Patents

Literature

436results about How to "Uniform processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exhaust apparatus configured to reduce particle contamination in a deposition system

InactiveUS7740705B2Reduce pollutionUniform processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

Owner:TOKYO ELECTRON LTD

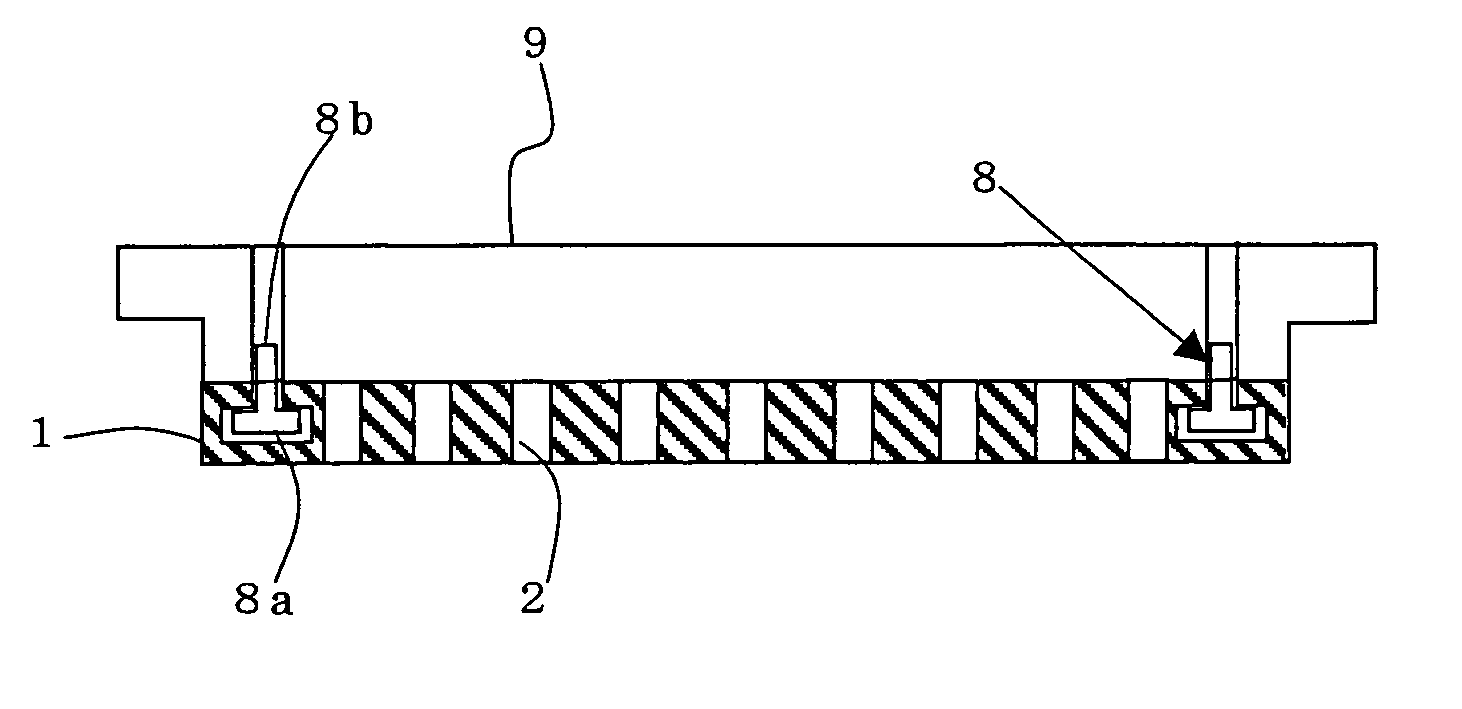

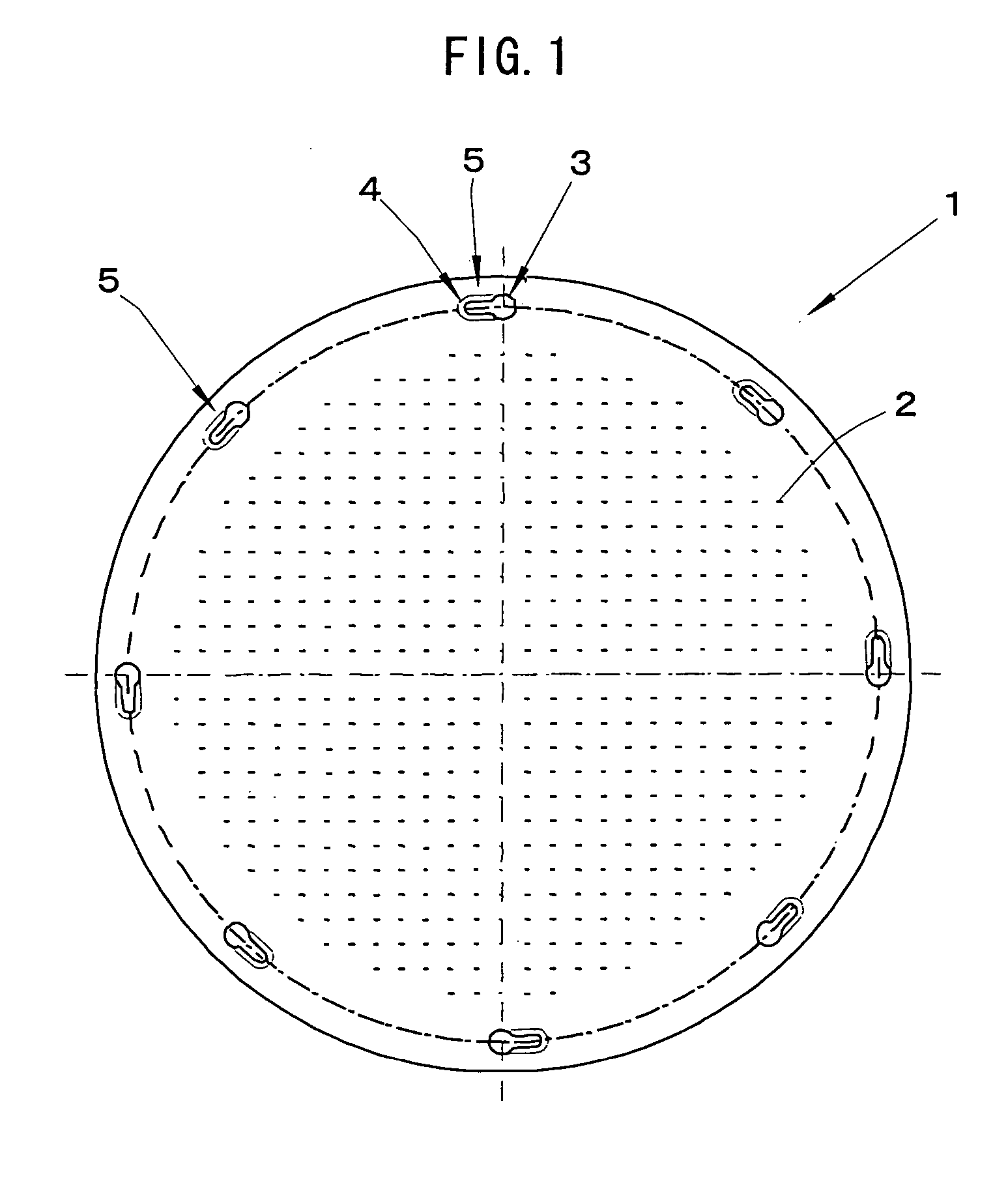

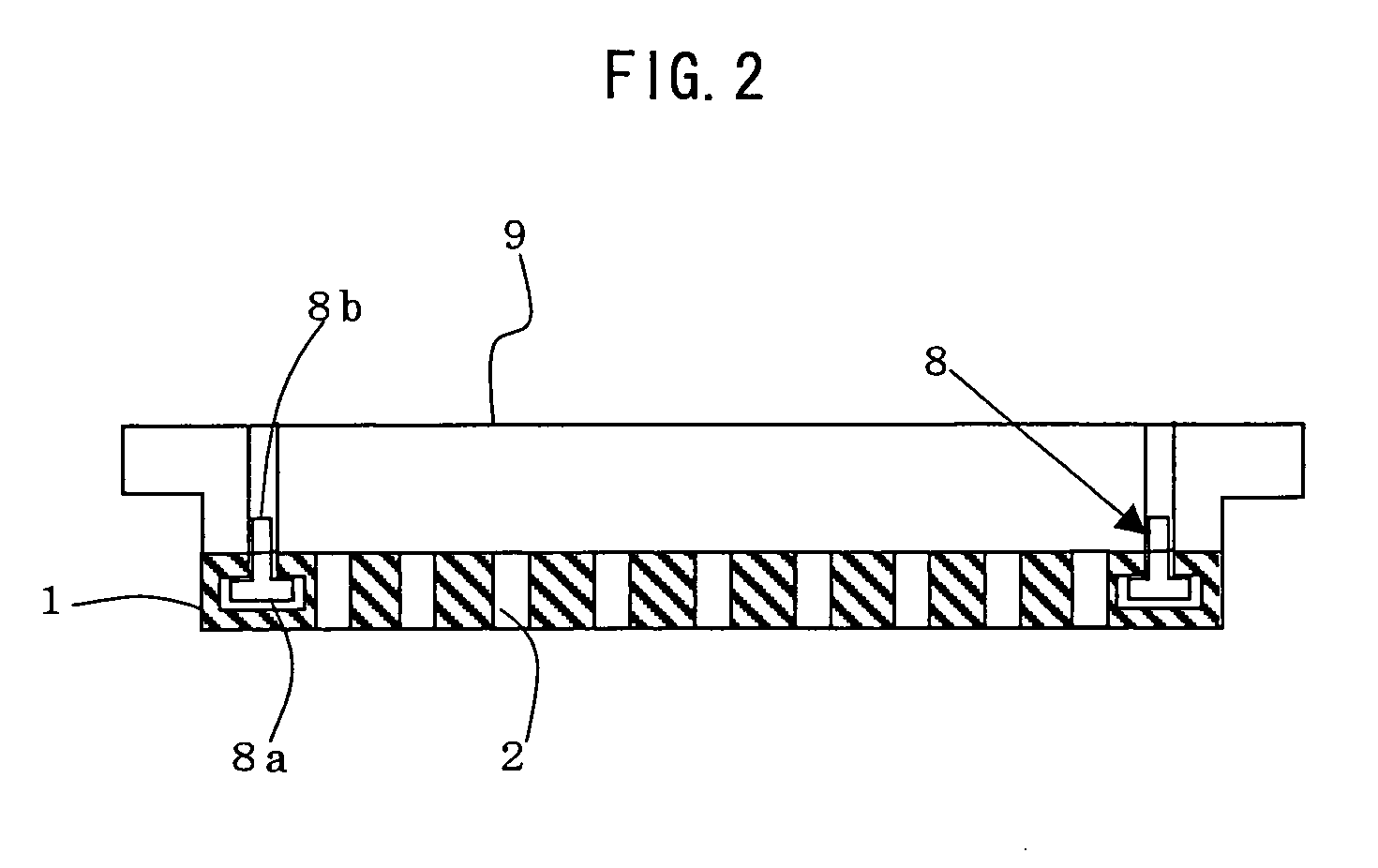

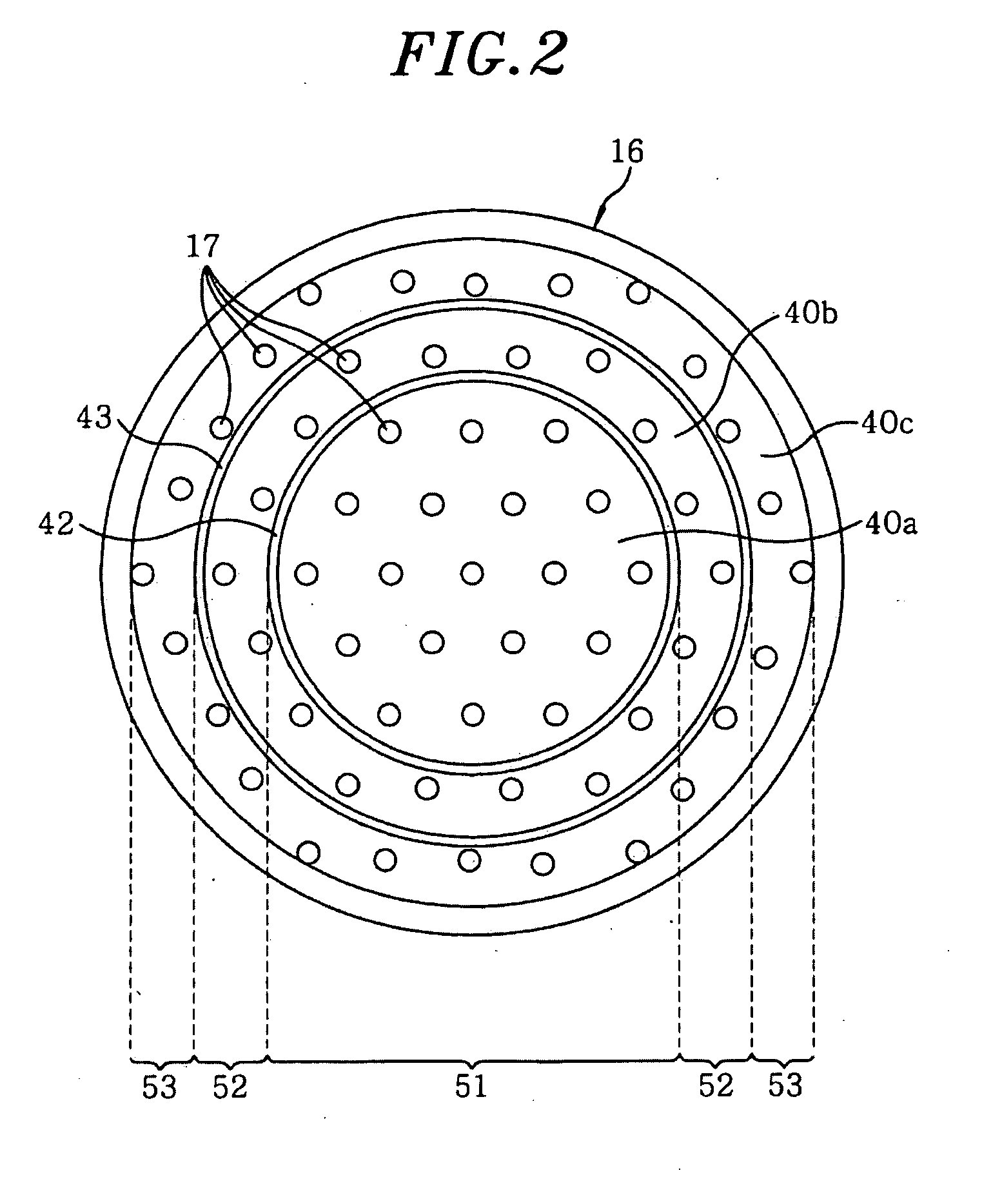

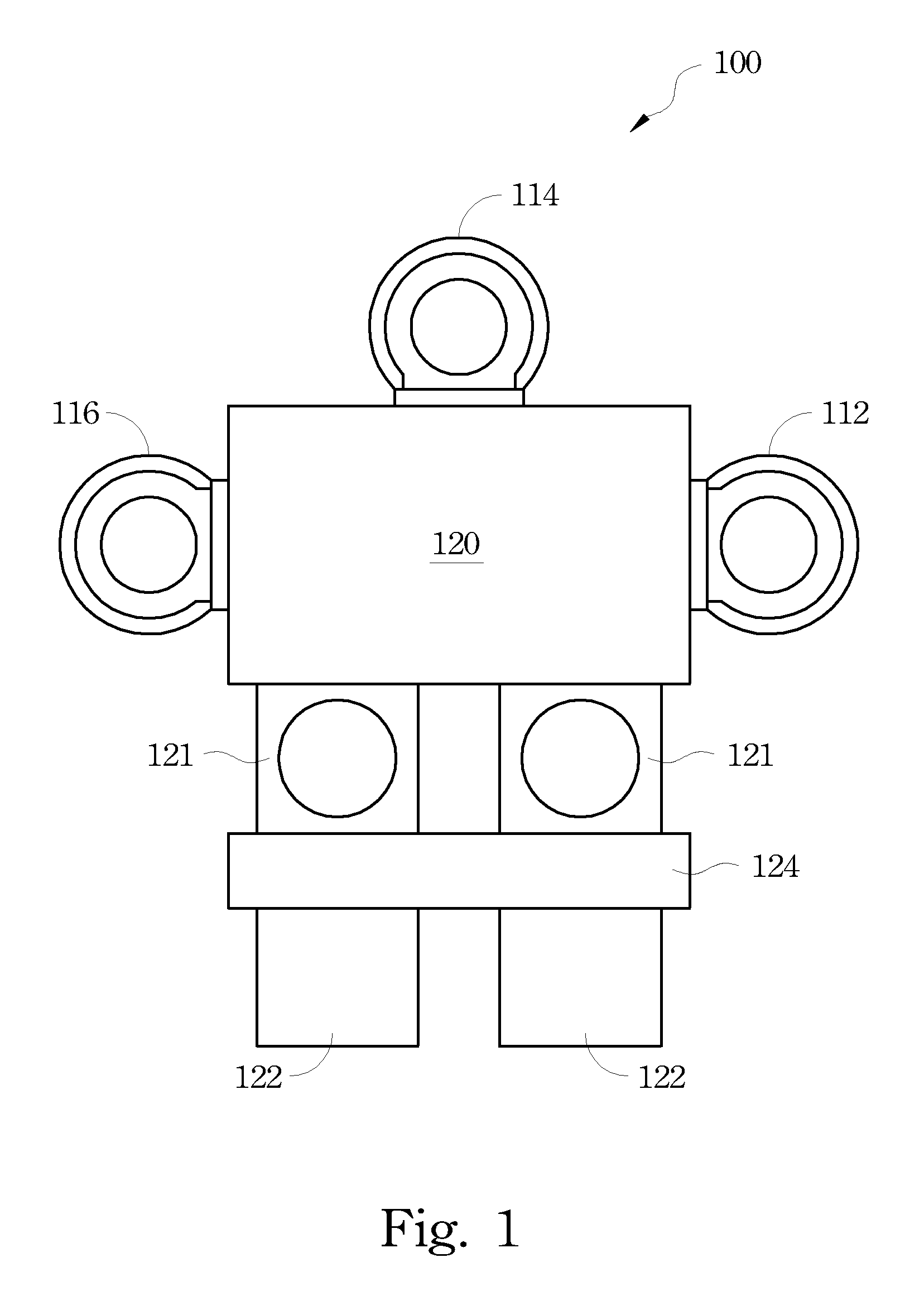

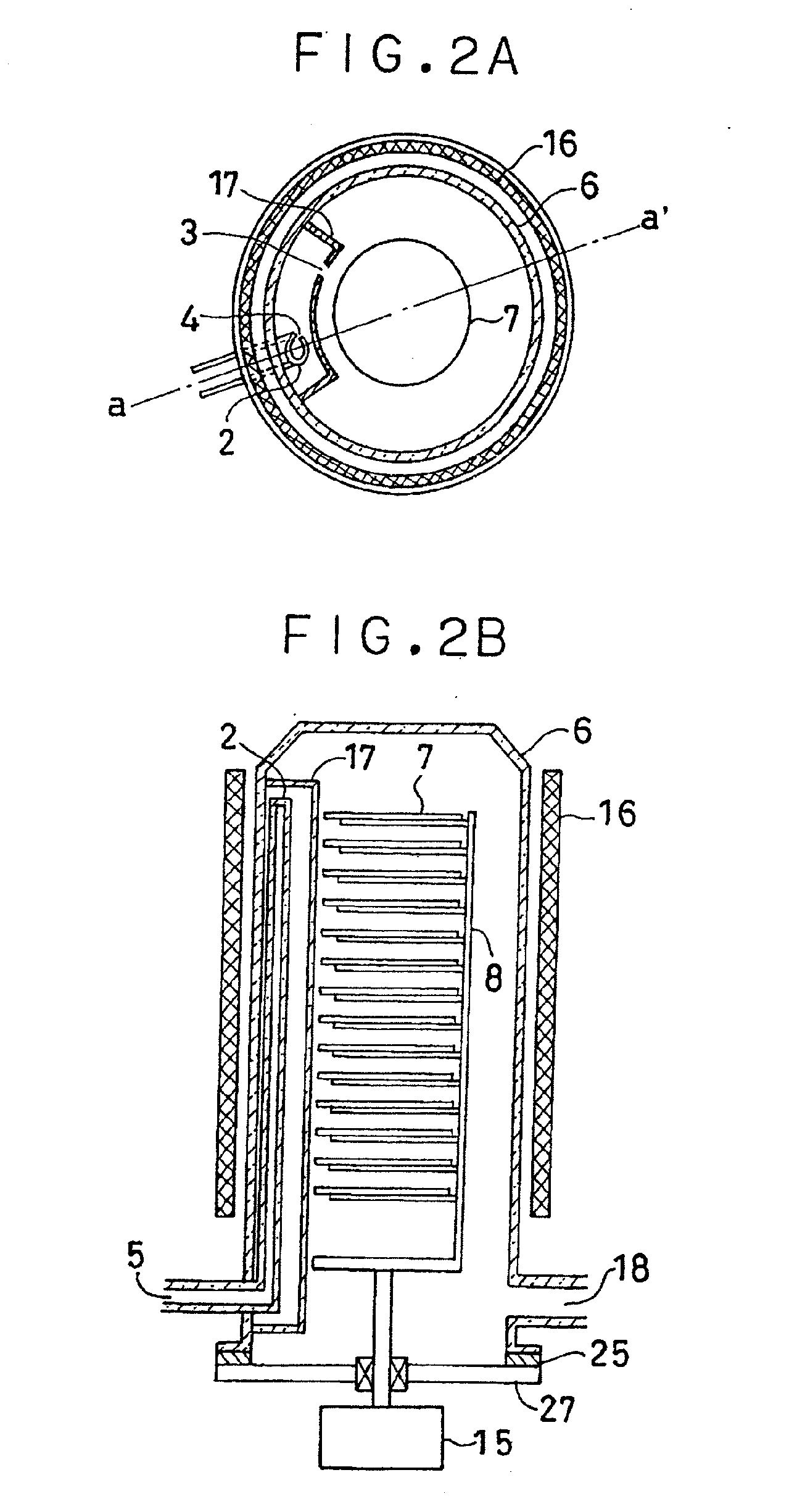

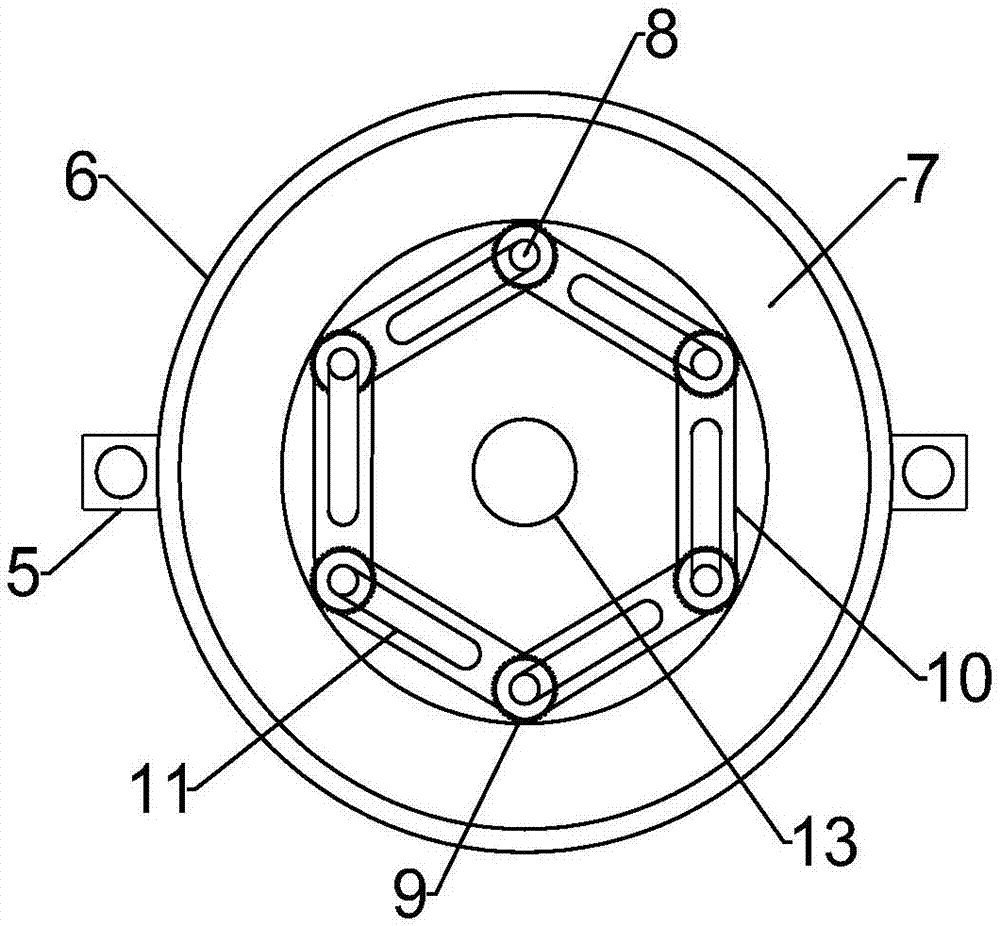

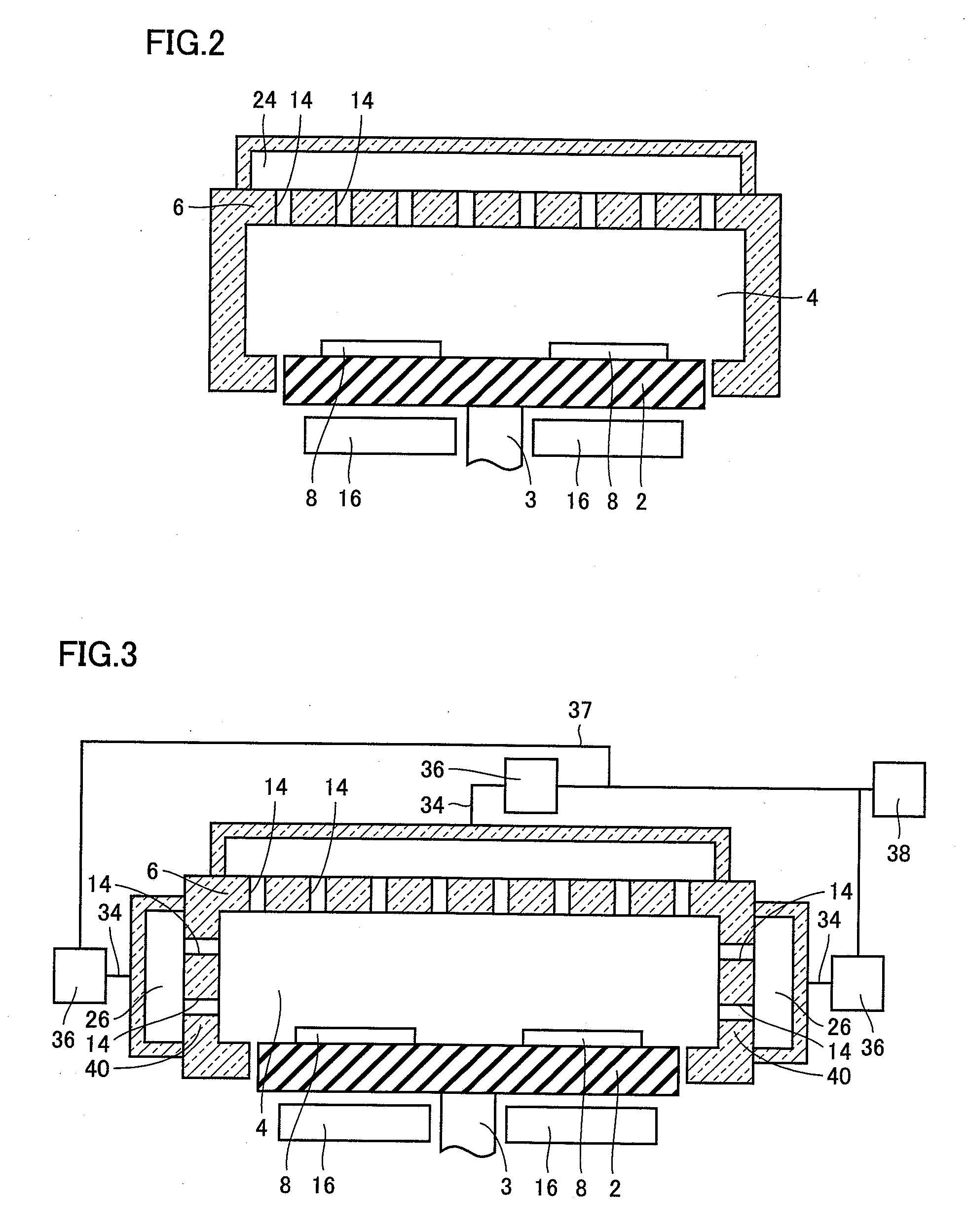

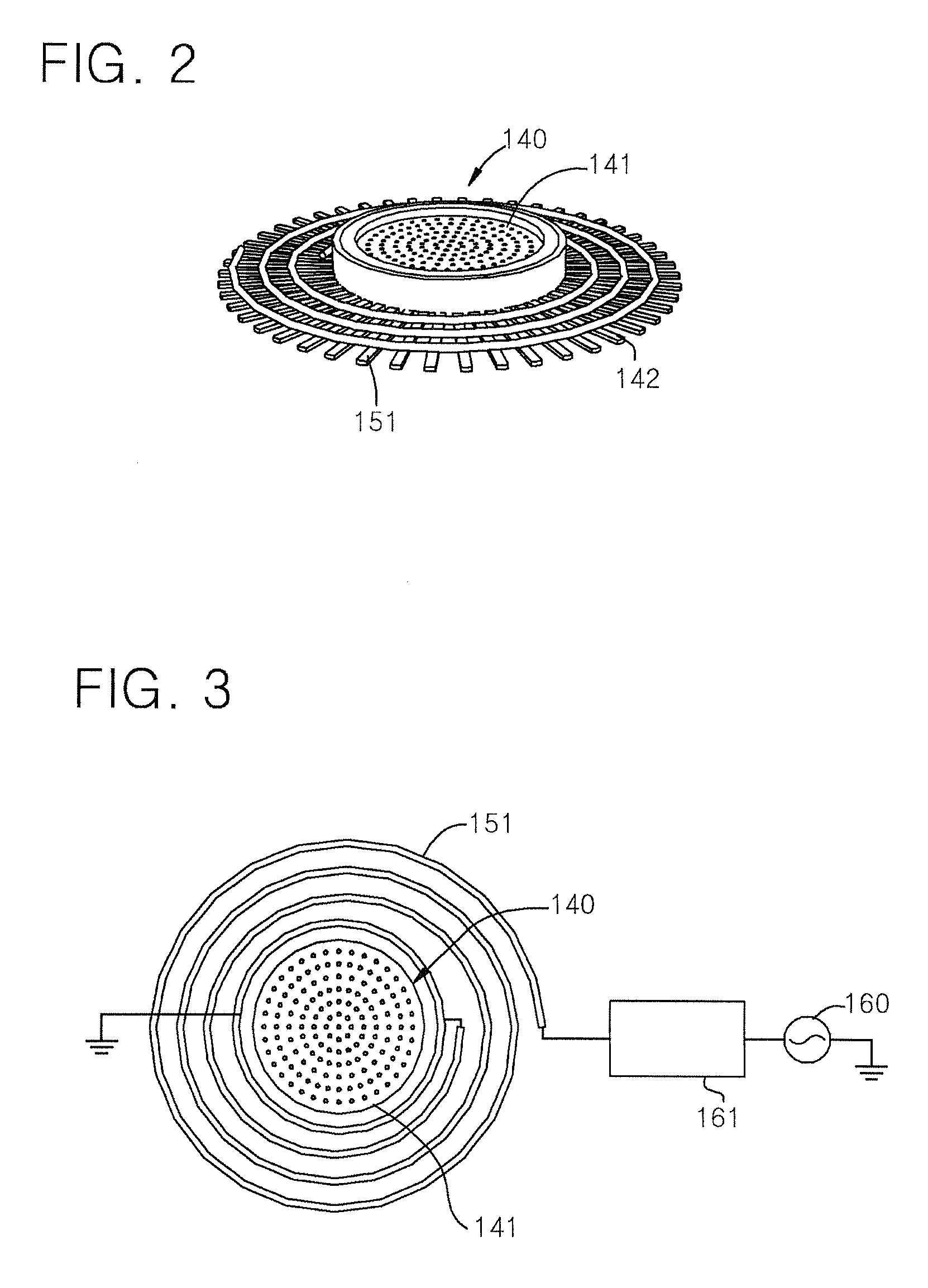

Shower plate for plasma processing apparatus and plasma processing apparatus

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

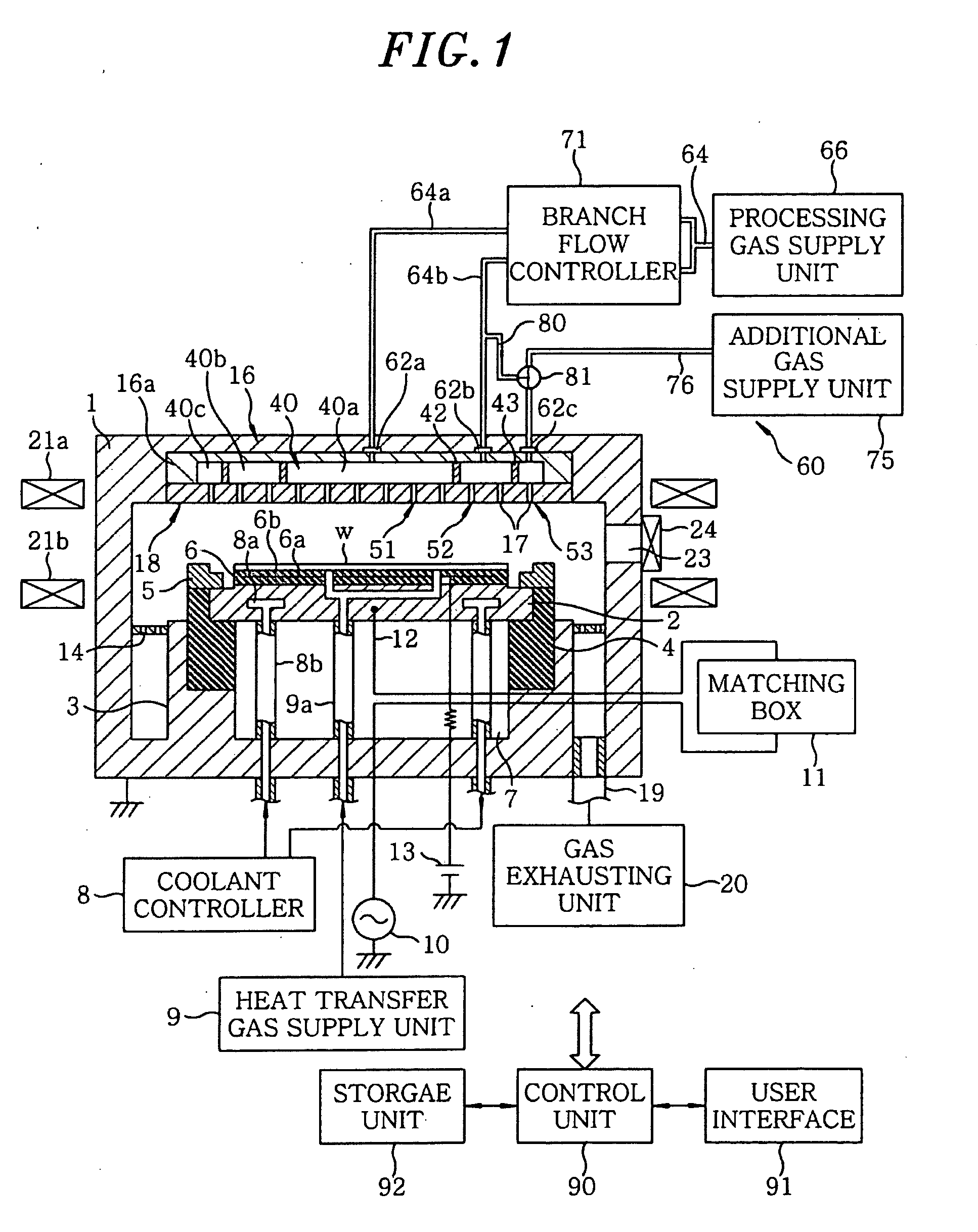

Gas supply device, substrate processing apparatus and substrate processing method

ActiveUS20090117746A1Effective correctionEfficiency optimizationLiquid surface applicatorsSemiconductor/solid-state device manufacturingGas passingProcess engineering

A gas supply mechanism includes a gas introduction member having gas inlet portions through which a gas is introduced into a processing chamber, a processing gas supply unit, a processing gas supply path, branch paths, an additional gas supply unit and an additional gas supply path. The gas inlet portions includes inner gas inlet portions for supplying the gas toward a region where a target substrate is positioned in the chamber and an outer gas inlet portion for introducing the gas toward a region outside an outermost periphery of the target substrate. The branch paths are connected to the inner gas inlet portions, and the additional gas supply path is connected to the outer gas inlet portion.

