Patents

Literature

190results about How to "Average force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

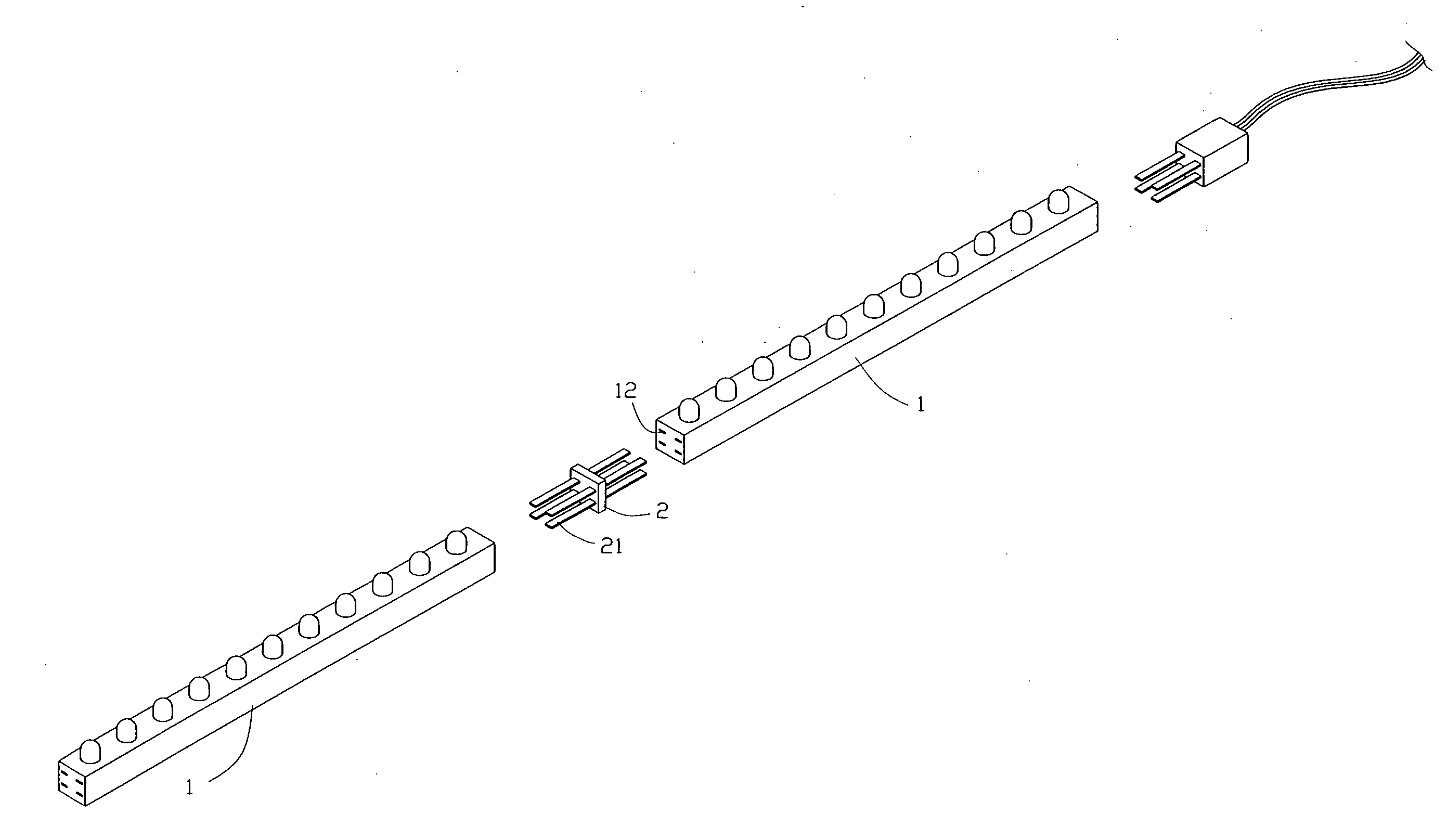

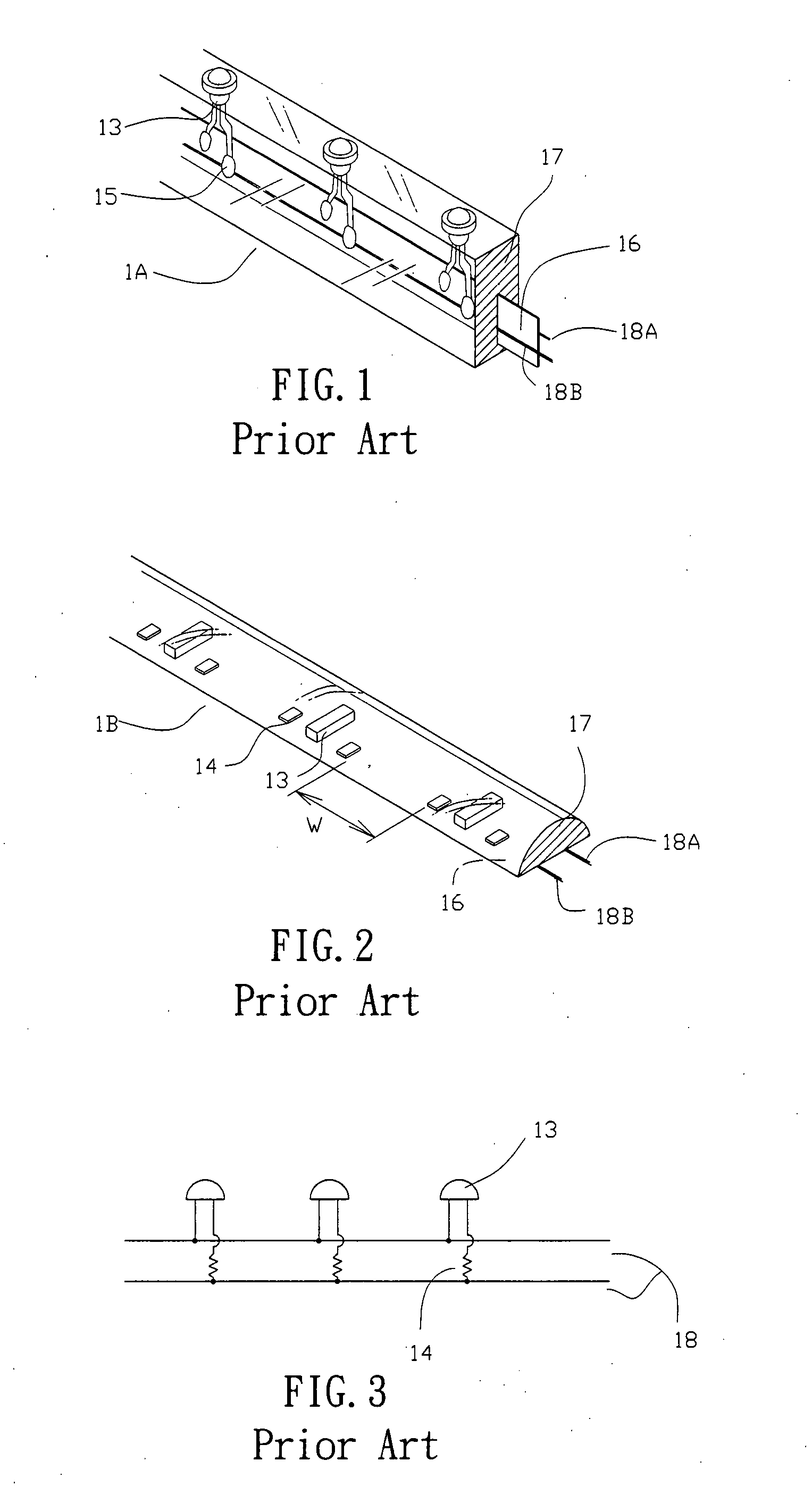

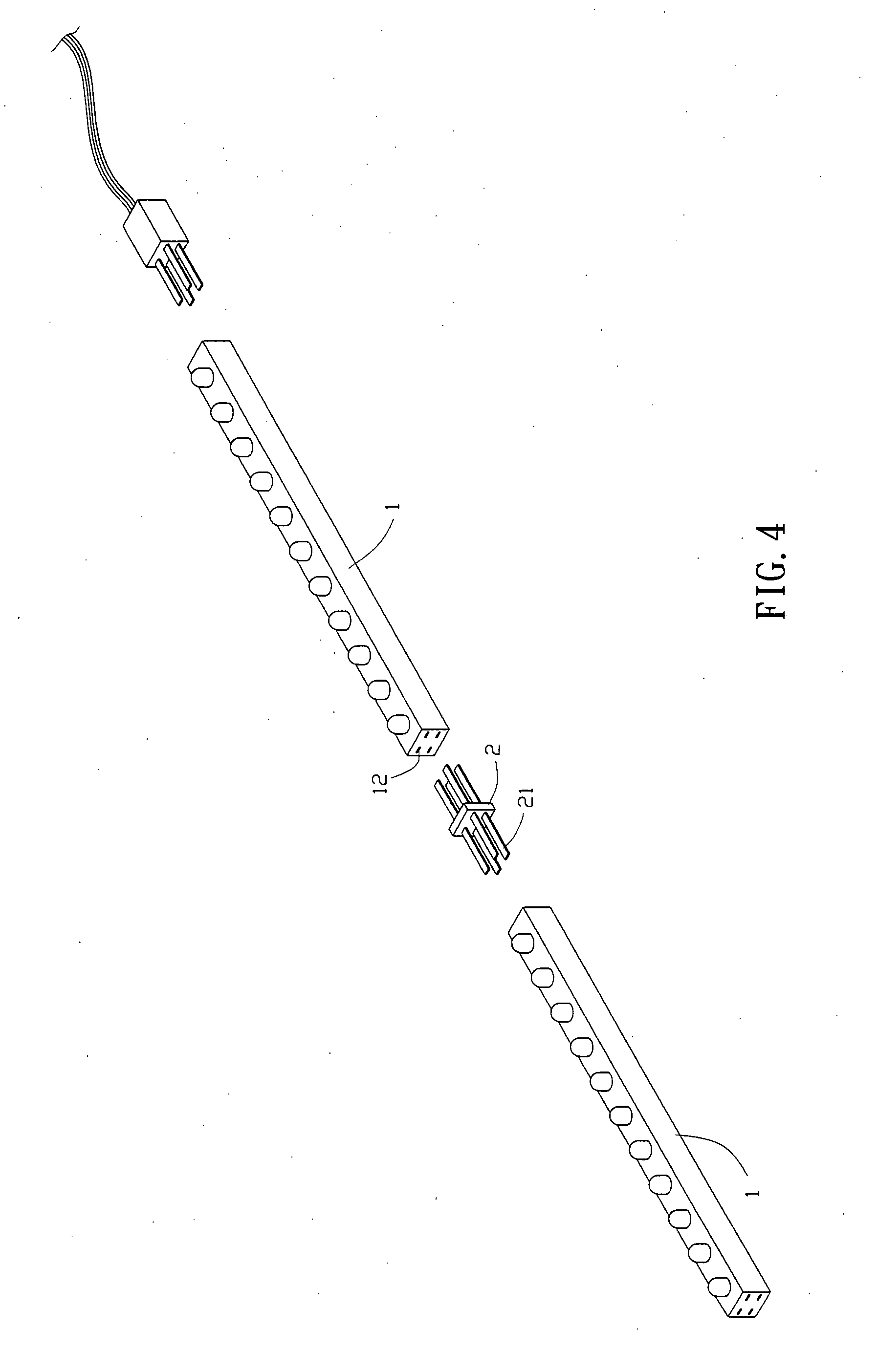

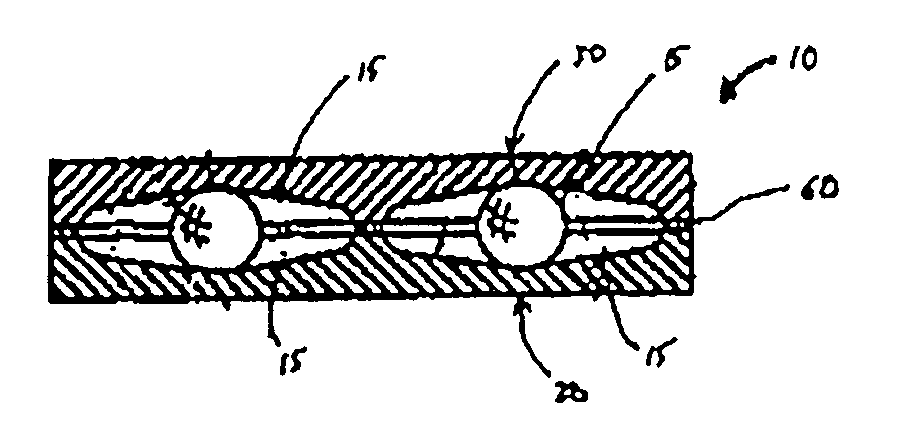

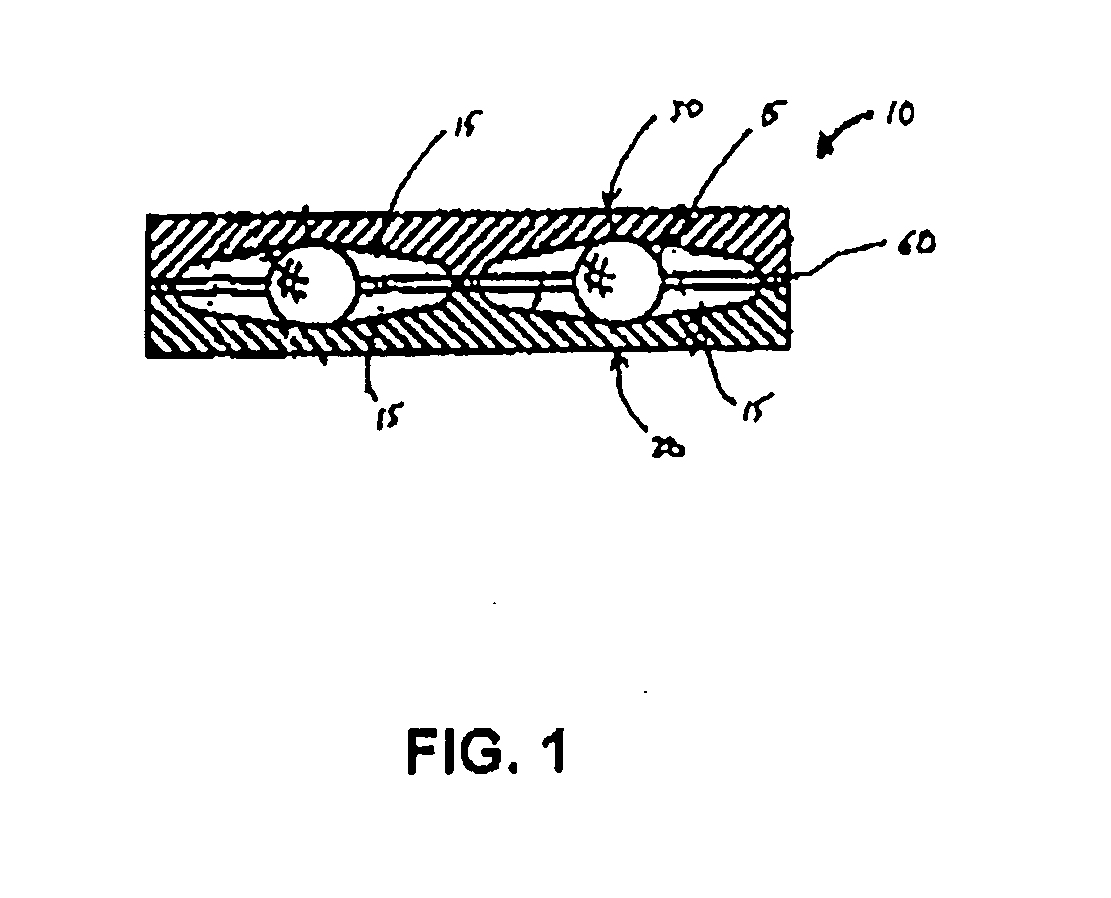

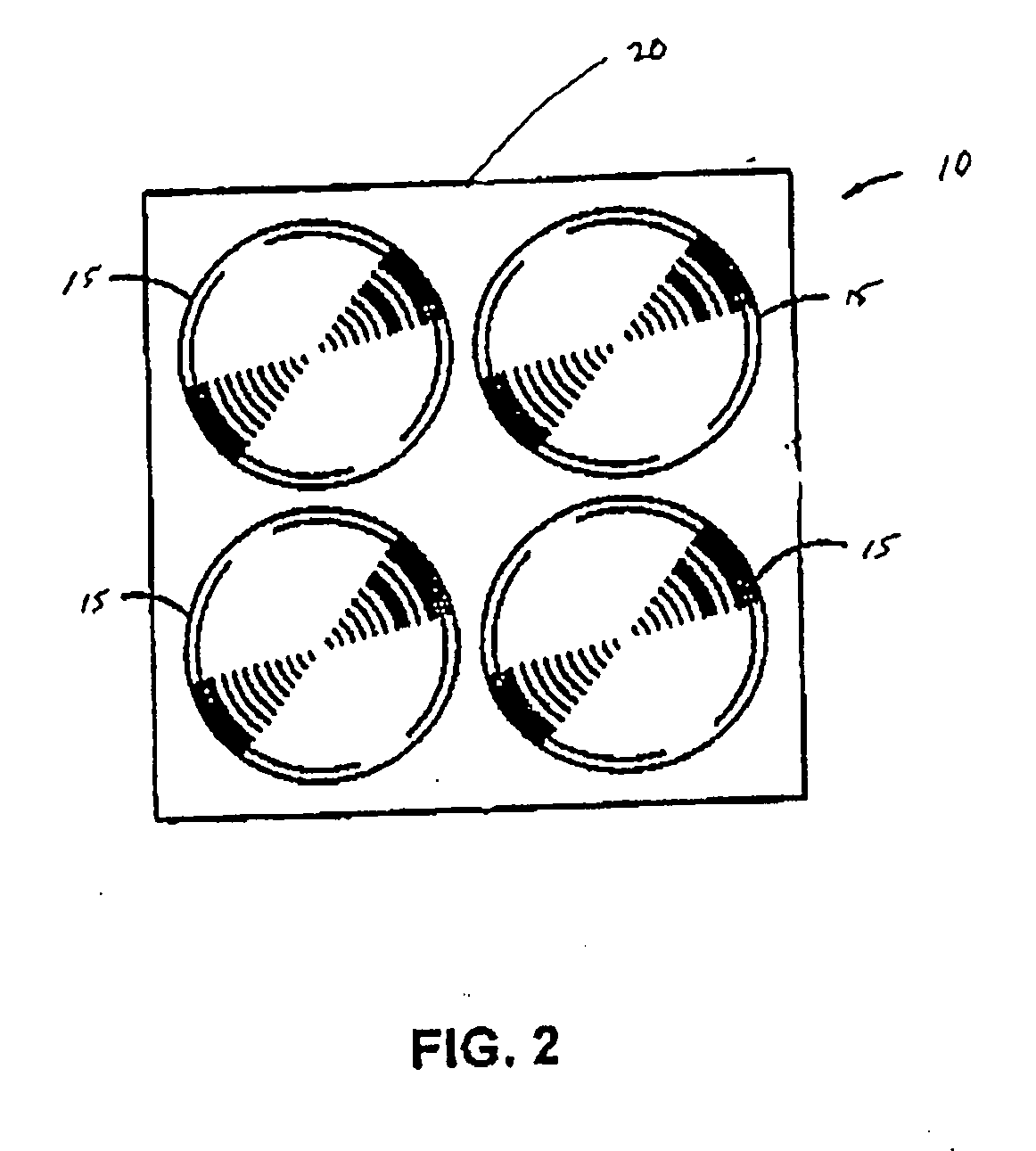

Light-emitting diode lamp bank

InactiveUS20080094828A1Increase shear forceFracture does not easilyPoint-like light sourceElongate light sourcesStress concentrationEngineering

An LED (Light-Emitting Diode) lamp bank is primarily formed with a plurality of LED lamps, a soft substrate, conduction wires, and soft vinyl. Two ends of each LED lamp bank are provided with female socket holes to connect with male connection terminals serially. A hard protective sheet is located at a position of the soft vinyl where each LED lamp is located, such that shear force of the soft vinyl at the location of the LED lamp can be increased, and an ill condition of fracture caused by stress concentration at the location of the LED lamp can be effectively prevented when the LED lamp bank is bended.

Owner:SHAO SHU FA

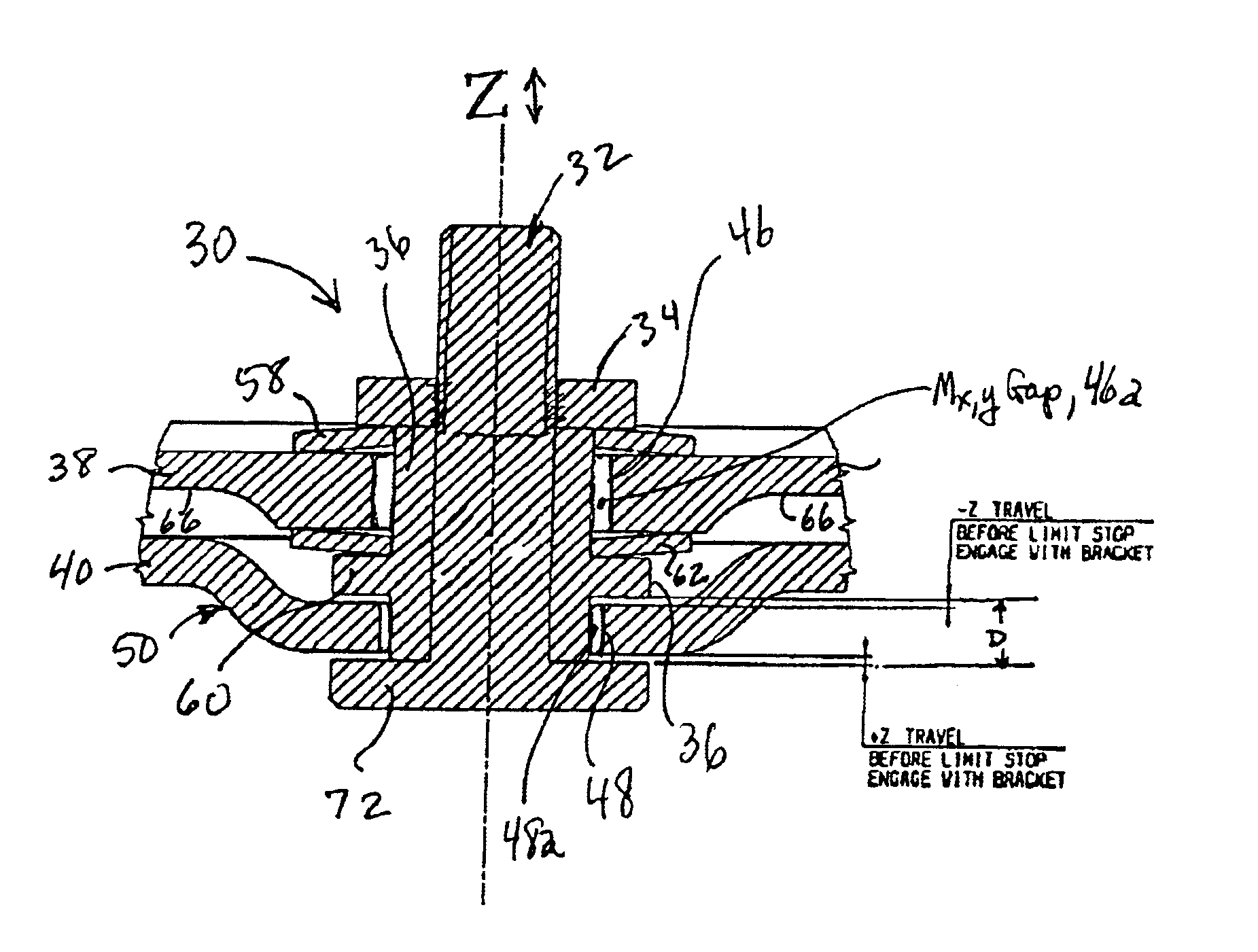

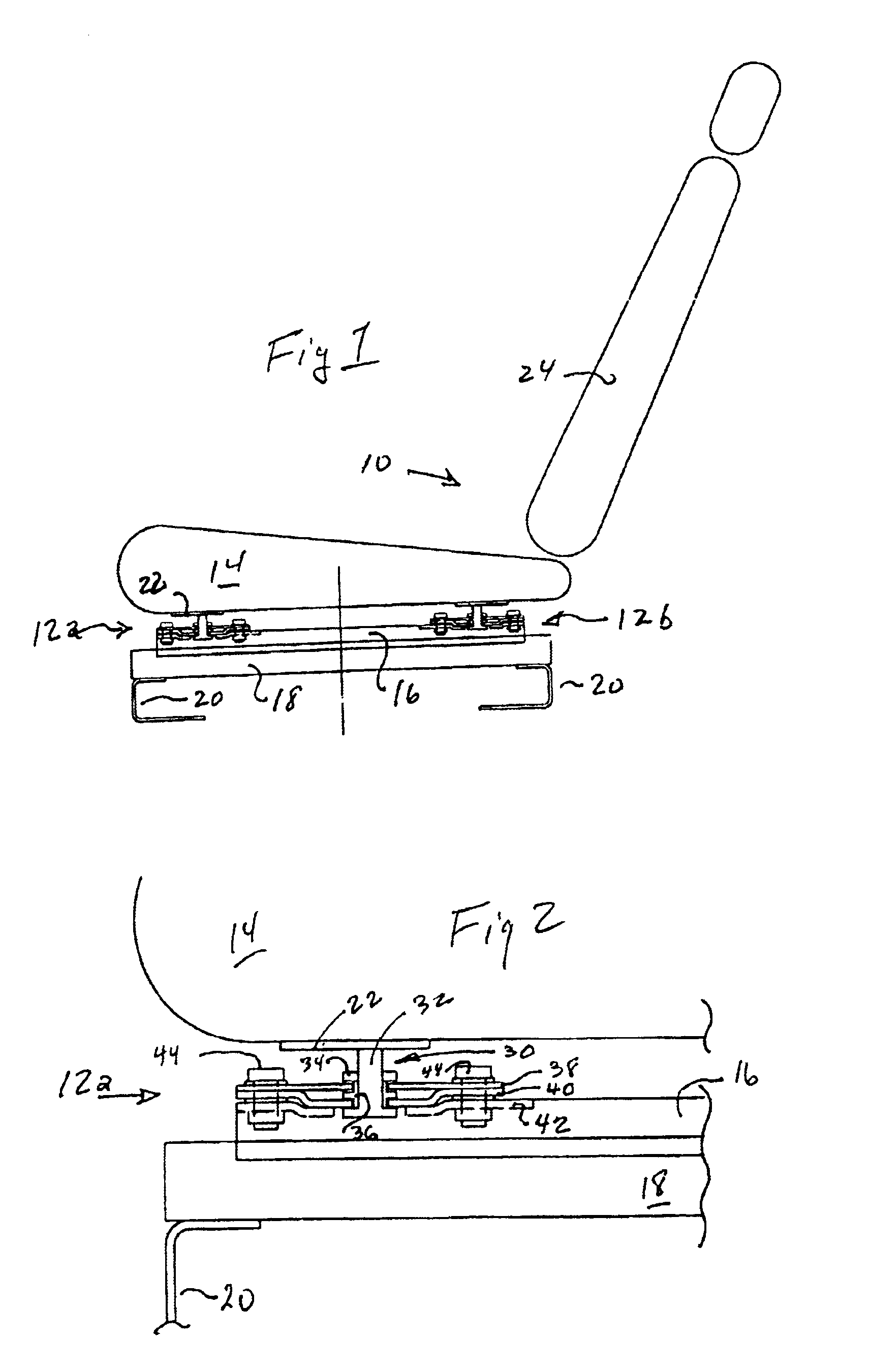

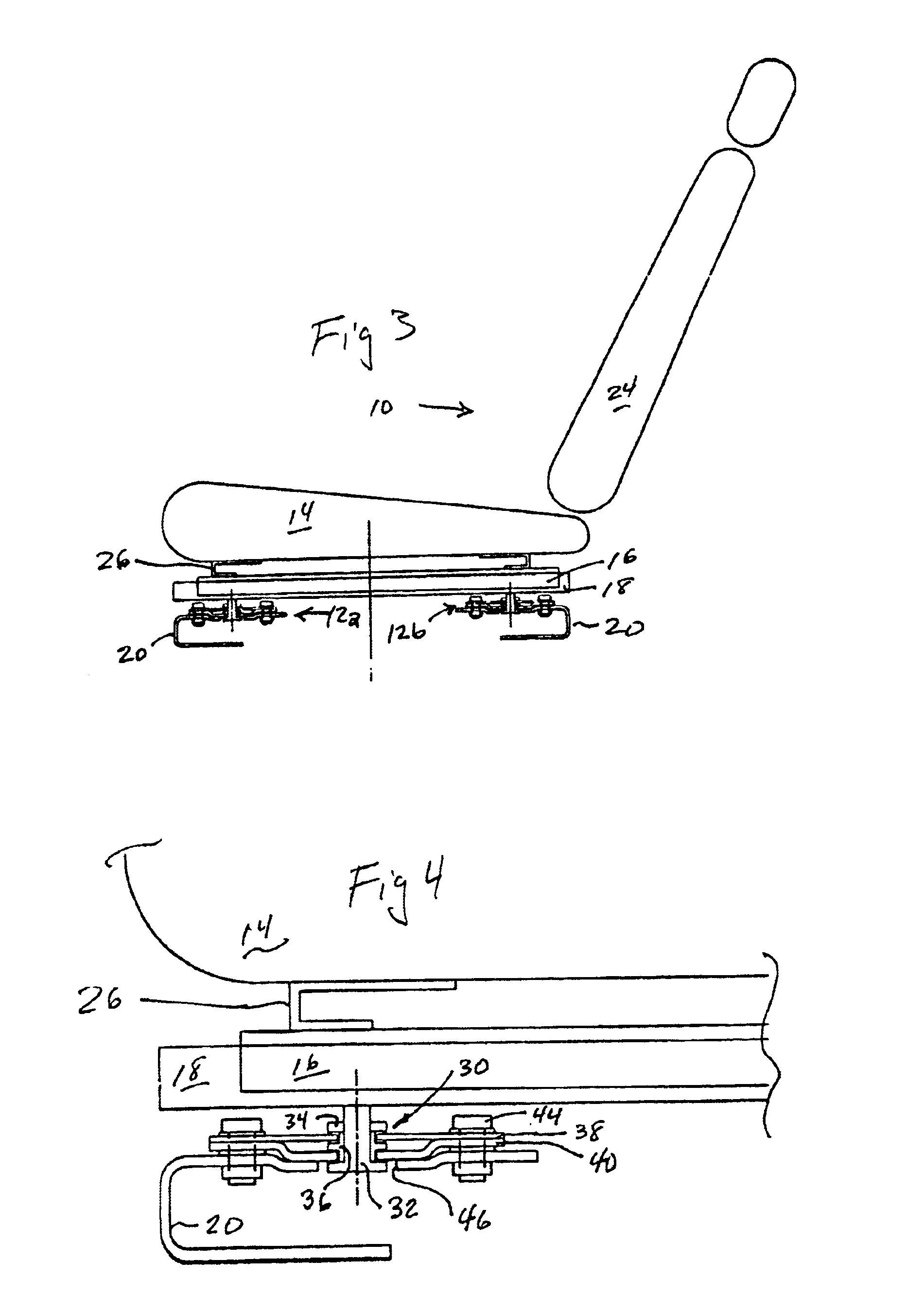

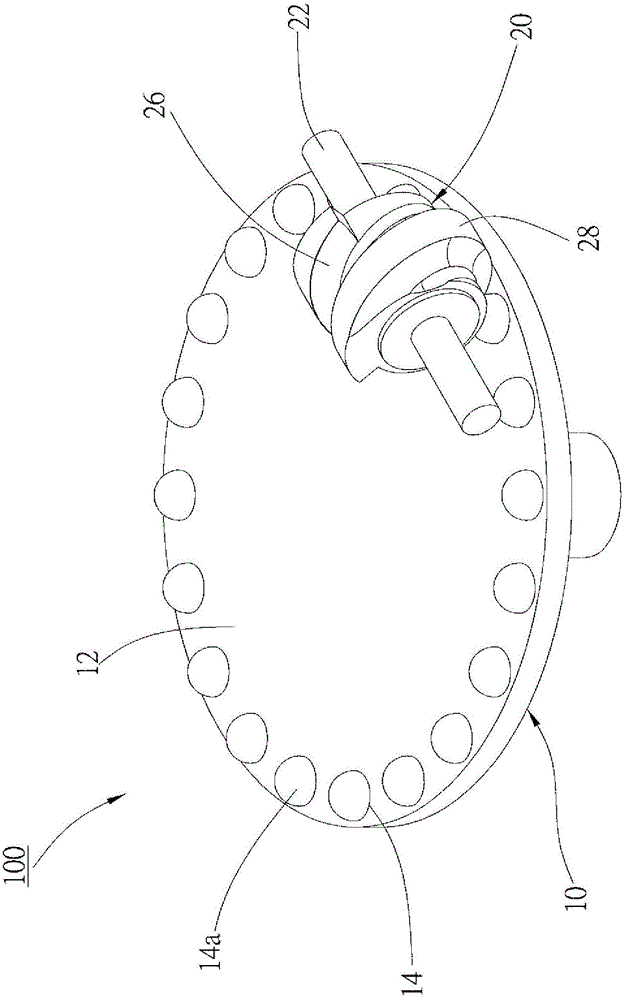

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS6916997B2Convenient travelReduce loadWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

