Patents

Literature

1276results about "Coupling-brake combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

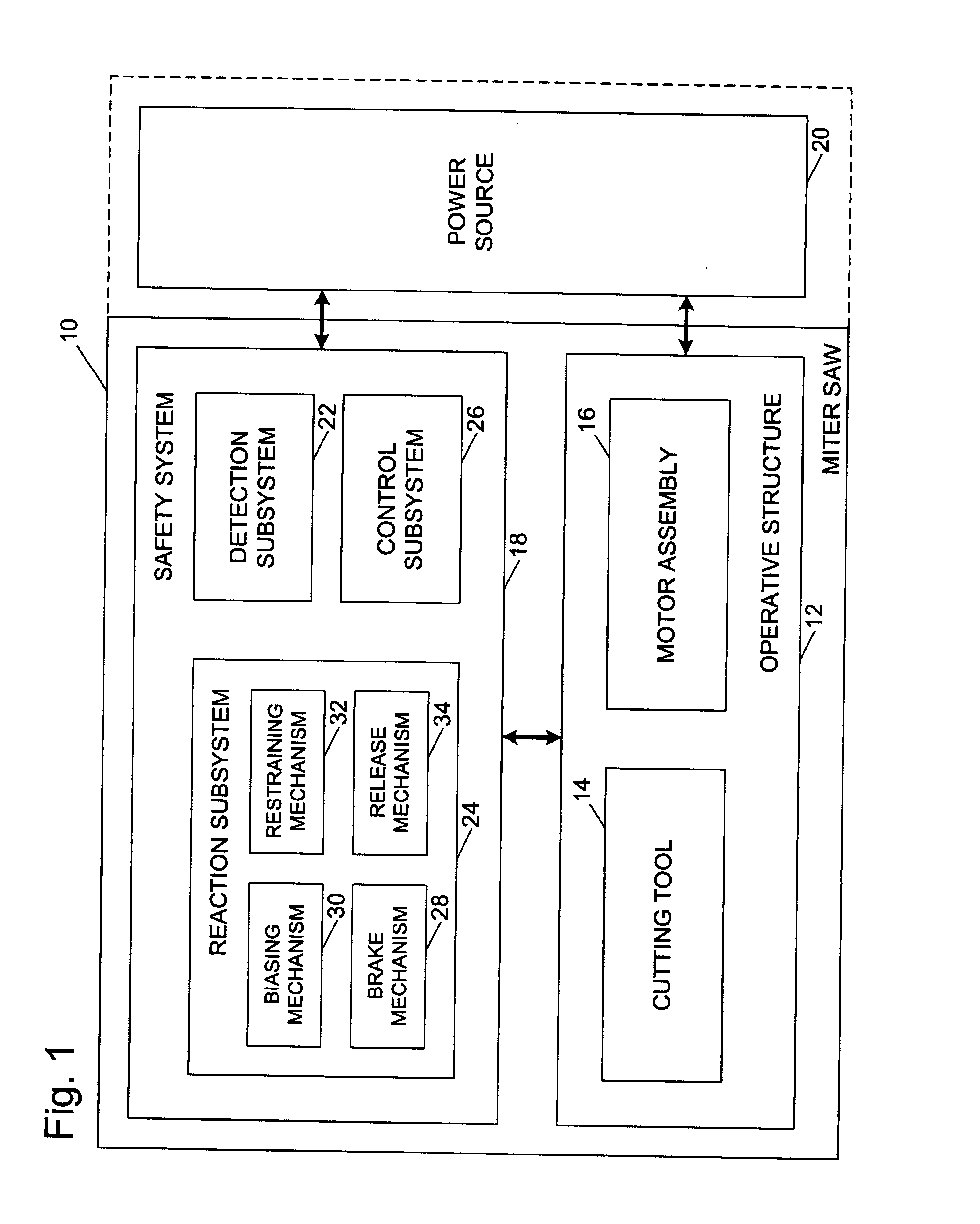

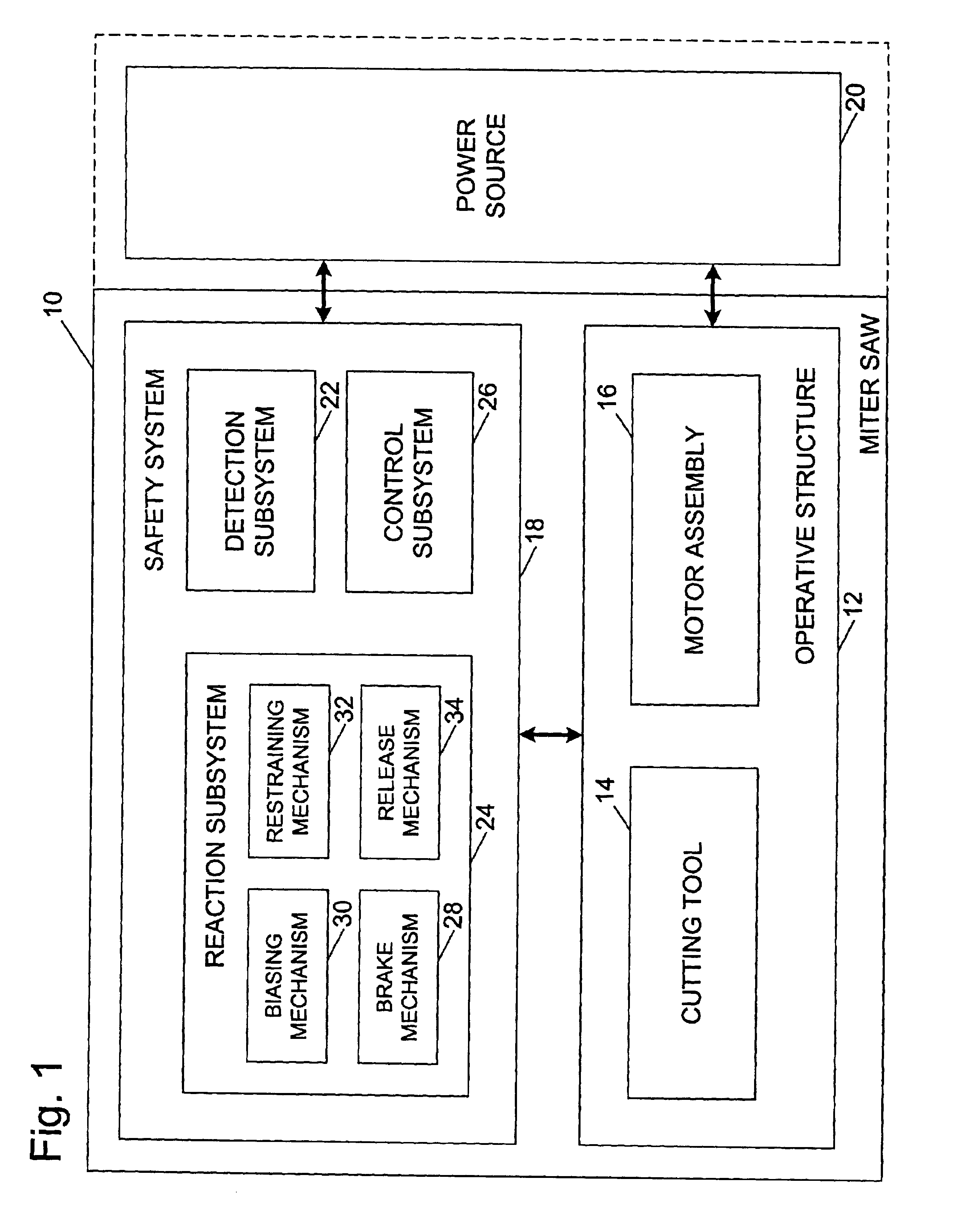

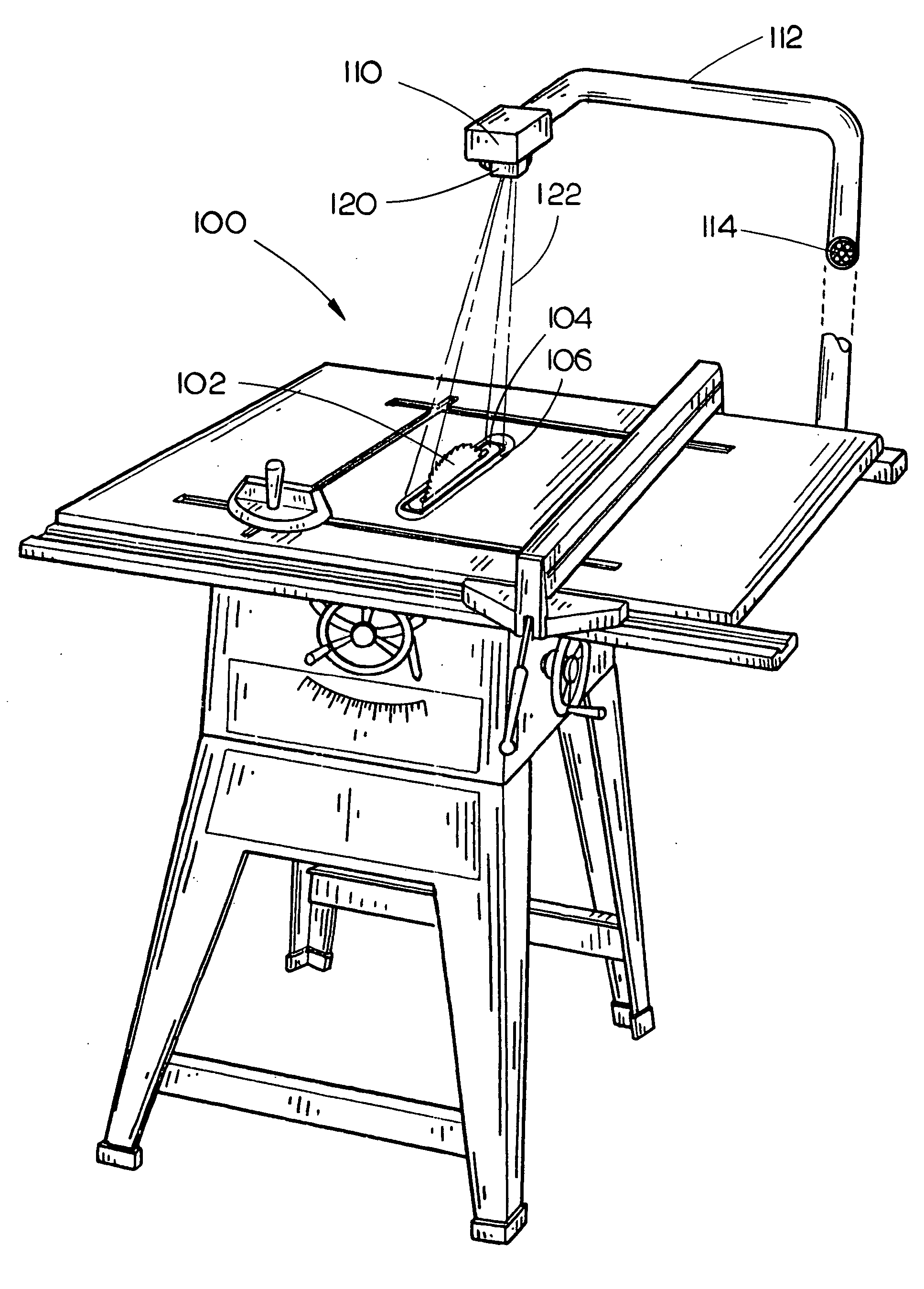

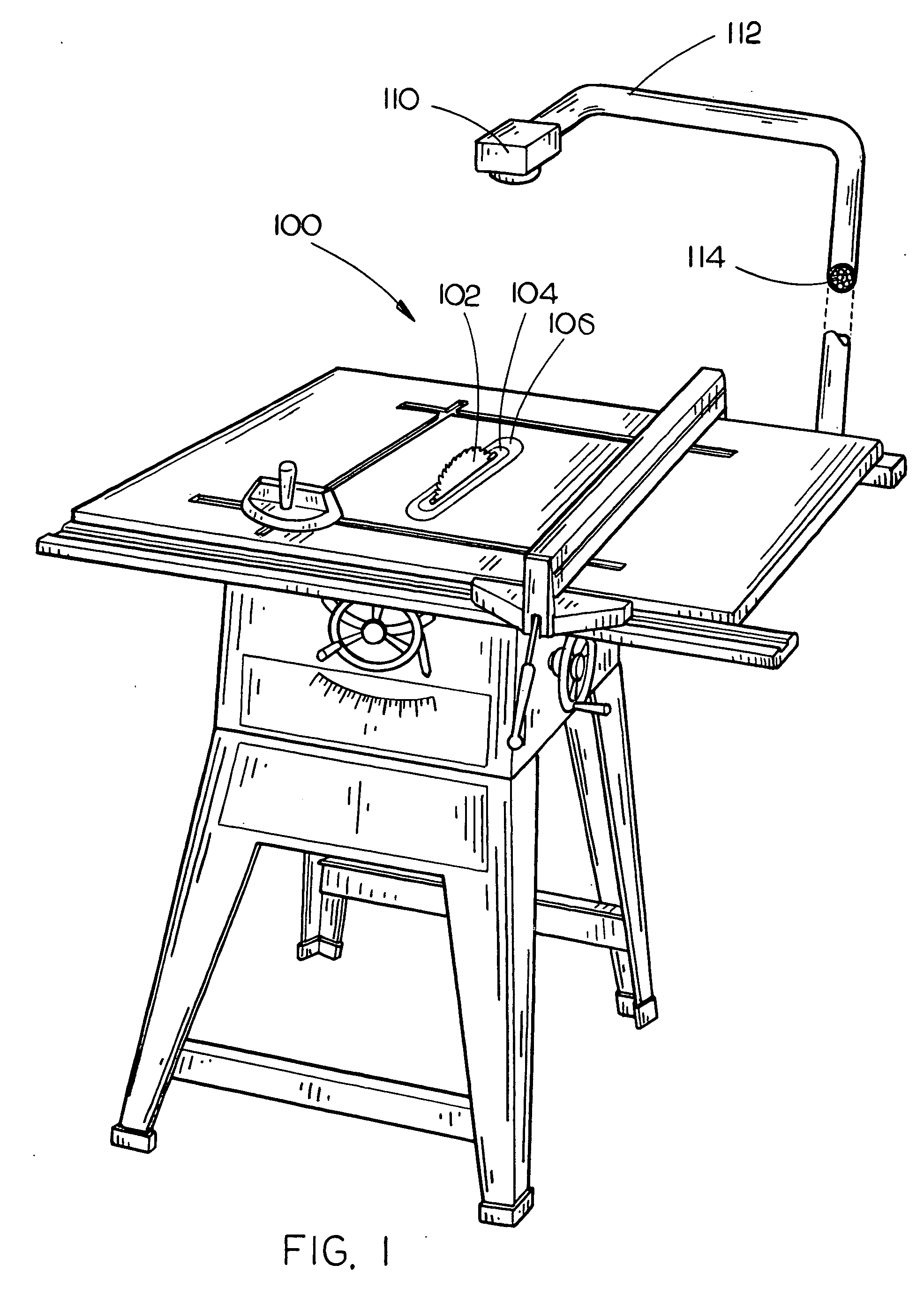

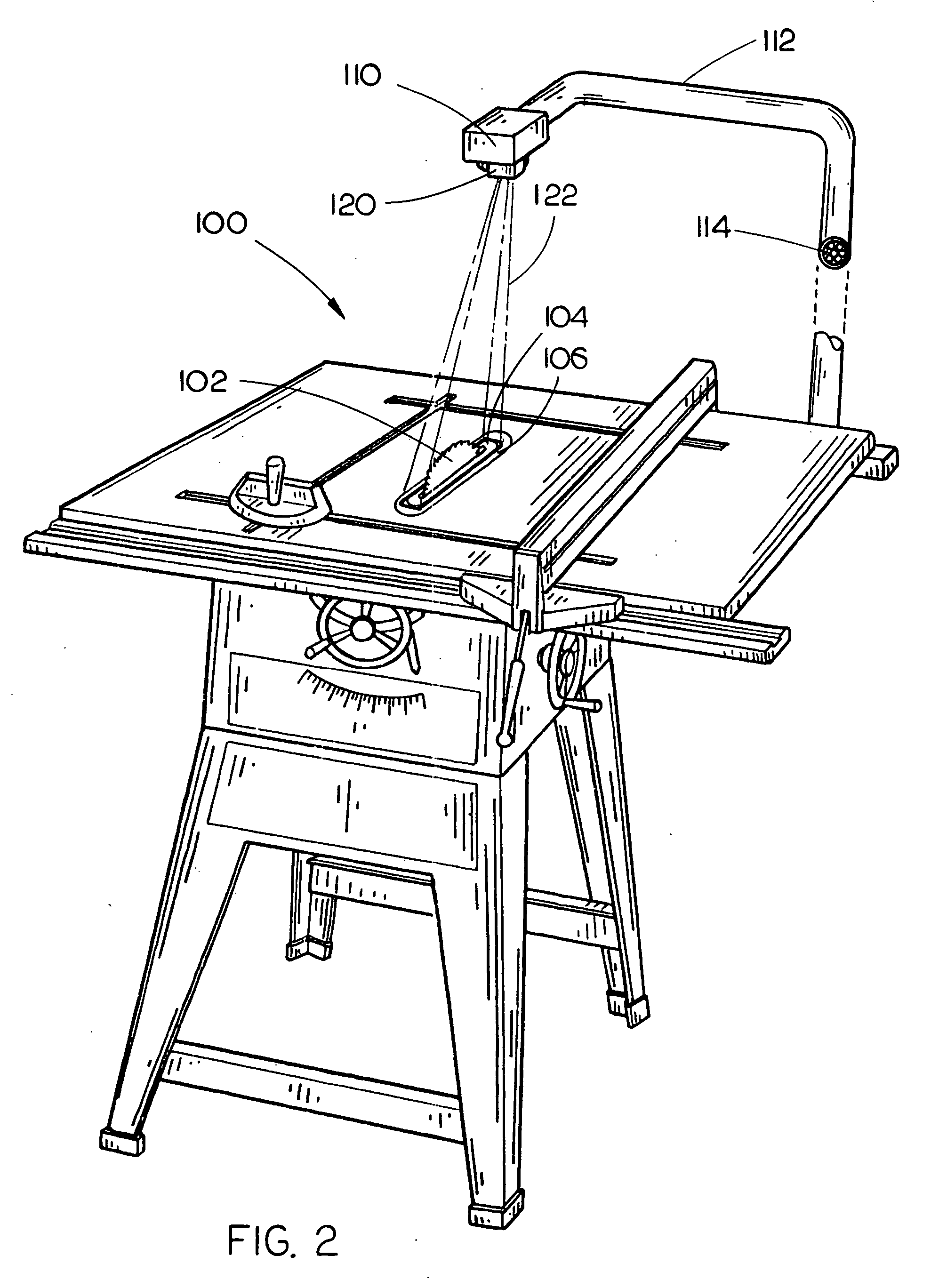

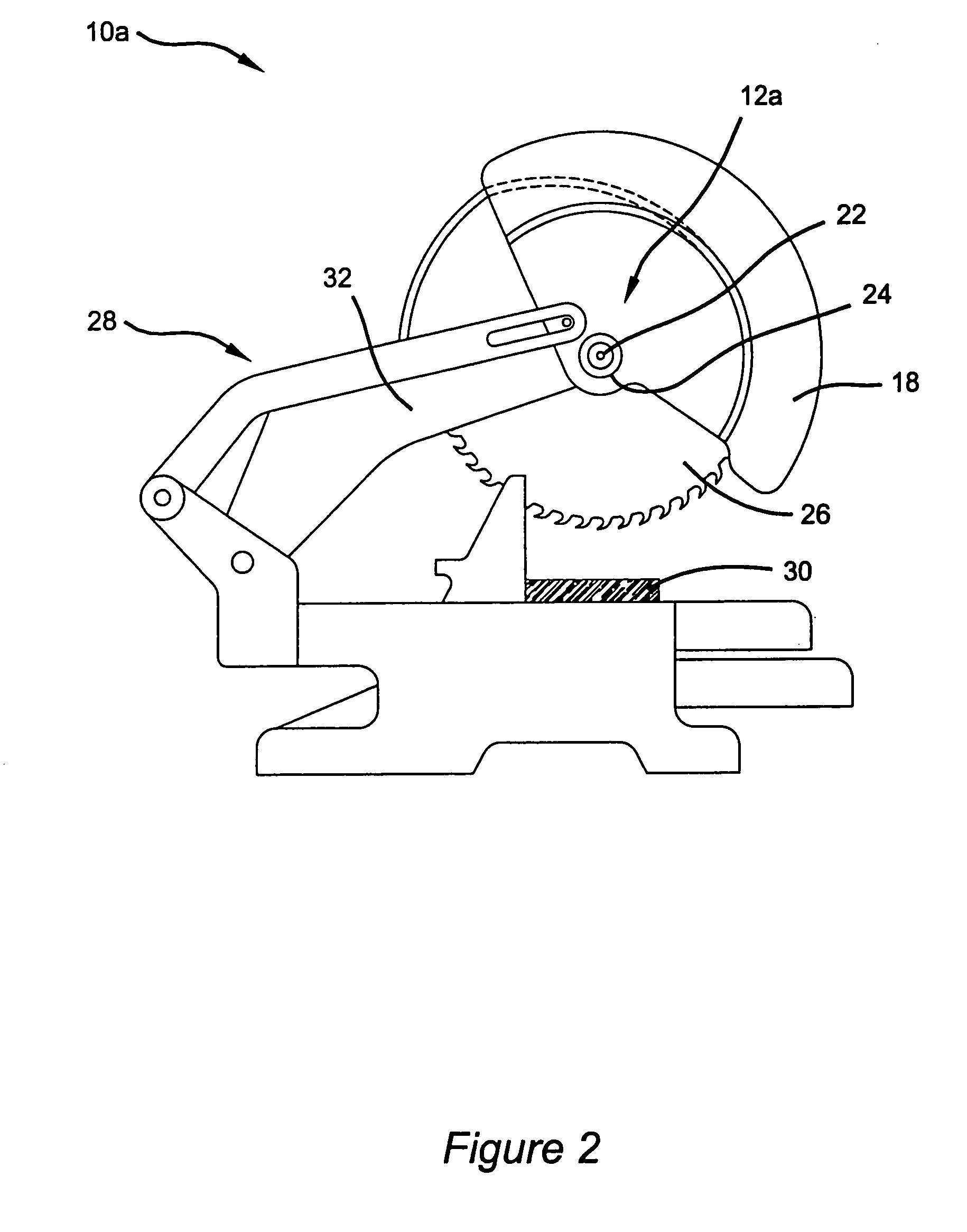

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

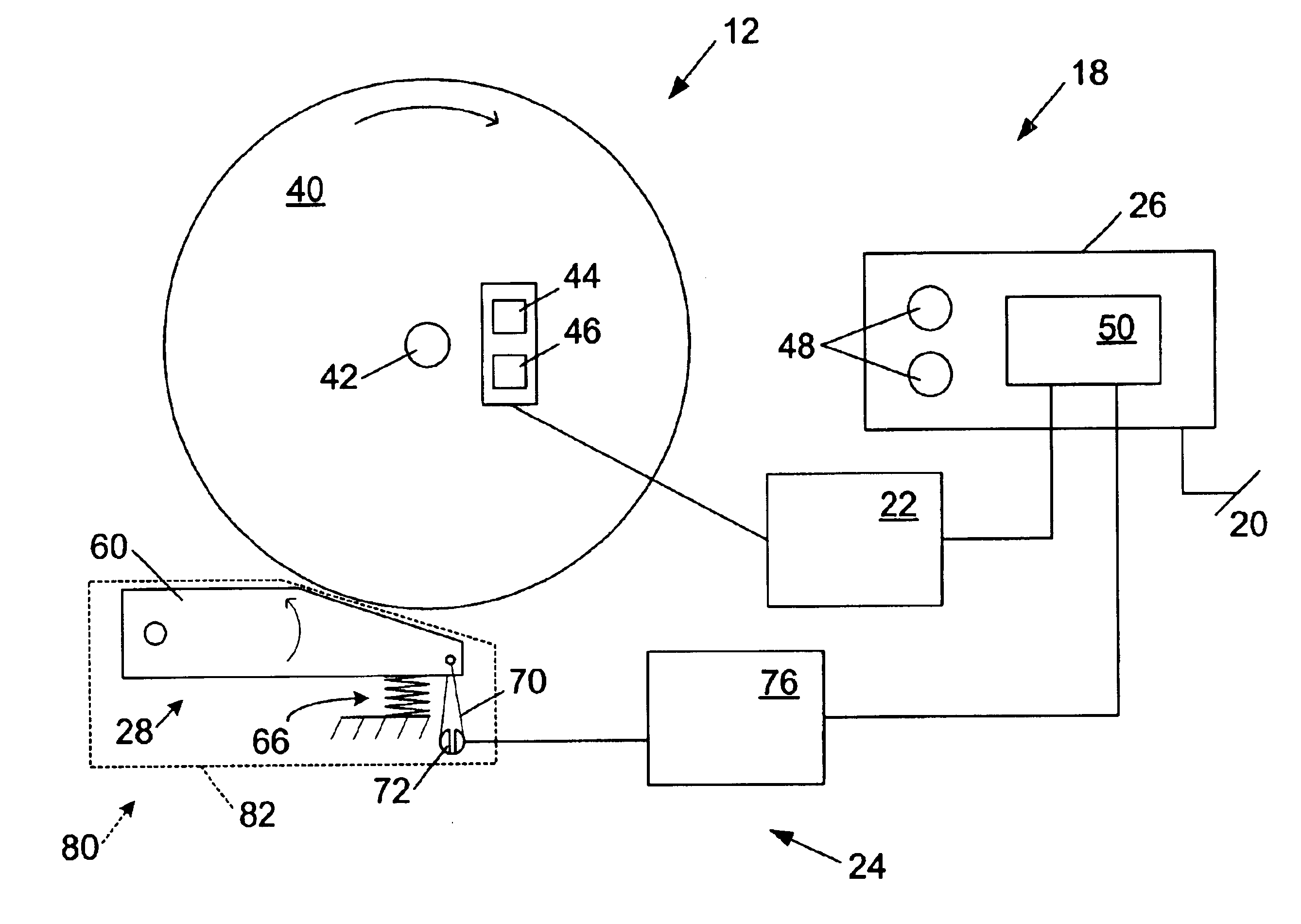

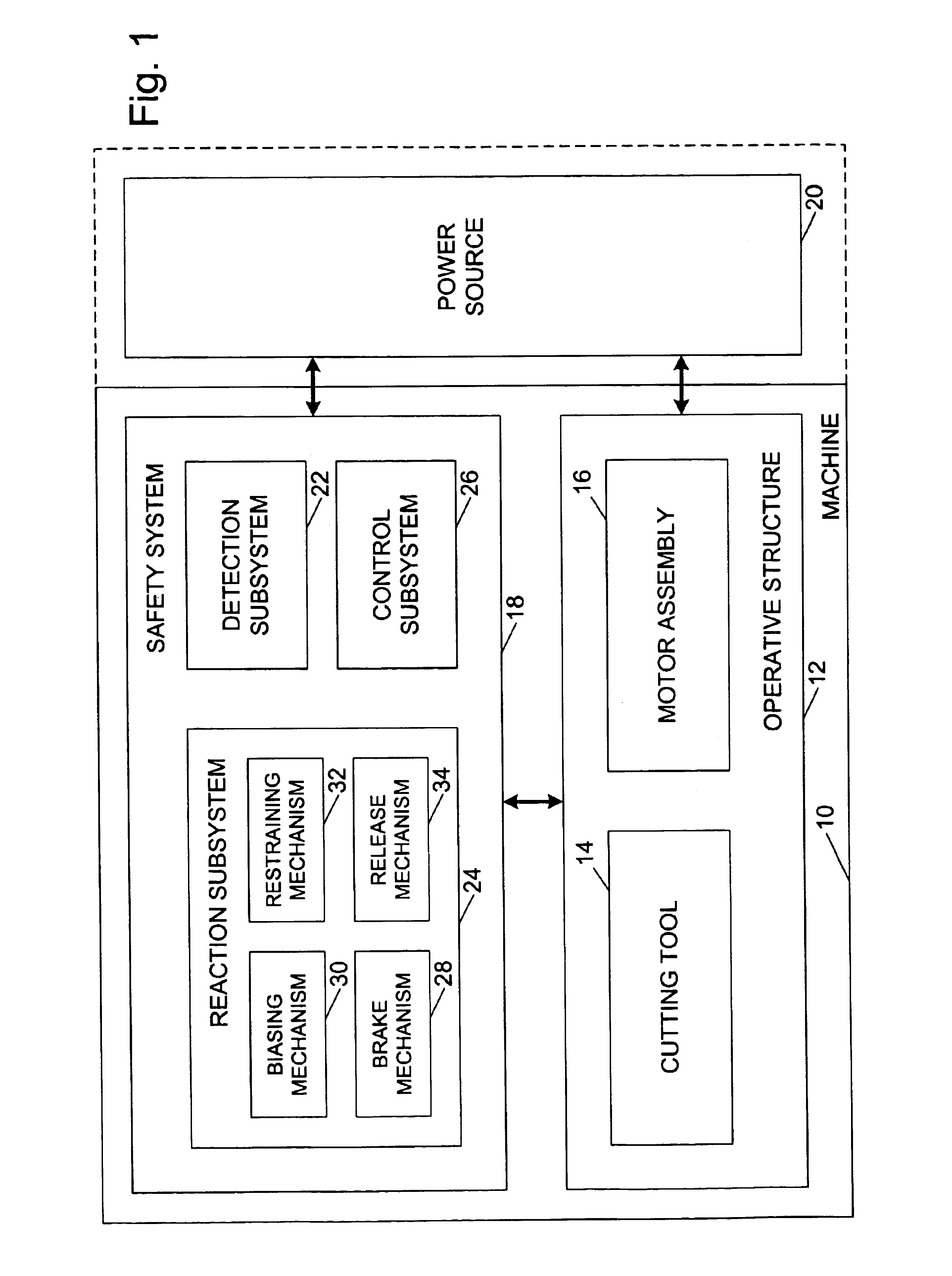

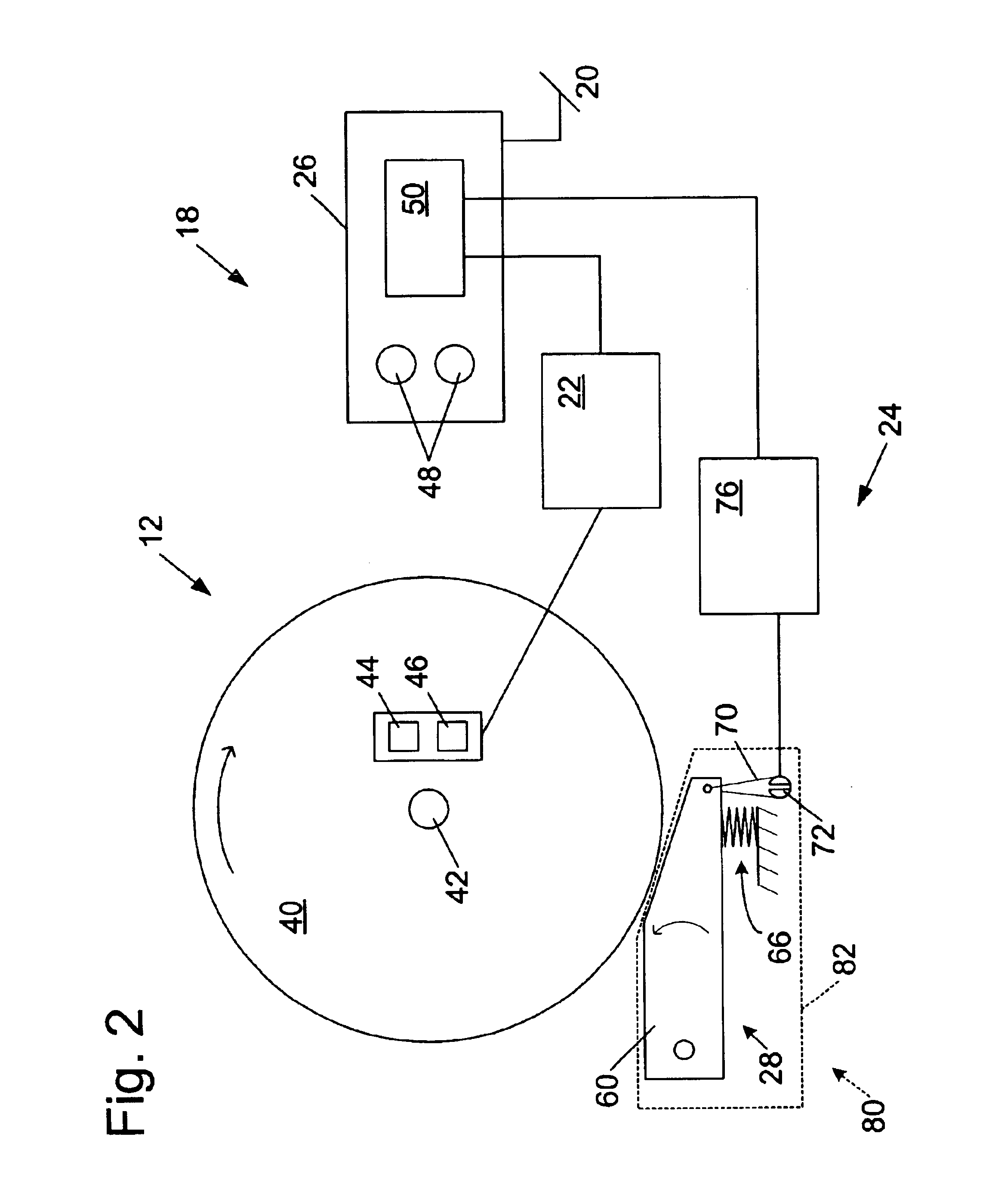

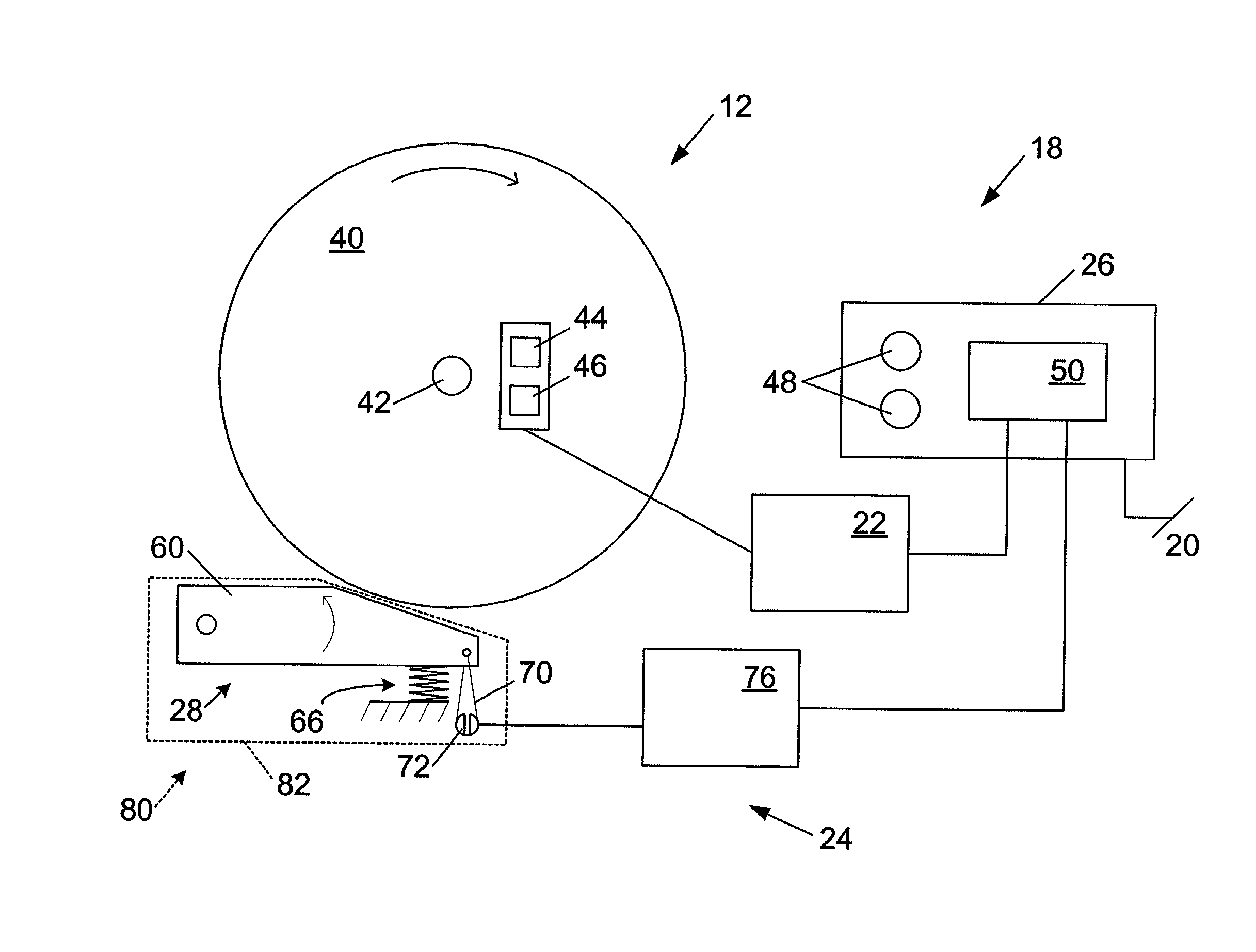

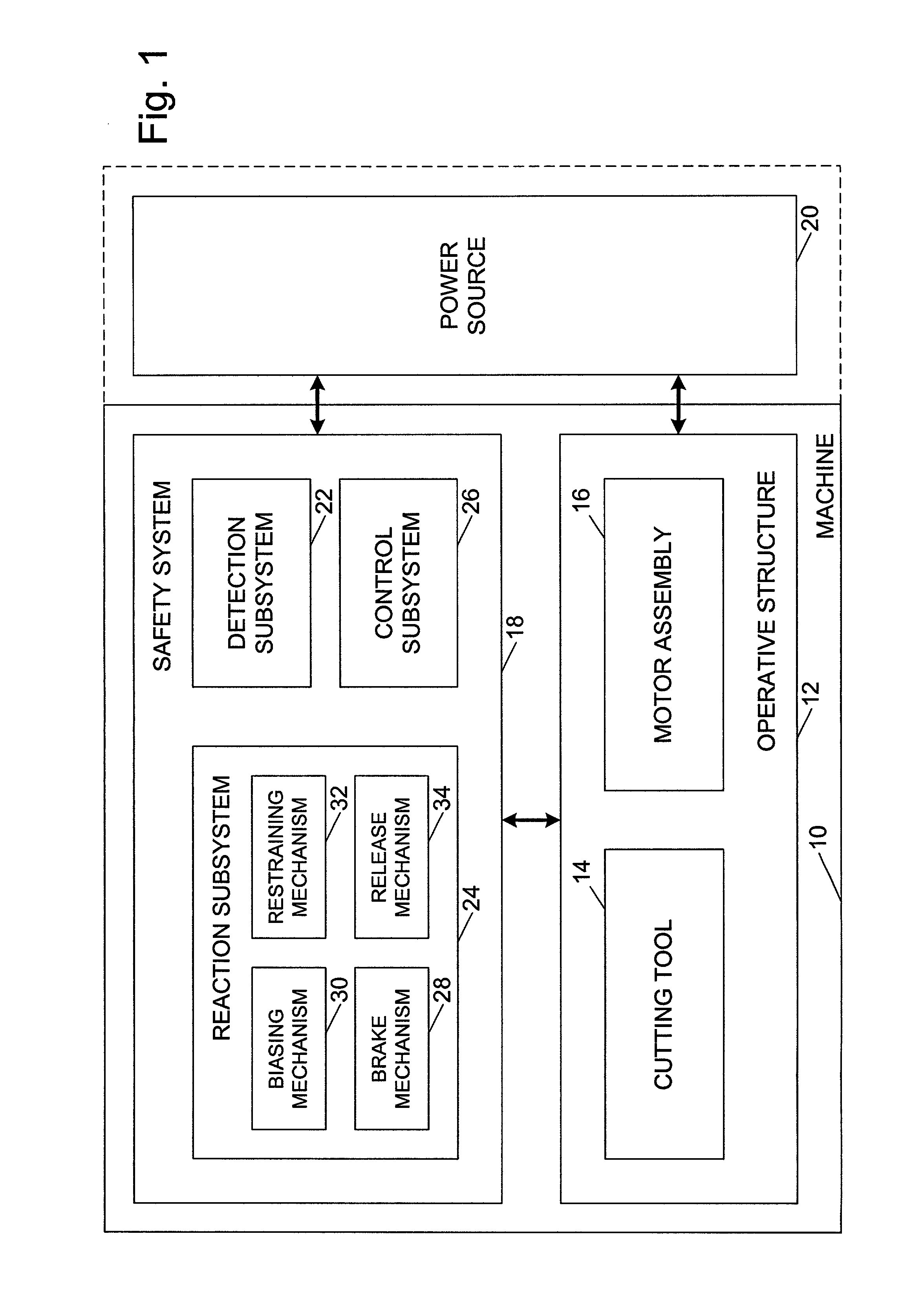

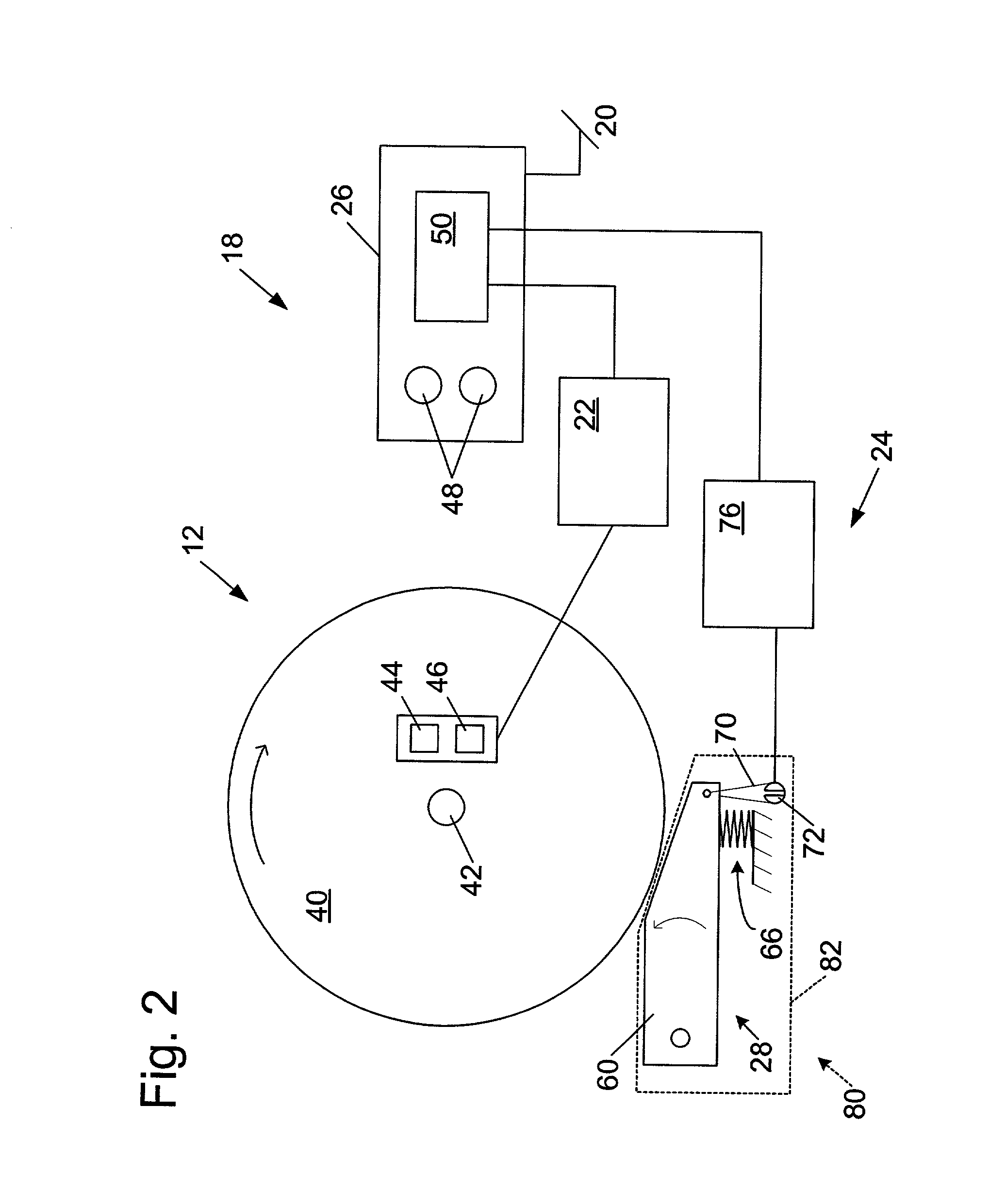

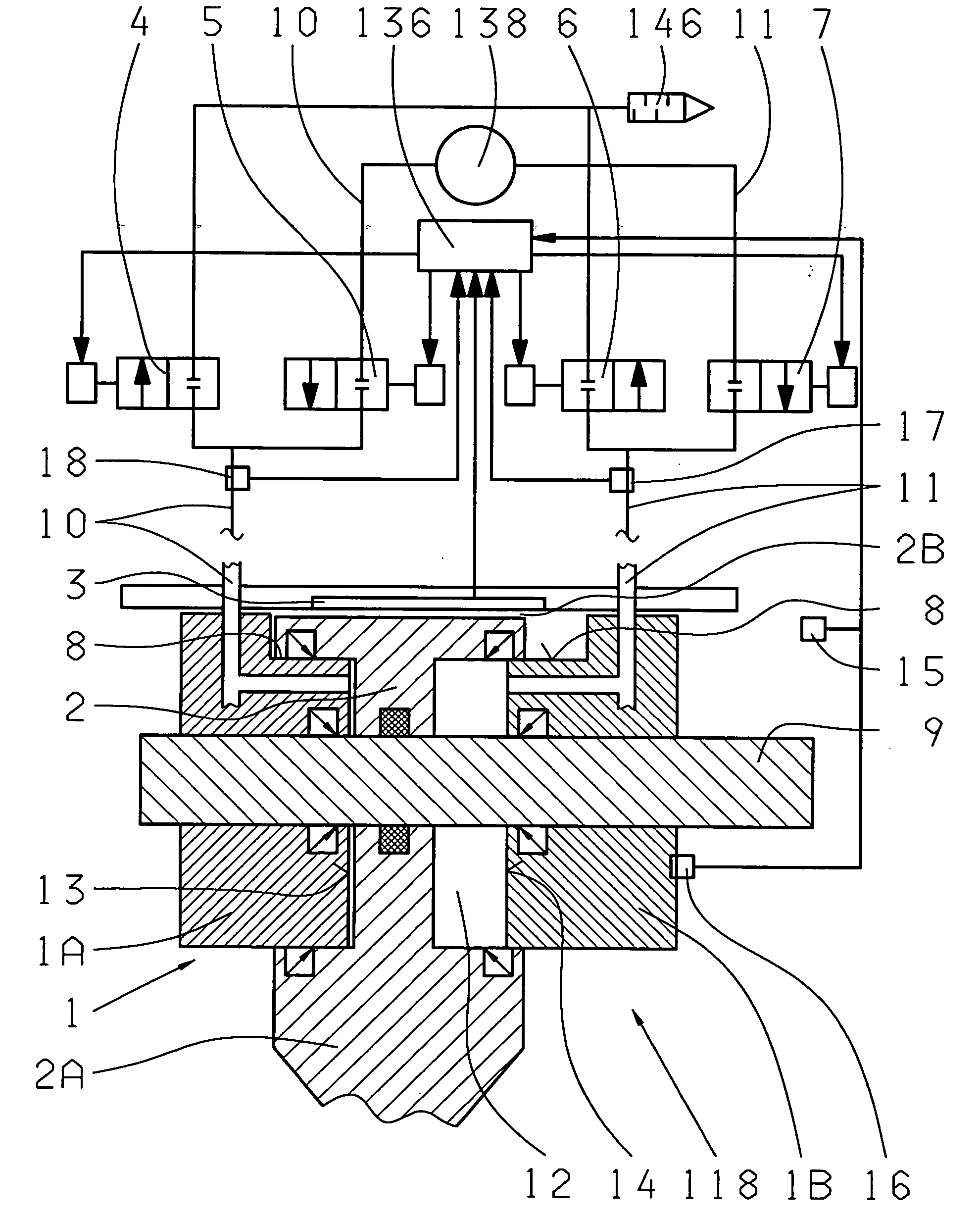

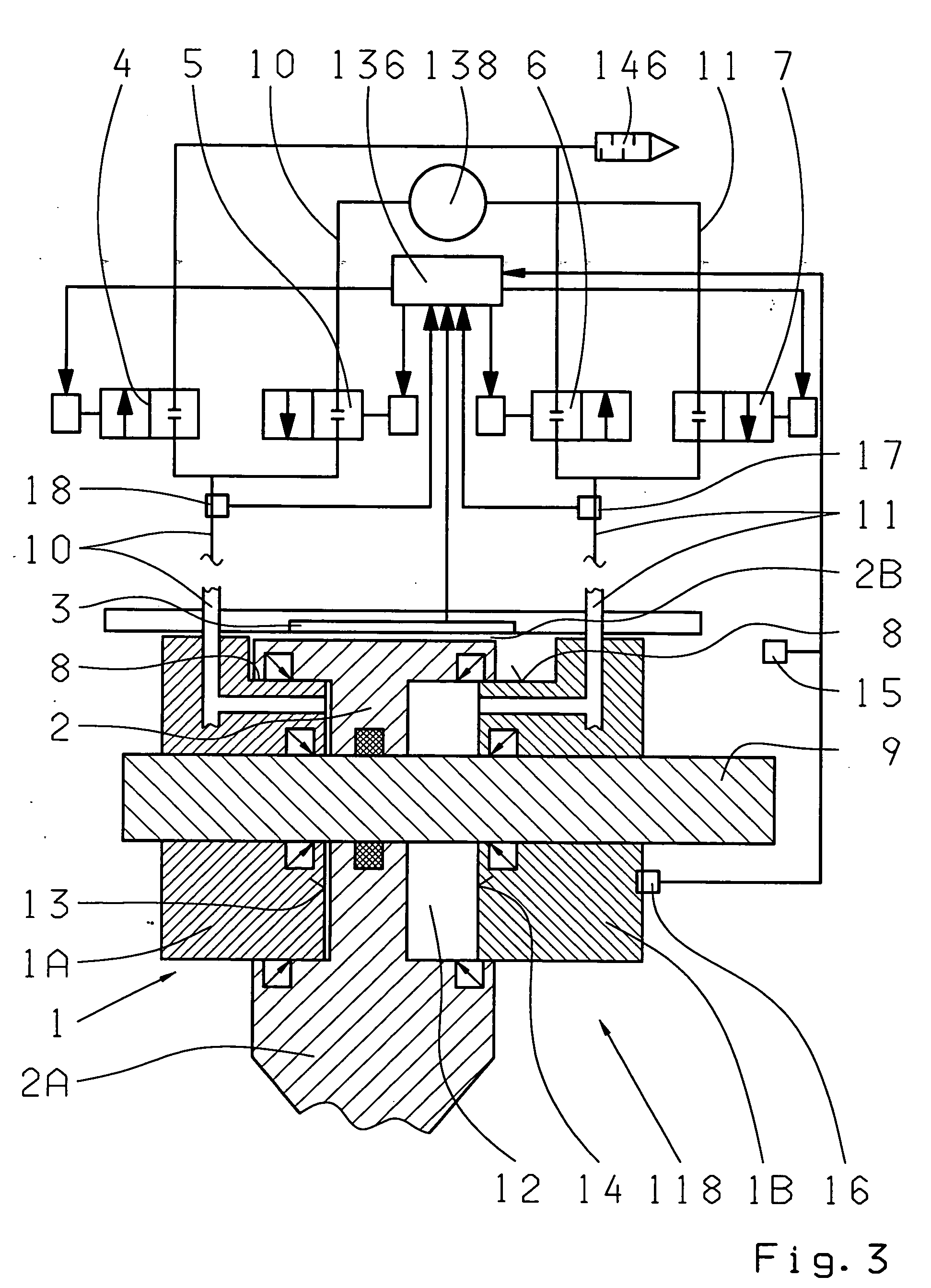

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

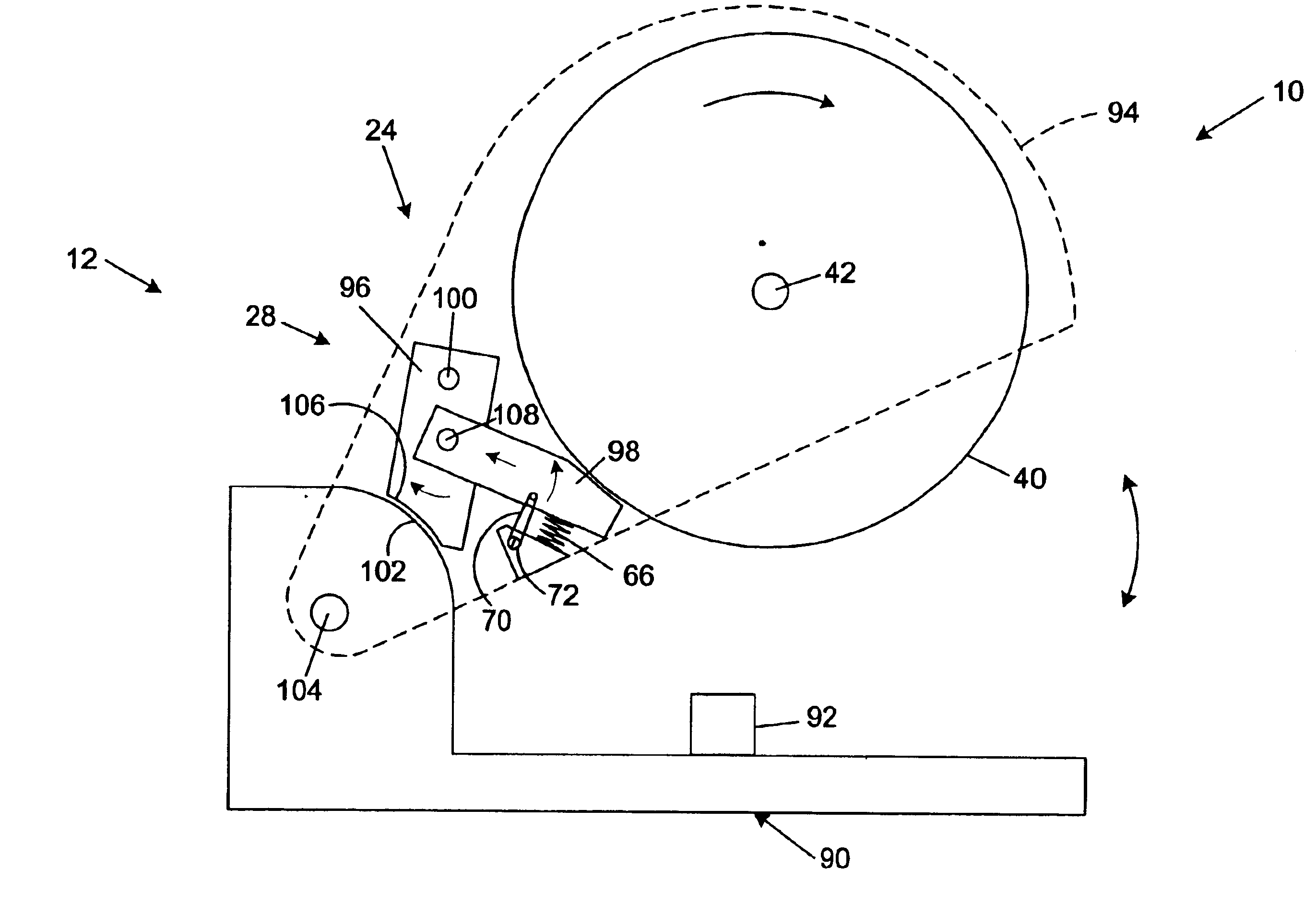

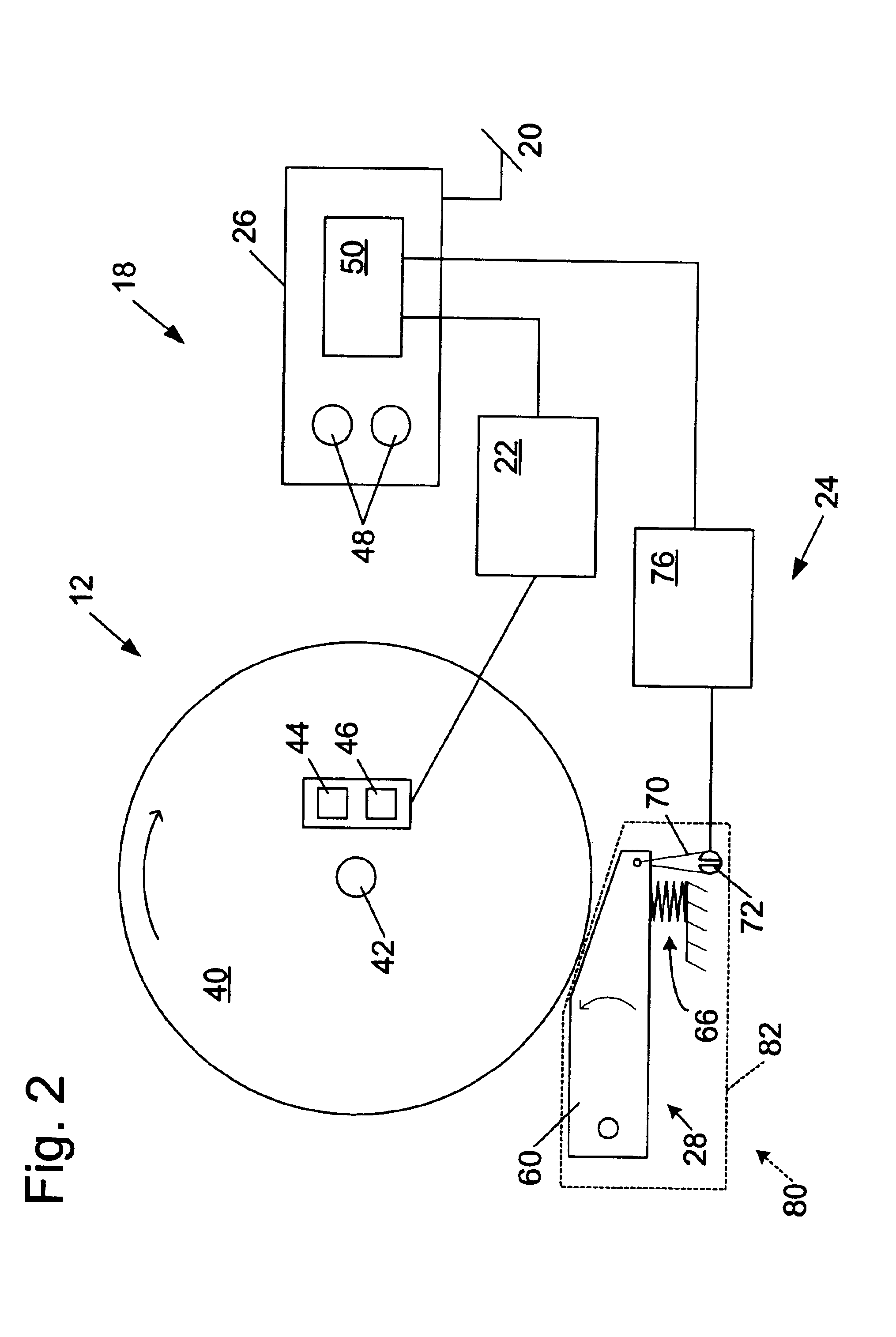

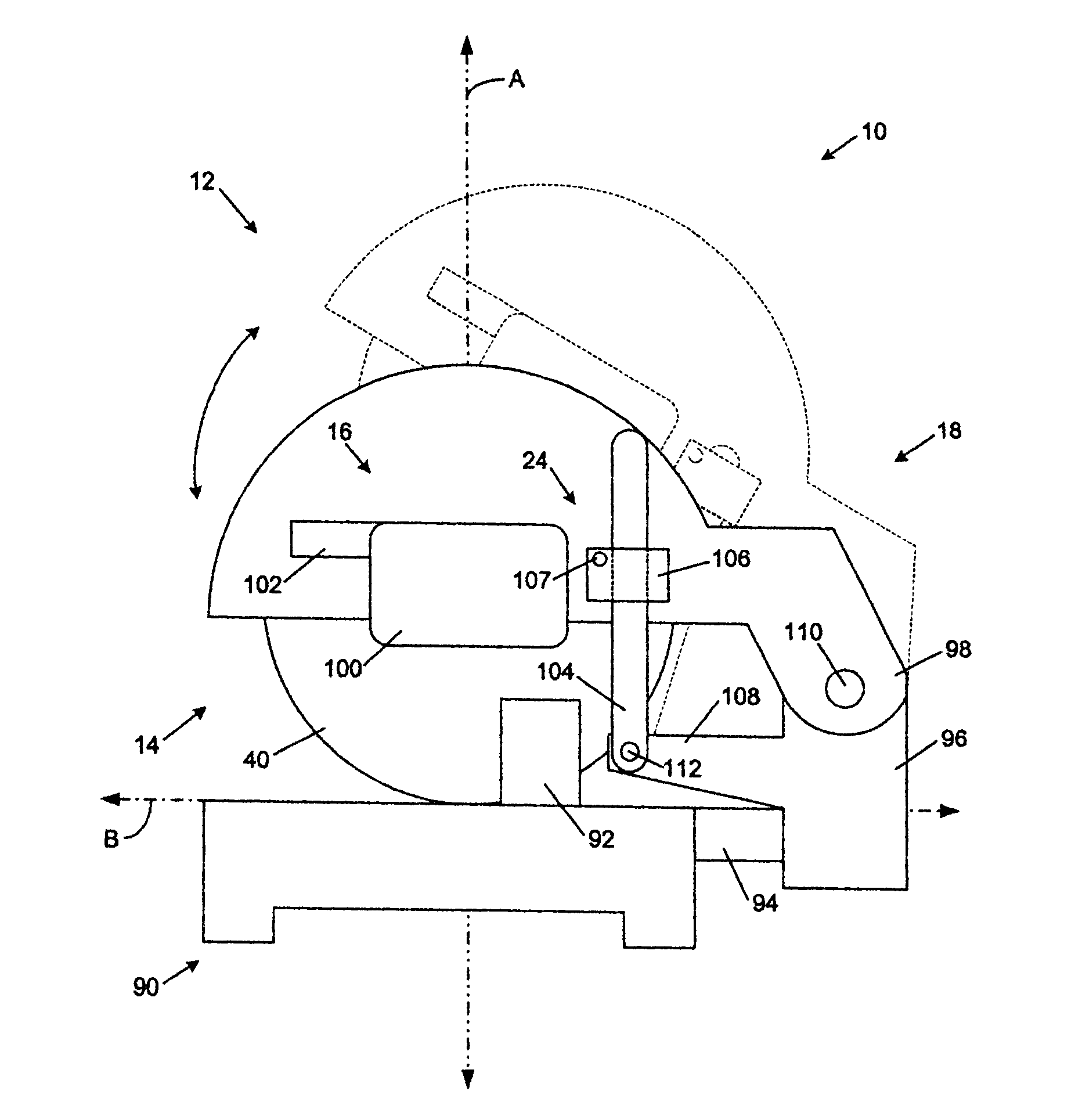