Owner:TOKYO ELECTRON LTD

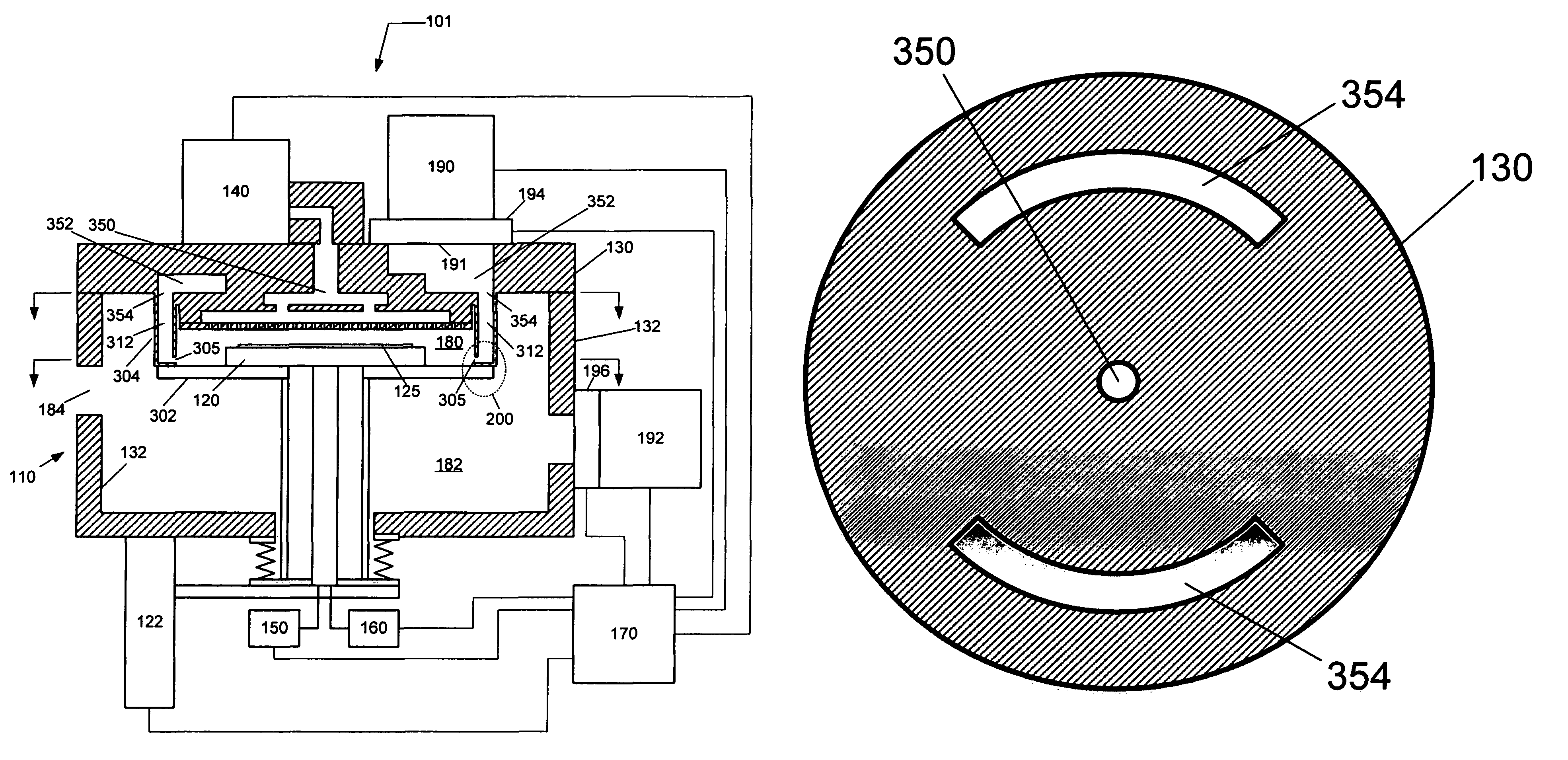

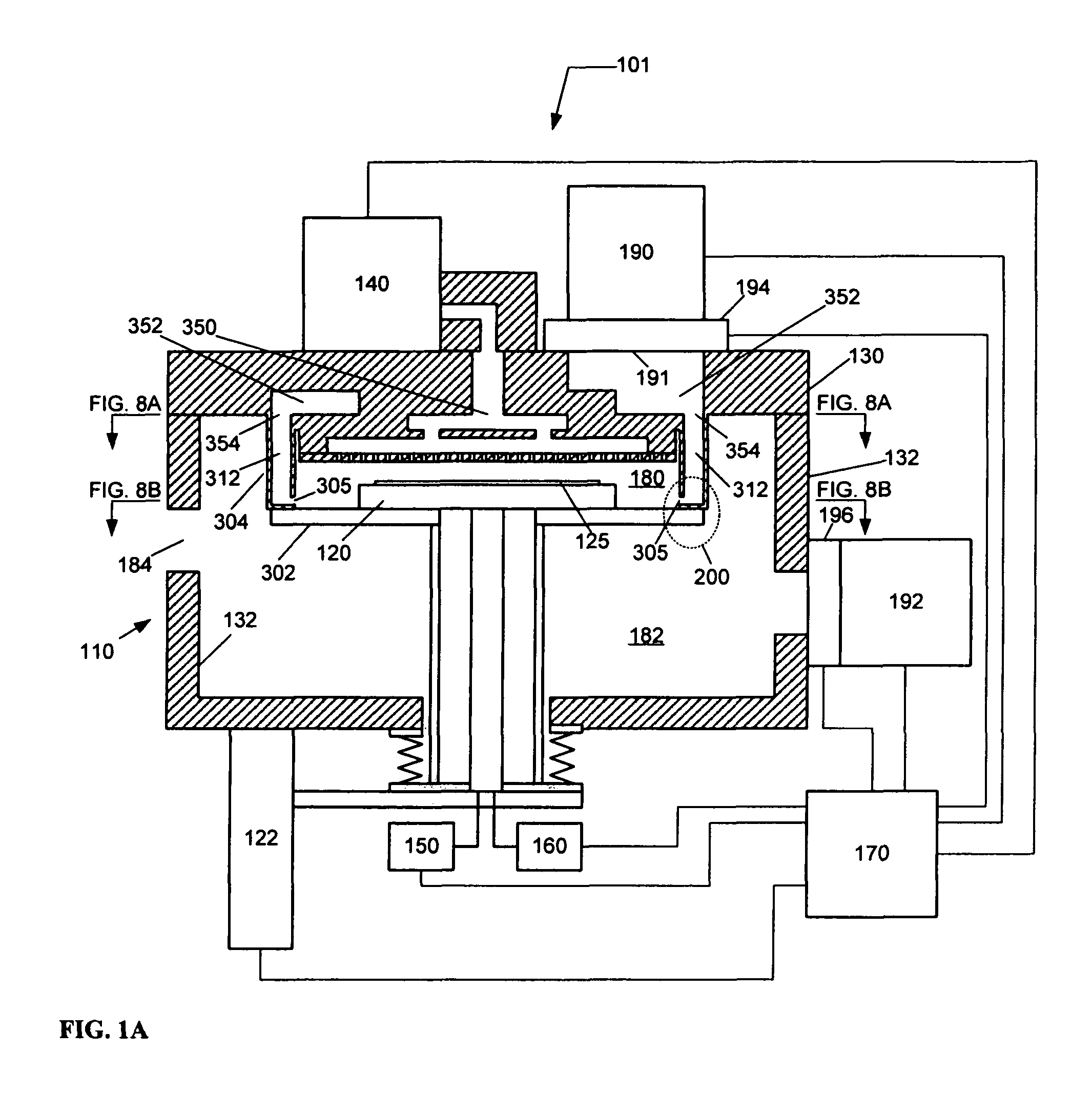

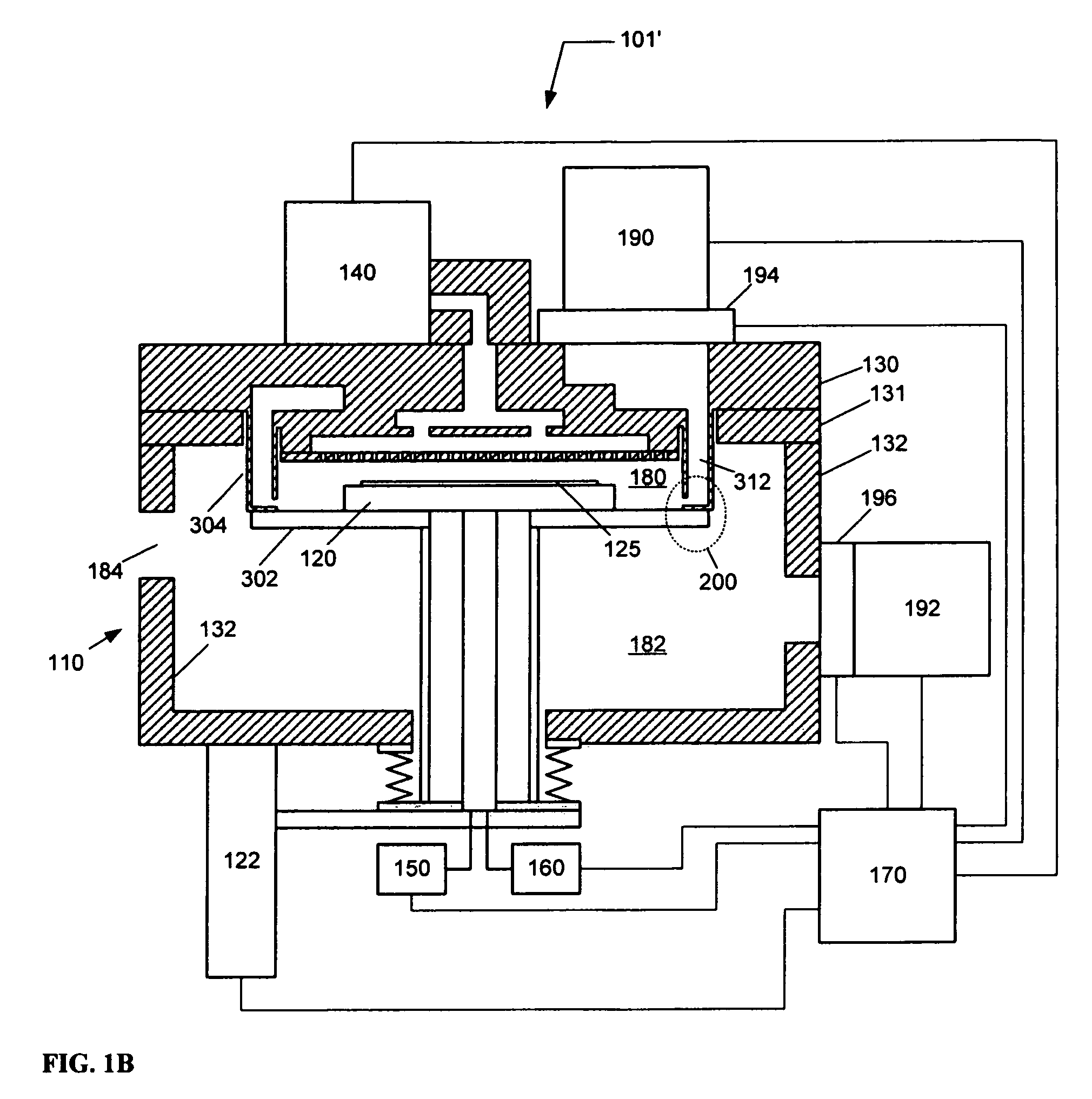

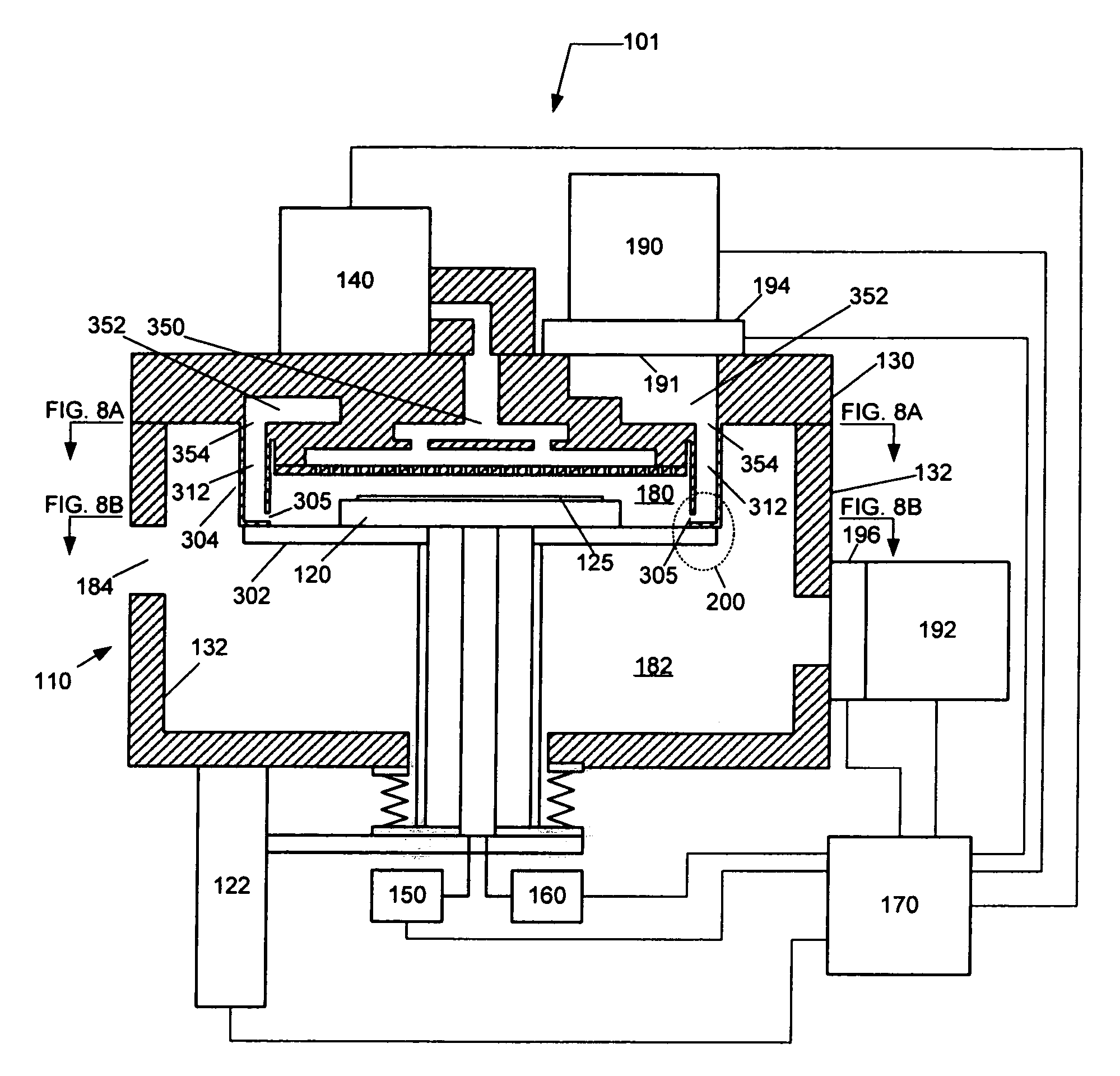

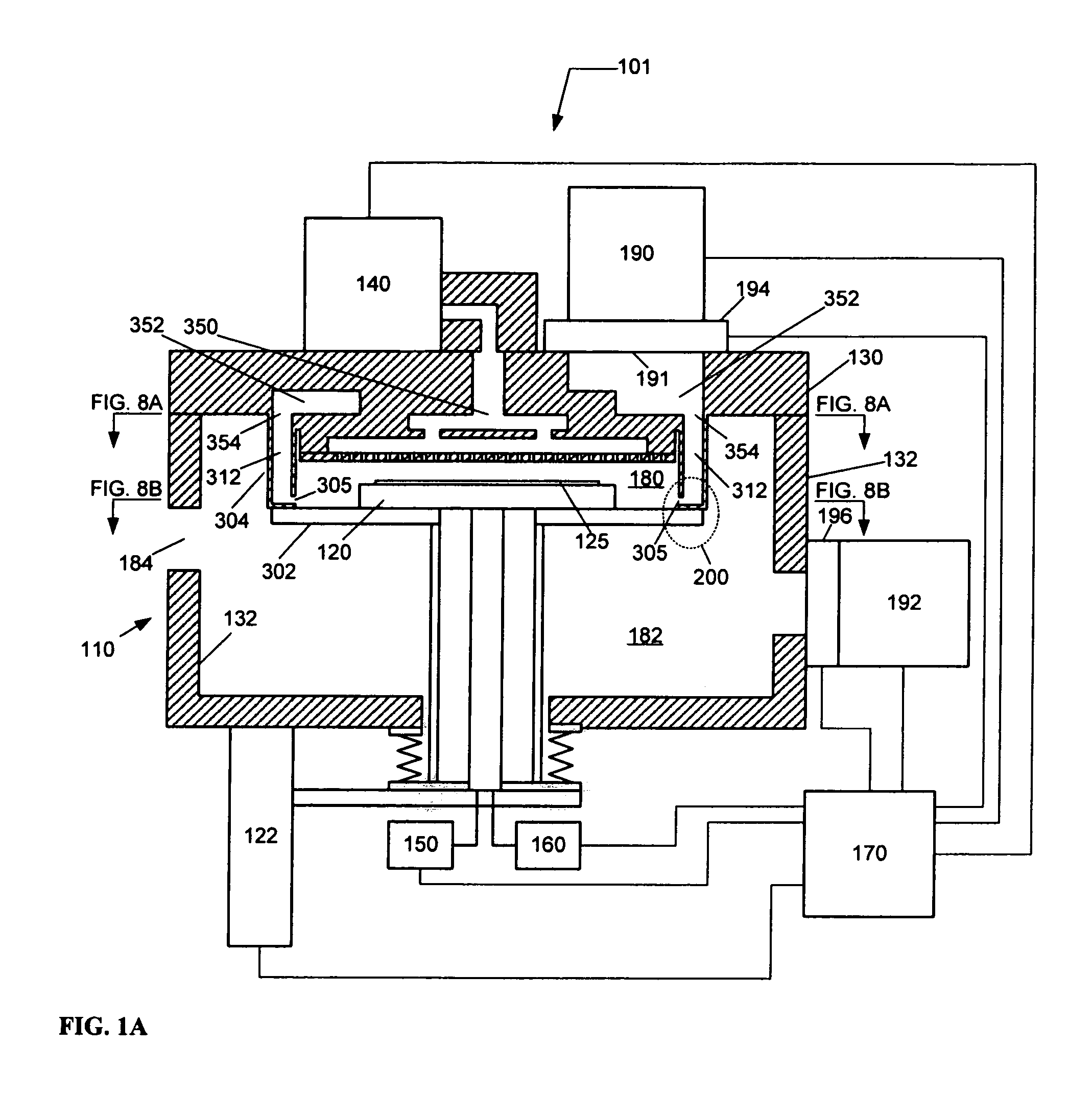

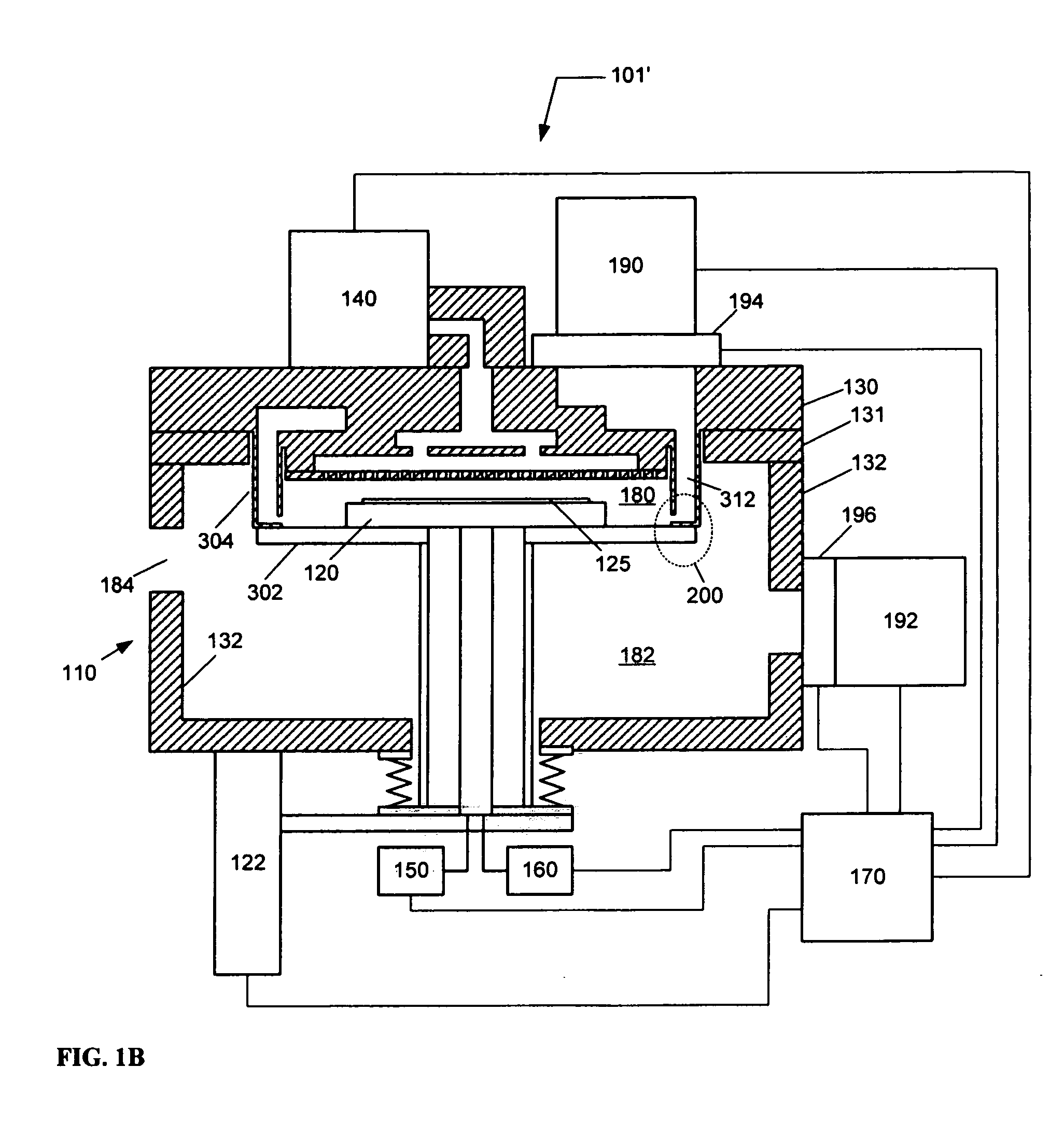

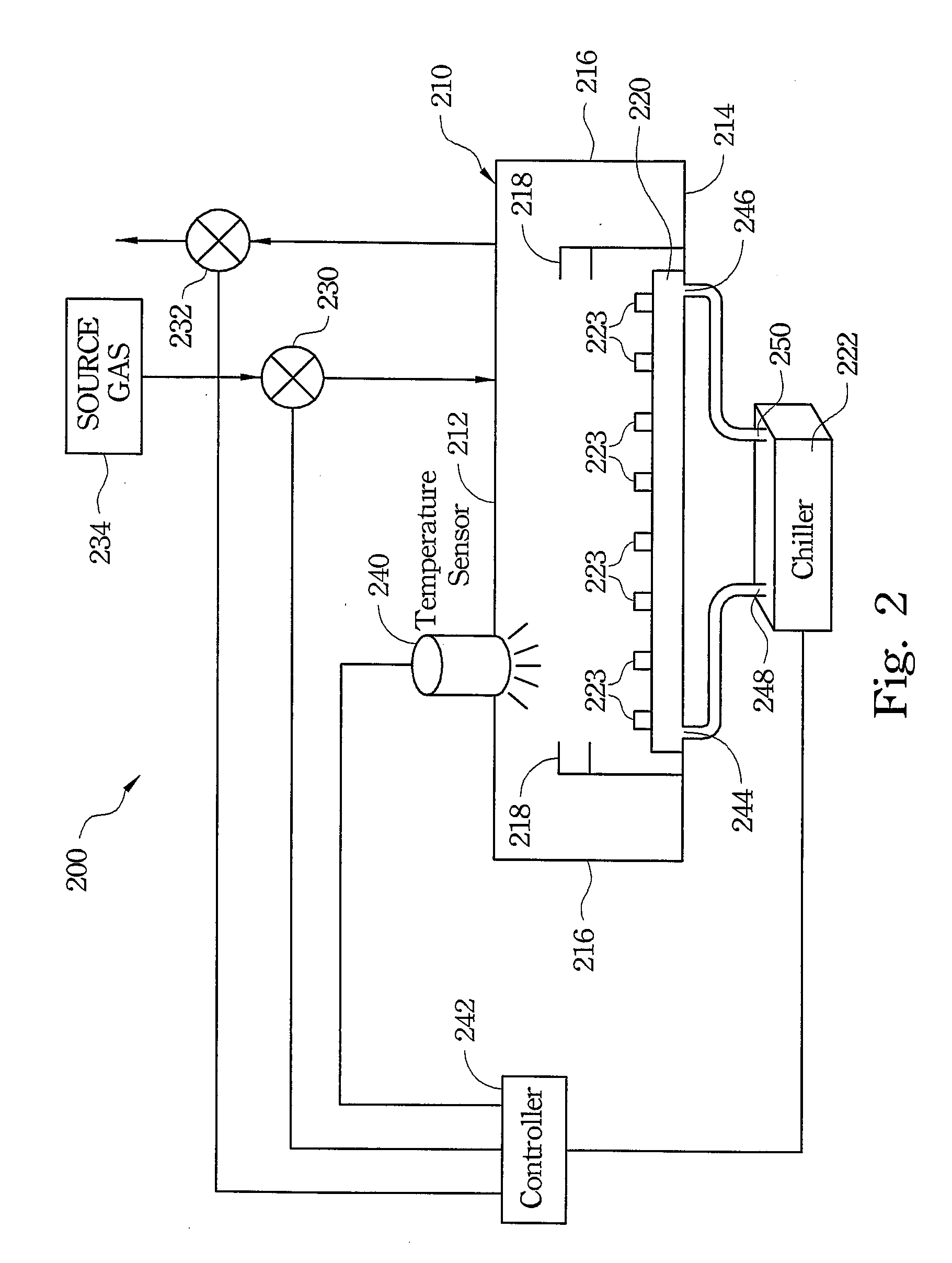

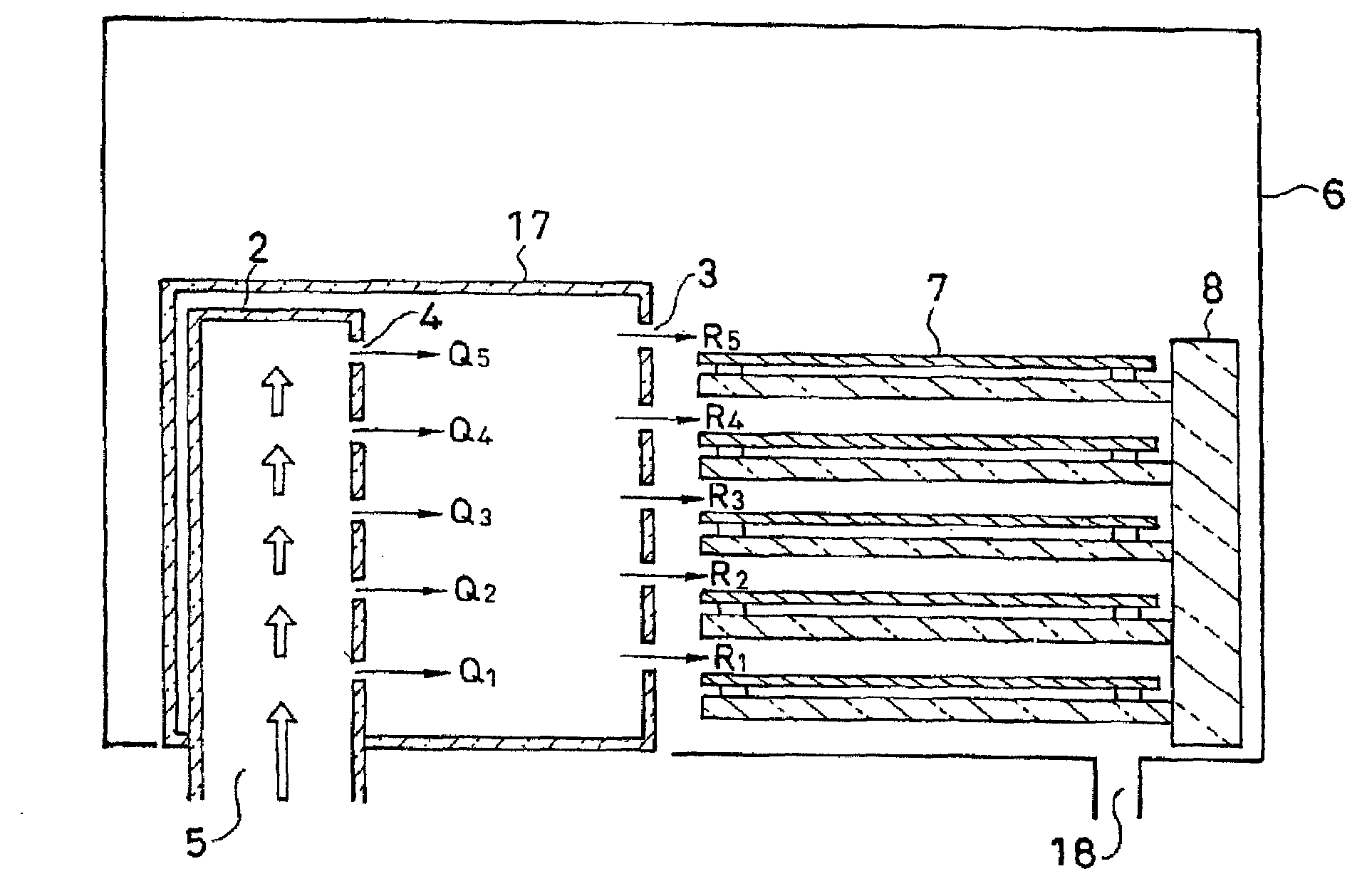

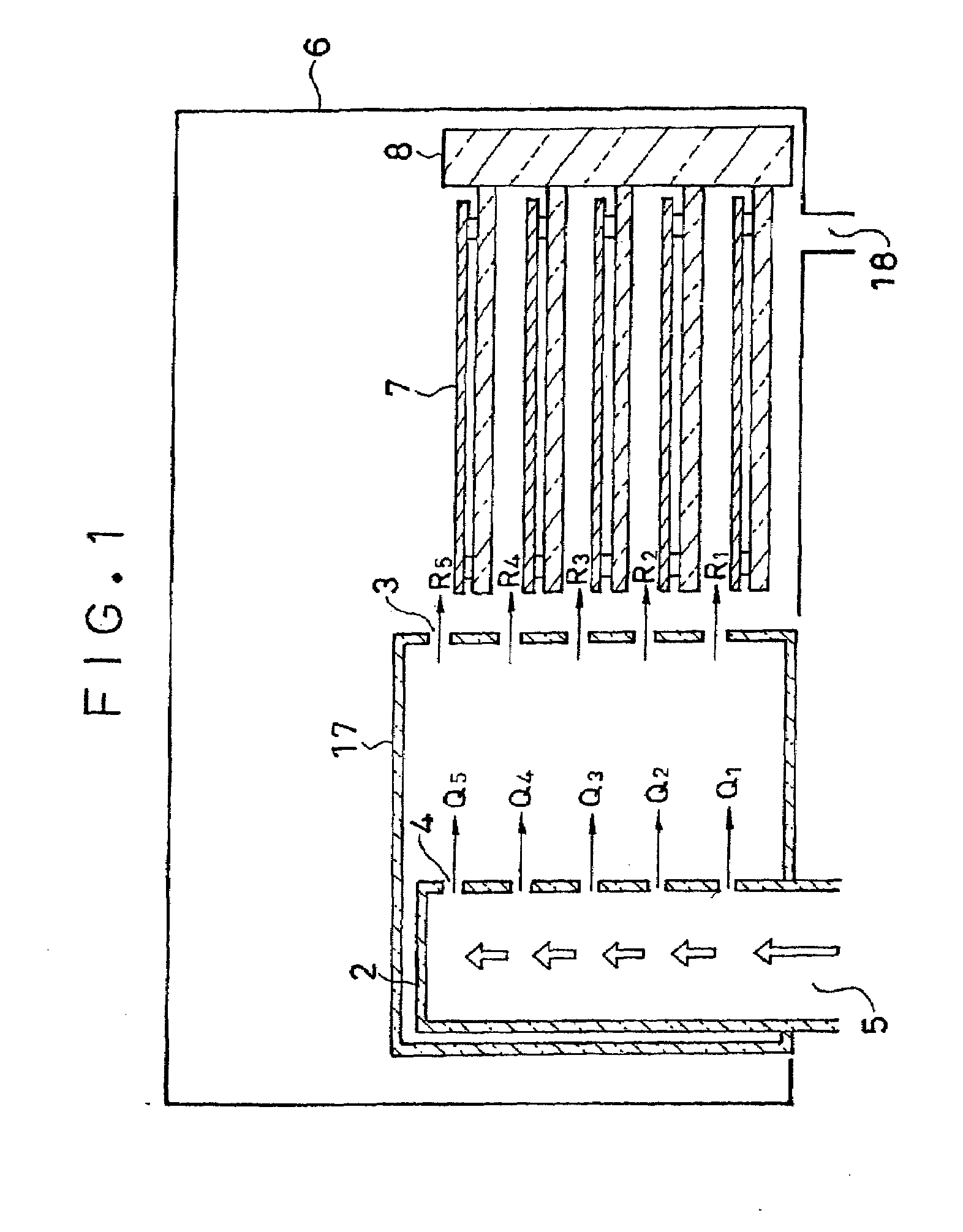

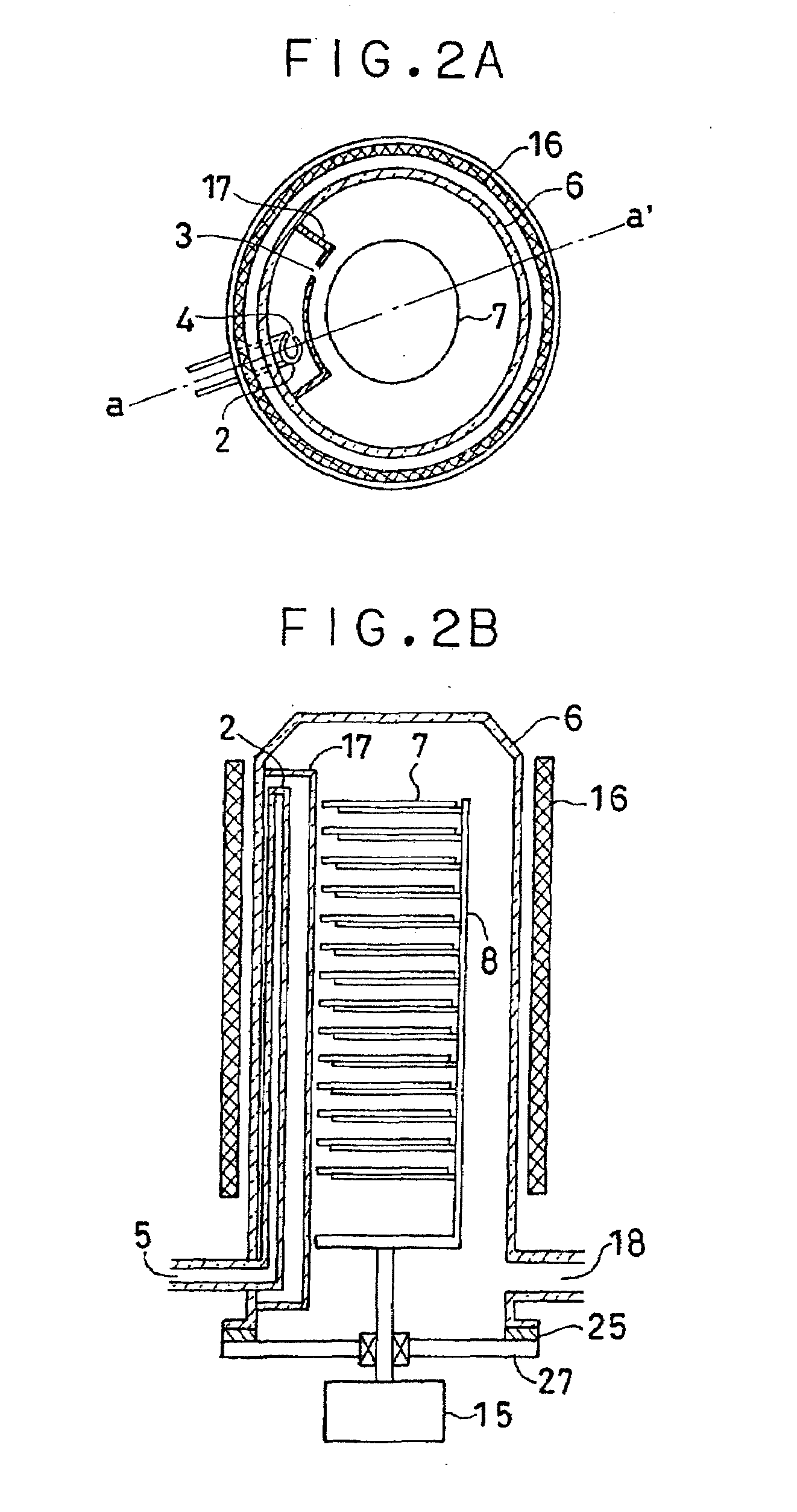

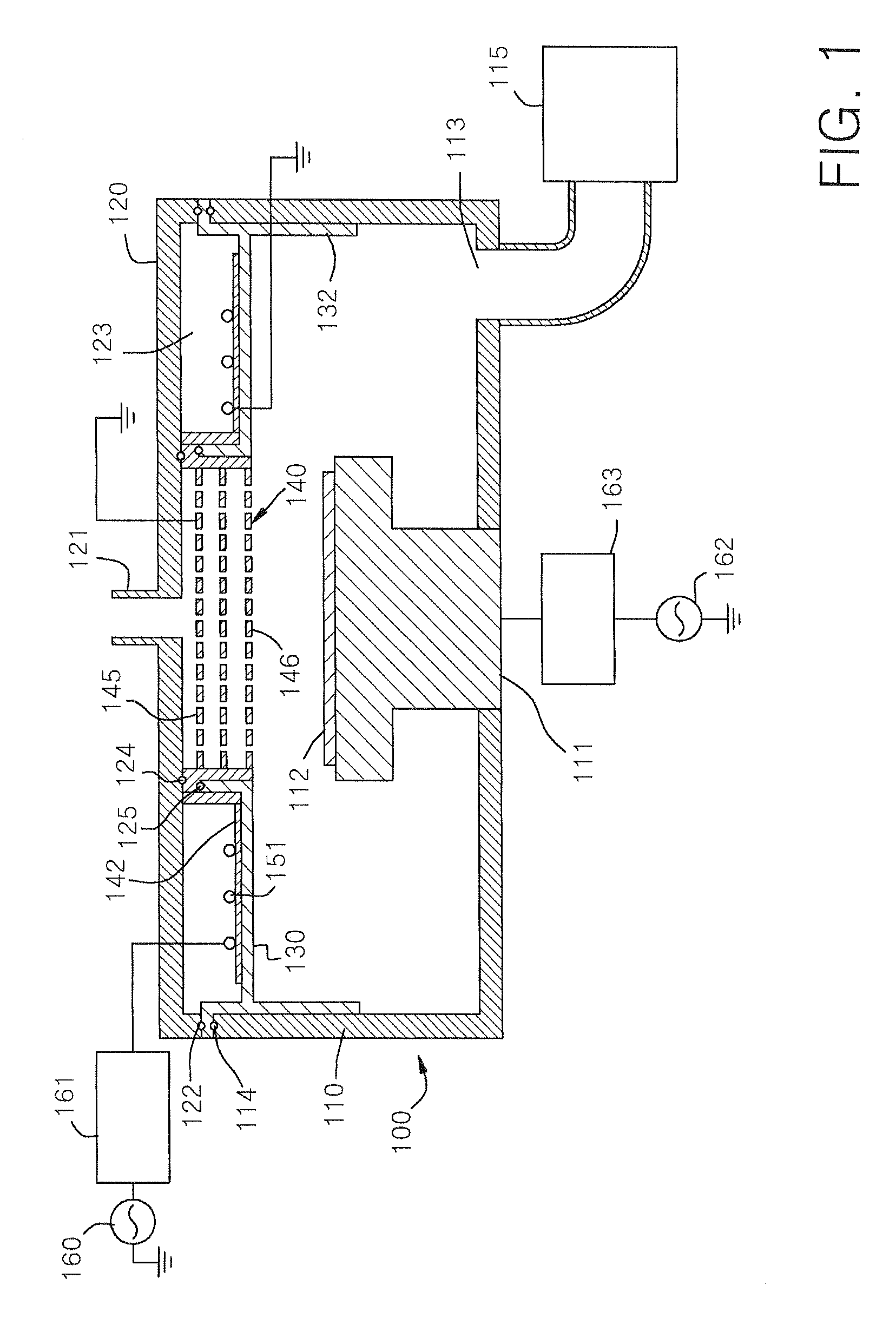

Exhaust apparatus configured to reduce particle contamination in a deposition system

InactiveUS20070212484A1Reduce pollutionUniform processingPretreated surfacesSemiconductor/solid-state device manufacturingGas phaseEngineering

A method and system for vapor deposition on a substrate that disposes a substrate in a process space of a processing system that is isolated from a transfer space of the processing system, processes the substrate at either of a first position or a second position in the process space while maintaining isolation from the transfer space, and deposits a material on said substrate at either the first position or the second position. Furthermore, the system includes a high conductance exhaust apparatus configured to be coupled to the process space, whereby particle contamination of the substrate processed in the deposition system is minimized. The exhaust apparatus comprises a pumping system located above the substrate and an evacuation duct, wherein the evacuation duct has an inlet located below the substrate plane.

Owner:TOKYO ELECTRON LTD

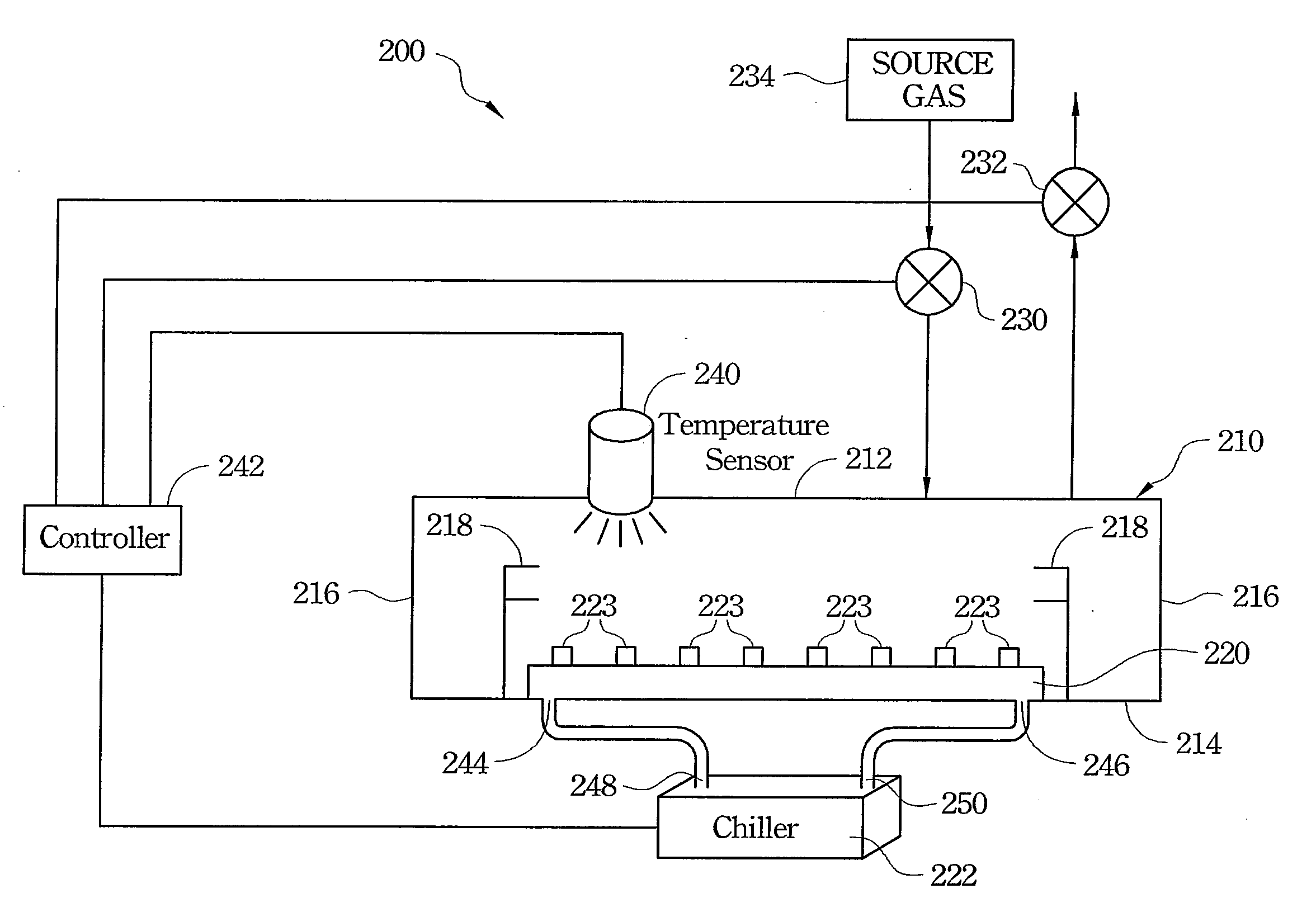

Temperature Controlled Loadlock Chamber

ActiveUS20090000769A1Uniform temperatureUniform processingTemperatue controlSemiconductor/solid-state device manufacturingEngineeringStreamflow

A temperature controlled loadlock chamber for use in semiconductor processing is provided. The temperature controlled loadlock chamber may include one or more of an adjustable fluid pump, mass flow controller, one or more temperature sensors, and a controller. The adjustable fluid pump provides fluid having a predetermined temperature to a temperature-controlled plate. The mass flow controller provides gas flow into the chamber that may also aid in maintaining a desired temperature. Additionally, one or more temperature sensors may be combined with the adjustable fluid pump and / or the mass flow controller to provide feedback and to provide a greater control over the temperature. A controller may be added to control the adjustable fluid pump and the mass flow controller based upon temperature readings from the one or more temperature sensors.

