Rotary type forearm with hinge pin auxiliary stress mechanism

A pin shaft and protection mechanism technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovelers, construction, etc., can solve the problems of pin shaft wear and tear, and achieve good rock breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

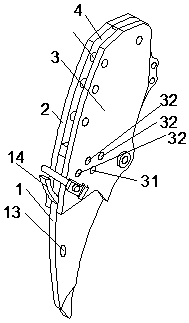

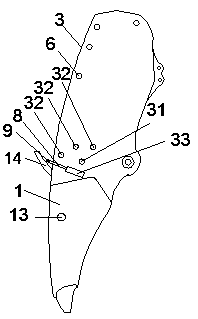

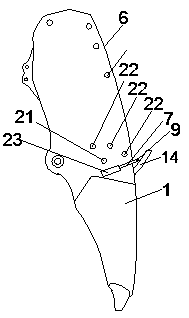

[0029] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It shows a rotating small arm with a pin auxiliary force receiving mechanism, including an upper clamping part, a lower clamping hook part 1 and a pin shaft protection mechanism, and the upper clamping part includes left splints 2 arranged side by side and the right splint 3, there is a clamping gap 4 between the left splint 2 and the right splint 3, the upper part of the lower clip digging hook part 1 is snapped into the bottom of the clamping gap 4, and the bottom of the left splint 2 is provided with a left fixing channel. Hole 21 and left angle adjustment through hole 22, left angle adjustment through hole 22 has more than two, all left angle adjustment through holes 22 take left fixed through hole 21 as the circle center and surround left fixed through hole 21 equidistantly, right splint 3 The bottom of the bottom is provided with the right fixed through hole 31 that is arranged correspondingly with the le...

specific Embodiment 2

[0031] This embodiment further explains the connection mode between the left splint 2 and the right splint 3 on the basis of the specific embodiment 1. The left splint 2 and the right splint 3 are connected by one or more than one short column 6 , The stub 6 is arranged along the edges of the left splint 2 and the right splint 3 .

[0032] The left splint and the right splint are fixed and positioned with short posts.

specific Embodiment 3

[0033] This embodiment is based on the specific embodiment 1 to further illustrate the lower clip digging hook 1, the lower clip digging hook 1 is a hollow structure, and the middle part of the lower clip digging hook 1 is provided with Filling port 13, and the filling port 13 communicates with the inner cavity of the lower clip digging hook part 1.

[0034] The filling port is set to fill the hollow structure of the lower clamping piece with weight-increasing materials. In this way, different weights of filling materials can be filled in according to different situations to improve its rock-breaking effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com