Patents

Literature

48results about How to "Securing uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

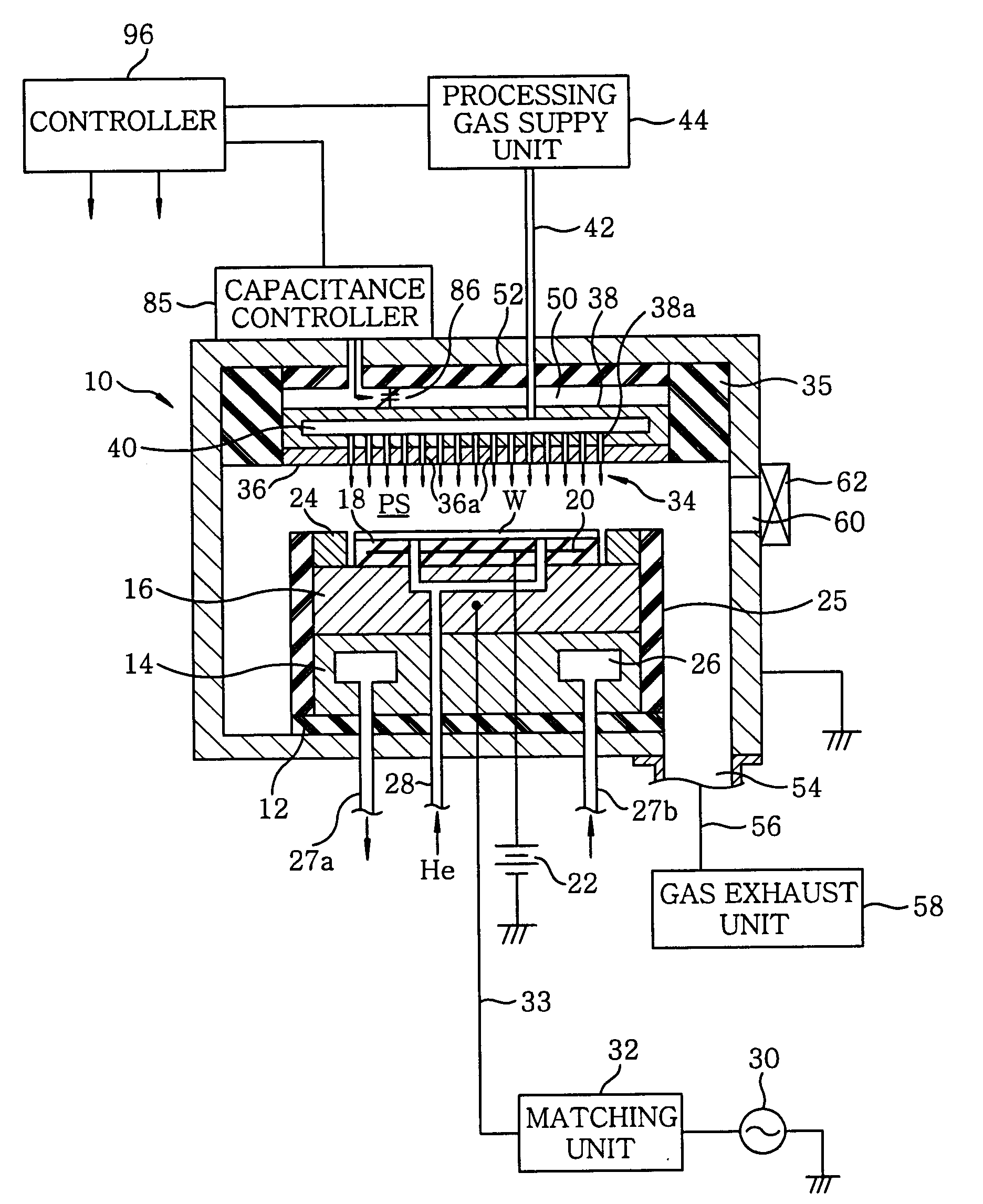

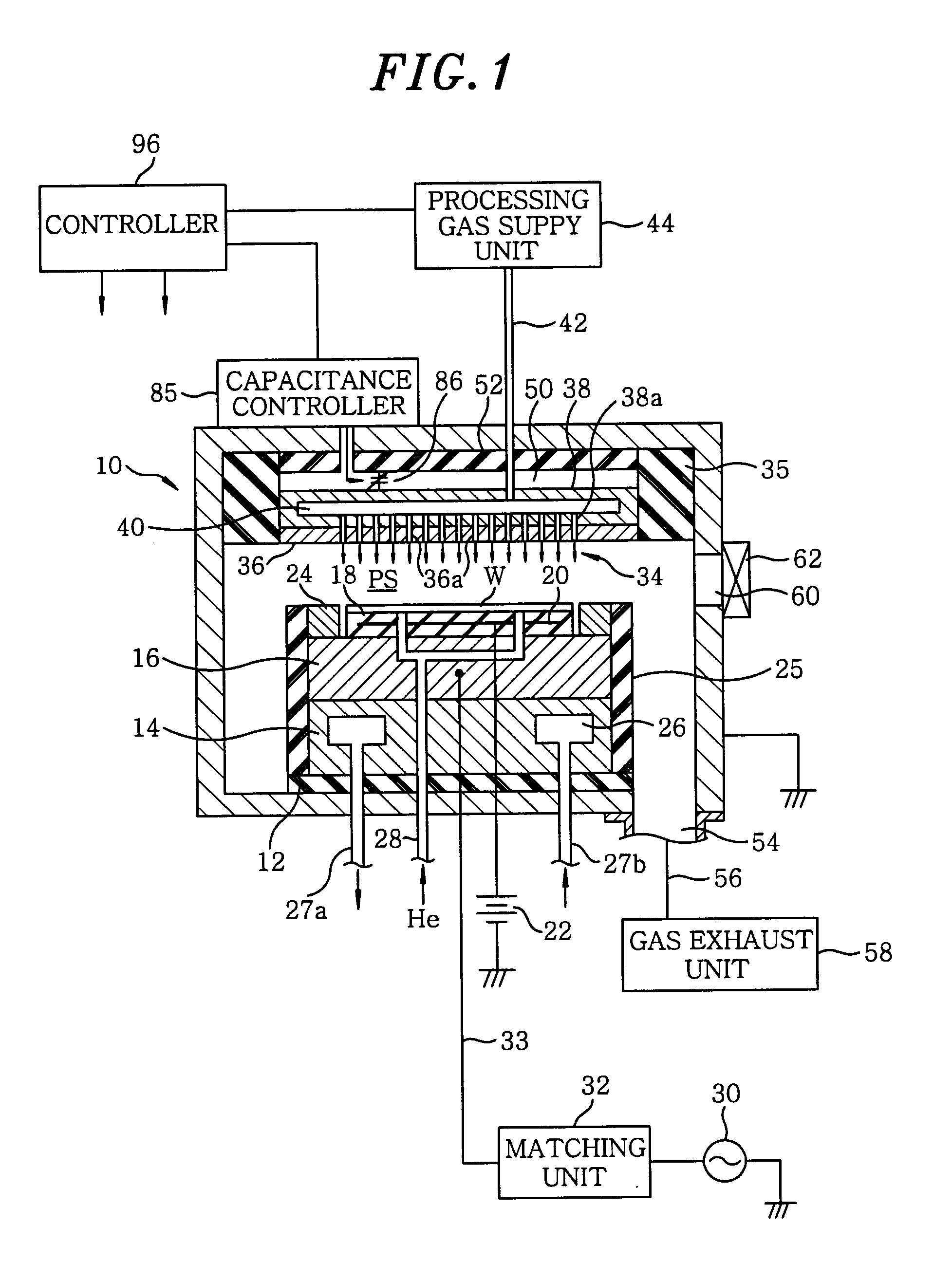

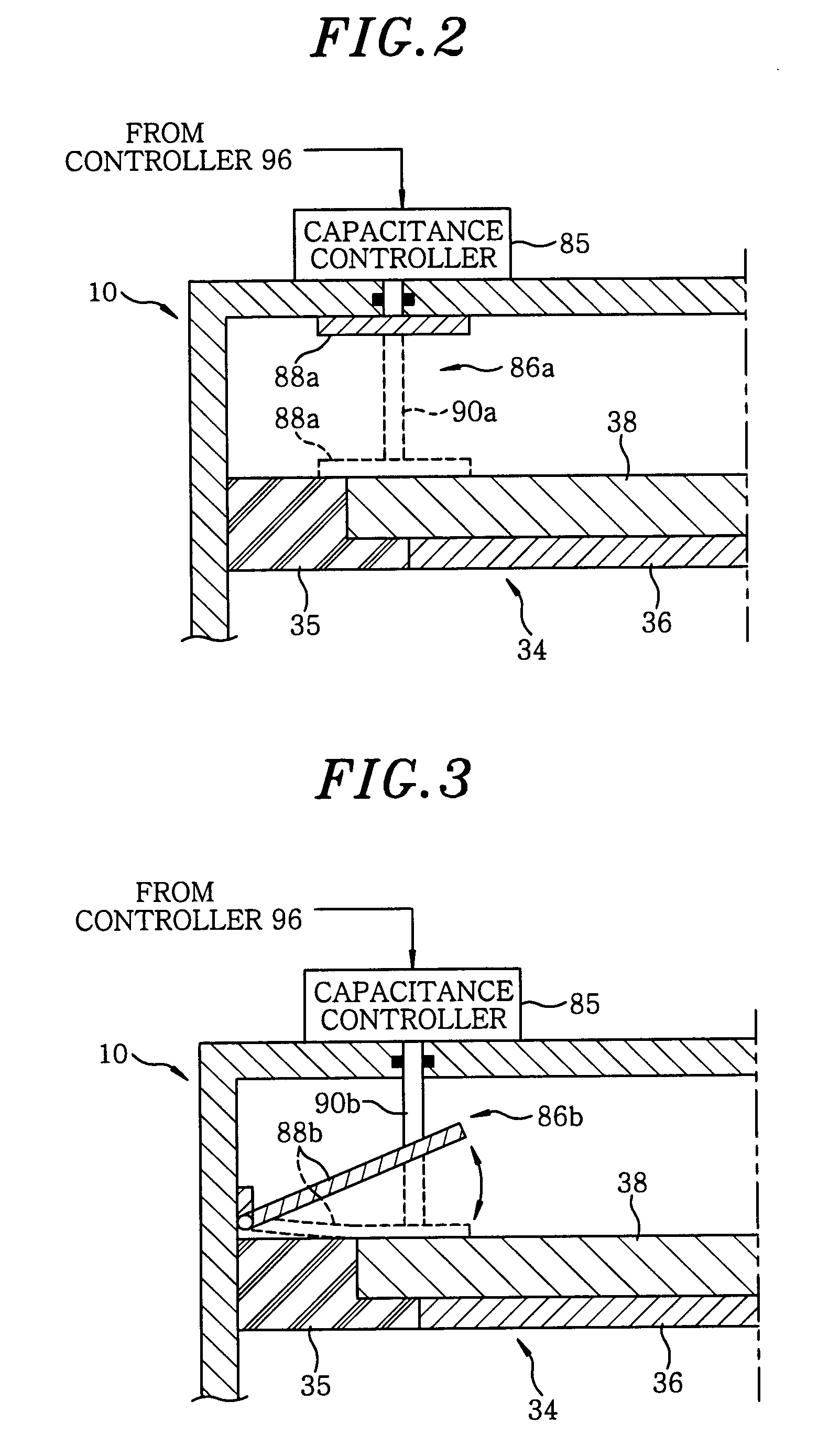

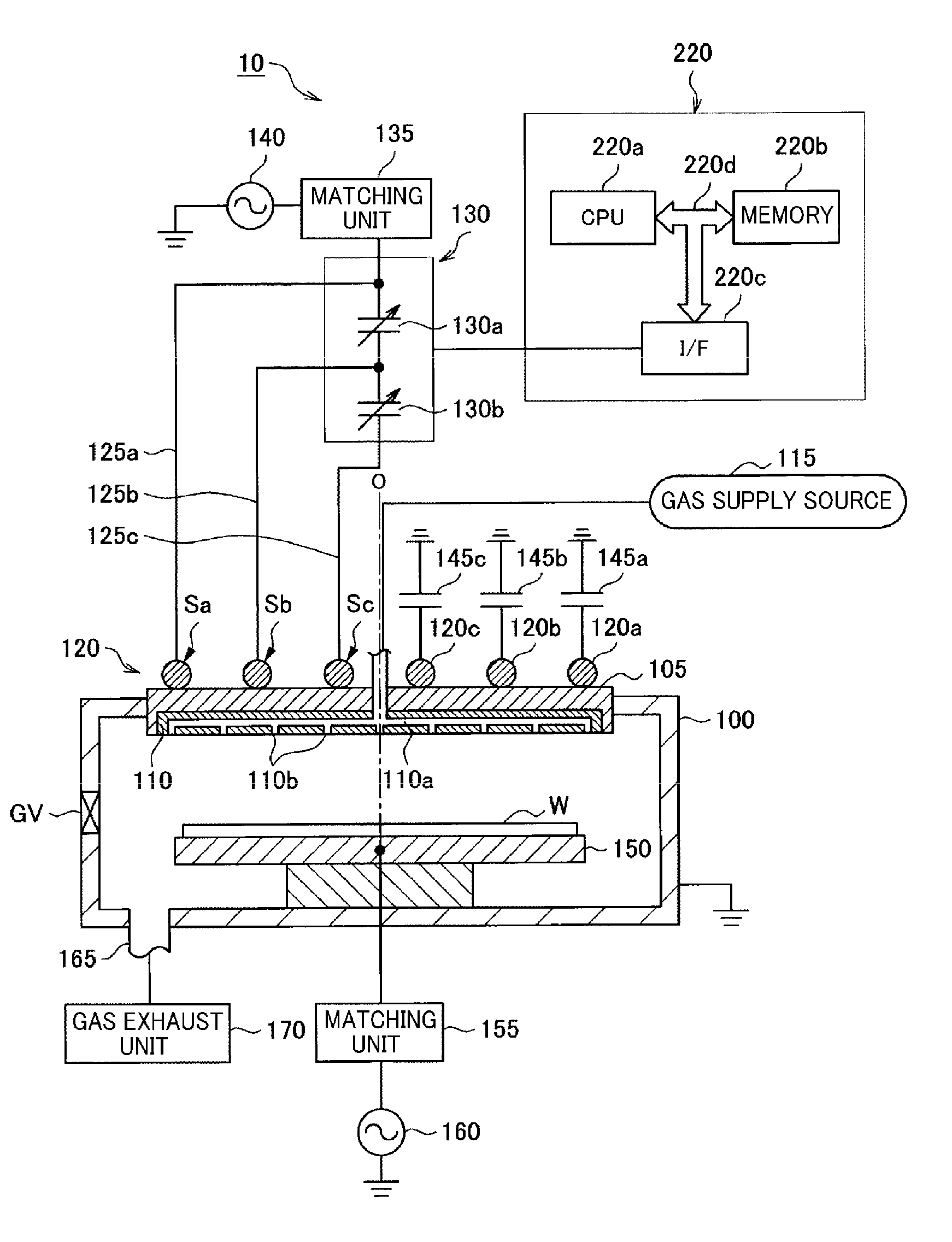

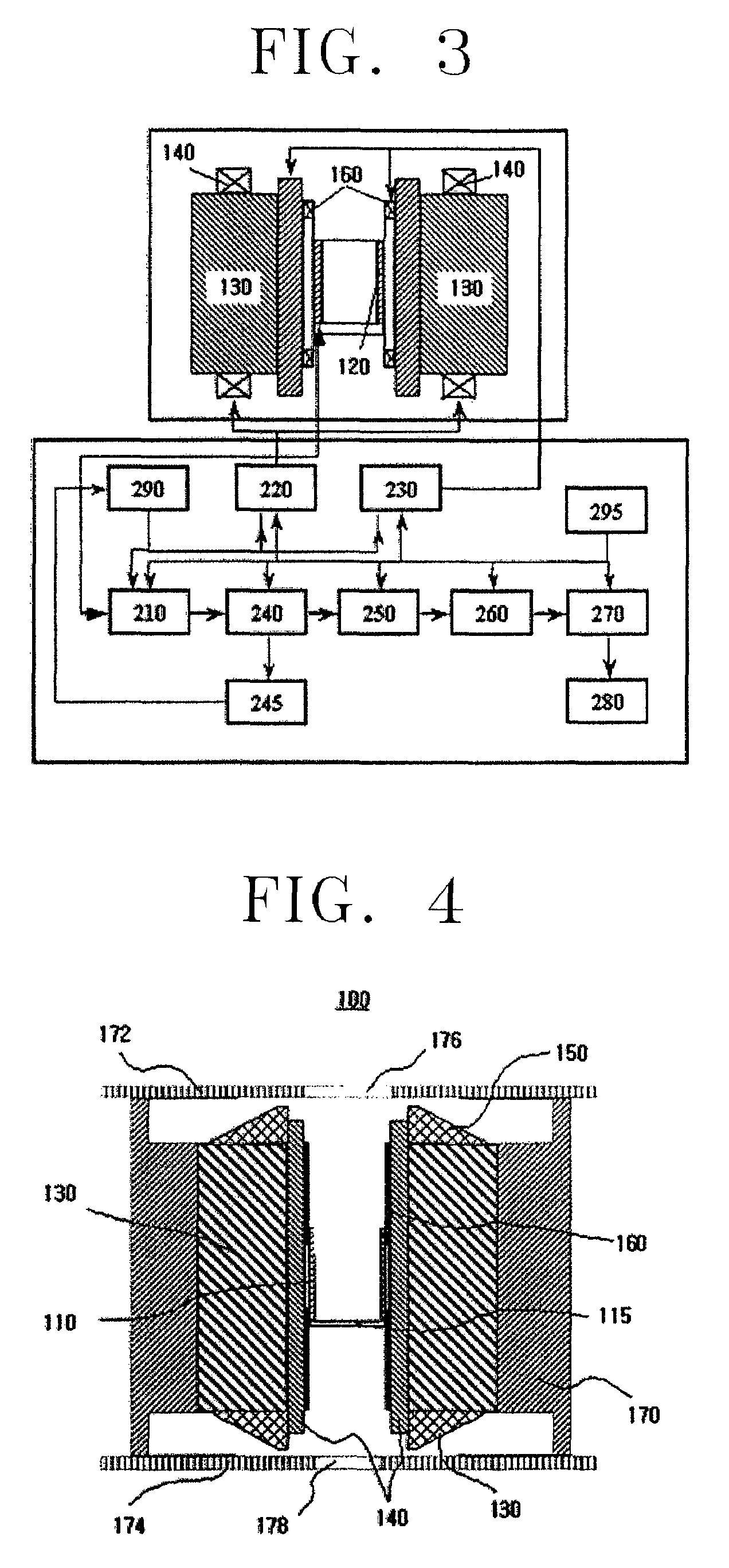

Plasma processing method and plasma processing apparatus

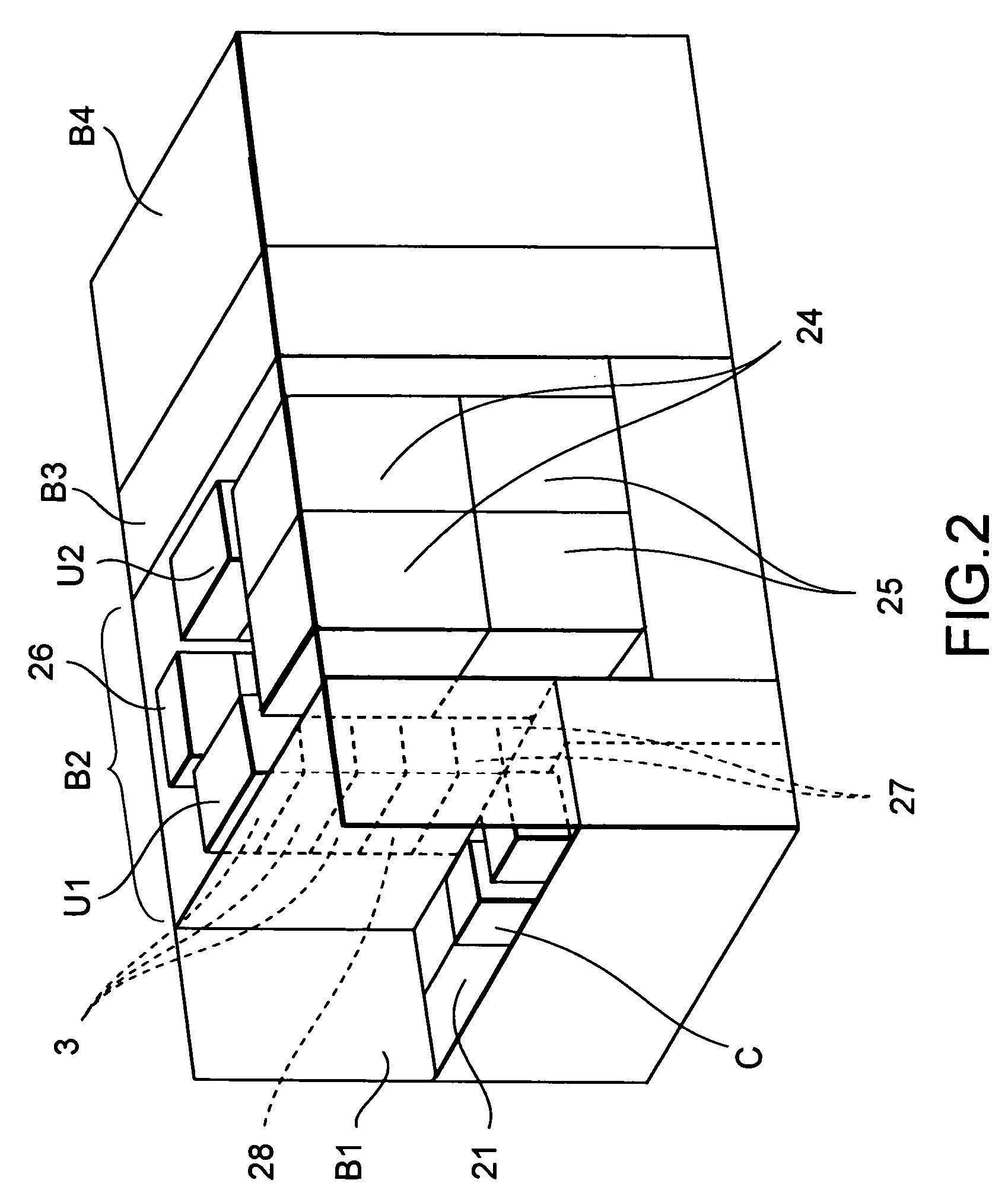

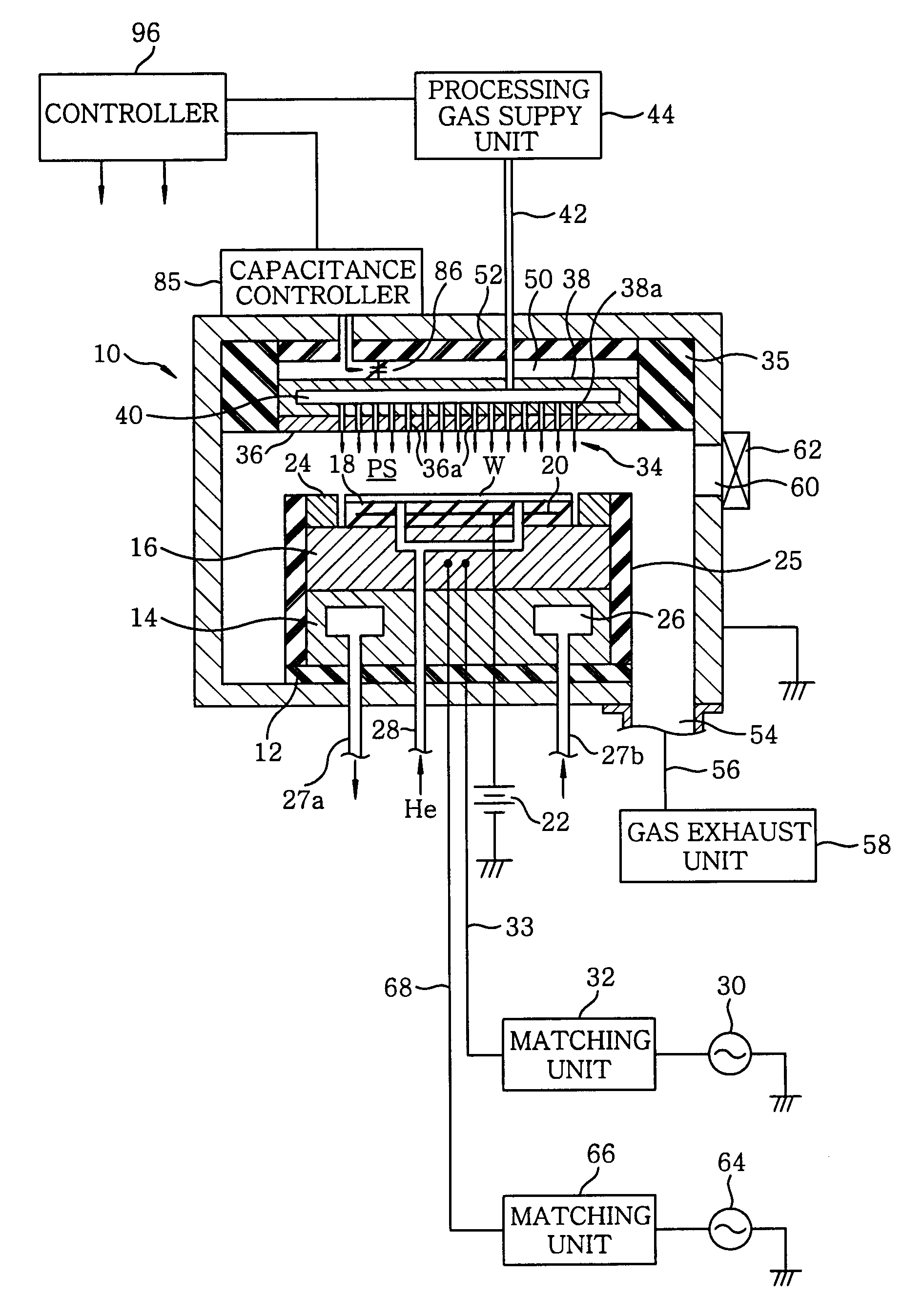

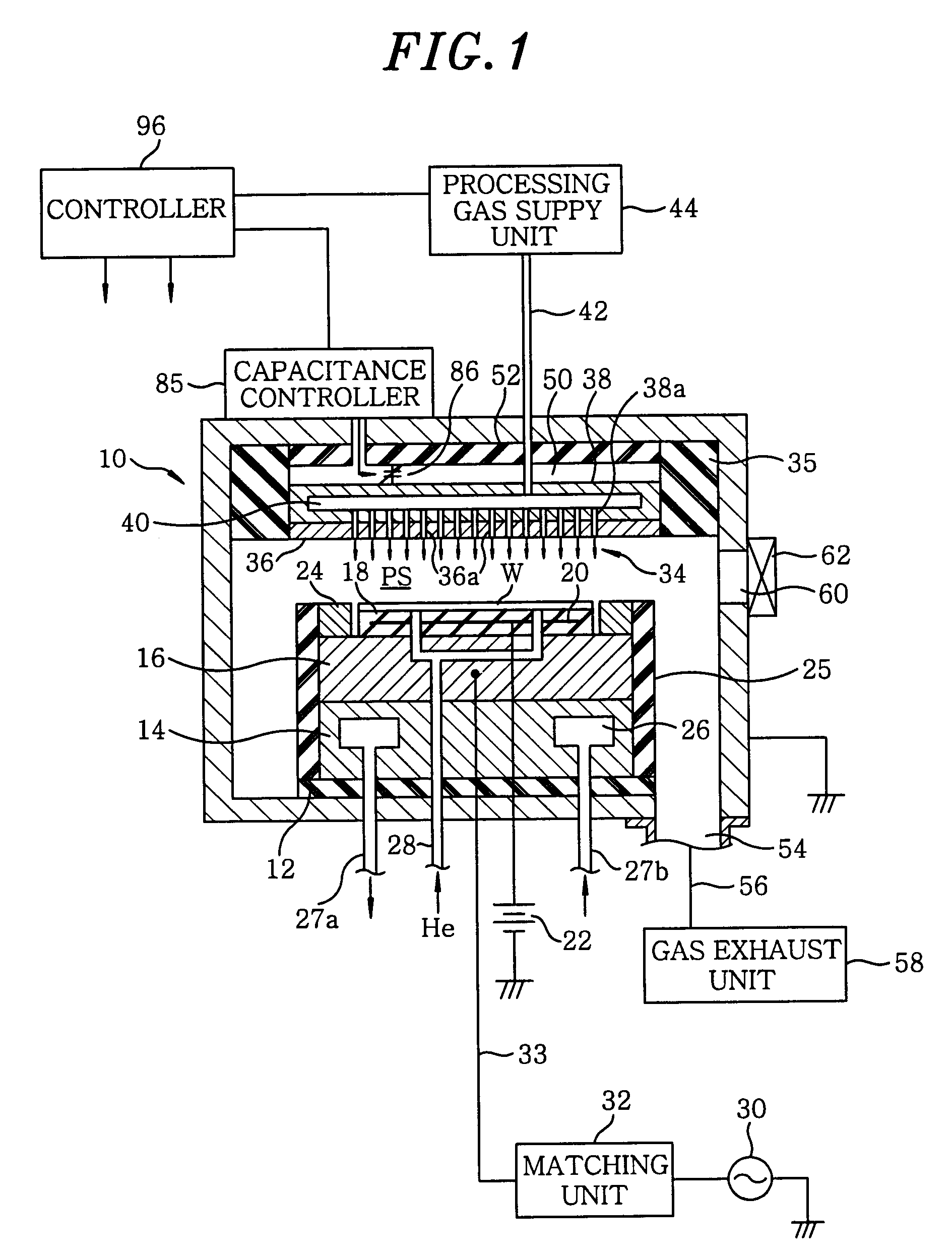

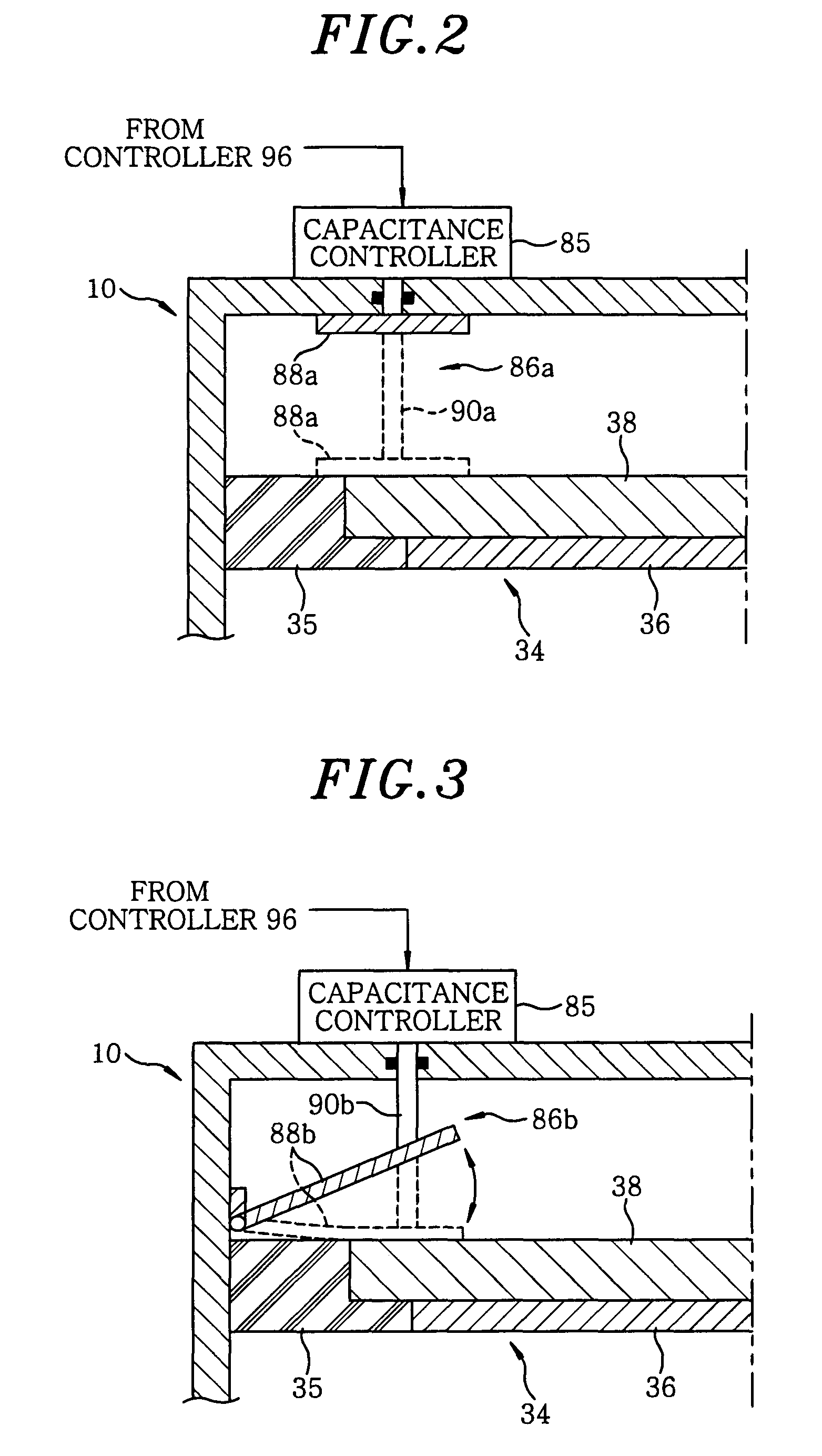

ActiveUS20070227665A1Uniform processingSecuring uniformityLiquid surface applicatorsElectric discharge tubesCapacitanceEngineering

A plasma processing method performs a desired plasma process on substrates by using a plasma generated in a processing space. A first and a second electrode are disposed in parallel in a processing vessel that is grounded, the substrate is supported on the second electrode to face the first electrode, the processing vessel is vacuum evacuated, a desired processing gas is supplied into the processing space formed between the first electrode, the second electrode and a sidewall of the processing vessel, and a first radio frequency power is supplied to the second electrode. The first electrode is connected to the processing vessel via an insulator or a space, and is electrically coupled to a ground potential via a capacitance varying unit whose electrostatic capacitance is varied based on a process condition of the plasma process performed on the substrate.

