Patents

Literature

122results about How to "Small reaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

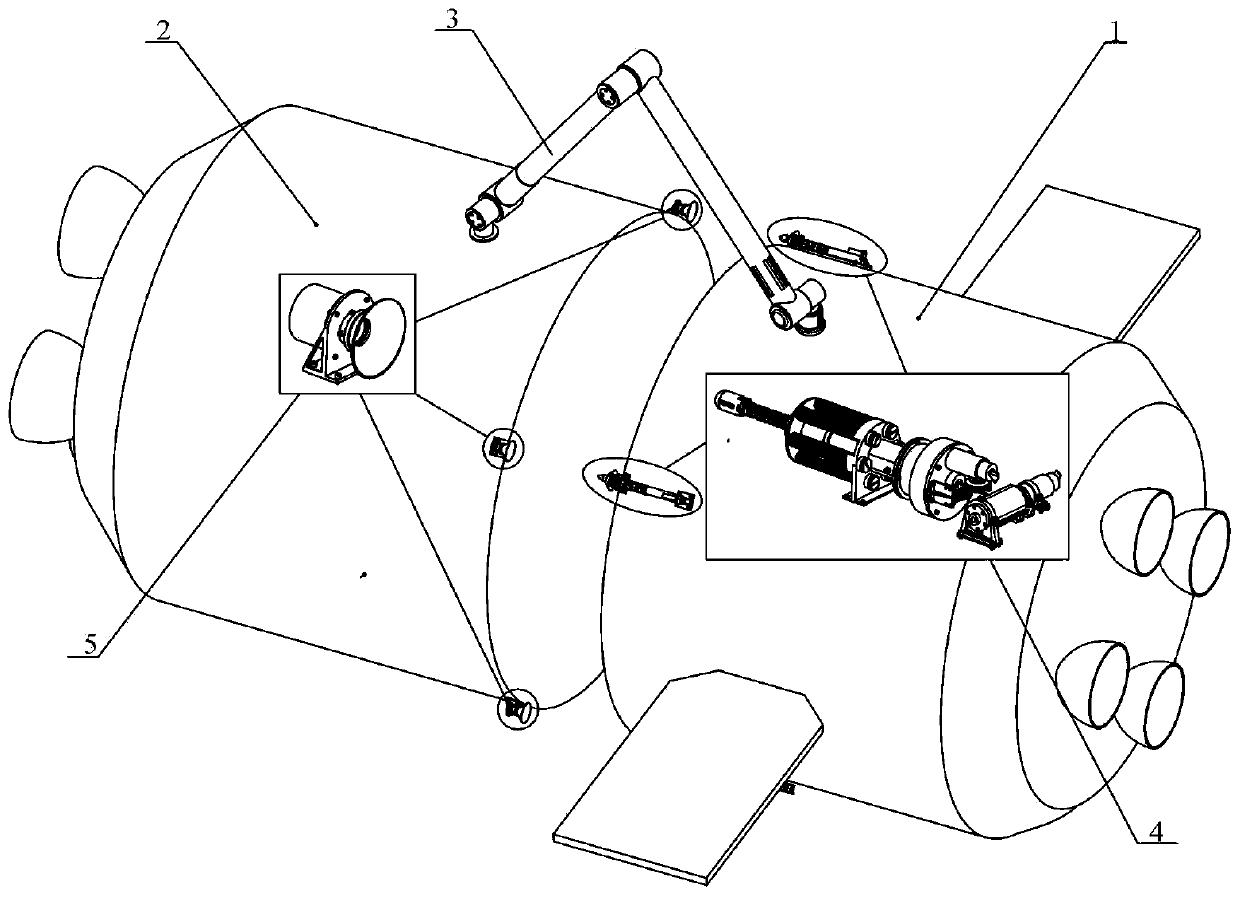

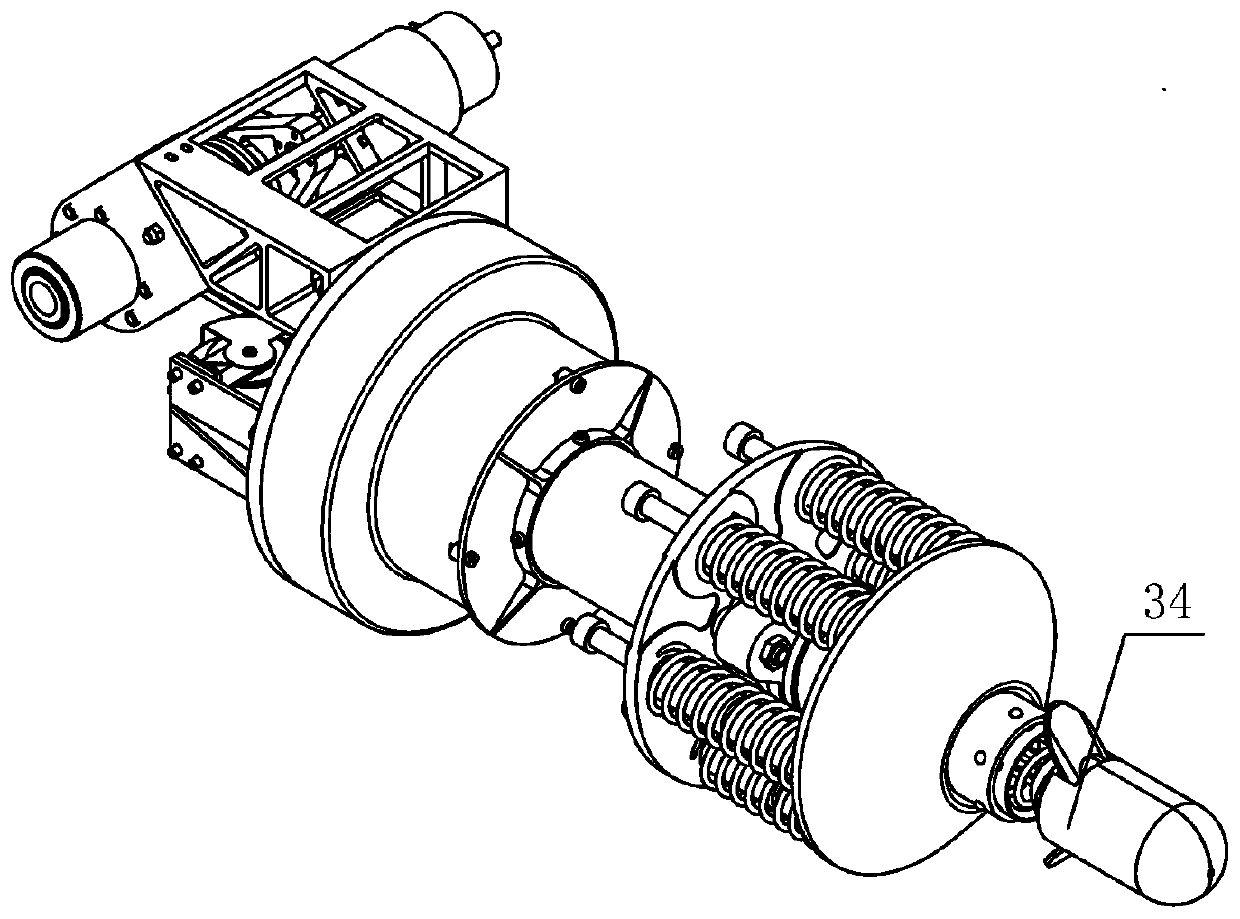

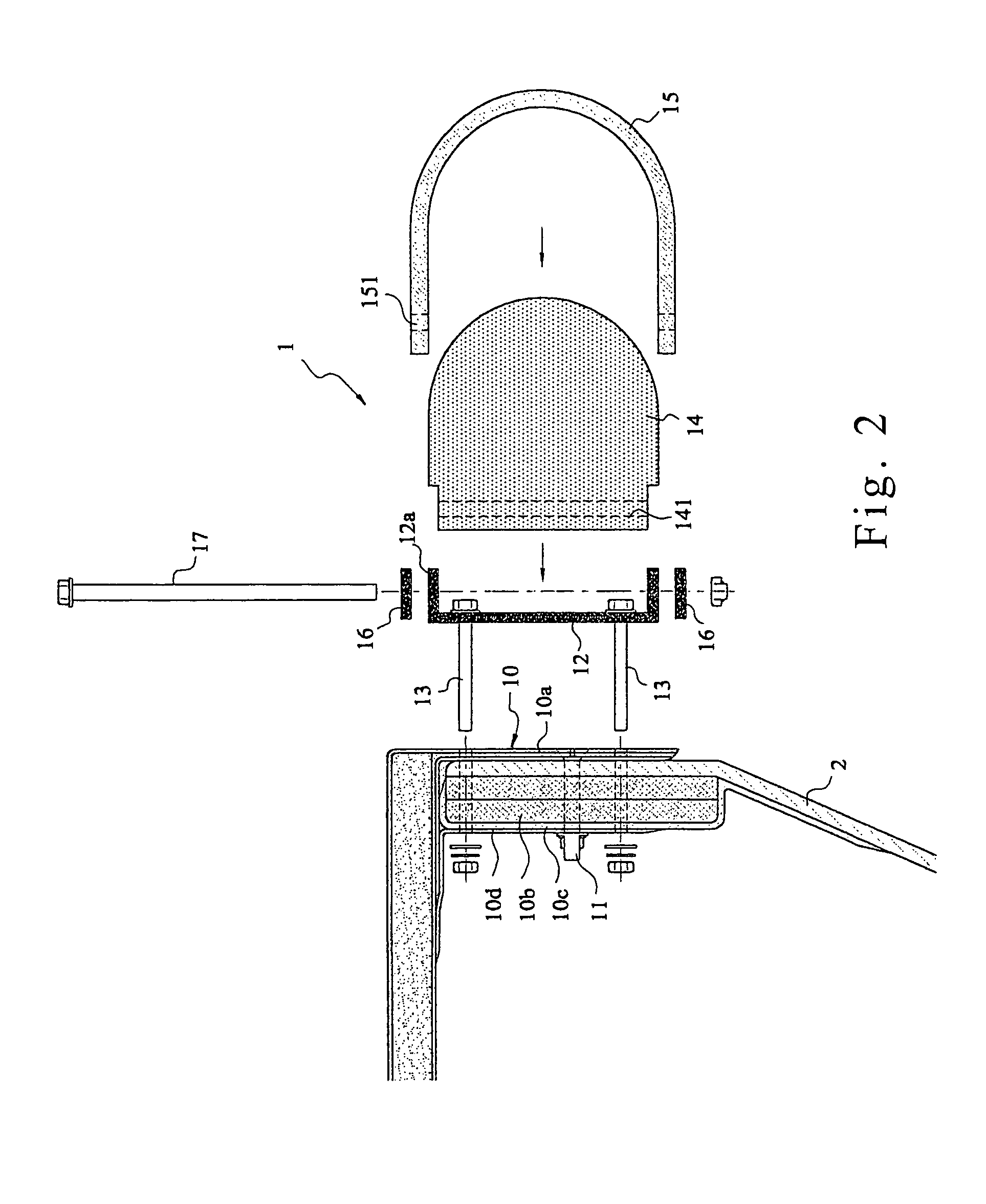

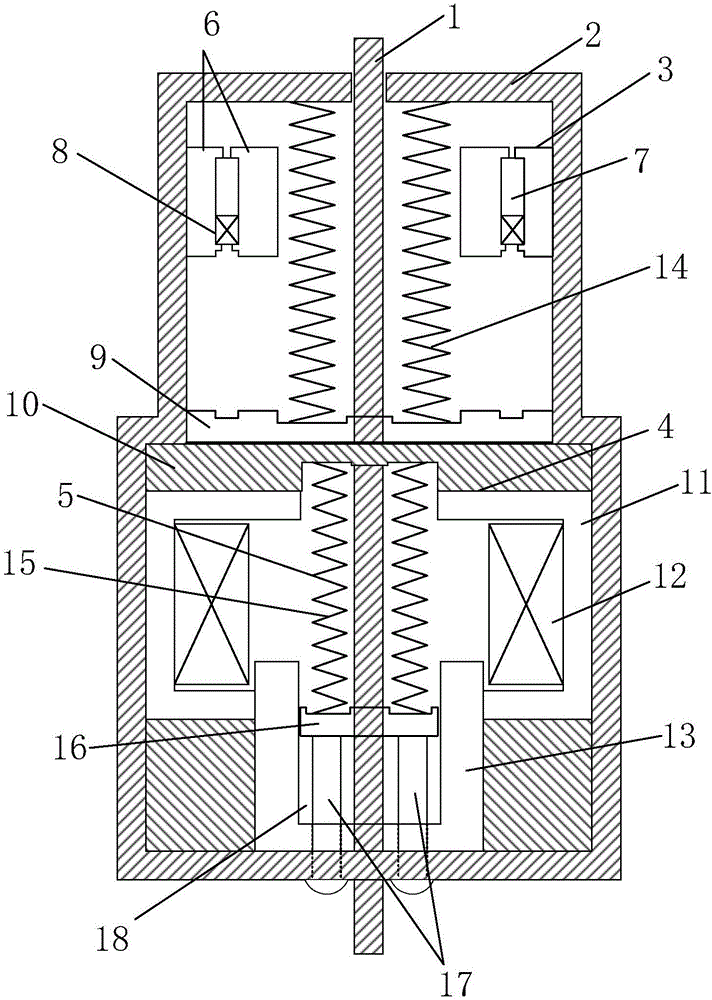

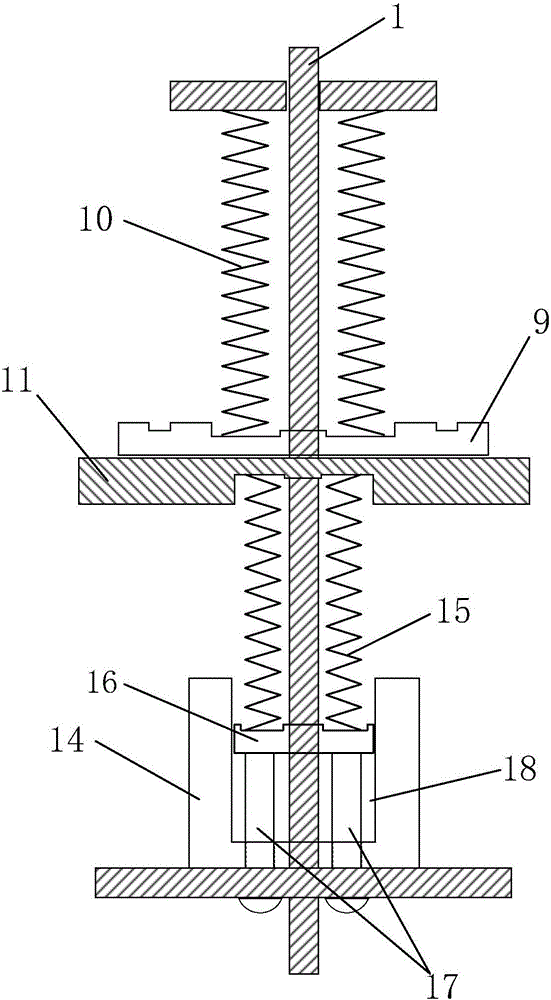

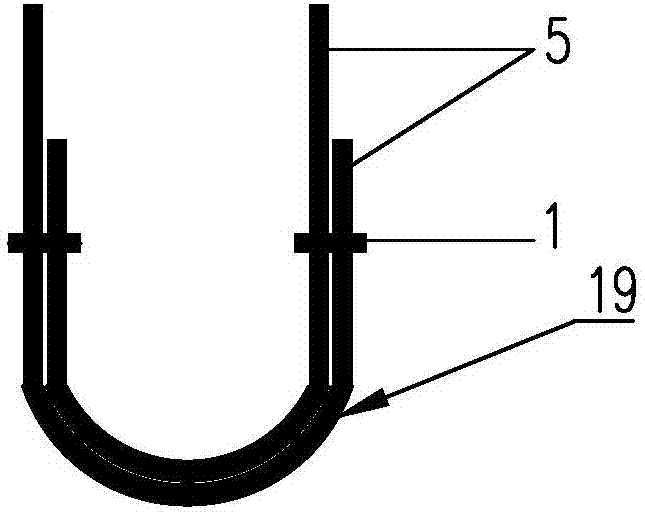

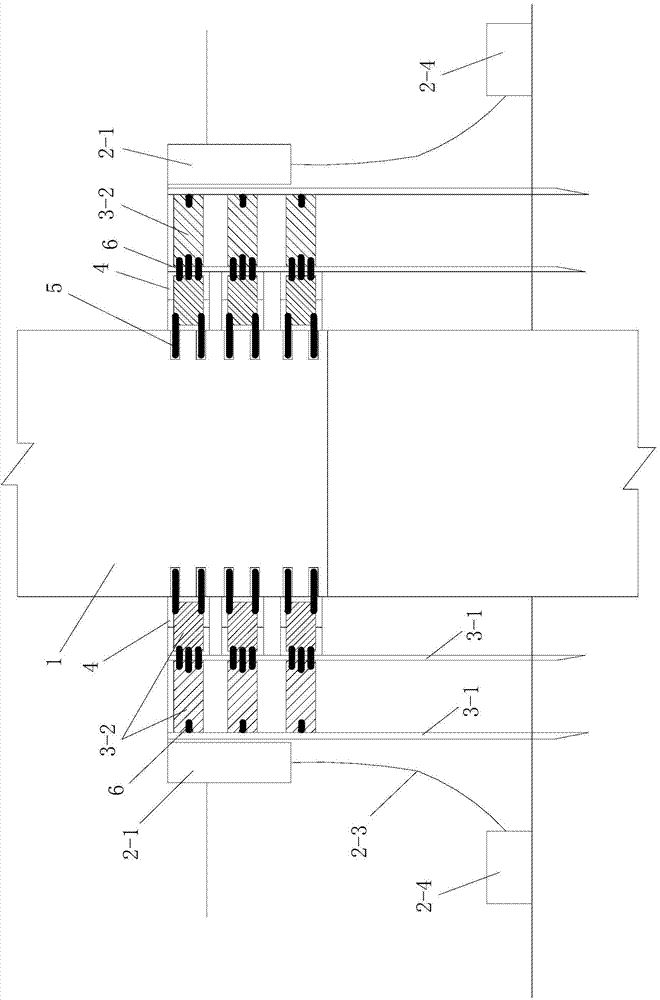

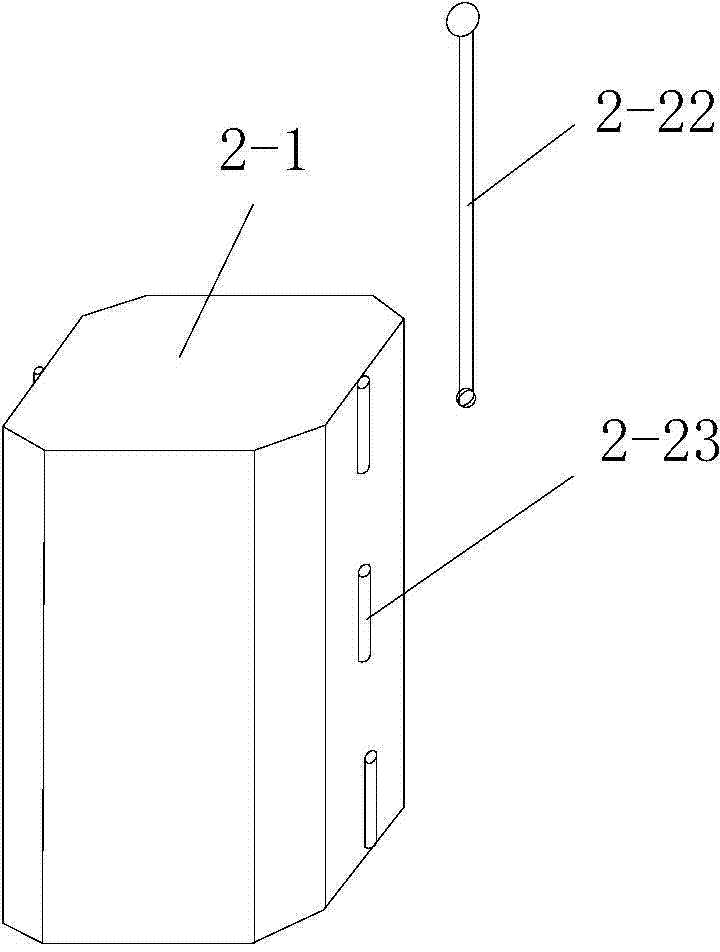

Spacecraft module flexible docking mechanism

ActiveCN110002011ASmall reaction forceReduce disturbanceCosmonautic vehiclesCosmonautic component separationRobotic armComputer module

The invention provides a spacecraft module flexible docking mechanism, belongs to the technical field of spacecraft docking, and specifically relates to a spacecraft module flexible docking mechanism.The problems that the existing rigid conical rod type docking mechanism is complicated in structure, a special energy absorbing mechanism is required, disturbance to the stars is great are solved, and the problems of low connection rigidity and large jitter of the existing flexible conical rod type docking mechanism are solved. The spacecraft module flexible docking mechanism comprises an activeend docking module and a passive end docking module,the active end docking module comprises a guiding head, a flexible rod, a separating component, a connecting and unlocking component, and a drivingcomponent, and the passive end docking module comprises a guiding cone, a bearing section, and a passive end flange.The spacecraft module flexible docking mechanism is mainly used for space docking tasks with spacecraftswhich are sensitive to impact and require precise operation with the aid of autonomous power or robotic arms.

Owner:HARBIN INST OF TECH +1

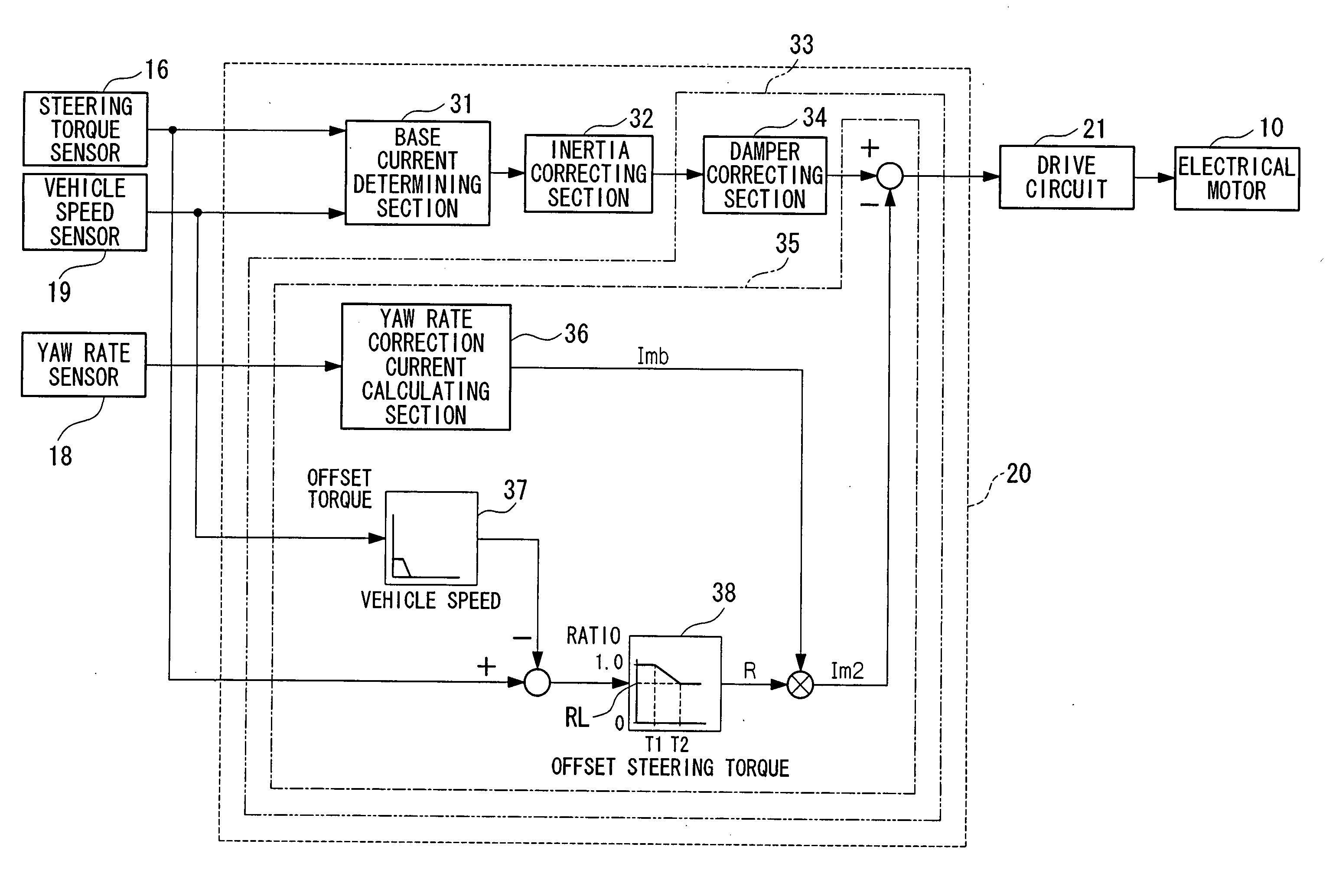

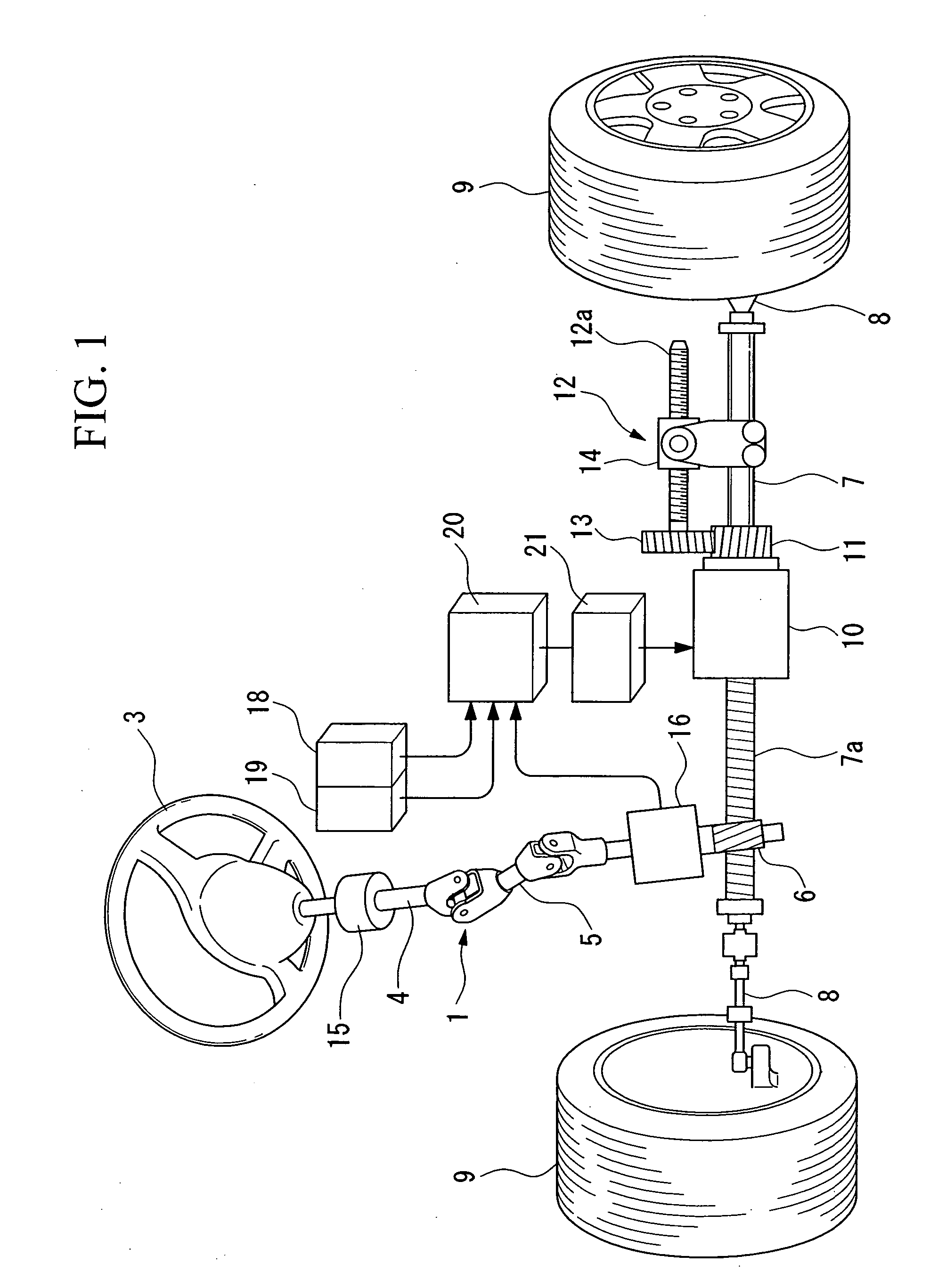

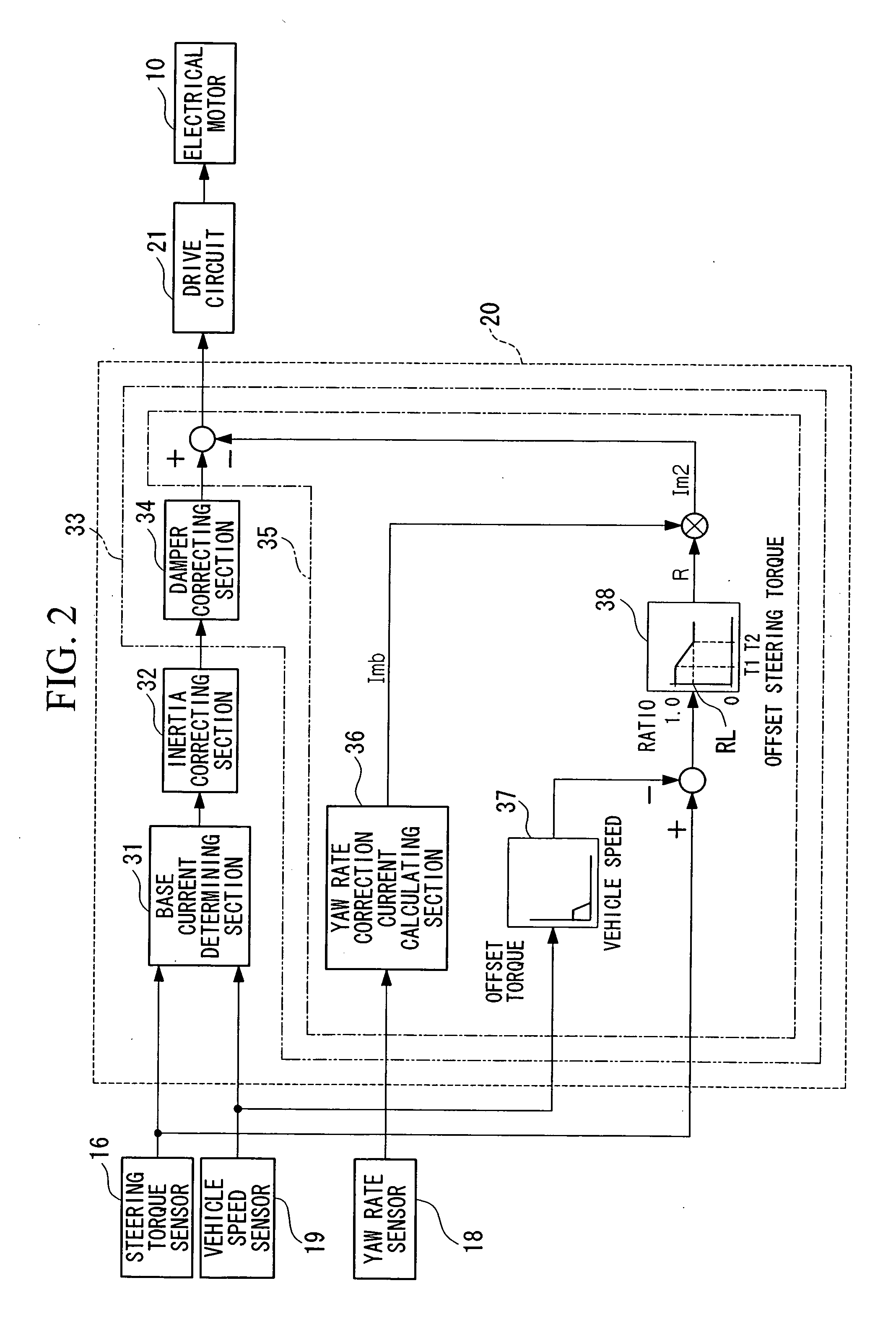

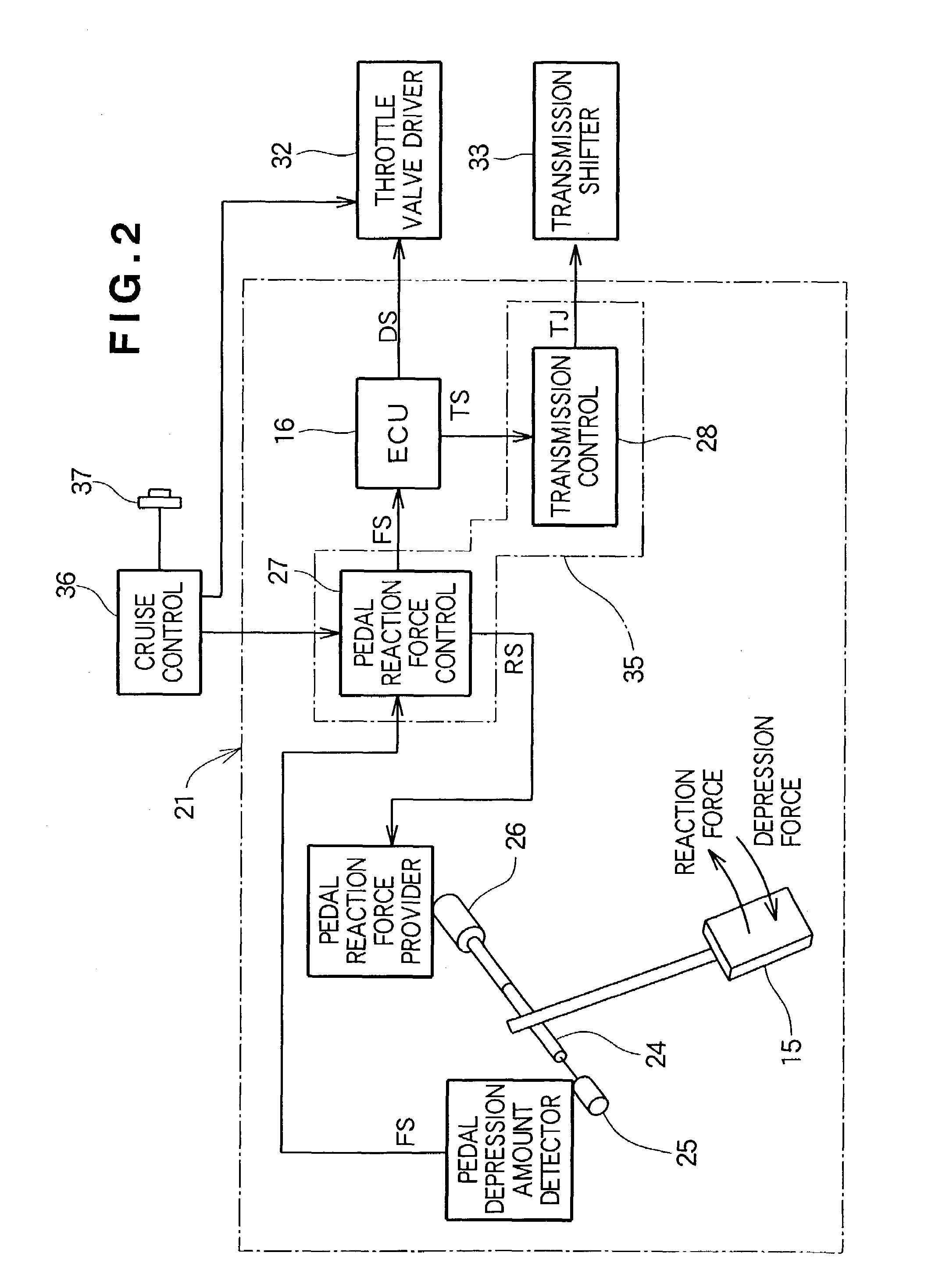

Reaction force control apparatus

ActiveUS20060000663A1Superior steering operation feelHigh lateral accelerationDigital data processing detailsSteering initiationsDriver/operatorGround reaction force

A reaction force control apparatus for controlling a reaction force to be applied to an operation unit operated by a driver of a vehicle, the reaction force control apparatus includes a steering operation torque measuring unit for measuring steering operation torque applied to the operation unit, a vehicle movement measuring unit for measuring movement of the vehicle, and a reaction force control unit setting the reaction force to be greater as a measured value measured by the vehicle movement measuring unit is greater, and setting the reaction force to be smaller as a measured value measured by the steering operation torque measuring unit is greater.