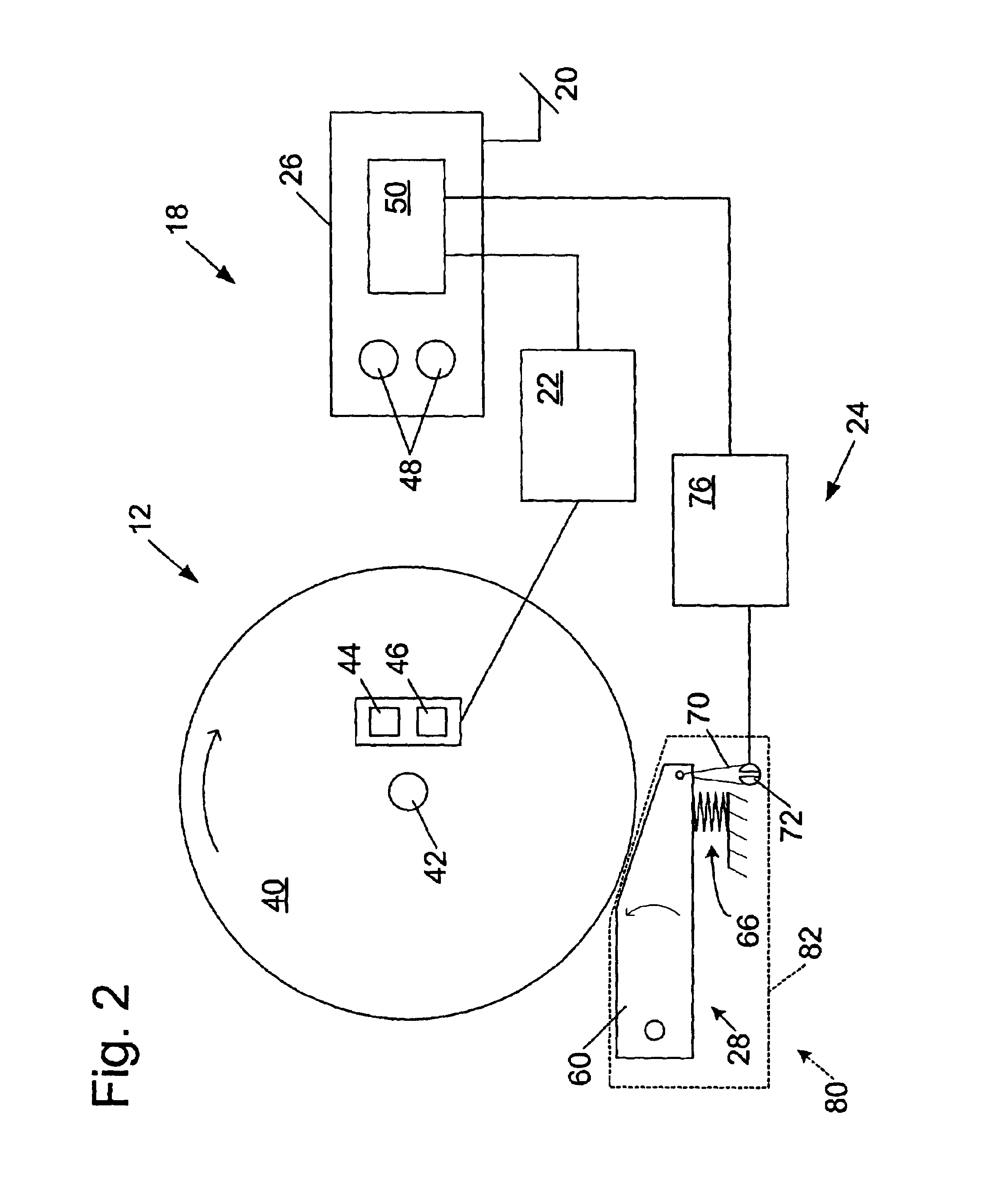

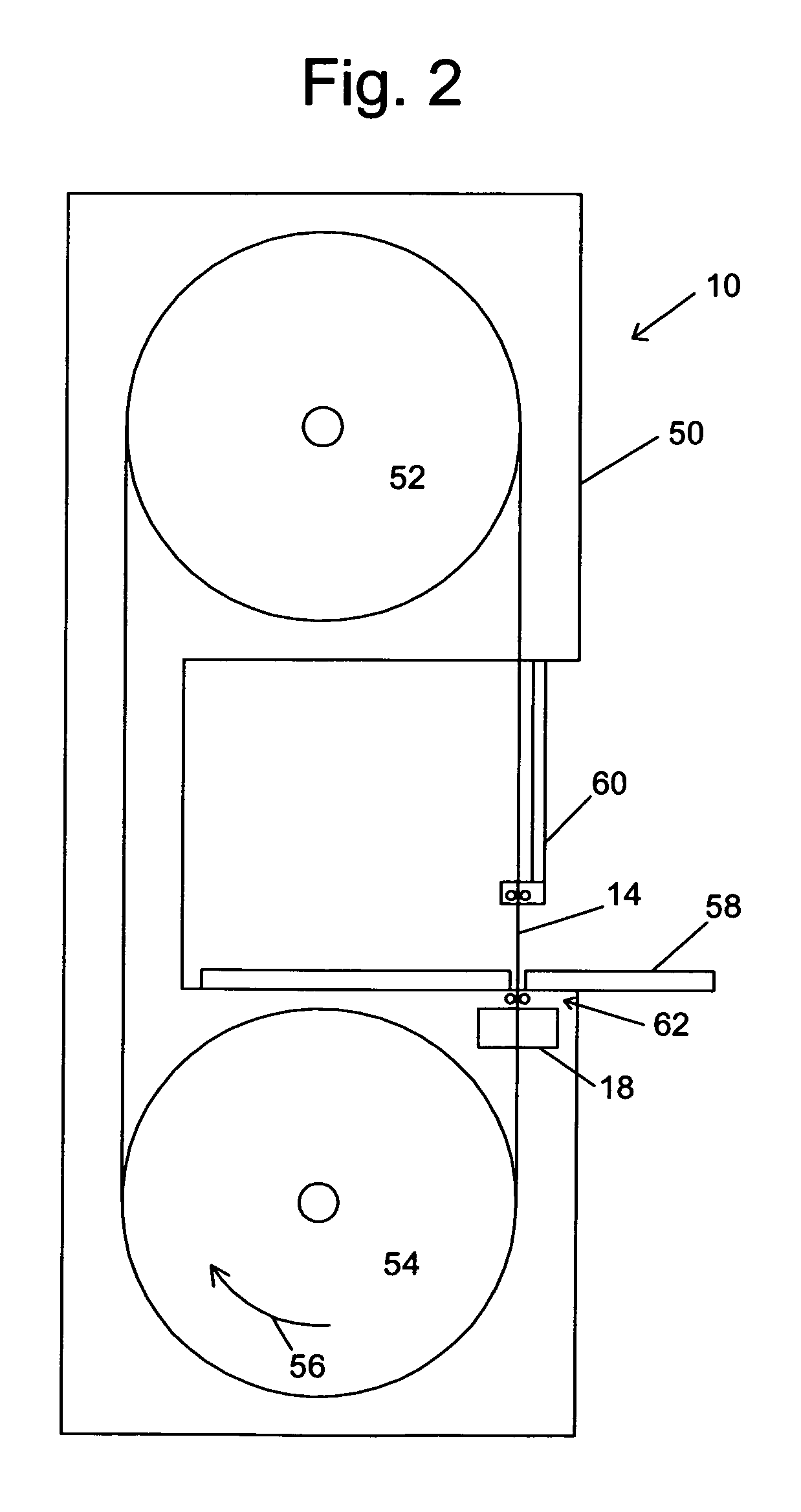

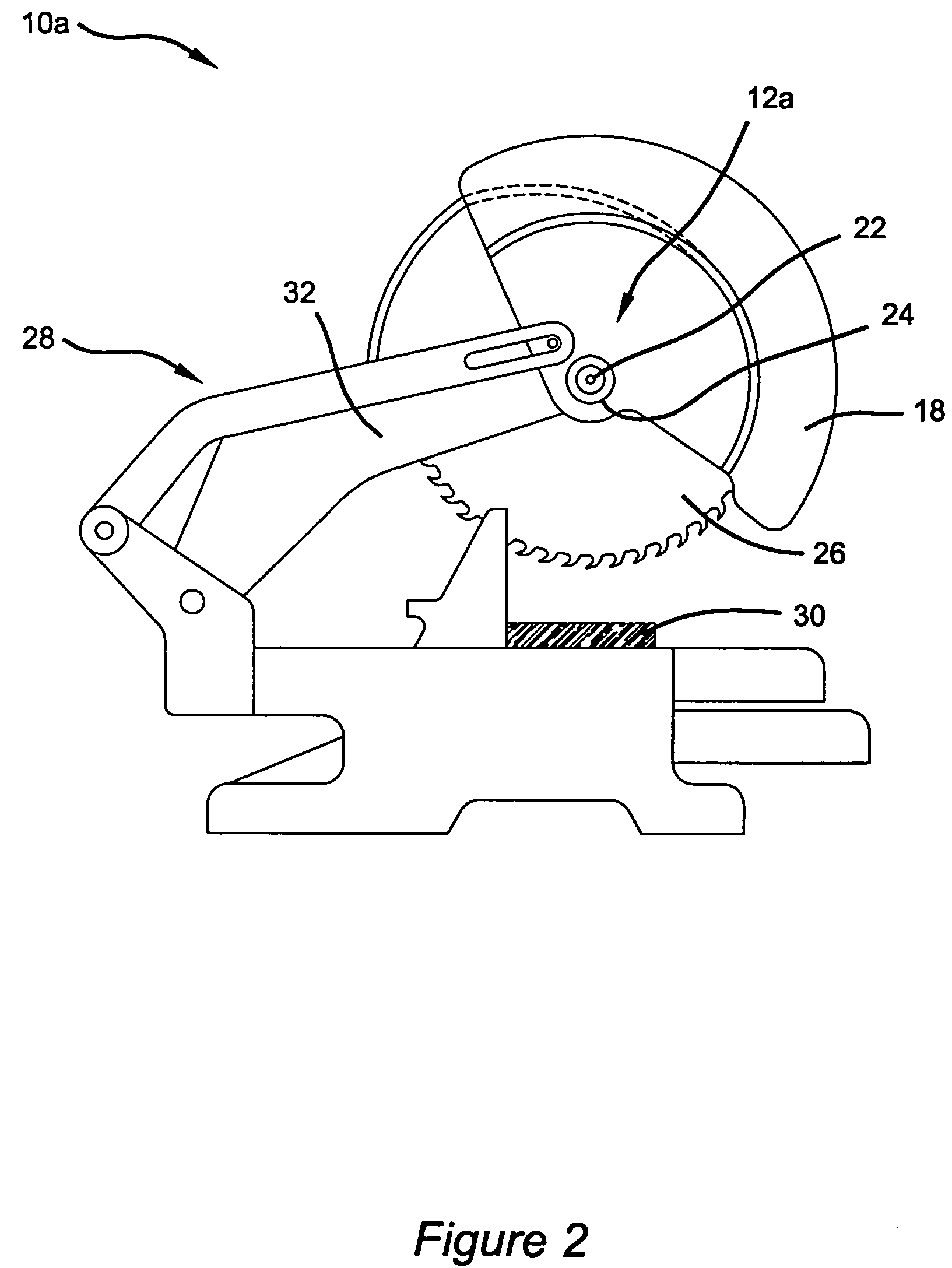

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

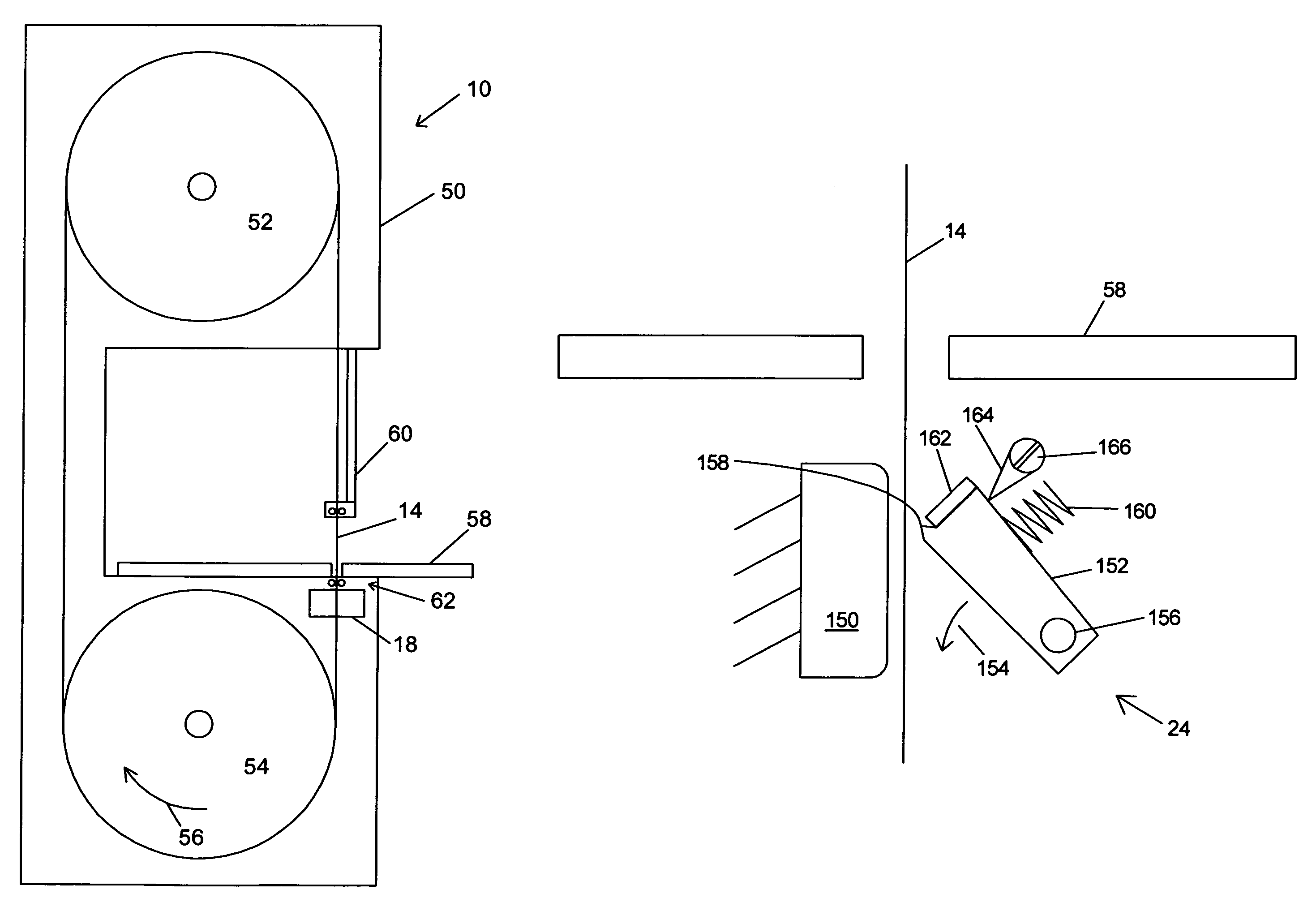

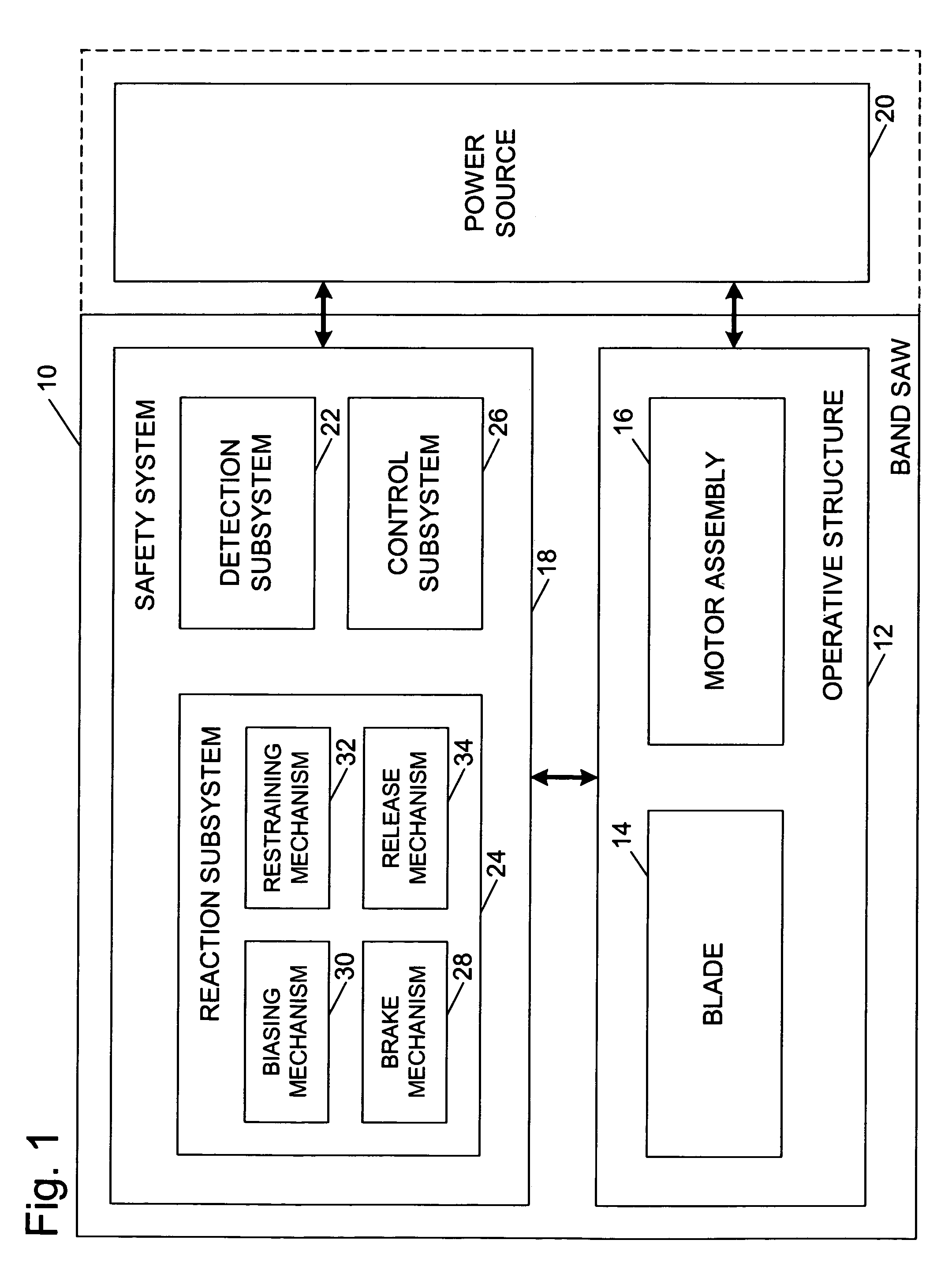

Safety systems for band saws

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

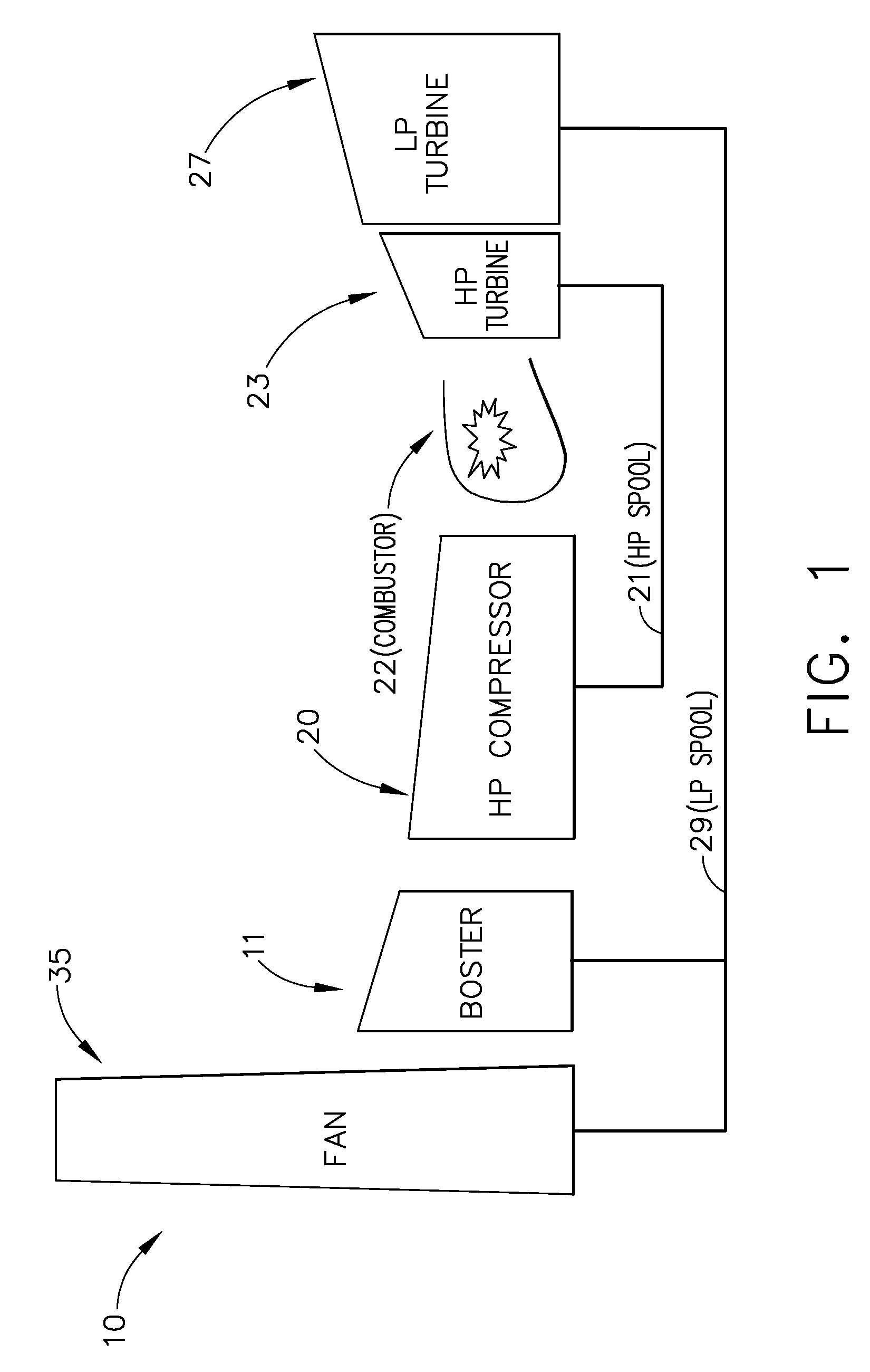

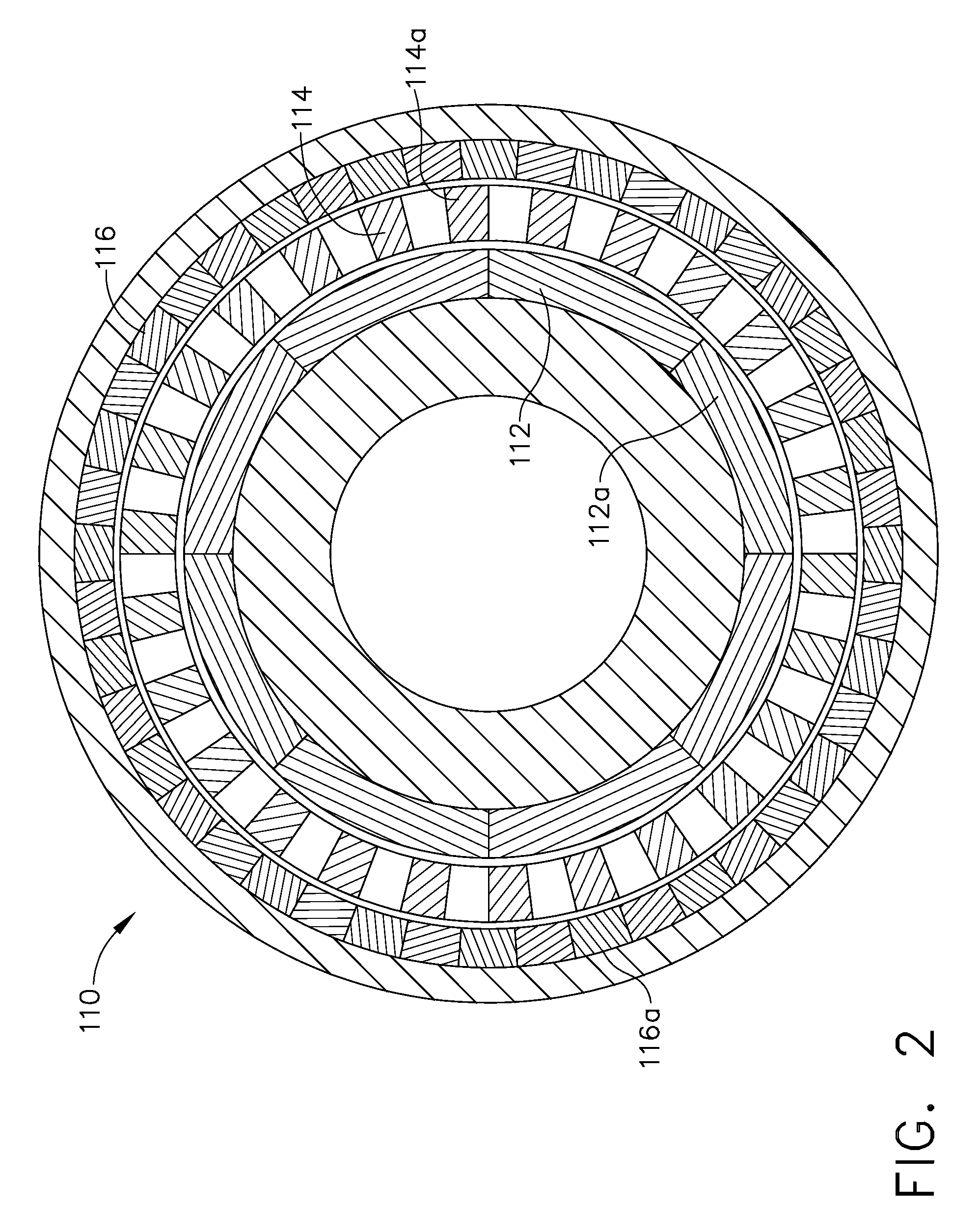

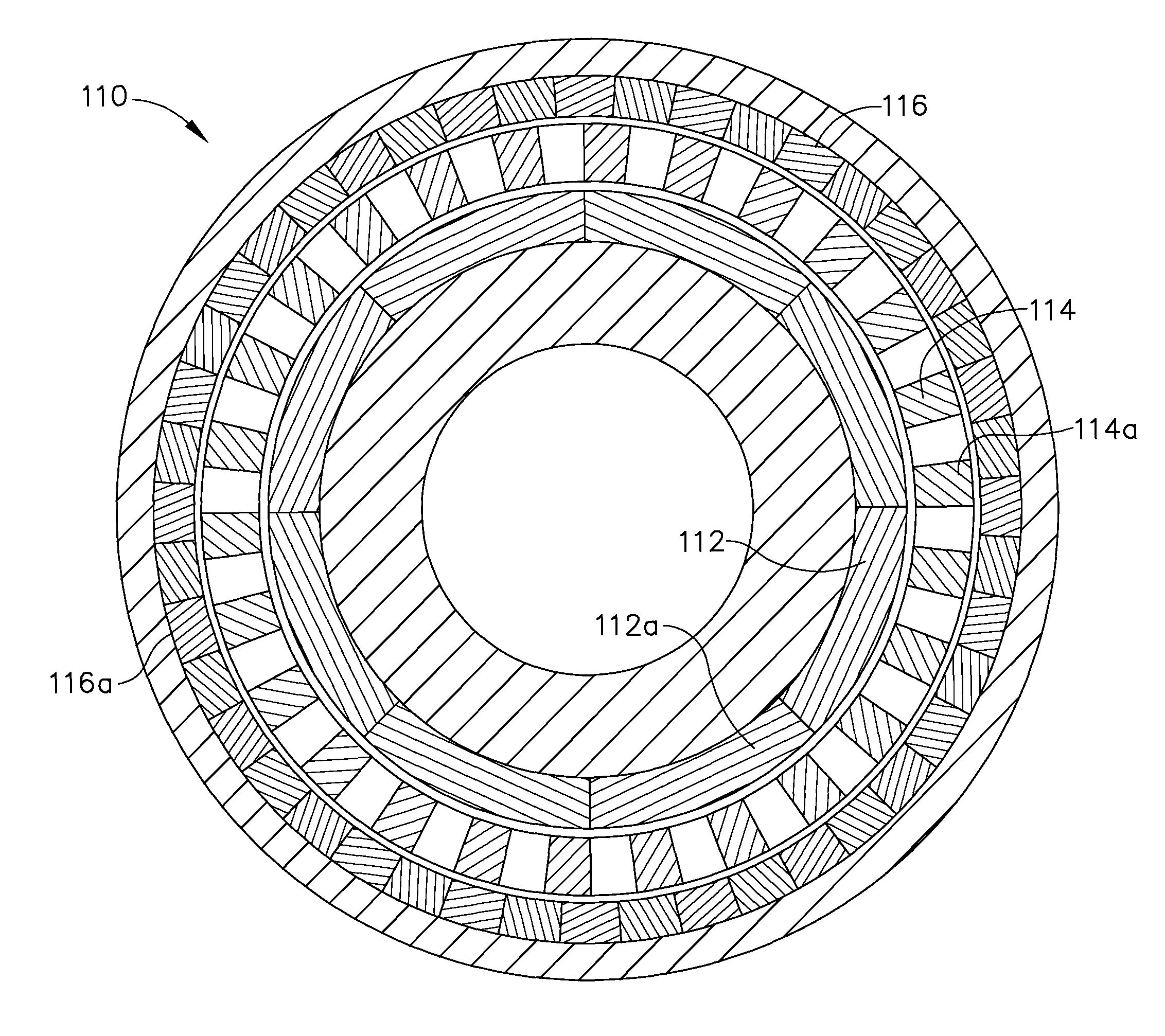

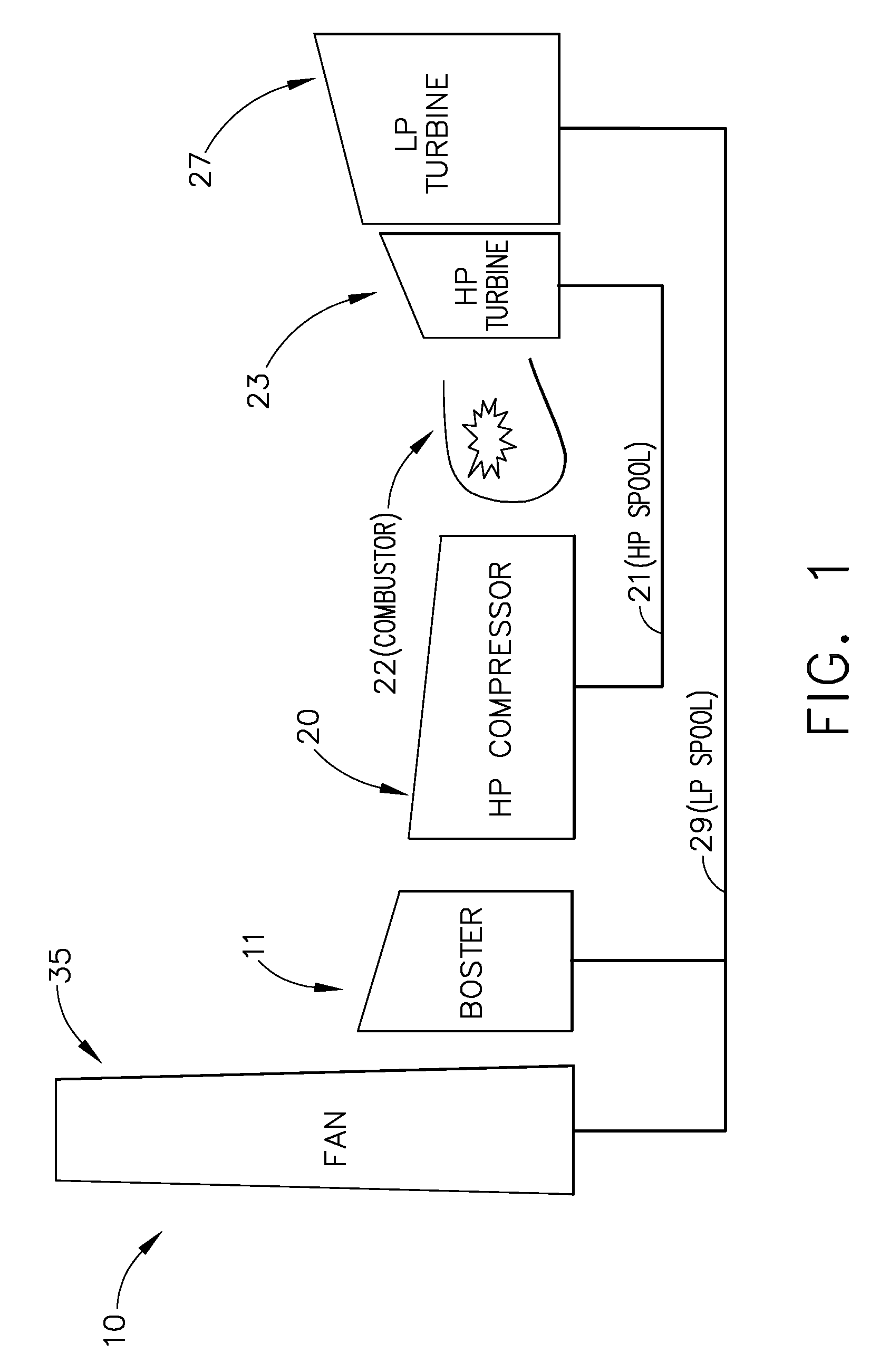

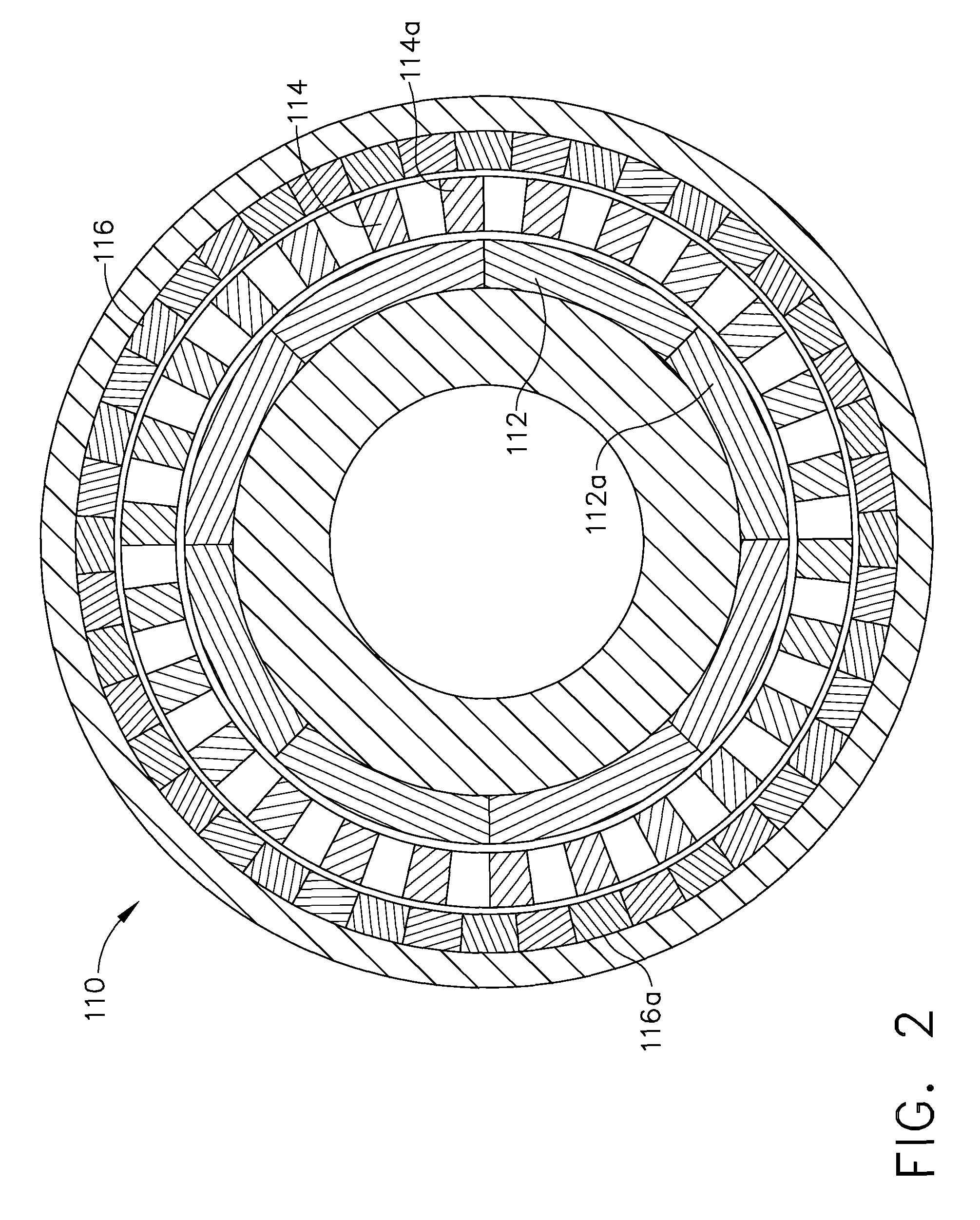

Variable Magnetic Coupling of Rotating Machinery

ActiveUS20080149445A1Reduce vibration transmissionMechanical actuated clutchesEngine fuctionsCouplingEngineering

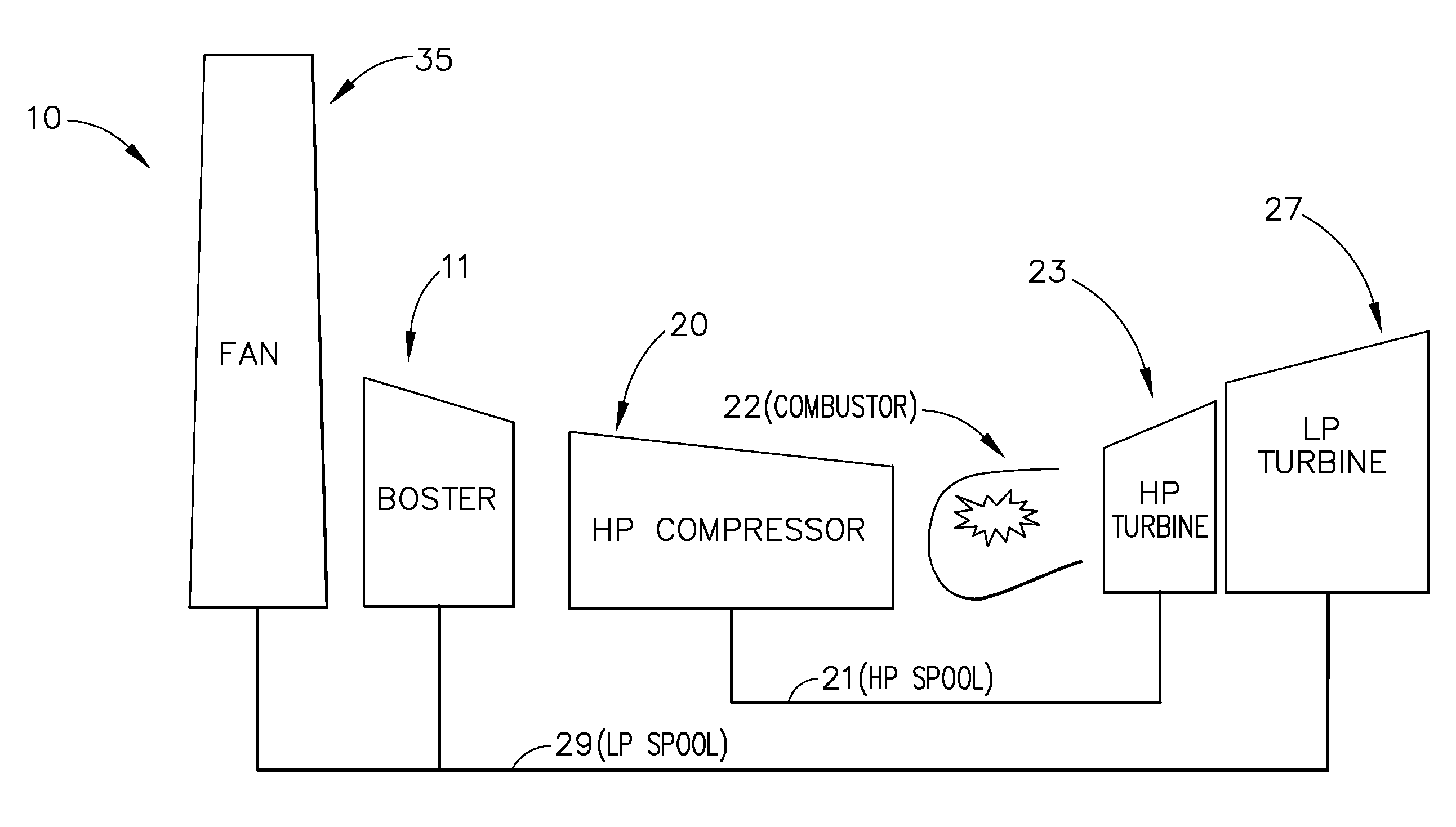

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

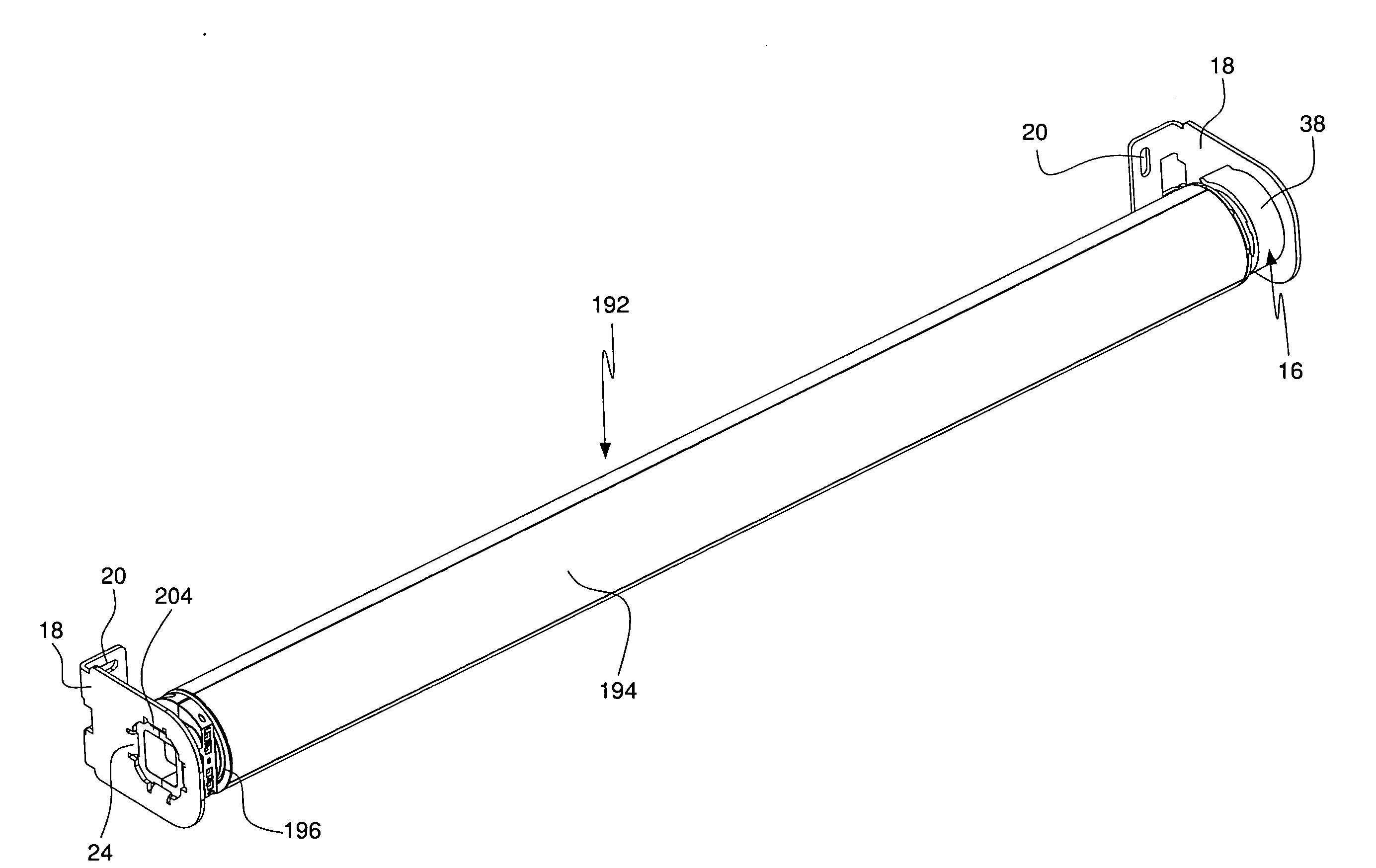

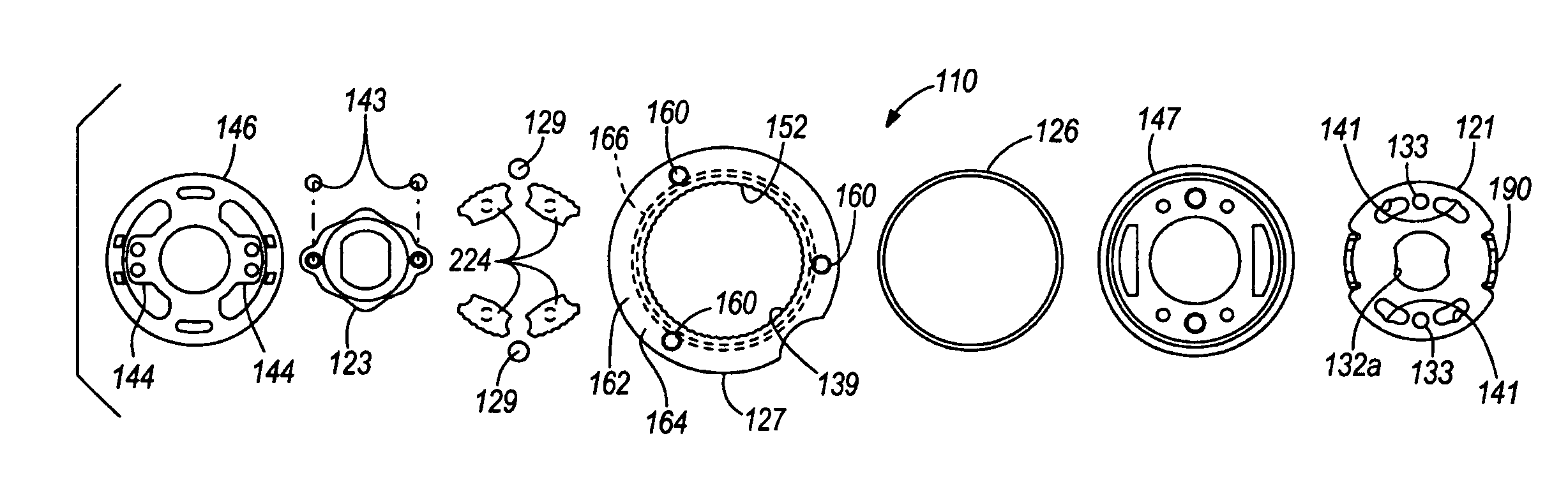

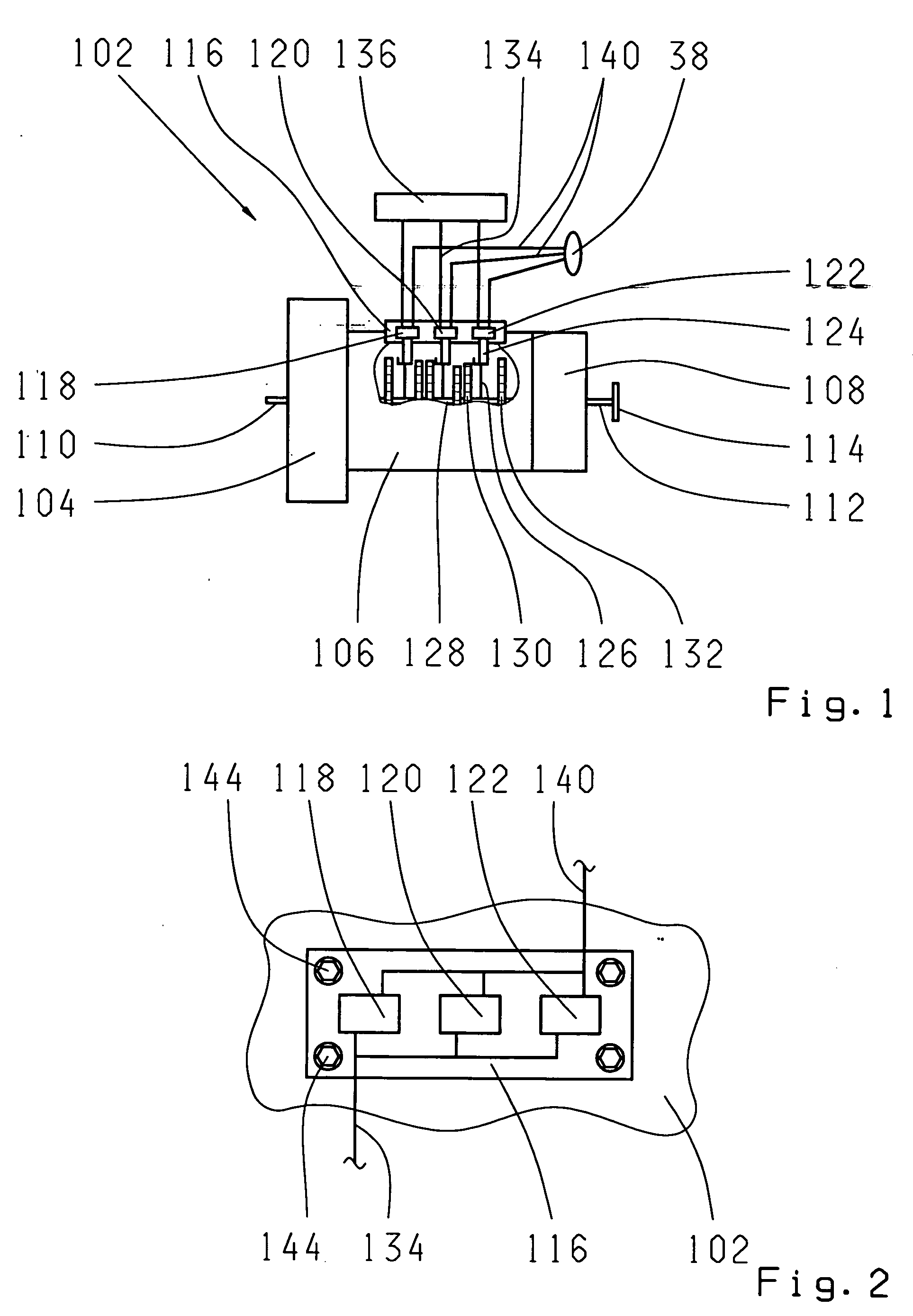

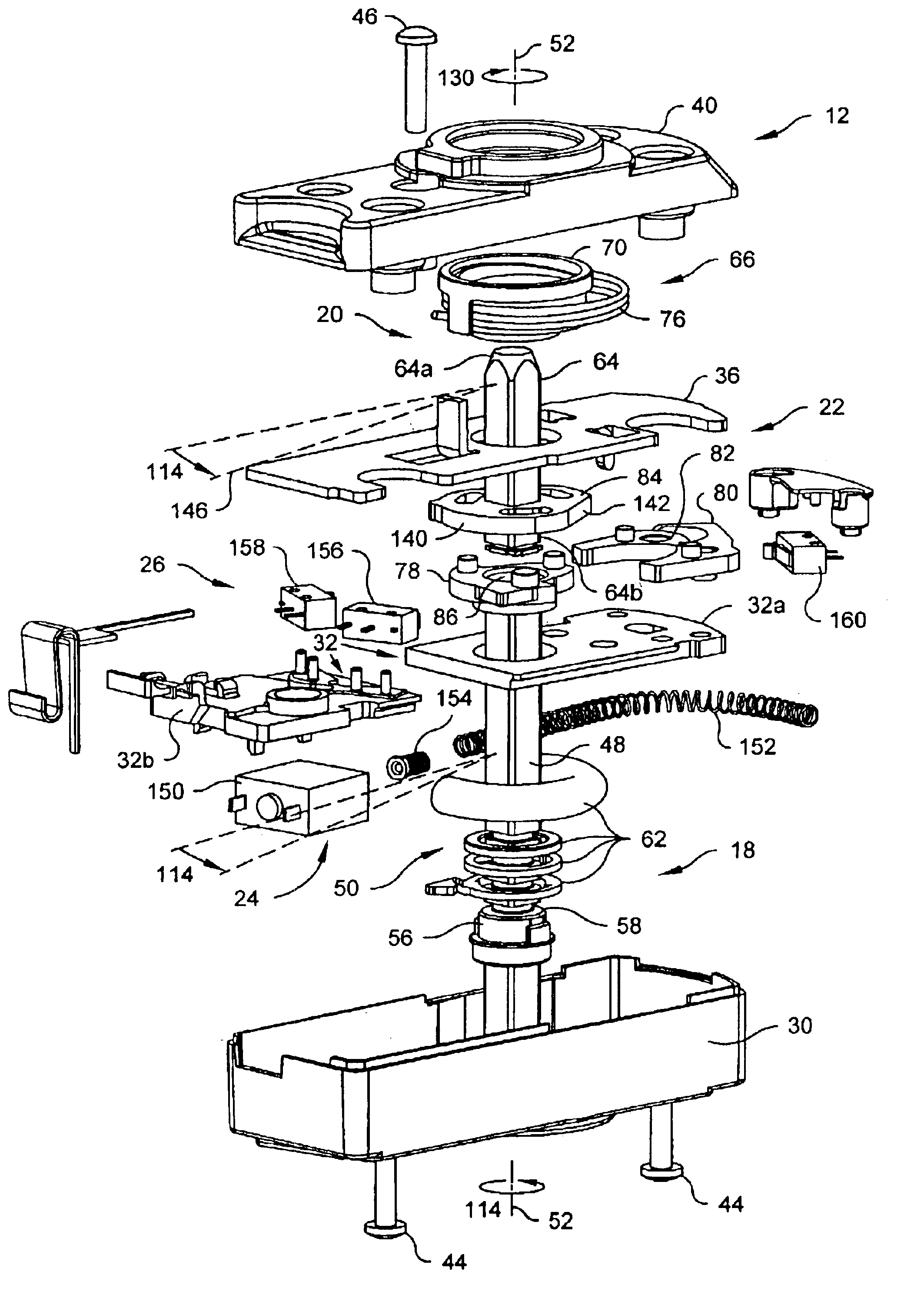

Manual roller shade having clutch mechanism, chain guide and universal mounting

A manual roller shade includes a clutch mechanism having a gear train transferring rotation of an input sprocket to rotation of an output member engaging a roller tube. The gear train includes a sun gear, planet gears supported by a carrier and engaging the sun gear, and a ring gear engaging the planet gears. According to one embodiment, the carrier does not rotate. The ratio between the diameters of the input sprocket and the roller tube is selected to offset mechanical advantage of the gear train to provide an effective gear train ratio of approximately 2:1. A drive chain guide system includes spaced guide wheels controlling where a drive chain is suspended from the manual shade. A roller shade mounting system includes a bracket receiving either an input assembly of the manual roller shade or a motor of a motorized roller shade to facilitate conversion.