Owner:TOKYO ELECTRON LTD

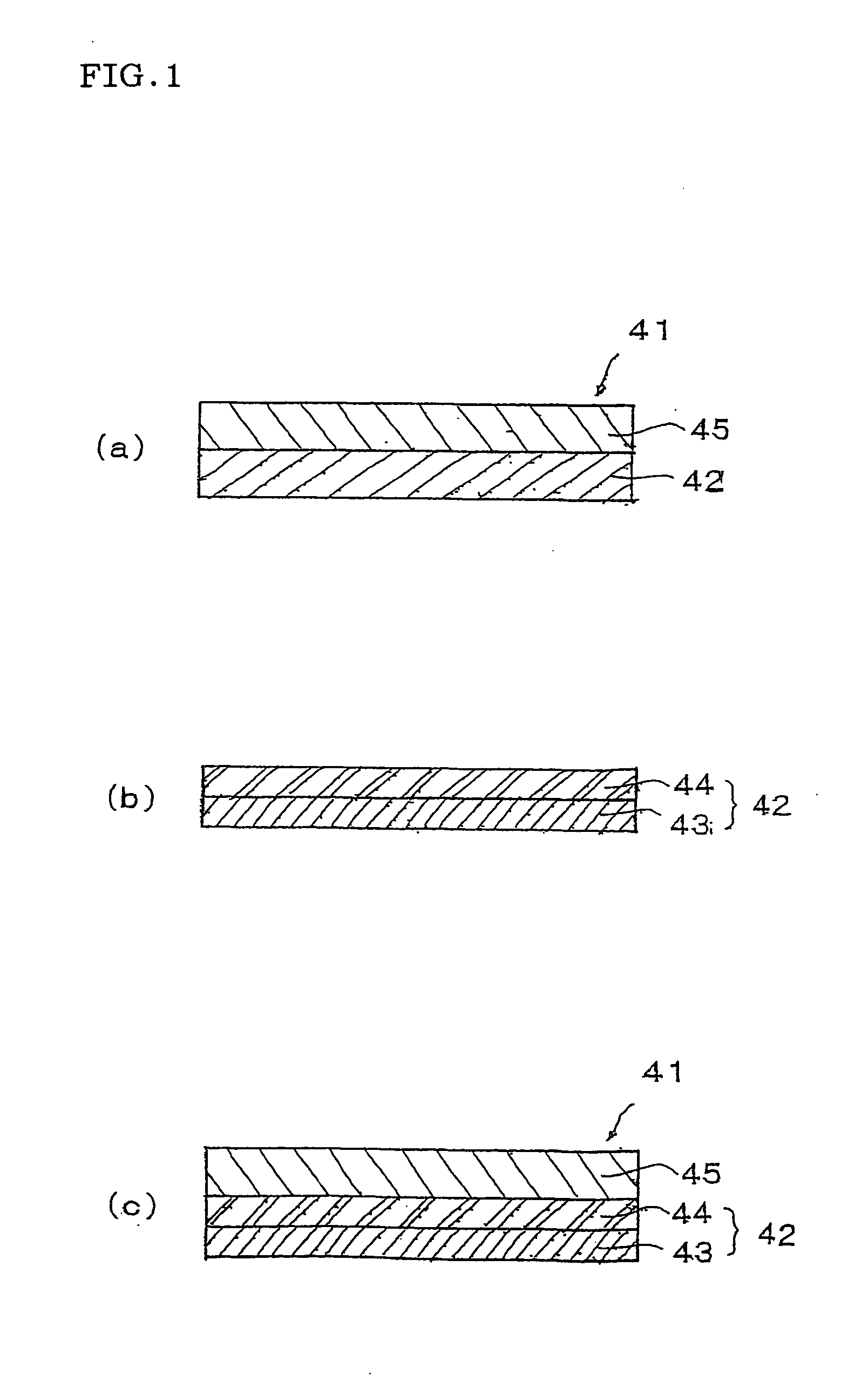

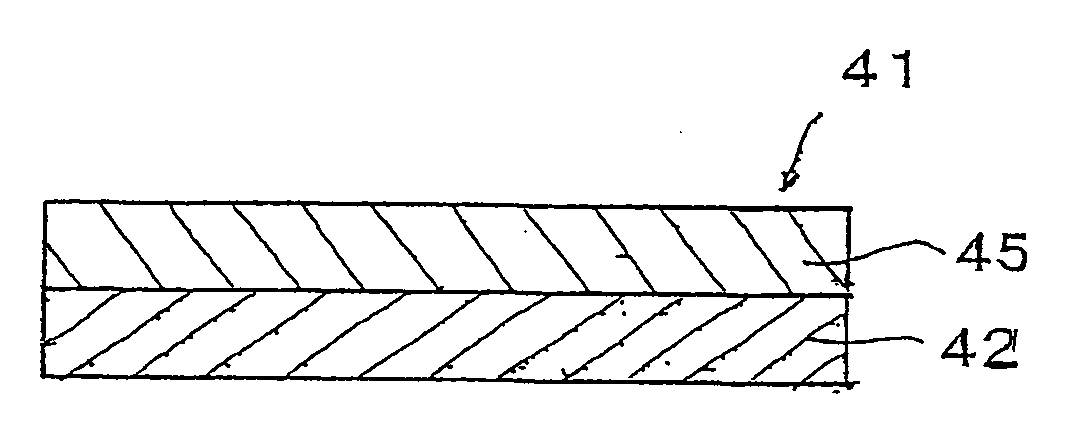

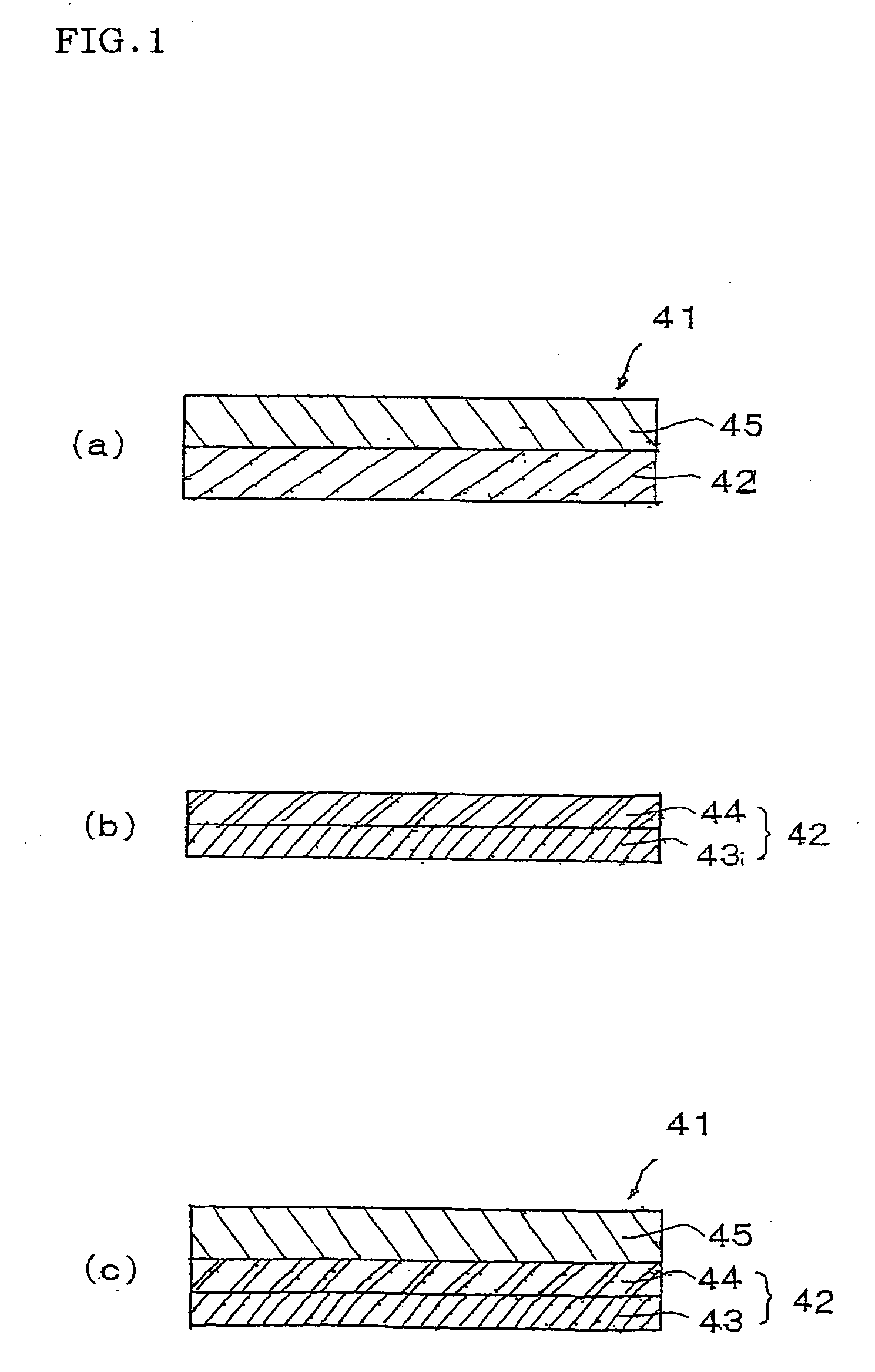

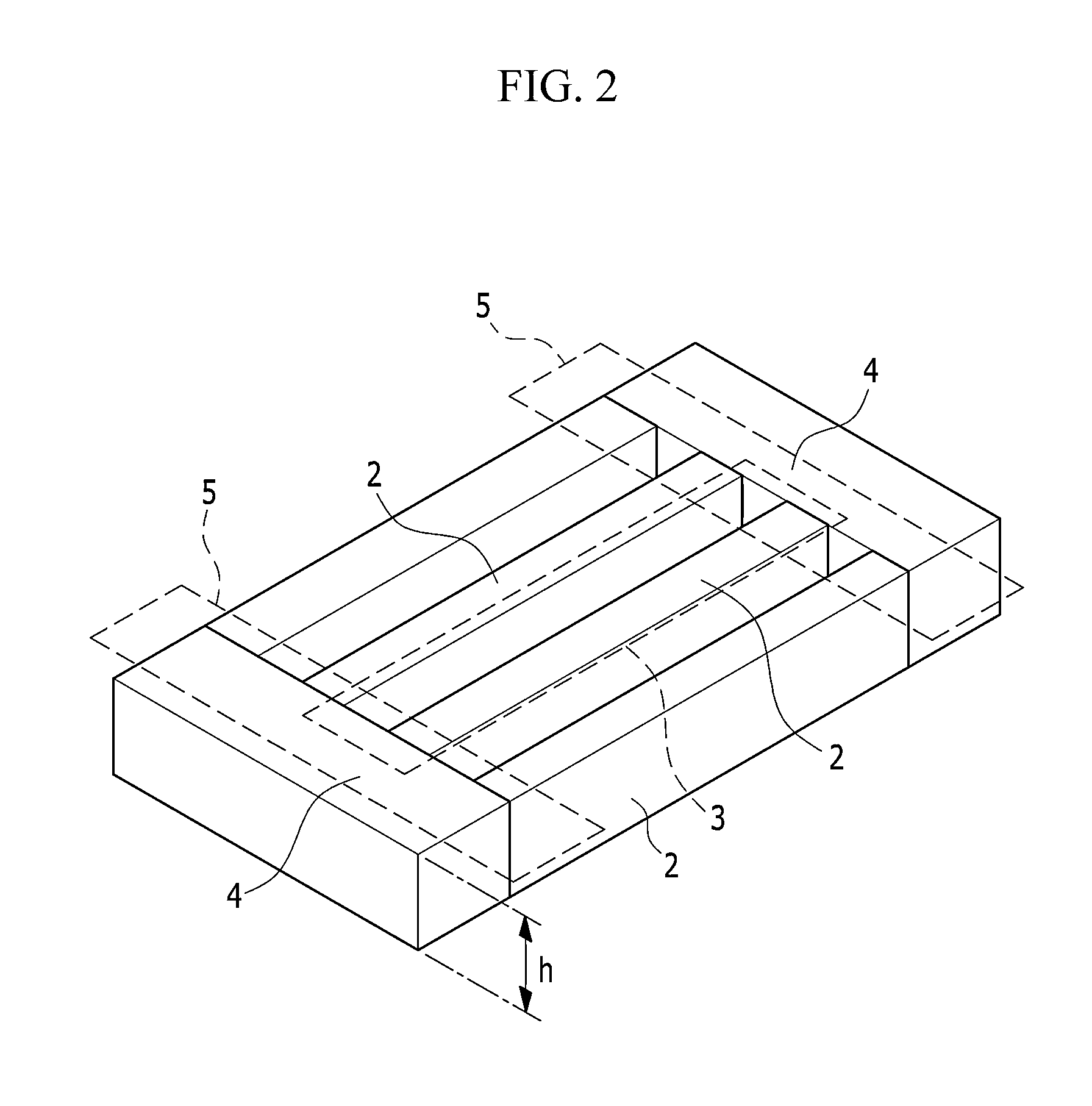

Polishing pad and cushion layer for polishing pad

InactiveUS20060148391A1Easy to processHigh thickness accuracyBelt grinding machinesAbrasion apparatusEngineeringHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

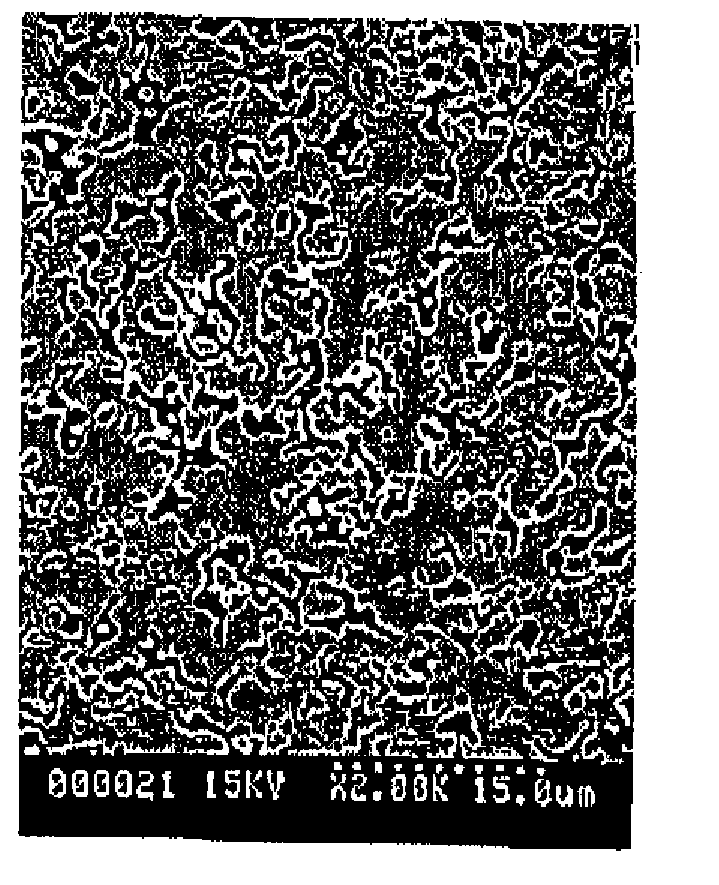

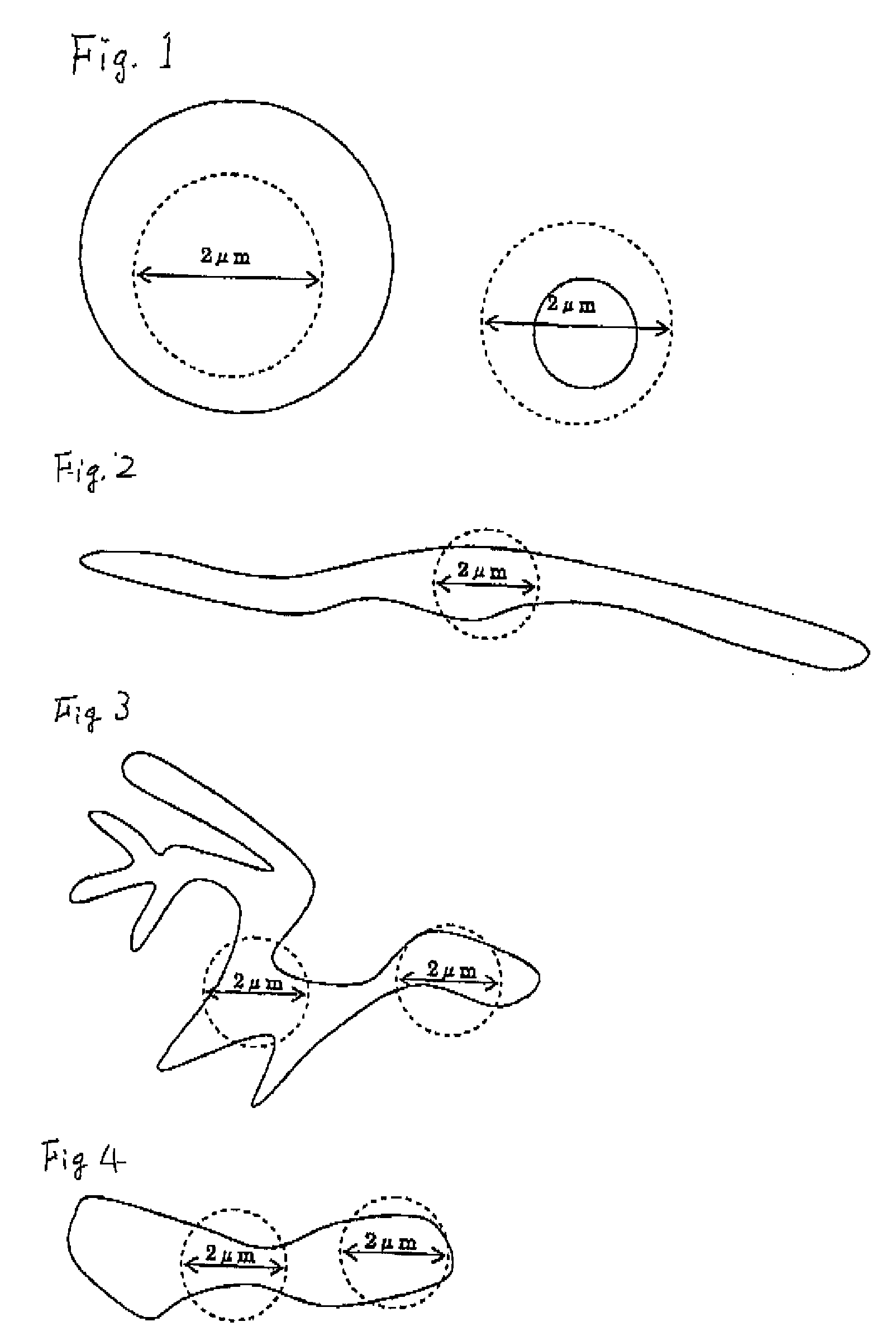

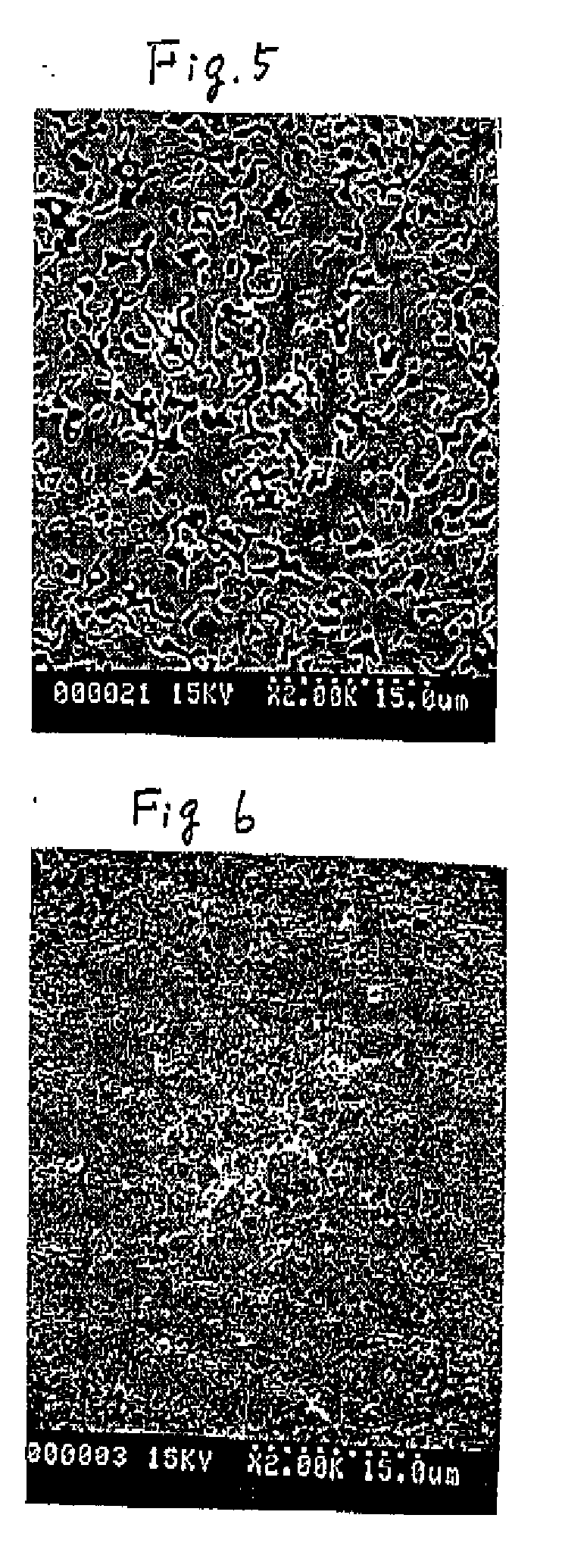

Nonmagnetic Material Particle Dispersed Ferromagnetic Material Sputtering Target

ActiveUS20090242393A1Good effectFast depositionCellsVacuum evaporation coatingProduction rateSputtering

Provided is a nonmagnetic material particle dispersed ferromagnetic material sputtering target comprising a material including nonmagnetic material particles dispersed in a ferromagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is characterized in that all particles of the nonmagnetic material with a structure observed on the material in its polished face have a shape and size that are smaller than all imaginary circles having a radius of 2 μm formed around an arbitrary point within the nonmagnetic material particles, or that have at least two contact points or intersection points between the imaginary circles and the interface of the ferromagnetic material and the nonmagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is advantageous in that, in the formation of a film by sputtering, the influence of heating or the like on a substrate can be reduced, high-speed deposition by DC sputtering is possible, the film thickness can be regulated to be thin, the generation of particles (dust) or nodules can be reduced during sputtering, the variation in quality can be reduced to improve the mass productivity, fine crystal grains and high density can be realized, and the nonmagnetic material particle dispersed ferromagnetic material sputtering target is particularly best suited for use as a magnetic recording layer.

Owner:JX NIPPON MINING& METALS CORP

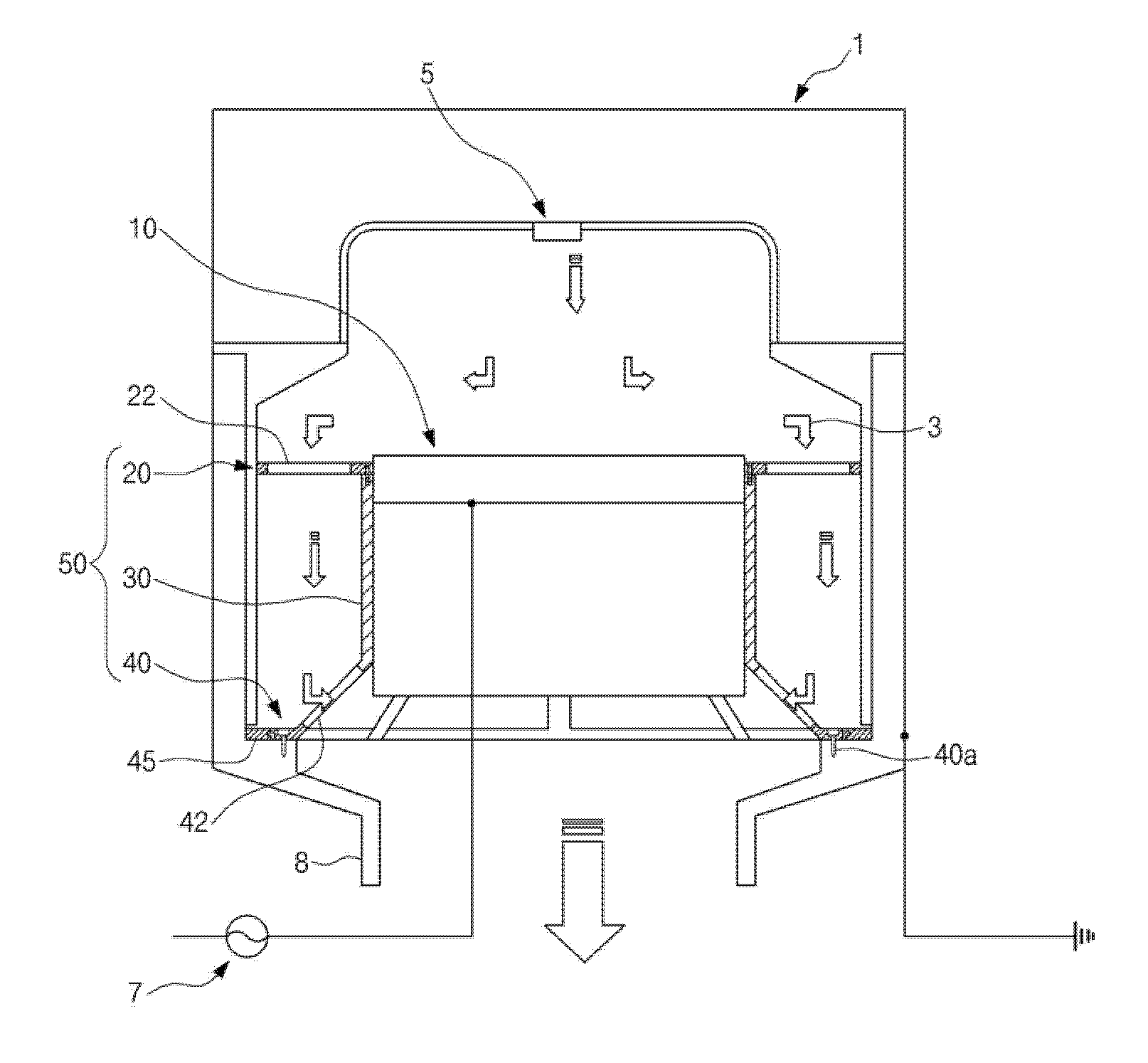

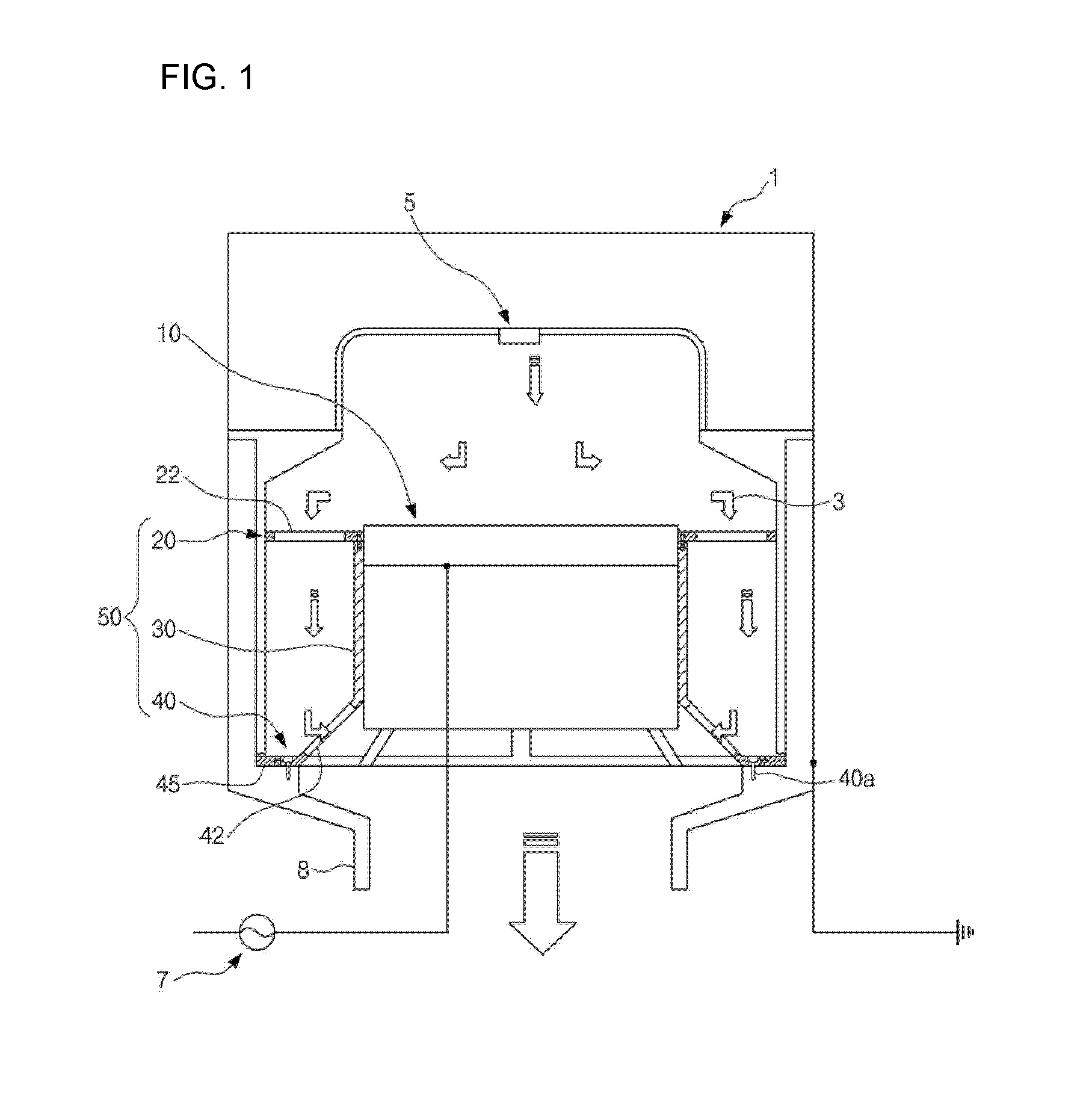

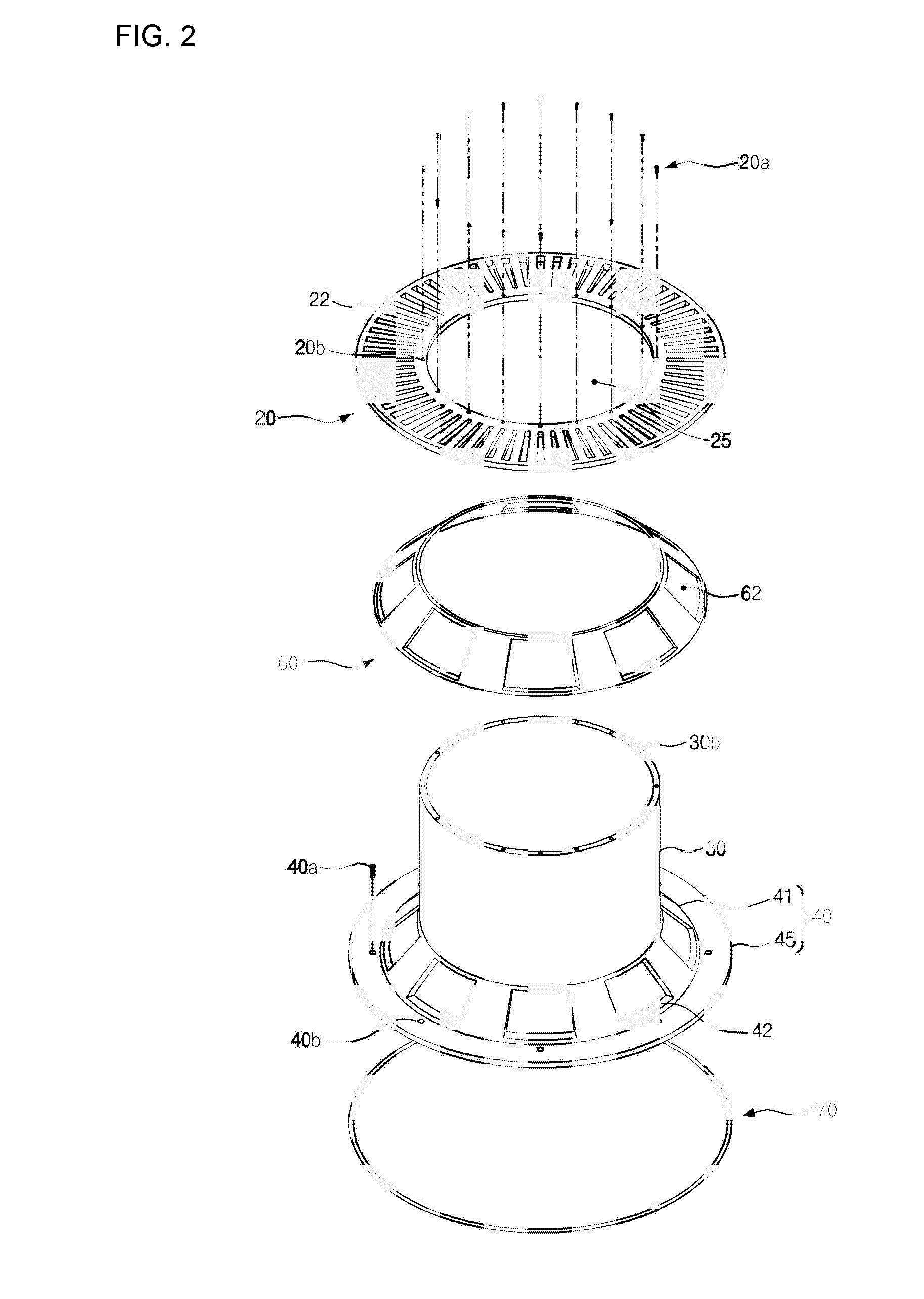

Plasma etching device

InactiveUS20110042009A1Plasma uniformity can be improvedImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma reaction

A plasma etching device is provided. The device includes a chamber, a cathode assembly, and an integral cathode liner. The chamber provides a plasma reaction space. The cathode assembly is positioned at an inner and central part of the chamber and supports a substrate. The integral cathode liner has a plurality of first vents and second vents formed at two levels and spaced apart respectively such that the uniformity of a gas flow and exhaust flow within the chamber is maintained, and is outer inserted to the cathode assembly and coupled at its lower end part to an inner surface of the chamber.

Owner:DMS CO LTD

Polishing pad and cushion layer for polishing pad

InactiveUS20060148393A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingCushionChemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

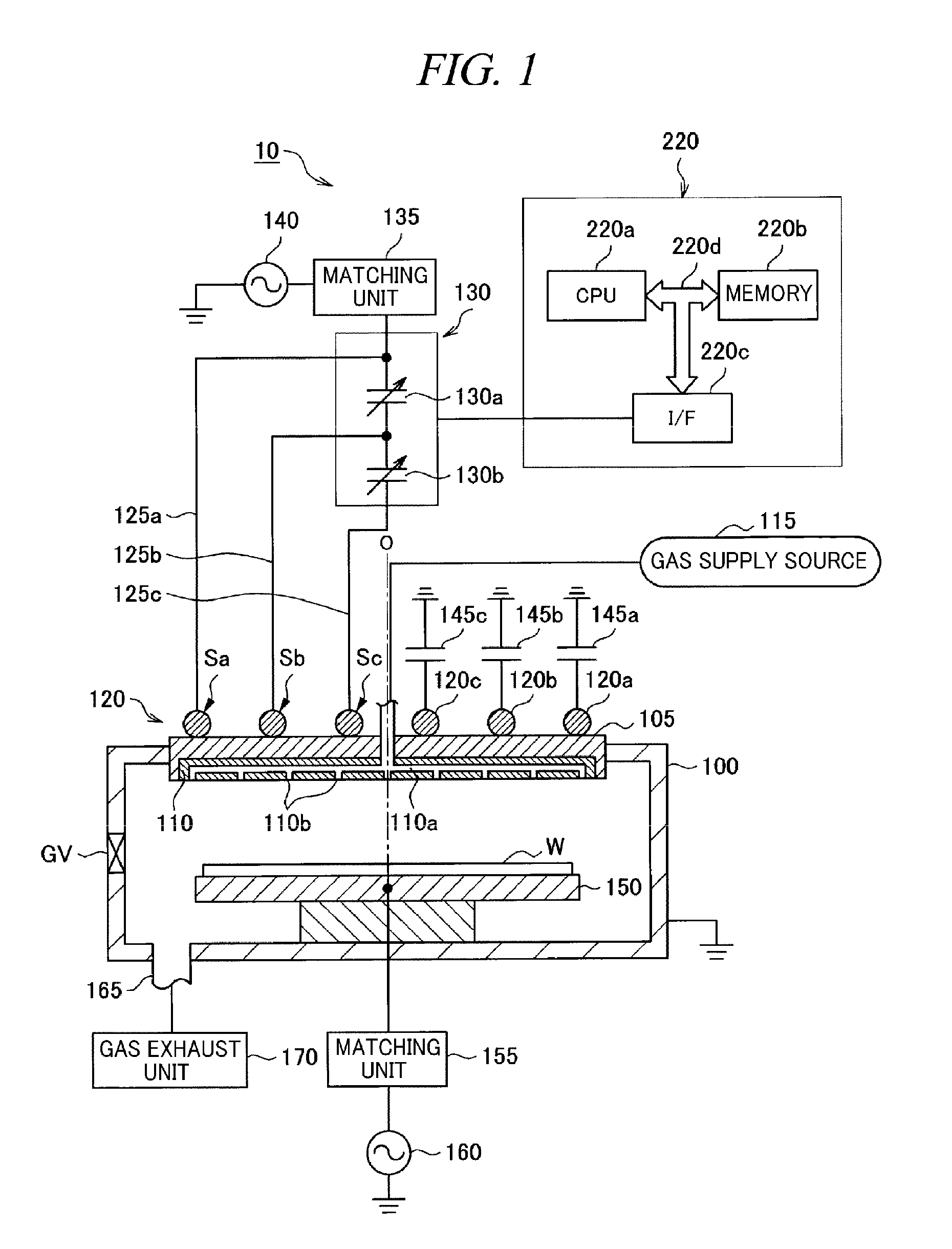

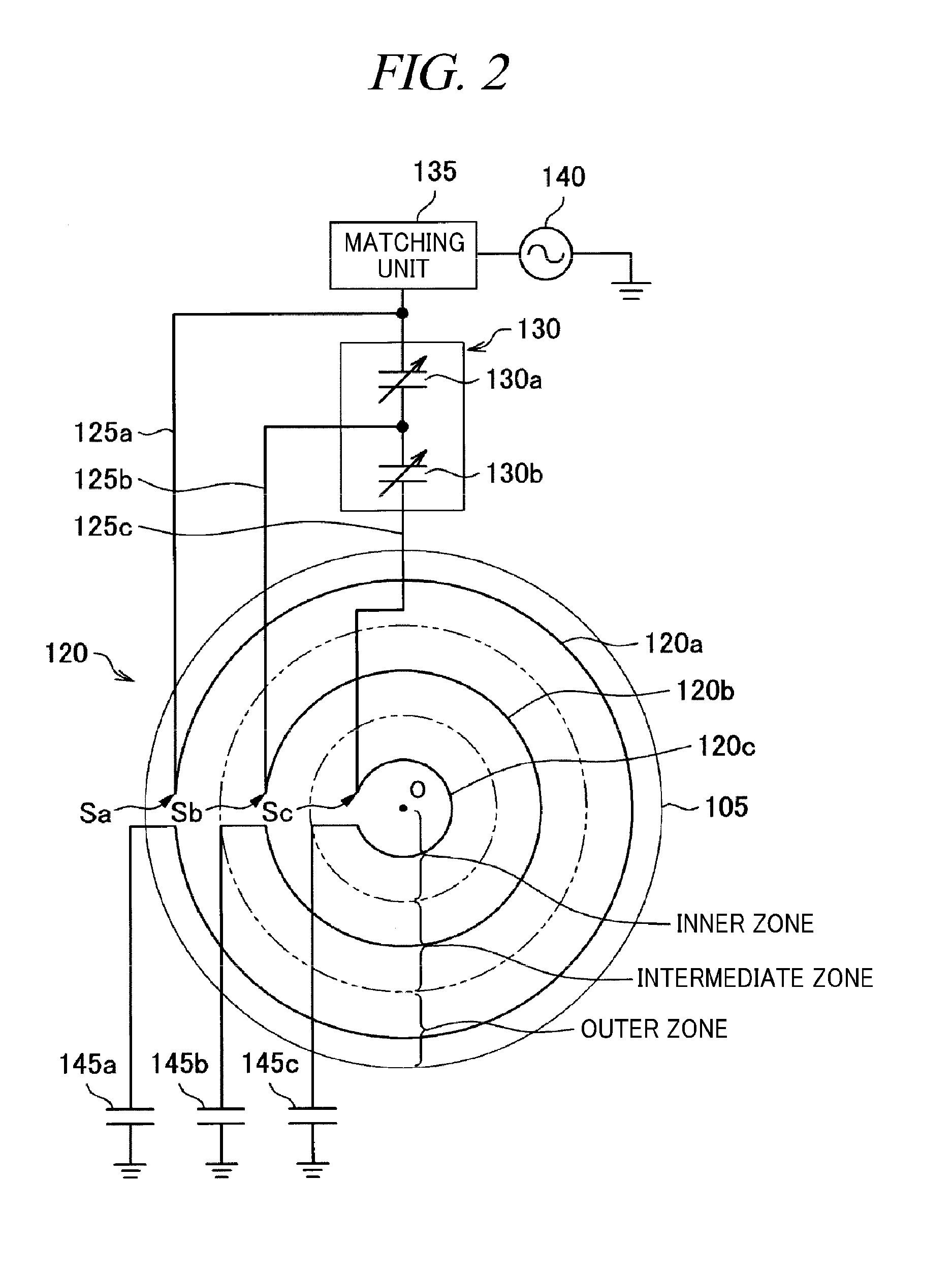

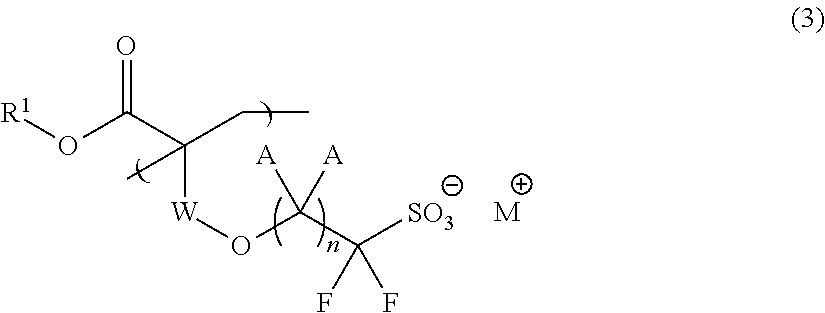

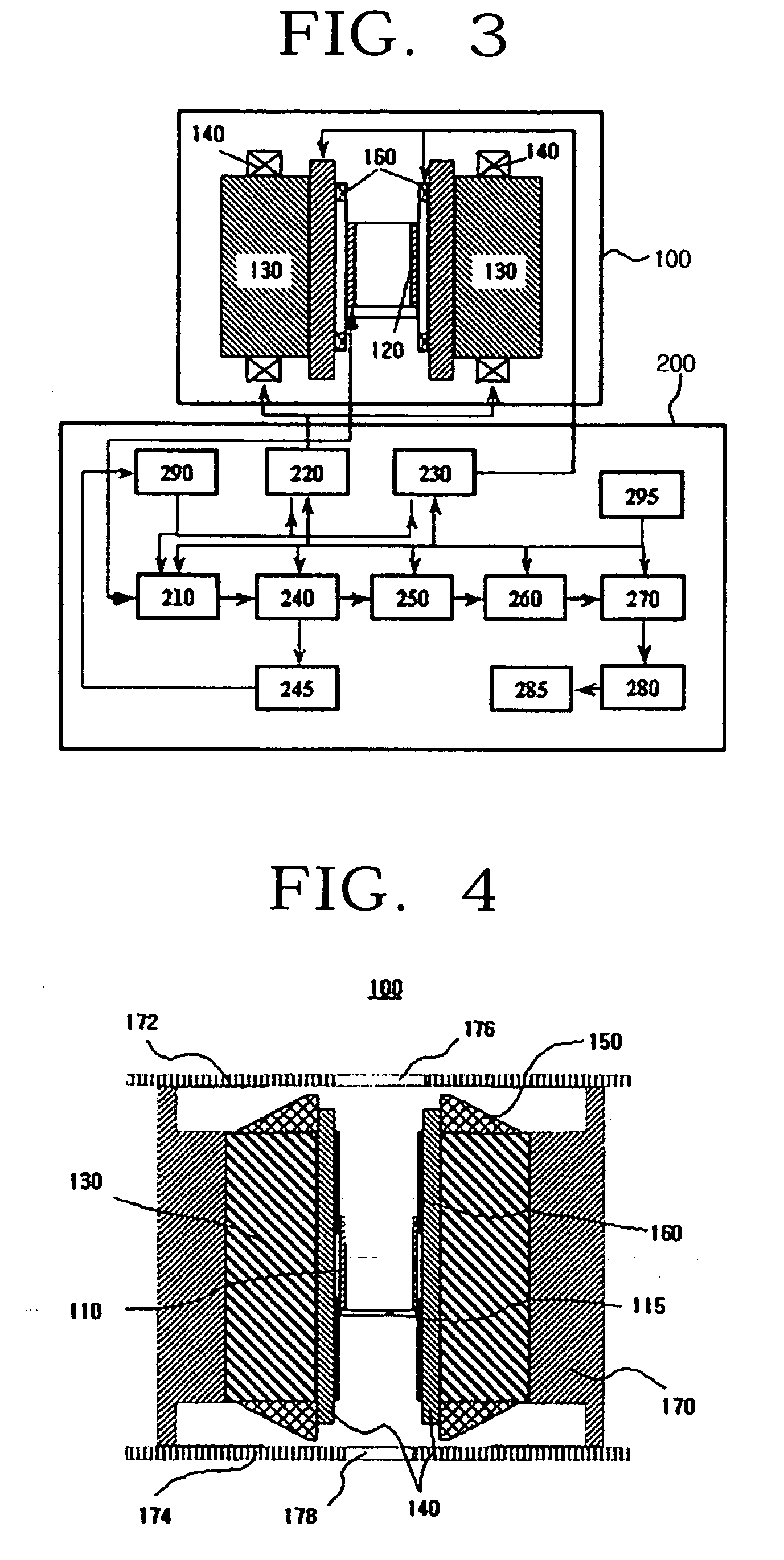

Plasma processing apparatus

InactiveUS20100243162A1Improve uniformityLow densityElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityHigh frequency power

A uniformity of plasma density in a target object surface and plasma processing characteristics can be improved. A plasma processing apparatus 10 includes: a processing chamber 100 in which a plasma process is performed on a wafer W; a first high frequency power supply 140 configured to output a high frequency power; a high frequency antenna 120 including an outer coil, an inner coil and n (n is an integer equal to or greater than 1) number of intermediate coil(s) that are concentrically wound about a central axis outside the processing chamber 100; and a dielectric window 105 provided at a part of a wall of the processing chamber 100 and configured to introduce electromagnetic field energy generated from the high frequency antenna 120 into the processing chamber 100.

