Patents

Literature

123 results about "Roll center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The roll center of a vehicle is the notional point at which the cornering forces in the suspension are reacted to the vehicle body. There are two definitions of roll center. The most commonly used is the geometric (or kinematic) roll center; the Society of Automotive Engineers uses a force-based definition.

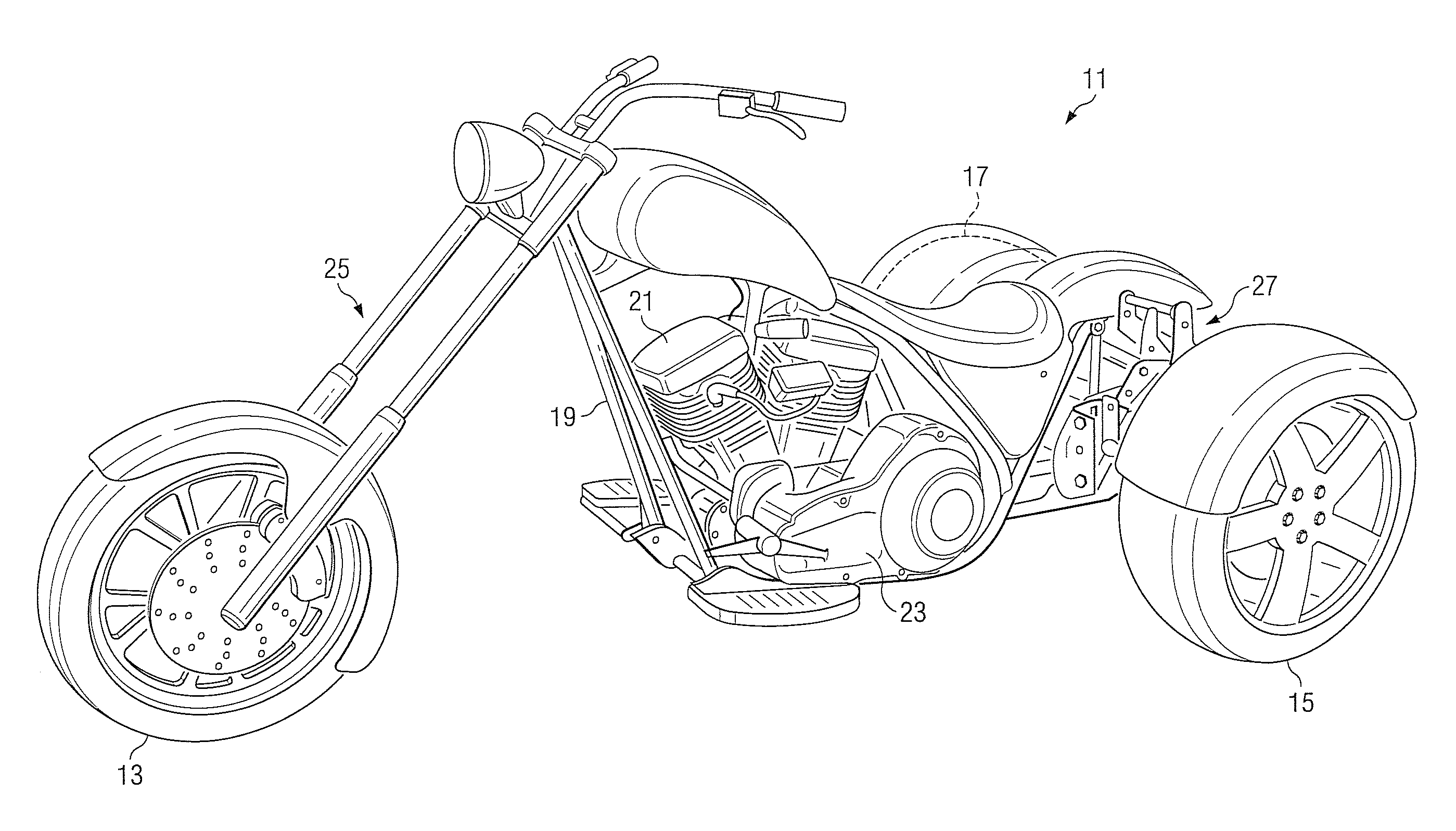

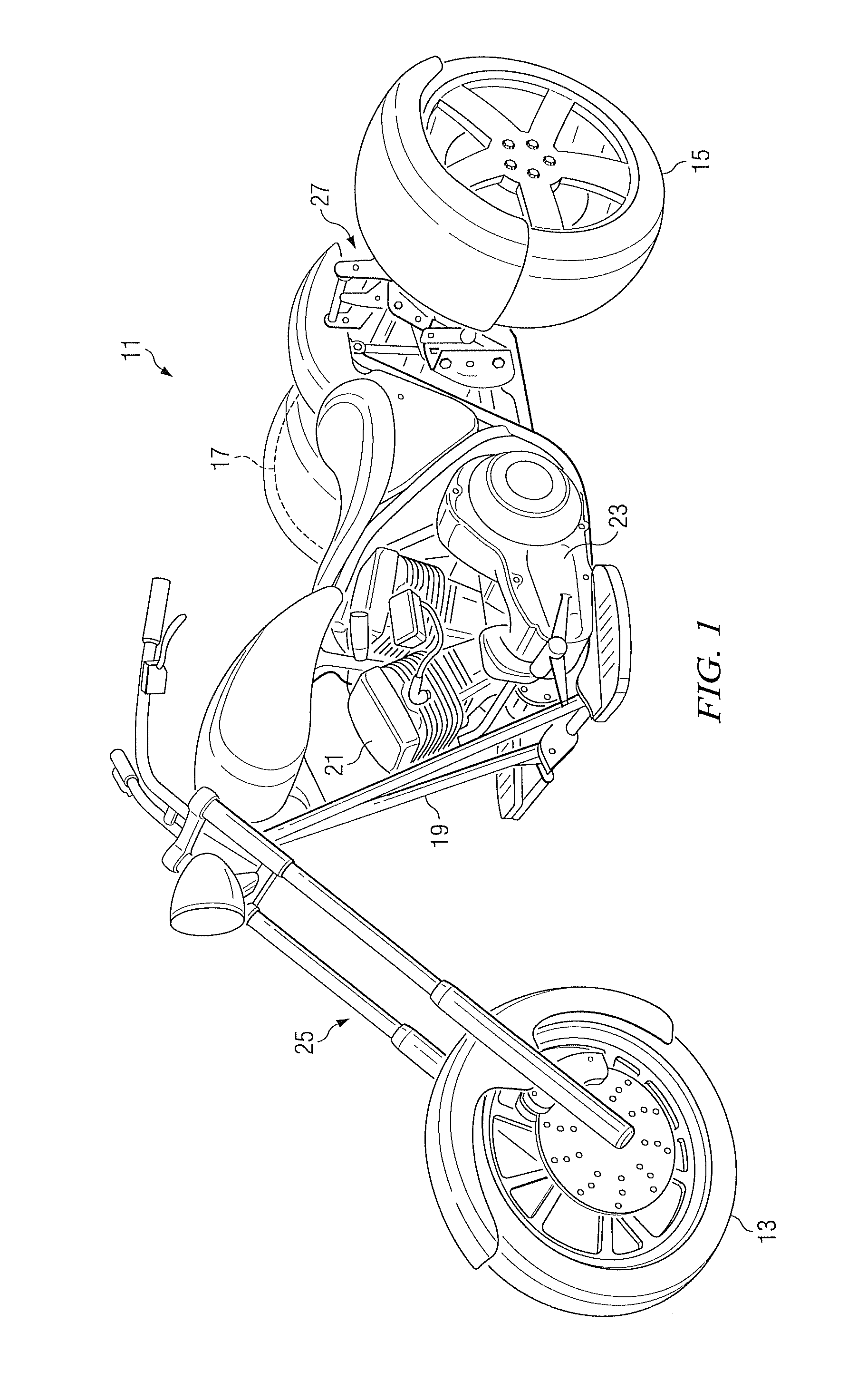

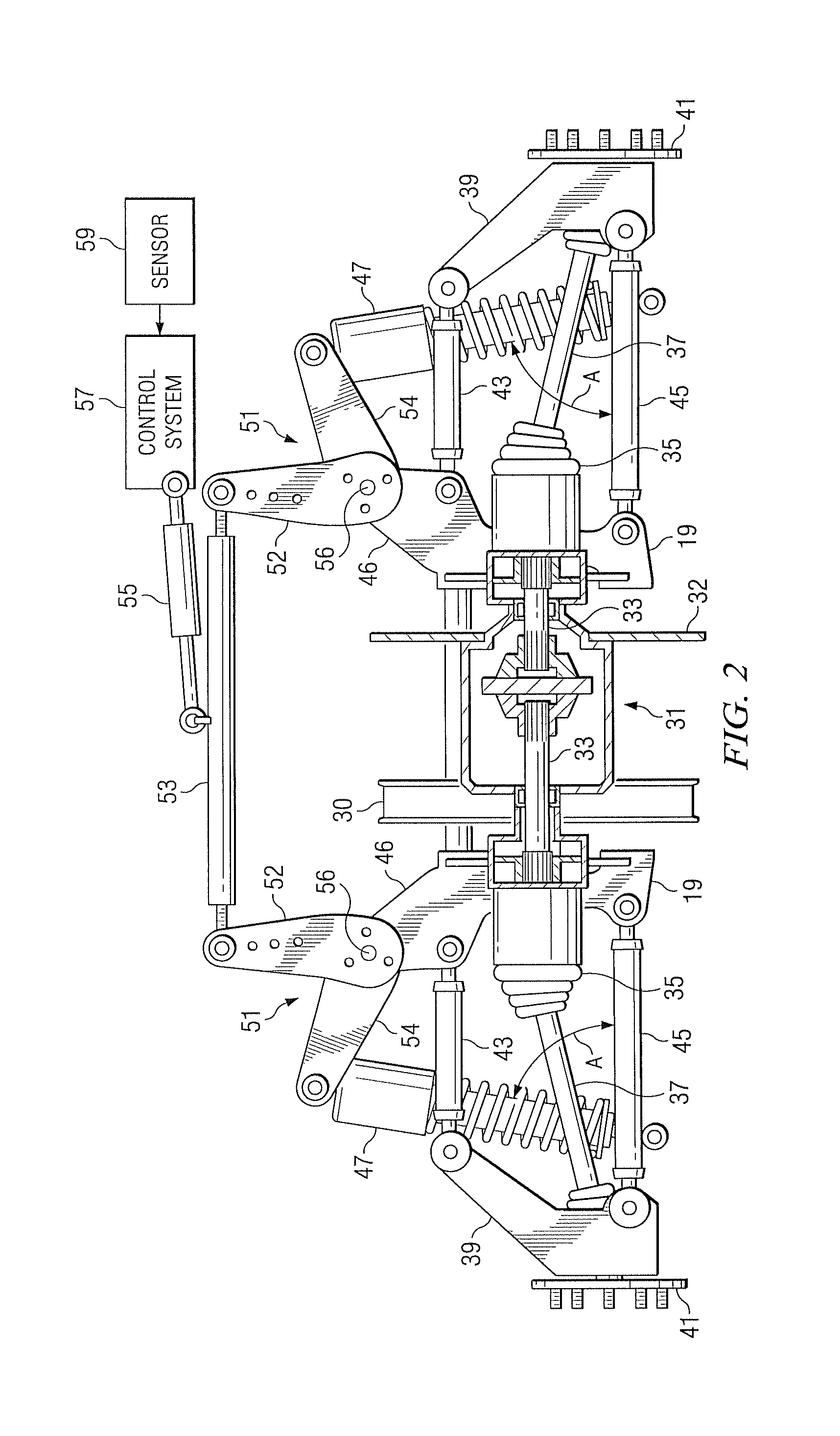

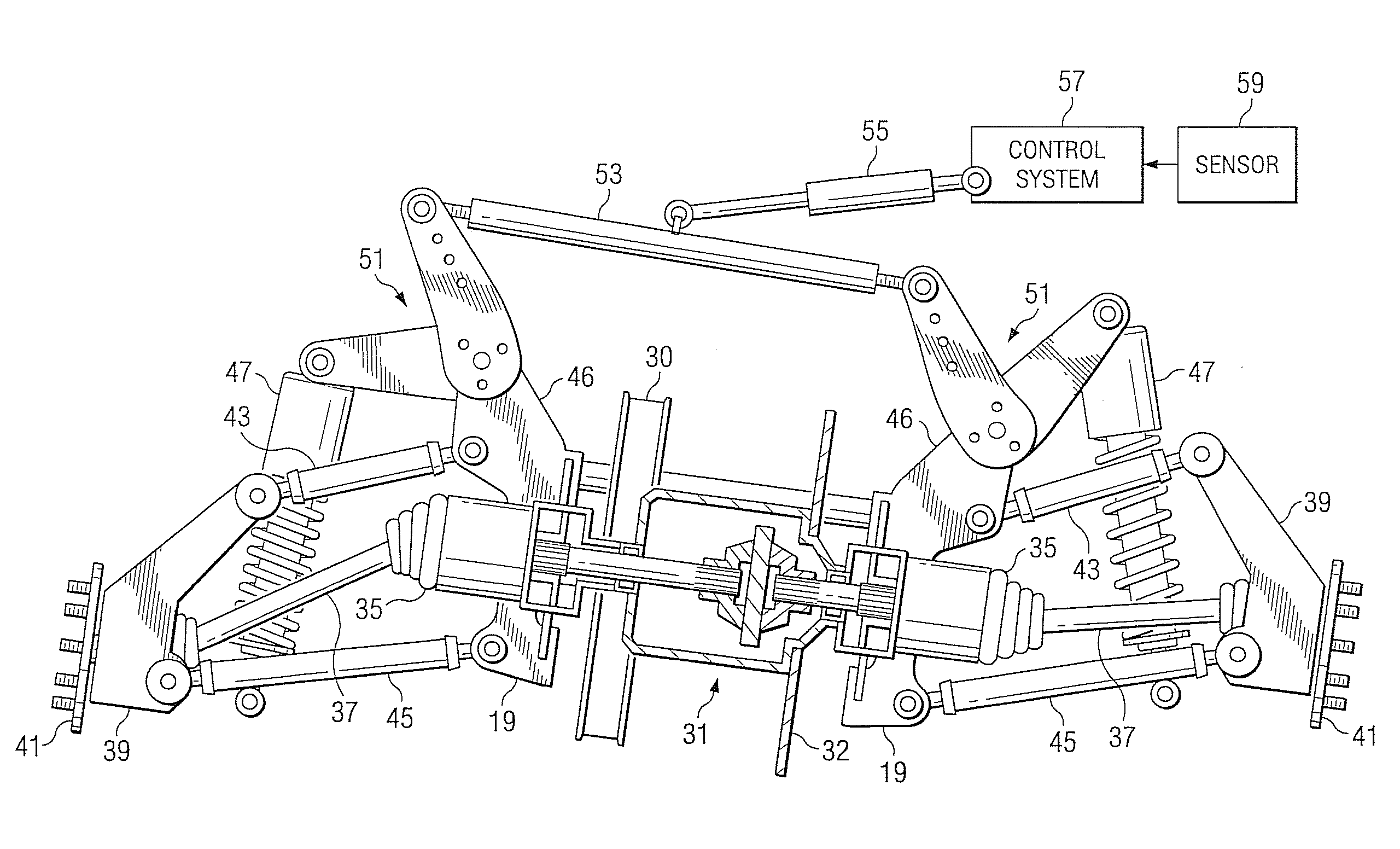

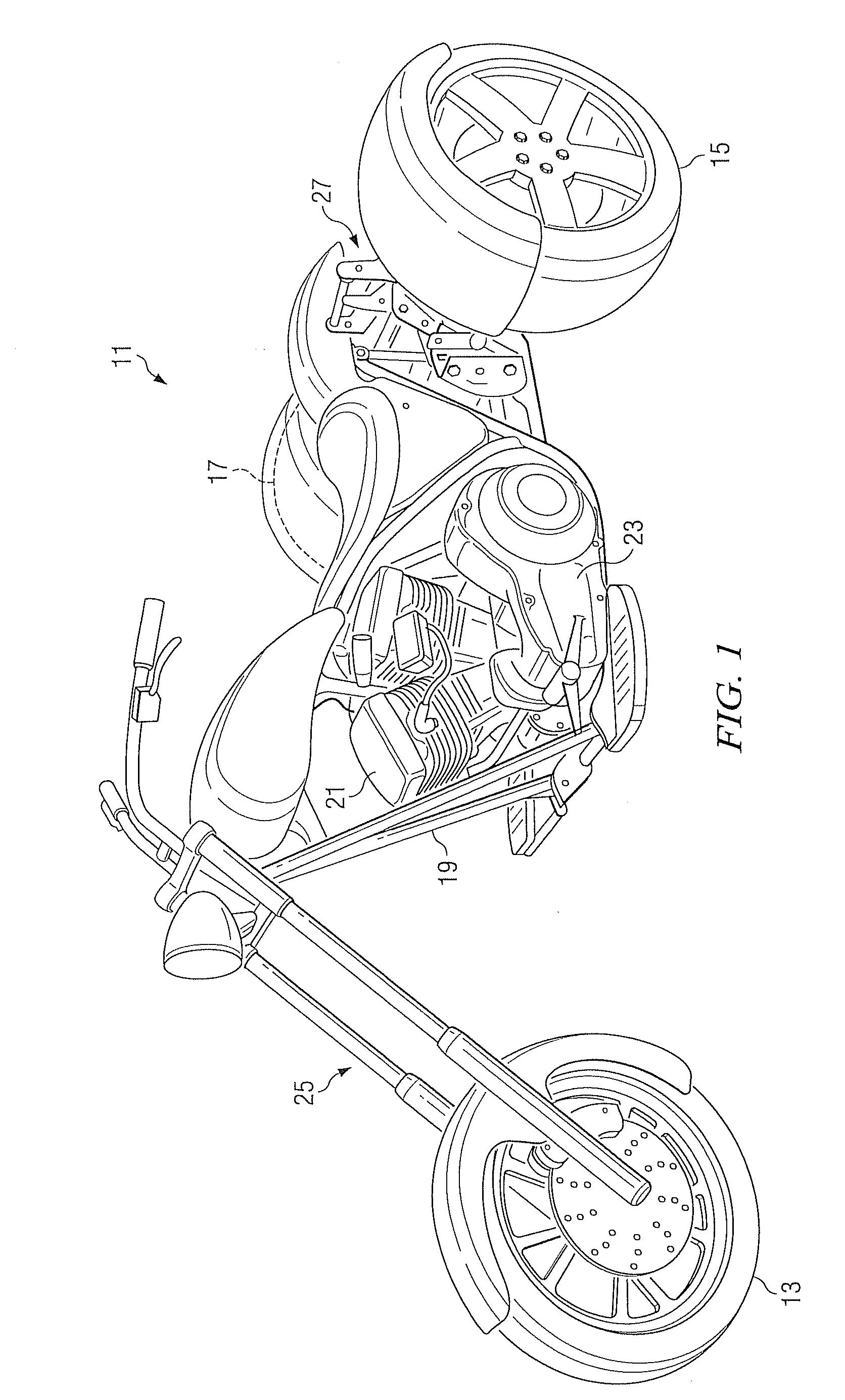

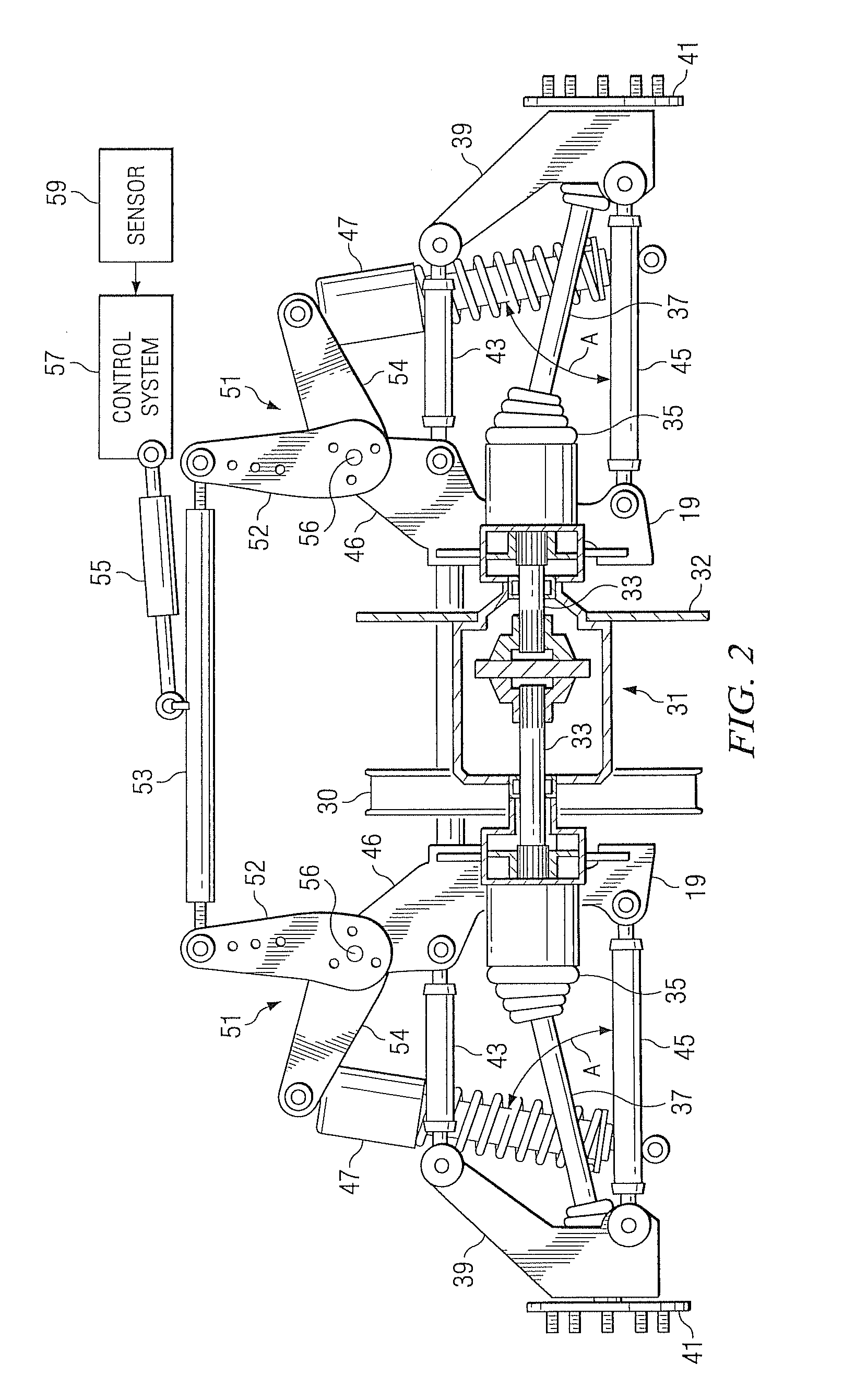

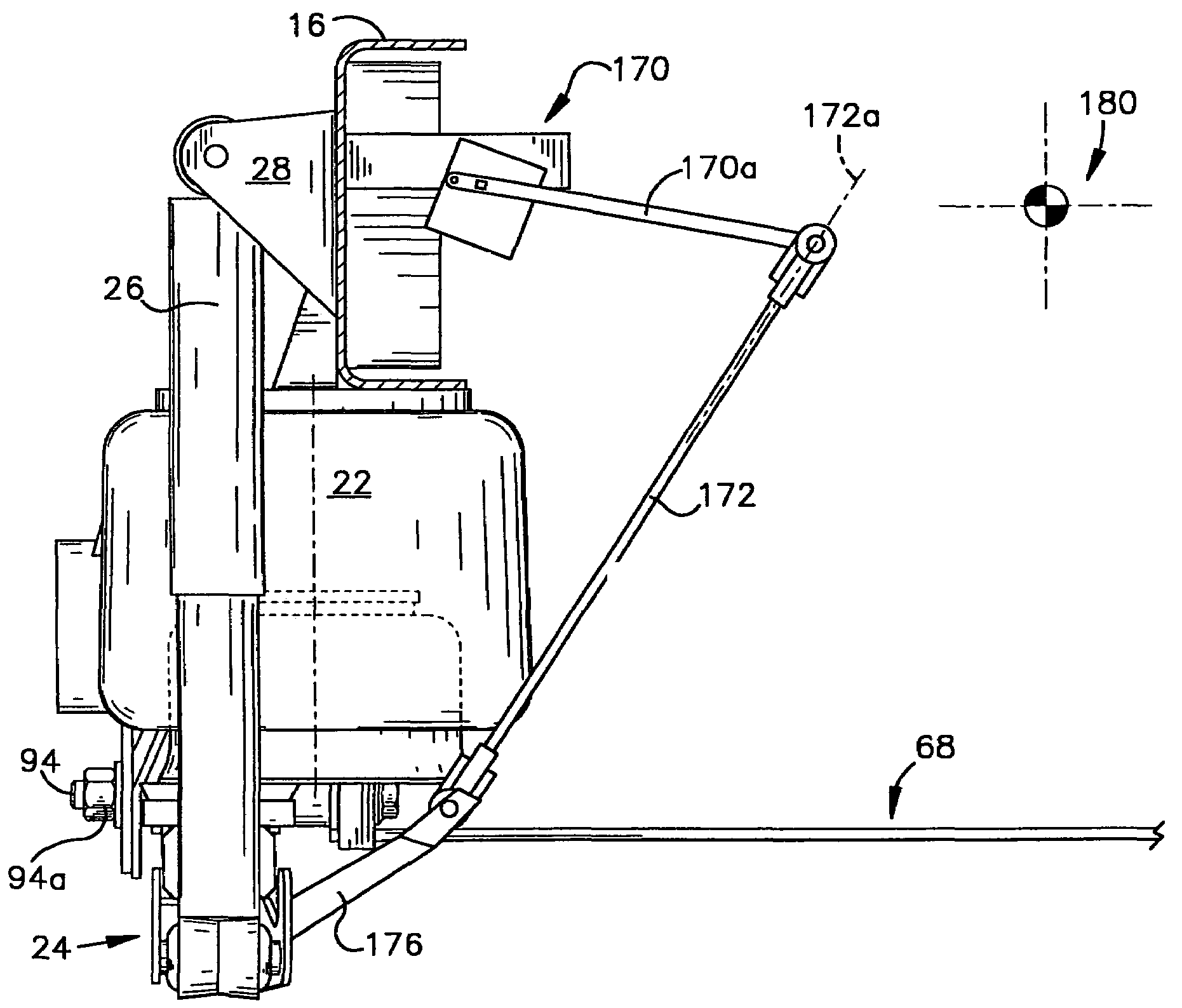

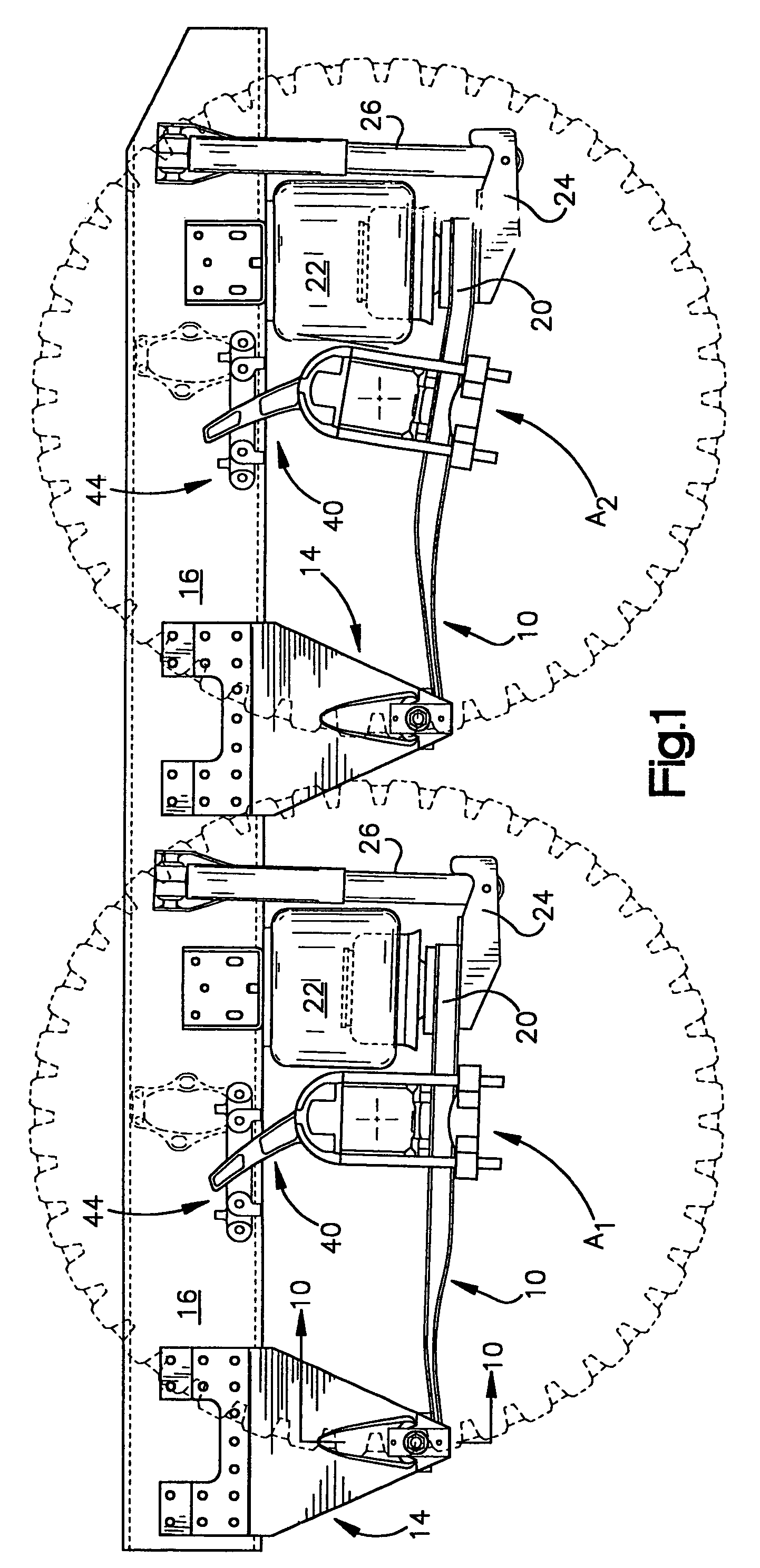

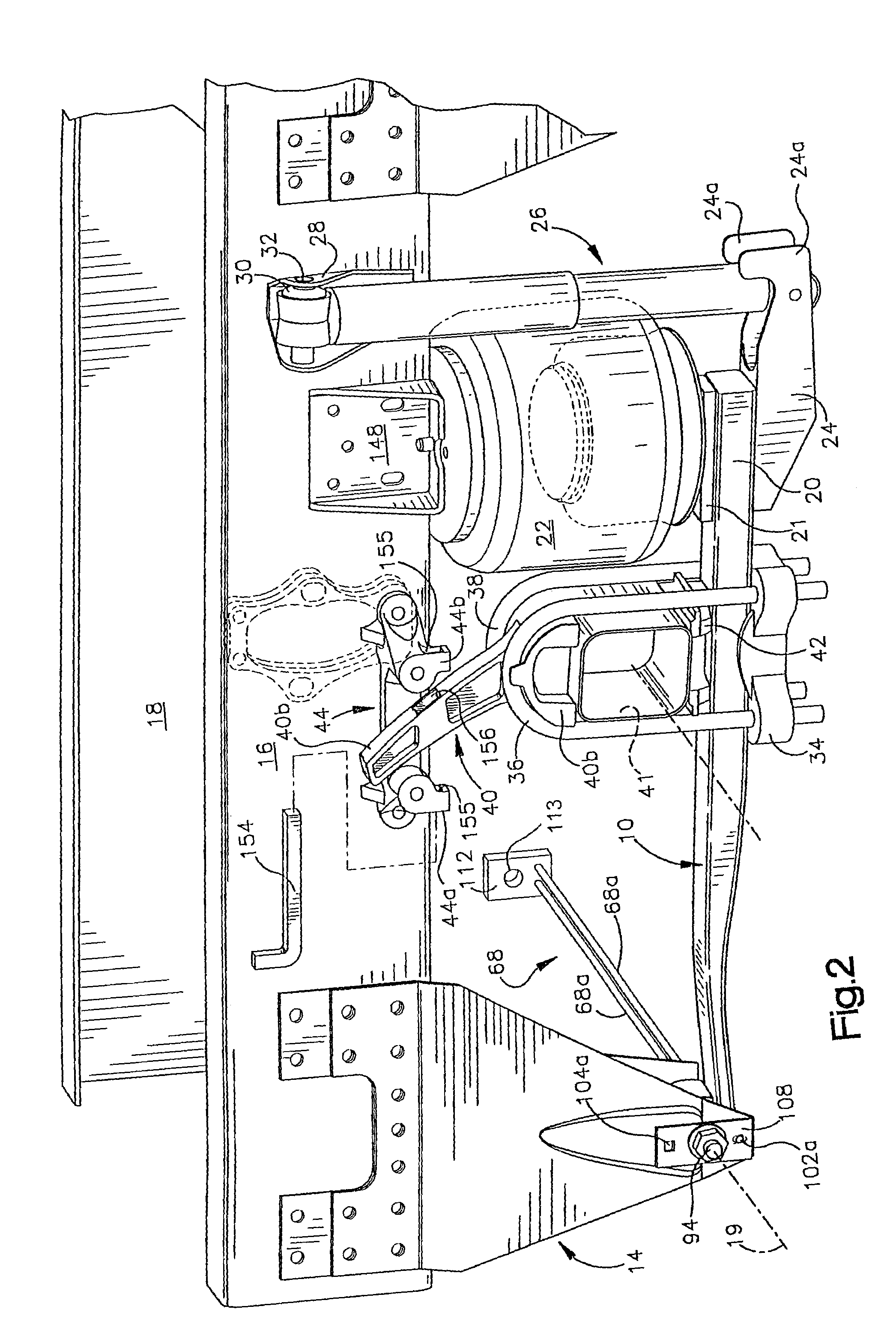

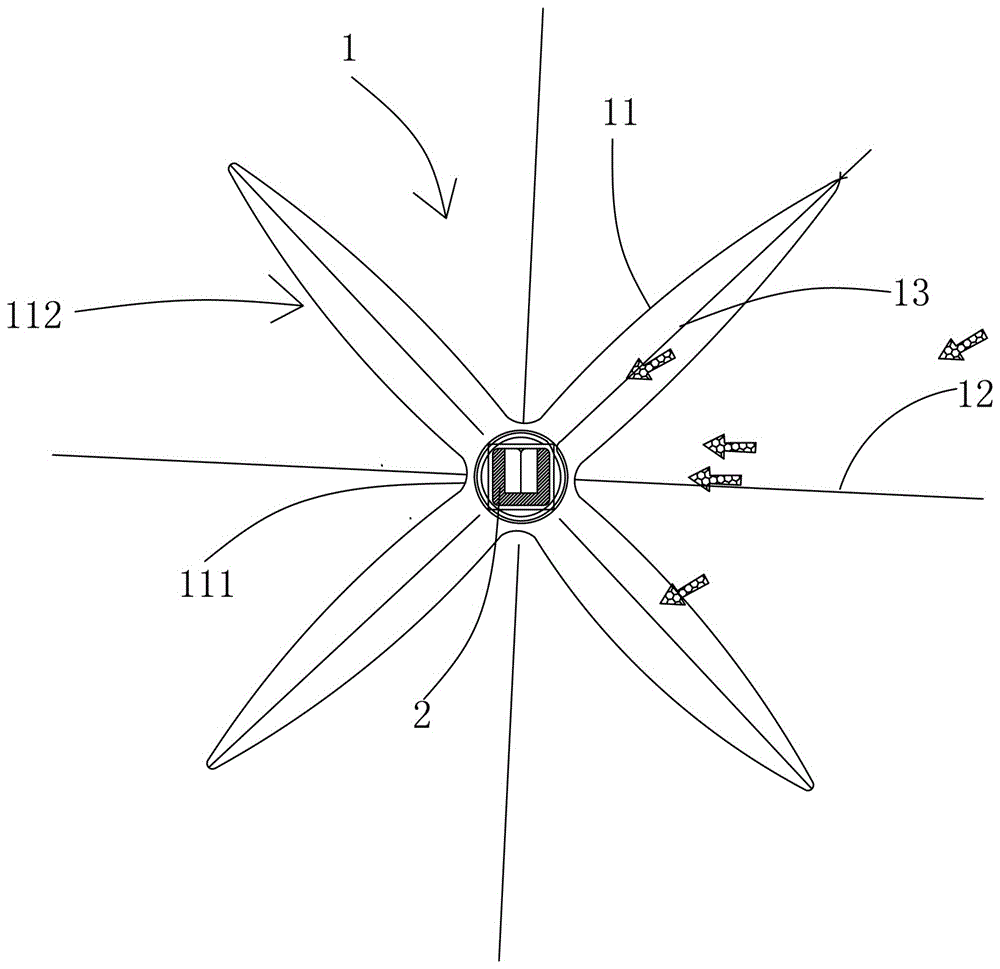

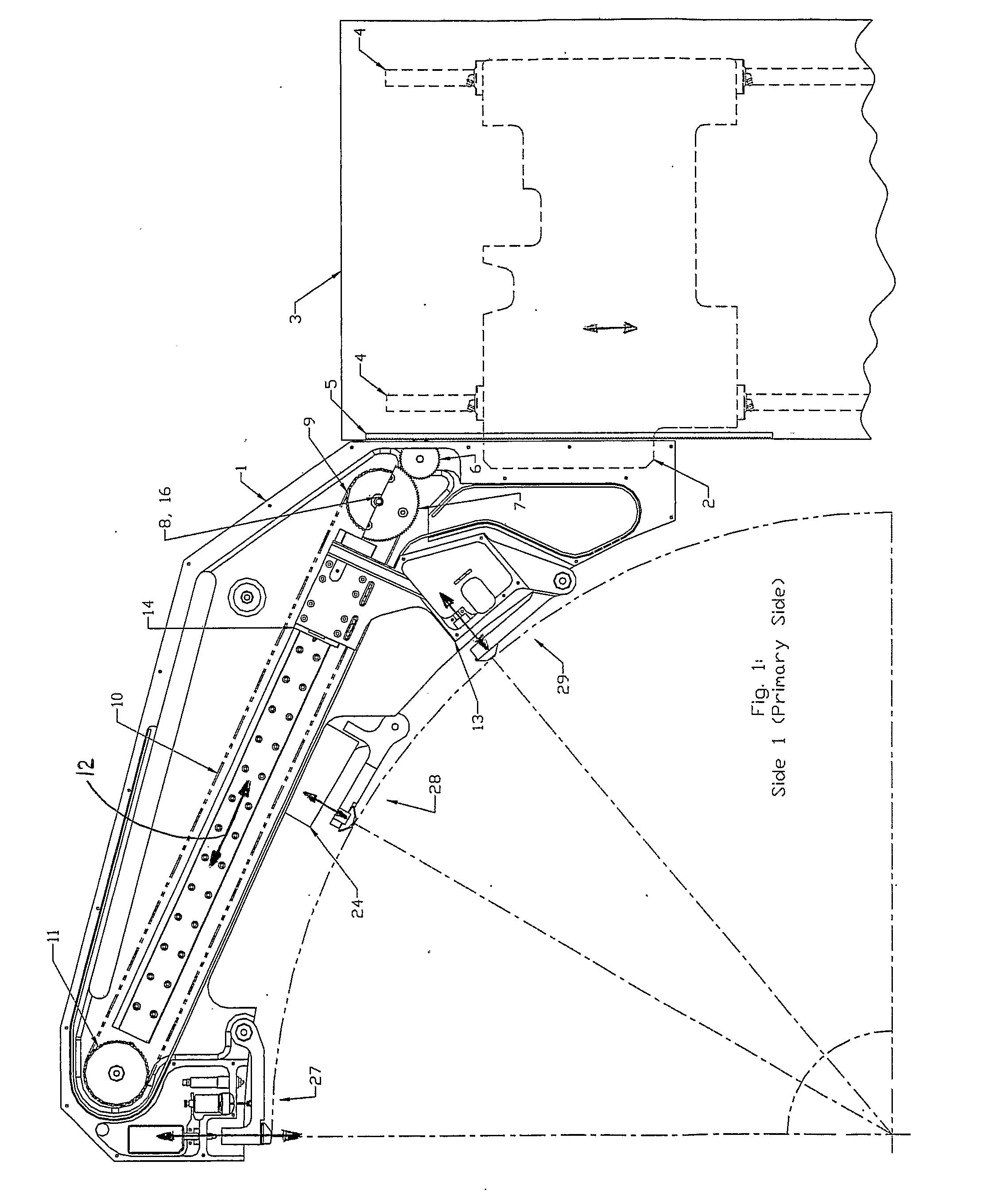

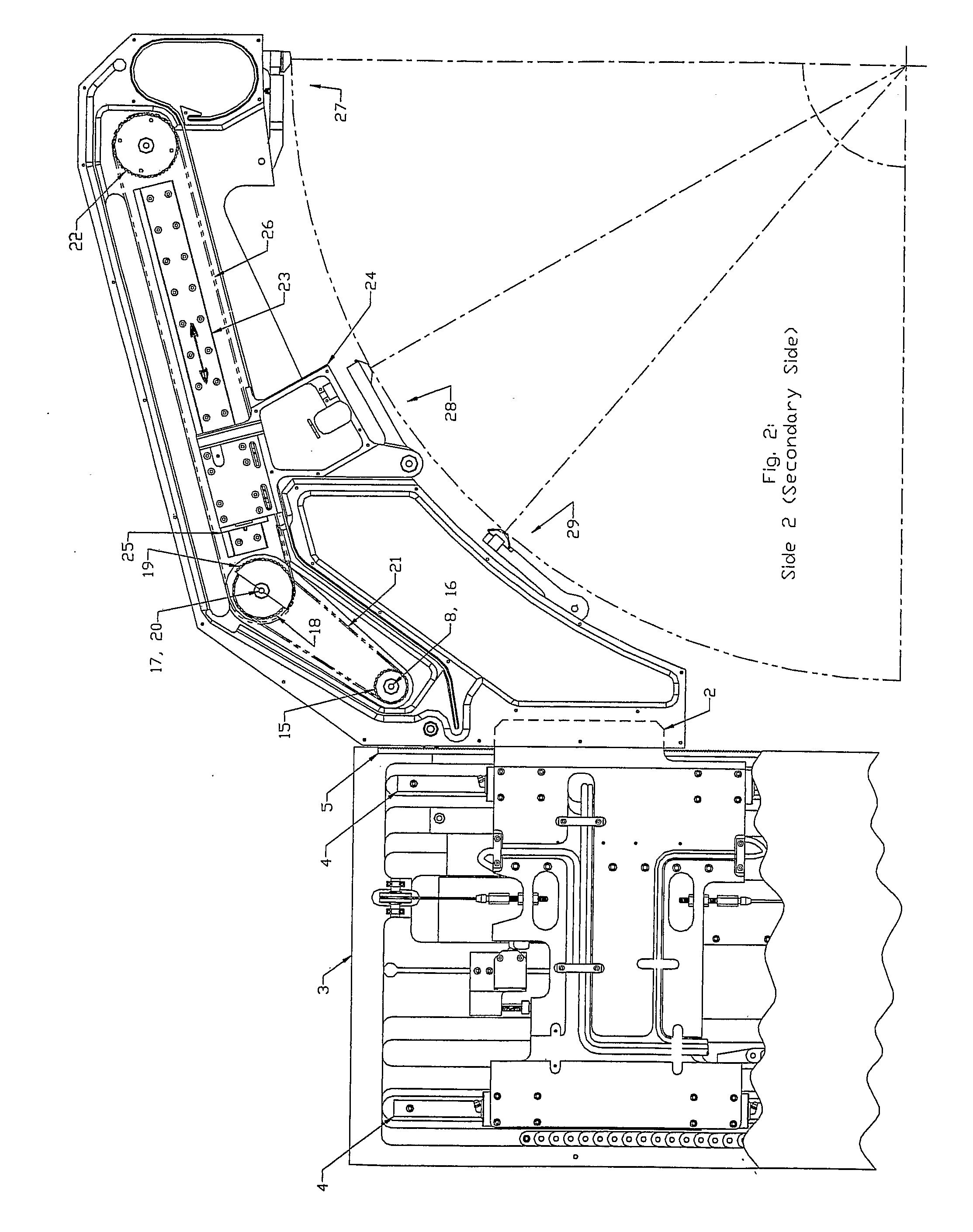

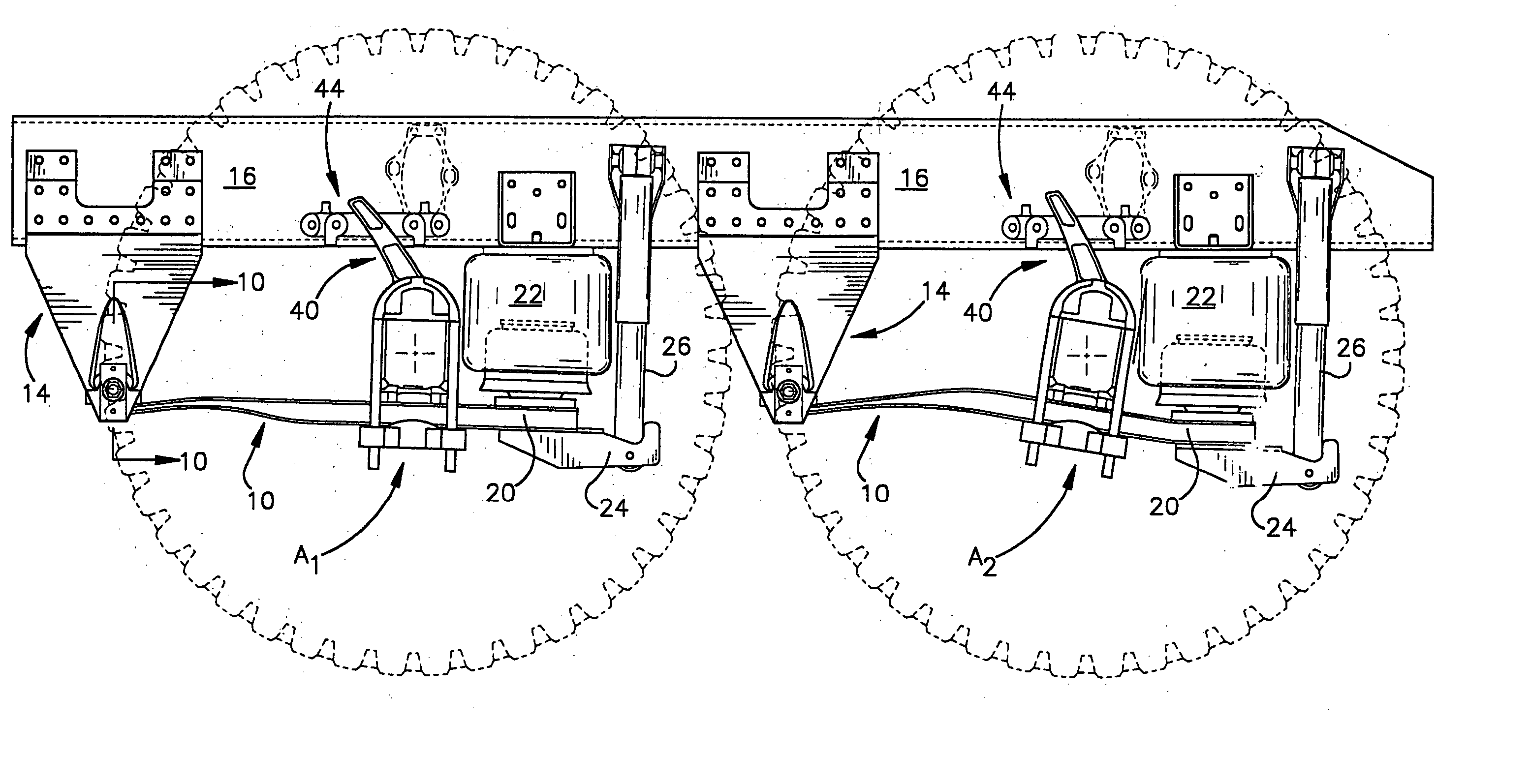

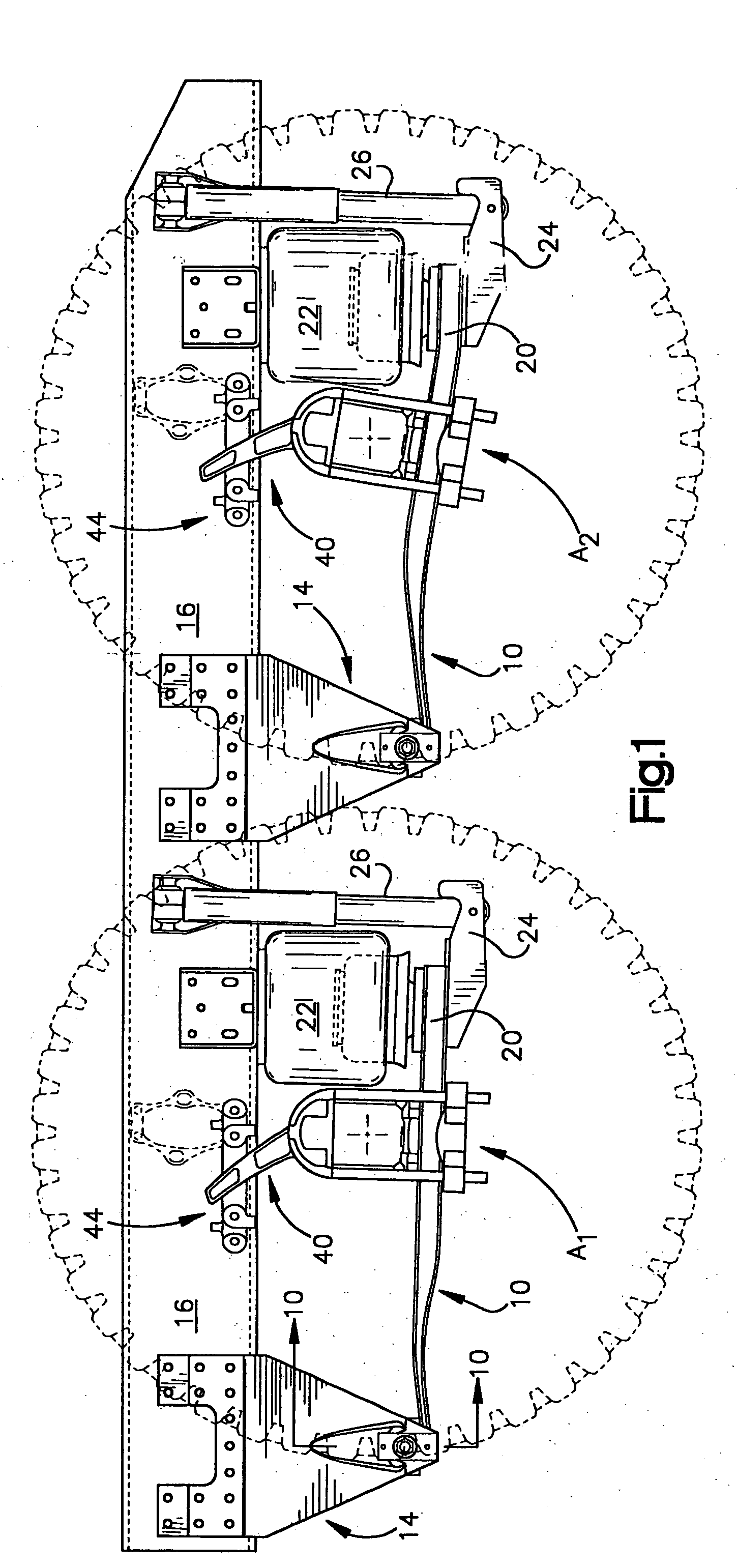

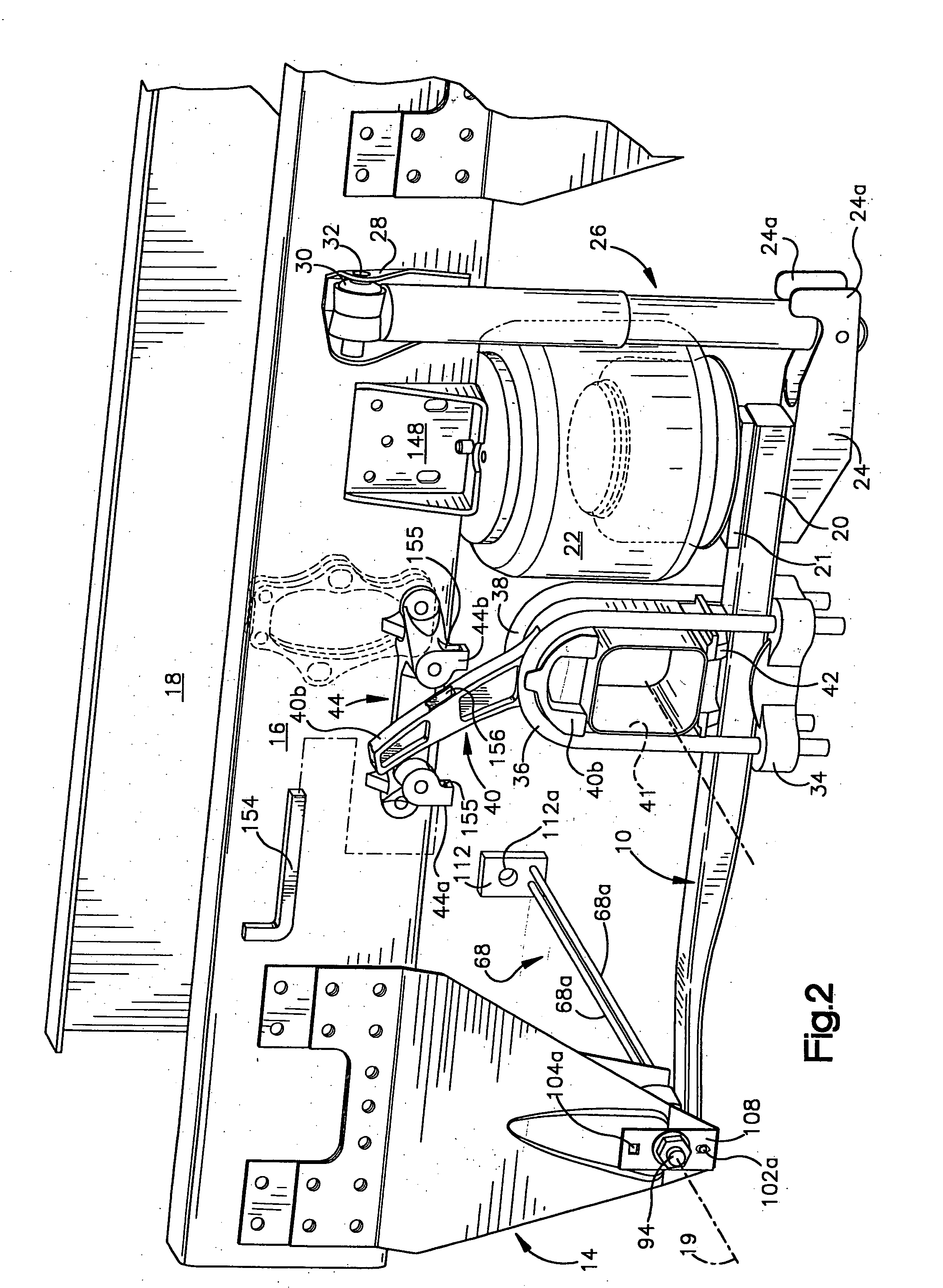

Tilting independent suspension system for motorcycle trike

A tilting suspension system is adapted for use with a vehicle having three wheels and a frame. The system has two sets of control arms, each set of control arms being pivotally connected to one side of the frame. An upright is pivotally connected to each set of control arms, each upright having a rotatable hub for allowing one of the wheels to be mounted thereto. Two rocker arms are pivotally connected to the frame, and a control link is pivotally connected to each of the rocker arms, such that pivoting of one rocker arm causes corresponding pivoting of the other rocker arm. A link member operably connects each rocker arm to a corresponding upright, such that pivoting of each rocker arm causes corresponding movement of the uprights. An actuator is configured to selectively pivot the rocker arms, such that actuation of the actuator pivots the rocker arms, thereby causing the frame to rotate about a generally longitudinal roll center and causing each upright to rotate about a generally longitudinal axis.

Owner:MATTHIES LAWAYNE

Tilting Independent Suspension System for Motorcycle Trike

A tilting suspension system is adapted for use with a vehicle having three wheels and a frame. The system has two sets of control arms, each set of control arms being pivotally connected to one side of the frame. An upright is pivotally connected to each set of control arms, each upright having a rotatable hub for allowing one of the wheels to be mounted thereto. Two rocker arms are pivotally connected to the frame, and a control link is pivotally connected to each of the rocker arms, such that pivoting of one rocker arm causes corresponding