Patents

Literature

271results about How to "High thickness accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

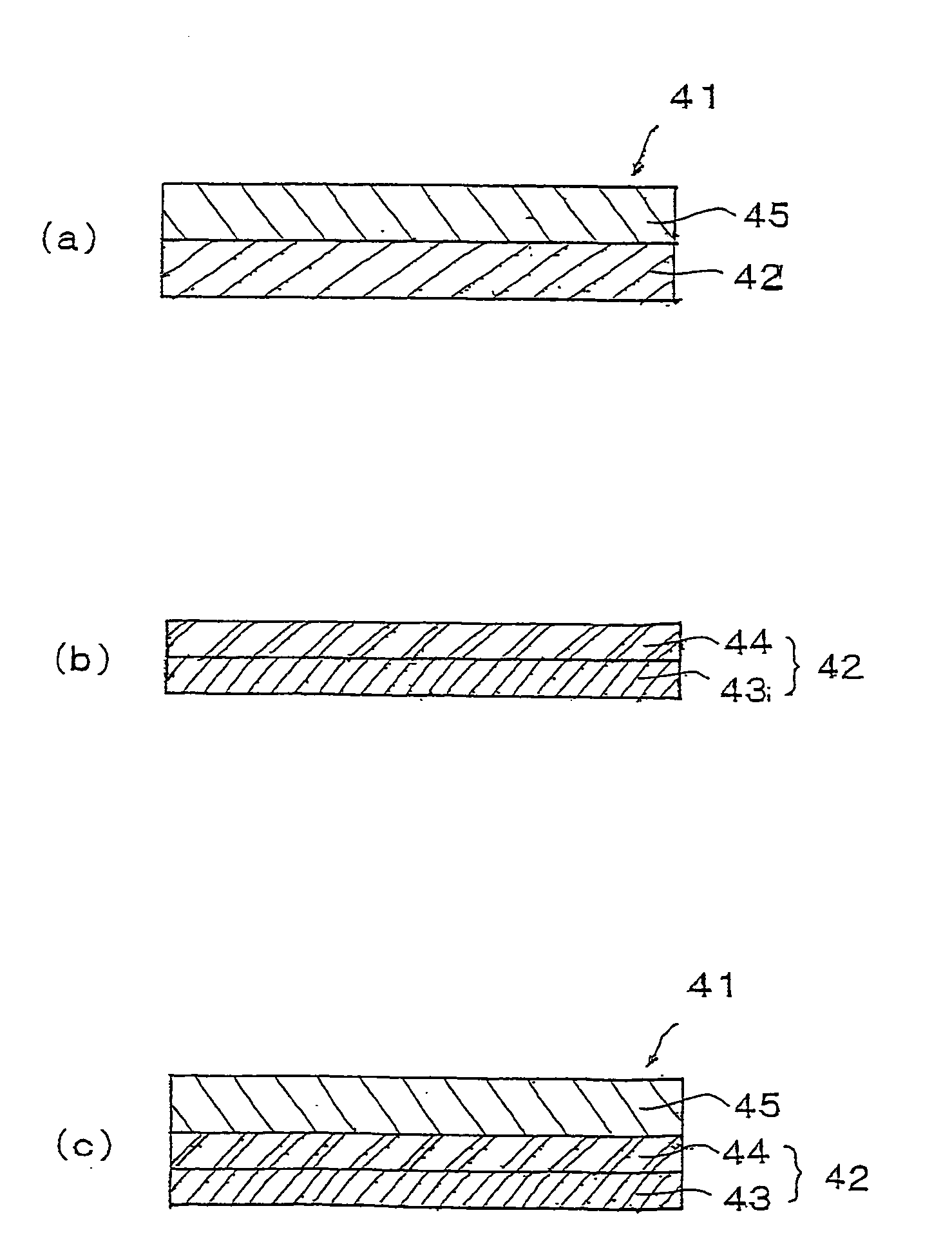

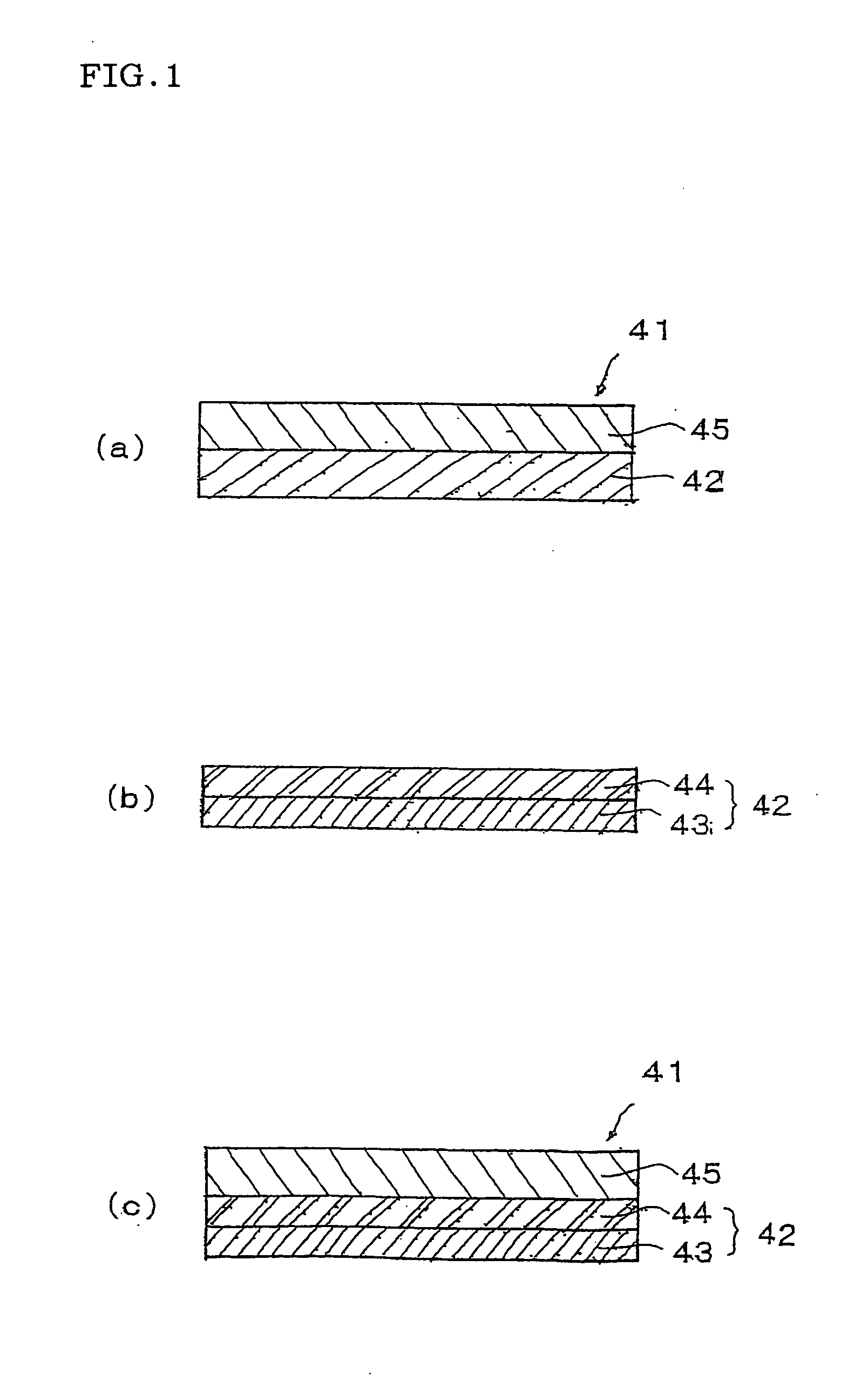

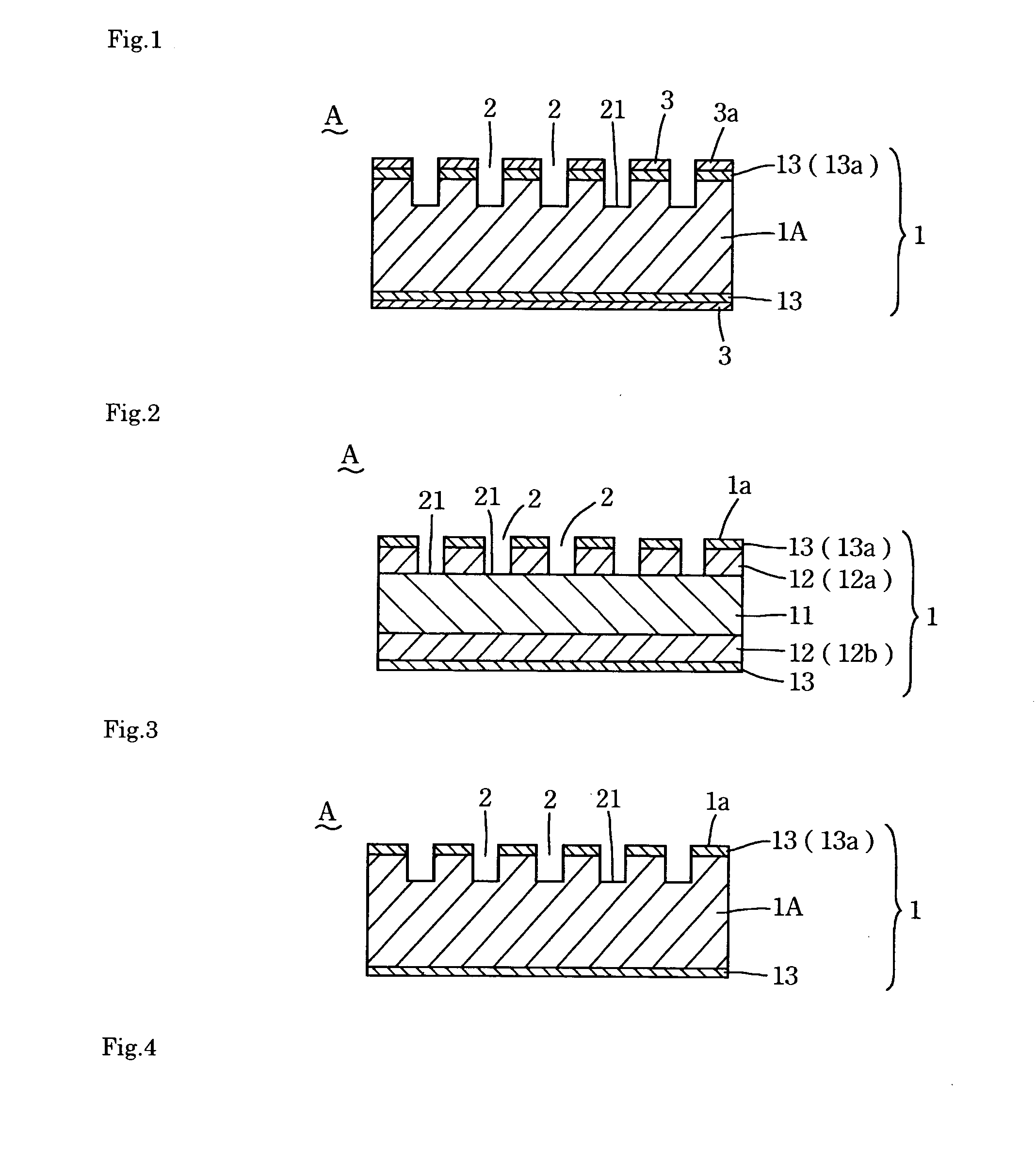

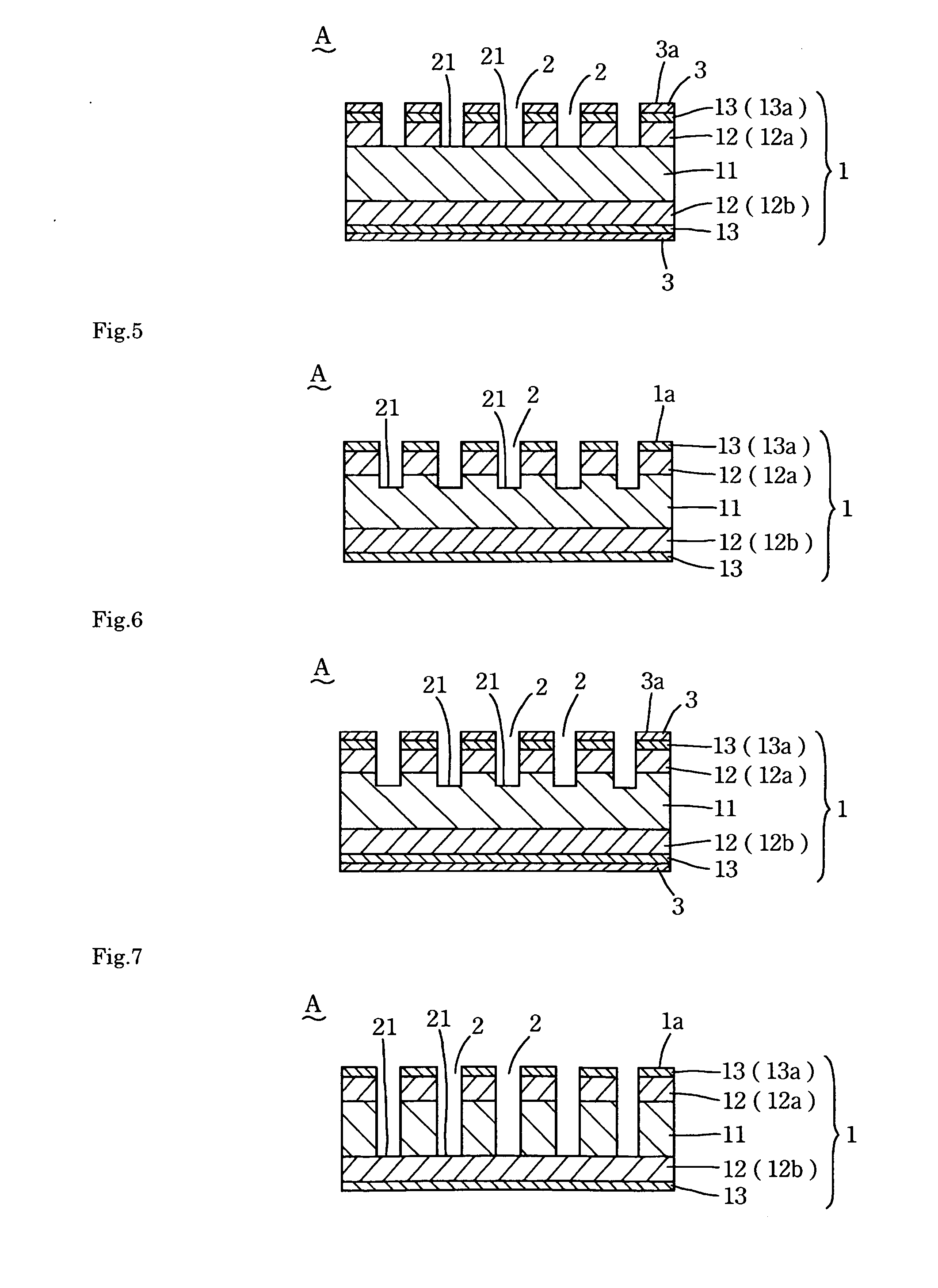

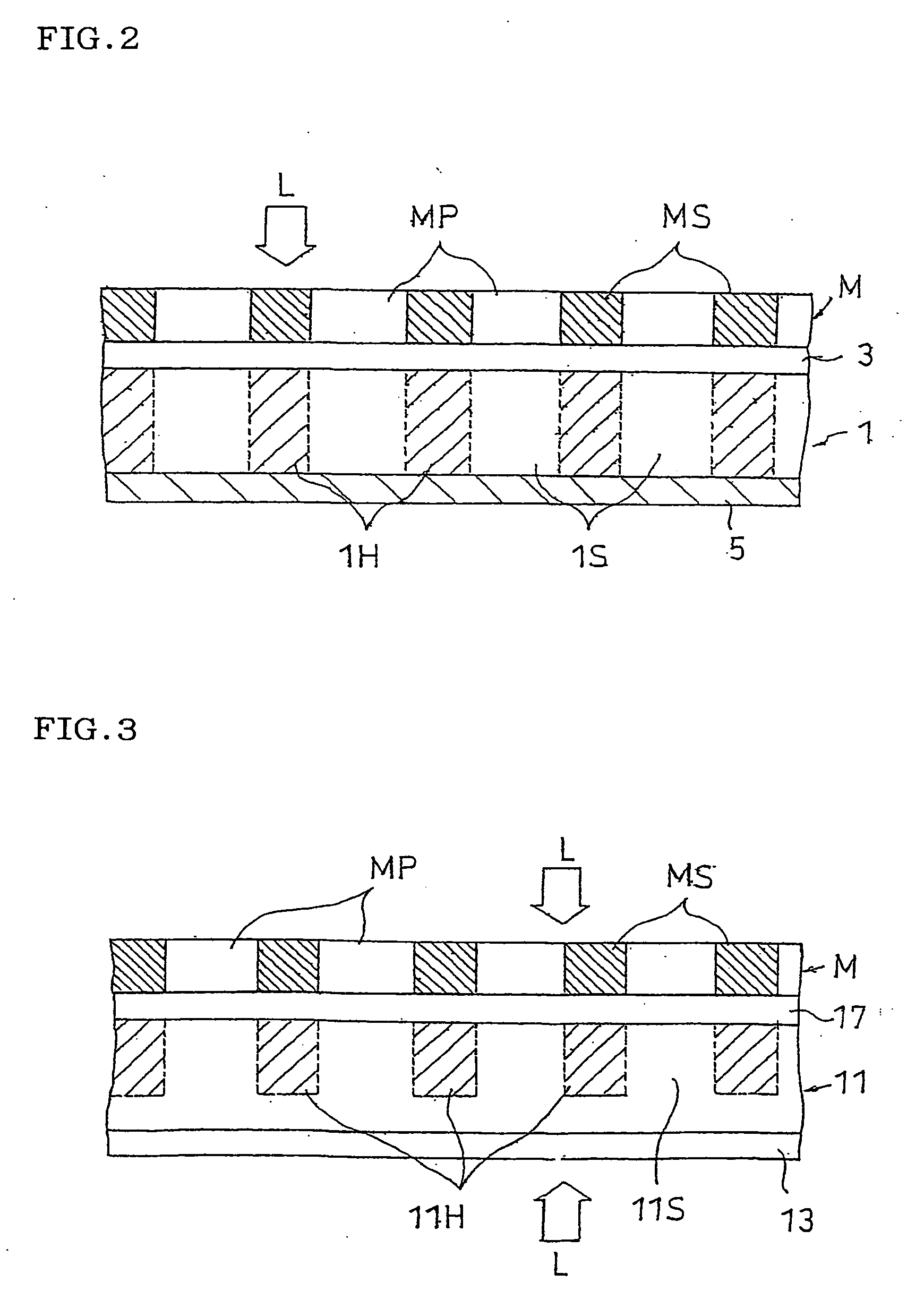

Polishing pad, method of manufacturing the polishing pad, and cushion layer for polishing pad

InactiveUS20040055223A1Easy to processHigh thickness accuracyOther chemical processesAbrasion apparatusSurface patternEngineering

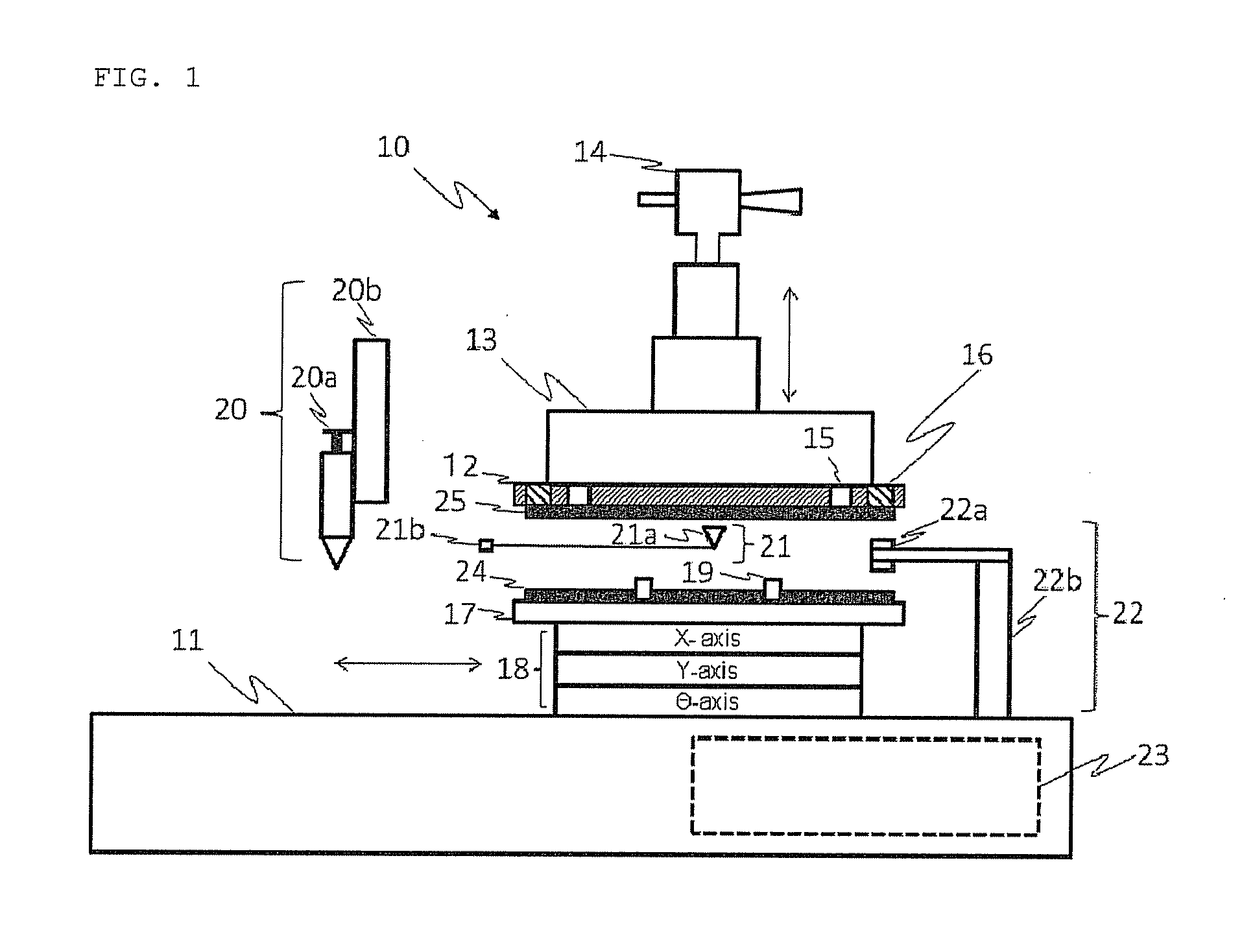

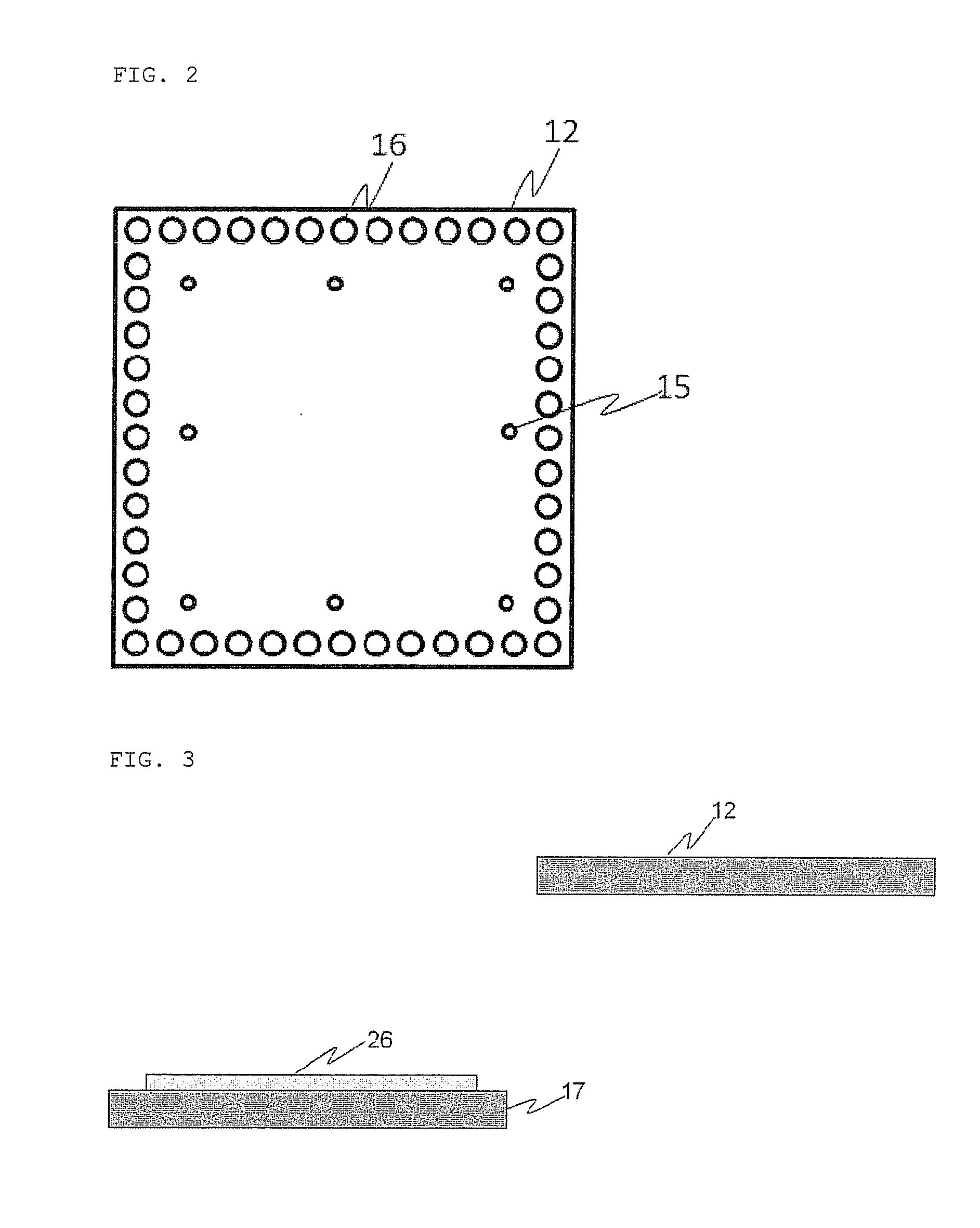

The polishing pad of this invention is a polishing pad effecting stable planarizing processing, at high polishing rate, materials requiring surface flatness at high level, such as a silicon wafer for semiconductor devices, a magnetic disk, an optical lens etc. This invention provides a polishing pad which can be subjected to surface processing to form a sheet or grooves, is excellent in thickness accuracy, attains a high polishing rate, achieves a uniform polishing rate, and also provides a polishing pad which is free of quality variations resulting from an individual variation, easily enables a change the surface patterns, enables fine surface pattern, is compatible with various materials to be polished, is free of burrs upon forming the pattern. This invention provides a polishing pad which can have abrasive grains mixed at very high density without using slurry, and generates few scratches by preventing aggregation of abrasive grains dispersed therein. The polishing pad of this invention has a polishing layer formed from a curing composition to be cured with energy rays, the polishing layer being formed surface pattern thereon by photolithography. The polishing pad of this invention comprises a polishing layer resin having abrasive grains dispersed therein, the resin containing ionic groups in the range of 20 to 1500 eq / ton.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Conductive curable resin composition and separator for fuel cell

InactiveUS7329698B2Improve conductivityMaintain good propertiesMaterial nanotechnologyFinal product manufactureElastomerPolymer science

There is provided a conductive curable resin composition comprising (A) a curable resin composition comprising an elastomer with a Mooney viscosity (ML1+4 (100° C.)) of 25 or greater at 2-80 wt % and (B) a carbon material, with a weight ratio of component (A) to component (B) of 70-5:30-95. The curable resin composition of component (A) preferably comprises (A1) an elastomer at 80-2 wt %, (A2) a radical reactive resin at 20-98 wt % and (A3) an organic peroxide at 0.2-10 parts by weight to 100 parts by weight of (A1+A2). Also provided are a process for production of a conductive cured resin by shaping and curing of the conductive curable resin composition, and a fuel cell separator, an assembly for a cell, an electrode or a heat releasing plate, obtained thereby.