Owner:LUTRON TECH CO LLC

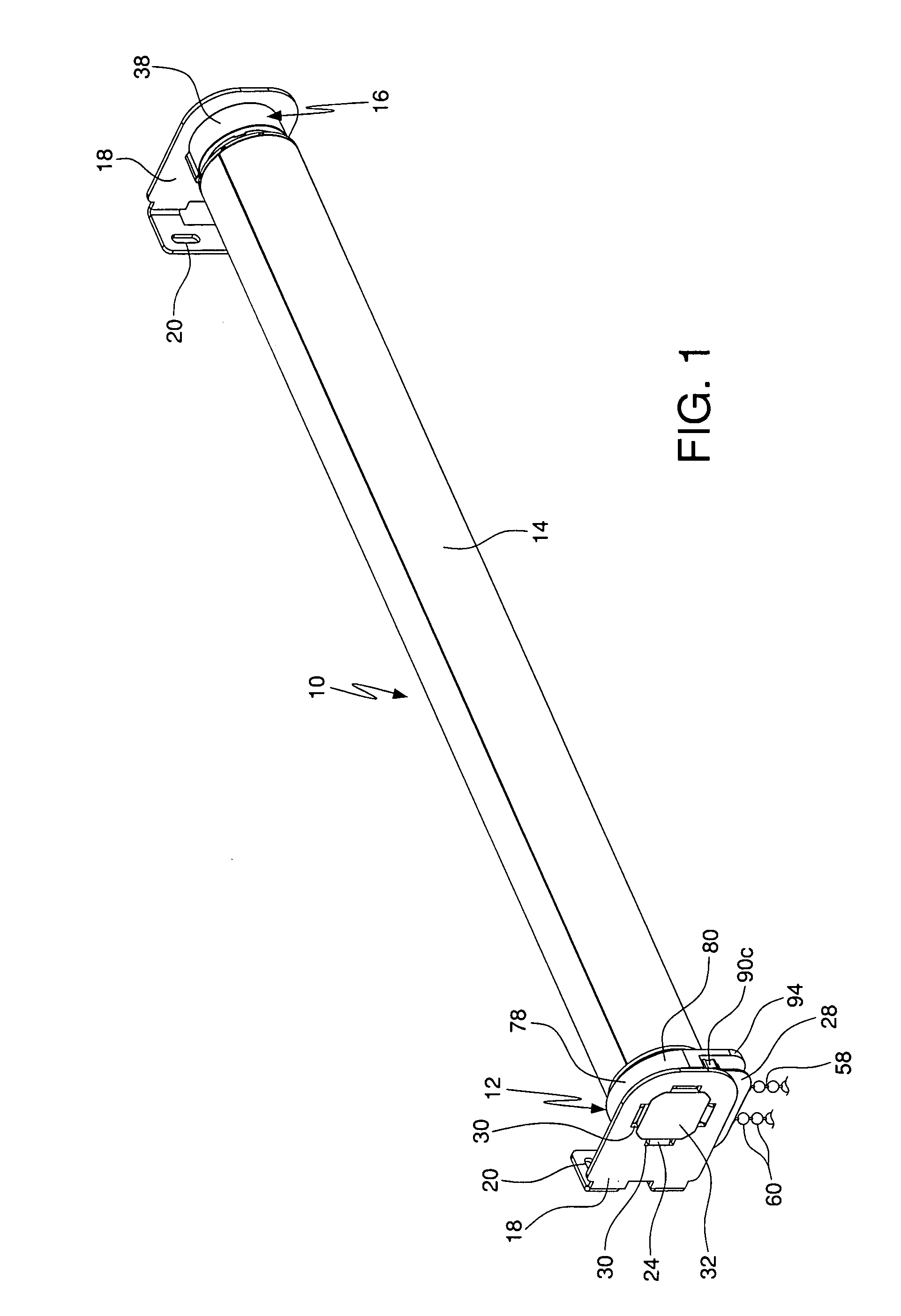

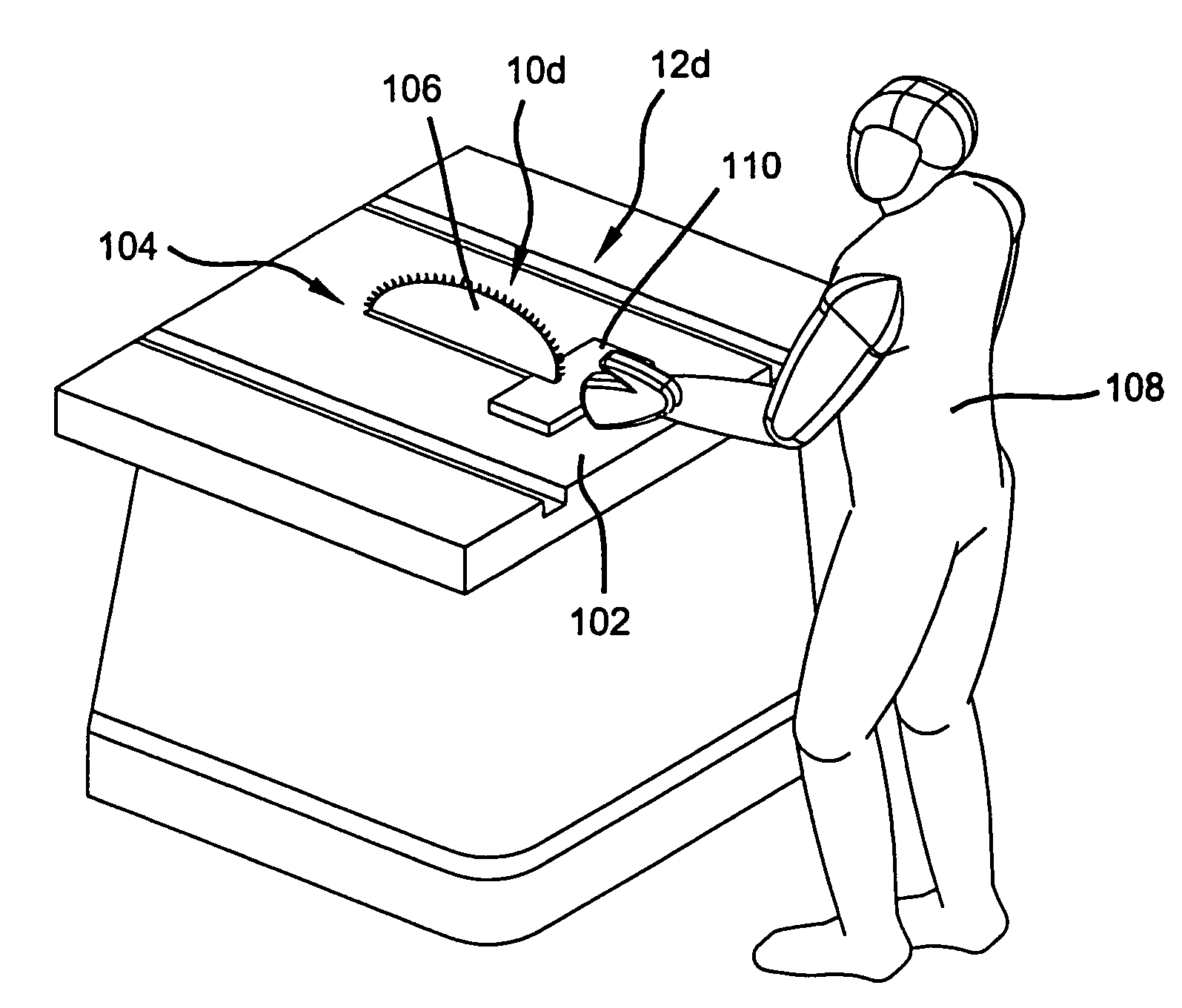

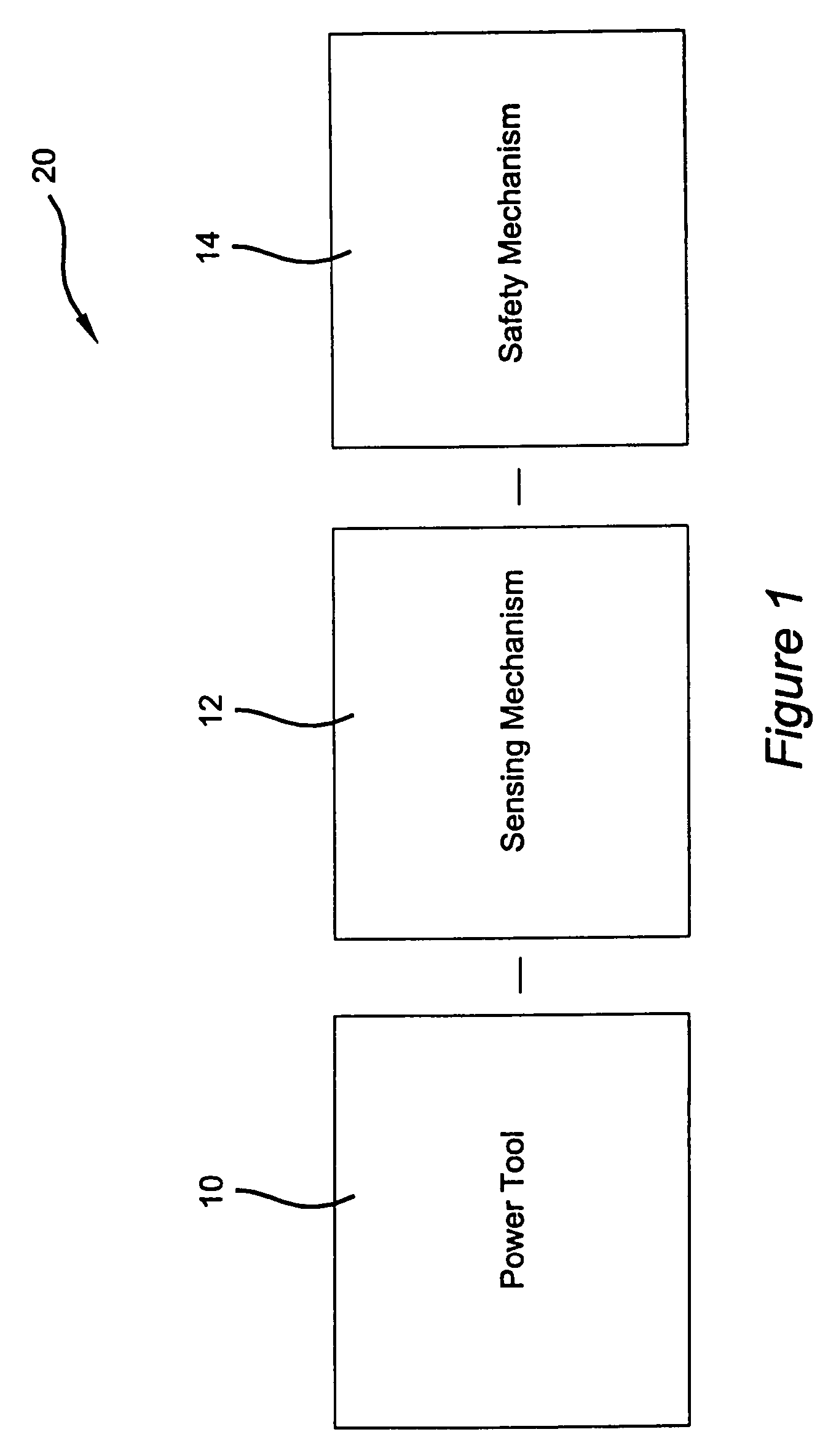

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

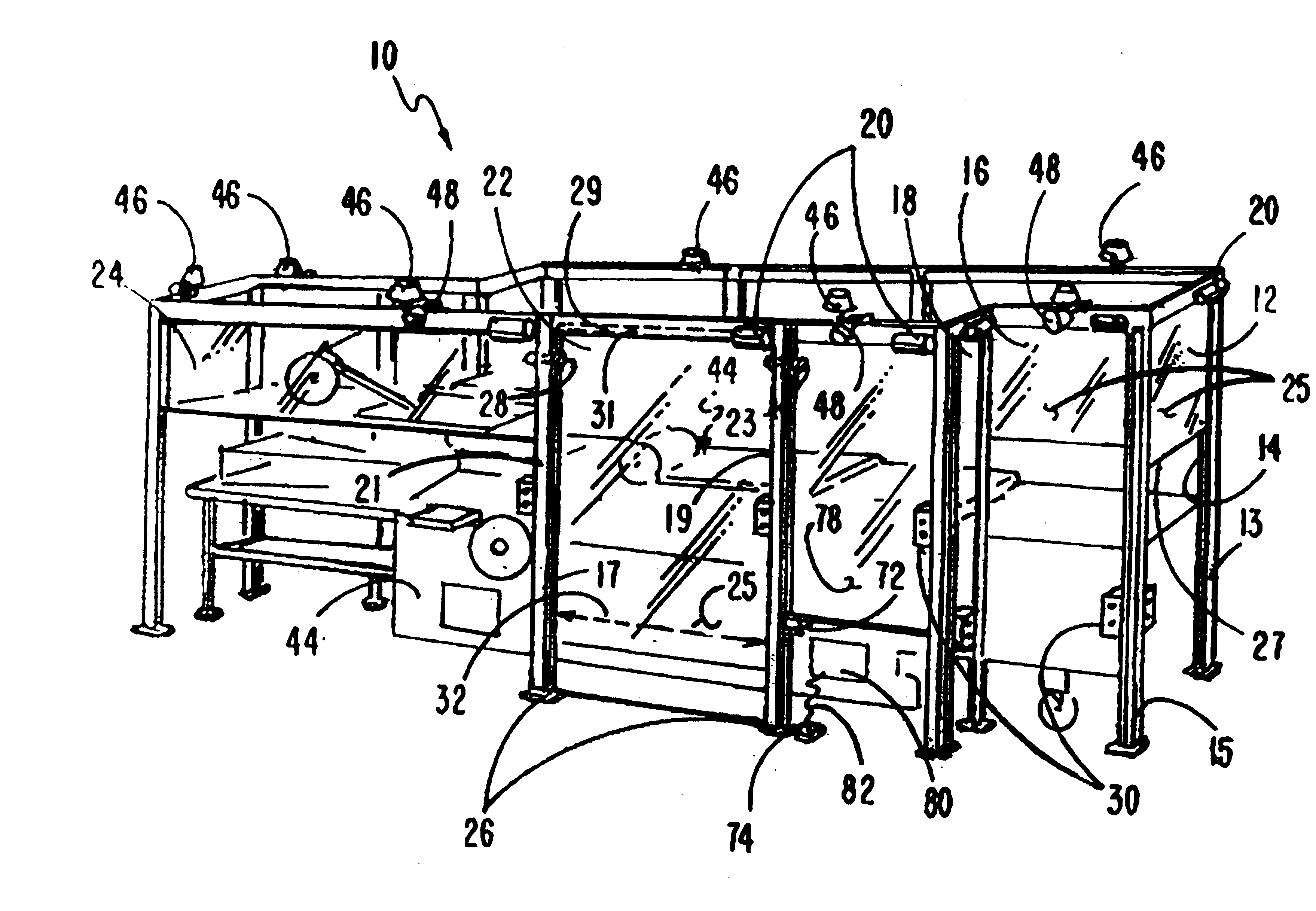

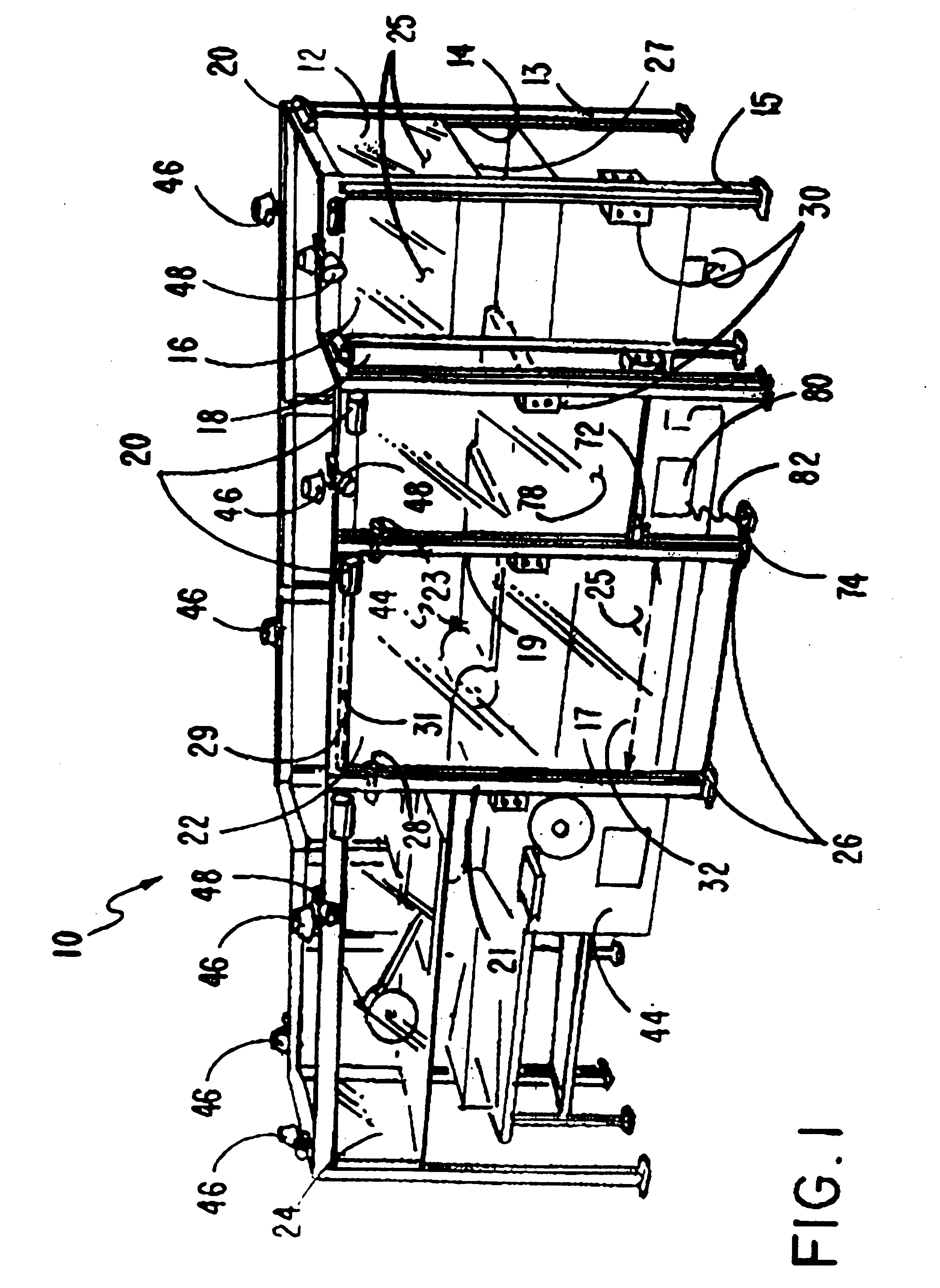

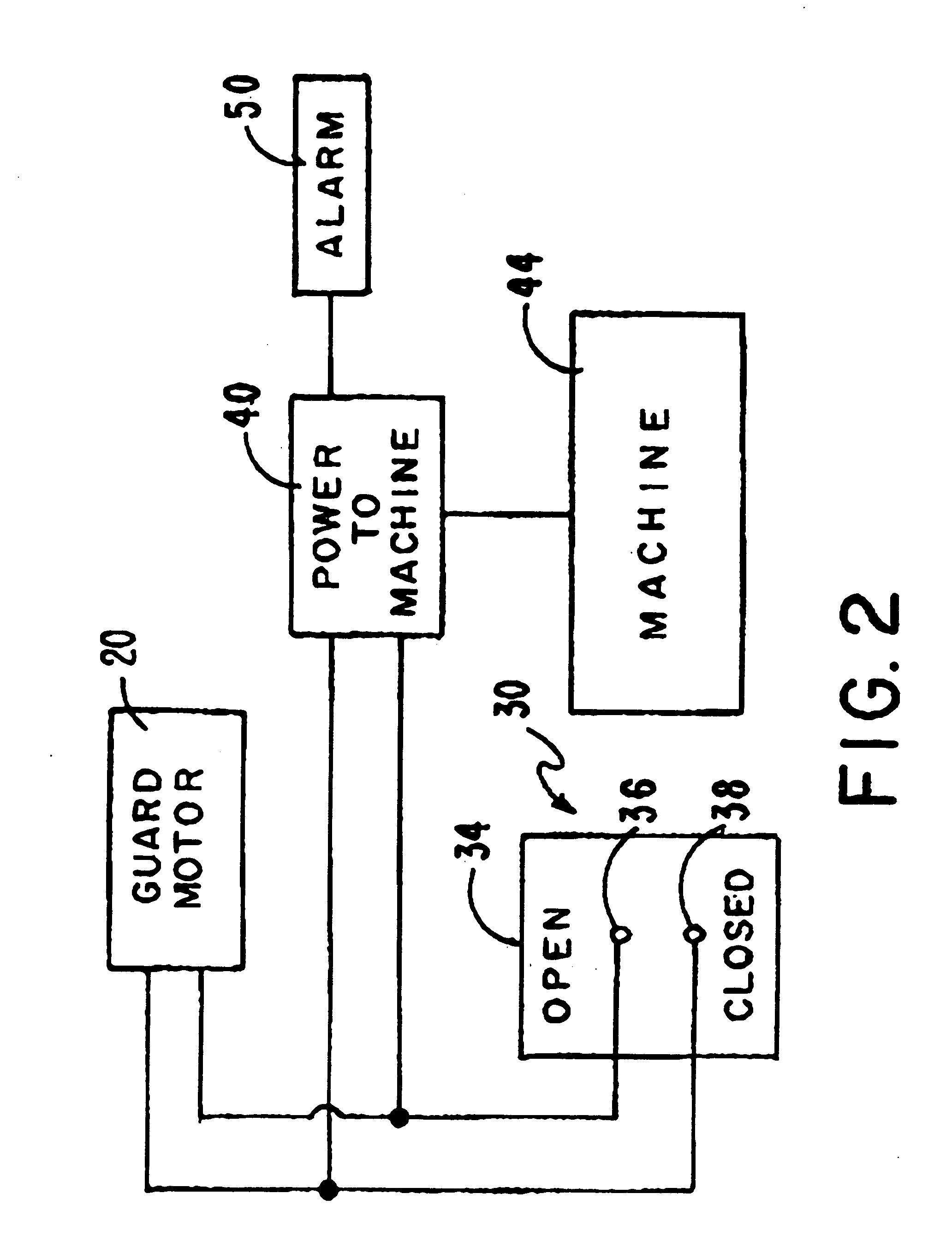

Machine safety guard

InactiveUS6325195B1Easy to operateProvide securityYielding couplingShutters/ movable grillesUnit systemEngineering

A machine safety guard unit system having a flexible panel moved upwards and downwards between track members with the system positioned between the operative parts of a machine and a machine operator, such panel when closed protecting the machine operator and when moved upwards into its open mode, allowing access to the machine and preventing the machine from operating. In some embodiments more than one of such units can be disposed around a machine with alarm means; and in yet other embodiments, with interengagement means connecting such units.

Owner:RITE HITE HLDG CORP

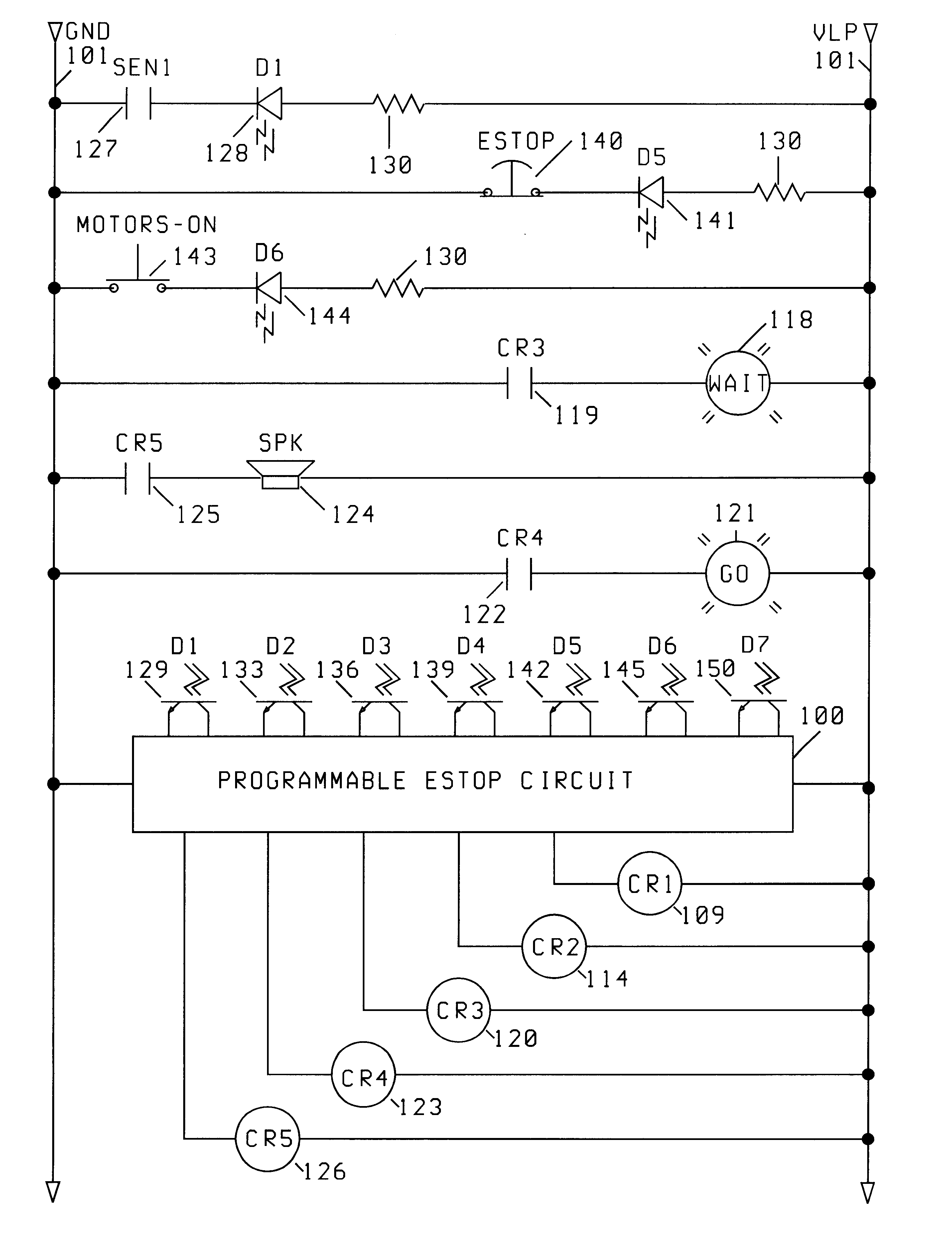

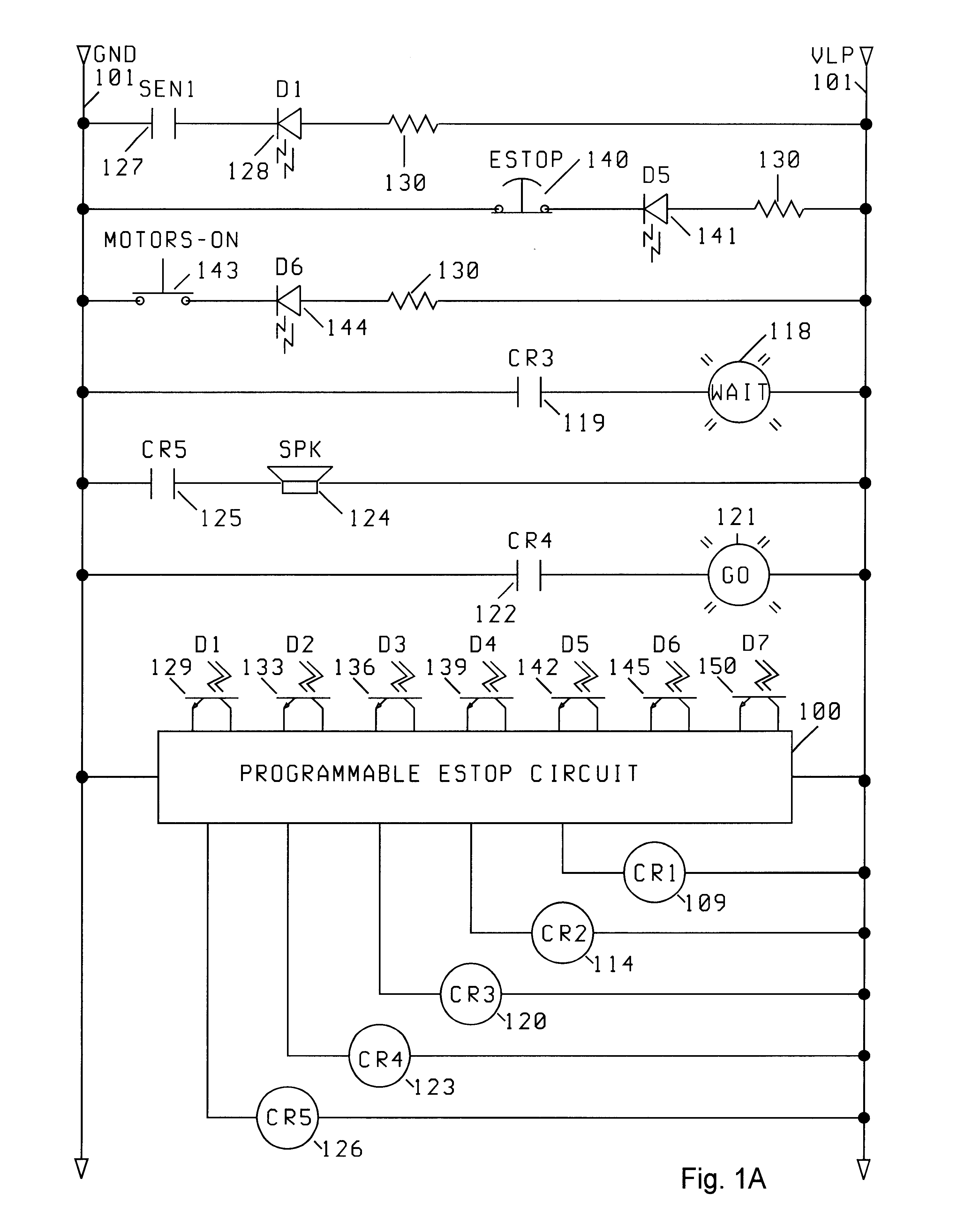

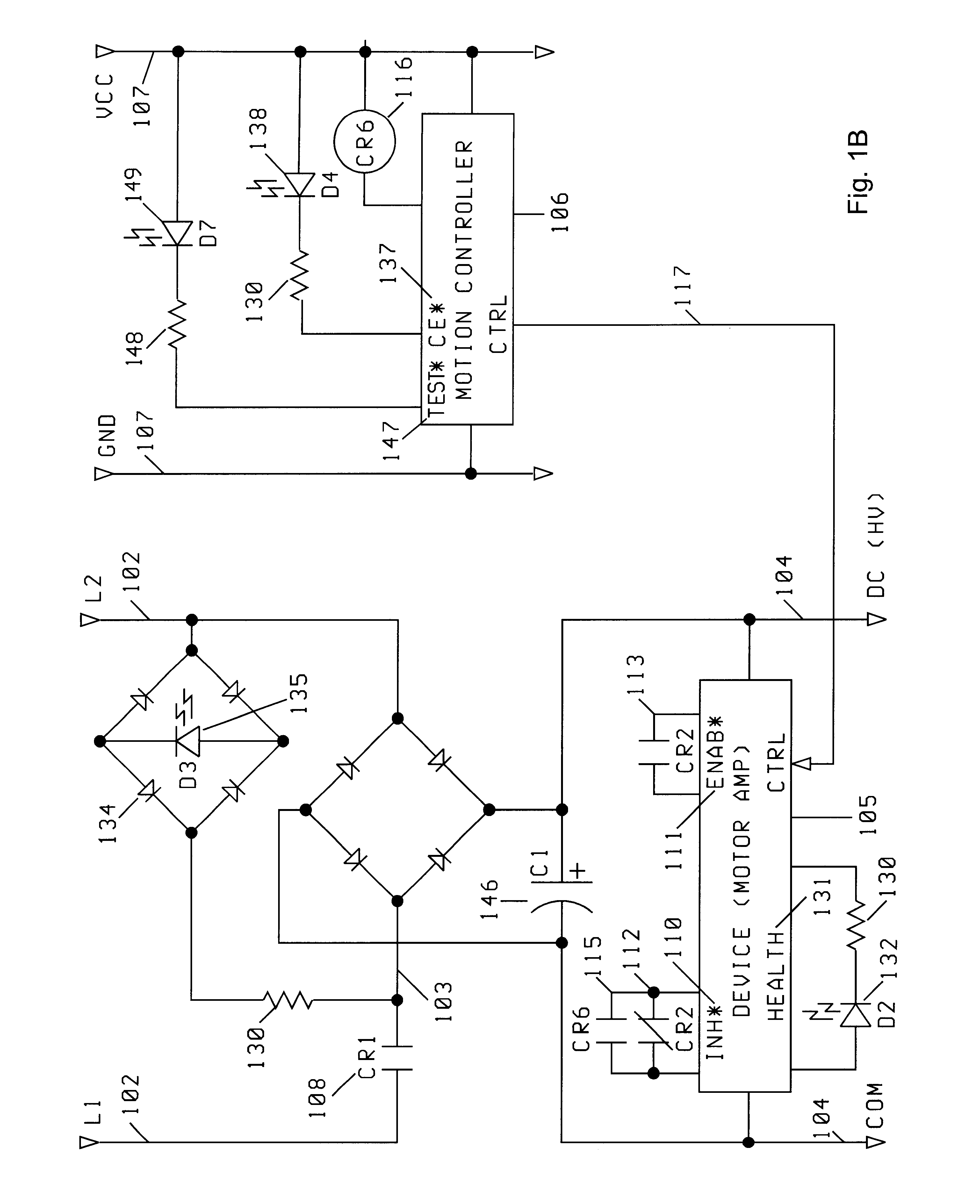

Programmable emergency-stop circuit with testing

InactiveUS6734581B1Safely incorporatedReduce sensitivityBatteries circuit arrangementsEmergency protective circuit arrangementsTest inputKill switch

The invention includes a programmable emergency-stop circuit apparatus and method that provides advanced function not found in other systems. The circuit centralizes the control of high voltage motor power into one place, by providing connections for, in its minimum configuration, several different kill switches, a motors-on button, and an AC motor power relay coil. In the present invention, kill switches, test inputs, emergency-stop and motors-on buttons, computer ready and watchdog signals are all conveniently connected in one location, alongside the AC motor power relay coil driver. Programmable options exist for testing kill inputs online, while the emergency stop is energized.

Owner:EIGENPOINT

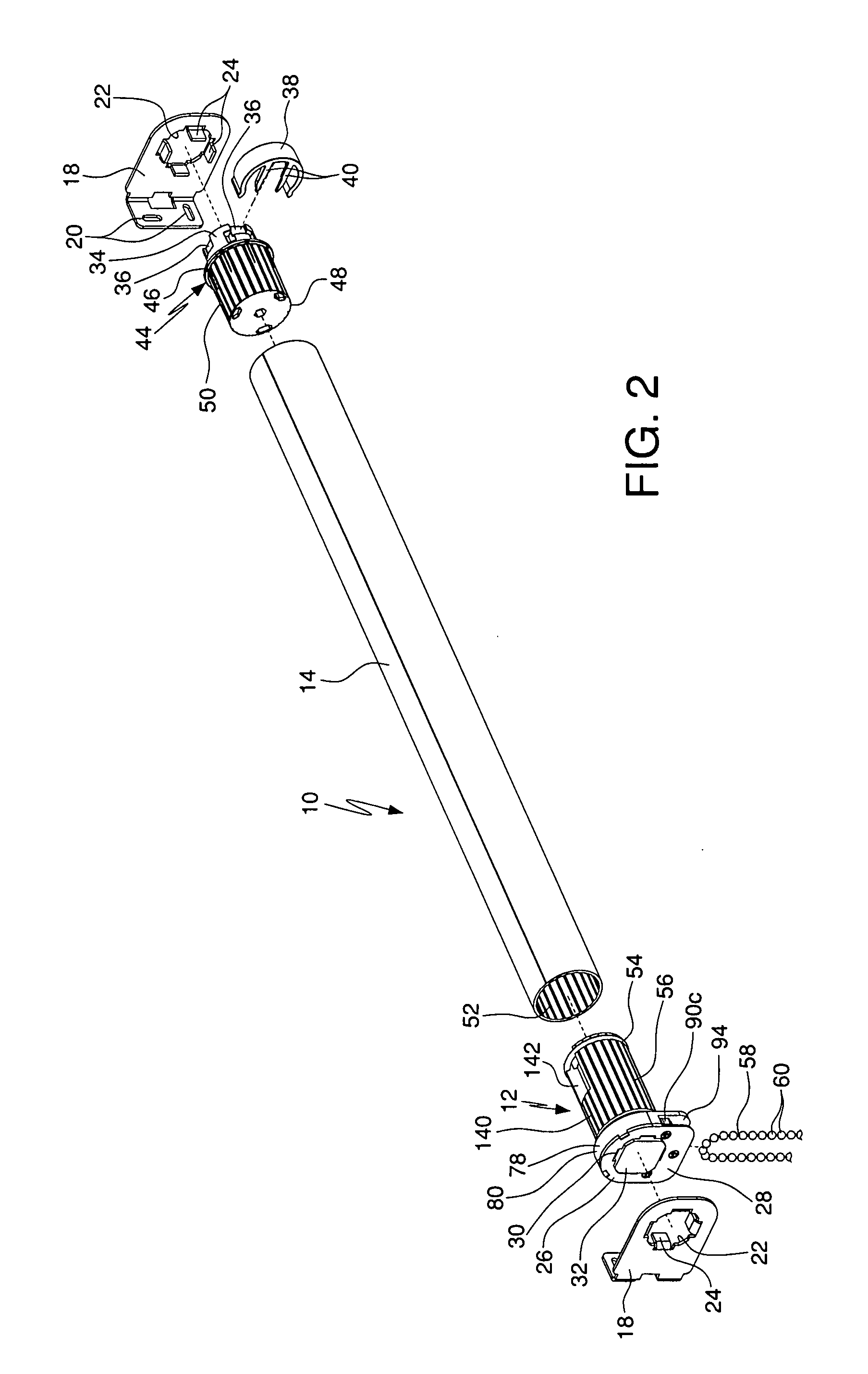

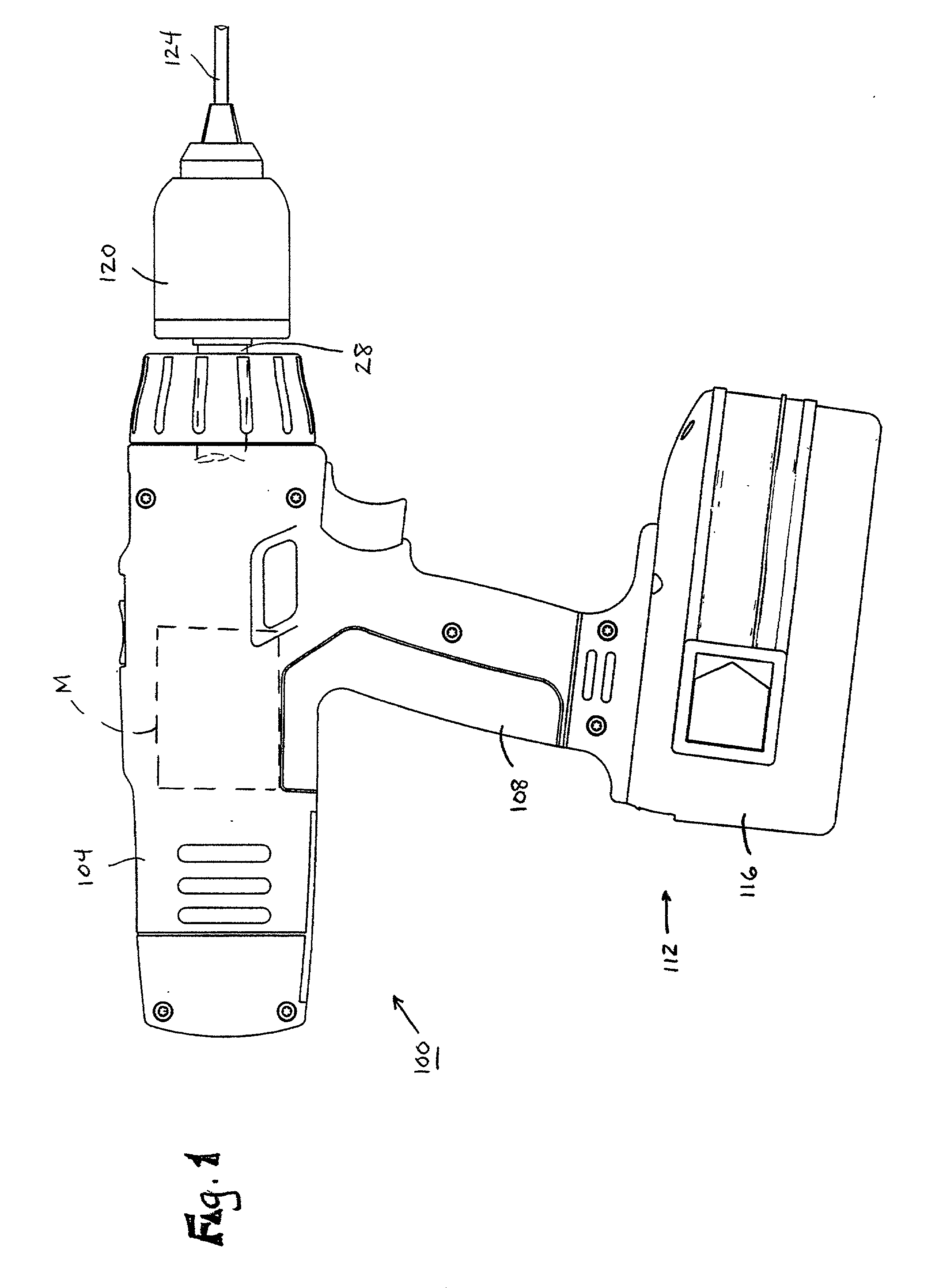

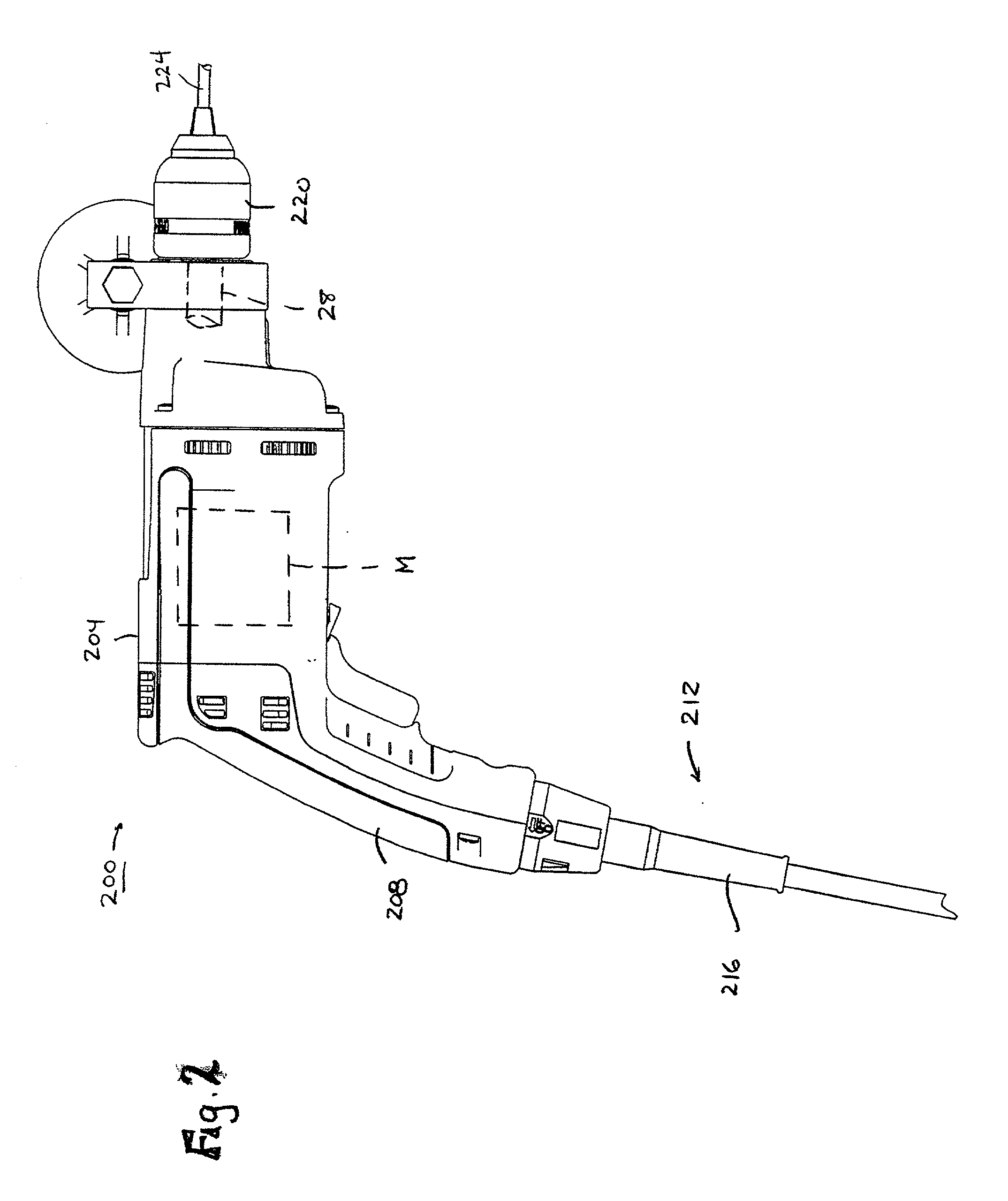

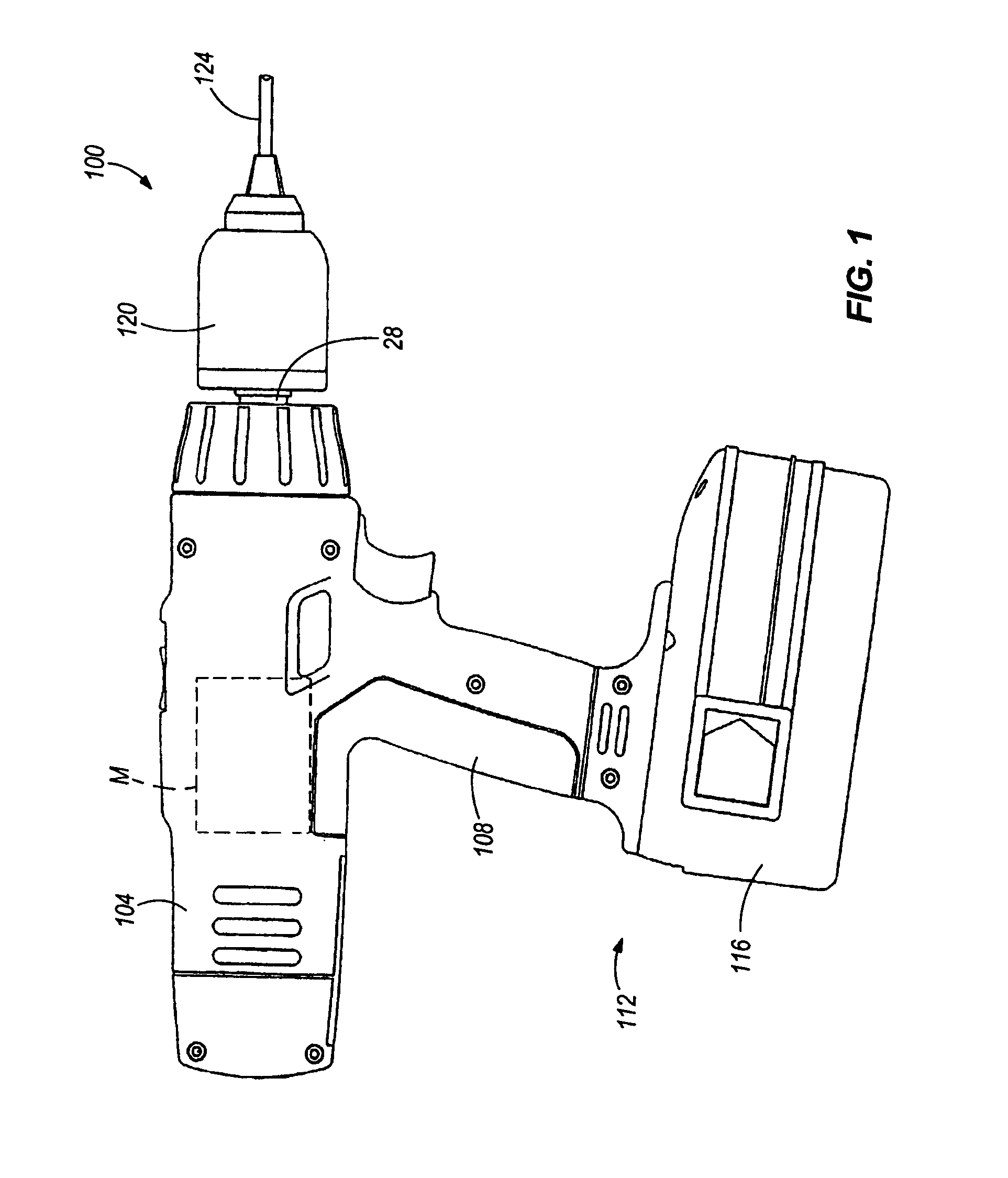

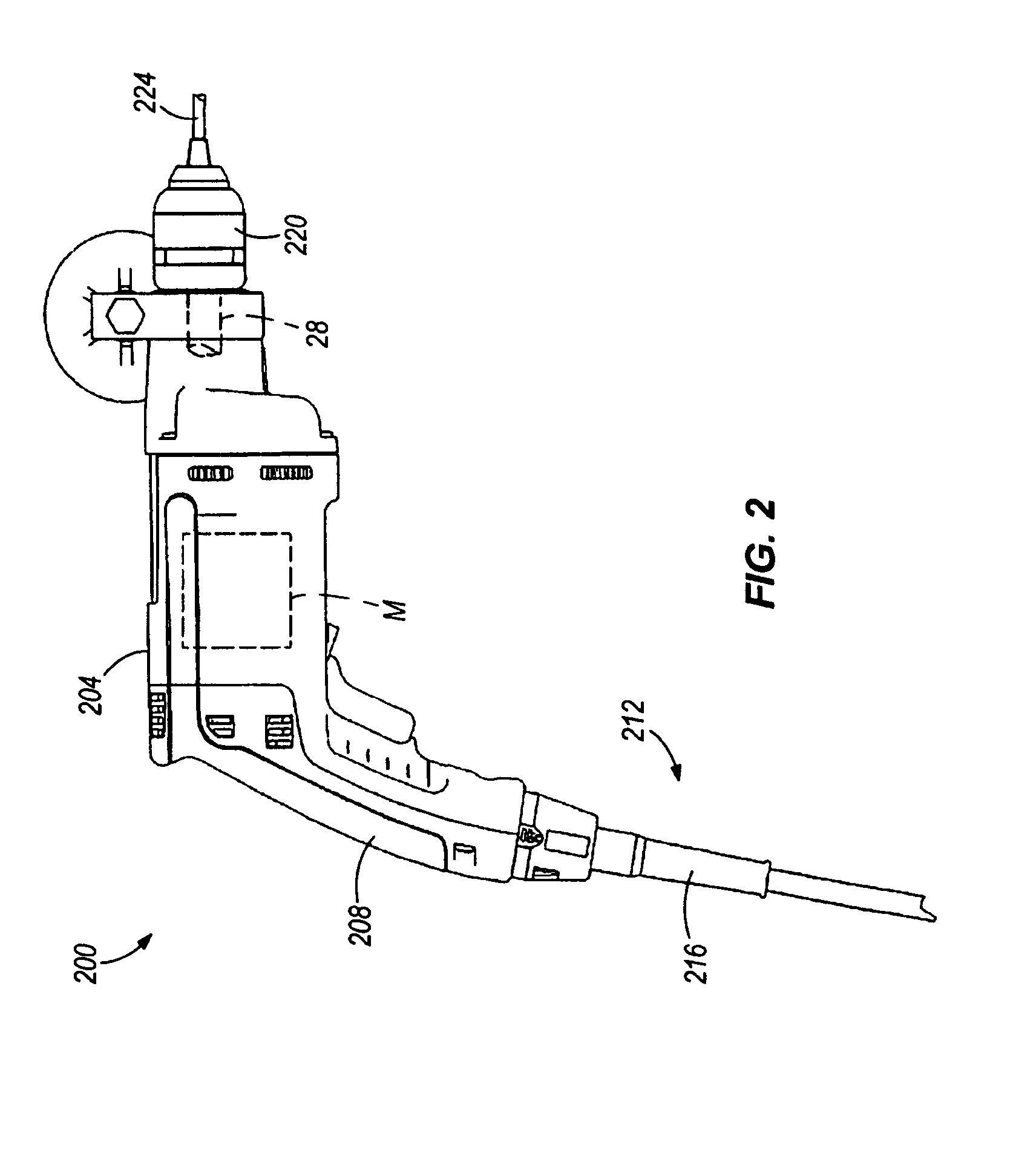

Power tool and spindle lock system

InactiveUS20020130007A1Dissipate rotating energyQuiet stoppingDrilling rodsConstructionsDetentSpring force

A power tool and spindle lock. The spindle lock includes a spring and a detent arrangement to control and buffer the rotation of the spindle and to delay the engagement of the locking elements. In some aspects, the invention provides a spindle lock including a spring element which applies substantially equal spring force to delay the operation of the spindle lock when the spindle is rotated in the forward direction or in the reverse direction. In some aspects, the invention provides two spring members which cooperate to apply the substantially equal force to delay the operation of the spindle lock when the spindle is rotated in the forward direction or in the reverse direction.

