Connector housing heat radiation structure

A heat dissipation structure and connector technology, which is applied in the direction of instrumentation, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problems of reduced EMI shielding effect, easy to be damaged by external force, weak buckle strength, etc., to achieve Increase the effective heat dissipation area, not easy to loose, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

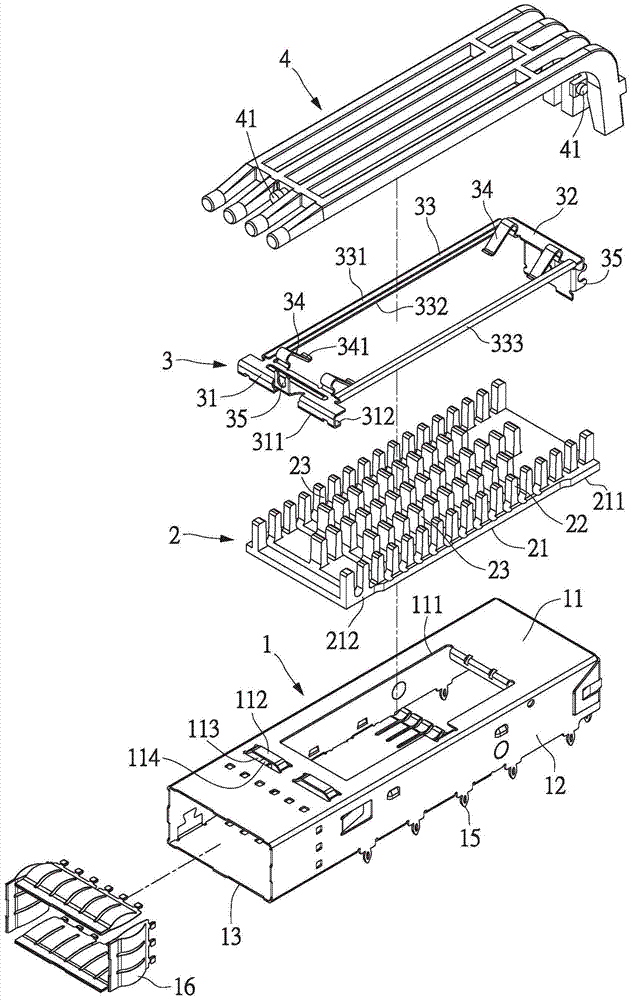

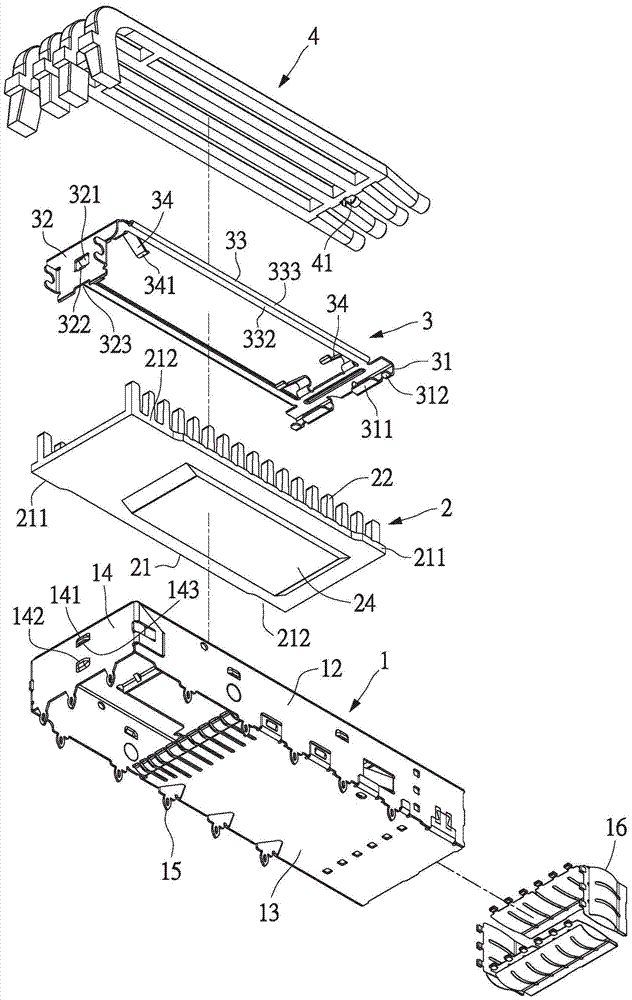

[0028] see figure 1 and figure 2 , the present invention provides a connector shell heat dissipation structure, which meets the requirements of the small pluggable connector specification, not only applicable to the structure of 1×1 specification, but also can be used in left and right side-by-side designs, such as 1×2~1× 6 gauge structure. The heat dissipation structure of the connector housing includes a housing 1, a heat sink 2 and a buckle 3. The housing 1 is provided with one, and its width can be changed corresponding to different specifications such as 1×1˜1×6. There are one, two, three, four, five or six cooling fins 2 and holding parts 3 corresponding to different specifications such as 1×1˜1×6. This embodiment discloses a structure with a size of 1×1, and there is one housing 1 , one cooling fin 2 and one holding member 3 .