Owner:TAIWAN SEMICON MFG CO LTD

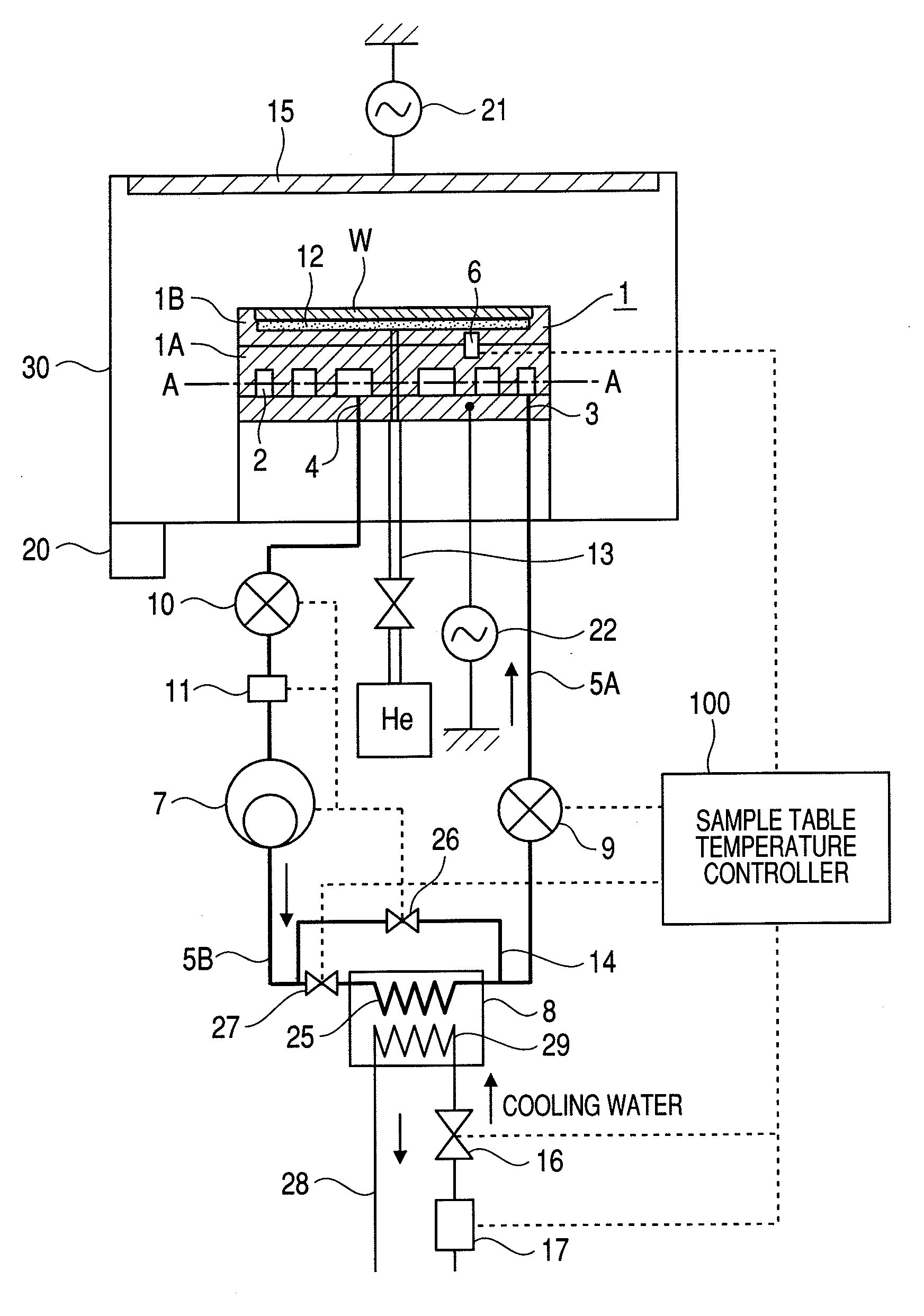

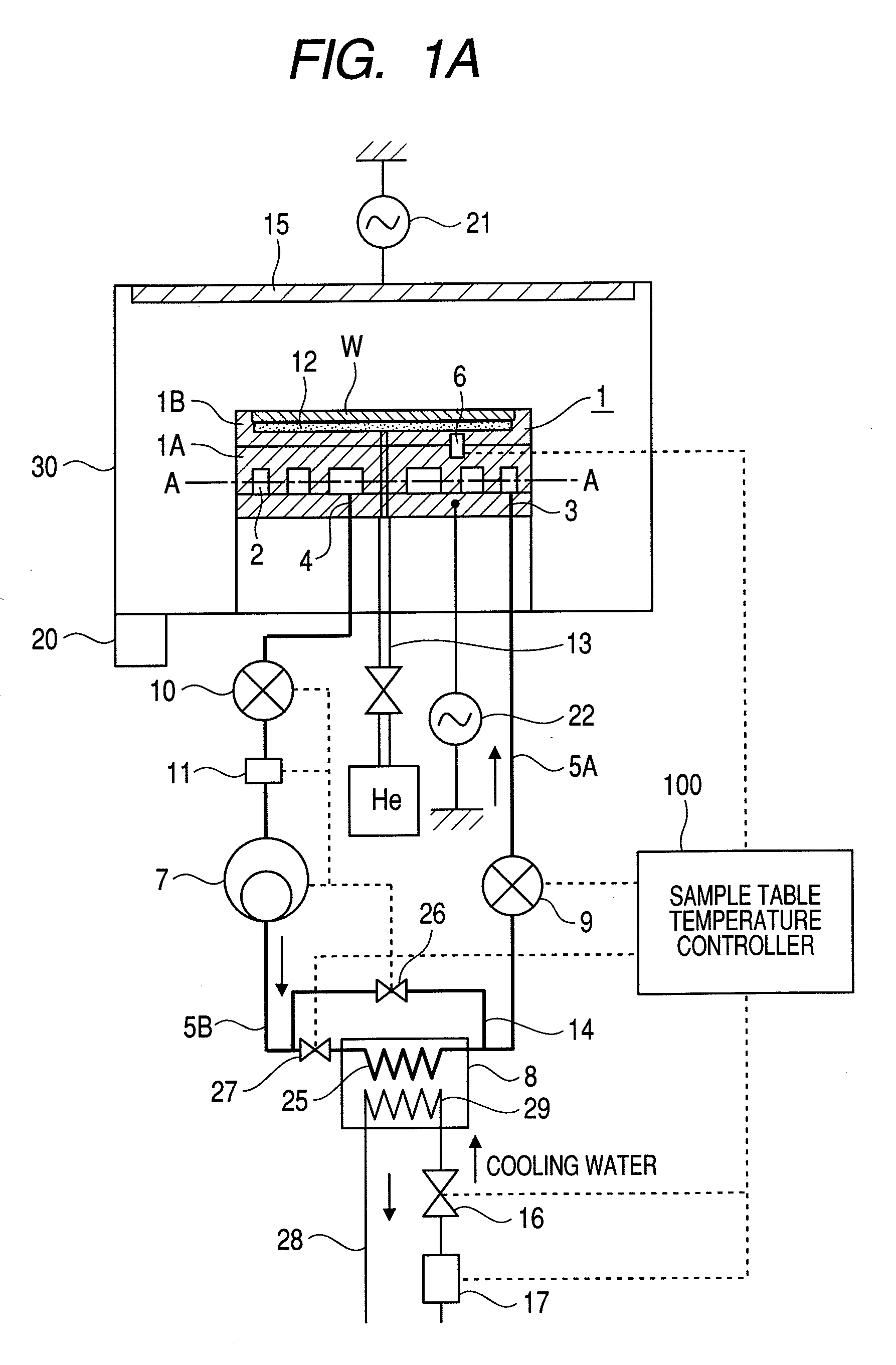

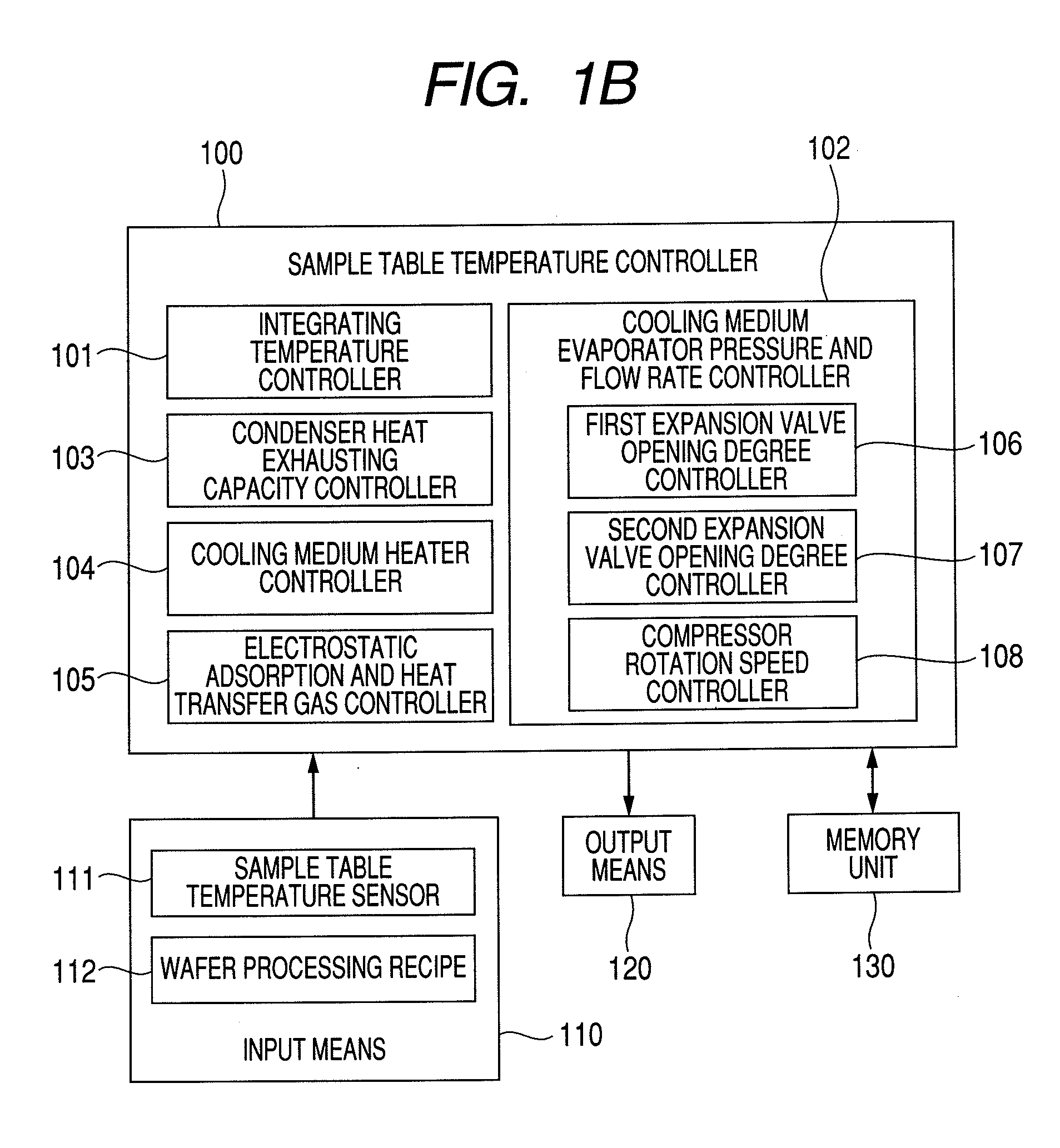

Plasma processing apparatus

InactiveUS20100126666A1Uniform processingUnified controlElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeEngineering

In a plasma processing apparatus; a refrigerant flow passage being formed in the sample table and constituting an evaporator of a cooling cycle and the in-plane temperature of the sample to be processed is controlled uniformly by controlling the enthalpy of the refrigerant supplied to the refrigerant flow passage and thereby keeping the flow mode in the refrigerant flow passage, namely in the sample table, in the state of a gas-liquid two-phase. If by any chance dry out of the refrigerant occurs in the refrigerant flow passage because the heat input of plasma increases with time or by another reason, it is possible to increase speed of a compressor and inhibit the dry out from occurring in the refrigerant flow passage. Further, if the refrigerant supplied to the refrigerant flow passage is liquefied, it is kept in the gas-liquid two-phase state.

Owner:HITACHI HIGH-TECH CORP

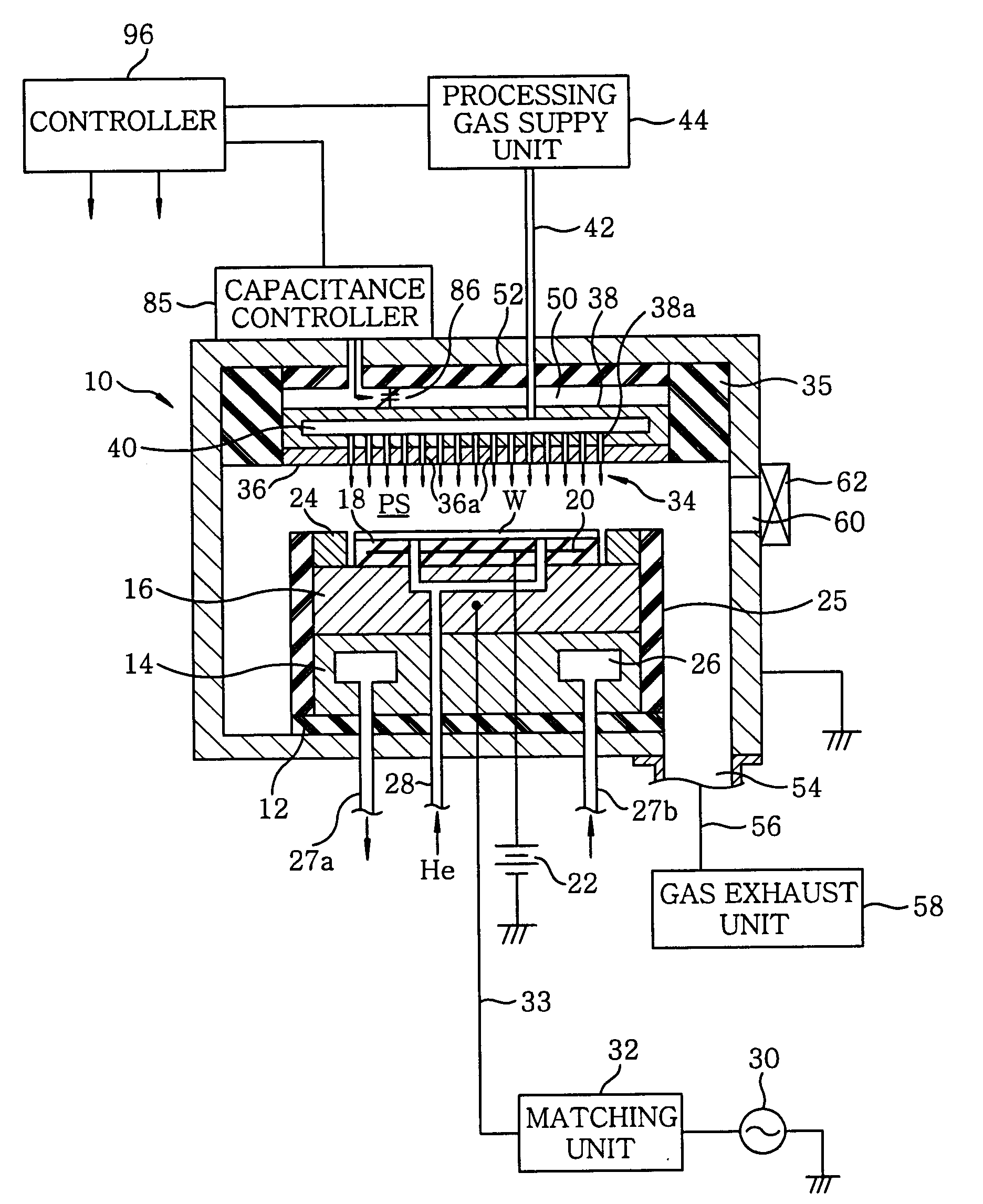

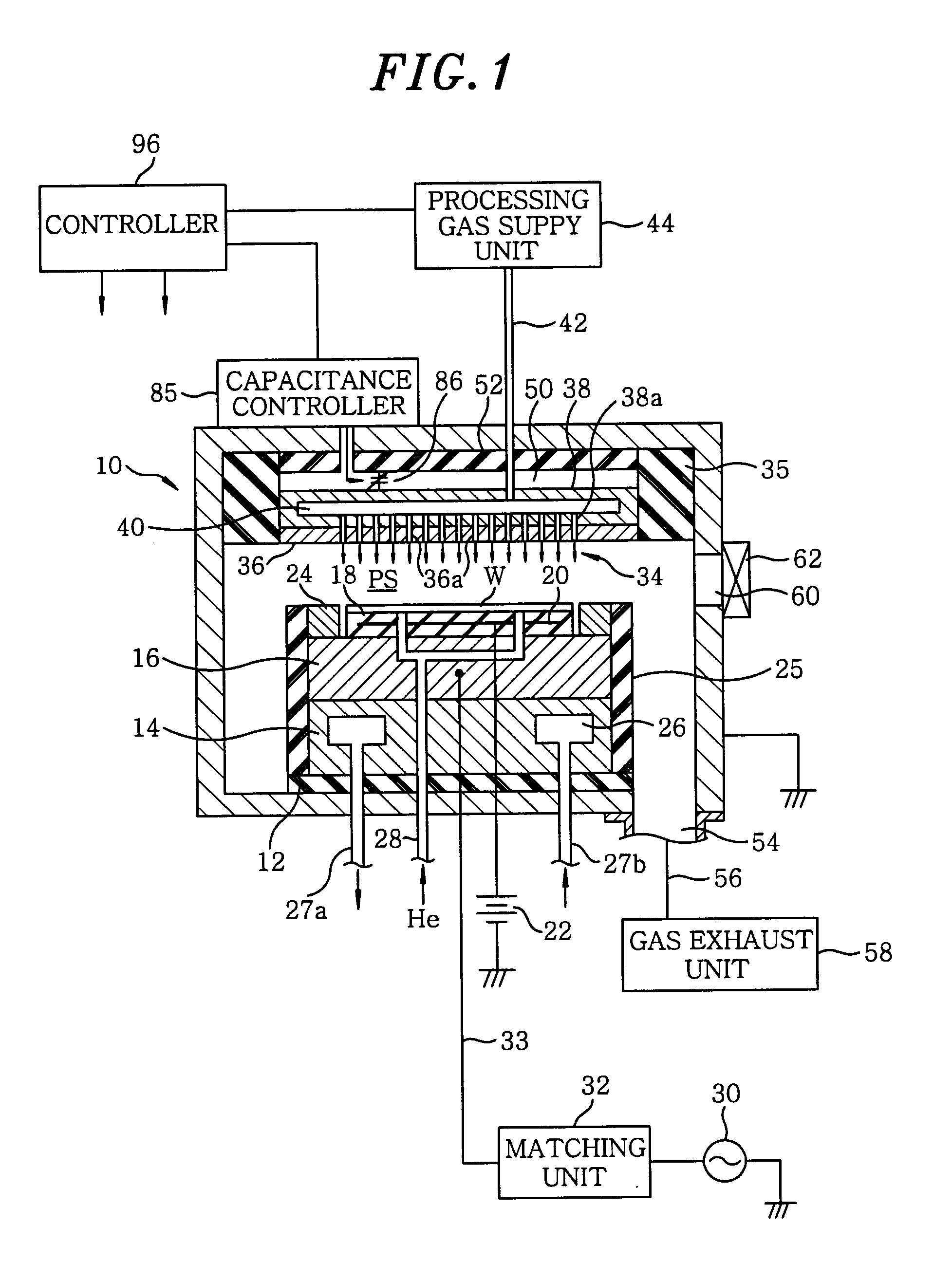

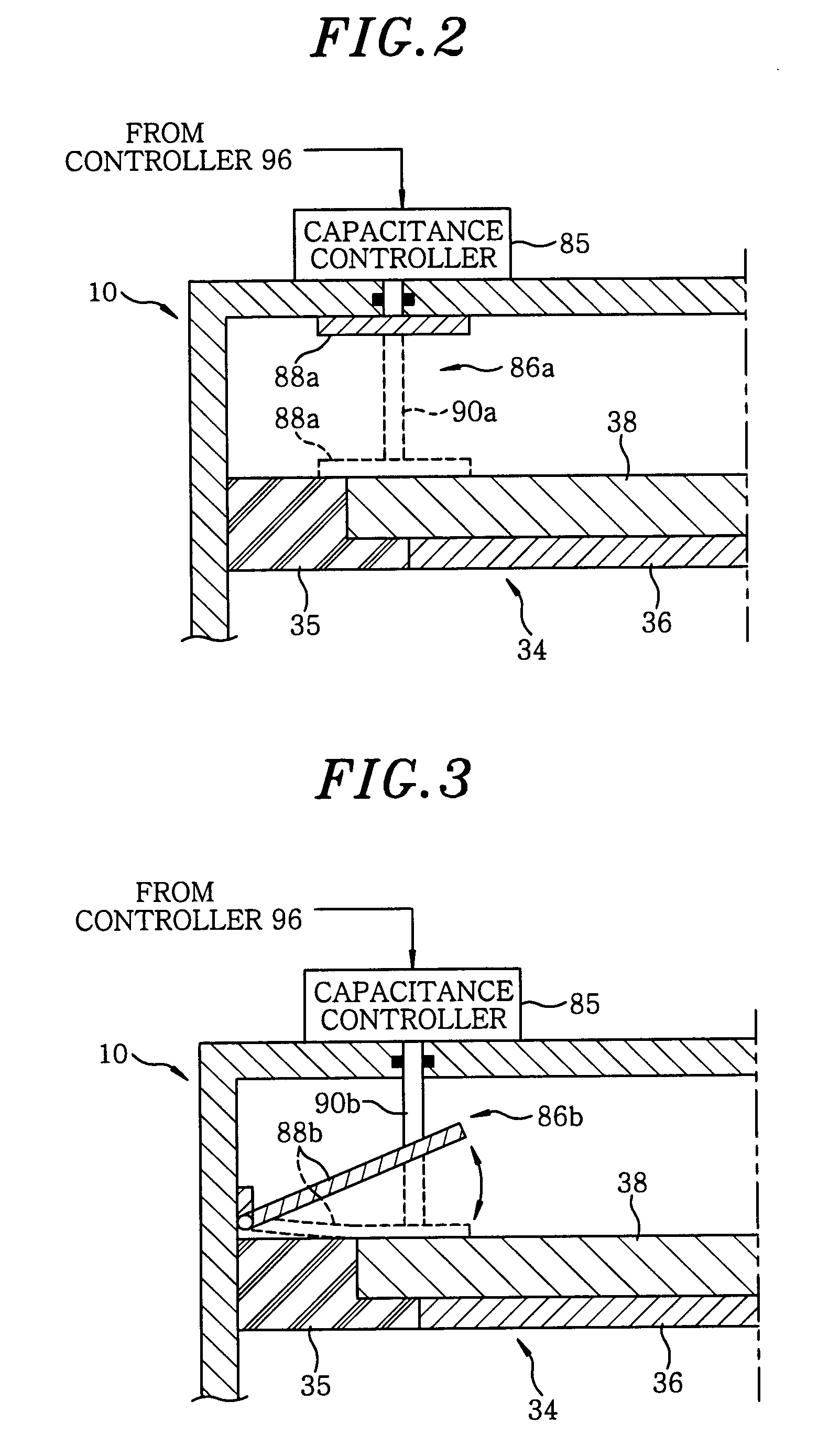

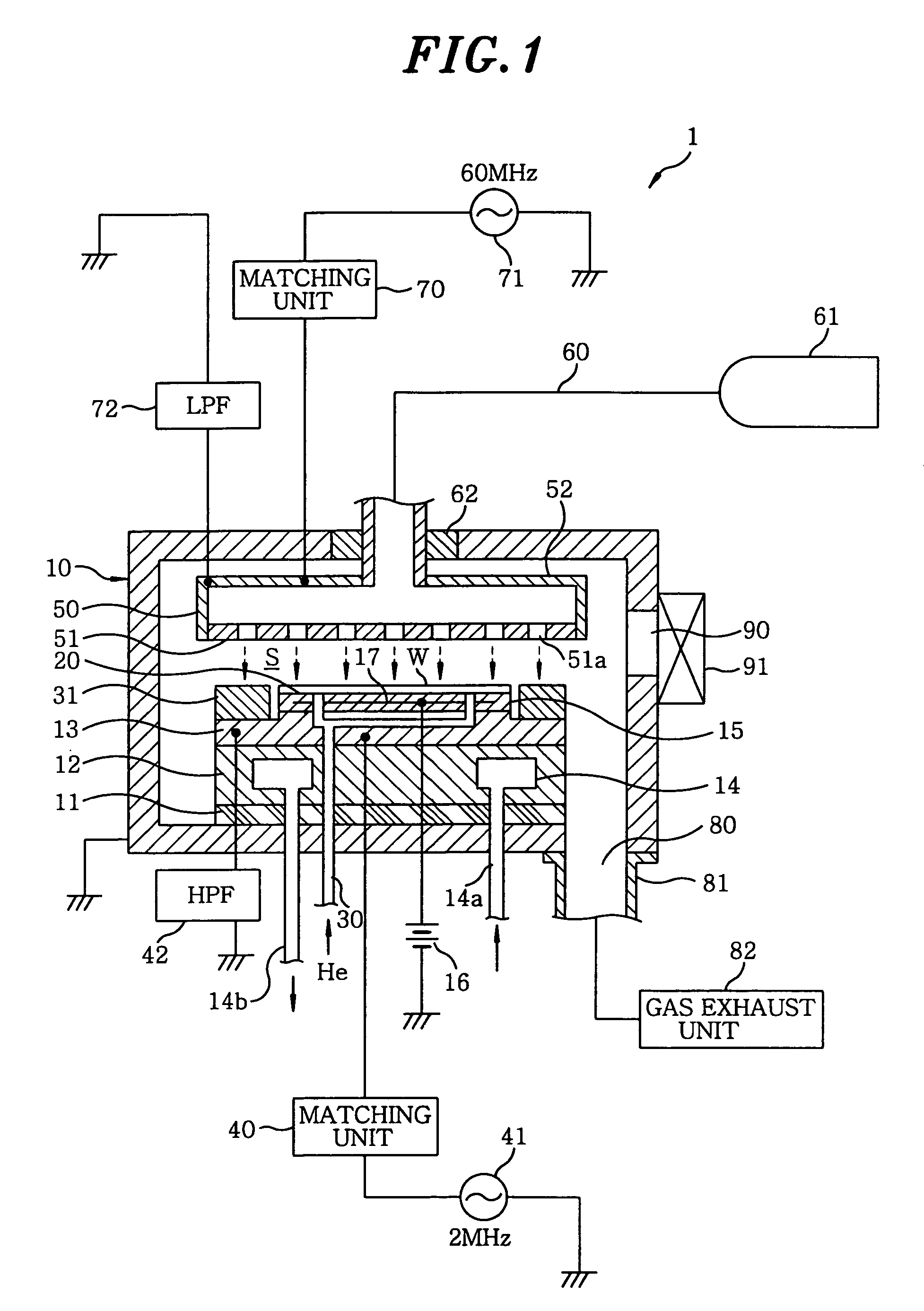

Plasma processing method and plasma processing apparatus

ActiveUS20070227665A1Uniform processingSecuring uniformityLiquid surface applicatorsElectric discharge tubesCapacitanceEngineering

A plasma processing method performs a desired plasma process on substrates by using a plasma generated in a processing space. A first and a second electrode are disposed in parallel in a processing vessel that is grounded, the substrate is supported on the second electrode to face the first electrode, the processing vessel is vacuum evacuated, a desired processing gas is supplied into the processing space formed between the first electrode, the second electrode and a sidewall of the processing vessel, and a first radio frequency power is supplied to the second electrode. The first electrode is connected to the processing vessel via an insulator or a space, and is electrically coupled to a ground potential via a capacitance varying unit whose electrostatic capacitance is varied based on a process condition of the plasma process performed on the substrate.

Owner:TOKYO ELECTRON LTD

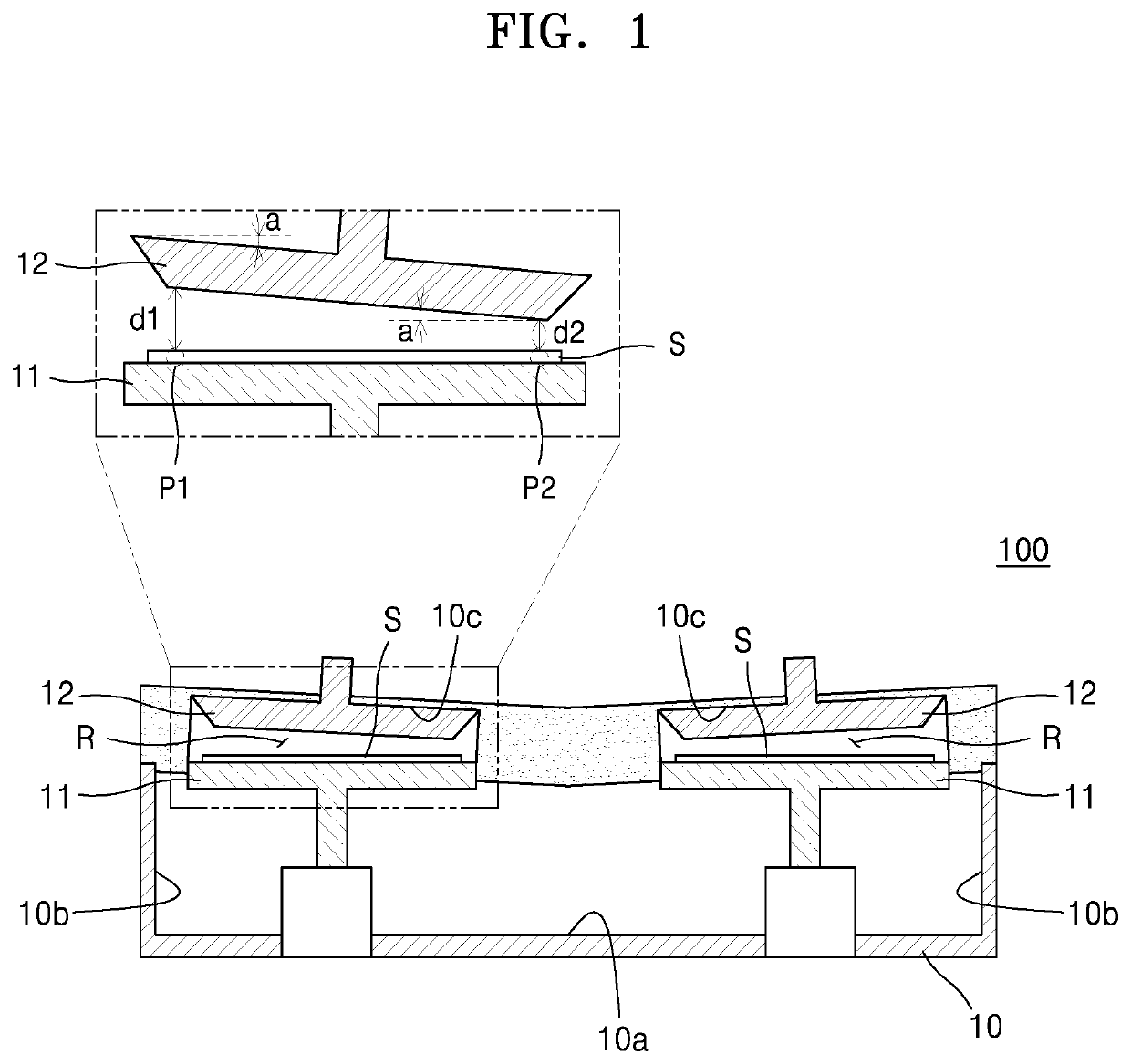

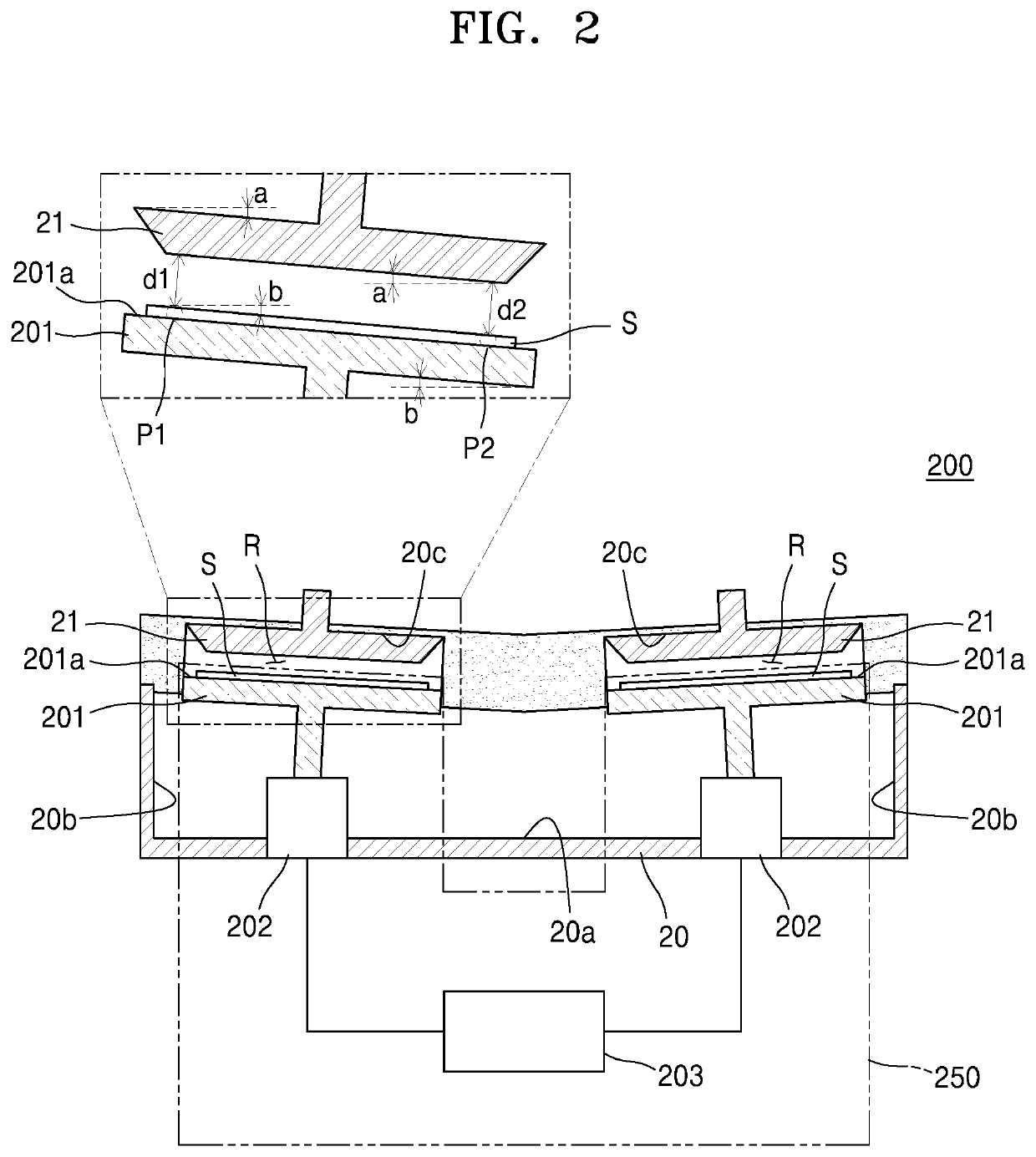

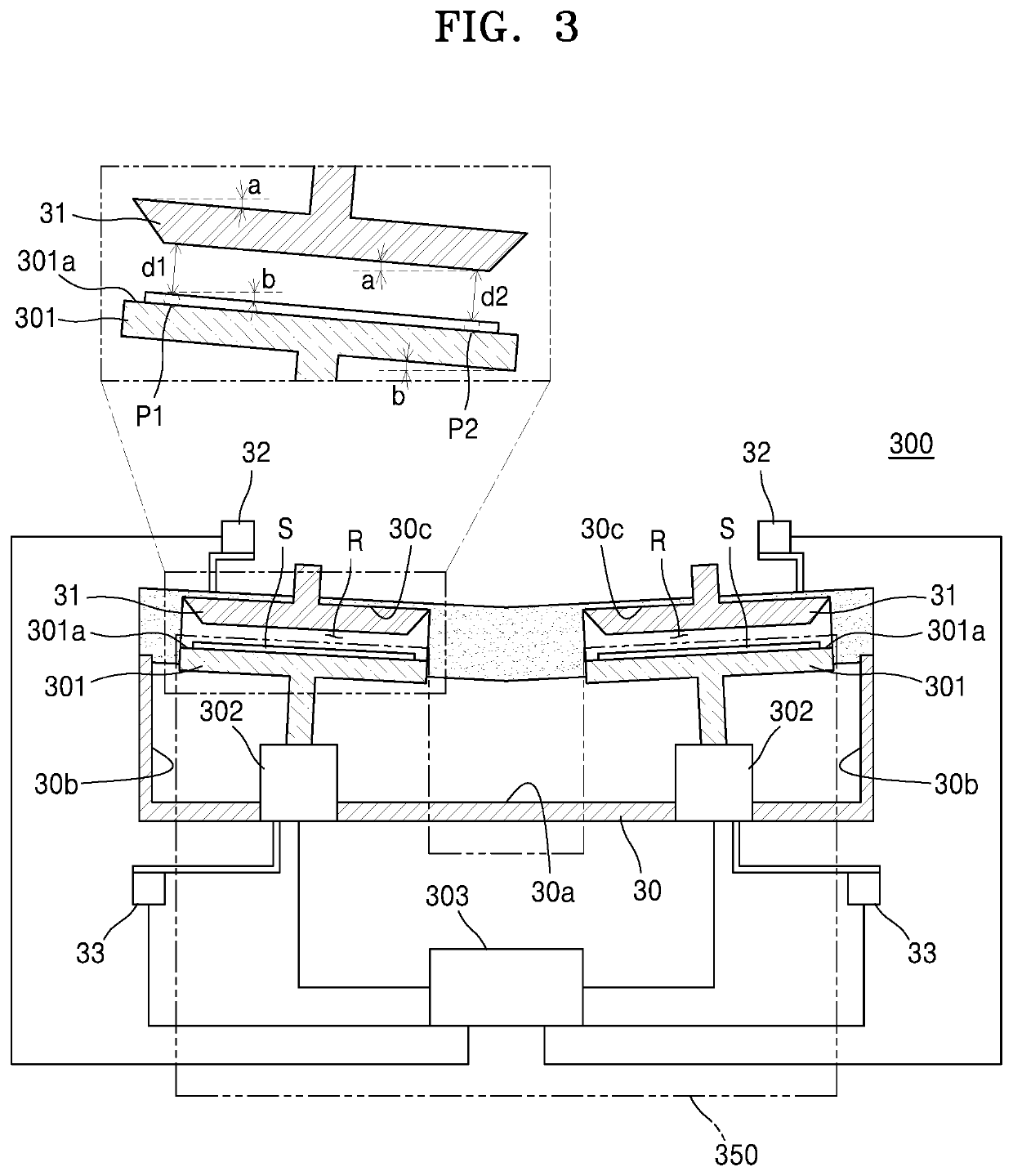

Substrate support assembly and substrate processing device including the same

ActiveUS20210013085A1Improve uniformityUniform processingElectric discharge tubesSemiconductor/solid-state device manufacturingClassical mechanicsControl theory

A substrate support assembly arranged in a chamber includes: a support plate including a first surface on which a substrate is seated; a driver configured to tilt the support plate such that the first surface is inclined with respect to a reference surface by a lower inclination angle; and a controller configured to control the driver such that the lower inclination angle is adjusted based on an upper inclination angle formed by the inclination of the gas supplier coupled to the upper surface of the chamber with respect to the reference surface.

