Heavy-duty roll static pressure steady rest

A steady rest and static pressure technology, which is applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve problems such as large moment of inertia, heavy roll weight, and equipment damage, and achieve rapid start and stop, improved start-up ability, and stability The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

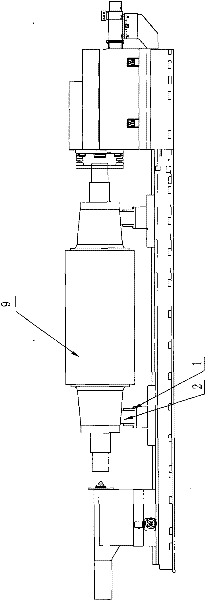

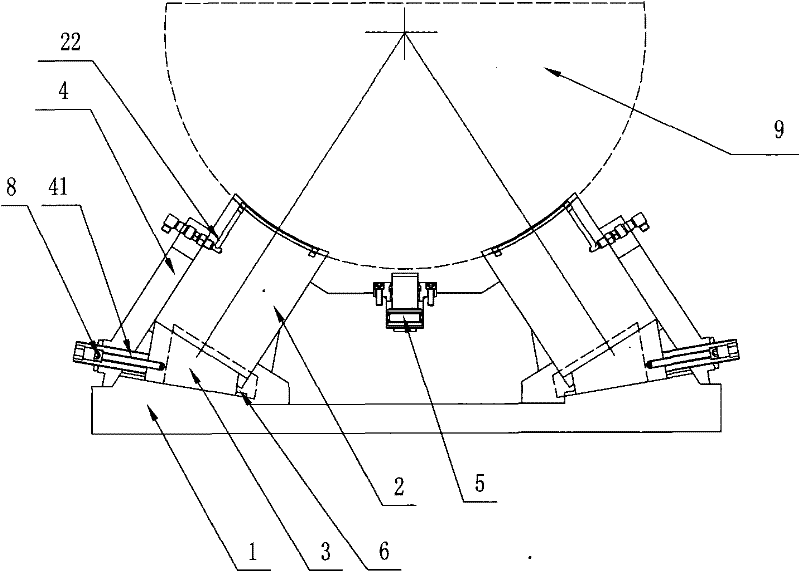

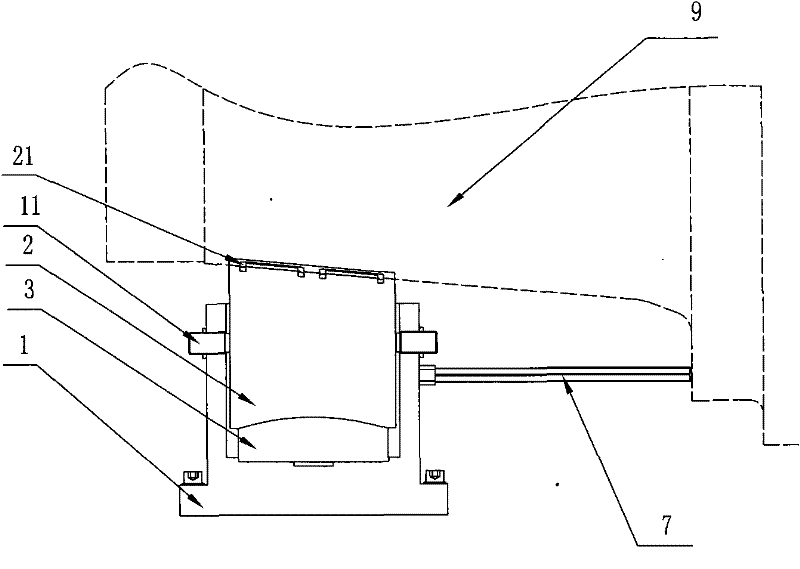

[0018] Embodiment: A heavy-duty roll static pressure center frame, including a static pressure center frame tile seat 1, a static pressure shoe 2, a wedge 3, a pressure plate 4 and a stop damping mechanism 5, based on the use direction, at least two static pressure The tiles 2 are inserted into the "U" groove of the static pressure center frame tile seat 1, each static pressure tile 2 is symmetrical along the axial vertical center plane of the static pressure center frame tile seat 1, and the upper end of the static pressure tile 2 is truncated Conical arc surface (matched with the outer conical surface of the roller 9 shaft shoulder), the truncated conical arc surface is provided with a concave static pressure oil groove 21, the lower end surface of the static pressure tile 2 and the upper end surface of the static pressure center frame tile seat 1 form a Trapezoidal space 6, the cross-sectional area of the trapezoidal space 6 on the side away from the static pressure tile 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com