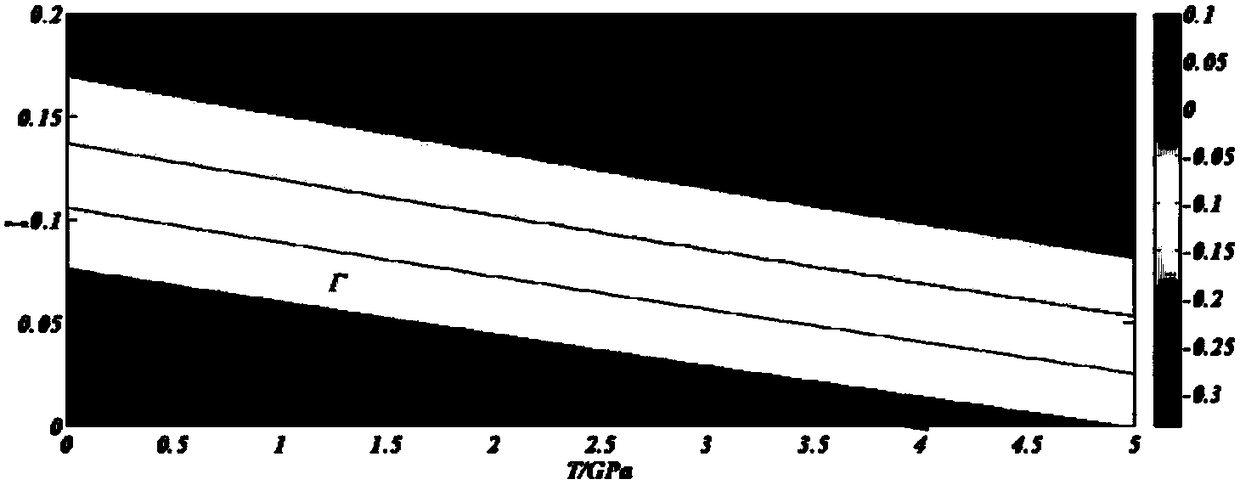

InactiveCN106012001AImprove single crystal qualitySimple preparation techniquePolycrystalline material growthAfter-treatment detailsType conversionPhotonics

The invention relates to a band gap modified Ge material and a preparation method thereof. The preparation method comprises: selecting a Si substrate; growing a Ge thin film layer on the Si substrate at a first temperature; growing a Ge layer on the Ge thin film layer at a second temperature; growing a Ge layer on the Ge layer growing a GeSn layer on it to form a Ge material to be modified; using a stress applying device to apply mechanical stress to the Ge material to be modified to finally form the band gap modified Ge material. The present invention realizes the transformation of the Ge bandgap type by means of co-action of alloying and stress, and overcomes the difficult process caused by the transformation of the Ge bandgap type by relying solely on alloying and stress alone due to low solid solubility and high stress intensity. question. The bandgap modified Ge material can be applied to both electronic devices and photonic devices, and can provide another technical approach for monolithic optoelectronic integration.

Owner:XIDIAN UNIV

Nitride single crystal manufacturing apparatus

ActiveUS9017479B2Increase ratingsReduce gradientAfter-treatment apparatusPolycrystalline material growthCrucibleManufactured apparatus

The apparatus has a crucible for storing a solution; an inner container for storing a crucible; a heating container for storing the inner container, the heating container including heating elements, a container body provided with the heating elements and a lid combined with the container body; and a pressure vessel for storing the heating container and for charging an atmosphere comprising at least nitrogen gas. The lid also has a fitting surface to the container body that is inclined to a horizontal plane.

Owner:NGK INSULATORS LTD +2

Single-crystal electromagnetic field

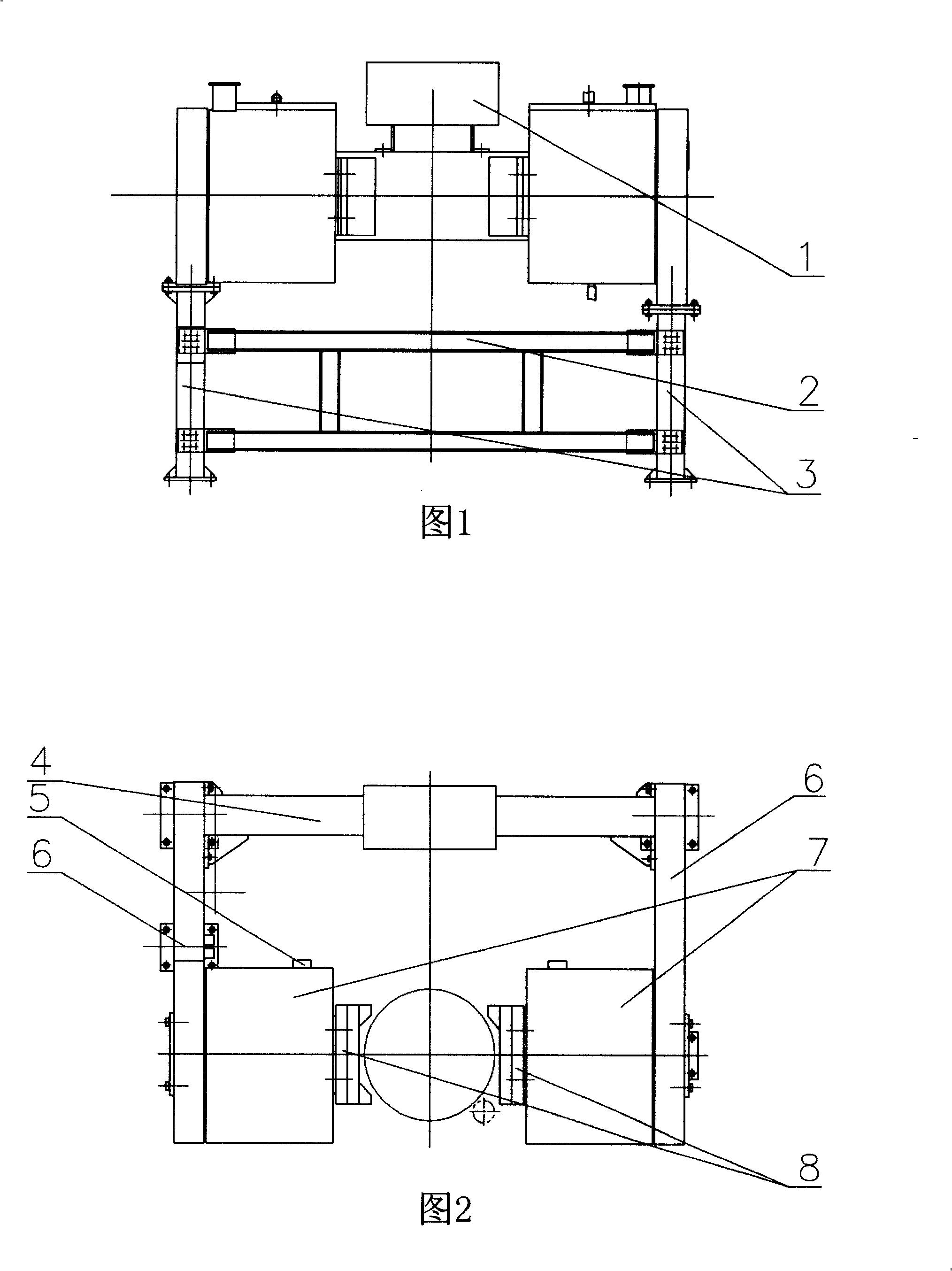

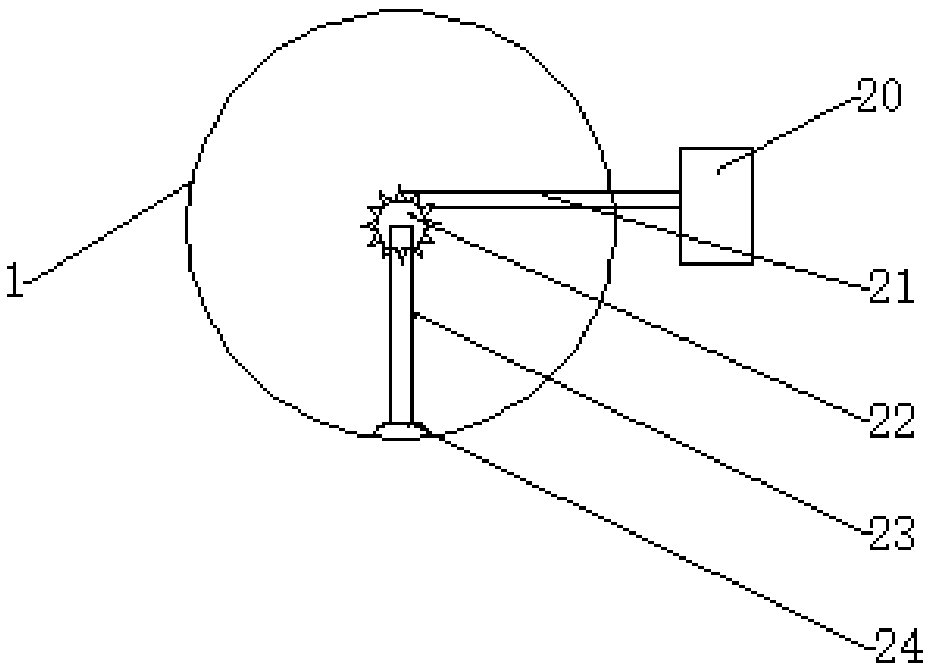

ActiveCN101245487AGood symmetryReasonable shape designBy pulling from meltSemiconductor materialsMagnetic poles

The invention discloses a mono-crystal electromagnetic field for being matched with a mono-crystal furnace in the production of semiconducting material, which consists of yoke plates, a concentrating flux plate, magnetic poles and pole heads. One end of each yoke plate is connected with each other by the concentrating flux plate and the other end thereof is connected with the magnetic poles; two magnetic poles are corresponding to each other and the corresponding face of the two magnetic poles is provided with the pole heads; the two yoke plates, the concentrating flux plate and the two magnetic poles form a C-shaped frame; the two yoke plates are respectively fixed on two columns that are connected by a connecting beam; the concentrating flux plate is connected with a cooling system. The mono-crystal electromagnetic field is stable and adjustable, can promote material utilization rate and the property index of a silicon chip and can improve the utilization rate of the material and the performance index of silicon chip. The mono-crystal electromagnetic field can change the exiting mono-crystal furnace to achieve the requirement for improving the quality of monocrystal, can design according to mono-crystal furnaces with different structures to satisfy the requirements of different users and has comparatively simple structure and lower production cost.