Owner:ASM IP HLDG BV

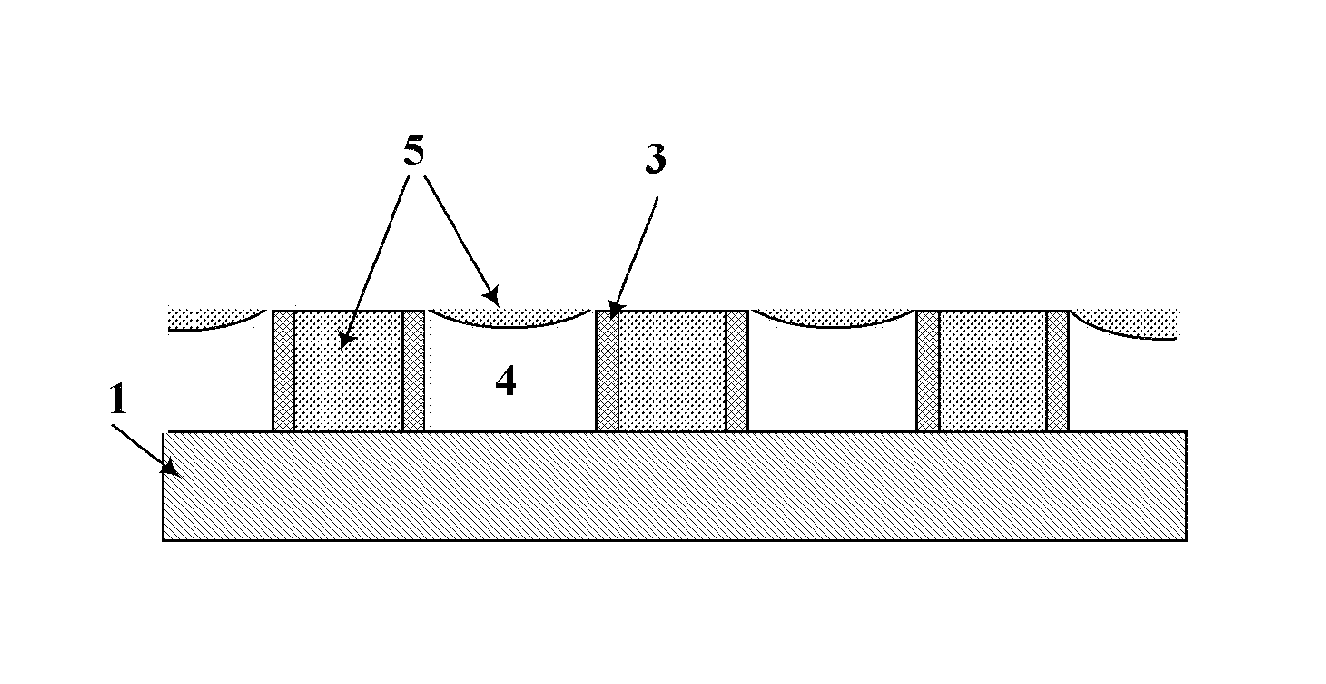

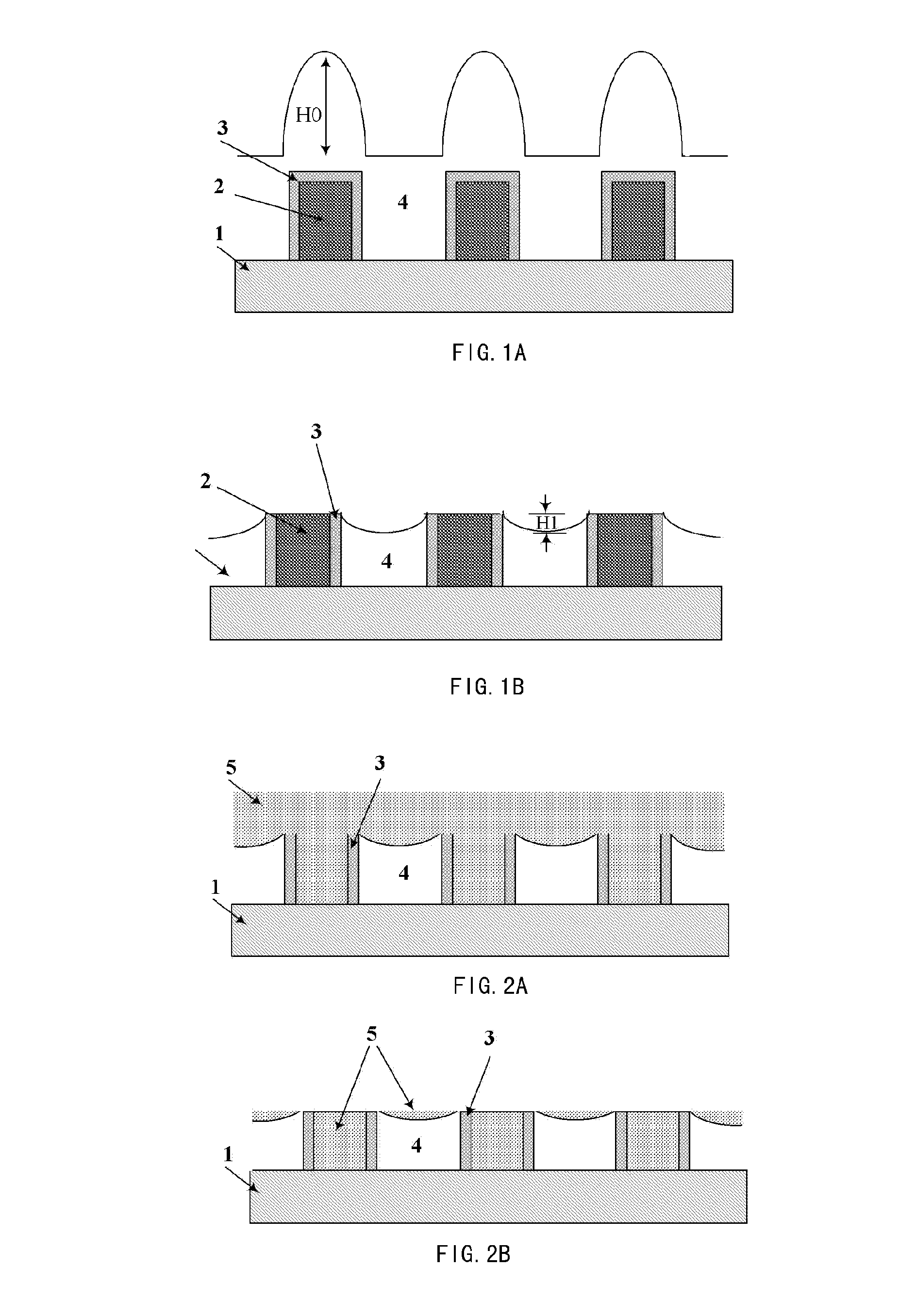

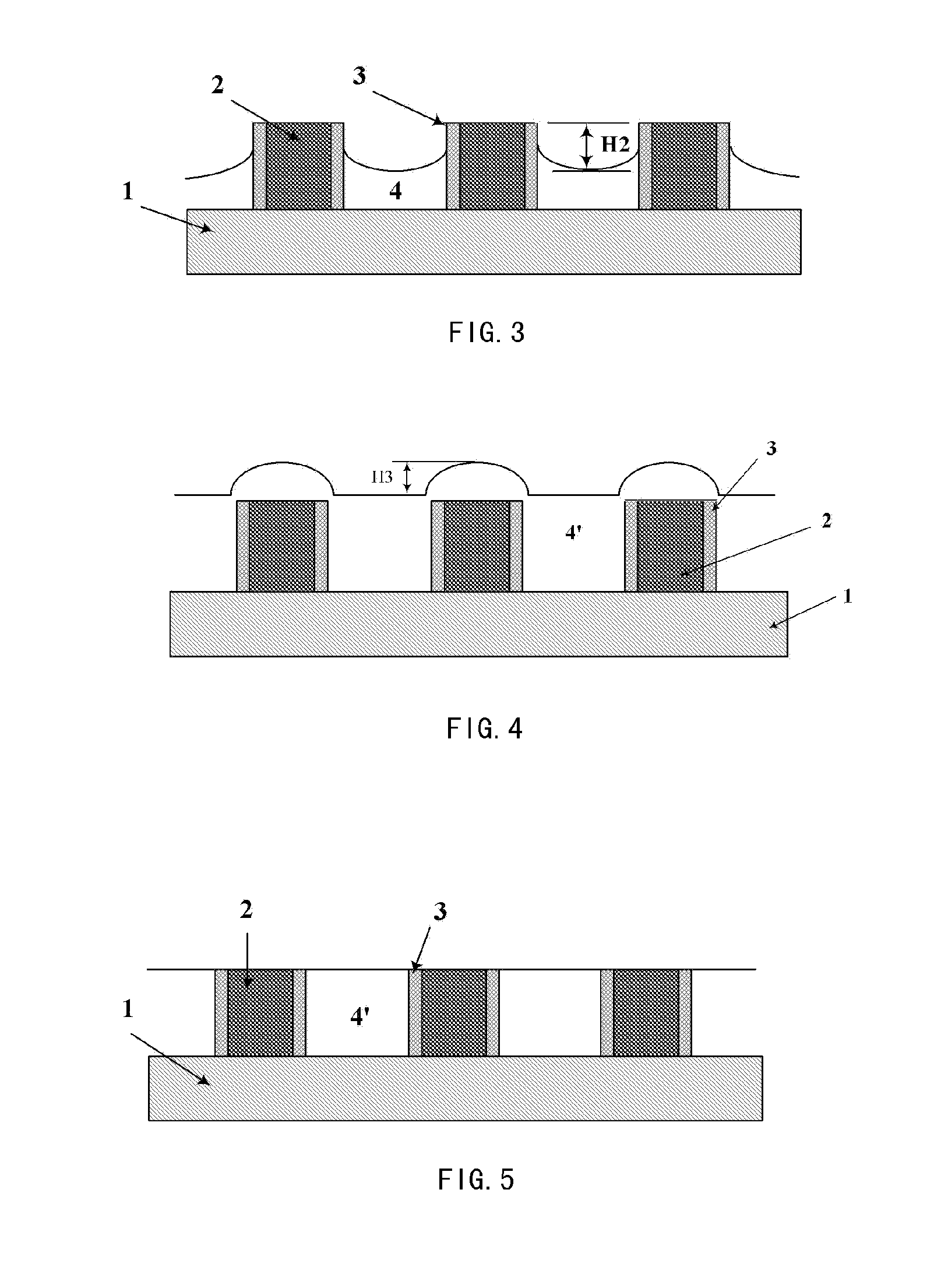

Method for improving uniformity of chemical-mechanical planarization process

ActiveUS8647987B2Improve uniformityReduce the differenceSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringDielectric layer

The invention provides a method for improving uniformity of chemical-mechanical planarization process, comprising the steps of: forming features on a substrate; forming a first dielectric isolation layer between the features; planarizing the first dielectric isolation layer until the features are exposed, causing the first dielectric isolation layer between the features to have a recess depth; forming a second dielectric isolation layer on the features and the first dielectric isolation layer, whereby reducing the difference in height between the second dielectric isolation layer between the features and the second dielectric isolation layer on the top of the features; planarizing the second dielectric isolation layer until the features are exposed. According to the method for improving uniformity of chemical-mechanical planarization process of the invention, a dielectric isolation layer is formed again after grinding the dielectric isolation layer on the top of the features, such that the difference in height between the dielectric layer between the features and the dielectric layer on the top of the features is effectively reduced, and the recess of the features is compensated, the within-in-die uniformity is effectively improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

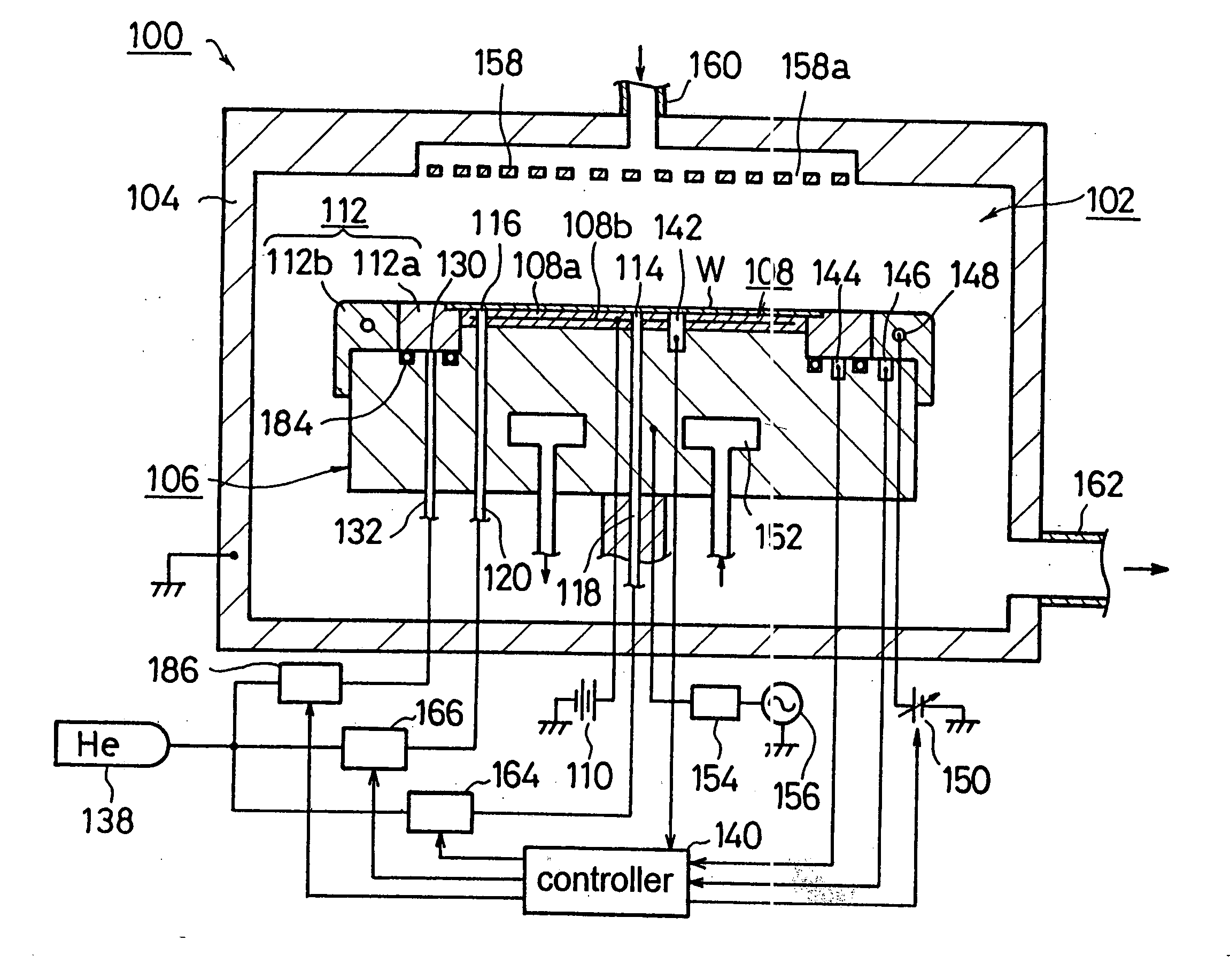

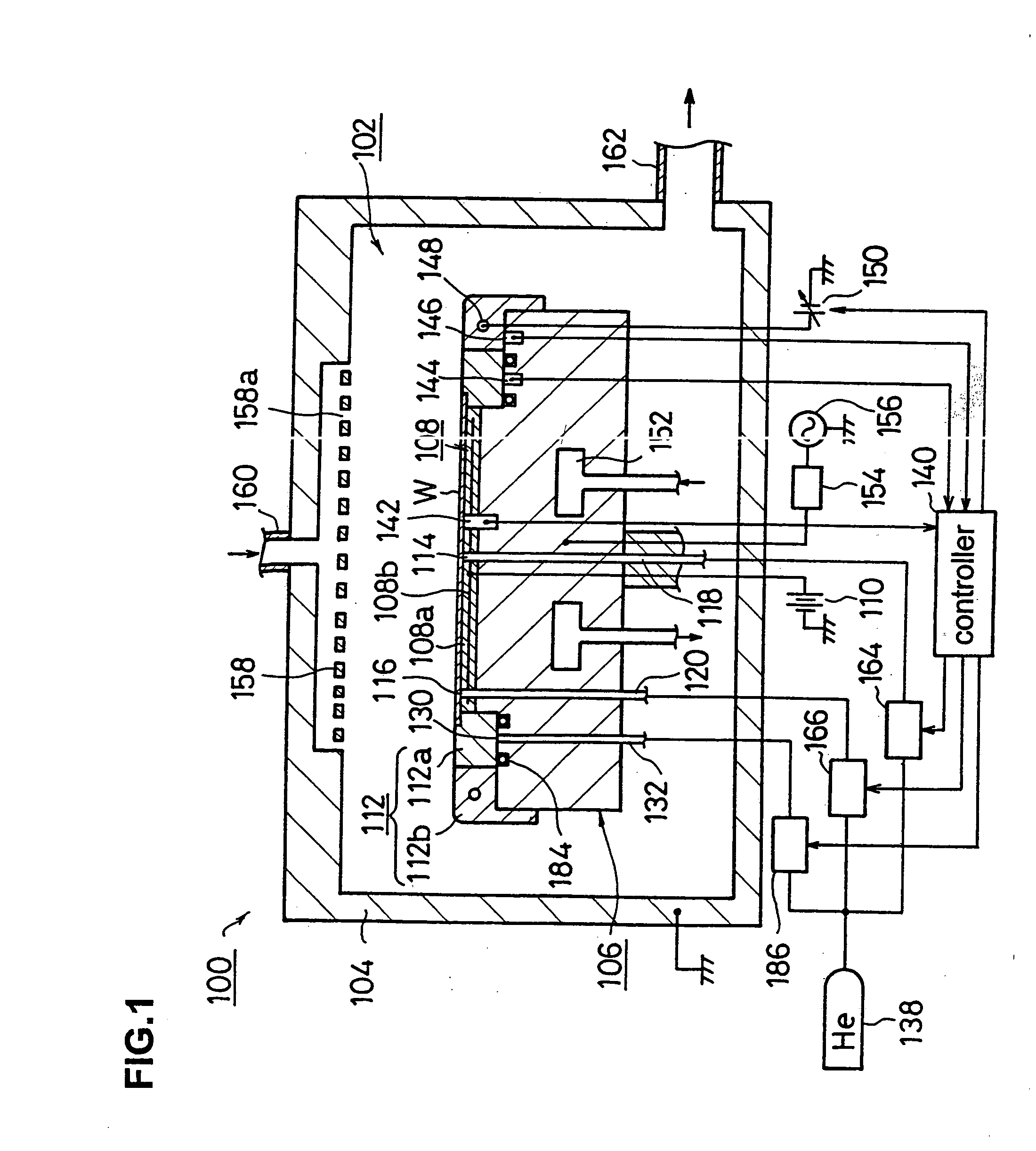

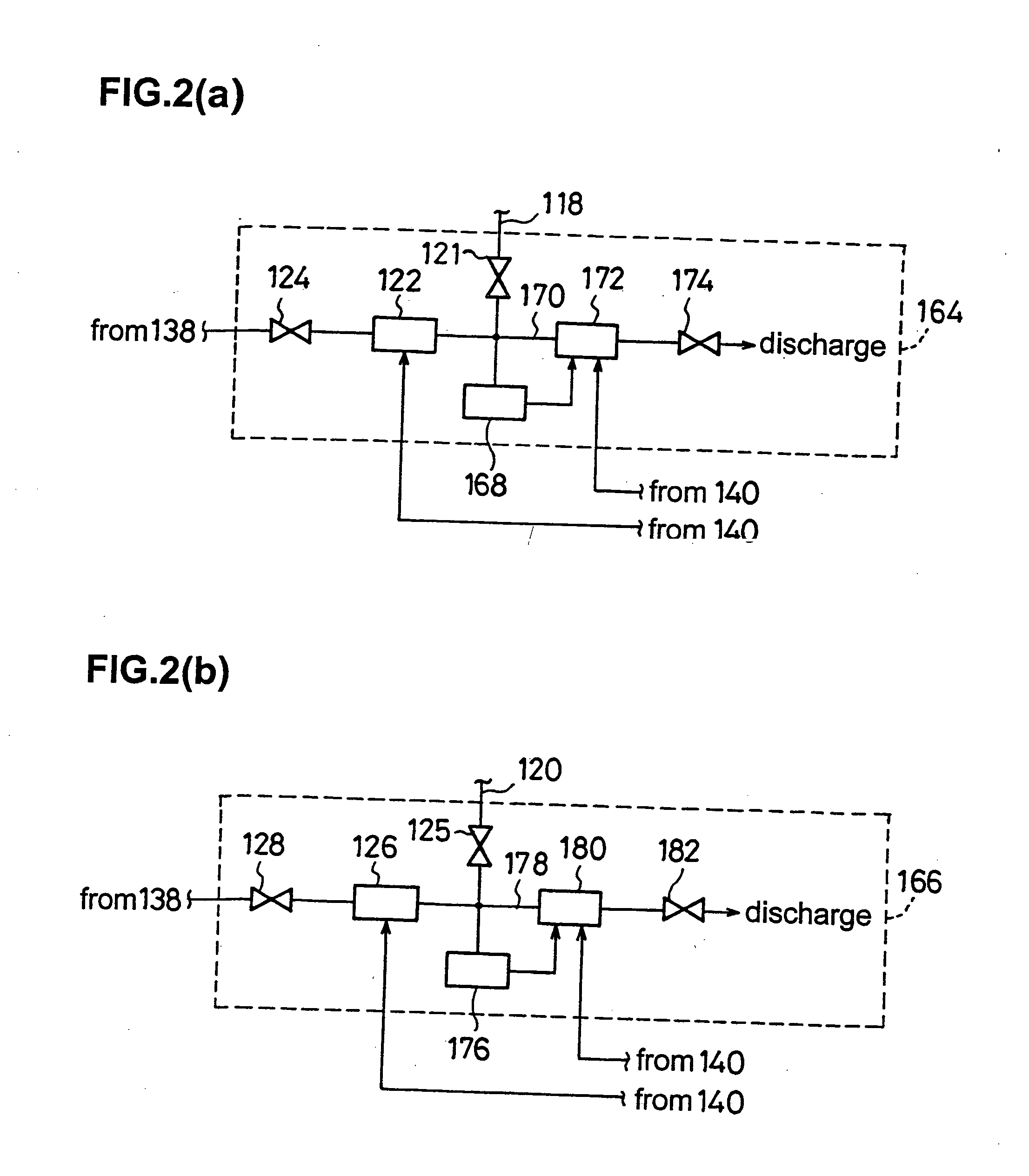

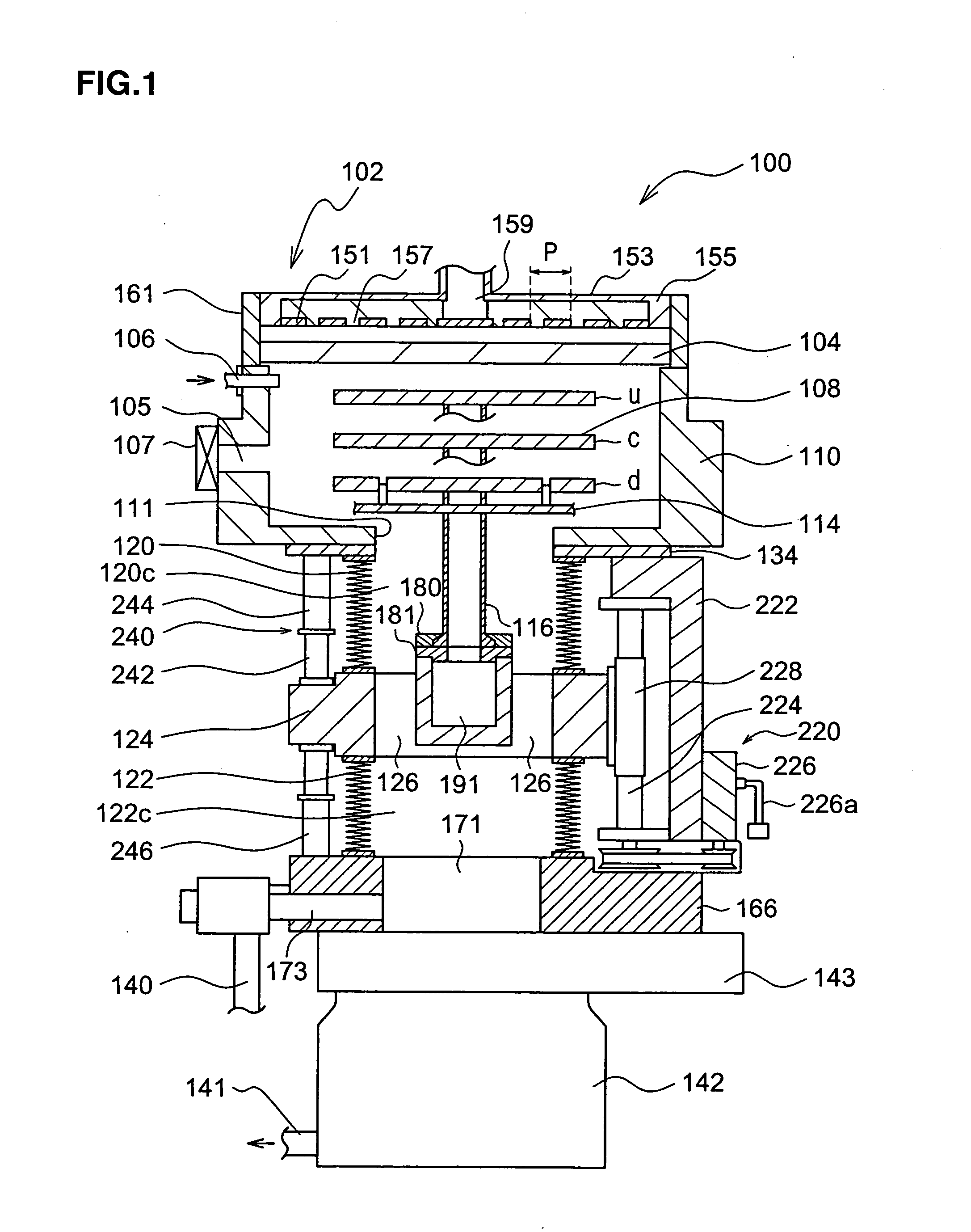

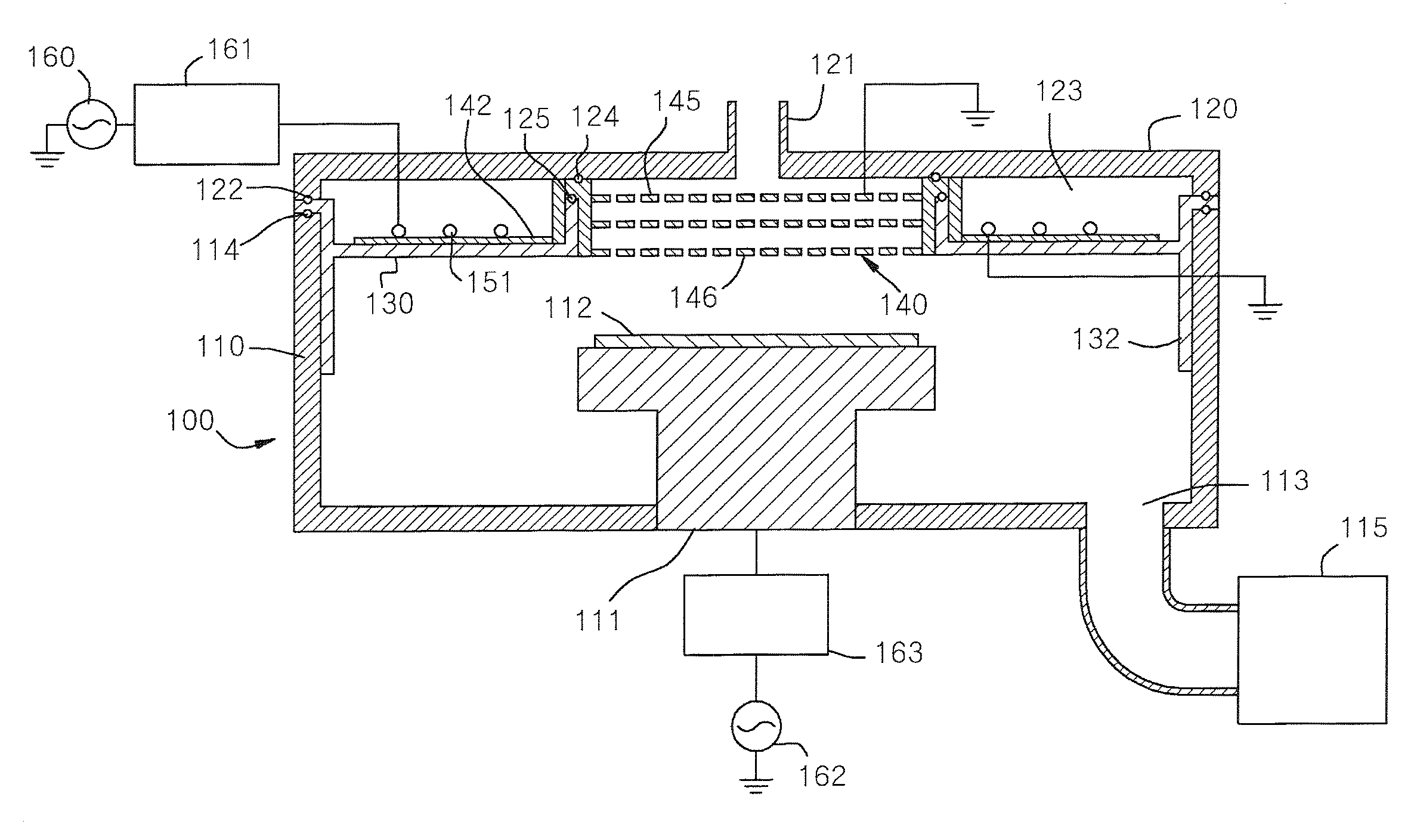

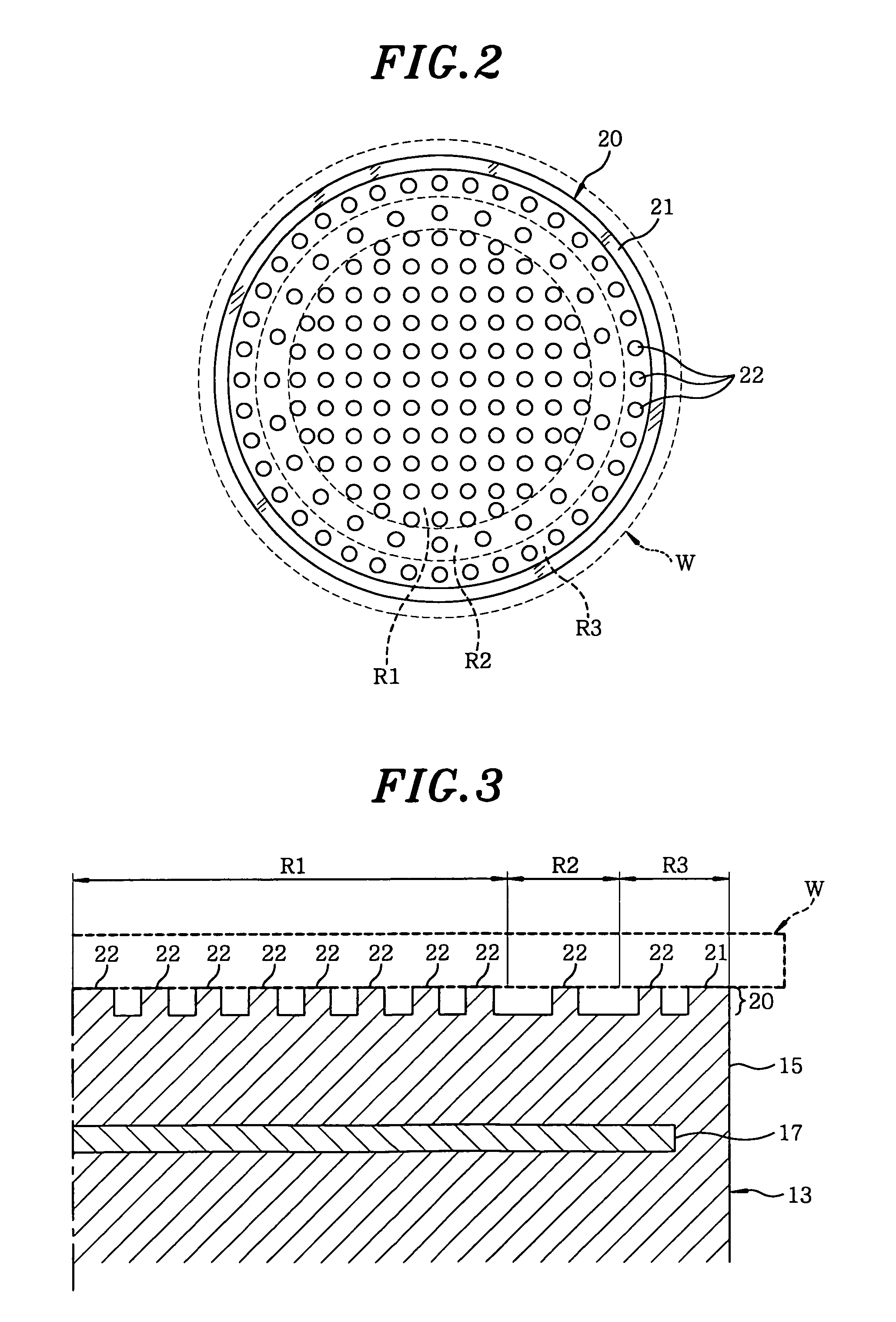

Plasma processing apparatus and plasma processing method

InactiveUS20050172904A1Improve consistencyThermal conductivityElectric discharge tubesVacuum evaporation coatingEngineeringPlasma processing

An electrostatic chuck 108 is provided on a lower electrode 106 provided inside a processing chamber 102 of an etching apparatus 100, and a conductive inner ring body 112a and an insulating outer ring body 112b are encompassing the outer edges of a wafer W mounted on the chuck surface. The temperatures of the wafer W and the inner and outer ring bodies 112a and 112b are detected by first third temperature sensors 142, 144 and 146. A controller 140 controls the pressure levels of He supplied to the space between the center of the wafer W and the electrostatic chuck 108 via first gas outlet ducts 114 and to the space between the outer edges of the wafer W and the electrostatic chuck 108 via second gas outlet ducts 116 and the quantity of heat generated by a heater 148 inside the outer ring body 112b based upon the information on the temperatures thus detected so that the temperatures of the wafer W and the inner ring body 112a are set roughly equal to each other.

Owner:TOKYO ELECTRON AT +1

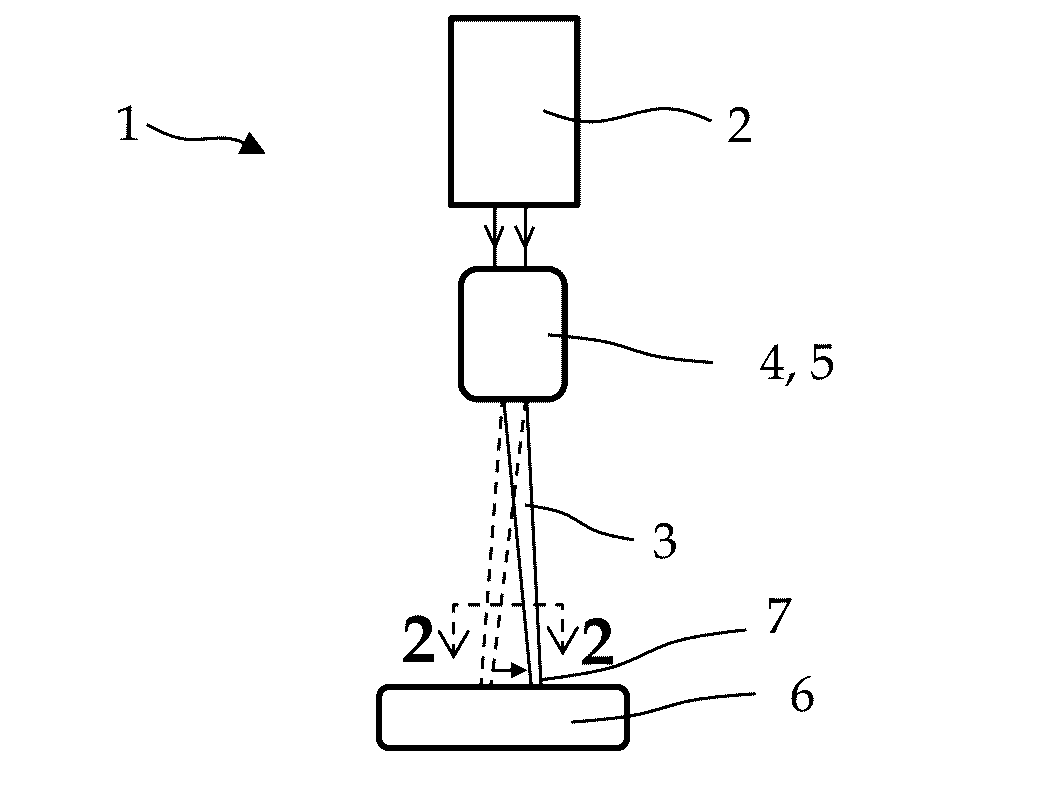

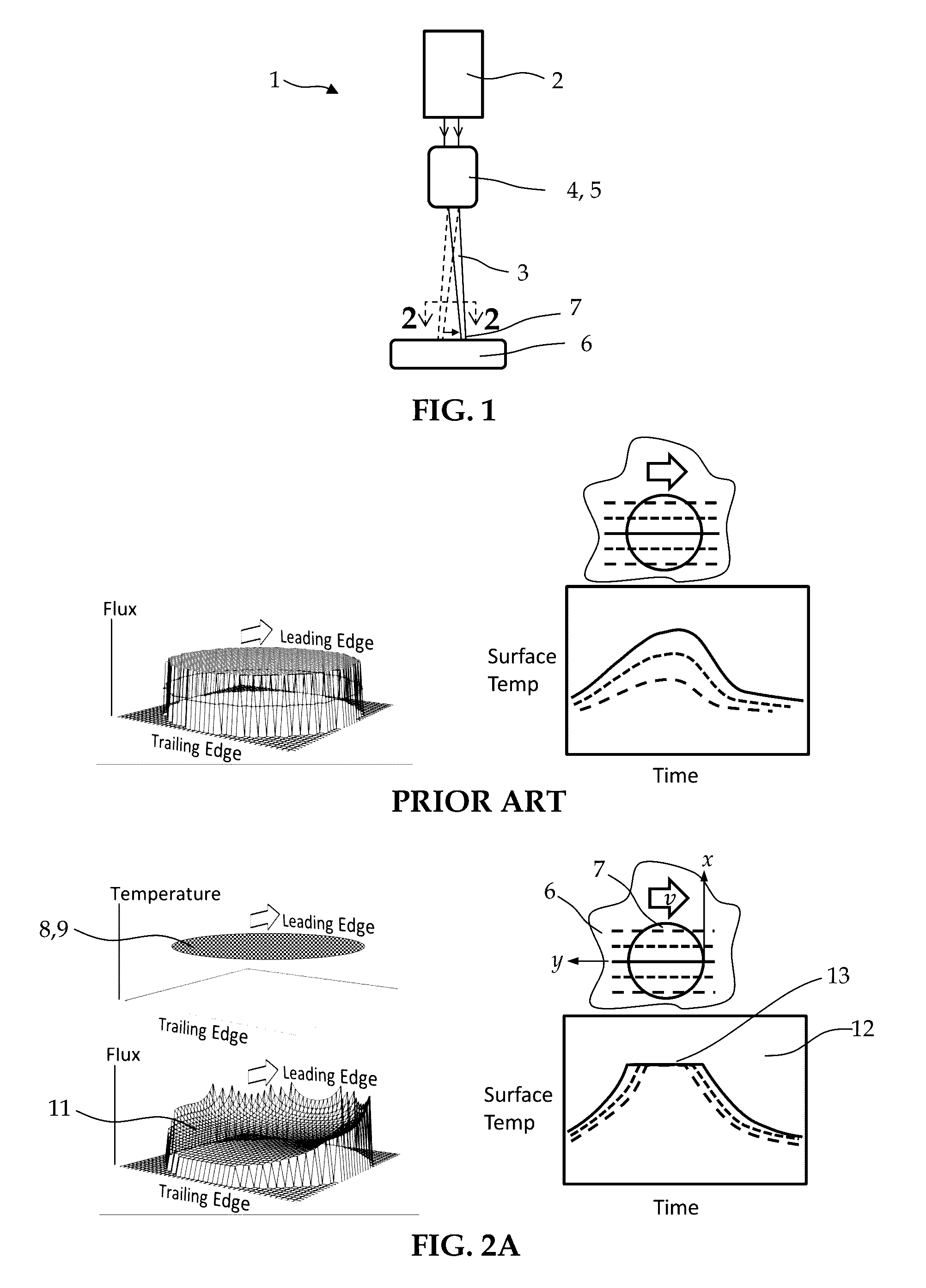

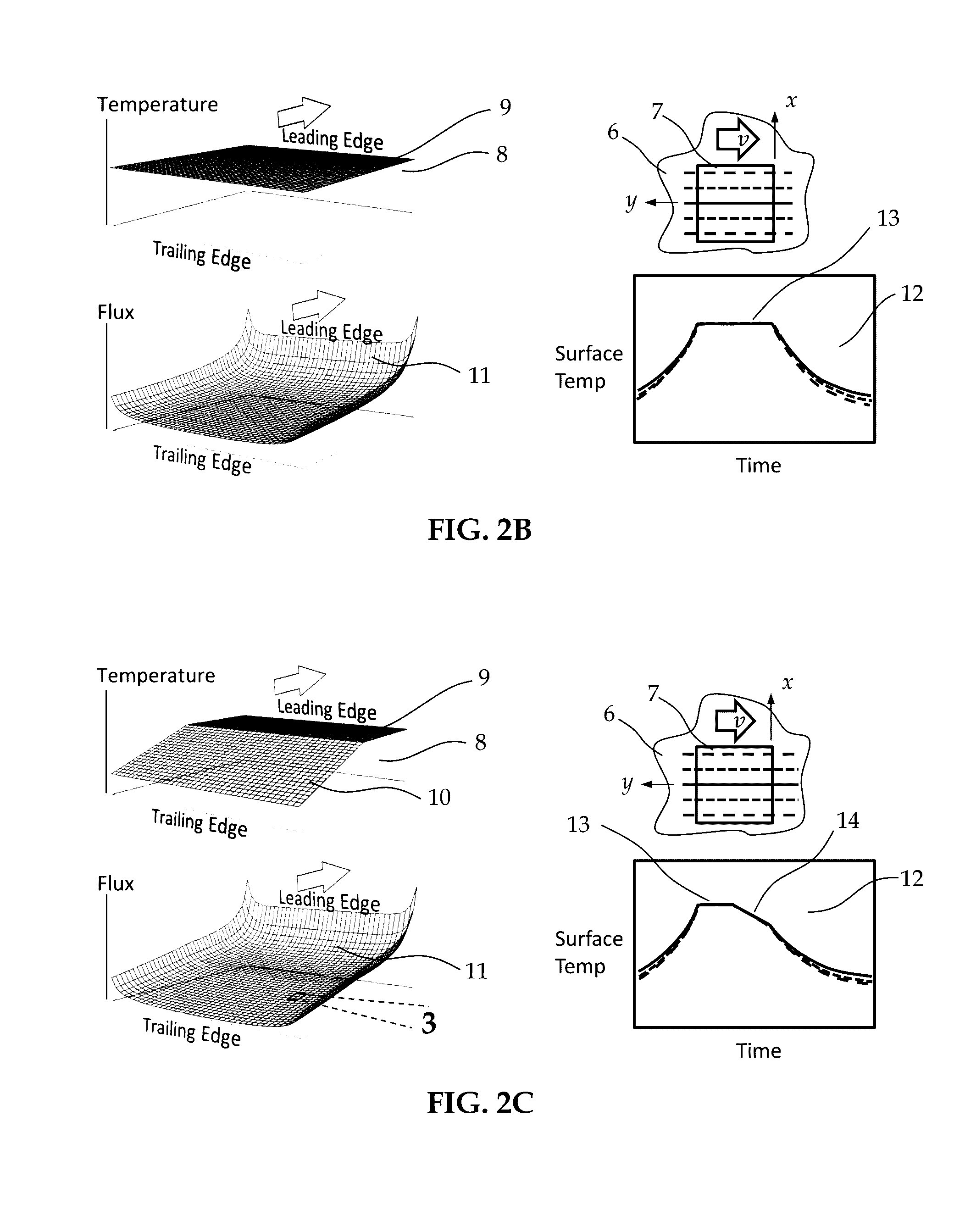

Apparatus and method for precision thermal processing of a body

InactiveUS20160288254A1Increases local heatingIncrease cooling rateTurbinesAdditive manufacturing apparatusBeam sourceThermal solution

The invention pertains to apparatus and method for precision thermal processing of a body. An energy beam emanating from an energy beam source is scanned across the surface of the body, creating heat input through a moving spot on the surface of said body. By means described herein to condition the spot shape and flux profile, the flux profile within the spot is configured to approximate a thermal solution obtained by solving a boundary condition of the third kind imposed upon the moving spot associated with the beam as it is scanned across the body. In this manner a predetermined surface temperature profile is imposed on the surface of the body within a moving, locally heated spot of predetermined shape and size.Potential uses include any application which would benefit from the ability to apply a prescribed uniform or variable thermal process to the surface of a body, thus including but not limited to thermal processing of inorganic materials, such as metals and ceramics, and thermal processing of polymeric or organic materials or tissues. Exemplary desired outcomes range from an improvement of surface properties, such as hardness or wear resistance, to the fabrication of a component through an additive manufacturing process.