Owner:SHOWA DENKO KK

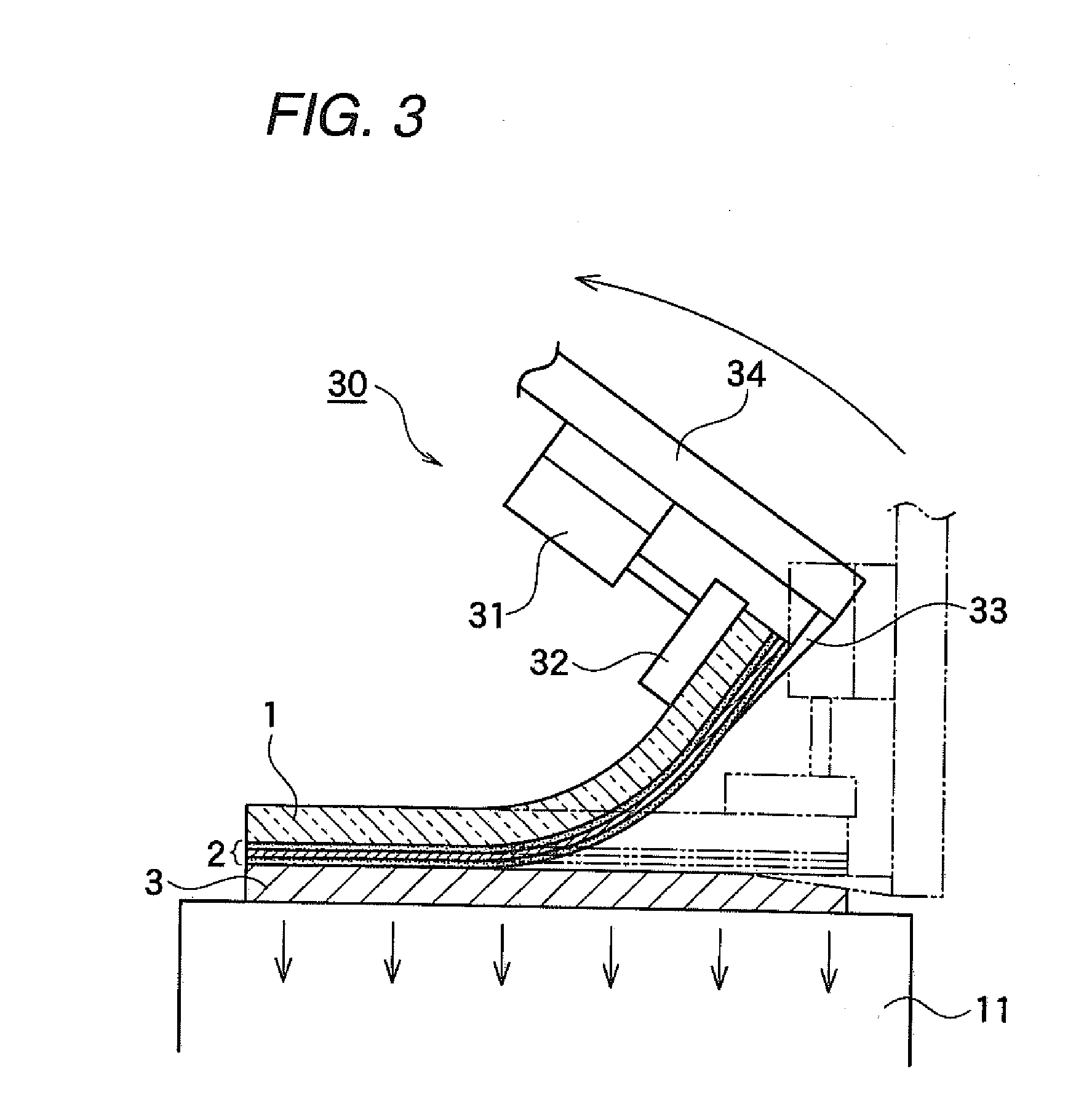

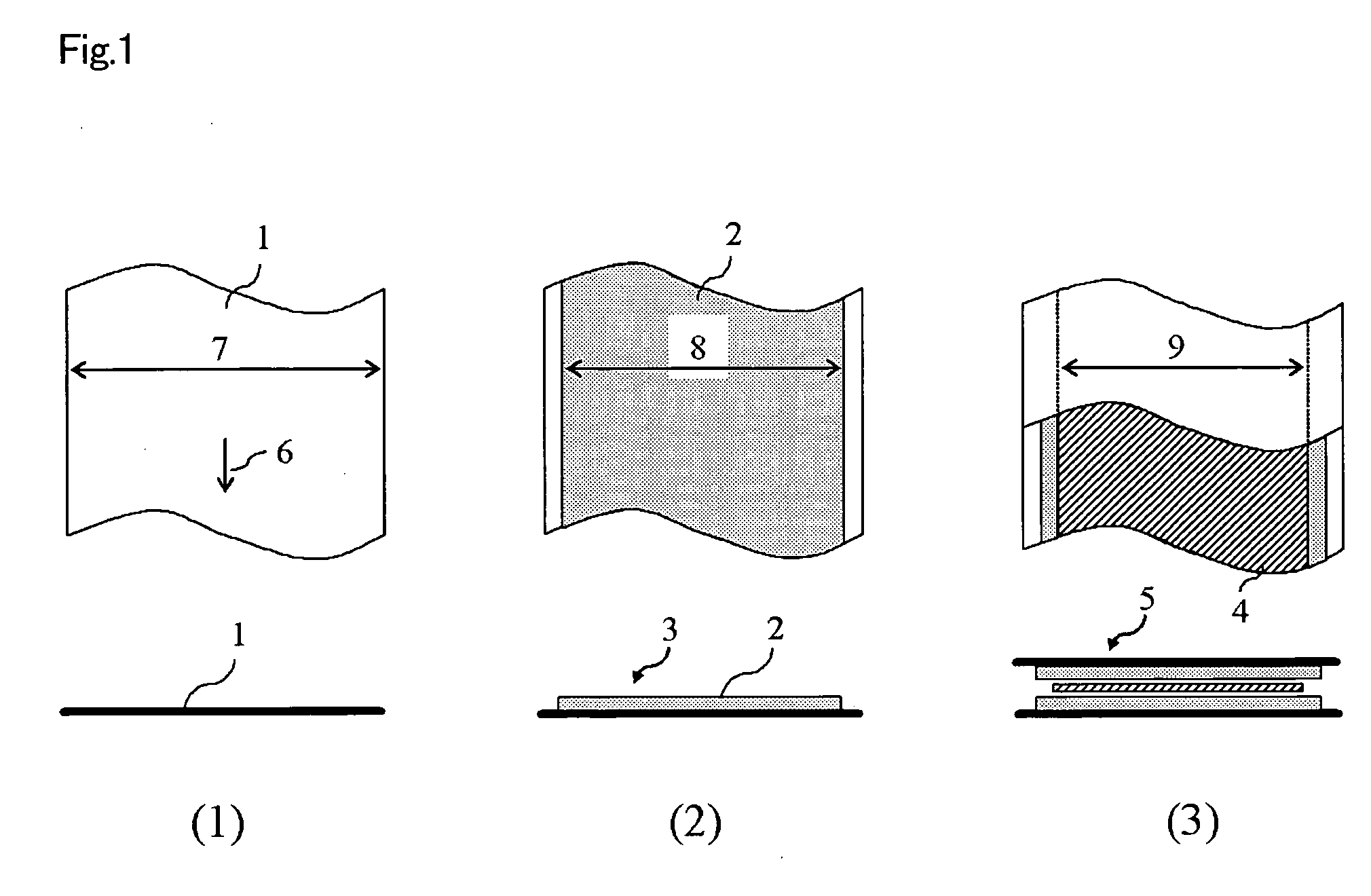

Treating method for brittle member

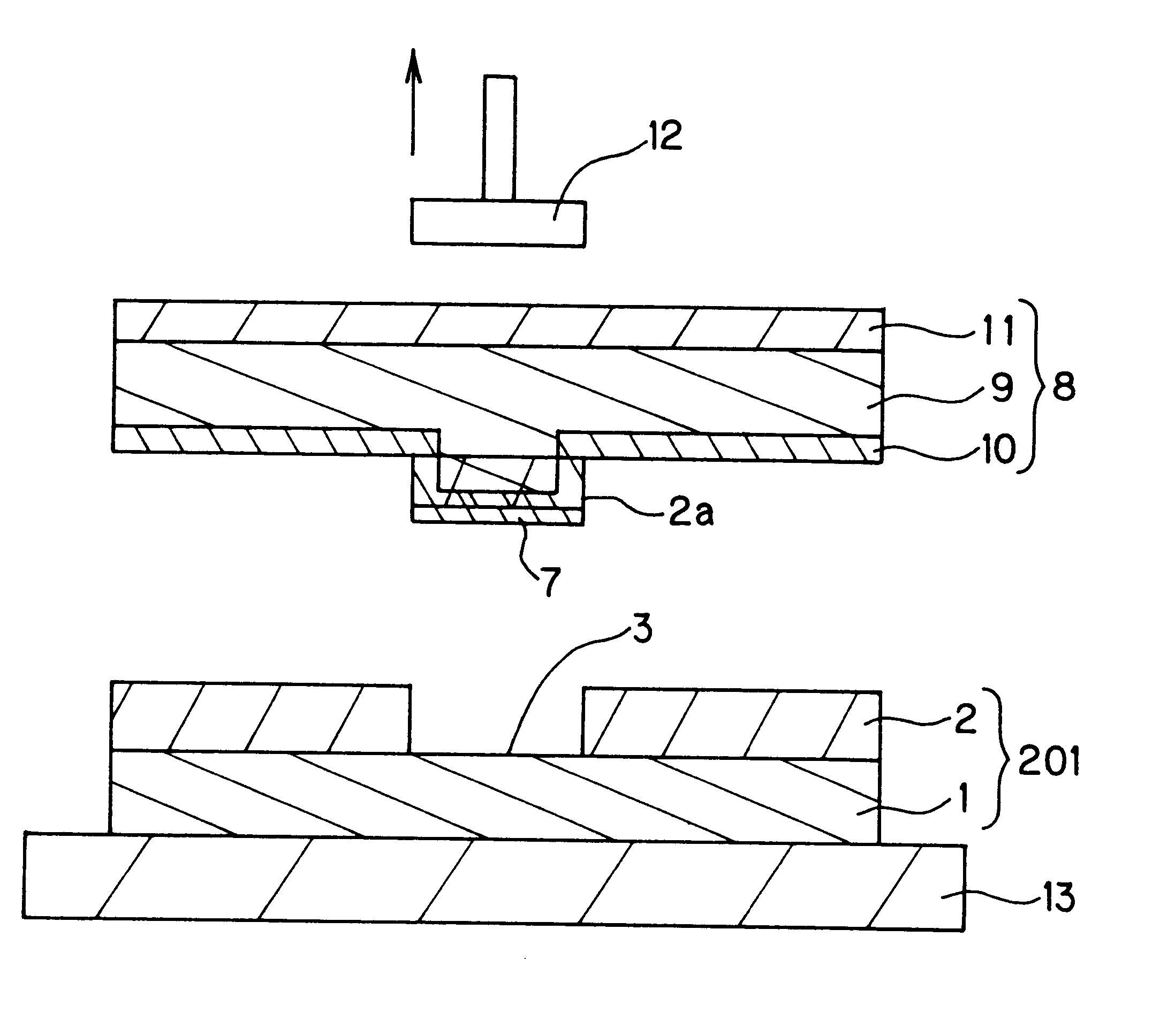

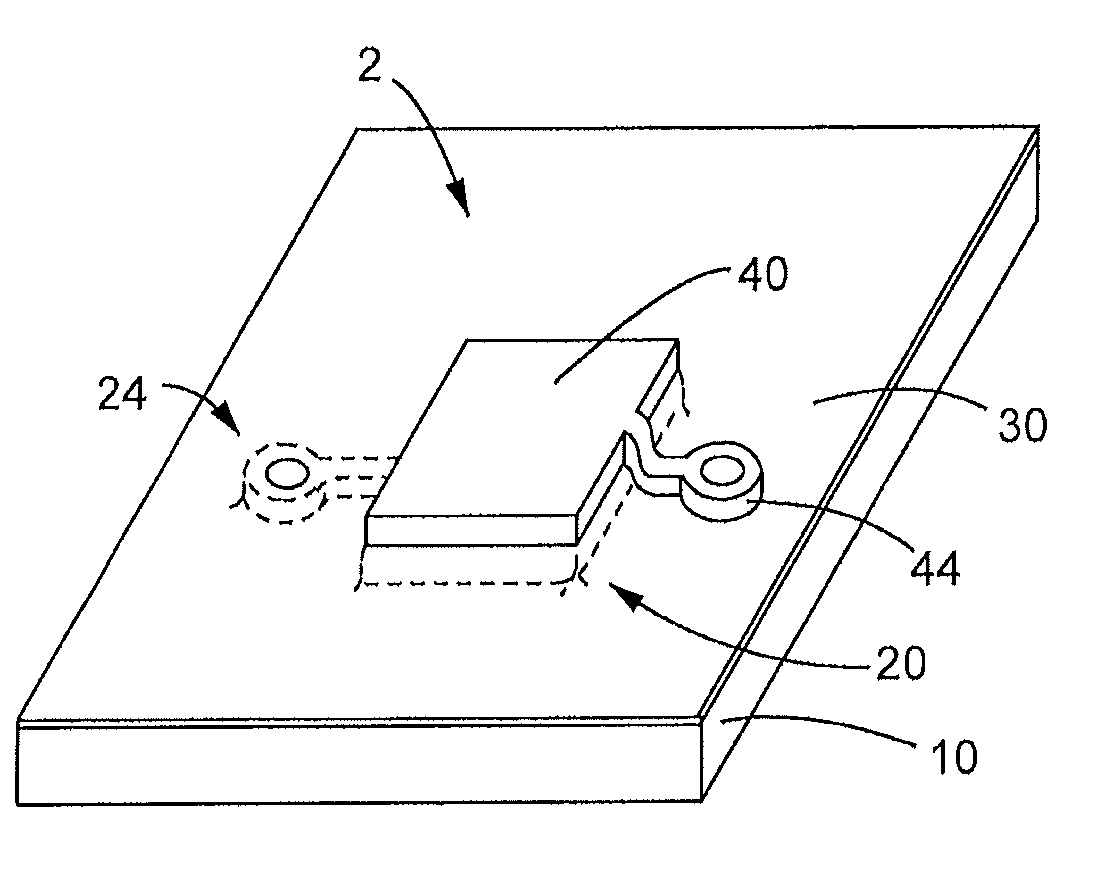

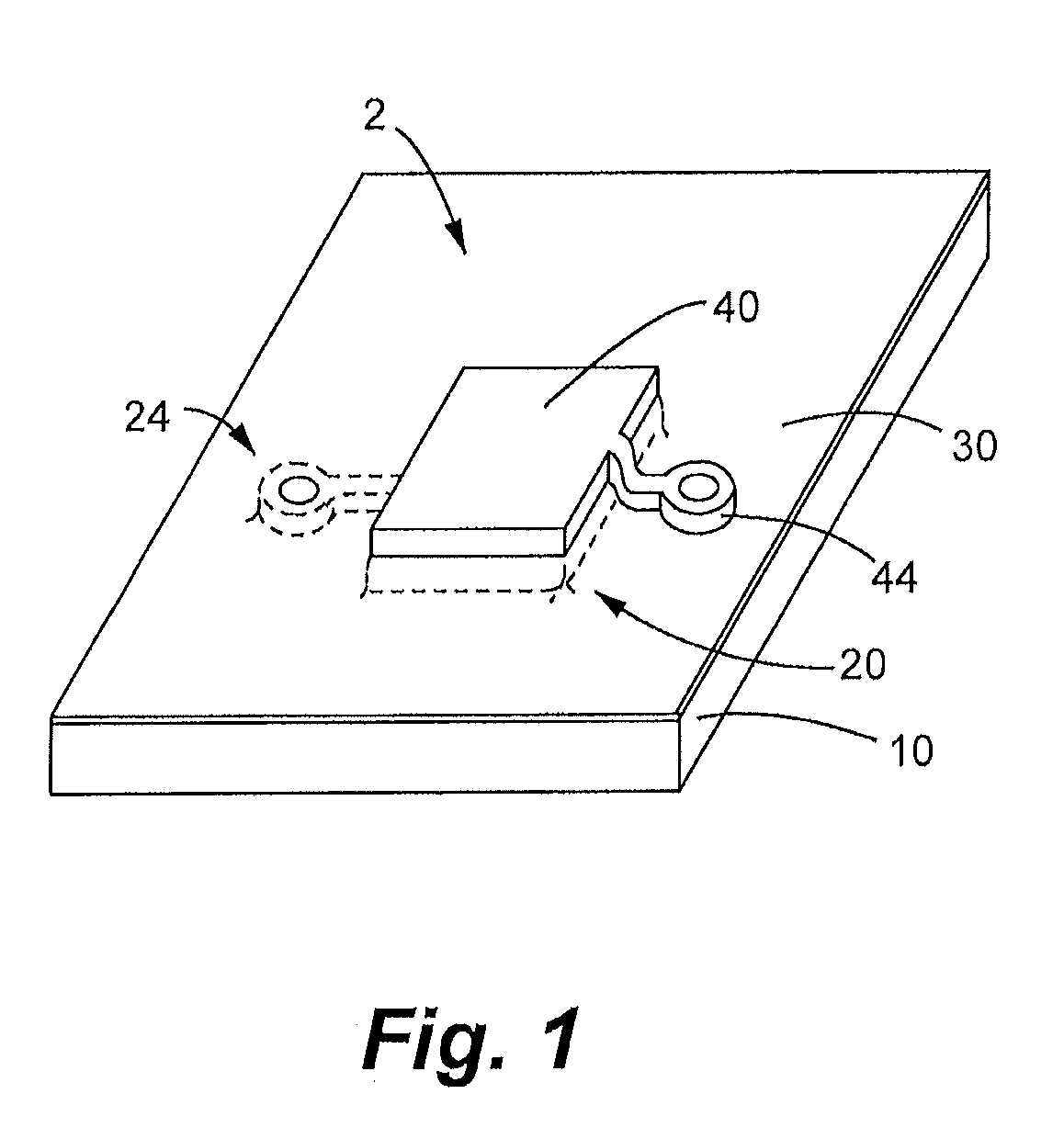

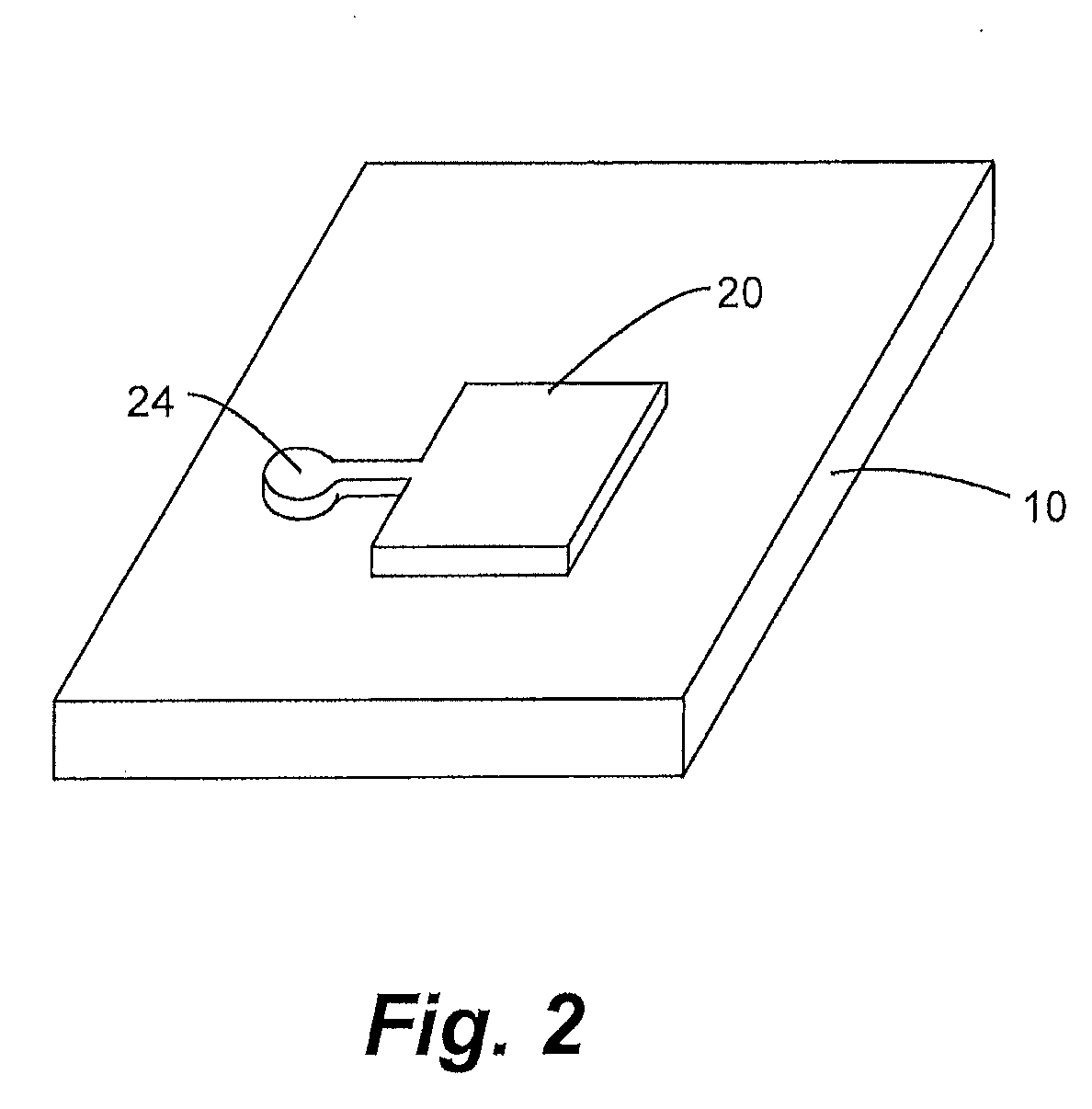

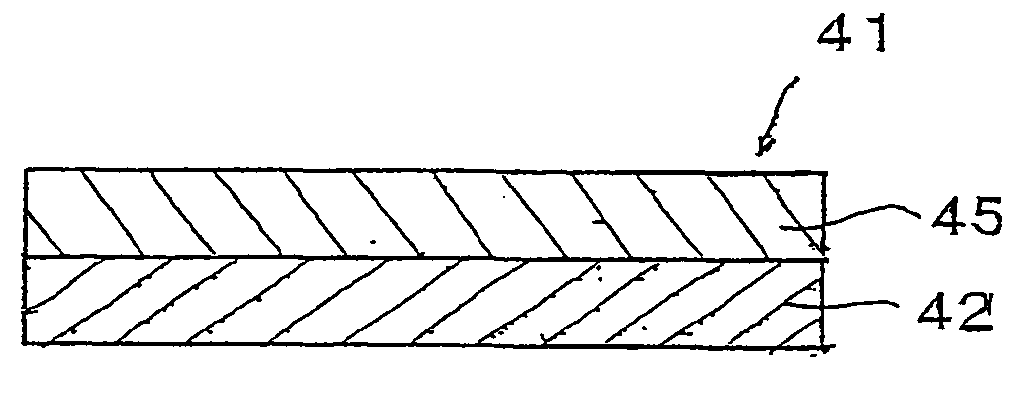

ActiveUS20080305721A1High thickness accuracyPrevent be breakLamination ancillary operationsLaminationStructural engineeringSemiconductor

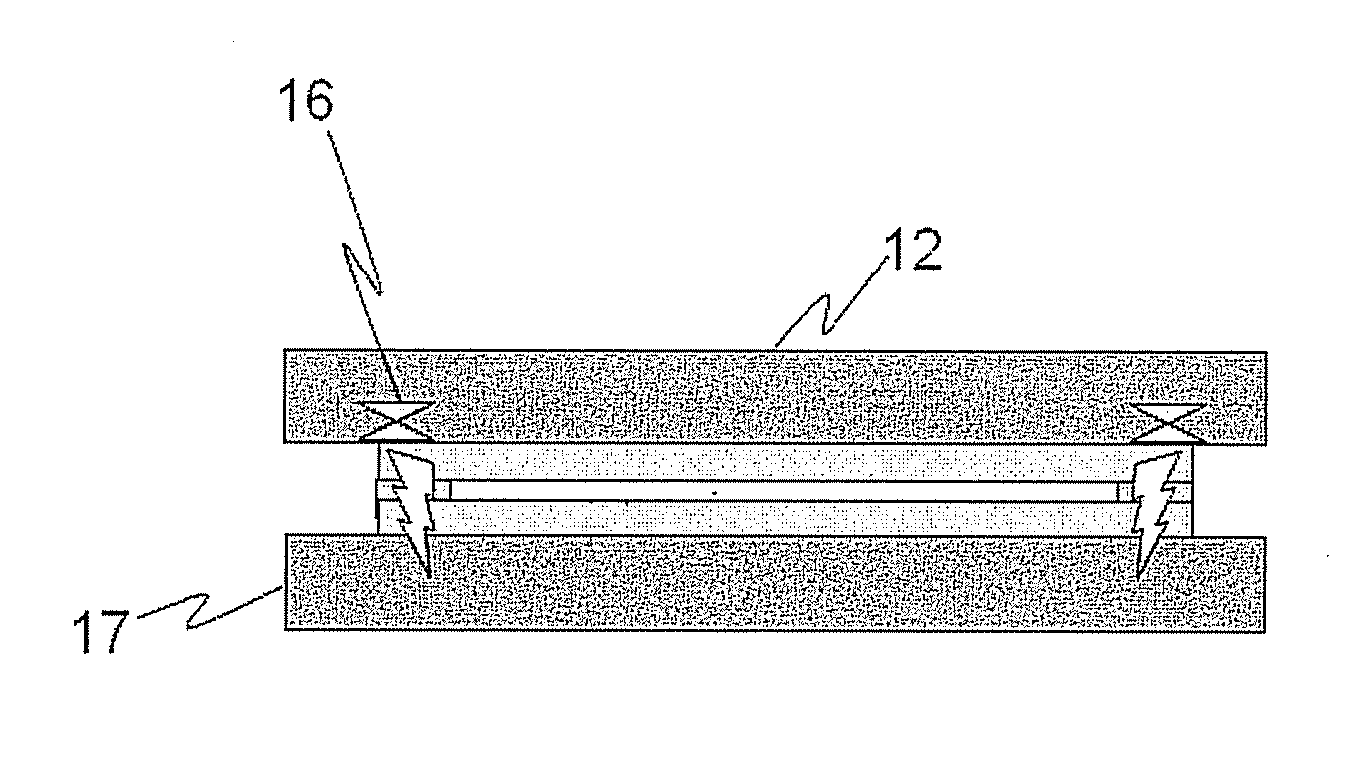

An object of the present invention is to provide a treating method for brittle member capable of stably holding the brittle member when applying predetermined treatments such as transportation and grinding back surface of a brittle member such as a semi-conductor wafer and separating the brittle member without breakage after finishing required treatment to thereby attaining high thickness accuracy of the brittle member.A treating method for brittle member comprising: a step of removably fixing a brittle member on a flexible glass base plate, a step of treating said brittle member, a step of fixing said brittle member side by holding means, and a step of separating said flexible glass base plate from said brittle member by bending said flexible glass base plate.

Owner:LINTEC CORP

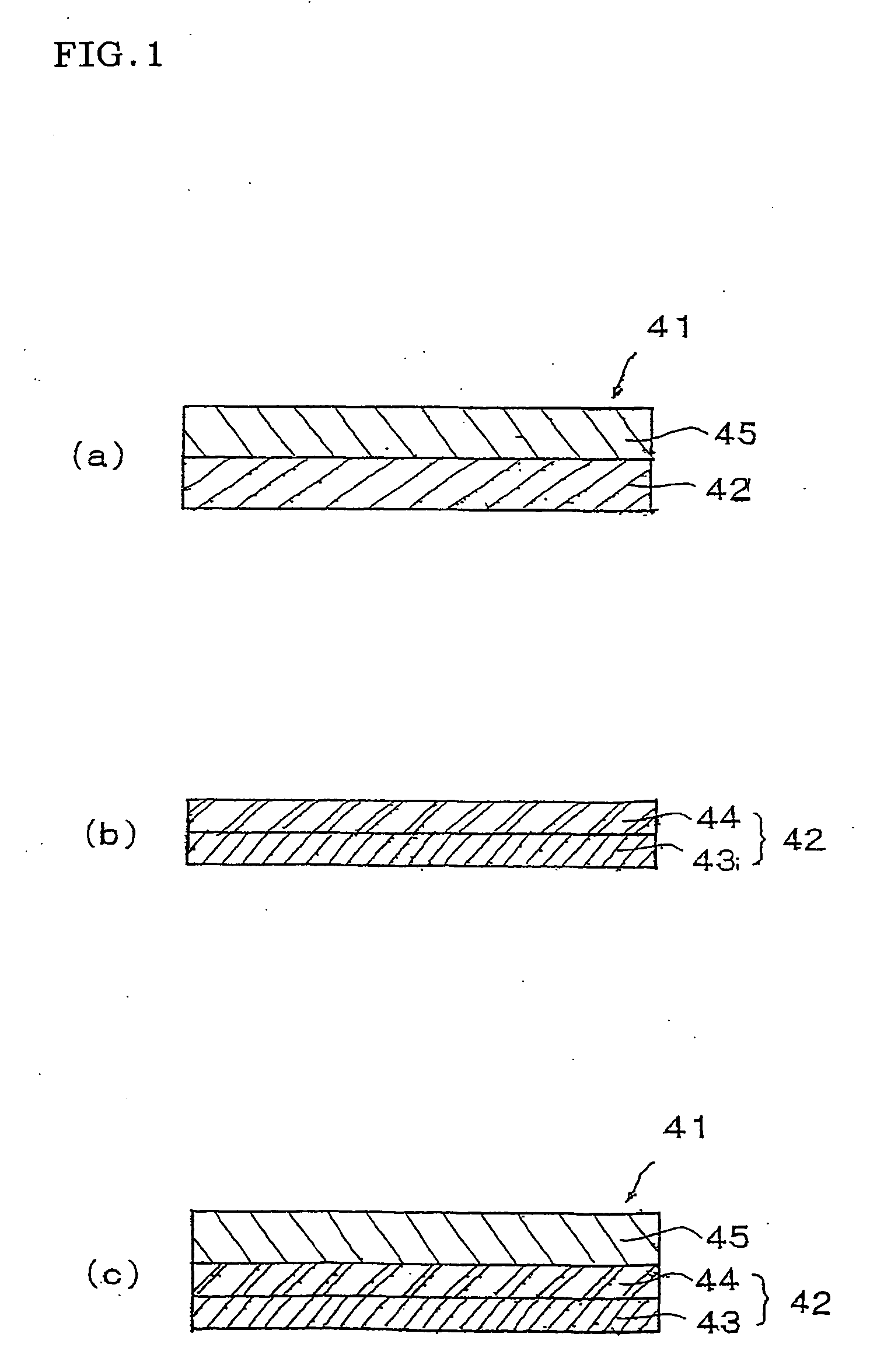

Polishing pad and cushion layer for polishing pad

InactiveUS20060148391A1Easy to processHigh thickness accuracyBelt grinding machinesAbrasion apparatusEngineeringHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