Owner:HONDA MOTOR CO LTD

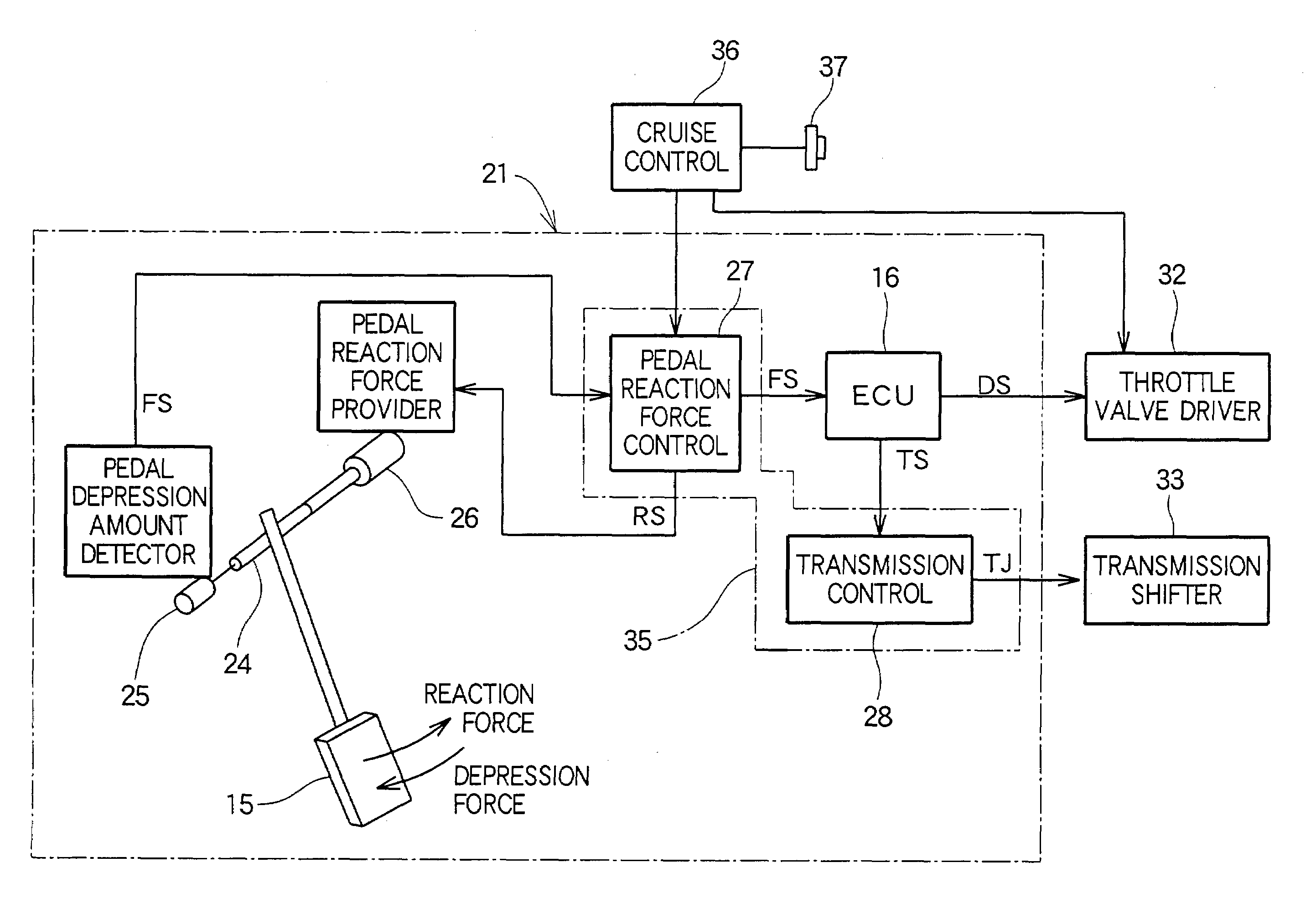

Vehicle accelerator pedal device

ActiveUS7022045B2Produce some attenuationReduce capacityControlling membersElectrical controlEngineeringThrottle opening

An accelerator pedal device includes a pedal reaction force providing device for providing a reaction force to an accelerator pedal according to an amount of depression of the accelerator pedal operated by a driver. The reaction force to be provided from the pedal reaction force providing device to the pedal is controlled based on the depression amount of the accelerator pedal. This reaction force control allows precise agreement between throttle opening timing and pedal reaction force timing to produce a predetermined pedal reaction force at a desired degree of throttle opening.

Owner:HONDA MOTOR CO LTD

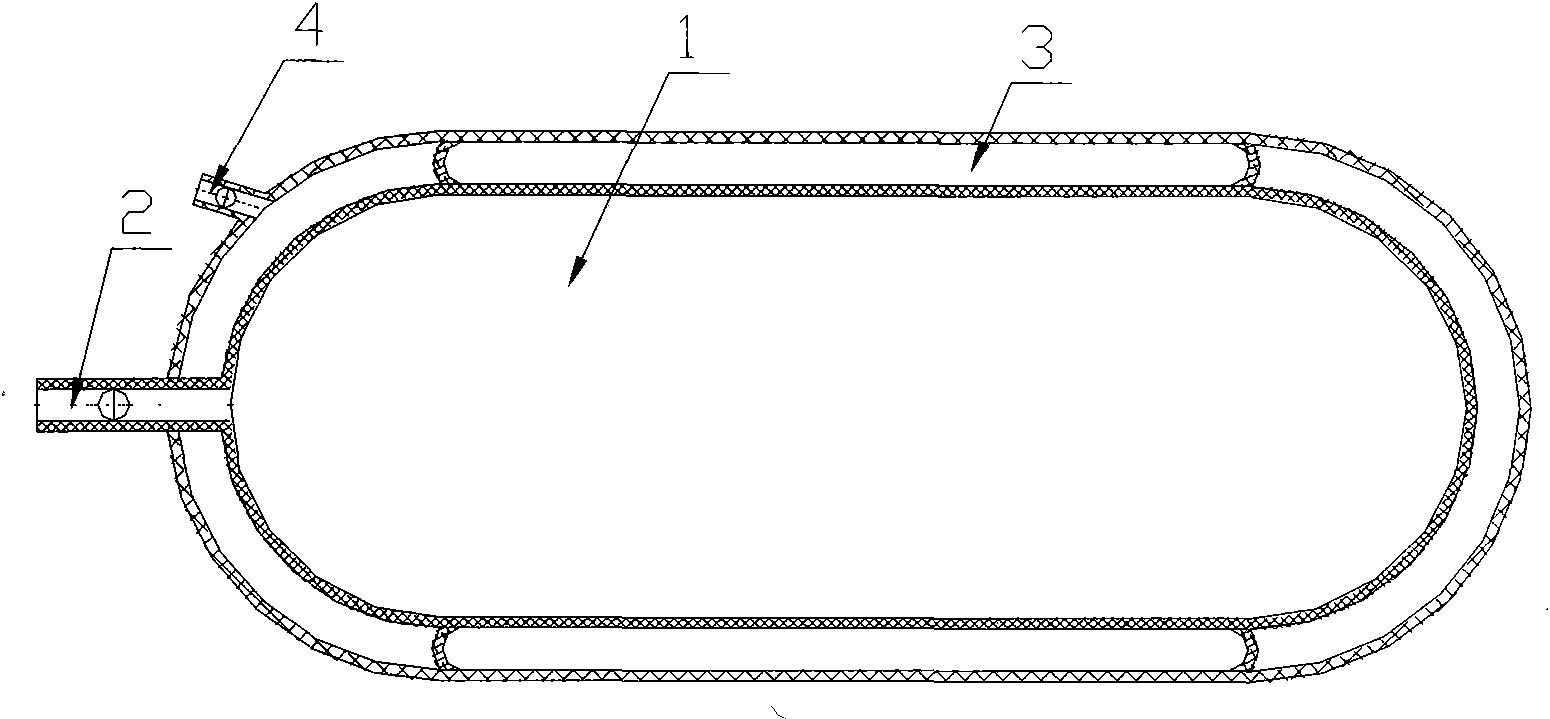

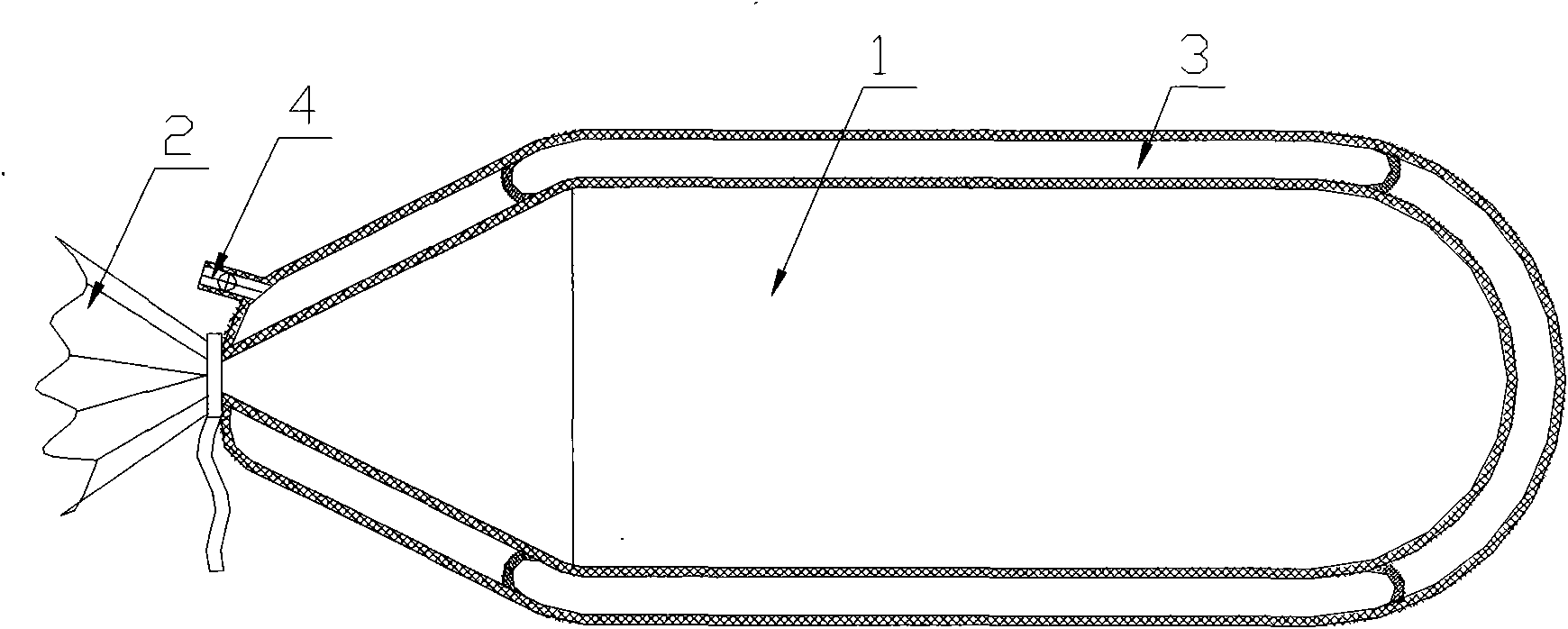

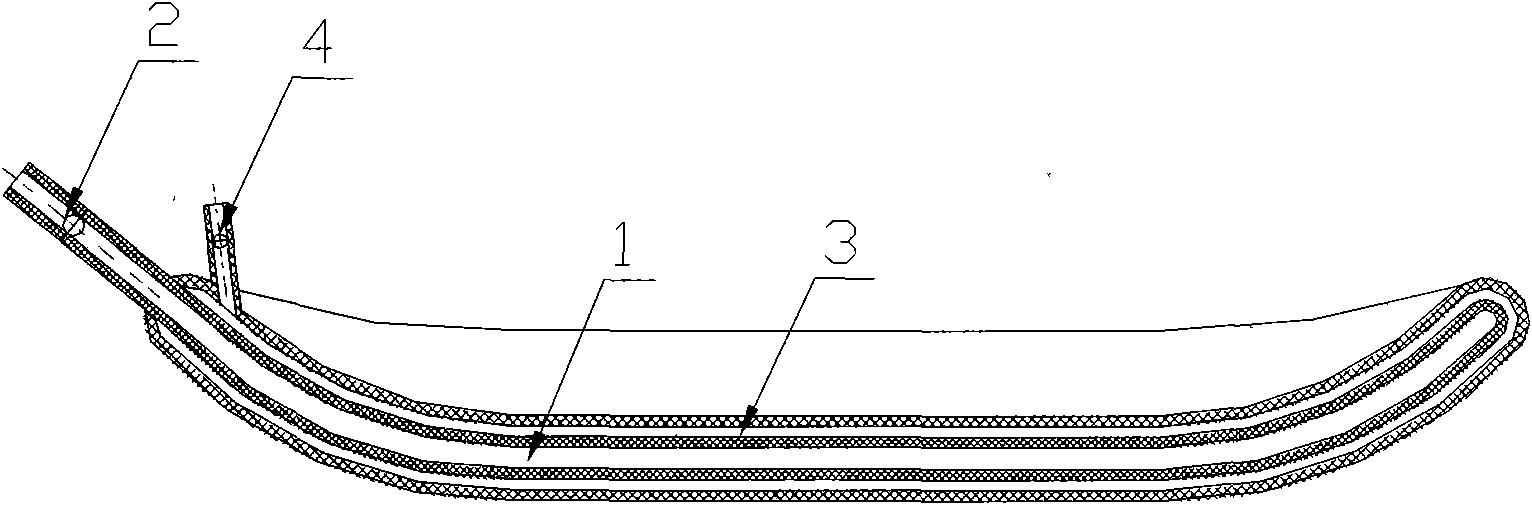

Air drop container

InactiveCN101596969AEasy to carryEasy to recycleAircraft componentsPackage recyclingEngineeringUltimate tensile strength

The invention relates to an air drop container, being composed of a container chamber, a container opening, an inflated protection layer and an inflating nozzle; the invention is characterized in that the air drop container is flexible, and an inflatable protection interlayer is arranged outside the container. The invention aims at solving the technical problem of providing a container to meet the demand of direct drop under the conditions of certain flight altitude and speed during air drop, thus achieving the aims of simple operation, exact drop, high efficiency, non-breakage and non-leakage caused by drop of the container, easy recycling, 100% of empting rate, easy carrying, grinding resistance and guarantee the safety of the dropped goods. The air drop container is used for containing various goods such as gas, liquid or solid, and the wall of the container is made of flexible material which has sufficient strength to avoid the container from breaking during air drop.

Owner:钟爱民

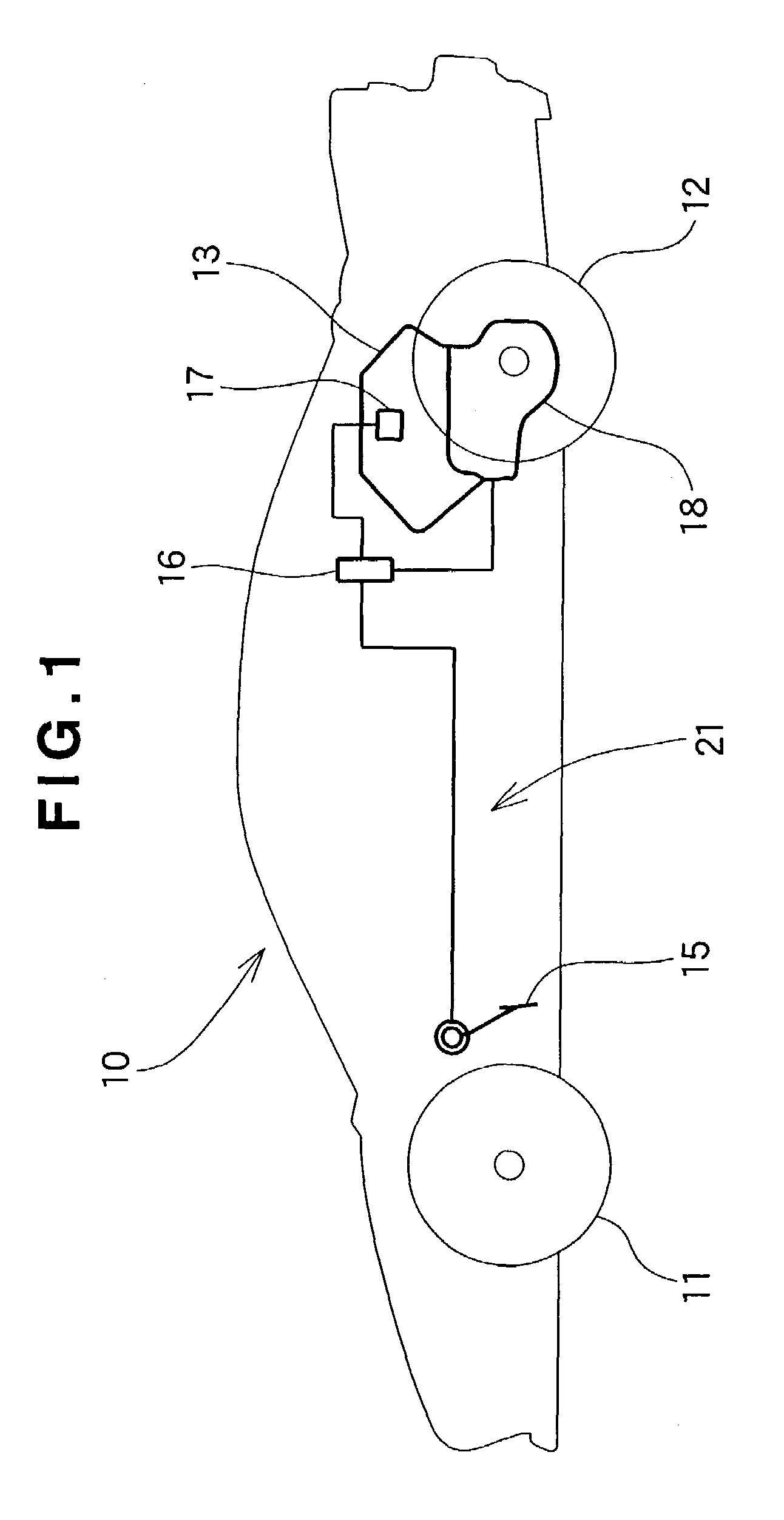

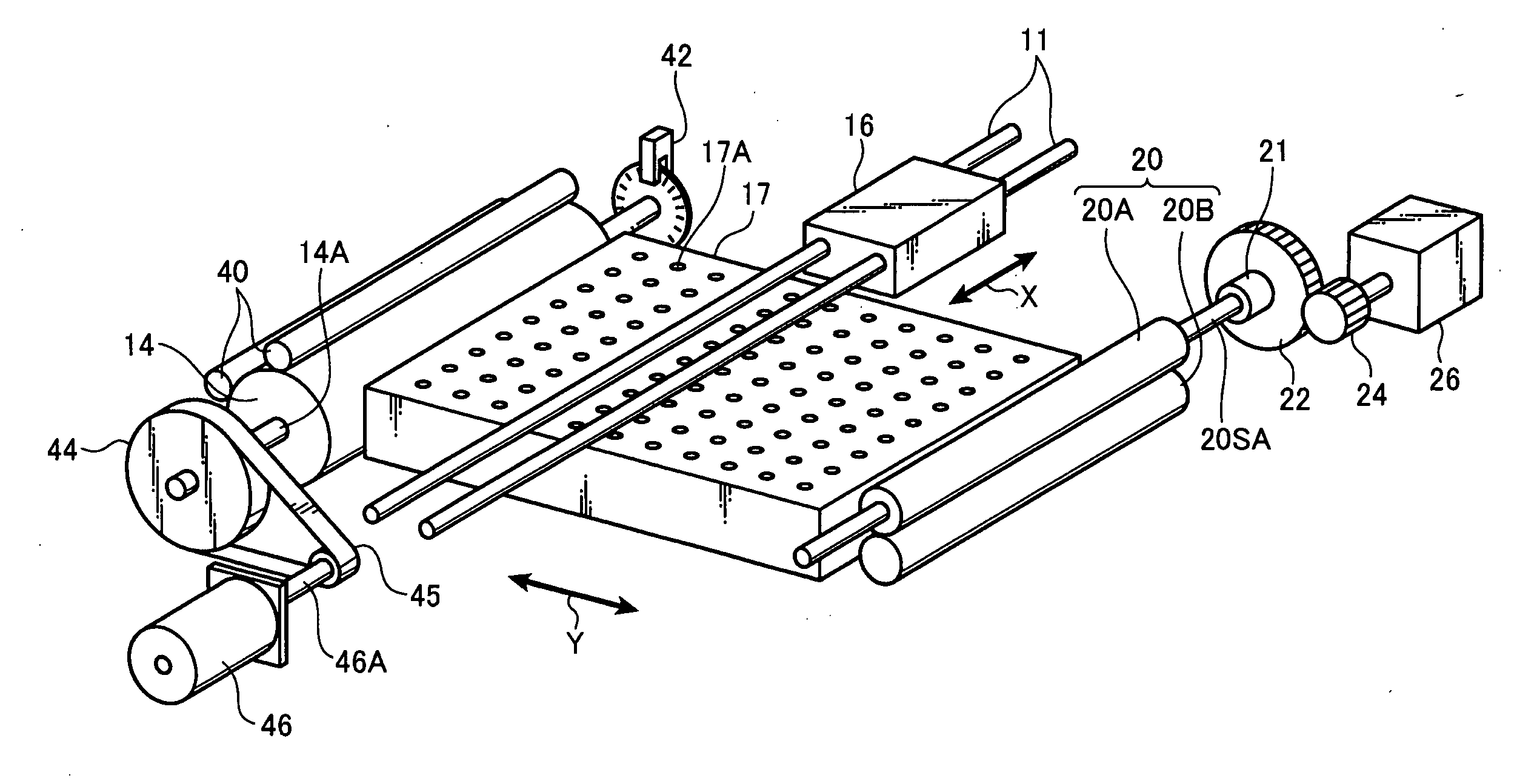

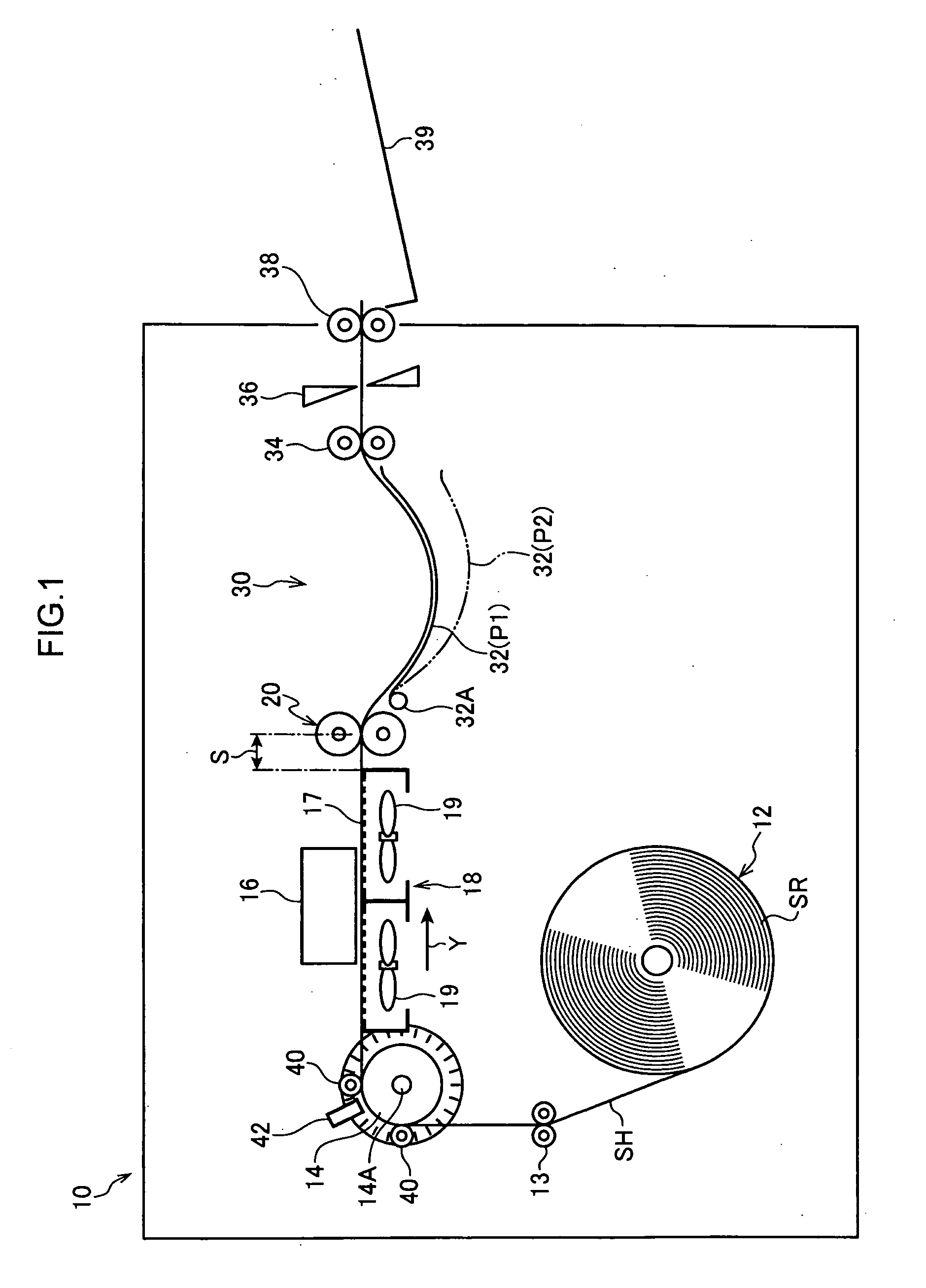

Image forming device

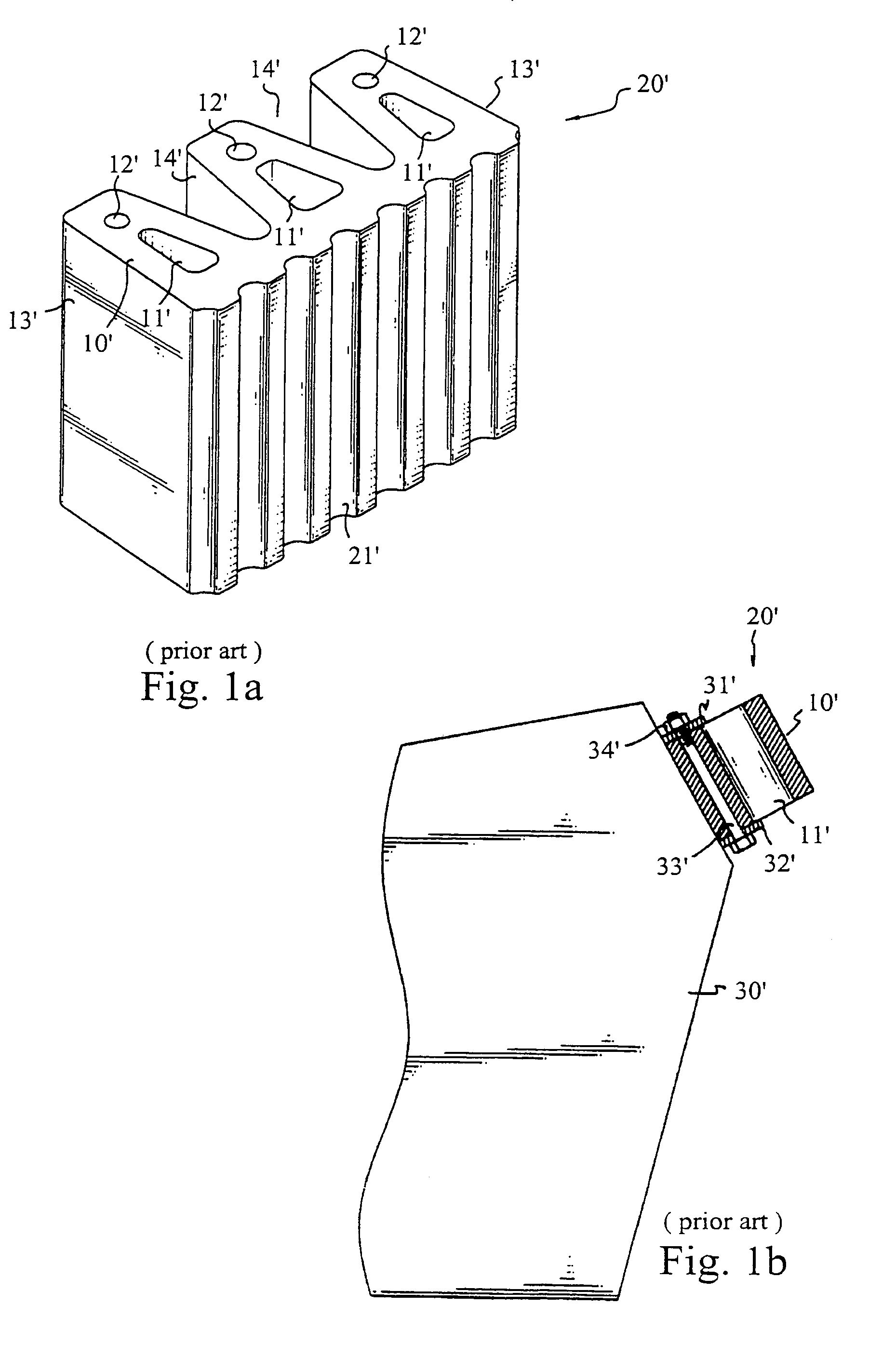

InactiveUS20100238250A1Reduce the impactSmall reaction forceOther printing apparatusImage formationComputer science

An image forming device provided with: a recording head that renders an image by ejecting liquid droplets onto a recording medium; an attraction image rendering section having a liquid droplet reception flat portion disposed facing the recording head, the attraction image rendering section attracting the recording medium onto the flat portion and maintaining the flatness of the recording medium; an upstream side conveying section that feeds the recording medium out toward the attraction image rendering section; and a reverse-feed-prevented conveying roller disposed at the downstream side of the attraction image rendering section, the reverse-feed-prevented conveying roller being capable of friction-pushed rotation toward the conveying direction downstream side, nipping the recording medium and feeding the recording medium toward the conveying direction downstream side, and prevented from rotation toward the conveying direction upstream side.

