Substrate processing system, gas supply unit, method of substrate processing, computer program, and storage medium

a substrate processing and processing method technology, applied in the direction of electrical discharge tubes, decorative arts, electrical equipment, etc., can solve the problems of difficult to ensure a high selective etching ratio, masks disappear, and patterns formed on substrate surfaces by processes are apt to be non-uniform in size, so as to improve reduce the non-uniformity of processing. , the effect of improving the uniformity of within-substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

Etching Rate

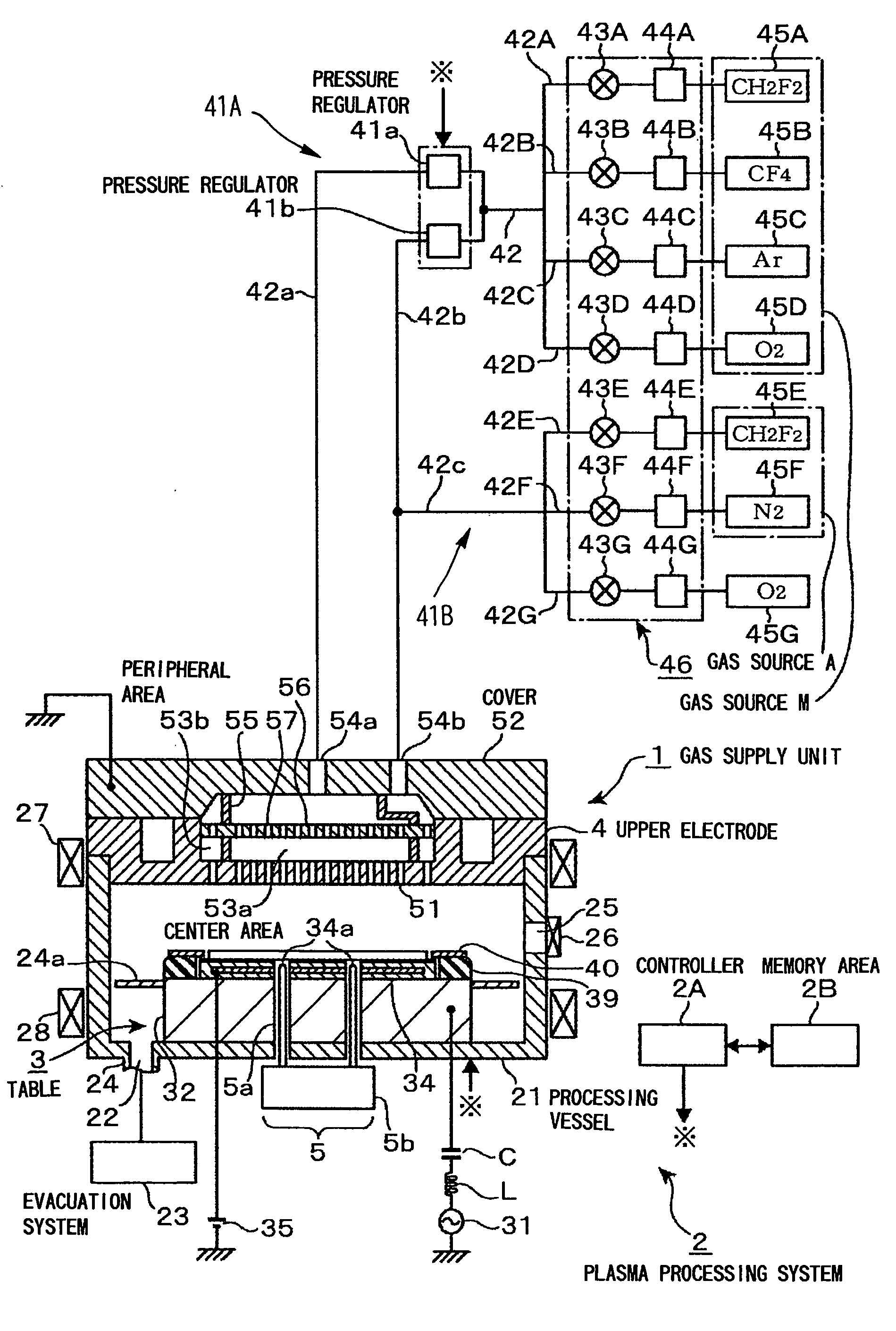

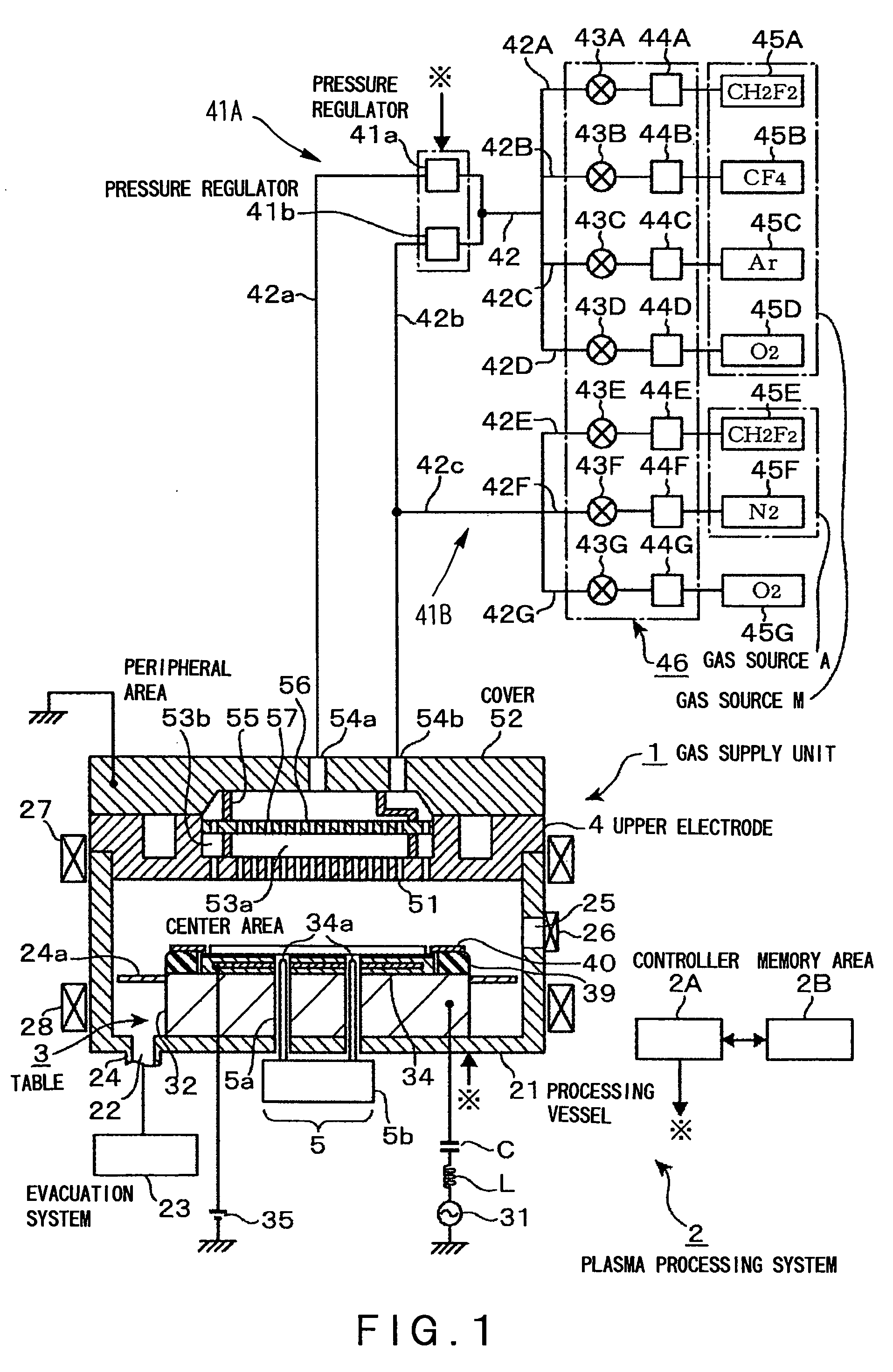

[0101] Prior to carrying out simulations, an experiment for estimating the amount of a gas to be generated from the wafer W in the step of etching the SiN film 74 was carried in order to determine more practical conditions. The SiN film 74 was etched under the following process conditions.

(Etching of Sin Film 74)

[0102] Frequency of high-frequency wave: 13.56 MHz

[0103] Power of high-frequency wave: 700 W

[0104] Process pressure: 18.7 Pa (140 mTorr)

[0105] Process gases (gas source M): [0106] CH2F2 / CF4 / Ar / O2=15 / 80 / 150 / 21 sccm

[0107] Process gas (gas source A): CH2F2=5 sccm

[0108] Pressures of pressure regulators: [0109] pressure regulator 41a / pressure regulator 41b=[0110] 55 / 45 (distance L=90 mm), [0111] 1 / 1 (distance L=110 mm), and [0112] 45 / 55 (distance L=130 mm)

Results of Experiments

[0113] The etching rates of the SiN film 74 determined in the above experiments are shown in Table 1.