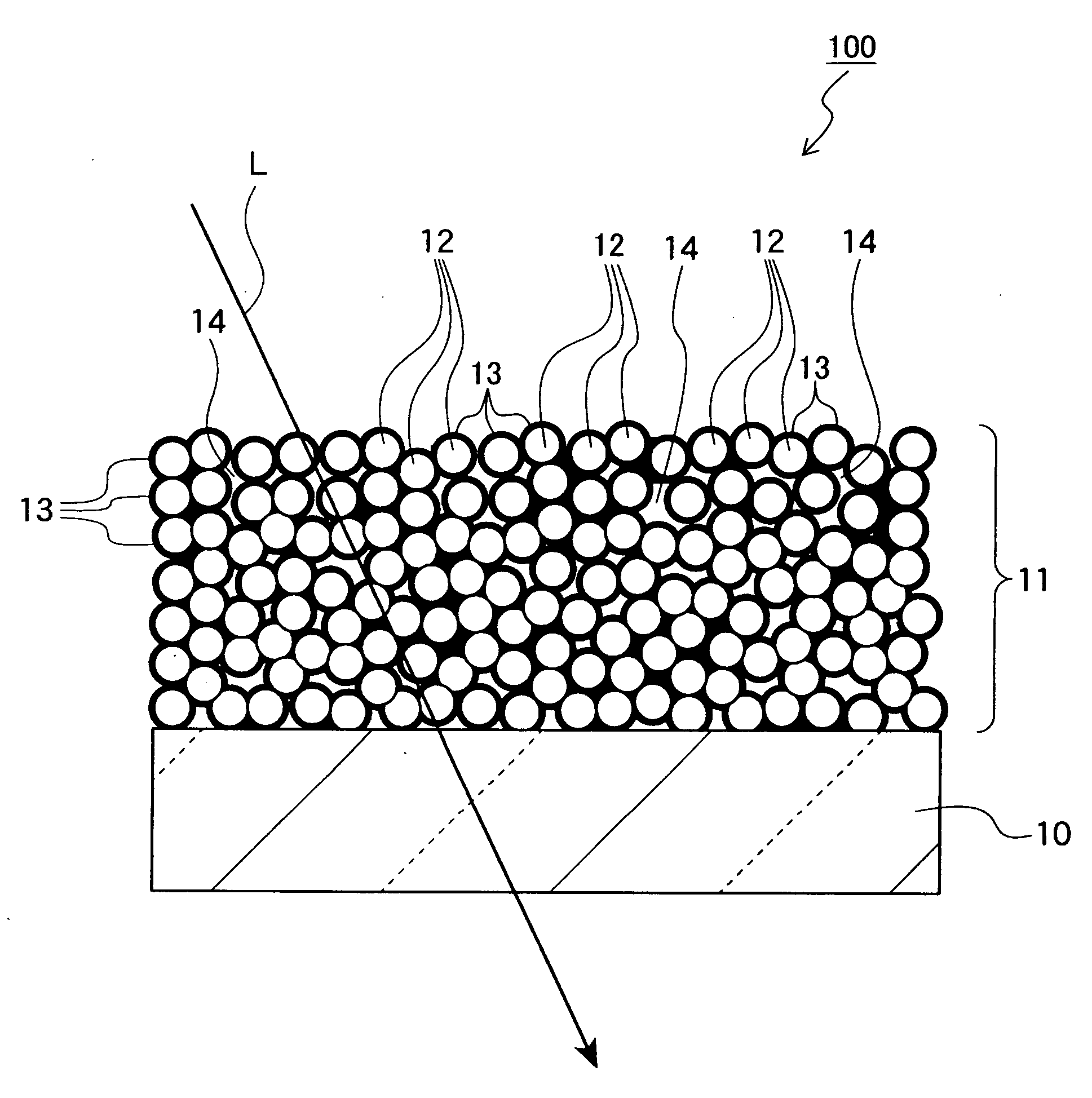

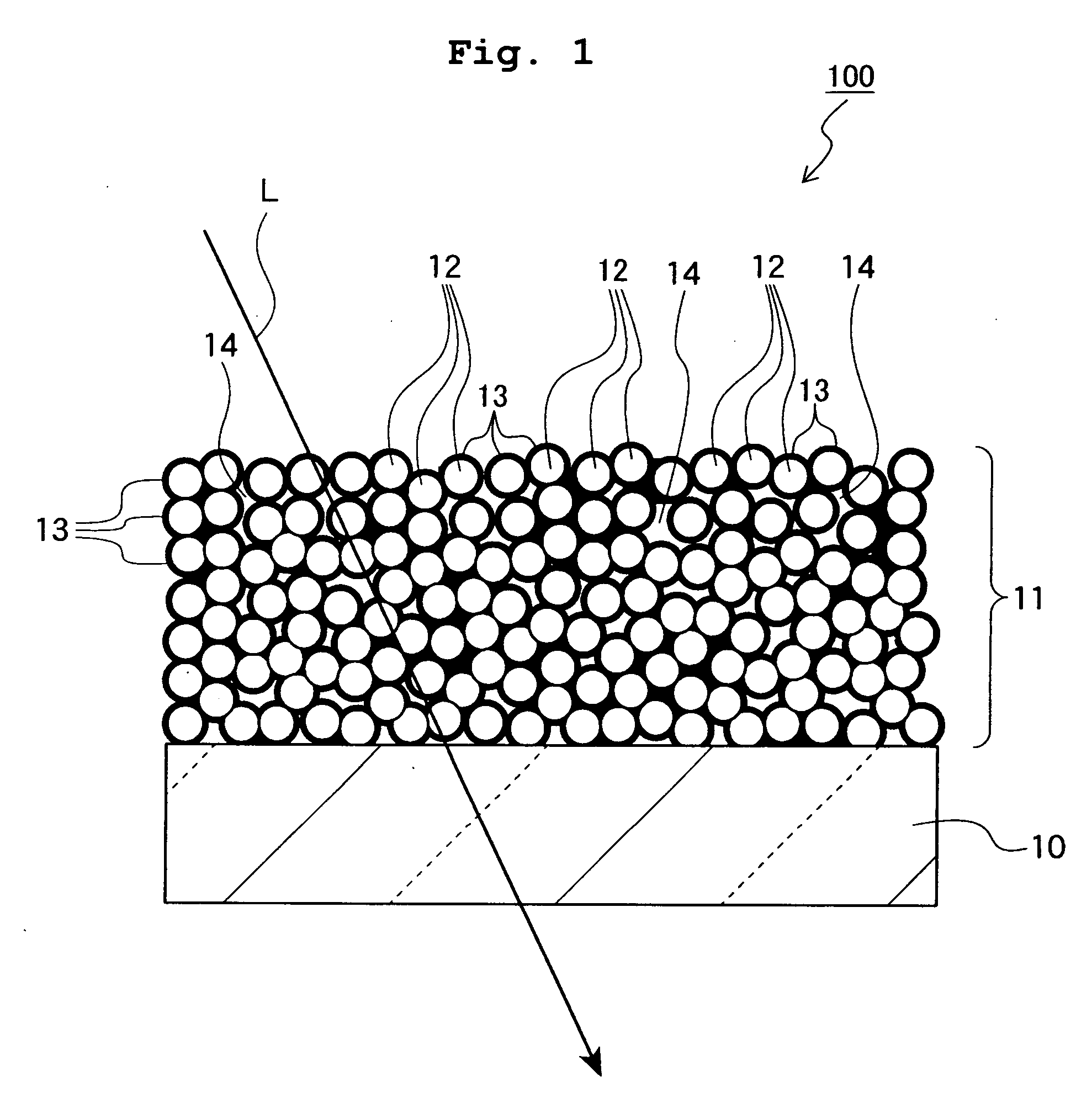

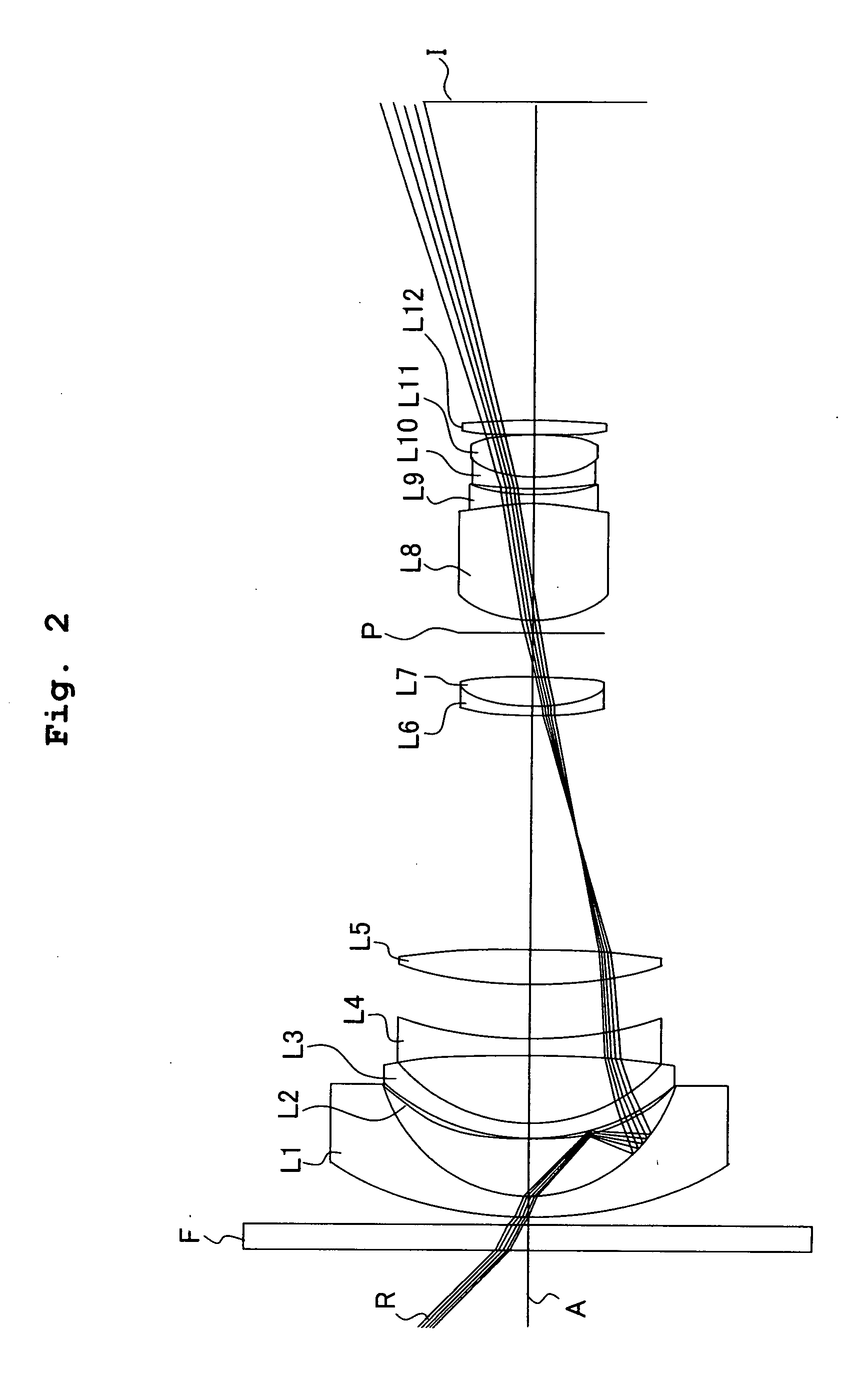

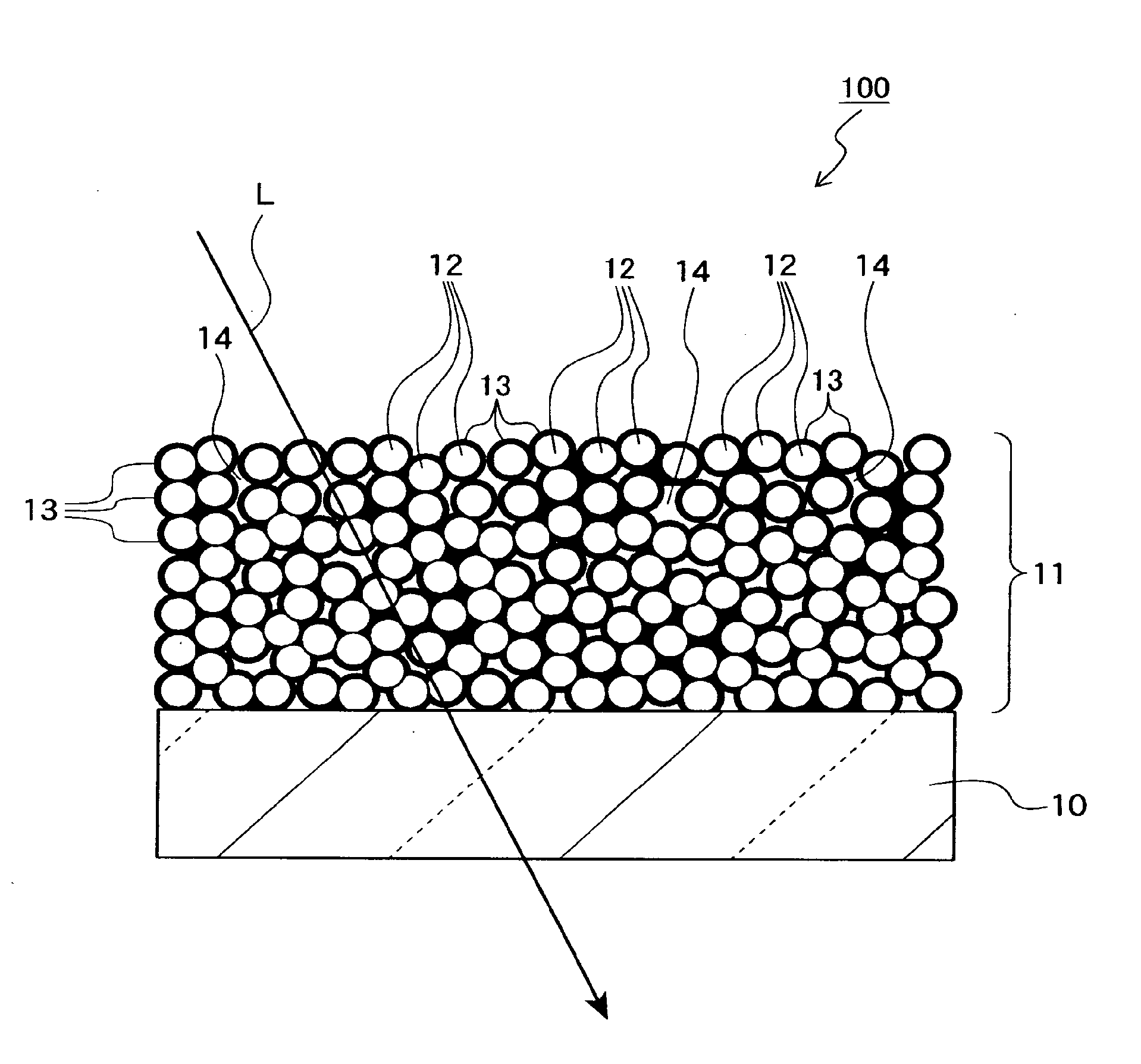

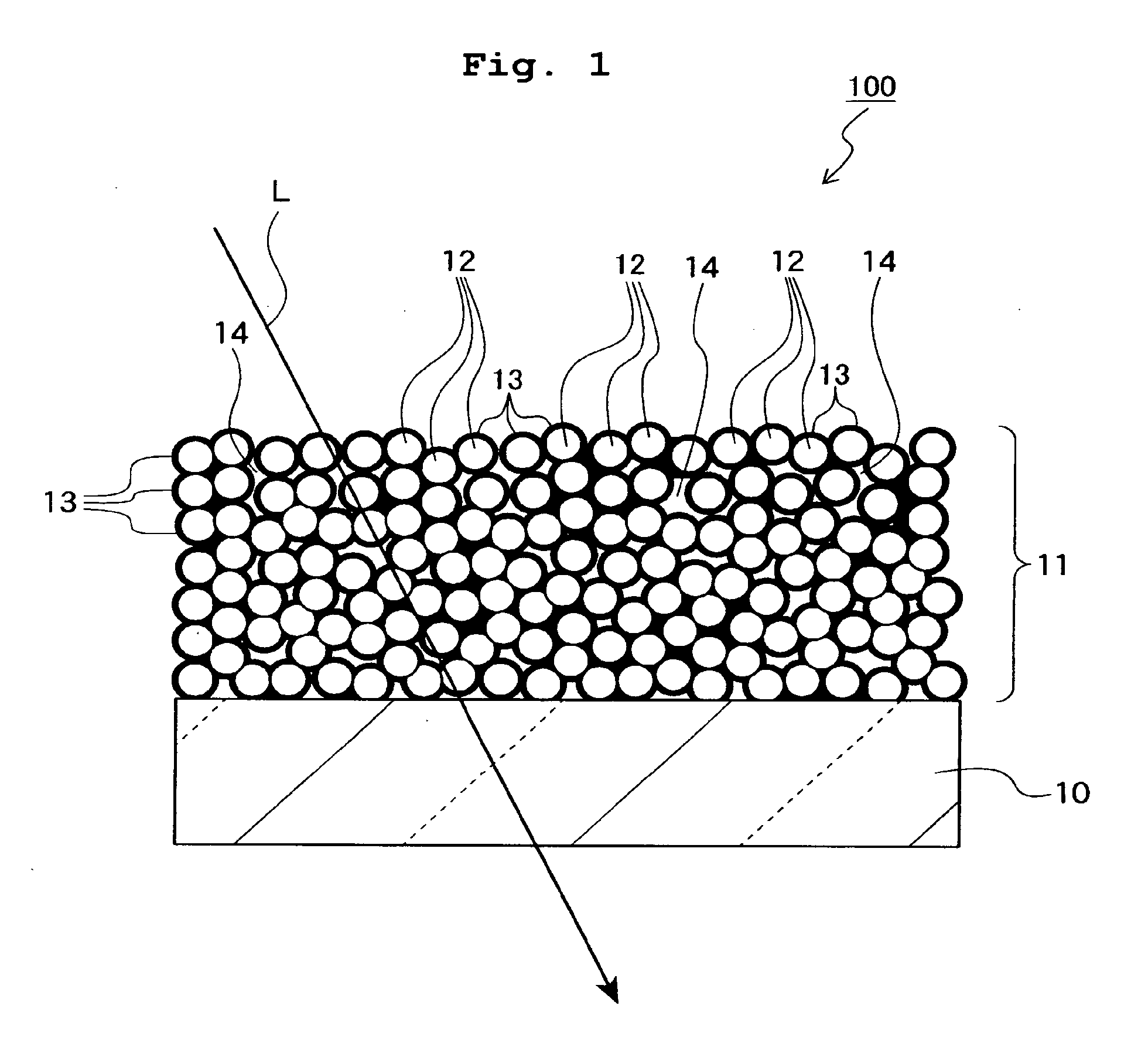

Mgf2 Optical Thin Film Including Amorphous Silicon Oxide Binder, Optical Element Provided With the Same, and Method for Producing Mgf2 Optical Thin Film

InactiveUS20080002259A1Excellent in environment resistance (durability)Secure environment resistanceMagnesium fluoridesMaterial nanotechnologyRefractive indexAmorphous silicon

An MgF2 optical thin film is formed on an optical surface of a base material. The MgF2 optical thin film includes MgF2 particles and an amorphous silicon oxide-based binder which exists on the surfaces of the MgF2 particles and between the MgF2 particles. Owing to this amorphous silicon oxide-based binder, the optical thin film can have high mechanical strength and high adhesion to the base material, while having excellent environment resistance and a lower refractive index.

Owner:NIKON CORP

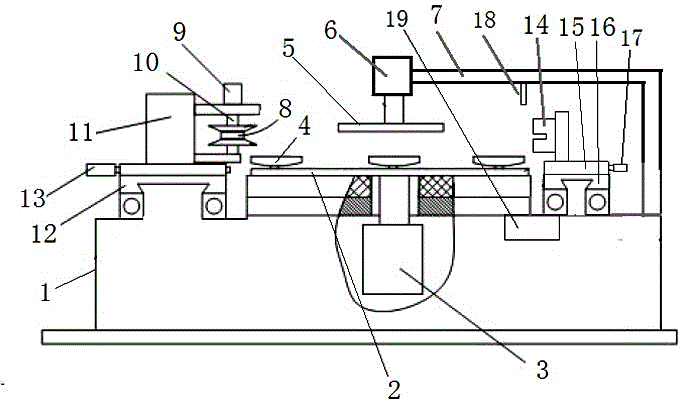

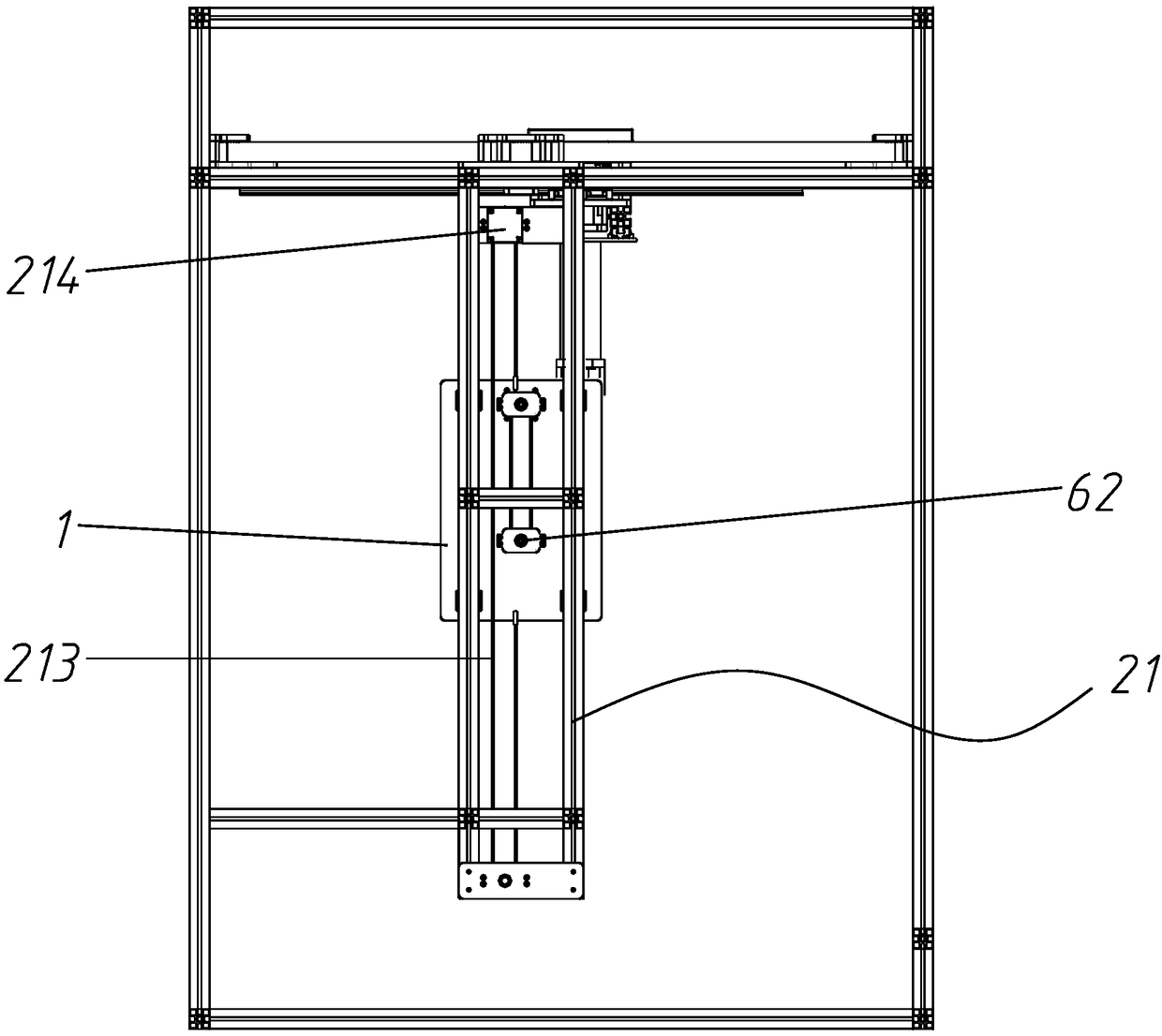

Glass edge grinding machine

InactiveCN105922098AAvoid damageAvoid affecting the grinding effectEdge grinding machinesGrinding work supportsDrive motorEngineering

The invention discloses a glass edge grinding machine which comprises a machine frame, wherein a glass fixing mechanism, a grinding mechanism and a scrap removing mechanism are mounted on the machine frame; the glass fixing mechanism comprises a rotary table, a rotary table driving motor, a pressing plate and a pressing plate driving air cylinder; the grinding mechanism comprises a grinding tool, a tool rotation driving motor, a tool bracket and a tool bracket driving motor; the scrap removing mechanism comprises a cleaner, a removing mechanism bracket and a sliding driving motor; the rotary table, sucking discs and the pressing plate can fix glass; the rotary table driving motor can drive the rotary table to rotate; the tool bracket is mounted on the machine frame in a sliding way; the tool rotation driving motor controls the grinding tool to rotate; a grinding surface of the grinding tool faces a glass mounting part between the rotary table and the pressing plate; the removing mechanism bracket is mounted on the machine frame in a sliding way; and a glass embedding opening is formed in the cleaner. According to the glass edge grinding machine, by removing glass scrap formed in a grinding process, the influence on a follow-up grinding procedure caused by the glass scrap is avoided, and the grinding efficiency and fineness are improved.

Owner:苏州市灵通玻璃制品有限公司

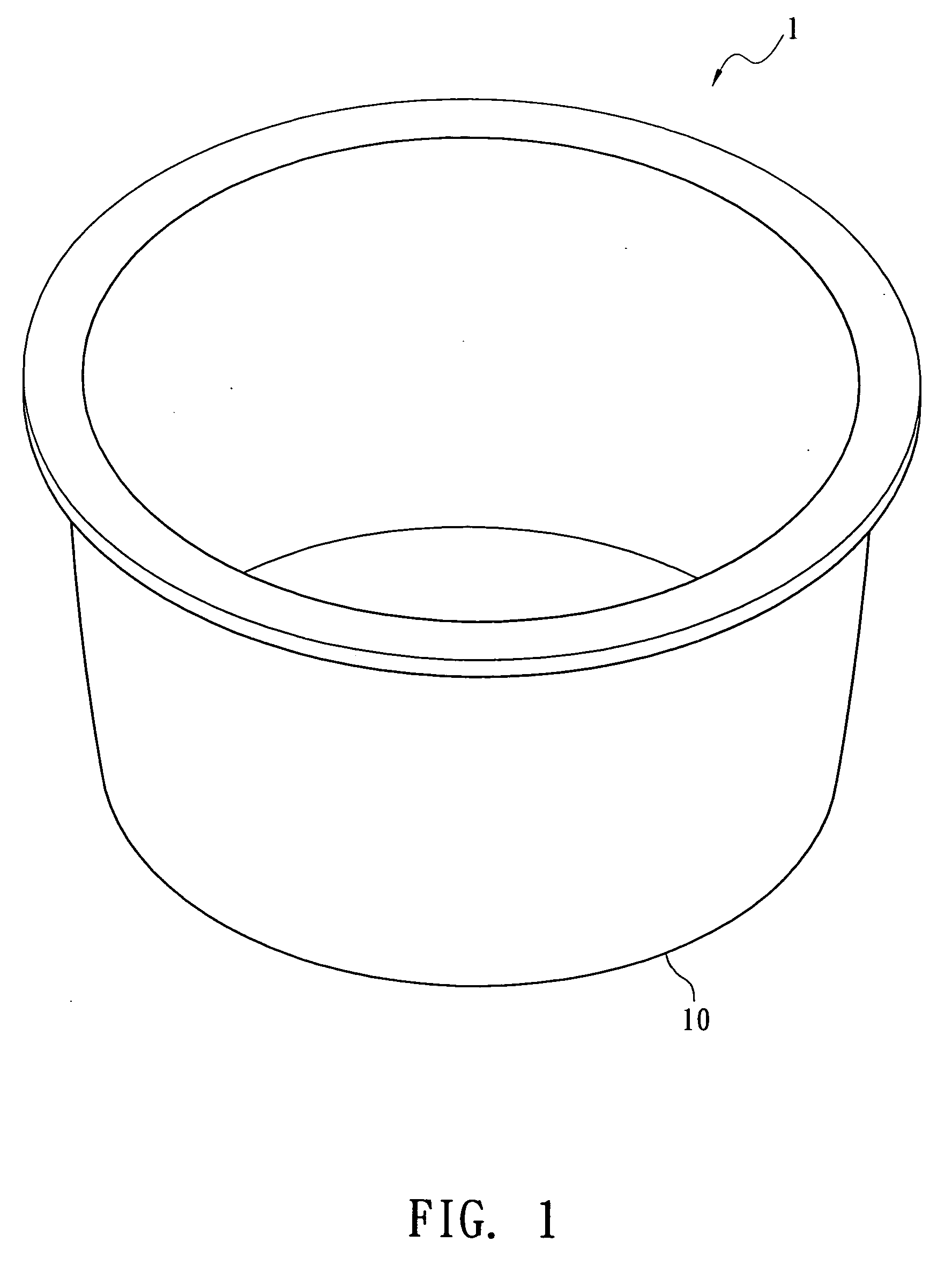

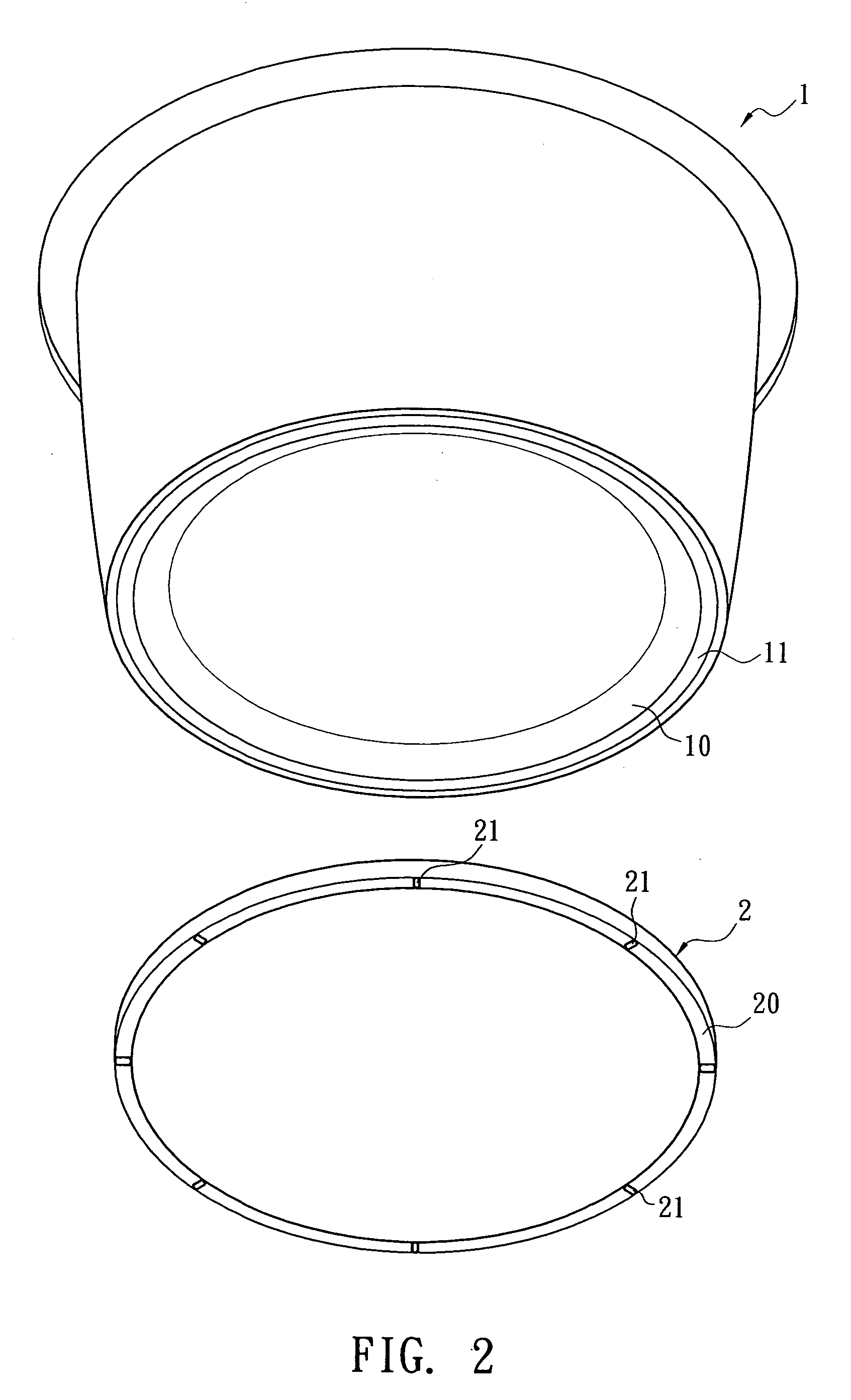

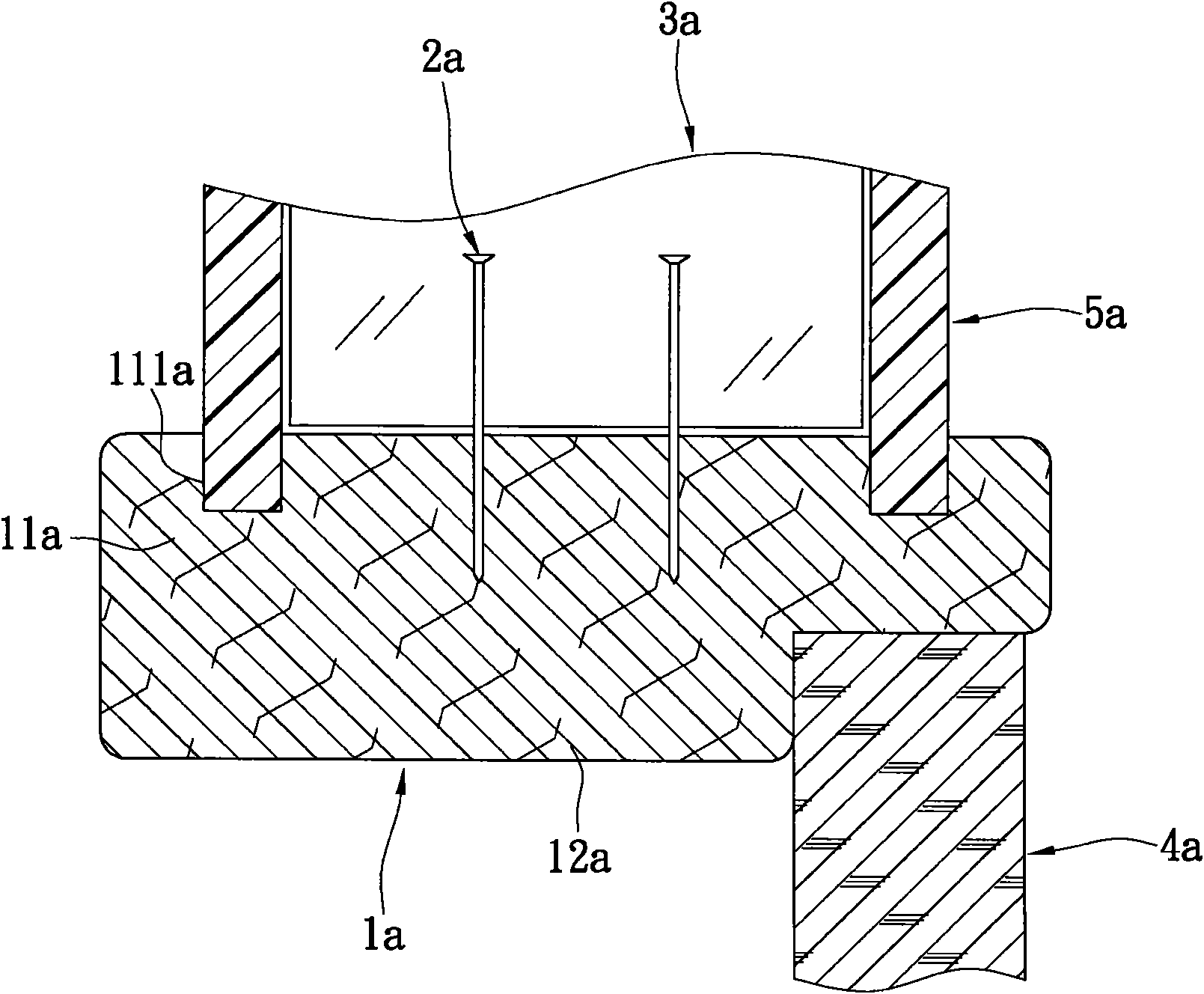

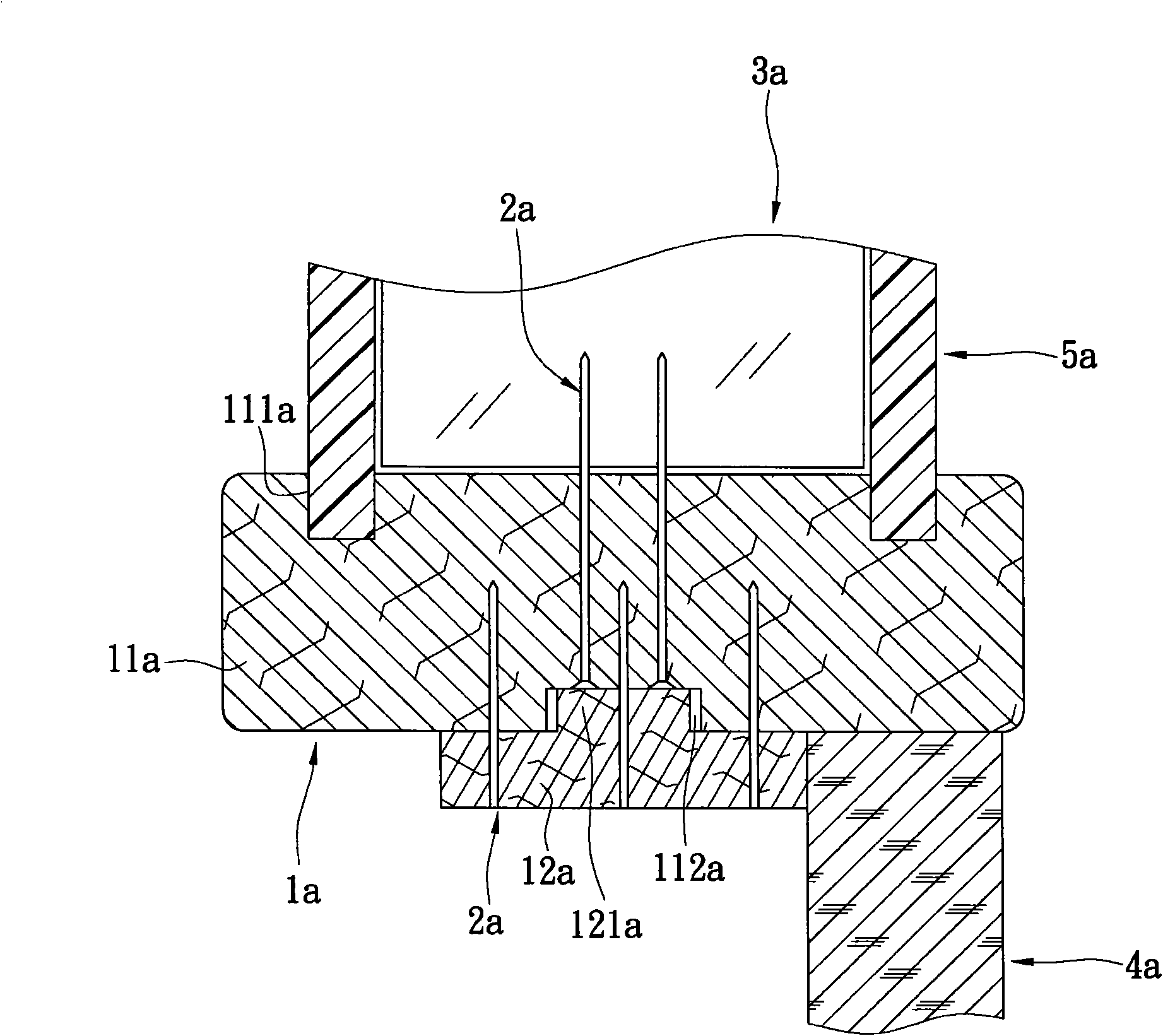

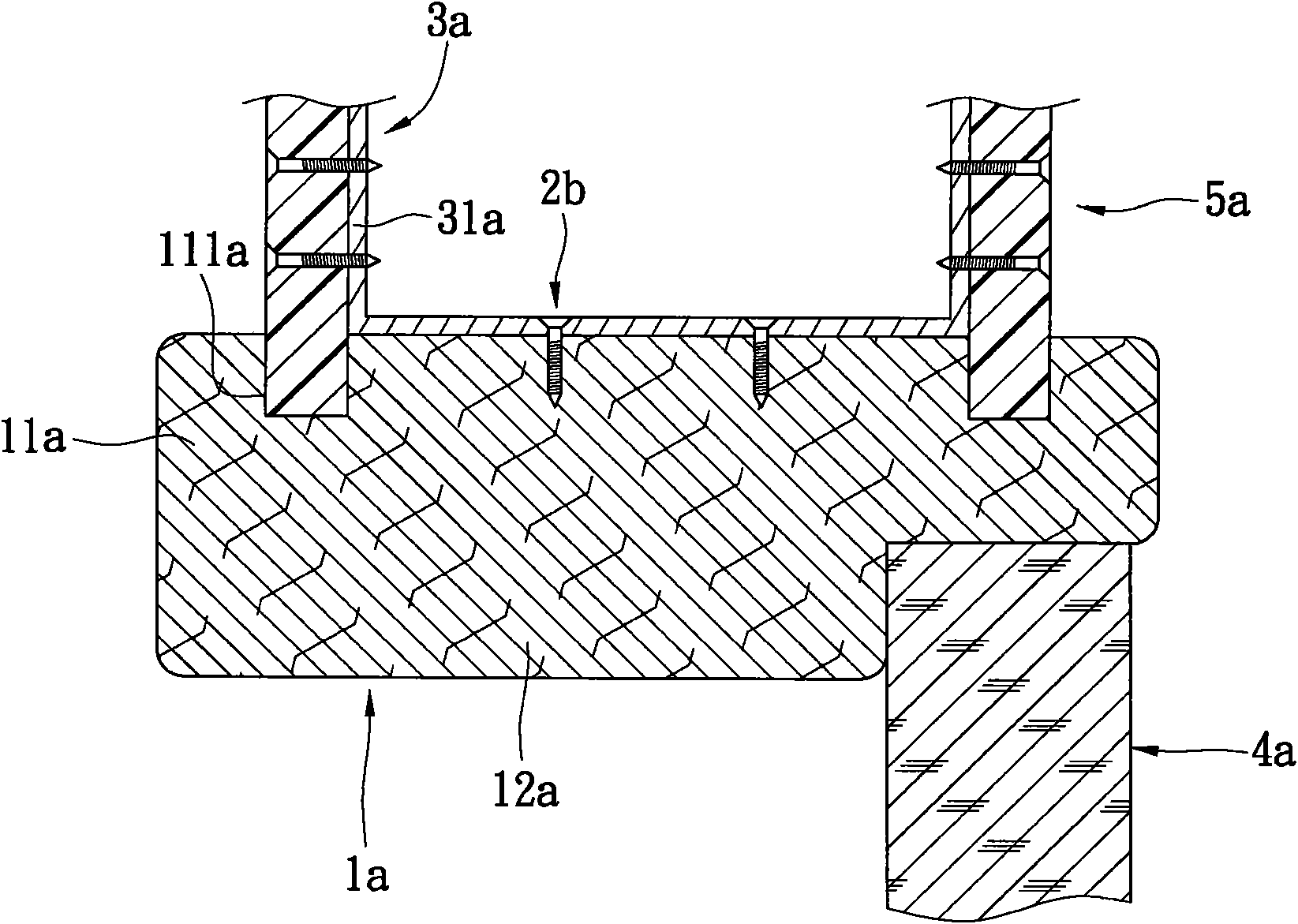

Skidproof structure for container

InactiveUS20080105694A1Inhibition of attachmentAverage forceLarge containersRigid containersAdhesion forceEngineering

A skidproof structure for containers includes at least one slot disposed on bottom of a container and at least one skidproof member whose shape corresponds to shape of the slot mounted into the slot. A plurality of separated projecting parts with the same height is integrated with the lower surface of the skidproof member that contacts with table surface. Thus the skidproof member contacts the table surface by the projecting parts so as to reduce contact area and adhesion force between the skidproof member and the table surface.