Owner:FUJIFILM CORP

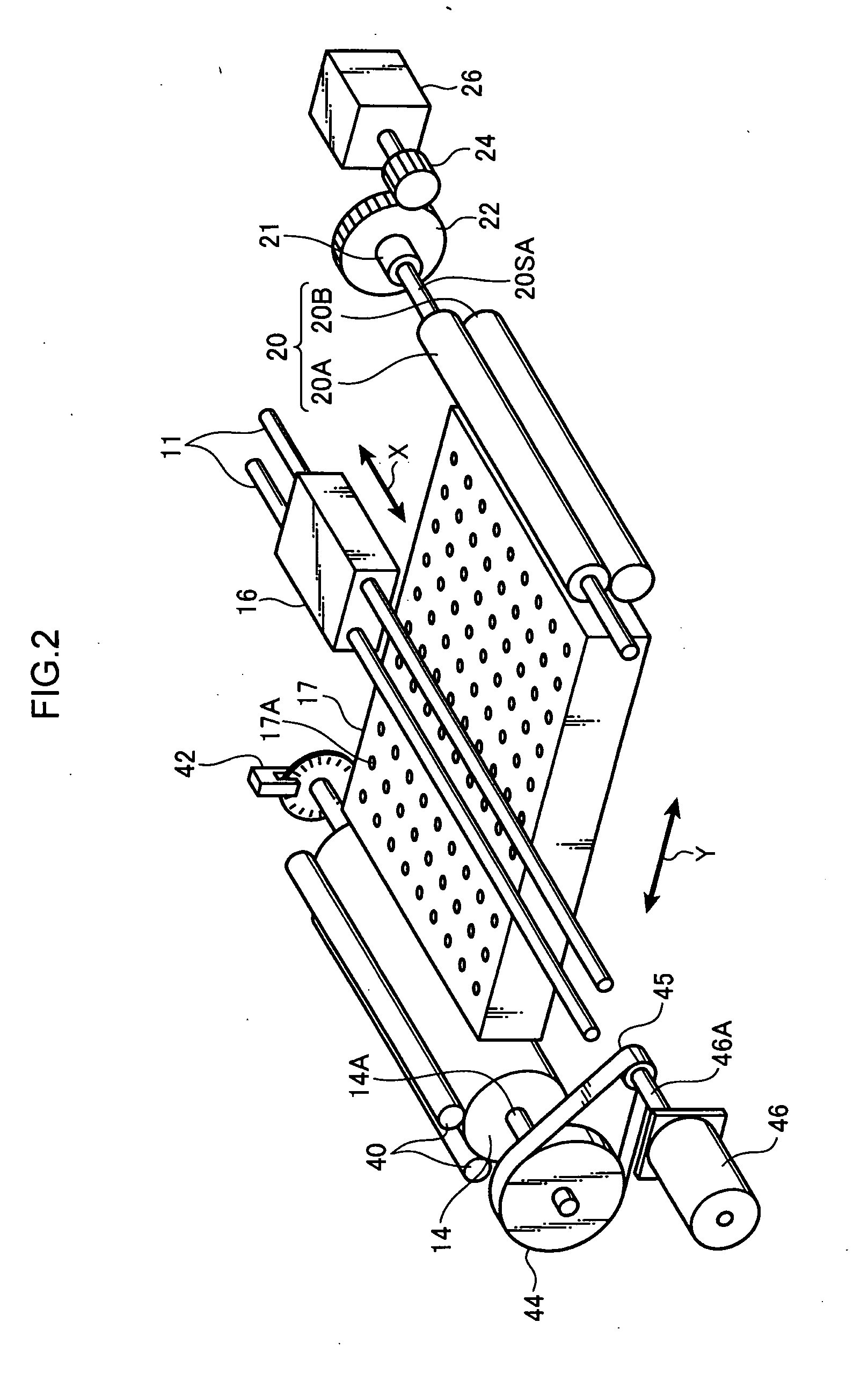

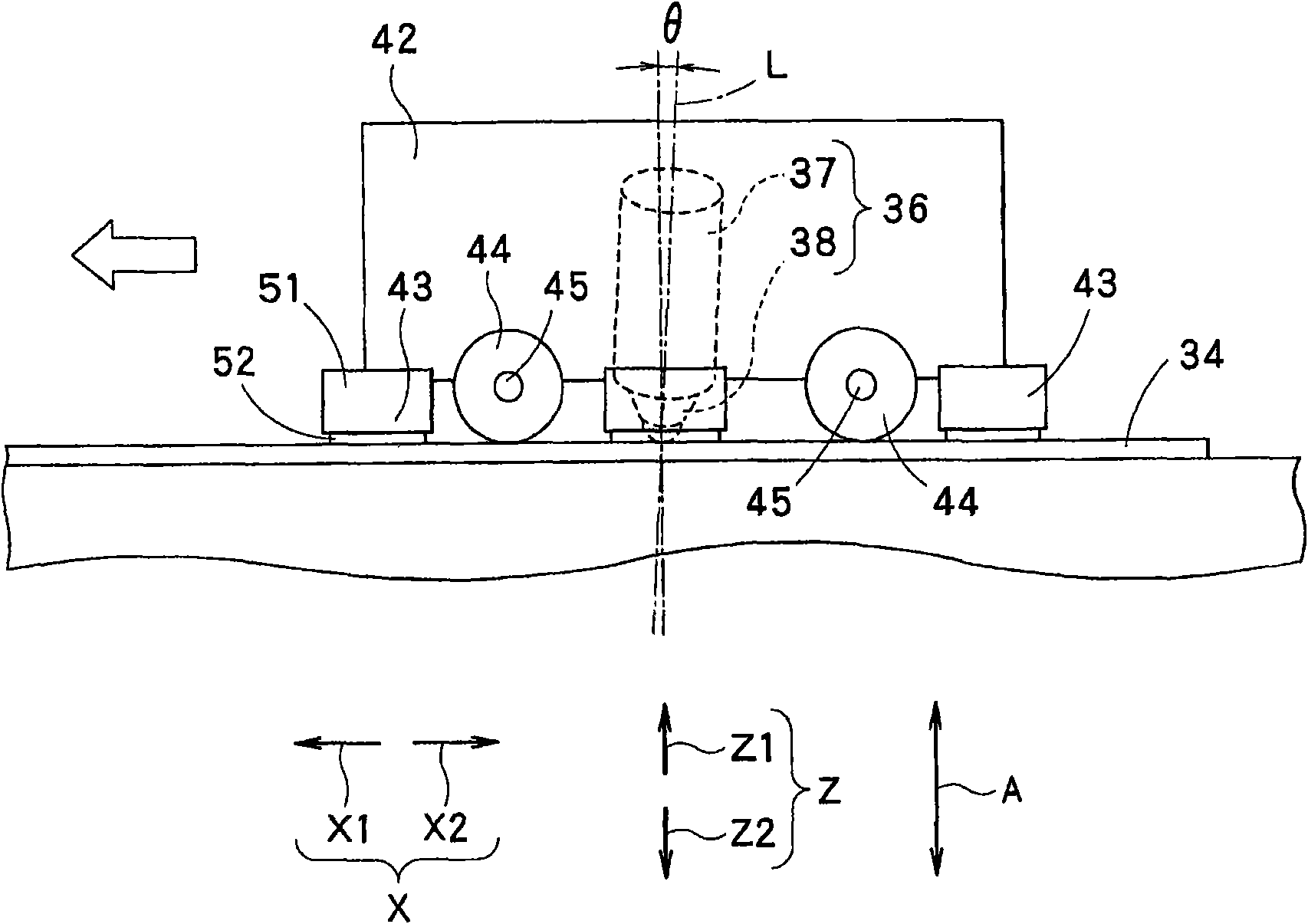

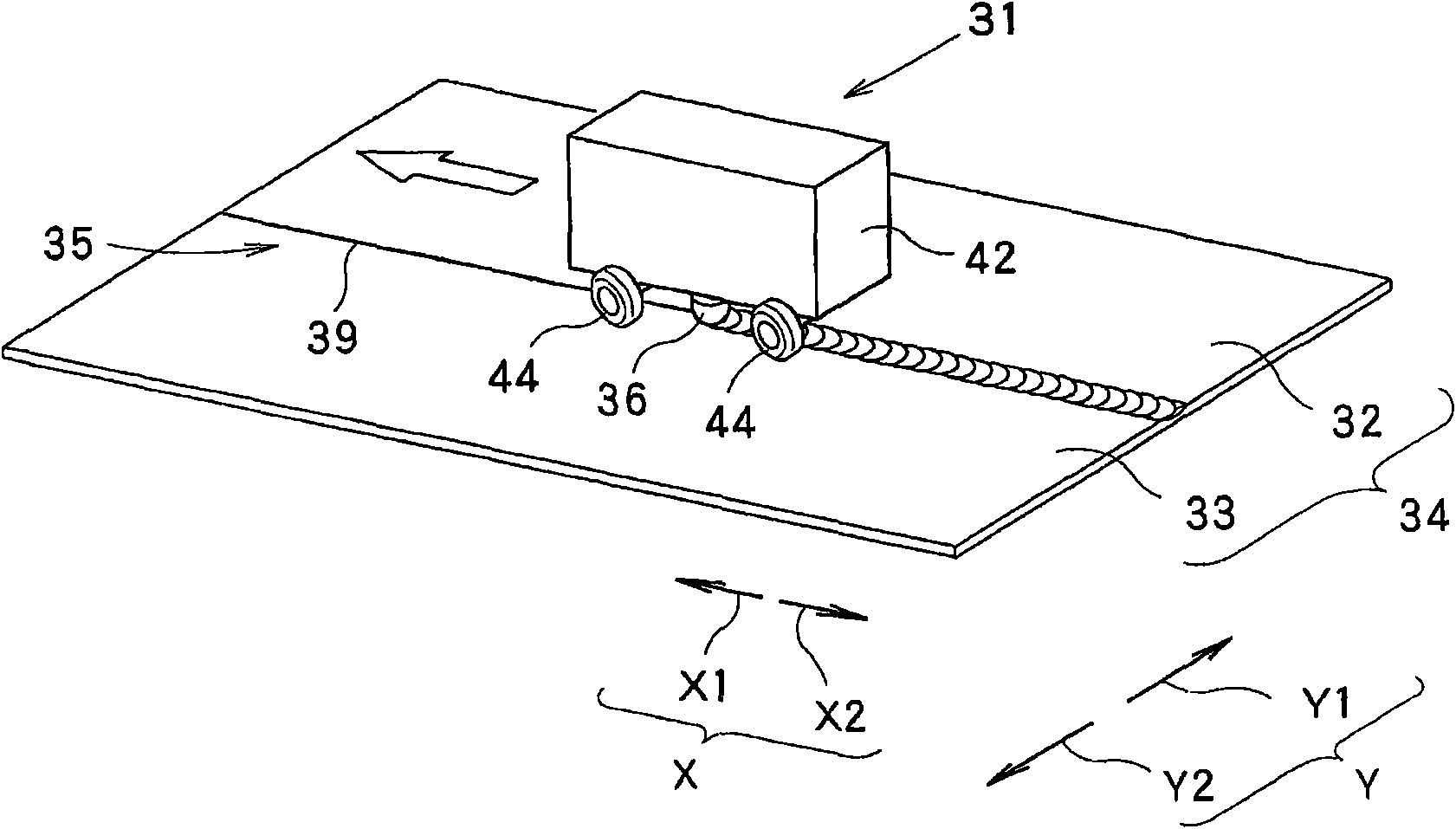

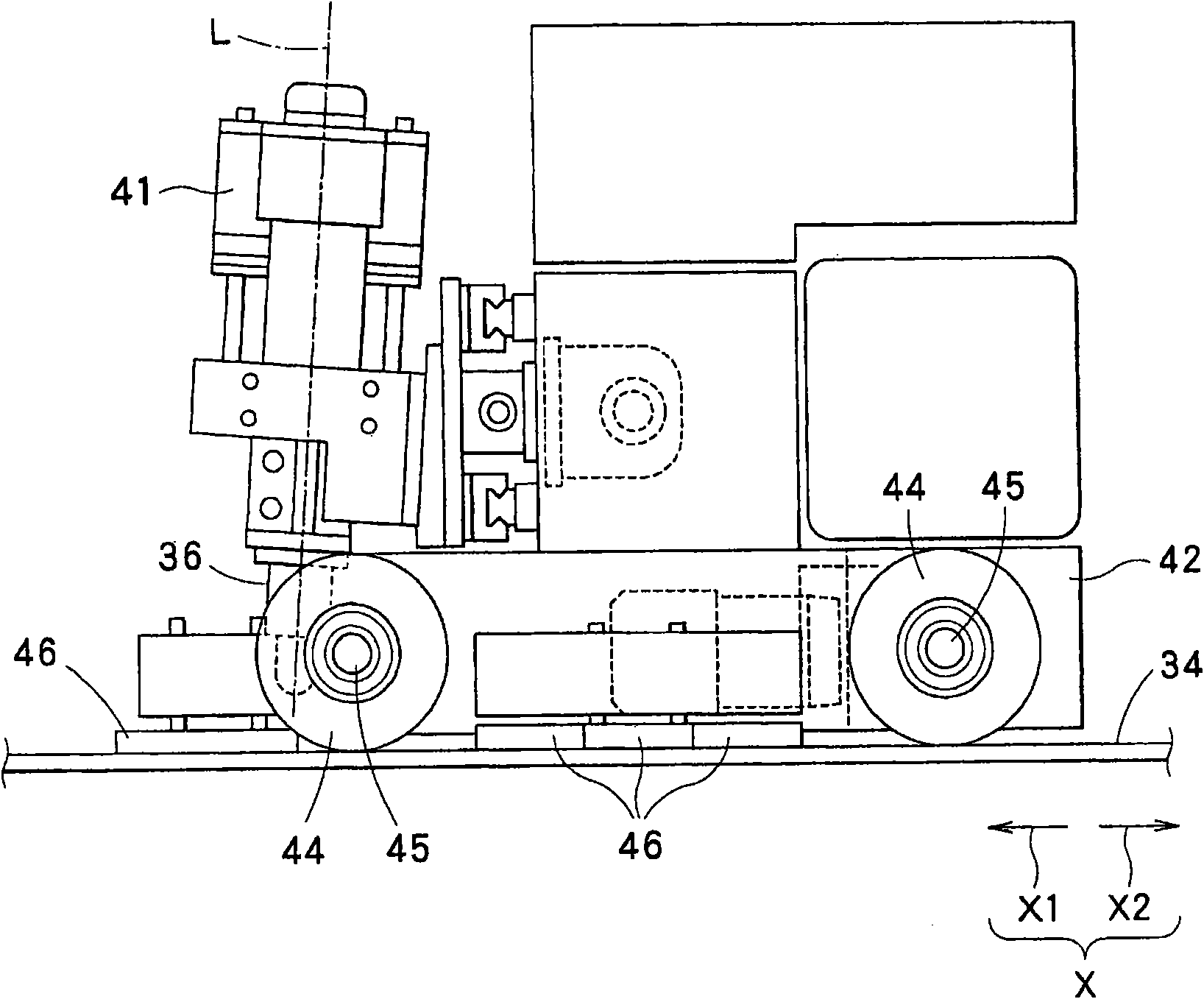

Suction pad, friction stir welding device, and friction stir welding system

ActiveCN101622093AEasy to slideIncrease splicing speedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Provided are a friction sir welding device that is light in weight and can travel by a small force, a suction pad used for the friction sir welding device, and a friction stir welding system. The suction pad (46) includes a plate-like facing section (51) facing an object to which the suction pad sticks; an annular pad section (52) projecting from one surface in the thickness direction of the facing section (51) at its end near the object and making a round on the surface of the facing section (51); a gliding body (53) provided on the surface of the pad section (52) at a portion near the object; and one or more deformation prevention projections (56) projecting from the one surface in the thickness direction of the facing section (51). The gliding body (53) is made of a material having a friction coefficient against the object which is smaller than the friction coefficient of the pad section (52) against the object.

Owner:KAWASAKI JUKOGYO KK

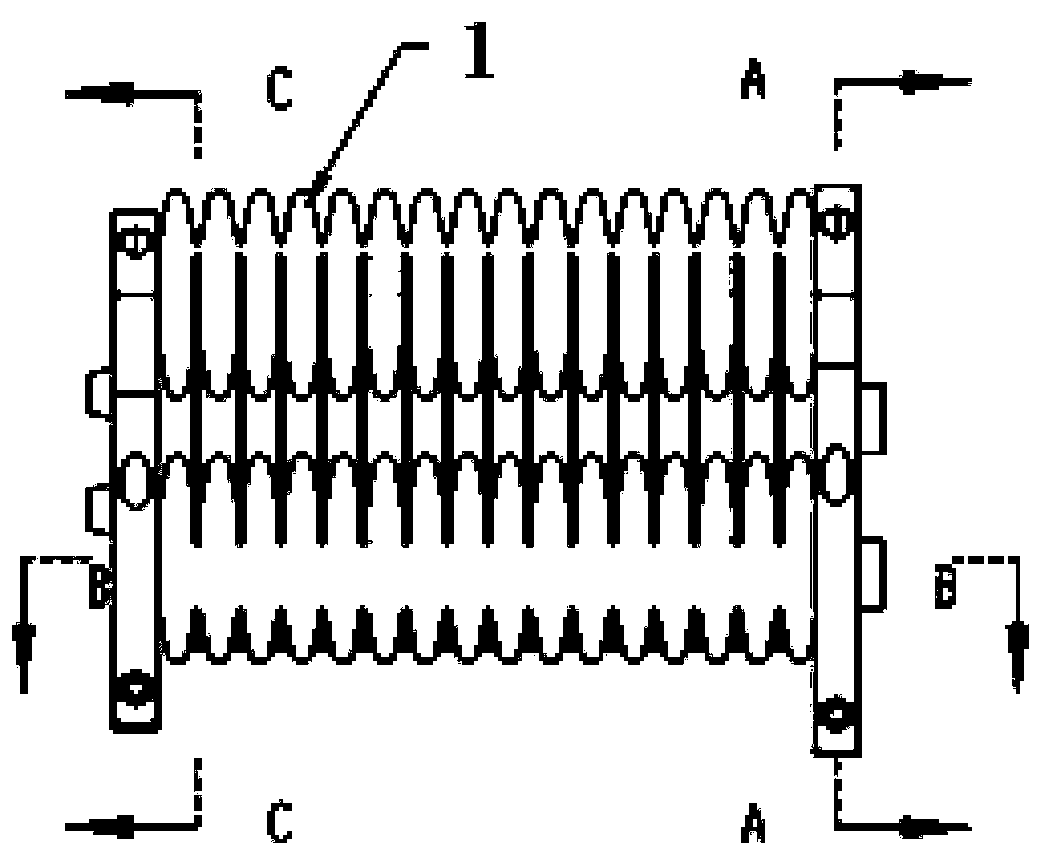

Bionic soft mechanical arm and grasping system

The invention belongs to the field of robot design, and particularly relates to a bionic soft mechanical arm and a grasping system. The bionic soft mechanical arm comprises at least two parallel corrugated pipes, two end plates and a supporting plate; the two end plates are located on two ends of at least two corrugated pipes, the end of each corrugated pipe is fixedly connected to the end plate on the corresponding end, the supporting plate is located between at least two corrugated pipes, and the supporting plate is arranged on the minimum diameter position of each pipe body. According to the bionic soft mechanical arm and the grasping system, control is convenient, the air pressure in an air cavity in each corrugated pipe only needs to be changed, and the postures of the bionic soft mechanical arm and the grasping system can be changed.