Owner:TOKYO ELECTRON LTD

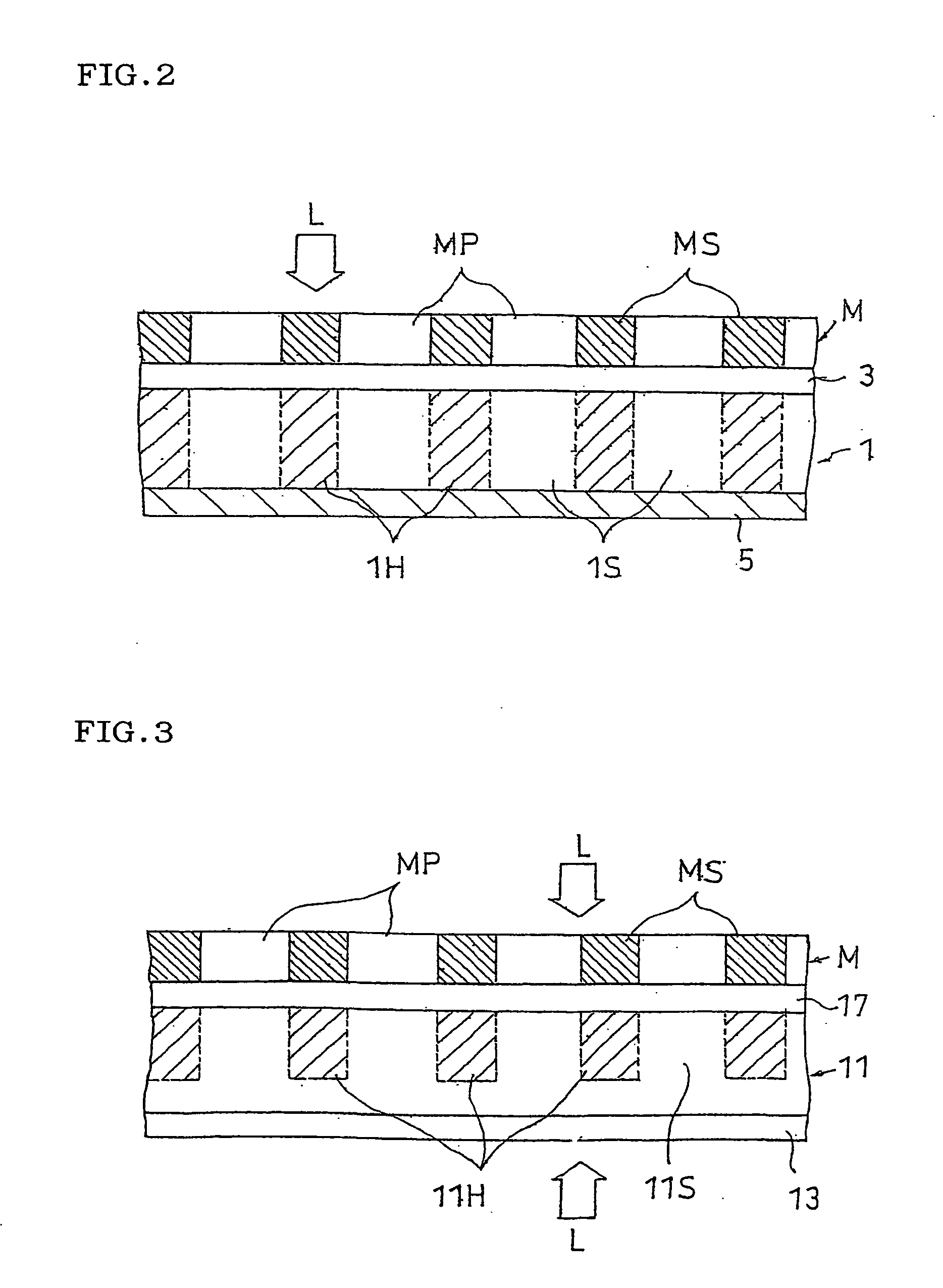

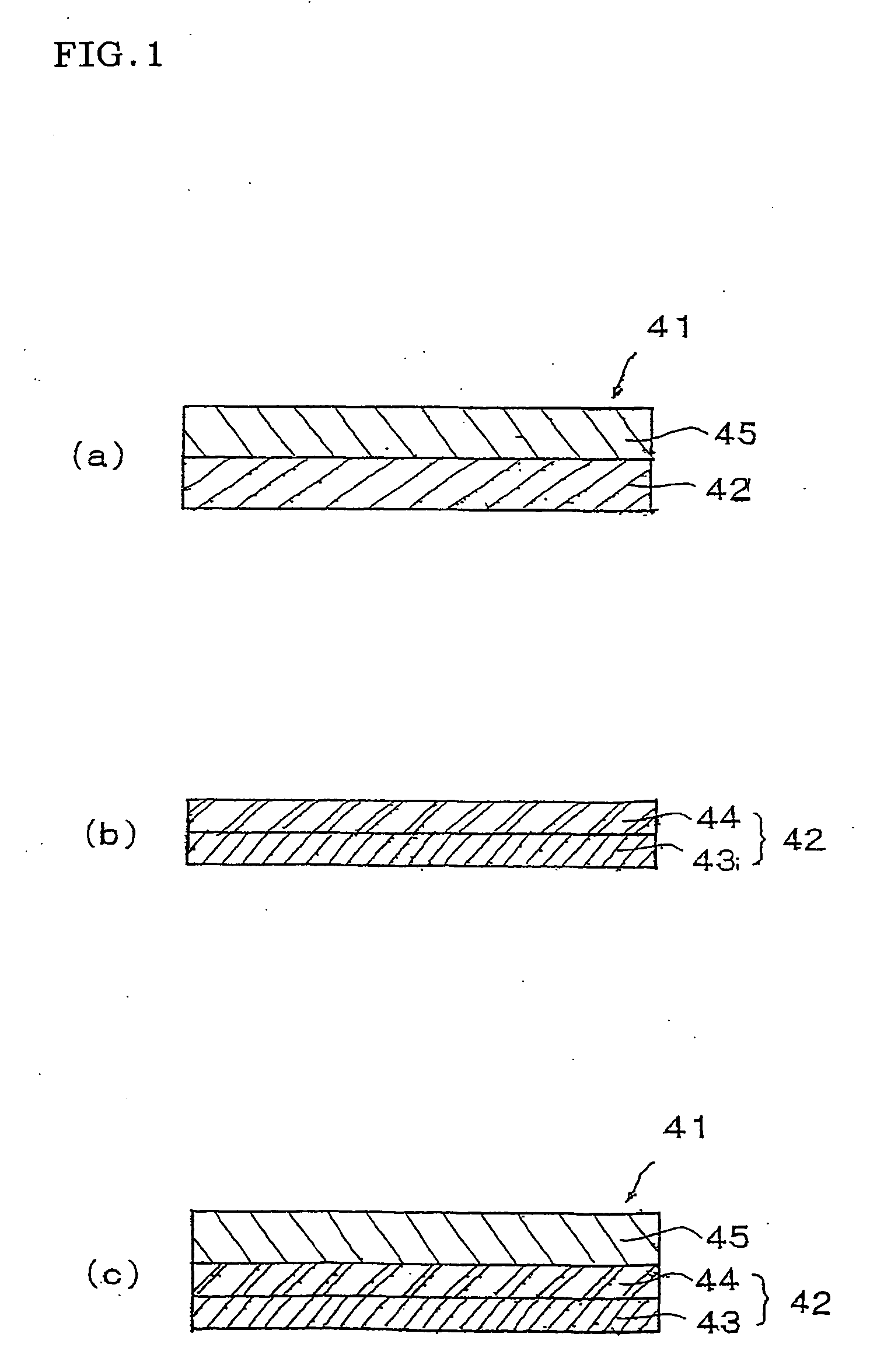

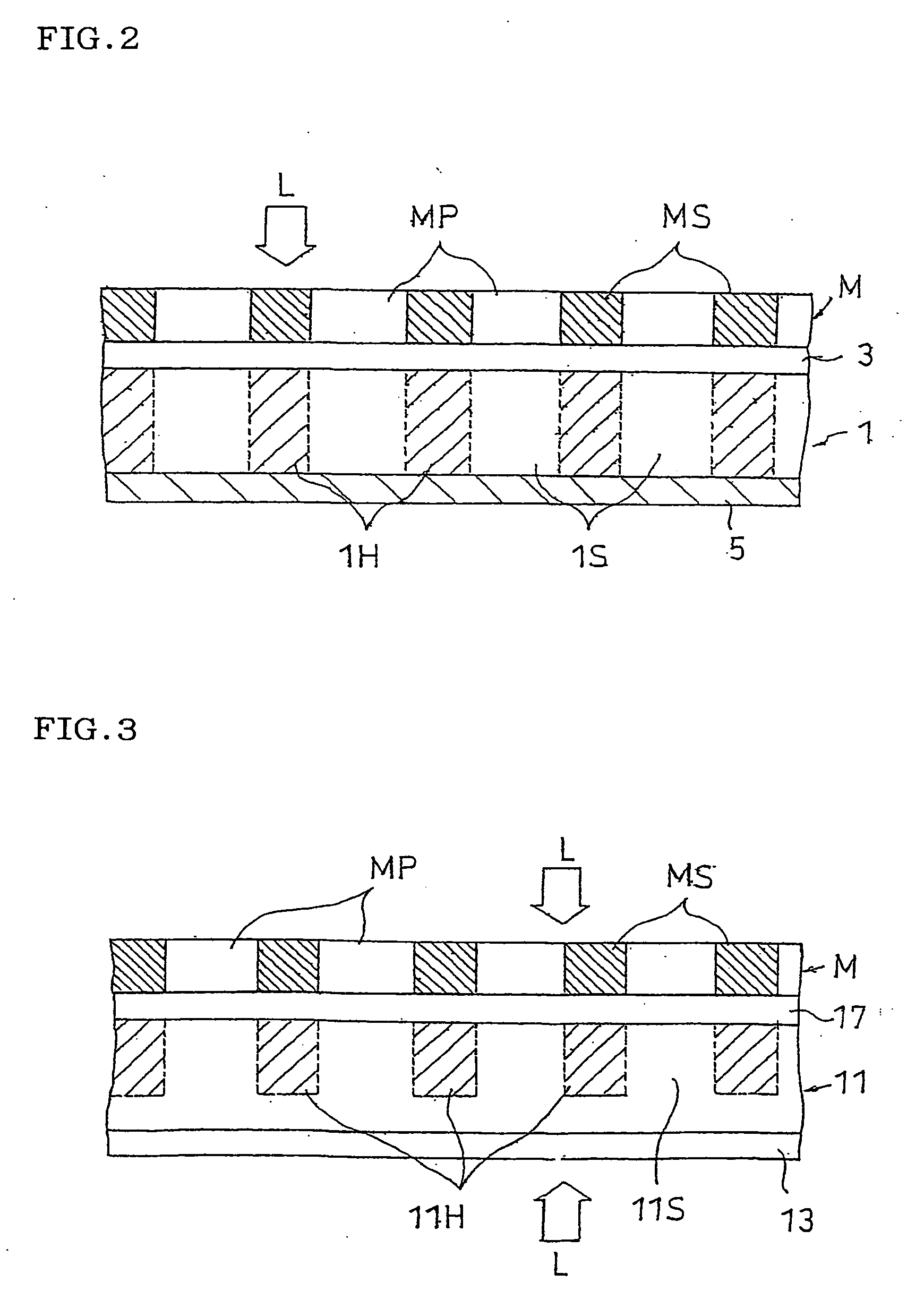

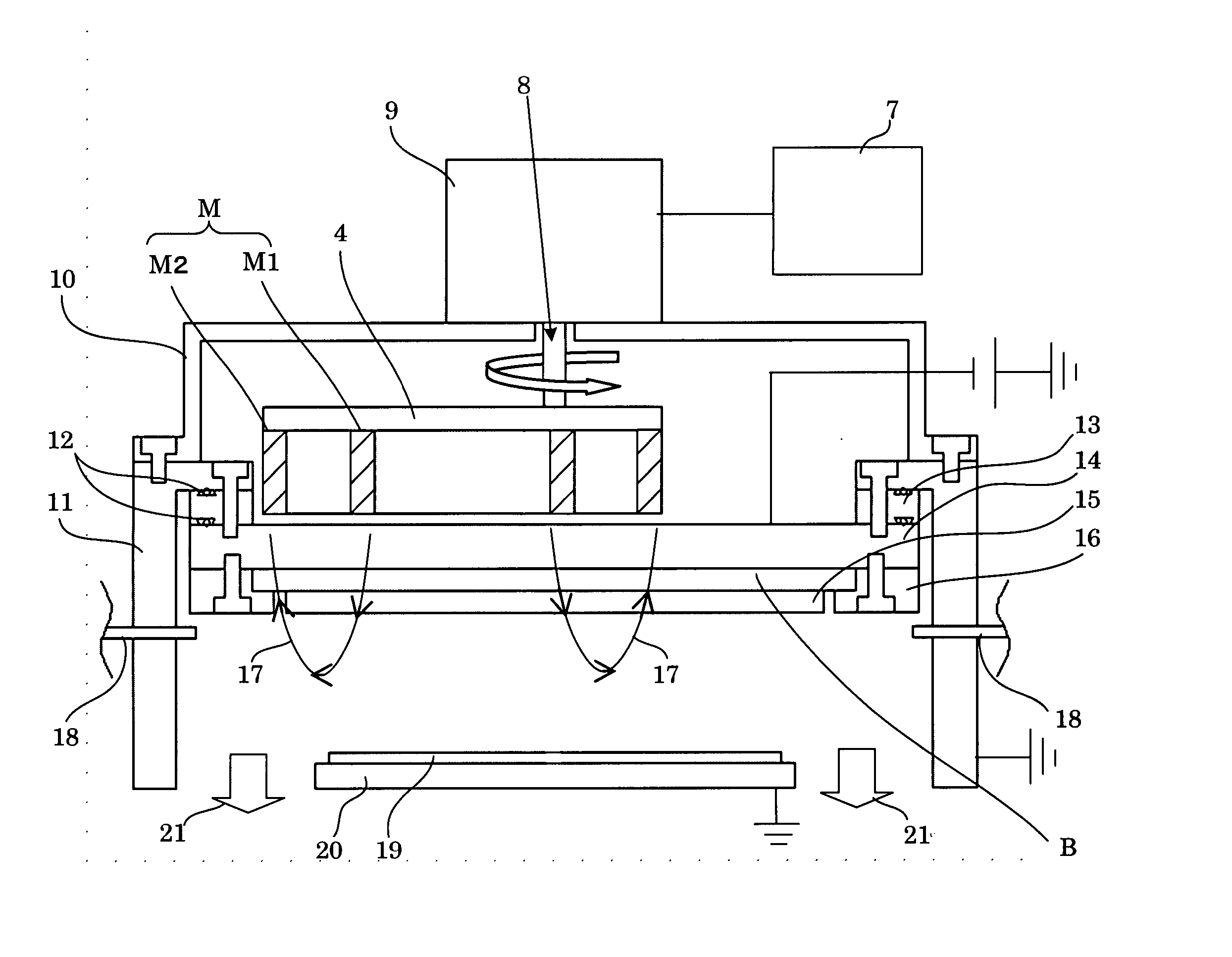

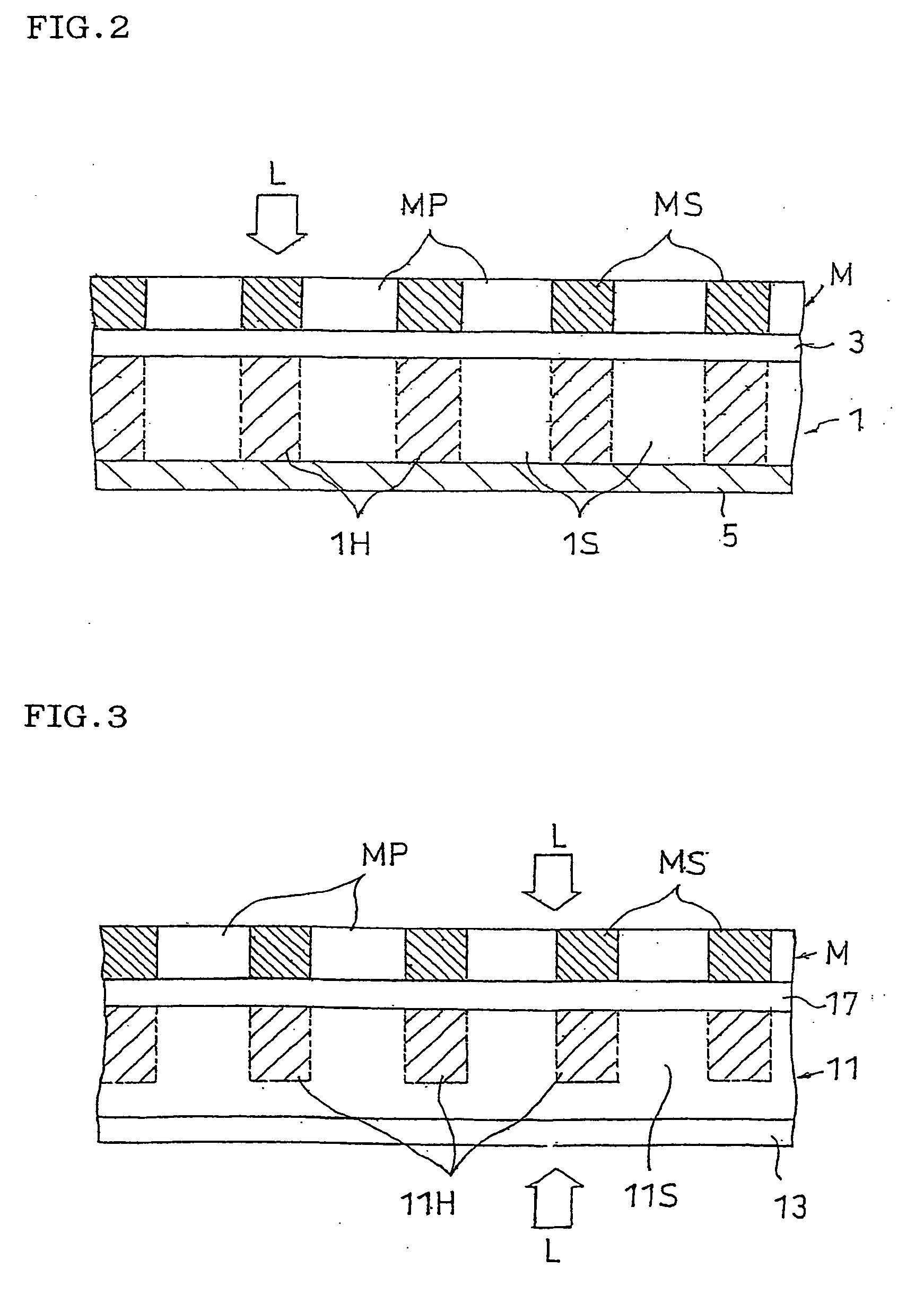

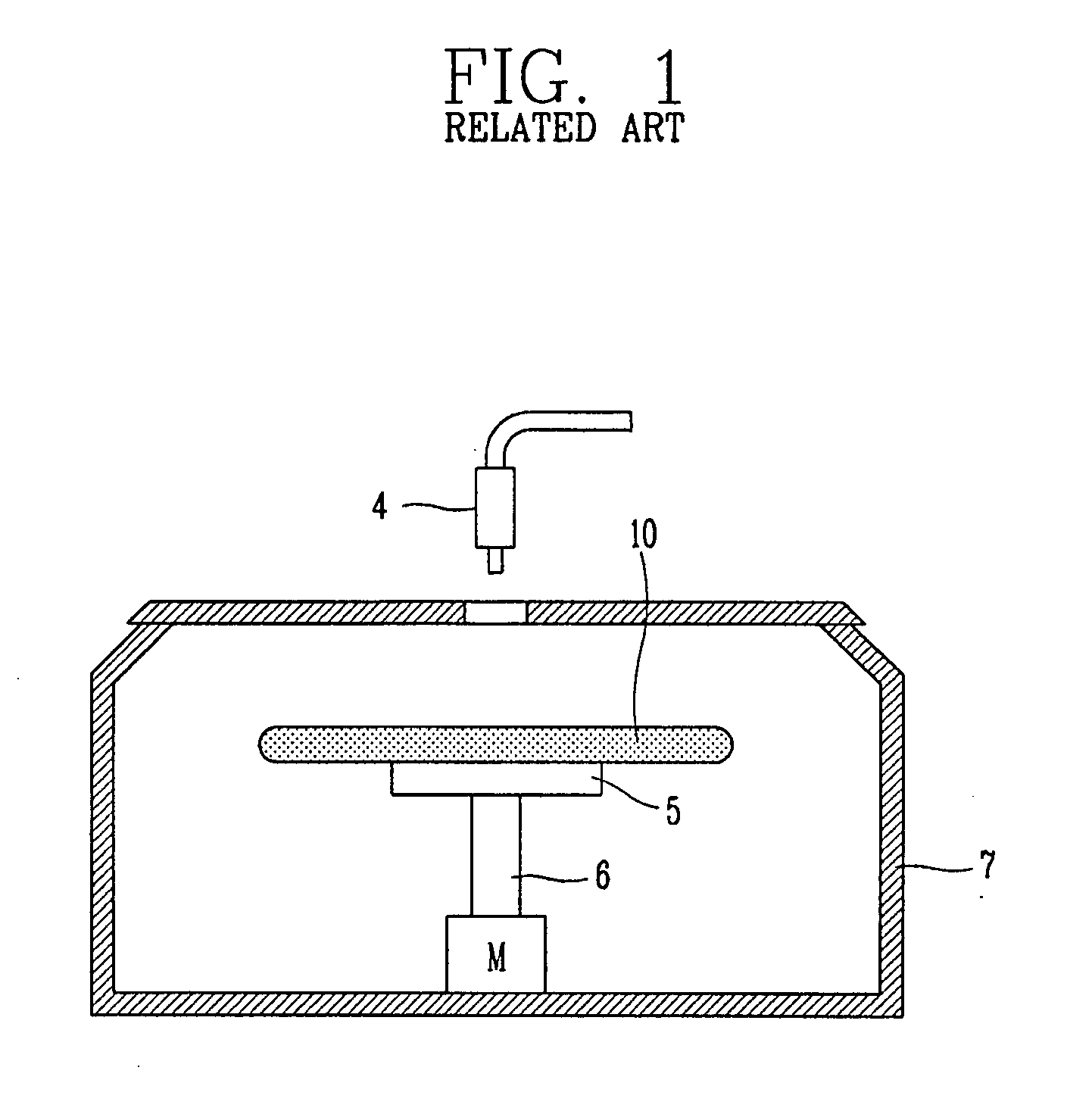

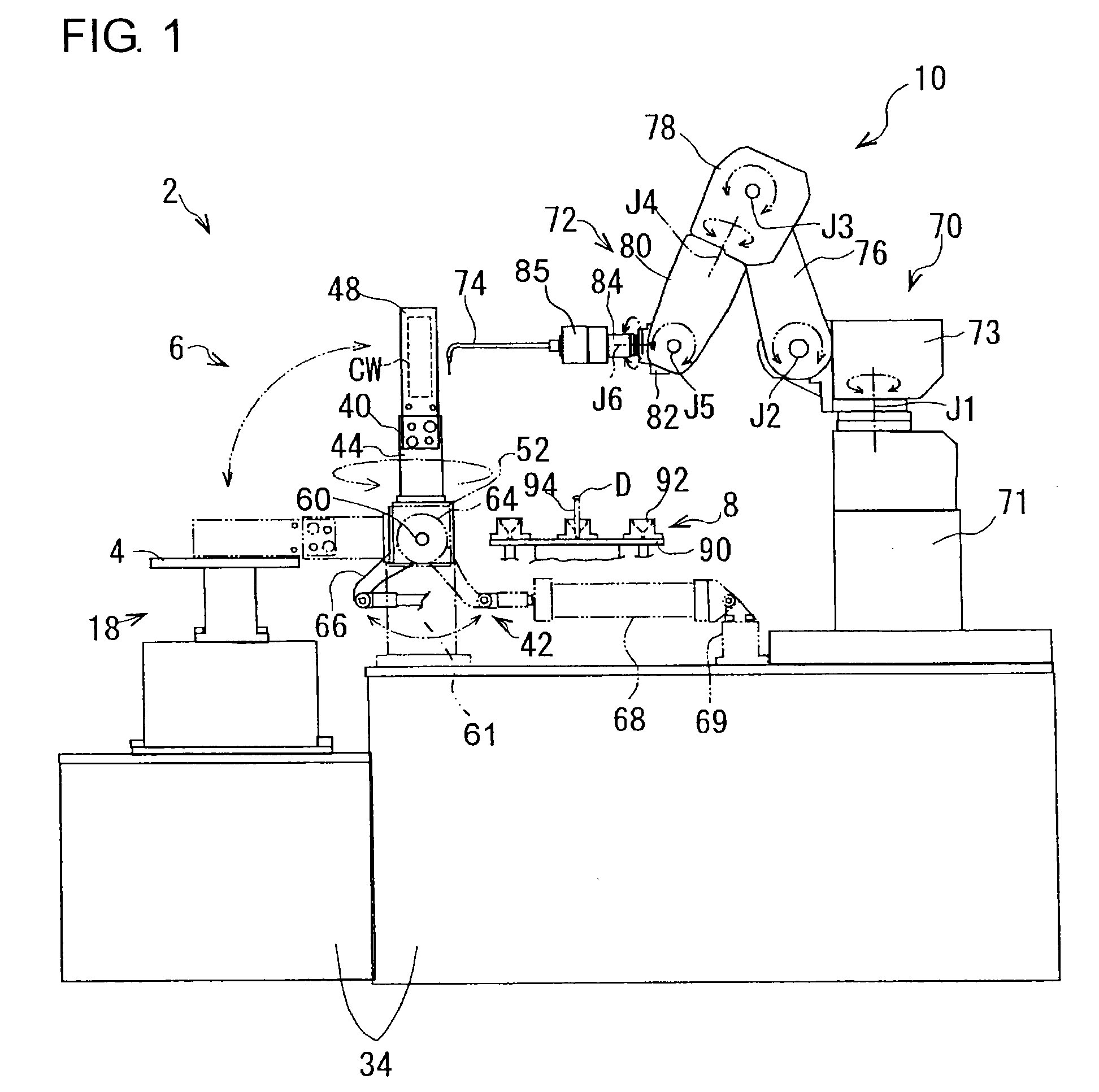

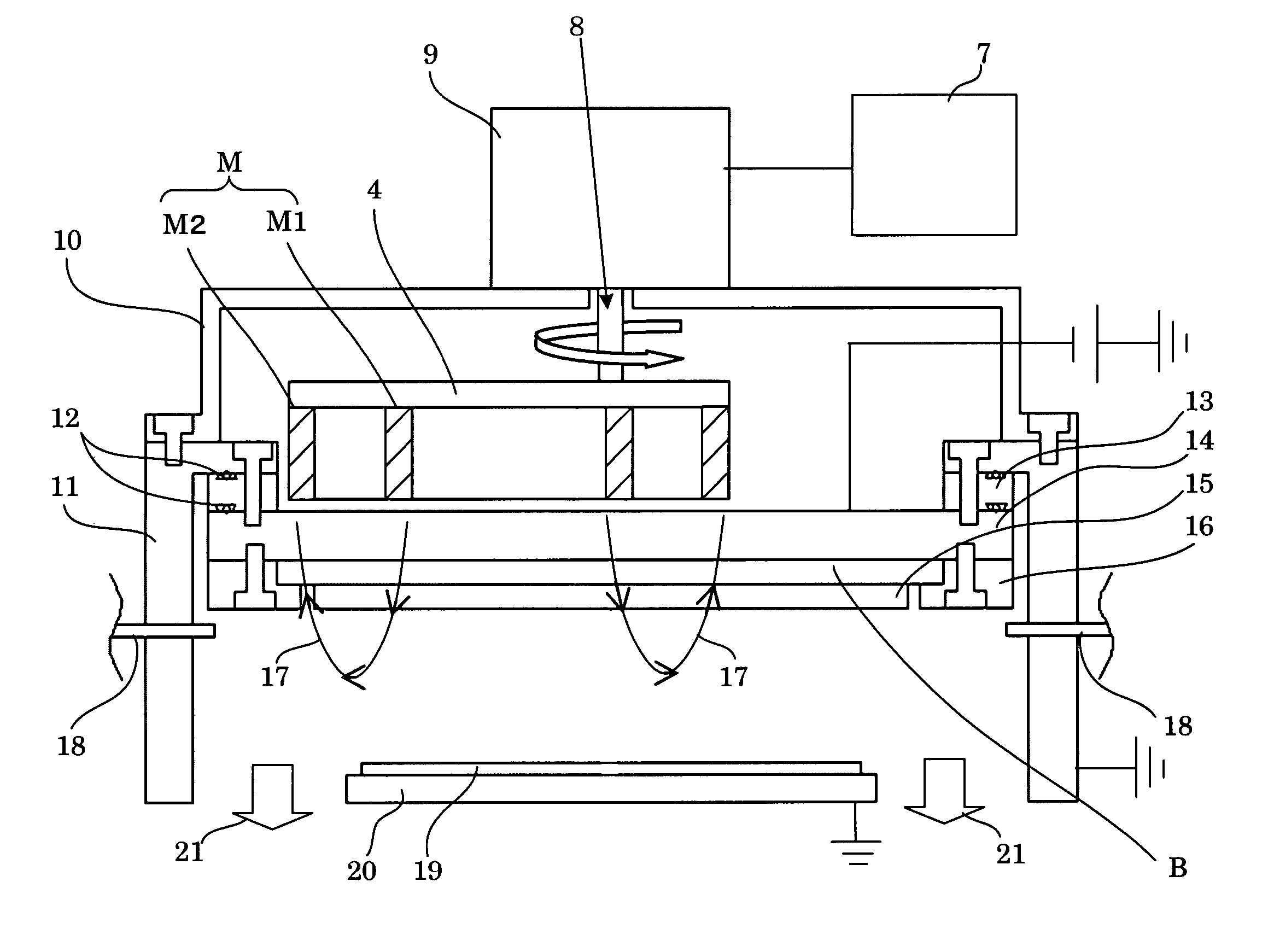

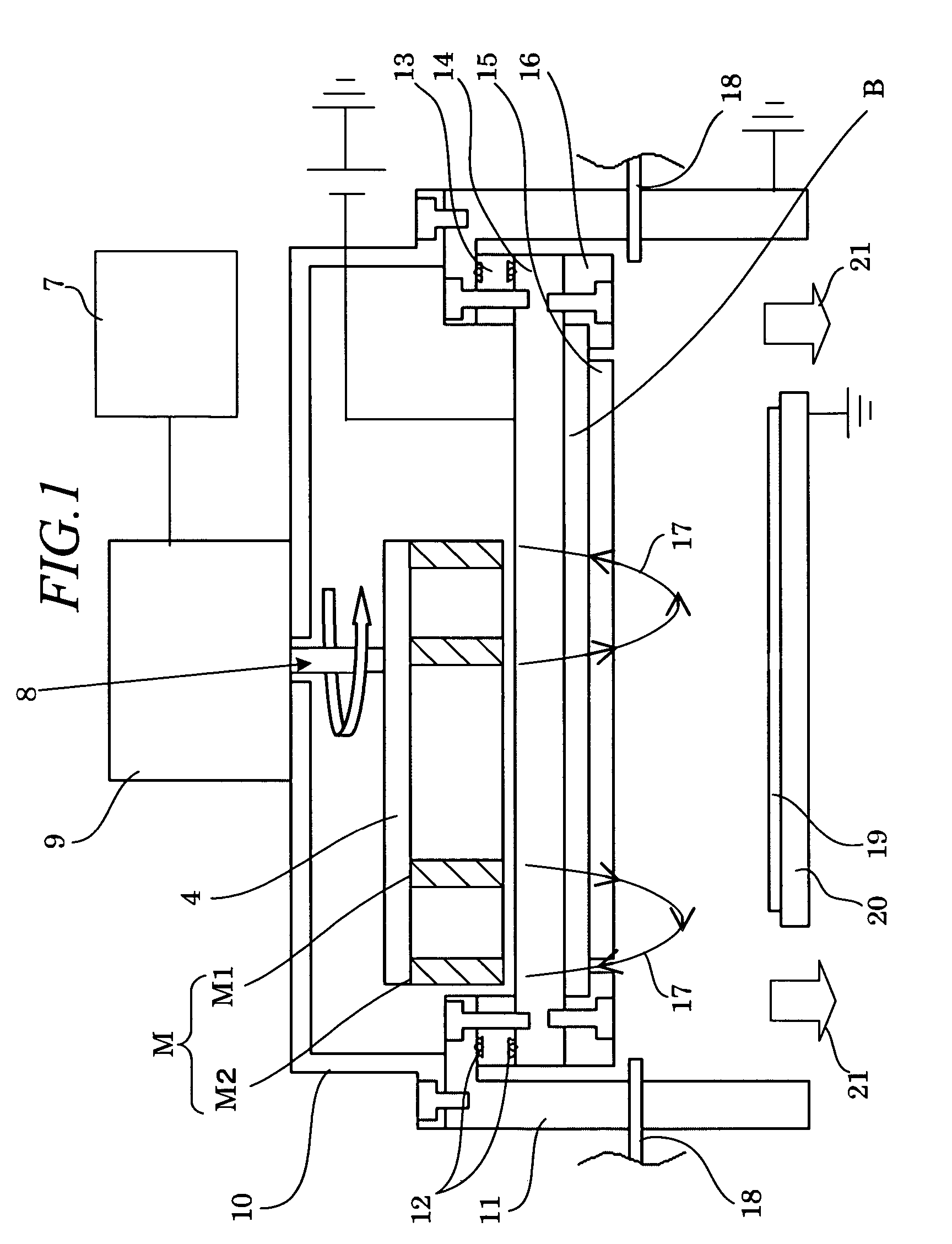

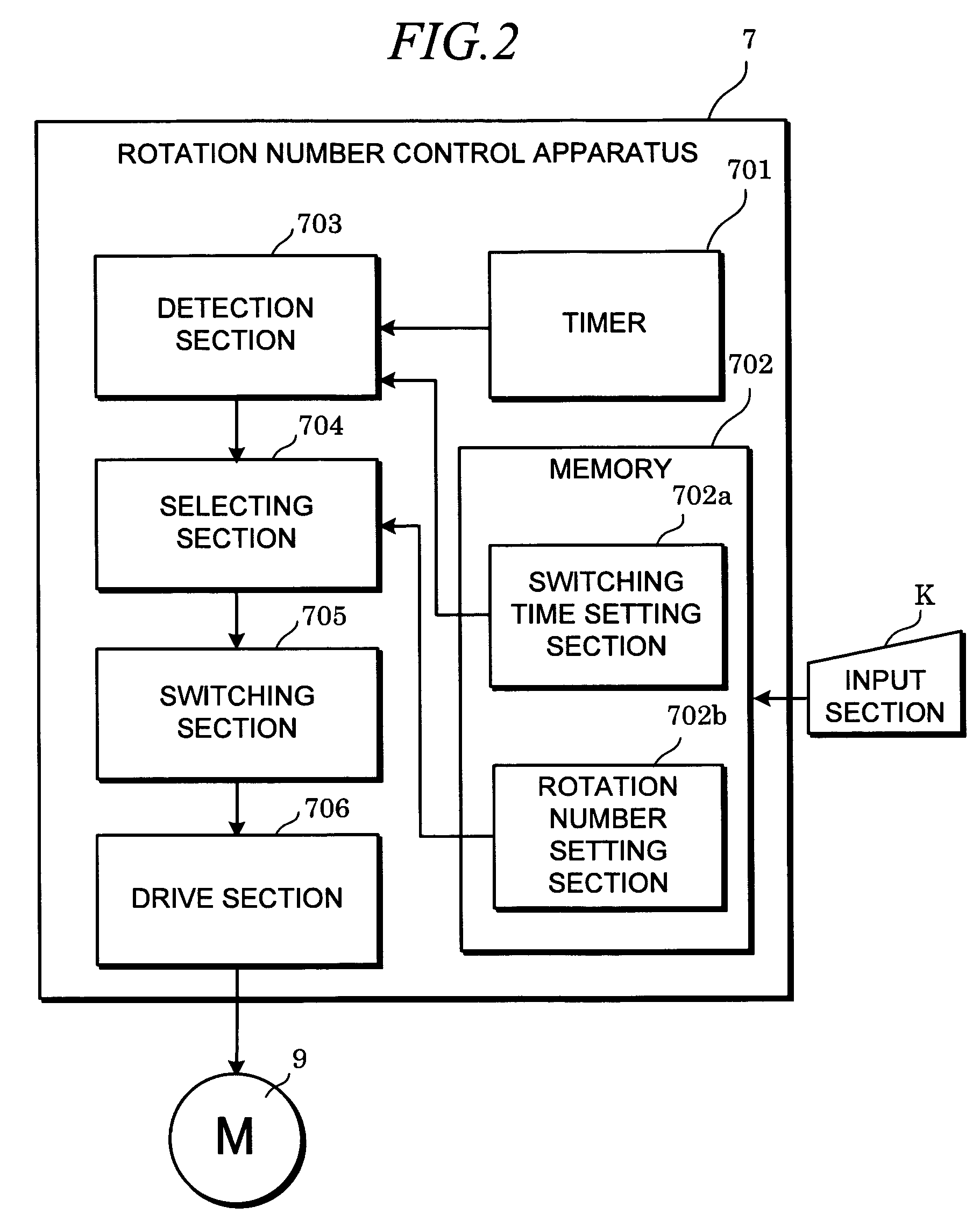

Sputtering Apparatus and Method, and Sputtering Control Program

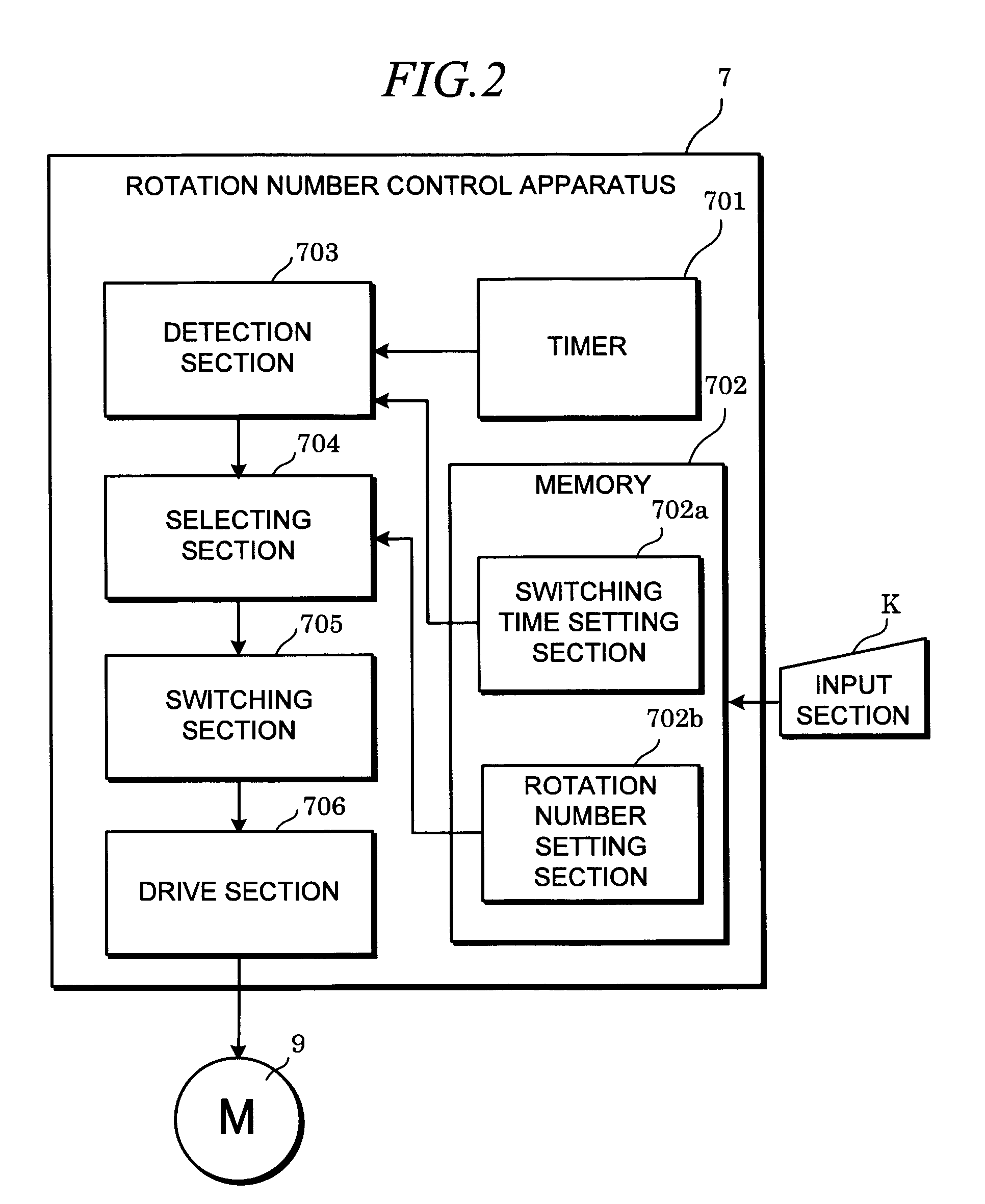

InactiveUS20080023318A1Deterioration of uniformity of film thicknessInhibit deteriorationCellsVacuum evaporation coatingHigh densitySwitching time

To provide a sputtering apparatus and method, and a sputtering control program which are configured simply and can secure the uniformity of the film thickness from the beginning to the end of the use of a target. There are provided: a target 15 disposed so as to face an object to be treated 19; a permanent magnet unit M which generates a high-density plasma by means of a magnetic field and deposits a material of the target 15 on the object to be treated, in the form of a film; a rotational mechanism 9 which rotates the permanent magnet unit M; and a rotation number control apparatus 7 which gradually changes the number of rotations of the permanent magnet unit M rotated by the rotational mechanism 9. The rotation number control apparatus 7 has a rotation number setting section 702b for setting the number of rotations to be switched, a switching time setting section 702a for setting the time for switching, a detection section 703 for detecting the switching time, a selecting section 704 for selecting the number of rotations at the switching time, and a switching section 705 for outputting an instruction of switching to the selected number of rotations.

