Compensation method of seamless steel pipe three-roll mill

A compensation method, seamless steel pipe technology, applied in the direction of metal rolling, metal rolling, rolling force/roll gap control, etc., can solve the problems of huge fluctuation of compensation value, increased vibration, inaccuracy, etc., to achieve convenient Tracking control, easy application, and the effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail in conjunction with accompanying drawing:

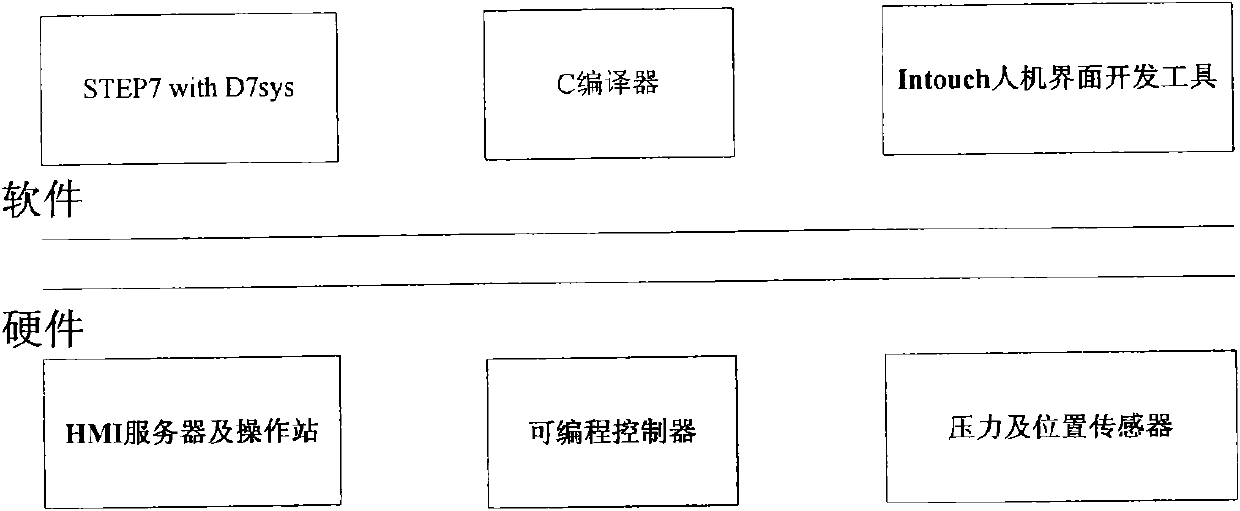

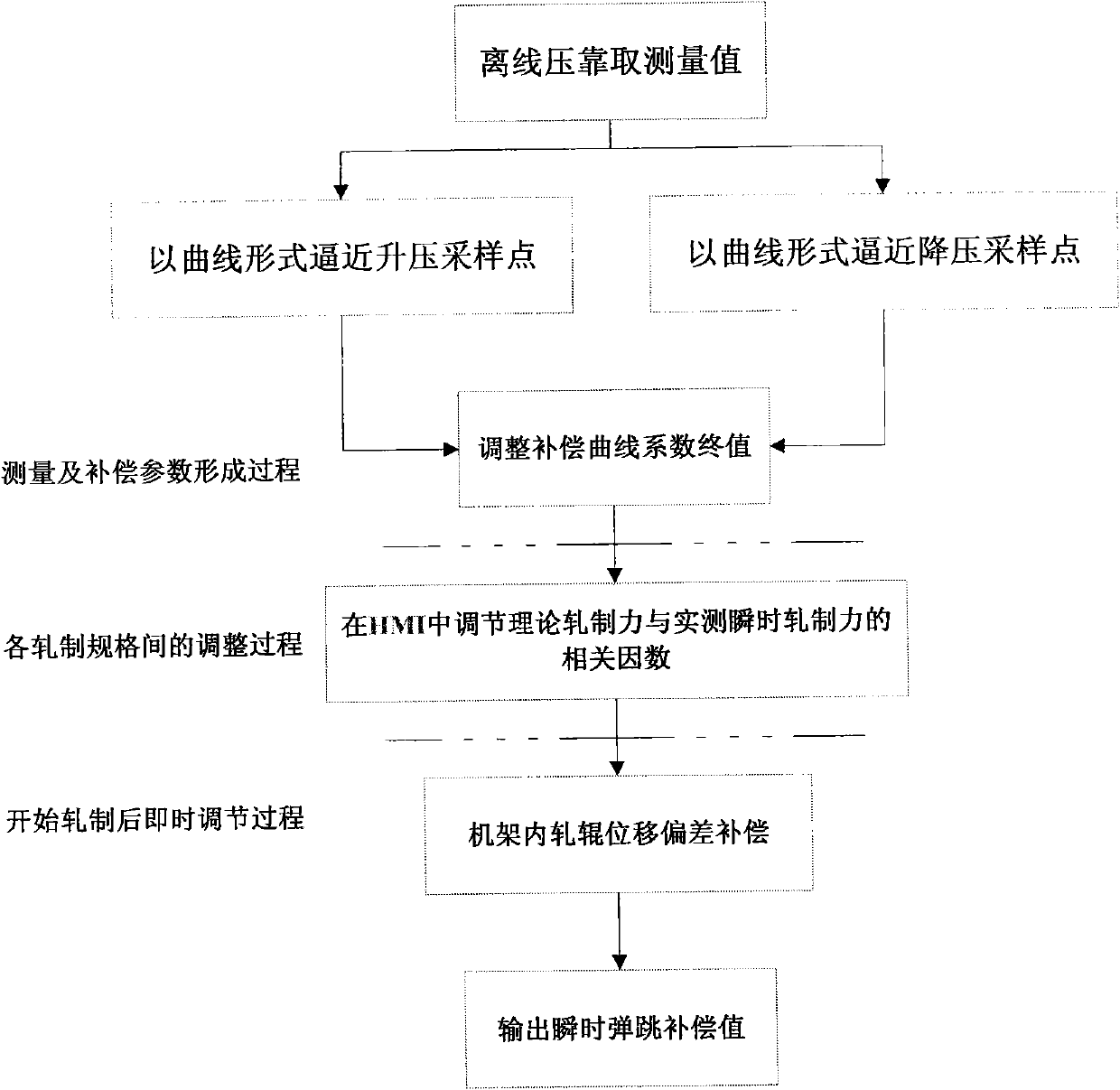

[0019] Such as figure 1 Shown is the software and hardware carrier required when the present invention is applied to steel rolling production. In terms of hardware, it is suitable for PLCs (programmable logic controllers) that support high-level languages, such as: Siemens S7-400 series PLCs and SIMATIC TDCs, etc., used to measure the SS I-type position sensor that feedbacks the current position, and form pressure Closed-loop pressure sensor, HMI (human-machine interface) server required for operation; as far as software is concerned, in addition to the C compiler used to form the software and the PLC programming tool used in the application software, it is also necessary to pass industrial control on the HMI screen. The configuration software is used to increase the setting control items of the pressure control closed-loop during measurement, the approximation rate of the curve ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com