pivoting of the other rocker arm. A link member operably connects each rocker arm to a corresponding upright, such that pivoting of each rocker arm causes corresponding movement of the uprights. An actuator is configured to selectively pivot the rocker arms, such that actuation of the actuator pivots the rocker arms, thereby causing the frame to rotate about a generally longitudinal roll center and causing each upright to rotate about a generally longitudinal axis.

Owner:MATTHIES LAWAYNE

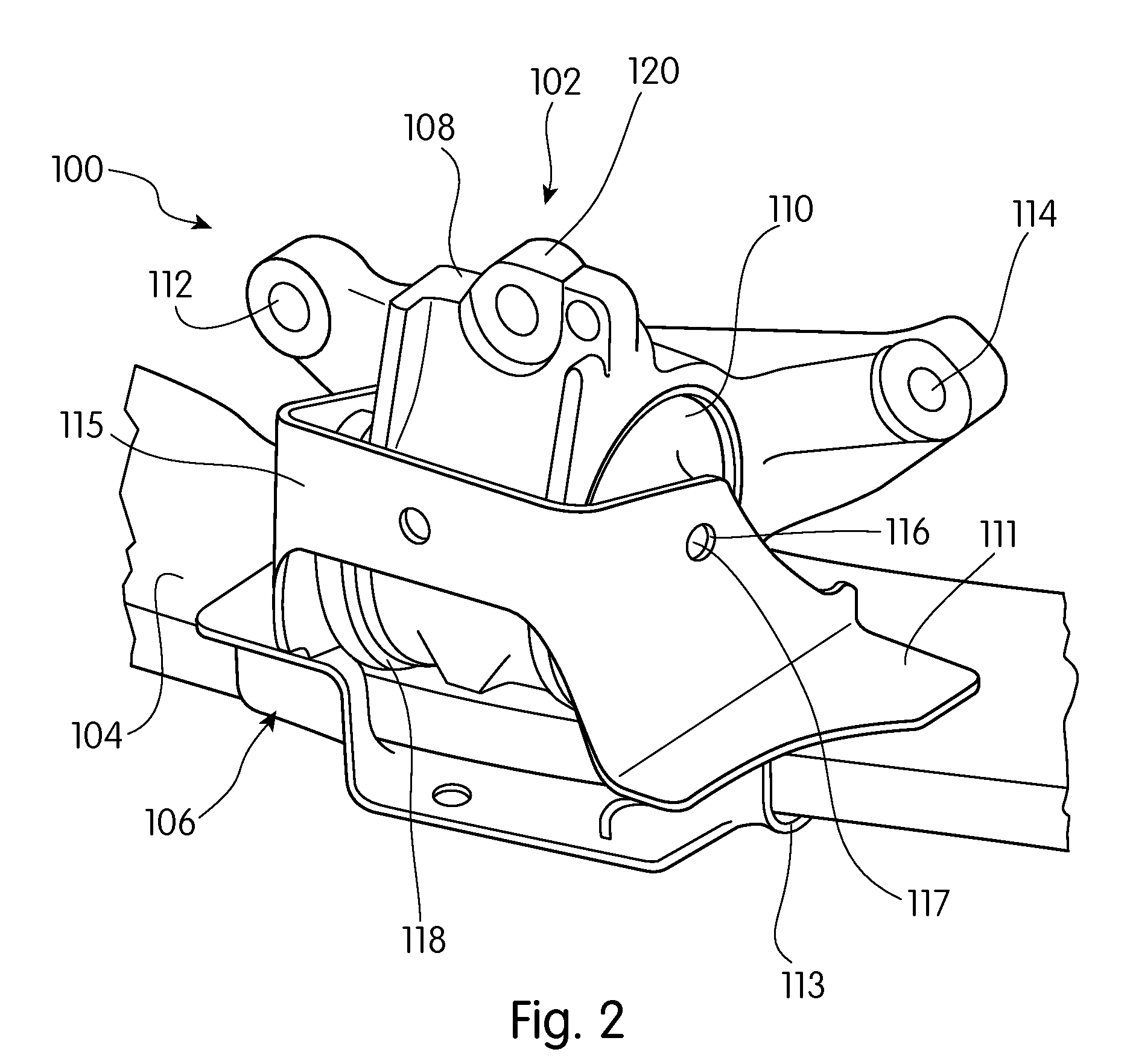

Solid Engine Mount

ActiveUS20080054538A1Portable framesPlural diverse prime-mover propulsion mountingMobile vehicleVehicle frame

A mounting scheme for attaching a power train to a motor vehicle frame includes a plurality of mounts. At least one of the mounts is a solid engine mount having a metal housing and an elastomeric bushing. The elastomeric bushing contains no voids other than a central bore used to attach the mount to a bracket. The elastomeric bushing includes frustoconical portions, where one end of each of the frustoconical portions is unconstrained by the metal housing. The stiffness of the mount may be tuned to reduce noise and improve handling. The stiffnesses of any of the axes may be adjusted so that the power train roll center aligns with the power train center of gravity.

Owner:HONDA MOTOR CO LTD

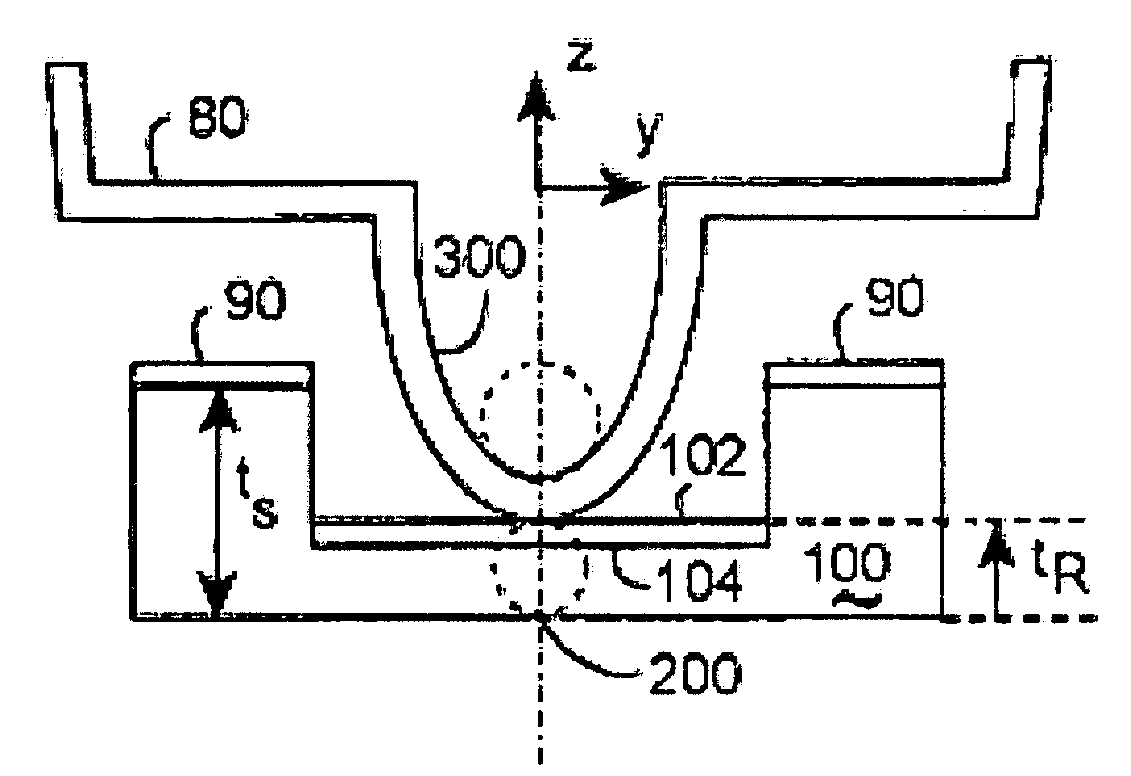

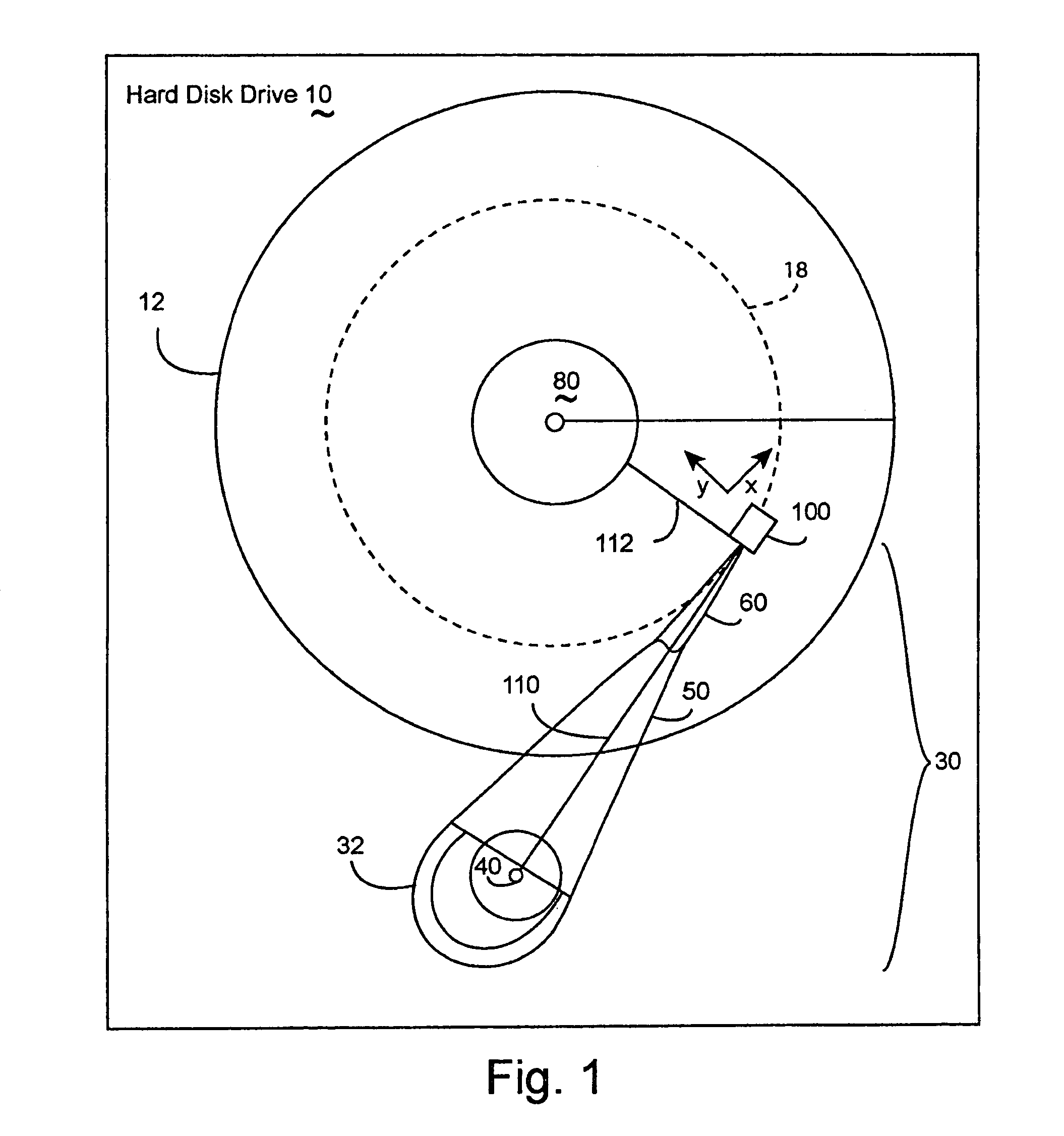

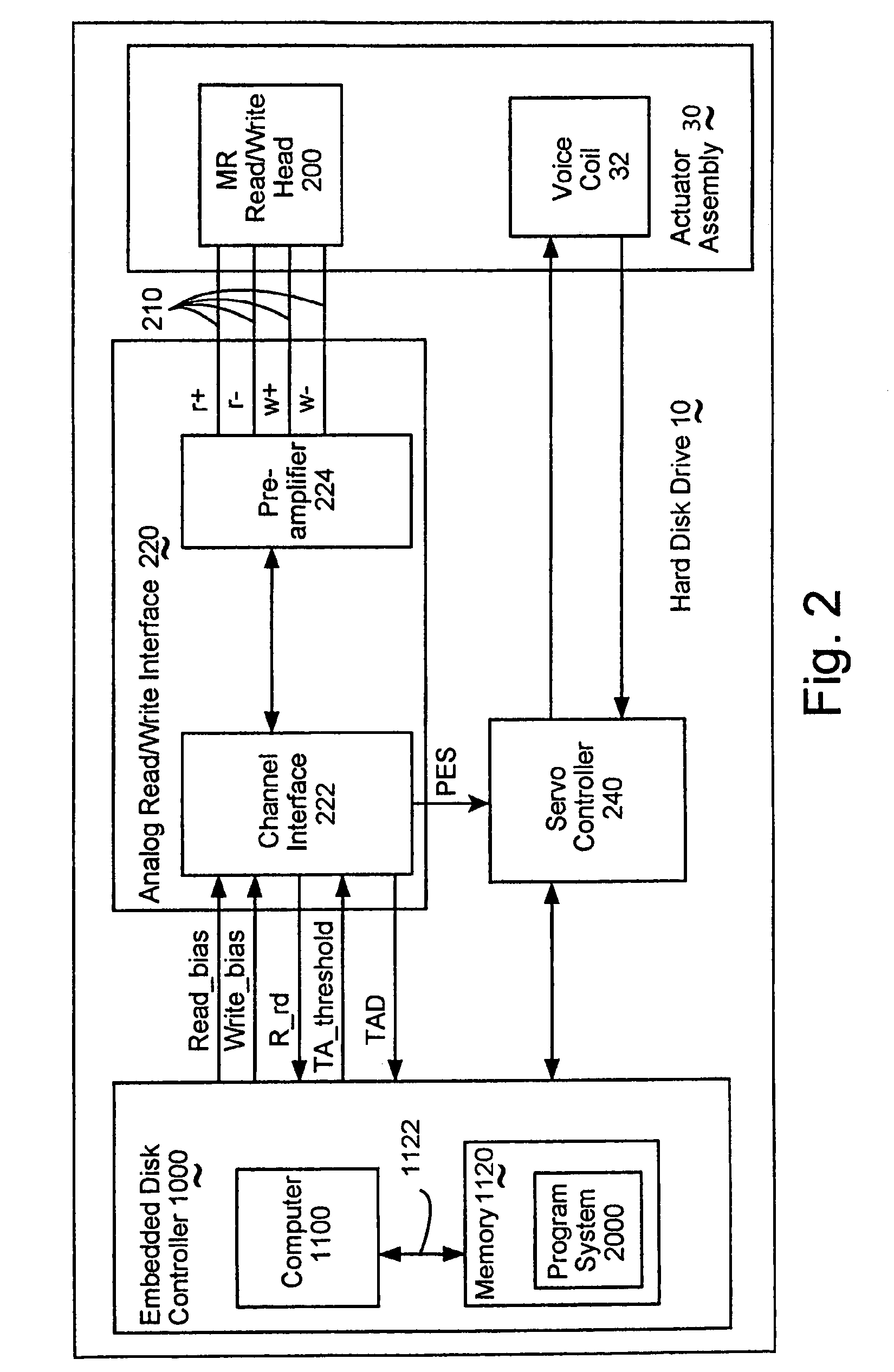

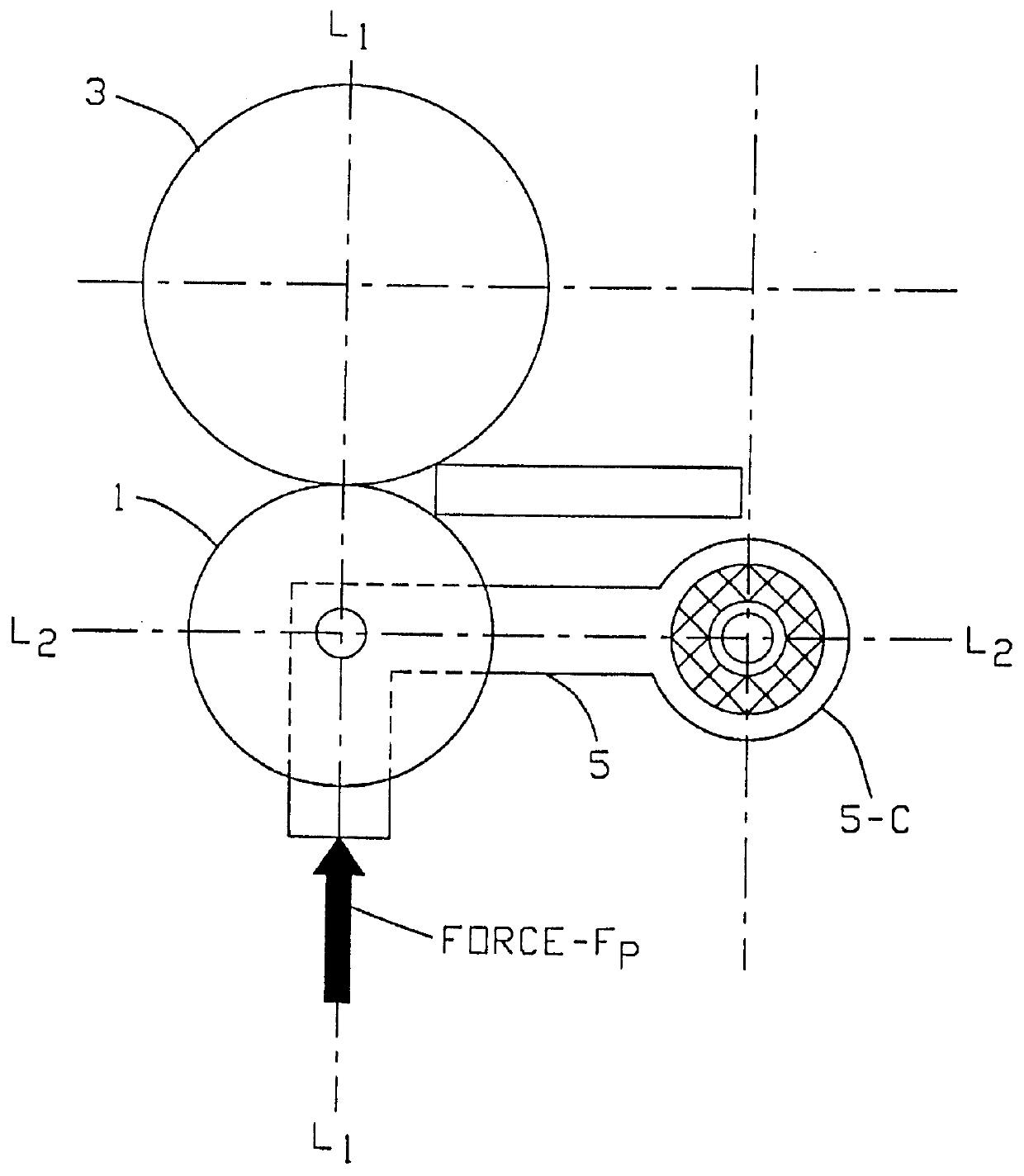

Method and apparatus reducing off track head motion due to disk vibration in a hard disk drive

InactiveUS7283331B2Reduce displacementMinimizes total TMR displacementRecord information storageFluid-dynamic spacing of headsHard disc driveActuator

The invention includes sliders provided with indented surfaces, reducing the roll center for head gimbal assemblies below the effective thickness of the slider. Head gimbal assemblies built with these sliders may reduce off-track displacements induced by disk vibration. The load beam gimbal may contact the indented surface, creating a slider roll center less than the slider thickness. Alternatively, the sliders may include a slider contact cover interfacing to the load beam forming the gimbal. The slider contact covers may couple with the slider through an indented surface located closer than the slider thickness. These may have a negative slider roll center. The invention includes actuator arms, actuator assemblies, and hard disk drives including these head gimbal assemblies. The invention includes making the invention's sliders, head gimbal assemblies, actuator arms, actuator assemblies, and hard disk drives. The invention includes the products of these processes.