Owner:SHIBAURA MECHATRONICS CORP

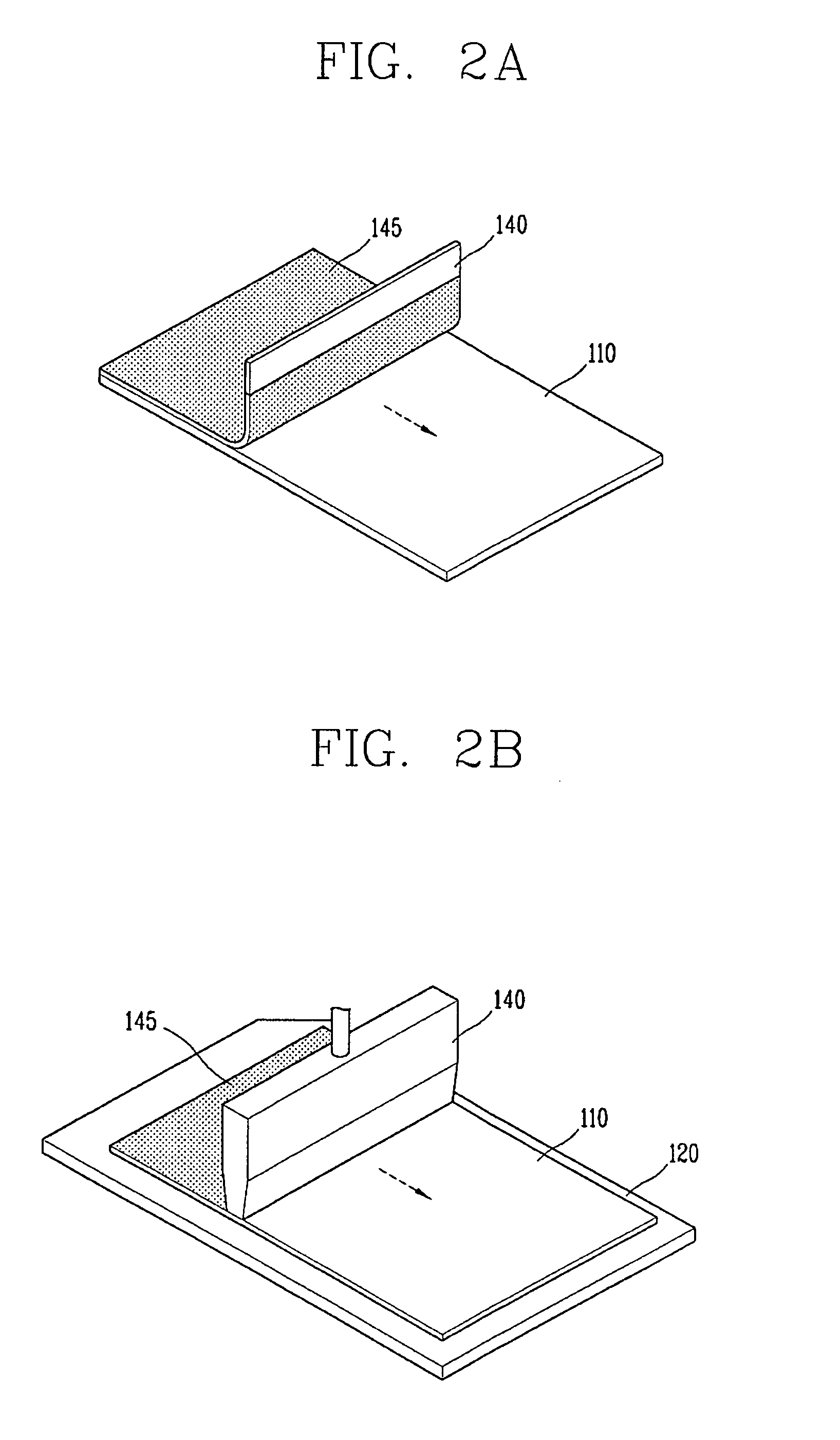

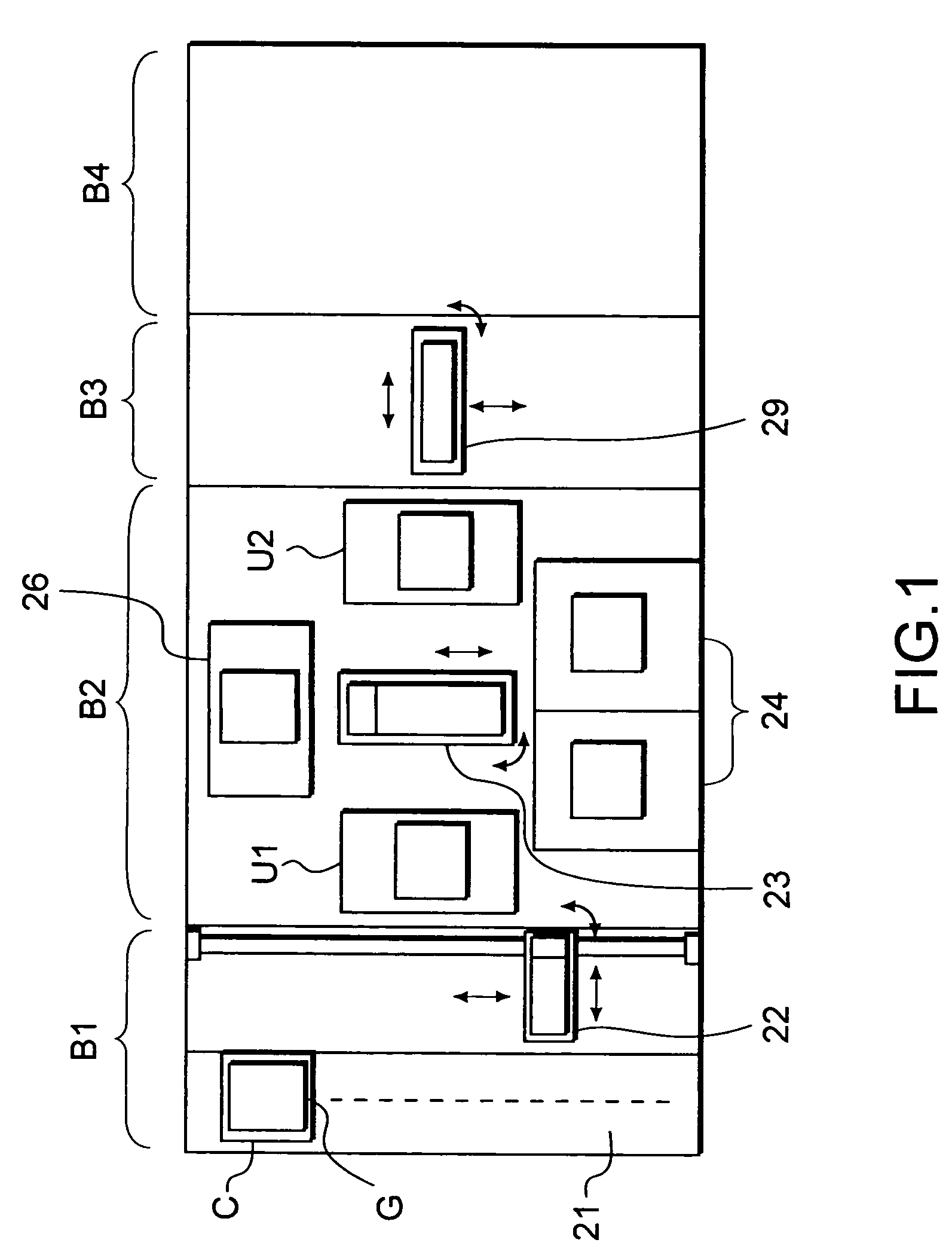

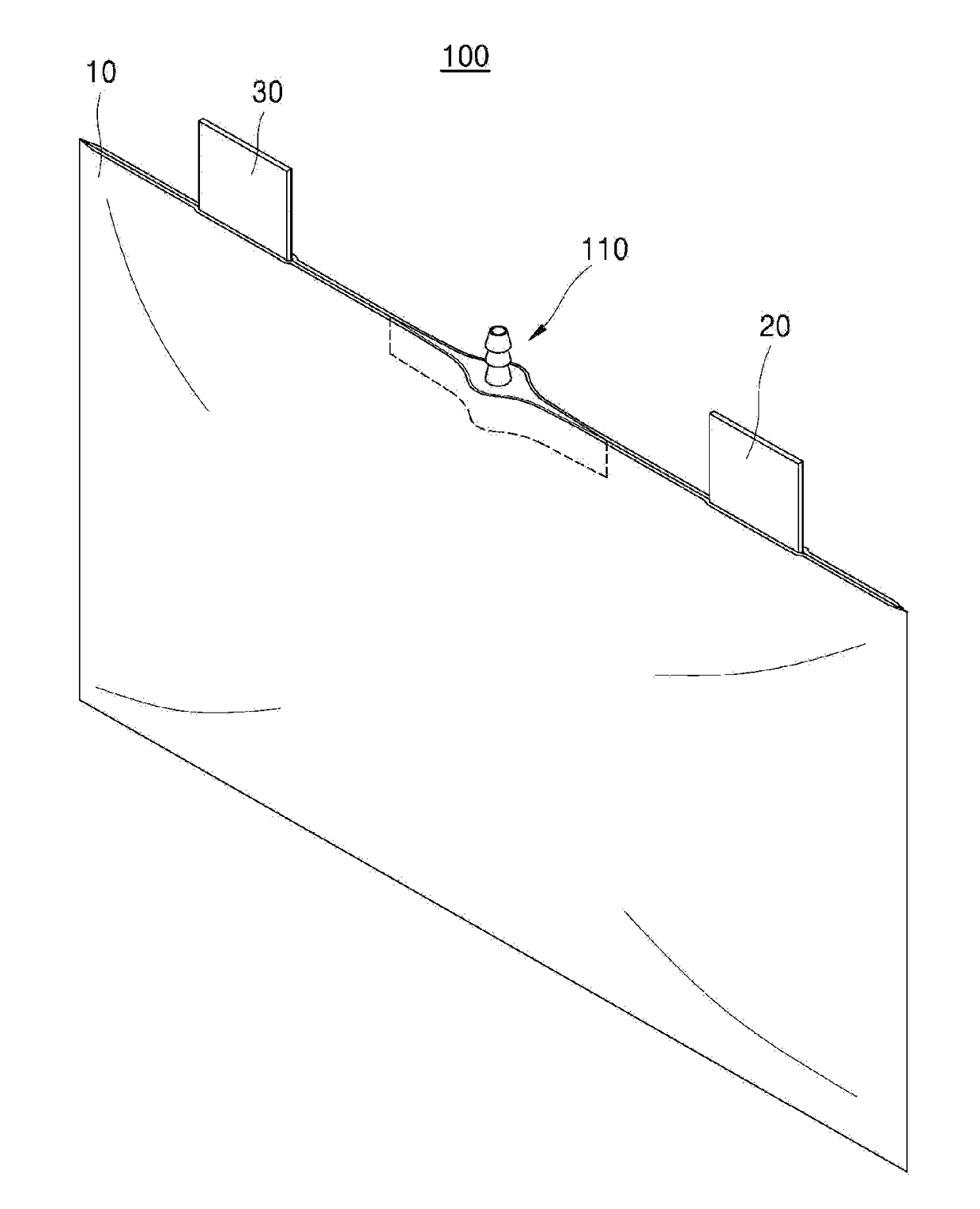

Ink jet recording apparatus and manufacturing method for functional liquid applied substrate

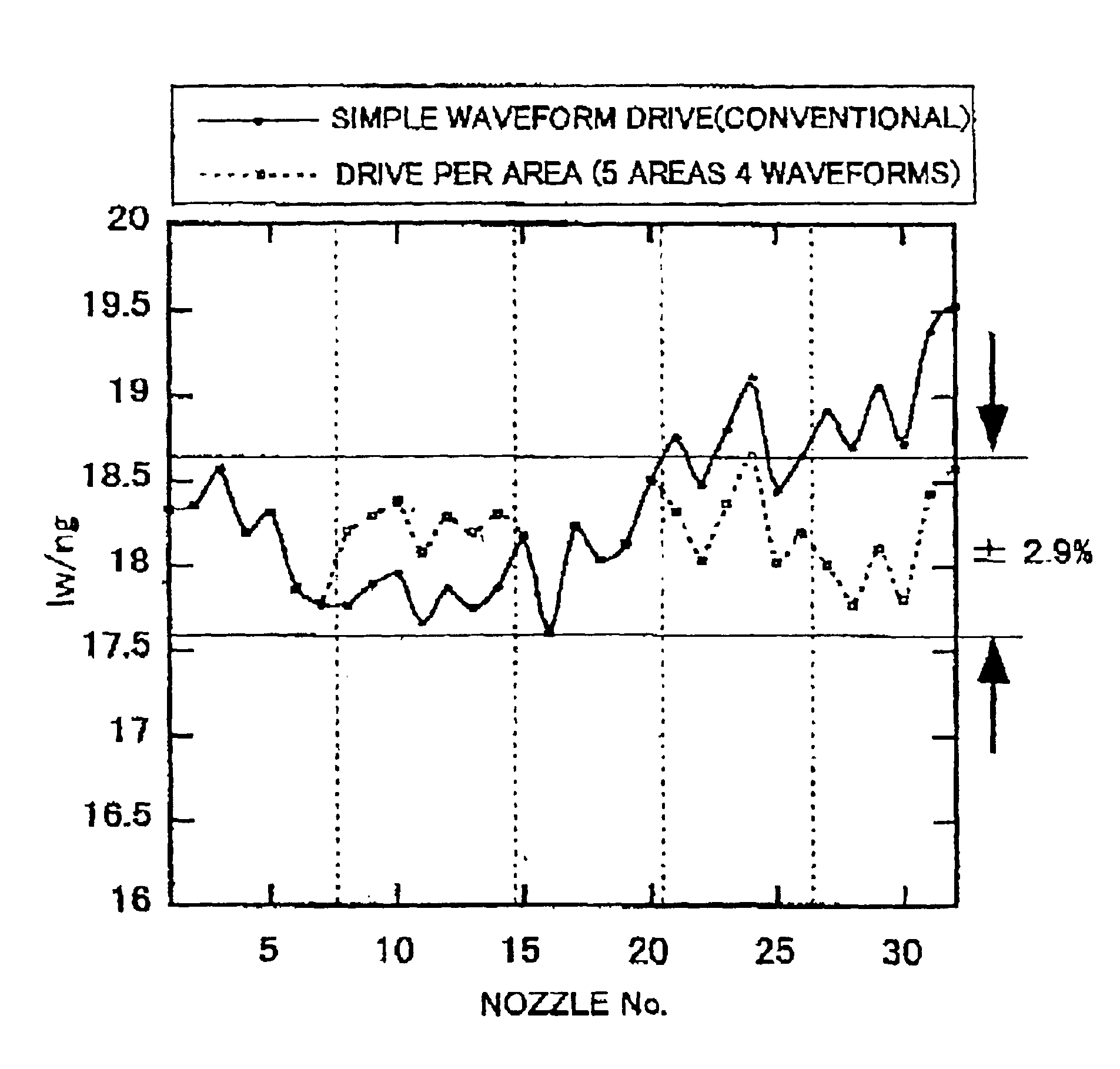

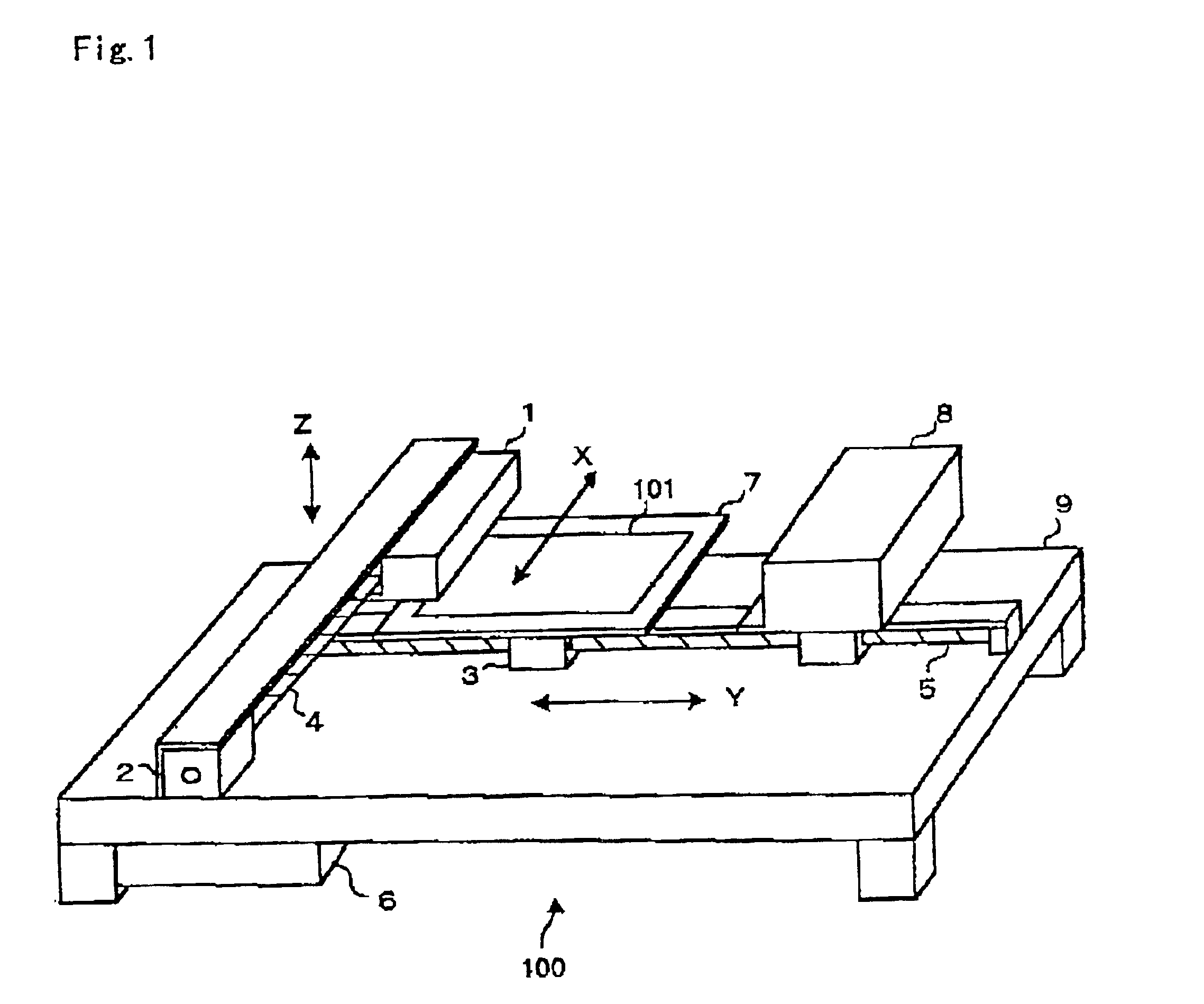

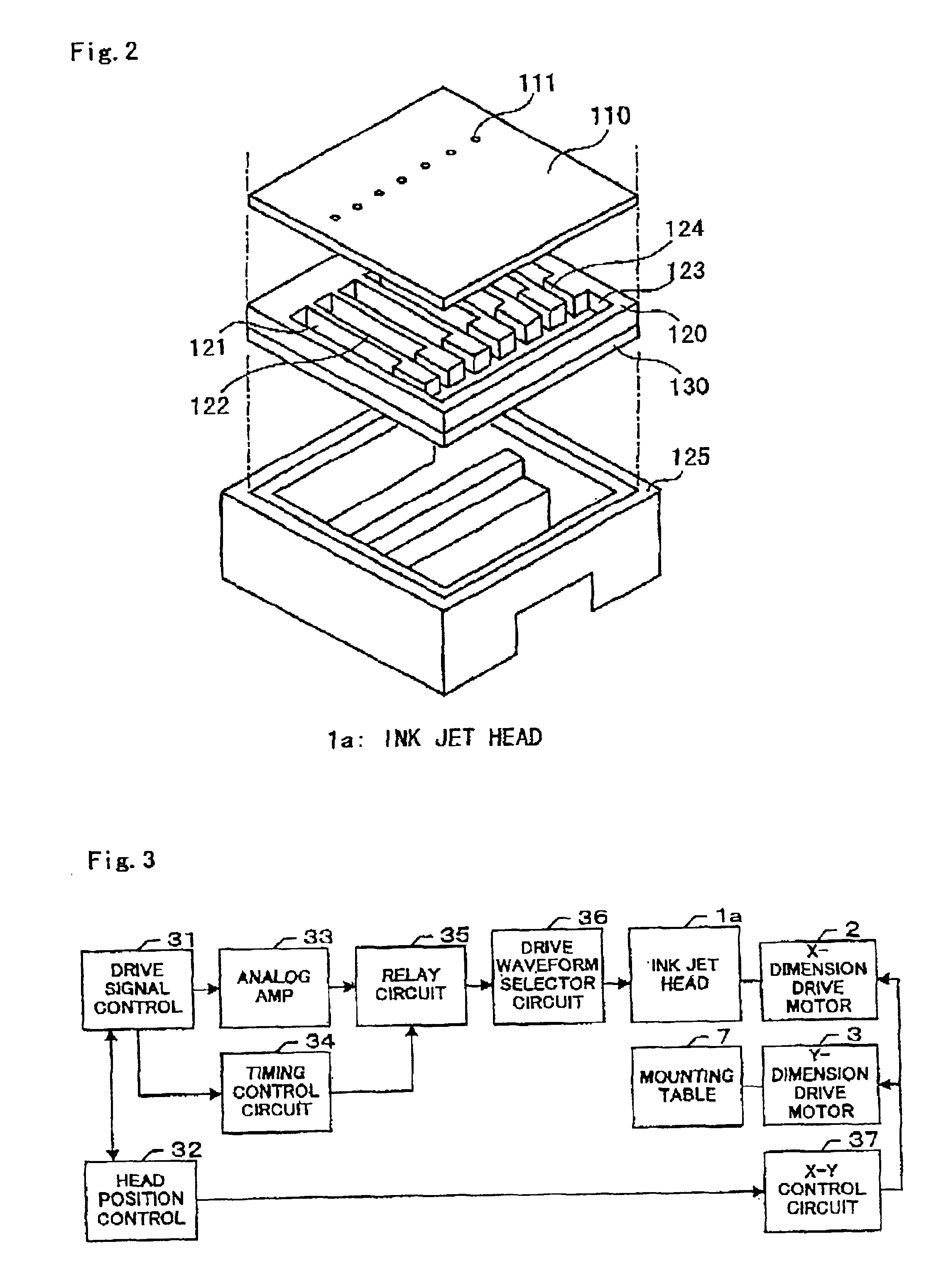

InactiveUS6893103B2Simple configurationEasy to operateInking apparatusIndividual molecule manipulationSpray nozzleHead parts

An ink jet printing device and a manufacturing method of a functional liquid applied substrate, which can equalize the discharge amount of the functional liquid with simple operations and structures. An ink jet printing device (100) comprises a plurality of nozzles (111) for discharging the functional liquid and the plurality of nozzles are divided into a plurality of groups, the number of the groups being less than the number of the nozzles, and the discharge amount of the functional liquid discharged from the nozzles is controlled in every group. A manner of grouping of the nozzles is performed such that a part of an ink jet head (1a), onto which the nozzles are located, is divided into a plurality of areas and those nozzles belonging to each area belong to one group.

Owner:KATEEVA

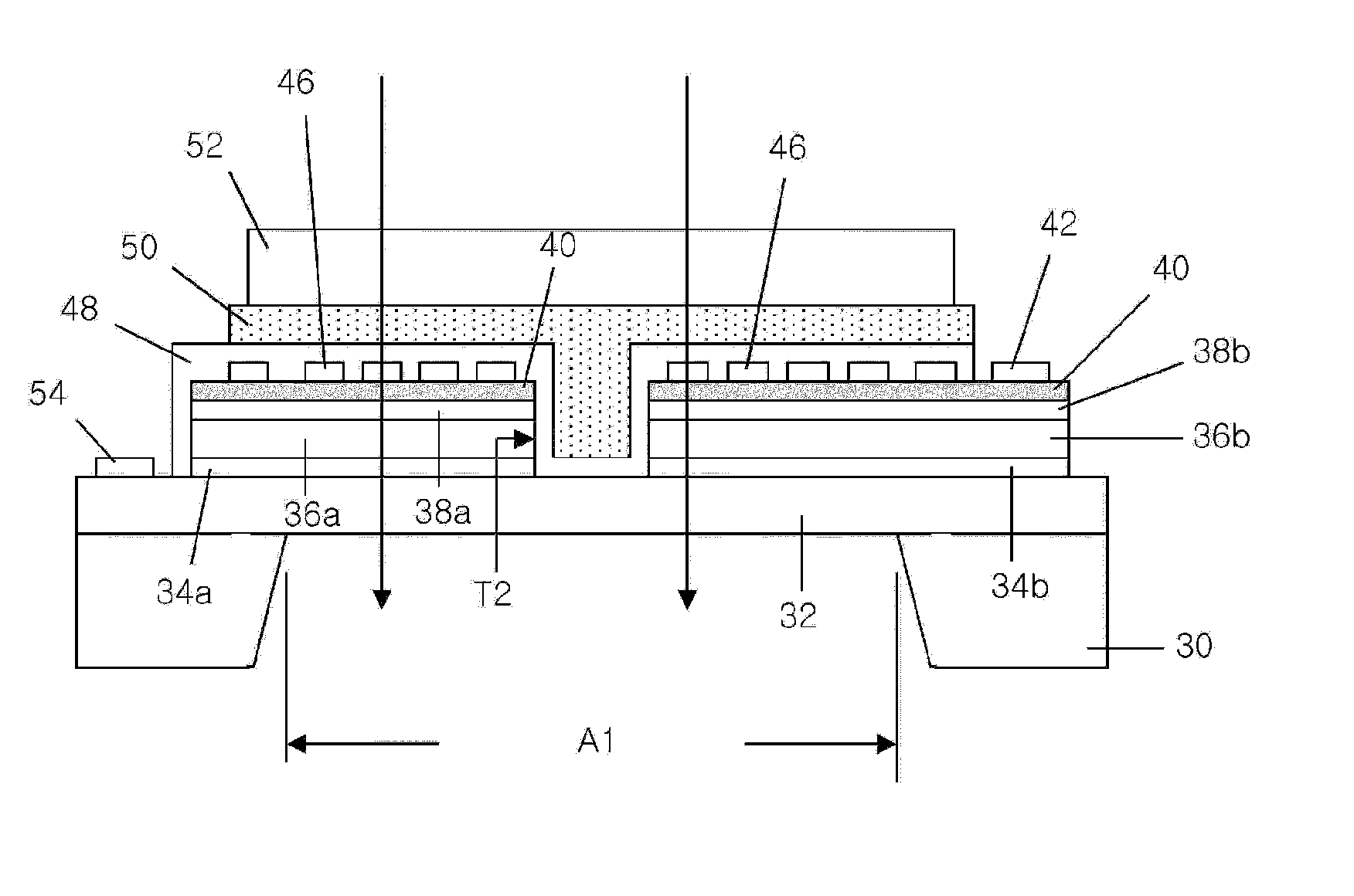

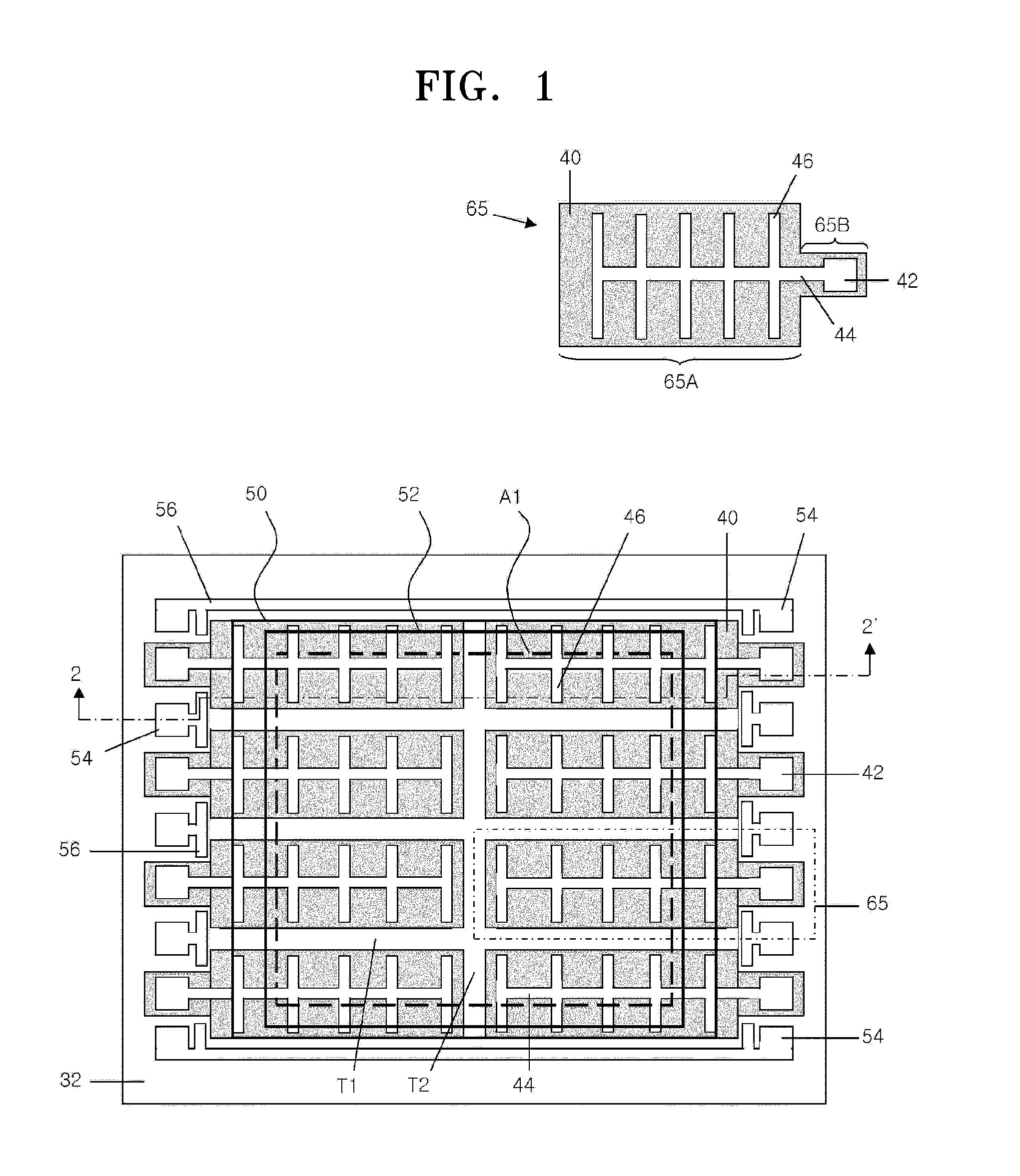

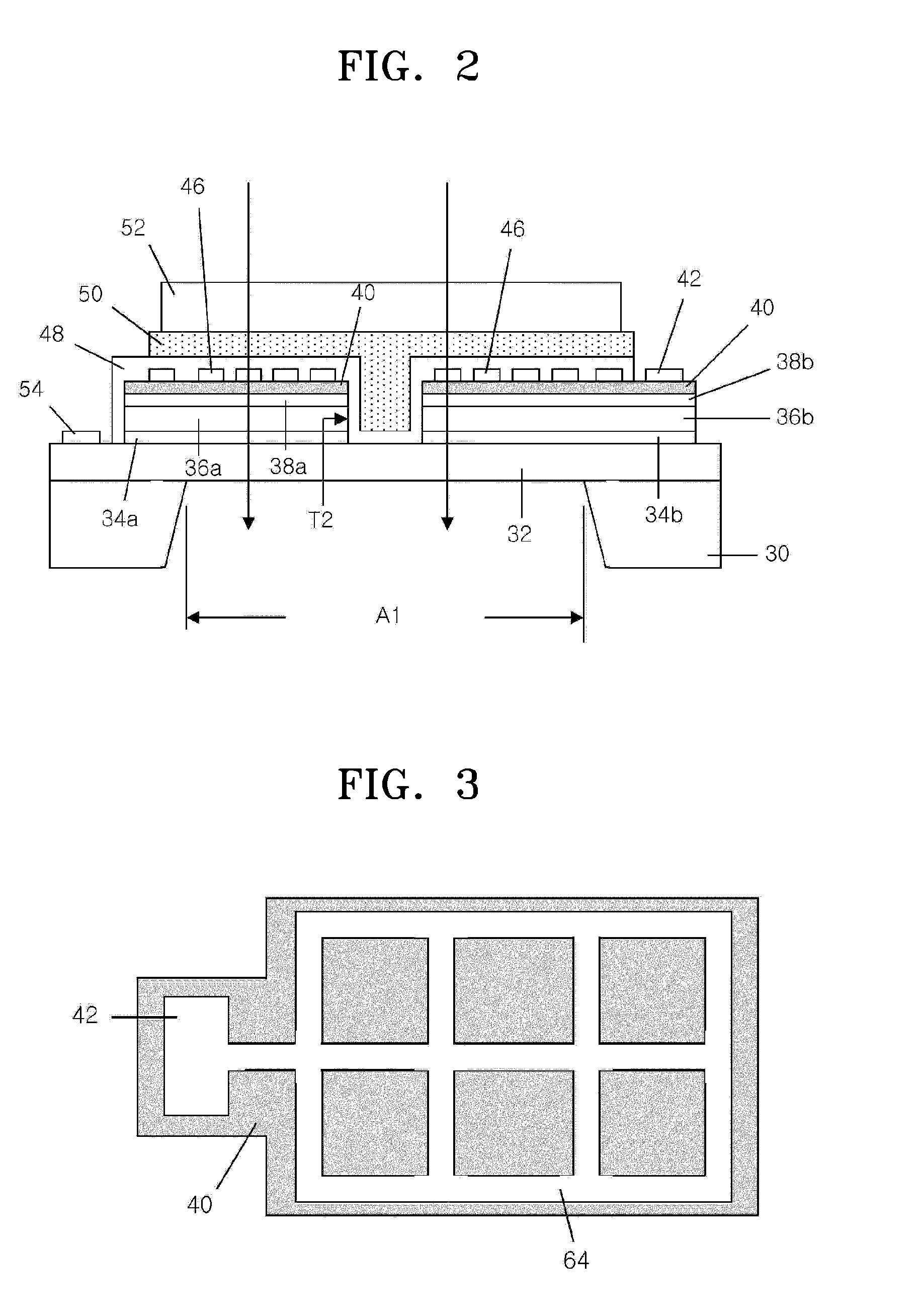

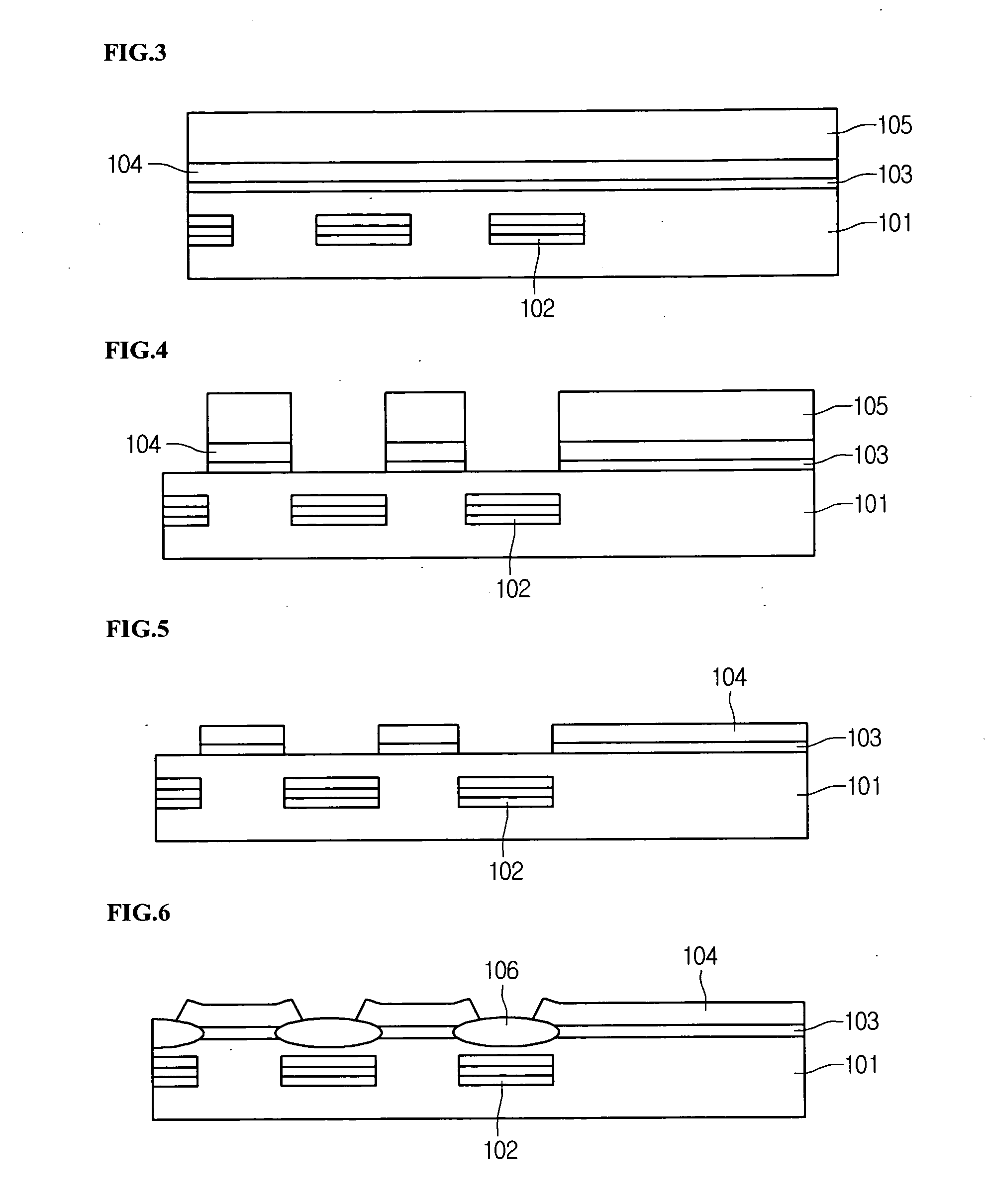

Large-area transmissive type optical image modulator and method of manufacturing the same and optical apparatus including transmissive type optical image modulator

ActiveUS20130270418A1Enhance toleranceSecure uniformityOptical rangefindersInstruments for comonautical navigationP type dopingOptoelectronics

A large-area transmissive type optical image modulator, a method of manufacturing the same, and an optical apparatus including the transmissive type optical image modulator are provided. The large-area transmissive type optical image modulator includes: a base substrate; a first expitaxial layer formed on the base substrate; a second expitaxial layer formed on the first expitaxial layer; a first electrode formed on the first expitaxial layer and spaced apart from the second expitaxial layer; a second electrode formed on the second expitaxial layer; and a transparent substrate covering the second expitaxial layer and the second electrode, wherein the base substrate includes a through hole corresponding to a light emitting area, and the first expitaxial layer may include an n-type or p-type doping material.