Owner:LONGI MAGNET CO LTD

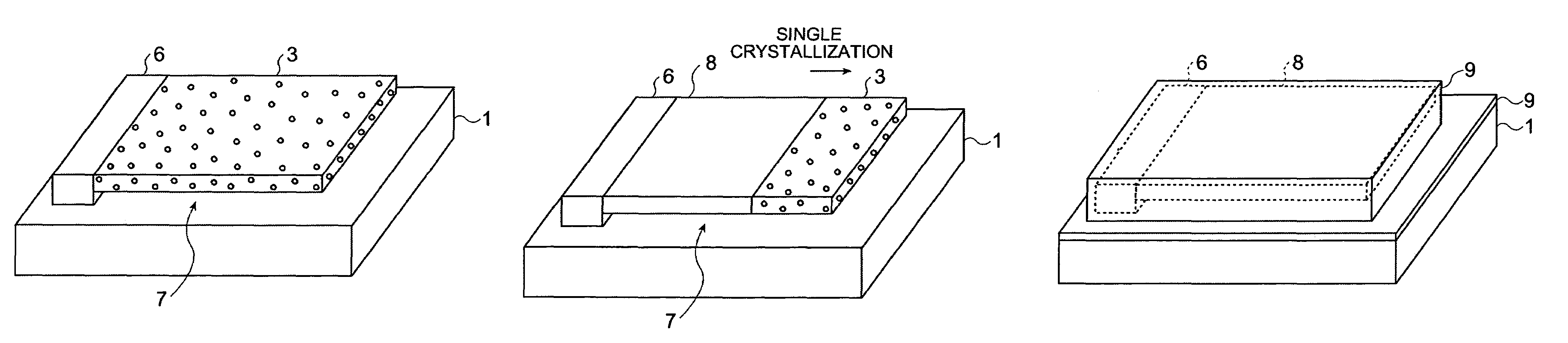

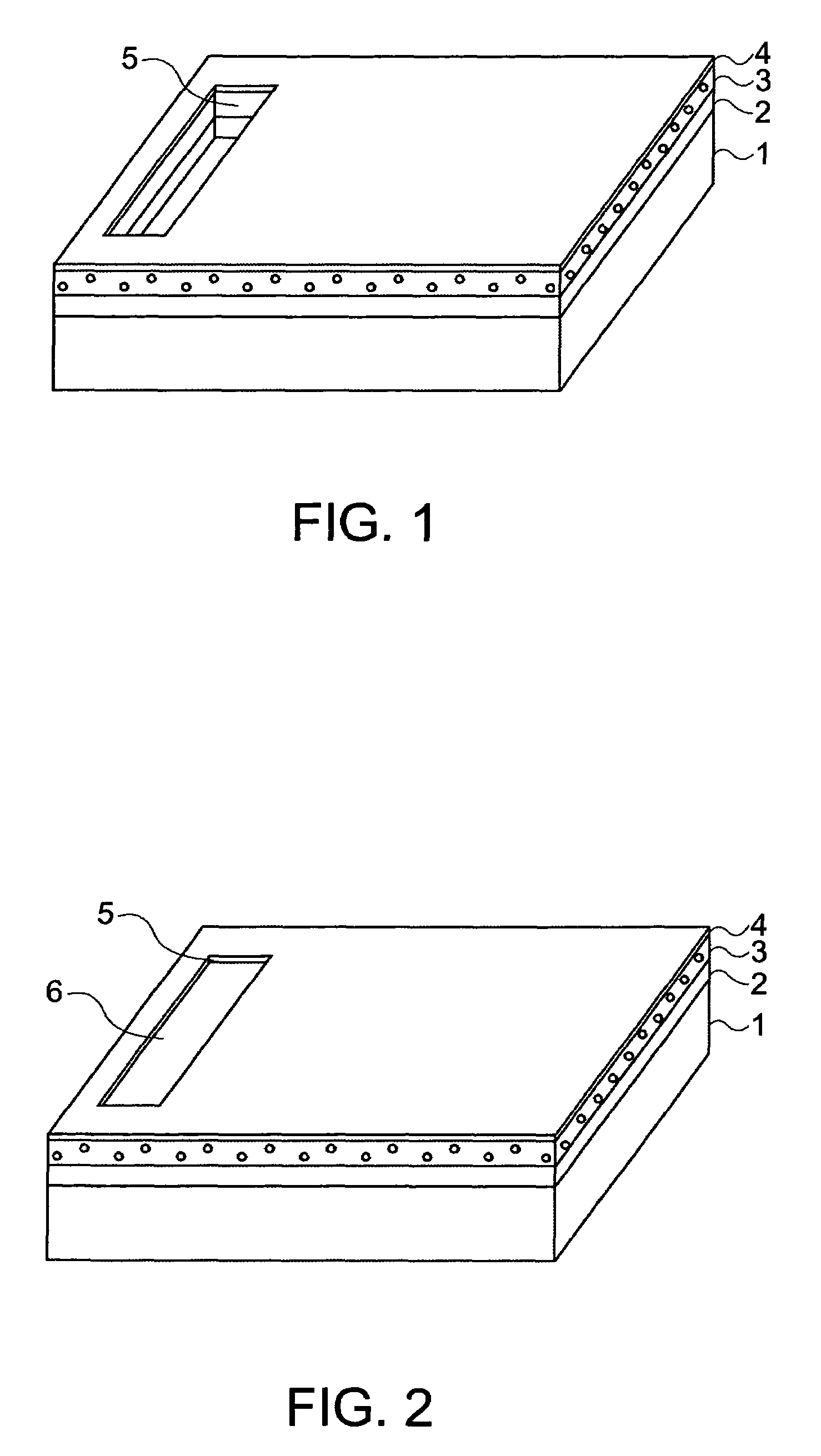

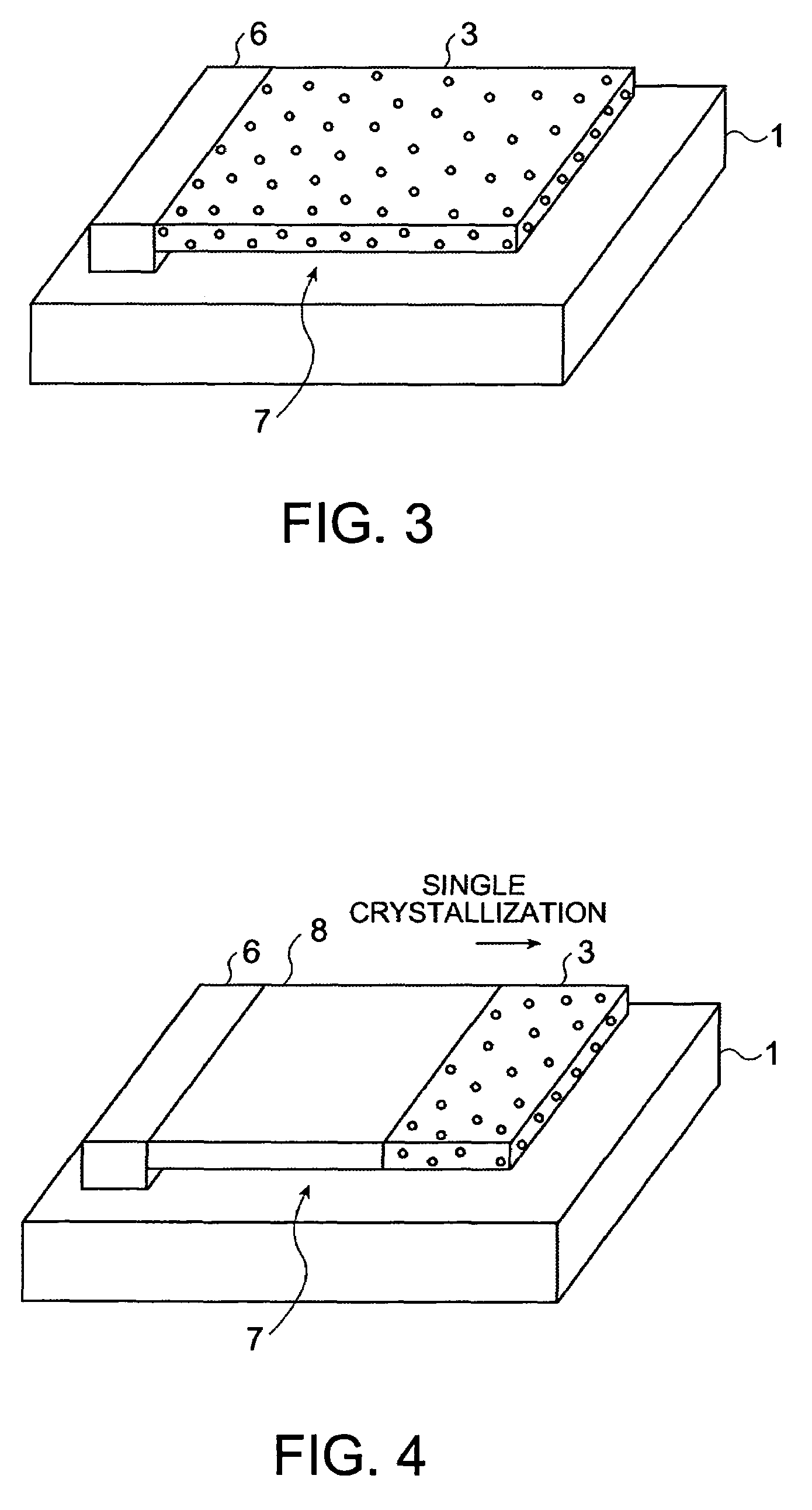

Semiconductor substrate, semiconductor device, method of manufacturing semiconductor substrate, and method of manufacturing semiconductor device

InactiveUS7294539B2Improve single crystal qualityLow costFrom gel statePolycrystalline material growthSingle crystalThermal treatment

A method of manufacturing a semiconductor device, includes: forming an insulating layer on a single crystal semiconductor substrate; forming a non-crystalline semiconductor layer on the insulating layer; forming an insulating film on the non-crystalline semiconductor layer; forming an opening section for exposing a part of a surface of the single crystal semiconductor substrate through the insulating film, the non-crystalline semiconductor layer and the insulating layer; forming a single crystal semiconductor layer embedded in the opening section so as to have contact with the non-crystalline semiconductor layer; removing the insulating film and the insulating layer while the single crystal semiconductor layer supporting the non-crystalline semiconductor layer above the single crystal semiconductor substrate; forming a single-crystallized semiconductor layer obtained by single-crystallizing the non-crystalline semiconductor layer using the single crystal semiconductor layer as a seed by providing a thermal treatment on the non-crystalline semiconductor layer from which the insulating film and the insulating layer are removed; filling a gap between the single-crystallized semiconductor layer and the single crystal semiconductor substrate with an embedded insulating layer; forming a gate electrode on the single-crystallized semiconductor layer; and forming in the single-crystallized semiconductor layer a source layer disposed on one side of the gate electrode and a drain layer disposed on the other side of the gate electrode.