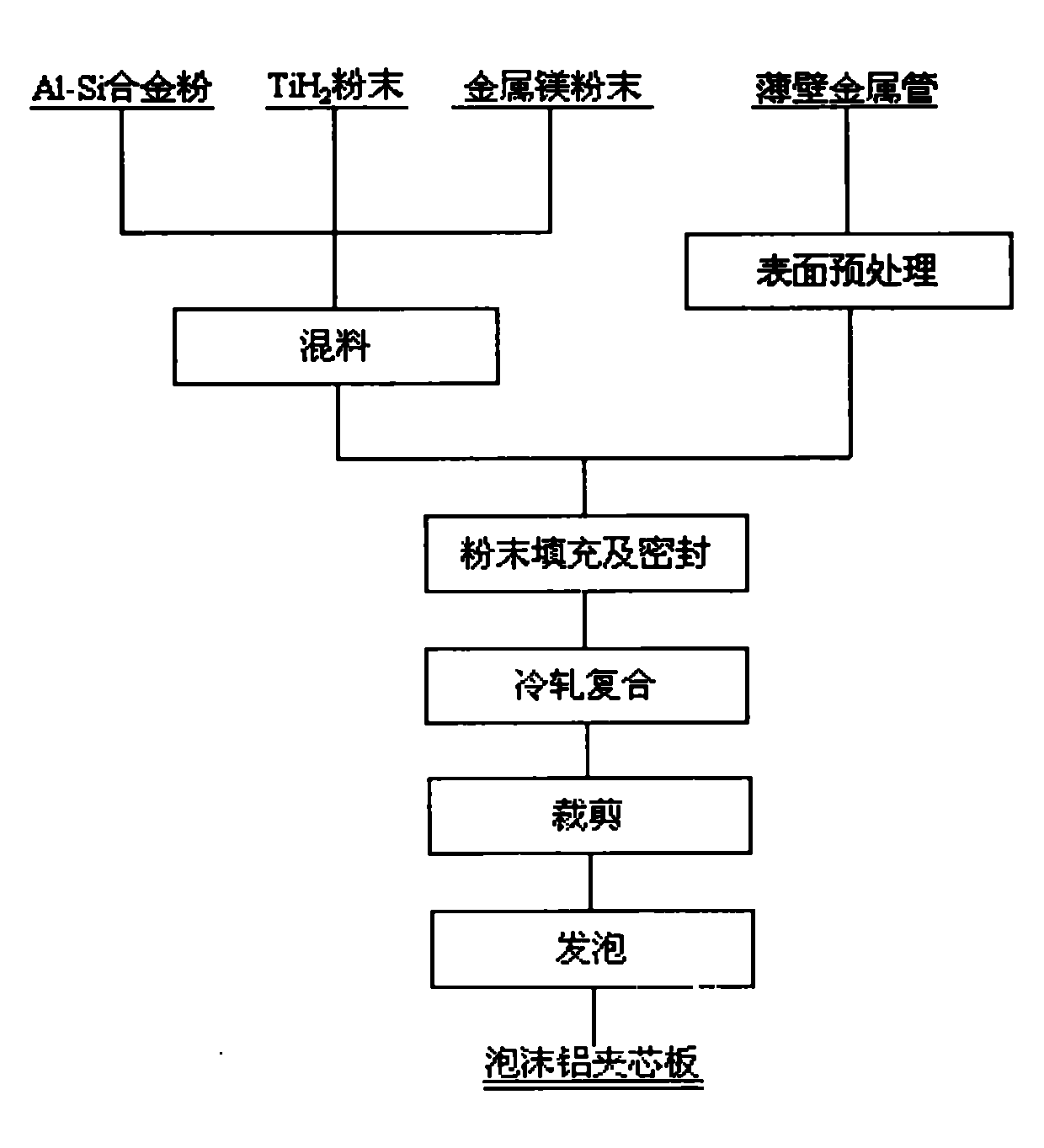

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

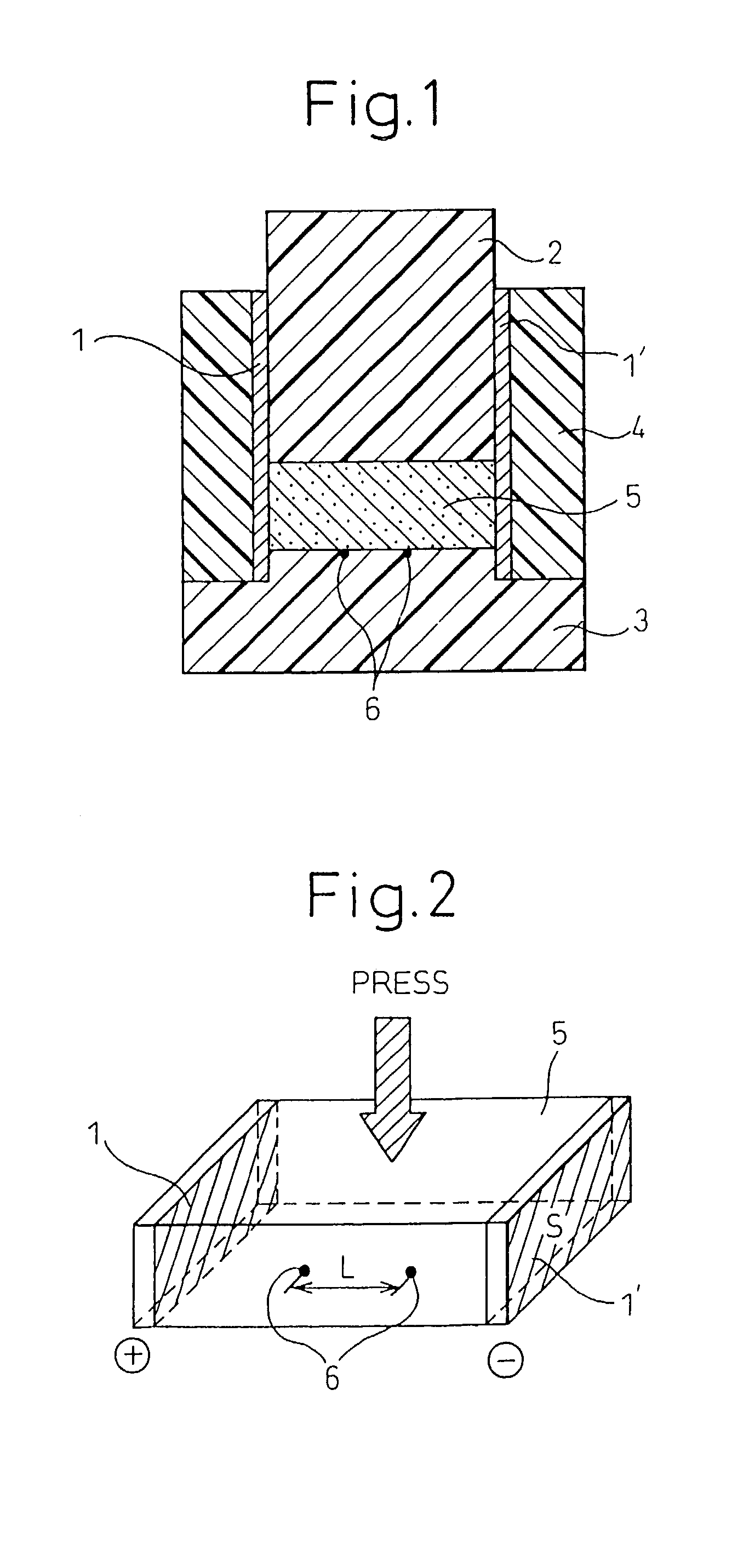

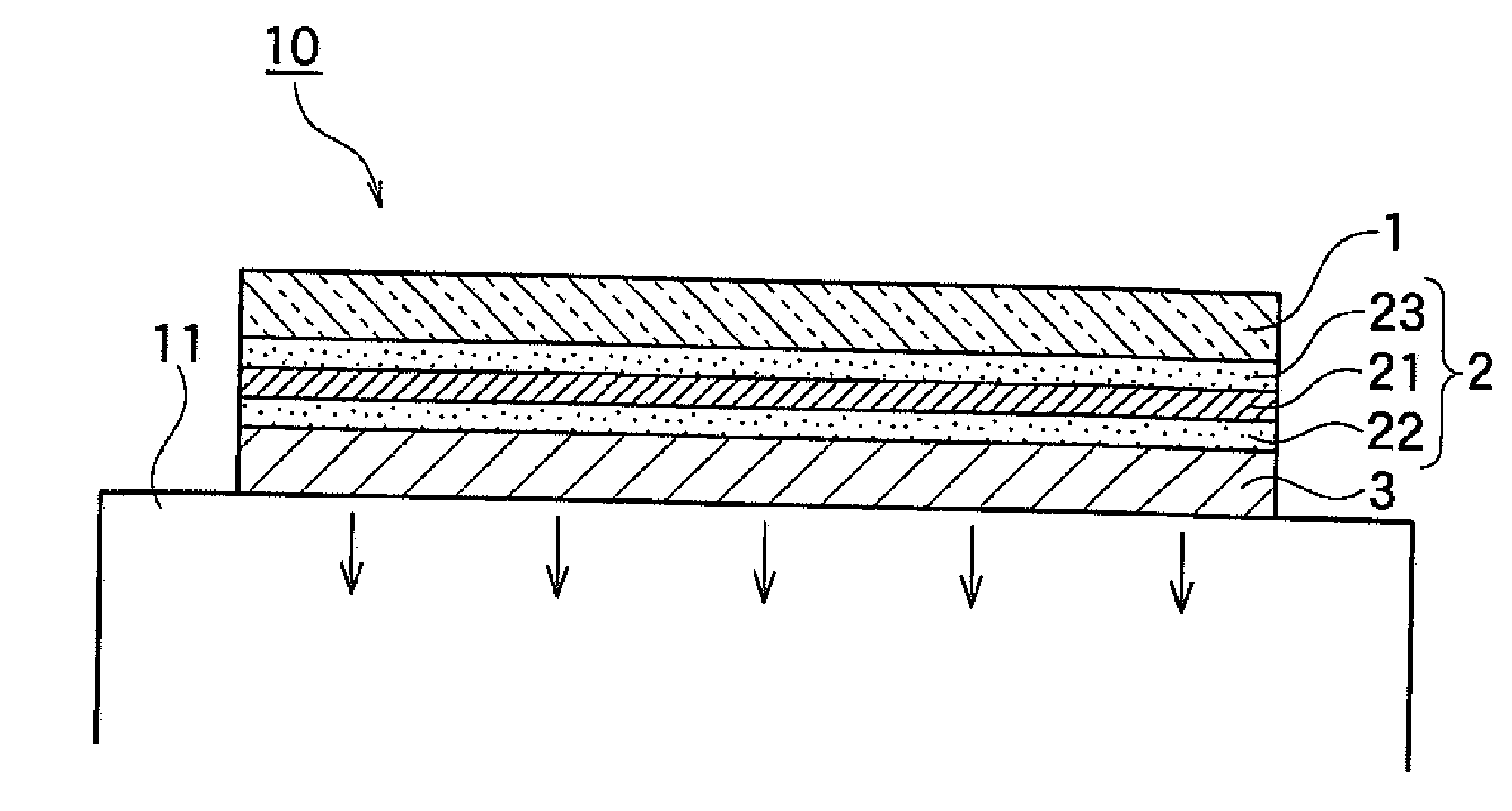

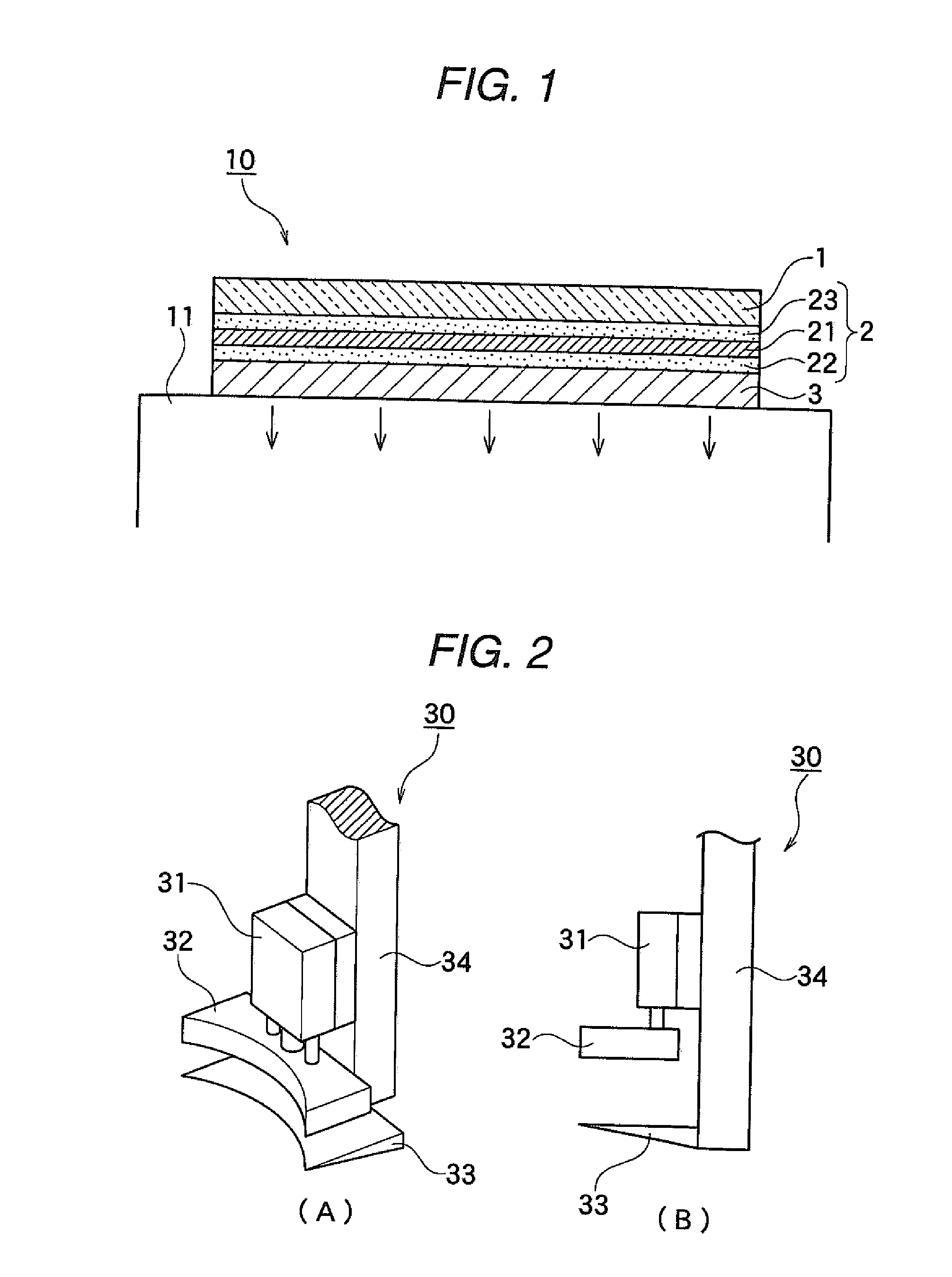

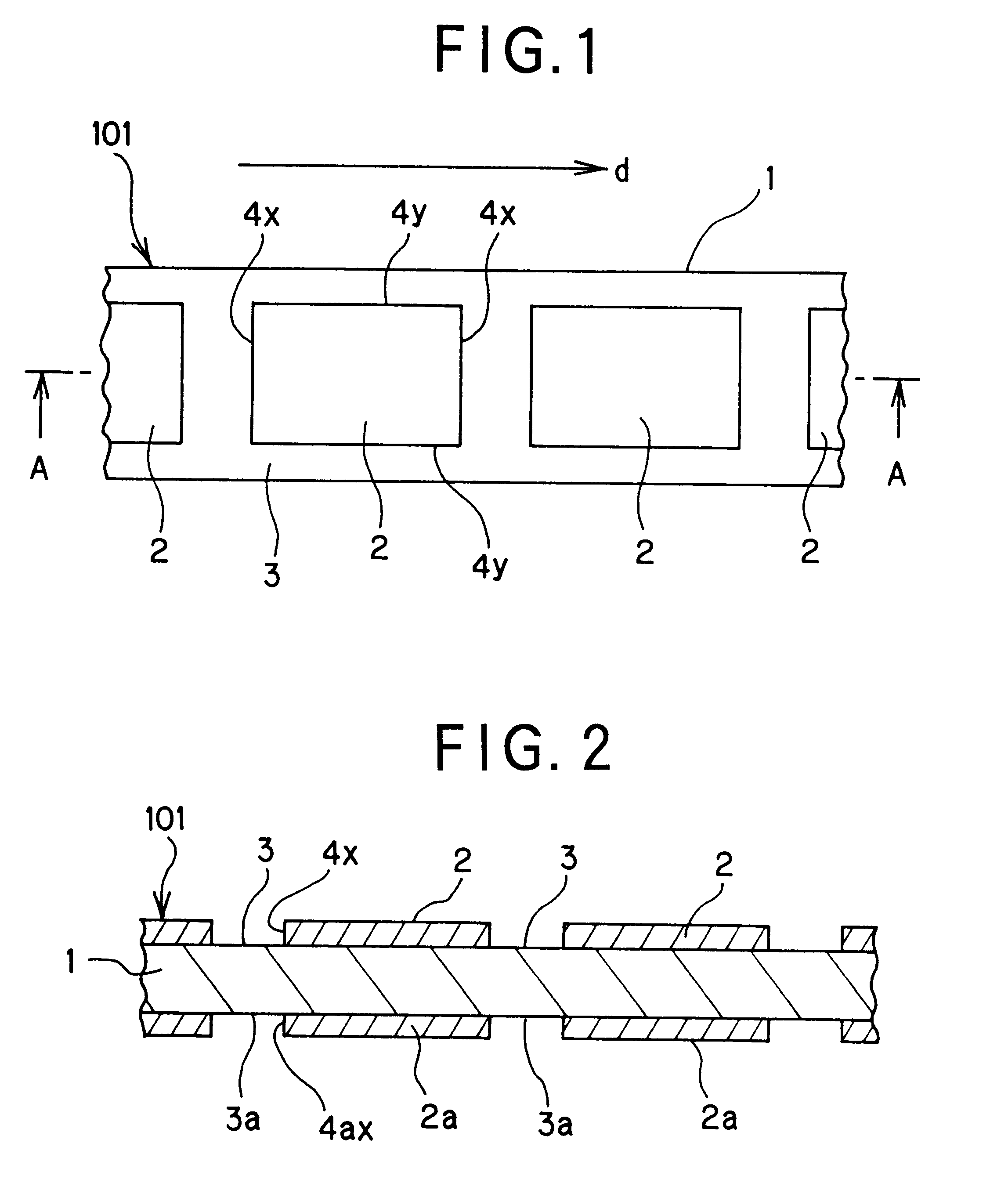

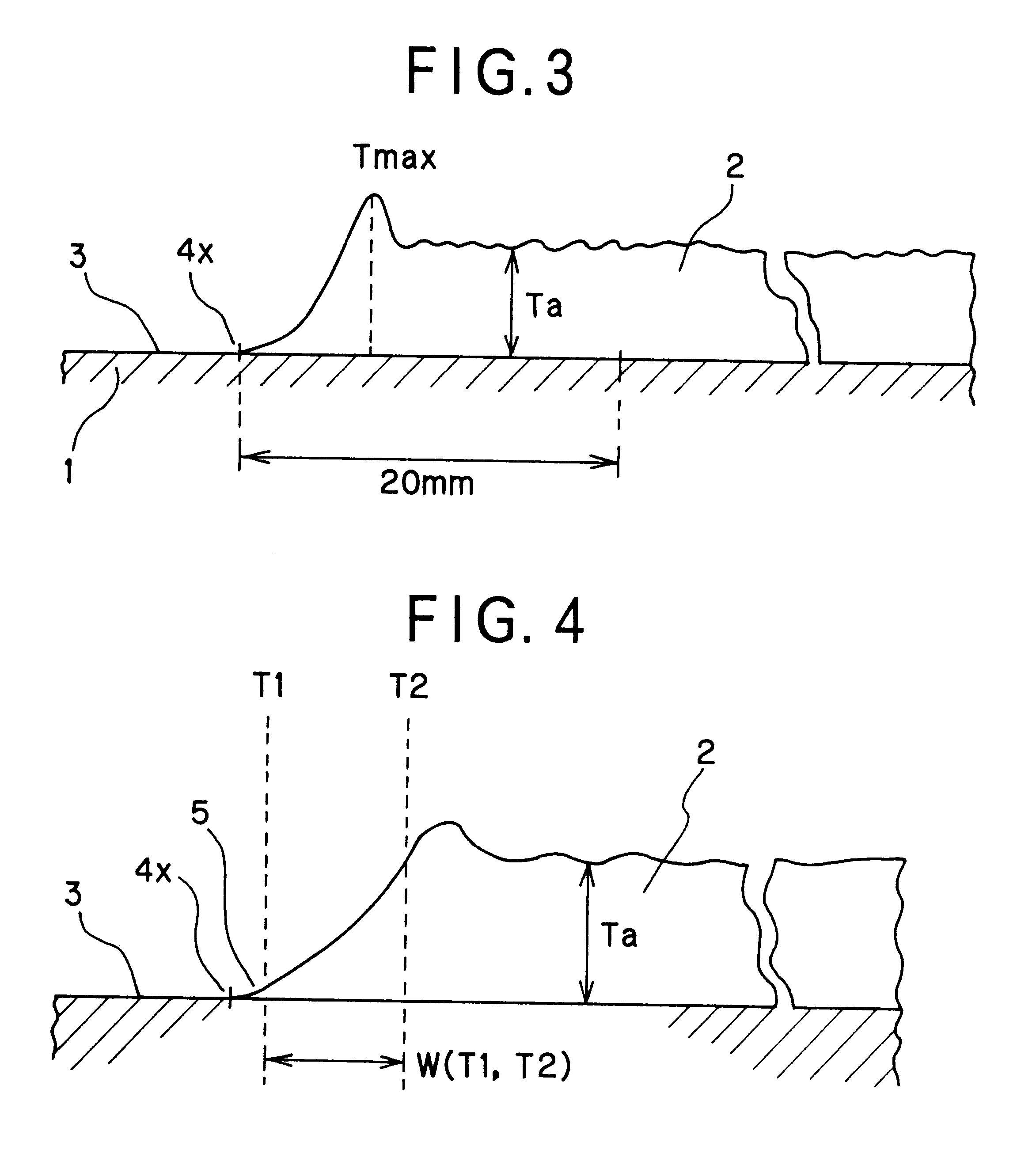

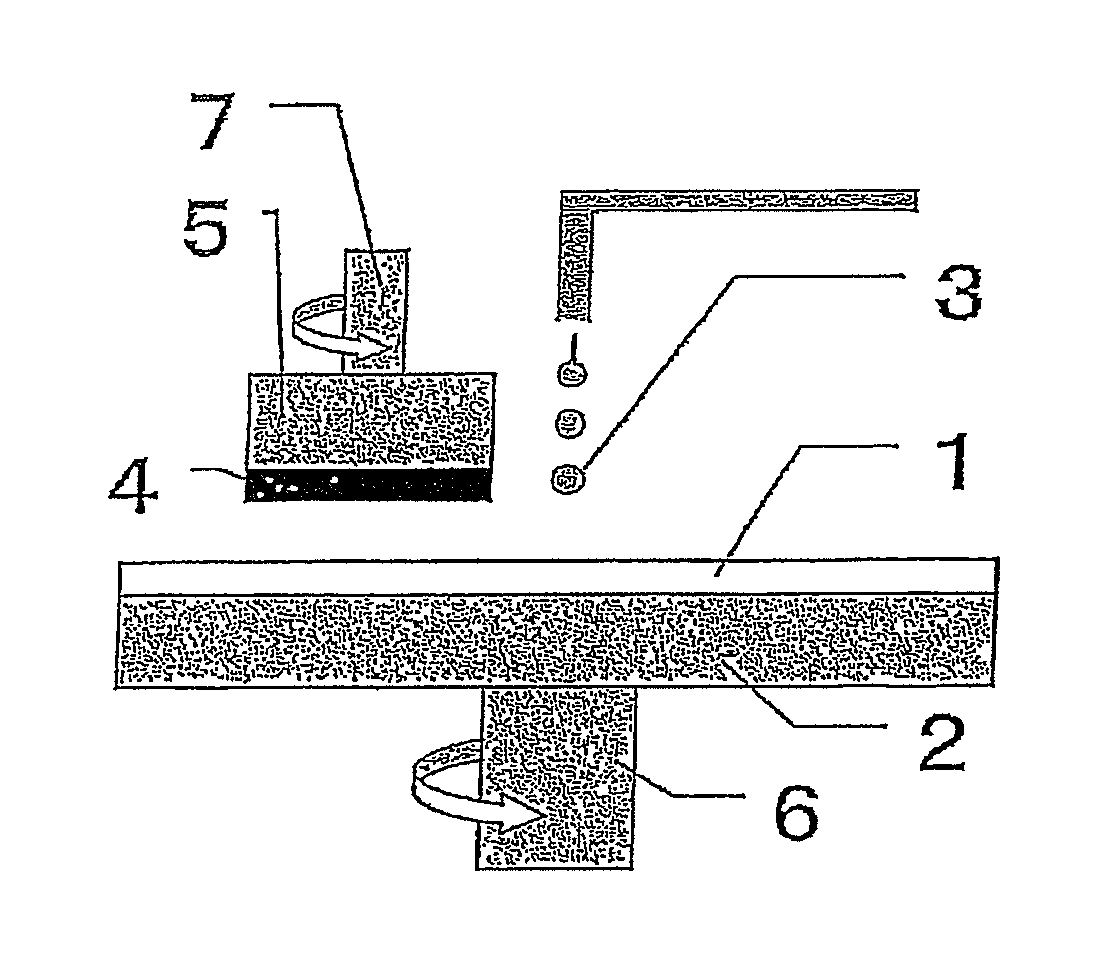

Electrode plate for secondary battery with nonaqueous electrolyte and process for producing same

InactiveUS6423446B1High dimensionalHigh thickness accuracyElectrode rolling/calenderingElectrode melt handlingEngineeringElectrolyte

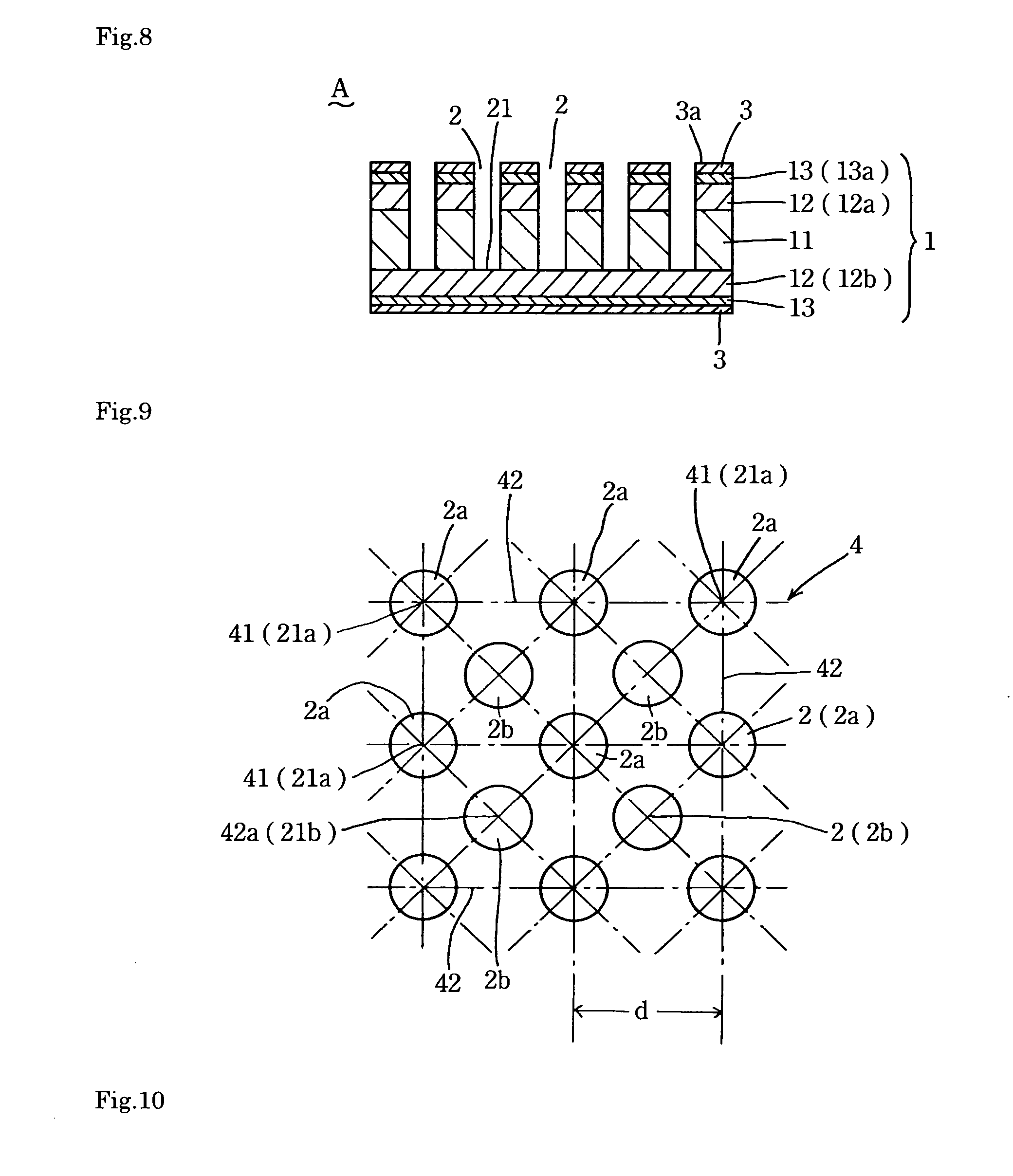

The present invention provides an electrode plate having a collector 1, an active material layer 2 and a non-coated portion 3 and satisfies at least one of the following conditions. (1) The maximum thickness in an area inside by 20 mm from an edge portion of the active material layer is not more than the sum of an average thickness of the active material layer and 10 mum. (2) In an inclined portion of the peripheral edge portion of the active material layer, an area in which the thickness of the active material layer is not less than 1 mum and less than an average thickness of the active material layer has a width of not more than 1 mm. (3) An absolute value of a positional shifting of an actually formed pattern with respect to a true boundary line of a predetermined pattern is not more than 1 mm. (4) The active material layers are formed in a plane symmetry to front and back surfaces of the collector, and an absolute value in the positional shifting between the patterns formed on front and back side surfaces of the collector is not more than 1 mm.