Owner:SAMSUNG ELECTRONICS CO LTD

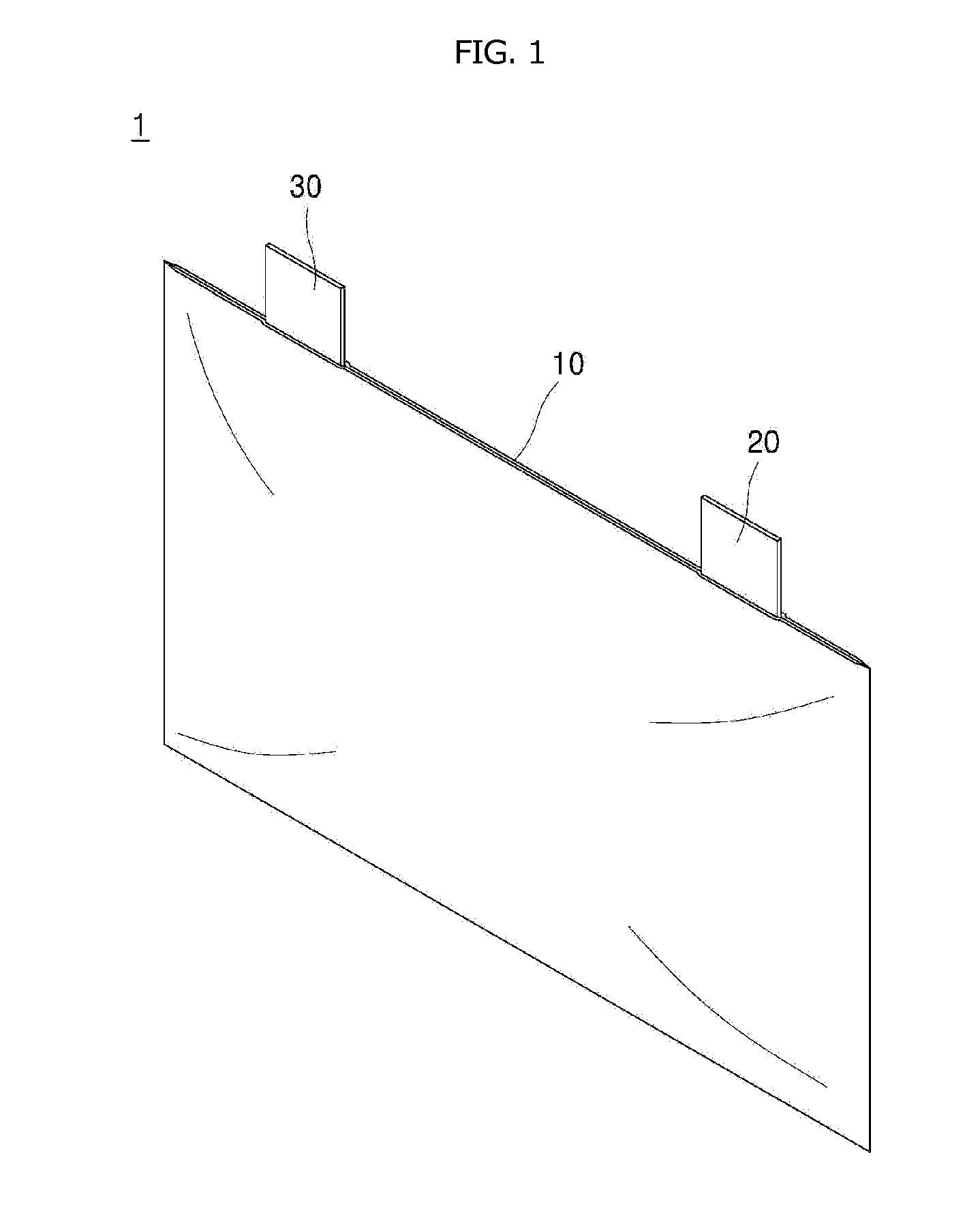

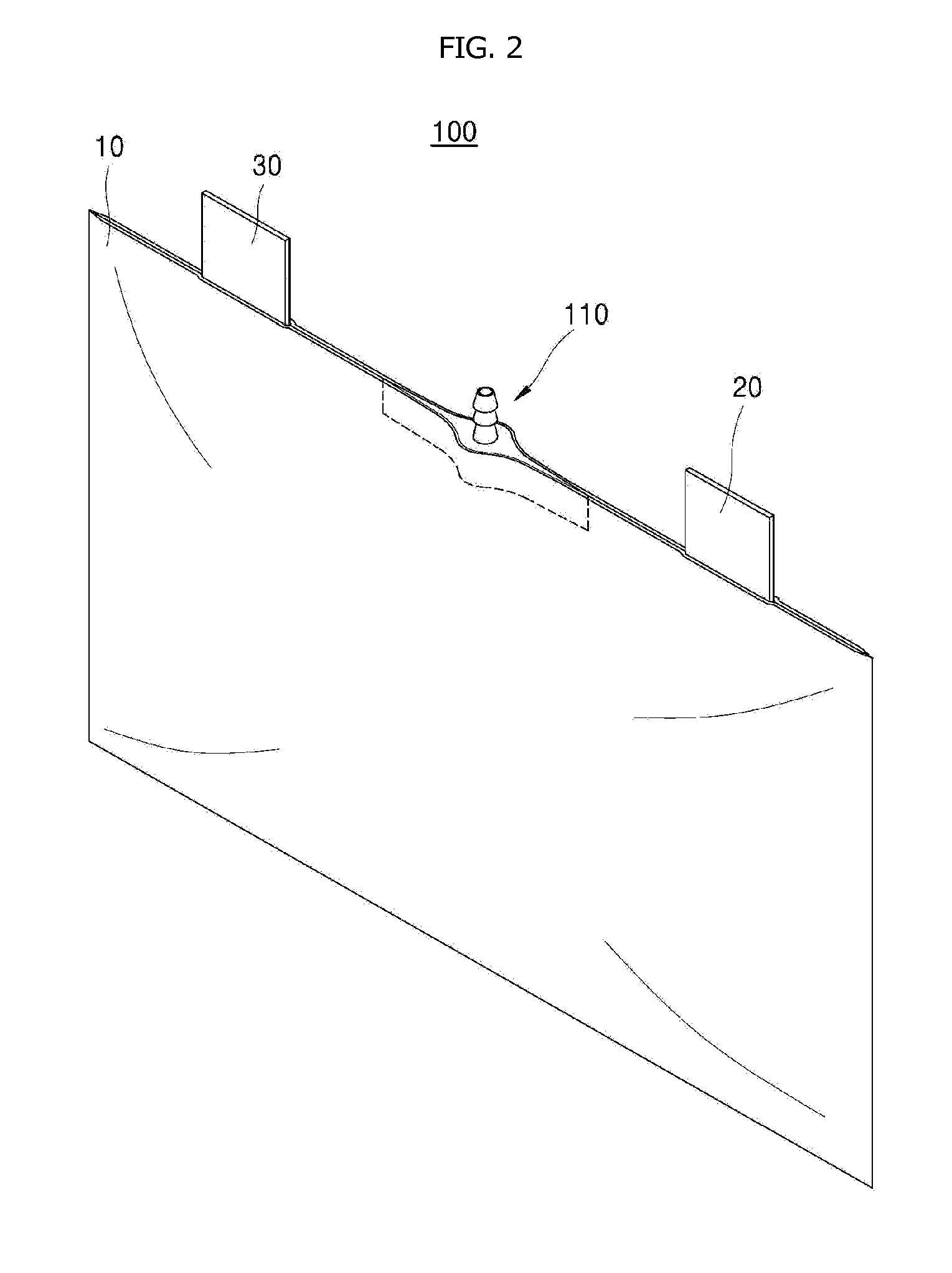

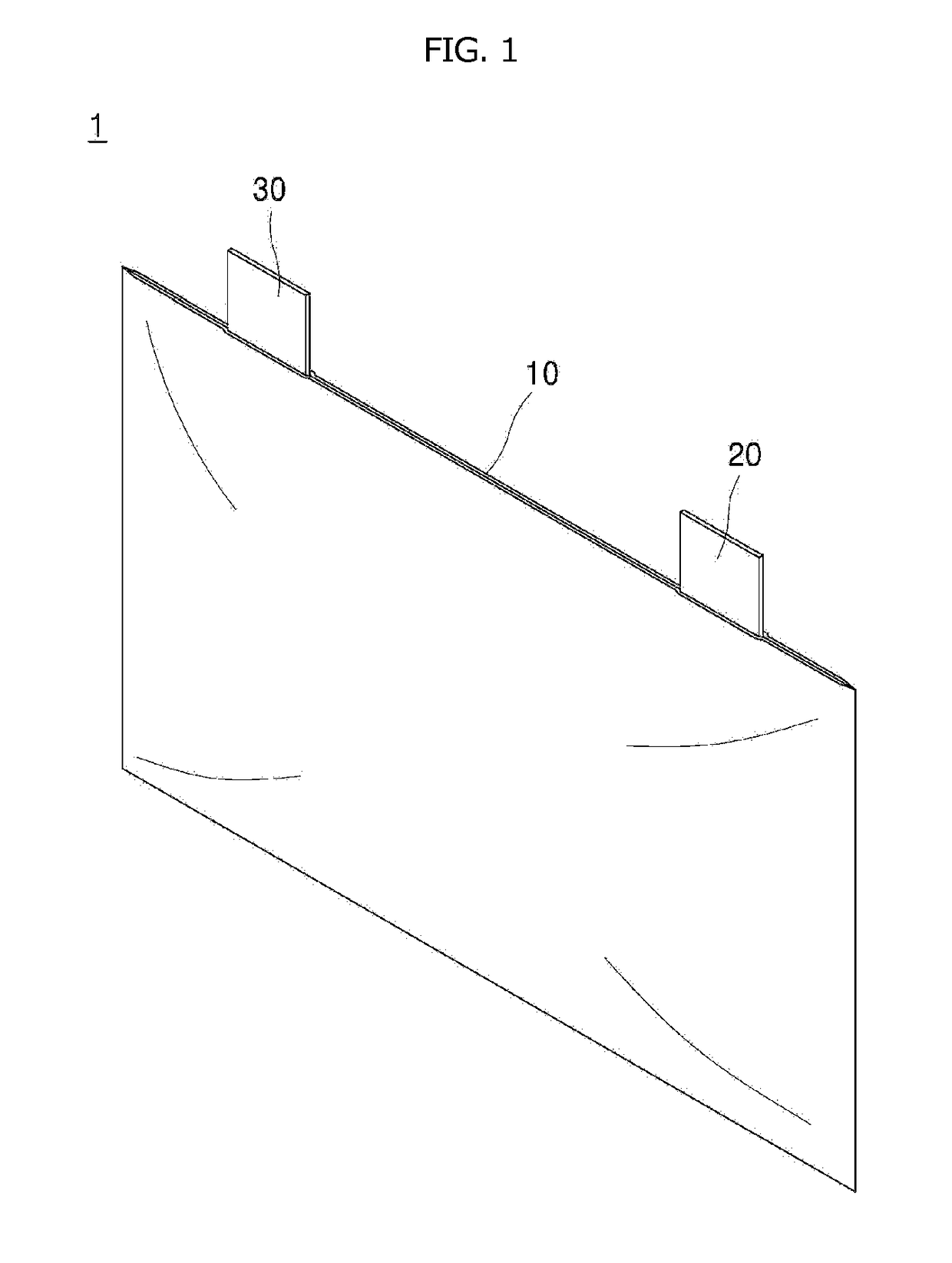

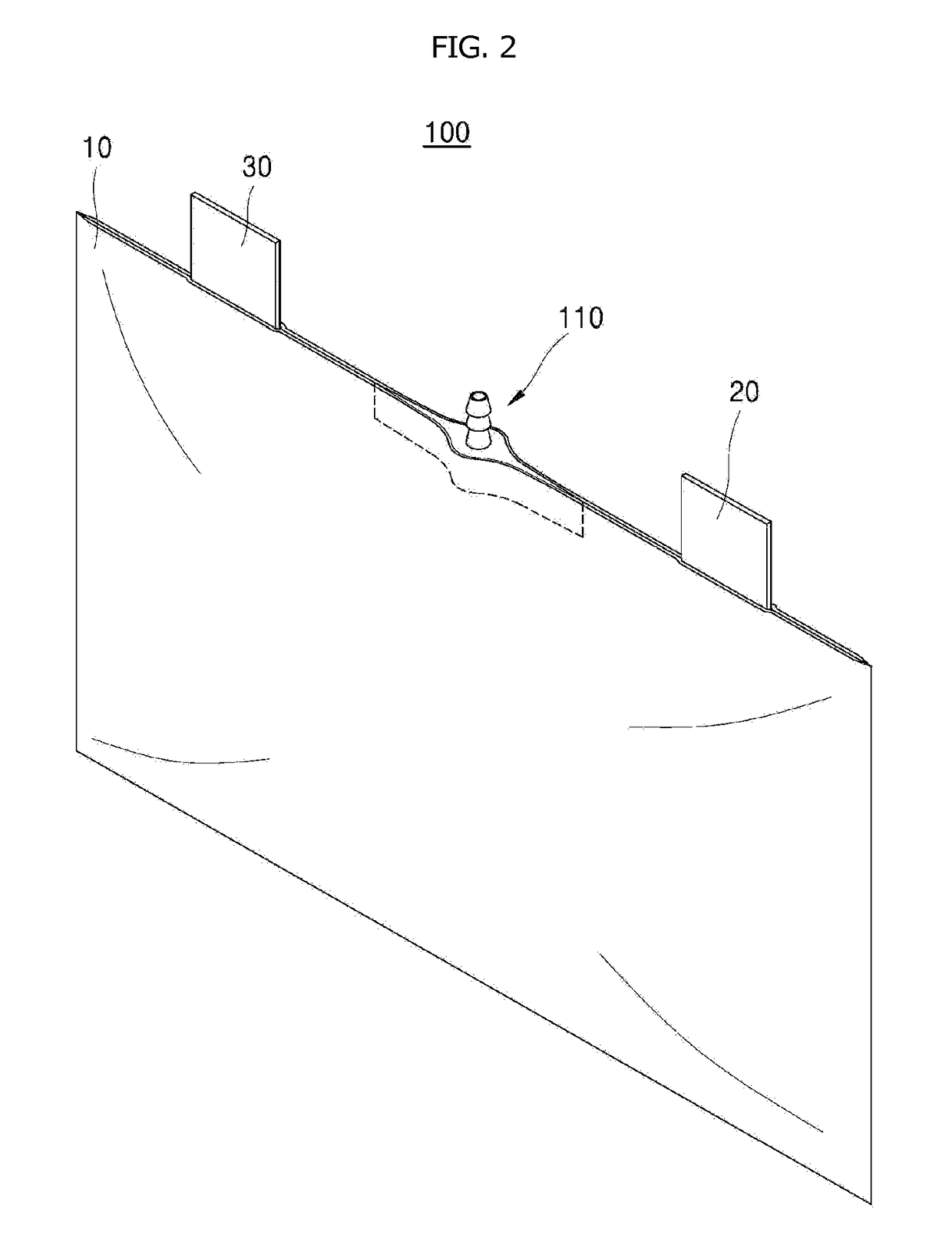

Pouch type lithium secondary battery having tubular passage structure

ActiveUS20160020452A1Simplify manufacturing processImprove performanceFinal product manufactureVent arrangementsUrologyElectrolyte

Provided is a pouch type lithium secondary battery having a tubular passage structure. The pouch type lithium secondary battery having a tubular passage structure includes: a tubular passage structure having a passage of injecting an electrolyte from an outer portion of a pouch and discharging gas from an inner portion of the pouch by communicating the inner portion of the pouch with the outer portion of the pouch.

Owner:SK ON CO LTD

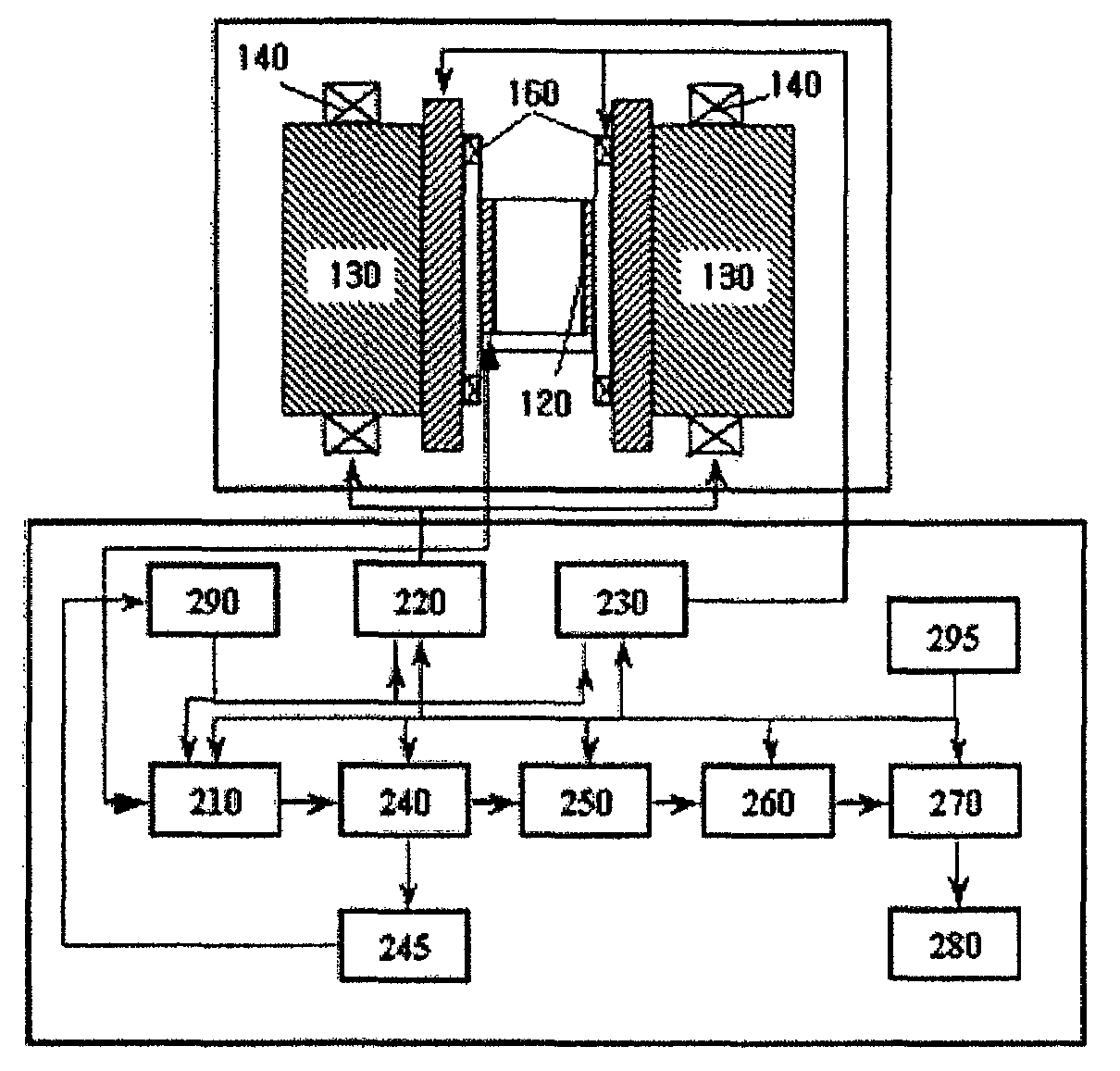

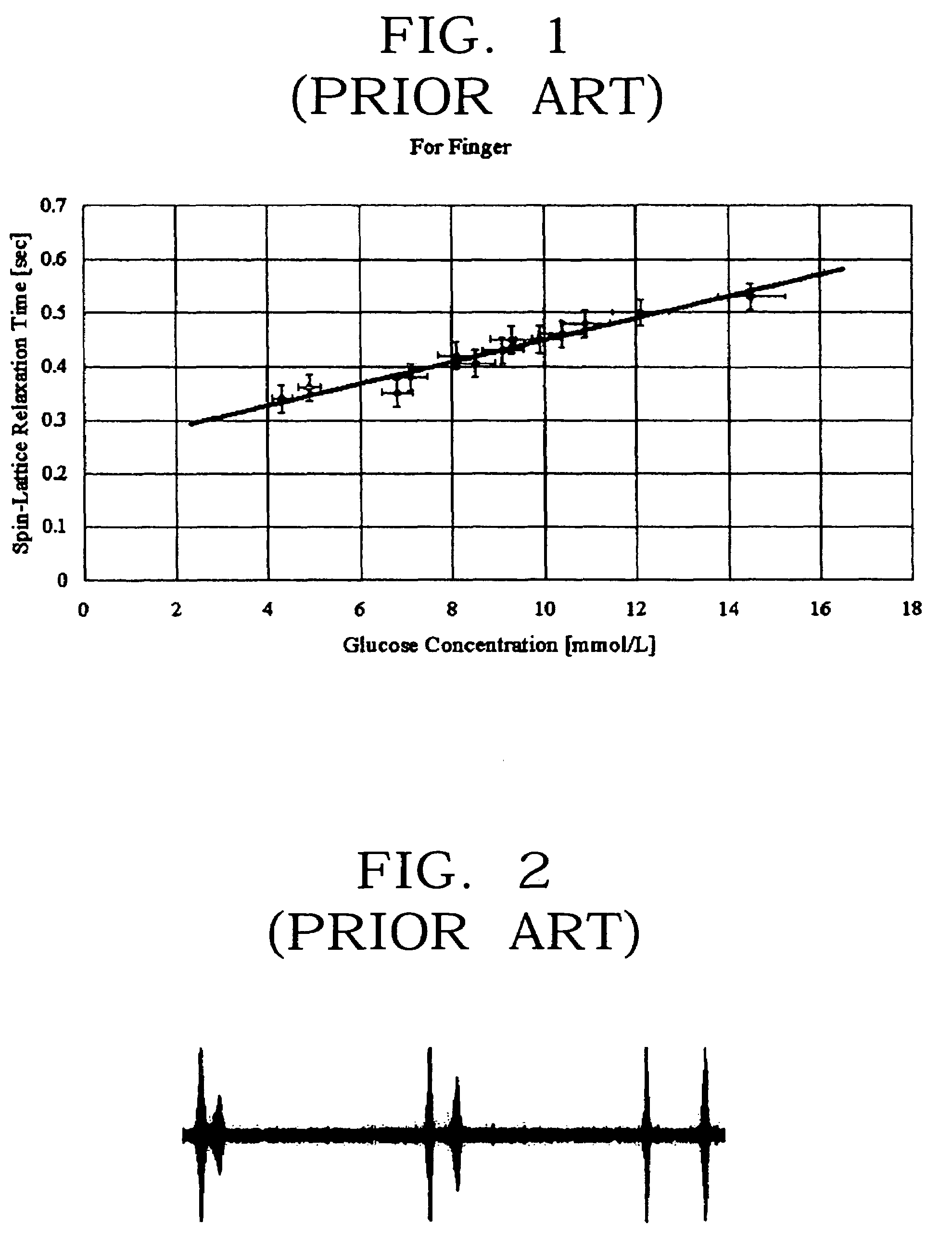

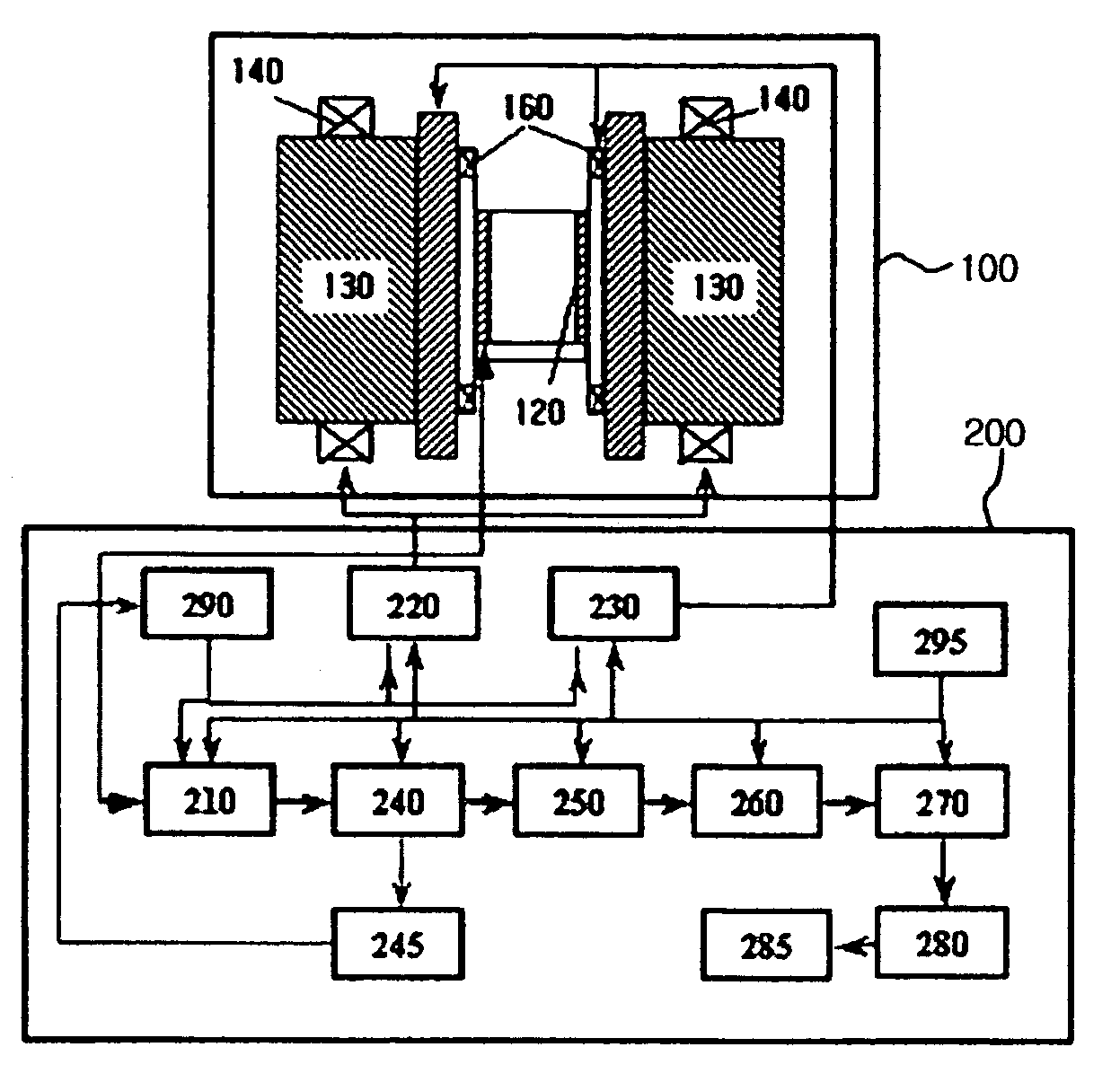

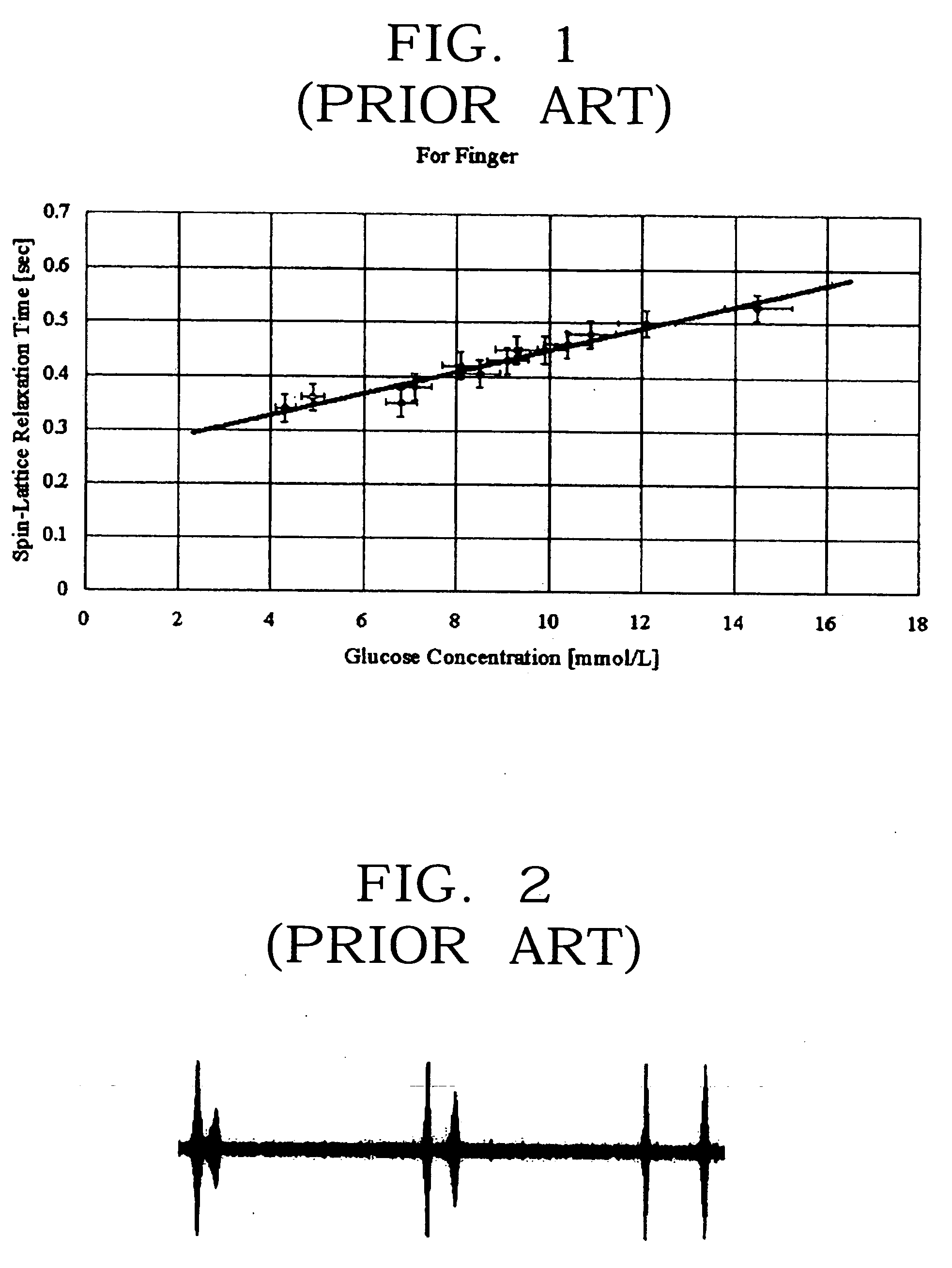

Non-invasive blood glucose sensors using a magneto-resonance absorption method and measurement methods thereof

InactiveUS7635331B2Easy to detectImproving a uniformity of the constant magnetic fieldDiagnostic recording/measuringSensorsGlucose sensorsBlood Glucose Measurement

A non-invasive blood glucose measurement method using a magneto-resonance absorption method. A constant magnetic field is applied using a pair of permanent magnets, the magnetic field having a uniform strength. A triangular waveform low frequency modulation magnetic field is applied using a low frequency generator and a pair of low frequency coils, the low frequency modulation magnetic field having a uniform strength. A weak acoustic wave modulation magnetic field is applied using an acoustic wave generator and a pair of acoustic wave coils. Electromagnetic waves are applied to a detector in which a finger is positioned to produce a nuclear magneto-resonance, the electromagnetic waves having a frequency varying in a specific frequency band step by step, the applying being done using a high frequency generator and a sensor coil. A magneto-resonance absorption signal produced by spin-lattice relaxation of protons in a tissue of the finger because of the nuclear magneto-resonance is detected. A magneto-resonance spin-lattice relaxation time of the finger from the magneto-resonance absorption signal is determined. A blood glucose concentration in a human body is determined from a correlation between a pre-determined blood glucose concentration in the human body and the determined magneto-resonance spin-lattice relaxation time.

Owner:SAMSUNG ELECTRONICS CO LTD

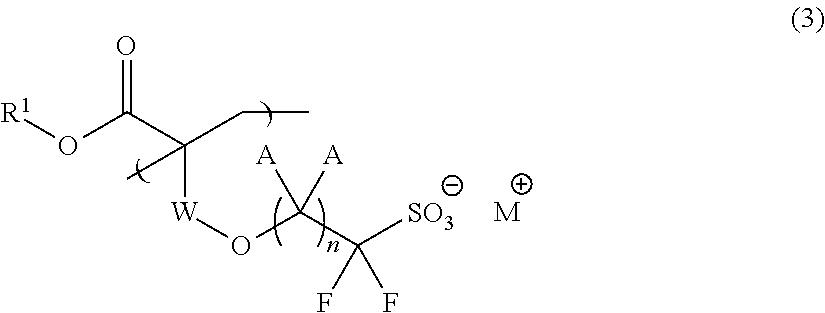

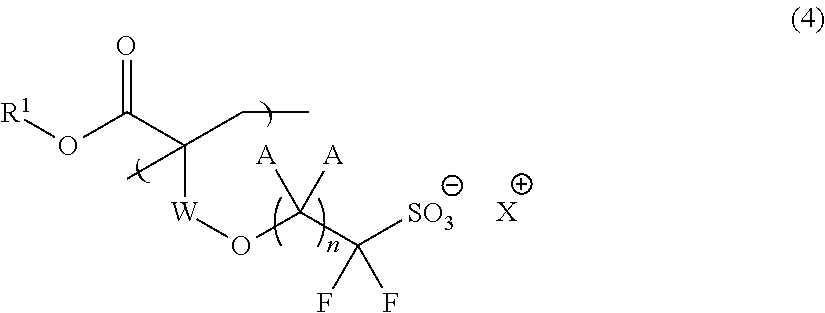

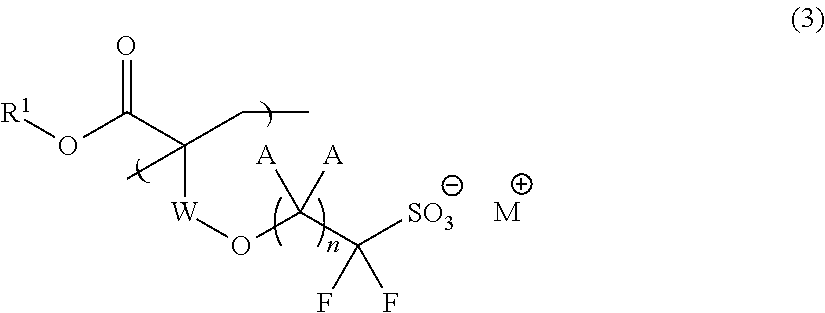

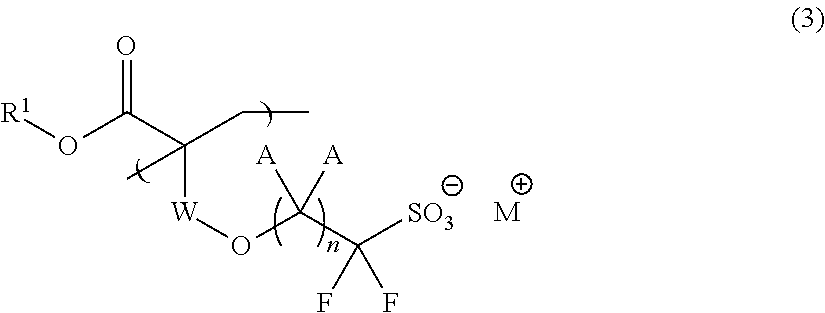

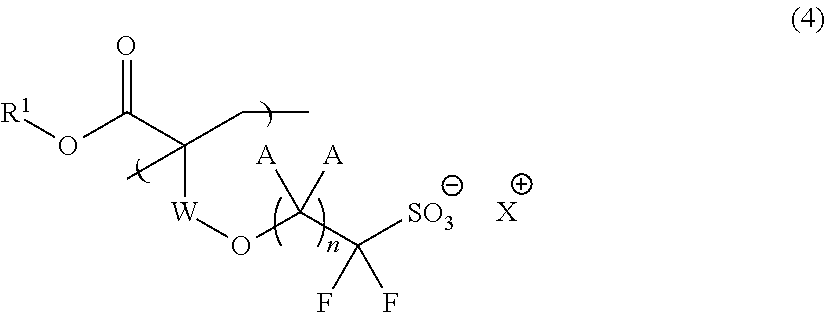

Fluorine-Containing Sulfonate, Fluorine-Containing Sulfonate Resin, Resist Composition and Pattern Formation Method

InactiveUS20130065182A1Avoid lack of uniformityHigh sensitivityOrganic compound preparationPhotosensitive materialsResistSulfonate

According to the present invention, there is provided a fluorine-containing sulfonate resin having a repeating unit of the following general formula (3).In order to prevent deficiency such as roughness after pattern formation or failure in pattern formation, the fluorine-containing sulfonate resin incorporates therein a photoacid generating function and serves as a resist resin in which “a moiety capable of changing its developer solubility by the action of an acid” and “a moiety having a photoacid generating function” are arranged with regularity.