Owner:DAIJIRO NAKAMURA +1

System and method for rapidly stopping a spinning table saw blade

A system for stopping a spinning table saw blade is comprised of a pin assembly disposed adjacent to a saw blade assembly for stopping a spinning saw blade. A receiving block is disposed on a side of the saw blade opposing the pin assembly for receiving the tip of the pin assembly. A driving assembly is coupled to the pin assembly for driving the pin assembly into the spinning saw blade into the receiving block. Finally, a sensing assembly is coupled to at least one of the saw blade assembly and the driving assembly for sensing encroachment of a user's hand in a pre-defined zone. In use, upon sensing a user's hand the sensing assembly signals the driving assembly to stop the spinning saw blade by driving the pin assembly through the saw blade and into the receiving block.

Owner:CHANG TYPE INDAL

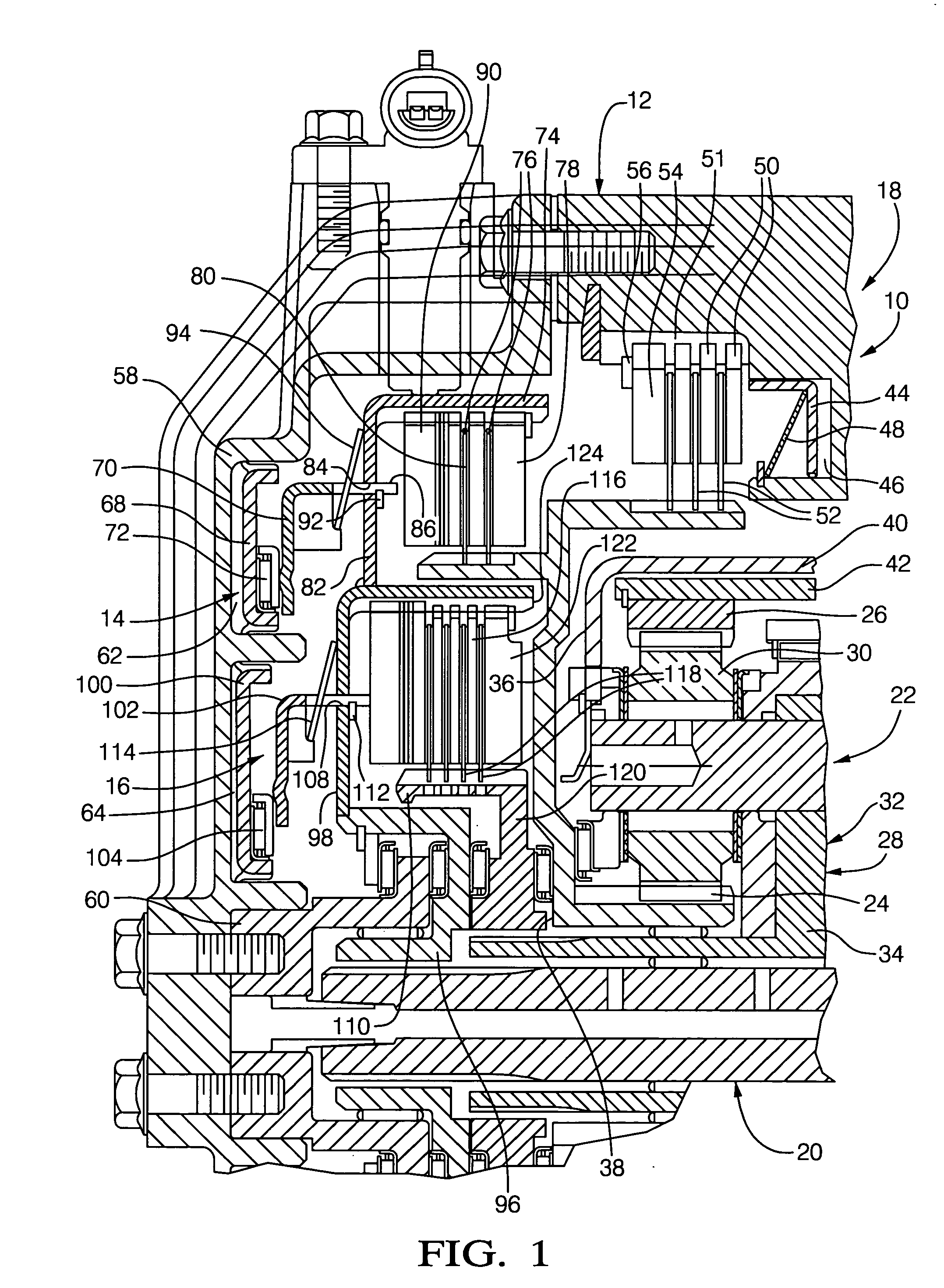

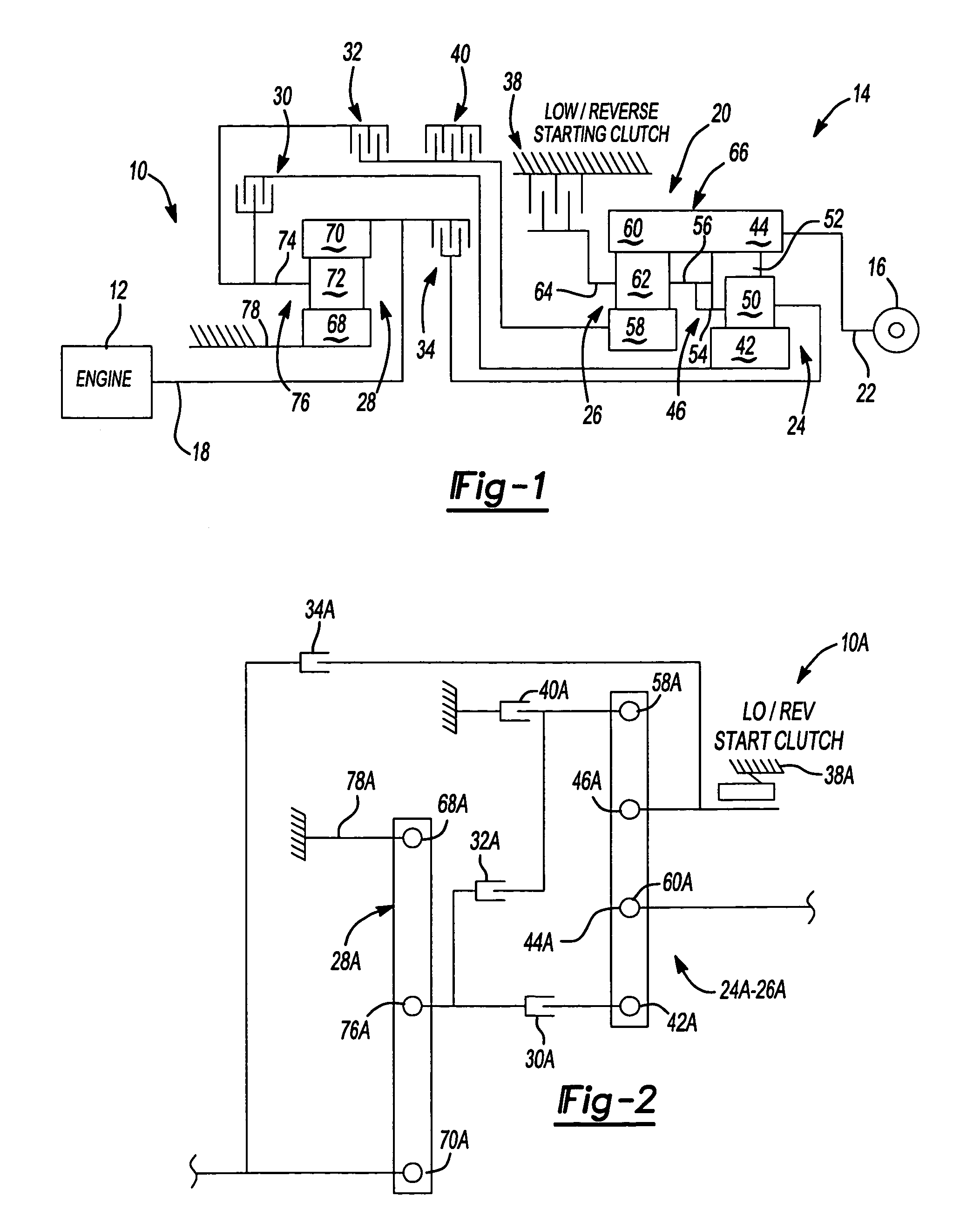

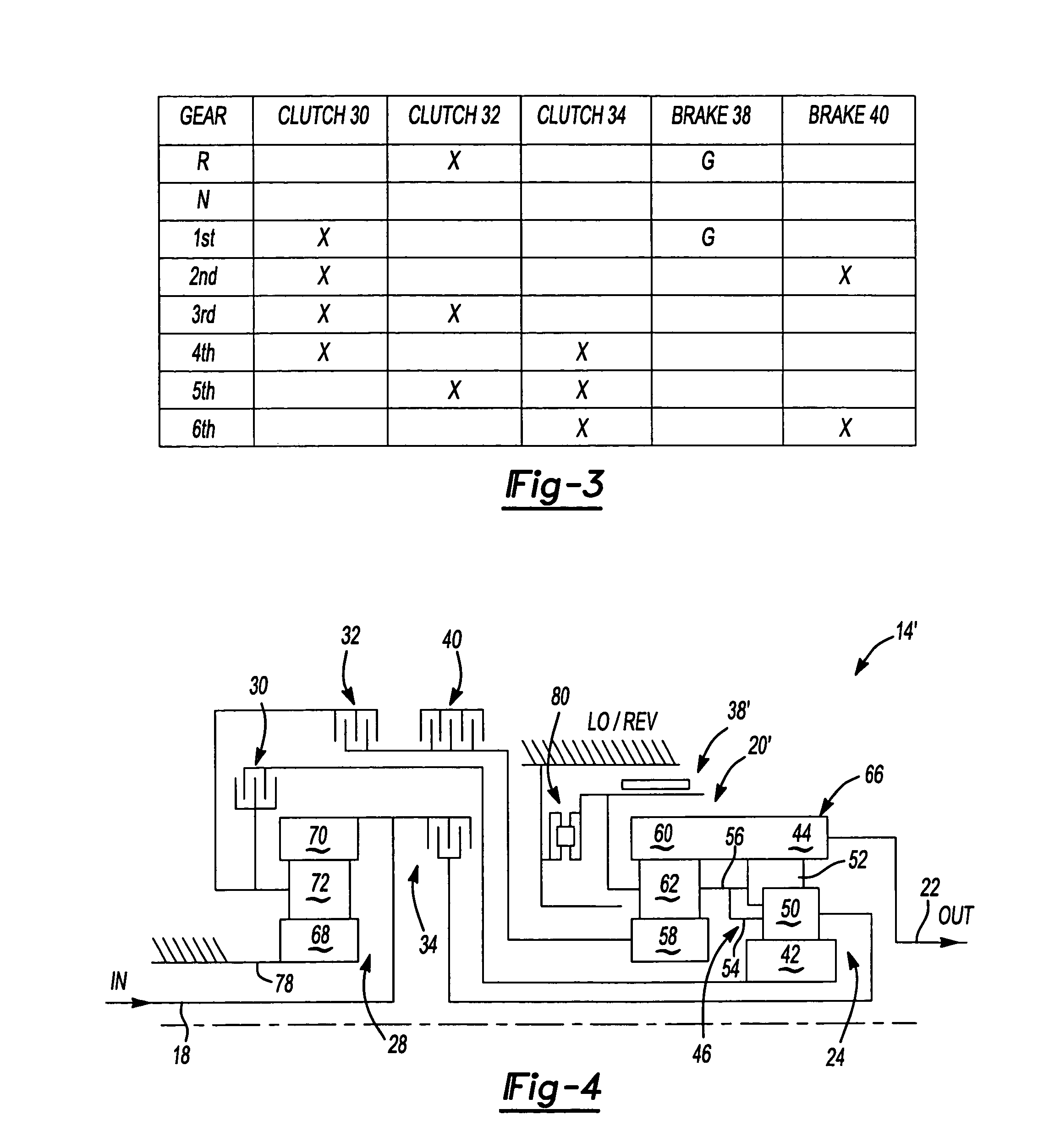

Electromagnetic brake for a multiple-ratio power transmission in a vehicle powertrain

InactiveUS20050217966A1Reduce the cross-sectional areaLimited amountBraking element arrangementsToothed gearingsActuatorControl theory

An electromagnetic brake, including an electromagnetic brake actuator coil surrounding a power input shaft for a multiple-ratio transmission in a vehicle powertrain, is disclosed. An electromagnetic flux flow path for the actuator coil is electromagnetically isolated from the power input shaft and other elements of the powertrain thereby avoiding residual magnetization.

Owner:EATON INTELLIGENT POWER LIMITED

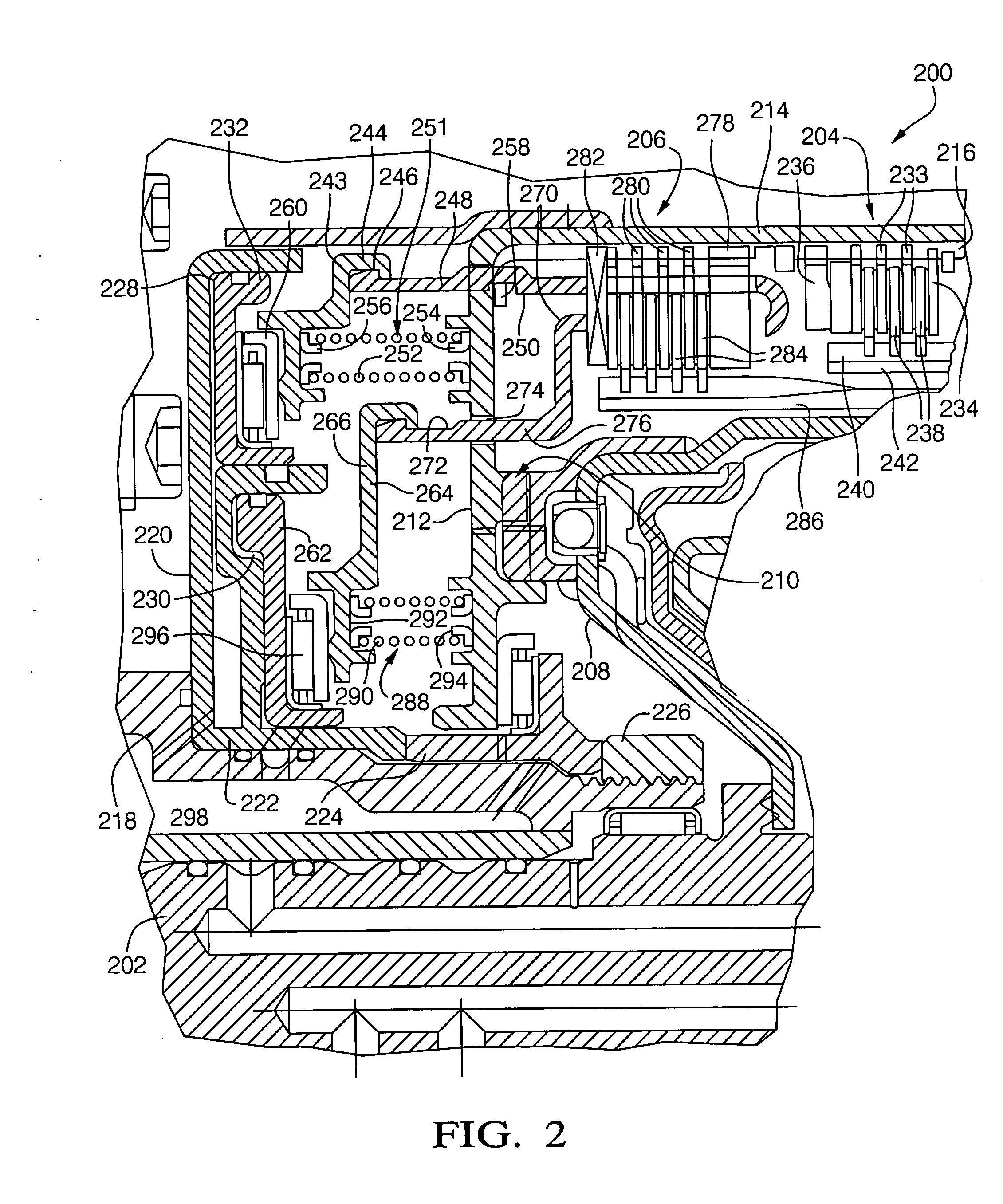

Rotating torque-transmitting apparatus

InactiveUS20050279605A1Reduce loadRotary clutchesFluid actuated clutchesTorque transmissionEngineering

A rotatable torque-transmitting apparatus includes a stationary piston and a rotatable apply plate. The rotatable apply plate is disposed adjacent a rotatable housing and separated therefrom by a return spring assembly which in a preload condition is trapped between the apply plate and the rotatable housing to limit the disengaged force which is transmitted between the rotatable housing and the stationary piston.

Owner:GM GLOBAL TECH OPERATIONS LLC

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

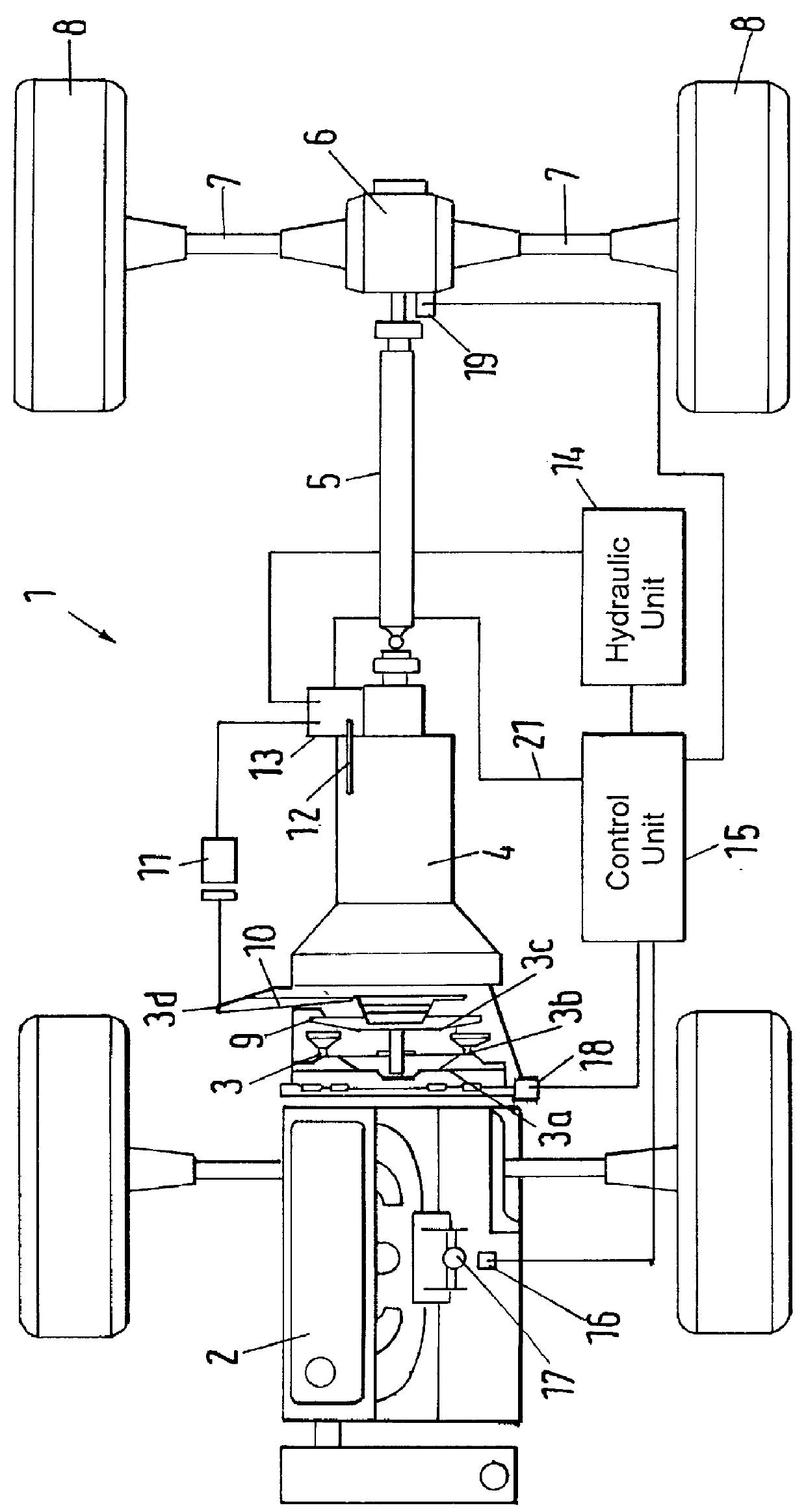

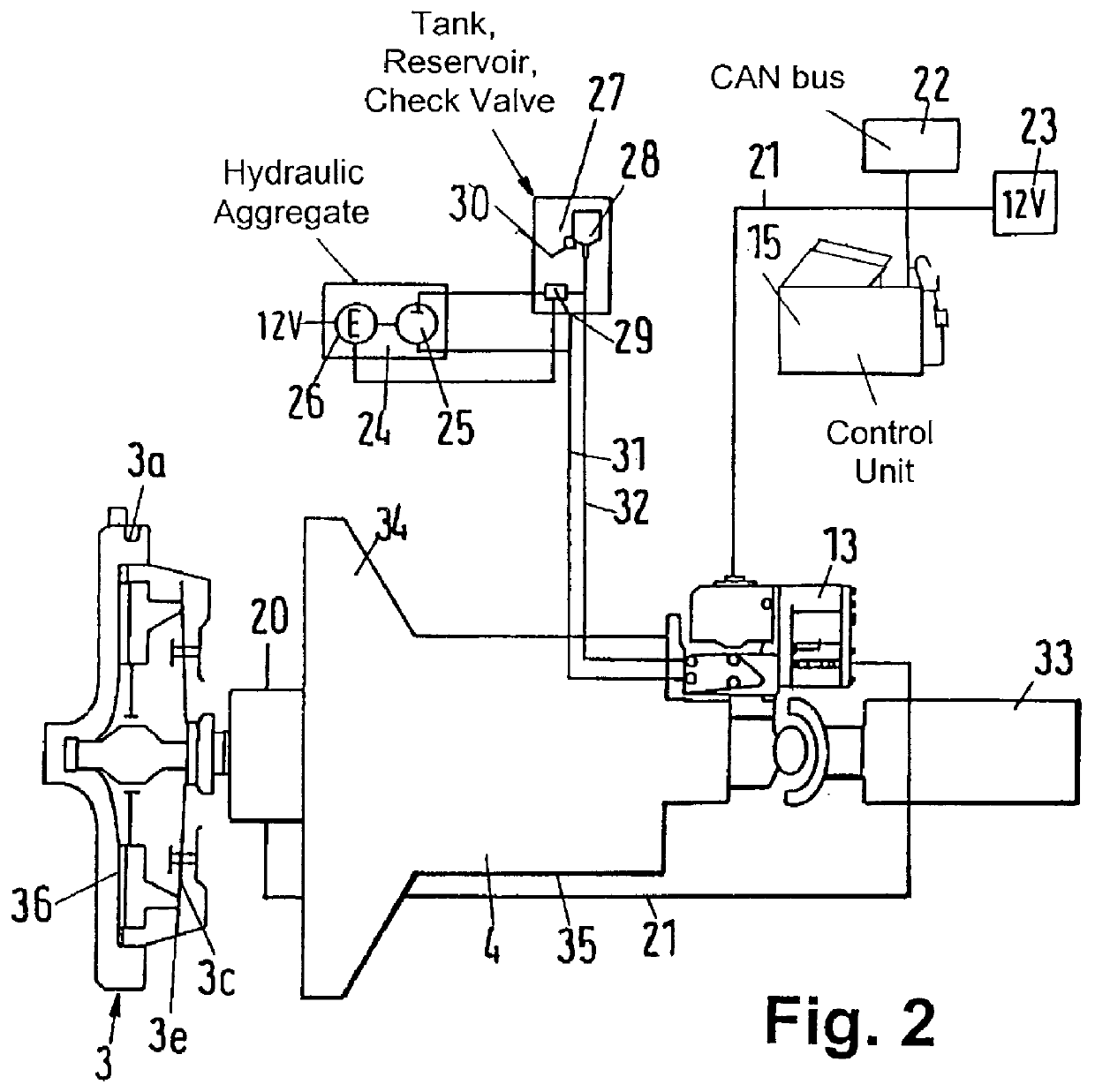

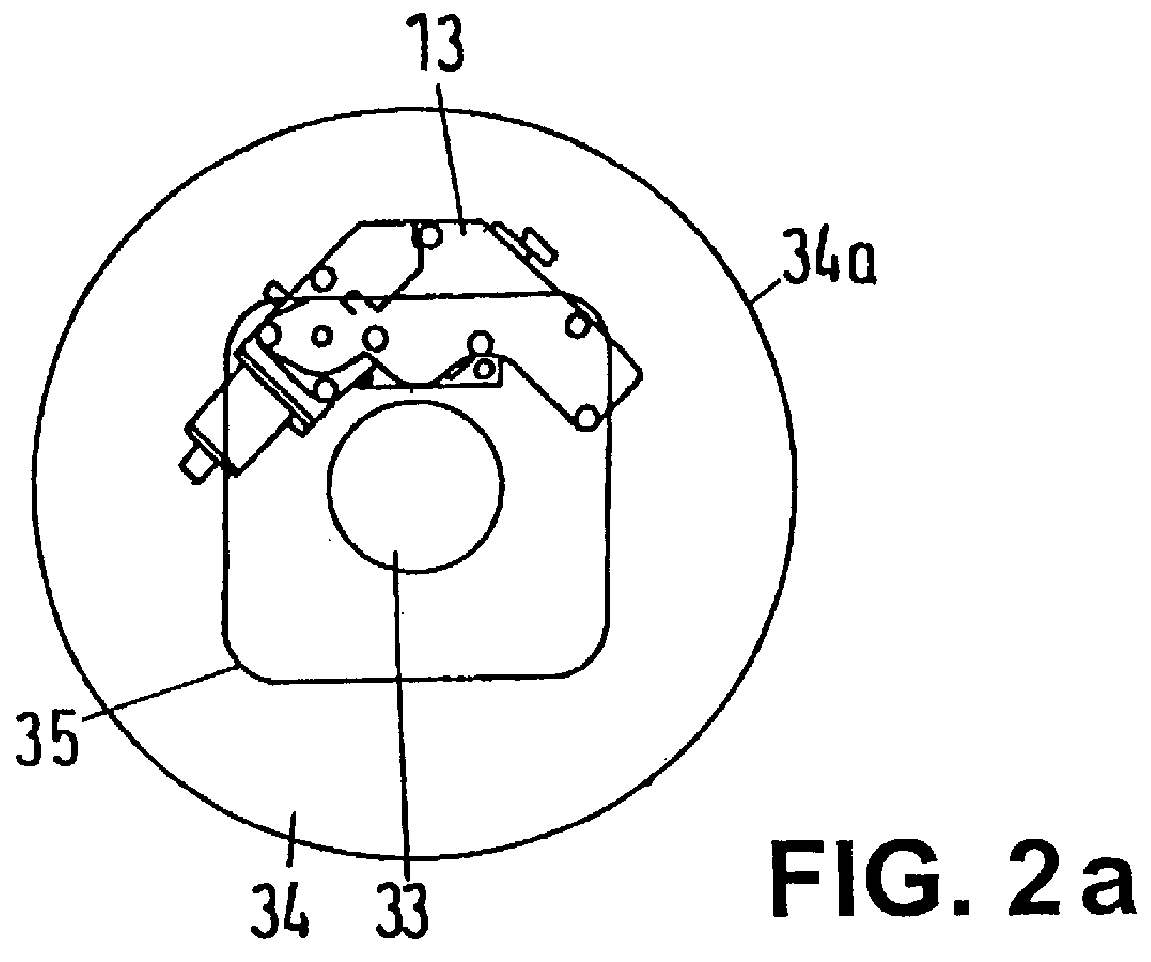

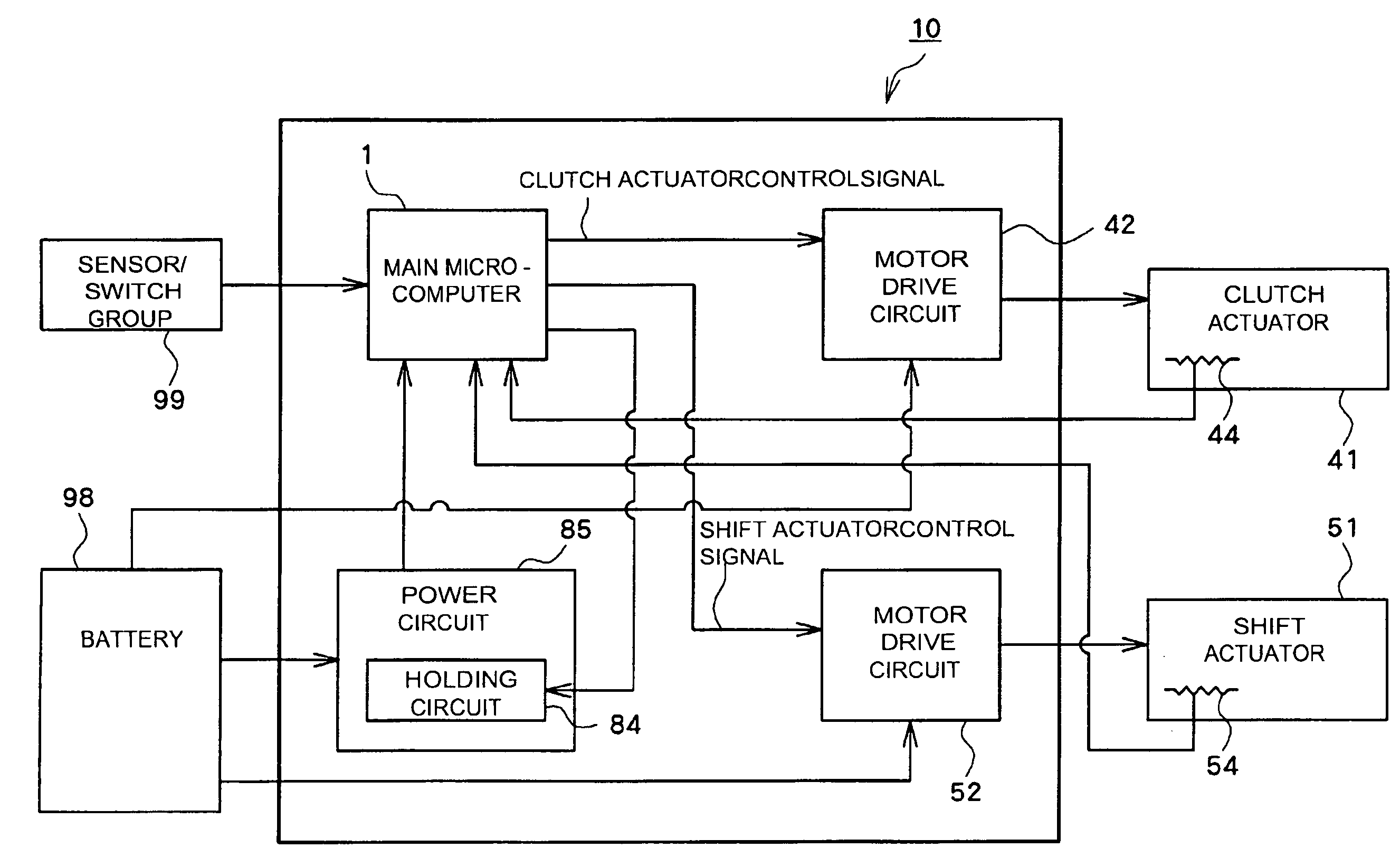

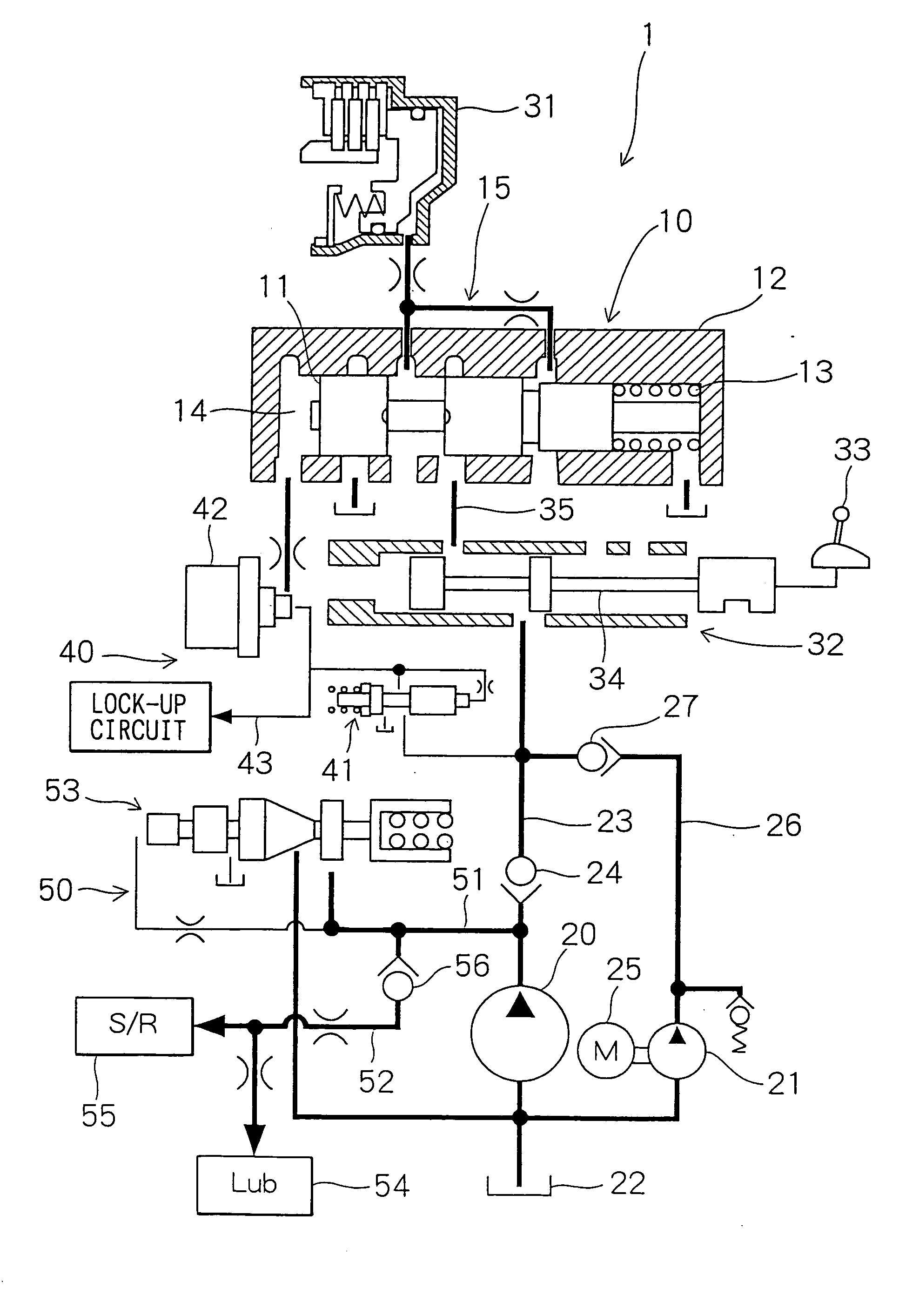

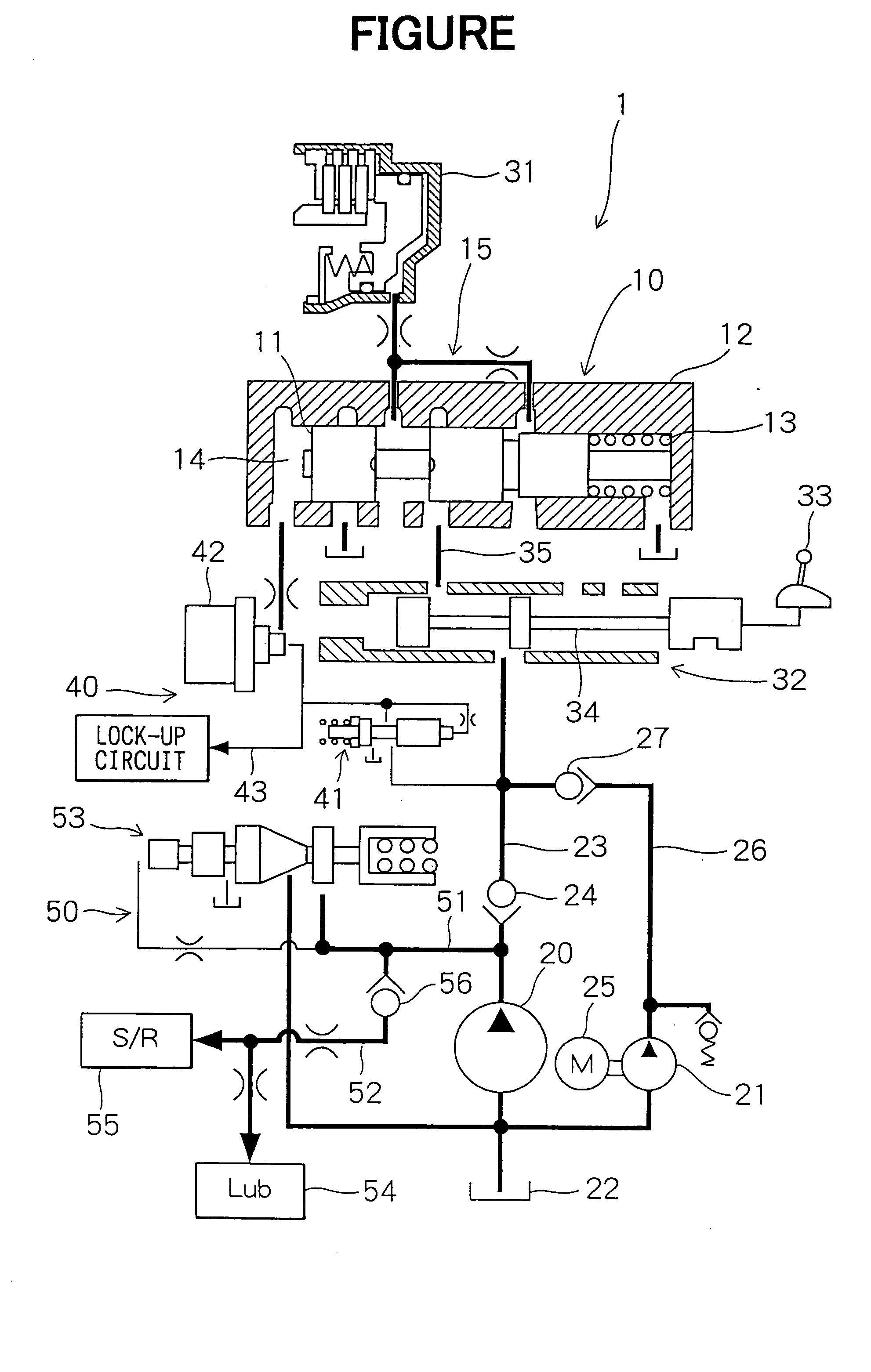

Method of and apparatus for actuating the torque transmitting system and the transmission in the power train of a motor vehicle

PCT No. PCT / DE96 / 01755 Sec. 371 Date Oct. 23, 1997 Sec. 102(e) Date Oct. 23, 1997 PCT Filed Sep. 12, 1996 PCT Pub. No. WO97 / 10456 PCT Pub. Date Mar. 20, 1997The friction clutch between the engine and an automated transmission in the power train of a motor vehicle are operated and controlled by an actuator which effects changes in the extent of engagement of the clutch as well as the selection of and shifting into particular gears. The actuator forms part of a unit which receives a pressurized hydraulic fluid from a source including an accumulator and a proportional valve which latter selects the fluid pressure necessary to shift the transmission into a selected gear.

