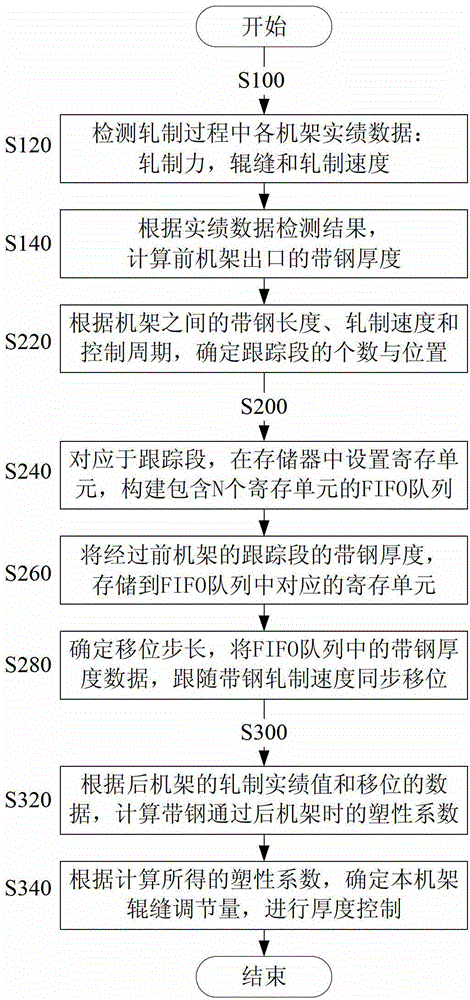

Hot-rolling and finish-rolling strip steel thickness control method

A technology of thickness control and strip steel, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of poor thickness control accuracy of hot-rolled and finished-rolled strip steel, so as to improve product thickness accuracy, avoid influence, Improve the effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

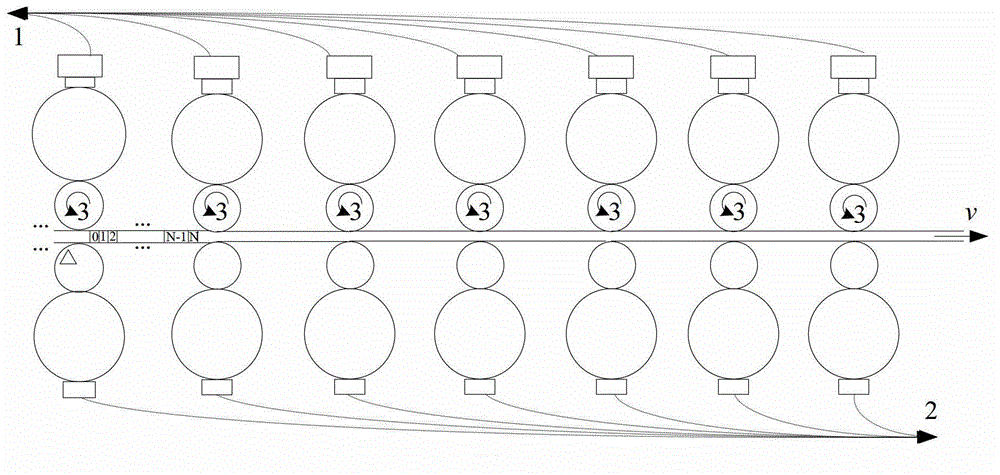

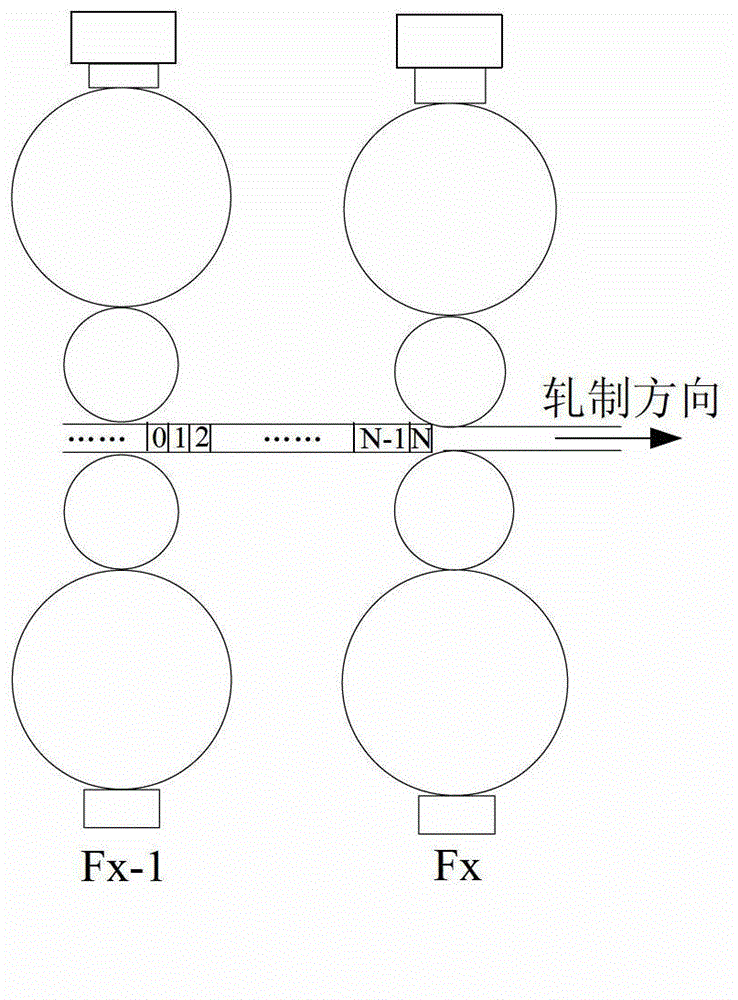

Method used

Image

Examples

Embodiment

[0090] The method for controlling the thickness of the hot-rolled finish-rolled strip of the present invention is implemented on all stands (F1-F7) of the finish-rolling unit of the 1580mm hot-rolling production line, starting from the F1 stand to track the exit strip data of the stand, and F2 -F7 adopts the control method of the present invention to calculate the plasticity coefficient of the strip steel in the frame and control the thickness. After the control method of the invention is implemented, the thickness control precision of the finish rolling of the 1580 hot rolling production line is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com