Owner:SEIKO EPSON CORP

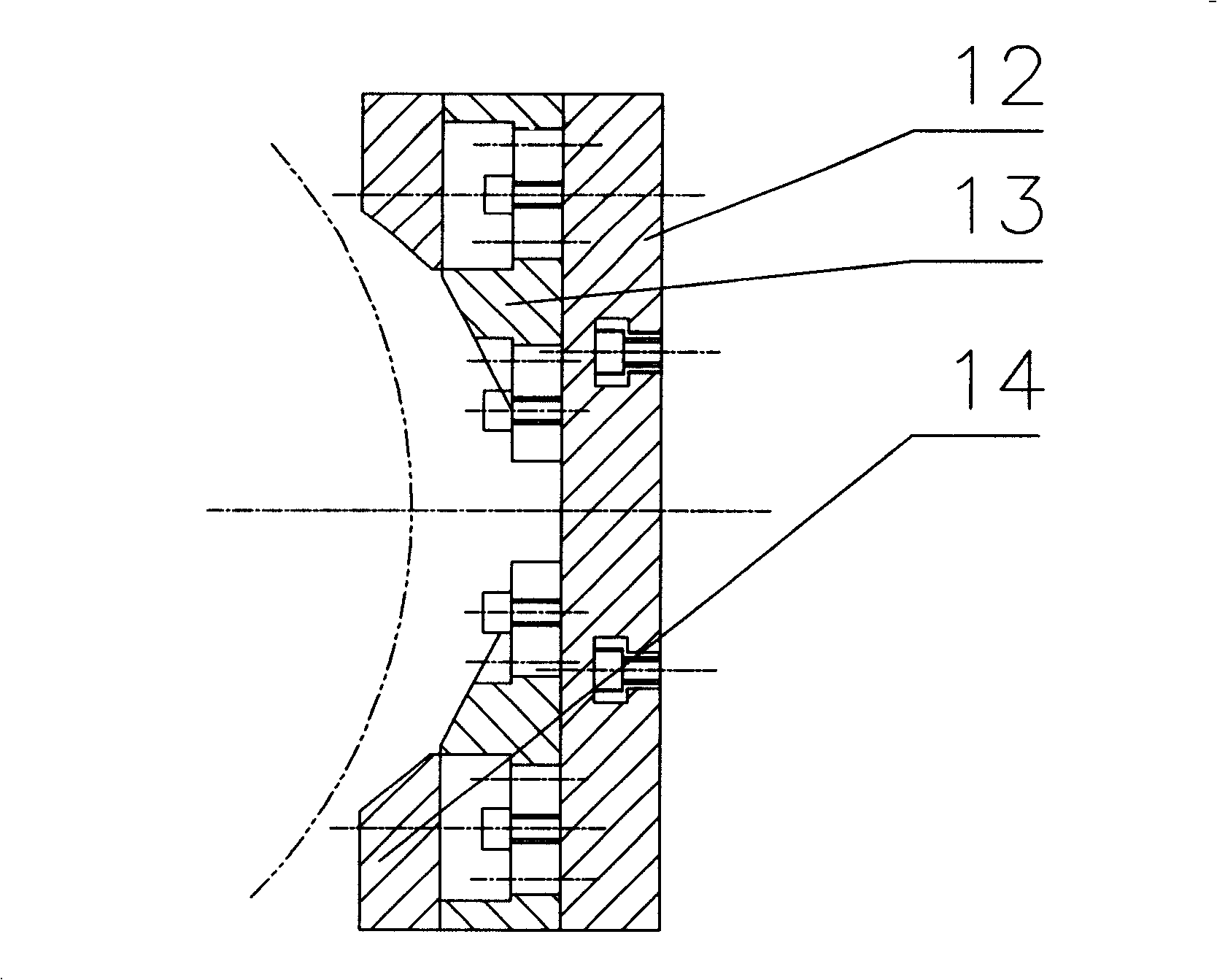

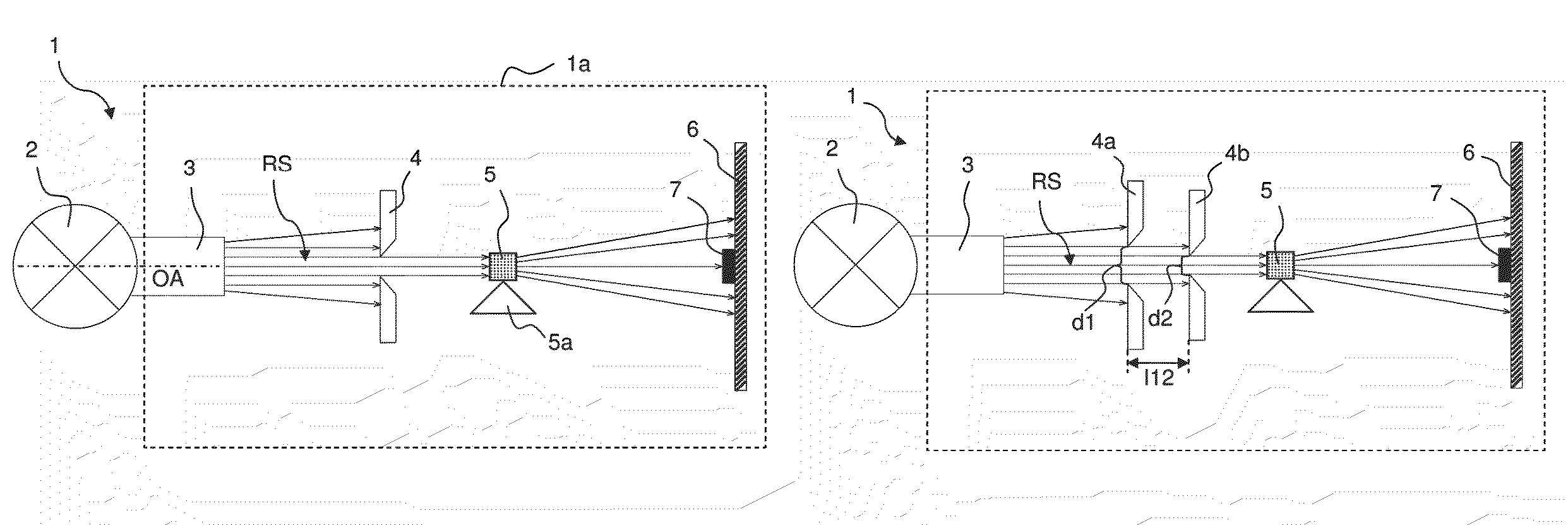

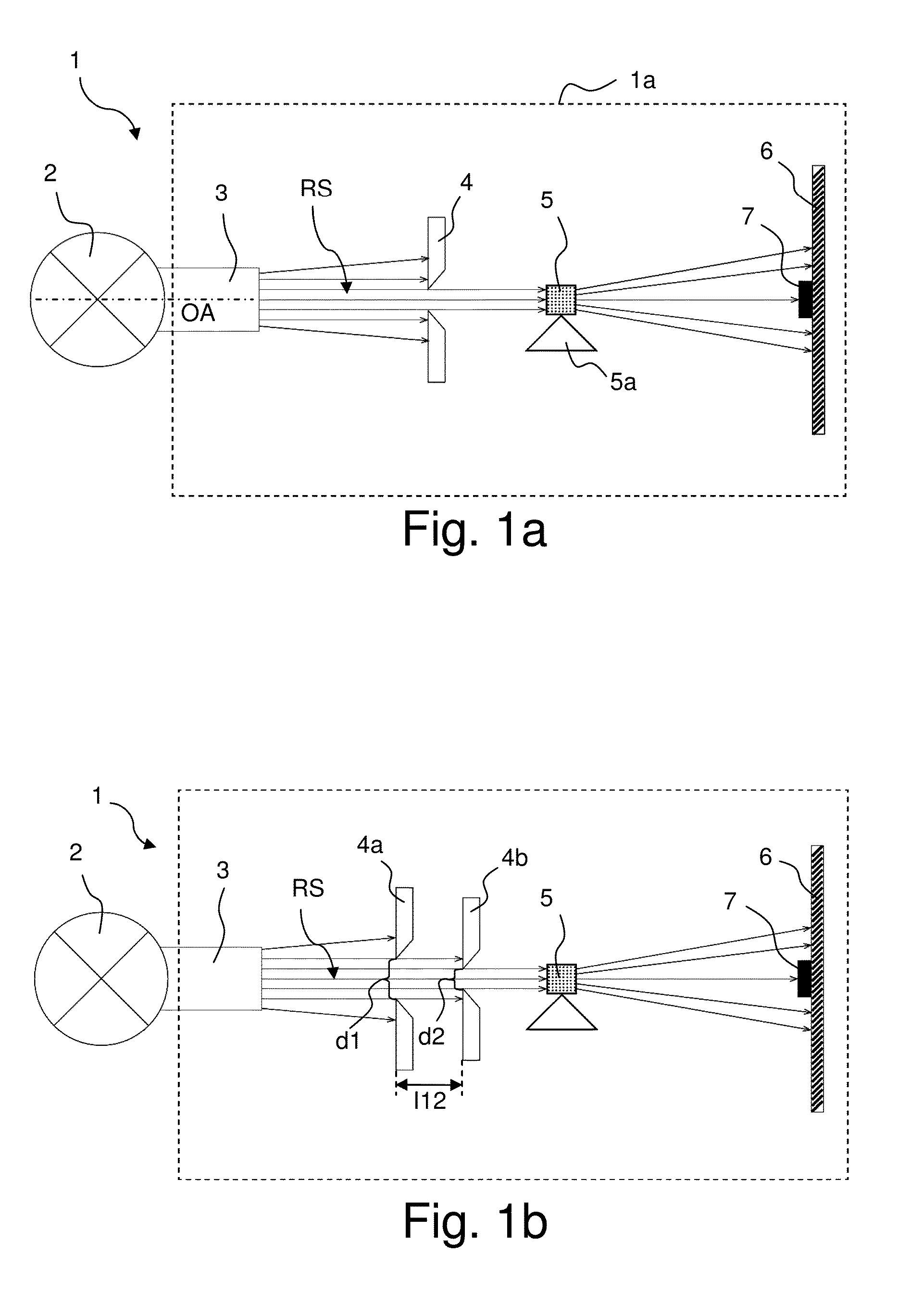

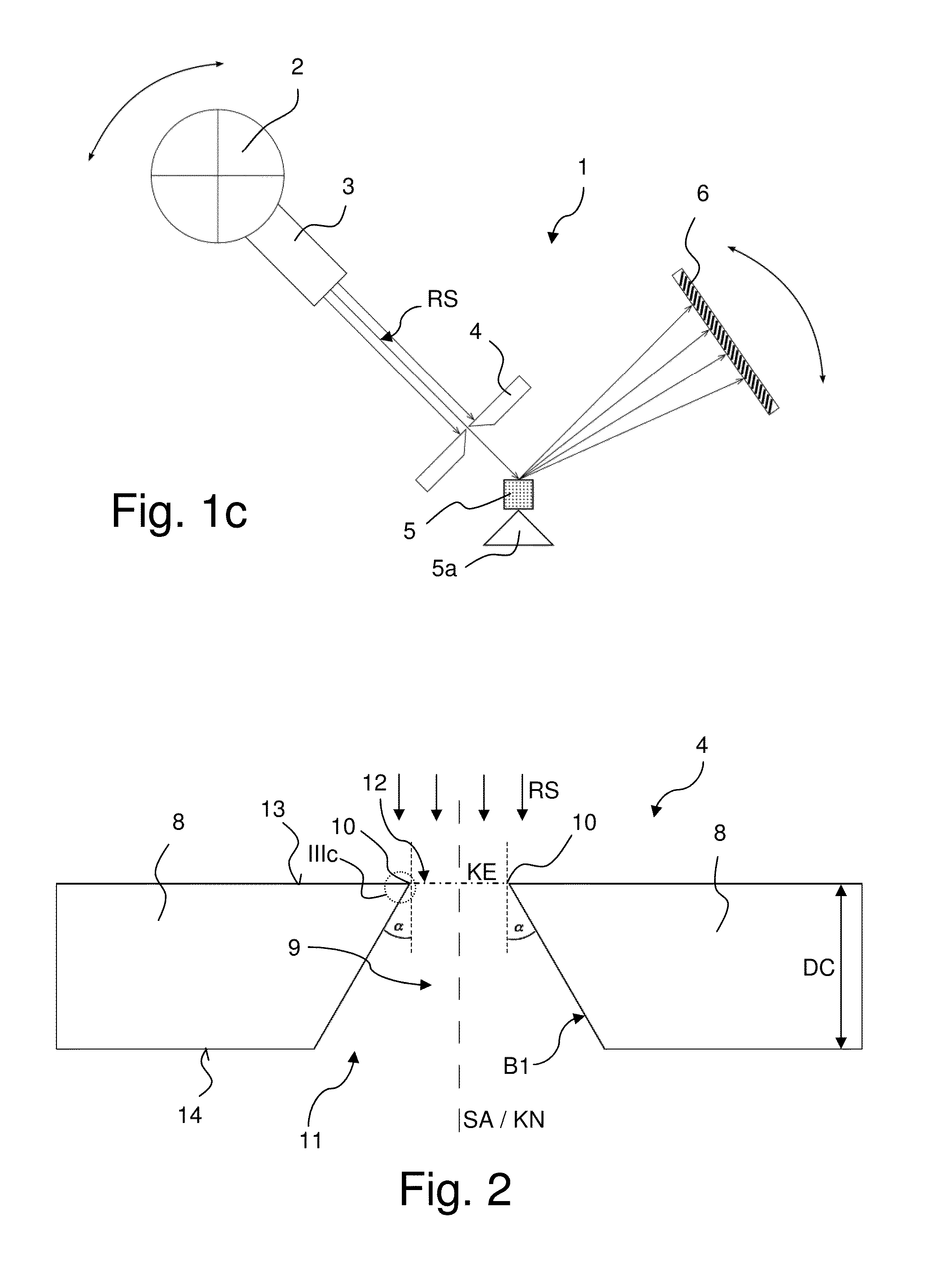

X-ray analysis apparatus with single crystal X-ray aperture and method for manufacturing a single crystal X-ray aperture

ActiveUS9279776B2Avoid reflectionsImprove single crystal qualityOptical articlesHandling using diaphragms/collimetersX-raySingle crystal

An X-ray analysis apparatus has at least one X-ray aperture (4; 4a, 4b) which delimits an X-ray beam (RS) emitted by an X-ray source (2). The at least one X-ray aperture (4; 4a, 4b) is disposed at a separation from the sample (5) and has a single crystal aperture body (8) with a through pinhole (9). The single crystal aperture body (8) forms a peripheral continuous edge (10) which delimits the X-ray beam (RS) and starting from which the pinhole (9) widens like a funnel in a direction of an outlet opening (11) of the X-ray aperture (4; 4a, 4b) in a first area (B1). The X-ray analysis apparatus reduces impairment of X-ray measurements due to parasitic scattered radiation and at little expense.

Owner:INCOATEC

Surface treatment method for stripping single crystal thin film through ion implantation

ActiveCN111403596AImprove single crystal qualityReduce secondary damageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingOxygen vacancy

The invention belongs to the technical field of single crystal thin films, and particularly relates to a surface treatment method for stripping a single crystal thin film through ion implantation. According to the surface treatment method for stripping the single crystal thin film through ion implantation, argon ion etching is selected for accurately removing a damaged layer on the surface of thesingle crystal thin film prepared through the ion implantation stripping technology; and besides, the problems of oxygen vacancy defects and surface modification of the film after the damaged layer isremoved are solved by respectively controlling the oxygen flux, the working power and the working parameters of the cleaning time in the oxygen plasma cleaning process, the cleaning effect is verified through the contact angle test, and finally, the single crystal thin film is completely infiltrated, so that the subsequent preparation of a graphical device structure is facilitated. According to the method, the single crystal quality of the single crystal thin film is greatly improved, the introduced secondary damage is minimum, and the process complexity is simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