Owner:ARBOR TECH CORP

Door frame structure

InactiveCN102373865AImprove convenienceEasy to assemble and disassembleWindow/door framesEngineeringStructural stability

The invention relates to a door frame structure. The door frame structure comprises a door frame component, wherein the door frame component comprises a door frame body and a door shield line; the door shield line is arranged on one side of the door frame body; an anticollision groove is formed between the door shield line and the door frame body; and an anticollision strip is arranged in the anticollision groove, so that construction convenience is enhanced, high structural stability is achieved, the attractive effect is increased, the collision force of a door plate on the door shield line is reduced, the collision sound is reduced, and the environment-friendly and energy-saving effect is achieved.

Owner:林俊桢

Mgf2 optical thin film including amorphous silicon oxide binder, optical element provided with the same, and method for producing mgf2 optical thin film

InactiveUS20110122497A1Improve environmental resistanceAverage forceMagnesium fluoridesMaterial nanotechnologyRefractive indexAmorphous silicon

An MgF2 optical thin film is formed on an optical surface of a base material. The MgF2 optical thin film includes MgF2 particles and an amorphous silicon oxide-based binder which exists on the surfaces of the MgF2 particles and between the MgF2 particles. Owing to this amorphous silicon oxide-based binder, the optical thin film can have high mechanical strength and high adhesion to the base material, while having excellent environment resistance and a lower refractive index.

Owner:NIKON CORP

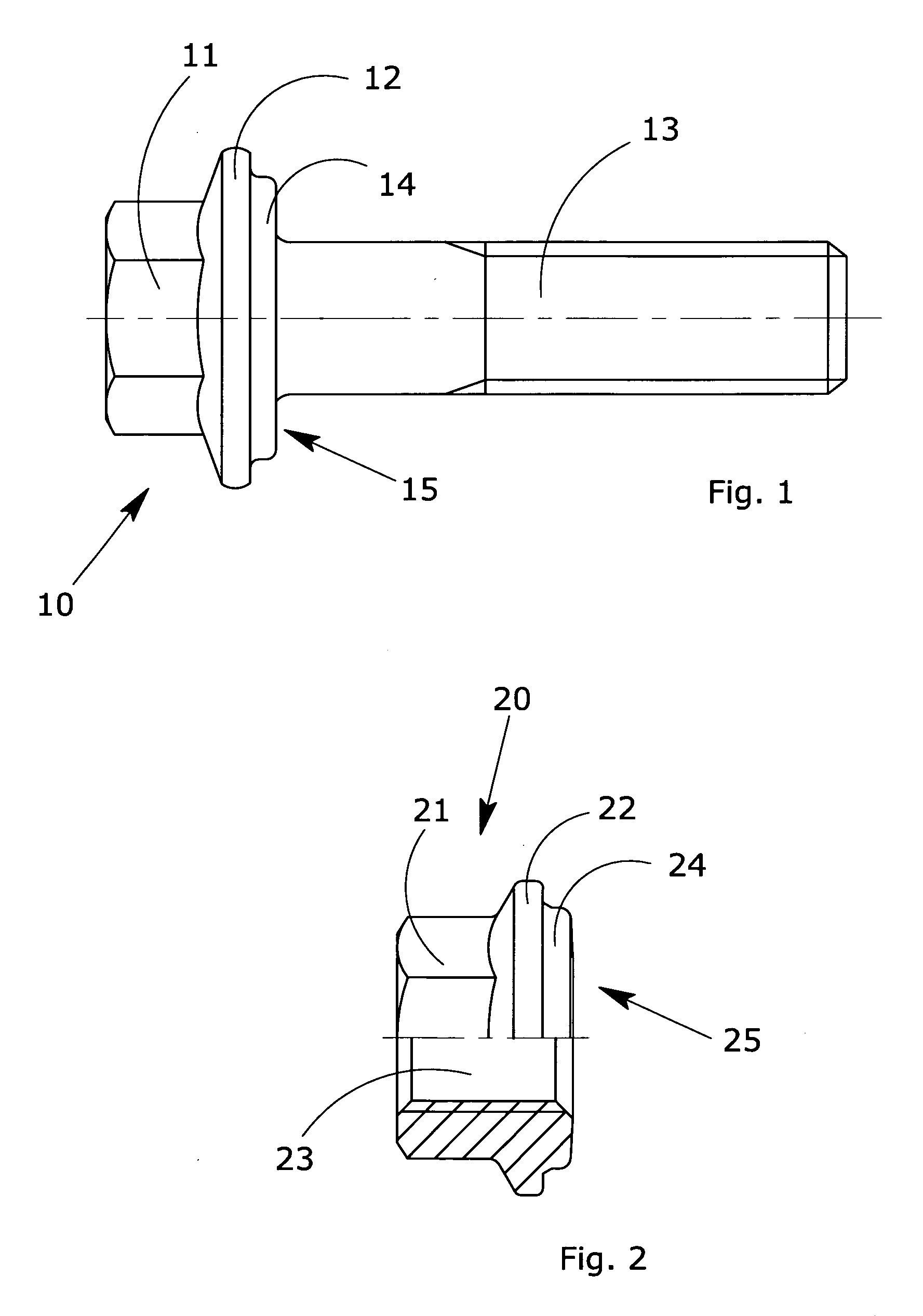

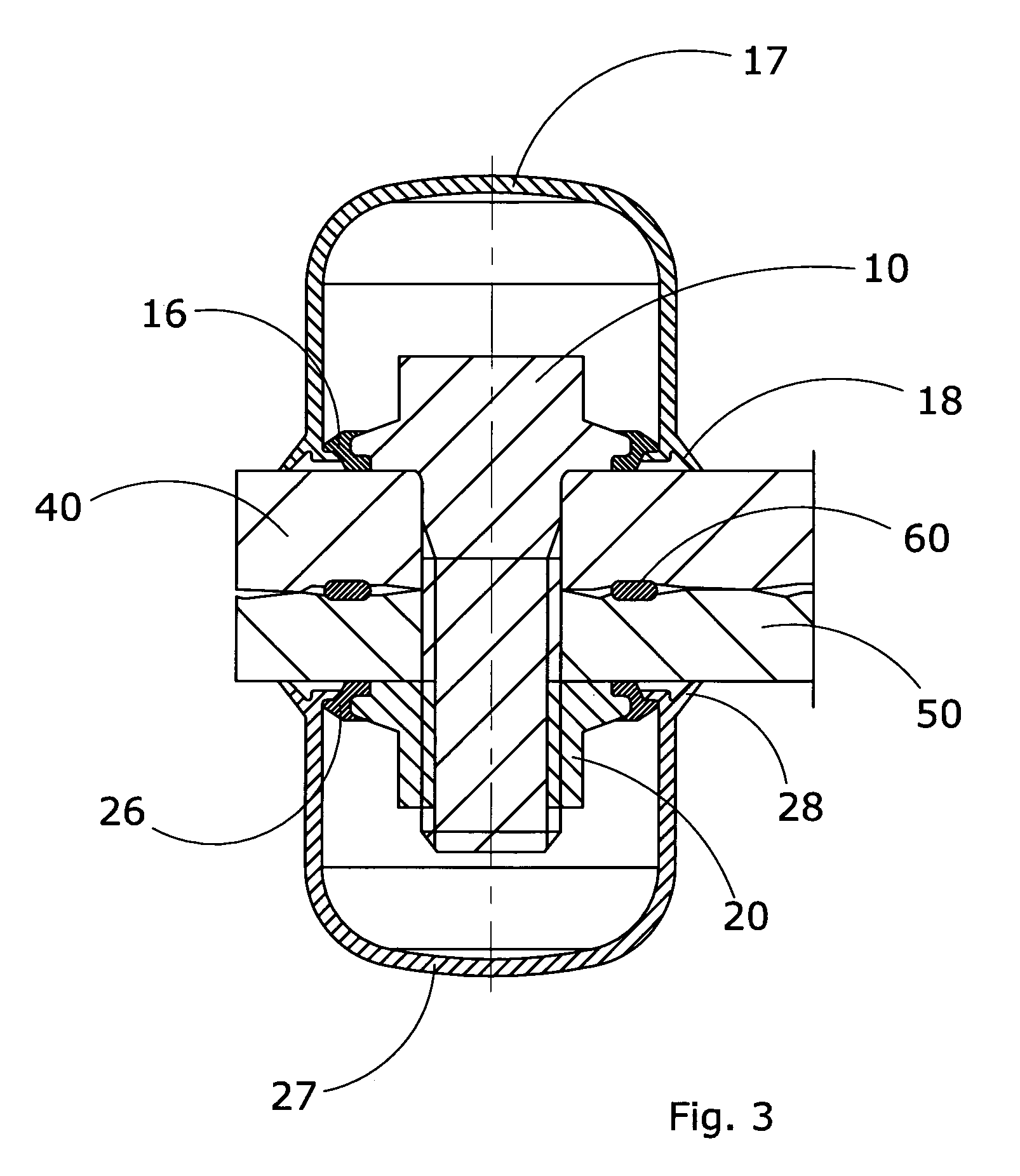

Structural fixing system with high clamping force and tightening precision with high corrosion resistance

A structural fixing system with high clamping force, tightening precision and high corrosion resistance, in particular for light and heavy metalwork elements, comprises a flanged metal bolt (10), and / or a flanged metal nut (20), obtained by hot or cold forming. In the space between the base of the flange (12) and the shank (13) of the bolt (10) or below the flange of the nut (20) is a precision collar with a smaller diameter than the diameter of the flange.

Owner:SOC BULLONERIA EURO S B E

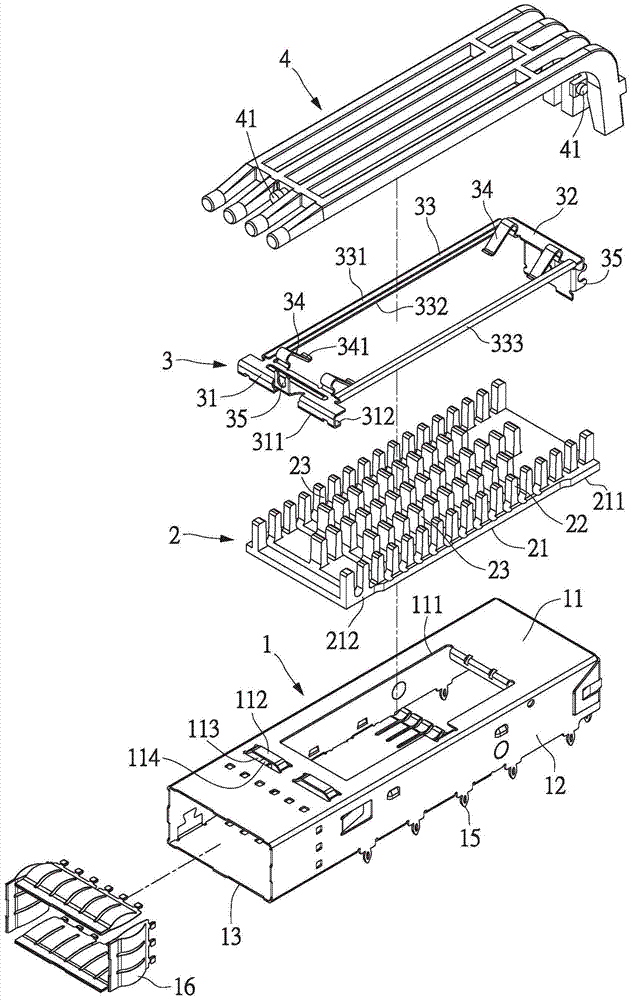

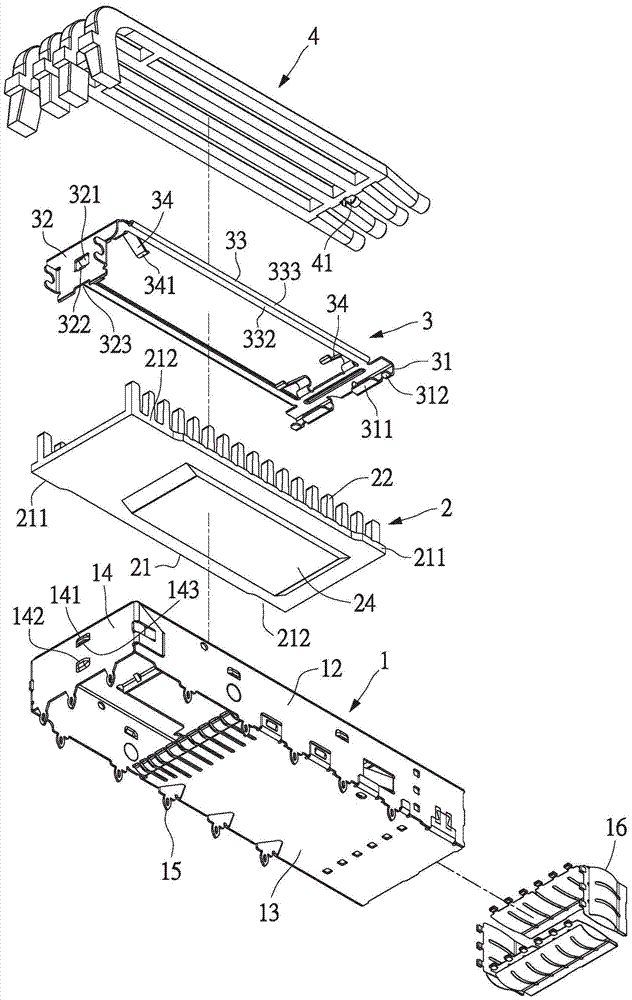

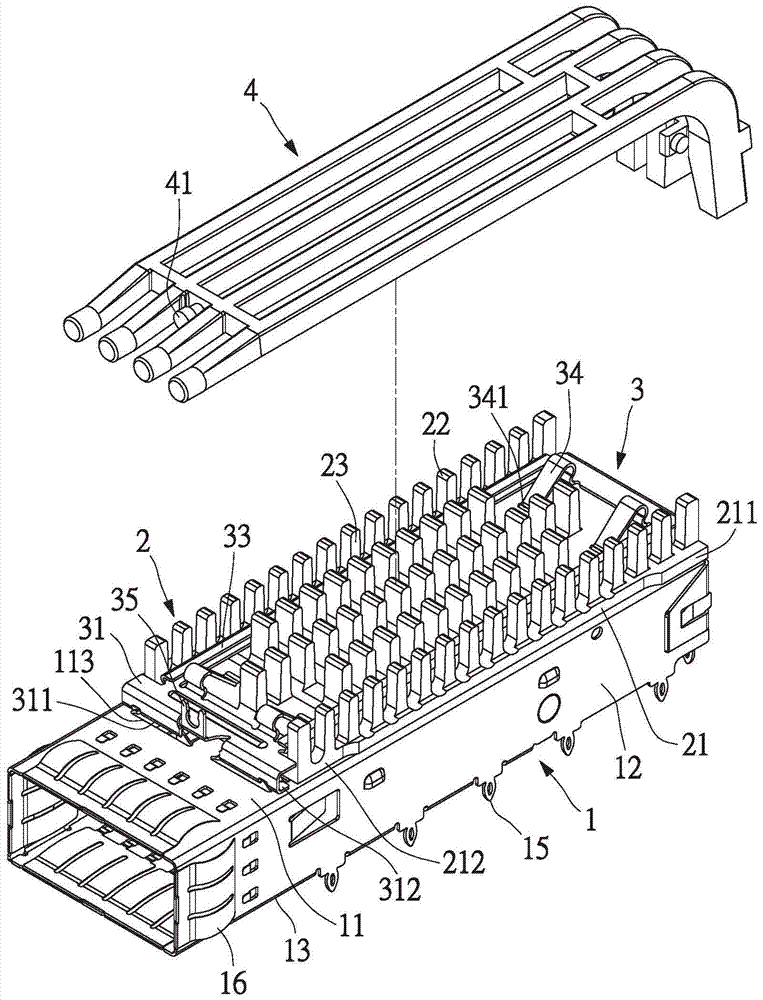

Connector housing heat radiation structure

ActiveCN106990488ANot easy to looseImprove shielding effectCoupling light guidesCooling/ventilation/heating modificationsHeat sinkRadiation

A connector housing heat radiation structure comprises a housing, a heat radiating plate and a buckling member. The first end of the buckling member is buckled and fixed with the top plate of the housing by means of a first tongue plate and a buckling plate, thereby reducing area of an opening on the top plate, and realizing relatively high EMI shielding effect. Two connecting arms of the buckling member penetrate through grooves in the heat radiating plate. Width of the heat radiation plate is not limited, and heat radiation area of the heat radiating plate can be increased. The second end of the buckling member is provided with a second tongue plate which is inserted into a bump at the back cover of the housing. Furthermore through making the abutting end of the second end abut against a backstop part, no easy loosening of the buckling member is realized. The buckling cannot be damaged in bearing pressing by a certain external force.

Owner:NEXTRONICS ENG CORP

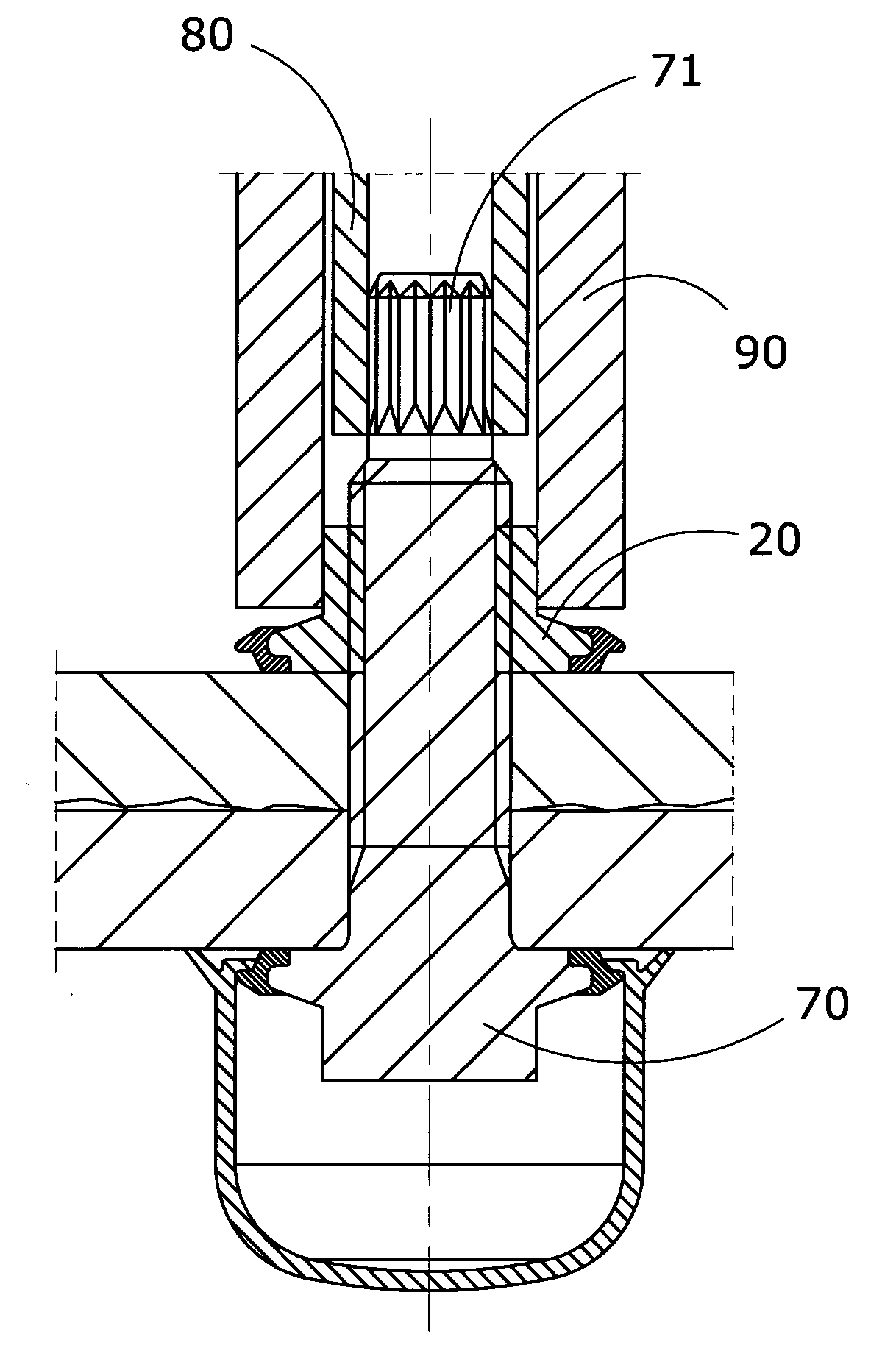

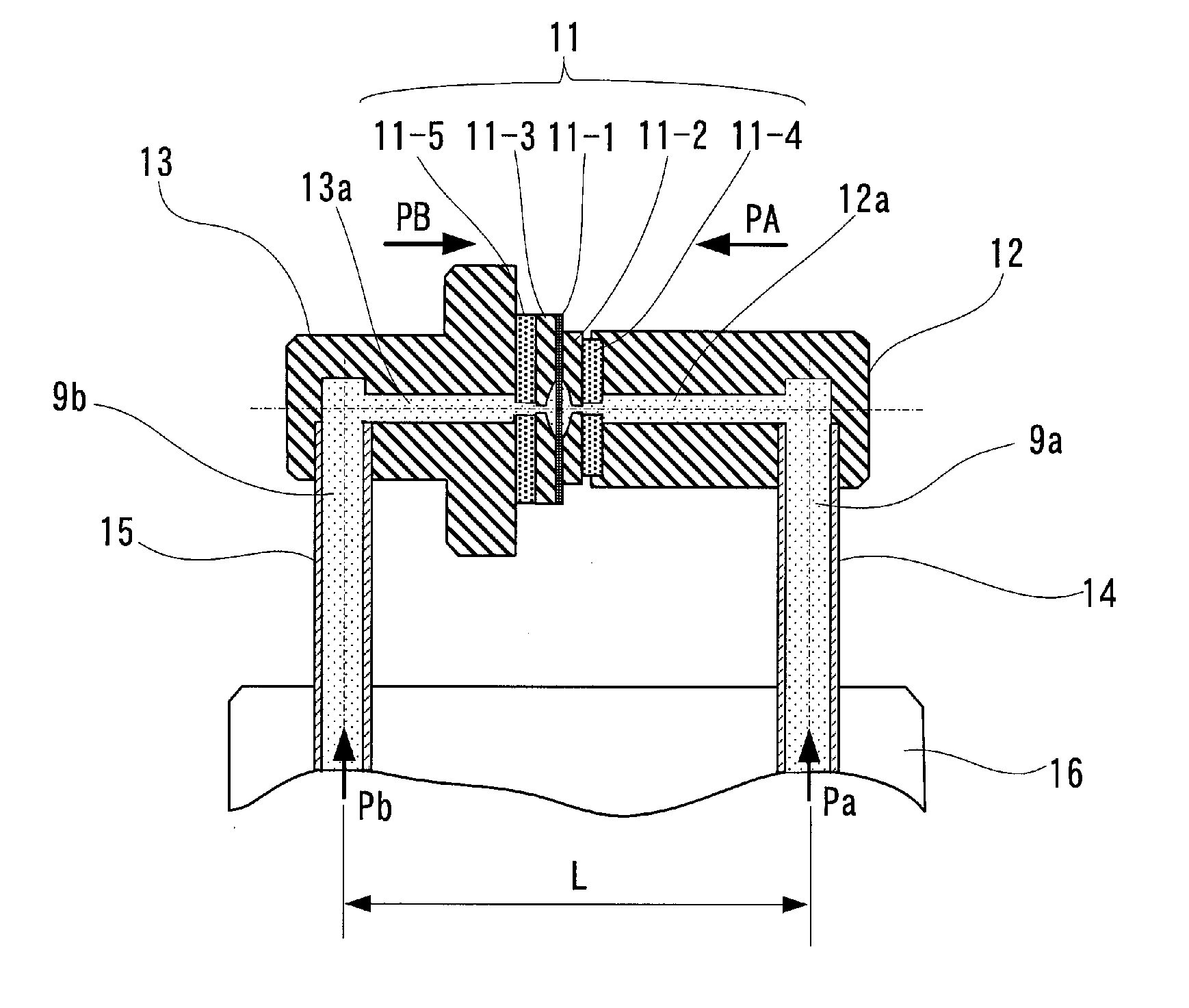

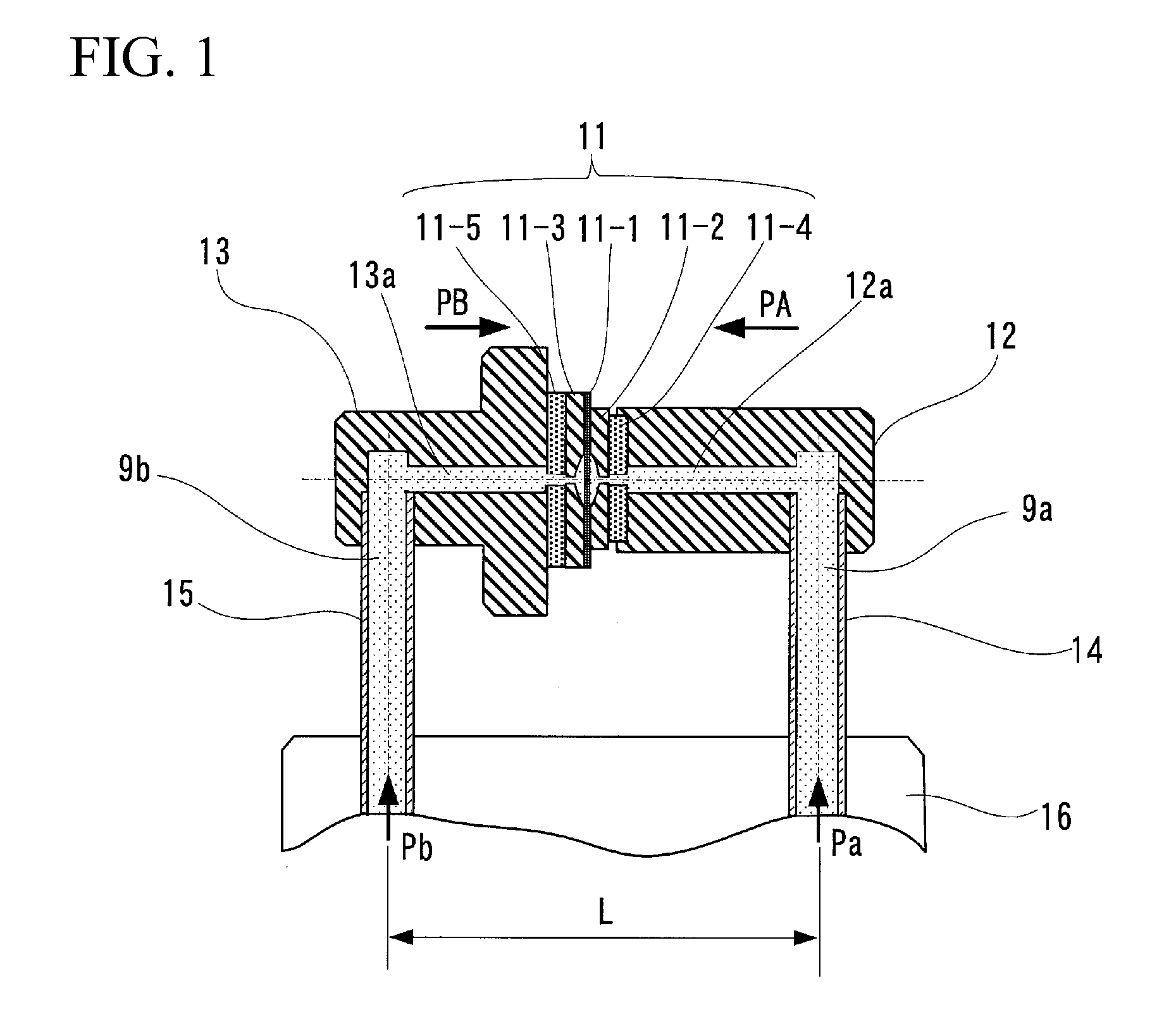

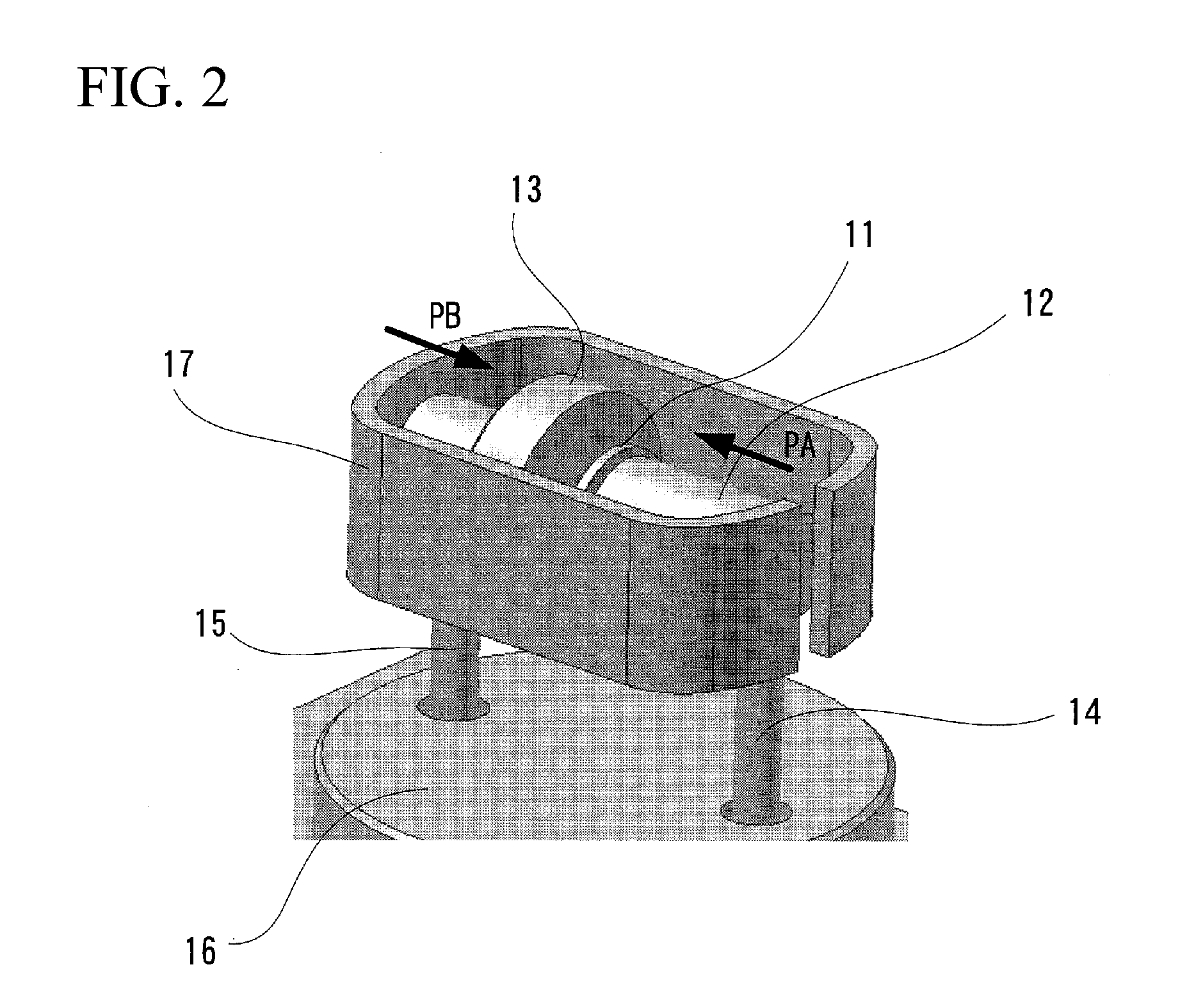

Differential pressure sensor

InactiveUS20130233085A1Stop excessive dislocationAverage forceFluid pressure measurement using elastically-deformable gaugesPressure difference measurement between multiple valvesDifferential pressureEngineering

A differential sensor includes a sensor chip having first and second stopper members provided to first and second faces of a sensor diaphragm, respectively, first and second duct members provided to first and second faces of the sensor chip, having, therein, pressure guiding ducts that guide measurement pressures to the first and second faces of the sensor diaphragm, respectively, and an elastic holding member that applies an elastic force to the first duct member in the direction of the first face of the sensor chip, applies an elastic force to the second duct member in the direction of the second face of the sensor chip, and holds the sensor chip under pressure between the first duct member and the second duct member.

