High precision strip rolling thickness control method based on feedback signals by thickness gauge

A feedback signal and thickness control technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of lack of practicability, fluctuation of rolled thickness cannot be reflected in time, and poor thickness control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

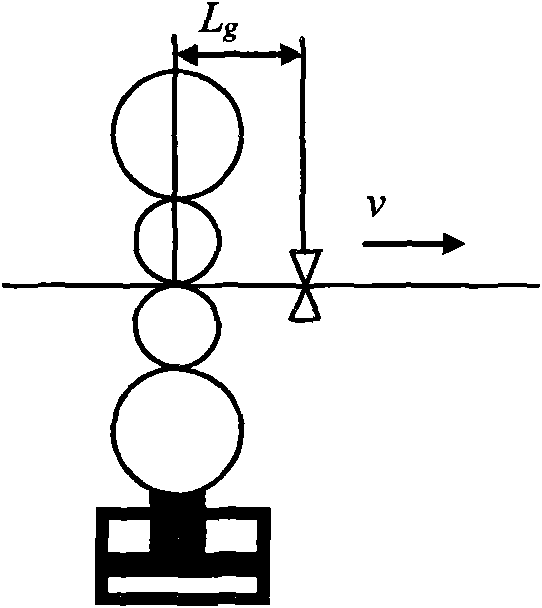

[0121] Select rolling steel grade: ST12

[0122] Incoming material width 250mm, incoming material thickness 0.50mm, outlet thickness 0.40mm, rolling speed 2.5m / s

[0123] Rolling mill stiffness M = 550kN / mm, strip plasticity coefficient Q = 450kN / mm

[0124] The thickness gauge is an X-ray thickness gauge, and the distance L between the thickness gauge and the center line of the rolling mill roll g =765mm

[0125] The monitoring AGC control parameters and methods based on the above conditions are as follows:

[0126] 1) Input the relevant data of the four-high reversible rolling mill and strip steel into the computer, the stiffness coefficient of the rolling mill M = 550kN / mm, the plasticity coefficient of the strip steel Q = 450kN / mm, the distance L between the thickness gauge and the roll center line of the rolling mill g =765mm;

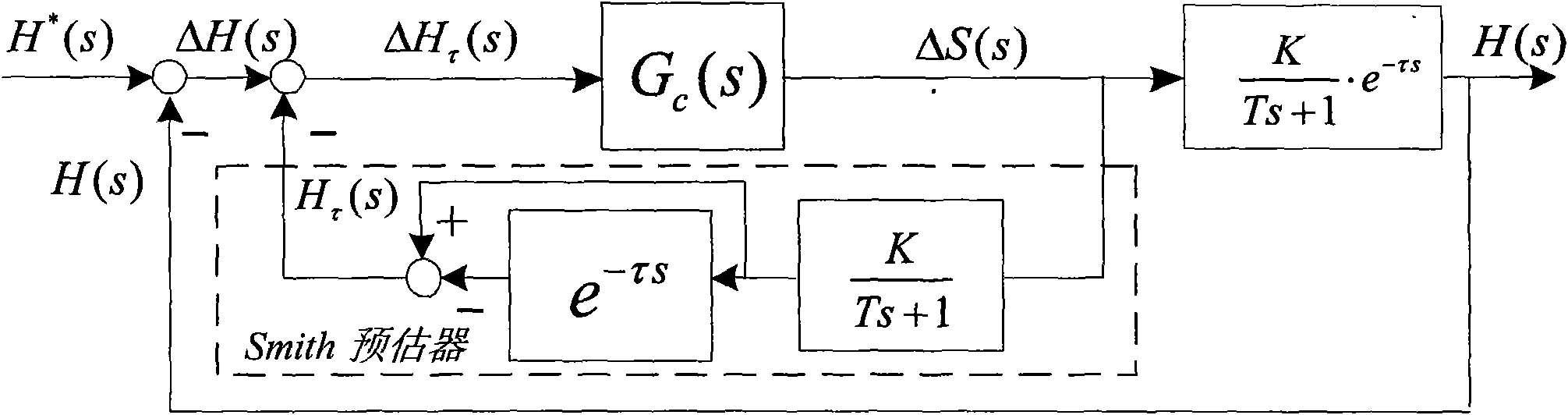

[0127] 2) Determine the proportional coefficient of the thickness control object of the four-high reversing rolling mill and the time constan...

Embodiment 2

[0144] Select rolling steel grade: 65Mn

[0145] Incoming material width 130mm, incoming material thickness 1.0mm, outlet thickness 0.80mm, rolling speed 3.0m / s

[0146] The parameters of the four-high reversible rolling mill are as follows: rigidity M = 400kN / mm, plasticity coefficient Q of the strip steel = 500kN / mm

[0147] The thickness gauge is an X-ray thickness gauge, and the distance L between the thickness gauge and the center line of the rolling mill roll g =500mm

[0148] The monitoring AGC control parameters and methods based on the above conditions are as follows:

[0149] 1) Input the relevant data of the four-high reversible rolling mill and strip steel into the computer, the stiffness coefficient of the rolling mill M = 400kN / mm, the plasticity coefficient of the strip steel Q = 500kN / mm, the distance L between the thickness gauge and the roll center line of the rolling mill g =500mm;

[0150] 2) Determine the proportional coefficient of the thickness contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stiffness coefficient | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

| Stiffness coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com