Paper roll fixing device of printer

A technology for fixing devices and printers, applied in printing devices, printing, etc., can solve problems such as falling off, label paper wear, and paper tape moving unsmoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

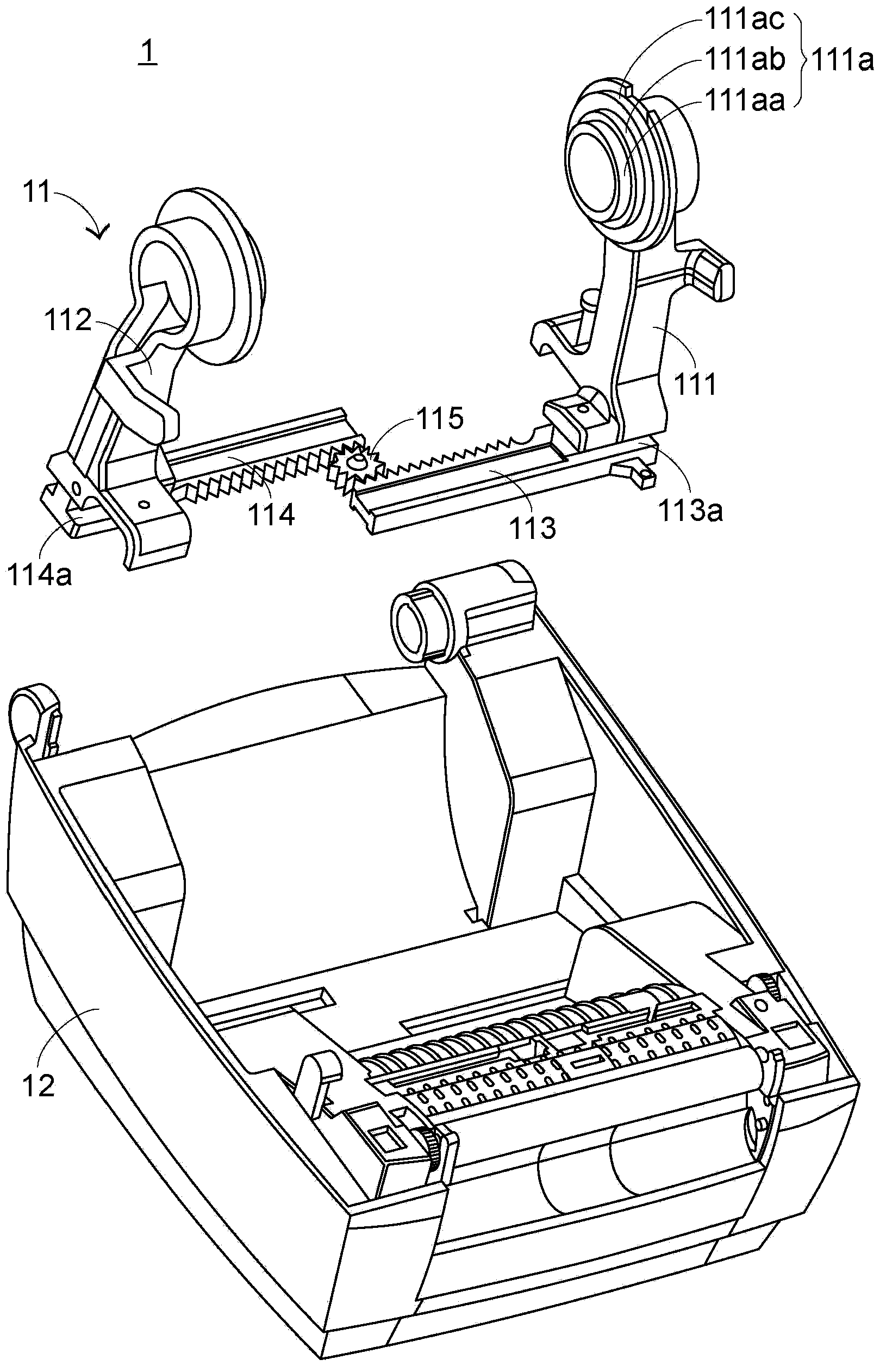

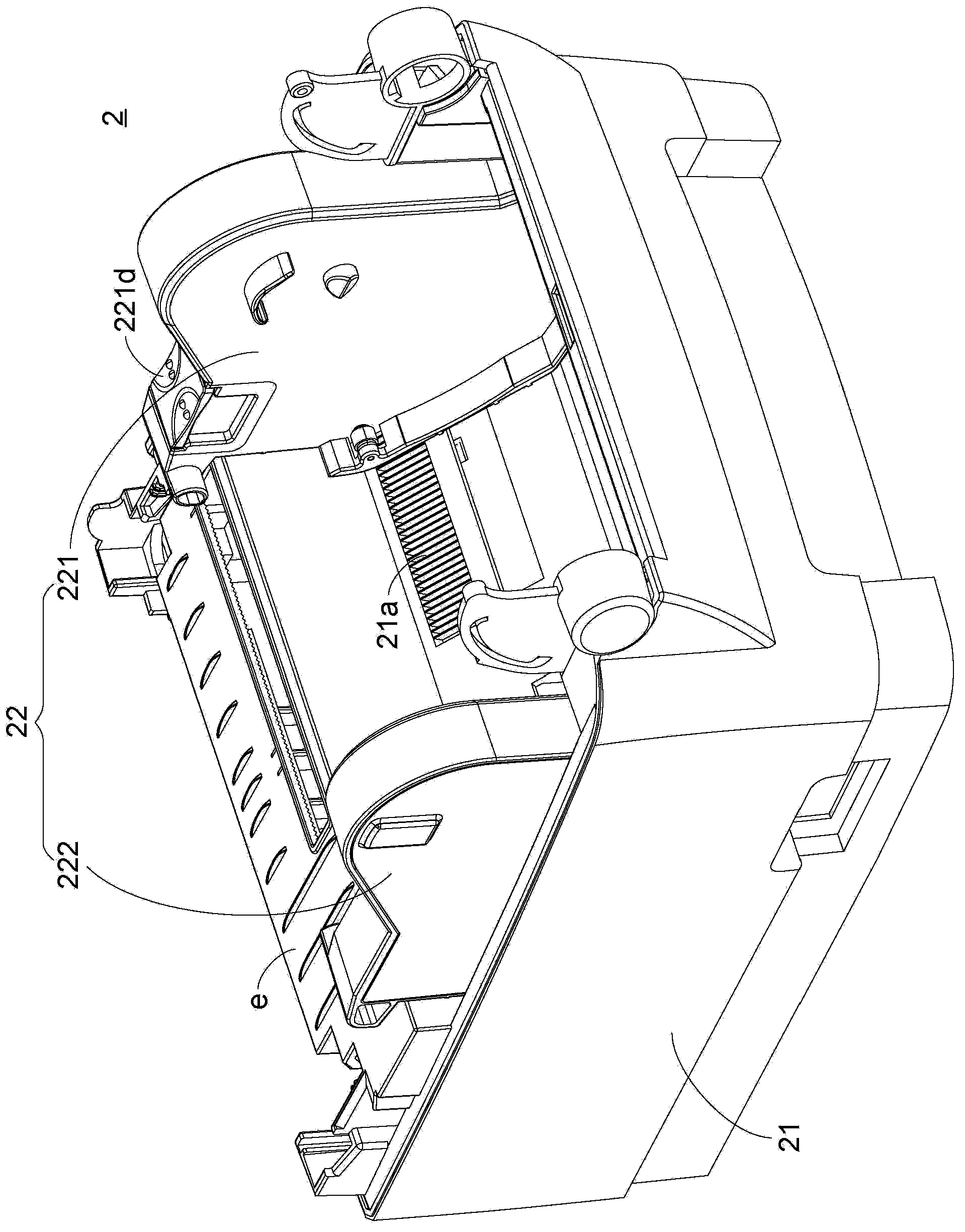

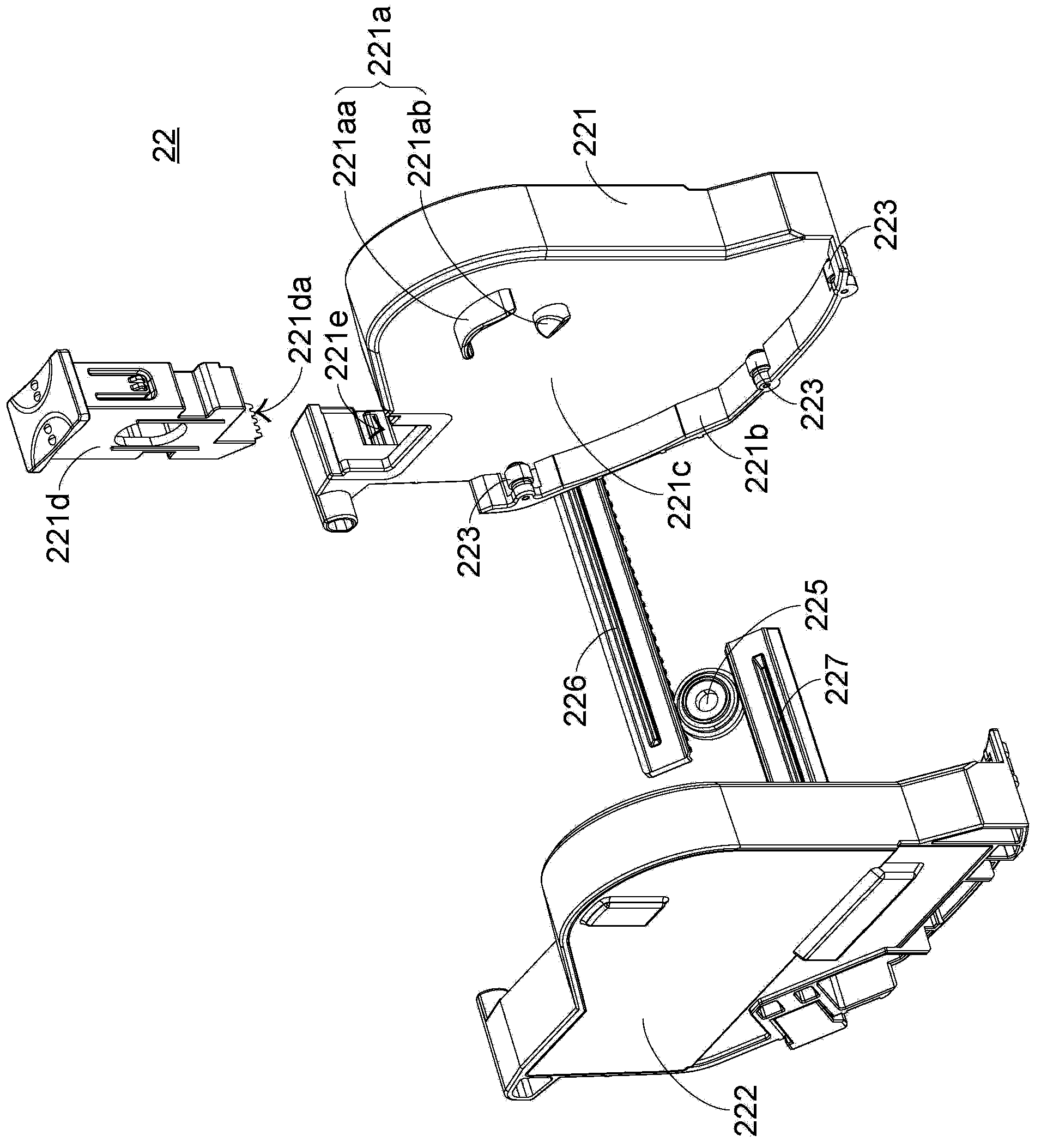

[0124] According to a specific embodiment of the present invention, a paper roll fixing device for a printer is provided, which can be applied to a label printer.

[0125] Please note that the first to third preferred embodiments of the present invention described below are all described in the case of setting three first auxiliary rollers and three second auxiliary rollers, but the first auxiliary rollers and the second auxiliary rollers of the present invention The number of the rollers is not limited thereto, as long as a plurality of first auxiliary rollers and a plurality of second auxiliary rollers are respectively arranged on the first support seat and the second support seat to support the paper roll, all belong to the scope of the present invention.

[0126] At first the components of the printer of a first preferred embodiment of the present invention are described, please refer to figure 2 , figure 2A perspective view of a printer according to a first preferred e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com