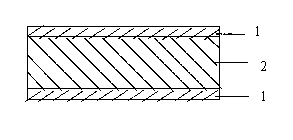

Method for preparing aluminium alloy compound foil by compounding cold rolling and warm rolling

A rolling composite and aluminum alloy technology, applied in the field of aluminum alloy, can solve problems affecting product quality, not meeting the requirements of scientific development, long production process, etc., and achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

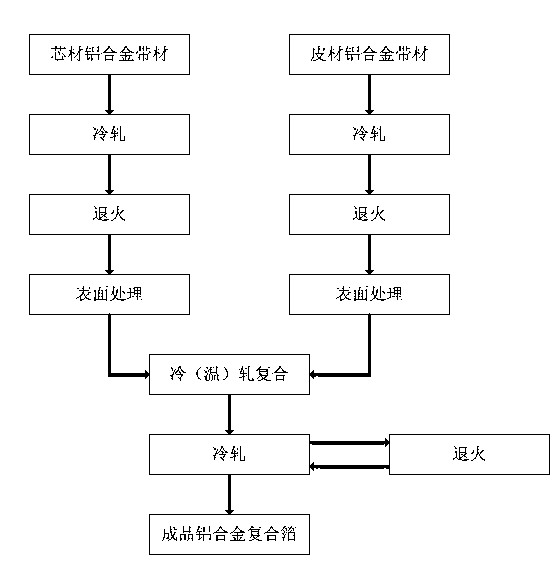

Method used

Image

Examples

Embodiment 1

[0017] (1) Cold-rolling the 4343 skin material aluminum alloy coil and 3003 core material aluminum alloy coil respectively to obtain 0.4mm thick 4343 skin material aluminum alloy cold-rolled strip and 3.6mm thick 3003 core material aluminum alloy cold-rolled strip , anneal the cold-rolled skin aluminum alloy and core aluminum alloy strip at 300 ℃ for 6h;

[0018] (2) Clean the surface of the annealed 4343 skin aluminum alloy and 3003 core aluminum alloy strip to remove oil, and clean it with sand belt or wire brush. After cleaning, the temperature of the skin aluminum alloy is 20 °C, and the core aluminum alloy The alloy was heated to 160°C, rolled and composited, and the reduction ratio was controlled to 54.5% to obtain an aluminum alloy composite strip with a thickness of 2.0mm;

[0019] (3) The aluminum alloy composite strip was annealed at 300 °C for 6 hours, the total cold rolling reduction rate was controlled to 95%, and the cold rolling was carried out for 3 passes to a...

Embodiment 2

[0022] (1) Cold-rolling the 4045 skin material aluminum alloy coil and 3003 core material aluminum alloy coil respectively to obtain 0.45mm thick 4343 skin material aluminum alloy cold-rolled strip and 4.0mm thick 3003 core material aluminum alloy cold-rolled strip , anneal the cold-rolled skin aluminum alloy and core aluminum alloy strip at 350℃ for 4h;

[0023] (2) Clean and remove oil from the surface of the annealed 4045 skin aluminum alloy and 3003 core aluminum alloy strip, clean with sand belt or wire brush, and clean the skin aluminum alloy and core aluminum alloy strip after cleaning. Rolling and cladding were carried out at 20°C, and the reduction ratio was controlled to 57% to obtain an aluminum alloy clad strip with a thickness of 2.1 mm;

[0024] (3) The aluminum alloy composite strip was annealed at 350 °C for 4 hours, the total cold rolling reduction rate was controlled to 94%, and the cold rolling was performed for 4 passes to a thickness of 0.12 mm. After cold...

Embodiment 3

[0027] (1) Cold-rolling 4045 skin material aluminum alloy coil and 3003 core material aluminum alloy coil respectively to obtain 0.5mm thick 4343 skin material aluminum alloy cold-rolled strip and 5.0mm thick 3003 core material aluminum alloy cold-rolled strip , anneal the cold rolled skin aluminum alloy and core aluminum alloy strip at 400℃ for 2h;

[0028] (2) Clean and remove oil from the surface of the annealed 4045 skin aluminum alloy and 3003 core aluminum alloy strip, clean with sand belt or wire brush, and clean the skin aluminum alloy and core aluminum alloy strip after cleaning. Heating to 250 ℃ for rolling and cladding, controlling the reduction rate to 40%, to obtain an aluminum alloy clad strip with a thickness of 3.6mm;

[0029] (3) The aluminum alloy composite strip was annealed at 350 ℃ for 4 hours, the total reduction rate of cold rolling was controlled to 95.2%, and the cold rolling was carried out for 5 passes to a thickness of 0.17mm. rolling, and the redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com