TABLE 1Distance L (mm)90110130Etching Rate180.4181.3180.9(nm)Standard1.81.41.9D...

experimental example 2

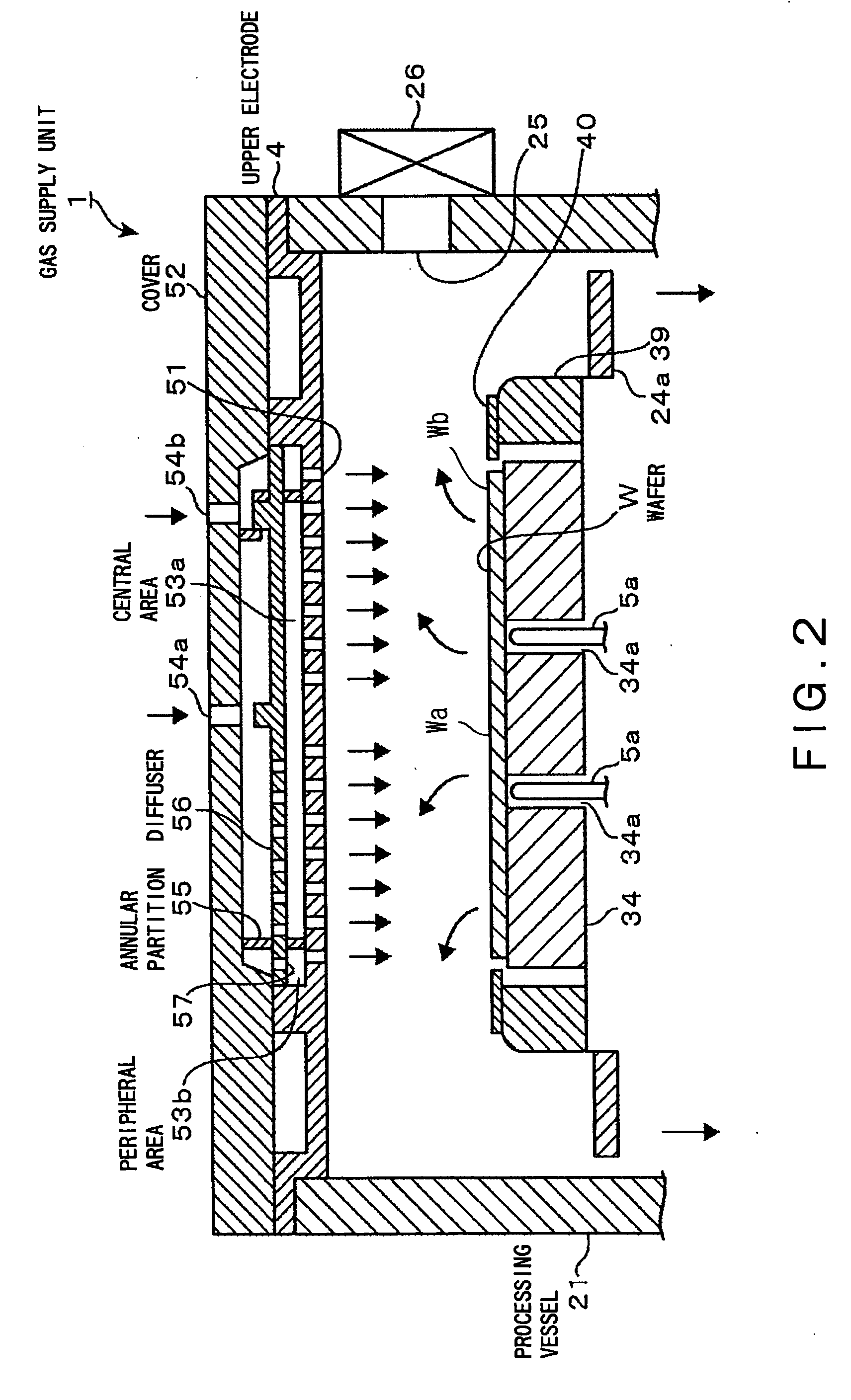

[0115] The gas distribution in the processing vessel 21 was simulated with the use of a fluid analysis soft, Fluent Vers. 6.2.16, manufactured by FLUENT Corp. The simulation was carried out on the assumption that gases are compressive fluids and that their flows are laminar. Further, calculations were made on the assumption that a gas causes slips in velocity and jumps in temperature on a solid surface such as a wafer W or upper electrode 4 surface.

[0116] The distance L from the center of the upper electrode 4 to the partition 55 was, as shown in FIG. 5, made 90 mm, 110 mm, or 130 mm so that the radius of the outermost circle of the gas-jetting pores 51 communicating with the center section 53a was 53%, 67%, or 80% of the radius of the wafer W, respectively.

[0117] The simulations were carried out under the same process conditions as in the above-described Experimental Example 1, except that the process pressure was set to the following three levels and that the gas flow...

experimental example 3

Verification of Simulations

[0130] Experiments were carried out in order to verify the results of the simulations carried out in Experimental Example 2. In the experiments, the same processing process as in Experimental Example 1 was carried out, and the wafer W in the state as shown in FIG. 4(b) was etched. The process conditions used were the same as in Experimental Example 2, except for the following conditions.

[0131] Distance L from the center of the upper electrode 4[0132] to the partition 55: as described above

[0133] Process pressure: 18.7 Pa (140 mTorr)

[0134] Process gases (gas source M): as described above

[0135] Process gas (gas source A): as described above

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com