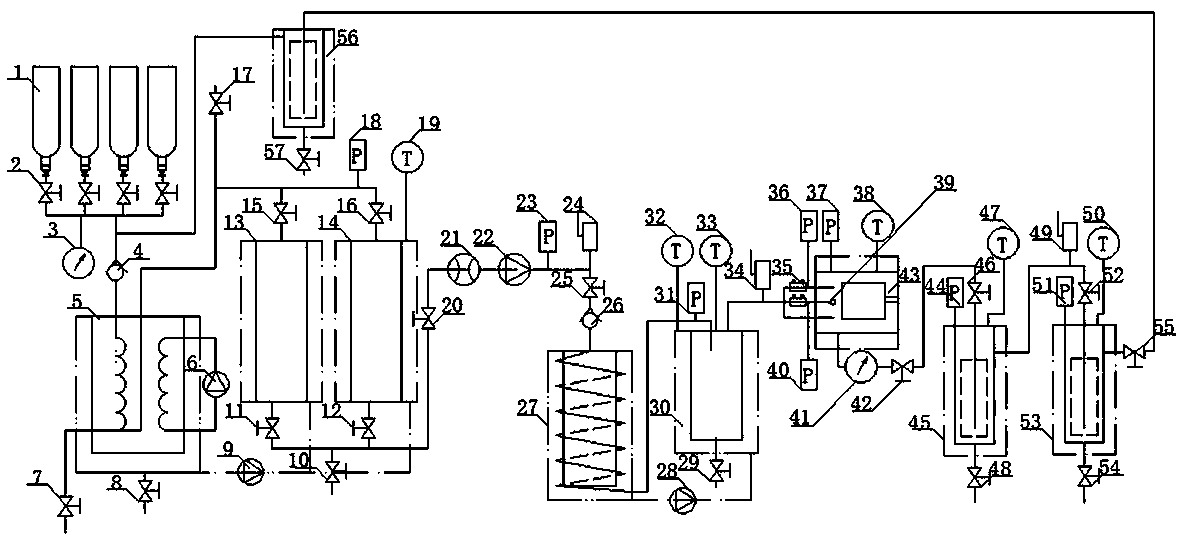

Patents

Literature

65results about How to "Improve rock breaking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