Owner:DAI NIPPON PRINTING CO LTD

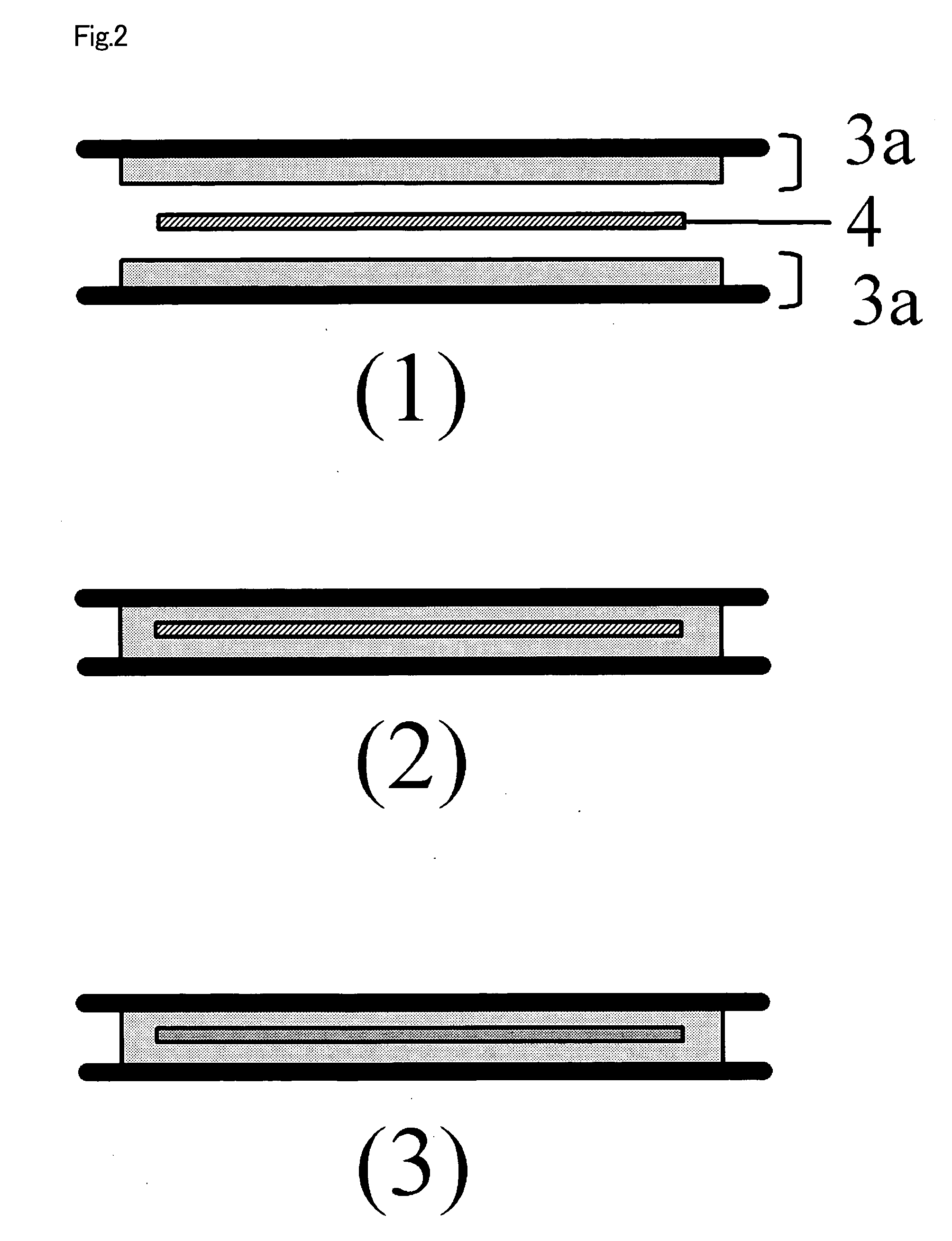

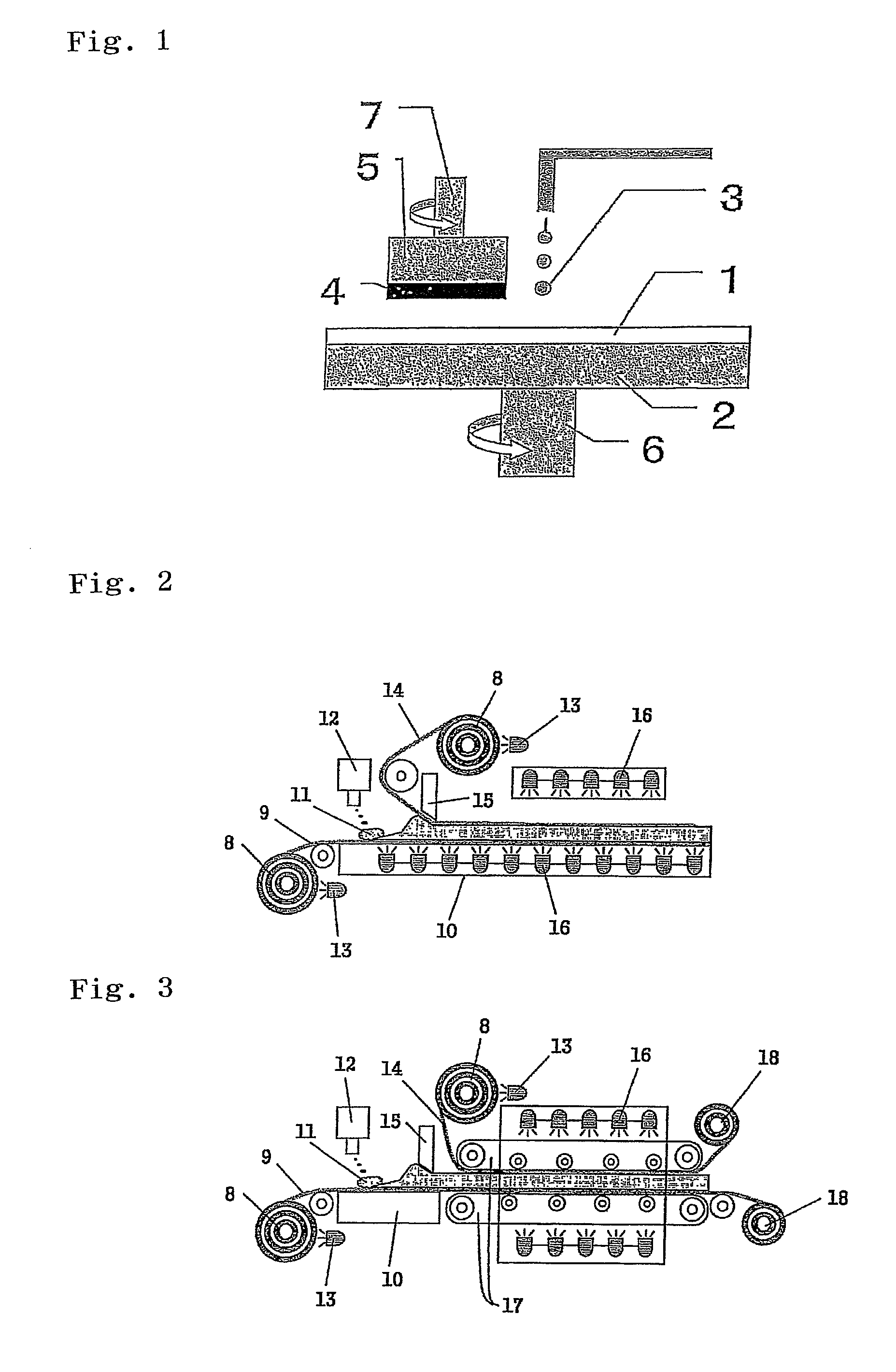

Method for manufacturing polishing pad

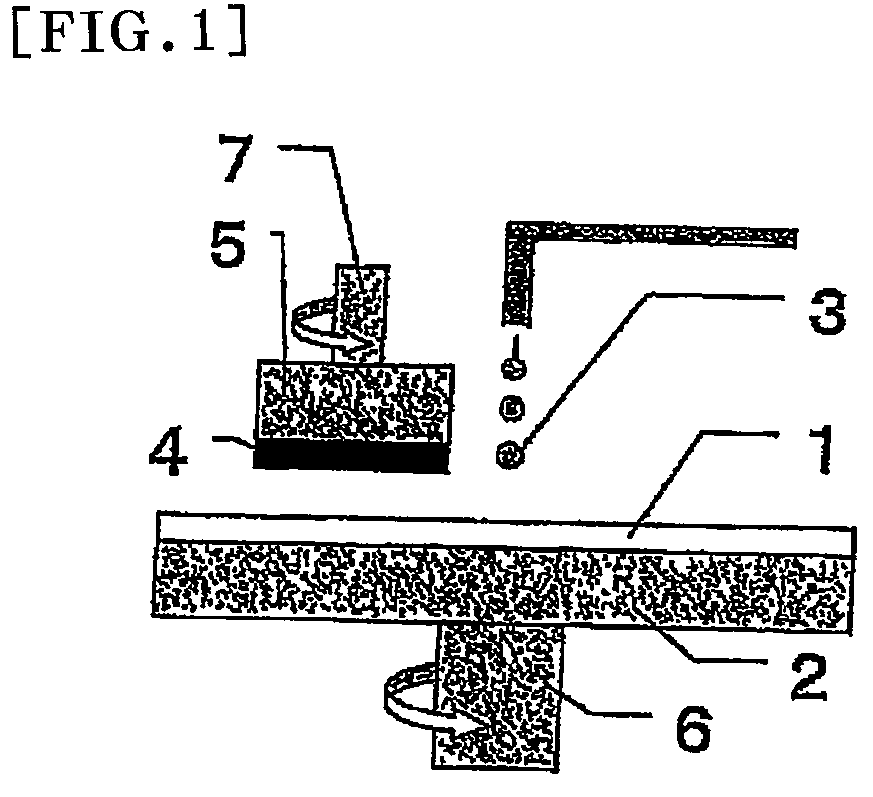

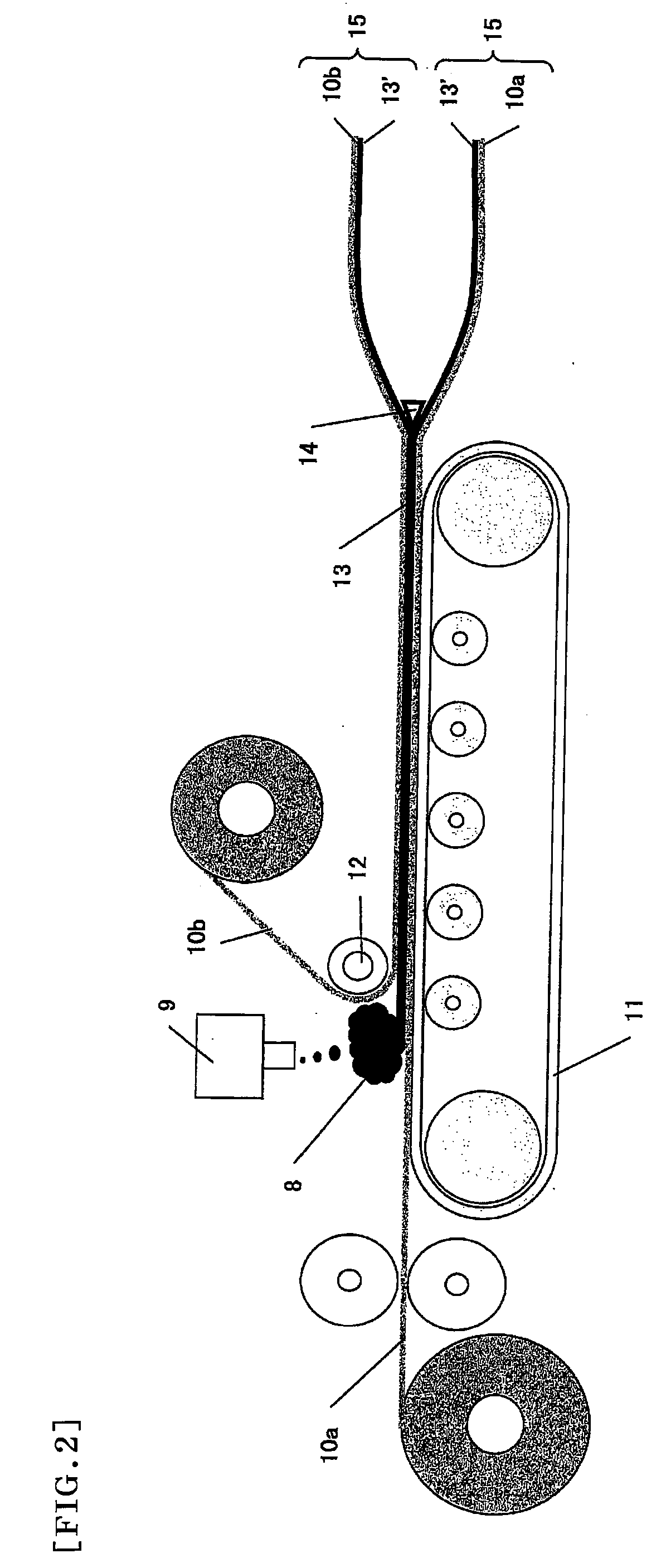

InactiveUS20090093202A1Improve productivityHigh thickness accuracyLamination ancillary operationsAbrasion apparatusProduction rateEngineering

A method for manufacturing a polishing pad, which may be laminated, with a small number of manufacturing steps, high productivity and no peeling between a polishing layer and a cushion layer includes preparing a cell-dispersed urethane composition by a mechanical foaming method; continuously discharging the cell-dispersed urethane composition onto a face material, while feeding the face material; laminating another face material on the cell-dispersed urethane composition; curing the cell-dispersed urethane composition, while controlling its thickness to be uniform, so that a polishing layer including a polyurethane foam is formed; cutting the polishing layer parallel to the face into two pieces so that two long polishing layers each including the polishing layer and the face material are simultaneously formed; and cutting the long polishing layers to produce the polishing pad.

Owner:TOYO TIRE & RUBBER CO LTD

Composite Particles for Electrochemical Device Electrode, Method of Production of Composite Particles for Electrochemica Device Electrode, and Electrochemical Device Electrode

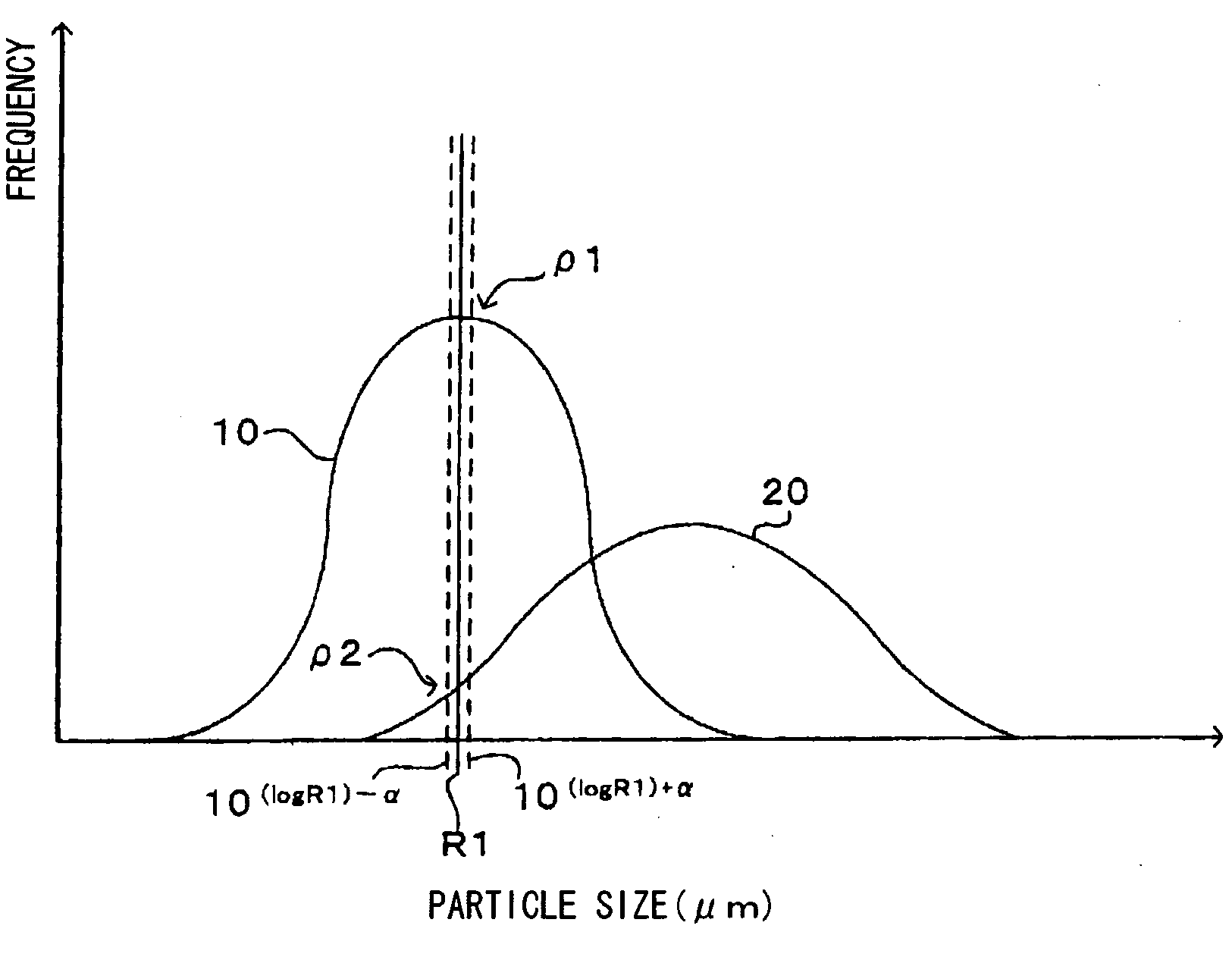

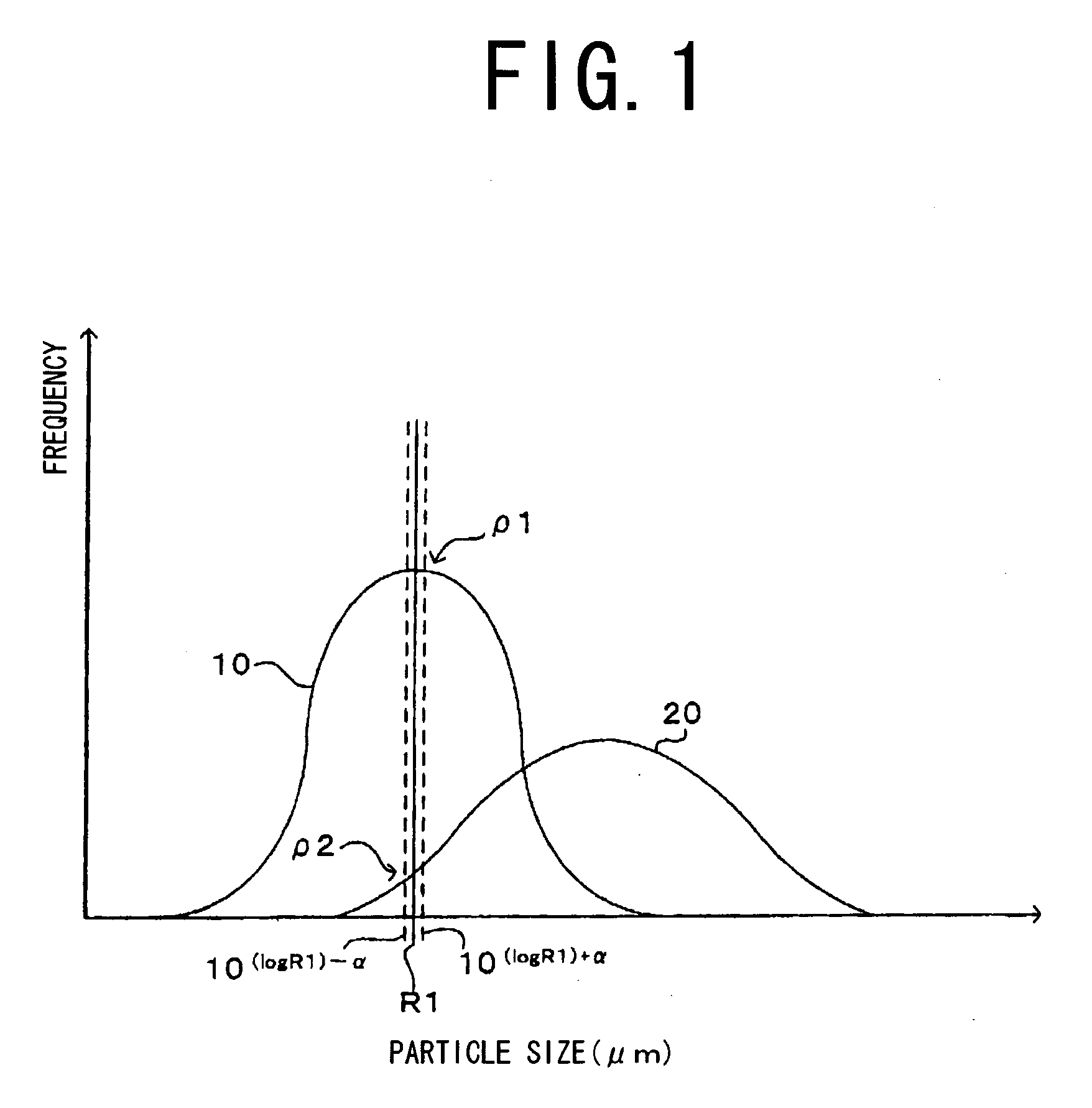

ActiveUS20090267028A1High thickness accuracyLarge thicknessElectrode manufacturing processesHybrid capacitor electrodesConductive materialsElectrochemistry

Composite particles for an electrochemical device electrode containing an electrode active material, a conductive material, and a binder, wherein primary particles of the composite particles have a volume average particle size of 1 to 500 μm and, when a relative particle amount of the primary particles having a particle size of a fine range near a mode radius R1 of the primary particles in the particle size distribution of the primary particles of the composite particles found by the volume standard is ρ1 and a relative particle amount of secondary particles having a particle size of the fine range in the particle size distribution of the secondary particles of the composite particles found by the volume standard in measurement at 23° C. is ρ2, ρ2 / ρ1 is 0.03 to 0.60.

Owner:ZEON CORP

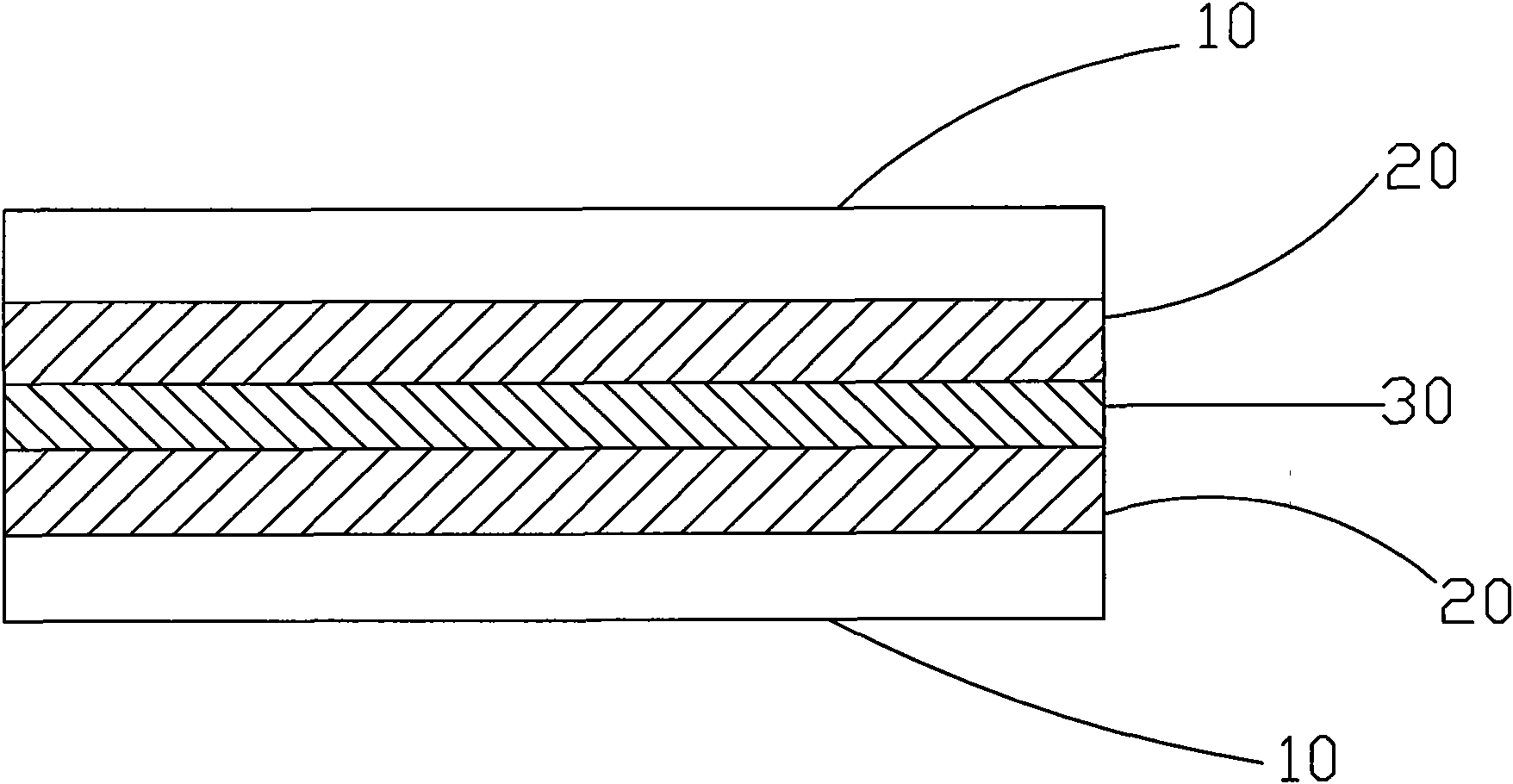

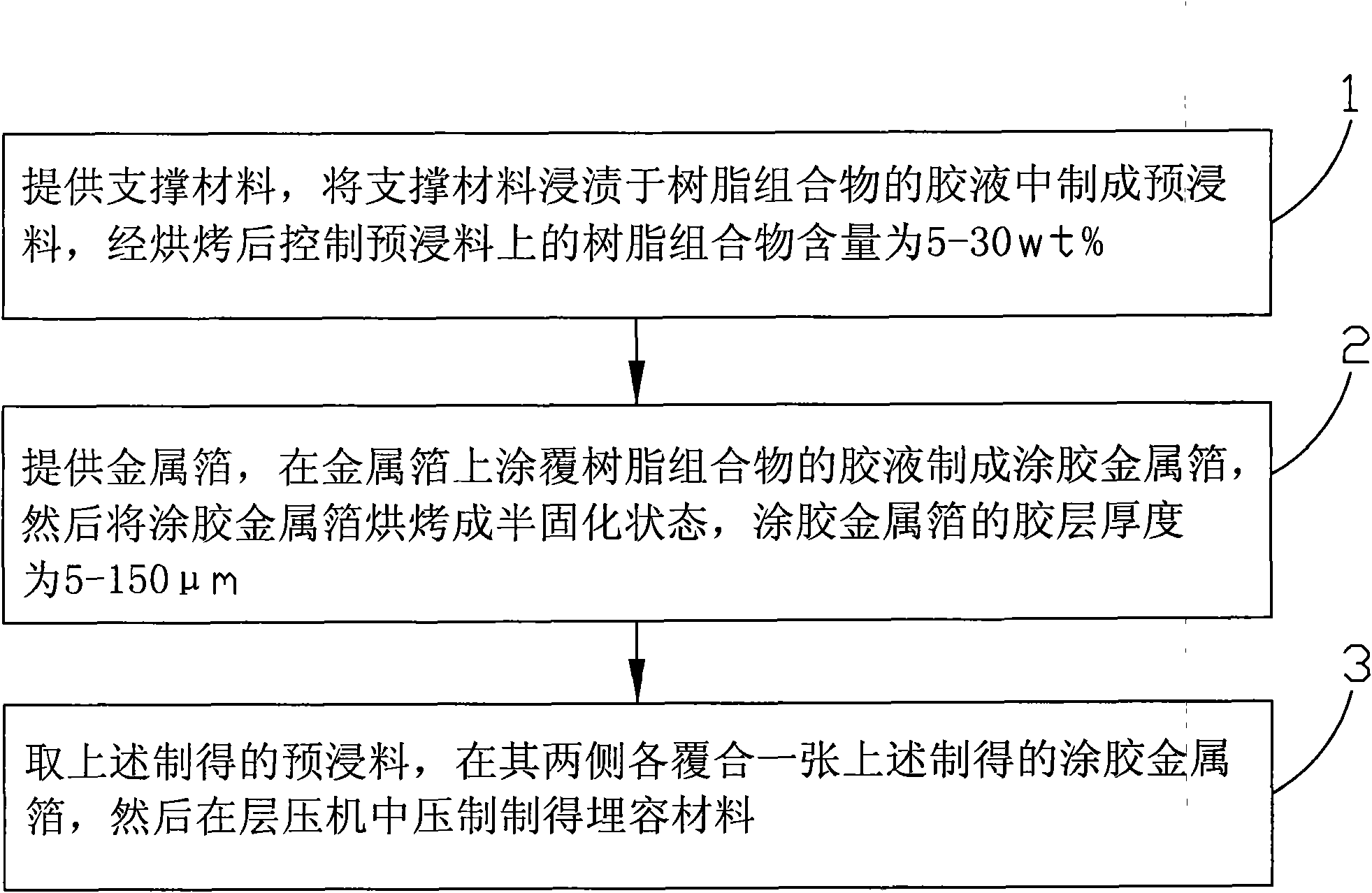

Method for preparing embedded material and embedded material prepared thereby

InactiveCN101973145AReduce thicknessHigh strengthSynthetic resin layered productsLaminationMetal foilComposite material

The invention provides a method for preparing an embedded material and the embedded material prepared thereby. The method for preparing the embedded material comprises the following steps of: 1, providing a supporting material, impregnating the supporting material in glue solution of a resin compound to prepare a prepreg, roasting, and controlling the content of the resin compound on the prepreg to be 5 to 30 weight percent; 2, providing a metal foil, coating glue solution of the resin compound on the metal foil to prepare a glued metal foil, and roasting the glued metal foil into a semi-curing state, wherein the thickness of an upper glue layer is 5 to 150 mu m; and 3, respectively coating the prepared glued metal foil on two sides of the prepreg, and laminating in a laminating machine to prepare the embedded material. The embedded material comprises one or more of laminated prepregs and glued metal foils coated on two sides of the prepregs, wherein each prepreg comprises a supporting material and a resin compound which is attached to the prepreg by impregnation drying; and each glued metal foil comprises a metal foil and a glue layer coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

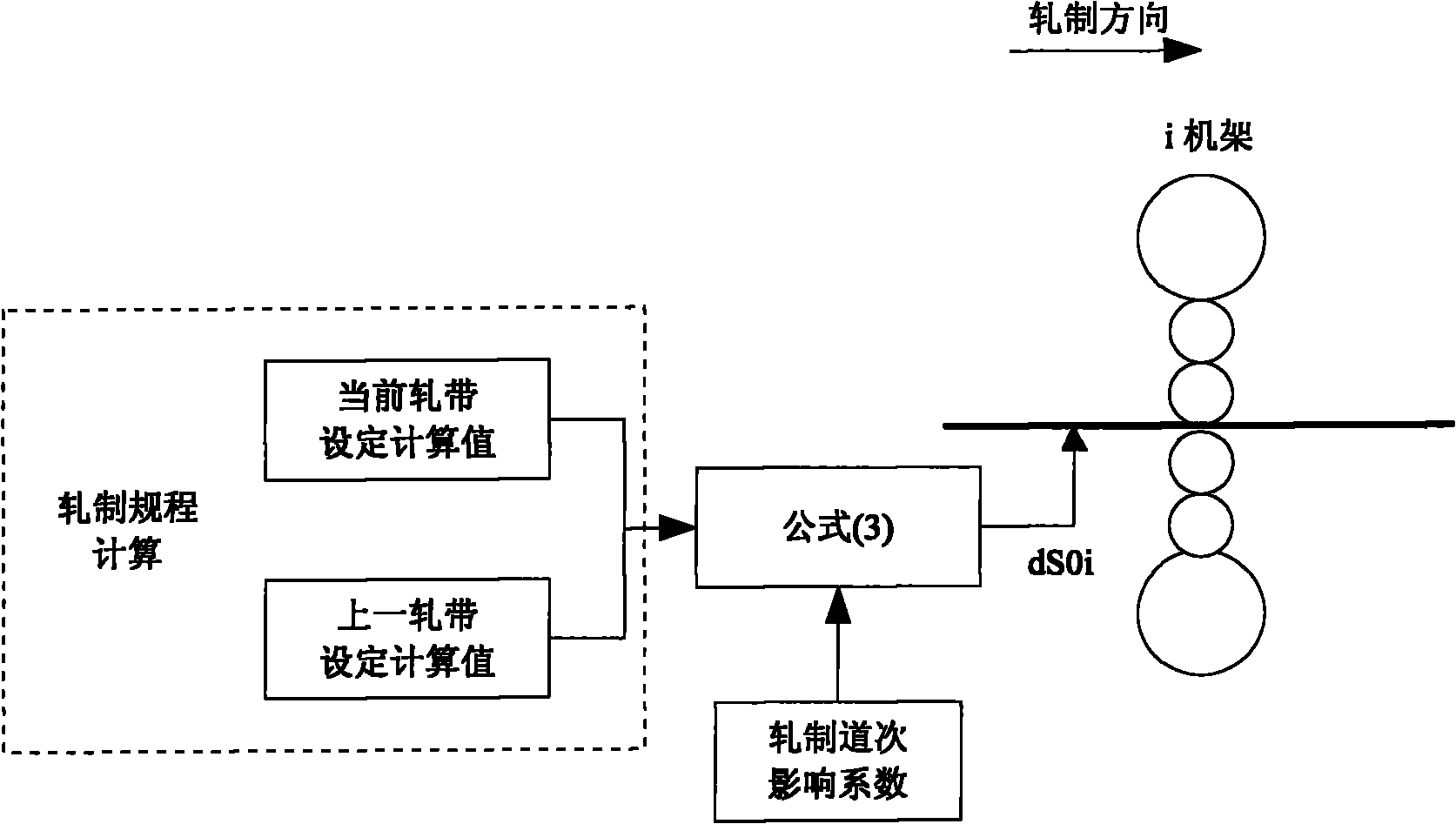

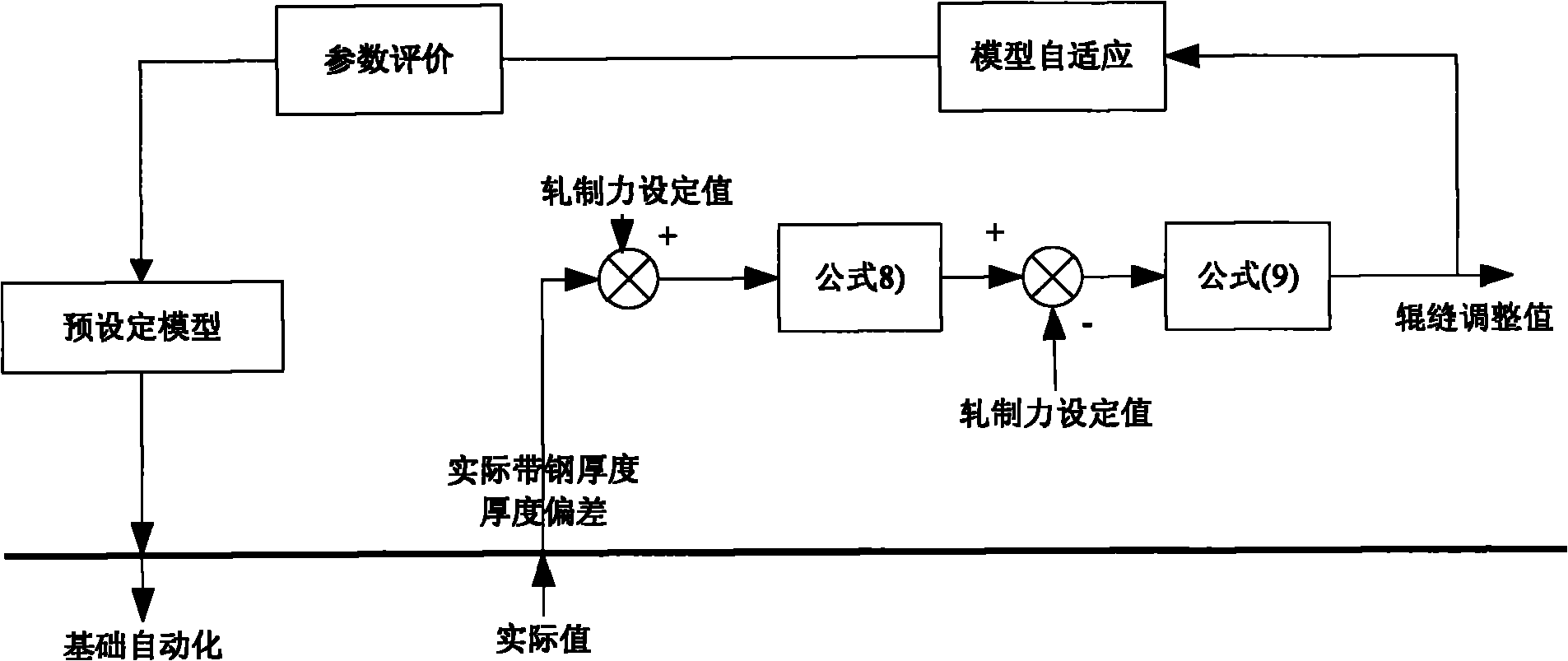

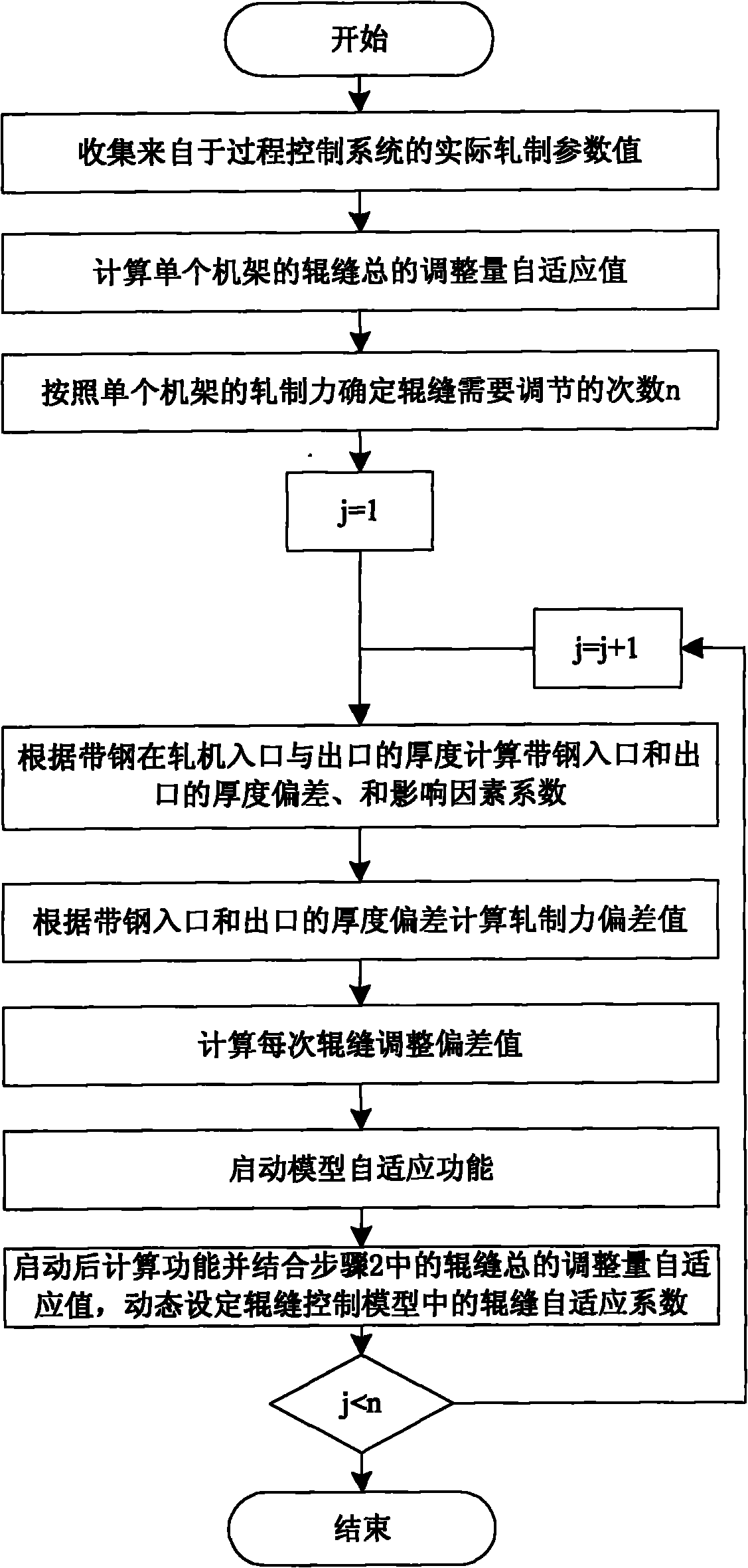

Thickness control compensation method of strip steel head part when welding line passes through rack