Owner:YAMATAKE HONEYWELL CO LTD

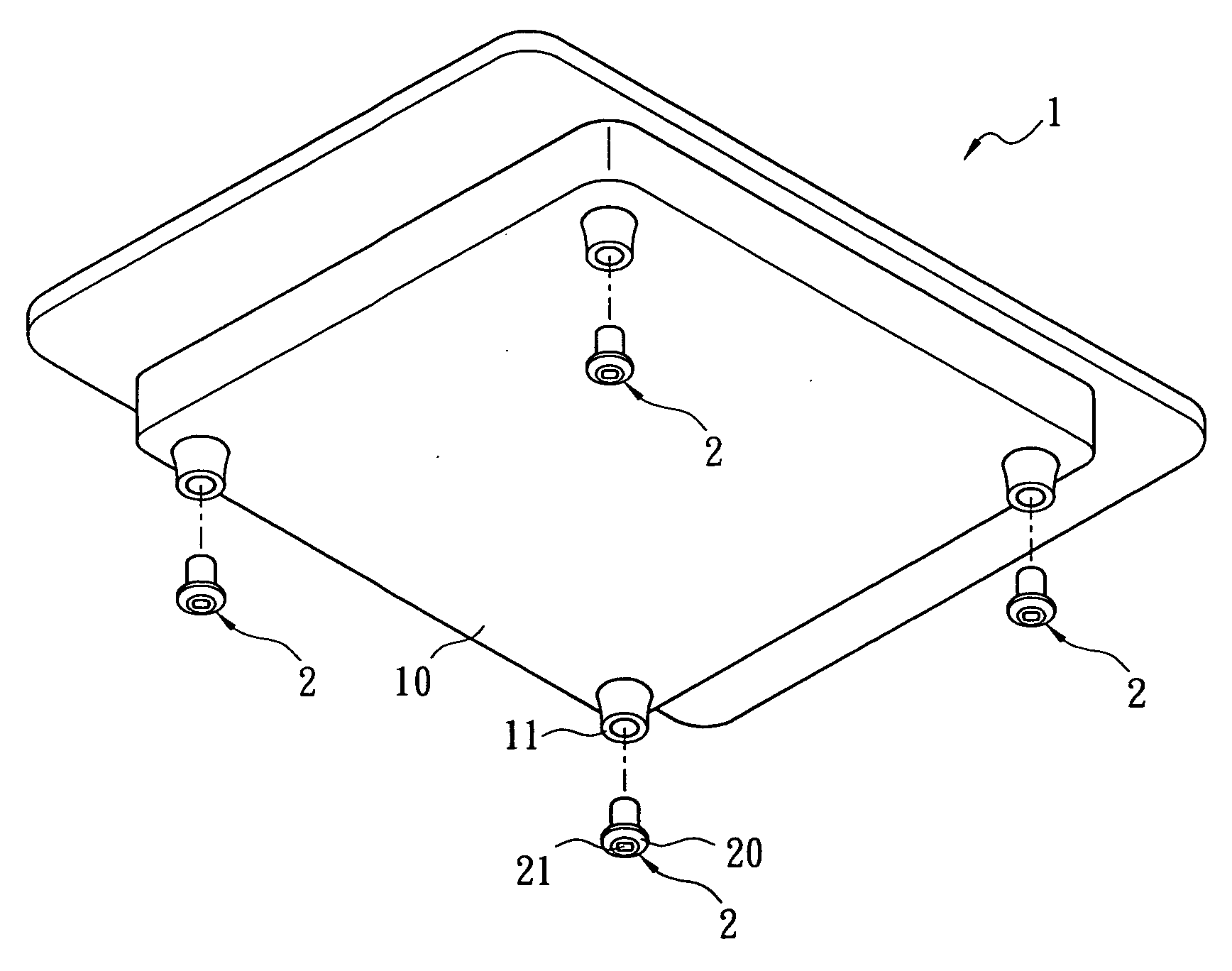

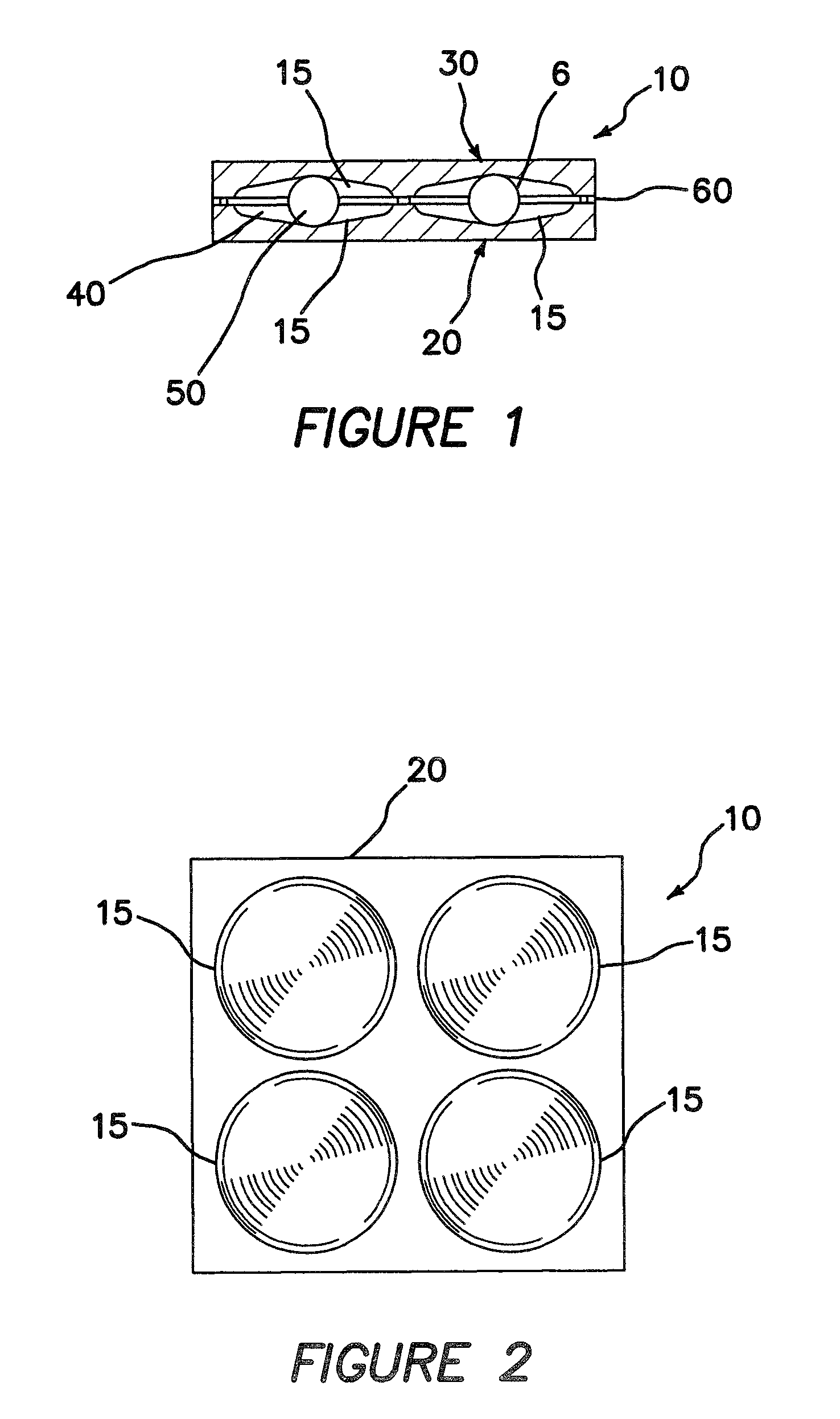

Isolation platform

ActiveUS7784225B2ConstantAverage forceMachine framesNon-rotating vibration suppressionSpherical bearingMarine engineering

The present invention provides a platform for supporting various equipment and / or structure which assists in isolating such structure from vibrations (“noise”) external to the platform. Generally, the platform comprises upper and lower plates, having conical depressions, upon which the upper plate supports the above-mentioned structure, and the lower plate contacting surface / area upon which the supported structure otherwise would have rested. Between the upper and lower plates, a plurality of rigid, spherical bearings are placed within the conical depressions, thereby allowing the upper and lower plates to displace relative to one another. Additionally, the platform may be provided with retaining mechanisms for holding the structure to be supported, maintaining the plates together and providing additional damping effects.

Owner:WORKSAFE TECHNOLOGY INC

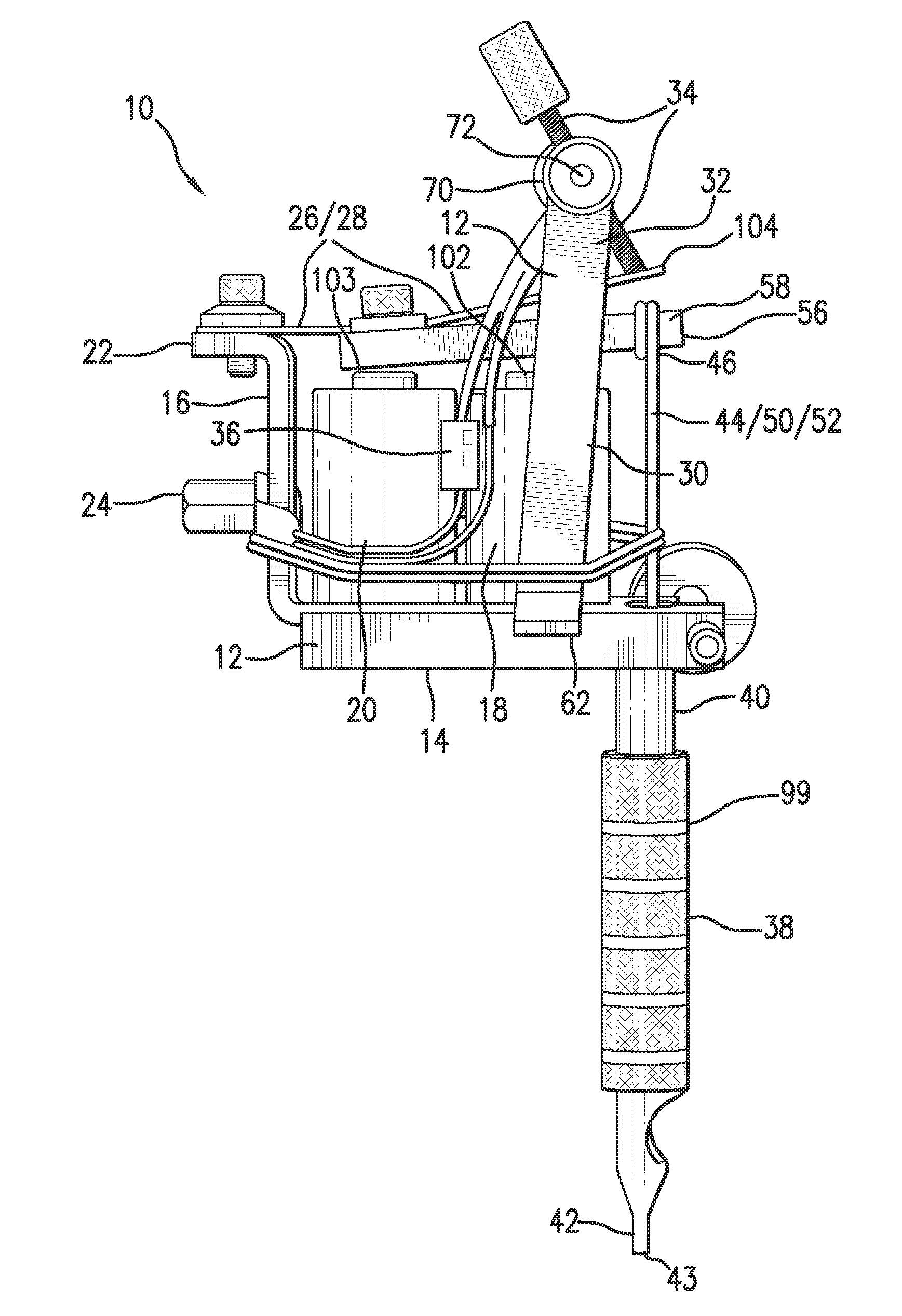

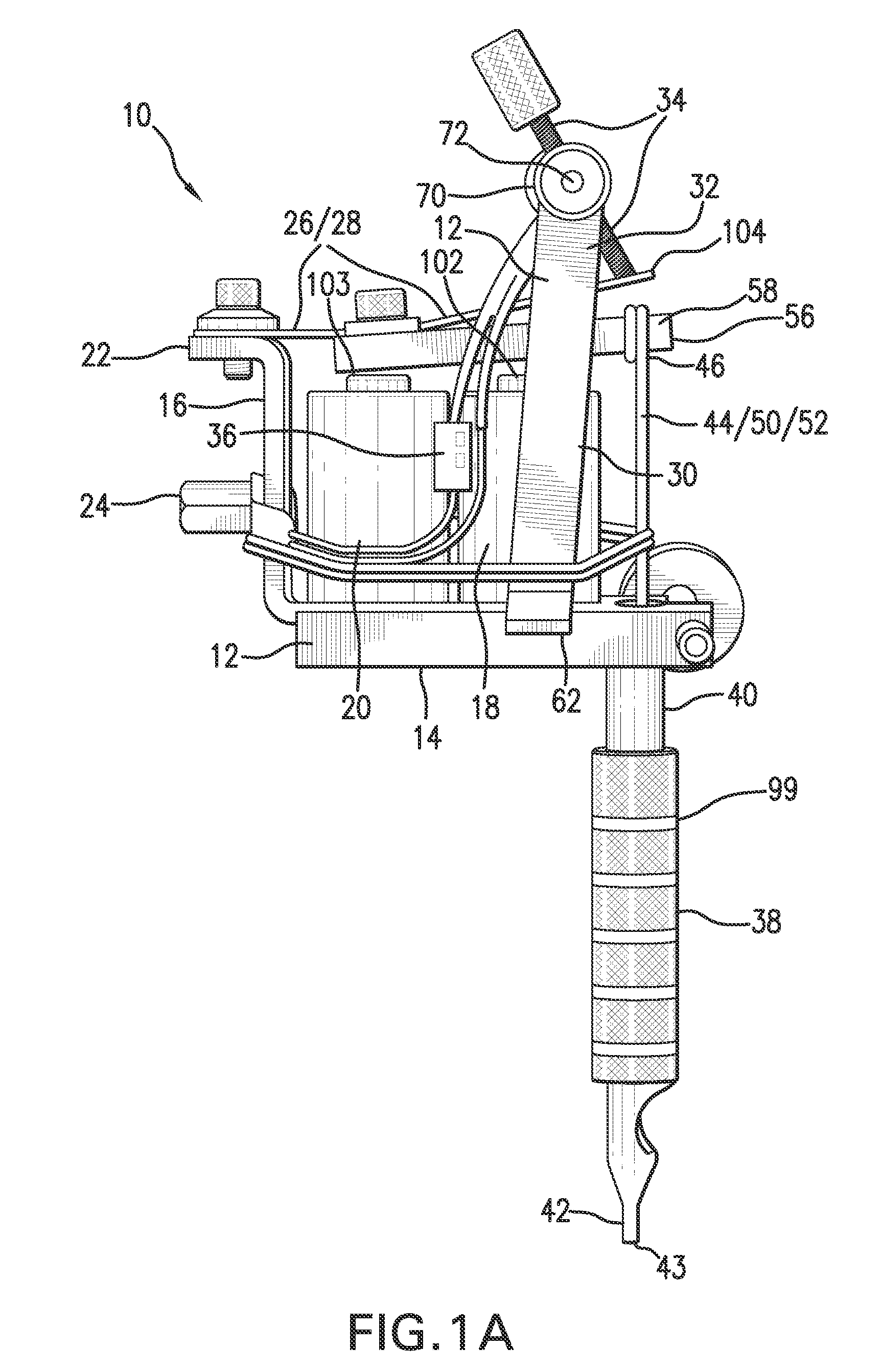

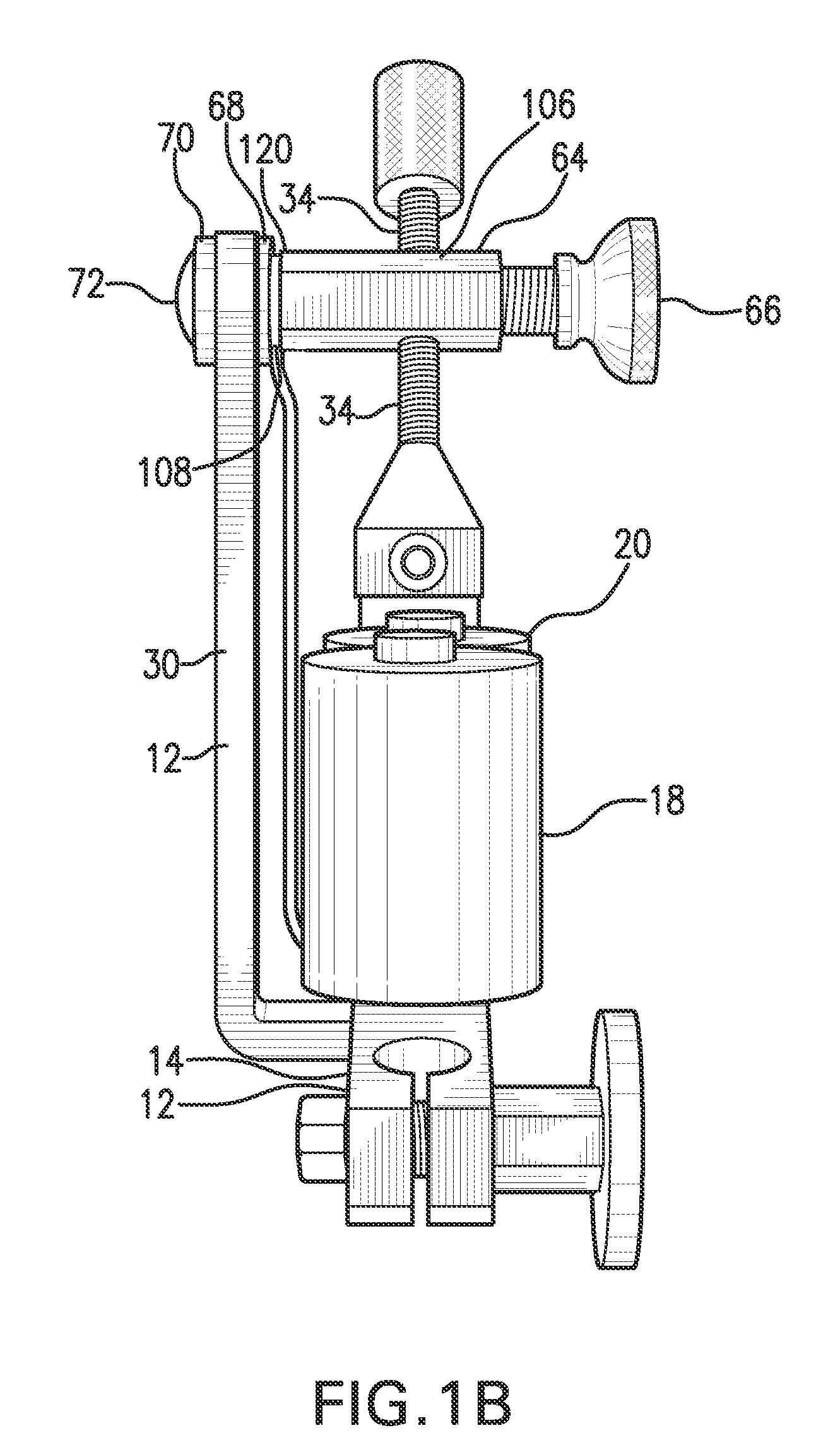

Control device for a tattoo machine, and tattoo system

InactiveUS20100192730A1Average forceTotal lengthSurgical needlesMedical devicesStroke frequencyElectrical and Electronics engineering

A control device for a tattoo machine, and a tattoo system. The control device adapted to control reciprocation of a needle assembly of the tattoo machine using a pulsed signal. A duty cycle of the pulsed signal controlling a stroke length of the needle assembly. A frequency of the pulsed signal controlling a stroke frequency of the needle assembly. Duty cycle and frequency may be controlled independently of one another.

Owner:DUBIN WILLIAM

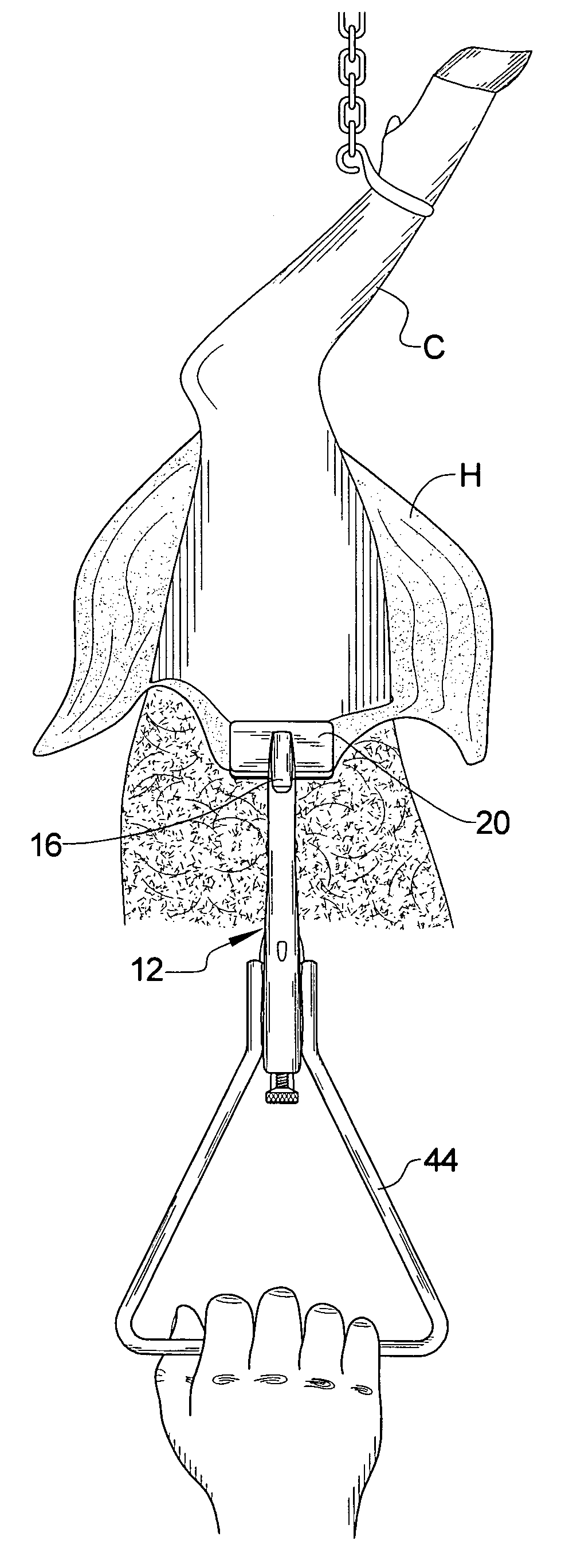

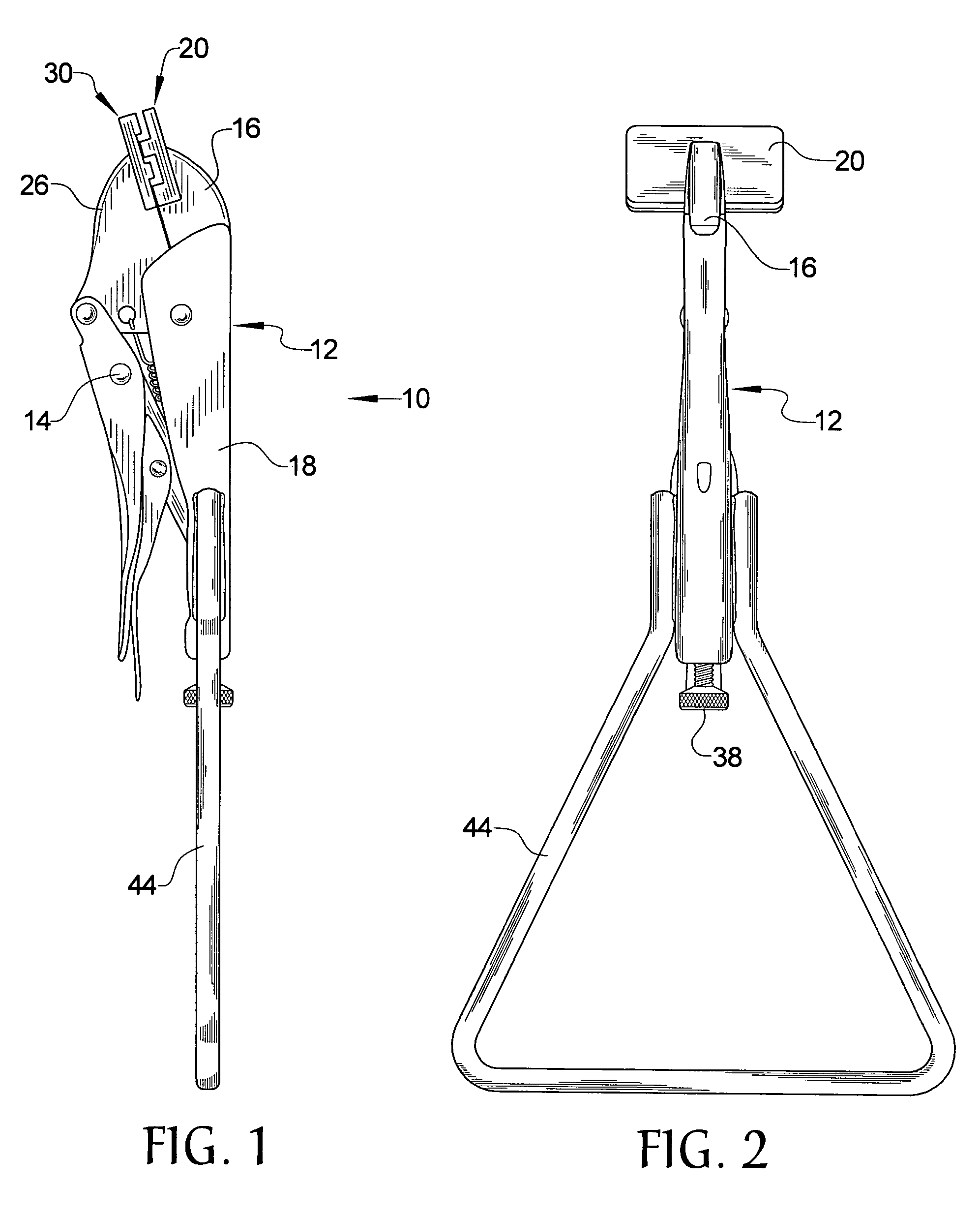

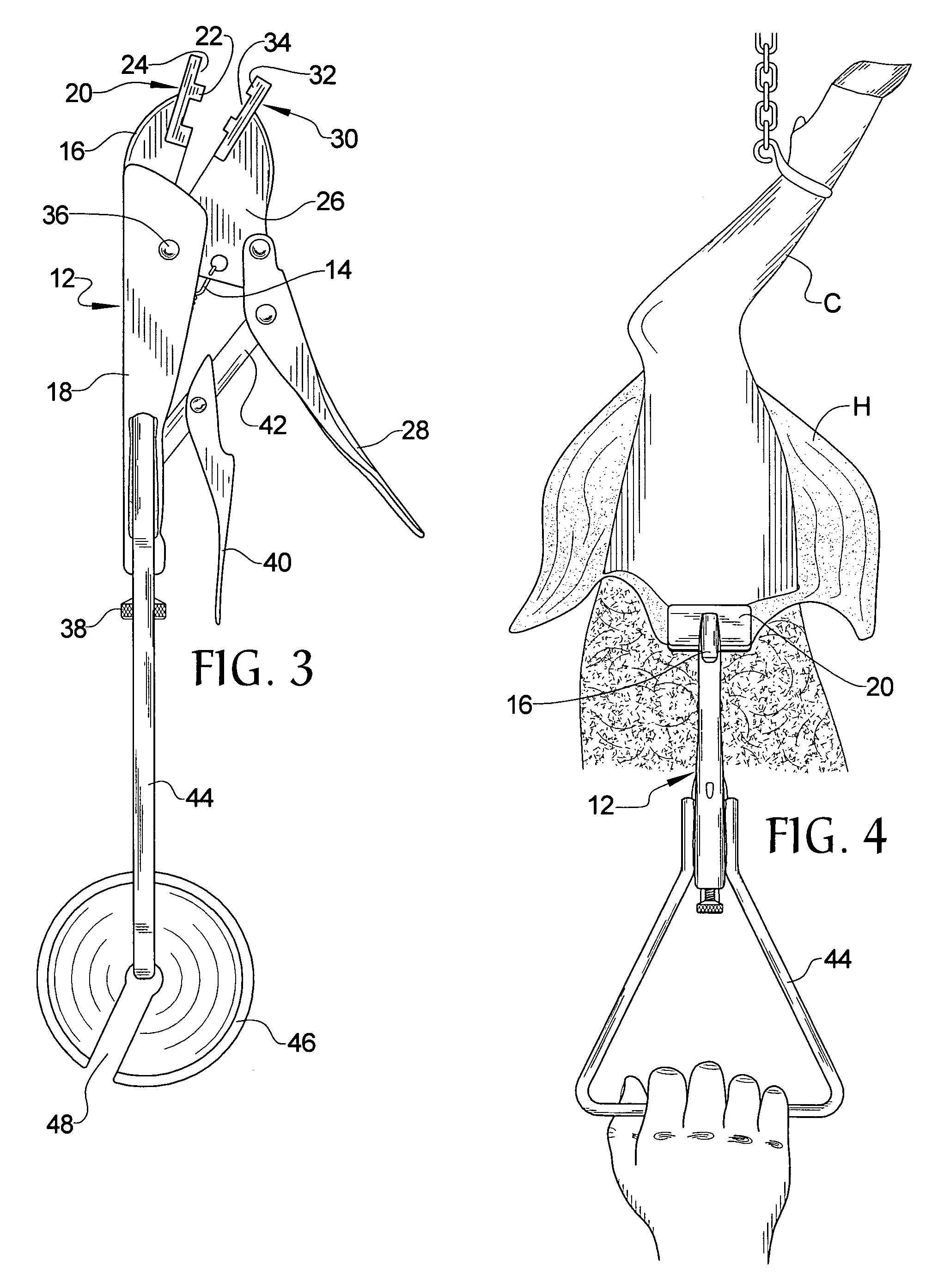

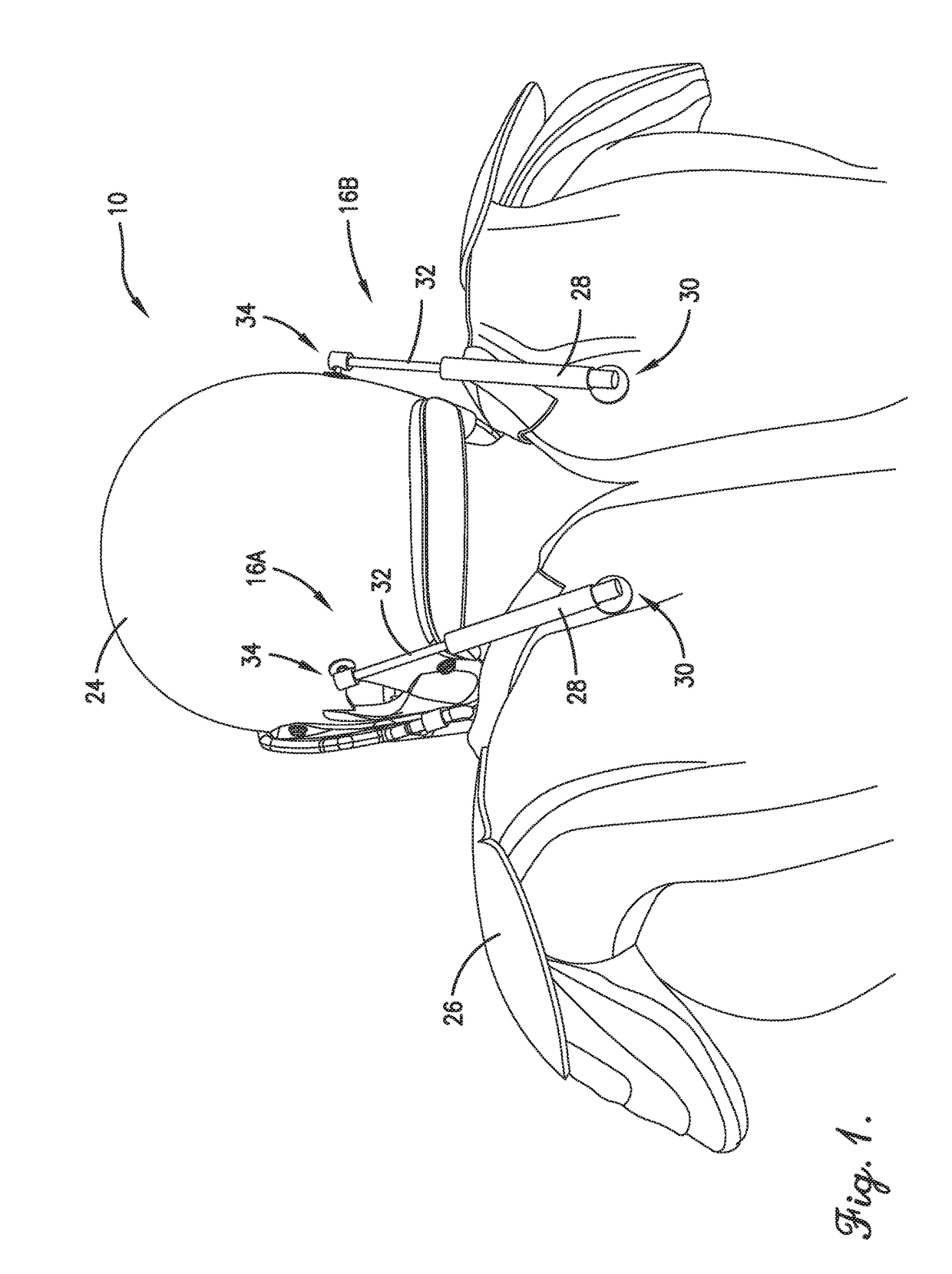

Game skinning pliers

InactiveUS7588487B1Improve gripLarge gripping footprintSkinning instrumentsRind cutting-off apparatusMechanical engineeringEngineering

A selectively locking plier-type tool for use in skinning game has a pair of opposing jaws, a main handle and a clamping handle for articulating the opposing jaws with respect to one another. A pair of plates are formed respectively on the pair of jaws such that the pair of plates each have straight teeth that mesh with one another whenever the pair of opposing jaws is brought into an apposed position. A pulling handle extends downwardly from the main handle of the tool and a weighted member is removably attached to the pulling handle.