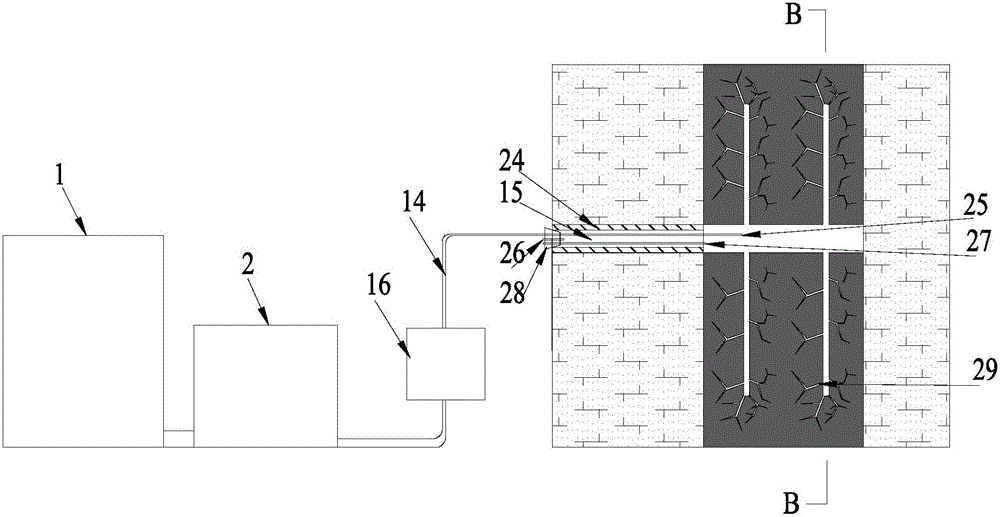

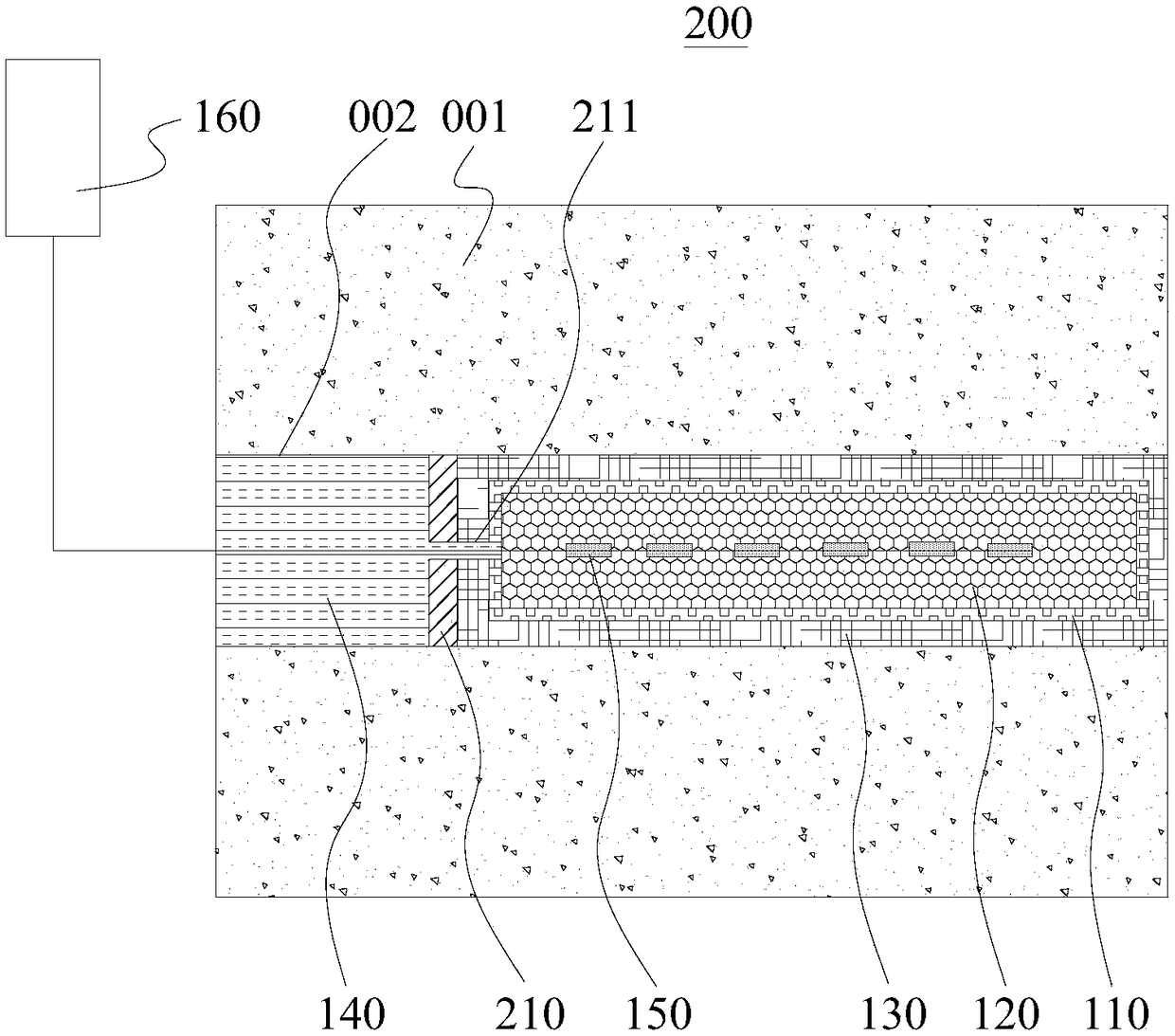

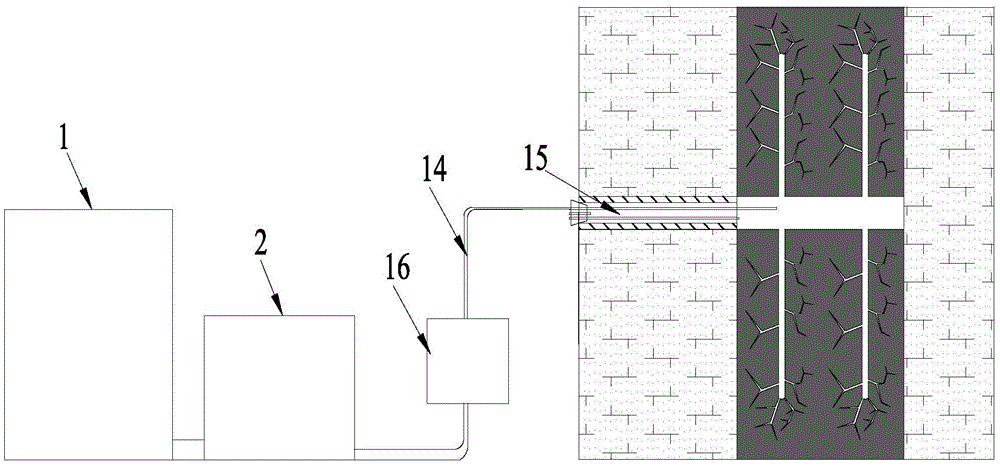

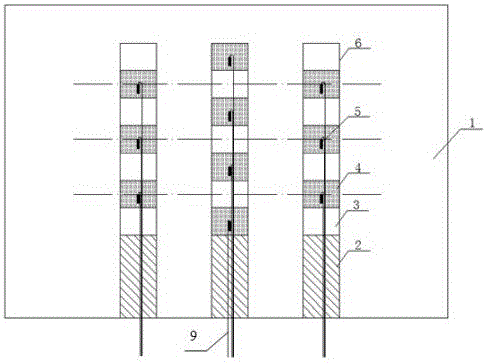

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

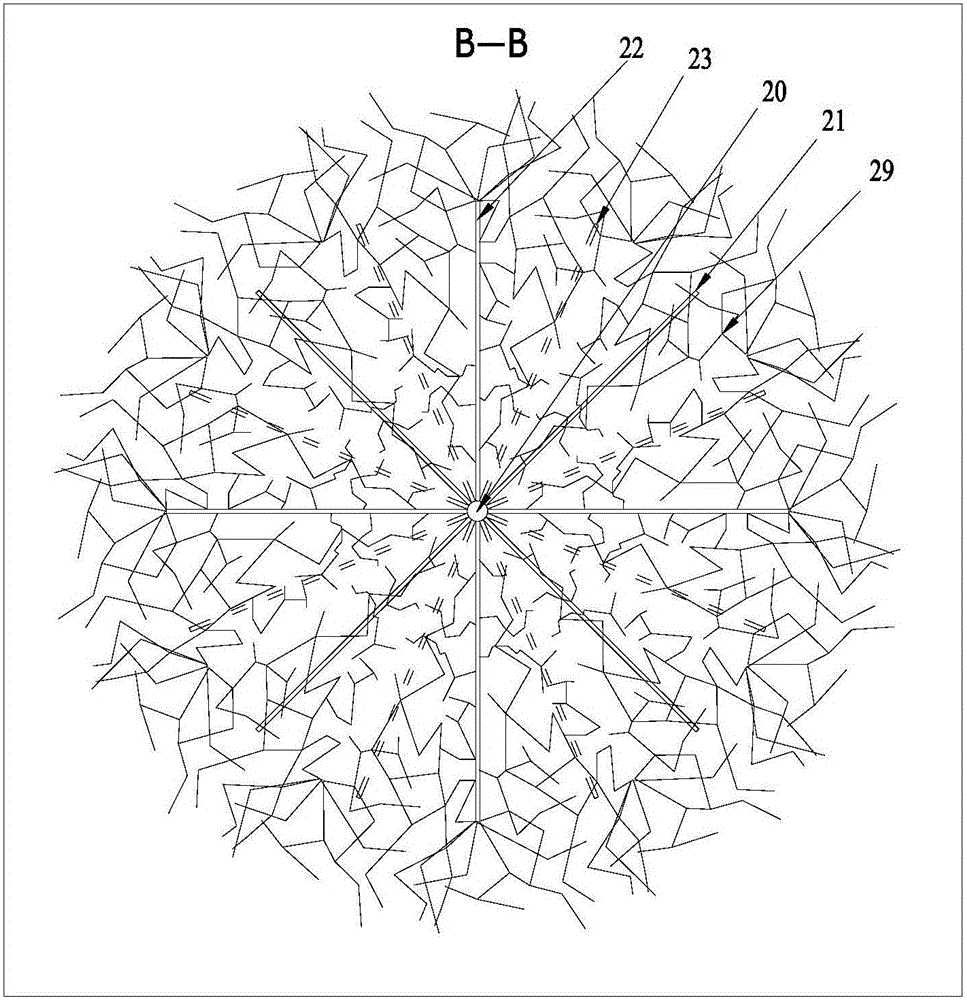

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

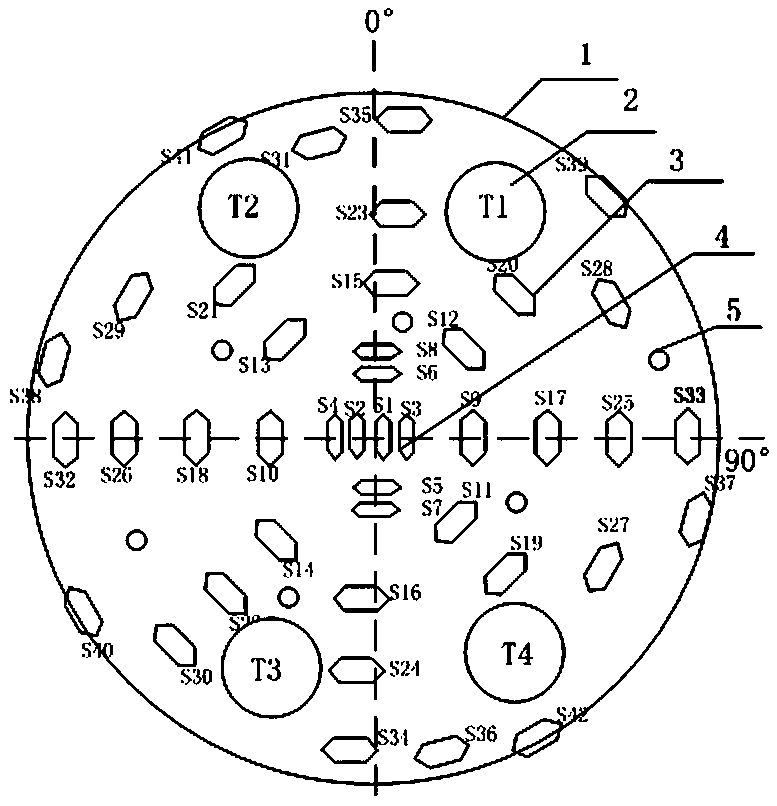

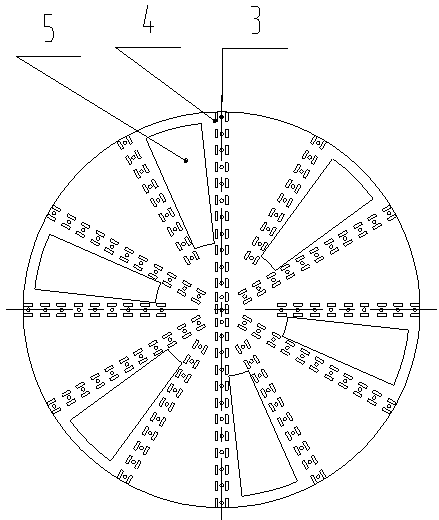

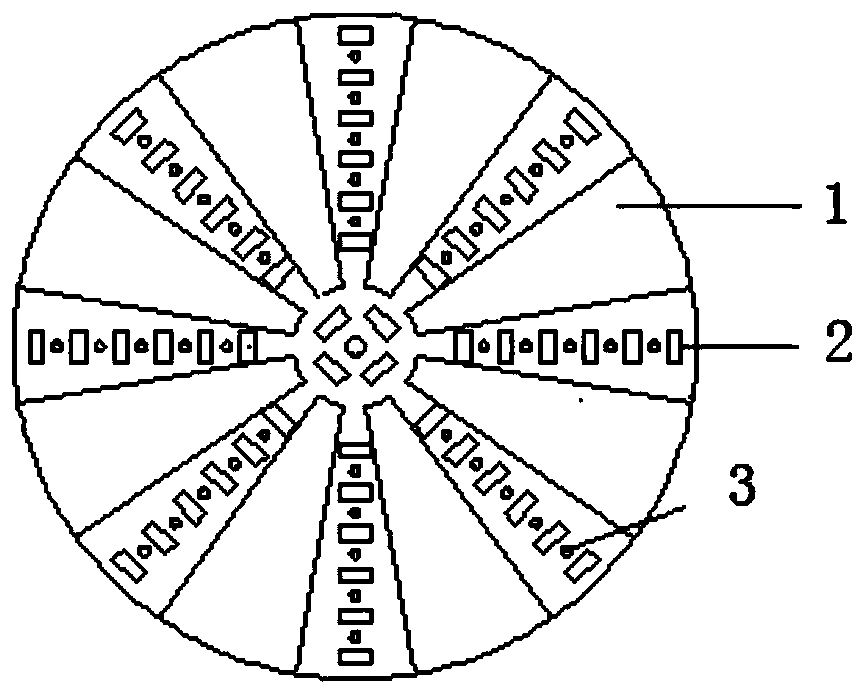

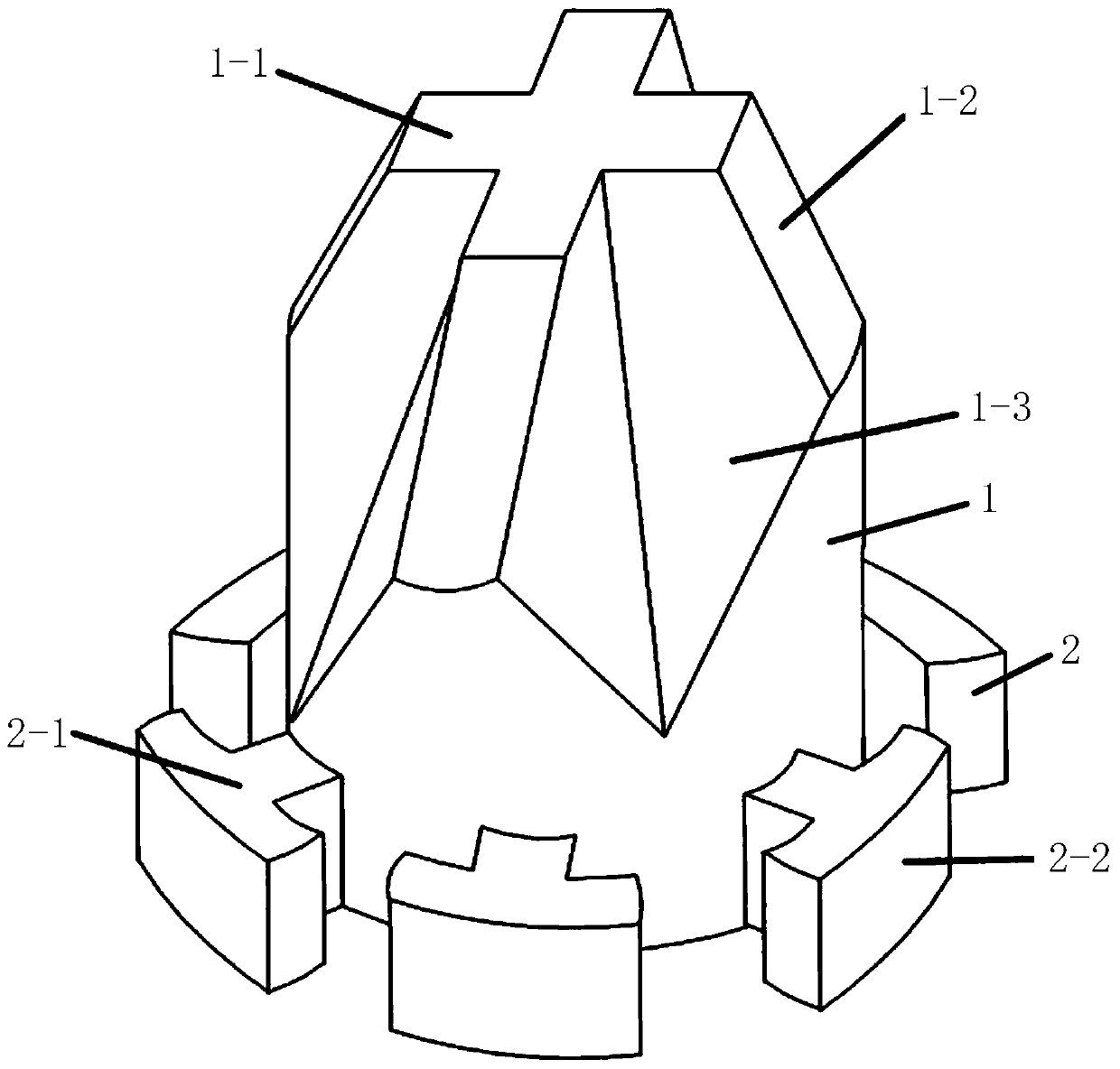

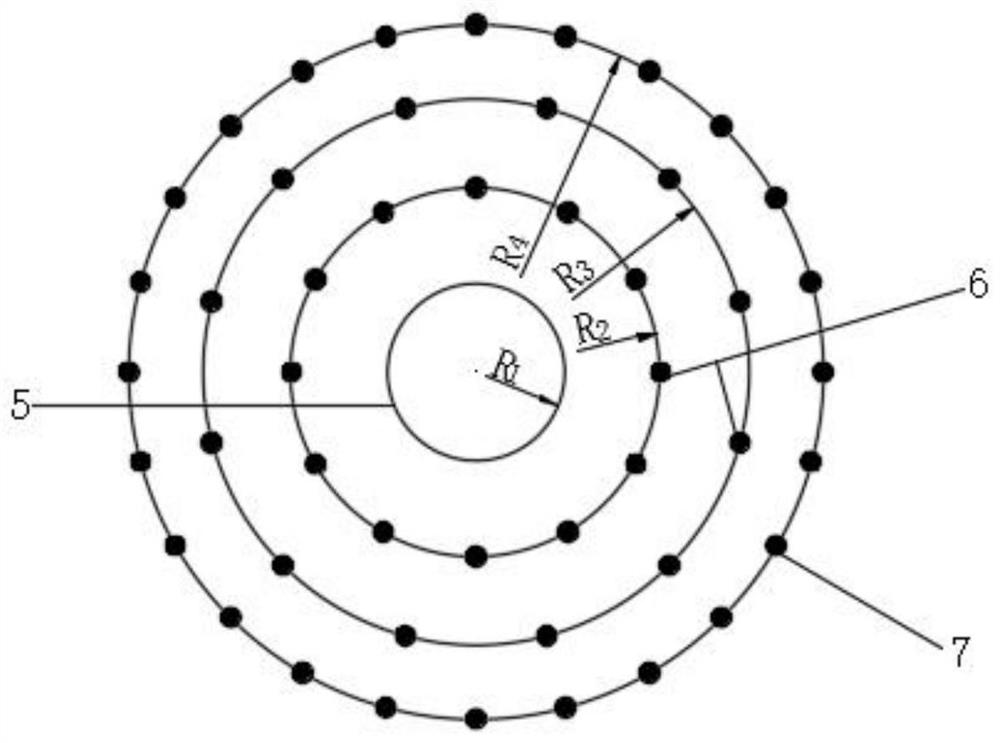

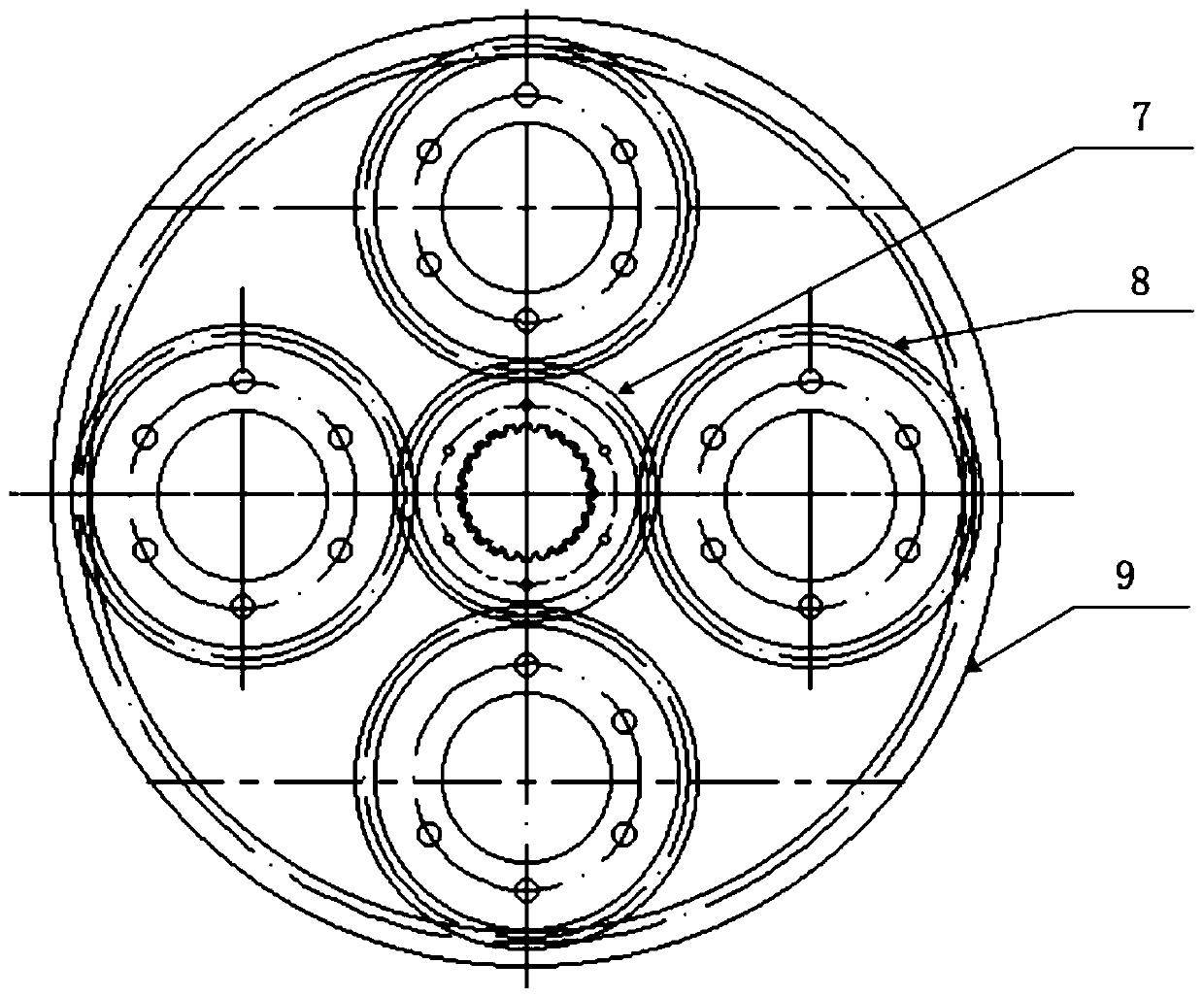

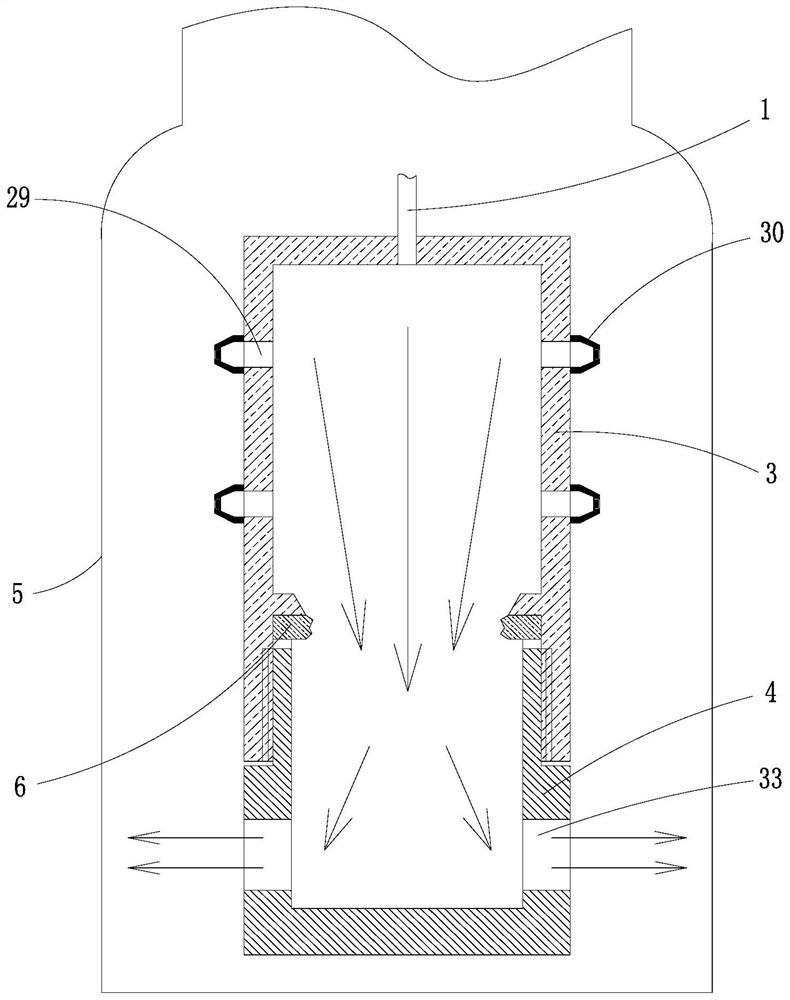

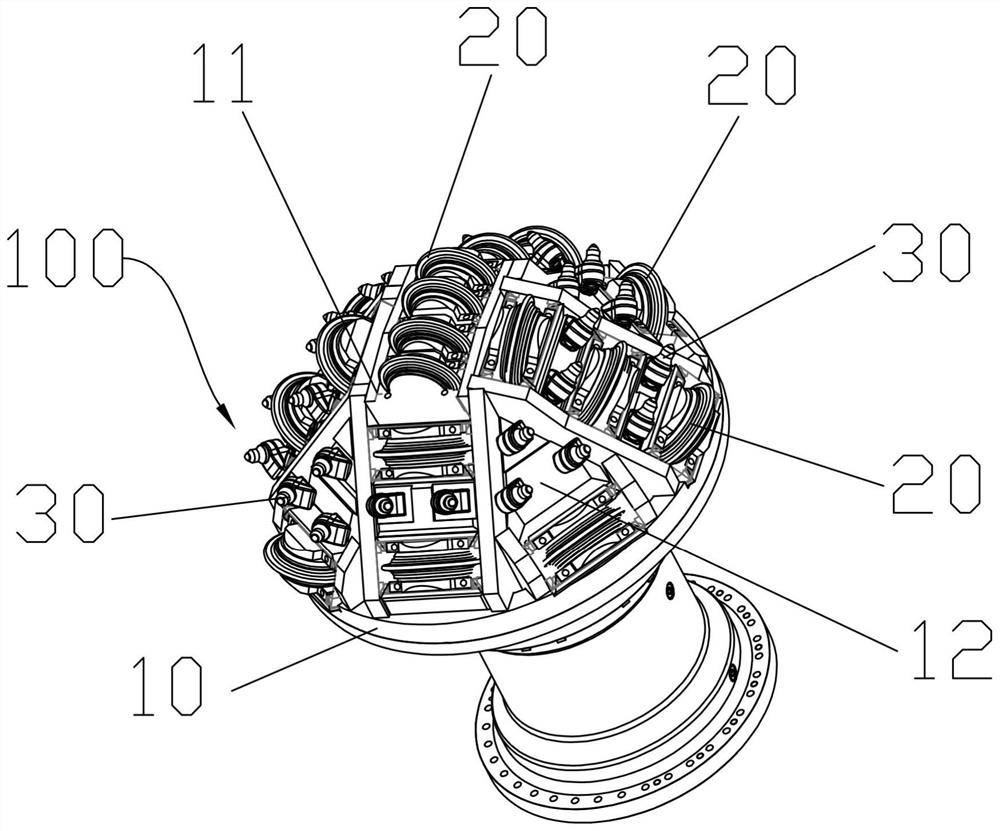

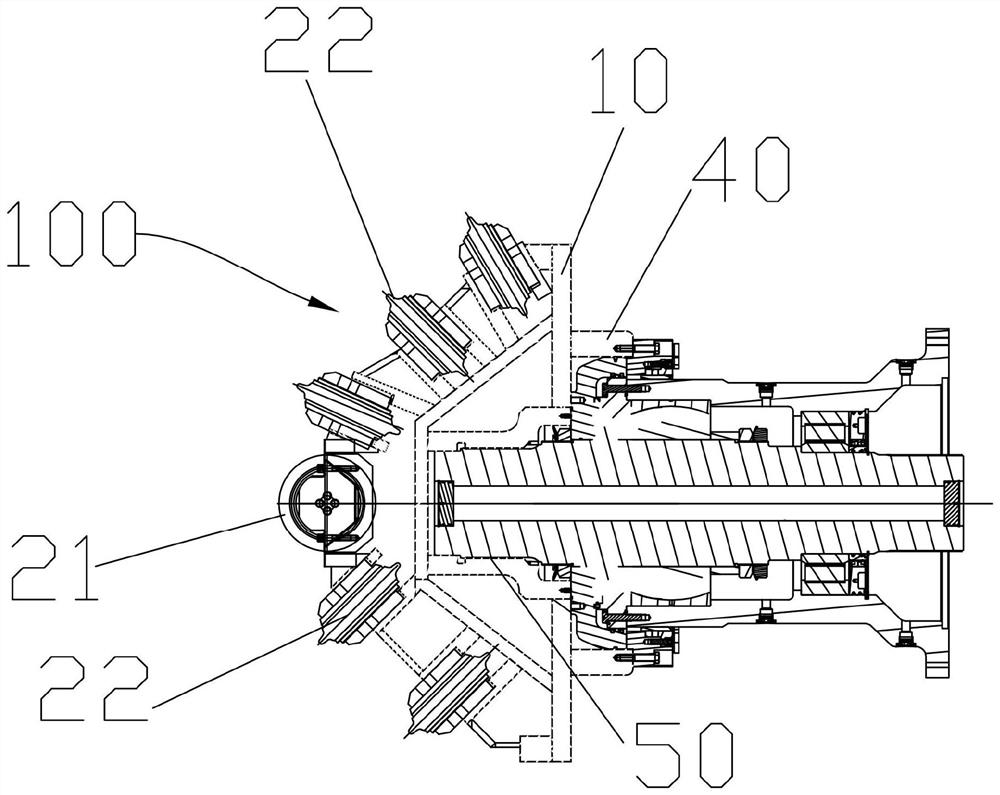

Microwave-assisted rock breaking TBM cutter head for hard rocks

PendingCN109763832AExpand coverageGood rock breaking effectDust removalFire preventionRock breakingDisc cutter

The invention discloses a microwave-assisted rock breaking TBM cutter head for hard rocks. The cutter head comprises a TBM cutter head body, wherein the TBM cutter head body mainly comprises a single-edge rock breaking hobbing cutter, a double-edge rock breaking hobbing cutter, a plurality of water injection dedusting openings and a plurality of microwave-assisted rock breaking emitters; the cutter head covers rock breaking paths in different tracks through the combination of the double-edge rock breaking hobbing cutter and the single-edge rock breaking hobbing cutter; a cutter head panel is provided with the water injection dedusting openings; the cutter head panel is provided with the microwave-assisted rock breaking emitters; each microwave-assisted rock breaking emitter comprises a microwave emitting disc, a wave guiding structure and a microwave emitting module. The cutter head has the advantages that a microwave emitting device is started in case of hard strata, rocks are rapidlyheated through microwave, mechanical properties of rocks, such as the point load strength, uniaxial compressive strength and tensile strength, are reduced, rock joint fissure assisted TBM hobbing cutter rock breaking is added, the penetration speed of disc cutters is improved, the rock breaking rate is improved, the thrust and torque of TBM equipment are reduced, abrasion of the hobbing cutters in hard rocks and cutter changing frequency are reduced, the construction period can be greatly reduced, and the construction investment can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