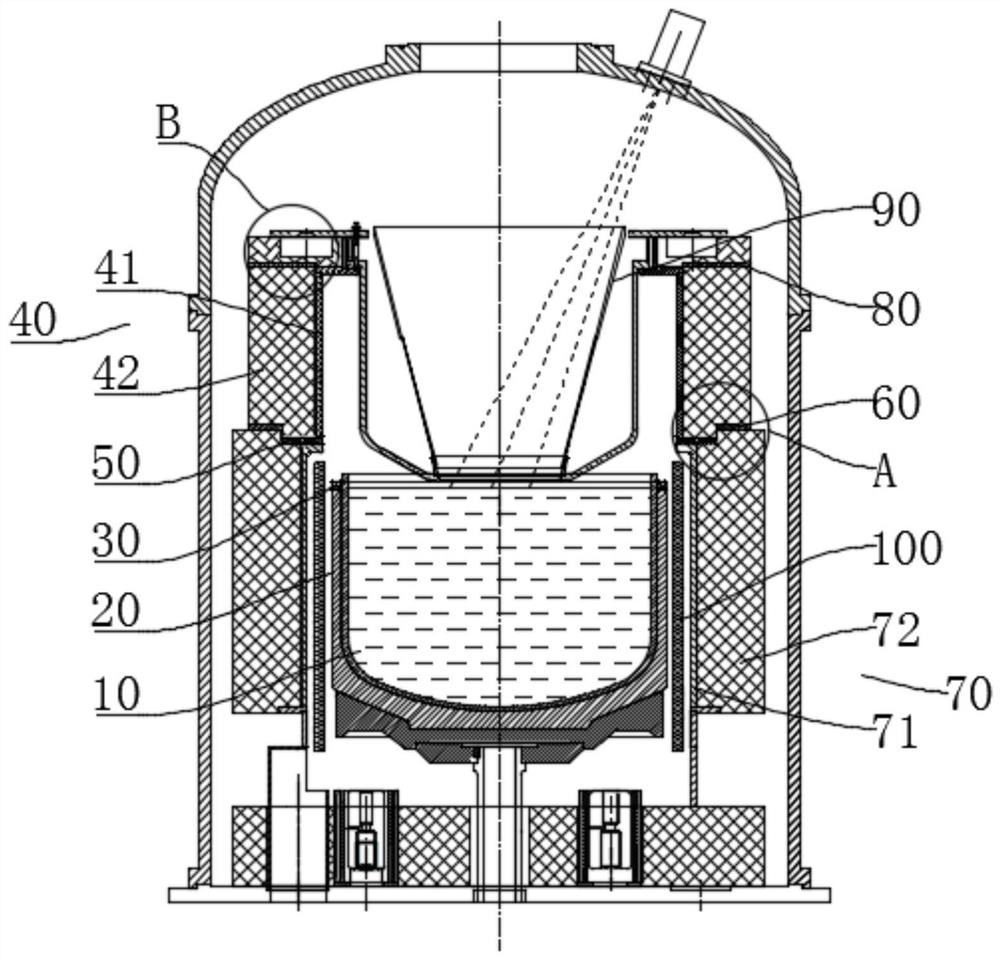

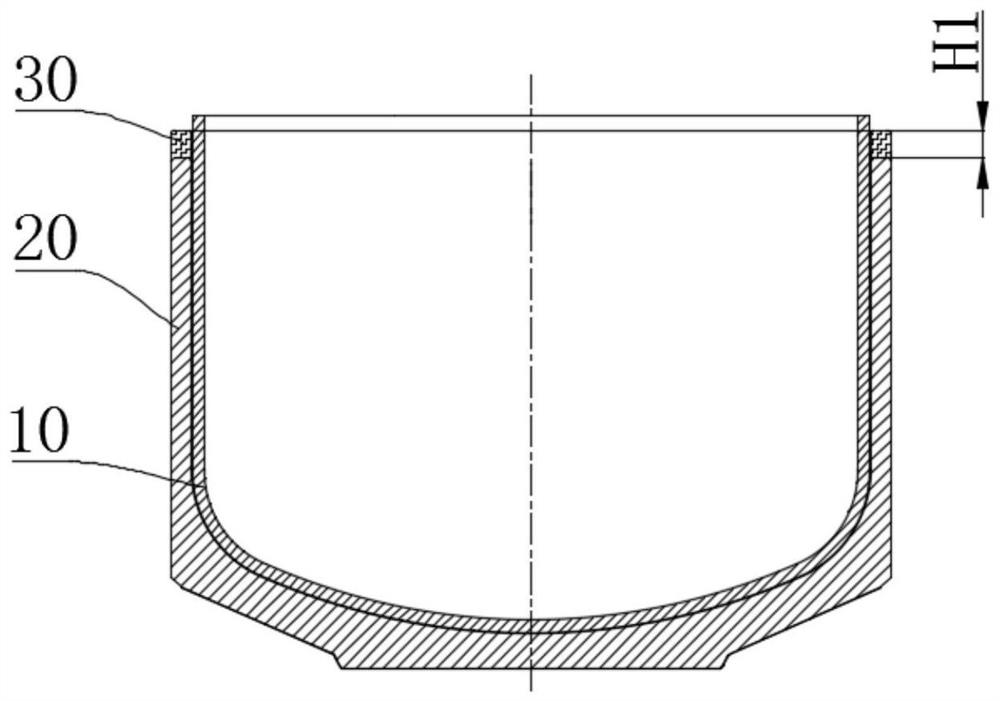

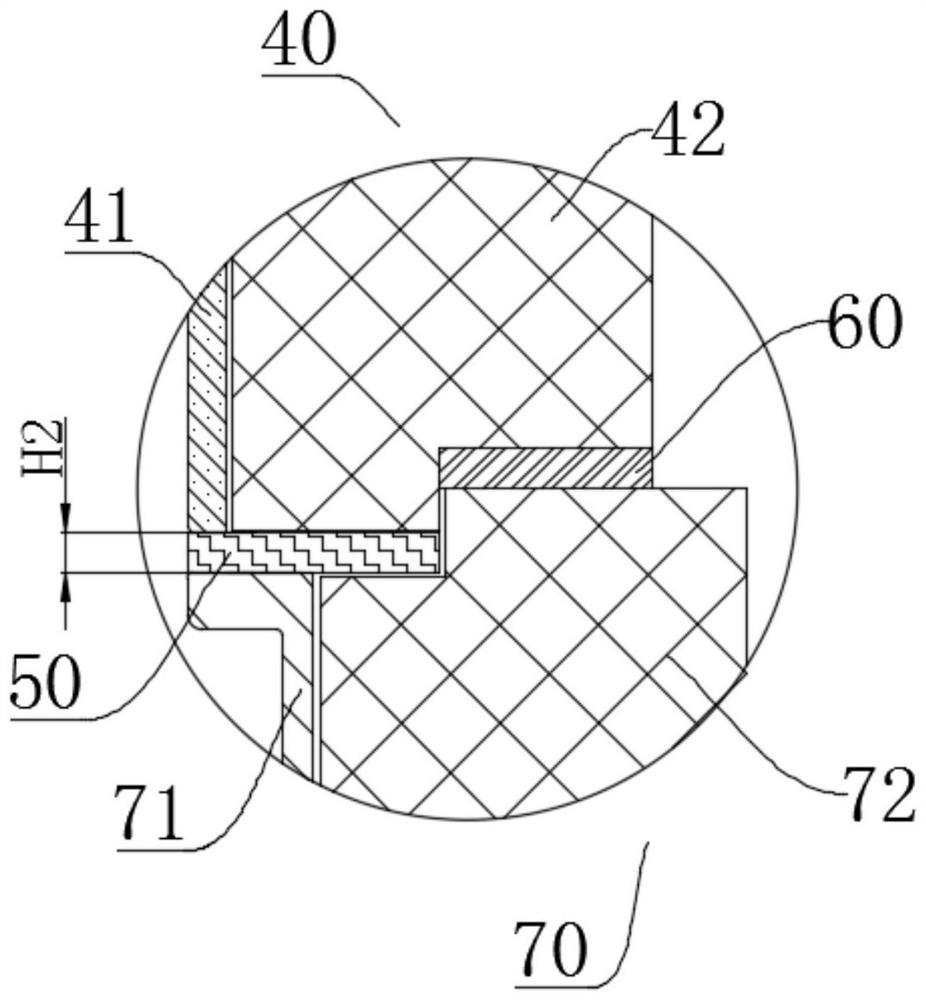

Czochralski single crystal thermal field and re-feeding process for thermal field

PendingCN114481292AImprove qualityReduce entryPolycrystalline material growthBy pulling from meltGraphite carbonPhysical chemistry

The Czochralski single crystal thermal field comprises a quartz crucible, a graphite / carbon-carbon crucible, an upper curing heat preservation cylinder, a middle curing heat preservation cylinder and a flow guide cylinder, and further comprises a supporting crucible arranged on the upper end face of the graphite / carbon-carbon crucible and a supporting heat preservation cylinder arranged between the upper curing heat preservation cylinder and the middle curing heat preservation cylinder; the upper end face of the supporting crucible is lower than the upper end face of the quartz crucible, and the height from the upper end face of the supporting crucible to the upper end face of the graphite / carbon crucible is a fixed value; the supporting heat preservation cylinder is connected with the upper curing heat preservation cylinder and the middle curing heat preservation cylinder, and the height of the supporting crucible is the same as that of the supporting heat preservation cylinder. According to the invention, under the condition of not changing the structures of the existing graphite / carbon-carbon crucible, the heater and all the curing heat preservation cylinders, a new quartz crucible with a certain height compared with the conventional quartz crucible is reconfigured, and re-throwing production is carried out in a new thermal field, so that not only can metal impurities entering the czochralski single crystal be reduced, but also the quality of the single crystal can be improved, and the single-edge bract breaking rate can be reduced.