Owner:FRACTURELAB

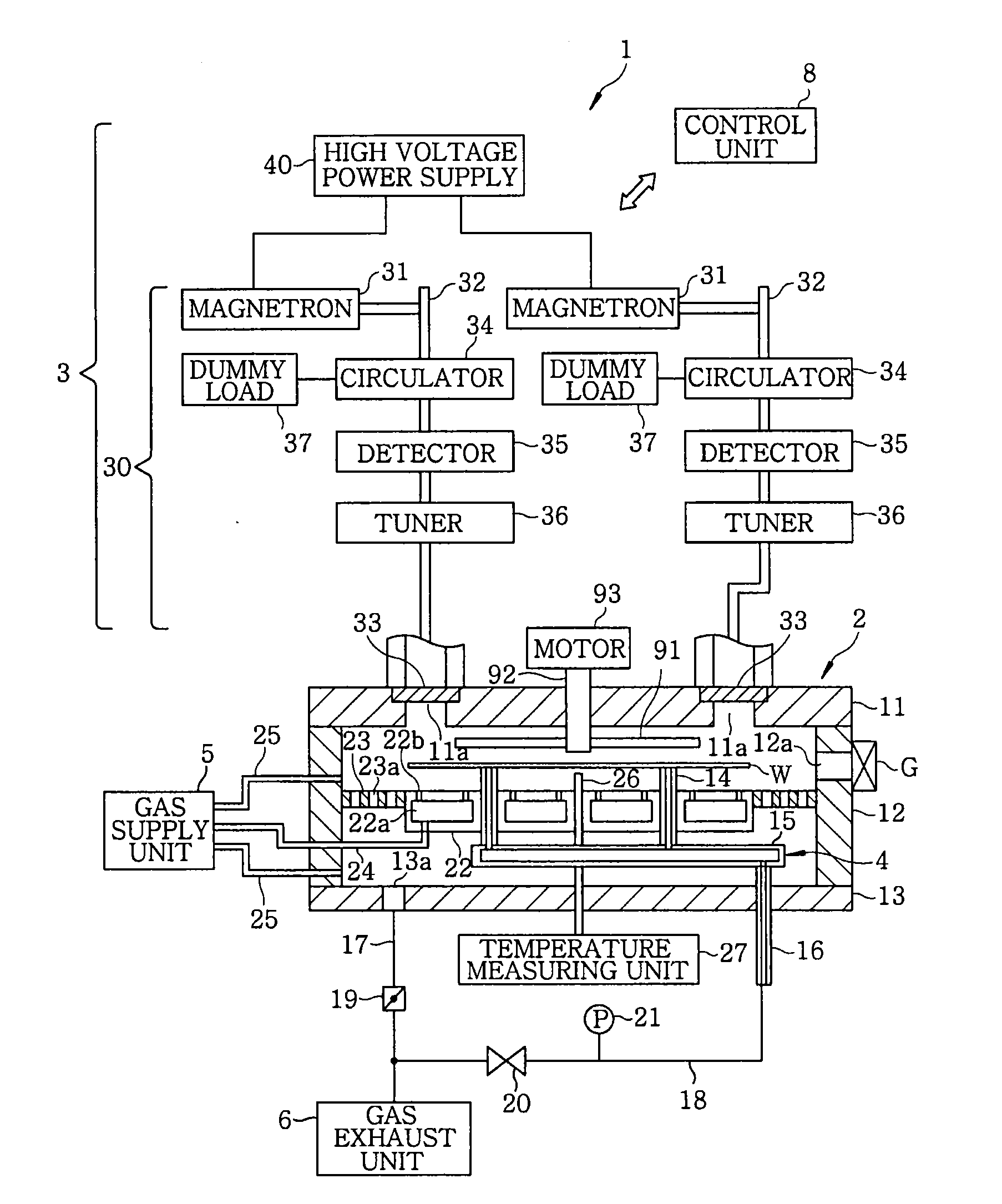

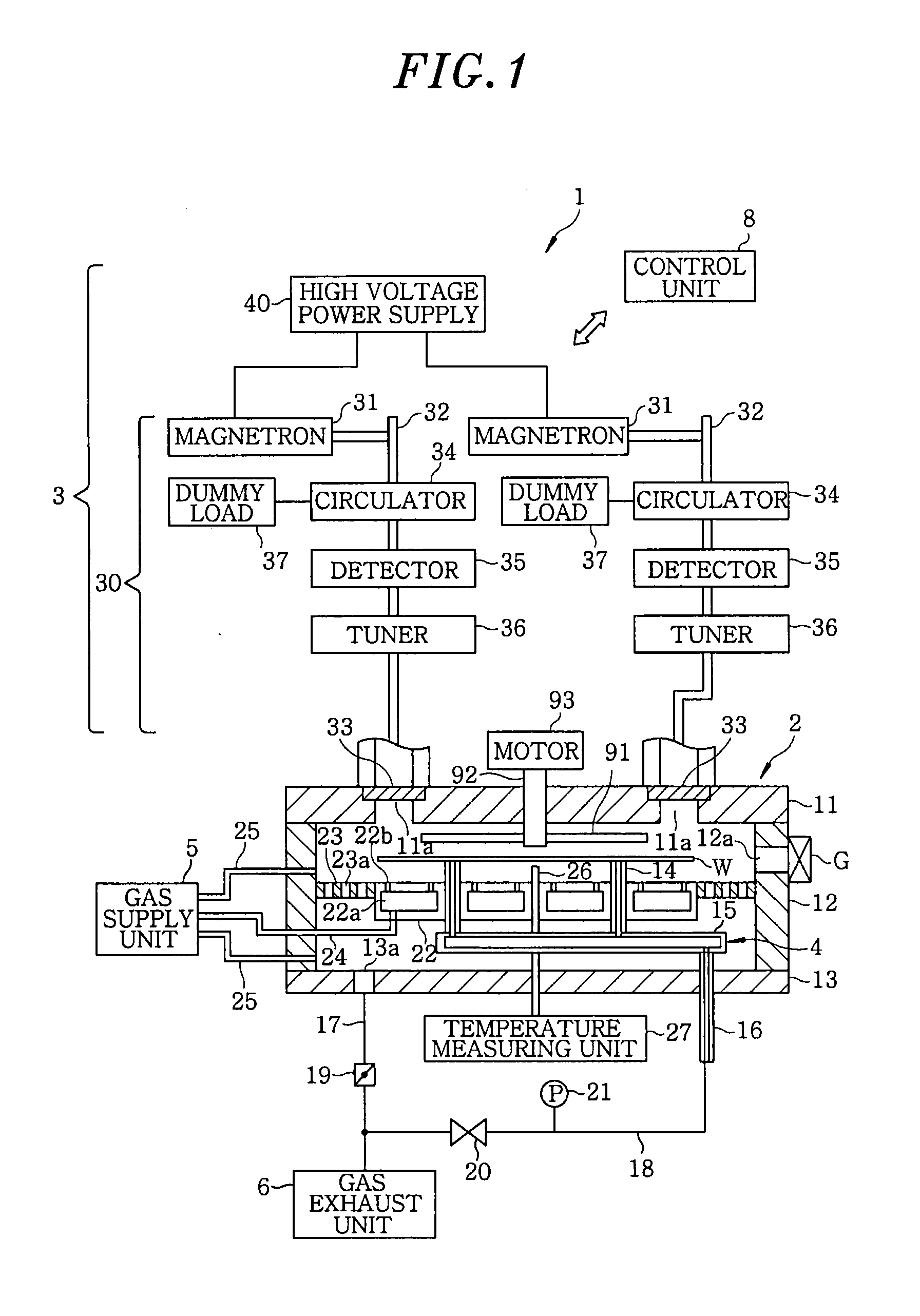

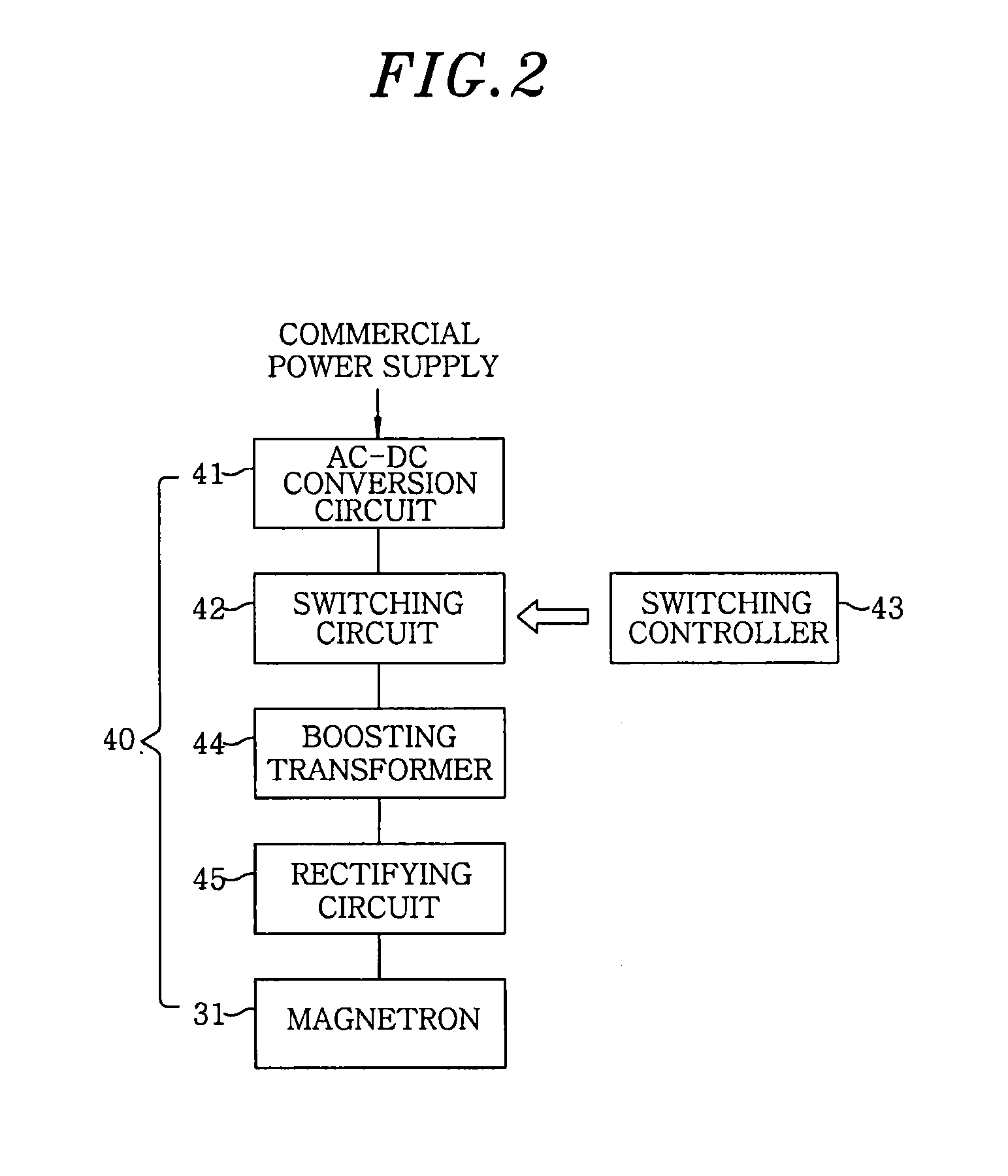

Microwave processing apparatus and method for processing object to be processed

InactiveUS20130075390A1Uniform processingElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveControl unit

A microwave processing apparatus includes a processing chamber which accommodates an object to be processed, and a microwave introducing unit which has at least one microwave source to generate a microwave used to process the object and introduces the microwave into the processing chamber. The microwave processing apparatus further includes a control unit which controls the microwave introducing unit. Furthermore, the control unit changes a frequency of the microwave during a state of processing the object.

Owner:TOKYO ELECTRON LTD

Apparatus for Processing Substrate

InactiveUS20120000425A1Uniform processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasProcess engineering

A substrate processing apparatus that simultaneously forms thin films on a plurality of substrates and performs heat treatment includes: a plurality of substrate holders, each including a substrate support that supports a substrate and a first gas pipe having one or a plurality of injection holes; a boat where the plurality of substrate holders are stacked and including a second gas pipe connected with the first gas pipe of each of the substrate holders; a process chamber providing a space in which the substrates stacked in the boat are processed; a conveying unit that carries the boat into / out of the process chamber; a first heating unit disposed outside the process chamber; and a gas supply unit including a third gas pipe connected with the second gas pipe and supplying a heated or cooled gas into the second gas pipe.

Owner:SAMSUNG DISPLAY CO LTD

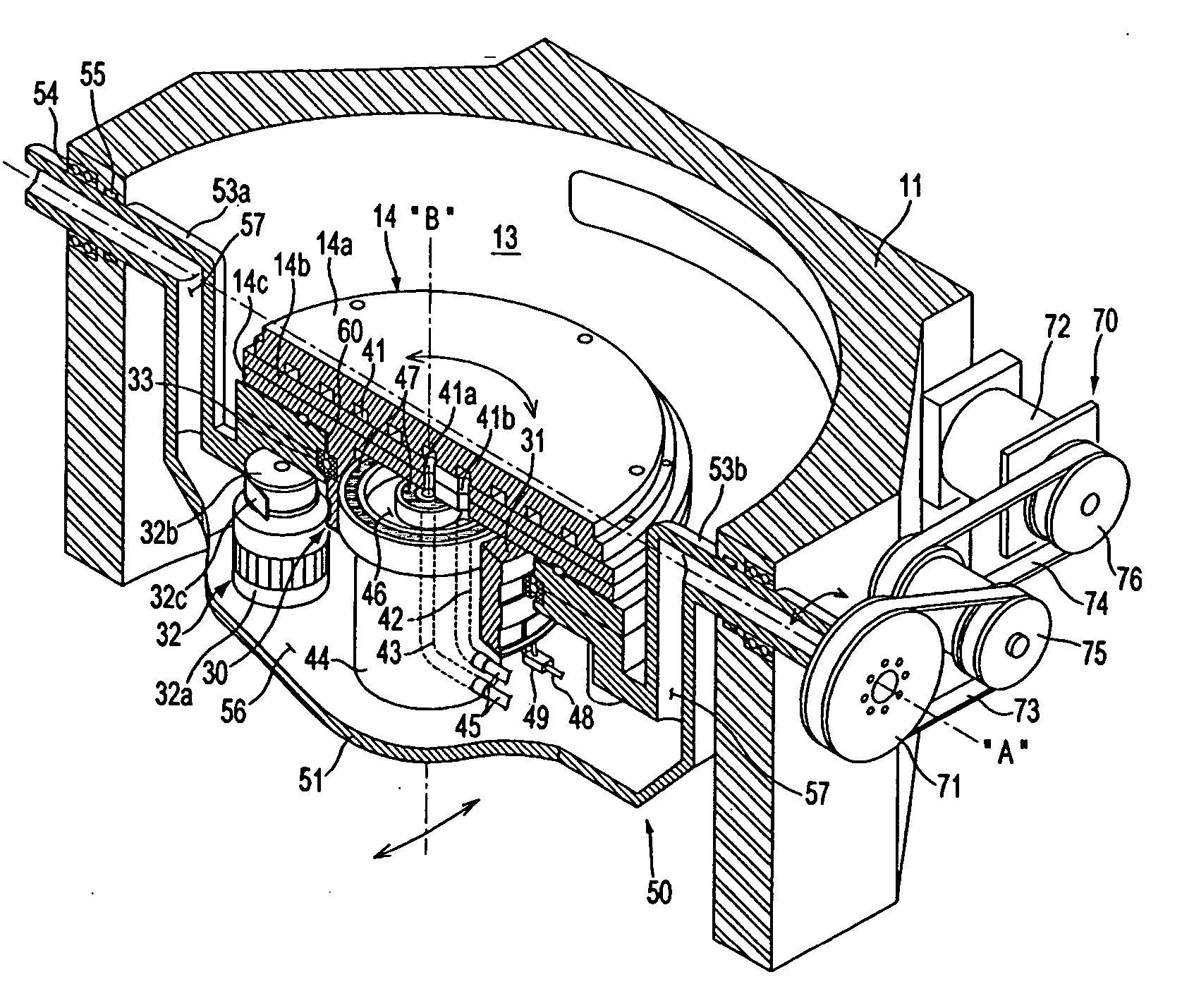

Semiconductor manufacturing apparatus

InactiveUS20060180968A1Uniform processingSemiconductor/solid-state device manufacturingLarge fixed membersManufactured apparatusEngineering

A semiconductor manufacturing apparatus includes a body having a reaction chamber formed therein to process a semiconductor wafer, a chuck provided within the reaction chamber to support the semiconductor wafer, a chuck rotating device provided within the reaction chamber to support and rotate the chuck, and a slant adjuster to support the chuck rotating device and to adjust a position of the chuck rotating device to adjust a slant of an upper surface of the chuck.

Owner:SAMSUNG ELECTRONICS CO LTD

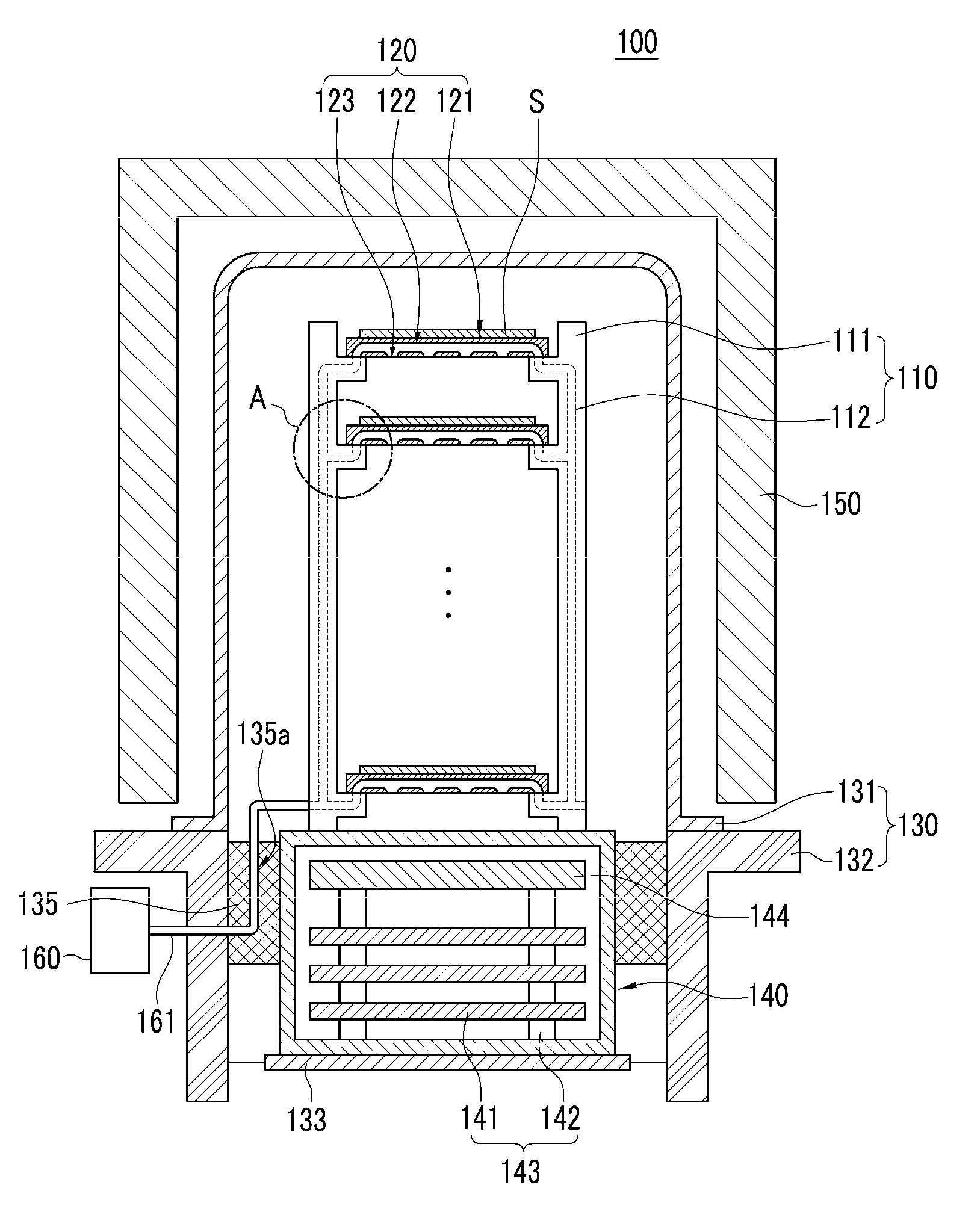

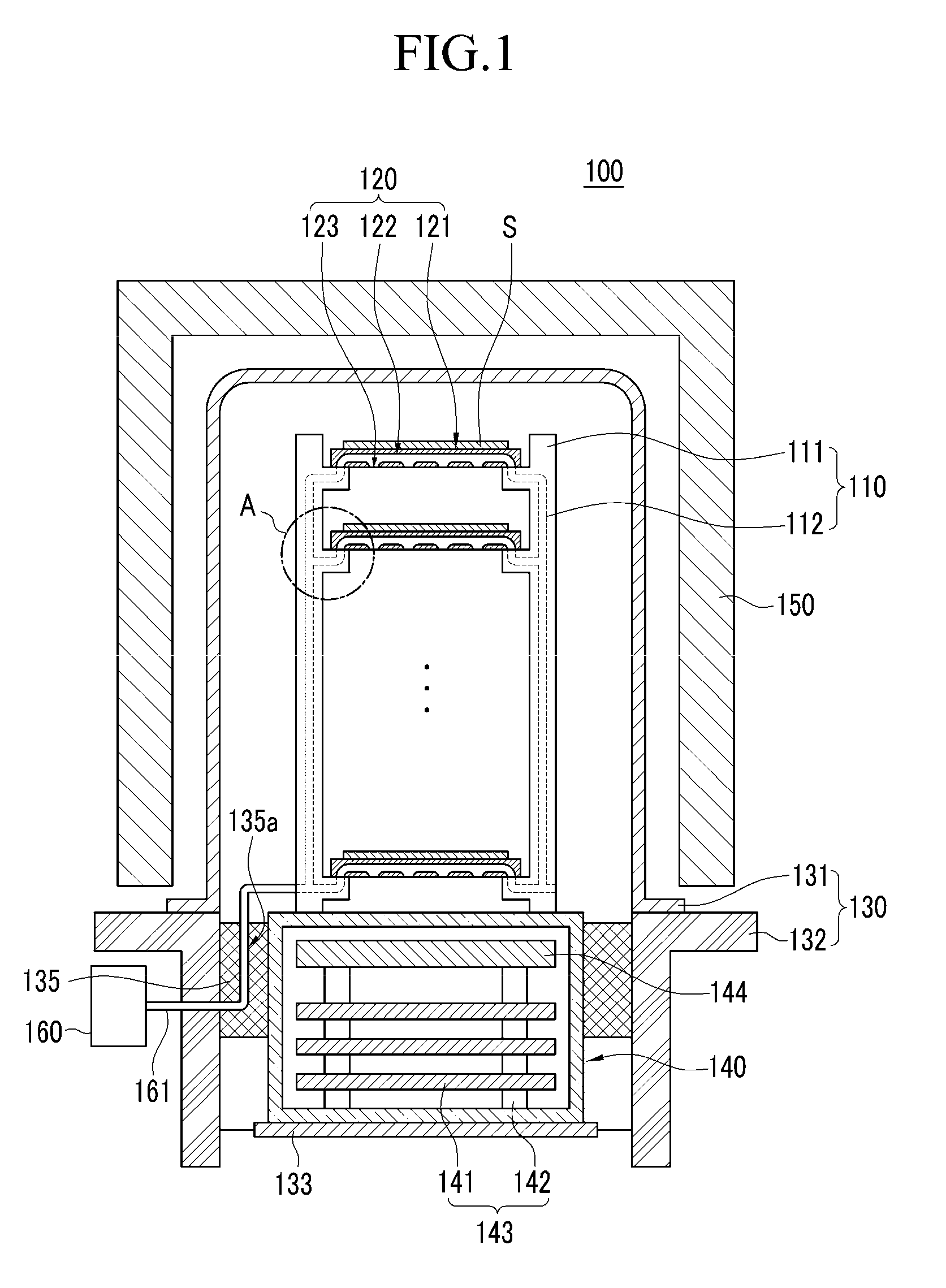

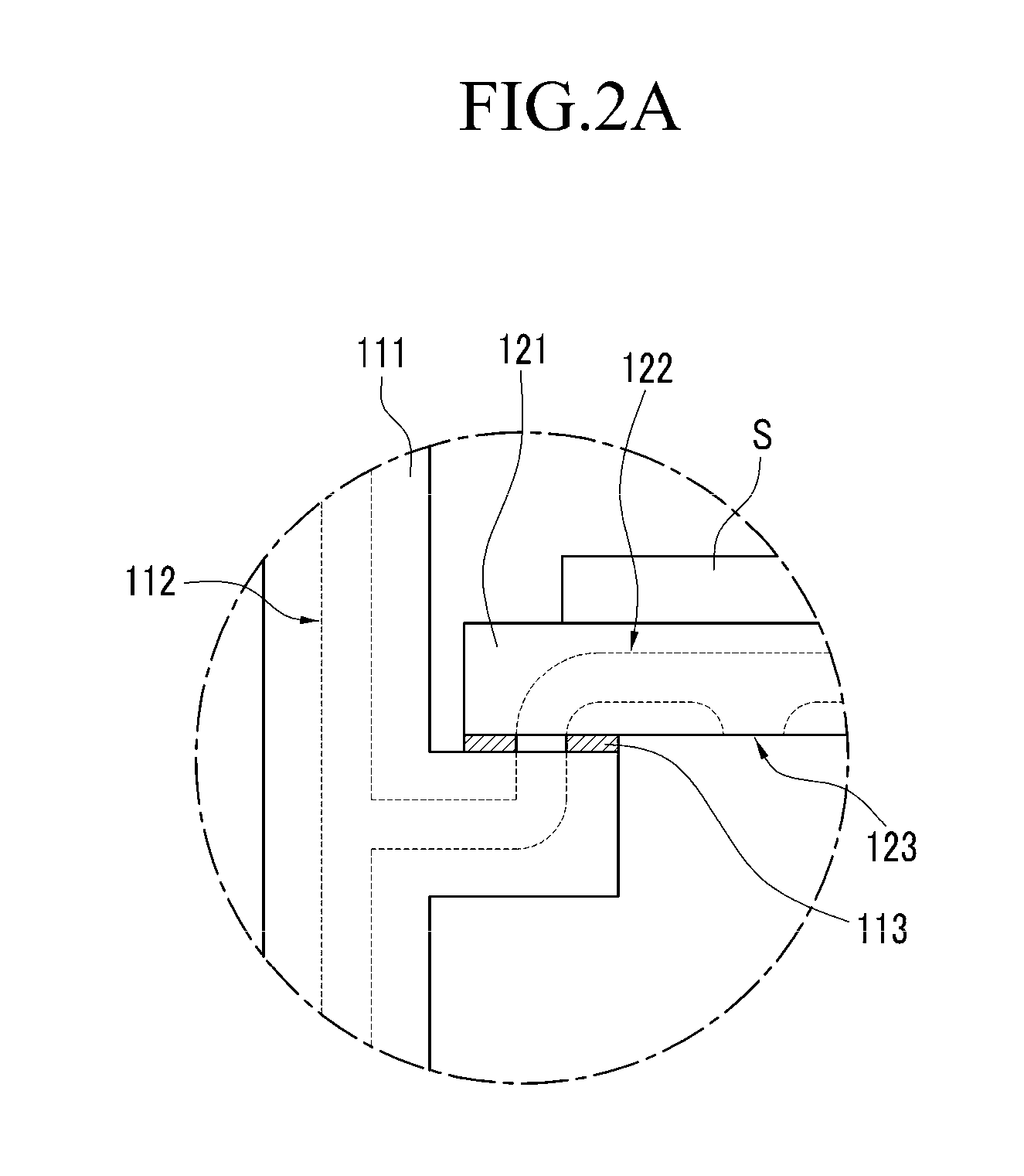

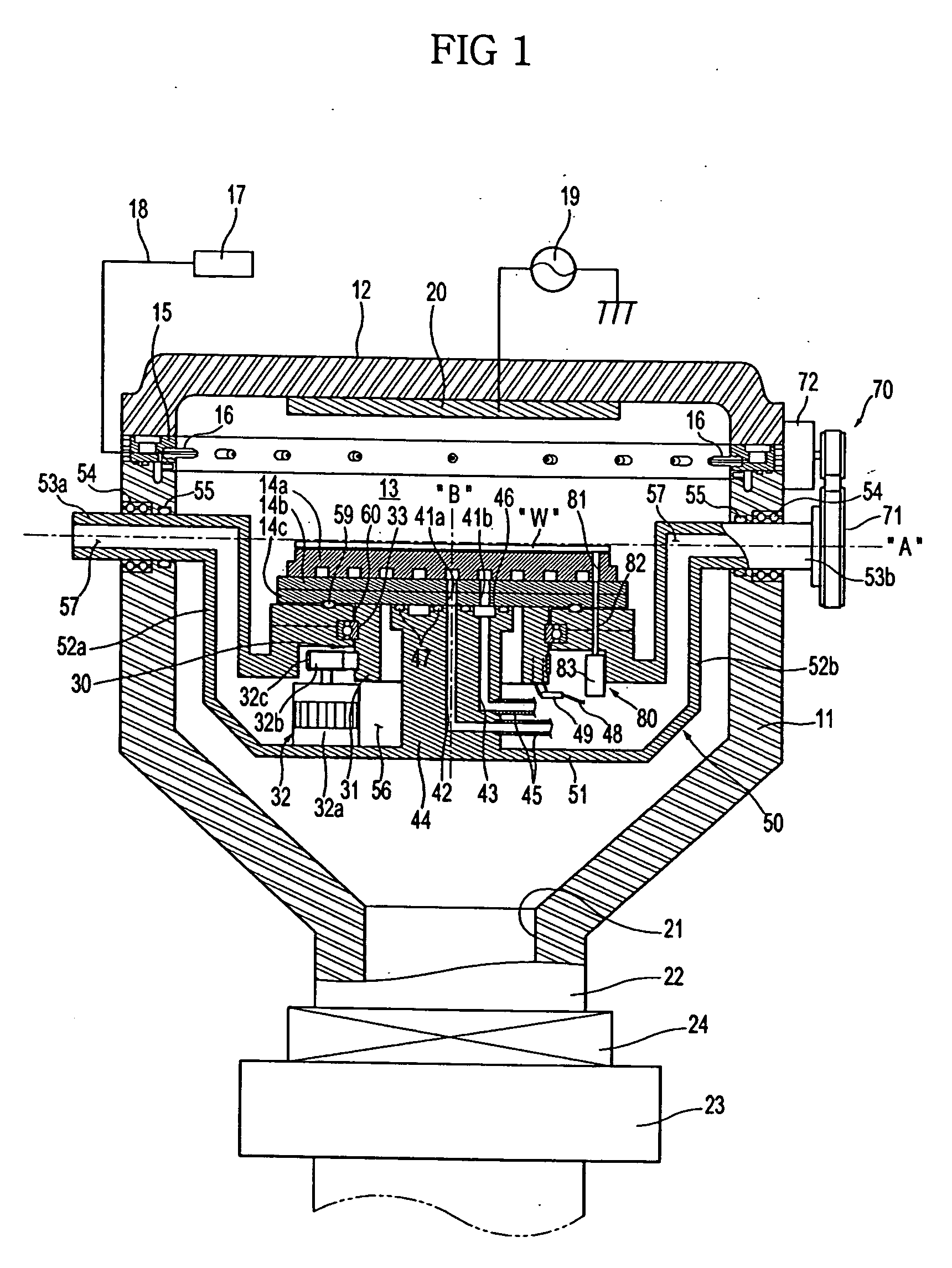

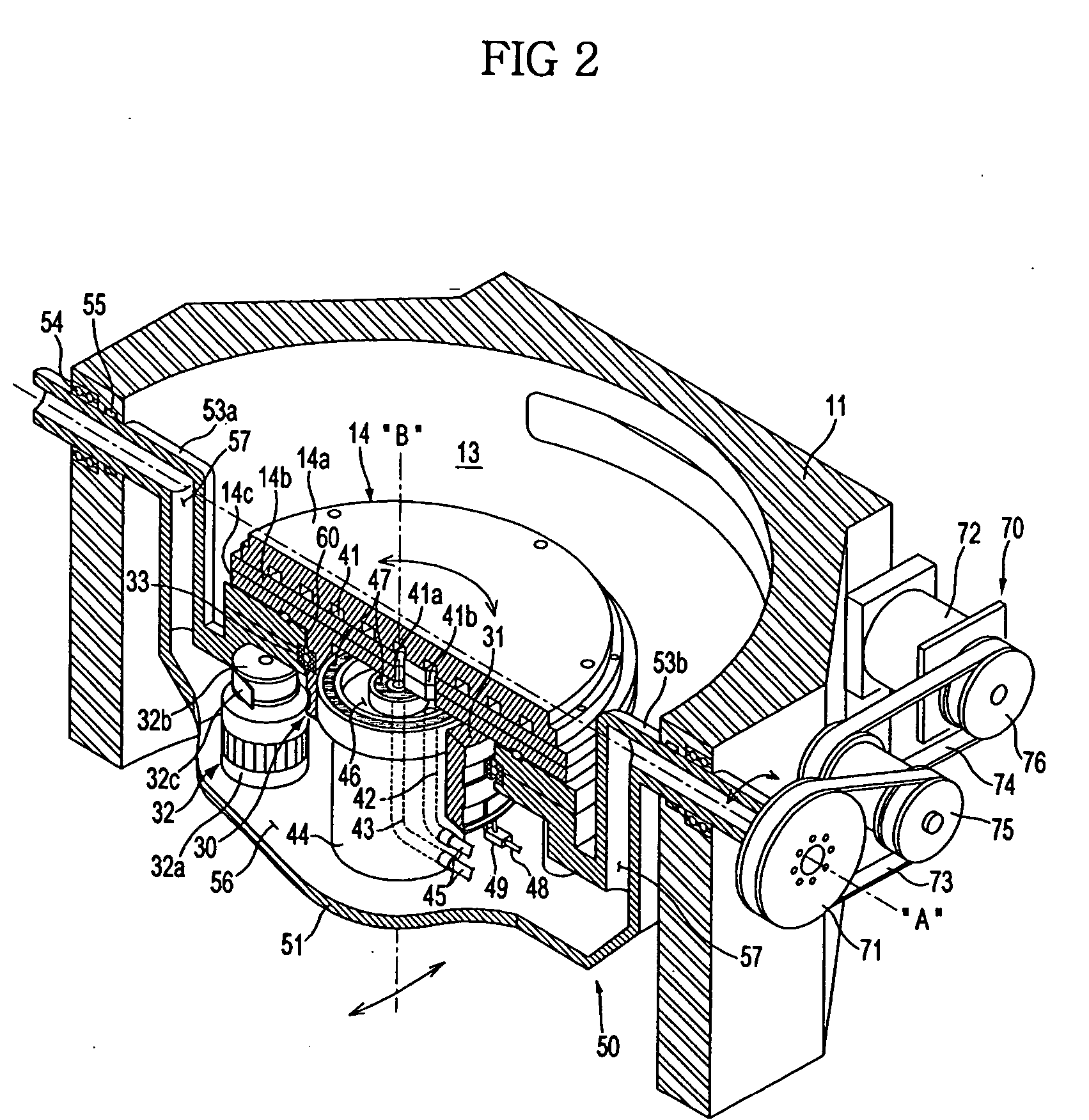

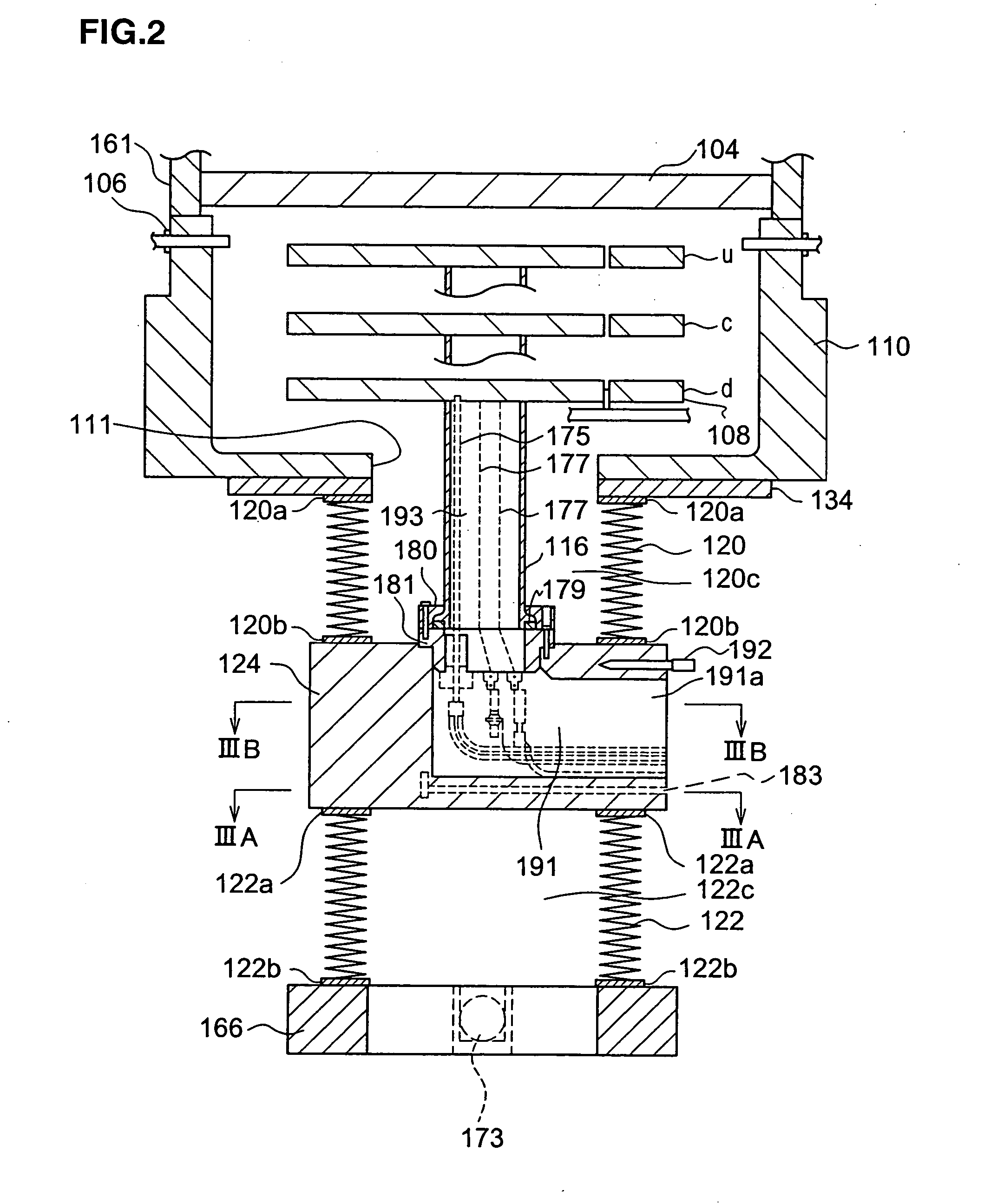

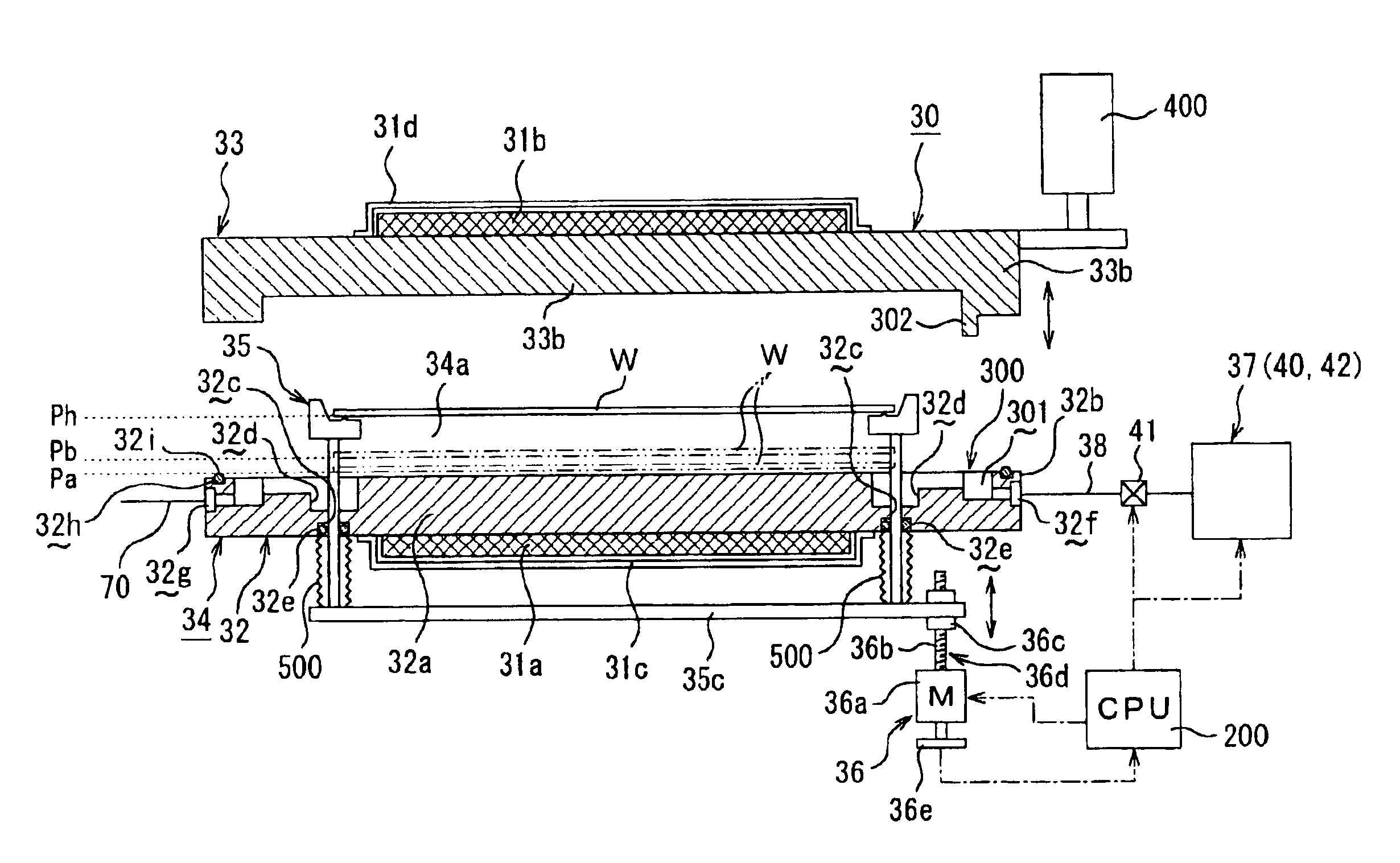

Processing apparatus

InactiveUS20050051520A1Slow conductionUniform processingMuffle furnacesElectric discharge tubesHigh frequency powerEngineering

A plasma processing apparatus 100 used to execute a specific type of processing such as plasma processing on a workpiece by supplying a processing gas into a chamber 110 while applying high-frequency power to generate plasma includes a stage 108 on which the workpiece is placed and a stage supporting unit 124 that holds the stage 108. Bellows 120 and 122 are disposed above and below the stage supporting unit 124 to support the stage 108 in a horizontal state relative to the chamber 110. Thus, a plasma processing apparatus that does not allow the workpiece stage to become tilted, affords ease of maintenance and is capable of stable processing is provided. In addition, the internal spaces at the bellows 120 and 122 are used as an exhausting pipe to achieve efficient and uniform exhaustion of the chamber 110.