ActiveCN101780480AThickness tolerance length controlHigh thickness accuracyRoll force/gap control deviceControl systemStrip steel

The invention introduces a thickness control compensation method of a strip steel head part when a welding line passes through a rack, which comprises the following steps: 1, collecting actual rolling parameter values from a process control system; 2, calculating the total adjustment amount self-adaption value of roll-gaps of a single rack; 3, determining the required adjustment time n of the roll-gap according to the roll force of the single rack; 4, setting j to be equal to 1; 5, calculating thickness deviation delta hj-1, delta hj and influencing coefficient factor of the inlet and the outlet of the strip steel according to the thickness of the strip steel at the inlet and the outlet of a rolling mill; 6, calculating rolling force deviation value according to the thickness deviation of the inlet and outlet of the strip steel; 7, calculating roll-gap adjustment deviation value of each time; 8, starting the self-adaptation function of a model; 9, starting calculating function, and dynamically setting roll-gap self-adaptation coefficients in a roll-gap control model by combing the total adjustment quantity self-adaptation value of the roll-gap in the step 2; and 10, carrying out the step 5 when j is less than n and j=j+1; and finishing the process when j is more than or equal to n. The method ensures that the indication error length of thickness of the strip steel head part is controlled.

Owner:BAOSHAN IRON & STEEL CO LTD

Foam Sheet For Car Interior Member, and Car Interior Member

InactiveUS20070020447A1Improve sound absorptionSmoothly inducedSynthetic resin layered productsVehicle componentsThermal energyEther

The present invention provides a foam sheet for a car interior member which is capable of being molded into a desired shape while keeping an excellent sound absorbency. The foam sheet for a car interior member according to the invention comprises a modified polyphenylene ether-based resin foam sheet having an open cell ratio of 50% or more, and the modified polyphenylene ether-based resin foam sheet has pore portions formed in a single face thereof so as to be open to the face thereof. Accordingly, vibration energy of sounds is smoothly induced through the pore portions to the open cells of the foam sheet 1 to vibrate cell walls of the open cells, thereby converting the vibration energy to thermal energy. Thus, an excellent sound absorbency is exhibited.

Owner:SEKISUI PLASTICS CO LTD +1

Method of manufacturing translucent rigid substrate laminate

InactiveUS20130081752A1Improve production efficiencyHigh positionalLamination ancillary operationsSynthetic resin layered productsEngineeringSemi transparent

Owner:DENKA CO LTD

Atomic layer deposition process for manufacture of battery electrodes, capacitors, resistors, and catalyzers

InactiveUS20100123993A1No leaksReduced series resistancePorous dielectricsSolid electrolytic capacitorsMulti materialMacroscopic scale

The present disclosure relates generally to the field of sequential surface chemistry. More specifically, it relates to products and methods for manufacturing products using Atomic Layer Deposition (“ALD”) to depose one or more materials onto a surface. ALD is an emerging variant of Chemical Vapor Deposition (“CVD”) technology with capability for high-quality film deposition at low pressures and temperatures, which may produce defect-free films, on a macroscopic scale, at any given thickness. The present disclosure includes, in varying embodiments, methods of manufacturing microelectronic assemblies and components such as battery electrodes, capacitors, resistors, catalyzers and PCB assemblies by ALD, and the products manufactured by those methods.

Owner:LAOR CONSULTING +1

Polishing pad and cushion layer for polishing pad

InactiveUS20060148393A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingCushionChemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

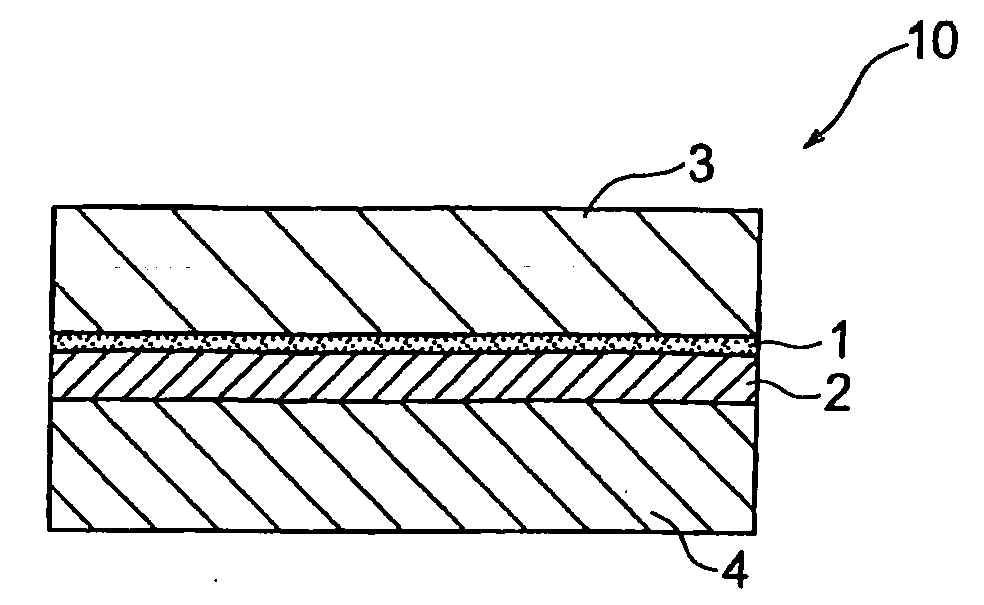

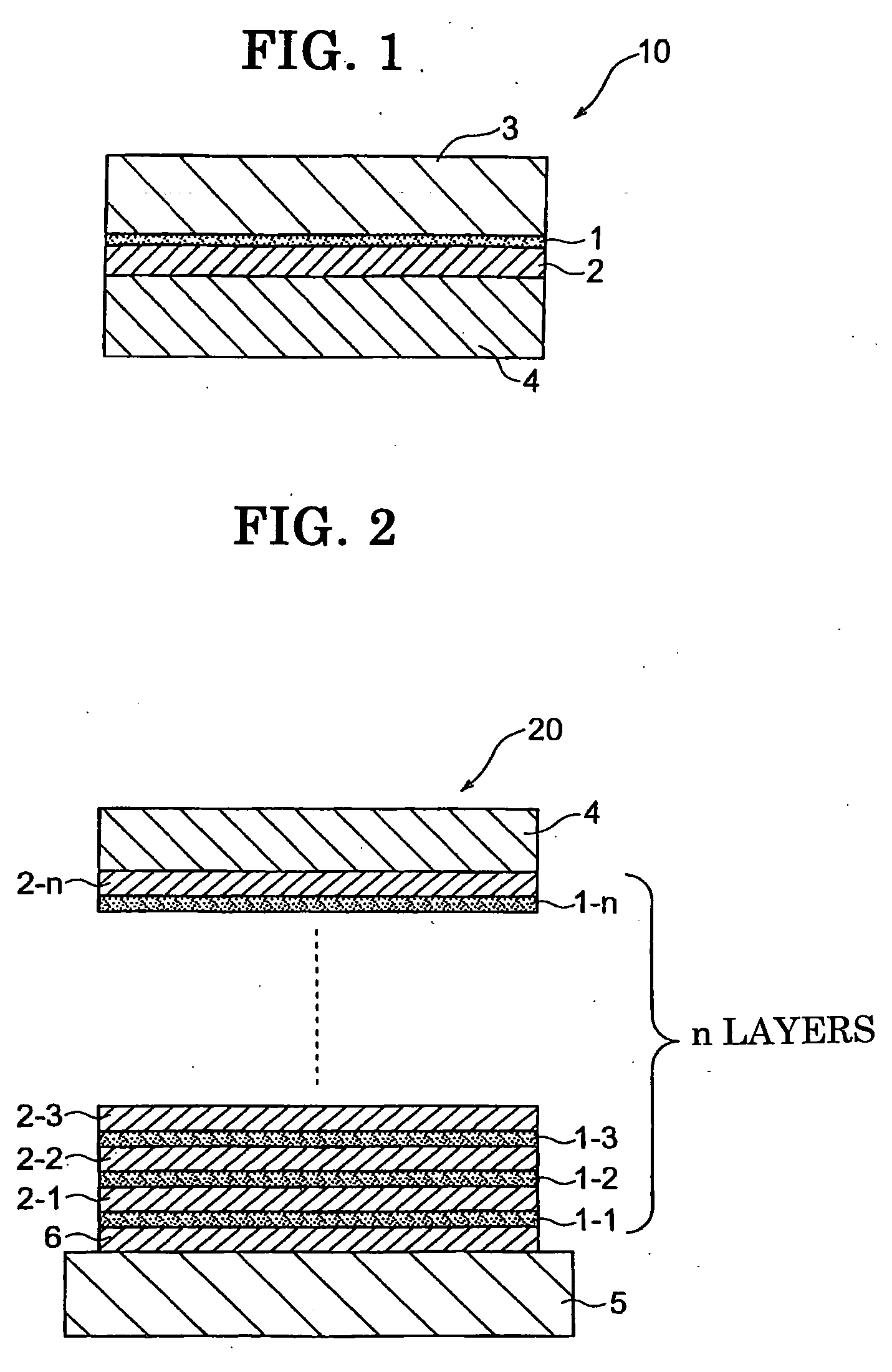

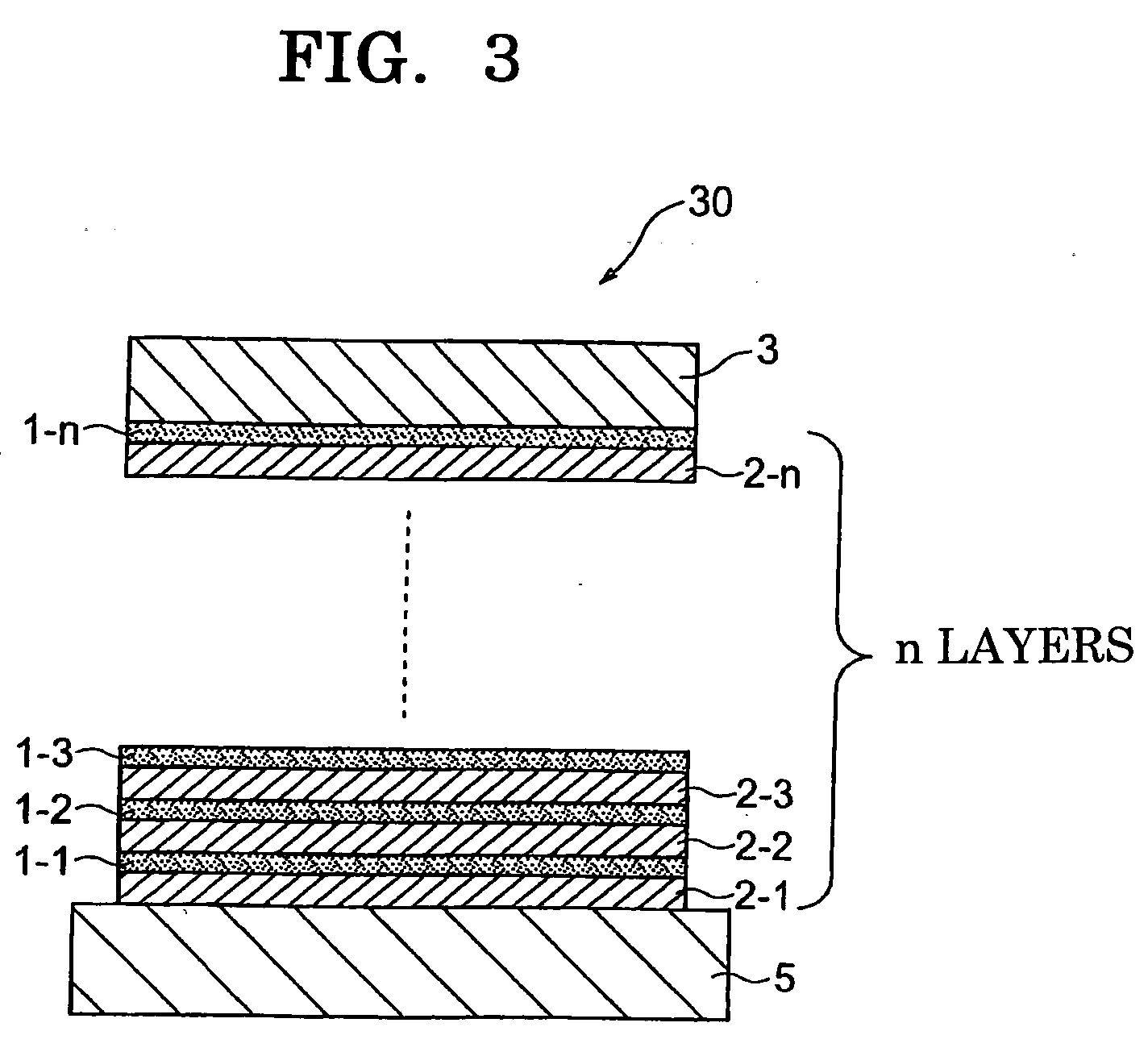

Pressure sensitive adhesive sheet, a multilayer structured article for photorecording media having the sheet and multilayer photorecording medium having the article

InactiveUS20050142318A1High thickness accuracyInhibition formationLayered productsRecord information storagePressure sensitiveChemistry

A pressure sensitive adhesive sheet which is a laminate of a photorecording layer containing a photosensitive material and a pressure sensitive adhesive layer which is a pressure sensitive adhesive layer or a pressure sensitive adhesive layer of the energy hardening type, a multilayer structured article for photorecording medium using this sheet in which the photorecording layer and the pressure sensitive adhesive layer are laminated alternately, and a multilayer photorecording medium having this article, are provided. The sheet, the article and the medium exhibit excellent accuracy of thickness and can be produced easily without restriction on the material. The sheet, the article and the medium having a great area can be produced. When the pressure sensitive adhesive layer is formed with a pressure sensitive adhesive layer of the energy hardening type, formation of press marks on the multilayer photorecording medium can be suppressed.

Owner:LINTEC CORP

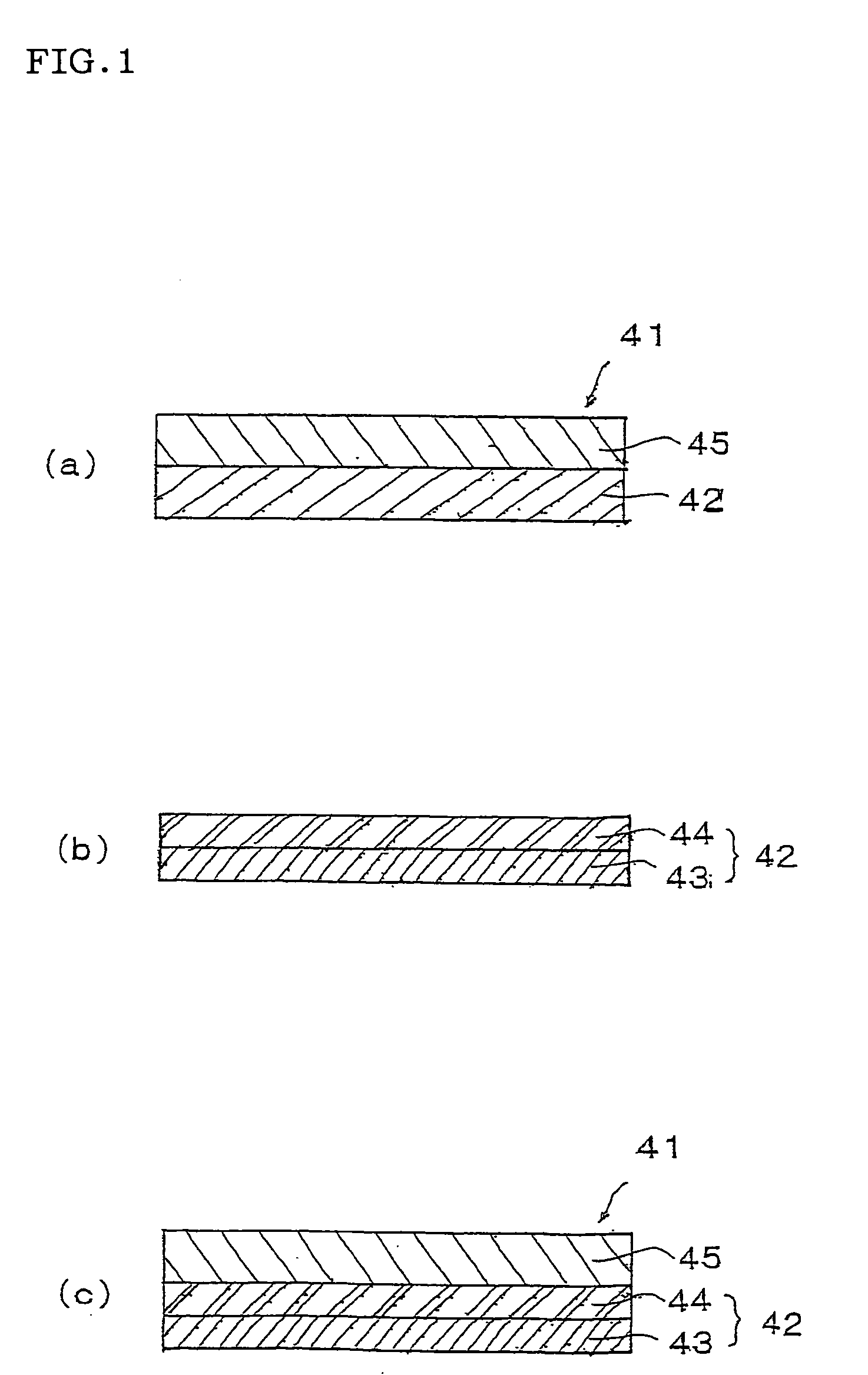

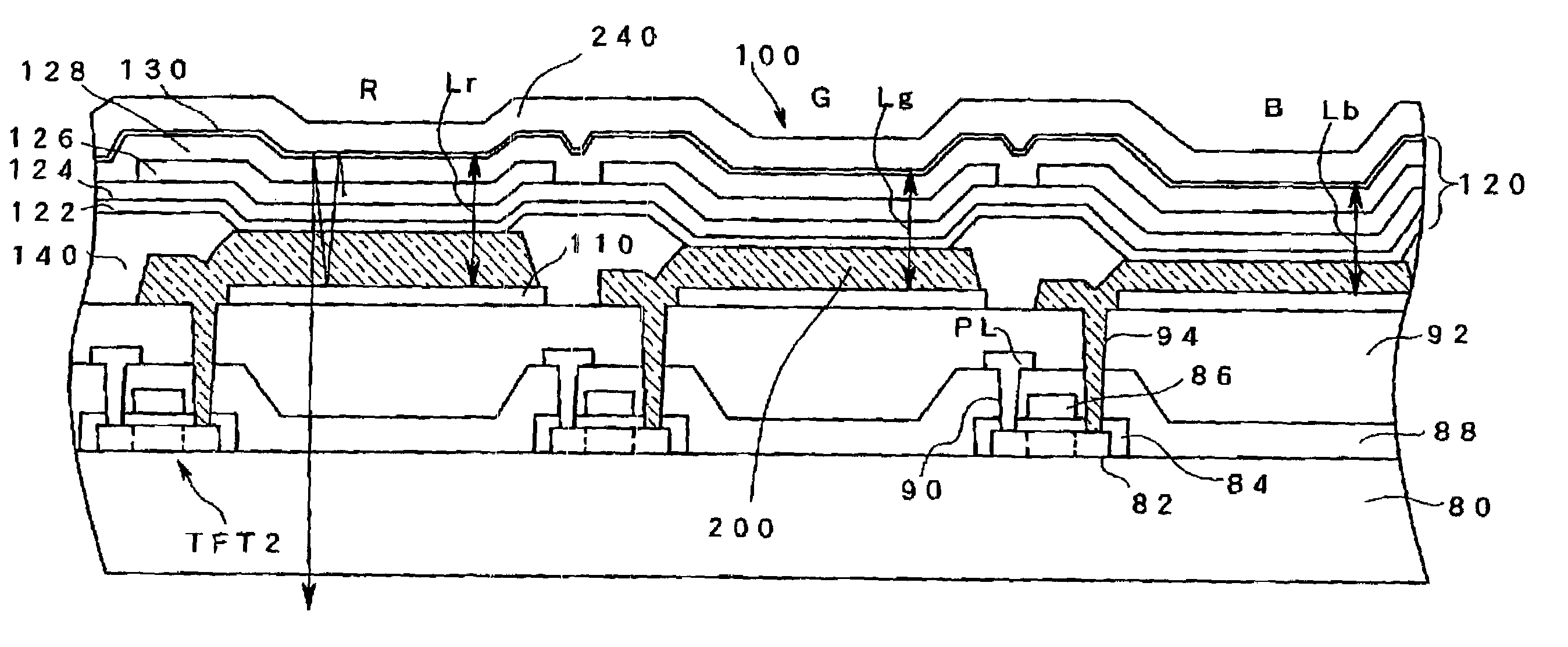

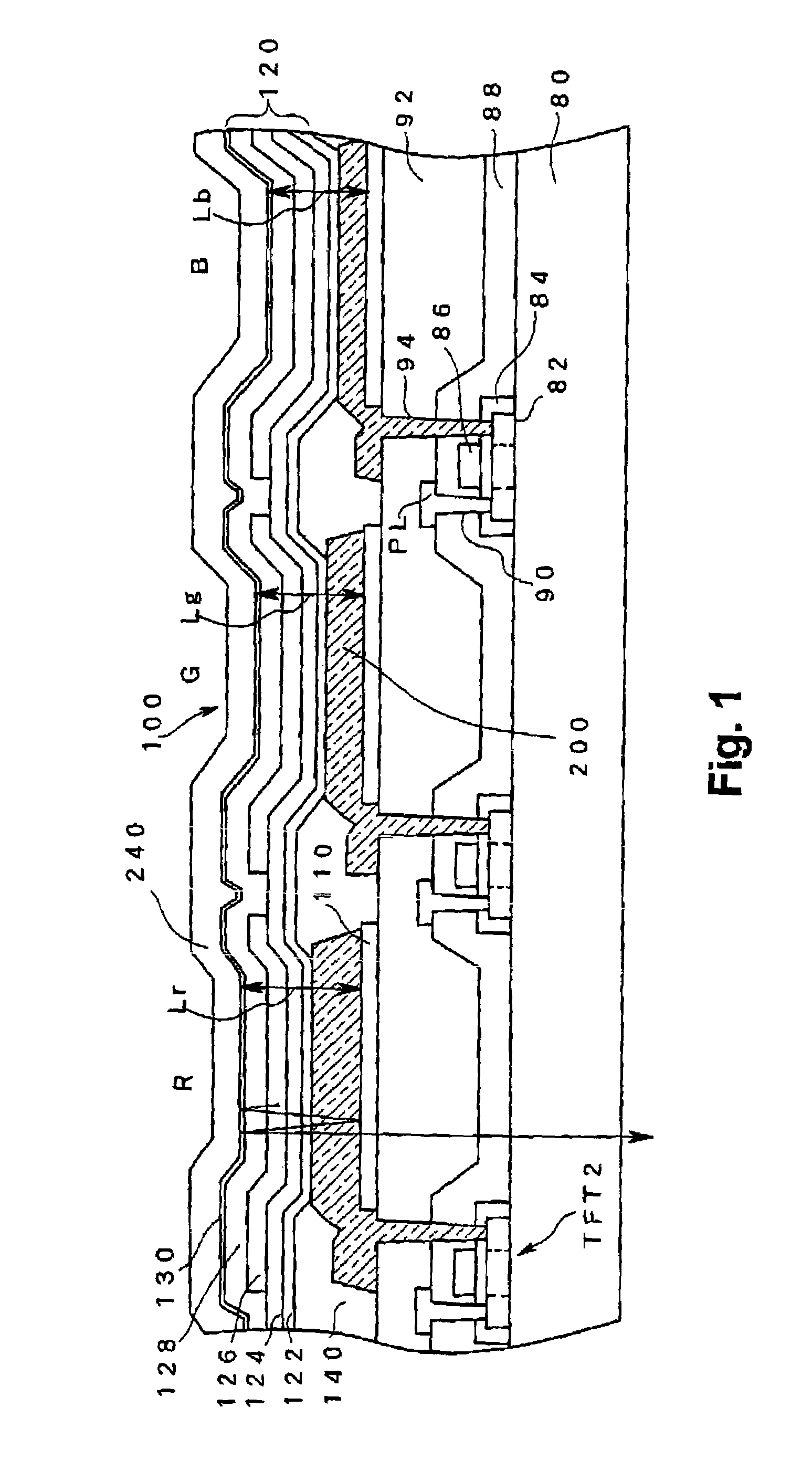

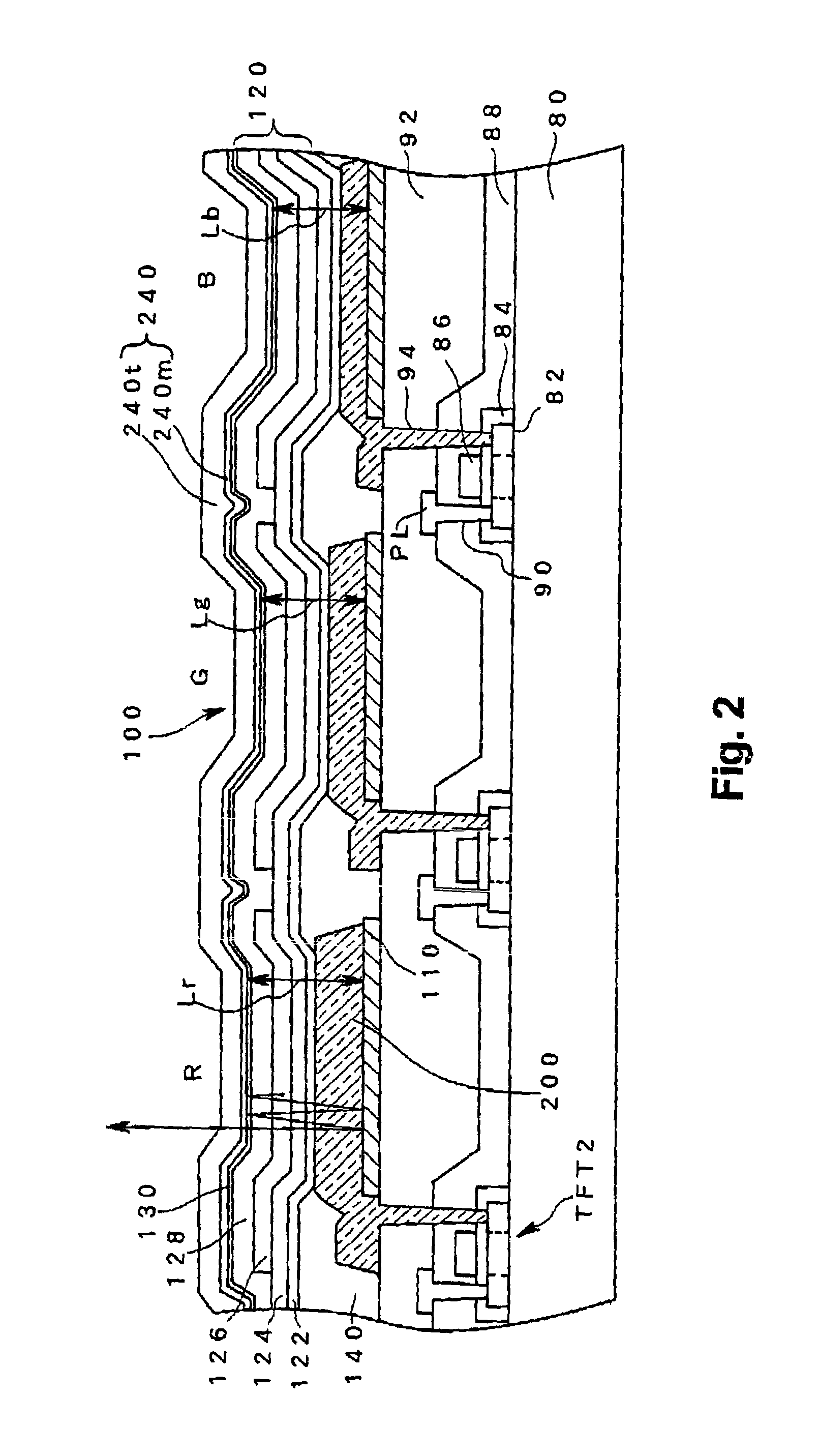

Method for manufacturing display device with conductive resonator spacer layers having different total thicknesses

ActiveUS7510455B2Easily and accurately formedHigh positioning accuracyElectroluminescent light sourcesSolid-state devicesDisplay deviceLength wave

A display device having a plurality of pixels and which realizes a color display with emitted light of at least two wavelengths wherein each pixel has a microresonator structure between a lower reflective film formed on a side near a substrate and an upper reflective film formed above the lower reflective film with an organic light emitting element layer therebetween. The lower reflective film is made of a metal thin film and a conductive resonator spacer layer which functions as a first electrode is provided between the lower reflective film and the organic light emitting element layer. A thickness of the conductive resonator spacer layer is changed by changing a number of layers or a number of remaining layers of transparent conductive metal oxide layers made of ITO corresponding to pixels of different light emission wavelengths. An amorphous ITO layer at an upper layer is selectively removed from above a polycrystalline ITO layer at a lower layer using the polycrystalline ITO layer as an etching stopper so that the thickness is changed corresponding to the thickness of the ITO layer to be formed and not removed. Light obtained in the organic light emitting element layer is intensified by the microresonator structure in which the optical length is adjusted by the conductive resonator spacer layer and is emitted to the outside.

