Semiconductor/metal/semiconductor quantum well structure, preparation method and application thereof

A semiconductor and quantum well technology, applied in the field of semiconductor/metal/semiconductor quantum well structure, can solve the problems that cannot be realized and difficult to obtain high-quality semiconductor/metal/semiconductor epitaxial structure, and achieve the elimination of twins and high quality single crystal , the effect of reducing environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

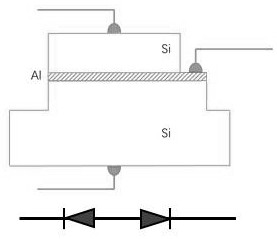

[0054] First, deoxidize the (111) crystal plane Si substrate, treat it with 8% hydrofluoric acid for 1 minute, the surface is hydrogen passivated surface, and then put it into the group IV molecular beam epitaxy equipment, at 900-1000 ℃ Under the condition of dehydrogenation treatment, a clean Si surface is obtained. The Si buffer layer can be grown on the Si surface, and the Si buffer layer can improve the surface flatness to a certain extent, thereby improving the surface flatness of subsequent film growth.

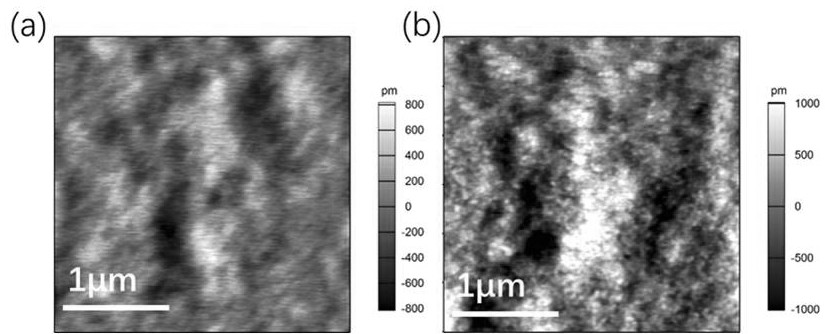

[0055] Next, an Al seed layer is grown under the condition of -50°C-50°C. The low-temperature growth and high-temperature annealing of the seed layer can obtain high-quality Al single crystal, which can be used as a template for subsequent epitaxial growth to ensure the quality of subsequent epitaxy.

[0056] The Al seed layer is heated at 100° C.-200° C. and annealed for 10-30 minutes.

[0057] Next, a layer of Al film with a thickness of 0.1-100nm is grown at a grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com