Owner:内蒙古中环晶体材料有限公司

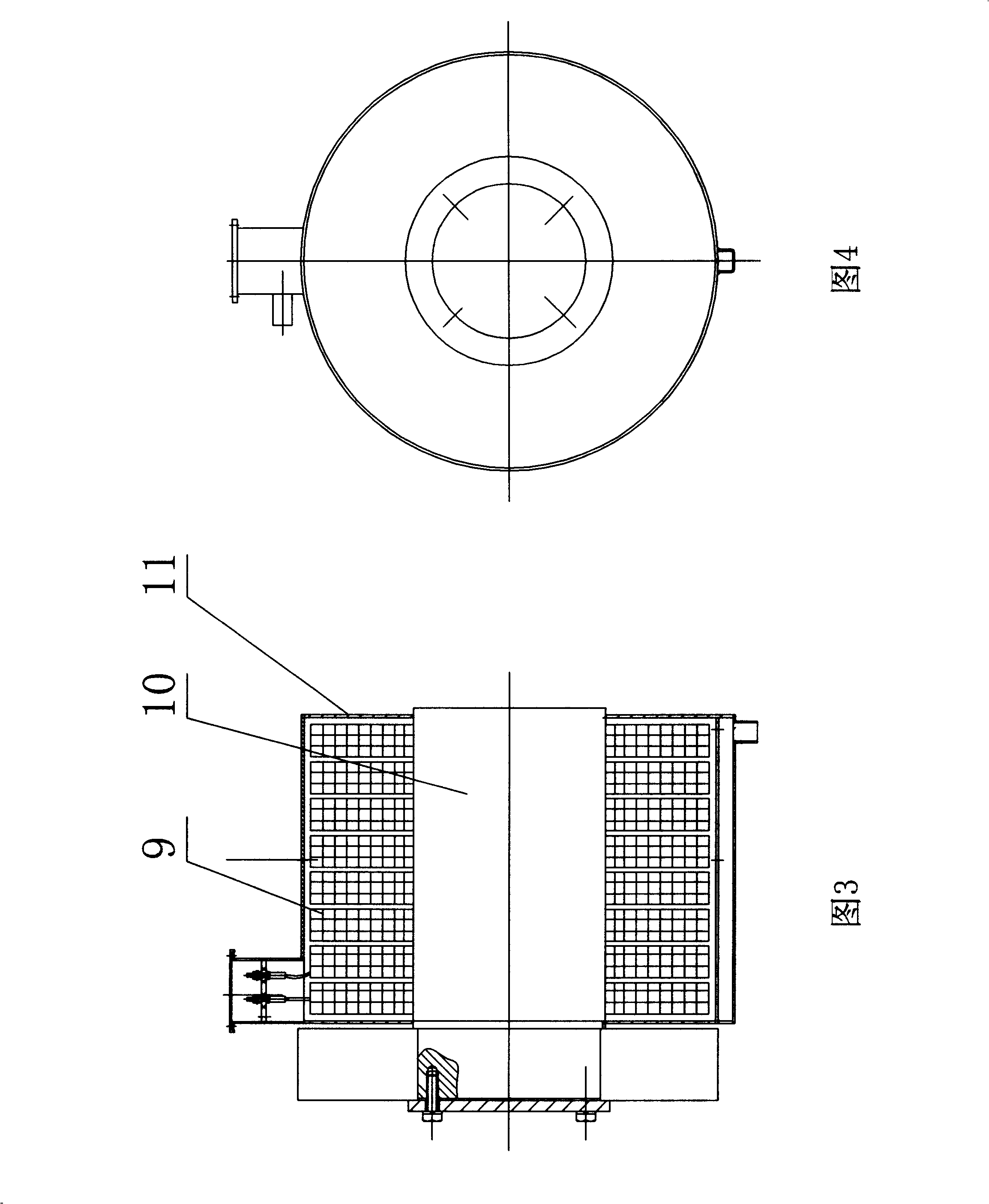

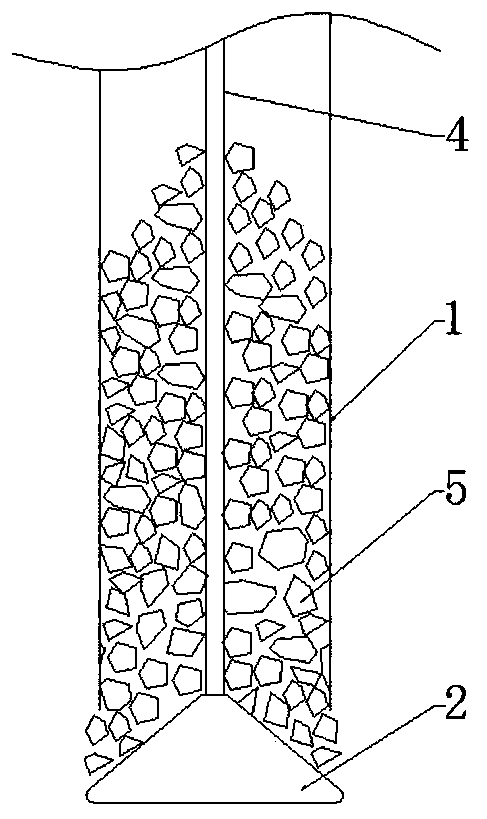

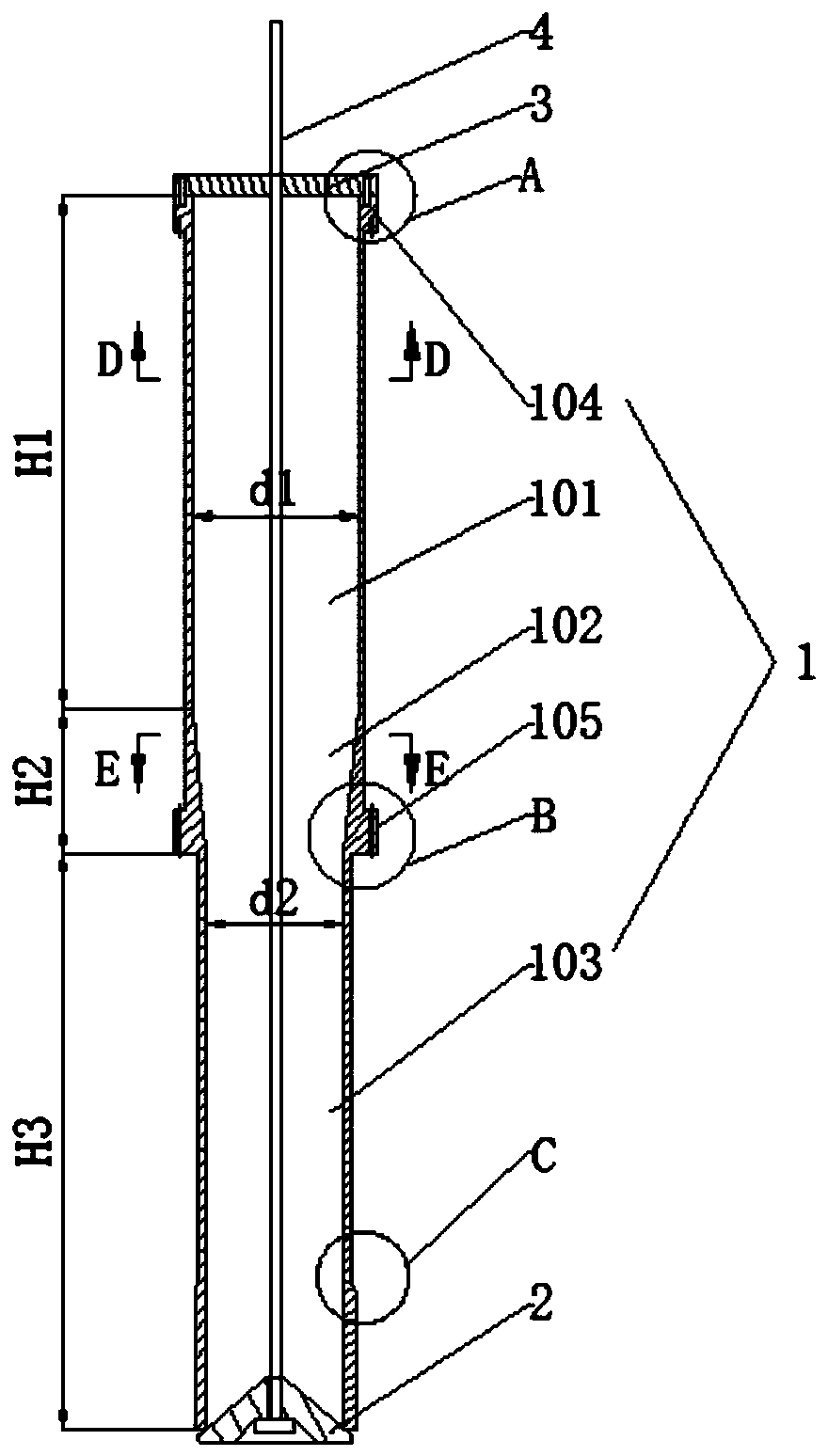

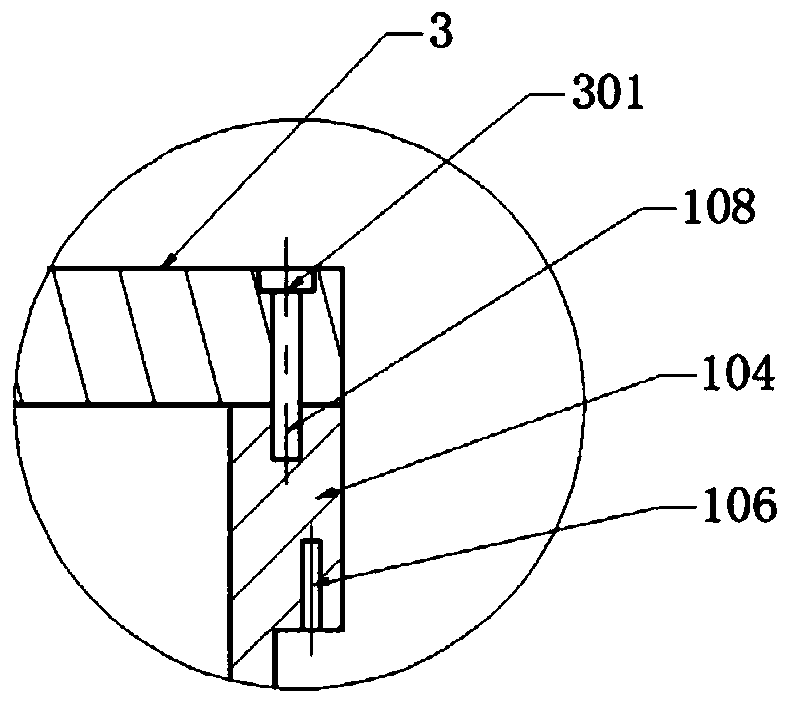

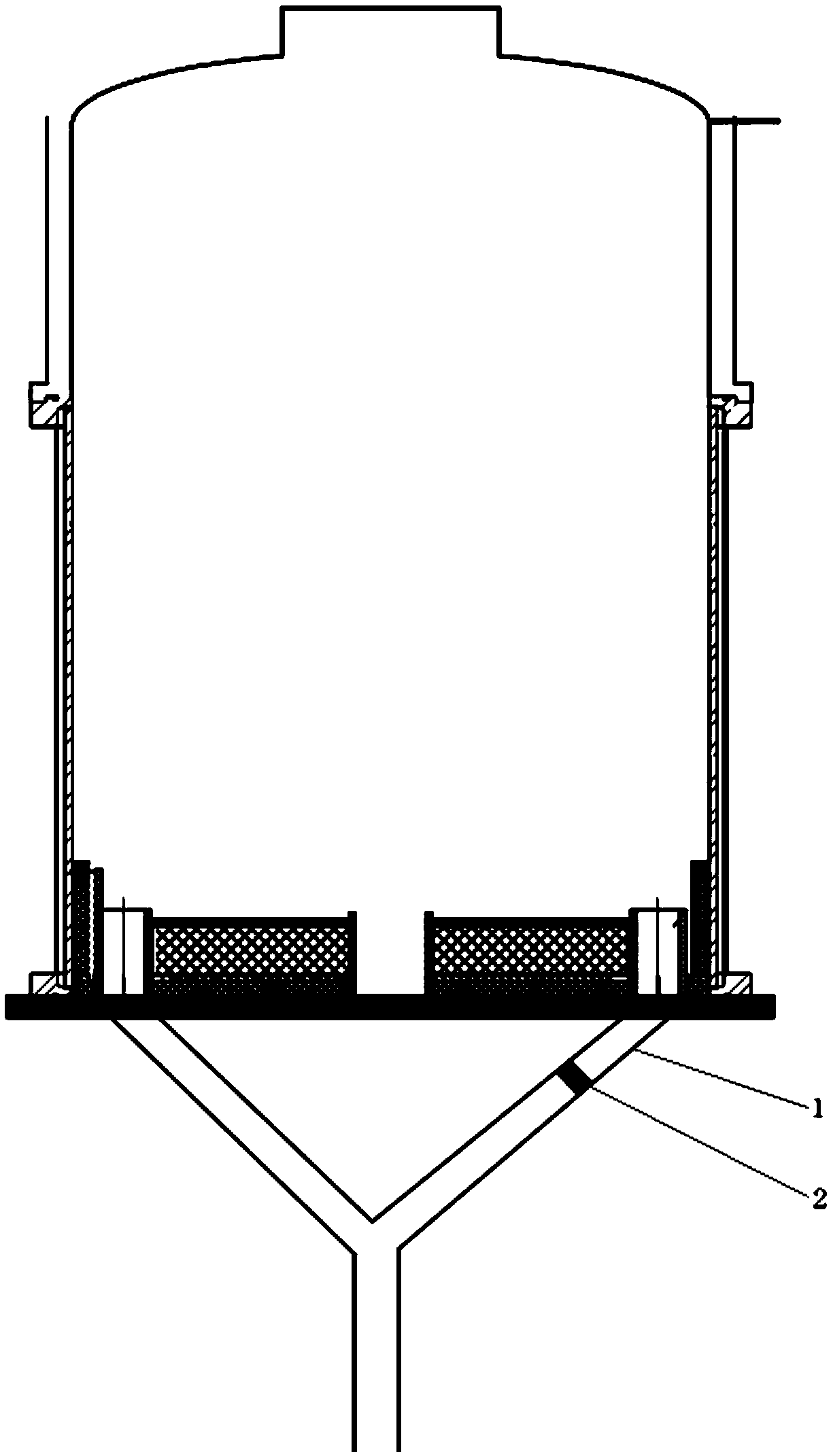

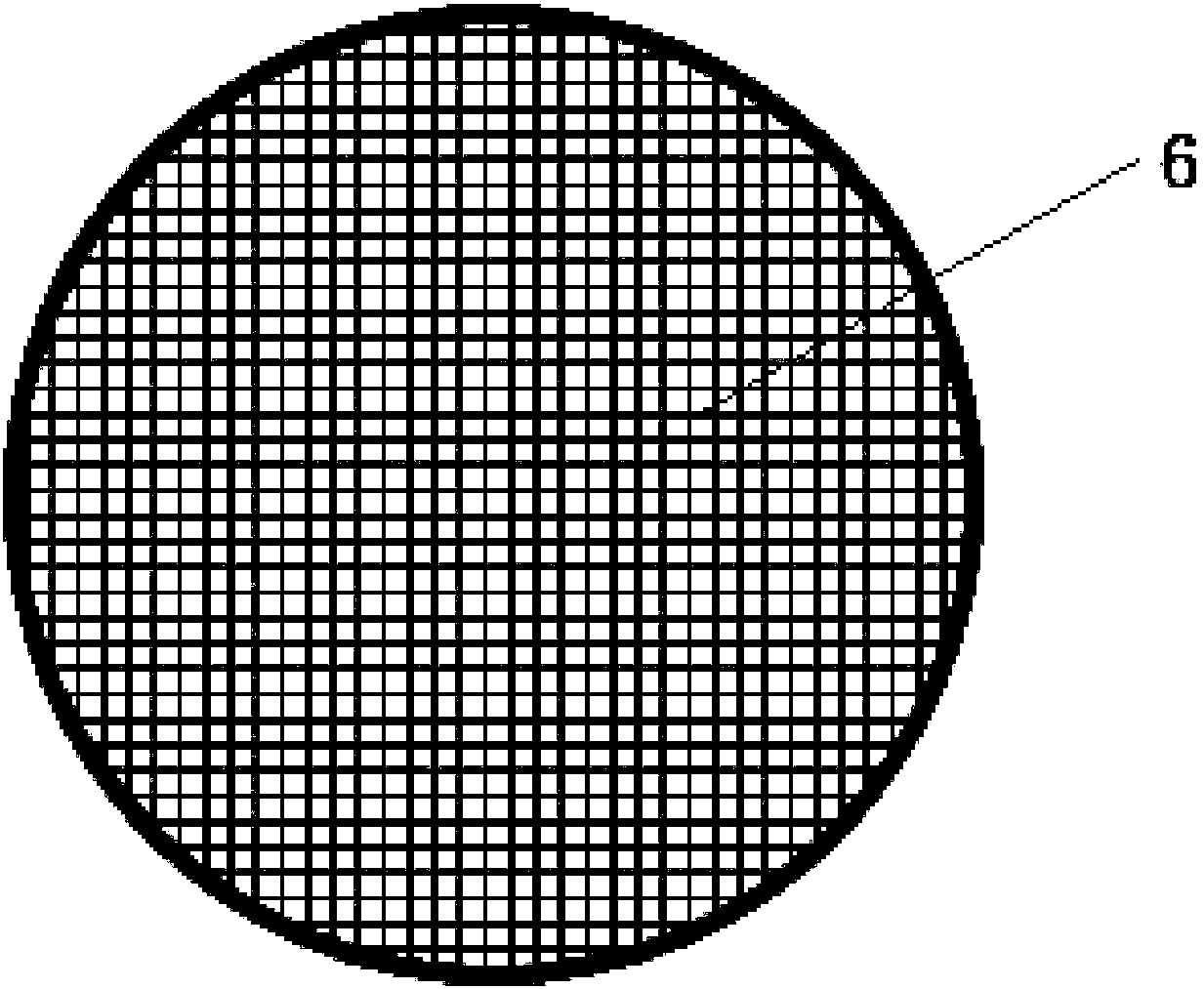

Crystal-guiding and impurity-removal device and method for preparing high-purity alumina polycrystals by virtue of cold crucible

ActiveCN107604435AIncrease packing densityImprove single crystal qualityPolycrystalline material growthSingle crystal growth detailsMaterial resourcesSingle crystal

The invention relates to a crystal-guiding and impurity-removal device and method for preparing high-purity alumina polycrystals by virtue of a cold crucible. The device comprises the cold crucible, an electromagnetic induction coil, a double-layer water-cooling copper pipe and a lifting system, wherein a high-purity alumina melt is filled into the cold crucible; the double-layer water-cooling copper pipe is connected to the lifting system which is used for controlling the lifting of the double-layer water-cooling copper pipe; the double-layer water-cooling copper pipe can be inserted into thehigh-purity alumina melt in the cold crucible. According to the method, the double-layer water-cooling copper pipe internally carrying circulating cooling water is inserted into the melt, impuritiesin the melt are gradually condensed to the double-layer water-cooling copper pipe in a directional solidification manner and can be extracted before the melt is completely crystallized and solidifiedin the cold crucible, the purity of alumina can be increased from 99.995% to 99.999%, and high-purity alumina polycrystals do not need to be subjected to crushing and impurity removal, so that a largequantity of manpower and material resources are saved, the filling density of the raw materials in a subsequent single crystal furnace is increased to a certain extent, the quality of sapphire singlecrystal is improved, and the energy sources are saved.

Owner:睿为电子材料(天津)有限公司

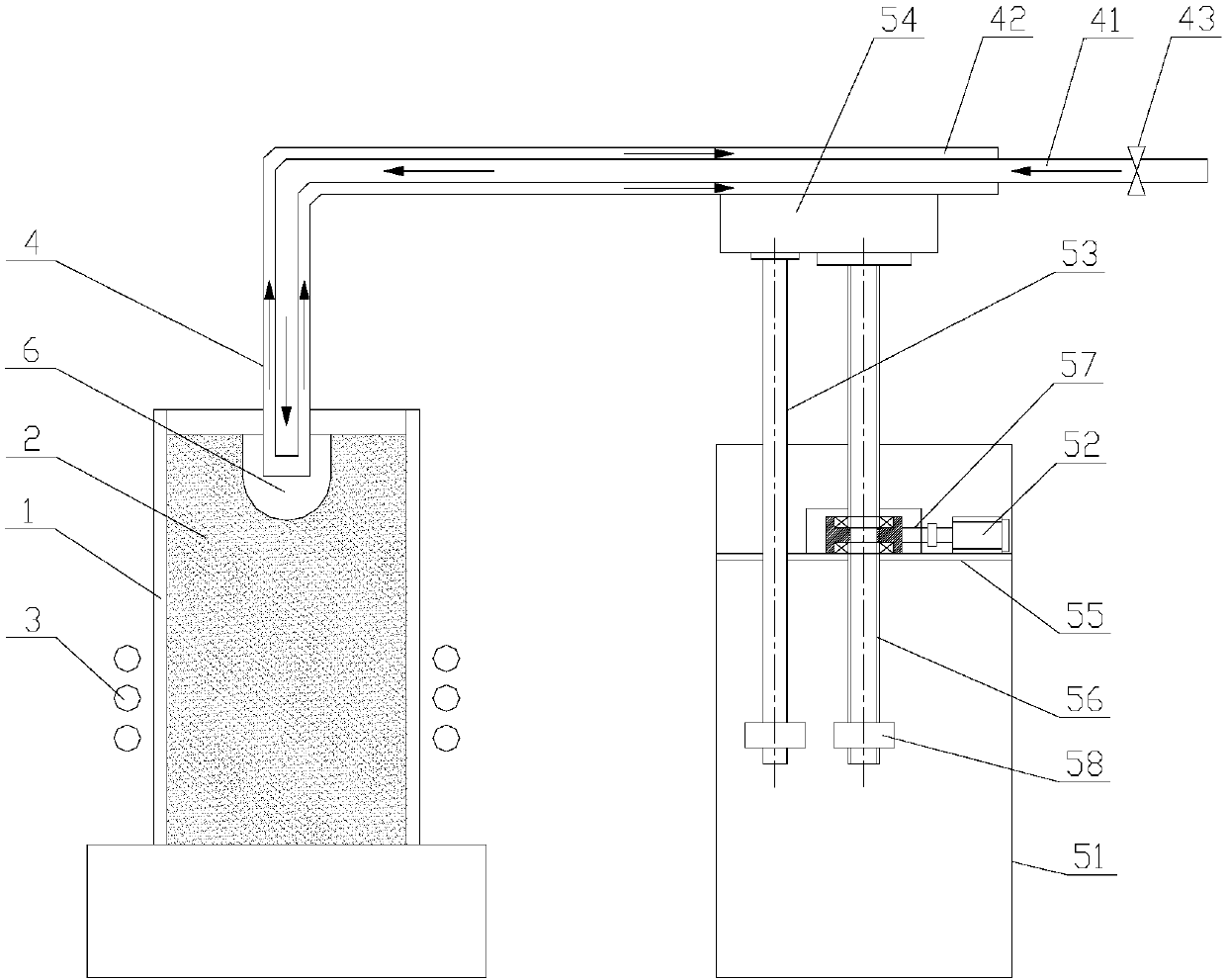

A novel re-feeding device for Czochralski grown monocrystalline and an operating method thereof