Owner:SANYO ELECTRIC CO LTD

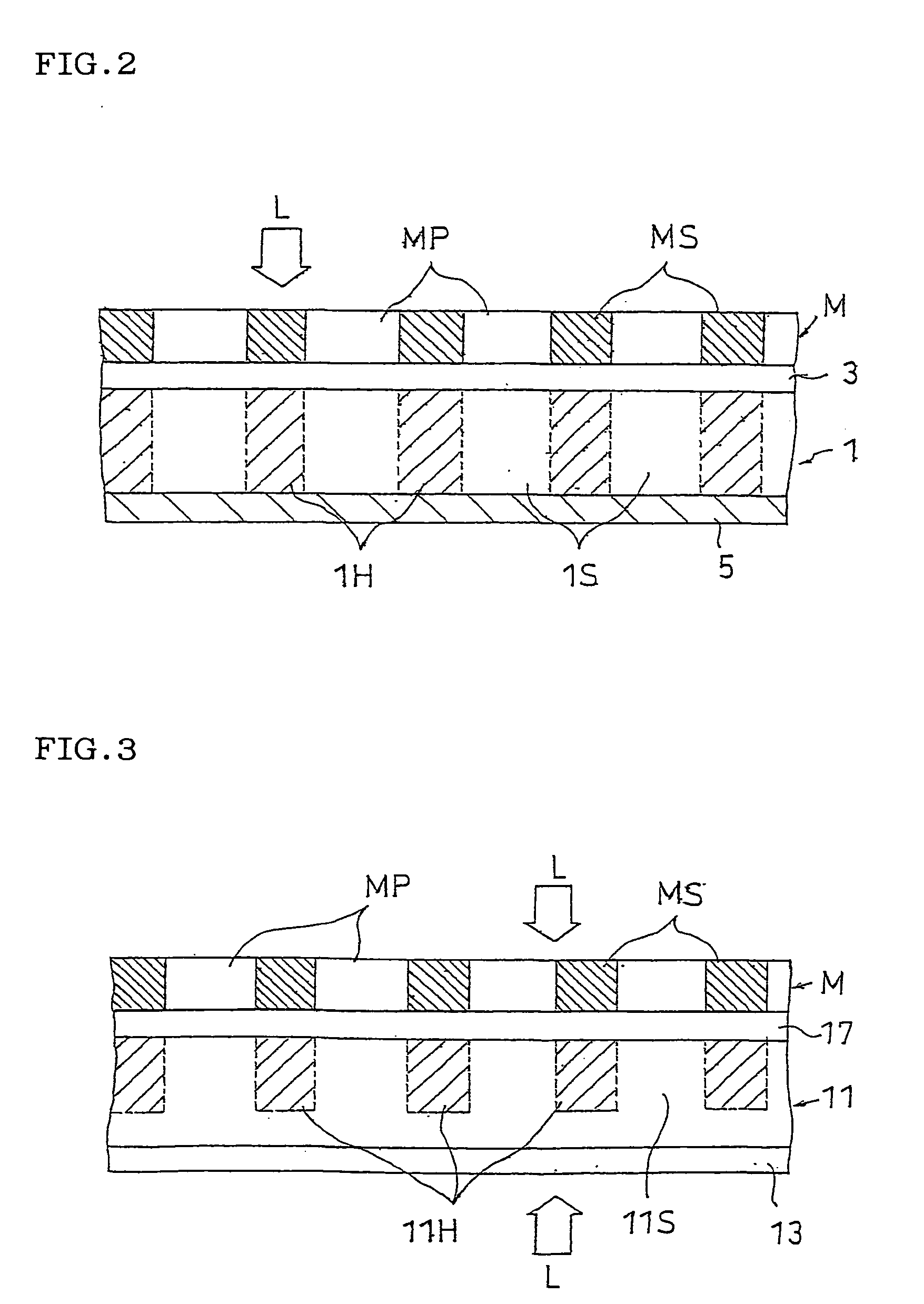

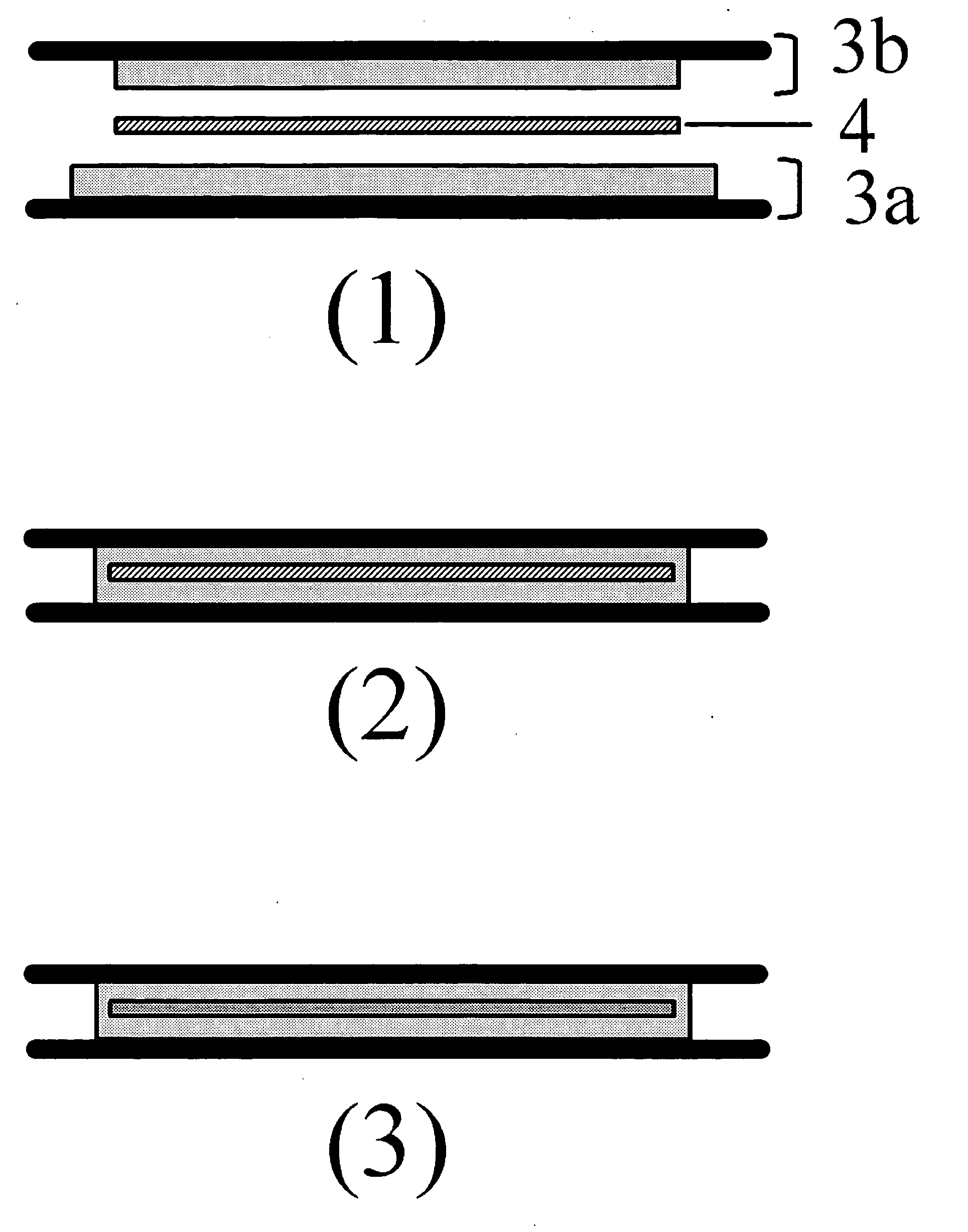

Manufacturing Process for a Prepreg with a Carrier, Prepreg with a Carrier, Manufacturing Process for a Thin Double-Sided Plate, Thin Double-Sided Plate and Manufacturing Process for a Multilayer-Printed Circuit Board

InactiveUS20090126974A1High thickness accuracyLess thermally expansibleSynthetic resin layered productsLaminationEngineeringMelting point

A process for manufacturing a prepreg with a carrier exhibiting excellent impregnating properties and thickness precision, which is particularly suitably used for preparing a build-up type multilayer-printed circuit board is provided. Also, a prepreg with a carrier prepared by the manufacturing process and a process for manufacturing a multilayer-printed circuit board utilizing the prepreg with a carrier are provided. There is provided a process for continuously manufacturing a prepreg with a carrier comprising an insulating resin layer having a backbone material of a textile fabric, (a) laminating the insulating resin layer side of a first and a second carriers comprising an insulating resin layer on one side on the both sides of the textile fabric, respectively, to form a laminate and bonding them under a reduced pressure, and (b) after the bonding, heating the laminate at a temperature equal to or higher than a melting point of the insulating resin.

Owner:SUMITOMO BAKELITE CO LTD

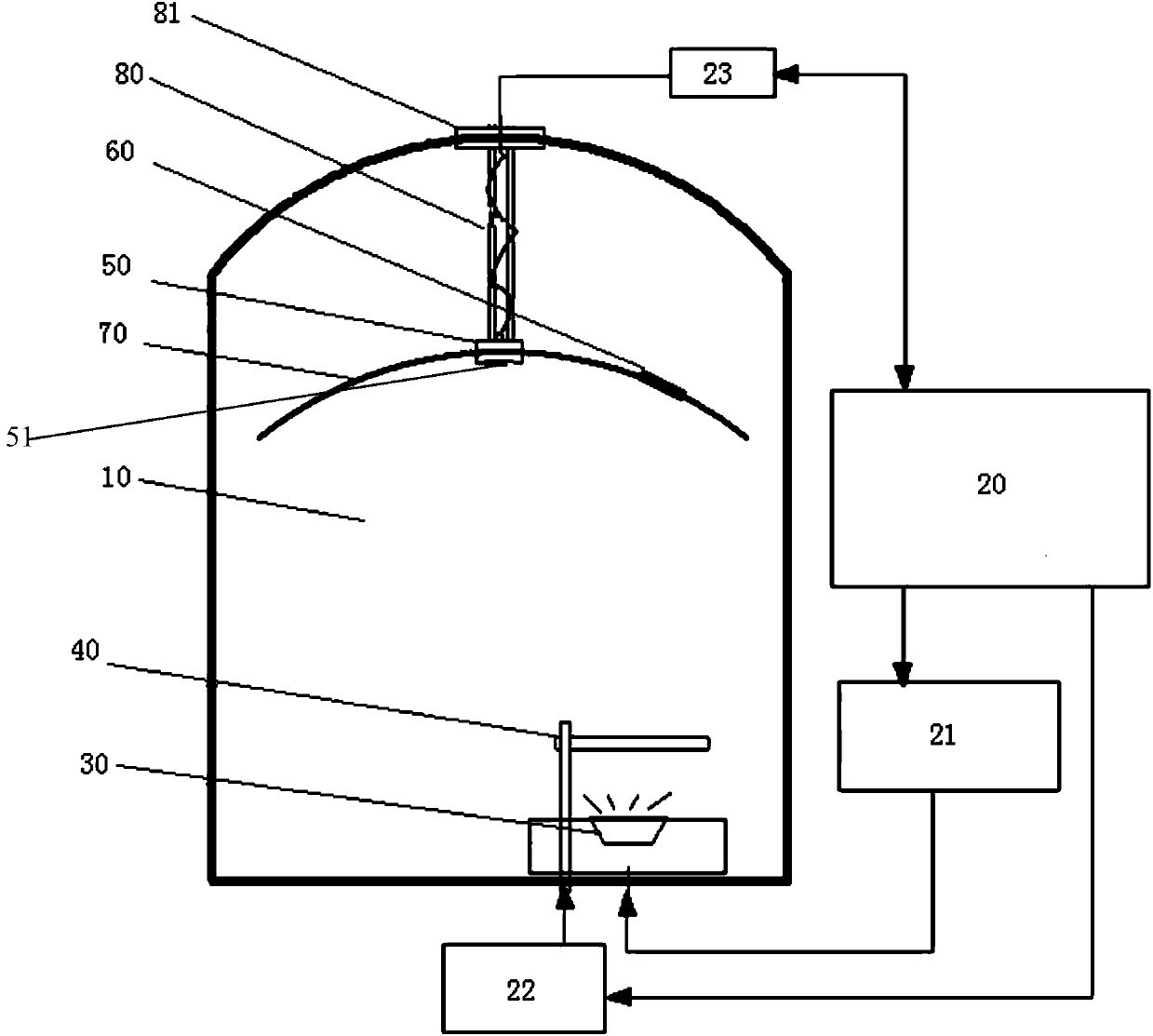

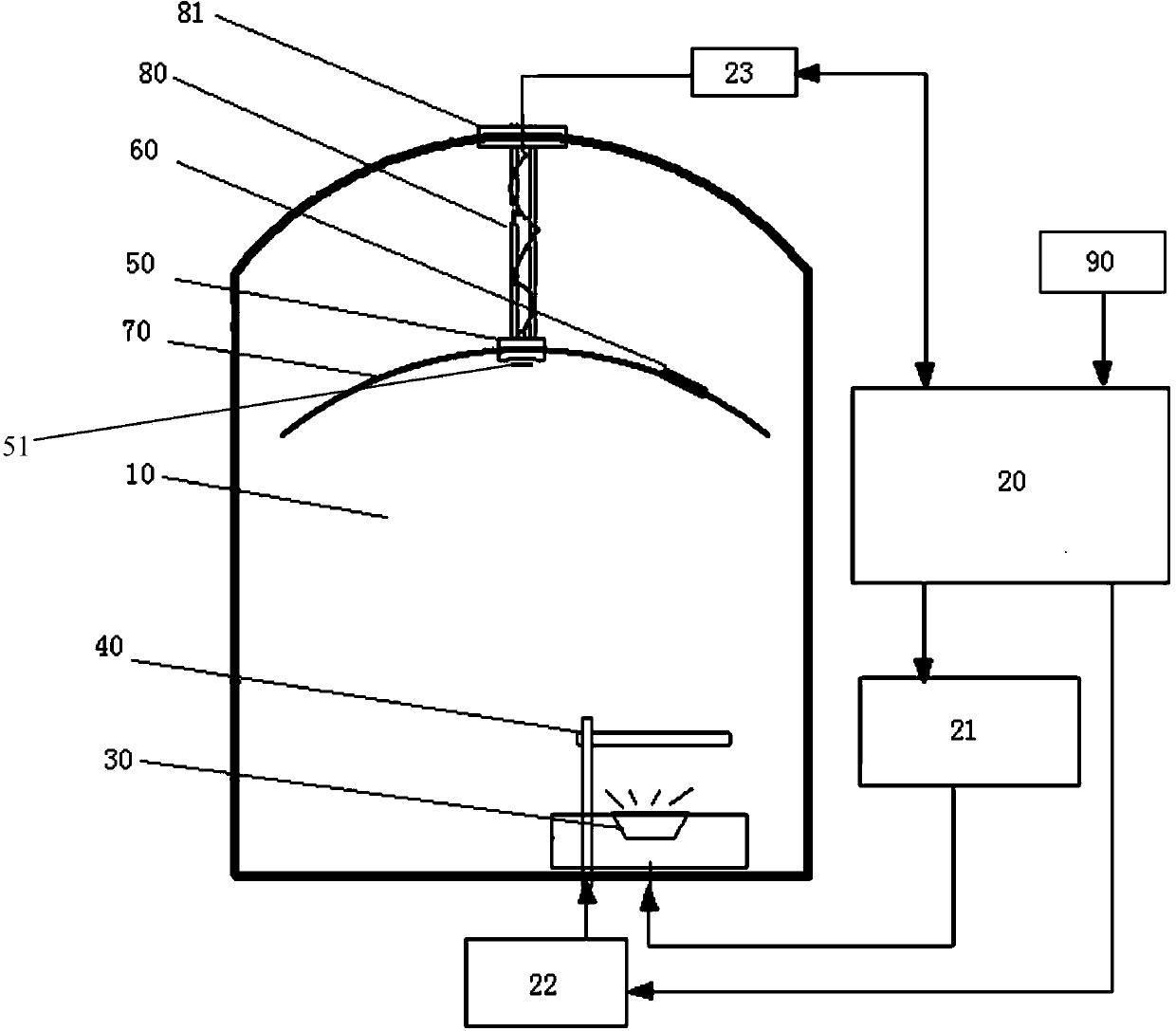

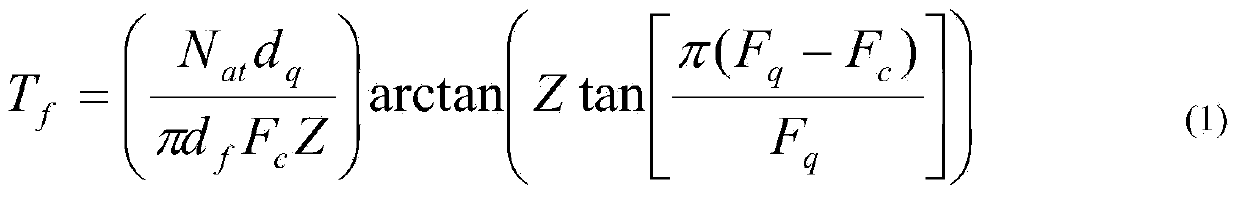

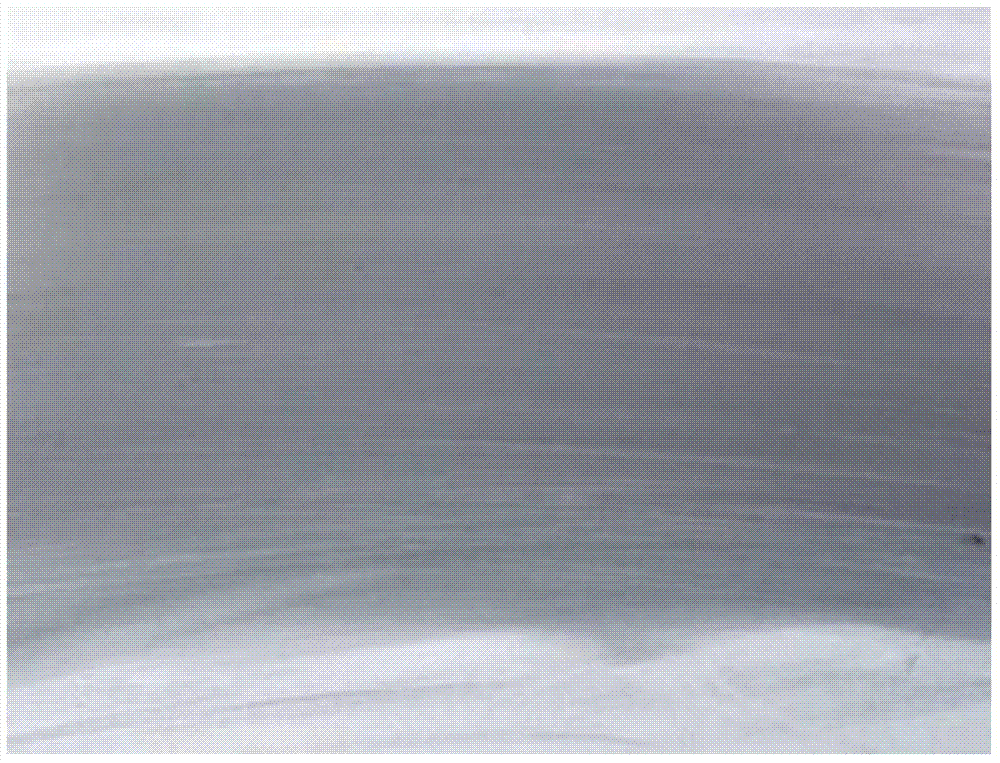

Control method of coating thickness of quartz crystal and coating device of quartz crystal

ActiveCN103469172AHigh thickness accuracySolve Thickness ProblemsVacuum evaporation coatingSputtering coatingHuman–machine interfaceControllability

The invention provides a control method of coating thickness of a quartz crystal, wherein the coating thickness is calculated according to the initial oscillation frequency of the quartz crystal before coating and the oscillation frequency of the quartz crystal after coating. The control method is characterized in that thickness measurement errors caused by rise of the oscillation frequency of the quartz crystal due to temperature increment of the quartz crystal are reduced. The coating device of the quartz crystal, provided by the invention, is convenient to operate, and the work efficiency is improved. A film thickness controller of the quartz crystal provided by the invention adopts a human-machine interface and is convenient for operators to monitor the coating process in real time and analyze the film forming data, thereby improving the controllability of the coating process. By adopting the control method and the device provided by the invention, the error on the coating thickness can be reduced to below 1 / 4 of the error in the prior art, so that the precision on the coating thickness is greatly improved.

Owner:SHANGHAI MOLIN TECH CO LTD

Preparation method of wide and thin hot-rolled steel plates with width-to-thickness ratio being greater than or equal to 500

InactiveCN104492810AReduce wave shapeLower camberAuxillary arrangementsMetal rolling arrangementsEngineeringStructural engineering

The invention discloses a preparation method of wide and thin hot-rolled steel plates with the width-to-thickness ratio being greater than or equal to 500, which belongs to the technical field of multi-layer metal stacking rolling. According to the preparation method, a multi-layer blank combined rolling method is adopted for producing the wide and thin hot-rolled steel plates and is characterized in that two to four layers of blanks are combined and welded into a whole so that the temperature reduction is relatively slow in the rolling process and accordingly the fluctuation in performance of the heads and the tails of the steel plates are relatively small; meanwhile, multiple layers of blanks are combined for rolling, so that the total thickness of the combined steel plates is increased, and accordingly, the phenomena, such as wave, edge camber, steel stacking and misroll, occurring in the rolling process are obviously reduced, and the buckling phenomenon and the like tend not to occur in the cooling process. According to the invention, multiple layers of steel plates are combined for rolling, so that control over the temperature uniformity is better, and the thickness precision is higher after the steel plates are separated.

Owner:NANJING IRON & STEEL CO LTD

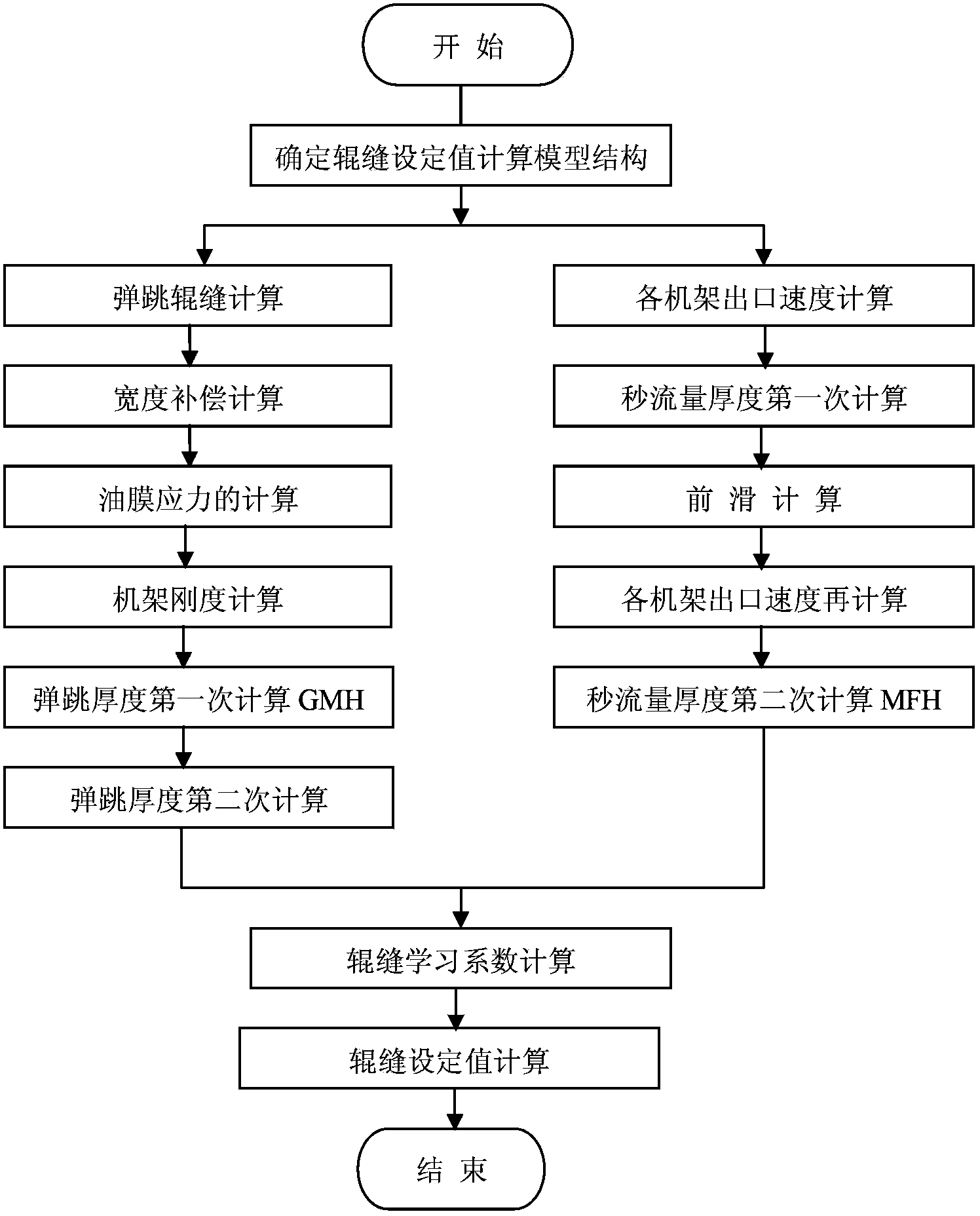

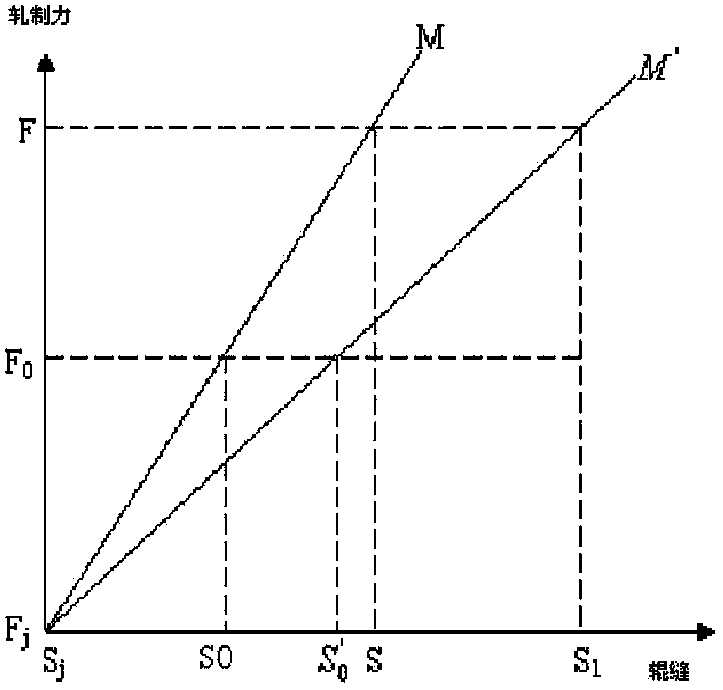

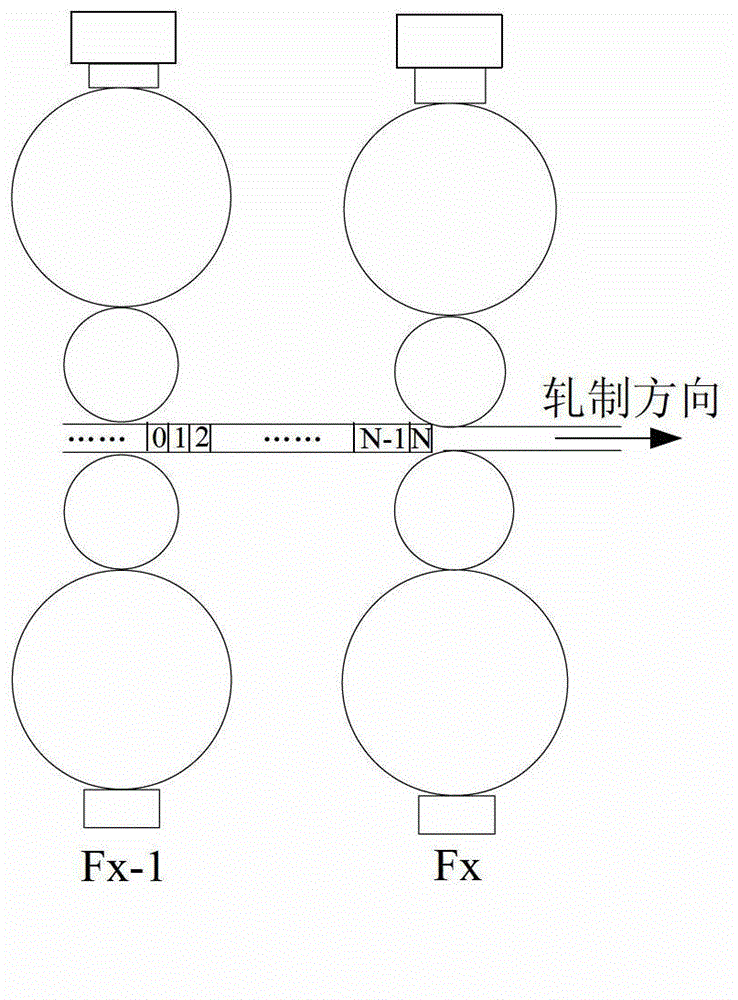

Method for controlling roll gap during finish rolling of strip steel

InactiveCN103506404AReduce drift calculation biasEffective self-learningRoll force/gap control deviceStrip steelMaterials science

The invention discloses a method for controlling a roll gap during finish rolling of strip steel. According to the method for controlling the roll gap during finish rolling of the strip steel, a set calculation model of the roll gap is , wherein the Gap in the formula is the set calculation value of the roll gap; a set calculation value of the outlet thickness of the strip steel is Fh; a width compensation and gain value is Gwid; an oil film compensation and gain value is Goil; an on-load roll gap value is S; a roll gap value when a roller is calibrated is S0; roll force is F; roll force when the roller is calibrated is F0; a roller gap self-learning coefficient is Lcs; a width compensation coefficient is WCX; initial rolling mill rigidity is M; rolling mill rigidity during calibration is M'; a roll gap value corresponding to a pressure value which is calculated when a rolling mill constant is calculated with the pressing method and is called initial roll gap value is Sj.