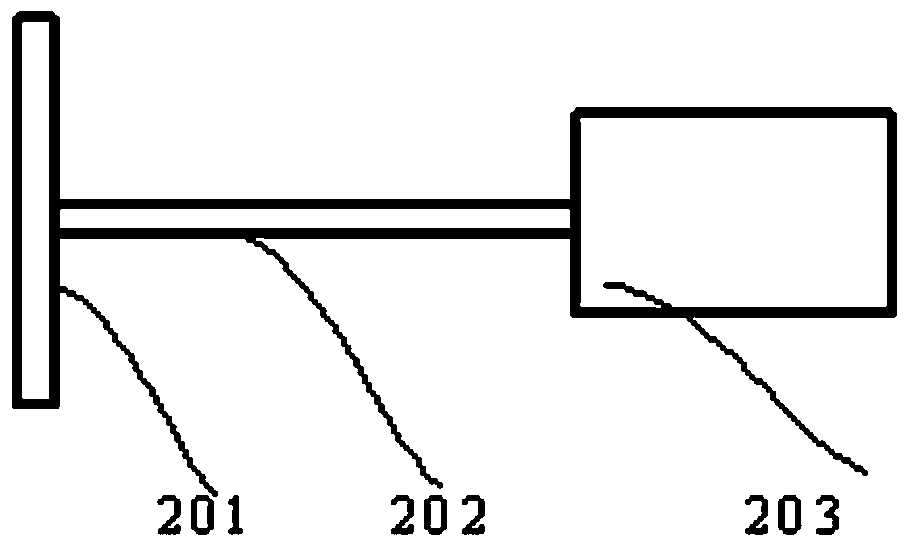

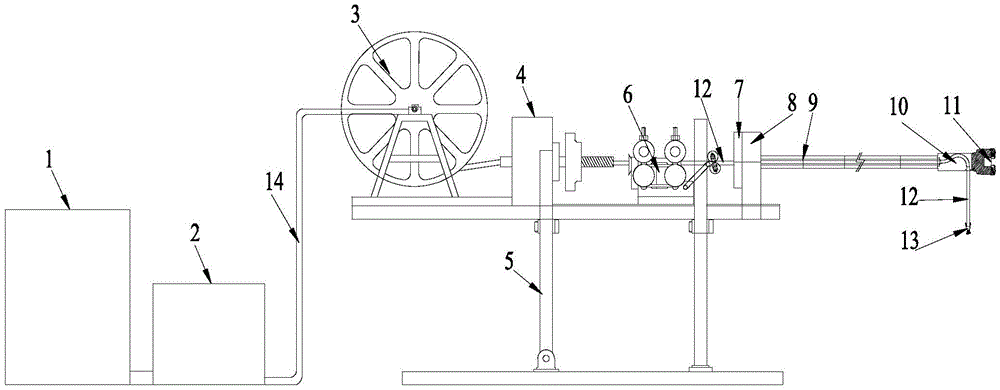

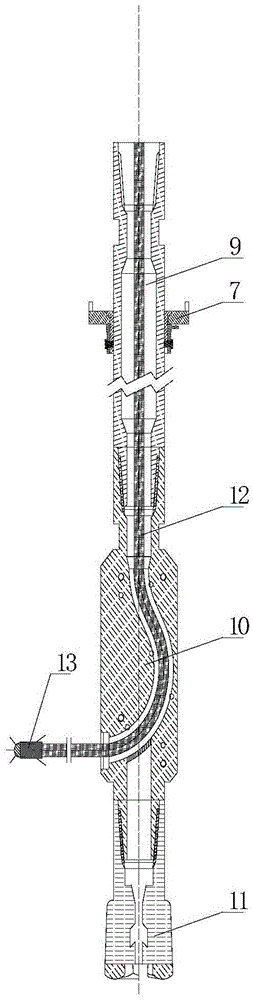

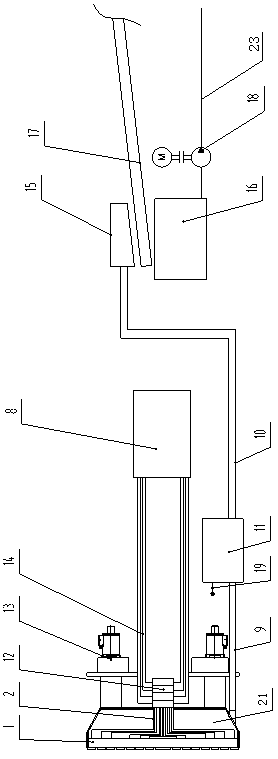

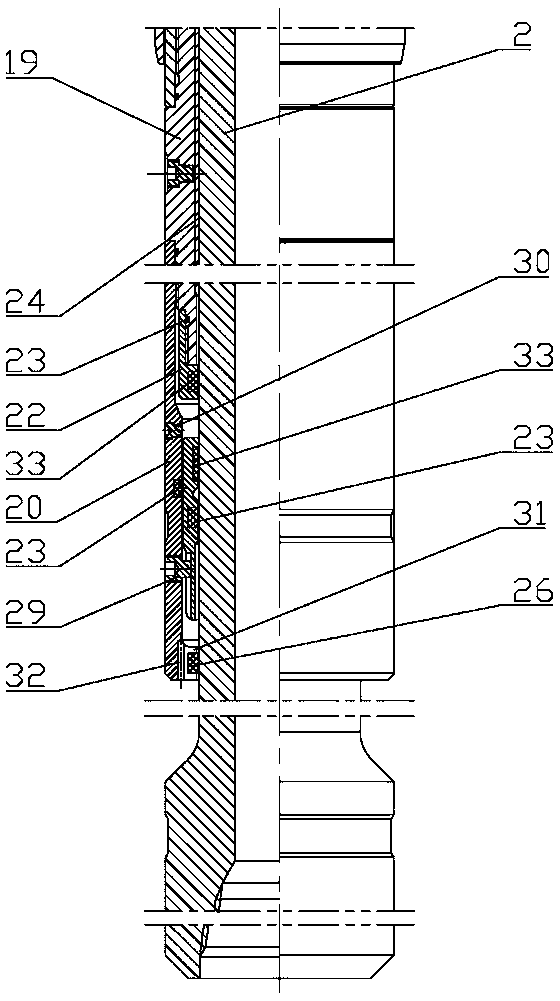

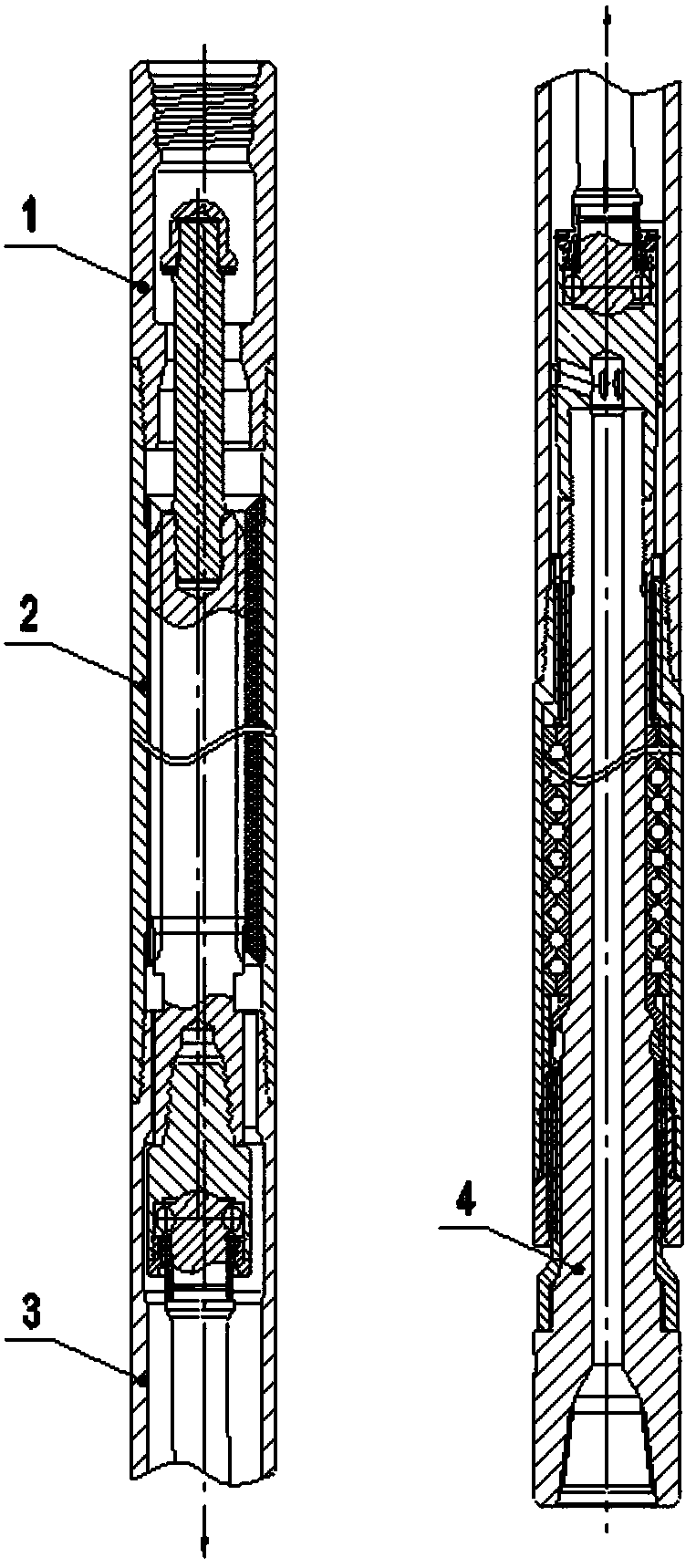

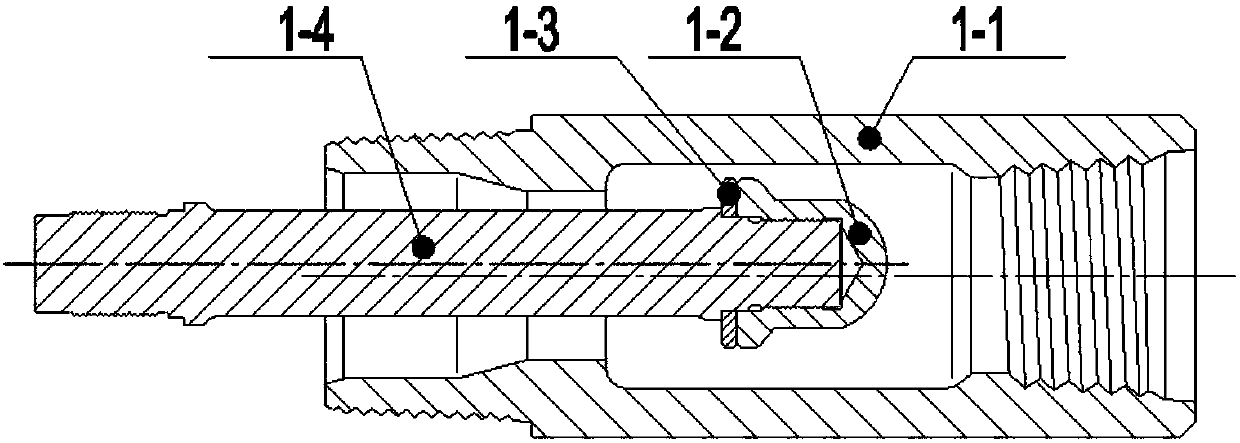

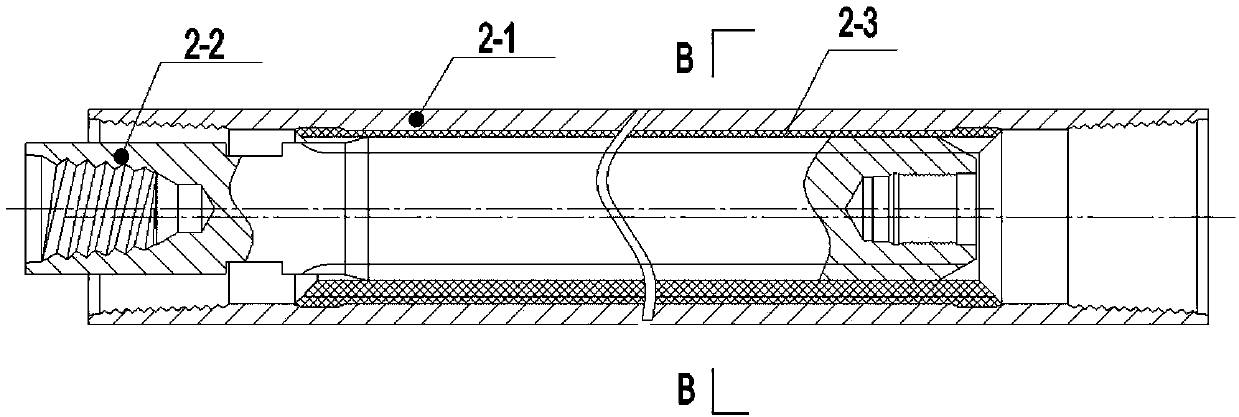

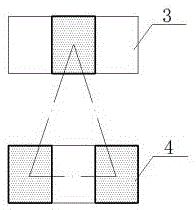

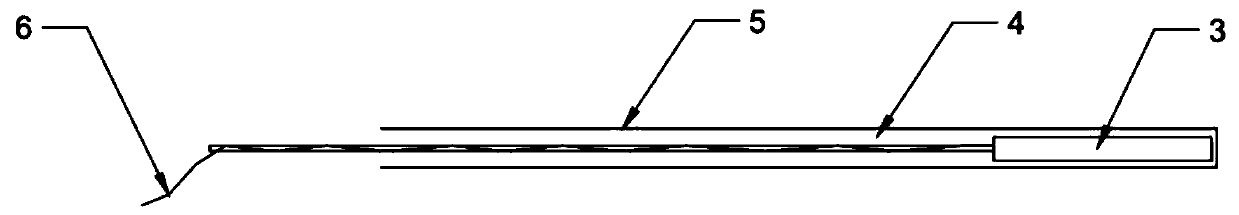

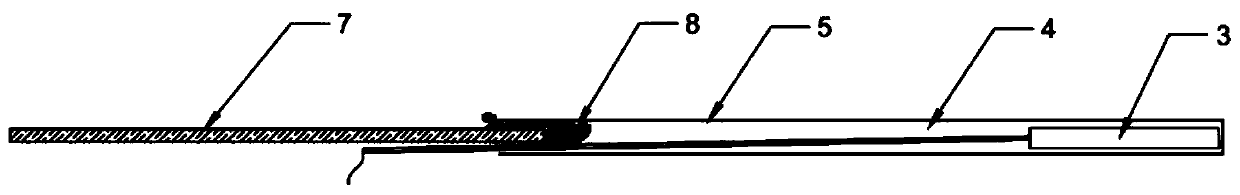

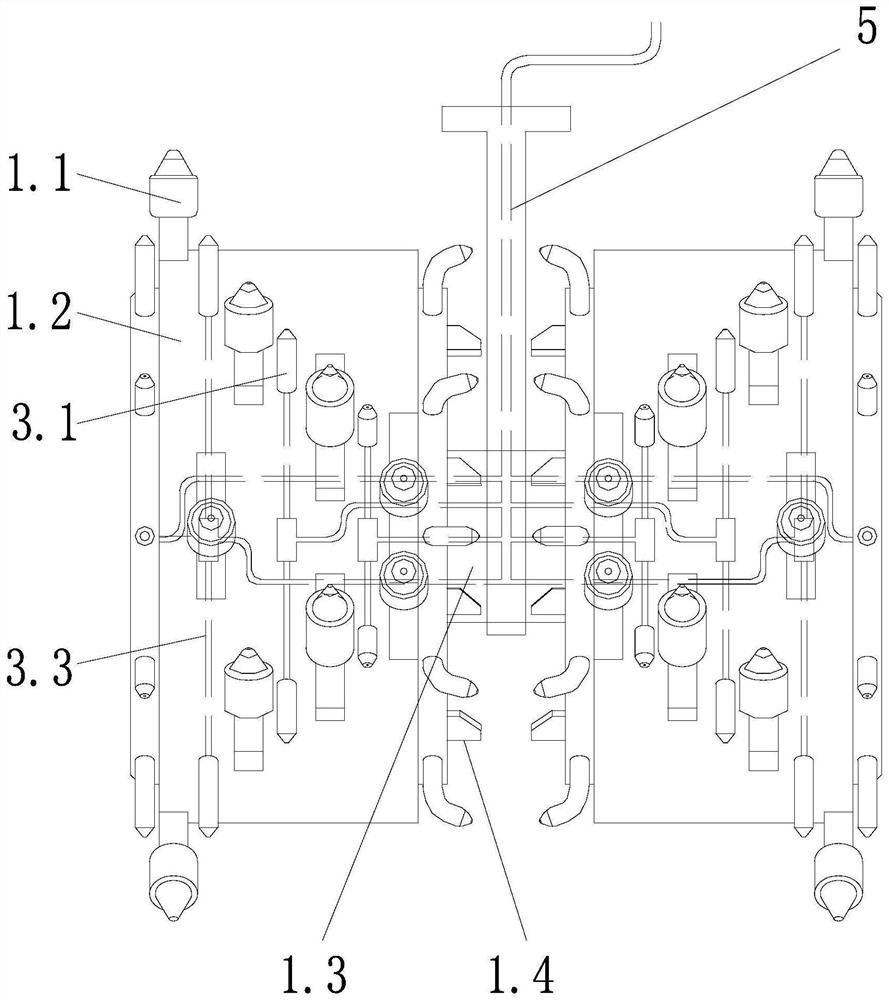

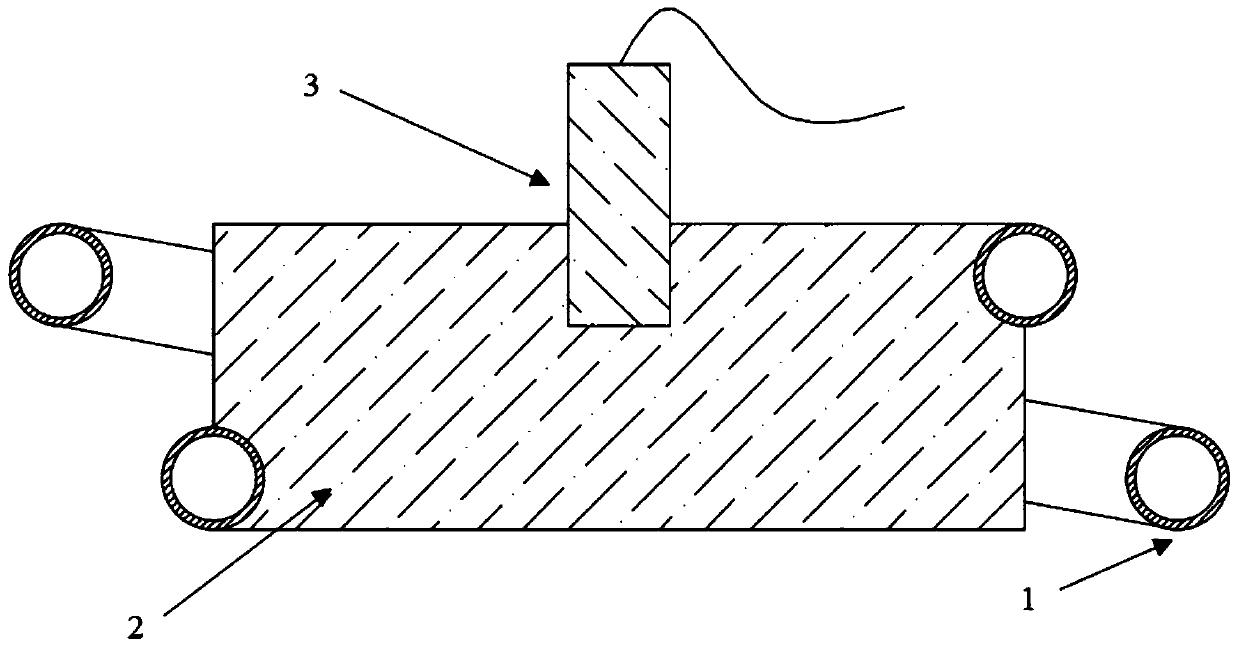

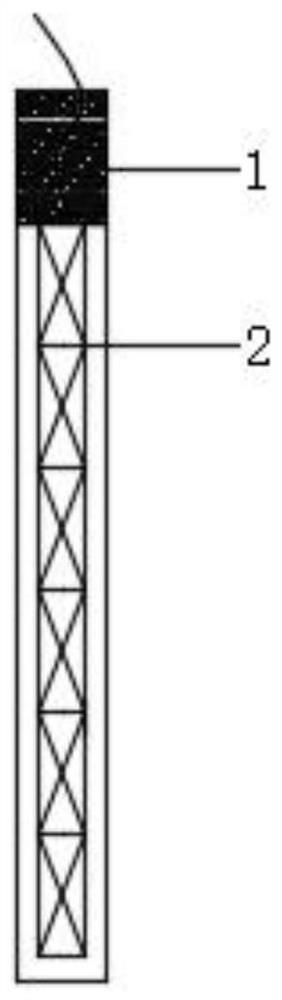

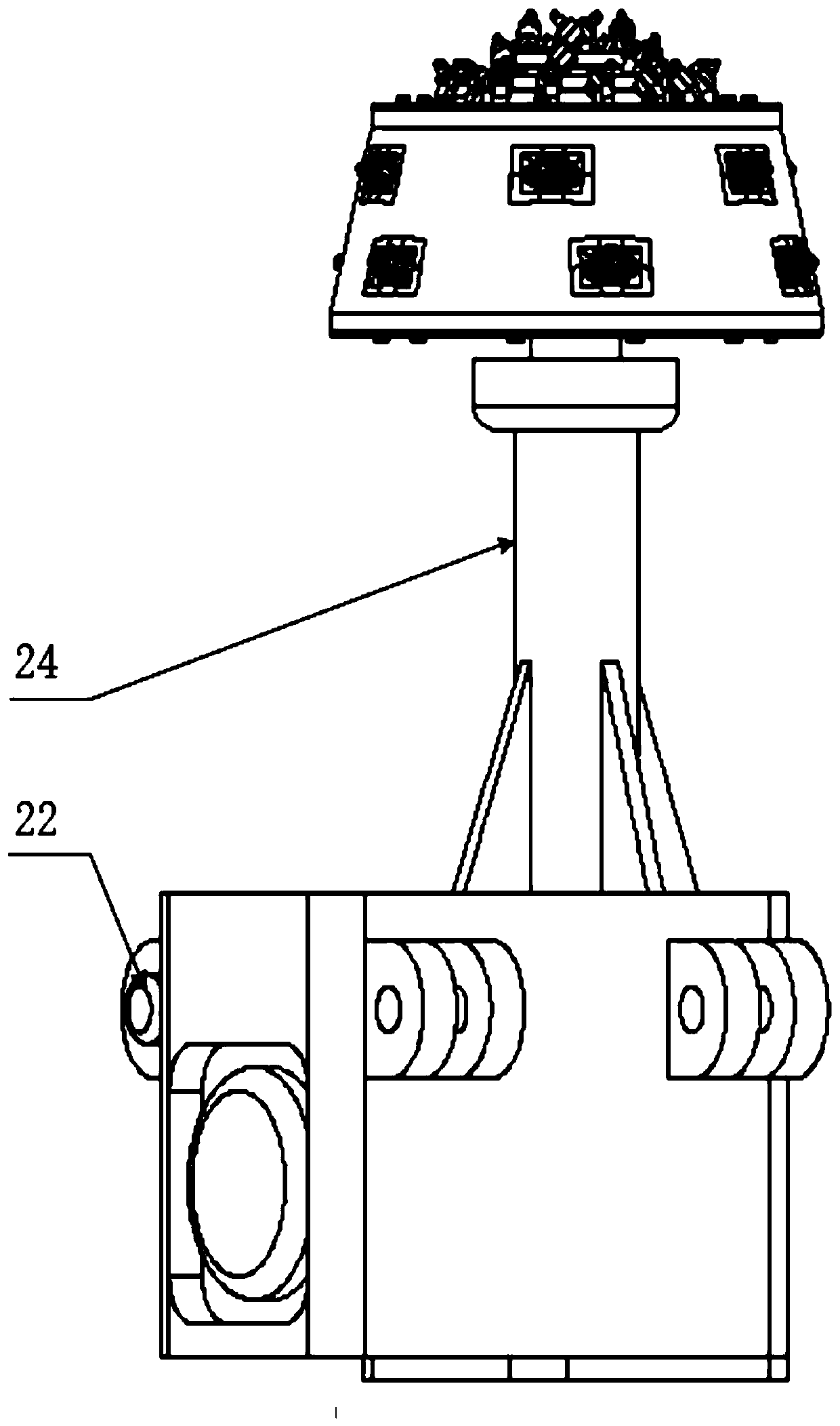

Coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit

ActiveCN105089500AEasy to useEasy to processLiquid/gas jet drillingDirectional drillingDrill lineTree shaped

The invention relates to a coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit. The drilling unit comprises drill rod, a guider, a drill bit, a high-pressure hose, a self-propelled drill bit and a dial. The drill rod is in threaded connection with the front end of the guider. The drill bit is in threaded connection with the tail end of the guider. The drill rod, the guider and the drill bit are used in cooperation, and the two steps of broaching and guider feeding-in can be finished at the same time. After broaching is finished, the high-pressure hose and the self-propelled drill bit are used for drilling tree-shaped drill holes in a coal seam. The distribution uniformity of the tree-shaped drill holes is controlled by the dial. The main effect of the drilling unit is to drill main holes of the tree-shaped drill holes of the coal seam and the tree-shaped drill holes, and uniform permeability increase of the coal seam is achieved. The drilling unit is simple in structure, convenient to operate and suitable for drilling the tree-shaped drill holes in the gas extraction process of the low-air-permeability coal seam.

Owner:CHONGQING UNIV +1

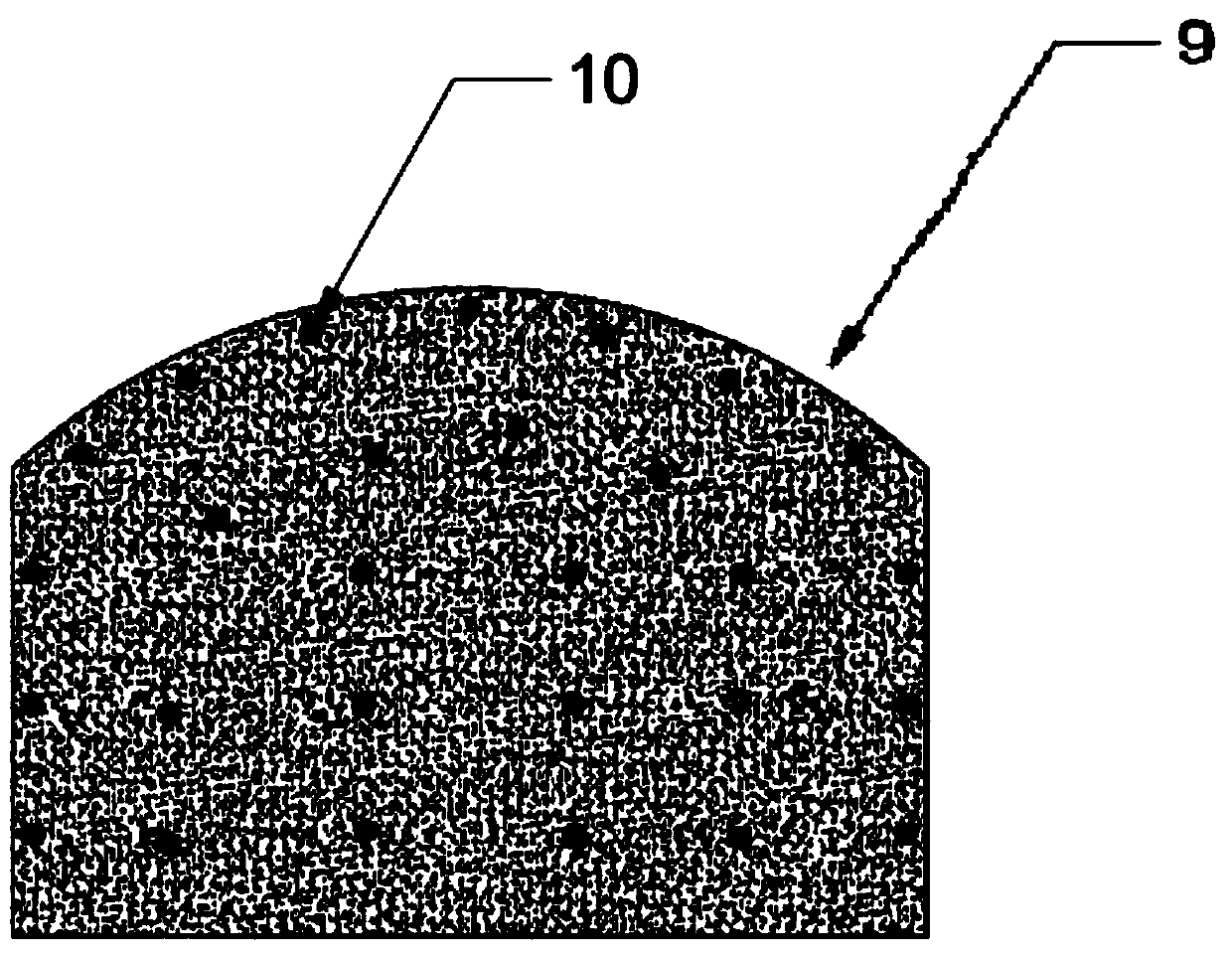

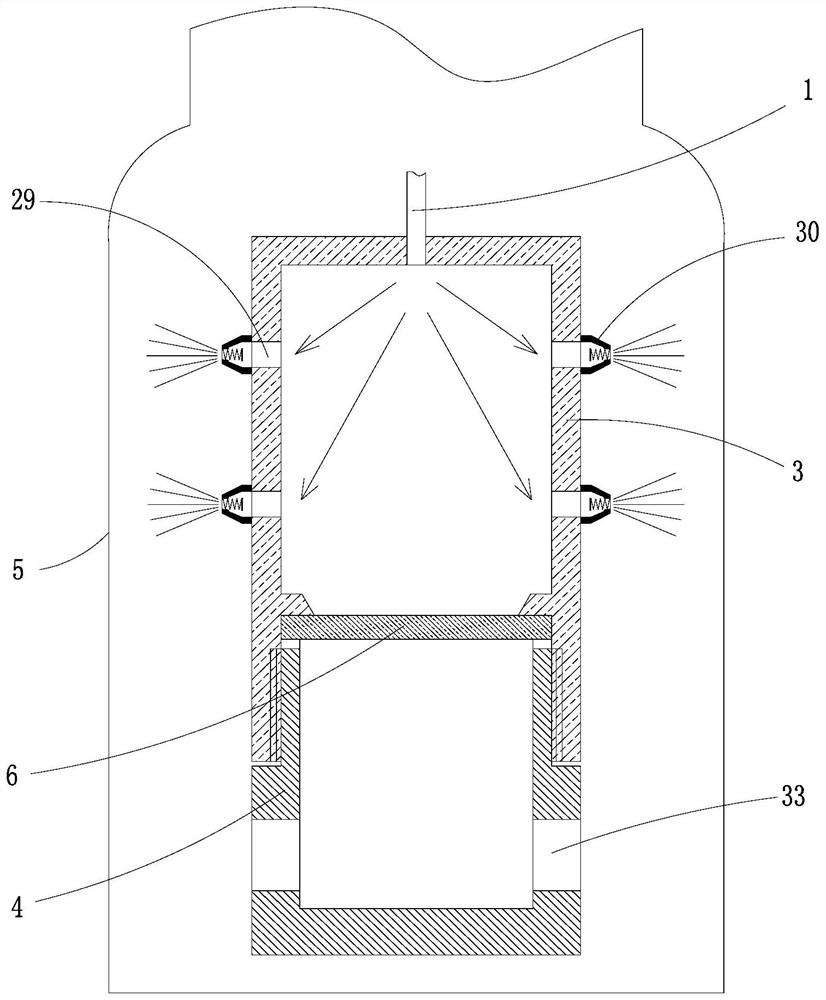

Dry ice powder dynamic rock breaking device, dry ice powder dynamic rock breaking system and dry ice powder dynamic rock breaking method

PendingCN108518225AGood rock breaking effectImprove securityDisloding machinesTunnelsDry iceOperation safety

The invention relates to a dry ice powder dynamic rock breaking device, a dry ice powder dynamic rock breaking system and a dry ice powder dynamic rock breaking method, and relates to the technical field of expansion rock breaking. The dry ice powder dynamic rock breaking device comprises an energy-gathered body arranged in a drilling hole of the surrounding rock of a stratum, and a curing layer filled between the energy-gathered body and the inner wall of the drilling hole, the energy-gathered body includes an impermeable and heat insulation shell and a cracking agent filled in the impermeable and heat insulation shell,the cracking agent comprises a mixture of dry ice powder and CO2 energy-gathered agent, and a resistance wire exciter is embedded in the impermeable and heat insulation shell; the dry ice powder dynamic rock breaking system comprises the dry ice powder dynamic rock breaking device and apunching device, wherein the dry ice powder dynamic rock breaking device and the dryice powder dynamic rock breaking system can achieve the ideal rock breaking effect, and the dry ice powder dynamic rock breaking system is high in safety and easy to operate. The dry ice powder dynamic rock breaking method is carried out by utilizing the dry ice powder dynamic rock breaking system, so that the operation safety can be improved, and the ideal rock breaking effect is achieved.