Owner:BEIHANG UNIV

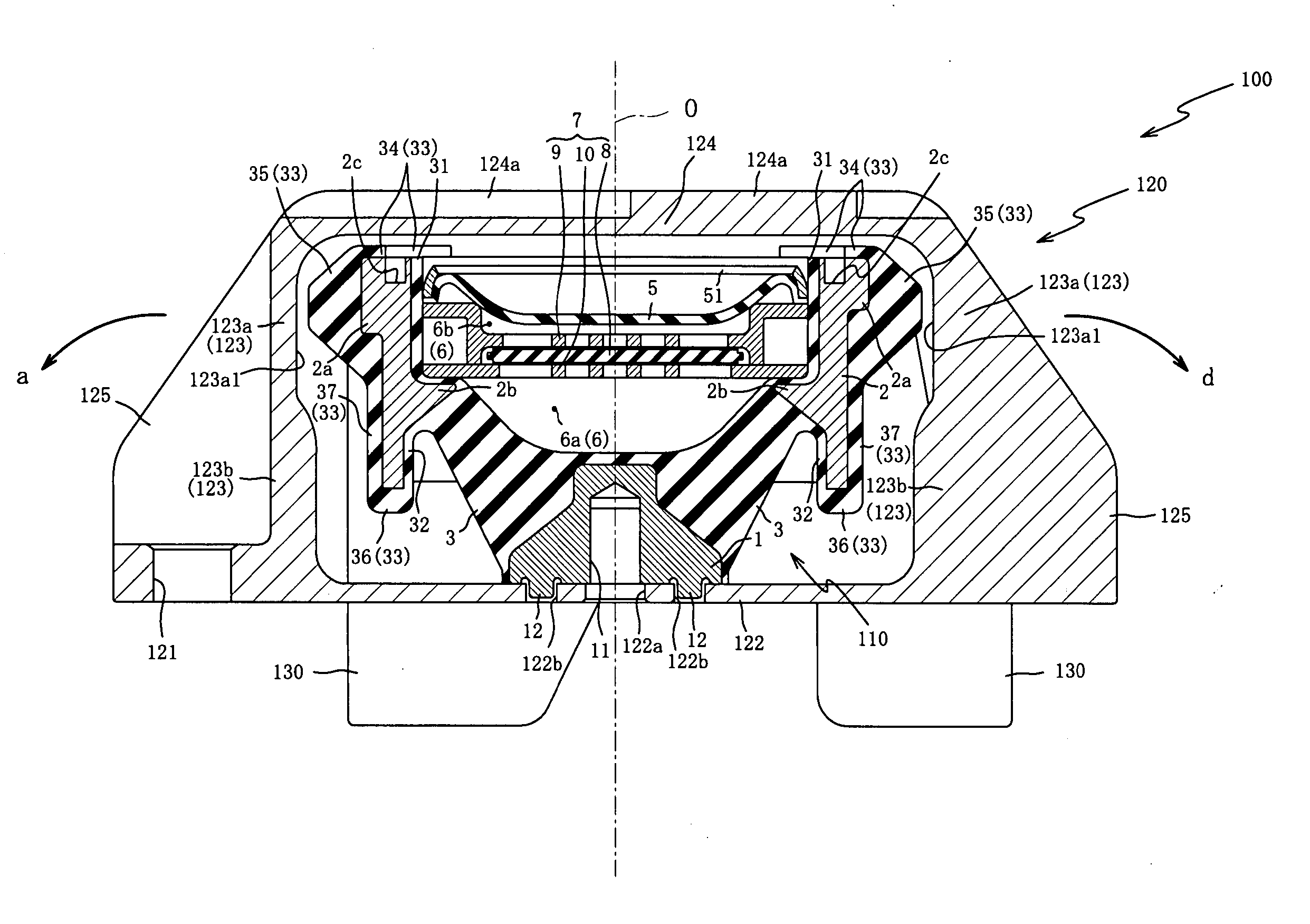

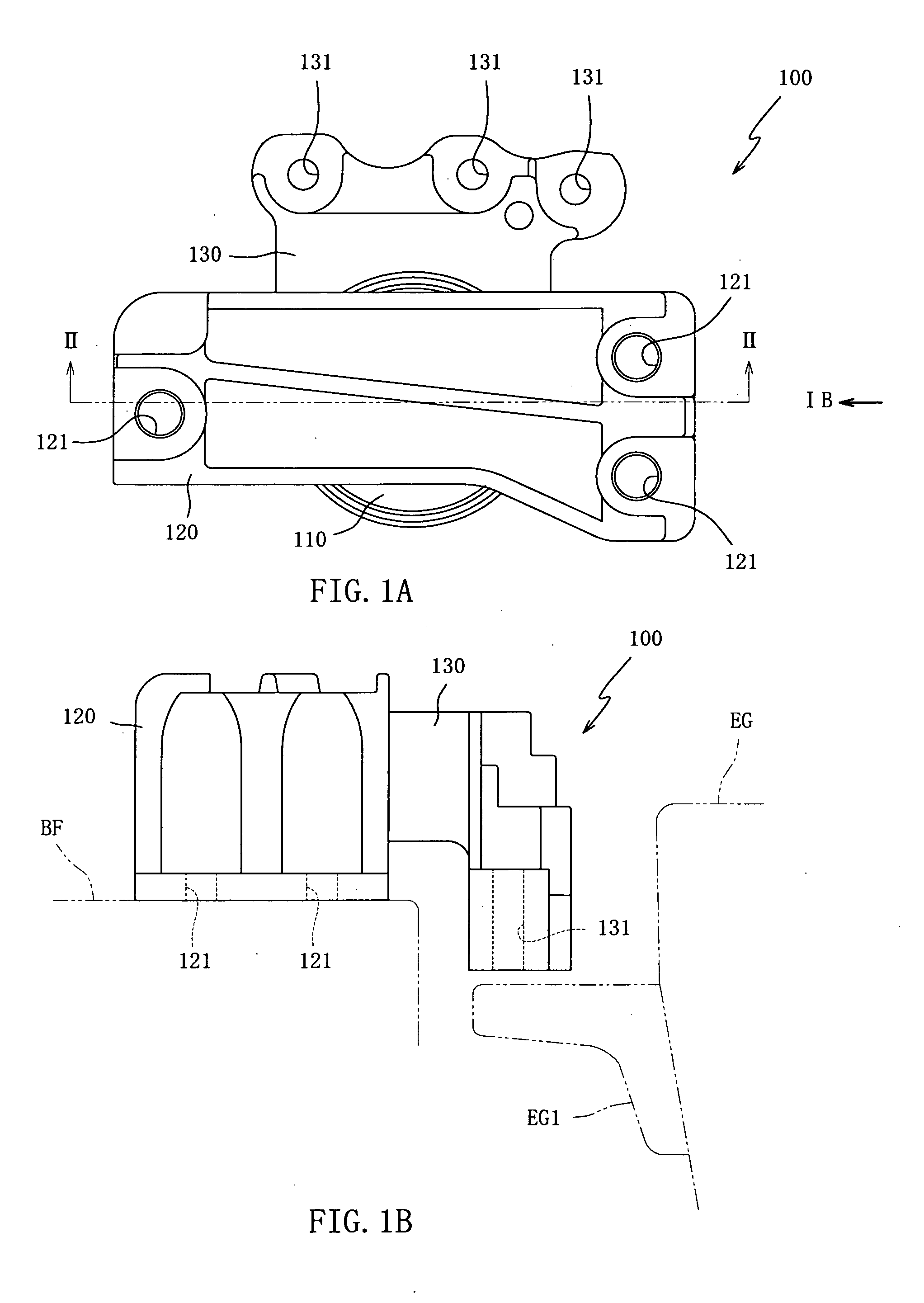

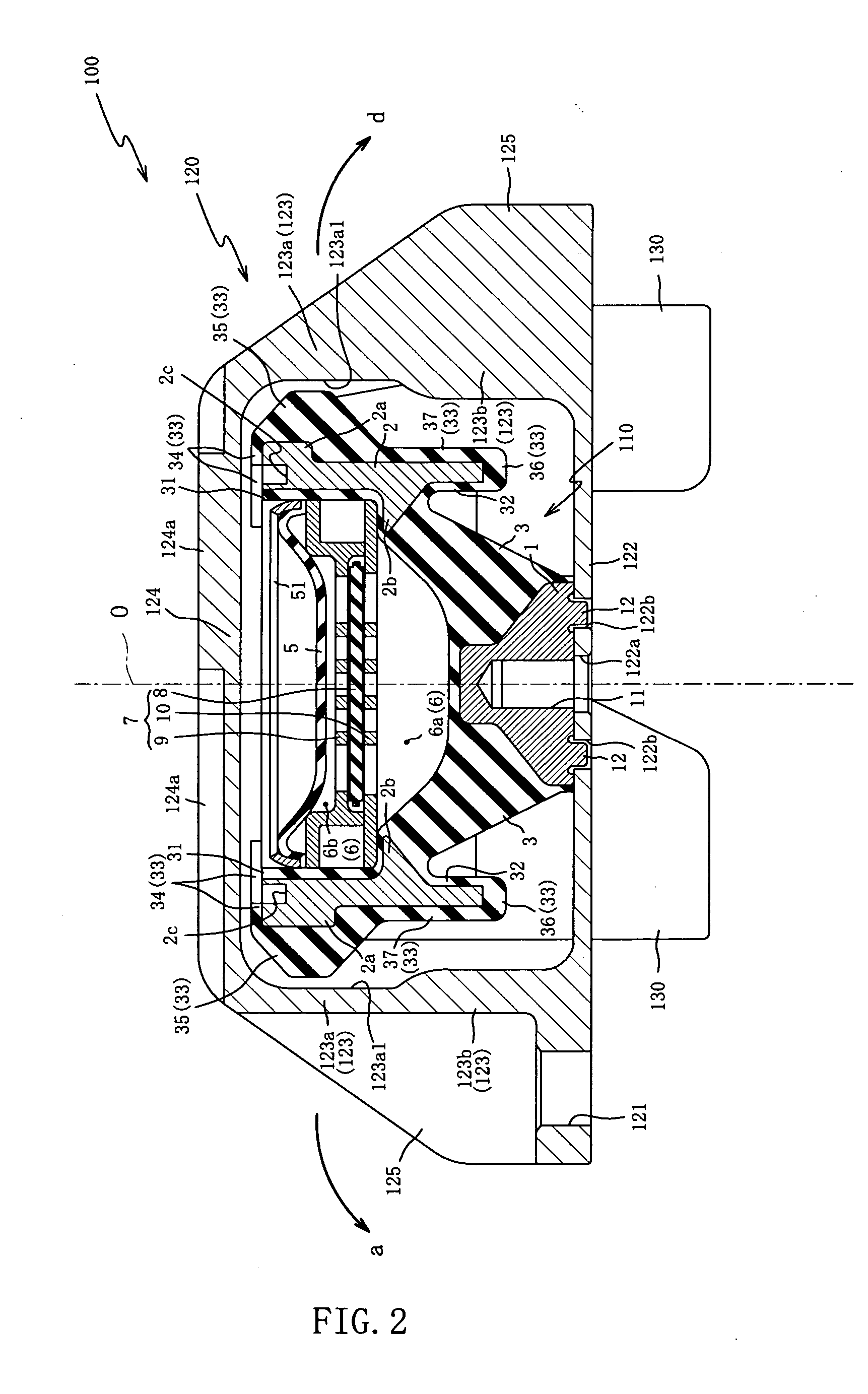

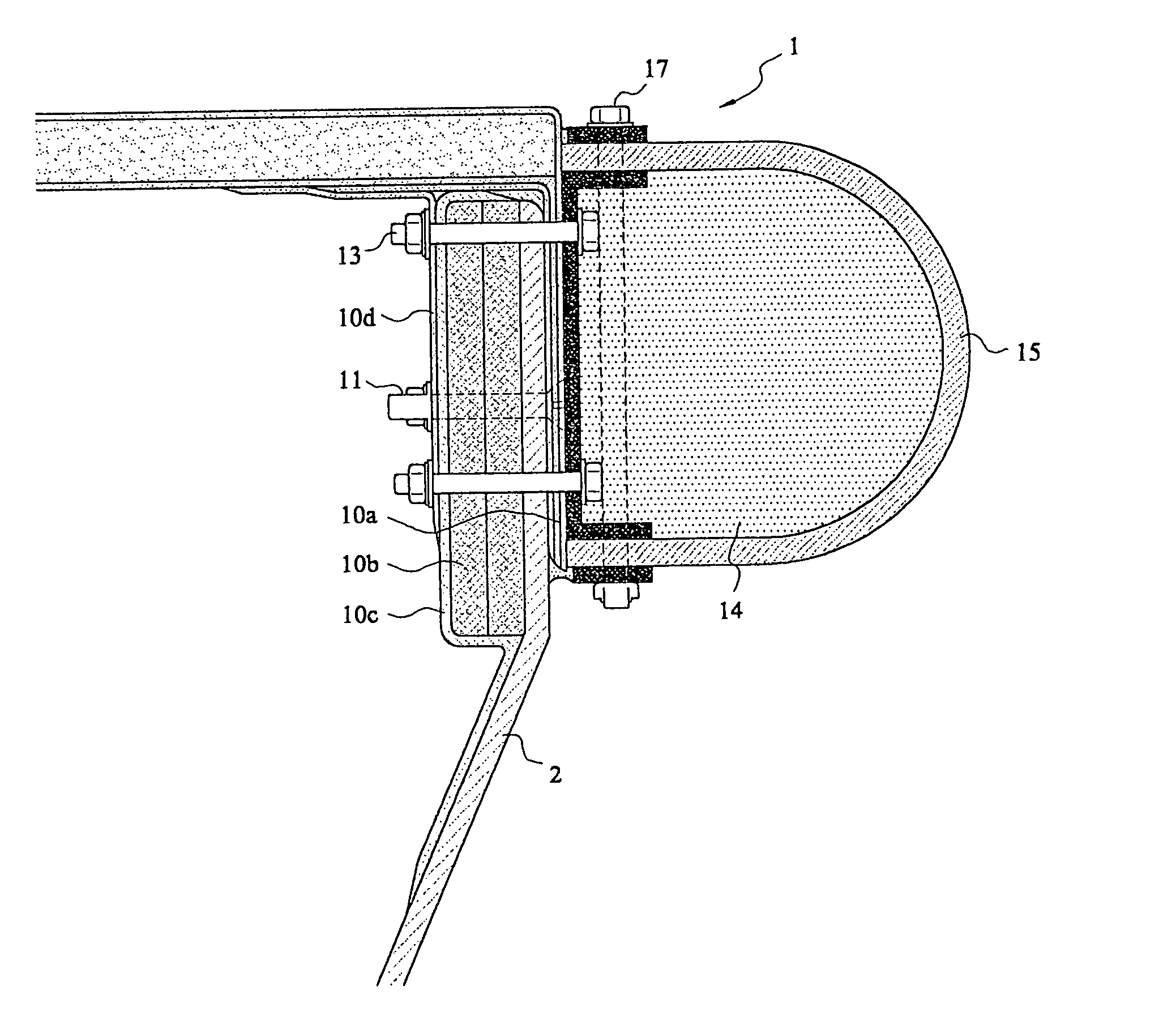

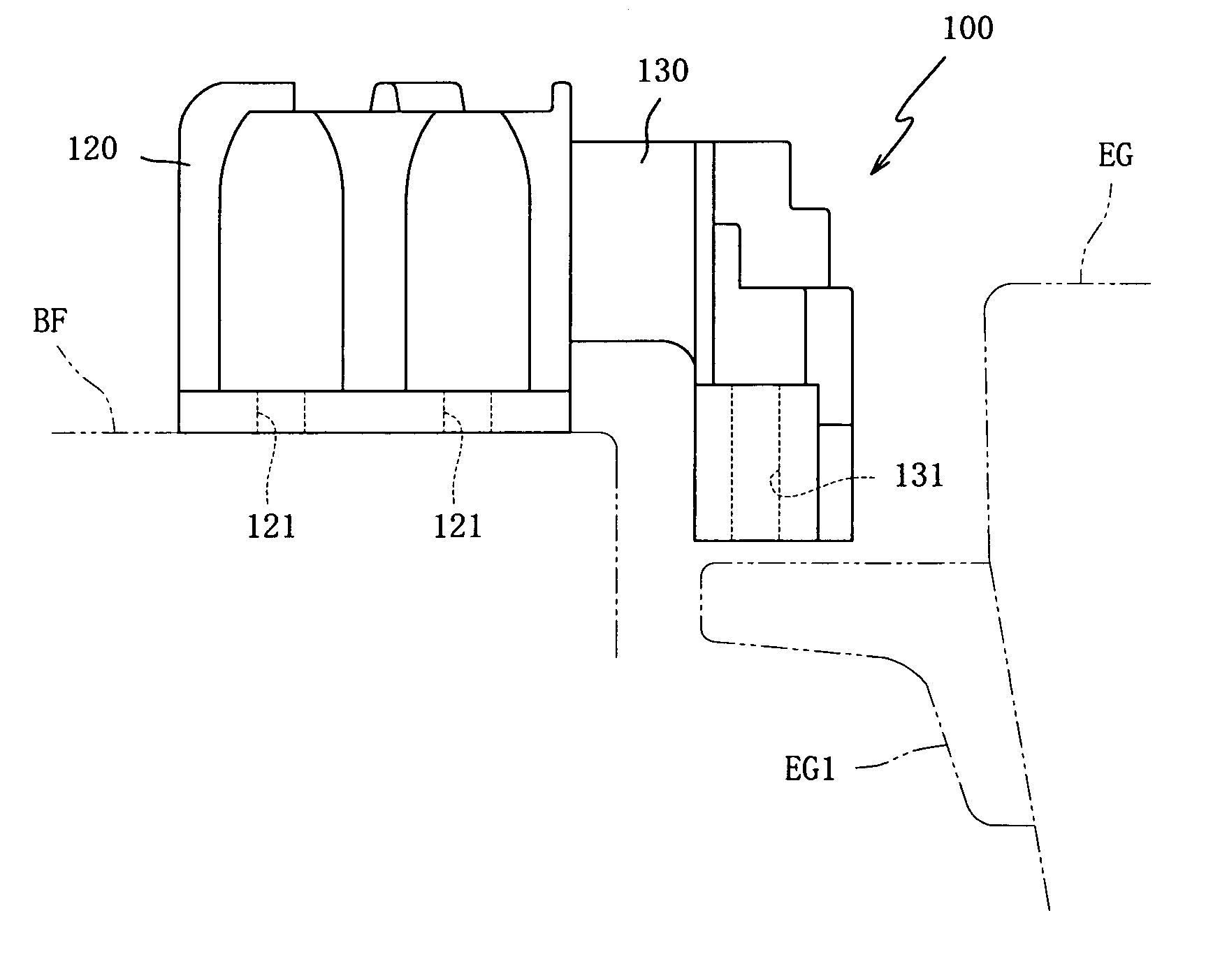

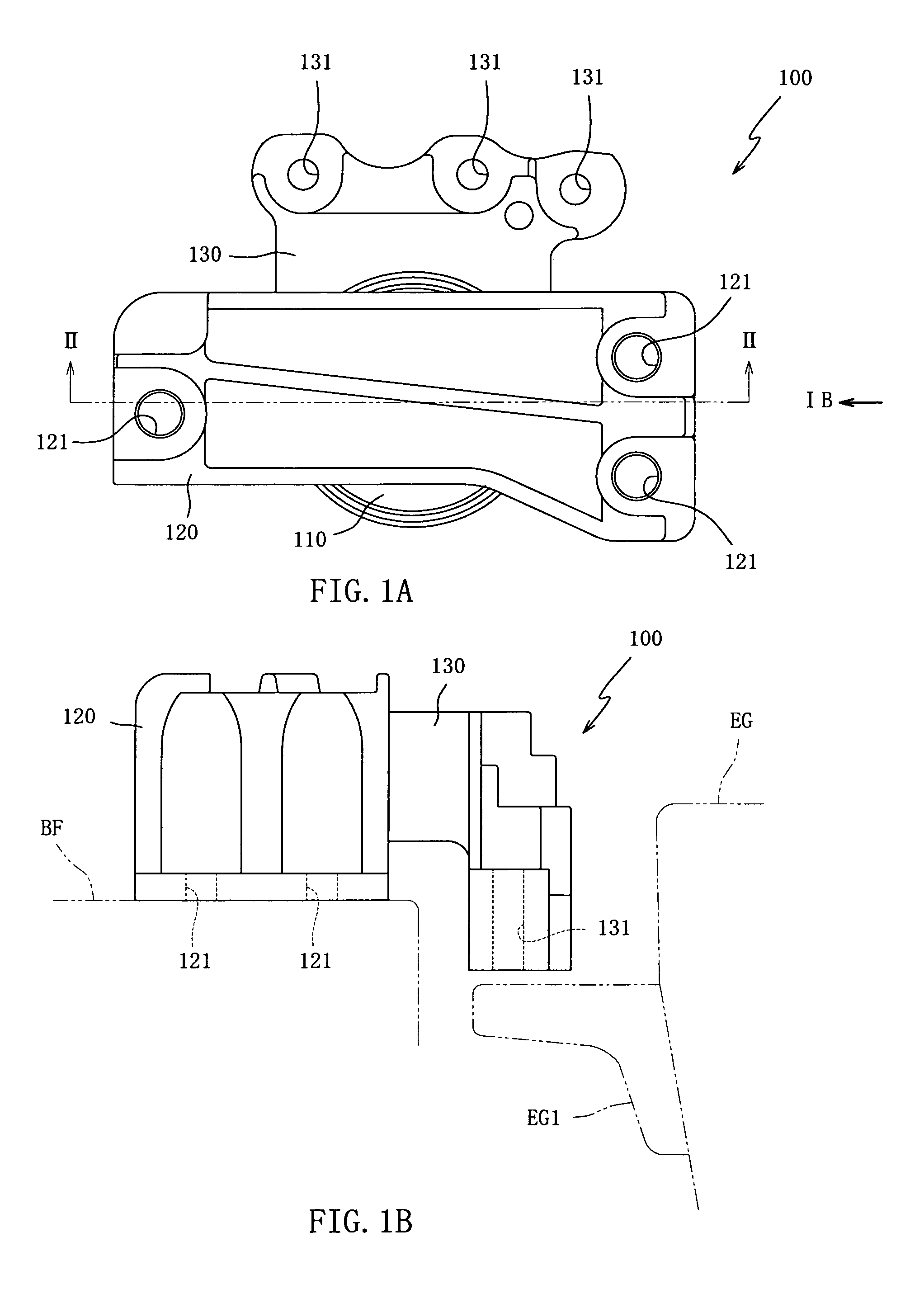

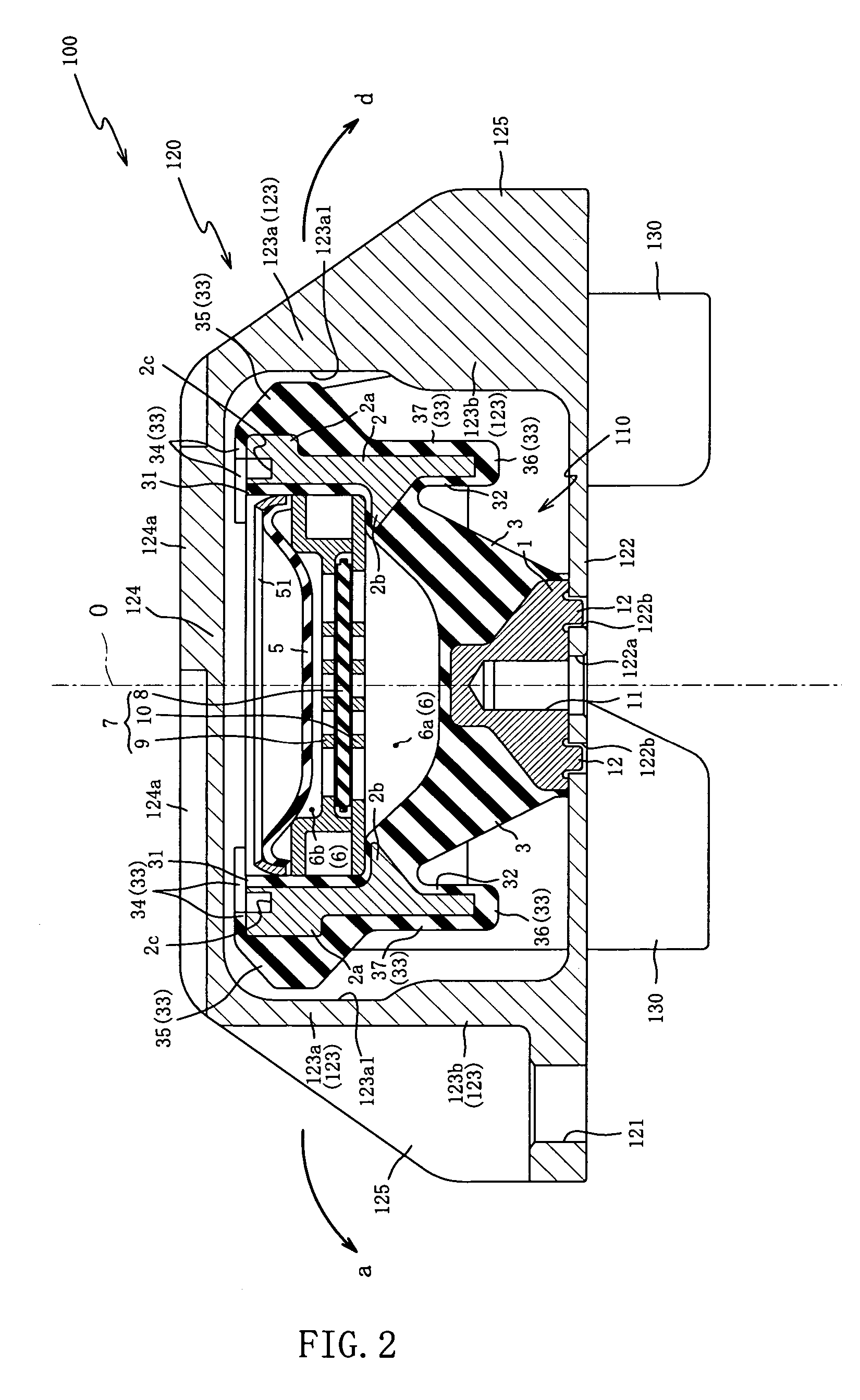

Hydraulic antivibration device arrangement, hydraulic antivibration device, and car body side bracket

InactiveUS20060261529A1Enhance durabilityLower stiffness and strengthMachine framesLiquid springsThin walledEngineering

A hydraulic antivibration device arrangement capable of achieving a downsizing and weight reduction, and a reduction of booming noise by suppressing a reaction force to impingement upon stopper action is provided. By disposing a protuberant rubber portion 35 at an upper end of a main body member 2, its spacing distance from a roll center can be lengthened, the reaction force to impingement can be diminished, and input load to the main body member 2 can be diminished. Consequently, reduction of rigidity and strength required for respective components as well as enhancement of durability is possible, which permits to make the components thin-walled thereby making a hydraulic antivibration device arrangement 100 lightweight as a whole. Diminishing of such reaction force upon stopper action also enables vibrations input through a car body side bracket 120 to the body frame to be suppressed, thereby reducing the generation of booming noise.

Owner:TOYO TIRE & RUBBER CO LTD

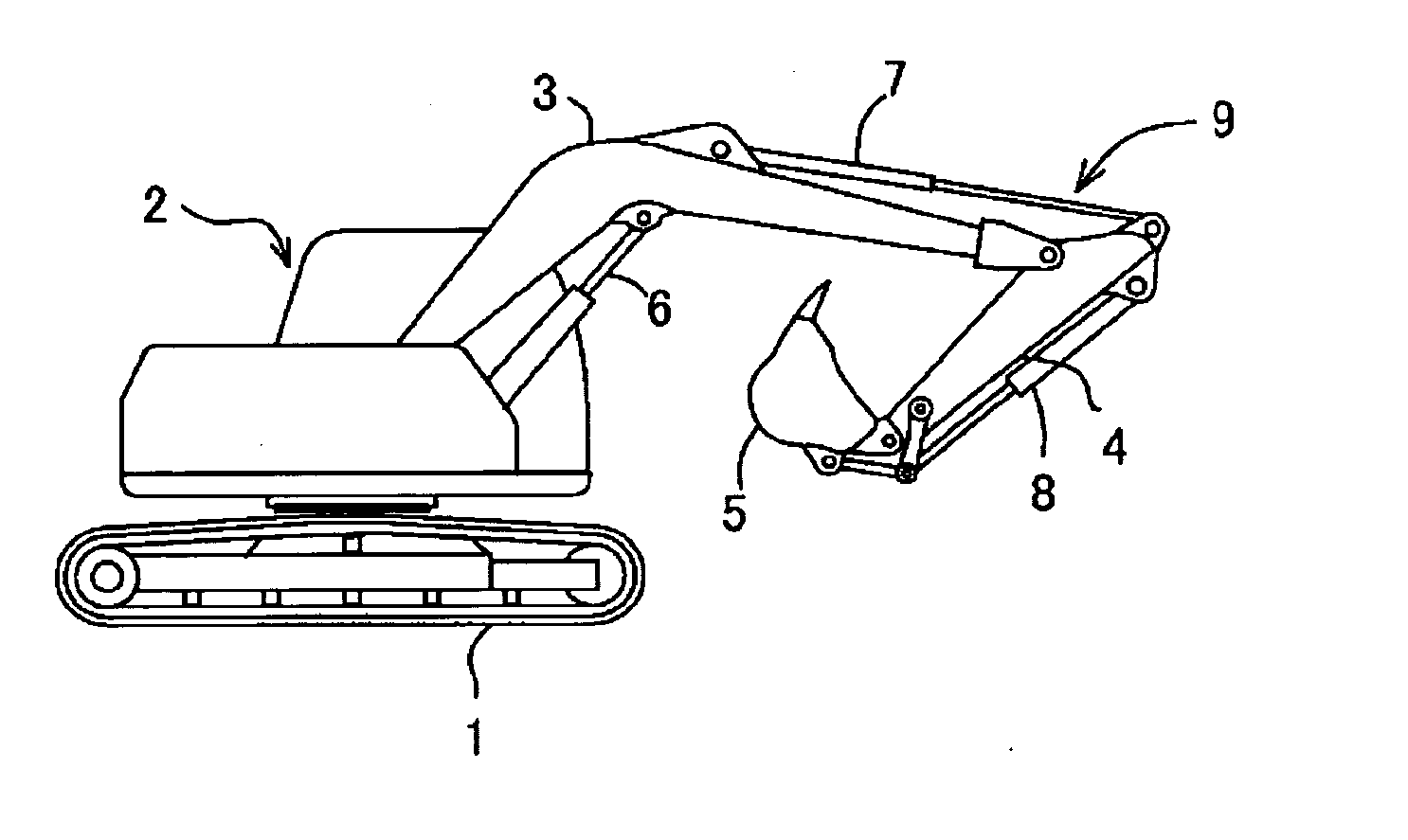

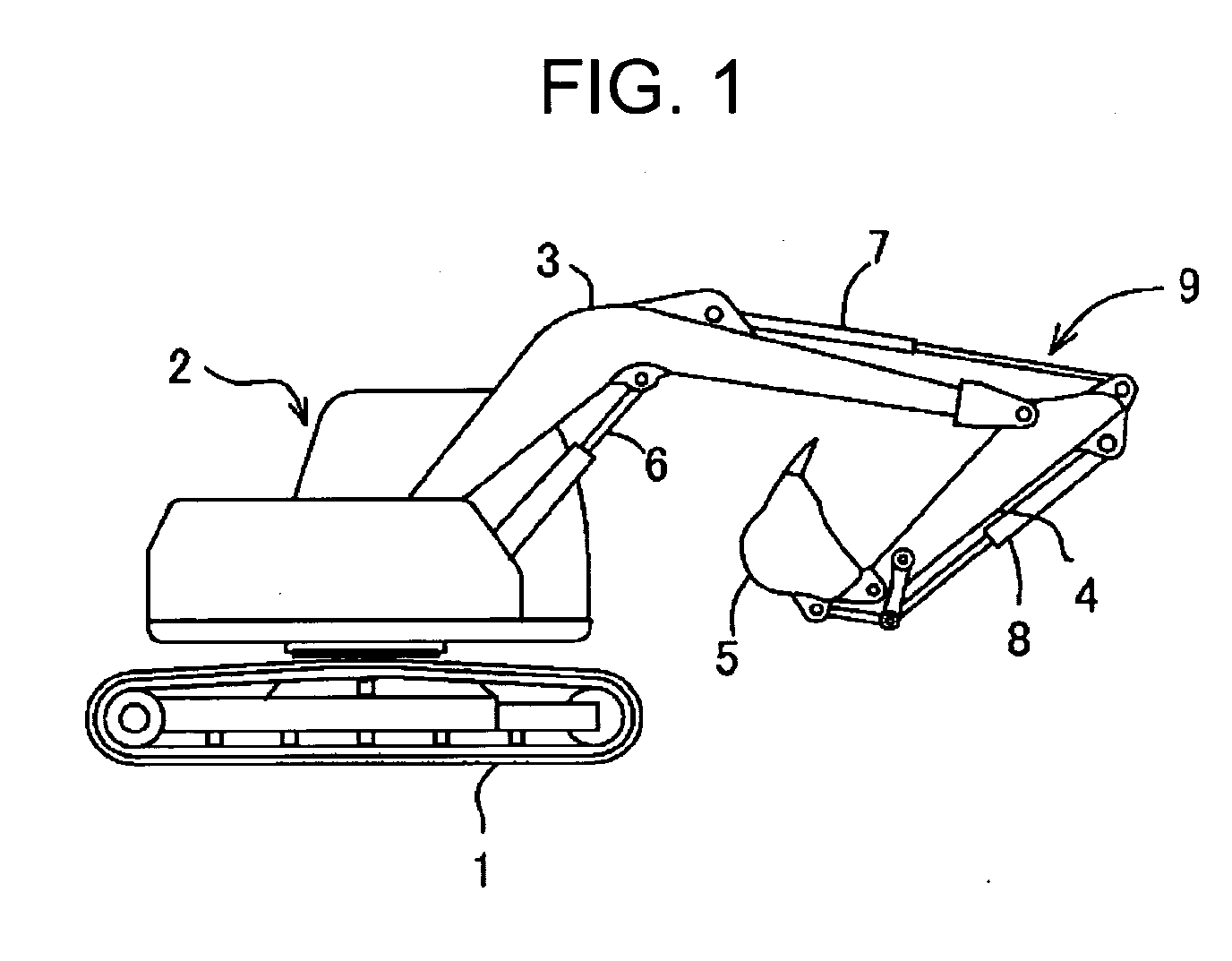

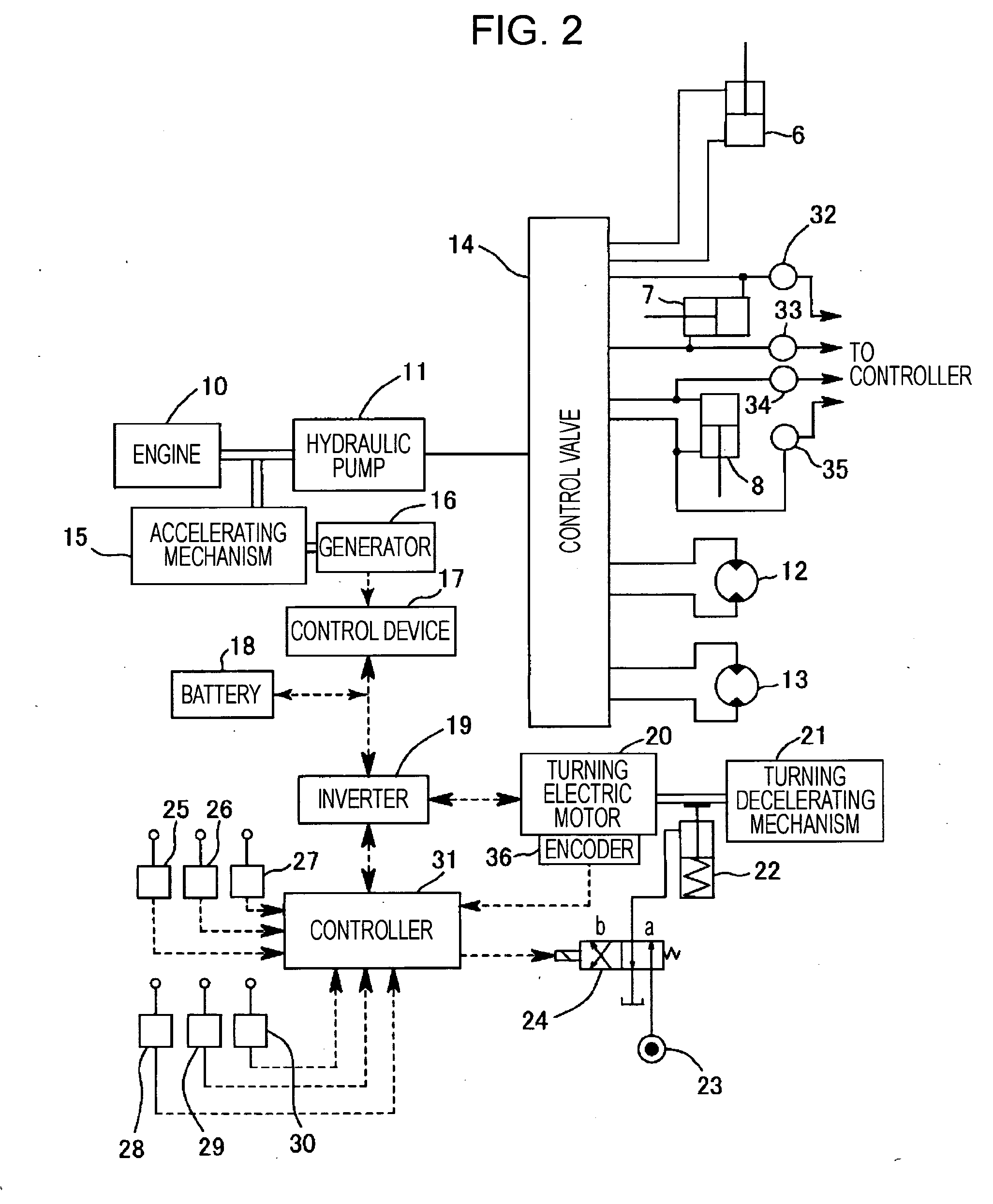

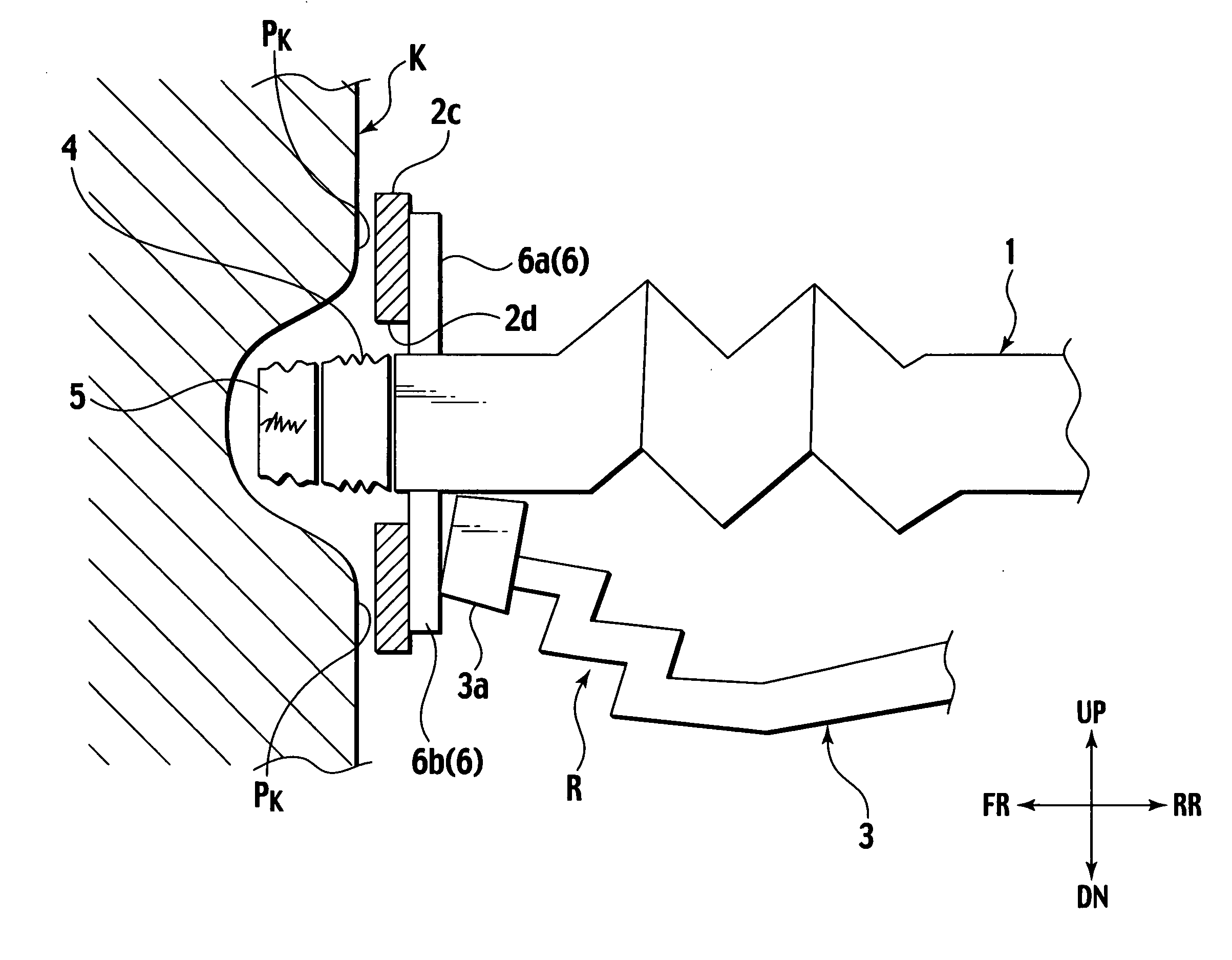

Rotation-type working machine

ActiveUS20070186451A1Work lessReduce reaction forceElectric motor controlServomotorsEngineeringFeedback control

A parking brake is released by a controller and a rotating electric motor is speed-feedback-controlled or position-feedback-controlled to stop and hold an upper rotating body if at least one of arm operation, bucket operation, and travel operation is carried out in a rotating stopped state and with respect to the arm operation and the bucket operation, cylinder thrust of an arm cylinder or a bucket cylinder is greater or equal to a set value. Thereby, a parking brake and a rotating driving part can be prevented from being damaged by rotating external force generated by excavation reaction force or the like and a rotating body can be stopped and held.

Owner:KOBELCO CONSTR MASCH CO LTD

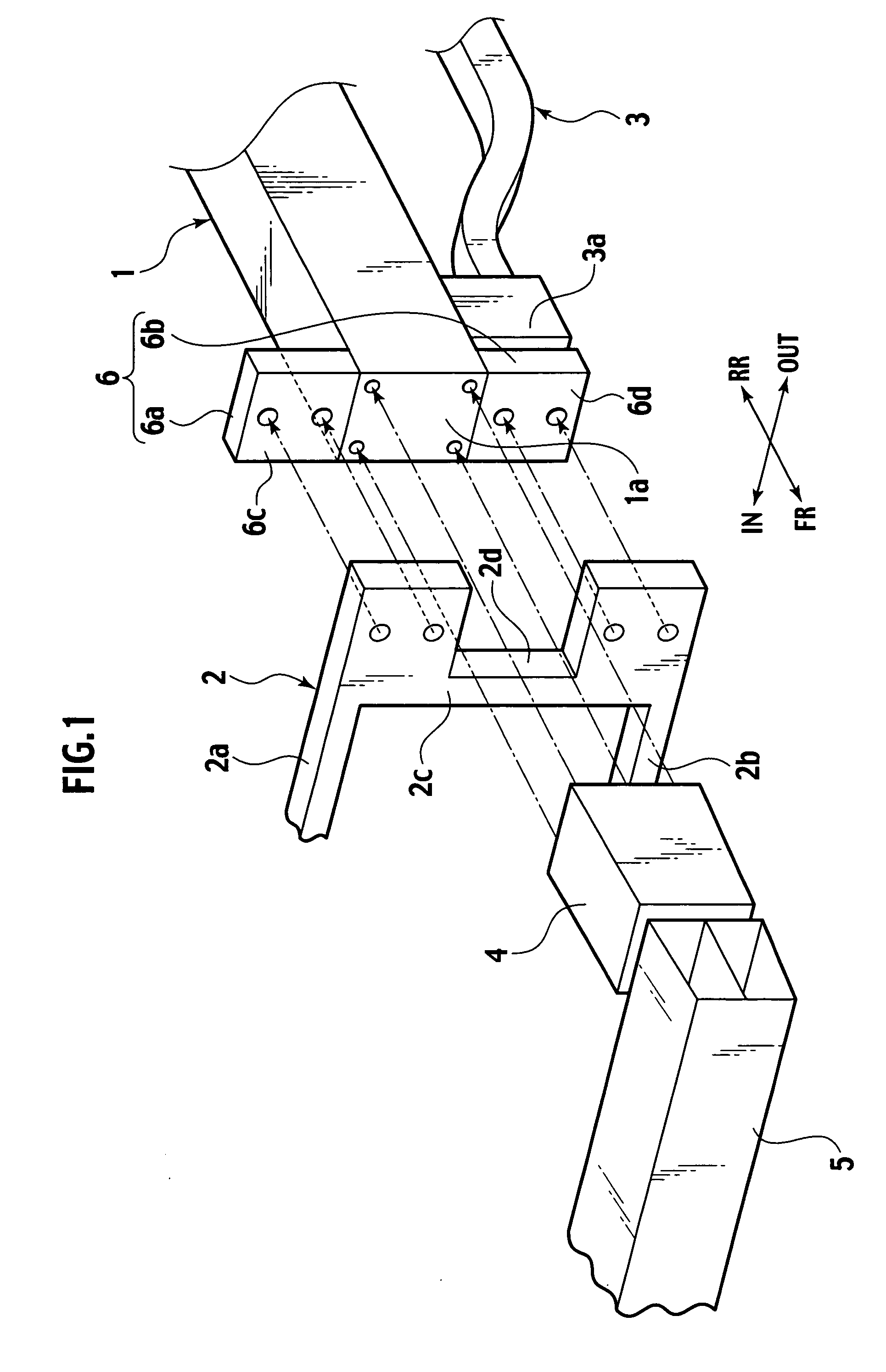

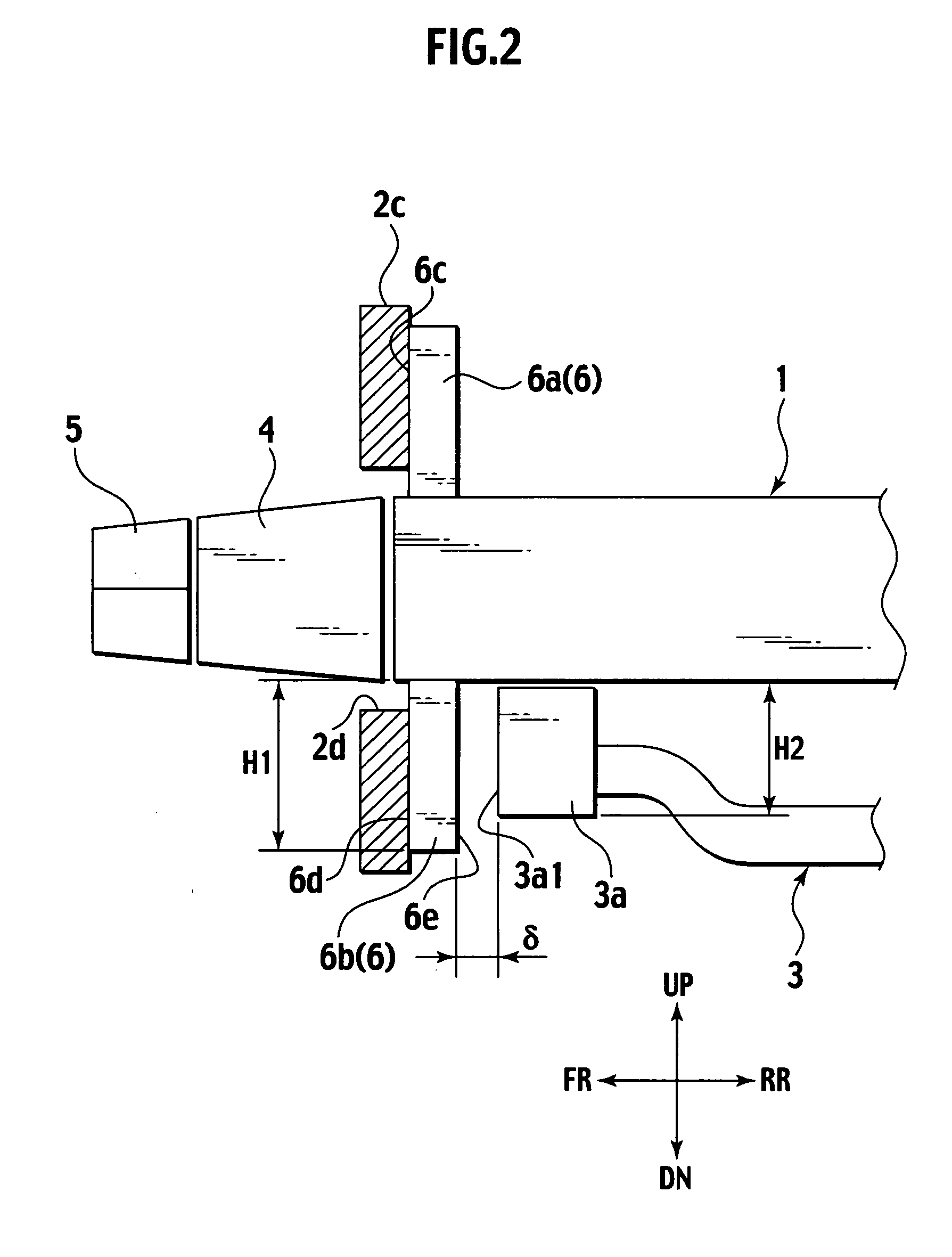

Vehicle front body structure

ActiveUS20050218645A1Prevent displacementPrevent forward movementSteering linkagesUnderstructuresStructural elementEngineering