Owner:ANGANG STEEL CO LTD

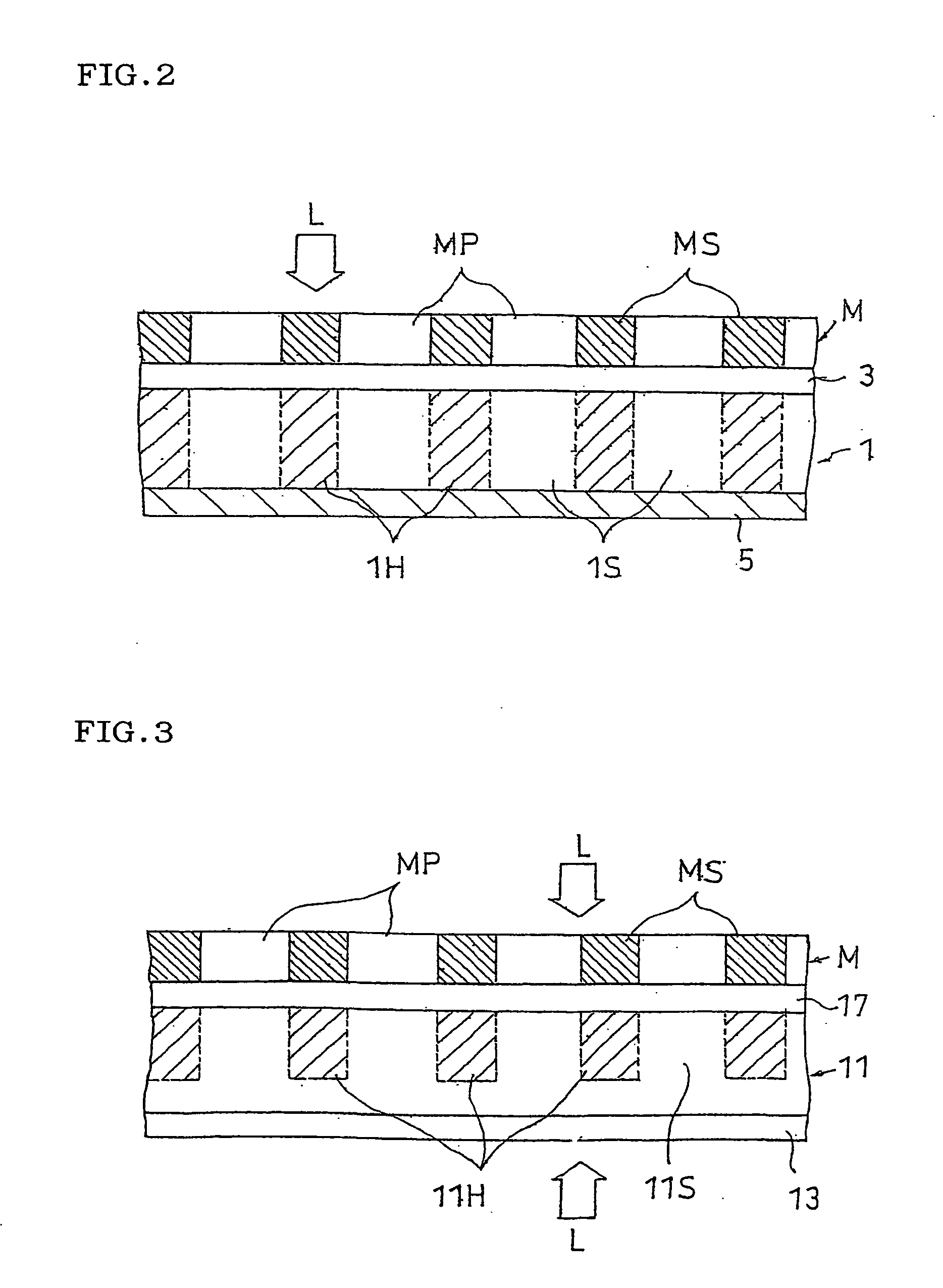

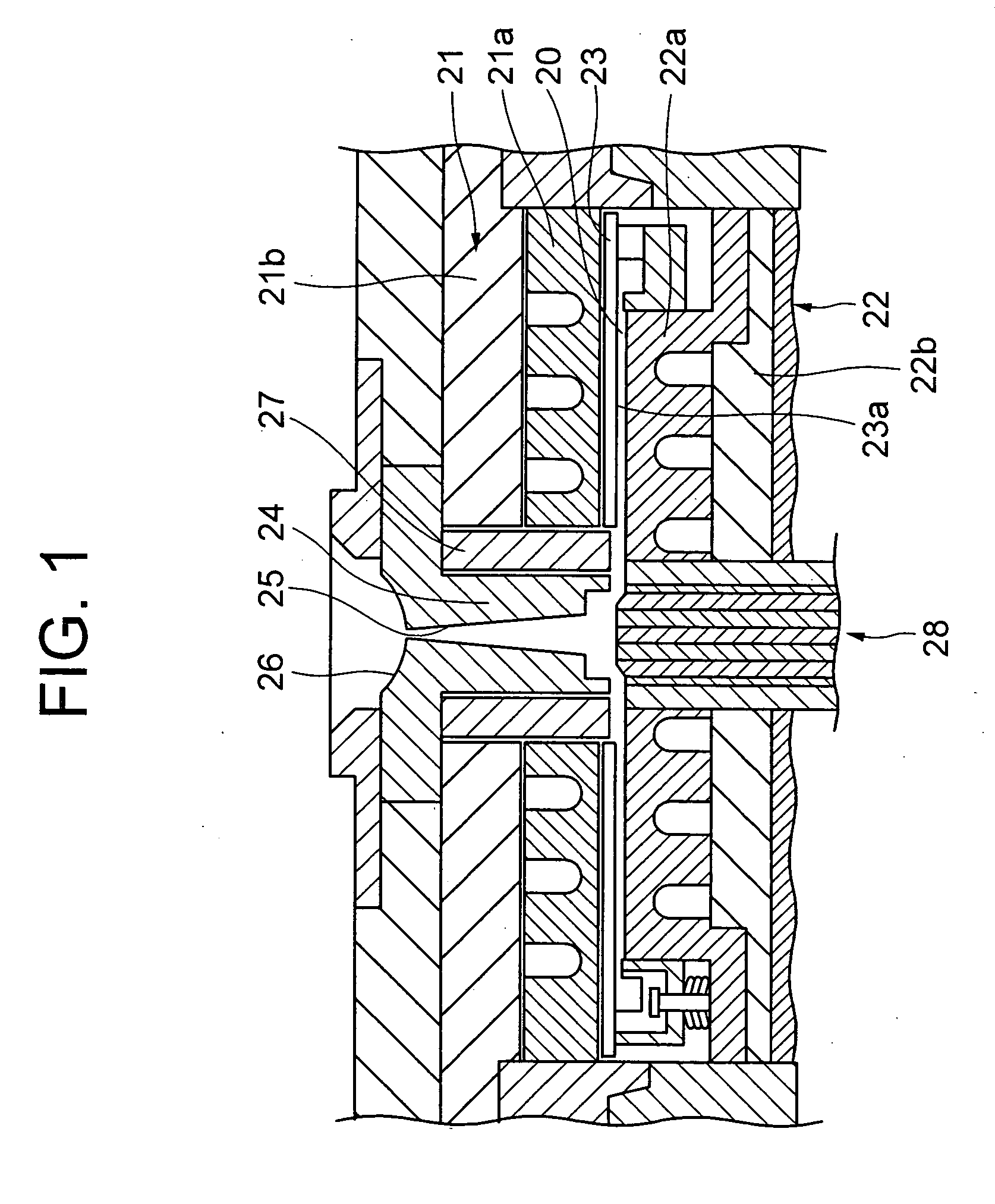

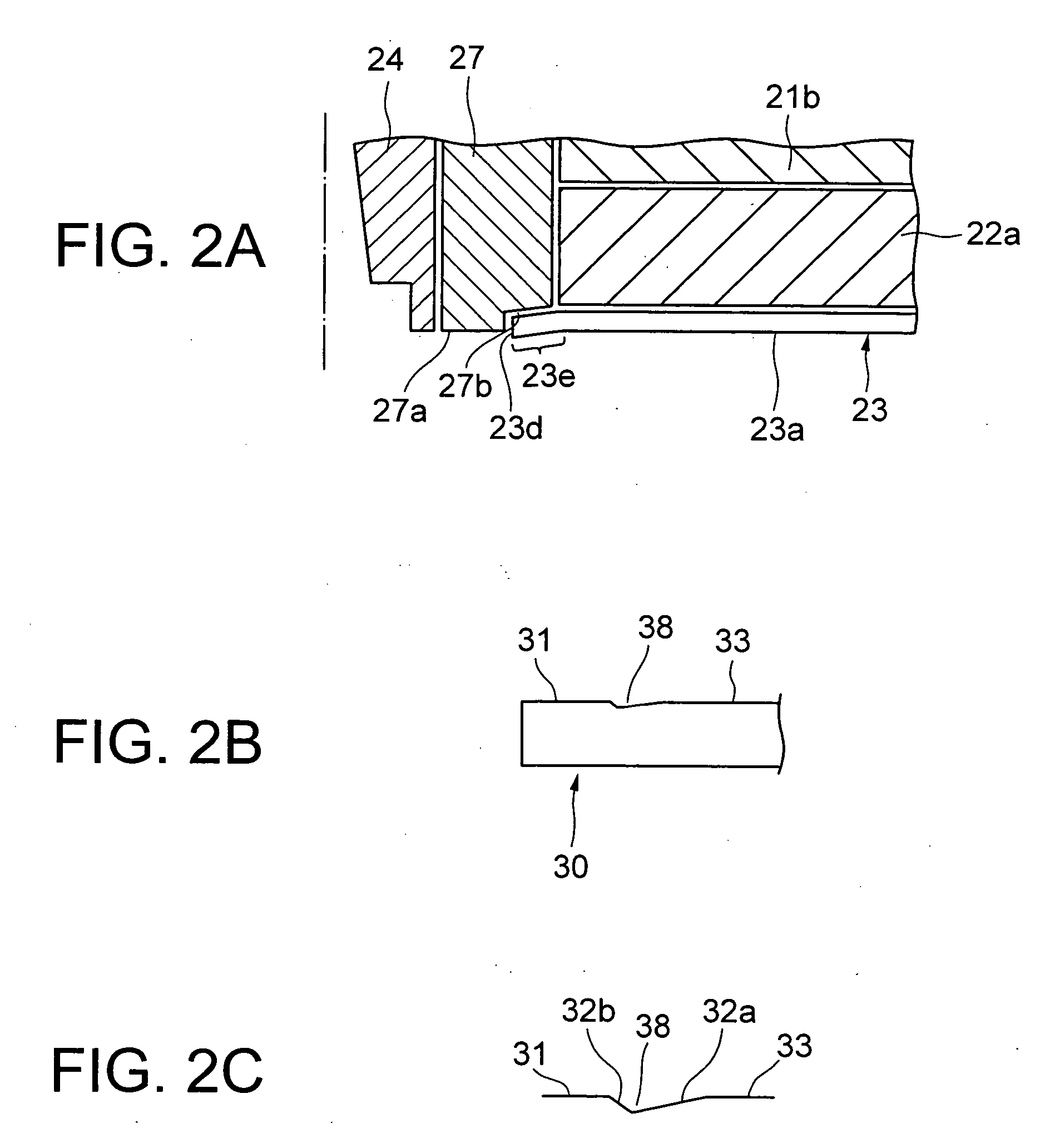

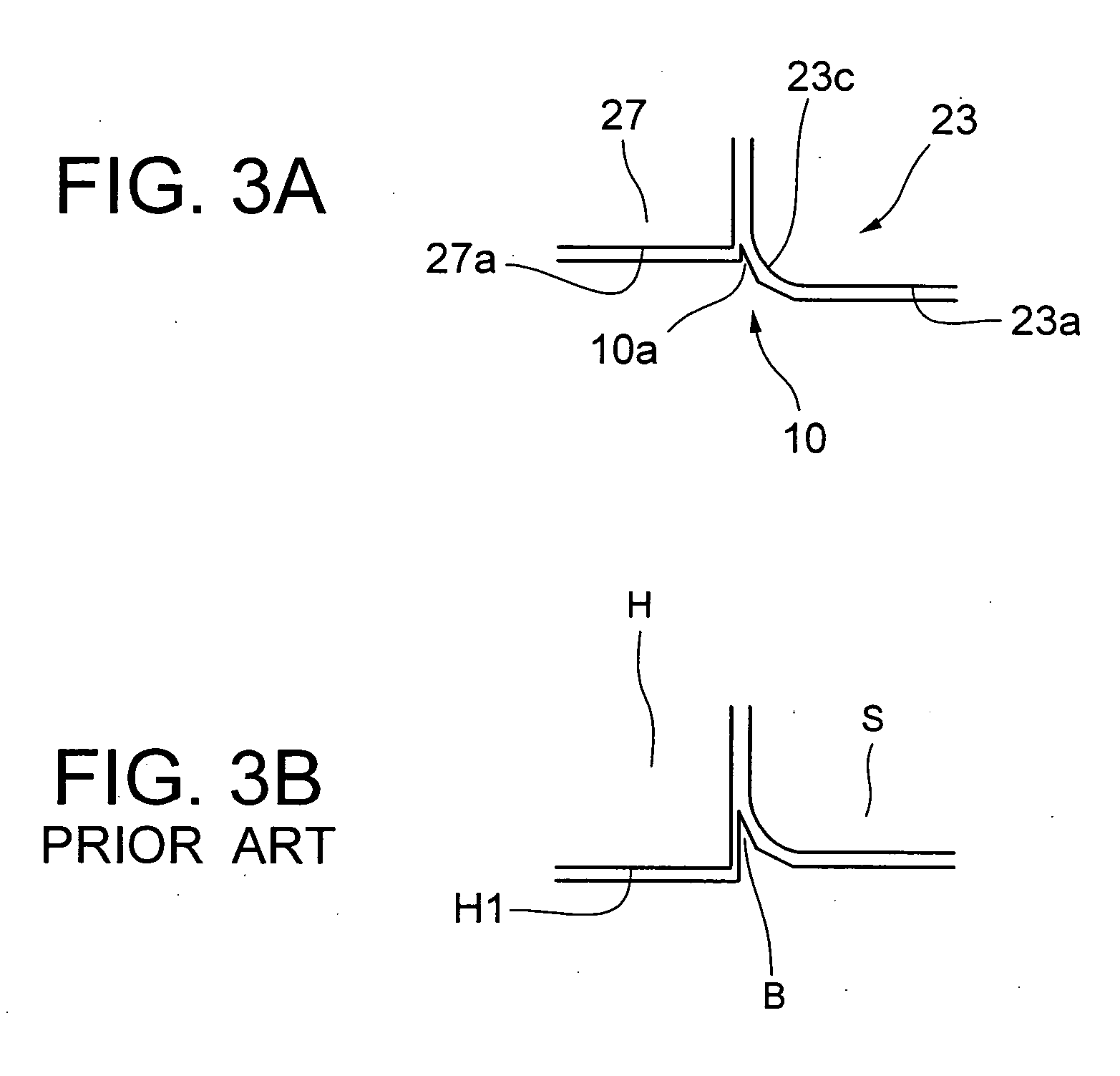

Molding mold, substrate for optical disc, and optical disc

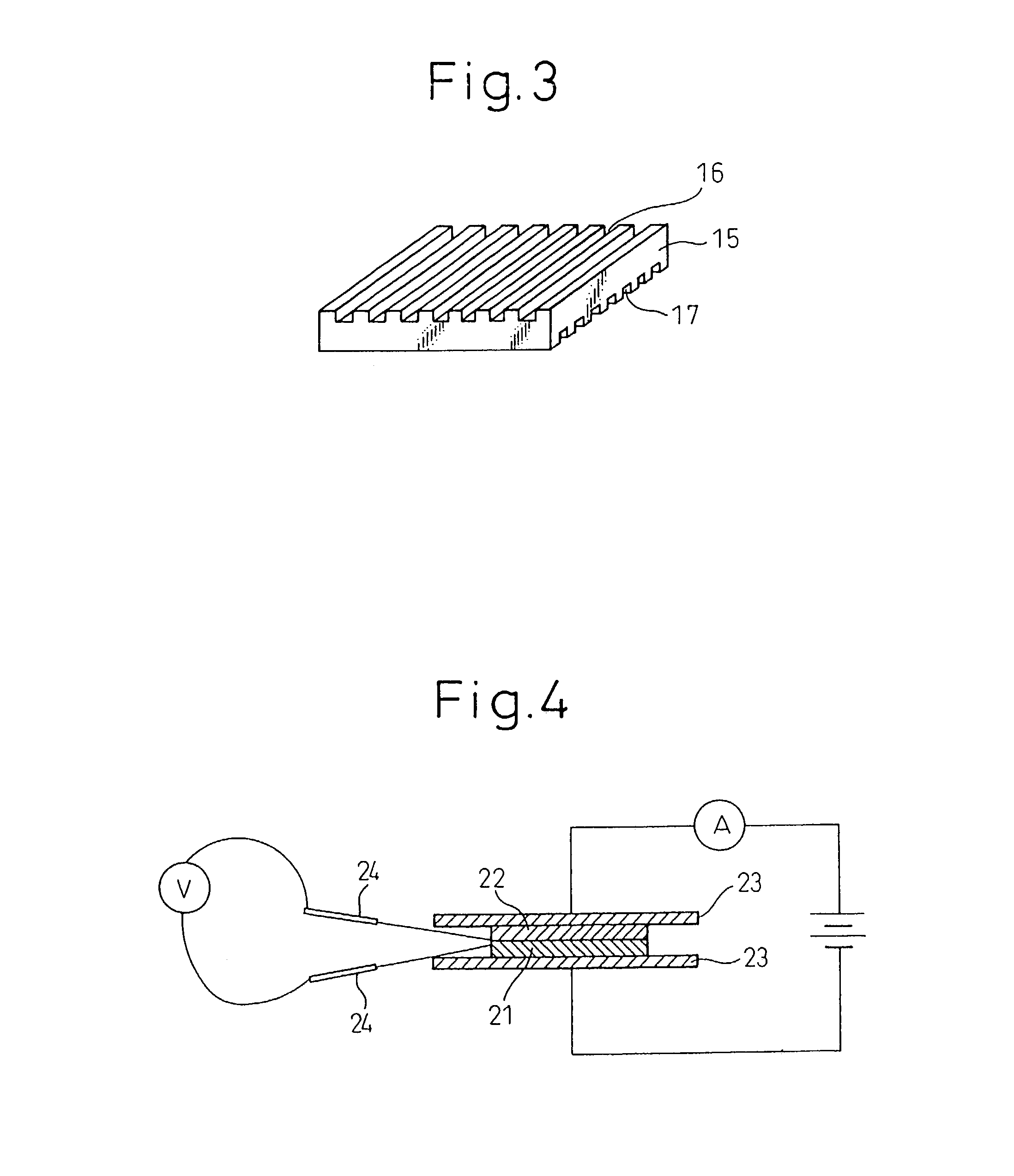

InactiveUS20050048250A1Avoid it happening againHigh thickness accuracyRecord carriersLayered productsOptoelectronicsOptical disc

A molding mold assembly is provided, for molding a mold substrate for an optical disc, to reduce an occurrence of burrs, etc. adversely affecting the optical disc and to improve accuracy of thickness of the optical disc made by the mold substrate. A substrate for an optical disc is provided that is capable of improving the accuracy of the thickness, as well as an optical disc with the improved accuracy of the thickness. The molding mold assembly is constructed such that a cavity for molding the mold substrate for the optical disc is configured, a stamper for transferring a hyperfine pattern onto the mold substrate is attached to the mold assembly so that a vicinal part of an innermost periphery portion of the stamper protrudes towards the cavity, and a face formed by a mold member configuring an inner peripheral portion of the mold substrate is substantially flush with an information area face on which the hyperfine pattern has been transferred.

Owner:TDK CORPARATION

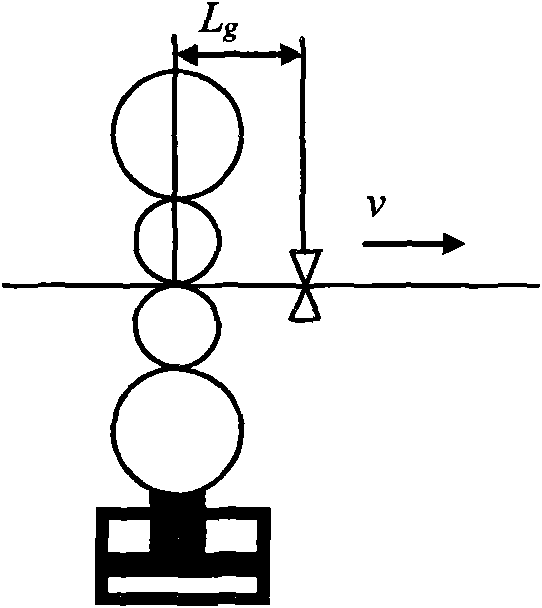

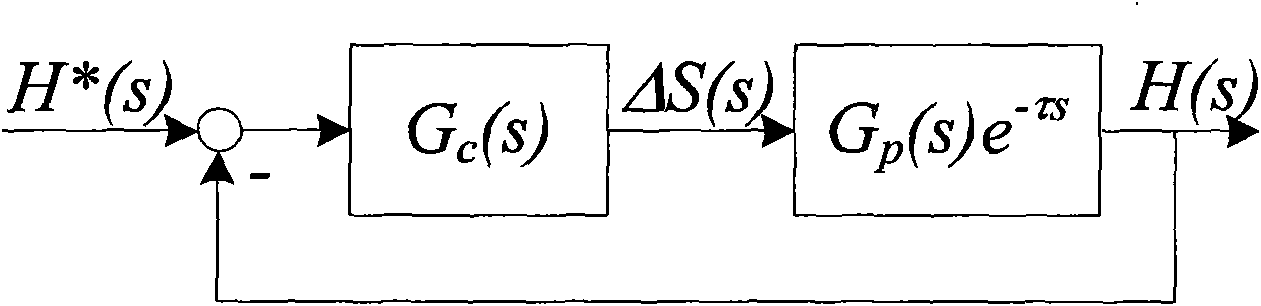

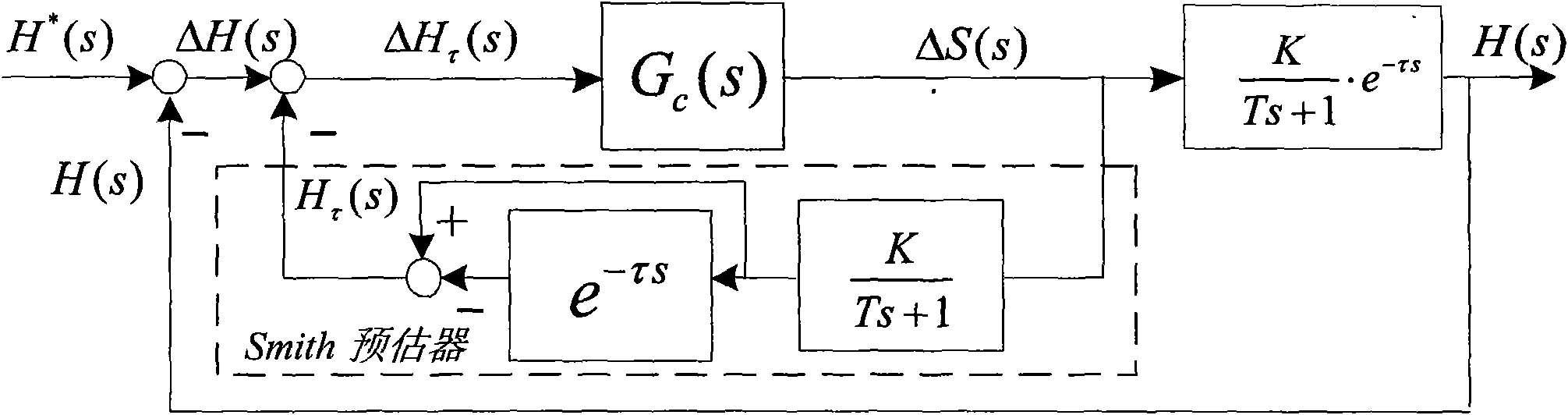

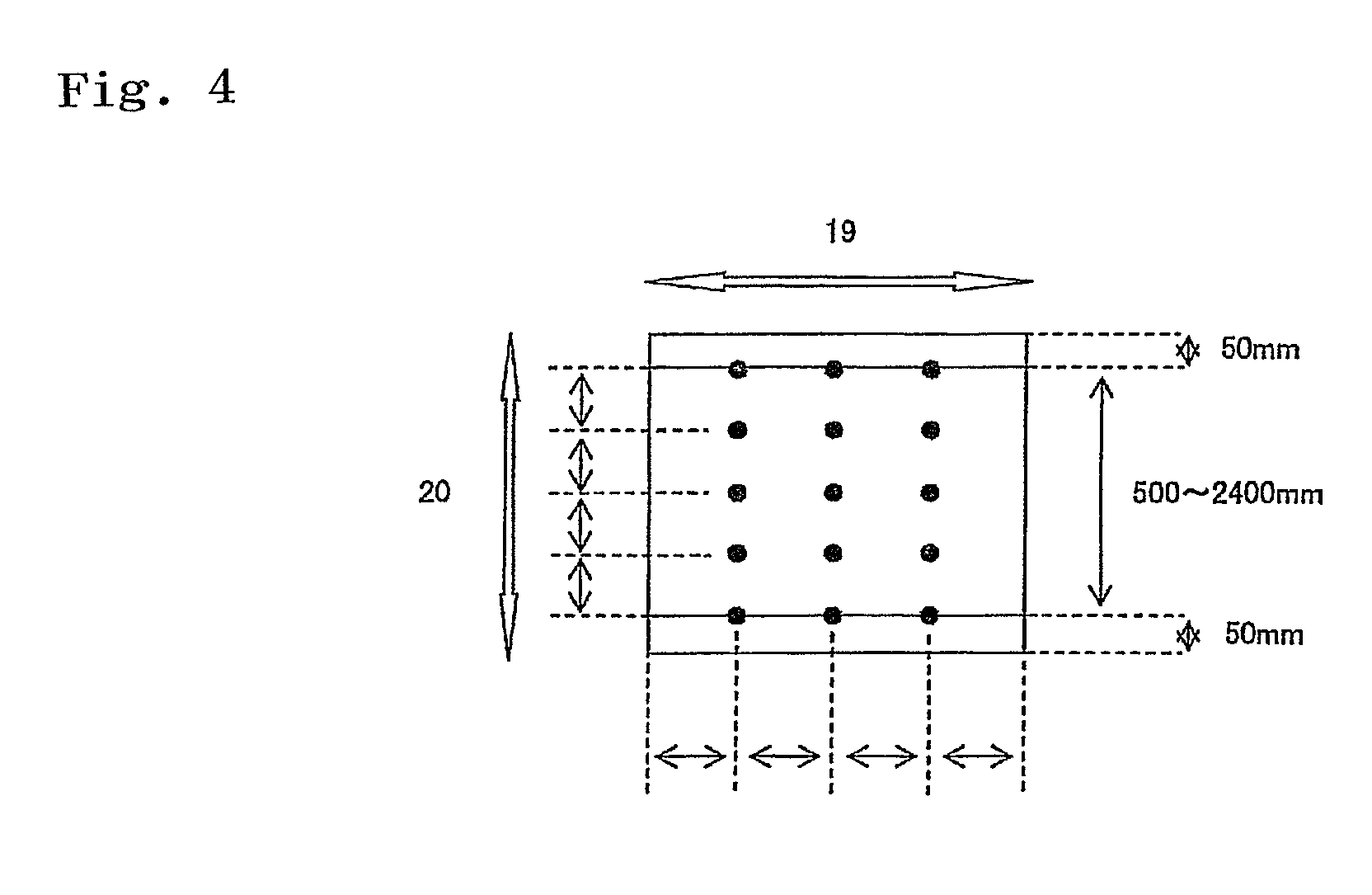

High precision strip rolling thickness control method based on feedback signals by thickness gauge

InactiveCN101618401AHigh thickness accuracyQuick responseRoll mill control devicesProgramme control in sequence/logic controllersAutomatic controlSample length

The invention relates to a high precision strip rolling thickness control method based on feedback signals from a thickness gauge, belonging to the technical field of automatic control of strip rolling. The method comprises the following steps: step 1, inputting rolling system data and strip data; step 2, determining the proportionality factor K of the thickness-control object; step 3, setting a tracking length of the strip sampling; step 4, carrying out multipoint acquisition on the thickness difference delta h measured value of the length Ls(i) of each strip sampling by a computer; step 5, determining delta s(i). The invention has the advantages of proposing length tracking of strip sampling, solving the problem that delay time changes with rolling speed in traditional methods, applying Smith predictive control method to monitoring AGC system, giving the control rate when the controller is under the integrated form; therefore, compared with the traditional control method, the invention not only has rapid response speed, but also has higher static control precision, so the invention can be widely promoted to strip rolling factories to improve the thickness and precision of strip products.

