Thin hot forming steel rolled directly through sheet billet and with tensile strength being larger than or equal to 1500MPa and production method

A technology of tensile strength and hot-formed steel, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of short process, high manufacturing cost, ultra-high-strength parts demand, low strength level, etc., to achieve short process, No rebound, good surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

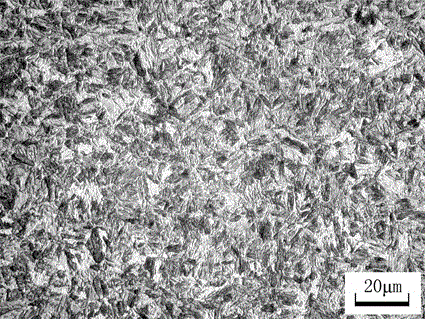

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below:

[0040] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

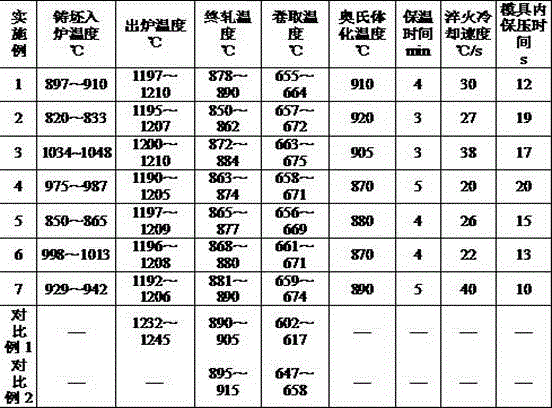

[0041] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative example;

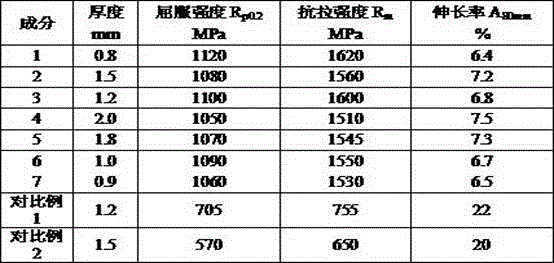

[0042] Table 3 is a list of performance testing conditions of each embodiment of the present invention and comparative examples.

[0043] Each embodiment of the present invention is all produced by the following process:

[0044] 1) Desulfurization of molten iron, and control S≤0.002%, and the exposed surface of molten iron after slag removal is not less than 96%;

[0045] 2) Conventional electric furnace or converter smelting, and conventional refining;

[0046] 3) Perform continuous casting, control the superheat of the tundish molten steel at 15-30°C, the thickness of the slab at 52-55mm, and the casting speed at 3.7-7.0 m / min;

[0047] 4) Carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com