Owner:江苏中控能源科技有限公司

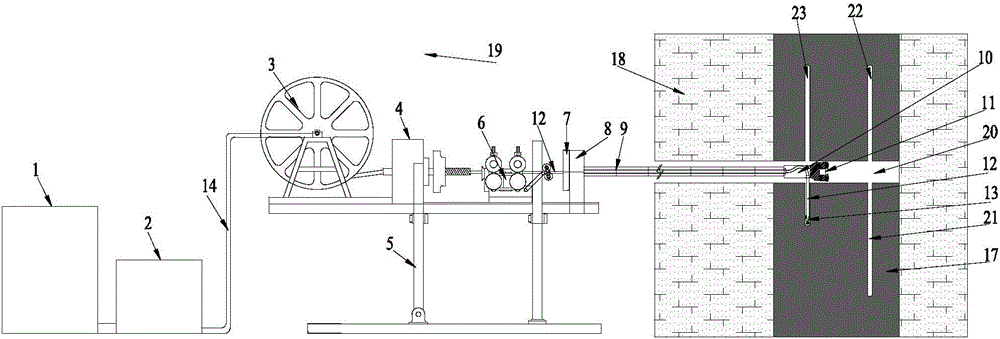

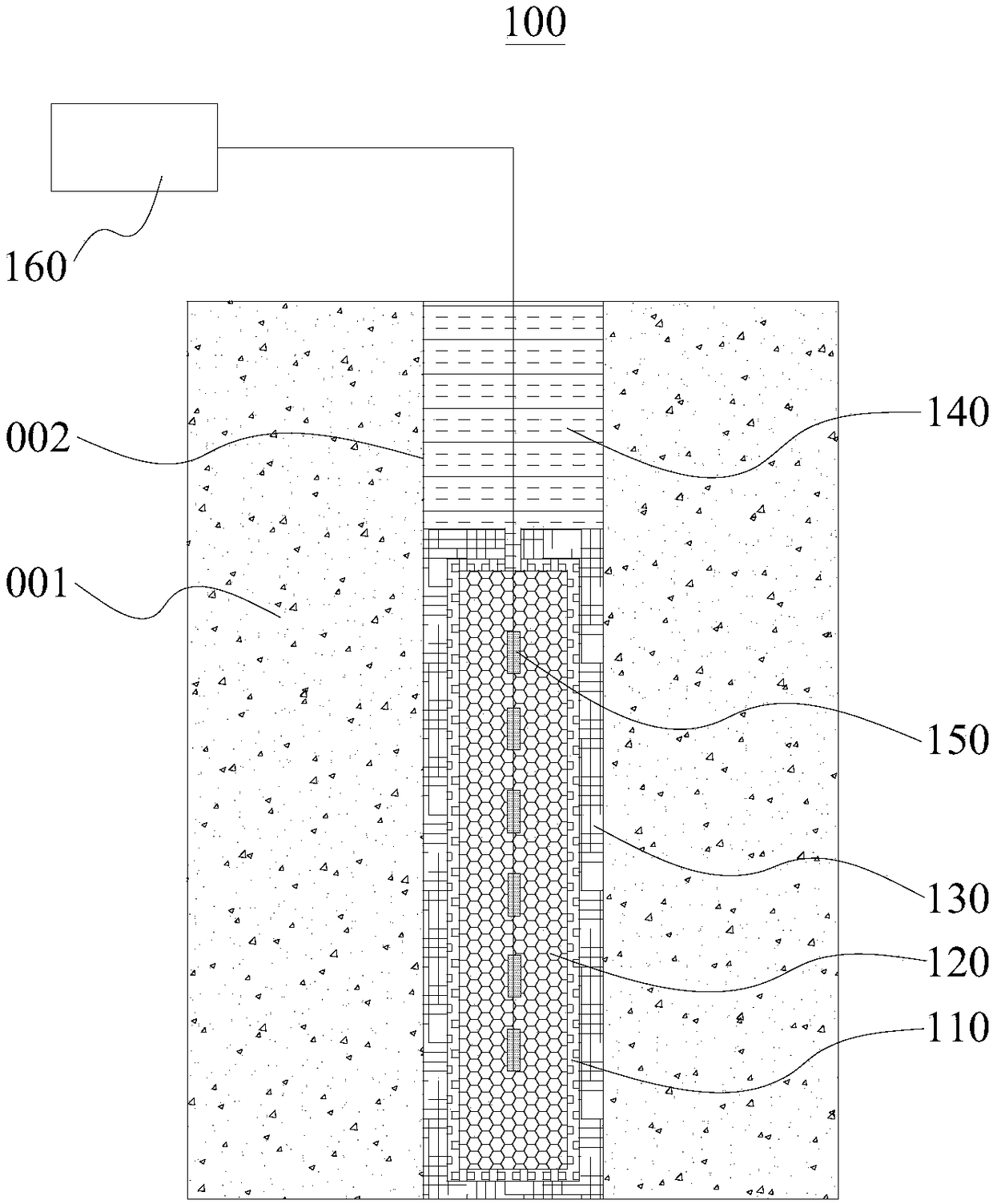

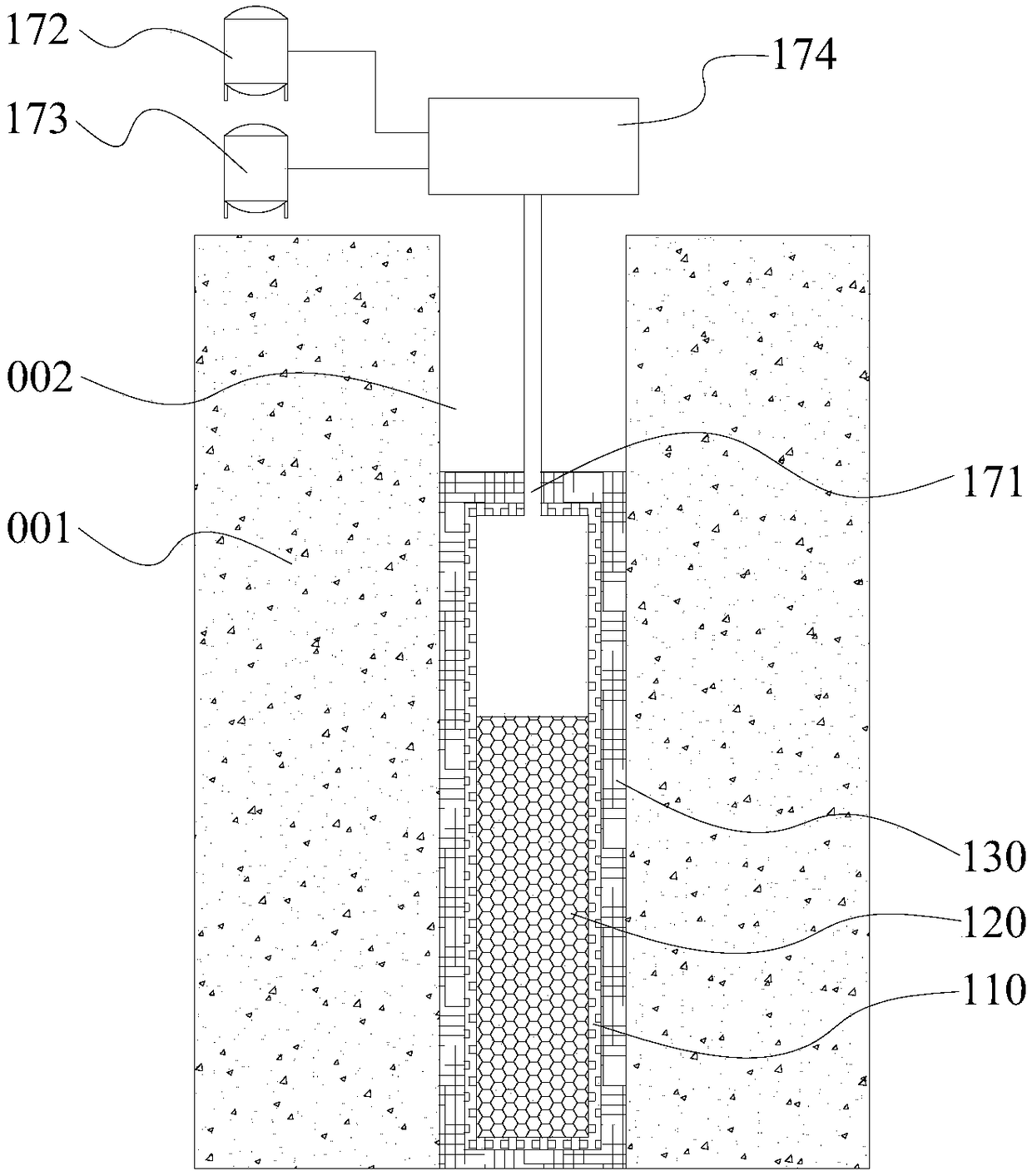

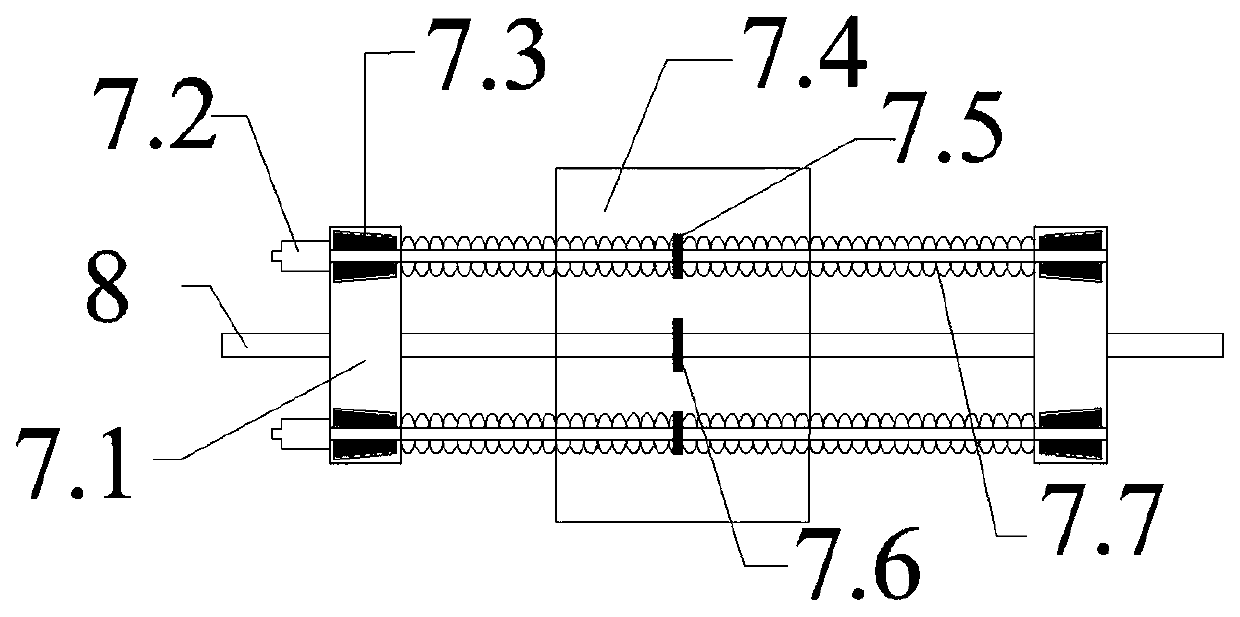

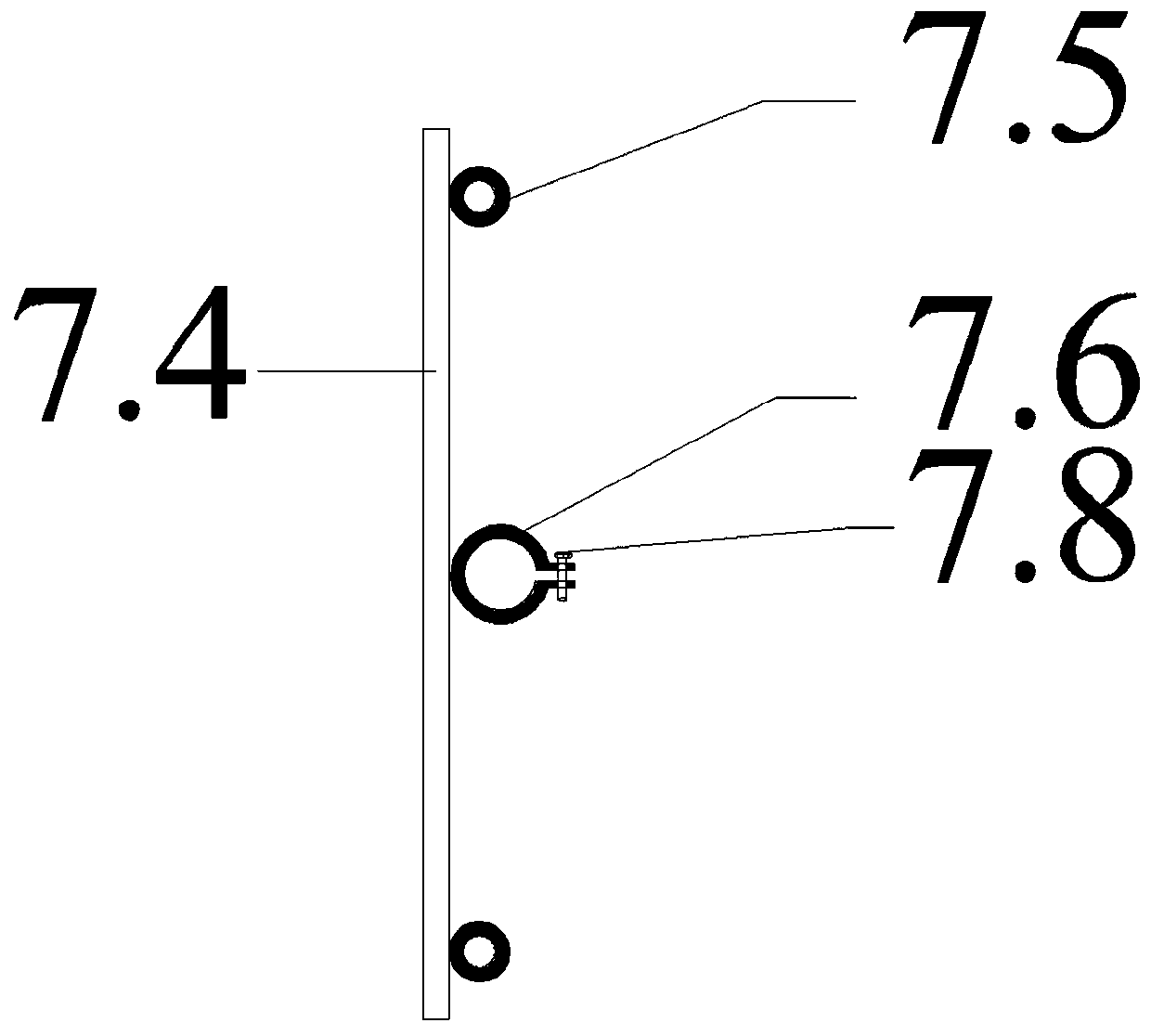

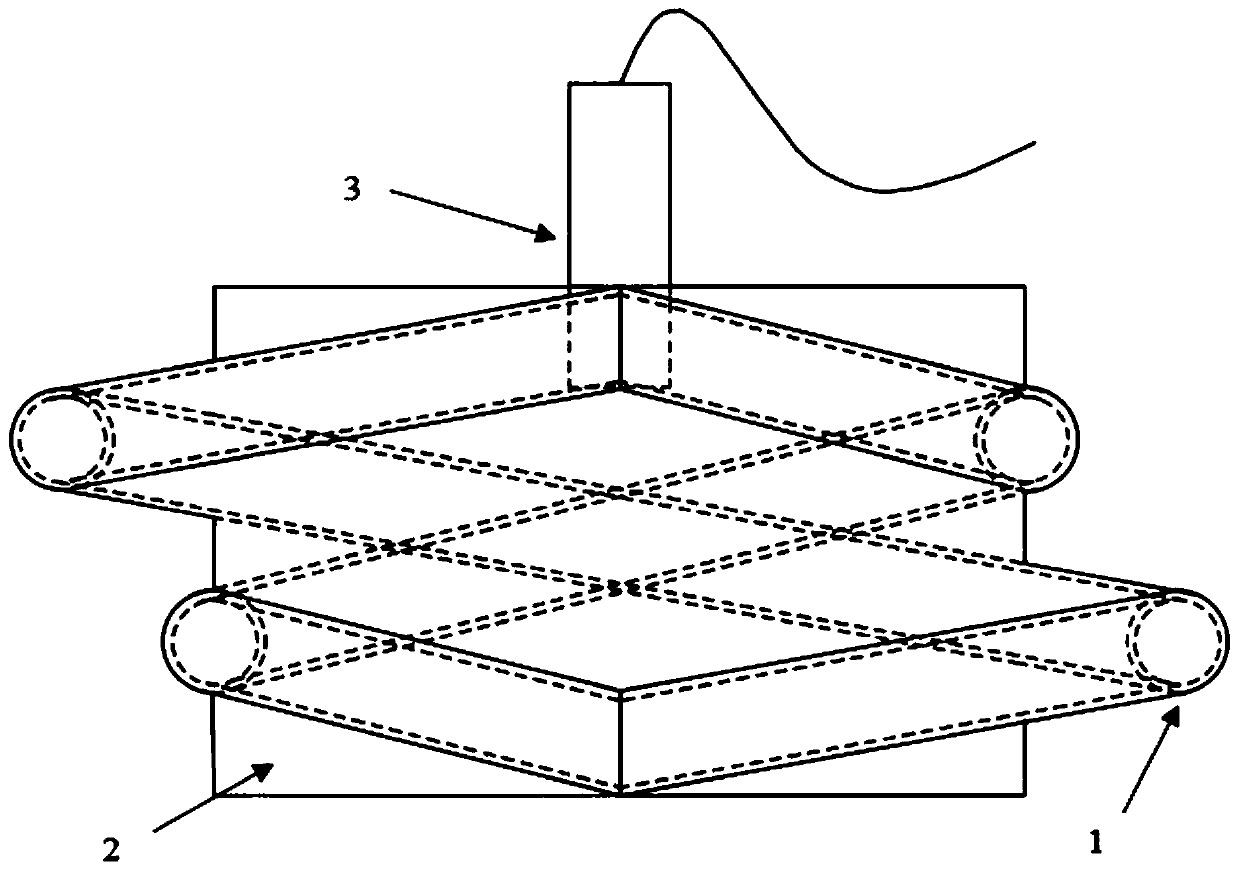

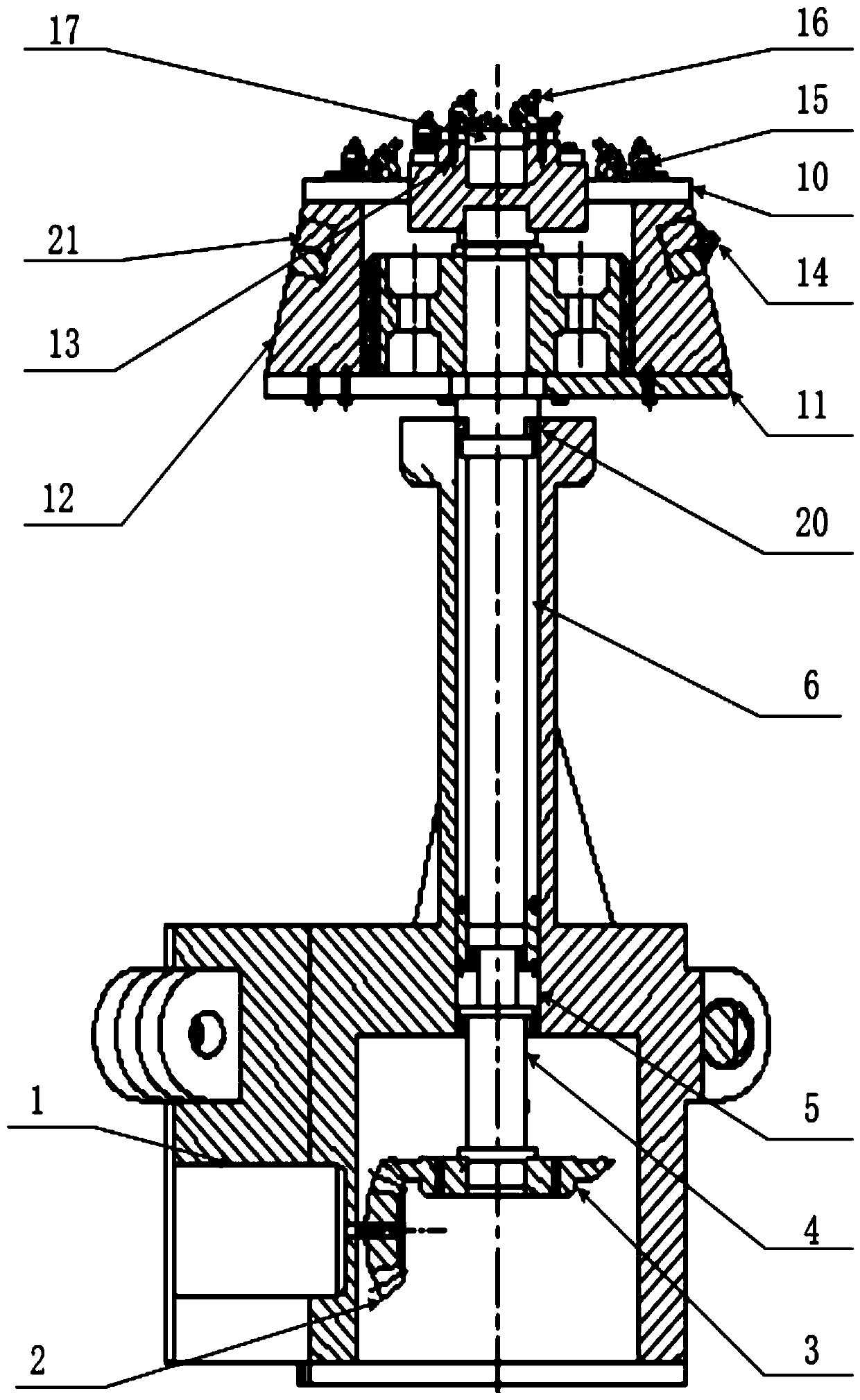

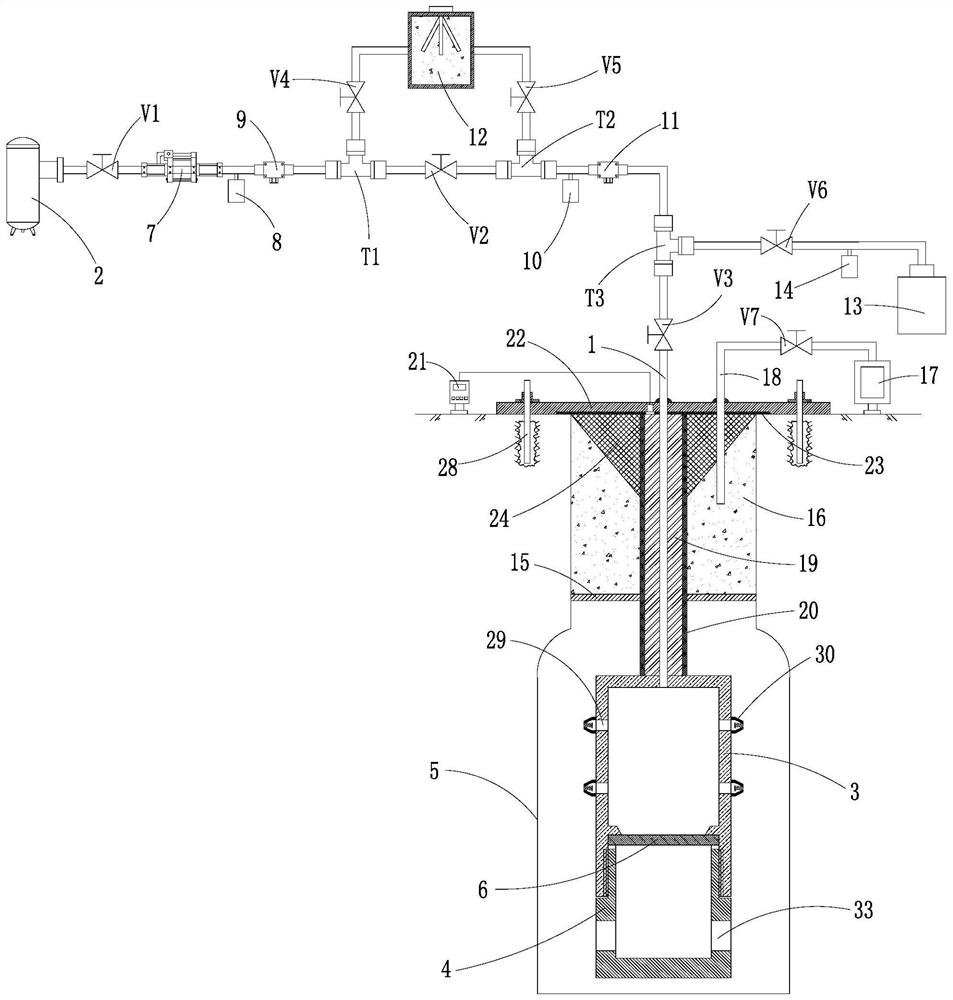

Composite fracturing and uniform permeability increasing equipment for treelike drilling in coal seam of underground coal mine

The invention discloses composite fracturing and uniform permeability increasing equipment for treelike drilling in a coal seam of an underground coal mine. The whole equipment can be divided into a hole forming system and a fracturing system. The hole forming system comprises a drilling machine, a drill stem, a drill bit, a support, a water tank, a high-pressure pump, a winch, a propelling mechanism, a chuck, a high-pressure hose, a self-propelled drill bit and the like. The fracturing system comprises the water tank, the high-pressure pump, a pressure meter, a high-pressure rubber pipe, a hole sealing device and the like. The composite fracturing and uniform permeability increasing equipment is suitable for carrying out volume fracturing on the coal seam of the underground coal mine, can reach the effects of carrying out uniform permeability increasing on the coal seam and increasing the gas extraction rate, and is easy to operate and good in economic performance.