Owner:BORN JR KENNETH A

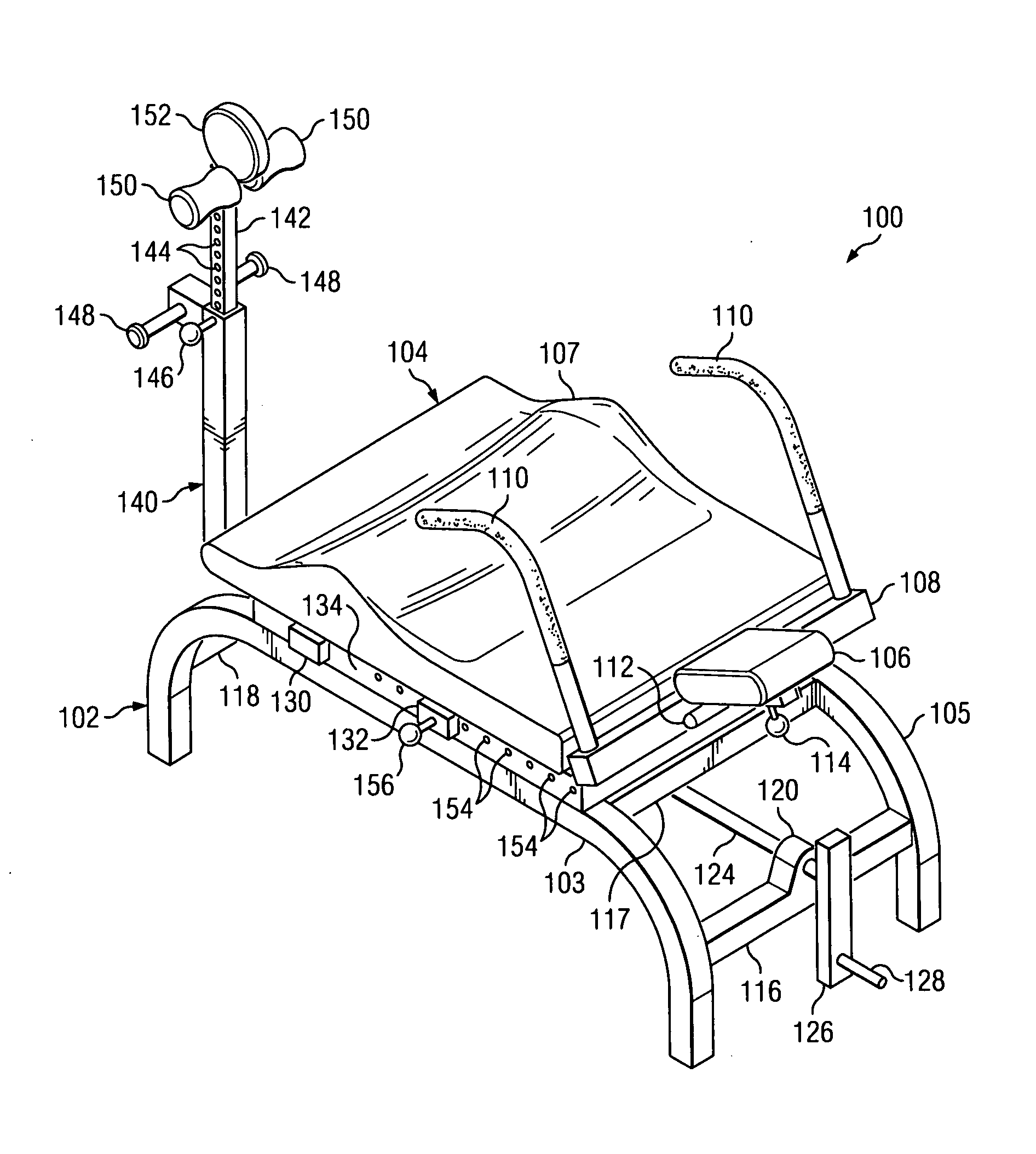

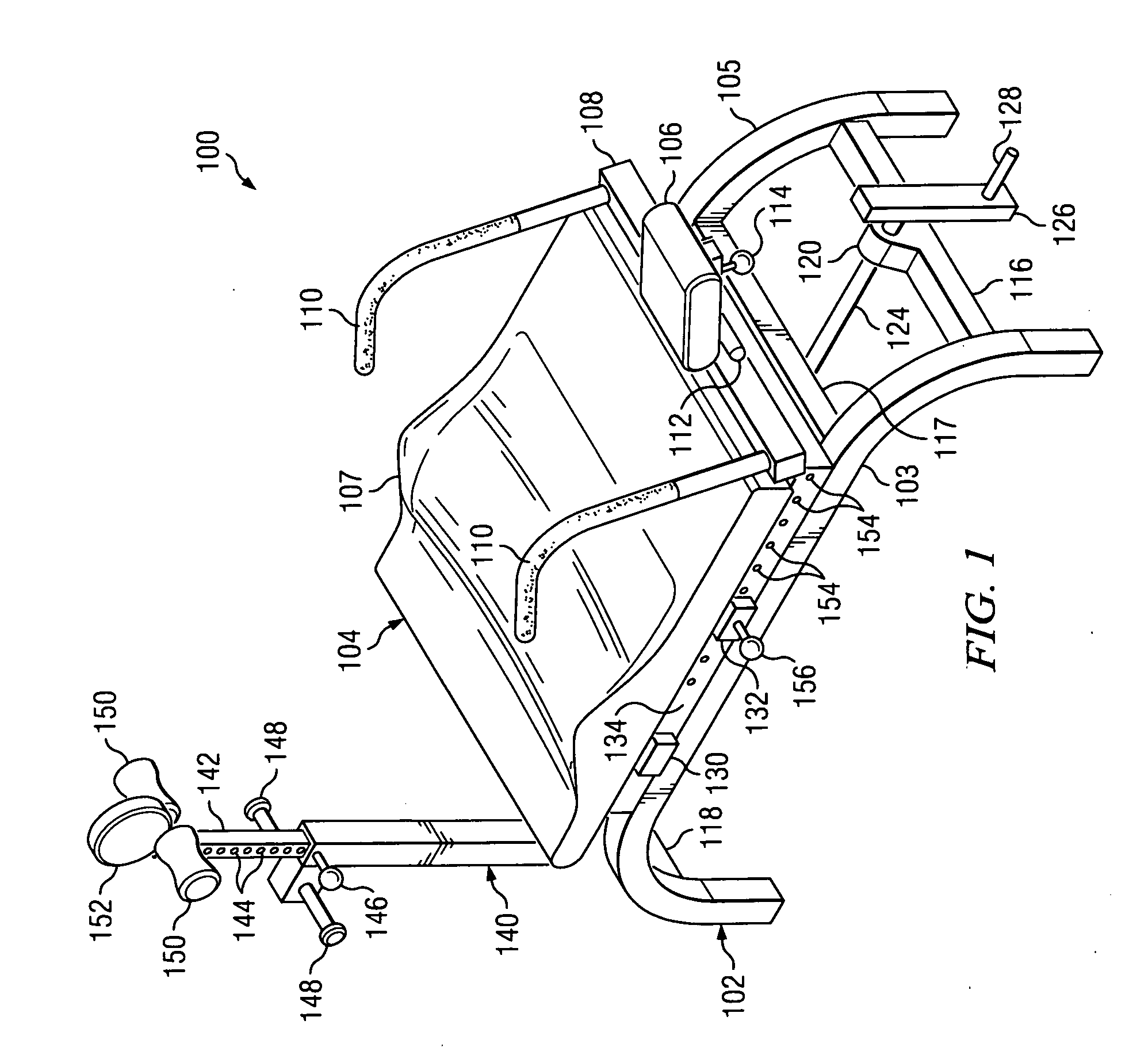

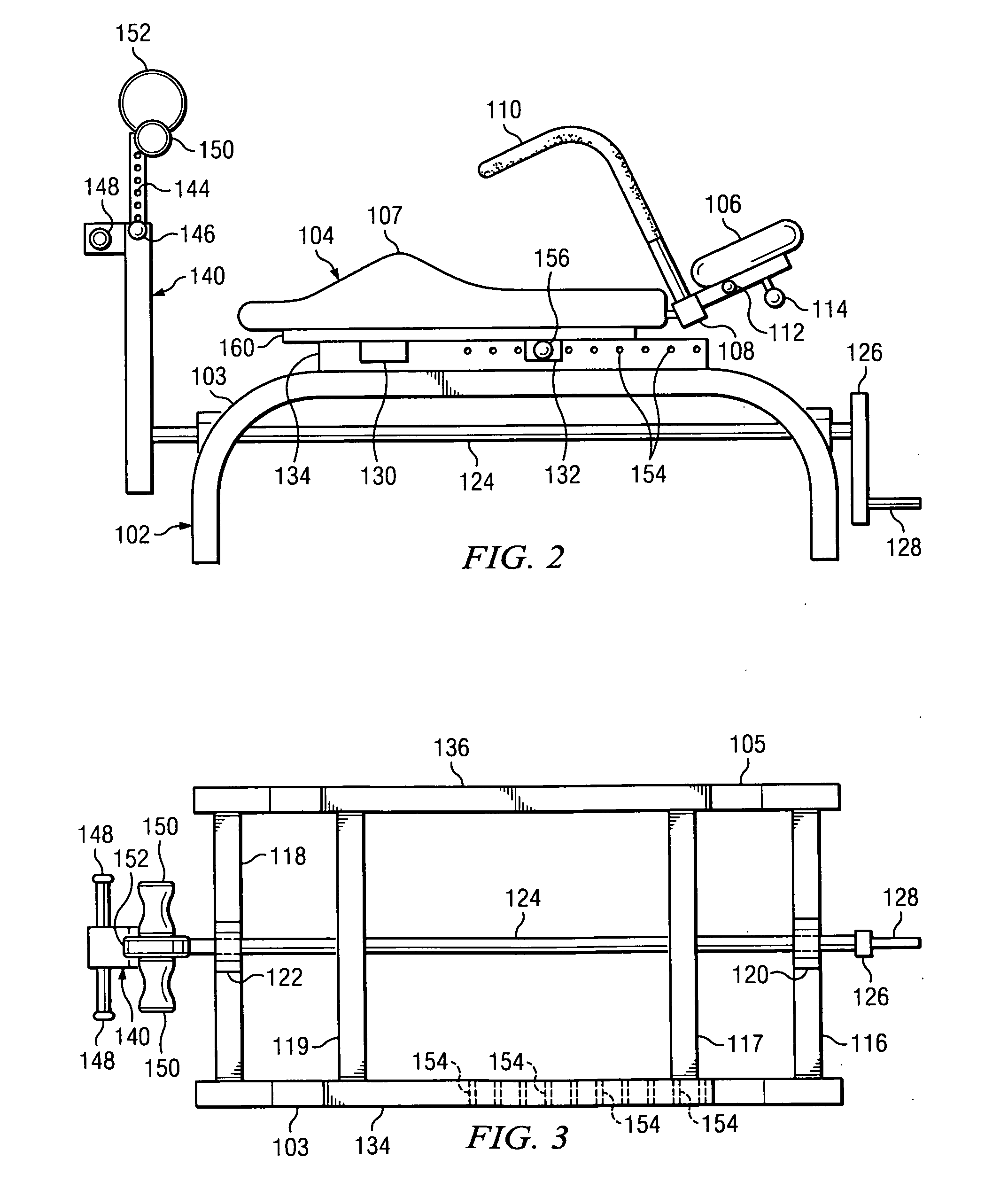

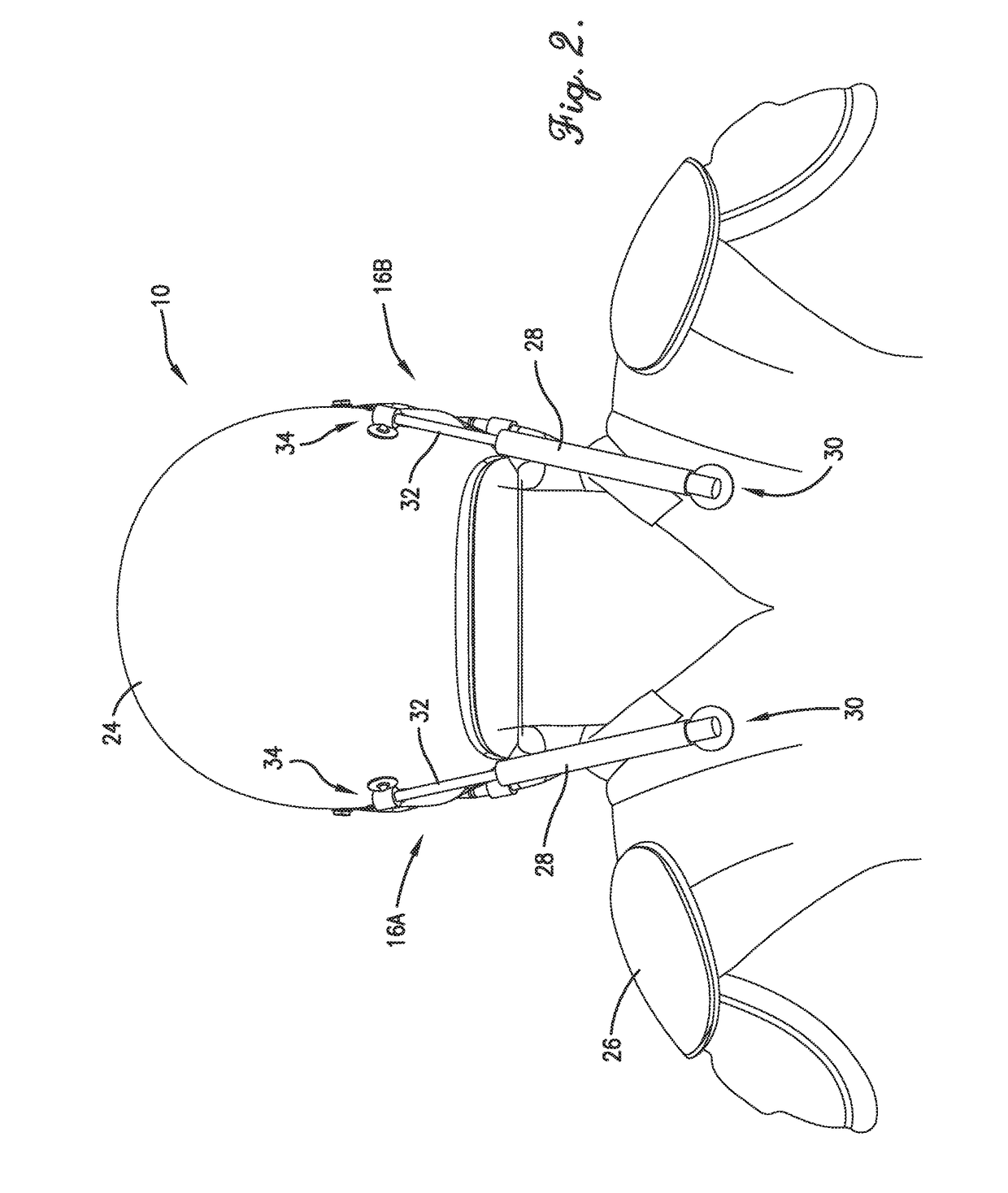

Horizontal rotary torso exercising apparatus and method

InactiveUS20090227435A1Increase flexibility and mobilityPrevents stiffnessStiltsMuscle exercising devicesEngineeringLumbar

A horizontal rotary torso exercising apparatus allows a user to strengthen the core muscles of the body and obtain maximum flexibility of the spine without squeezing or pinching the intervertebral discs or nerves. The apparatus is comprised of a frame supporting a longitudinally adjustable bench covered by a contoured pad. The contoured pad follows the natural curvature of the spine by providing a raised lumbar region with lateral pads. A rod is supported by the frame with two collars including bearings. At one end of the rod is a rack for holding weights and at the opposite end is a height adjustable leg rest. The user lies supine on the bench, places knees over the leg rest, and rotates the lower body at the waist side to side through a number of repetitions. The movement rotates the leg rest, the rod, and the rack about the axis of the rod.

Owner:CORE FITNESS SYST

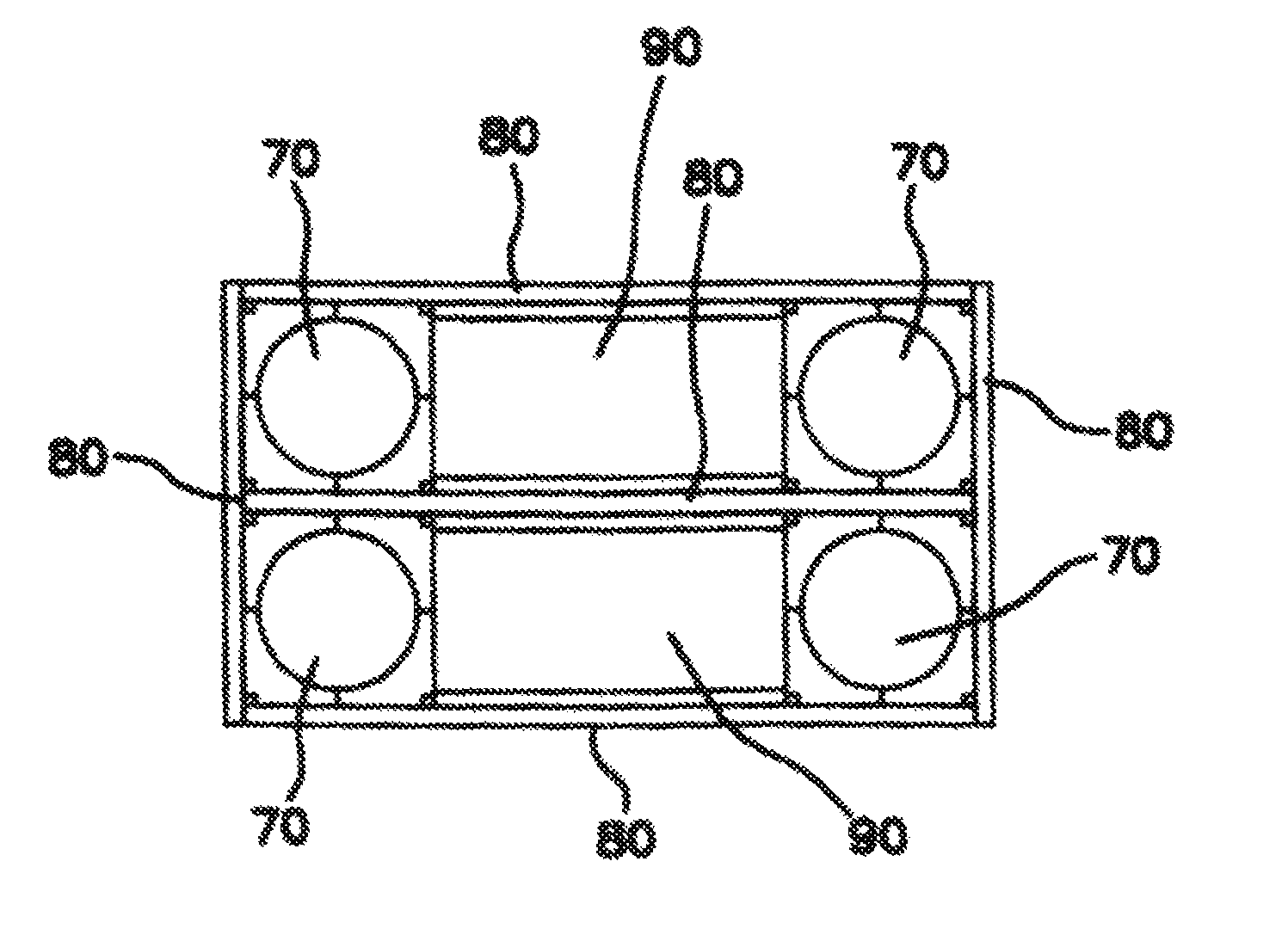

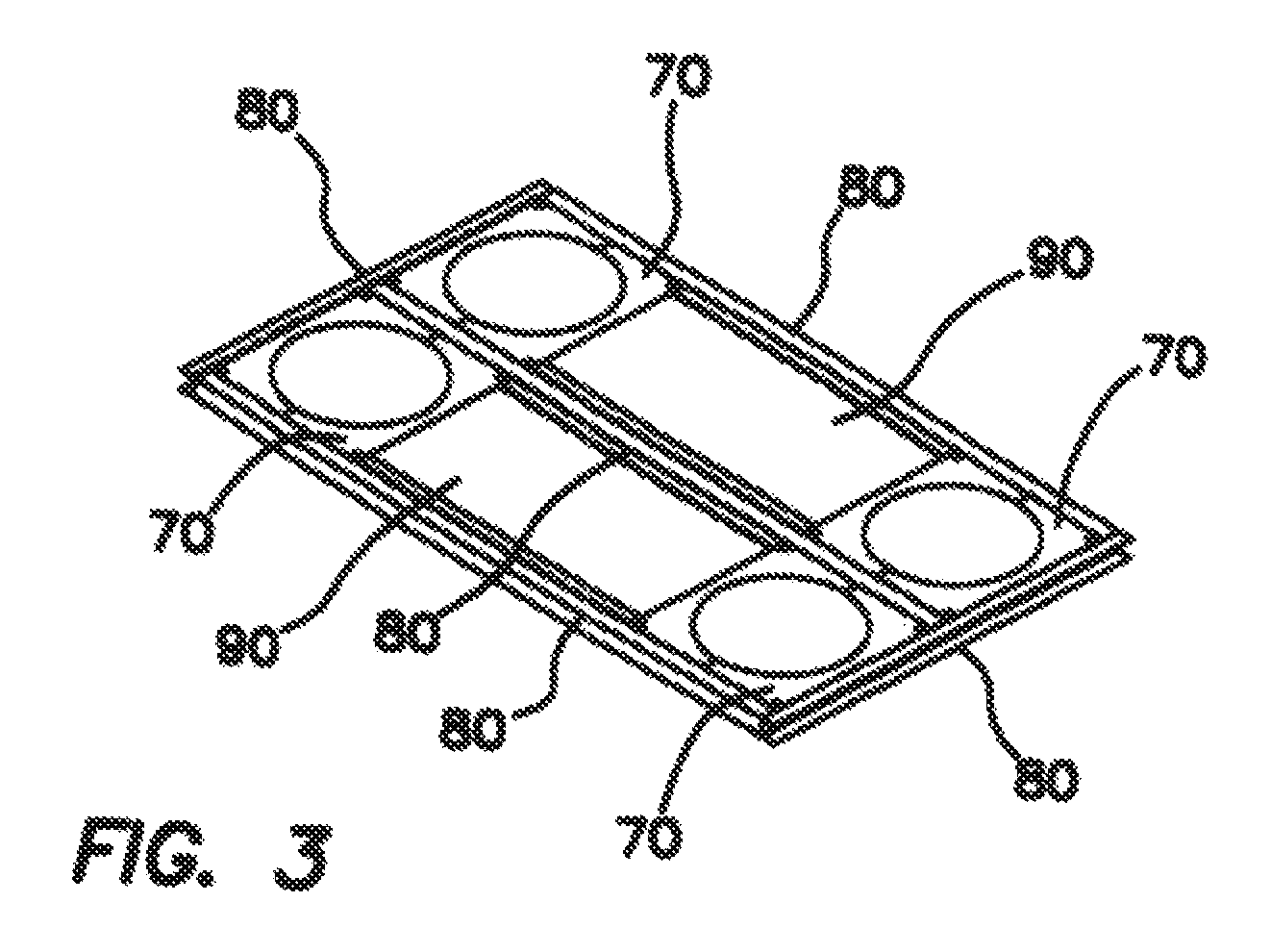

Isolation platform

ActiveUS20060260221A1ConstantAverage forceMachine framesNon-rotating vibration suppressionSpherical bearingMarine engineering

The present invention provides a platform for supporting various equipment and / or structure which assists in isolating such structure from vibrations (“noise”) external to the platform. Generally, the platform comprises upper and lower plates, having conical depressions, upon which the upper plate supports the above-mentioned structure, and the lower plate contacting surface / area upon which the supported structure otherwise would have rested. Between the upper and lower plates, a plurality of rigid, spherical bearings are placed within the conical depressions, thereby allowing the upper and lower plates to displace relative to one another. Additionally, the platform may be provided with retaining mechanisms for holding the structure to be supported, maintaining the plates together and providing additional damping effects.

Owner:WORKSAFE TECHNOLOGY INC

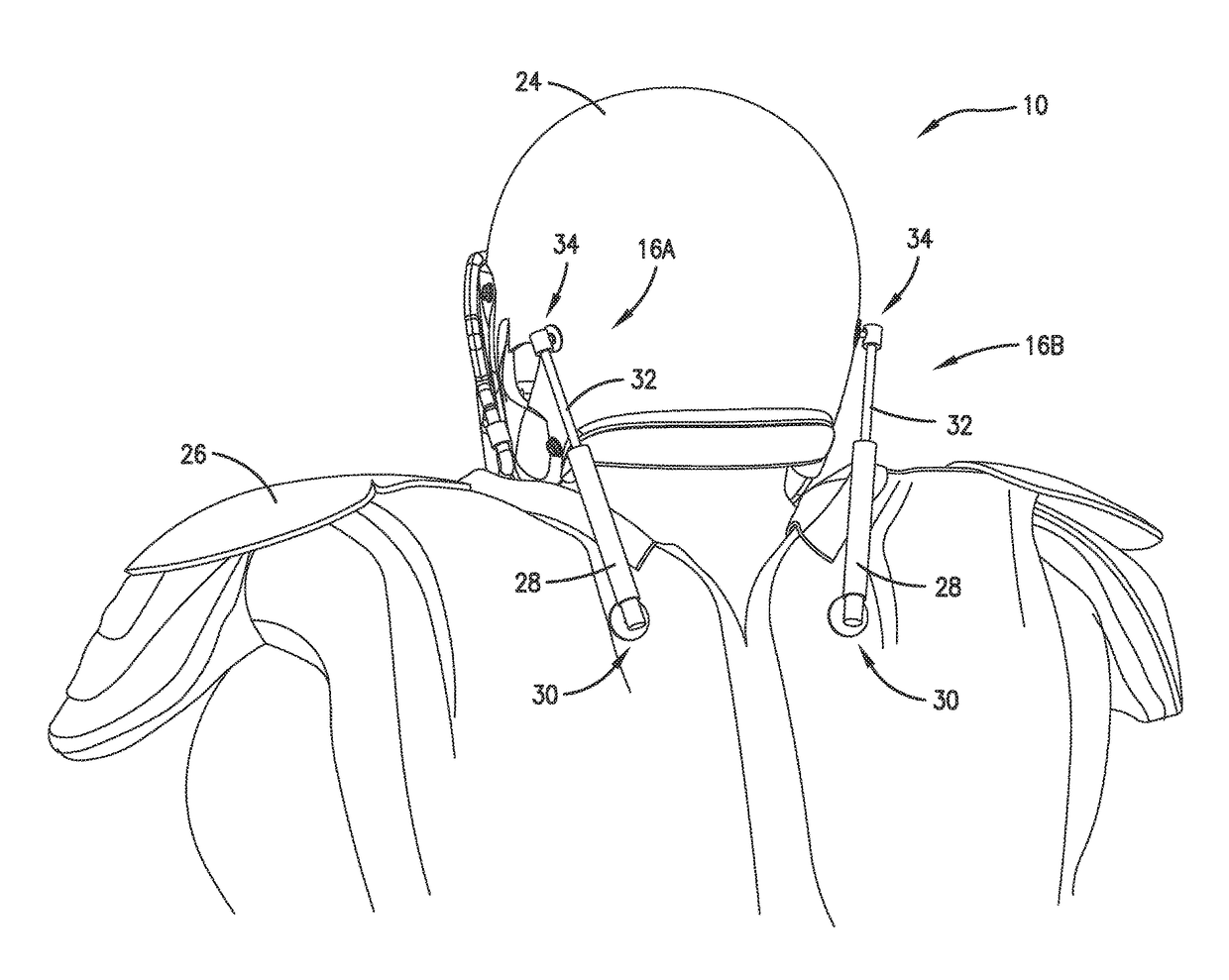

Device to reduce traumatic brain injury

InactiveUS20180028091A1Reduction in traumatic brain injuryEnergeticElectroencephalographyRestraining devicesBrain traumasEngineering

A device for reducing traumatic brain injury comprises a first sensor, a first linkage element, and a processing element. The first sensor is coupled to a head component and configured to measure an acceleration of a user's head and to generate a sequence of real-time measured samples. The first linkage element is configured to connect the head component to a body component and is able to switch between a first state in which it is relatively flexible and a second state in which it is relatively rigid. The first linkage element is switched from its first state to its second state by a locking signal. The processing element is configured to receive the real-time measured samples and to generate the locking signal when each of a portion of the real-time measured samples is greater than one of a corresponding portion of a plurality of dynamic concussion thresholds.

Owner:HUANG CHIMING

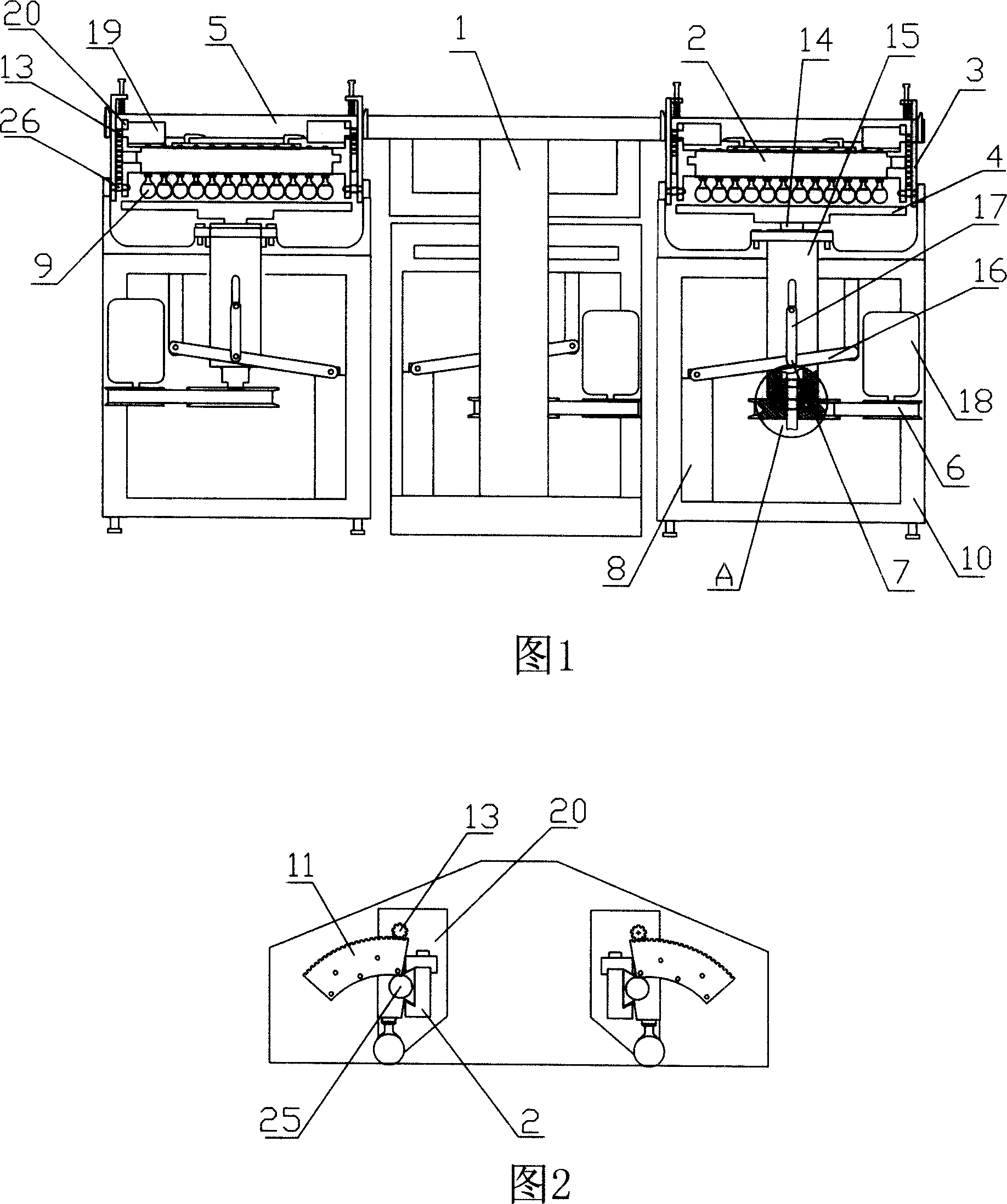

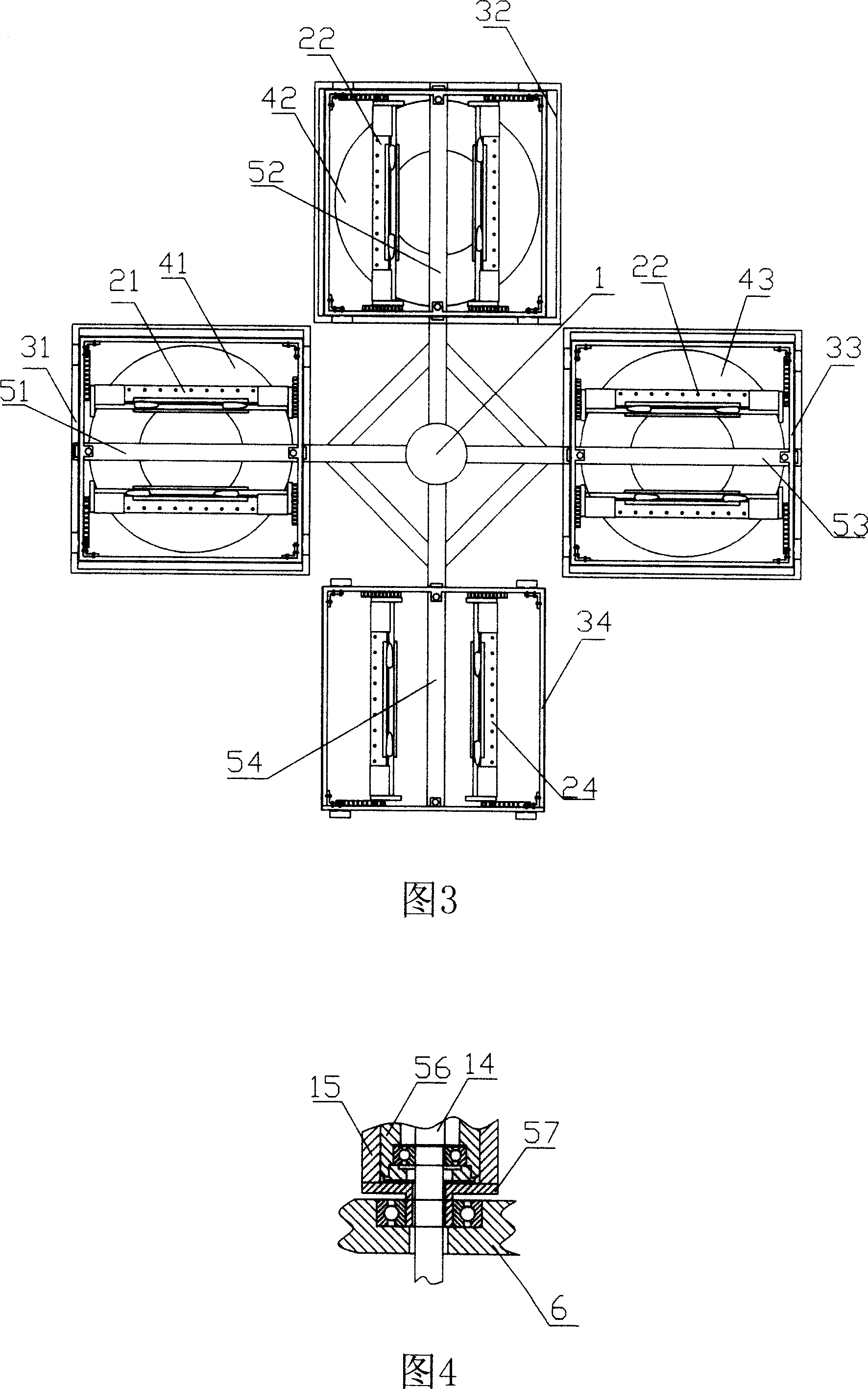

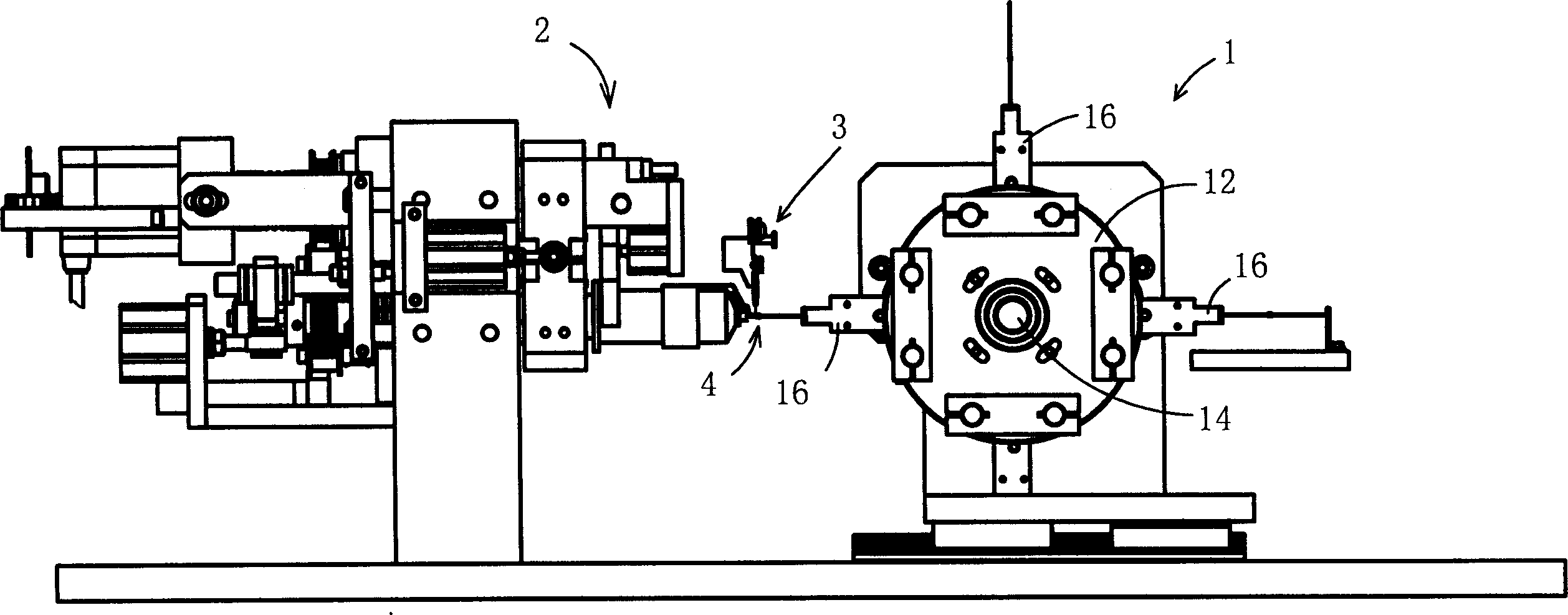

Automatic surface grinder for crystal glass

InactiveCN101007391AIncrease productivityReduce scrap rateEdge grinding machinesEngineeringRotation control

The invention belongs to crystal glass workpiece machining equipment field. An automatic glass crystal milling surface machine includes rotary control aircraft (1), at least two racks (10), at least three frame heads (3); Each rack (10) is respectively equipped with milling disc (4), motor ( 18)controlling milling plate (4) rotating and cylinder (8) controlling milling disc (4) lifting; said rotary control aircraft (1) is equipped with support arms (5) which arrangement is regular and number matches with number of frame heads (3); the frame heads (3) is fixed under the support arms (5) and is equipped with clamping device installing crystal workpiece (9). The automatic glass crystal milling surface machine not only improve the efficiency of crystal workpiece production, and the grinding, throwing accuracy of crystal workpiece is improved, the operation of milling surface machine is easier and more convenient.

