Tension and compression complementary type anchor cable structure adopting external anchoring and locking and construction method thereof

An external anchoring and complementary technology, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of difficult to guarantee the reaction force of frame beams, failure of external anchor head locking, loss of prestress, etc., so as to improve frictional resistance, Reduce the risk of anchor cable prestress loss, the effect of reducing the risk of prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

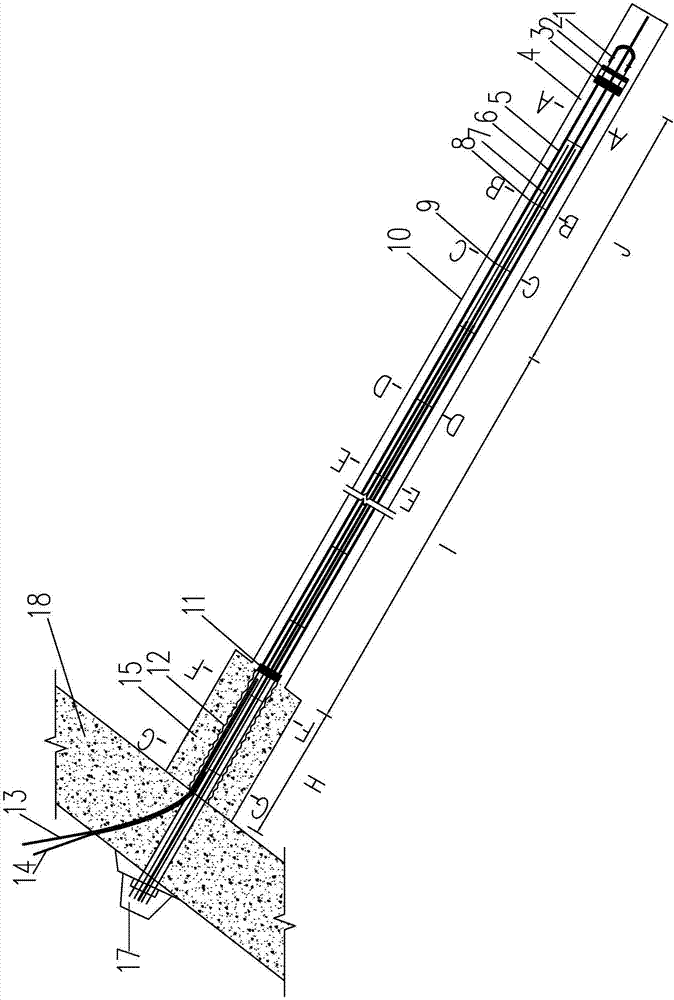

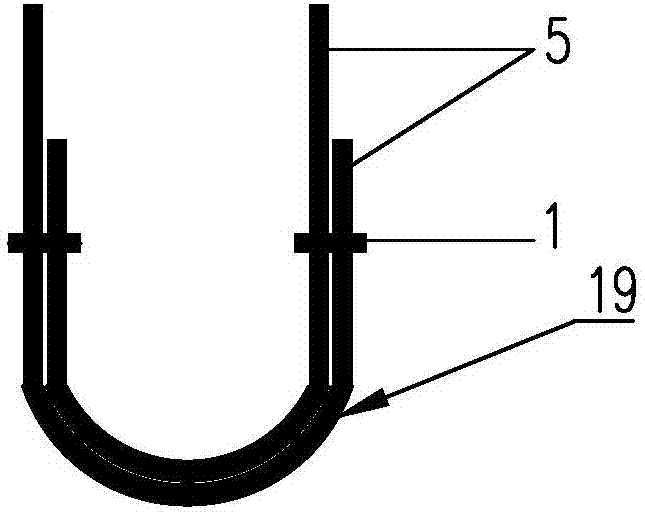

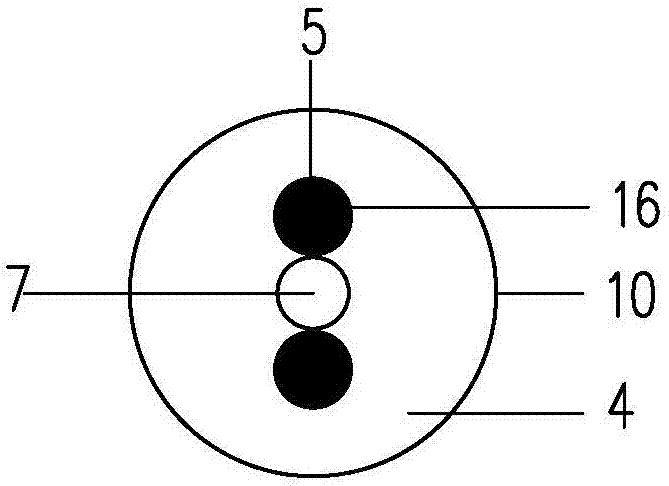

[0053] Such as Figure 1-9 As shown, it is a kind of pull-compression complementary external anchoring and locking anchor cable structure of the present invention, including the anchor cable hole 10 and the anchor system provided on the slope, the anchor system mainly consists of the anchor cable body, the outer anchor head 17 and the inner anchor head Composition, the anchor cable body and the inner anchor head are placed in the anchor cable hole 10, the anchor cable body includes tension type steel strand 6, pressure type steel strand 5, casing 16, bellows 12, expansion ring 9, hoop 8, the second The first grouting pipe 7, the second grouting pipe 13 and the exhaust pipe 14, the tension type steel strand 6, the first grouting pipe 7 and the pressure type steel strand 5 are combined and provided with expansion rings 9 and hoops at intervals The ring 8 constitutes the anchor cable bundle, and the number of the tension-type steel strand 6 and the pressure-type steel strand 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com