[0029] The shell 1 is a metal shell, and the shell 1 includes a top plate 11 , two side walls 12 , a bottom plate 13 and a rear cover 14 . ...

no. 2 example

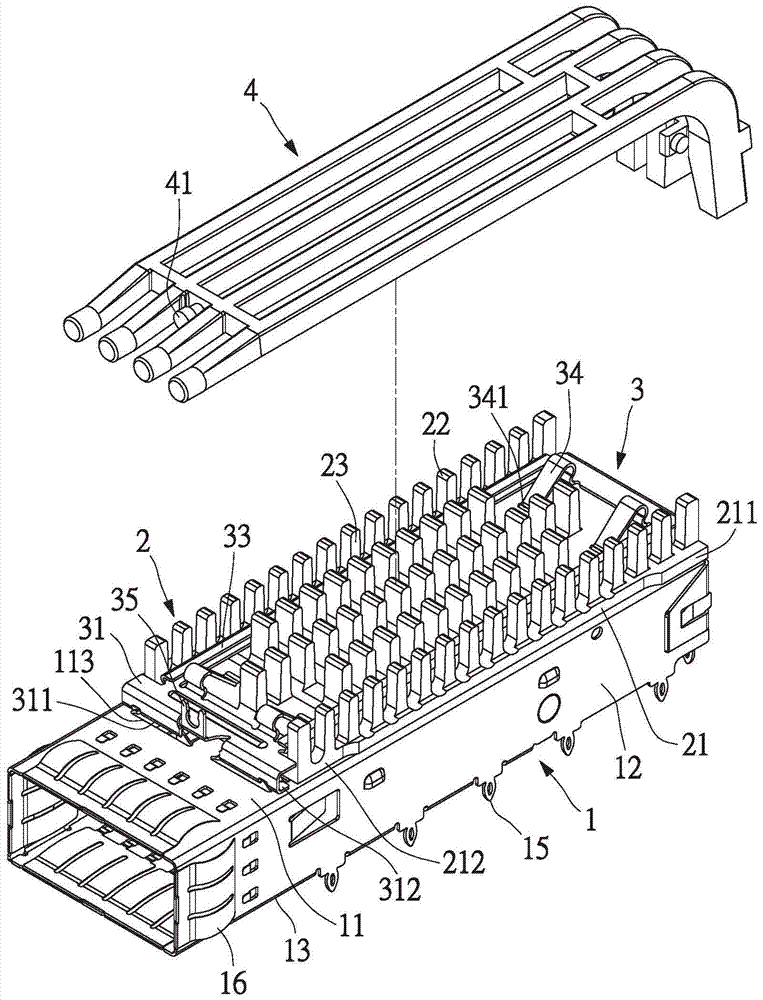

[0041] see Figure 8 and Figure 9 , the housing 1 can be provided with at least one middle partition 17, the middle partition 17 and the two side walls 12 are parallel to each other, in order to divide the inside of the housing 1 into at least two spaces, the heat sink 2 and the At least two fasteners 3 are provided corresponding to the at least two spaces. This embodiment discloses a structure with a 1×4 specification. The casing 1 is provided with one. The width of the casing 1 is increased, and its width is roughly four times that of the 1×1 specification. The heat sink 2 and the buckle 3 There are four correspondingly. In this embodiment, there are three intermediate partitions 17 , which divide the interior of the housing 1 into four spaces. The number of the middle partitions 17 can also be changed according to different specifications of the connectors, for example, one or two, or four or five, etc. can be provided. The through hole 111, buckle piece 112, opening 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com