Owner:SAMSUNG ELECTRONICS CO LTD

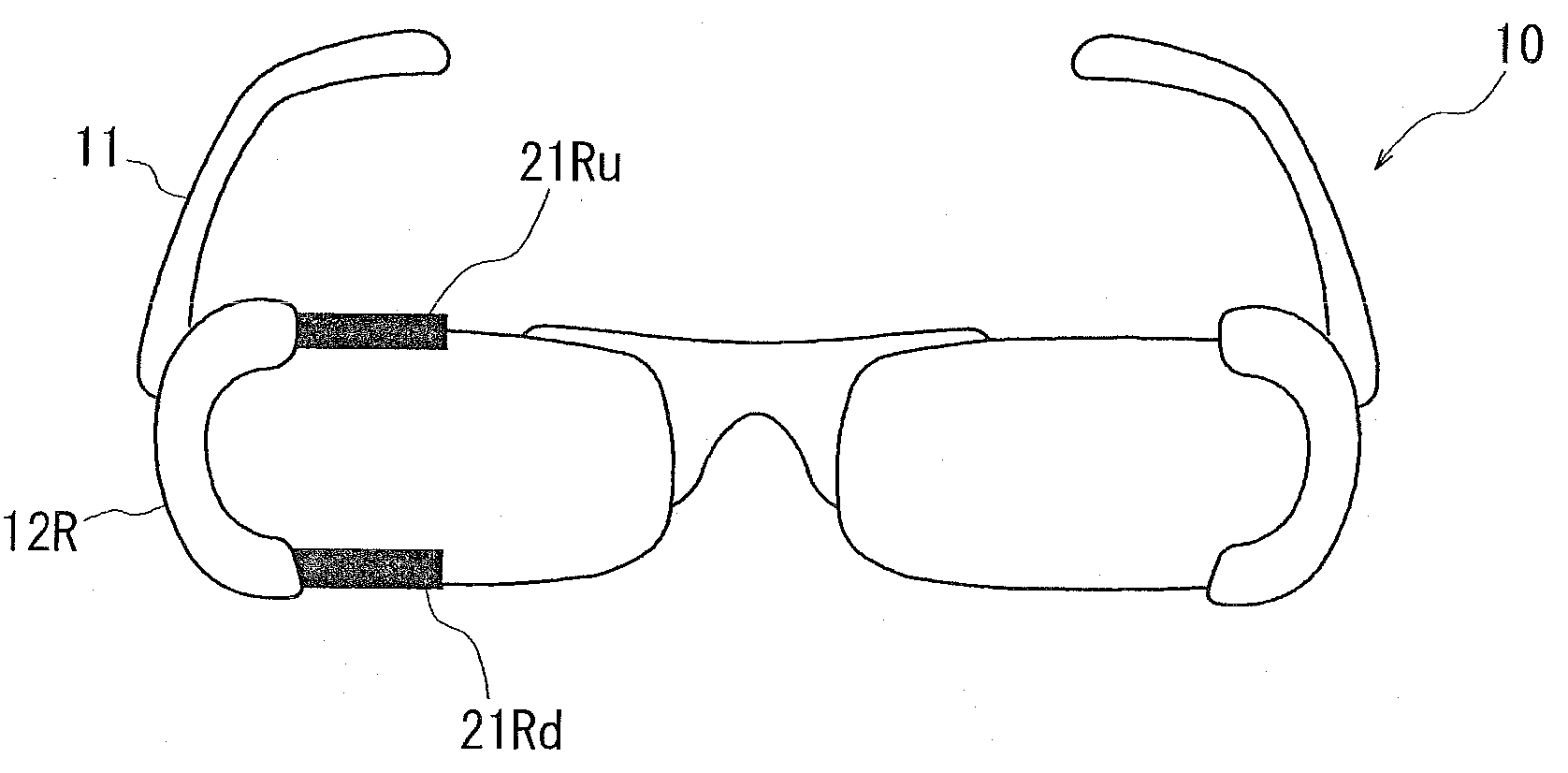

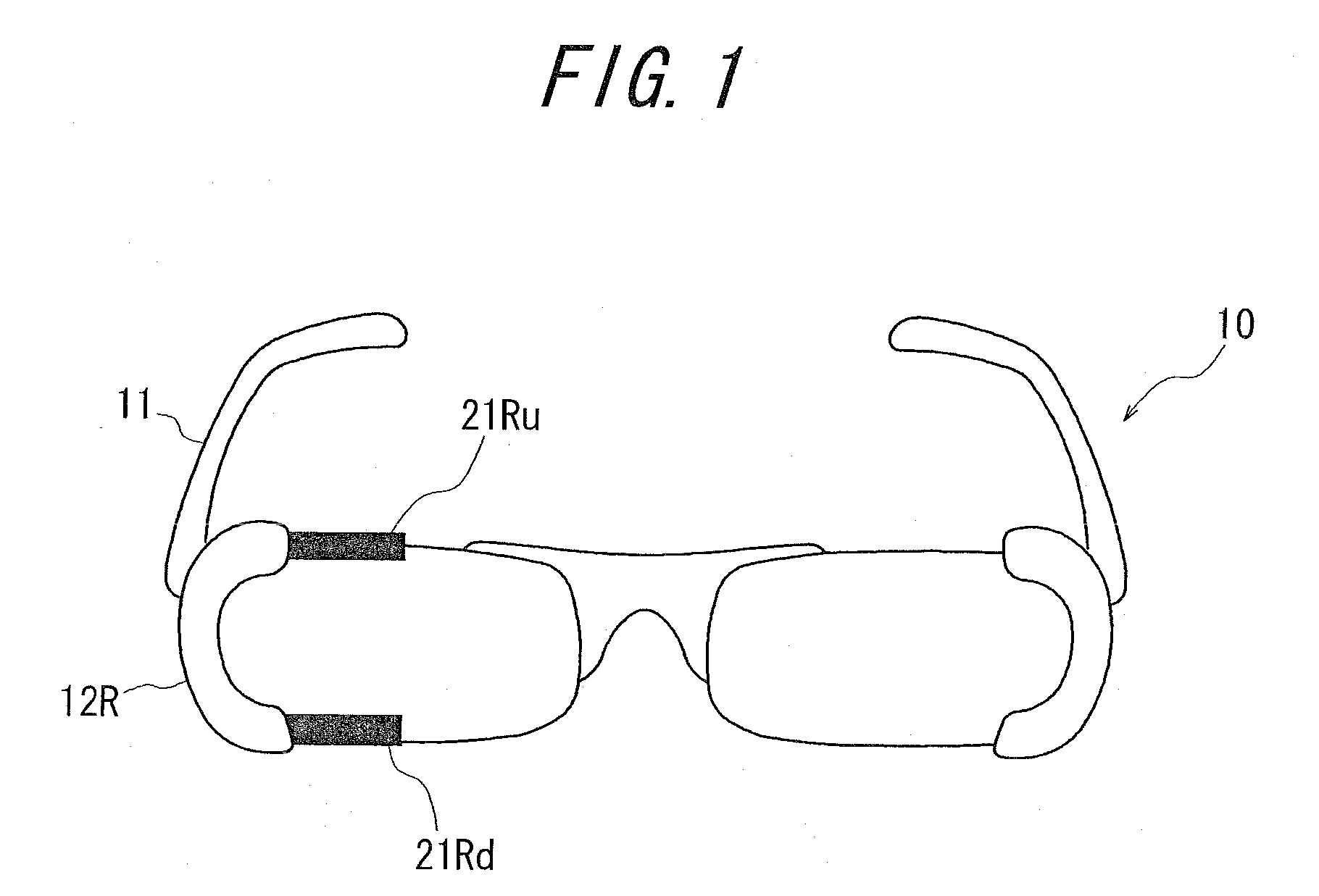

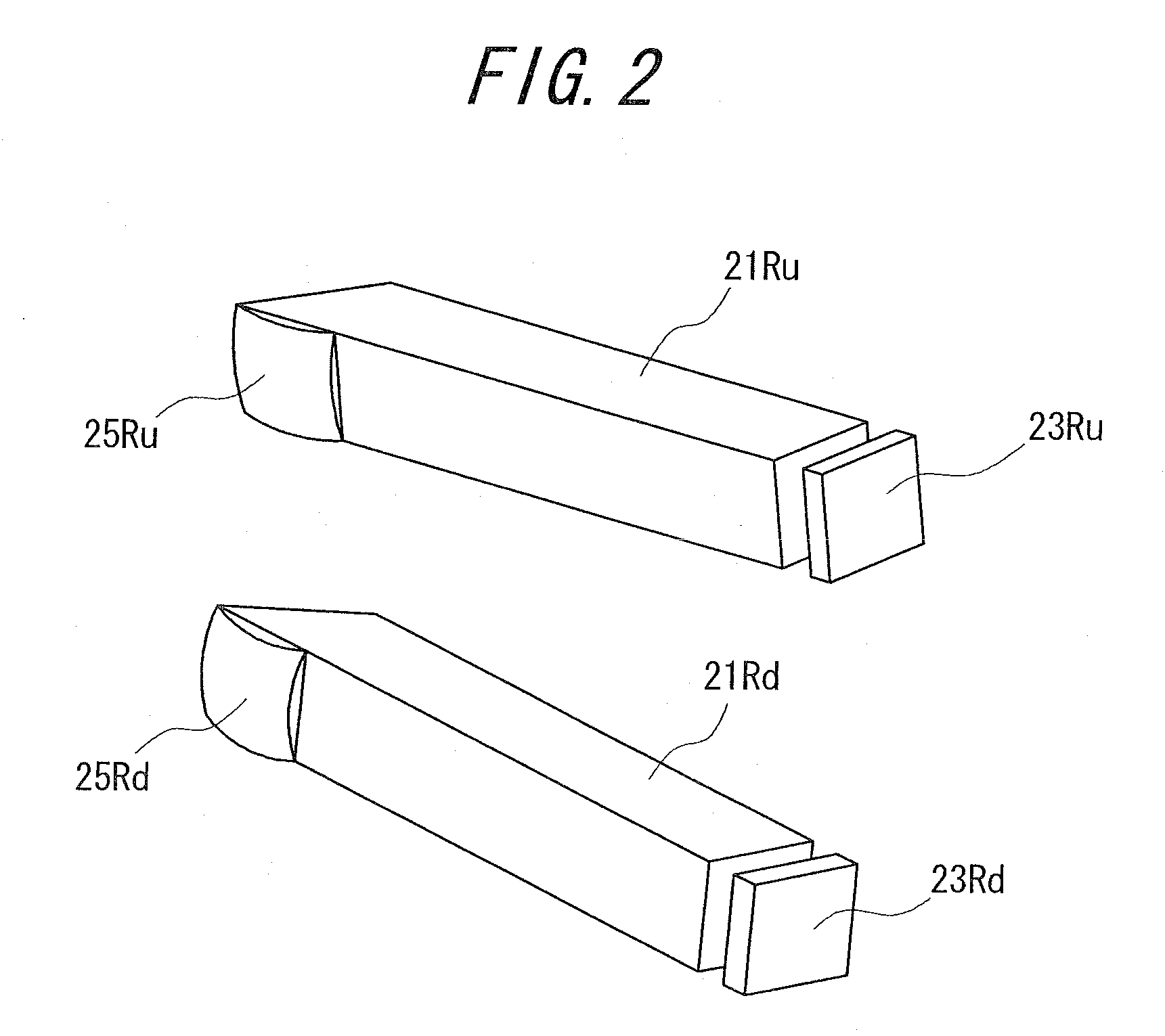

Head-mounted type image display device

ActiveUS20100157432A1Improve visibilityWithout impairing mobilityNon-optical adjunctsCathode-ray tube indicatorsEyepieceOptical axis

The present invention provides a novel head-mounted type image display device capable of displaying a lot of information with good viewability by multi-screens without impairing mobility of the device. The device comprises a plurality of eyepiece optical units 25Ru, 25Rd emitting image light to be displayed toward corresponding eye balls respectively and a head-mounting unit 11 for supporting the plurality of eyepiece optical units 25Ru, 25Rd and adapted to detachably attached to the head of an observer. The head-mounting unit 11 in a state where the unit is attached to the head of the observer supports the plurality of eyepiece optical units 25Ru, 25Rd such that an emitting optical axis of each eyepiece optical unit 25Ru, 25Rd substantially passes through the eyeball rolling center of the corresponding eyeball and, when the emitting optical axis of one eyepiece optical unit passes through a pupil of the corresponding eyeball thereof as a result of rolling of the eyes, the emitting optical axis of another eyepiece optical unit does not pass through a pupil of the corresponding eyeball thereof.

Owner:OLYMPUS CORP

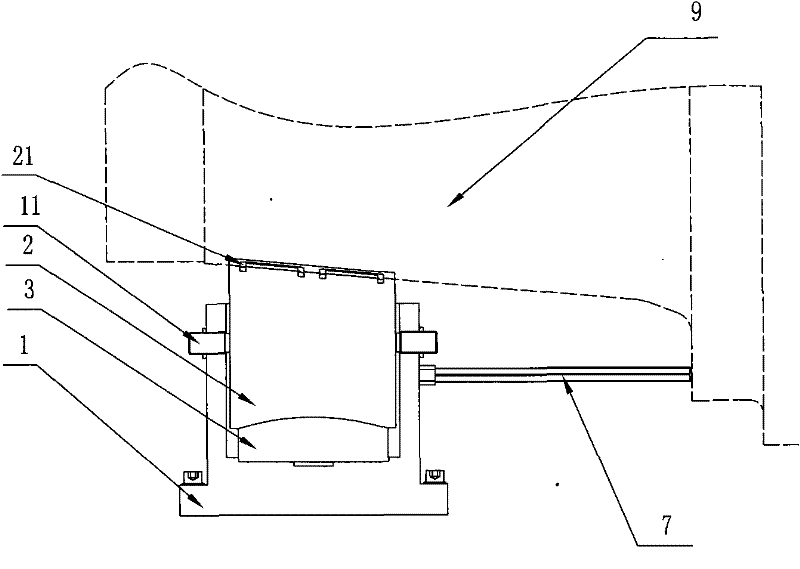

Method for adjusting housings outside single stand reversible rolling mill

ActiveCN101664760AHigh adjustment accuracyMeet the acceptance criteriaMetal rolling stand detailsMeasuring devicesEngineeringRoll center

The invention relates to a method for adjusting a single stand reversible rolling mill, in particular to a method for adjusting housings outside the single stand reversible rolling mill, which comprises the following steps: a, determining that a housing base reaches assembly accuracy, and suspending the housings to correct positions; b, hanging a steel wire, checking vertical and transverse central lines of the rolling mill; c, connecting earphones to the vertical and transverse central lines of the rolling mill by lead wires; d, moving housings on a transmission side and an operation side towards the housing base direction on a discharge side respectively by a hydraulic jack to ensure that a bracket side of the housings is close to the lateral surface of the base on an outlet side, and moving a rail rest on an inlet side towards the outlet side; e, adjusting sizes of the housing rolling center and the transverse center of the rolling mill, and fastening a foundation bolt by 70 percentof a design torque; and f, hanging steel wires on housing windows and the rolling directions of the housings, and measuring the verticality and the horizontality of the windows and the rolling directions of the housings of the rolling mill. The method uses the steel wires and the earphones to ensure numerical reading, eliminates reading errors caused by visual errors of staff, and improves the assembly accuracy of equipment.

Owner:CHINA MCC20 GRP CORP

In-wheel motor vehicle

Owner:TOYOTA JIDOSHA KK

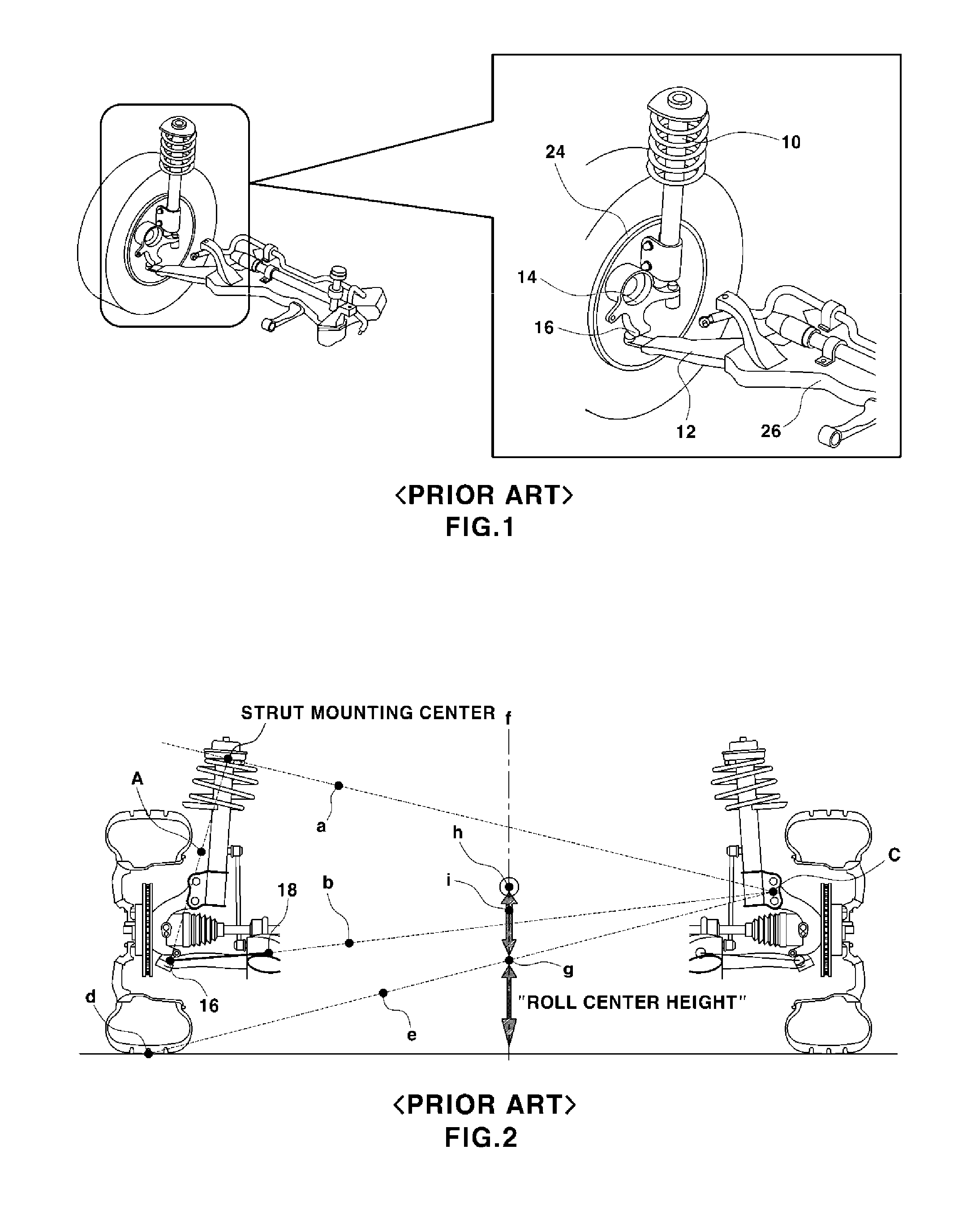

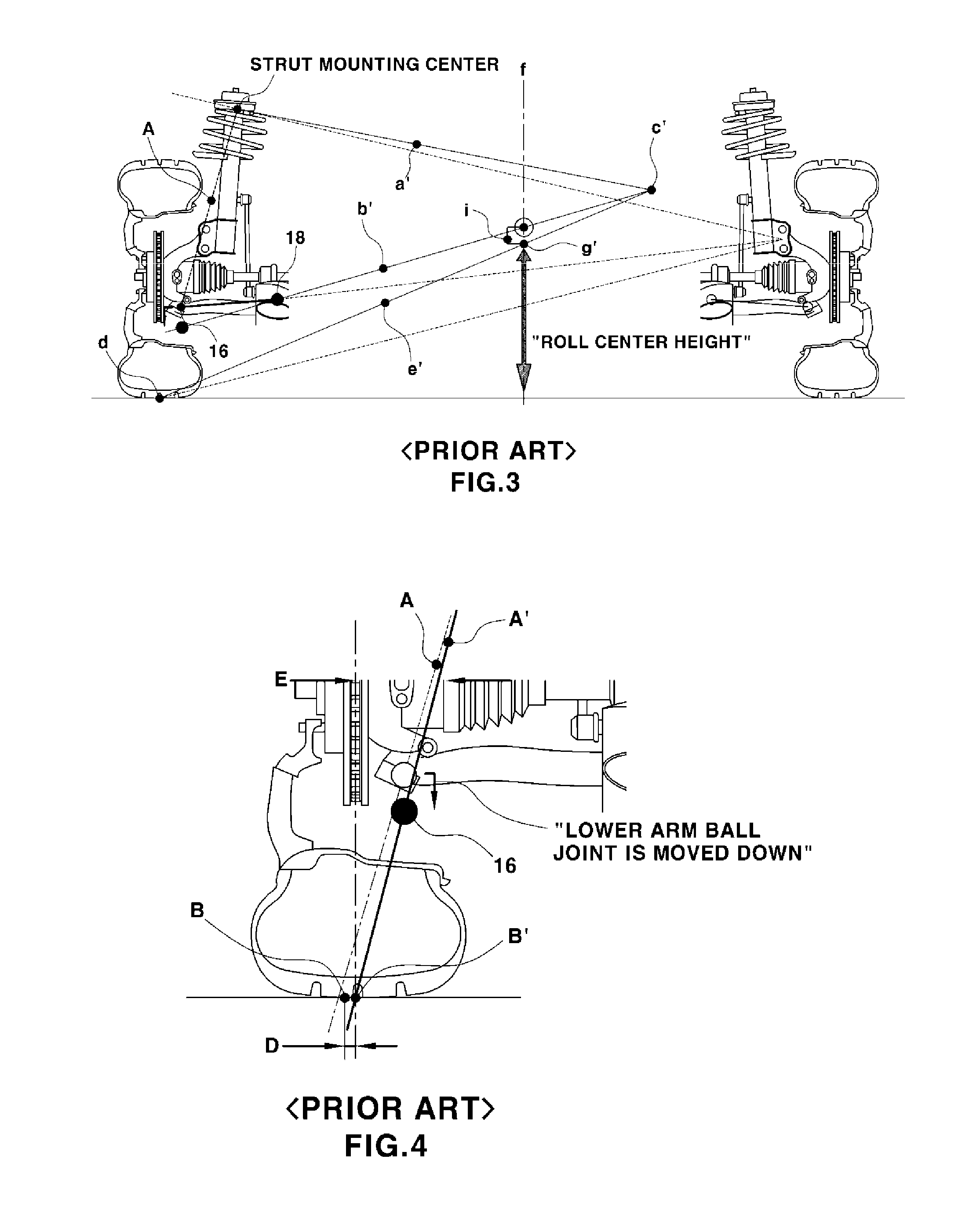

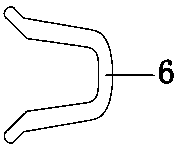

Method for designing McPherson suspension

ActiveCN101826125ALower the thresholdSpeed up research and developmentSpecial data processing applicationsControl armEngineering

The invention aims at providing a method for simply designing a McPherson suspension. The method comprises the following steps: firstly, establishing a coordinate system; then, obtaining hard point position parameters of connecting positions of each component in the McPherson suspension such as the shock absorber upper point, the tire grounding point, the control arm outer point and the control arm front point or back point and the like through measurement or calculation; carrying out calculation according to the parameters to obtain an equation of a main pin axial line and a control arm axial line; calculating the coordinates of an instantaneous rotation center through setting a first auxiliary line on the basis; and then, calculating the side inclination center height through setting a second auxiliary line. Thereby, the hard point positions of the connecting positions of each component in the McPherson suspension can be regulated according to the design requirements, and the side inclination center height of the McPherson suspension can be regulated. The method for designing the McPherson suspension of the invention has the characteristics of low threshold, convenience, accuracy and the like, is suitable for being used in the development work of the McPherson suspension, and can improve the developing speed.

Owner:CHERY COMML VEHICLE ANHUI

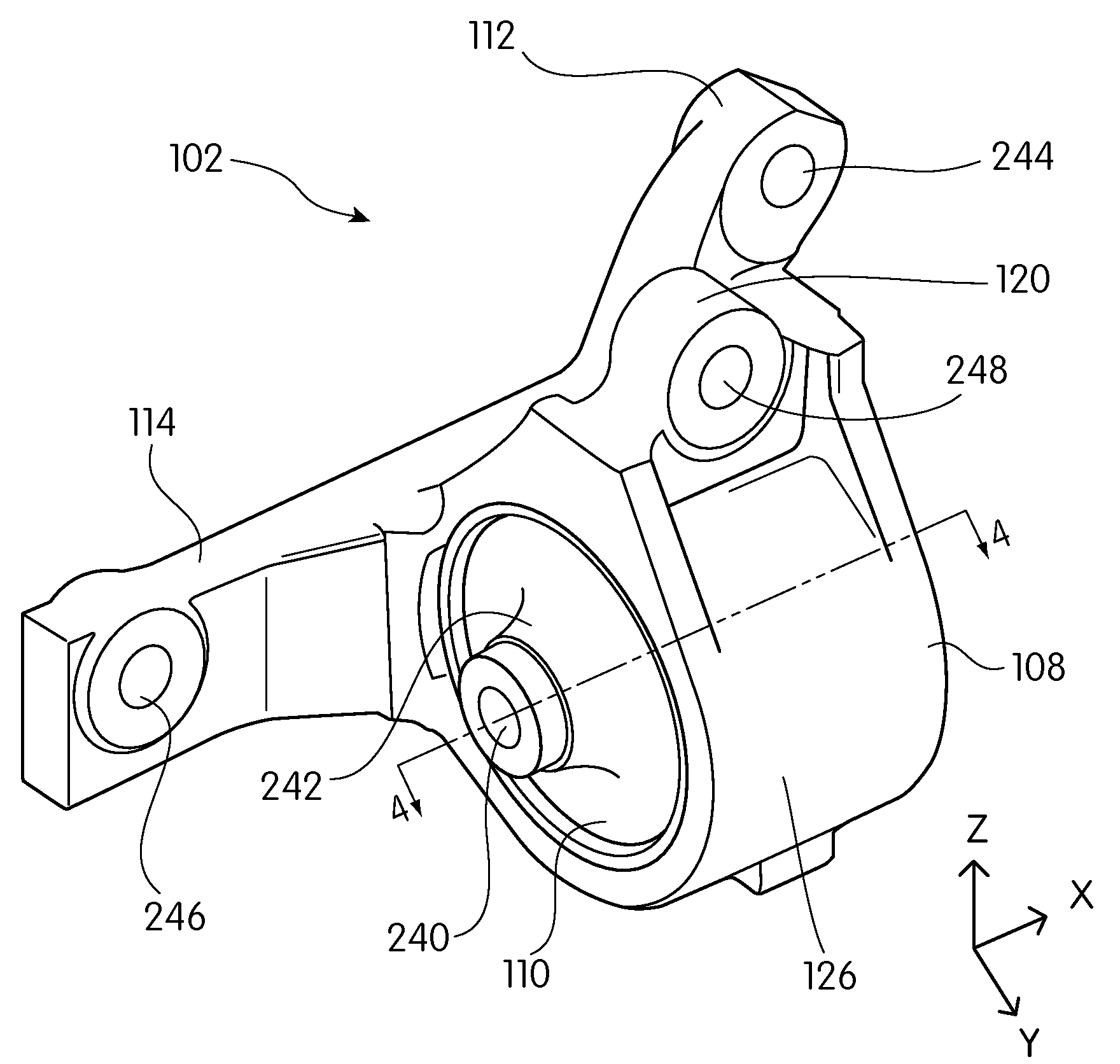

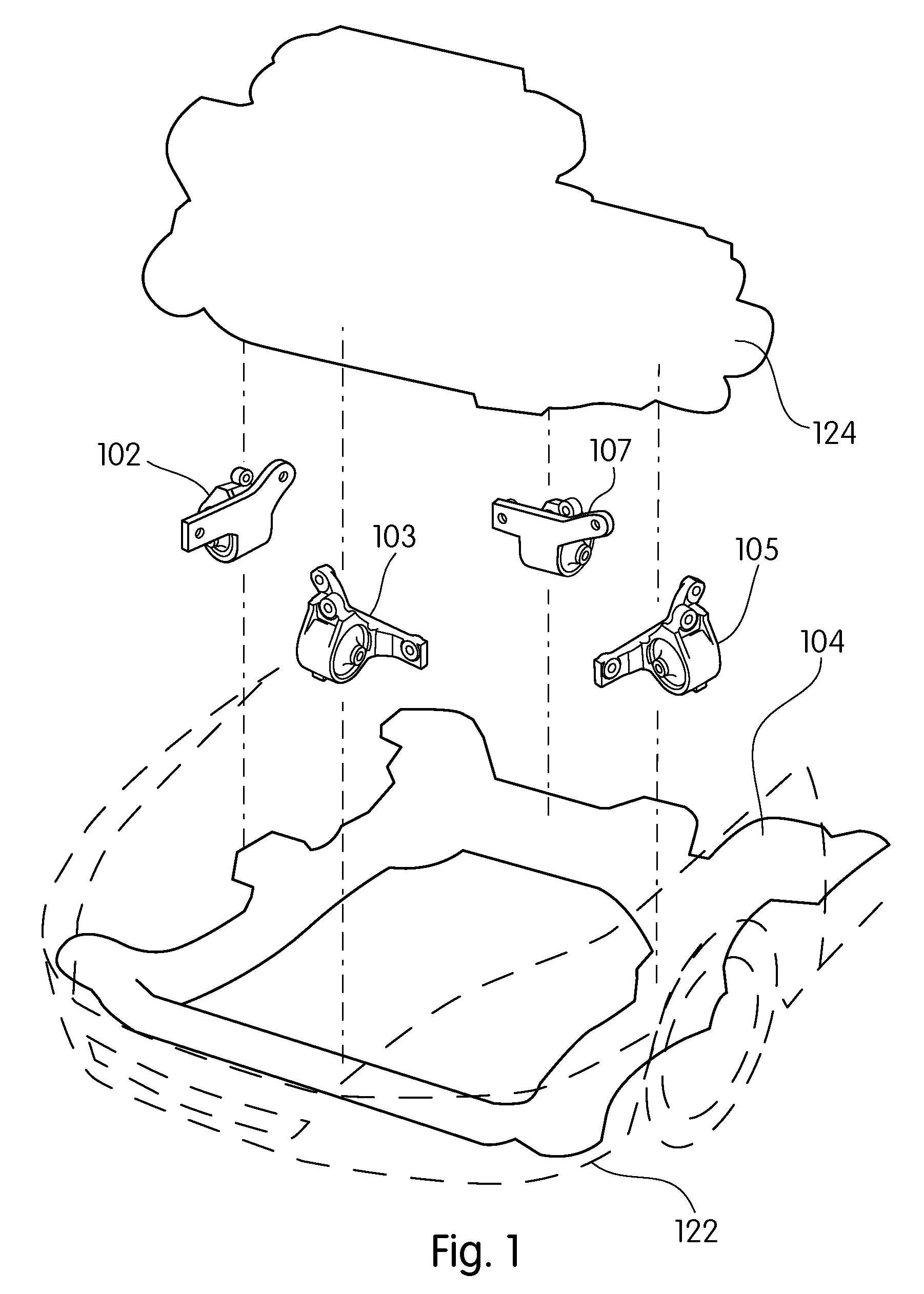

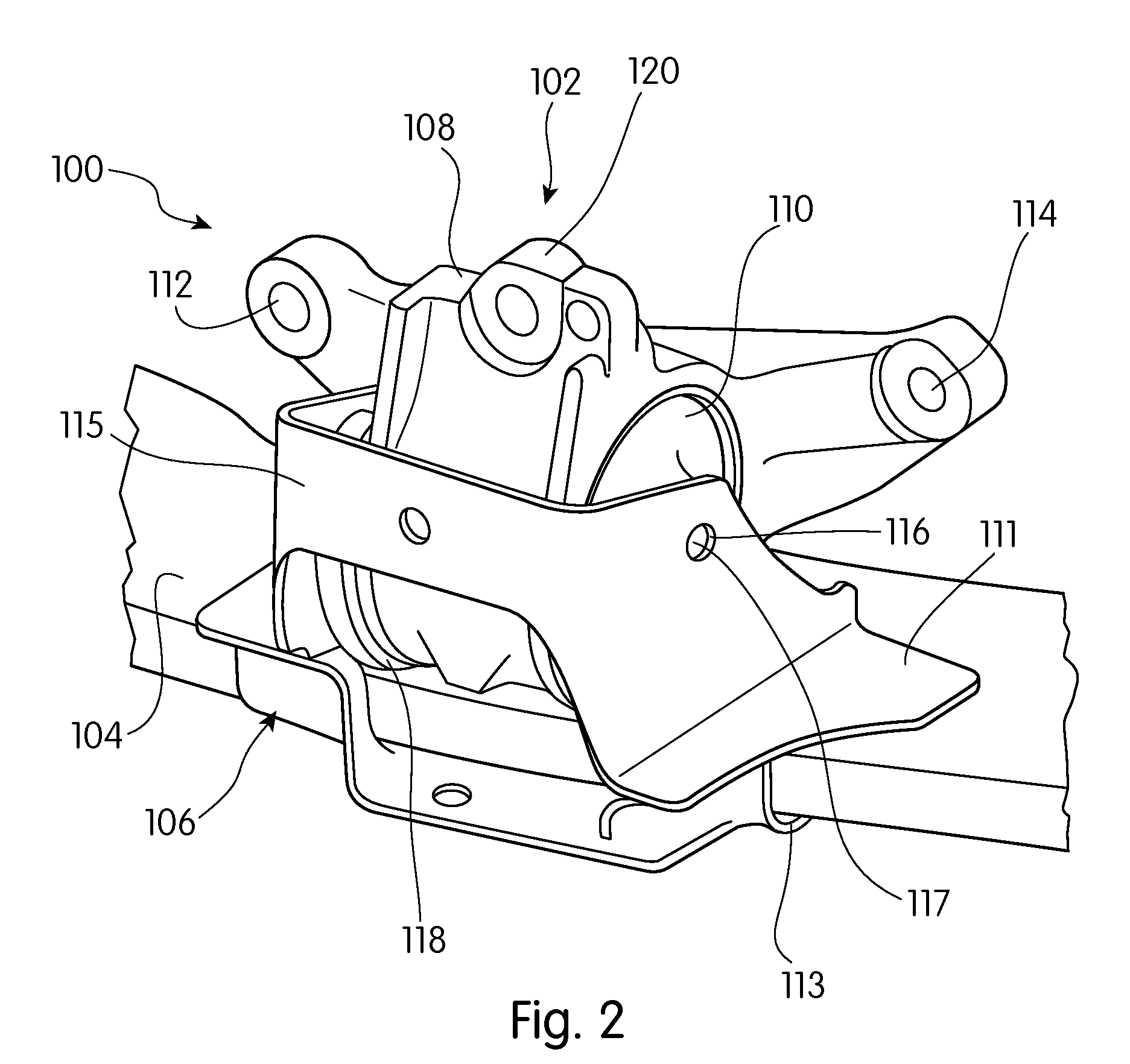

Solid engine mount

ActiveUS8042793B2Portable framesPlural diverse prime-mover propulsion mountingVehicle frameEngine mount

A mounting scheme for attaching a power train to a motor vehicle frame includes a plurality of mounts. At least one of the mounts is a solid engine mount having a metal housing and an elastomeric bushing. The elastomeric bushing contains no voids other than a central bore used to attach the mount to a bracket. The elastomeric bushing includes frustoconical portions, where one end of each of the frustoconical portions is unconstrained by the metal housing. The stiffness of the mount may be tuned to reduce noise and improve handling. The stiffnesses of any of the axes may be adjusted so that the power train roll center aligns with the power train center of gravity.