Owner:LUK GETRIEBE SYST +3

Variable magnetic coupling of rotating machinery

ActiveUS7791235B2Reduce vibration transmissionDynamo-electric brakes/clutchesMechanical actuated clutchesCouplingEngineering

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

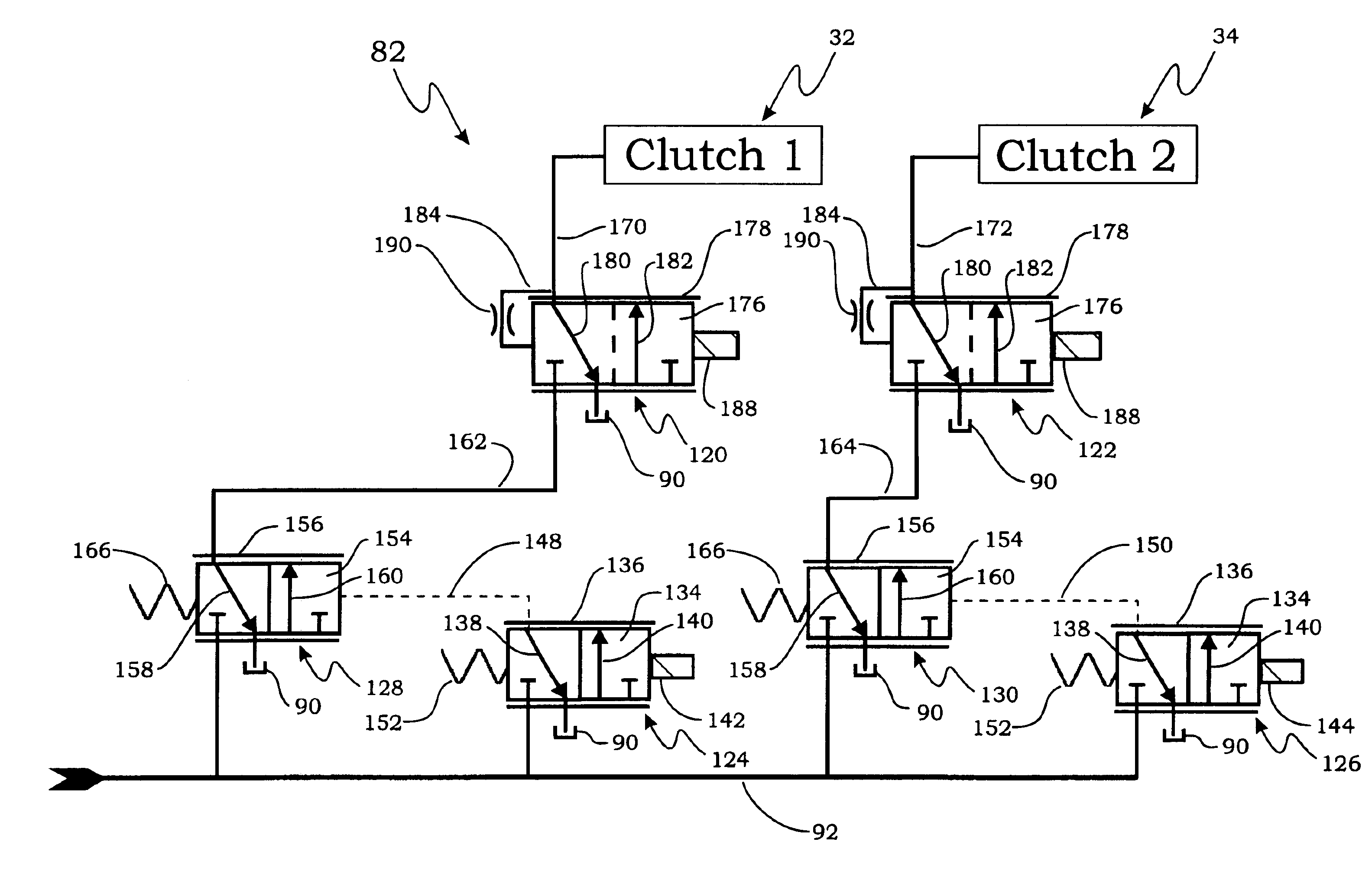

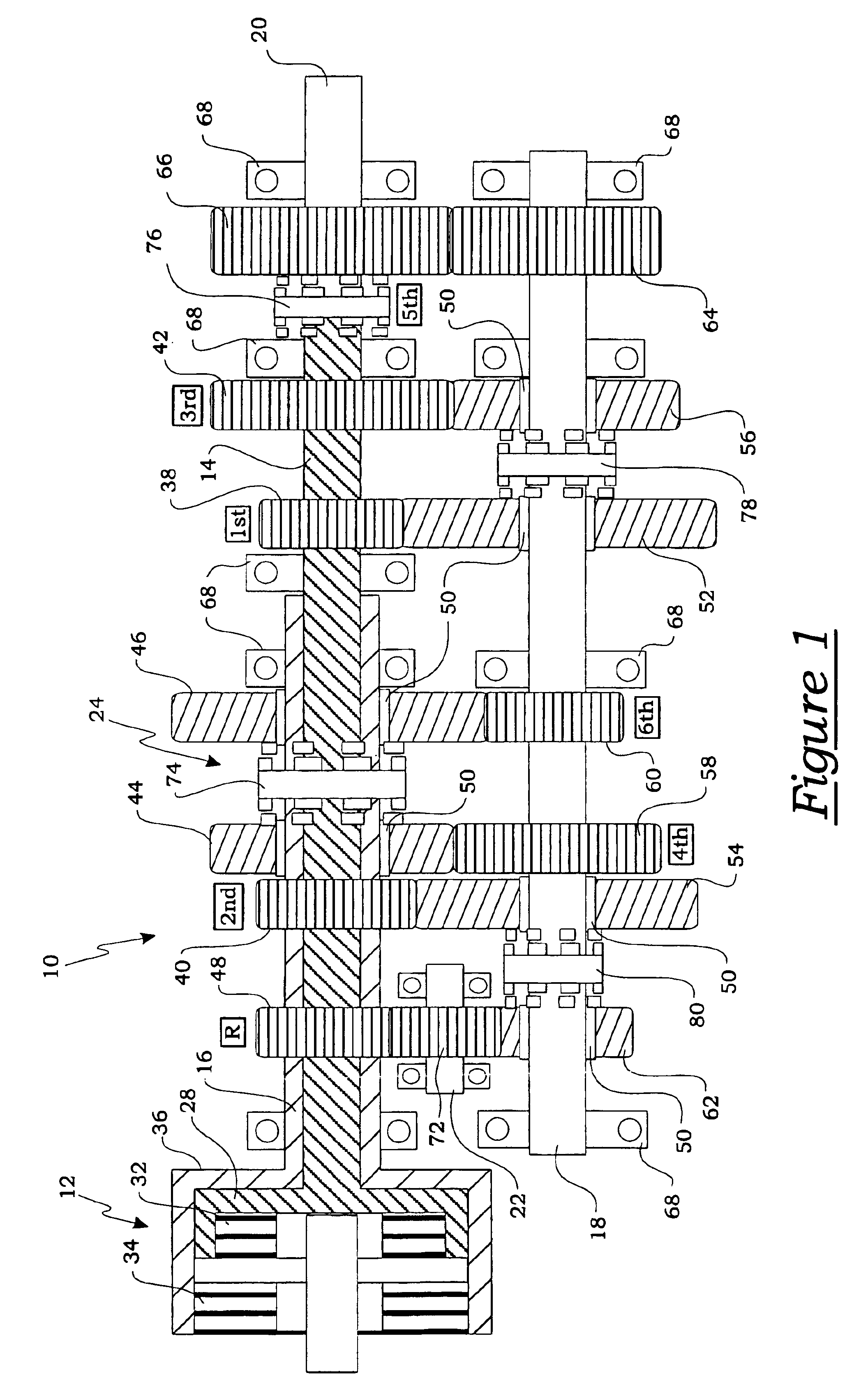

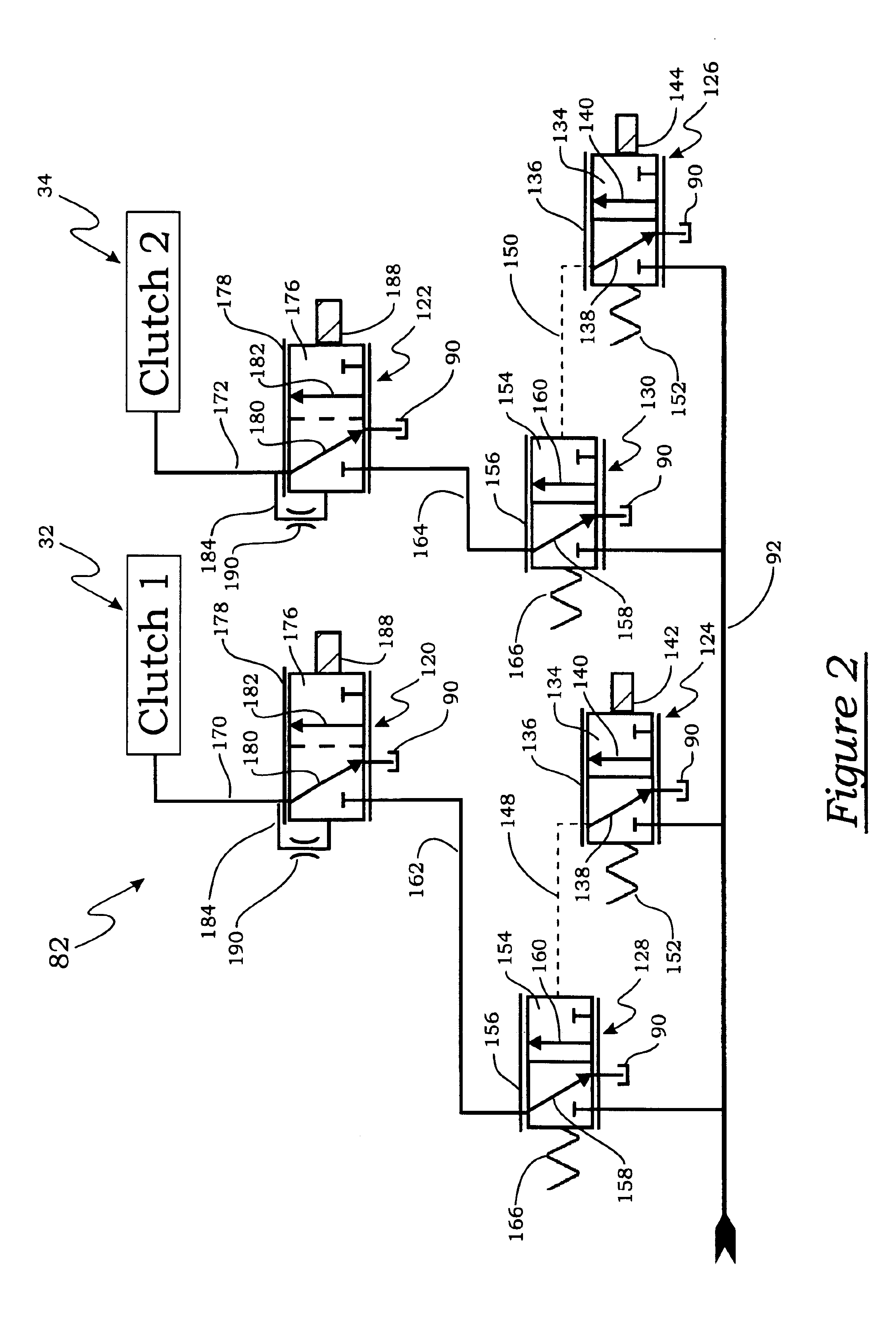

Method of controlling a dual clutch transmission

InactiveUS6909955B2Improving overall drivability and comfortClutchesDigital data processing detailsEngineeringClutch

A method of controlling the timing of the shift events of a dual clutch transmission that includes the steps of sensing the current output speed of the transmission, determining the time required to complete each possible shift event within the transmission, and determining an output speed modification value for each possible shift event. The method also includes the steps of determining a modified shift point output speed for each possible shift event by summing the determined output speed modification value with a predetermined shift pattern output speed, and commanding the shift when the current output speed reaches the determined modified shift point output speed.

Owner:BORGWARNER INC

Power tool and spindle lock system

InactiveUS7063201B2Without impactDissipate rotating energyDrilling rodsConstructionsDetentSpring force

A power tool and spindle lock. The spindle lock includes a spring and a detent arrangement to control and buffer the rotation of the spindle and to delay the engagement of the locking elements. In some aspects, the invention provides a spindle lock including a spring element which applies substantially equal spring force to delay the operation of the spindle lock when the spindle is rotated in the forward direction or in the reverse direction. In some aspects, the invention provides two spring members which cooperate to apply the substantially equal force to delay the operation of the spindle lock when the spindle is rotated in the forward direction or in the reverse direction.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

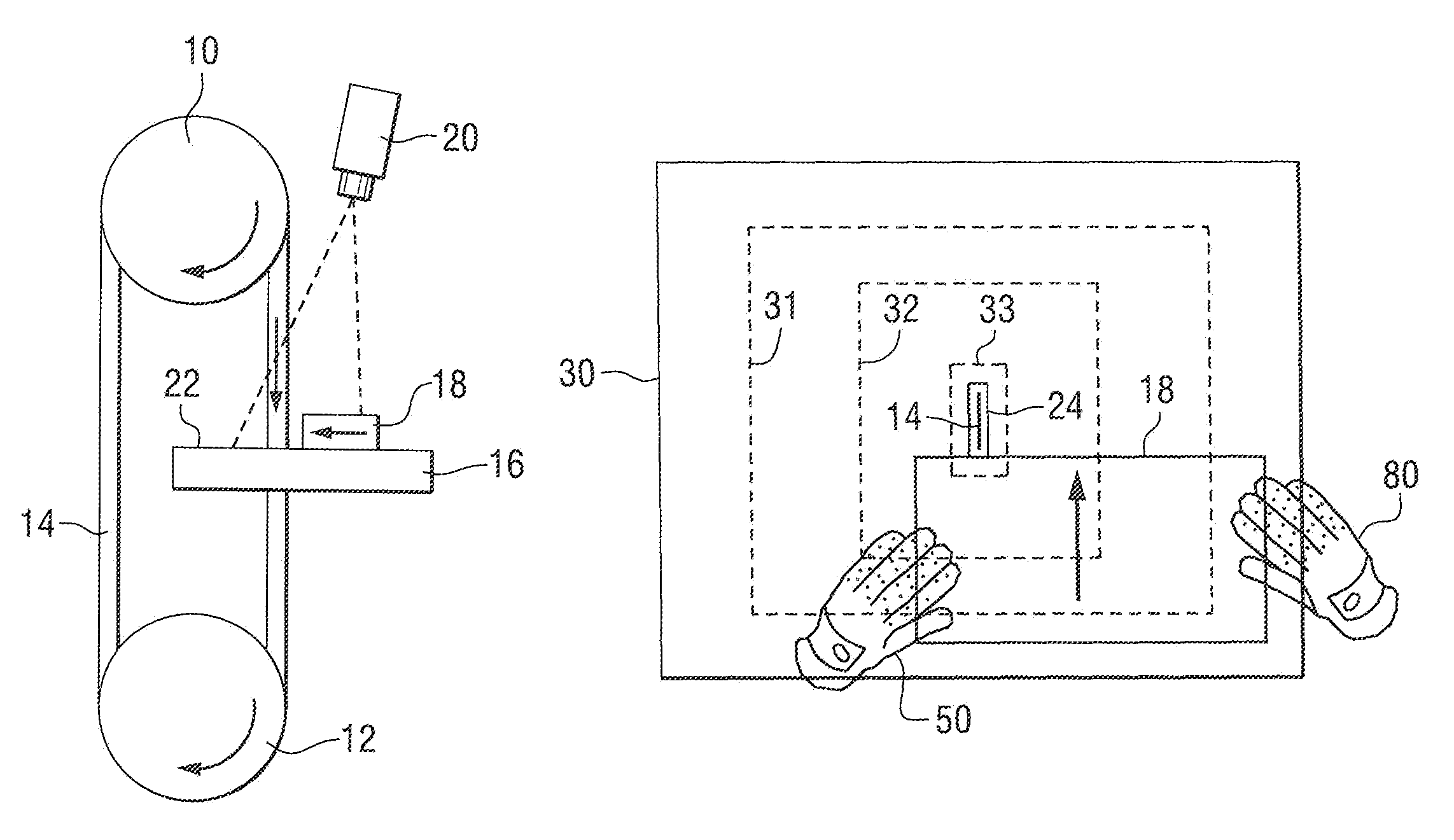

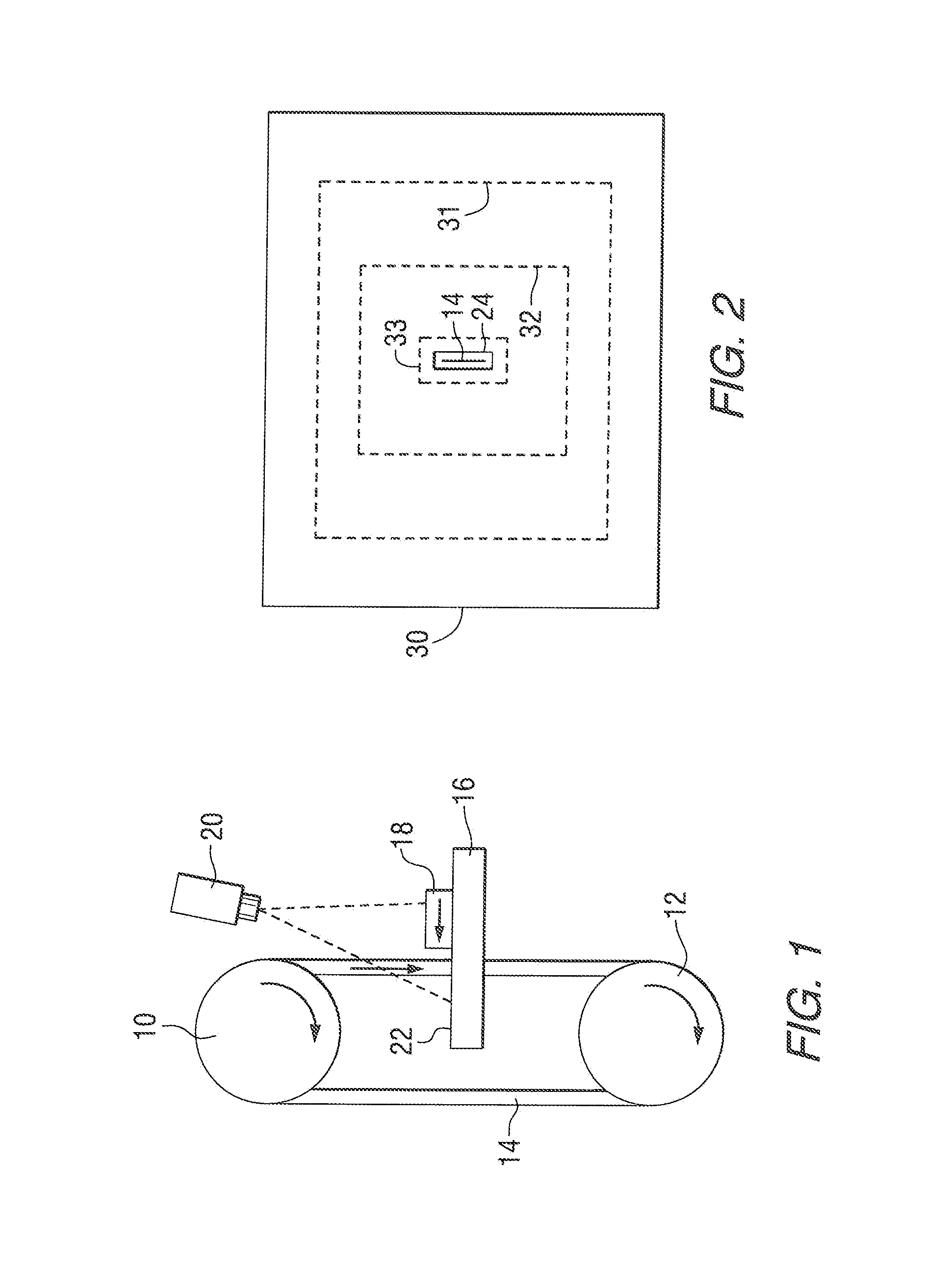

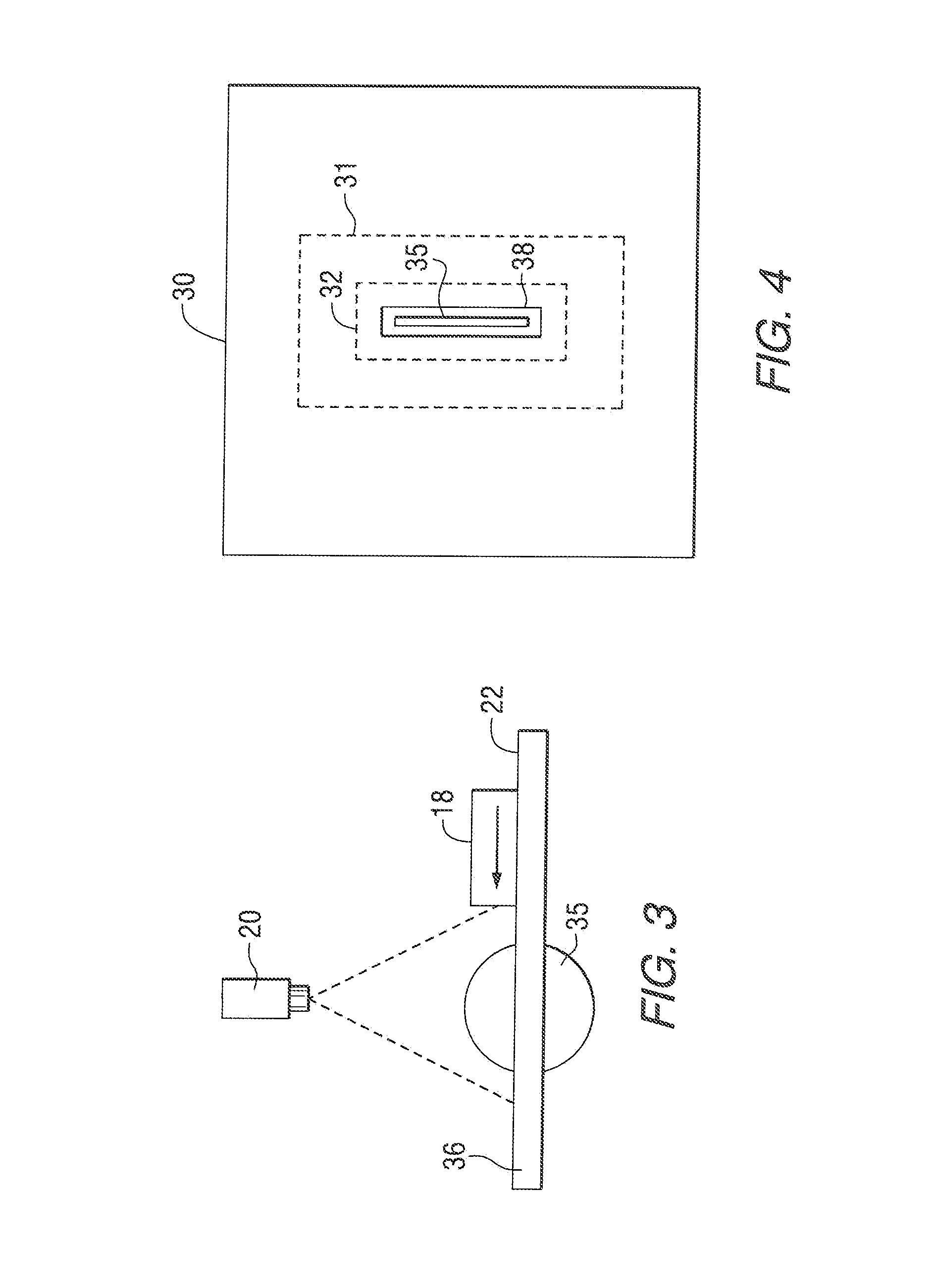

Method for sensing the presence of a human body part within a region of a machine tool

A detection system senses the location of a preselected color within one or more monitored zones of a machine tool. If the operator of a machine tool wears a red glove, the system detects the location of the color red and defines various monitored zones through the use of synchronization signals and a time circuit. The system can take action based on the location of the particular monitored zones in which the red glove is sensed. These actions can include the sounding of a horn, the lighting of a light, or the deactivation of the machine tool.

Owner:BRUNSWICK CORPORATION

Method for the control of operational sequencing in an automatic transmission of auxiliary construction

InactiveUS20060213300A1Fluid actuated clutchesMagnetically actuated clutchesAutomatic transmissionEngineering

A method for controlling operational sequencing of gears in an automatic transmission (102) which has been built in an auxiliary mode. In the case of such a shifting transmission it is possible that during the engagement of its transmission gear stage, impact noises or contact noises are present in the shifting procedure. This can occur by the generation of a tooth-on-tooth positioning between the toothing of a sliding collar (126) and the come-along toothing of an idler gear (130, 132). Provision is made for the control of the activation movement of the sliding collar (126) carried out in such a manner that an activation condition impact of the transmission parts, which are partakers in the shifting associated transmission part onto other transmission parts with the least possible impact force and / or with a least possible impact noise level.

Owner:ZF FRIEDRICHSHAFEN AG

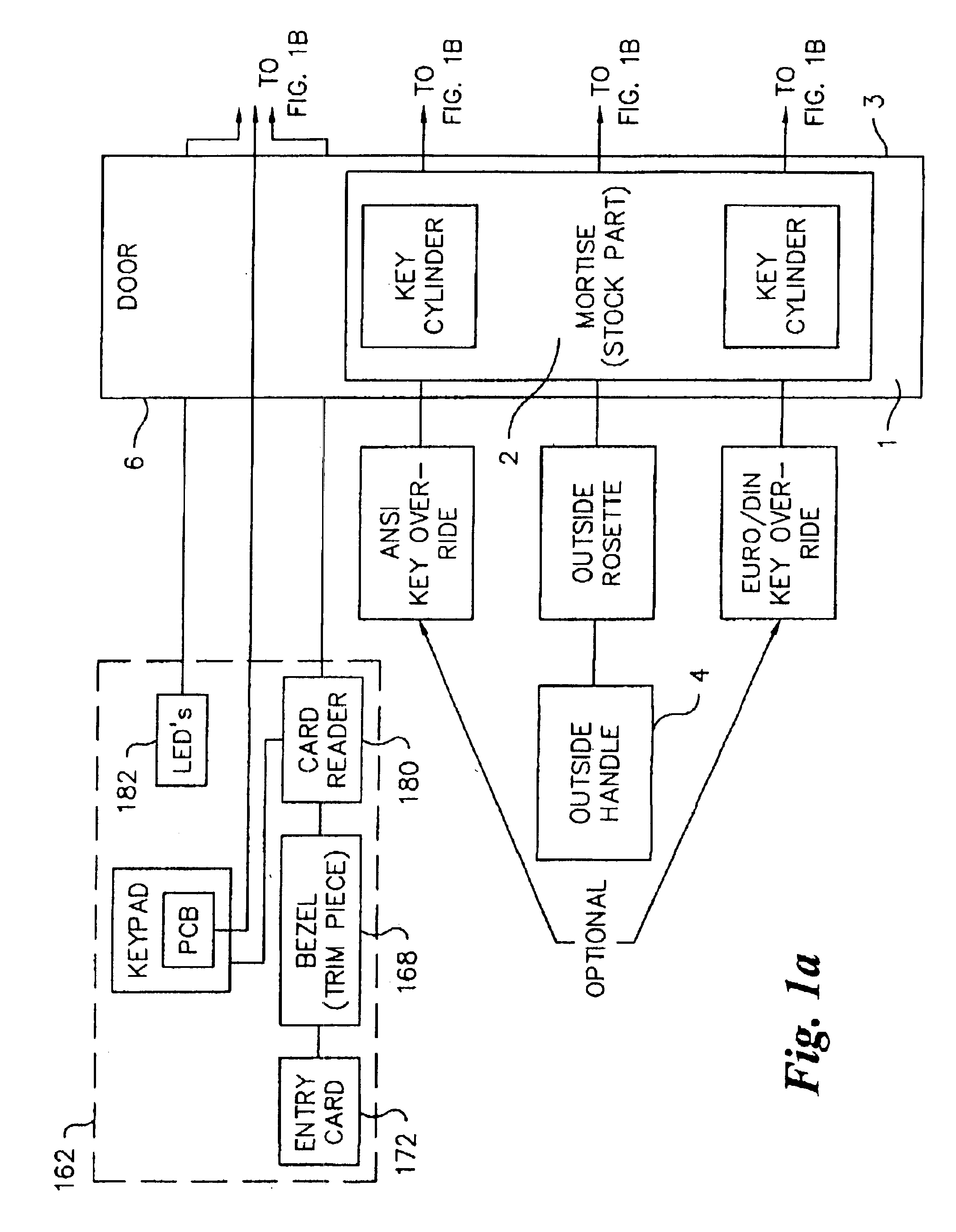

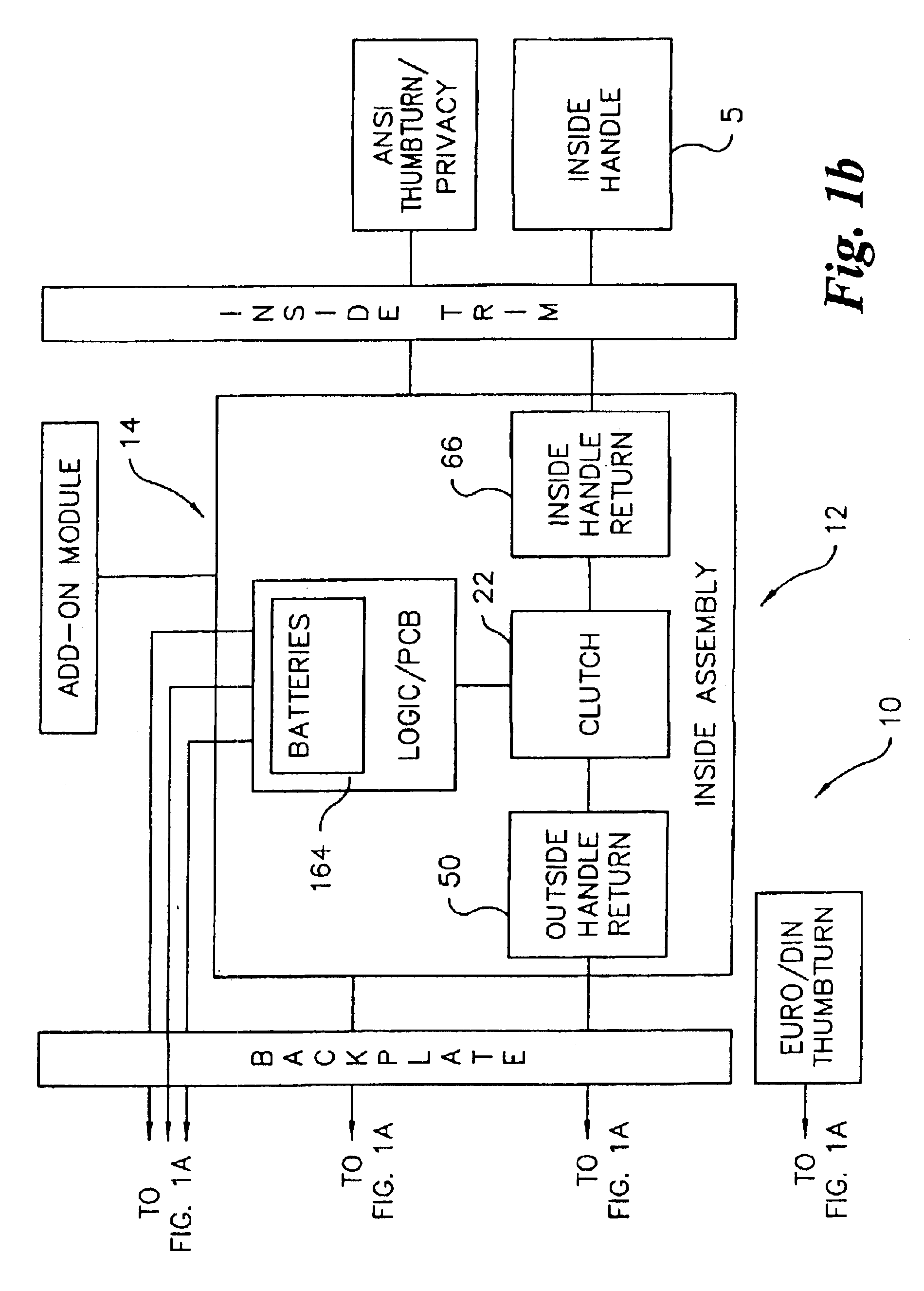

Electronic lock system

A clutch assembly for coupling a first spindle to a second spindle. The clutch assembly has a first disc connectable to the first spindle. A first finger is operatively coupled to the first disc and pivotable between a first engaged position and a first disengaged position. The first finger opposes rotation of the first disc in a first direction when the first finger is in the first engaged position. A second disc is connectable to the second spindle. The second disc pivots the first finger from the first engaged position to the first disengaged position when the second disc is rotated in the first direction through a first range of angular positions and rotates the first disk in the first direction when the second disc is rotated beyond the first range of angular positions.

Owner:ONITY

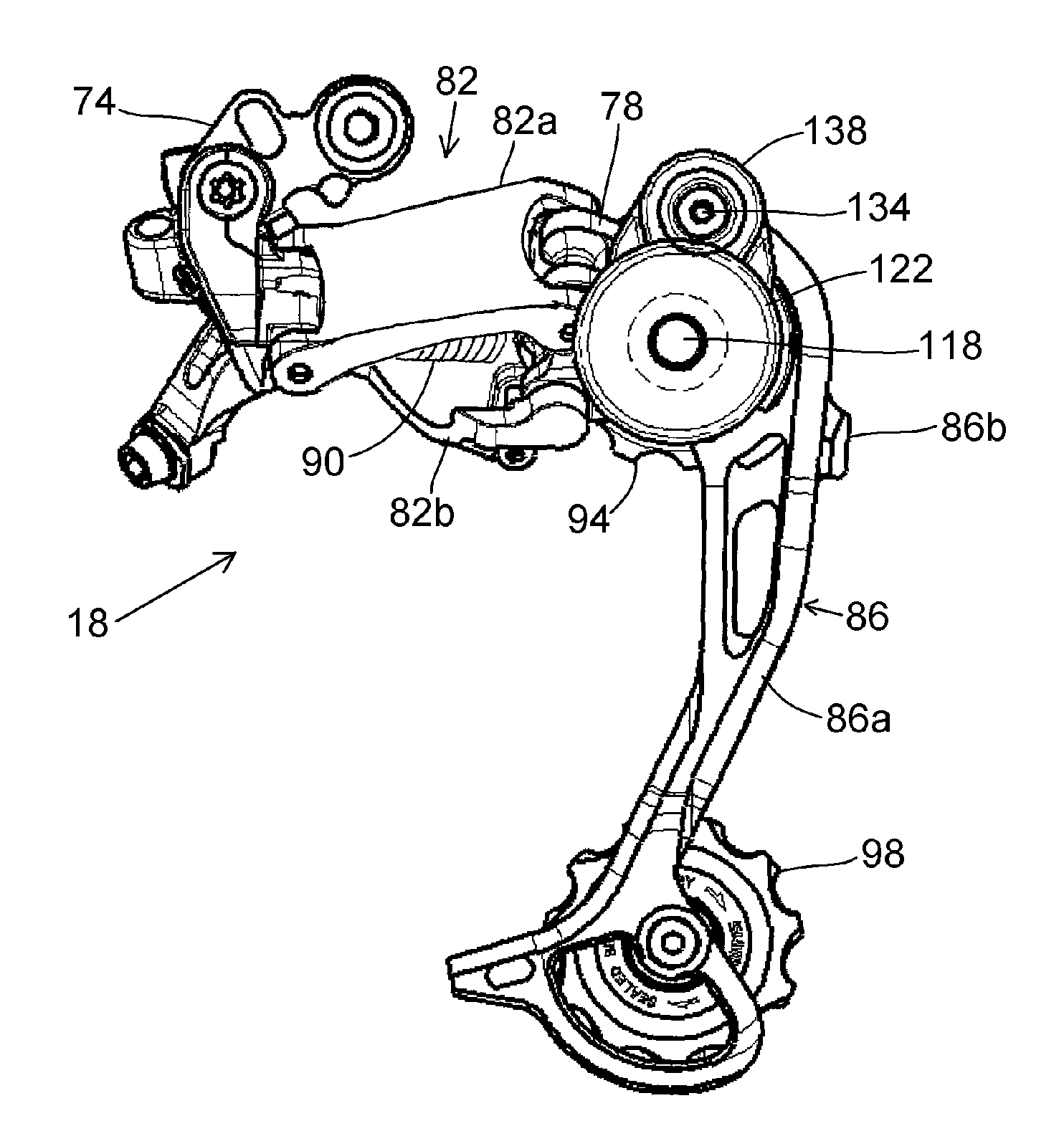

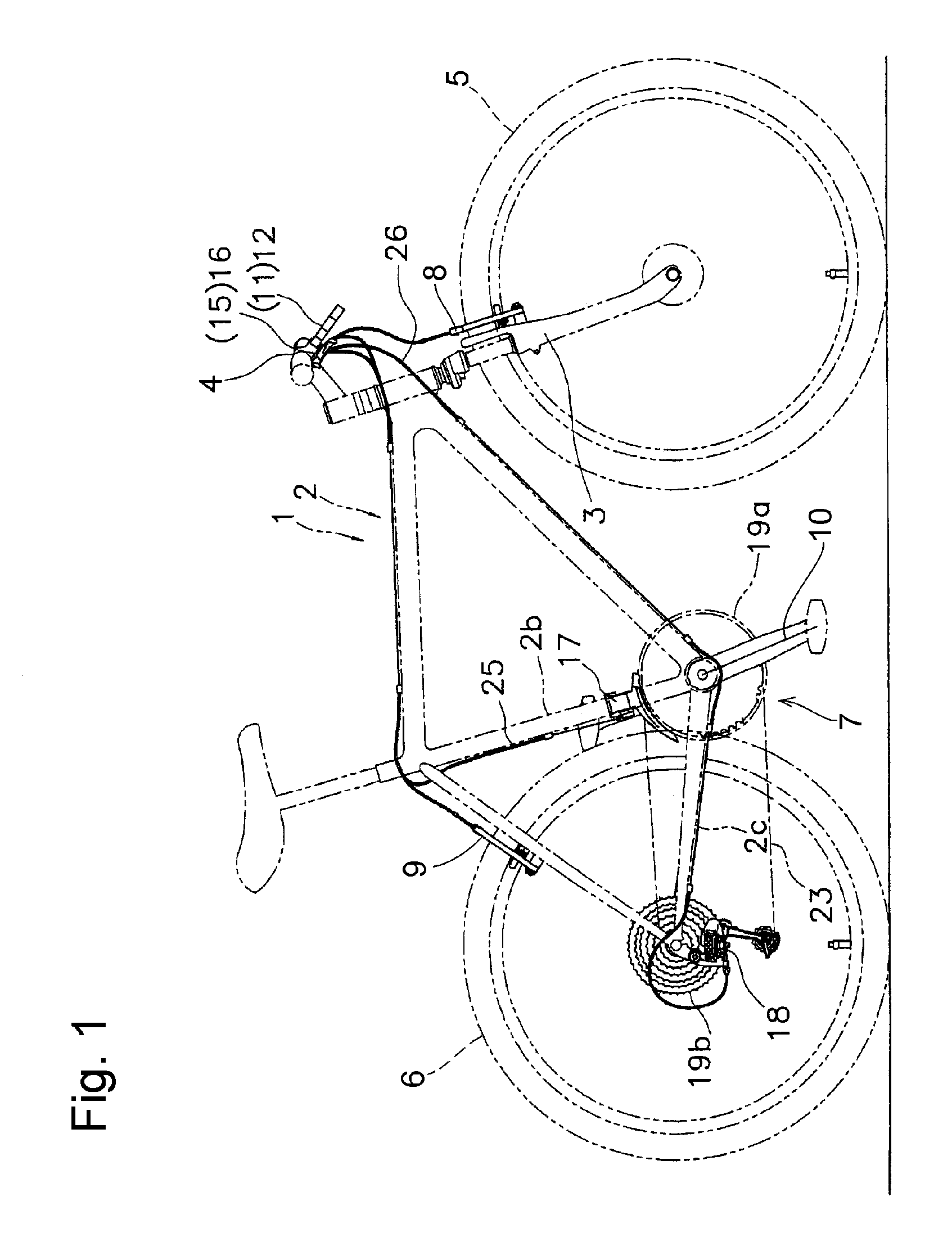

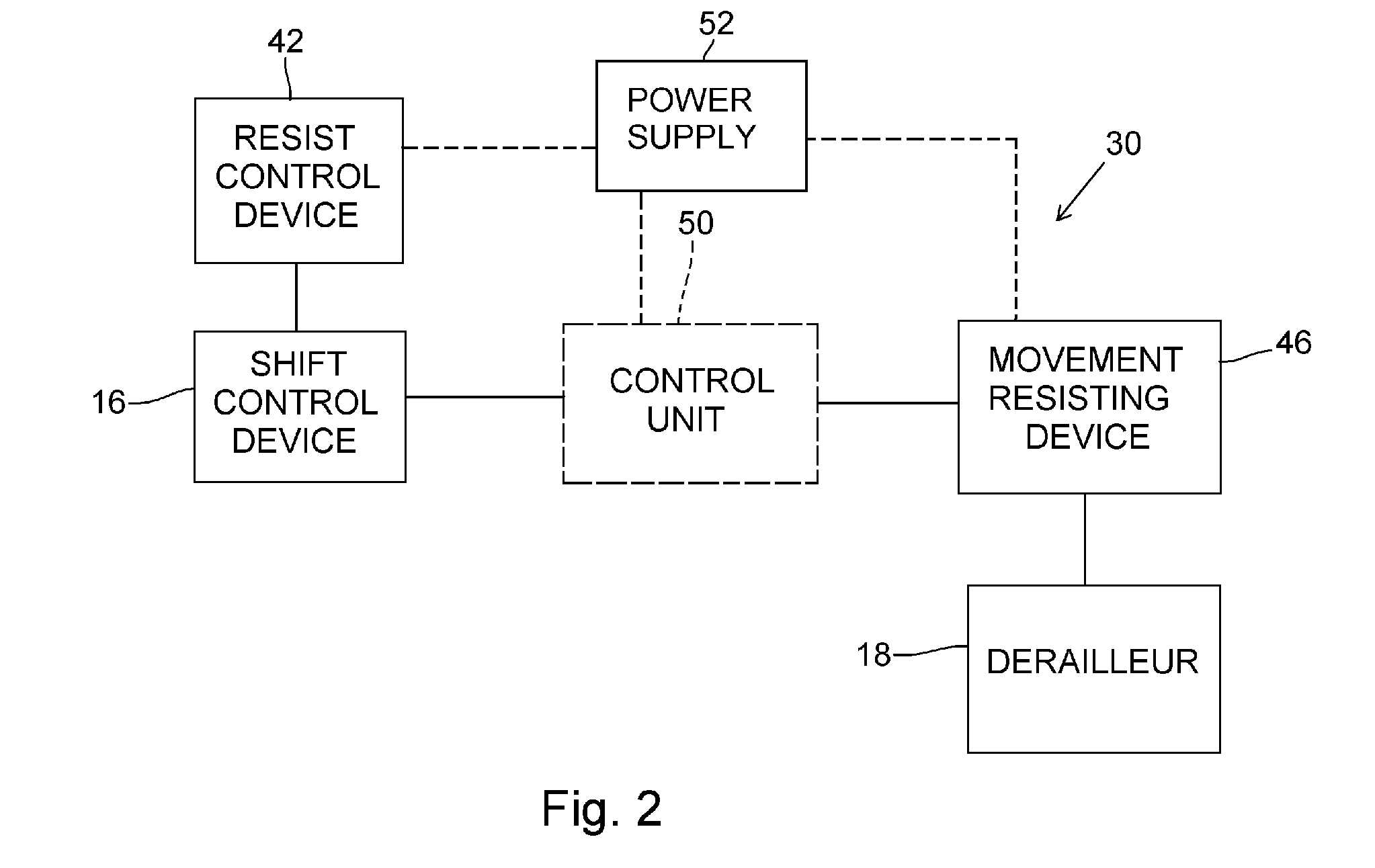

Motion resisting apparatus for a bicycle derailleur

A bicycle derailleur apparatus comprises a base member for coupling to a bicycle frame, a movable member coupled for movement relative to the base member, a chain guide coupled to the movable member for guiding a chain among a plurality of sprockets in response to movement of the movable member, and a biasing device that provides a biasing force to the chain guide for tensioning the chain. A movement resisting device has a control element for the application of a signal that causes the movement resisting device to change resistance to movement of the chain guide.