Owner:邱培育

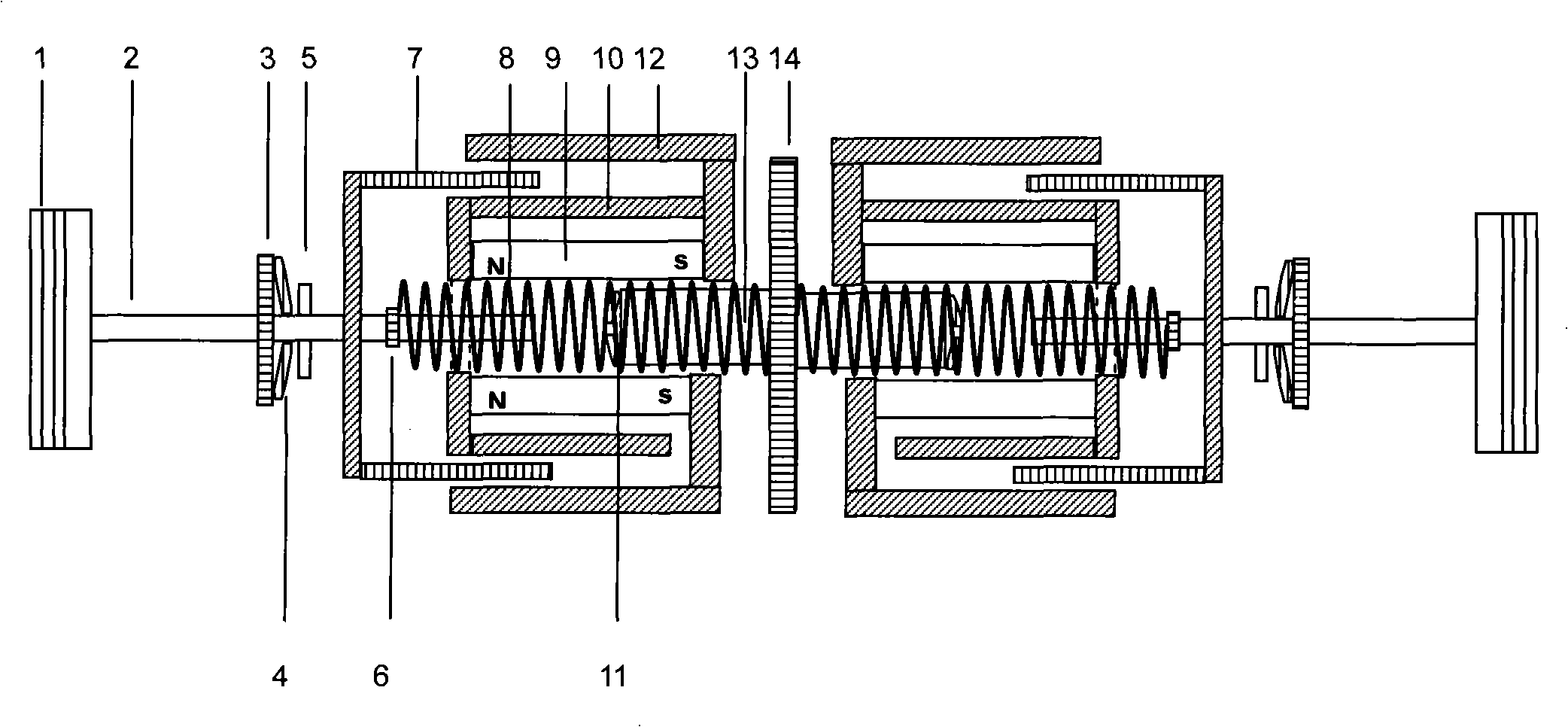

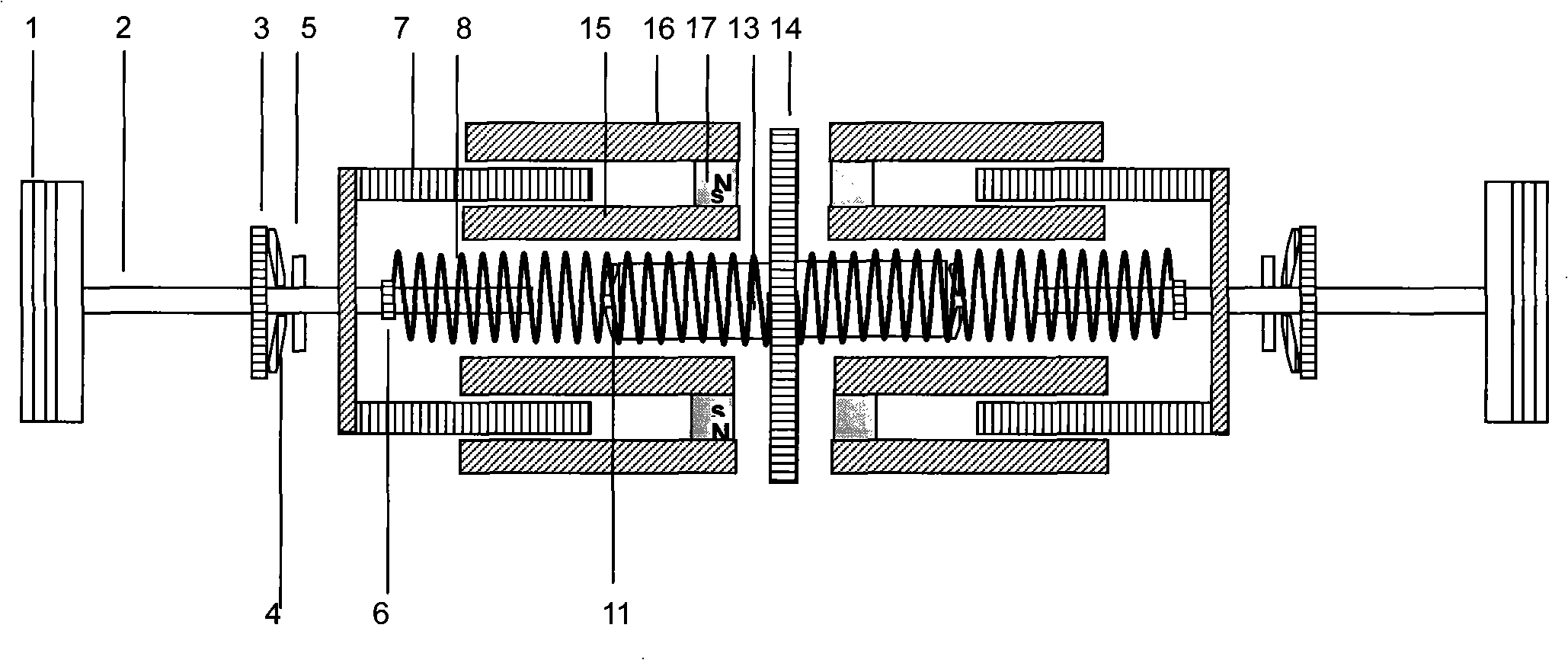

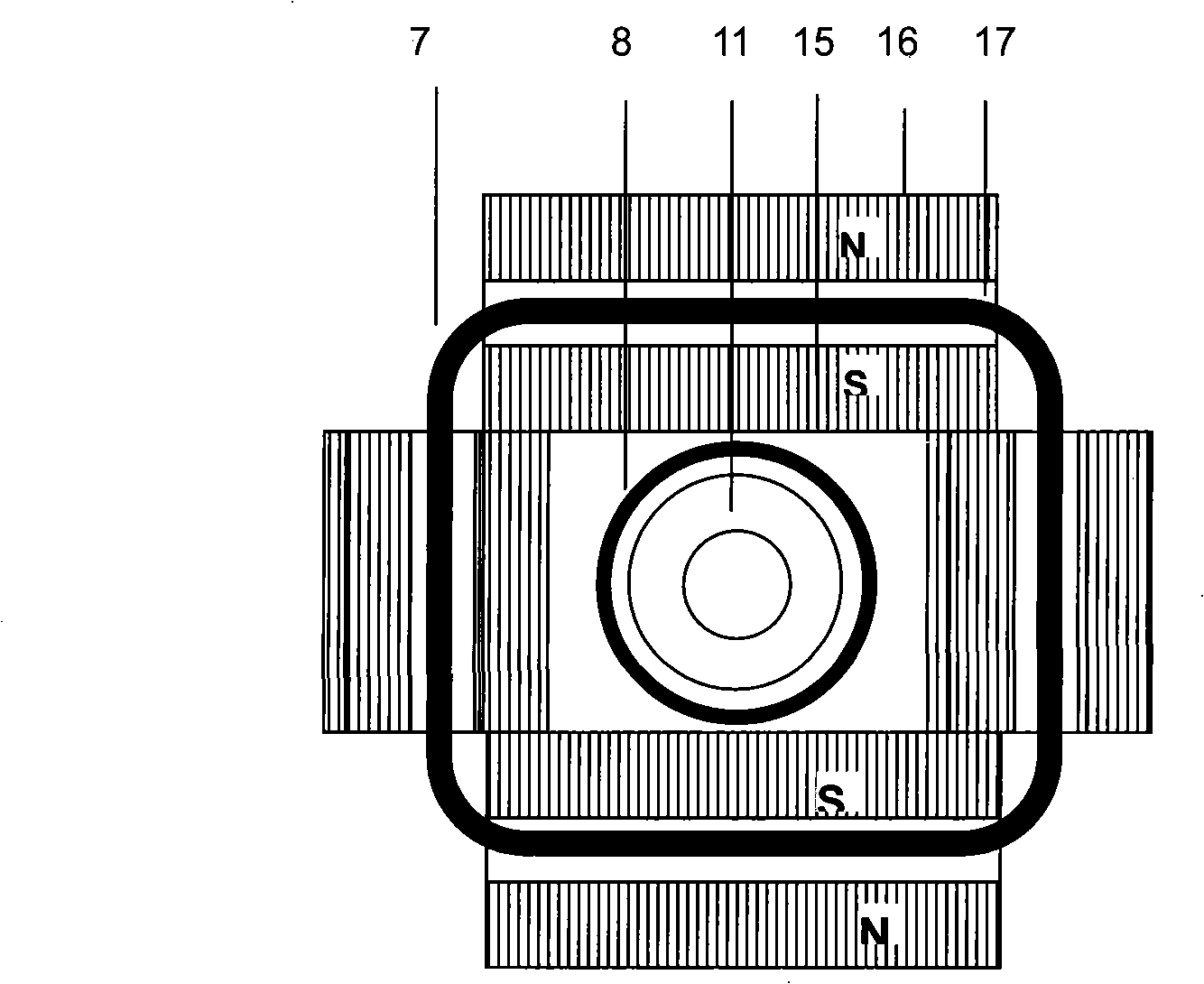

Direct-action power generation system with speedup spring forced vibration

InactiveCN101353981AIncrease volume capacityIncrease coil strengthInternal combustion piston enginesOutput powerTop dead centerReciprocating engine

The invention discloses a directly operated power generation system which directly utilizes the rectilinear motion of a reciprocating engine piston to drive coils or a magnet to generate electric current for power generation. During the period of non-expansion stroke, the motion of the piston is driven by utilizing a vibrating system and the electromagnetic force of the coils; in the system, the piston, power generation coils and a linking mechanism are connected with a coil spring. The piston and the coils connected with the piston are controlled by a balancing spring at the near end of the piston and an accelerating spring at the remote end of the piston by a stress board and a connecting rod and then a forced vibration system is formed. The system uses a method for adjusting the movement velocity of the piston in the last phase of the expansion stroke so as to realize the adjustment of the system frequency and also uses a method for adjusting the number of working cylinders and the air input capacity to carry out the power regulation; by utilizing that the system is characterized by no fixed top dead center and the easily adjustable compression ratio, a compression-ignition type ignition is adopted and the volume compression ratio can be adjusted according to the air inlet capacity so as to realize the comparatively high compression ratio within a wide working range, thereby improving the efficiency.

Owner:TIANJIN CHANGING POWER TECH

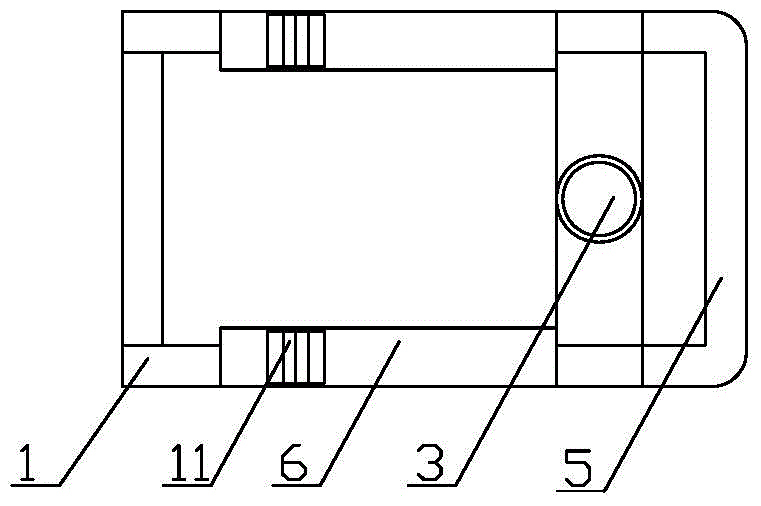

Winding device and its winding method

InactiveCN1822261AAvoid wastingReduce consumptionCoils manufactureResistive element windingsEngineeringConductor Coil

Present invention relates to a wire winder. It contains an inner rotor shaft having collet for holding said electronic assembly connecting pin, an outer rotation sleeve set outer part of said inner rotor shaft, wire feeding device set between rotating wheel device and winder having a lead rod for winding wire on said electronic assembly.

Owner:廖木山

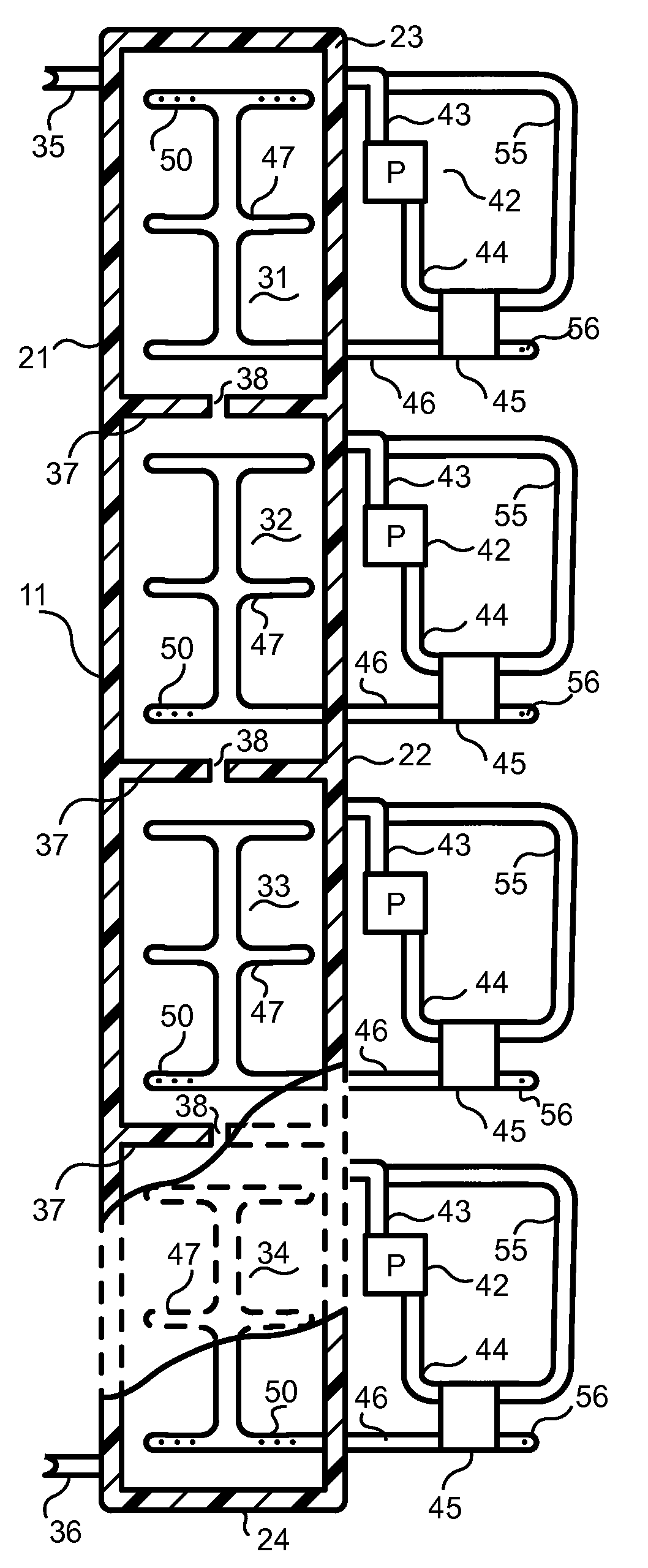

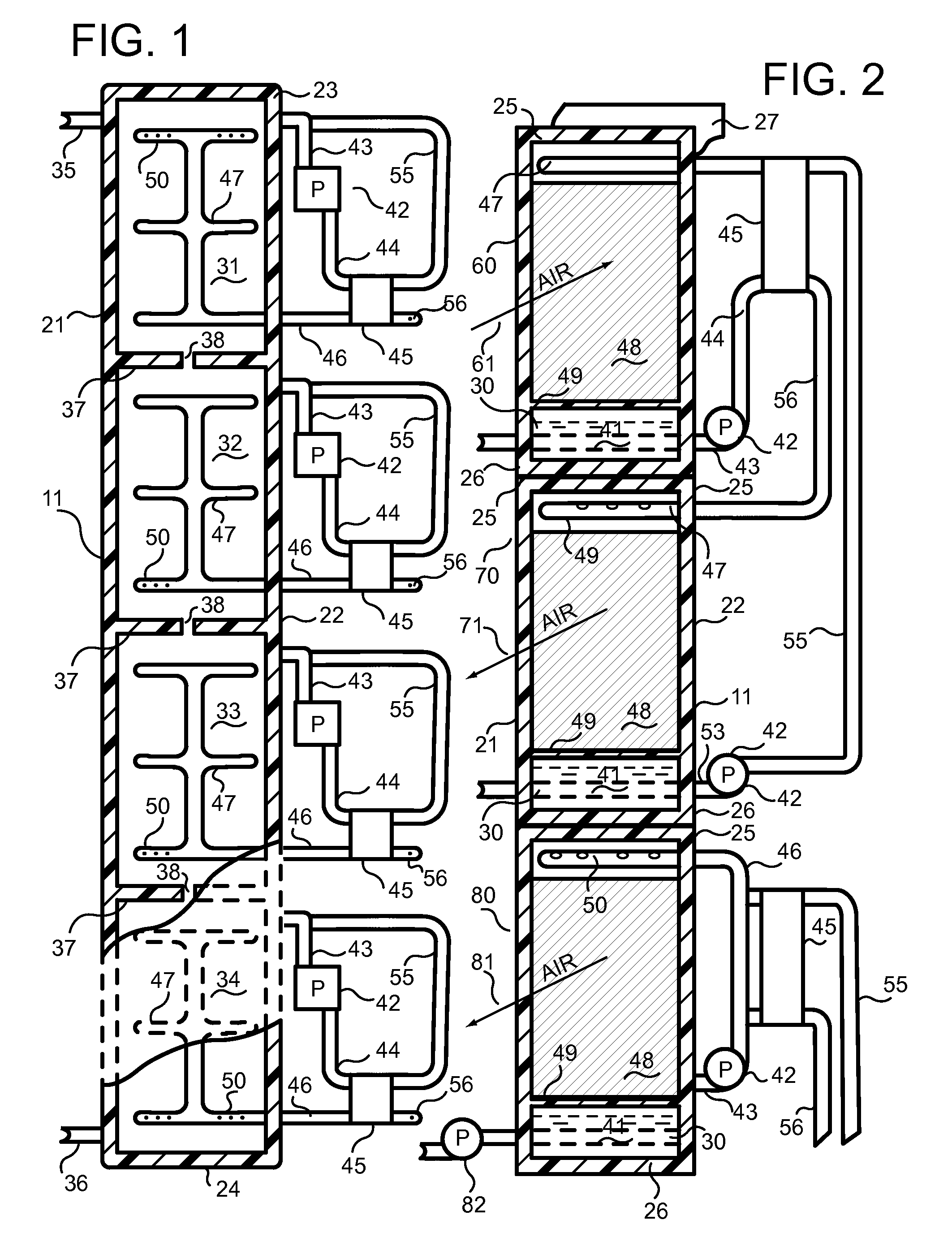

Air energy reduction method and apparatus using waste heat from condensers or other low grade heat

InactiveUS20100175394A1Reduce humidityImprove efficiencyCooling fluid circulationAir conditioning systemsLower gradeLow graded

The present invention provides a process for utilizing waste heat released by condensers of conventional air conditioning systems and more particularly using this low grade heat or other low grade sources that are slightly above ambient air temperatures to alter concentration of a liquid desiccant that contacts an ambient air stream thereby reducing its relative humidity while its temperature is controlled and generally reduced by heat exchange with another air stream that is saturated with water.