Owner:NISSAN MOTOR CO LTD

Structure for fastening shipboard-protecting fender

Owner:TSAI CHENG FUNG

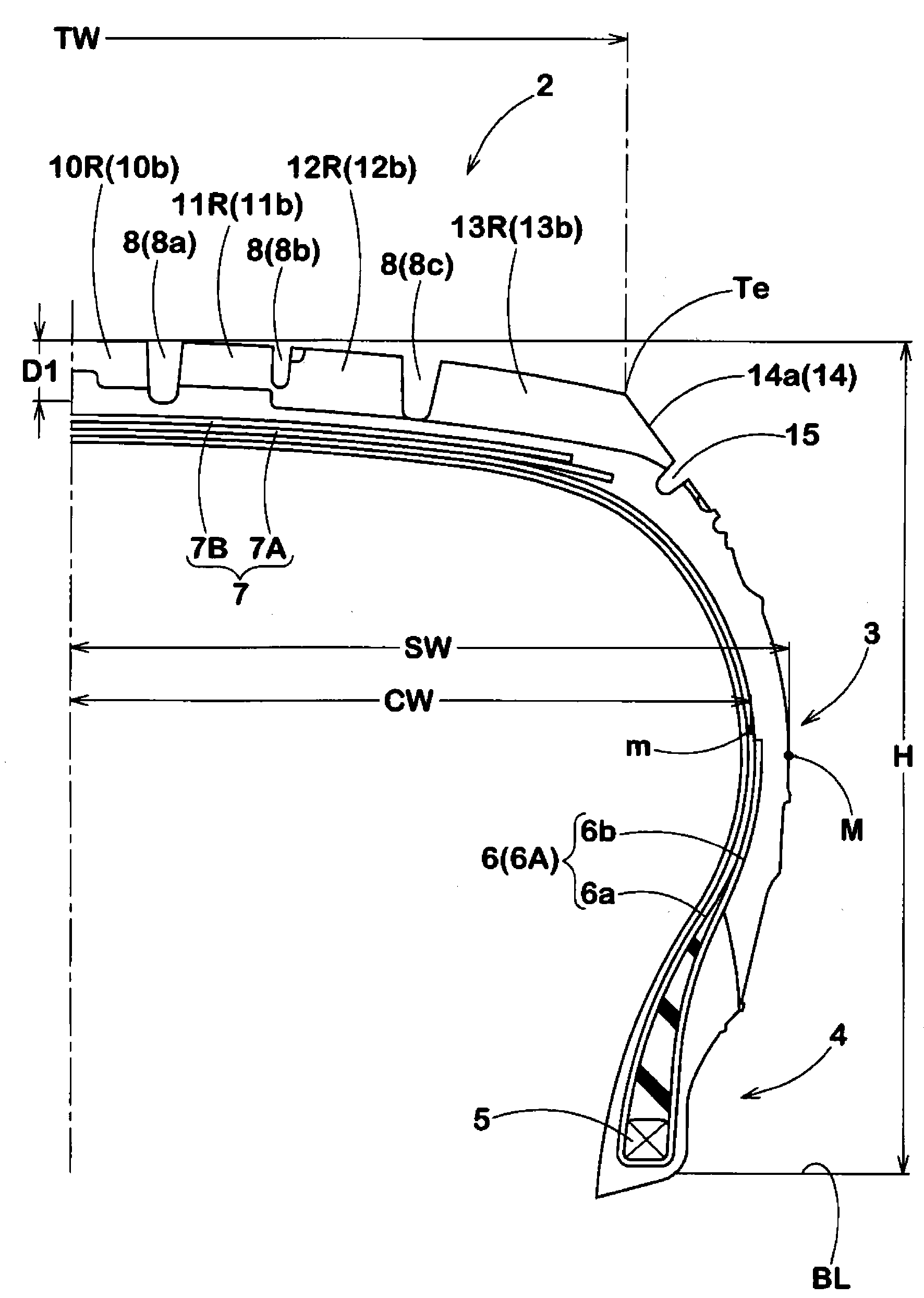

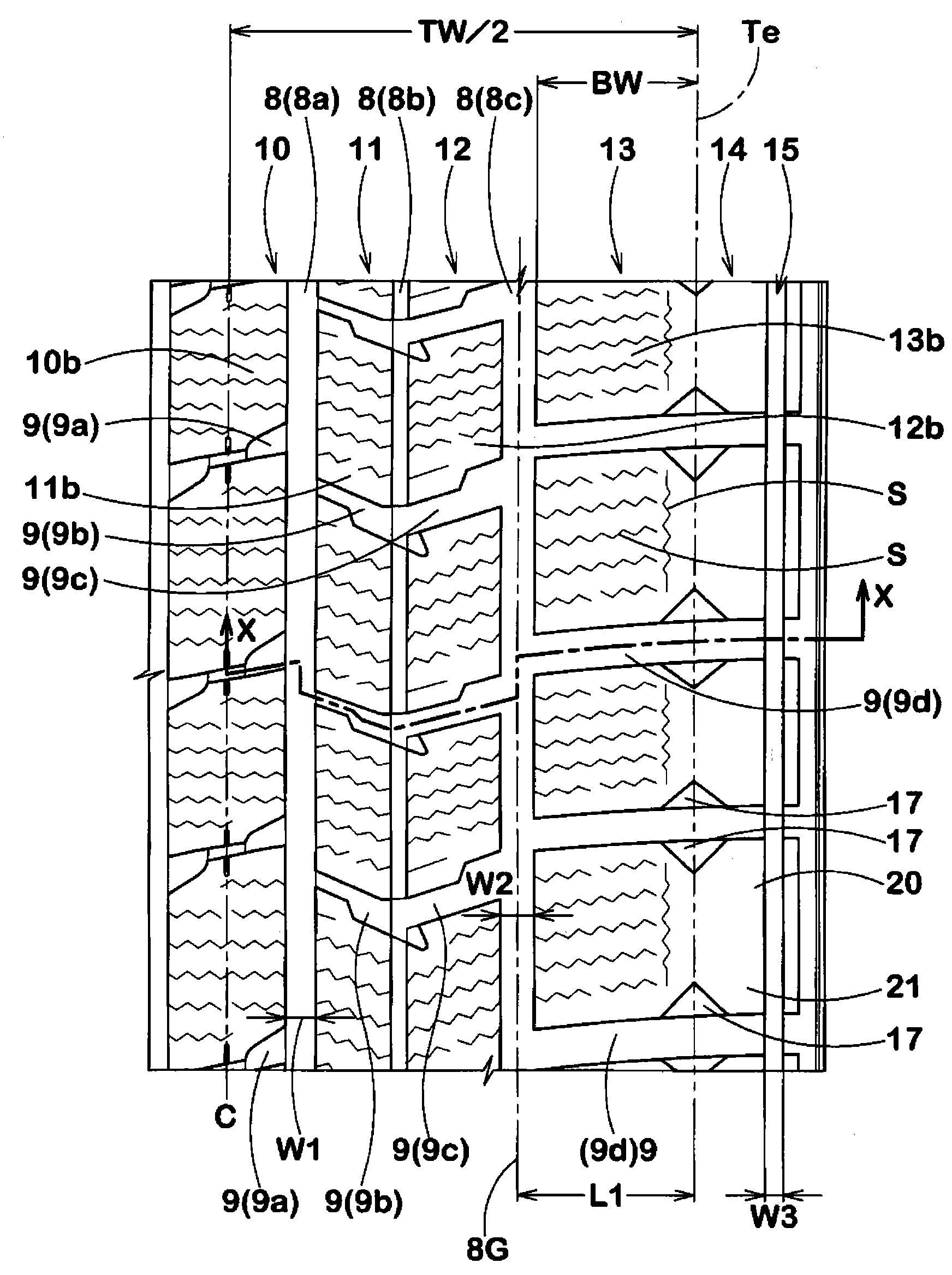

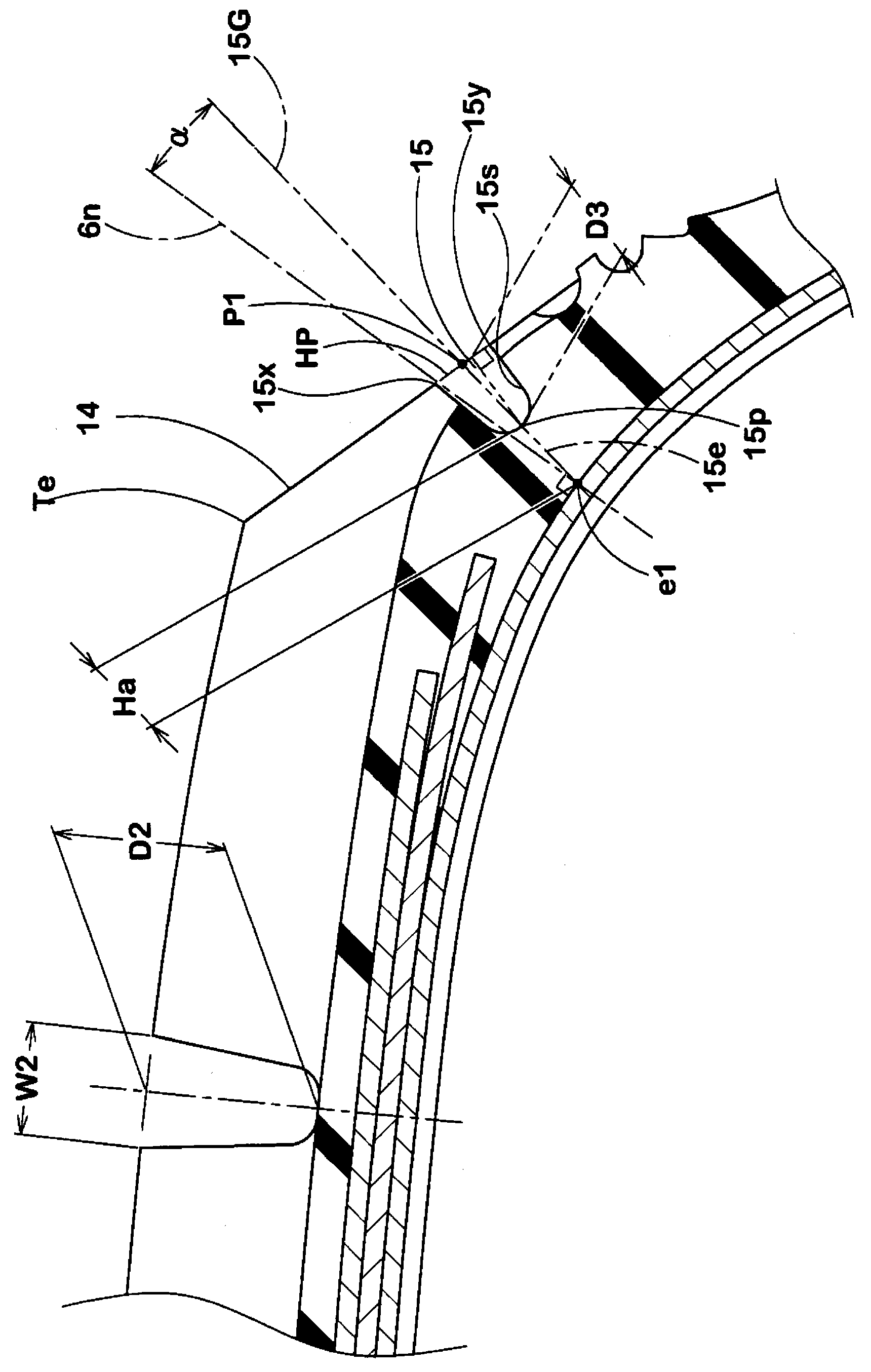

Pneumatic tire

InactiveCN102049973AReduce rigidityImprove performancePneumatic tyre reinforcementsTyre tread bands/patternsInternal pressureEngineering

The invention provides a pneumatic tire, which symmetrically improves the on-ice performance and the driving performance of a vehicle. When the pneumatic tire is assembled to a regular rim and filled with a regular inner pressure of a normal state without load, the ratio (TW / SW) of the tread width (TW) between the tread ends (Te) to the maximum width (SW) of a tire is 0.75 to 0.95. The tire surface (14) is equipped with a continuously extending thin groove (15) along the circumferential direction of the tire. The center line (15G) of the groove (15) and the normal (6n) of the carcass are at an angle (alpha) of small than 10 degrees, wherein the normal (6n) of the carcass passes through the extension line (15e) of the center line (15G) and the point of intersection thereof with the carcass (6) is (e1). A pair of shoulder main grooves (8c) continuously extending along the circumferential direction of the tire are arranged on the outer side of the tread end (Te) of the tread portion (2). The depth (D3) of the thin groove (15) is 20% to 50 % of the depth (D2) of the shoulder main grooves (8c).

Owner:SUMITOMO RUBBER IND LTD

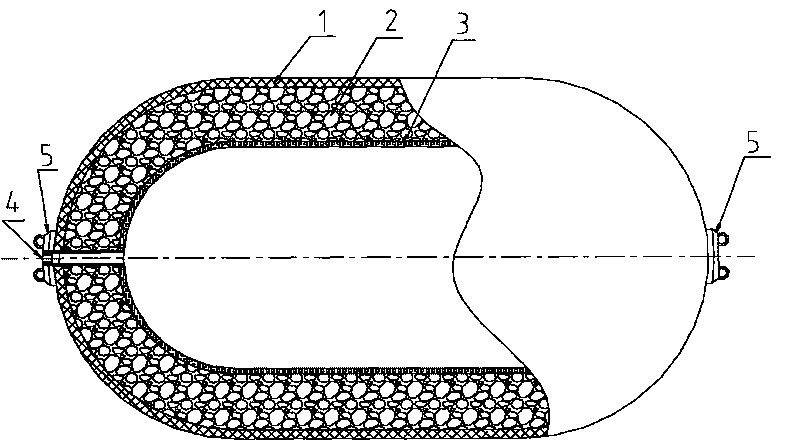

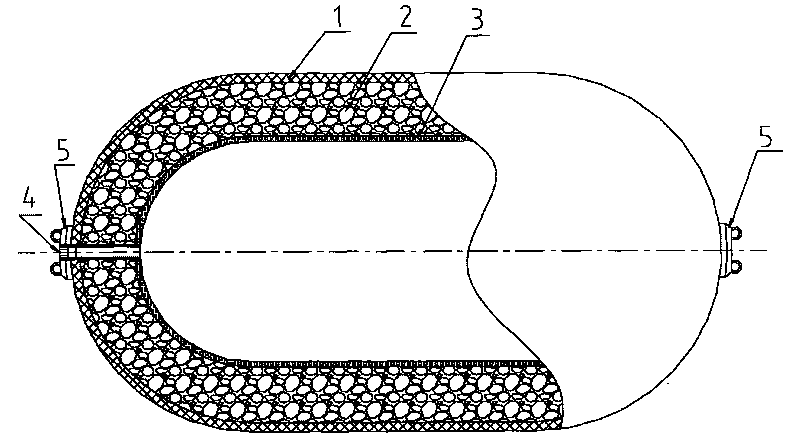

Combined type fender

InactiveCN101698424AAnti-agingExtended service lifeVessel cleaningClimate change adaptationEnergy absorptionEngineering

The invention relates to a combined type fender, which is a protective device to be used in docks, shipping and oceanographic engineering. The combined type fender is characterized by consisting of a shell, a buffering protective layer and a liner. The combined type fender integrates the advantages of various fenders, has the characteristics of toughness, extrusion resistance, fatigue resistance, ageing resistance and long service life of a fender taking rubber as a buffering medium, and avoids the disadvantages that the weight is large, the fender cannot float on a water surface, energy absorption is less and counter-force is large; the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force and pricking resistance which are possessed by a fender taking a foaming material as the buffering medium, and avoids the disadvantages of slow response speed and short service life; and in addition, the combined type fender also has the advantages of light weight, convenient installation, large energy absorption, small counter-force, quick response speed, capability to backpressure adjustment on the energy absorption and the counter-force and the like which are possessed by an air inflation type fender taking gas as the buffering medium, and avoids the defects that the combined type fender is easy for pricking, aging and air leakage, and needs to be maintained frequently.

Owner:钟爱民

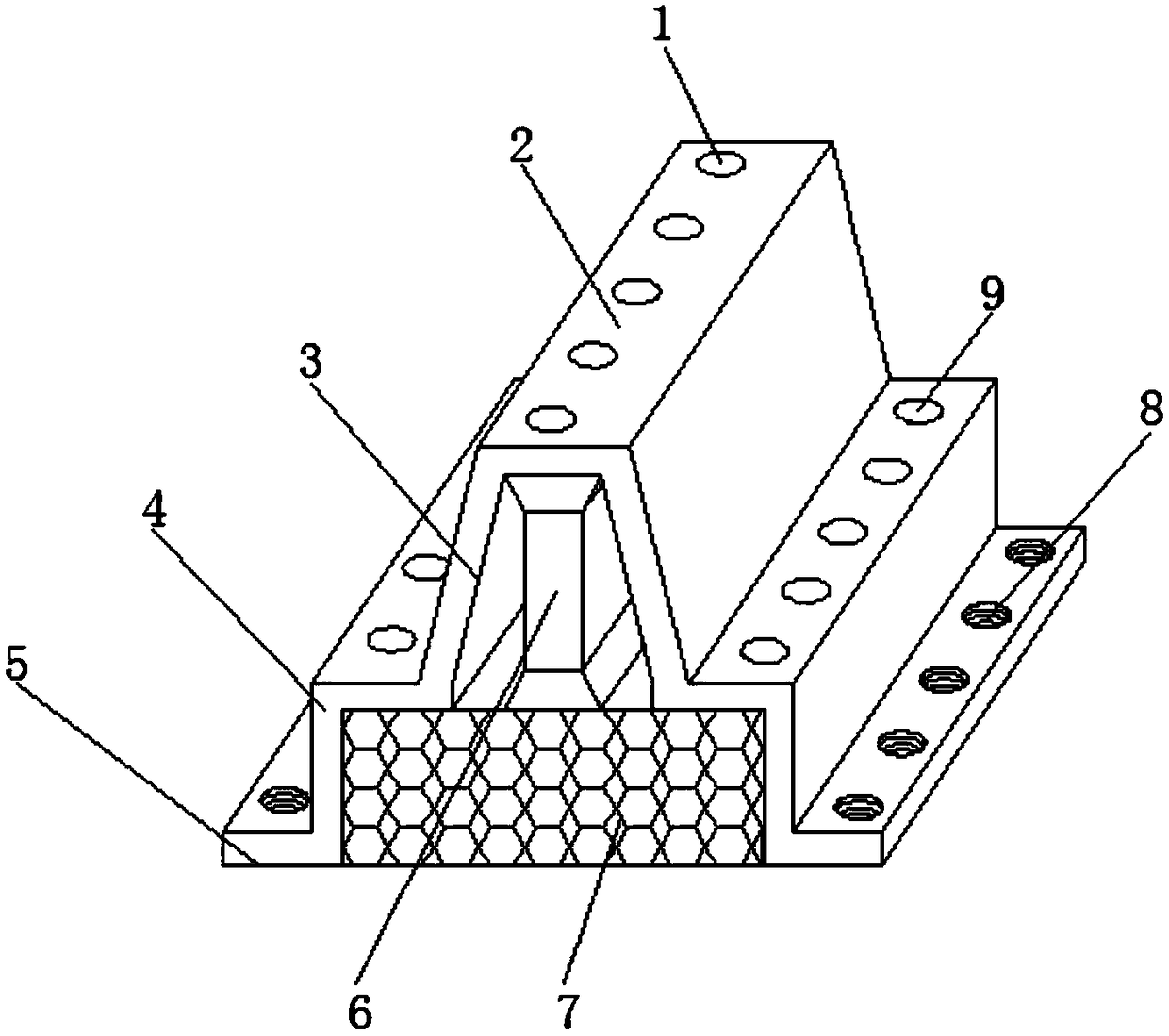

Transverse cushioning, energy absorption, anti-seismic and anti-drop beam structure with conical butting balls and check blocks

PendingCN107988893AAvoid local damageSmall reaction forceBridge structural detailsCushioningEnergy absorption

The invention discloses a transverse cushioning, energy absorption, anti-seismic and anti-drop beam structure with conical butting balls and check blocks. The transverse cushioning, energy absorption,anti-seismic and anti-drop beam structure comprises check block bodies, the conical rubber butting balls, steel frame anti-collision plates and veneers. The trapezoidal check block bodies are arranged at two ends of the upper portion of a pier top cover beam; seismic reduction and isolation supports are arranged on the top surface of the pier top cover beam, and a beam is supported on the seismicreduction and isolation supports; the hollow conical rubber butting balls are anchored on the inner sides of the trapezoidal check block bodies at the two ends of the upper portion of the pier top cover beam and are anchored with the steel frame anti-collision plates, the ultrahigh-molecular-weight polyethylene veneers are arranged on the surfaces of the steel frame anti-collision plates, the steel frame anti-collision frames are constrained on the trapezoidal check block bodies by iron chains, and a certain distance is reserved between each of the conical rubber butting balls and the steel frame anti-collision plates and the beam. The transverse cushioning, energy absorption, anti-seismic and anti-drop beam structure has the advantages of simple structure, high practicality and compatibility, good coordinability, low cost, convenience in construction and the like. Besides, the beam can be effectively prevented from being locally destroyed, effects of anti-drop beams can be realized,the conical rubber butting balls are high in energy absorption and low in reaction force and are not in direct contact with the beam, and accordingly bodies are free of abrasion and long in service life.

Owner:NANCHANG UNIV

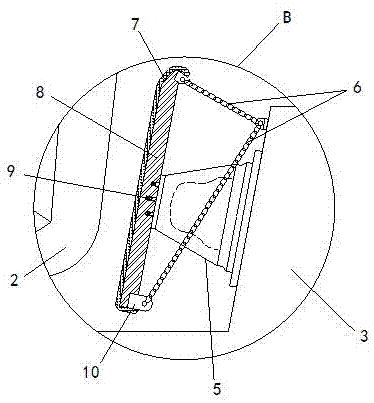

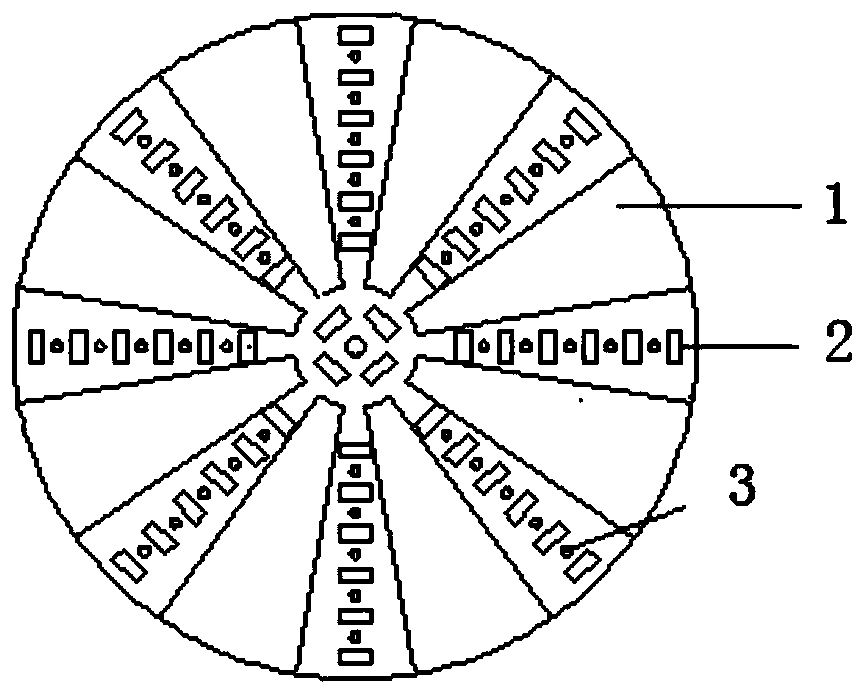

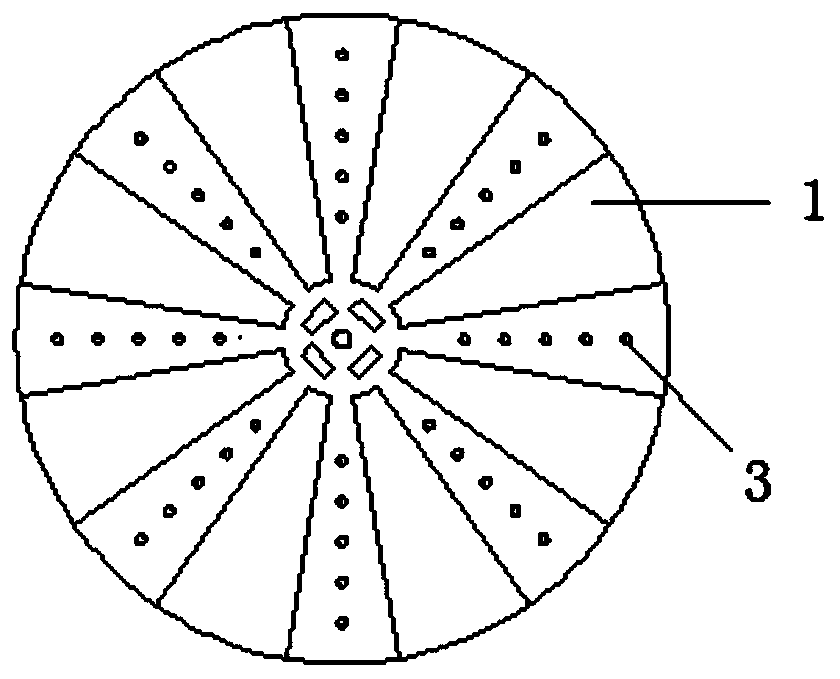

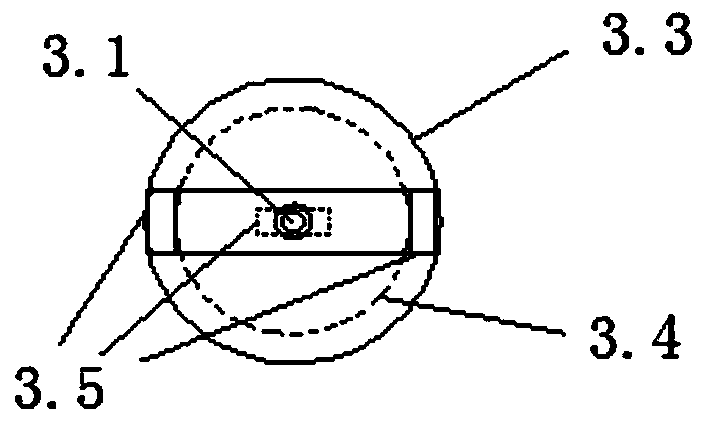

Hydraulic power-mechanical TBM cutter head combined rock breaking method, hydraulic power-mechanical combined rock breaking TBM cutter head and hydraulic power-mechanical combined rock breaking TBM device

PendingCN110219660AGood rock breaking effectFor the purpose of joint rock breakingTunnelsRock breakingPetrology

The invention discloses a hydraulic power-mechanical TBM cutter head combined rock breaking method. The hydraulic power-mechanical TBM cutter head combined rock breaking method comprises the steps that a combined rock breaking TBM cutter head is installed, and the combined rock breaking TBM cutter head is aligned to the position of a to-be-excavated grotto; a TBM outer machine frame is fixed, anda combined rock breaking TBM is started and is enabled to tunnel forwards for a stroke; and the referred steps are repeated, the next stroke operation is started until tunneling is carried out to a specified distance, and excavation of the grotto is completed. The hydraulic power-mechanical TBM cutter head combined rock breaking method has the advantages of suitable penetration degree and high rock breaking efficiency. The invention further discloses the hydraulic power-mechanical combined rock breaking TBM cutter head adopted by the hydraulic power-mechanical TBM cutter head combined rock breaking method. The invention further discloses a hydraulic power-mechanical combined rock breaking TBM device adopted by the hydraulic power-mechanical TBM cutter head combined rock breaking method.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