Owner:SHIMANO INC

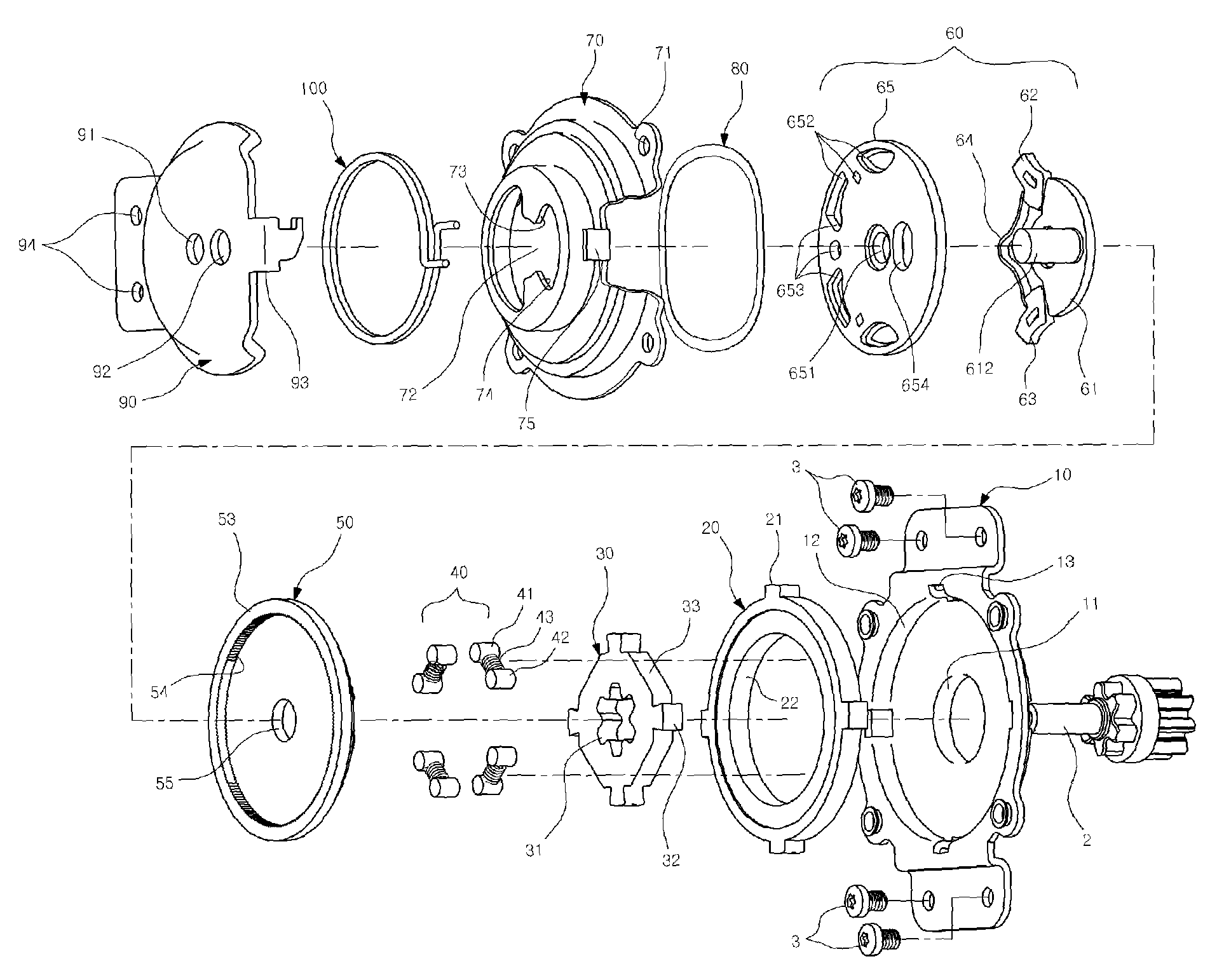

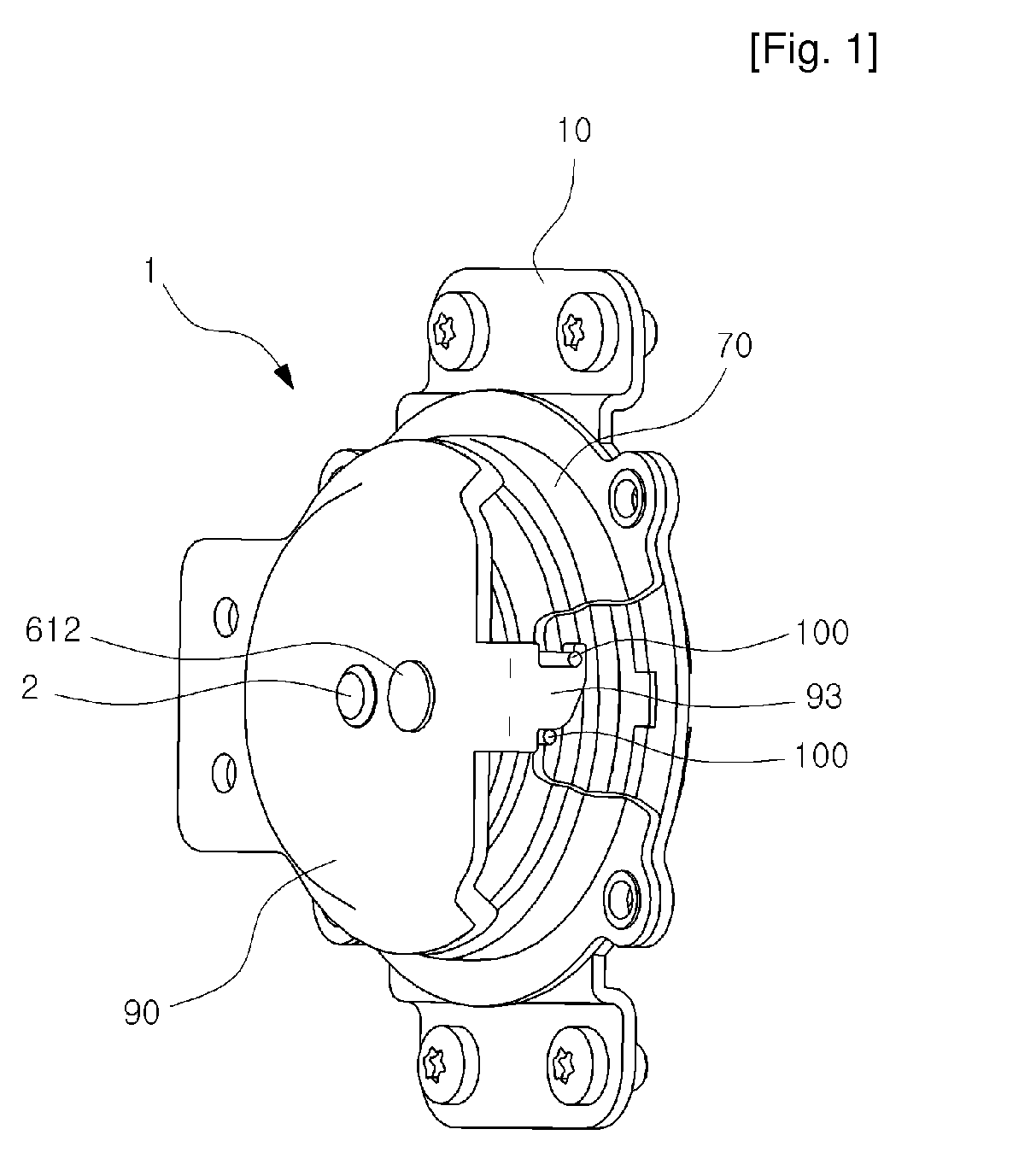

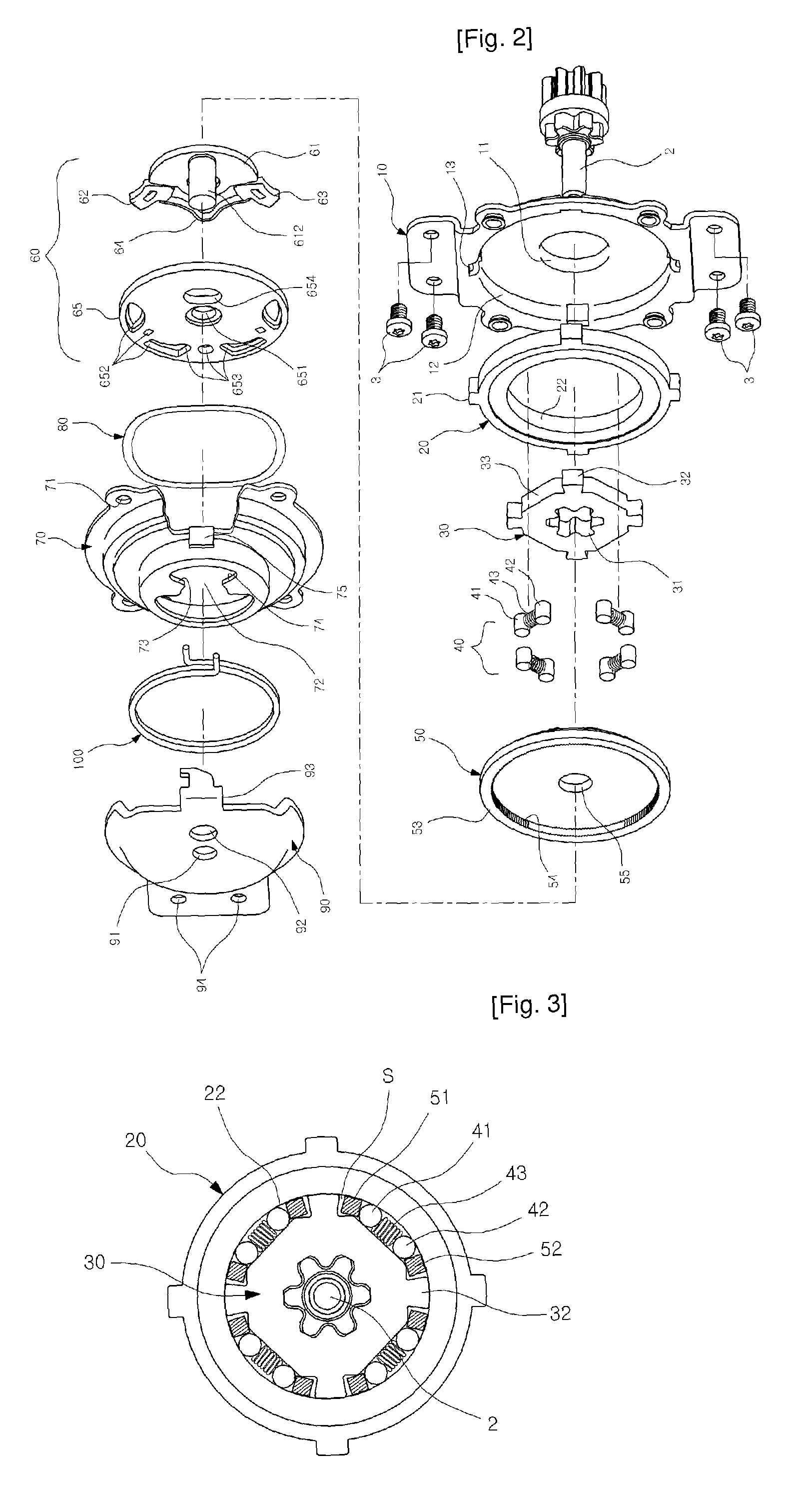

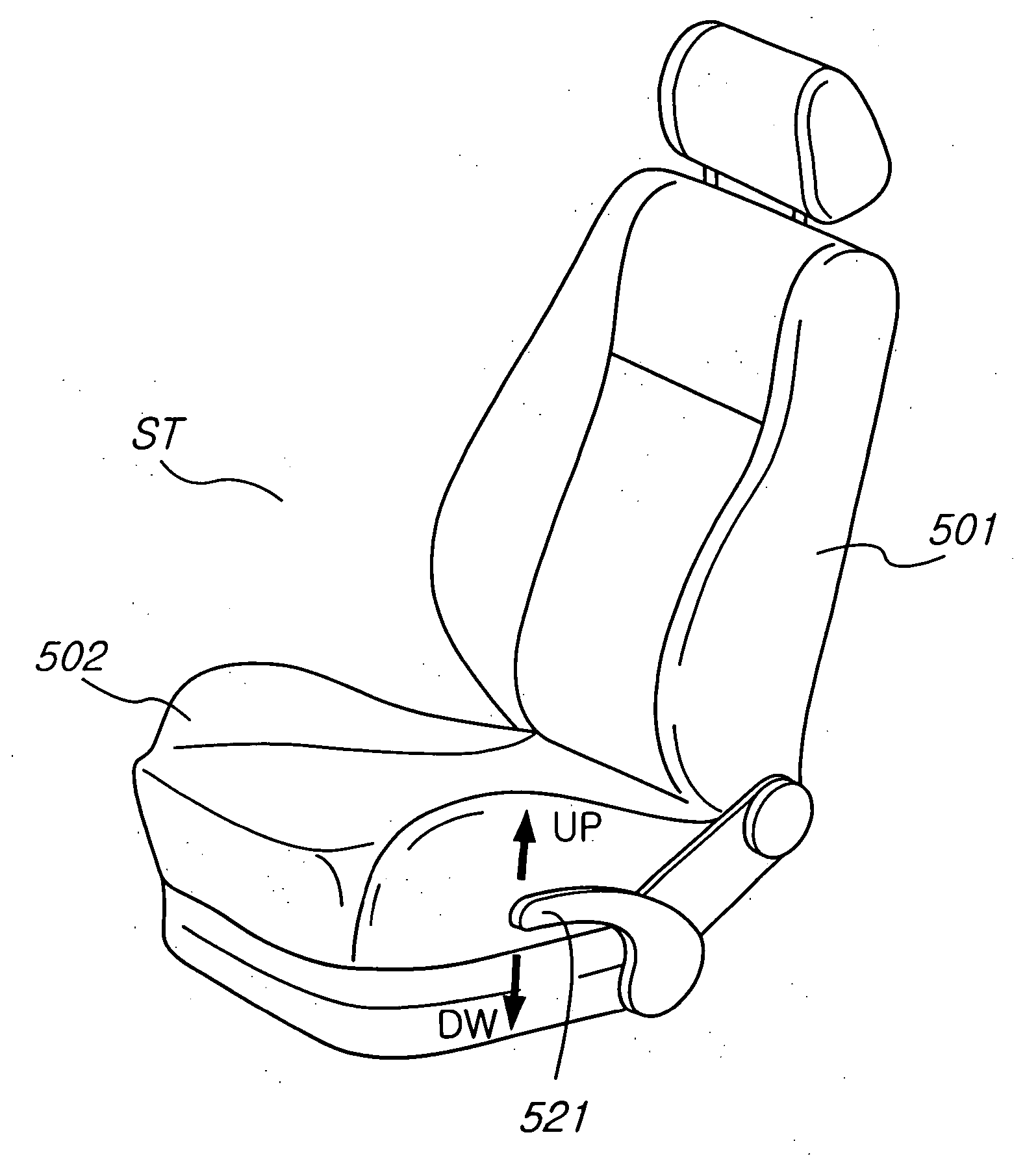

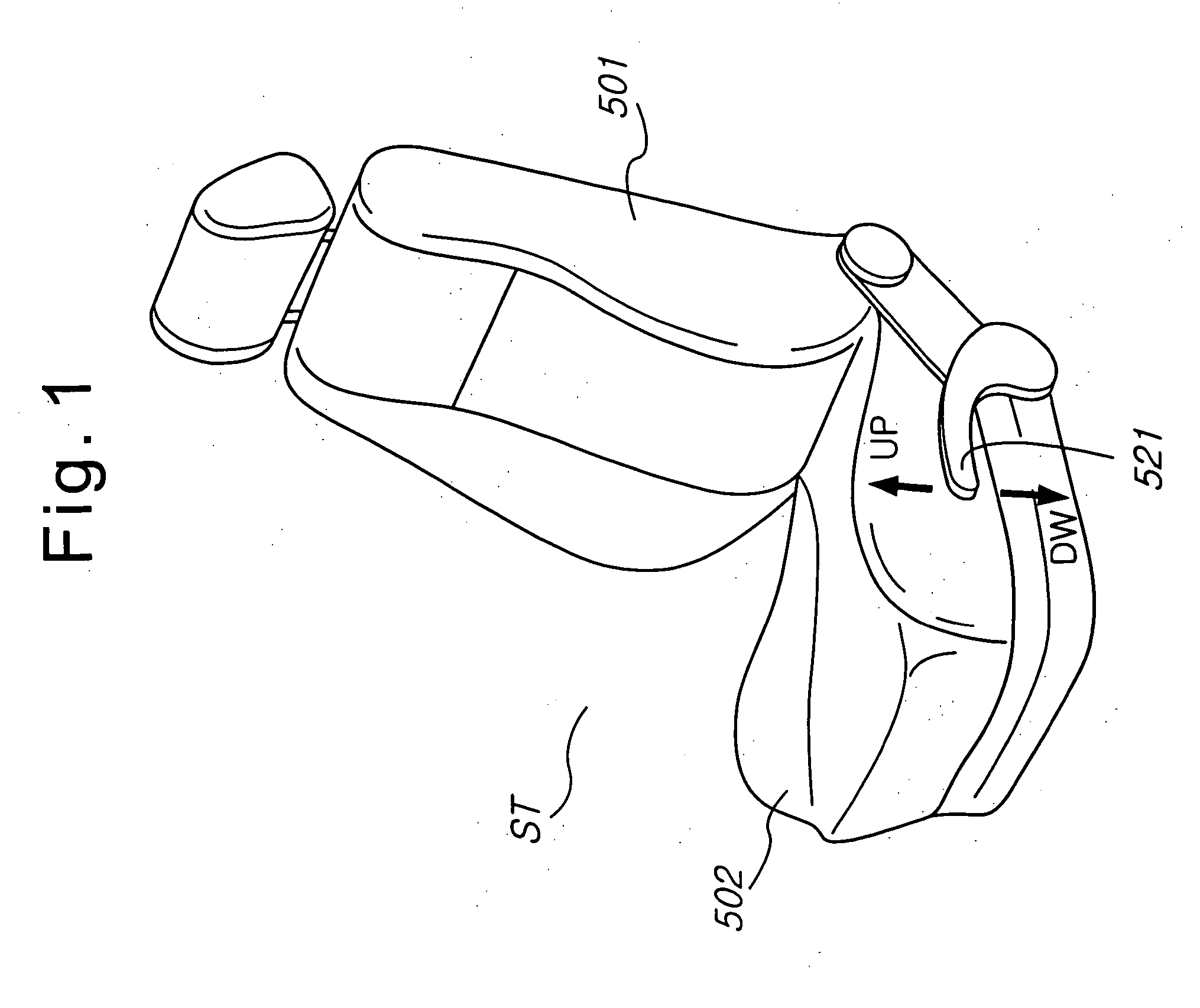

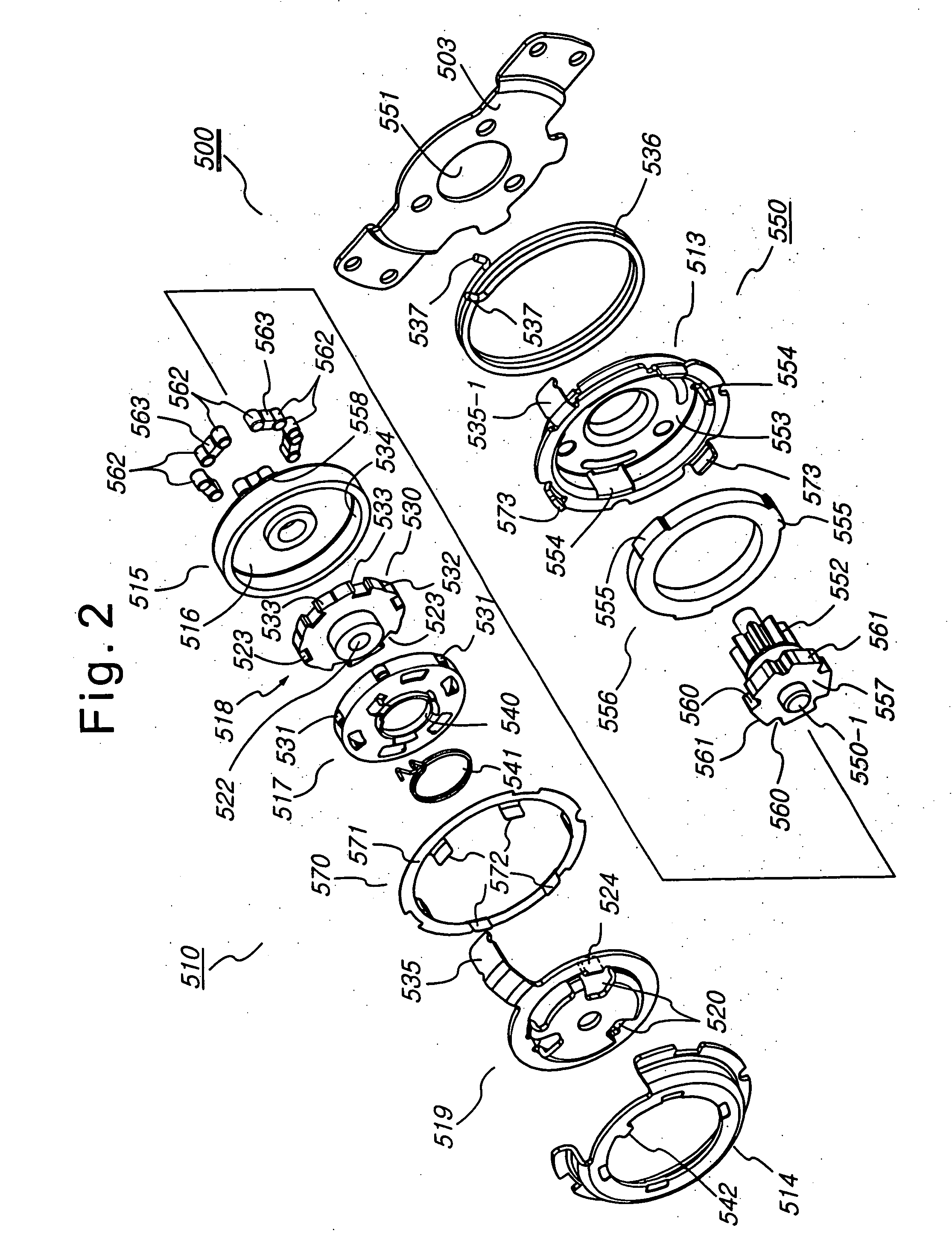

Pumping device and height adjuster for vehicle seat

InactiveUS20090184554A1Easy to operateSpace minimizationPositive displacement pump componentsAdjustable chairsEngineeringCam

A pumping device and a height adjuster for a vehicle seat are disclosed. The pumping device comprises a support plate; a cam receiver accommodated in the support plate; a brake cam received in the cam receiver to be integrally rotated with the shaft, and defining receiving spaces between the brake cam and the cam receiver; locking means received in each receiving space to allow and prevent rotation of the brake cam in the cam receiver; a control plate for applying the pushing force to the locking means; a bidirectional clutch coupled to the control plate if rotating force is applied and returned to a state of being decoupled from the control plate if the rotating force is not applied; a cover plate assembled with the support plate; a lever plate provided outside the cover plate; and elastic returning means for returning the lever plate to a predetermined reference position.

Owner:AUSTEM CO LTD

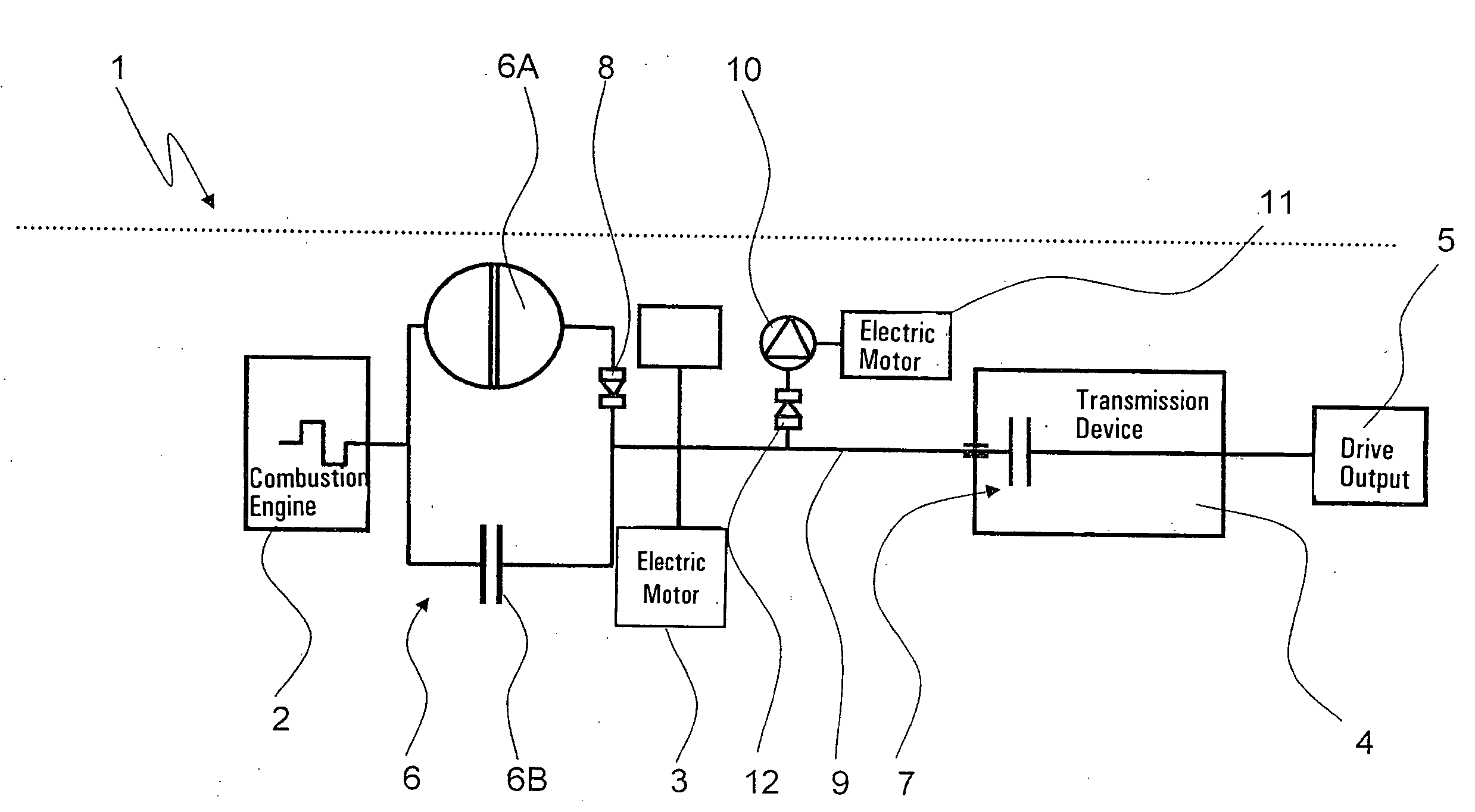

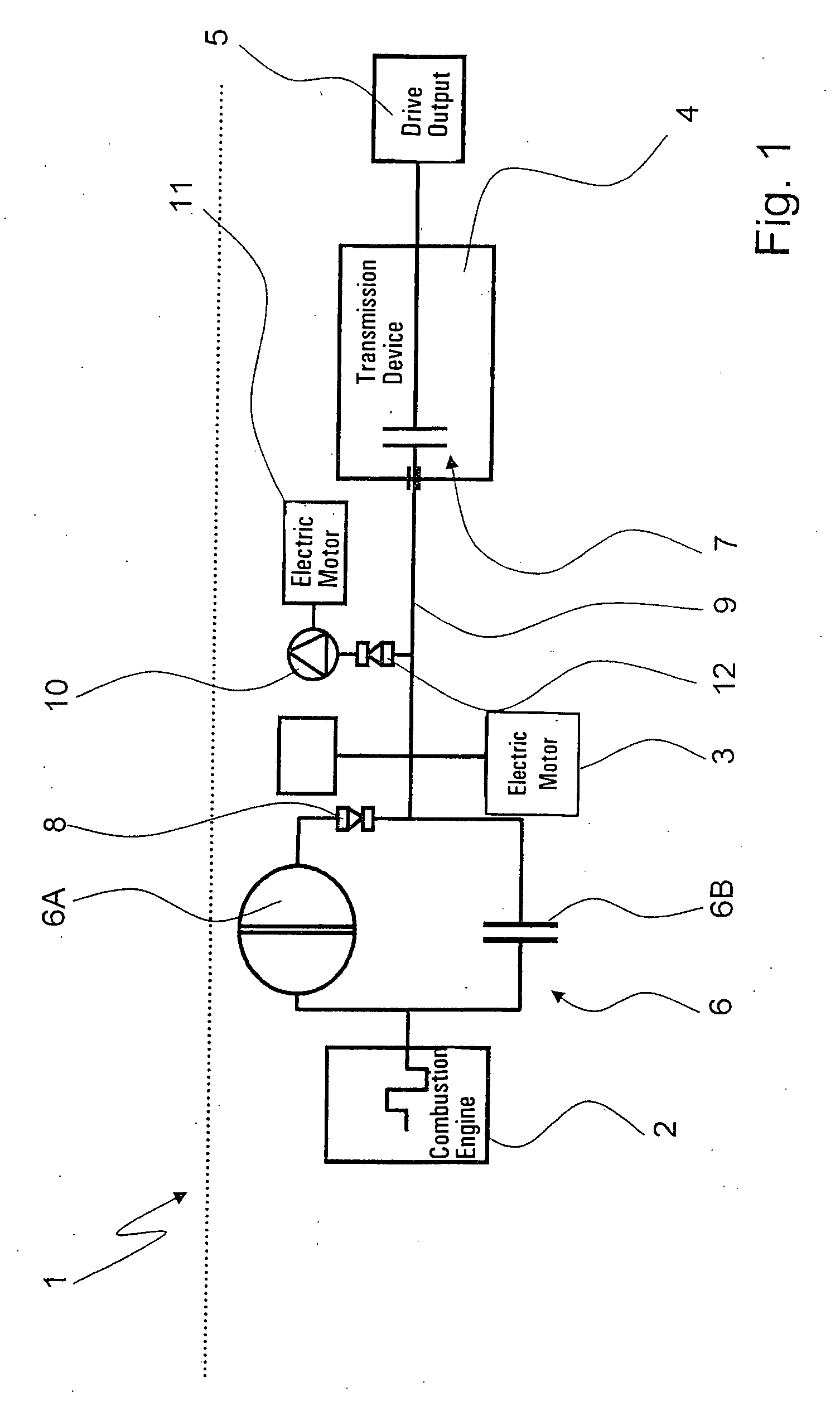

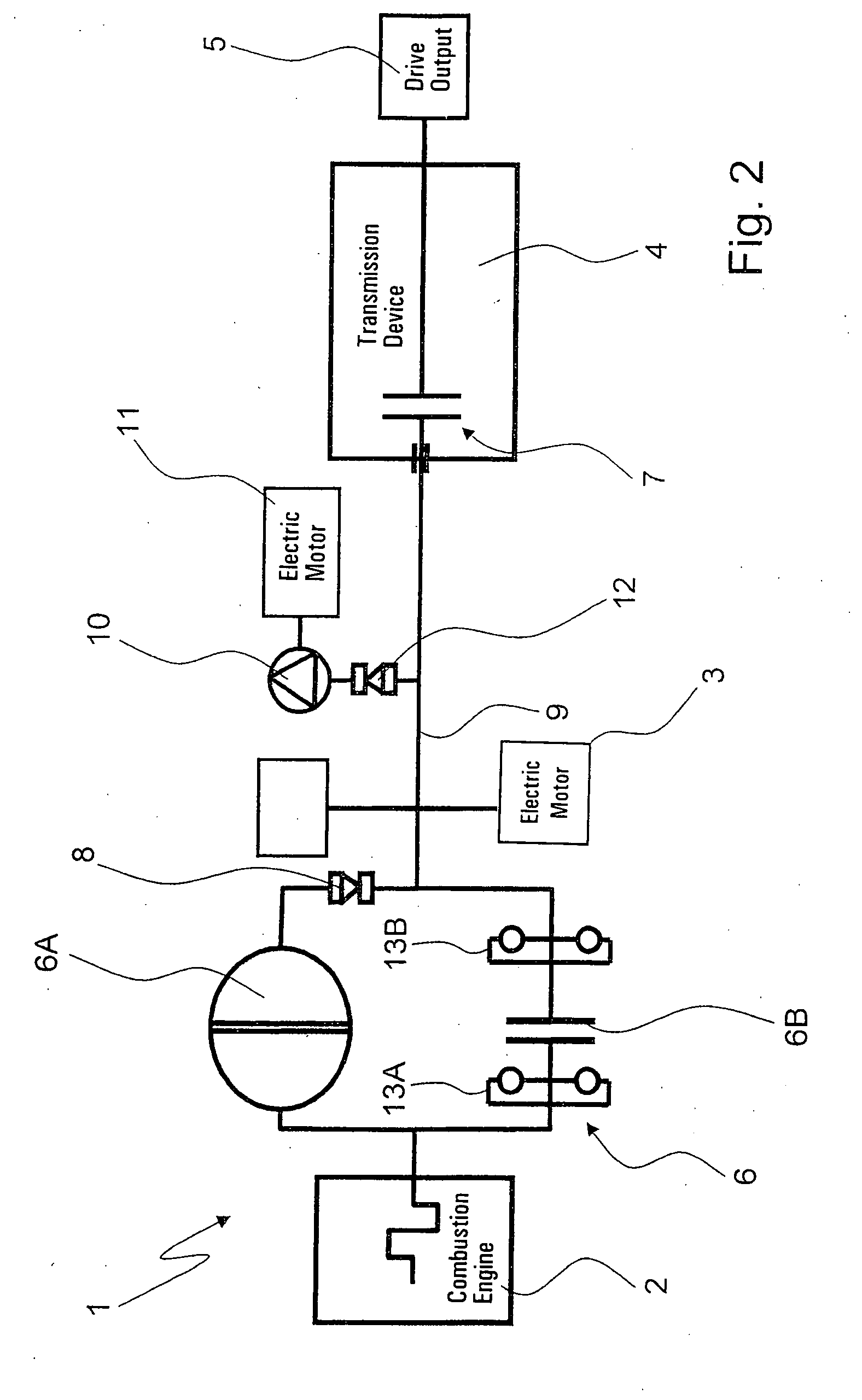

Drivetrain arrangement and method for operating a drivetrain arrangement

InactiveUS20080000746A1Disengage connectionHigh friction loadElectric propulsion mountingEngine controllersCombustionCoupling

A vehicular parallel hybrid drivetrain contains a combustion engine, electric motor and drive output and a method of operating the drivetrain. A respective shift element device (6, 7) with continuously variable transmission capacity is provided, between the combustion engine and the electric motor and between the electric motor and the drive. The shift element device (6), between the combustion engine and electric motor, comprises a speed-dependent hydraulic coupling element and a frictional shift element in a parallel power branch. The shift element device (6) has continuously adjustable transmission capacity and is bridged, via the hydraulic coupling element. The hydraulic coupling element actively couples with the electric motor, via a free-wheel overrunning connection (8). This coupling disengages when the speed of the coupling element side of the coupling element is lower than the speed of the electric motor in the area of the free-wheel overrunning connection.

