Extrusion preparation process for obtaining iron-based superconducting wire in single pass and product thereof

A technology for iron-based superconductivity and preparation process, applied in the field of metallurgy, can solve the problems of cumbersome preparation process, lengthy time, unsatisfactory superconductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An extrusion preparation process for obtaining an iron-based superconducting wire in a single pass, comprising the following steps:

[0040](1) Preparation of superconducting core powder: Ba122 is used as the raw material, and the raw material composition is Ba, K, Fe, As, wherein the mass ratio of Ba:K:Fe:As is 0.6:0.4:2:2, mixed under an inert atmosphere 1. Prepare iron-based superconducting precursor powder by ball milling.

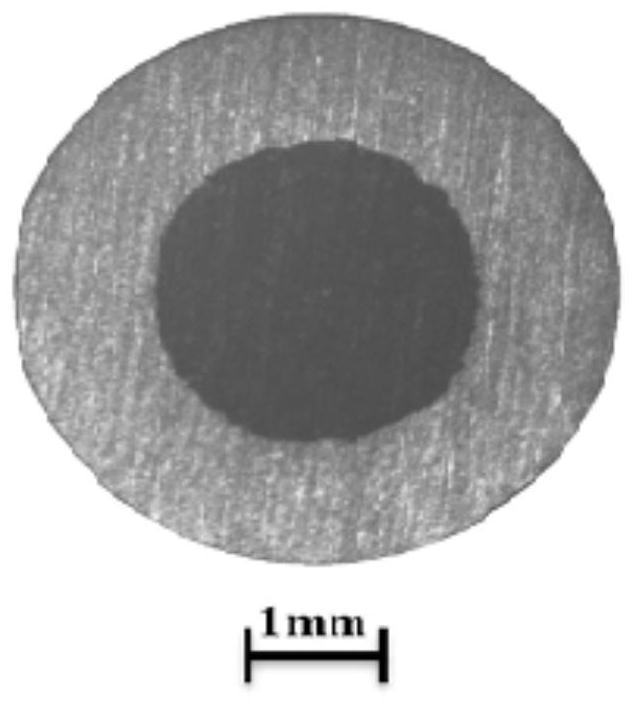

[0041] (2) Preparation of extrusion billet: put the sintered precursor powder into a clean Ag metal tube, the inner diameter of the Ag metal tube is Φ5mm, the outer diameter is Φ8mm, and the two ends of the Ag metal tube are blocked with metal Ag, every 4cm The powder content in the high Ag metal tube is about 2.8g.

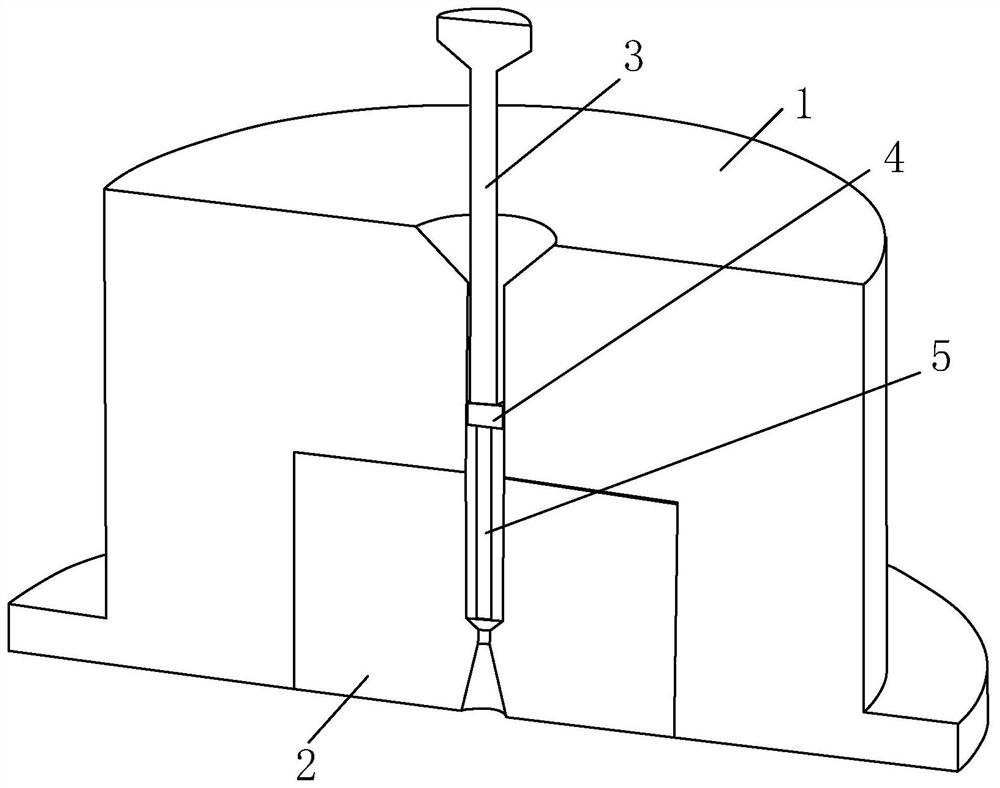

[0042] (3) Place the extrusion billet in the extrusion tooling, the structure of the overall extrusion tooling is as follows figure 1 As shown, it includes an extrusion cylinder 1, an extrusion die 2, an extrusion rod 3 and an ex...