Owner:ALBERS WALTER F

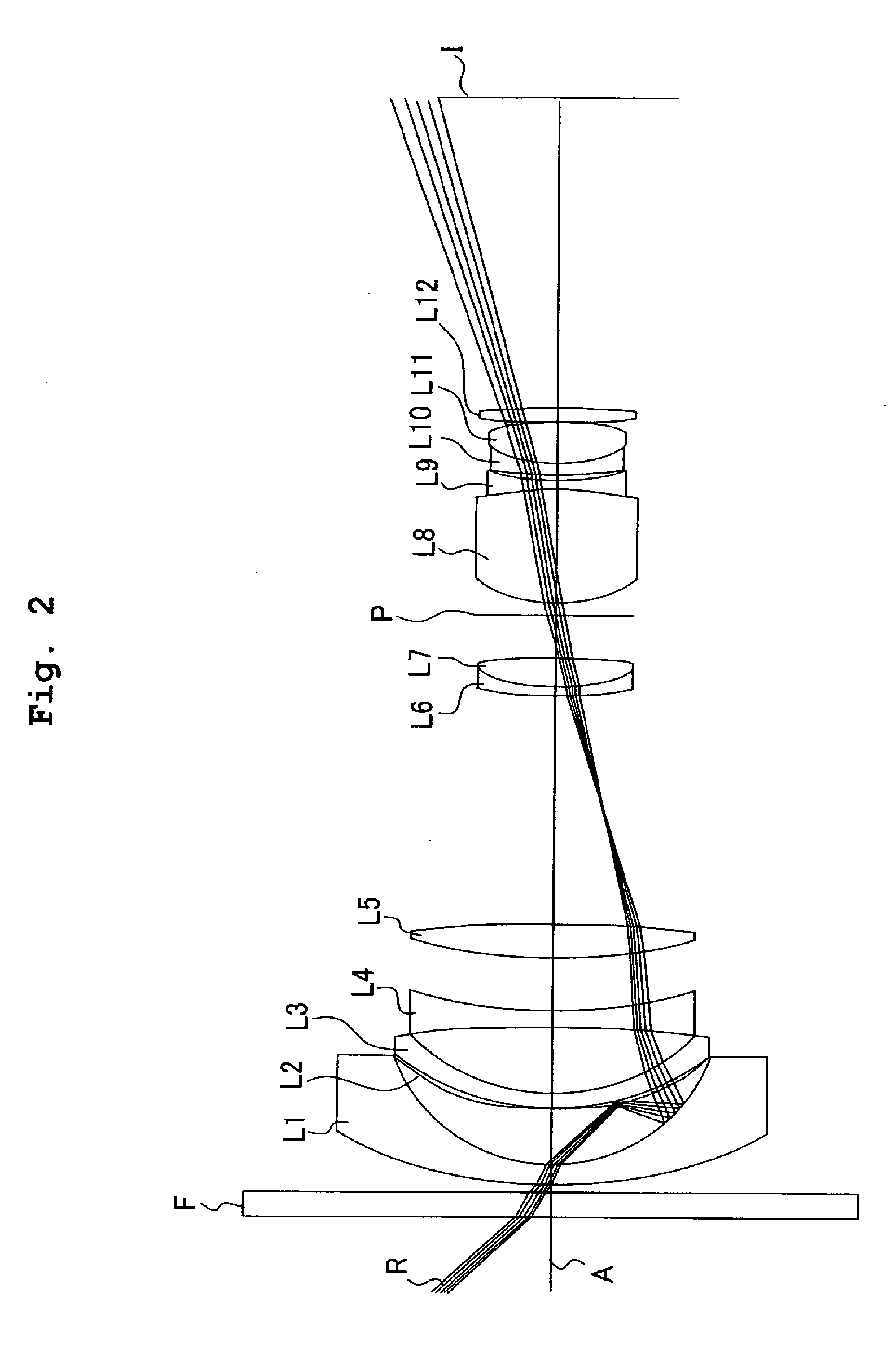

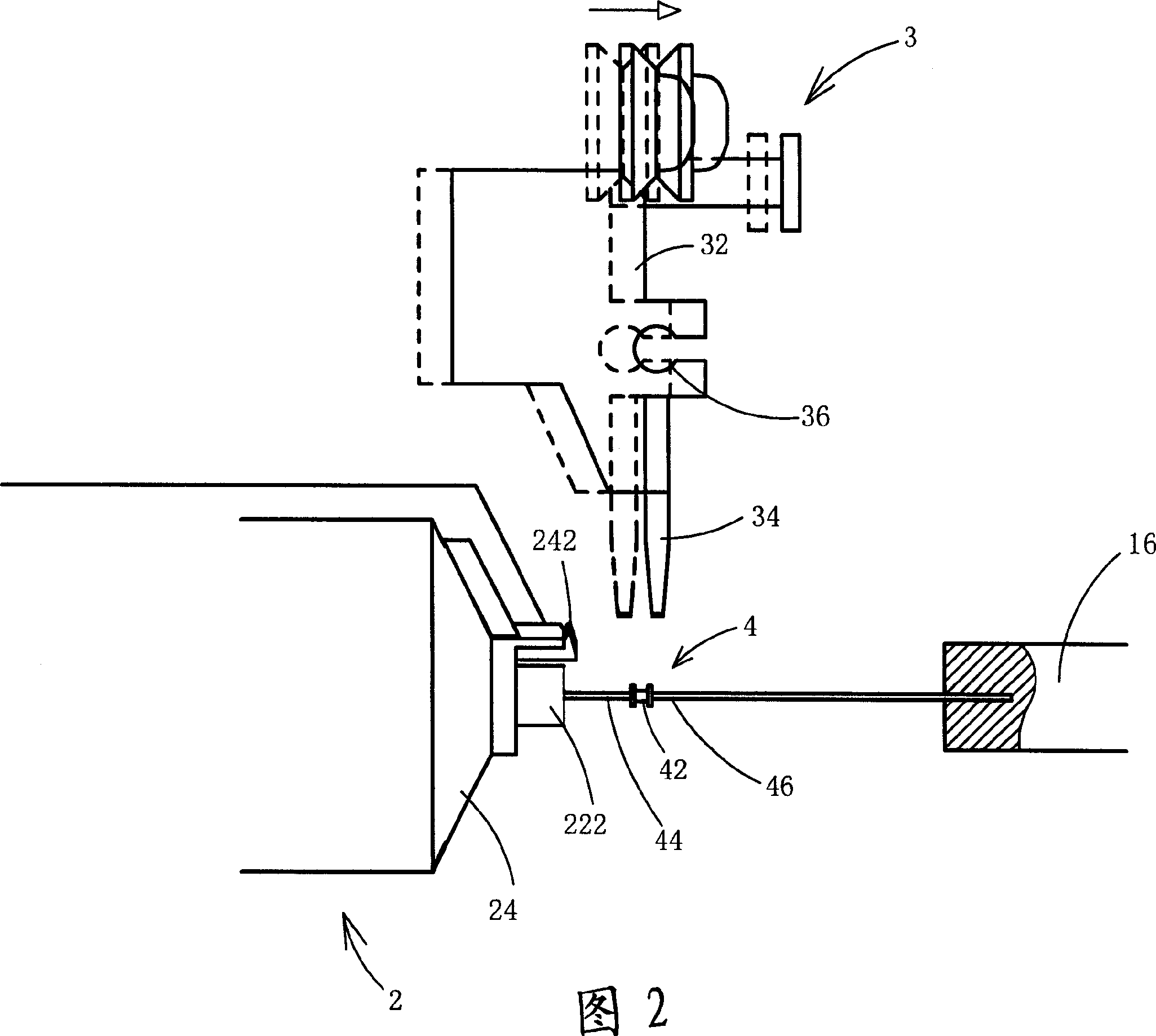

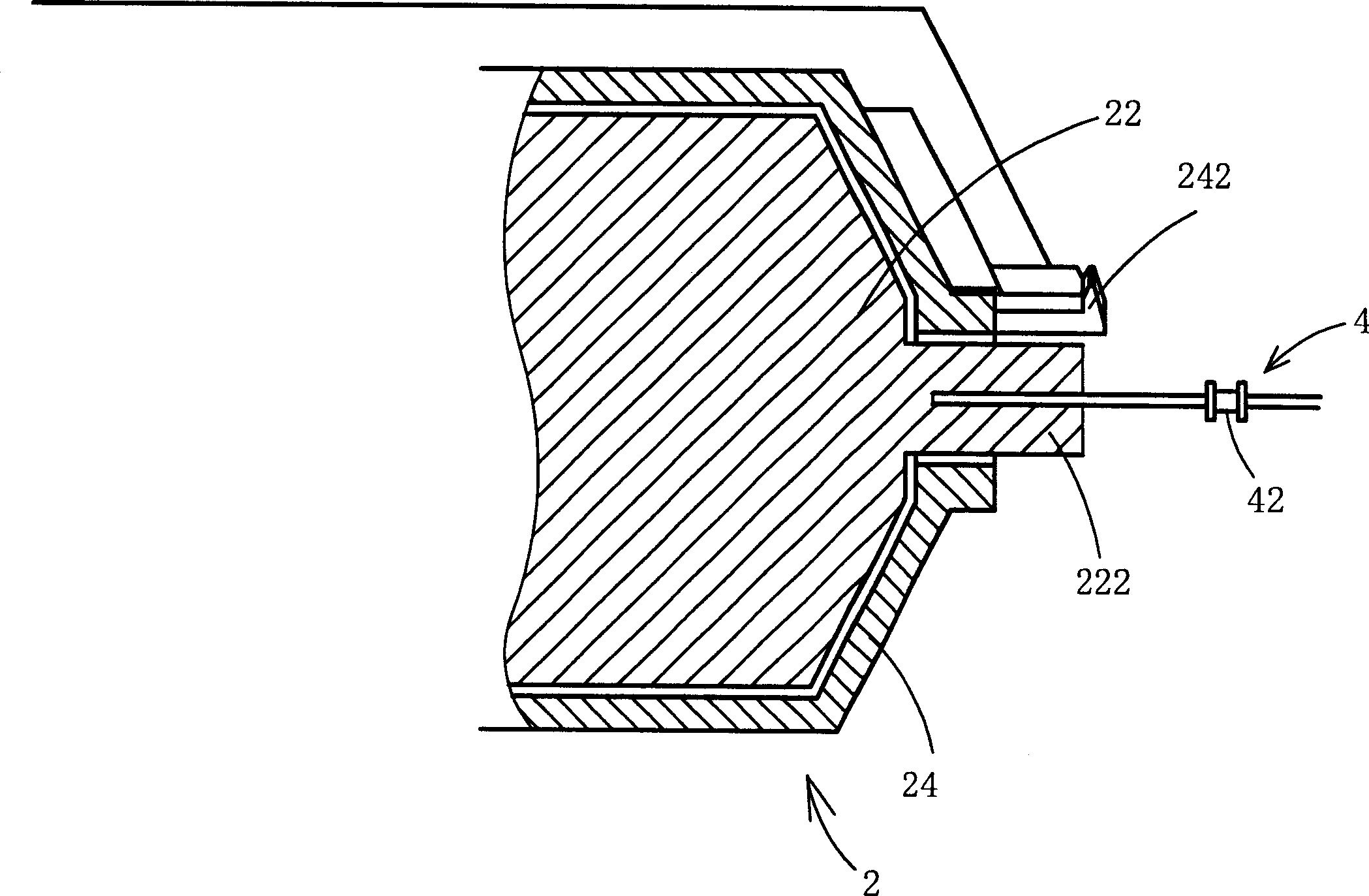

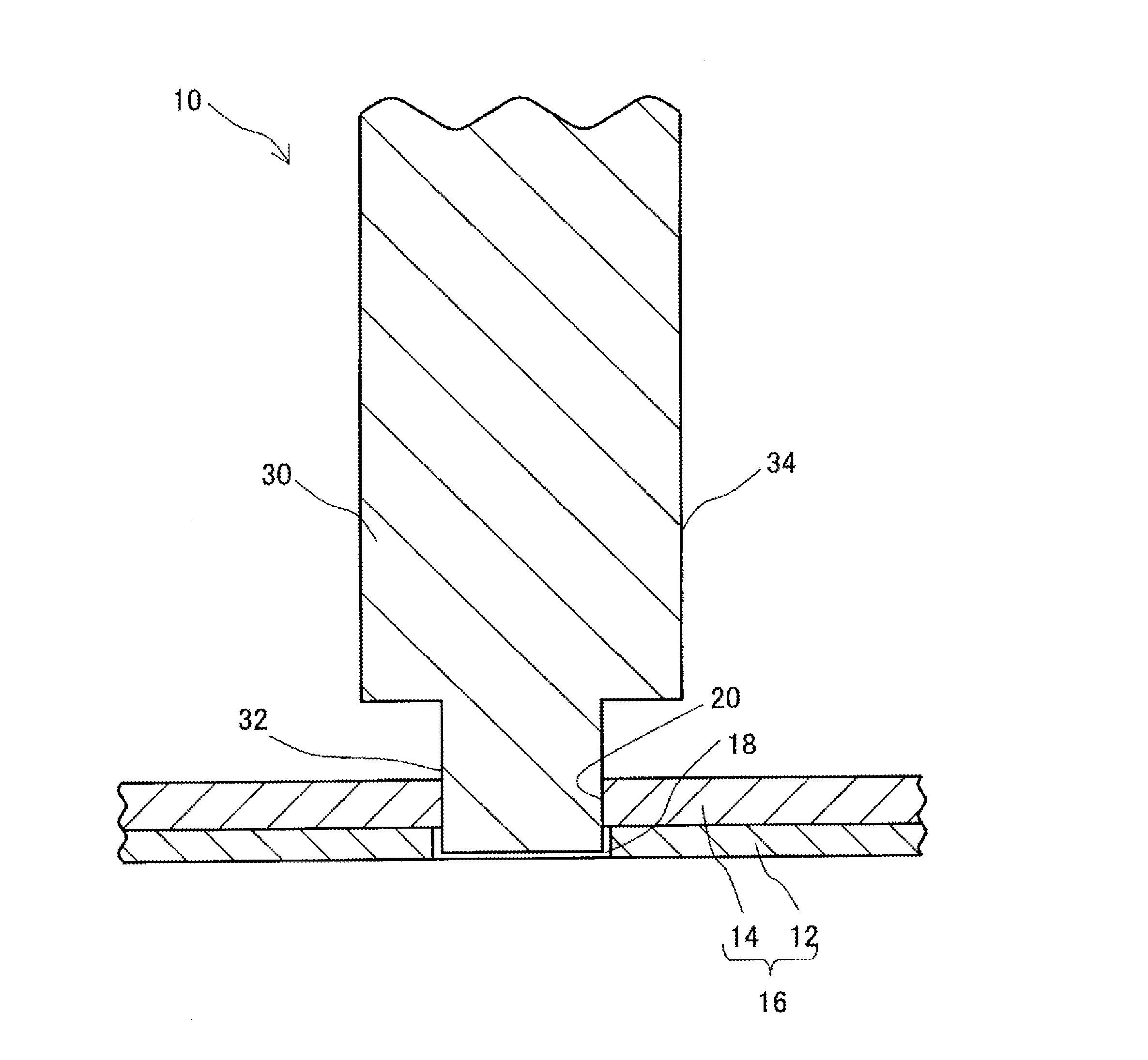

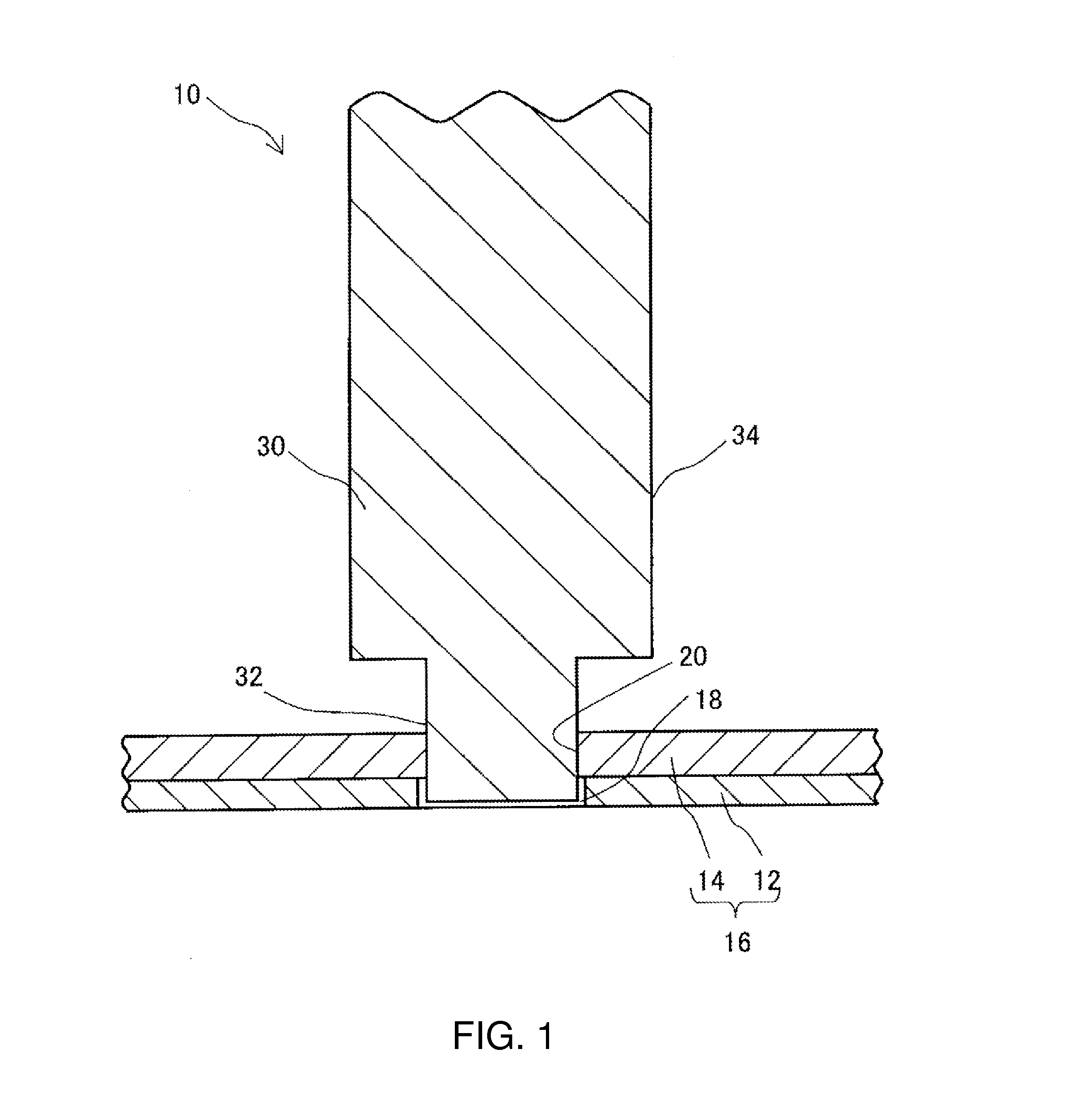

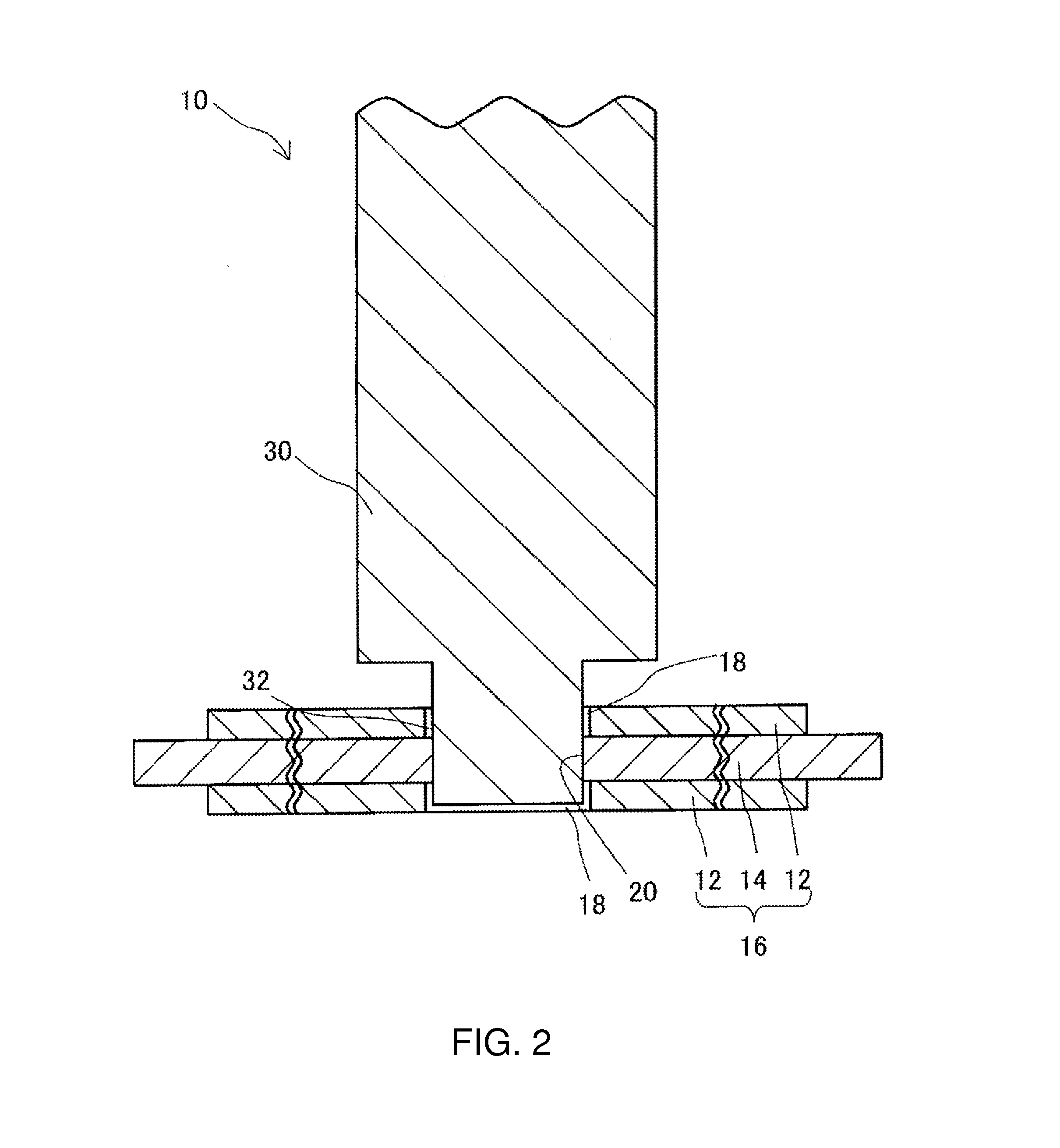

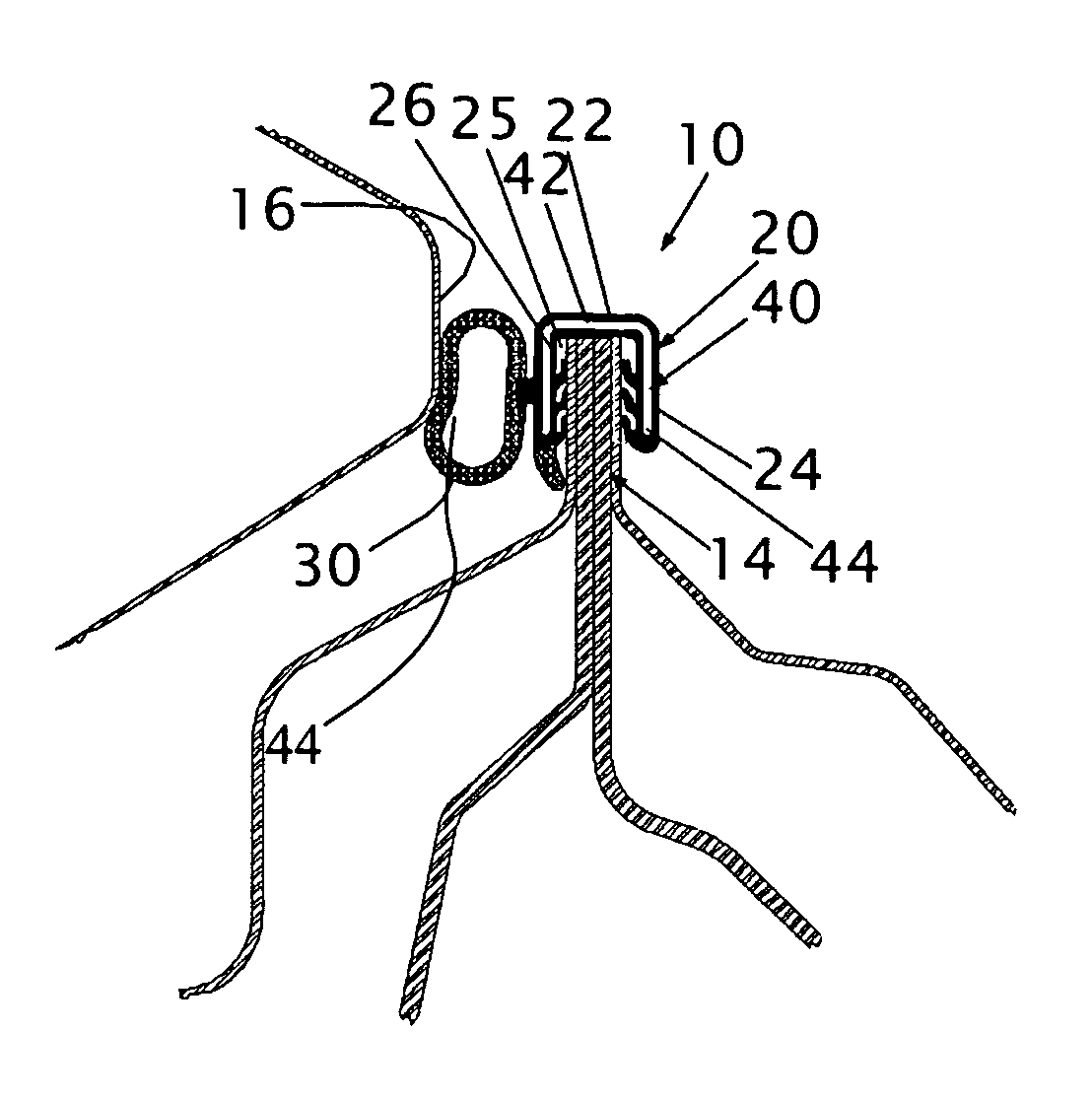

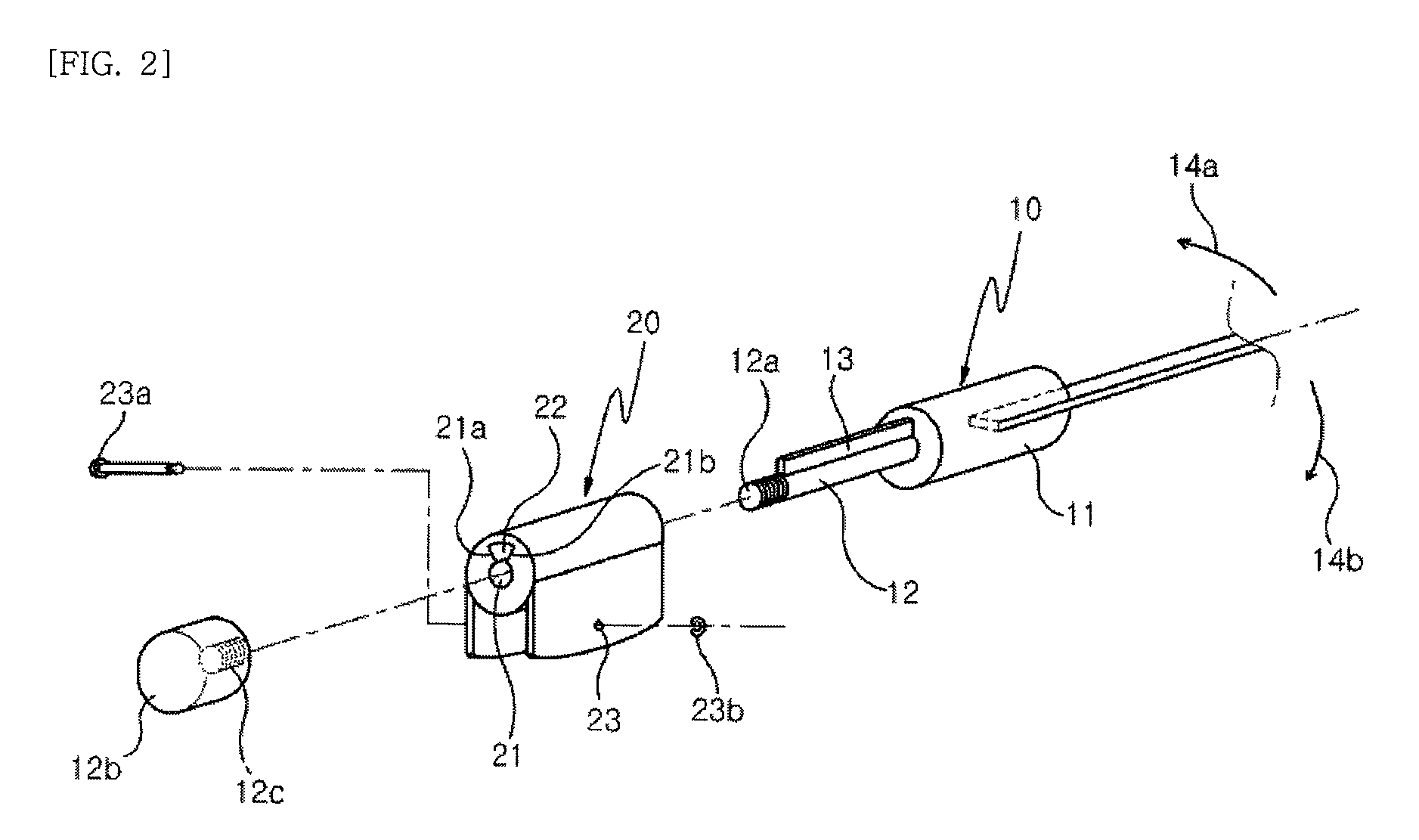

Driving member, linear driving device, camera, device and electronic device

ActiveUS20140362280A1Drive capability can be improvedImprove rendering capabilitiesTelevision system detailsColor television detailsDrive shaftEngineering

A driving member, a linear driving device using the driving member, a camera device and an electronic device are provided. The driving member (10) includes a deformable thin plate (16) having a flexible thin plate (12) capable of expanding and contracting itself under the applied voltage and an elastic thin plate (14) having at least one side thereof rigidly fixed to the flexible thin plate (12) and a driving shaft (30) having its one axial end rigidly fixed to the deformable thin plate (16) and being capable of undergoing displacements that are operatively associated with the deformation of the deformable thin plate (16), wherein the driving shaft (30) has the lateral side portion (32) of the one axial end thereof rigidly fixed to the corresponding inner side portion of a through hole formed on the deformable thin plate (16).

Owner:NEW SHICOH MOTOR CO LTD

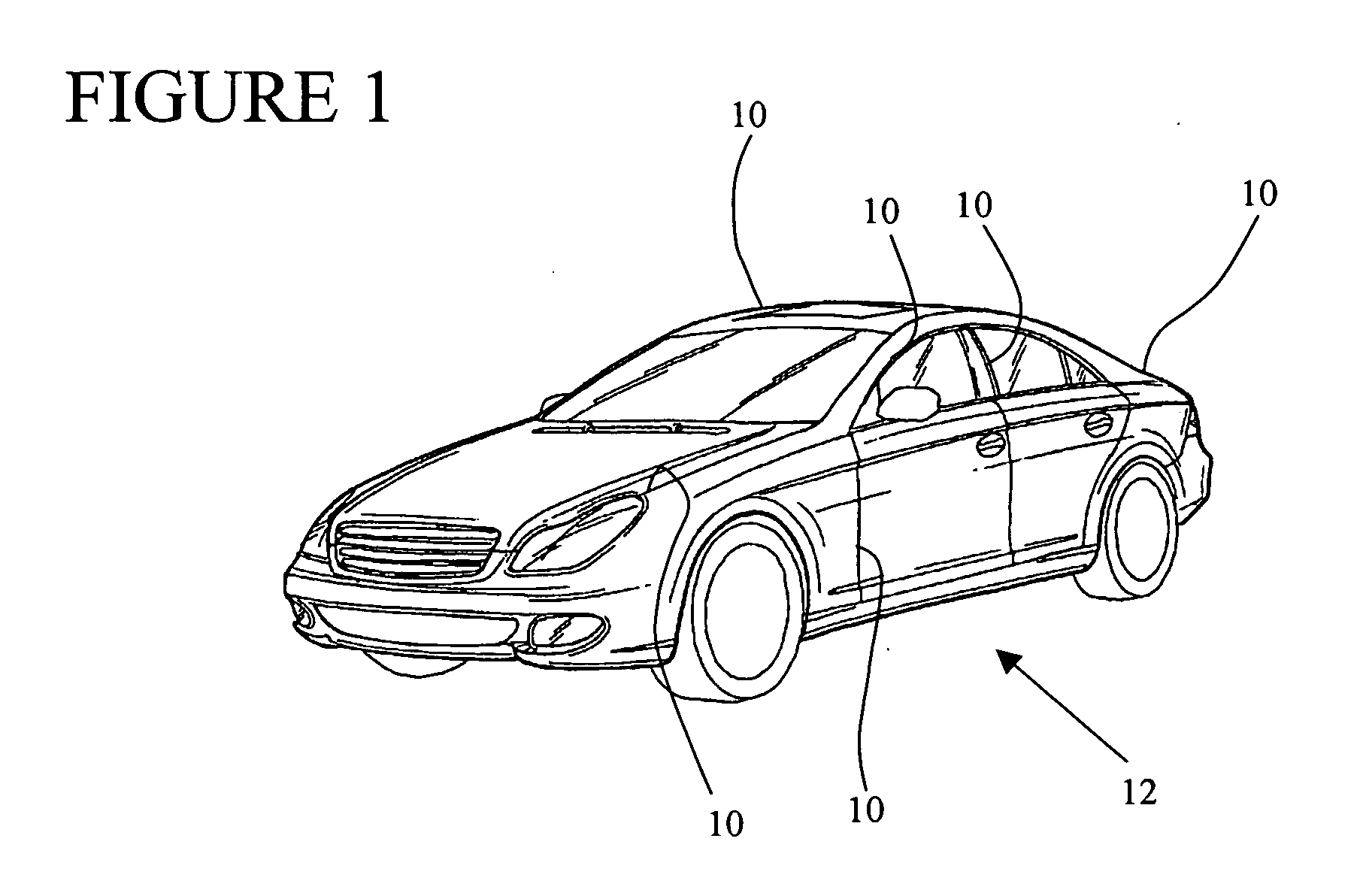

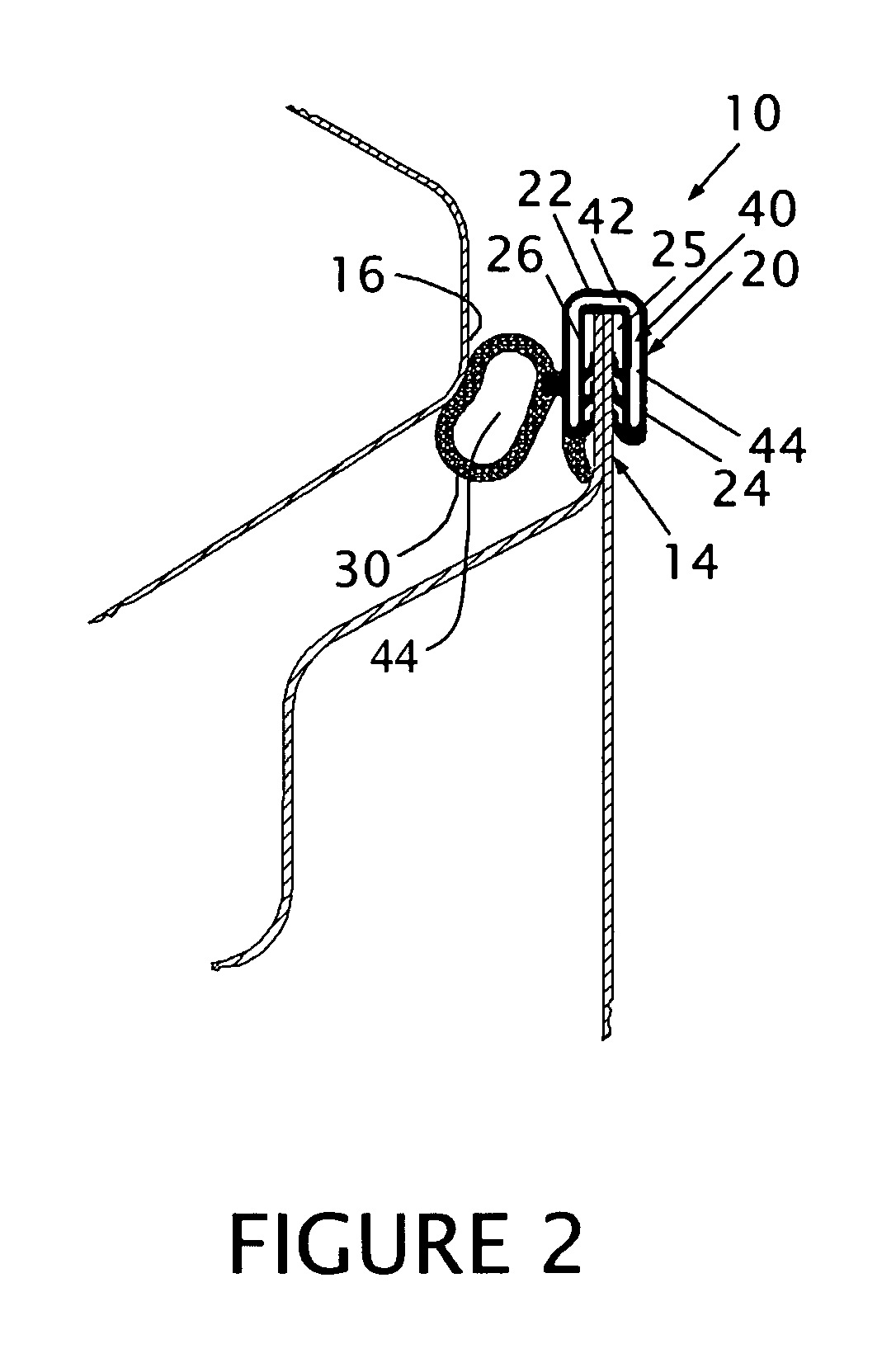

Flange engaging strip with a carrier for engaging a flange having a varying thickness along a longitudinal dimension

InactiveUS20070209313A1ConstantSame directionVehicle sealing arrangementsSealing arrangementsEngineeringVarying thickness

A flange engaging strip is provided for engaging a vehicle flange, wherein the flange has a varying thickness along a longitudinal dimension. The flange engaging strip has a closed end and projecting limbs and can include a carrier having a corresponding base and projecting legs that define a constant combined cross sectional length, wherein the cross sectional length of the closed end varies corresponding to the thickness of the flange along a longitudinal dimension of the flange engaging strip.

Owner:SCHLEGEL +1

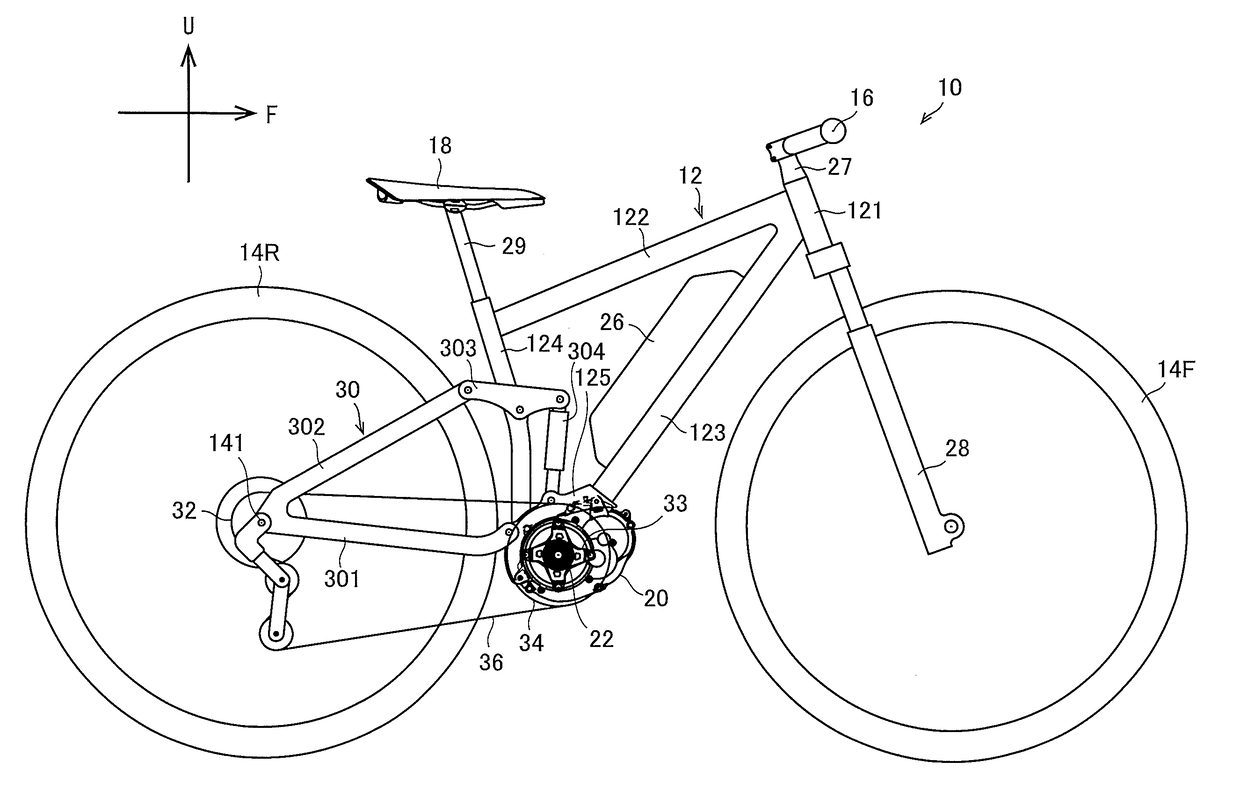

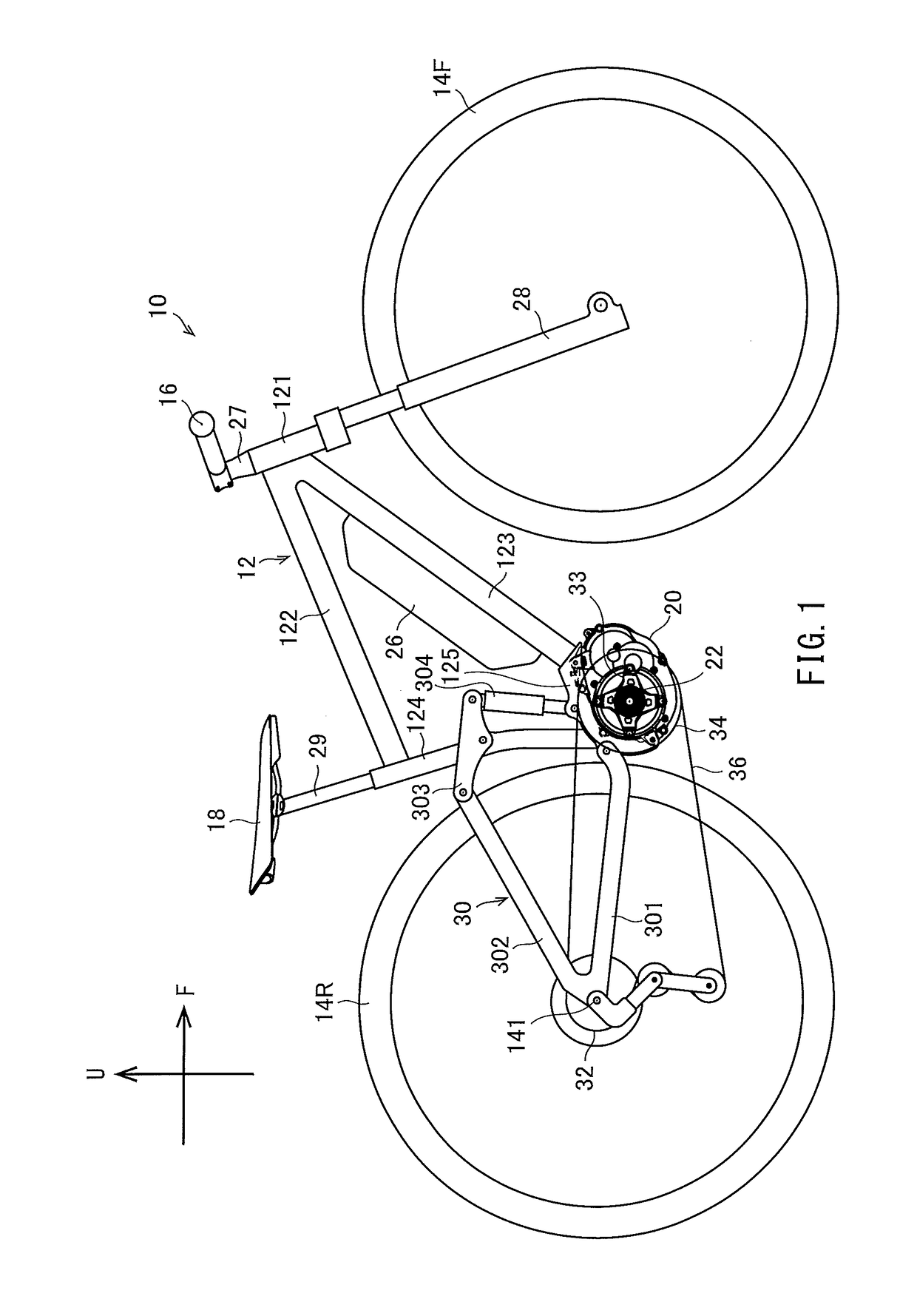

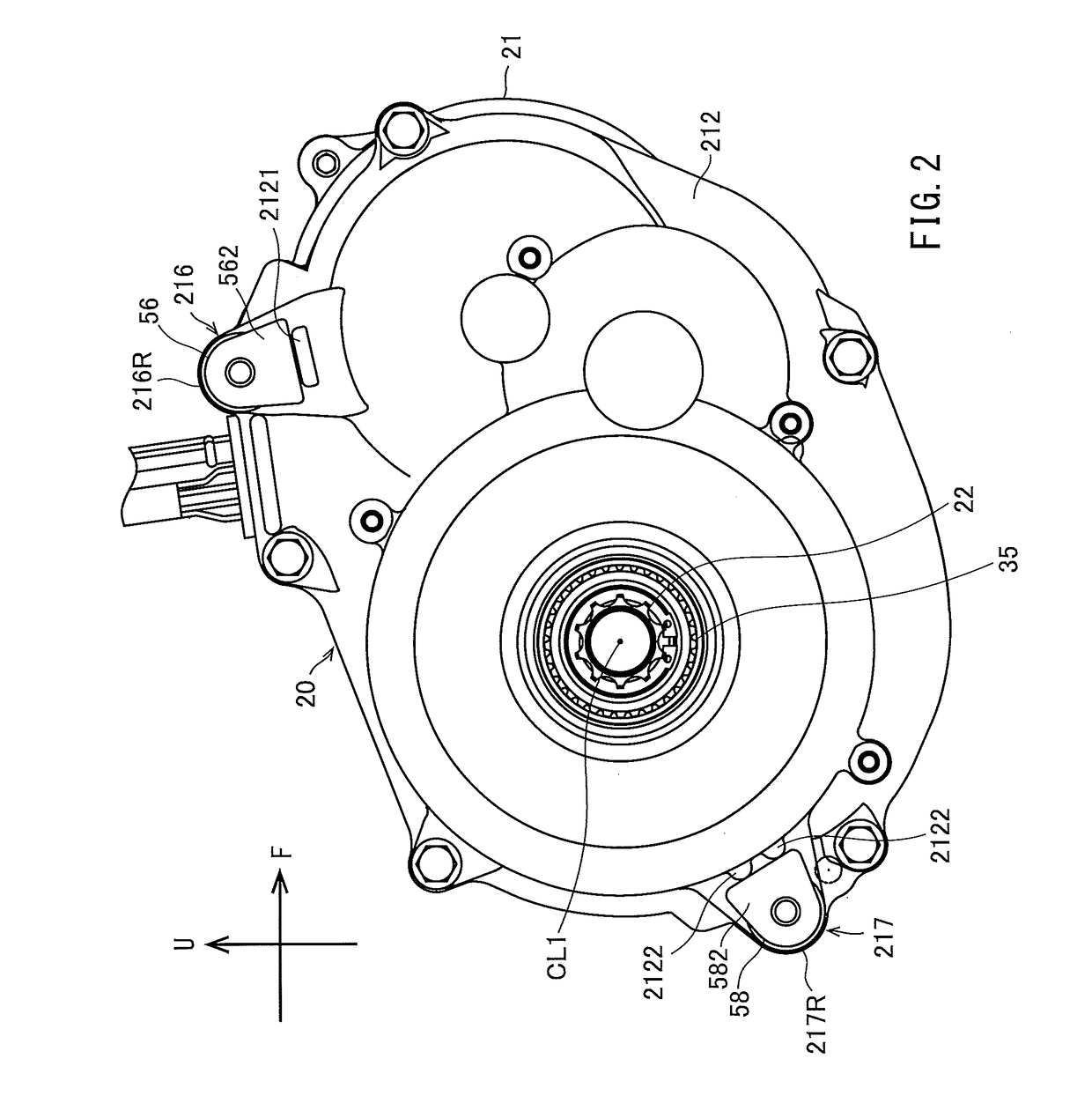

Electric-motor-assisted bicycle

ActiveUS20170314593A1Increase stiffnessIncrease forceChain/belt transmissionSheet joiningHigh stiffnessEngineering

A drive unit reliably and stably attached to a bracket, even if the bracket has high stiffness, includes a housing including first and second suspension bosses located between first and second side plates of the bracket in a left-right direction of a bicycle. A first bolt is fastened to the first suspension boss and inserted from an outside in the left-right direction of the bicycle into a hole in the first side plate. A cylindrical member is fitted into an insertion hole in the second suspension boss that is open toward the second side plate. The cylindrical member is slidable in the left-right direction of the bicycle and includes a thread groove located on an inner periphery thereof engaging a thread located on an outer periphery of a second bolt that is inserted from the outside in the left-right direction of the bicycle into a hole in the second side plate.

Owner:YAMAHA MOTOR CO LTD

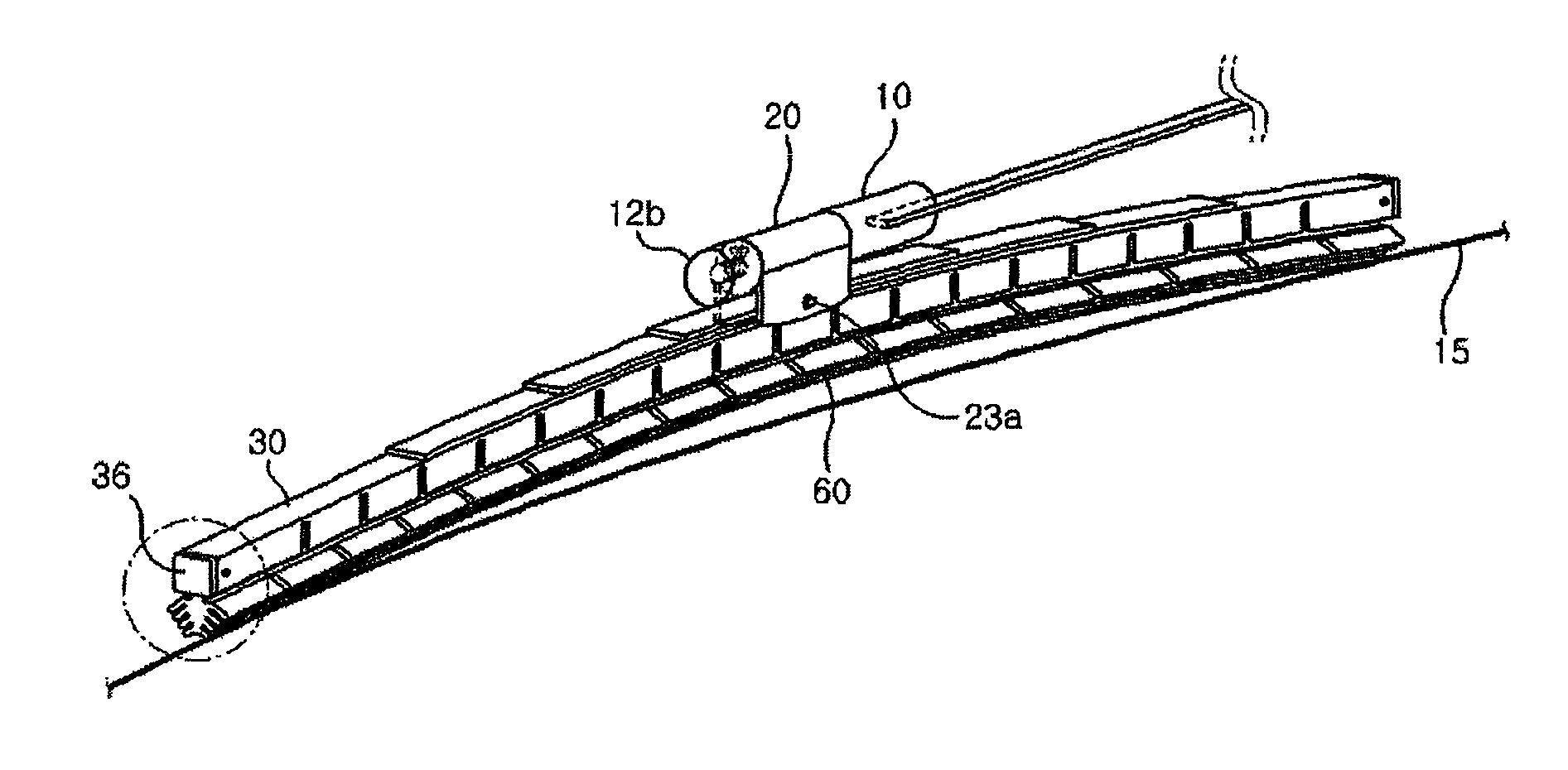

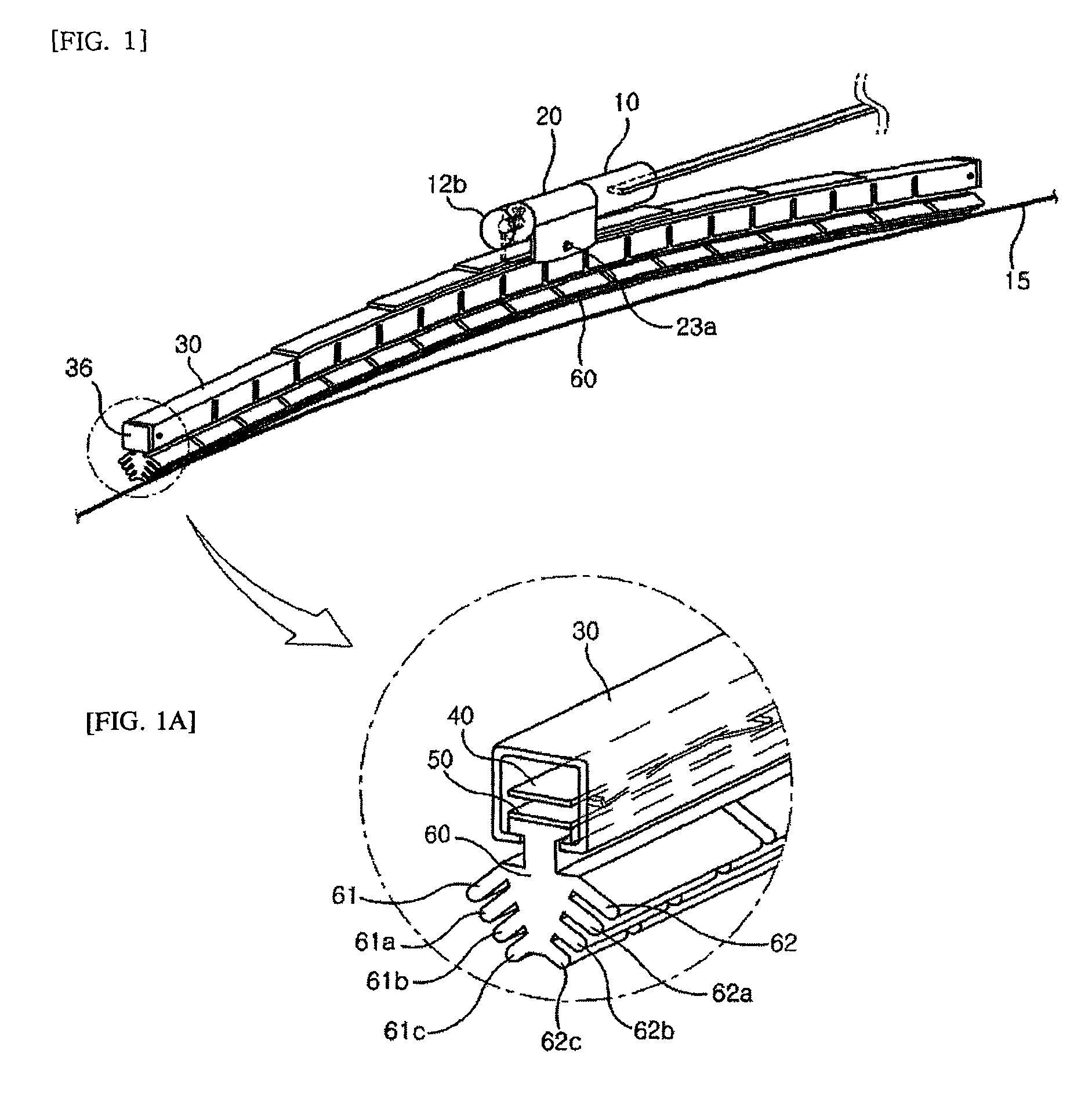

Wiper having tilting multi-blade

InactiveUS8201301B2Average forceImprove washing effectWindow cleanersVehicle cleaningEngineeringKnife blades

Disclosed herein is a wiper having a tilting multi-blade to wipe a windshield of a transportation means. The wiper includes a wiper arm, a reciprocating tilting device, a blade holder, a multi-blade and a blade compressing plate. The wiper arm has a tilting control stopper. The reciprocating tilting device has a tilting angle control hole into which the tilting control stopper is inserted such that the reciprocating tilting device is rotatable within a limited angular range. The blade holder is coupled to the reciprocating tilting device and has holder compressing plate springs. The blade holder has an elastic notch to provide uniform elastic repulsive force. The multi-blade includes a coupling part which is inserted into the blade holder, and multiple blade lips which are symmetrically provided on left and right sides. The blade compressing plate is inserted into the blade holder and has plate springs to evenly compress the multi-blade.