Owner:HONDA MOTOR CO LTD

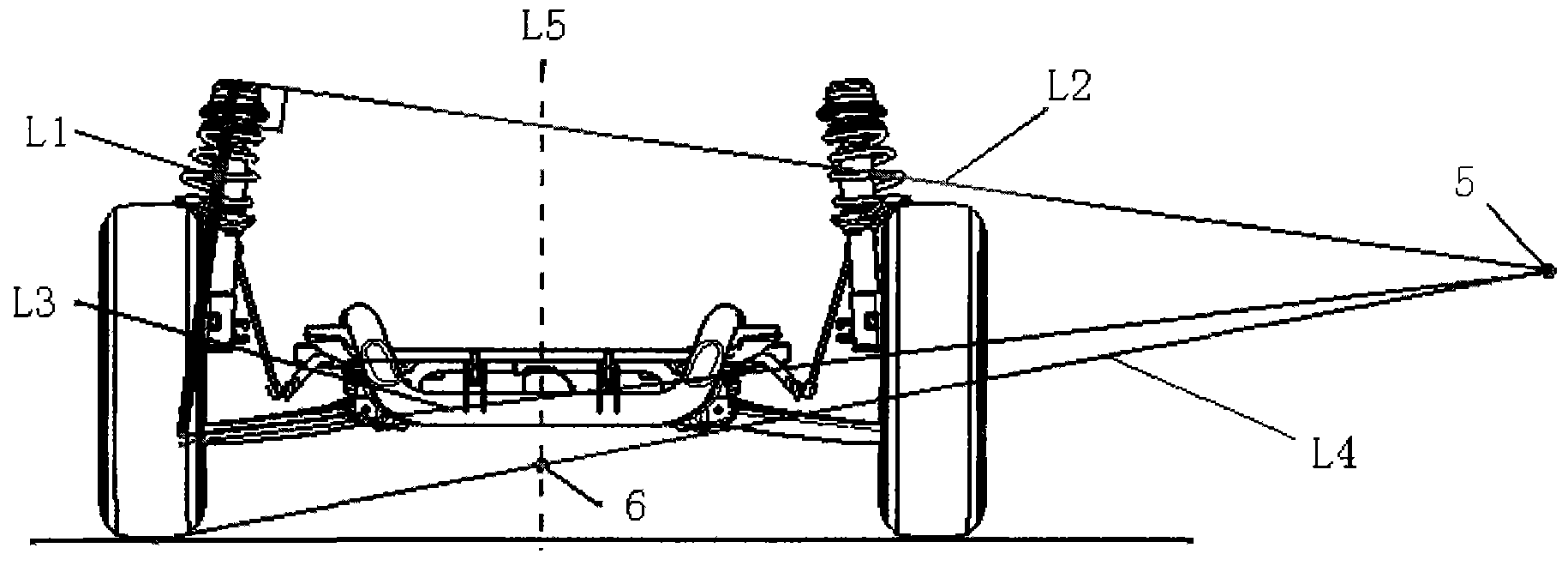

Torsion girder-like rear suspension

InactiveCN101284487AImprove handling stabilityEnhanced inhibitory effectResilient suspensionsBody rollPipe fitting

Owner:CHERY AUTOMOBILE CO LTD

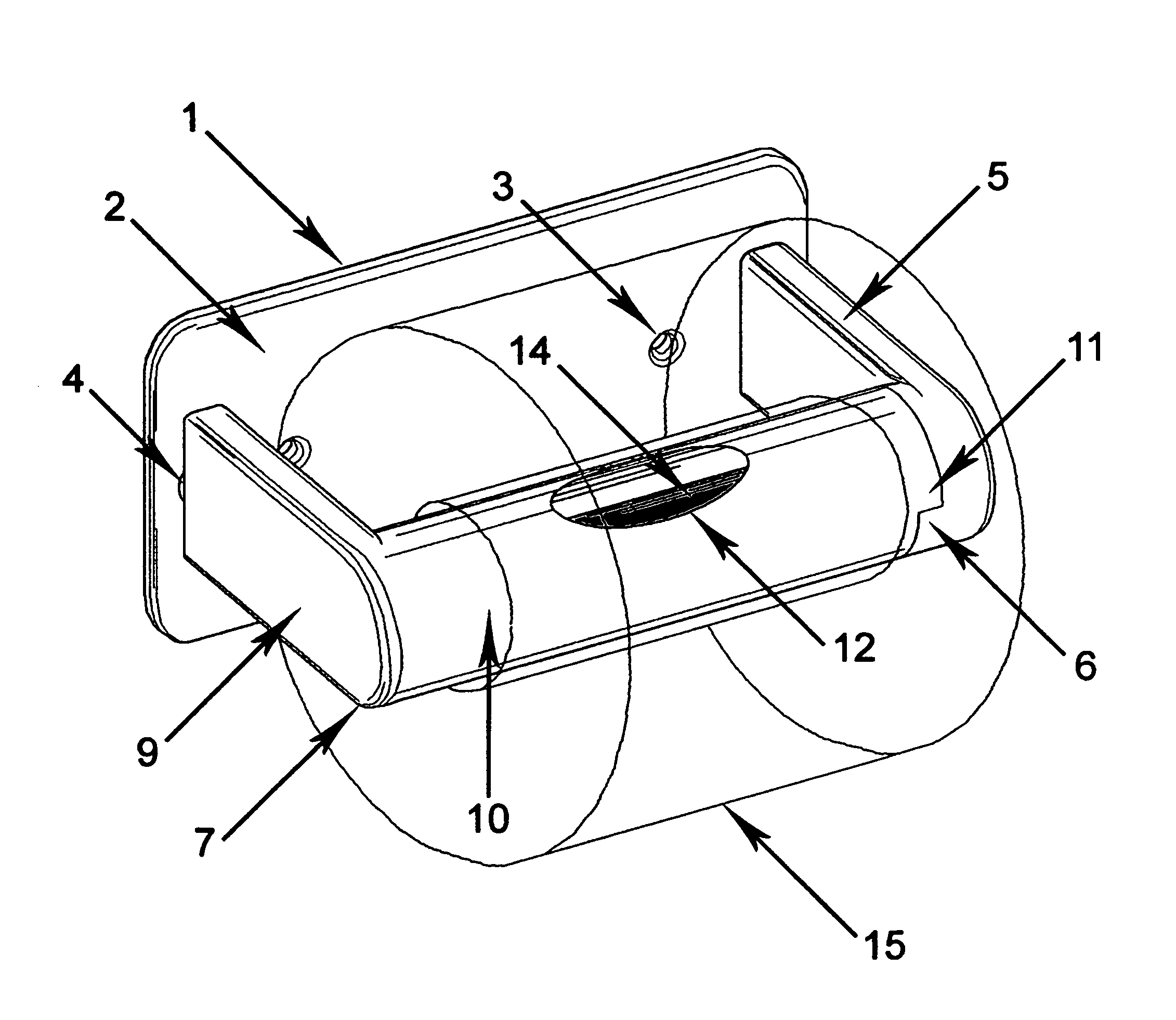

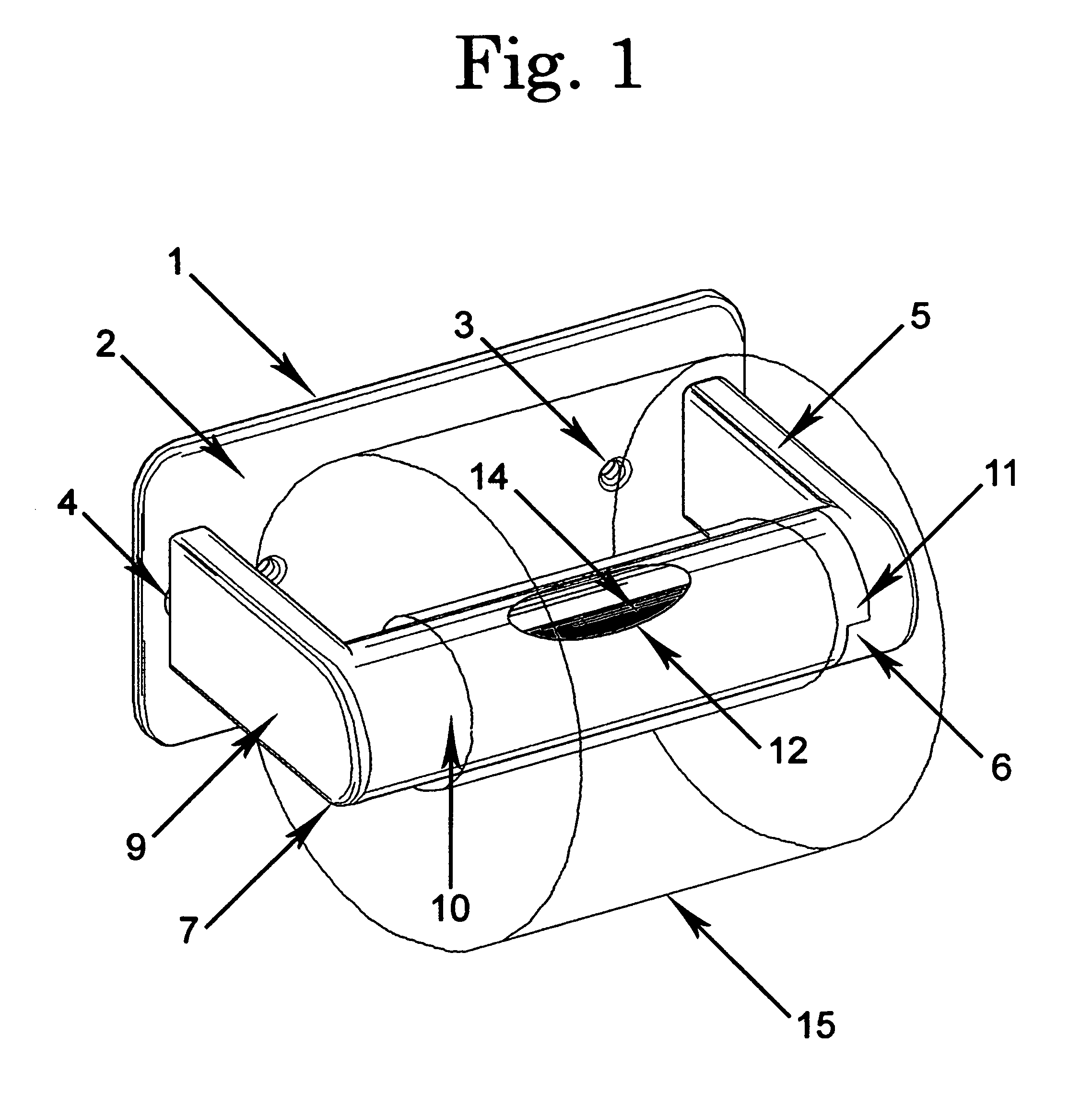

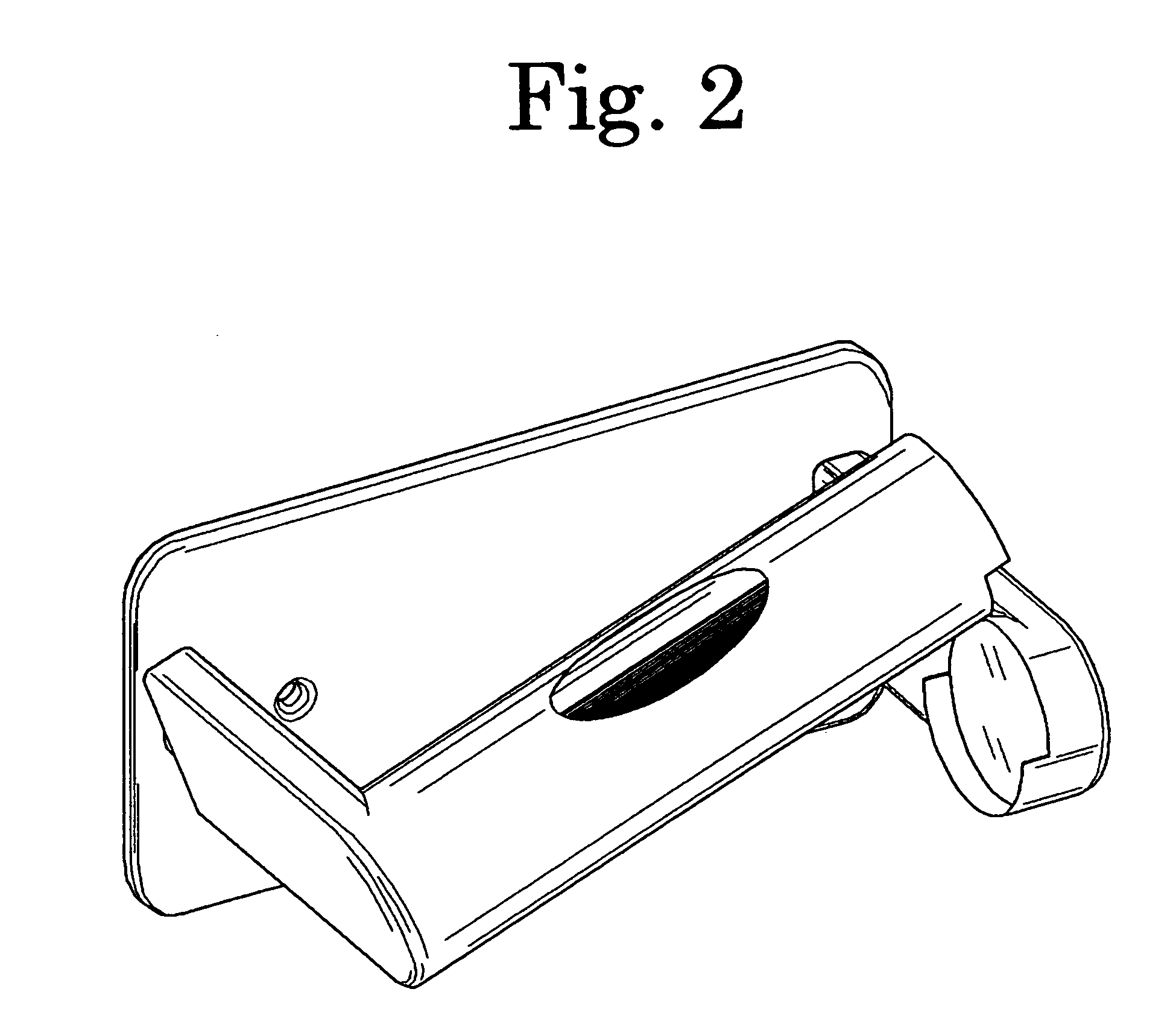

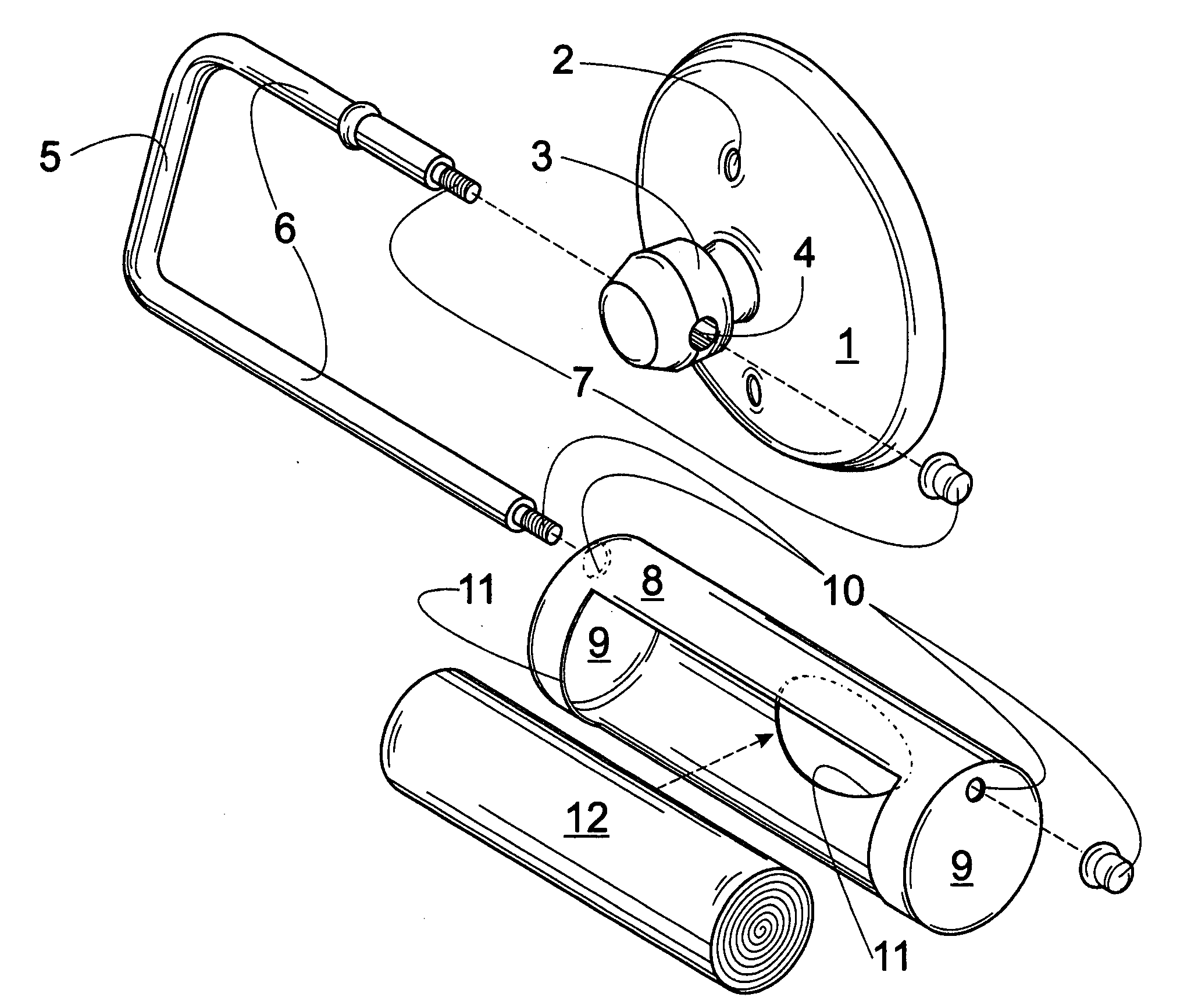

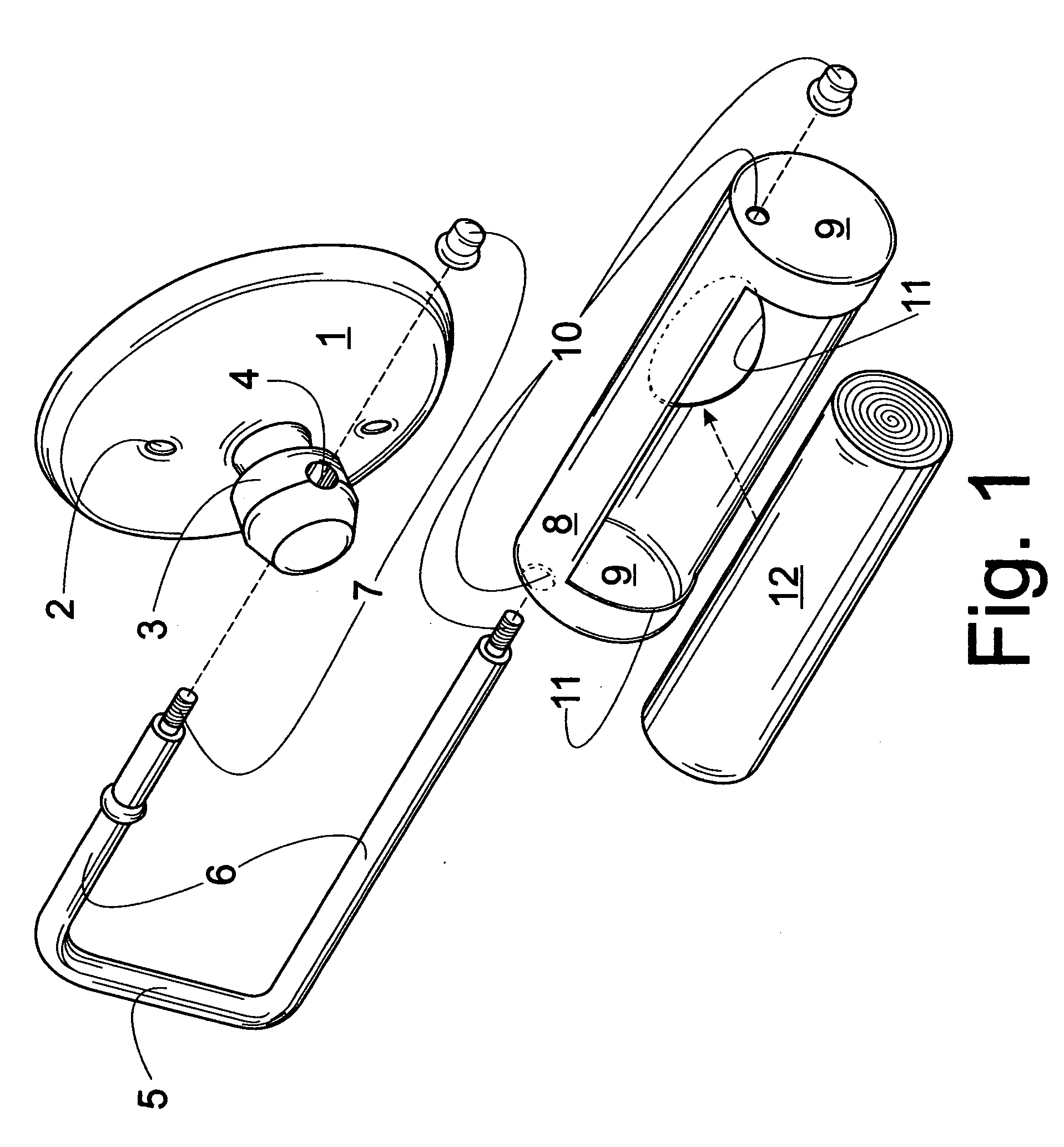

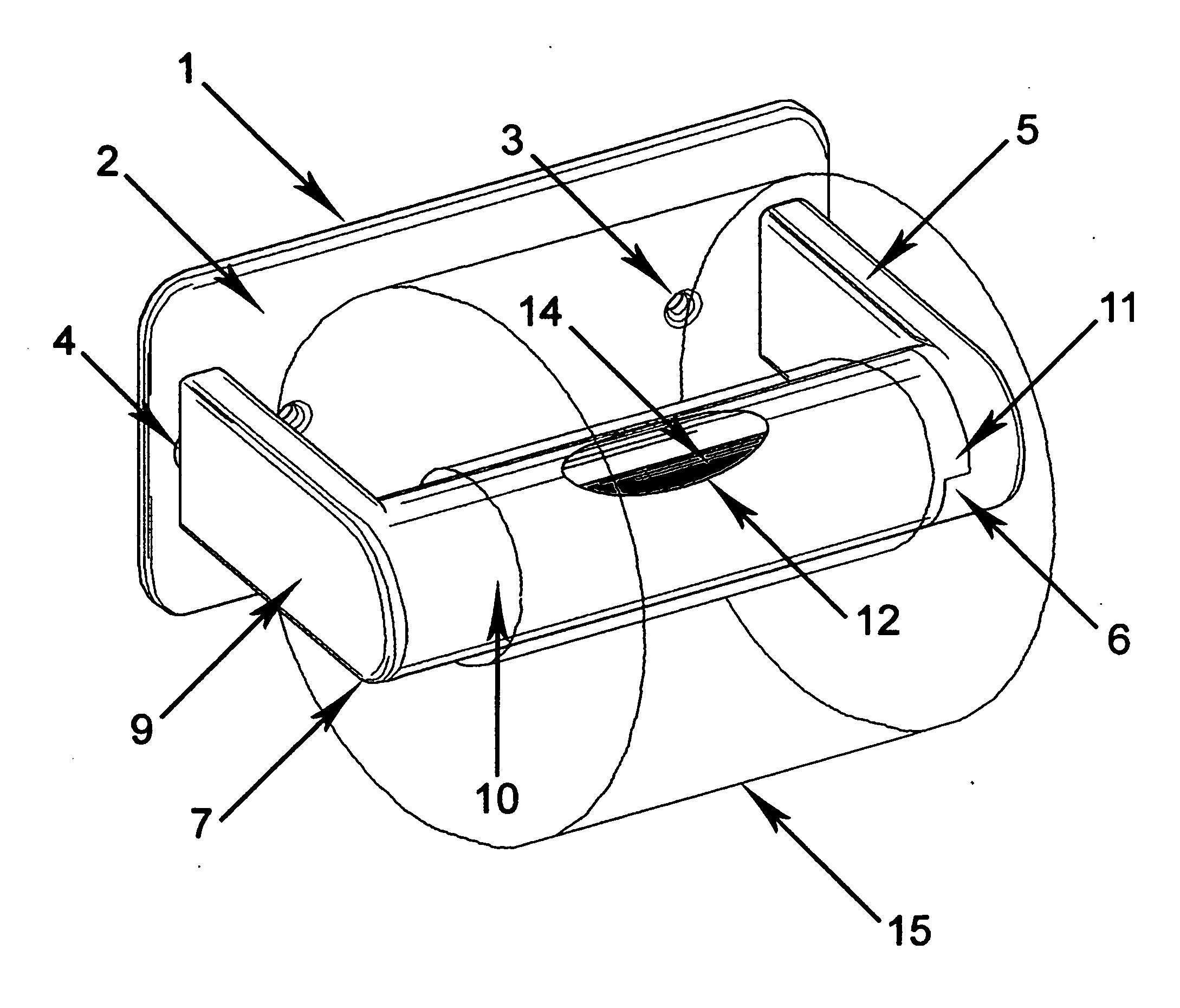

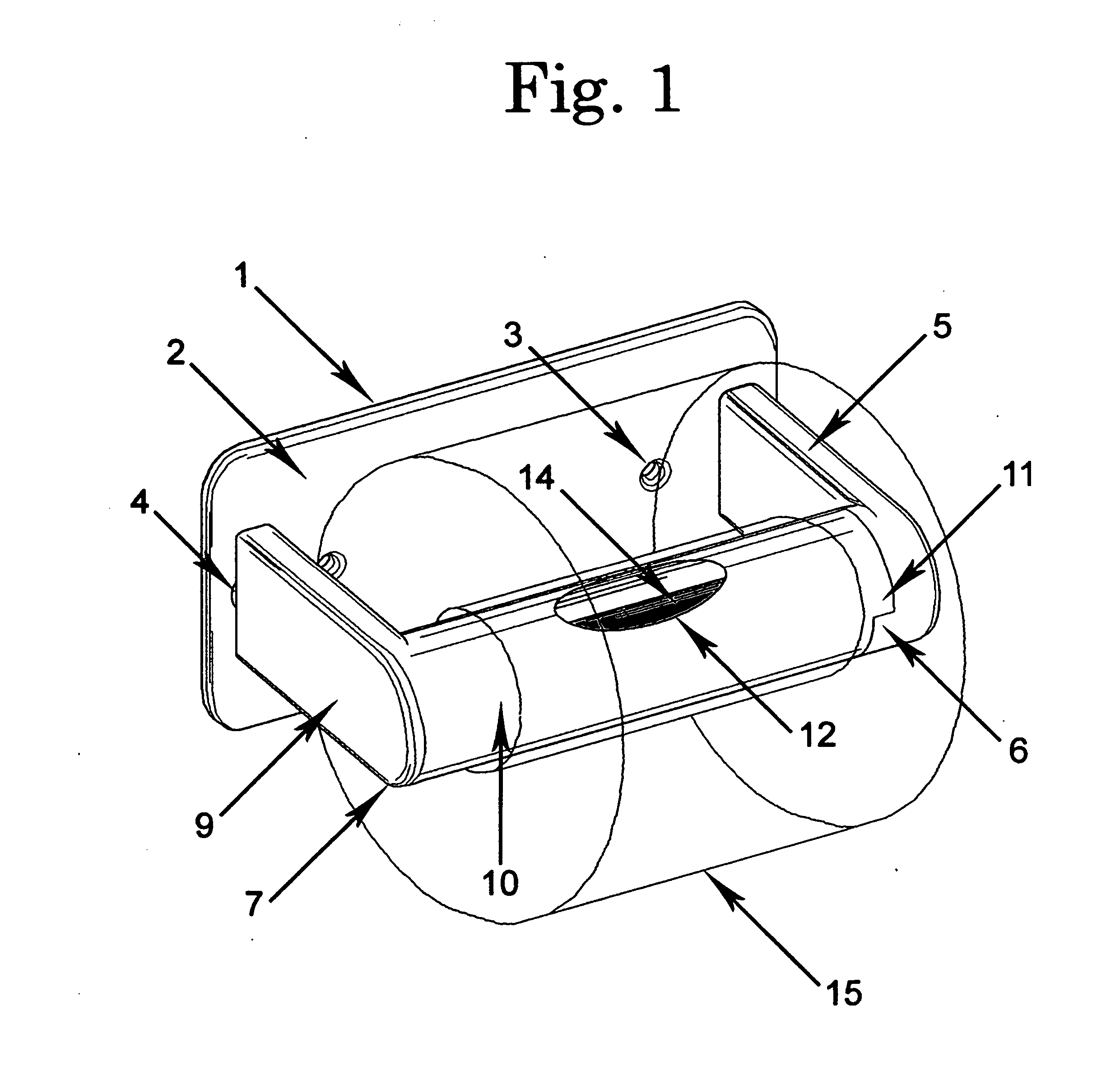

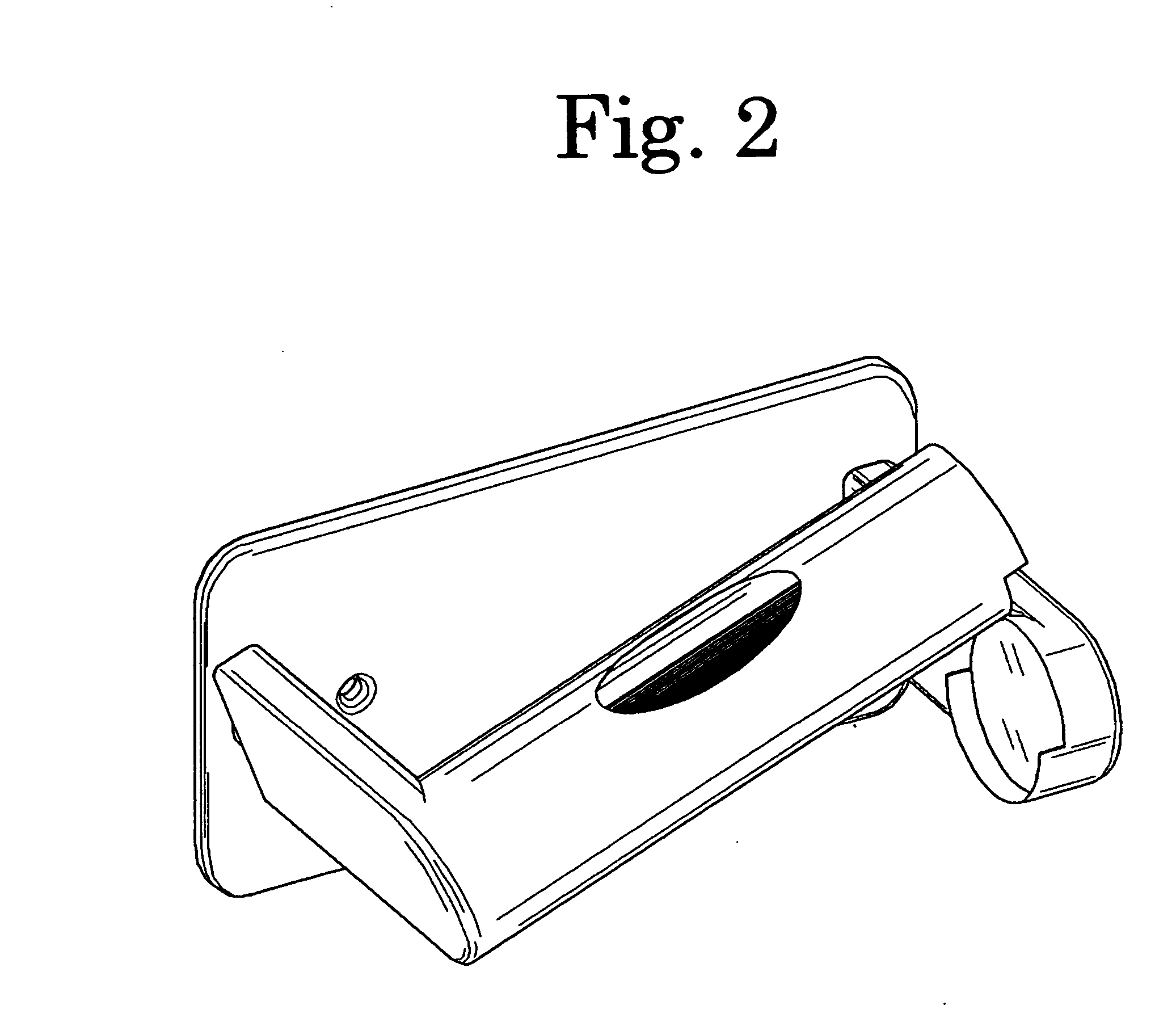

Pivoting toilet tissue roll holder with auxiliary toilet tissue

A wall mounted holder to support a standard toilet tissue roll, and within a pivoting hollow axle contain an auxiliary tissue roll. The attached axle pivots by mechanical means for manipulation of the standard toilet tissue roll and the auxiliary tissue roll. The axle outer diameter is slightly less than the inner diameter of a standard toilet tissue roll center tube allowing the hollow compartment of the axle to provide the maximum space for the auxiliary tissue roll. Auxiliary tissue is tightly rolled and contained in the hollow compartment of the axle.

