Online wet steam dryness gauge

A technology of wet steam and measuring instrument, which is applied in the direction of material moisture content, etc., can solve the problems that the dryness value of wet steam cannot be displayed in real time, and can only be measured offline, and achieves the effects of convenient tracking control, simple structure, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

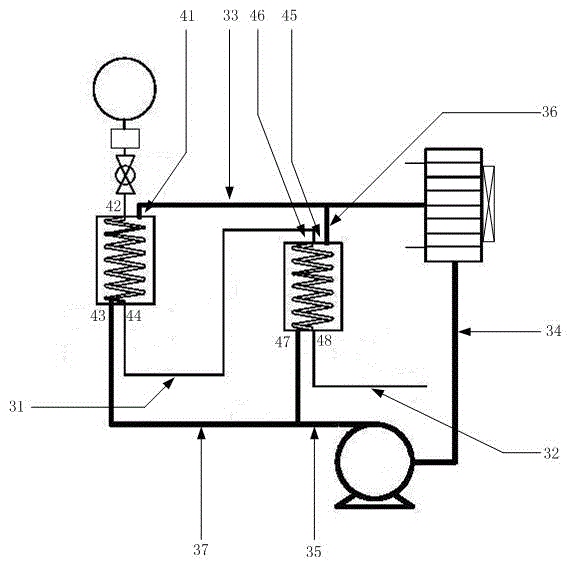

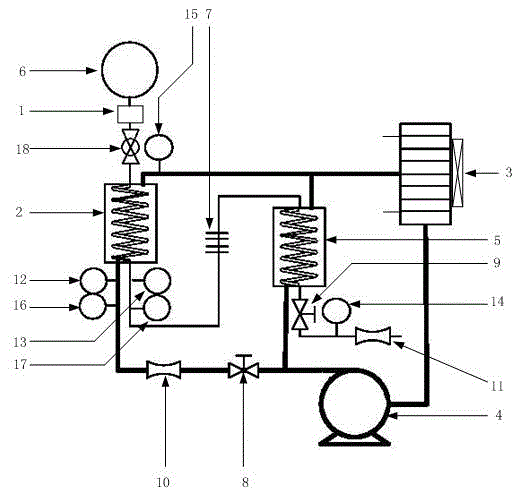

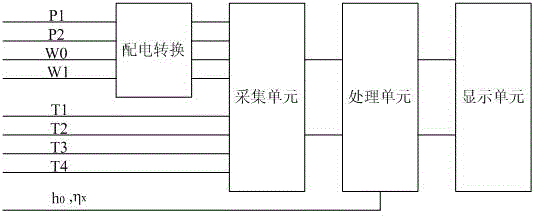

[0043] The sampler is connected with the steam pipe 6 and the steam is sampled from the steam pipe, and the sampled steam is input into the heat exchanger 2 .

[0044] The first enthalpy measuring device includes the first temperature measuring device 13 installed at the outlet 44 of the heat exchanger medium, the first pressure measuring device 17 and the second temperature measuring device 14 installed at the second sampling branch 32 .

[0045] The second enthalpy measuring device includes a third temperature measuring device 12 installed at the cooling water inlet 43 of the heat exchanger, a second pressure measuring device 16 and a fourth temperature measuring device 15 installed at the cooling water outlet 41 of the heat exchanger.

[0046] Each temperature measuring device is a platinum resistor arranged upstream, the pressure measuring device is a pressure transmitter, and the first flow measuring device 8 and the second flow measuring device 9 are electromagnetic flowm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com