Owner:TOKYO ELECTRON LTD

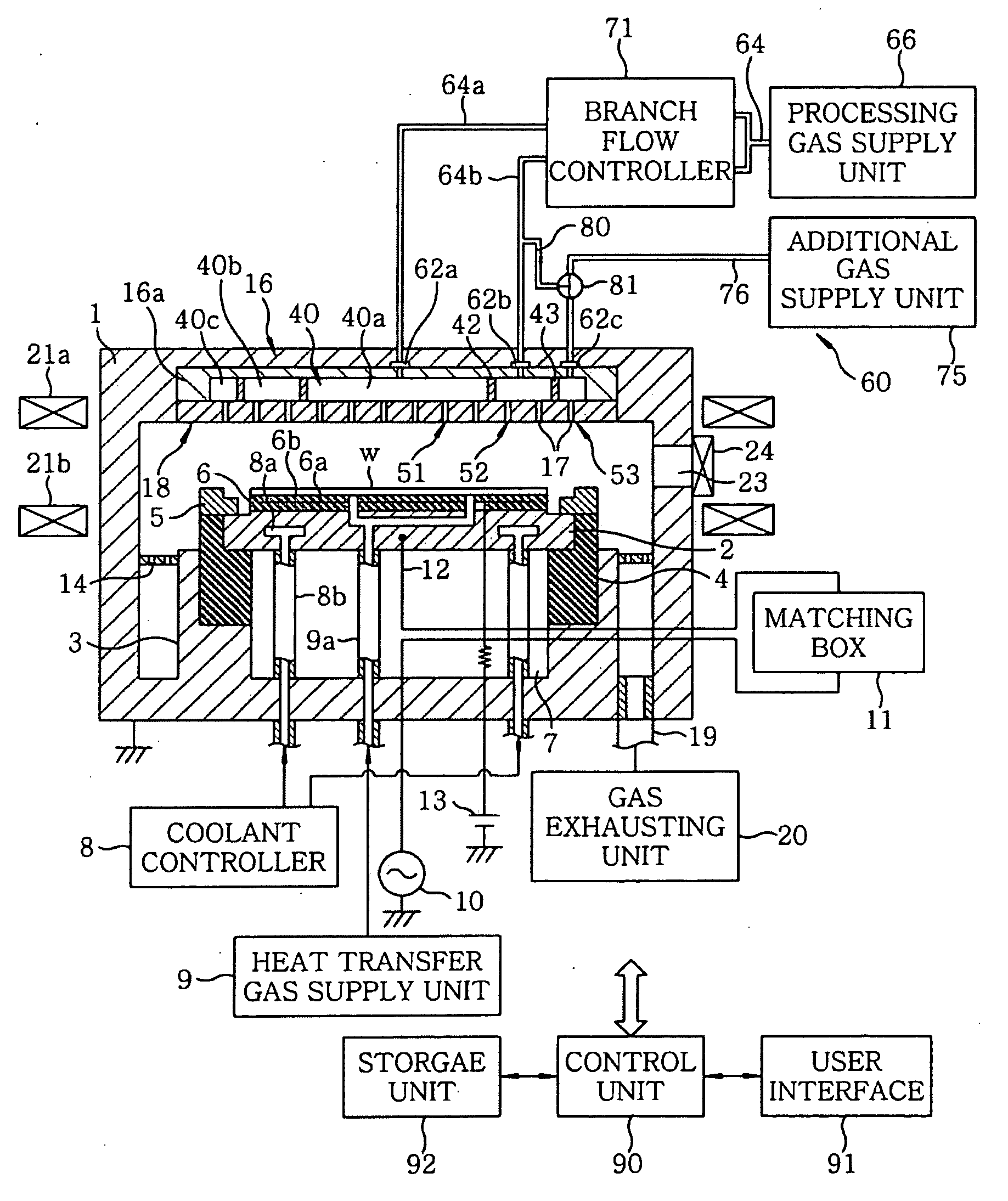

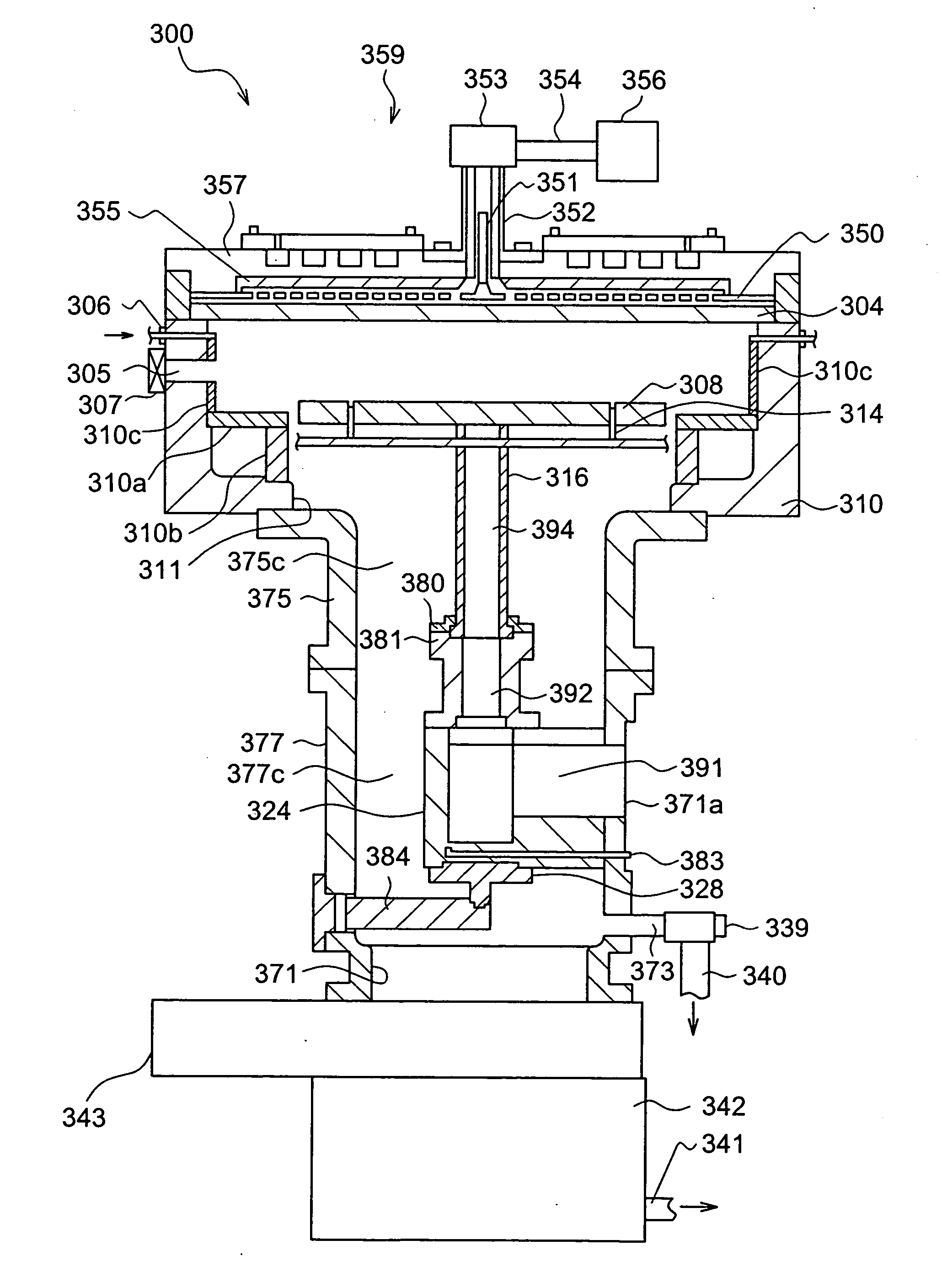

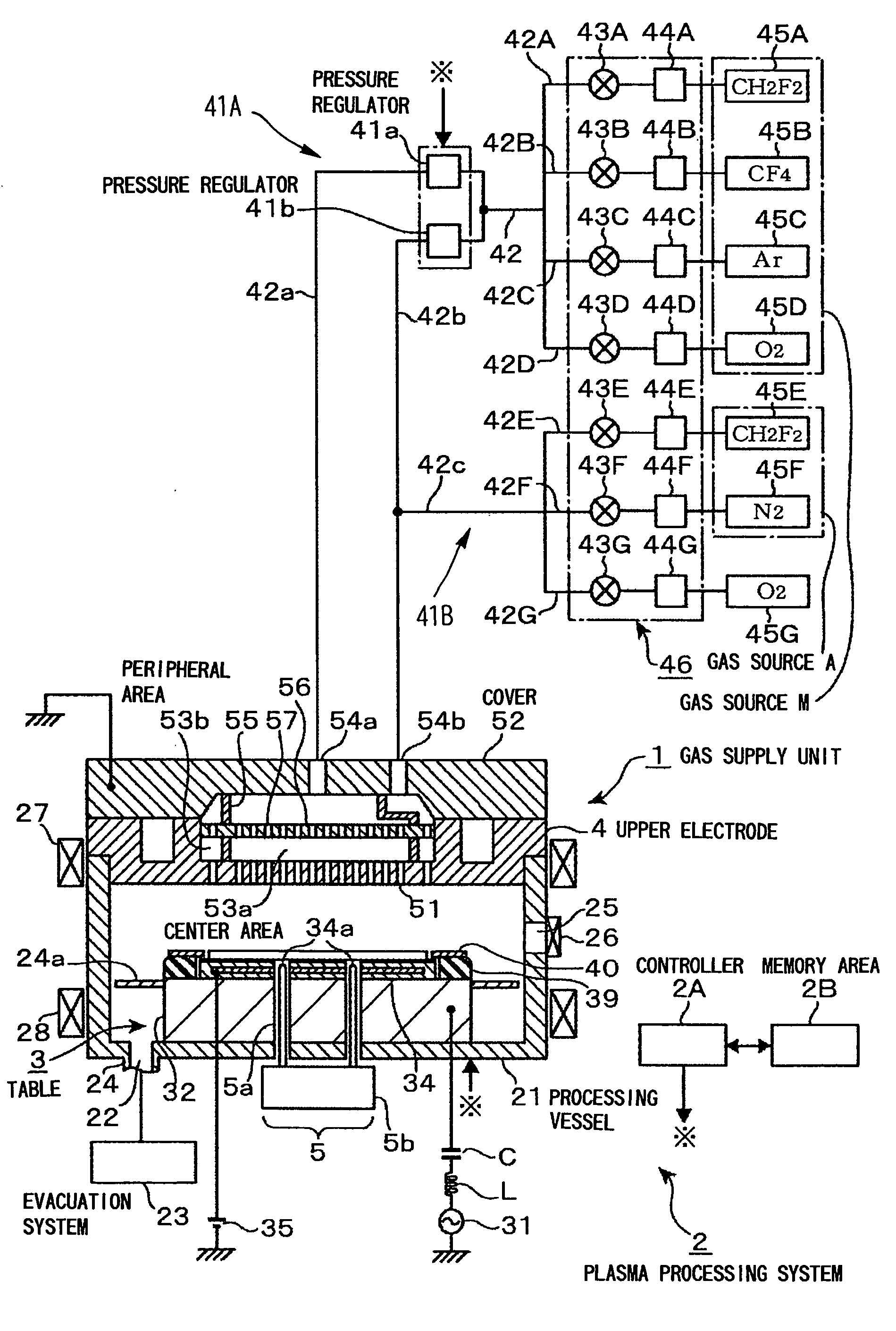

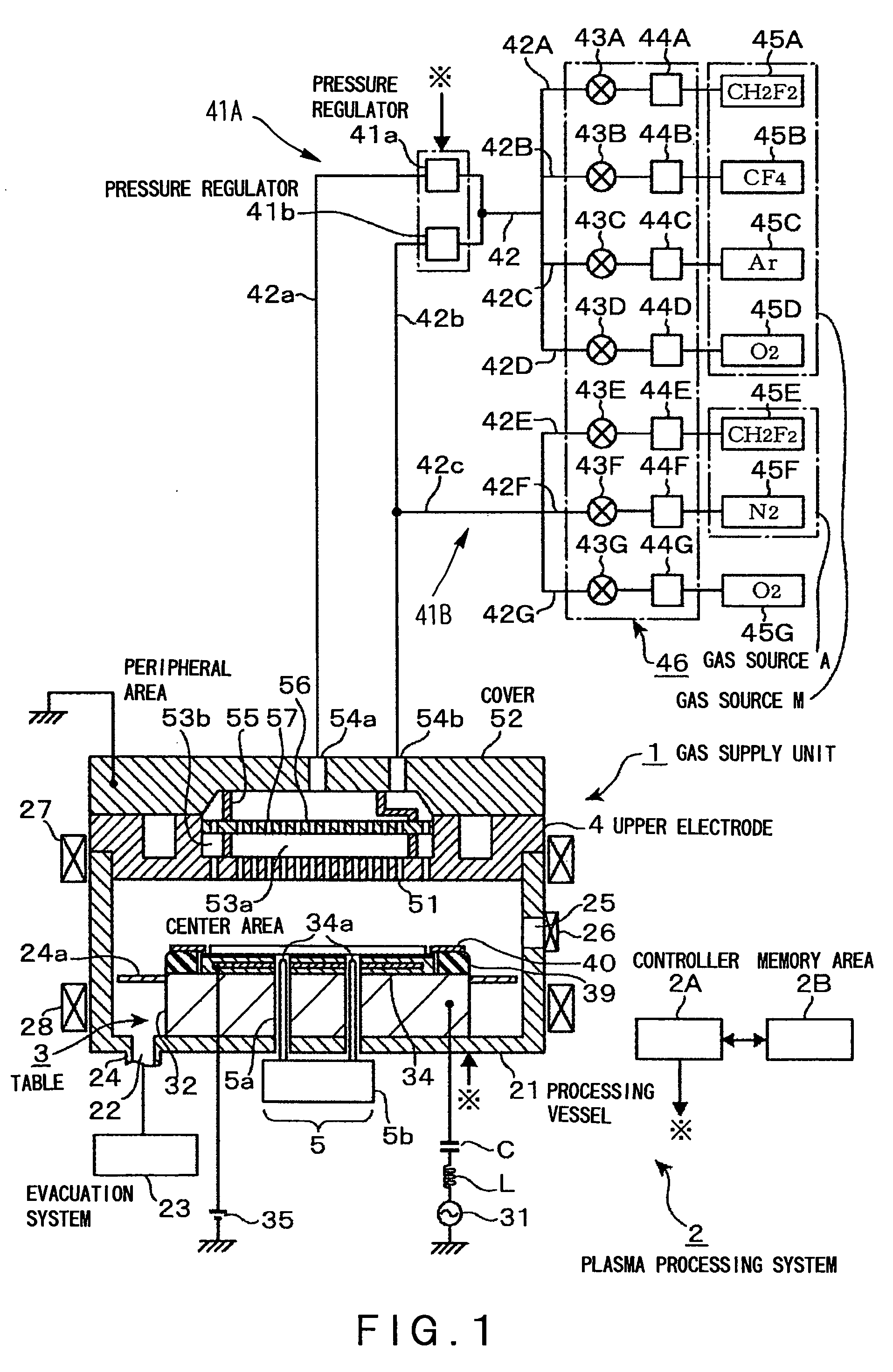

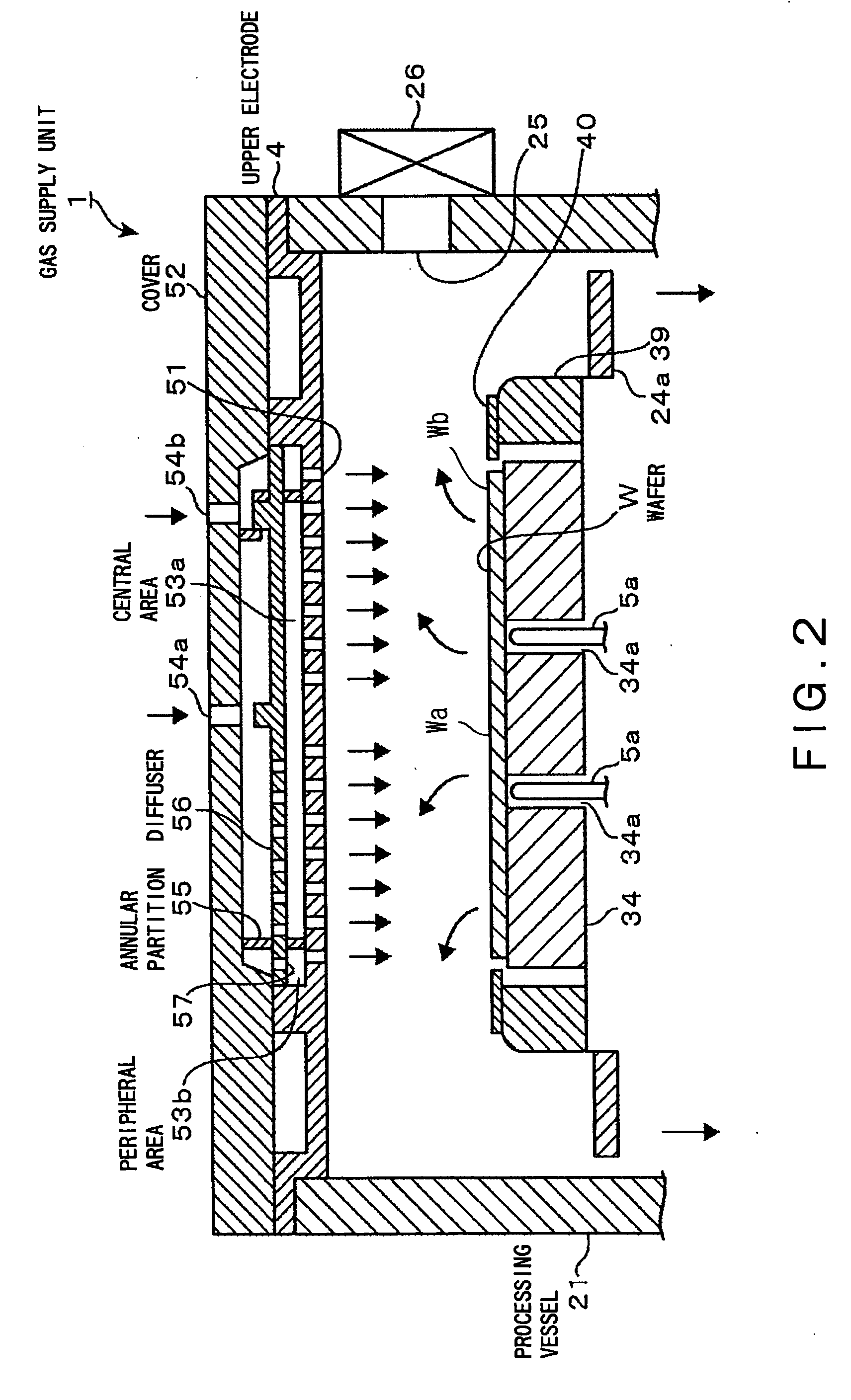

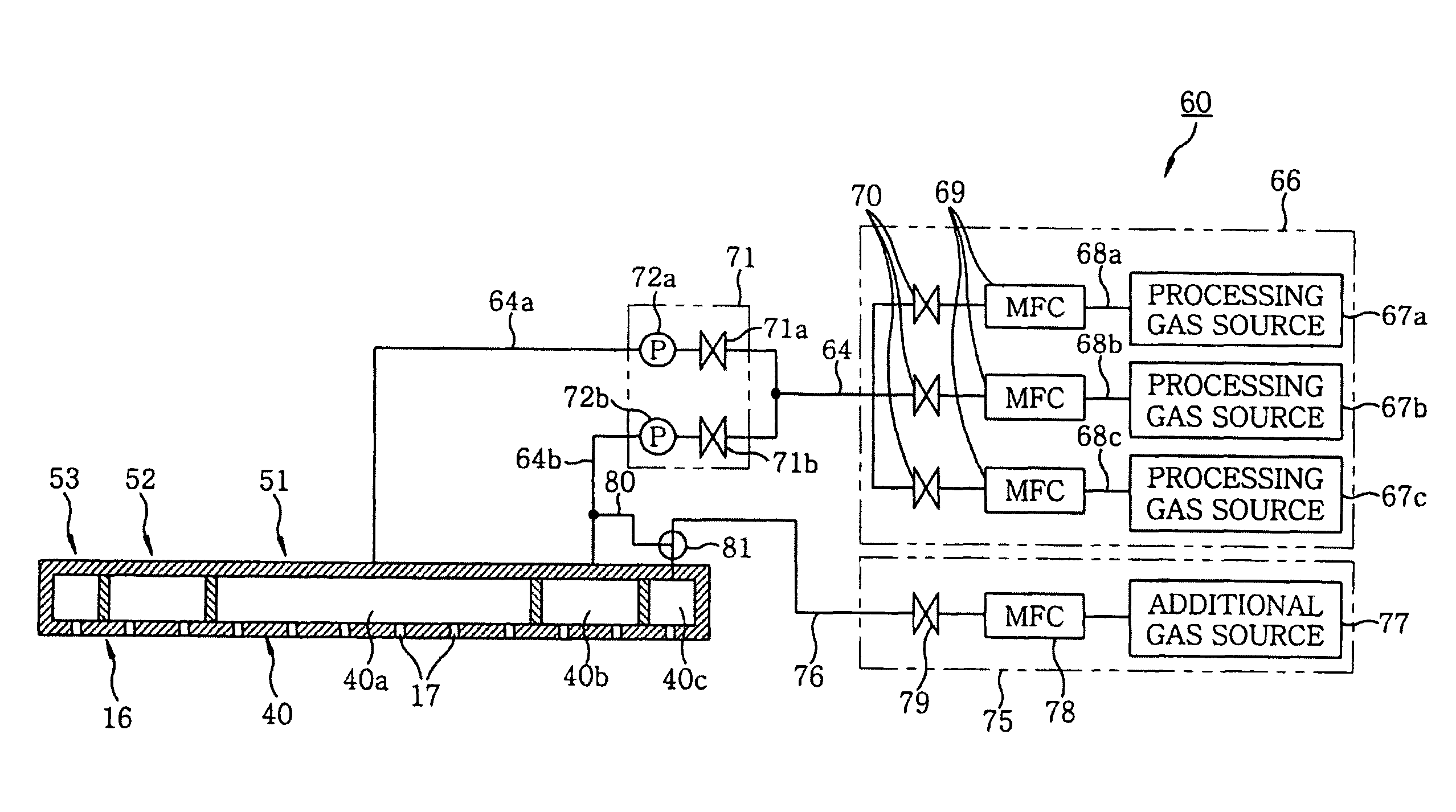

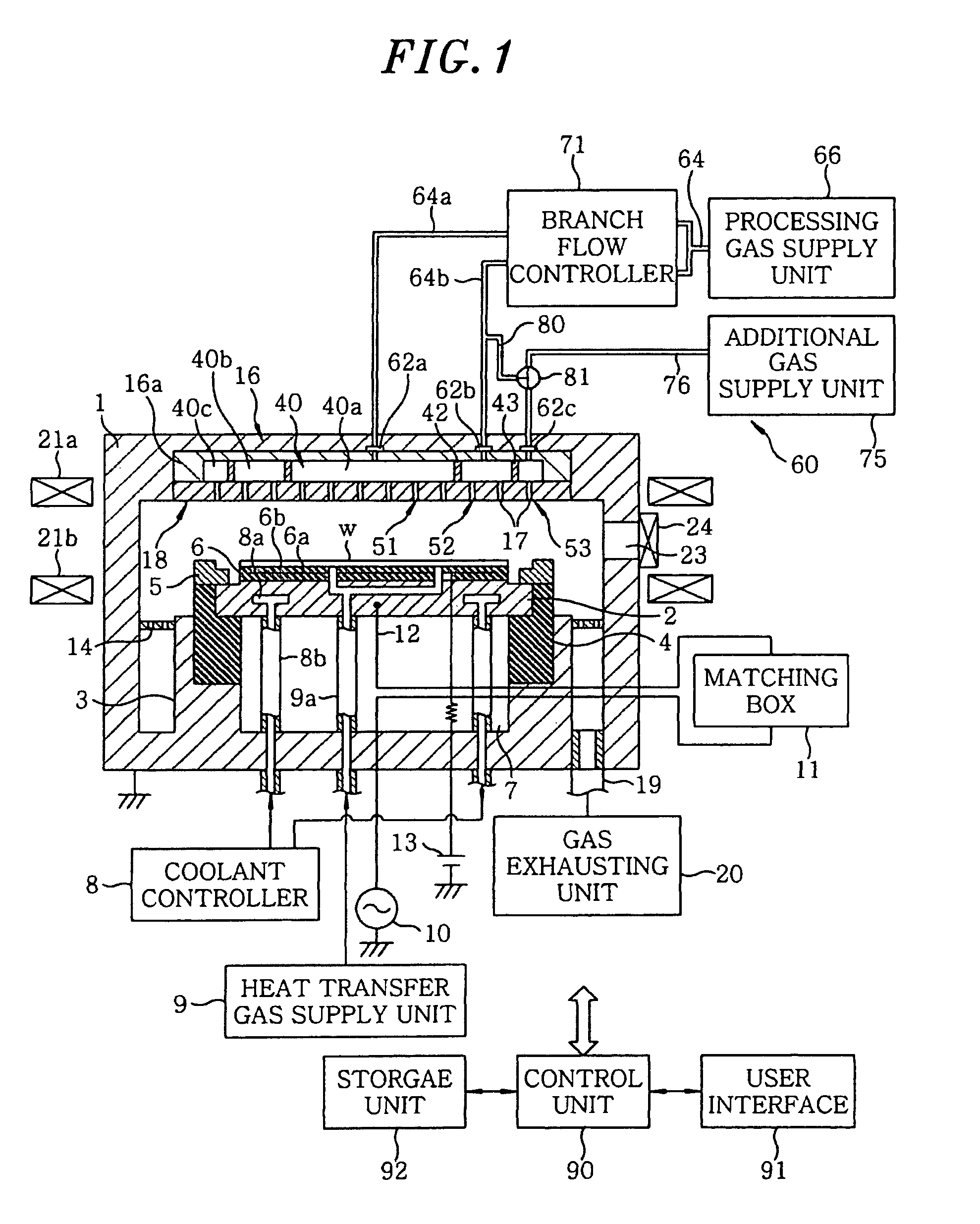

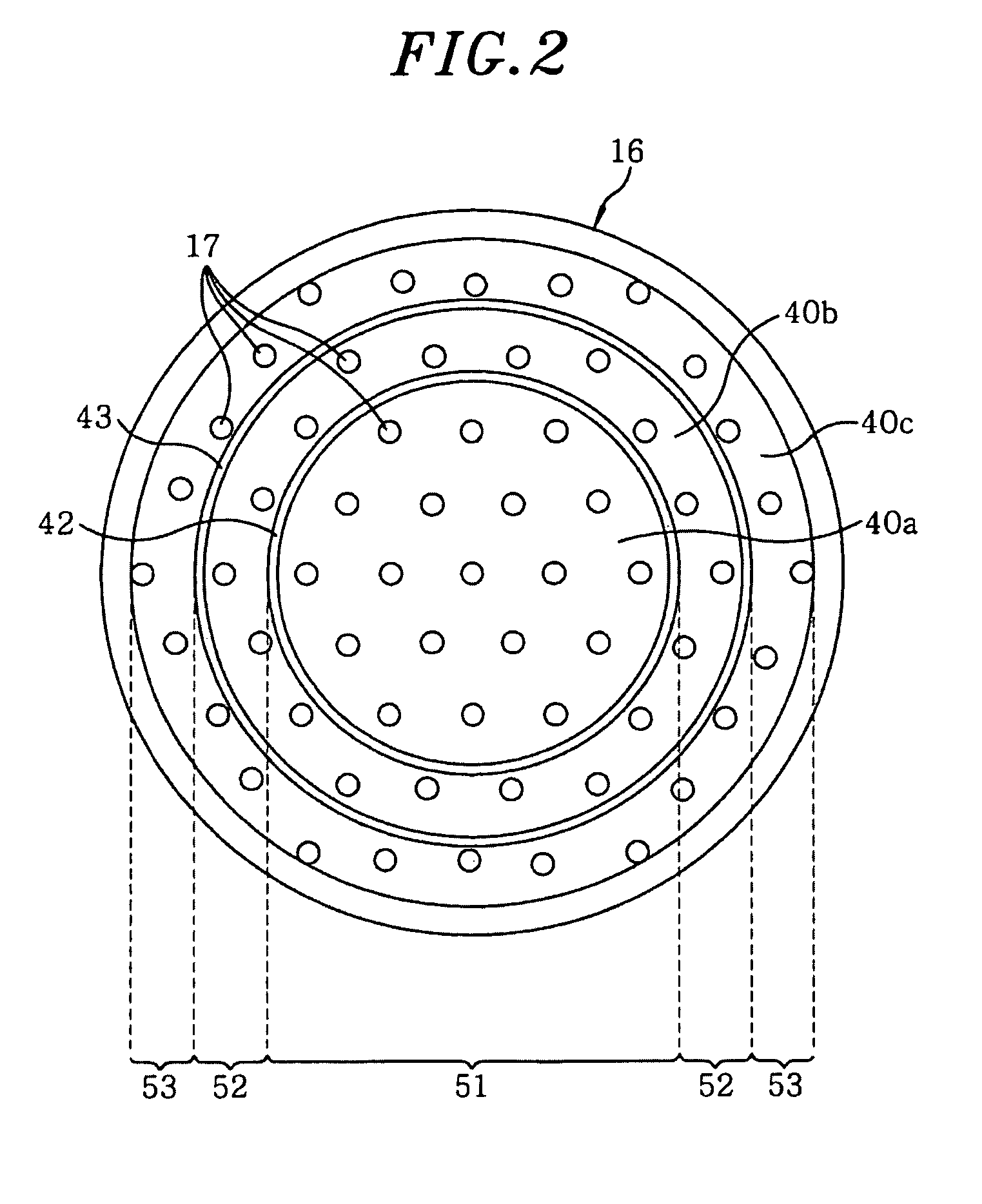

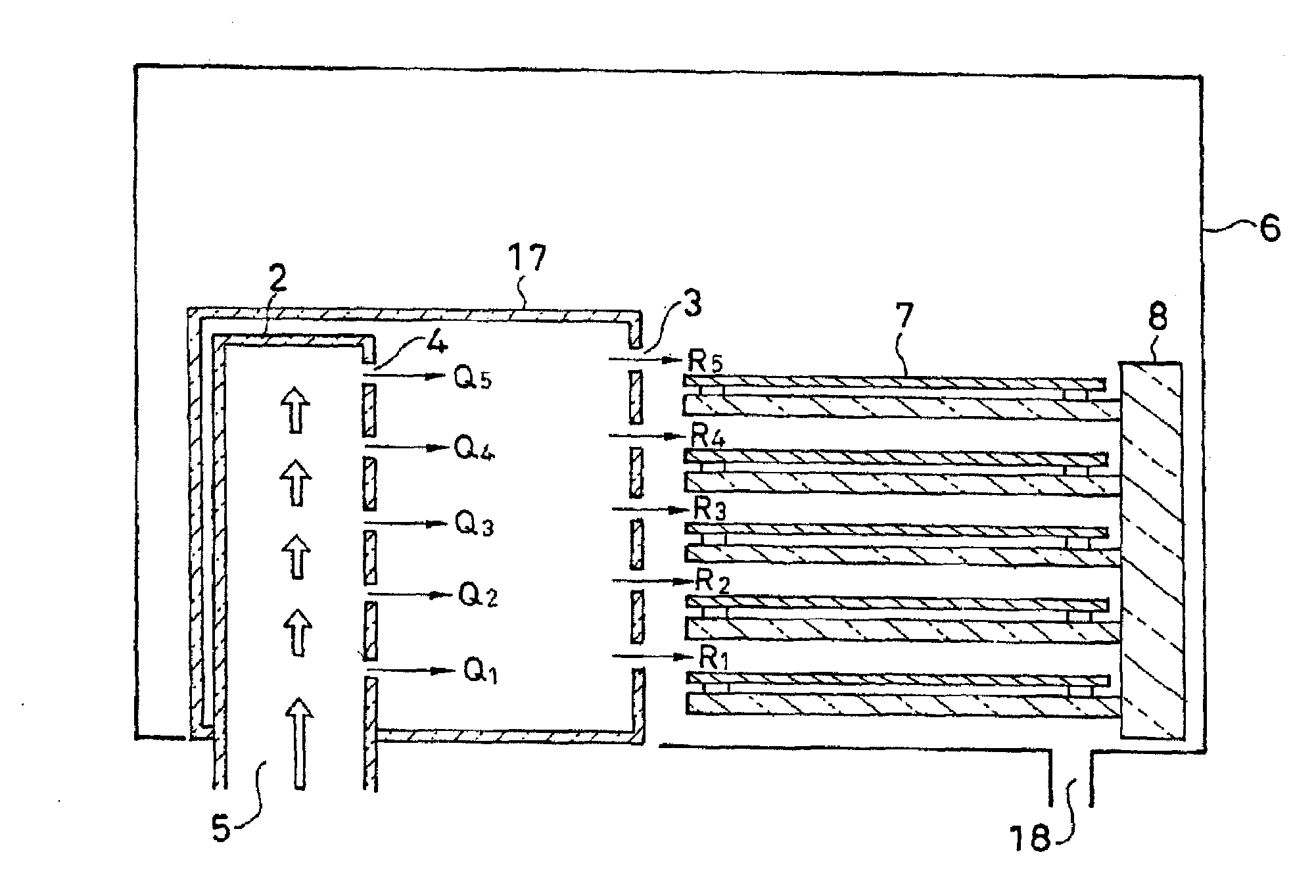

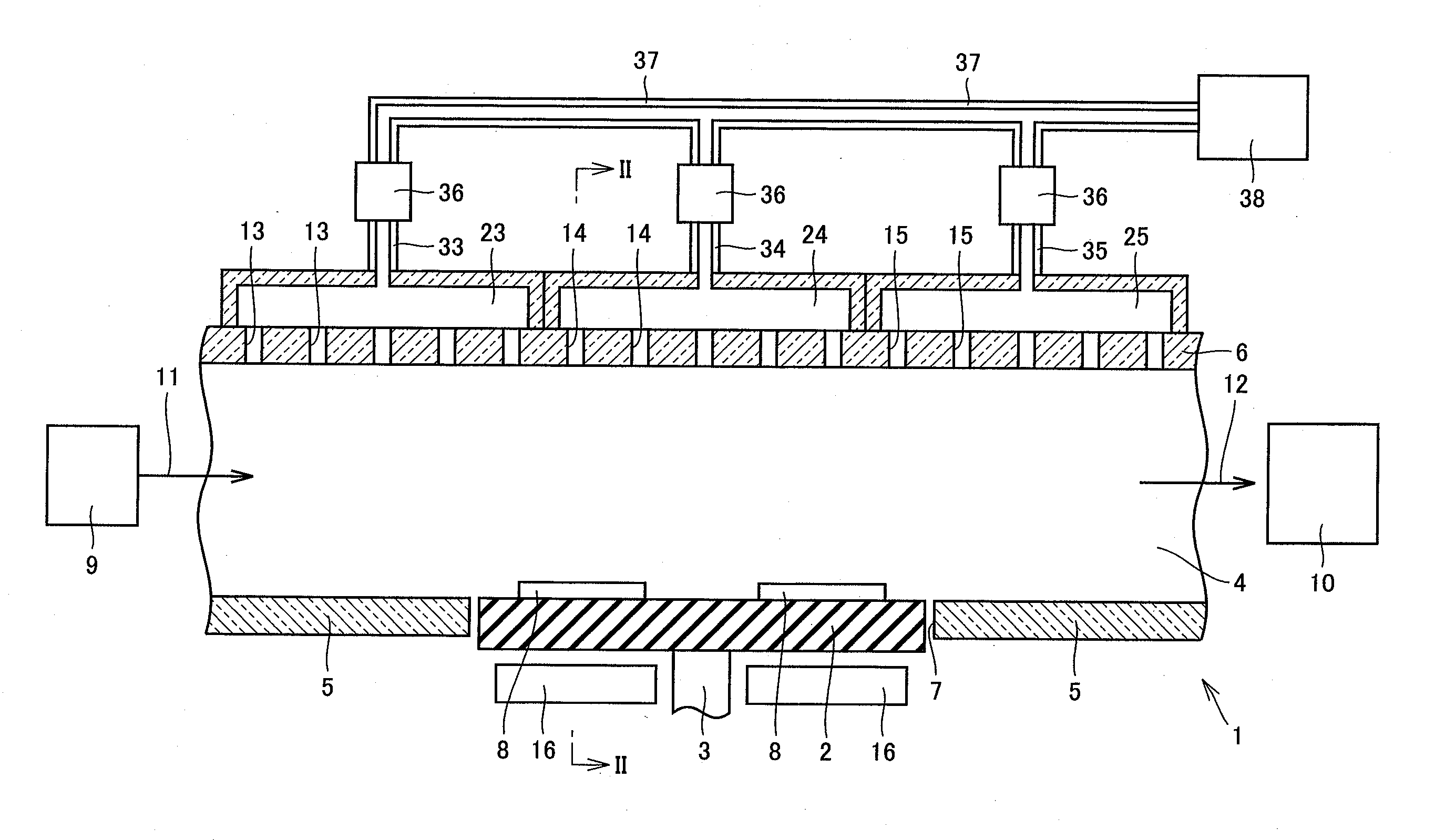

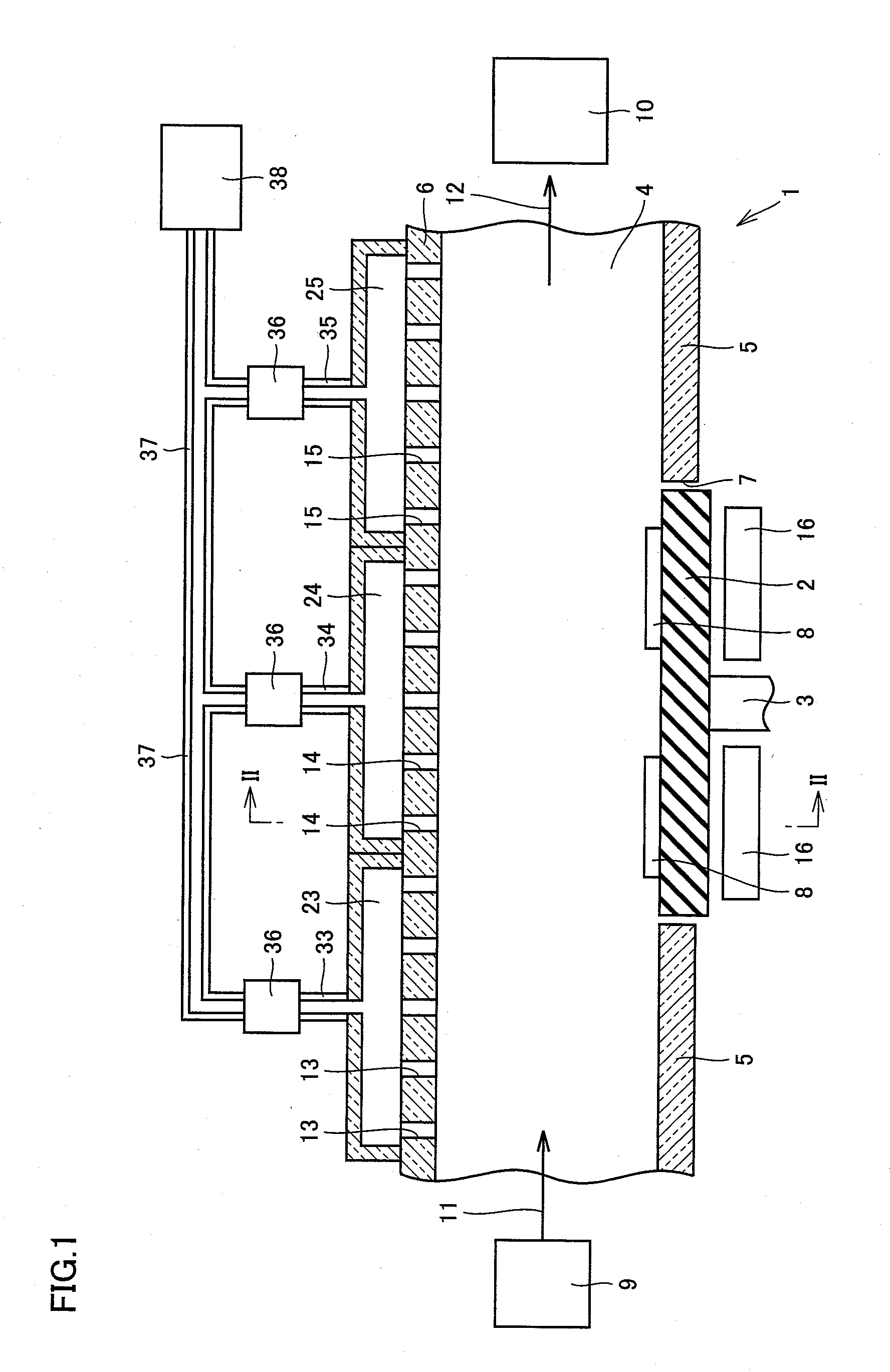

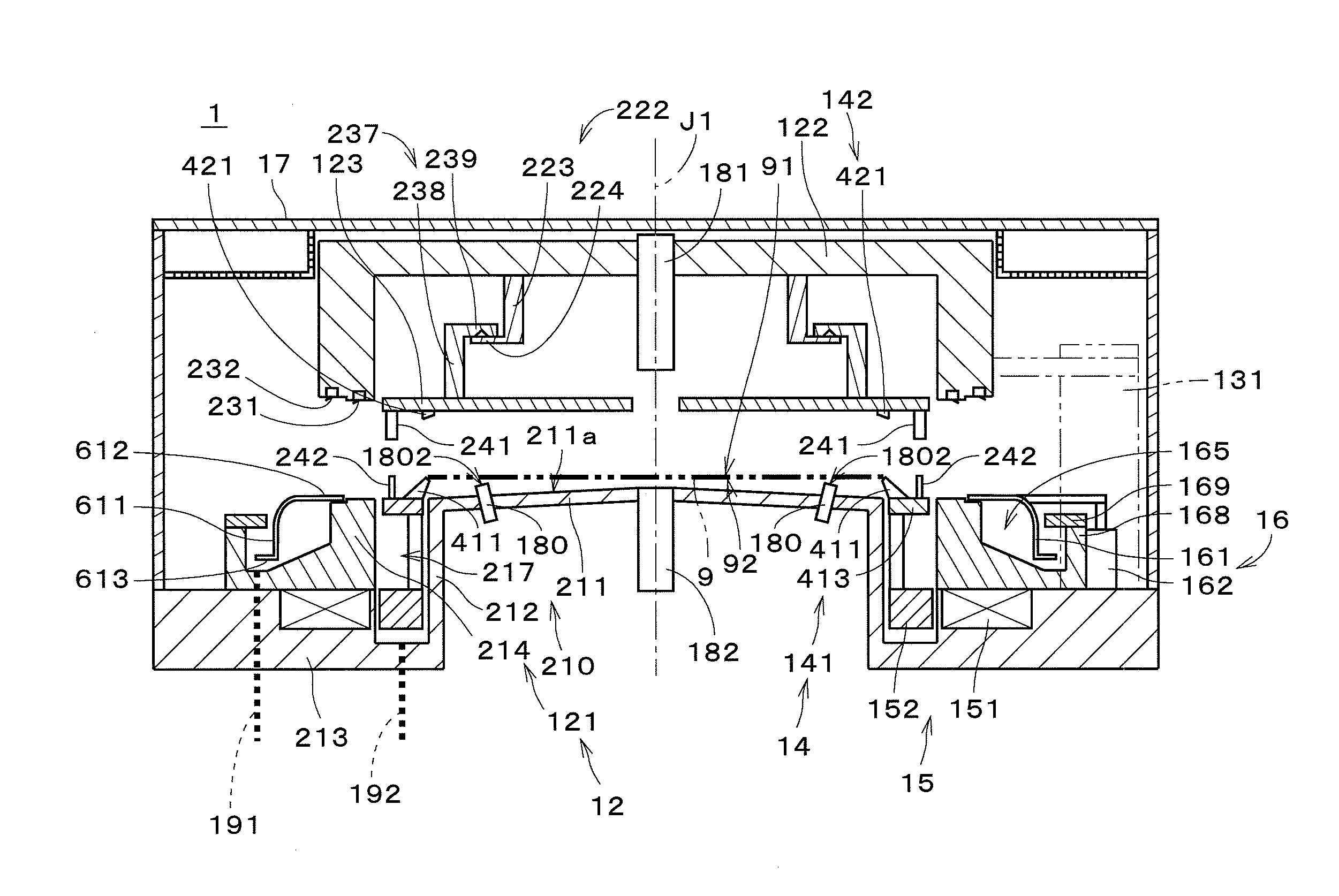

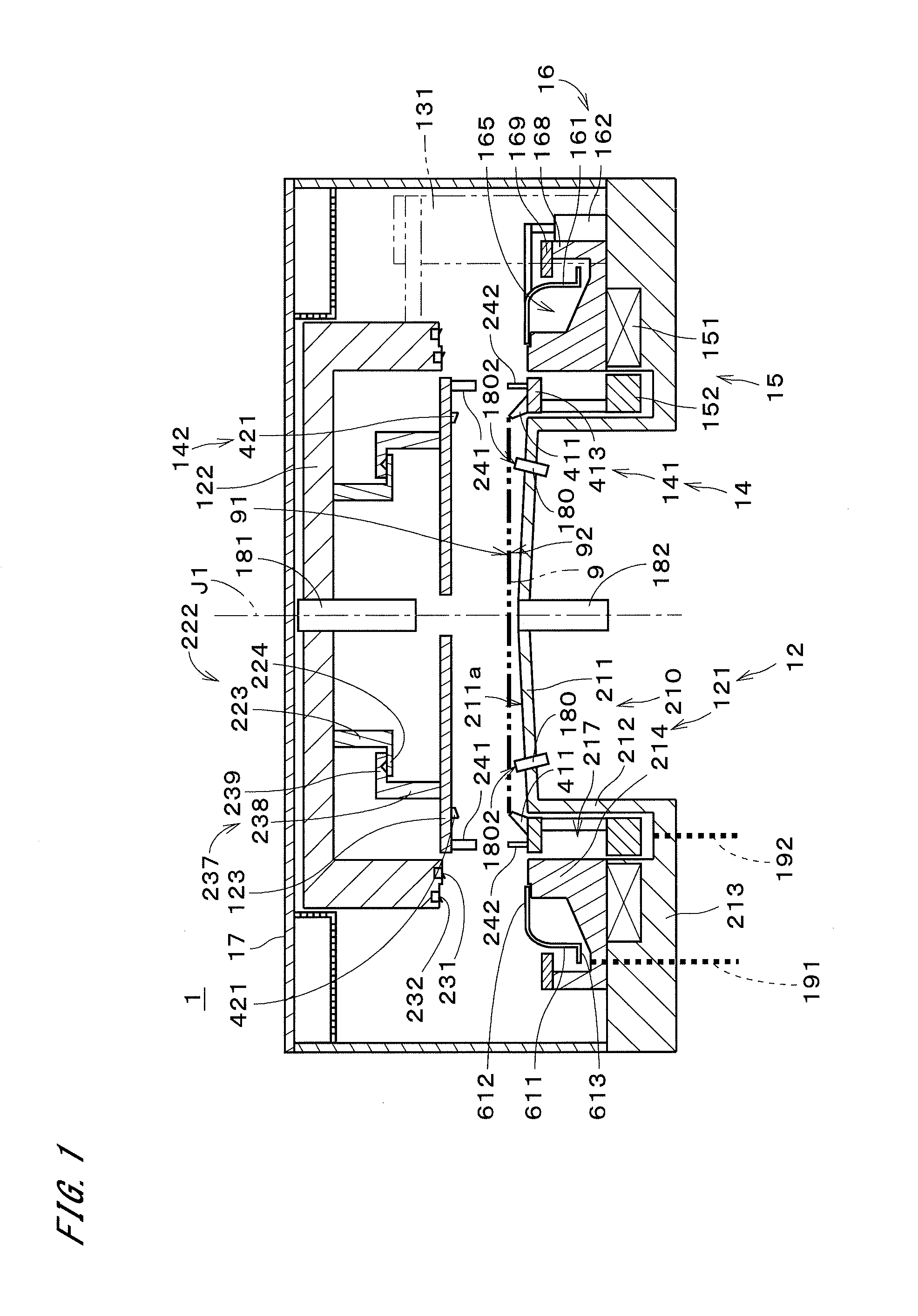

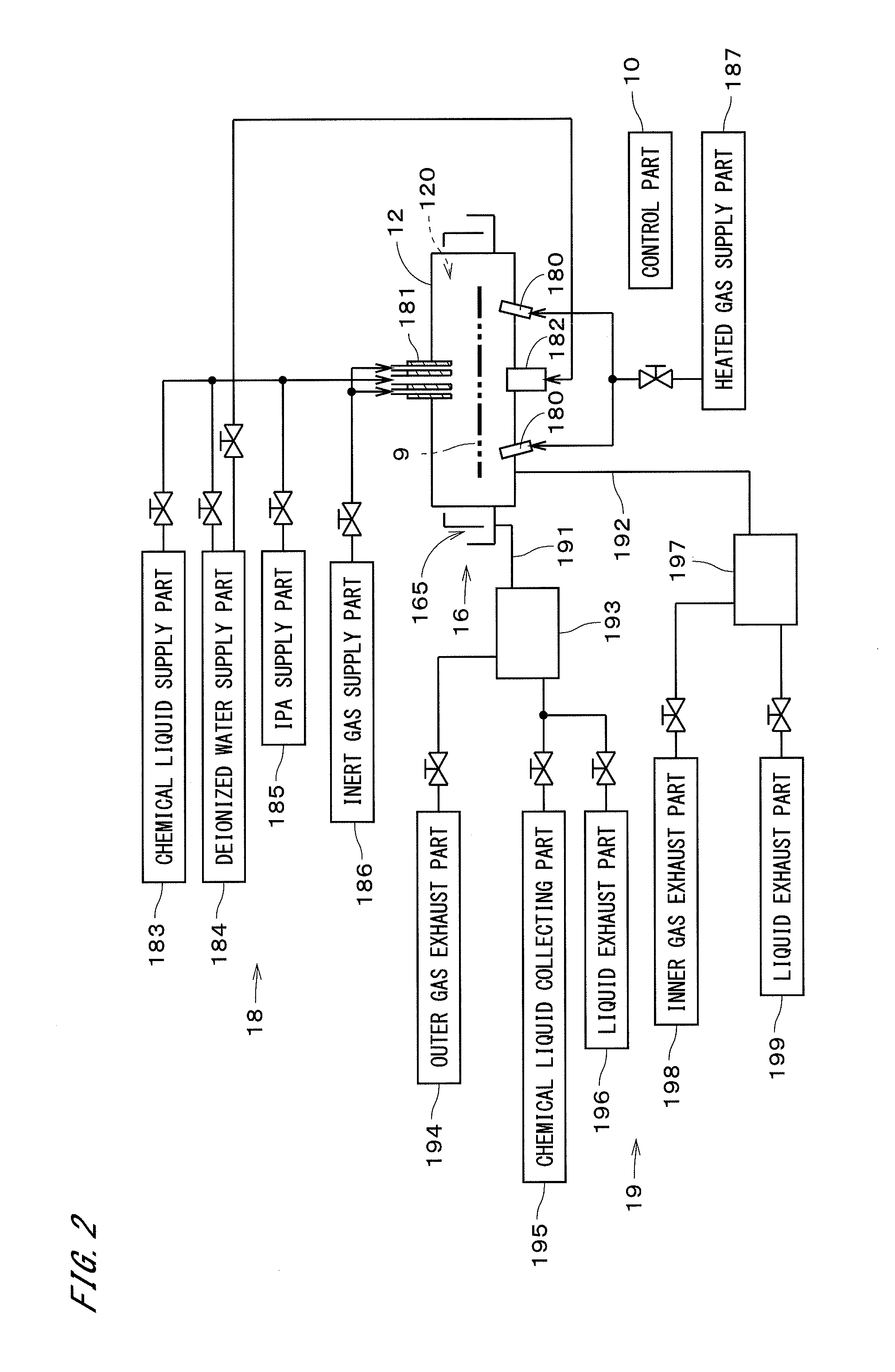

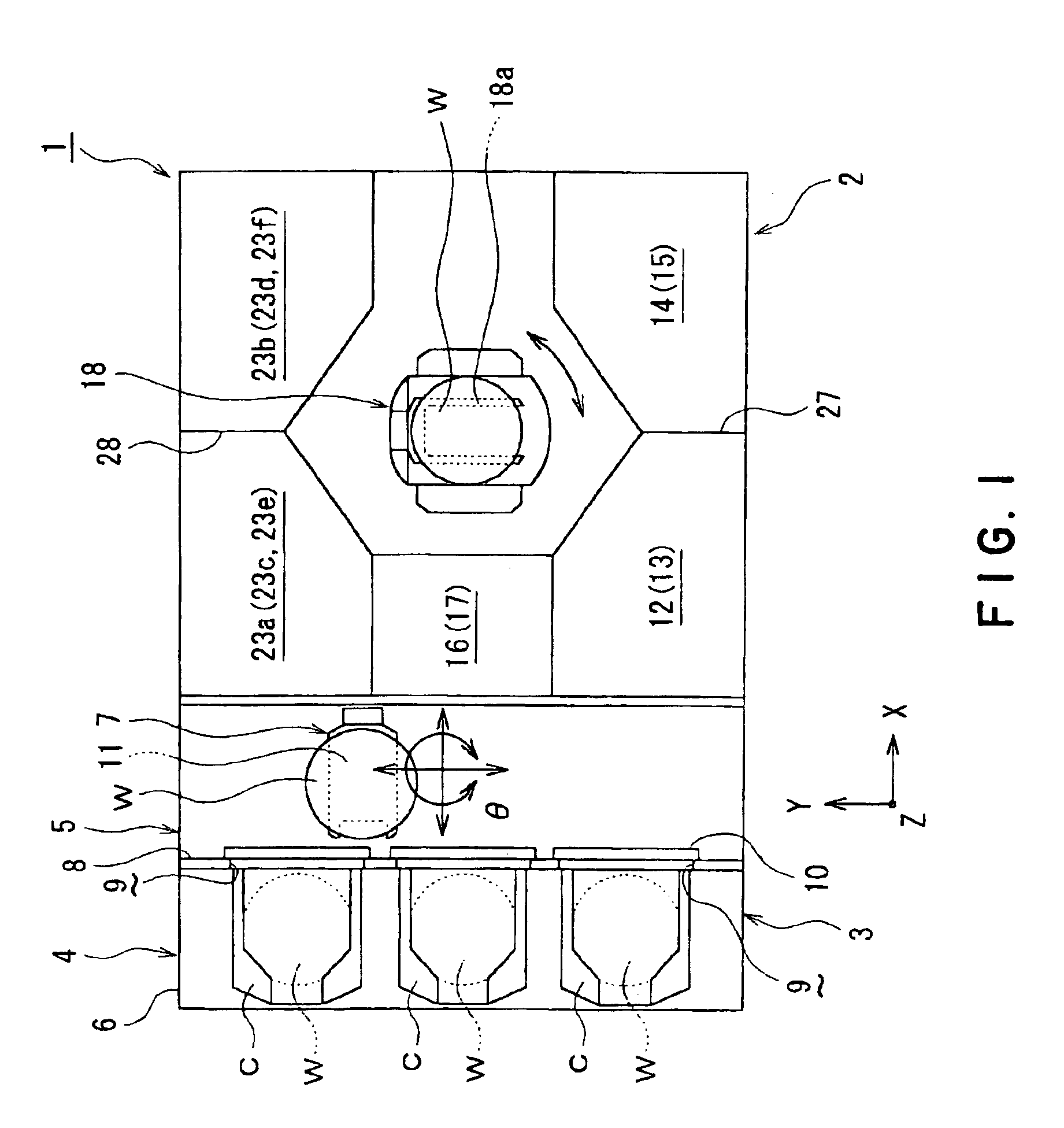

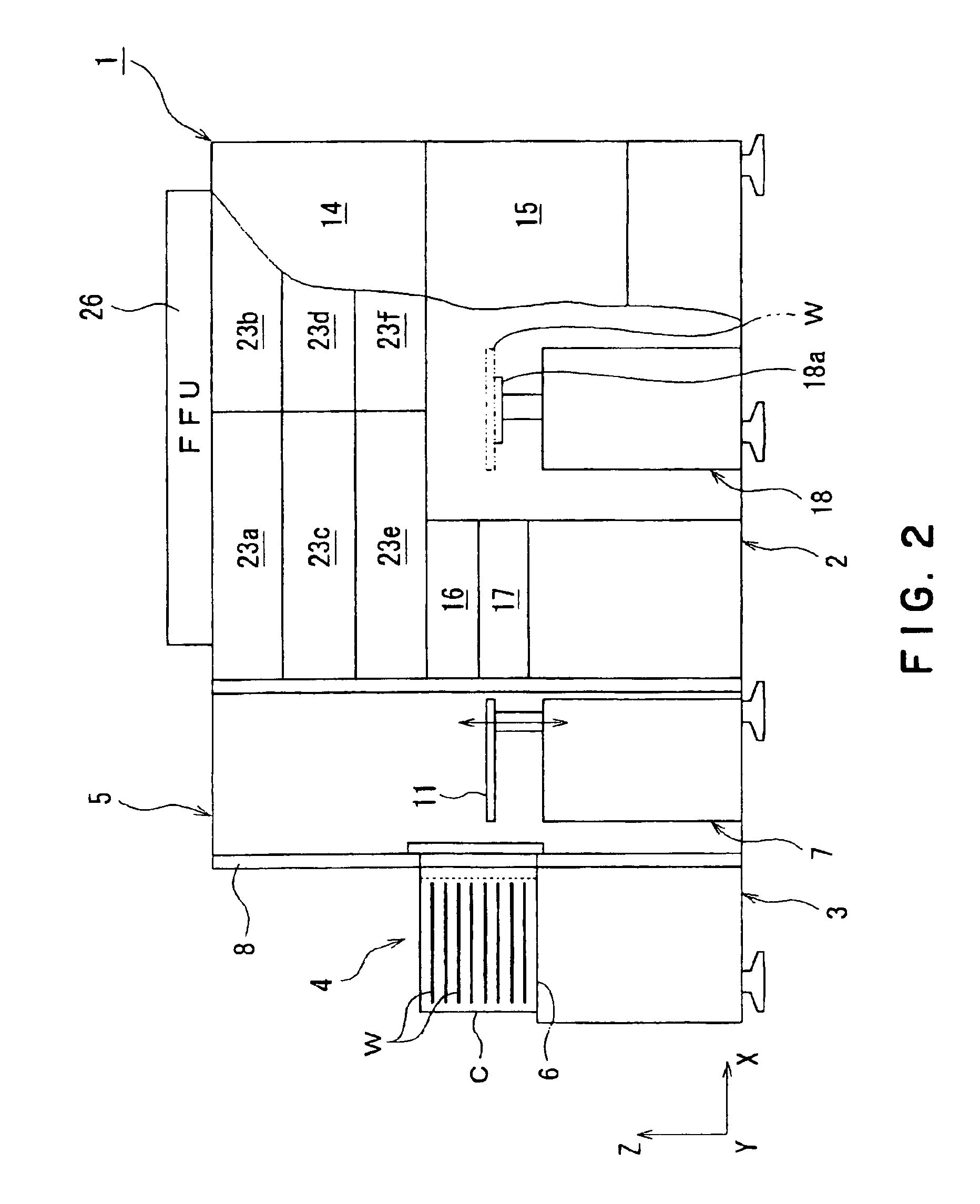

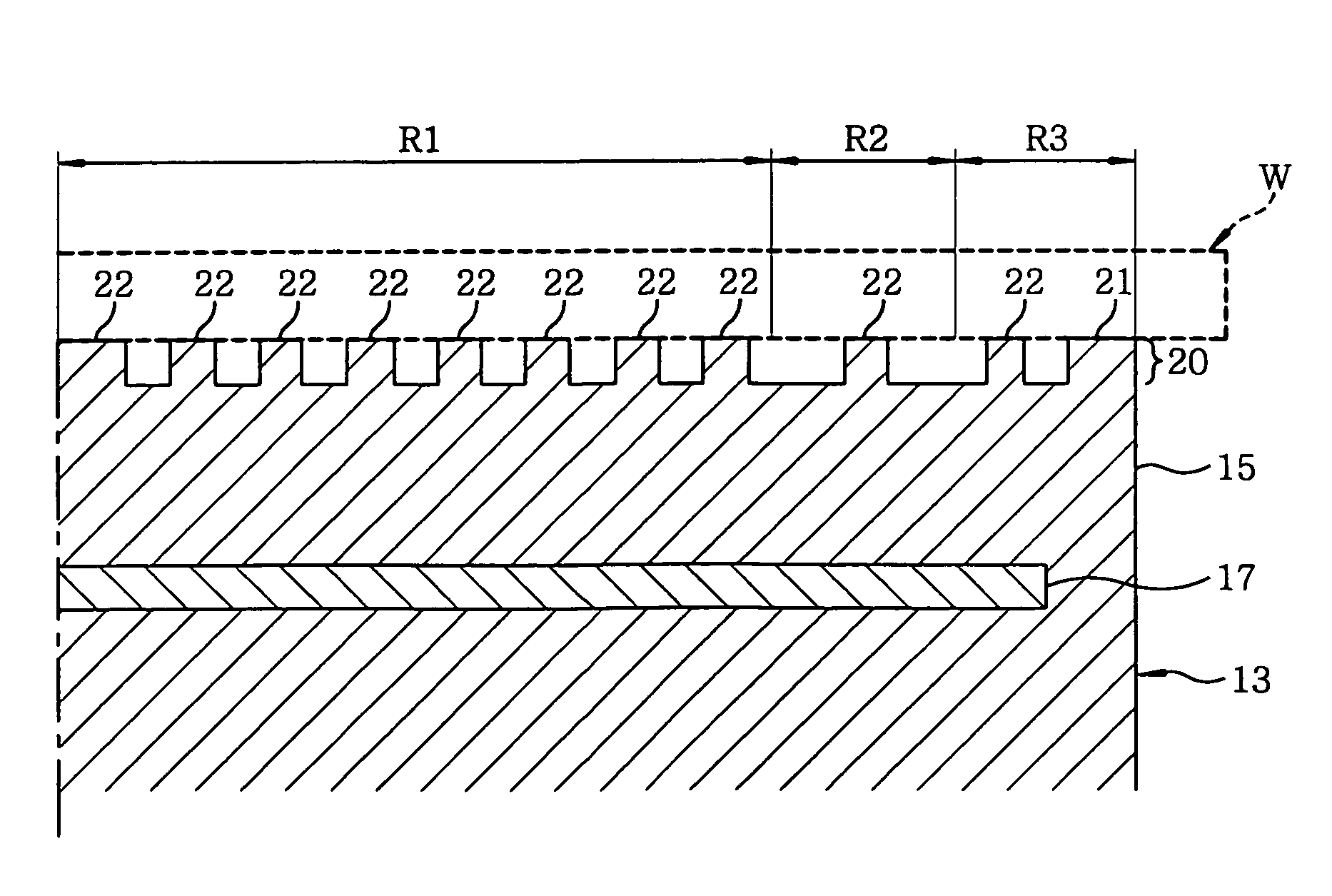

Substrate processing system, gas supply unit, method of substrate processing, computer program, and storage medium

InactiveUS20080078746A1Non-uniform processingUniform processingElectric discharge tubesDecorative surface effectsGas supplySubstrate surface

The present invention is to provide a technique for uniformly processing a substrate surface in the process of processing a substrate by supplying a gas. The inside of a shower head having gas-jetting pores for supplying a gas to a substrate is partitioned into a center section from which a gas is supplied to the center portion of a substrate, and a peripheral section from which a gas is supplied to the peripheral portion of the substrate, and the same process gas is supplied to the substrate from these two sections at flow rates separately regulated. The distance from the center of the center section of the gas supply unit to the outermost gas-jetting pores in the center section is set 53% or more of the radius of the substrate. Moreover, an additional gas is further supplied to the peripheral portion of the substrate.

Owner:TOKYO ELECTRON LTD

Gas supply device, substrate processing apparatus and substrate processing method

ActiveUS8430962B2Accurate representationSimple configurationLiquid surface applicatorsSemiconductor/solid-state device manufacturingGas passingProduct gas

A gas supply mechanism includes a gas introduction member having gas inlet portions through which a gas is introduced into a processing chamber, a processing gas supply unit, a processing gas supply path, branch paths, an additional gas supply unit and an additional gas supply path. The gas inlet portions includes inner gas inlet portions for supplying the gas toward a region where a target substrate is positioned in the chamber and an outer gas inlet portion for introducing the gas toward a region outside an outermost periphery of the target substrate. The branch paths are connected to the inner gas inlet portions, and the additional gas supply path is connected to the outer gas inlet portion.

Owner:TOKYO ELECTRON LTD

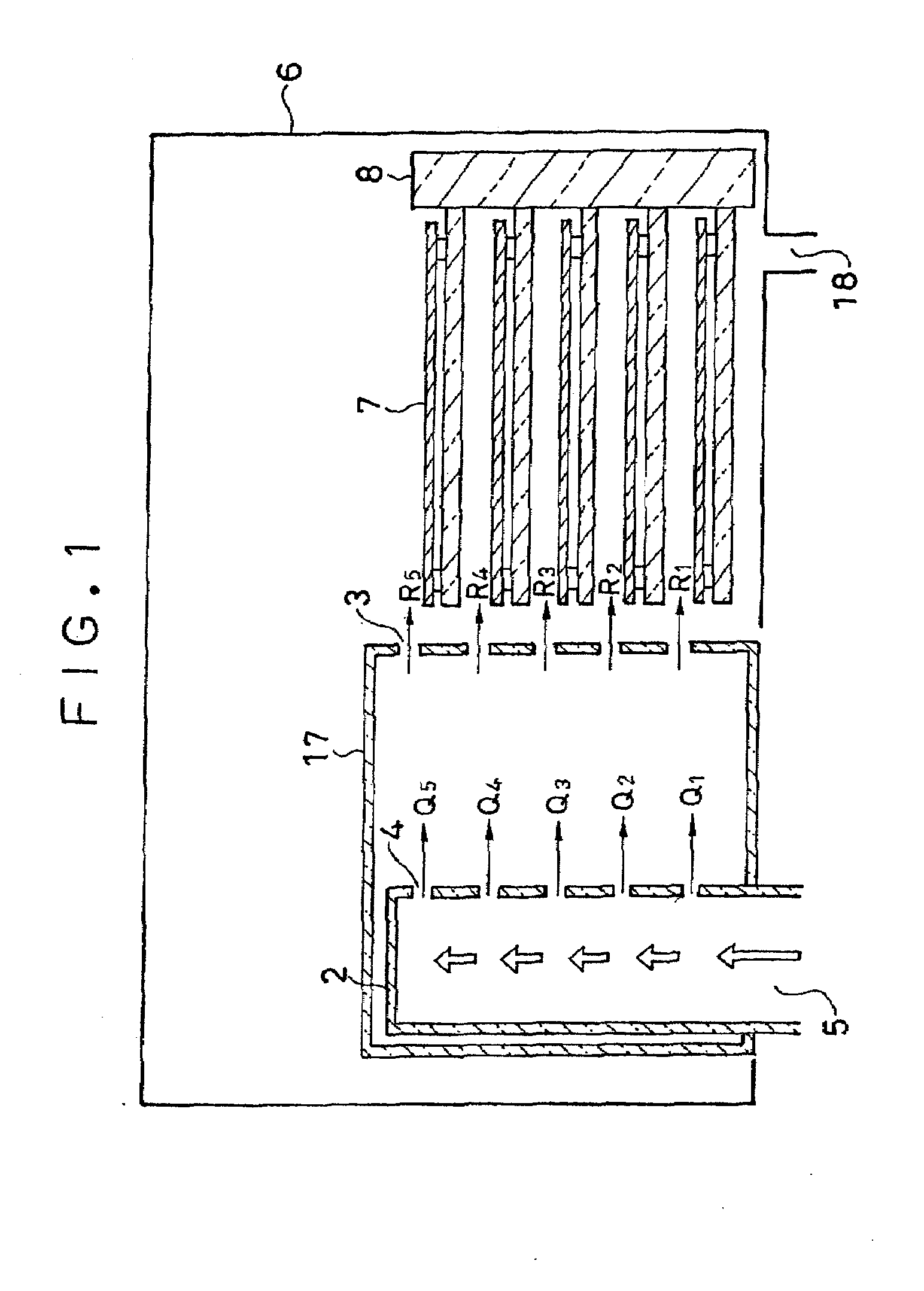

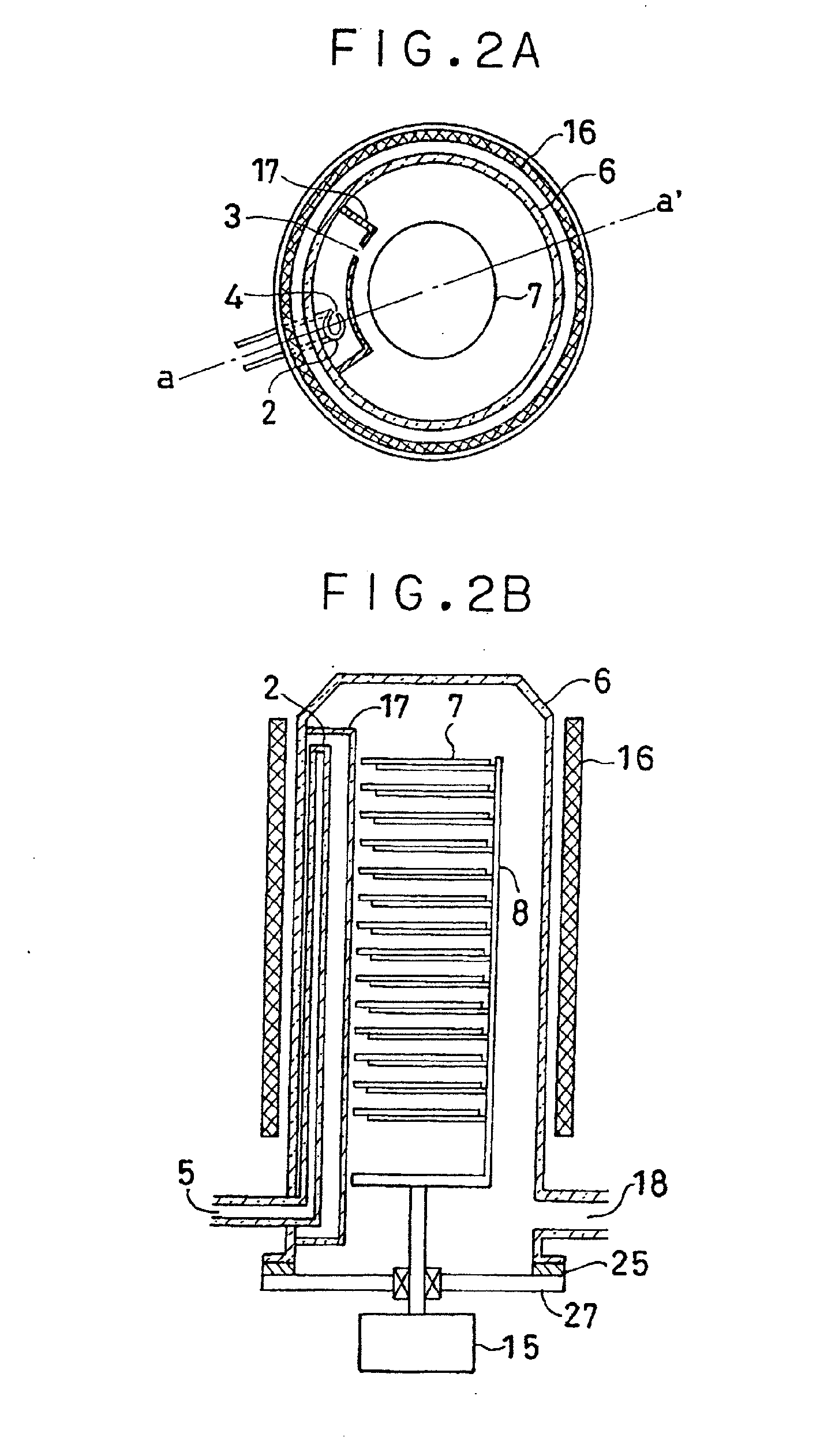