Owner:BURNETT ALLEN GARRETT

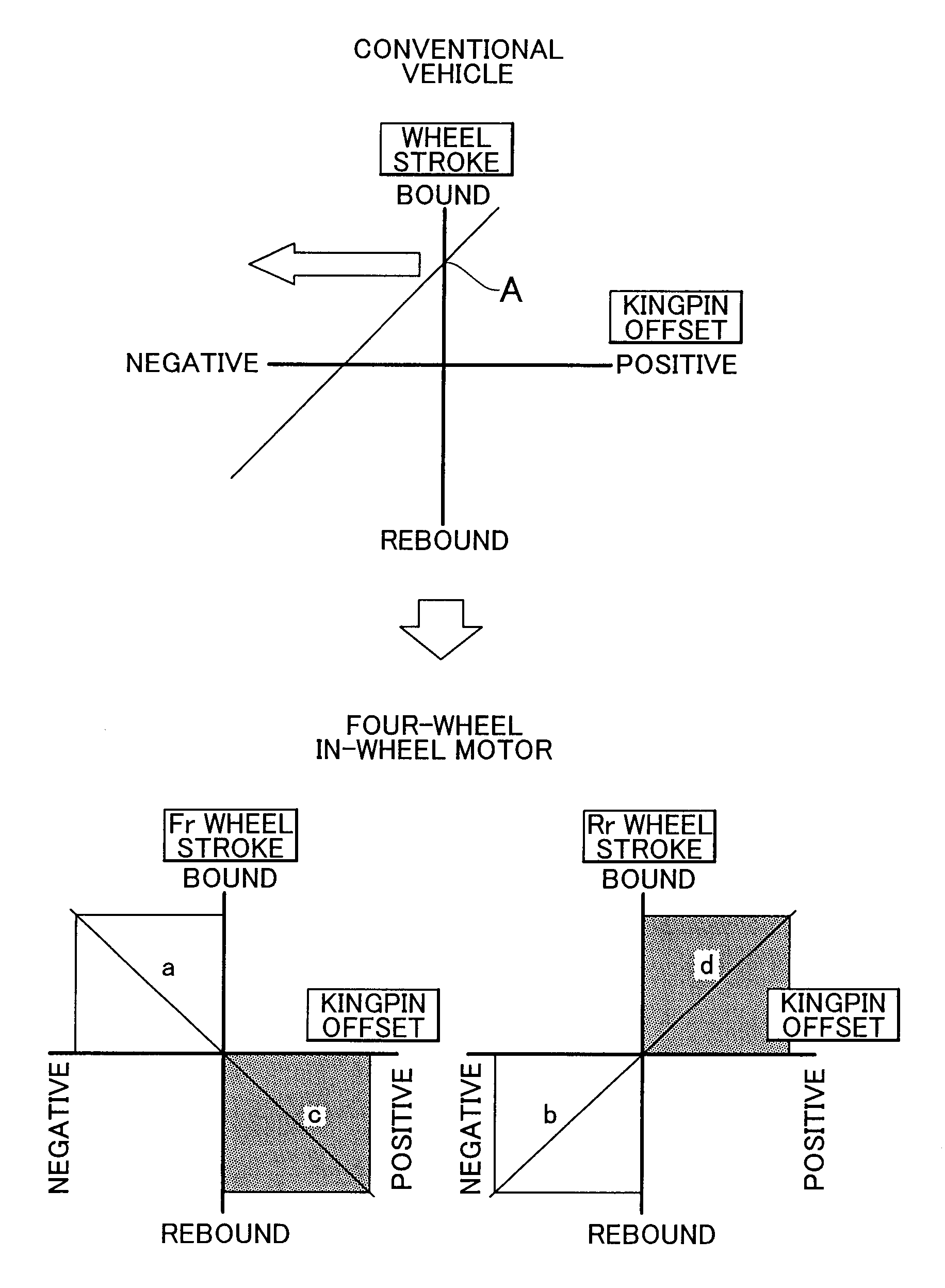

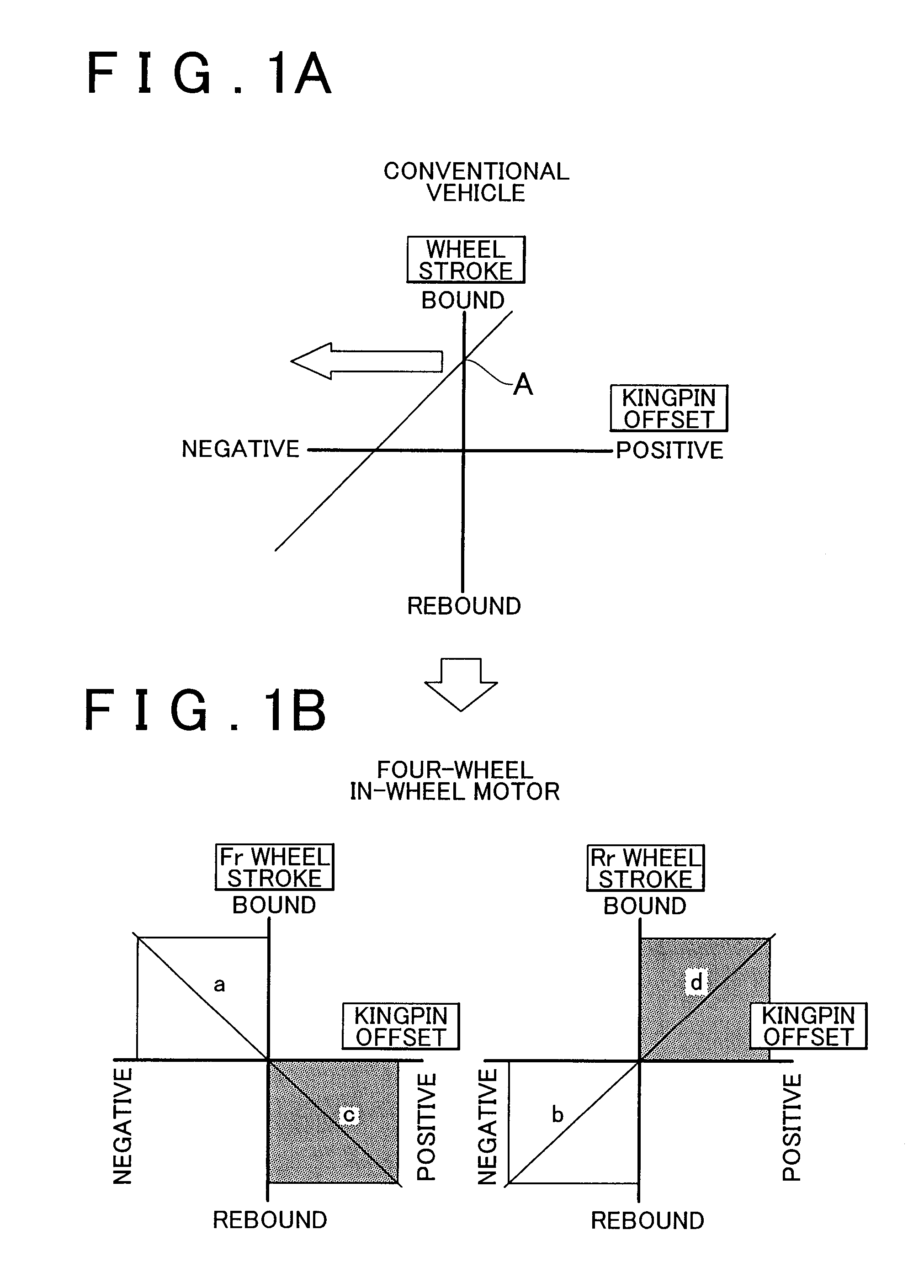

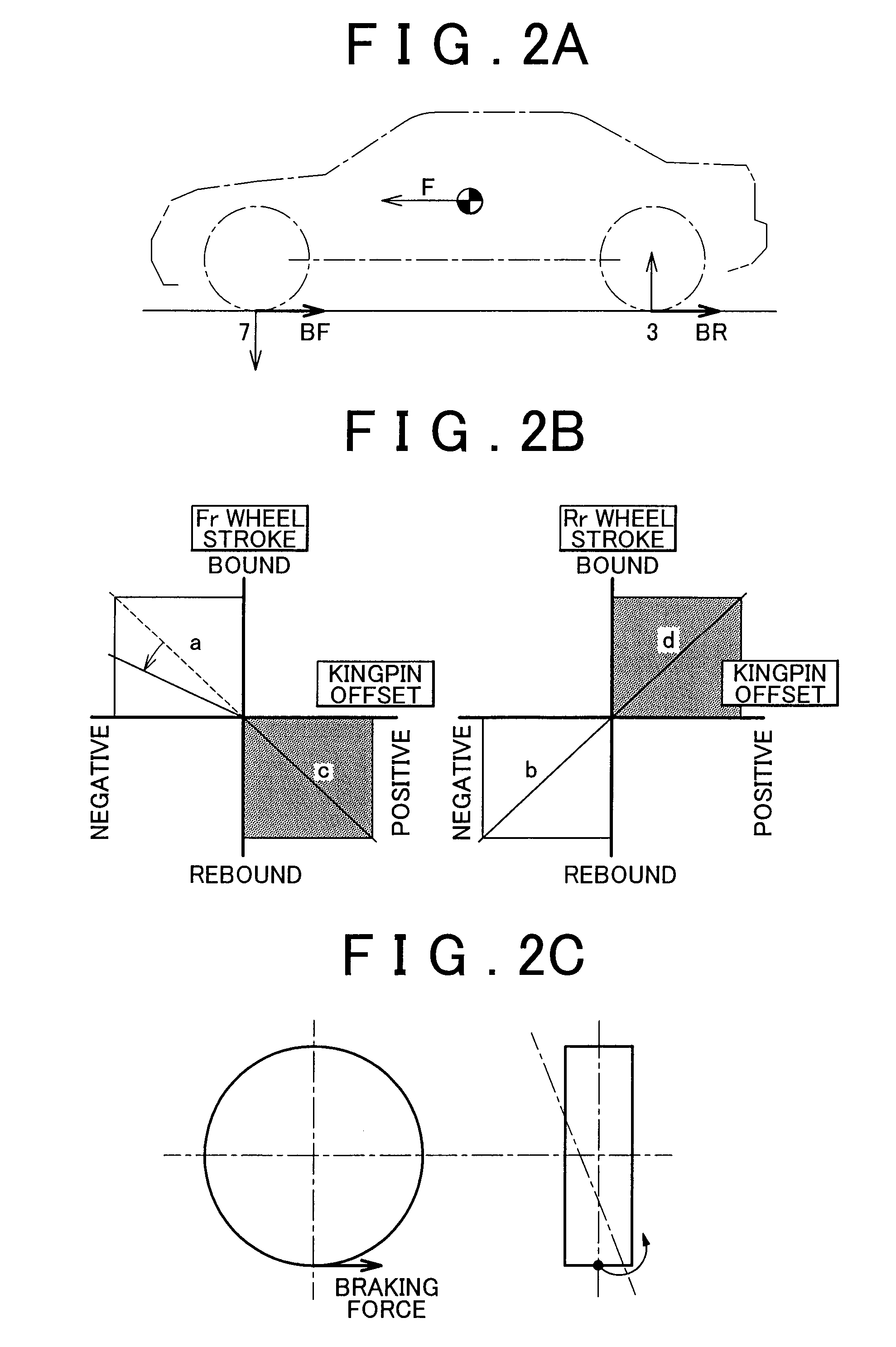

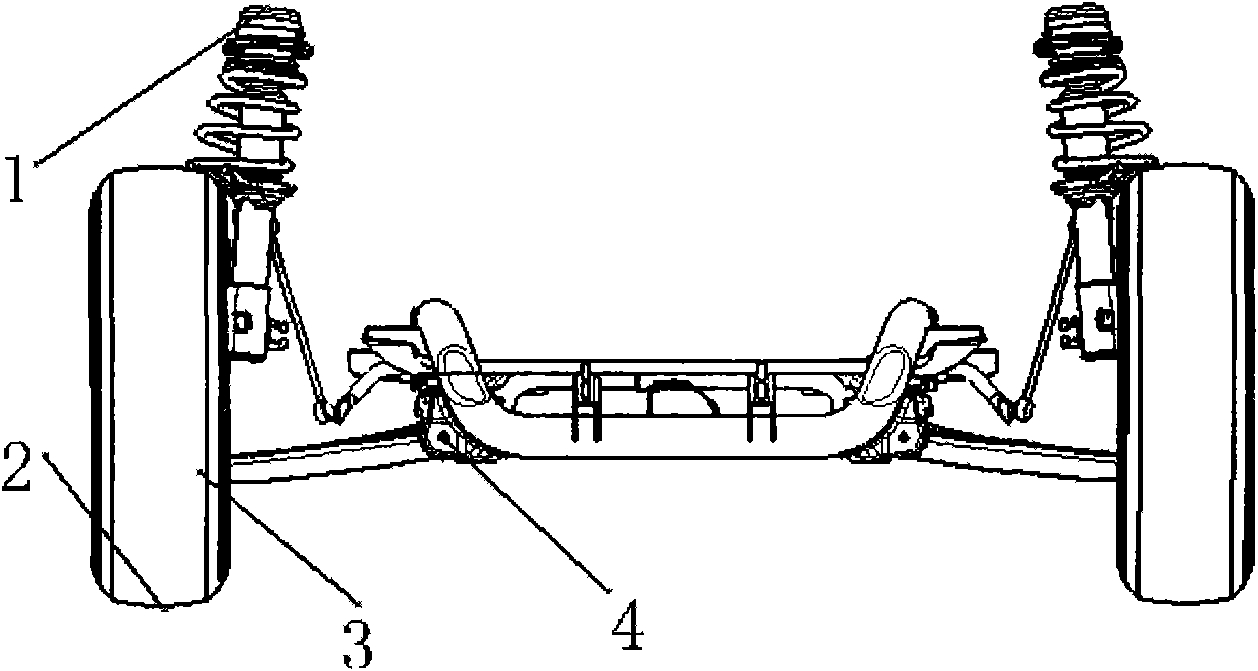

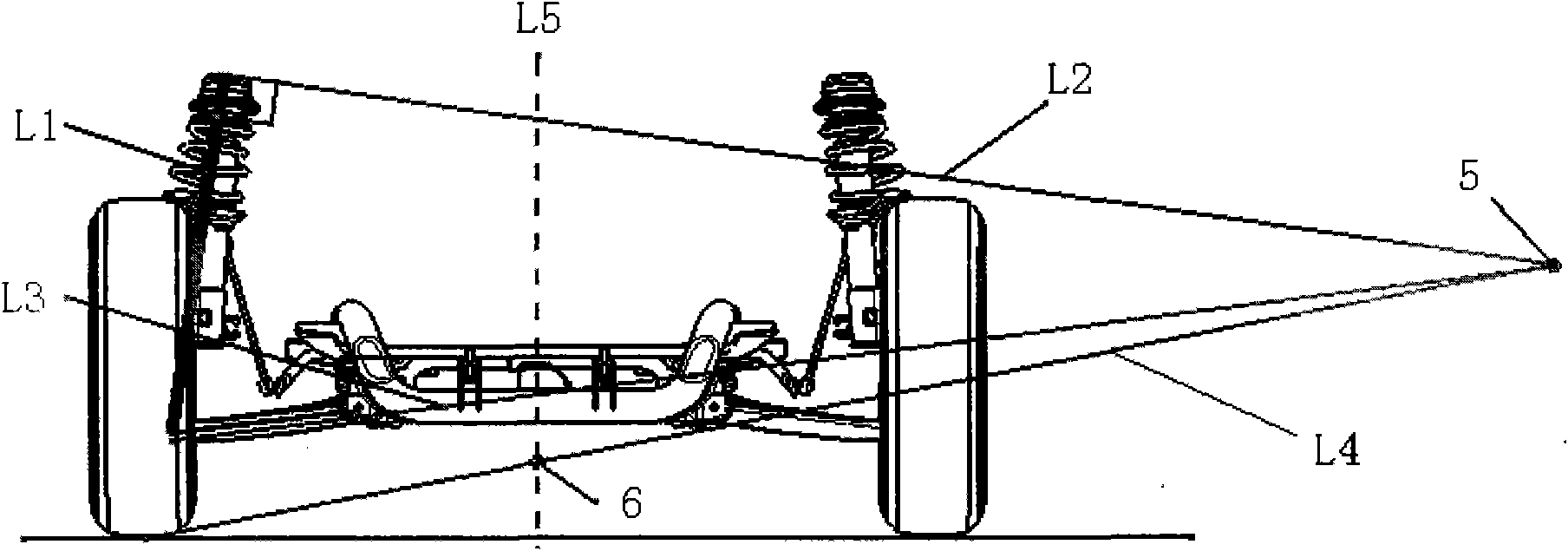

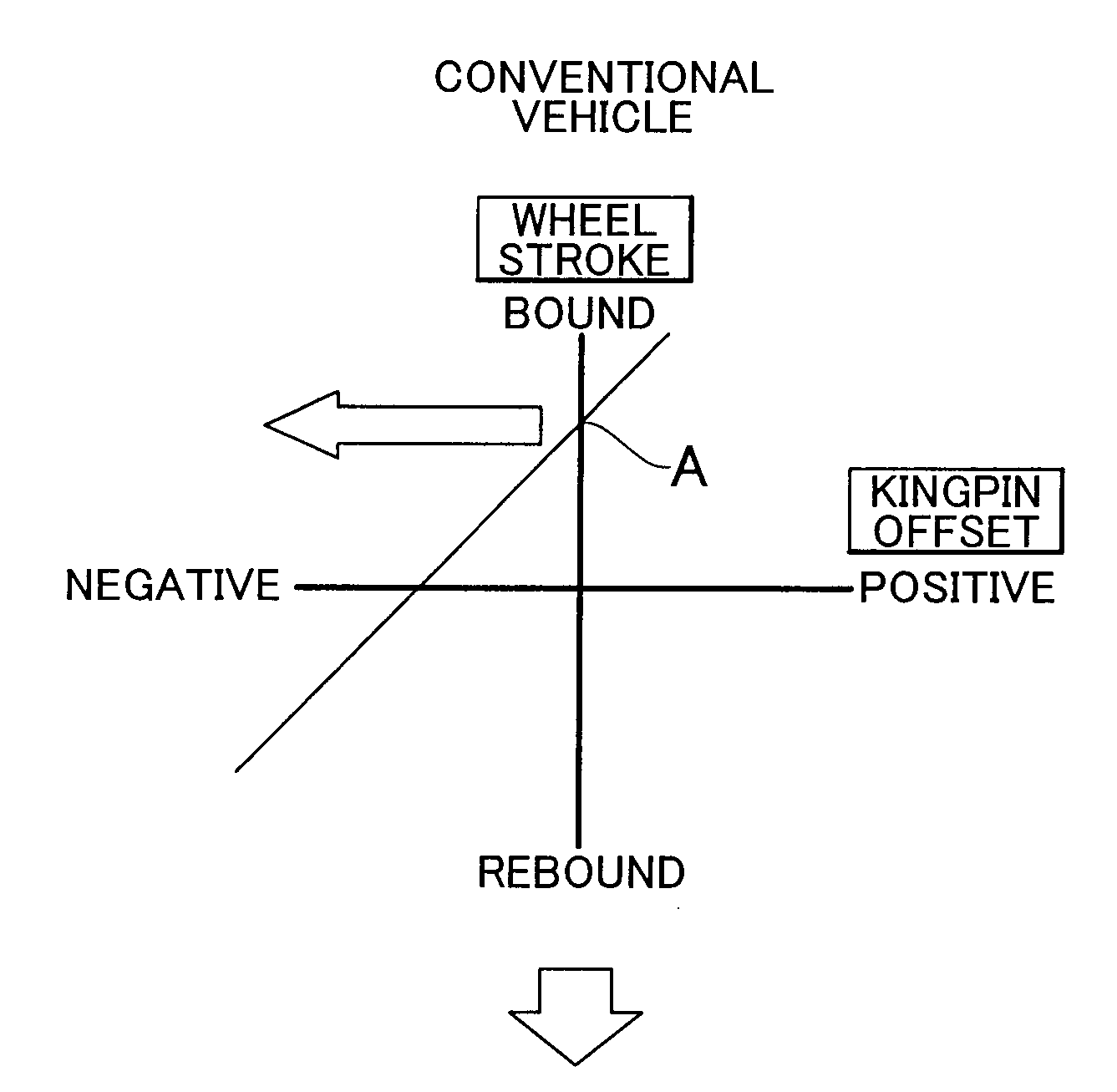

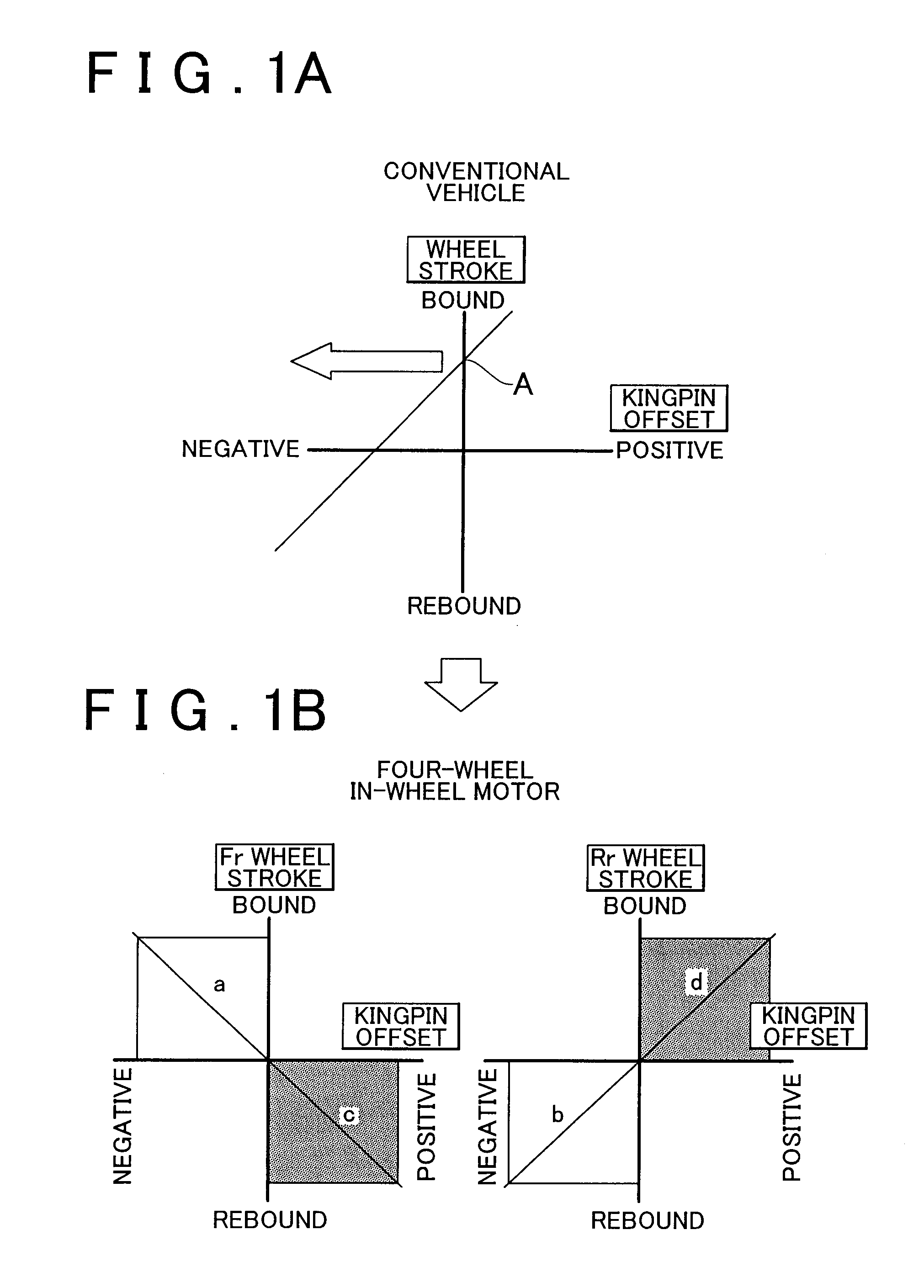

In-wheel motor vehicle

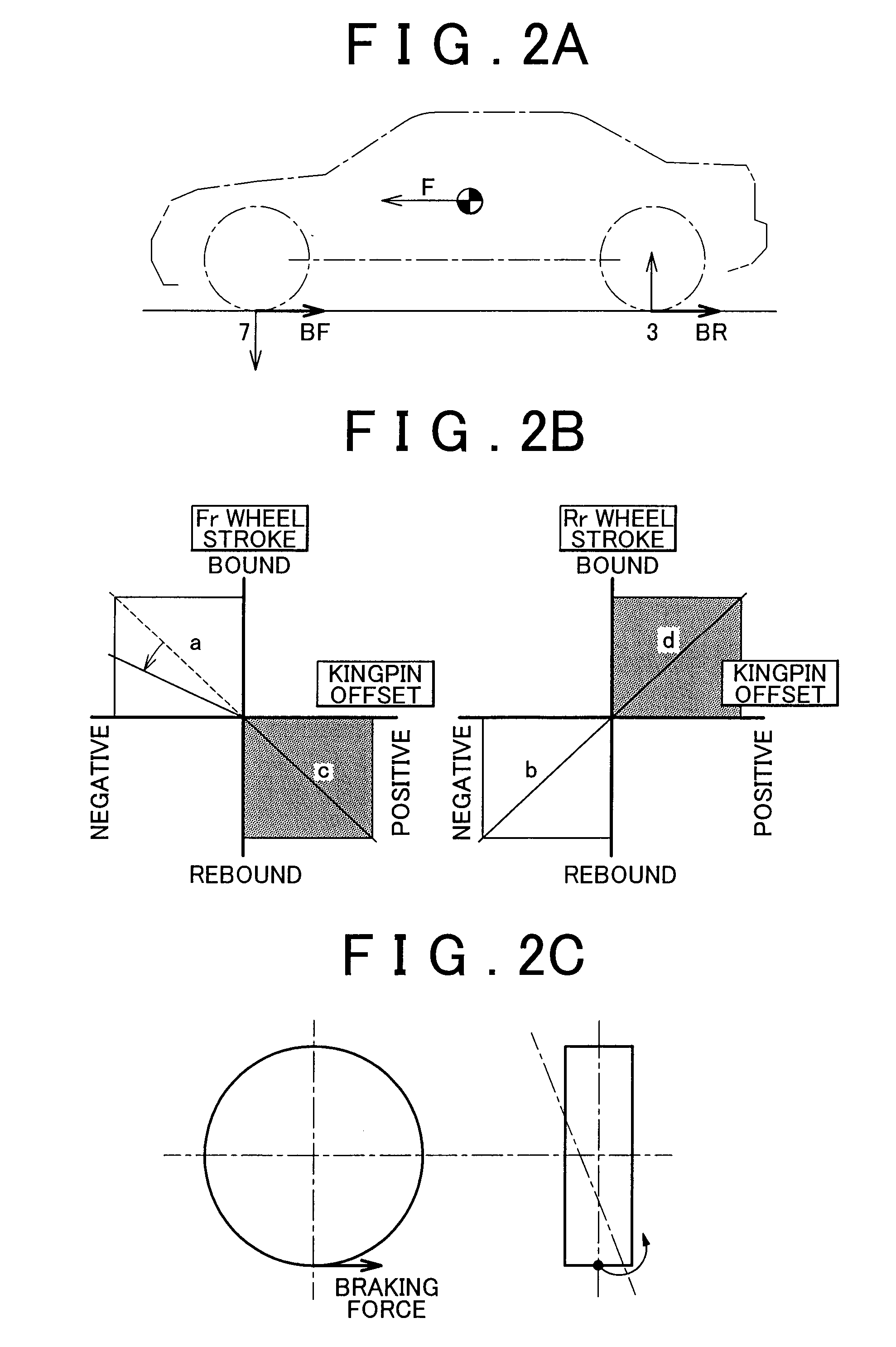

A four-wheel vehicle is provided with an in-wheel motor in each of a front wheel and a rear wheel and has approximately the same roll center heights of the front wheel and the rear wheel. The relation between a change in a kingpin offset and a change in a wheel stroke for at least any one of the front wheel and the rear wheel of the four-wheel vehicle is determined based on at least any one of braking force distribution and driving force distribution between the front wheel and the rear wheel.

Owner:TOYOTA JIDOSHA KK

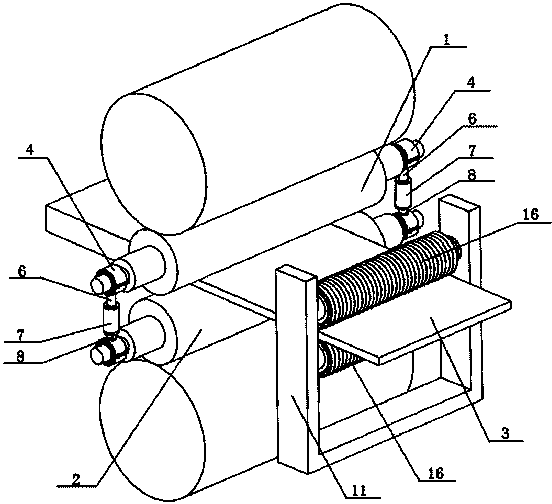

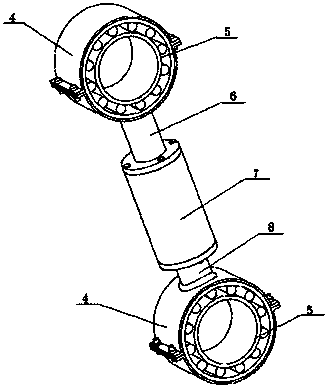

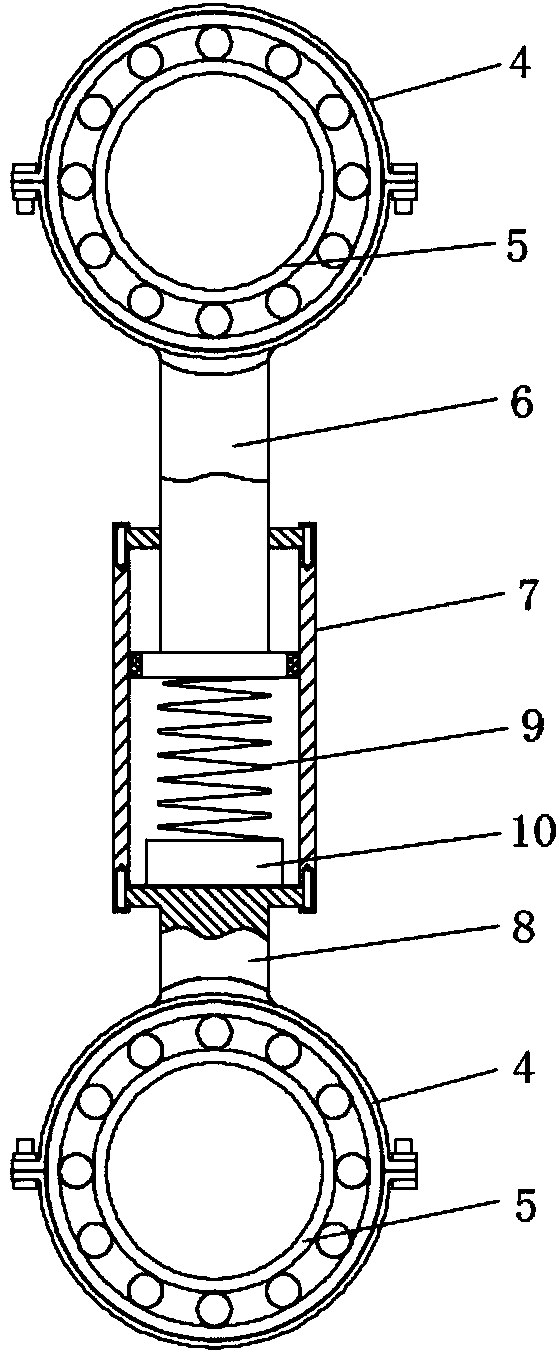

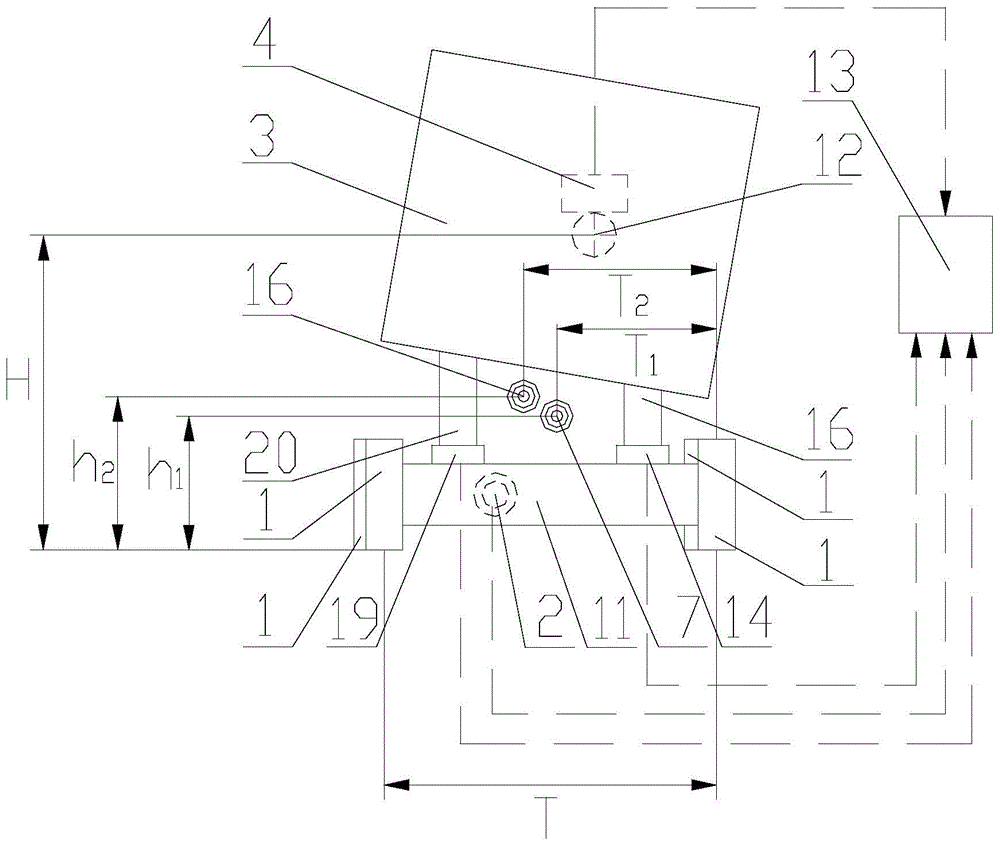

Device and method for measuring thickness of lubricating oil film on high-speed rolling interface

InactiveCN104028563ARealize measurementSimple structureMeasuring devicesMetal rolling arrangementsVertical vibrationMeasurement device

The invention discloses a device and method for measuring the thickness of a lubricating oil film on a high-speed rolling interface. The measuring device comprises a dynamic roll center distance measuring device, a sheet thickness measuring device, a data processing module and a display device. The dynamic roll center distance measuring device can accurately measure the distance between the roll center of an upper working roll and the roll center of a lower working roll, and the sheet thickness measuring device can measure the variations in horizontal thickness and vertical thickness of a sheet. After being obtained, the distance between the roll center of the upper working roll and the roll center of the lower working roll and the thickness of the sheet are processed by the data processing module, and then the variations in thickness of the lubricating oil film on the rolling interface are obtained. The measuring device can measure the thickness of the lubricating oil film on the high-speed rolling interface, is simple in structure and convenient to maintain, and eliminates the influences of vertical vibration of a rolling mill on the measurement result, furthermore, the elastic flattening of the working roll and the thickness difference of cross sections of the sheet are also taken into consideration, so that the result is more accurate.