Owner:CHONGQING UNIV

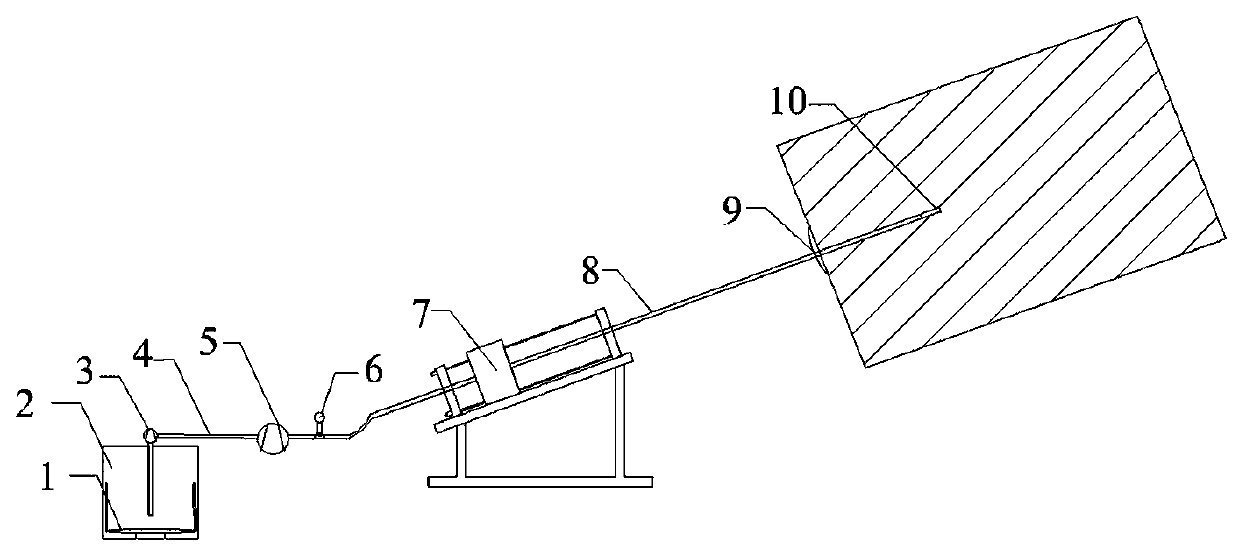

Carving device and method for front mixing type abrasive water jet directional cutting top plate

PendingCN110685683AStable and continuous supplyGuaranteed stabilityDisloding machinesUnderground miningMining engineeringAgitator

The invention belongs to the technical field of coal stope and roadway surrounding rock control, and particularly discloses a carving device and method for a front mixing type abrasive water jet directional cutting top plate. The carving device comprises a water supply box and an anchor agitator mounted in the water supply box. A water pump is arranged at the top of the water supply box, abrasivewater in the water supply box is pumped into a slush pump through the water pump, and a pressure gauge is arranged on a water outlet pipeline of the slush pump. An outlet of the water outlet pipelinecommunicates with a directional drilling rod, and a drilling rod transmission device is arranged at the inlet end of the directional drilling rod. A drilling rod direction control device is arranged at the outlet end of the directional drilling rod, and a slotting drill bit is arranged at an outlet of the directional drilling rod. The carving device has the advantages of being convenient to use and safe in use.

Owner:HENAN POLYTECHNIC UNIV

High-pressure-water cavitation rock breaking TBM and construction method thereof

InactiveCN110410093AGood rock breaking effectImprove rock breaking effectTunnelsStructural engineeringHigh pressure water

The invention discloses a high-pressure-water cavitation rock breaking TBM and a construction method thereof. The TBM comprises a main machine. A cutter disc is arranged at the front end of the main machine and provided with pulse cavitation nozzles. The pulse cavitation nozzles are connected with a high-pressure-water system. A vacuum sewage discharge system is connected to the rear portion of the cutter disc. The cutter disc is connected with a main driver arranged in the main machine. A slag inlet is formed in the front end face of the cutter disc. A muddy water bin is arranged on the rearportion of the cutter disc. A slag outlet is formed in the lower portion of the muddy water bin and connected with the vacuum sewage discharge system. According to the TBM, the multiple pulse cavitation nozzles are reasonably arranged on the cutter disc, the high pressure water forms cavitation water jet flow after passing through the cavitation nozzles and directly impacts, corrodes and crushes rock, full-fracture-surface pure water rock breaking is achieved, the rock breaking efficiency is improved, and the construction risk is reduced. According to the TBM, non-contact type rock breaking isadopted, torque and total thrust of the main driver can be reduced effectively, power of the main driver is reduced, meanwhile, vibration of the TBM is reduced, and abrasion and replacement of cutters are reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

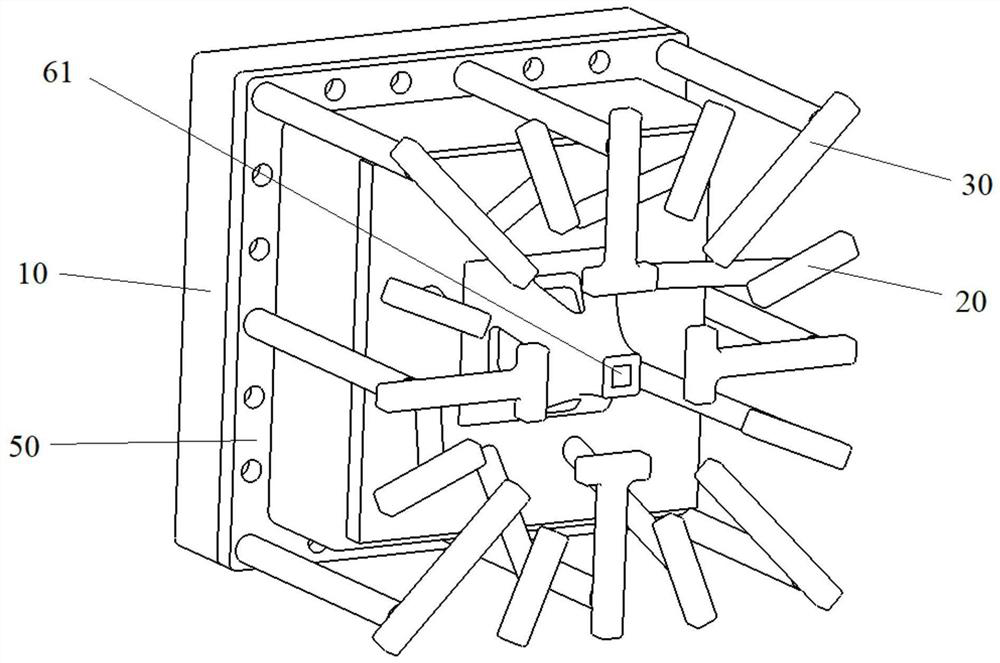

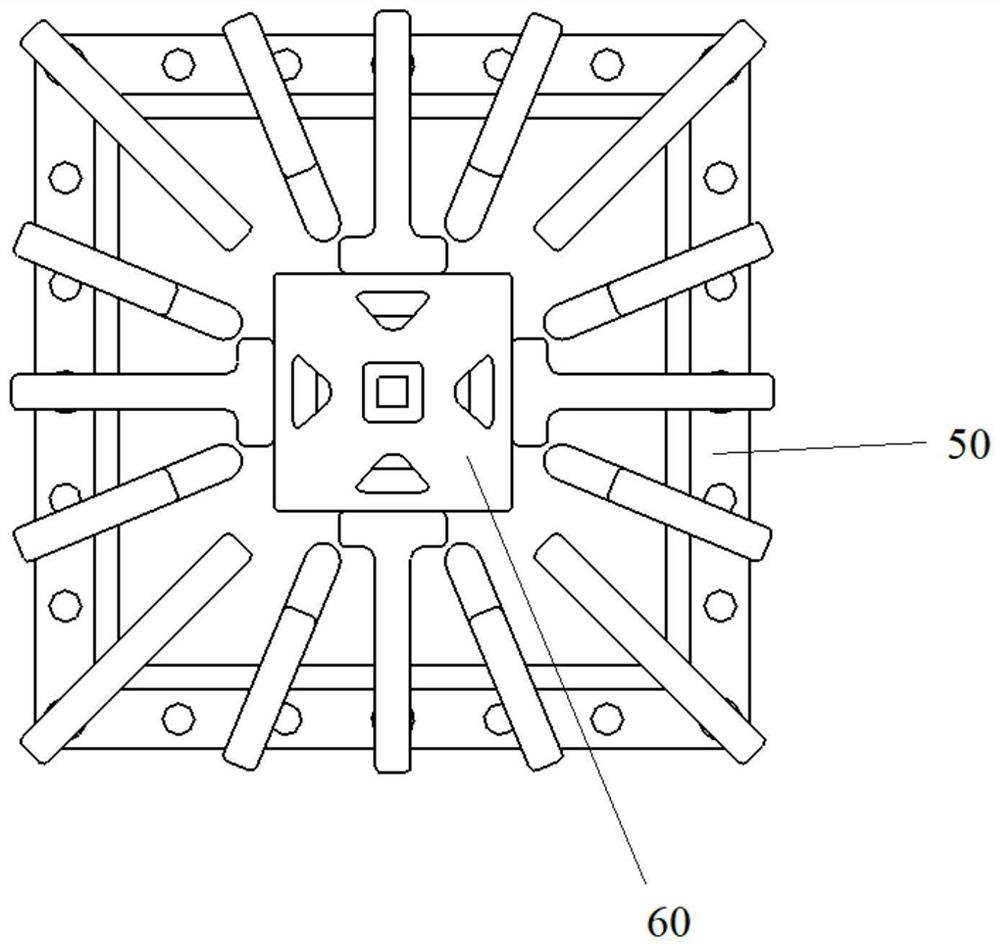

Hydraulic power-mechanical TBM cutter head combined rock breaking method, hydraulic power-mechanical combined rock breaking TBM cutter head and hydraulic power-mechanical combined rock breaking TBM device

PendingCN110219660AGood rock breaking effectFor the purpose of joint rock breakingTunnelsRock breakingPetrology

The invention discloses a hydraulic power-mechanical TBM cutter head combined rock breaking method. The hydraulic power-mechanical TBM cutter head combined rock breaking method comprises the steps that a combined rock breaking TBM cutter head is installed, and the combined rock breaking TBM cutter head is aligned to the position of a to-be-excavated grotto; a TBM outer machine frame is fixed, anda combined rock breaking TBM is started and is enabled to tunnel forwards for a stroke; and the referred steps are repeated, the next stroke operation is started until tunneling is carried out to a specified distance, and excavation of the grotto is completed. The hydraulic power-mechanical TBM cutter head combined rock breaking method has the advantages of suitable penetration degree and high rock breaking efficiency. The invention further discloses the hydraulic power-mechanical combined rock breaking TBM cutter head adopted by the hydraulic power-mechanical TBM cutter head combined rock breaking method. The invention further discloses a hydraulic power-mechanical combined rock breaking TBM device adopted by the hydraulic power-mechanical TBM cutter head combined rock breaking method.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Pulse-impact rock breaking drill bit

ActiveCN108756733AGood rock breaking effectIncrease mechanical speedEarth drilling toolsDrill bitsGeotechnical engineeringDrill bit

The invention discloses a pulse-impact rock breaking drill bit. The upper end of an upper joint is in threaded connection with an upper drill column, and the lower end of the upper joint is in threaded connection with the upper end of a drill bit base body. Fixed cutting teeth are mounted in an interference mode in blind holes which are regularly distributed in the surface of the lower portion ofthe drill bit base body. A nozzle and a water outlet in the lower portion of the outer circumference of the drill bit base body are fastened in a threaded mode, impact cutting teeth and a disc springare integrally mounted in a stepped hole of the drill bit base body, and a sealing cover and the outlet end of the stepped hole in the drill bit base body are fastened in a threaded mode. A spiral blade is arranged on the upper portion of a spiral rotor, and the spiral rotor, a rolling bearing, a bearing seat and a dynamic valve ring are integrally placed in an inner cavity of a bushing pipe. Thedrill bit can generate impact rock-breaking loads to rock strata while completing the conventional PDC drill bit rock breaking mechanism, a good rock breaking effect to hard stratum brittle rock is achieved, and the mechanical rotating speed is effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

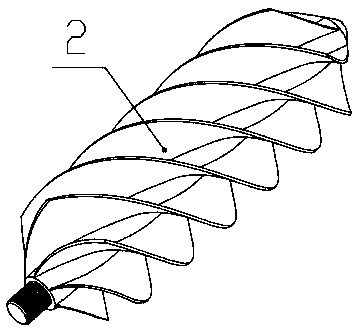

Formation method and device of self-excited oscillation supercritical carbon dioxide jet

The invention belongs to the technical field of supercritical carbon dioxide jet, and discloses a formation method and device of self-excited oscillation supercritical carbon dioxide jet. The device includes a carbon dioxide gas supply system, a cooling liquefaction system, a pressurization system, a temperature rise system, an experimental system, a filtering system, a recovery system and a control system, and particularly includes a high-pressure carbon dioxide cylinder, a cold bath box and an air-cooled compressor, a liquid carbon dioxide storage tank, a high-pressure plunger pump, a hot bath box, a heating buffer tank, a circulating pump, an experimental kettle, at least two desambers, purifiers and control cabinets. According to the device, supercritical carbon dioxide is prepared byusing the systems, an improved self-excited oscillation nozzle is used for producing the self-excited oscillation supercritical carbon dioxide jet, impact force of the self-excited oscillation jet is1.5-2.5 times of stagnation pressure of continuous jet, the impact damage effect of the jet can be enhanced, and the self-excited oscillation supercritical carbon dioxide jet can obtain the better rock breaking and erosion effect and has broad prospects in unconventional oil and gas development.

Owner:HENAN POLYTECHNIC UNIV

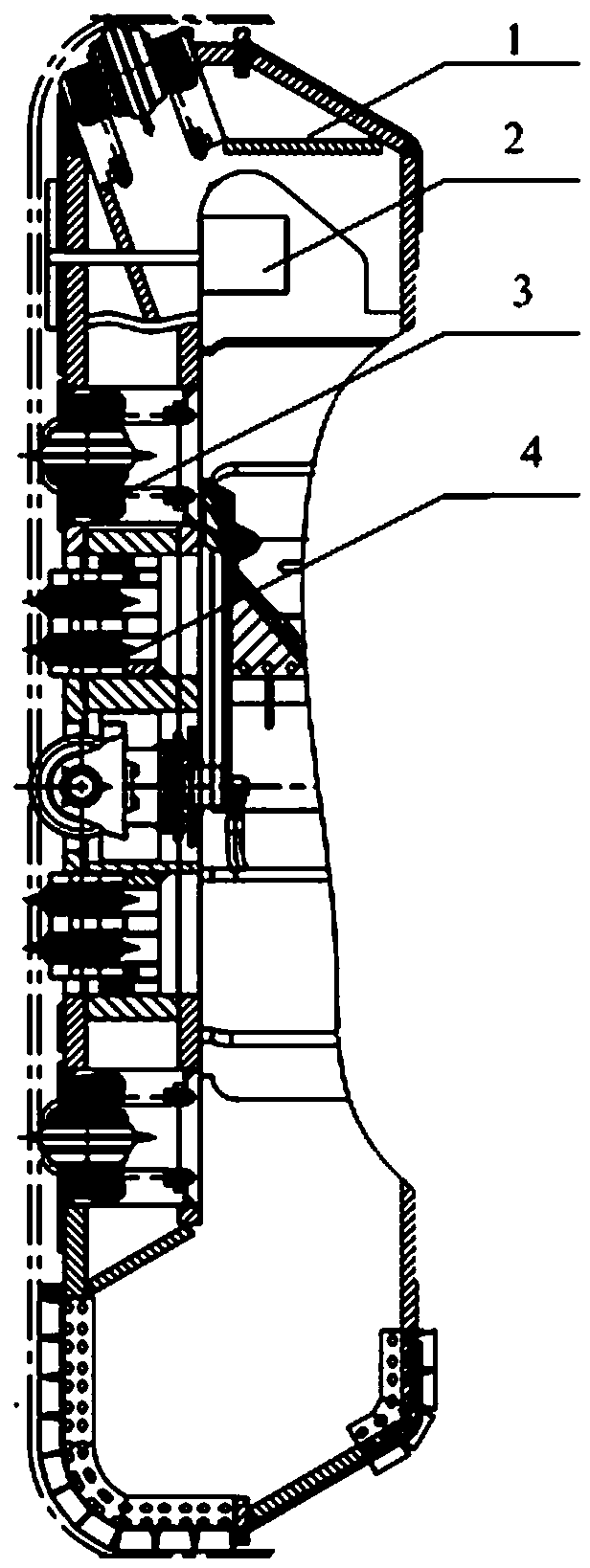

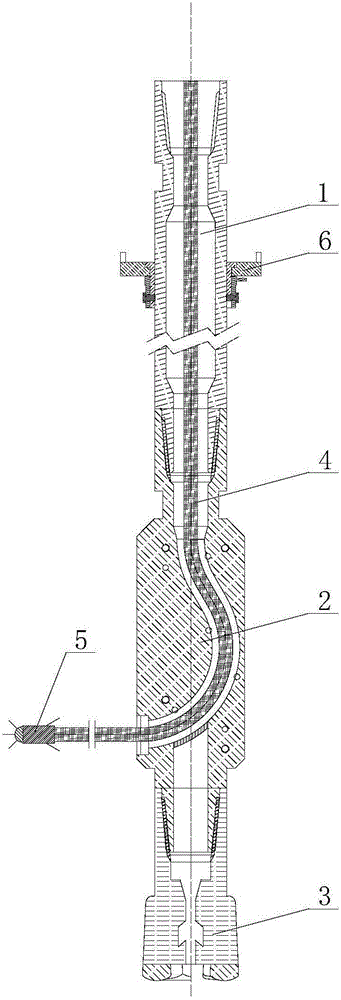

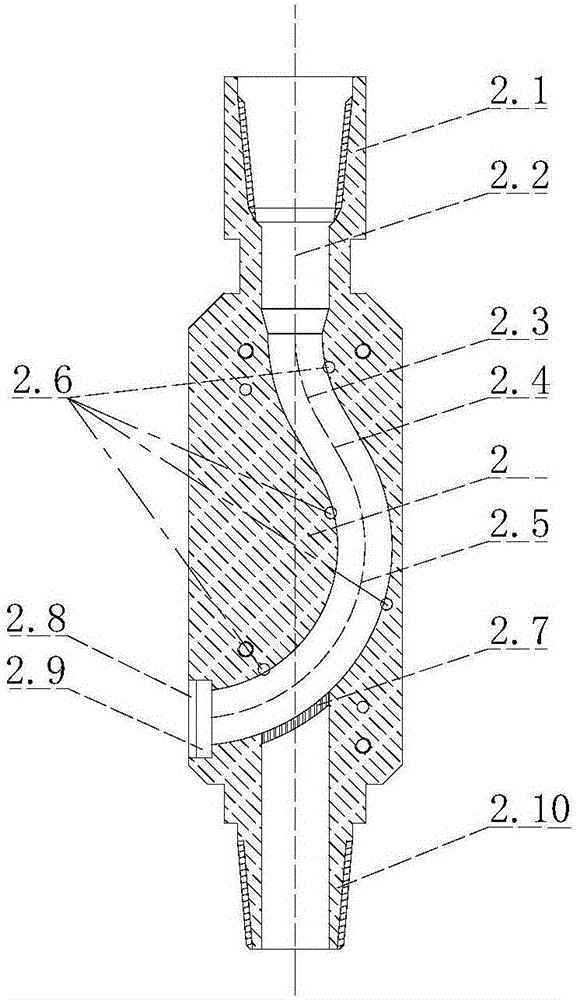

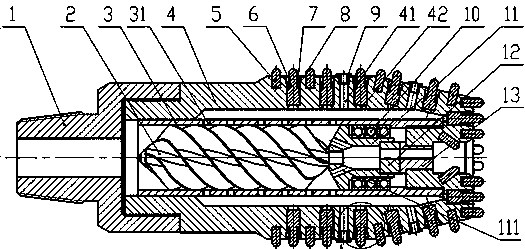

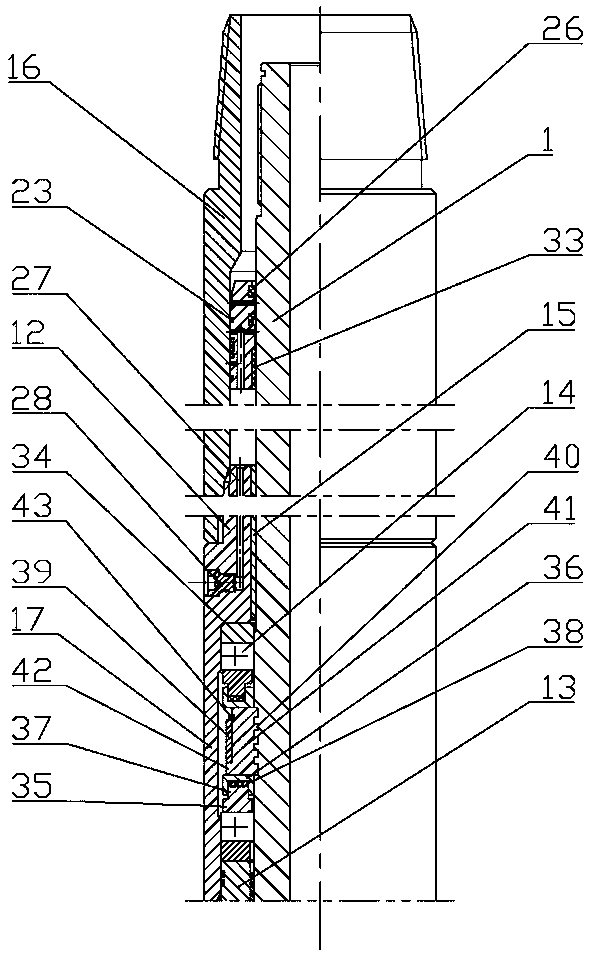

Rotary impacting device

PendingCN109555472ACompact and reasonable structureImprove rock breaking effectBorehole drivesReciprocating motionEngineering

The invention relates to the technical field of down-hole operating equipment, in particular to a rotary impacting device. The rotary impacting device comprises an outer tube, an upper mandrel, a lower mandrel, a mandrel anvil, an impacting generating piece, an impacting driving assembly and an impacting executing assembly; the upper mandrel capable of rotating relative to the outer tube is hung on the inner side of the upper part of the outer tube, and the lower mandrel capable of rotating relative to the outer tube is mounted on the inner side of the lower part of the outer tube in a limitedmode; the mandrel anvil is mounted in a mounting annular groove, the mounting annular groove sleeves the lower part of the upper mandrel, and the lower part of the upper mandrel is located above themandrel anvil; and the lower part of the upper mandrel and the upper part of the lower mandrel are connected together in a transmission mode. Through arrangement of the impacting driving assembly andthe impacting executing assembly, the upper mandrel can periodically move up and down in a reciprocating mode relative to the lower mandrel, thus downward collision acting force can be periodically generated for the mandrel anvil through the impacting generating piece, a downstream drill bit is downwards impacted in a pulsed mode in the drilling process, and the rotary impacting device has a goodrock breaking effect in drilling operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

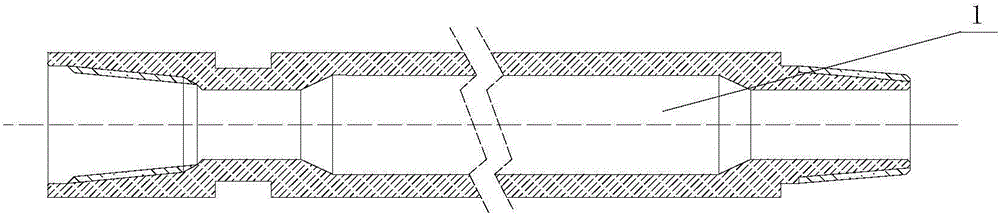

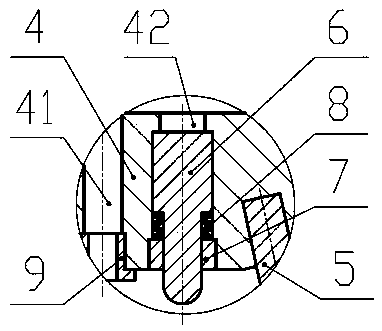

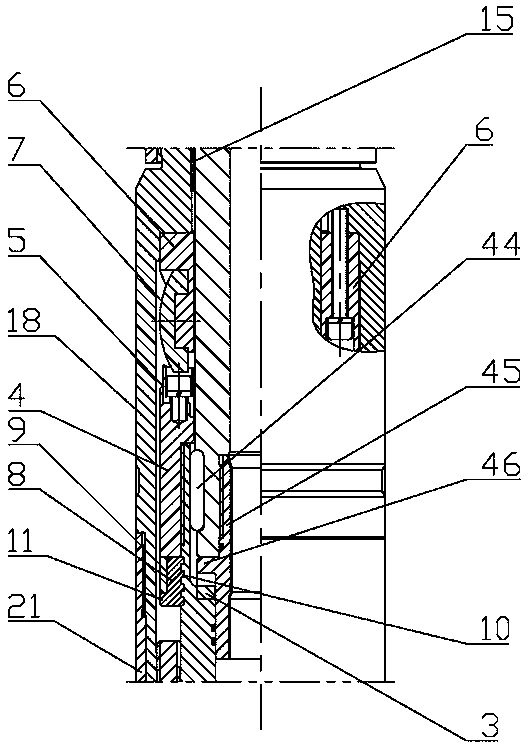

Method for improving percussion drilling capability of screw drill and pulse screw

PendingCN108035679AIncreased percussion drilling capabilitiesImprove rock breaking effectDrill bitsBorehole drivesDrive shaftDrill