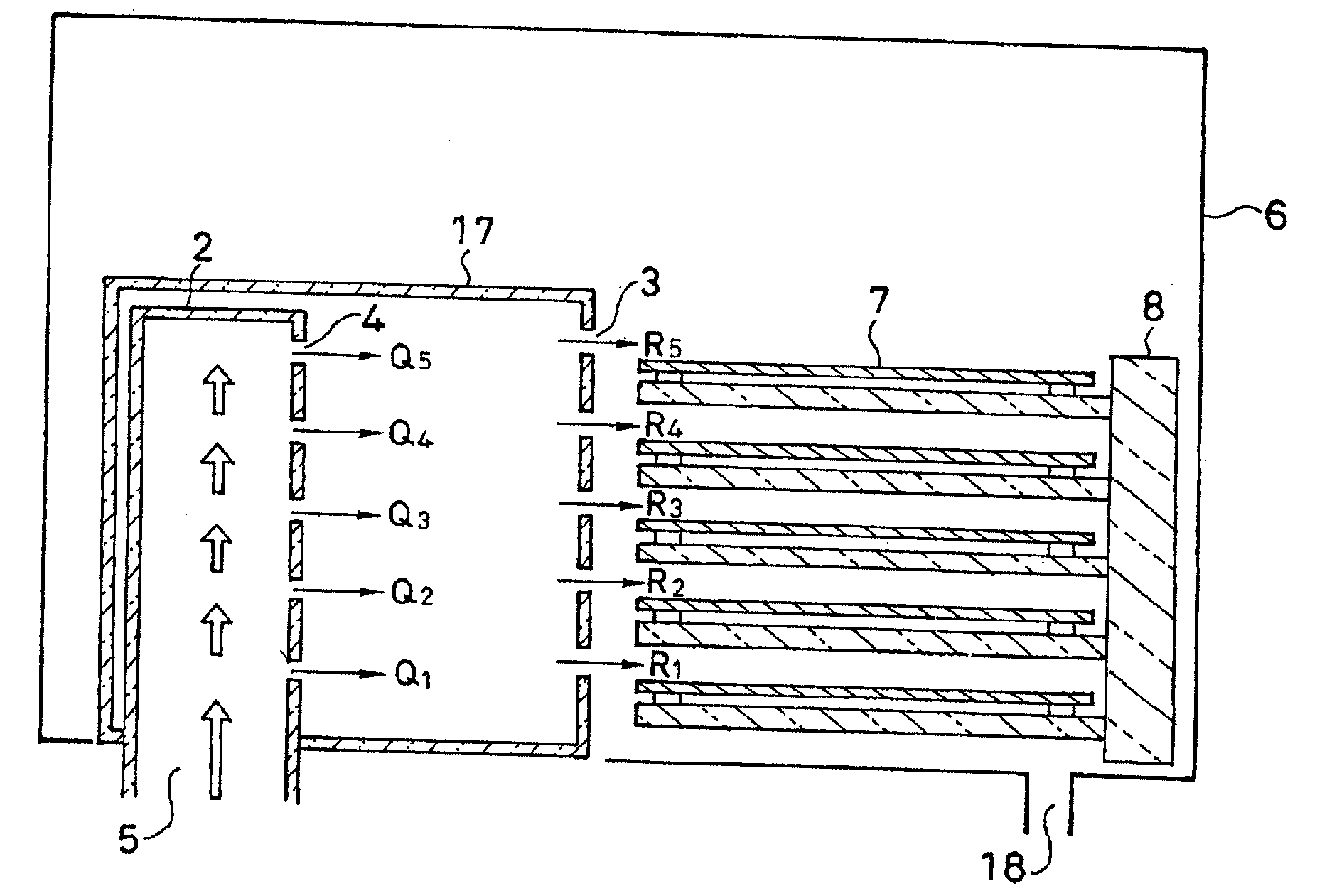

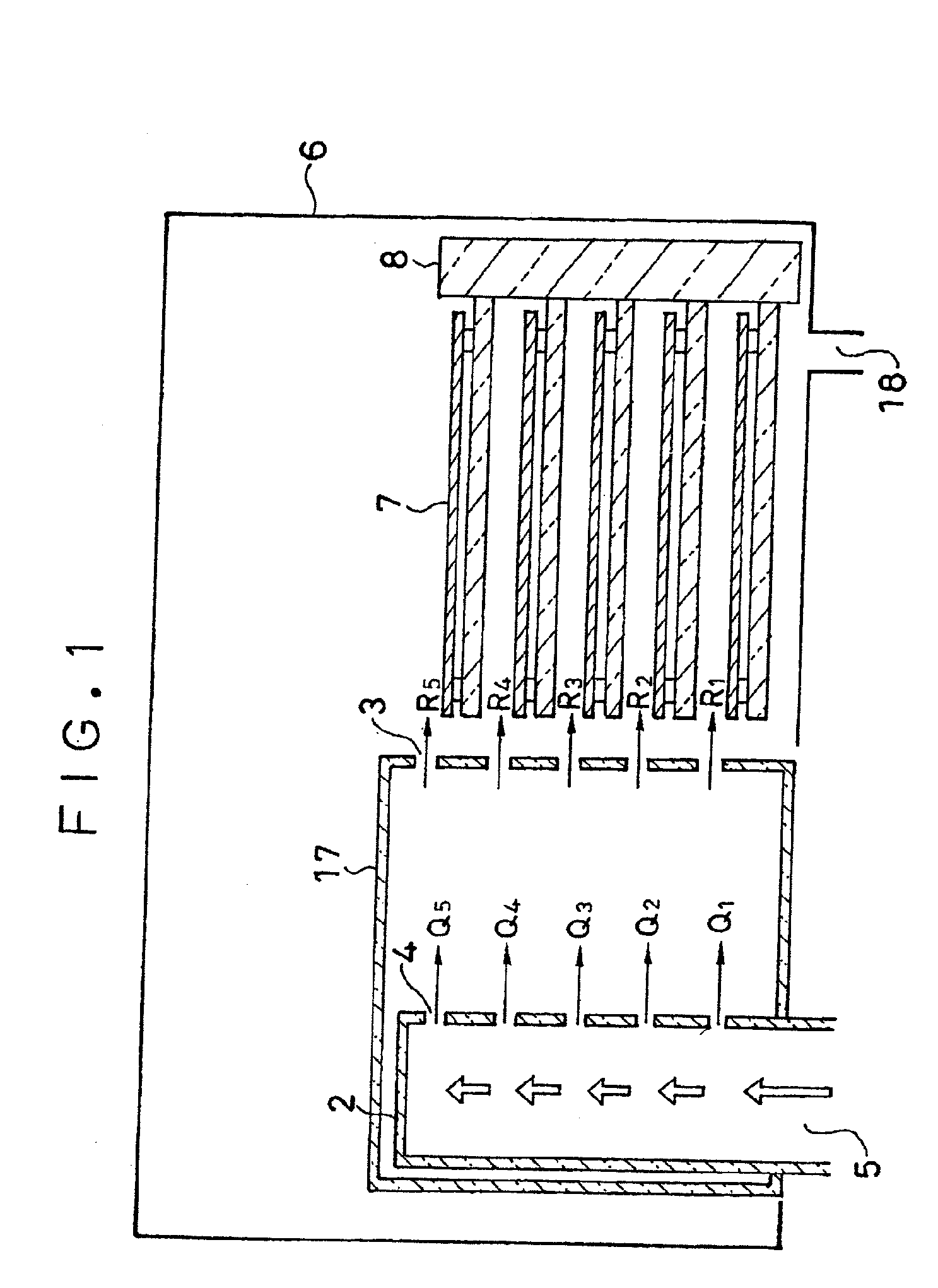

Substrate Processing Apparatus and Reaction Container

InactiveUS20080251015A1Uniform processingElectric discharge tubesChemical vapor deposition coatingEngineeringProduct gas

A substrate processing apparatus comprises a reaction chamber which is to accommodate stacked substrates, a gas introducing portion, and a buffer chamber, wherein the gas introducing portion is provided along a stacking direction of the substrates, and introduces substrate processing gas into the buffer chamber, the buffer chamber includes a plurality of gas-supply openings provided along the stacking direction of the substrates, and the processing gas introduced from the gas introducing portion is supplied from the gas-supply openings to the reaction chamber.

Owner:KONTANI TADASHI +10

Substrate Processing Apparatus and Reaction Container

InactiveUS20080121180A1Uniform processingElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasProcess engineering

A substrate processing apparatus comprises a reaction chamber which is to accommodate stacked substrates, a gas introducing portion, and a buffer chamber, wherein the gas introducing portion is provided along a stacking direction of the substrates, and introduces substrate processing gas into the buffer chamber, the buffer chamber includes a plurality of gas-supply openings provided along the stacking direction of the substrates, and the processing gas introduced from the gas introducing portion is supplied from the gas-supply openings to the reaction chamber.

Owner:KOKUSA ELECTRIC CO LTD

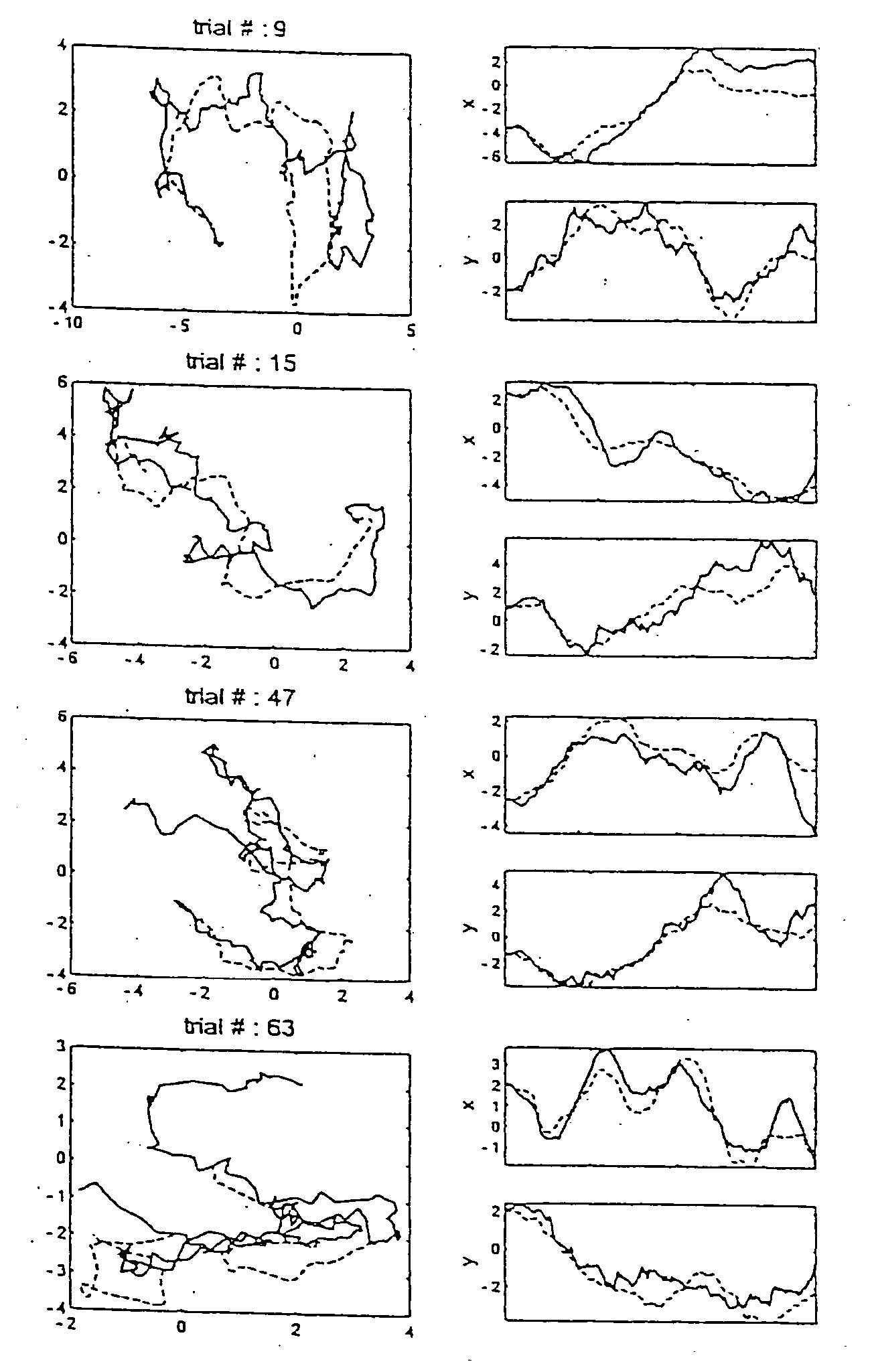

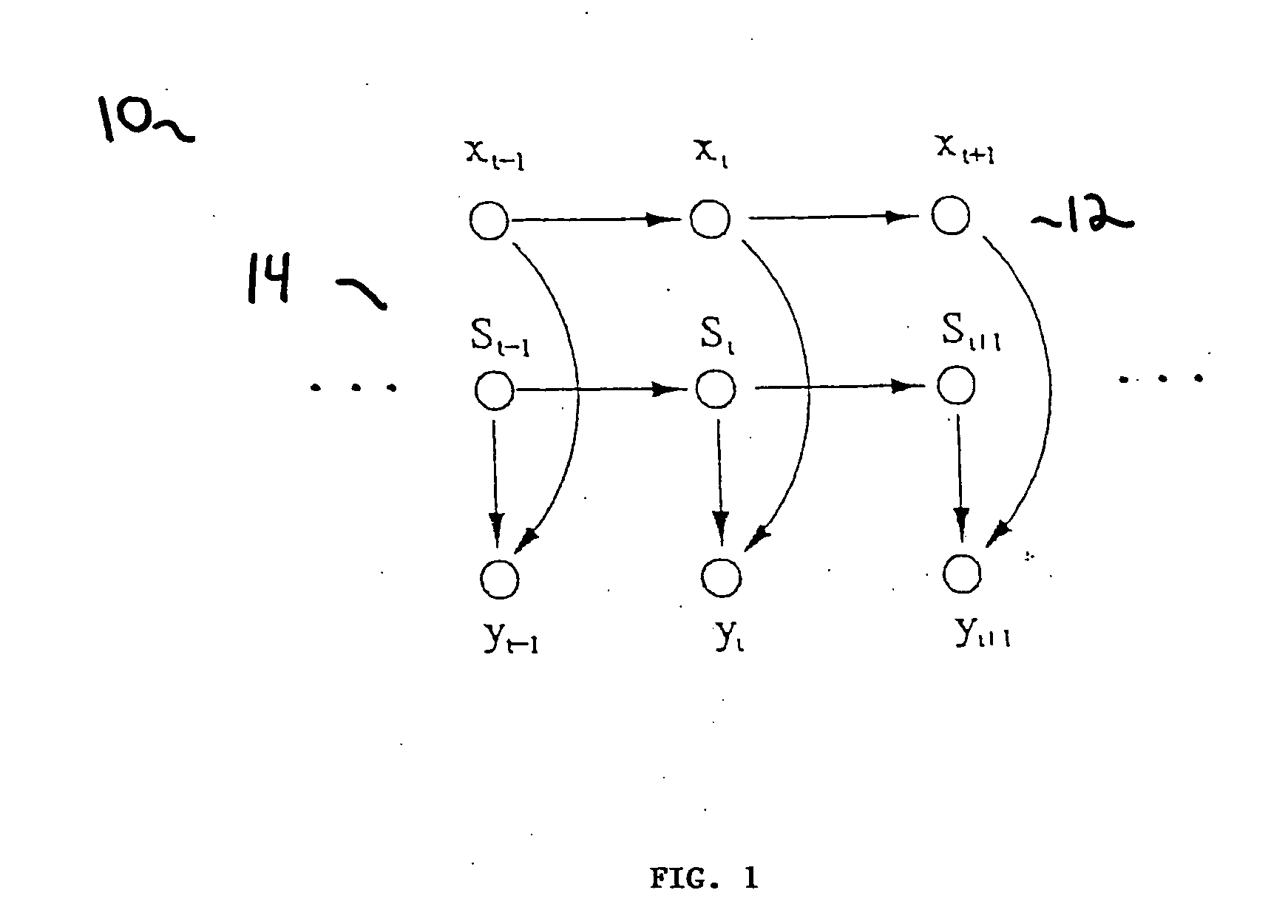

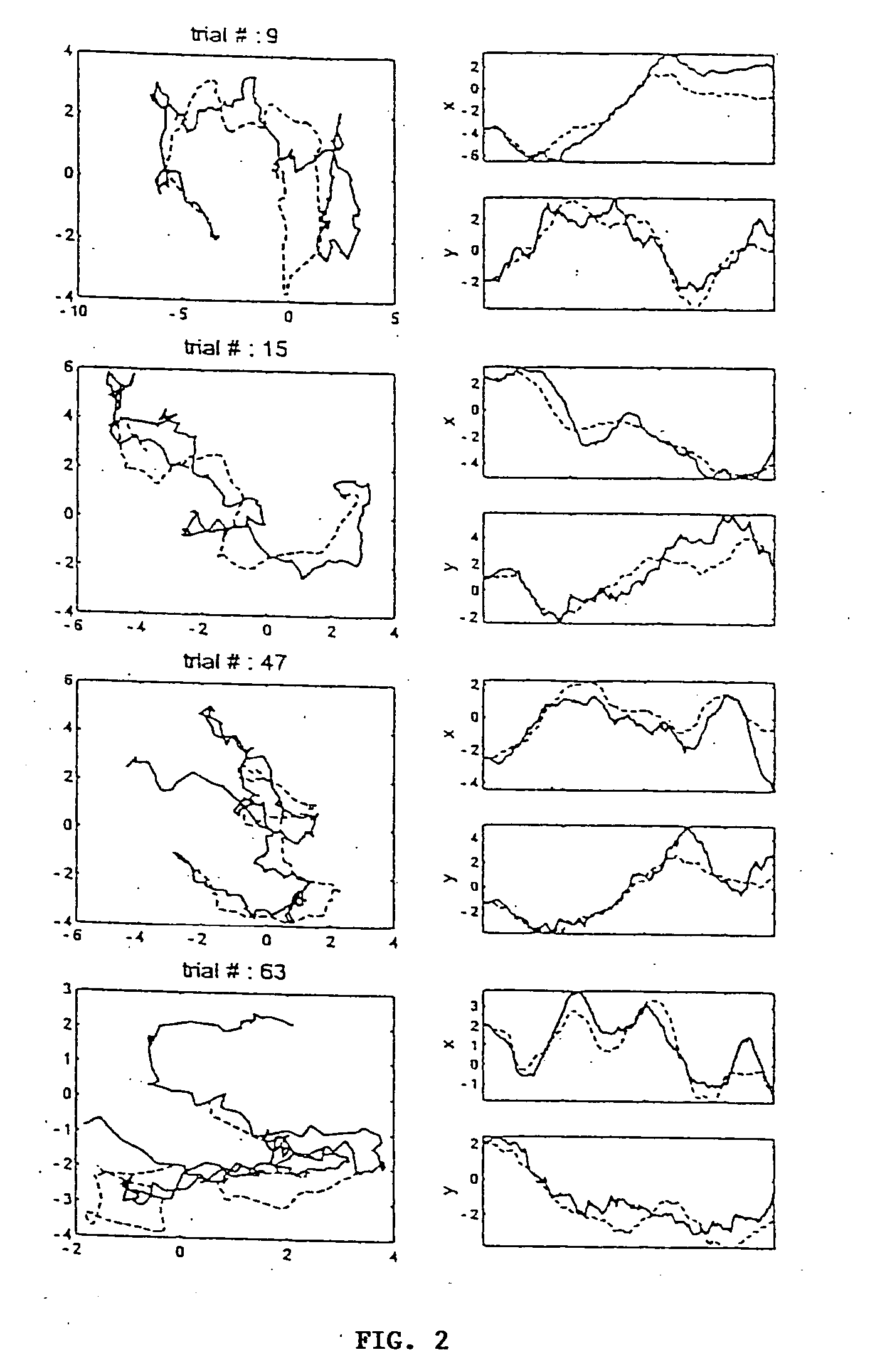

Method and system for automatic decoding of motor cortical activity

InactiveUS20060165811A1Accurate neural decodingEasy to initializeElectroencephalographyMedical data miningClosed loopProbit

A Switching Kalman Filter Model for the real-time inference of hand kinematics from a population of motor cortical neurons. Firing rates are modeled as a Gaussian mixture where the mean of each Gaussian component is a linear function of hand kinematics. A “hidden state” models the probability of each mixture component and evolves over time in a Markov chain. Gaussian mixture models and Expectation Maximization (EM) techniques are extended for automatic spike sorting. Good initialization of EM is achieved via spectral clustering. To account for noise, the mixture model is extended to include a uniform outlier process. A greedy optimization algorithm that selects models with different numbers of neurons according to their decoding accuracy is used to automatically determine the number of neurons recorded per electrode. Closed loop neural control of external events are demonstrated using neural control of a computer curser.