Owner:ZF FRIEDRICHSHAFEN AG

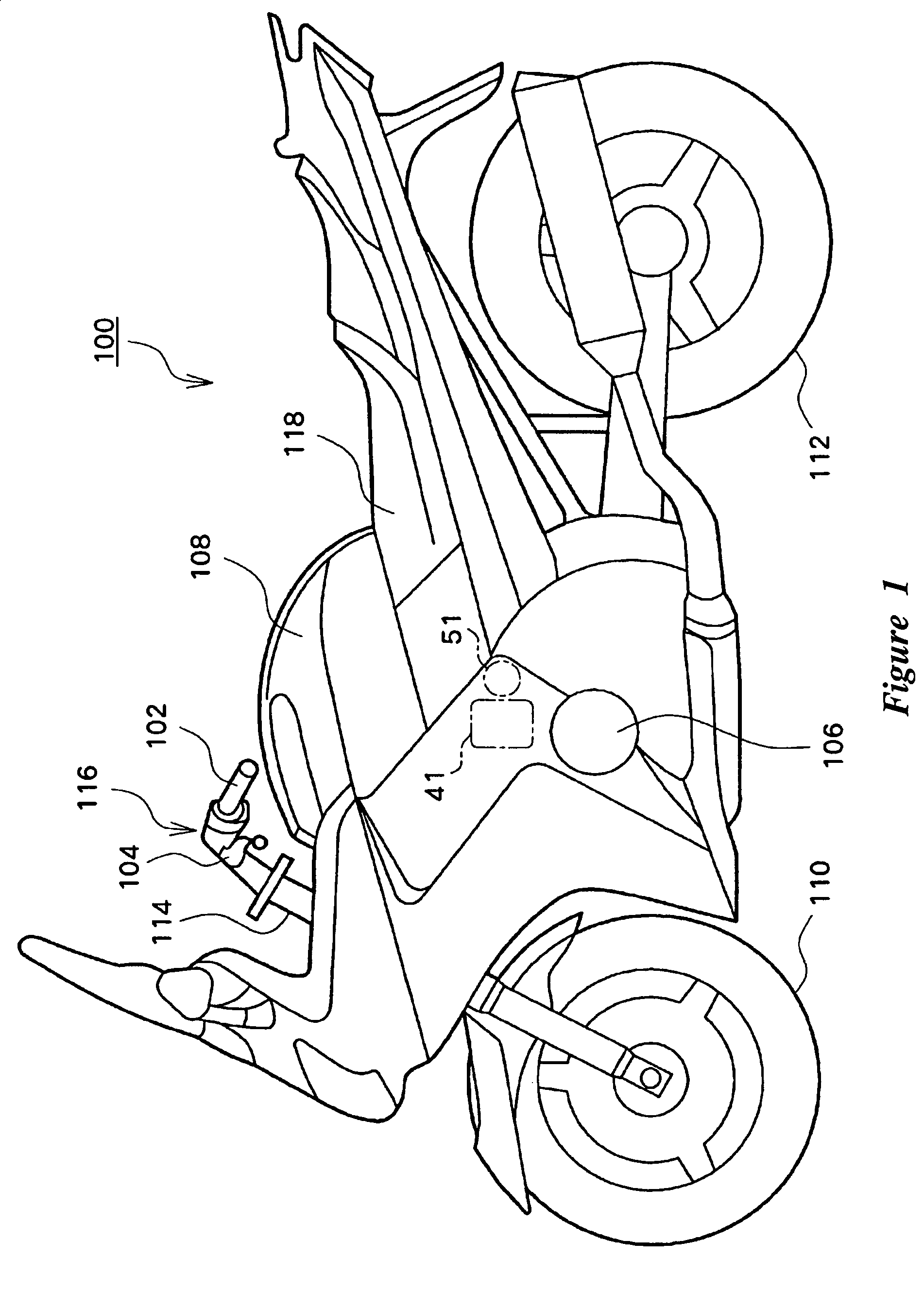

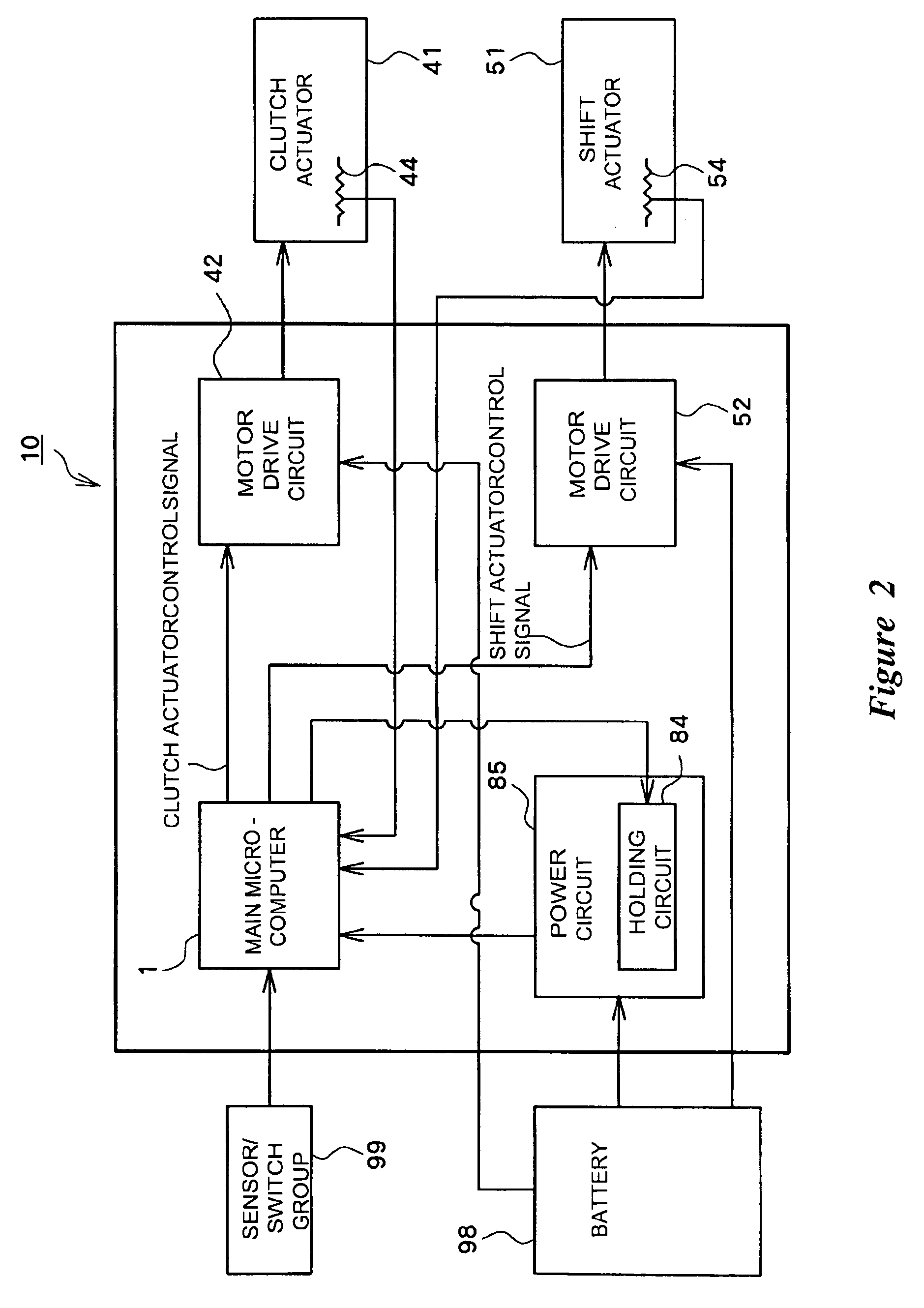

Straddle-type vehicle having clutch engagement control device and method of using clutch engagement control device

Engagement of a clutch is at least partially controlled based upon the difference in rotational speed between the drive side of the clutch and the driven side of the clutch. As the rotational speed difference varies, the approach rate of the drive side and the driven side also varies for at least part of the total distance defined between the drive side and the driven side when the clutch is disengaged.

Owner:YAMAHA MOTOR CO LTD

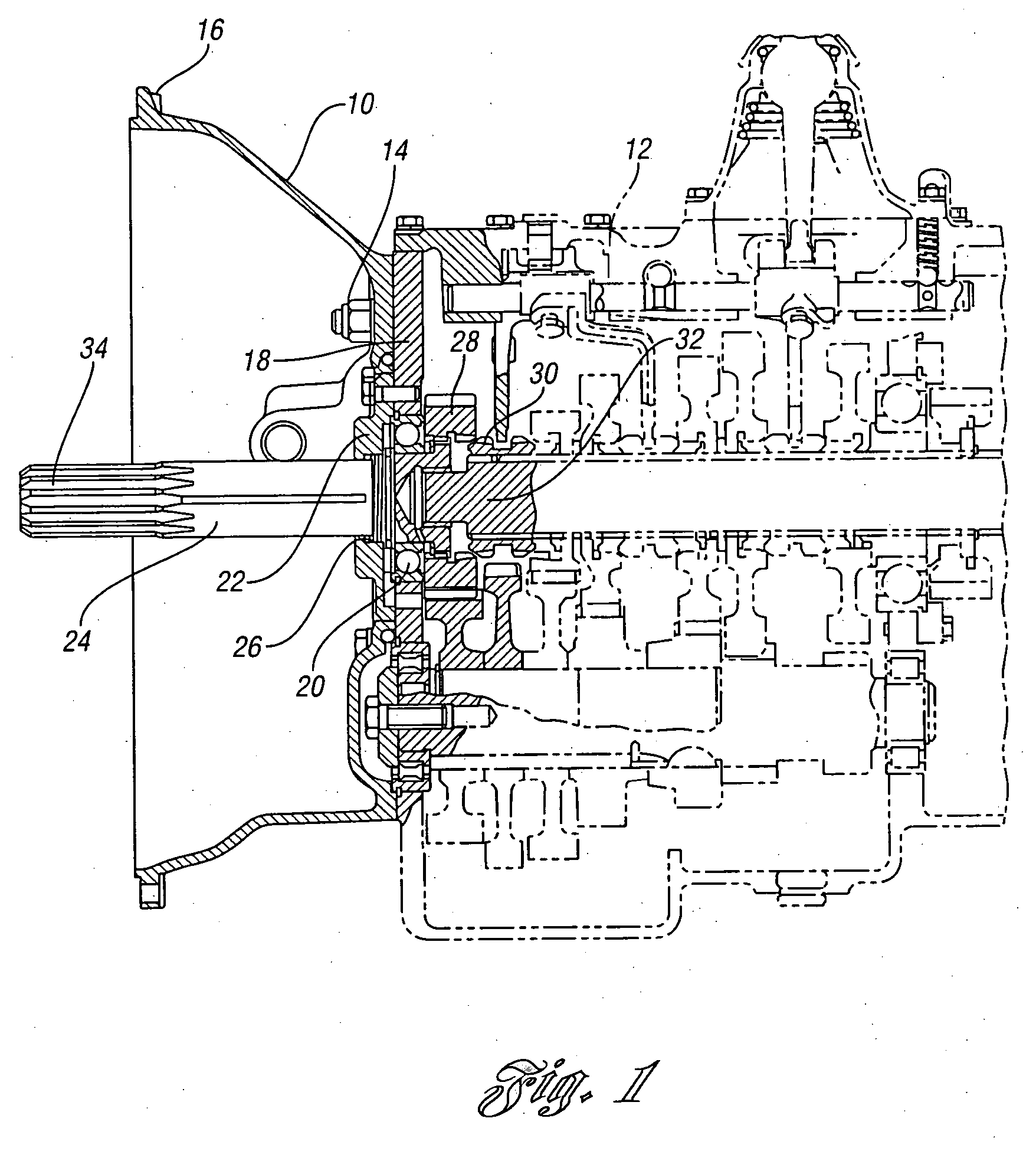

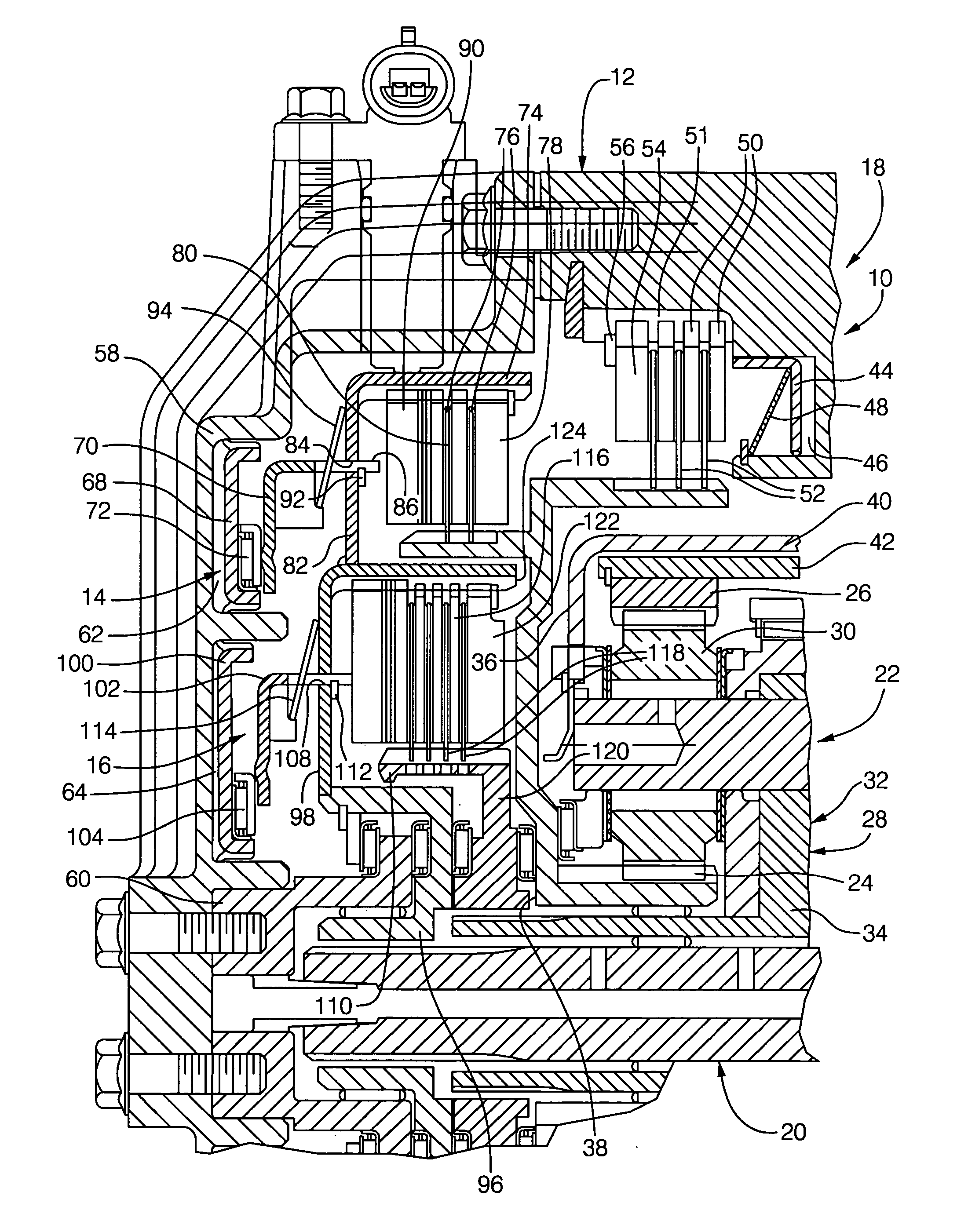

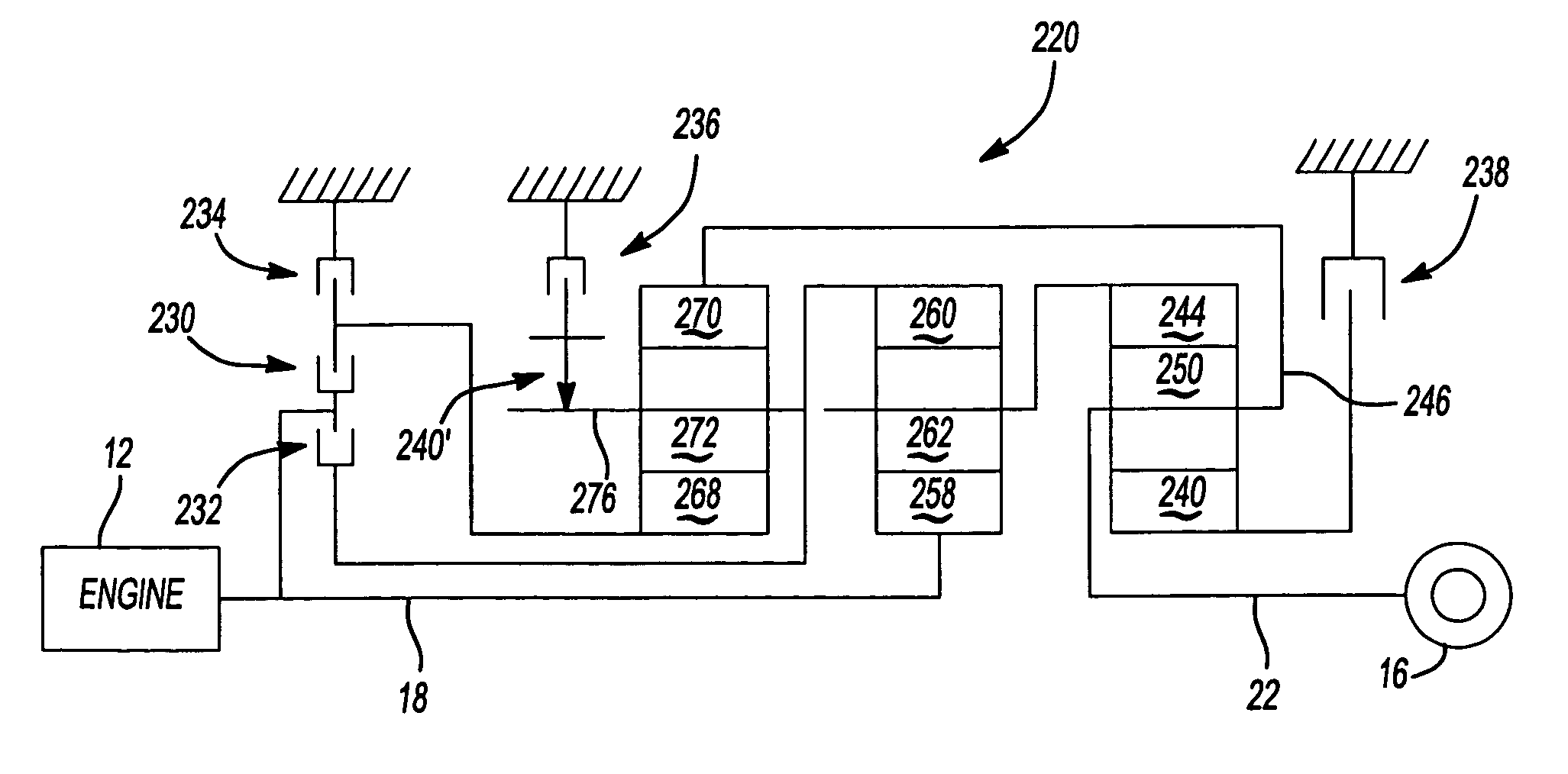

Transmission with friction launch mechanism

Owner:GM GLOBAL TECH OPERATIONS LLC

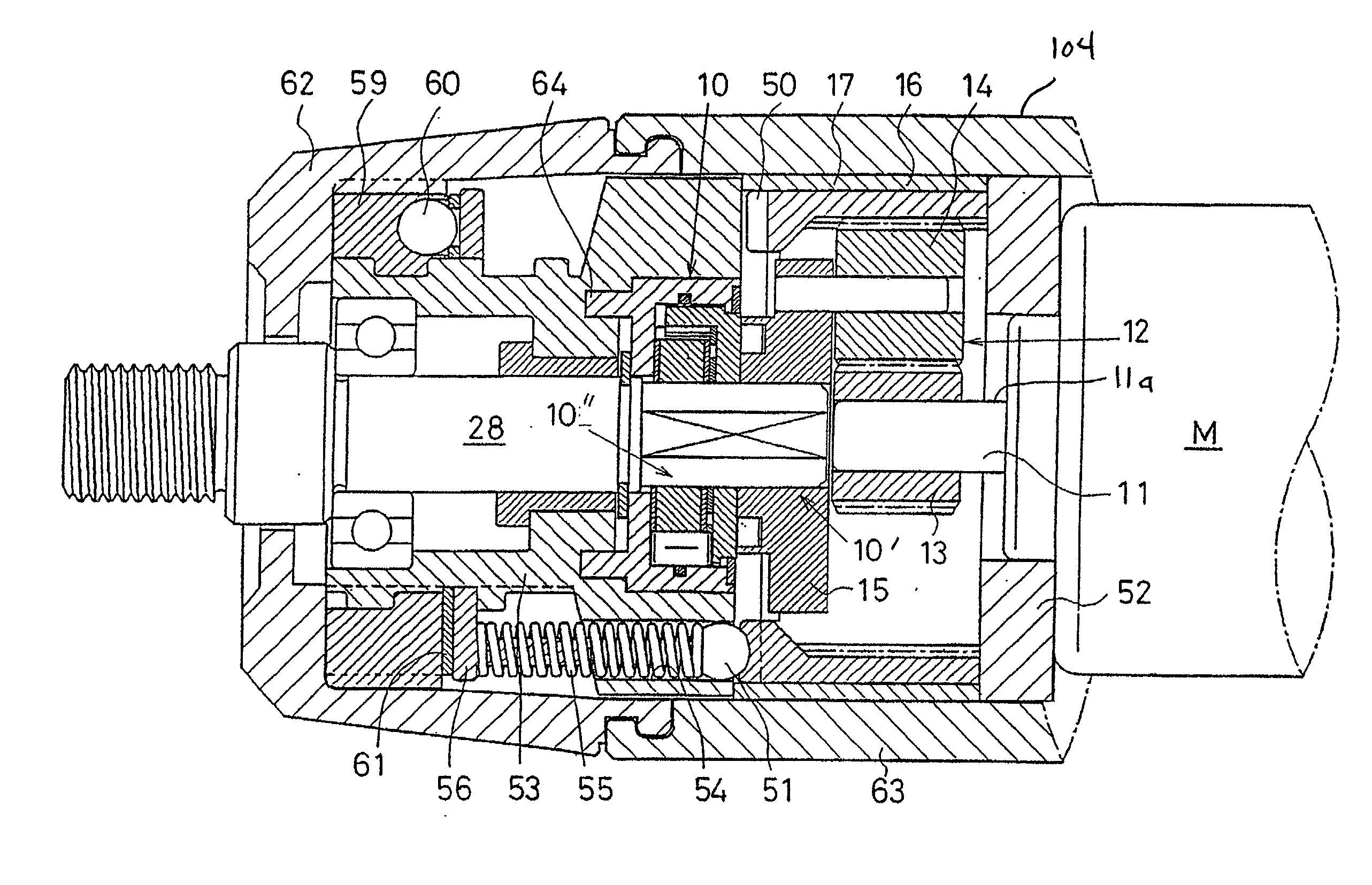

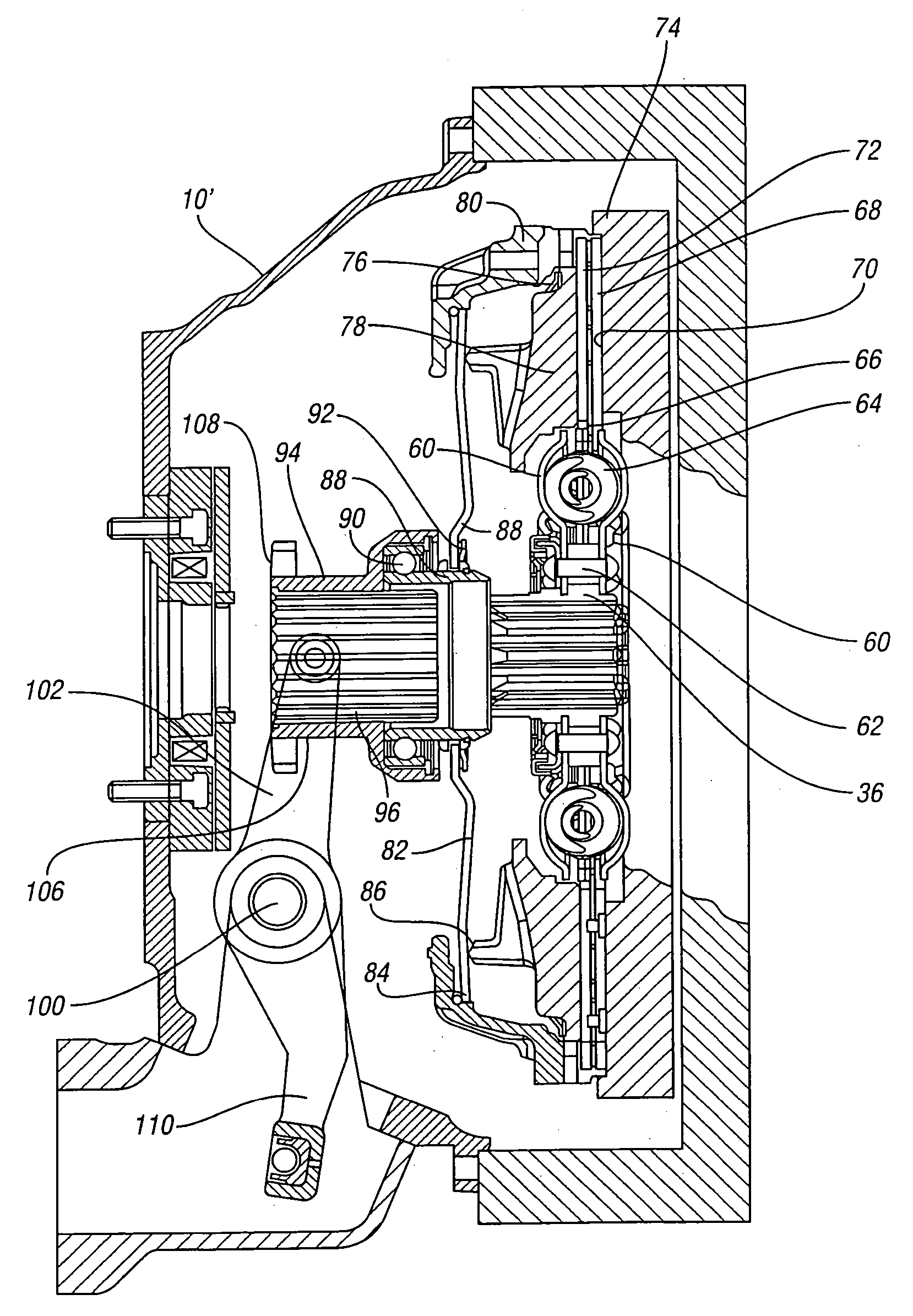

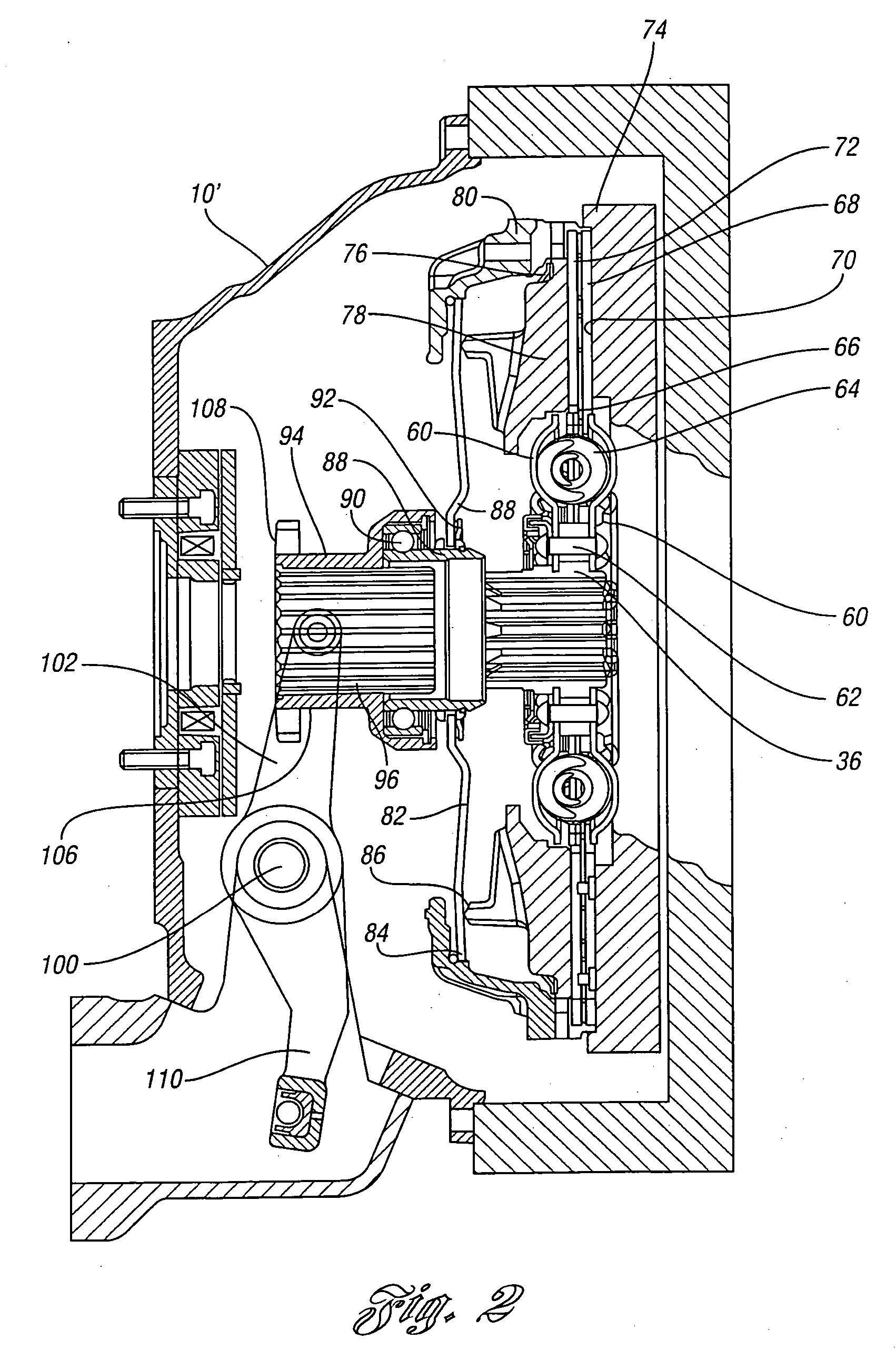

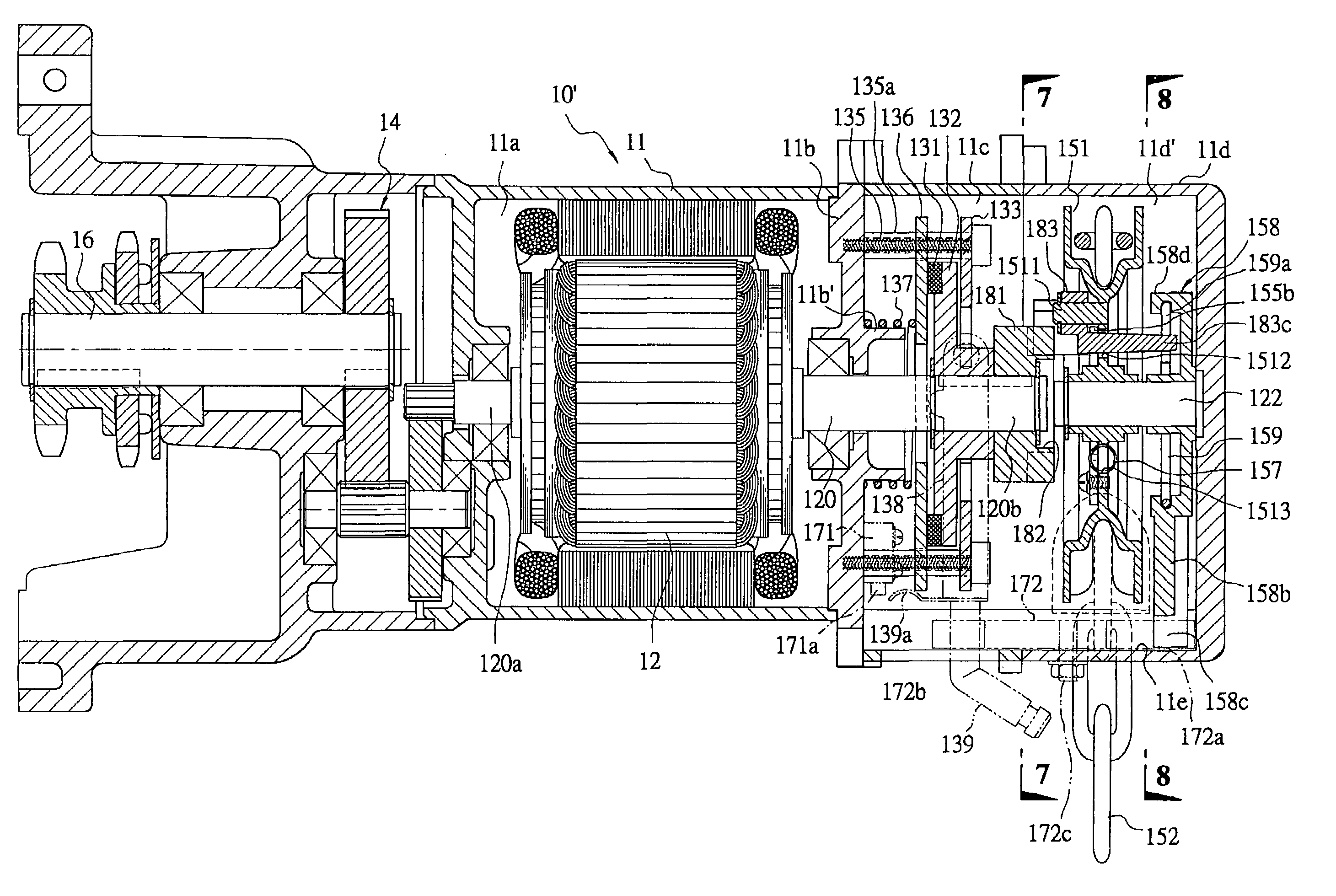

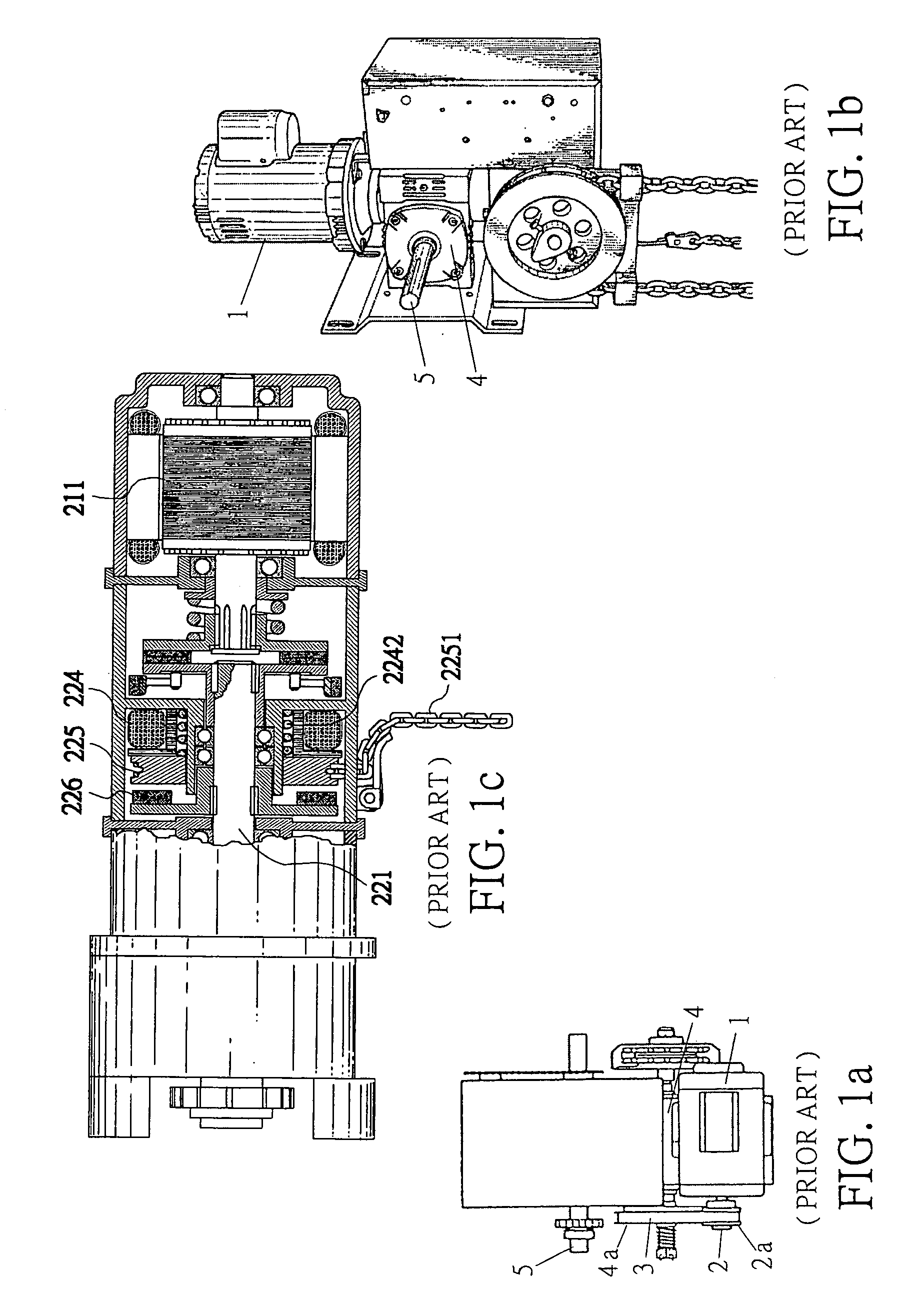

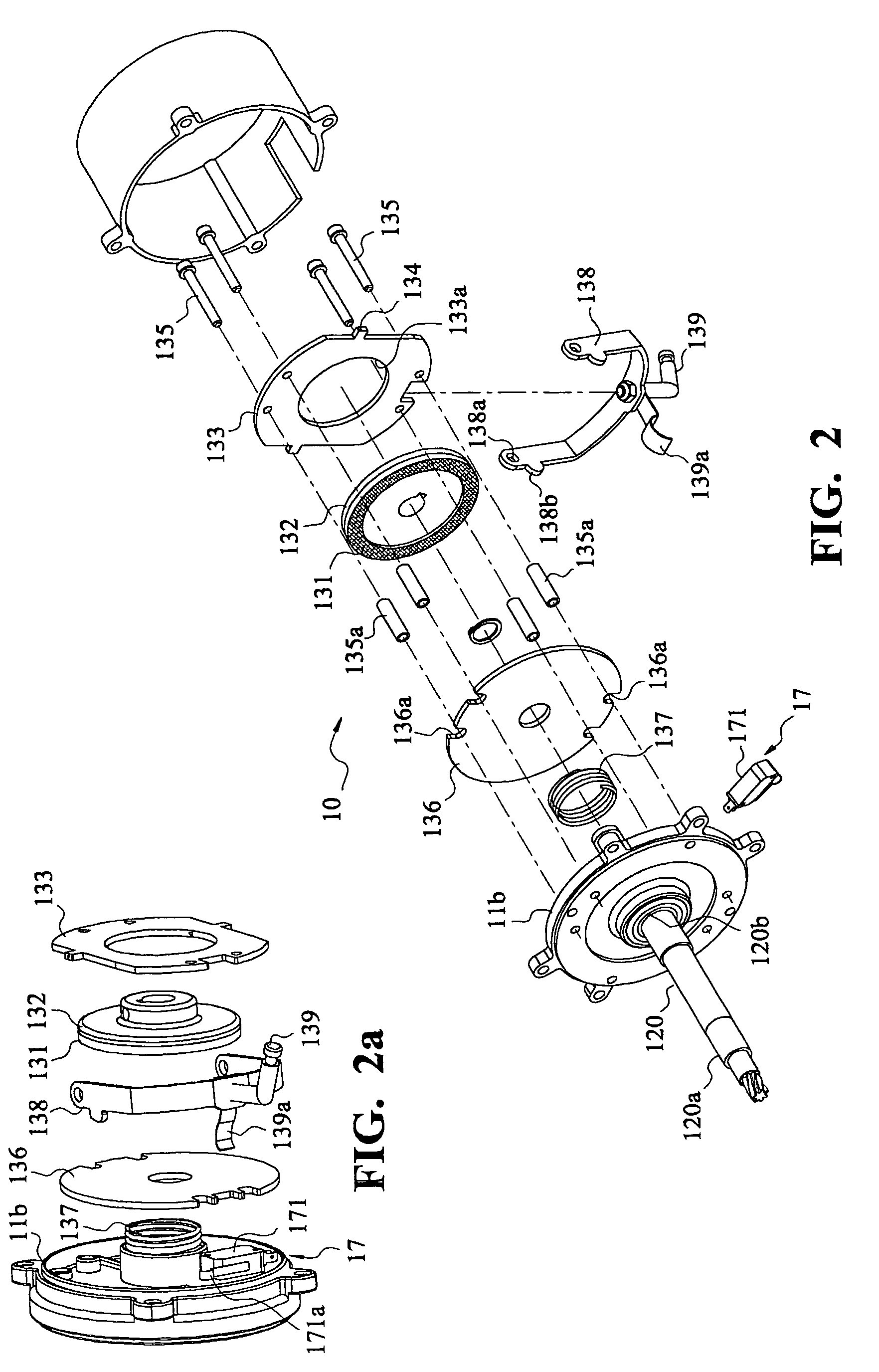

Control system for door opener

A control system for switching an electric operation to a manual operation of a door opener comprises: a housing 11, including a power unit 12 driving a shaft 120 electrically and transmitting the power to an output shaft 16; a braking device 13, used for braking the shaft 120 and releasing the shaft 120; a pull-chain disk device 15 allowed for exerting an external force via a pull chain 152 to rotate the shaft 120; a clutch device 18, disposed between the shaft 120 and the pull-chain disk device 15, used for unidirectionally rotating the shaft 120 controllably when the pull-chain disk device is rotated by the external force; a protective device 17 used for cutting off a circuit of a door opener 10′ in an abnormal mode; and a driven disk 158 interlocked with the clutch device 18 so as to swing by an angle for actuating the protective device 17 to switch. As such, the circuit of the door opener 10′ is cut off and the brake is released jointly to automatically switch to a safe manual mode in any situation, once the pull chain 152 is pulled.

Owner:HSIEH CHUNG HSIEN

Driving force transmitting system

ActiveUS20050064975A1Small sizeGuaranteed uptimeFluid actuated clutchesGearing controlWorking fluidAutomatic transmission

According to the present invention, a change-over means is provided between a mechanical oil pump and a clutch of an automatic transmission device for connecting an engine with the automatic transmission device, a first check valve is provided in a passage connecting the mechanical oil pump with the change-over means so that it allows the flow of working fluid discharged from the mechanical oil pump to the change-over means, and an electric oil pump is provided in parallel with the mechanical oil pump, wherein the electric oil pump is operated during an idling stop of the engine and an output side of the electric oil pump is connected to the passage between the first check valve and the change-over means so that the working fluid from the electric oil pump is supplied to the clutch of the automatic transmission device through the change-over means. Accordingly, the electric oil pump can be made smaller and the supply of the working fluid from the electric oil pump to the clutch can be surely prevented by the change-over means when the supply of the working fluid is not necessary.

Owner:DENSO CORP

Seat cushion pumping device for vehicle

Disclosed herein is a seat cushion pumping device for a vehicle adapted to adjust a height of a seat cushion. The seat cushion pumping device comprises a clutch unit adapted to transmit a rotating force to gears of link means in a desired direction where the seat cushion is to be moved, and a brake unit for fixing the operated link means so as not to move. The clutch unit and the brake unit are accommodated between a lower bracket and an upper bracket, which are positioned in front of a mounting bracket for accommodating the entire pumping device there between.

Owner:DAS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com