The invention discloses a method for improving a percussion drilling capability of a screw drill and a pulse screw. The pulse screw includes an anti-drop conversion assembly, a motor assembly, a pulsecardan shaft assembly and a transmission shaft assembly; the anti-drop conversion assembly comprises an anti-drop conversion connector head, an anti-drop disc and an anti-drop connecting rod, the anti-drop disc is arranged in the anti-drop conversion connector head, the upper end of the anti-drop connecting rod is sleeved with the anti-drop disc and fixed through tightening nuts, and the other end of the anti-drop connecting rod is connected with the upper end of a rotator of the motor assembly. The method is simple in structure, safe and reliable. Not only can output torque and rotation speed be increased through the motor assembly, but also the percussion drilling capability of the screw drill can be improved through the pulse cardan shaft assembly, and the drilling efficiency is effectively improved.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

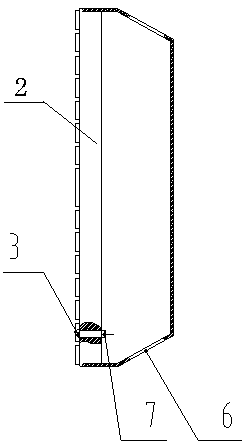

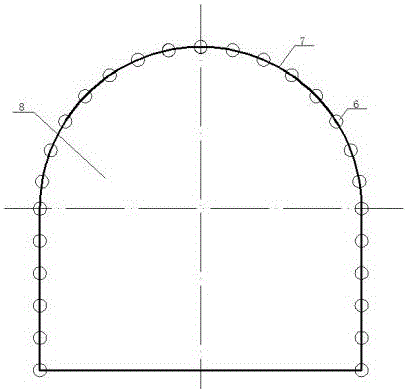

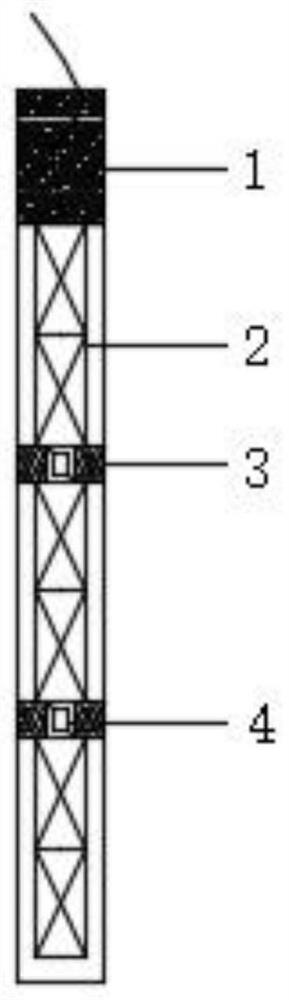

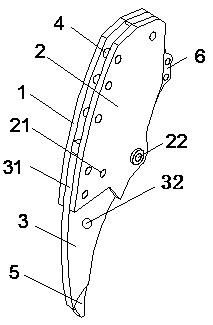

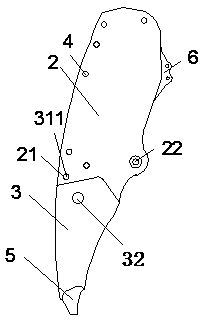

Drivage peripheral hole homoenergetic blasting method

The invention discloses a drivage peripheral hole homoenergetic blasting method. Peripheral holes (6) are dug on a roadway contour line of a surrounding rock (1) at the end part of a roadway; explosives (4) and cushioning materials (3) are alternatively arranged in each peripheral hole (6) from inside to outside; the explosives (4) in the adjacent peripheral holes (6) are distributed in a shape of a Chinese character pin; detonators (5) are arranged in sections along the explosives (4); nonel tubes (9) of the detonators (5) are led out of the holes along the hole walls of the peripheral holes (6); hole orifices of the peripheral holes (6) are plugged by stemming (2); then detonation is carried out according to a designed detonation network connecting line. According to the method disclosed by the invention, the explosives (4) and the cushioning materials (3) are distributed symmetrically, so that energy is more uniformly distributed, an energy utilization rate of the explosives is improved, a contour of a roadway section is well controlled, the back break phenomenon is avoided, and roadway supporting cost is reduced; meanwhile, the uniformly distributed explosive energy can enable a fragment size for blasting to be uniform, obviously improve a blasting effect and improve shovel-loading efficiency after blasting.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Drilling insert, roller cone bit and drilling insert machining method

ActiveCN110145239AImprove work efficiencyStrong rock breaking forceDrill bitsMolten spray coatingStress concentrationEngineering

The invention discloses a drilling insert, a roller cone bit and a drilling insert machining method. The drilling insert comprises an insert tooth portion. The insert tooth portion comprises a drilling surface arranged at the top portion and chip removal inclined surfaces arranged on the side. The drilling surface is of a plane structure. Recessed tooth grooves are formed between the two adjacentchip removal inclined surfaces in the insert tooth portion. The top ends of the tooth grooves are connected with the drilling surface. According to the drilling insert, the roller cone bit and the drilling insert machining method, the tooth grooves are formed between the two adjacent chip removal inclined surfaces, the top ends of the tooth grooves are jointed with the drilling surface, that is, the drilling surface is provided with a notch structure, and the drilling surface is of a multi-tooth structure. The drilling surface and the tooth grooves meet the stress concentration at the joint corner positions, and the rock breaking force is large. The insert has better rock breaking effect under the larger driving force, so that the working efficiency in the hard formation is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

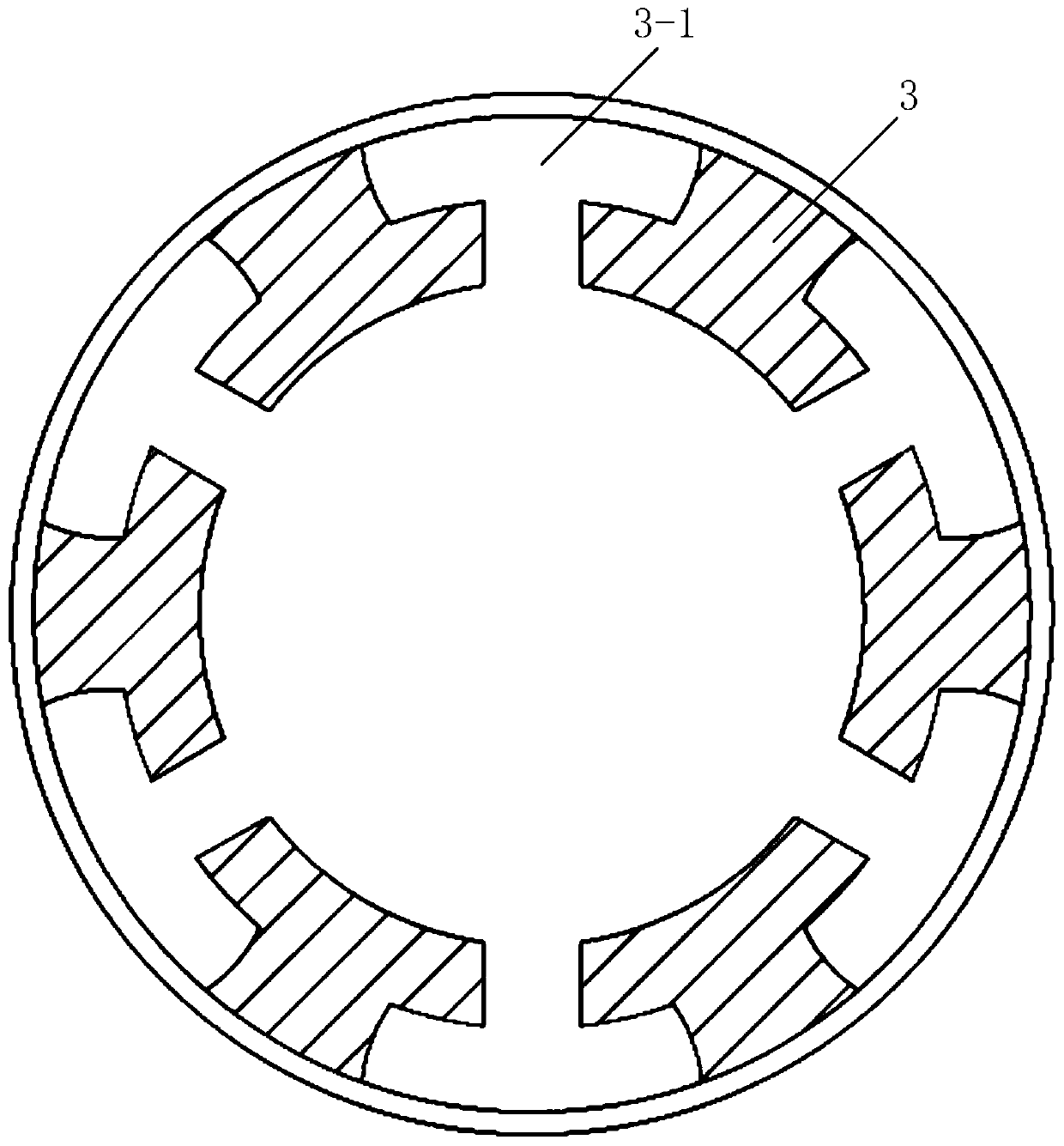

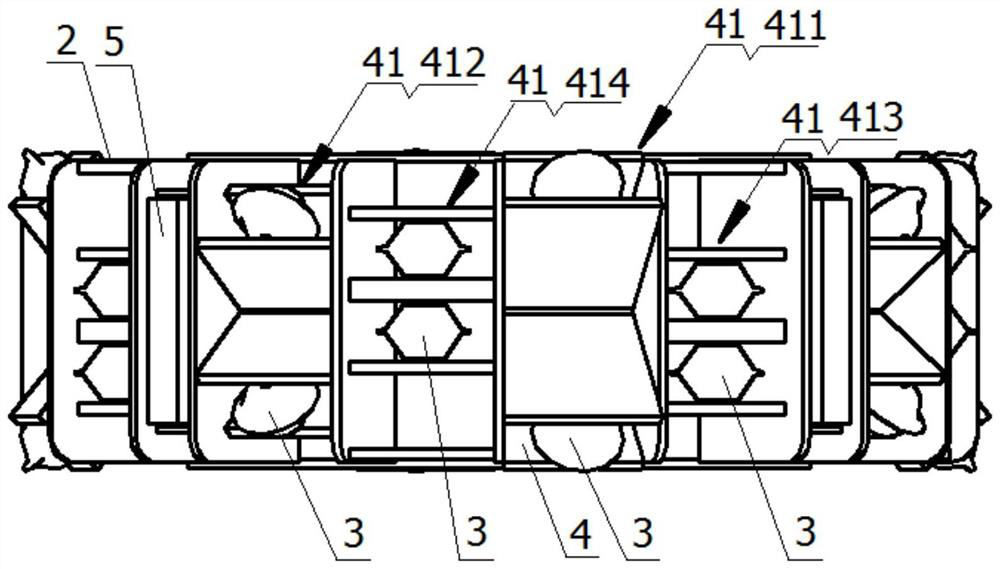

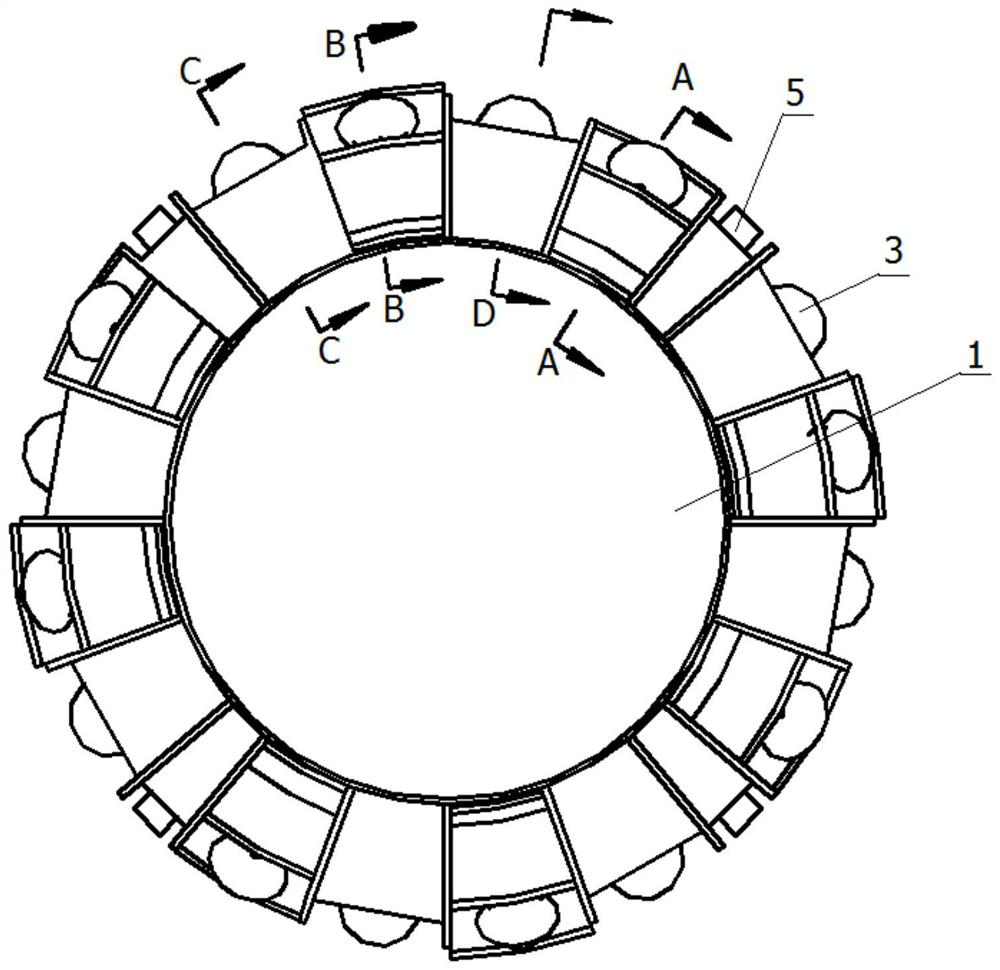

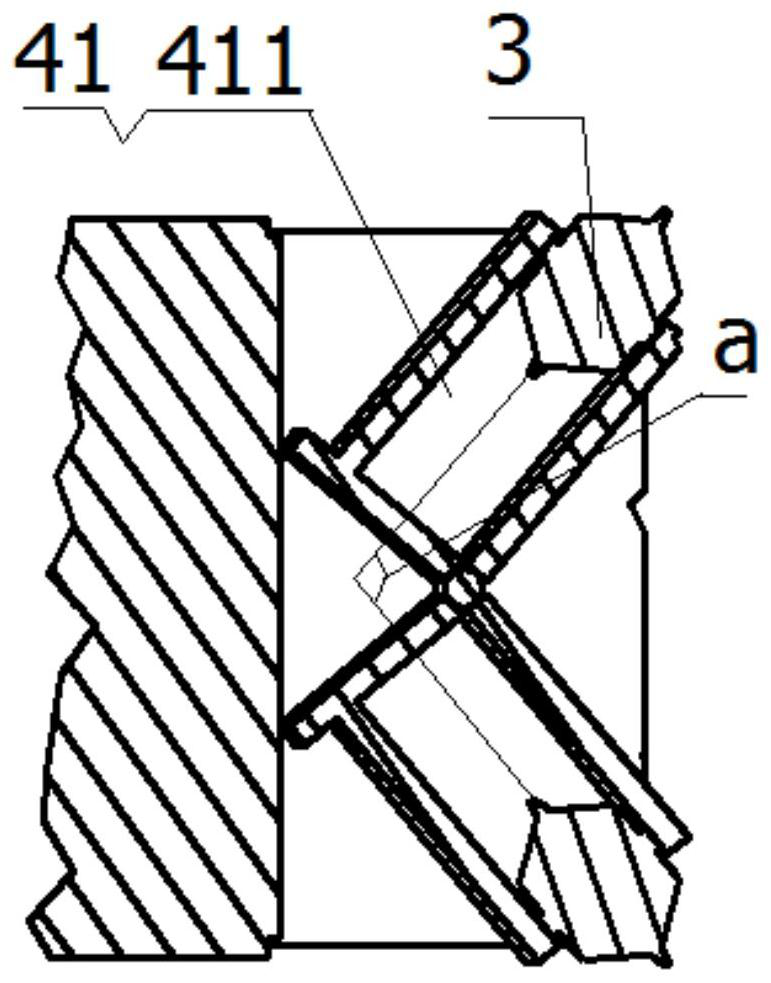

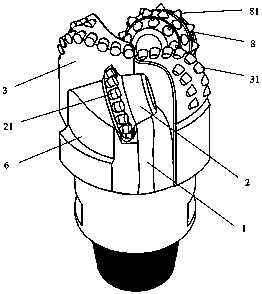

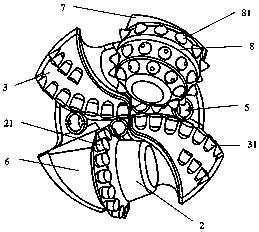

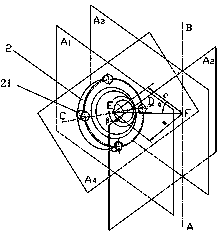

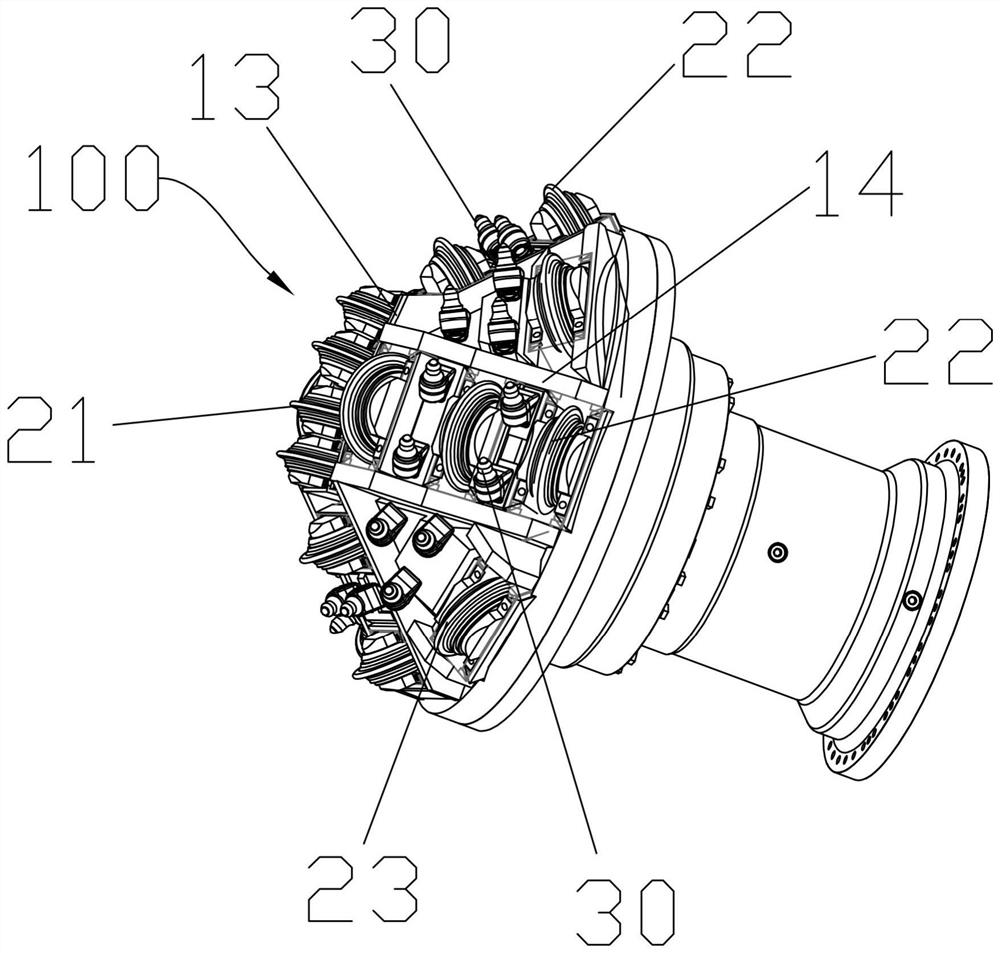

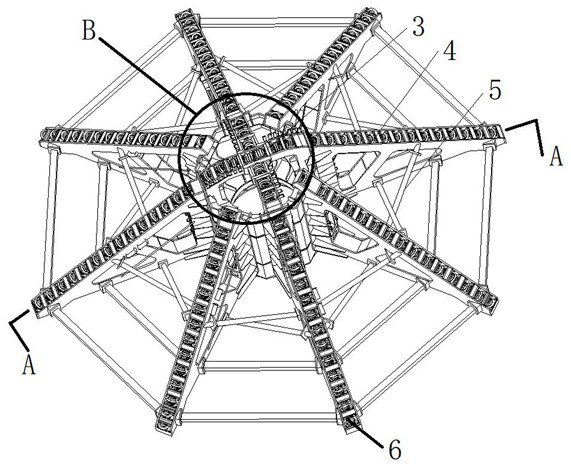

Cutter head suitable for hard rock mining and hard rock mining method

ActiveCN114412462AEnough turning torqueAverage forceDisloding machinesSlitting machinesHydraulic motorMining engineering

The invention discloses a cutterhead suitable for hard rock mining and a hard rock mining method.The cutterhead comprises a rotary shaft hole used for receiving radial driving force, a cutterhead frame and a rock breaking roller, the rock breaking roller is installed on the cutterhead frame, and the arrangement direction of the rock breaking roller meets the requirement that the rock breaking roller breaks rock and is suitable for radial propelling. The hard rock mining method using the cutterhead is a method that the cutterhead is propelled in the radial direction. The cutterhead structure can form an ultra-large high-strength disc type structure, and the cutterhead is driven by the large-torque hydraulic motor to ensure that the cutterhead has enough rotation torque during rock breaking work; and through reasonable arrangement of the rock breaking rollers, it is guaranteed that the rock breaking rollers evenly cut the rock surface when the cutter head rotates, it is guaranteed that the overall stress of the cutter head is average, meanwhile, it is guaranteed that stress in the rock mass is balanced, the optimal rock breaking effect is achieved, rocks with the rock hardness f larger than or equal to 8 can be cut, continuous rock breaking operation can be achieved, and the rock breaking device can be used for intelligent equipment so as to achieve intelligent efficient excavation.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

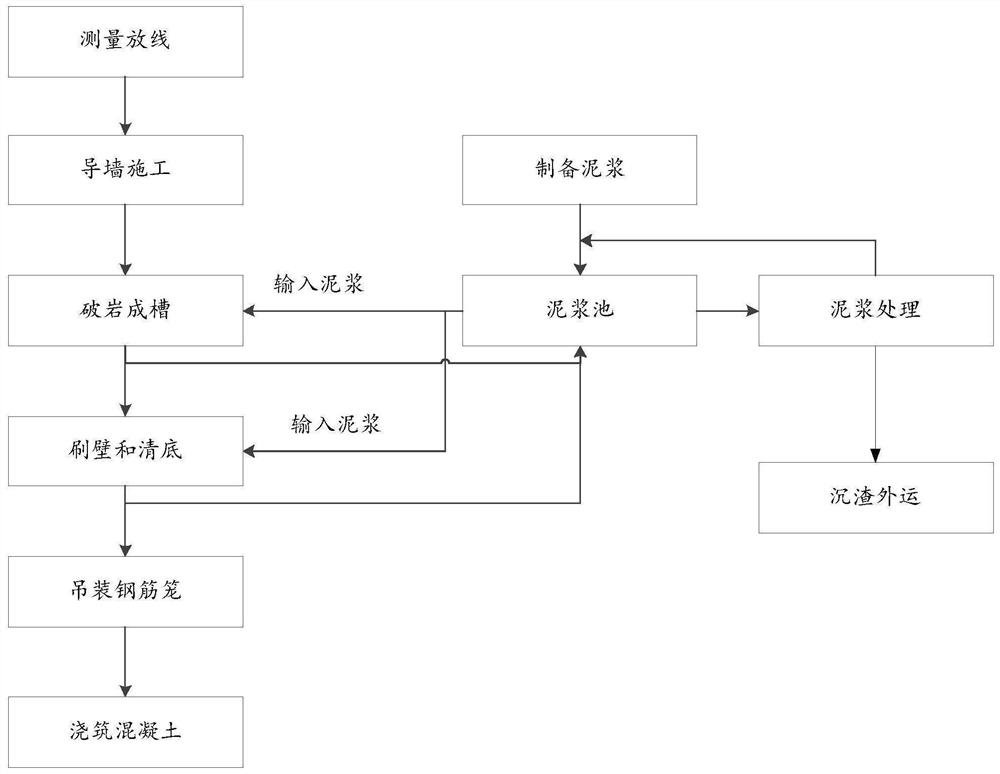

Grooving construction method

InactiveCN113123388AImprove construction efficiencyImprove rock breaking effectSoil-shifting machines/dredgersGrain treatmentsClassical mechanicsEngineering