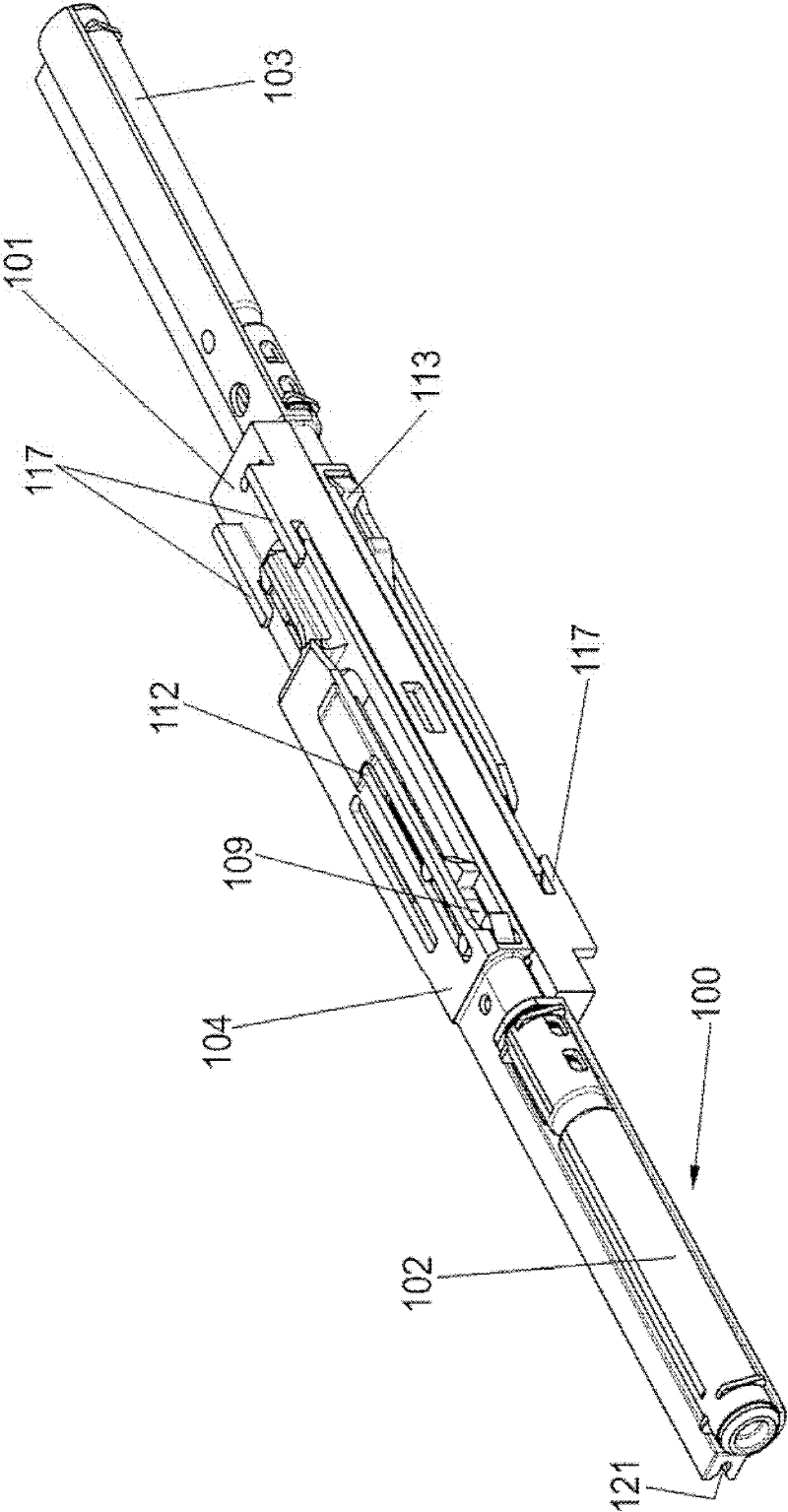

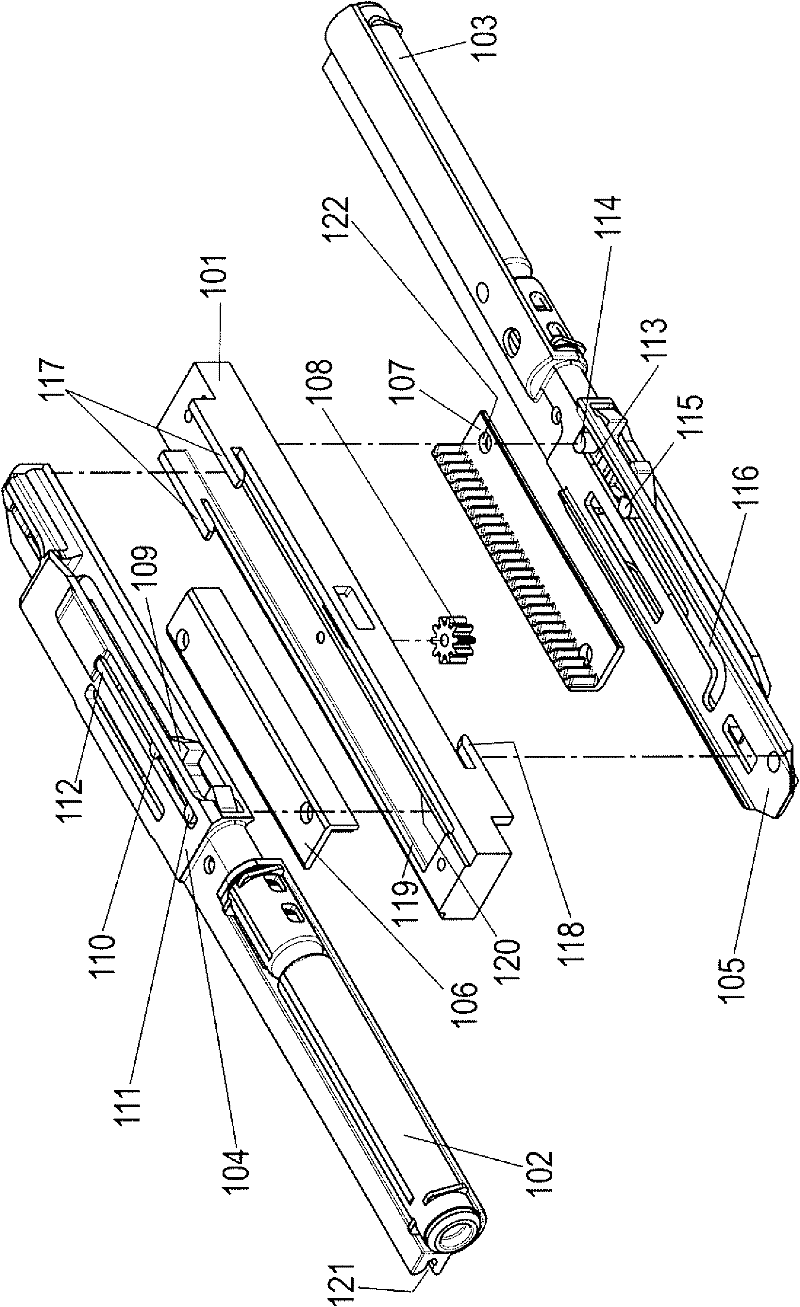

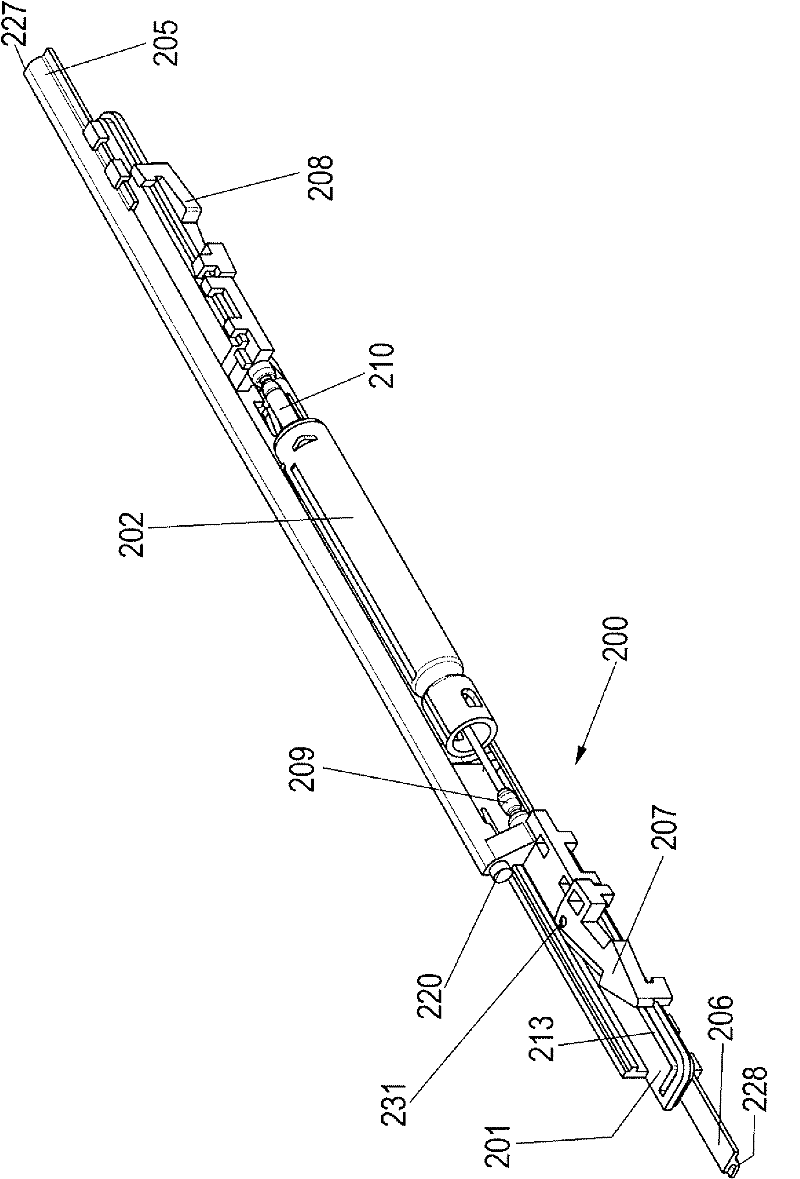

Automatic retraction apparatus and pull-out guide

Automatic retraction apparatus (100, 200, 300, 400) for a pull-out rail-guided moving furniture part, having - a base body (101, 201, 301, 401), - an energy store which is arranged on the base body (101, 201, 301, 401) and is subjected to tension when the moving furniture part is opened, and the stored energy of which energy store can be used during the closing process as a retraction aid for retraction into the final closed position, - a tensioning mechanism for pretensioning the energy store, which tensioning mechanism is coupled to the moving furniture part up to a predetermined opening position and is automatically decoupled after said specific opening position is exceeded and blocks the tensioned energy store in this position, wherein the tensioning mechanism has two drivers (109, 113, 207, 208, 305, 306, 405, 406); which are coupled to the energy store and synchronously block or activate the tensioning mechanism, and which can be guided separately by respective pull-out rails. The invention also describes a pull-out guide (1) for drawers, pull-out furniture components or the like.

Owner:PAUL HETTICH

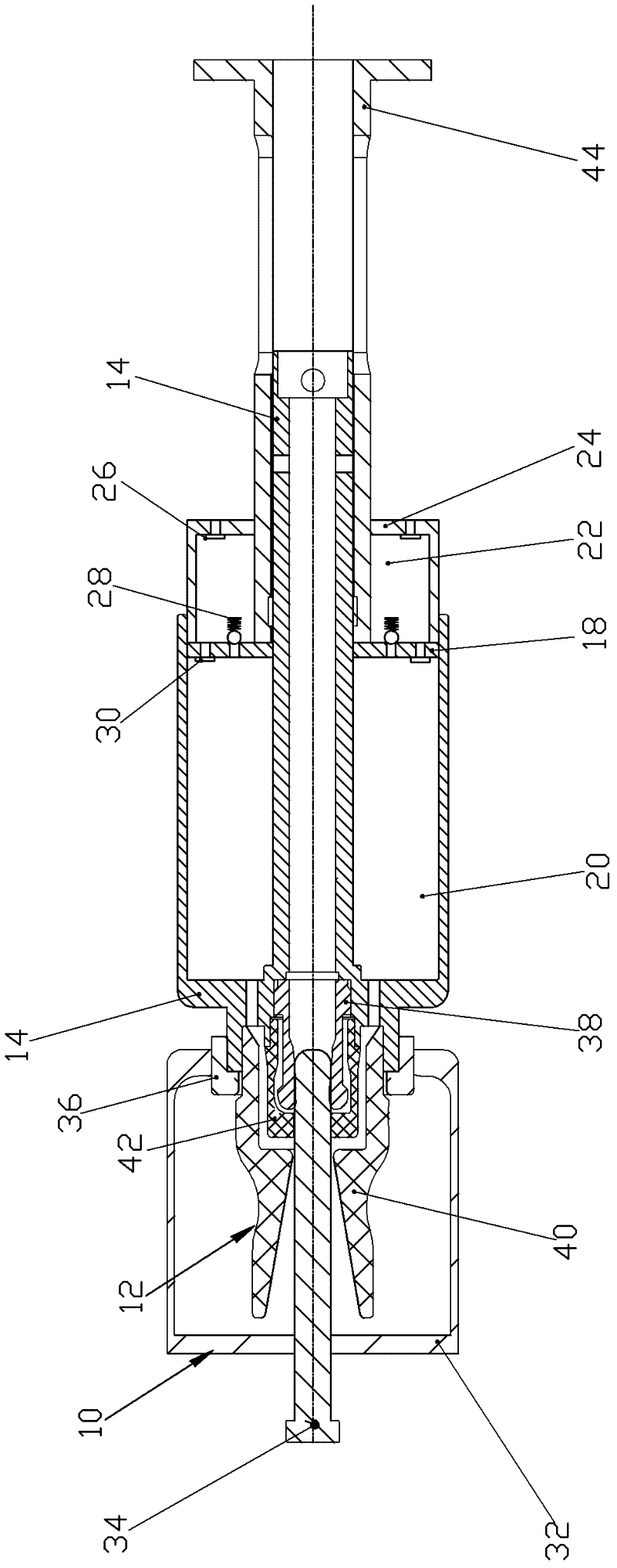

Arc extinguishing chamber of circuit breaker

ActiveCN102306590AImproved breaking capacity and product reliabilityAir chamber reaction force decreasesHigh-tension/heavy-dress switchesAir-break switchesPistonProcess engineering

The invention discloses an arc extinguishing chamber of a circuit breaker, which comprises a static contact module (10), a dynamic contact module (12), a gas pressing cylinder (14), a piston (18), a gas storing chamber (22) and a valve unit, wherein a gas pressing chamber (20) is formed between the piston (18) and the gas pressing cylinder (14); the movable contact module (12) and the gas pressing cylinder (14) are connected together; the valve unit is arranged between the gas pressing chamber (20) and the gas storing chamber (22); when a pressure difference between the gas pressing chamber and the gas storing chamber is higher than a preset value, gas in the gas pressing chamber is charged into the gas storing chamber; and when the pressure of the gas storing chamber is higher than the pressure of the gas pressing chamber, gas in the gas storing chamber is poured back into the gas pressing chamber for realizing the process of firstly storing and then supplementing the gas in the gas pressing chamber by the gas storing chamber, so as to generate the following technical effects of: preventing the gas pressing chamber from generating over-high air pressure when the circuit breaker is opened, reducing the operating work of an operating mechanism, extending effective gas blowing time for electric arcs, enhancing opening capability of the circuit breaker and product reliability andreducing the cost of the operating mechanism.

Owner:XIAMEN HUADIAN SWITCHGEAR

Hydraulic antivibration device arrangement, hydraulic antivibration device, and car body side bracket

InactiveUS7278633B2Small reaction forceLong distanceMachine framesLiquid springsEngineeringUltimate tensile strength

A hydraulic antivibration device arrangement capable of achieving a downsizing and weight reduction, and a reduction of booming noise by suppressing a reaction force to impingement upon stopper action is provided. By disposing a protuberant rubber portion 35 at an upper end of a main body member 2, its spacing distance from a roll center can be lengthened, the reaction force to impingement can be diminished, and input load to the main body member 2 can be diminished. Consequently, reduction of rigidity and strength required for respective components as well as enhancement of durability is possible, which permits to make the components thin-walled thereby making a hydraulic antivibration device arrangement 100 lightweight as a whole. Diminishing of such reaction force upon stopper action also enables vibrations input through a car body side bracket 120 to the body frame to be suppressed, thereby reducing the generation of booming noise.

Owner:TOYO TIRE & RUBBER CO LTD

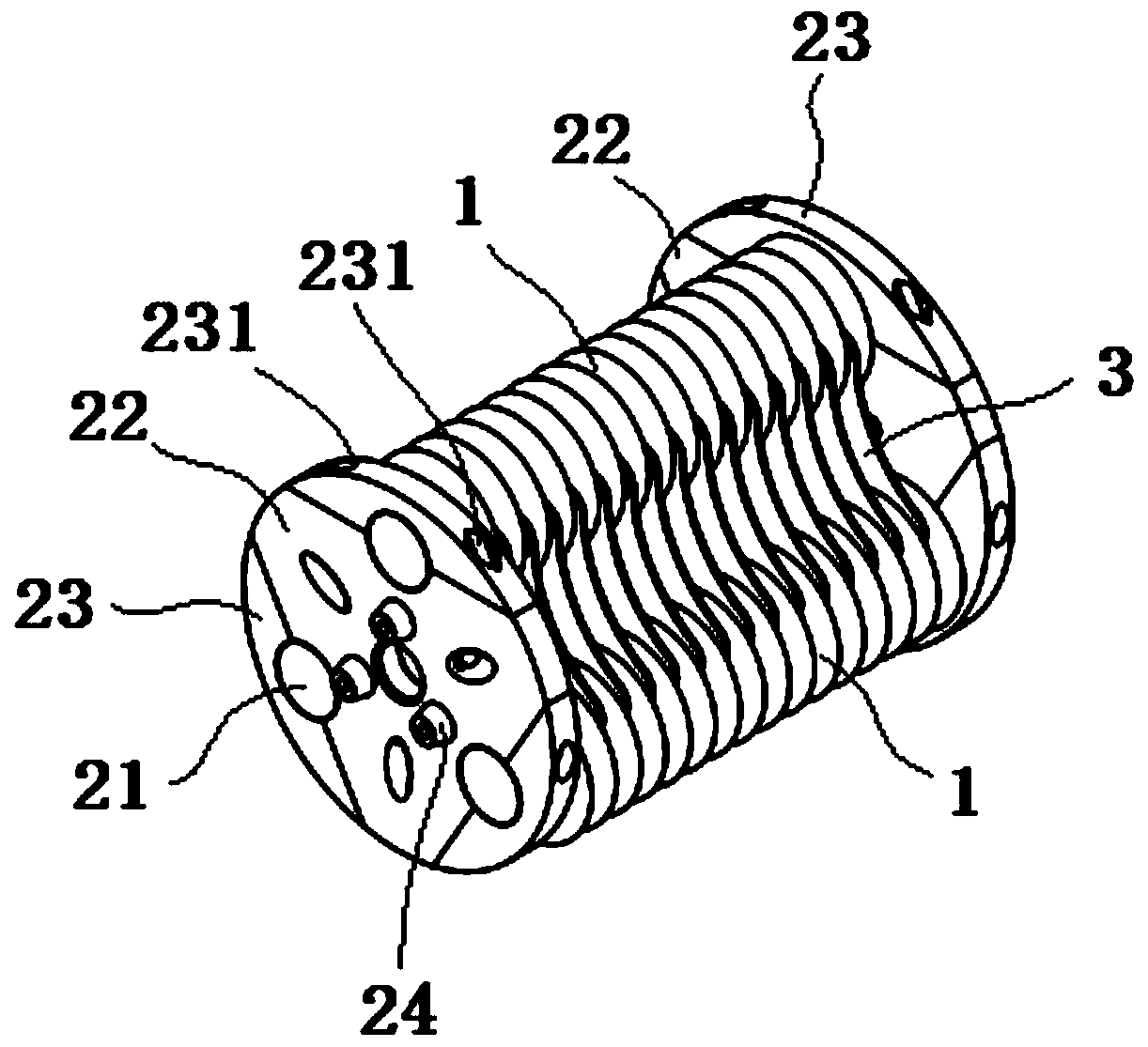

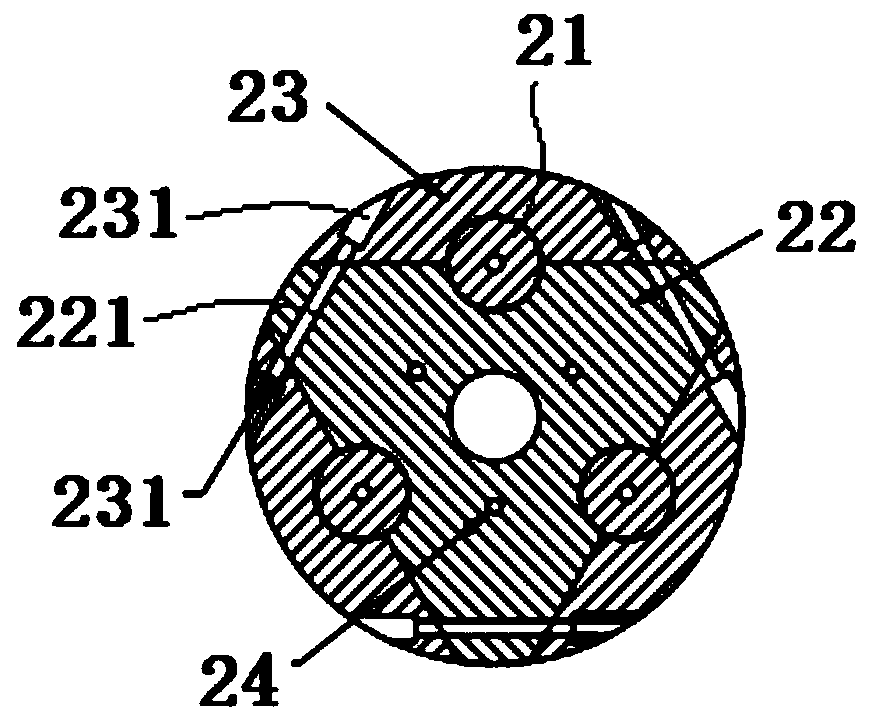

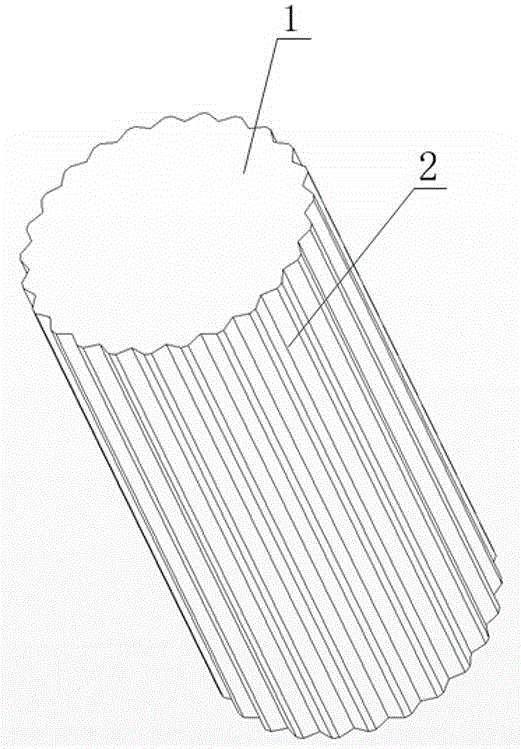

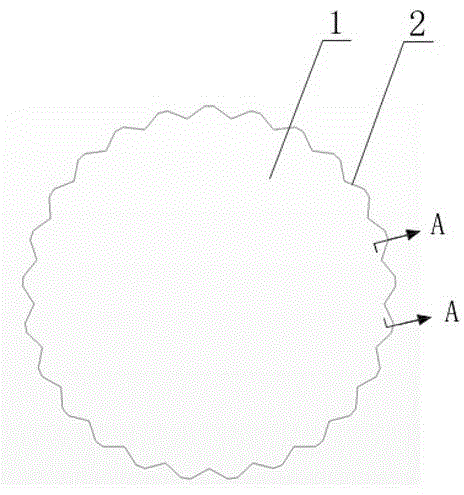

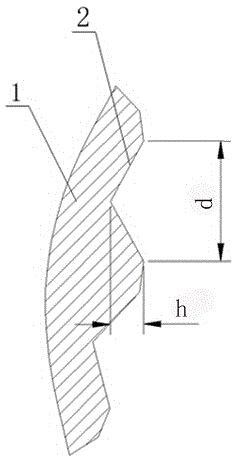

Buoyancy block surface structure for reducing ocean current resistance borne by waterproof pipe column

InactiveCN104453730AReduced pressure resistance of ocean currentsLess current resistanceDrilling rodsFluid dynamicsWater pipeEngineering

The invention discloses a buoyancy block surface structure for reducing ocean current resistance borne by a waterproof pipe column. The buoyancy block surface structure comprises a buoyancy block (1) of the waterproof pipe column. The external diameter D of the buoyancy block (1) ranges from 0.9144 m to 1.397 m. Multiple triangular grooves (2) are formed in the column face of the buoyancy block (1) in the length direction of the buoyancy block and evenly distributed in the circumferential direction of the buoyancy block (1). The depth h of each triangular groove (2) is (0.01 to 0.03) D, the width d of each triangular groove (2) is (0.05 to 0.1) D, and the number n of the triangular grooves (2) ranges from 15 to 30. The buoyancy block surface structure has the advantages that the ocean current resistance borne by the waterproof pipe column is reduced, so that connection bearing reaction of the end of the waterproof pipe column is reduced, vortex-induced vibration of the waterproof pipe column is lowered, the service life of the waterproof pipe column is prolonged, and an element does not need to be additionally arranged on the waterproof pipe column.

Owner:SOUTHWEST PETROLEUM UNIV

Anti-collision device for stem of park yacht based on non-Newtonian fluid

InactiveCN108609130AViscous instantaneous enhancement phenomenonPersonal Safety ProtectionCollision preventionFixed frameEngineering

The invention relates to the technical field of ship fittings, in particular to an anti-collision device for a stem of a park yacht based on non-Newtonian fluid. The anti-collision device solves the problem that an existing anti-collision device for a stem of a yacht is not high in protection. The anti-collision device comprises a fixing frame, wherein the fixing frame is in an arc shape, a positioning pin is fixedly connected to the middle portion of the inner side of the fixing frame, an anti-skid pad is fixedly connected to the inner side of the fixing frame, a protective bag is fixedly connected to the outer side of the fixing frame, and the inner portion of the protective bag is filled with the non-Newtonian fluid. According to the anti-collision device, when the stem of the yacht isimpacted, the non-Newtonian liquid shows the characteristics of being as strong as steel under the instant impact, the anti-collision performance of the anti-collision device is maintained, a certaindegree of protection is brought to the personal safety of the yacht, and the damage to the stem caused by the impact is reduced.

Owner:马鞍山海明船舶配件有限公司

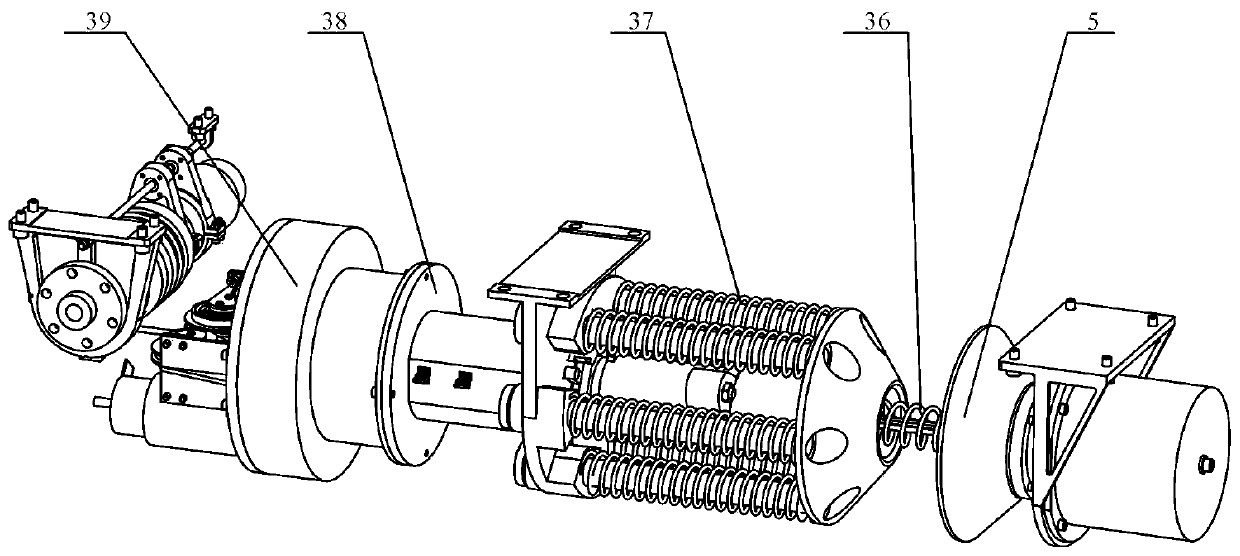

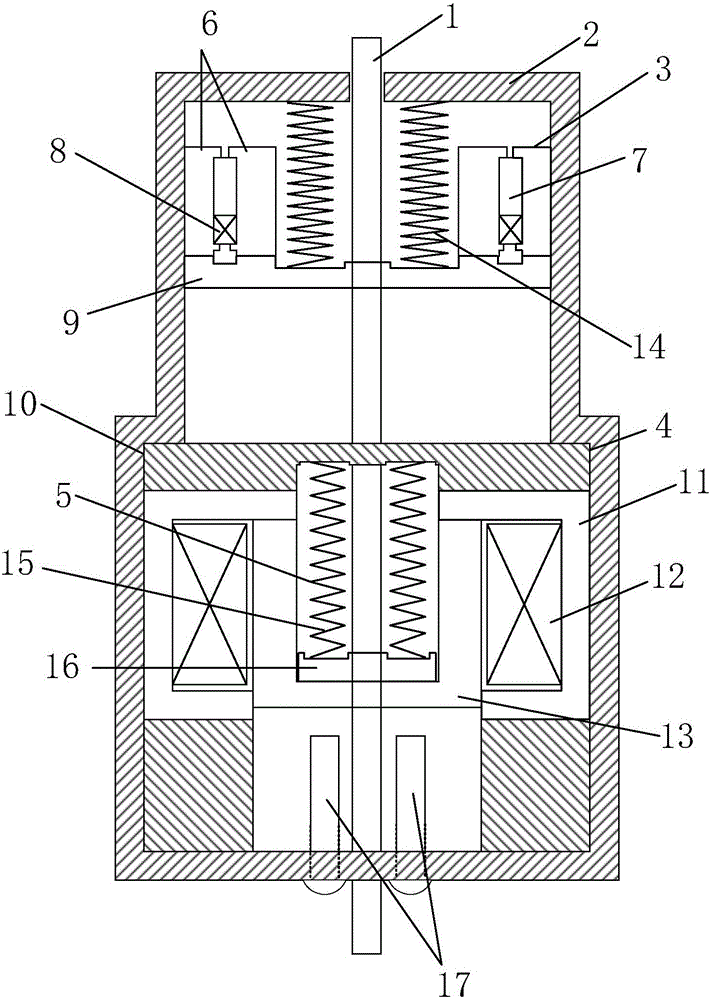

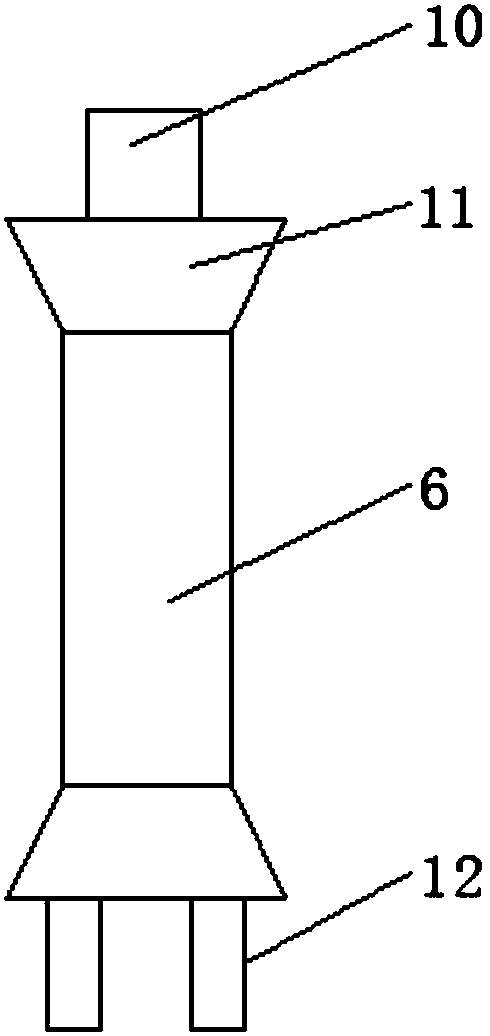

Monostable permanent magnet mechanism provided with combined breaking springs and used for high-voltage circuit breaker

ActiveCN105869946AReduce energy consumptionSmall reaction forceHigh-tension/heavy-dress switchesAir-break switchesBreak springEngineering

The invention discloses a monostable permanent magnet mechanism provided with combined breaking springs and used for a high-voltage circuit breaker. The mechanism comprises a non-magnetic casing (2), a permanent magnet retaining mechanism (3), an electromagnetic driving mechanism (4), a combined breaking spring system (5), a non-magnetic material cushion block (10) and a guide bar (1), wherein the permanent magnet retaining mechanism (3), the electromagnetic driving mechanism (4), the combined breaking spring system (5) and the non-magnetic material cushion block (10) are arranged in the non-magnetic casing (2); the guide bar (1) penetrates the non-magnetic casing (2) and is in sliding connection with the non-magnetic casing (2); the permanent magnet retaining mechanism (3) and the electromagnetic driving mechanism (4) are isolated by the non-magnetic material cushion block (10); the combined breaking spring system (5) is arranged in the permanent magnet retaining mechanism (3) and the electromagnetic driving mechanism (4) along the guide bar (1). By means of the breaking spring system combined by a whole-course breaking spring and an interval breaking spring, the counter force on the closing front half section is reduced, and accordingly, the closing current peak value is decreased, the closing time is shortened, and energy consumed by closing is reduced.

Owner:WUJIANG TRANSFORMER CO LTD

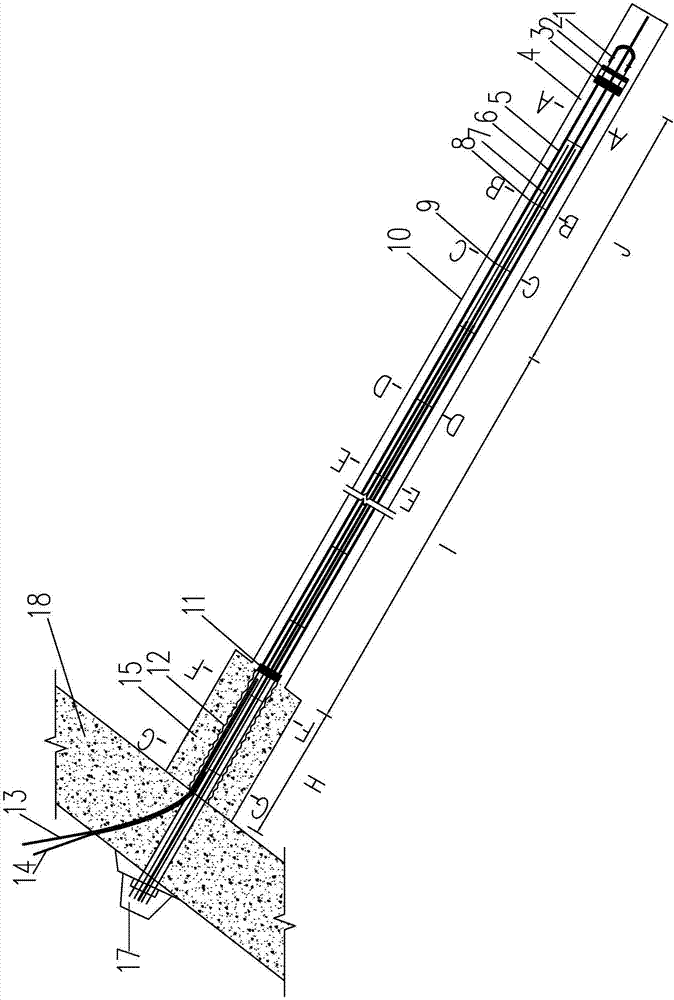

Tension and compression complementary type anchor cable structure adopting external anchoring and locking and construction method thereof

PendingCN106917411ASmall reaction forceReduced risk of prestress lossExcavationsBulkheads/pilesEngineeringPre stress

The invention discloses a tension and compression complementary type anchor cable structure adopting external anchoring and locking and a construction method thereof. The anchor cable structure comprises an anchor cable hole and an anchoring system, wherein the anchoring system comprises an anchor cable body, an outer anchor head and an inner anchor head; the anchor cable body comprises tensile type steel strands, pressure type steel strands, casing pipes, a corrugated pipe, an expansion ring, a shroud ring, a primary grouting pipe, a secondary grouting pipe and an exhaust pipe; the tensile type steel strands and the pressure type steel strands which are positioned at the middle of the anchor cable bundle are sleeved with the casing pipes and a free section is formed by grouting the anchor cable hole through the primary grouting pipe; the upper part of the anchor cable bundle is sleeved with the corrugated pipe, and secondary grouting is performed on the corrugated pipe after the anchor cables are tensioned; the hole wall between the corrugated pipe and the anchor cable hole is filled with gravels and grouted through the primary grouting pipe to form a cement-aggregate cementation body, namely the external anchoring section; the pressure type steel strands at the lower part of the anchor cable bundle are sleeved with the corresponding casing pipes while the tensile type steel strands at the lower part of the anchor cable bundle are not sleeved with the casing pipes and an internal anchoring section is formed by grouting the anchor cable hole through the primary grouting pipe. According to the tension and compression complementary type anchor cable structure adopting external anchoring and locking and the construction method thereof, the internal anchoring section and the external anchoring section have a combined action, so that the framed girder counter force is reduced; besides, the outer anchor head and the external anchoring section have a combined action, the risks that the outer anchor head is out of work or the stressing loss occurs are reduced.