Embodiment 2

[0047] An extrusion preparation process for obtaining an iron-based superconducting wire in a single pass, comprising the following steps:

[0048] (1) Preparation of superconducting core powder: mixing and ball milling under an inert atmosphere to prepare iron-based superconducting precursor powder, the raw material composition of the iron-based superconducting precursor powder is Ba, K, Fe, As, wherein, Ba:K:Fe: The mass ratio of As is 0.6:0.5:2:2.

[0049] (2) Preparation of extrusion billet: put the sintered precursor powder into a clean Ag metal tube, the inner diameter of the Ag metal tube is Φ5mm, the outer diameter is Φ8mm, and the two ends of the Ag metal tube are blocked with metal Ag, every 4cm The loading amount of iron-based superconducting precursor powder in the highly Ag metal tube is 2.1g.

[0050] (3) Place the extrusion billet in such as figure 1 In the extrusion tooling with the structure shown, preliminary preheating is carried out, the preheating temper...

Embodiment 3

[0054] An extrusion preparation process for obtaining an iron-based superconducting wire in a single pass, comprising the following steps:

[0055] (1) Preparation of superconducting core powder: mixing and ball milling under an inert atmosphere to prepare iron-based superconducting precursor powder.

[0056] (2) Preparation of extrusion billet: put the sintered precursor powder into a clean Cu metal tube with an inner diameter of Φ5 mm and an outer diameter of Φ8 mm, and plug both ends of the Cu metal tube with metal Cu.

[0057] (3) Place the extrusion billet in the exact same extrusion tooling as in Example 1 for preliminary preheating, the preheating temperature being 200°C.

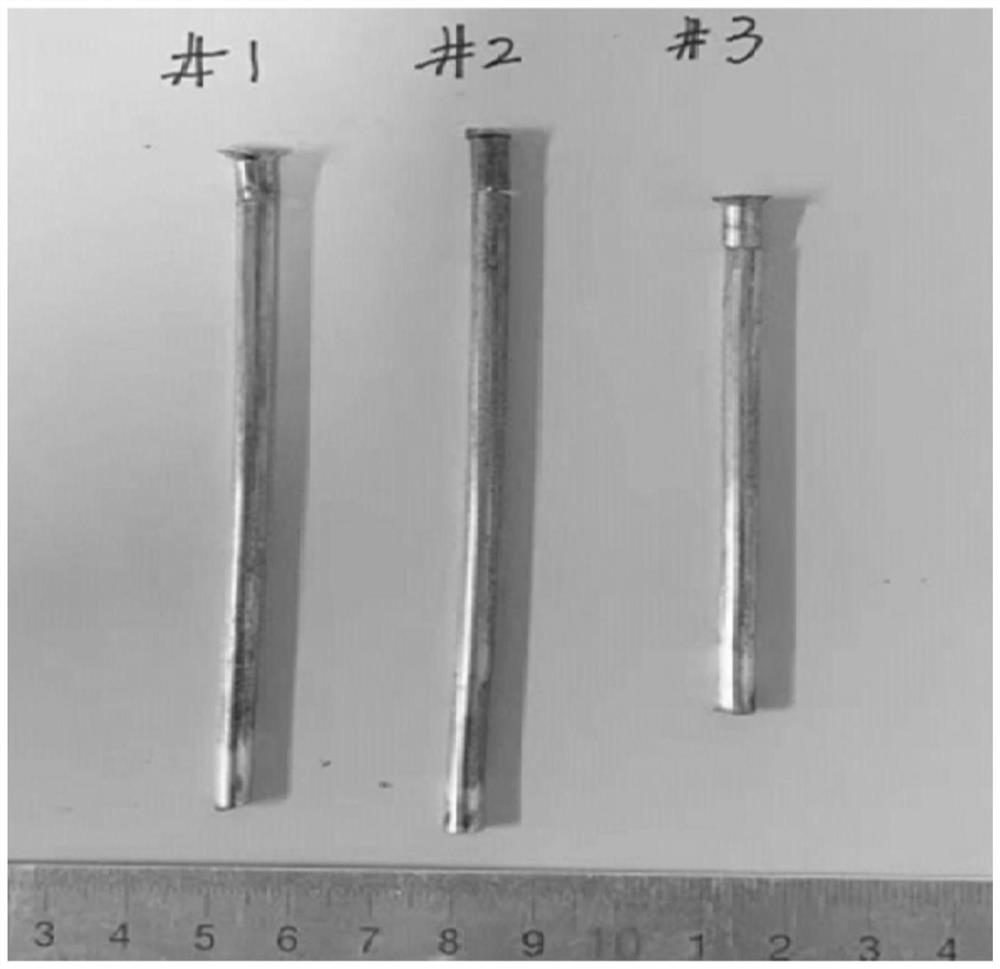

[0058] (4) A common press is used to apply extrusion force to the extrusion rod 3 to realize vertical forward cold extrusion, and the extrusion speed of the iron-based superconducting wire can be realized by controlling the extrusion speed to 5 mm / s when applying pressure. In this embodiment, the ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com