Owner:CENT GLASS CO LTD

Method of producing polishing pad

InactiveUS20060148392A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingSolubilitySolvent

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

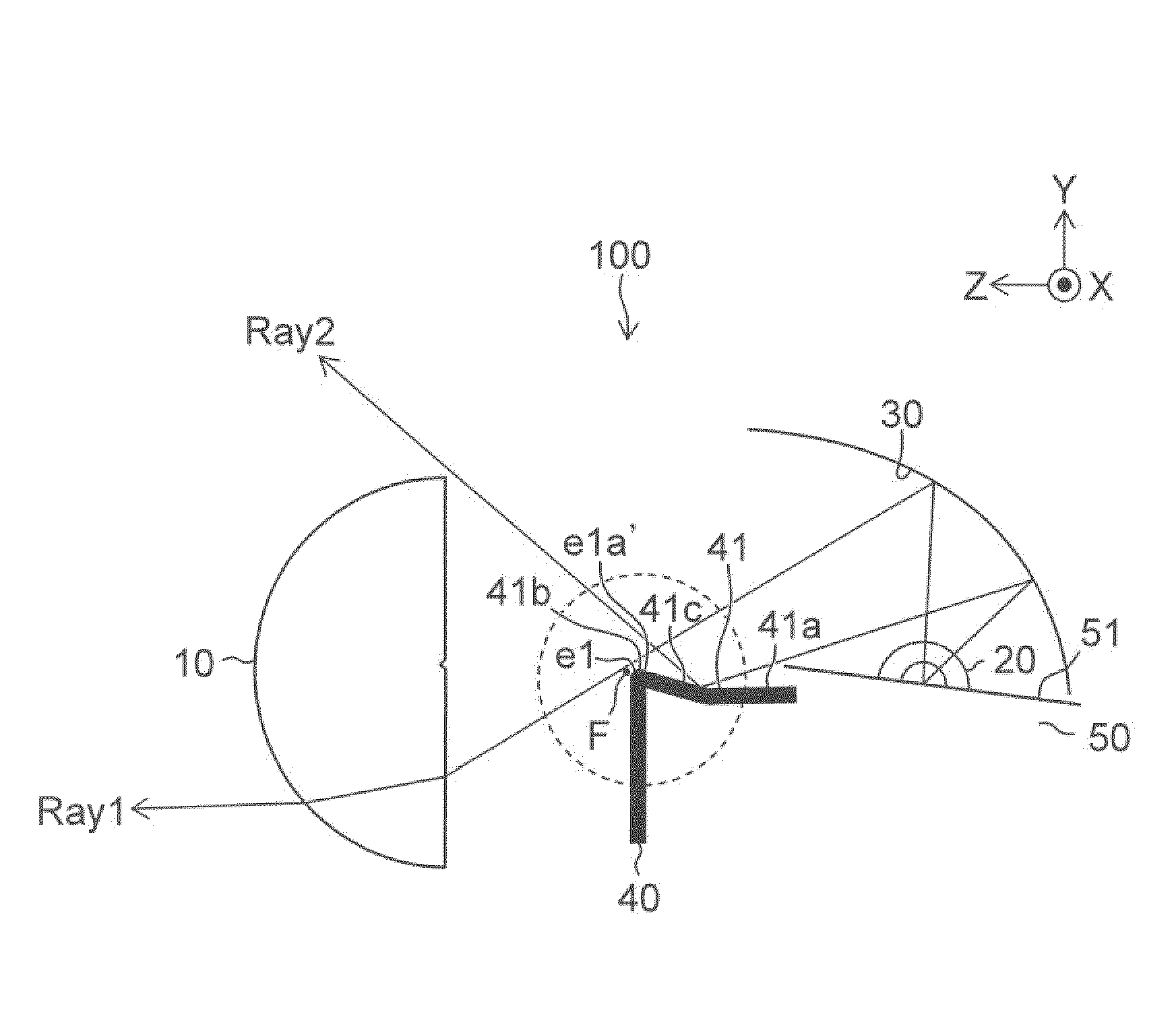

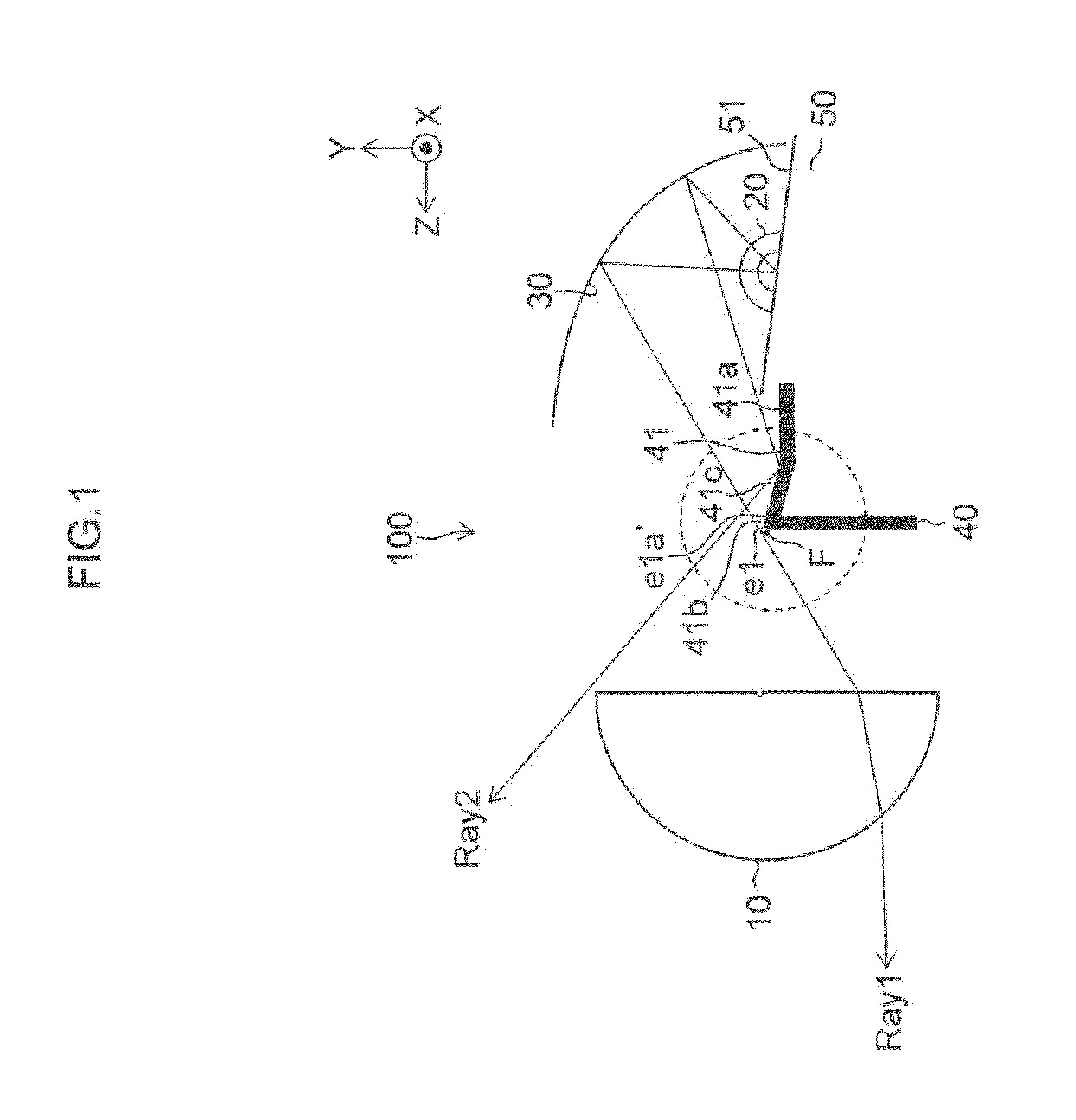

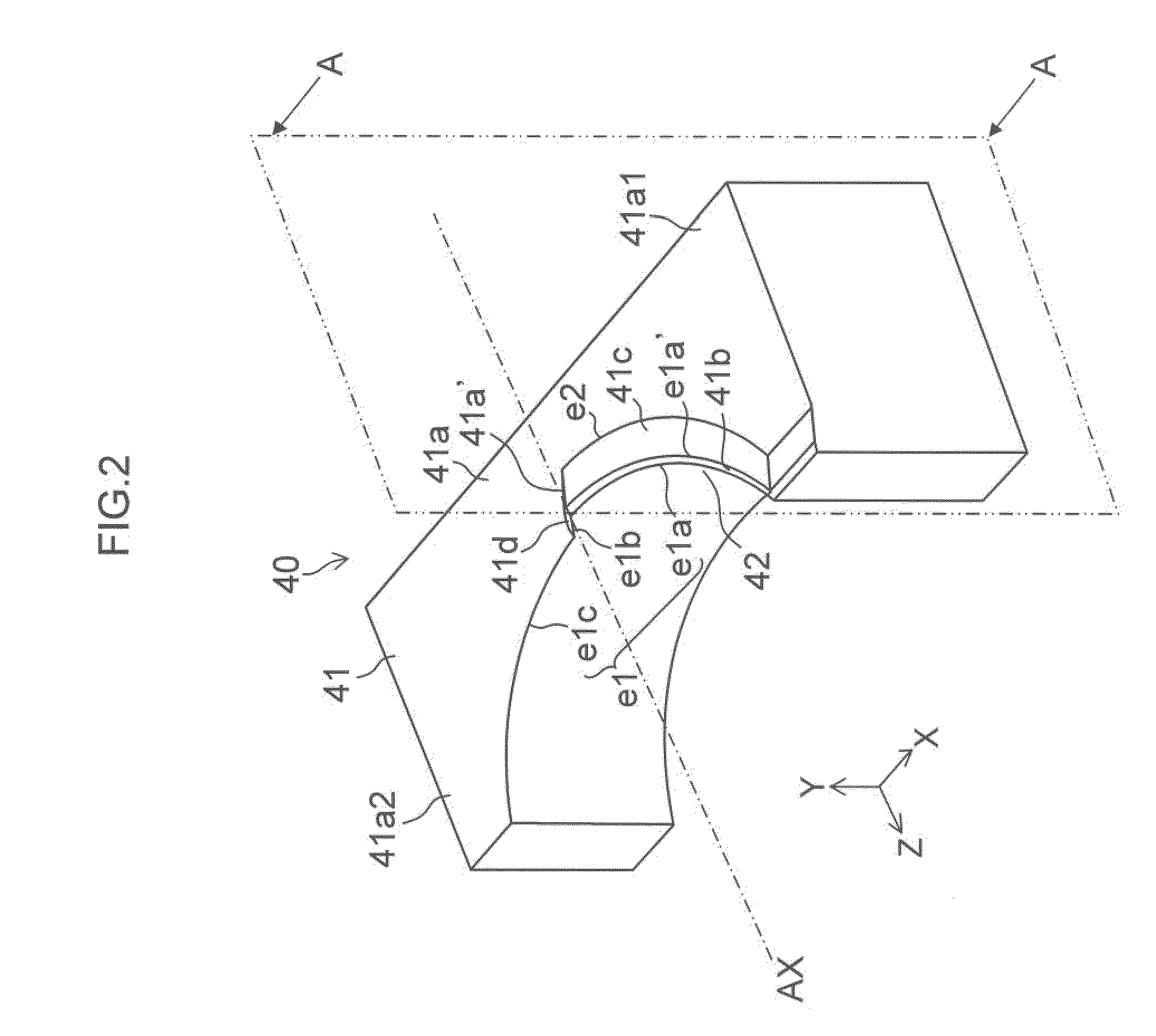

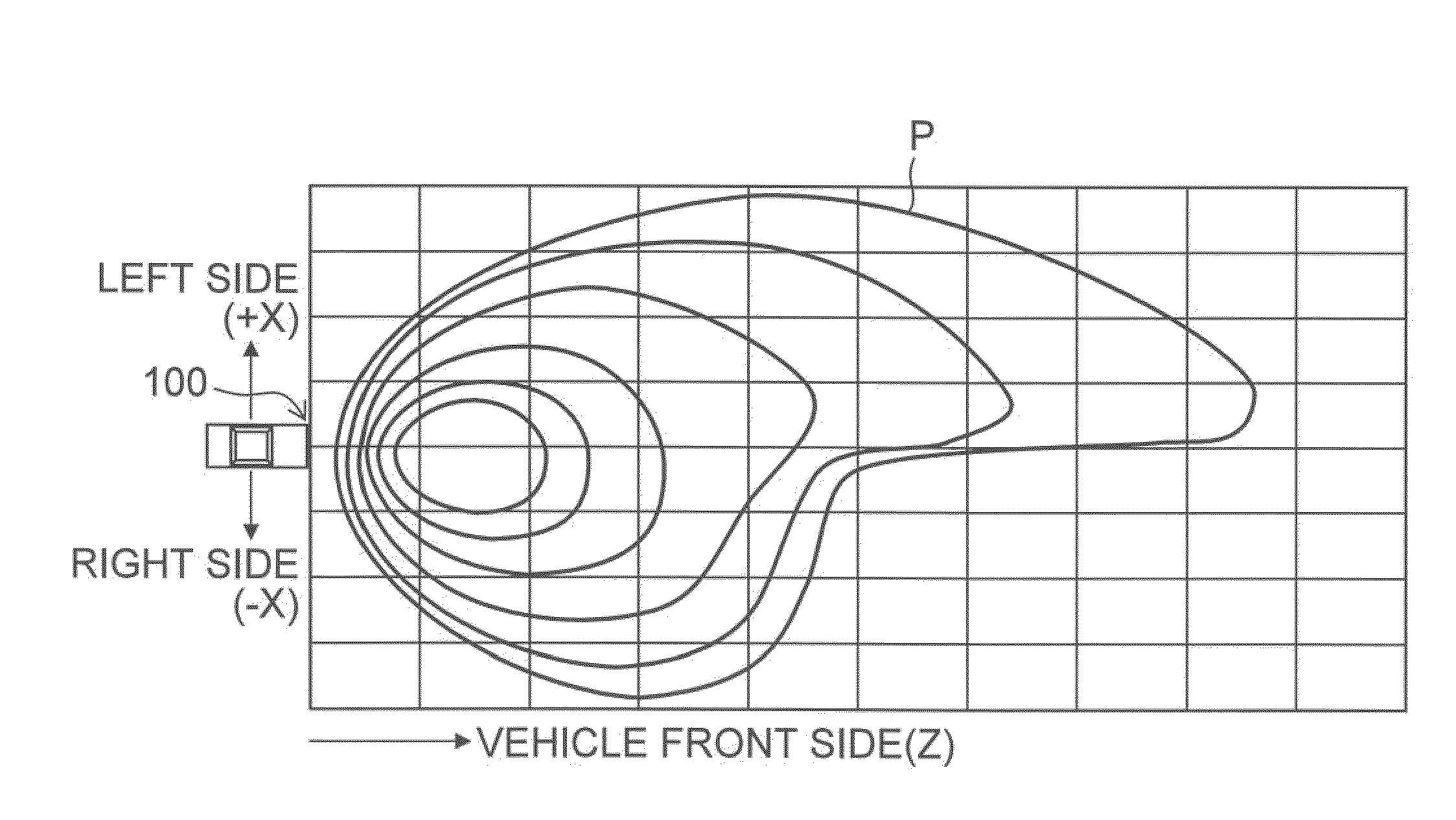

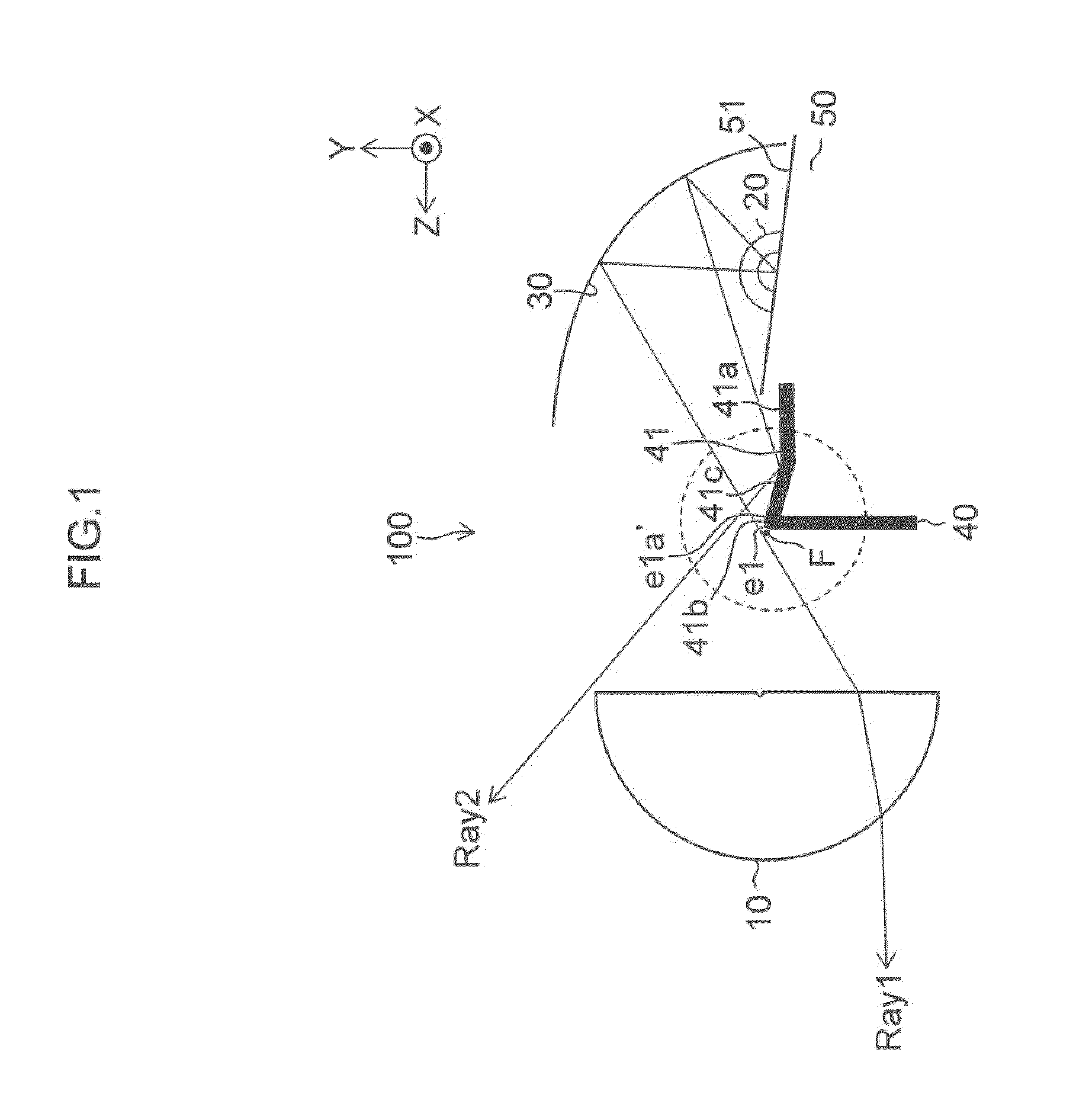

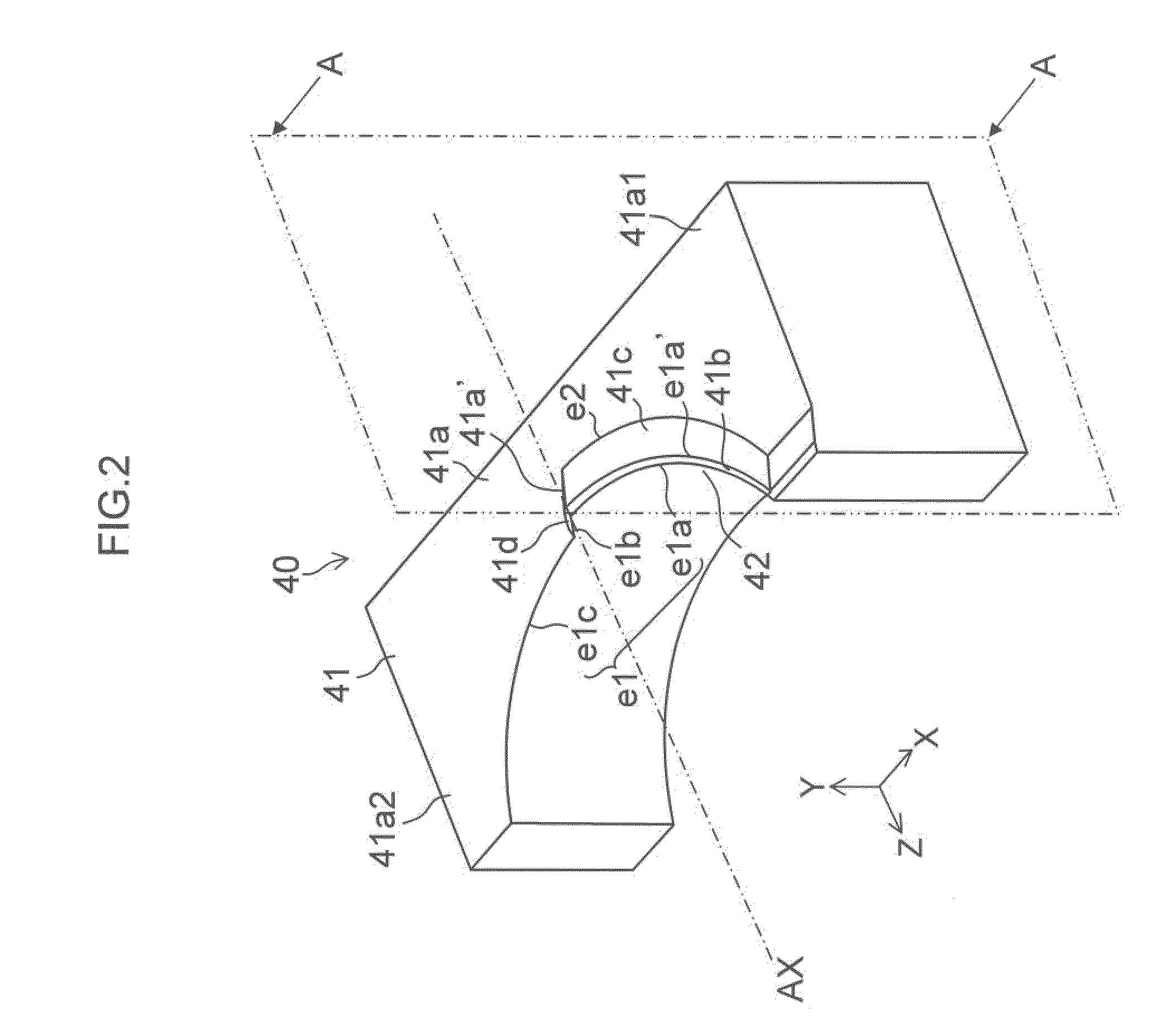

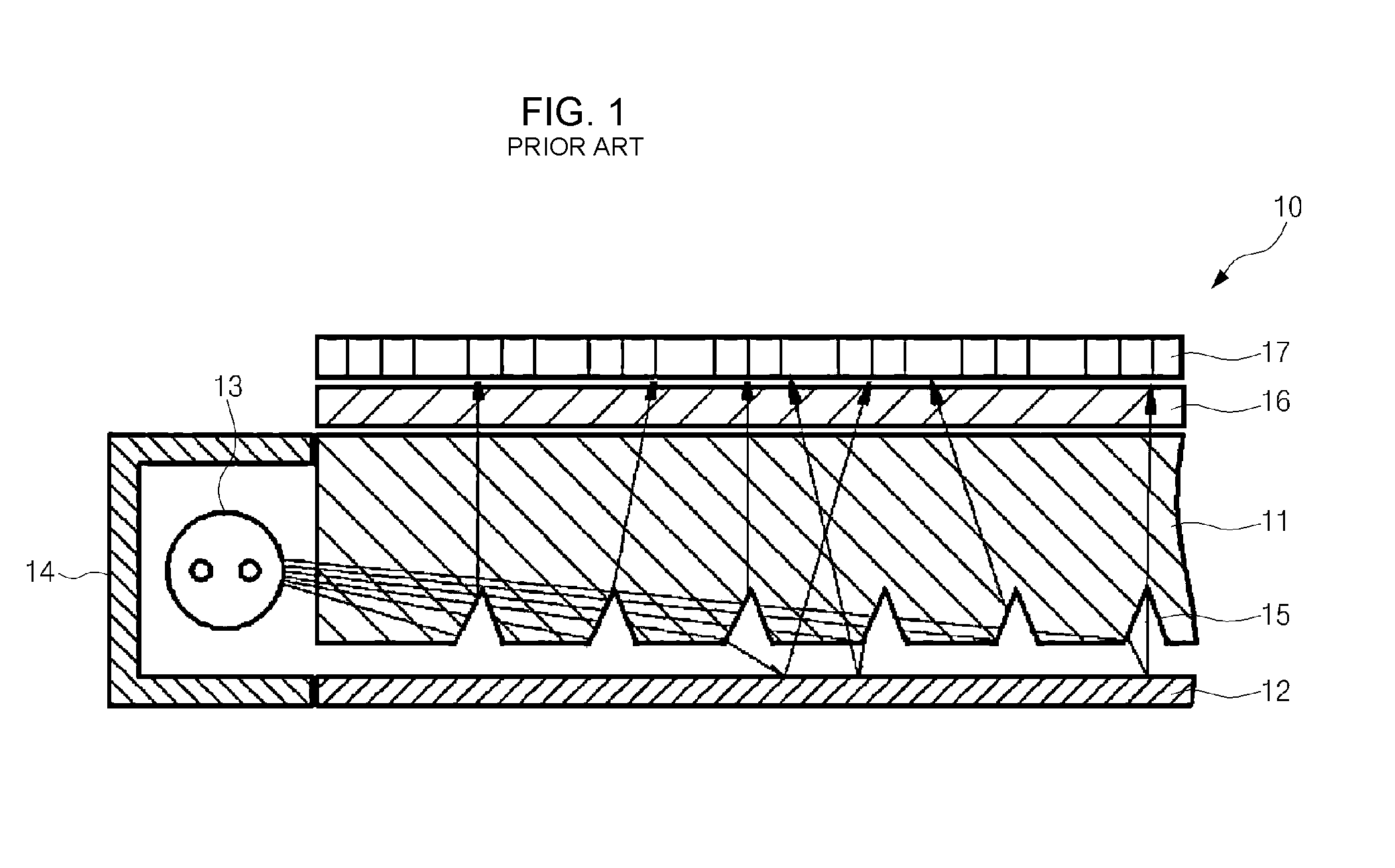

Vehicular lighting fixture

InactiveUS8092059B2Avoid formingIncrease awarenessVehicle headlampsLighting support devicesDistribution patternEffect light

A vehicular lighting fixture can include a shade wherein an end edge of an upper surface of the shade is positioned at or in a vicinity of a focus of a projection lens. A first reflection surface can be provided to condense light from a light source in a vicinity of the end edge and to form a basic light distribution pattern by the projection lens. A second reflection surface which can comprise one planar reflection surface and can reflect light from the first reflection surface to form a first additional light distribution pattern. A third reflection surface can be provided on a higher surface of a step section of the upper surface, and can reflect light from the first reflection surface to form a second additional light distribution pattern. A fourth reflection surface can connect the second and third reflection surface, and can reflect the light from the first reflection surface in a direction not incident on the projection lens.

Owner:STANLEY ELECTRIC CO LTD

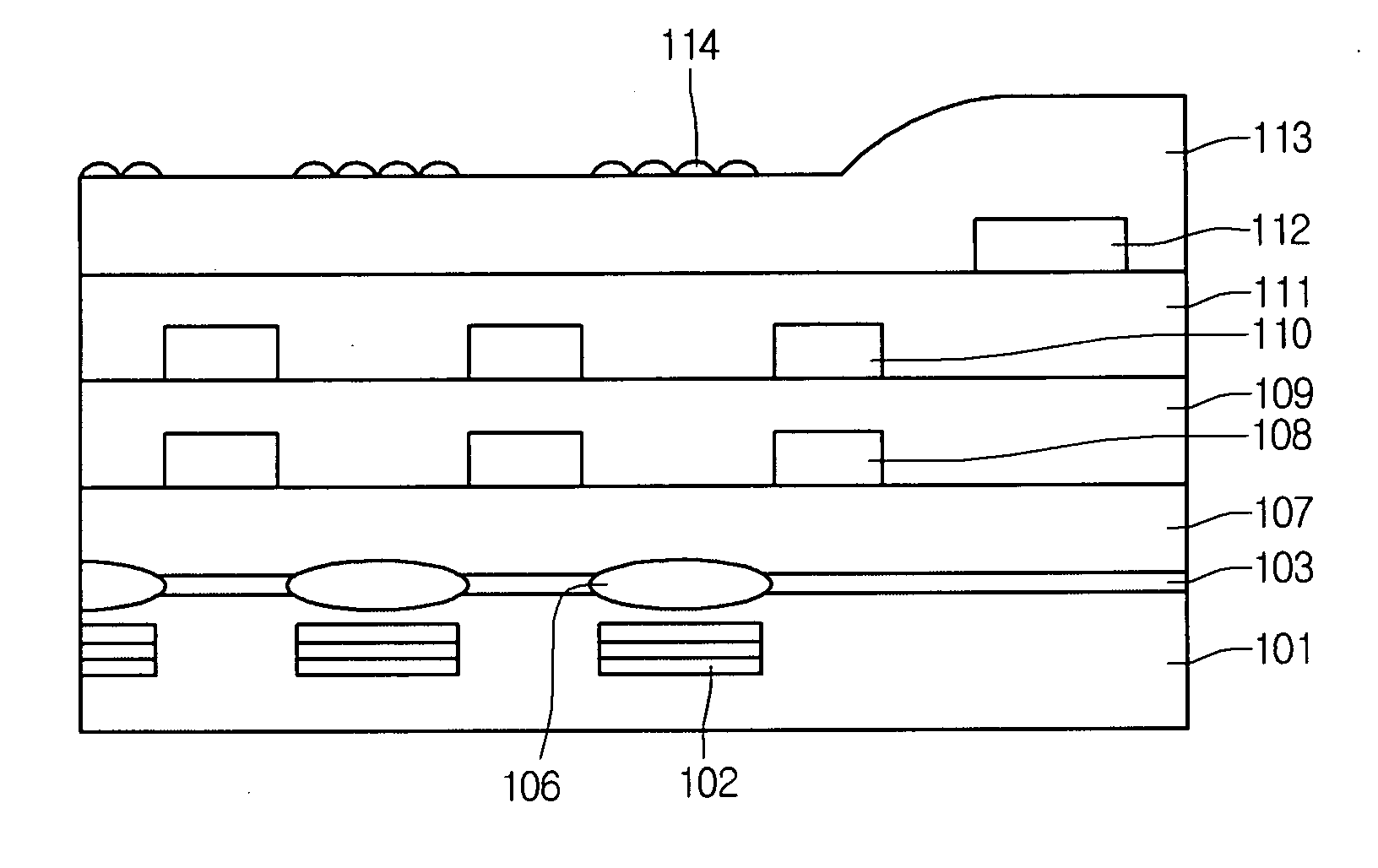

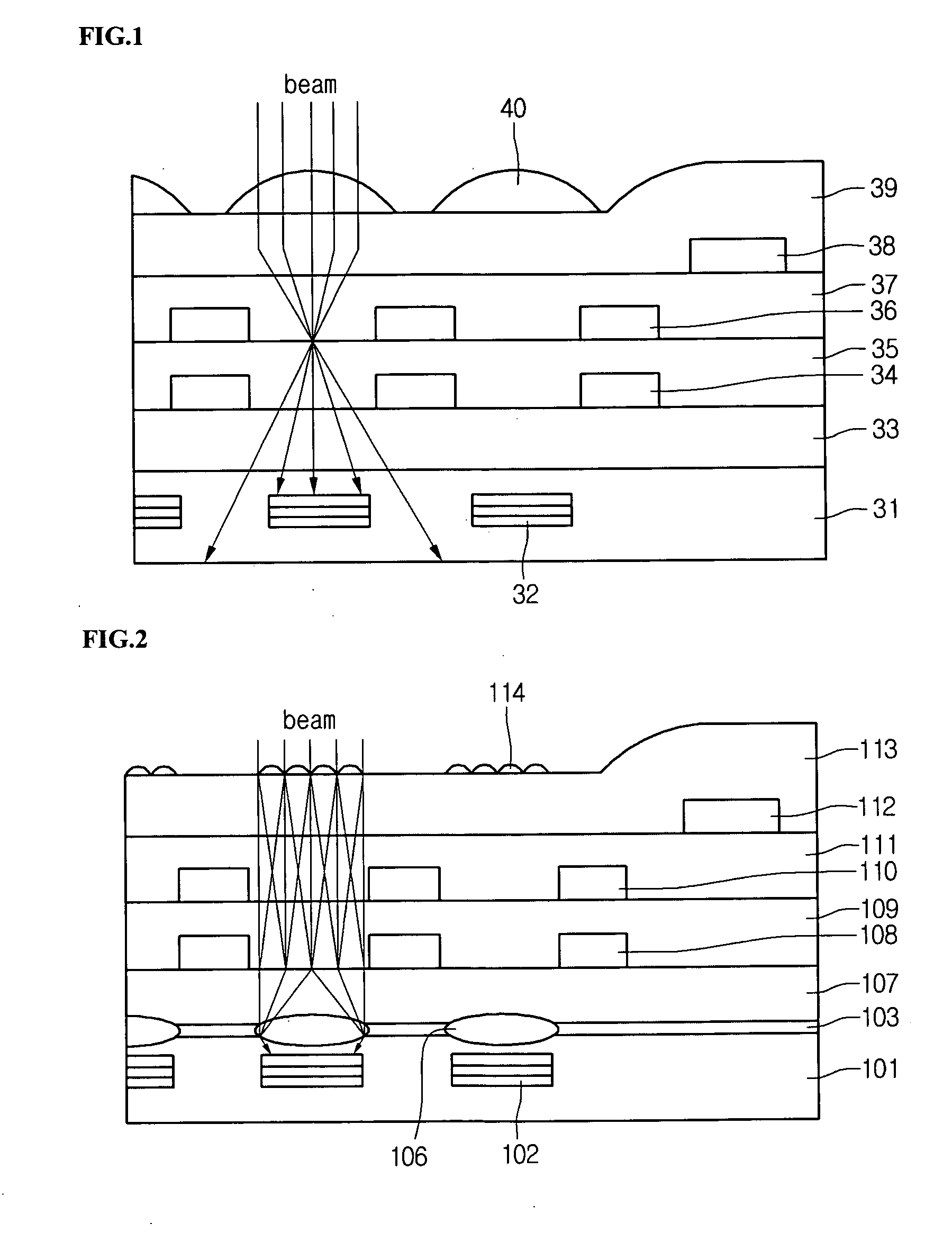

CMOS image sensor and manufacturing method thereof

InactiveUS20070090419A1Reduce dispersionImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingDielectricCMOS

A CMOS image sensor and a method for manufacturing the same are provided. The CMOS image sensor includes: a photo diode formed in a semiconductor substrate for generating an optical signal from incident light; a first micro lens formed on the semiconductor substrate above the photo diode; a plurality of inter-layer dielectrics and metal wires formed on the semiconductor substrate having the first micro lens; a planarization layer formed above the plurality of inter-layer dielectrics metal wires; and a second micro lens formed on the planarization layer. In one embodiment, the second micro lens incorporates a fly-eye pattern.

Owner:DONGBU ELECTRONICS CO LTD

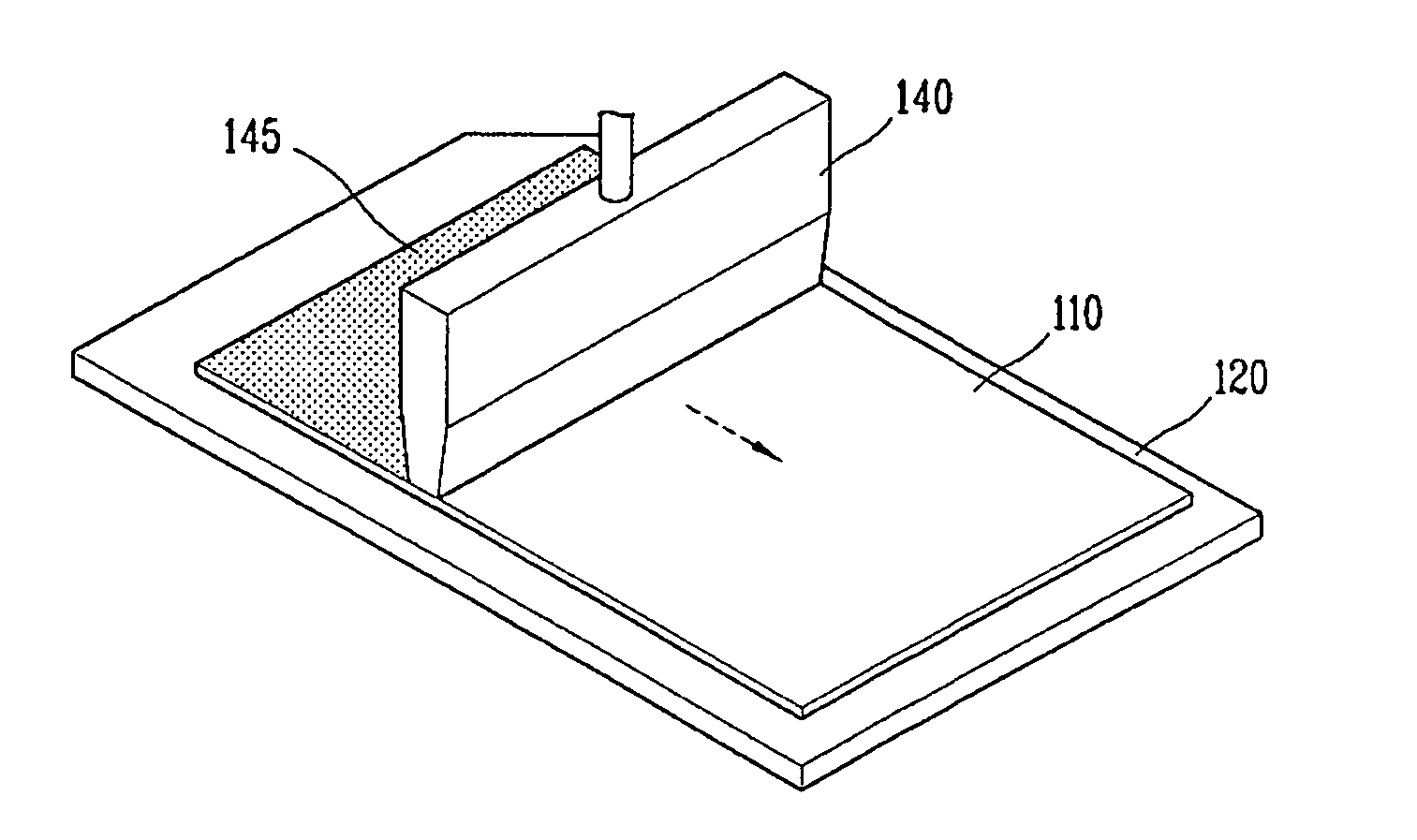

Apparatus for applying coating solution and method of fabricating liquid crystal display device using the same

InactiveUS20060283535A1Uniform applicationEasy to shapeSemiconductor/solid-state device manufacturingPretreated surfacesLiquid-crystal displaySpray nozzle

An apparatus for applying a coating solution and a method of fabricating a liquid crystal display device using the same are provided. In order to improve the shape of the inside of the nozzle and to secure the geometrical uniformity of the inside of the nozzle, the apparatus includes a nozzle comprising a nozzle body, the nozzle body including an external body and an internal body. A distance between the external body and the internal body is controlled. An inlet port is provided on the nozzle body so that coating solution is received, and a discharge port is provided below the nozzle body to coat the surface of a material to be processed with the coating solution and a driving unit for moving the nozzle in a predetermined direction.