Owner:廖萍

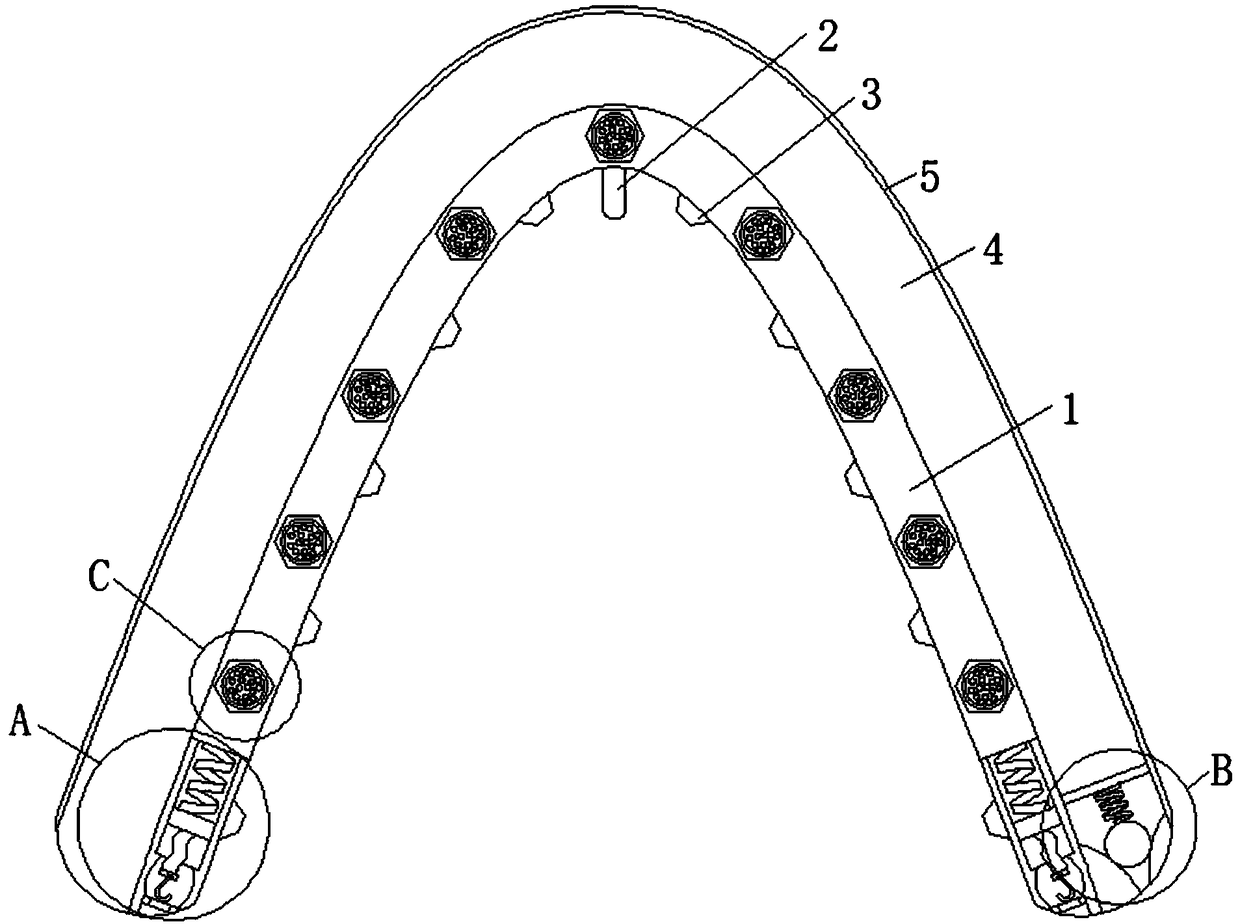

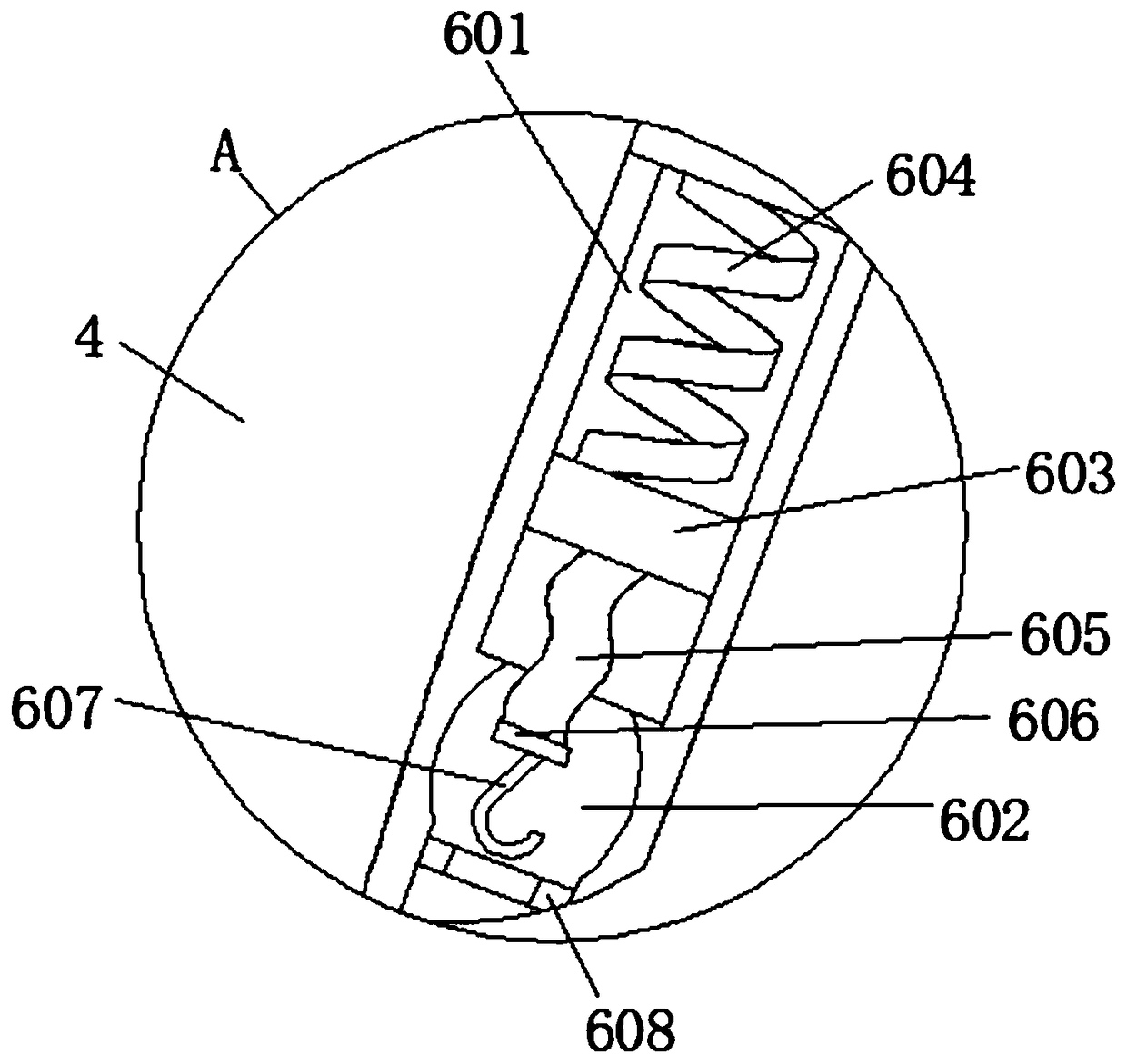

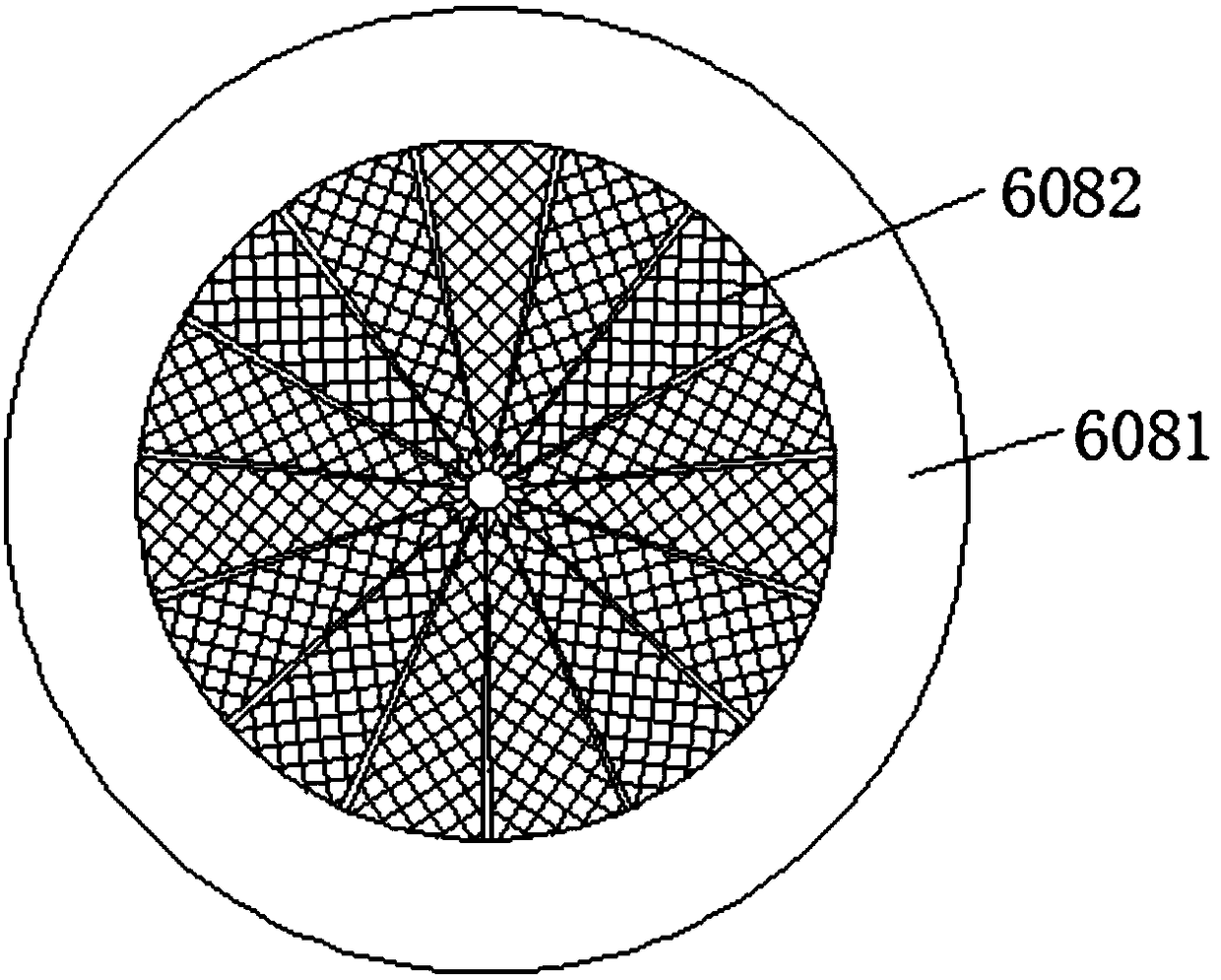

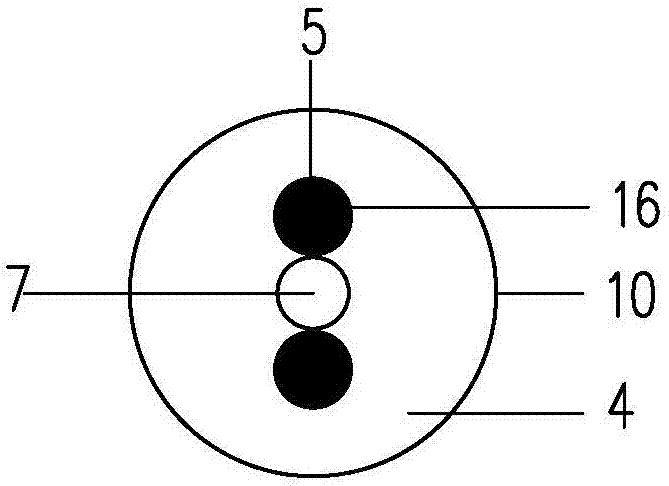

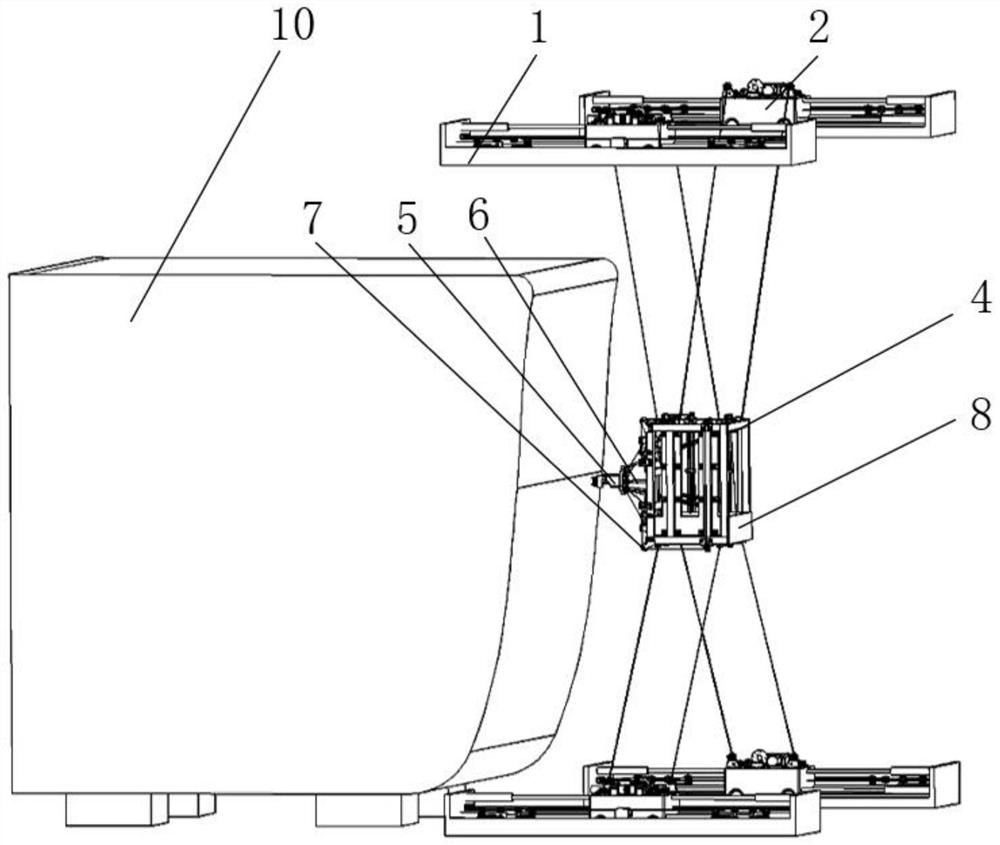

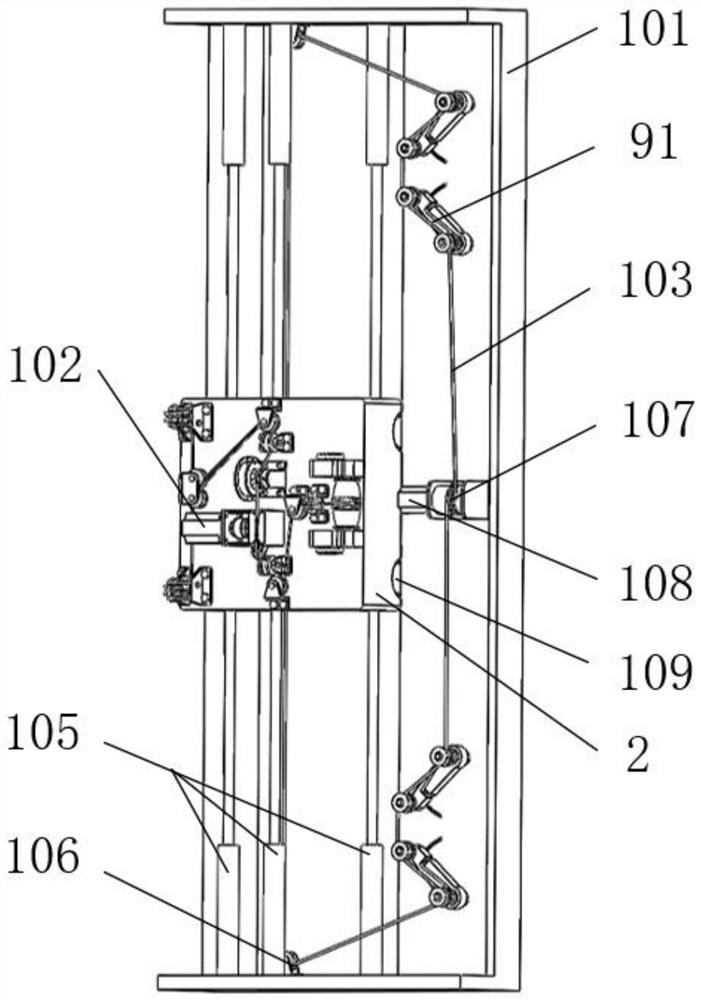

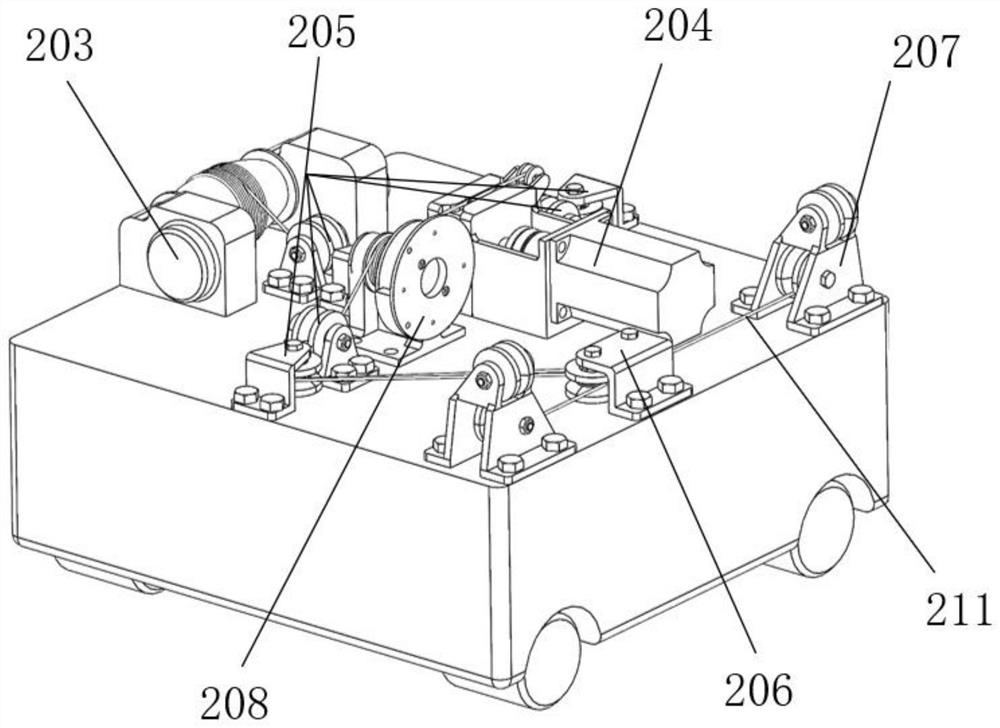

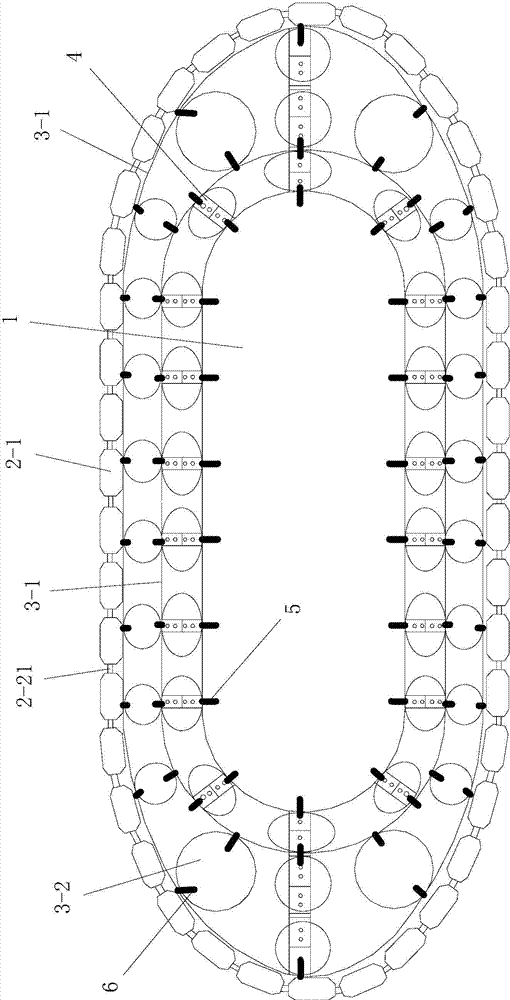

Cable-strut hybrid drive spraying robot with variable working interval

ActiveCN113058778AImprove positioning overall rigidityHigh positioning accuracySpraying apparatusManipulatorHybrid driveWorkspace

The invention discloses a cable-strut hybrid drive spraying robot with a variable working interval, and relates to the technical field of spraying robots. The cable-strut hybrid drive spraying robot comprises a hanging basket frame, an end effector angle control mechanism, a traction and working interval control mechanism, a tail end execution structure, a damping rope driving mechanism, a platform rope traction mechanism and a rope traction vibration reduction mechanism,and the end effector angle control mechanism, the traction and working interval control mechanism and the tail end execution structure are mounted on the hanging basket frame. The damping rope driving mechanism is used for driving stable translation of the hanging basket frame in the space. The hanging basket frame is dragged to move through the damping rope driving mechanism and the platform rope traction mechanism, and large-range rapid movement of the tail end execution structure is achieved. The end effector angle control mechanism and the traction and working interval control mechanism are used for driving and dragging the tail end execution structure to carry out accurate positioning movement of three-degree-of-freedom translation and two-degree-of-freedom rotation in an effective working interval range, so that the positioning rigidity and precision are high, the spraying quality is high, and the cable-strut hybrid drive spraying robot is particularly suitable for spraying the surfaces of large parts.

Owner:HEFEI UNIV OF TECH

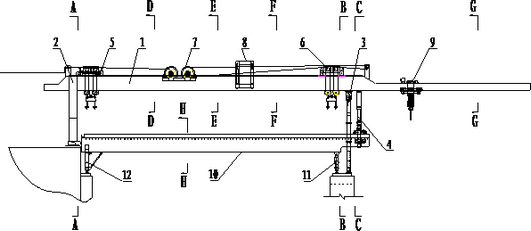

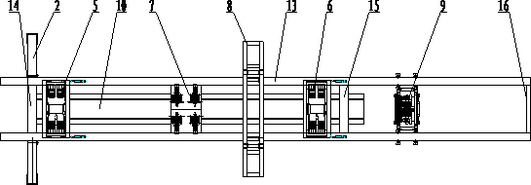

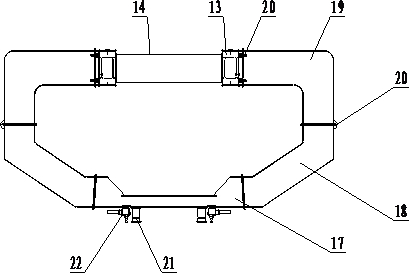

Through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine

InactiveCN102094394ARealize zero-distance erectionLower the altitudeBridge erection/assemblyOverhead craneBuilding construction

The invention relates to a through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine which belongs to the field of railway bridge erection equipment. A folding front support leg and an auxiliary support leg are connected on the bottom surface at the front part of a main girder of the lifting bridge girder erection machine, and the rear end of the main girder is connected with an O-shaped rear support leg; a front lifting girder overhead crane and a rear lifting girder overhead crane are arranged on the main girder, a hoisting component is mounted at the middle part of the main girder, a pilot girder lifting machine and a pilot girder through-hole overhead crane are connected on a track on the upper end surface of the main girder, and the pilot girder through-hole overhead crane is positioned at the front end of the main girder; and a lower pilot girder machine comprises a pilot girder front support leg and a pilot girder rear support leg of the main girder of a lower pilot girder, and the pilot girder front support leg and the pilot girder rear support leg are arranged at the front end part and the rear end part of the main girder of the lower pilot girder. The through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine has the advantages that the packing through-tunnel state of the through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine is the pilot girder front-mounted type state, and the pilot girder machine can be in place when going out of a tunnel, thereby greatly improving the erection efficiency for resetting the whole machine after going out of the tunnel, being good in adaptability to working conditions, saving construction time, saving construction cost, and being smooth, safe and reliable.

Owner:徐州徐工铁路装备有限公司

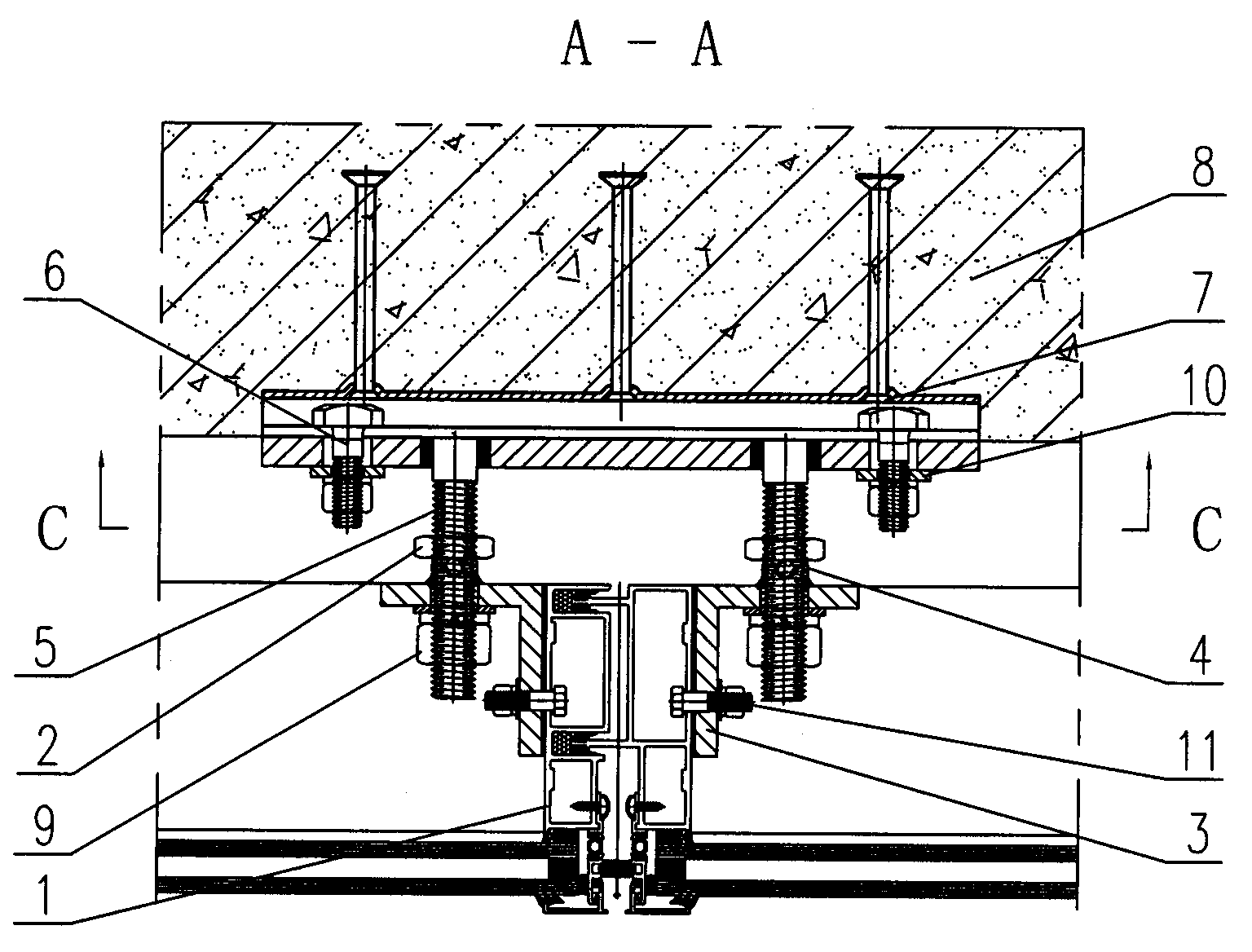

Switch-over regulating device for unitized curtain walls

A switch-over regulating device for unitized curtain walls solves the problems that the conventional hitch device is troublesome to operate and low in mounting efficiency, and a counterforce is generated. The switch-over regulating device comprises C-shaped steel channel embedded parts, T-shaped bolt assemblies, unit switch-over assemblies and unit hitch assemblies, wherein the C-shaped steel channel embedded parts and the T-shaped bolt assemblies are fixed on a main structure; and the unit switch-over assemblies and the unit hitch assemblies are used for connecting unit boards with the main structure. The switch-over regulating device is characterized in that teethed hitch plates of the unit switch-over assemblies are connected with the C-shaped steel channel embedded parts by the T-shaped bolt assemblies and teethed anti-slip spacers in a positioning manner; and one sides of the unit hitch assemblies are fixedly connected with vertical frames of unit boards through connecting bolt assemblies, and the other sides are hitched on fixed bolts of the unit switch-over assemblies, and are connected with the fixed bolts in a positioning manner through front limiting nuts and rear limiting nuts assembled on the fixed bolts as well as limiting fine-adjusting bolts on the unit hitch assemblies. The switch-over regulating device is simple in structure, easy to mount, convenient to regulate, fast and accurate to hitch, and reasonable in stress, does not need secondary switch-over, is safe and reliable to use, improves the mounting efficiency, and reduces the workload.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