Owner:NORTHEASTERN UNIV

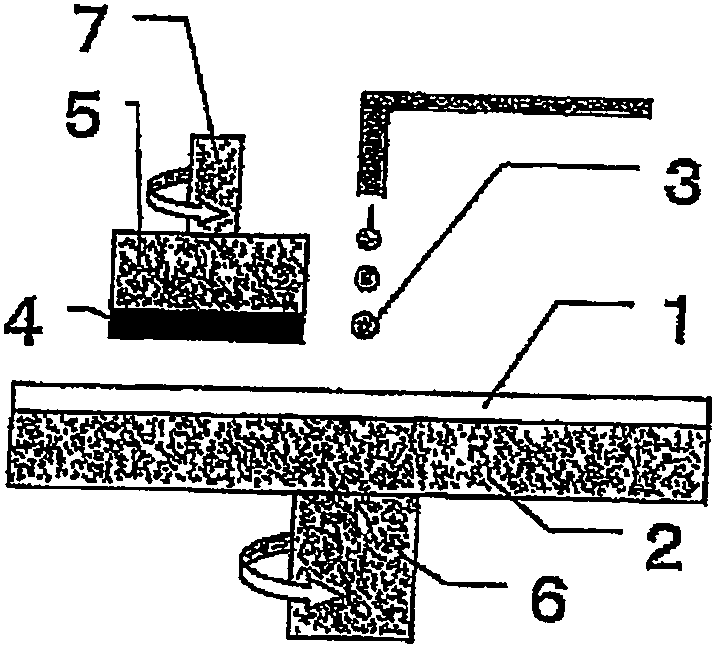

Process for producing optical element, optical element, optical films using optical element, and illuminator and liquid crystal display each using optical element or optical films

InactiveUS20030090617A1Improve efficiencyShort timeLiquid crystal compositionsPolarising elementsCrystallographyLiquid-crystal display

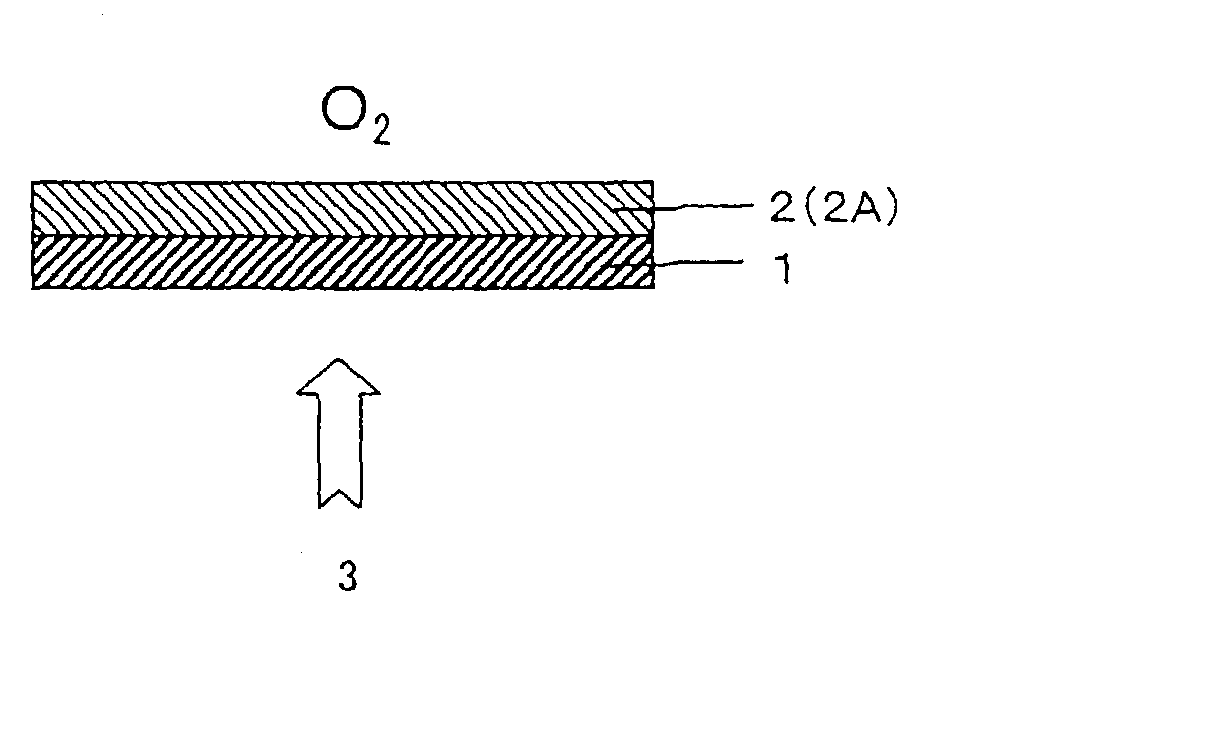

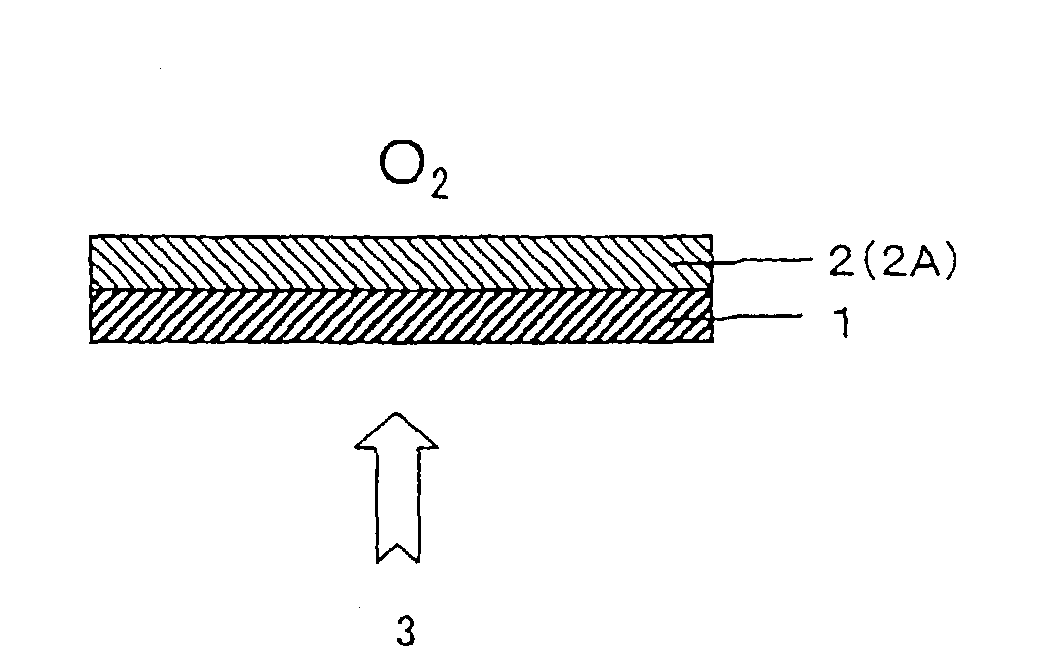

A process for producing an optical element which comprises a polymeric liquid crystal layer having a helically twisted molecular structure and has satisfactory thickness precision and satisfactory optical properties. The process comprises applying a mixed solution containing a polymerizable nematic liquid crystal compound and a polymerizable chiral reagent to an oriented substrate, followed by drying, to orient the liquid crystal compound; and irradiating the mixed solution applied with radiation from the oriented substrate side while maintaining the mixed solution in contact with a gas comprising oxygen to thereby polymerize and cure the mixed solution.

Owner:NITTO DENKO CORP

Method for producing metal laminated substrate for oxide superconducting wire, and oxide superconducting wire using the substrate

ActiveUS20120040840A1Poor workabilityLarge widthSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentMetal foilRoom temperature

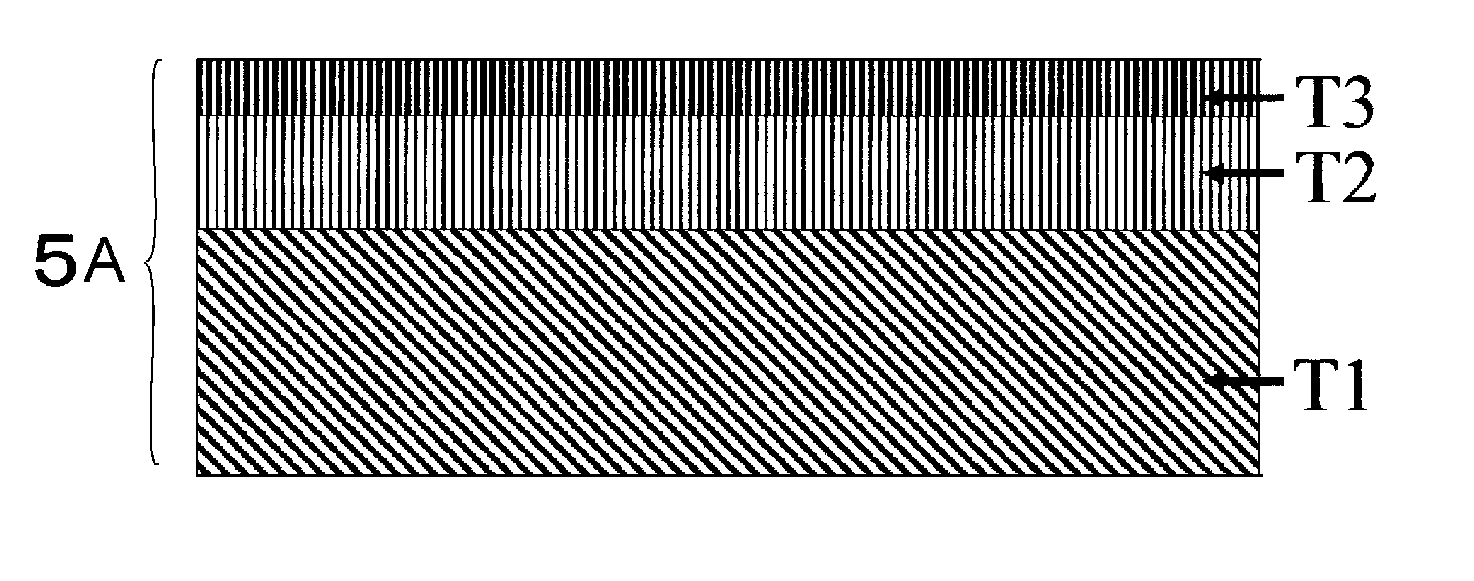

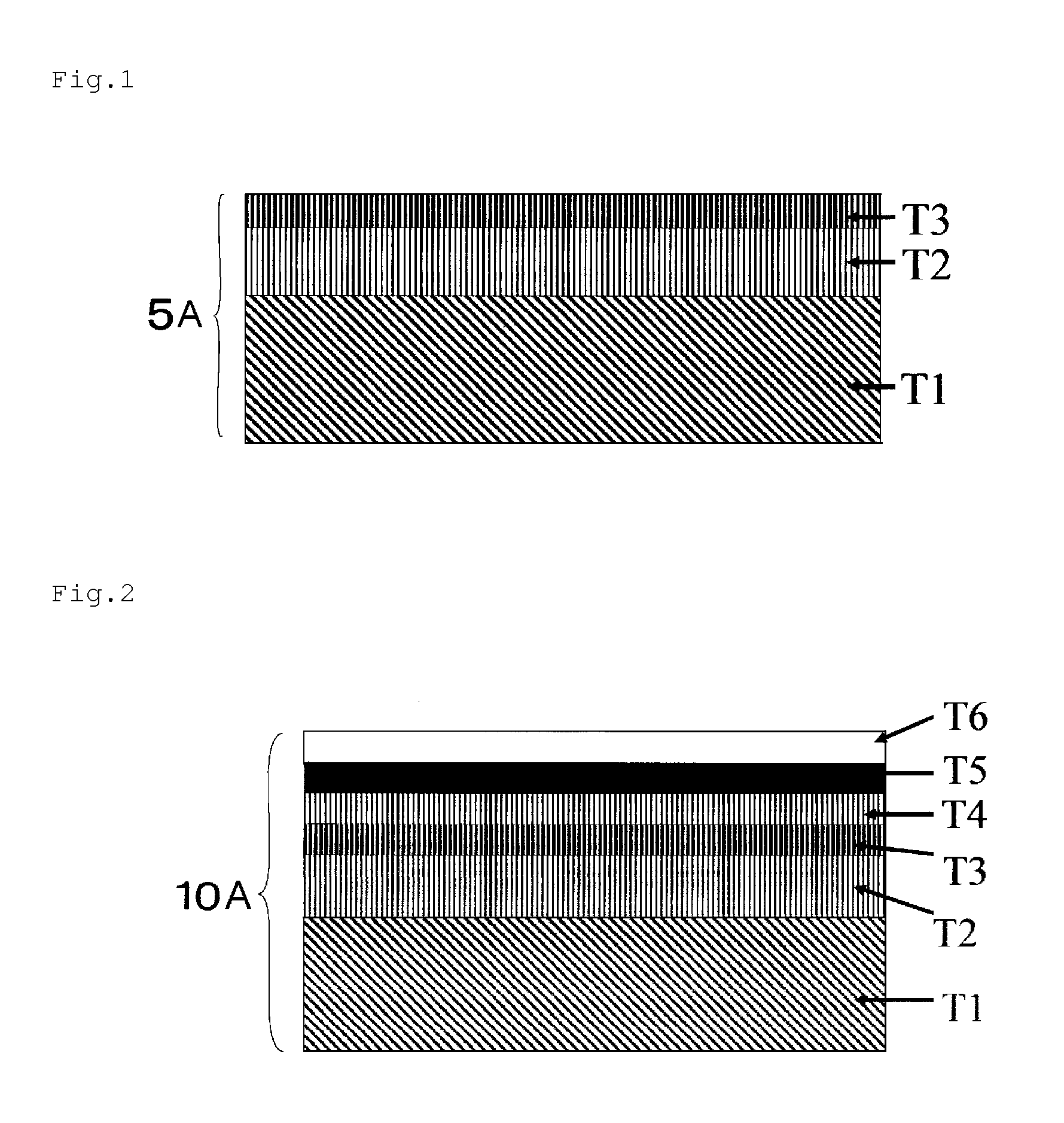

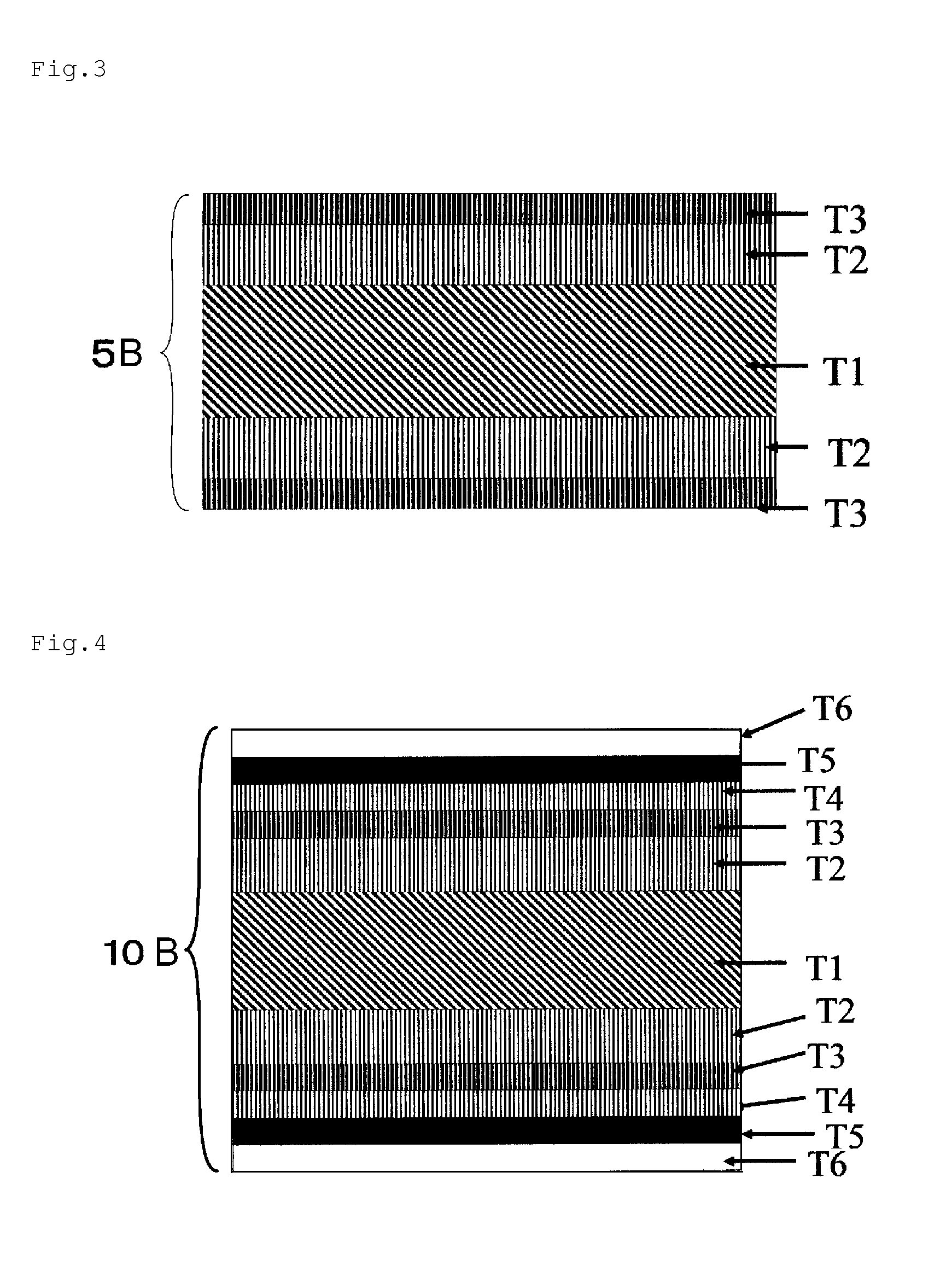

[Problem]A metal laminated substrate for an oxide superconducting wire is provided at a low cost. The metal laminated substrate has high strength, and stable high biaxial orientation in the longitudinal direction.[Means for Resolution]A metal laminated substrate for an oxide superconducting wire is manufactured such that a non-magnetic metal plate T1 having a thickness of not more than 0.2 mm and a metal foil T2 made of Cu alloy which is formed by cold rolling at a draft of not less than 90% and has a thickness of not more than 50 μm is laminated to each other by room-temperature surface active bonding, after lamination, crystal of the metal foil is oriented by heat treatment at a temperature of not less than 150° C. and not more than 1000° C. and, thereafter, an epitaxial growth film T3 made of Ni or an Ni alloy having a thickness of not more than 10 μm is laminated to the metal foil.

Owner:TOYO KOHAN CO LTD +1

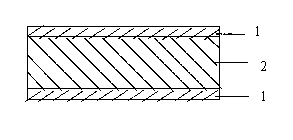

Method for preparing aluminium alloy compound foil by compounding cold rolling and warm rolling

The invention belongs to the technical field of an aluminium alloy and particularly relates to a method for preparing an aluminium alloy compound foil by compounding cold rolling and warm rolling. The method discloses by the invention comprises the following steps: firstly, respectively carrying out cold rolling on an aluminium alloy strip coil and a core aluminium alloy strip coil and annealing the aluminium alloy strip coil and the core aluminium alloy strip coil for 0.5 to 6 hours at a temperature of 300 to 450 DEG C; carrying out rolling compounding on the annealed skin alumium alloy and core aluminium alloy at a temperature of 20 to 250 DEG C to obtain an aluminium alloy composite strip; and carrying out annealing treatment on the aluminium alloy composite strip for 0.5 to 6 hours at a temperature of 300 to 450 DEG C, then carrying out multi-pass cold rolling, controlling the screw-down rate of carrying out cold rolling into the range that epsilon is more than or equal to 90 percent and less than or equal to 96 percent, carrying out annealing treatment for 0.5 to 6 hours in the temperature range of 300 to 450 DEG C after cold rolling, carrying out cold rolling again and controlling the screw-down rate of carrying out cold rolling again into the range that epsilon is more than or equal to 10 percent and less than or equal to 50 percent so as to obtain the finished aluminium alloy compound foil. According to the method disclosed by the invention, complex technical processes of ingot casting, hot-rolling cogging, assembly welding, hot-rolling compounding and the like of a conventional production process are omitted; energy is saved and consumption is reduced; and meanwhile, harmful effects brought to product quality by the hot-rolling compounding process are avoided.

Owner:NORTHEASTERN UNIV

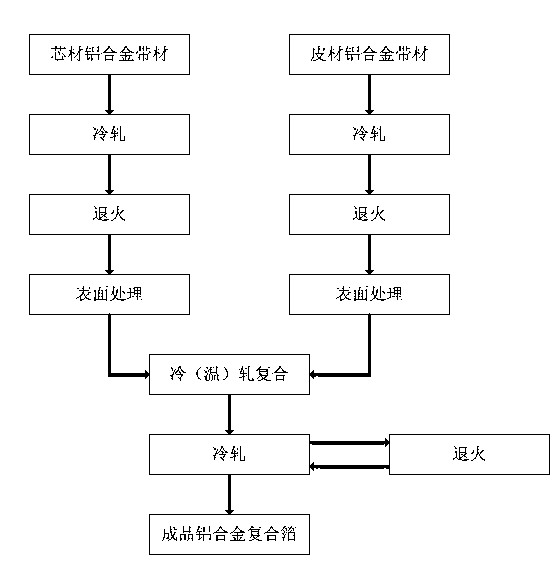

Resin compositions, films using the same and process for producing the films

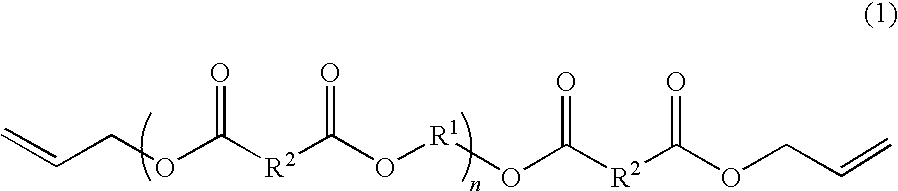

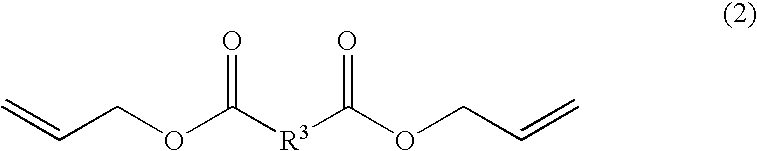

ActiveUS20090209718A1High transparencyHigh thickness accuracyPretreated surfacesCoatingsOligomerMeth-

The present invention provides a resin composition containing a reactive monomer and / or oligomer having allyl ester groups, a film of the resin composition which is excellent in transparency and heat resistance and has a high thickness precision, and a process for producing such a film. The resin composition includes (A) a reactive oligomer having allyl ester groups and represented by the general formula (1):wherein R1 represents an alkanediyl or alkenediyl group having 1 to 4 carbon atoms with the proviso that a plurality of R1 groups may be the same or different, R2 represents a cycloalkanediyl, cycloalkenediyl or arenediyl group with the proviso that a plurality of R2 groups may be the same or different, and n represents an average degree of polymerization and is a number of 1 to 30; (B) a polyfunctional (meth)acrylic monomer and / or oligomer; and (C) a thermal polymerization initiator.

Owner:RESONAC CORP

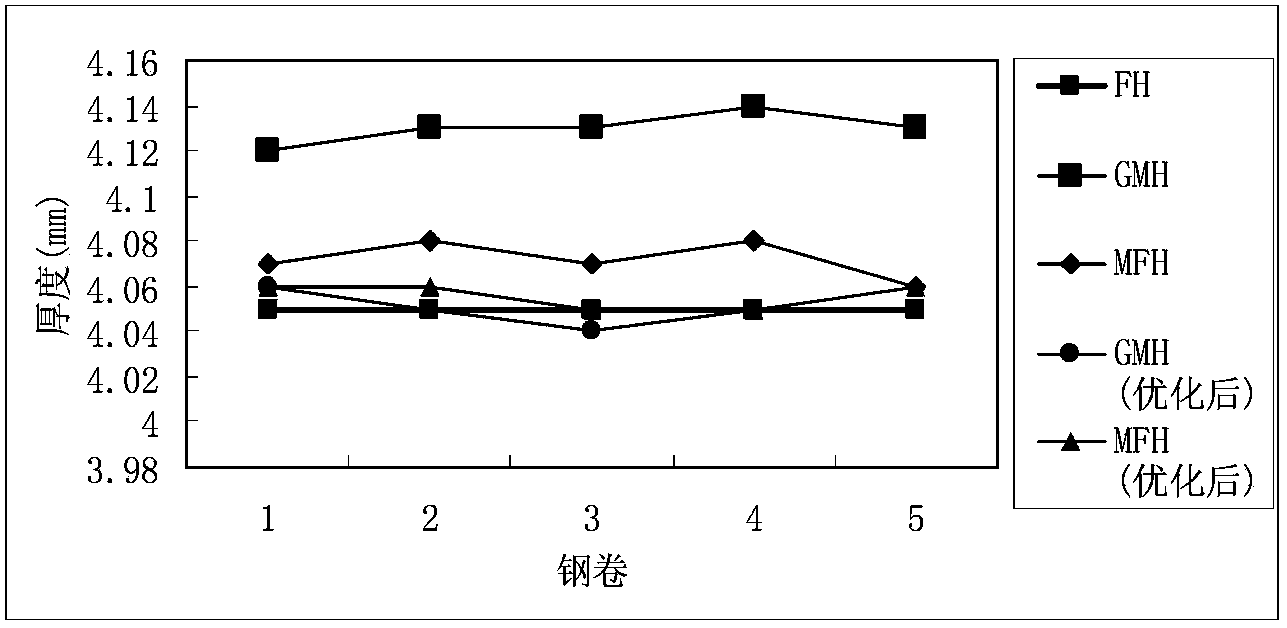

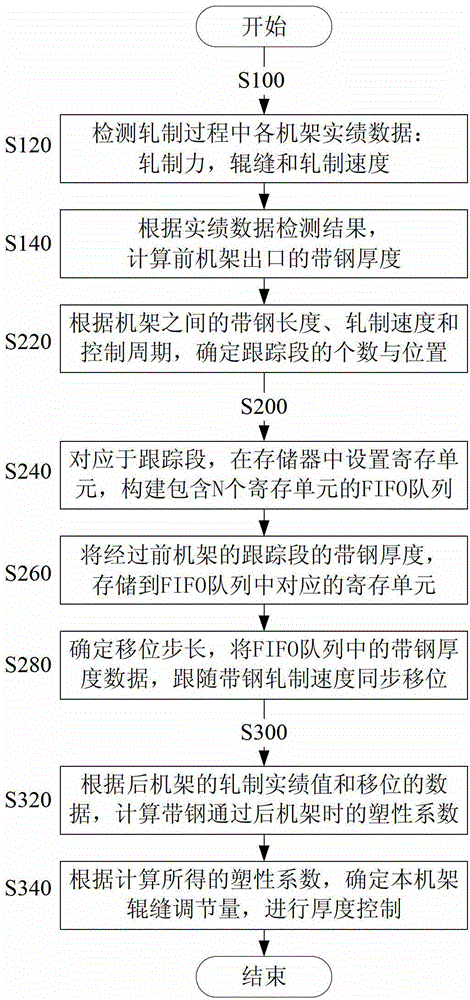

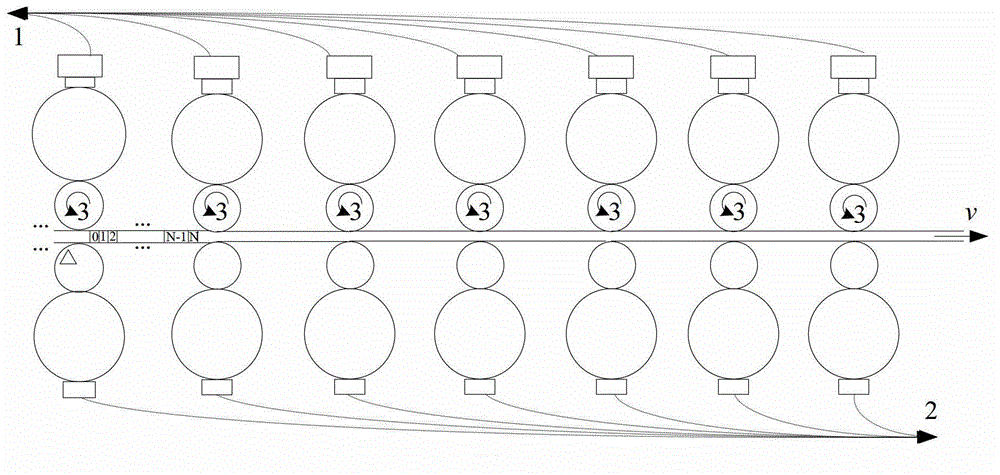

Hot-rolling and finish-rolling strip steel thickness control method

ActiveCN103934278AAccurately obtain the plasticity coefficientImprove thickness control accuracyRoll mill control devicesMetal rolling arrangementsProduction lineStrip mill

The invention provides a hot-rolling and finish-rolling strip steel thickness control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling the thickness of hot-rolling and finish-rolling strip steel through computer programs. According to the detection value of rolling actual performance value of a machine frame, the thickness of strip steel at the outlet of the machine frame is calculated; the moment the calculated strip steel thickness data reaching the machine frame is tracked and combined with the rolling actual performance value data, the plasticity coefficient of the strip steel passing through the machine frame is calculated in real time; according to the plasticity coefficient, which is obtained through real-time calculation, of the strip steel, the roll gap adjustment amount of the machine frame is determined, and feed-forward control is carried out on the thickness of the strip steel in real time. The control method can accurately obtain the plasticity coefficients of different sections of the strip steel, the plasticity coefficients are shown in roll gap adjustment amount of the different sections so as to be adaptive to hardness changes of the strip steel, control precision of the thickness of a finish rolling area is improved, a software programming control method is adopted, hardware investment is not needed, and the method is widely applied to new production lines and production line renovation projects.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing polyurethane foam

InactiveUS8314029B2High thickness accuracyAir can be trappedOther chemical processesDecorative surface effectsCarbamateSpherical cell

A method for manufacturing a polishing pad containing substantially spherical cells and having high thickness accuracy includes preparing a cell-dispersed urethane composition by a mechanical foaming method; continuously discharging the cell-dispersed urethane composition from a single discharge port to a substantially central portion in the width direction of a face material A, while feeding the face material A; laminating a face material B on the cell-dispersed urethane composition; then uniformly adjusting the thickness of the cell-dispersed urethane composition by thickness adjusting means; curing the cell-dispersed urethane composition with the thickness adjusted in the preceding step without applying any additional load to the composition so that a polishing sheet including a polyurethane foam is formed; and cutting the polishing sheet.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Rare earth metal-based permanent magnet, and process for producing the same

InactiveUS7053745B2High thickness accuracyImprove corrosion resistancePermanent magnetsInorganic material magnetismMetal formingRare earth

A rare earth metal-based permanent magnet has a film layer formed substantially of only a fine metal powder on a metal forming the surface of the magnet. The rare earth metal-based permanent magnet having the film layer on its surface is produced in the following manner: A rare earth metal-based permanent magnet and a fine metal powder forming material are placed into a treating vessel, where both of them are vibrated and / or agitated, whereby a film layer made of a fine metal powder produced from the fine metal powder producing material is formed on a metal forming the surface of the magnet. Thus, the formation of a corrosion-resistant film such as plated film can be achieved at a high thickness accuracy by forming an electrically conductive layer uniformly and firmly on the entire surface of the magnet without use of a third component such as a resin and a coupling agent.

Owner:SUMITOMO SPECIAL METAL CO LTD

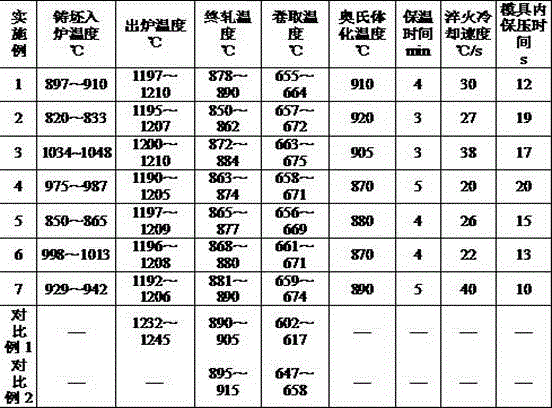

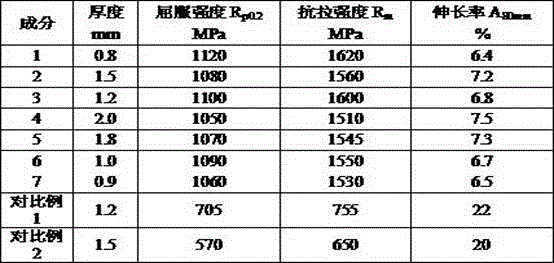

Thin hot forming steel rolled directly through sheet billet and with tensile strength being larger than or equal to 1500MPa and production method

ActiveCN106086685AImprove surface qualityUniform tissueWork treatment devicesMetal rolling arrangementsThin slabHigh pressure water

The invention discloses thin hot forming steel rolled directly through a sheet billet and with the tensile strength being larger than or equal to 1500MPa. The thin hot forming steel comprises, by weight, 0.21%-0.25% of C, 0.26%-0.30% of Si, 1.0%-1.3% of Mn, 0-0.01% of P, 0-0.005% of S, 0.015%-0.060% of Als, 0.25%-0.30% of Cr, 0.026%-0.030% of Ti or 0.026%-0.030% of Nb or 0.026%-0.030% of V or a mixture of any two of the above components, 0.003%-0.004% of B and 0-0.005% of N. The production method includes the production steps of molten iron desulphurization, smelting and refining through an electric furnace or converter, continuous casting, dephosphorization treatment before entering a soaking pit, soaking, heating, high pressure water dephosphorization before entering a rolling mill, rolling, cooling, coiling, austenitizing, mold stamping forming and quenching. The thin hot forming steel is short in process, good in surface quality and high in thickness precision; the quality requirement of cold-rolled products can be met, and complex deformation can be achieved smoothly; and moreover, no resilience exists after deformation, and dimensional accuracy of parts is high.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com