PendingCN110093662AExtended service lifeImprove single crystal qualityPolycrystalline material growthBy pulling from meltFixed frameSingle crystal

A novel re-feeding device for Czochralski grown monocrystalline is provided, including a re-feeding cylinder, a quartz umbrella disposed at the lower end of the re-feeding cylinder and a fixed frame at the upper end of the re-feeding cylinder. The re-feeding cylinder sequentially includes, from one end close to the fixed frame, a first cylinder part, a second cylinder part and a third cylinder part. The first, second and third cylinder parts are integrally connected, the inner diameter of the first cylinder part is greater than the inner diameter of the third cylinder part, and the height of the first cylinder part is not less than the height of the third cylinder part. The re-feeding device can increase the re-feeding amount of each cylinder, can reduce the oxygen content of head gaps ofmonocrystalline silicon rods, and can improve monocrystalline silicon quality. The service lifetime of the re-feeding device is prolonged, the production efficiency is increased and the production cost is reduced. The invention also provides an operating method of the novel re-feeding device for Czochralski grown monocrystalline. The method is particularly suitable for re-feeding for monocrystalline silicon with a large size and a large feeding amount. Through the method, quality of monocrystalline silicon rods can be ensured, and the crystal yield is increased by about 4%.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Self-purifying device for exhaust port of single-crystal furnace

PendingCN109440192AImprove work efficiencySimple structureAfter-treatment apparatusSingle crystalEngineering

The invention provides a self-purifying device for an exhaust port of a single-crystal furnace, comprising a first rotating device, a second rotating device and a cleaning device. The first rotating device cooperates with the second rotating device, and the cleaning device is connected with the second rotating device. The self-purifying device for the exhaust port of the single-crystal furnace hasthe advantages that by means of worm-gear cooperation, the cleaning device is connected with a worm gear, the cleaning device is rotated by the worm gear, an exhaust pipe is cleaned, the working is reliable, the cleaning efficiency is high, oxides deposited are continuously cleaned during the operation of a furnace body, the oxide accumulation is prevented from blocking the exhaust pipe, the working efficiency of the single-crystal furnace is improved, and the quality of a single crystal is improved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Fixing device and fixing method for seed crystal or substrate in single crystal growth of aluminum nitride

ActiveCN107687023AAvoid disadvantagesConducive to play a single crystal inductionPolycrystalline material growthFrom condensed vaporsGas phaseCrucible

The invention discloses a fixed device and a fixing method for a seed crystal or a substrate in the single crystal growth of aluminum nitride. A detachable growth platform is arranged between an aluminum nitride powder source and a crucible head cover, so that the seed crystal or substrate material is fixed by means of gravity or in a mechanical mode, crystal growth can be carried out on double surfaces of the seed crystal or substrate simultaneously by setting a first gap and a second gap, the crystal growth efficiency is relatively high, the problem of seed crystal fixation is effectively solved, various adverse factors caused by adhesion of the seed crystal are avoided, and advantages are provided for homoepitaxial growth of aluminum nitride; the seed crystal or substrate gets close toa high temperature area from a low temperature area, a gas phase substance generated through degradation of the aluminum nitride powder source has preferable transfer ability in the high temperature area, and is beneficial for further homoepitaxial / heteroepitaxial growth to further enlarge crystal size; the formation of a white ceramic layer can be avoided completely on the surface of the seed crystal, the single crystal induction effect of the seed crystal is developed, and the aluminum nitride single crystal obtained through the method has extremely high single crystal quality and has relatively high crystal growth rate.

Owner:ULTRATREND TECH INC

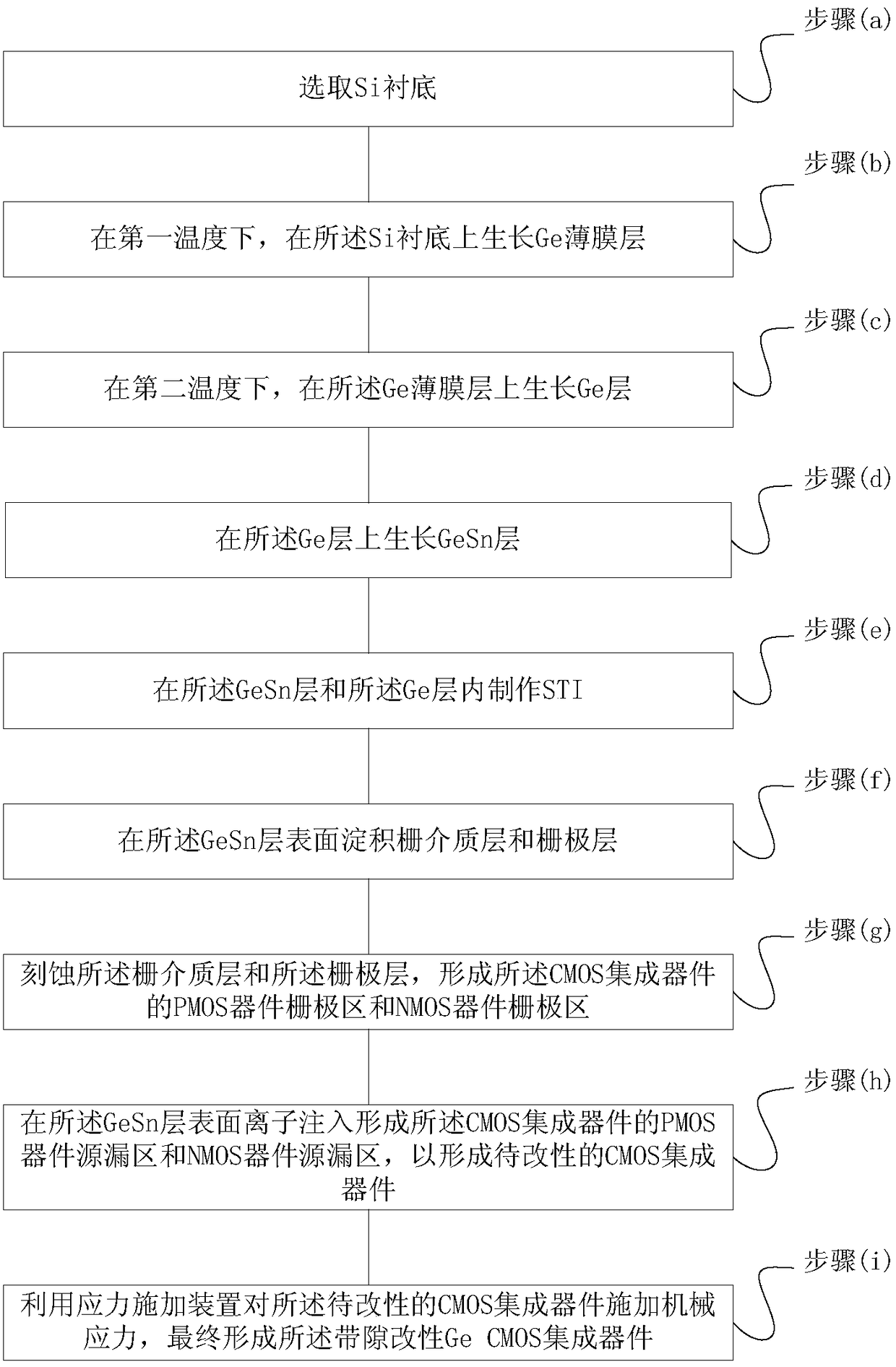

Band-gap modified Ge CMOS integrated device and manufacturing method thereof

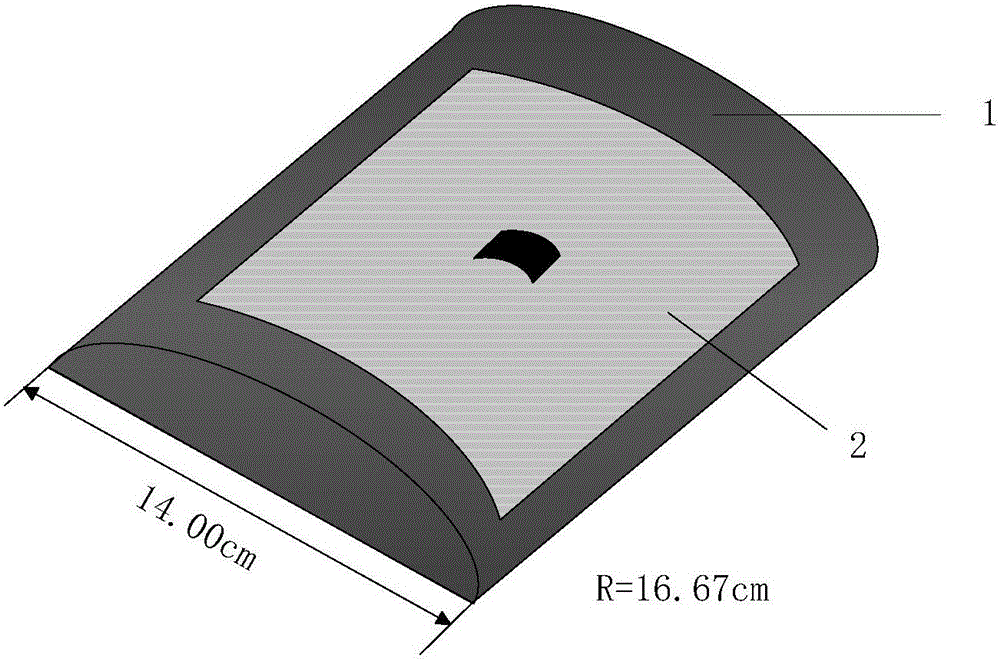

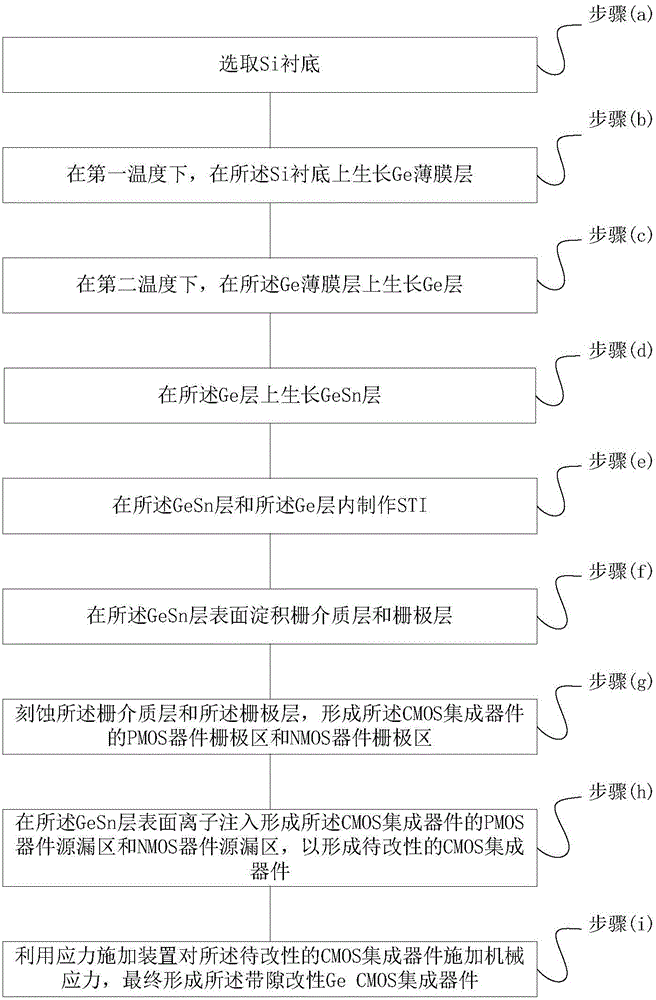

ActiveCN106024717AImprove single crystal qualitySimple preparation techniqueTransistorSemiconductor/solid-state device manufacturingCMOSPower flow

The invention relates to a band-gap modified Ge CMOS integrated device and a manufacturing method thereof. The manufacturing method comprises the steps of: selecting an Si substrate; growing a Ge thin film layer and a Ge layer on the Si substrate; growing a GeSn layer on the Ge layer; manufacturing an STI in the GeSn layer and the Ge layer; depositing a gate dielectric layer and a gate layer on the surface of the GeSn layer; etching the gate dielectric layer and the gate layer and forming gate regions of a PMOS device and an NMOS device; and carrying out ion implantation on the surface of the GeSn layer to form a PMOS device source-drain region and an NMOS device source-drain region of the CMOS integrated device, applying mechanical stress to the to-be-modified CMOS integrated device by a stress applying device and finally forming the band-gap modified Ge CMOS integrated device. A channel material utilized by the CMOS device is a direct band-gap modified Ge material; the carrier mobility of the channel material is improved by multiple times in comparison with that of a traditional Si material; the current drive and frequency characteristics of the CMOS integrated device are improved; and the device is suitable for monolithic optoelectronic integration with a photonic device.