Owner:HANGZHOU DIANZI UNIV

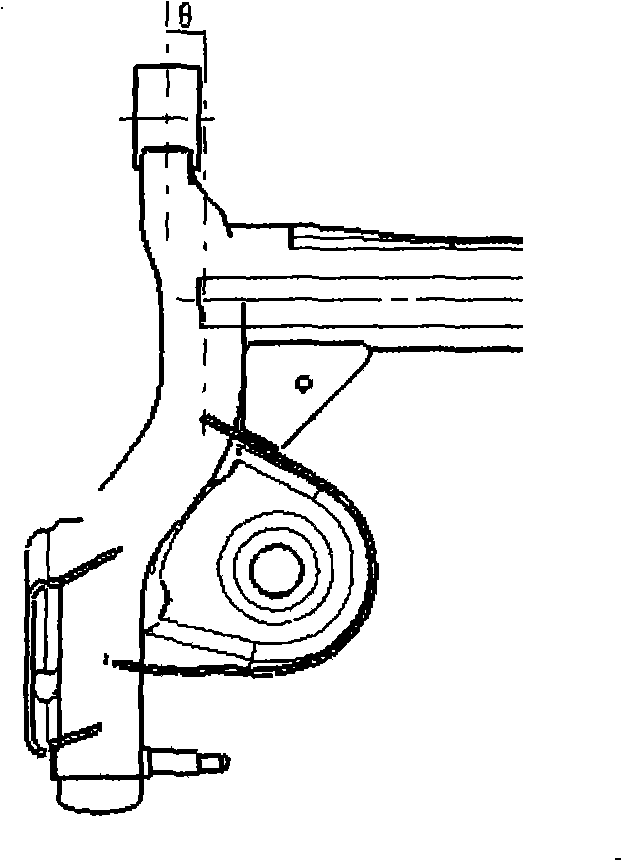

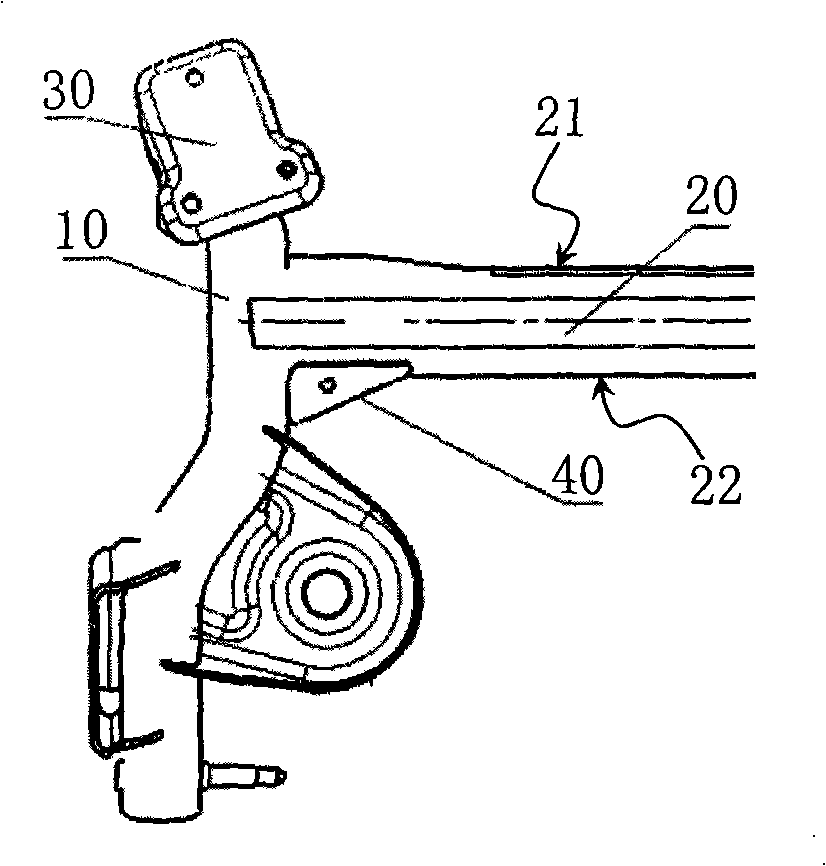

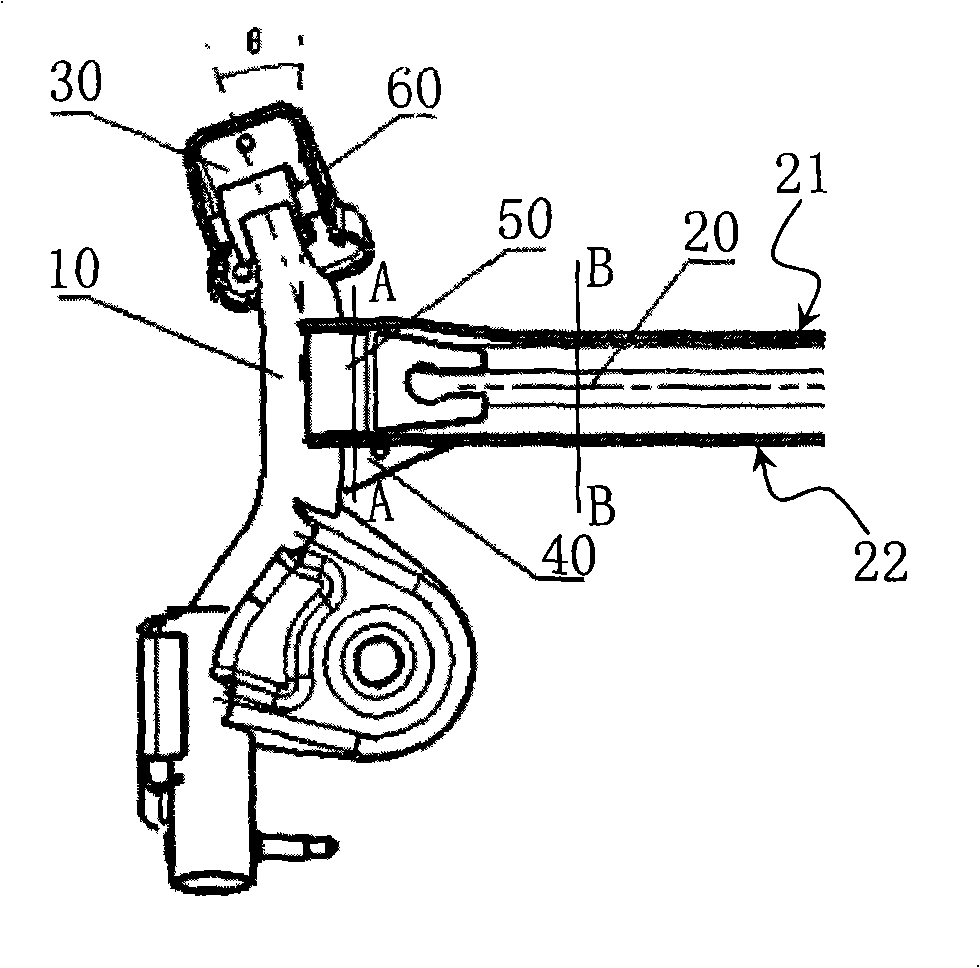

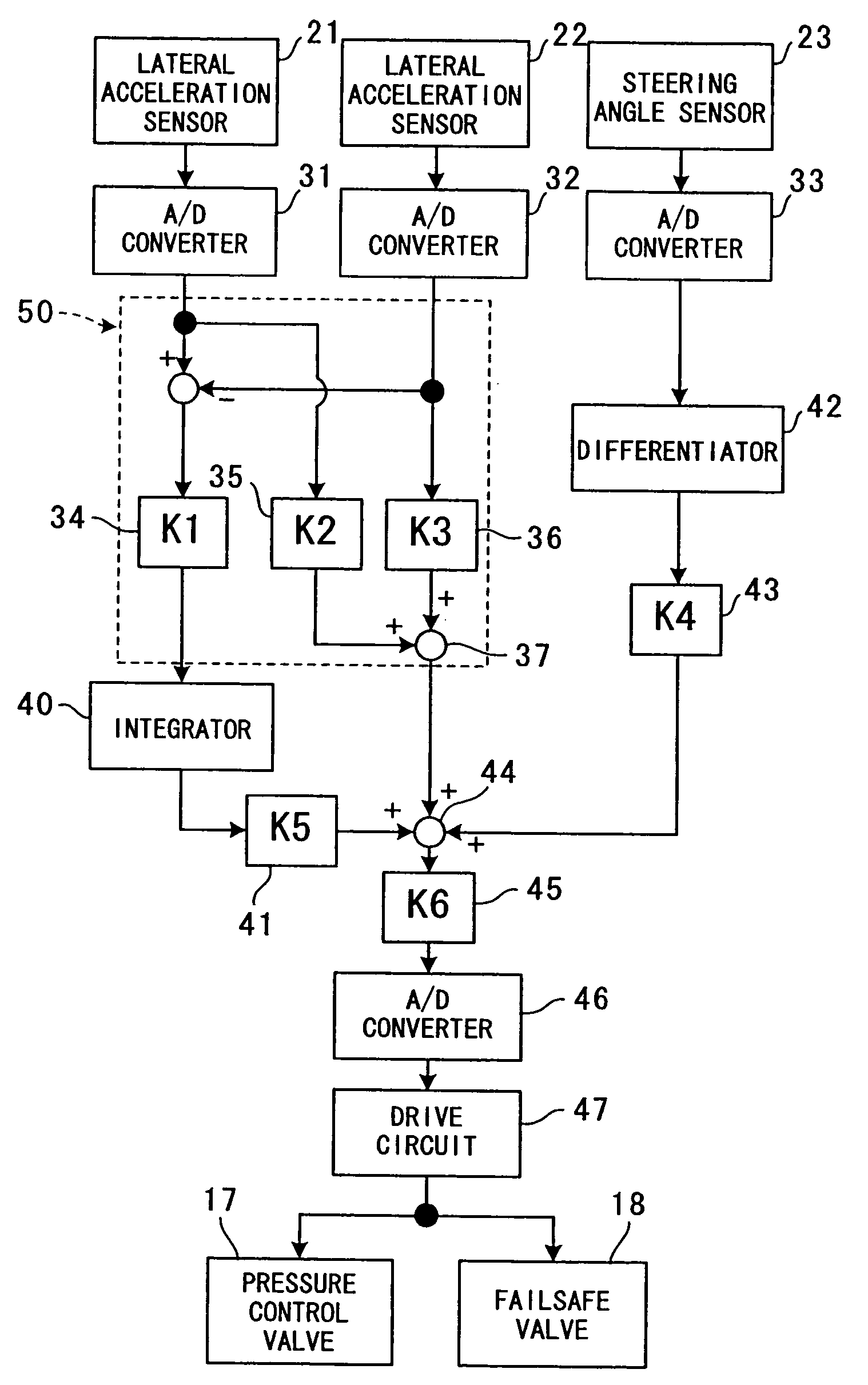

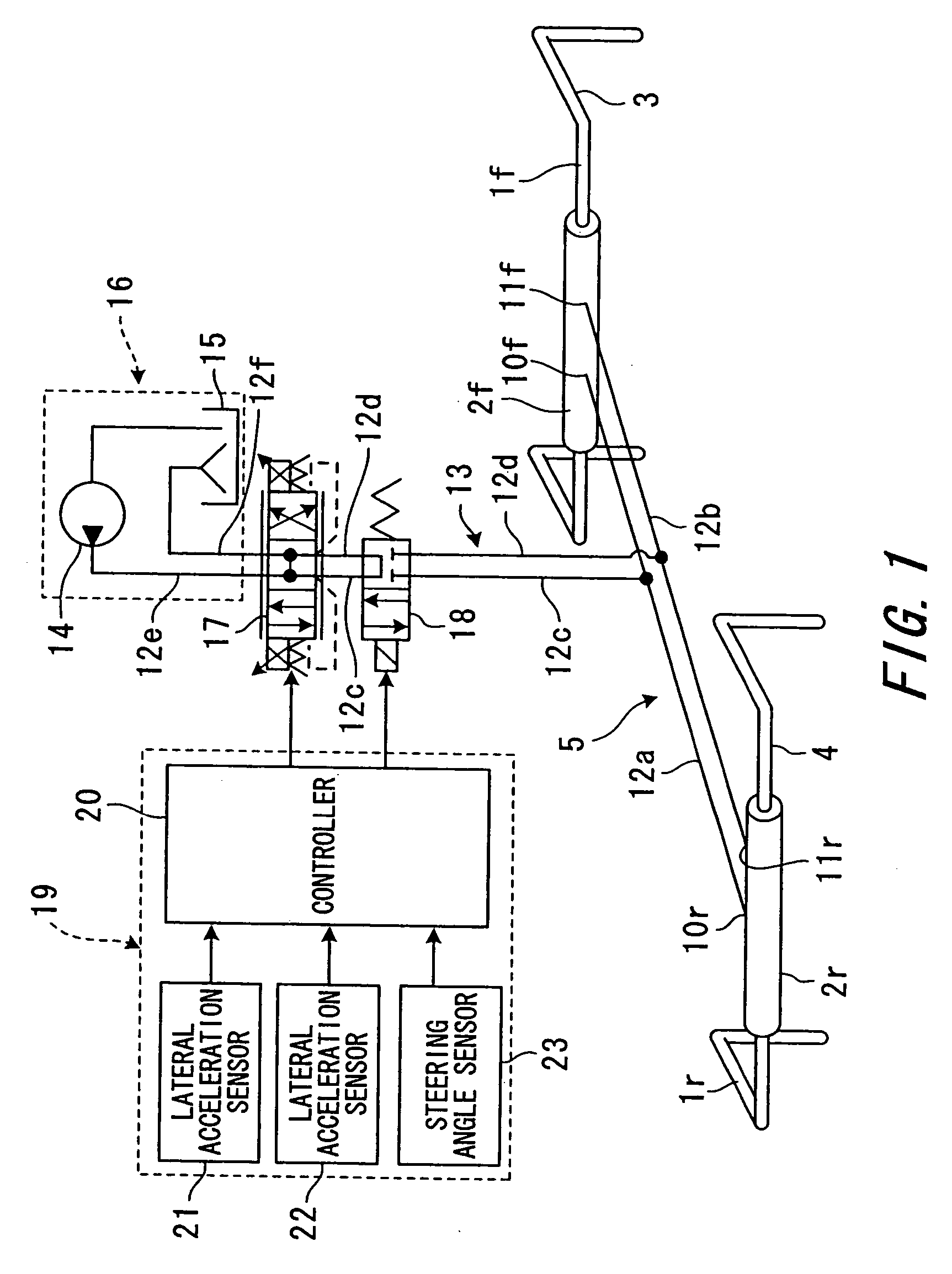

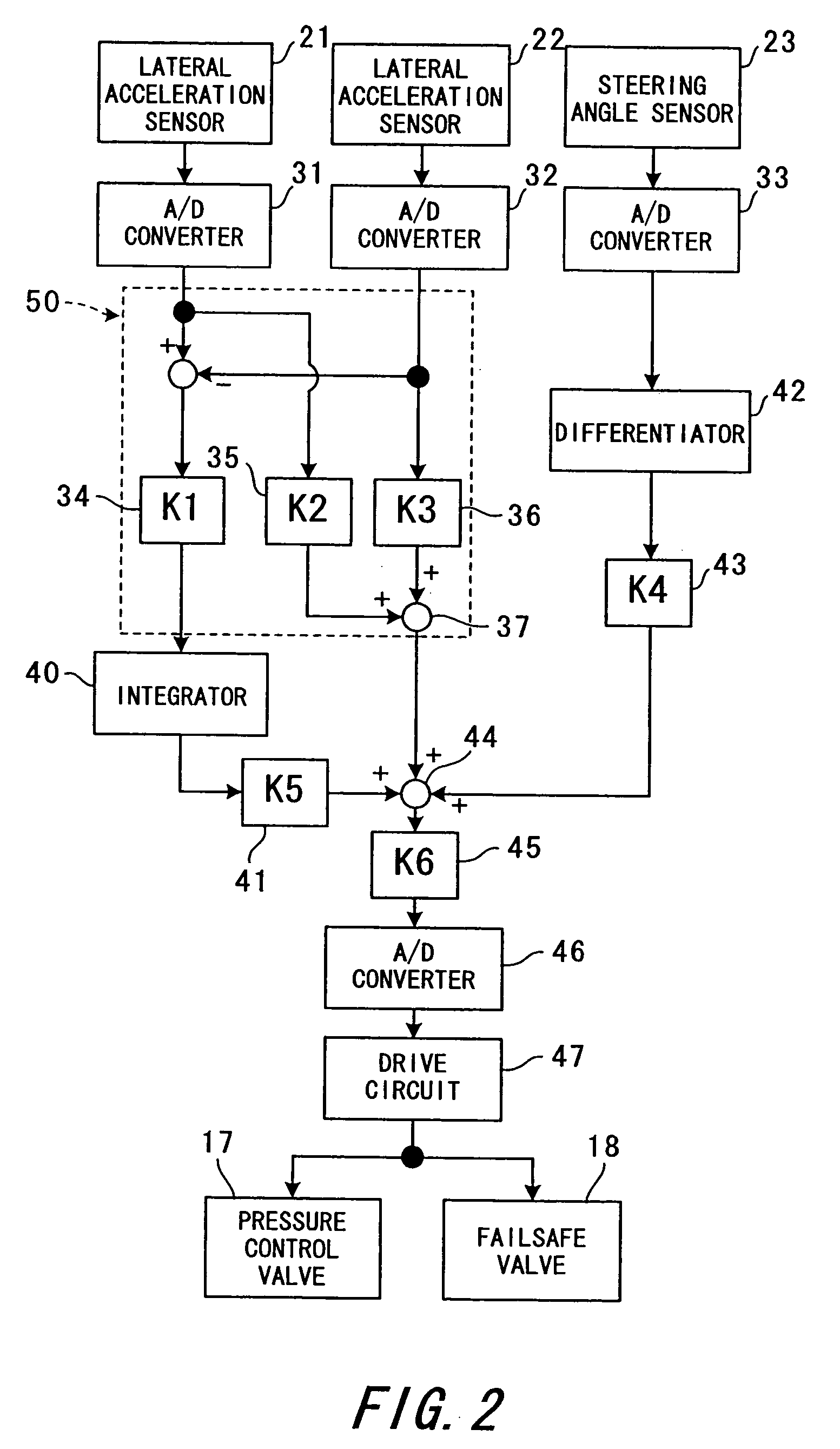

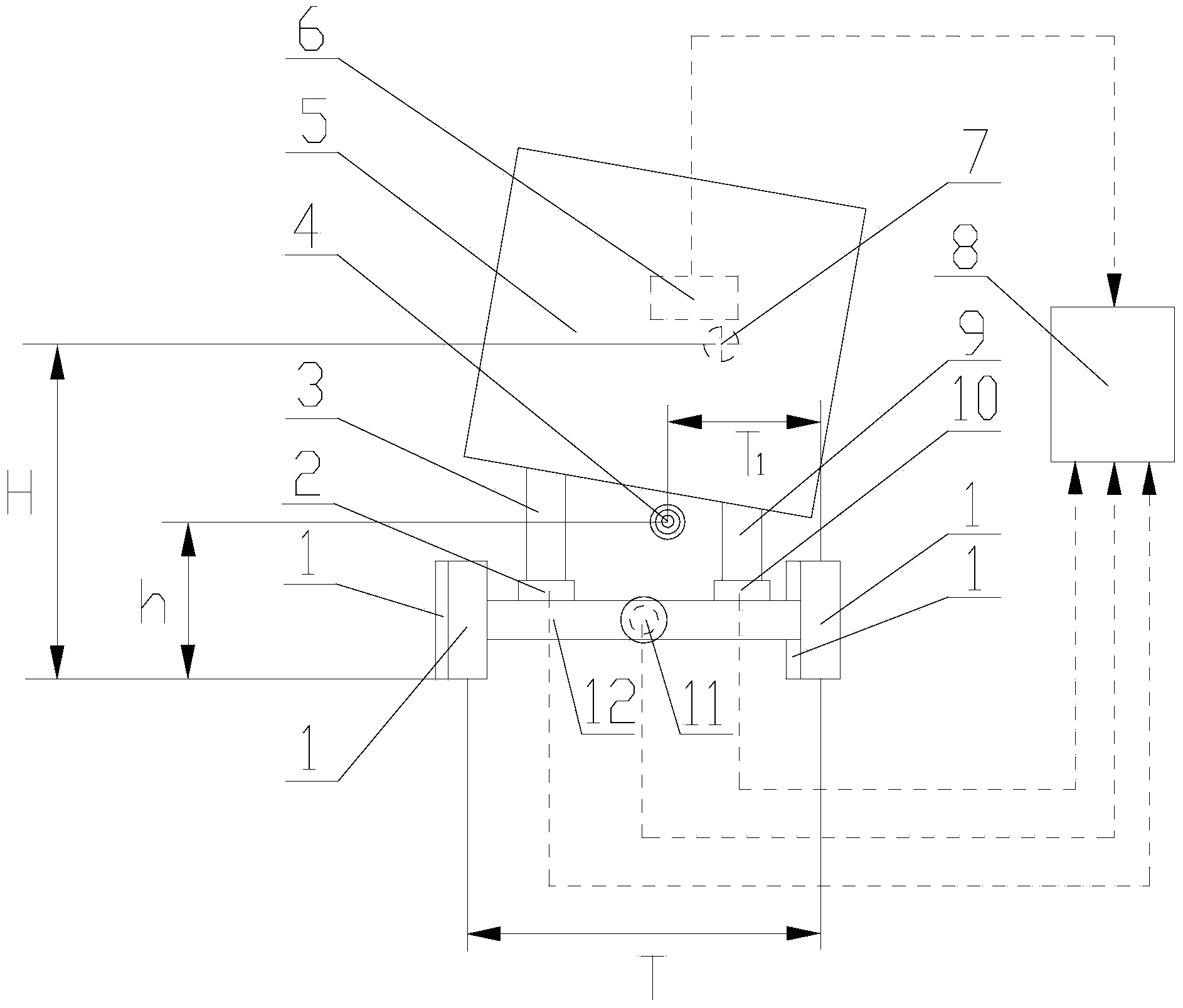

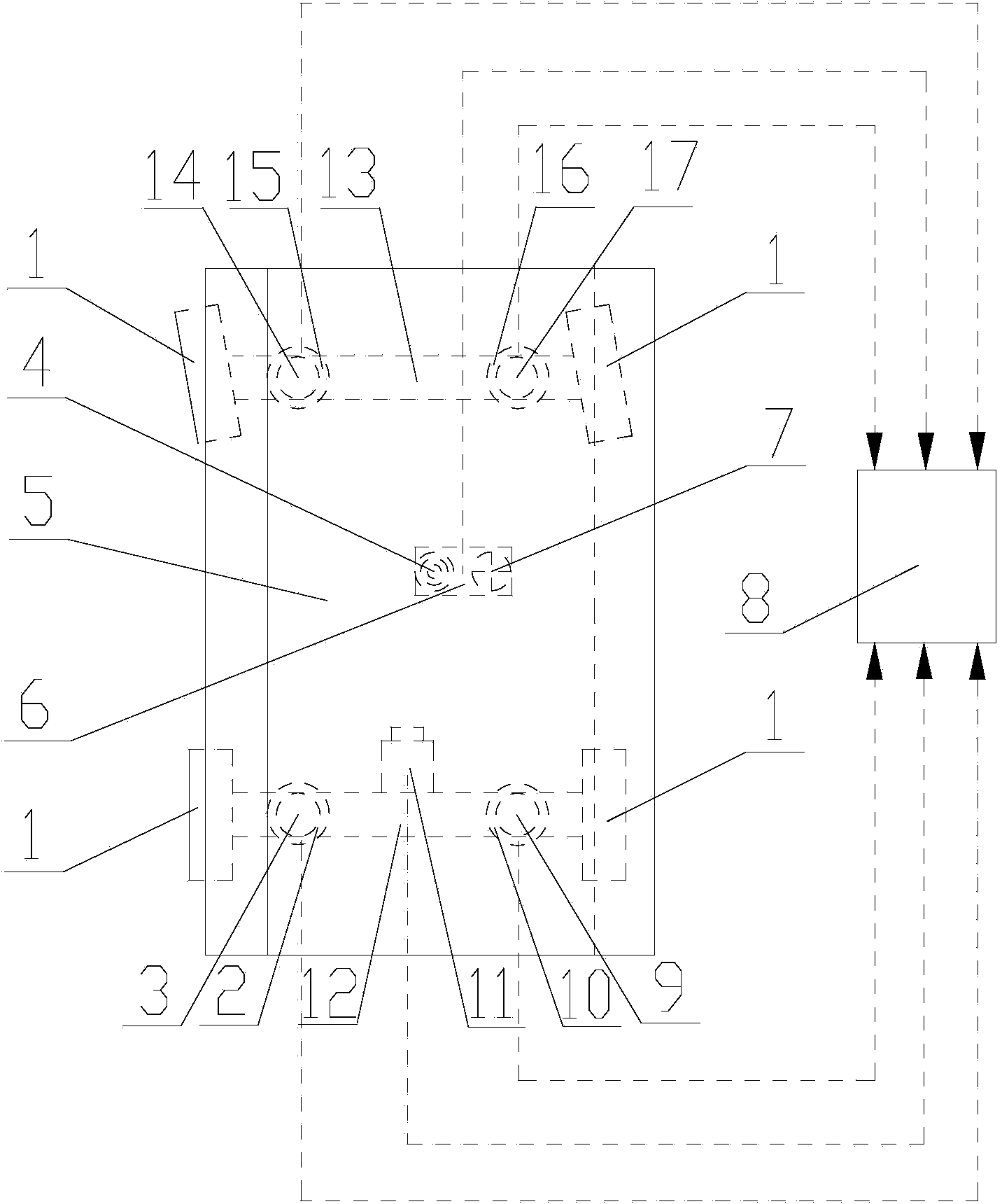

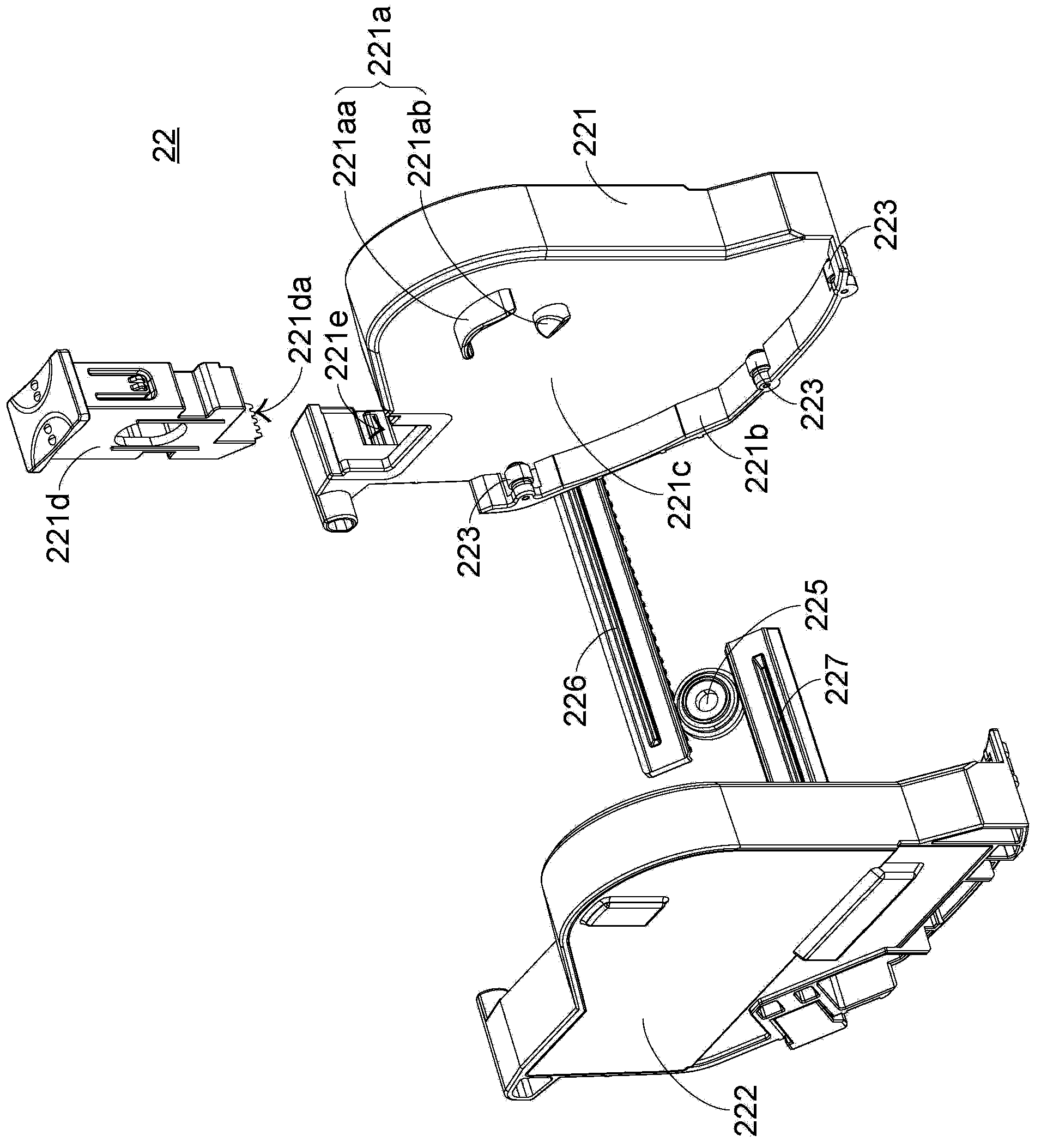

Apparatus and method of roll control for vehicle

InactiveUS20050209750A1Accurate extractionImprove controlDigital data processing detailsPedestrian/occupant safety arrangementEngineeringCentrifugal force

at least two lateral acceleration sensors (21) (22) located at different positions of a vehicle body (100) to detect lateral acceleration acting on the vehicle body; and a calculator (50) to separate and calculate actual lateral acceleration (GL) acting on the vehicle body by a centrifugal force, and roll angular acceleration (φ) acting on the vehicle body around the roll center, based upon a distance (La, Lb) from a roll center of the vehicle body to each of the sensors, an intersection angle (θa, θb) of each line connecting each of the sensors and the roll center, and outputs (GLa, GLb) of the sensors are provided.

Owner:KYB CORP

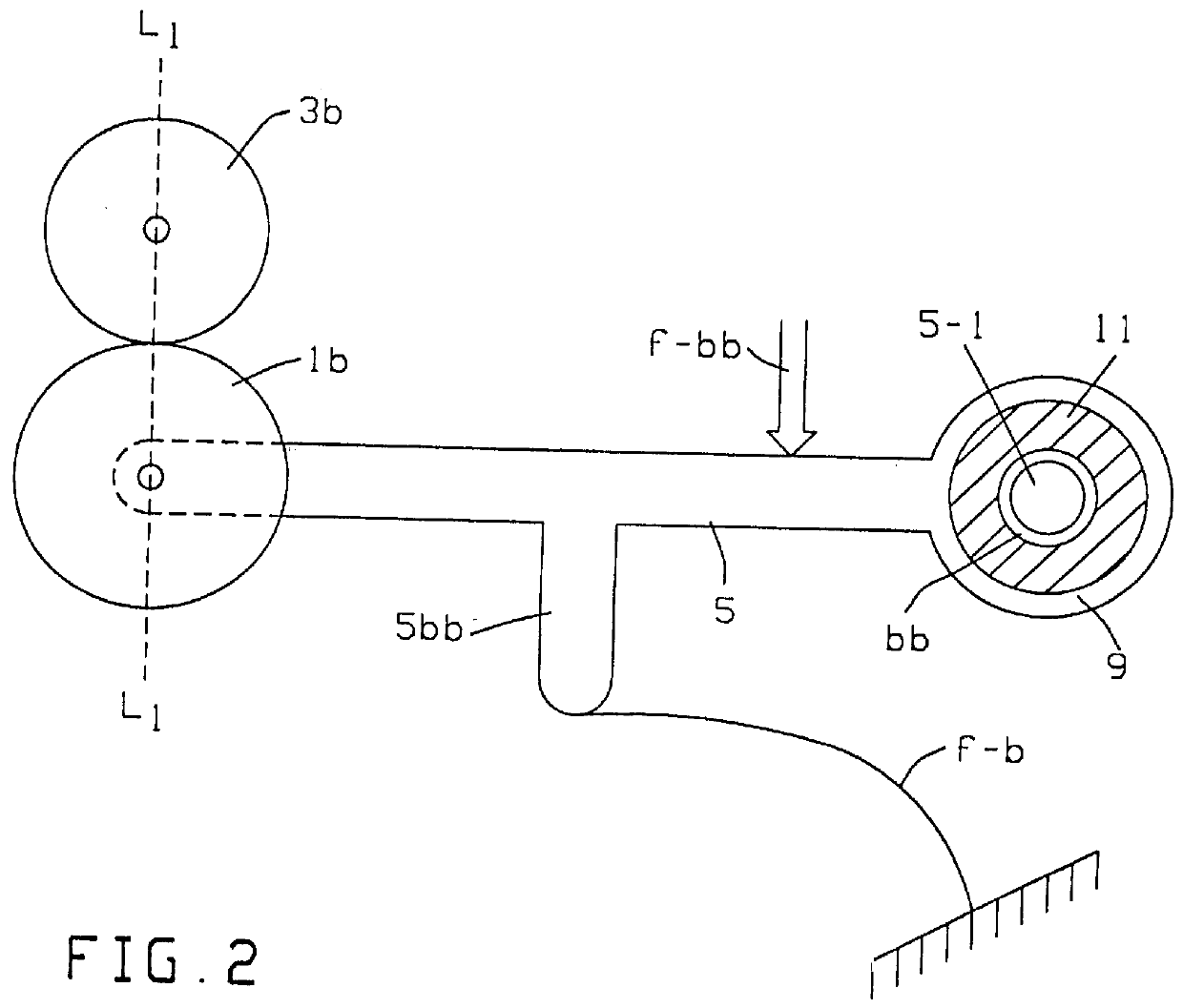

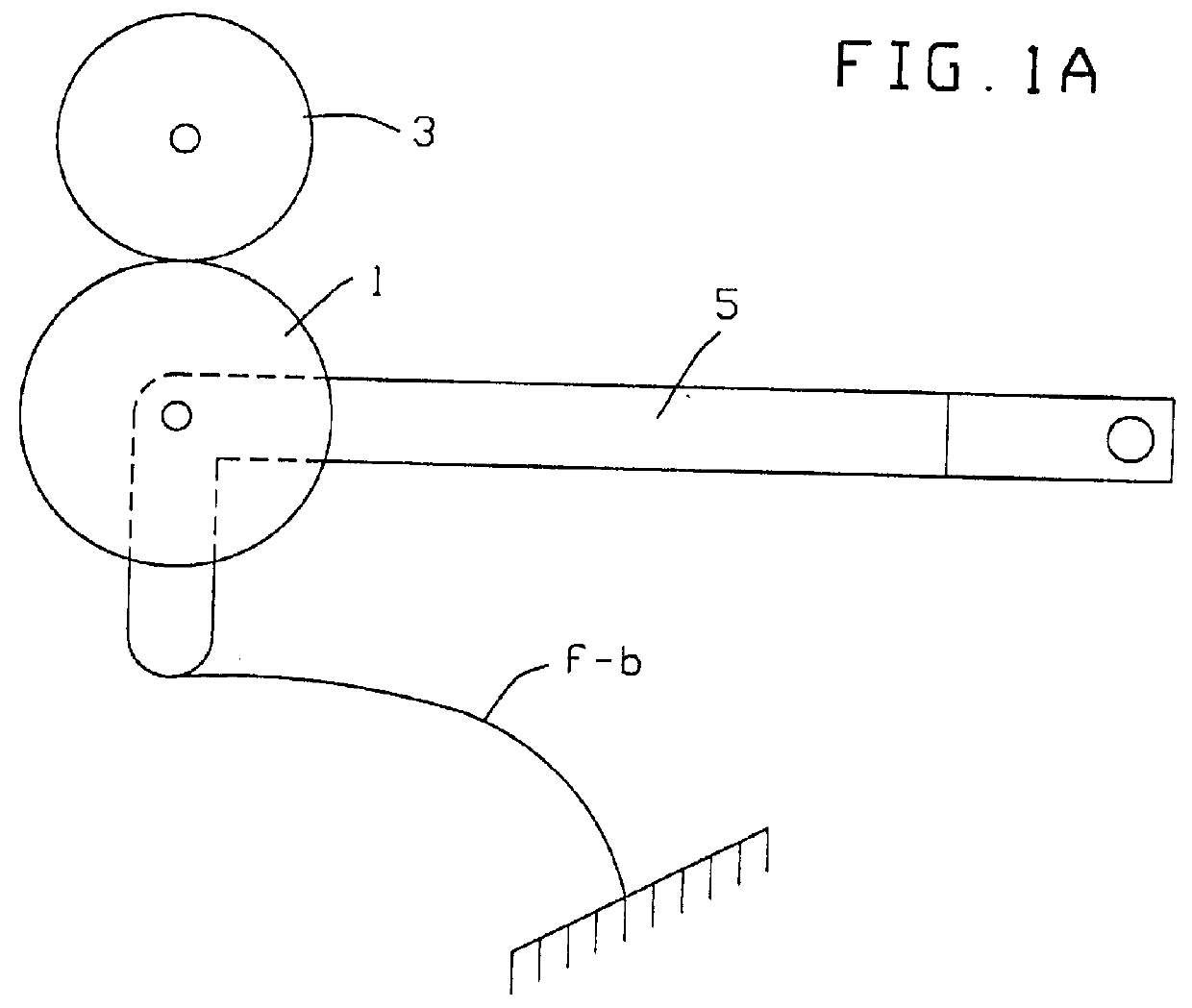

Elastomer damping of pivoted pinch roll

A document feed array comprising a pinch-roll mounted to rotate about its center to engage documents, being mounted on a cantilever-arm pivoted at a point distal from the roll-center and including an elastomeric sleeve which, alone, couples the arm to its pivot point (in operation), the sleeve comprising high-damping, durable elastomeric material adapted to accommodate thickness anomalies in the documents, yet to maximize driving contact therewith.

Owner:BURROUGHS CORP

Vehicle roll center position measuring device and calculating method of vehicle roll center position

The invention relates to a vehicle roll center position measuring device. The invention provides the vehicle roll center position measuring device, aiming at the deficiencies in vehicle roll and rollover studies at present. The vehicle roll center position measuring device comprises a left rear wheel vertical load sensor, a left rear suspension, a centroid sensing unit, a calculating unit, a right rear suspension, a right rear wheel vertical load sensor, a vehicle speed sensor, a left front suspension, a left front wheel vertical load sensor, a right front wheel vertical load sensor, a right front suspension and the like. The invention also relates to a calculating method of a vehicle roll center position. With the adoption of the vehicle roll center position measuring device and the calculating method, as the positions of roll centers when a vehicle rolls and is in side tumbling can be calculated according to the vertical load of each wheel, the yaw angle speed of the vehicle, the roll angle of the vehicle and the running speed of the vehicle, the effects of the roll forecast and a roll prevention controlling system of the vehicle are effectively improved.