The invention relates to the technical field of building construction, in particular to a grooving construction method. The grooving construction method comprises the following steps: determining a grooving position; constructing a guide wall to form a guide wall groove; placing a rectangular drill bit at the bottom of the guide wall groove; crushing a rock stratum by utilizing plasmas generated by the rectangular drill bit to form a groove section; cleaning the bottom and the side wall of the groove section; and hoisting a reinforcement cage, and pouring concrete. According to the grooving construction method, the plasmas are generated through the rectangular drill bit, a plasma channel is formed, the pressure in the plasma channel is rapidly increased under the action of high temperature along with the high temperature and high pressure while the plasma channel is formed, so that the plasma channel is expanded and breaks down rocks, and the surrounding rocks are crushed; and the plasmas are adopted to crush various rock stratums, so that the rock crushing effect is good, construction equipment does not need to be replaced, the construction efficiency is high, and the construction cost is reduced.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

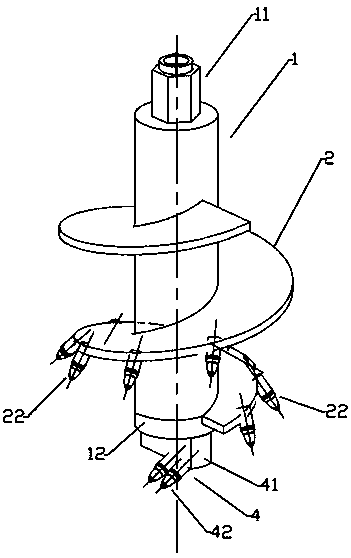

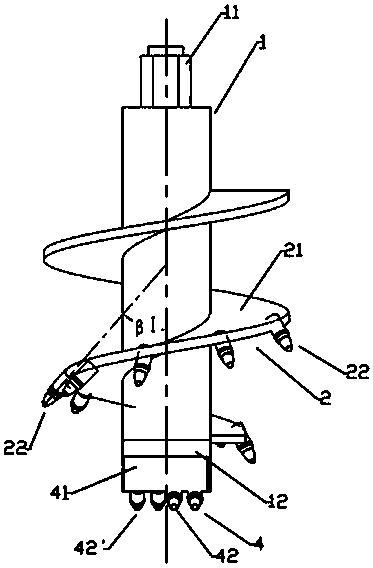

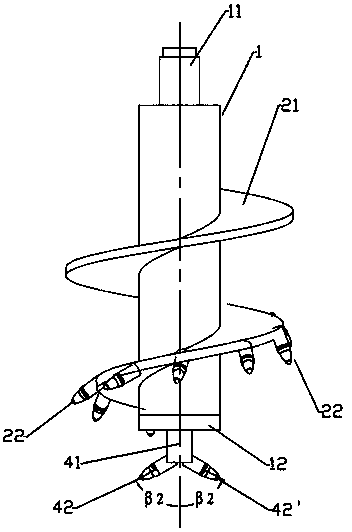

Reducing drilling rig

PendingCN108086914AThe quantity is set appropriatelyImprove rock breaking effectDrill bitsConstructionsConical formsHigh intensity

The invention discloses a reducing drilling rig, which comprises a drilling rig pipe body, a spiral cutting wing consisting of a wing piece and a first cutting pick, and a front end drill bit consisting of a front end seat plate and a second cutting pick; the spiral cutting wing is arranged at the outer wall of the pipe body of the drilling rig in a radiating form; the wing piece is a spiral pieceof which upper part is conical and the lower part is cylindrical; the outside diameter of the conical free end at the lower part is risen along its rotation direction and gradually increased in the conical form; every first cutting pick is fixedly connected to the free end at the outside of the wing piece, two adjacent first cutting picks are arranged equally at the arc face of the free end of the wing piece and outwards expanded; several first cutting picks are risen at 360 degrees around the rotation direction of the wing piece and then arranged at intervals along the arc face of the outside free end of the wing piece; the front end drill bit is fixed on the outer end face of the drilling rig pipe body through a front end seat plate, two lines of second cutting picks are outwards inclined to fix at the lower side of the front end seat plate. The reducing drilling rig is featured by high intensity of cutting bit, wide adaptation scale, wear-resistance and reliability, and can realizemultilayered cutting and drilling, and effectively improve the drilling and rock breaking ability and construction working efficiency.

Owner:SHANGHAI GUANGDA FOUND ENG

A scraping-impact compound drill bit

ActiveCN102678055BReduce difficultyReduce rock breaking energy consumptionDrill bitsConstructionsMining engineeringFoundation engineering

Owner:SOUTHWEST PETROLEUM UNIV

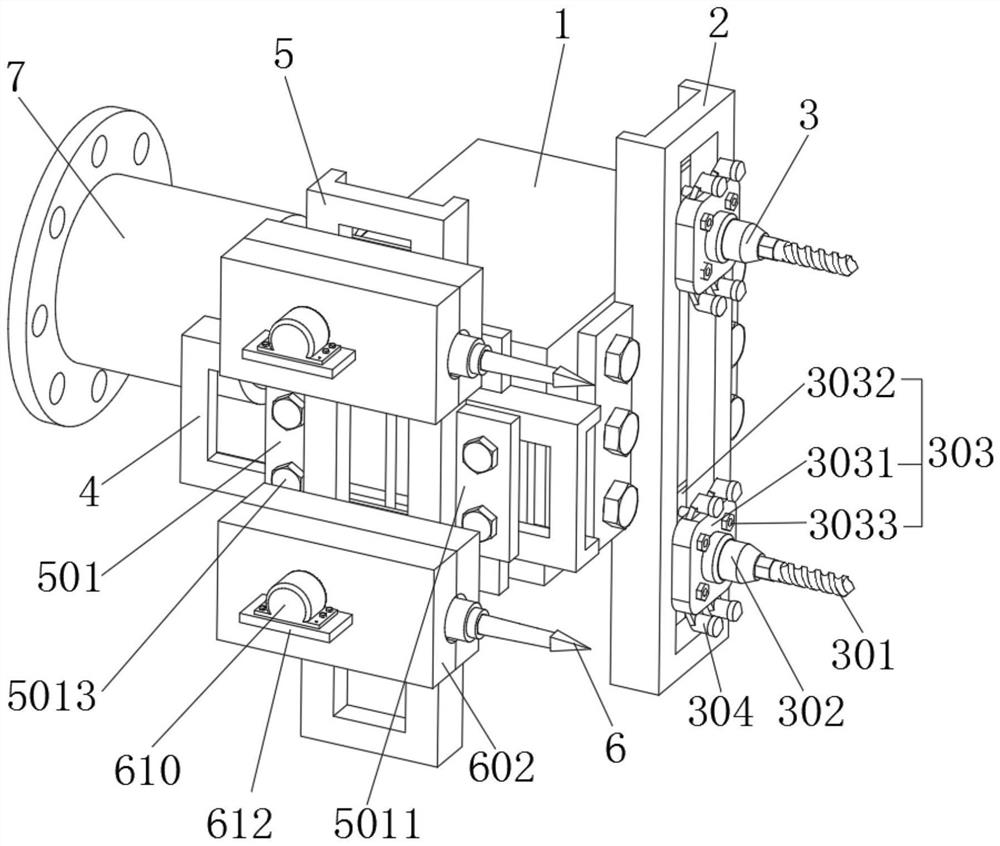

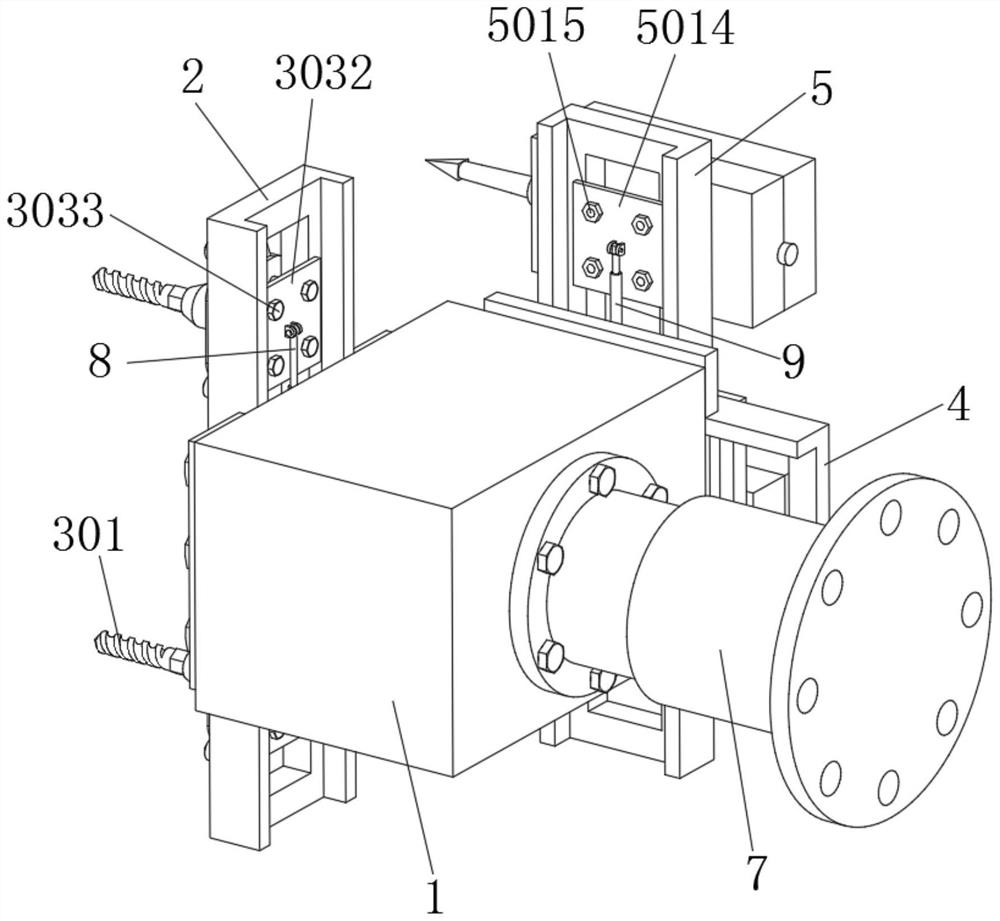

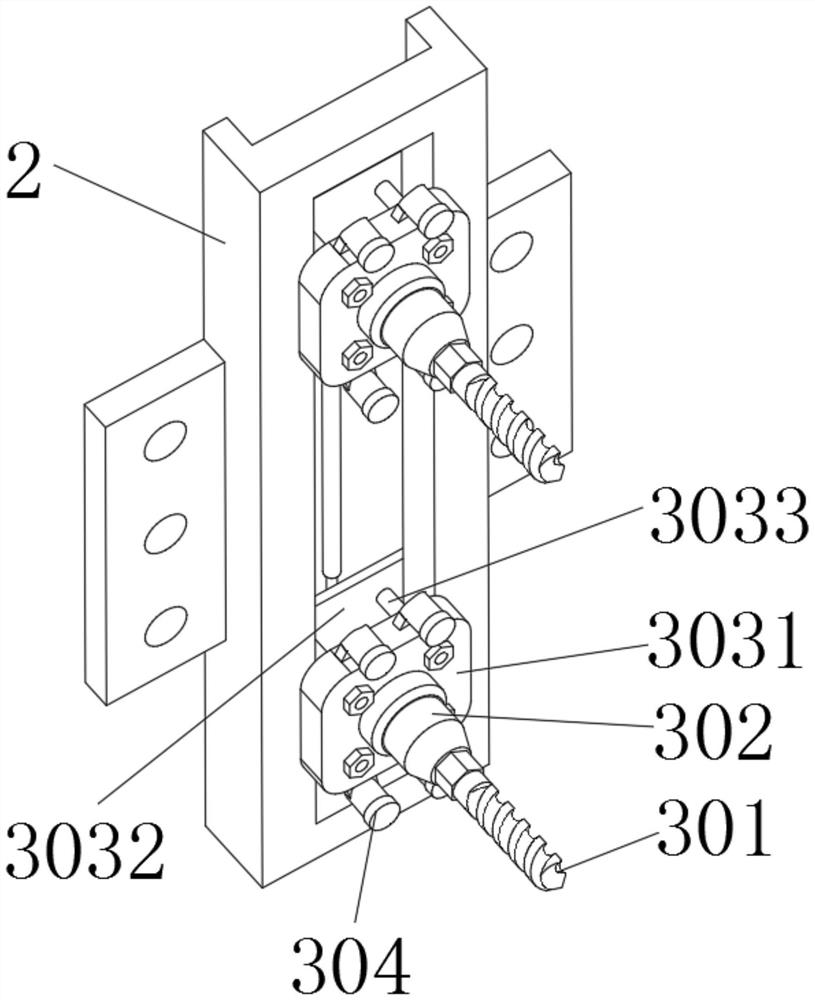

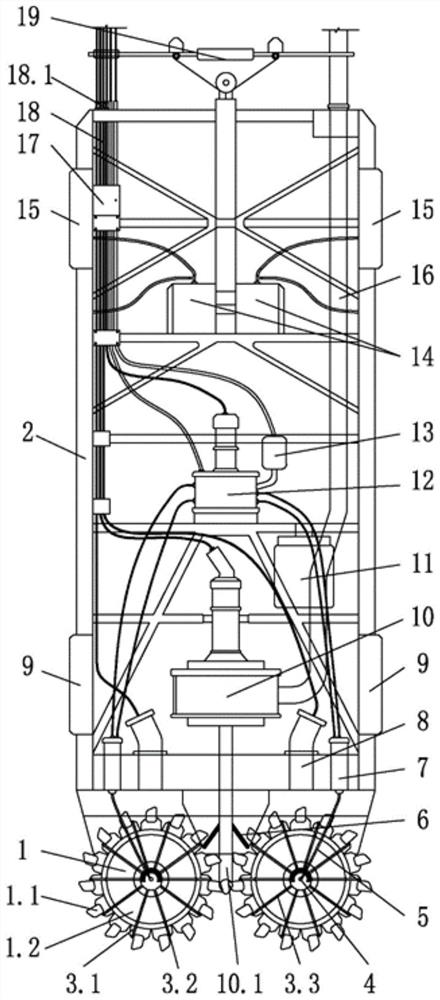

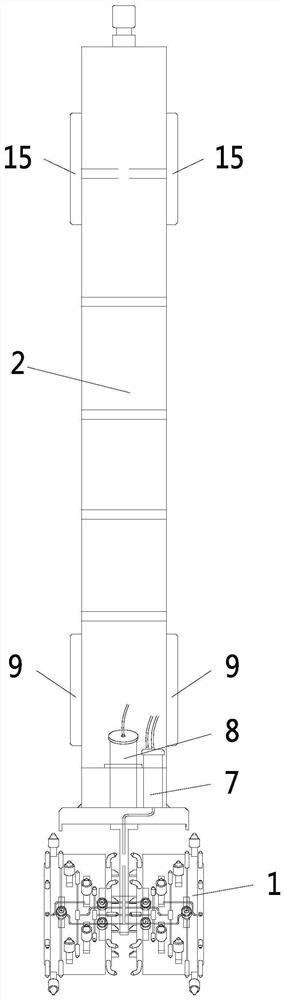

Drilling and punching combined type rock breaking device for roadway tunneling

ActiveCN114278329AIncrease in sizeReduce distractionsDrilling rodsConstructionsHydraulic cylinderClassical mechanics

The invention discloses a drilling and punching combined type rock breaking device for roadway tunneling. The drilling and punching combined type rock breaking device comprises a support. A drilling hydraulic cylinder is arranged on the support, and the end of a piston rod of the drilling hydraulic cylinder is fixedly connected with the workbench. A drilling assembly and an impact assembly are arranged on the workbench. The drilling assembly comprises a drilling guide rail, two drill bit assemblies are arranged on the drilling guide rail, and each drill bit assembly comprises a drill rod; the impact assembly comprises a transverse guide rail which is in sliding fit with an impact guide rail. Two groups of punch assemblies are arranged on the impact guide rail, and each punch assembly comprises an impact rod; the central axis of the drill rod, the central axis of the impact rod and the central axis of the piston rod of the drilling hydraulic cylinder are parallel; the sliding direction of the impact guide rail along the transverse guide rail is consistent with the axis direction of the impact rod; the plane where the central axes of the two drill rods are located is parallel to the plane where the central axes of the two impact rods are located. Through the arrangement of the drill bit assembly and the punch assembly, the purpose of crushing local rocks is achieved through expansion connection of local cracks of the rocks.

Owner:SHANDONG UNIV OF SCI & TECH

Hole filling device and method for tunnel high-pressure gas rock breaking

The invention discloses a hole filling device and method for tunnel high-pressure gas rock breaking, and relates to the technical field of hard rock breaking. The device comprises a filling pipe and afilling rod, wherein a through hole with two through ends is formed in the filling pipe; the outer diameter of the filling pipe is smaller than the hole diameter of a cracking hole; the length of thefilling pipe is larger than the depth of the cracking hole; a horizontal discharging groove is formed in a port of one end of the filling pipe; a filling pipe guide groove is formed in the portion, from one side close to the handheld end to the port of the handheld end of the filling pipe, of the discharging groove; a filling rod guide groove is formed in the side wall of the filling rod; the length of the filling rod is larger than that of the filling pipe; the outer diameter of the filling rod is smaller than the hole diameter of the filling pipe; and the width of the filling rod guide groove is larger than that of the filling pipe guide groove. By adopting the hole filling method for tunnel high-pressure gas rock breaking on the basis of the filling device, the technical problems thatin the implementation process of safe and efficient rock breaking through high-pressure gas in a tunnel, grouting hole blocking operation is difficult, filling is not dense, the rock breaking effect is poor due to poor filling quality, and the filling material is seriously wasted are solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Hydraulic-mechanical combined rock-breaking milling wheel and double-wheel slot milling machine

PendingCN111622288AReduce wearImprove rock breaking efficiencyMechanical machines/dredgersEngineeringStructural engineering

The invention relates to a hydraulic-mechanical combined rock-breaking milling wheel and a double-wheel slot milling machine. The milling wheel comprises a milling wheel body, multiple milling teeth,multiple cutting teeth, a milling wheel spindle and a high-pressure water jet device, wherein the multiple milling teeth are fixed to the circumference of the milling wheel body; the multiple cuttingteeth are arranged in a ring at the inner side of the milling wheel body; the milling wheel spindle drives the milling wheel body to rotate through a milling wheel driving mechanism; the high-pressurewater jet device comprises a nozzle controller, multiple edge-trimming nozzles, multiple rock-breaking nozzles, multiple blind area milling nozzles and multiple fixing components; the nozzle controller is fixed into a through hole of the milling wheel spindle to rotate synchronously with the milling wheel spindle; and the edge-trimming nozzles, the rock-breaking nozzles and the blind area millingnozzles are fixed to the milling wheel body through the fixing components respectively. Through the double-wheel slot milling machine, the rock-breaking efficiency and the rock-breaking effect are both improved to a certain extent compared with a traditional mechanical rock-breaking mode, tool wear is small, a milling blind area has a good milling effect, and improvement to construction efficiency and reduction of construction cost are benefited.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

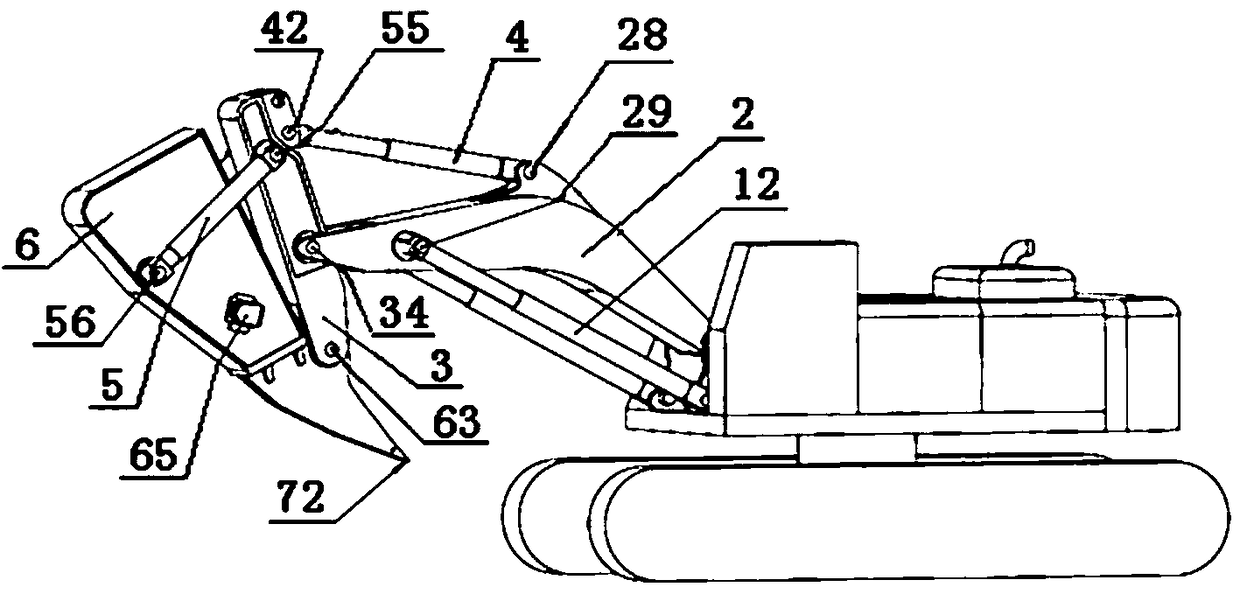

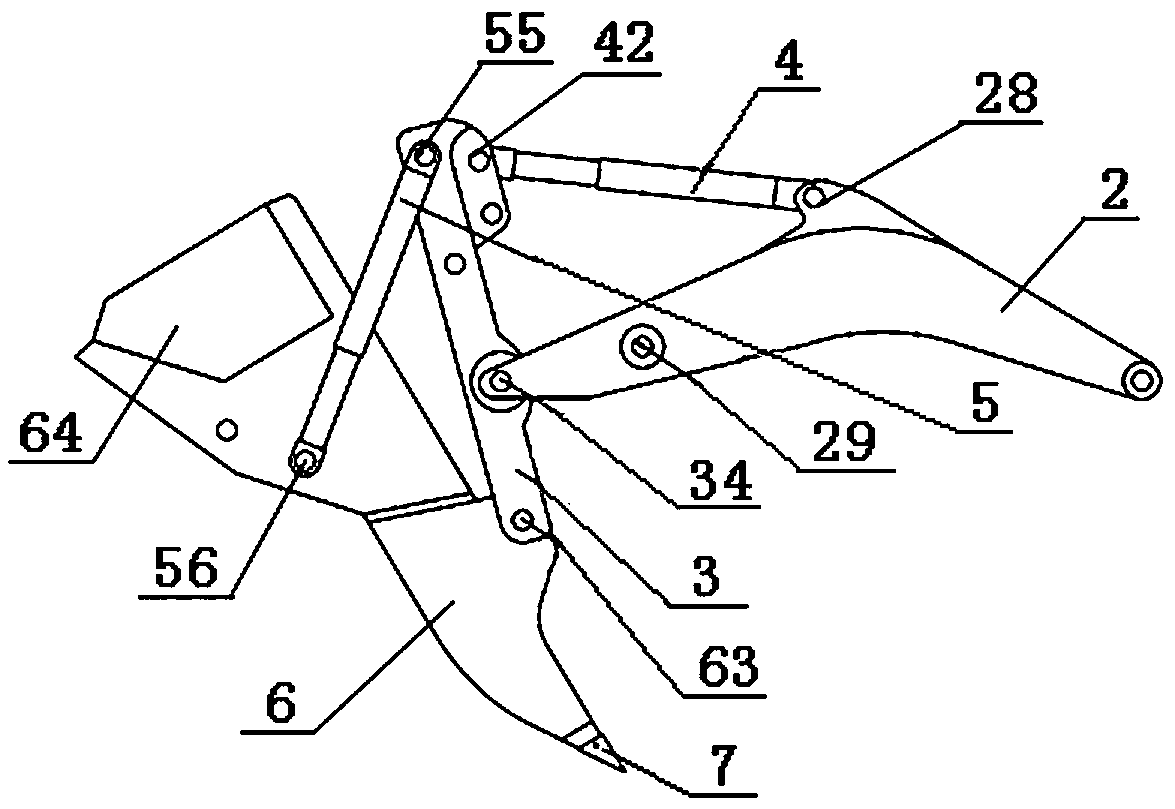

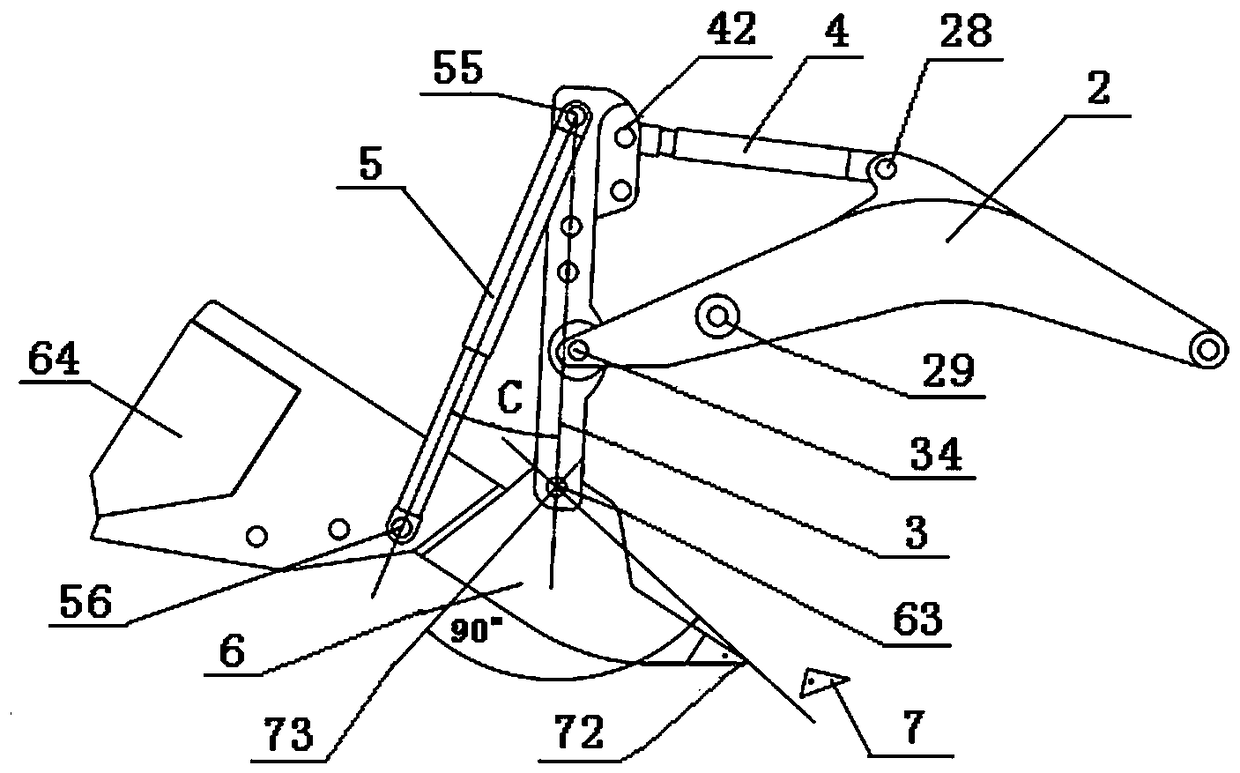

Rock breaking device

ActiveCN108487347AGreat momentumImprove rock breaking effectMechanical machines/dredgersSlitting machinesShortest distanceEngineering