Owner:XIDIAN UNIV

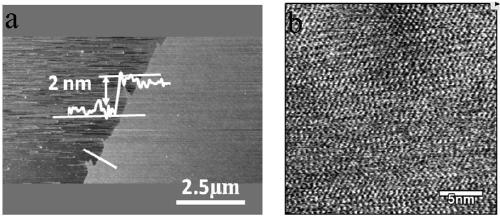

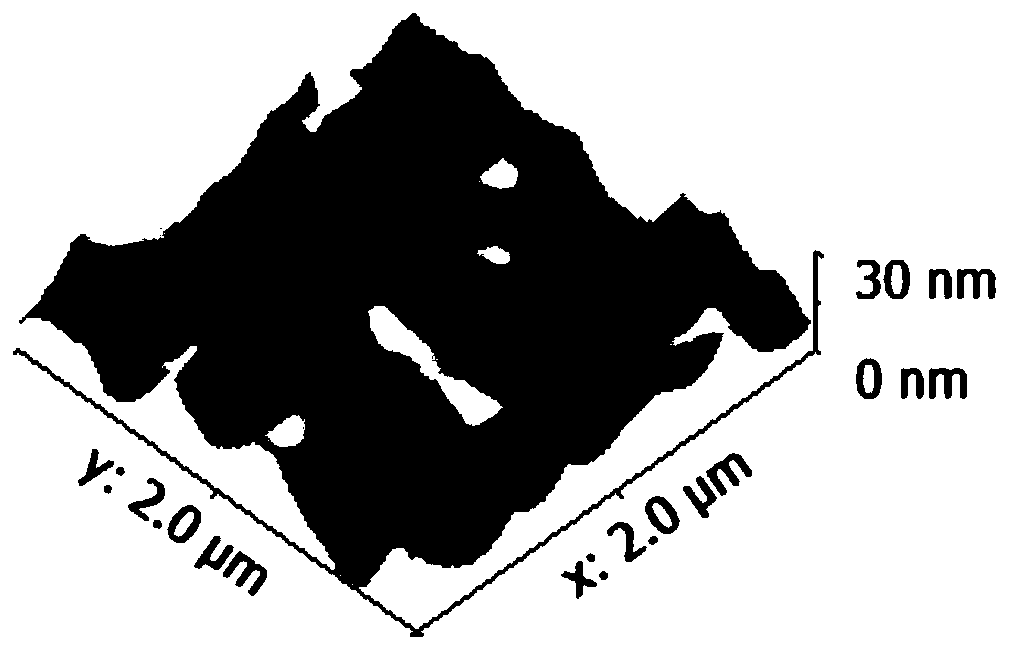

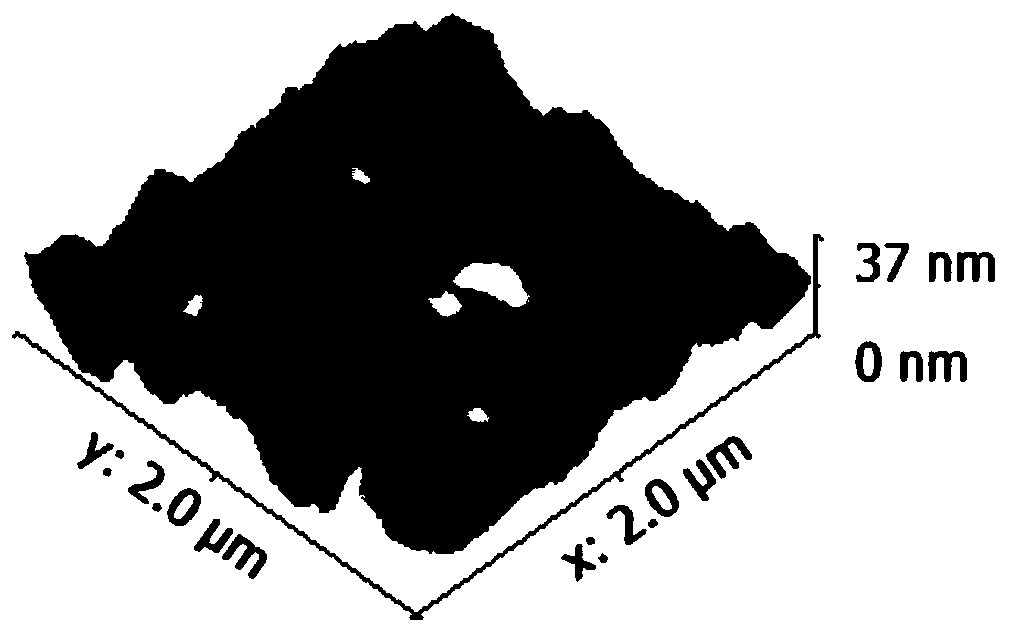

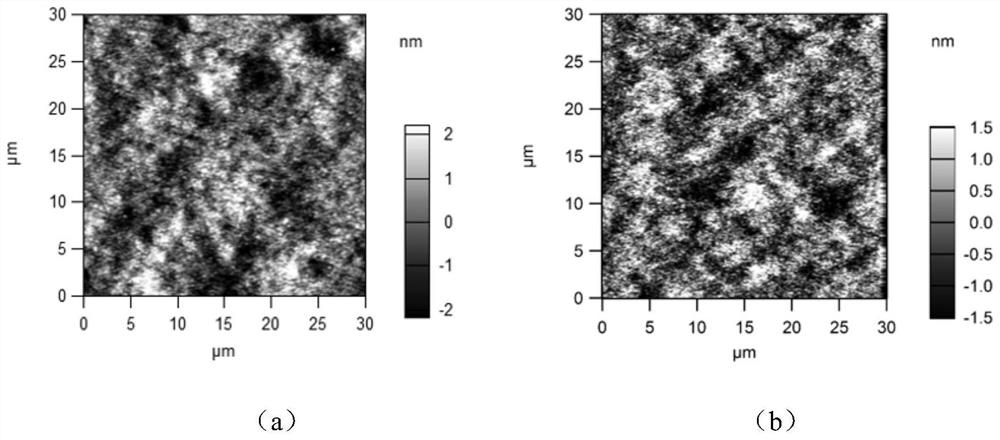

Preparation method of high-quality wafer-level graphene single crystal

ActiveCN110453280AImprove flatnessInhibition of oxidation and passivationPolycrystalline material growthFrom chemically reactive gasesMetal foilSingle crystal

The invention provides a preparation method of a high-quality wafer-level graphene single crystal. The method comprises the following steps: placing plasma-treated metal foil into a reaction furnace,introducing an inert atmosphere, performing heating to an annealing temperature, introducing hydrogen gas, and performing annealing treatment, wherein the metal foil is one selected from the group consisting of copper foil, nickel foil, molybdenum foil and cobalt foil, the plasma treatment atmosphere is at least one selected from the group consisting of air, hydrogen gas, argon gas, oxygen gas, and nitrogen gas, the power is 100-150 W, the pressure is 400-500 Pa, and the time is 1-30 min; and introducing a carbon source into the reaction furnace, adjusting the annealing temperature to a growthtemperature of the graphene single crystal, starting growth of the graphene single crystal, and after growth is completed, performing cooling to a room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Band gap modified ge CMOS integrated device and its preparation method

ActiveCN106024717BImprove single crystal qualitySimple preparation techniqueTransistorSemiconductor/solid-state device manufacturingCMOSGate dielectric

The invention relates to a band-gap modified Ge CMOS integrated device and a manufacturing method thereof. The manufacturing method comprises the steps of: selecting an Si substrate; growing a Ge thin film layer and a Ge layer on the Si substrate; growing a GeSn layer on the Ge layer; manufacturing an STI in the GeSn layer and the Ge layer; depositing a gate dielectric layer and a gate layer on the surface of the GeSn layer; etching the gate dielectric layer and the gate layer and forming gate regions of a PMOS device and an NMOS device; and carrying out ion implantation on the surface of the GeSn layer to form a PMOS device source-drain region and an NMOS device source-drain region of the CMOS integrated device, applying mechanical stress to the to-be-modified CMOS integrated device by a stress applying device and finally forming the band-gap modified Ge CMOS integrated device. A channel material utilized by the CMOS device is a direct band-gap modified Ge material; the carrier mobility of the channel material is improved by multiple times in comparison with that of a traditional Si material; the current drive and frequency characteristics of the CMOS integrated device are improved; and the device is suitable for monolithic optoelectronic integration with a photonic device.

Owner:XIDIAN UNIV

Chromogenic solution and method for distinguishing P/N-type silicone materials

ActiveCN102004101BEasy to classifyImprove the discrimination rateMaterial analysis by observing effect on chemical indicatorHydrofluoric acidAmorphous silicon

The invention discloses chromogenic solution and a method for distinguishing P / N-type silicone materials. The chromogenic solution comprises nitric acid and hydrofluoric acid in a volume ratio of 1: 80-120, wherein hydrofluoric acid accounts for 40 to 45 mass percent and the nitric acid accounts for 65 to 68 percent. The N-type electronic conductive silicon material washed by using the chromogenic solution is bright and the P-type hollow conductive silicon material washed by using the chromogenic solution is dark gray, so that the advantages that the P / N-type silicone materials are easy to wash and sort are achieved. The brightness and the darkness on the surface of an amorphous silicon material pickled by the chromogenic solution of the invention are in sharp contrast; the P type silicone material and the N type silicone material can be seen by naked eyes clearly; furthermore, the used acidic solution can be recycled for washing impurities on the surface of the silicon material. Moreover, the chromogenic solution has the advantages of enhancing distinguishing rate, improving work efficiency, promoting monocrystal quality and reducing cost.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

A kind of large-area molecular crystal and its preparation method

ActiveCN109137083BSimple methodGood repeatabilityPolycrystalline material growthLiquid-phase epitaxial-layer growthXylyleneHeterojunction

The invention discloses a large-area molecular crystal and a preparation method thereof. The preparation method of the large-area molecular crystal comprises the following steps: placing an organic semiconductor solution on a hydrophobic substrate, covering the hydrophobic substrate with a hydrophilic substrate, and obtaining molecular crystals on the hydrophilic substrate through growth The solvent used in the organic semiconductor solution is at least one of chlorobenzene, chloroform, dichlorobenzene and xylene; the mass volume concentration of the organic semiconductor solution is 0.01mg / mL~15mg / mL; The solute of the semiconducting solution is an organic semiconducting molecule. The large-area molecular crystals provided by the present invention have the characteristics of large area, high uniformity and smooth surface, and field-effect transistors prepared from these large-area two-dimensional molecular crystals have higher carrier mobility and lower threshold voltage, It laid a solid foundation for the subsequent preparation of P-N heterojunction.