Owner:JEONG HYUN CHAN

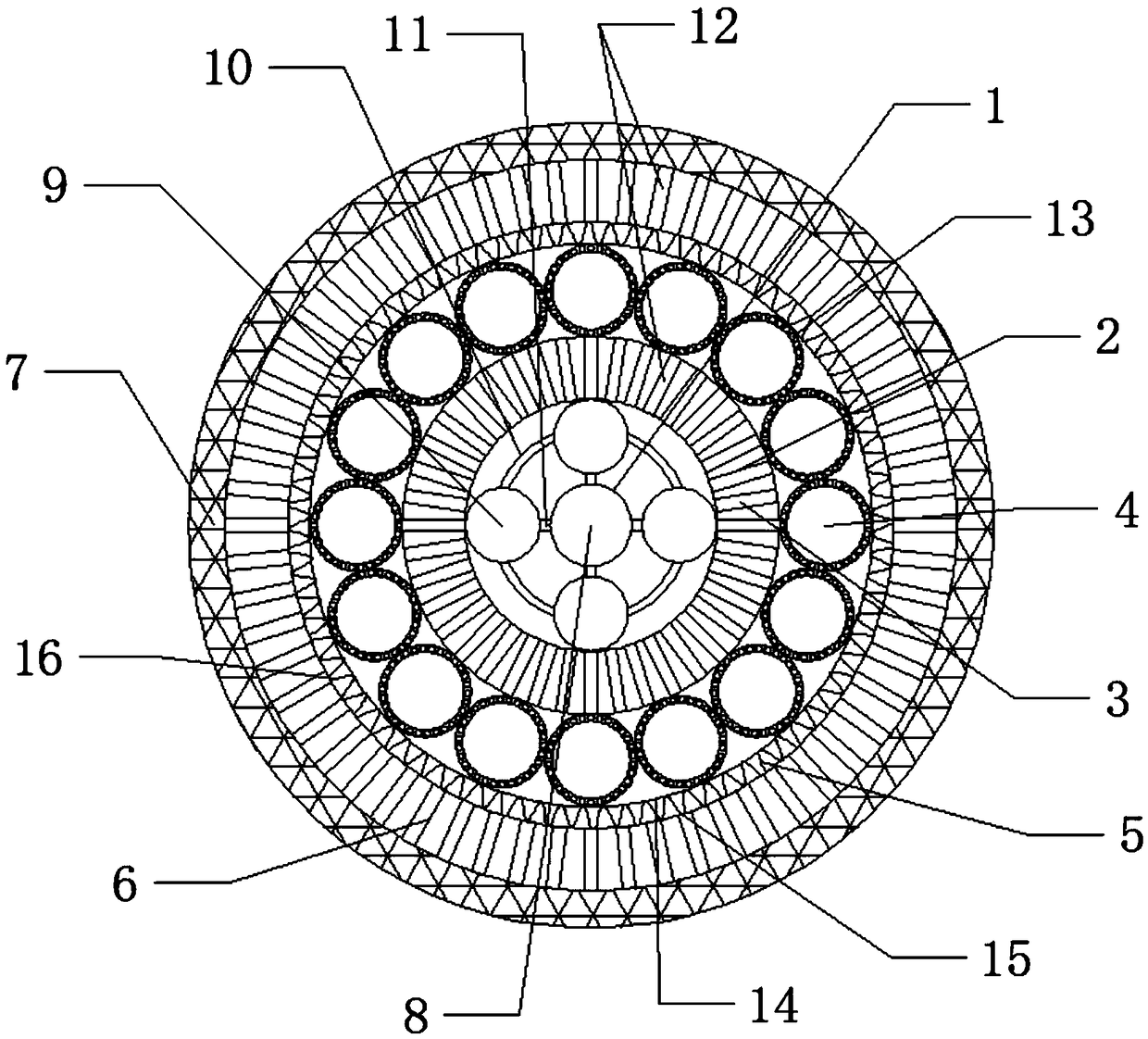

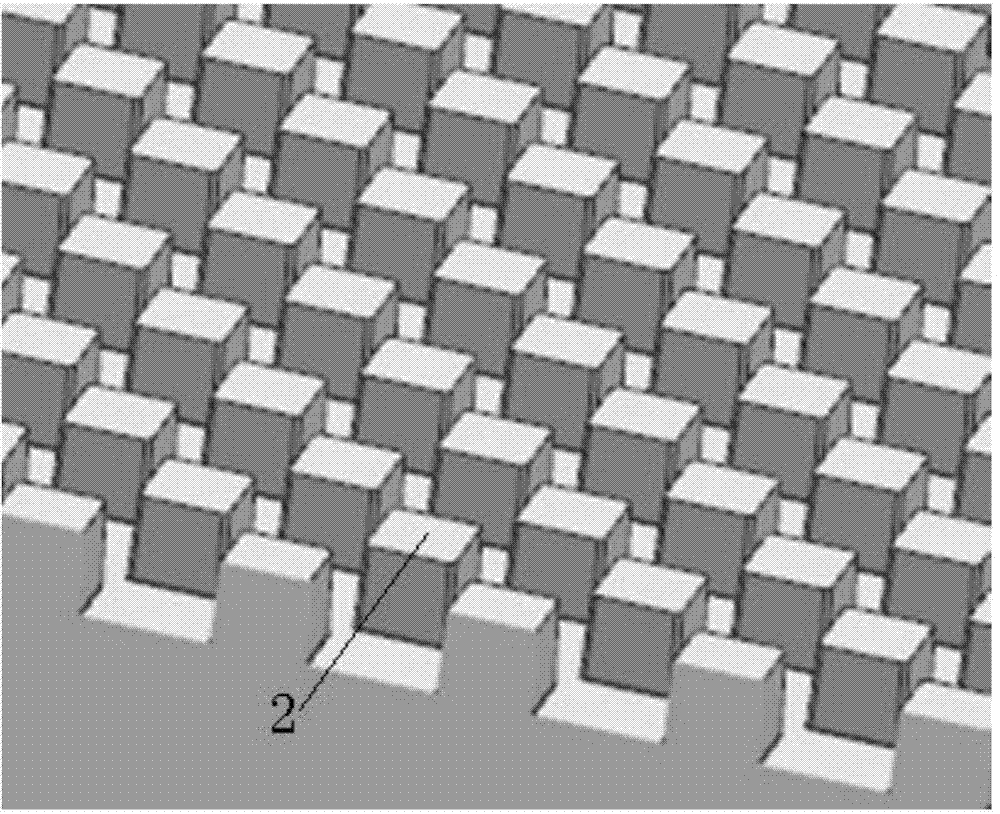

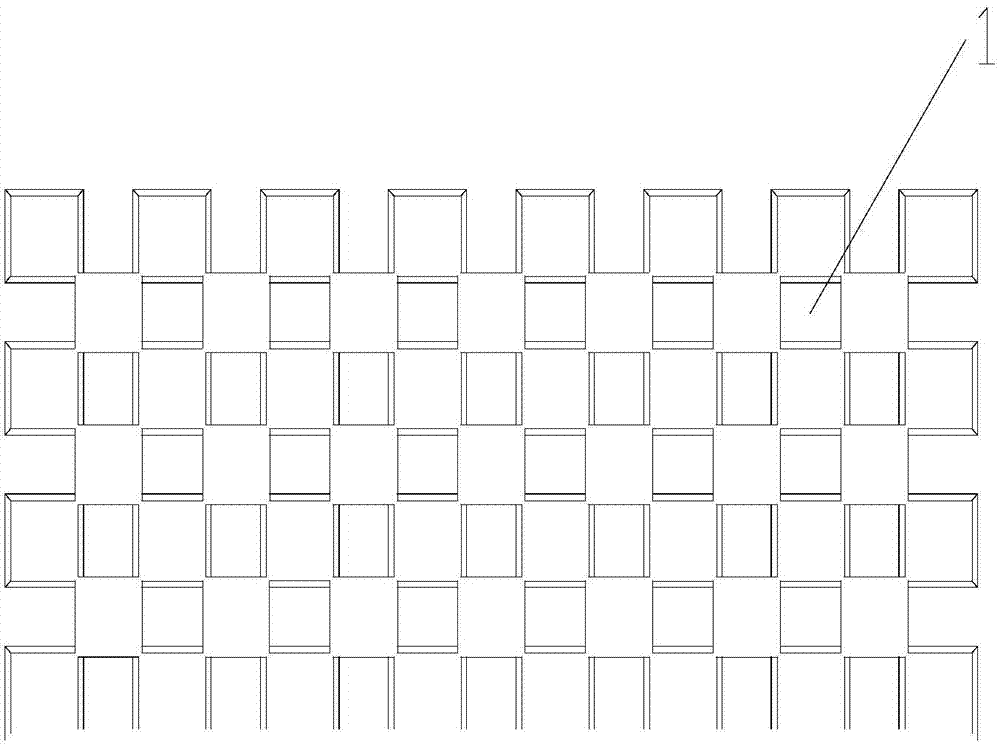

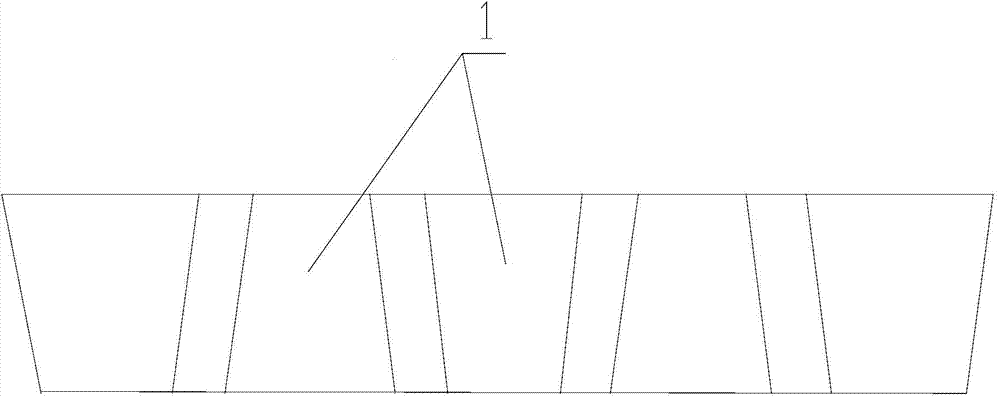

Flexible cable with heat dissipation effect

InactiveCN108735353ASafeguard ResilienceImprove toughnessFlexible cablesFlexible conductorsEngineeringElectric cables

The invention discloses a flexible cable with a heat dissipation effect, belongs to a multifunctional cable in the technical field of cables and aims at providing the flexible cable with the heat dissipation effect. According to the technical scheme, the flexible cable comprises a flexible cable core group arranged in the middle, wherein a first heat dissipation grid tube group is arranged outsidethe flexible cable core group; the length directions of grid tubes in the heat dissipation grid tube group are set along the radial direction of the flexible cable core group; a plurality of elasticcables are arranged outside the first heat dissipation grid tube group and are uniformly distributed along the external circumferential direction of the first heat dissipation grid tube group; a spring coil is arranged outside the elastic cables; a second heat dissipation grid tube group is arranged outside the spring coil; and a heat absorption layer is arranged outside the second heat dissipation grid tube group. The flexible cable with the heat dissipation effect has a good heat dissipation function while the flexibility of the cable is strengthened, and can be widely applied to a relatively harsh environment.

Owner:ZHENGZHOU JIZHI TECH CO LTD

Grating and preparation method thereof

The invention relates to the field of grating processing, and particularly relates to a grating and a preparation method thereof. The preparation method of the grating comprises the following steps: (A) putting raw materials for preparing the grating into a mold, and compressing by the mold, wherein the mold comprises an upper mold and a lower mold; (B) carrying out compression molding, controlling the molded surface temperature of the upper mold to be 135-145 DEG C, controlling the molded surface temperature of the lower mold to be 140-150 DEG C, controlling the pressure to be 10-15MPa and controlling the running dwell time to be 400-600s; and (C) opening the mold to take out a product out subjected to compression molding, polishing the upper surface and the lower surface of the product, thereby preparing the grating. Compared with the preparation method of the grating in the prior art, the preparation method of the grating, which is provided by the invention, has the advantages that the grating is prepared by adopting the double-sided mold, and the demolding force is distributed to front and rear sides by demolding double sides after molding, so that the grating is stressed uniformly; according to the preparation method, the product defective rate is reduced greatly, and the product quality is high.

Owner:浙江慧凯模塑科技有限公司

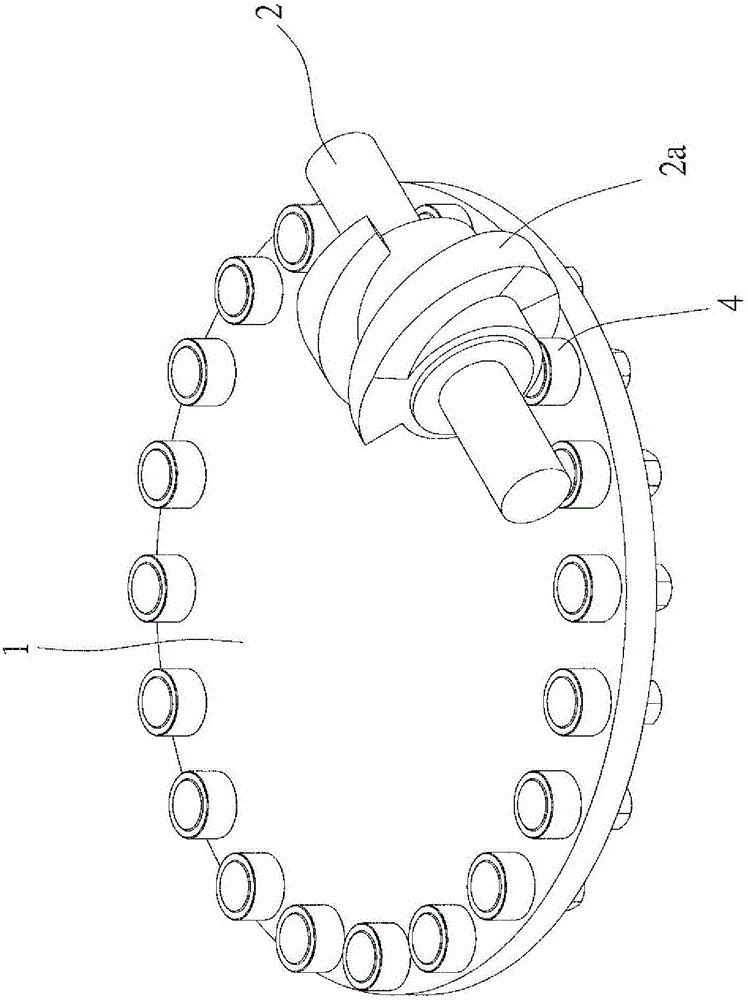

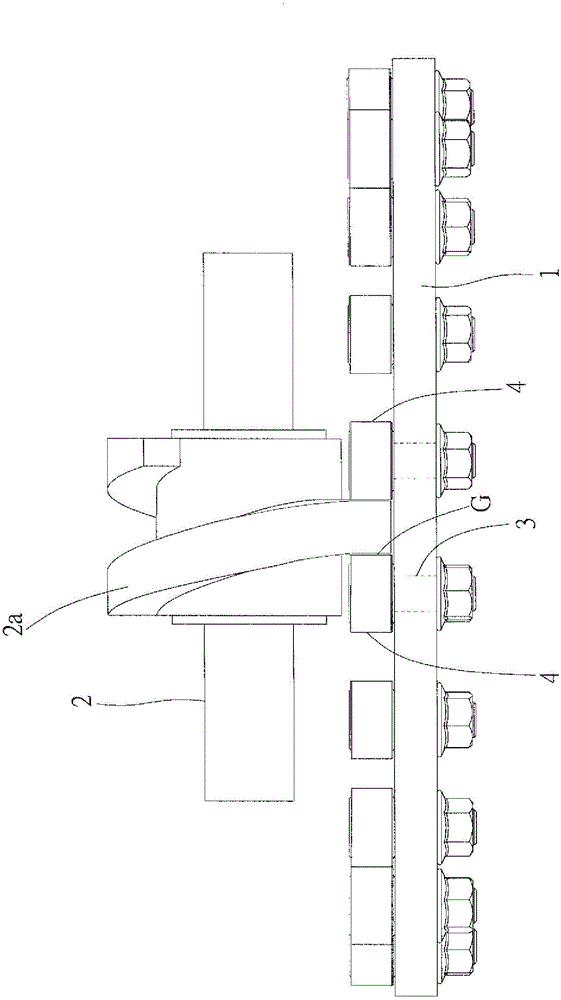

Intermittent motion transmission mechanism

An intermittent motion transmission mechanism comprises a rotating disc and a camshaft; a plurality of contact parts are arranged on the surface of the rotating disc in the circumferential direction, and each contact part is provided with a hemispherical portion which is exposed out of the disc surface; the camshaft is arranged on one side of the surface of the rotating disc, and comprises a spiral groove; and the bottom of the spiral groove is matched with the hemispherical portions of the contact parts to serve as curved surfaces. The good contact effect between the camshaft and the rotating disc is achieved, and the transmission process is smooth.

Owner:SANJET INT

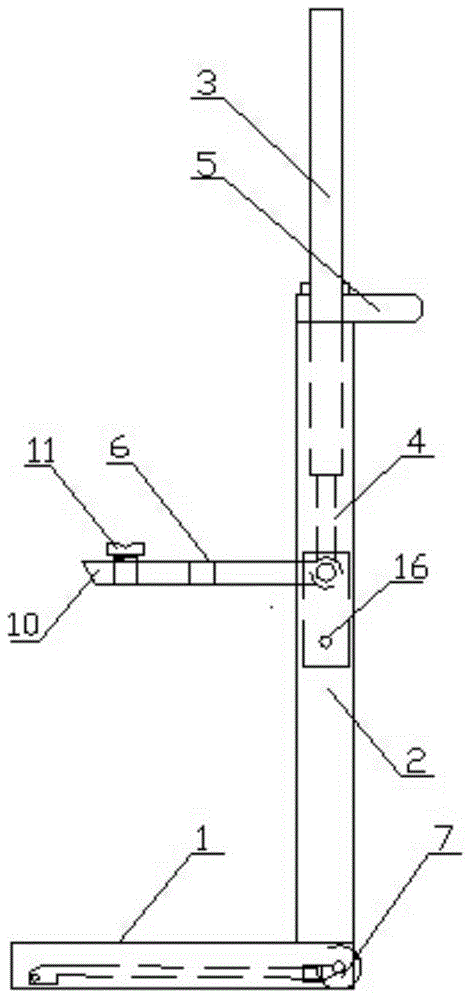

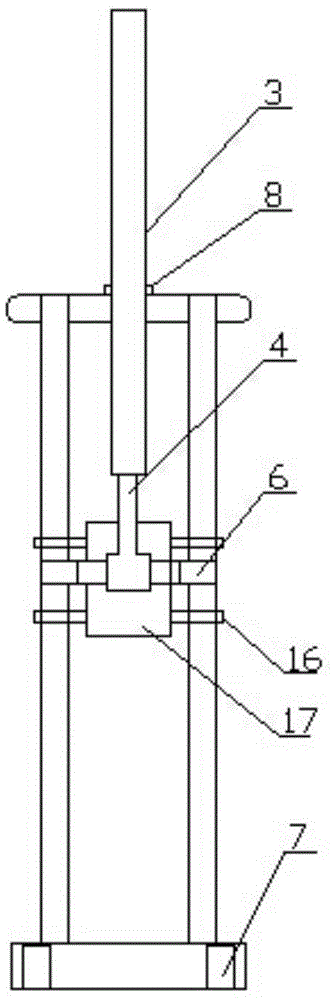

Inverse hydraulic movable lifter and use method thereof

The invention relates to an inverse hydraulic movable lifter and an use method thereof. The lifter is of a separated structure, and comprises a travelling wheel, a portal, a support mechanism, supporting legs and an oil pump. The supporting legs are fixedly connected with the portal, the oil pump drives the support mechanism to move vertically along the portal, and the oil pump is fixedly connected with the support mechanism. The inverse hydraulic movable lifter and the use method thereof have the advantages that the separated structure is adopted, so that the transport is more convenient, the occupation space is small, and field assembly is facilitated; the oil pump and the portal are of a separated structure, so that separated transporting and temporary assembling are achieved; at the same time, the oil pump maintenance and part replacement are facilitated; the oil pump is used for lifting, the lifter is lifted to a certain height, a user can conveniently move, and both time and labor are saved. The whole structure is simple, the size is small, and the use is flexible and convenient.

Owner:常州鸣人信息科技有限公司

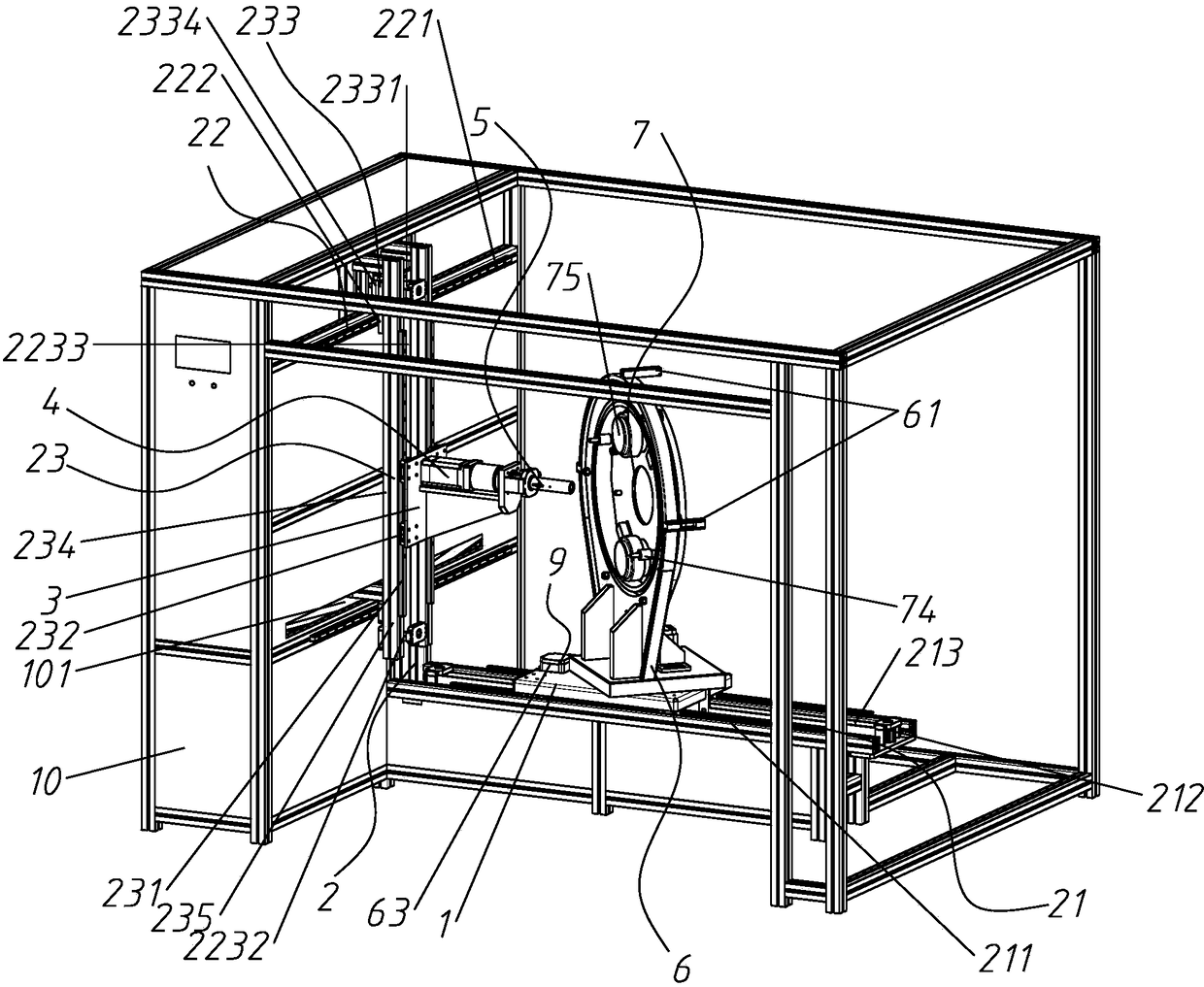

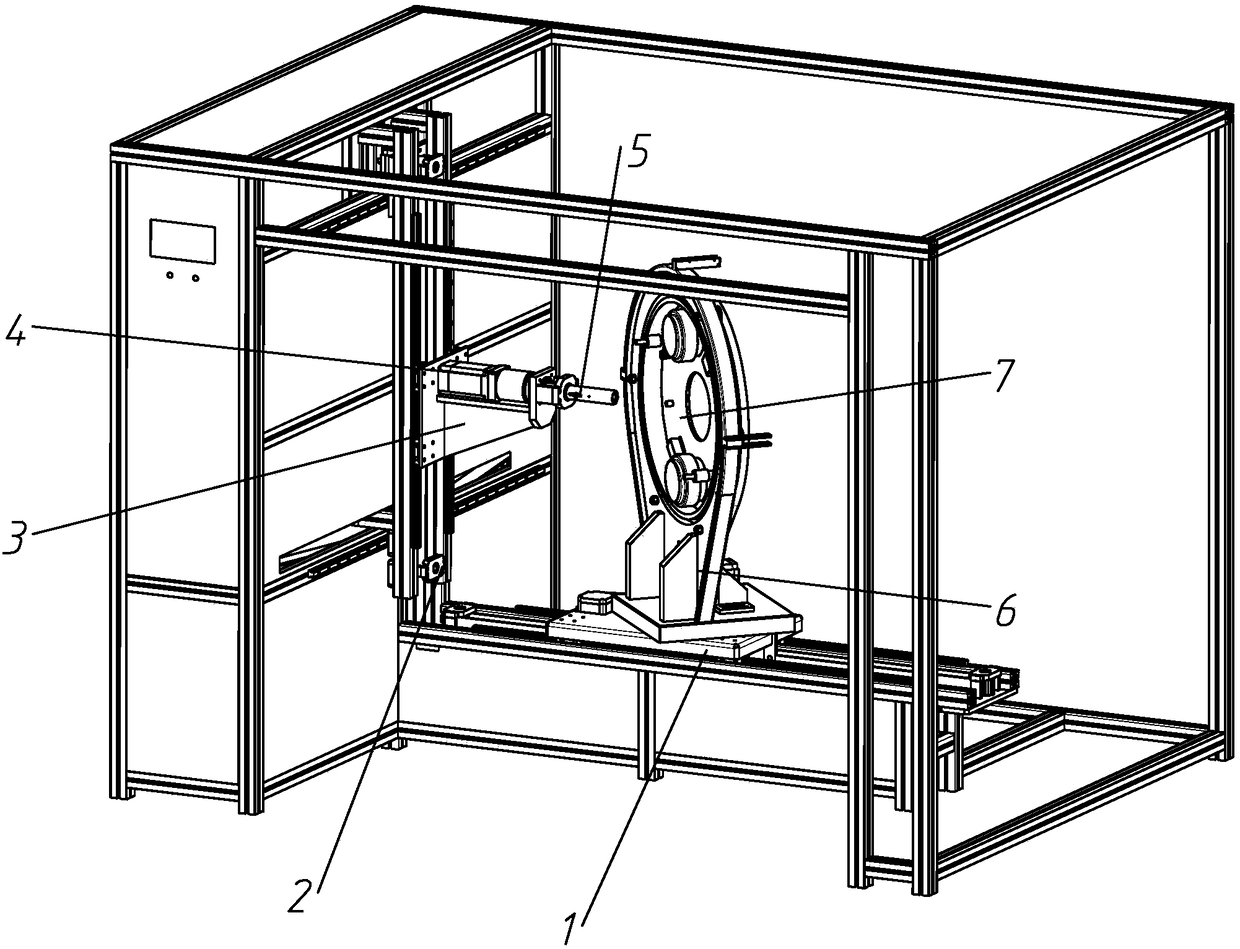

Multi-axis linkage winding machine for wrapping irregular pipe body

ActiveCN108423220AGuaranteed normal windingGuaranteed wrappingWrapping with article rotationWinding machineMulti axis

The invention belongs to the technical field of a winding machine, and provides a multi-axis linkage winding machine for wrapping an irregular pipe body. The multi-shaft linked winding machine comprises a foundation support, wherein the foundation support is connected with a clamping support by virtue of a moving apparatus, the clamping support makes the translation movement in a three-dimensionalspace relative to the foundation support by virtue of the moving apparatus, the clamping support is provided with a clamping portion in a rotating manner by virtue of a rotating apparatus I, the foundation support is provided with a winding frame in a rotating manner by virtue of a rotating apparatus II, a rotating shaft of the winding frame is perpendicular to a rotating shaft of the clamping support, the winding frame is provided with a winding disc in a rotating manner, and the winding disc is provided with a supporting apparatus for supporting a wound strip coil. By virtue of the technical scheme, the technical problems in the prior art that no winding machine for winding the irregular tubular article is provided can be solved.

Owner:河北海赞自动化科技有限公司

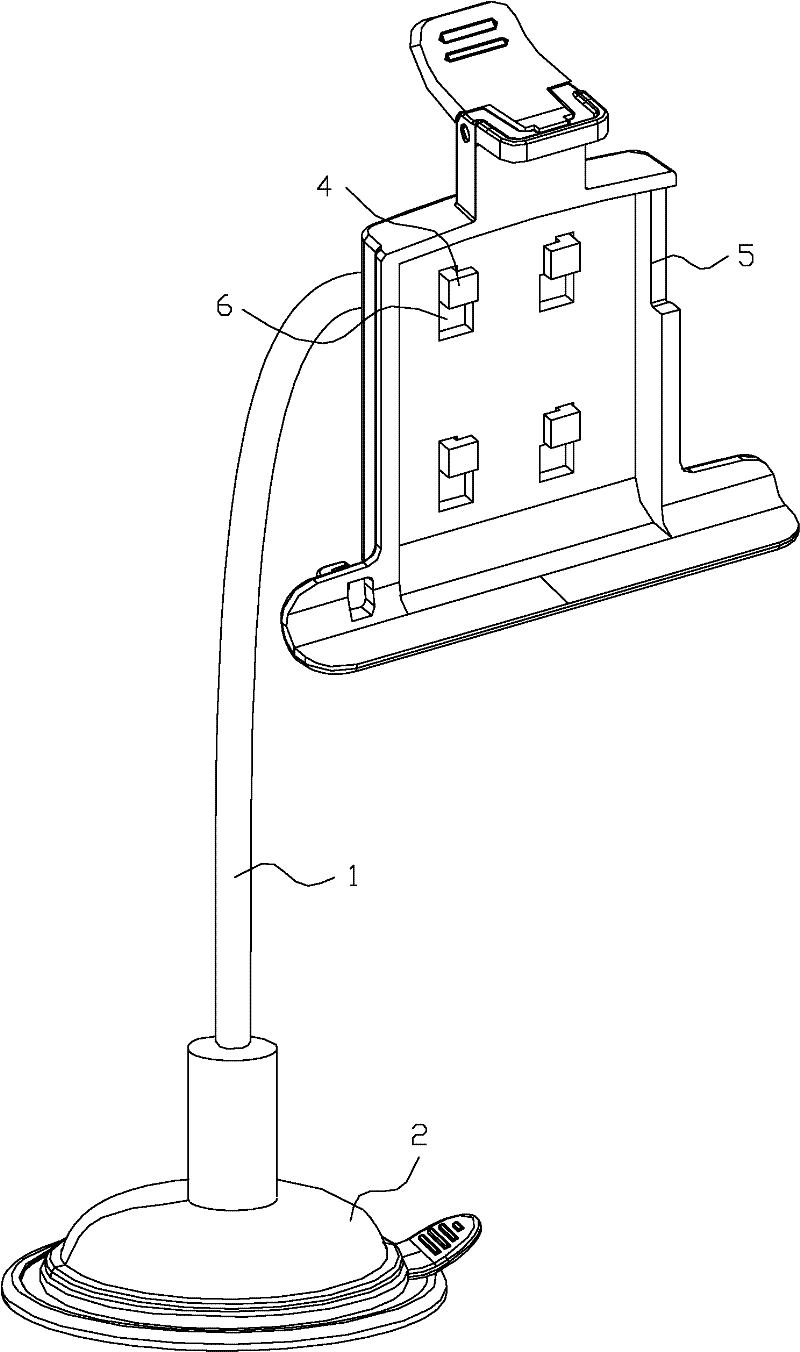

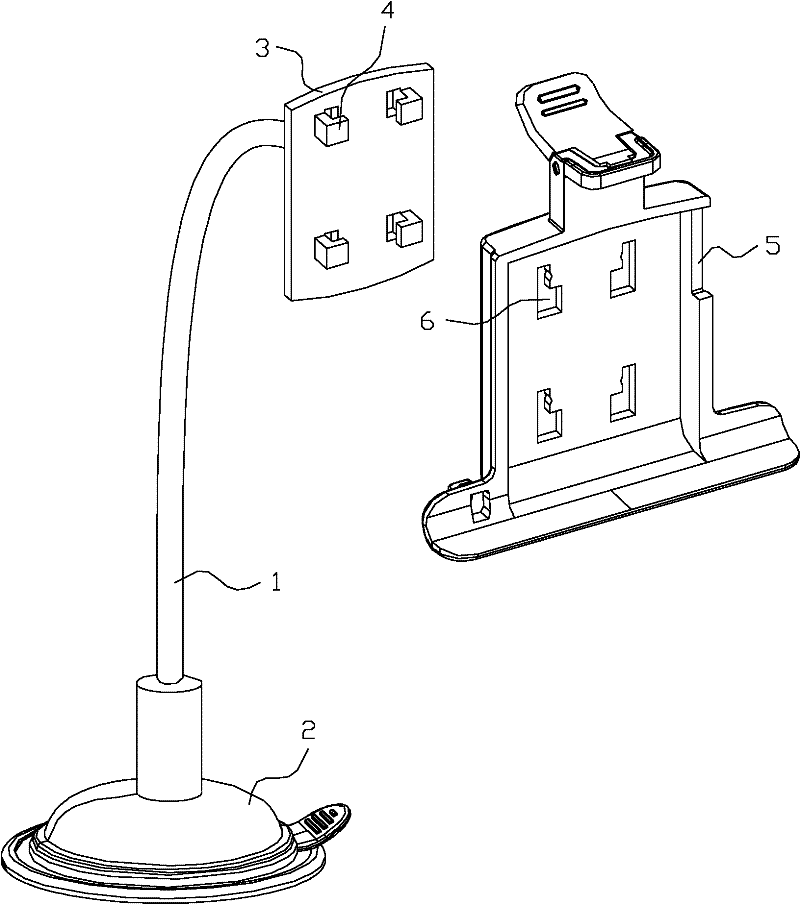

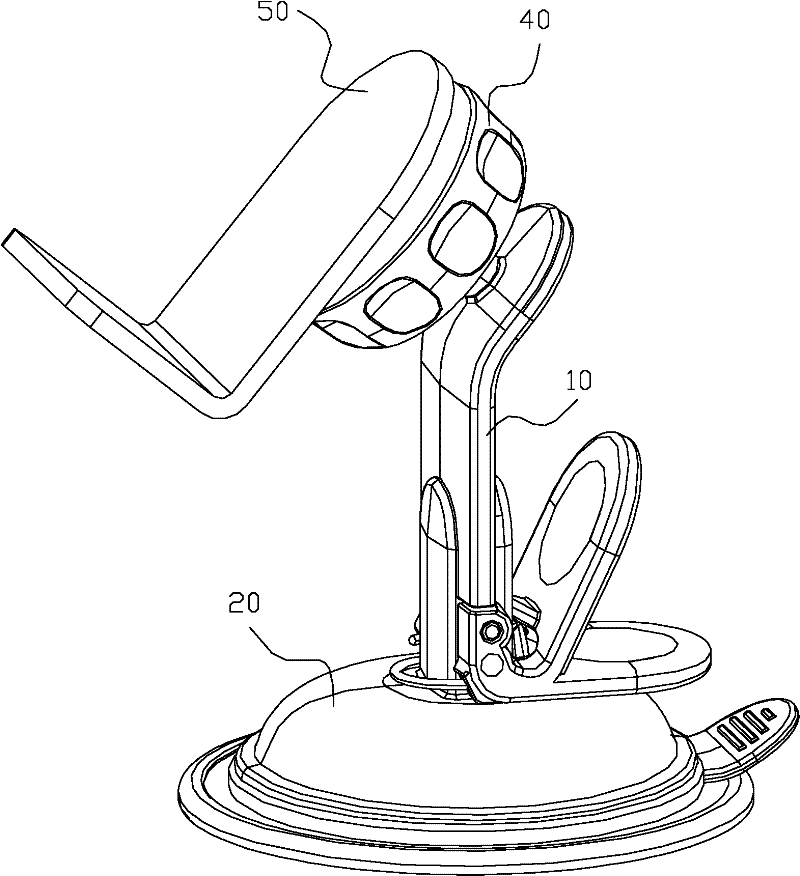

Rotary fixing support

The invention discloses a rotary fixing support, which is used for fixing an electronic product and comprises a base, a connecting plate and a supporting frame. The connecting plate is provided with a through hole and a plurality of fasteners arranged around a point, a plurality of fastening holes matched with the fasteners are arranged on the back surface of the supporting frame circularly, and the supporting frame is provided with screw holes and an arched ring. The connecting plate is connected and fixed with the supporting frame by rotary fastening action between the fasteners and the fastening holes and is locked by an easy-locking screw. The top of the base extends integrally to form the connecting plate, or the connecting plate is connected and fixed with the base through a fixing component having a thread structure. The rotary fixing support is simple in operation, the fasteners can be fastened into the fastening holes rotationally easily, and evident stepping effect is generated when the fasteners are fastened into the fastening holes. Since the fasteners are distributed at the same interval and are restrained by the same mode, the rotary fixing support is uniform in stress and higher in impact and vibration resistance capacity.

Owner:KUNDA COMP TECHKUSN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com