Owner:LG DISPLAY CO LTD

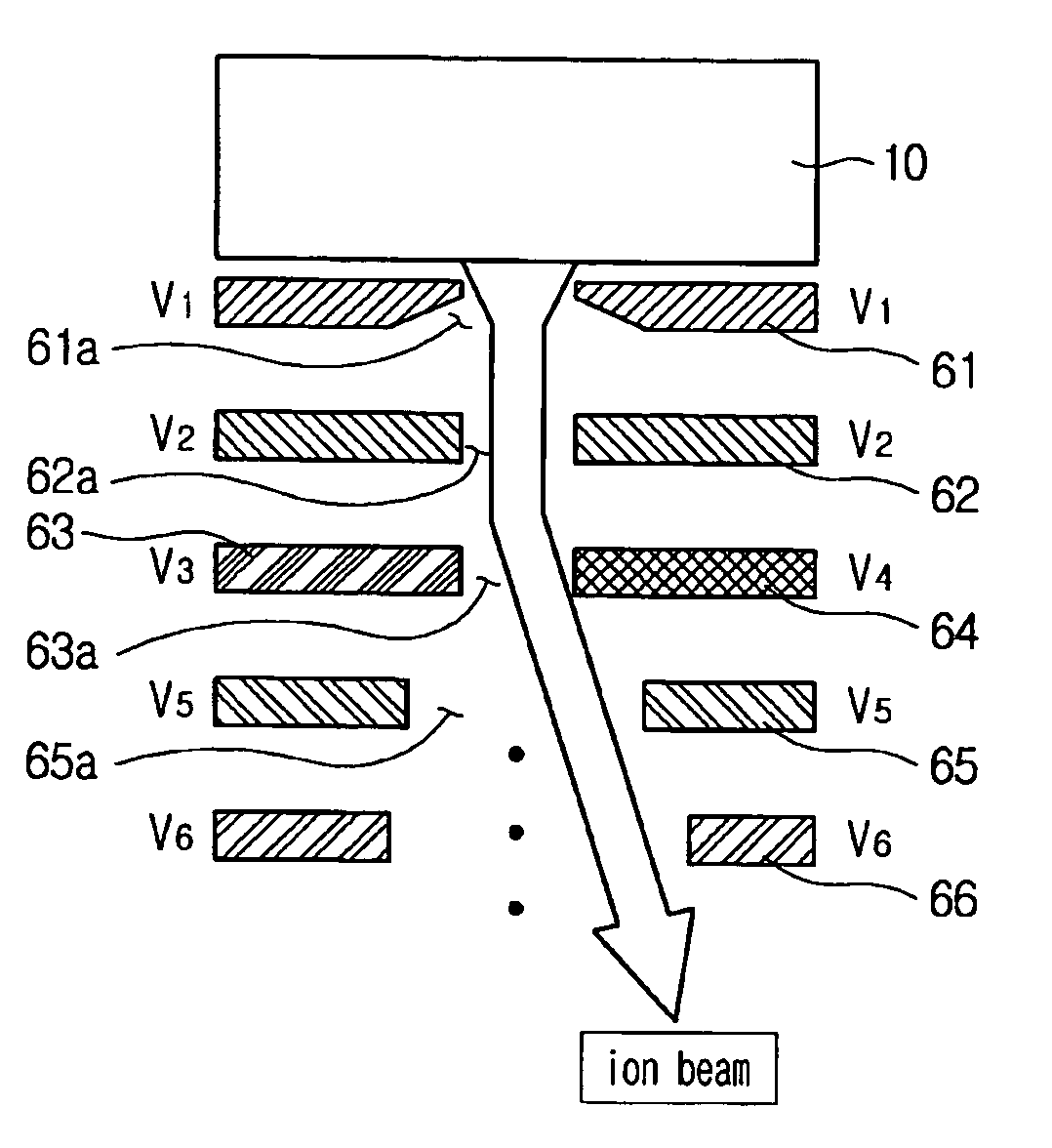

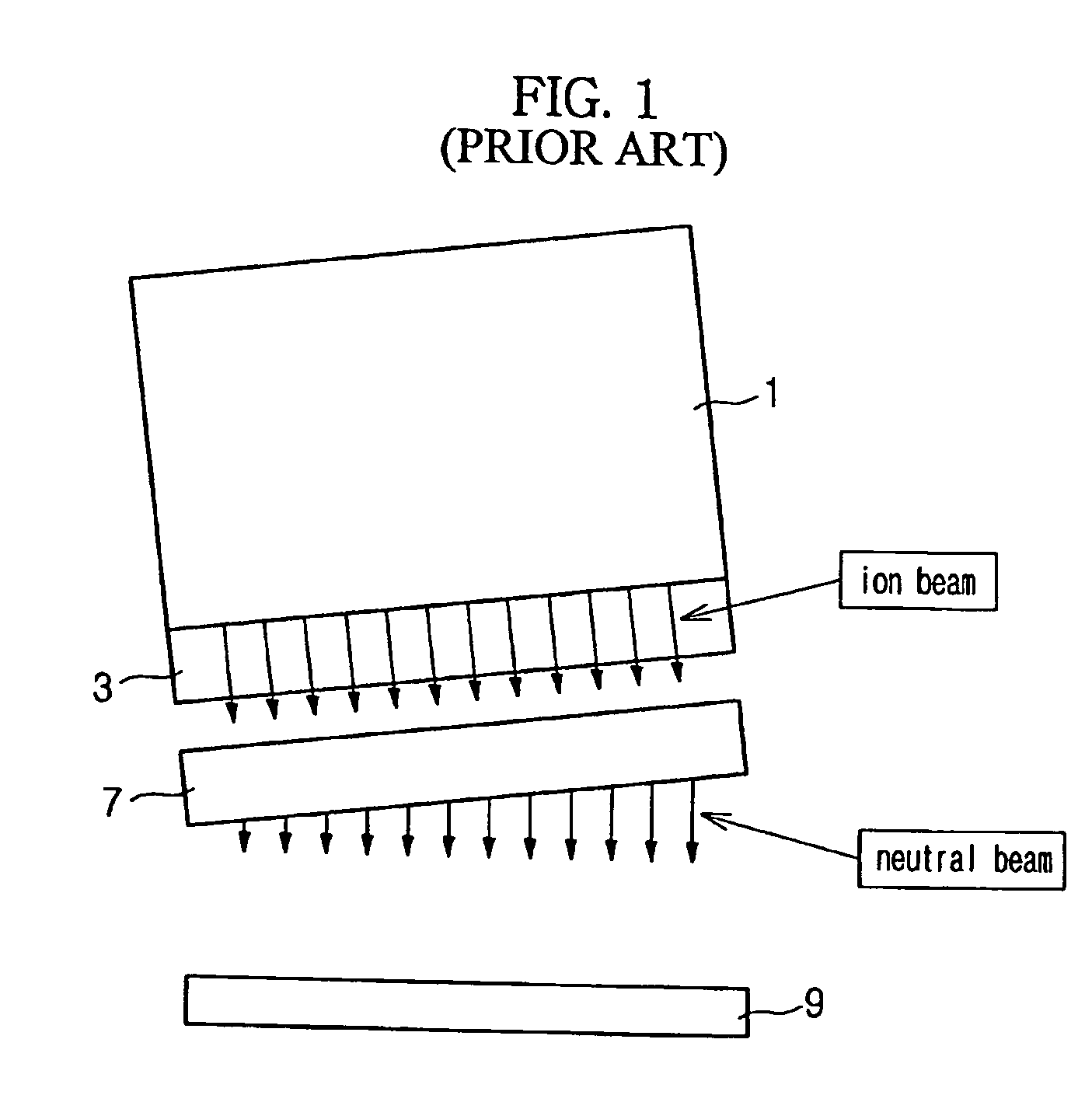

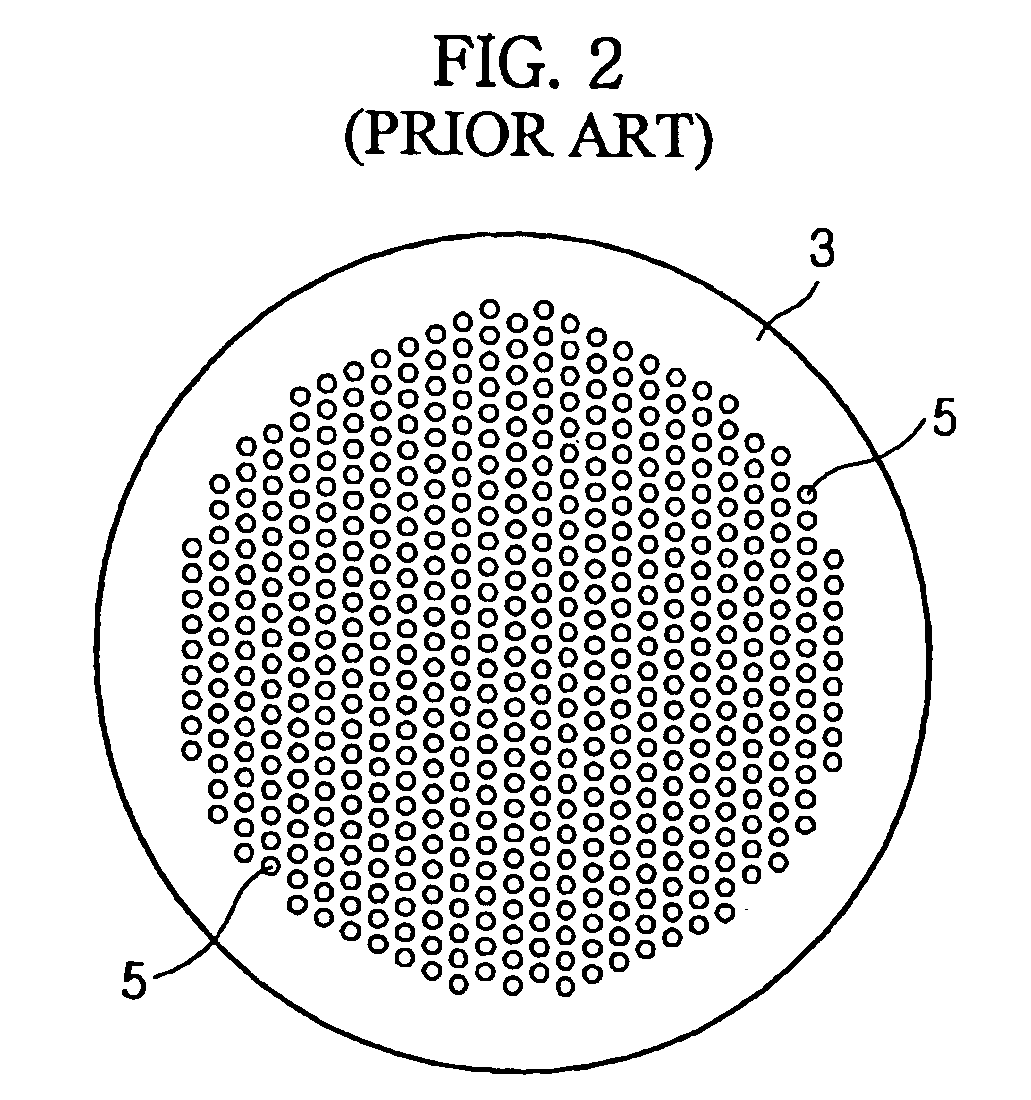

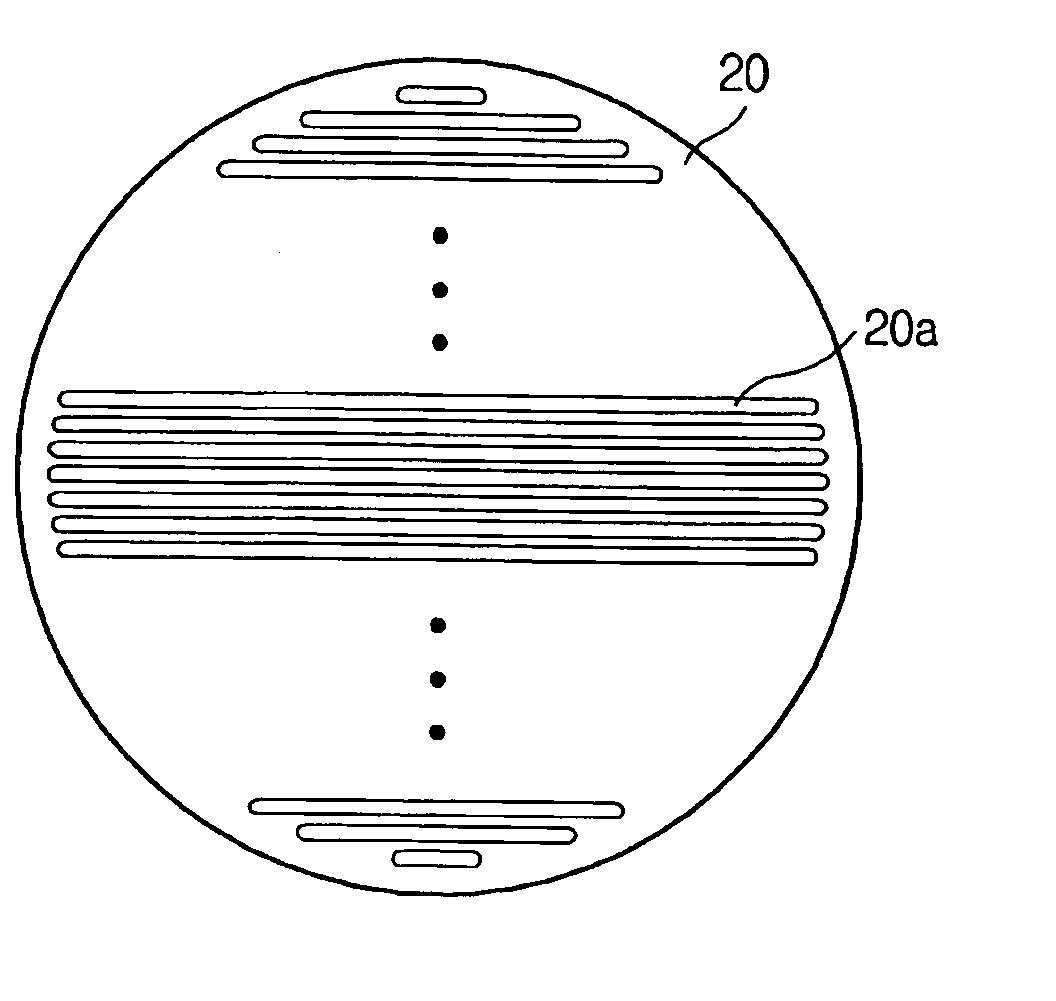

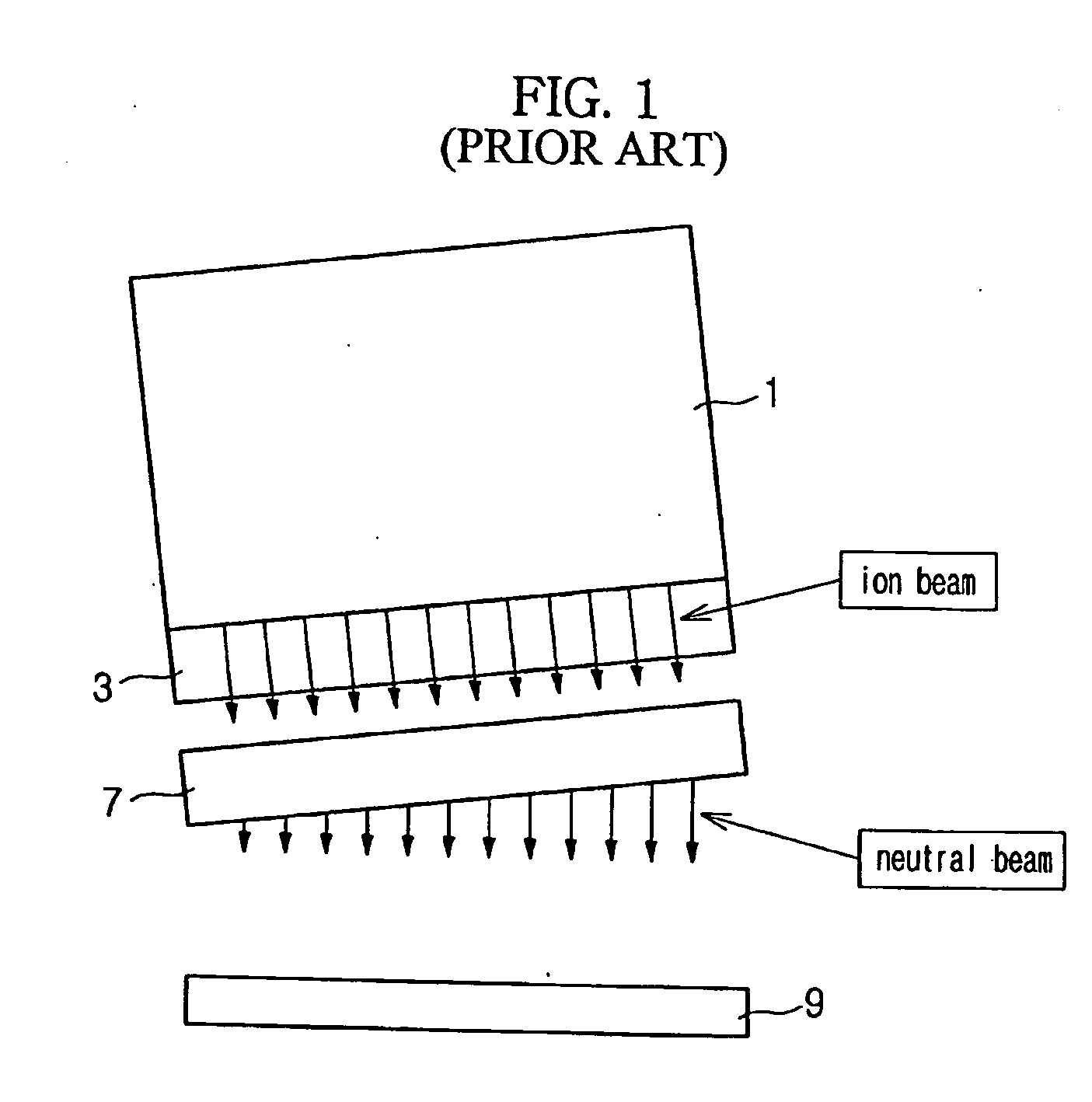

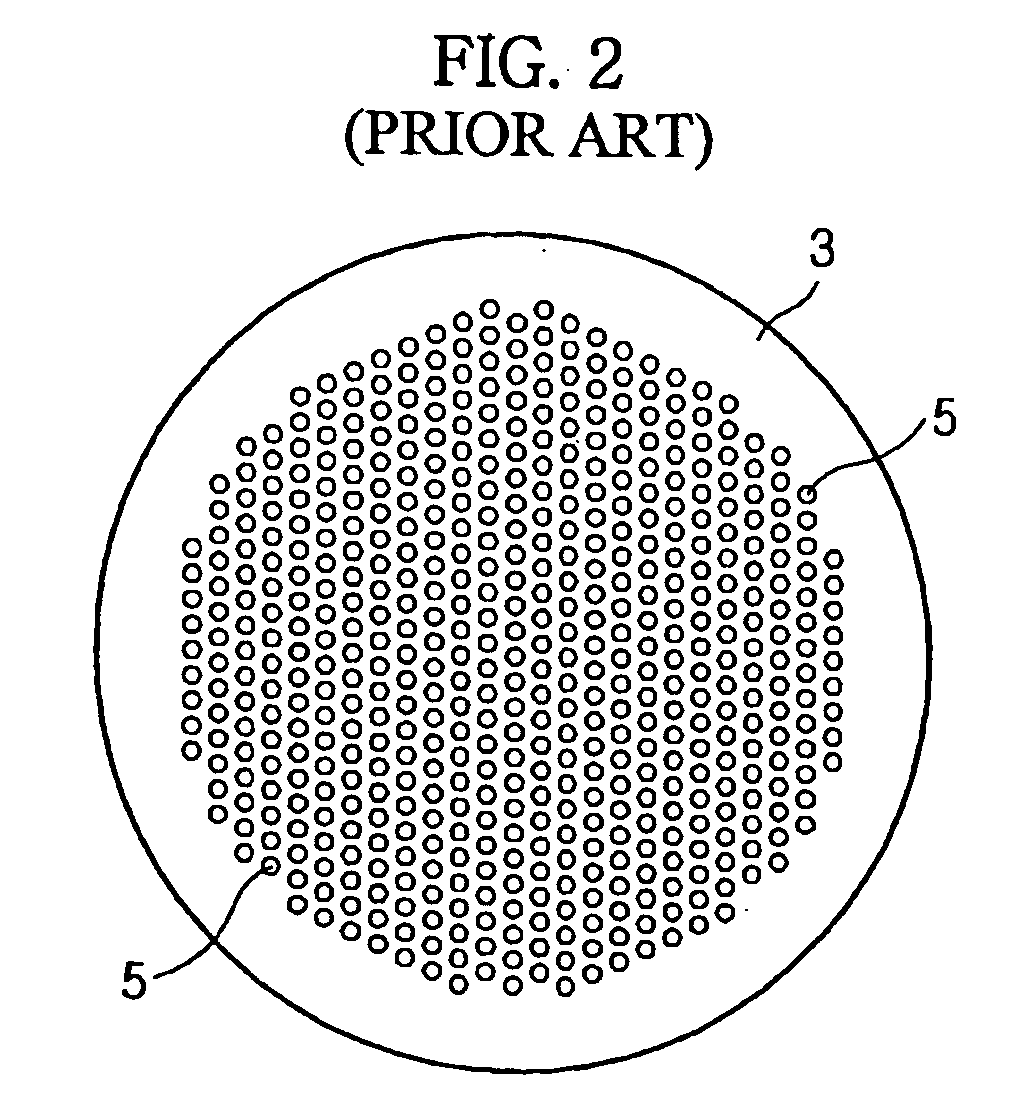

Ion beam extractor

InactiveUS7285788B2Increase the areaHigh ion fluxStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsIon beamSemiconductor

An ion beam extractor controls a direction and an intensity of ion beams by adjusting a voltage applied to a grid having slits formed therein, thereby enhancing uniformity of an etching rate of a wafer, leading to an increase of productivity of semiconductor diodes. The ion beam extractor comprises an ion source to produce an ion beam and at least one grid located at a rear end of the ion source in a progressing path of the ion beam produced by the ion source to adjust a direction of the ion beam by controlling a voltage applied to the at least one grid.

Owner:SAMSUNG ELECTRONICS CO LTD

Ion beam extractor

InactiveUS20060152164A1Increase the areaHigh ion fluxControl electrodesElectric arc lampsIon beamSemiconductor

An ion beam extractor controls a direction and an intensity of ion beams by adjusting a voltage applied to a grid having slits formed therein, thereby enhancing uniformity of an etching rate of a wafer, leading to an increase of productivity of semiconductor diodes. The ion beam extractor comprises an ion source to produce an ion beam and at least one grid located at a rear end of the ion source in a progressing path of the ion beam produced by the ion source to adjust a direction of the ion beam by controlling a voltage applied to the at least one grid.

Owner:SAMSUNG ELECTRONICS CO LTD

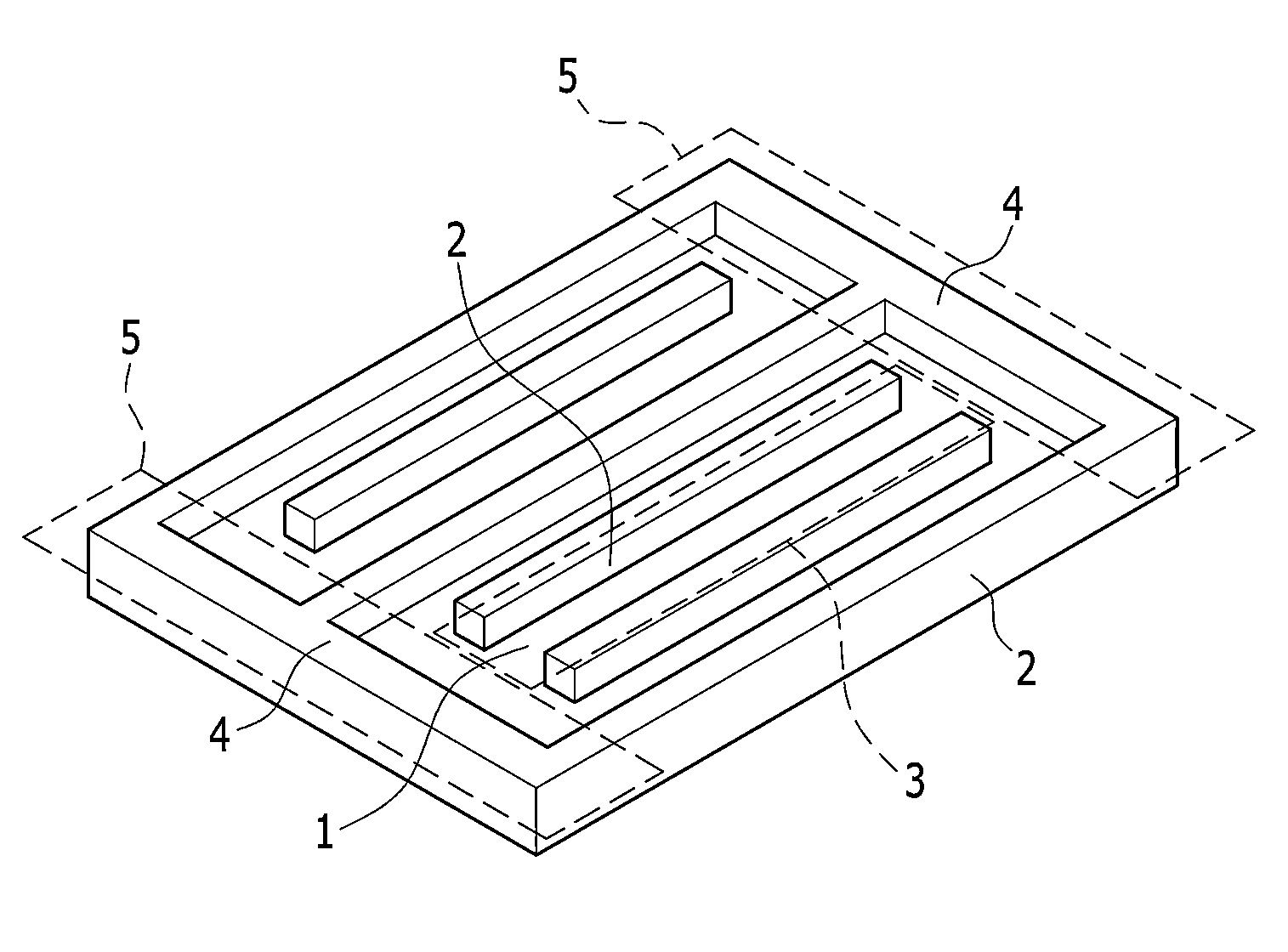

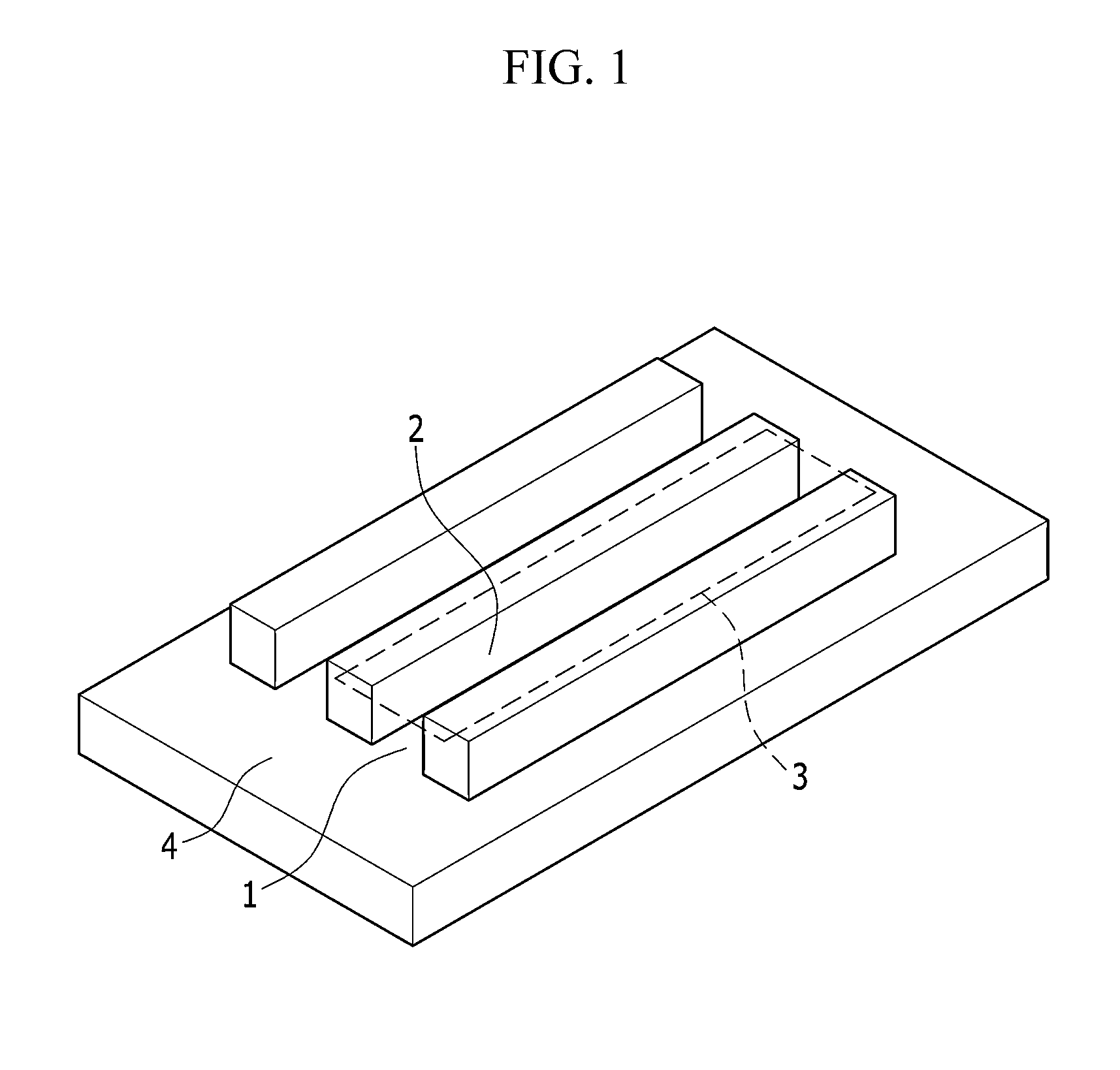

Methods of patterning block copolymer layers

InactiveUS20140187054A1Increase in pattern areaDegree of improvementNanoinformaticsSemiconductor/solid-state device manufacturingPolymer scienceSelf-assembly

A method of patterning a block copolymer layer includes: providing a guide pattern on a surface of a substrate, the guide pattern including sidewalls each elongated in a longitudinal direction and spaced apart from each other, a trench defined by a bottom surface and facing surfaces of the sidewalls, and having a uniform width over an entire length thereof in the longitudinal direction, and a latitudinal wall perpendicular to the longitudinal direction of the trench; providing a block copolymer layer on the surface of the substrate; and annealing the block copolymer to cause self-assembly of the block copolymer and to direct the same in the trench. The block copolymer has a microphase-separation into anisotropic discrete domains aligned with a period λo in the trench by the annealing.

Owner:SAMSUNG ELECTRONICS CO LTD

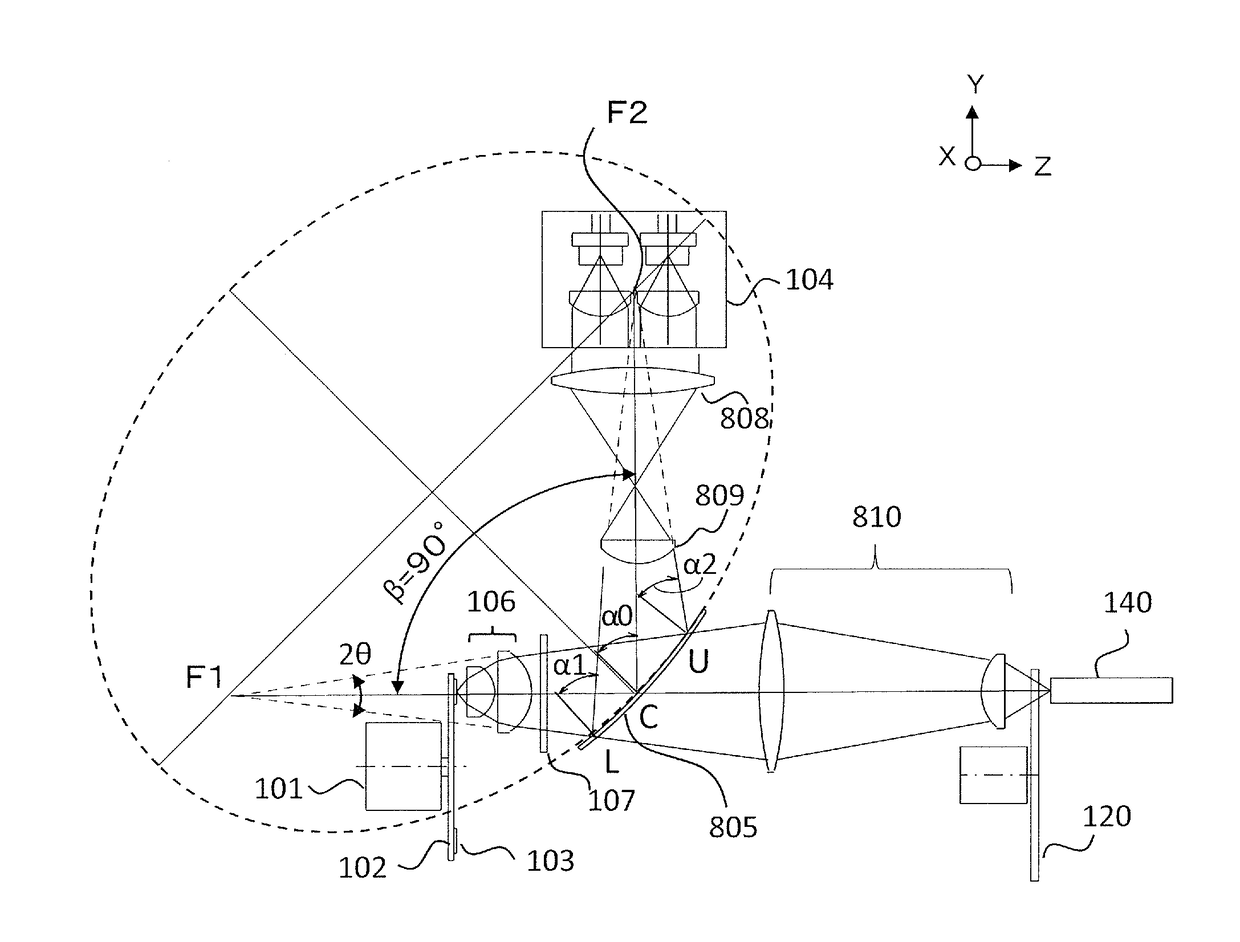

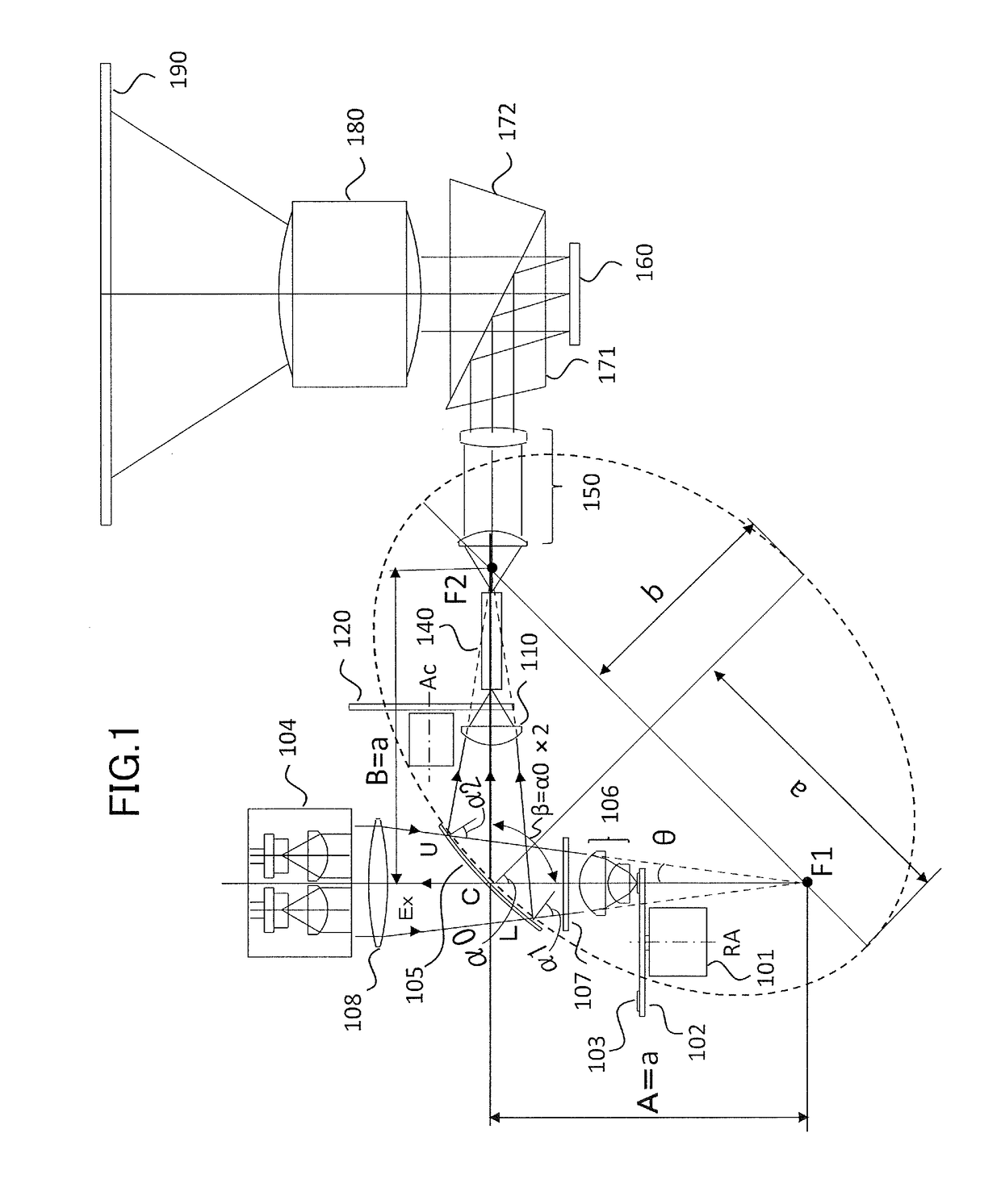

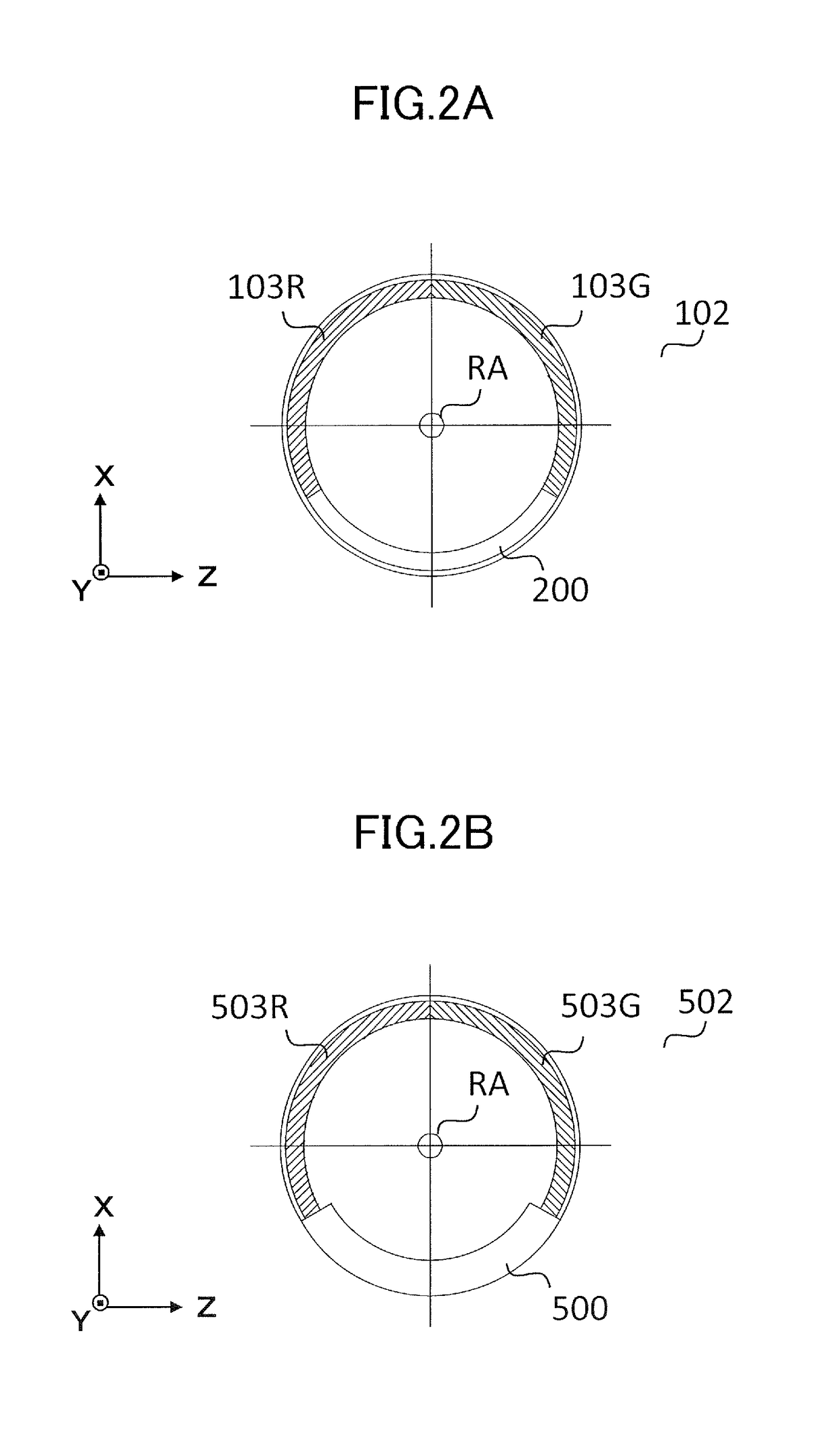

Light source device and projection type display apparatus

ActiveUS20180314141A1Low costUniformity of the transmission and reflection characteristics is securedProjectorsColor photographyFluorescencePhosphor

A light source device for a projection type display apparatus includes a phosphor, an excitation light source, a surface-curved dichroic minor, and a converging lens. The excitation light source configured to output excitation light for exciting the phosphor. The surface-curved dichroic minor has a curved surface and configured to cause one of excitation light from the excitation light source and fluorescence from the phosphor to pass through the curved surface and to cause the other to be reflected on the curved surface. The surface-curved dichroic mirror causes the light that passes through, neither to substantially converge, nor to substantially diverge, but performs a converging operation on the light that is reflected.

Owner:LIGHT SHOW TECH CO LTD

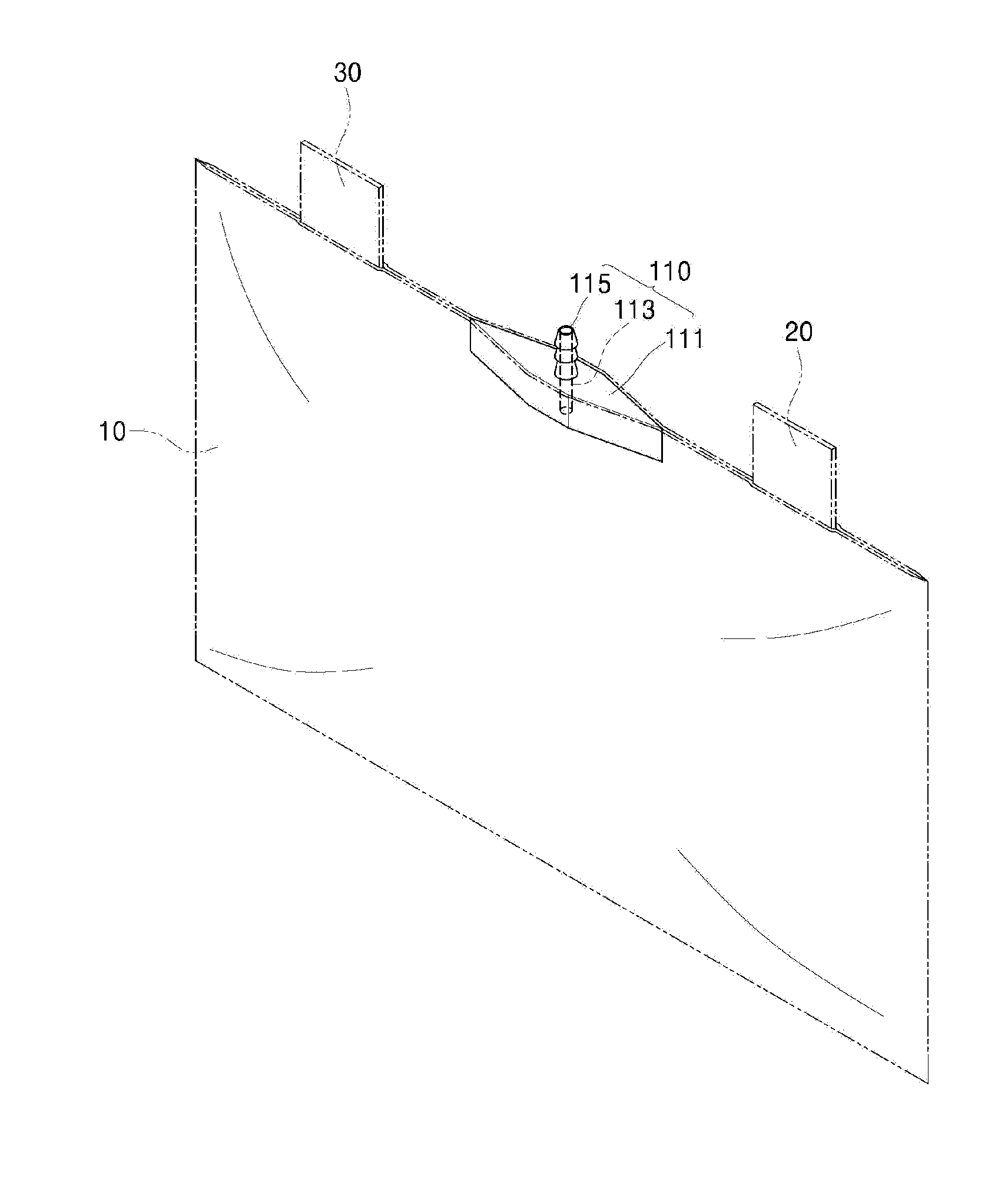

Vehicular lighting fixture

InactiveUS20100309678A1Avoid formingIncrease awarenessVehicle headlampsLighting support devicesDistribution patternEffect light

A vehicular lighting fixture can include a shade wherein an end edge of an upper surface of the shade is positioned at or in a vicinity of a focus of a projection lens. A first reflection surface can be provided to condense light from a light source in a vicinity of the end edge and to form a basic light distribution pattern by the projection lens. A second reflection surface which can comprise one planar reflection surface and can reflect light from the first reflection surface to form a first additional light distribution pattern. A third reflection surface can be provided on a higher surface of a step section of the upper surface, and can reflect light from the first reflection surface to form a second additional light distribution pattern. A fourth reflection surface can connect the second and third reflection surface, and can reflect the light from the first reflection surface in a direction not incident on the projection lens.