Owner:INST OF CHEM CHINESE ACAD OF SCI

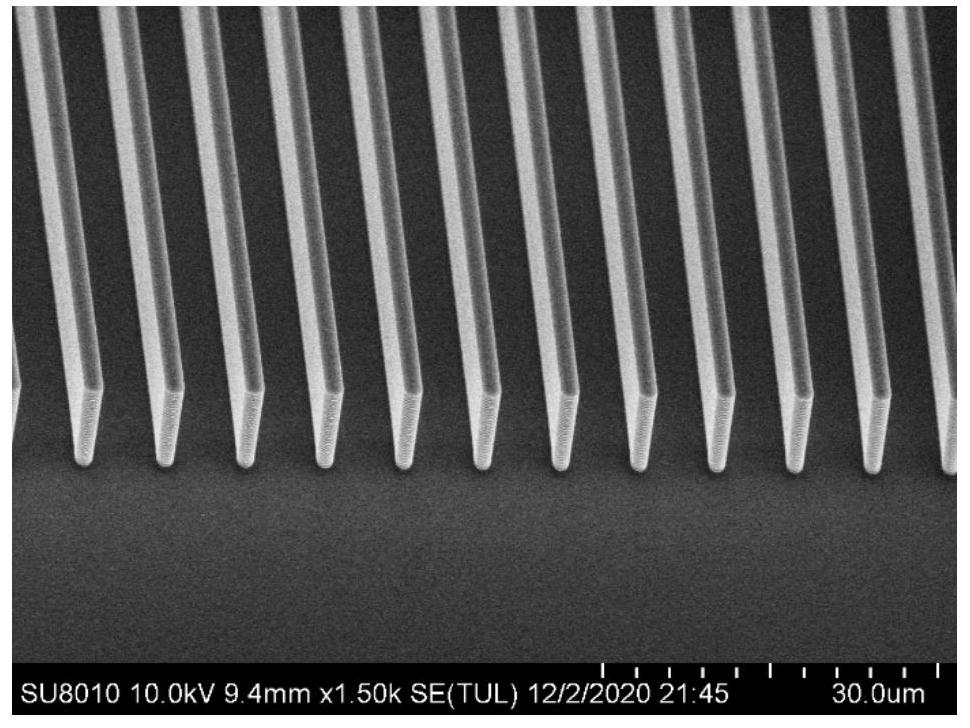

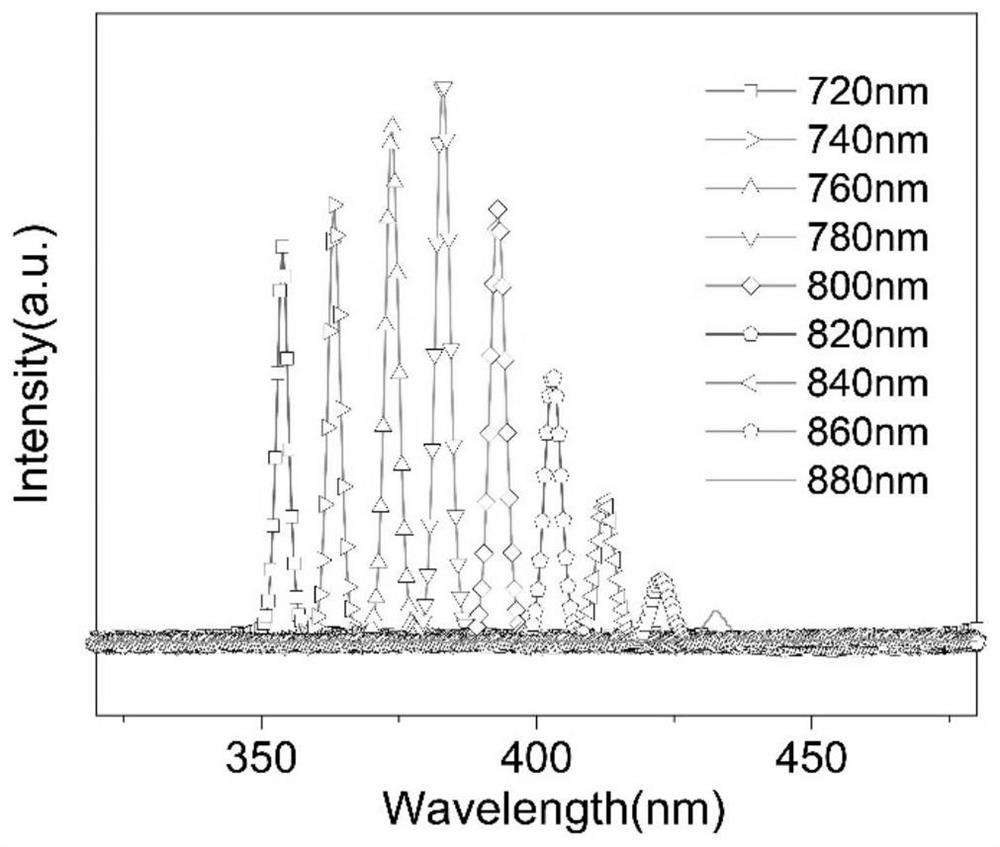

Perovskite nanowire array and preparation method thereof

InactiveCN112821171ACrystal stableStable directional growthMaterial nanotechnologyLaser detailsPhysical chemistryThin membrane

The invention discloses a perovskite nanowire array and a preparation method thereof, and the preparation method comprises the following steps: S1, preparing a silicon column template with a plurality of silicon column arrays, and carrying out the selective modification of the silicon column template; S2, preparing a perovskite solution; S3, dropwise adding a perovskite solution to the top end of the silicon column of the silicon column template; S4, covering the top of the silicon column template with a substrate to form a sandwich assembly system; S5, carrying out heating and drying treatment on the sandwich assembly system; S6, standing and cooling the heated and dried sandwich assembly system; and S7, dismounting the sandwich assembly system. According to the preparation method, the equipment cost is effectively reduced, and the perovskite nanowire array of which the frequency doubling conversion efficiency is far higher than that of the perovskite polycrystalline thin film is prepared and obtained simply and universally at the same time.

Owner:JIHUA LAB

Preparation method and application of organic semiconductor two-dimensional molecular crystal material

ActiveCN106159092BIncrease the areaThe overall thickness is thinOrganic chemistrySolid-state devicesCharge carrier mobilityPhysical chemistry

The present invention provides an organic semiconductor two-dimensional molecular crystal material preparation method and application. The preparation method comprises: an organic semiconductor compound solution is dropped at the water surface, after the solution is volatilized, and an organic semiconductor two-dimensional molecule crystal nucleus is obtained at the water surface; and the organic semiconductor compound solution is continuously dropped at the organic semiconductor two-dimensional molecule crystal nucleus and is still standing, and the organic semiconductor two-dimensional molecule crystal materials are obtained on the water surface. The application of the organic semiconductor two-dimensional molecule crystal materials in the preparation field effect transistor device also belongs to the protection range of the invention. The water surface and a seed crystal formed on the water surface in advance are taken as a growth core, the solution is subjected to self assembly, a large-scale two-dimensional molecule crystal structure is grew up on the water surface, and the field effect transistor prepared by the two-dimensional molecule crystal structure has high carrier mobility and low threshold voltage.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of large single crystal graphene and preparation method thereof

ActiveCN104674343BEasy to prepareReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesReducing atmosphereSingle crystal

Owner:PEKING UNIV

Preparation method of monocrystal diamond film

InactiveCN111962148AAchieve strippingImprove single crystal qualityPolycrystalline material growthAfter-treatment detailsPhysical chemistrySingle crystal

The invention provides a preparation method of a monocrystal diamond film. The preparation method comprises the following steps: obtaining a diamond substrate and a heterogeneous substrate, carrying out He ion implantation on the surface of the diamond substrate, so that implanted ions are gathered at the corresponding depth of the diamond substrate to form a defect layer, and the diamond film onthe defect layer in the diamond substrate is used as a substrate for homoepitaxy, growing a layer of single crystal diamond film on the diamond film by adopting homoepitaxy, bonding the single crystaldiamond film with the heterogeneous substrate to form a bonding structure, performing wet etching or electrochemical etching on the bonding structure, removing the defect layer, and transferring thediamond film to the surface of the heterogeneous substrate, and if the bonding structure is subjected to electrochemical corrosion, carrying out high-temperature annealing on the diamond substrate subjected to homoepitaxy before the step of bonding the diamond film subjected to epitaxy with the heterogeneous substrate, so that the defect layer is graphitized to form a graphitized defect layer, wherein the implantation energy and implantation dose of the He ions are set in a gradient manner according to a defect layer dissolution method.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A method for directly epitaxially growing germanium dummy substrate on silicon substrate

ActiveCN109166788BImprove single crystal qualityReduce stressSemiconductor/solid-state device manufacturingHydrofluoric acidPhysical chemistry

Owner:NANJING UNIV

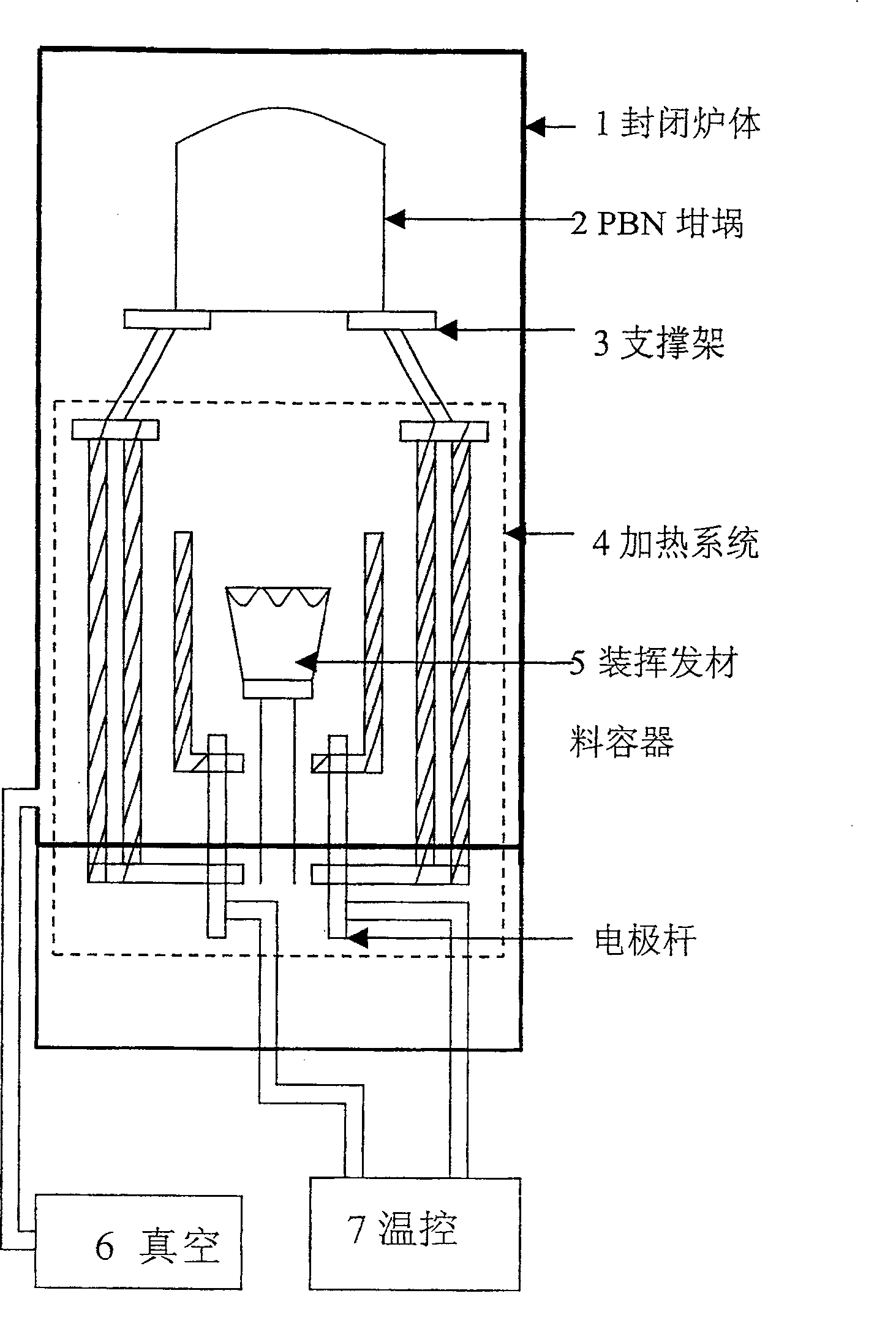

Boron nitride pyrolyzing crucible coating method

ActiveCN100494473CAvoid contaminationImprovement of inner wall conditionVacuum evaporation coatingSputtering coatingSupporting systemTemperature control

Owner:云南中科鑫圆晶体材料有限公司

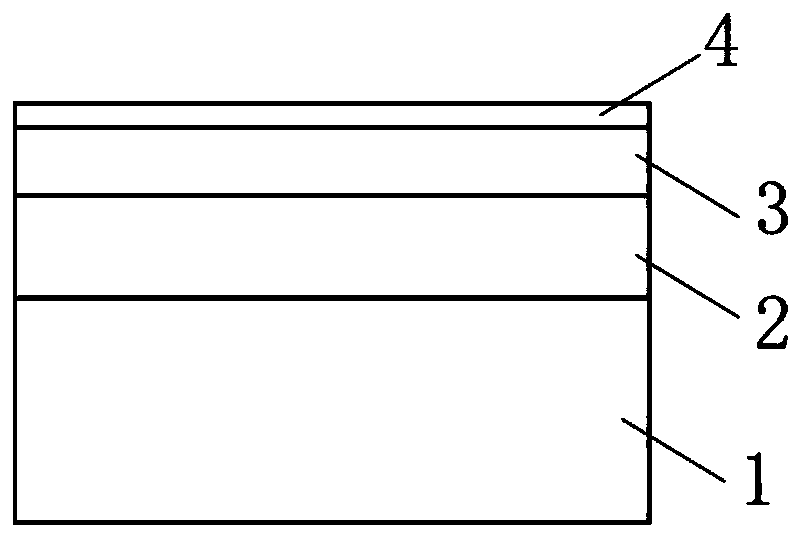

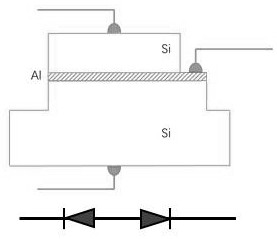

Semiconductor/metal/semiconductor quantum well structure, preparation method and application thereof

PendingCN113972319AImprove the means of preparationImprove single crystal qualitySolid-state devicesSingle crystalSemiconductor quantum wells

The invention provides a semiconductor / metal / semiconductor quantum well structure, which is characterized in that the semiconductor / metal / semiconductor quantum well structure comprises a first semiconductor layer, a metal Al film layer and a second semiconductor layer, the metal Al film layer is sandwiched between the first semiconductor layer and the second semiconductor layer, and the metal Al film layer is a single crystal with unique orientation and has no twin crystal. The invention also provides a preparation method of the semiconductor / metal / semiconductor quantum well structure. The metal Al thin film epitaxially prepared by the two-step method is flat in surface, high in single crystal quality, free of twin crystal and low in optical loss, and the semiconductor / metal / semiconductor quantum well structure can be used for a semiconductor quantum information device.

Owner:NANJING UNIV +1

Band gap modified ge PMOS device and its preparation method

InactiveCN106024632BImprove single crystal qualitySimple preparation techniqueSemiconductor/solid-state device manufacturingGate dielectricCharge carrier mobility

Owner:XIDIAN UNIV

A method for preparing high-quality wafer-scale graphene single crystals

ActiveCN110453280BSimple processing methodGood repeatabilityPolycrystalline material growthFrom chemically reactive gasesMetal foilSingle crystal

The invention provides a method for preparing a high-quality wafer-level graphene single crystal, comprising: placing the plasma-treated metal foil in a reaction furnace and passing it into an inert atmosphere, then raising the temperature to the annealing temperature and then passing hydrogen gas Carry out annealing treatment, the metal foil is a kind of in copper foil, nickel foil, molybdenum foil, cobalt foil; Into the reaction furnace, introduce carbon source, adjust the annealing temperature to the growth temperature of graphene single crystal and then start graphene single crystal After the growth is completed, cool to room temperature; the atmosphere of the plasma treatment is at least one of air, hydrogen, argon, oxygen and nitrogen, the power is 100-150W, the pressure is 400-500Pa, and the time is 1 ~30 minutes.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com