Owner:BROWN UNIVERSITY

Substrate Processing Apparatus and Reaction Container

InactiveUS20080251014A1Uniform processingElectric discharge tubesChemical vapor deposition coatingProcess engineeringGas supply

A substrate processing apparatus comprises a reaction chamber which is to accommodate stacked substrates, a gas introducing portion, and a buffer chamber, wherein the gas introducing portion is provided along a stacking direction of the substrates, and introduces substrate processing gas into the buffer chamber, the buffer chamber includes a plurality of gas-supply openings provided along the stacking direction of the substrates, and the processing gas introduced from the gas introducing portion is supplied from the gas-supply openings to the reaction chamber.

Owner:KOKUSA ELECTRIC CO LTD

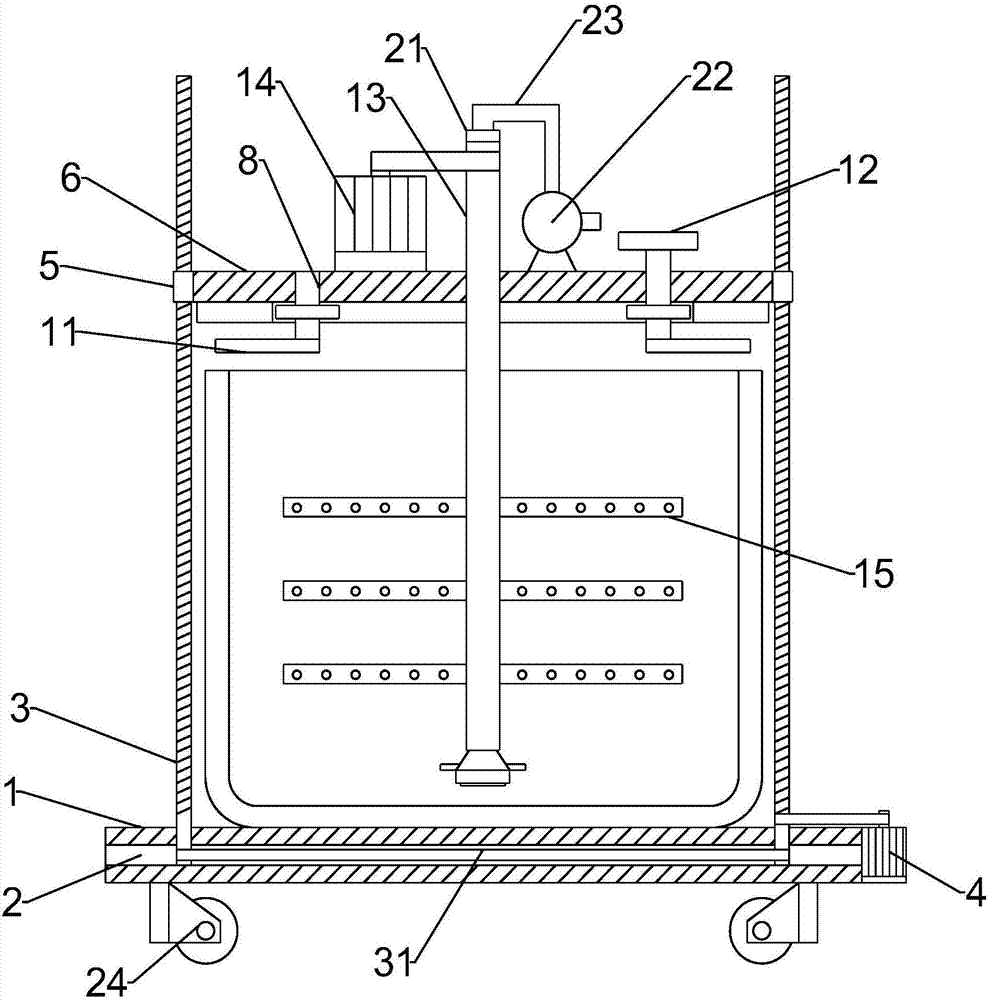

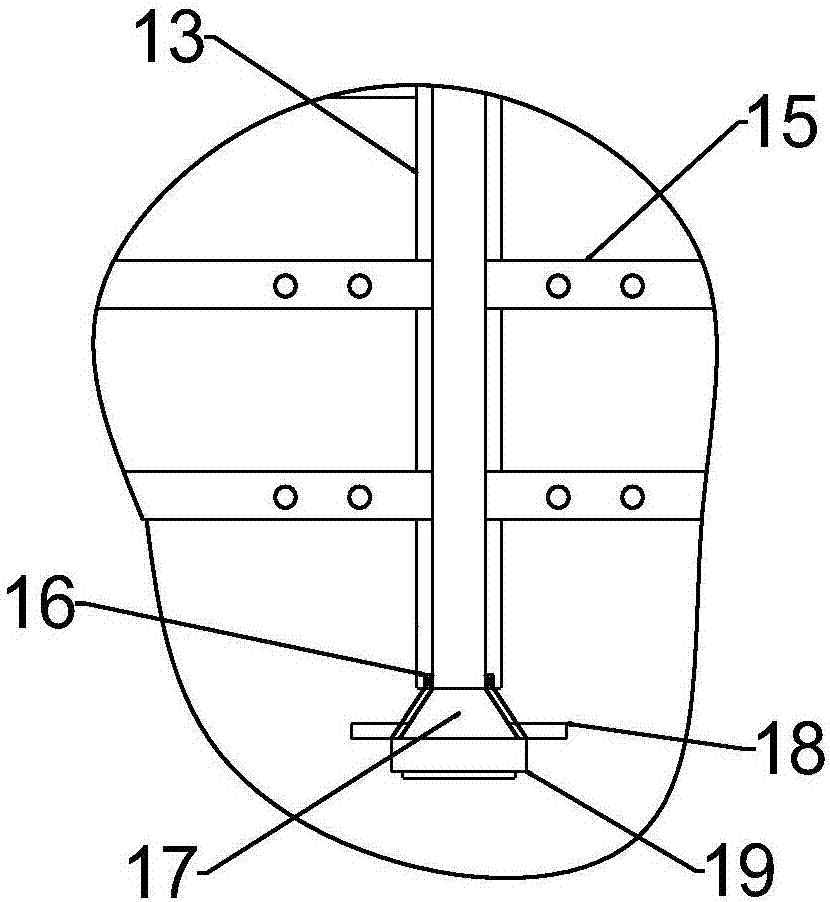

Movable stirring device of reaction kettle

InactiveCN107321290AGuaranteed uptimeUniform processingTransportation and packagingRotary stirring mixersArchitectural engineeringAir pump

Owner:武晓丹

Vapor-phase process apparatus, vapor-phase process method, and substrate

InactiveUS20090148704A1Reduce amountReduce amount of depositPolycrystalline material growthElectric discharge tubesProcess engineeringProduct gas

A vapor-phase process apparatus and a vapor-phase process method capable of satisfactorily maintaining quality of processes even when different types of processes are performed are obtained. A vapor-phase process apparatus includes a process chamber, gas supply ports serving as a plurality of gas introduction portions, and a gas supply portion (a gas supply member, a pipe, a flow rate control device, a pipe, and a buffer chamber). The process chamber allows flow of a reaction gas therein. The plurality of gas supply ports are formed in a wall surface (upper wall) of the process chamber along a direction of flow of the reaction gas. The gas supply portion can supply a gas into the process chamber at a different flow rate from each of one gas supply port and another gas supply port different from that one gas supply port among the plurality of gas supply ports.

Owner:SUMITOMO ELECTRIC IND LTD

Substrate processing apparatus and substrate processing method

InactiveUS20140227883A1Avoid flowHeat wideSemiconductor/solid-state device manufacturingEngineeringNozzle

In a substrate processing apparatus, an outer edge portion of a substrate in a horizontal state is supported from below by an annular substrate supporting part, and a lower surface facing part having a facing surface facing a lower surface of the substrate is provided inside the substrate supporting part. A gas ejection nozzle for ejecting heated gas toward the lower surface is provided in the lower surface facing part, and the substrate is heated by the heated gas when an upper surface of the rotating substrate is processed with a processing liquid ejected from an upper nozzle. Further, a lower nozzle is provided in the lower surface facing part, to thereby perform a processing on the lower surface with a processing liquid. Since the gas ejection nozzle protrudes from the facing surface, a flow of the processing liquid into the gas ejection nozzle can be suppressed during the processing.

Owner:DAINIPPON SCREEN MTG CO LTD

Substrate processing method and apparatus

ActiveUS6954585B2Uniform processingUniform supplyDrying solid materials with heatMuffle furnacesEngineering

A method for heating a wafer to a predetermined temperature, the wafer being held by a holding unit and being accommodated in a processing container equipped with a heater. The wafer is heated to a processing temperature while positioning the wafer at an adjacent position that results form making the wafer approach the heating surface of the heater. After heating the wafer to the predetermined temperature, the wafer is separated from the flat bottom surface of the container body to a processing position. In this state, a processing chamber of the processing container is supplied with a processing fluid, while the holding unit and the heater are relatively moved close to and apart from each other intermittently or continuously. Accordingly, it is possible to quickly heat the substrate to a processing temperature while supplying the substrate with the processing fluid uniformly. This improves throughout and the homogenization in processing.

Owner:TOKYO ELECTRON LTD

Inductively Coupled Plasma Reactor

InactiveUS20080124254A1High control ability on plasma ion energyIncrease the areaElectric discharge tubesEnergy based chemical/physical/physico-chemical processesCapacitanceInductively coupled plasma

There is provided a plasma reactor comprising: a vacuum chamber having a substrate support on which a treated substrate is positioned; a gas shower head supplying gas into the interior of the vacuum chamber; a dielectric window installed at an upper portion of the vacuum chamber; and a radio frequency antenna installed above the dielectric window. The gas shower head and the substrate support are capacitively coupled to plasma in the interior of the vacuum chamber and the radio frequency antenna is inductively coupled to the plasma in the interior of the vacuum chamber. The capacitive and inductive coupling of the plasma reactor allows generation of plasma in a large area inside the vacuum chamber more uniformly and more accurate control of plasma ion energy, thereby increasing the yield and the productivity. The plasma reactor includes a magnetic core installed above the dielectric window so that an entrance for a magnetic flux faces the interior of the vacuum chamber and covers the radio frequency antenna. Since the radio frequency antenna is covered by the magnetic core, the magnetic flux can be more strongly collected and the loss of the magnetic flux can be minimized.

Owner:GENERAL CO LTD

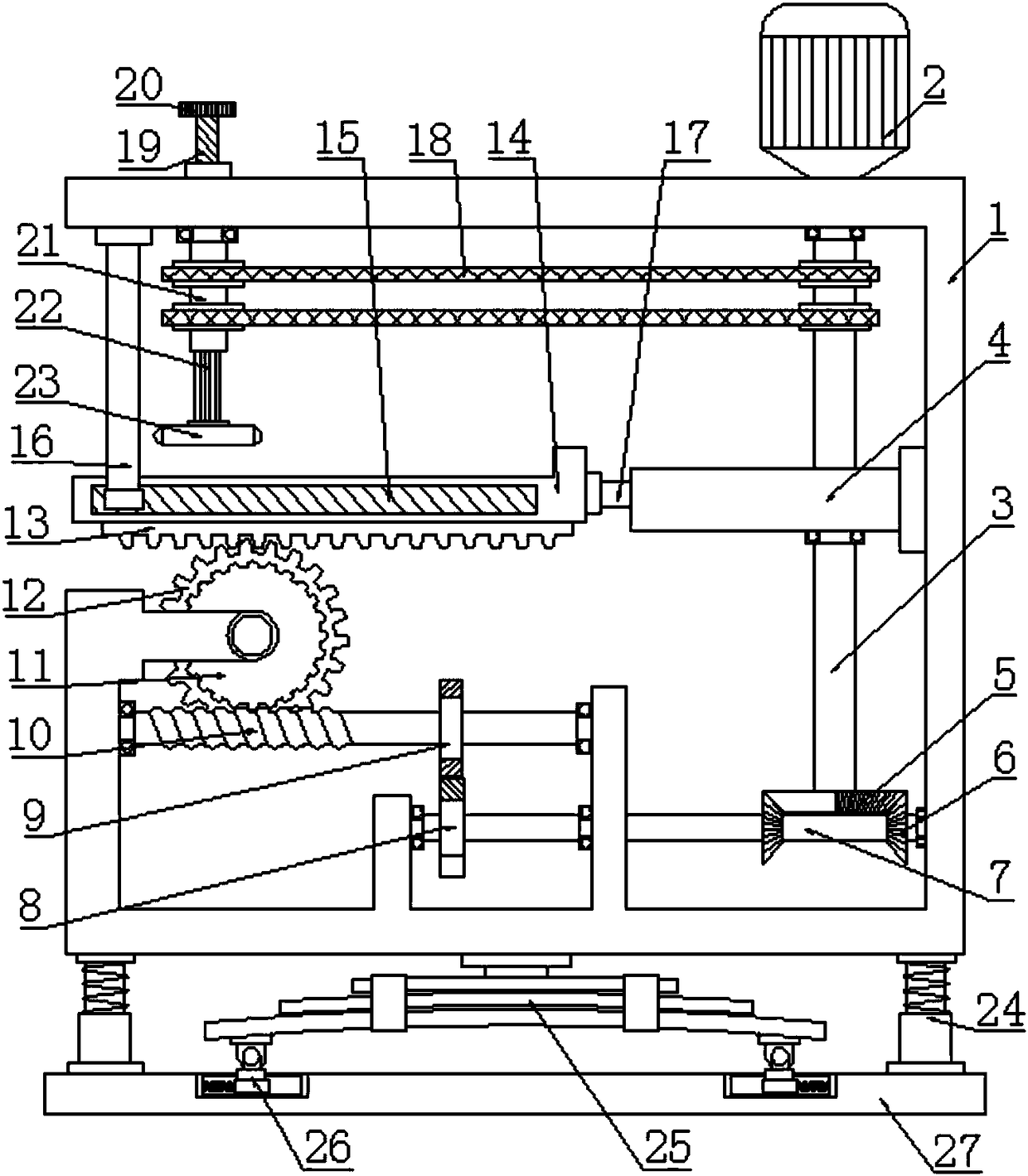

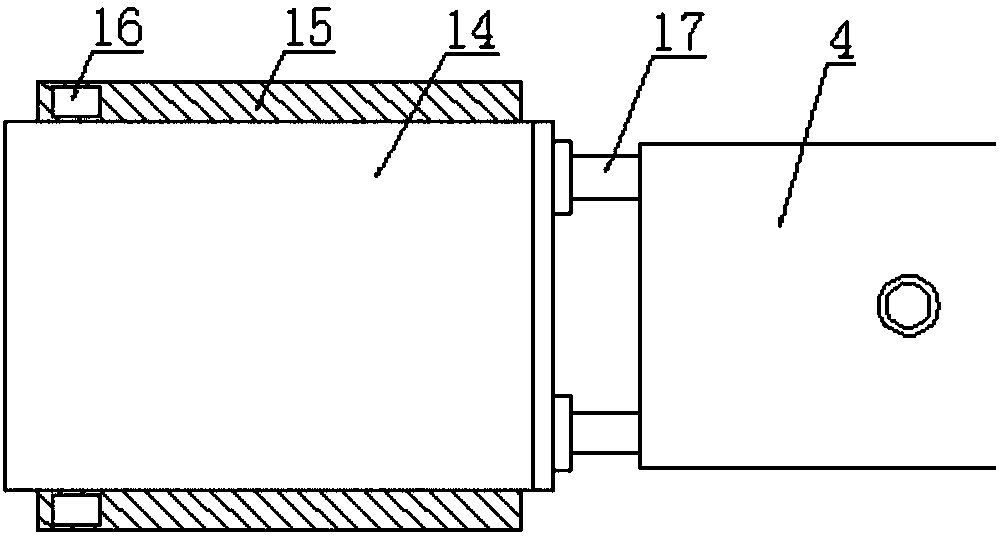

Building steel plate intermittent polishing device

The invention discloses a building steel plate intermittent polishing device. The middle of a guide rail is rotatably connected with the middle of a driving shaft, the guide rail is fixedly connectedwith the right wall of a device body, the lower end of the driving shaft is fixedly connected with a semi-circular bevel gear, the toothed part of the semi-circular bevel gear is engaged with bevel gears, the bevel gears are fixedly connected with a driven shaft, the left end of the driven shaft is fixedly connected with a semi-circular gear, and the toothed part of the semi-circular gear is engaged with a first gear; and the first gear is fixedly connected with a worm, the upper end of the worm is engaged with a worm wheel, the rear portion of the worm wheel is fixedly connected with a secondgear, and the second gear and the worm wheel are both rotatably connected with the device body. According to the building steel plate intermittent polishing device, the bevel gears at the left end and the right end are driven to rotate through the semi-circular bevel gear, further the driven shaft is driven to conduct reciprocating forward and reverse rotation, the toothed part of the semi-circular gear intermittently drives the first gear to conduct forward and reverse rotation so that the worm can be driven to conduct intermittent forward and reverse rotation, and thus reciprocating left-right intermittent moving of a working table can be achieved; and the structural design of the building steel plate intermittent polishing device is reasonable and applicable, the polishing efficiency of a building steel plate is greatly improved, machining of all the parts of the steel plate is even, and the polishing effect is excellent.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

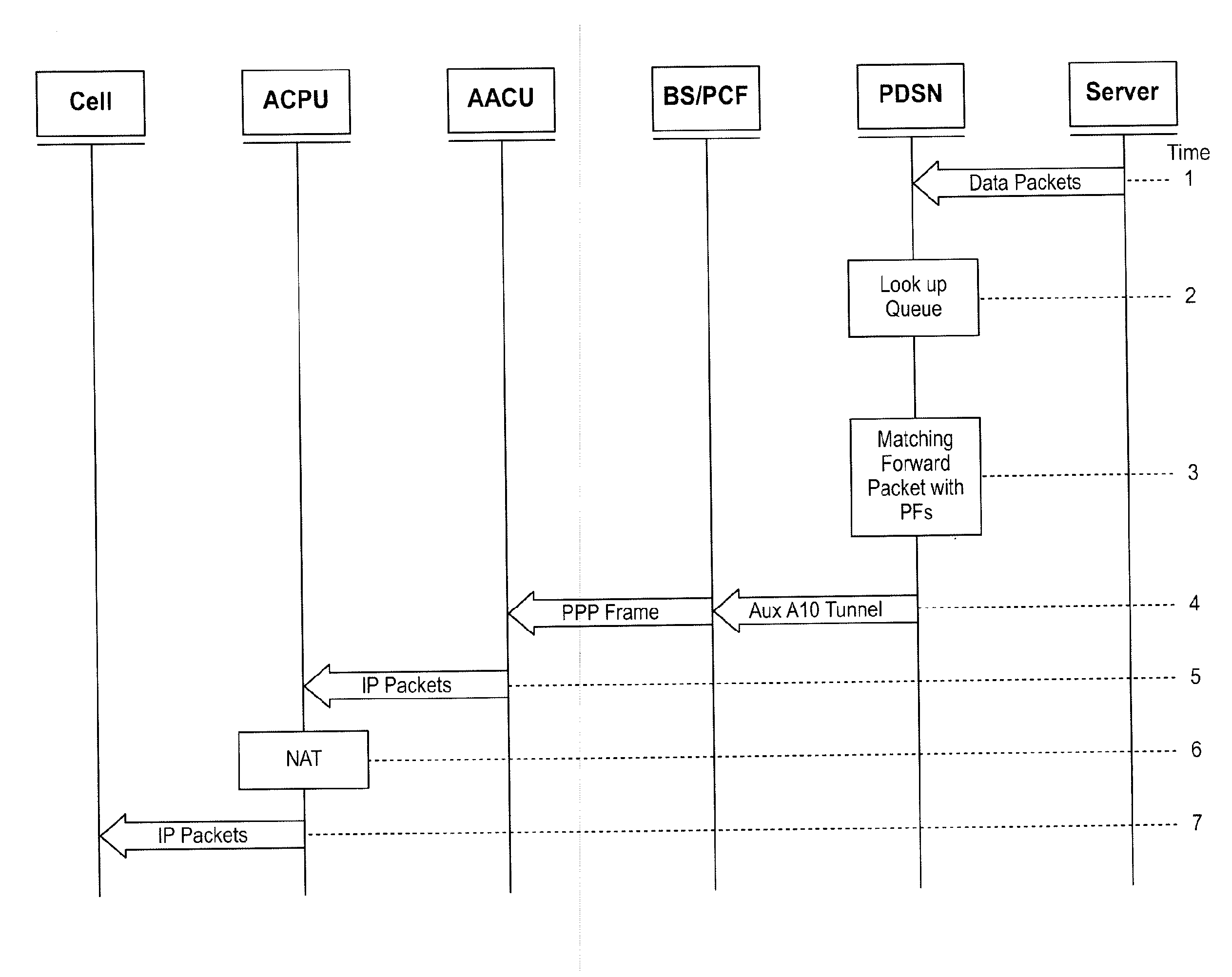

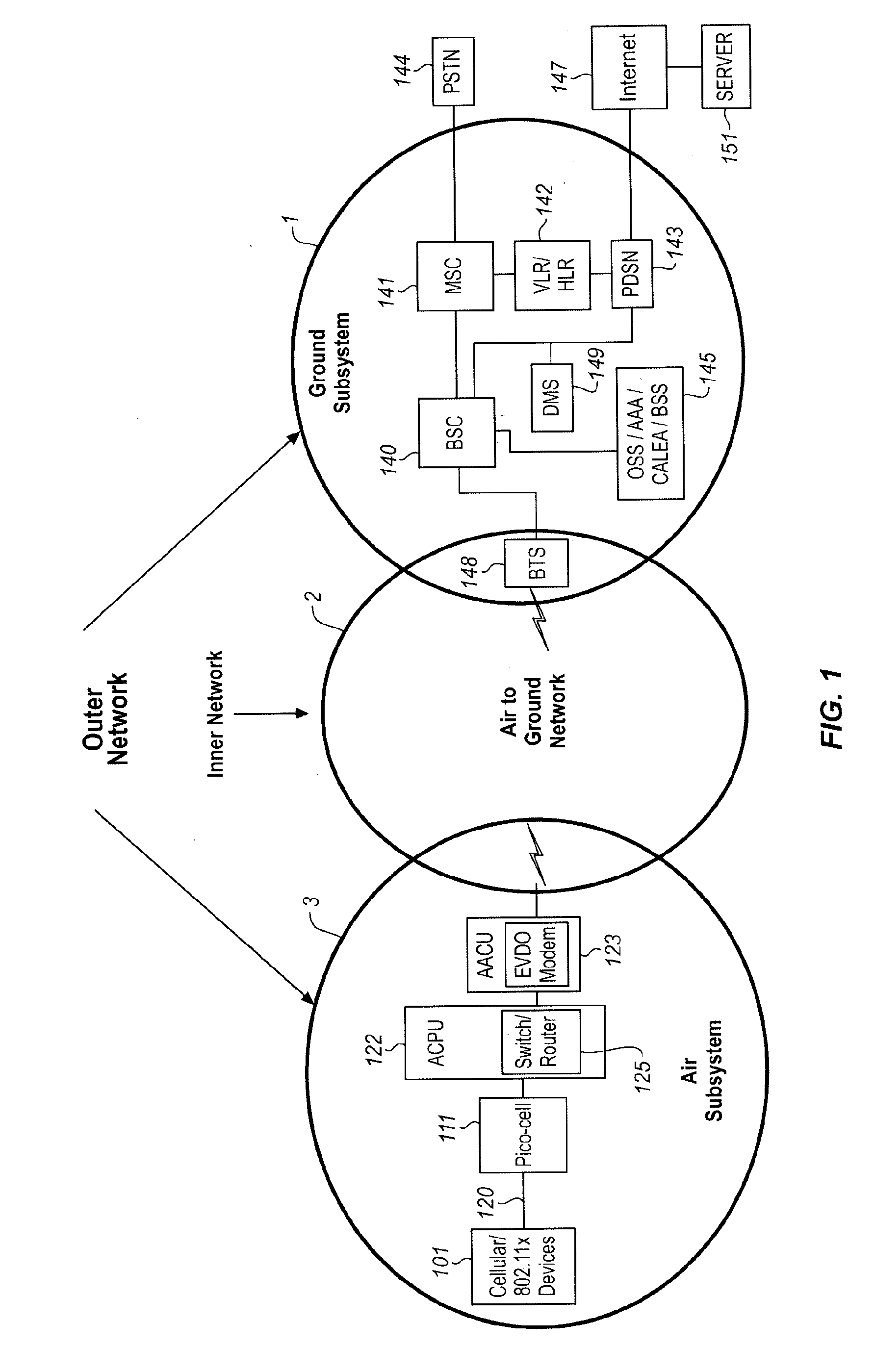

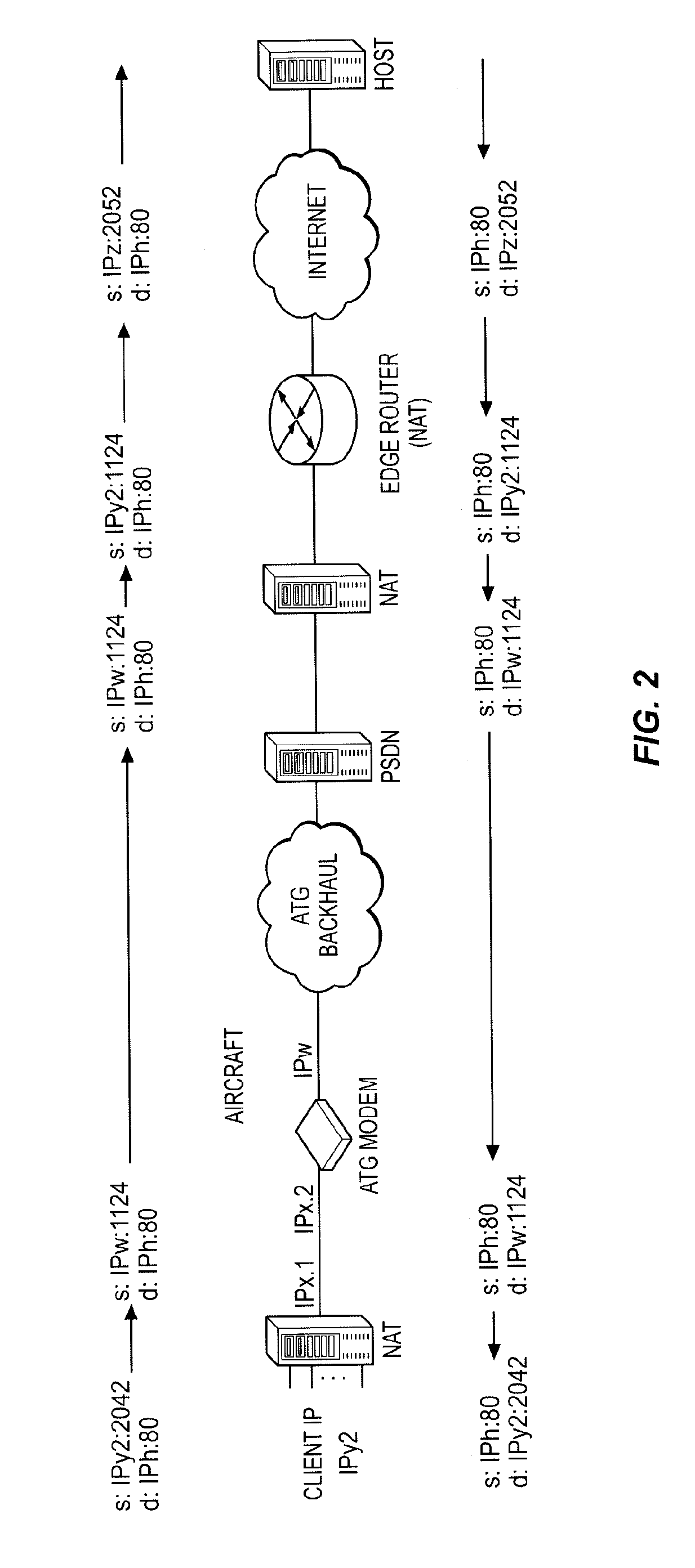

Differentiated Services Code Point Mirroring For Wireless Communications

InactiveUS20110286331A1Optimize and guarantee performanceOptimize and guarantee and low latencyError preventionFrequency-division multiplex detailsTraffic capacityDifferentiated services

The DSCP Mirroring System enables the automatic reuse of the Differentiated Services Code Point header by the user devices that are served by a network to enable delivery of wireless services to the individually identified user wireless devices and manage the various data traffic and classes of data to optimize or guarantee performance, low latency, and / or bandwidth without the overhead of the management of the Differentiated Services Code Point header.

Owner:GOGO LLC

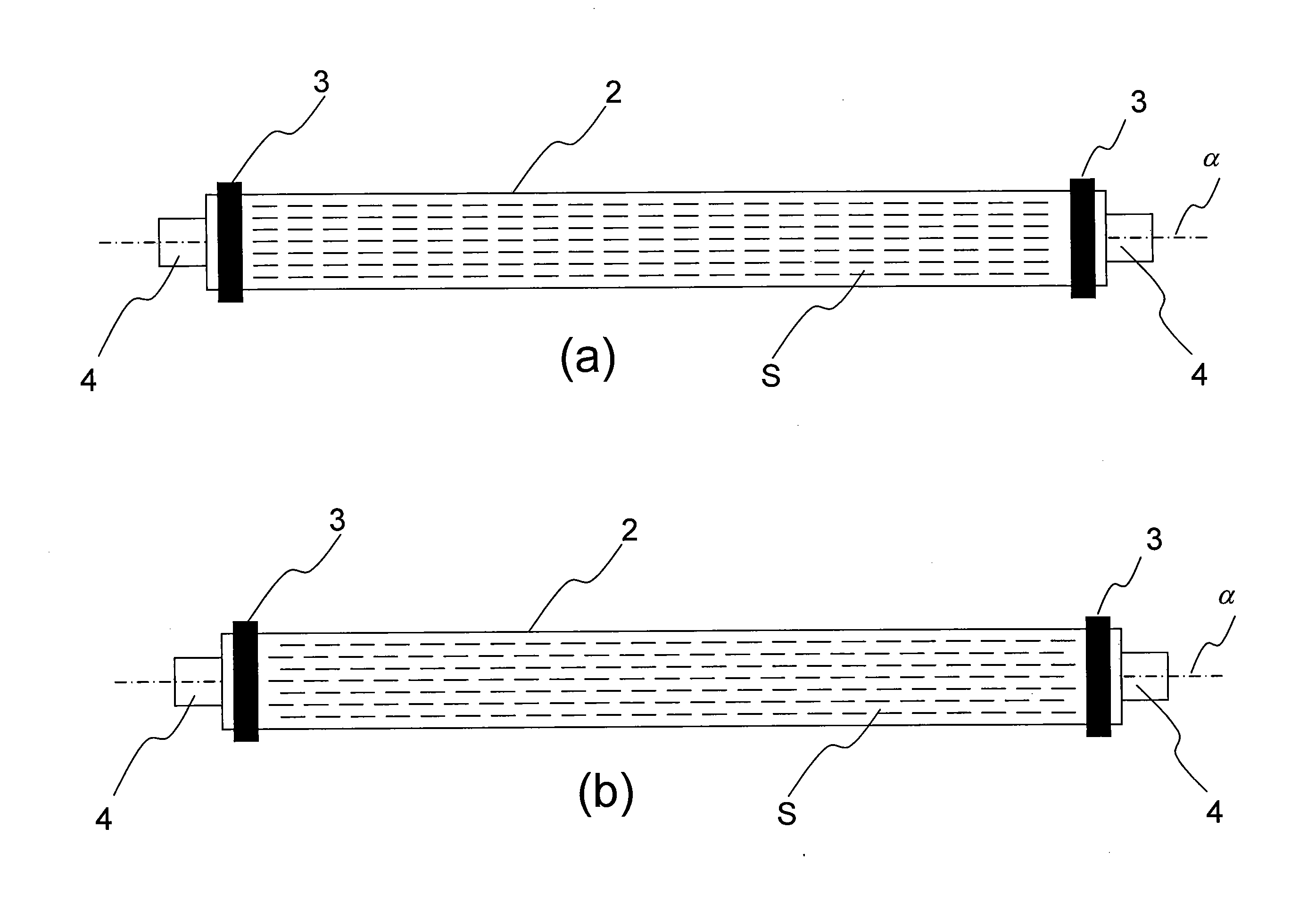

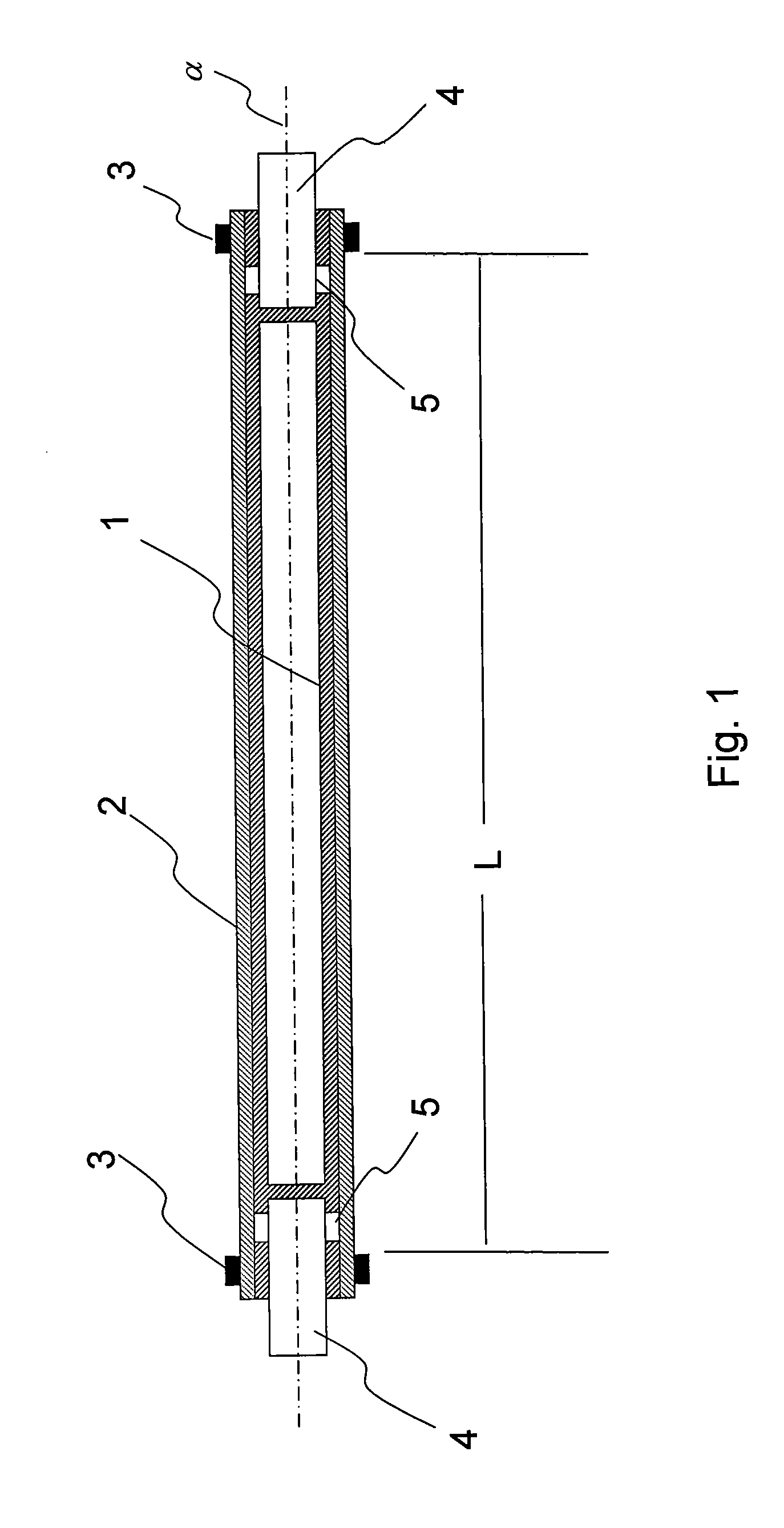

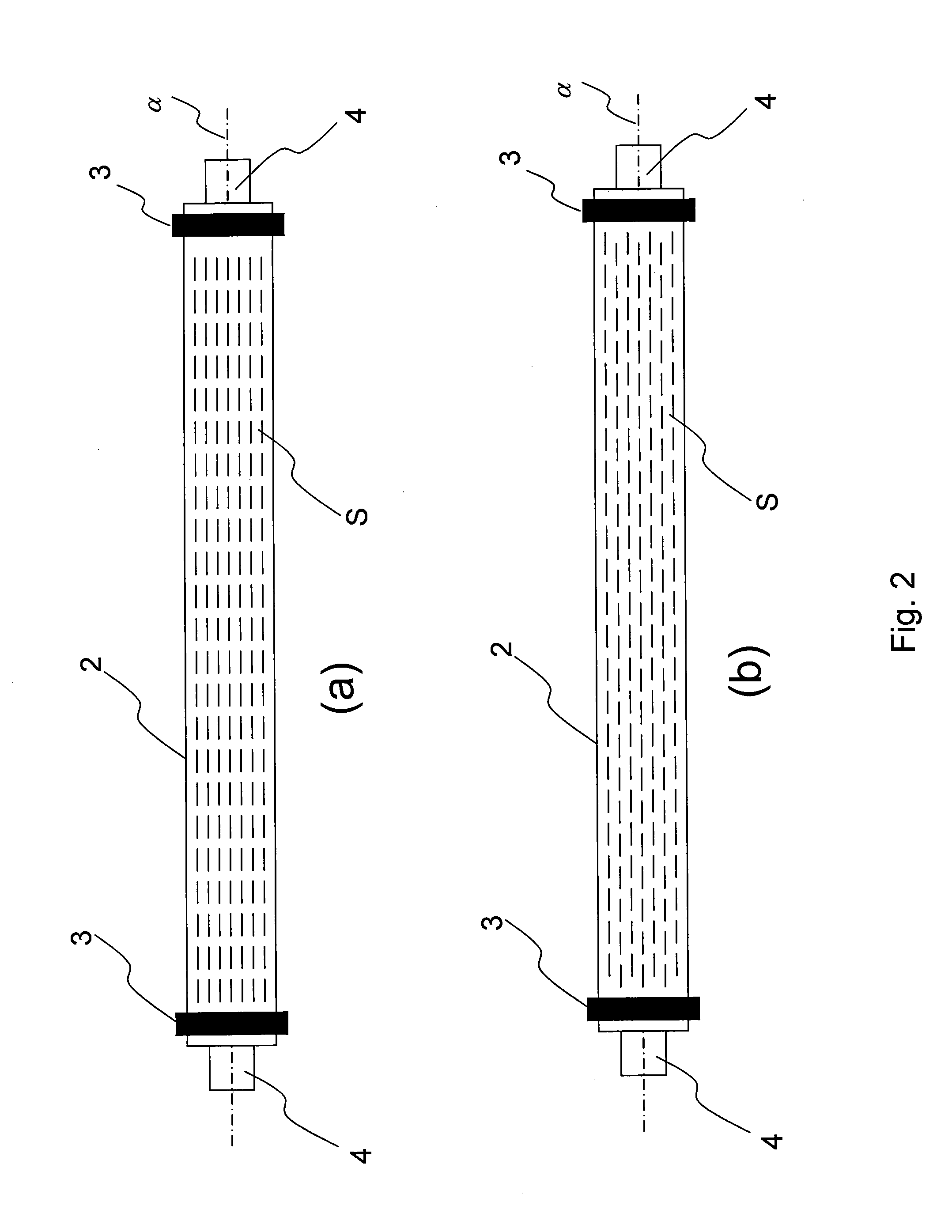

Fine bubble diffusing pipe, fine bubble diffusing apparatus, and submerged membrane separation apparatus

InactiveUS20100224541A1Even amountStable membrane filtrating operationLighting and heating apparatusTransportation and packagingEngineeringGas supply

A fine bubble diffusing tube that can generate fine bubbles evenly and uniformly even when the diffusing tube has a long length, a fine bubble diffusing device using such a tube and a submerged membrane separation apparatus are produced. The fine bubble diffusing tube is provided with a cylindrical supporting tube 1, and an elastic sheet 2 with fine slits formed therein, with the elastic sheet 2 being placed to cover the outer circumference of the supporting tube 1, so that, upon supplying a gas to a space between the elastic sheet 2 and the supporting tube 1, the fine slits of the elastic sheet 2 are opened to generate fine bubbles, and the supporting tube 1 has a length L of 1000 mm or more in the longitudinal direction, with gas supply units 4 serving as gas flow inlets being attached to the two ends of the supporting tube.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com