Owner:STANLEY ELECTRIC CO LTD

Fluorine-containing sulfonate, fluorine-containing sulfonate resin, resist composition and pattern formation method

InactiveUS8791293B2Securing uniformityHigh sensitivity and resolution and mask pattern reproductivityOrganic compound preparationPhotosensitive materialsResistSulfonate

According to the present invention, there is provided a fluorine-containing sulfonate resin having a repeating unit of the following general formula (3).In order to prevent deficiency such as roughness after pattern formation or failure in pattern formation, the fluorine-containing sulfonate resin incorporates therein a photoacid generating function and serves as a resist resin in which “a moiety capable of changing its developer solubility by the action of an acid” and “a moiety having a photoacid generating function” are arranged with regularity.

Owner:CENT GLASS CO LTD

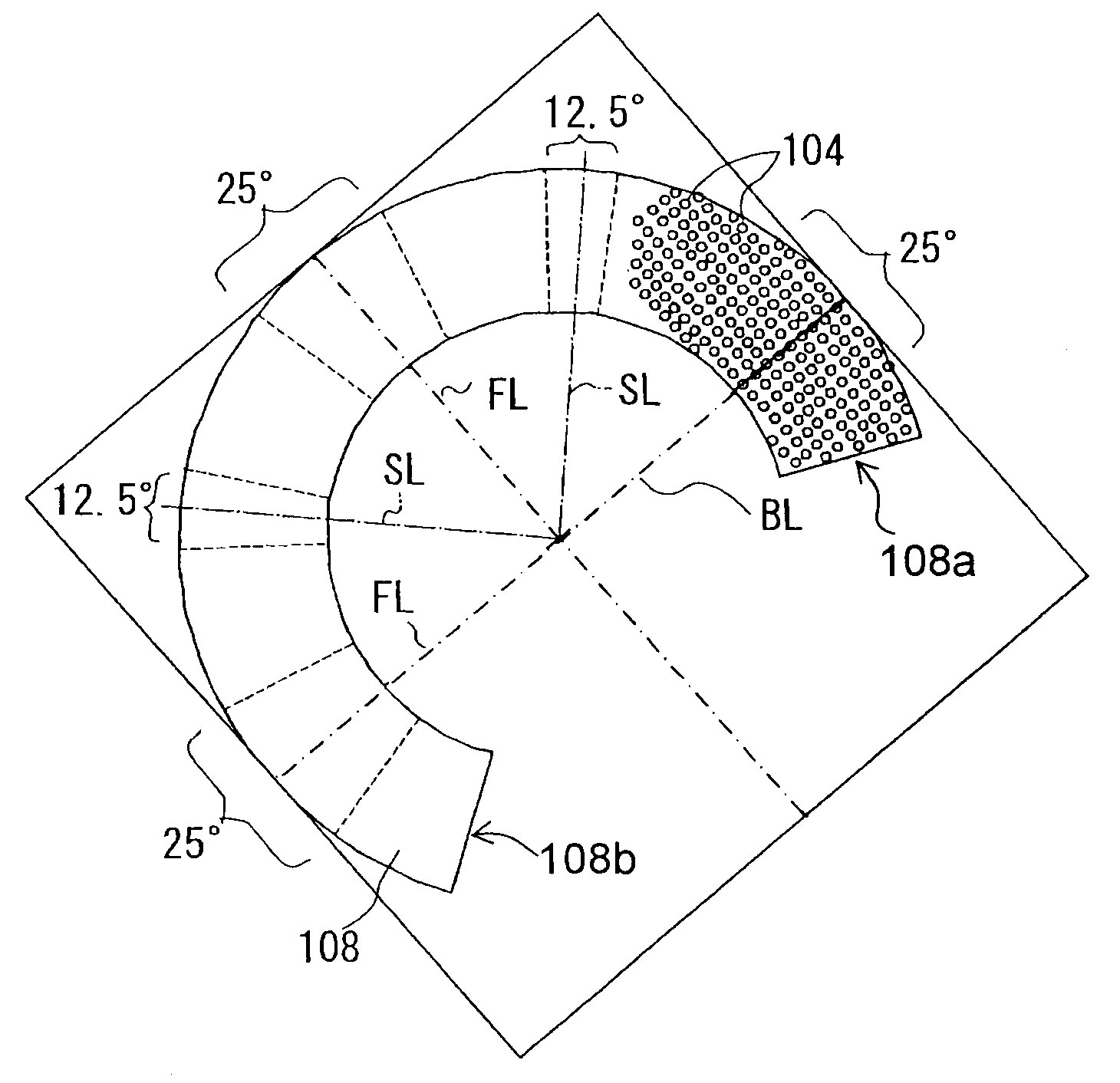

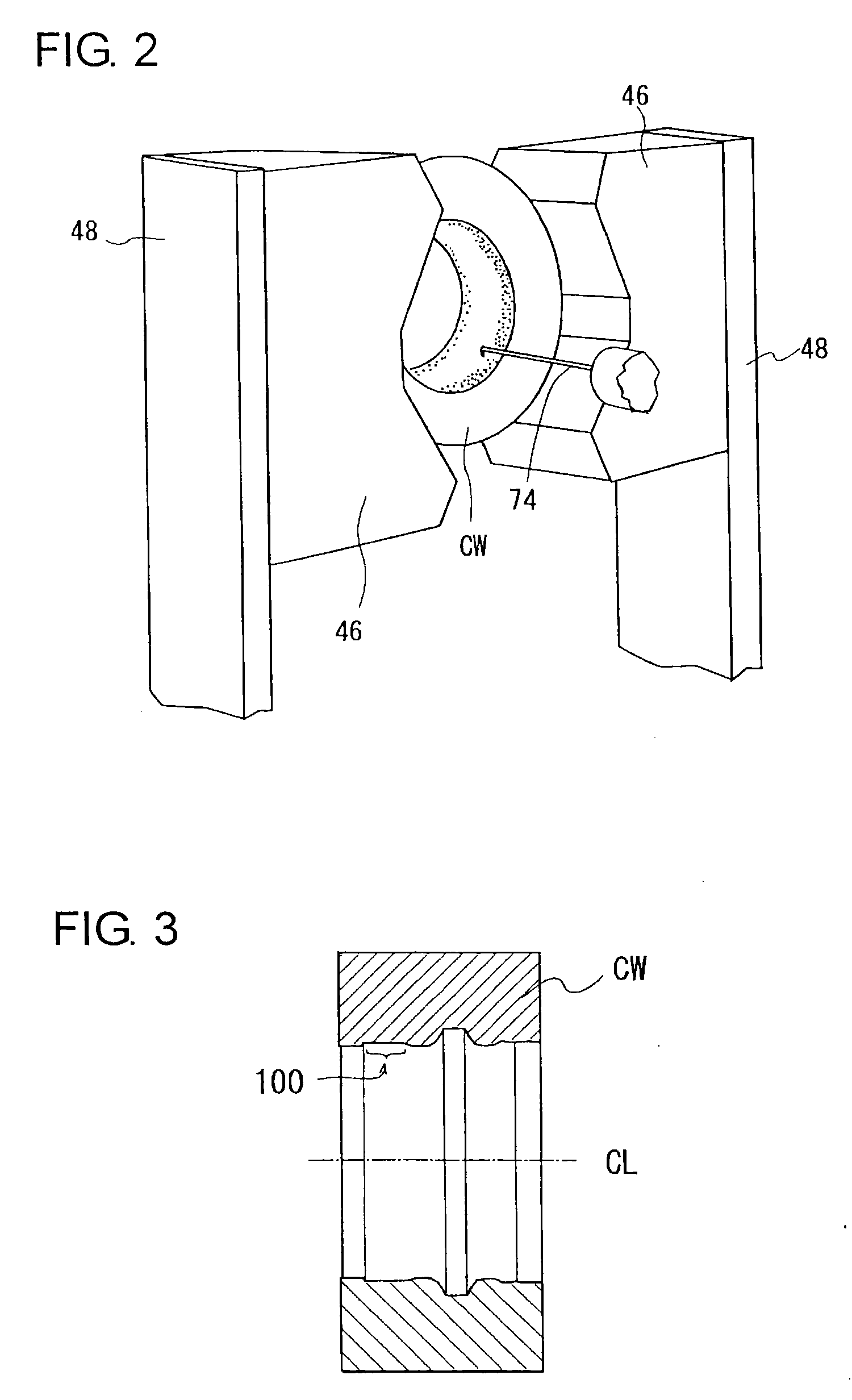

Superabrasive grain setting method

InactiveUS20090139148A1Accurate operationSecuring uniformityOther chemical processesFlexible-parts wheelsGrid patternEngineering

In a superabrasive grain setting method, a two-dimensionally developed coordinate preparation step is taken, wherein a non-cylindrical area of a mounting surface where a tangential line to the mounting surface in a plane including the axis of the manufacturing mold crosses with the axis of a manufacturing mold is developed into a circular-arc belt-like surface, and a plurality of mounting points are set on the circular-arc belt-like surface in a grid pattern in dependence on mounting positions for superabrasive grains. Then, a rectification step is taken, wherein the grid pattern of the mounting points is rectified in predetermined angular ranges so that the mounting points do not make consecutive point lines in the circumferential direction of the circular-arc belt-like surface. A mounting step is thereafter taken of mounting the superabrasive grains on the mounting surface of the manufacturing mold based on the grid pattern rectified at the rectification step.

Owner:TOYODA VAN MOPPES

Non-invasive blood glucose sensors using a magneto-resonance absorption method and measurement methods thereof

InactiveUS20060020193A1Improve accuracyImprove precisionDiagnostic recording/measuringAnalysis using nuclear magnetic resonanceGlucose sensorsBlood Glucose Measurement

A non-invasive blood glucose measurement method using a magneto-resonance absorption method. A constant magnetic field is applied using a pair of permanent magnets, the magnetic field having a uniform strength. A triangular waveform low frequency modulation magnetic field is applied using a low frequency generator and a pair of low frequency coils, the low frequency modulation magnetic field having a uniform strength. A weak acoustic wave modulation magnetic field is applied using an acoustic wave generator and a pair of acoustic wave coils. Electromagnetic waves are applied to a detector in which a finger is positioned to produce a nuclear magneto-resonance, the electromagnetic waves having a frequency varying in a specific frequency band step by step, the applying being done using a high frequency generator and a sensor coil. A magneto-resonance absorption signal produced by spin-lattice relaxation of protons in a tissue of the finger because of the nuclear magneto-resonance is detected. A magneto-resonance spin-lattice relaxation time of the finger from the magneto-resonance absorption signal is determined. A blood glucose concentration in a human body is determined from a correlation between a pre-determined blood glucose concentration in the human body and the determined magneto-resonance spin-lattice relaxation time.

Owner:SAMSUNG ELECTRONICS CO LTD

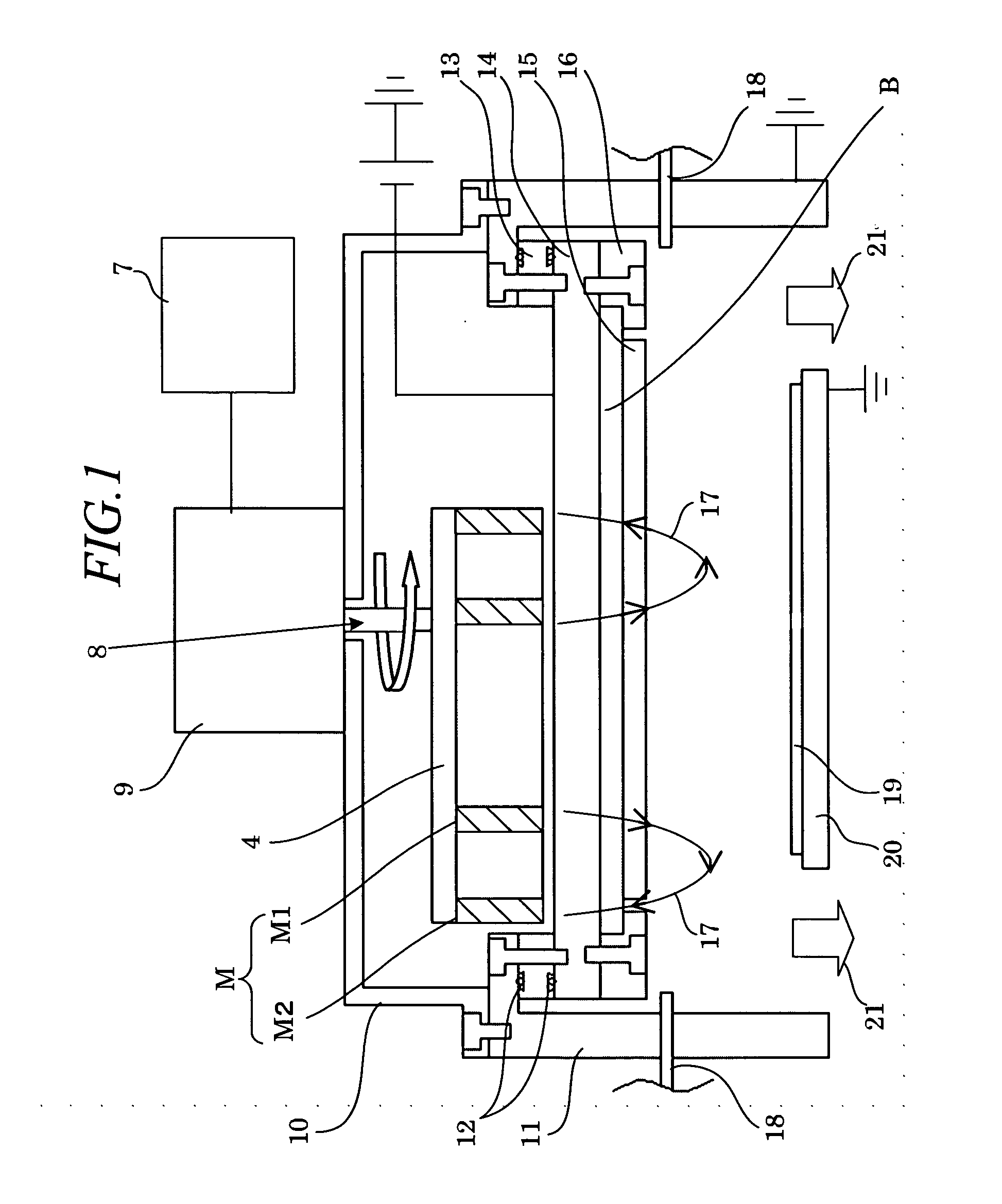

Sputtering apparatus and method, and sputtering control program

InactiveUS7935232B2Inhibit deteriorationSecuring uniformityCellsVacuum evaporation coatingHigh densitySwitching time

To provide a sputtering apparatus and method, and a sputtering control program which are configured simply and can secure the uniformity of the film thickness from the beginning to the end of the use of a target.There are provided: a target 15 disposed so as to face an object to be treated 19; a permanent magnet unit M which generates a high-density plasma by means of a magnetic field and deposits a material of the target 15 on the object to be treated, in the form of a film; a rotational mechanism 9 which rotates the permanent magnet unit M; and a rotation number control apparatus 7 which gradually changes the number of rotations of the permanent magnet unit M rotated by the rotational mechanism 9. The rotation number control apparatus 7 has a rotation number setting section 702b for setting the number of rotations to be switched, a switching time setting section 702a for setting the time for switching, a detection section 703 for detecting the switching time, a selecting section 704 for selecting the number of rotations at the switching time, and a switching section 705 for outputting an instruction of switching to the selected number of rotations.

Owner:SHIBAURA MECHATRONICS CORP

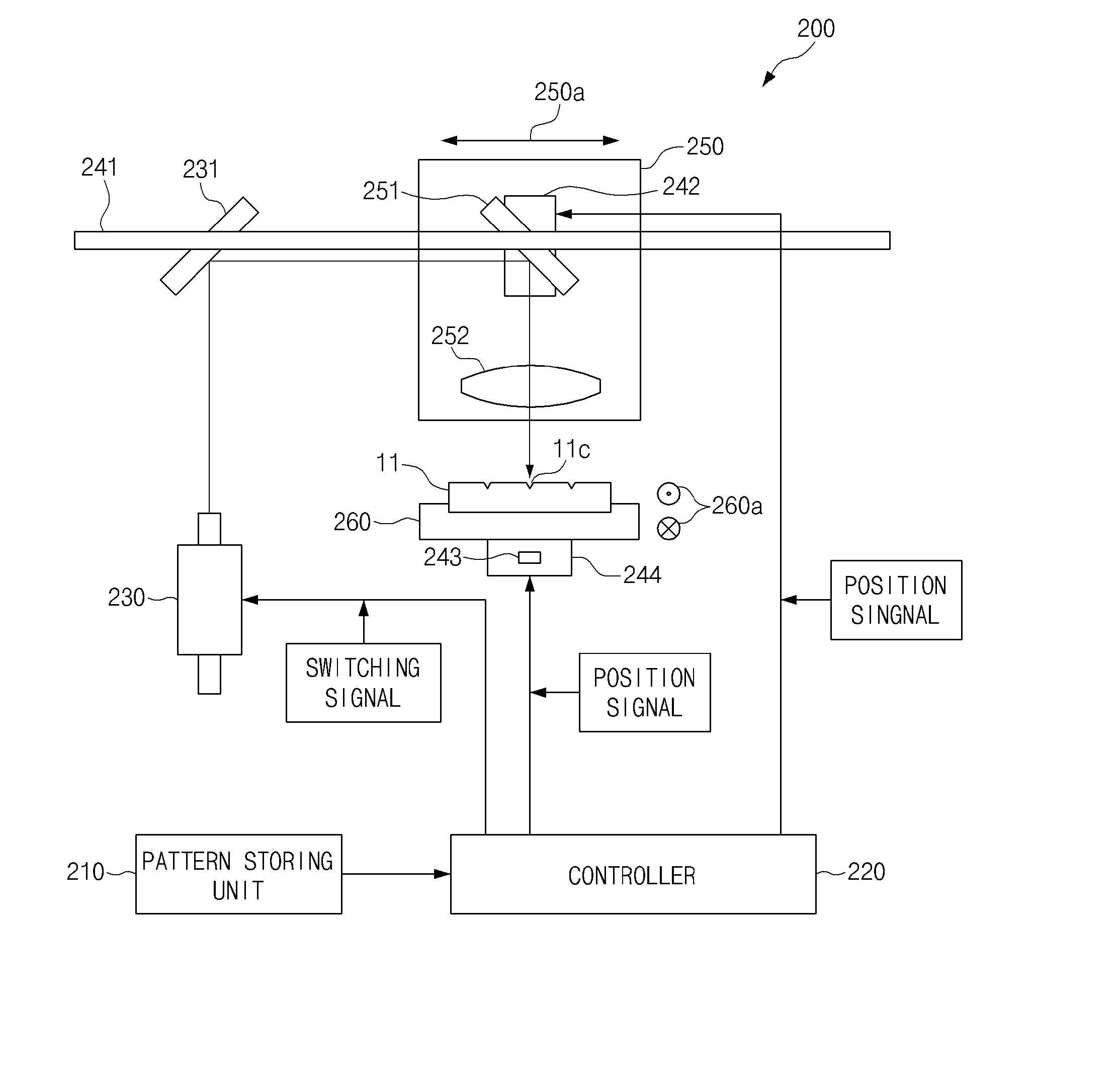

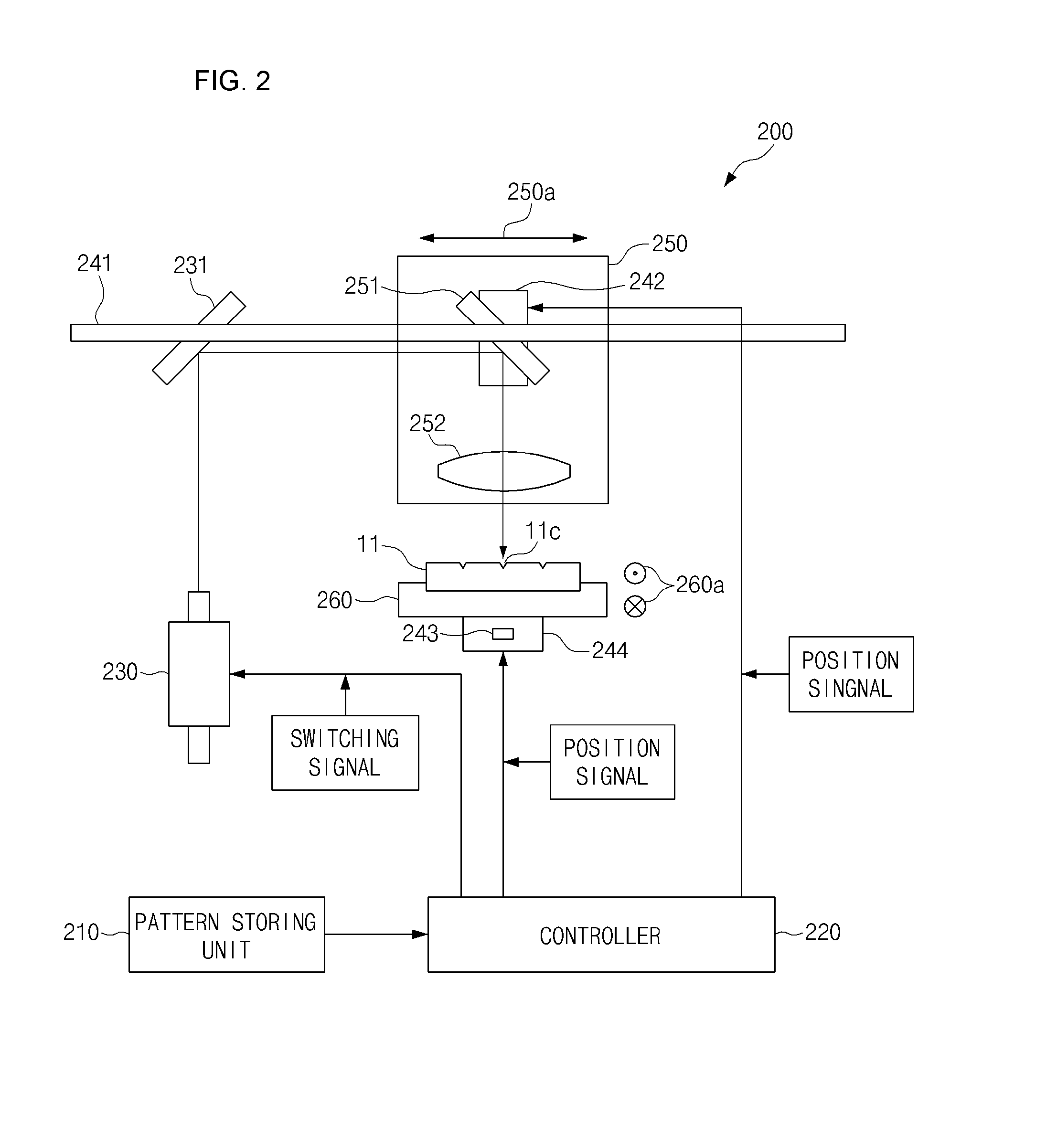

Apparatus for forming pattern using laser

InactiveUS20110006043A1Securing uniformityImprove productivityPrintingOptical light guidesLight guideSwitching signal

An apparatus for forming a pattern using a laser is provided. The apparatus includes a pattern storing unit, a controller, a laser oscillating unit, an X-Y driver, a header unit, and a stage. The pattern storing unit stores data on light guide patterns of a discontinuous straight line shape. The controller transmits position signal of the light guide patterns to the X-Y driver and simultaneously, transmits a switching signal to the laser oscillating unit. The laser oscillating unit outputs a laser beam synchronized with a movement of the header unit. The X-Y driver moves the header unit and the stage. The header unit moves along a first guide rail. The stage moves along a fixed second guide rail in the front and rear direction of the light guide panel.

Owner:HB TECH CO LTD

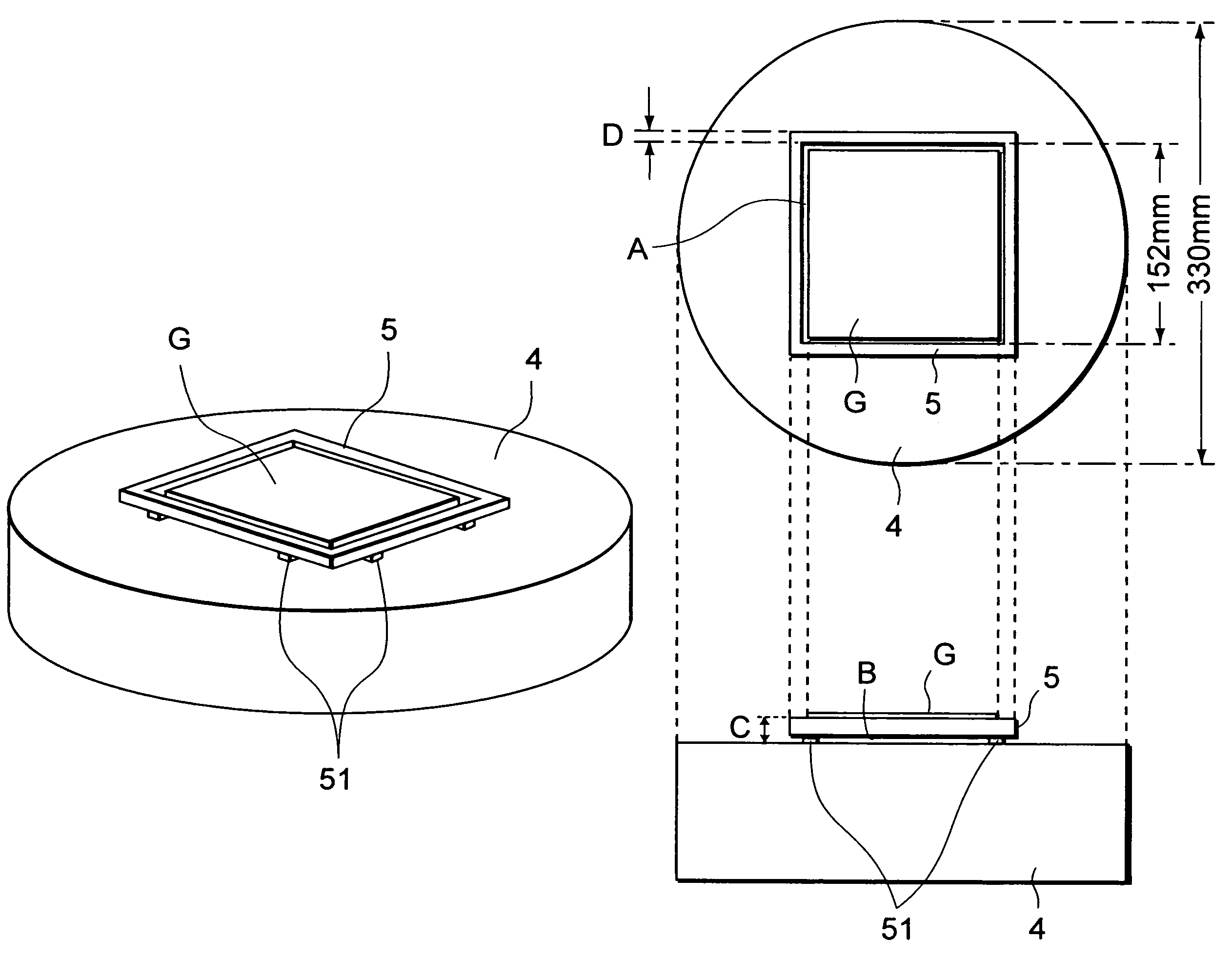

Heat processing apparatus and heat processing method

InactiveUS7431584B2Uniform surfaceSecuring uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringHeat processing

A heat processing apparatus for heating a mask substrate is disclosed. A mask substrate on which a coating solution has been coated is placed on a heating plate that heats the substrate. A frame member is disposed on the heating plate so that the frame member faces a side surface of the mask substrate placed on the heating plate when the frame member is attached to the heating plate and that a clearance is formed between the frame member and the heating plate when the frame member is attached to the heating plate. The frame member suppresses heat radiated from the side surface of the substrate. As a result, the temperature uniformity of the surface of the substrate can be improved. In addition, since the clearance is formed between the frame member and the heating plate, particles do not accumulate in the region. Thus, adhesion of particles to the substrate can be suppressed.

Owner:TOKYO ELECTRON LTD

Plasma processing method and plasma processing apparatus

ActiveUS7829463B2Improve uniformityMaintain consistencyLiquid surface applicatorsElectric discharge tubesCapacitanceEngineering

A plasma processing method performs a desired plasma process on substrates by using a plasma generated in a processing space. A first and a second electrode are disposed in parallel in a processing vessel that is grounded, the substrate is supported on the second electrode to face the first electrode, the processing vessel is vacuum evacuated, a desired processing gas is supplied into the processing space formed between the first electrode, the second electrode and a sidewall of the processing vessel, and a first radio frequency power is supplied to the second electrode. The first electrode is connected to the processing vessel via an insulator or a space, and is electrically coupled to a ground potential via a capacitance varying unit whose electrostatic capacitance is varied based on a process condition of the plasma process performed on the substrate.

Owner:TOKYO ELECTRON LTD

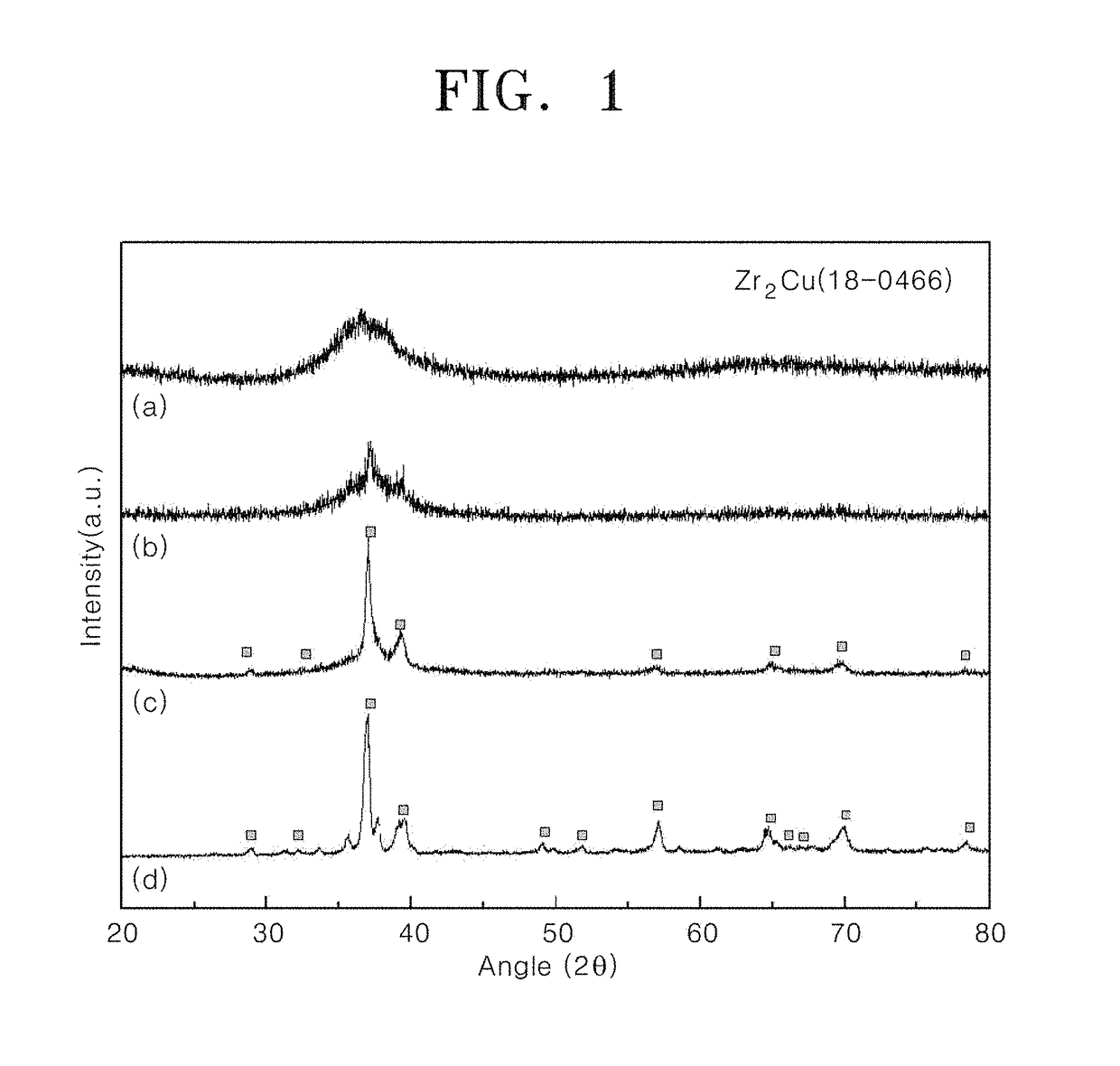

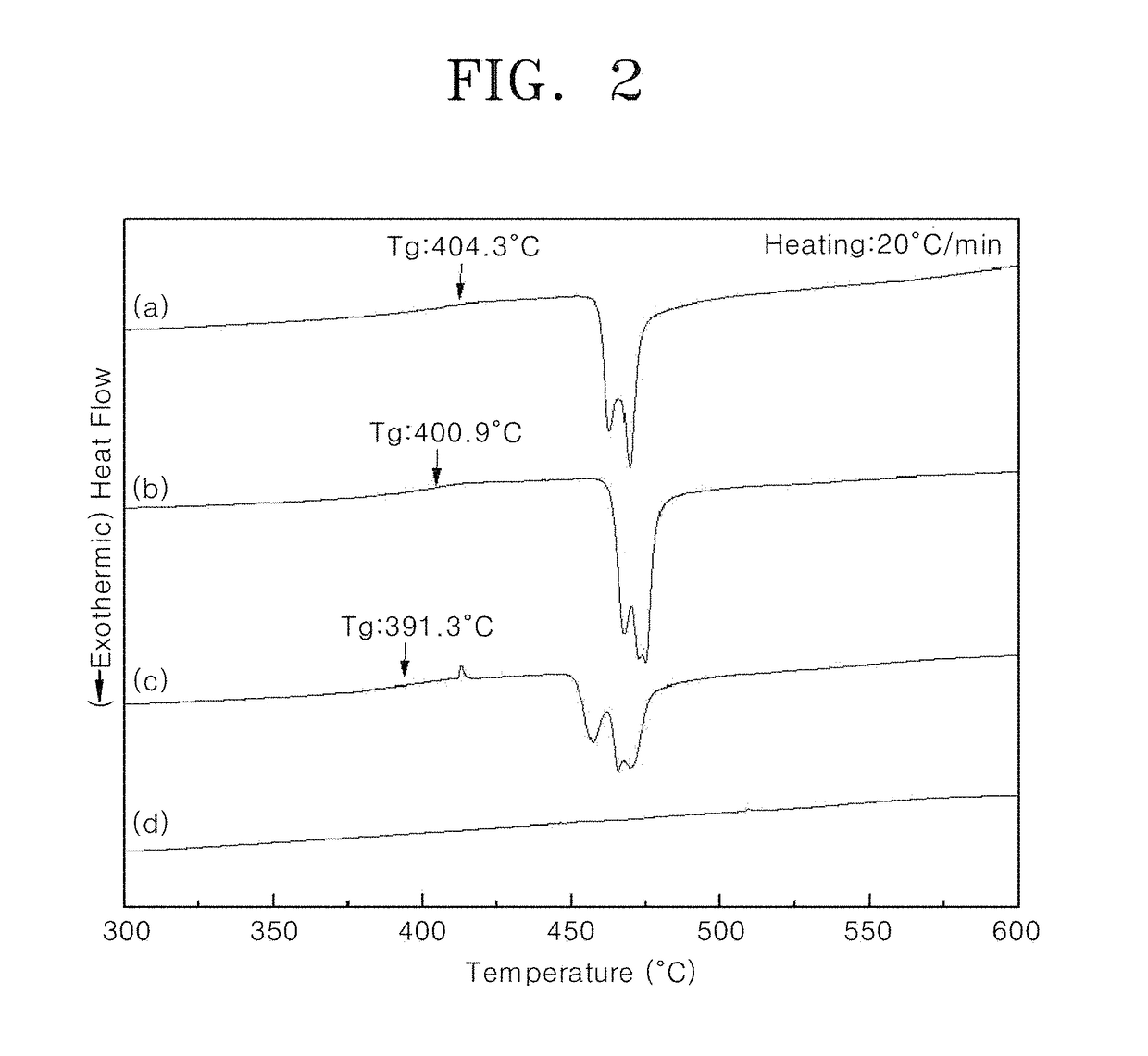

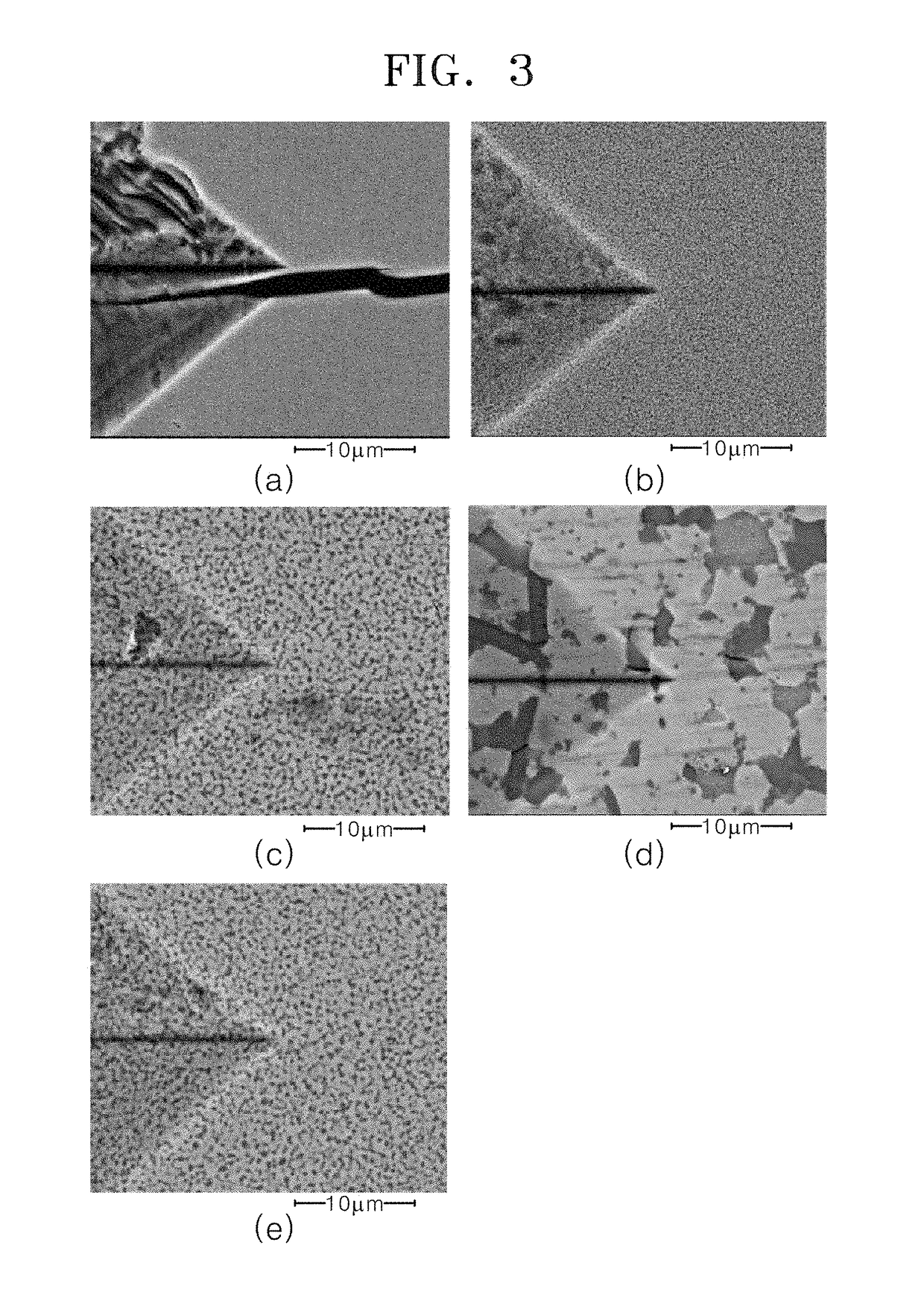

Crystalline alloy having glass-forming ability, preparation method thereof, alloy target for sputtering, and preparation method thereof

ActiveUS9734994B2Improve performanceMinimizing compositional deviationElectric discharge tubesVacuum evaporation coatingSputteringAlloy

Owner:KOREA INST OF IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com