Owner:SHANDONG JIAOTONG UNIV

Suspension

InactiveUS7350795B2Provide protectionLower ride heightRigid suspensionsInterconnection systemsRide heightTrailing arm

A rear axle suspension for a highway truck that includes a pair of trailing arms suspended below a frame by a pair of hanger brackets. The hanger brackets define a pivot axis for the trailing arms. A supplemental axle locating member is attached to the axle and includes an extension member that is engageable with a bracket held by the frame. The hanger brackets are laterally compliant and each comprise an inner and outer plate, one of which is bent outwardly to define a gap within which an associated trailing arm is mounted. A moment canceling member extends between the hanger brackets and resists outward bending of the brackets. A height control valve is operated by an operating rod having an axis that passes through, or in close proximity, to the roll center of the vehicle in order to reduce ride height errors.

Owner:VOLVO TRUCKS NORTH AMERICA

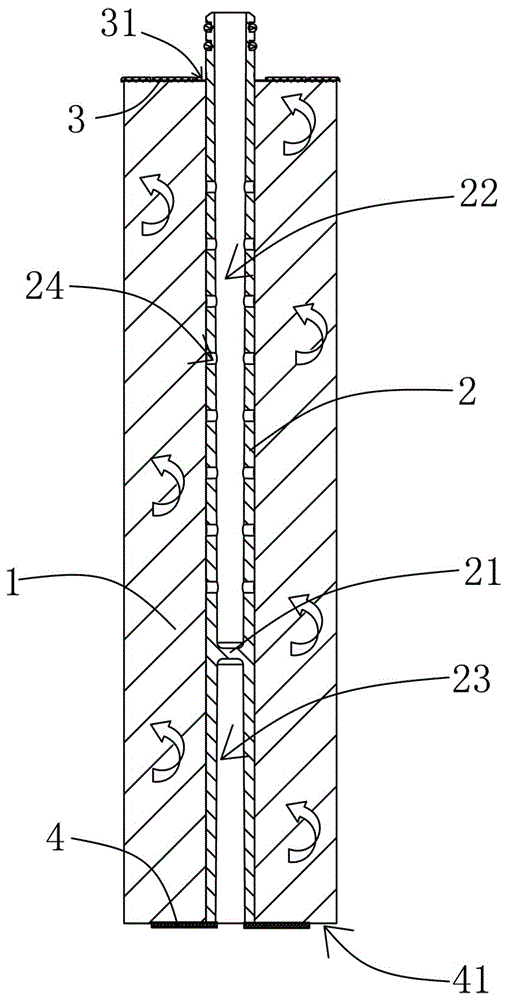

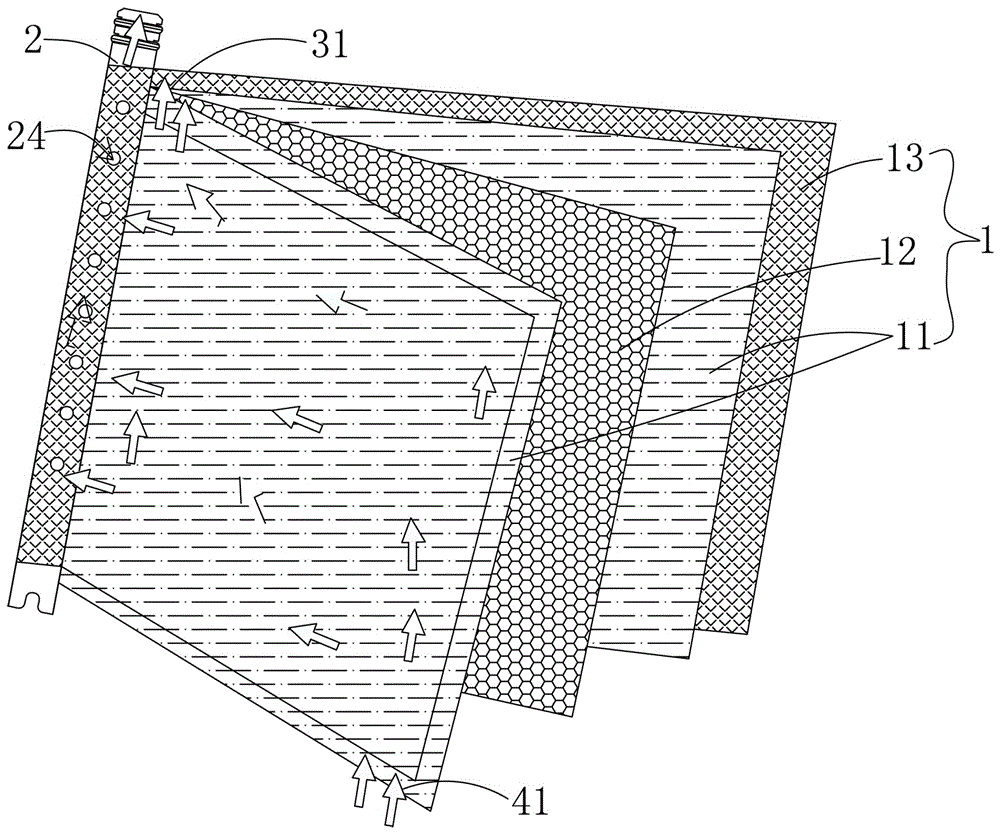

Water-saving membrane component and filter structure thereof

ActiveCN106110893ATake advantage ofReduce lossSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater savingFiltration

The invention discloses a water-saving membrane component and a filter structure thereof. The water-saving membrane component comprises a center tube, a filter membrane component, an upper seal part and a lower seal part, and the filter membrane component is rolled centering on the center tube. The upper seal part seals the outer periphery of the upper end face of the filter membrane component to make the inner periphery, close to the center tube, of the upper end face, serve as a wastewater outlet. The lower seal part seals the inner periphery, close to the center tube, of the lower end face of the filter membrane component to make the outer periphery of the lower end face serve as a water inlet. Due to adoption of the water-saving membrane component, during filtering, raw water enters the outermost layer of the water-saving membrane component from the water inlet of the outer periphery of the lower end face and then spirally flows into the innermost layer of the water-saving membrane component from the outermost layer of the water-saving membrane component, pure water flows into the center tube, and waste water flows out from the wastewater outlet. The water-saving membrane component and the filter structure thereof have advantages of complete utilization of the filter membrane component, low loss, high pure water flux, less wastewater, uniformity in water feeding, long filter flow passage, effectiveness in filtration and the like.

Owner:FOSHAN MICRO MIDEA FILTER MFG CO LTD

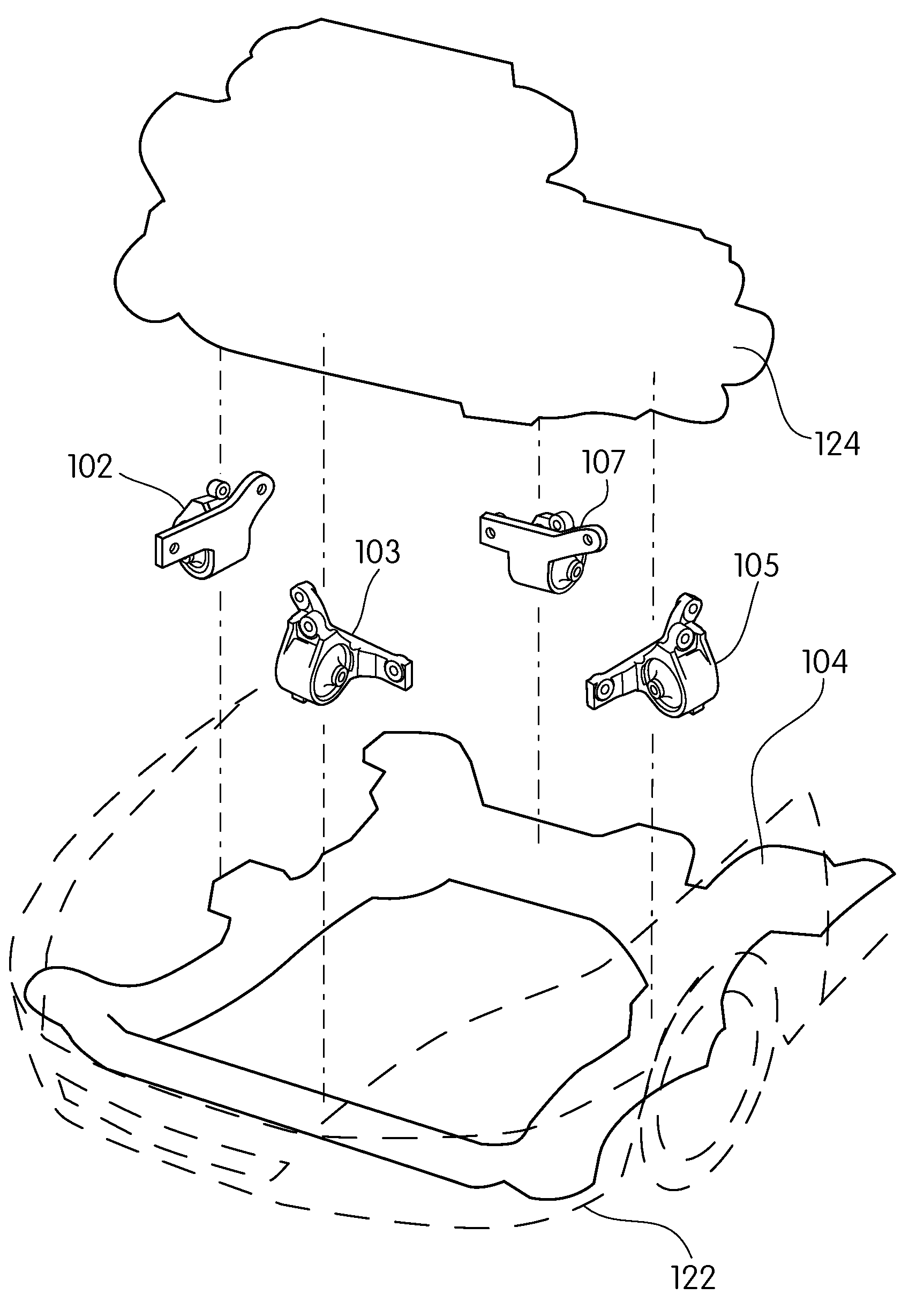

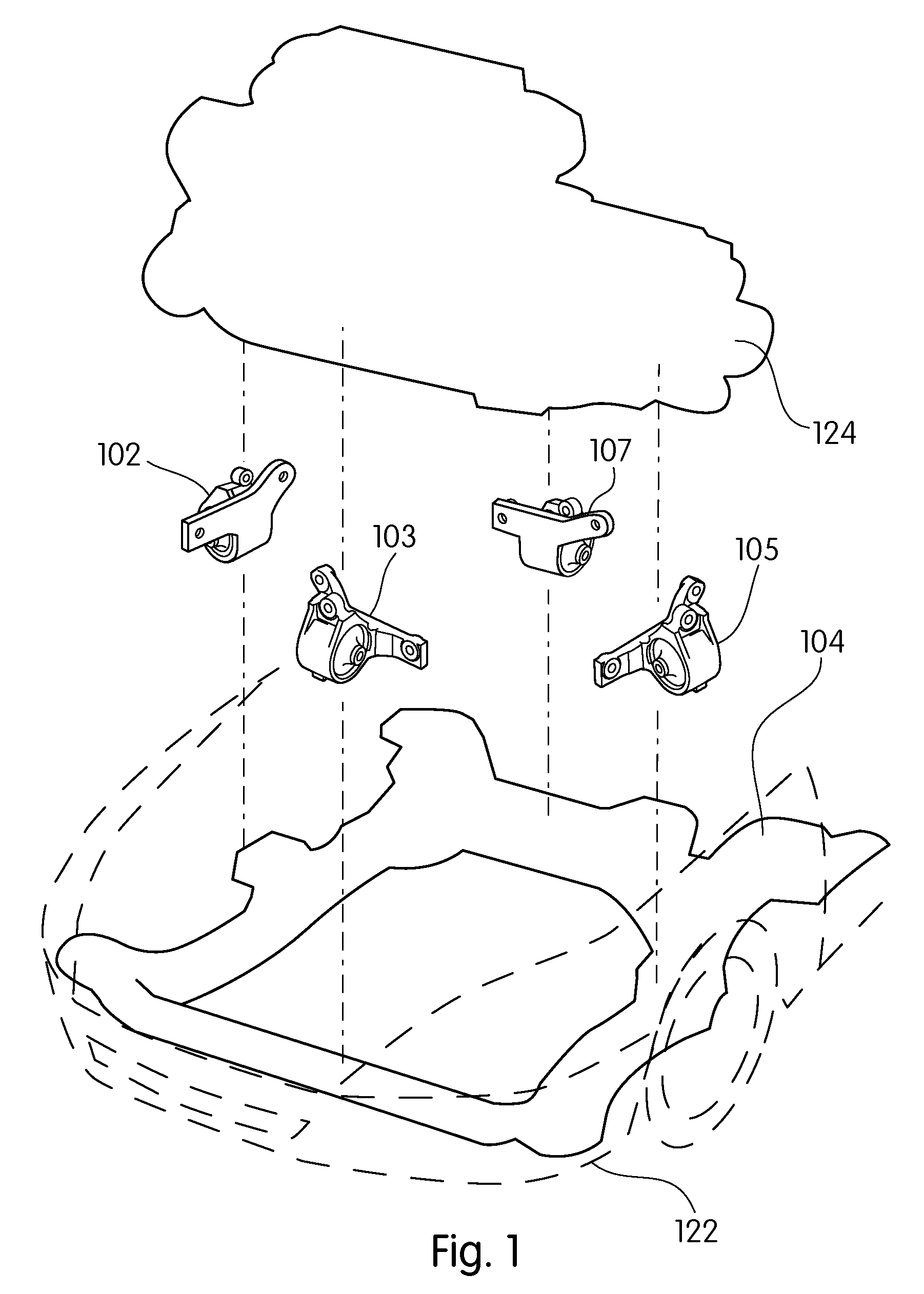

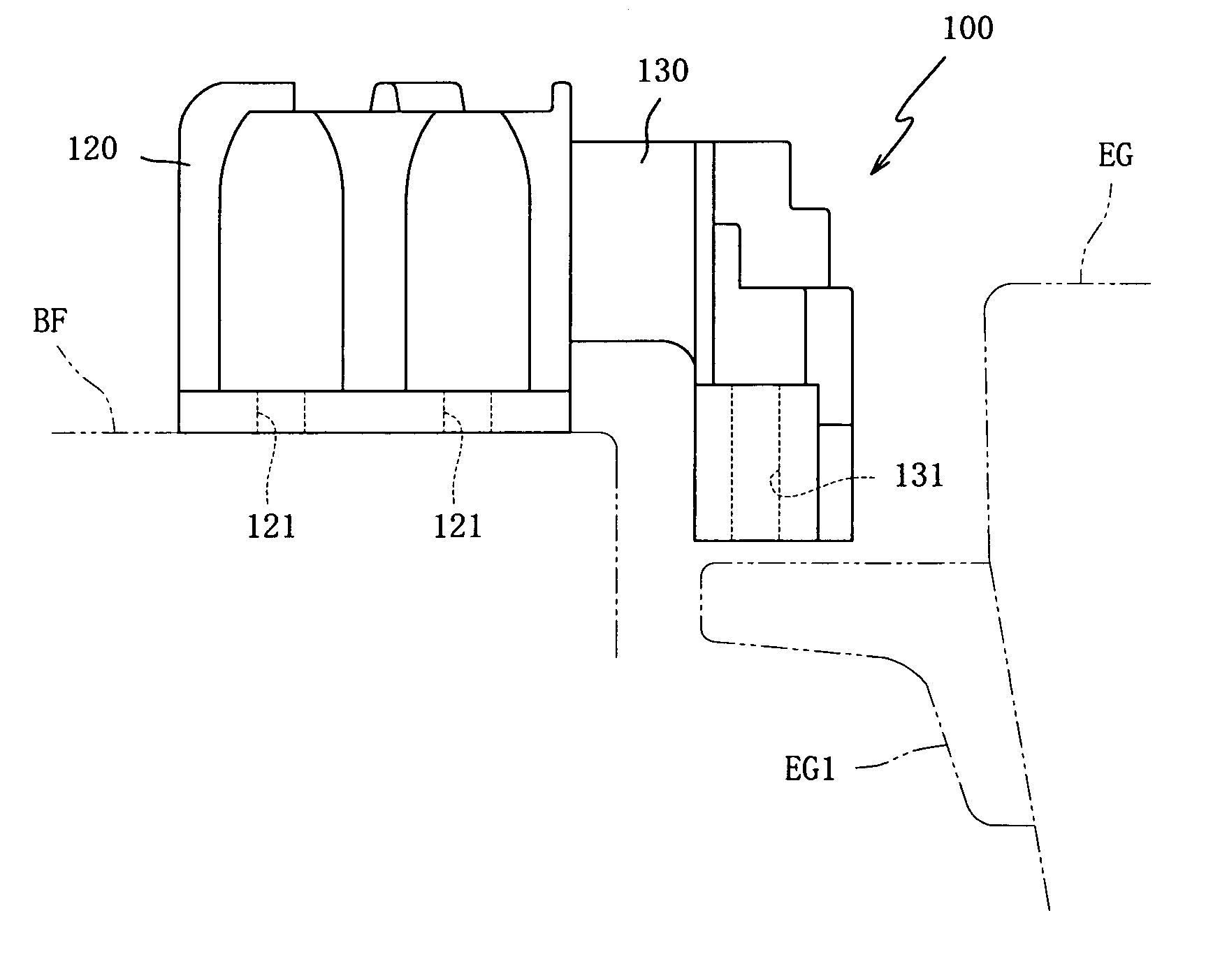

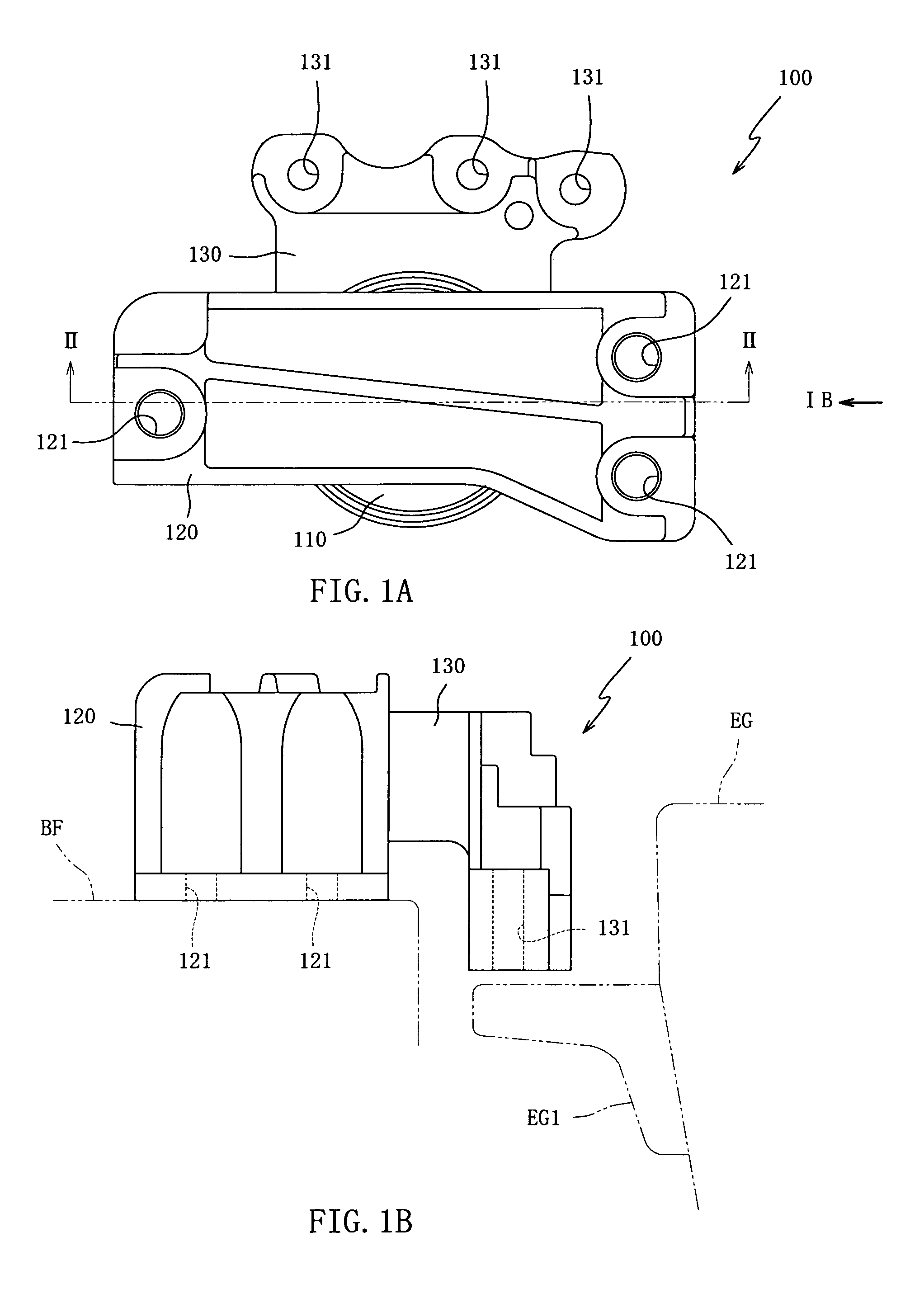

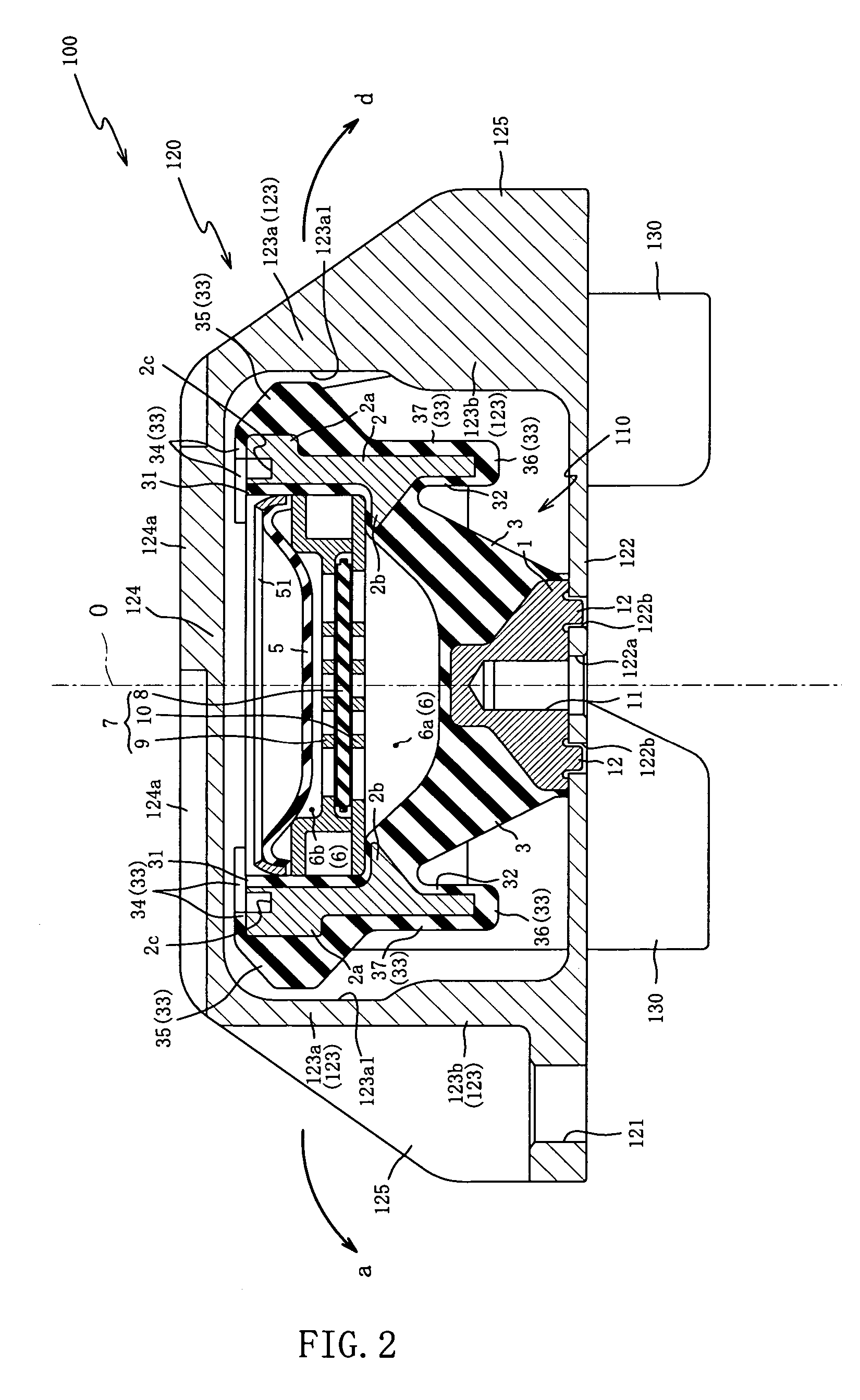

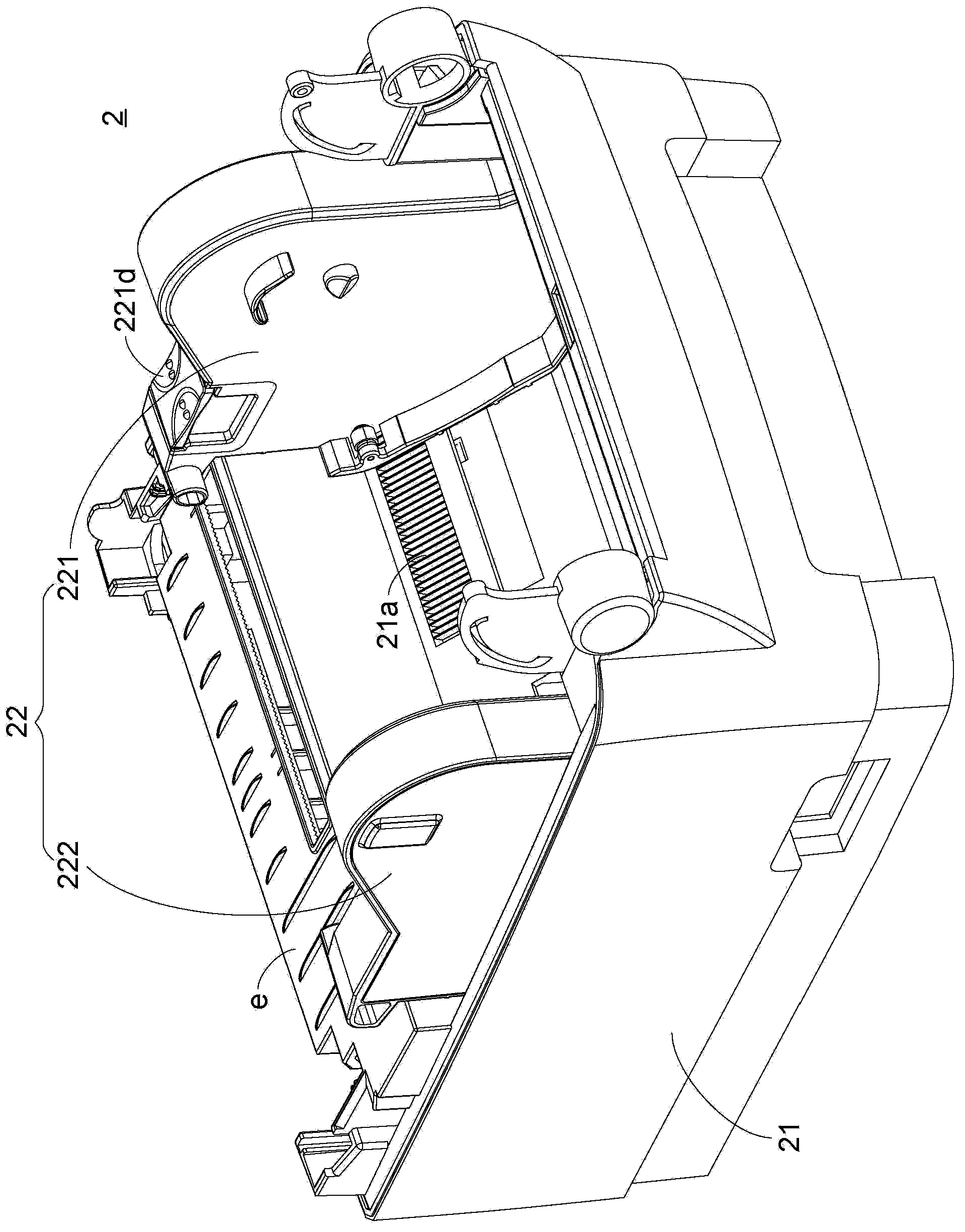

Hydraulic antivibration device arrangement, hydraulic antivibration device, and car body side bracket

InactiveUS7278633B2Small reaction forceLong distanceMachine framesLiquid springsEngineeringUltimate tensile strength

A hydraulic antivibration device arrangement capable of achieving a downsizing and weight reduction, and a reduction of booming noise by suppressing a reaction force to impingement upon stopper action is provided. By disposing a protuberant rubber portion 35 at an upper end of a main body member 2, its spacing distance from a roll center can be lengthened, the reaction force to impingement can be diminished, and input load to the main body member 2 can be diminished. Consequently, reduction of rigidity and strength required for respective components as well as enhancement of durability is possible, which permits to make the components thin-walled thereby making a hydraulic antivibration device arrangement 100 lightweight as a whole. Diminishing of such reaction force upon stopper action also enables vibrations input through a car body side bracket 120 to the body frame to be suppressed, thereby reducing the generation of booming noise.

Owner:TOYO TIRE & RUBBER CO LTD

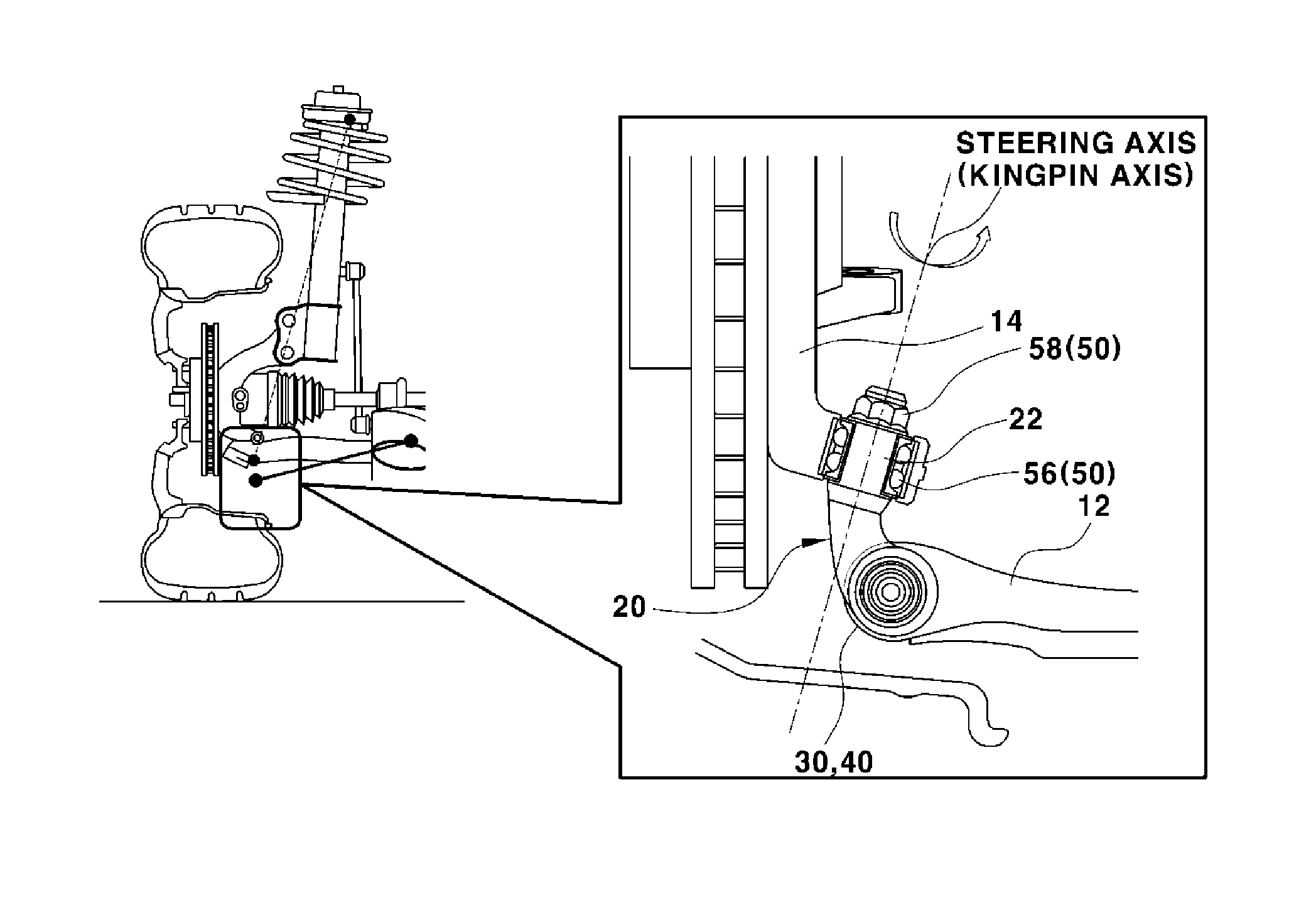

Suspension arm device for vehicle

A suspension arm jointing device for a vehicle includes a steering axis and a roll center can be independently controlled. By dualizing a joint between a lower arm and a knuckle into a rotation portion based on wheel steering and a rotation portion based on wheel's up / down movement, a lower aim joint's function for determining a roll center height during turning and determination of an steering axis position which affects wheel vibration and braking stability during linear driving can be controlled independently of each other, thereby heightening the roll center and determining an optimal steering axis (kingpin axis) position.