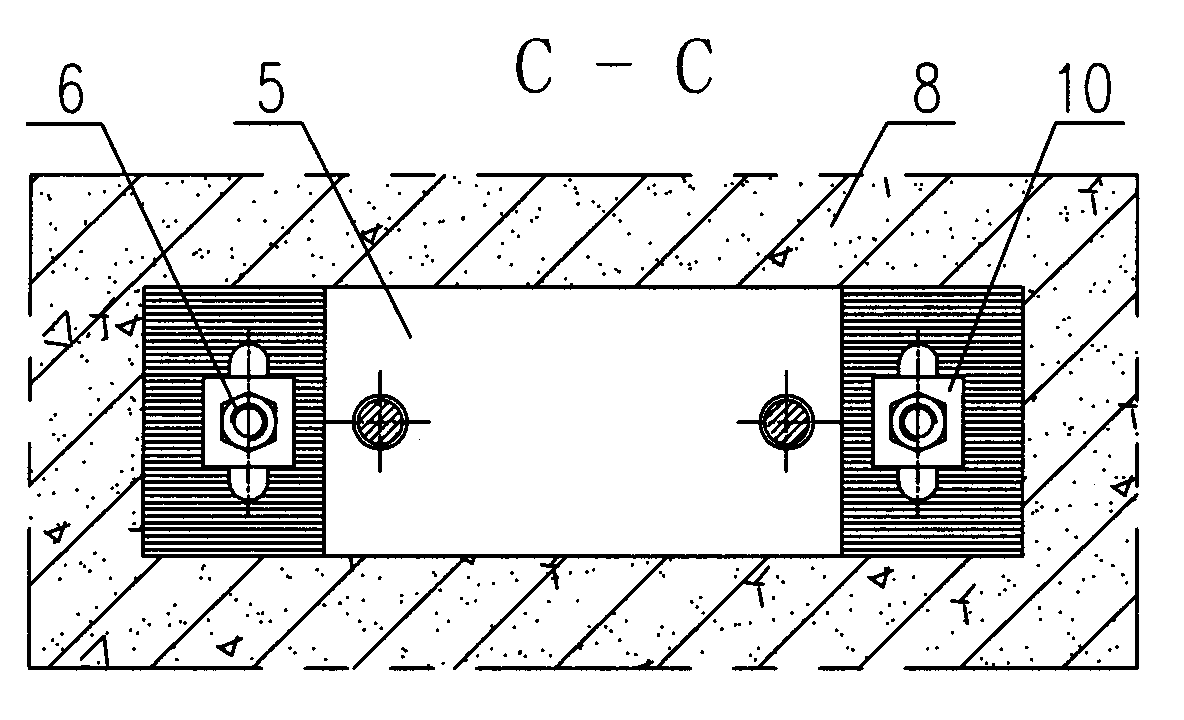

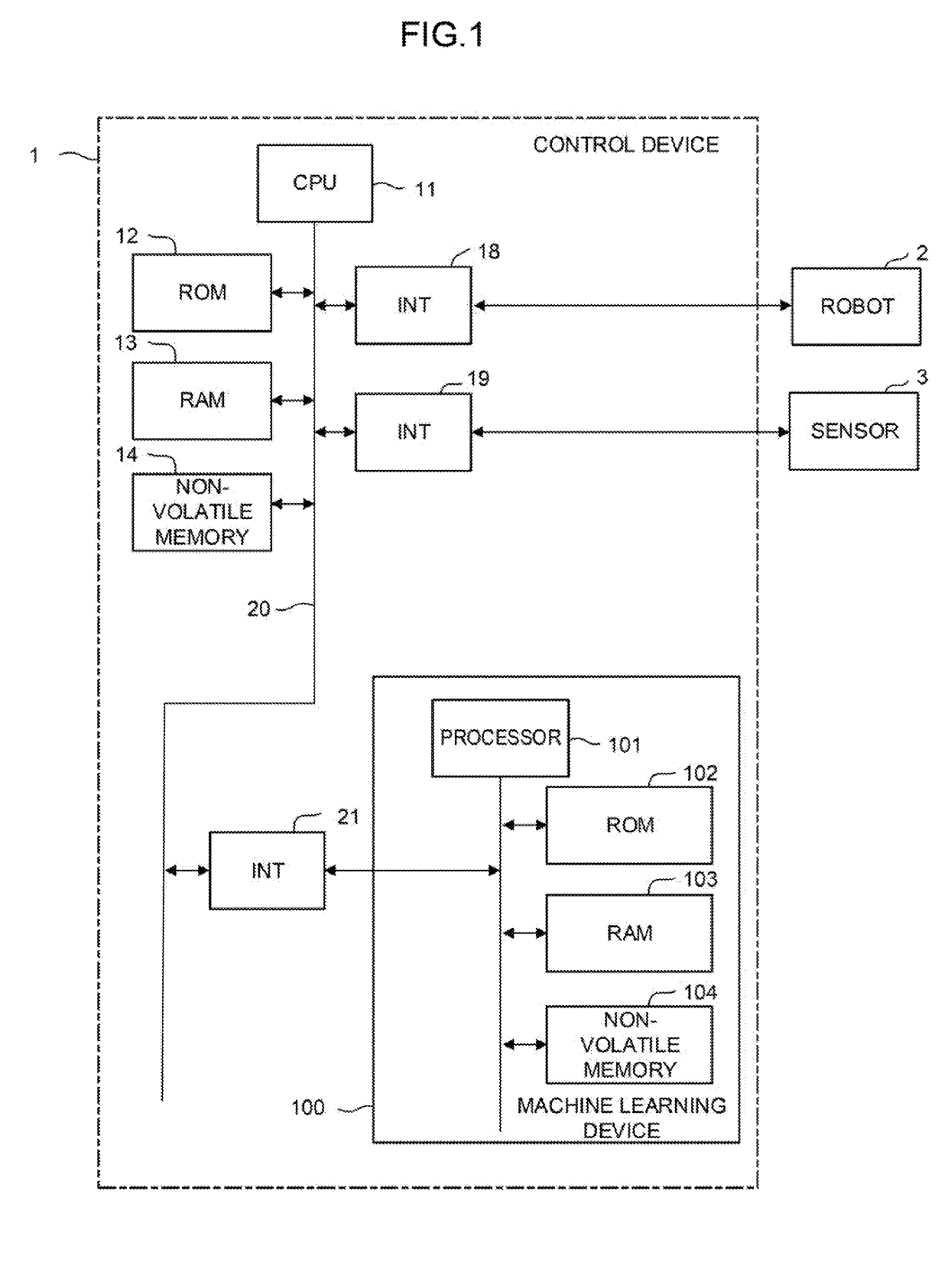

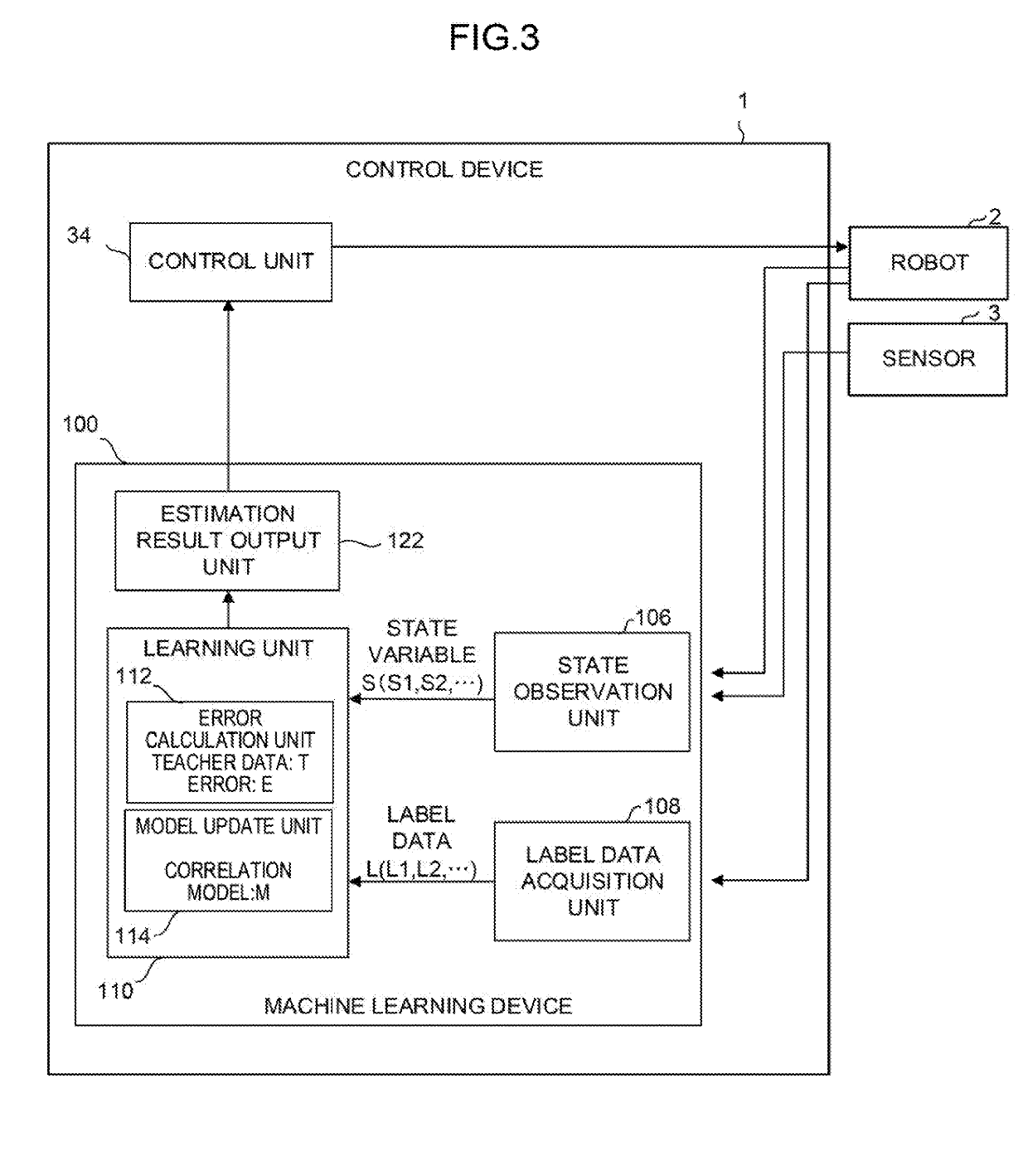

Control device and machine learning device

ActiveUS20190152055A1Improve gripSmall reaction forceProgramme controlProgramme-controlled manipulatorLearning unitState variable

A control device and a machine learning device enable control for gripping an object having small reaction force. The machine learning device included in the control device includes a state observation unit that observes gripping object shape data related to a shape of the gripping object as a state variable representing a current state of an environment, a label data acquisition unit that acquires gripping width data, which represents a width of the hand of the robot in gripping the gripping object, as label data, and a learning unit that performs learning by using the state variable and the label data in a manner to associate the gripping object shape data with the gripping width data.

Owner:FANUC LTD

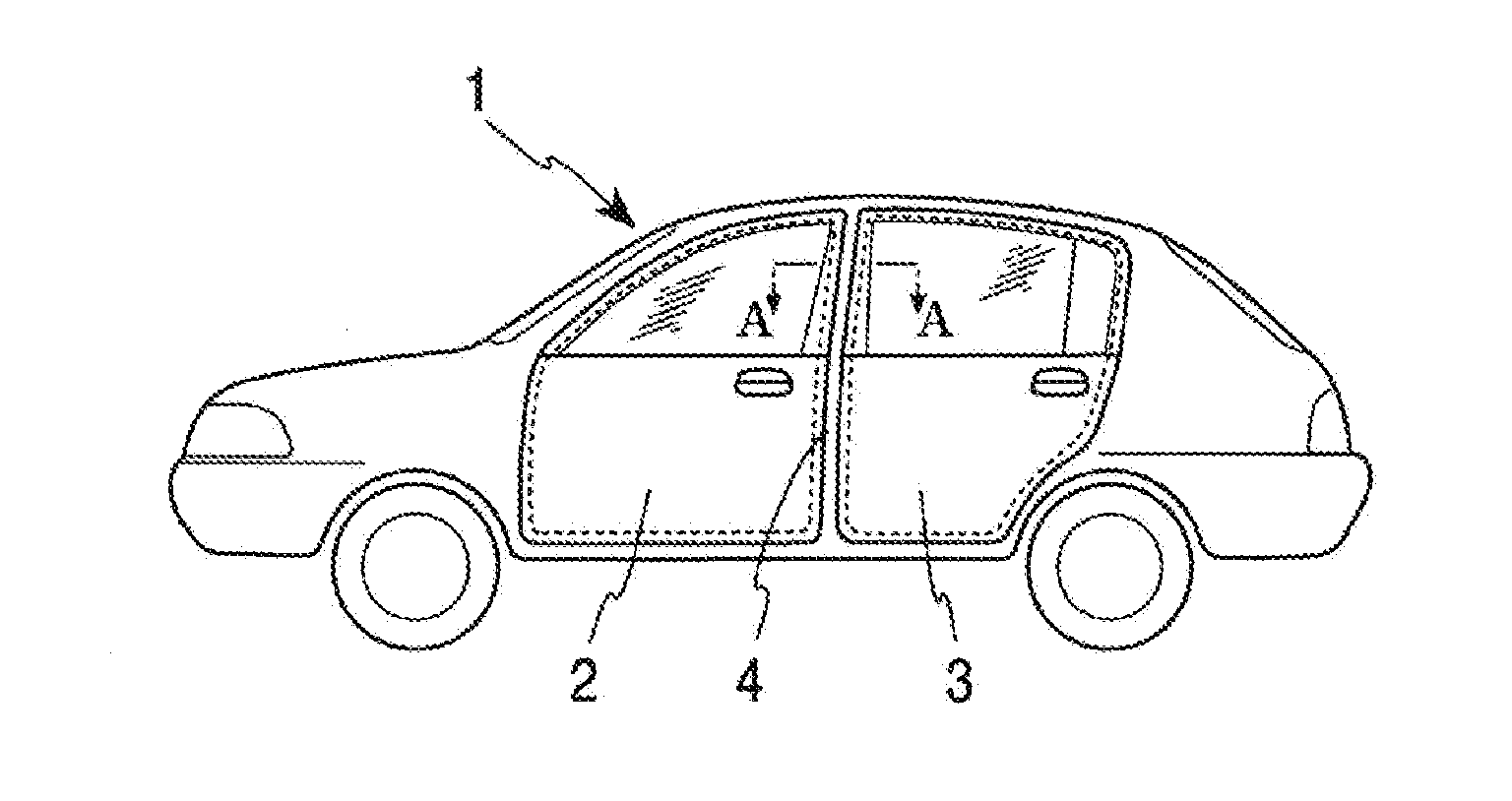

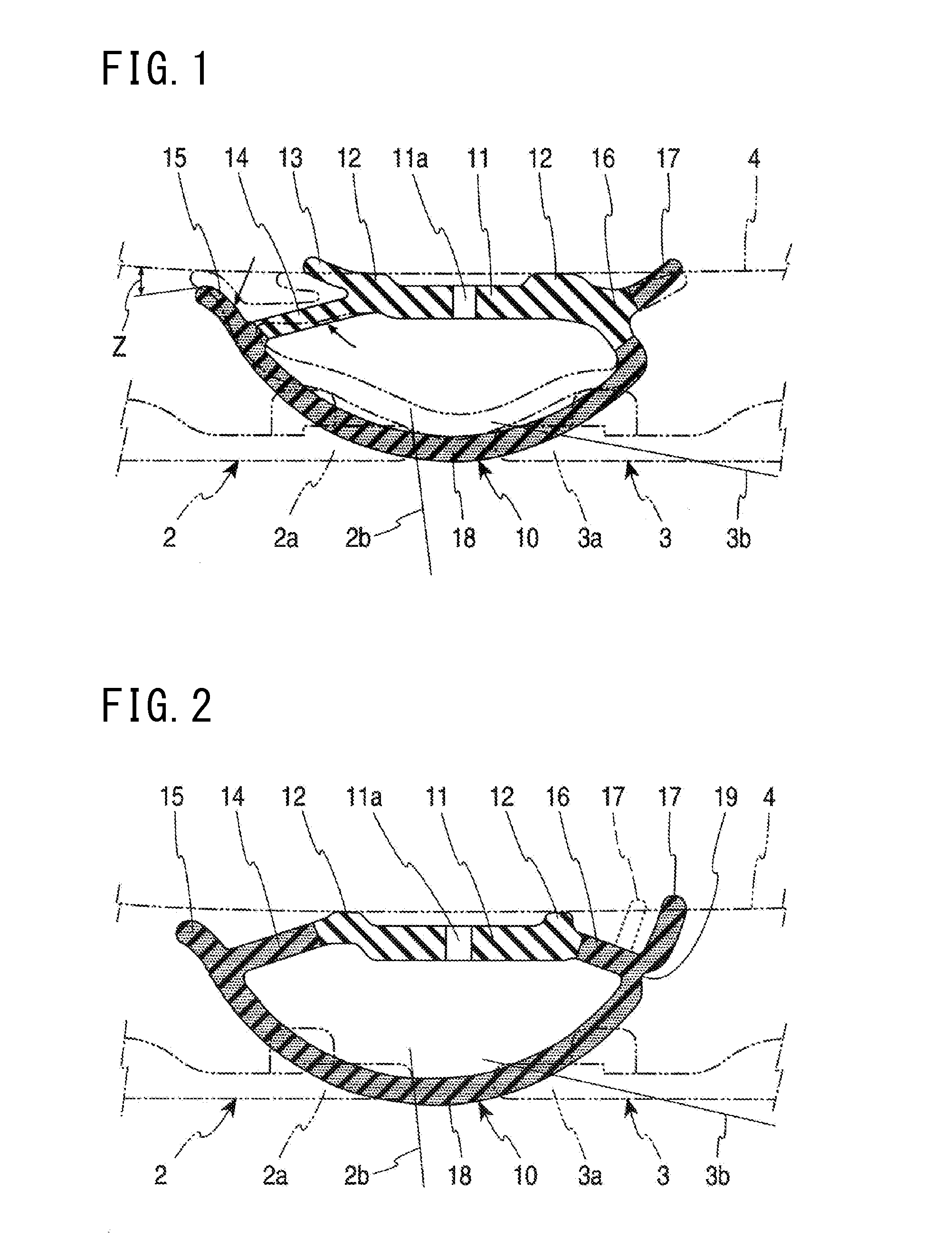

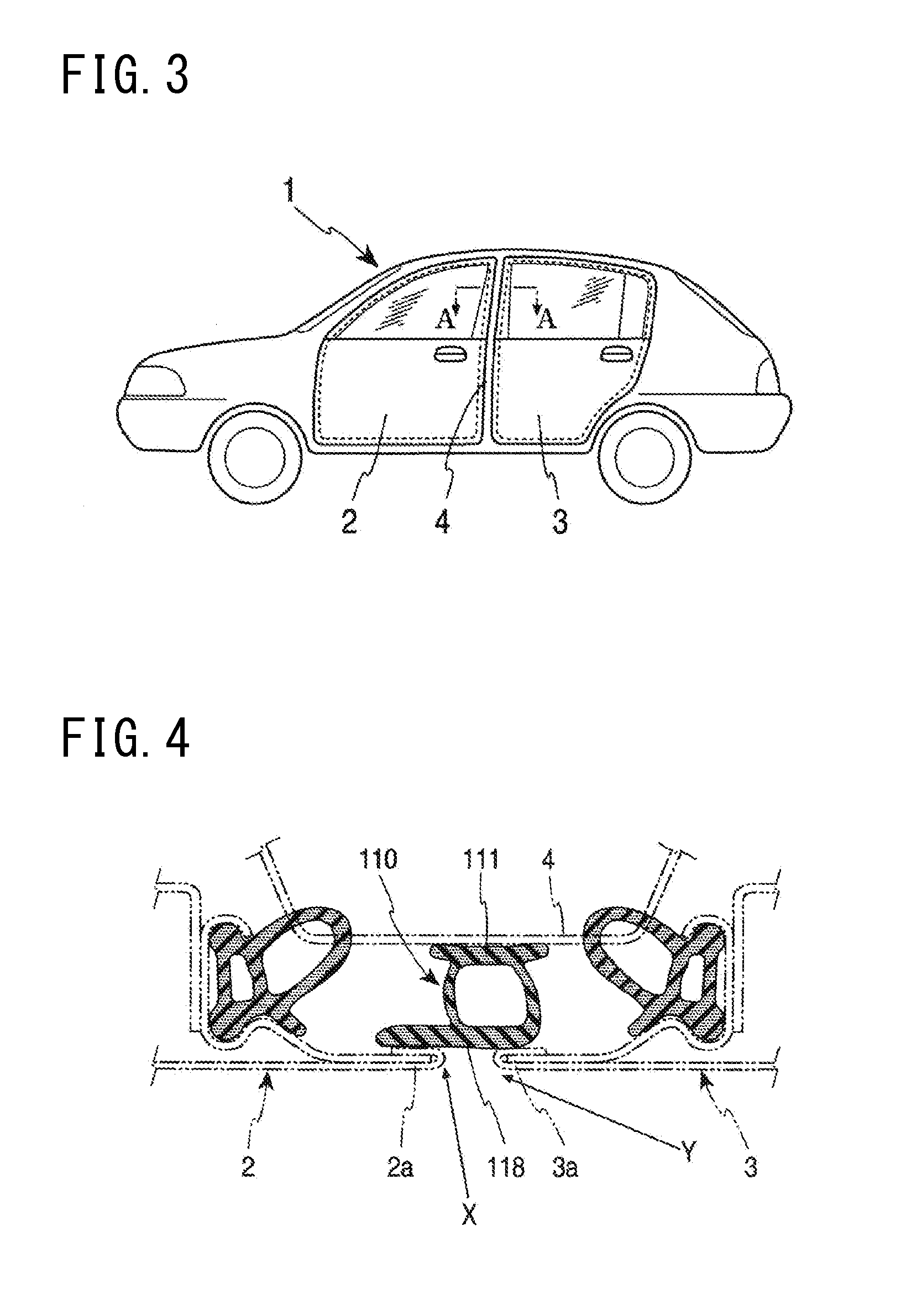

Center pillar weather strip

ActiveUS20150273993A1Easy to bendSealing propertyEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

Owner:TOYODA GOSEI CO LTD

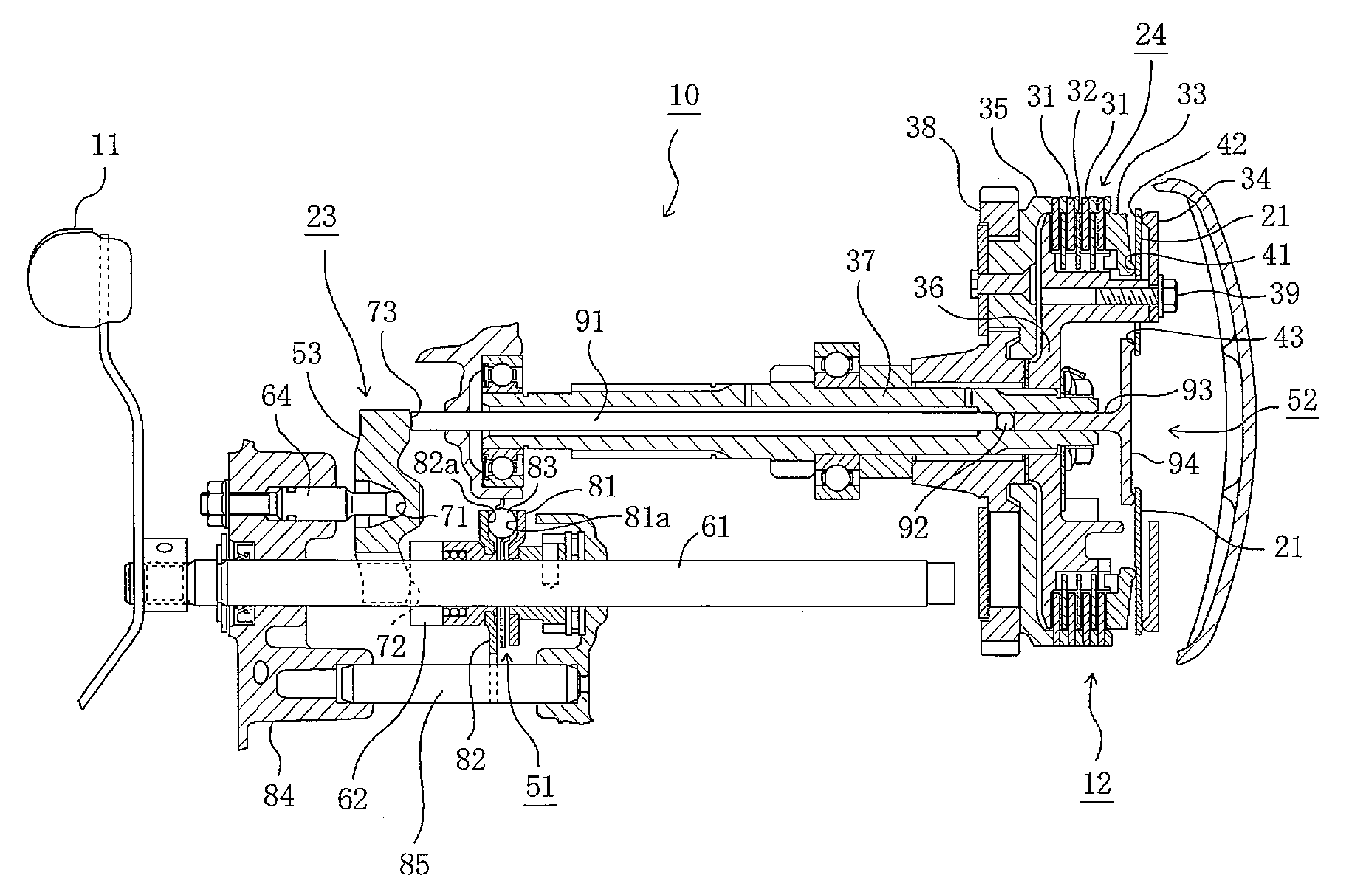

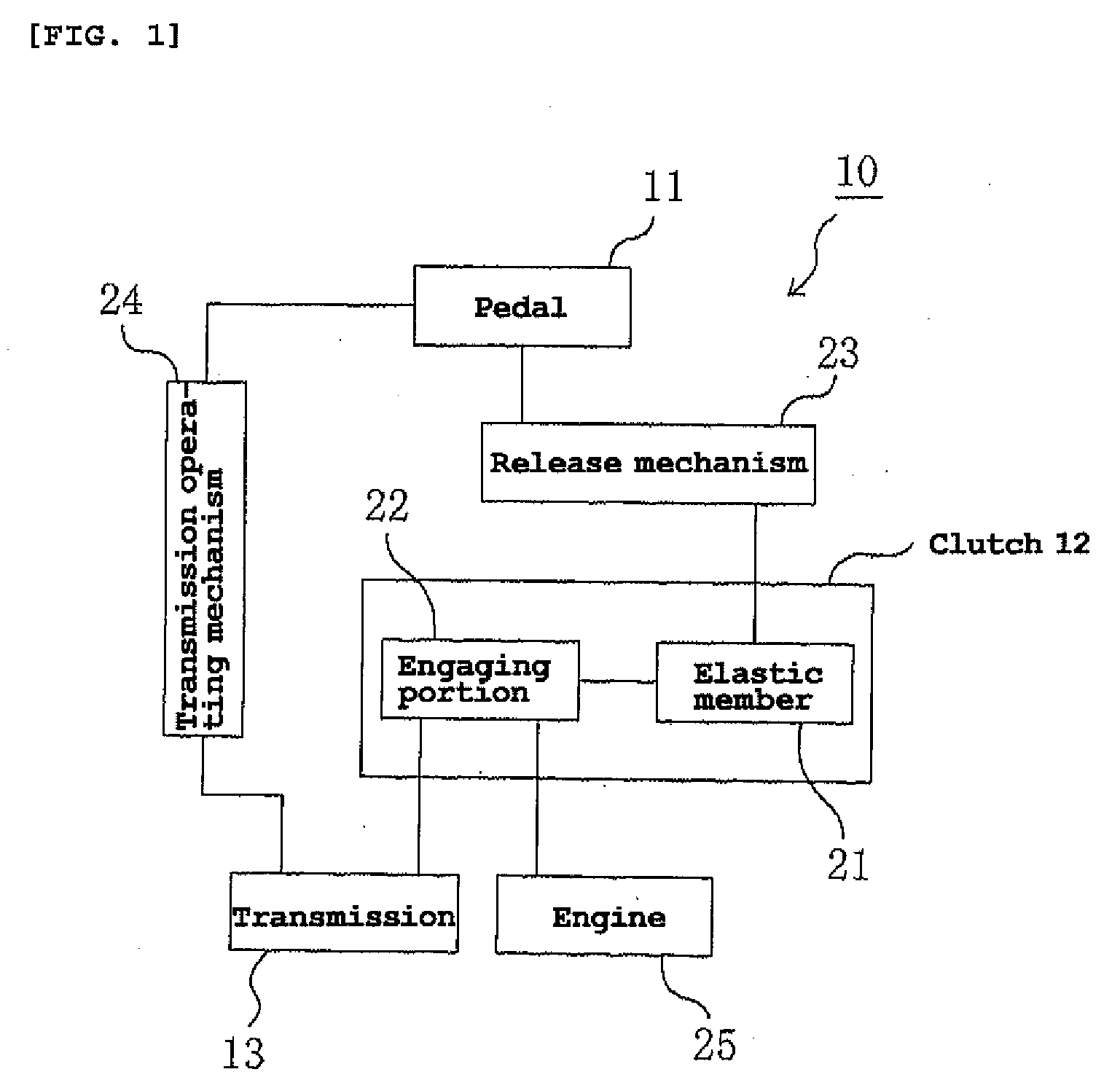

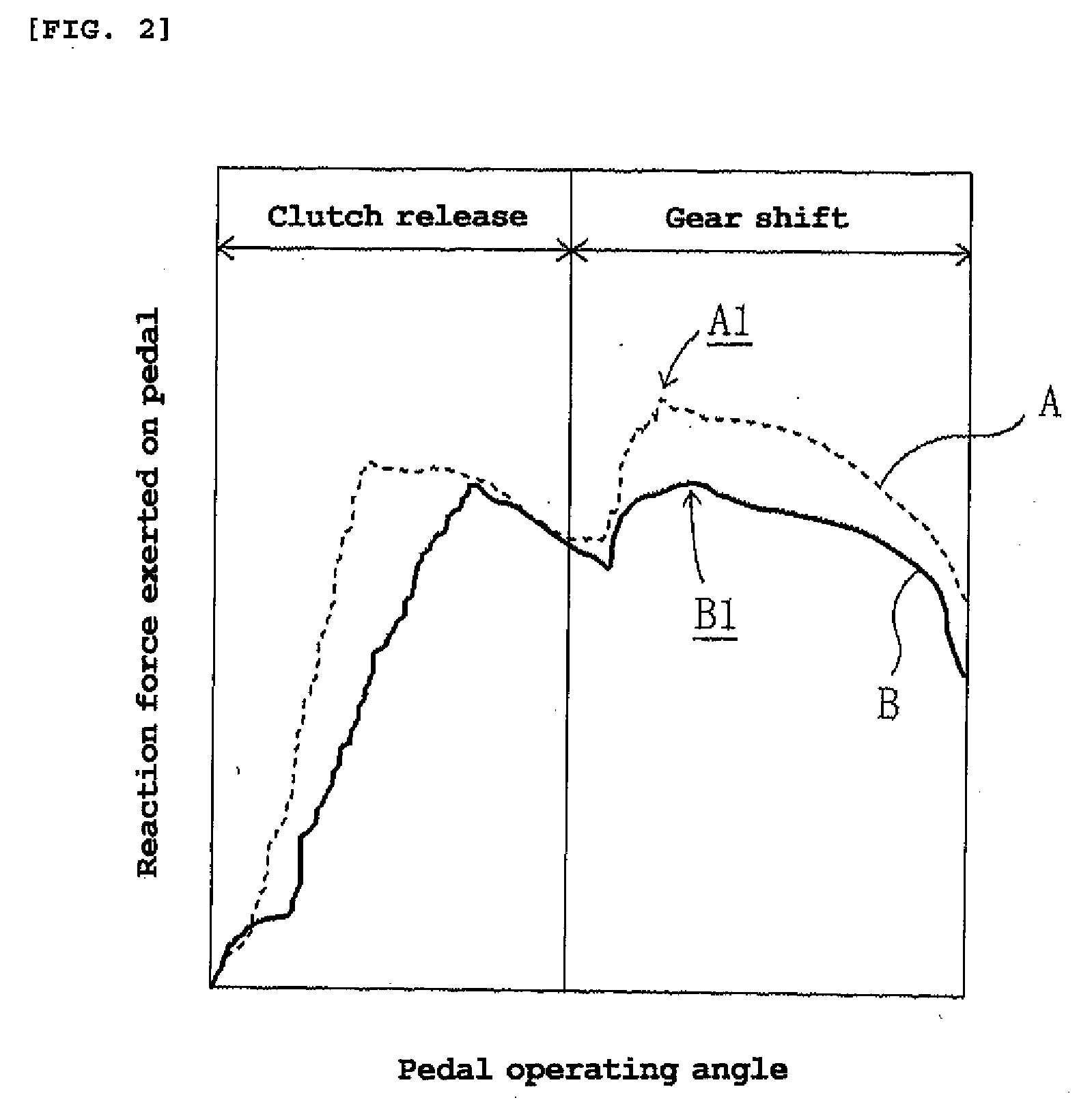

Automatic Clutch Mechanism, Automatic Clutch Mechanism for Straddle-Type Vehicle, and Straddle-Type Vehicle

InactiveUS20080029360A1Easy to operateSmall reaction forceFriction clutchesCoupling-brake combinationEngineeringStraddle

An automatic clutch mechanism that allows the feel of gear shifting to be readily transmitted to a rider through a pedal. The automatic clutch mechanism shifts gears while disengaging a clutch in conjunction with one pedal operation. A transmission effects a gear shift in conjunction with a pedal operation. The clutch includes an elastic member, and an engaging portion for bringing the transmission and an engine into engagement with each other by the elastic reaction force of the elastic member. The elastic member has a gradient-decreasing range in which the gradient of a change in elastic load with respect to deformation of the elastic member decreases as the deformation increases. The gradient-decreasing range is included in the use range of the elastic member determined by operation of the clutch.

Owner:YAMAHA MOTOR CO LTD

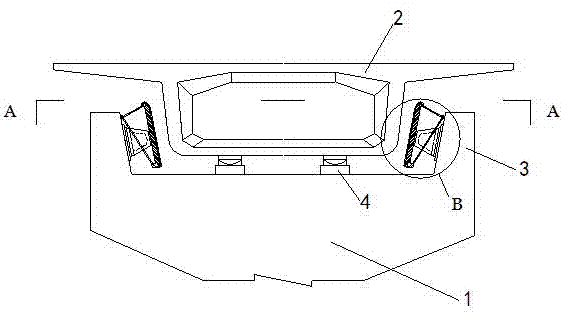

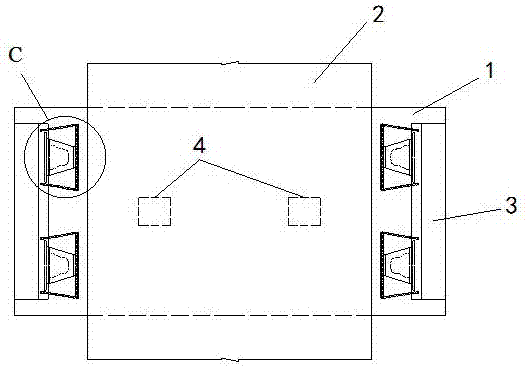

Date-pit-type composite anti-collision system for pier and construction method for date-pit-type composite anti-collision system for pier

InactiveCN104775355ASimple structureReasonable designClimate change adaptationBridge structural detailsArchitectural engineeringCofferdam

The invention discloses a date-pit-type composite anti-collision system for a pier and a construction method for the date-pit-type composite anti-collision system for the pier. The composite anti-collision system comprises a prepressing-type anti-collision device which is arranged at the outer side of the pier, and a floating-type external retaining device which sleeves the outer side of the prepressing-type anti-collision device, wherein the floating-type external retaining device is in a date pit shape, and is formed by connecting a plurality of anti-collision boxes which float on the water surface; the prepressing-type anti-collision device comprises one or a plurality of date-pit-type anti-collision structures; each date-pit-type anti-collision structure comprises an external cofferdam, and an energy consumption layer which is arranged at the inner side of the external cofferdam and is composed of a plurality of energy consumption rings; each external cofferdam is in the date pit shape; each energy consumption ring comprises an elastic ring which is formed through prepressing, and an external protective sleeve which sleeves the outer side of the elastic ring. The construction method comprises the following steps of (1) building a horizontal construction platform; (2) conveying parts in place; (3) constructing fixing elements at the outer side of the pier; (4) constructing the prepressing-type anti-collision device; (5) constructing the floating-type external retaining device. The date-pit-type composite anti-collision system for the pier and the construction method for the date-pit-type composite anti-collision system for the pier have the advantages that the design is reasonable, the construction is simple and convenient, the use effect is good, and the pier can be effectively protected.

Owner:XIAN UNIV OF SCI & TECH

Anti-collision ship protection rubber fender

InactiveCN109457668AImprove qualityImprove protectionClimate change adaptationShipping equipmentHoneycombEngineering

The invention discloses an anti-collision ship protection rubber fender. The anti-collision ship protection rubber fender comprises a rubber fender body. Connecting screw holes are formed in the center line position of the rubber fender body at equal intervals. First rubber side plates are symmetrically welded to the two sides of the bottom of the rubber fender body, second rubber side plates aresymmetrically welded to the two sides of the two first rubber side plates, a bottom fixing plate is welded to the outer sides of the bottoms of the two second rubber side plates and provided with installing screw holes at equal intervals, the installing screw holes are used for fixing the rubber fender body, and a honeycomb damping pad is embedded in the part between the two second rubber side plates. In the anti-collision ship protection rubber fender, through the arrangement of the first rubber side plates and the second rubber side plates, a V-shaped damping structure and a U-shaped dampingstructure can be formed, compared with a traditional rubber fender, the anti-collision ship protection rubber fender has a double damping effect, the damping effect is obviously improved, and accordingly ships and wharfs are better protected against damage.

Owner:扬州市远望橡胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com