Hydraulic power-mechanical TBM cutter head combined rock breaking method, hydraulic power-mechanical combined rock breaking TBM cutter head and hydraulic power-mechanical combined rock breaking TBM device

A technology of mechanical and cutter head, applied in the fields of hydraulic-mechanical TBM cutter head combined rock breaking, hydraulic-mechanical combined rock breaking TBM device, hydraulic-mechanical combined rock breaking TBM cutter head, can solve the problem of low achievability, cutting The overall structure of the disc has changed greatly, so as to reduce the energy consumption of rock breaking, optimize the arrangement of the cutter head, and improve the rock breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

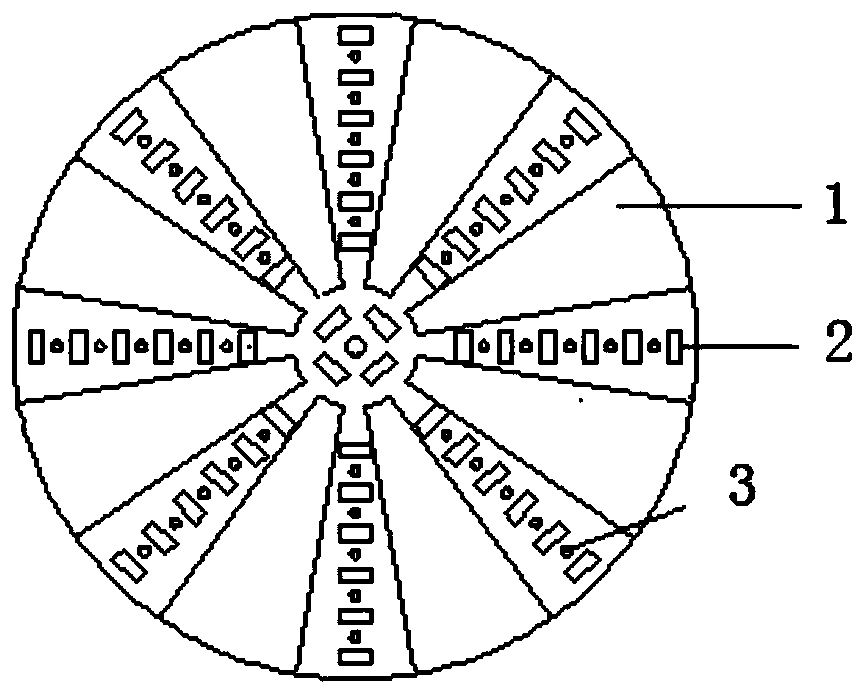

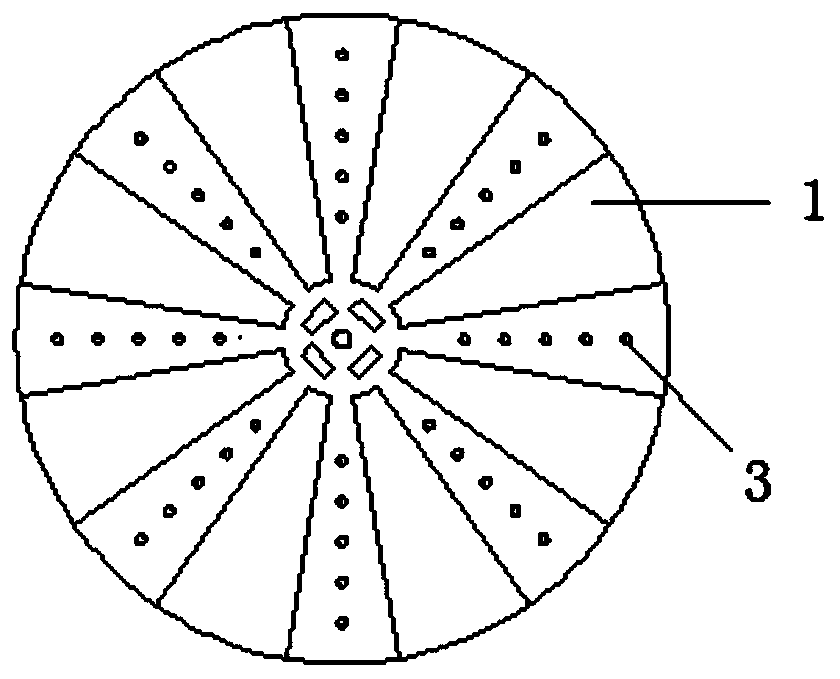

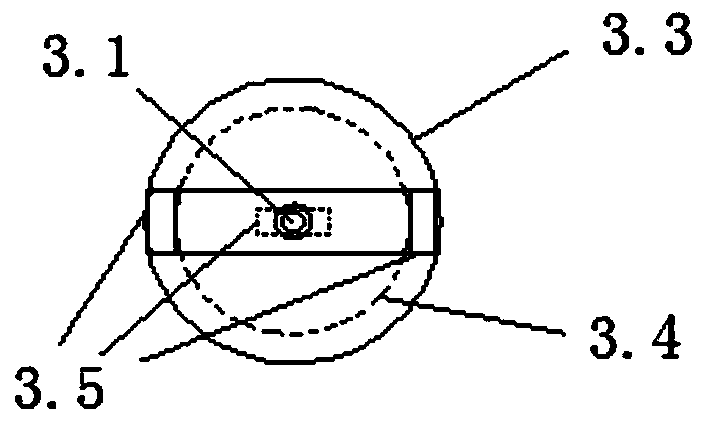

[0082] Referring to the accompanying drawings, it can be seen that the hydraulic-mechanical TBM cutter head combined rock breaking method includes the following steps,

[0083] Step 1: Install the combined rock-breaking TBM cutter head 4, and align the combined rock-breaking TBM cutter head 4 with the position of the cavern to be excavated (ie, the tunnel surface 18); the mechanical hob structure equipped on the TBM cutter head has enough Strong strength and rigidity, able to withstand the huge reaction force and shear stress generated by the cutterhead rotation and advancement during the excavation of the main engine;

[0084] Step 2: Fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com