The invention relates to a rock breaking device carried to an excavator, and the problems that an existing device scarifier is poor in rock entering angle, energy consumption is high, and the rock breaking effect is poor are solved. One end of a bucket rod cylinder is hinged to the upper edge of the middle portion of a big arm, and the other end of the bucket rod cylinder is hinged to the upper end of a small arm. The upper end of the small arm and one end of a scarifier oil cylinder are hinged, the other end of the scarifier oil cylinder is hinged to the upper end of the scarifier, the lowerend of the scarifier is connected with bucket teeth, and the ratio of the distance between a fourth hinge shaft and a first hinge shaft to the distance between the first hinge shaft and a seventh hinge shaft is larger than 0.8, the length of an upper part of the scarifier is larger than the distance between a fourth hinge shaft and the first hinge shaft, and when the fourth hinge shaft has multiple installing positions, the shortest distance serves as the criterion for the distances between the fourth hinge shaft and the first hinge shaft, and the length of the upper part of the scarifier is larger than the distance between the first hinge shaft and the seventh hinge shaft, and when the first hinge shaft has multiple installing positions, the shortest distance serves as the criterion for the distances between the first hinge shaft and the seventh hinge shaft, the total length of the scarifier is larger than the distance between the fourth hinge shaft and the seventh hinge shaft, and when the fourth hinge shaft has multiple installing positions, the shortest distance serves as the criterion for the distances between the fourth hinge shaft and the seventh hinge shaft.

Owner:凌夕珈

DNA double-spiral ejection and explosion integrated medium-length hole blasting device

The invention discloses a DNA double-spiral ejection and explosion integrated medium-length hole blasting device. The device comprises a DNA double-spiral tubular explosive cover, explosives and an igniter. The explosive cover is formed by spiral staggered winding of two hollow round pipes according to a certain pitches; the explosives are general explosives positioned in a spiral cavity; and theigniter is a general priming device. The device changes explosive loading and acting modes of traditional explosives; each single-chain spiral pipe forms spiral jet flows sprayed to the periphery after priming of the explosives to invade rock masses; the jet flows are overlapped in staggered areas of two round pipe space to strengthen a local invasion effect; and meanwhile, impact waves and explosion gas are generated in positions without the spiral pipes for directly acting on rocks. The device integrates ejection and explosion to obtain excellent blasting sections during reduction of the uselevel of the explosives. The introduced DNA double-spiral explosive cover is simple in form, various in shape, easy to machine and convenient to use, improves the efficiency, and reduces the cost.

Owner:UNIV OF SCI & TECH OF CHINA +1

Large-diameter offshore wind power rock-socketed single pile excavating method

The invention discloses a large-diameter offshore wind power rock-socketed single pile excavating method. The large-diameter offshore wind power rock-socketed single pile excavating method comprises the following steps that immersion of a pilot shaft pile casing is carried out; a petroleum drilling machine is adopted for excavating a pilot shaft through the pilot shaft pile casing; a geological drill is adopted for drilling two to three rings of main blast holes and one ring of outline blast holes, and a casing off hole is lowered down; a dedicated CO2 phase change expansion crack pipe is mounted, the interiors of the main blast holes are mounted in a segmented manner, and the interiors of the outline blast holes are continuously mounted; a blast network is connected; a rock-socketed single pile steel pile casing is lowered down; mud and weathering sand between the pilot shaft pile casing and the rock-socketed single pile steel pile casing are sucked away; the pilot shaft pile casing and a drilling casing pile are pulled out; underwater slag cleaning is carried out; and concrete is poured to form a rock-socketed single pile foundation. Pilot shaft mechanical excavating and CO2 expansion rock breaking and expanded excavating are combined, the technical problem that a 2-4mm-diameter petroleum drilling machine and a common geological drill are used for finishing excavating of an offshore rock-socketed single pile foundation with the diameter being 8 to 10 m and above can be solved, the expansion pressure generated by a CO2 phase change is controllable, the explosion impact waves and the vibration speed are small, and the method is economic and environment-friendly.

Owner:WUHAN UNIV

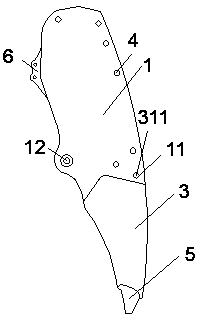

Hook digging rock arm small arm with material filling mechanism

ActiveCN107630482AWeight increaseReduce maintenance costsMechanical machines/dredgersEngineeringRock breaking

The invention discloses a hook digging rock arm small arm with a material filling mechanism. The hook digging rock arm small arm comprises a left clamping plate, a right clamping plate and a hook digging plate, wherein the left clamping plate and the right clamping plate are arranged side by side; the upper part of the hook digging plate is clamped between the left clamping plate and the right clamping plate; the hook digging plate is detachably connected with the left clamping plate and the right clamping plate; the hook digging plate is of a hollow structure; a filler port is formed in the middle part of one side of the hook digging plate. The problems that the connected structure of an existing hook digging rock arm small arm and a digging hook is complicated and the maintenance cost after the integration of the hook digging rock arm small arm and the digging hook is high are solved, and further, the problem that the weight of the hook digging rock arm small arm is inconvenient to adjust according to the harness condition of rock stratum since the weight of the existing hook digging rock arm small arm is constant is solved, so that the hook digging rock arm small arm has a preferable rock breaking effect.

Owner:CHENGDU KAILONG MACHINERY MAINTENANCE

Drilling and milling type tunneling machine cutting experimental mechanism

The invention relates to a drilling and milling type tunneling machine cutting experimental mechanism. The drilling and milling type tunneling machine cutting experimental mechanism comprises a cutting head and a rocker arm part; the cutting head is composed of a tooth part cutting rotating cutter disc, a hobbing cutter disc, an end cover, a planetary gear, a sun gear and an inner gear; the rockerarm part is composed of a reduction gearbox and a driving motor; the driving motor drives the tooth part cutting rotating cutter disc and the hobbing cutter disc to rotate through the reduction gearbox, and a traction portion drives a rocker arm to swing left and right through a pin shaft, so that the cutting radius and the cutting area are increased, the cutting capacity is improved, rock breaking is easier in the tunneling process, the purpose of rapid tunneling is achieved, the rock breaking capacity of an underground space project can be improved, the construction progress time is shortened, tooth cutting and hobbing are integrated, and the cutting efficiency is greatly increased. The tunneling machine cutting mechanism is compact in structure, simple in mechanism, low in cost and good in rock breaking effect, and effectively reduces the tunneling ratio energy consumption of the tunneling.

Owner:LIAONING TECHNICAL UNIVERSITY

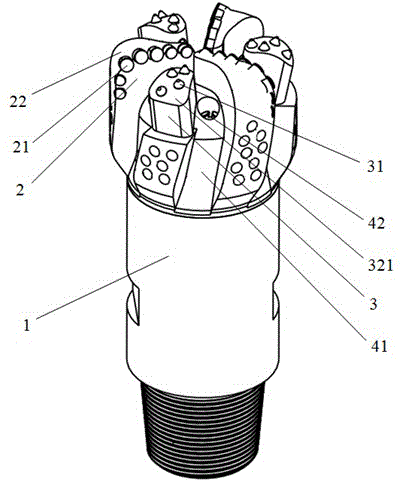

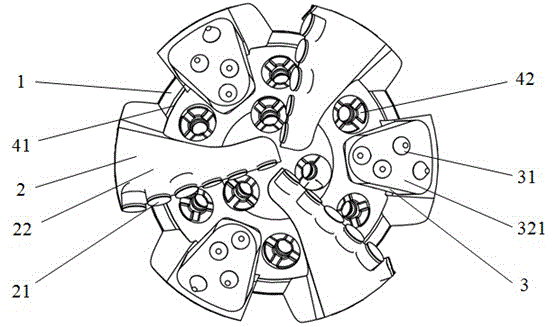

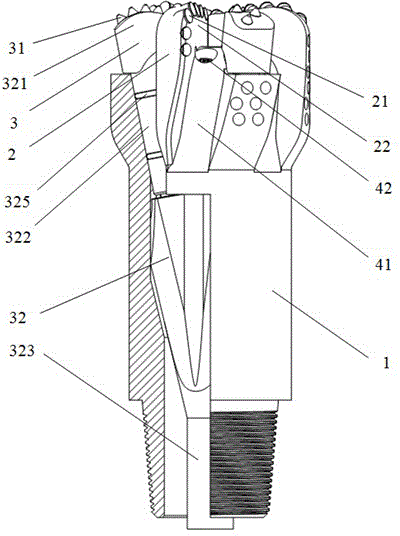

Combined type diamond drill bit under complex and difficult drilling conditions

The invention discloses a combined type diamond drill bit under complex and difficult drilling conditions. The drill bit comprises a drill bit body, a cutter wing, a nozzle or a jet nozzle, wherein the cutter wing extends from the drill bit body or is fixed to the drill bit body, a fixed cutting element is arranged on the fixed knife wing, meanwhile, one or more roller cones composed of roller cone bodies and teeth and one or more disc cutters composed of disc cutter bodies and disc cutter cutting elements are arranged on the drill bit, and the roller cones and the disc cutters are separatelyrotatably connected with the drill bit body through a roller cone support and a disc cutter support. The advantages of a roller cone-PDC combined drill bit and an intersecting cutter PDC drill bit arecombined, in this way, the working performance of the drill bit under the complex and difficult drilling conditions is improved, and the application range of the drill bit on the stratum is further enlarged.

Owner:SOUTHWEST PETROLEUM UNIV +1

Carbon dioxide rock breaking device and method for open-pit mine

ActiveCN112665472AAvoid unsafe factorsImprove securityBlastingOpen-pit miningThermal insulationLiquid carbon

The invention relates to a carbon dioxide rock breaking device and method for an open pit mine. The device comprises a gas injection pipe, a booster pump, a stirring type carbon dioxide and abrasive mixing mechanism, a liquid carbon dioxide storage tank, an energy storage chamber and a fracturing chamber, a packing sheet is arranged between the energy storage chamber and the fracturing chamber, and the gas injection pipe is provided with a pressure sensor, a flow sensor and a plurality of valves; and a ceramic electric heating sleeve and a thermal insulation sleeve are sequentially arranged on the portion, between the energy storage chamber and an opening of a drilled hole, of the gas injection pipe in a sleeving manner. The method comprises the following steps of distributing holes; determining rock breaking parameters; conducting hole drilling; performing thermal reaming on the drilled hole; sending an energy storage chamber and fracturing chamber series-connection body into the drilled hole; sealing the opening of the drilled hole; introducing carbon dioxide abrasive mixed fluid into an inner cavity of the energy storage chamber, and injecting liquid carbon dioxide while blocking cracks in the wall of the drilled hole; pressurizing and heating the liquid carbon dioxide to form supercritical carbon dioxide and seal the energy storage chamber; and continuously introducing supercritical carbon dioxide to break the packing sheet, enabling the liquid carbon dioxide in the drilled hole to be rapidly gasified and expanded, and enabling the energy of the liquid carbon dioxide to directly crack a rock stratum.

Owner:NORTHEASTERN UNIV LIAONING

Conical cutterhead and heading machine

InactiveCN113217006AReduce shock vibrationGood rock breaking effectTunnelsClassical mechanicsEngineering

The invention provides a conical cutterhead and a heading machine, and relates to the technical field of engineering tunnel equipment. The conical cutterhead comprises a cutterhead body; the cutterhead body is in a frustum shape; a plurality of hobs are rotatably installed on the cone top and the side wall of the cutterhead body; and a plurality of cutting teeth are further installed on the side wall of the cutterhead body. The conical cutterhead and the heading machine provided by the invention have good rock breaking efficiency on soft rocks and hard rocks.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

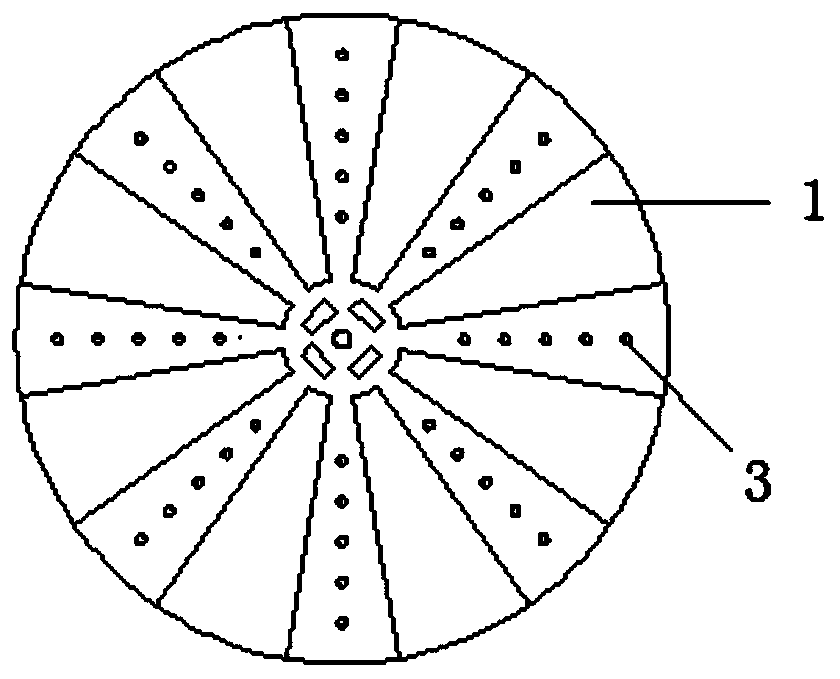

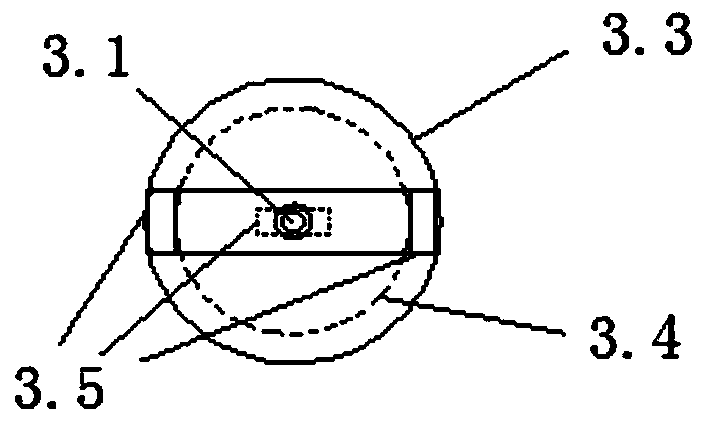

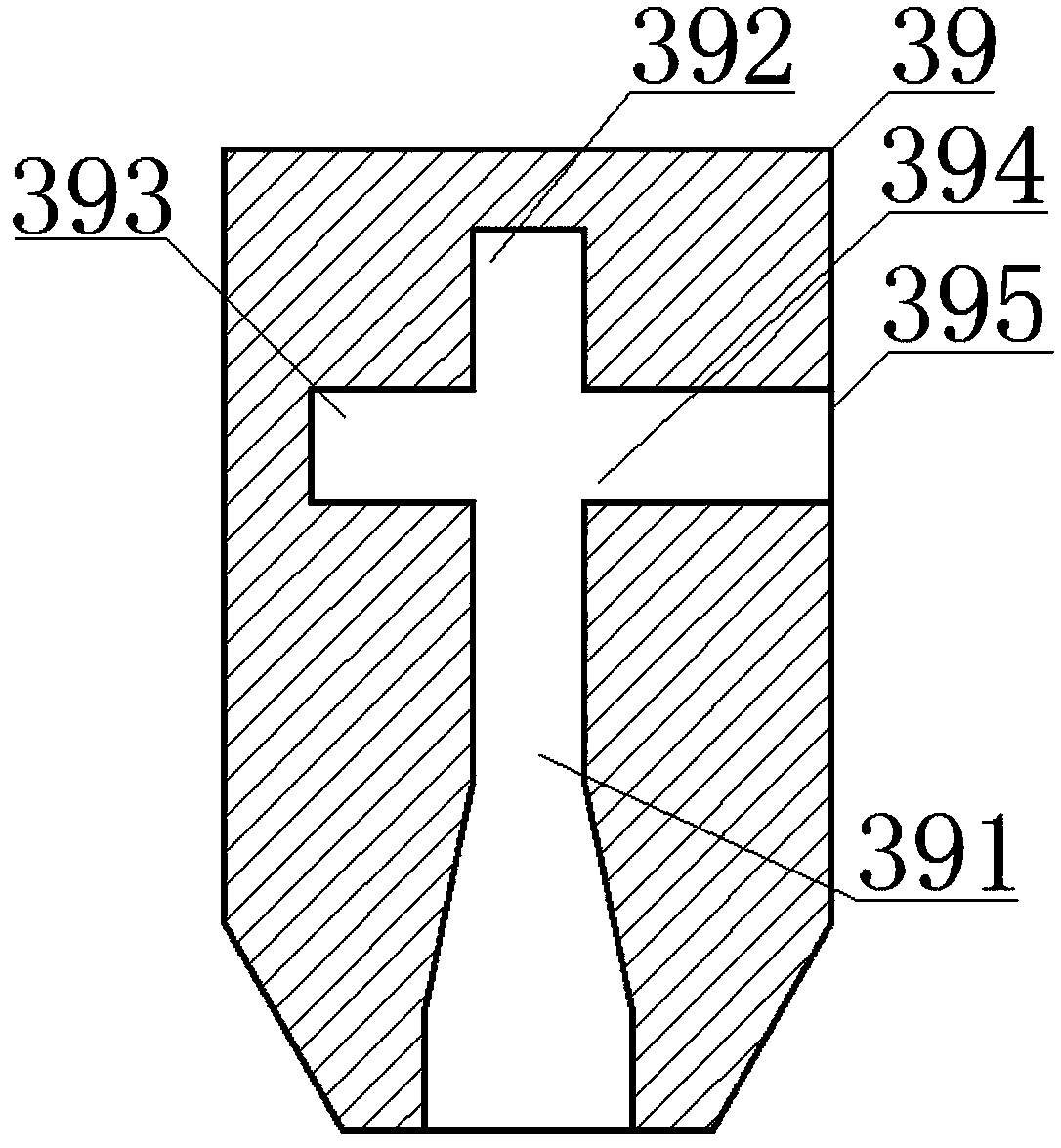

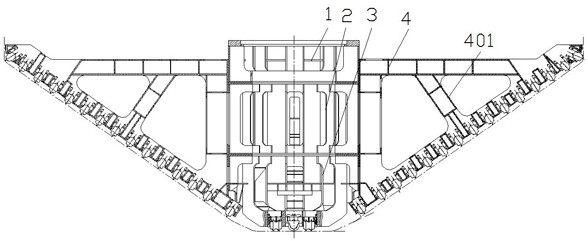

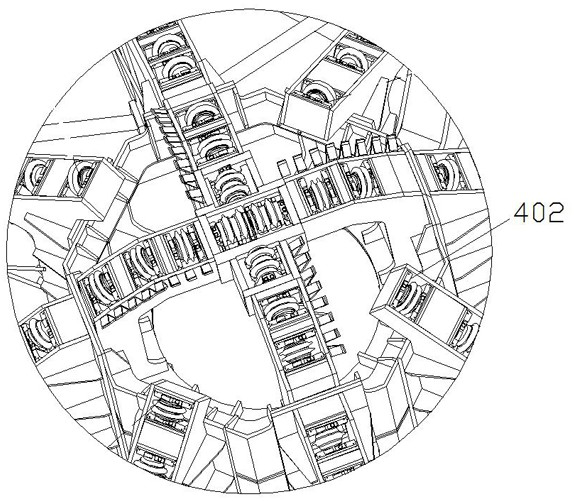

Cutter head structure for full-section shaft heading machine

PendingCN113250700AReduce lateral forceImprove rock breaking effectShaft sinkingEngineeringKnife blades

The invention provides a cutter head structure for a full-section shaft heading machine. The cutter head structure comprises a cutter head body, a cutter holder assembly and a hob, wherein the cutter head body comprises a plurality of amplitude arms and a shaft connecting body, the shaft connecting body is connected with a main drive of the heading machine and is used for mounting the amplitude arms, the amplitude arms are circumferentially distributed along the shaft connecting body, and the shaft connecting body comprises a central connecting block which is arranged at an operating end and is provided with a transition cavity between the central connecting block and part of the amplitude arms; the cutter holder assembly is arranged on the amplitude arms and the central connecting block and is used for mounting the hob, and the hob can rotate relative to the cutter holder assembly; and the hob comprises a cutter body and blades which are circumferentially arranged along the cutter body, and cutting edges of the blades are obliquely arranged towards one end of a central axis relative to the central axis of the cutter body. According to the cutter head structure, the central connecting block is arranged to be of a cross-shaped frame structure, so that an opening of a central region of a cutter head is enlarged, the problems that muck is easily accumulated in the central region of the vertical cutter head and the fluidity of slurry is relatively poor are solved, and meanwhile, a mounting space is provided for a cutter holder in a transition region.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com