Owner:HYUNDAI MOTOR CO LTD

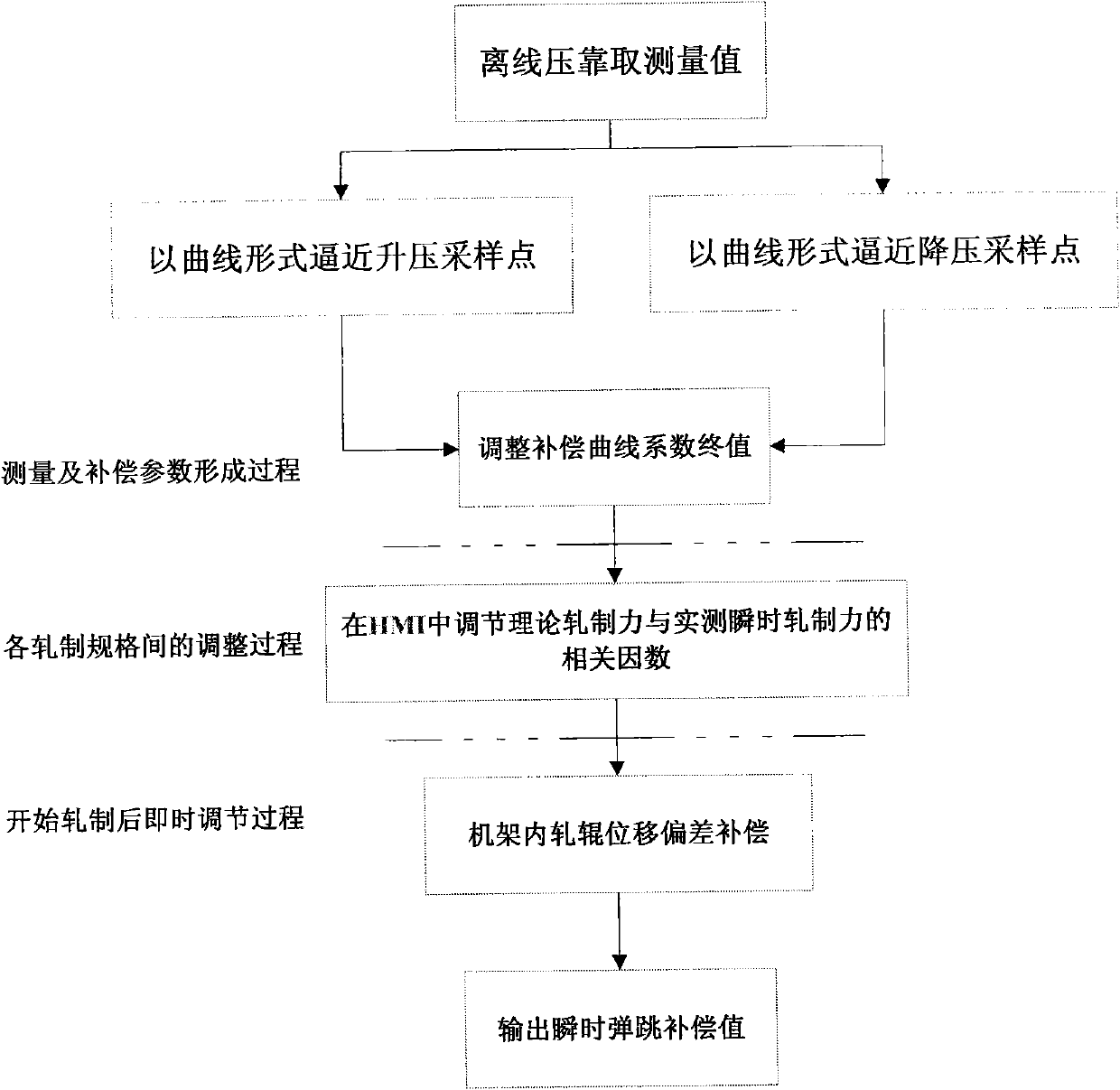

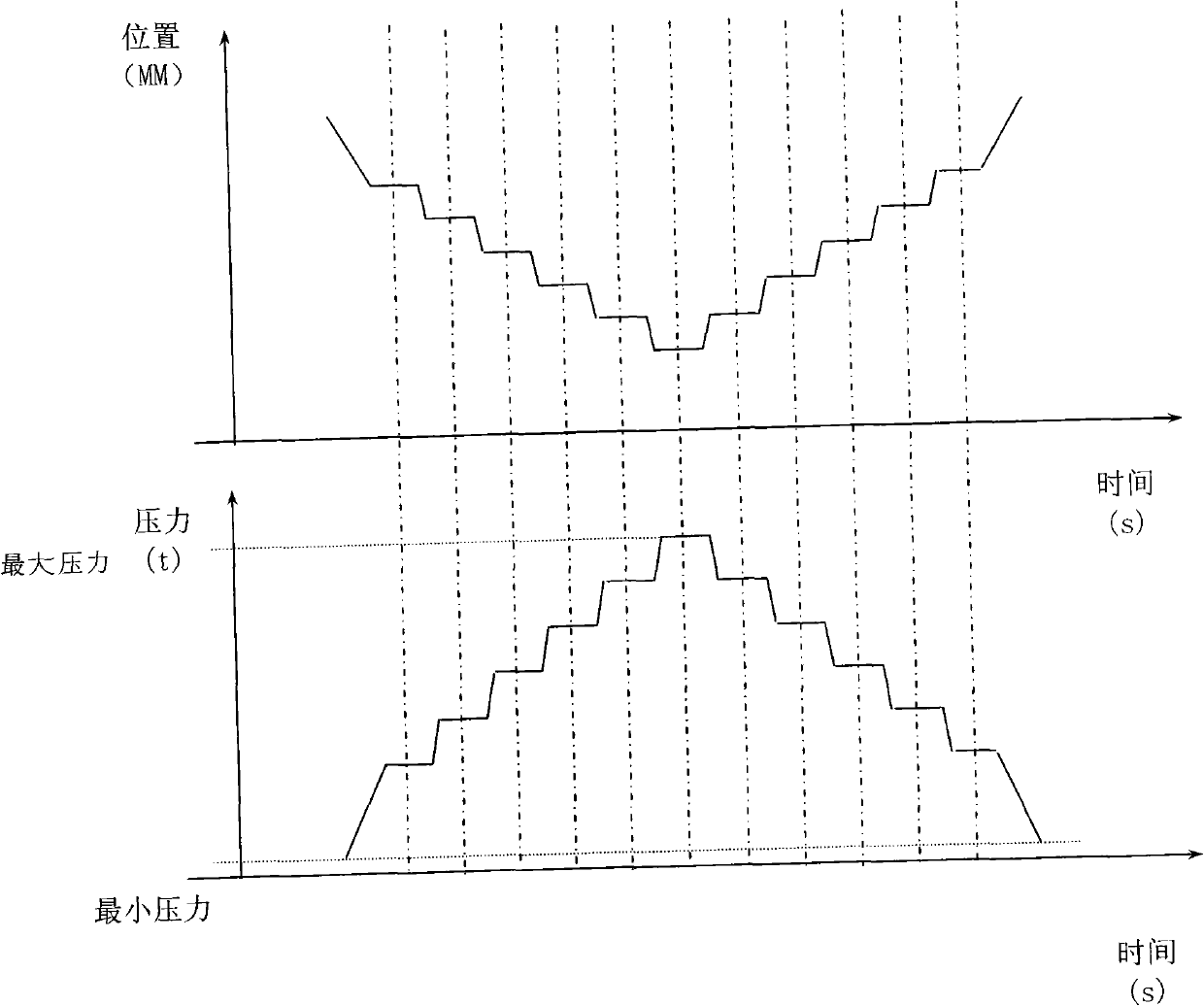

Compensation method of seamless steel pipe three-roll mill

InactiveCN101658863AEasy to track and controlImprove portabilityRoll force/gap control deviceRolling equipment maintainenceElastic curveEngineering

The invention belongs to the technical field of forming and particularly relates to a compensation method of seamless steel pipe three-roll mill. The method comprises: 1, an equation of an elastic curve: T(x)=sigma ciphii; 2, a three-roll centering compensation method; 3, disturbance influence reduction method; and 4, elastic deformation compensation input adjustment method. The compensation method of the invention solves an elastic deformation problem of a seamless steel pipe three-roll mill and takes the characteristics and the influences of smooth adjustment into consideration. Simply, a smooth curve approximation mode of elastic deformation compensation can be used in three-roll mills and also can be used in production processes of other various mills, such as other hot rolling processes, cold rolling processes and the like.

Owner:CISDI ENG CO LTD

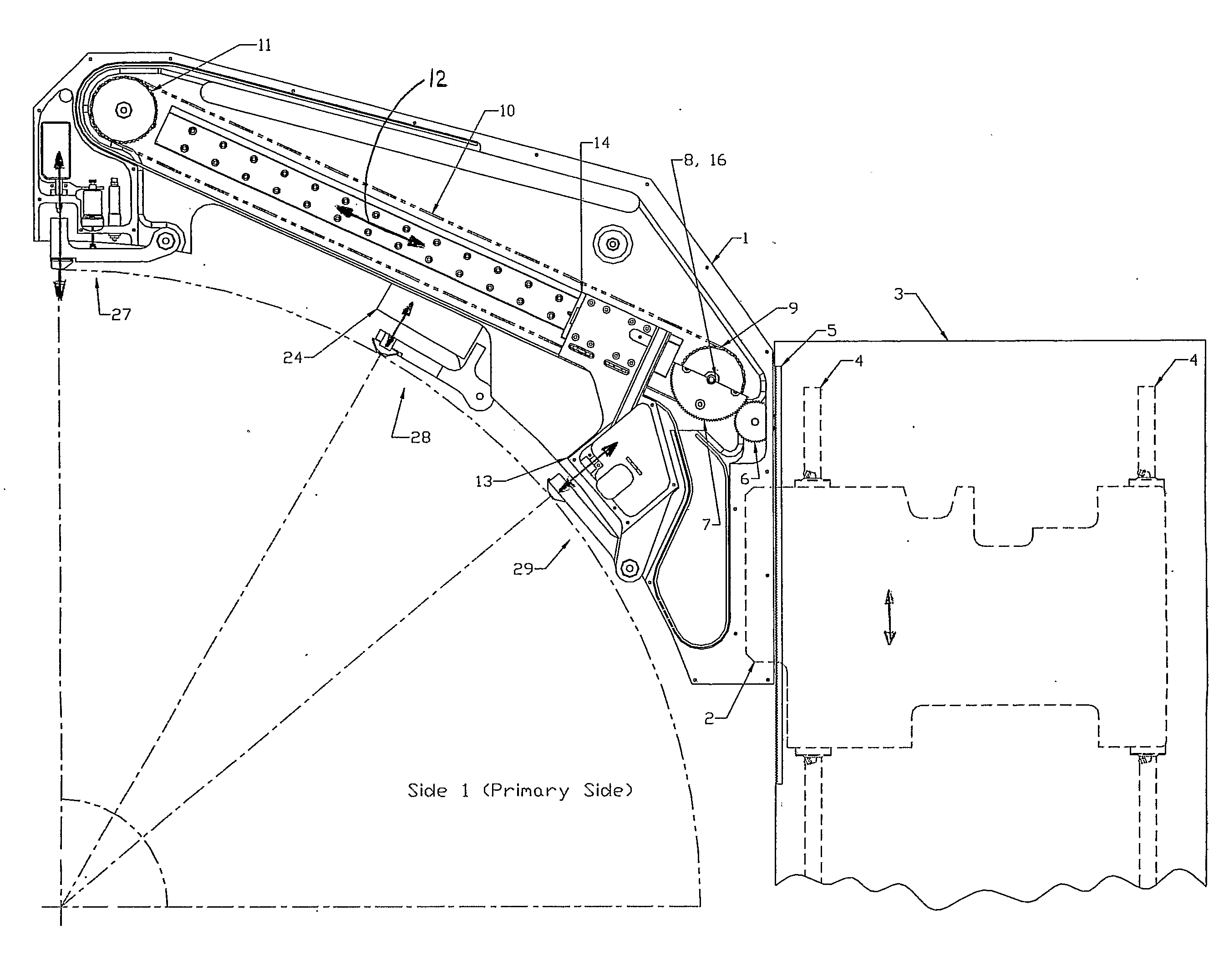

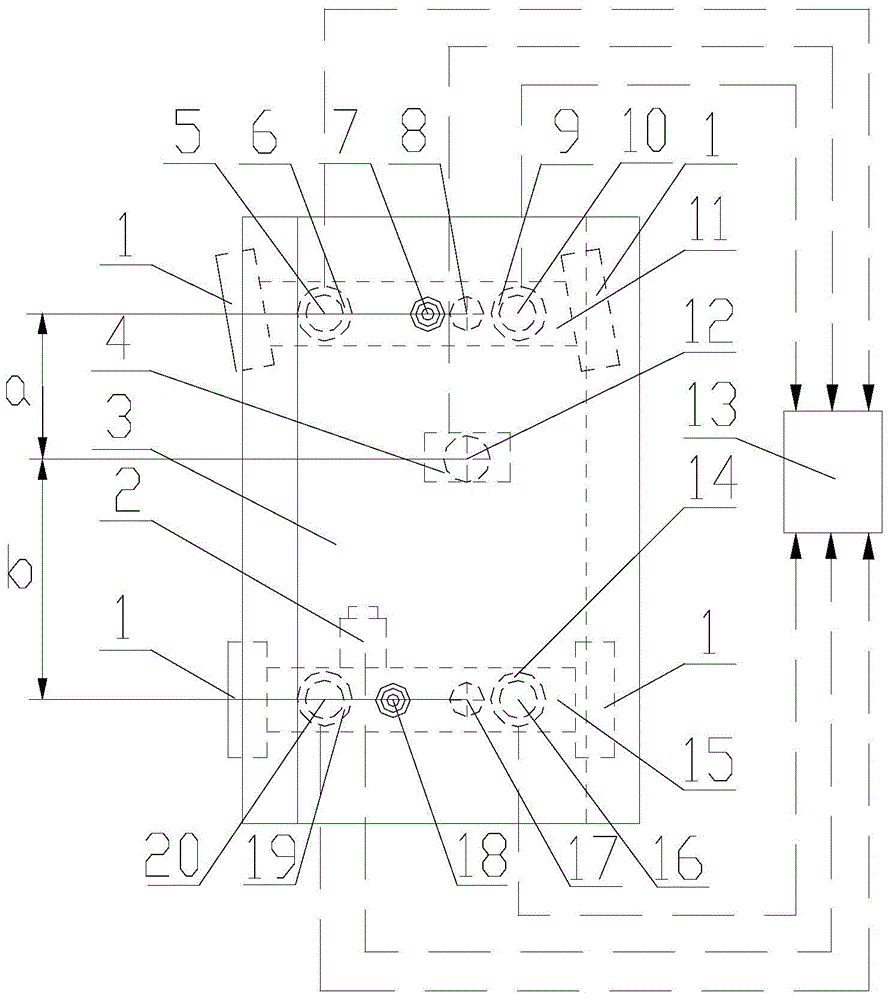

Shape-Measuring Assembly for a Grinding Machine

InactiveUS20080163509A1Revolution surface grinding machinesMechanical counters/curvatures measurementsMeasurement pointEngineering

A linked transport mechanism and method that uses a single source of motive force to synchronously position multiple displaceable sensors of a shape-measuring assembly onto a roll received in a roll grinding machine. At least two sensors (28, 29) are mounted on linear slides on at least one measuring arm (1). The complete shape-measuring assembly includes at least three sensors (27, 28, 29) or measuring points to allow the calculation of the cross-sectional shape of the roll and the extraneous error movement of the roll. At least one measuring arm is connected to a linear guide (4) of the frame (3). The linear motor is connected between the frame and the measuring arms. The linked transport mechanism assures the synchronous accurate positioning of the sensors, each at a fixed angle through the roll center, over the entire range of roll diameters that the grinding machine may receive.

Owner:HCC KPM LLC

Dynamic measuring device for position of automobile heeling center axis and confirming method thereof

ActiveCN104573322AHigh precisionGood effectMeasurement devicesSpecial data processing applicationsMeasurement deviceControl system

The invention relates to a dynamic measuring device for a position of an automobile heeling center axis and a confirming method thereof. In order to overcome the defects of the present research on automobile heeling and lateral overturning, the invention provides the dynamic measuring device for the position of the automobile roll center axis. The dynamic measuring device comprises an automobile speed sensor, an automobile body, a mass center sensing unit, a left front suspension, a left front wheel vertical load sensor, a right front wheel vertical load sensor, a right front suspension, a calculating unit, a right rear wheel vertical load sensor, a right rear suspension, a left rear wheel vertical load sensor and a left rear suspension. The invention also relates to the confirming method for the position of the automobile roll center axis. The dynamic measuring device and the confirming method provided by the invention can be used for calculating the position of the automobile roll center axis when an automobile heels and laterally overturns according to the vertical loads of wheels of the automobile, the yaw velocity of the automobile, the heeling angle of the automobile and the driving speed of the automobile, so that the effect of an automobile lateral overturning predicting and lateral overturning preventing control system is effectively promoted.

Owner:SHANDONG JIAOTONG UNIV

Suspension

InactiveUS20050189736A1Provide protectionLower ride heightRigid suspensionsInterconnection systemsRide heightTrailing arm

A rear axle suspension for a highway truck that includes a pair of trailing arms suspended below a frame by a pair of hanger brackets. The hanger brackets define a pivot axis for the trailing arms. A supplemental axle locating member is attached to the axle and includes an extension member that in engageable with a bracket held by the frame. The hanger brackets are laterally compliant and each comprise an inner and outer plate, one of which is bent outwardly to define a gap within which an associated trailing arm is mounted. A moment canceling member extends between the hanger brackets and resists outward bending of the brackets. A height control valve is operated by an operating rod having an axis that passes through, or in close proximity, to the roll center of the vehicle in order to reduce ride height errors.

Owner:VOLVO TRUCKS NORTH AMERICA

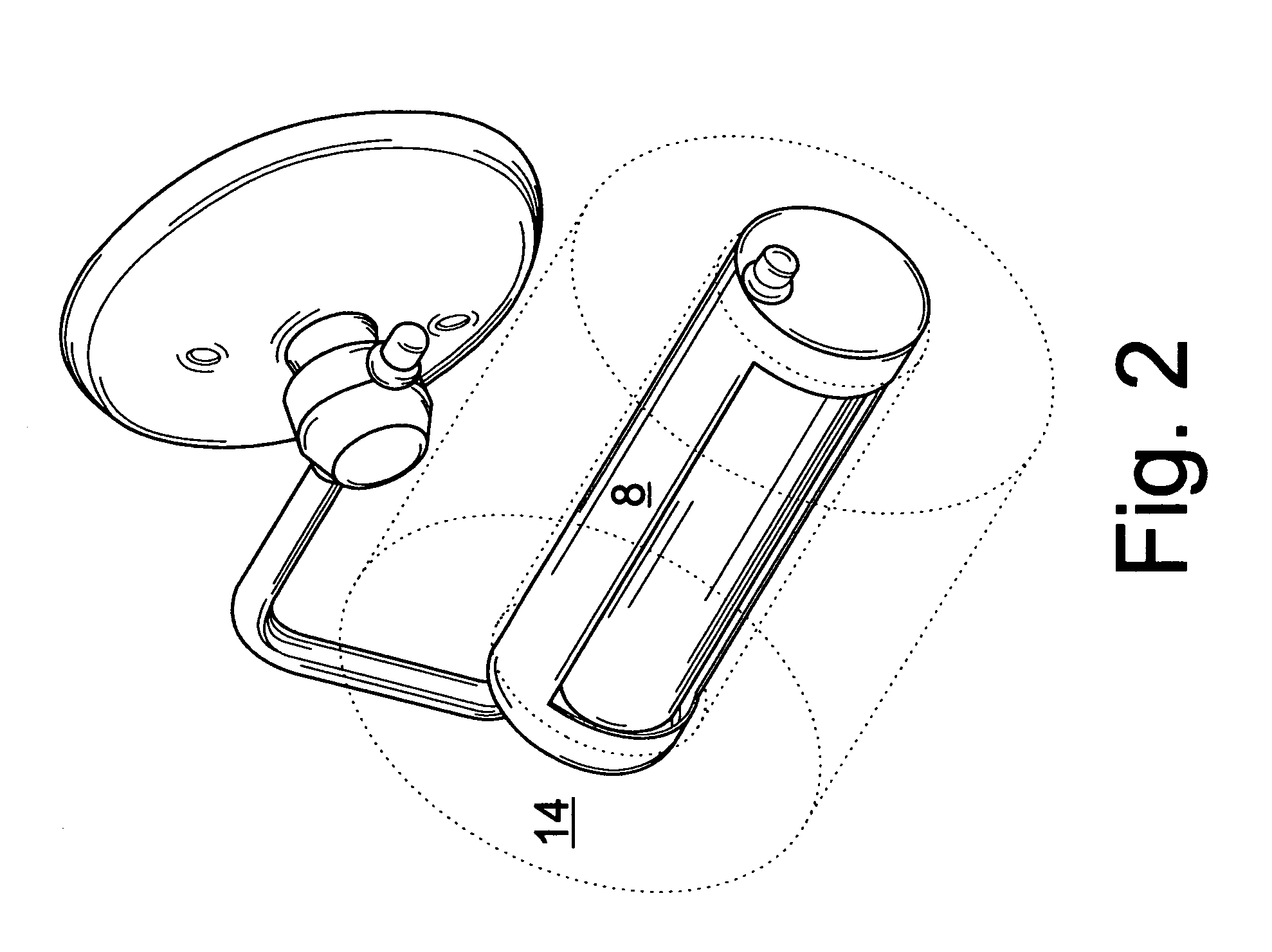

Suspended toilet tissue roll holder with auxiliary toilet tissue

A wall mounted holder to support a standard toilet tissue roll, and within a suspended hollow axle contain an auxiliary tissue roll. The suspended axle dynamically alters position dependent upon the outside diameter of the supported standard toilet tissue roll. The suspended axle has means for manipulation of the supported standard toilet tissue roll and the contained auxiliary tissue roll. The axle outer diameter is slightly less than the inner diameter of the supported standard toilet tissue roll center tube. The hollow compartment of the axle provides the maximum space for the auxiliary tissue roll. Auxiliary tissue is tightly rolled and contained in the hollow compartment of the axle.

Owner:BURNETT ALLEN GARRETT

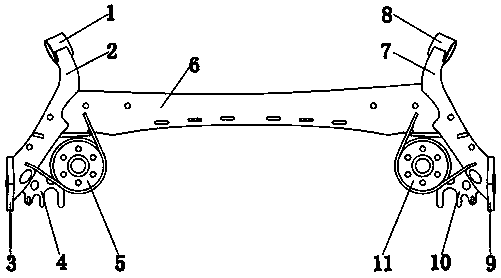

U-shaped variable cross-section rear torsion beam assembly

PendingCN107914533AMeet functional requirementsEnsure stabilityInterconnection systemsPivoted suspension armsClassical mechanicsDamper

The invention discloses a U-shaped variable cross-section rear torsion beam assembly of the technical field of automobiles. A left longitudinal arm is installed at the bottom of a left casing pipe, aleft wheel hub plate is installed at the bottom of the left longitudinal arm, a left damper support is installed at the bottom of the right side of the left longitudinal arm, a left spring plate is installed at the top of the left damper support, the left side of the left spring plate is connected with the left longitudinal arm, a torsion beam is installed on the right side of the left longitudinal arm, the top of the left spring plate is connected with the bottom of the torsion beam, a right longitudinal arm is installed at the right end of the torsion beam, a right casing pipe is installed at the top of right longitudinal arm, a right wheel hub plate is installed at the bottom of the right longitudinal arm, and a right damper support is installed at the bottom of the left side of the right longitudinal arm. The U-shaped variable cross-section rear torsion beam assembly has strong rigidity, can satisfy functional requirements of targets well, has a simple forming process and light weight, increases advantages of the torsion beam, and guarantees stability of a roll center.

Owner:安徽万安汽车零部件有限公司

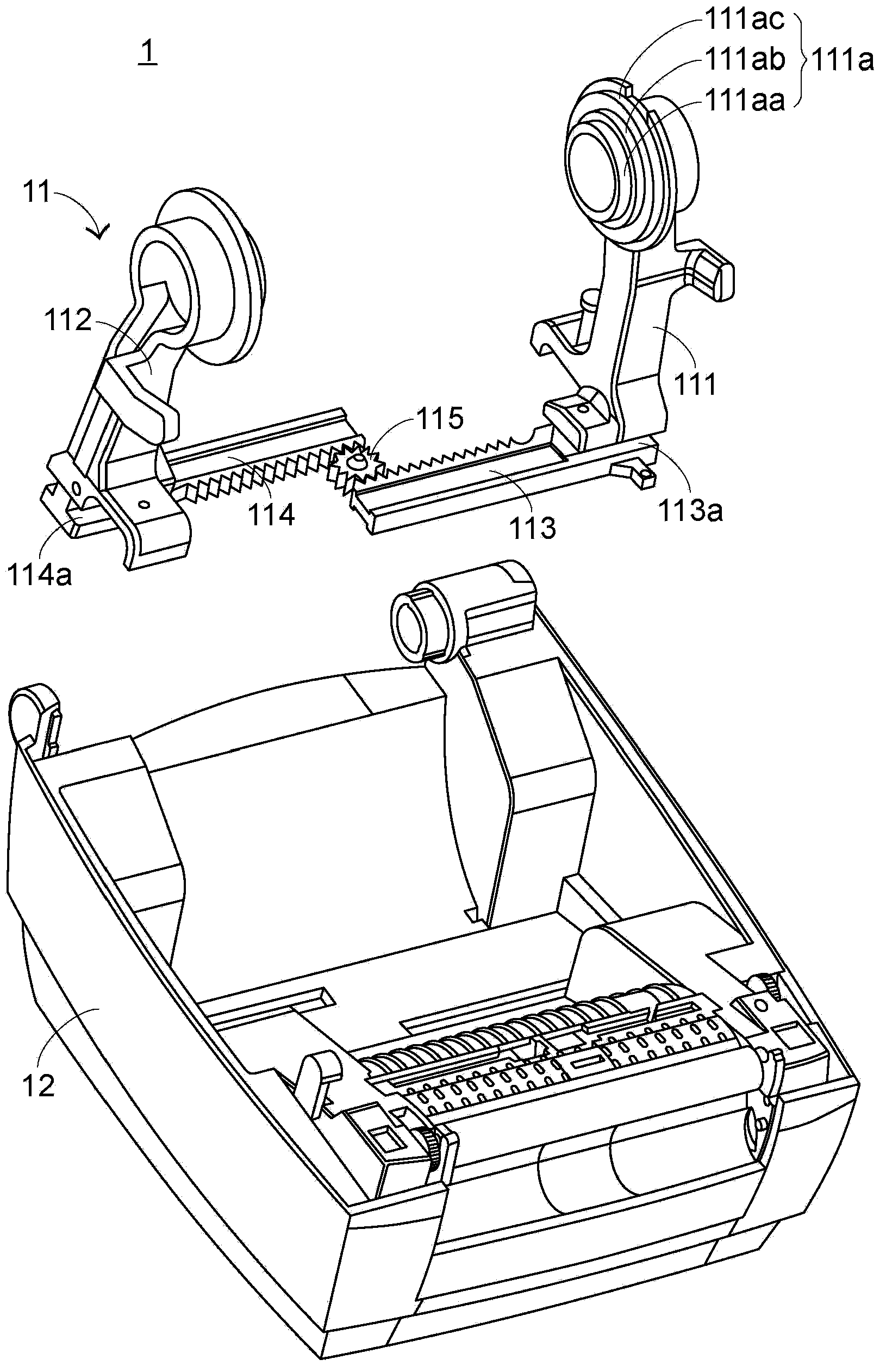

Paper roll fixing device of printer

The invention provides a paper roll fixing device of a printer. The paper roll fixing device of the printer comprises a first supporting base and a second supporting base, wherein the first supporting base comprises a first supporting protruding portion and a plurality of first idler wheels, and the second supporting base comprises a second supporting protruding portion and a plurality of second idler wheels. The first supporting protruding portion and the second supporting protruding portion extend into the two ends of a hollow roll center of a paper roll respectively so that the paper roll can be fixedly arranged between the first supporting base and the second supporting base, and can be supported by the first idler wheels and the second idler wheels. The paper roll fixing device of the printer can be applicable to paper rolls with hollow roll centers with different diameters.

Owner:PRIMAX ELECTRONICS LTD

Pivoting toilet tissue roll holder with auxiliary toilet tissue

A wall mounted holder to support a standard toilet tissue roll, and within a pivoting hollow axle contain an auxiliary tissue roll. The attached axle pivots by mechanical means for manipulation of the standard toilet tissue roll and the auxiliary tissue roll. The axle outer diameter is slightly less than the inner diameter of a standard toilet tissue roll center tube allowing the hollow compartment of the axle to provide the maximum space for the auxiliary tissue roll. Auxiliary tissue is tightly rolled and contained in the hollow compartment of the axle.

Owner:BURNETT ALLEN GARRETT

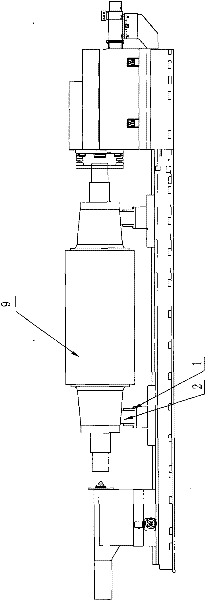

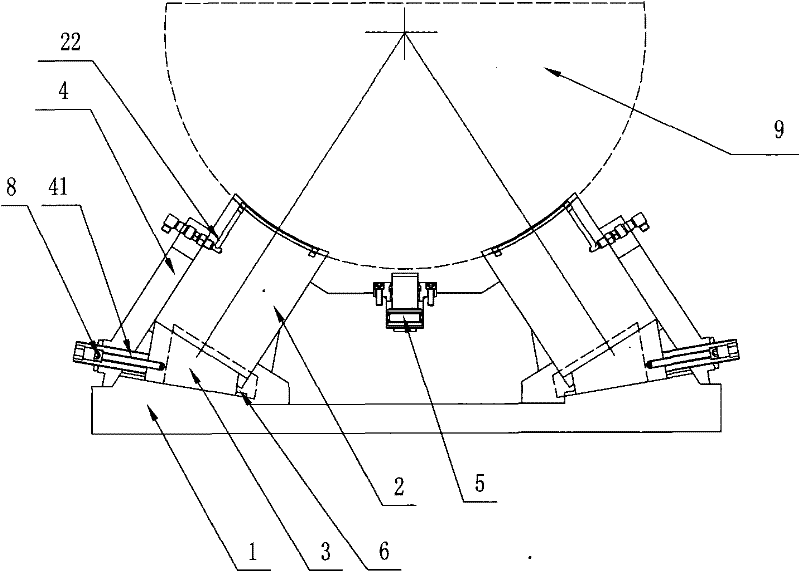

Heavy-duty roll static pressure steady rest

ActiveCN102275104AStable supportImprove startup performanceRevolution surface grinding machinesGrinding work supportsCircular coneEngineering

The invention discloses a static pressure central frame of a heavy-duty mill roll. At least two static pressure tiles inserted into a 'U'-shaped slot of a tilting fillet of the static pressure central frame are symmetrical along the axial vertical central surfaces of the tilting fillet of the static pressure central frame. A concave static pressure oil groove is arranged on a truncated conical cambered surface at the upper ends of the static pressure tiles. A trapezoid space is formed between the lower end surfaces of the static pressure tiles and the upper end surface of the tilting fillet of the static pressure central frame. A wedge block can be just inserted into the trapezoid space. The depth of the wedge block in the trapezoid space in the inclined direction can be adjusted. Intersecting lines of the axial central surfaces of the static pressure tiles are collinear. The side wall of a pressing plate fixedly arranged on the tilting fillet of the static pressure central frame is tightly stuck with the back side walls of the static pressure tiles. A penetrating opening in the pressing plate is matched with the position of an oil supply port communicated with the static pressureoil groove. An oil cylinder barrel of a stop damping mechanism is fixedly located on the upper side surface of the tilting fillet of the static pressure central frame. A piston rod of an oil cylinderis fixedly connected with the lower end of a damping block. The piston rod of the oil cylinder can drive the damping block to move along the vertical direction. The static pressure central frame of the heavy-duty mill roll realizes quick starting and stopping of grinding of the mill roll.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

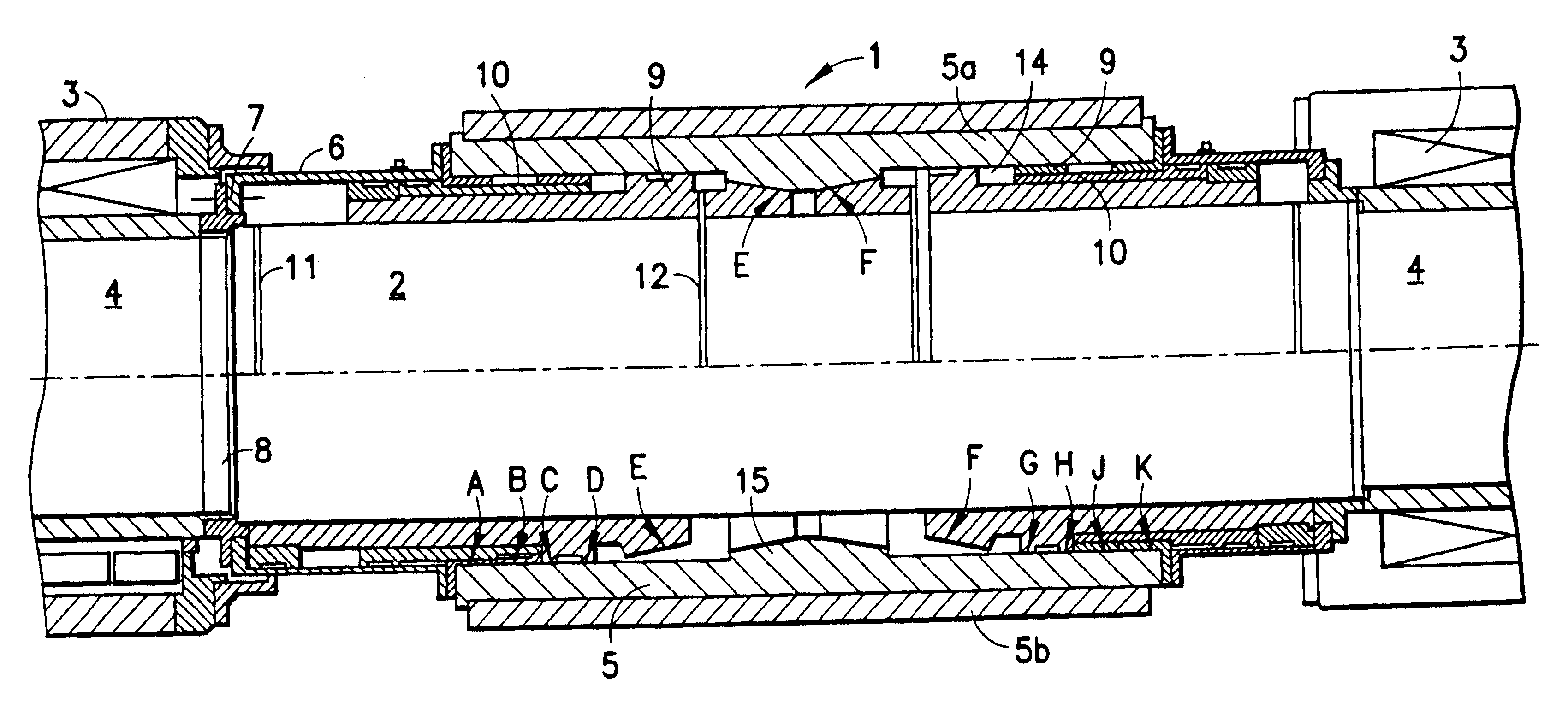

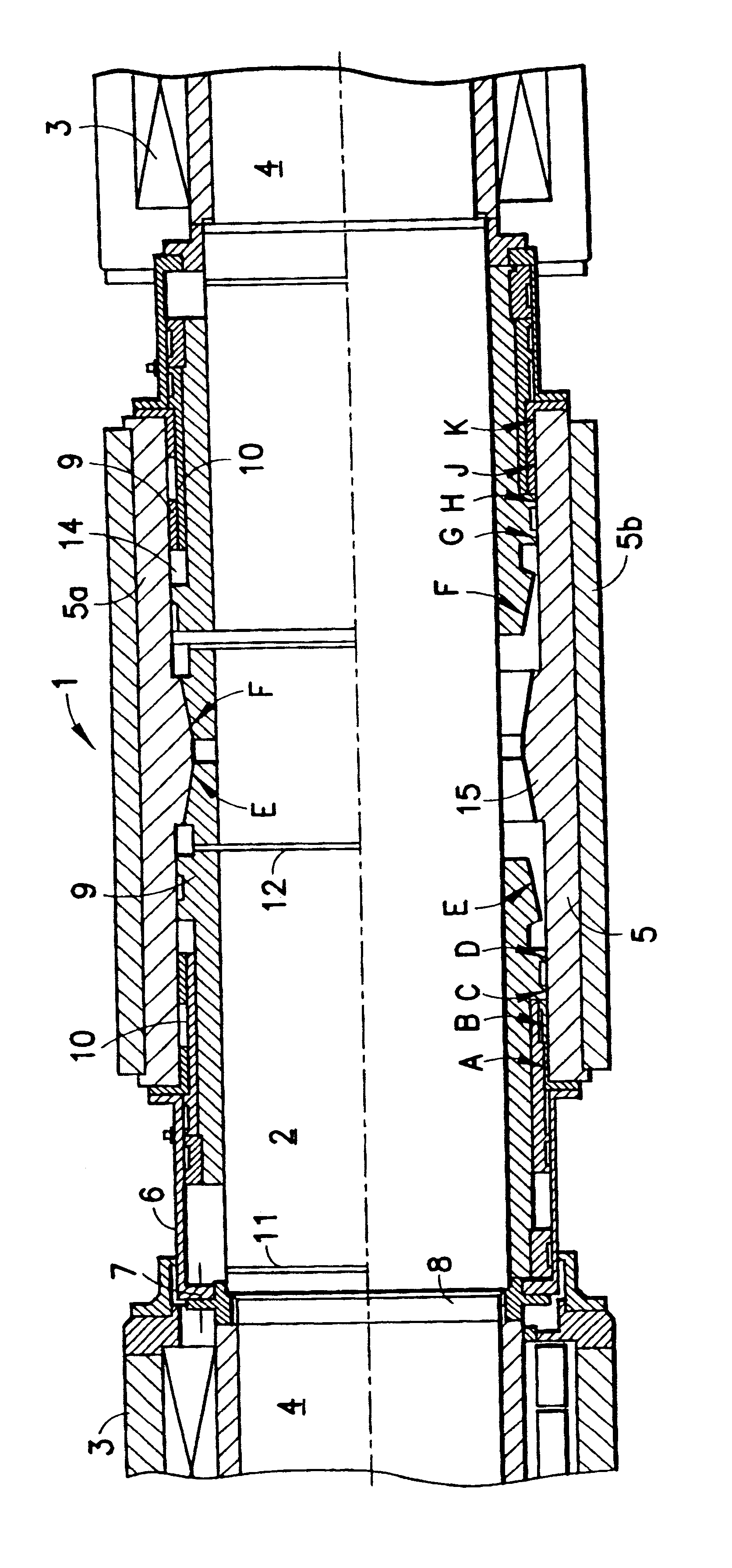

Back-up or intermediate roller for producing a flat rolled product in a rolling mill

A supporting or intermediate roll in rolling mills for rolling flat rolling stock, in particular strip material, having a cylindrical roll core and a tubular sleeve which is connected in a rotationally fixed manner to said roll core, engages coaxially around the same and between which and the roll core there are arranged hydraulically axially displaceable supporting bodies which support the roll sleeve against the roll core. In this case, the supporting bodies are formed with at least two annular pistons, which are arranged symmetrically in relation to the roll center and are sealed in relation to the roll core and the inside of the roll sleeve, and include a plurality of annular supporting bearings, which are arranged on the outer circumference of the pistons, are spaced apart from one another in the longitudinal direction of the roll and against which the inner surface of the roll sleeve can be positioned.

Owner:SMS DEMAG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com